Patents

Literature

389results about How to "Adjust the tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

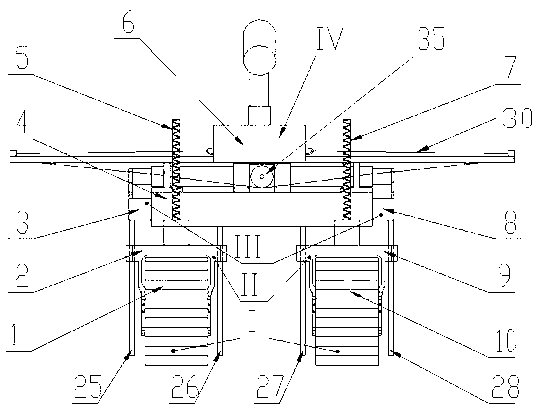

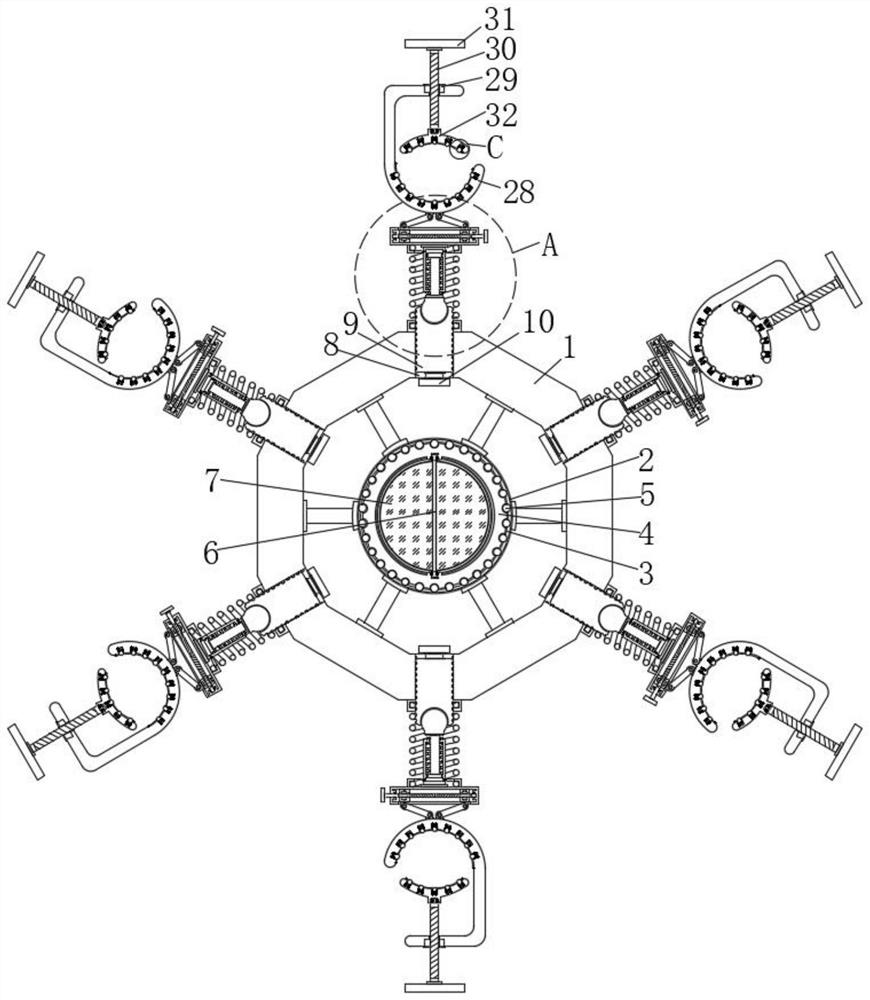

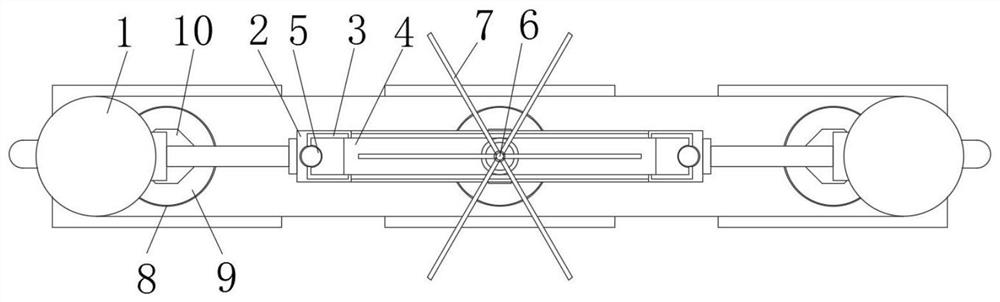

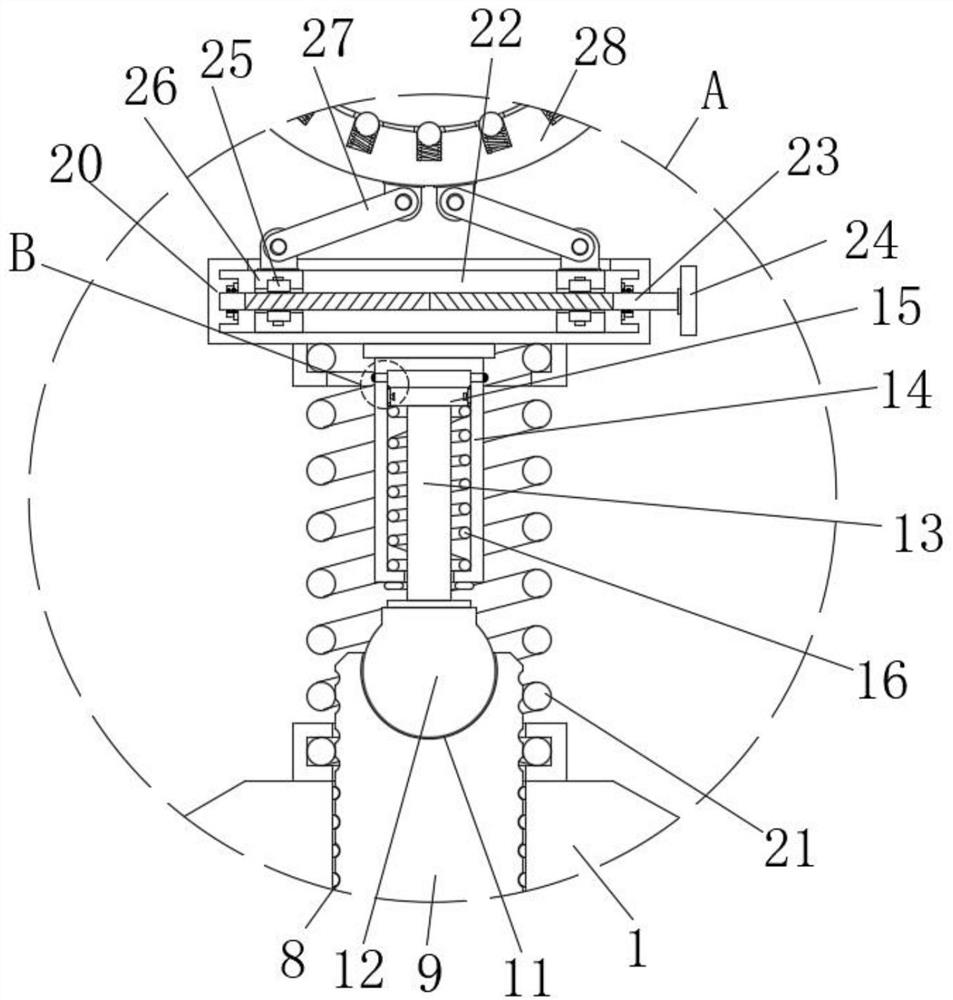

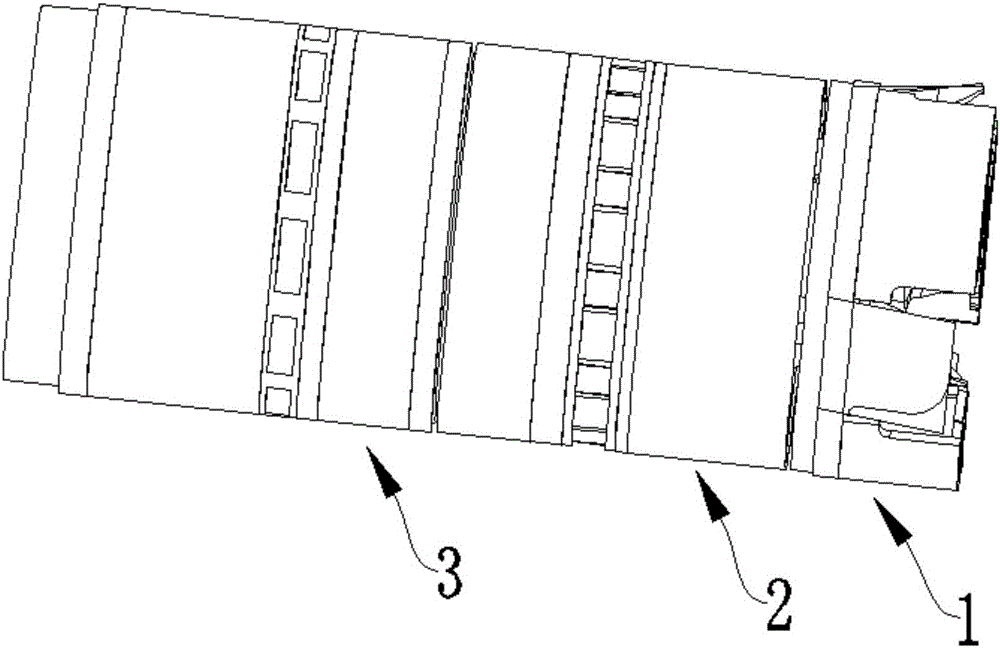

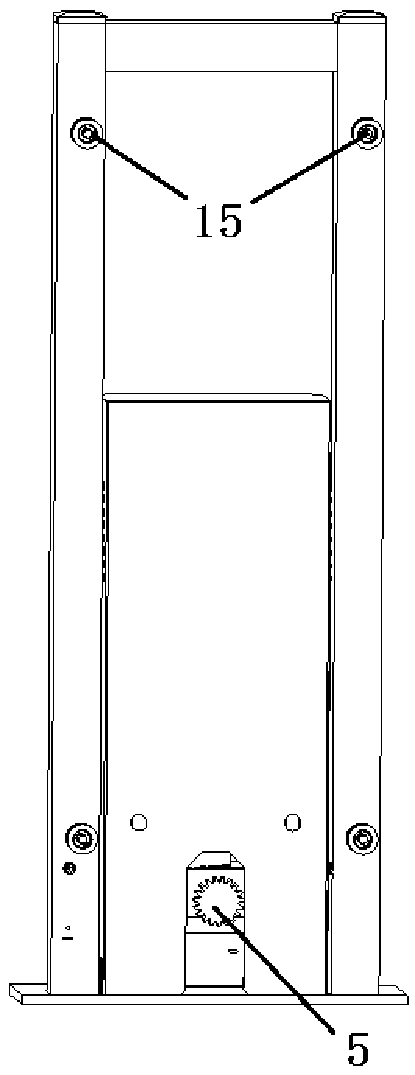

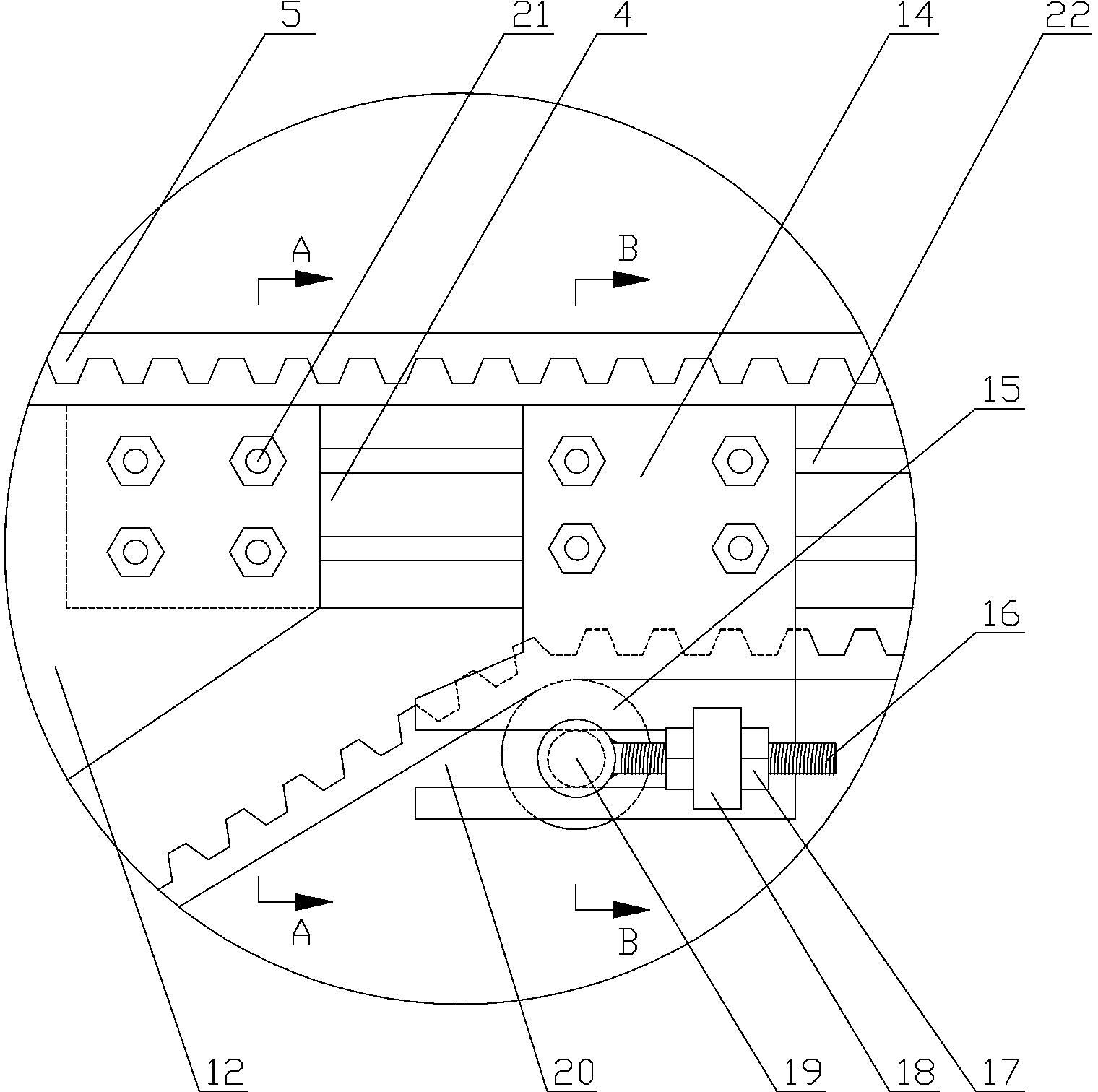

Weeding robot with adjustable center of gravity for paddy fields

InactiveCN102696294ALower center of gravityReal-time monitoring of distributionSoil-working equipmentsWhole bodyPaddy field

The invention relates to a weeding robot with the adjustable center of gravity for paddy fields. The weeding robot comprises a hub driving type caterpillar track device, a caterpillar track lifting device, an extension movement device and a slider balance device. The hub driving type caterpillar track device is used for driving a hub through a hub motor, thereby driving caterpillar tracks to run, enabling the robot to walk between rice seedling lines, pressing weeds into mud and even cutting off or pulling out weeds; the caterpillar track lifting device and the extension movement device are used for realizing the lifting and extension of the caterpillar track device so that line changing walking and field ridge crossing walking can be carried out; the slider balance device is matched with the caterpillar track lifting device and the extension movement device and is used for adjusting the center of gravity of the robot and realizing the self balance of the whole body of the robot in the line changing process and the field ridge crossing process and the self-restoring function after the robot sinks into a pit in a paddy field environment with pits; and the weeding robot has the advantages of simple structure, small volume, light weight, convenience in carrying and high universality.

Owner:SOUTH CHINA UNIV OF TECH

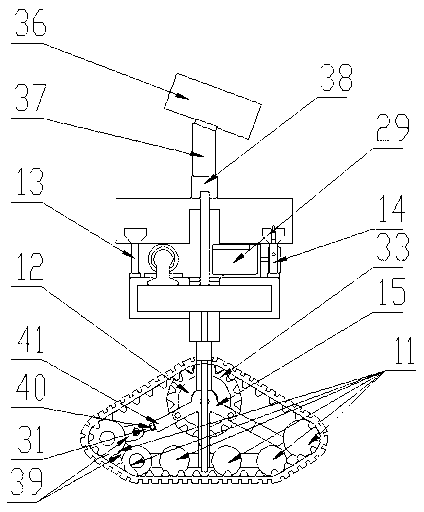

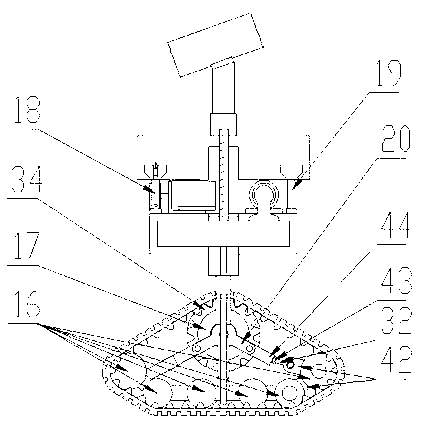

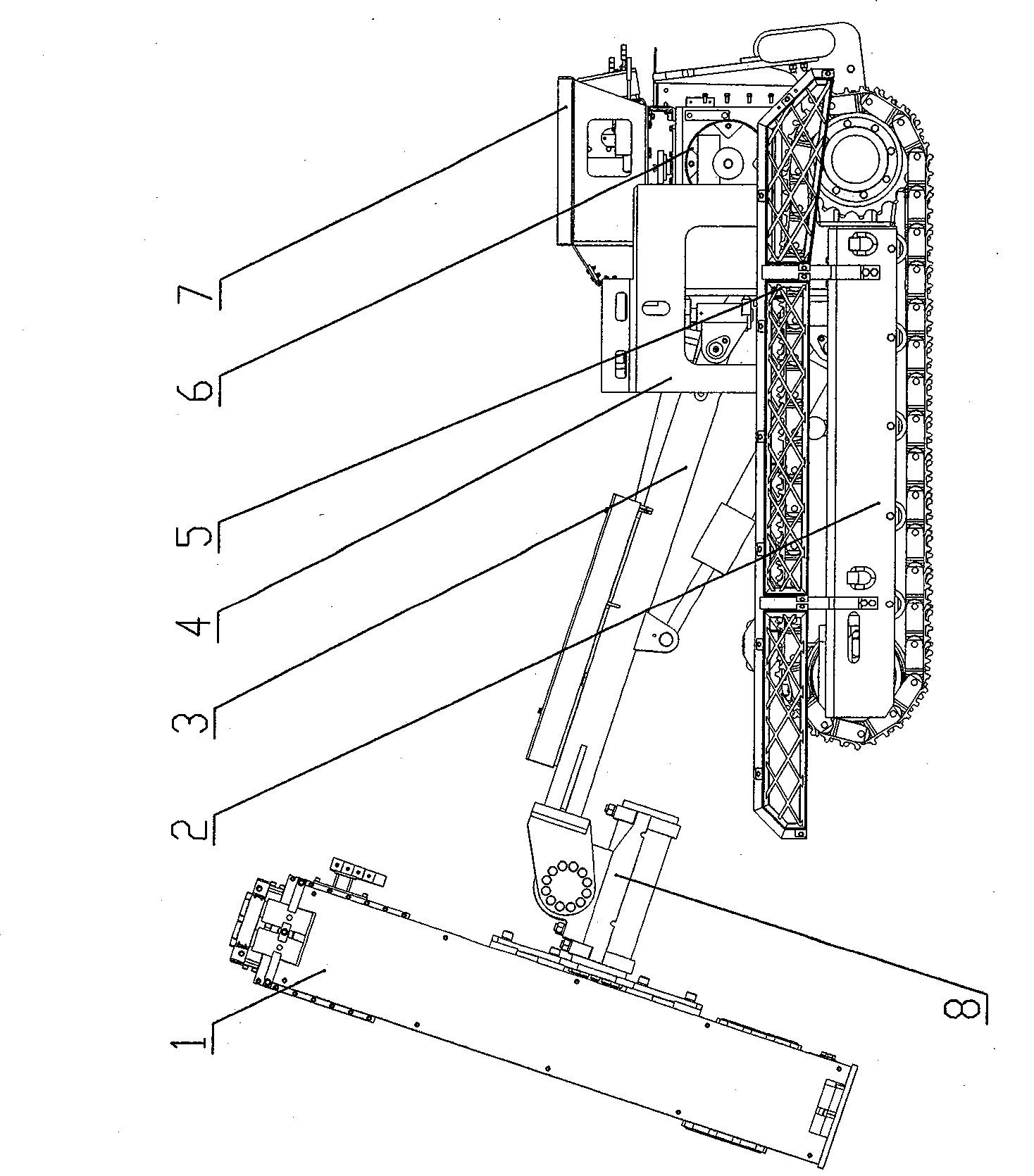

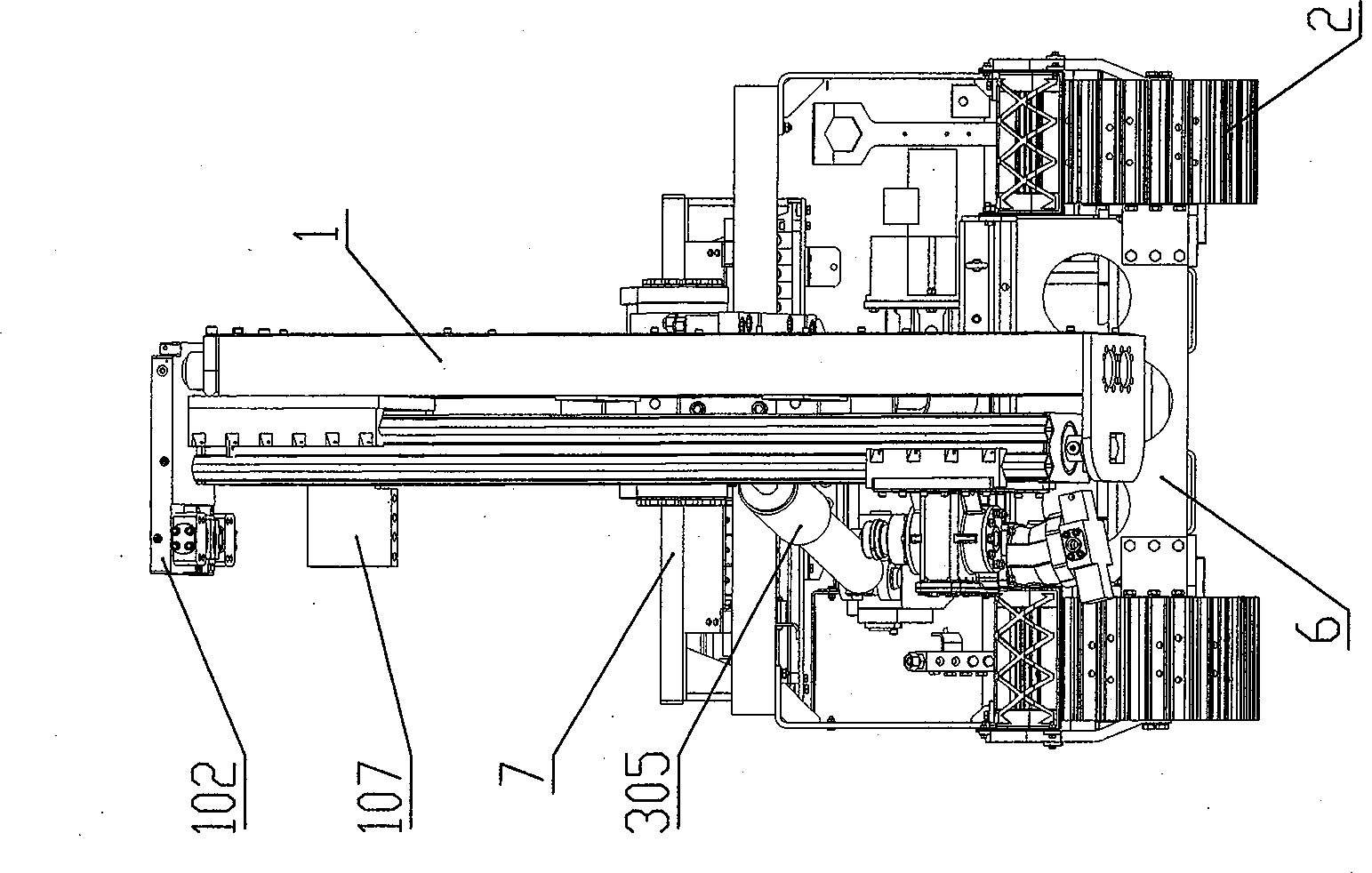

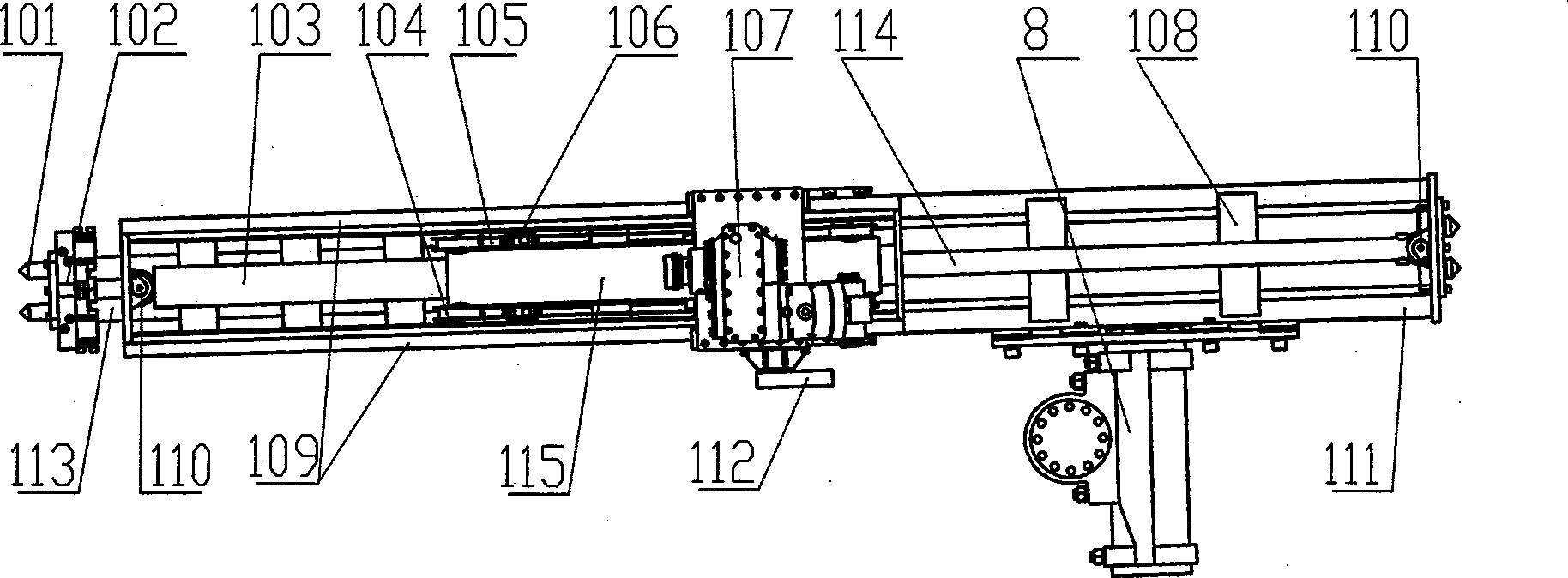

Pneumatic crawler hydraulic jumbo

InactiveCN101509350AAvoid it happening againTimely processingConstructionsDrilling drivesClosed loop designElectric devices

The invention discloses a pneumatic crawler-type hydraulic drill carriage which comprises a carriage body, a travelling gear, a working device for drilling connected with the carriage body, a hydraulic system for driving the devices, and an operating device; a pneumatic motor is used as power of the hydraulic system and operation of the drill carriage; an operating device, which adopts closed loop design, is used for driving the pneumatic motor, the pneumatic system, the hydraulic system and the various acting components to act; the travelling device is crawler-typed; a swinging device, which consists of a swinging arm and a cylinder, is arranged at the front of the carriage body; the front end of the swinging device is connected with the working device for drilling by a universal rotating device; the working device consists of a feeding device which comprises a supporting device, a secondary cylinder, and a chain pushing mechanism; and the pneumatic crawler-type hydraulic drill carriage uses a method combining water and gas to clean the boreholes. The pneumatic crawler-type hydraulic drill applies especially to mass drilling work sites of which change continuously; the whole carriage is free of electric devices and the pneumatic crawler-type hydraulic drill applies particularly to high gassy mine and can carry out universal hole drilling.

