Patents

Literature

118results about How to "Reduce high energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

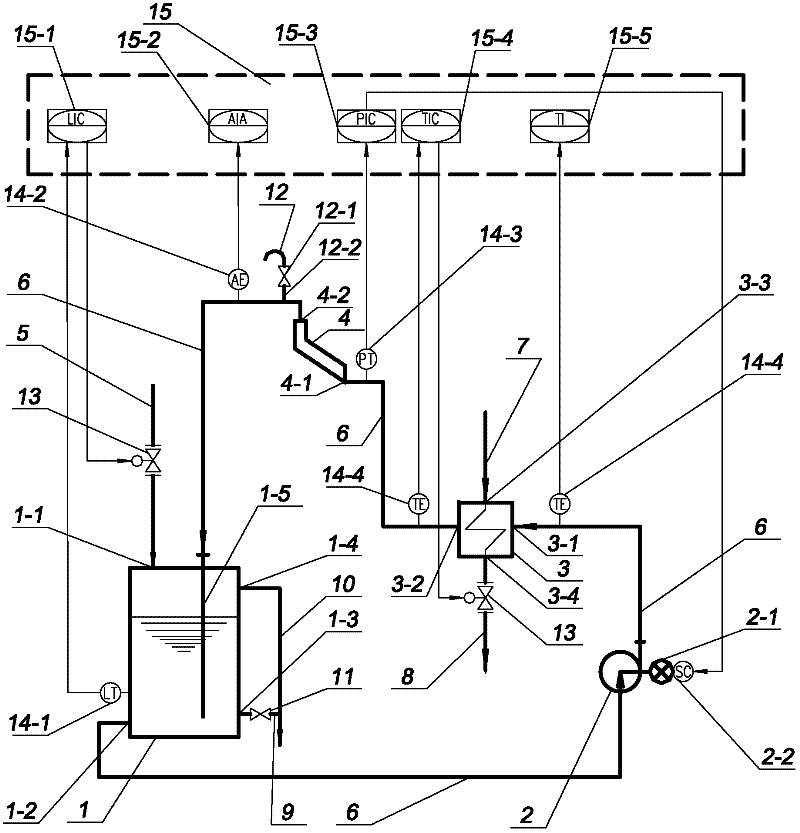

Energy saving method for circulating water system

InactiveCN101666319AImprove efficiencyImprove manufacturing precisionPump installationsNon-positive displacement fluid enginesCooling towerOperating point

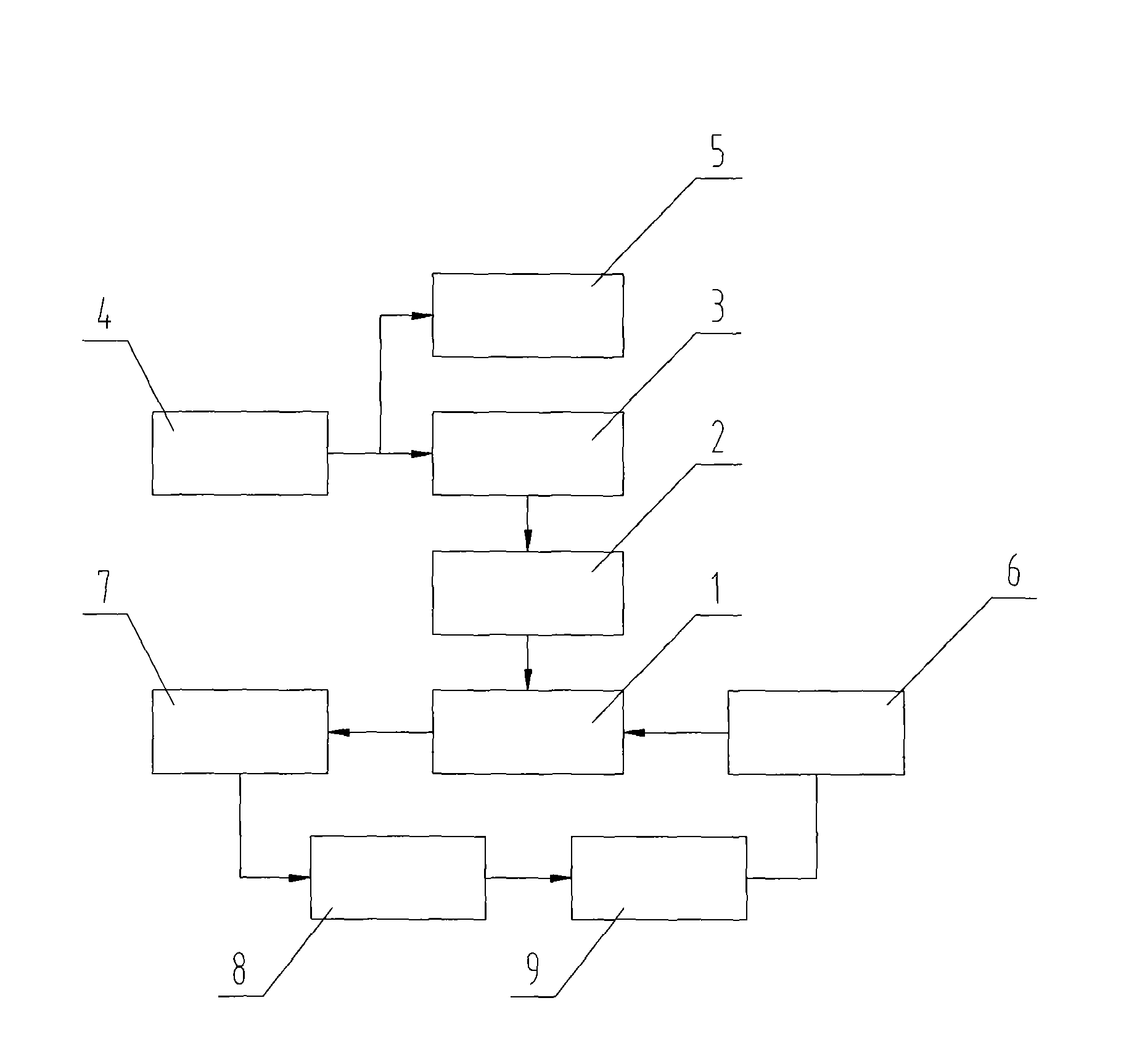

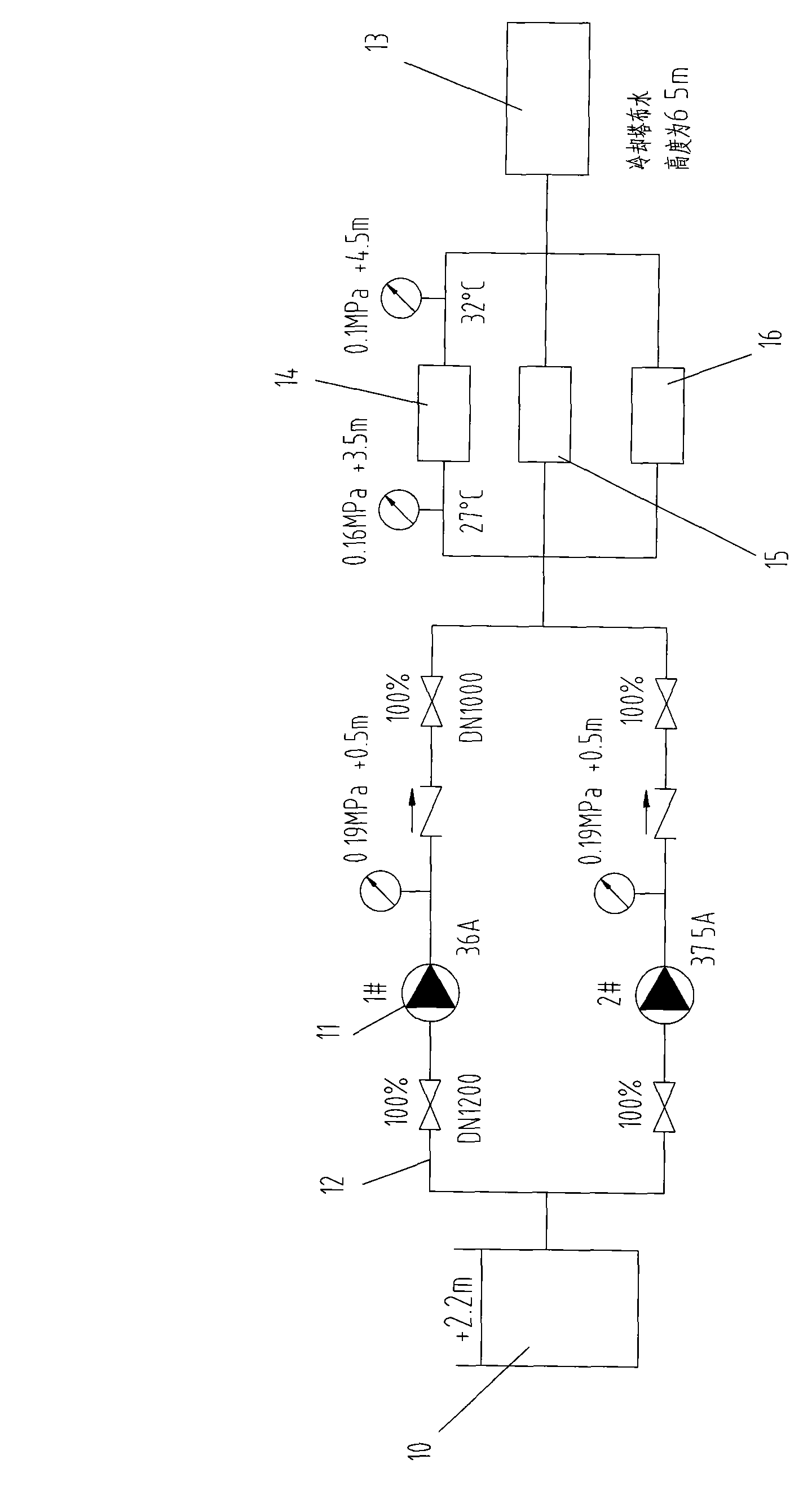

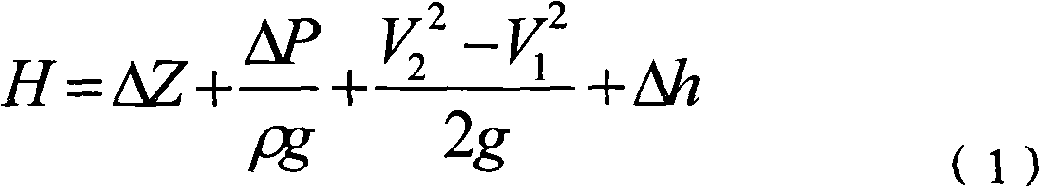

The invention discloses an energy saving method for a circulating water system. The method comprises the following steps: firstly, detecting duty parameters of the current operation of the system andparameters of related devices; then, in accordance with the principle of economic operation of the circulating water system, creating a standard for the balance test and the calculation of the systemenergy by starting with a circulating water pump group, a pipe network, a heat-exchange device, a refrigeration device, a cooling tower and the like, analyzing the use efficiency of the system energy,evaluating the current use efficiency index of the system energy, and finding out the cause for the high energy consumption of the system; finally, by combining production process requirements, accurately finding out the optimum operating point where the devices are matched with the liquid transportation, and giving an optimum solution for the process energy of the system so as to achieve the purposes of high efficiency and energy saving. By detecting and analyzing the circulating water system, the invention provides a comprehensive, systemic and thorough energy saving method for the circulating water system.

