Patents

Literature

374 results about "Air barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air barriers control air leakage into and out of the building envelope. Air barriers are divided into air barrier materials, air barrier accessories, air barrier components, air barrier assemblies and air barrier systems.

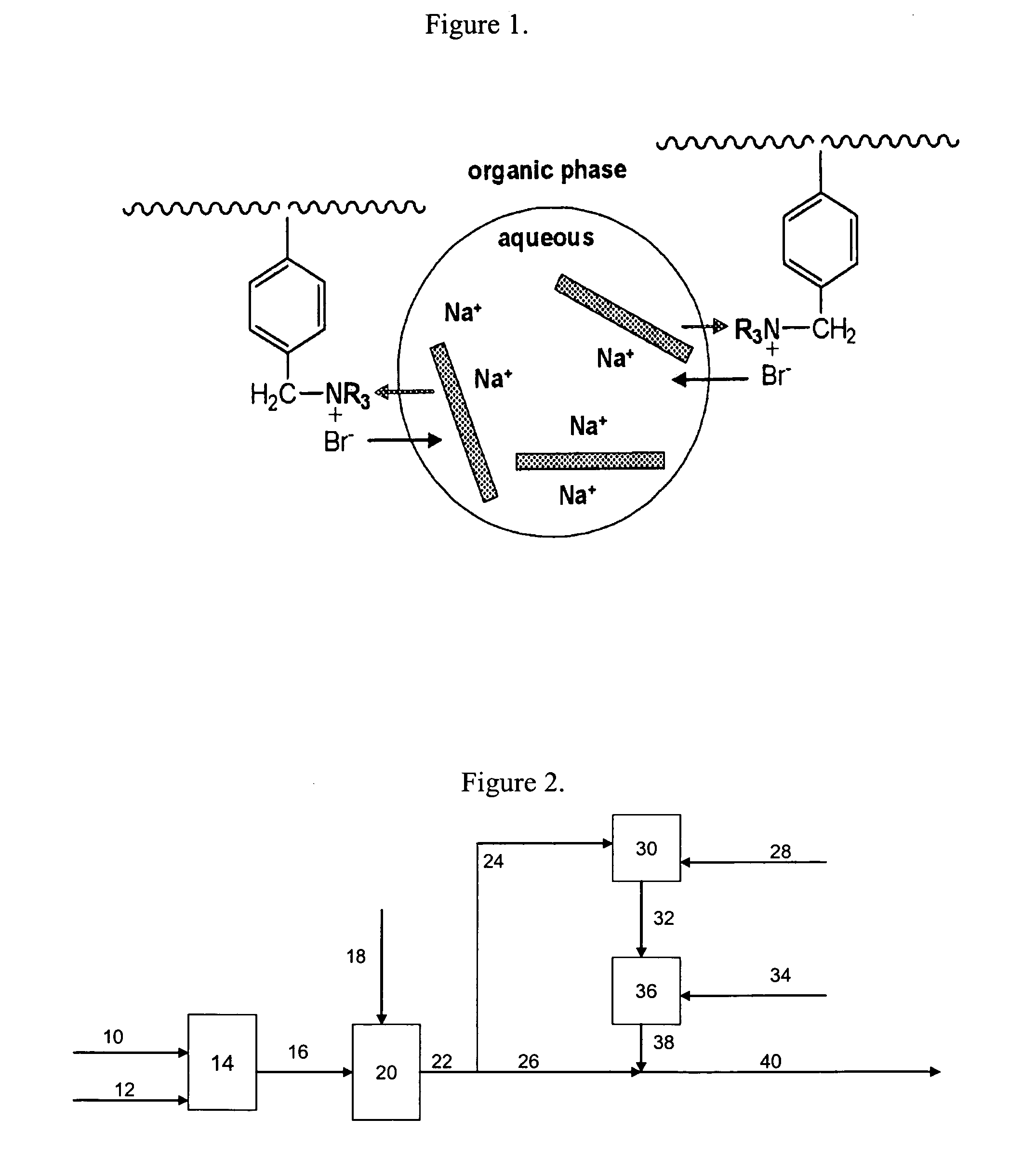

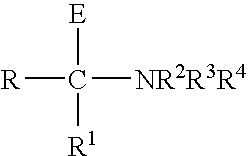

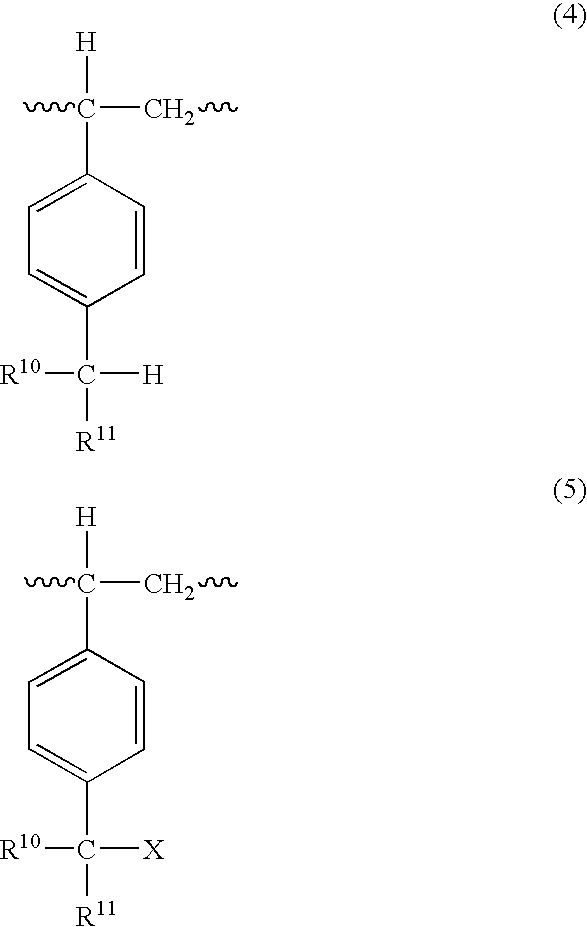

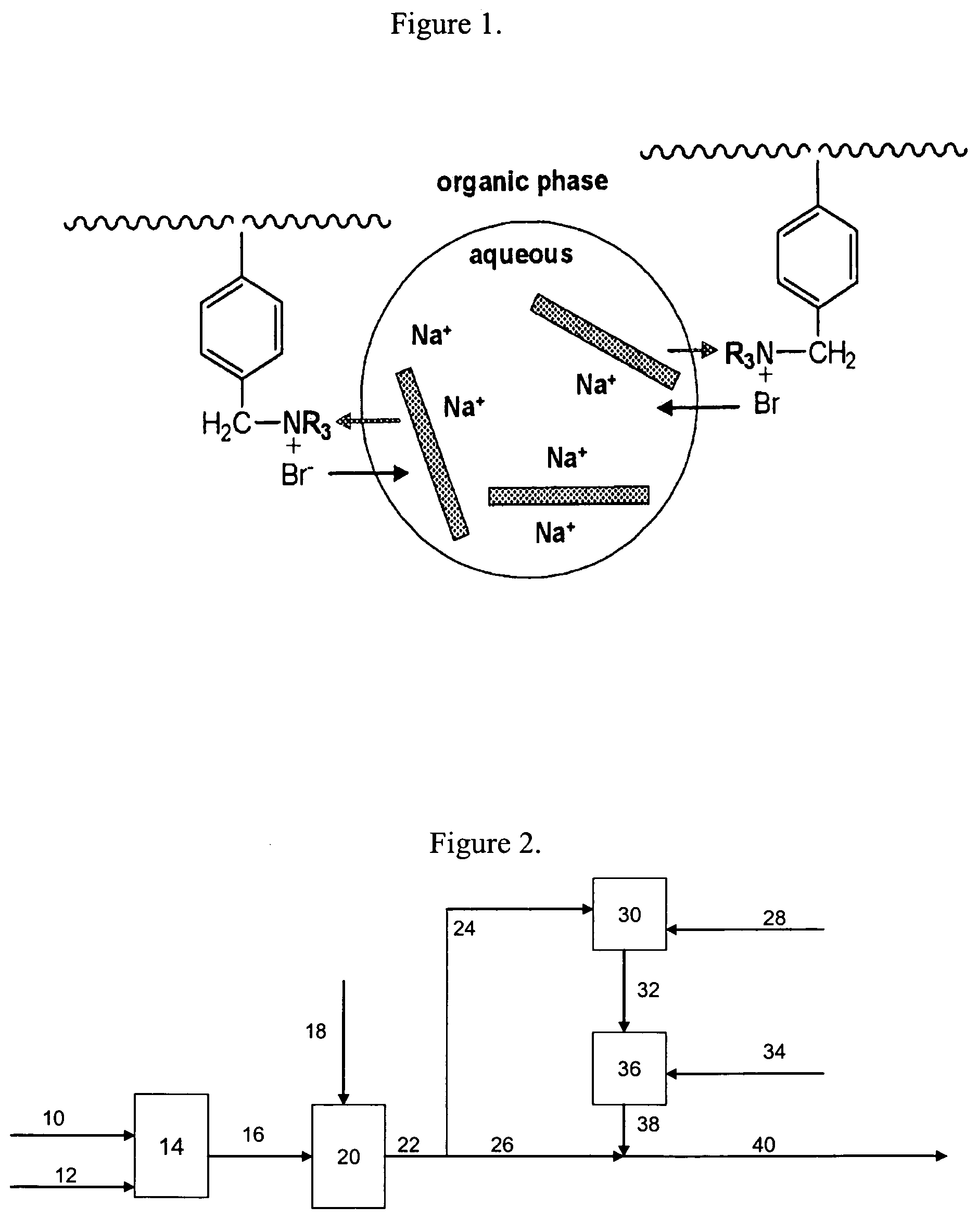

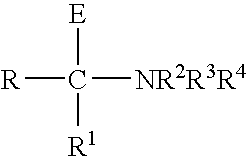

Functionalized isobutylene polymer-inorganic clay nanocomposites and organic-aqueous emulsion process

A nanocomposite of a halogenated elastomer and an inorganic, exfoliated clay, suitable for use as an air barrier, is disclosed. The halogenated elastomer can be a polymer comprising C4 to C7 isoolefin derived units, para-methylstyrene derived units, and para(halomethylstyrene) derived units, or can be a butyl-type rubber. The nanocomposite can be formed by contacting an aqueous slurry of inorganic clay with a polymer cement while agitating vigorously to form emulsions or micro-emulsions to intimately mix the inorganic clay and the elastomer. The nanocomposite so formed has improved air barrier properties and is suitable for use as an innerliner or innertube.

