Patents

Literature

374results about How to "Improve tribological performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

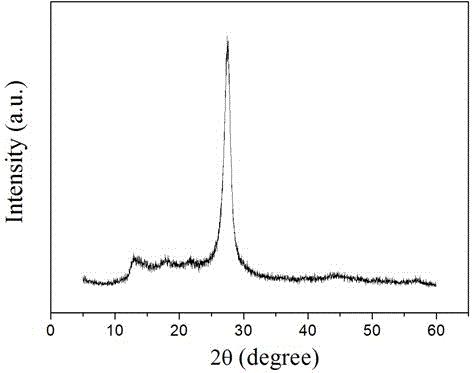

Compound nano material of graphene and MoS2 and preparation method thereof

InactiveCN102142548AMild reaction conditionsSimple preparation processMaterial nanotechnologyCell electrodesCysteine thiolateNew energy

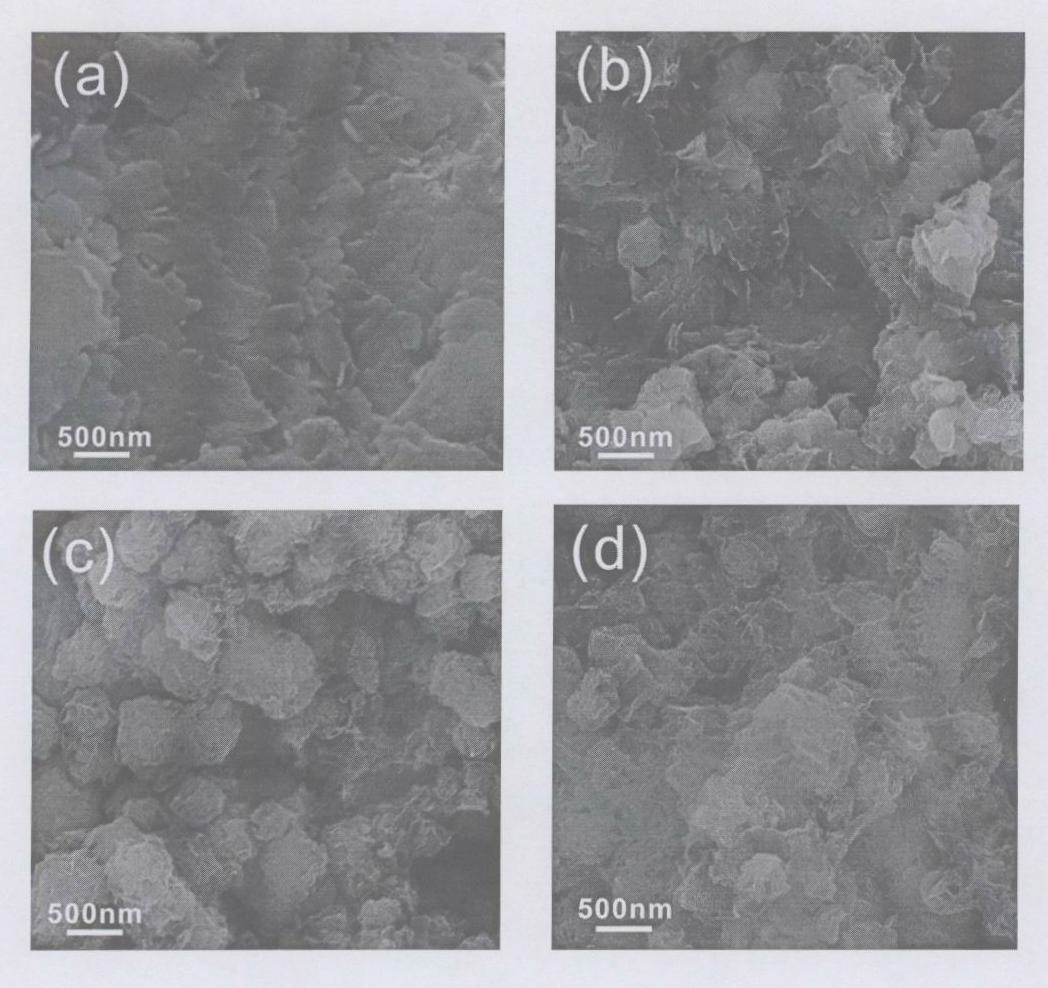

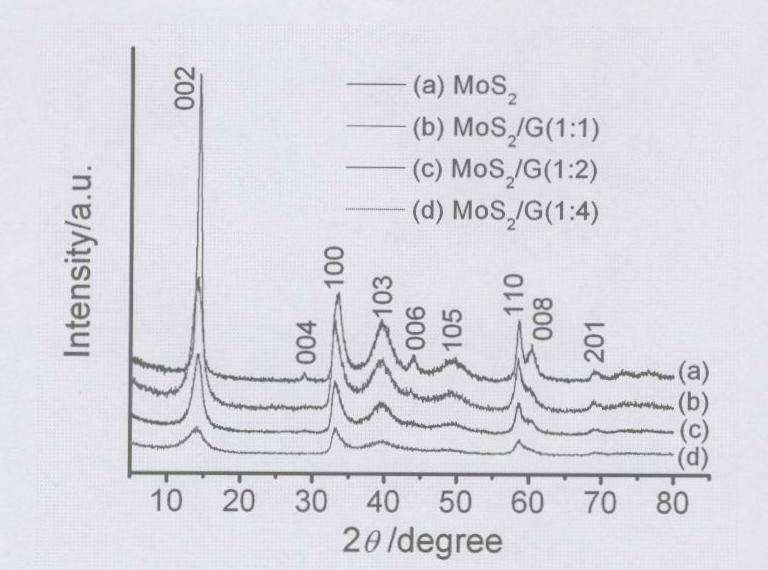

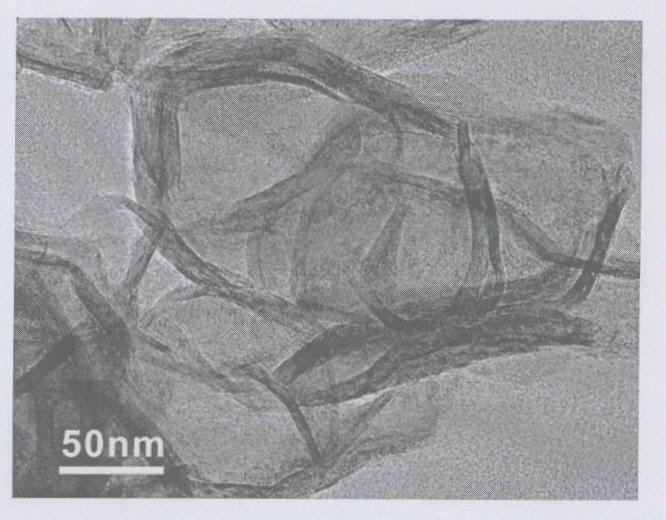

The invention discloses a compound nano material of graphene and molybdenum disulfide (MoS2) and a preparation method thereof. The compound material is formed by mixing graphene and a MoS2 nano material in a mass ratio of (1 to 1)-(4 to 1). The preparation method comprises the following steps of: preparing an oxidized graphite nano slice from graphite by a chemical oxidization method; then dissolving molybdate into deionized water so as to form 0.02 to 0.07M of solution; adding L-cysteine serving as a sulfur source and a reduction agent, wherein the mass ratio of the L-cysteine to the molybdate is (5 to 1)-(12 to 1); adding the oxidized graphite nano slice into the solution, and ultrasonically treating so that the oxidized graphite nano slice can be fully dispersed in the hydrothermal reaction solution; transferring the mixture into a hydrothermal reaction kettle and sealing; and synthesizing by a one-step hydrothermal method to obtain the compound nano material of graphene and MoS2, wherein the mass ratio of the graphene nano slice to the MoS2 is (1 to 1)-(4 to 1). The method has the characteristics of mild reaction condition and simple process. The compound nano material of graphene and MoS2 synthesized by the method can be widely used as electrode materials of new energy batteries, high-performance national lubricants, catalyst carriers and the like.