Owner:长沙翔鹅节能技术有限公司

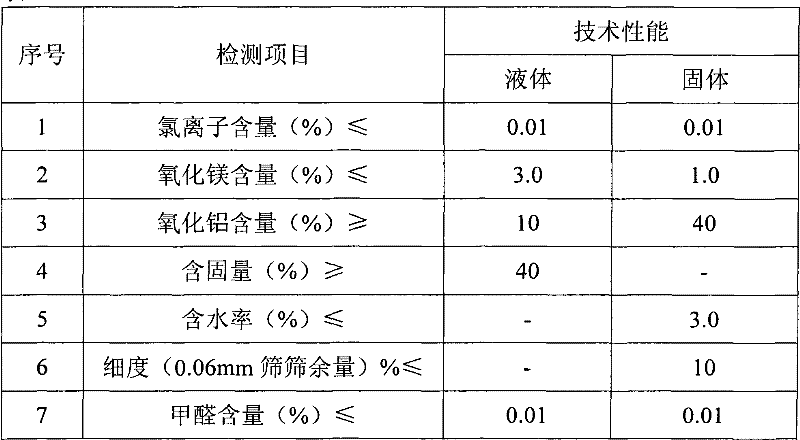

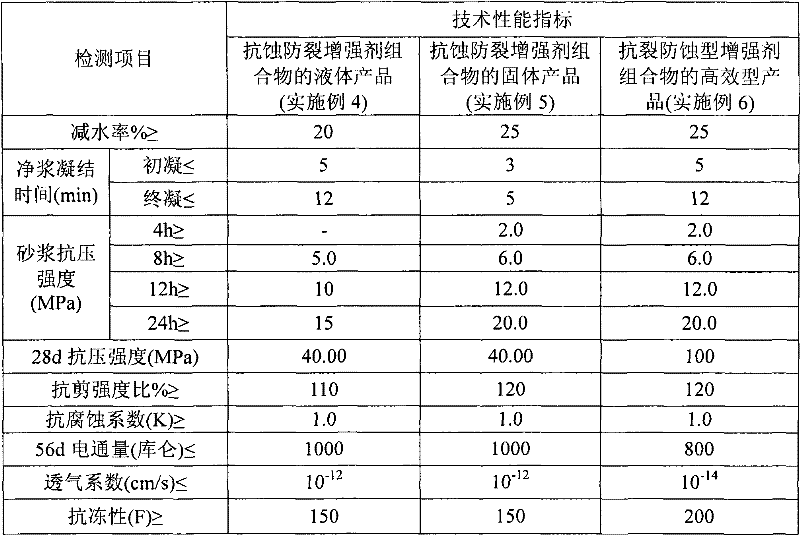

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

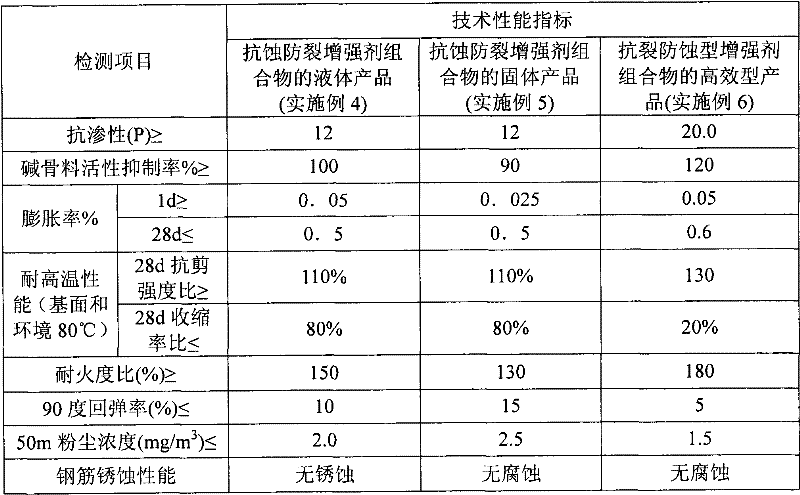

Method and device for co-producing dimethyl carbonate and dimethyl oxalate

ActiveCN101830806AReasonable deployment of productionLower energy requirementsOrganic compound preparationPreparation by carbon monoxide or formate reactionGas phaseTower

The invention discloses a method and a device for co-preparing di(C1-3) alkyl carbonate and di(C1-3) alkyl oxalate. The method comprises the following steps of: a) separating a product of a di(C1-3) alkyl carbonate synthesis reactor into a first liquid phase and a first gas phase; b) separating a product of a di(C1-3) alkyl oxalate synthesis reactor into a second liquid phase and a second gas phase; c) conveying the first liquid phase to a first rectifying tower from the tower top, conveying the combined first gas phase and second gas phase to the first rectifying tower from the middle lower part of the tower, conveying the second liquid phase to the first rectifying tower from the tower bottom, and generating basically pure di(C1-3) alkyl oxalate fraction from the bottom of the first rectifying tower during rectifying; d) separating the overhead fraction produced in the first rectifying tower into a third liquid phase and a third gas phase; and e) conveying the third liquid phase to a second rectifying tower from the middle part of the tower, and generating basically pure di(C1-3) alkyl carbonate from the bottom of the second rectifying tower. Only three rectifying towers are designed in the whole process through reasonable process design, so the energy requirement and operation expense are effectively reduced, and the equipment investment expense is saved.

Owner:PUJING CHEM IND SHA +1

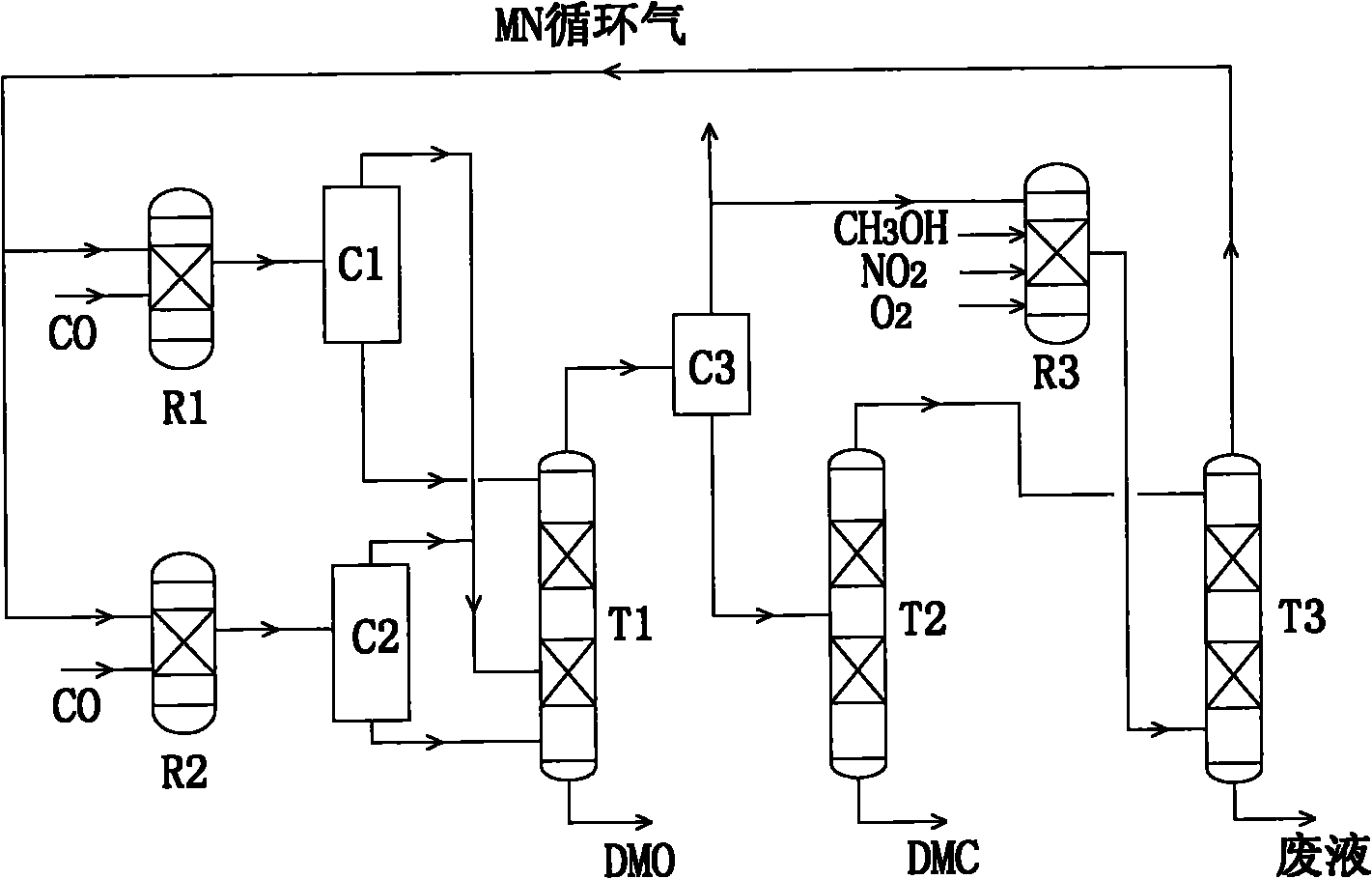

Method for producing hot-rolled pickling-free plate by combining thin-strip continuous casting with reducing annealing

The invention belongs to the technical field of material metallurgy, and particularly relates to a method for producing a hot-rolled pickling-free plate by combining thin-strip continuous casting with reducing annealing. The method specifically includes the steps: obtaining refining molten steel, preparing a cast-rolling strip blank, uncoiling a cast-rolling thin strip after thermal leveling for reducing annealing, removing scale on the surface of the cast-rolling thin strip in a reduction section, and adopting H2 atmosphere condition to protect reduction, wherein reduction temperature is 800-1100 DEG C and reduction time is 10-30min; adopting H2 and N2 atmosphere for protection in a high-temperature annealing section, wherein reduction temperature is 500-1000 DEG C and reduction time is 1-5min, realizing texture and performance control of the thin strip, and obtaining a thin-strip steel product. By the technical scheme, the cast-rolling thin strip is free of pickling and is directly subjected to reducing annealing, so that cold-rolled pickling process is omitted, pre-oxidation process before continuous annealing can be completely abolished, continuity of thin strip production process can be greatly improved, production efficiency is improved, production cost is lowered, discharging of pollutants like waste acid is reduced, and great economic benefit and social benefit are created.

Owner:NORTHEASTERN UNIV LIAONING

Inner crosslinking type caster oil-based waterborne polyurethane emulsion and preparation method thereof

InactiveCN106188457AImprove cross-linking efficiencySimple processPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolEmulsion

The invention relates to inner crosslinking type caster oil-based waterborne polyurethane emulsion and a preparation method thereof. The preparation method of the inner crosslinking type caster oil-based waterborne polyurethane emulsion is characterized by comprising the following steps of (1) adding polymer polyol, castor oil, diisocyanate, a catalyst and a small molecule chain extender into a reactor for reaction, so as to obtain caster oil-based waterborne polyurethane low polymers; (2) adding a hydrophilic chain extender and a polyfunctional-group crosslinking agent into the caster oil-based waterborne polyurethane low polymers, then, performing reaction; adding butanone to regulate the viscosity to be 16.5mPa*S, so as to obtain inner crosslinking type caster oil-based waterborne polyurethane; (3) adding a neutralizer into the inner crosslinking type caster oil-based waterborne polyurethane; after reaction, adding deionized water; performing high-speed shearing emulsification, thus obtaining the inner crosslinking type caster oil-based waterborne polyurethane emulsion after butanone is steamed out. The method has the advantages that the technical process is simple; the crosslinking efficiency is greatly improved; the mechanical property of the product is good.

