Patents

Literature

118 results about "Bar product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In information theory, the bar product of two linear codes C₂ ⊆ C₁ is defined as C₁∣C₂={(c₁∣c₁+c₂):c₁∈C₁,c₂∈C₂}, where (a | b) denotes the concatenation of a and b. If the code words in C₁ are of length n, then the code words in C₁ | C₂ are of length 2n. The bar product is an especially convenient way of expressing the Reed–Muller RM (d, r) code in terms of the Reed–Muller codes RM (d − 1, r) and RM (d − 1, r − 1).

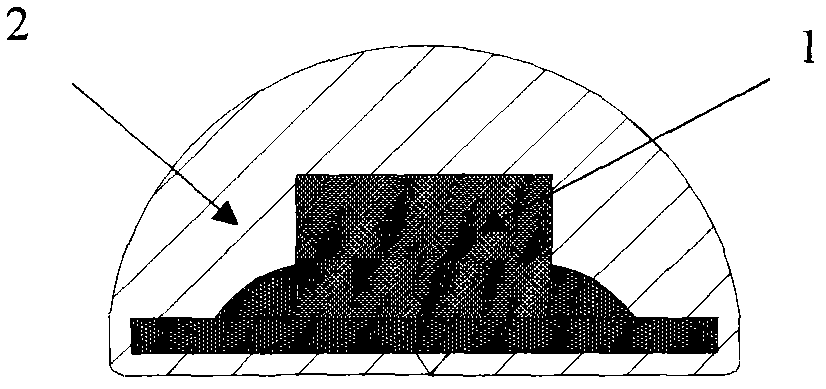

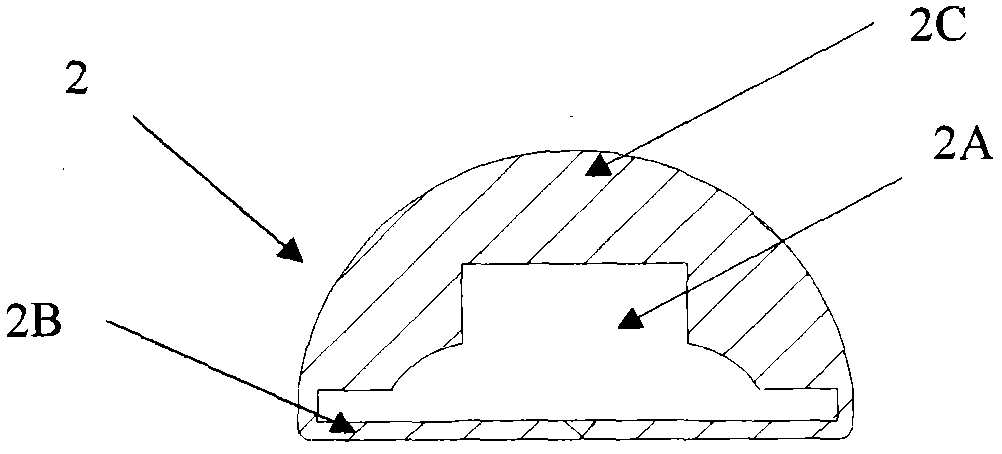

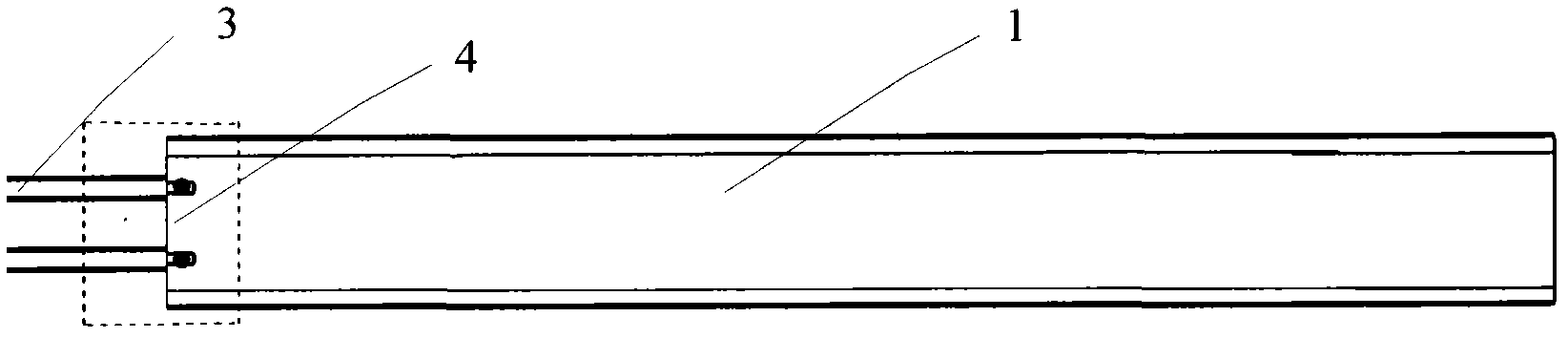

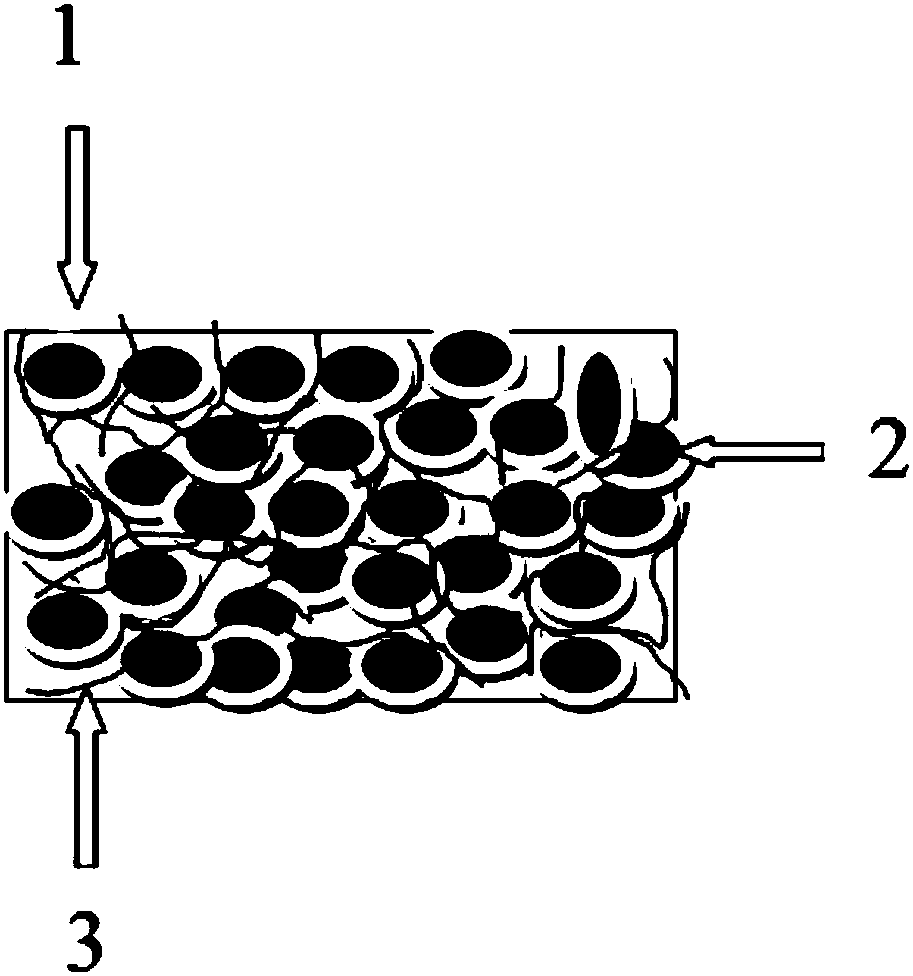

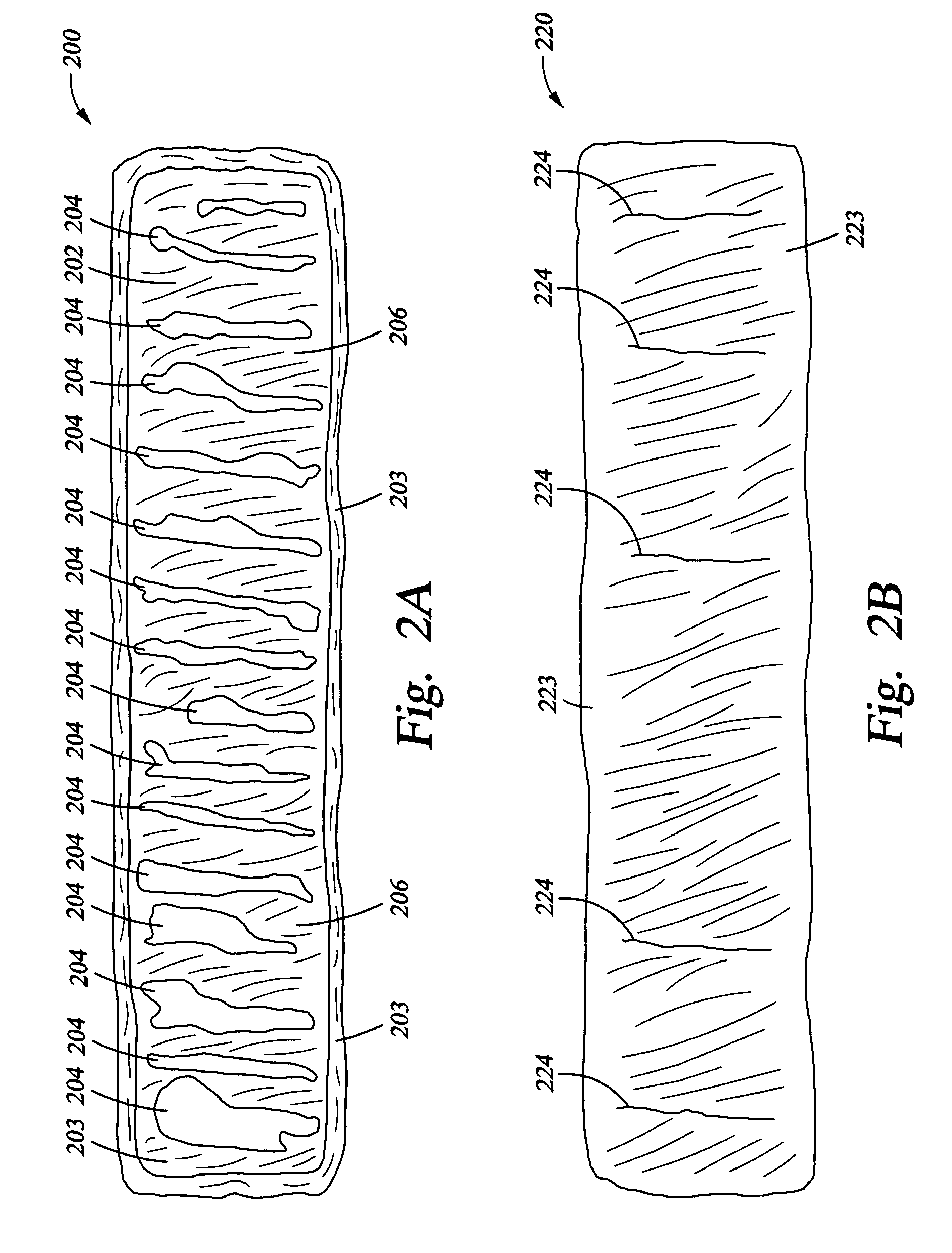

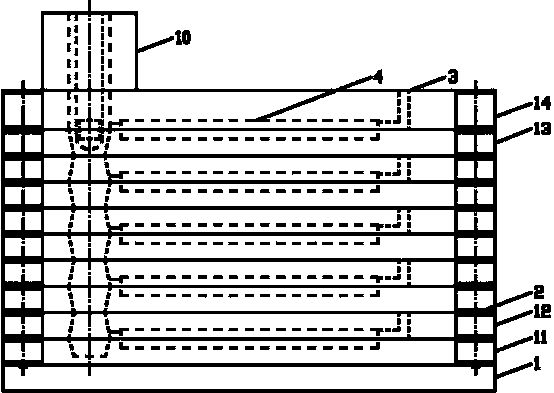

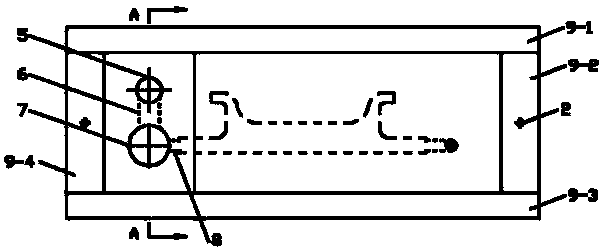

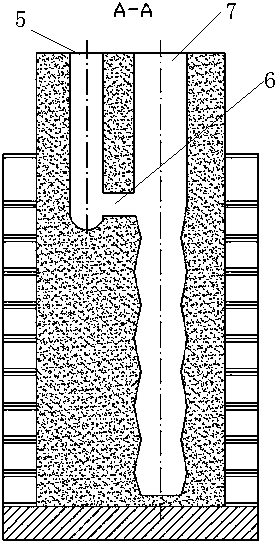

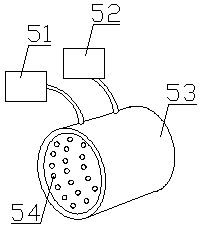

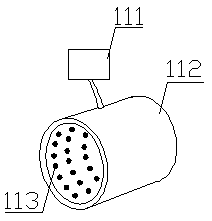

Light-emitting diode lamp bar with fully waterproof glue pouring structure and manufacturing method thereof

InactiveCN102628562AGood waterproof sealingGood weather resistancePoint-like light sourceElectric lightingWeather resistanceBar product

The invention relates to a light-emitting diode lamp bar with a fully waterproof glue pouring structure and a manufacturing method thereof. Specifically, an LED lamp bar is provided. The LED lamp comprises an LED lamp bar body (1) and a fully waterproof glue pouring structure (2) which is extruded and enclosed on the LED lamp bar body (1). The invention further provides a glue sealing method for the LED lamp bar. The method comprises the following steps: providing the LED lamp bar body (1); and extruding and molding a glue sealing material on the LED lamp bar body (1) by an extrusion molding process, so as to form the fully waterproof glue pouring structure (2) annularly enclosing the LED lamp bar body (1). The LED lamp bar has a high waterproof and sealing property on waterproof glue sealing. The LED lamp bar product subjected to glue sealing greatly improves weather resistance and reliability, prolongs the service life, and has a simple and quick production process and high production efficiency.

Owner:惠州市串联电子科技有限公司

Bubble-free yellowing resistant polyurethane electronic potting adhesive composition and preparation method thereof

ActiveCN102174171AAddress inherent shortcomingsGuaranteed light transmittanceOther chemical processesPolyureas/polyurethane adhesivesWeather resistanceAlcohol

The invention relates to a bubble-free yellowing resistant polyurethane electronic potting adhesive composition and a preparation method thereof. The raw material of the composition is a double-component system which mainly comprises a polyatomic alcohol compound, a polyisocyanate compound and other accessory agents with favorable weather resistance; and the proportion of the mole equivalent weight of an isocyanate group to the mole equivalent weight of an active hydrogen compound component in the system is 1.0:0.8-1.0:1.5. The composition disclosed by the invention solves the problems of yellowing, embrittlement, hardening, breakage, and the like which are generated after long-term use, of the traditional transparent potting adhesive; the potting adhesive composition is produced by adopting the raw materials with favorable weather resistance and a special synthesis process; the composition also has excellent weather resistance, and the product can not generate the adverse phenomena after long-term use; and the composition can be applied to a flexible printed circuit board LED soft strip light bar products with extremely high requirements on bending performance and yellowing resistant performance and can be also greatly applied to the industries of optical devices, photoelectric and solar cell panels, and the like in quantity.

