Graphite-like carbon nitride/polyimide composite material and preparation method thereof

A technology of graphite-type carbon nitride and polyimide, which is applied in the field of high-performance polymer composite materials and their preparation, polyimide composite materials and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

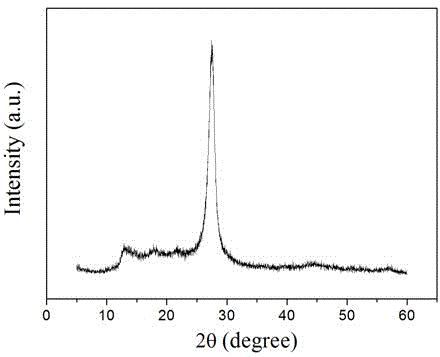

[0032] Weigh 3g of melamine, put it in a corundum crucible and cover it, raise the temperature to 550°C in a muffle furnace, and the heating rate is 3°C min -1 , and calcined at 550°C for 4 h, then naturally cooled to room temperature to obtain a yellow solid, which was ground to obtain g-C 3 N 4 , the XRD pattern of the prepared powder is shown in figure 1 .

[0033] Weigh the yellow g-C prepared above 3 N 4 Powder 1g, added volume is g-C3 N 4 Powder volume 5 times the absolute ethanol solution, then g-C 3 N 4 The mixture of powder and absolute ethanol was dispersed in an ultrasonic vibrator for 30 minutes, and g-C was added to the suspension during the ultrasonic vibration 3 N 4 Coupling agent γ-aminopropyltriethoxysilane with 2% powder mass, then place the mixed solution with coupling agent in an oven and dry for 20 hours at a temperature of 80°C, and dry the alcohol to obtain a dispersion And surface treated g-C 3 N 4 powder raw material.

[0034] The polyimide...

Embodiment 2

[0040] Weigh 2g of melamine, put it in a corundum crucible and cover it, raise the temperature to 550°C in a muffle furnace, and the heating rate is 3°C min -1 , and calcined at 550°C for 4 h, then naturally cooled to room temperature to obtain a yellow solid, which was ground to obtain g-C 3 N 4 , the XRD pattern of the prepared powder is shown in figure 1 .

[0041] Weigh the yellow g-C prepared above 3 N 4 Powder 0.5g, added volume is g-C 3 N 4 Powder volume 5 times the absolute ethanol solution, then g-C 3 N 4 The mixture of powder and absolute ethanol was placed in an ultrasonic vibrator to disperse for 40 minutes, and g-C was added to the suspension during the ultrasonic vibration 3 N 4 Coupling agent β-(3,4 epoxycyclohexyl)propyltrimethoxysilane with 2% powder mass, then place the mixed solution with coupling agent in an oven and dry for 10 hours, the drying temperature is 80°C, After drying the alcohol to obtain the g-C after dispersion and surface treatment ...

Embodiment 3

[0048] Weigh 2g of melamine, put it in a corundum crucible and cover it, raise the temperature to 550°C in a muffle furnace, and the heating rate is 3°C min -1 , and calcined at 550°C for 4 h, then naturally cooled to room temperature to obtain a yellow solid, which was ground to obtain g-C 3 N 4 , the XRD pattern of the prepared powder is shown in figure 1 .

[0049] Weigh the yellow g-C prepared above 3 N 4 Powder 0.5g, added volume is g-C 3 N 4 Powder volume 5 times the absolute ethanol solution, then g-C 3 N 4 The mixture of powder and absolute ethanol was placed in an ultrasonic vibrator to disperse for 40 minutes, and g-C was added to the suspension during the ultrasonic vibration 3 N 4 Coupling agent γ-(2,3-glycidoxy)propyltrimethoxysilane with 2% powder mass, and then place the mixed solution with coupling agent in an oven for 10 hours and dry at 80°C , dry the alcohol to obtain the dispersed and surface-treated g-C 3 N 4 powder raw material.

[0050] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com