Owner:WUHAN UNIV OF TECH

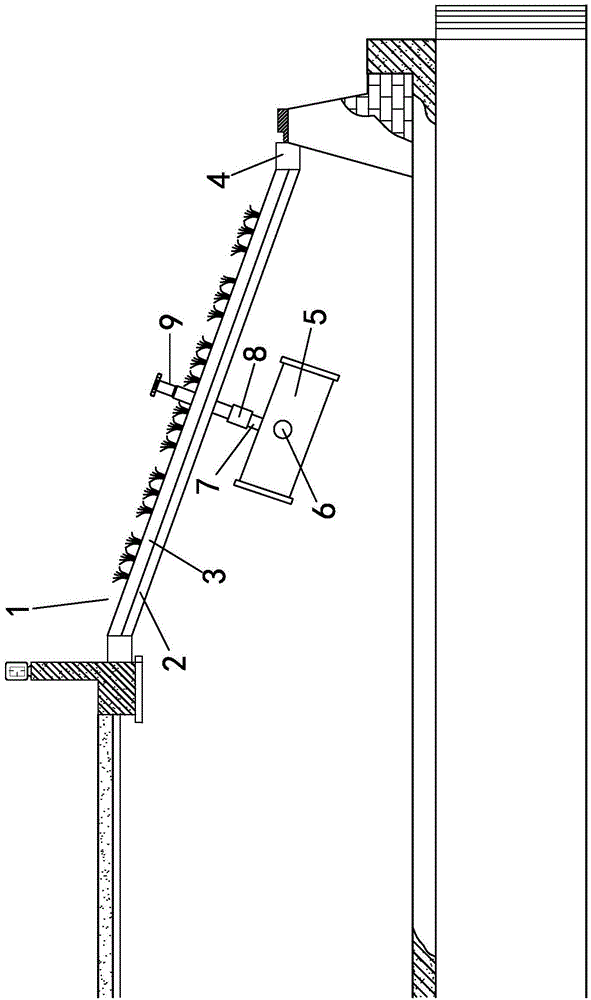

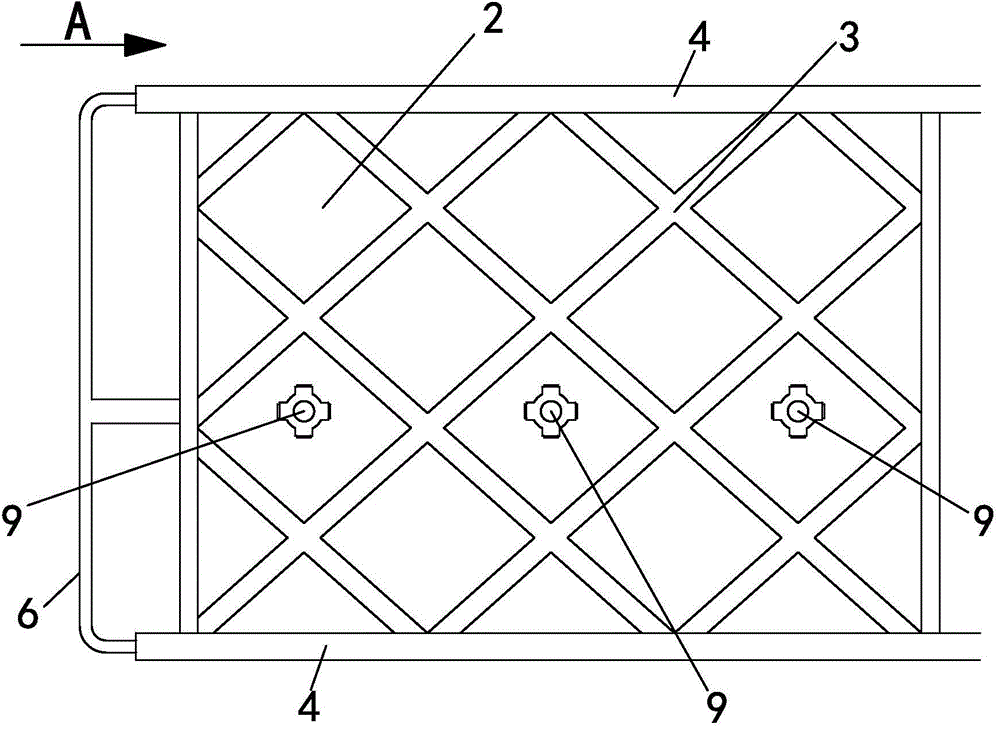

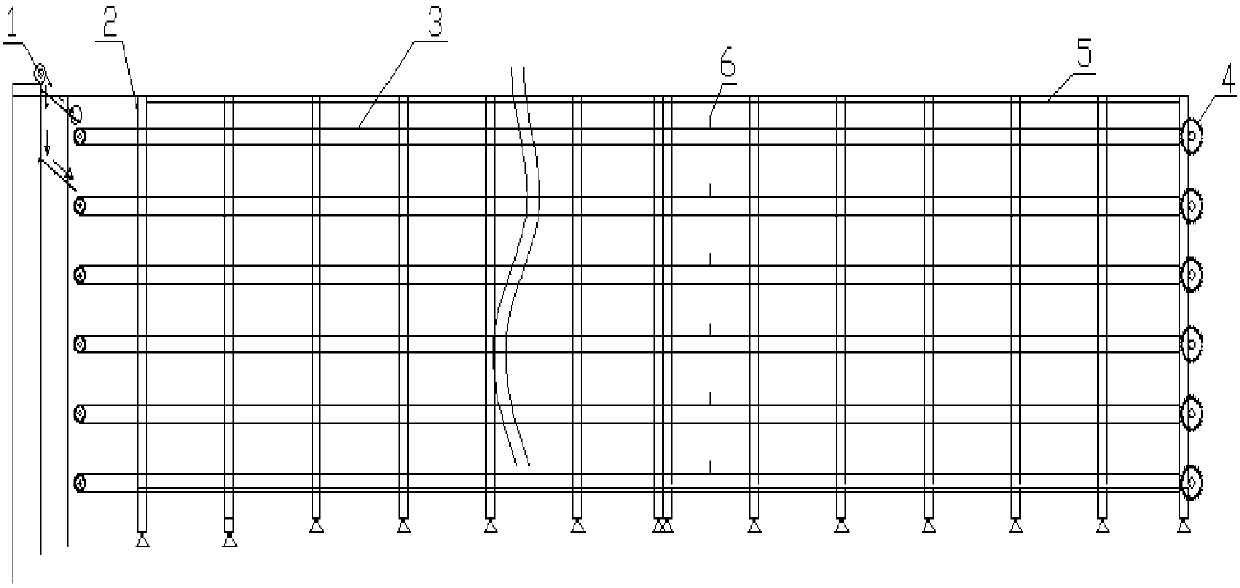

Vegetation bag ecological slope protection construction method and vegetation bag rainwater treatment system

ActiveCN104652360ARelieve stressFlushing helpsCoastlines protectionExcavationsGrowth plantVegetation

The invention discloses a vegetation bag ecological slope protection construction method and a vegetation bag rainwater treatment system. The vegetation bag ecological slope protection construction method comprises the following steps: (a) performing construction preparation; (b) measuring and lining; (c) excavating a foundation pit; (d) pouring concrete to obtain a slope foundation; (e) performing primary rainwater treatment system construction; (f) performing whole slope construction; (g) manufacturing beam grillages; (h) performing secondary rainwater treatment system construction; (i) stacking vegetation bags; (j) planting plants. According to a vegetation bag ecological slope protection system, plant growth substrates are fixed to the interiors of vegetation bags, so that a side slope is more stable and has erosion resistance by utilizing the anchoring effect of the roots of plants; the slope protection foundation which is erosion-resistant, firm and breathable, and suitable for the growth of the plants is formed by combining the characteristics of the beam grillages and the vegetation bags. Meanwhile, the rainwater treatment system is added, so that rainwater is stored in a rainy season and can be used for irrigating the plants in a dry season; on one hand, the slope protection pressure is relieved, and the water and soil loss is further prevented; on the other hand, the rainwater treatment system is favorable to the growth of the plants.

Owner:CHENGLONG CONSTR GROUP

Solvent recovery method in cellulosic fiber preparation with ionic liquid as solvent

The invention discloses a method for reclaiming solvent in cellulose fiber preparation taking ionic liquid as the solvent, which comprises the following steps: filtering solution containing the ionic liquid to remove solid particle impurities; performing film condensation by a reverse osmosis membrane; and distilling the condensed solution containing the ionic liquid under reduced pressure to make the mass content of water in the solution containing the ionic liquid less than or equal to 2 percent, and obtaining the reclaimed ionic liquid. The method is suitable for reclaiming the solution containing the ionic liquid in wide concentration range, and has low energy consumption and easy implementation.

