Patents

Literature

220results about How to "Dense tissue structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

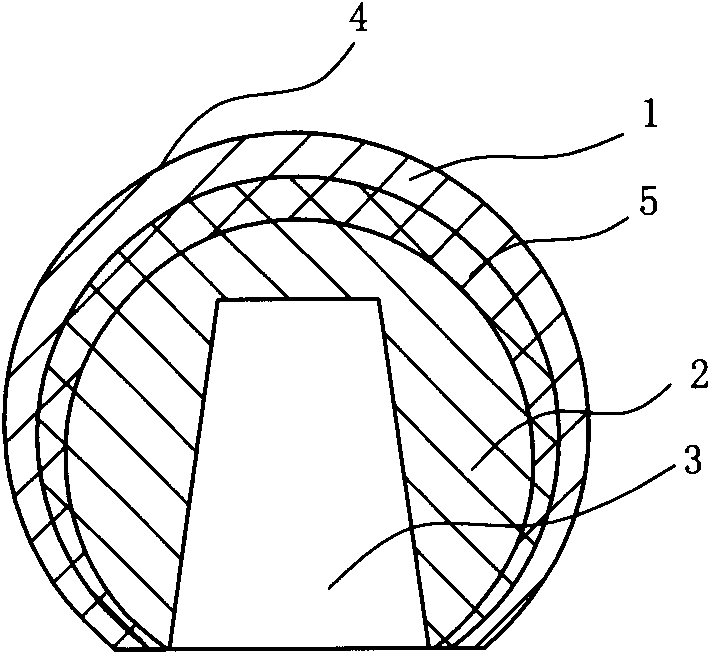

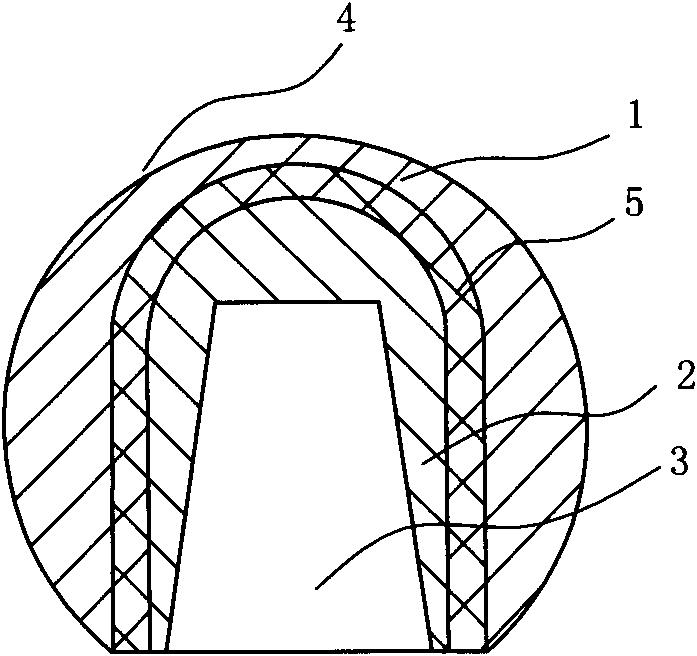

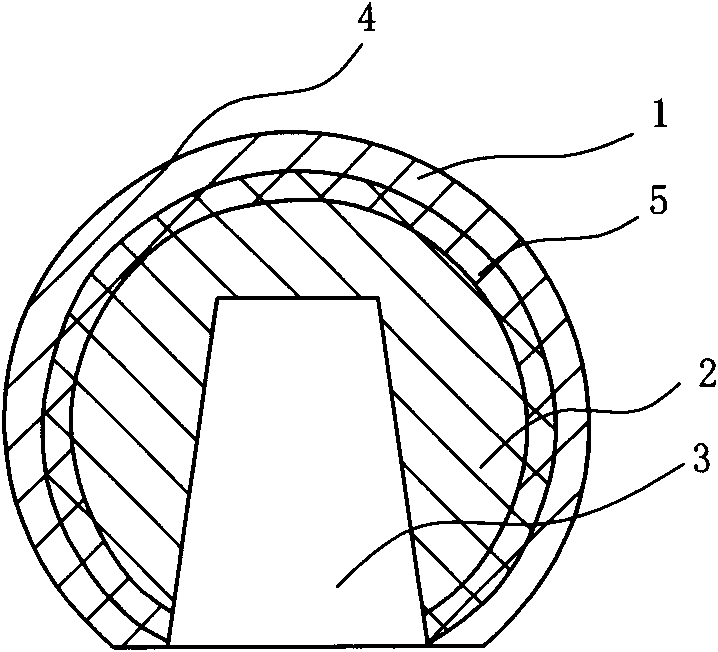

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

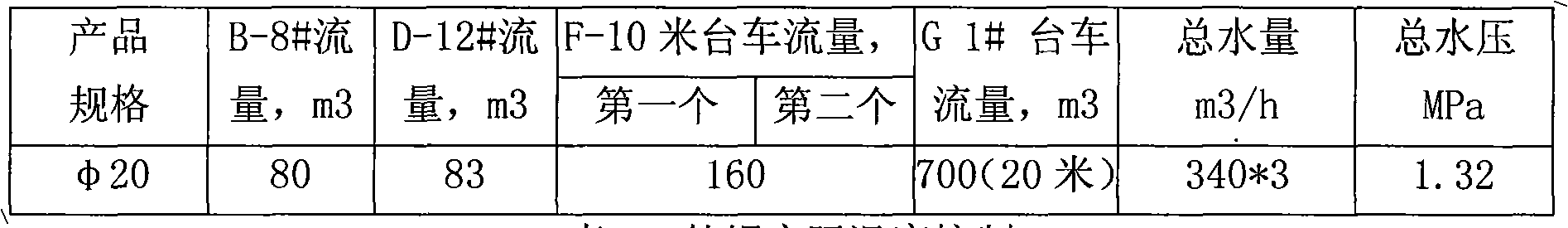

Ultrahigh-malleability tunnel supporting anchor rod steel of converter continuous cast billet and production method

The invention relates to ultrahigh-malleability tunnel supporting anchor pile steel of converter continuous cast billet and a production method, which belongs to the technical field of a mine anchor rod. The anchor rod steel comprises the following components by weight percent: 0.5 to 0.70 percent of carbon, 0.15 to 1.20 percent of silicon, 0.5 to 2.5 percent of manganese, less than or equal to 0.045 percent of phosphorus, less than or equal to 0.045 percent of sulfur, 0 to 1.00 percent of chrome, 0 to 1.00 percent of nickel, 0 to 1.00 percent of molybdenum, 0 to 0.30 percent of copper, 0.03 to 0.40 percent of vanadium, 0.01 to 0.2 percent of aluminum, 0 to 0.10 percent of titanium, 0 to 0.10 percent of boron, 0.001 to 0.0 percent of niobium, 0.004 to 0.020 percent of nitrogen, and iron for the surplus; the yield strength Rel is larger than or equal to 600 MPa, the percentage elongation delta 5 is larger than or equal to 20 percent, the impact strength is 20 DEG C, Akv is larger than or equal to 27 J, and the breaking load is larger than or equal to 300 KN. By adopting the production process flow of converter crude metallurgy, LF furnace fine metallurgy and full protection continuous casting, the steel grade has the advantages that the purity is high, the structure is dense, the grain is fine, the physical chemistry properties of the steel are stable, the over-all mechanical property is good, the production operation and process flow are simple, and the rolled metal finished product can be directly used without heat treatment to the rear part.

