Heat-dissipating structure of cement kiln

A heat dissipation structure, cement kiln technology, applied in lighting and heating equipment, furnace cooling, furnace, etc., can solve the problems of refractory brick falling off, waste heat cannot be recovered, violation, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

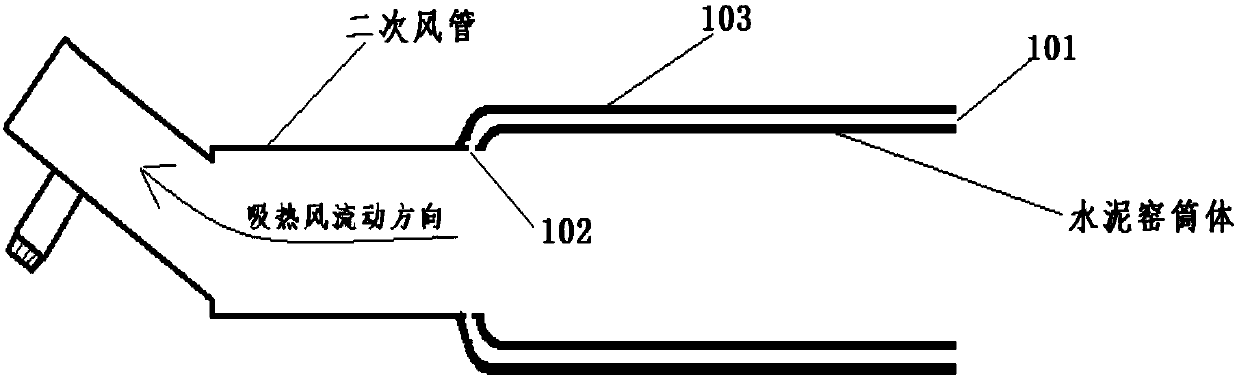

[0029] Below, refer to the attached Figure 1 to Figure 2 As shown, a heat dissipation structure of a cement kiln includes: an air inlet 101, an air outlet 102 and a Venturi heat dissipation pipe 103;

[0030] Further, the number of the air inlets 101 is at least four groups, and the number of the air outlets 102 is at least four groups;

[0031] As an example, the shape of the air inlet 101 and the air outlet 102 is set as an oblate arc shape;