Owner:CHTC HELON

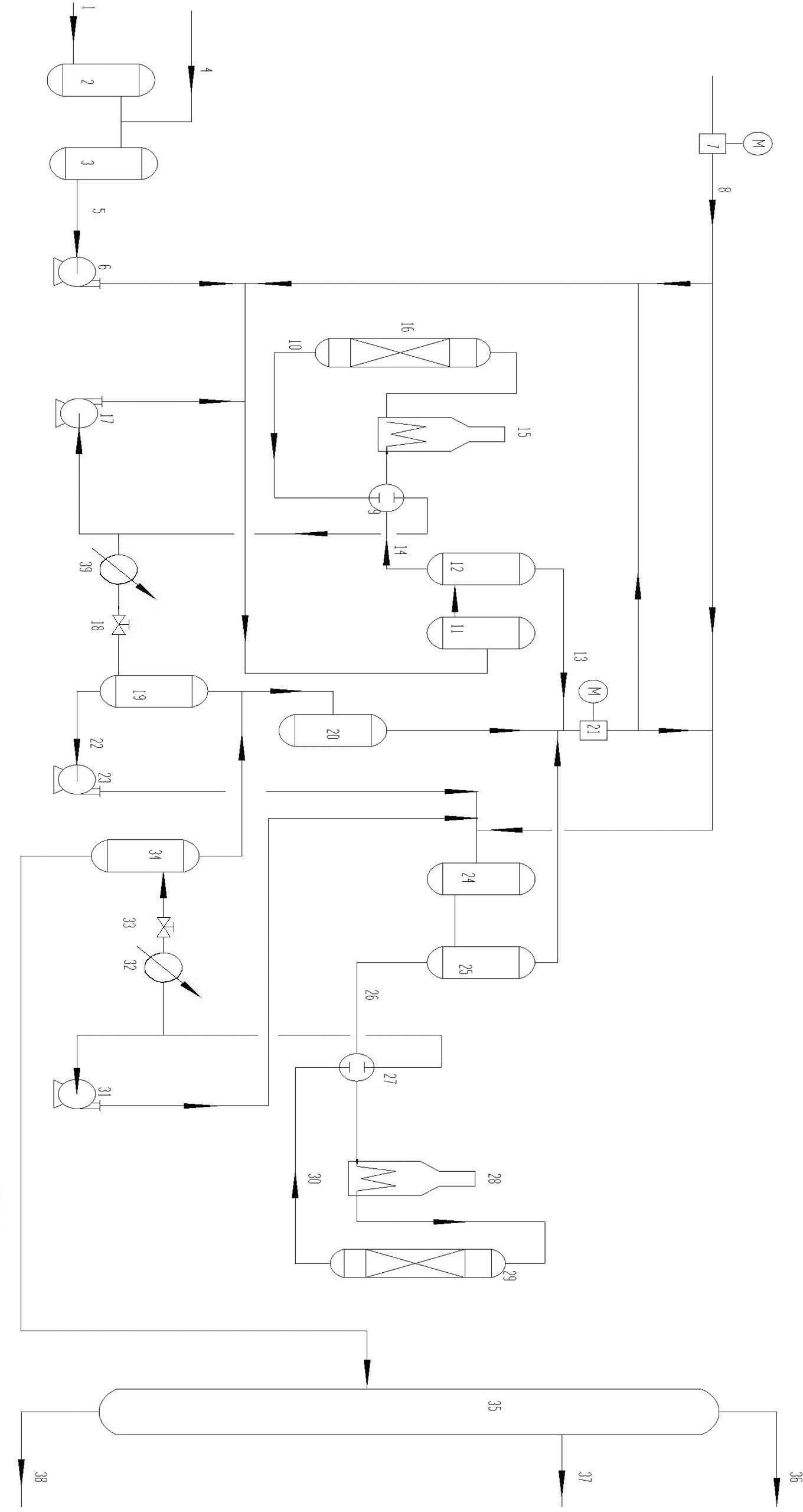

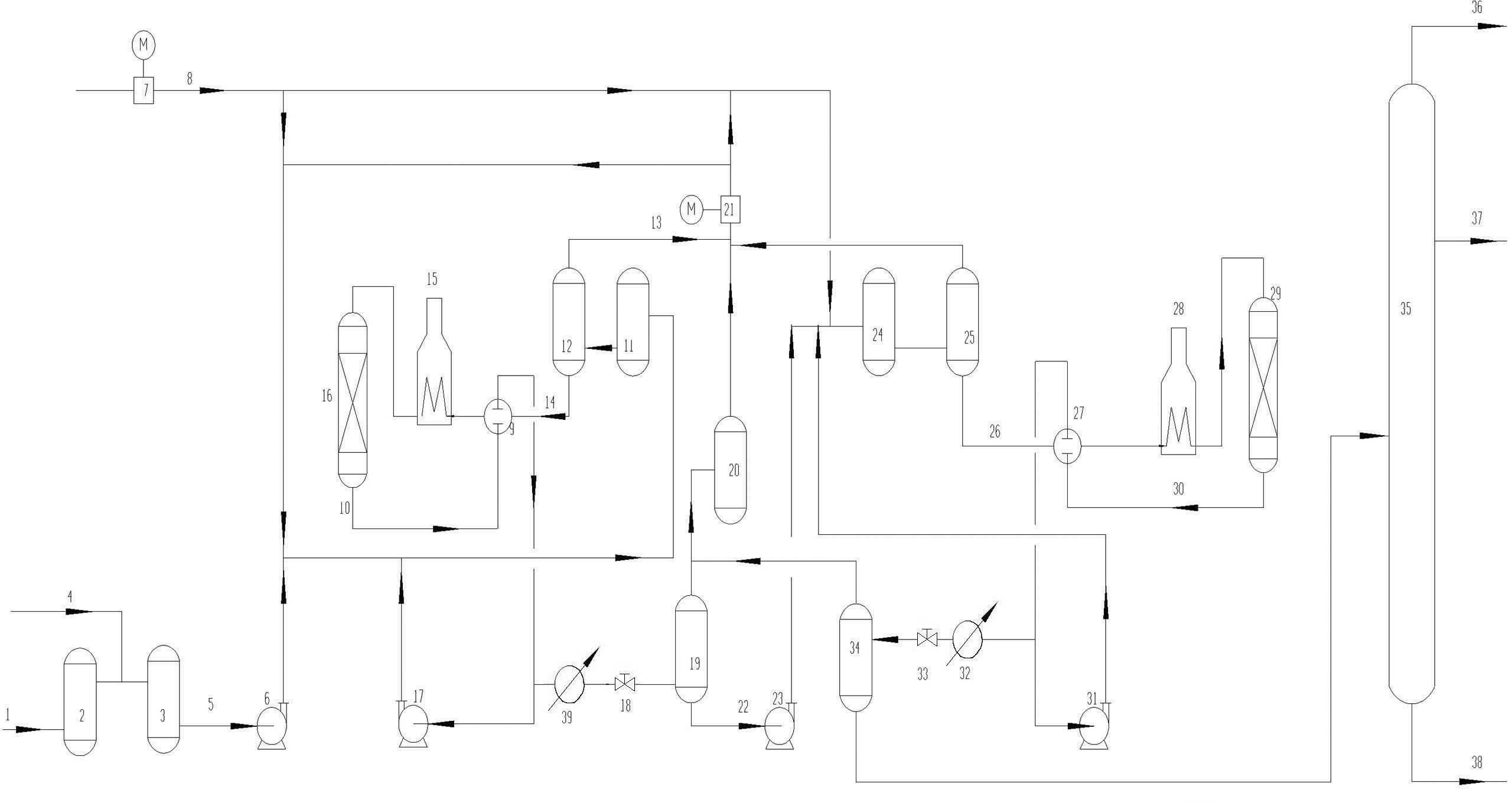

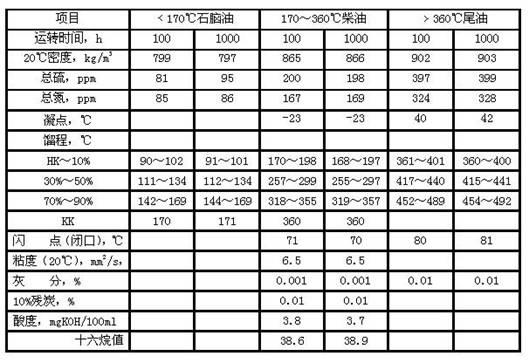

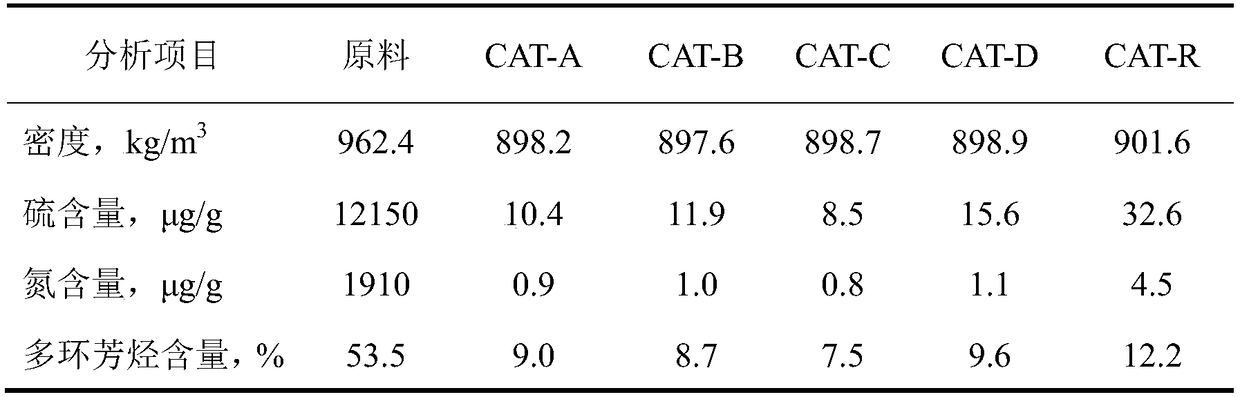

Full liquid phase hydrogenation method of coal tar

ActiveCN102585899ALess investmentRealize long cycle operationTreatment with hydrotreatment processesNaphthaFluid phase

The invention discloses a full liquid phase hydrogenation method of coal tar, which is characterized by comprising the following steps that coal tar raw materials respectively perform full liquid phase pre-hydrogenation reaction and full liquid phase main hydrogenation reaction, and main hydrogenation generated oil respectively generates naphtha products, diesel products and tail oil products through oil gas-liquid separation and distillation. The full liquid phase hydrogenation method enables the coal tar to perform the pre-hydrogenation reaction and the main hydrogenation reaction under the full liquid phase. The method can be suitable for hydrogenation modification of full fraction coal tar of any one or more of high-temperature coal tar, middle-temperature coal tar and low-temperature coal tar. During hydrogenation, coking can be effectively inhibited, reaction heat is controlled, energy loss is reduced, long-period running of a coal tar hydrogenation device is achieved, hydrogen consumption of the whole hydrogenation device can be reduced, investment of a compressor is reduced, and clean naphtha, diesel and tail oil products with sulfur nitrogen contents smaller than 400 parts per million (ppm) can be obtained.

Owner:CHANGLING PETRO CHEM ENG DESIGN

Red mud permeable brick and preparation method thereof

InactiveCN102336543ASimple preparation processReduce high energy consumptionSolid waste managementBuilding materialMaterials science

The invention discloses a red mud permeable brick and a preparation method thereof, and belongs to the technical field of building materials and construction. The red mud permeable brick comprises the following raw materials in percentage by weight: 50 to 90 weight percent of red mud, 3 to 20 weight percent of cement, 0 to 20 weight percent of sand, 0.03 to 0.16 weight percent of admixture, and 5 to 40 weight percent of water. The preparation method comprises the following steps of: fully mixing a certain amount of cement, admixture and the like and the red mud, molding the mixture by compacting, pressing or compacting and pressing, and obtaining a red mud permeable brick pavement material product by drying. Compared with the conventional red mud sintered brick, the red mud permeable brick has the advantages of high utilization rate of the red mud, simplicity in production process and low cost; and the invention has significance for improving the comprehensive utilization of the red mud and reducing environmental pollution of red mud discharge.

Owner:北京翰高兄弟科技发展有限公司

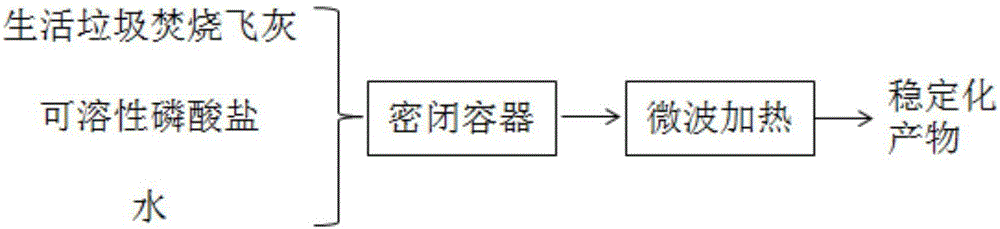

Disposition method for municipal solid waste incineration fly ash with microwave hydrothermal method applied

InactiveCN106077031AImprove adsorption capacityLow costSolid waste disposalTransportation and packagingMicrowaveResource utilization

The invention discloses a stabilizing method for municipal solid waste incineration fly ash with microwave applied. The stabilized products can be obtained by adding fly ash to be processed, a certain concentration of additive agent and water into a polytetrafluoroethylene container directly and then performing heating by the microwave to solidify heavy metal in the fly ash. After disposed by the method, the leaching concentration of the heavy metal in the fly ash can be far below the limiting value of national standard 16889-2008. By means of the stabilizing method, hazardous wastes such as the municipal solid waste incineration fly ash can be processed efficiently and rapidly to meet the requirements of secure landfill and post resource utilization. The method is simple in technology, convenient to operate, high in heavy metal solidified rate, capable of making up for deficiencies that the conventional hydrothermal disposition is high in energy consumption, long in computing time and the like, and high in practical application potential of large-scale disposition of the municipal solid waste incineration fly ash.