Owner:厦门誉匠复合材料有限公司

Manufacturing method of aluminum alloy thick wall tubular product with high strength and high electric conductivity for power equipment

ActiveCN104131200AImprove labor productivityTo meet the order requirementsBar productPower equipment

The invention discloses a manufacturing method of an aluminum alloy thick wall tubular product with high strength and high electric conductivity for power equipment. The manufacturing method comprises the following steps: (1) casting an aluminum alloy cast ingot; (2) cutting a rough material and homogenizing; (3) extruding an aluminum alloy thick wall tubular product; (4) carrying out an aging treatment after tension-drawing the aluminum alloy thick wall tubular product; (5) sampling, examining and packaging the aluminum alloy thick wall tubular product. A section bar product produced by the method can be used for satisfying the standard request, improving the labor productivity, saving the cost, satisfying the ordering requirement of users and improving the production efficiency by 13.5-21%, so that the section bar product is suitable for industrial production.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

Laundry bars comprising non-staining water soluble polymeric colorants

InactiveUS6417155B1Low costEasy to useOrganic detergent compounding agentsAnionic surface-active compoundsStainingHazardous substance

Colored detergent bars are provided comprising water soluble polymeric colorants that exhibit excellent non-staining performance on fabrics and other contacted surfaces, including manufacturing and / or washing equipment, are easy to process into the desired detergent bar compositions, and do not exhibit any appreciable harmful effects to the environment. The particular polymeric colorants utilized in this respect are of very high molecular weight (in order to assure staining will not occur on target cleaning surfaces), are extremely water soluble, provide excellent vivid and aesthetically pleasing color shades within the target bar compositions, and are present as liquid or waxy pastes at room and at processing temperatures. The ultimate laundry bar product thus exhibits highly pleasing colors for product distinction as well as for aesthetic purposes.