Owner:SHOUGANG CORPORATION

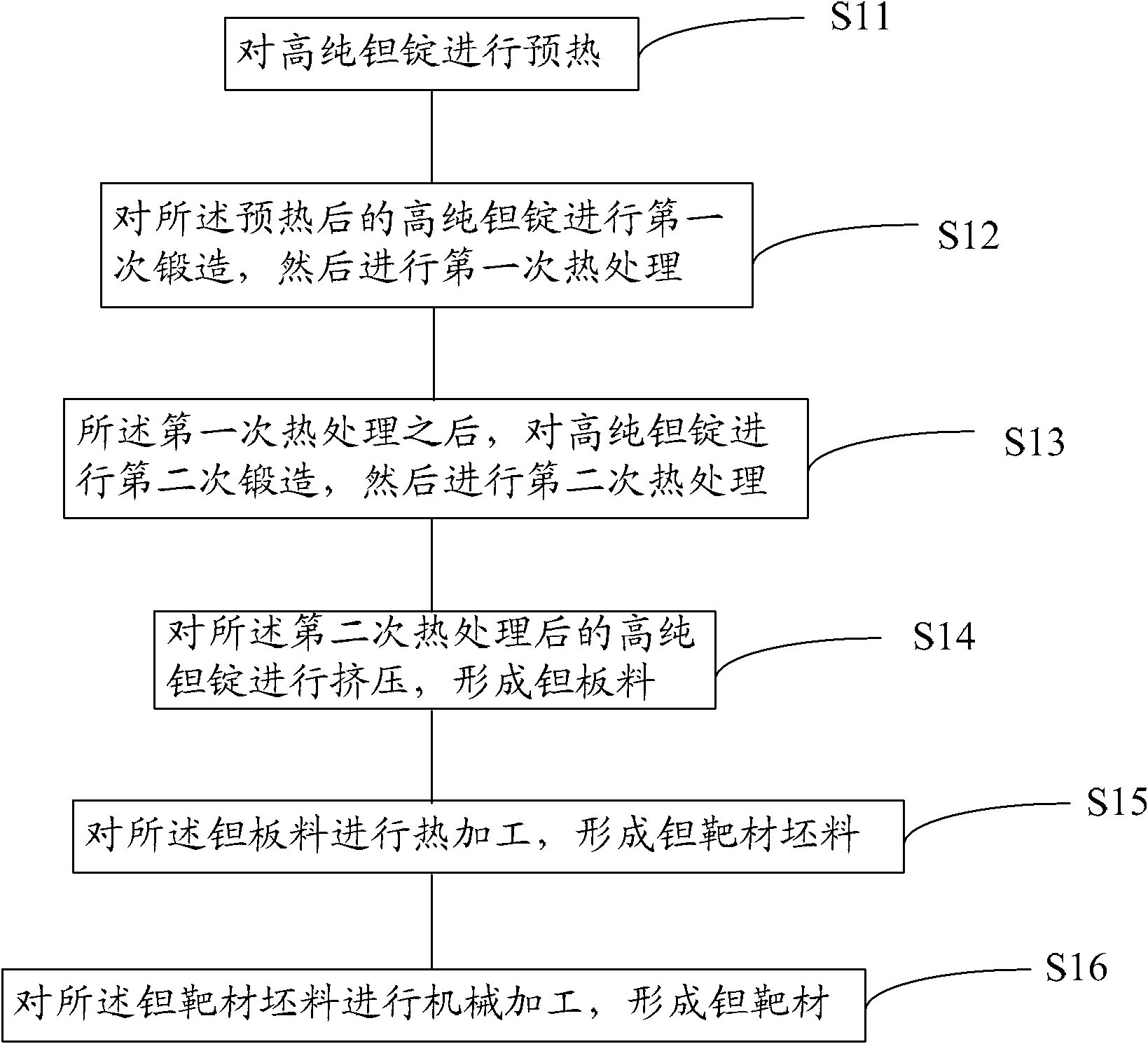

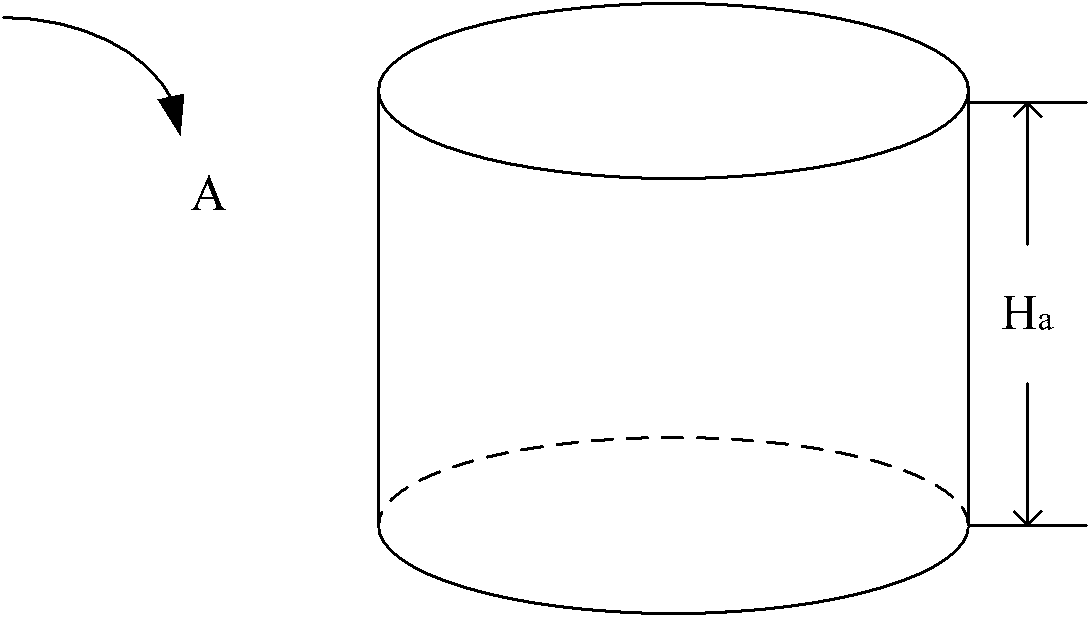

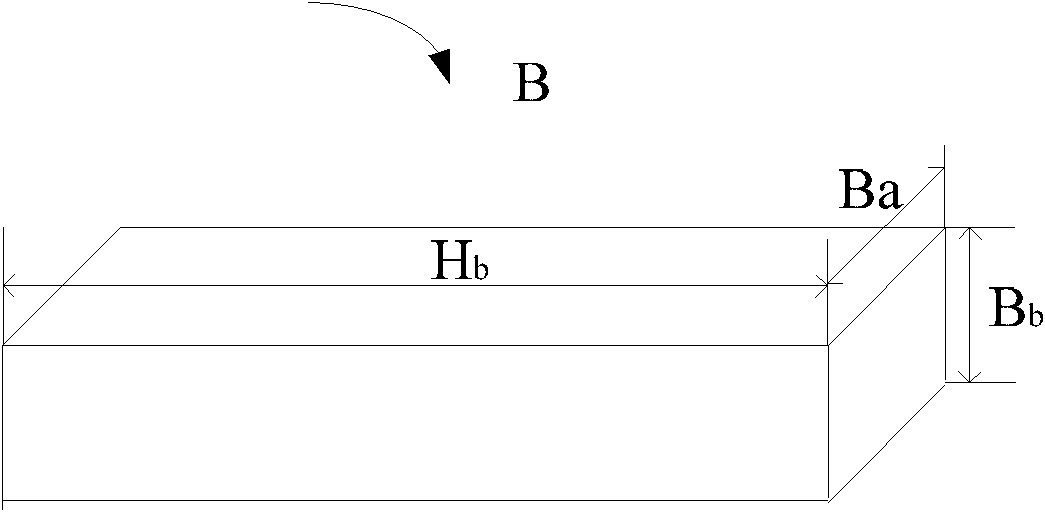

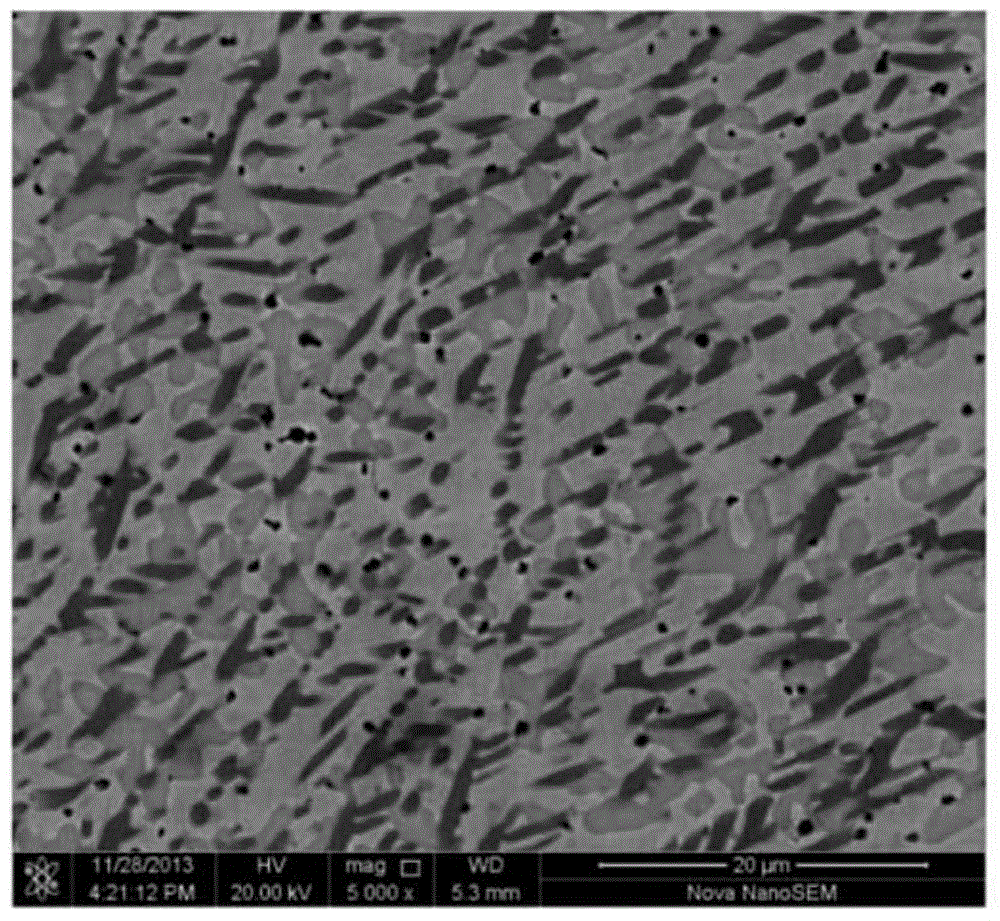

Method for preparing high-purity tantalum target

ActiveCN102517531ADense tissue structureFine and uniform grainVacuum evaporation coatingSputtering coatingSputteringCrystal orientation

A method for preparing a high-purity tantalum target comprises the following steps: preheating high-purity tantalum ingots; forging the preheated high-purity tantalum ingots by at least two times, wherein the high-purity tantalum ingots are heated after being forged each time; extruding the high-purity tantalum ingots after the high-purity tantalum ingots are heated for the last time, so as to obtain a tantalum board; heating the tantalum board to obtain a tantalum target blank; and machining the tantalum target blank to obtain the tantalum target. According to the process for preparing the tantalum target, the uniformity and the compactability of the tantalum target can be better, so as to meet the crystal particle requirements and the crystal orientation requirements of the tantalum target for semi-conductor sputtering.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Terylene super fine denier double-faced short floss textile and production method thereof

InactiveCN101760896AAvoid churnSilkyWarp knittingHeating/cooling textile fabricsYarnTextile technology

The invention relates to the textile technology field, in particular to a terylene super fine denier double-faced short floss textile and a production method thereof; the terylene super fine denier double-faced short floss textile is characterized in that: polyester yarns or poly / nylon composite yarns with 0.42dtex and / or 0.58dtex or lower than the specification of the single-fiber fineness are adopted as felted yarn raw material, polyester FDY or polyester DTY with 55.5dtex-111dtex is used as bottom yarns; the invention further discloses a production method of the terylene super fine denier double-faced short floss textile. The terylene super fine denier double-faced short floss textile in the invention has the advantages that: 1) the textile has super smoothness, the single-fiber fineness reaches 0.42dtex and 0.58dtex, the advanced printing and dyeing process is adopted, so as to ensure the super smoothness, really achieve the purpose that the touch sense is more comfortable than the feeling of touching baby skins and have excellent fitting performance; 2) the textile has strong heat retention, the texture structure is compact and can reach 36 stitches per hour; 3) the textile has super long using cycle, the weaving structure is contact without depilation and balling-up, and the anti-tearing strength is high.

Owner:SHANGHAI WEILE TEXTILES CO LTD

Preparation method of nanometer iron-based soft magnetic block

InactiveCN101752074ALow costSimple processInductances/transformers/magnets manufactureAutomatic controlLaser scanning

The invention discloses a preparation method of a nanometer iron-based soft magnetic block. Nanometer iron-based soft magnetic powder is served as the main raw material. The shape of a nanometer iron-based soft magnetic block to be prepared is designed by professional 3D graphics software on a computer; then, computer graphics processing software decomposes the designed 3D graphics into a series of processing signals controlling laser scanning speed, output power, sintering paths, feeder feeding amount, feeding position and the like by an automatic control device; the feeder and the laser feed and sinter by layers under the control of the signals until the shape of the nanometer iron-based soft magnetic block to be prepared is sintered. The novel nanometer iron-based soft magnetic block is different from the block produced by nanometer ligatures, forms a unified entity, does not have gaps and has favourable permeability; with respect to the known production process of other nanometer soft magnetic blocks, the preparation method has low requirements of environment and technology and does not need to manufacture the corresponding mould in advance.

Owner:WUHAN FUHAN TECH

High-adsorption nanofiber composite filter material and preparation method thereof

ActiveCN104014196AEvenly dispersedDense tissue structureSynthetic resin layered productsFiltration separationSolventFilter material

The invention relates to a high-adsorption nanofiber composite filter material which comprises a non-woven base material and a nanofiber membrane applied to the surface of the non-woven base material, wherein nanofibers forming the nanofiber membrane comprise continuous-phase thermoplastic polymers and disperse-phase active nanoparticles. A preparation process of the composite filter material comprises the steps of performing double-screw extruding and granulating on the active nanoparticles and the thermoplastic polymers according to a ratio to prepare a composite material; mixing the composite material with cellulose acetate butyrate according to a ratio, performing melt spinning, and performing solvent extraction to prepare thermoplastic nanofibers containing the active nanoparticles; finally, coating the surface of the non-woven base material with ethanol suspension of the thermoplastic nanofibers, and drying to obtain the high-adsorption nanofiber composite filter material. The preparation process is simple, the cost is low, the energy consumption is low, and the yield is high. The thermoplastic nanofibers containing the active nanoparticles are dense in tissue structure and controllable in diameter. The composite filter material has the characteristics of stable structural performance and excellent adsorption filtration performance.

Owner:武汉维晨科技有限公司

A kind of preparation method of nano rare earth oxide doped molybdenum alloy electrode material

The invention relates to a preparation method of a molybdenum alloy electrode material doped with nano rare oxides. According to the preparation method, molybdenum powder is used as a raw material, the molybdenum powder and nano rare oxide powder are uniformly mixed by adopting a solid-solid doping method, wherein the nano rare oxides are lanthana oxide, cerium oxide or mixed rare earth oxide; and then the molybdenum alloy electrode material doped with different kinds and contents of nano rare earth oxides is prepared through adopting the processes of sieving, pressing and forming, sintering,forging and vacuum annealing heat treatment under certain temperature. The preparation method disclosed by the invention and the heat treatment process are simple and feasible; and the molybdenum alloy electrode material doped with the nano rare earth oxides, which is prepared by using the method disclosed by the invention, has the characteristics of uniform tissues, high compactness, high strength, high recrystallization temperature, high elongation rate, favorable deep processing performance, and the like.

Owner:XIAN FULAI ELECTRICAL ALLOY

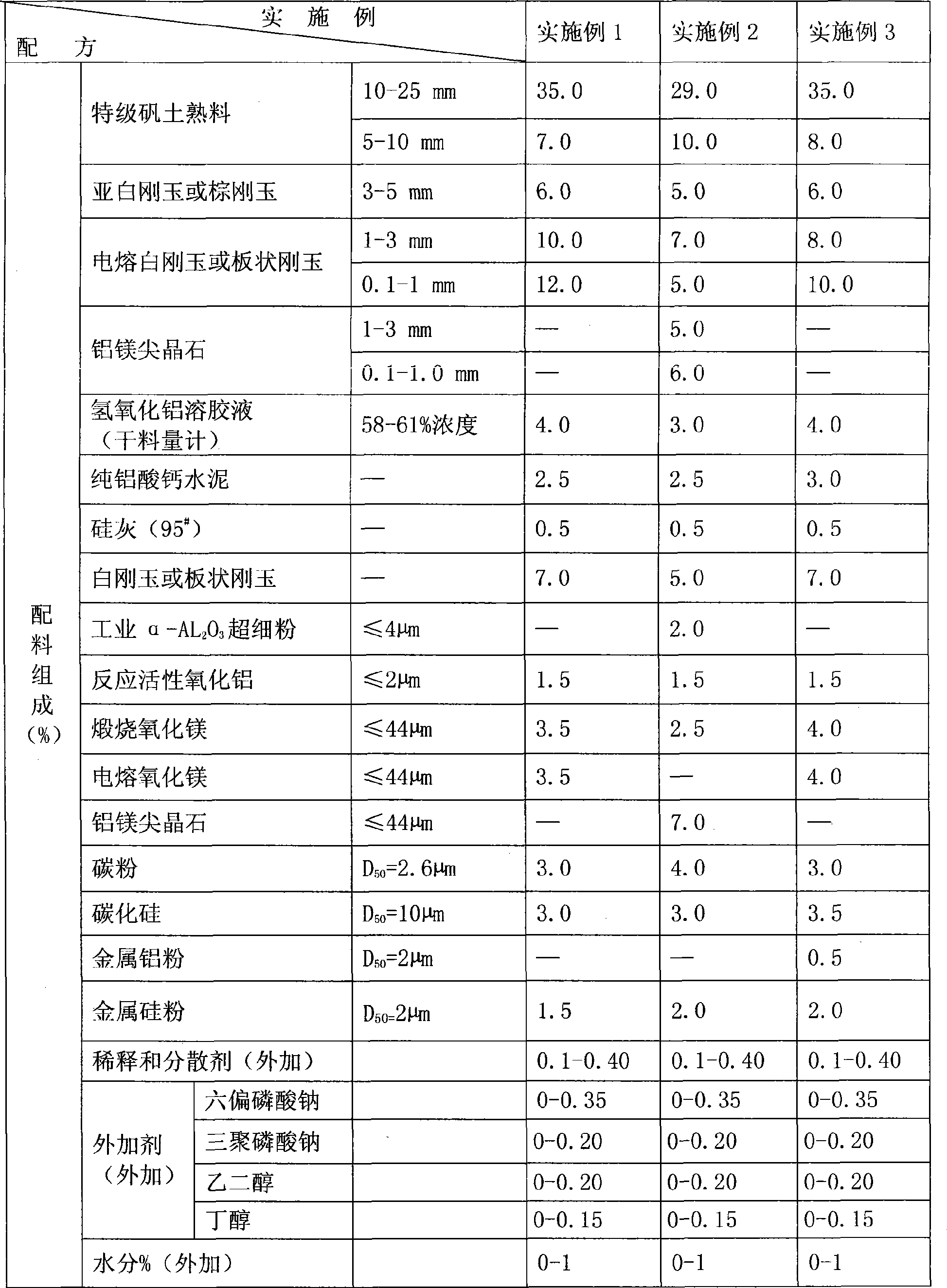

Nano Al2O3 film encapsulated carbon-aluminum spinelle refractory castable and preparation method thereof

InactiveCN101417884APerformance indicators improved and enhancedDense tissue structureHydration reactionManufacturing technology

The invention relates to a carbon-aluminum spinel refractory castable material wrapped up by a nano AL2O3 film and a preparation method thereof. The preparation method of the carbon containing castable material firstly puts the mixture of hydrated alumina, carbon powders and water in a high speed impact mixing-stirring mill for coating processing treatment, the materials impact and collide with each other after high-speed impact treatment, thus forming a composite sol suspension liquid of carbon and aluminum hydroxide and causing the aluminum hydroxide to be strongly absorbed on the surface of the carbon, therefore, the manufacture technology for coating carbon powders by using aluminum hydroxide is realized, then the composite sol suspension liquid is directly added to the mixed materials for preparing alumina gel coatings by controlling the conversion process from the aluminum hydroxide to the gel, and hence the whole-covered, crack-free and high-strength compact alumina wrapping layer is formed; and during the mixing and stirring process of the castable material, magnesium hydroxide sols are generated by the hydration reaction of magnesia powders and mixed water in matrix powders, then the nanostructure matrix of carbon-aluminum-spinel is generated by the in-situ synthesized reaction of the magnesium hydroxide sol and aluminum hydroxide sol suspension liquid, and finally the carbon-aluminum refractory castable material is prepared.