Owner:EXXONMOBIL CHEM PAT INC

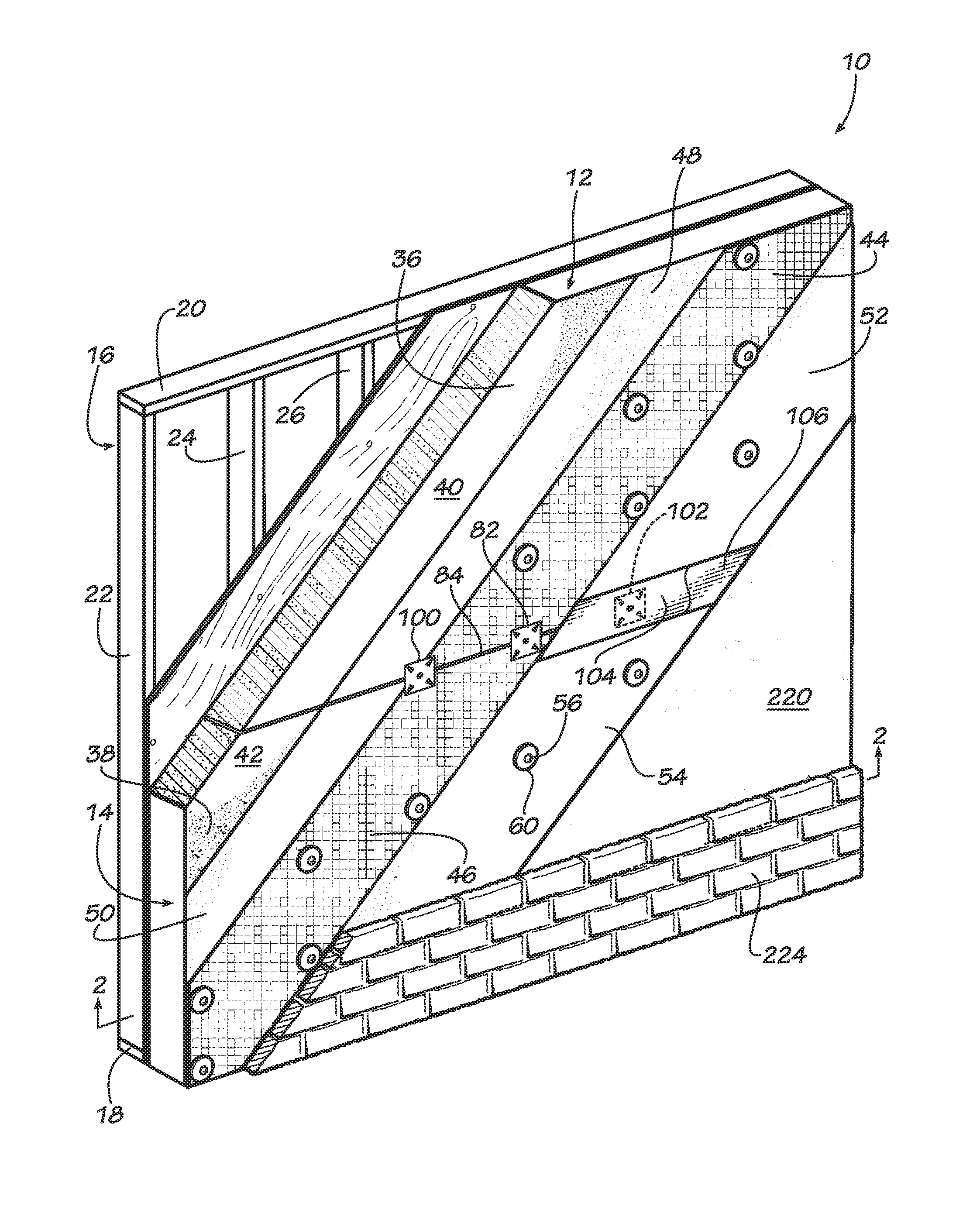

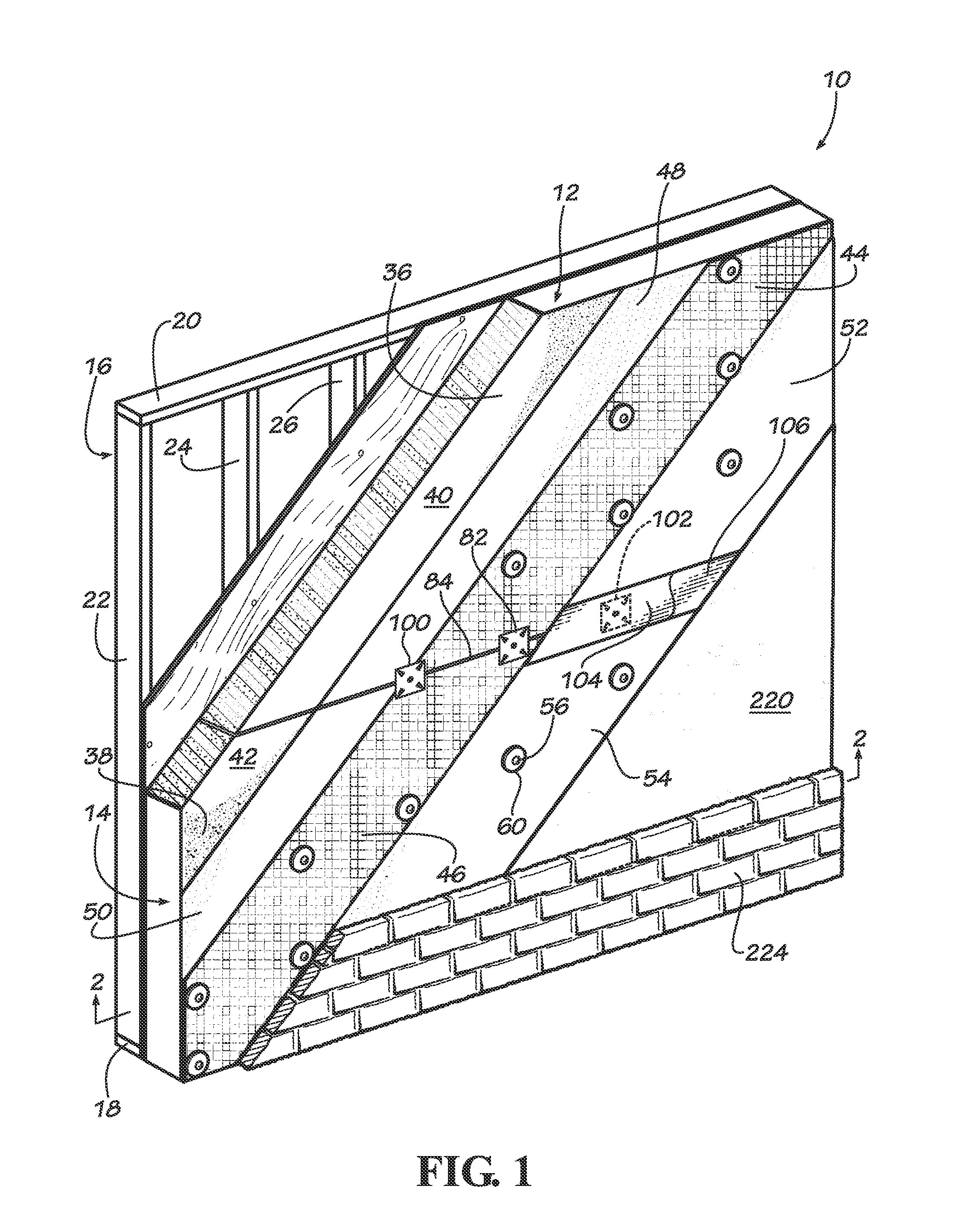

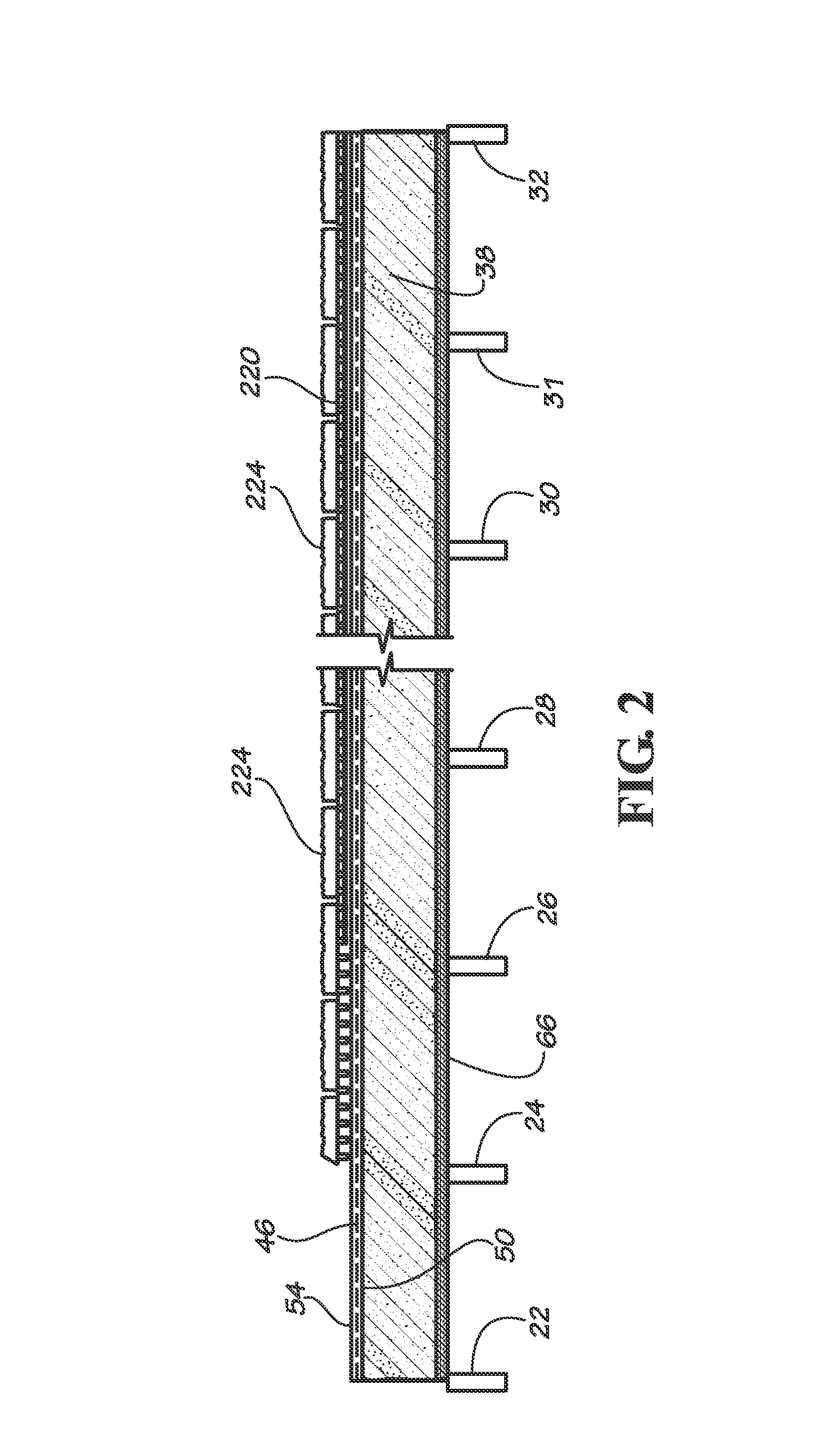

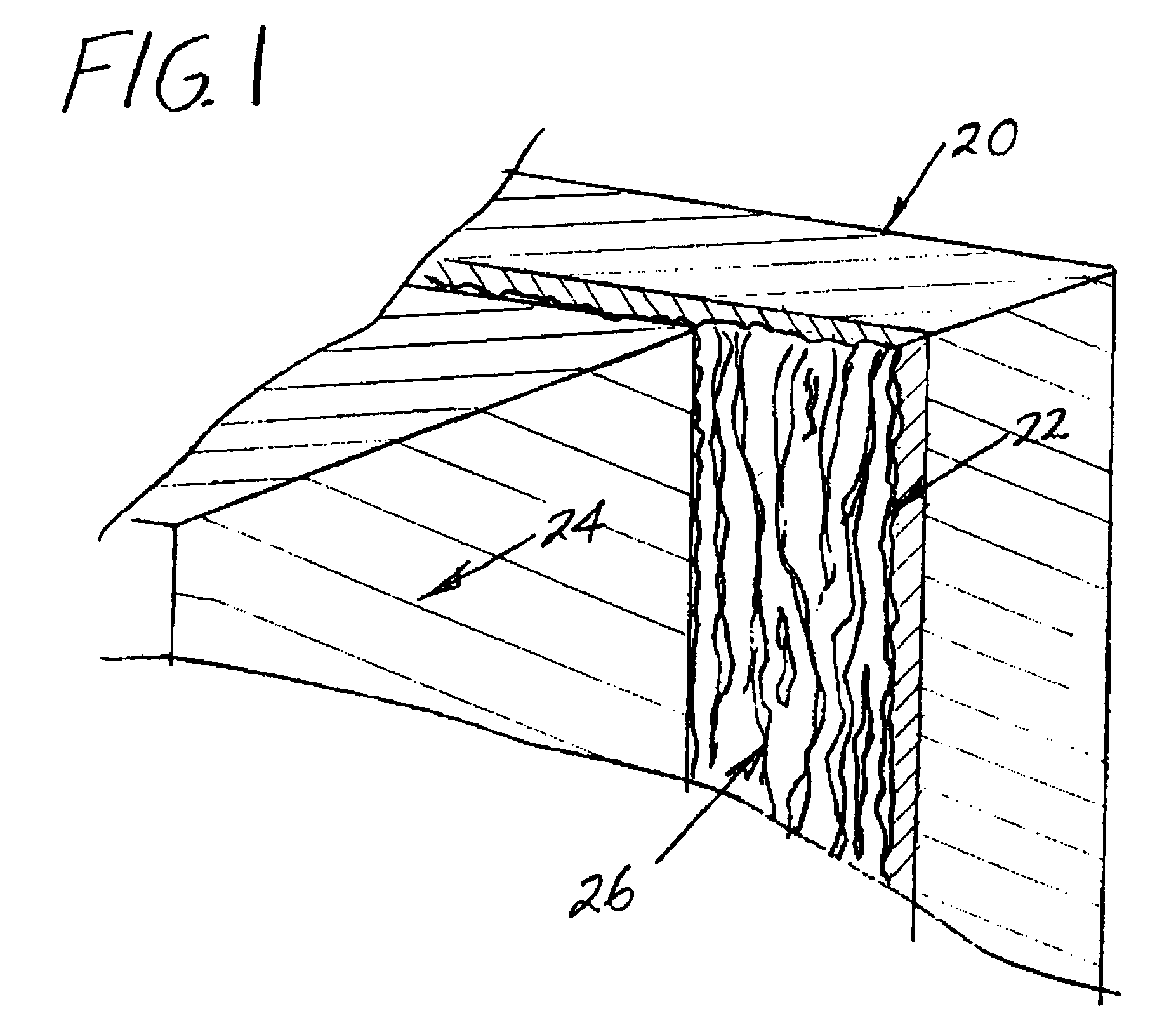

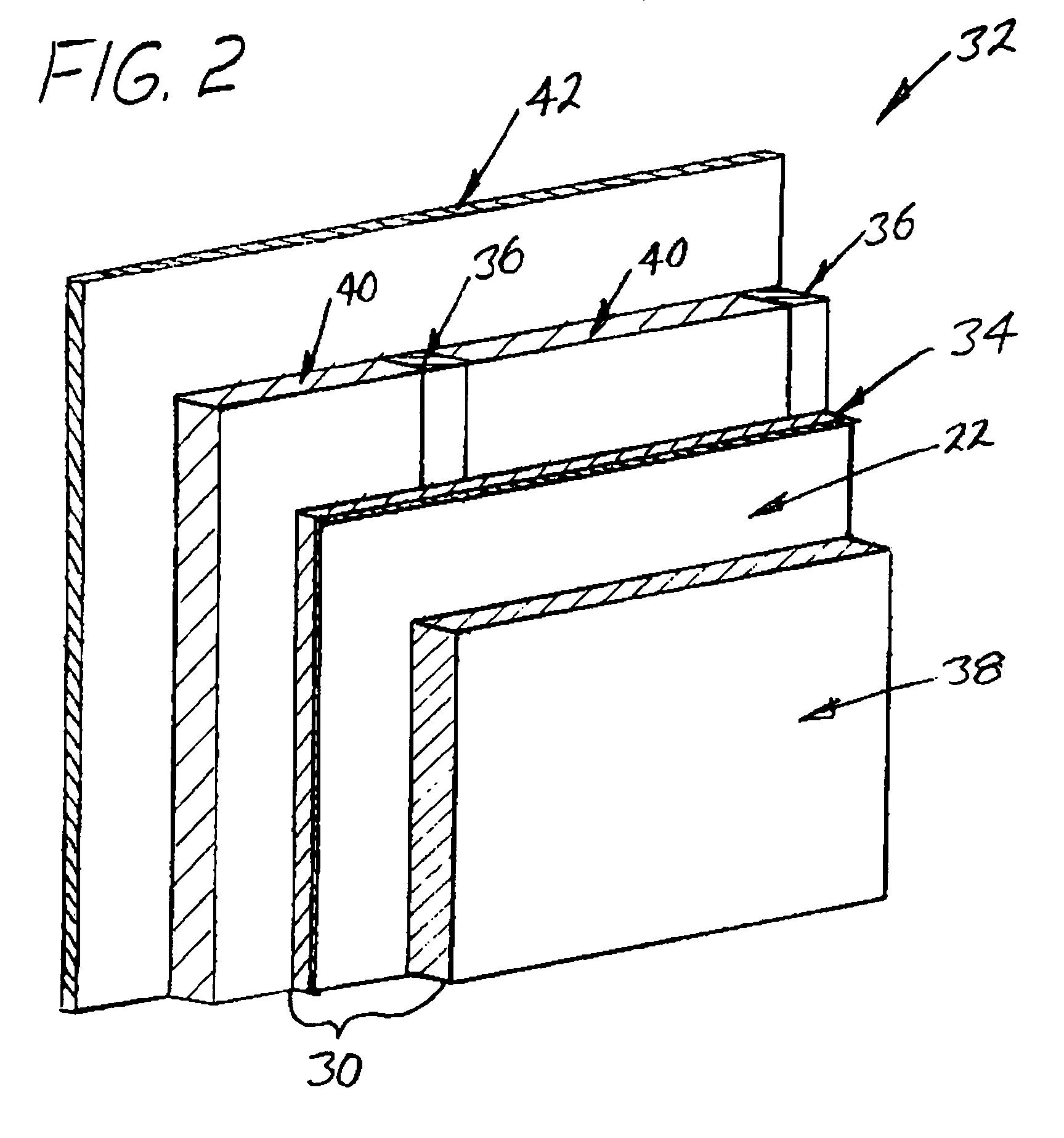

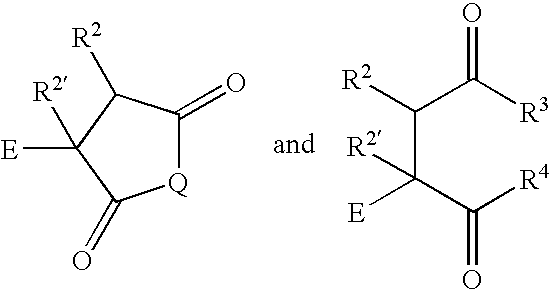

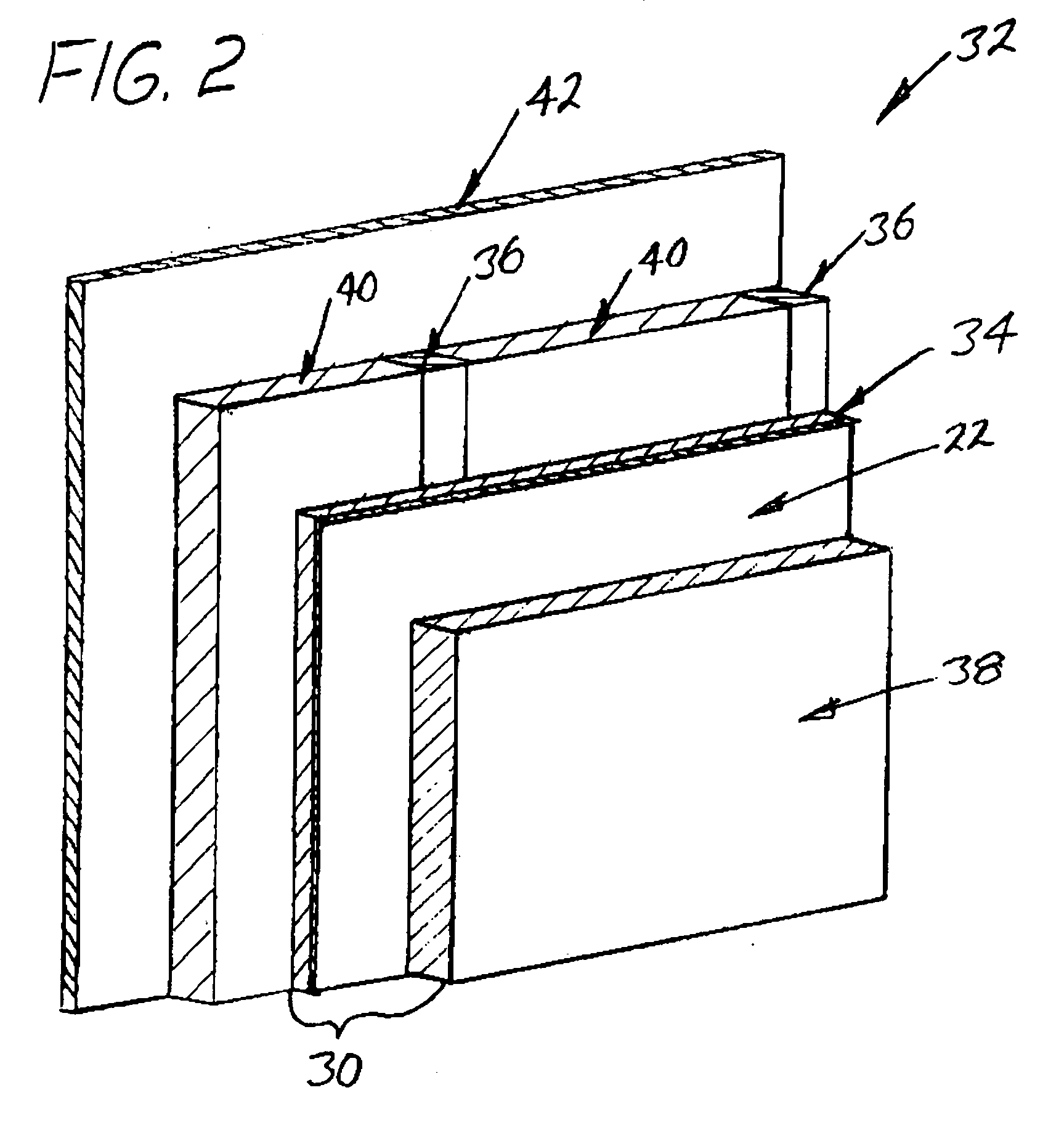

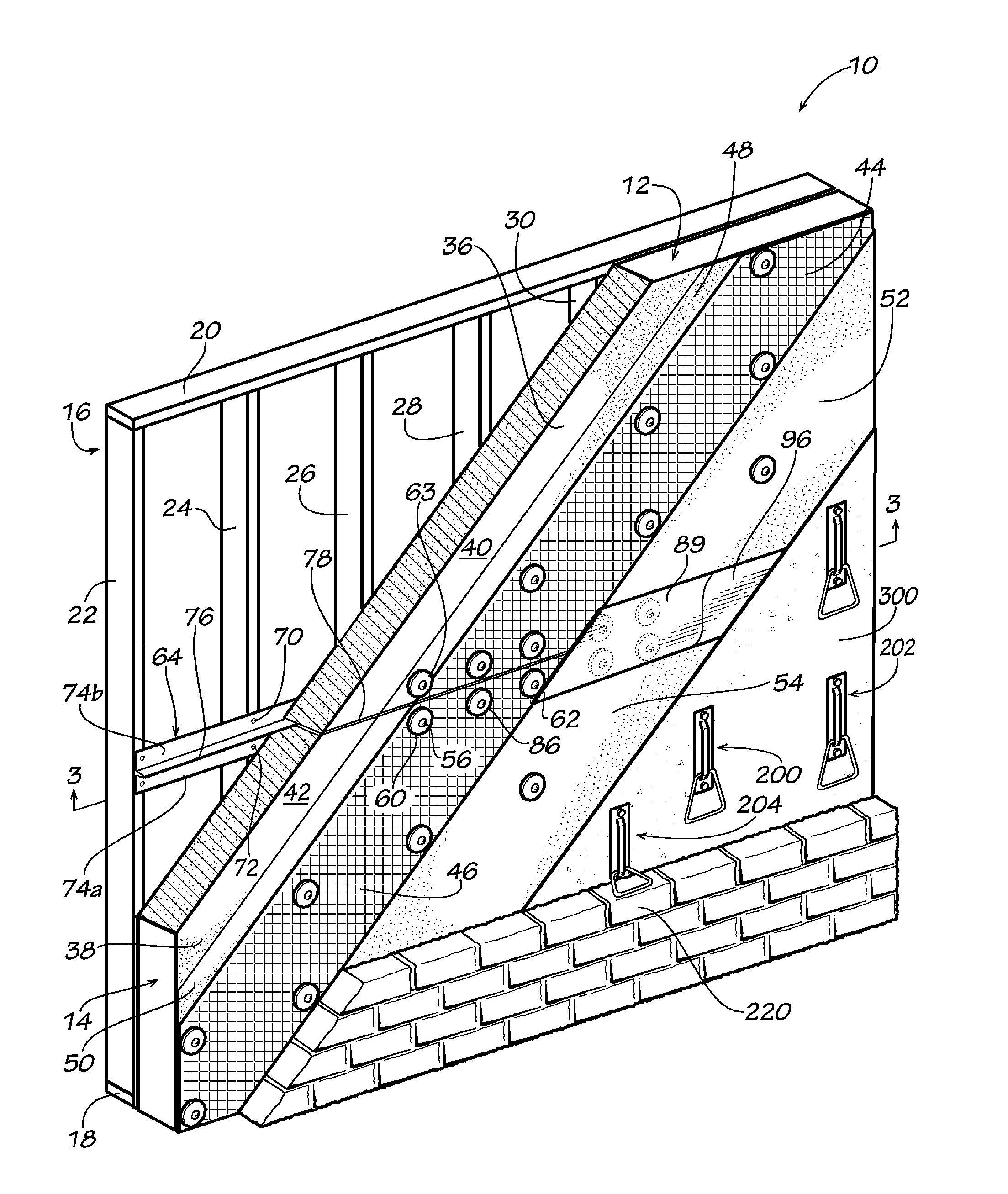

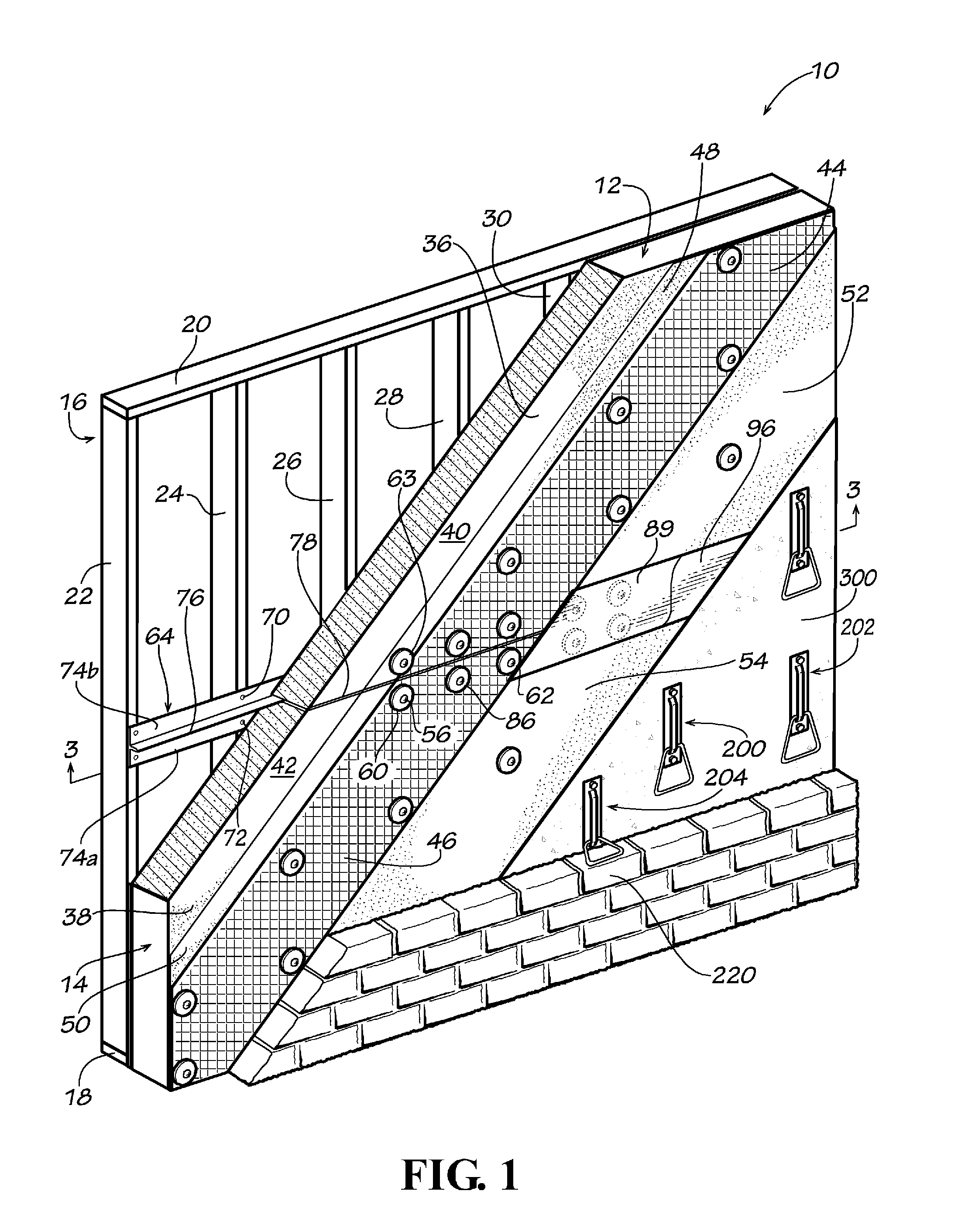

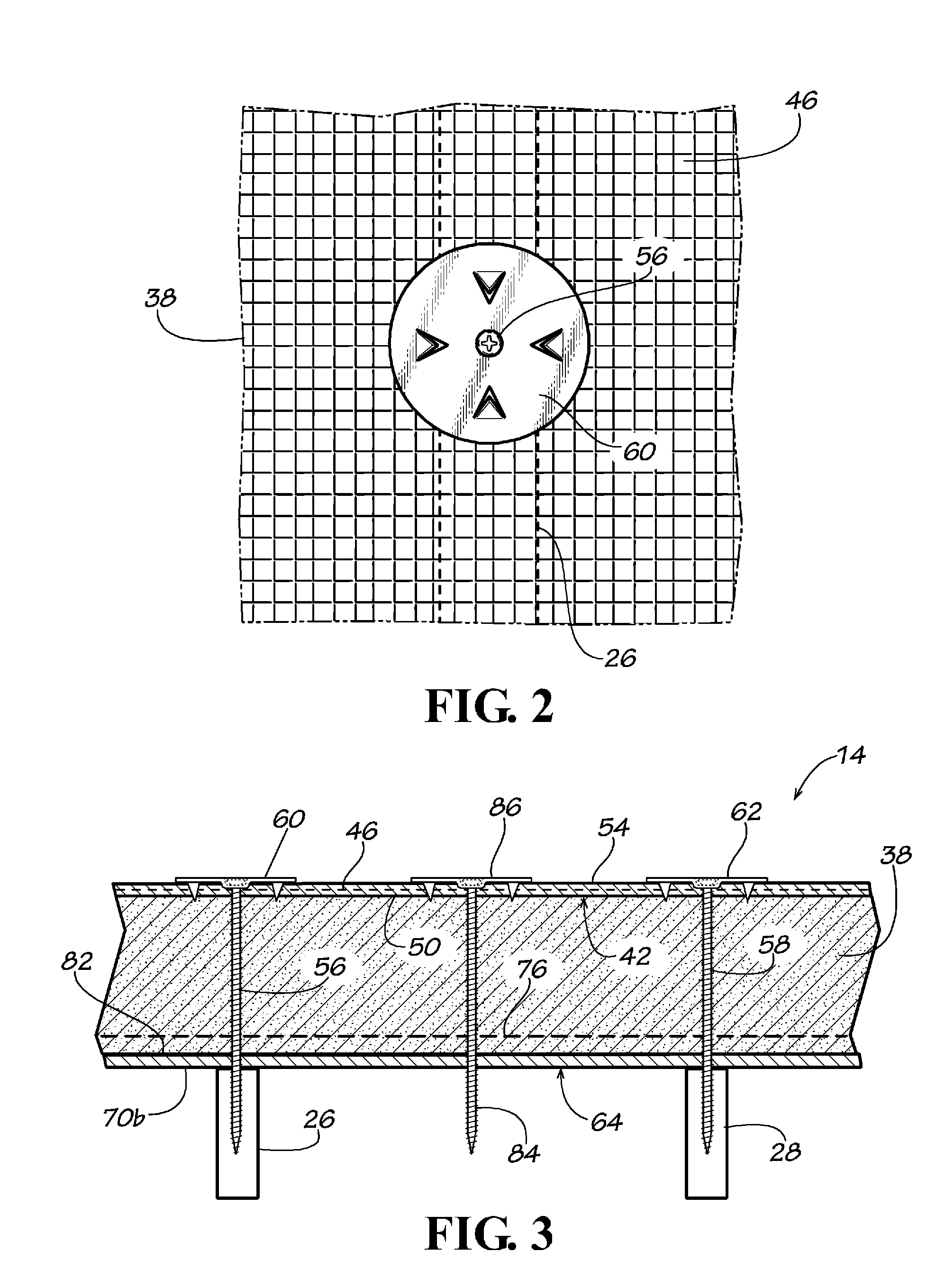

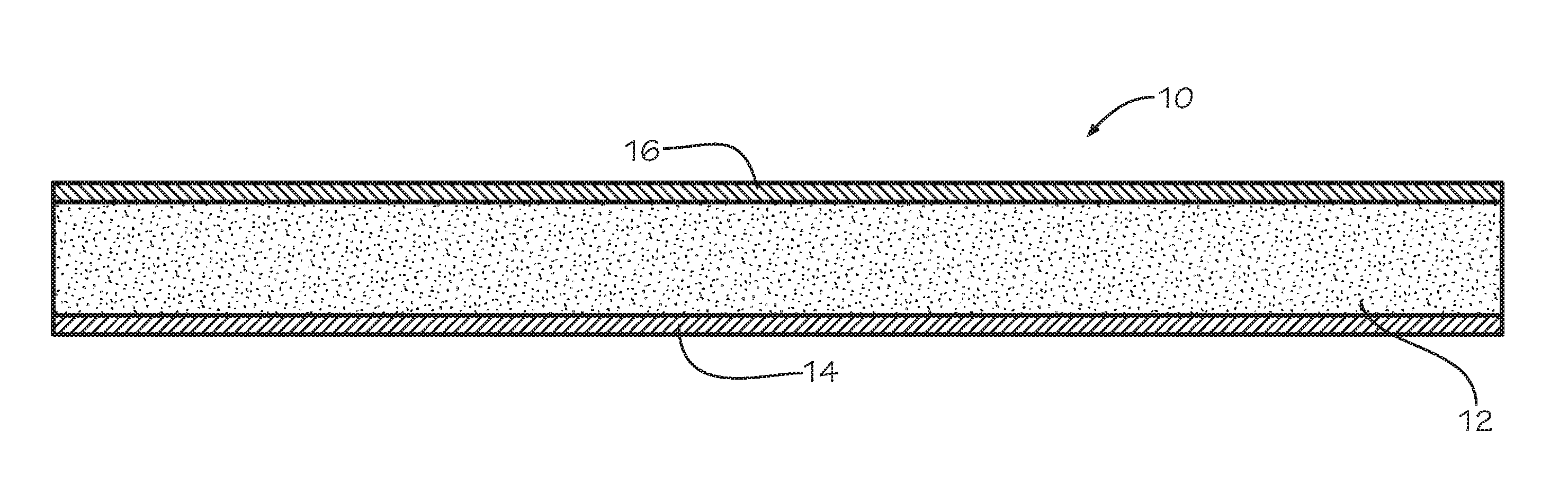

Insulated reinforced foam sheathing, reinforced vapor permeable air barrier foam panel and method of making and using same

InactiveUS8966845B1Prevent leakageIncreased and decreasedCovering/liningsWashersElastomerEngineering

The invention comprises a product. The product comprises a composite panel comprising a foam insulating panel having a first primary surface and an opposite second primary surface, and a first layer of a polymeric elastomeric material on the first primary surface such that at least a portion of a first layer of reinforcing material is at least partially embedded in the polymeric elastomeric material. The composite panel also comprises a fastener for attaching the composite panel to a framing structure, wherein the fastener comprises a washer and wherein at least a portion of the first layer of a polymeric elastomeric material and the first layer of reinforcing material are disposed between the washer and the first primary surface. A method of making and using the composite panel is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