Owner:ZHEJIANG UNIV

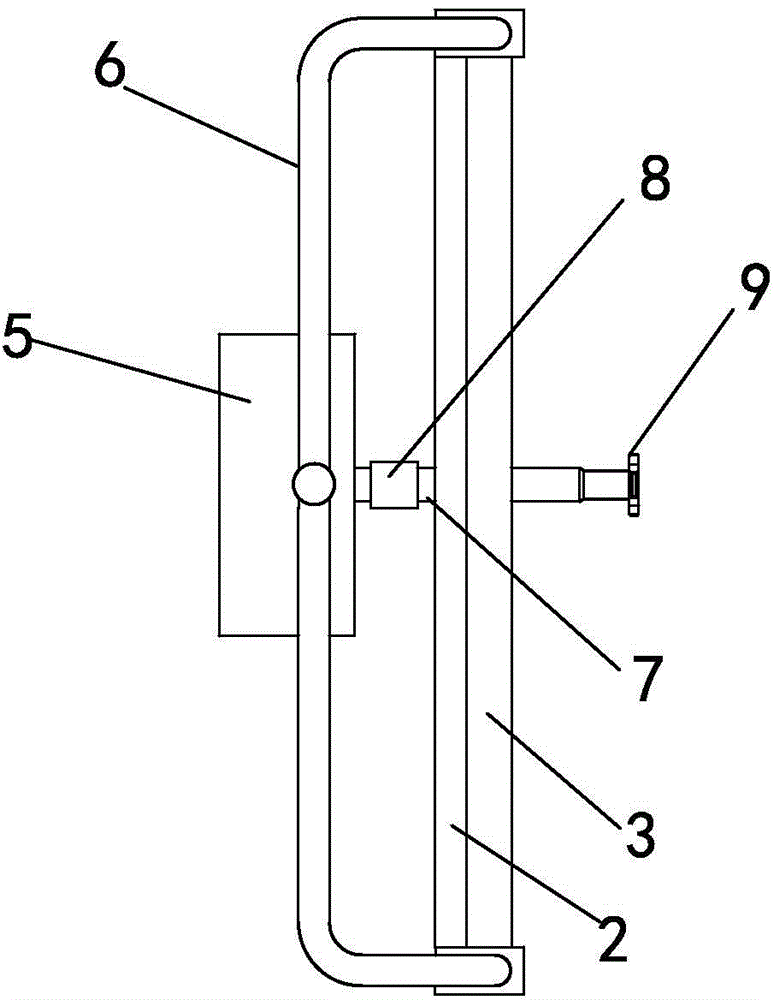

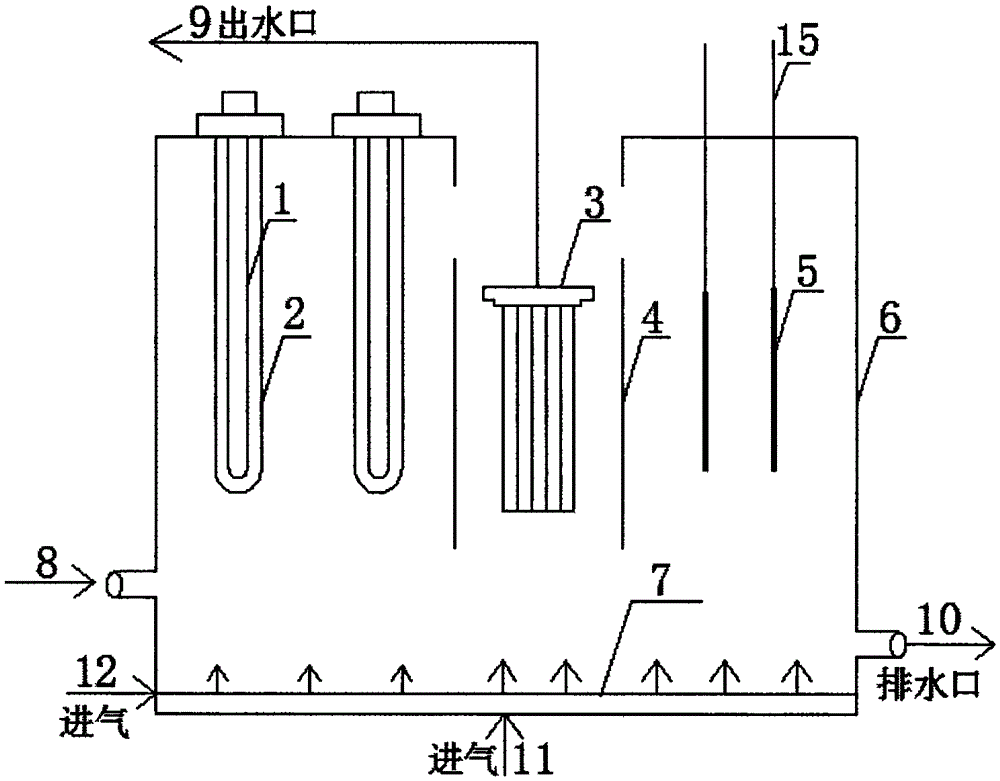

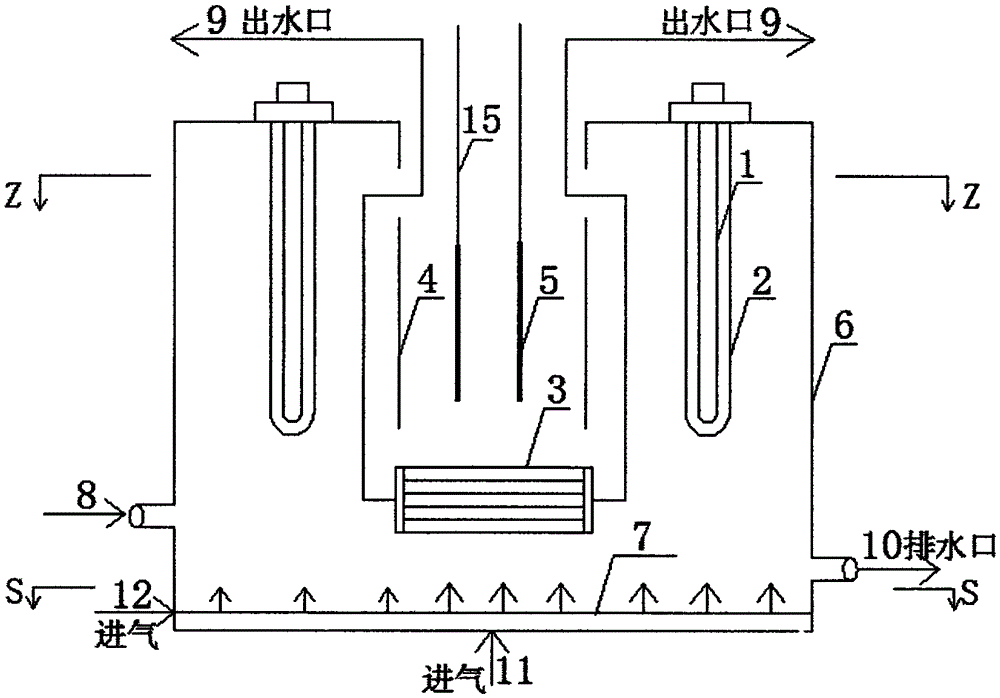

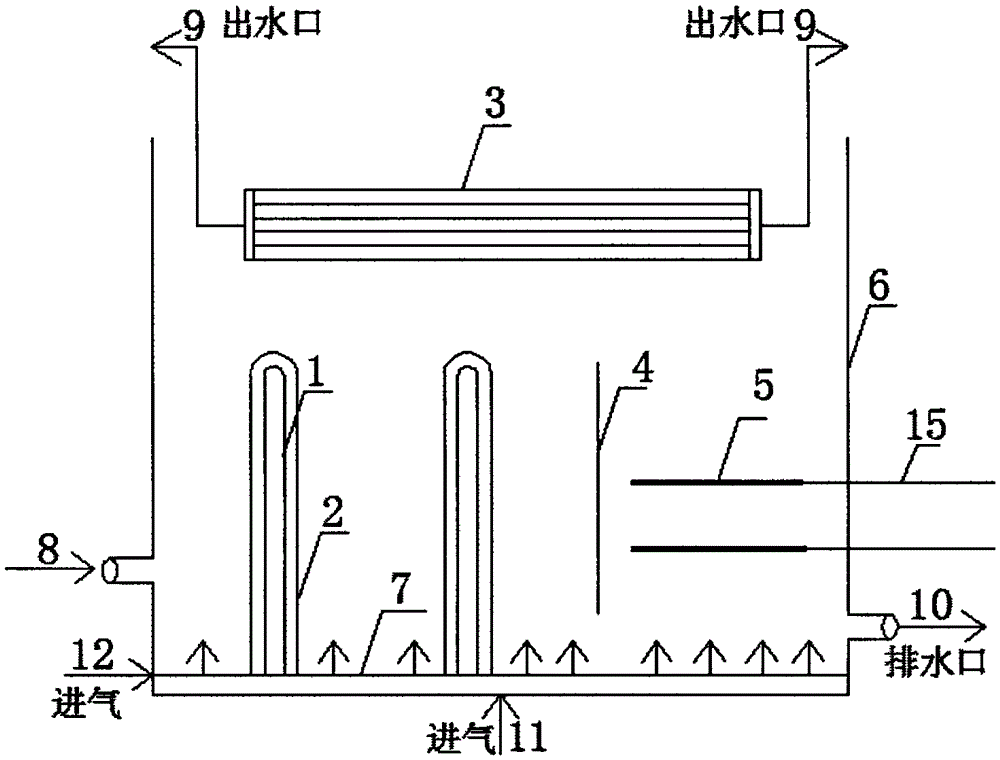

Integrated photoelectrocatalysis-membrane separation fluidized bed reaction device

InactiveCN105481051AEfficient decompositionEasy to separateWater/sewage treatment by irradiationWater treatment compoundsFluidized bedUltraviolet lights

The invention discloses an integrated photoelectrocatalysis-membrane separation fluidized bed reaction device. The reaction device comprises a housing, an ultraviolet source, an electrode plate, a membrane component and an aerating unit. A water inlet and a water outlet are formed in the bottom of the housing. The aerating unit, the ultraviolet source, the electrode plate and the membrane component are arranged in the housing. The membrane component is connected with the housing. The distance between the ultraviolet source and the membrane component as well as the distance between the electrode plate and the membrane component are larger than or equal to the penetrating distance of ultraviolet light and the reaction distance of the electrode plate respectively. According to the integrated photoelectrocatalysis-membrane separation fluidized bed reaction device, multiple functions, including a photocatalysis function, an electrocatalysis function and a membrane separation function, are achieved, the mass transfer performance is good, the catalyst utilization efficiency is high, the catalyst can be recycled, waste water treatment efficiency is high, the structure is simple, and energy consumption is reduced.