Owner:高树森

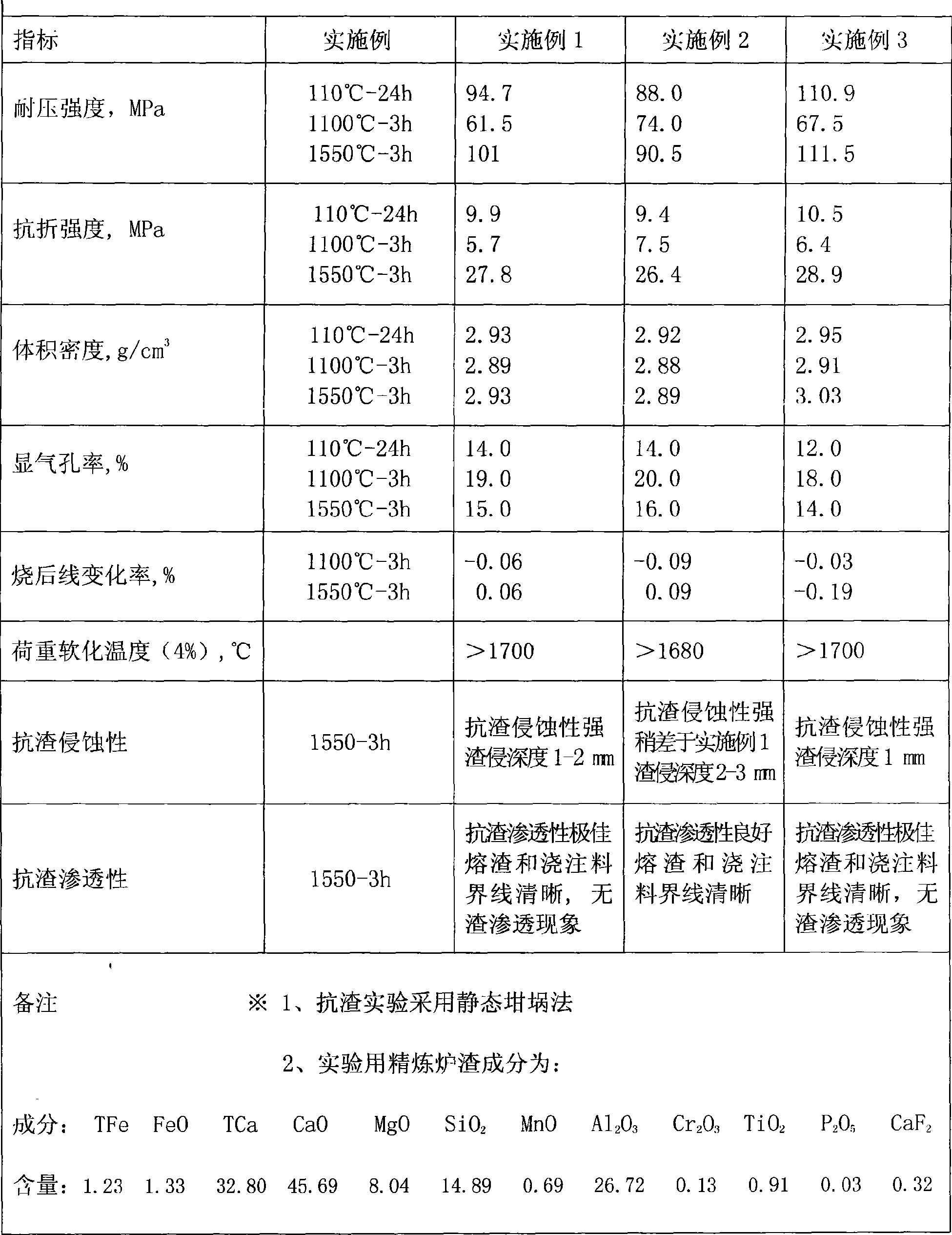

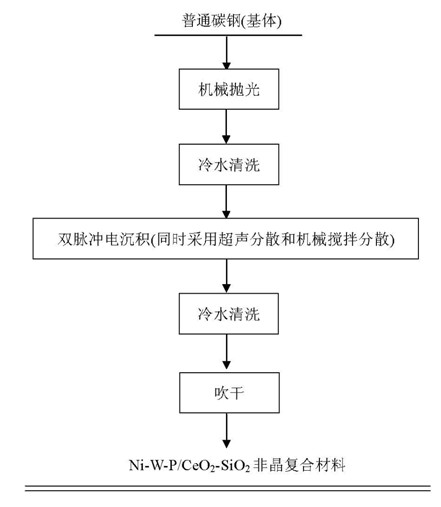

Nanometer granule reinforced metal-based amorphous composite material and preparation method thereof

InactiveCN102400066APrevent precipitationImprove stabilityElectrolytic coatingsElectrolytic agentChemical industry

The invention provides a nanometer granule reinforced metal-based amorphous composite material and a preparation method thereof. In the method, the Ni-W-P / CeO2-SiO2 amorphous composite material of which the thickness is between 54 and 251 micrometers is prepared on the surface of ordinary carbon steel in electrolyte by utilizing dipulse electrolytic deposition for 1.5 to 6 hours under the action of ultrasound, mechanical stirring and the common dispersion of two surfactants. In the nanometer granule enhanced metal-based amorphous composite material, the electrolyte is high in stability, homogeneous plating capacity, current efficiency and deposition rates. CeO2 and SiO2 nanometer granule reinforced phases in the amorphous composite material are dispersed, the sizes of matrix metal granules ranges from 1 to 2 micrometers, and the composite material has a compact tissue structure, a thick deposition layer and high plating microhardness, is combined with a matrix firmly and can be used as surface functional plating layers of equipment parts of metallurgy, chemical industries, tobaccos, machines and the like.

Owner:KUNMING UNIV OF SCI & TECH

Functional duck meat square leg and preparation method thereof

ActiveCN102885322AImprove emulsion stabilityDense tissue structureFood preparationLactic bacteriaLeavening agent

The invention discloses a functional duck meat square leg and a preparation method of the functional duck meat square leg. The method comprises the steps of: slaughtering the duck, scalding hair, removing internal organs, cleaning, taking breast meat and leg meat, coating a mixture of nitrate, sodium isoascorbate and composite phosphate to pickle, adding a medlar juice and a walnut and lactoprotein mixed enzymatic solution, pig backfat, accessories, and glutamine transaminase and a lactic acid bacteria leavening agent, chopping, agitating and mixing uniformly, injecting in a mold way, preserving temperature and enzymolyzing, freezing and molding, demolding, packaging in vacuum, decocting and curing, sterilizing by microwave, and cooling to obtain the functional duck meat square leg which is rich in extracellular polysaccharide of lactic acid bacteria and polypeptide and amino acids. The method has the advantages that the amount of phosphate is reduced, and the emulsion stability, heat stability, water-retaining property and gel capacity of meat product are improved. The functional duck meat square leg is not only unique in flavor, but also has the functions of preventing oxidation, resisting angiotensin converting enzyme, and promoting calcium absorption and immune adjustment.

Owner:NINGBO UNIV

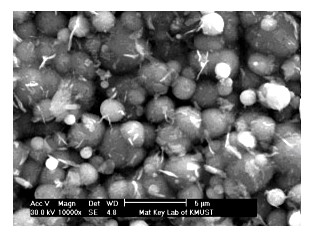

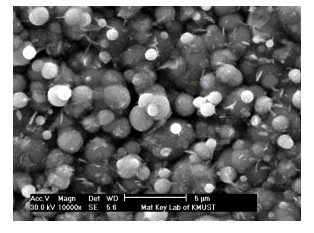

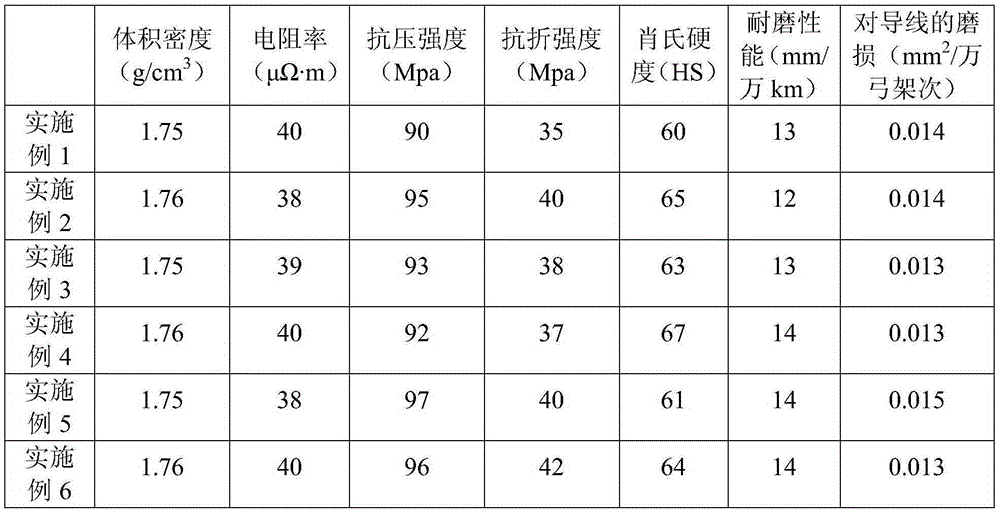

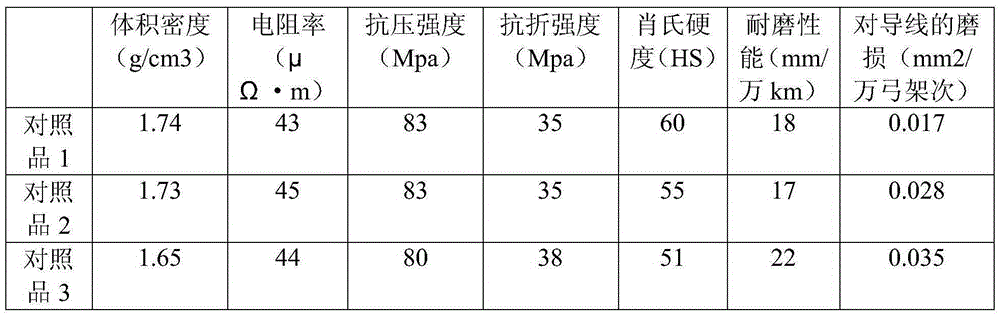

Method for preparing pantograph carbon slide strip material from graphene oxide

The invention discloses a method for preparing a pantograph carbon slide strip material from graphene oxide. The method comprises the following steps: mixing graphene oxide, semi-reinforced carbon black and graphite powder with crushed, milled and screened pitch coke to form aggregate for preparing carbon slide strips; adding a binder to the aggregate, and mixing and kneading the aggregate and the binder to form a paste; carrying out pre-compression molding on the paste; and calcining the pre-compression molded paste to finally obtain the material suitable for pantograph carbon slide strips. The required carbon strip material can be obtained only through one-time calcination, so the production period is short. The pantograph carbon slide strips produced by using the graphene oxide have the advantages of good electricity conduction performance, high heat conduction performance, strong friction and wear resistance, and low cost of raw materials.