Owner:MILLIKEN & CO

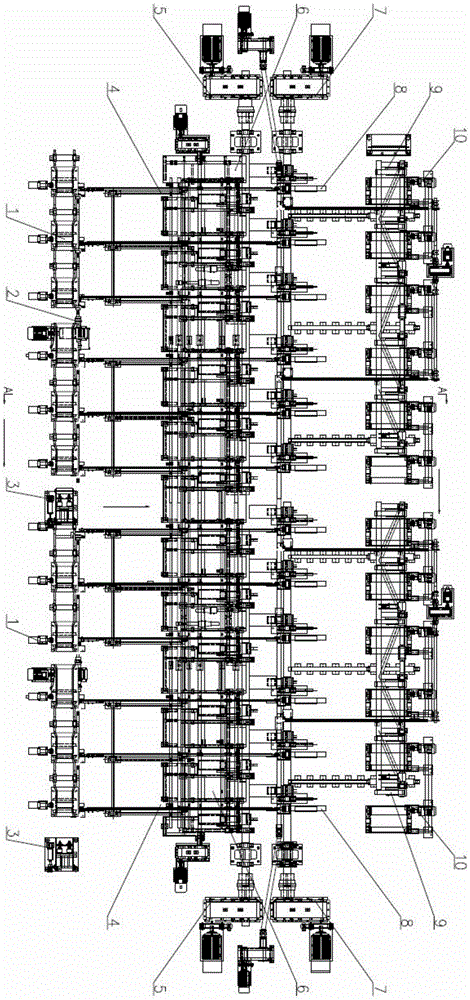

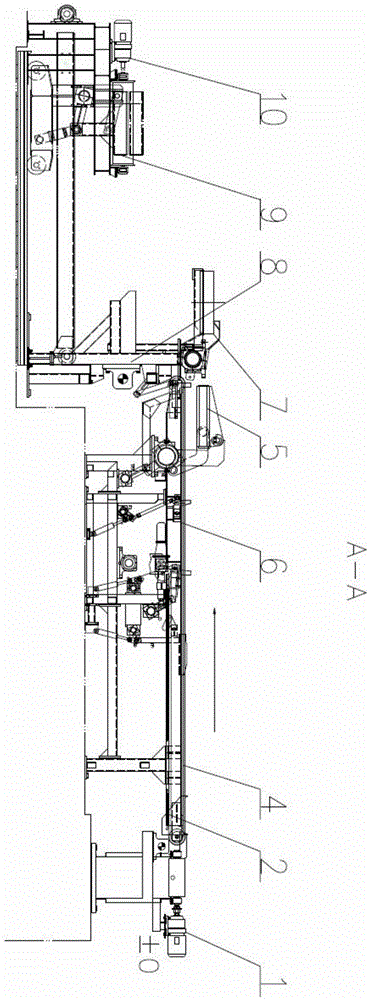

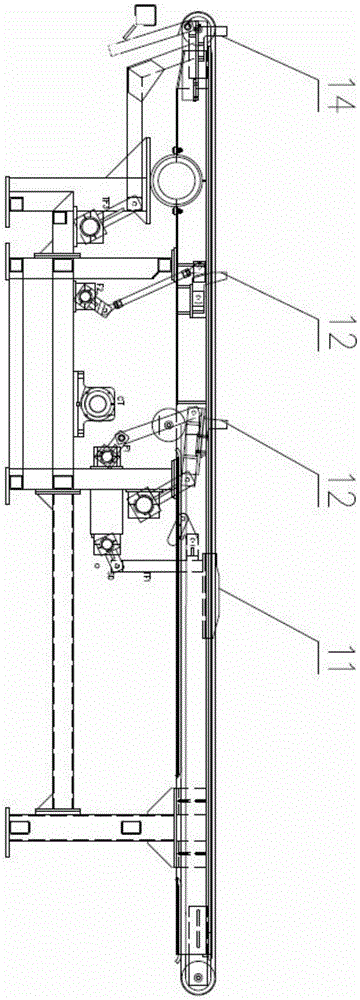

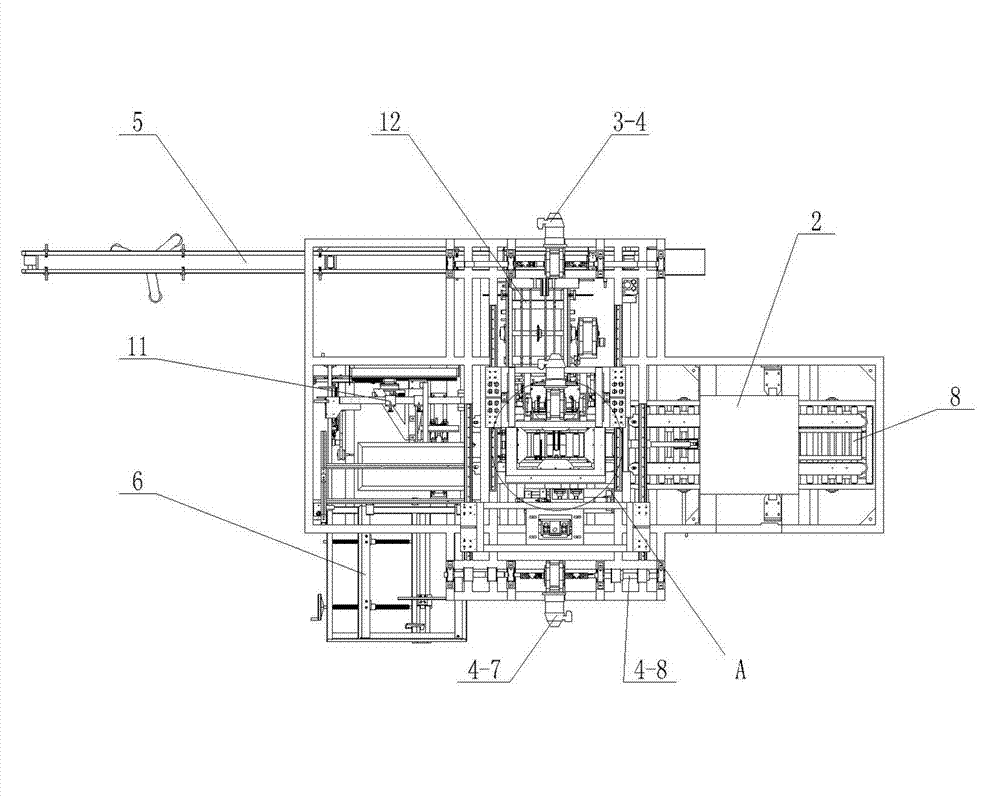

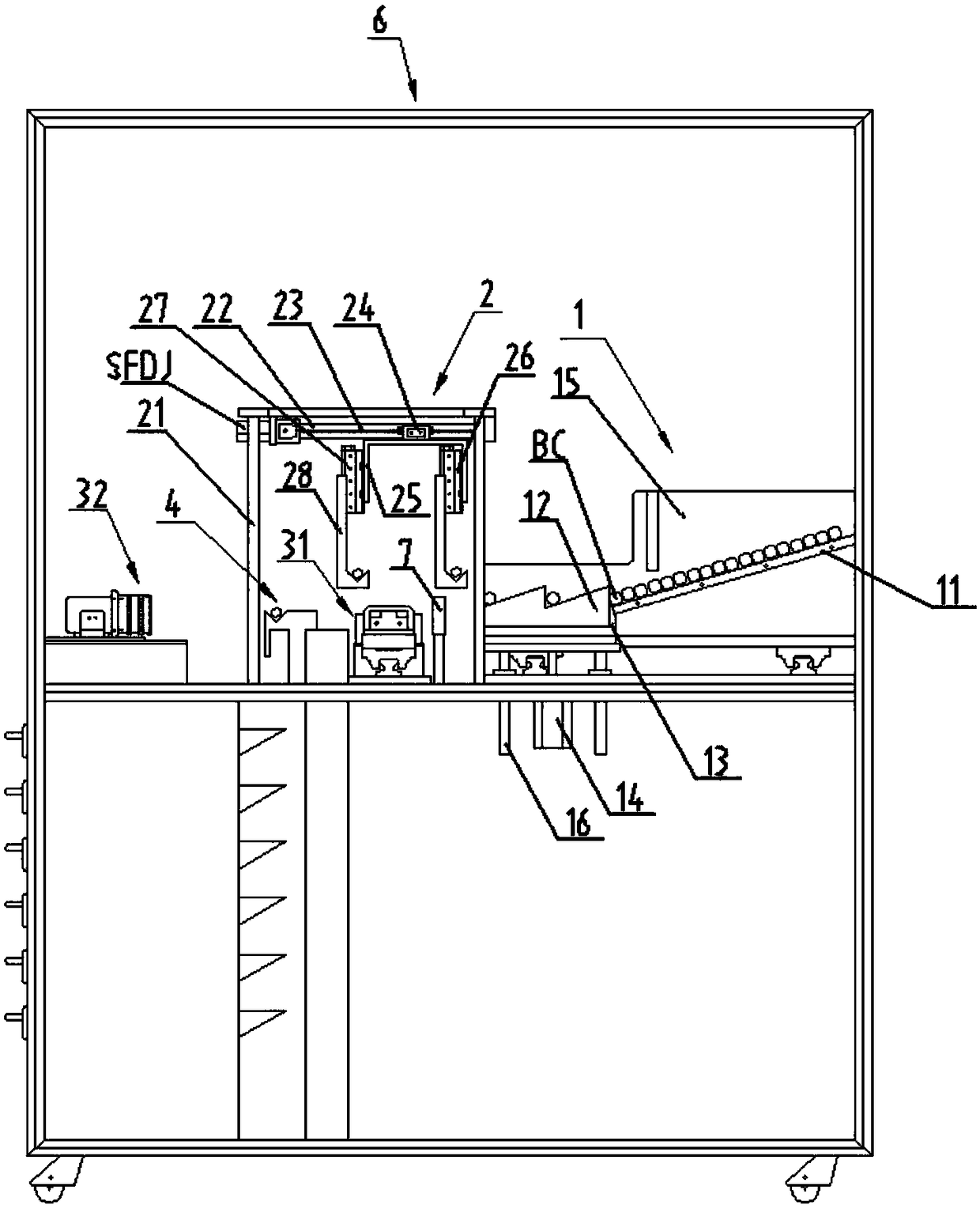

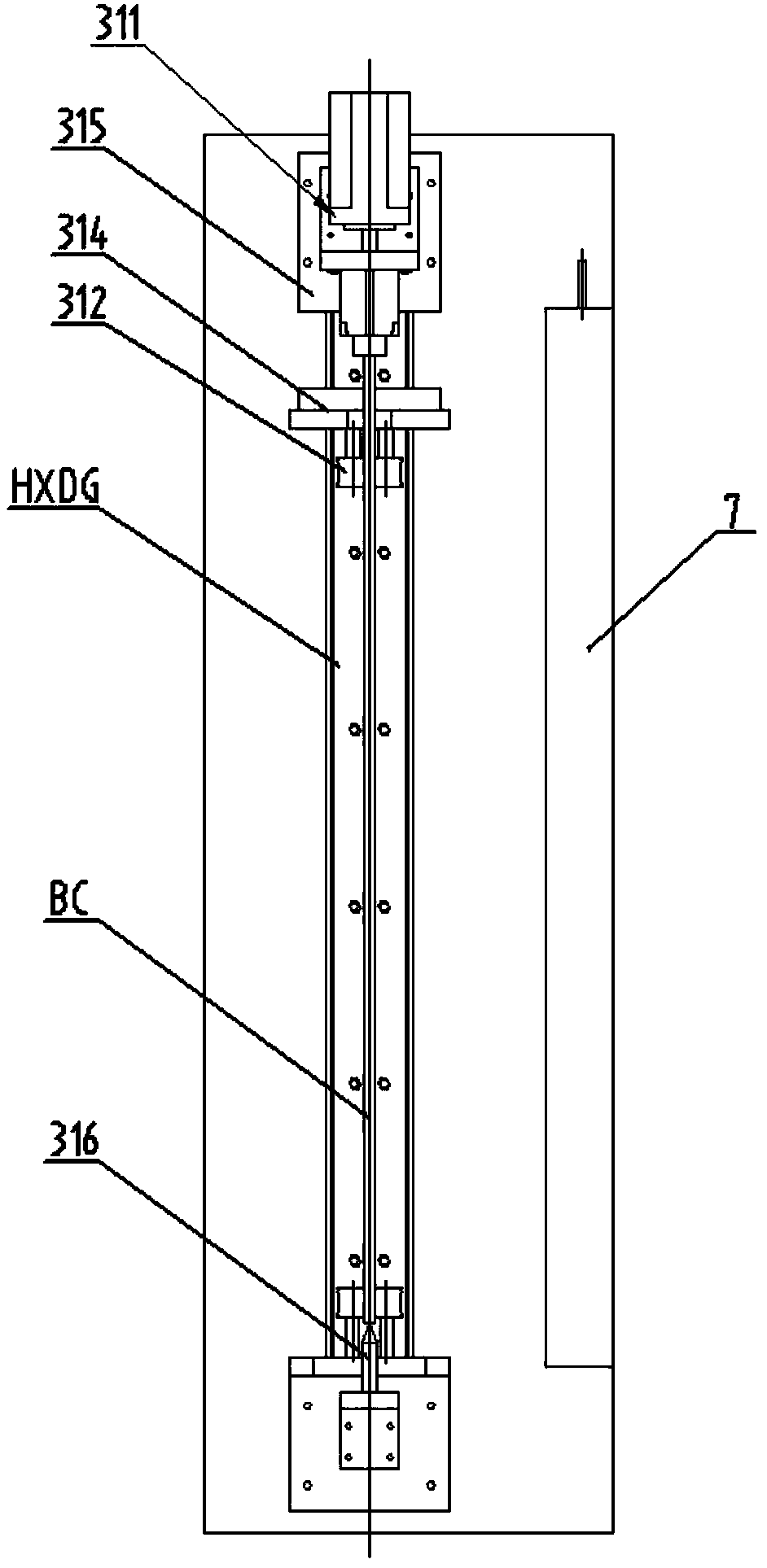

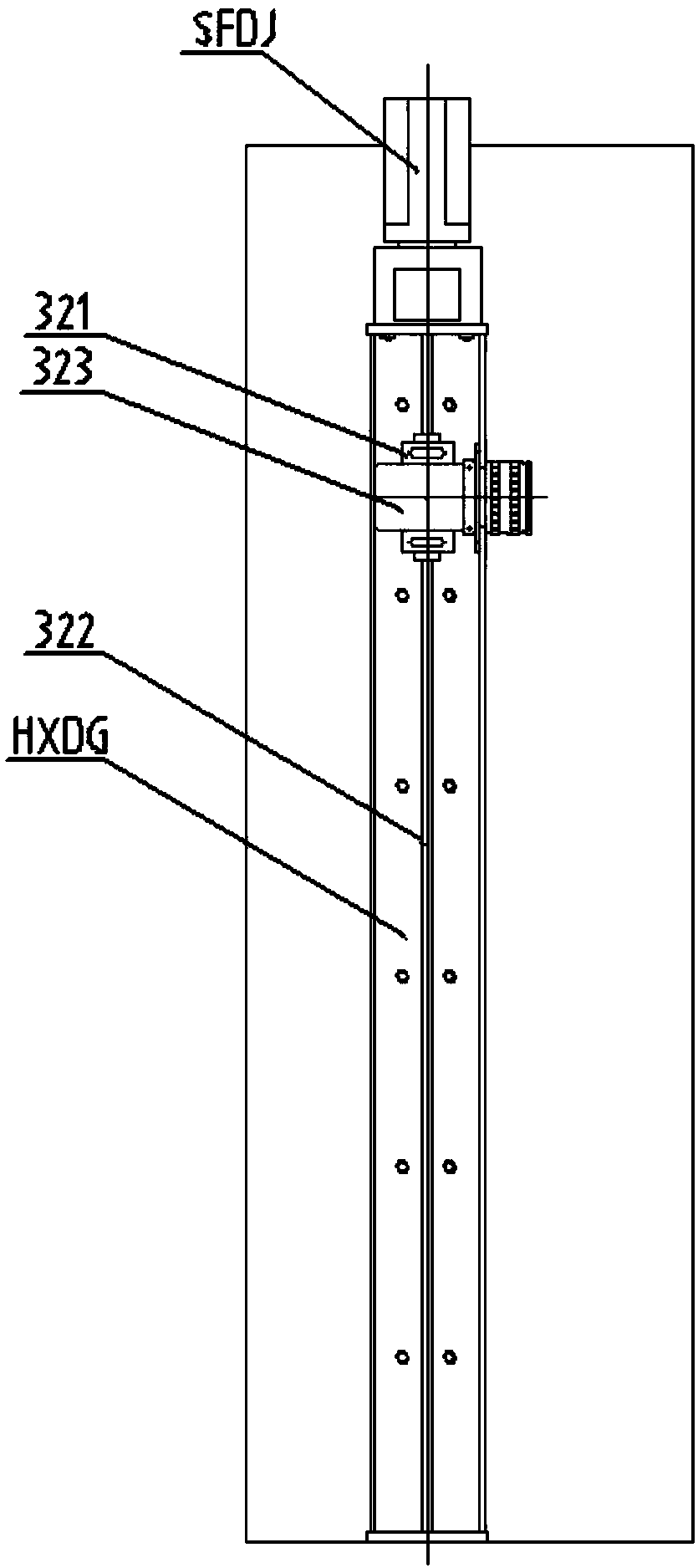

Steel bar splitting-forming and chain transfer machine, section steel stacking device and section steel stacking system

ActiveCN105329674ARealize group stackingRealize the wrong sideStacking articlesBar productEngineering

The invention relates to the technical field of section steel stacking, in particular to a steel bar splitting-forming and chain transfer machine, a section bar stacking device adopting the steel bar splitting-forming and chain transfer machine and a section bar stacking system consisting of a plurality of sets of the section bar stacking devices. The steel bar splitting-forming and chain transfer machine is provided with a plurality of groups of baffle plates, so that grouped stacking of section bar products is realized, and misalignment of the section bar products also can be realized. The section bar stacking device adopts a stacking electromagnet to carry out 180-degree turnover stacking on section steel; an turnover electromagnet is additionally arranged for being matched with the stacking electromagnet for carrying out 360-degree turnover stacking on the section steel, so that positive buckling and negative buckling of channel steel and angle steel can be realized; compared with a conventional translation stacking mode, the stacking mode can effectively improve the stacking quality and the stacking efficiency, and equipment operation is stable and reliable, and high in safety. According to specified length of a section steel product, the section steel stacking system adopts one set of section steel stacking devices to carry out stacking, and adopts two sets of section steel stacking devices to carry out combined stacking, so that the stacking efficiency is high and operation is convenient.

Owner:WISDRI ENG & RES INC LTD

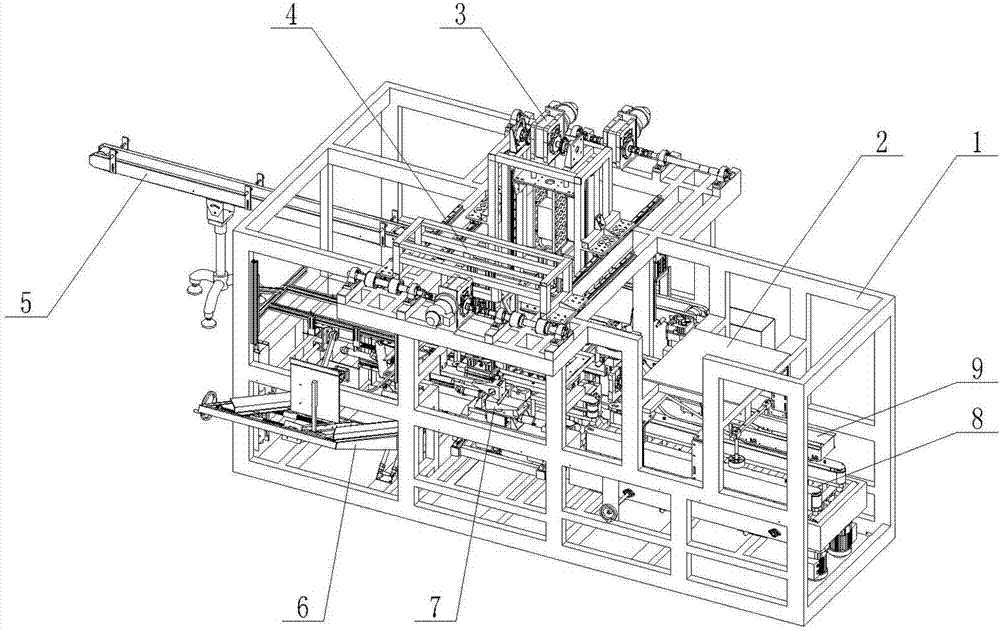

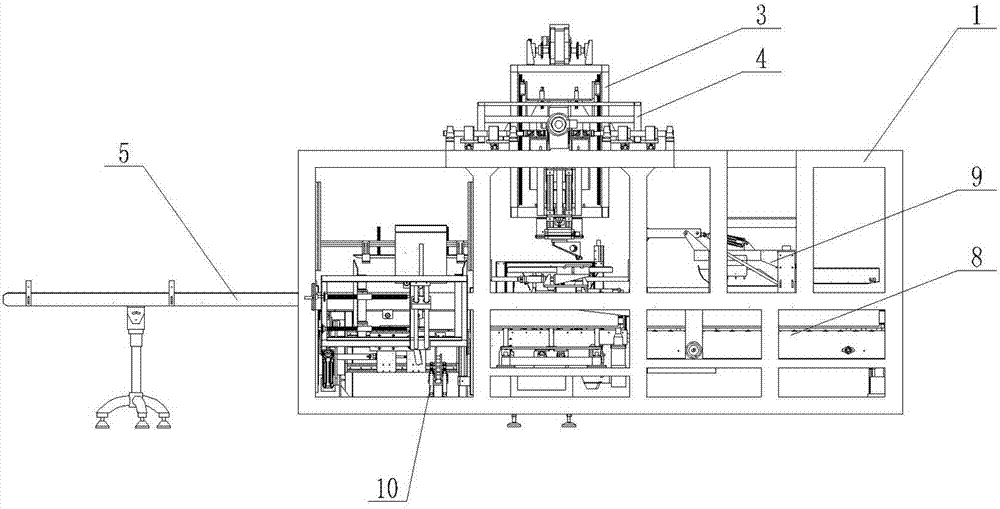

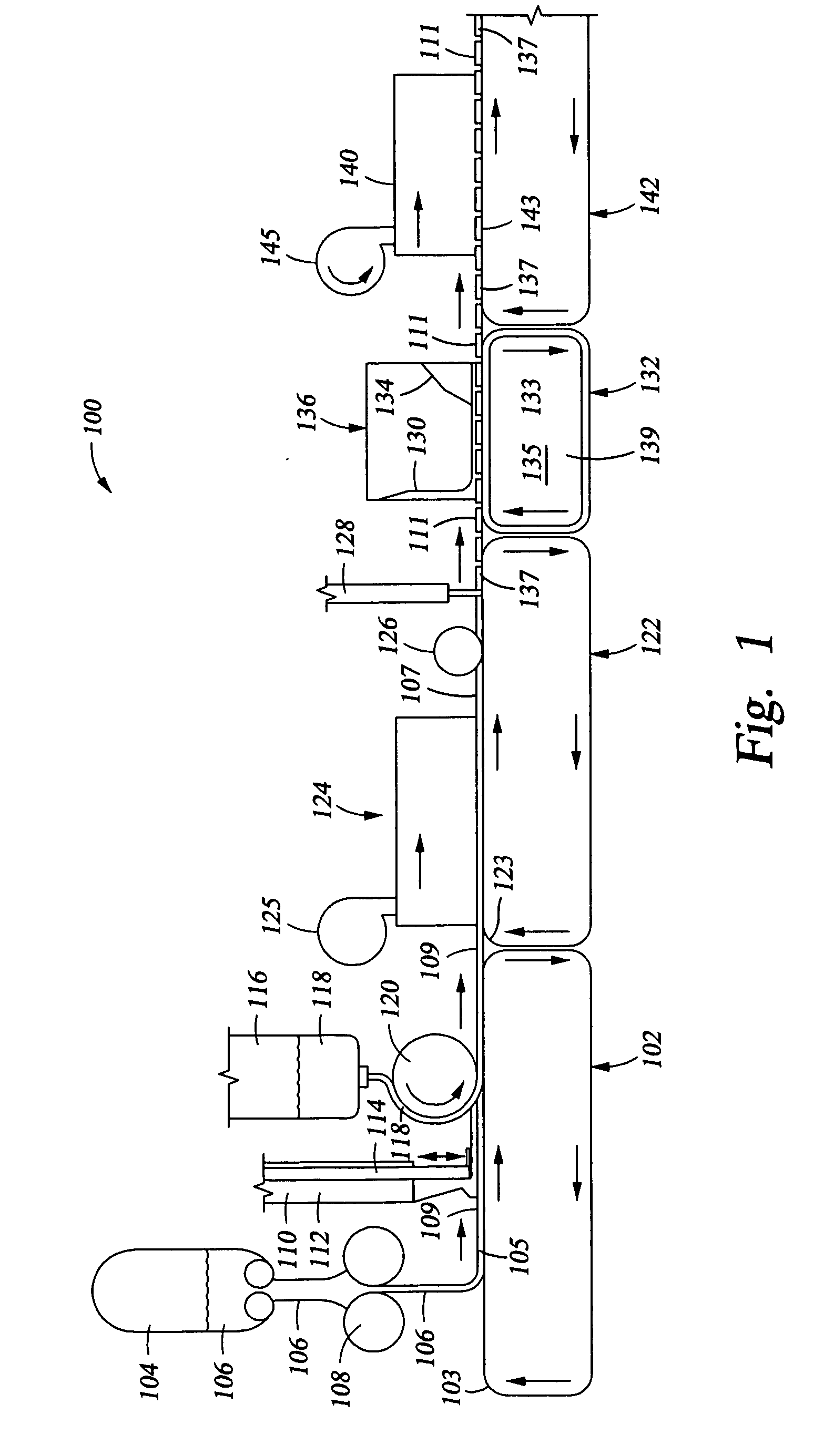

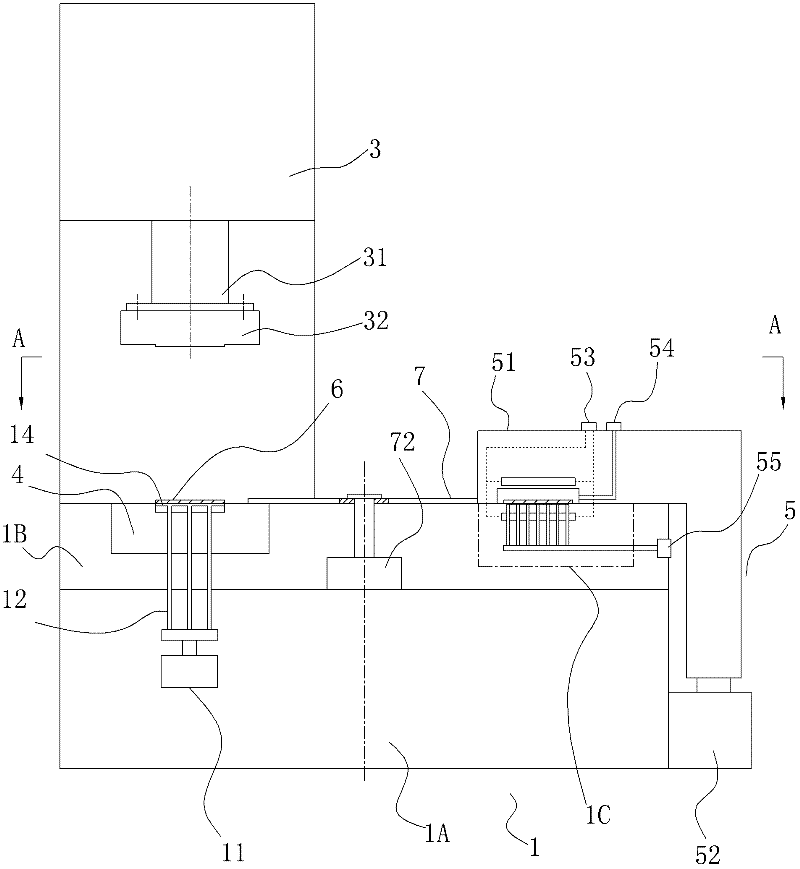

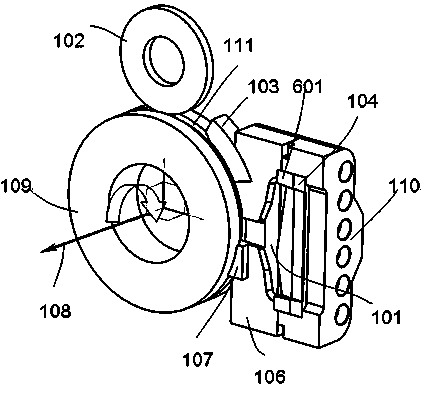

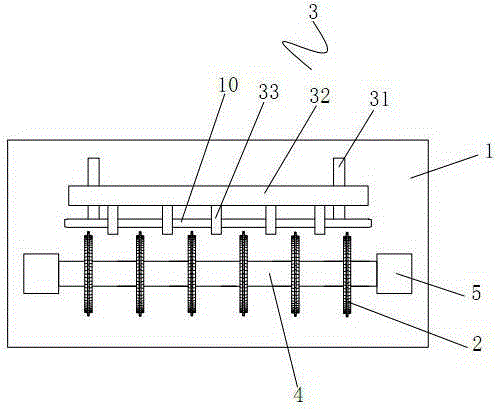

Opening-loading-sealing all-in-one machine for packaging bar products

InactiveCN103662138ALow input costShorten working timeWrapper twisting/gatheringPackaging automatic controlBar productCarton

The invention discloses an opening-loading-sealing all-in-one machine for packaging bar products. A combination box opening machine is arranged on one side of a main frame of the all-in-one machine, a conveying roller way is connected to the box opening machine, a box loading station is arranged on the conveying roller way, and paper boxes are opened and molded through the box opening machine to be conveyed to the box loading station for waiting for box loading; the conveying roller way is respectively connected with a hose sausage body conveying mechanism and a squeezing-out mouth conveying mechanism, a movable hose sausage body box loading mechanism and a squeezing-out mouth box loading mechanism are arranged at the position, above the box loading station, of the conveying roller way, and the box loading mechanisms grab hose sausage bodies and squeezing-out mouths from the conveying mechanisms respectively into the empty paper boxes. The hose sausage body conveying mechanism is provided with a hose sausage body quality testing mechanism and a grouping mechanism, the quality testing mechanism screens out and conveys the qualified hose sausage bodies to the grouping mechanism, and the hose sausage bodies are grouped by the grouping mechanism according to a preset number to be grabbed and carried by the hose sausage body box loading mechanism. The squeezing-out mouth conveying mechanism is also provided with a grouping mechanism, and the squeezing-out mouths are grouped by the grouping mechanism according to a preset number to be grabbed and carried by the squeezing-out mouth box loading mechanism.