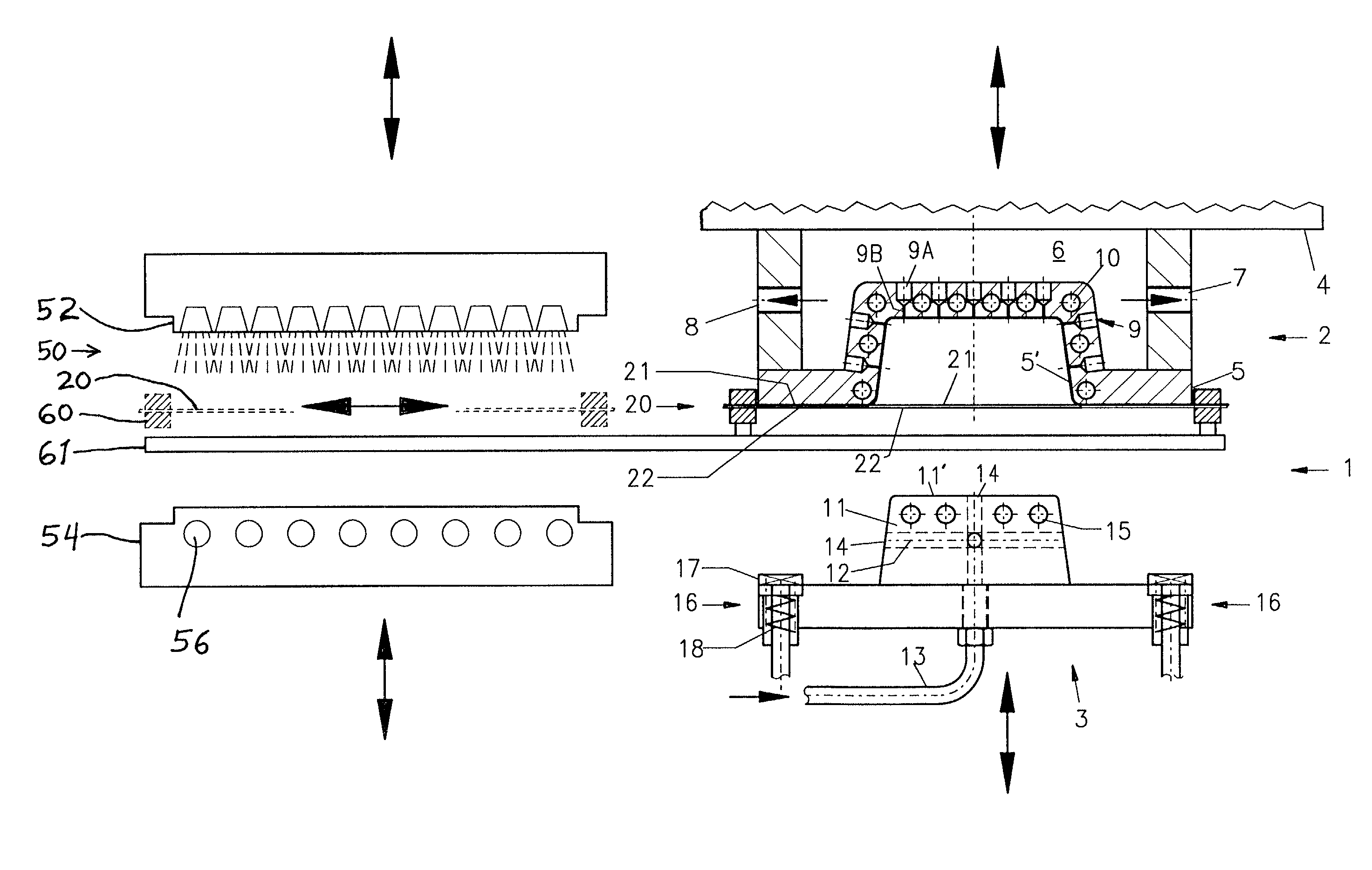

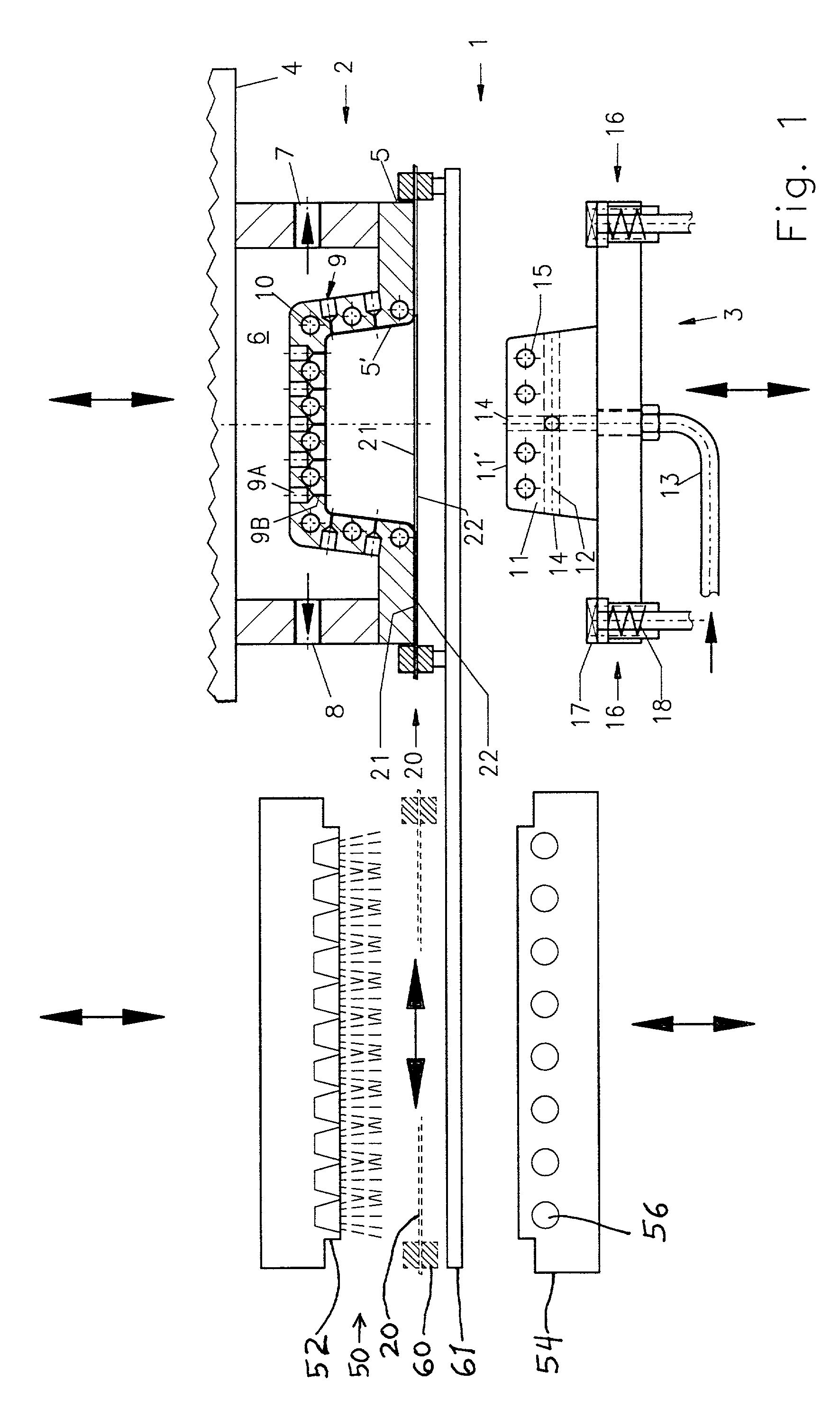

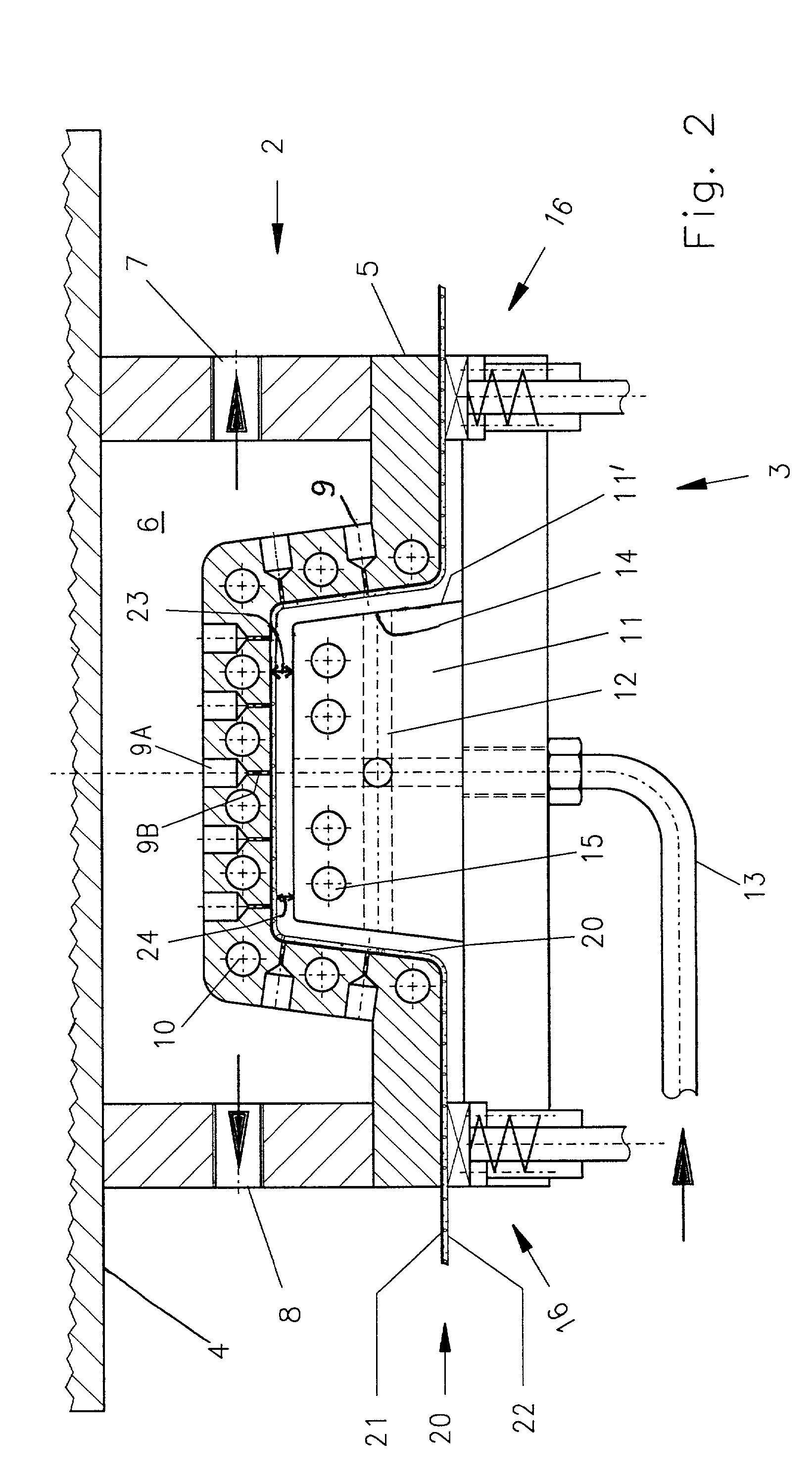

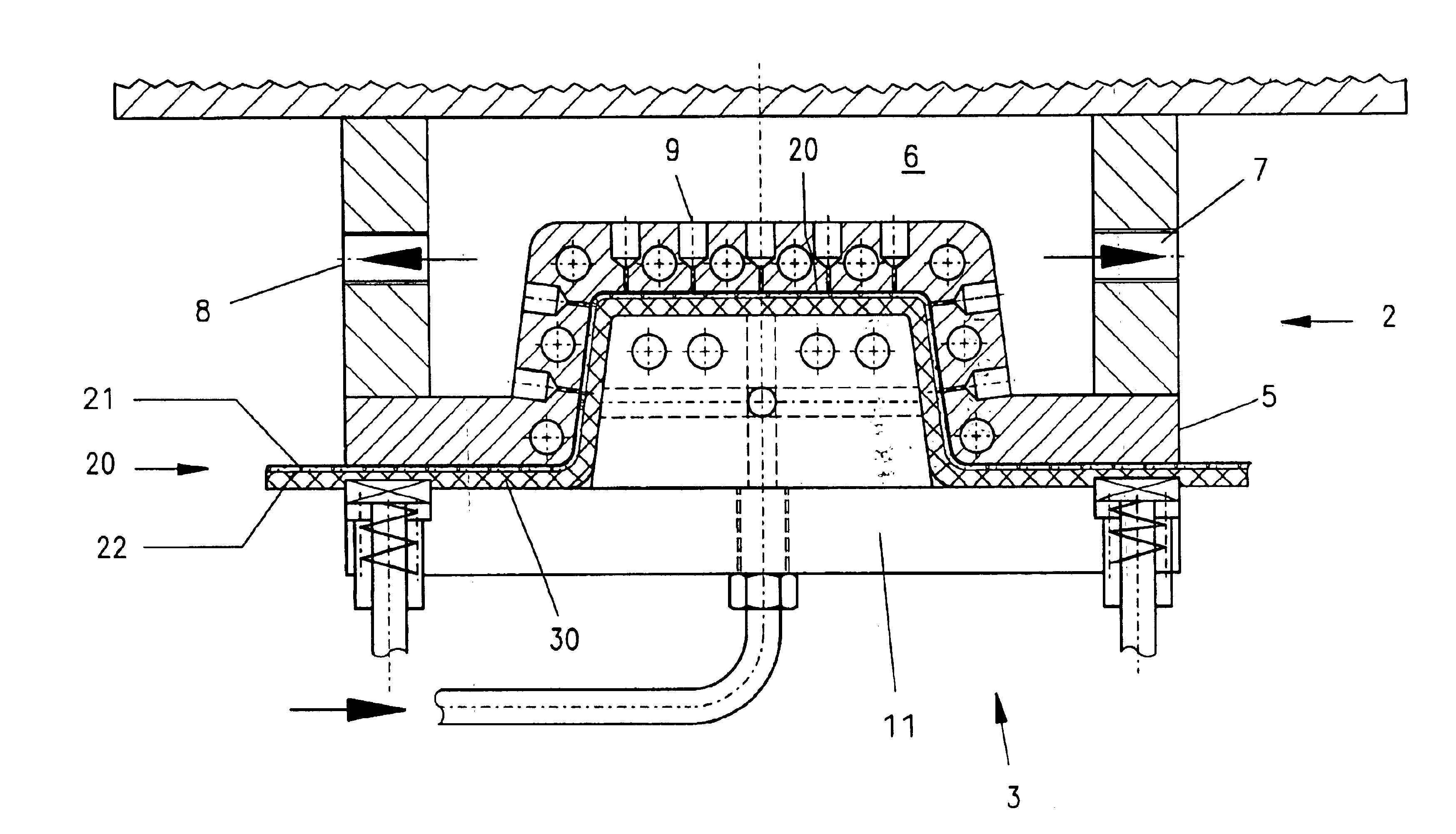

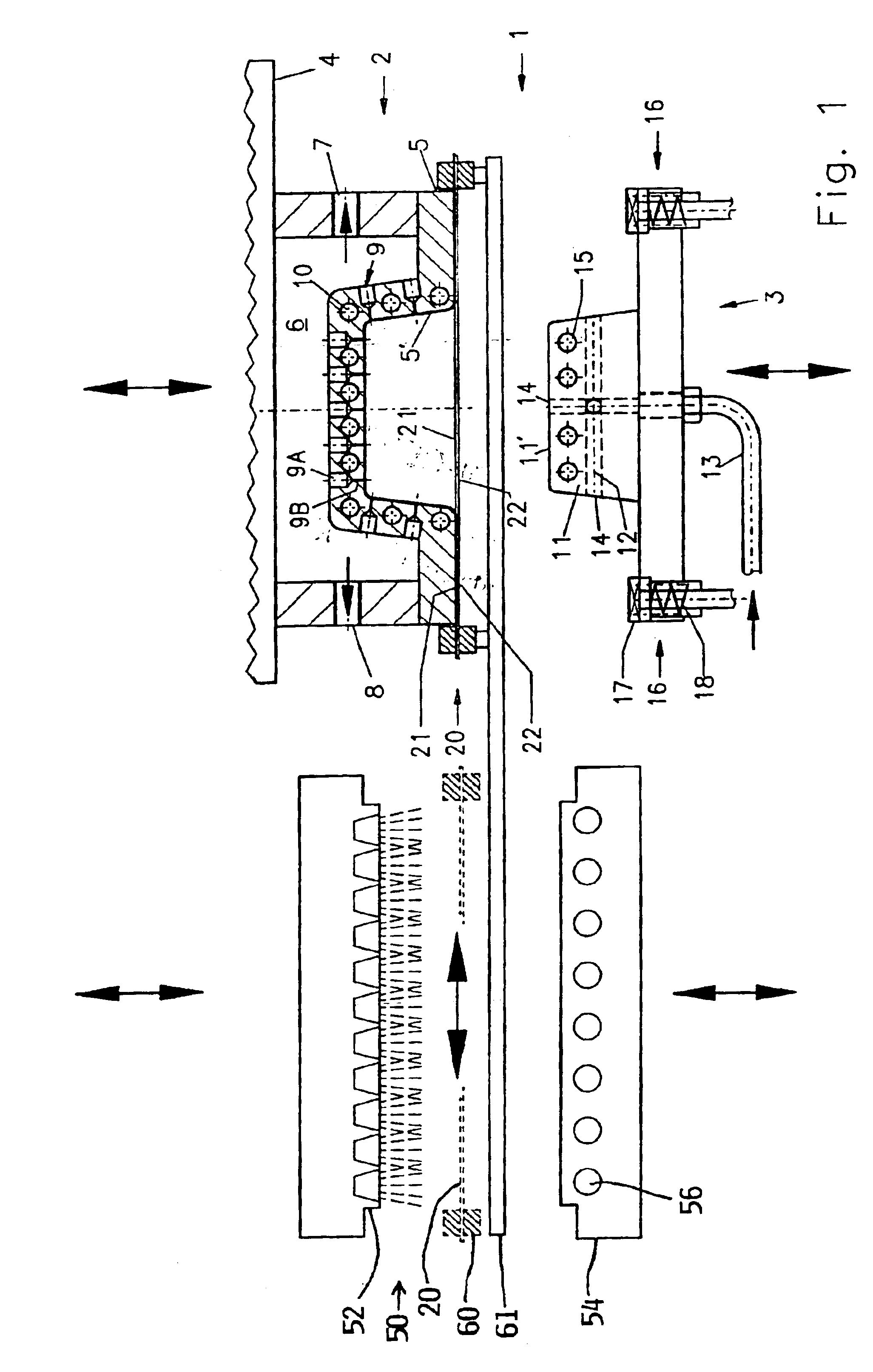

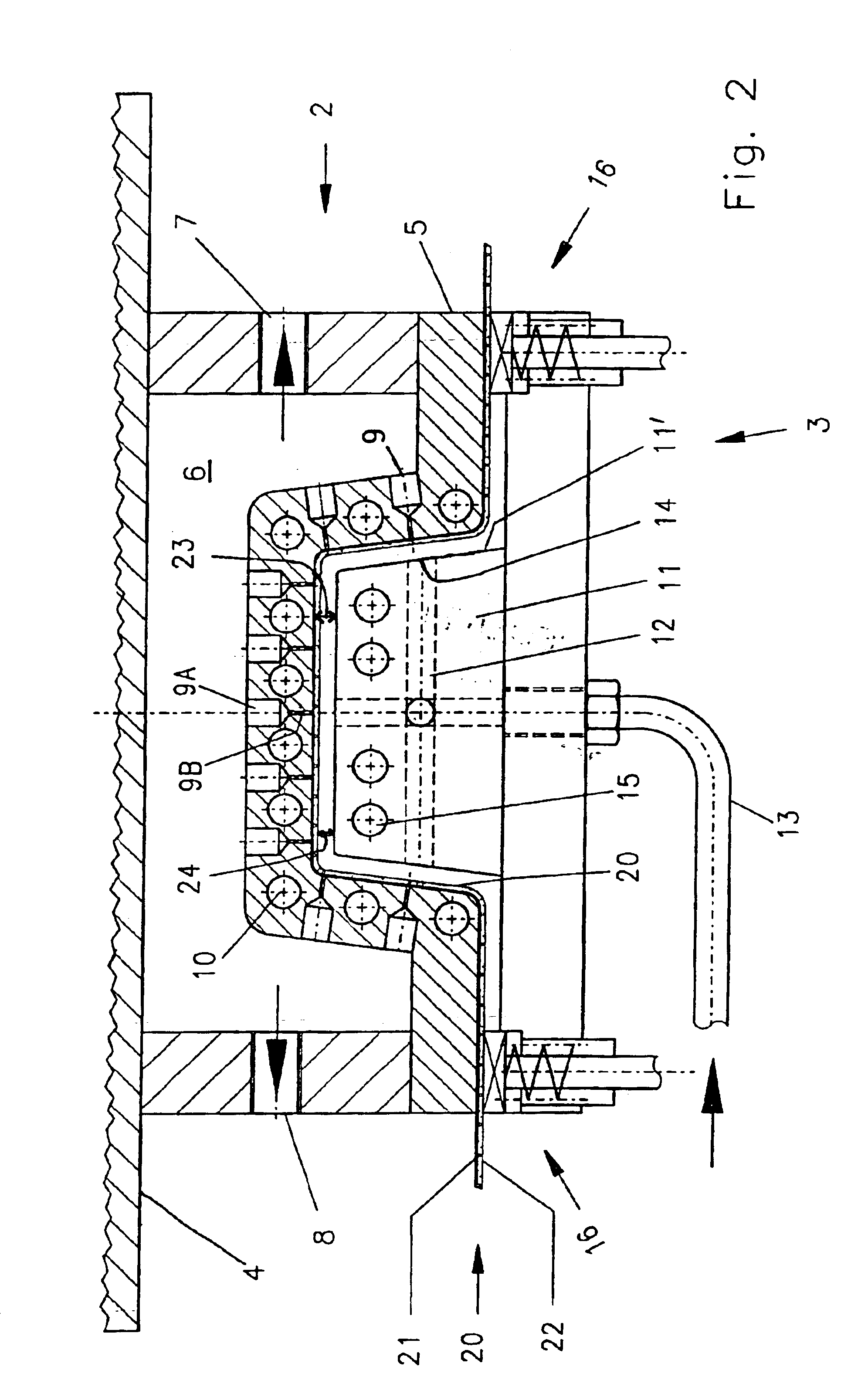

Method and apparatus for molding components with molded-in surface texture

An automobile interior trim component includes a molded substrate laminated onto a cover sheet including a foam backing and a skin film having a surface texture. The cover sheet is preheated so the skin film is in a melted viscous liquid state above its melting temperature, and the foam backing remains in a solid elastic foam state below its melting temperature. The preheated cover sheet is mechanically pre-molded by a back mold into a front mold. Pressurized air is applied through the back mold, to blow-mold the cover sheet against the front mold, so the melted skin film reproduces a surface texture of the front mold surface while the solid foam backing acts as a buffer and air barrier layer. Vacuum is applied through the front mold surface. The mold is opened, a substrate is introduced, and the back mold then molds and thermally laminates the substrate against the foam backing of the cover sheet.

Owner:HERBERT OLBRICH

Method and apparatus for molding components with molded-in surface texture

An automobile interior trim component includes a molded substrate laminated onto a cover sheet including a foam backing and a skin film having a surface texture. The cover sheet is preheated so the skin film is in a melted viscous liquid state above its melting temperature, and the foam backing remains in a solid elastic foam state below its melting temperature. The preheated cover sheet is mechanically pre-molded by a back mold into a front mold. Pressurized air is applied through the back mold, to blow-mold the cover sheet against the front mold, so the melted skin film reproduces a surface texture of the front mold surface while the solid foam backing acts as a buffer and air barrier layer. Vacuum is applied through the front mold surface. The mold is opened, a substrate is introduced, and the back mold then molds and thermally laminates the substrate against the foam backing of the cover sheet.

Owner:HERBERT OLBRICH

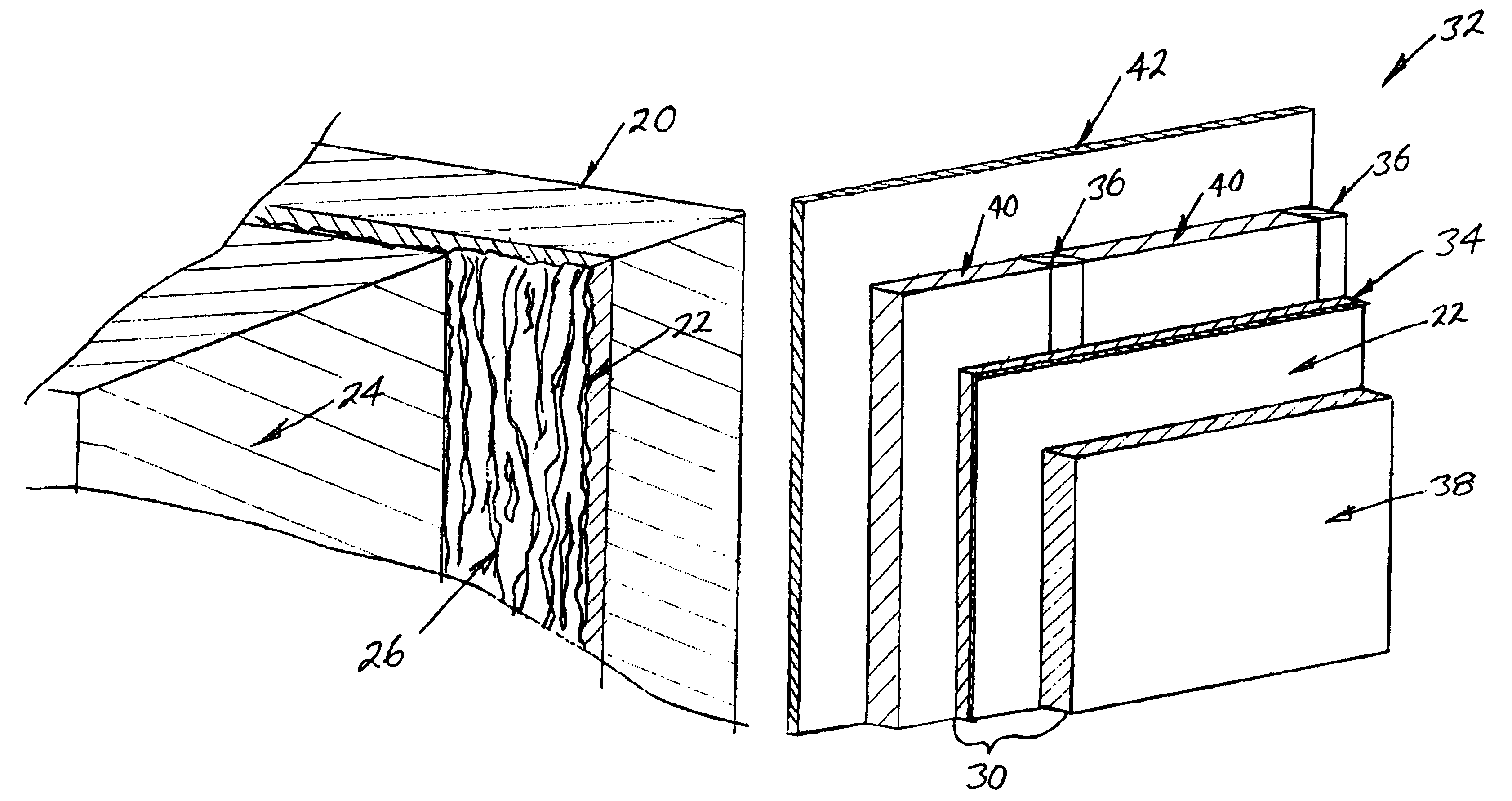

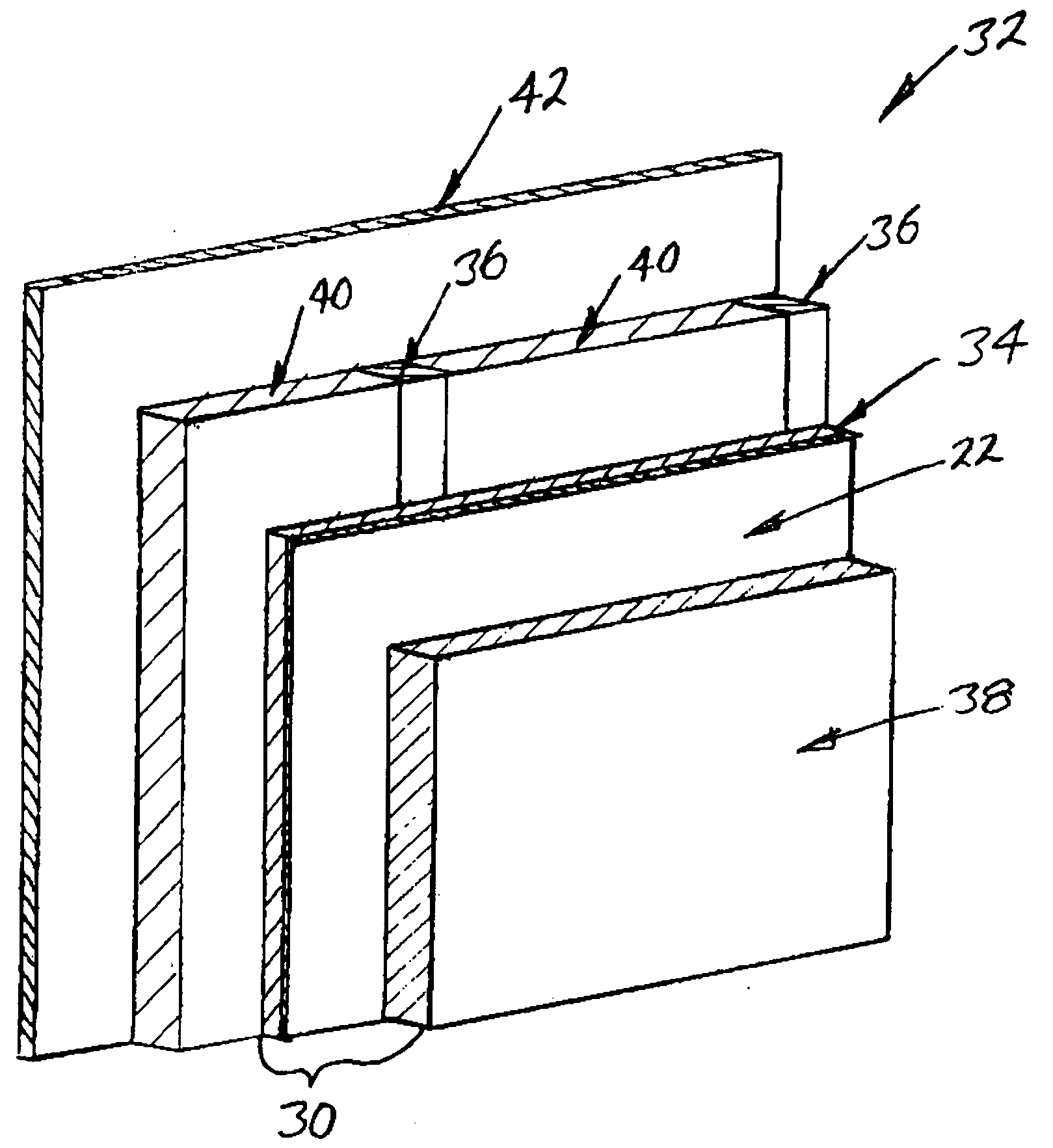

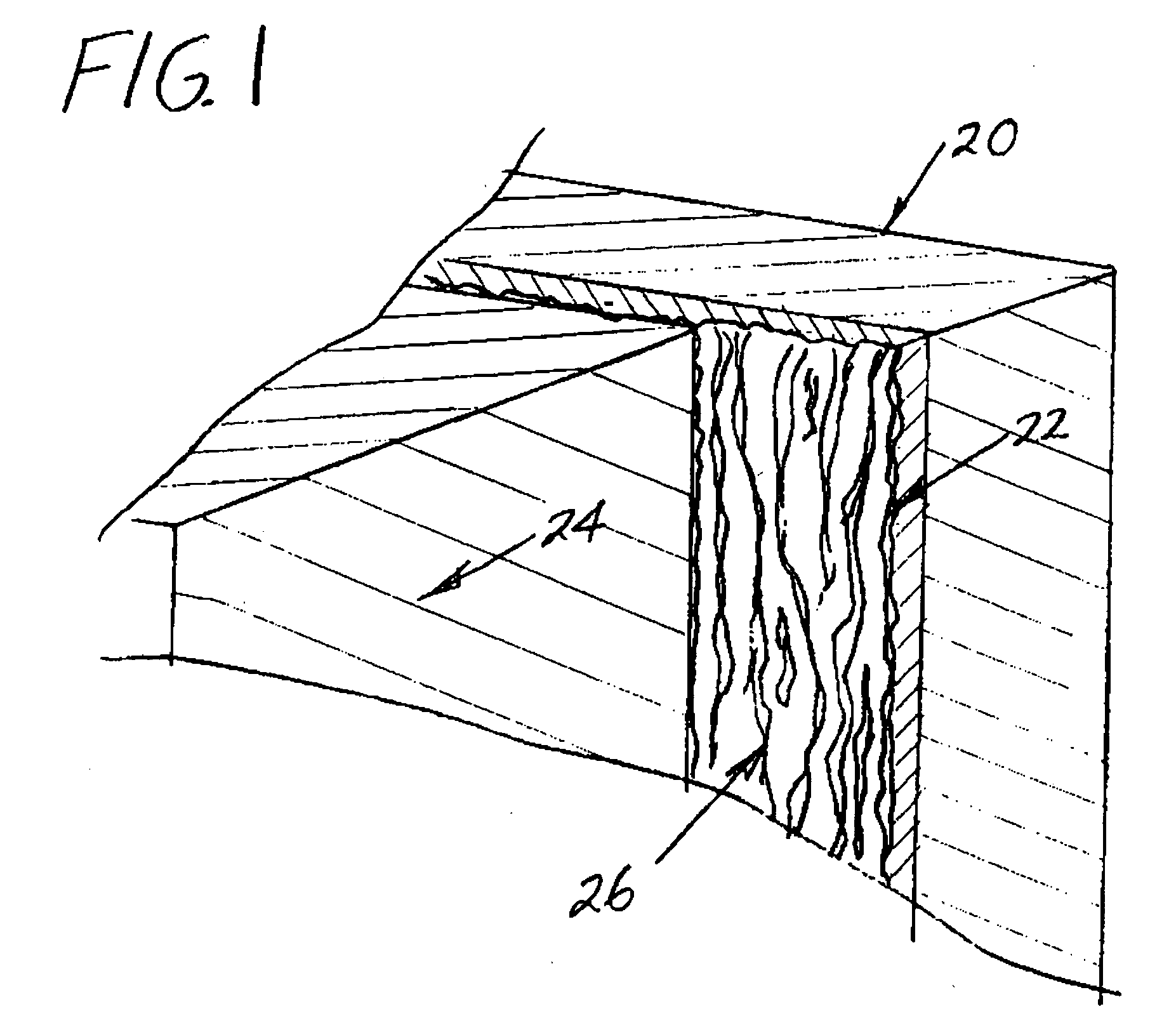

Spray applied building wrap coating material, spray applied building wrap, and building construction assembly

ActiveUS7662221B2Improve performanceLow emissivityAntifouling/underwater paintsFloorsWater vaporSpray coating

A spray applied building construction coating material forms a waterproofing, water vapor permeable, air barrier, building wrap coating layer between an exterior facing surface of a building sheathing layer and an interior facing surface of an exterior building cladding layer. A building construction assembly is formed by spray coating the exterior surface of the sheathing layer with the coating material or by spray coating gaps in the sheathing layer with the coating material and spray coating the exterior surface of the sheathing layer and previously coated gaps in the sheathing layer with a second coat of the coating material and applying an exterior cladding layer over the coating layer(s). For most applications, the coating material is formulated or includes additives whereby it solidifies on the sheathing to form a coating layer that has an exterior facing, textured surface. This exterior facing, textured surface provides passages between the exterior facing surface of the coating layer and an interior facing surface of the exterior cladding layer for draining water from between and permitting air flow between the exterior facing surface of the coating layer and the interior facing surface of the exterior cladding layer.