Owner:JIKAI EQUIP MFG CO LTD

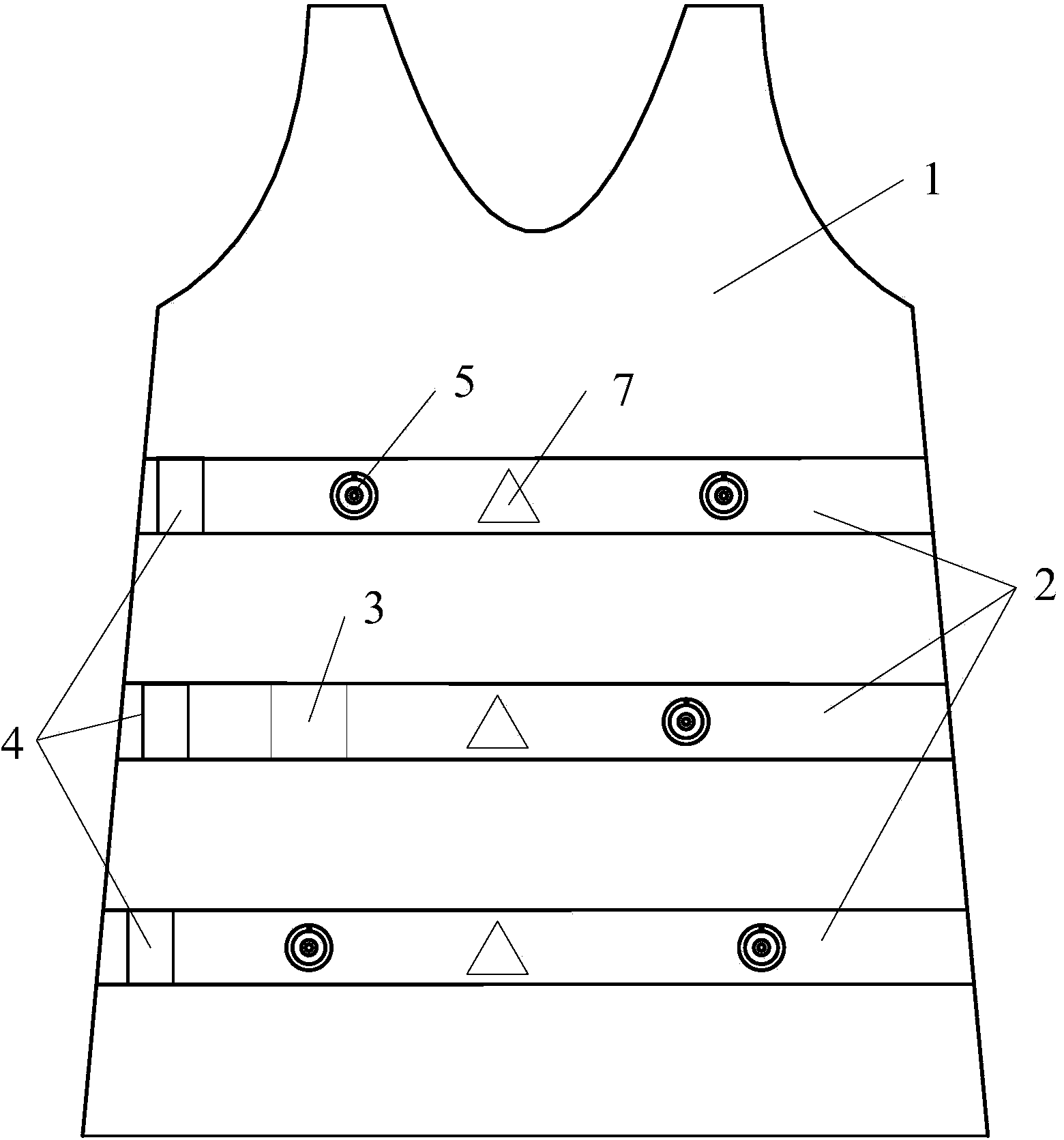

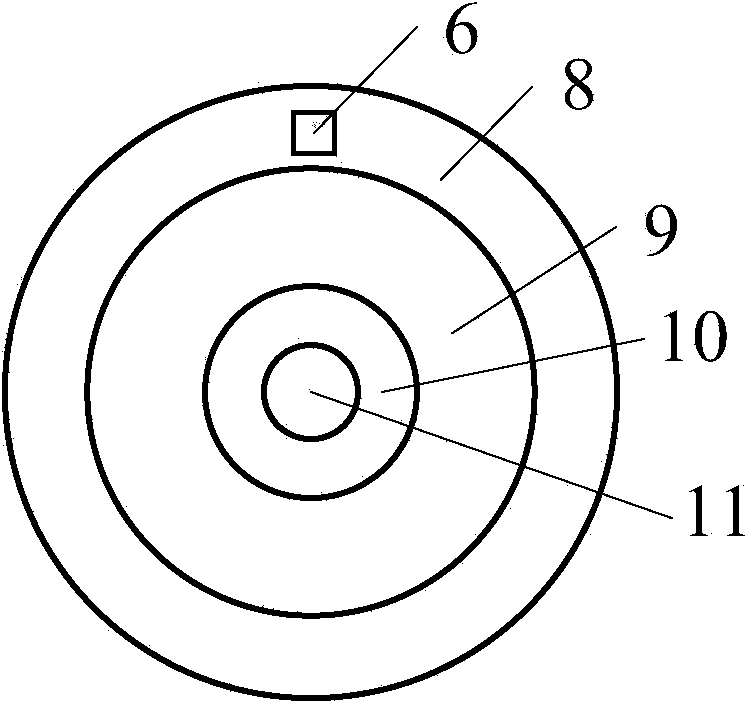

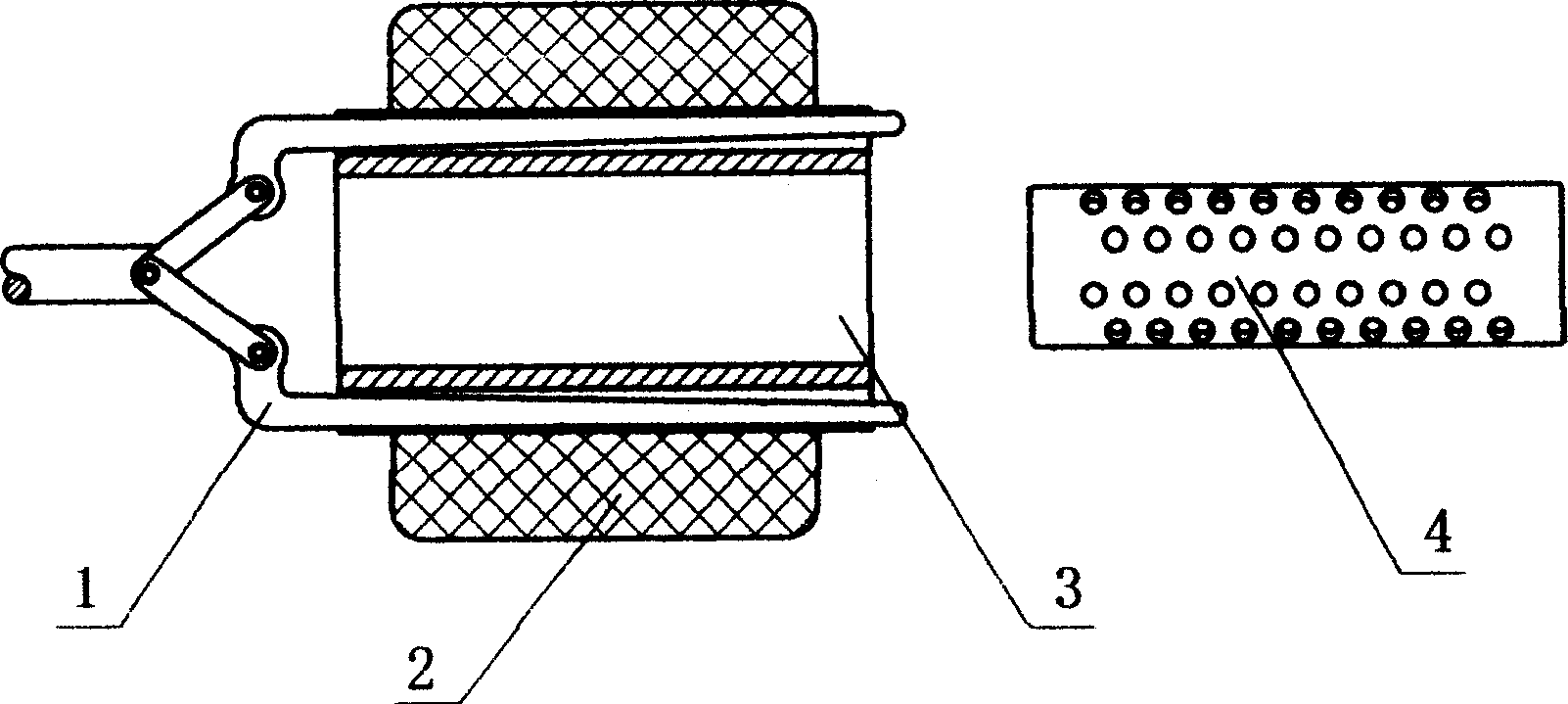

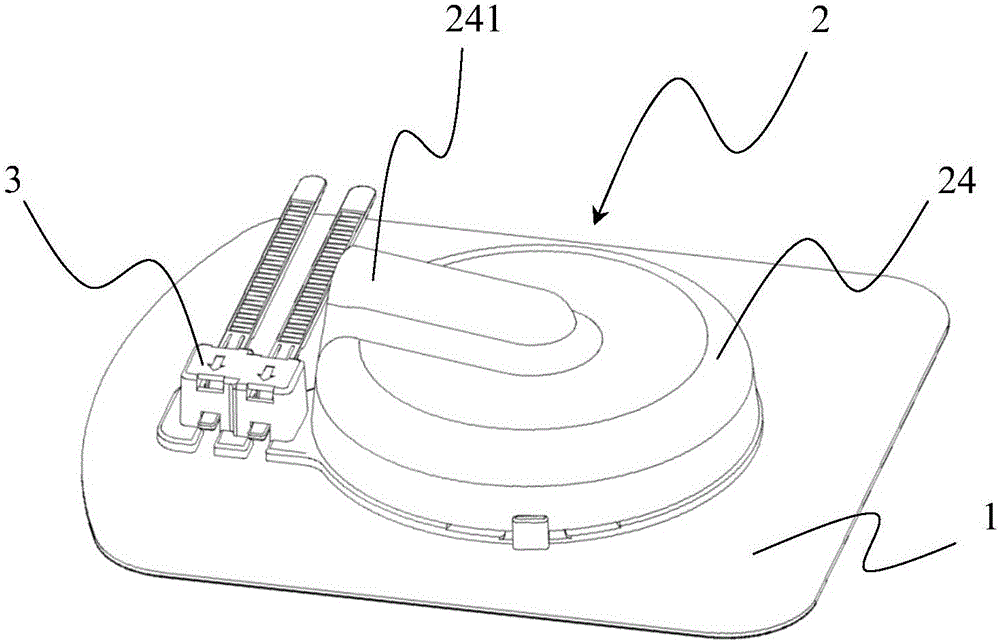

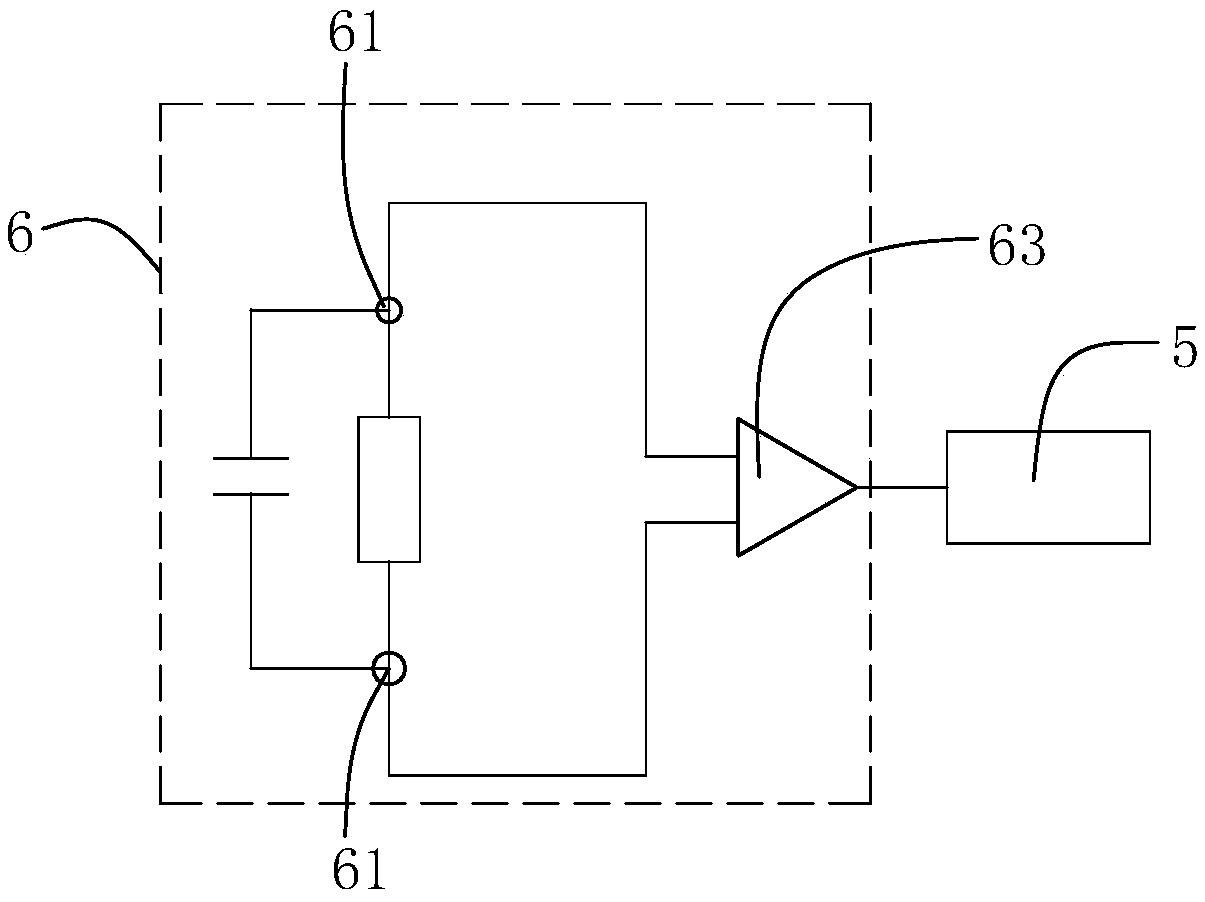

Wearable real-time electrical signal acquisition device

InactiveCN103908247AAdjust the tightnessIncrease contactDiagnostic recording/measuringSensorsContact pressureEngineering

The invention relates to a wearable real-time electrical signal acquisition device. The wearable real-time electrical signal acquisition device is characterized by comprising a wearable vest, and a plurality of bandages are horizontally arranged on the inner side of the vest at intervals; an embedded controller is fixed on any one of the bandages, a micro-motor used for adjusting tightness of the bandages is arranged at the joint of the bandages, more than one electrocardiograph collection electrode is movably arranged on the bandages, buzzers are fixedly arranged on the bandages, pressure sensors are arranged on the electrocardiograph collection electrodes, and the micro-motor, the pressure sensors and the buzzers are connected with the embedded controller through leads; contact pressure between the electrocardiograph collection electrodes and skin of a subject is detected through the pressure sensors transmitting detected pressure signals to the embedded controller, and the embedded controller controls the micro-motor to adjust tightness of the bandages; when contact problems arise between the electrocardiograph collection electrodes and the skin of the subject, the buzzers alarm to prompt the subject to have the corresponding electrocardiograph collection electrodes examined. The wearable real-time electrical signal acquisition device can be widely applied to acquisition of human electrocardiograph signals.

Owner:BEIJING UNIV OF POSTS & TELECOMM

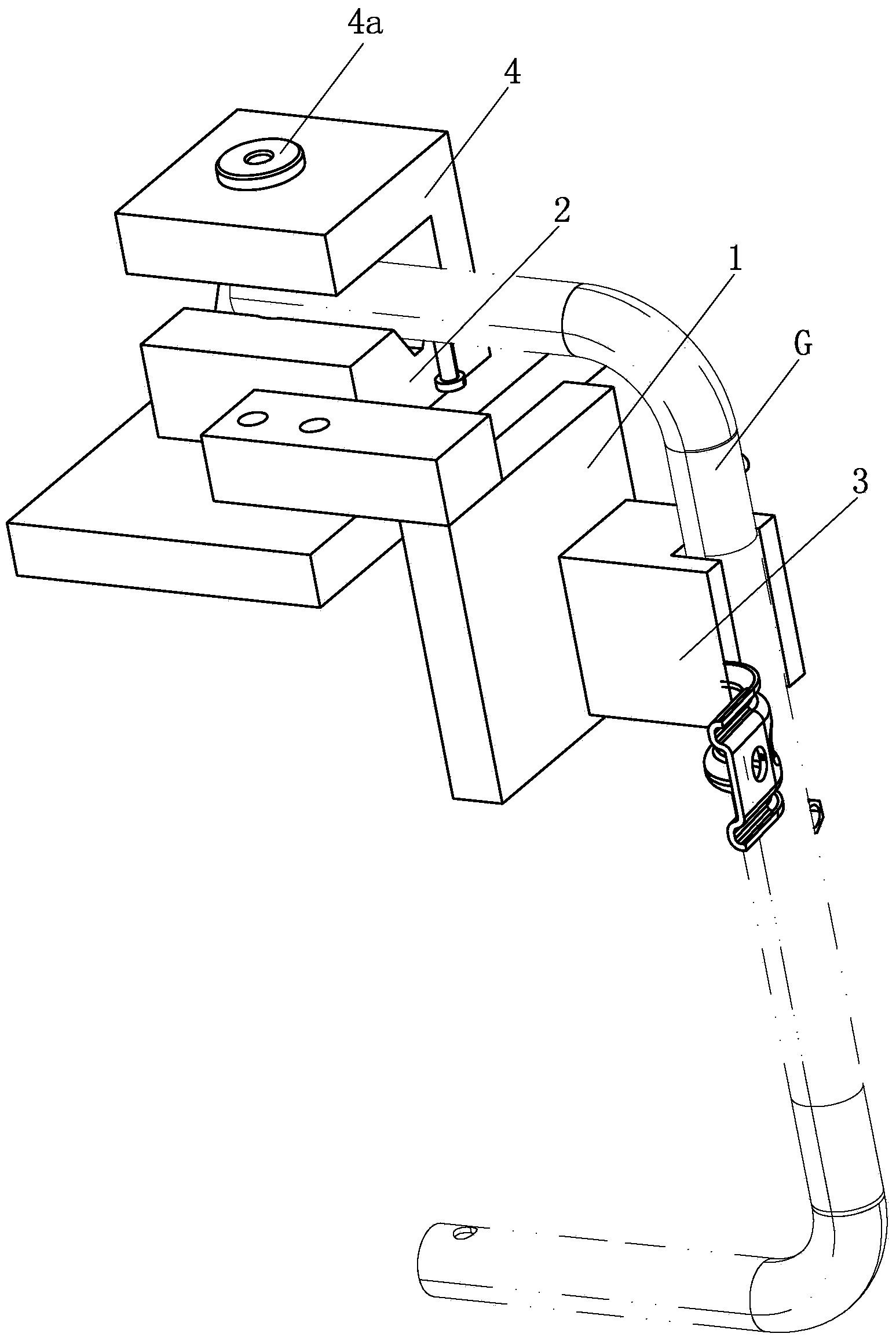

U-shaped pipe landing leg punching tool

InactiveCN103480721AEliminate height errorsImprove machining accuracyPerforating toolsMetal-working feeding devicesEngineeringPunching

The invention discloses a U-shaped pipe landing leg punching tool, which is characterized in that a U-shaped pipe locating assembly and two side punching assemblies are arranged on the top surface of a horizontal bottom plate, wherein the side walls of a U-shaped pipe locating sleeve in the U-shaped pipe locating assembly are provided with punch via holes, the two side punching assemblies are symmetrical about the U-shaped pipe locating sleeve, a slider in each side punching assembly can slide left and right, the top surface of each slider is fixedly provided with a declivity wedge and a punch stopper, the end face, close to the U-shaped pipe locating sleeve, of each punch stopper is provided with a punch, a punching die is arranged right above the horizontal bottom plate, when the punching die downwards moves, two acclivity wedges push the two declivity wedges in the two side punching assemblies to simultaneously move towards the opposite direction, so that the two sliders can drive the two punches to simultaneously move towards the opposite direction. The U-shaped pipe landing leg punching tool can be used for well locating a U-shaped pipe and further machining holes in landing legs of the U-shaped pipe in a side punching manner, since the U-shaped pipe can be precisely located via the operation, the height error of machined holes in the two landing legs of the U-shaped pipe can be effectively eliminated.

Owner:重庆宏华唯实达汽车部件有限公司

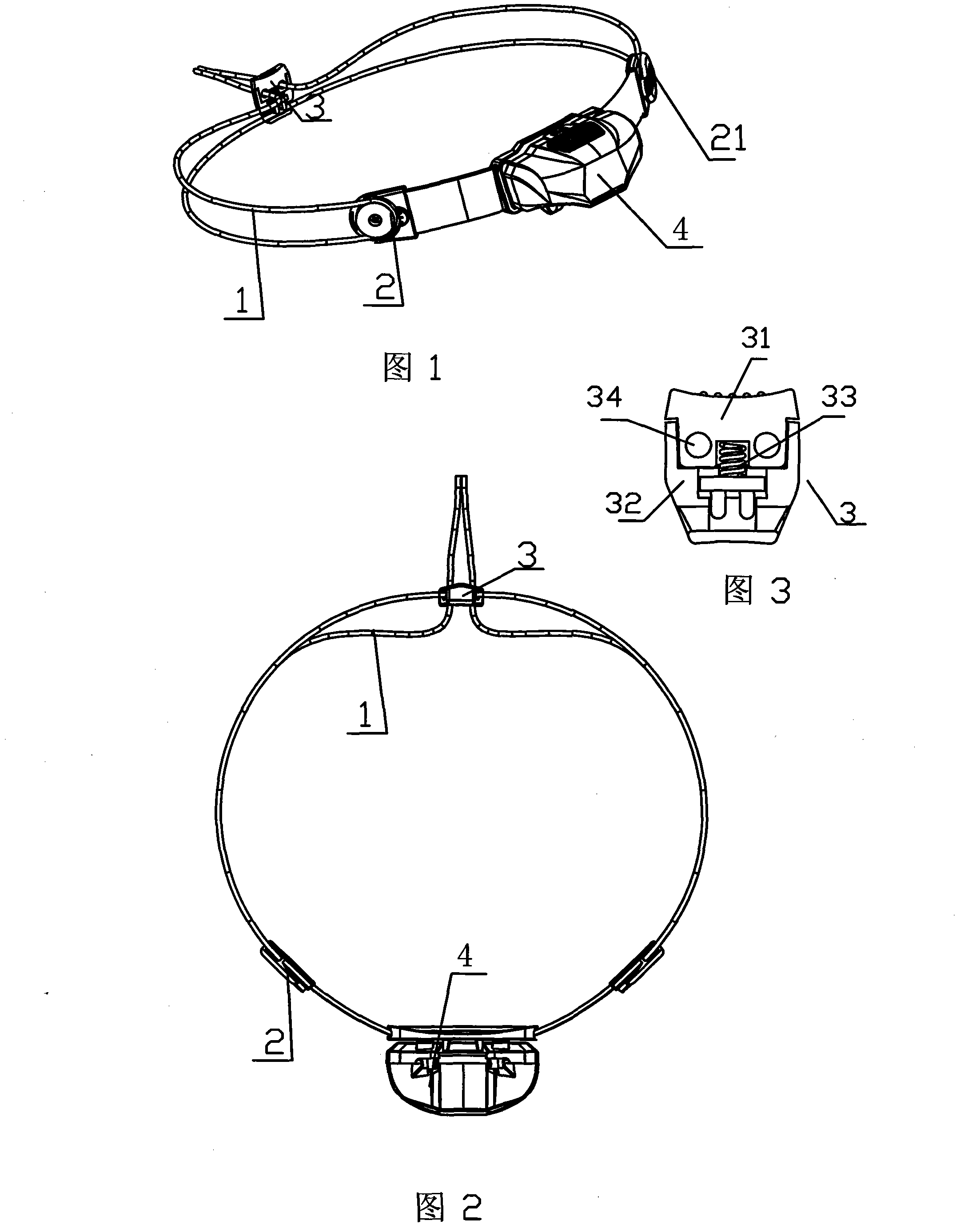

Device for regulating size of head of head lamp

The invention discloses a device for regulating the size of a head of a head lamp. The device comprises ropes or belts and a lamp cap. Rotating wheels are placed on two side edges of the lamp cap, and a groove is formed on the circumference of each rotating wheel. After the ropes or the belts are wound around the grooves in the rotating wheels, two tail ends respectively penetrate through a hole of a regulator. The regulator structurally comprises a first connection part and a second connection part, wherein the second connection part can move opposite to the first connection part, the first connection part and the second connection part are respectively provided with a through hole through which the ropes or the belts can penetrate, and a spring is placed between the first connection part and the second connection part. When the first connection part is pressed down, the through hole in the first connection part and the through hole in the second through hole are aligned, and the ropes or the belts can move freely in the holes. When a hand loosens the first connection part, the first connection part is bounded, and the ropes or the belts are clamped.