Owner:北京阔博包装机械设备有限公司

Foaming section bar of multi-point positive feedback springback material with memorability and preparation method thereof

PendingCN107722602AWith positive multi-point feedback functionUnable to adjust melt viscosity in real timeSolesFoaming agentThermoplastic elastomer

The invention relates to a foaming section bar of multi-point positive feedback springback material with memorability and a preparation method thereof. The foaming section bar comprises a structural support which is composed of distributed enclosed air bags, and network pressure releasing structures which are distributed between enclosed air bags and comprise intercommunicated and open air passages that extend to the outside; the formula comprises the following components: 70-98 parts of degradable thermoplastic elastomers, 0.1-15 parts of a foaming agent, 0.05-0.5 parts of a nucleating agent,and 0-10 parts of a functional auxiliary agent. Compared with the prior art, compressive deformation and bounciness of countless enclosed air bags in the foaming section bar product are restrained and concentrated on relatively uniform surfaces by open air passages or capillaries, so that the product has positive multi-point feedback function.

Owner:上海德亿化工有限公司

Stimulant-containing nutrition bar product and method of manufacture

A stimulant-containing nutrition bar where the stimulant added to the bar exhibits a physical structure which is compatible with the manufacturing process used to prepare a nutrition bar. Simultaneously, the physical structure and the chemical composition of the stimulant reduces the amount of bitter taste which is experienced by a person eating the nutrition bar. Stimulants of the kind which are useful in the nutrition bar must be approved as food grade materials and are typically selected from the group consisting of caffeine, theobromine, green tea with high EGCG, taurine, ginseng, synephrine, and combinations thereof. The amount of stimulant present in the nutrition bar ranges from about 0.08% by weight to about 0.16% by weight of the nutrition bar.