Owner:TIANJIN POLYTECHNIC UNIV

Preparation process of neopentyl polyol oleate

InactiveCN104945247ATake advantage ofReduce high energy consumptionOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePolyol

The invention relates to a preparation process of neopentyl polyol oleate. The preparation process comprises the following steps: by aiming at different batches of purchased neopentyl polyol and oleic acid, firstly determining a theoretical molar ratio required by a complete esterification reaction between neopentyl polyol and oleic acid according to the number of hydroxide radicals in molecules of utilized neopentyl polyol or mixed neopentyl polyol, or carrying out multiple small experiments according to a previous experience molar ratio of neopentyl polyol or mixed neopentyl polyol to oleic acid, ending the experiment when the acid value of a small experiment sample is less than or equal to 1.5mgKOH / g and synthetic liquid and water is well separated, and producing by taking the raw material batch and raw material ratio of the last small experiment as the raw material ratio for large-scale production. The preparation process has the advantages that the raw materials can be adequately utilized, and troubles in after-treatment of products are reduced.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

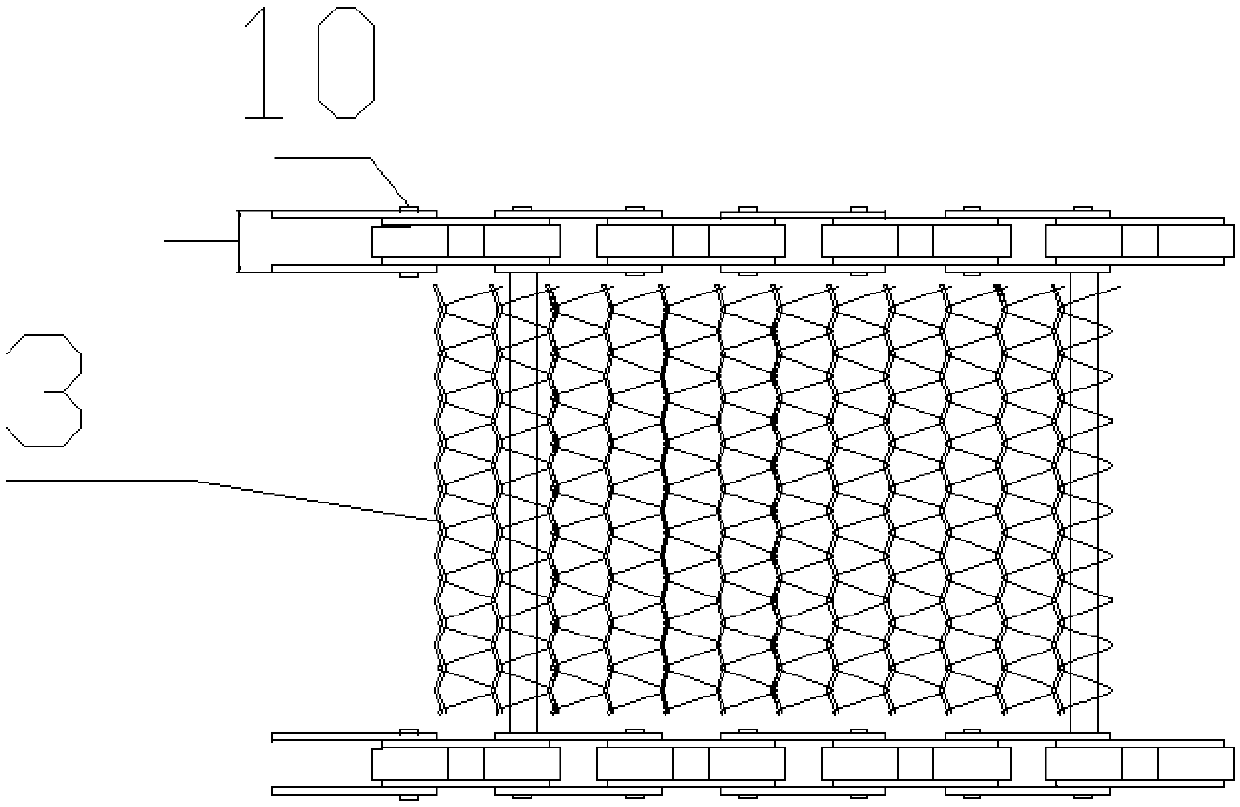

Device and method for treating sludge through earthworm cultivation

PendingCN107721109AImprove farming efficiencySimple structureBiological sludge treatmentAnimal husbandryAgricultural scienceSludge

The invention belongs to the field of sludge treatment, and particularly relates to a device and a method for treating sludge through earthworm cultivation. An earthworm cultivation device comprises abracket, a plurality of transporting and cultivating units, a feeding end and a discharging end; the plurality of transporting and cultivating units are arranged on the bracket at up-and-down intervals; the feeding end and the discharging end are arranged at the left side end and the right side end of the transporting and cultivating units correspondingly; each transporting and cultivating unit comprises a supporting net, chains, a gear and a motor; the supporting net is used for placing sludge and annularly closed in the left-and-right direction; the chains are arranged at the front end andthe back end of the supporting net and used for driving the supporting net to move; the gear is used for driving the chains to move; the motor is used for driving the gear; a supporting frame is arranged at the feeding end; a foldable transporting plate corresponding to each transporting and cultivating unit is arranged on the supporting frame. Compared with the existing equipment, the earthworm cultivation device adopts automation, is simple in structure, easy to operate and low in manpower demand, and greatly reduces labor cost. Moreover, the occupied area is reduced, the earthworm cultivation efficiency can be effectively improved, the cultivation time is shortened, the yield of the earthworms is increased, energy consumption is reduced and the cultivation cost is reduced.

Owner:北京派润环境科技有限公司 +2

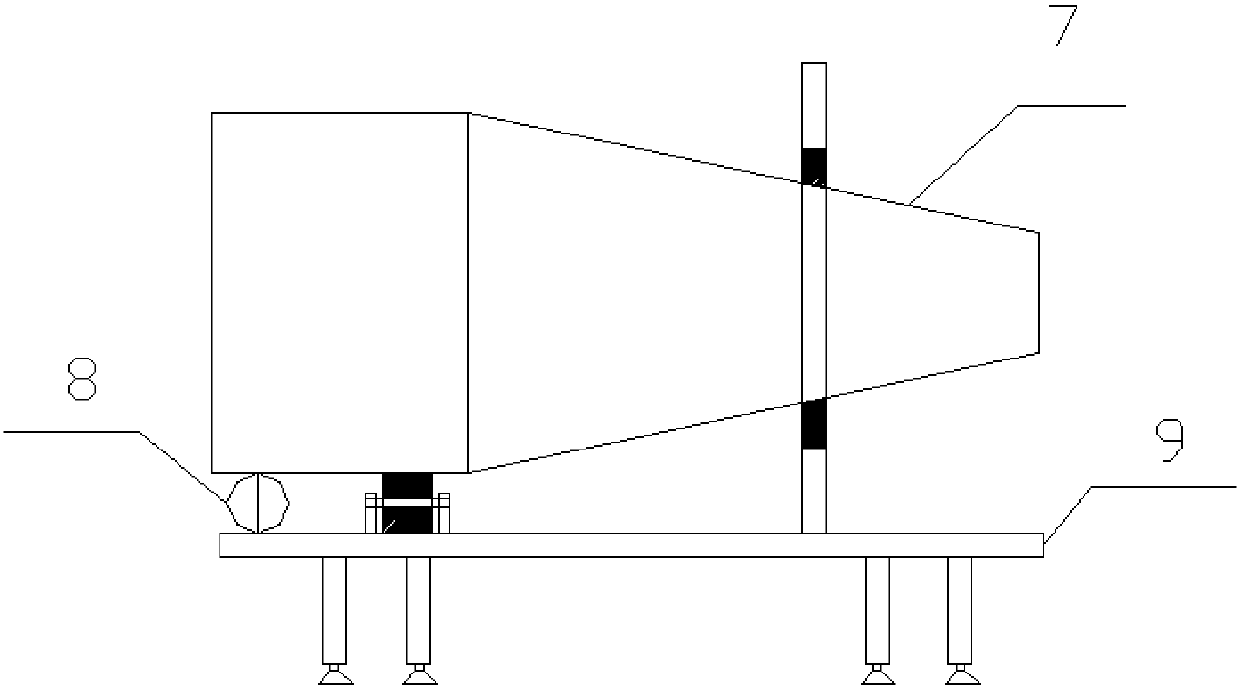

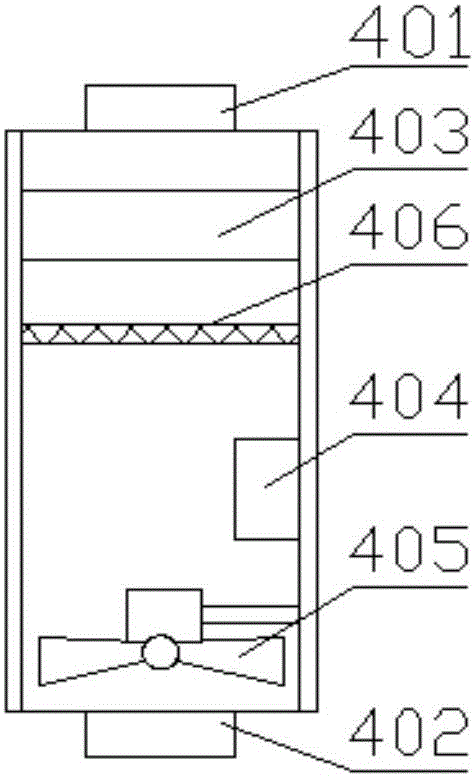

Atmospheric particulate sampling system

ActiveCN106153403AMeet load requirementsReduce high energy consumptionWithdrawing sample devicesParticulatesAtmospheric air

The invention relates to an atmospheric particulate sampling system, and belongs to the technical field of atmosphere monitoring. The atmospheric particulate sampling system comprises an aircraft with a sampling apparatus and a ground moving power supply apparatus, wherein the aircraft is connected with the ground moving power supply apparatus by virtue of a cable, the aircraft is a rotorcraft, the sampling apparatus comprises a rotary gas collection mechanism and a gas sampler, an opening of a gas input end of the rotary gas collection mechanism faces upwards and is disposed below an annular area formed by distributing all rotors, the sampling system is provided with a controller, and the gas sampler forms a mechanism for sampling atmospheric particulates in all directions for a long time by virtue of the control of the controller on the rotary gas collection mechanism and the rotorcraft. The rotary gas collection mechanism is switched between a working position and a nonworking position by the rotary gas collection mechanism, the atmospheric particulates are collected by virtue of airflow generated by rotors, the load capacity is greatly reduced, the flight duration is greatly prolonged, and the requirement on a power sully is also reduced.