Owner:广西鑫锋电源科技有限公司

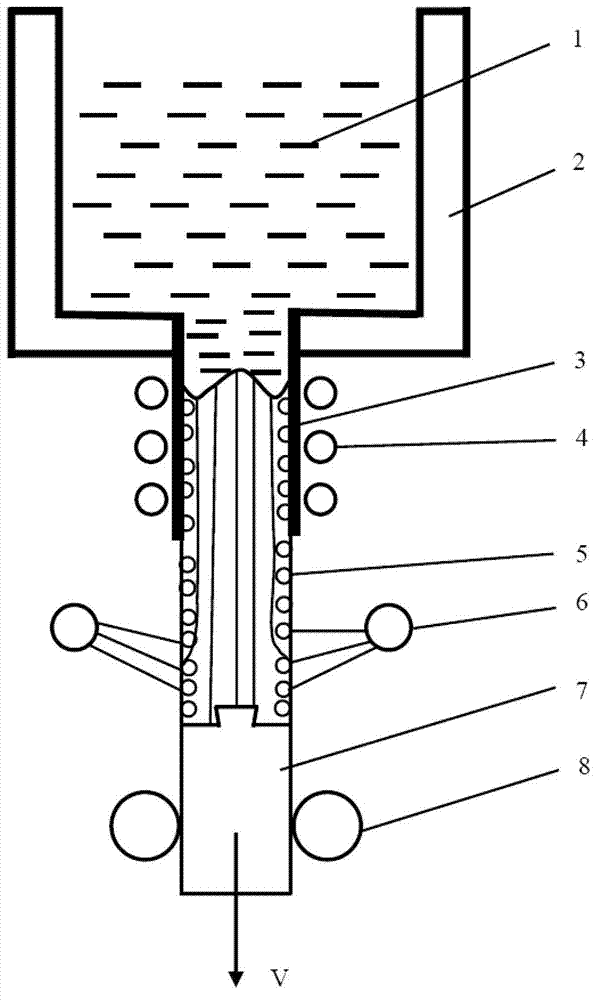

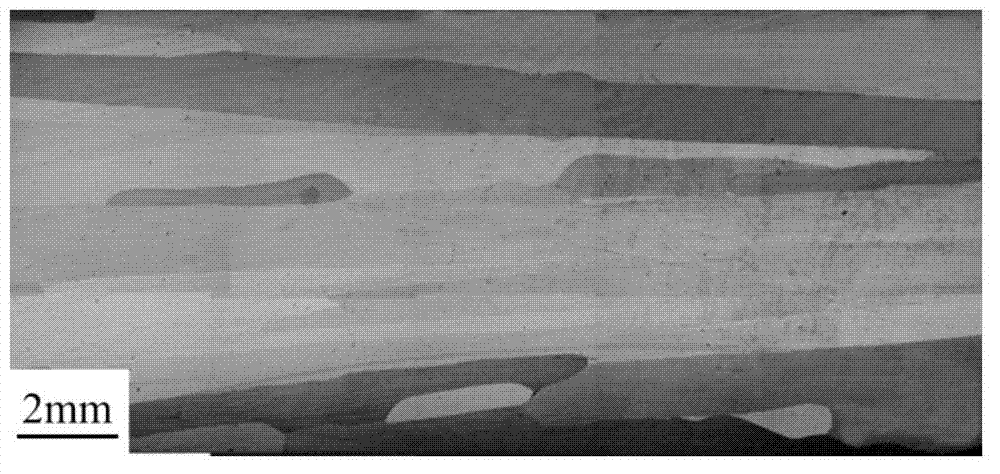

Thermal mold casting method

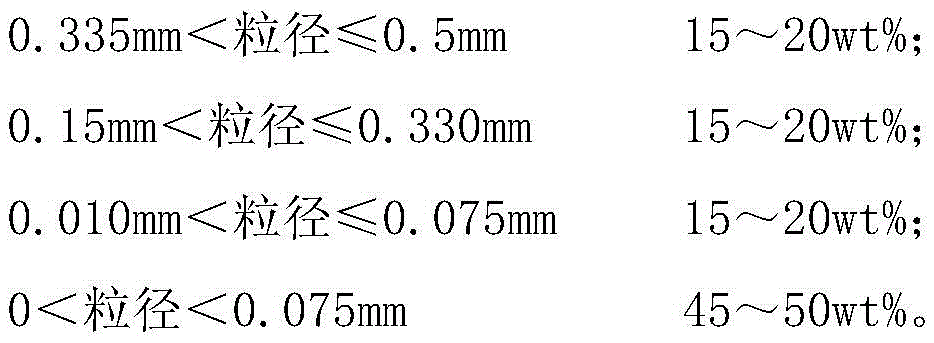

The invention provides a thermal mold casting method. The thermal mold casting method is characterized by comprising the following steps of: heating a casting mold by a heater, or heating the casting mold by utilizing heat conducted by a metal melt before entering the casting mold so as to maintain the temperature of the casting mold to be in the range lower than the temperature of a solid phase line of metal and higher than the cooling temperature of the casting mold; carrying out forced cooling on the metal by a cooler arranged near an outlet of the casting mold; and drawing a metal casting blank by using a traction mechanism. The thermal mold casting method provided by the invention has the advantages that the application range is wide, the promotion value is very large, high-quality metal casting blanks with excellent performance, good surface smoothness, high size accuracy, high compactness, more uniform components, columnar crystal parallel or approximately parallel to the jiggering direction in the metal and isometric crystal concurrent microstructures on the surface layer of the metal can be produced with low energy consumption and high efficiency, and the subsequent plastic processing with a large screw-down rate can be carried out according to the need.