Owner:NEXTPROTEINS INC

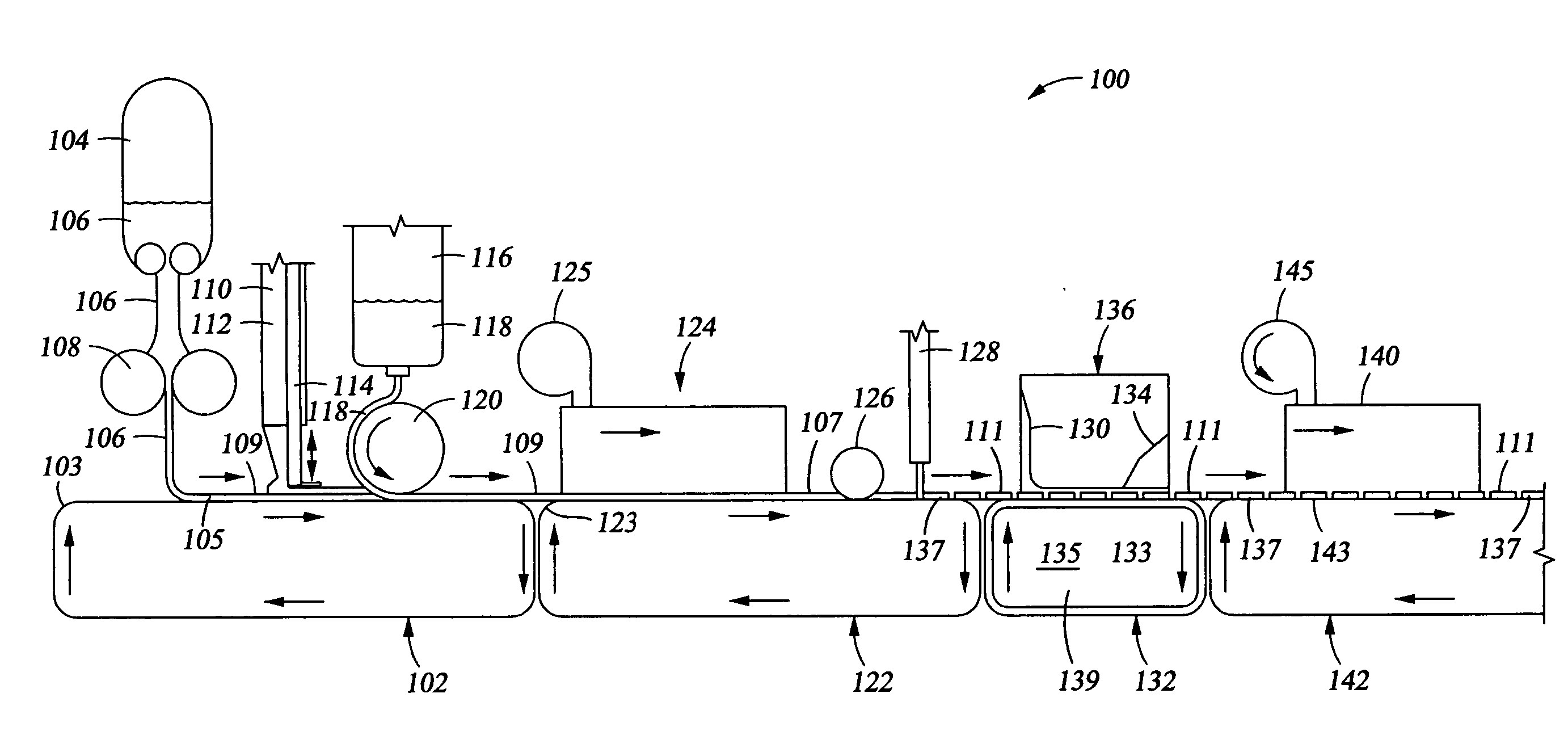

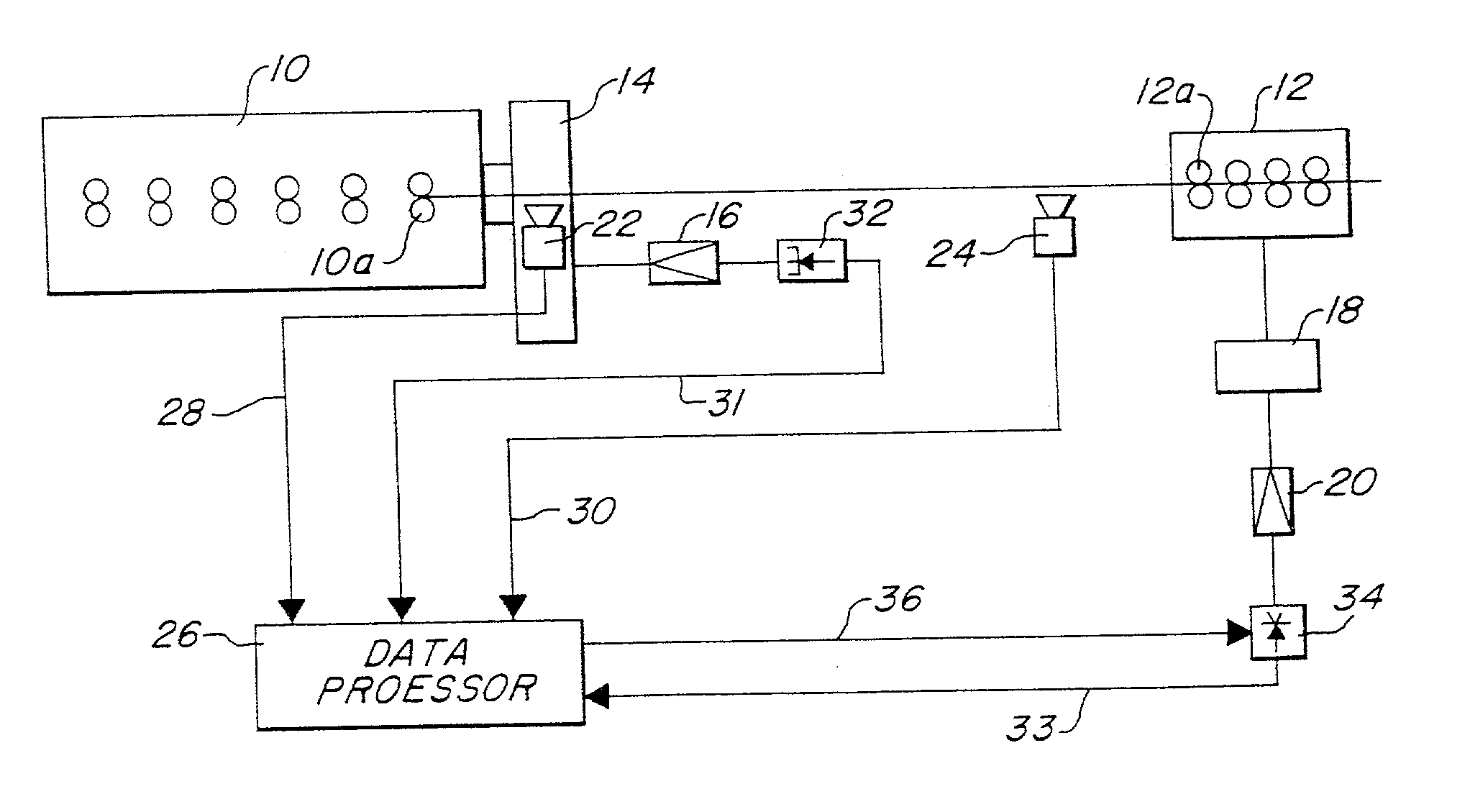

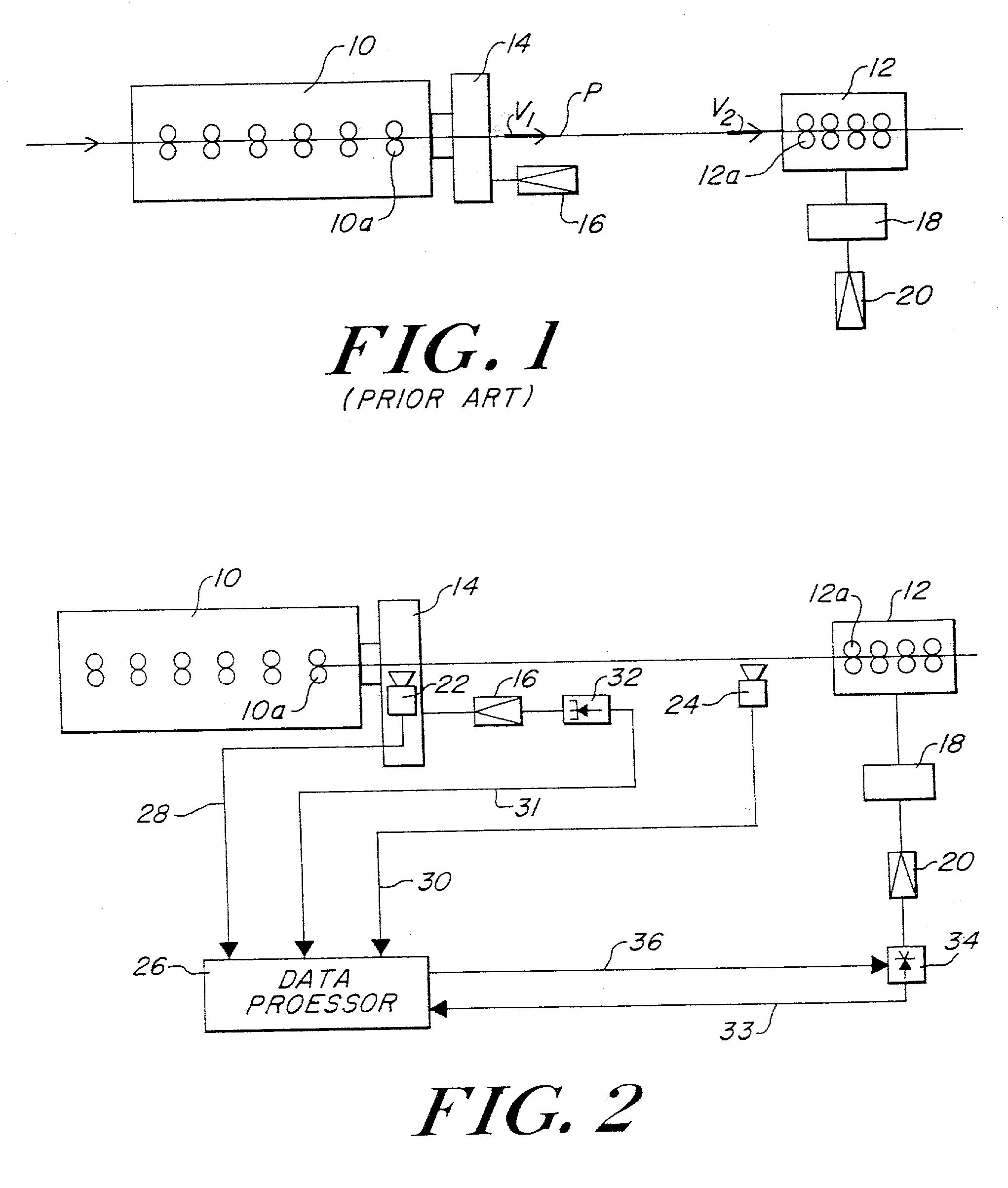

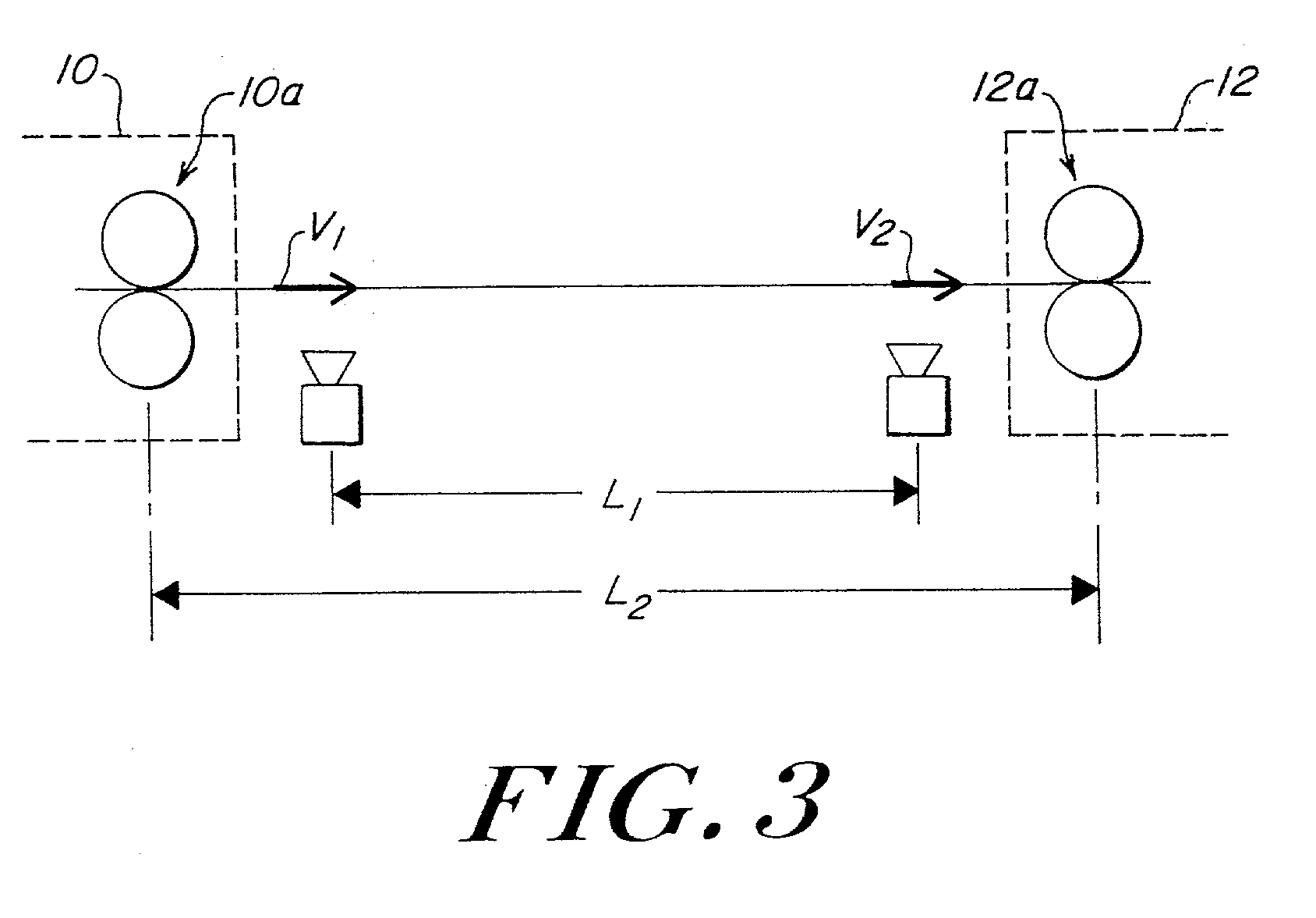

Tension control system for rod and bar mills

InactiveUS20020177972A1Speed measurement using accelerationAverage speed measurementContinuous measurementControl signal

A system is disclosed for controlling the tension in rod or bar products being rolled continuously in first and second roll stands independently driven by drive motors. A first surface velocity gauge is positioned at the delivery side of the first roll stand and a second surface velocity gauge is positioned at the entry side of the second roll stand. The first and second gauges are operative, respectively, to continuously measure and generate control signals representative of the exit surface velocity of the product exiting the first roll stand and the entry surface velocity of the product entering the second roll stand. Separately operable controllers are provided for varying the operating speeds of the roll stand drive motors. A data processor operates in response to the control signals generated by the velocity said gauges to determine in real time the differential between the product exit and entry surface velocities, and to generate command signals to the speed controller unit of at least one drive motor to vary the operating speed of that drive motor in order to maintain the differential between the product exit and entry surface velocities within a desired range.

Owner:MORGAN CONSTR CO

Electroplating preparation method of copper-clad aluminium bars

ActiveCN101665966AUniform internal stressReduce use costSingle bars/rods/wires/strips conductorsMetal/alloy conductorsManufacturing technologyCopper plating

The invention relates to the manufacturing technology of power transmission conducting bars, in particular to an electroplating preparation method of copper-clad aluminium bars, which comprises the following steps: 1. preparing an aluminium bar, and drawing the aluminium bar to achieve the required size by a mould; 2. washing the aluminium bar with alkali; 3. preliminarily copperplating the aluminium bar washed with the alkali; 4. putting the aluminium bar in a main plating bath for copper sulphate copperplating: continuously blowing the surface of a workpiece in the electroplating process; 5.moving the plated product to a rinse bath and cleanly rinsing the plated product in running clean water; 6. drawing the electroplated product by a dimensioning mould to lead the size of the product to reach requirements; and 7. annealing the drawn product at the annealing temperature of 330-335 DEG C, preserving heat for 5 hours and then carrying out furnace cooling. The conducting bar products obtained by the method have smooth copperplating surfaces, different bimetallic separation in the processing process and low manufacturing cost.

Owner:镇江艾喜恩科技有限公司

Grate bar material and production method thereof as well as combined pouring unit of sintering machine

ActiveCN103849819AReduce contentHigh hardnessFoundry mouldsFurnace typesChemical compositionBar product

The invention relates to a production method of a grate bar material of a sintering machine. The production method mainly solves the problems that a high-alloy grate bar is complex in production process, relatively high in production cost, difficult in casting flaw control, non-uniform in performance and the like in the prior art. The technical scheme of the invention is as follows: the grate bar material of the sintering machine comprises the following chemical components in percentage by mass: 1-1.5% of C, 1.5-2.5% of Si, 1.2-2.2% of Al, 2.5-3% of Mn, 11-15% of Cr, 0.3-0.8% of Mo, 0.01-0.03% of Nb, 0.01-0.03% of Ti, 0.03-0.1% of Re, less than or equal to 0.06% of P, less than or equal to 0.06% of S, and the balance of Fe and inevitable impurity elements. A sand casting process of 'one pouring with more molds' is applied, so that the aluminum content and the casting flaws of a silicon grate bar are reduced, and the production cost is reduced. A heat treatment furnace provided with a flow guide circulating fan is applied to low-temperature uniform heat treatment on a cast so as to improve the performance uniformity of casts of the same batch. By adopting the production method disclosed by the invention, a grate bar product of the sintering machine, which is good in process stability, good in performance and relatively low in production cost, can be obtained.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

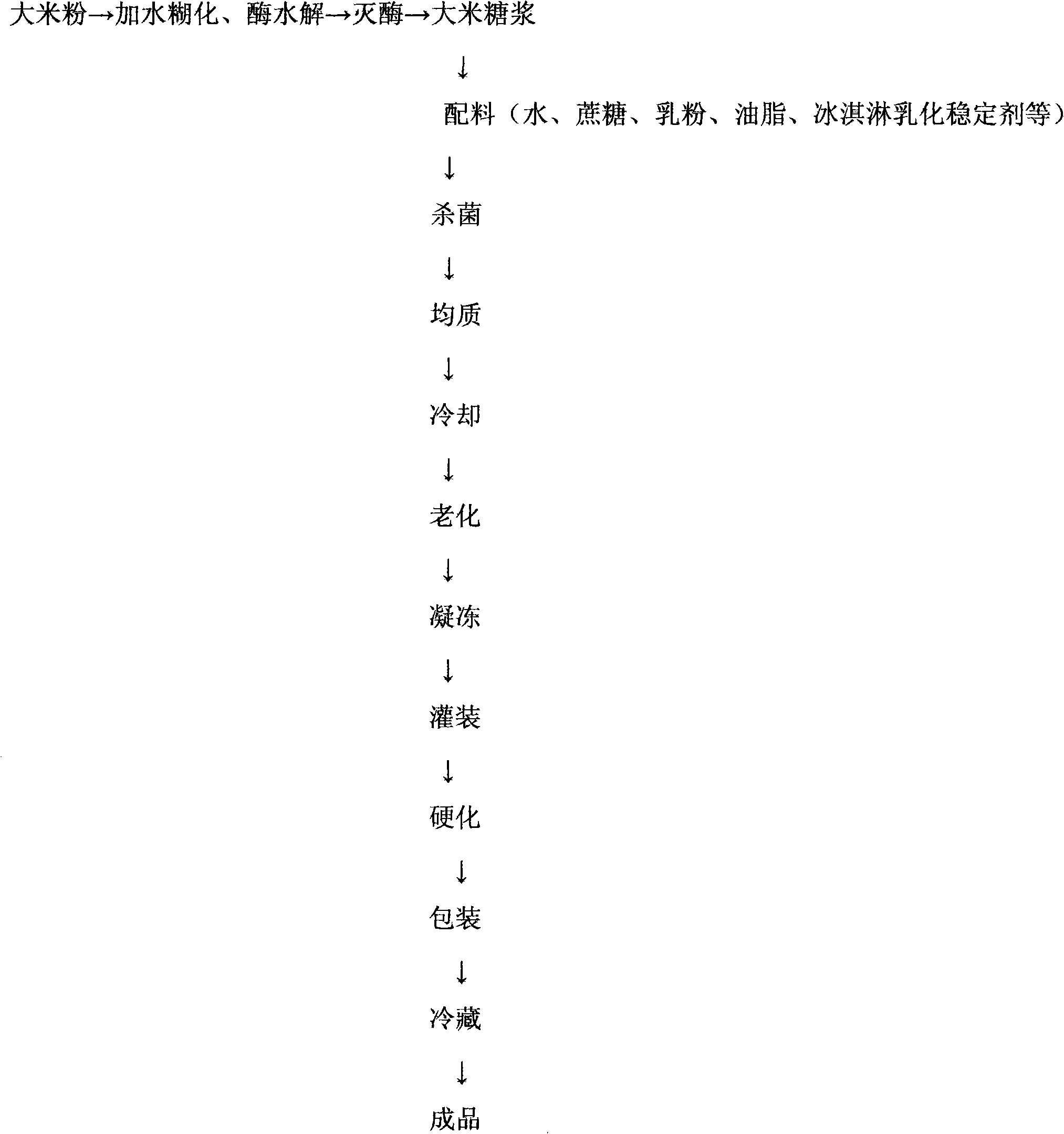

Ice cream/frozen stick confection with additive rice flour, and method of preparing the same

InactiveCN101313726AHigh biological potencyHigh-quality protein resourcesFrozen sweetsGlucose-Fructose SyrupSucrose

The invention discloses ice-cream / an ice cream bar added with rice meal and a production method thereof. The production method adds the rice meal in compositions of the ice-cream / ice cream bar, and the rice meal is hydrolyzed by amylase into rice syrup containing rice proteins and used to replace or partially replace glucose syrup or partial sucrose, thereby the protein content of an ice-cream / ice cream bar product can be improved and the ice-cream / ice cream bar with double proteins can be obtained. The ice-cream / ice cream bar has rich nutrition, smooth mouthfeel, and milk and rice flavor; and the cost per unit protein is reduced.

Owner:贝惠玲

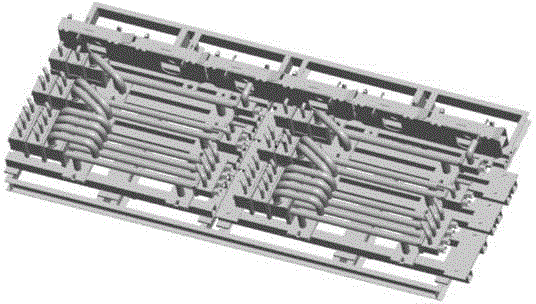

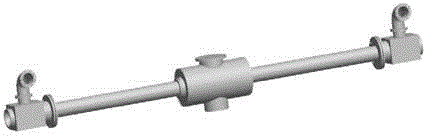

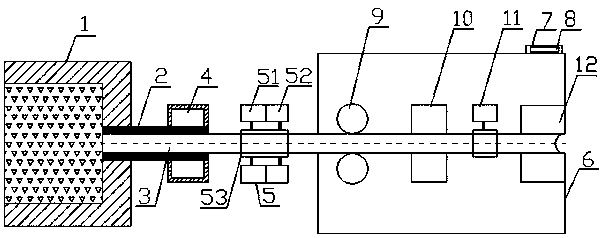

Multifunctional bar graded temperature control rolling and controlled cooling equipment

InactiveCN104148408AMeet cooling needsTemperature control deviceWork treatment devicesTemperature controlStrip mill

The invention provides multifunctional bar graded temperature control rolling and controlled cooling equipment, and belongs to the technical field of hot-rolled bar on-line controlled rolling and cooling equipment. The equipment comprises four cooling sections of the 1# A cooling section which is arranged on an outlet of a 12# rolling mill, the B cooling section which is arranged between a 14# rolling mill and a 18# rolling mill, the 2# C cooling section which is arranged behind the 18# rolling mill, and the 3# D cooling section which is arranged behind 3# double length shears. The multifunctional bar graded temperature control rolling and controlled cooling equipment has the advantages that the specifications of suitable products range from 10 mm to 60 mm in diameter; the yield strength grade of suitable steel ranges from 400 MPa to 1100 MPa; the ultimate temperature after controlled rolling can achieve 800 DEG C; the cooling area ranges from 300 DEG C to 1000 DEG C; the cooling speed adjustable range is 30-500 DEG C / s; the temperature fluctuation of a finish rolling inlet after controlled rolling and cooling and an upper cooling bed is smaller than or equal to + / -7.5 DEG C. The multifunctional bar graded temperature control rolling and controlled cooling equipment has obvious advantages on generality, cooling evenness, the controlled rolling and ultra fast cooling mode, the cooling area, the cooling speed adjustable range and the like, and the cooling demand for various steel kinds, full specifications and precise evenness of bar products is met for the first time.