Owner:JOHNS MANVILLE CORP

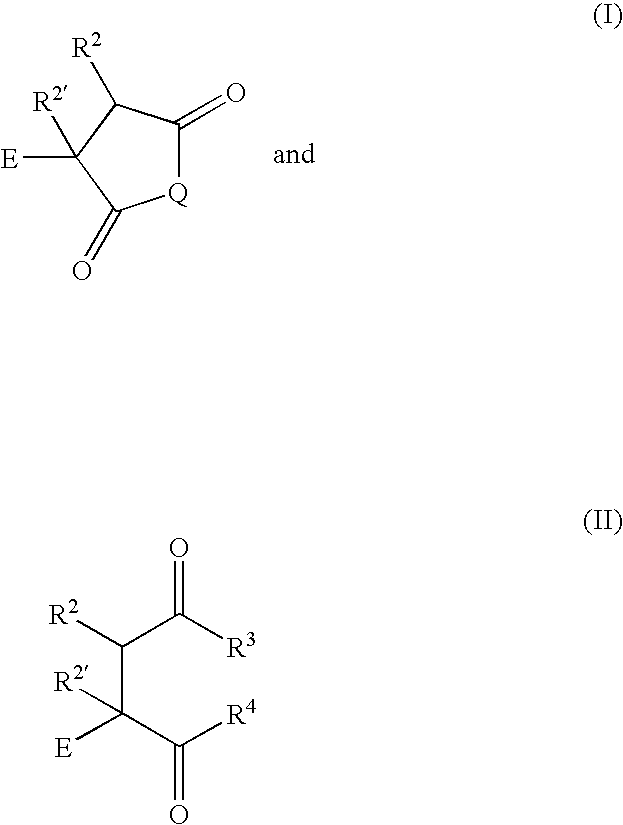

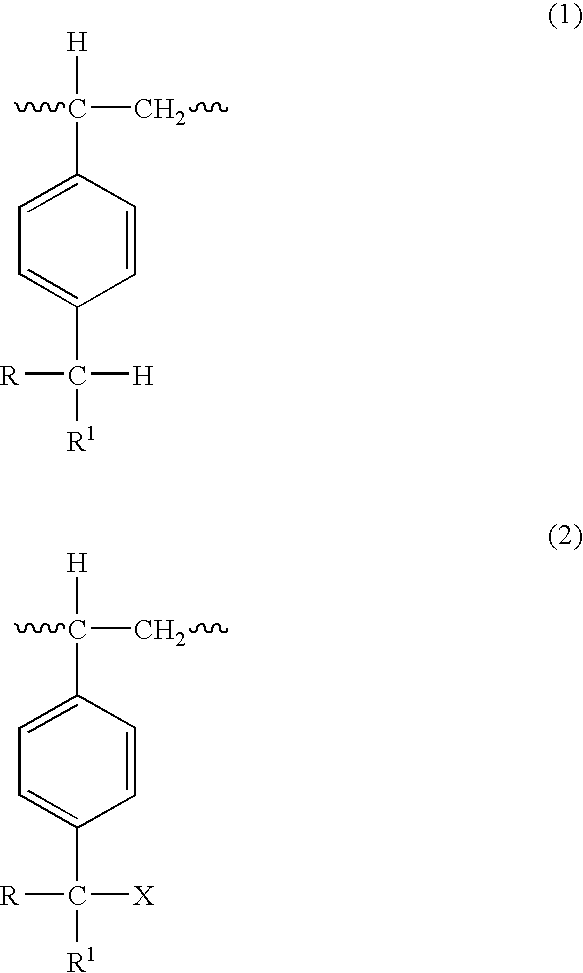

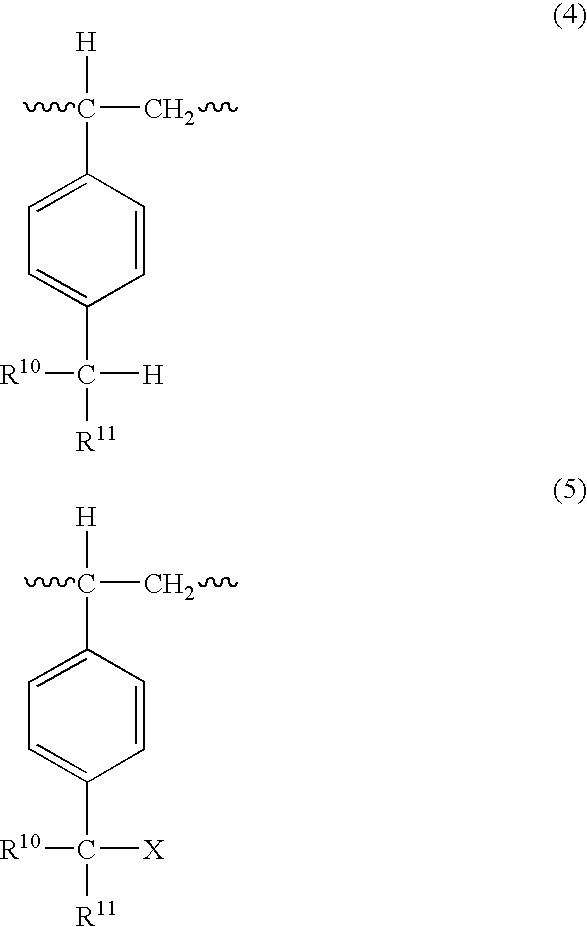

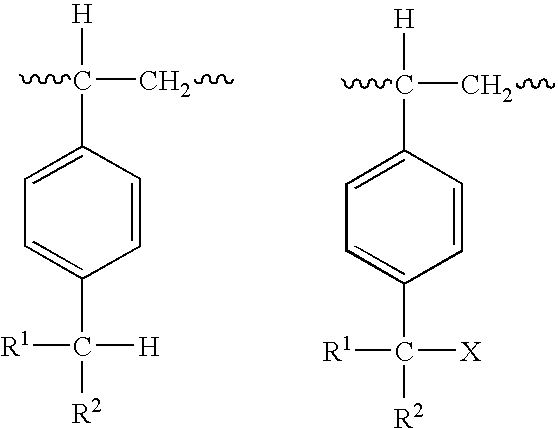

Functionalized elastomer nanocomposite

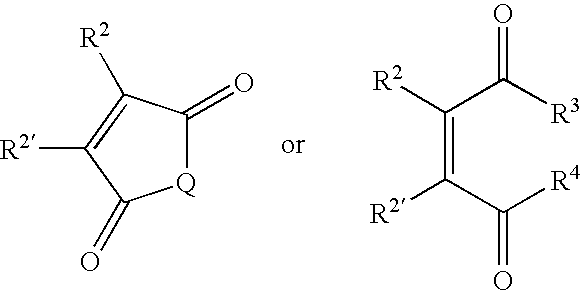

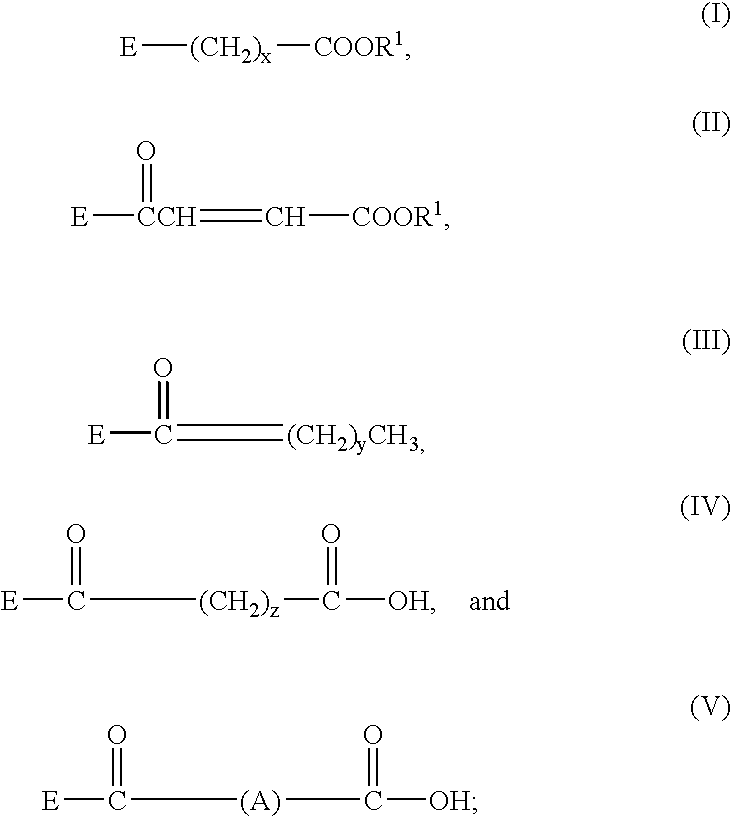

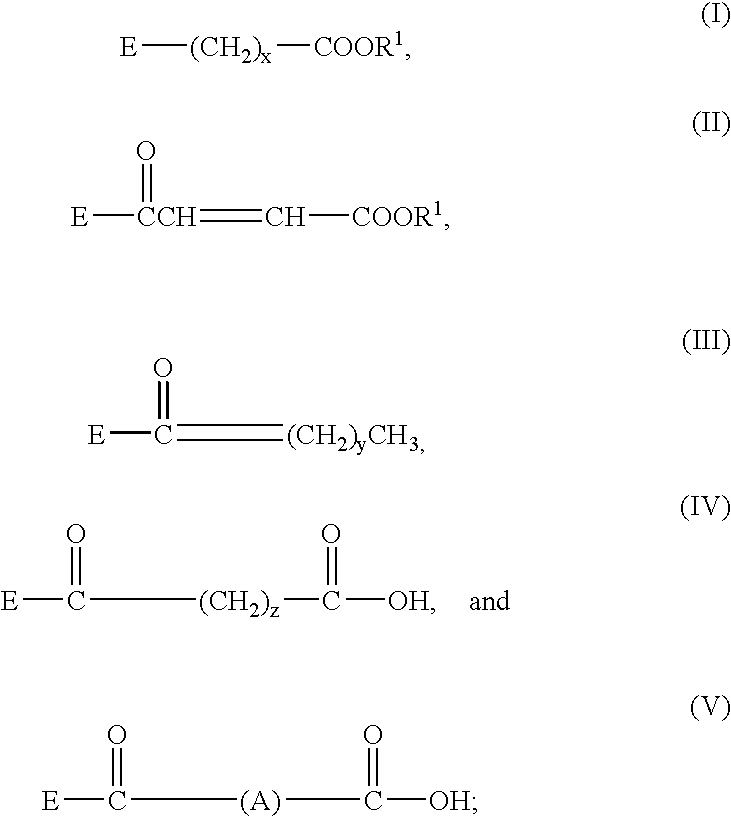

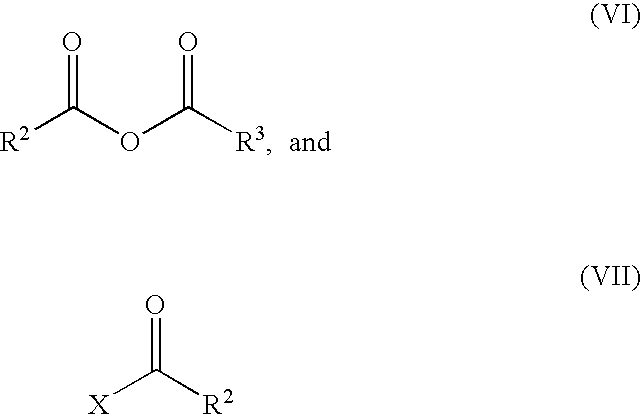

ActiveUS20060100339A1Improve air tightnessPigmenting treatmentMaterial nanotechnologyElastomerGeneral purpose

An embodiment of the present invention is a nanocomposite comprising a clay and an elastomer comprising at least C2 to C10 olefin derived units; wherein the elastomer also comprises functionalized monomer units pendant to the elastomer. Desirable embodiments of the elastomer include poly(isobutylene-co-p-alkylstyrene) elastomers and poly(isobutylene-co-isoprene) elastomers, which are functionalized by reacting free radical generating agents and unsaturated carboxylic acids, unsaturated esters, unsaturated imides, and the like, with the elastomer. The clay is exfoliated in one embodiment by the addition of exfoliating agents such as alkyl amines and silanes to the clay. The composition can include secondary rubbers such as general purpose rubbers, and curatives, fillers, and the like. The nanocomposites of the invention have improved air barrier properties such as are useful for tire innerliners and innertubes.

Owner:EXXONMOBIL CHEM PAT INC

Spray applied building wrap coating material, spray applied building wrap, and building construction assembly

A spray applied building construction coating material forms a waterproofing, water vapor permeable, air barrier, building wrap coating layer between an exterior facing surface of a building sheathing layer and an interior facing surface of an exterior building cladding layer. A building construction assembly is formed by spray coating the exterior surface of the sheathing layer with the coating material or by spray coating gaps in the sheathing layer with the coating material and spray coating the exterior surface of the sheathing layer and previously coated gaps in the sheathing layer with a second coat of the coating material and applying an exterior cladding layer over the coating layer(s). For most applications, the coating material is formulated or includes additives whereby it solidifies on the sheathing to form a coating layer that has an exterior facing, textured surface. This exterior facing, textured surface provides passages between the exterior facing surface of the coating layer and an interior facing surface of the exterior cladding layer for draining water from between and permitting air flow between the exterior facing surface of the coating layer and the interior facing surface of the exterior cladding layer.

Owner:JOHNS MANVILLE CORP

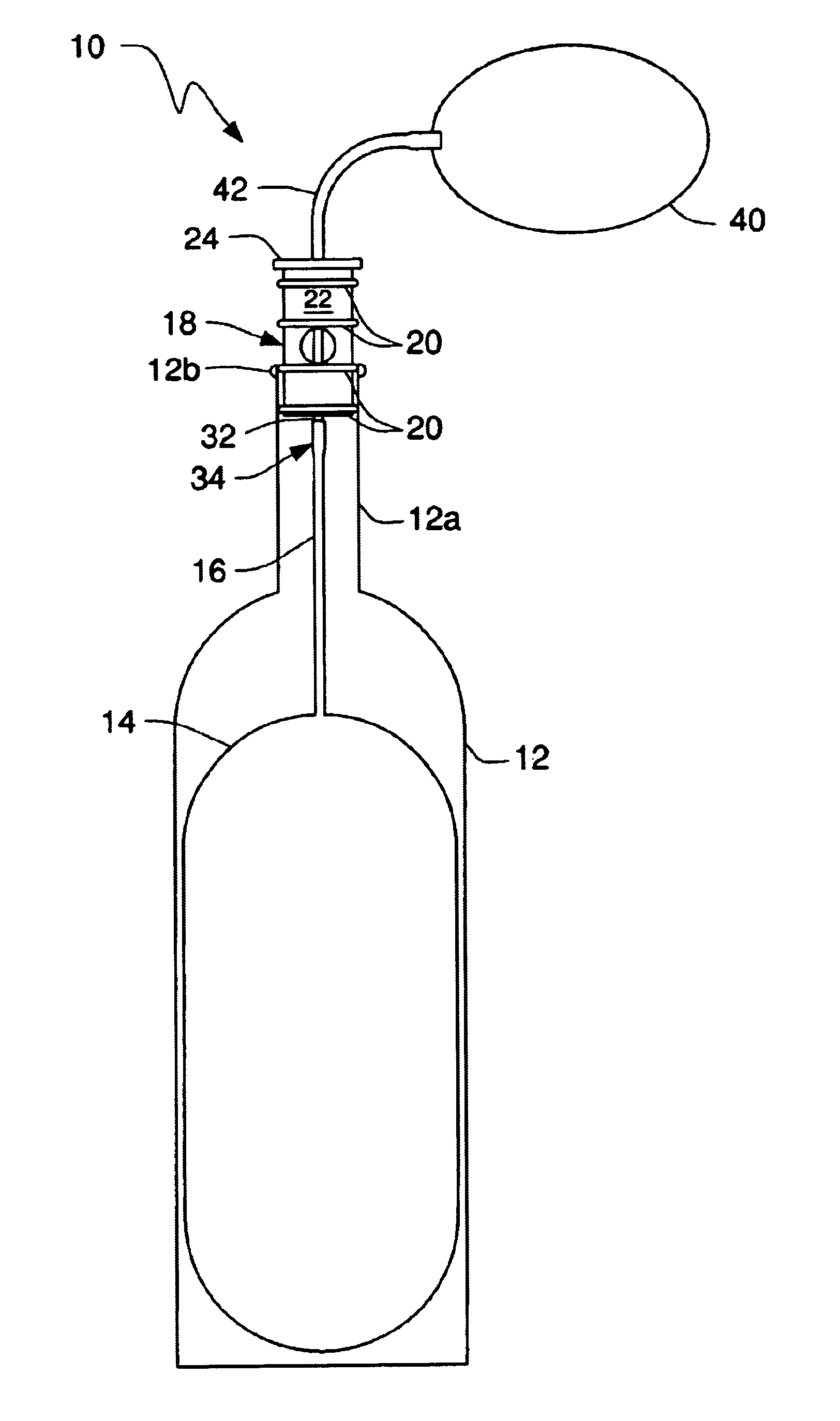

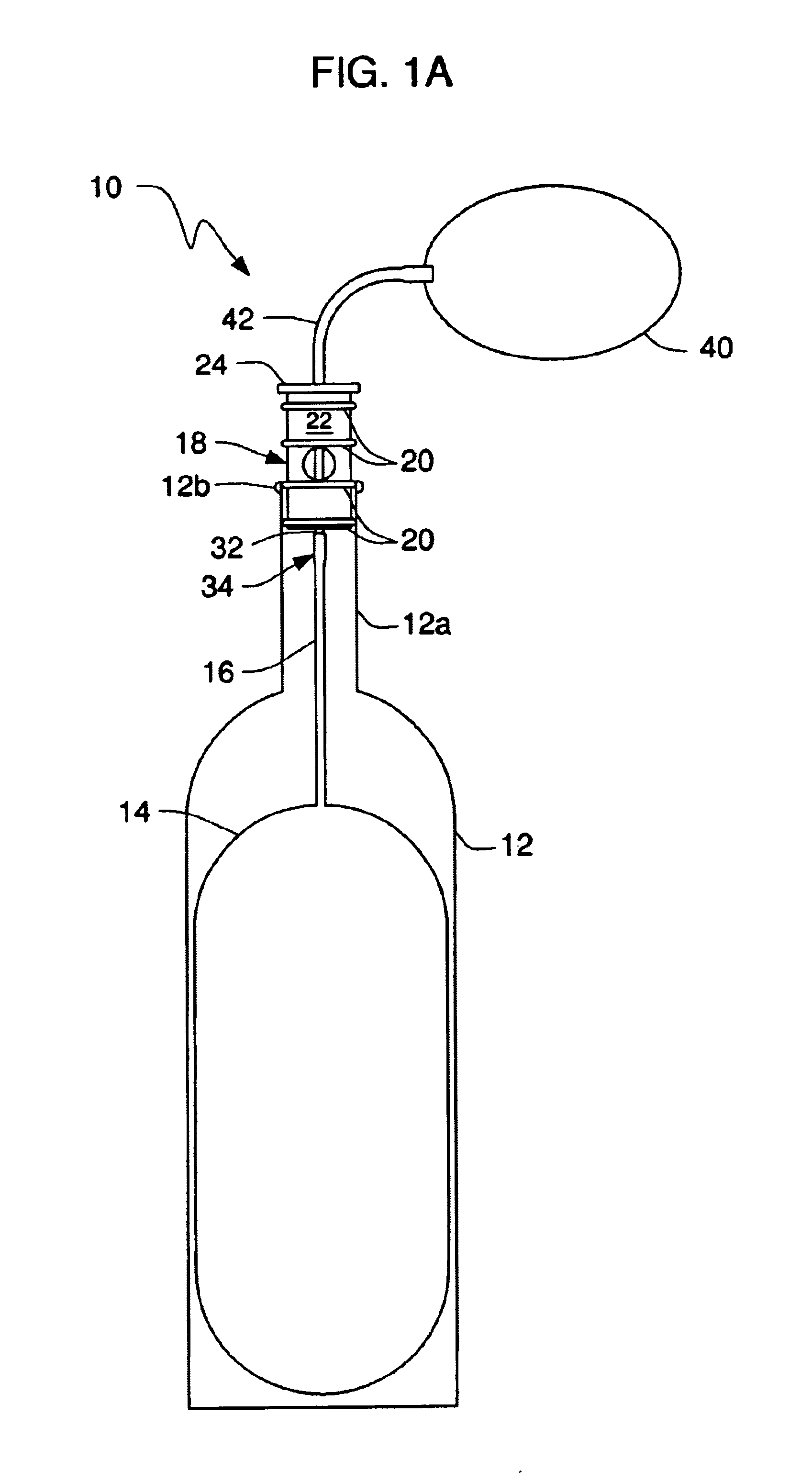

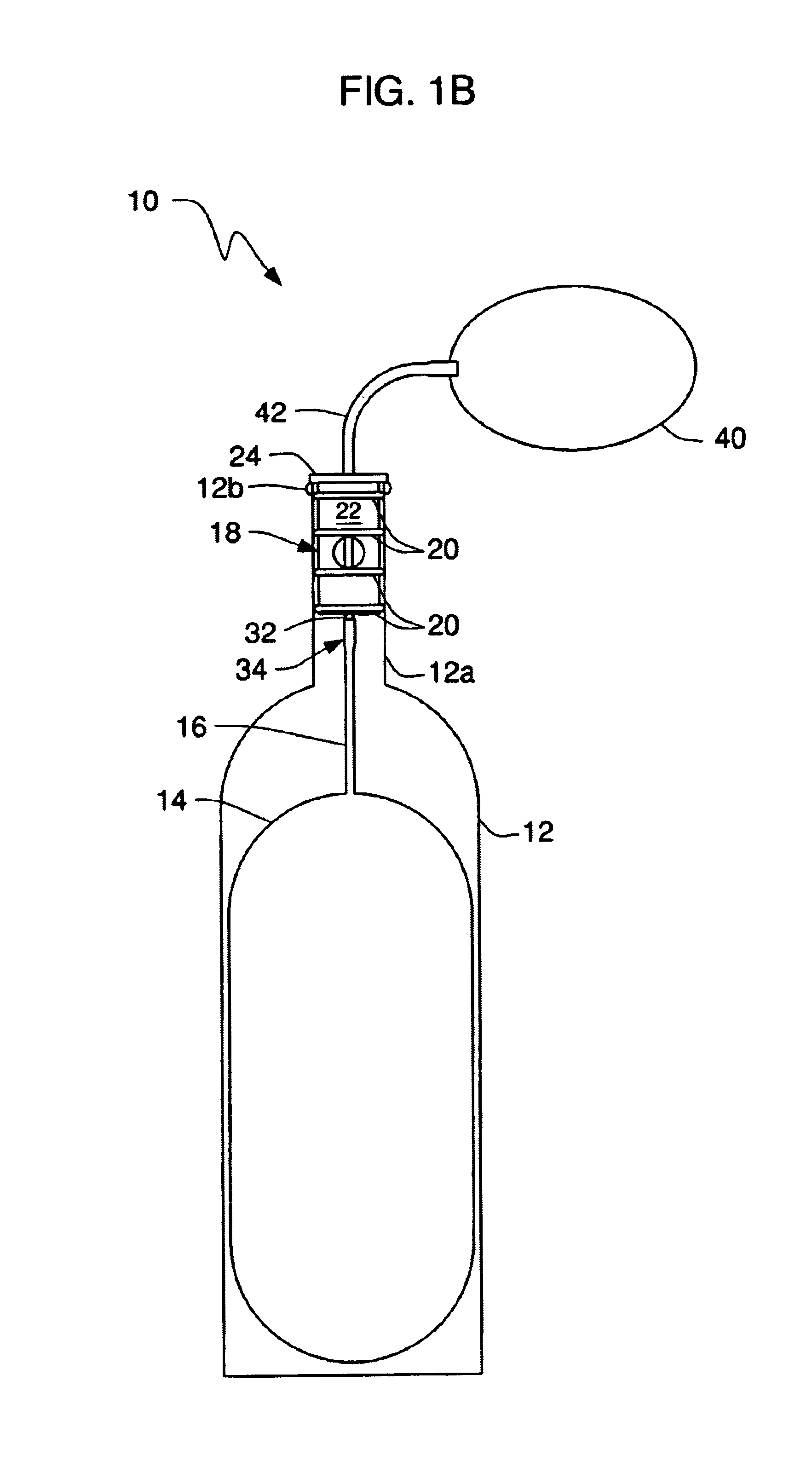

Air barrier device for protecting liquid fluids in opened containers

InactiveUS7051901B2Improve the level ofSimple processOpening closed containersBottle/container closureForced-airEngineering

A device inhibits oxidation of wine remaining in a bottle. A stopper and an inflatable bladder replace the cork. In a first embodiment, a wine duct formed in the stopper is open when the stopper is in an extended position and is closed when the stopper is retracted. Air displaces but does not contact the wine by filling the bladder through an air duct formed in the stopper. After decanting, air that seeps into the wine chamber is removed by forcing air into the bladder, using an external hand pump inserted into the air duct. When sufficient air is pumped into the bladder to raise the wine level to contact the stopper, the stopper is placed into its retracted position. In an additional embodiment, a valve controls opening and closing of the wine duct and the stopper has no extended and retracted position.