Owner:ZHEJIANG UNIV

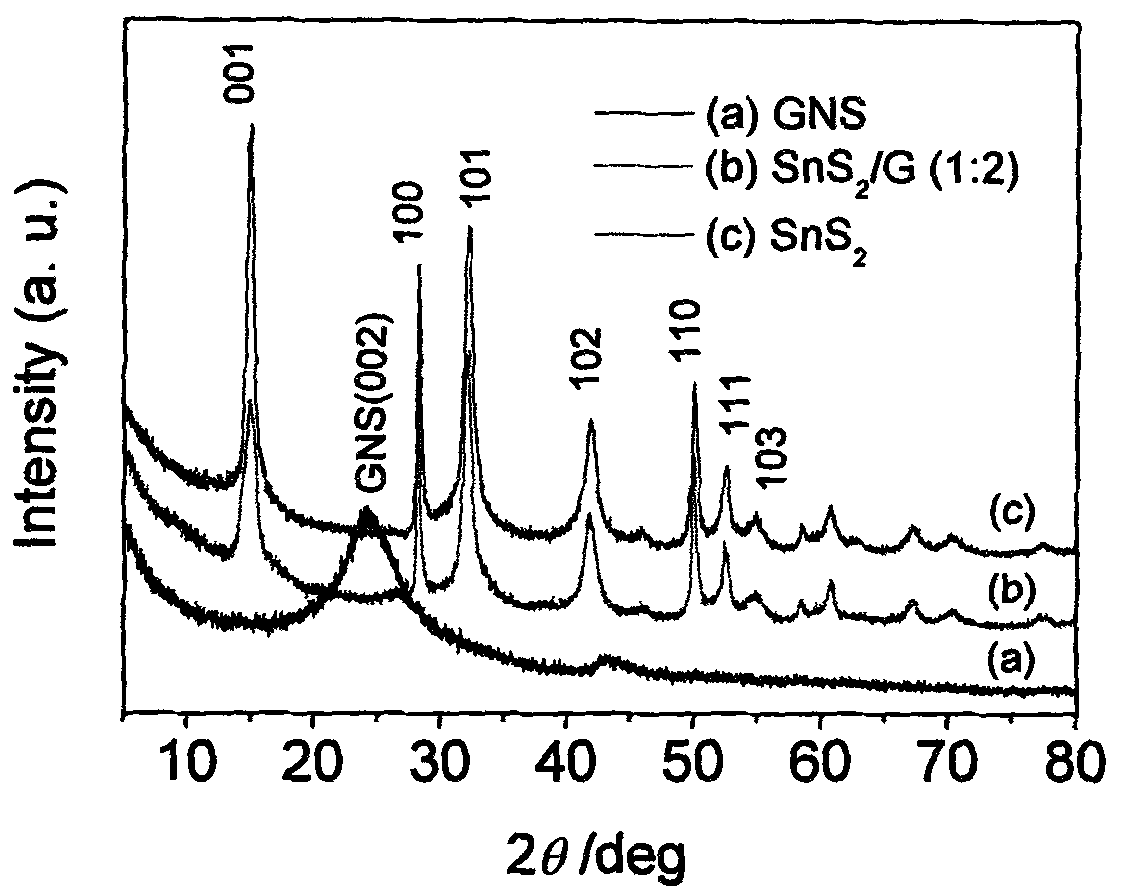

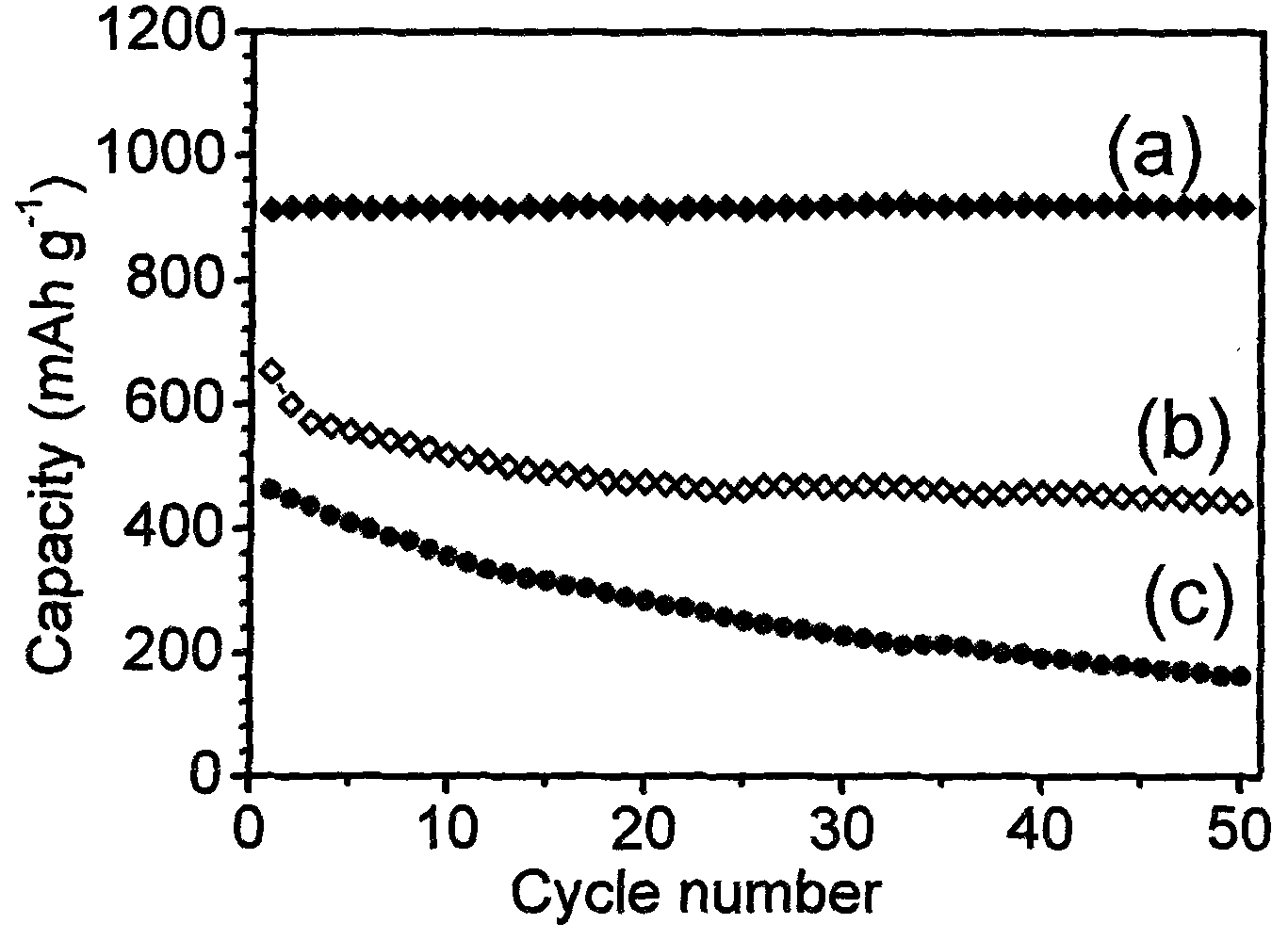

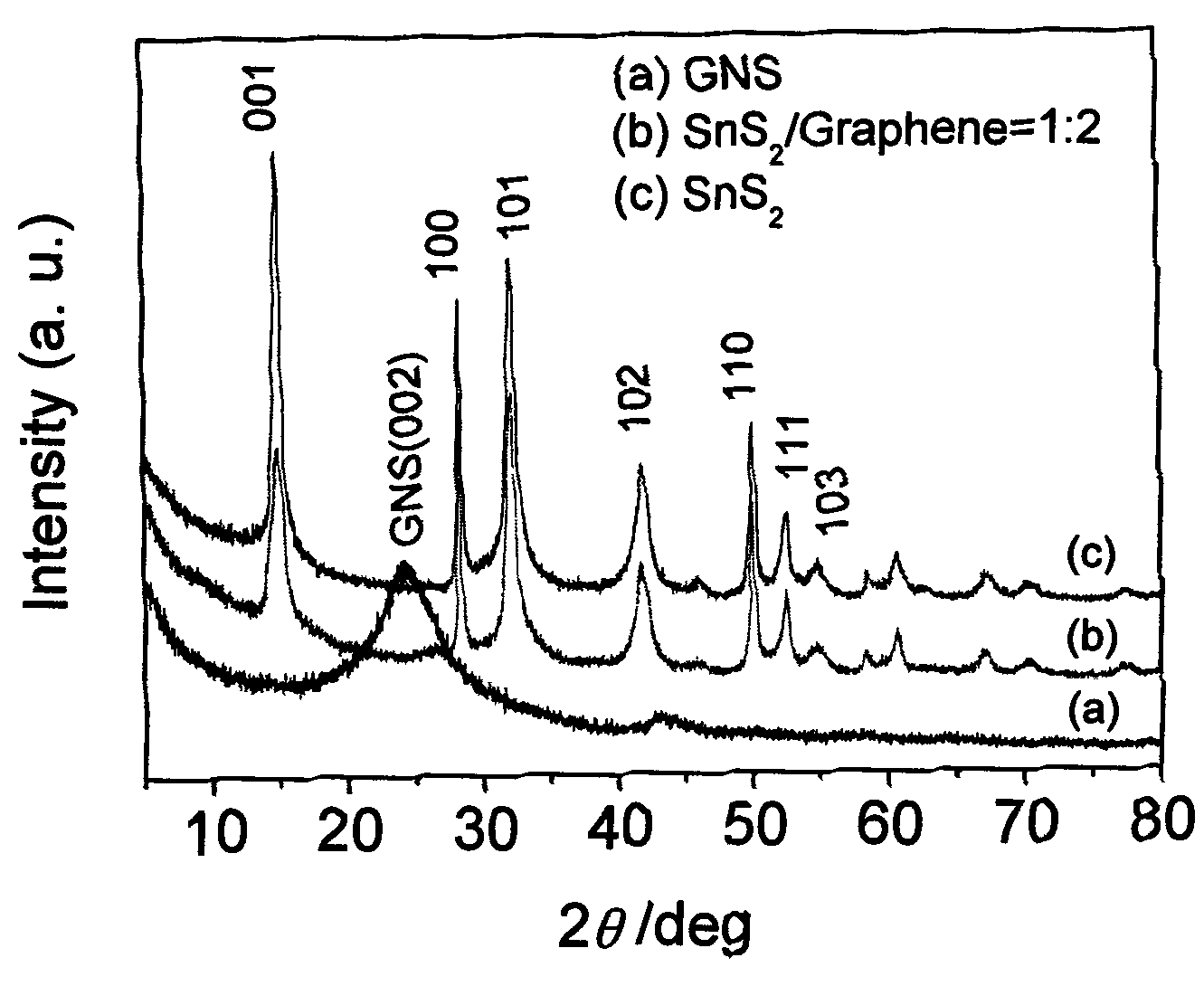

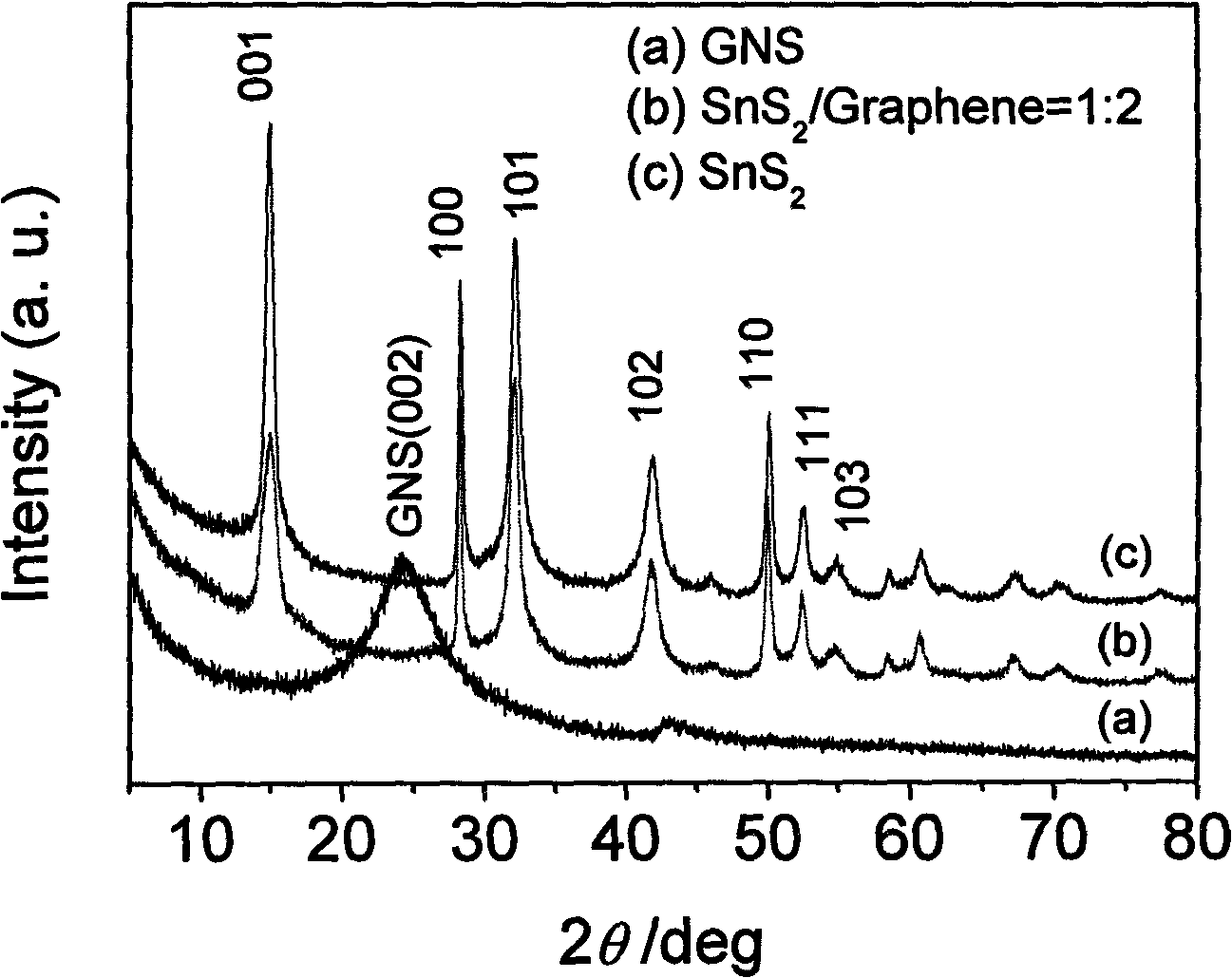

Lithium ion battery electrode made of graphene/SnS2 composite nanometer material and preparation method thereof

InactiveCN102142540AMild reaction conditionsSimple processCell electrodesMass ratioLithium-ion battery

The invention discloses a lithium ion battery electrode made of a graphene / SnS2 composite nanometer material and a preparation method thereof. The lithium ion battery electrode is characterized in that the active substance of the electrode is the graphene / SnS2 composite nanometer material, and the other components of the electrode are acetylene black and polyvinylidene fluoride. The lithium ion battery electrode comprises the following components in percentage by weight: 75-85% of the composite nanometer material active substance, 5-10% of the acetylene black and 10% of the polyvinylidene fluoride; and the mass ratio of the graphene to SnS2 nanometer material in the composite nanometer material active substance is (1:1)-(4:1). The electrode preparation method disclosed by the invention comprises the following steps: preparing a graphite oxide nanometer sheet by taking graphite as a raw material by virtue of a chemical oxidation method; in the presence of the graphite oxide nanometer sheet, synthetizing to obtain the graphene / SnS2 composite nanometer material by virtue of a one-step hydrothermal in-situ reduction method; and finally, taking the graphene / SnS2 composite nanometer material as the active substance to prepare the electrode. The electrode disclosed by the invention has the advantages of higher electrochemical lithium storage capacity and excellent cyclical stability and can be widely used in the new generation of lithium ion batteries.

Owner:ZHEJIANG UNIV

Metal/ ceramic nano composite additive of self-rehabilitation and its preparation method

The invention relates to a metal / ceramic nano complex self-repairing additive, which comprises metal nano micropowder and nano natural ore powder as main material, detergent, catalyst, antioxidant, and solvent, and can be used in lube, grease and ultrasonic medium. The advantages of this invention include: it can form rapidly high-hardness self-repairing protection layer on a plurality of metal friction surfaces with thickness adjustable to optimize gap and improve surface physical and chemical property, and has wide application in friction dual parts.