Owner:SHOUGANG CORPORATION

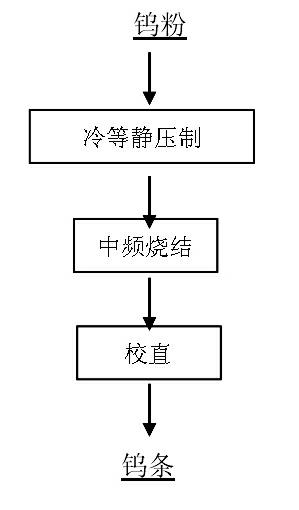

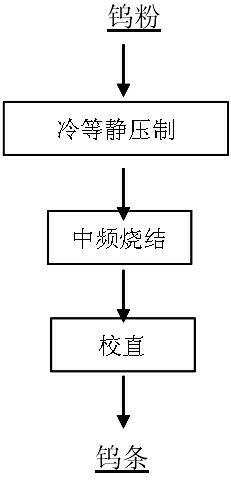

Method for producing tungsten bar for calendering

InactiveCN102101170AUniform densityHigh strengthTurbinesOther manufacturing equipments/toolsBar productHeating furnace

The invention discloses a new method for producing a tungsten bar for calendaring. The method sequentially comprises the following steps of: moulding prepared tungsten powder and performing cold isostatic pressing; sintering pressed billets at the temperature of between 2,150 and 2,500 by using a heating furnace under vacuum or protective atmosphere; preserving the heat for 2 to 15 hours to obtain the sintered billets; placing the sintered billets into the heating furnace at the temperature of between 1,000 and 1,400 DEG C and under the protective atmosphere to heat for 15 to 50 minutes; taking out the sintered billets; and straightening the sintered billets to obtain the final tungsten bar product. By the method, crack-generating, edge-losing and corner-losing phenomena of the product are avoided; density of the product is uniform; the internal quality of the product is improved; the product is not required to be subjected to heat cutting or low-temperature sintering or be processed; the actual yield of the products is greatly improved; and energy consumption is greatly reduced.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

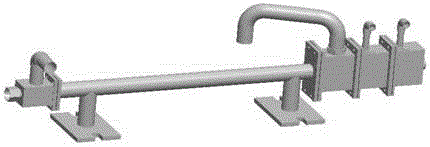

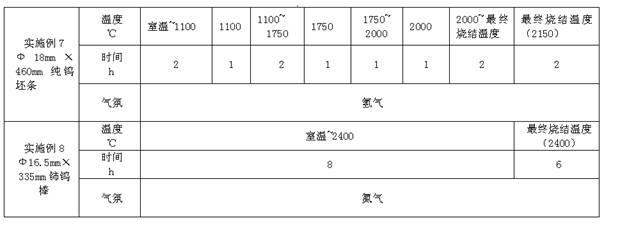

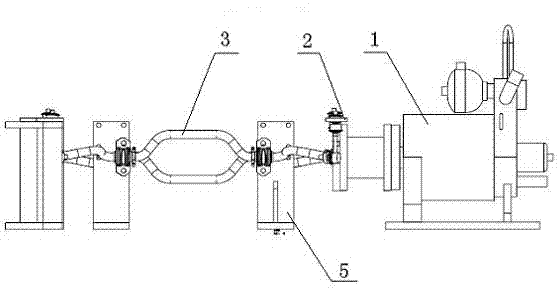

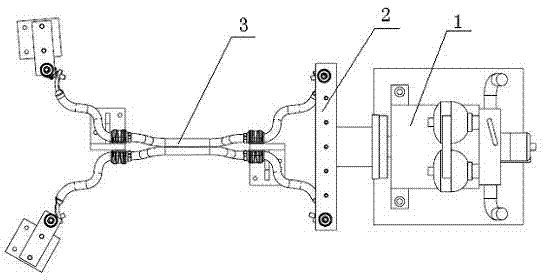

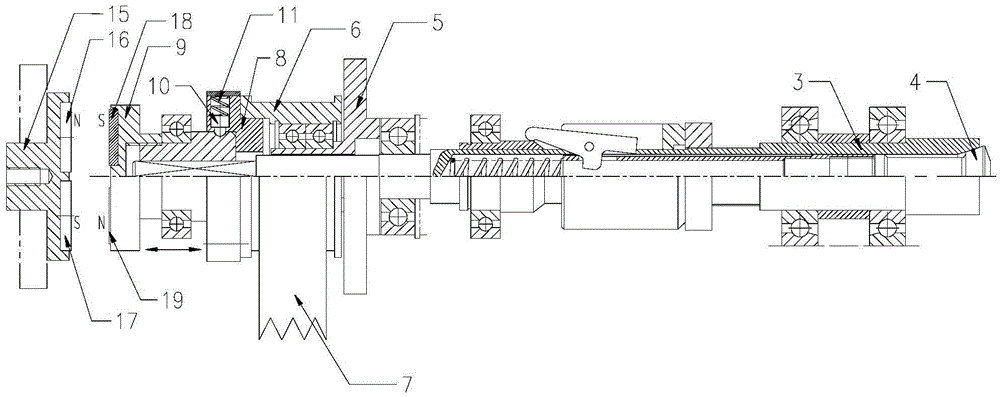

Fatigue durability testing device for transverse stabilizer bar

ActiveCN102331338ASimple resultWork reliablyMachine part testingVehicle suspension/damping testingBar productEngineering

The invention relates to the technical field of mechanical testing equipment, in particular to a fatigue durability testing device, and solves the problem that an automobile transverse stabilizer bar product is subjected to fatigue durability test under various working conditions. The fatigue durability testing device comprises a power device. A torsion driving cylinder is arranged in the power device. An output end of the torsion driving cylinder is provided with a torsion driving swing arm. The torsion driving swing arm is of a strip bar structure, is vertical to the axial center line of the torsion driving cylinder and is eccentrically arranged. The transverse stabilizer bar is provided with two pieces in the horizontal direction. The torsion driving cylinder can load a sinusoidal waveform, triangular wave, random wave or path spectrum signal under the control of a computer. By using the fatigue durability testing device, the test is stable and the efficiency is high. Various actual using working conditions are simulated. The comprehensive cost is relatively low.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Chinese medicinal health-care bra for treating hyperplasia of mammary glands and preparation method thereof

InactiveCN102178357AMaintain and develop aestheticsMaintain and promote the role of body sculptingAnthropod material medical ingredientsBrassieresSide effectMedicine

The invention discloses a Chinese medicinal health-care bra for treating hyperplasia of mammary glands and a preparation method thereof. The Chinese medicinal health-care bra for treating the hyperplasia of mammary glands comprises a bra and medicament pads which are arranged in cups of the bra, wherein medicament extract is adsorbed to the medicament pads; and the medicament pads are positioned at outer lower quadrant or outer upper quadrant in the cups and are arranged in small hidden bags in the cups or arranged in the cups serving as linings. The Chinese medicinal health-care bar product has the advantages of simple structure, attractive appearance, practicability, definite curative effect, no toxic or side effect, convenience for use and economy and is an ideal product for treating the hyperplasia of mammary glands.

Owner:XI AN JIAOTONG UNIV

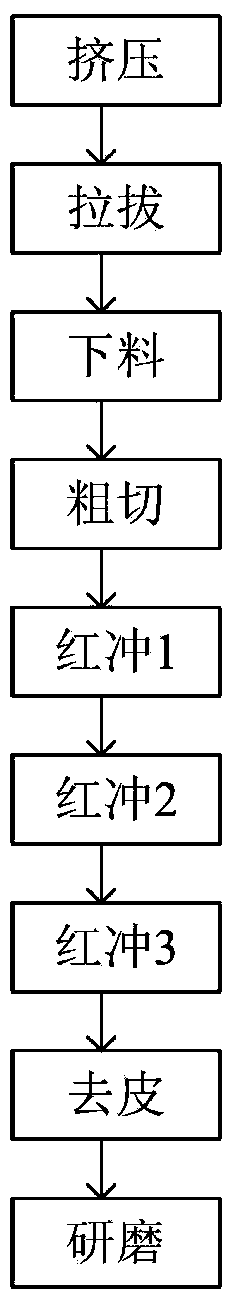

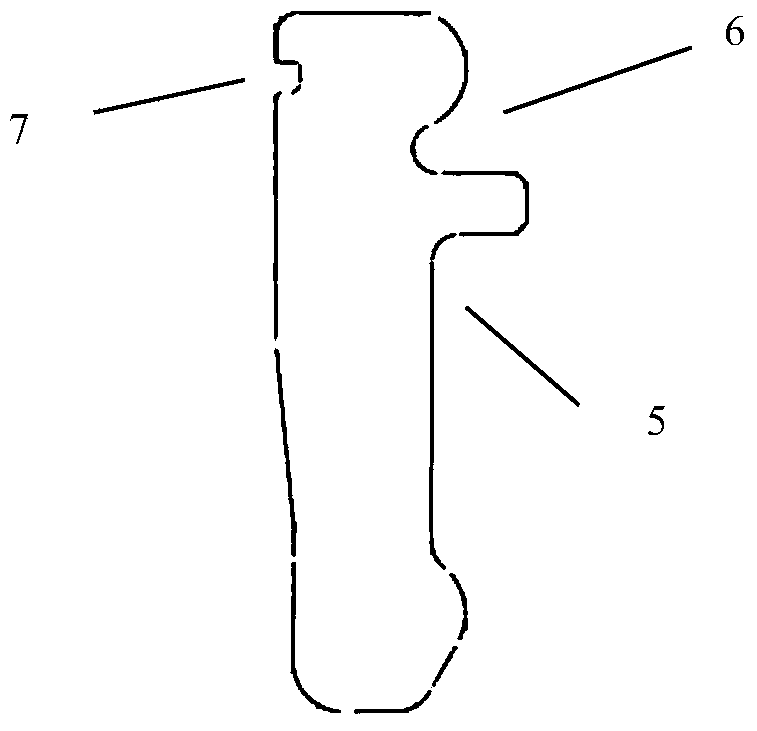

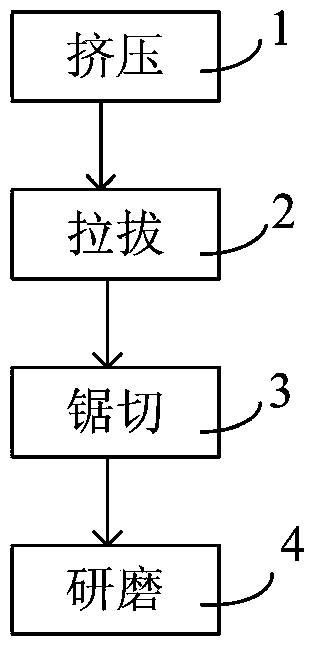

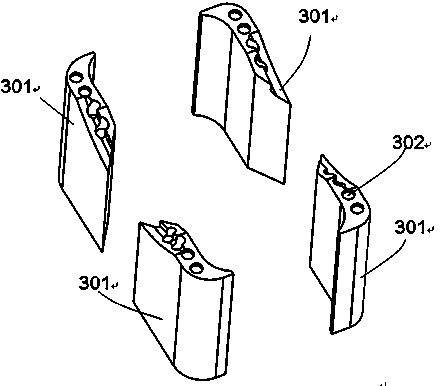

Production method for processing contacts by special-shaped copper bars

InactiveCN103909387AReduce the waste of secondary sawing timeReduce wasteElectric switchesBar productTime cost

The invention discloses a production method for processing contacts by special-shaped copper bars. The production method includes the following steps: continuously extruding the copper bars by an extrusion die to form contact-shaped copper bar blanks, drawing the copper bar blanks by a drawing machine to form high-precision special-shaped copper bar products, sawing the whole copper bars to the thickness needed by single workpiece, and polishing the whole copper bars to acquire finished products. Compared with conventional methods, the production method has the advantages that working procedure is reduced and production cost and labor time cost are saved.

Owner:厦门艾瑞克斯铜业有限公司

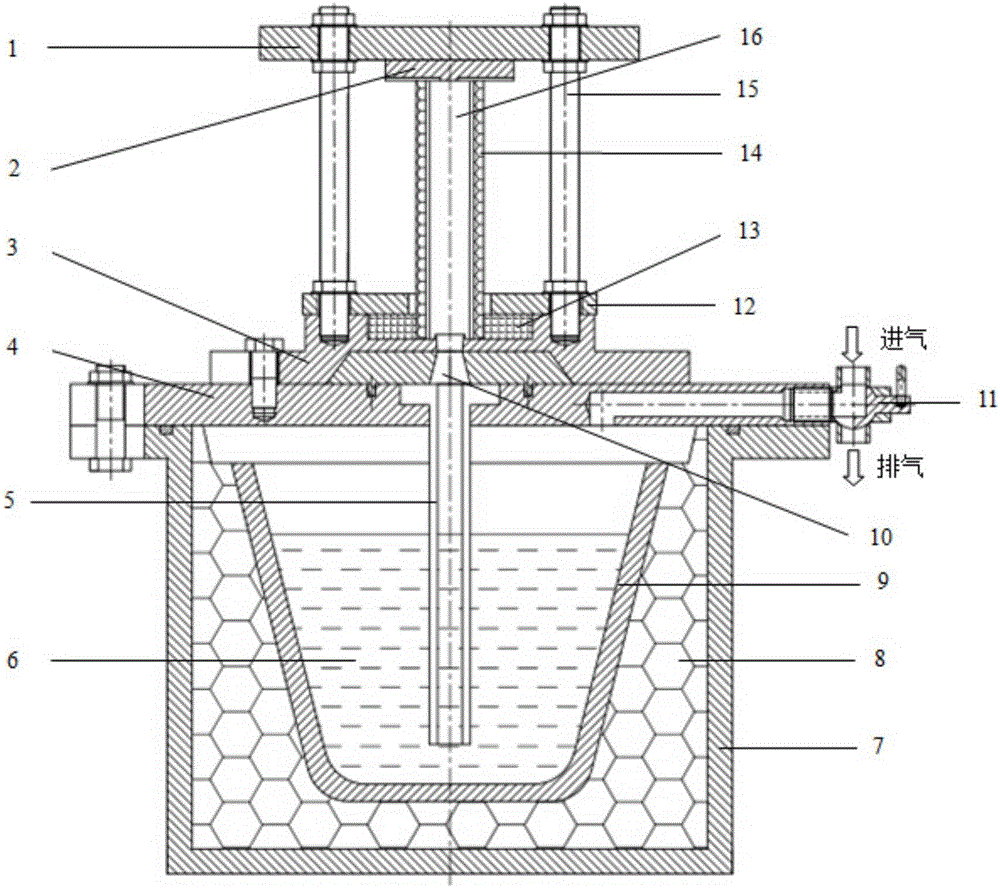

Low-pressure core filling preparation technology of copper-clad aluminum composite material

The invention discloses a low-pressure core filling preparation technology of a copper-clad aluminum composite material. The low-pressure core filling preparation technology comprises the steps that degreasing and descaling are carried out on the inner wall of a copper pipe, an anti-oxidation film is prepared on the inner wall of the copper pipe, and then the copper pipe is dried; smelting is carried out to obtain molten aluminum, and the copper pipe is preheated when the smelting temperature of the molten aluminum is close to set temperature; then a crucible is put in a low-pressure core filling machine, and the copper pipe and the low-pressure core filling machine are in butt joint and are sealed; compressed gas is used for core filling, pressurization and pressure maintaining; and pressure relief is carried out after solidification, and a copper-clad aluminum bar product is taken down. According to the method, the process of the technology is simple; technological parameters are controlled easily; production efficiency is high; the occupied area is small; the production cost is low; the product quality is good; and good environmental friendliness is achieved.