Owner:HICKERT PAUL R

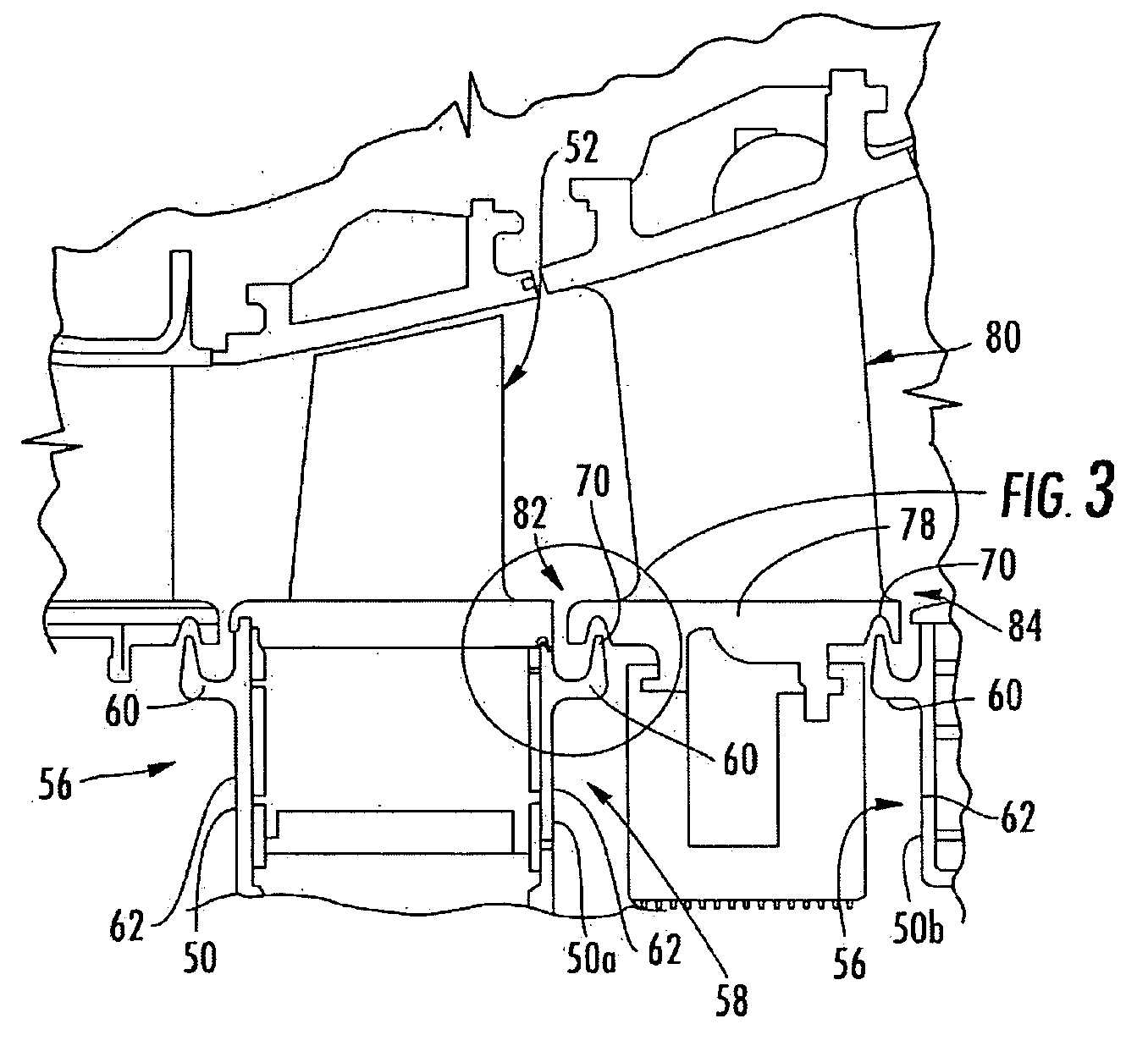

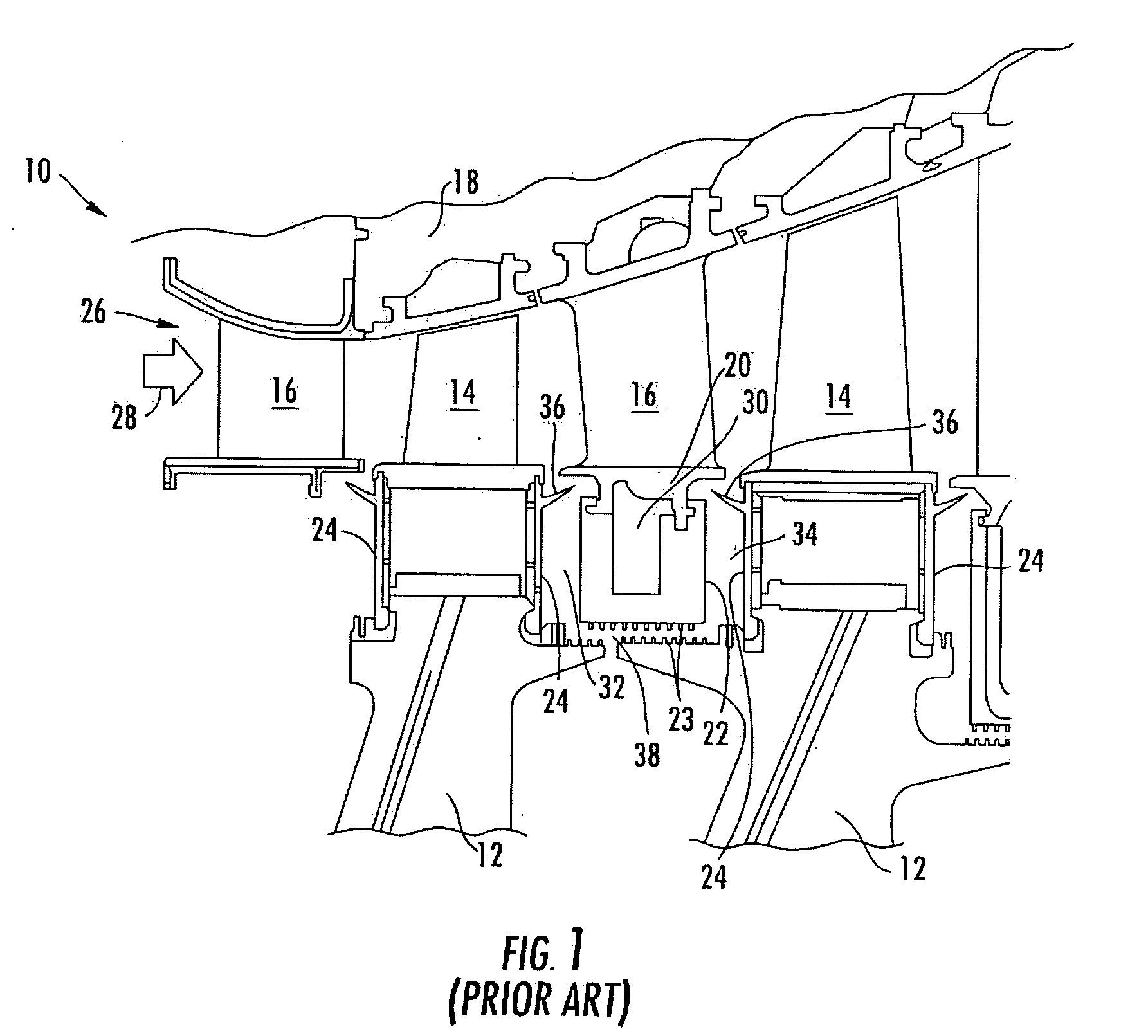

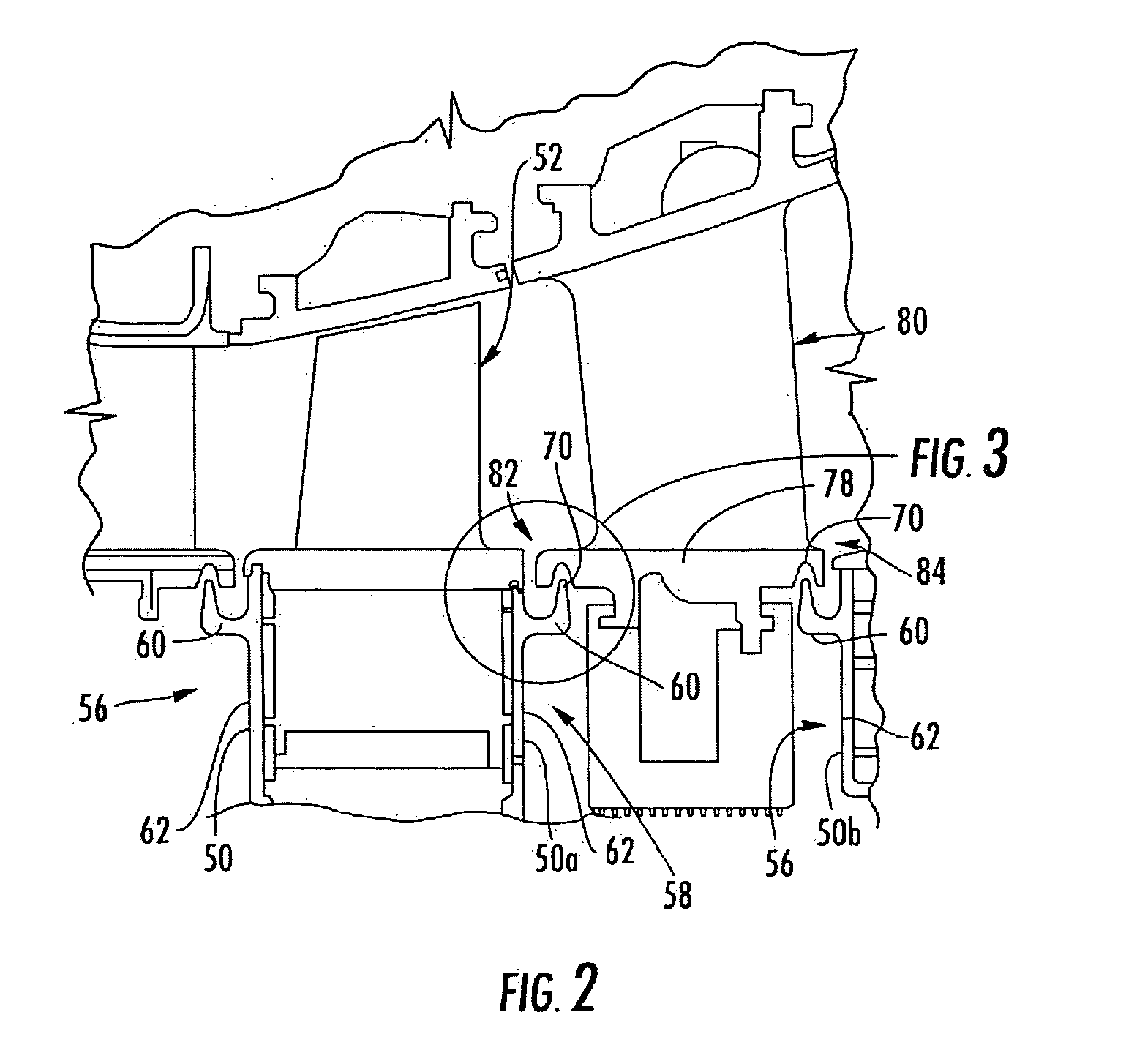

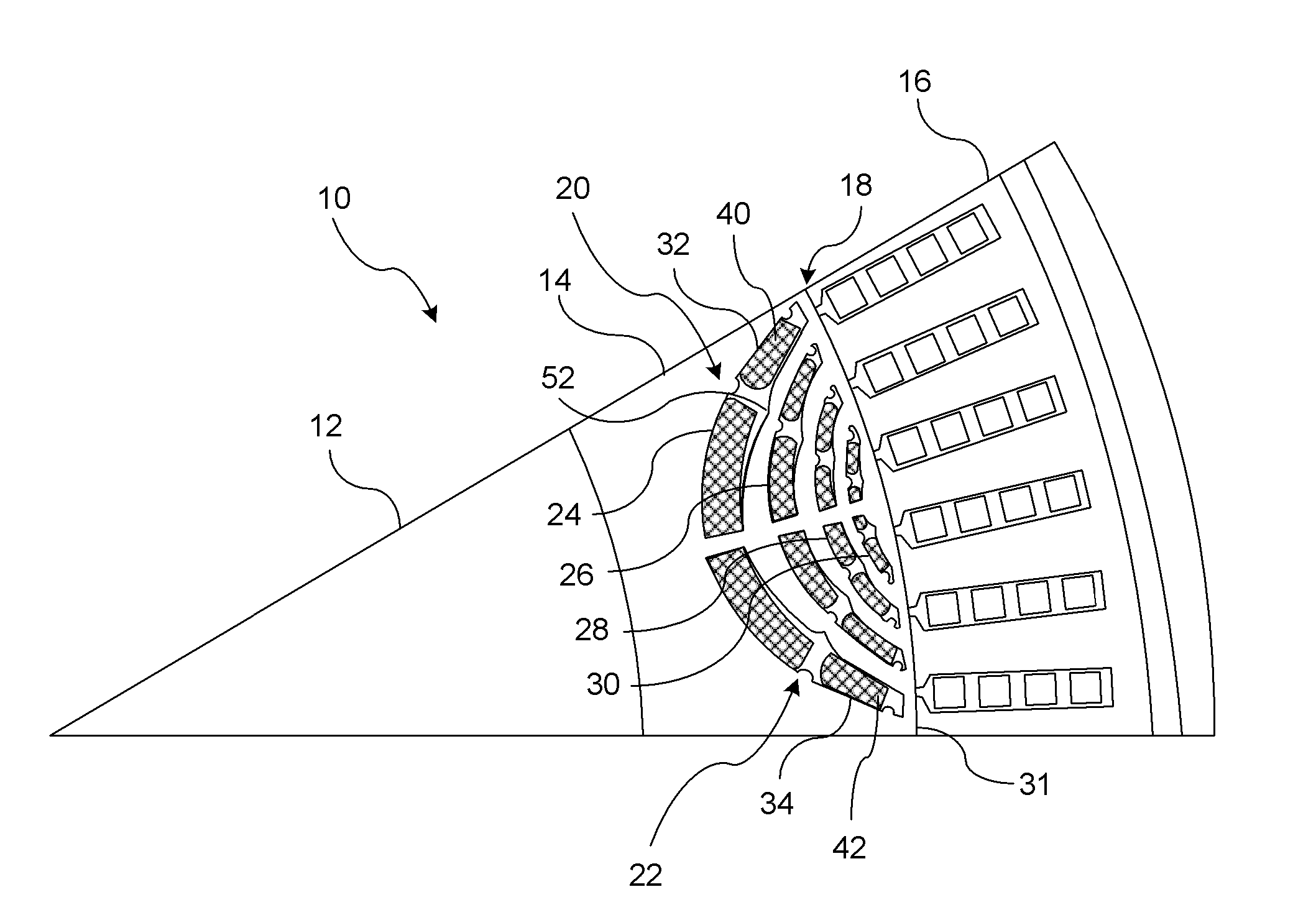

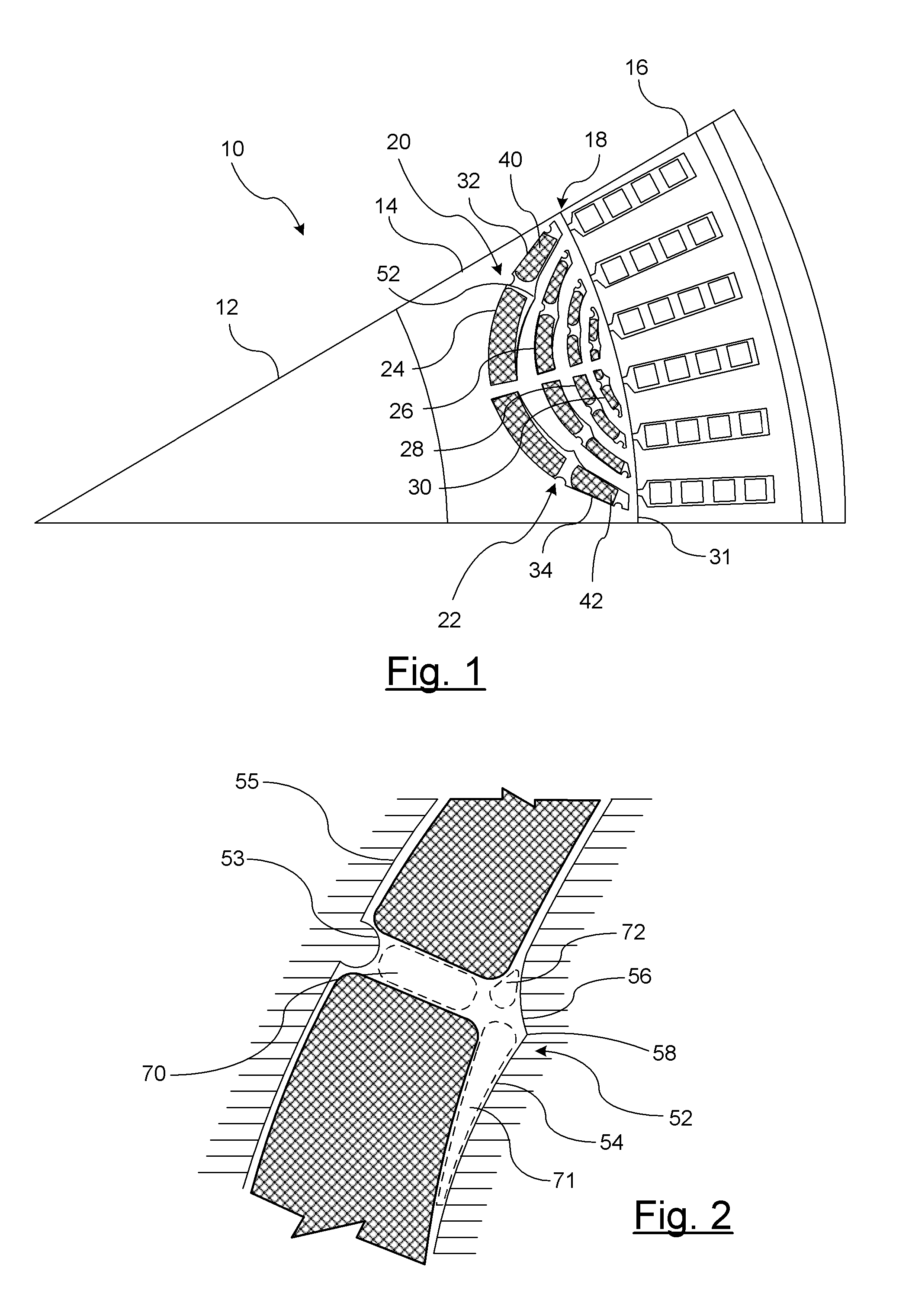

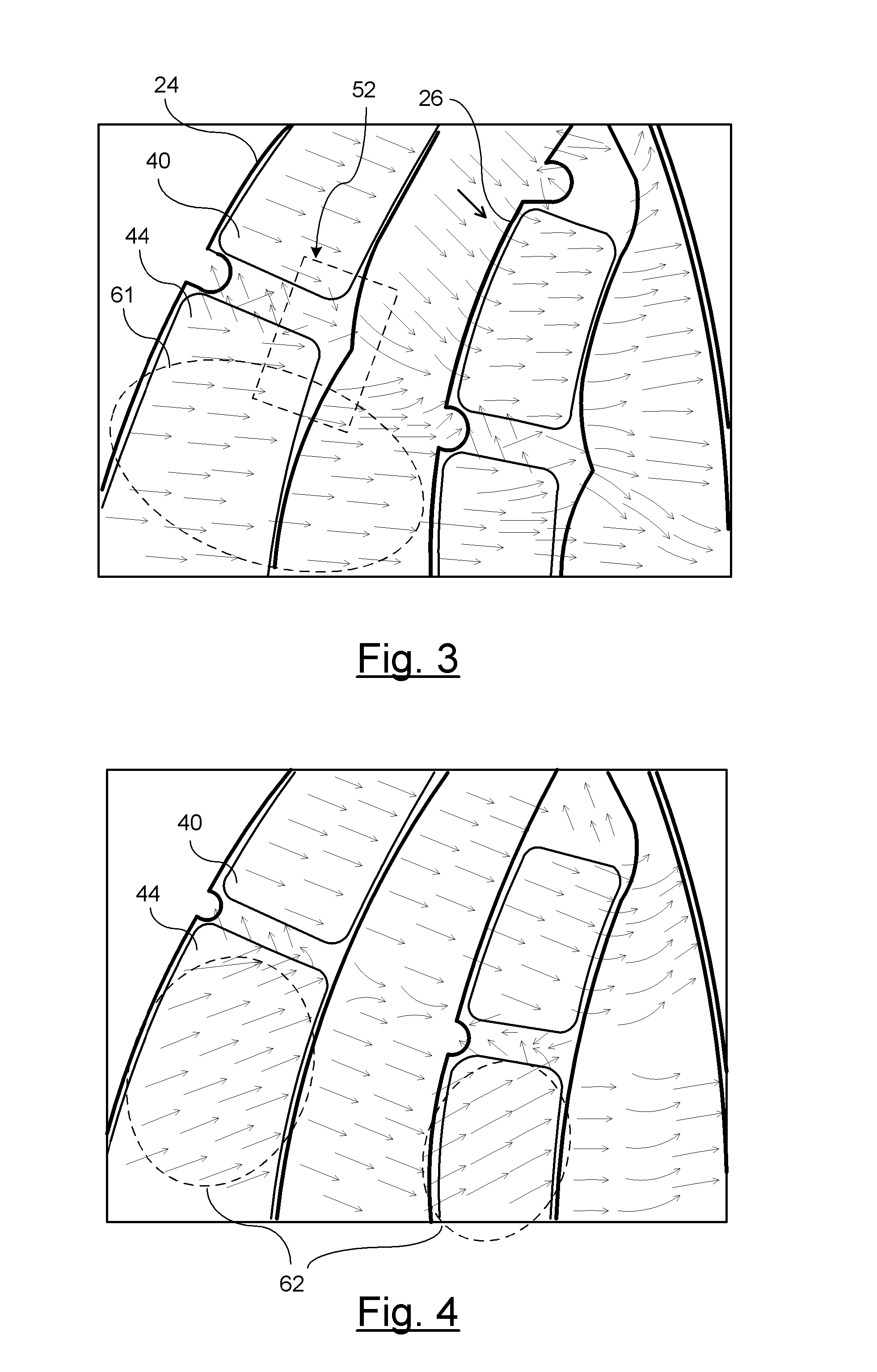

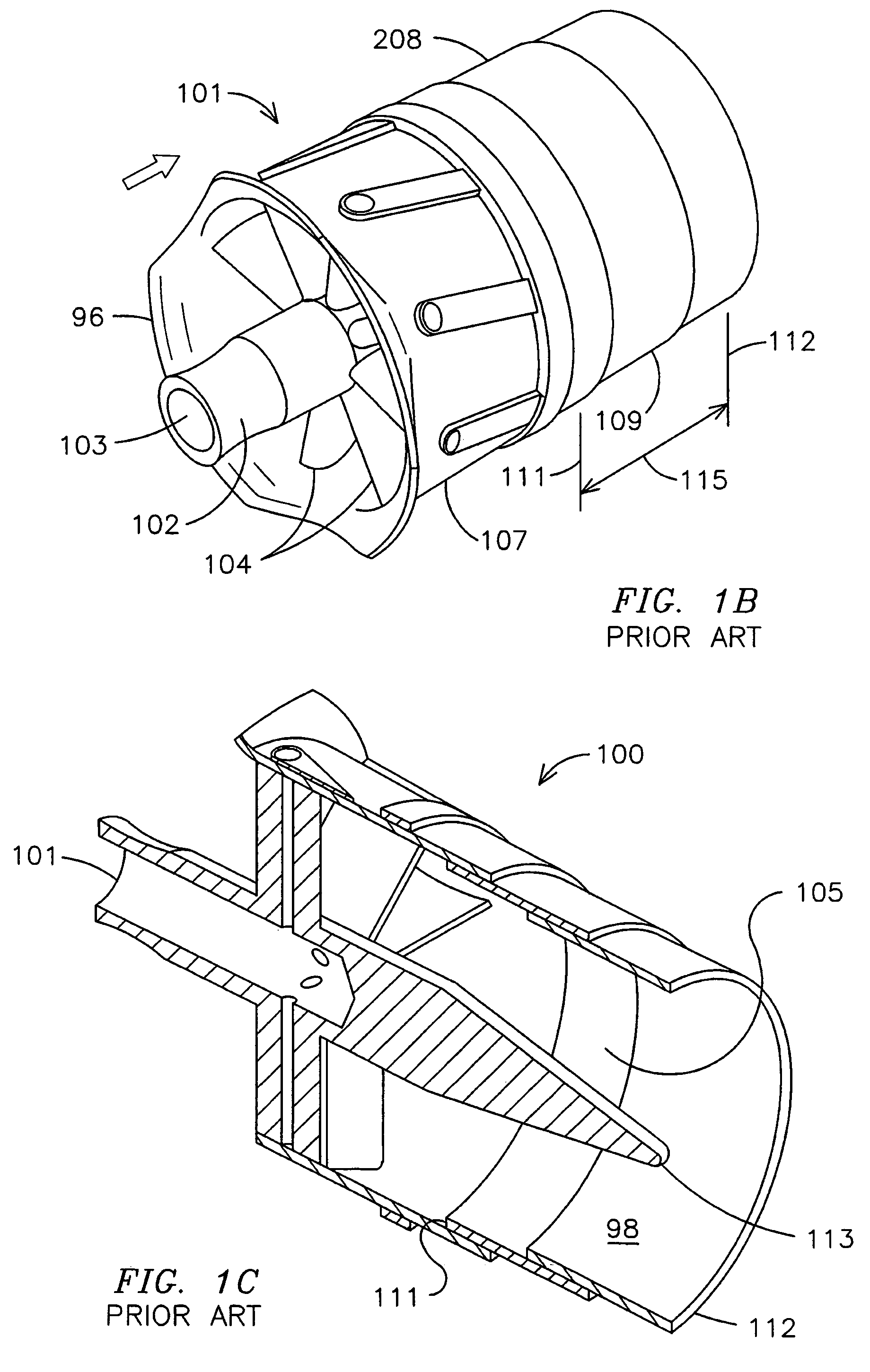

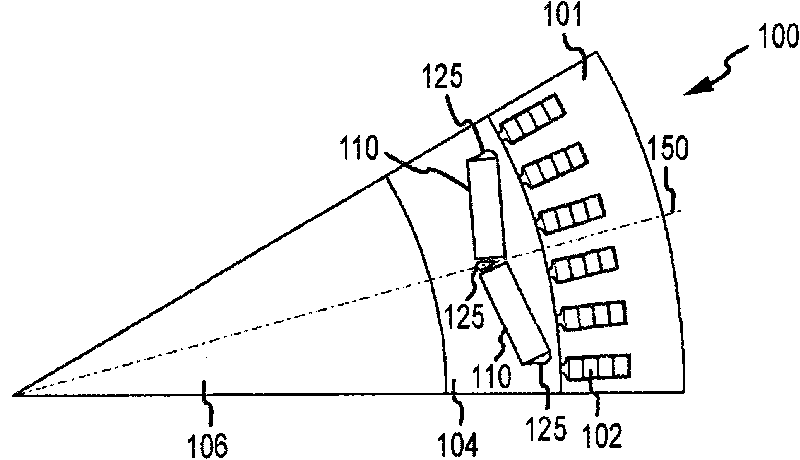

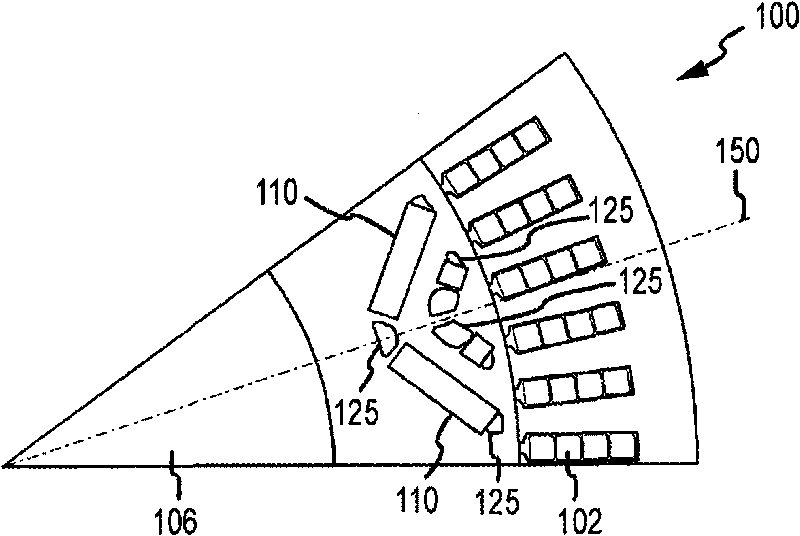

Fluidic rim seal system for turbine engines

InactiveUS20100183426A1Ingestion of hot gasMinimize hot gas ingestionEngine sealsPump componentsTurbineAir barrier

A fluidic rim seal system can be provided between a neighboring stationary and rotatable components in the turbine section of a turbine engine. For instance, the stationary component can be an inner shroud associated with a vane. The inner shroud can include a groove that extends circumferentially about the shroud. The rotatable component can be a blade cover plate. The blade cover plate can include a protrusion that culminates at a tip. One or more passages can extend through the protrusion. The passages can have an inlet in fluid communication with a coolant source and an outlet at the tip. A tip region of the protrusion is received in the groove. During engine operation, an air barrier is formed in the groove by the air discharging from the outlet. This air also provides cooling to the protrusion as well as a portion of the inner shroud.

Owner:SIEMENS ENERGY INC

Fire Retardant Coating Composition

ActiveUS20170029632A1Minimizing fire spreadFireproof paintsConjugated diene hydrocarbon coatingsPolystyreneGraphite

A fire retardant, vapor impermeable coating composition is disclosed which is useful for protecting gypsum, wood, polyurethane, polystyrene, and other construction materials and surfaces, such as components for buildings. The composition does not require halogenated compounds and is considered environmentally friendly. The composition is provided in the form of a liquid-applicable aqueous latex comprising at least one latex polymer and an expandable graphite, optionally a hydrophobic thickener, and optionally other fire retardants such as metal hydroxides, wherein the polymer is selected such that the composition, when coated onto a substrate and allowed to dry, has a vapor permeability not exceeding one perm (5.70×10−8 g / Pa.s.m2 when tested according to ASTM E96B-10 at an average dry film thickness of 40 mils). The invention provides fire retardant air barrier layers for construction materials, such as polyurethane or polystyrene insulation beads or panels, as well as vapor impermeable laminates for construction applications.

Owner:GCP APPL TECH INC

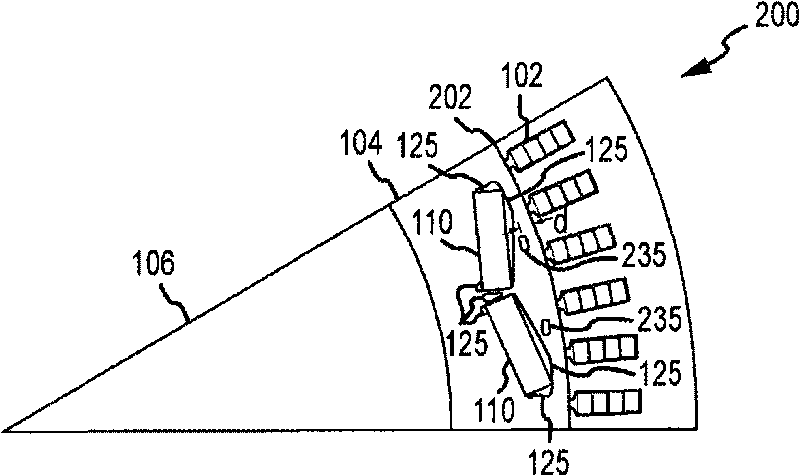

Magnetic barrier for minimizing demagnetization in bi-permanent magnet synchronous machines

ActiveUS20130320797A1Low costReduce in quantityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic barrierPermanent magnet synchronous machine

A rotor for a permanent synchronous machine includes a rotor having a plurality of arcuately-shaped cavities formed within a rotor core structure. The plurality of arcuately-shaped cavities substantially concentrically layered with respect to an outer cylindrical wall of the rotor core structure. A plurality of permanent magnets is inserted within the plurality of arcuately-shaped cavities. Each cavity layer retains a permanent magnet of a first magnetic field strength disposed in end sections and a permanent magnet of a second magnetic field strength in a center section of each cavity layer. Each respective cavity includes an air barrier formed between the magnets having different magnetic field strengths. The air barrier generates a reluctance within an air barrier gap for directing a flow of flux generated by each third permanent magnet in a preceding layer in a direction toward each third permanent magnet in a succeeding layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