Owner:UNIV OF SCI & TECH BEIJING

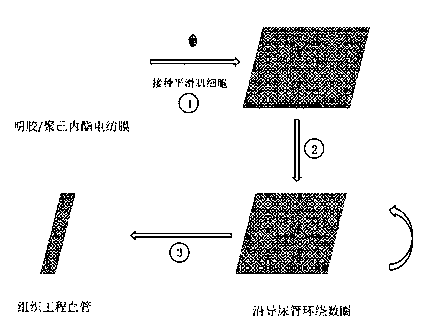

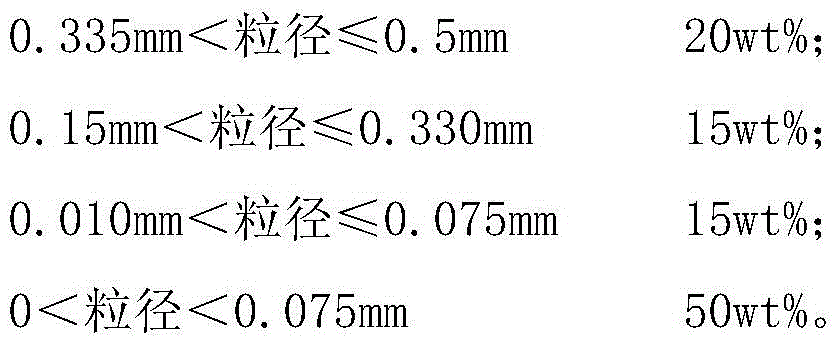

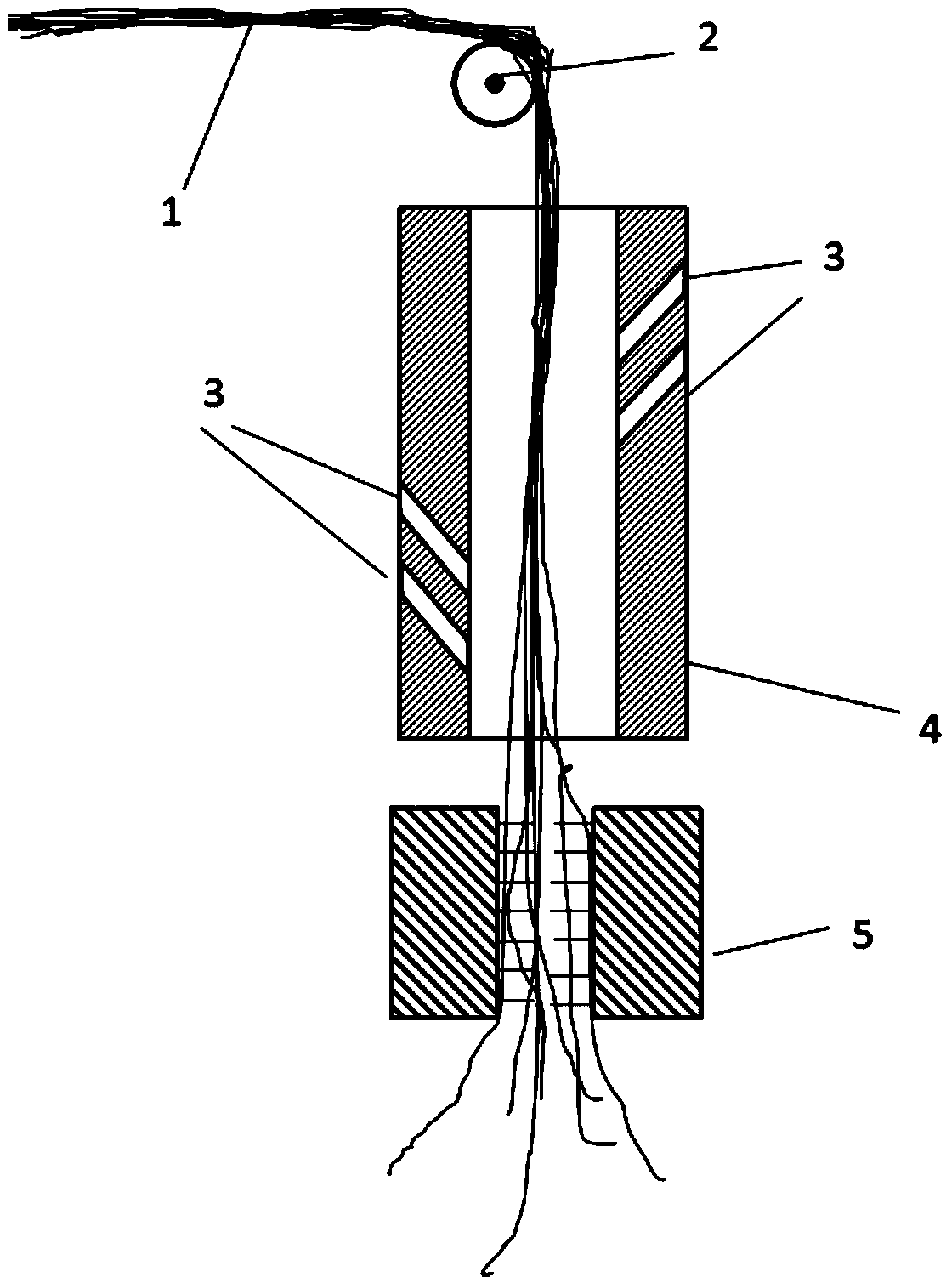

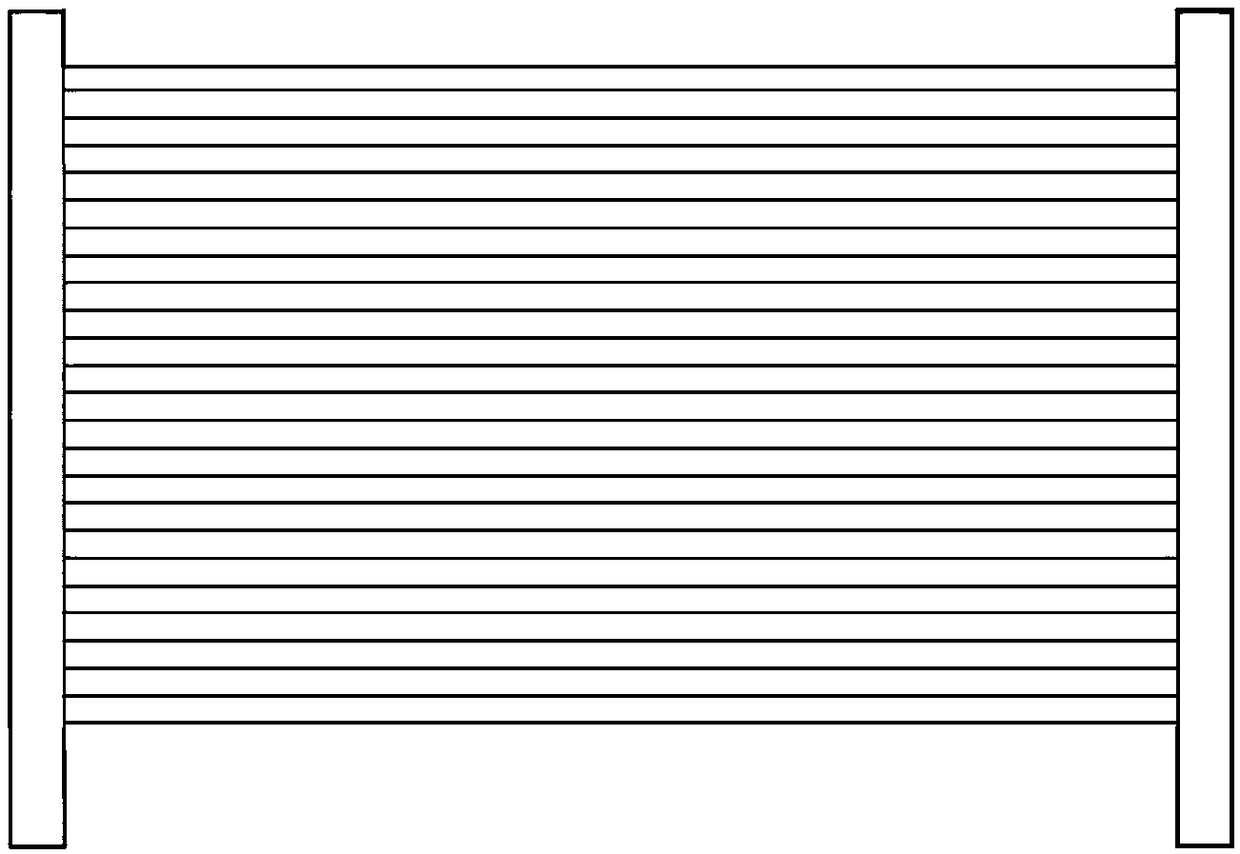

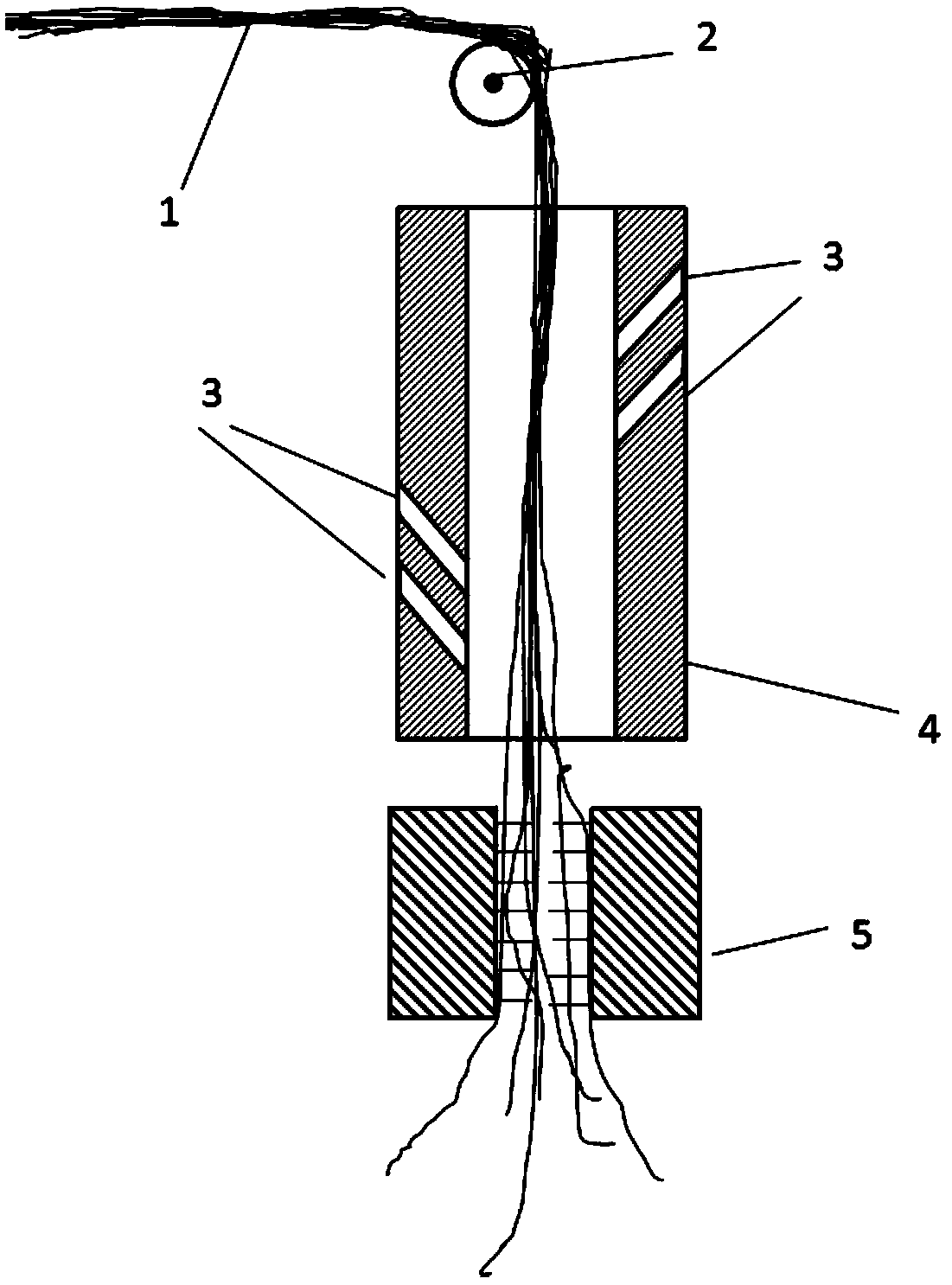

Tissue engineering vessel and preparation method and application thereof

The invention relates to a tissue engineering vessel and a preparation method and an application thereof. The tissue engineering vessel uses a tubular gelatin / polycaprolactone electricity texture membrane as a support, and smooth muscle cells are evenly distributed in the support. The preparation method includes: a) spreading disinfected gelatin / polycaprolactone materials in a culture dish; b) collecting umbilical artery smooth muscle cells, evenly inoculating the umbilical artery smooth muscle cells on the surface of the gelatin / polycaprolactone electricity texture membrane to culture over the night, and forming a cell material composite electricity texture membrane; and c) twisting the cell material composite electricity texture membrane on a polyvinyl chloride (PVC) tube for culturing, and finally forming the tubular tissue engineering vessel. Cells of the tissue engineering vessel prepared by the method are evenly distributed, simultaneously the tissue engineering vessel has the advantages of being good in elasticity, moderate in hardness and compact in tissue structure, having smooth inner walls and abundant collagenous fibers, and being clear in self tissue boundary and the like. The characteristics of the tissue engineering vessel are close to that of living body vessels.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

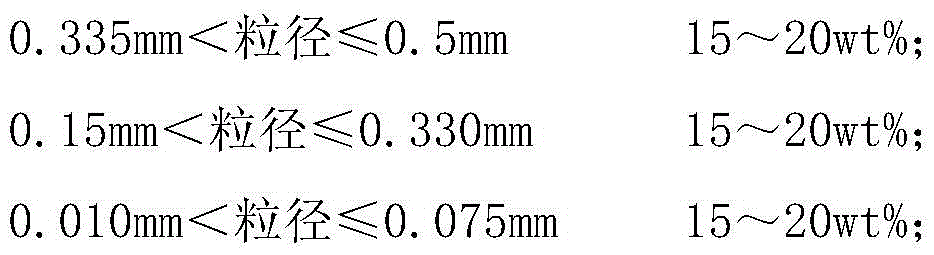

Raw material composition and method for preparing special graphite material

The invention belongs to the field of graphite materials, and particularly relates to a raw material composition and method for preparing a special graphite material. The raw material composition is prepared from, by weight, 70-75% of isotropic coke and 5-30% of medium temperature coal-tar pitch, and preferably 70-72% of isotropic coke and 28-30% of medium temperature coal-tar pitch. The method comprises the following steps that the isotropic coke is crushed, screened and blended, medium temperature coal-tar pitch is added for mixing kneading, vibration molding, primary roasting, primary impregnation, secondary roasting and graphitization, and the special graphite material is obtained. The physical and chemical indexes of the prepared special graphite material can compare favourably with other mid-to-high end graphite materials and also can replace the mid-to-high end graphite materials; due to the fact that the raw material sources are wide, the price is low, the preparation process is easier, the technical difficulty is low, the production cost is low, the product performance is high, the quality is good, and the price is lower than other similar or mid-to-high end graphite materials, the raw material composition is very successful in business.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

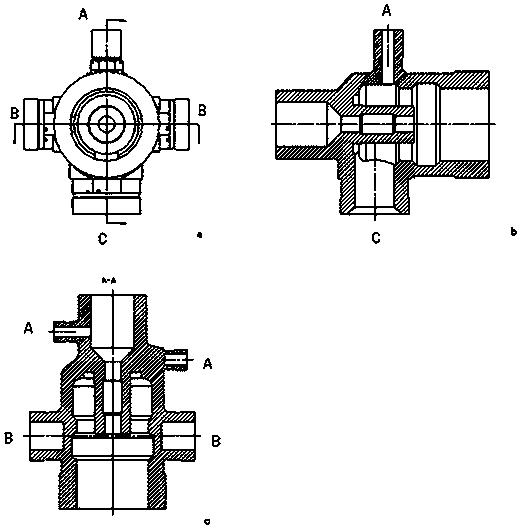

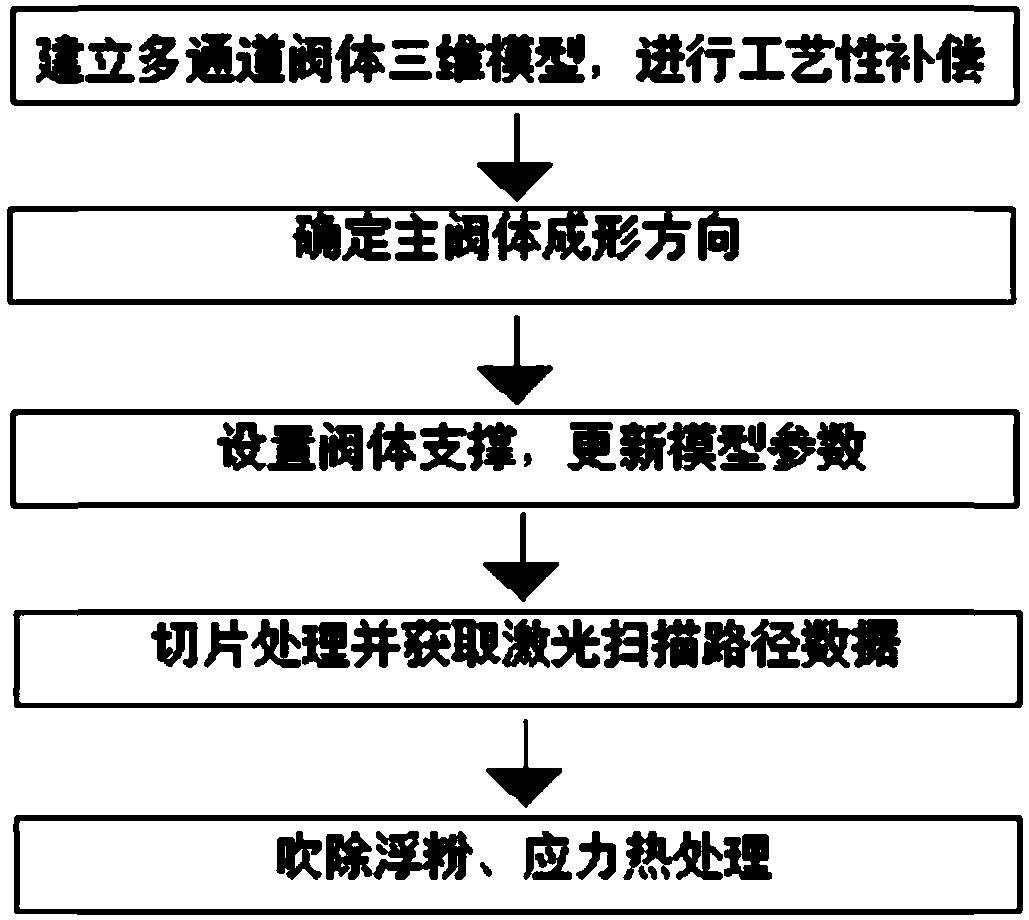

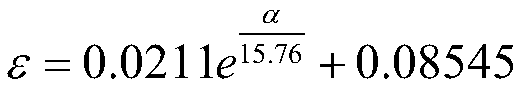

TC4 titanium alloy multi-channel valve body laser selective area melting forming method

ActiveCN109530694ARealize integrated formingEasy to useAdditive manufacturing apparatusIncreasing energy efficiencyStress concentrationProcess support

The invention discloses a TC4 titanium alloy multi-channel valve body laser selective area melting forming method. A multi-channel valve body three-dimensional model is established, manufacturabilitycompensation is added, and the size precision and the shape precision are improved; meanwhile, the valve body character and a complex stress and strain environment formed in the valve body in the forming process are aimed, a stress / strain simulation result is utilized, and the forming direction is determined, a specially-made process support is arranged, alleviating the stress concentration phenomenon is optimized, and machining parameters with the minimum stress strain are selected; and then laser scanning path data of each slice layer are obtained by means of slicing software, and laser selective area melting forming is carried out according to the scanning path data; and finally, after the valve body removes floating powder and is subjected to thermal stress treatment, a substrate plateof the valve body is separated, and the problem that the size precision of the forming valve body is low by utilizing the laser selective area melting forming technology is solved.

Owner:XIAN SPACE ENGINE CO LTD

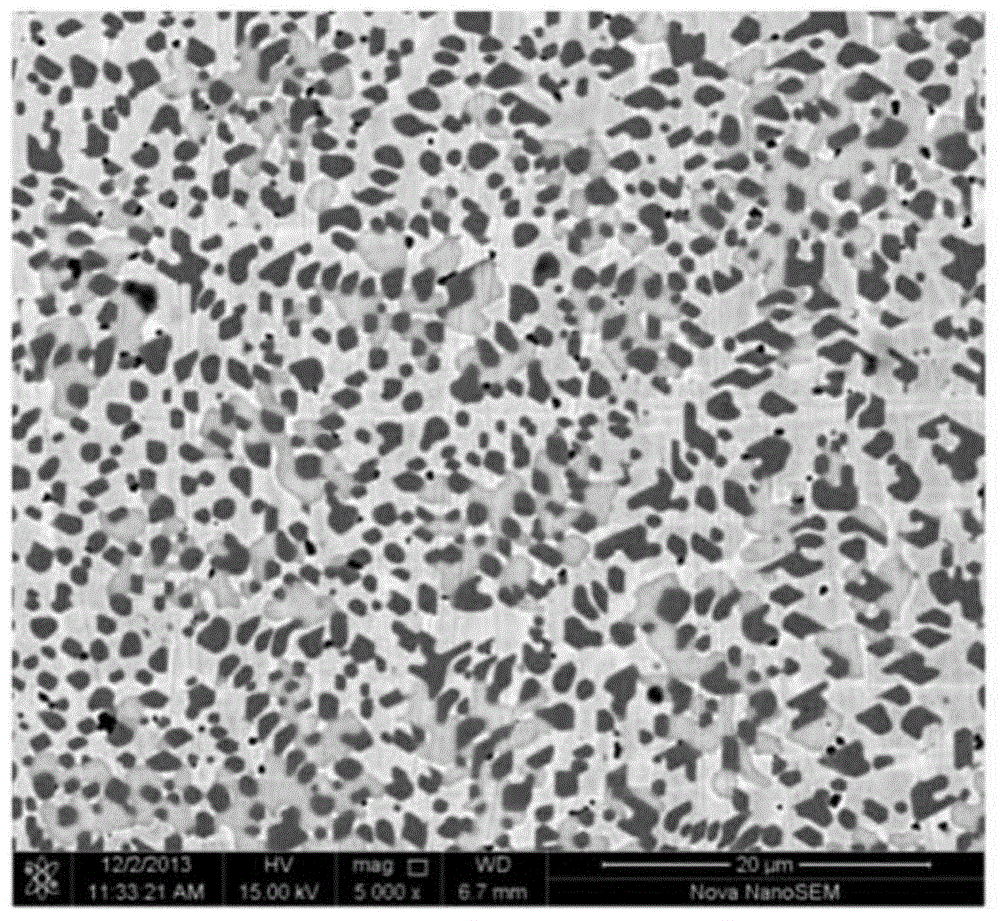

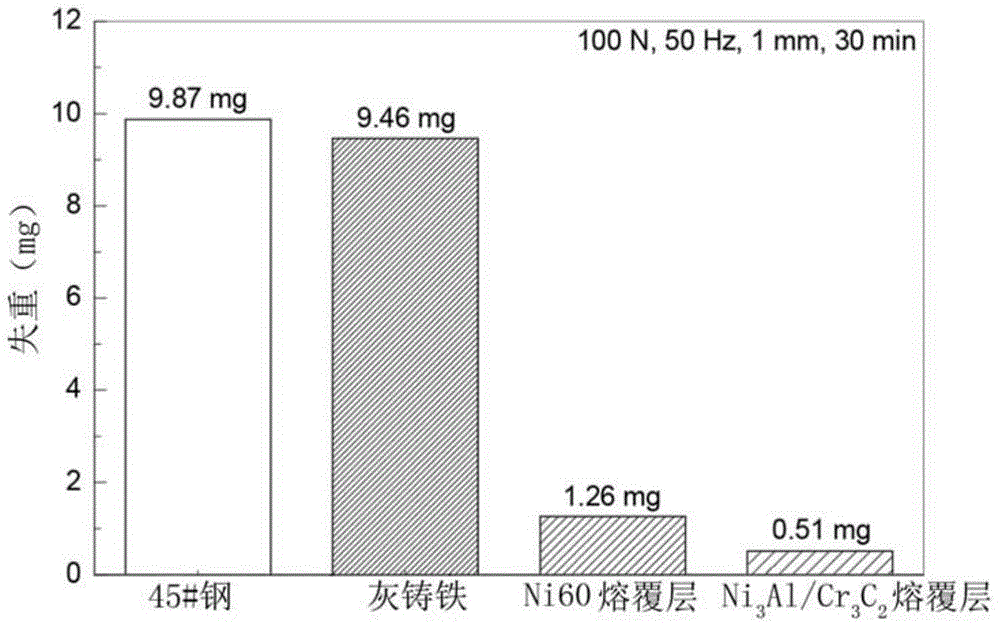

Method for preparing composite coating Ni3Al/Cr3C2 by use of laser cladding technique