Owner:JIANGSU MOLEDN PETROCHEM

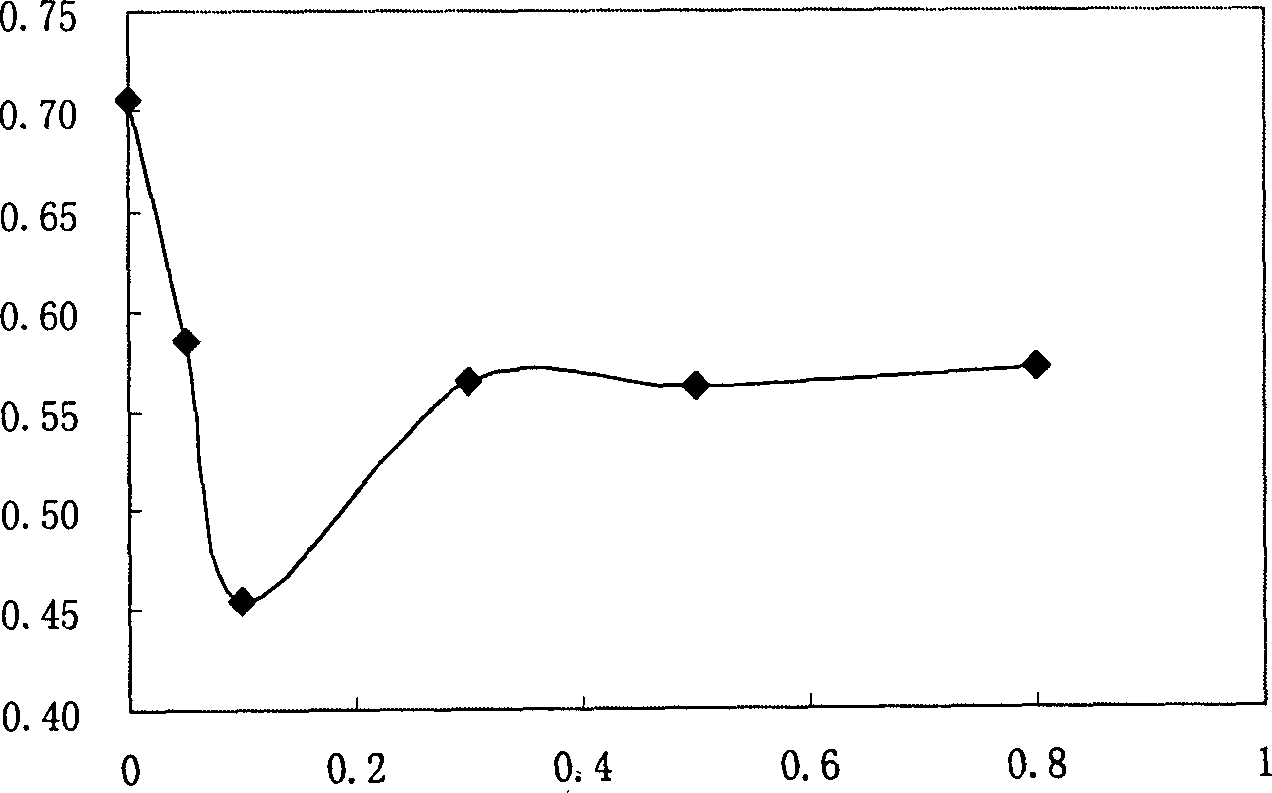

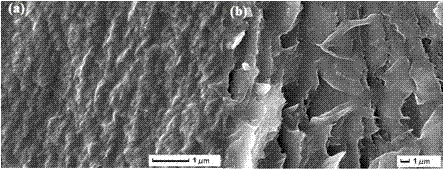

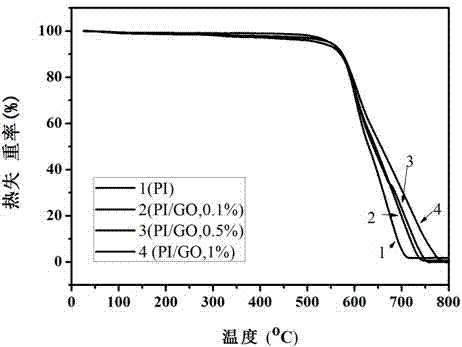

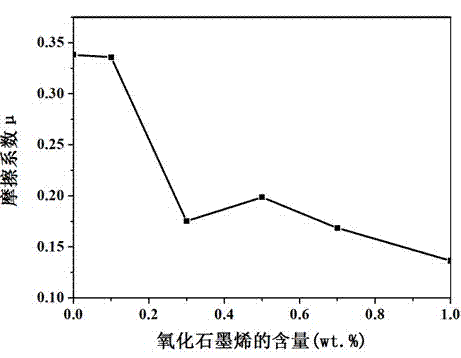

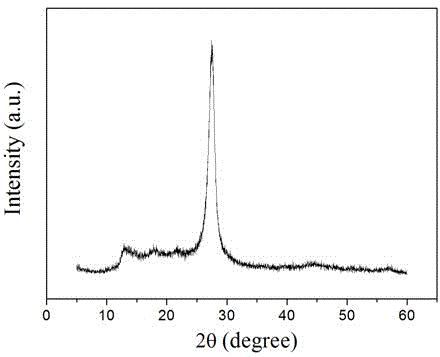

Preparation method for polyimide/oxidized graphene nanocomposite film

InactiveCN103589152ASolve the shortcomings of poor wear resistanceSolving Dispersion ProblemsPolyamideDissolution

The invention relates to a preparation method for a polyimide / oxidized graphene nanocomposite film, and belongs to the technical field of preparation of functional polymer materials. The preparation method comprises the following steps: performing ultrasonic even dispersion on the oxidized graphene in an organic solvent to obtain an oxidized graphene sheet suspension, wherein per ml of the oxidized graphene sheet suspension contains 1.3*10<-5>-1.3*10<-4>g oxidized graphene sheets; introducing nitrogen for carrying out deoxidization protection, adding diamine monomers into the suspension, mechanically stirring until full dissolution is achieved, adding dianhydride monomers, the moles of which are equal to that of the diamine monomers, in batches, and mixing for one to six hours under the ice bath conditions, so as to obtain polyamide acid / oxidized graphene composite solution; pouring the polyamide acid / oxidized graphene composite solution onto a die, removing the organic solvent, performing gradient temperature rise within 100-300DEG C, and carrying out thermal imidization to obtain the polyimide / oxidized graphene nanocomposite film.

Owner:JIANGSU UNIV

Nanomer vibration-reducing noise-reducing self-repairing material and its prepn process

InactiveCN1740290AAutomatically adjust thicknessOptimizing friction pair clearanceBase-materialsMachine partsRepair material

The nanometer vibration-reducing and noise-reducing self repairing material is prepared with nanometer level metal powder and natural ore powder as main material and through adding several kinds of supplementary material and certain technological process, and is added into lubricating oil or ultrasonic medium as high performance repair material. The present invention features that the high performance repair material can create high hardness self-repairing lubricating film fast on the surface of metal friction pairs to regulate the interval of the friction pair, reduce friction coefficient, raise bearing capacity, leveling the friction surface, reduce vibration and noise caused by the unbalance, friction and damage of the moving machine parts, and prolong the service life of the machine parts. The present invention may be used widely in improving performance of mechanical friction parts.

Owner:JIANGSU MOLEDN PETROCHEM

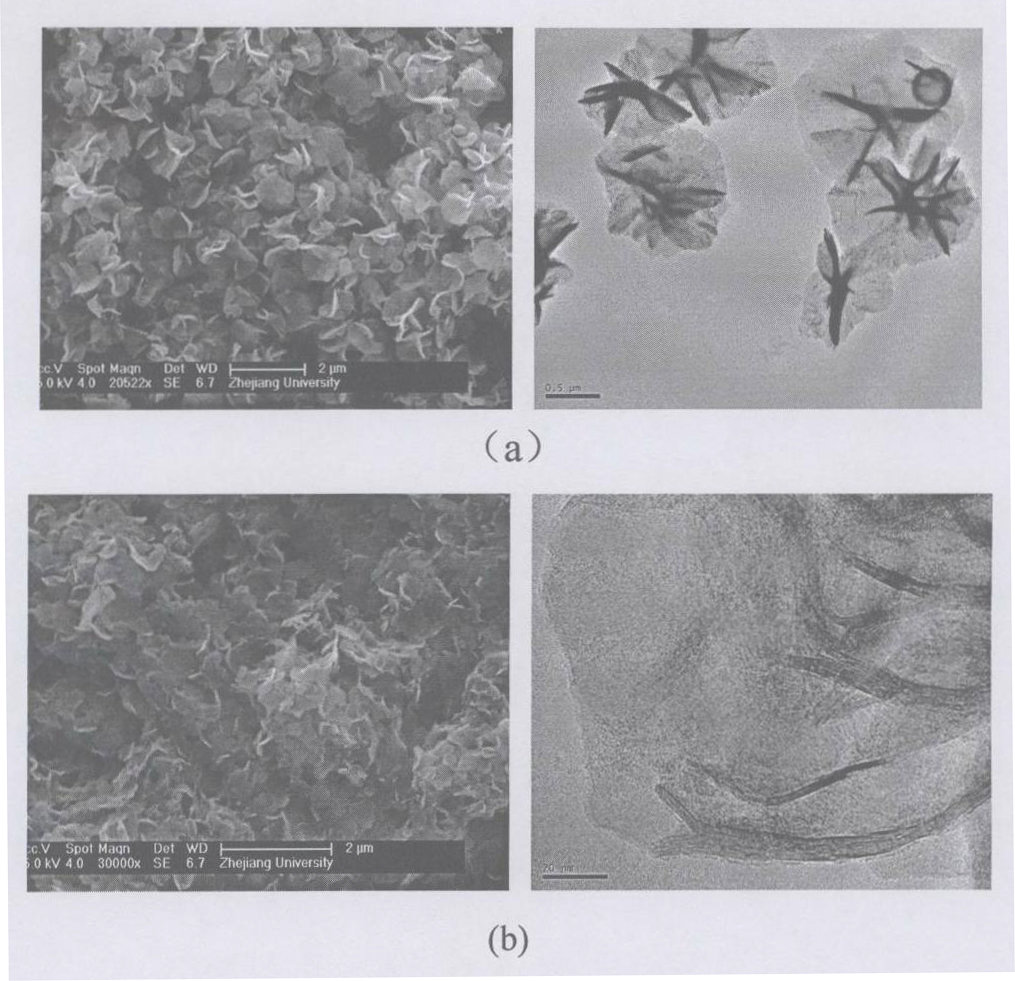

Graphene nano sheet and SnS2 composite nano material and synthesis method thereof

InactiveCN102142549ALarge specific surface areaStrong mechanical propertiesMaterial nanotechnologyCell electrodesSynthesis methodsTin

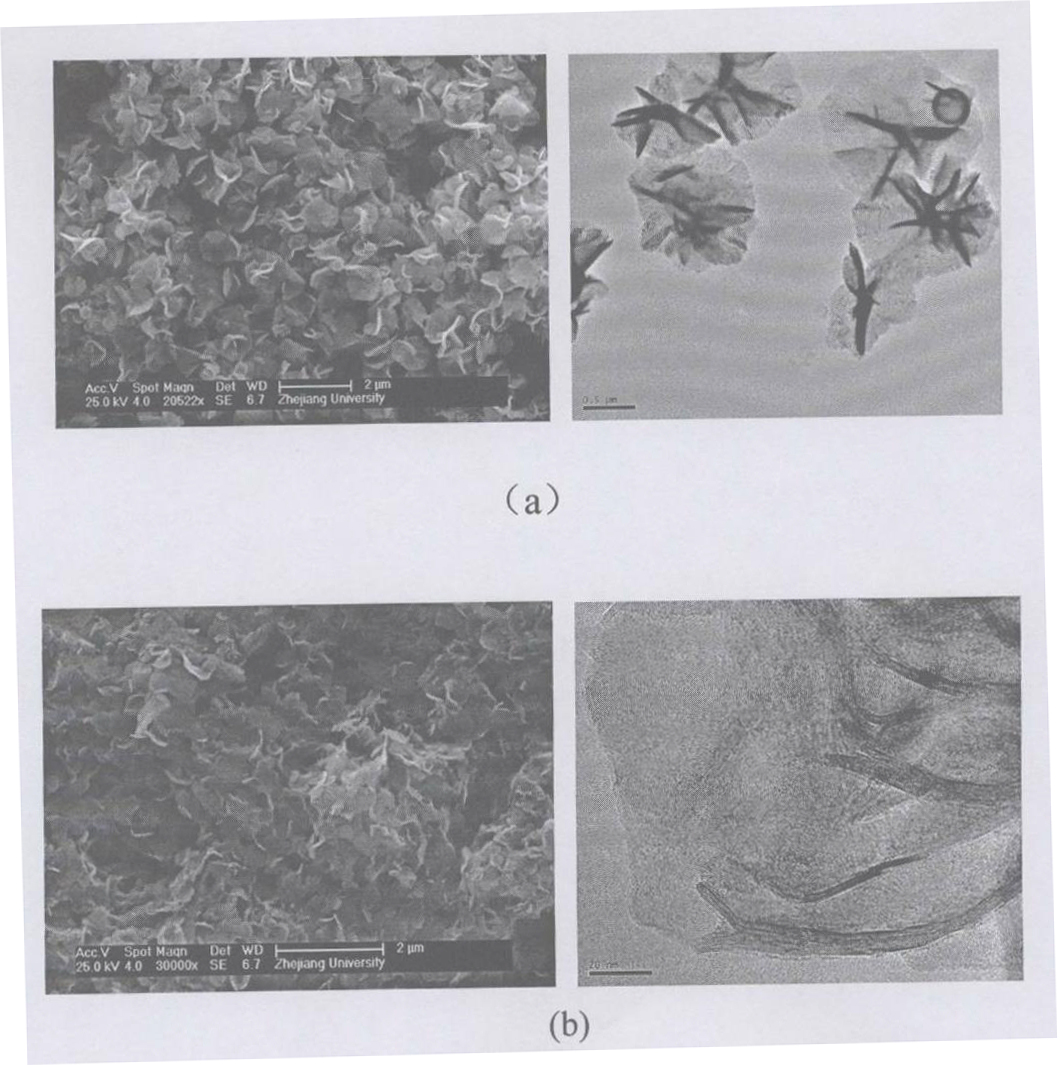

The invention discloses a graphene nano sheet and SnS2 composite nano material and a synthesis method thereof. The composite material is characterized by being formed by compounding a graphene nano sheet and a SnS2 nano material, wherein the substance amount ratio of the graphene nano sheet to the SnS2 nano material is 1:1-4:1. The preparation method comprises the following steps of: preparing a graphite oxide nano sheet from graphite by using a chemical oxidation method, then dissolving L-cysteine into deionized water, adding stannic chloride, and dissolving the stannic chloride with full stirring, wherein the molar ratio of the L-cysteine to the stannic chloride in the solution is 6:1-12:1; and adding the graphite oxide nano sheet into the solution, performing ultrasonic treatment so that the graphite oxide nano sheet is fully dispersed in the hydrothermal reaction solution, and synthesizing the graphene nano sheet and SnS2 composite nano material by a one-step hydrothermal method, wherein the mass ratio of the graphene nano sheet to the SnS2 nano material in the composite material is 1:1-4:1. The method has the characteristics of mild reaction condition and simple process. The synthesized graphene nano sheet and SnS2 composite nano material serving as an electrode material of a new energy battery or serving as other materials has wide application.