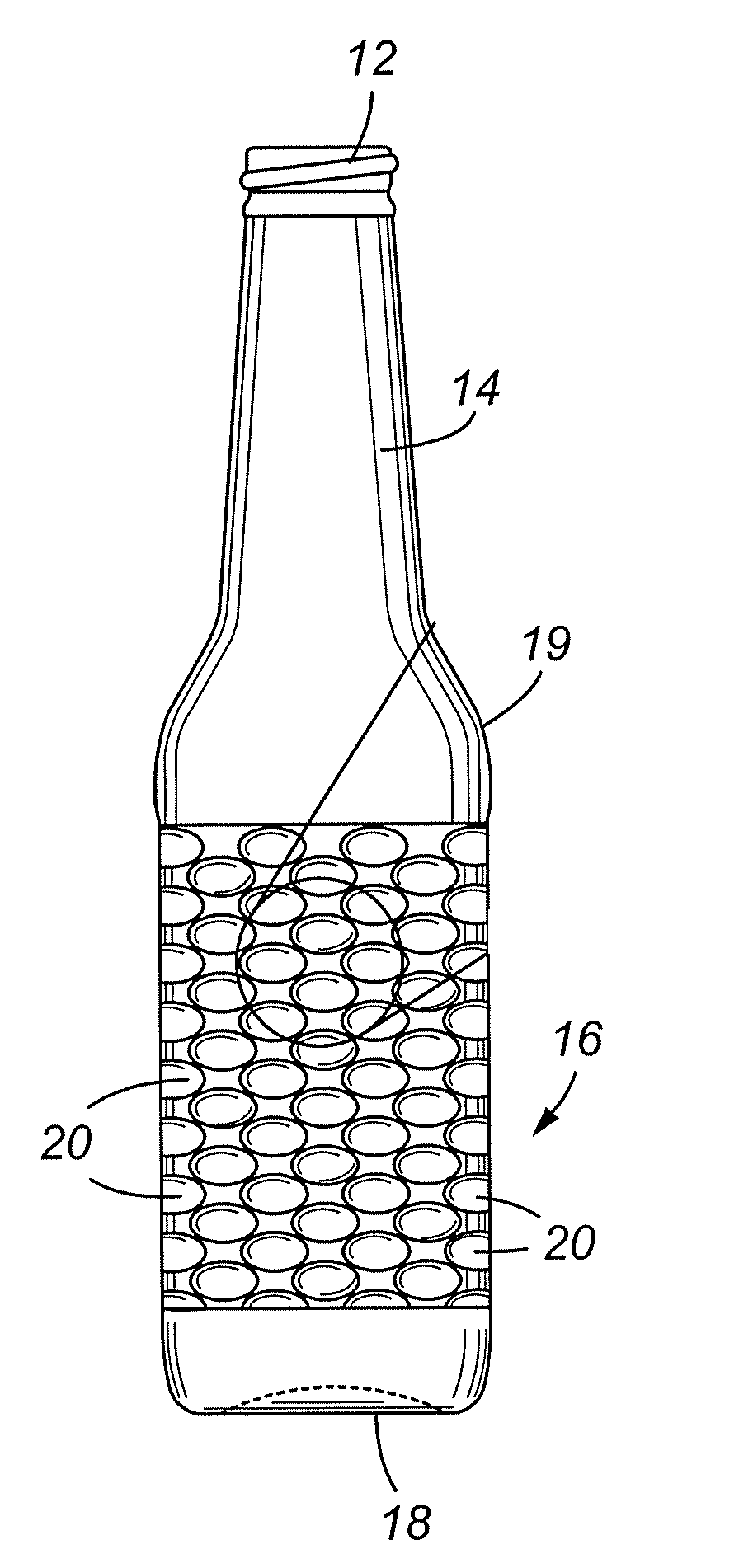

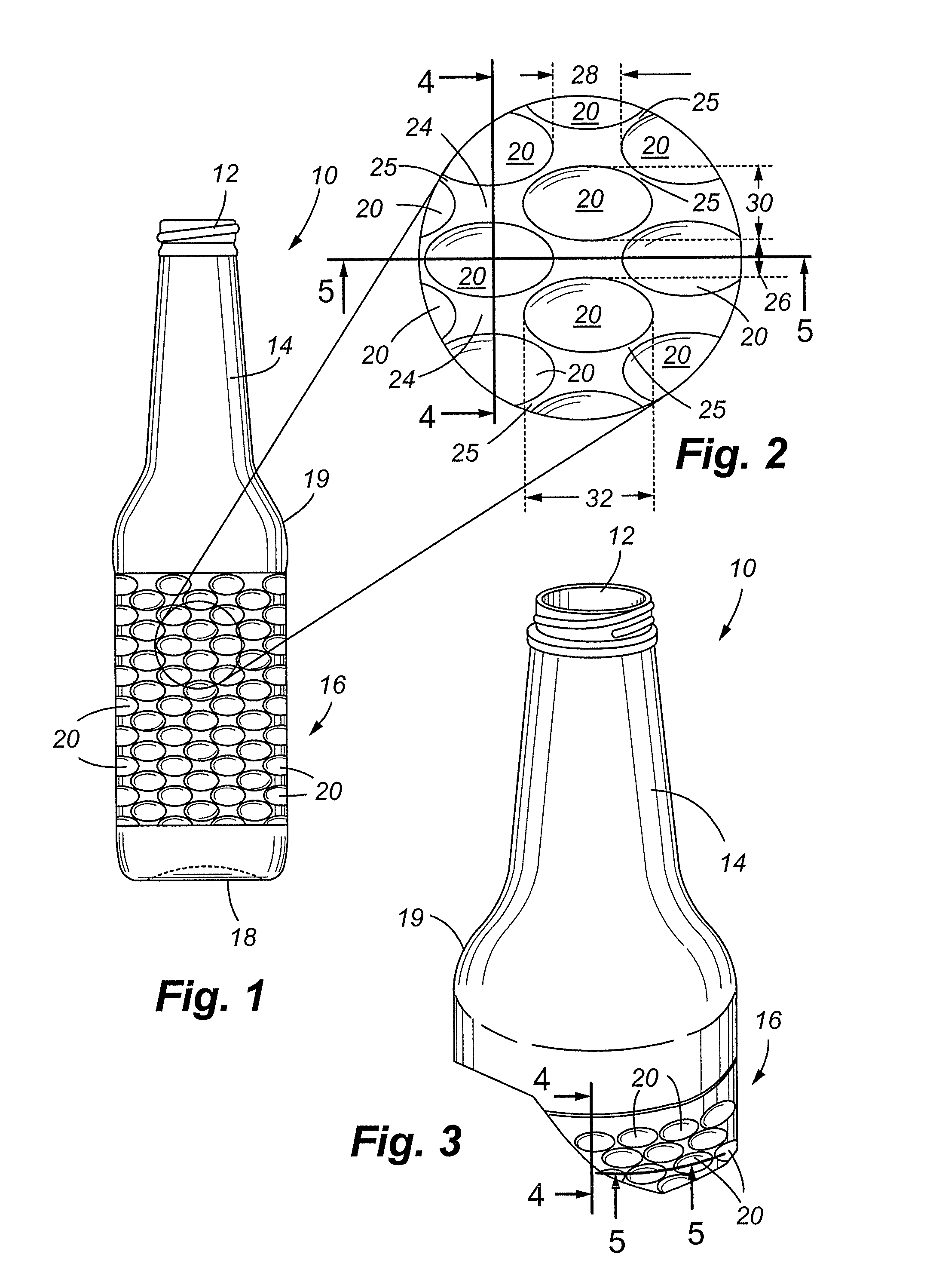

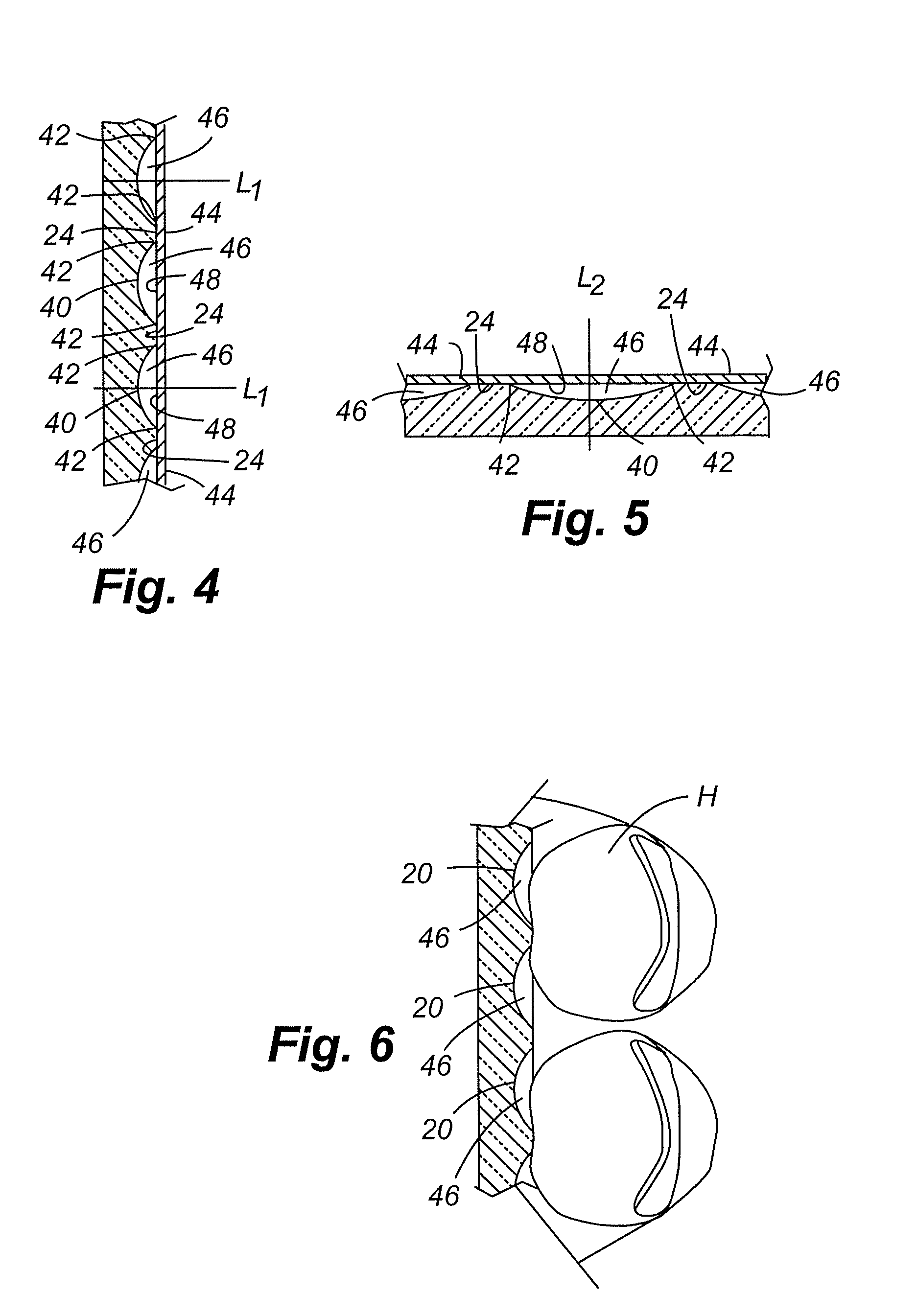

Container With Multiple Surface Depressions for Enhancing Insulative Properties

InactiveUS20080110853A1Volume maximizationImprove insulation performanceBottlesLarge containersAir barrierBiomedical engineering

A container is provided with multiple surface depressions for enhancing the insulative properties of the container. The surface depressions are tightly grouped, and a label placed over the surface depressions results in a greater surface area of the label that is suspended over the depressions as compared to a surface area of the label that is in contact with the exterior surface of the container. The air gaps or chambers defining the space between the applied label and the surfaces of the depressions provides an insulating air barrier to better maintain the beverage in the container at a desired temperature. The surface depressions may also be used alone without a label to provide insulative benefits. The surface depressions may be spaced and sized such that, under normal grasping conditions, the consumer's hand does not penetrate the entire depth of the depressions, and an air barrier is still maintained between the consumer's hand and the exterior surface of the container.

Owner:MILLERCOORS

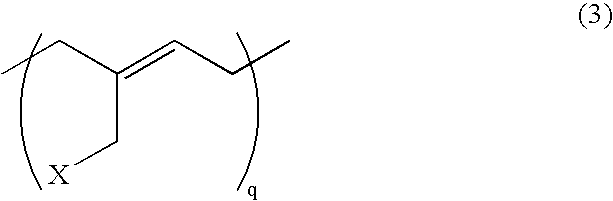

Low permeability nanocomposites

The present invention includes blends of a halogenated elastomer such as a butyl rubber or an interpolymer of, on one embodiment, a C4 to C7 isomonoolefin, a para-methylstyrene and a para-(halomethylstyrene), the interpolymer having been pre-mixed with an exfoliating compound and clay, the entire blend forming a nanocomposite in one embodiment. The clay may or may not have undergone an additional exfoliating treatment prior to blending with the halogenated elastomer. The interpolymer / clay mixture forms a distinct phase in the nanocomposite blend of the invention. The blend of the invention has improved air barrier properties and is suitable as an air barrier.

Owner:EXXONMOBIL CHEM PAT INC

Functionalized isobutylene polymer-inorganic clay nanocomposites and organic-aqueous emulsion process

A nanocomposite of a halogenated elastomer and an inorganic, exfoliated clay, suitable for use as an air barrier, is disclosed. The halogenated elastomer can be a polymer comprising C4 to C7 isoolefin derived units, para-methylstyrene derived units, and para(halomethylstyrene) derived units, or can be a butyl-type rubber. The nanocomposite can be formed by contacting an aqueous slurry of inorganic clay with a polymer cement while agitating vigorously to form emulsions or micro-emulsions to intimately mix the inorganic clay and the elastomer. The nanocomposite so formed has improved air barrier properties and is suitable for use as an innerliner or innertube.

Owner:EXXONMOBIL CHEM PAT INC

Insulated reinforced foam sheathing, reinforced elastomeric vapor permeable air barrier foam panel and method of making and using same

ActiveUS20160069067A1Simple systemVapor permeability can be variedWallsBuilding repairsMetal stripsElastomer

The invention comprises a product. The product comprises a first foam panel having an edge, a first primary surface and an opposite second primary surface and a second foam panel having an edge, a first primary surface and an opposite second primary surface, wherein the first and second foam panels are disposed such that their edges are adjacent each other and define a joint therebetween. The product also comprises an elongate metal strip having a body portion and a projection extending outwardly from the body portion, the metal strip being disposed such that at least a portion of the projection is disposed in the joint between the foam panels and at least a portion of the body portion covers a portion of the second primary surface of the first foam panel and a portion of the second primary surface of the second foam panel. A method of making and using the composite panel is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

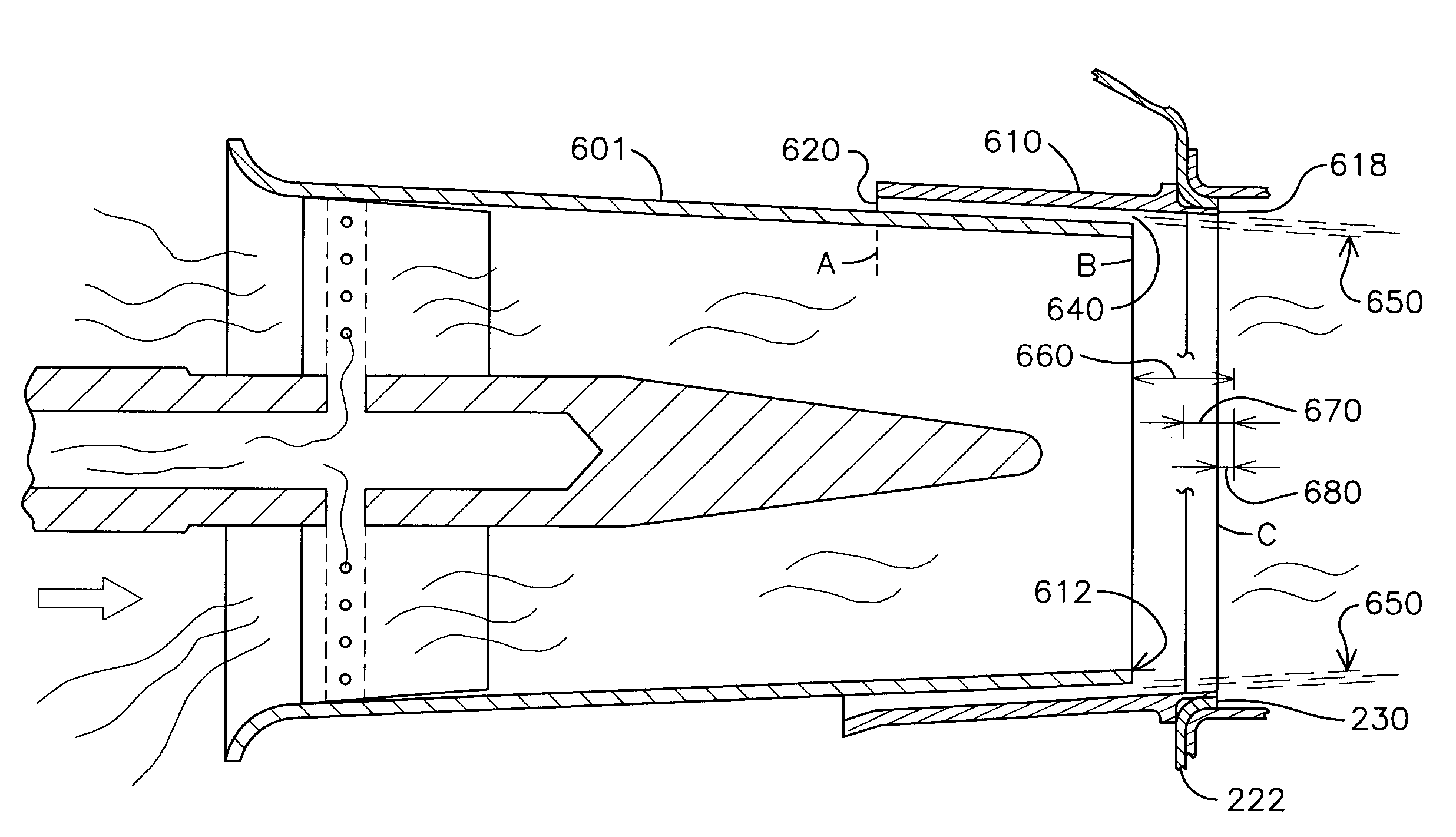

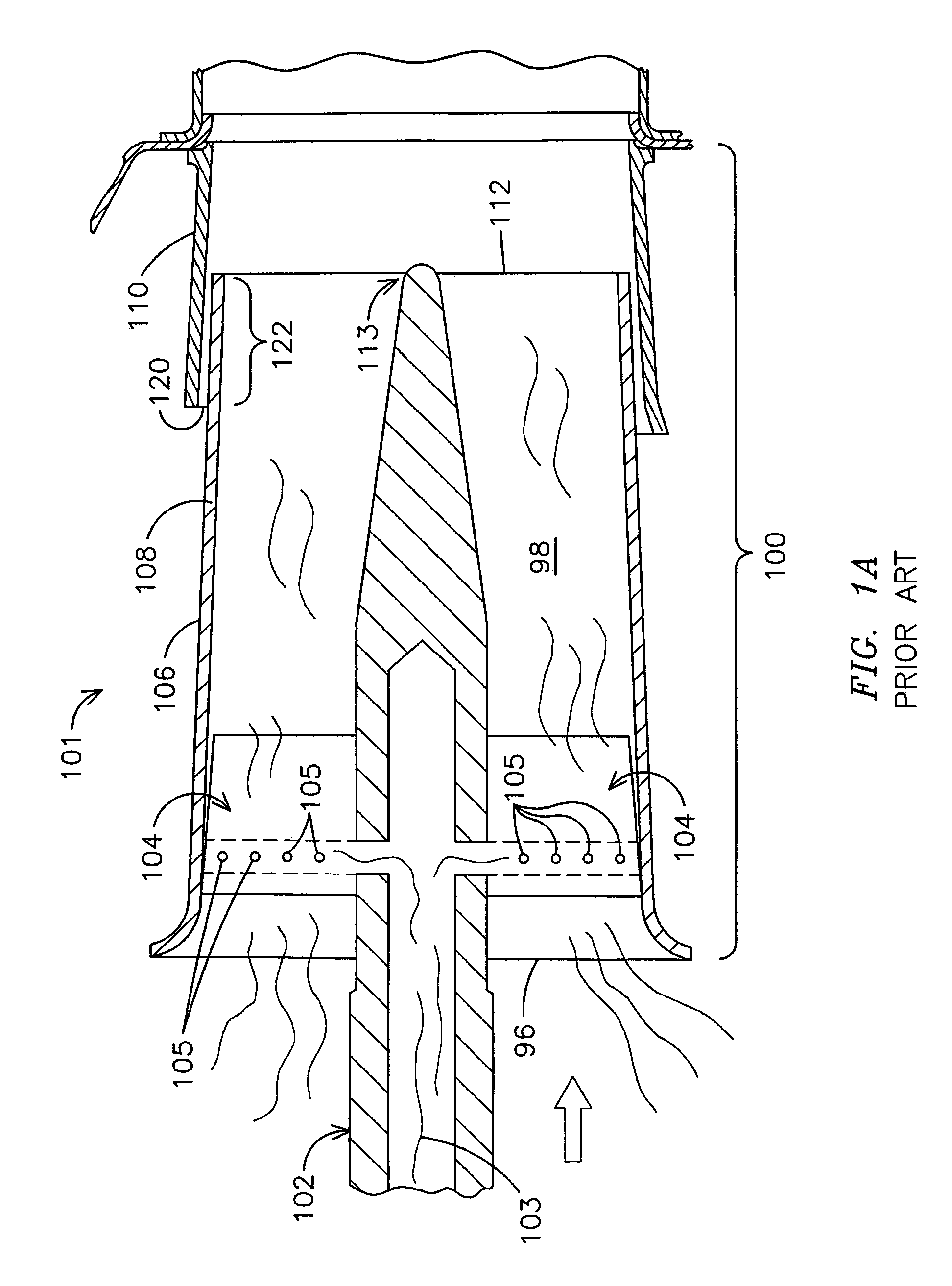

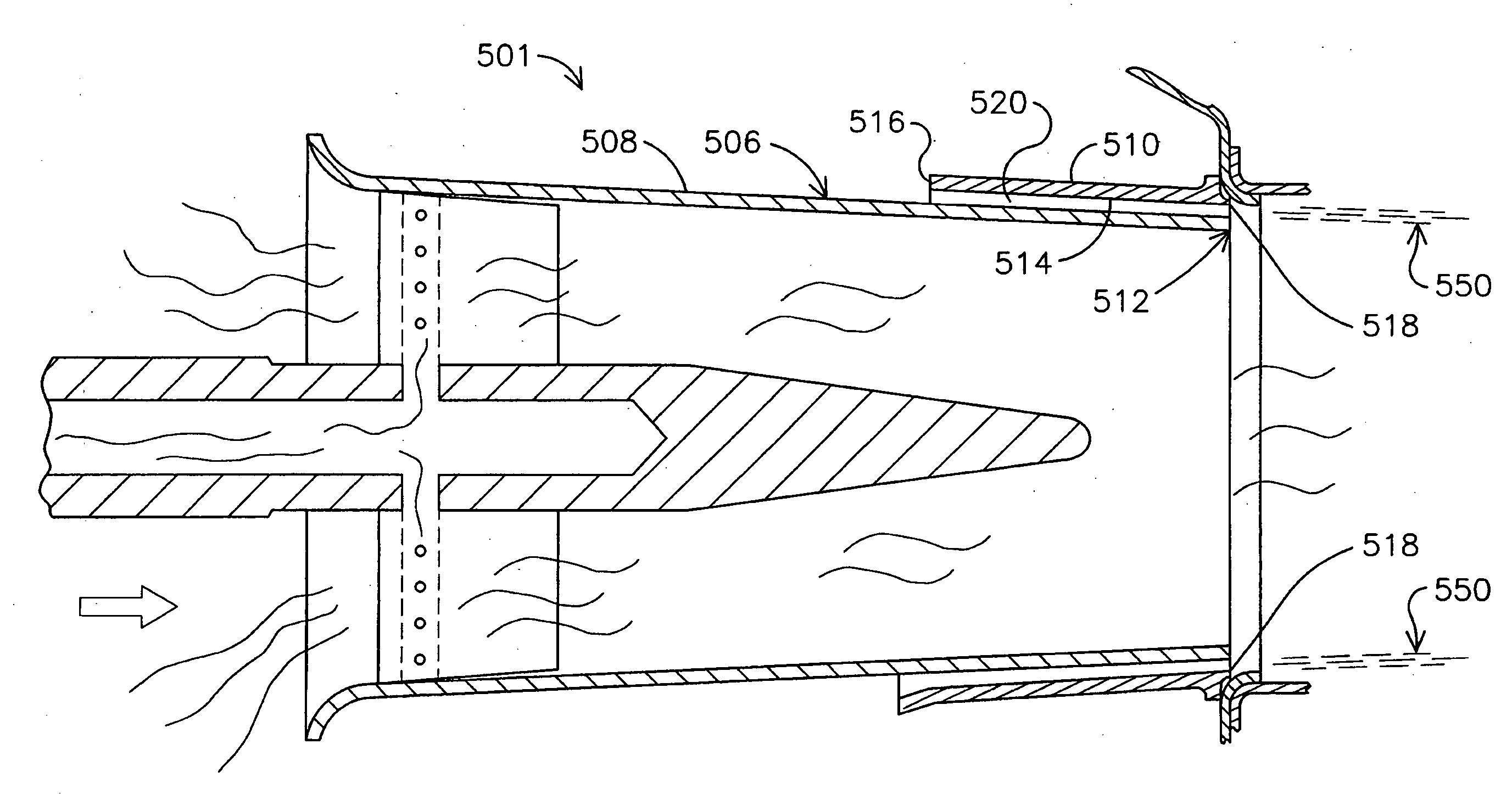

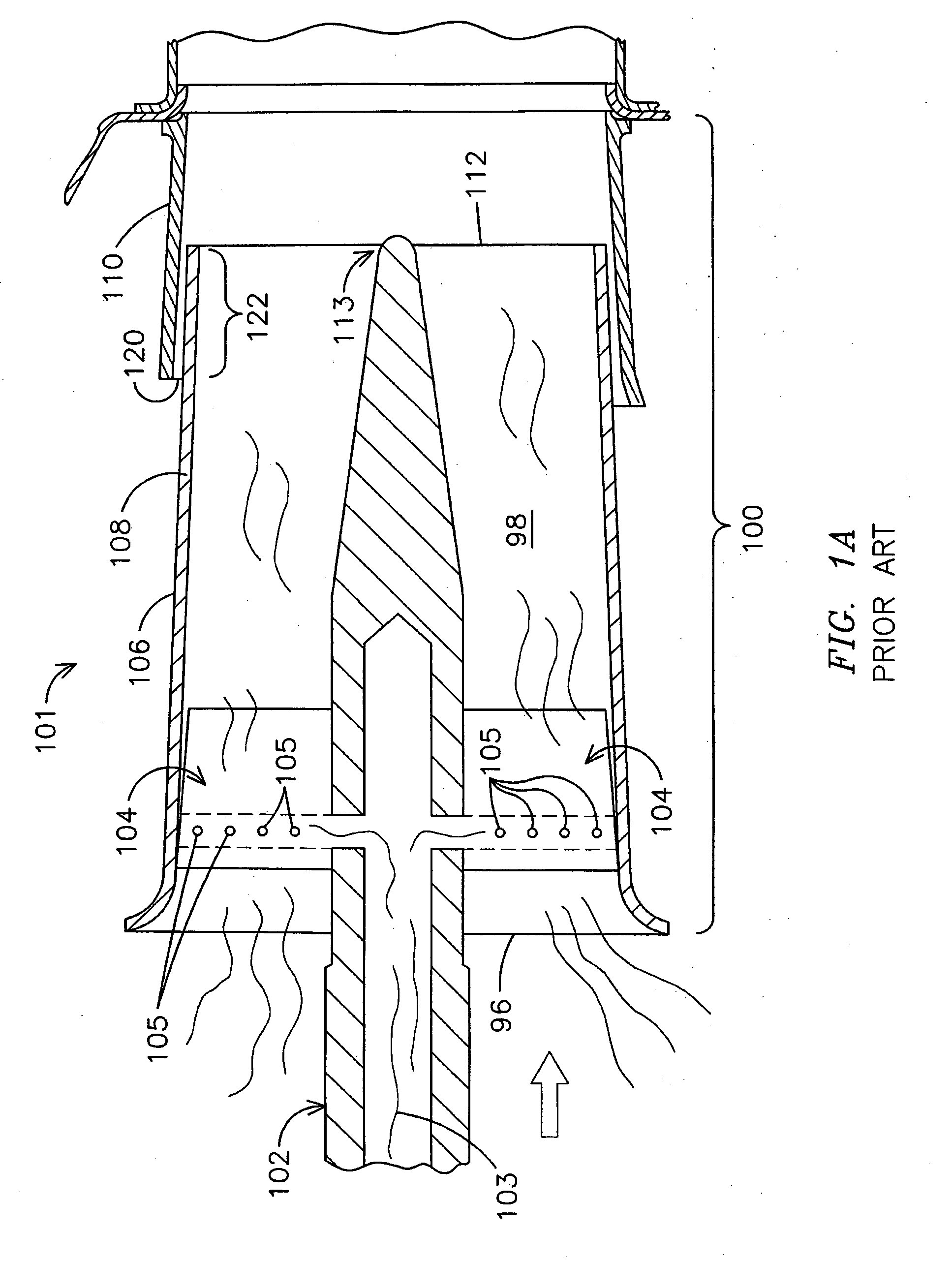

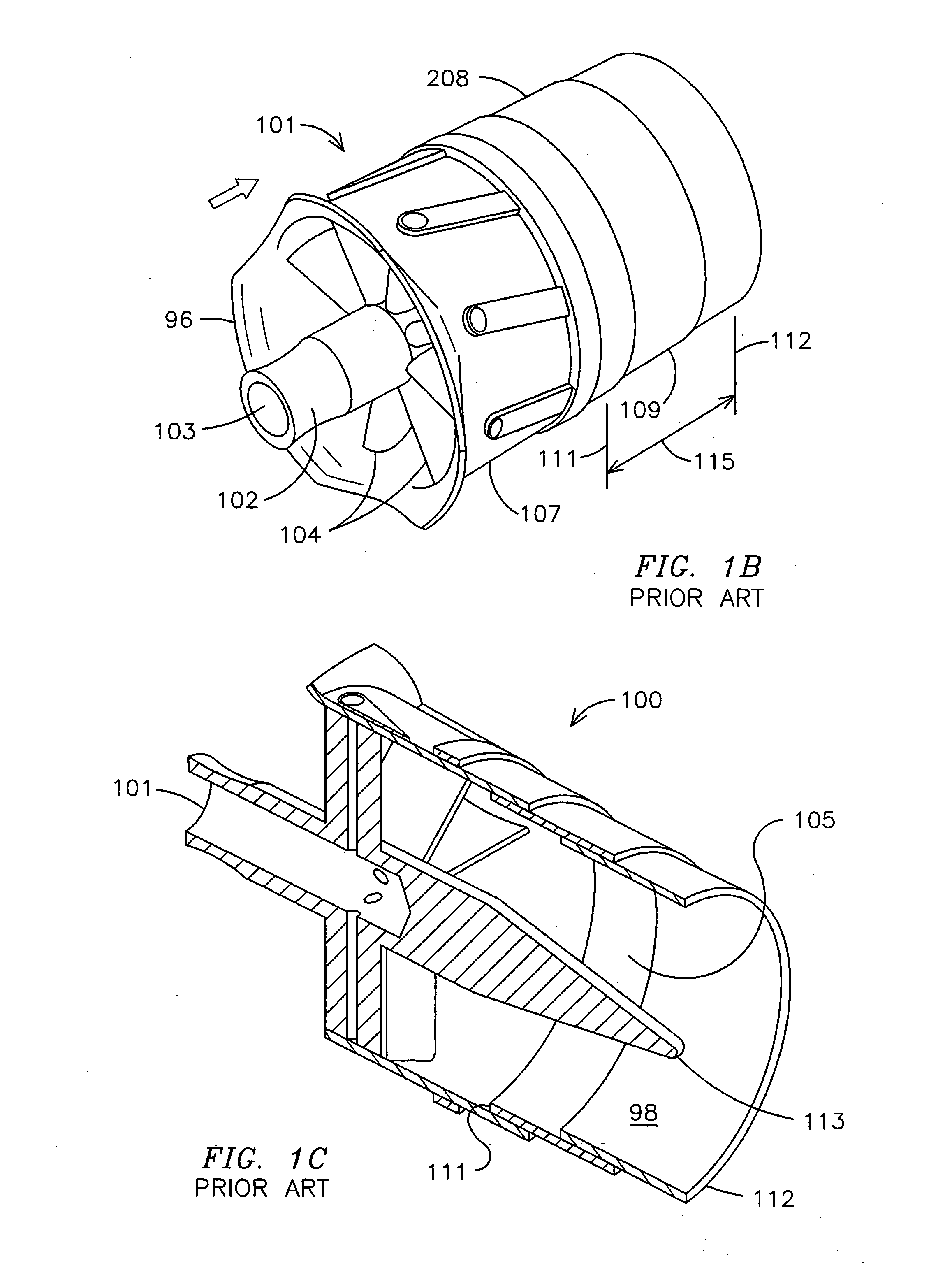

Extended flashback annulus in a gas turbine combustor

An extended flashback annulus (520) is formed between an exterior surface (506) of a shroud or casing (508) associated with a main swirler assembly inner body (500) or other fuel / air mixing device and the inner surface (514) of an annulus casting (510) which are in operational relationship with one another in a gas turbine combustor assembly. The extended flashback annulus (520) is capable of forming an extended protective cylindrical air barrier (550) that extends farther into the combustion zone, this barrier being more robust and providing for the reduction or prevention of flashback to the baseplate and other heat-susceptible upstream components.