InactiveCN104532231ADense tissue structureImprove wear resistanceMetallic material coating processesPre treatmentMetallurgy

The invention discloses a method for preparing a composite coating Ni3Al / Cr3C2 by use of a laser cladding technique. The method comprises the following steps: pretreating the surface of a steel material to remove oil contamination and impurities attached on the surface of the steel material; adding Cr3C2 powder to Ni3Al powder and mixing evenly to obtain the mixture of the Ni3Al and the Cr3C2, wherein the content of the Cr3C2 in the mixture is 10wt% to 50wt%; and cladding the mixture on the surface of the steel material by use of the laser cladding technique so that the mixture is formed into the composite coating Ni3Al / Cr3C2 on the surface of the steel material. The composite coating Ni3Al / Cr3C2 obtained by use of the method has remarkable wear-resisting property.

Owner:CHINA IRON & STEEL RES INST GRP +2

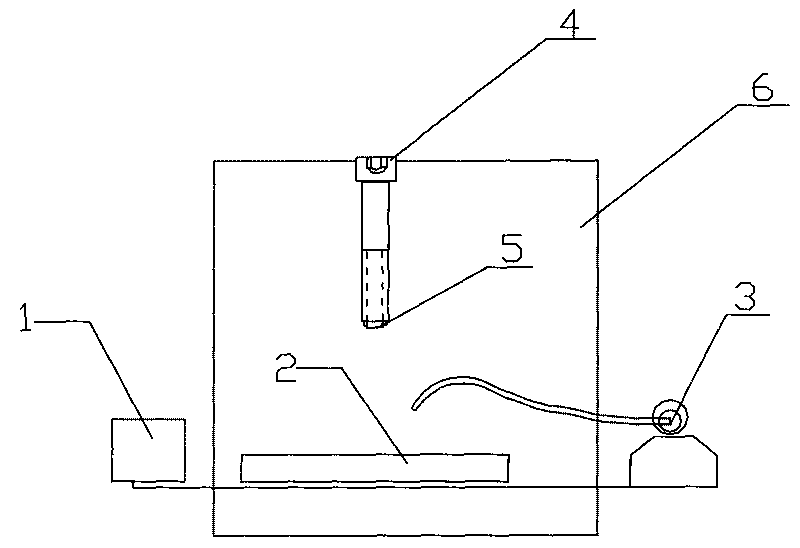

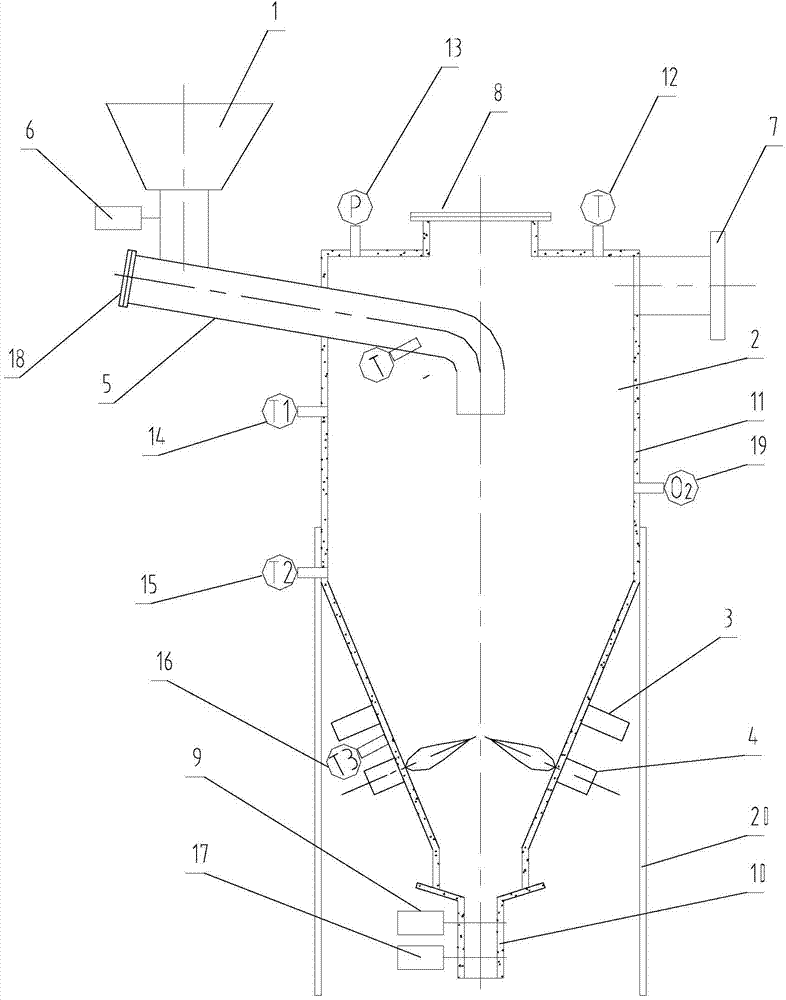

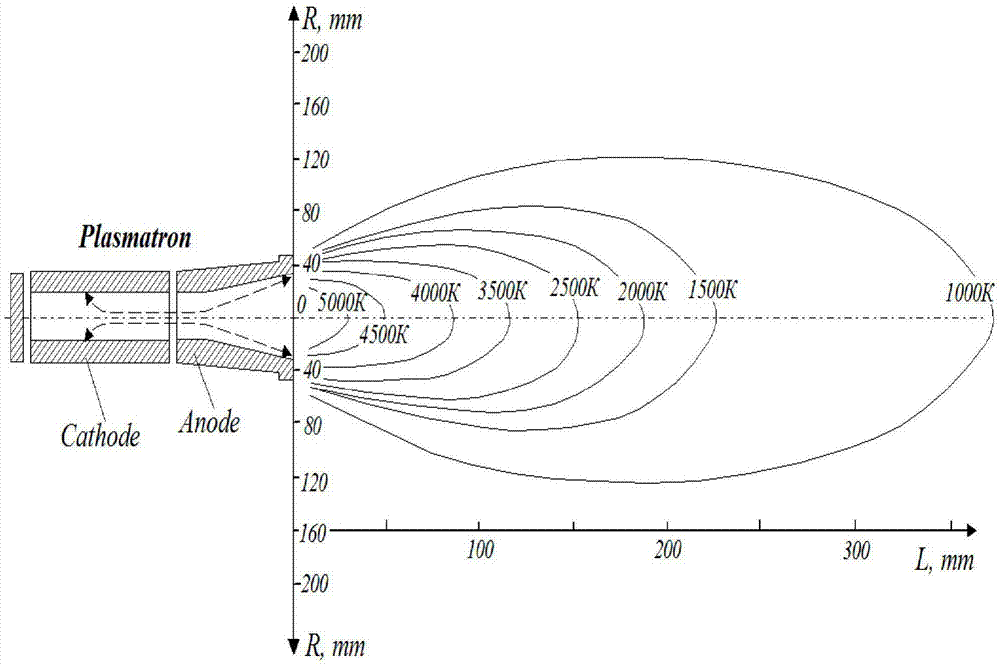

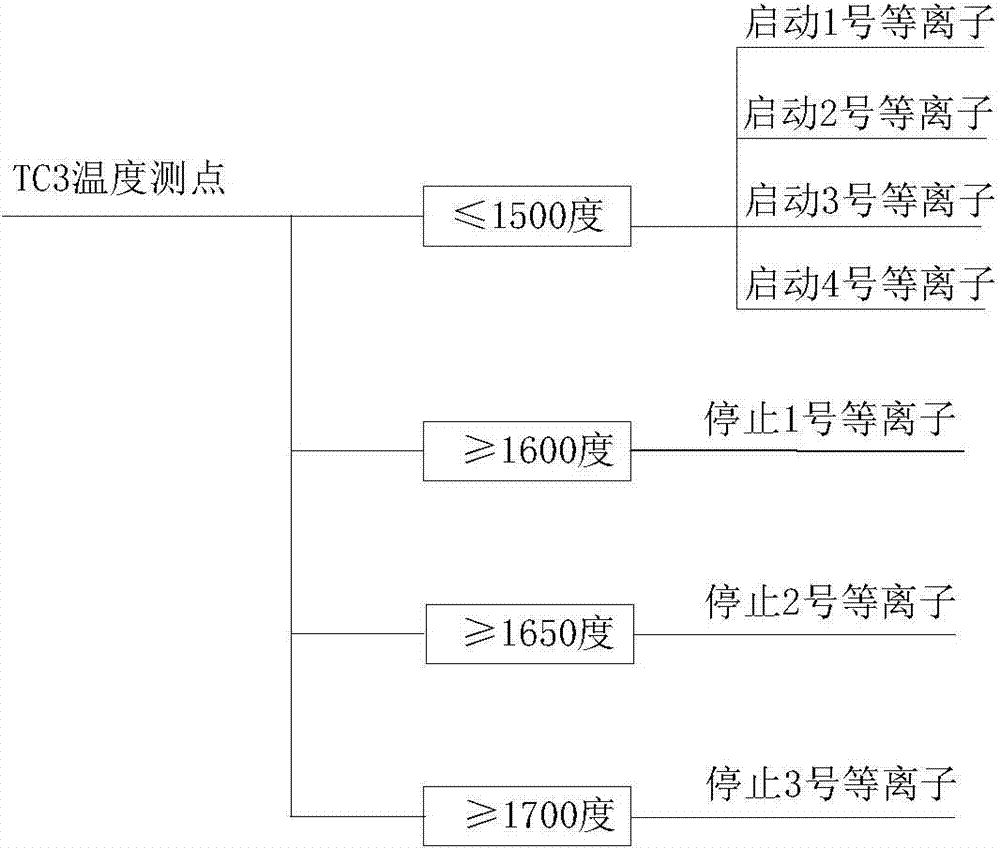

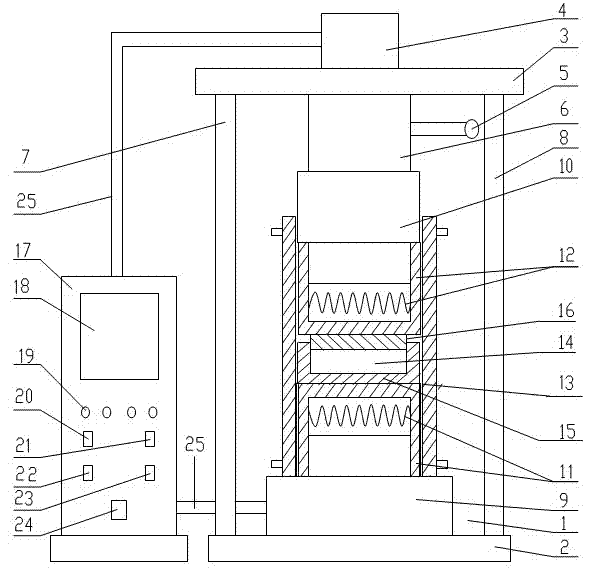

High-temperature plasma waste gasification and cracking furnace

InactiveCN104711032ARealize harmless treatmentDense tissue structureSolid waste disposalTransportation and packagingPlasma generatorCombustible gas

The invention discloses a high-temperature plasma waste gasification and cracking furnace, which comprises a furnace body, a feeding system arranged on one side of the furnace body, a discharge system arranged at the bottom end of the furnace body and a gas outlet formed in one side of the furnace body, wherein a group of plasma generators is arranged at the lower end of the furnace body; a group of rotating nozzles forming certain included angles with the central perpendicular line of the furnace body is arranged at the upper ends of the plasma generators; a group of temperature thermocouples is arranged on the outer side of the furnace body respectively. According to the high-temperature plasma waste gasification and cracking furnace, arc temperature higher than 5,500 DEG C can be achieved by high-temperature plasmas, the gasification and cracking furnace is heated to more than 1,500 DEG C and even higher temperature to gasify and crack waste to generate synthetic gas to provide heat energy, generate steam, generate power and refine multiple fuels and combustible gas by utilizing the high heat density and high-temperature arcs of the plasma generators, and is applied to any solid waste, secondary pollution is avoided, and discharged glass ash residues are free of toxic substances such as dioxin and heavy metal.