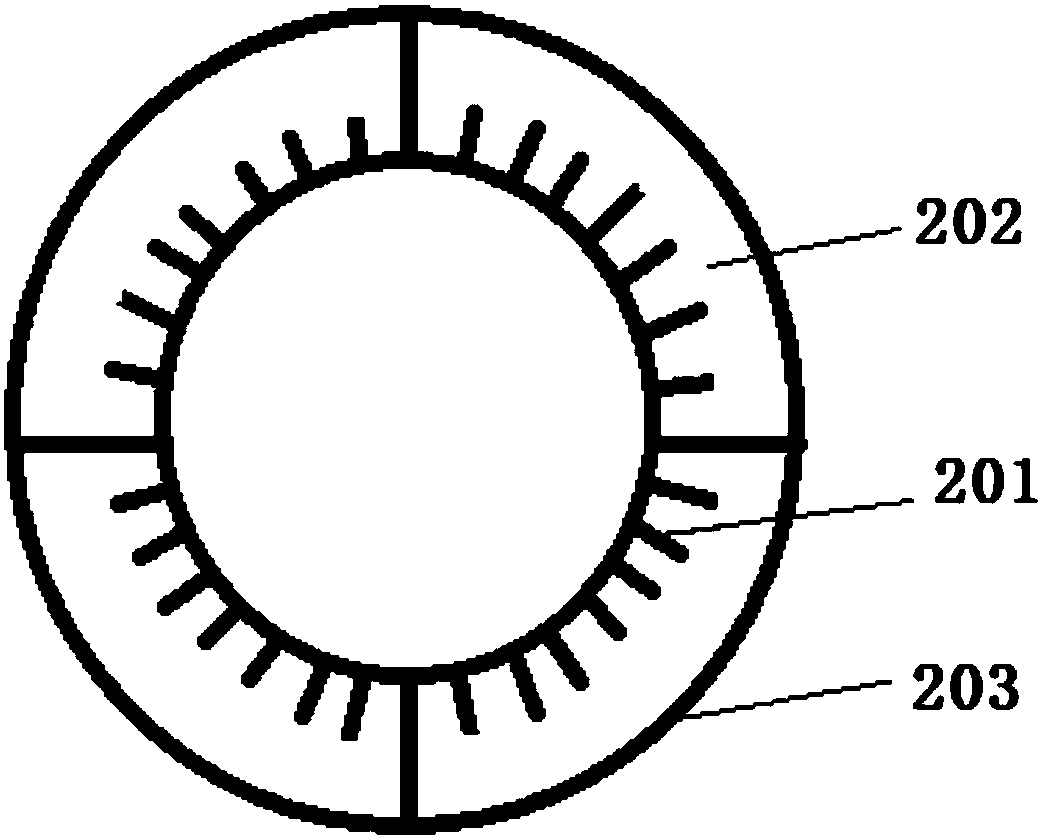

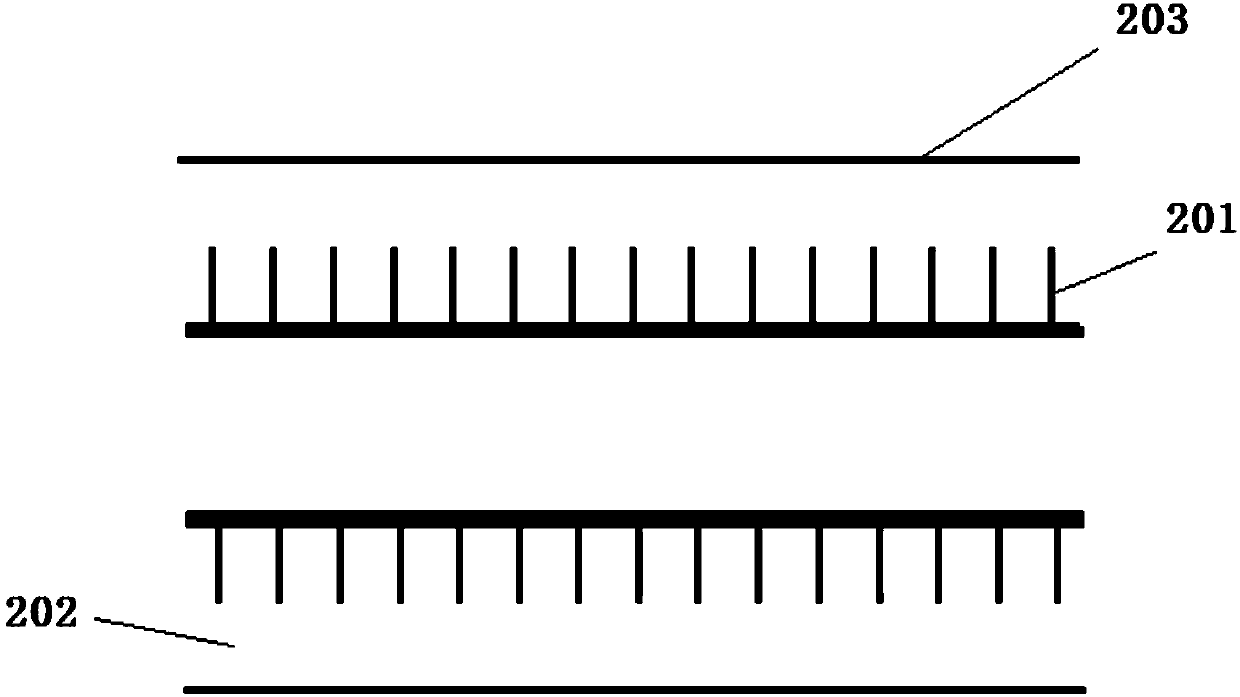

[0032] Further, the Venturi heat dissipation pipe 103 is set in the shape of a cylinder, wrapped outside the cement kiln cylinder, including: a heat sink layer 201, a Venturi ventilation heat dissipation layer 202 and an external protective layer 203; the heat sink layer 201 is closely attached to The cement kiln shell is set, and the Venturi ventilation heat dissipation layer 202 is located between the heat dissipation sheet layer 201 and the outer protective layer 203;

[0033] As an example, the outer protective layer 203 is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com