Owner:SIEMENS ENERGY INC

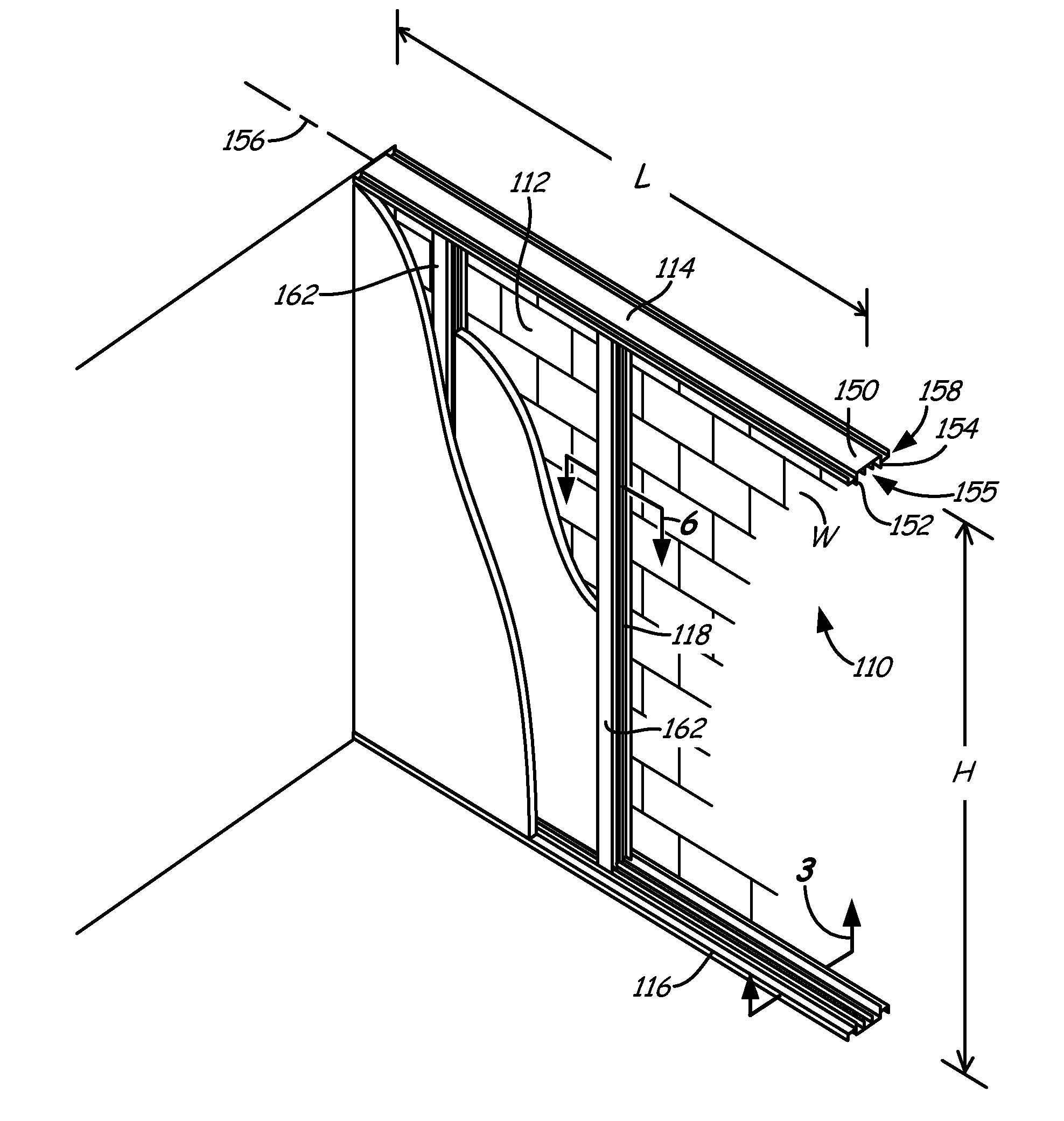

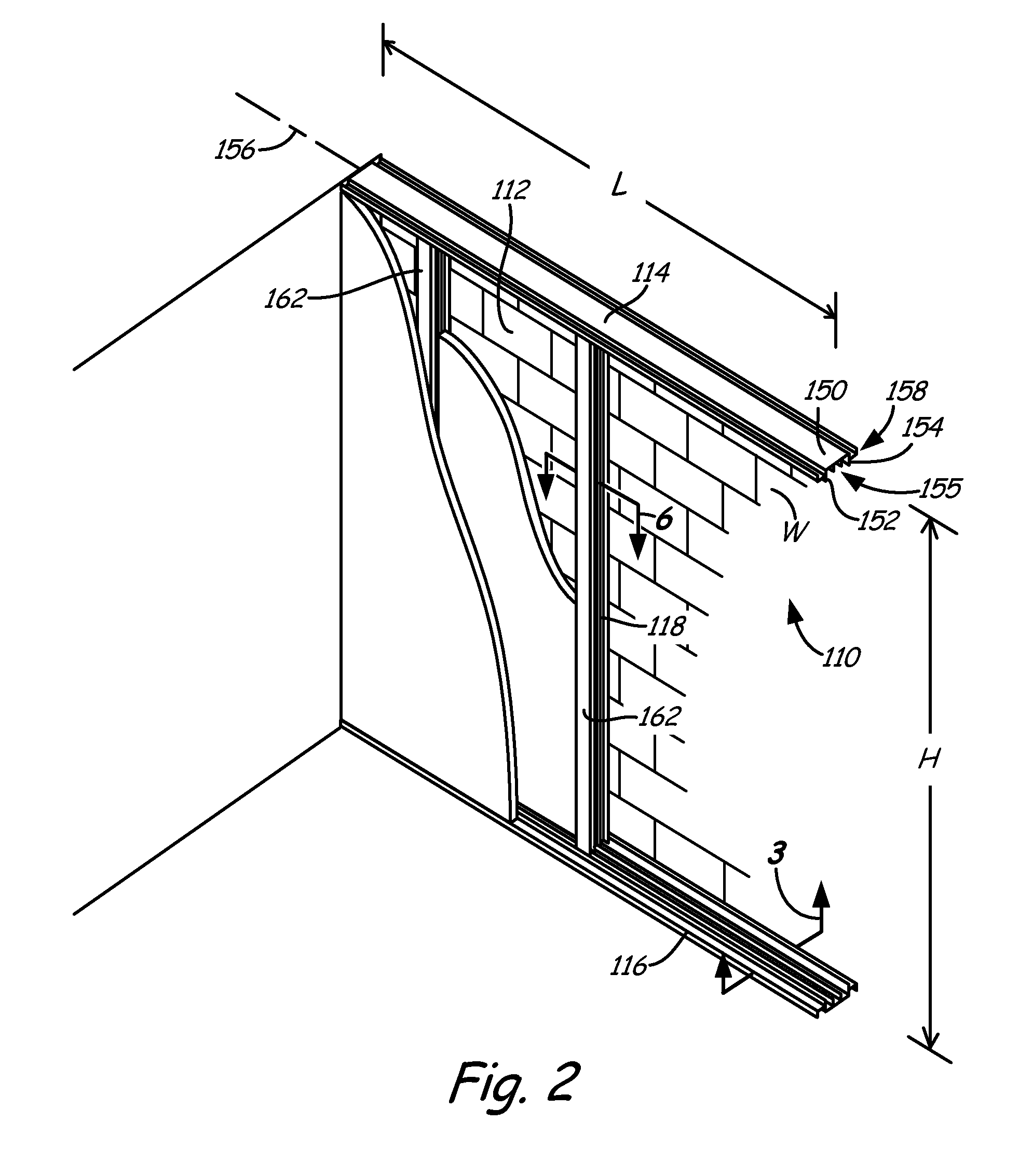

Wall Framing System

InactiveUS20130232902A1Easy and fast constructionMinimize the possibilityCovering/liningsWallsStructural engineeringEngineering

A wall framing system for supporting an interior wall in spaced proximity to an exterior wall includes one or more stud members extending between upper and lower frame channel members, which are configured to self-locate in relation to the exterior wall in a manner which establishes a moisture and air barrier between the exterior wall and the interior wall supported by the wall framing system. The interior wall supported by the wall framing system is resistant to moisture degradation, and maintains desired R-value insulation properties throughout the wall.

Owner:ADIRONDACK GRP

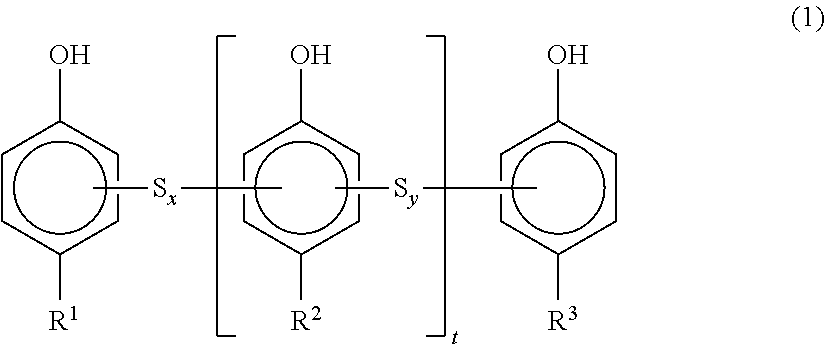

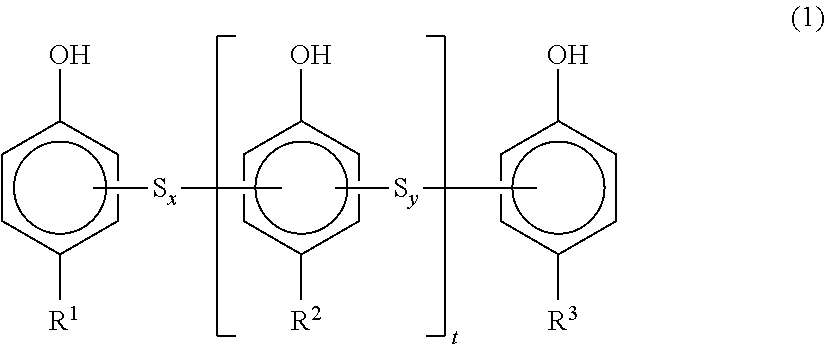

Elastomeric blend for air barriers comprising grafted resin components

A composition suitable for an air barrier such as an automotive tire innertube, innerliner, and aircraft tire innertube or innerliner, curing bladders, and other pneumatic devices is disclosed. The composition comprises an elastomer, a processing oil, and a grafted resin component.

Owner:EXXONMOBIL CHEM PAT INC

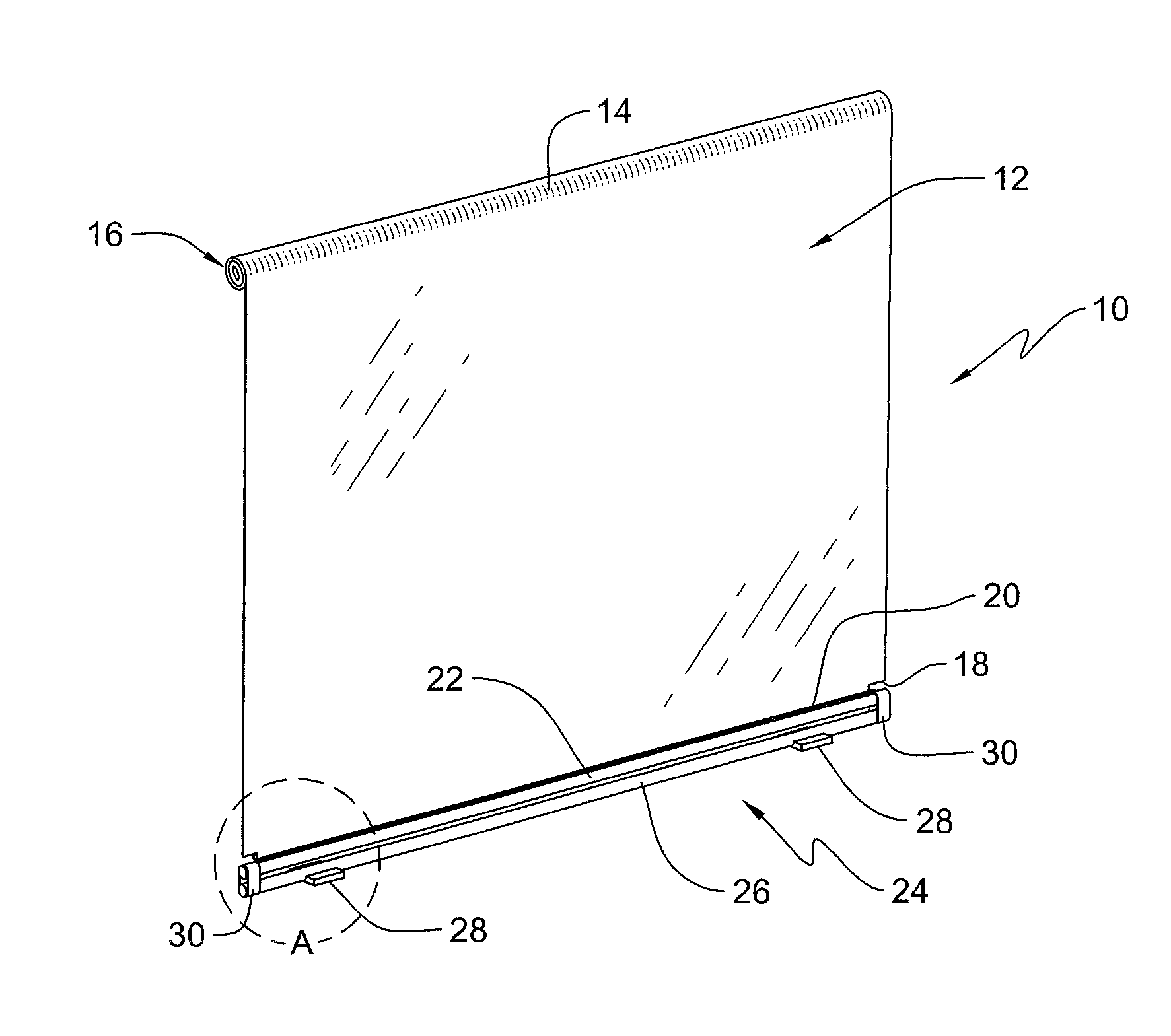

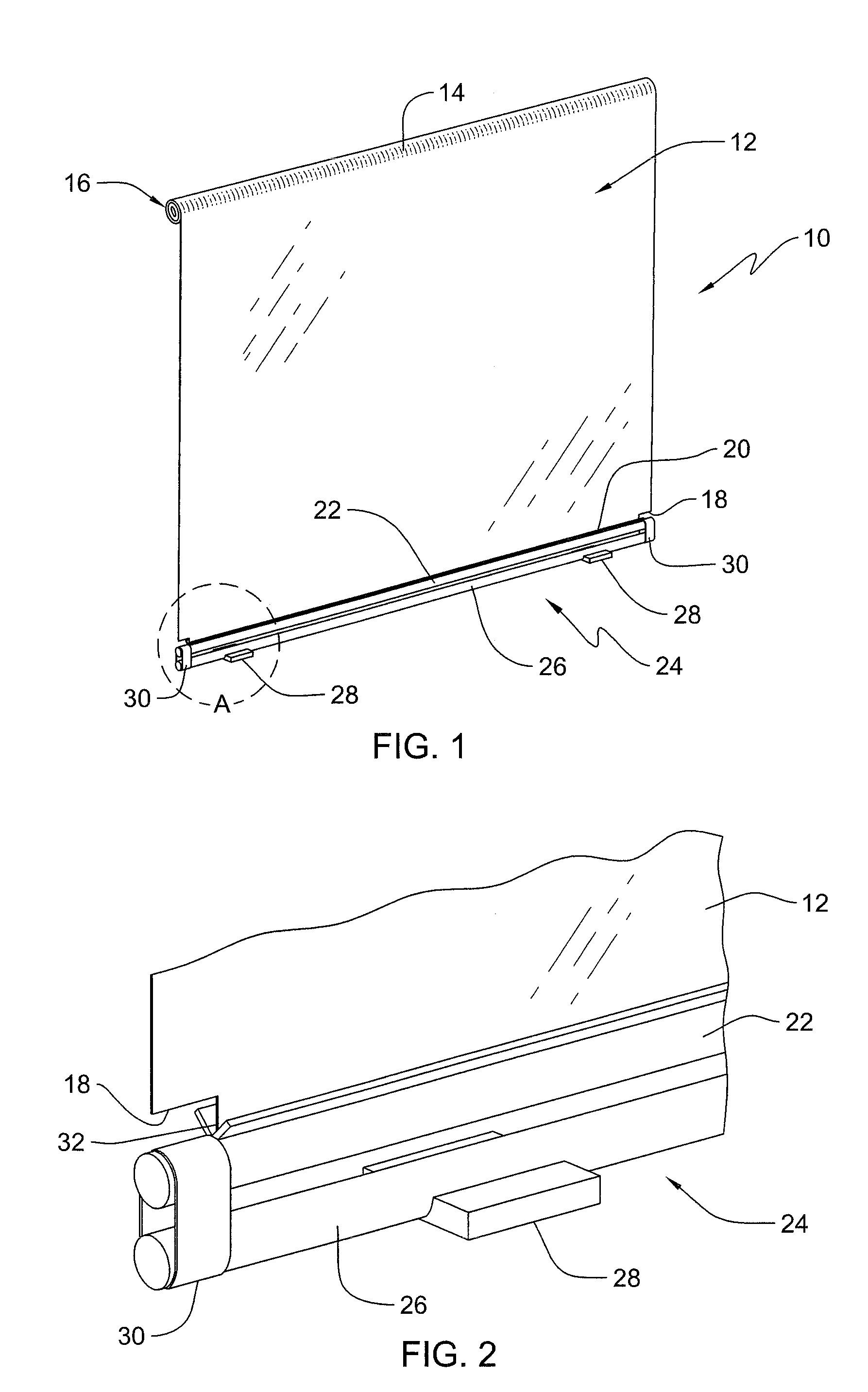

Air barrier for datacenter usage which automatically retracts when fire sprinklers are activated

InactiveUS20100108272A1Easy to operateEasy to changeScreensCurtain suspension devicesFire sprinklerData center

An air barrier structure located in an airflow passageway for datacenter usage, which is automatically retractable upon activation of fire sprinklers in the event of a conflagration. The barrier structure is a shade-type roll up member, which in the absence of any complex mechanical structure, will automatically retract about a spring-loaded roller upon the activation of a fire sprinkler, and whereby the barrier incorporates water-soluble structural aspects which will facilitate such automatic retraction upon being impinged upon and dissolved by a flow of water emanating from the fire sprinkler.

Owner:IBM CORP

Extended flashback annulus in a gas turbine combustor

An extended flashback annulus (520) is formed between an exterior surface (506) of a shroud or casing (508) associated with a main swirler assembly inner body (500) or other fuel / air mixing device and the inner surface (514) of an annulus casting (510) which are in operational relationship with one another in a gas turbine combustor assembly. The extended flashback annulus (520) is capable of forming an extended protective cylindrical air barrier (550) that extends farther into the combustion zone, this barrier being more robust and providing for the reduction or prevention of flashback to the baseplate and other heat-susceptible upstream components.

Owner:SIEMENS ENERGY INC

Functionalized elastomer nanocomposite

InactiveUS20050277723A1Improve air tightnessWithout separate inflatable insertsWith separate inflatable insertsElastomerGeneral purpose

An embodiment of the present invention is a nanocomposite comprising a clay and an elastomer comprising at least C2 to C10 olefin derived units; wherein the elastomer also comprises functionalized monomer units pendant to the elastomer. Desirable embodiments of the elastomer include poly(isobutylene-co-p-alkylstyrene) elastomers and poly(isobutylene-co-isoprene) elastomers, which are functionalized via Friedel-Crafts reaction with a Lewis acid and a functionalizing agent such as acid anhydrides and / or acylhalides. The clay is exfoliated in one embodiment by the addition of exfoliating agents such as alkyl amines and silanes to the clay. The composition can include secondary rubbers such as general purpose rubbers, and curatives, fillers, and the like. The nanocomposites of the invention have improved air barrier properties such as are useful for tire innerliners and innertubes.

Owner:EXXONMOBIL CHEM PAT INC

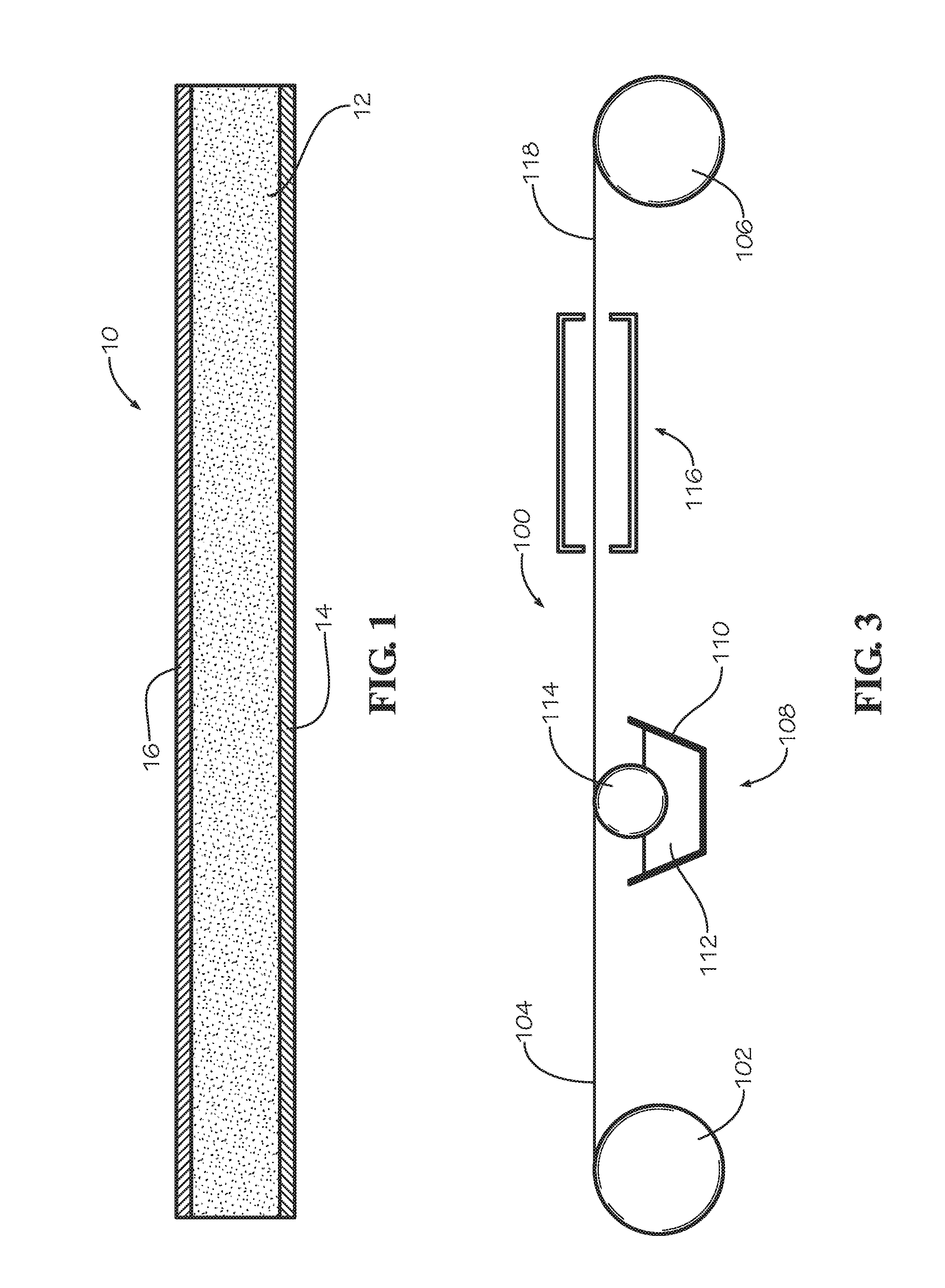

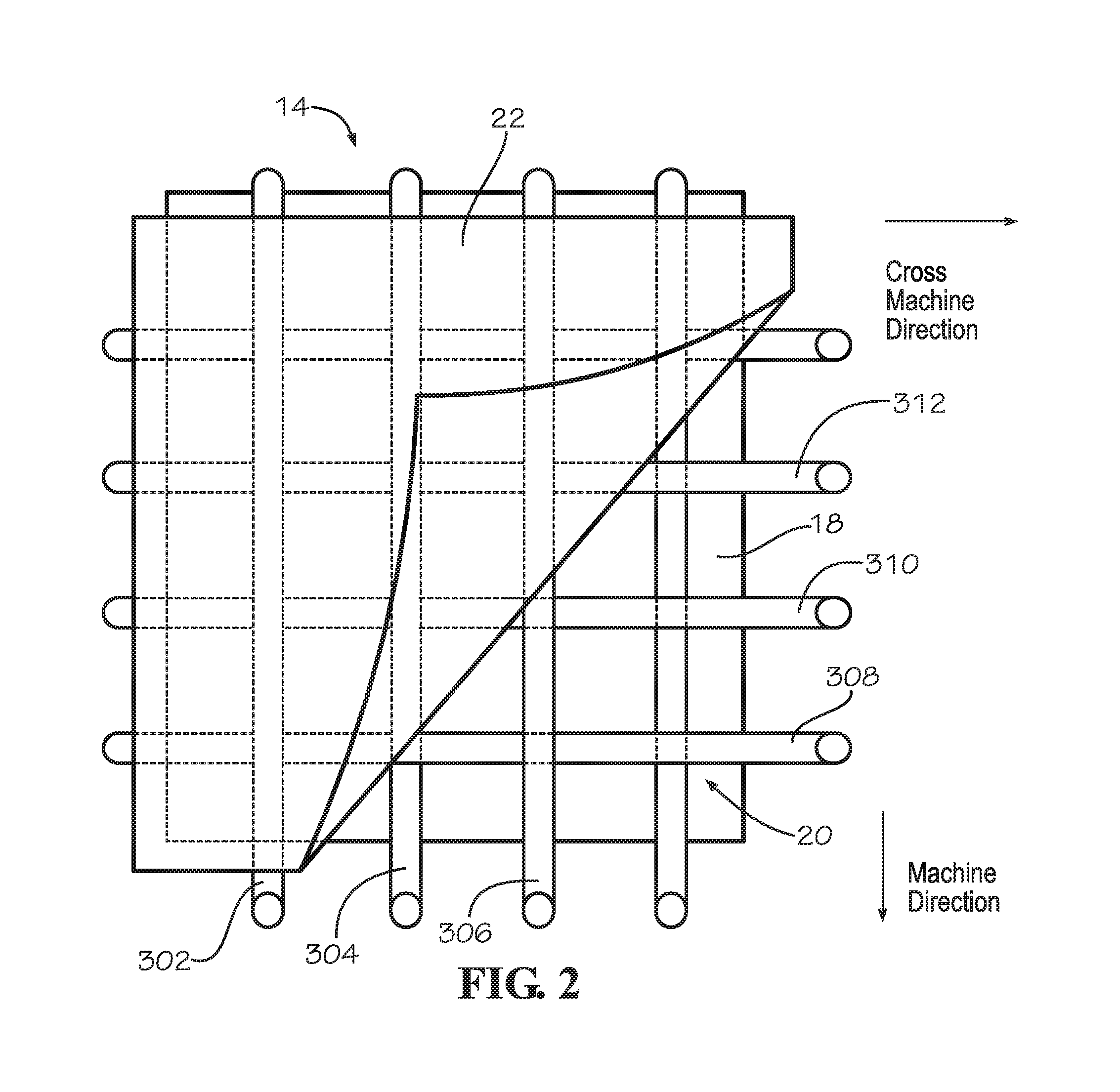

Foam sheathing reinforced with hybrid laminated fabric impregnated with vapor permeable air barrier material and method of making and using same

InactiveUS20160361894A1Simple methodEffective wayLamination ancillary operationsLaminationElastomerWater vapor

The invention comprises a product. The product comprises a foam insulating panel having a first primary surface and an opposite second primary surface and a laminated fabric attached to the first primary surface of the foam insulating panel. The laminated fabric is impregnated with an air-resistant, water-resistant, vapor permeable, elastomeric polymeric material, wherein the air-resistant, water-resistant, vapor permeable elastomeric polymeric material has an elongation factor of greater than 100%, a water vapor transmission rating of at least 0.1 perm and an air permeance of less than 0.004 cfm / sq. ft. under a pressure differential of 0.3 inches of water, whereby the air-resistant, water-resistant, vapor permeable elastomeric polymeric material provides a water-resistant, vapor permeable air barrier. The laminated fabric comprises a woven or nonwoven carrier portion and a woven or nonwoven reinforcing portion attached to the carrier portion. A method of making a composite sheathing panel is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

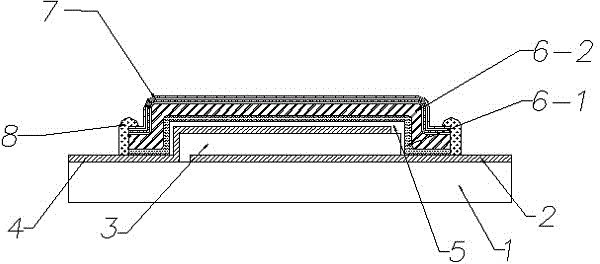

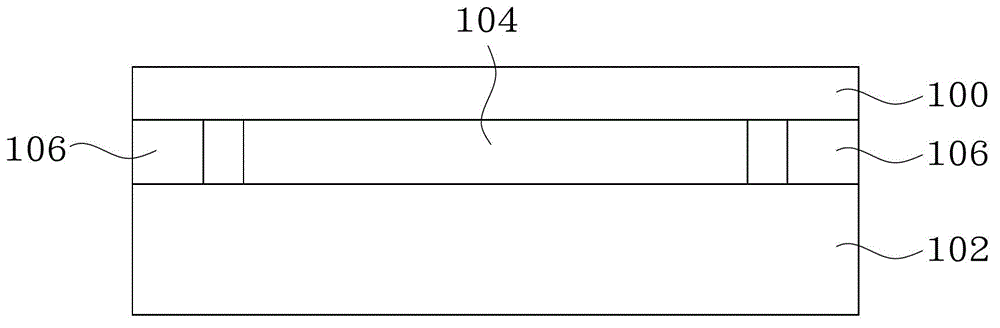

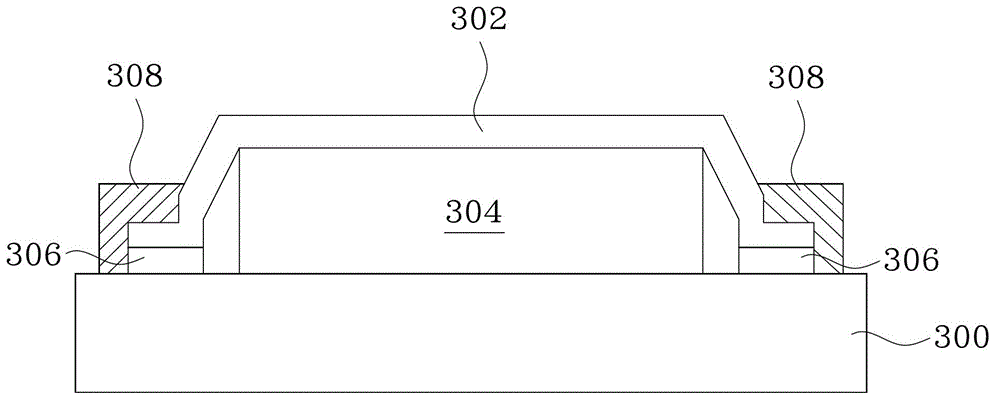

Adhesive tape encapsulating structure of organic light emitting diode

InactiveCN103956435ASimple processIncrease production speedSolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerProtection layer

The invention relates to an adhesive tape encapsulating structure of an organic light emitting diode (OLED). According to the adhesive tape encapsulating structure of the OLED, adhesive tape encapsulation is carried out on the OLED formed by a front electrode, an organic layer, a back electrode and a protection layer, the front electrode, the organic layer and the back electrode are arranged on the upper face of a substrate, the OLED is sealed through adhesive tape which is arranged on the upper face of the OLED and formed by an adhesive sticker and a flexible film strip capable of preventing water vapor and oxygen from passing through, an air barrier layer formed by multilayer films of multilayer thin films made of different materials is further arranged on the upper face or the lower face of the flexible film strip, a layer of filter film can be further arranged on the lower face of the flexible film strip, a sealing rubber ring is arranged on the periphery of the sealing adhesive tape to cover the adhesive tape and the substrate so that air cannot permeate into the OLED from the periphery, and a thin glass sheet or a thin metal sheet can be further arranged on the upper face of the sealing rubber ring to prevent air from entering from the upper face. According to the adhesive tape encapsulating structure of the OLED, due to the fact that the main encapsulating process is the adhesive tape adhering process, the technological process of the adhesive tape encapsulating structure is much simpler relative to a previous method, the production speed can be improved, production cost is lowered, and the adhesive tape encapsulating structure is especially suitable for large-area and large-batch production.