Owner:ZHEJIANG UNIV

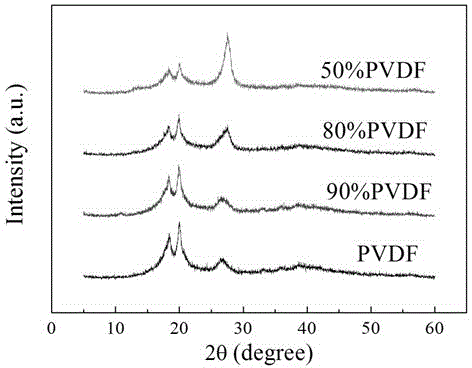

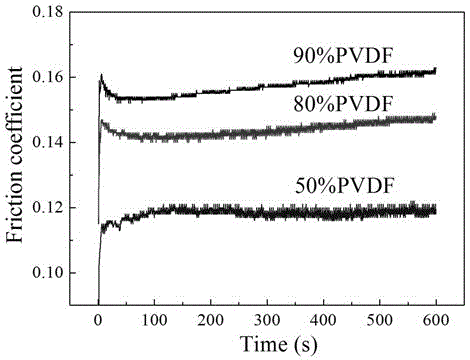

Graphite-like carbon nitride/polyvinylidene fluoride composite material and preparation method thereof

InactiveCN104017313AImprove tribological performanceImprove the interface binding forceChemical stabilityMechanical property

The invention discloses a graphite-like carbon nitride / polyvinylidene fluoride composite material and a preparation method thereof. The composite material comprises 50-99wt% of polymer matrix polyvinylidene fluoride (PVDF), and 1-50wt% of graphite-like carbon nitride g-C3N4 processed by a surface modifier. The preparation method of the composite material comprises the following steps: preparing the graphite-like carbon nitride g-C3N4, processing a packing surface, mixing two powdery raw materials in a liquid phase and carrying out quick agitation and drying treatment, hot press molding or plastic extrusion molding. Compared with a pure polyvinylidene fluoride material, the graphite-like carbon nitride / polyvinylidene fluoride composite material has the advantages that the heat stability, the chemical stability and the mechanical property of the material can be effectively improved when the tribological property is greatly improved, the coefficient of linear expansion of the material is reduced, the barrier property of the material is improved, and the graphite-like carbon nitride / polyvinylidene fluoride composite material is widely applied to the industries such as space flight and aviation, electrics, microelectronics and automobiles.

Owner:JIANGSU UNIV

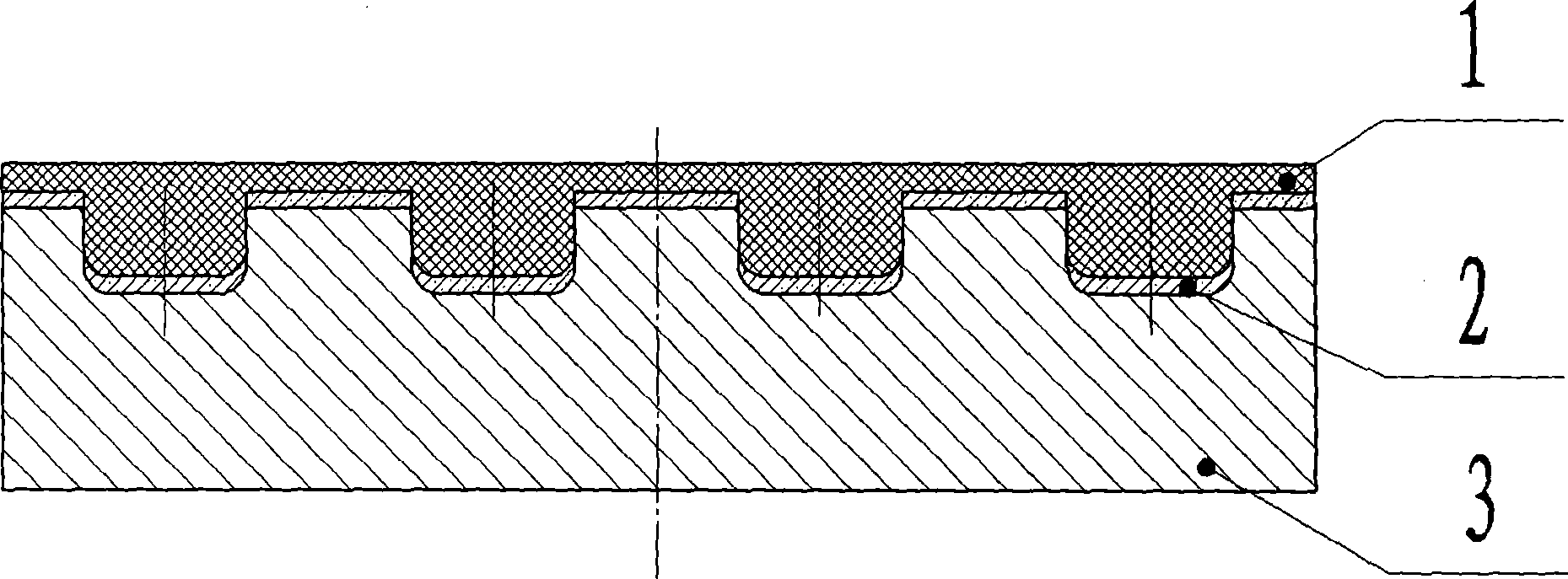

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

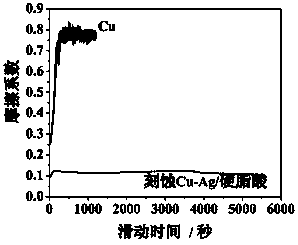

Copper based super-hydrophobic surface with low friction coefficient and preparation method thereof

ActiveCN103469215AIncreased static contact angleReduce coefficient of frictionLiquid/solution decomposition chemical coatingMicron scaleEtching

The invention relates to a copper based super-hydrophobic surface with a low friction coefficient and a preparation method thereof. The copper based super-hydrophobic surface with a low friction coefficient is characterized in that chemical etching is performed on the surface of a copper based material to form a coarse structure with a micron-scale pit structure and submicron / nano-scale metal silver particles, and then a product is obtained through surface chemical modification. The copper based super-hydrophobic surface with low friction coefficient has a contact angle of more than 150 degrees to water, is low in friction coefficient, can be stably maintained, and has good super-hydrophobic properties and low friction coefficient.

Owner:XUCHANG UNIV

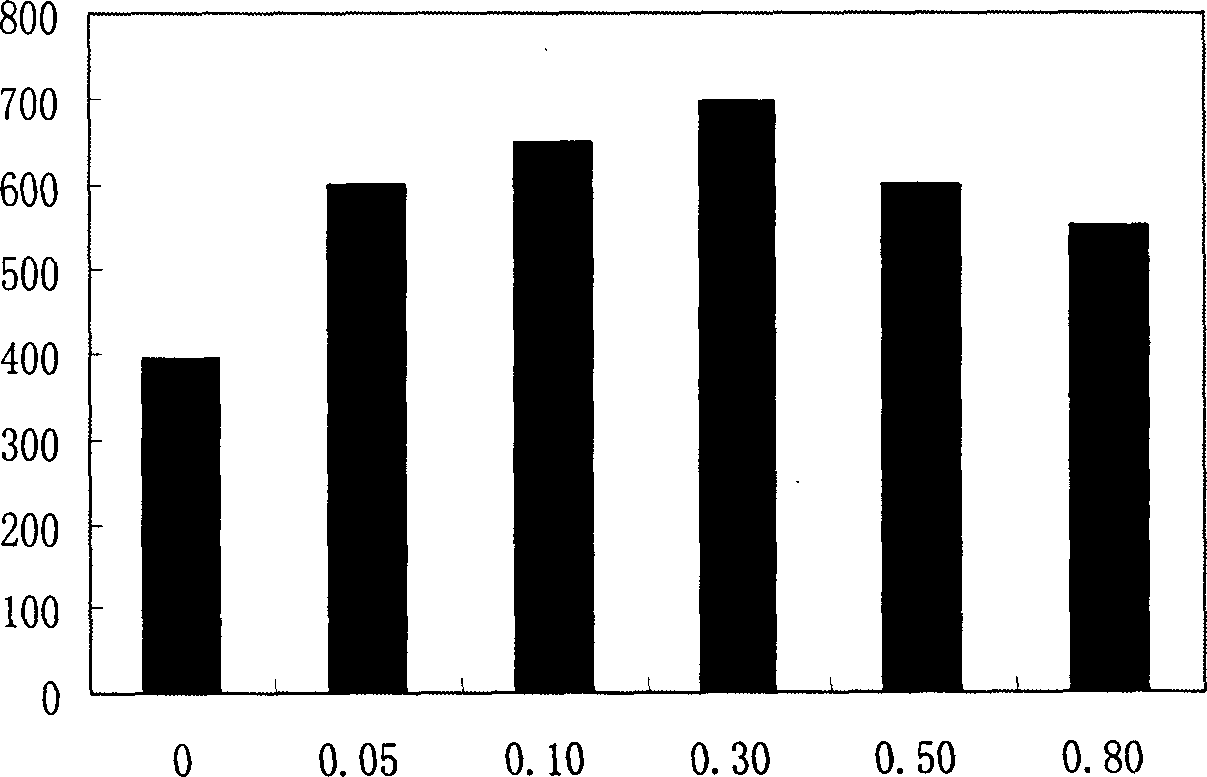

Oil-filled monomer casting nylon composite material

InactiveCN102942694AImprove tribological performanceImprove wear resistancePolymerizationRaw material

The invention discloses an oil-filled monomer casting nylon composite material which is formed by catalytic polymerization of hexanolactam doped with liquid paraffin and grapheme, wherein the weight ratio of hexanolactam to liquid paraffin to grapheme is 100 : (3-10) : (0.05-0.075). The prepared composite material is enhanced in tribological properties, particularly obviously decreased friction coefficient and greatly increased abrasion resistance. The friction coefficient of the composite material is 23.5%-41.1% based on that of a conventional material; the volume abrasion rate of the composite material is 31.8%-55.5% based on that of the conventional material; and the composite material can be widely used as raw materials of manufactured parts.

Owner:HENAN UNIV OF SCI & TECH

High-temperature alloy base self-lubricating composite material and surface pattern treatment method thereof

InactiveCN101078072AExtended service lifeReduce coefficient of frictionBearing componentsLaser beam welding apparatusSurface patternSuperalloy

A kind of high temperature alloy group self-lubricating compound material and the method to pattern surface of it. The components and the mass percent of them are as following: Ni: 28.8-56.8%, Fe: 10.0-30.0%, Cr: 7.2-14.2%, W: 5.0- 15.0%, C: 3.0-6.0%, Si: 0.8%-1.2%, MoS2: 5.0%-15.0%. The method to pattern it' s surface contains the following steps: The surface of the nickel chromium alloy group self-lubricating compound material sample after being hot pressed and mould will be polished. A gammaray laser will be used to corrase micropore on the surface, the focus of the focusing lens will be adjusted to 40-60mm, the facula diameter at the focus is 0.15- 0.20mm, the impulse duration will be adjusted to 450-500ns, the laser bean will process micropore according to ring shape from outside to inside. The surface after being corrased and polished will be lubricated by daubing the fat of solid layered dry lubricant. The alloy group material not only owns high mechanical strength but also owns high temperature self-lubricating ability. The coefficient of friction can be decreased, the application life can be prolonged, and low attrition abrasion in wide temperature range can also be realized by patterning the surface.