Owner:SOUTHEAST UNIV

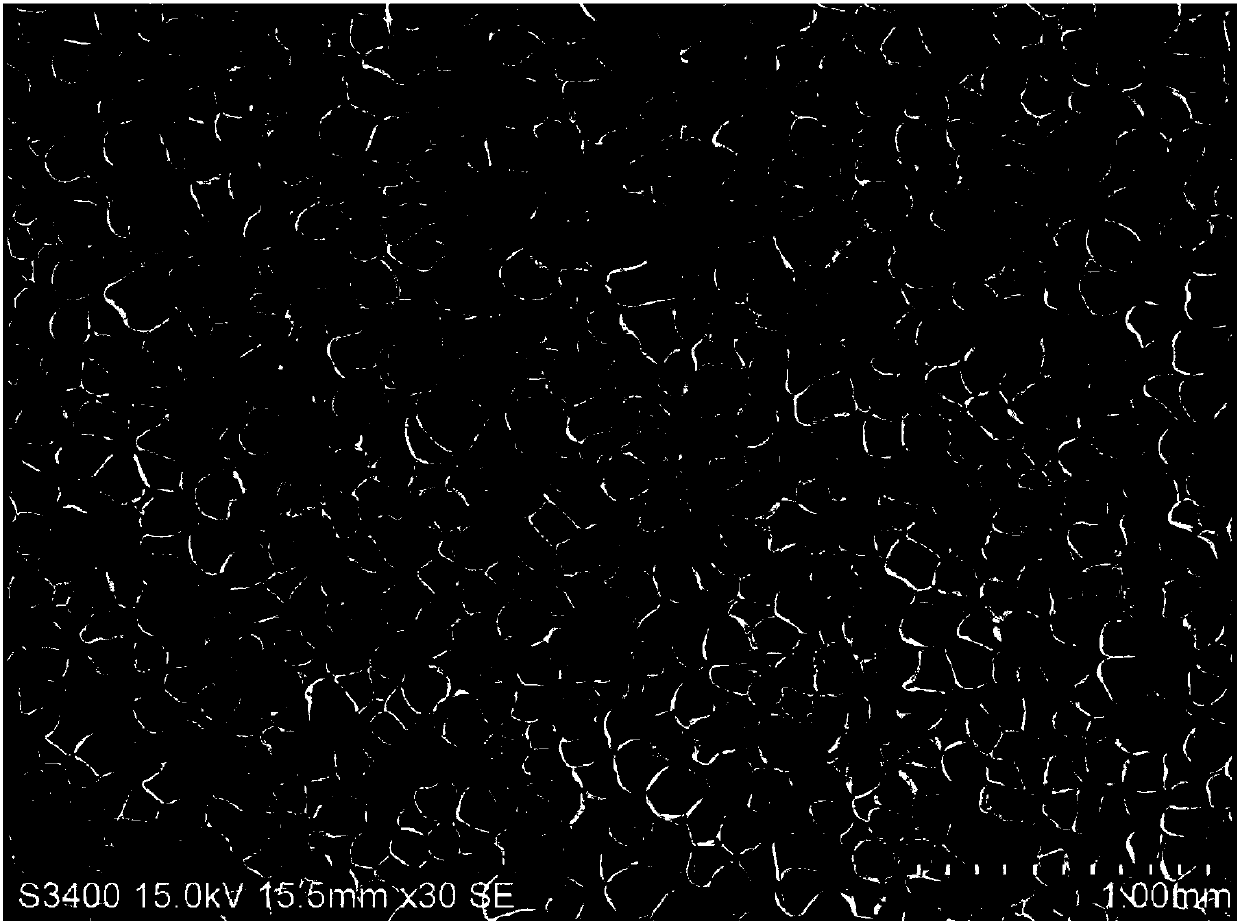

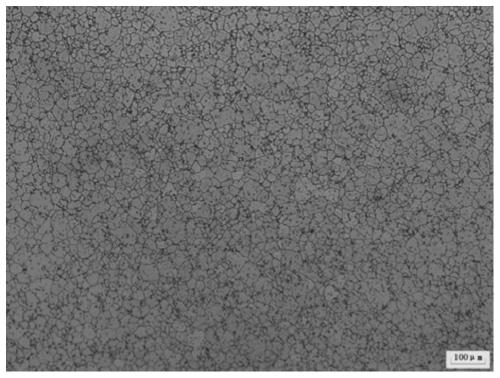

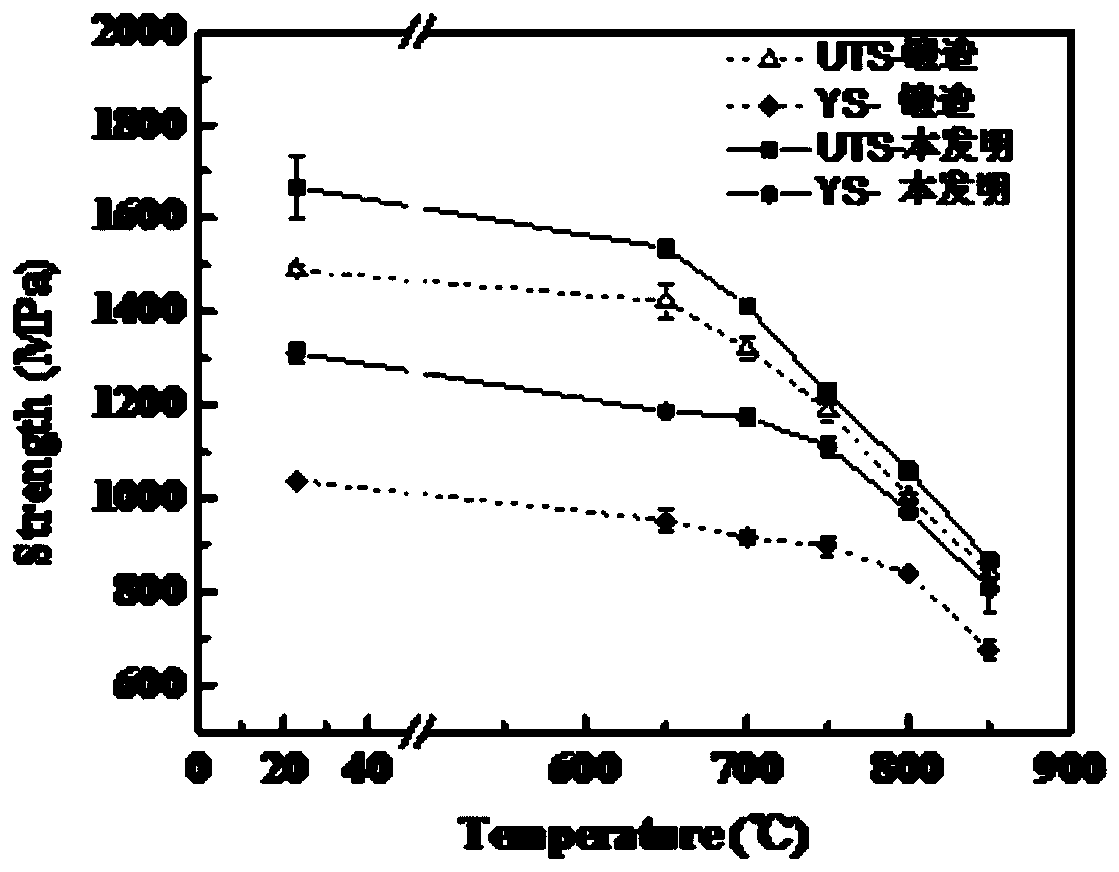

Preparation method for wrought superalloy fine-grain bar

The invention belongs to the technical field of advanced processing for superalloys, and relates to a preparation method for a wrought superalloy fine-grain bar. The preparation method for the wroughtsuperalloy fine-grain bar comprises the following steps: raw material preparation, vacuum induction furnace smelting, vacuum self-consuming re-melting, high-temperature diffusion homogenizing annealing, upsetting and blank preparation, thermal sheathing, sand blasting for a sheathed blank, glass lubricant brushing, extrusion preparation for a bar material, and sheath removal. According to the preparation method for the wrought superalloy fine-grain bar, an upsetting process and an extrusion cogging process are organically combined, and a small-specification ingot case is innovatively adoptedfor preparing the large-specification bar, so that the problems of high process deformation difficulty and difficulty to process and form, of the material, are solved; the bar is fine and uniform in grain structure; the produced complex alloyed wrought superalloy bar product is high in quality, and ideal in microstructure control; the mechanical property is enhanced and improved; and high materialqualification rate and remarkable economical benefits are achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Manufacturing method of platinum bar and platinum bar mould-pressing device

The invention discloses a manufacturing method of a platinum bar and a platinum bar mould-pressing device. The manufacturing method of the platinum bar comprises the following steps of: preparing materials: preparing blank materials according to a corresponding style of the platinum bar; carrying out surface treatment: immersing the blank materials into acid to remove impurities on the surfaces of the blank materials; polishing: utilizing a polishing machine provided with a cloth wheel to polish the blank materials; spraying sand: uniformly carrying out sand spraying treatment on front and rear surfaces of the blank materials; continuously and repeatedly carrying out first-annealing and second-oil-pressing for six times, wherein the annealing temperature is 950 DEG C; parameters of a mould cavity correspond to those of the blank materials; buffing: buffing six faces of the platinum bar by a flying disc of a buffing machine to remove surplus burrs, respectively; electroplating platinum bar: immersing the platinum bar after the buffing treatment into rhodium solution to carry out electroplating on the surface of the platinum bar; and checking: carrying out qualification checking on an electroplated platinum bar product. The platinum bar manufactured by the manufacturing method, provided by the invention, has the advantages of flat character fonts, qualified weight, uniform line, complete and beautiful sanded surface, uniform and smooth and mutually-vertical frames, and obvious comparison effect as a whole.

Owner:SHENZHEN BOFOOK JEWELRY

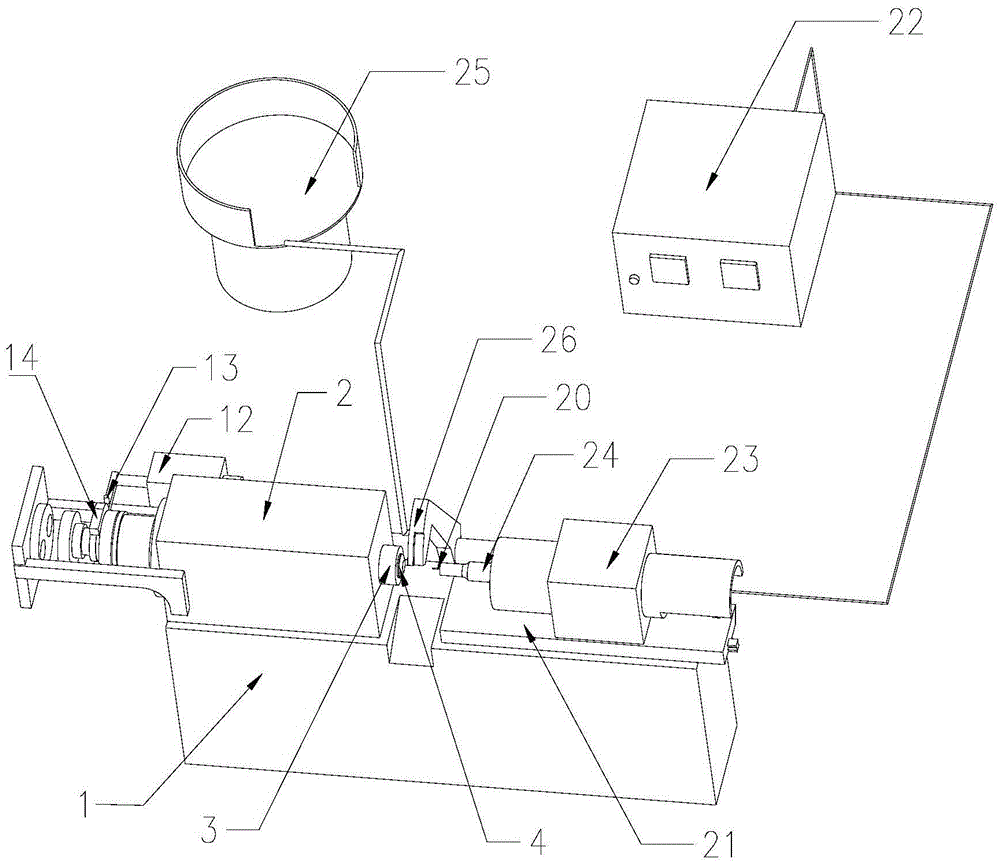

Novel copper bar drawing casting process and equipment

The invention discloses a novel copper bar drawing casting process and equipment. The technical method specifically comprises the following steps: (a) smelting: extruding molten liquid in a heat preservation furnace by an extruder into a graphite sleeve for forming; (b) condensation: condensing a copper bar initially formed in the step a through a water-cooled crystallizer; and (c) cooling: cooling the copper bar condensed in the step b through a cooling device, blowing out cold air by a cold air machine, uniformly spraying the cold air onto the copper bar through spraying holes in the inner wall of an annular sleeve, then blowing out air at normal temperature through a fan, and uniformly spraying the air onto the copper bar through the spraying holes in the inner wall of the annular sleeve to gradually cool the copper bar. The cooling effect is good, and the product quality is high. By procedures of smelting, twice cooling, drawing, drawing for stripping, cleaning and discharging, thenumber of subsequence procedures can be reduced, and the labor cost is reduced; furthermore, an all-in-one machine is controlled by a PLC (Programmable Logic Controller), so that the automation degree is high; and the produced copper bar product is stable in quality, clean, attractive and relatively high in quality.

Owner:三花股份(江西)自控元器件有限公司

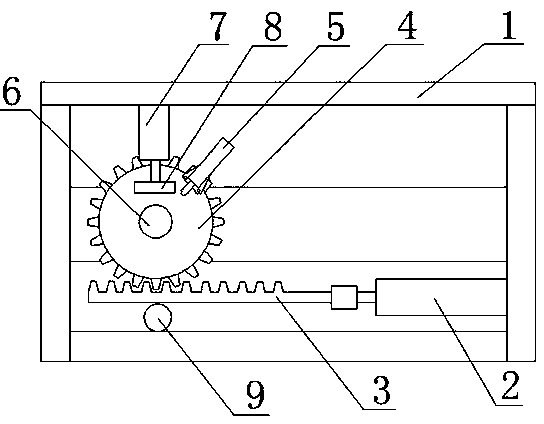

Multi-purpose gear type metal tubular product arc bending machine

The invention provides a multi-purpose gear type metal tubular product arc bending machine which comprises a machine frame. The bottom on one side of the machine frame is provided with a power hydraulic device which is connected with a rack, the rack is meshed with a gear, a bending hydraulic device is arranged on the edge of the gear, a cylindrical nuclear column is arranged at the circle center position of the gear, an abutting-pressing hydraulic device is arranged at the position, corresponding to the position of the cylindrical nuclear column, of the top of the machine frame, an abutting block is arranged at the bottom end of the abutting-pressing hydraulic device, an idler wheel is arranged at the position, corresponding to the position of the rack, of the bottom of the machine frame, and the idler wheel is arranged on the machine frame. The multi-purpose gear type metal tubular product arc bending machine has the advantages of being simple in structure, convenient to use, low in noise, capable of machining metal tubular products at multiple angles, and also suitable for metal bar products.

Owner:NANTONG HONGJINGTIAN MACHINERY EQUIP TECH

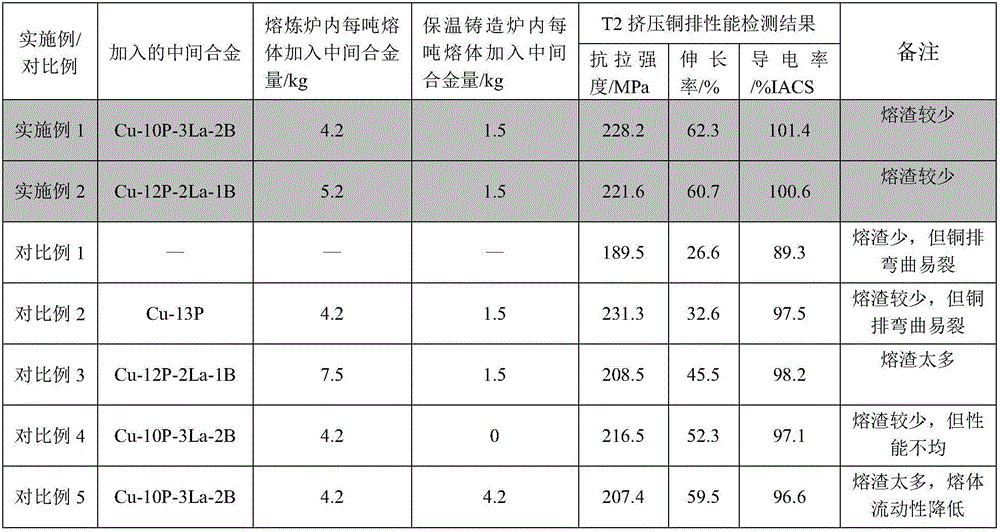

Multi-element intermediate alloy for impure copper refining, preparation thereof and application thereof

ActiveCN106399744AReduce brittlenessReduced propensity for hydrogen sicknessSmelting processBar product

The invention belongs to the technical field of non-ferrous metal material processing, and particularly relates to a multi-element intermediate alloy for impure copper refining, preparation thereof and application thereof. A Cu-P-La-B multi-element intermediate alloy is adopted, and strengthened refining is carried out on impure copper in a smelting process and a casting process, so that good deoxidation and deslagging effects are achieved; the quality of a copper bar product produced by the alloy is equivalent to that of a copper bar which is produced by taking cathode copper as a raw material; and moreover, operations are simple and convenient, and cost is relatively low. According to the multi-element intermediate alloy, the preparation thereof and the application thereof, equivalent or value-added recycling of the impure copper can be expected to be realized, and the application prospect is wide.

