Packaging structure of organic light emitting diode

A technology of light-emitting diodes and packaging structures, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc. It can solve problems such as the inability of adhesive materials to block water vapor and damage to OLED devices, so as to isolate damage and improve the ability to prevent , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical content disclosed in this application more detailed and complete, reference may be made to the drawings and the following various specific embodiments of the present invention, and the same symbols in the drawings represent the same or similar components. However, those skilled in the art should understand that the examples provided below are not intended to limit the scope of the present invention. In addition, the drawings are only for schematic illustration and are not drawn according to their original scale.

[0036] The specific implementation manners of various aspects of the present invention will be further described in detail below with reference to the accompanying drawings.

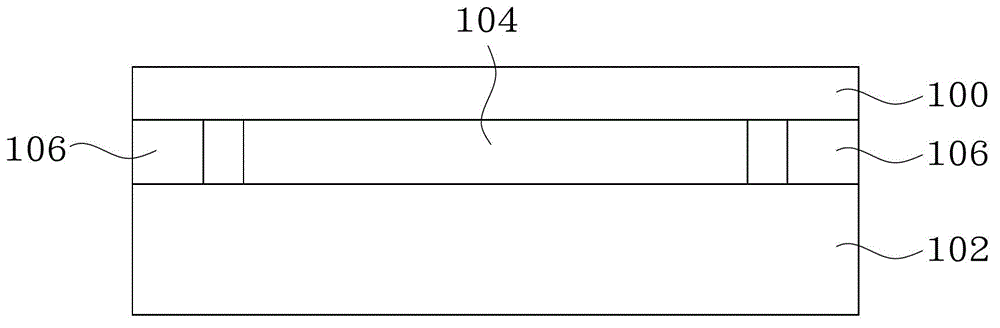

[0037] figure 1 A schematic diagram showing the composition of an organic light emitting diode packaging structure in the prior art.

[0038] refer to figure 1 , the organic light emitting diode packaging structure includes a glass substrate 102 , an org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com