Owner:NANJING UNIV OF SCI & TECH

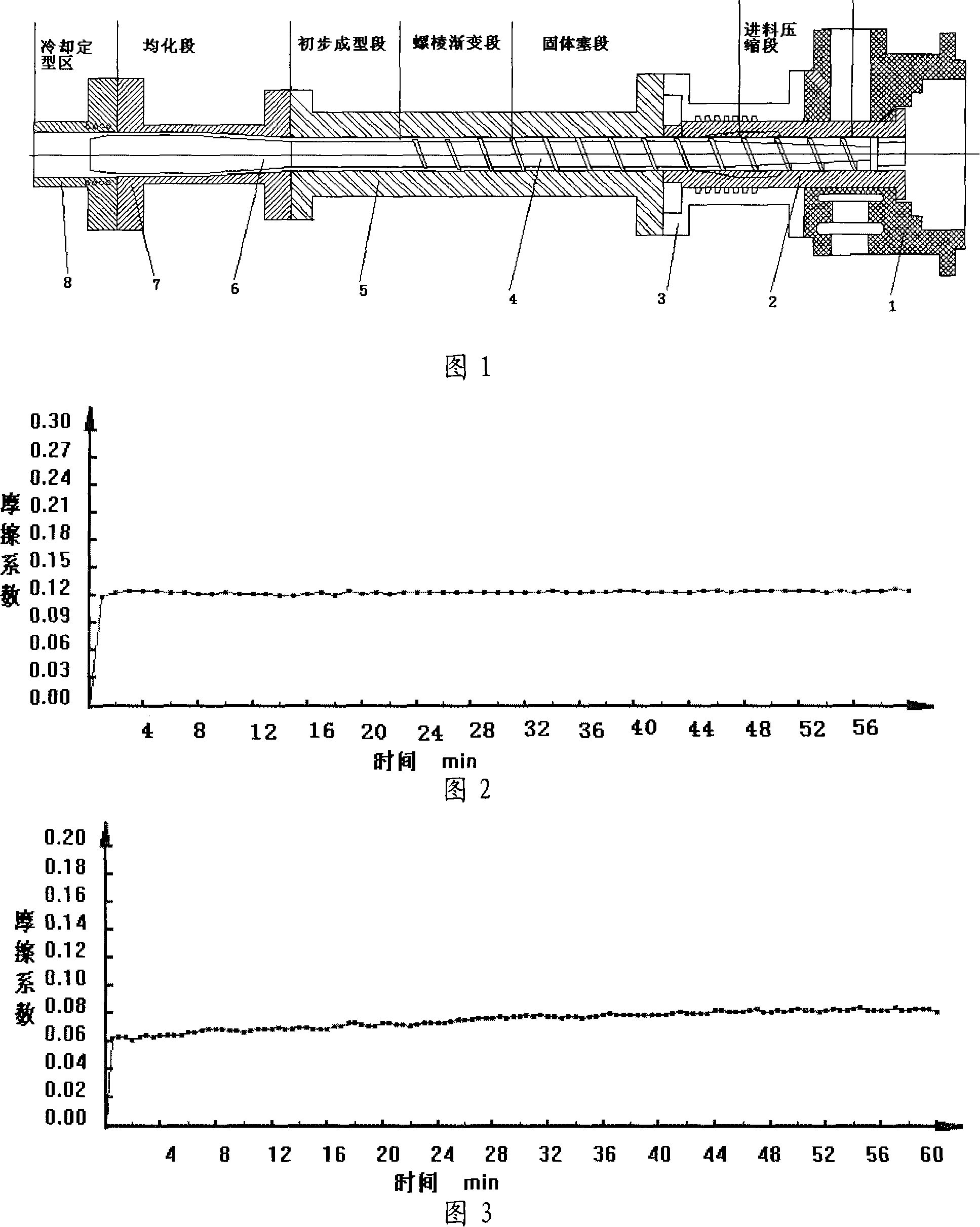

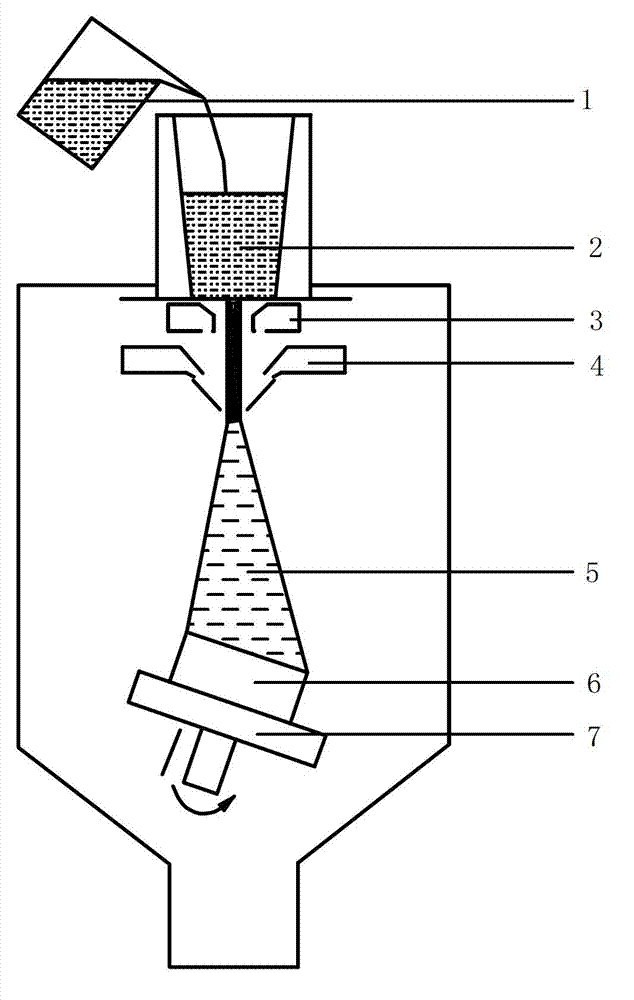

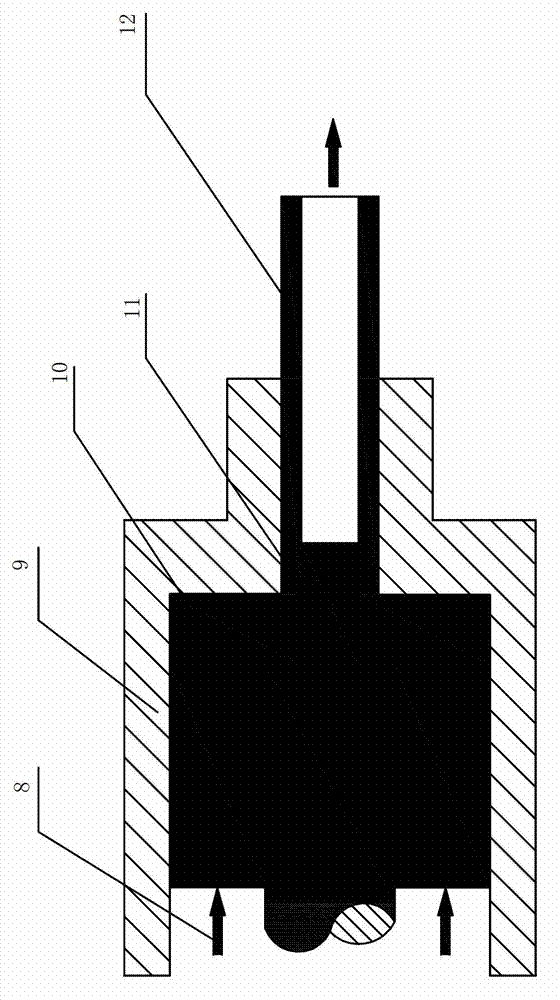

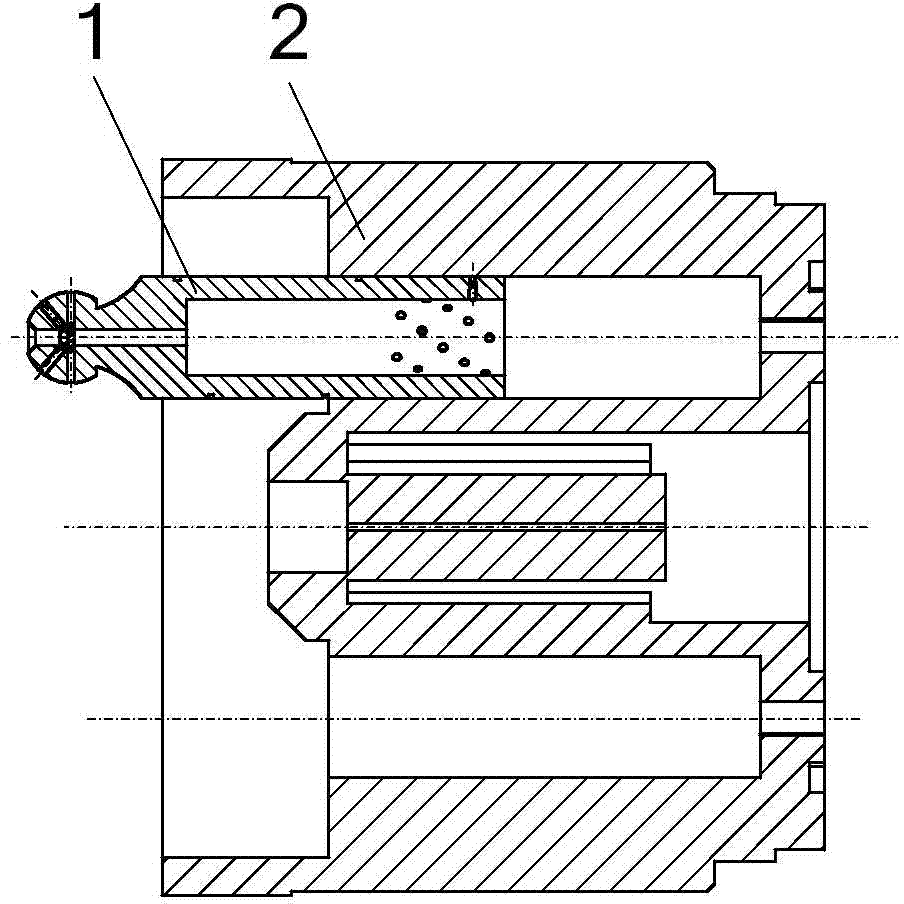

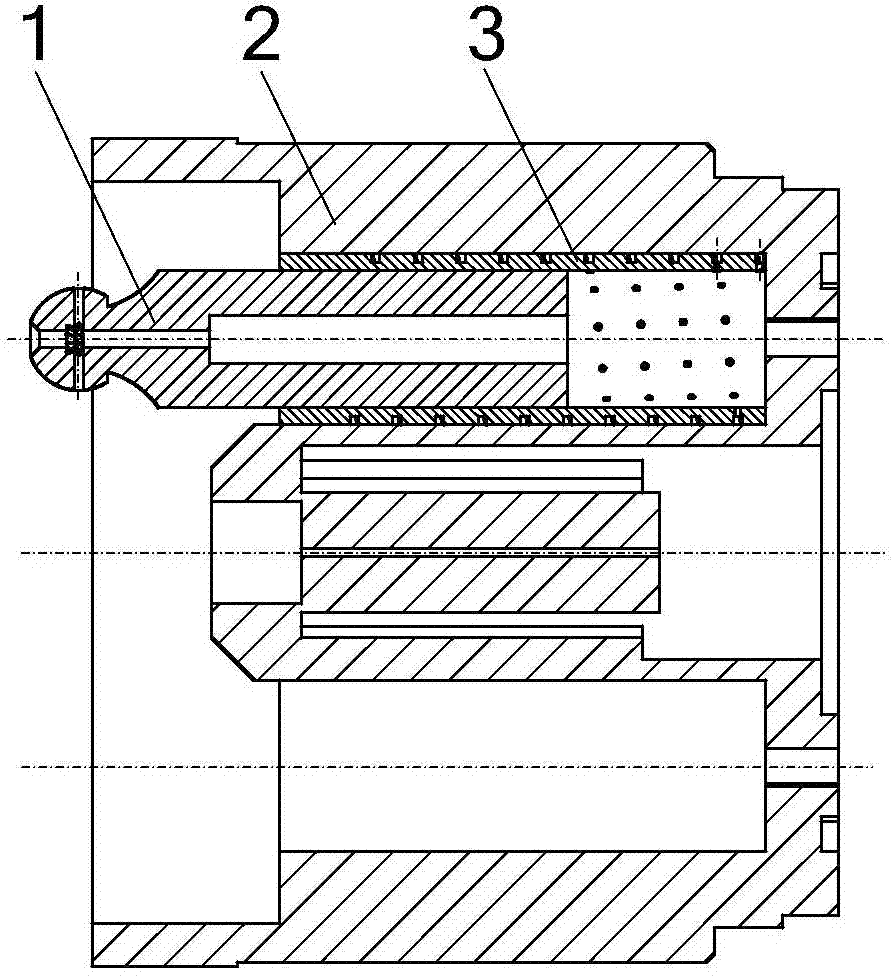

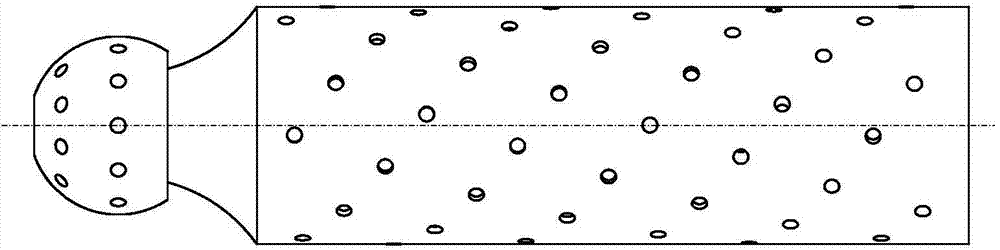

Ultrahigh molecular weight polyethylene tube single screw extruder barrel forming method and the forming device thereof

InactiveCN101117017AImprove performanceRealize continuous extrusion moldingTubular articlesMolten stateEngineering

The present invention relates to a molding method and a molding device for an ultra-high Molecular Weight Polyethylene (UHMWPE) tubular product single-screw extruding machine barrel. With extrudability and calendering properties of ultra-high Molecular Weight Polyethylene in an elastomeric state, when the ultra-high Molecular Weight Polyethylene in an elastomeric state in extrusion force action fills a molding chamber which is formed between a feed rod screw and a machine barrel, preliminary molding of the ultra-high Molecular Weight Polyethylene tubular product is achieved; with continuous action of the extrusion force, preliminary molding tubular products achieve a homogenization process of temperature and geometric dimension through a shaping mandrel and a shaping set; then the tubular products complete cooling and shaping processes rapidly when passing a cooling set. The invention solves difficult technical problems that nearly no ultra-high Molecular Weight Polyethylene with a viscous state can process single-screw extruding molding in a molten state; on the premise of keeping excellent performance of the ultra-high Molecular Weight Polyethylene well, a goal of continuous production of the ultra-high Molecular Weight Polyethylene tubular product is achieved.

Owner:WUHAN XIAOHONG ULTRA HIGH MOLECULAR WEIGHT NEW MATERIALS TECH

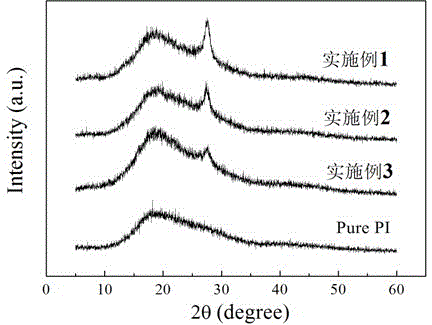

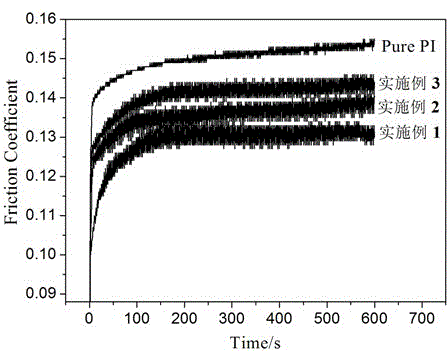

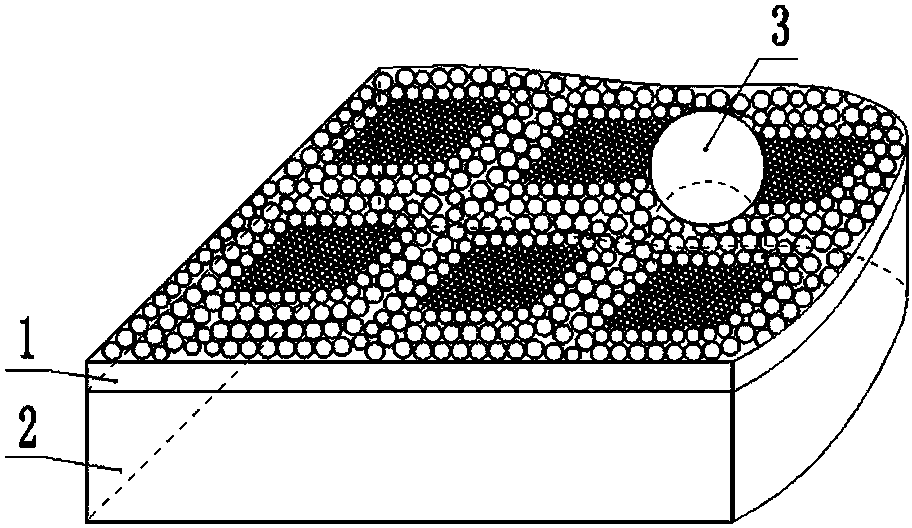

Graphite-like carbon nitride/polyimide composite material and preparation method thereof

The invention discloses a graphite-like carbon nitride / polyimide composite material and a preparation method thereof. The composite material comprises a polymer matrix polyimide PI, a toughening agent, a surface-modifier-treated filler graphite-like carbon nitride g-C3N4 and a surface modifier. The preparation method of the composite material comprises the following steps: preparation of graphite-like carbon nitride, filler surface treatment, high-speed stirring and mixing of raw material powder in a stirrer, hot pressing and hardening treatment. The preparation method has the advantages of simple technique and low cost, is convenient to operate, and can easily implement industrialization; and the prepared composite material has excellent mechanical properties and tribological properties, has potential application values in the aspects of structural materials, friction materials, heat-resistant materials and the like, and can be widely used in the technical fields of automobiles, electricity and electronics, aviation and the like.