Owner:南京创能电力科技开发有限公司

Processing method for convenient rice wine soaking duck food

The invention relates to a processing method for convenient rice wine soaking duck food, which belongs to the technical field of meat product processing. A fresh or frozen duck without viscera serves as raw materials, and the duck is orderly processed into rice wine sauce, a duck neck, a duck tongue and duck wings to obtain the convenient rice wine soaking duck food. The processing technology andparameters, brine and a drunk brine formula are determined. The fishy smell of the raw materials is eliminated by precooking and rising modes, the wine soaking time is shortened with a vacuum wine soaking slot, and the wine soaking consistency is enhanced. The vacuum packaging is integrated with a high temperature sterilization technology to ensure the food hygiene and the guarantee period. Soup made of the duck skeleton is used for processing the convenient rice wine soaking duck food so as to enhance the utilization ratio of the raw materials. The convenient rice wine soaking duck food has the flavors of the duck, the duck neck, the duck tongue or the duck wings and the rice wine, and has strong flavor of rice wine but no preservatives. The package of the convenient rice wine soaking duck food is small, and the convenient rice wine soaking duck food can be instantly eaten after being opened. The convenient rice wine soaking duck food is stored at the normal temperature, and the guarantee period of the convenient rice wine soaking duck food is longer than or equal to six months.

Owner:QIONGZHOU UNIVERSITY +1

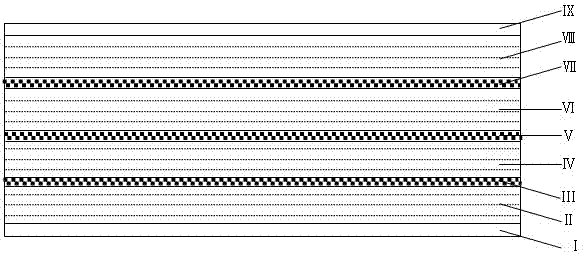

Preparation method of carbon fiber strengthened aluminum-base-layer-shaped composite board

The invention relates to a preparation method of a carbon fiber strengthened aluminum-base-layer-shaped composite board, and aims to solve the condition that the intensities of aluminum and aluminum alloy are low and the tenacity is poor. According to the preparation method, aluminum powder and carbon fiber cloth are heated, fused and combined, vibrated and pressurized so as to manufacture an aluminum base-layer-shaped composite board, the carbon fiber strengthened aluminum base-layer-shaped composite board is manufactured on a heating and vibrating press machine in a heating, pressurizing and vibrating process, so that a nine-layer structure is formed, an aluminum solution is utilized for wetting the carbon fibers under low temperature, pressure and vibration actions, and a fragility compound can not be formed, so that the organization structure is compact, the tensile strength achieves 144MPa, the elongation achieves 21.2%, the process is advanced, the data is full and accurate, the process flow path is short, and the preparation method is an ideal method for preparing the carbon fiber strengthened aluminum base-layer-shaped composite board.

Owner:TAIYUAN UNIV OF TECH

Anti-rust spraying fluid for metals

ActiveCN104294274AShort film forming timeImprove quick-drying performanceSodium molybdateIsobutyl alcohol

The invention provides anti-rust spraying fluid for metals, which is composed of the following components in parts by mass: 12-15 parts of triethanolamine, 4-5 parts of borax, 1-2 parts of sodium molybdate, 3-5 parts of sodium bisulfate, 1-2 parts of diethanolamine, 2-3 parts of isobutanol, 0.5-1 parts of isopropyl alcohol, 0.5-1 parts of sodium chloride, 8-12 parts of ethanol, and 85-95 parts of water. When the anti-rust spraying fluid for metals disclosed by the invention is splayed on a metal workpiece, an anti-oxidation protection film can be formed on the surface of the metal workpiece, and the film is compact in tissue structure and fine in particles, so that a rust protection effect is achieved; the anti-rust spraying fluid for metals disclosed by the invention is short in film-forming time and good in fast drying property, and can form a film in 2-3 minutes; and in a normal environment, metals can be prevented from rusting in 5-6 months.

Owner:武汉腾耀新材料工程有限公司

Method for preparing molybdenum-silicium-boron alloy

The invention discloses a method for preparing molybdenum-silicon-boron alloy, which comprises the steps that: molybdenum powder, silicon powder and boron powder are taken as raw materials; after even mixed treatment, the alloy powder is subjected to smelting in an arc-melting furnace, a smelting operating current is 700A to 800A; a lump after smelting is subjected to crushing and annealing treatment, the annealing temperature is 1200 DEG C to 1300 DEG C, the time is 0.5 hour to 1.5 hours; and then the alloy powder after the annealing treatment is put in an electricity-discharging plasma sintering furnace for sintering, the sintering temperature is 1400 DEG C to 1600 DEG C, the sintering time is 2min to 5min and the sintering pressure is 10MPa to 30MPa. The molybdenum-silicon-boron alloy prepared by the method has the advantages of simple method and fast speed, and has high organization compaction, strength and extensibility.

Owner:山东铭特金属材料科技有限公司

Defatted cheese and preparation method thereof

InactiveCN101167499ADense tissue structureGood glossCheese manufactureFood preparationFat substituteSucrose

The invention relates to a fermentation dairy product in food field, which is a lean cheese and process for preparation. Crystalline cellulose is utilized as fat substitute and sucrose fatty acid ester is utilized as fat imitation to produce novel low-caloric lean cheese with rich nutrition. During producing, the crystalline cellulose and the sucrose fatty acid ester is pro rata mixed and swelled with part butter milk as premix compound. After high speed shearing type stirring, the crystalline cellulose forms a micro-mesh shape cellulose dispersion with high viscosity, and the stereo meshed structure is filled with fat imitation sucrose fatty acid ester for improving physical arrangement of products. Then the above premix compound is charged to the rest butter milk or low-caloric butter milk powder reconstructed milk to evenly stir, to high pressure homogeneously treat, and to be charged with leaven and other addition agents, such as perfume compounds, condiment, coloring matter and the like, thereby producing the lean cheese product of the invention after fermenting, with missible oil shape appearance and taste similar to that of whole cheese.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Magnesium-chromium composite spinelle brick

The invention discloses a magnesium-chrome composite spinel brick which is made from synthetical magnesium-chrome spinel sand, magnesia, chromium concentrate and chrome oxide according the weight percentages as follows: taking 65 percent to 70 percent of MgO, 20 percent to 25 percent of Cr2O3, 0.5 percent to 1.2 percent of SiO2, 4 percent to 6 percent of Fe2O3, 2 percent to 4 percent of Al2O3 and 0.5 percent to 1.2 percent of CaO to the material of the number one synthetical magnesium-chrome spinel sand; taking 55 percent to 60 percent of MgO, 30 percent to 35 percent of Cr2O3, 0.5 percent to 1.2 percent of SiO2, 4 percent to 6 percent of Fe2O3, 2 percent to 4 percent of Al2O3 and 0.5 percent to 1.2 percent of CaO to the material of the number two synthetical magnesium-chrome spinel sand; taking 70 percent to 75 percent of MgO, 14 percent to 19 percent of Cr2O3, 0.8 percent to 1.2 percent of SiO2, 4.5 percent to 7 percent of Fe2O3, 2 percent to 4 percent of Al2O3 and 0.8 percent to 1.5 percent of CaO to the material of the number three synthetical magnesium-chrome spinel sand; taking 97 percent to 98.5 percent of MgO, 0.5 percent to 1.3 percent of SiO2, 0.5 percent to 1.3 percent of CaO and 0.2 percent to 0.5 percent of Fe2O3 to the material of the magnesia; taking 50 percent to 60 percent of Cr2O3, 9 percent to 15 percent of MgO, 0.3 percent to 1.5 percent of SiO2, 15 percent to 25 percent of Fe2O3 and 8 percent to 15 percent of Al2O3 to the material of the chromium concentrate; taking 92 percent to 96 percent of Cr2O3 and 4 percent to 8 percent of ZrO to the material of the chrome oxide. The invention has the advantage of having the characteristics of compact structure, thermal shock resistance, anti-scaling off, erosion resistance etc.

Owner:ZHENGZHOU HUAWEI REFRACTORIES

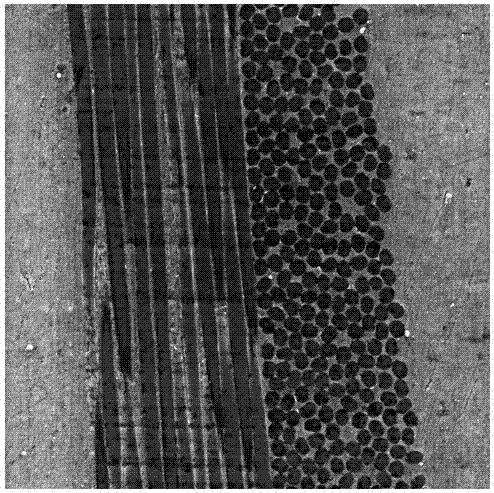

Preparation method of continuous carbon fiber enhanced copper-based composite material

The invention provides a preparation method of a continuous carbon fiber enhanced copper-based composite material. A method of adhering and curing copper powder on the surface of a continuous carbon fiber through organogel is adopted, the thickness of a copper layer adhering to the surface of the carbon fiber can be controlled, and therefore the content and the interval of the carbon fiber in a composite material after hot pressing sintering are controlled, so that the carbon fiber is distributed in a copper base body in parallel, and the copper-based composite material high in carbon fiber content can be prepared. According to the preparation method, a carbon fiber surface copper plating process complicated in process is omitted, cost is extremely low, operation is easy, and industrialized production can be achieved; and the electrical conduction performance and the strength of the carbon fiber enhanced copper-based composite material obtained through the preparation method are obviously superior to those of a carbon fiber enhanced copper-based composite material prepared through an existing impregnation method, and broad application prospects are achieved.

Owner:HEBEI COLLEGE OF IND & TECH

Preparation method of continuous carbon fiber reinforced aluminum-based composite material

The invention provides a preparation method of a continuous carbon fiber reinforced aluminum-based composite material. According to the preparation method provided by the invention, the thickness of an aluminum layer adhered to the surface of the carbon fiber can be controlled by adopting a method of adhering curing aluminum powder to the surface of continuous carbon fiber through organogel, so that the content and the spacing of the carbon fiber in a composite material after hot pressing sintering can be controlled, the carbon fiber can be parallelly distributed in an aluminum matrix, and analuminum-based composite material with high carbon fiber content can be prepared. The preparation method disclosed by the invention is low in cost and easy to operate and is capable of realizing industrialized production; the strength of the carbon fiber reinforced aluminum-based composite material obtained through the preparation method provided by the invention is obviously superior to that of the carbon fiber reinforced aluminum-based composite material prepared through an existing infiltration method, and a wide application prospect is obtained.