Owner:中国科学院遗传与发育生物学研究所农业资源研究中心 +1

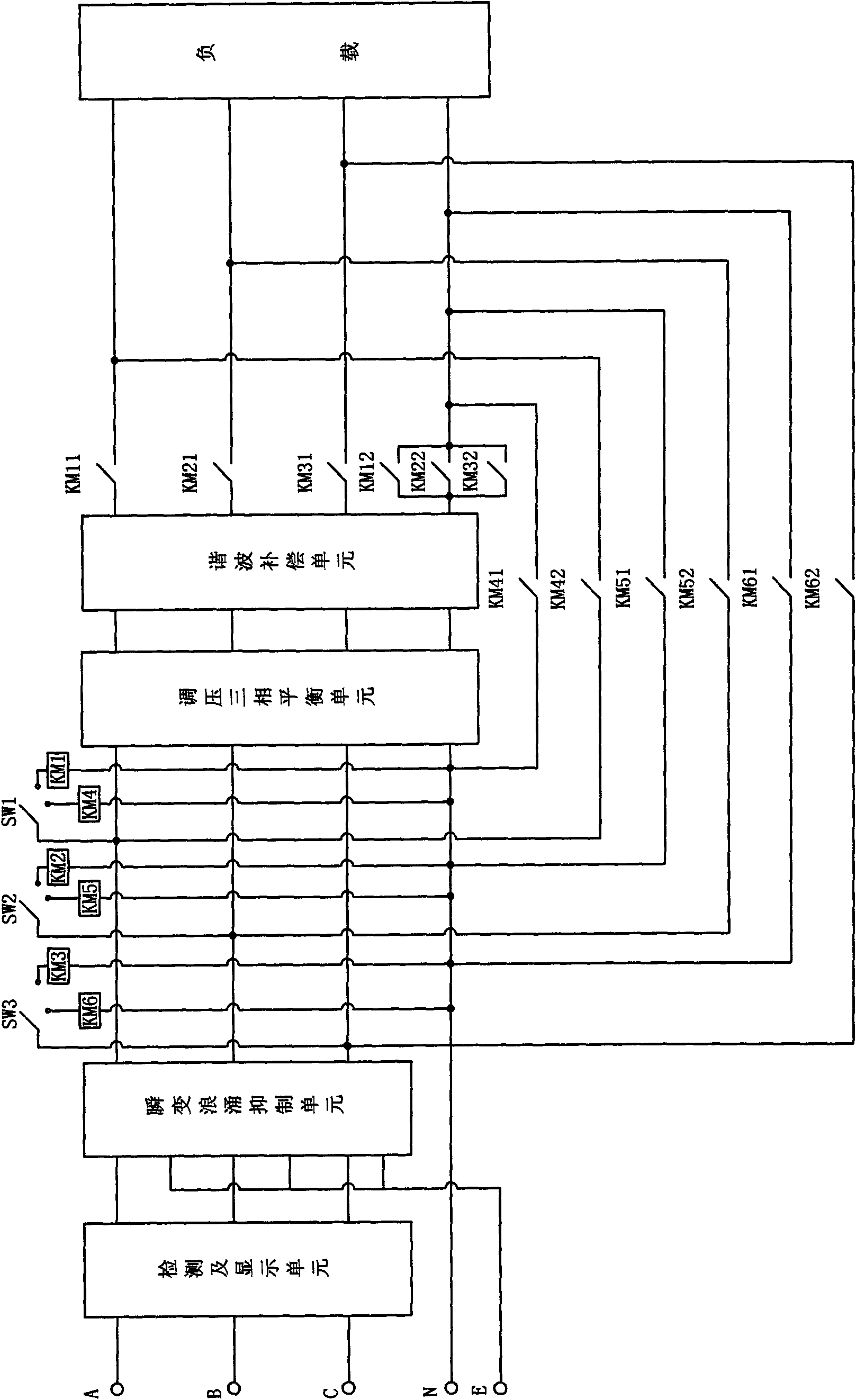

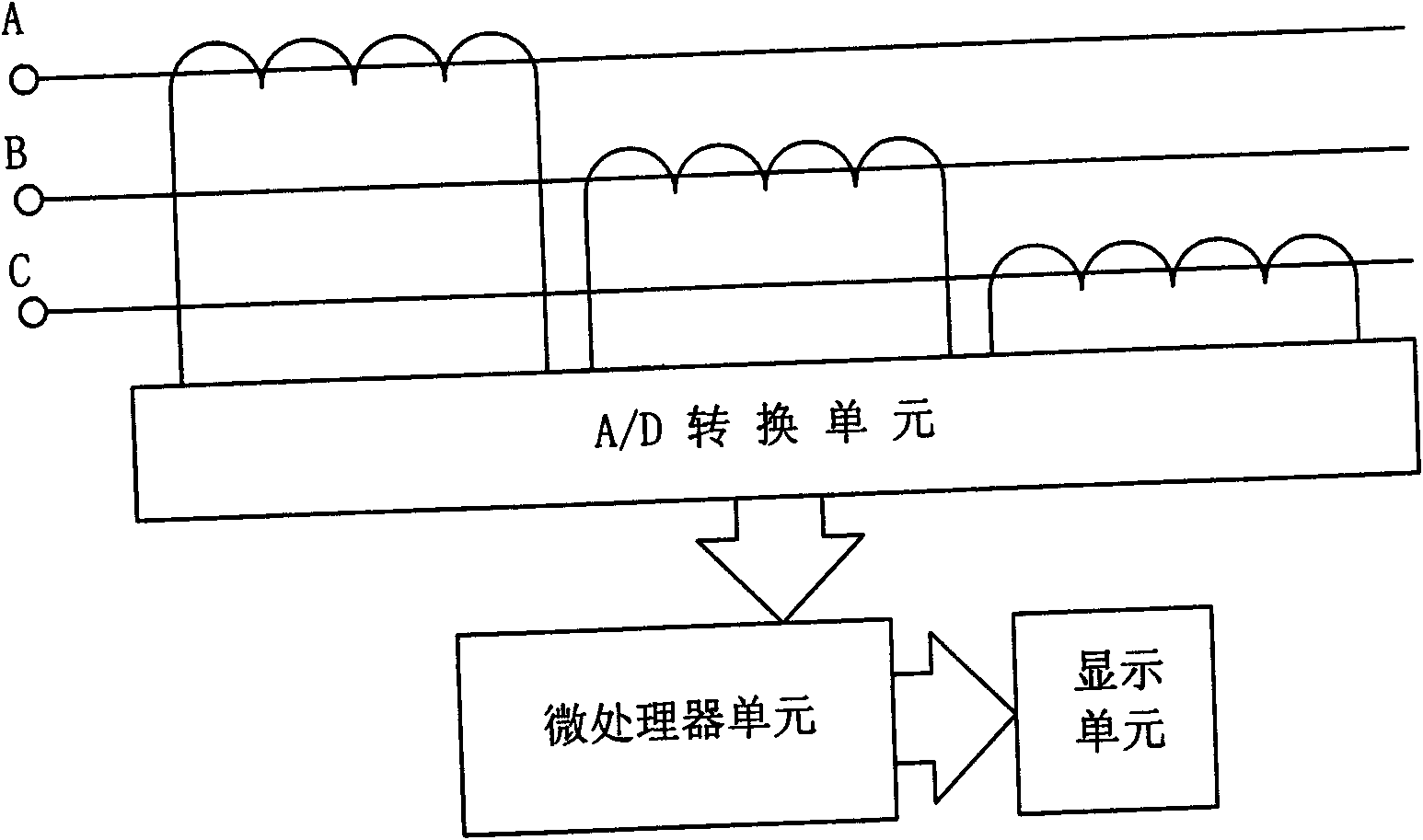

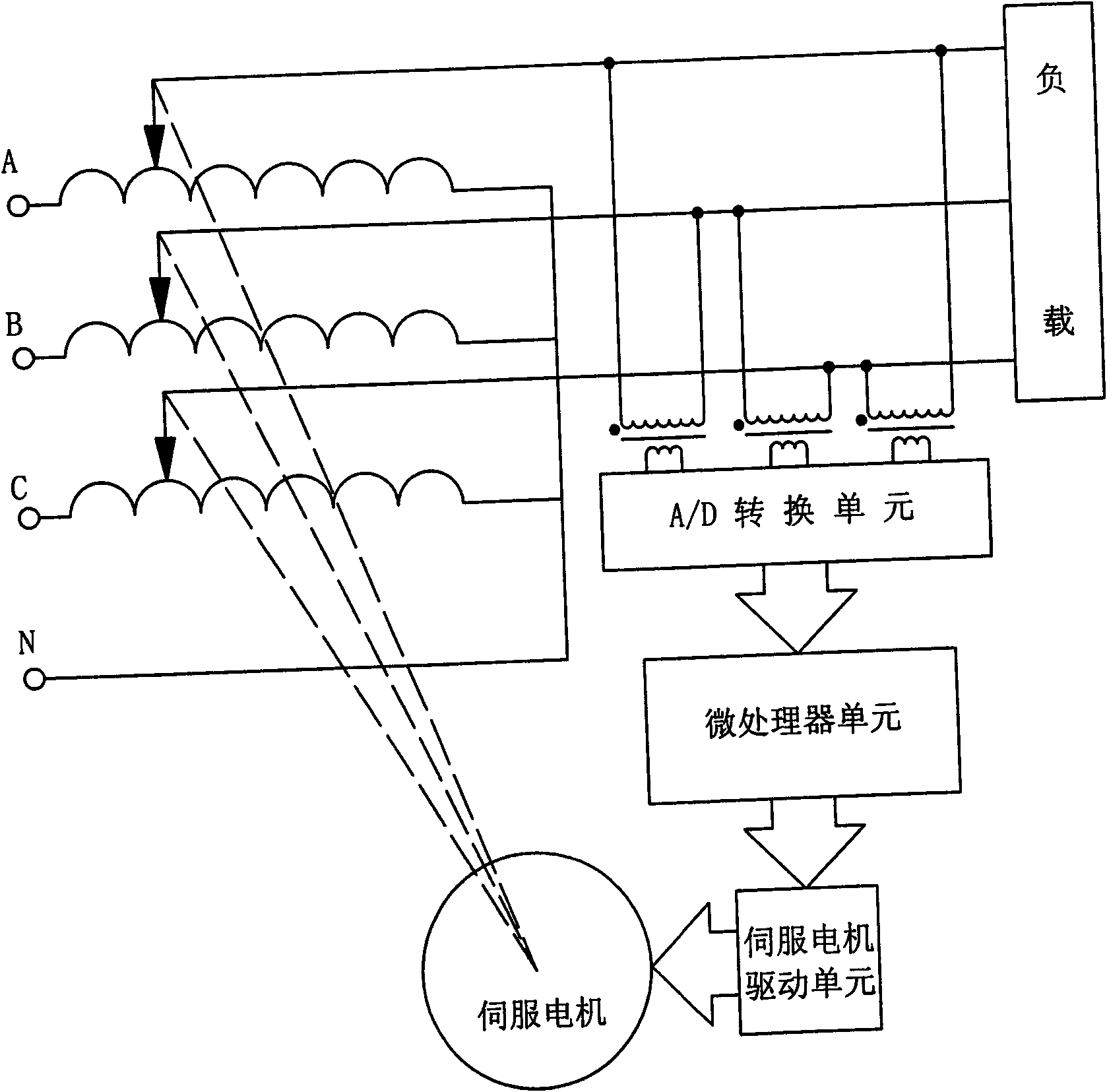

Intelligent three-phase electricity-saving protection controller

InactiveCN101609990AReduce energy consumption increaseImprove efficiencyReactive power adjustment/elimination/compensationAc network voltage adjustmentTreatment effectElectricity

Owner:SHENZHEN VICLAND SHENGSHI ENERGY SAVING TECH CO LTD

Method for manufacturing steel wire hydraulic knitted rubber hose containing formaldehyde modified lignin

ActiveCN102173066AGood dispersionGood physical and mechanical propertiesTubular articlesDispersityEngineering

The invention relates to a method for manufacturing a steel wire hydraulic knitted rubber hose containing formaldehyde modified lignin, belonging to the technical field of the methods for manufacturing rubber products. Mixing rubber produced by utilizing a mixing process serves as a rubber hose and used for producing the high-performance steel wire knitted hydraulic rubber hose for an inner liner. The technical scheme of the method comprises the following steps of: a sizing material mixing process: adopting a two-stage mixing method, that is, mixing and producing one-stage rubber by utilizingan internal mixer, placing the rubber for 8-24 hours and then carrying out second-stage sulfur adding in an open mill, wherein a reverse-order mixing method and variable-speed mixing are utilized in the one-stage mixing in the internal mixer and the heat treatment is carried out on the sizing material during the two-stage mixing in the open mill; extruding the inner liner of the steel wire hydraulic knitted rubber hose by utilizing the mixing rubber; and manufacturing the steel wire hydraulic knitted rubber hose via a knitted steel wire enhancing layer and an extrusion external coating and through cladding, setting and vulcanizing. By utilizing the mixing process, the dispersity of the lignin is greatly improved; the physical and mechanical properties of the steel wire hydraulic knitted rubber hose are good; and compared with nitrile rubber separately using carbon black as a reinforcing agent, the steel wire hydraulic knitted rubber hose containing the formaldehyde modified lignin hasobvious advantages of rigidity, aging resistance and oil resistance at a normal temperature.