Owner:NINGBO SUNREE OUTDOOR PROD CO LTD

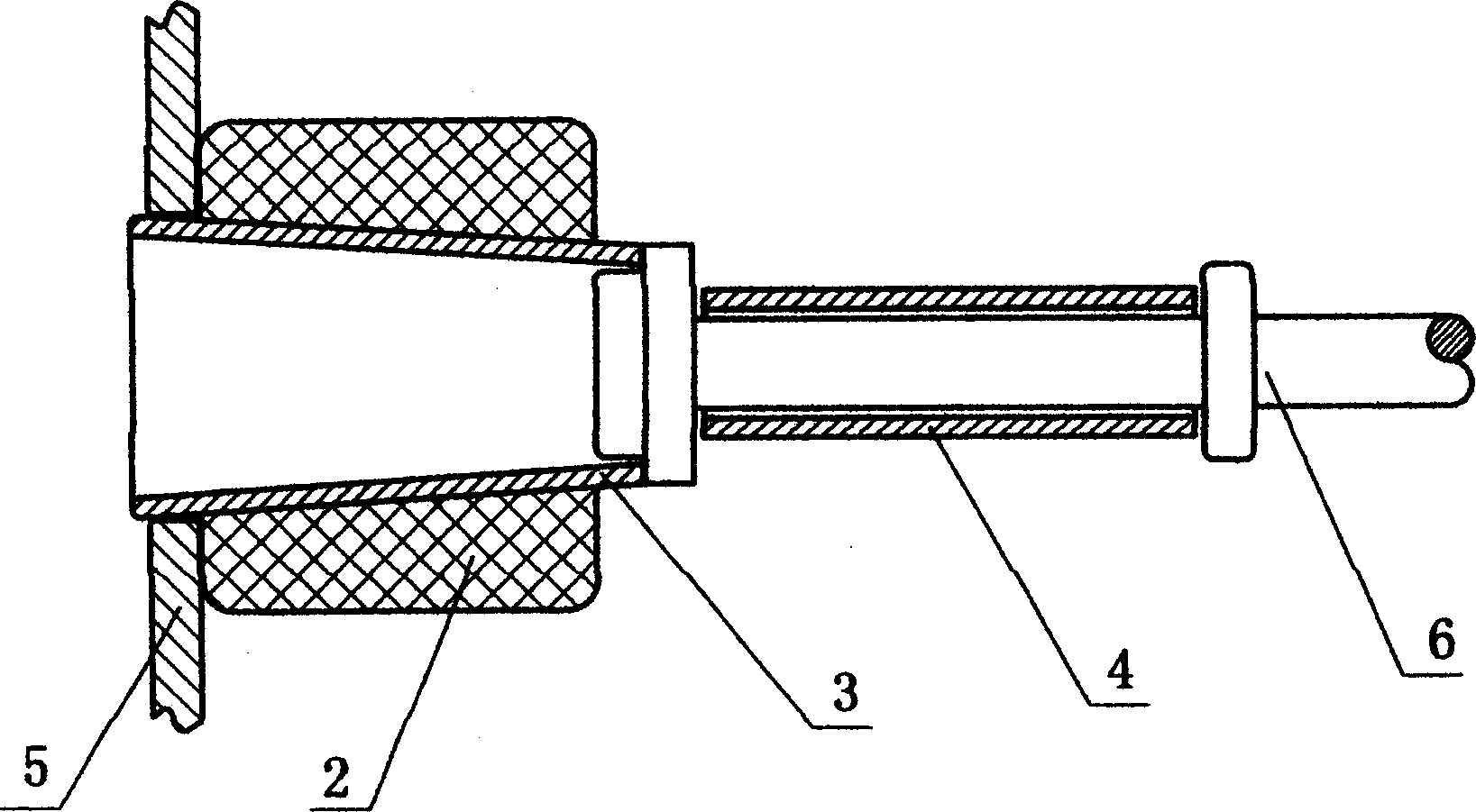

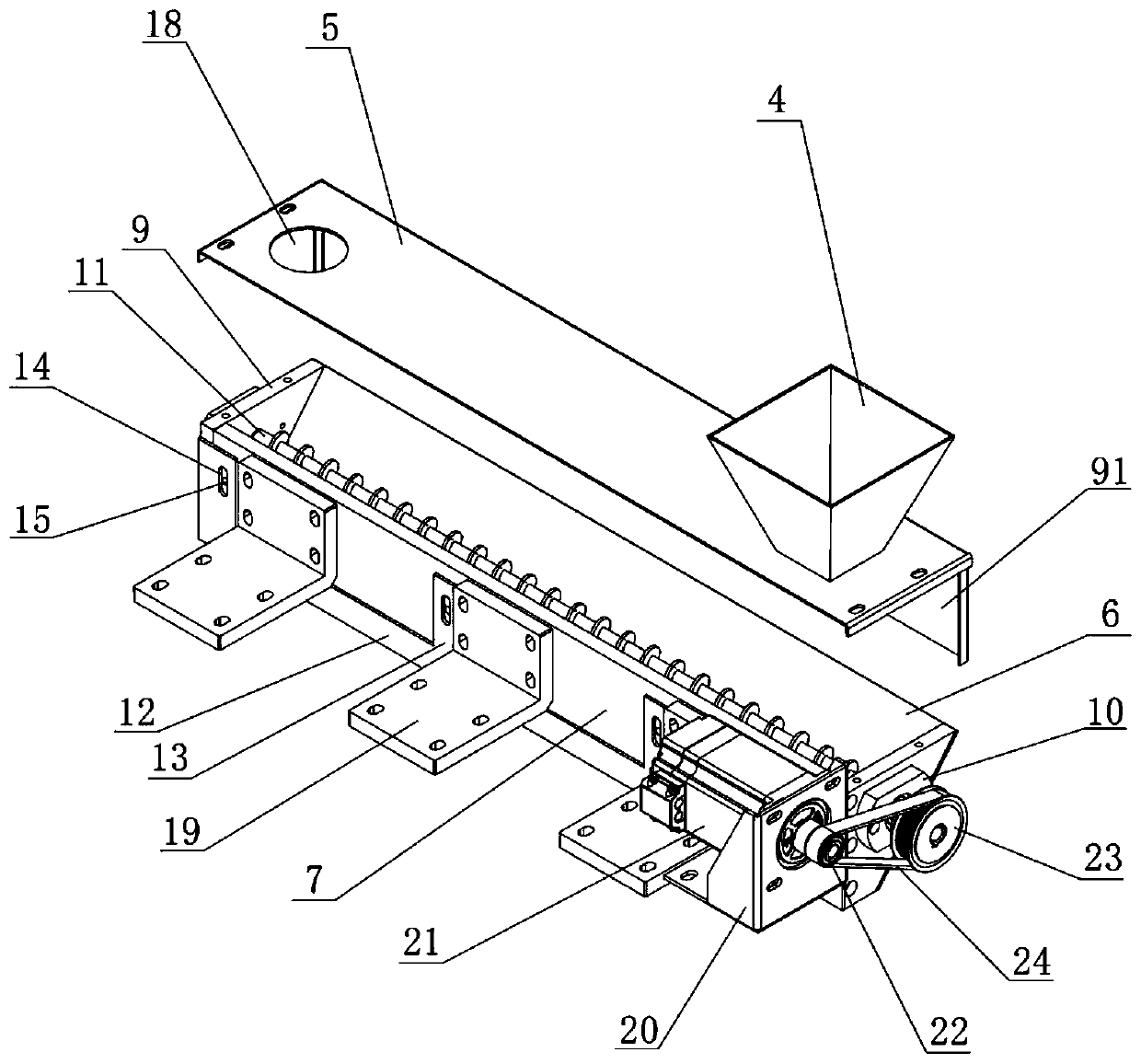

Rice bowl seedlings cast-seedling device

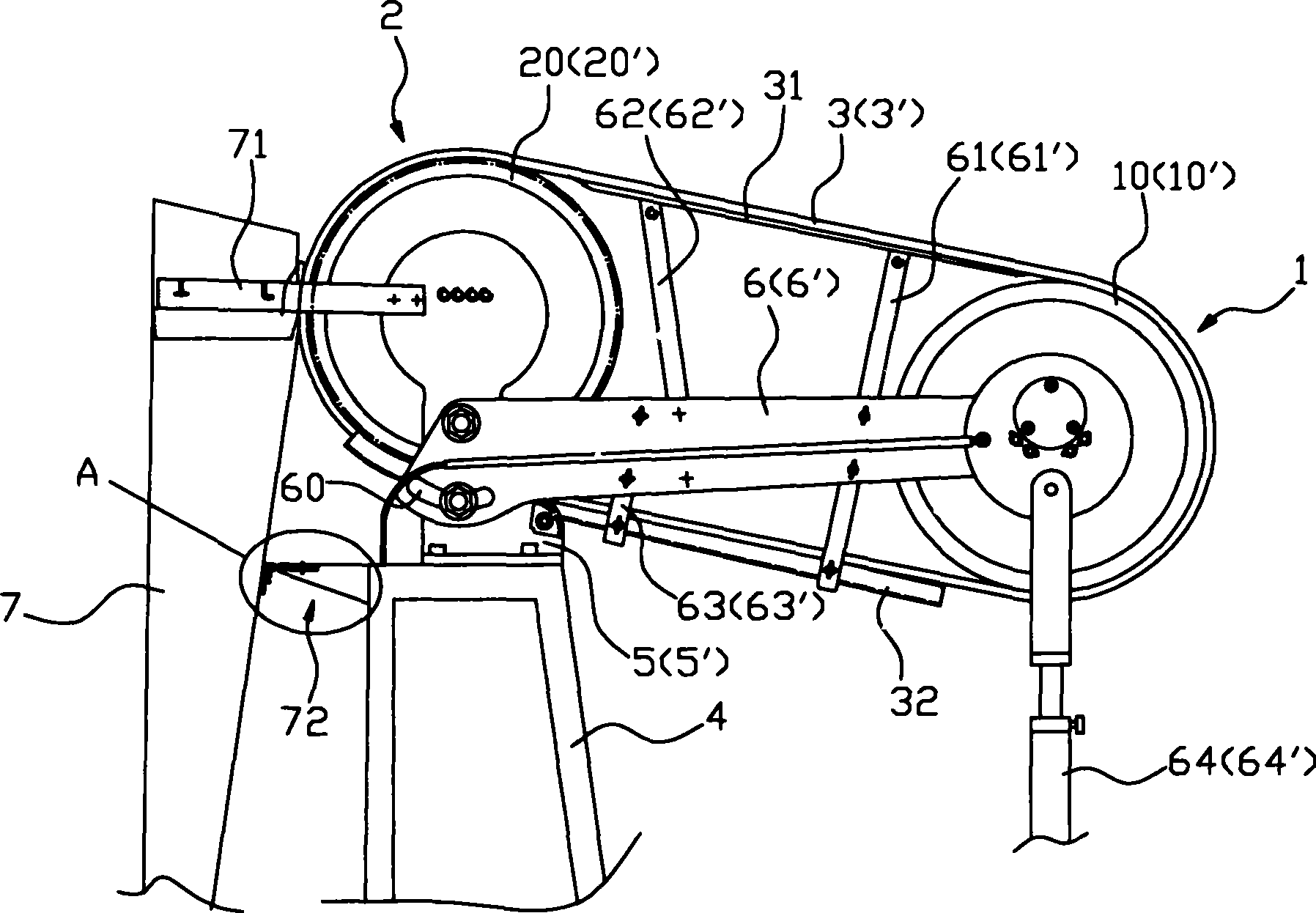

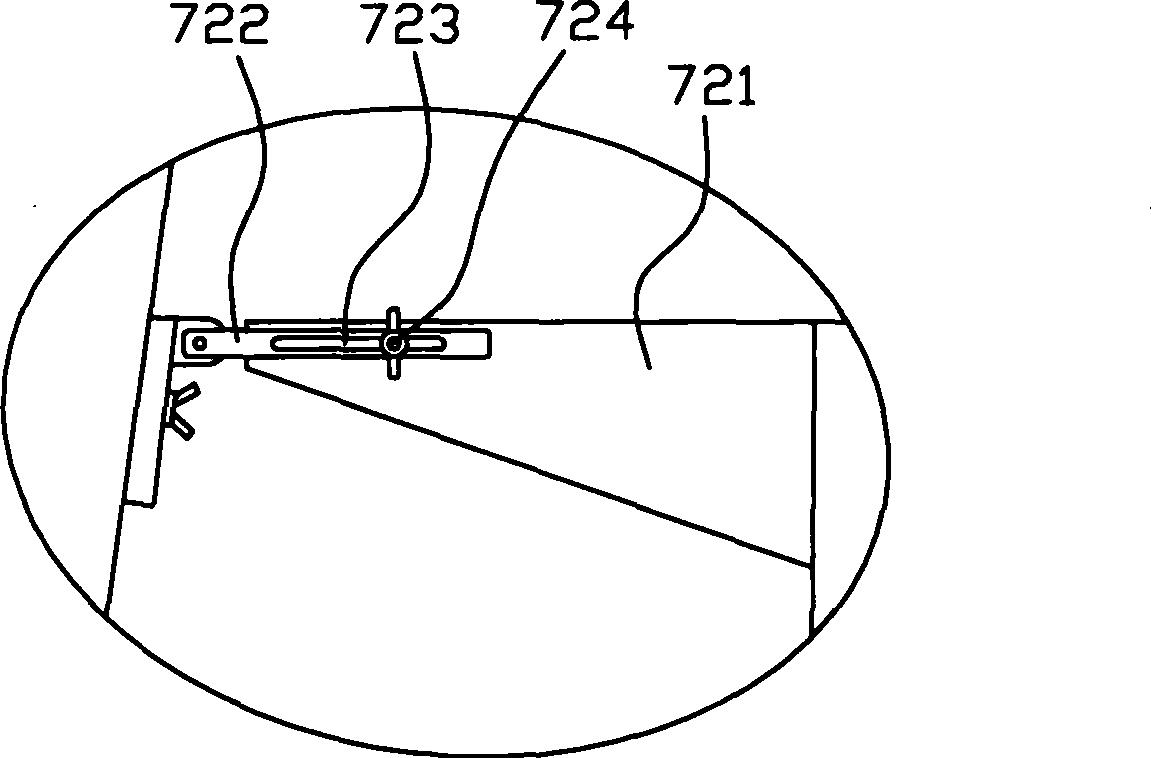

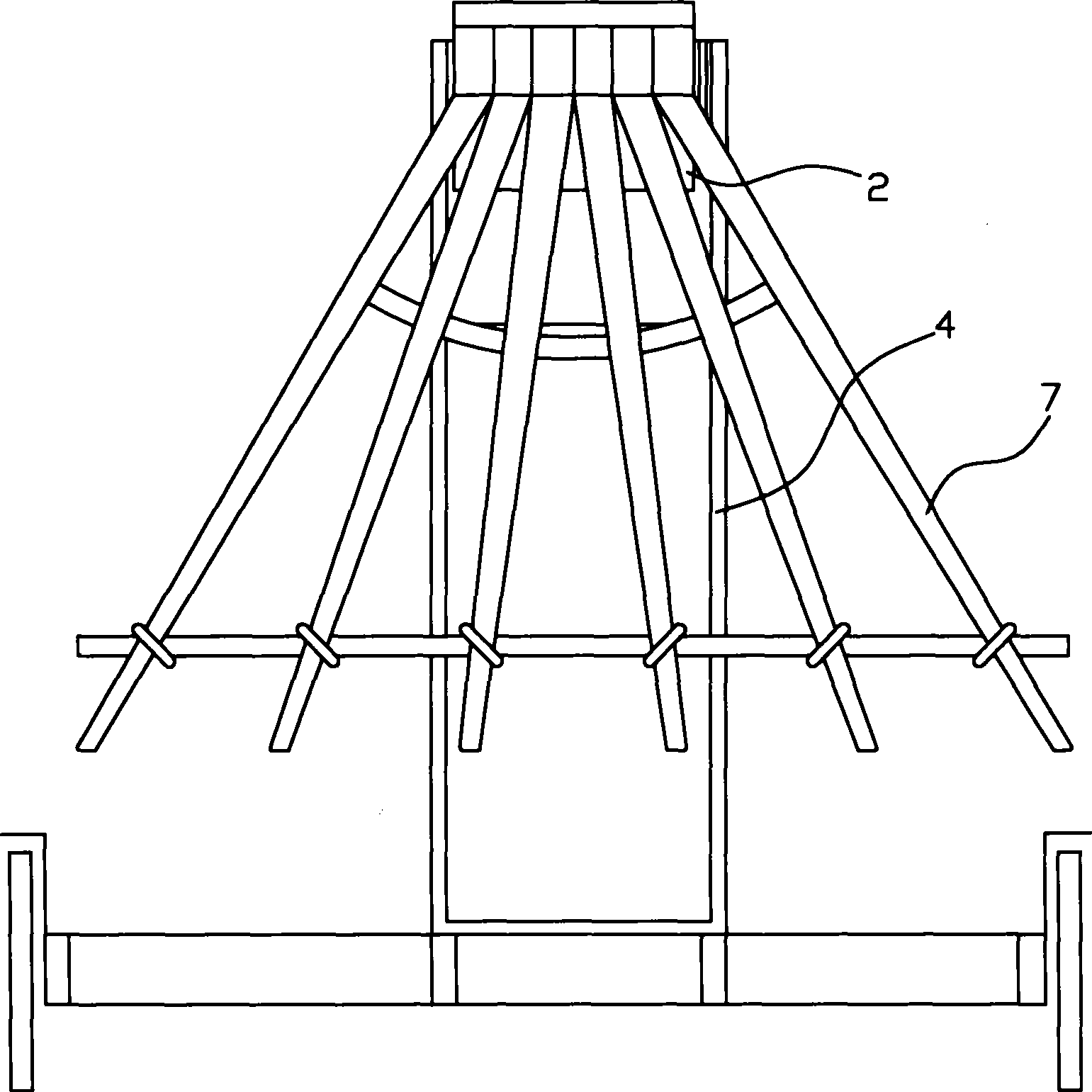

InactiveCN101455145ASimple structureGood throwing effectTransplantingDrive wheelReciprocating motion

A paddy rice pot seedling throwing machine includes a driving wheel comprising a first left synchronizing wheel and a first right synchronizing wheel which rotate synchronously, wherein, inside of one of the wheels is provided with a stepper motor for driving the wheel to rotate; a driven wheel comprising a second left synchronizing wheel and a second right synchronizing wheel which rotate synchronously, and a frontward seedling-pulling head and a cylinder for driving the seedling-pulling head to perform reciprocating motions; the first left synchronizing wheel and the first right synchronizing wheel, the second left synchronizing wheel and the second right synchronizing wheel being connected through a left synchronous belt and a right synchronous belt respectively; a seedling disk, of which the left and right ends are respectively positioned on the left synchronous belt and the right synchronous belt, earthen bowl grooves being arranged in the left and right directions on the seedling disk, a seedling-pulling corresponding to the seedling-pulling head being provided on the bottom of the earthen bowl groove; a seedling-guiding tube positioned below the front side of the driven wheel. The present invention has advantages of simple transmission structure, low fault rate, convenient use and the like.

Owner:张国梁

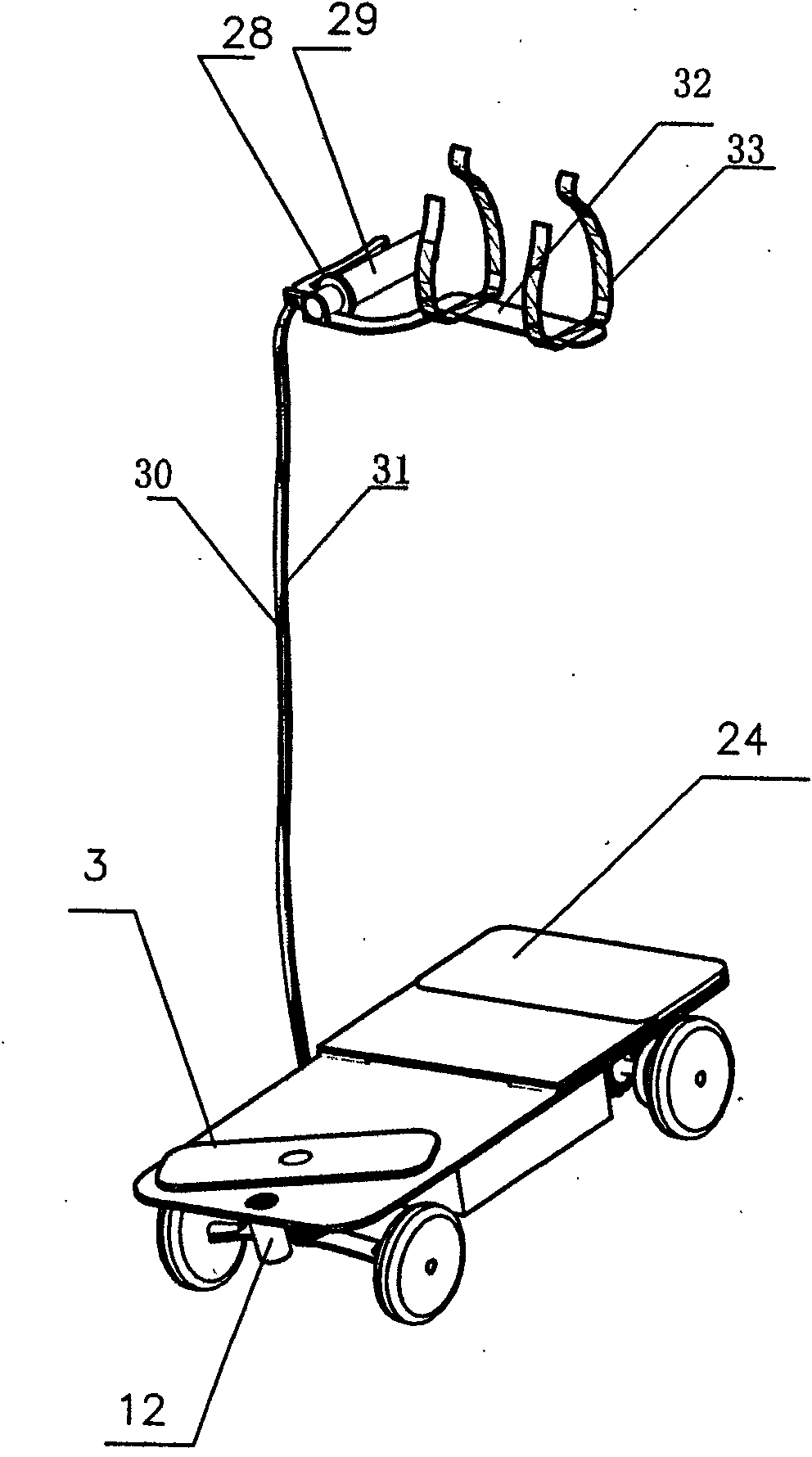

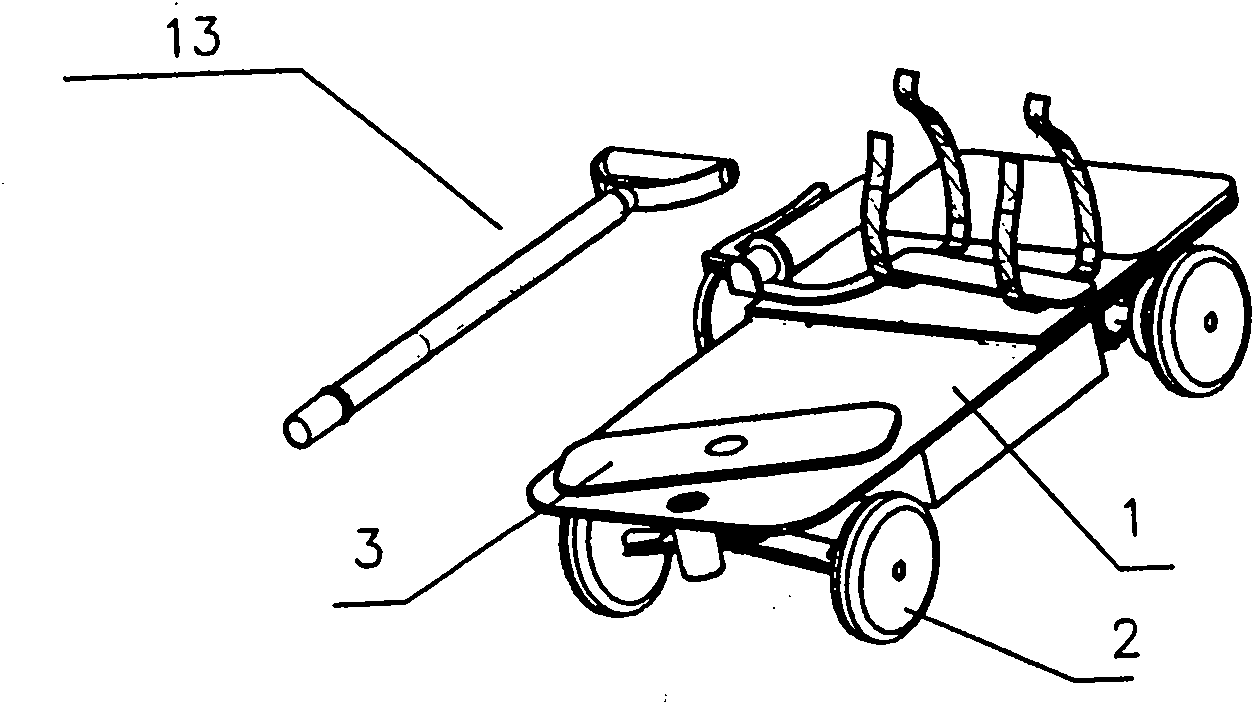

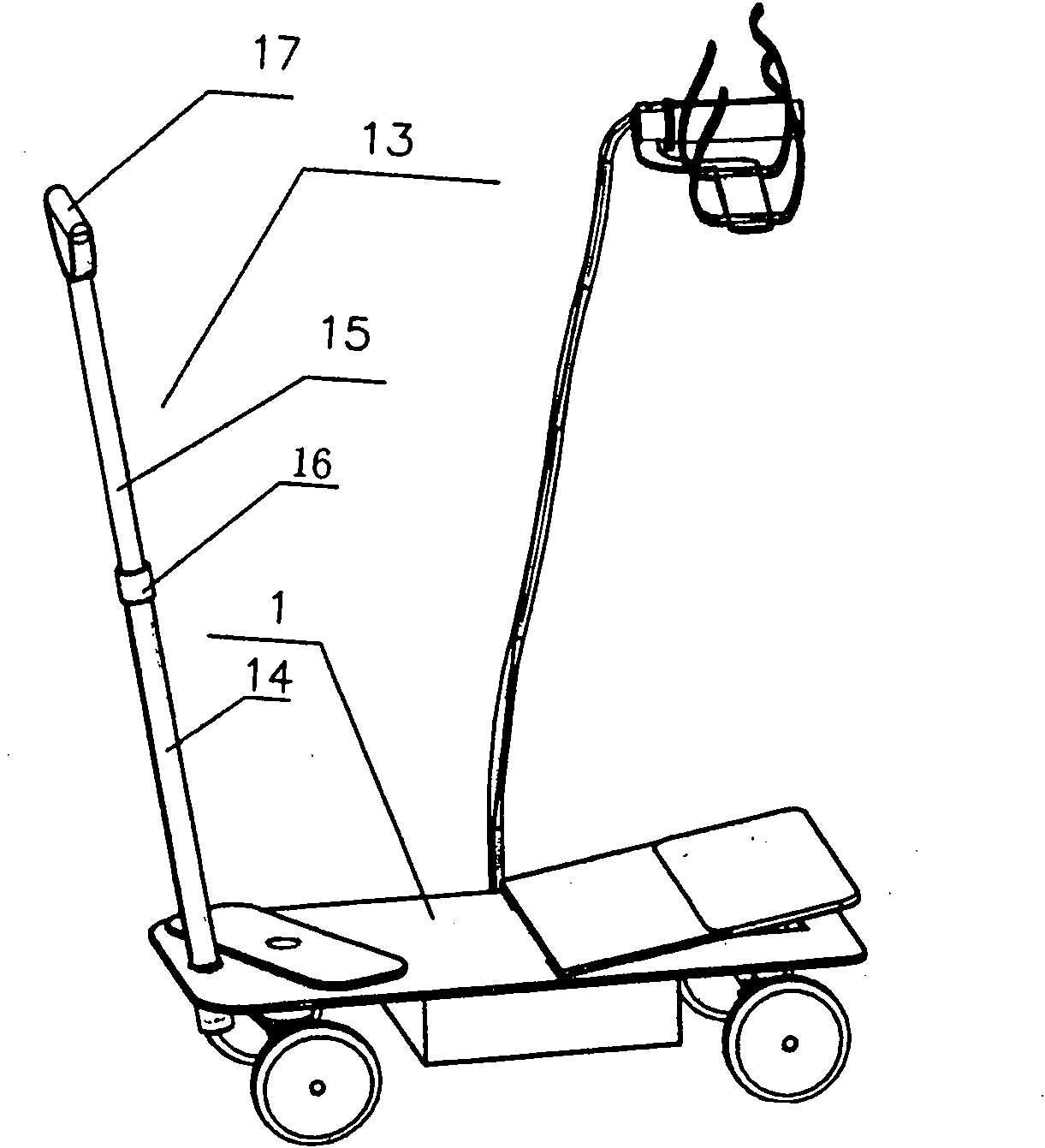

Multifunctional electric scooter

InactiveCN101817380AEasy to controlPrevent collapseCyclesRider propulsionEngineeringElectric scooter

The invention discloses a multifunctional electric scooter, which comprises a main bottom plate and a power device and is characterized in that: direction wheels are arranged below the main bottom plate; a pedal direction plate is arranged above the main bottom pate; and a driving mechanism is arranged between the pedal direction plate and the direction wheels. The multifunctional electric scooter has the advantage that: directions of the direction wheels can be controlled in a way that a user steps on the pedal direction plate and controls the steering direction of the pedal direction plate, so, compared with the conventional scooter of which an advancing direction is adjusted by wriggling a body, the direction of the scooter is easier to control.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