Owner:江苏戍卫新材料科技有限公司

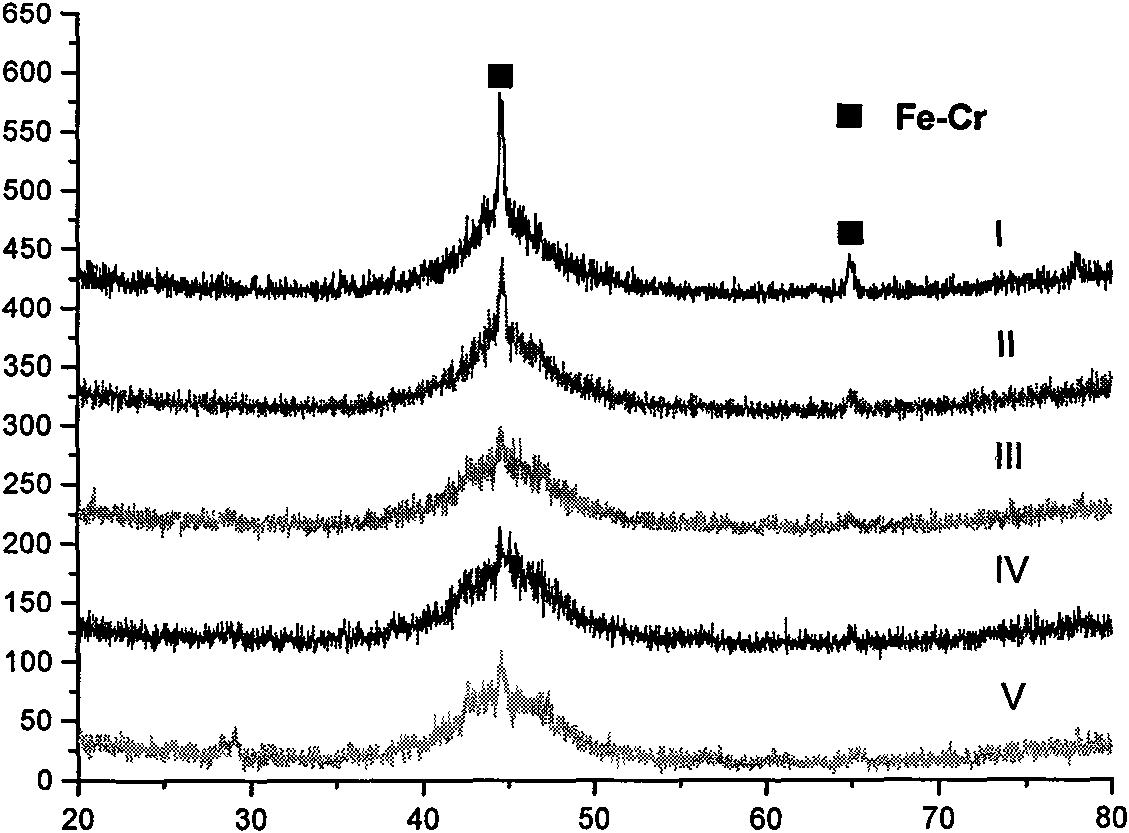

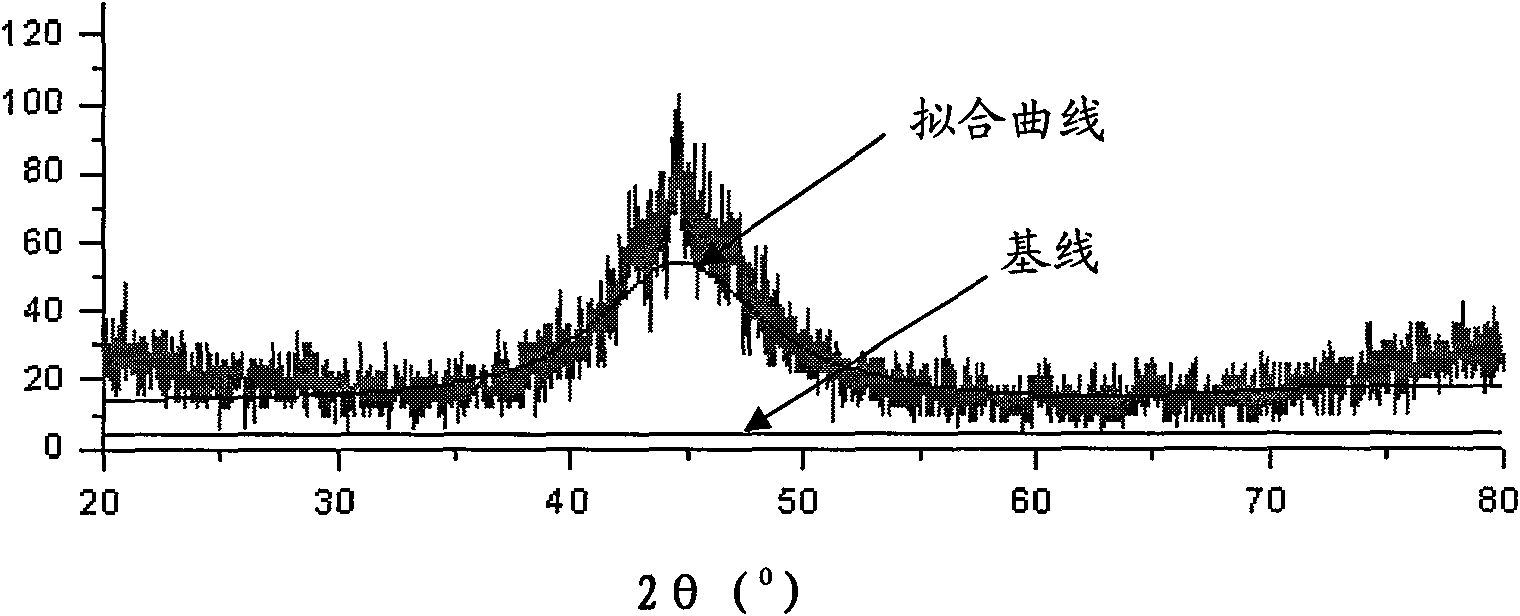

Steel-based surface chrome-contained abrasion-resistant ceramic coating and preparing method of steel-based surface chrome-contained abrasion-resistant ceramic coating

The invention relates to a steel-based surface chrome-contained abrasion-resistant ceramic coating layer and a preparing method of the steel-based surface chrome-contained abrasion-resistant ceramic coating, and belongs to the technical field of methods for preparing steel-based protective coatings. The steel-based surface chrome-contained abrasion-resistant ceramic coating and the preparing method are characterized in that the steel-based surface chrome-contained abrasion-resistant ceramic coating is composed of silicon carbide ceramic abrasion-resistant powder, silicon dioxide, water glass, ferrochromium powder and the like; structure defects are overcome through the ferrochromium powder, the compactness of the coating structure is improved, and the metallurgical bonding strength between the coating and a steel base is greatly improved. By means of the preparing method, as a two-time curing technology is adopted, the curing time can be shortened, the coating quality can be improved, and a ceramic phase between the steel base and the coating can be easily generated; meanwhile, the coating has the abrasion resistance several times higher than that of the steel base, and the overall performance such as the surface rigidity and the corrosion resistance of the coating is improved. The preparing method is simple, construction is convenient, the production efficiency is high, and the economical effect and the practical effect are achieved. The problem that as a ceramic coating prepared in the prior art is poor in structure compactness, the overall performance of the ceramic coating can not be guaranteed through one-time curing is solved.

Owner:YANGTZE UNIVERSITY

Production process of goose liver paste

The invention relates to a production process of foie gras, comprising the following steps of: putting goose livers into a vacuum cut mixer to roughly cut after clearing and cleaning; putting the goose livers and ingredients into the vacuum cut mixer again to finely cut; cutting and mixing the goose livers into foie gras; and finally, canning, sealing in vacuum, sterilizing at high temperature, cooling by spraying water, entering a constant-temperature tank and canning at the temperature of 37 DEG C sequentially. The invention has simple process and low production cost and can effectively eliminate fishy smell and peculiar smell in the foie gras by cutting and mixing the goose livers at high temperature and high speed, and the foie gras has fine mouthfeel and just melts in the mouth.

Owner:天津宝鹅园鹅业发展有限公司

Preparation method for periclase composite spinel brick used for cement kiln clinkering zone

The invention discloses a preparation method for a periclase composite spinel brick used for a cement kiln clinkering zone. The method comprises the following steps: firstly, preparing a magnesium sand granule material, a ferric oxide powder and an alumina powder; and synthetizing into hercynite granule material and pleonaste granule material at a certain ratio; weighing the above materials as follows: 6-15 parts of synthetized hercynite granule material, 40-55 parts of synthetized pleonaste granule material, 35-45 parts of magnesium sand granule material, 1-3 parts of ferric oxide powder and 1-2 parts of alumina powder; adding 2-5 parts of magnesium chloride solution or sulphurous acid paper pulp solution in the above materials for milling; then pressing the mixture in a press to obtain a green brick; and after drying, sintering and forming. The preparation method has the advantages that the sintered finished brick has the characteristics of compact tissue structure, high strength, excellent alkali corrosion resistance and thermal shock stability, good spalling resistance and is an ideal product for a large cement kiln clinkering zone and kiln coating is easy to hung. The product fills up the national blank, reaches the international leading level and can replace the same type of imported products.

Owner:ZHENGZHOU HUAWEI REFRACTORIES

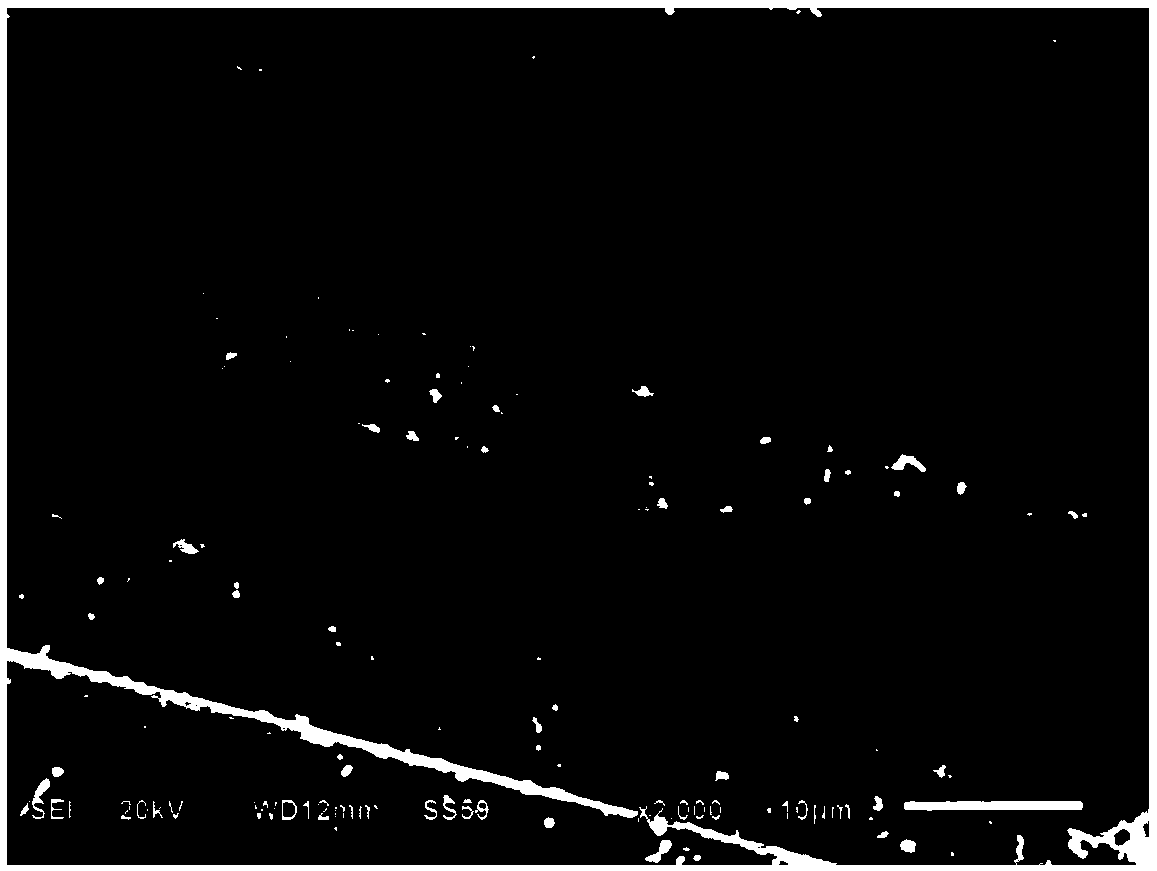

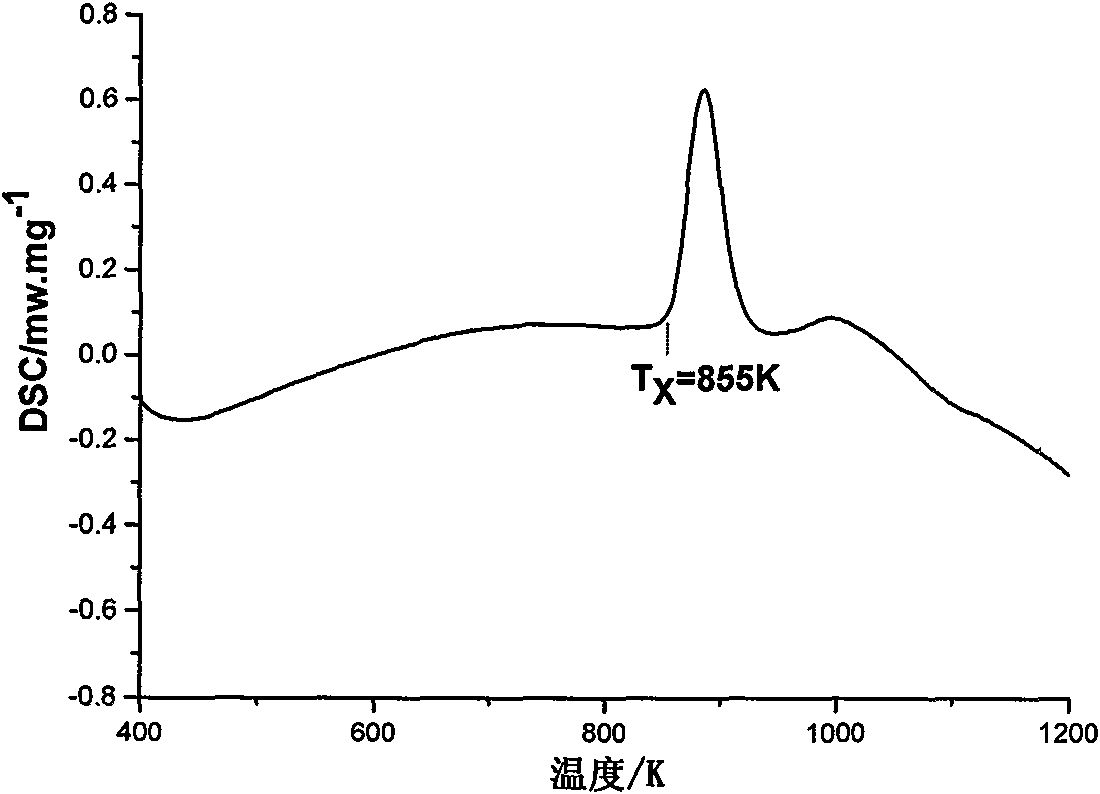

Powered core coil for spraying low alloy quantity Fe-base amorphous alloy coating by electric arc

InactiveCN101619432ADense tissue structureImprove thermal stabilityMolten spray coatingWire rodChromium carbide

The invention belongs to the field of hot spray in material processing engineering and aims at providing a powered core coil for spraying low alloy quantity Fe-base amorphous alloy coating by electric arc. In the powered core coil, a stainless steel band is coated on a powered core; the diameter of the coil is 2.0mm, and the powered core occupies 25-42 percent of the coil by weight percent. The powered core comprises the components by weight percent: 40-70 percent of ferroboron, 1-5 percent of ferromanganese, 5-15 percent of silicoferrite, 1-20 percent of chromium powder, 5-20 percent of ferromolybdenum, 5-15 percent of chromium carbide and 1-5 percent of misch metal. The powered core coil has higher noncrystalline forming ability; the coating prepared by an electric arc spraying technology has compact organization structure and good thermal stability, the amorphous phase content is larger than 70 percent, and the microhardness HV0.1 is larger than 1300.

Owner:BEIJING UNIV OF TECH

Hard thin film and preparation method thereof

InactiveCN107541710AImprove wear resistanceRelief of stressful situationsVacuum evaporation coatingSputtering coatingGas phaseCrystal orientation

The invention relates to a hard thin film and a preparation method thereof and belongs to the technical field of coating. By adoption of the physical vapor deposition technology and the ionic nitriding technology, a nitride layer and a W / Mo-doped multi-element compound CrTiAlN hard thin film are formed on the surface of a hard alloy, the surface of the thin film is smooth and flat, the thin film grows in a columnar crystal mode, the texture structure is compact, no obvious defect exists, the area, close to a substrate, of the fracture of the thin film is of an obvious fine crystal structure, the growth direction of the thin film is slightly oblique by means of nitriding treatment and shows predominant crystal orientation to a certain extent, and the abrasion resistance and the bonding strength with the substrate of the CrTiAlN thin film are improved; and meanwhile the thin film is more compact after nitriding is completed, as the element compositions of the thin film show gradient change, continuous transition of the physical and chemical performance and the texture structure of the film layer is achieved, the stress condition of an interface can be relieved, and the abrasion resistance is enhanced.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com