Owner:JIANGSU UNIV

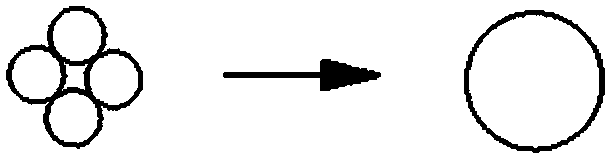

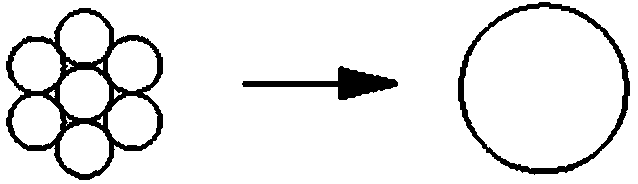

Surface texture of indium-iron grid-shaped spherical composite microcrystal composite layer

The invention discloses a surface texture of an indium-iron grid-shaped spherical composite microcrystal composite layer. A surface material layer is arranged on a part and mainly comprises larger indium-iron composite spherical microcrystal units of which the indium content exceeds 50% (Wt%) and the total content of indium and iron exceeds 55% (Wt%), each larger indium-iron composite spherical microcrystal unit is formed by close connection of at least four spherical crystal grains or nearly-spherical crystal grains, the larger indium-iron composite spherical microcrystal units are distributed regularly to form a grid, multiple single crystal grains or smaller indium-iron microcrystal units are closely distributed in the grid, each smaller indium-iron microcrystal unit is formed by close connection of at least two spherical crystal grains or nearly-spherical crystal grains, and the surface material layer and a base body material of the part are integrated to form the indium-iron grid-shaped spherical composite microcrystal composite layer; then a surface texture is machined on the part surface provided with the indium-iron grid-shaped spherical composite microcrystal composite layer and consists of multiple surface texture units, and the surface texture of the indium-iron grid-shaped spherical composite microcrystal composite layer is formed.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

High-silicon aluminum alloy cylinder sleeve material and fabrication method thereof

ActiveCN103045920ASolve the disadvantages of unfavorable wear resistanceEasy to useLubricationMechanical property

The invention relates to a high-silicon aluminum alloy cylinder sleeve material, which is characterized by comprising the following components by weight percent: 18.0-26.0 percent of Si, 2.0-5.0 percent of Fe, 3.0-7.0 percent of Ni, 1.8-3.0 percent of Cu, 0.5-0.8 percent of Mg, 0.5-0.8 percent of Mn, 0.1-0.3 percent of V and the balance of Al, wherein the amount of Fe and Ni is larger than or equal to 7 percent and less than or equal to 10 percent, and the amount of Fe, Ni and Si is larger than or equal to 27 percent and less than or equal to 33 percent. The high-silicon aluminum alloy cylinder sleeve material and products, which are prepared by the invention, are high in technological property, mechanical property and tribological property; such functions of a hard-spot phase of the cylinder sleeve working face, as bearing, abrasion resistance, oil storage in peripheral concave pits, cooling and lubrication, are prominent to the utmost; and size of particles in the cylinder sleeve and working face tribological shape size are effectively controlled, so that the use effect is better.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

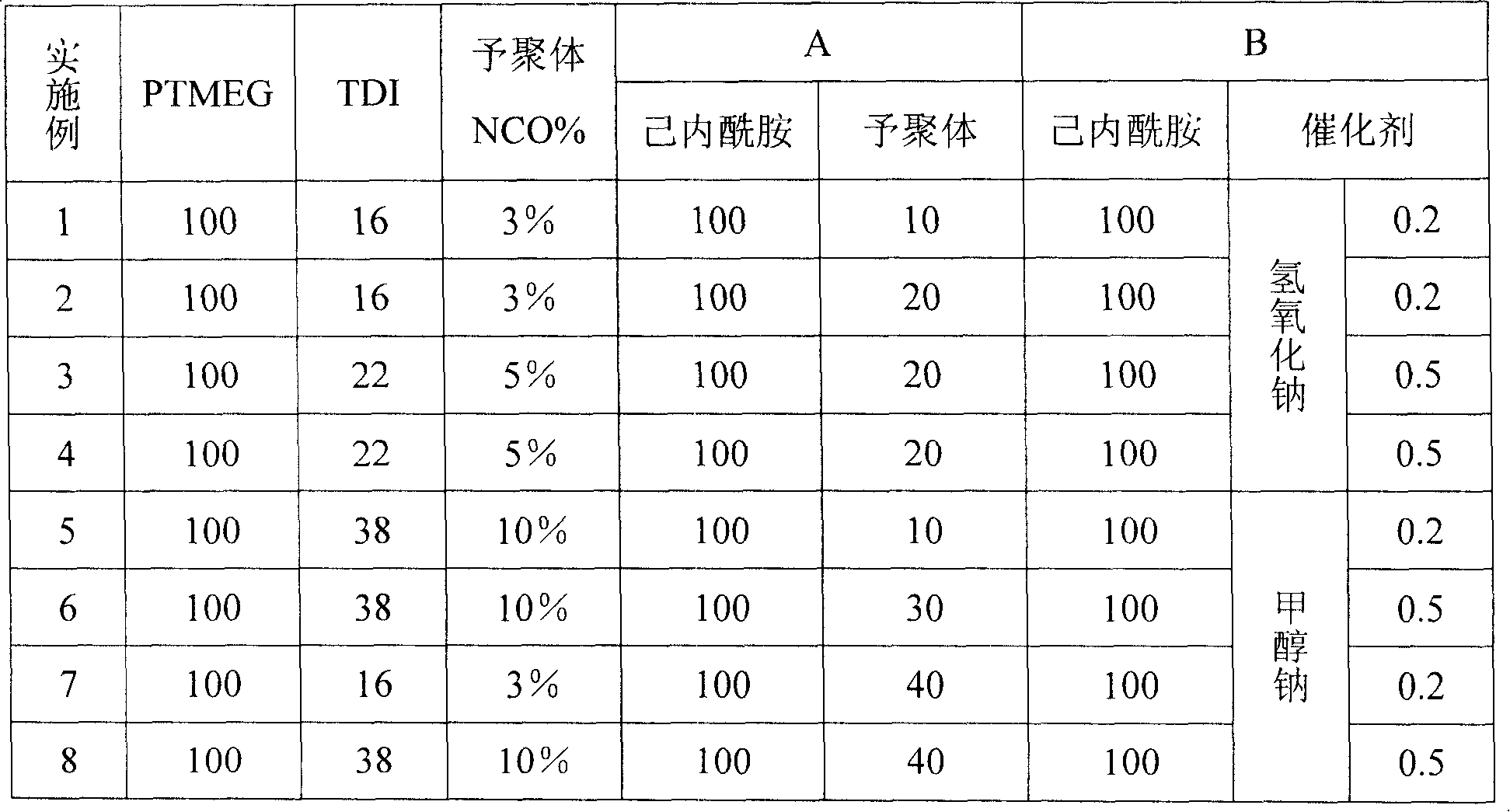

Method for producing polyurethane toughness-reinforcing cast form nylon composite material

InactiveCN101195706AHigh mechanical strengthIncreased tensile elongation at breakNylon materialToughness

The invention relates to a preparation method of polyurethane plasticizing monomer casting nylon compound material. The material is made through pouring the raw material of polyurethane prepolymer, and caprolactam, etc. The main performance of the material is characterized in that the mechanical strength is improved, the tensile fracture elongation rate is increased along with increasing of the use amount of the polyurethane prepolymer, the impact strength is enhanced along with the increasing of the use amount of the polyurethane prepolymer, and the tribology performance and the antistatic performance are improved remarkably.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Plunger friction pair of high-pressure seawater axial plunger pump with bionic non-smooth surface

ActiveCN103867432AImprove performanceSimple structurePositive displacement pump componentsLiquid fuel engine componentsHigh pressureCylinder block

The invention discloses a plunger friction pair of a high-pressure seawater axial plunger pump with a bionic non-smooth surface. The plunger friction pair is mainly characterized in that through hole unit bodies communicated with an inner cavity of a plunger are arranged on the friction surface positioned in a cylinder body in the operation process of the outer surface of a plunger of the friction pair; the other friction surfaces of the plunger are provided with pit unit bodies. Preferably, a bush with the bionic non-smooth surface is added between the plunger and the cylinder body, a groove type trench is arranged on the outer wall of the bush, and the through hole unit bodies are regularly arranged at the bottom part of the trench. The plunger friction pair disclosed by the invention has the advantages that the lubricating capability, the bearing characteristic and the friction and wear properties of the plunger friction pair can be reasonably improved by high cost performance.

Owner:赛腾机电科技(常州)有限公司

Method for preparing carbon nanotube/polybenzoate composite

InactiveCN102174248AImprove mechanical propertiesImprove tribological performanceActivated carbonEthylene diamine

The invention relates to a method for preparing carbon nanotube / polybenzoate composite, which belongs to the technical field of the composite and comprises the following steps: carrying out polycondensation reaction on an oxidized and modified carbon nanotube and ethylene diamine tetraacetic acid solution, carrying out chemical complexing reaction on the product of reaction and rare earth solution to generate an activated carbon nanotube, blending the activated carbon nanotube with polybenzoate solution with ultrasound waves to prepare carbon nanotube / polybenzoate blend, cold pressing the carbon nanotube / polybenzoate blend, and sintering to form the carbon nanotube / polybenzoate composite. The process for preparing the carbon nanotube / polybenzoate composite is simple and can better improve the carbon nanotube and polybenzoate matrix interface binding force and further improve the comprehensive mechanical properties and tribological properties of the carbon nanotube / polybenzoate composite.

Owner:SHANGHAI JIAO TONG UNIV

Carbon fiber reinforced polymer-based self-lubricating material and preparation method thereof

InactiveCN101747626AReduce coefficient of frictionGood wear resistanceCarbon fiber reinforced polymersPolyimide

The invention relates to a carbon fiber reinforced polymer-based self-lubricating material and a preparation method thereof. The composition and mass fraction of the material are: polyimide of 30-50 percent, chopped carbon fiber of 10-20 percent, molybdenum disulfide of 10-40 percent and antimony trioxide of 10-30 percent. The invention has the advantages of high mechanical strength, low friction coefficient, low wear rate and the like, and can be processed to be used as a sliding vane, a bearing and the like. Moreover, the invention improves the friction reducing capability and the wear resistance of the material, and prolongs the service life of the material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Unleaded Cu-based sliding bearing material and preparation method thereof

InactiveCN101576118AAchieve lead-freeImprove mechanical propertiesLiquid/solution decomposition chemical coatingSliding contact bearingsGraphiteHigh intensity

The invention relates to an unleaded Cu-based sliding bearing material and a preparation method thereof and the invention has the characteristics that: the material is composed of nickel, tin, zinc, iron, graphite, bismuth, copper and assistants, the substrate of the material is unleaded copper alloy, and the antifriction and antisticking constituent element is bismuth and graphite. The Cu-based bearing material features high intensity, and good antifriction and antisticking, thus realizing an unleaded Cu-based bearing material. The lead is cancelled in an original bearing material with lead and copper, and a synergistic effect of bismuth and graphite can replace the use of lead, thus completely overcoming the defect of lead pollution; moreover, the service performance of the bearing remains nearly the same, therefore the unleaded Cu-based sliding bearing material can completely replace the bearing material with lead and copper. The material of the invention can be applied in food machinery, drugs machinery, construction machinery, automobile and other products, and has advantages of good antifriction and antisticking, good heat dissipation effect, oxidation resistance and corrosive resistance.