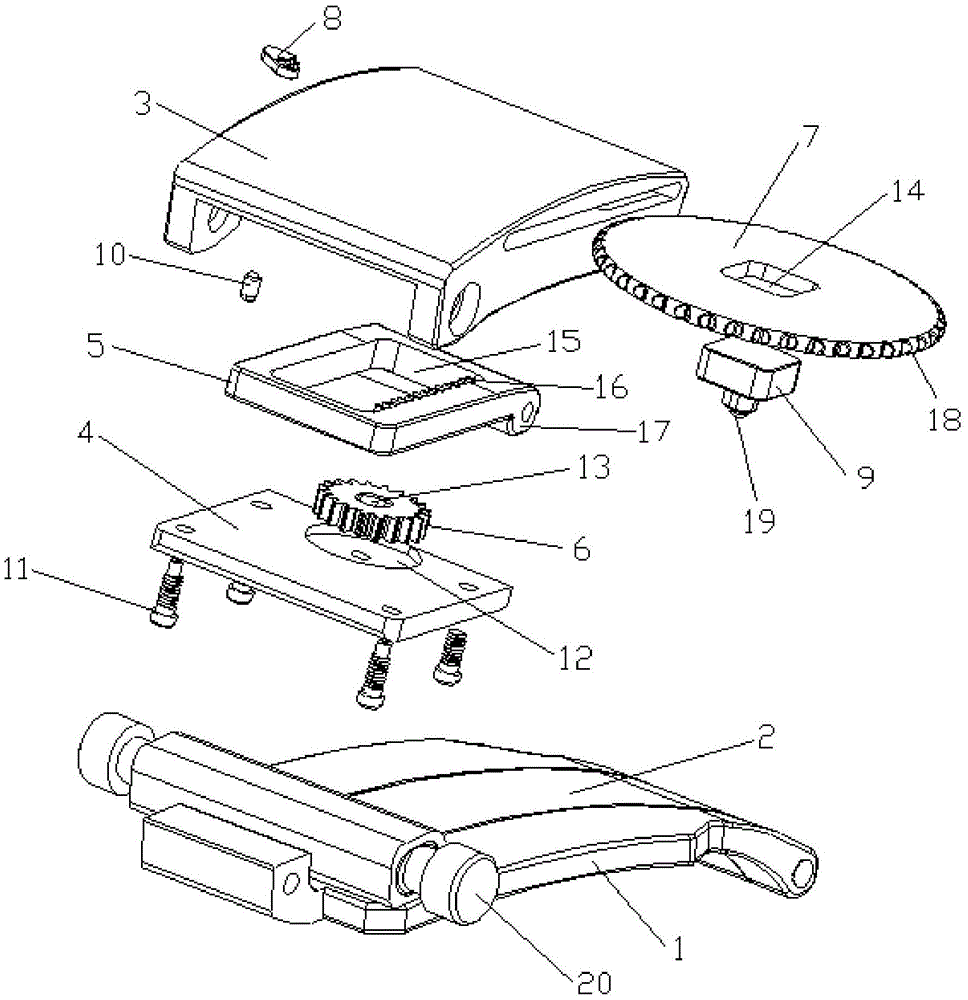

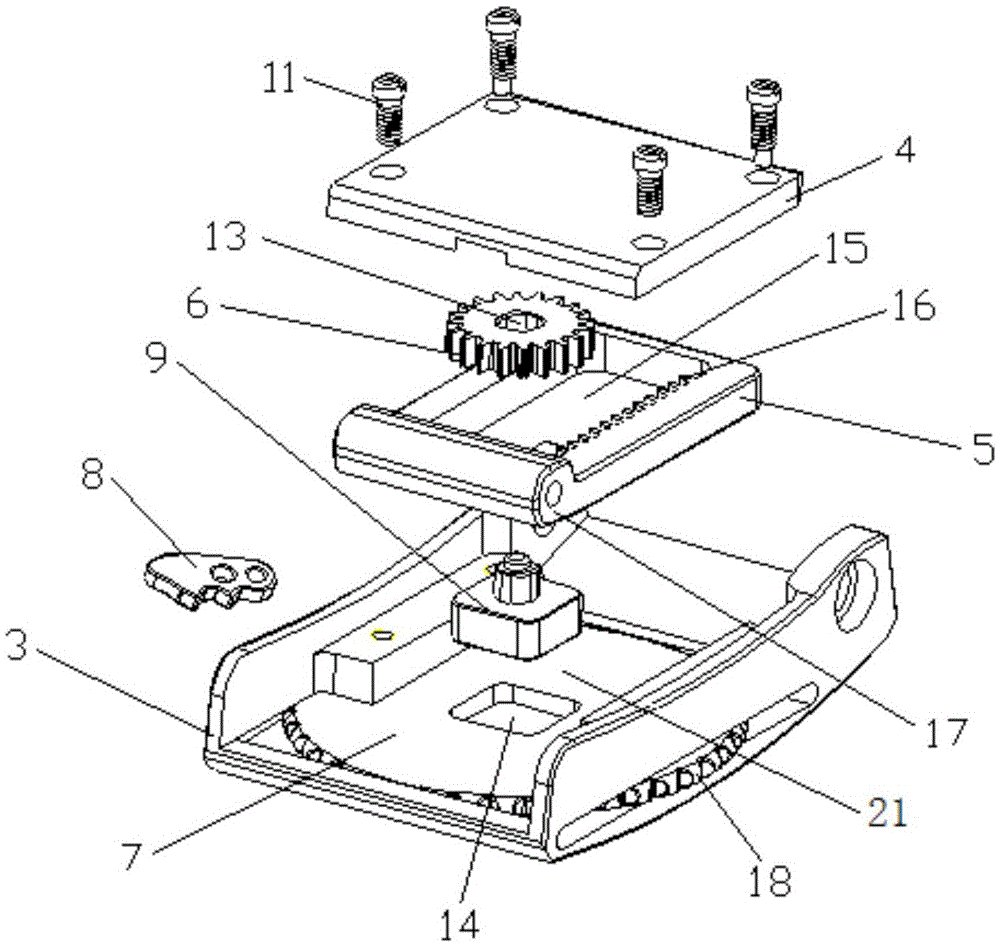

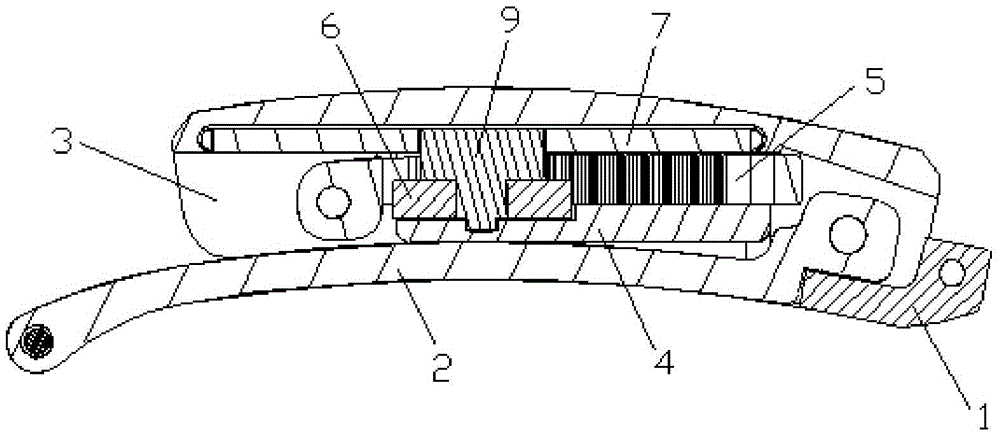

Telescopic watch button

ActiveCN105476200AAdjust the tightnessThe degree of tightness is convenient and direct adjustmentBraceletsWrist-watch strapsEngineeringSurface cover

The invention discloses a telescopic watch button. The telescopic watch button comprises a button bottom board, a surface cover and a surface cover bottom board which form a main structure of the watch button, wherein the button bottom board comprises a frame and a core, wherein the frame is hinged with the first end of the core, and the surface cover is hinged to the second end of the core; a telescopic regulating mechanism is arranged between the surface cover bottom board and the surface cover; the telescopic regulating mechanism comprises a sliding chute, a drive gear, a rotating part, and a sliding part for connecting with a watchband, which are arranged between the surface cover and the surface cover bottom board, wherein the sliding part is arranged in the sliding chute and is provided with a rack meshed with the drive gear; the edge of the rotating part protrudes out of the surface cover, and the drive gear is driven when the rotating part is stirred to rotate, and drives the sliding part to move in the sliding chute through the meshed rack. According to the invention, the sliding part capable of being subjected to telescopic adjustment through the rotating part is arranged in the watch button, so that the tightness degree of the watch button can be conveniently and directly regulated without other tools, the structure is simple, and the operation is simple.

Owner:RAISING METAL CO LTD

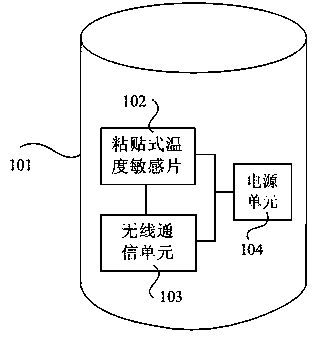

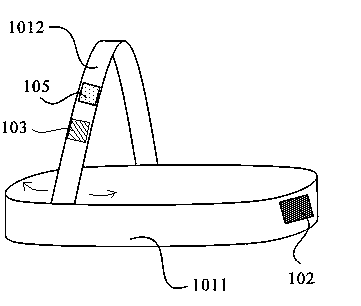

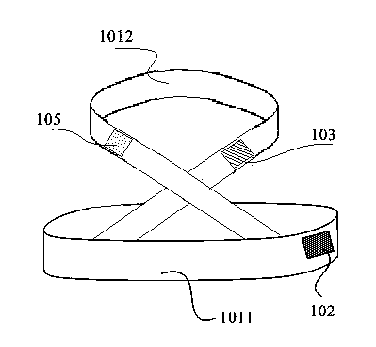

Body temperature measurement device and system

ActiveCN103565421AConvenient temperature measurementBody temperature measurement safetyDiagnostic recording/measuringSensorsPhysical medicine and rehabilitationCommunication unit

The invention provides a body temperature measurement device and system. The body temperature measurement device comprises a flexible base belt, a paste type temperature sensitive piece, a wireless communication unit and a power supply unit, wherein the flexible base belt is used for being wound and bound onto the body of a user; the paste type temperature sensitive piece is used for measuring body temperature and is arranged on the flexible base belt; the wireless communication unit is used for sending body temperature to an external terminal and is arranged on the flexible base belt; the power supply unit is used for supplying electric power to the paste type temperature sensitive piece and the wireless communication unit; and the paste type temperature sensitive piece and the wireless communication unit are connected through a flexible wire. In the embodiment of the body temperature measurement device and system, the paste type temperature sensitive piece is arranged on the flexible base belt, when the flexible base belt is wound and bound onto the body of an infant, the infant has no uncomfortable feelings, and normal activities of the infant are not affected, meanwhile, the paste type temperature sensitive piece is placed at the position of the axilla of the infant to measure the body temperature smoothly, then the wireless communication unit sends the body temperature to the external terminal, and other guardians can conveniently know the body temperature of the infant, so that the body temperature measurement of the infant is safe, convenient and efficient.

Owner:BEIJING CHOICE ELECTRONICS TECH CO LTD

Rotary drum treatment method before dyeing or bleaching of elastic yarn or fiber

InactiveCN1718900AUniform penetrationAdjust the tightnessTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentYarnWinding machine

The present invention relates to a drum treatment method of elastic yarn or fibre before which is dyed or bleached. Sid method includes the following steps: using cone winding machine to make elastic yarn or fibre roll to be dyed or bleached be winded on a large bobbin, then using mechanical equipment to take out said large bobbin and replace it with small bobbin covered with eyelet all over so as to make the yarn or fibre roll with elasticity obtain natural constraction to meet required tightness and density for dyeing or bleaching.

Owner:邓兆铭

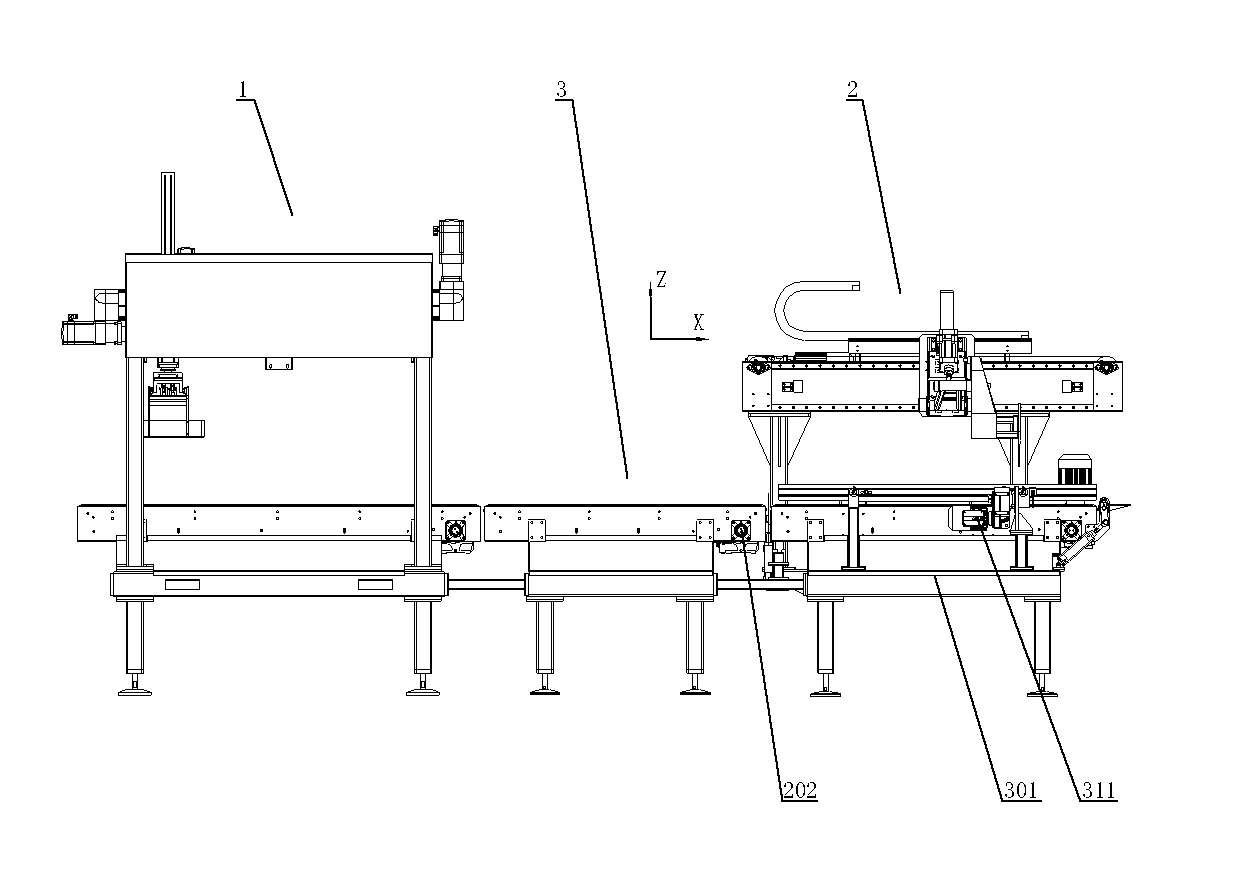

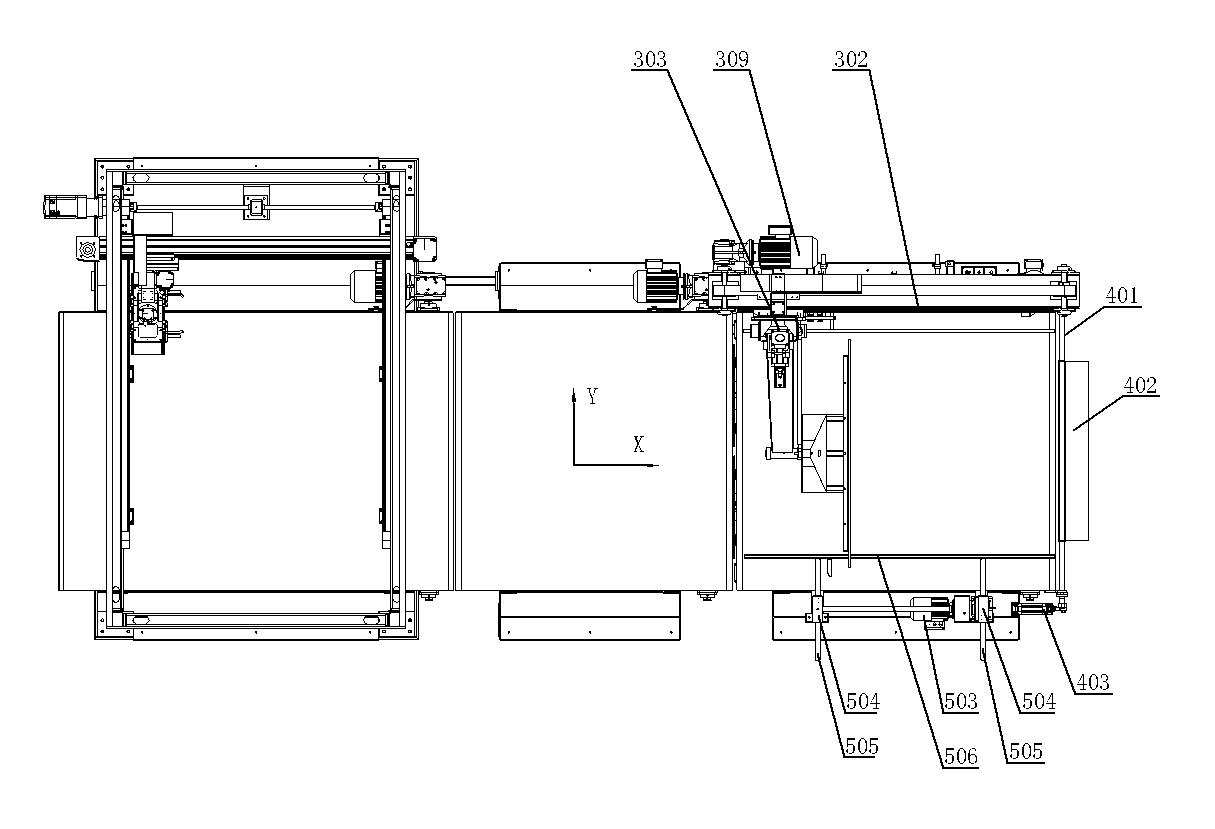

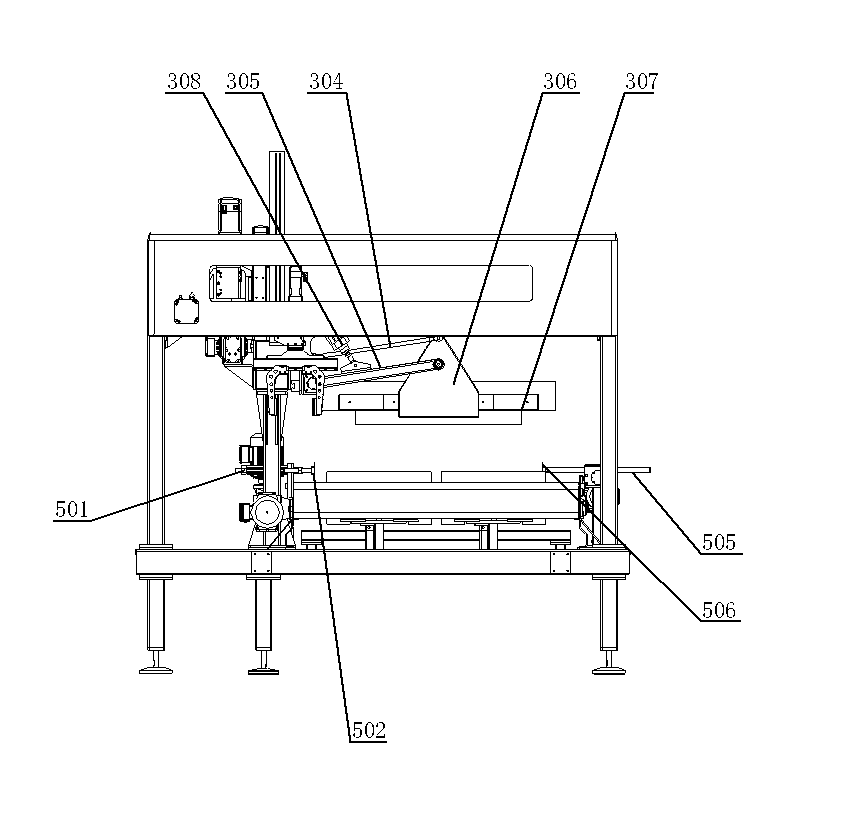

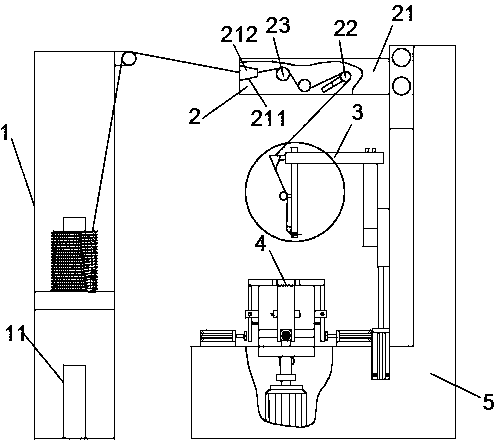

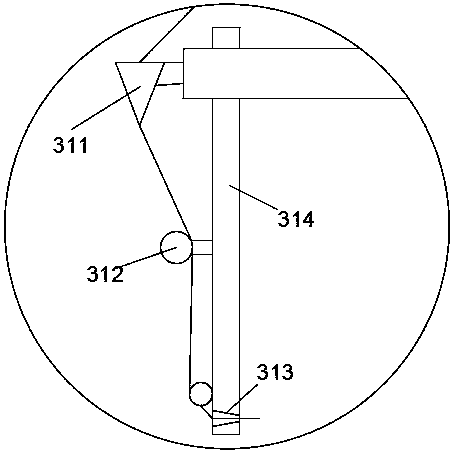

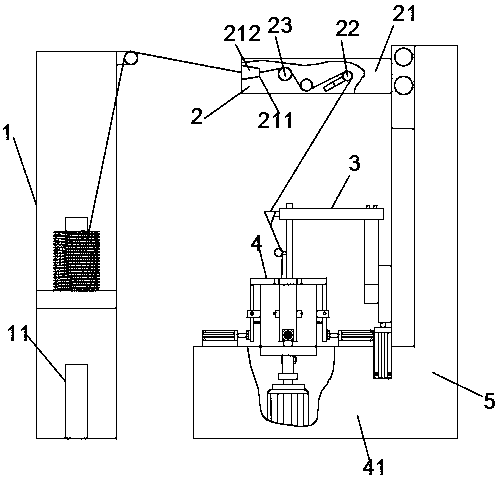

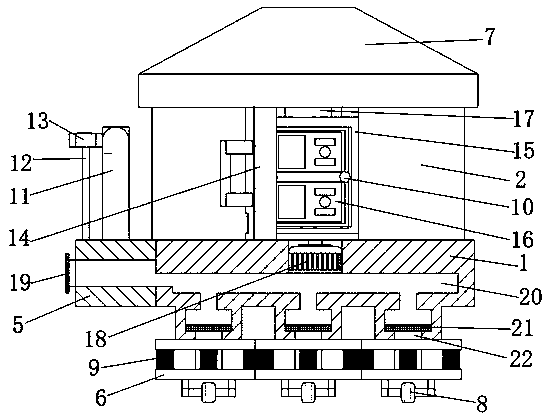

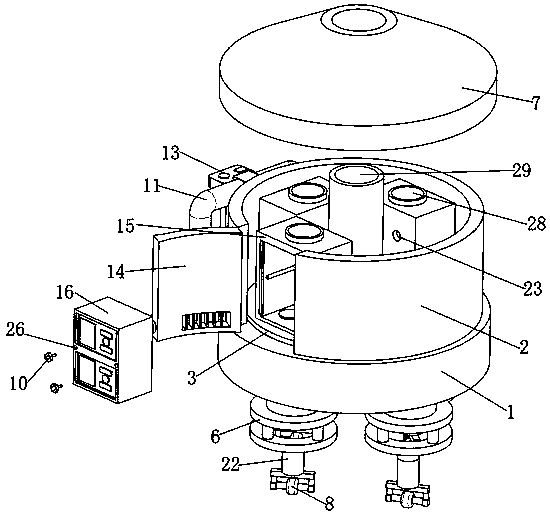

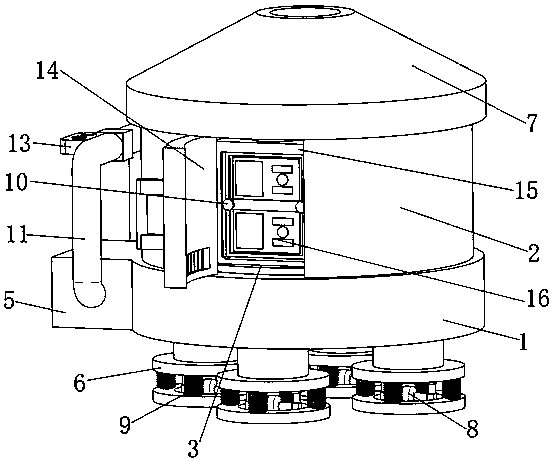

Truss box distribution robot

ActiveCN101920847ASimple structureBinning implementationConveyor partsMechanical conveyorsEngineeringMechanical engineering

The invention discloses a truss box distribution robot, which comprises a box distribution device, wherein the box distribution device comprises a first frame provided with a first conveyer device; a Y-direction guide rail is arranged above the first conveyer device on the first frame, and is provided with a sliding rack; the first frame is provided with a first driving mechanism which drives the Y-direction guide rail to move; the sliding rack is provided with an X-direction guide rail which is provided with a first sliding block; the sliding rack is provided with a second driving mechanism which drives the first sliding block to move; the first sliding block is provided with a Z-direction sliding groove; a sliding rail is arranged in the sliding groove; the first sliding block is provided with a third driving mechanism which drives the sliding rail to move; and the lower end of the sliding rail is provided with a hand grab mechanism. The truss box distribution robot has high distribution box efficiency and simple structure, and can rotate boxes.

