Multi-element intermediate alloy for impure copper refining, preparation thereof and application thereof

A technology for master alloy and purple miscellaneous copper, which is applied to the multi-element master alloy for the refining of purple miscellaneous copper and its preparation and application fields, can solve the problems of complicated operation, high cost, poor effect, etc., and achieves the reduction of Fe content, brittleness, The effect of shortening the refining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

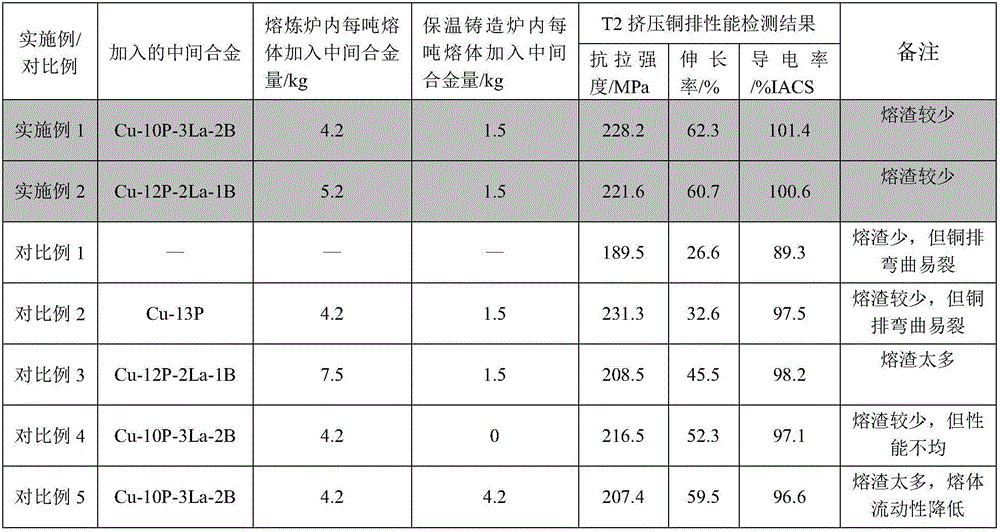

Embodiment 1

[0018] Put the electrolytic copper into the smelting device for melting. The melting temperature is 1150℃~1160℃. Cu-P alloy containing 50% P element, Cu-La alloy containing 30% La element and Cu-B alloy containing 20% B element are added to the copper melt and stirred until melting, electrolytic copper, Cu-P, Cu-La The weight and number ratio of Cu-B and Cu-B is 2:1:0.5:0.5, the melt is left to stand, the slag is discharged, and poured into a mold to form an intermediate alloy Cu-10P-3La-2B, which is broken into small pieces; using 100% Red miscellaneous copper is used as raw material, the ingot is prepared by the horizontal continuous casting method, and the T2 red copper bar is produced by the extrusion method; After refining the agent, fully stir the melt, remove slag and let it stand for 15-30 minutes before pouring. In the continuous casting process, the intermediate alloy fragments are regularly added to the melt in the heat-retaining casting furnace, the amount of ad...

Embodiment 2

[0020] Put the electrolytic copper into the smelting device for melting. The melting temperature is 1150℃~1160℃. Cu-P alloy containing 48% P element, Cu-La alloy containing 32% La element and Cu-B alloy containing 20% B element are added to the copper melt and stirred until melting, electrolytic copper, Cu-P, Cu-La The ratio of parts by weight to Cu-B is 1:1:0.25:0.2, the melt is left to stand, the slag is discharged, and poured into a mold to form an intermediate alloy Cu-12P-2La-1B, which is broken into small pieces; using 100% Red miscellaneous copper is used as raw material, the ingot is prepared by the horizontal continuous casting method, and the T2 red copper bar is produced by the extrusion method; After refining the agent, fully stir the melt, remove slag and let it stand for 15-30 minutes before pouring. In the continuous casting process, the intermediate alloy fragments are regularly added to the melt in the heat-retaining casting furnace, the amount of addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com