Warp beam yarn leasing device and leasing method thereof

A warp yarn and warp yarn technology, which is applied in the directions of skeining, textiles and papermaking, and tool manufacturing, can solve the problems of two people working at the same time, low production efficiency, and high labor intensity, so as to save operating time and improve production efficiency , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

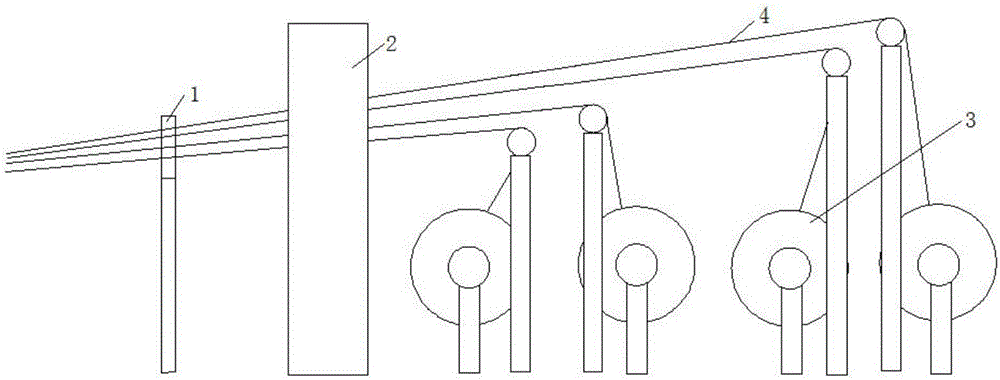

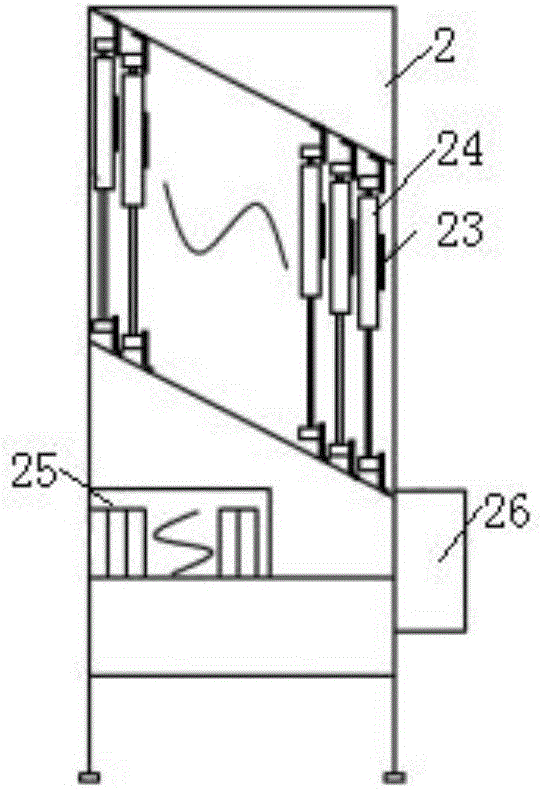

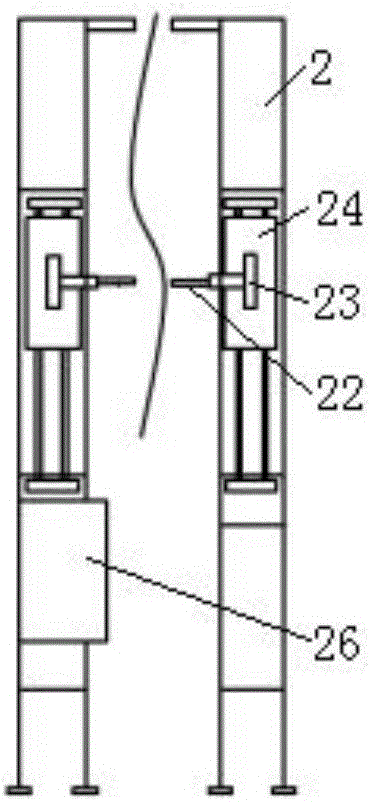

[0057] In an exemplary embodiment of the present invention, a stranding device is provided. figure 1 It is a structural diagram of the splitting device according to the first embodiment of the present invention. Such as figure 1 As shown, it adopts four warp beams 3 for paralleling, and the warp yarn 4 passes through the splitting machine to complete the splitting of warp beam warp yarns. There is a straight reed 11 on the frame 1, and the function of the yarn pressing device 2 is mainly to realize the pressing down of different warp yarn layers in sequence, and separate them from other warp yarn layers, while the function of the straight reed frame 1 is to press down the corresponding warp yarn layers, passing through the left and right Swing, control the warp yarns to fall into the high and low reed teeth of the straight reed 11, because the warp yarn layers are pressed down sequentially, and each time it is pressed down, the straight reed frame 1 performs a left or right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com