Owner:广州市万世德智能装备科技有限公司

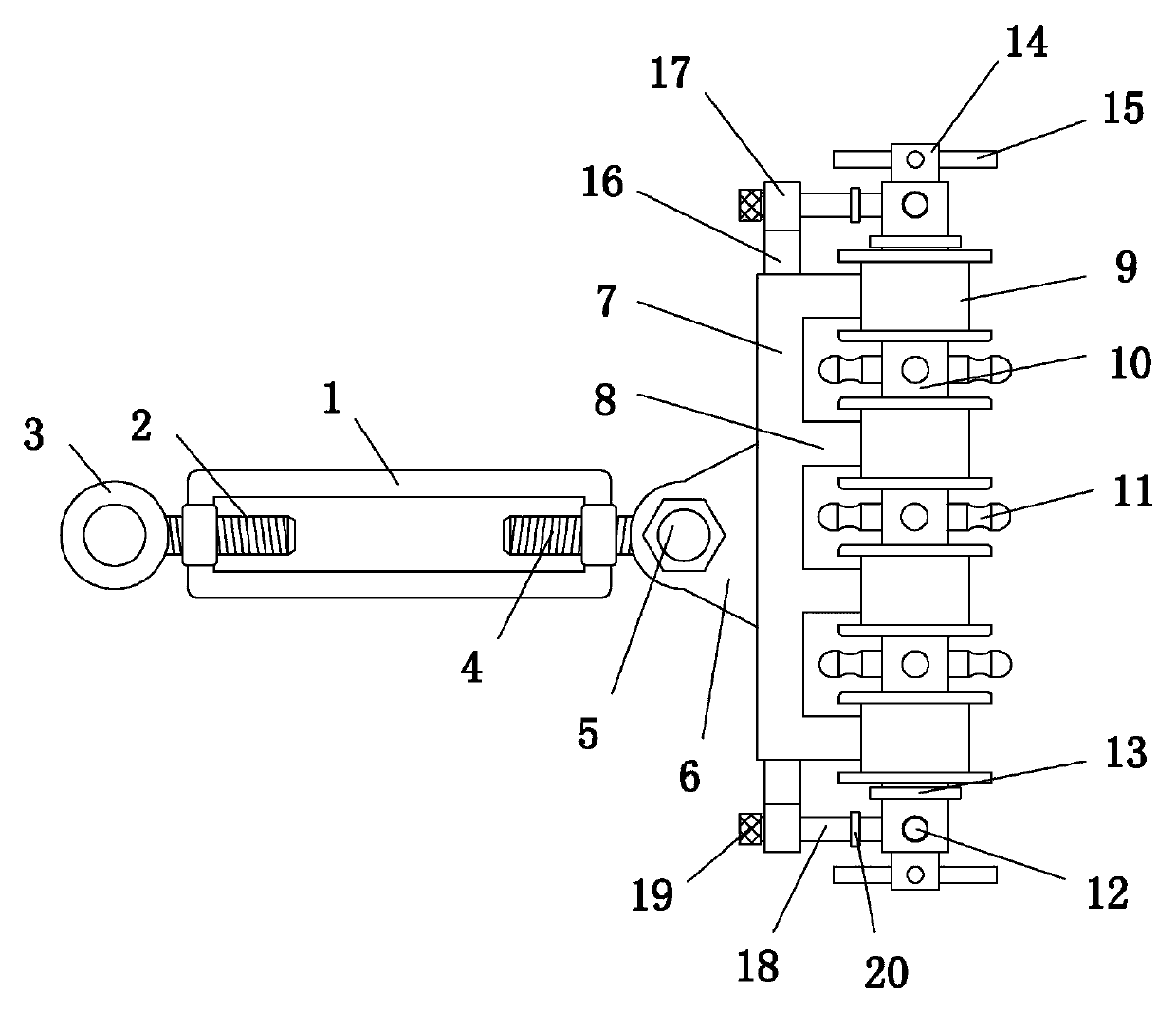

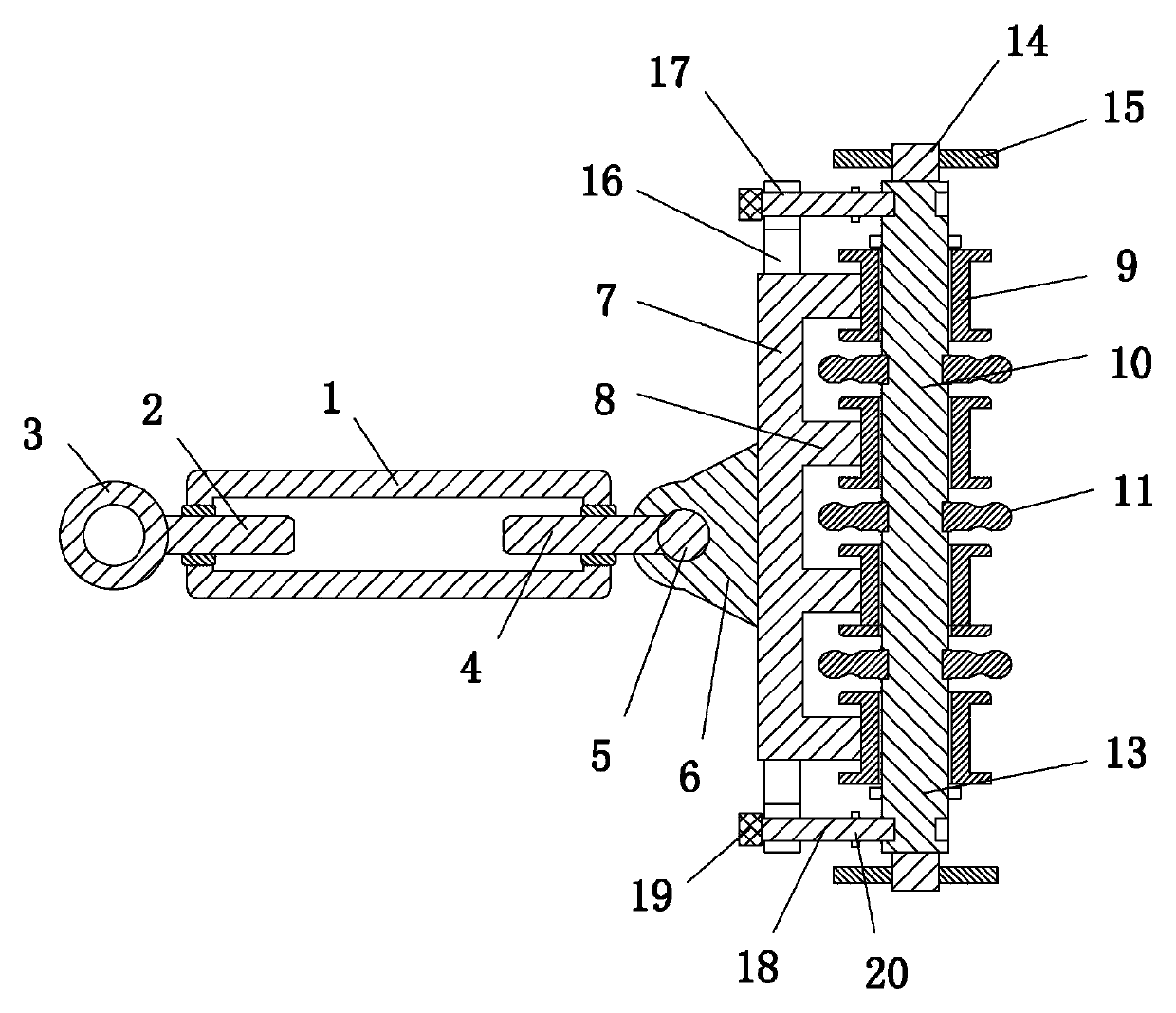

Cable anti-galloping device based on communication base station

InactiveCN113013819AAdjust the tightnessImprove applicabilityDevices for damping mechanical oscillationsAnimal repellantsScrew threadElectrical and Electronics engineering

The invention relates to the technical field of communication base stations, in particular to a cable anti-galloping device based on a communication base station, which comprises a fixing frame, the fixing frame is hexagonal, a blade is arranged at the center position of the fixing frame through a rotating mechanism, a reflective coating is sprayed on the surface of the blade, threaded holes are formed in the six corners of the fixing frame, and the threaded holes are communicated with the fixing frame. And a threaded column is connected into the threaded hole through threads, a rotary knob is fixedly welded to the inner end of the threaded column, a ball groove is formed in the outer end of the threaded column, a ball body is installed in the ball groove, and rubber pads are glued to the contact faces of the ball groove and the ball body. According to the invention, through the arrangement of the first spring and the second spring, when the cable vibrates or gallops, a part of vibration and galloping energy is consumed through work, and the first spring and the second spring absorb and relieve the energy through elastic deformation, so that the cable can be subjected to damping and anti-galloping protection.

Owner:黄杰

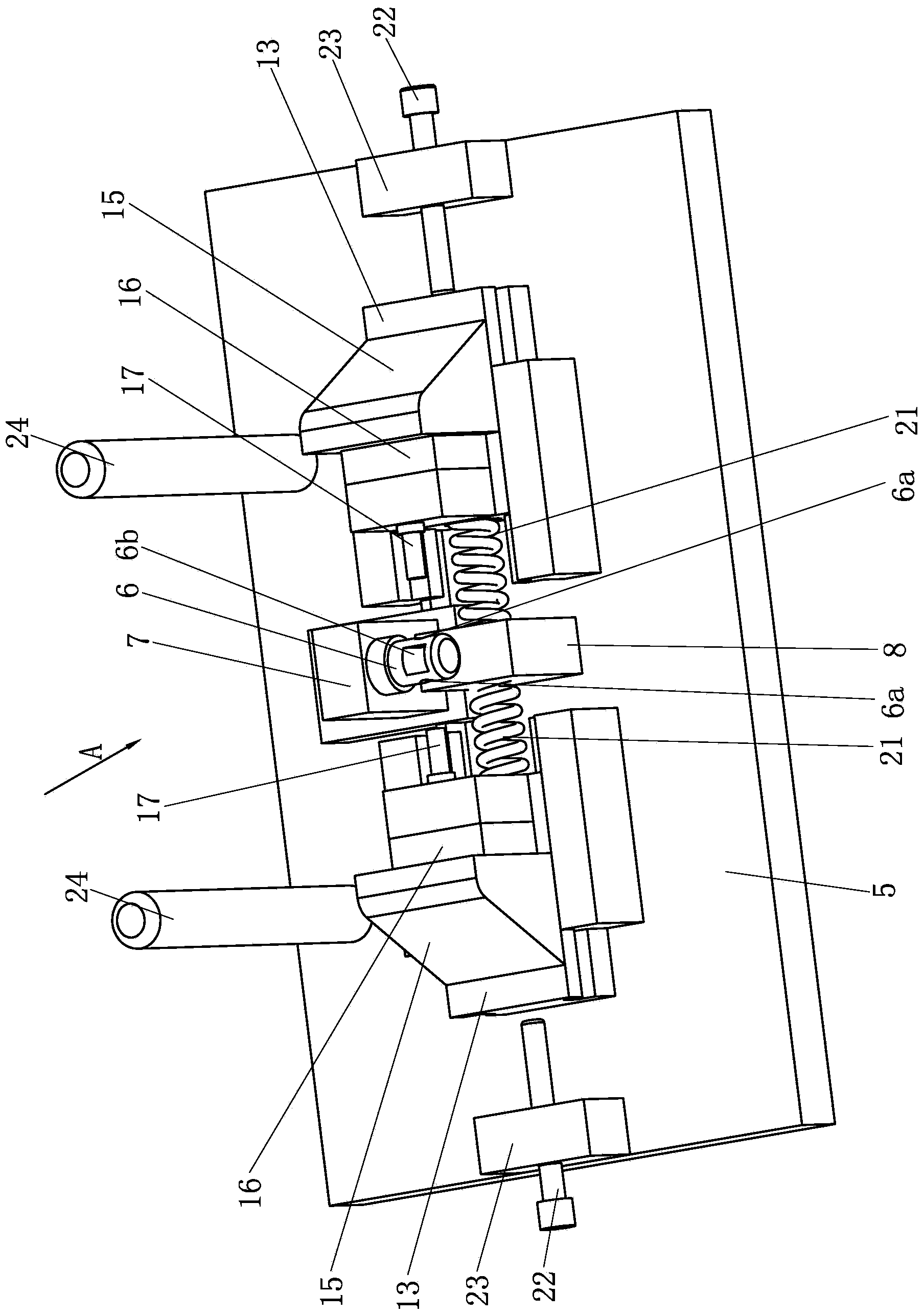

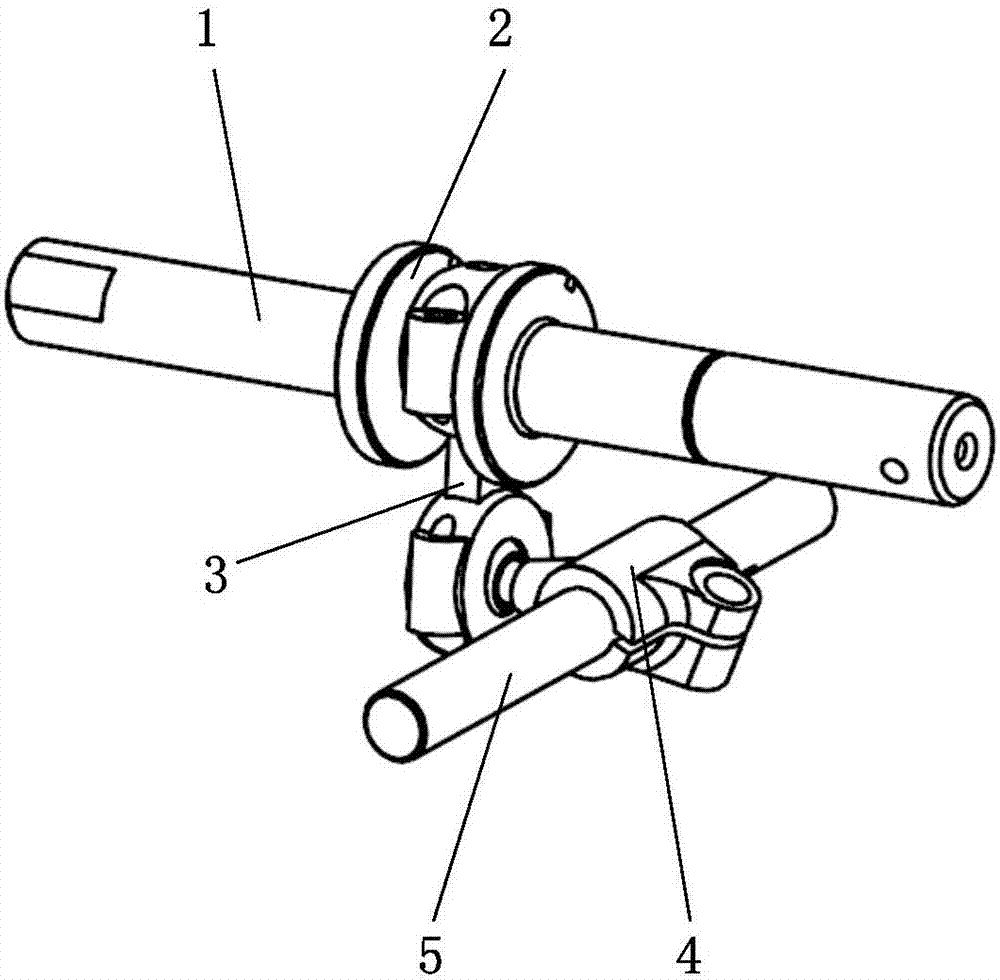

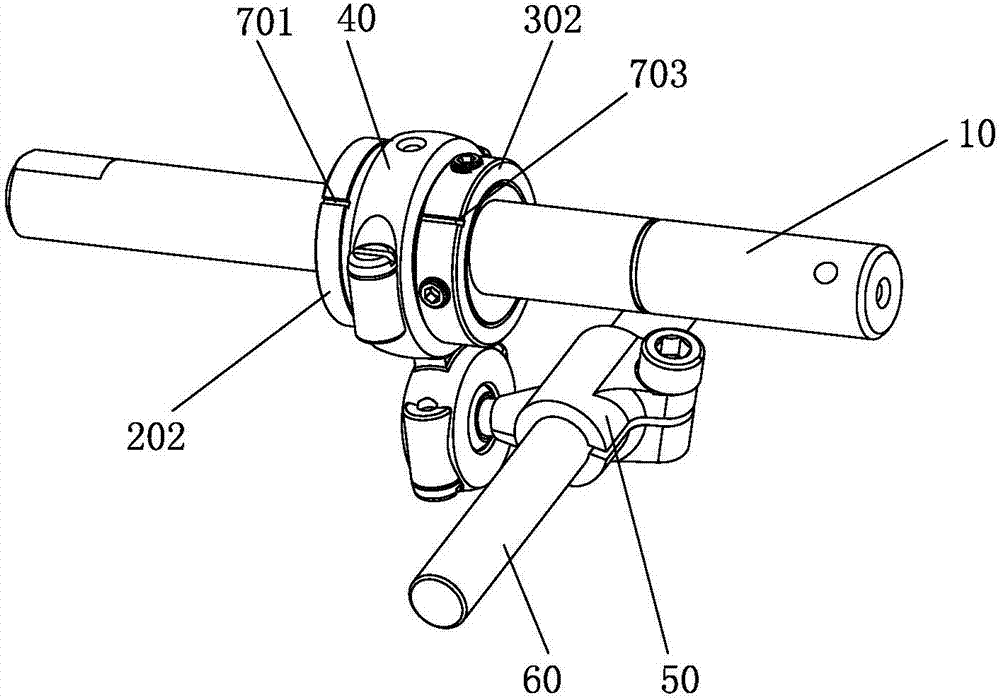

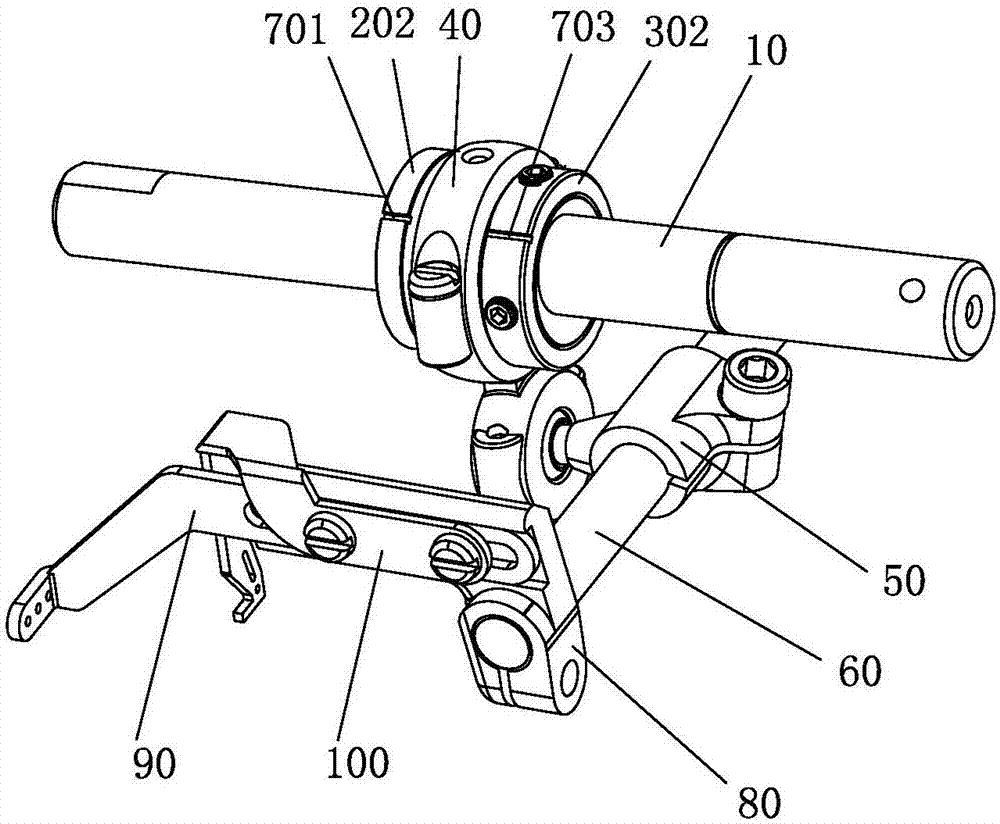

Take-up stroke adjustable structure and sewing machine

ActiveCN107099947AAdjust the tightnessImprove versatilityTake-up devicesVertical motionSewing machine

The invention belongs to the technical field of sewing machines, and relates to a take-up stroke adjustable structure and a sewing machine. The take-up stroke adjustable structure comprises an upper shaft, an eccentric wheel I arranged on the upper shaft in a sleeving mode, and an eccentric wheel II arranged on the eccentric wheel I in a sleeving mode, wherein the eccentric wheel II can rotate on the eccentric wheel I to adjust the eccentricity dimension. A connecting rod is arranged outside the eccentric wheel II in a sleeving mode; the other end of the connecting rod is connected to a crank, and the crank is arranged on a take-up shaft; the upper shaft rotates and drives the eccentric wheel I and the eccentric wheel II to rotate, the eccentric wheel II drives the connecting rod to move vertically, and the vertical motion of the connecting rod is converted into rotary swing of the take-up shaft through the crank. Adjustment of the eccentricity dimension is achieved by arranging the eccentric wheel I and the eccentric wheel II on the upper shaft, so that change of the rotation angle of the take-up shaft is achieved, adjustment of the take-up amount is achieved, the tightness of needle thread is better adjusted, the university of the sewing machine is greatly improved, the use cost is reduced, and stitch optimization is achieved.

Owner:JACK SEWING MASCH CO LTD

Conduit fixing device and fixing method

The invention discloses a conduit fixing device and a fixing method. The conduit fixing device comprises a fixing main body, wherein the fixing main body comprises a fixed ring and a rotating ring which are concentric and controllable and are in two-way rotary connection, wherein a non-adhesive side of a skin adhesive layer is fixedly connected with the fixed ring, and an opening is formed in a region, limited by the fixed ring, of the skin adhesive layer; one end of a strake is connected on the fixed ring, and the other end of the strake is connected on the rotating ring; and due to the rigidity of the strake, the own shape of the flexible strake can be maintained under the effect of gravity. The conduit fixing device ensures that a conduit is kept stationary relative to patient skin, so that uncomfortable feeling can be prevented, and conduit falloff or patient pains caused by drawing can be prevented; and conduit fixing can be relieved by simple operation in use, so that water-absorbing dressing can be replaced conveniently.

Owner:ZHEJIANG HAICHUANG MEDICAL DEVICE CO LTD

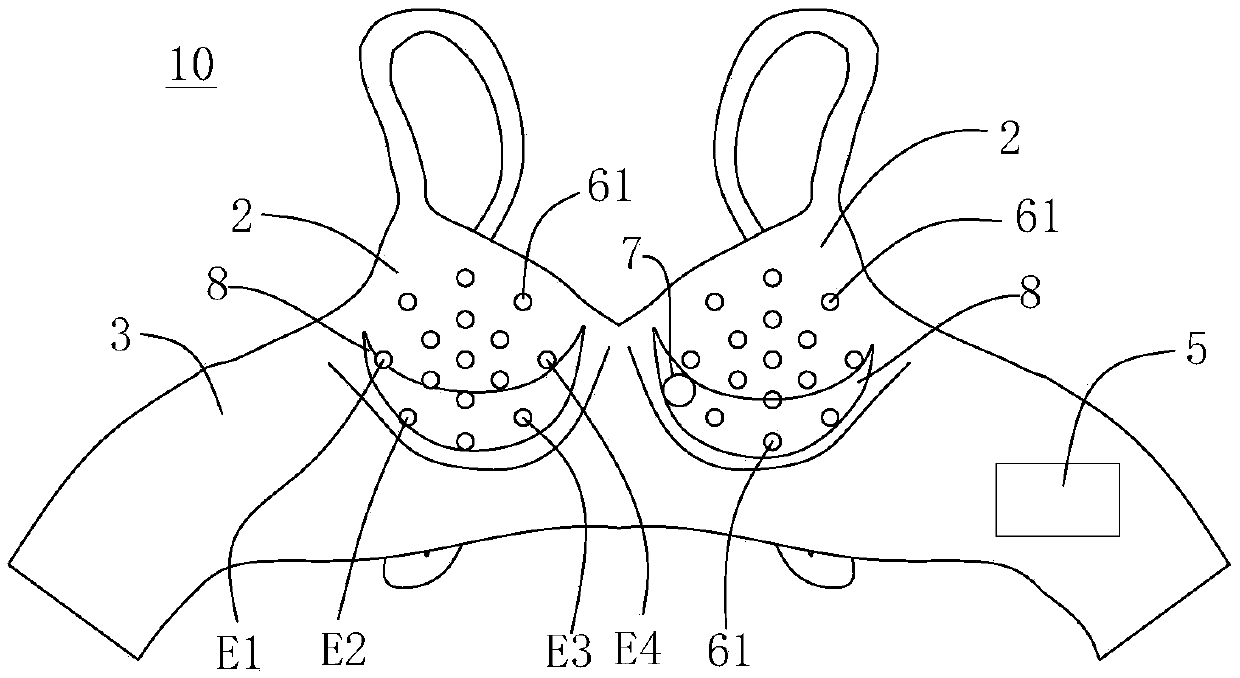

Bra assembly

InactiveCN105495712AImprove comfortReduce manufacturing costBrassieresHandkerchiefsAirbagBiomedical engineering

The invention relates to a bra assembly. The bra assembly comprises cups, chest pad airbags and an air inflation mechanism. The chest pad airbags are arranged on the inner surfaces of the cups. The air inflation mechanism is connected with the chest pad airbags, and is used for adjusting the quantity of gas in the chest pad airbags. With respect to the bra assembly, through the volume change of the chest pad airbags, breasts of most of users can be attached to the cups of the bra assembly comfortably, the bra assembly can adapt to most of users, and therefore the production cost of the bra assembly can be greatly reduced easily.

Owner:BEIJING ZHIGAN SENSOR TECH RES INST CO LTD

Hard rock push bench

The invention discloses a hard rock push bench. The hard rock push bench comprises a cutter head, a crushing compartment and a housing, wherein the front end of the crushing compartment is connected with the back side of the cutter head, and the tail end of the crushing compartment is connected with the front end of the housing. The hard rock push bench is used for performing excavation work in a pebble bed, or a gravel bed, or continuous hard rock. No single bearing is arranged on a hob of the hard rock push bench, but a bearing inner ring is integrated onto a cutter shaft, a bearing outer ring is integrated onto a cutter body, and therefore structure of the hob is simplified, and production cost and manufacturing difficulty are reduced. .By regulating degrees of tightness between a hob seal ring and an annular gland through a gland regulation bolt, starting torque of the hob can be quickly regulated, and then the hob can adapt to different geological environments.