Owner:JIANGXI BAOTAI NON FERROUS METAL GRP

Cereal energy bar and making method thereof

InactiveCN107258855AAdd new usesBreak the monotonyDough treatmentModified nutritive productsDietary fiberHigh-fructose corn syrup

The invention relates to a cereal energy bar and a making method thereof. The cereal energy bar is made from, by weight, 30-70 parts of corn grains, 10-30 parts of puffed olive kernels, 20-40 parts of caramel biscuits, 20-50 parts of oatmeal, 2-10 parts of orange peels, 2-10 parts of cranberries, 1-10 parts of dried grape, 15-25 parts of white granulated sugar powder, 25-50 parts of malt syrup, 5-15 parts of fructo-oligose, 2-10 parts of high fructose corn syrup, 2-5 parts of honey, 1-3 parts of water-soluble dietary fiber, 0.2-0.8 part of salt, 5-15 parts of coconut oil, 1-3 parts of cream, 5-15 parts of coconut milk powder, 0.1-0.3 part of phospholipid and 10-25 parts of water. The rich-caramel-flavored biscuits are mixed in the cereal energy bar, the monotony of traditional cereal energy bars and the homogenization characteristics of cereal energy bar products in the market are broken through, and the new application of the biscuits is widened.

Owner:焦作荣利达食品有限公司

Straightness detection method of cylindrical bar and application system of straightness detection method

InactiveCN108120375AImprove efficiencyQuality assuranceUsing optical meansSize measurementMachine vision

The invention discloses a straightness detection method of a cylindrical bar and application system of the straightness detection method. In the detection method, the dimension of the bar is measuredby adopting a laser element, and straightness of the bar can be detected by adopting an industrial grade digital camera automatically in a non-contact manner while the bar is rotated. The system comprises a feeding device, a transfer device and a detection device; the detection device comprises two parts of a bar bearing and rotating device and a bar straightness scanning device that are arrangedin parallel; the feeding device is used for feeding one bar every time; the transfer device is used for transferring the bar onto the bar bearing and rotating device; the bar is rotated stably by thebar bearing and rotating device; and the bar straightness scanning device is used for scanning the bars while the bar straightness scanning device moves in the length direction of the bar. As a machine has the characteristics of being high in vision flexibility and high in efficiency, a reference basis is provided by a high-accuracy datum background plate, the straightness of the cylindrical bar is automatically detected, and non-qualified products are removed. According to the detection method, the detection efficiency is improved, and the quality of a cylindrical bar product is ensured.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

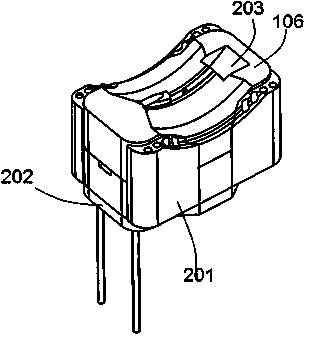

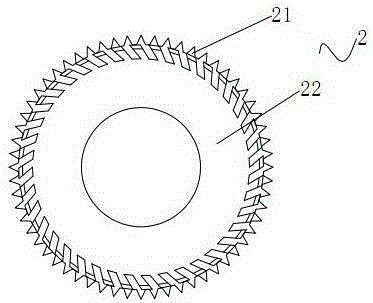

Continuous extrusion machine with symmetry plane of large surfaces of expanded cavity perpendicular to axis of extrusion wheel

ActiveCN104174678AReduce manufacturing costReduce use costExtrusion control devicesBar productEngineering

The invention belongs to equipment used for continuous extrusion and discloses a continuous extrusion machine with a symmetry plane of large surfaces of an expanded cavity perpendicular to an axis of an extrusion wheel. A divergent die is arranged behind a cavity feeding hole and the expanded cavity; a die is arranged behind the divergent die; the divergent die and the die are fixed in the cavity through a cavity cover; the cavity cover and the cavity are connected through a screw; the axis of the extrusion wheel is basically perpendicular to the symmetry plane of large surfaces of the expanded cavity; and a divergent die with a splayed divergent groove is arranged between the die and the expanded cavity. Generally speaking, according to the invention, the expansion direction of the expanded cavity is changed into a direction perpendicular to a traditional expanded cavity, extrusion of copper bar products is changed from an original horizontal mode to a vertical mode, the cavity feeding hole is greatly enlarged in the arc tangential direction, and the flow velocity of a blank in the cavity die is adjusted by utilizing the divergent die, so that the extruded products are kept straight.

Owner:大连康丰科技有限公司

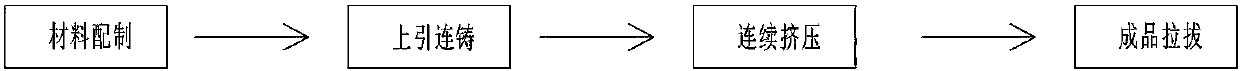

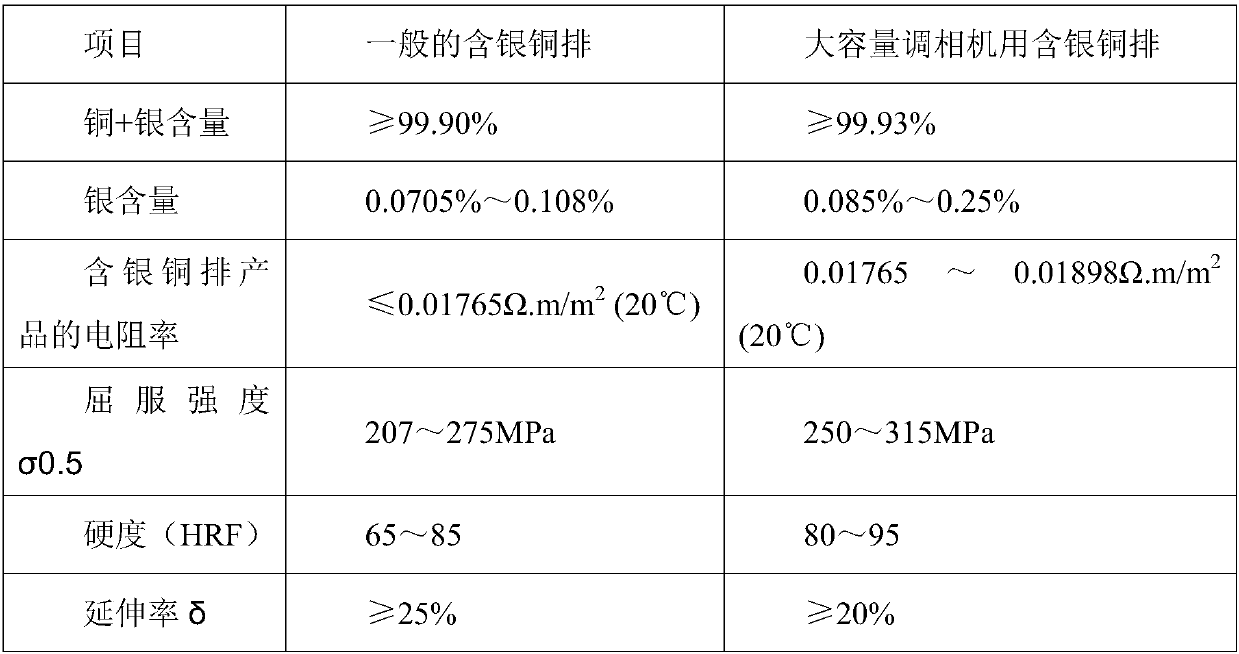

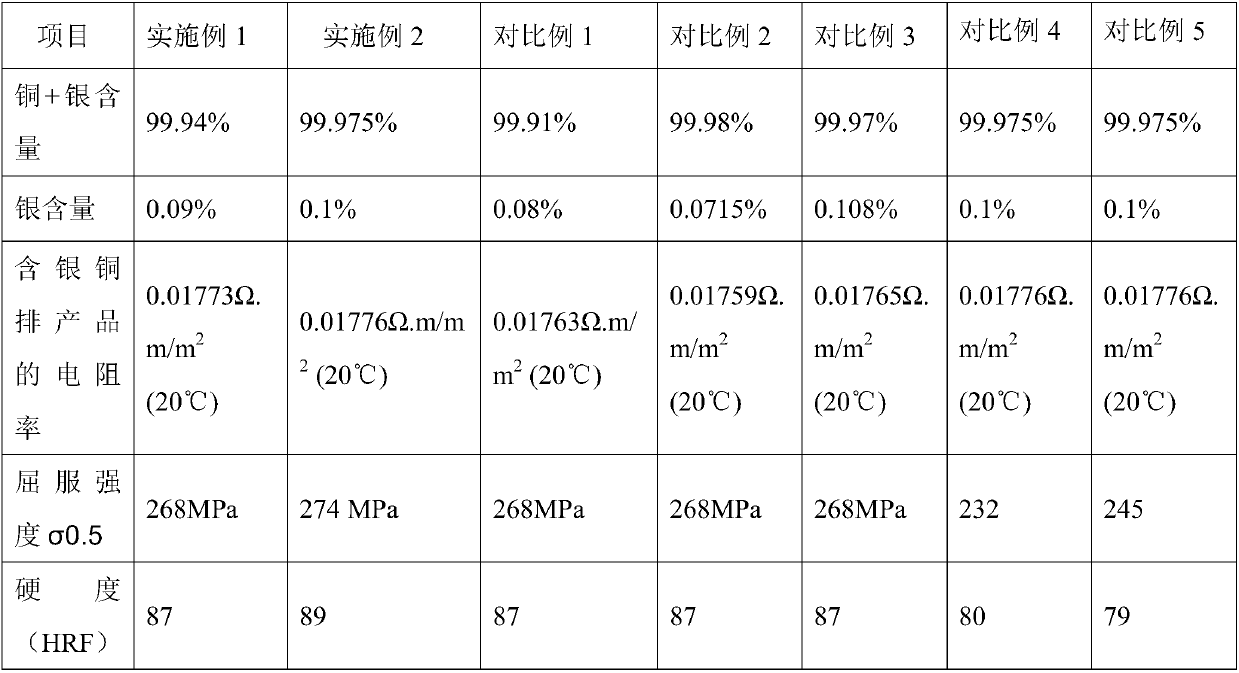

Preparation method of silver-containing copper bar for large-capacity phase regulator

ActiveCN107755451AReduce running noiseReduce vibrationMetal/alloy conductorsMaterials preparationMetalworking

The invention relates to the field of nonferrous metal processing, in particular to a preparation method of a silver-containing copper bar for a large-capacity phase regulator. The preparation methodcomprises the following steps: material preparation; step 2, up-drawing continuous casting; step 3, continuous extrusion; step 4, finished product drawing. The scheme has the beneficial effects that the resistivity of the silver-containing copper bar product is controlled within 0.01765-0.01898 omega.m / m<2>, the conductivity deviation is small, and the use demands of a rotor coil of the large-capacity air-cooled phase regulator are met.

Owner:重庆鸽牌电线电缆有限公司

Method for industrially producing L-tyrosine by using poultry feather as raw materials

ActiveCN101823975AReduce traditional reaction timesShorten the production cycleOrganic chemistryUnknown materialsManufacturing technologyDecomposition

The invention discloses a method for industrially producing L-tyrosine by using poultry feather as raw materials, which comprises the following steps: adopting waste poultry feather after the production of poultry white bar products as major raw materials; carrying out hydrochloric acid catalysis, heating and heat-insulating protein in the hydrolytic poultry feather; and then, carrying out production through processes such as separation, neutralization, decoloration, concentration and the like to obtain pure natural safe and innoxious L-tyrosine finished products in white crystal solid type. The method greatly reduces the traditional reaction time of the industrial production of the L-tyrosine, and shortens the production period. The protein hydrolysis thoroughly solves the technical problems of low decomposition rate and incomplete decomposition of the traditional process. The antioxidant capability of the products per se is improved, and the storage lives of the products can be prolonged. The raw material yield is improved. Compared with the traditional manufacture technology, the invention improves the raw material yield by about 40 percent. The environment pollution caused by waste poultry feather is reduced, so the added value of the poultry processing is improved from the original 120 percent to 300 to 350 percent.

Owner:XINYI HANLING BIO ENG

Cutting machine

InactiveCN106737945AReasonable structural designBeautiful chamfer qualityMulti-purpose machinesRotary cutting toolsBar productEngineering

The invention relates to a cutting machine comprising a rack, cutters and a feeding mechanism arranged on the rack and used for conveying a product to be cut. A rotating main shaft is further arranged on the rack. The cutters are mounted on the rotating main shaft which is connected with motors. Each cutter comprises a saw blade in the middle and chamfering blades located on the two sides of the saw blade, and the outer diameter of each chamfering blade is less than the outer diameter of each saw blade. The cutting machine is reasonable in structure design. After the saw blades cut the product to be cut with a certain depth, the chamfering blades conduct chamfering on the two ends of the cut product to be cut separately, and after chamfering is finished, the saw blades cut off the product to be cut to form a plurality of circular wood strips or circular plastic bars with chamfers. Automatic cut-off and chamfering of wooden plug bar products or plastic bar products are achieved. The cutting and chamfering are high in speed, good in quality and high in good product rate. The production cost is saved greatly, the labor intensity is reduced, and the production efficiency is improved. The circular wood strip products or the circular plastic bar products have the attractive chamfering quality.

Owner:曾胜发

Automatic punching machine for bar products

ActiveCN105618810ASimple structureEasy to operateDriving apparatusBoring/drilling componentsPunchingLocking mechanism

The invention discloses an automatic punching machine for bar products. The automatic punching machine comprises a rack, a controller, a feeding device, a main shaft box and a punching device; a rotating driving device is constructed by an installation base, a belt wheel, a belt wheel driving mechanism, a first clutch, a second clutch, a stirring mechanism and a positioning limiting mechanism; the stirring mechanism is connected with the controller, the installation base is fixed to a box body, the belt wheel is in shaft connection to the installation base, the first clutch is fixedly connected with the belt wheel, an inner hole is formed in the first clutch, and a locking mechanism is arranged in the first clutch; the second clutch is arranged on the back side of the first clutch and installed at the back end of a main shaft, and the stirring mechanism is used for driving the second clutch to move front and back; and the positioning limiting mechanism is used for stopping rotation of the main shaft after the bar products are punched and enabling a cavity position of a collet chuck to be matched with a containing position of the bar products. The automatic punching machine has the beneficial effect that the automatic punching machine can be used for automatic drilling of round bar products and polygonal bar products at the same time.

Owner:NINGBO YUNSHENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com