Owner:SHANGHAI UNIV

Methods and apparatus for a permanent magnet machine with an added air barrier

InactiveCN101741199AClaims are obviousMagnetic circuit rotating partsSynchronous machine detailsEngineeringElectric vehicle

An internal permanent magnet machine (''IPM machine'') of the type used, for example, with traction motors and hybrid electric vehicles, includes a rotor with an additional air barrier provided above the first magnet barrier in the same rotor slot. Each magnet only fills a portion of each cavity, thereby defining the air barriers. The added air barrier above the permanent magnet of the first layer acts as a barrier to the first layer magnet and lowers the magnet flux.

Owner:GM GLOBAL TECH OPERATIONS LLC

Airtight rubber of all-steel radial tyre and preparation method thereof

The invention discloses an air-barrier glue for all-steel-wire truck radial tires, as well as a preparation method thereof. The glue comprises the following components in weight portion: 60 to 80 portions of natural glue, 20 to 40 portions of butadiene-styrene rubber, 40 to 65 portions of carbon black N660 as a reinforcing agent, 3 to 7 portions of zinc oxide as an activator, 1 to 4 portions of stearic acid, 2.5 to 5 portions of 204 resin as a tackifier, 2 to 5 portions of homogenizing agent UB4000 or 2 to 5 portions of homogenizing agent 40MSF, 0.5 to 2 portions of antiager 4020, 0.5 to 2 portions of antiager RD, 1 to 3 portions of protective wax, 2 to 4 portions of aromatic oil as a softening plasticizer, 0.5 to 1.0 portions of sulfur as a vulcanizing agent and 1.0 to 3.0 portions of accelerator NS or 1.0 to 3.0 portions of accelerator TBBS.

Owner:JIANGSU GENERAL SCI TECH

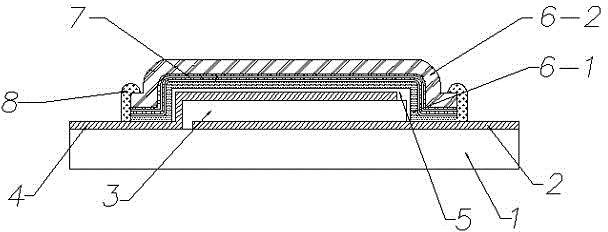

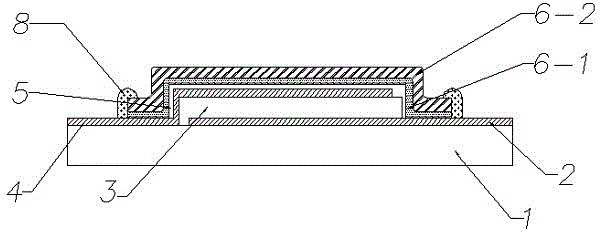

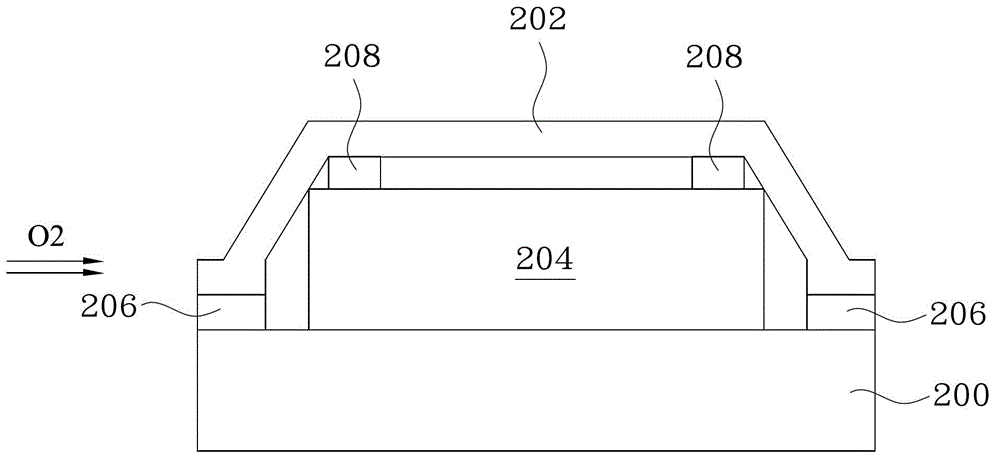

Packaging structure of organic light emitting diode

InactiveCN102983279AIsolation damageImprove the blocking effectSolid-state devicesSemiconductor/solid-state device manufacturingEvaporationMoisture absorption

The invention provides a packaging structure of an OLED (organic light emitting diode), which comprises a substrate, an OLED device, an air-barrier film and a metal packaging film, wherein the OLED device is arranged above the substrate; the air-barrier film is positioned above the OLED device; the OLED device is covered with the air-barrier film; the air-barrier film is glued to the substrate by virtue of a seal to form an enclosed space for sealing the OLED device; and the metal packaging film is arranged in a neighbor area where the substrate is glued with the air-barrier film, so that external moisture is prevented from entering the enclosed space. Compared with the prior art, after the air-barrier film is glued with the substrate, the metal packaging film is coated in the seal neighbor area in a sputter or evaporation coating mode at the side edges of the air-barrier film and the seal, the damage of the external moisture to the OLED device is thoroughly isolated by the metal packaging film, the stopping capacity of the packaging structure to the moisture is improved, and moisture absorption layers can be coated on the two sides of the OLED device before the seal is coated, thereby reducing the damage of the moisture in a glue material to the OLED device during coating.

Owner:AU OPTRONICS CORP

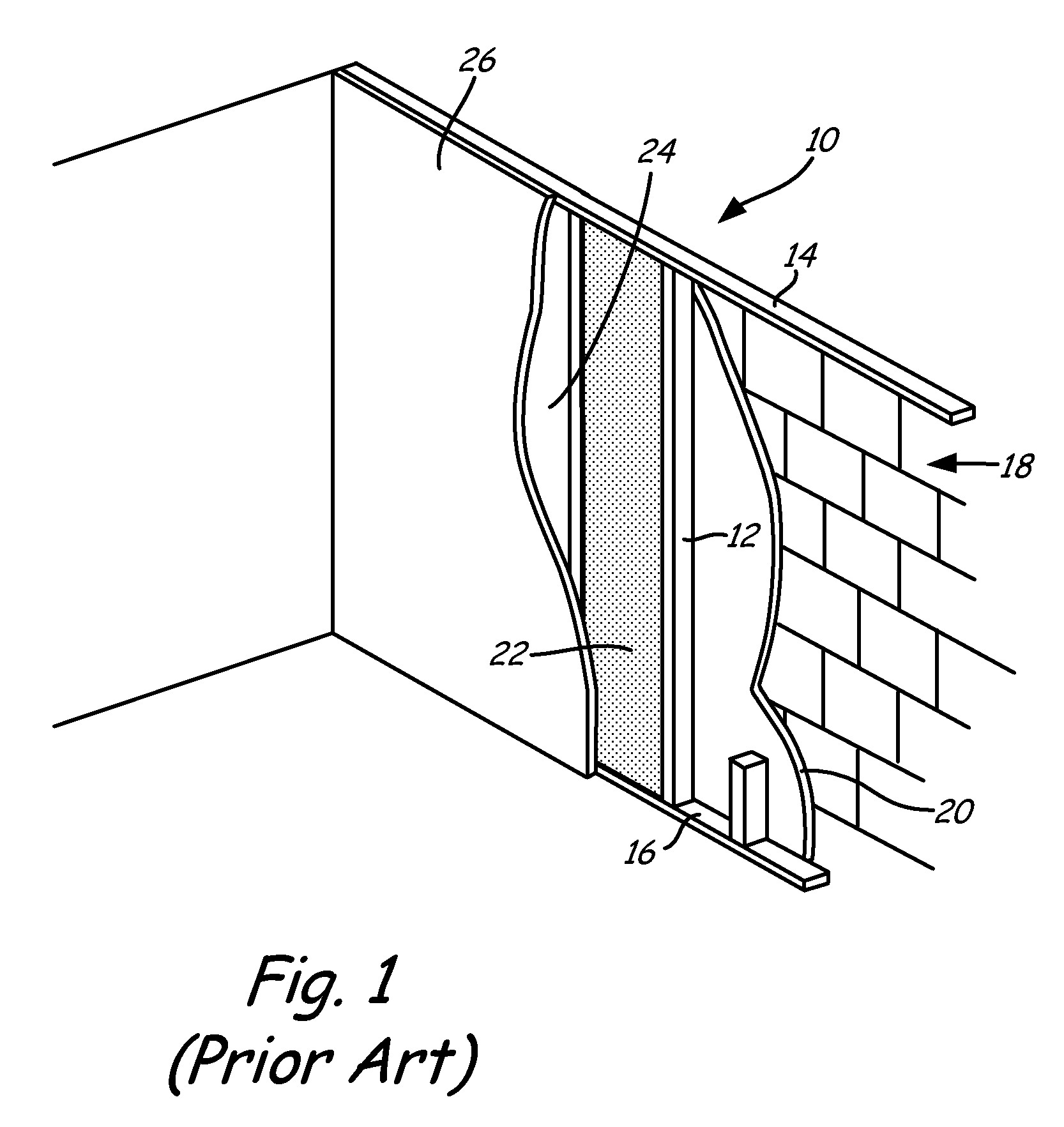

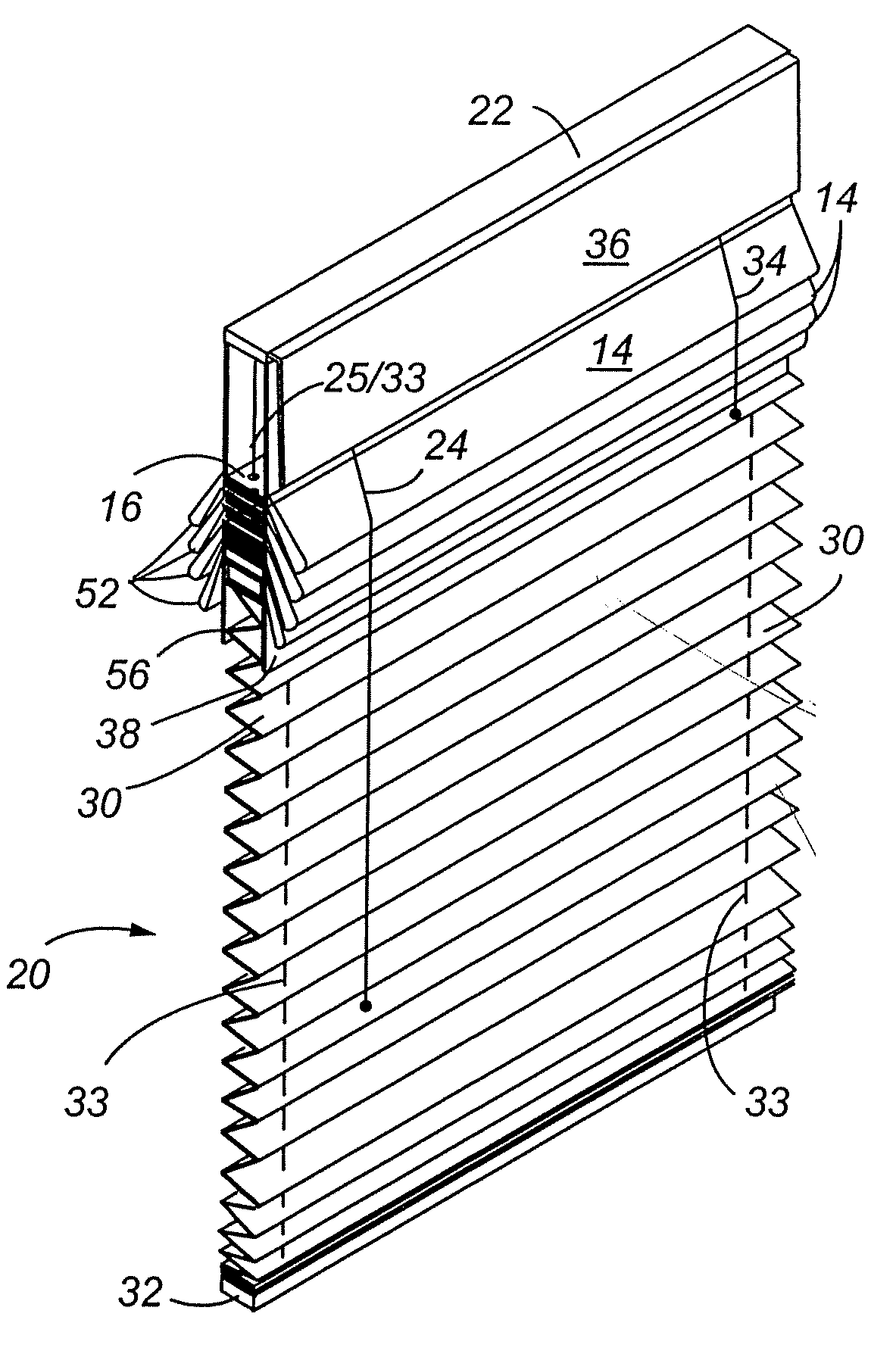

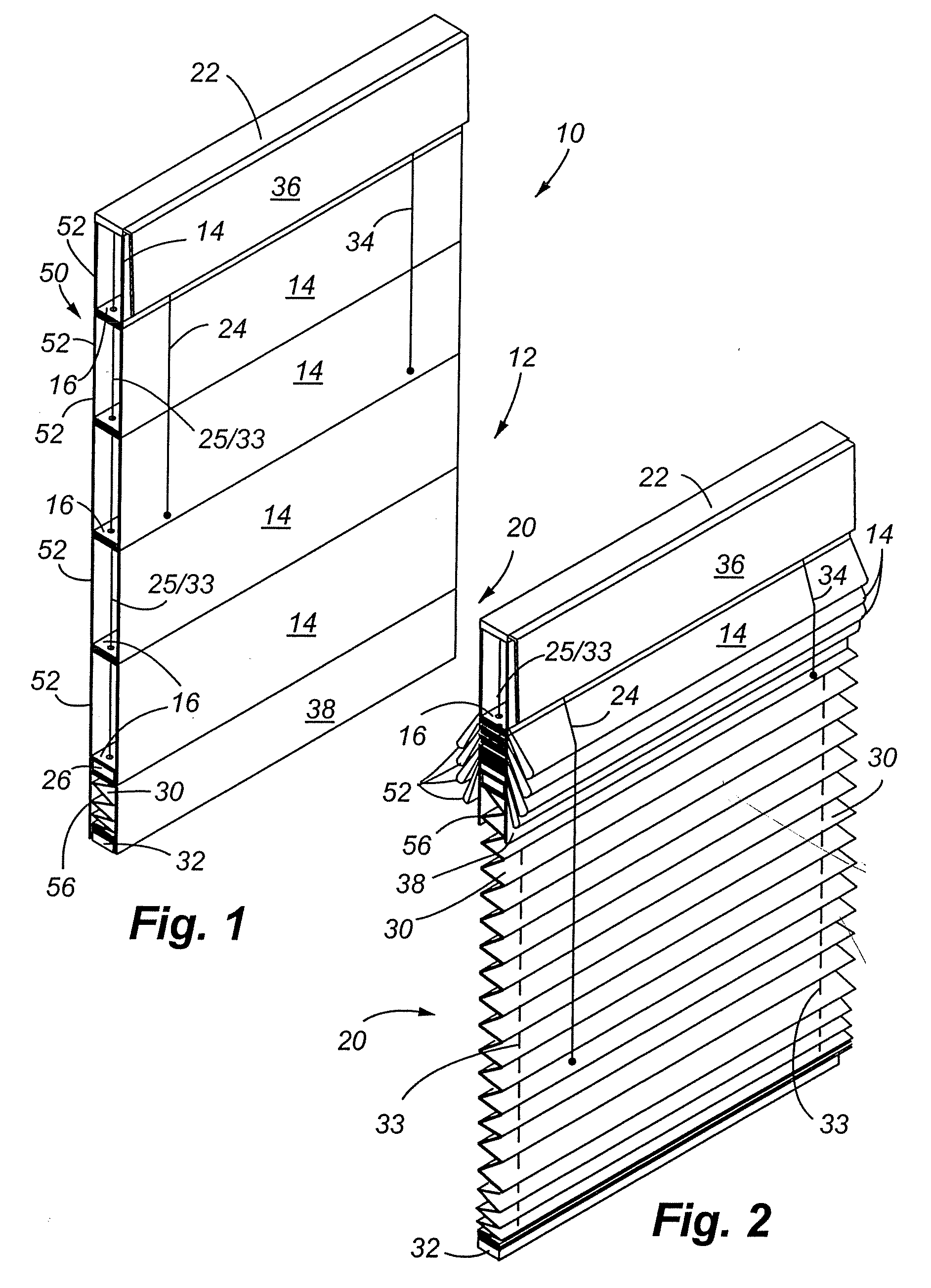

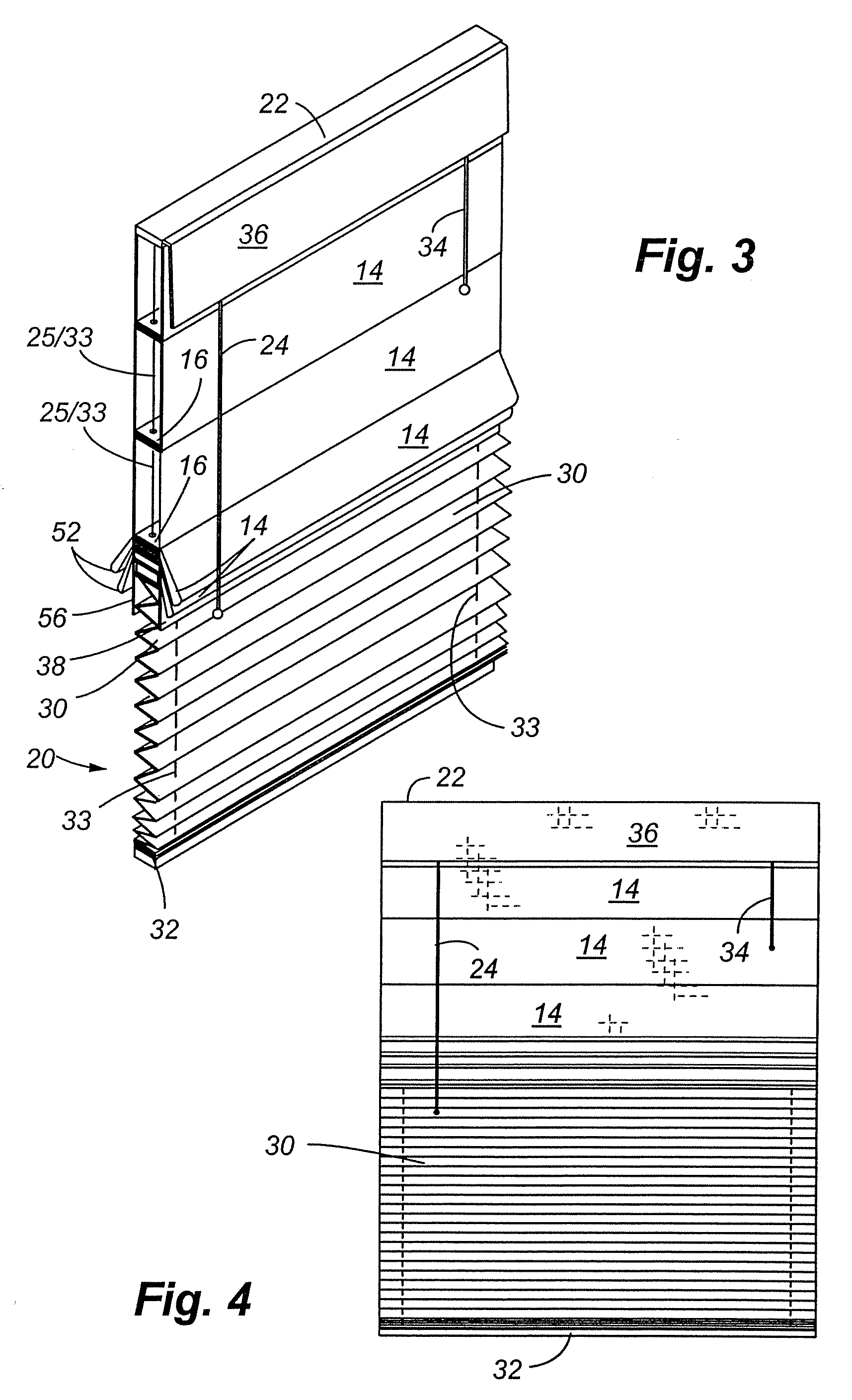

Roman Shade

InactiveUS20080173409A1Raise and shadeRaise and shearExtensible doors/windowsCurtain accessoriesEngineeringAir barrier

A Roman shade is constructed of two continuous sheets of material forming the front and rear faces thereof. Pleat assemblies create panels in the shade, and oppositely disposed panels form insulating cells that help the shade to create an air barrier for insulating the window covered by the shade. Horizontal folds made in the front and rear faces form the pleat assemblies. Retaining strips are provided along with eyelets to assemble the pleat assembly. An optional sheer assembly may be hung below the shade wherein lower overhangs of the shade hide the sheer assembly when the sheer assembly is raised.

Owner:D S C FABRICS

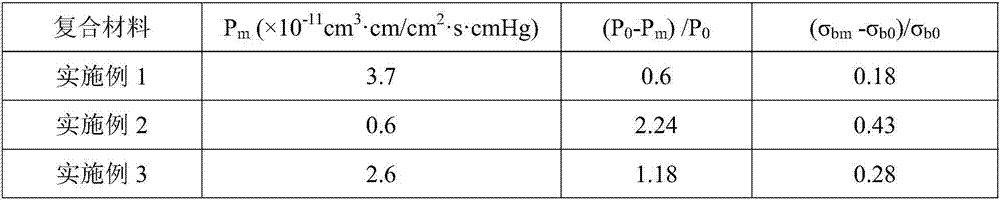

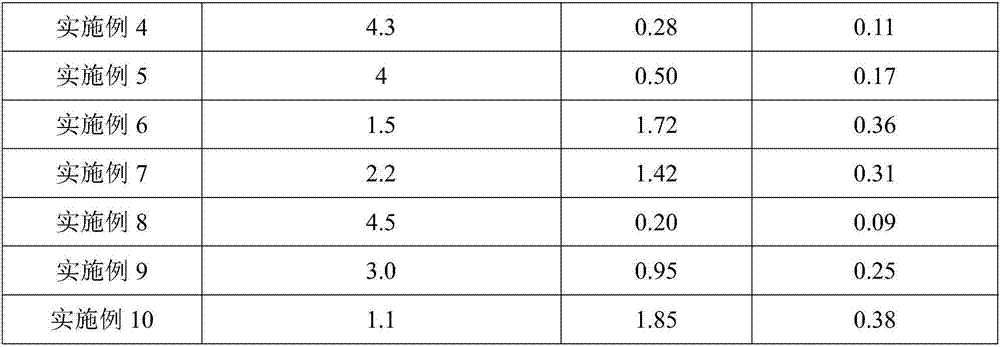

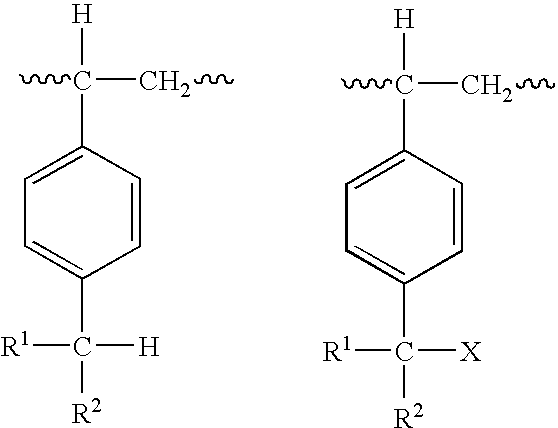

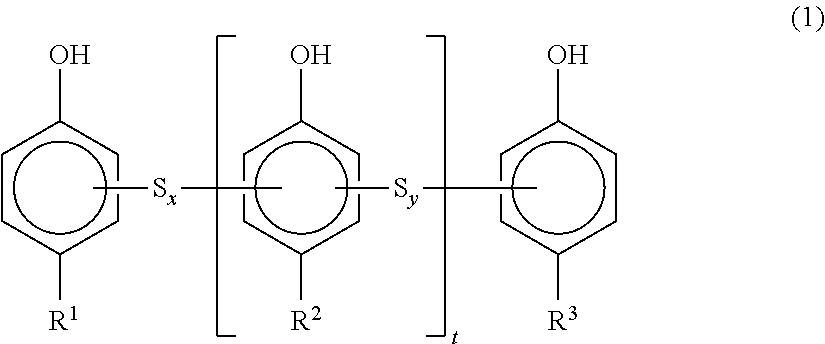

Nanometer composite material high in air barrier property and preparation method thereof

The invention discloses a nanometer composite material high in air barrier property and a preparation method thereof, and belongs to the technical field of nanometer composite materials. The method comprises the following steps that firstly, laminar nanometer filler is dispersed into a surface modifier solution, stirred for a time after ultrasonic treatment and then filtered, washed and dried to obtain surface modified laminar nanometer filler; secondly, the surface modified laminar nanometer filler is pre-mixed with a polymer, then placed in an internal mixer, mixing is conducted after heating and fusion to obtain a nanometer composite material, the nanometer composite material is subjected to hot-press molding, and the nanometer composite material high in air barrier property is obtained. The nanometer composite material high in air barrier property has the advantages of being excellent in barrier property, low in filler consumption, easy to process and good in integrated mechanicalproperty and has a good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Elastomeric blend for air barriers comprising grafted resin components

A composition suitable for an air barrier such as an automotive tire innertube, innerliner, and aircraft tire innertube or innerliner, curing bladders, and other pneumatic devices is disclosed. The composition comprises an elastomer, a processing oil, and a grafted resin component.

Owner:EXXONMOBIL CHEM PAT INC

Inner liner rubber composition and pneumatic tire

ActiveUS20140116594A1Cost is compoundedImprove economyWithout separate inflatable insertsWith separate inflatable insertsEngineeringButyl rubber

The invention provides an inner liner rubber composition that enables improvements in handling stability, fuel economy, elongation at break, sheet processability, air barrier properties, and compounding cost in a balanced manner; and a pneumatic tire including an inner liner formed from the rubber composition. The rubber composition includes: a reclaimed butyl rubber; a halogenated butyl rubber other than the reclaimed butyl rubber; at least one semi-reinforcing filler selected from the group consisting of finely ground bituminous coal, talc, mica, and hard clay; and carbon black having a specific N2SA and / or silica having a specific N2SA, wherein the finely ground bituminous coal has a specific average particle size, and the rubber composition has a predetermined reclaimed butyl rubber content, a predetermined combined content of the reclaimed butyl rubber and the halogenated butyl rubber, a predetermined total semi-reinforcing filler content, and a predetermined combined content of the carbon black and the silica.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com