Owner:FOSHAN CONSTANT HYDRAULIC MACHINERY

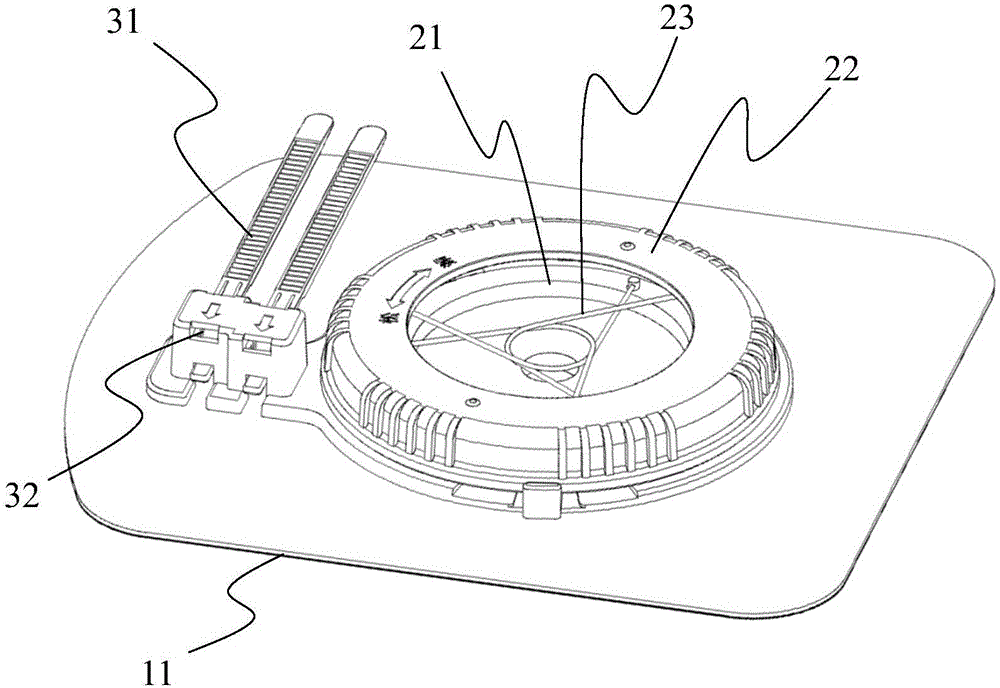

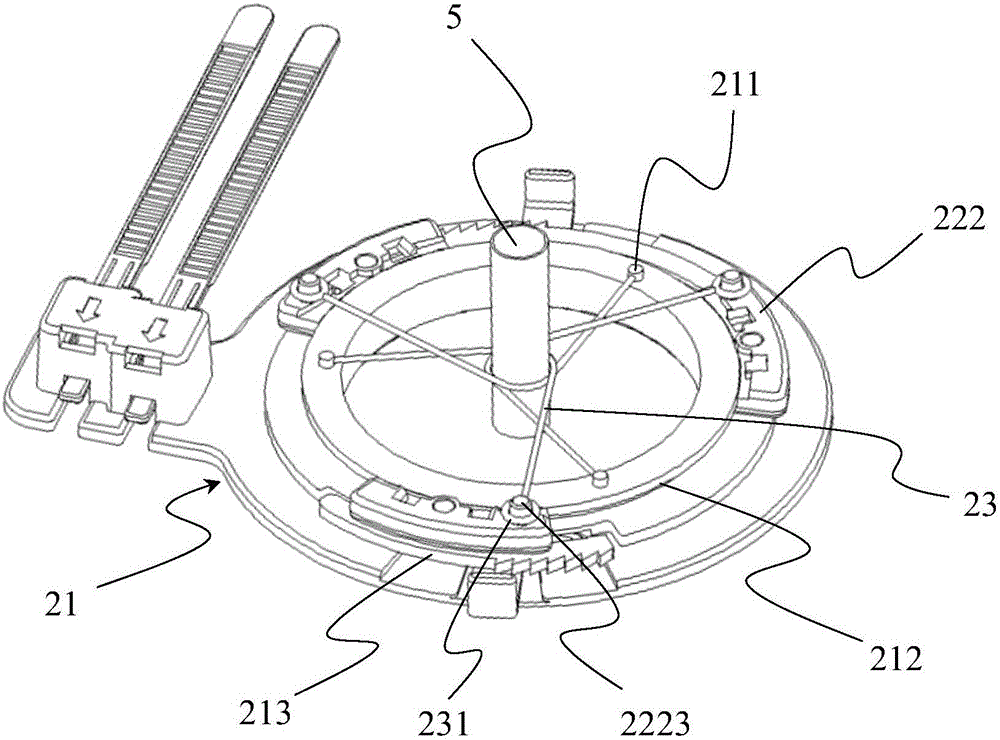

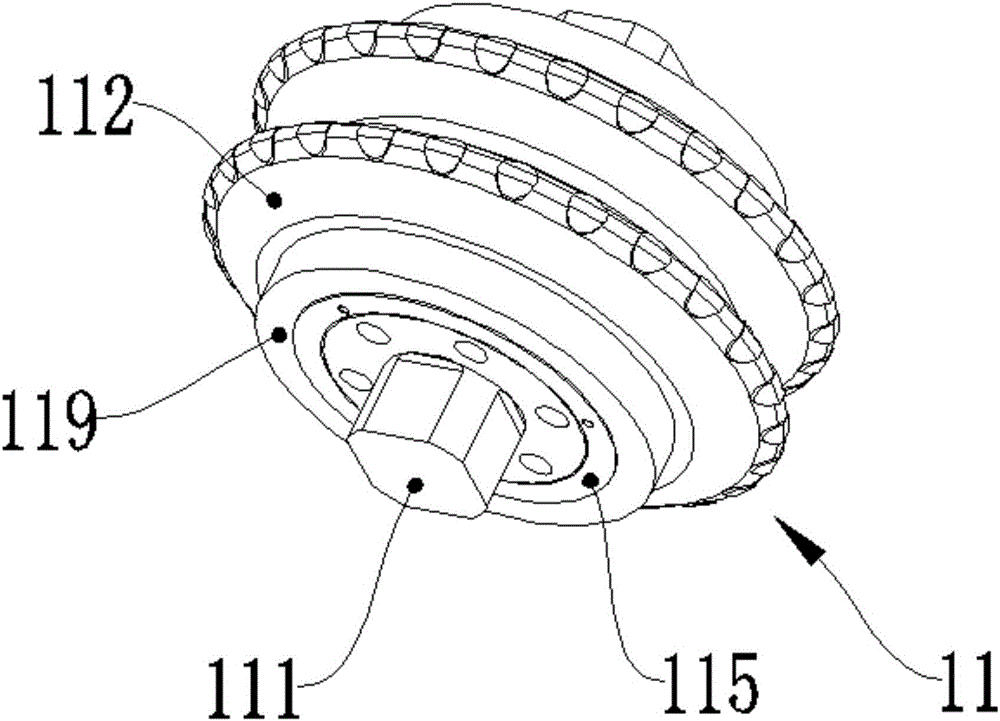

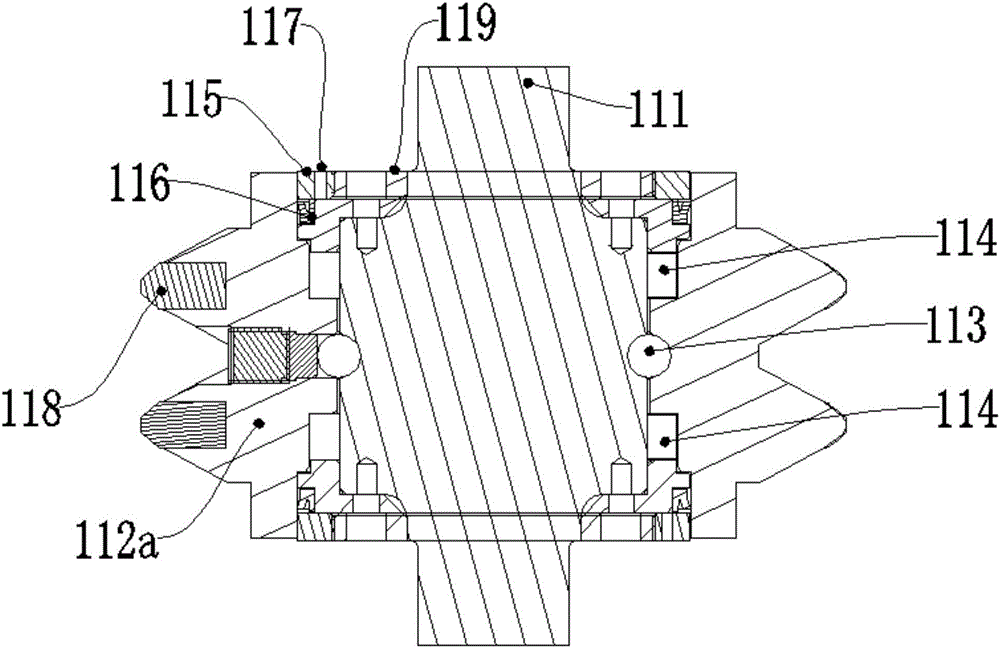

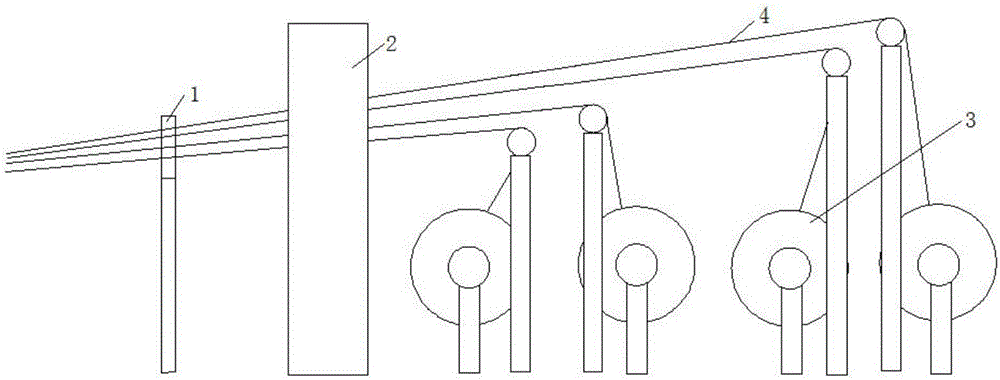

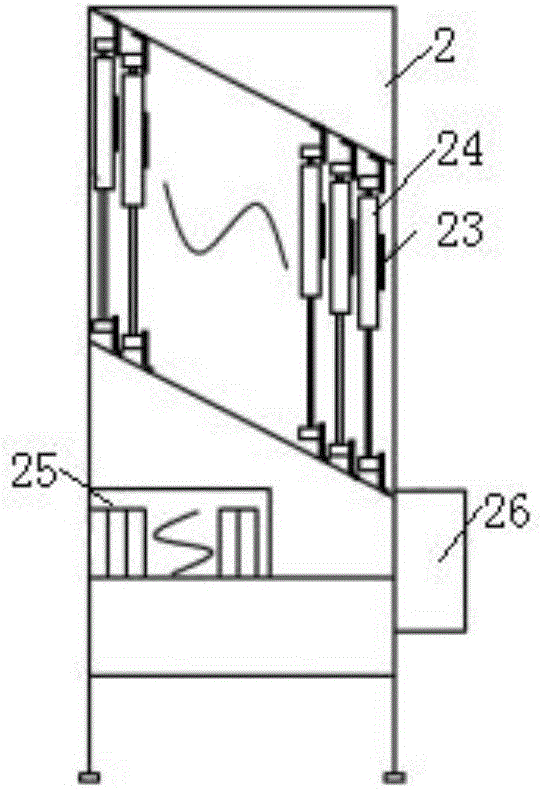

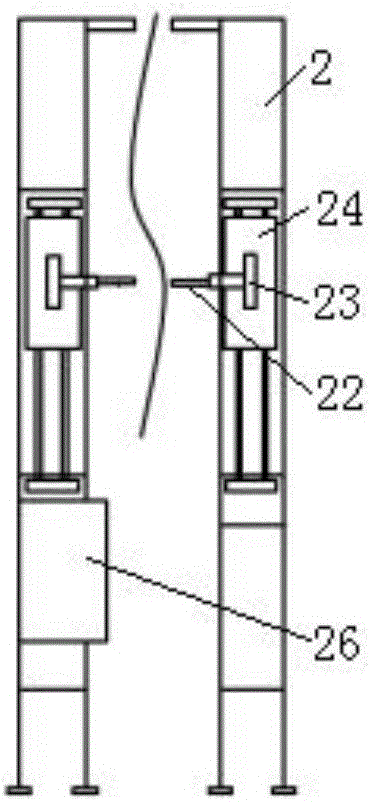

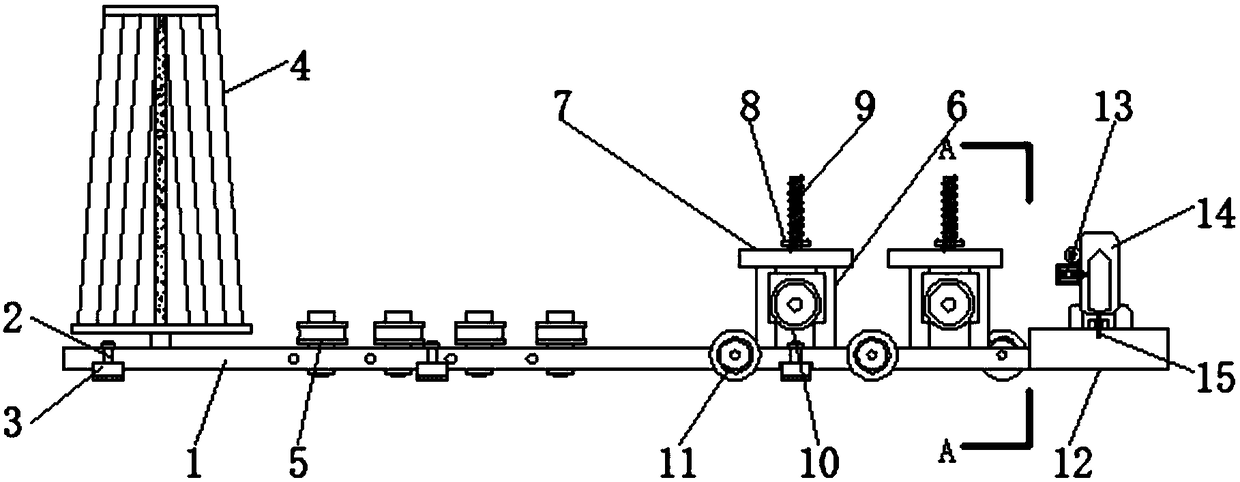

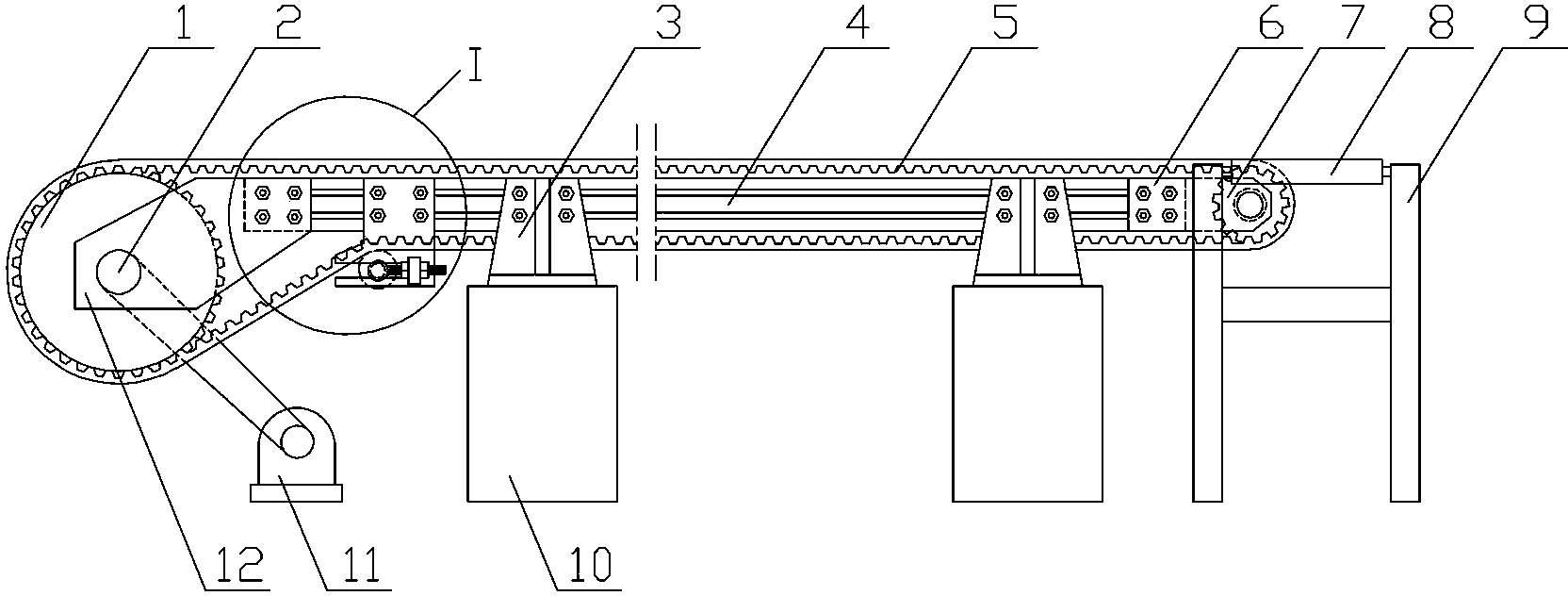

Automatic winding equipment and winding method for motor coil

ActiveCN109687660AFast windingPrecise windingManufacturing dynamo-electric machinesCopper wireLocking mechanism

The invention relates to automatic winding equipment and a winding method for a motor coil, which are mainly used for winding the motor coil and aim to solve the problems of low winding efficiency andeasy error in the prior art. The invention provides a technical scheme that the automatic winding equipment and the winding method for the motor coil. The automatic winding equipment for the motor coil comprises a coil frame, a wire feeding mechanism, a frame, a clamping and breaking mechanism and a winding mechanism; the winding mechanism comprises a winding device for clamping and winding copper wires, and a winding die fixing device for clamping and rotating the winding die; the winding device comprises a winding mechanical arm, a rotating wheel, a lifting module and a translation module;the winding die fixing device comprises a rotating motor, a bearing, a second rotating connecting component, a coil sleeve and a locking mechanism. According to the automatic winding equipment and thewinding method for the motor coil, winding is carried out by utilizing the lifting of the winding mechanical arm in the winding device and the rotary reciprocating of the winding die fixing device, so that the winding step is simplified into two single reciprocating processes, and the production efficiency is effectively improved.

Owner:ZHEJIANG JEAMO MOTOR

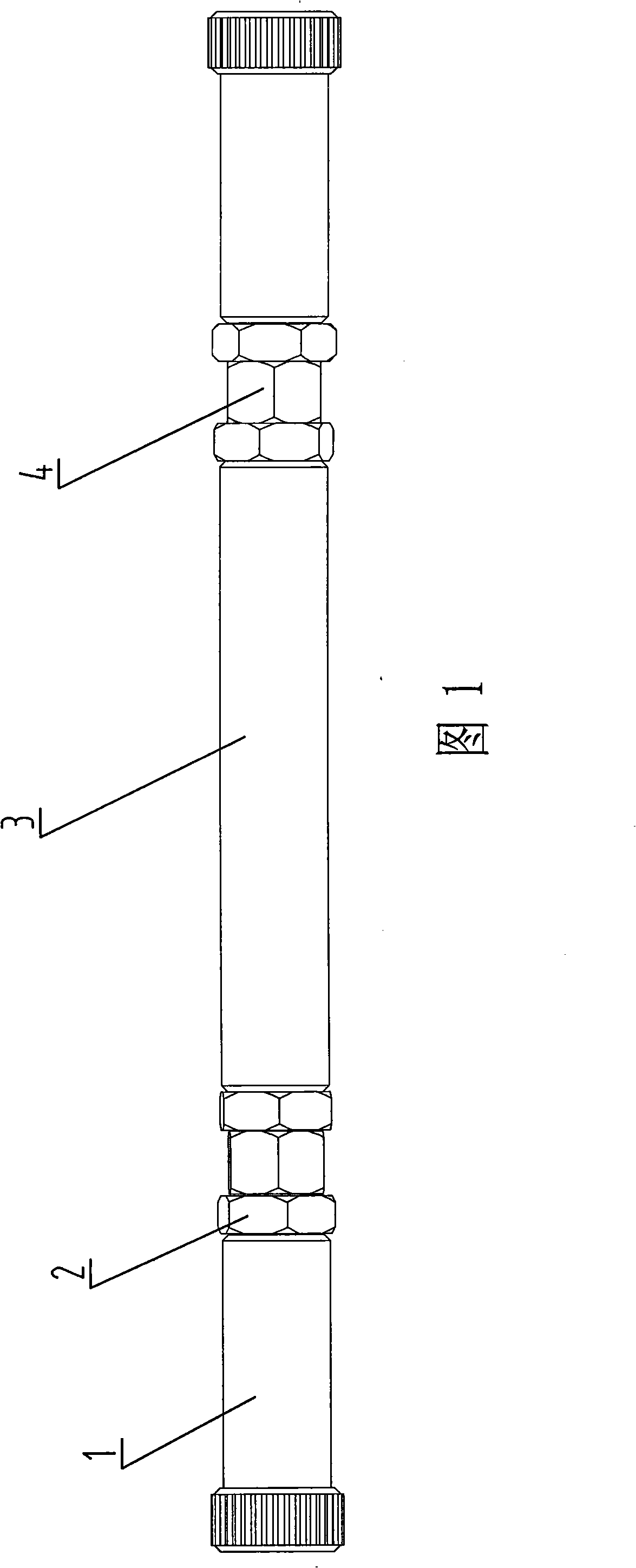

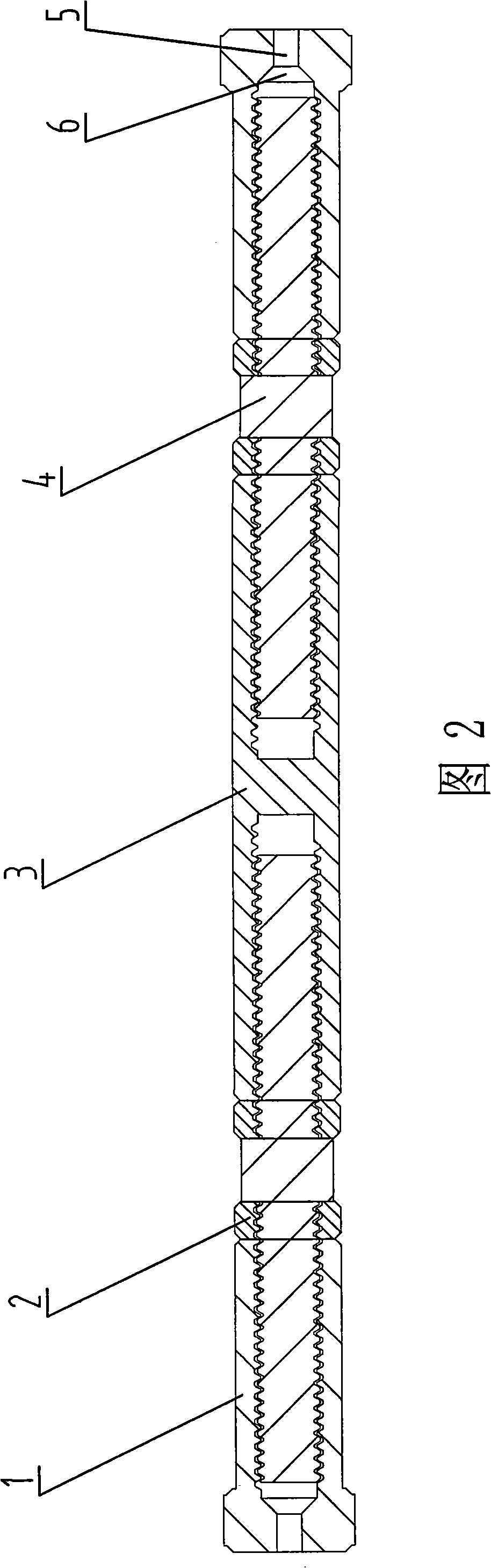

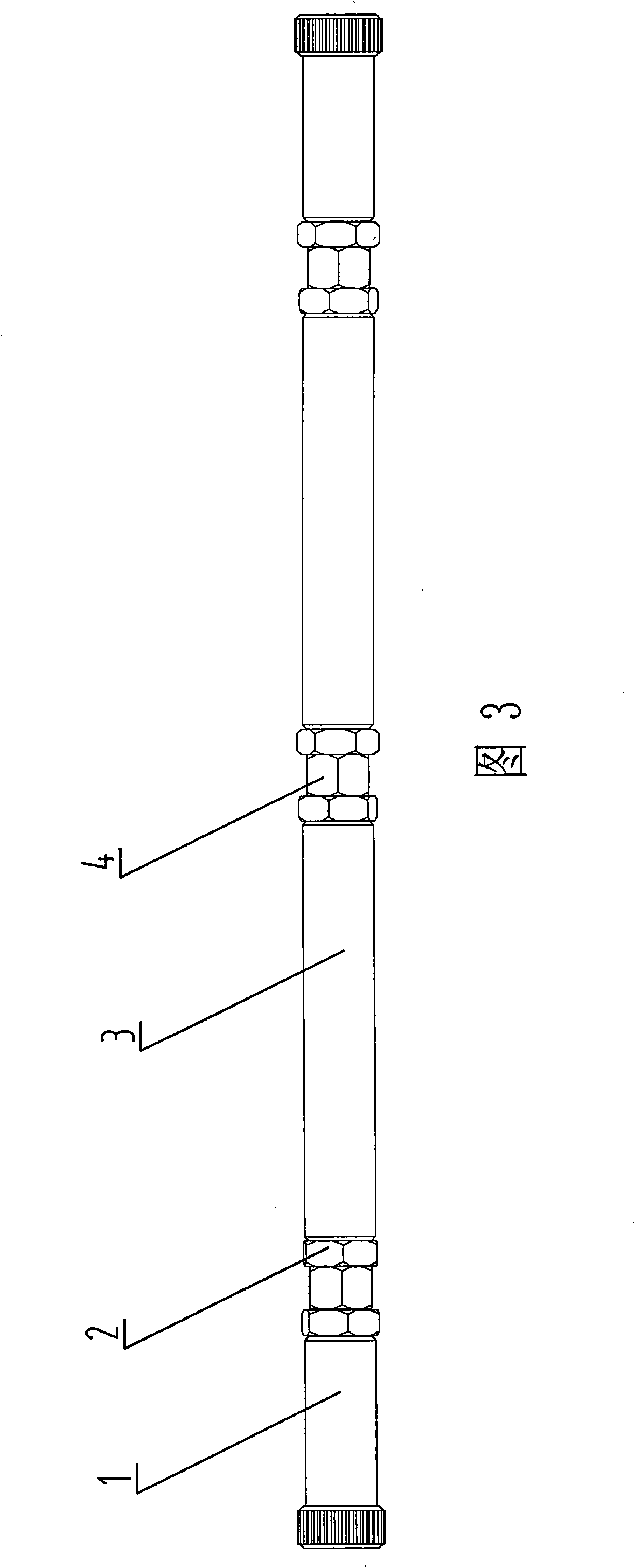

Tighten positioning bolt

InactiveCN101280821ALarge adjustment rangeAdjust the tightnessRopes and cables for vehicles/pulleyTextile cablesPulp and paper industryScrew thread

The invention discloses a tightening positioning bolt, which comprises two steel wire positioning bolts (1) with internal thread, at least two double-end studs (4) with tightening nuts (2) at both ends and at least an internal thread positioning bolt (2). Both ends of the internal thread positioning bolt (3) are provided with internal threads, and the internal threads of the internal thread positioning bolt (3) are respectively screwed with the external threads of two double-end studs (4) at each end; the external threads of the end, away from the internal thread positioning bolt (3) of the double-end stud (4) are respectively screwed with the internal threads of two steal wire positioning bolts (1); the external end plant of the steel wire positioning bolts (1) are provided with through holes (5) for passing the steel wires, and the internal ends of the through holes of the steel wire positioning bolts (1) are provided with an internal cavity (6) for containing a steel wire heading with a diameter larger than that of the through holes (5). The tightening positioning bolt of the invention has the advantages of large bolt adjusting amplitude, good fastening effect, and flexible and convenient assembly and disassembly.

Owner:NINGBO EASTPORT FASTENER MFG

Strain clamp device for electric power engineering

PendingCN109861149ARealize the effect of tightness adjustmentPracticalAdjusting/maintaining mechanical tensionSuspension arrangements for electric cablesElectric power systemElectric power

The invention discloses a strain clamp device for electric power engineering, relates to the technical field of electric power engineering equipment, and particularly relates to a strain clamp devicefor electric power engineering. The strain clamp device comprises a tightening ring, one end of the tightening ring is in threaded connection with a first threaded column, one end of the first threaded column is fixedly connected with a fixing ring, the other end of the tightening ring is in threaded connection with a second threaded column, and one end of the second threaded column is fixedly connected with a fixing handle. According to the strain clamp device for electric power engineering, the device can achieve an effect of adjusting the tightness of an entire wire just by rotating the tightening ring, so that a plurality of wires can not only be installed on the device for fixing, and different types of wires can also be installed for fixing, accordingly, the device achieves the purpose of high practicability, and when an adjusting rod is screwed, a rotating rod drives a winding bar to rotate, so that the strain clamp device for electric power engineering not only saves time and labor, but also achieves the effect of convenient use.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