Owner:HEFEI UNIV OF TECH

Nickel-base composite coat containing nano diamond and ultrasound wave auxiliary preparation method thereof

InactiveCN101122044AGrain refinementHigh hardnessElectrolytic coatingsUltrasound - actionUltrasonic cavitation

The invention discloses a nickel-based composite plating layer containing nano diamonds and an ultrasonic auxiliary preparation method for the plating layer. The invention relates to the nickel-based composite plating layer and the preparation method of the plating layer. The nickel-based composite plating layer containing nano diamonds is with metal nickel or nickel alloy as the matrix, and nano diamond grains evenly diffused in. The preparation method includes the following procedures: preparation of the nano composite bath liquid: the nano composite plating layer is prepared in ultrasonic wave. In the plating layer, the nano diamond grains are evenly diffused in the nickel matrix in nano scale, so as to refine the metal grains and obviously improve the hardness and tribological performance of the original nickel plating layer. The invention uses ultrasonic cavitation to make sure of even scattering of the nano diamonds in the bath solution and plating layer, and promotes the codeposition of the nano grains and the metal. The nano composite plating layer can effectively improve the anti-abrasion and abrasion reduction performances of the surface of work pieces, extend the service life of them, and is widely applicable to easily wearable work pieces, such as moulds, all bearings, gears, engines, drive parts, etc.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

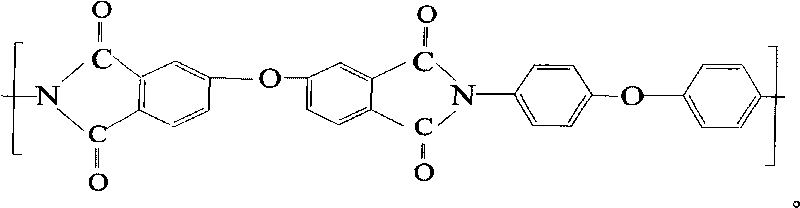

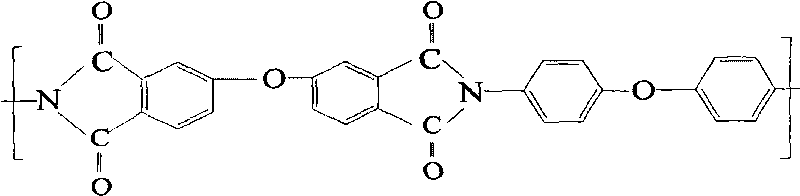

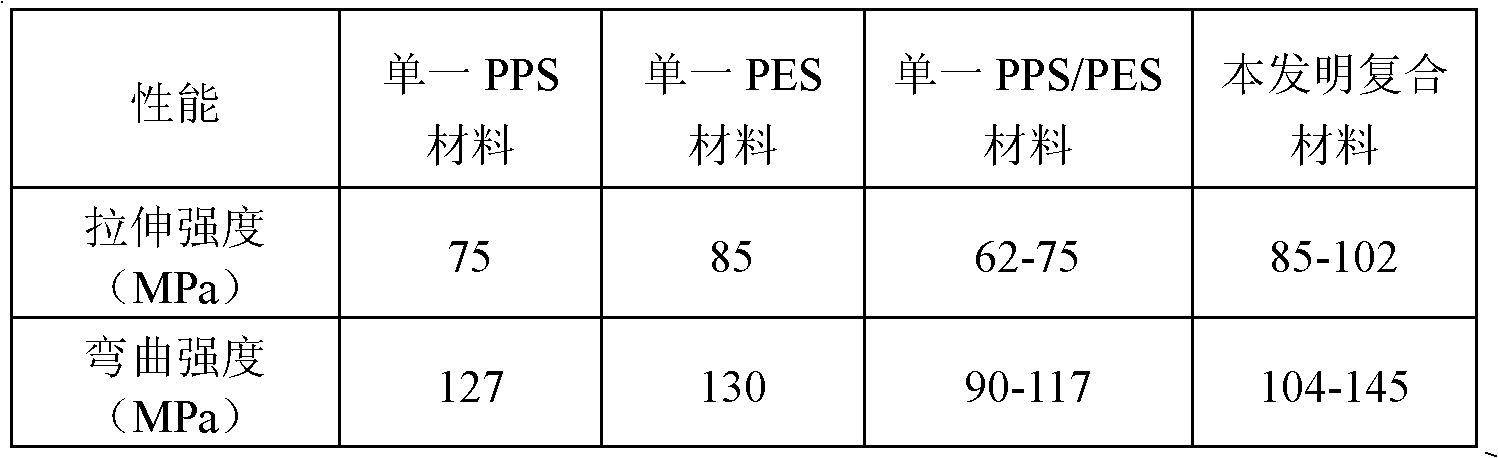

Polyphenylene sulfide/polyether sulfone-based compound material and preparation method thereof as well as wear-resistant part prepared from polyphenylene sulfide/polyether sulfone-based compound material

InactiveCN102093716AHigh glass transition temperatureImprove brittlenessEngine sealsBearing componentsPolymer scienceHeat resistance

The invention provides a polyphenylene sulfide / polyether sulfone-based compound material which comprises the following components in percentage by weight: 30-50% of polyphenylene sulfide, 20-50% of polyether sulfone, 10-30% of potassium titanate processed by a coupling agent, 8-12% of teflon and a proper amount of processing agent, and the polyphenylene sulfide / polyether sulfone-based compound material is used for preparing various high temperature resistant wear-resistant parts. Compared with the existing polyphenylene sulfide or polyether sulfone compound material, the abrasive resistance and heat resistance of the polyphenylene sulfide / polyether sulfone-based compound material are obviously improved, and the polyphenylene sulfide / polyether sulfone-based compound material has the advantages of simple preparation process, low cost, wide use application and highlight application value.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Reinforced poly-ether-ether-ketone composite material with nano SiO2 chemically grafted to surfaces of carbon fibers and preparation method of material

The invention discloses a reinforced poly-ether-ether-ketone composite material with nano SiO2 chemically grafted to the surfaces of carbon fibers and a preparation method of material. The composite material is prepared from, by weight, 65-100 parts of poly-ether-ether-ketone, 5-30 parts of the carbon fibers, 0-10 parts of the nano SiO2, 0.5-3 parts of gamma-aminopropyl triethoxysilane and 0.5-3 parts of gamma-glycidyl ether oxypropyl trimethoxysilane. According to the composite material, modified carbon fibers are obtained by chemically grafting the nano SiO2 to the surfaces of the carbon fibers, so that the interface bonding performance between the carbon fibers and matrix resin is improved. Meanwhile, the modified carbon fibers are added into PEEK matrix as a reinforcing filler to improve the mechanical performance and wear resistance of PEEK and reduce the friction coefficient and wear rate of the material so that the modified-carbon-fiber-reinforced PEEK-based composite material can be applicable to extreme working conditions such as high speed, heavy loads and oil-free lubrication.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Adhesive solid lubricating coating and preparation method thereof as well as self-lubricating joint bearing and preparation method thereof

ActiveCN104497738AReduce surface tensionGood adhesionBearing componentsAnti-corrosive paintsEpoxyPolytetrafluoroethylene

The invention discloses an adhesive solid lubricating coating and a preparation method thereof as well as a self-lubricating joint bearing and a preparation method thereof, and belongs to the technical field of solid lubricants. The coating consists of epoxy resin, a curing agent, polytetrafluoroethylene, molybdenum disulfide and a fluorocarbon surfactant by compounding, wherein the adopted fluorocarbon surfactant is a non-ionic surfactant, has excellent wetting property and leveling property, and can efficiently reduce the surface tension of the coating to greatly improve the cohesive property of the coating; and the epoxy resin with excellent adhesive strength and mechanical strength is adopted as a bonding agent to ensure that mixed powder of molybdenum disulfide and polytetrafluoroethylene is firmly adhered to a friction surface to form a solid lubricating coating layer which has good wear resistance, corrosion resistance, self-lubricating property and high temperature resistance. The self-lubricating joint bearing prepared by the method disclosed by the invention is relatively low in friction coefficient, wearing capacity and friction temperature, so that the tribological property of the joint bearing is greatly improved. The preparation methods disclosed by the invention are simple to operate, low in cost and suitable for large-scale industrial production.

Owner:HENAN UNIV OF SCI & TECH

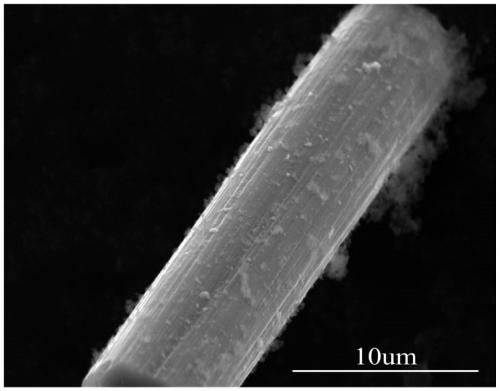

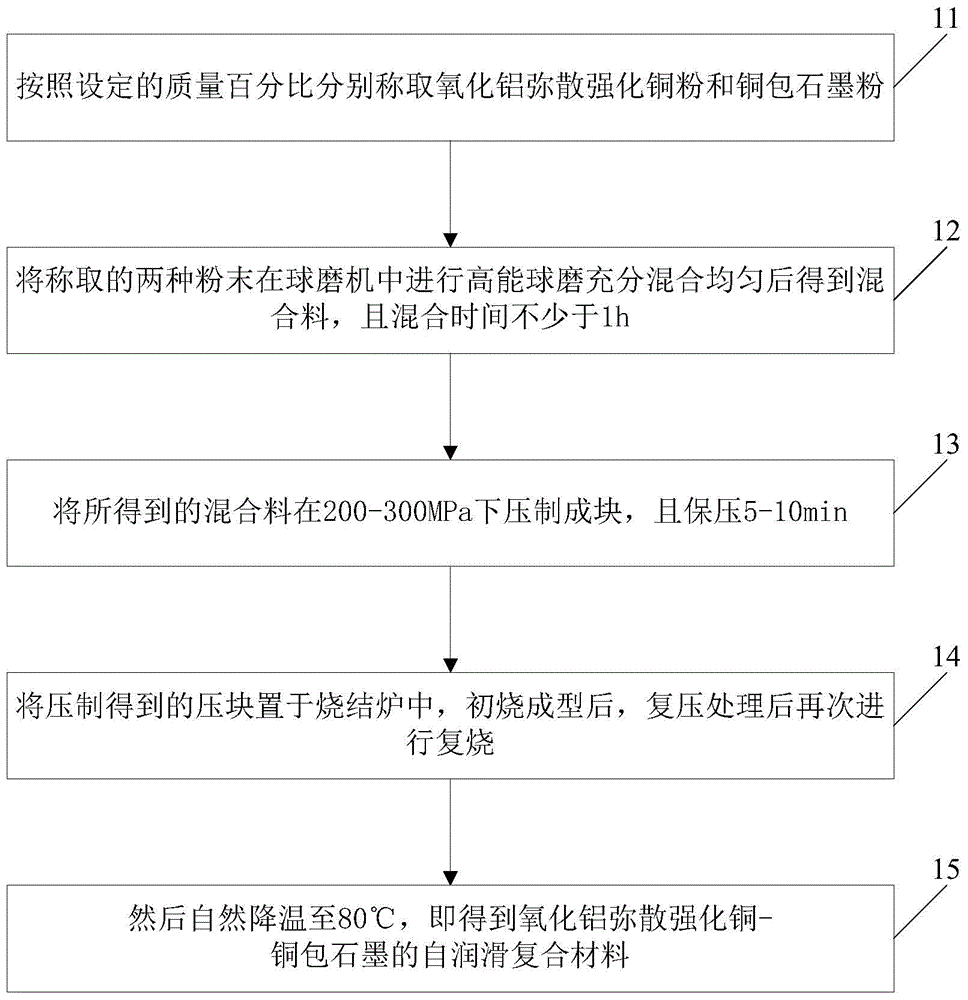

Preparation method of self-lubricating composite material

The invention discloses a preparation method of a self-lubricating composite material. The preparation method comprises the following steps: respectively weighing aluminum oxide dispersion strengthened copper powder and copper-coated graphite powder according to a set mass percentage ratio; performing high-energy ball milling on two weighed powders in a ball mill, and fully and uniformly mixing to obtain a mixed material under the condition that the mixing time is not less than 1 hour; pressing the obtained mixed material into blocks at 200-300MPa, and maintaining pressure for 5-10 minutes; putting briquettes obtained by virtue of pressing into a sintering furnace, performing initial sintering and molding, then performing re-pressing treatment, and then performing re-sintering again; and then naturally cooling to 80 DEG C to obtain the self-lubricating composite material. By adopting the preparation method disclosed by the invention, the problems that a copper-based graphite composite material is poor in interface bonding force, and graphite and copper are poor in wettability can be solved, and the high-temperature strength, heat conduction performance and tribological performance of the copper-based graphite composite material can be improved.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH +1

