Preparation method of continuous carbon fiber enhanced copper-based composite material

A copper-based composite material and carbon fiber technology, applied in the field of composite material preparation, can solve the problems of easy segregation of carbon fibers, difficult to control the content and spacing of carbon fibers, etc., and achieve the effects of avoiding segregation, low cost, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of continuous carbon fiber reinforced copper-based composite material:

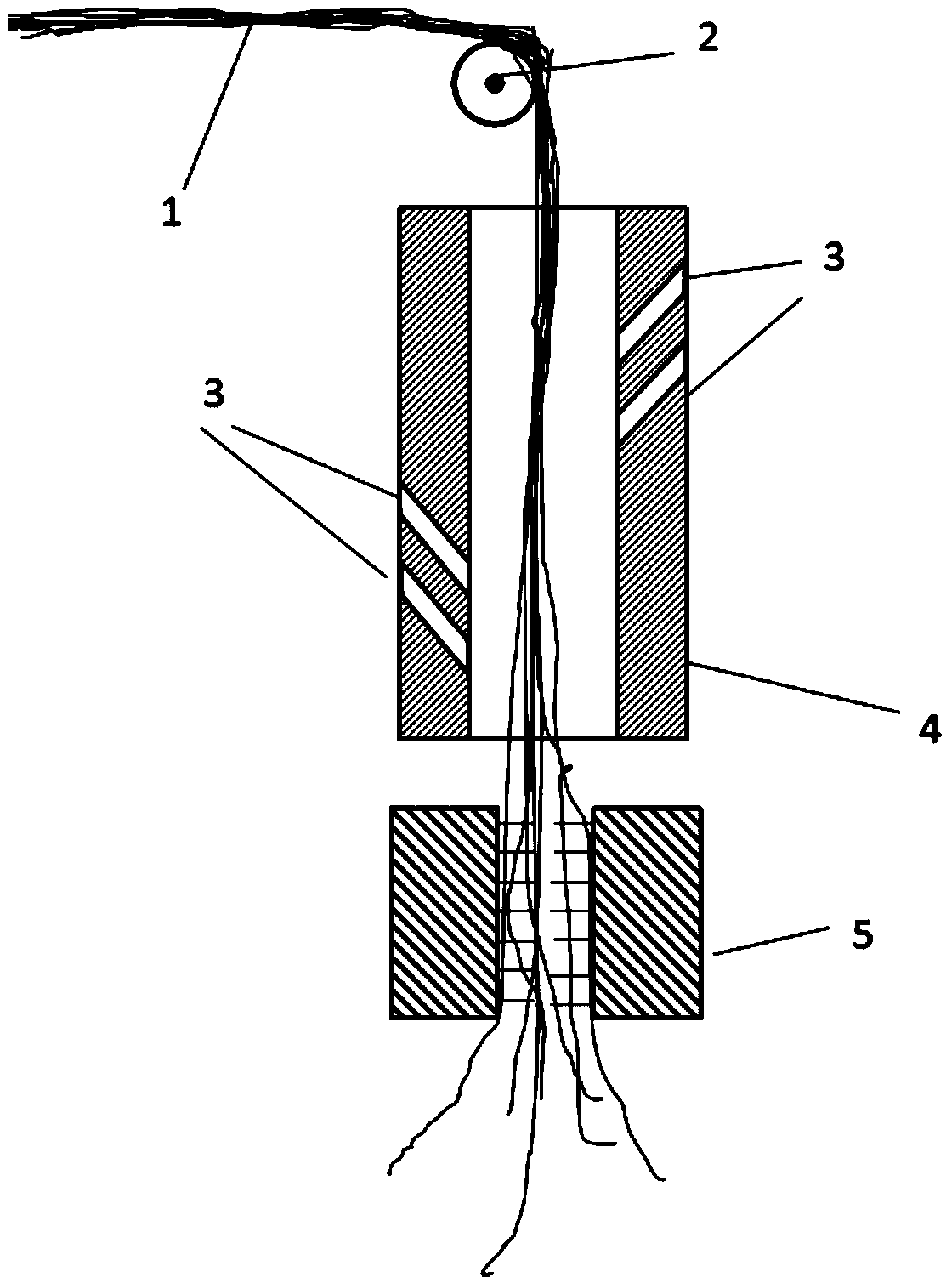

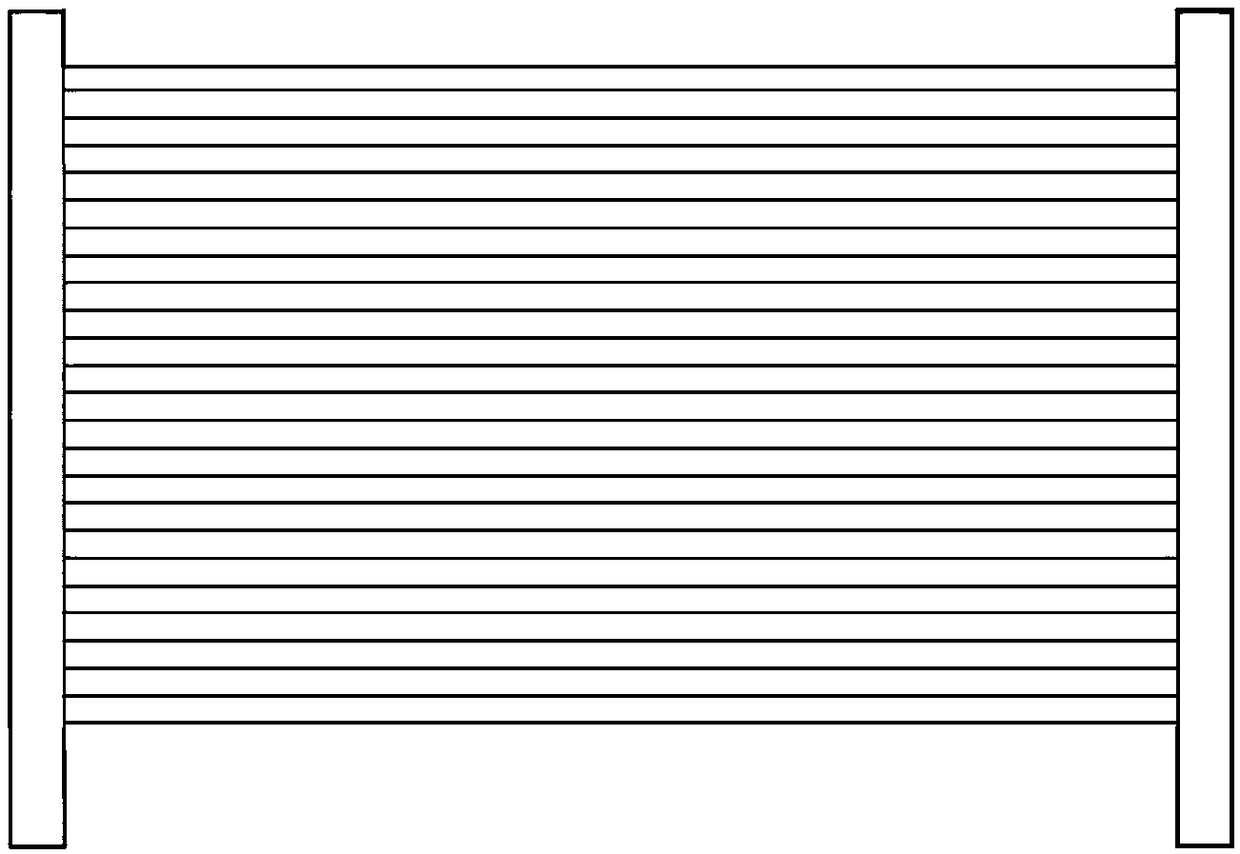

[0044] Step 1. Immerse the carbon fiber bundles in concentrated sulfuric acid for 10 minutes, take out and rinse the residual acid on the surface until neutral, disperse the carbon fiber bundles into carbon fiber monofilaments, take 50-200 carbon fibers as a cluster, arrange each cluster in parallel, and use clamps at both ends fixed, cut off the excess carbon fiber at both ends to obtain a prepreg, such as figure 2 shown;

[0045] Step 2, 400ml hydroxyethyl methacrylate is dissolved in 600ml toluene to get a gel solution, add 10% acrylic resin of gel solution weight to the gel solution, mix well, then add 0.5% gel weight benzoyl peroxide to obtain an organic adhesive;

[0046]Step 3: Immerse the prepreg in the organic adhesive for 5-10 seconds, take it out, immerse the prepreg with the organic adhesive in titanium powder with an average particle size of 40nm and vibrate rep...

Embodiment 2

[0054] A preparation method of continuous carbon fiber reinforced copper-based composite material:

[0055] Step 1. Immerse the carbon fiber bundles in concentrated sulfuric acid for 15 minutes, take out and rinse the residual acid on the surface until neutral, disperse the carbon fiber bundles into carbon fiber monofilaments, take 50-200 carbon fibers as a cluster, arrange each cluster in parallel, and use clamps at both ends fixed, cut off the excess carbon fiber at both ends to obtain a prepreg, such as figure 2 shown;

[0056] Step 2, 500ml hydroxyethyl methacrylate is dissolved in 500ml toluene to get a gel solution, add 7% acrylic resin of gel solution weight to the gel solution, mix well, then add 0.8% gel weight benzoyl peroxide to obtain an organic adhesive;

[0057] Step 3: Immerse the prepreg in the organic adhesive for 5-10 seconds, take it out, immerse the prepreg with the organic adhesive in titanium powder with an average particle size of 50 nm and vibrate re...

Embodiment 3

[0064] A preparation method of continuous carbon fiber reinforced copper-based composite material:

[0065] Step 1. Immerse the carbon fibers in concentrated sulfuric acid for 20 minutes, take out and rinse the residual acid on the surface until neutral, disperse the carbon into carbon fiber monofilaments, take 100 to 200 carbon fibers as carbon fiber bundles, fix both ends of the carbon fiber bundles, and arrange them in parallel One row, cut off the excess carbon fiber at both ends to get a prepreg, such as figure 2 shown;

[0066] Step 2, 600ml hydroxyethyl methacrylate is dissolved in 400ml toluene to obtain a gel solution, add 5% acrylic resin of gel solution weight to the gel solution, mix well, then add 1.0% gel weight benzoyl peroxide to obtain an organic adhesive;

[0067] Step 3: Immerse the prepreg in the organic adhesive for 5-10 seconds, take it out, immerse the prepreg with the organic adhesive in titanium powder with an average particle size of 80nm and vibra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com