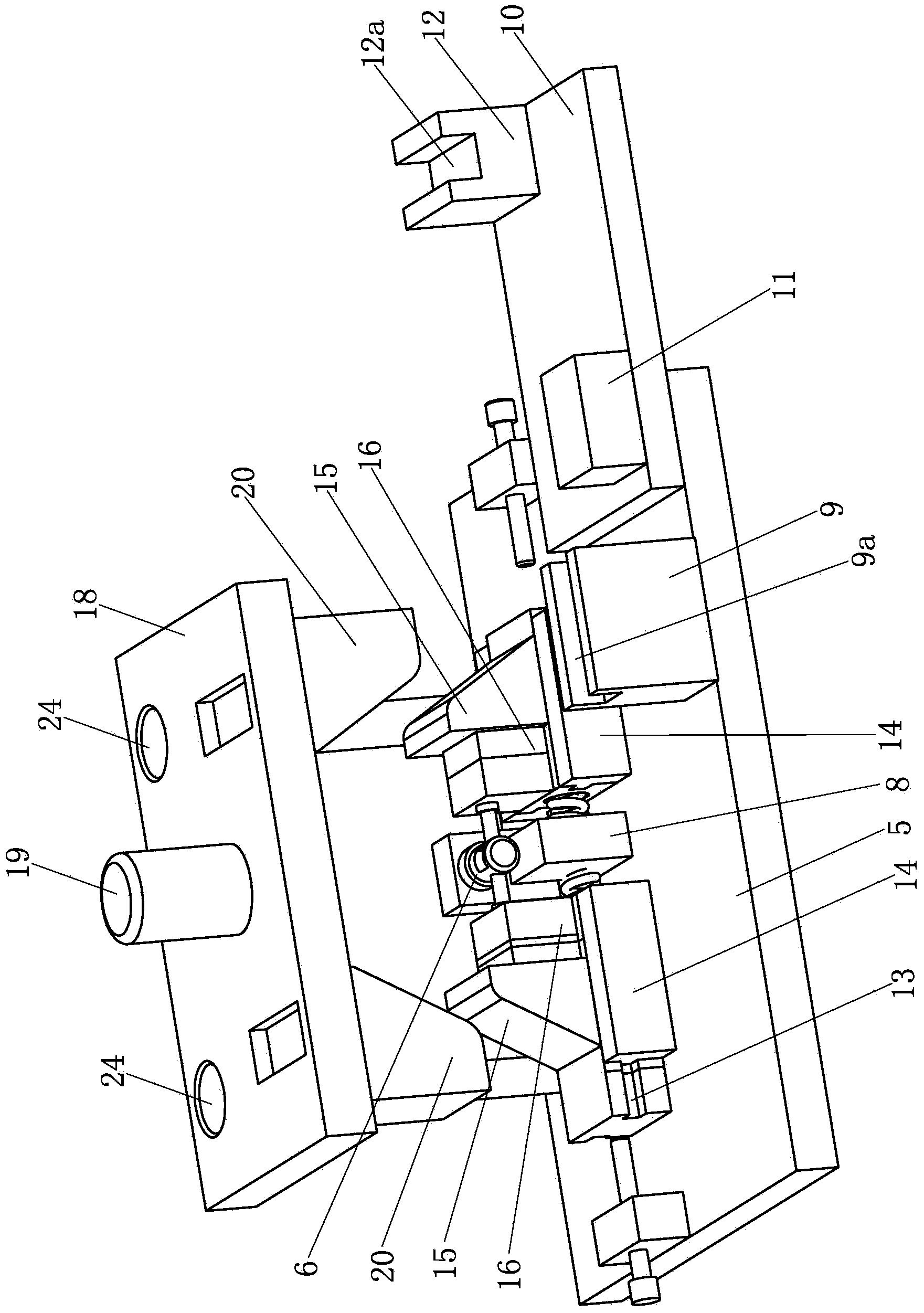

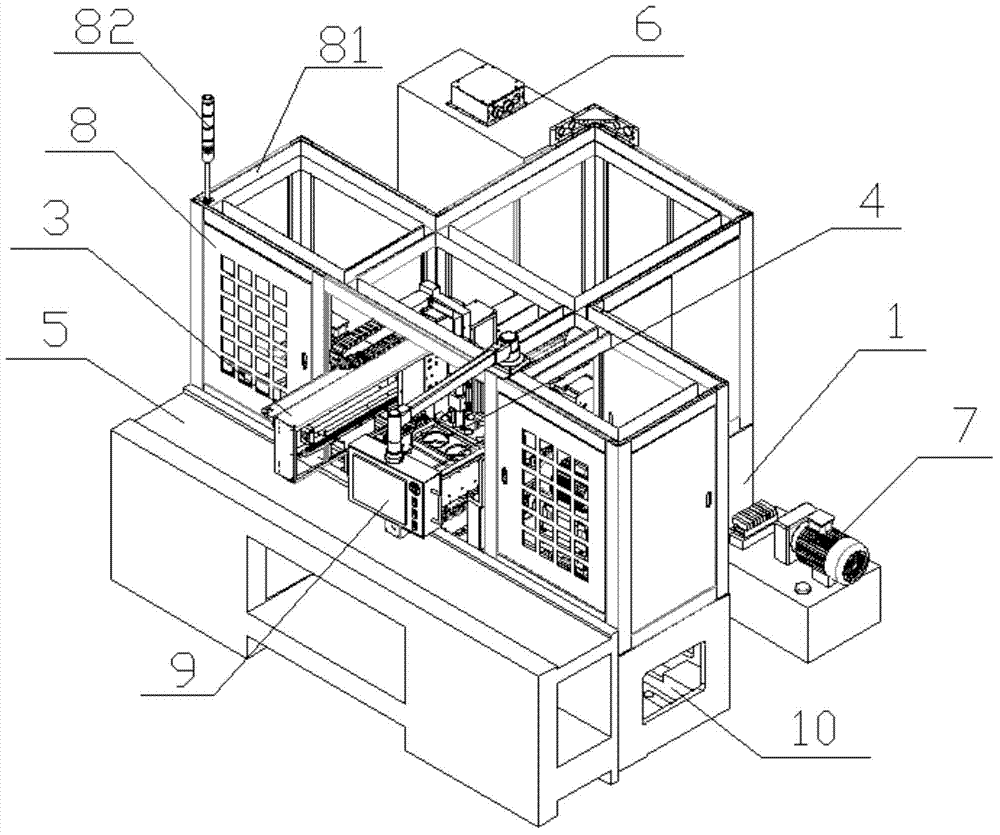

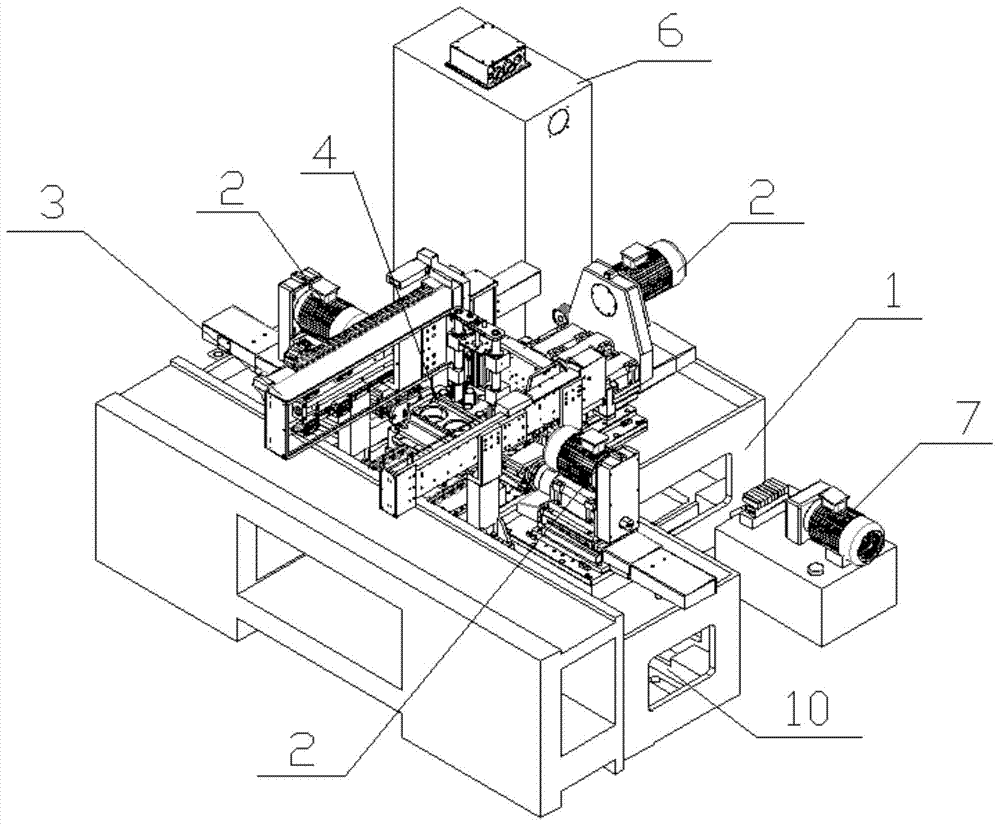

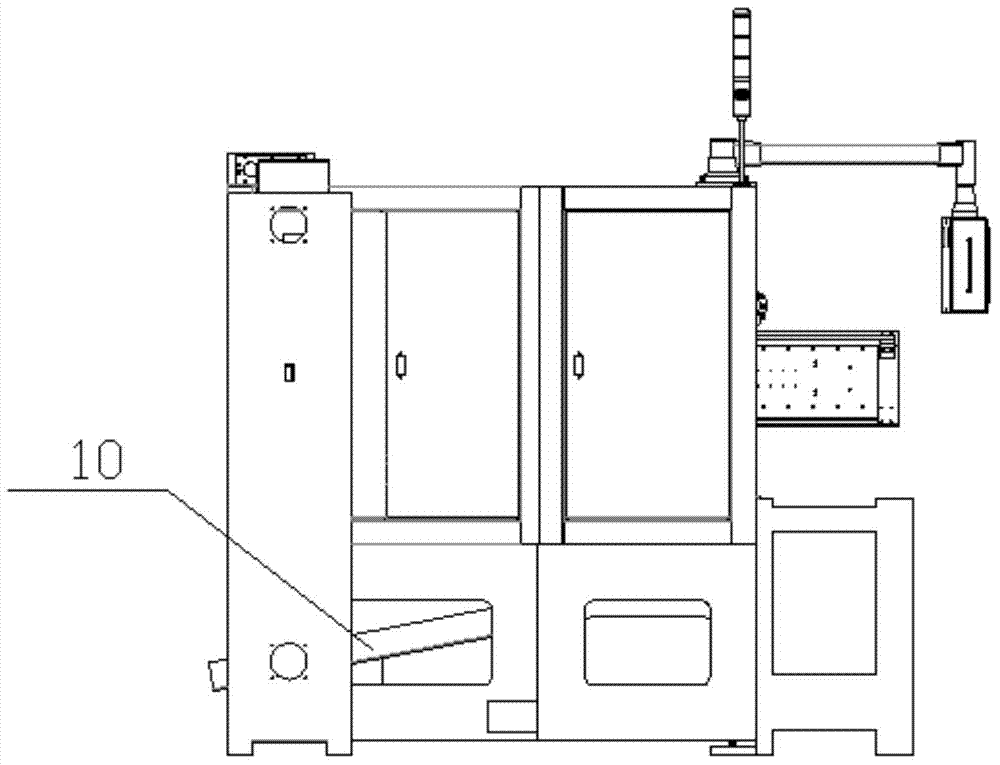

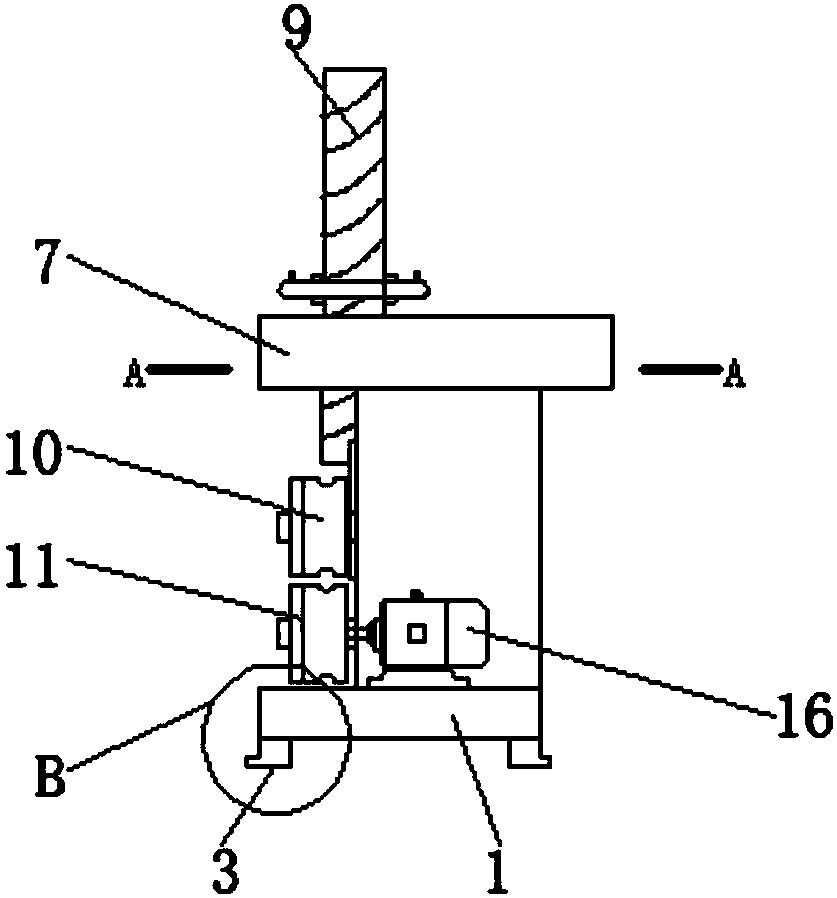

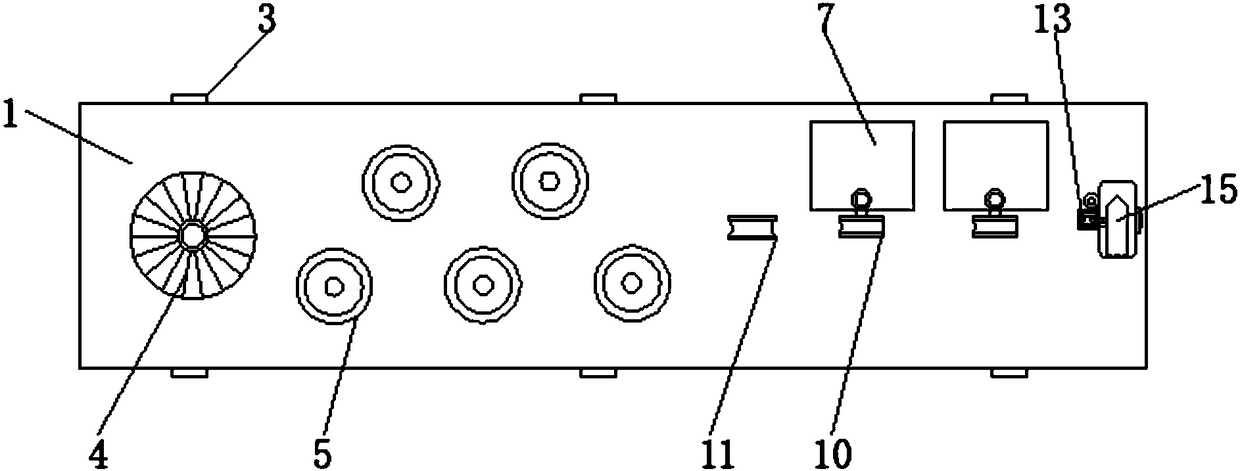

Yaw brake machine tool

ActiveCN104741932AReduce labor costsReduce manual labor intensityOther manufacturing equipments/toolsControl systemEngineering

The invention relates to a yaw brake machine tool. The yaw brake machine tool comprises a base which is of an inverted T-shaped structure, a cutting tool system, a manipulator system, a workpiece clamping auxiliary system, an assembly line workbench, an electric appliance control system and a hydraulic system; the cutting tool system is formed by a left cutting tool unit, a right cutting tool unit and a rear cutting tool unit which are arranged at the left position, the right position and the rear position of the base respectively; the manipulator system is located between the left cutting tool unit and the right cutting tool unit; the workpiece clamping auxiliary system is fixed on the base and located below the manipulator system; the assembly line workbench is fixed at the front end of the base; a position of the assembly line workbench, which is corresponding to a manipulator, is provided with a sensor and a jack-up cylinder; the electric appliance control system and the hydraulic system are arranged at two ends behind the base respectively; the hydraulic system is connected with the workpiece clamping auxiliary system. According to the yaw brake machine tool, the simultaneous machining can be performed on a plurality of machining surfaces, a fixture, a cutting tool and a milling machine do not need to be replaced, the machining accuracy is high, and the intelligent automation control is implemented.

Owner:嘉兴德威高传动系统股份有限公司

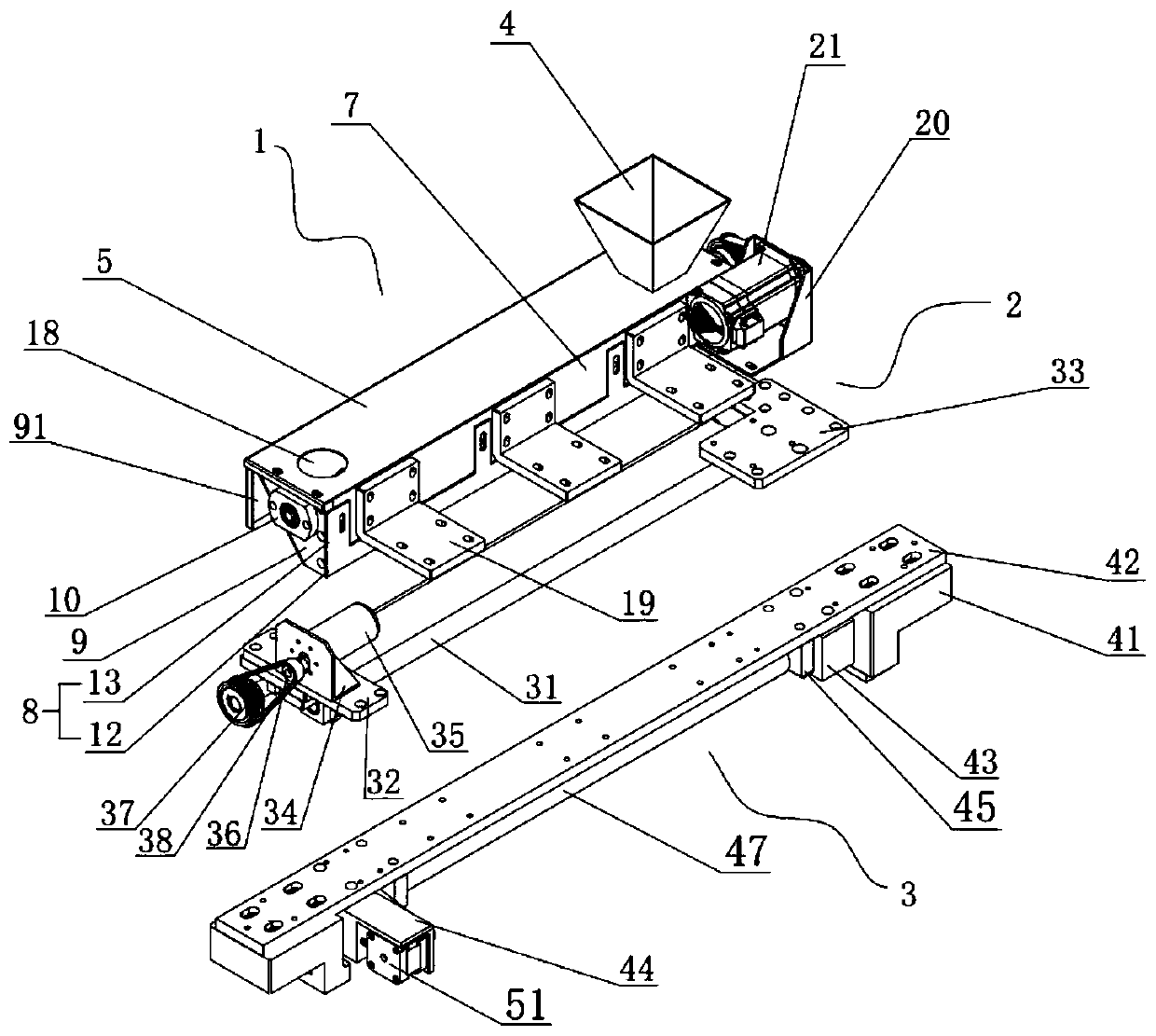

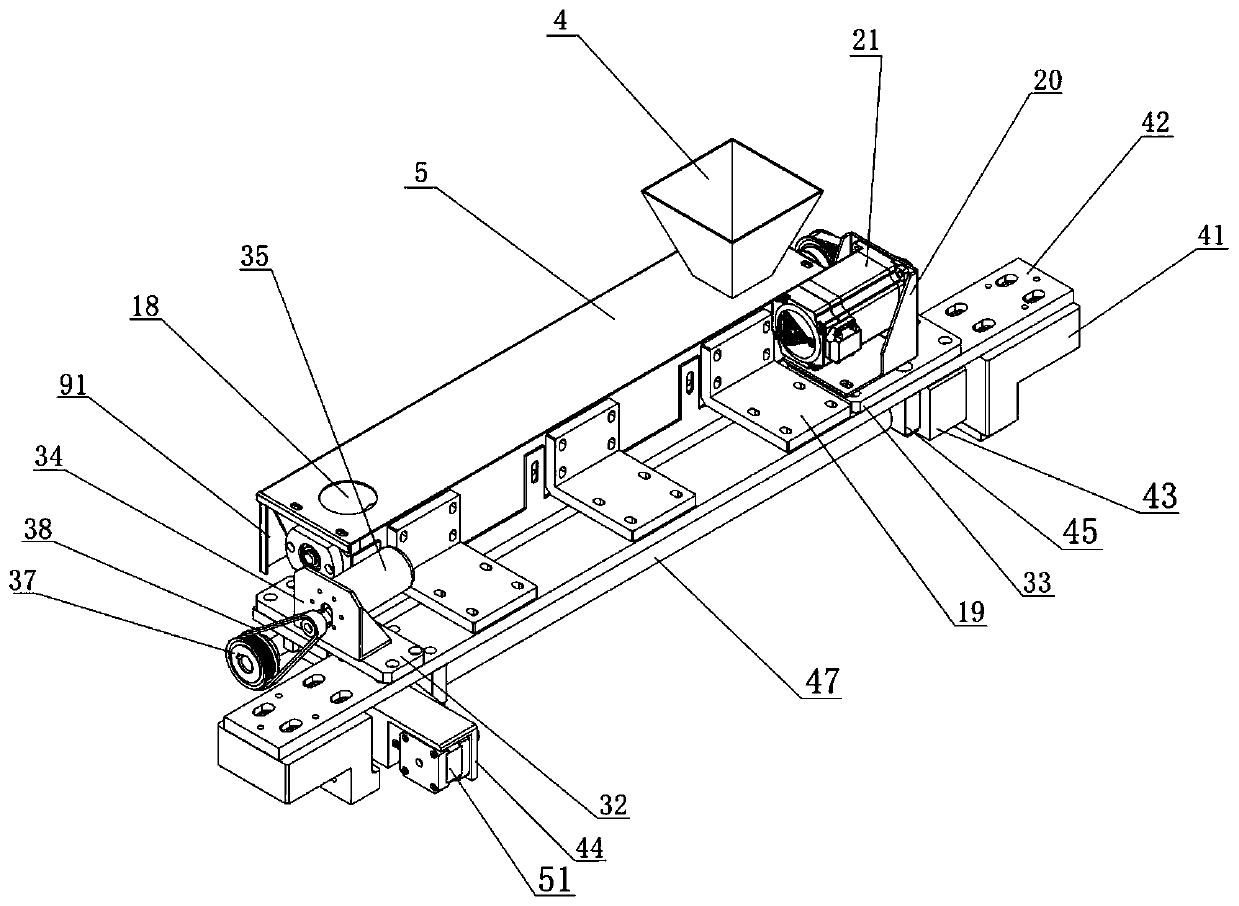

Powder spreading device of 3D printer

ActiveCN111231317ACompatible with compact spaceControl powder outputAdditive manufacturing apparatus3D object support structuresComputer printingElectric machinery

The invention discloses a powder spreading device of a 3D printer. The device comprises a powder falling part, a powder feeding part and a powder spreading part, the powder falling part comprises a powder falling hopper and a powder storage bin, the powder storage bin comprises an upper end plate, a side baffle, an adjusting plate after powder falling, a side plate, an adjusting plate before powder falling, a spiral shaft and a powder falling assembly fixed support, a powder falling motor is mounted at one end of the side plate, the powder feeding part comprises two powder feeding assembly fixed supports, a powder feeding driving shaft, a powder feeding driven shaft bearing pedestal, and a powder feeding driven shaft, a powder feeding conveying belt is mounted between the powder feeding driven shaft and the powder feeding driving shaft, a powder feeding motor is mounted beside the powder feeding assembly fixed supports, the powder spreading part comprises two powder spreading assemblyfixed supports, a powder spreading cross beam, a powder spreading roller bearing pedestal and a powder spreading motor base, a powder spreading roller is rotatably connected between the powder spreading roller bearing pedestal and the powder spreading motor base, and a powder spreading motor is fixedly mounted on the powder spreading base. Through the above arrangement, powder is not prone to blocking the powder falling opening, and the powder can be evenly spread on the whole powder spreading path at the same time.

Owner:武汉易制科技有限公司

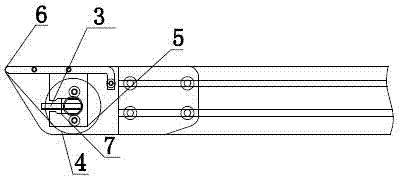

Standard one-sided knife edge structure of belt conveyer

InactiveCN102234010AAdjust the tightnessImprove work efficiencyConveyorsRollersEdge structureEngineering

The invention relates to a standard one-sided knife edge structure of a belt conveyer. The structure comprises a roller central shaft installation plate, a roller and a frame end installation plate, wherein the two ends of a roller central shaft are fixed by a U-shaped clamping groove on the roller central shaft installation plate; the roller central shaft installation plate is fixedly connected to the frame end installation plate and is provided with a standard one-sided knife edge; and through threaded holes are formed at the two ends of the roller central shaft and are in threaded fit with an adjusting rod. By the standard one-sided knife edge structure, a knife edge has a circular arc surface structure with a small R angle, so that a circumference ratio generated by the roller edge structure of the conventional belt conveyer is reduced, the conveyer product smoothly flows, the condition that articles are accumulated and the like due to a gap generated by butting the arc surface to influence normal work in the prior art is avoided, the work efficiency of the conveyer is greatly improved, and loss caused by the falling of a too small article is reduced.

Owner:WUXI JIESI LOGISTICS EQUIP

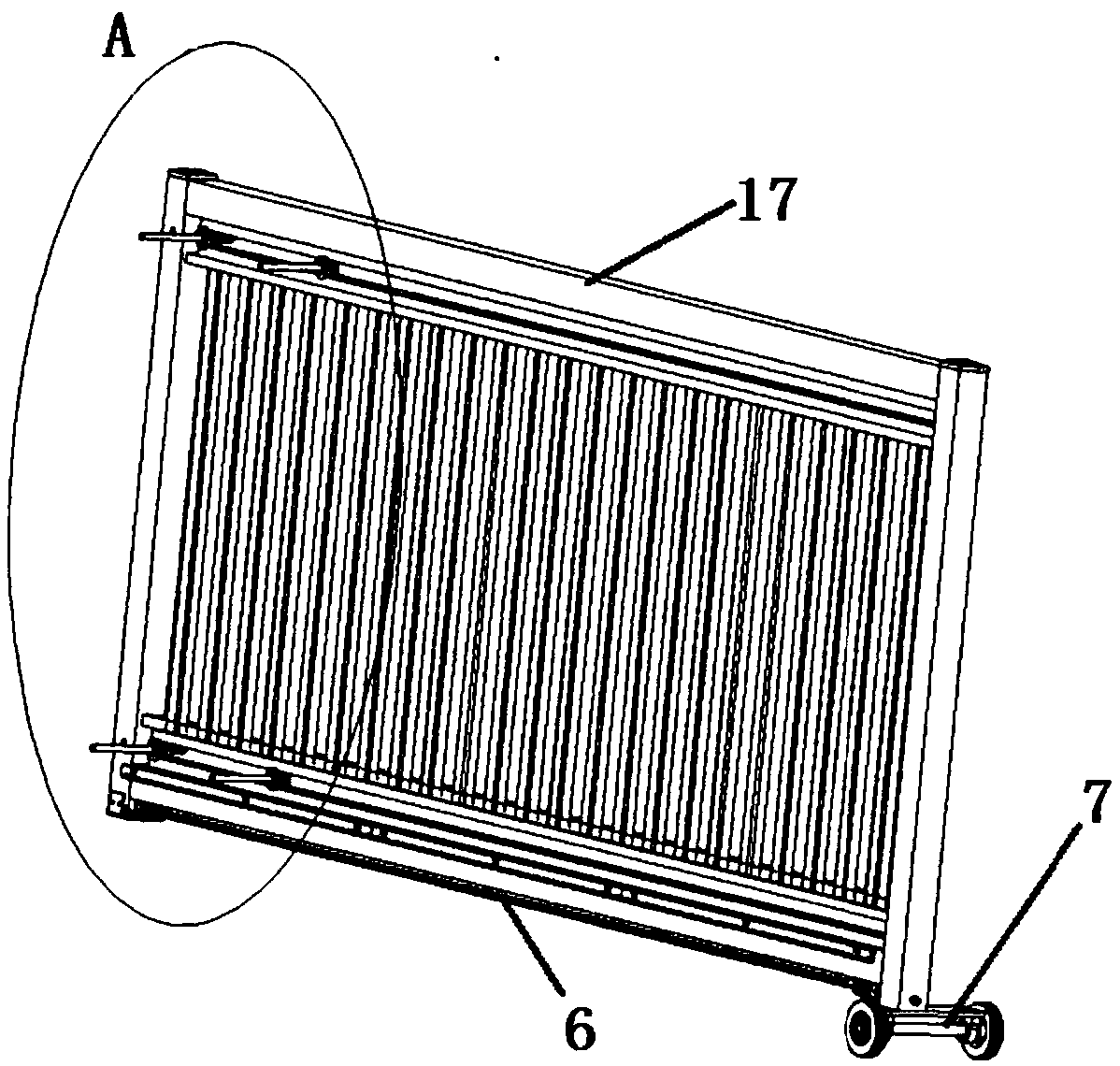

Warp beam yarn leasing device and leasing method thereof

ActiveCN106835422AShorten working timeRealization of Yarn PressingLeasingTextiles and paperYarnEngineering

The invention belongs to the field of textile machinery and discloses a warp beam yarn leasing device and a leasing method thereof. The warp beam yarn leasing device comprises a yarn pressing device and a straight reed carriage which are arranged front to back, and a straight reed is arranged on the straight reed carriage. The yarn pressing device comprises a mounting support, yarn pressing lifting devices, yarn pressing strips and yarn pressing strip connectors. The yarn pressing lifting devices in more than two pairs are fixed to two sides of the mounting support, and two ends of each yarn pressing strip are connected to the corresponding pair of yarn pressing lifting devices through the corresponding yarn pressing strip connectors. The warp beam yarn leasing device and the leasing method thereof have advantages that by adoption of the yarn pressing strips for replacement of traditional iron rods, operation time is saved; one person can control ascending and descending of the yarn pressing strips through a switch to realize yarn pressing, two-person operation is avoided, operator quantity is decreased, and one person can complete yarn pressing and leasing operations in ten minutes finally, so that production efficiency is greatly improved.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Power distribution cabinet

ActiveCN109301721AAchieve cycleEasy to installSubstation/switching arrangement casingsAnti-seismic devicesRotary stageEngineering

The invention discloses a power distribution cabinet comprising a working support table in a cylindrical shape. Four base support columns distributed in a peripheral array are arranged at the lower end surface of the working support table; a boss is fixedly welded to the left end of the arc outer wall of the working support table; and a housing is made at the edge of the upper end surface of the working support table in an integrated manner. A rotary table is arranged at the bottom surface inside the housing; and a moisture-proof cover is welded to the upper end surface of the housing. According to the application environment of the power distribution cabinet, moisture-proof, dust-proof and heat-proof objectives are achieved; and the convenient movement and stable and reliable installationare realized.