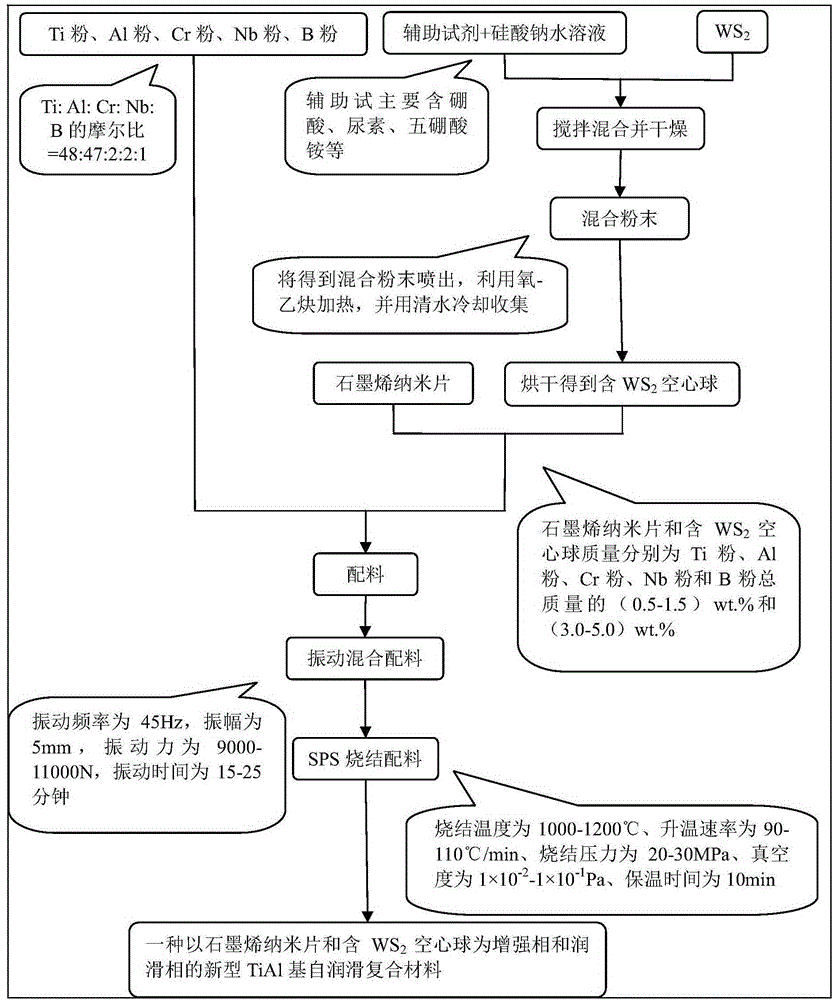

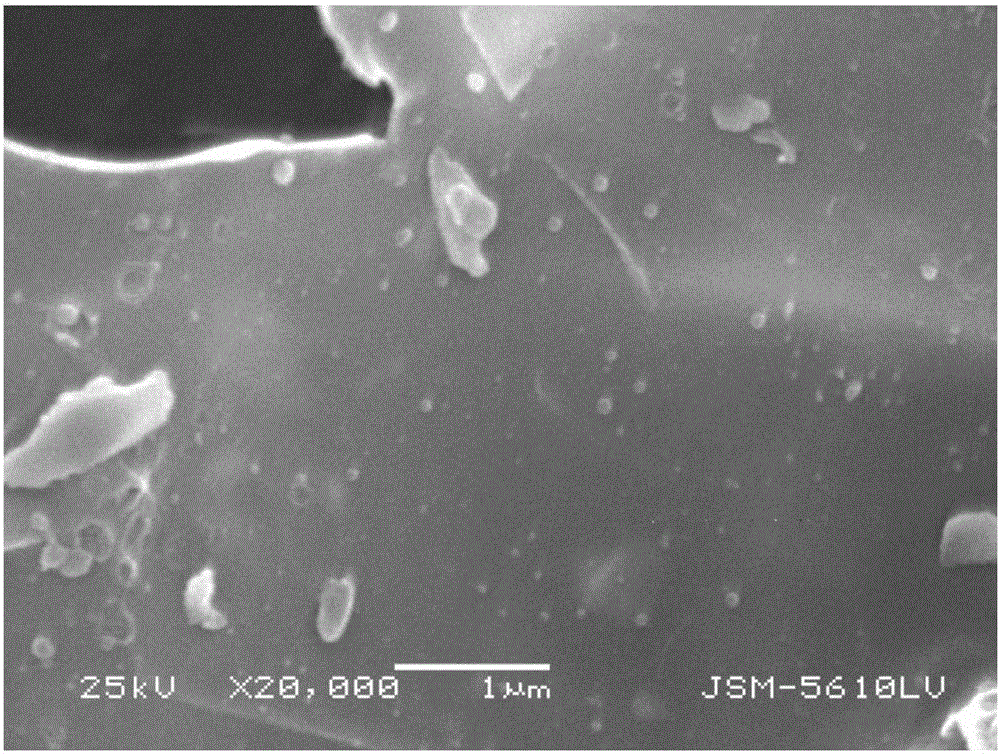

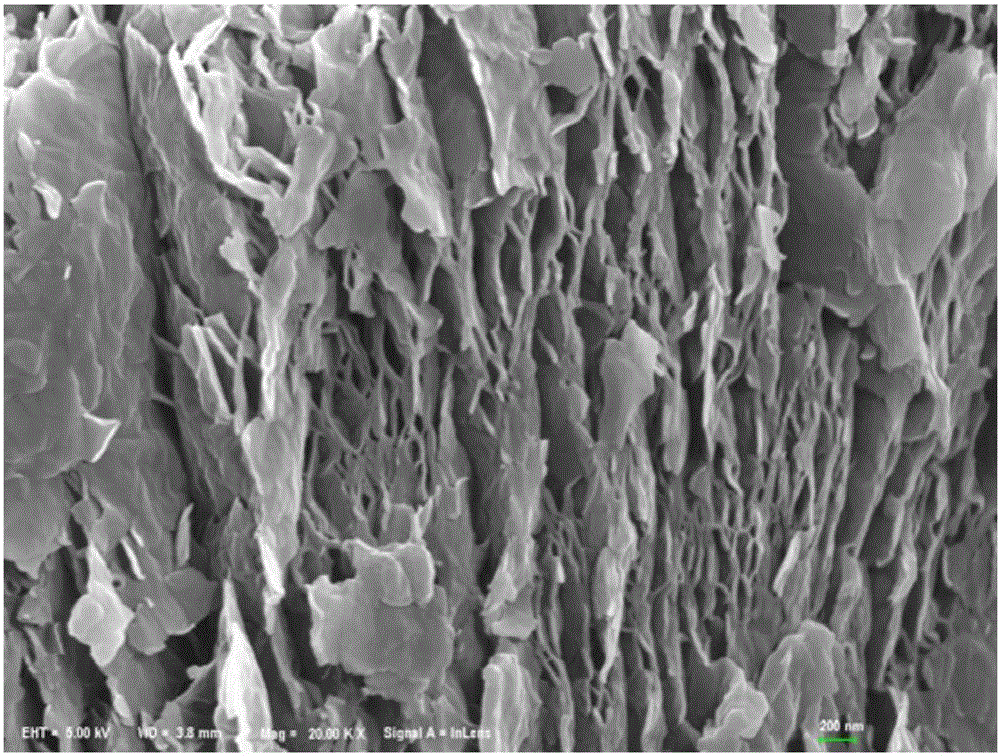

Novel TiAl base self-lubricating composite and preparing method

InactiveCN105861876AImprove mechanical propertiesGood wear reductionGraphene nanoplateletMechanical property

The invention relates to a novel TiAl base self-lubricating composite. The novel TiAl base self-lubricating composite is characterized in that a TiAl base serves as a matrix, and graphene nanosheets and hollow spheres containing WS2 serve as an enhancing phase and a lubricating phase. The graphene nanosheets account for 0.5-1.5 wt.% of the matrix by mass, and hollow spheres containing WS2 account for 3.0-5.0 wt.% of the matrix by mass. A preparing method of the novel TiAl base self-lubricating composite comprises the following steps that elementary substance powder is weighed according to the mole ratio of elements contained in the TiAl base to serve as matrix materials, the graphene nanosheets and the hollow spheres containing WS2 are weighed according to the proportion, the materials are evenly mixed and then subjected to spark plasma sintering, and the novel TiAl base self-lubricating composite is obtained. With the graphene nanosheets and the hollow spheres containing WS2 as the enhancing phase and the lubricating phase, the TiAl base self-lubricating composite is high in compactness, good in mechanical property and high in abrasion relieving and resisting performance.

Owner:WUHAN UNIV OF TECH

Method for preparing wet friction material of nano silicon carbide modified carbon cloth

ActiveCN103320092AImprove rigidityImprove tribological performanceOther chemical processesCorrosion resistantHot press

The invention discloses a method for preparing a wet friction material of a nano silicon carbide modified carbon cloth. The method comprises the following steps: on the basis of taking carbon cloth, nano silicon carbide (SiC) and modified phenolic resin as materials, dissolving the nano SiC and the modified phenolic resin into an anhydrous ethanol solution at a certain ratio; adding a silane coupling agent, and magnetically stirring to obtain evenly dispersed suspension; immersing the preprocessed carbon cloth for 1-1.5 hours, naturally airing, and then carrying out hot press molding by adopting a vulcanizing machine to obtain the wet friction material of the nano silicon carbide modified carbon cloth. By adding certain content of nano SiC, excellent performance such as abrasive resistance, corrosion resistance, high thermal conductivity and high strength of the nano SiC can be integrated into the wet friction material of the carbon cloth. Thus, the tribological property of the wet friction material of the carbon cloth is greatly improved; abrasion of a dual material is greatly reduced due to the nanometer effect of the nano powder represented in a micro friction process; the service life of a friction pair is prolonged.

Owner:SHAANXI UNIV OF SCI & TECH

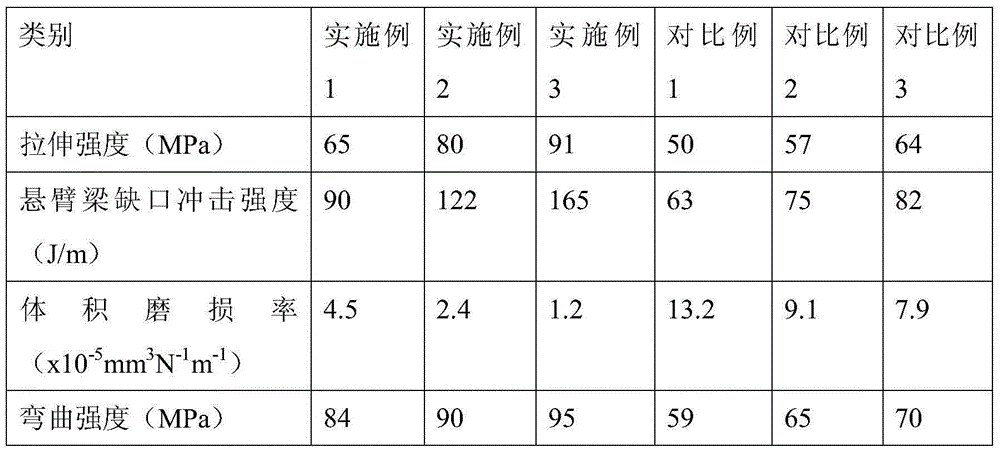

Graphene in-situ modified nylon 6 composite and preparation method and application thereof

ActiveCN105295028AImprove tribological performanceReduce coefficient of frictionDispersitySelective laser sintering

The invention relates to the field of polymer materials, aims to solve the problems that a conventional modifier is poor in graphene dispersity and interfacial adhesional force, unstable in material property and the like, and provides a graphene in-situ modified nylon 6 composite and a preparation method thereof. The graphene in-situ modified nylon 6 composite has the tensile strength of 60-100 MPa, the impact strength of 90-170 J / m, and the volume abrasion rate of 1.0-5.0 (x10<-5>mm<3>N<-1>m<-1>). The graphene in-situ modified nylon 6 composite has the characteristics of being excellent in dispersity and compatibility and stable in performance, can be applied to the field of selective laser sintering, and ensures that the dimensional stability, the abrasion resistance and the ductility of a workpiece are remarkably improved.

Owner:HANGZHOU NORMAL UNIVERSITY

Aluminum-containing diamond-like carbon film and method for preparing same

InactiveCN101665904AImprove adhesionSolve Adhesion ProblemsVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention discloses an aluminum-containing diamond-like carbon film and a method for preparing the same. The film adopts a diamond-like structure and comprises 3 to 20 percent of metal aluminum and the balance of carbon; the metal aluminum is dispersed in the amorphous diamond-like carbon film in an atomic state and is not bonded with the carbon, and the thickness of the film is between 500 and 5,000 nanometers. The aluminum containing diamond-like carbon film has the advantages of lower internal stress, higher hardness, good film-substrate bonding force and good abrasion proof property.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

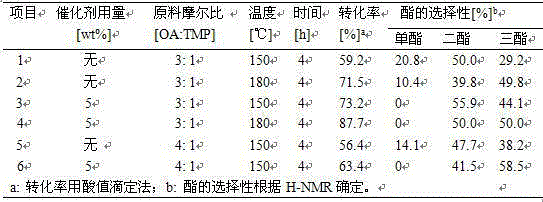

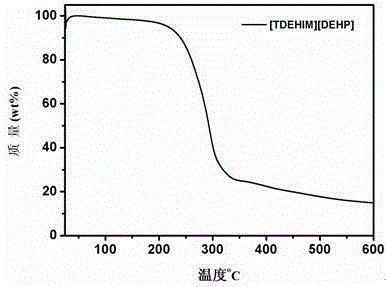

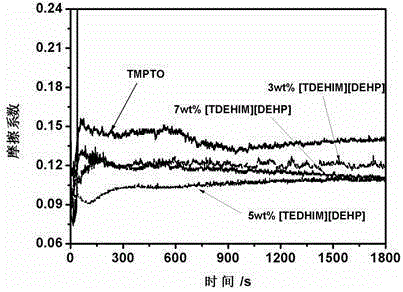

Long-chain alkyl imidazole phosphate ionic liquid, preparation method and application thereof

ActiveCN105254663ACatalytically activeImprove anti-friction and anti-wear propertiesOrganic compound preparationGroup 5/15 element organic compoundsFriction reductionPhosphate

The invention discloses a long-chain alkyl imidazole phosphate ionic liquid, i.e. 1-tetradecyl-3-(2-ethylhexyl)-imidazole diisooctyl phosphate. The invention also discloses a preparation method and application of the ionic liquid. The ionic liquid involved in the invention has certain catalytic activity, and is also soluble in the reaction product trimethylolpropane oleate, so that catalyst separation is omitted after esterification reaction, and the industrial production cost is greatly reduced. More importantly, the ionic liquid soluble in trimethylolpropane trioleate has excellent friction reduction and antiwear effects, and can significantly improve the tribological properties of base oil.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com