Hard thin film and preparation method thereof

A thin film and hard technology, applied in the field of hard thin film and its preparation, can solve the problems of large surface roughness of the thin film, easy peeling off of the thin film, and limited application, so as to improve the tribological performance, enhance the wear resistance and prolong the lubrication time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

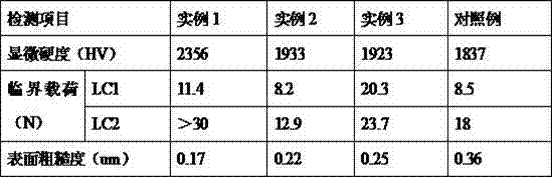

Examples

example 1

[0023] Take 30mm×20mm×1mm cemented carbide, grind and polish it with sandpaper, put it in acetone and ultrasonically clean it for 15 minutes, then soak it in absolute ethanol, and clean it with 300W ultrasonic wave for 15 minutes, take it out and dry it, and put it in a nitriding furnace. And evacuate to the pressure of 10Pa in the furnace, then heat to 240 ° C, and pass nitrogen gas at 50 mL / min, under the voltage of 300 V, nitriding treatment for 2 hours, after cooling to room temperature, the pretreated cemented carbide is obtained. The quality alloy is placed in a compound ion coating machine, and the vacuum degree of the coating chamber is controlled to be 2×10 -3 Pa, and then inject high-purity nitrogen gas to the vacuum chamber to 0.6Pa, and control the arc current to 50A, the substrate temperature to 200°C, and the substrate DC negative bias amplitude to 600V. + The glow discharge effect is used for sputtering cleaning, and then the DC negative bias voltage amplitude o...

example 2

[0025] Take 30mm×20mm×1mm cemented carbide, grind and polish it with sandpaper, put it in acetone and ultrasonically clean it for 18 minutes, then soak it in absolute ethanol, and use 300W ultrasonic wave to clean it for 18 minutes, take it out and dry it, and put it in a nitriding furnace. And evacuated to the furnace pressure of 50Pa, then heated to 270 ° C, and nitrogen gas was introduced at 50 mL / min, and the nitriding treatment was carried out at 500 V for 2 hours. After cooling to room temperature, the pretreated cemented carbide was obtained. The quality alloy is placed in a compound ion coating machine, and the vacuum degree of the coating chamber is controlled to be 2×10 -3 Pa, and then feed high-purity nitrogen to the vacuum chamber to 0.7Pa, and control the arc current to 55A, the substrate temperature to 220°C, and the substrate DC negative bias amplitude to 700V. +The glow discharge effect is used for sputtering cleaning, and then the DC negative bias voltage ampl...

example 3

[0027] Take 30mm×20mm×1mm cemented carbide, grind and polish it with sandpaper, put it in acetone and ultrasonically clean it for 20 minutes, then soak it in absolute ethanol, and clean it with 300W ultrasonic wave for 20 minutes, take it out and dry it, then place it in a nitriding furnace. And evacuate to the pressure of 100Pa in the furnace, then heat to 300°C, and pass nitrogen gas at 50mL / min, nitriding treatment at 600V for 3 hours, and cool to room temperature to obtain pretreated cemented carbide. The quality alloy is placed in a compound ion coating machine, and the vacuum degree of the coating chamber is controlled to be 2×10 -3 Pa, and then feed high-purity nitrogen gas to the vacuum chamber to 0.8Pa, and control the arc current to 60A, the substrate temperature to 240°C, and the substrate DC negative bias amplitude to 800V. + The glow discharge effect is used for sputtering cleaning, and then the DC negative bias voltage amplitude of the substrate is reduced to 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com