Owner:贵州长源电气科技有限公司

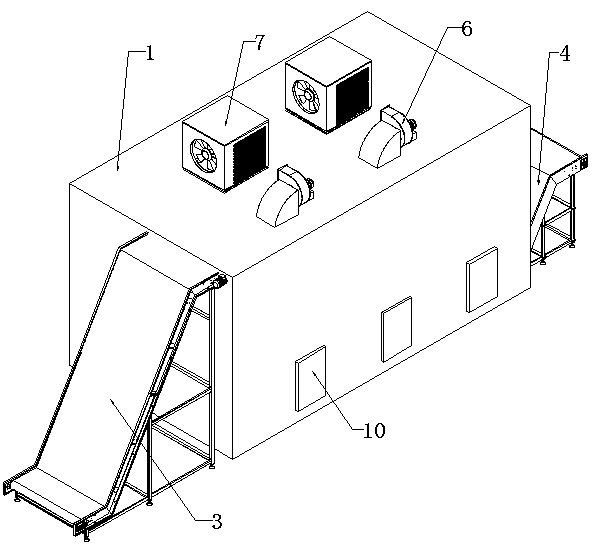

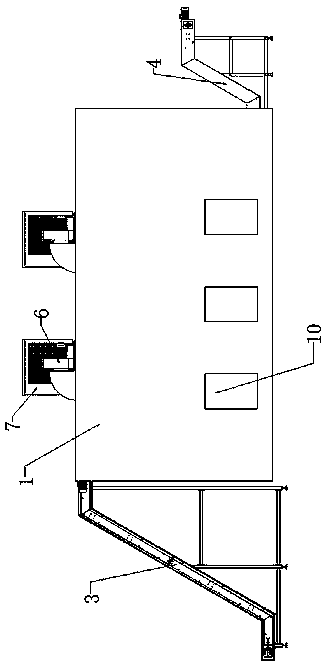

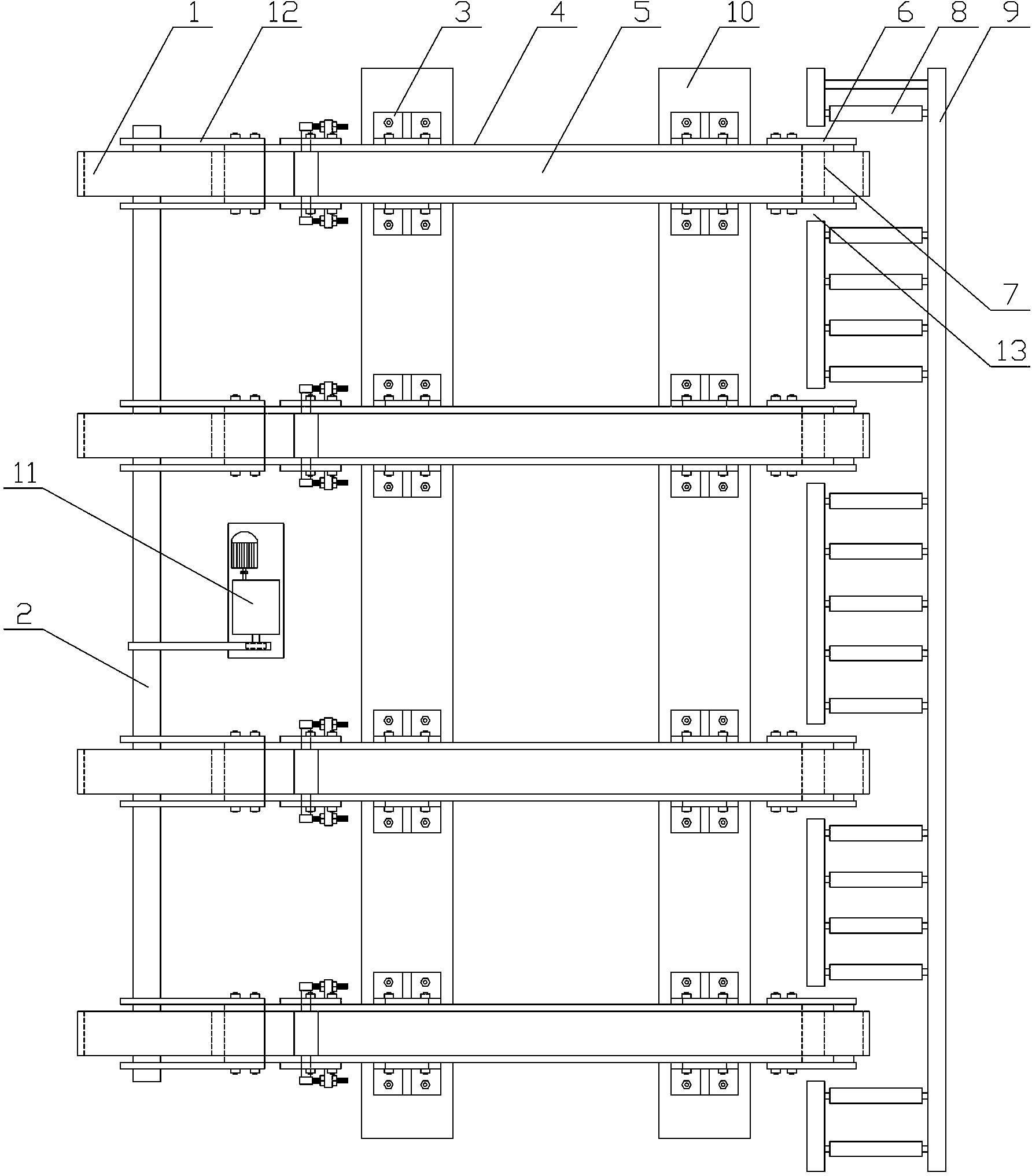

Continuous automatic energy-saving and efficient agricultural product drying device

PendingCN111288778AImprove circulation efficiencyAdjust the tightnessDrying gas arrangementsDrying machines with progressive movementsAgricultural scienceAgricultural engineering

The invention discloses a continuous automatic energy-saving and efficient agricultural product drying device. The continuous automatic energy-saving and efficient agricultural product drying device comprises a box body, a framework, a feeding machine, a discharging machine, a conveying device, dehumidifying centrifugal fans, heat pumps, a surface cooler and axial flow fans. The box body is of a hollow cubic structure. The framework and the conveying device are mounted in the box body side by side in the front-back direction. The surface cooler connected with the heat pumps is fixedly arrangedon the lower portion of the framework. The axial flow fans are mounted on the upper middle portion of the framework. The conveying device is fixedly mounted on the front side of the framework. The dehumidifying centrifugal fans are mounted above the box body. As a whole, the continuous automatic energy-saving and efficient agricultural product drying device has the beneficial effects that throughheat recycling, the heat utilization efficiency is improved, the energy consumption is greatly reduced, feeding and discharging are automatically carried out, the labor intensity is reduced, the drying efficiency is improved, the chain utilization rate is effectively increased, and the use value is extremely high.

Owner:河南玖德智能设备有限公司

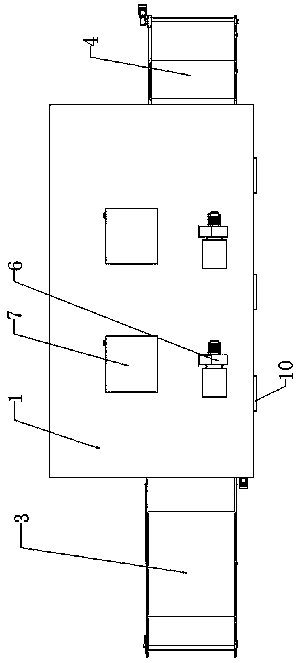

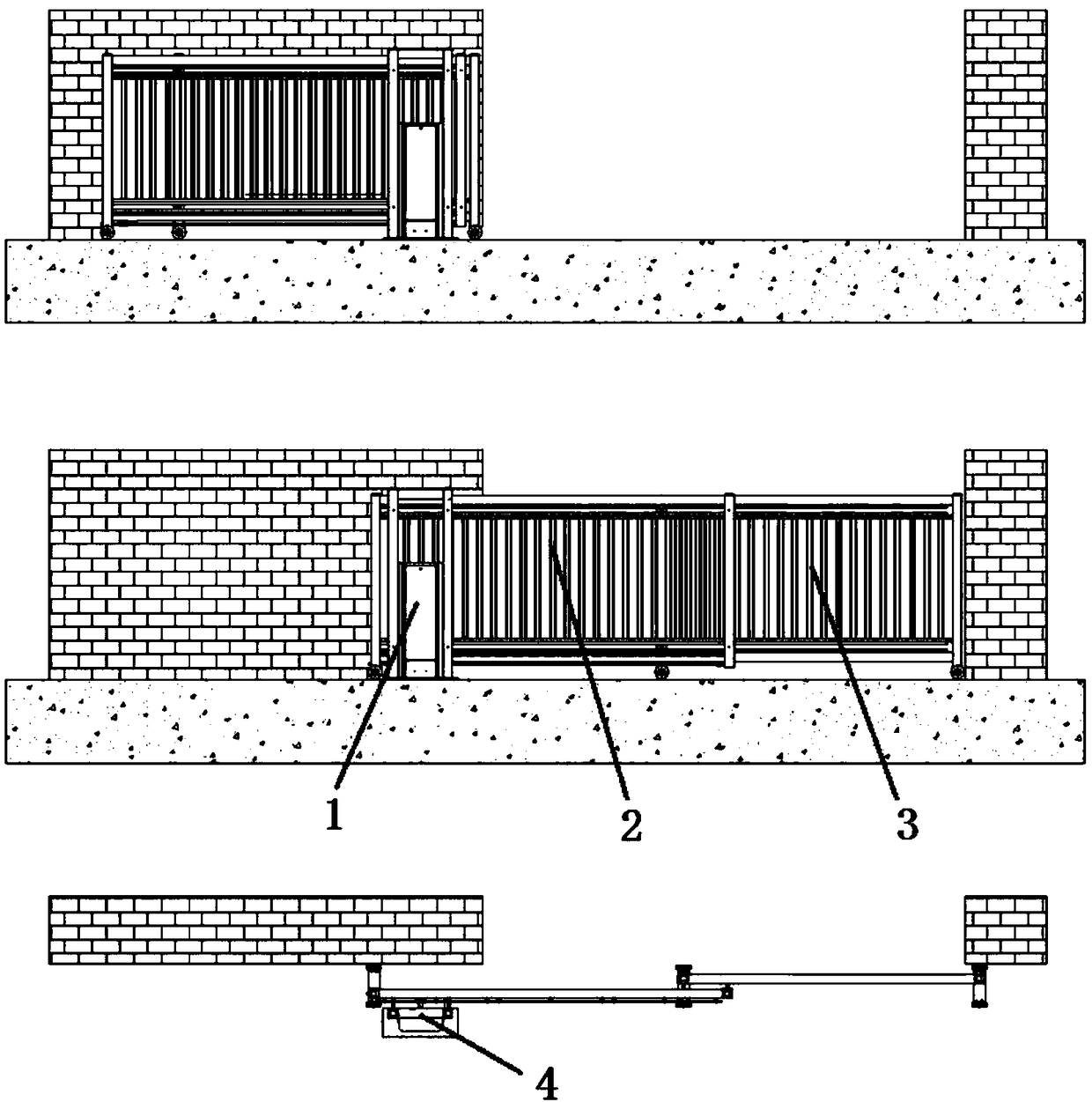

Novel sliding door

InactiveCN108825111AReduce opening and closing timeAdjust the tightnessGates/doorsPower-operated mechanismEngineeringPulley

Owner:广东启功实业集团有限公司

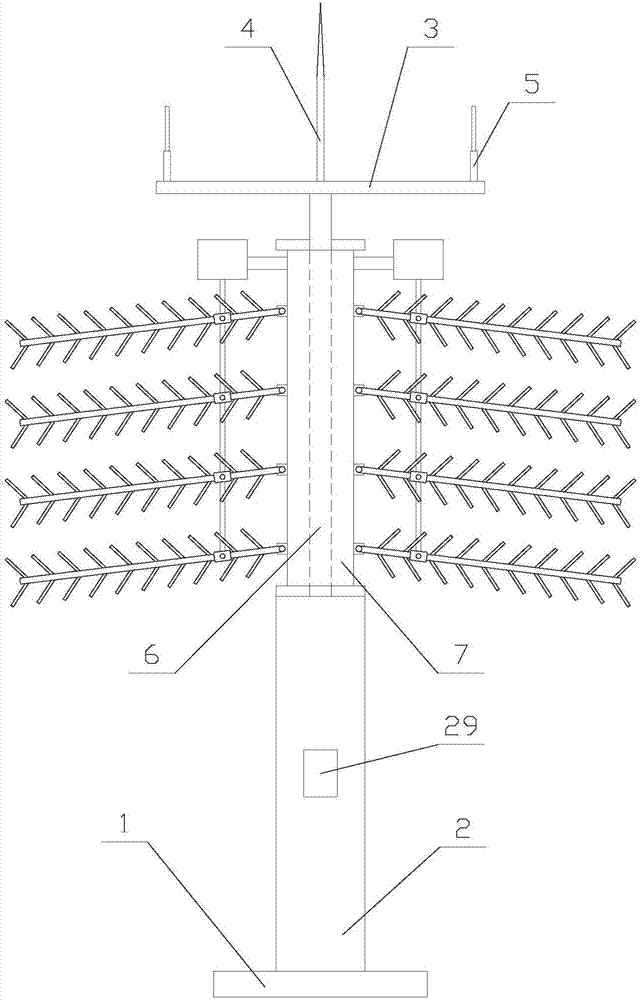

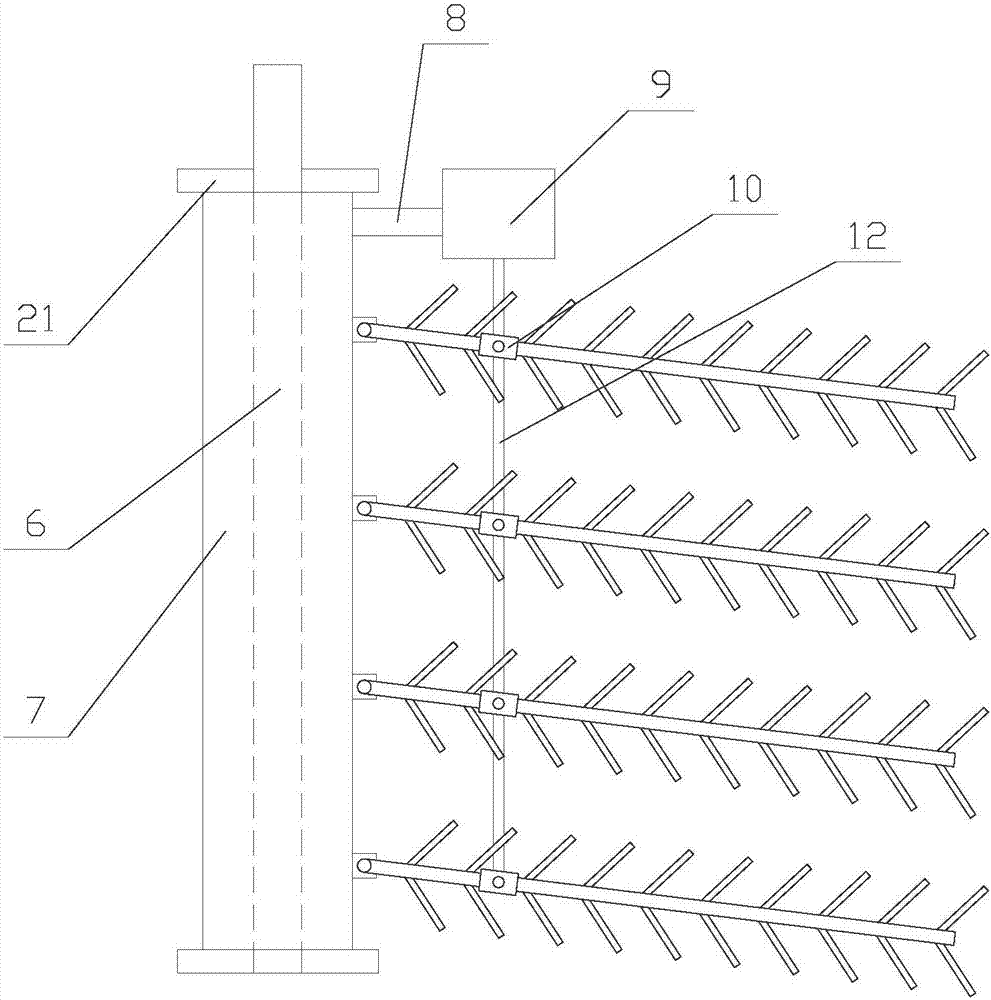

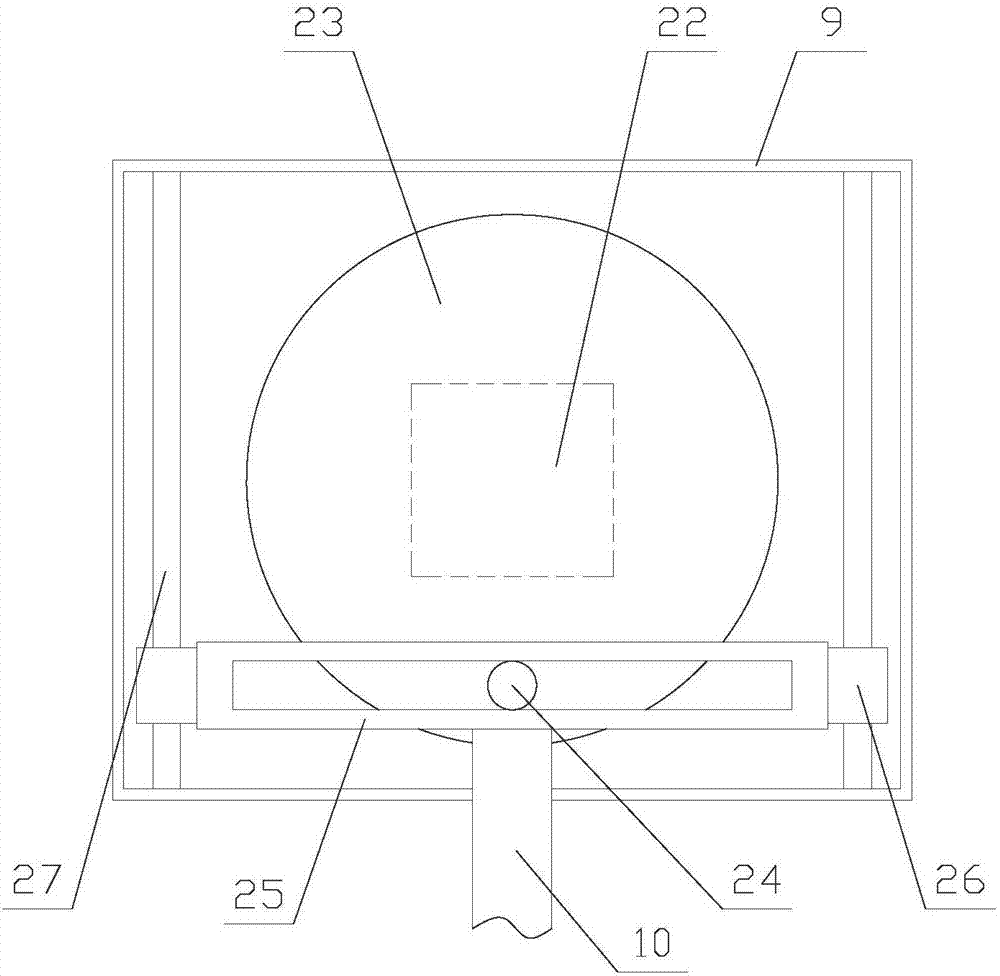

Anti-fracture intelligent bionic tower with rotation function

ActiveCN107989454AAvoid breakingReduce wind resistanceArtificial flowers and garlandsTowersRotation functionLightning rod

The invention relates to an anti-fracture intelligent bionic tower with a rotation function. The anti-fracture intelligent bionic tower includes a bionic mechanism, a platform, a lightning rod and atleast two antennas. The bionic mechanism includes a center rod, a rotation pipe and two bionic assemblies. The rotation pipe is internally provided with a fixing mechanism. Each bionic assembly includes a driving box, a driving rod and at least two bionic branches. The fixing mechanism includes two fixing assemblies. Each fixing assembly includes multiple fixing units. Each fixing unit includes afirst motor, a first driving shaft, a sliding block, a first connecting rod, a second connecting rod, an extruding block and a fixing rod. According to the anti-fracture intelligent bionic tower withthe rotation function, in strong wind weather, the extruding blocks are made to be separated from the inner wall of the rotation pipe through the fixing mechanism; the rotation pipe is made to drive the bionic branches to rotate; wind force borne by the bionic branches is reduced; fracture is avoided; and more than that, through the driving units, the driving rods are driven to move up and down, so that the bionic branches shake off accumulated snow through swing, and fracture of the bionic branches due to the excessively heavy accumulated snow is avoided.

Owner:河北峻威铁塔有限公司

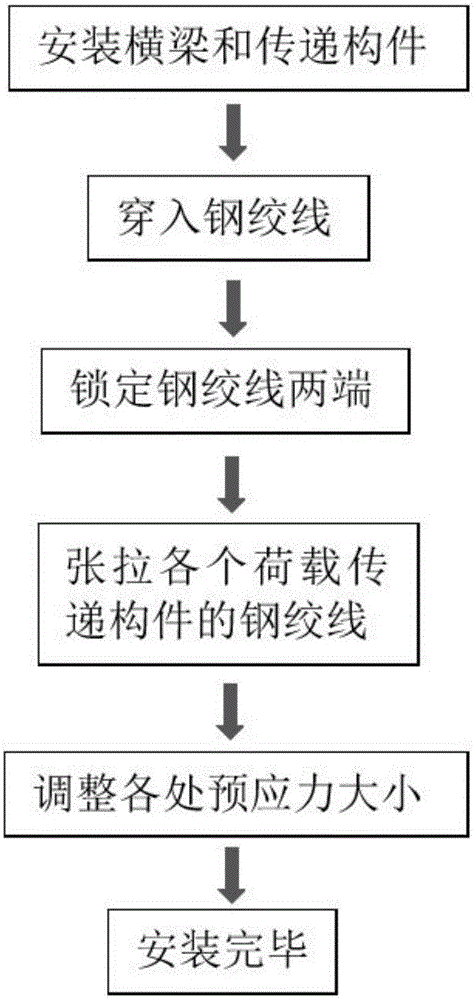

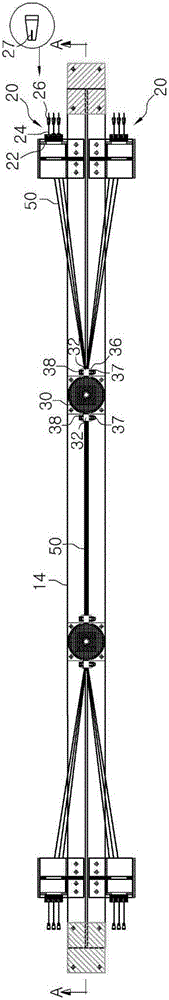

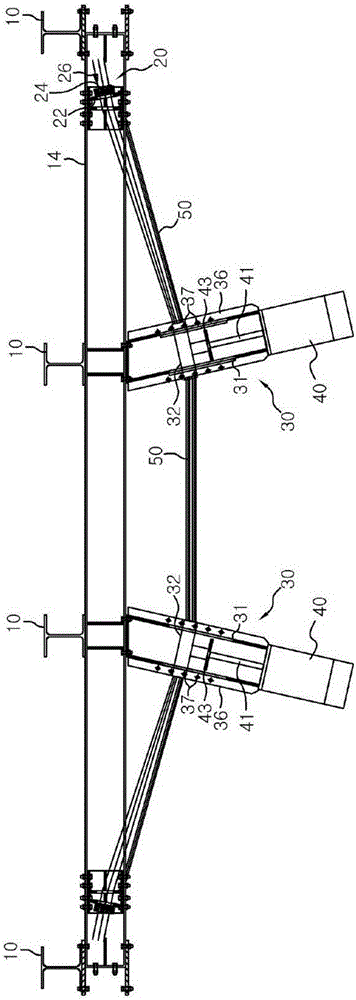

Novel detachable foundation pit bracing system and construction mounting method thereof

The invention relates to the field of geotechnical engineering bracing of foundation pits, slopes, embankments and the like, and particularly discloses a novel detachable foundation pit bracing system and a construction mounting method thereof. A hydraulic jack is used for tensioning each stress application point of a steel strand, so that prestressing force of the steel strand is transmitted, and acting force is provided for the retaining structure of a foundation pit. After penetrating through a middle load transmission component, the steel strand is locked through locking devices on a cross beam. In order to monitor the prestressing force applied by the steel strand in real time and to keep stress balance between all parts, force sensors are arranged at the two ends of the steel strand and the middle load transmission component. The steel strand passes through a preformed hole in the load transmission component, the degree of tightness of the steel strand can be adjusted through a controller on the load transmission component, and the controller can move along a groove. According to the novel detachable foundation pit bracing system and the construction mounting method thereof, by adjusting the magnitude of pre-applied force of the prestressed steel strand continuously, certain supporting force and reverse acting force can be provided for a supporting structure on the side wall of the foundation pit, and the purpose of controlling deformation of the foundation pit side wall can be achieved.

Owner:NORTHEASTERN UNIV

Reinforcing steel bar straightening and cutting all-in-one machine

The invention relates to a reinforcing steel bar straightening and cutting all-in-one machine. The reinforcing steel bar straightening and cutting all-in-one machine comprises a bottom plate, a horizontal guide wheel, a straightening machine body and a driving straightening wheel; an adjusting mechanism is arranged in the bottom plate in a penetrating manner, the lower end of the adjusting mechanism is connected with a fixed frame, the fixed frame is arranged in the bottom plate, a paying-off cage is arranged at the upper end of the bottom plate, and the horizontal guide wheel is arranged above the bottom plate; the paying-off cage is arranged on one side of the horizontal guide wheel, the straightening machine body is arranged above the bottom plate, the horizontal guide wheel is arrangedon one side of the straightening machine body, a worktable is fixed to the upper end of the straightening machine body, a thread rod is arranged in the upper end of the worktable in a penetrating manner, the lower end of the thread rod is connected with the driven straightening wheel, the thread rod penetrates into the adjusting wheel, the driving straightening wheel is arranged on the outer sideof the bottom plate, one side of the driving straightening wheel is connected with a second motor, and a cutting table is arranged at one end of the bottom plate. The reinforcing steel bar straightening and cutting all-in-one machine can achieve straightening and cutting of reinforcing steel bars, and use is convenient.

Owner:冼辉

Automatic horizontally-moving conveyer for aluminum profile packaging

The invention discloses an automatic horizontally-moving conveyer for aluminum profile packaging. The automatic horizontally-moving conveyer for aluminum profile packaging comprises racks. A plurality of conveying belt devices are arranged on the tops of the racks. Each conveying belt device is provided with a supporting beam mounted on the tops of the racks. Each supporting beam is provided with a driving wheel, a driven wheel and a conveying belt. A material bracket is arranged on the right sides of the driven wheels. The diameter of each driving wheel is larger than that of each driven wheel. The side, close to the corresponding driving wheel, of each supporting beam is provided with a tensioning adjustment device, wherein the tensioning adjustment device is provided with two supporting plates C mounted on the front side and the rear side of the supporting beam, the lower portions of the two supporting plates C are respectively provided with an adjusting groove, a rotary shaft is arranged between the two adjusting grooves, the middle of the rotary shaft is provided with a tensioning wheel in rolling connection with the corresponding conveying belt, the two ends of the rotary shaft are provided with adjusting bolts, two fixing blocks aligned with the adjusting bolts are welded to the outer sides of the two supporting plates C respectively, the adjusting bolts penetrate through the corresponding fixing blocks, and a screw of each adjusting bolt is provided with adjusting nuts which are arranged on the two sides of the corresponding fixing block in a clamping mode. According to the automatic horizontally-moving conveyer, the tightness of the conveying belts can be adjusted automatically, and the conveying belts can be prevented from slipping, so the automatic horizontally-moving conveyer is more flexible in use.

Owner:HUBEI SHIMEI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com