Owner:GUANGZHOU TIANHE HOSE PRODS

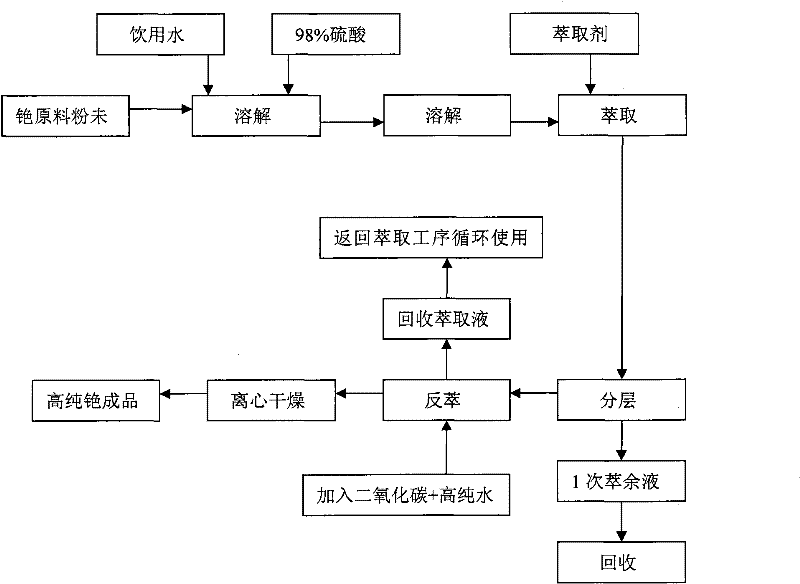

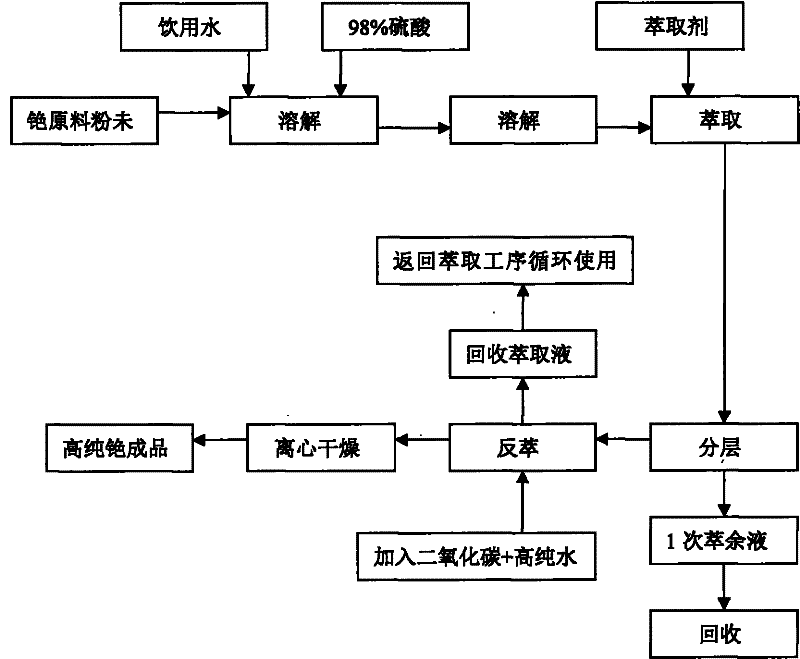

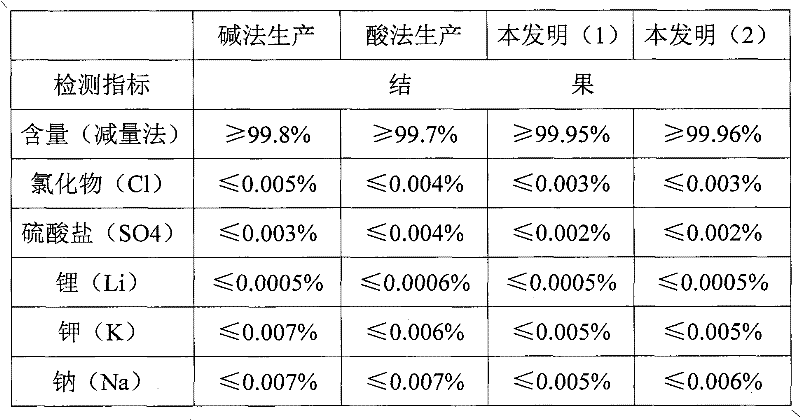

Preparation method of cesium carbonate

ActiveCN102241409AReduce manufacturing costReduce high energy consumptionRubidium/caesium/francium compoundsHigh energyToxic material

The invention relates to a preparation method of cesium carbonate. The cesium carbonate is prepared from raw materials of cesium powder, 98% of sulfuric acid and water, wherein a weight ratio of cesium powder to 98% of sulfuric acid to water is 1:0.7 to 0.8:1.8 to 2.2. The preparation method comprises the steps that: cesium powder is pretreated, such that a leached stock solution is obtained; the pH value of the stock solution is regulated; the stock solution is extracted, layered, back-extracted, dried by centrifugation, dried by baking, and packaged. After the processes, a finished product is obtained. The cesium carbonate preparation method provided by the invention is advantaged in that: (1) a high energy consumption of traditional alkali production methods is reduced, a requirement to equipment is reduced, and cesium carbonate production cost is greatly reduced; (2) generation of toxic substances during a production process with an acid method is avoided, production period is shortened, and productivity is improved; (3) a cesium ion leaching rate of the product provided by the present invention in a metal ion solution reaches 98.5%, while a cesium ion leaching rate of products provided with traditional technologies in a metal ion solution is 80%; (4) product quality is improved, and application scope of the product is enlarged.

Owner:上海实验试剂有限公司 +1

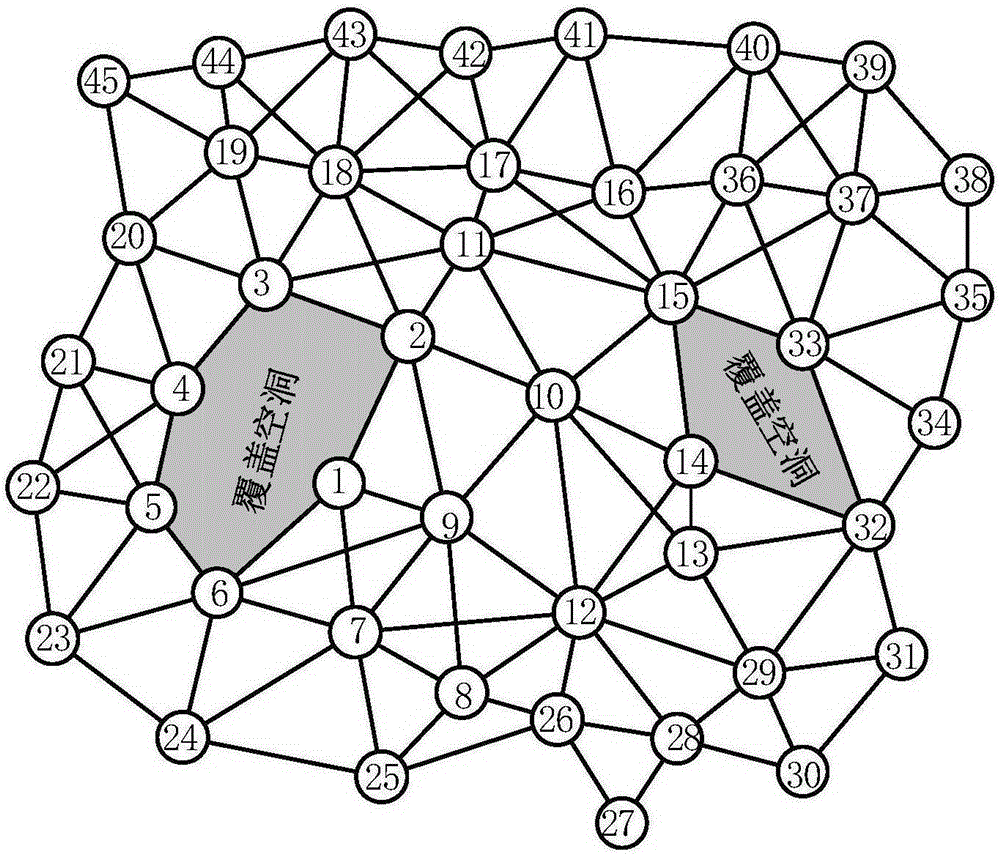

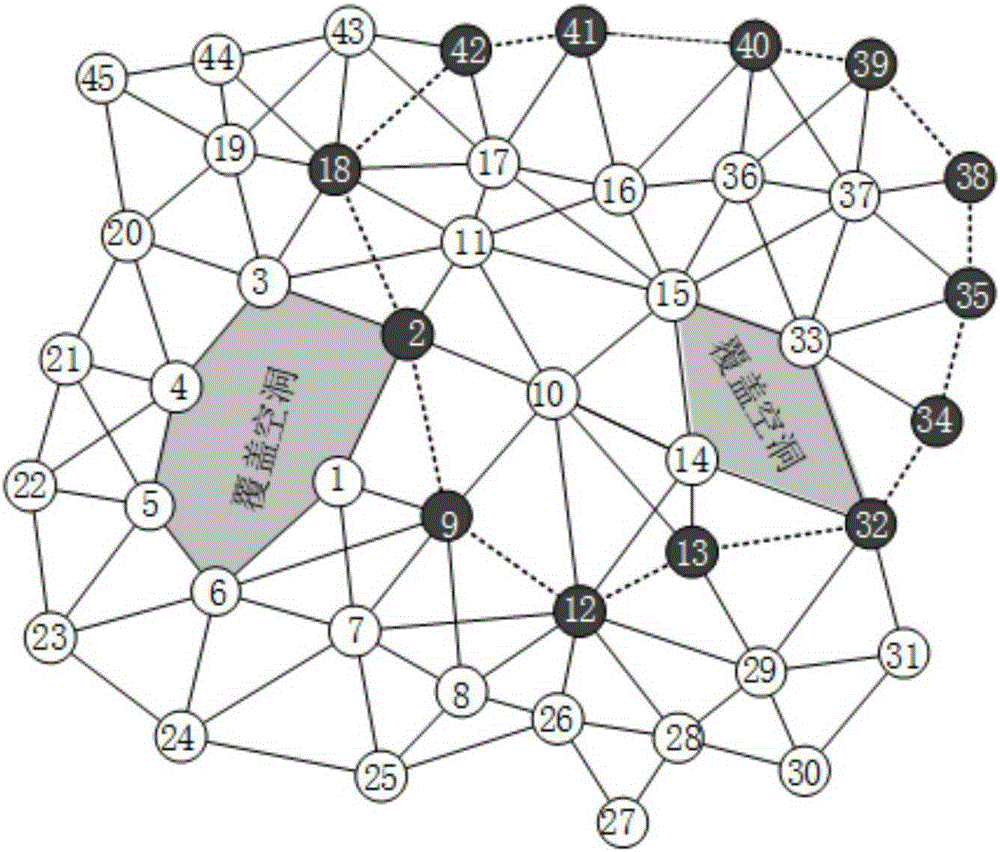

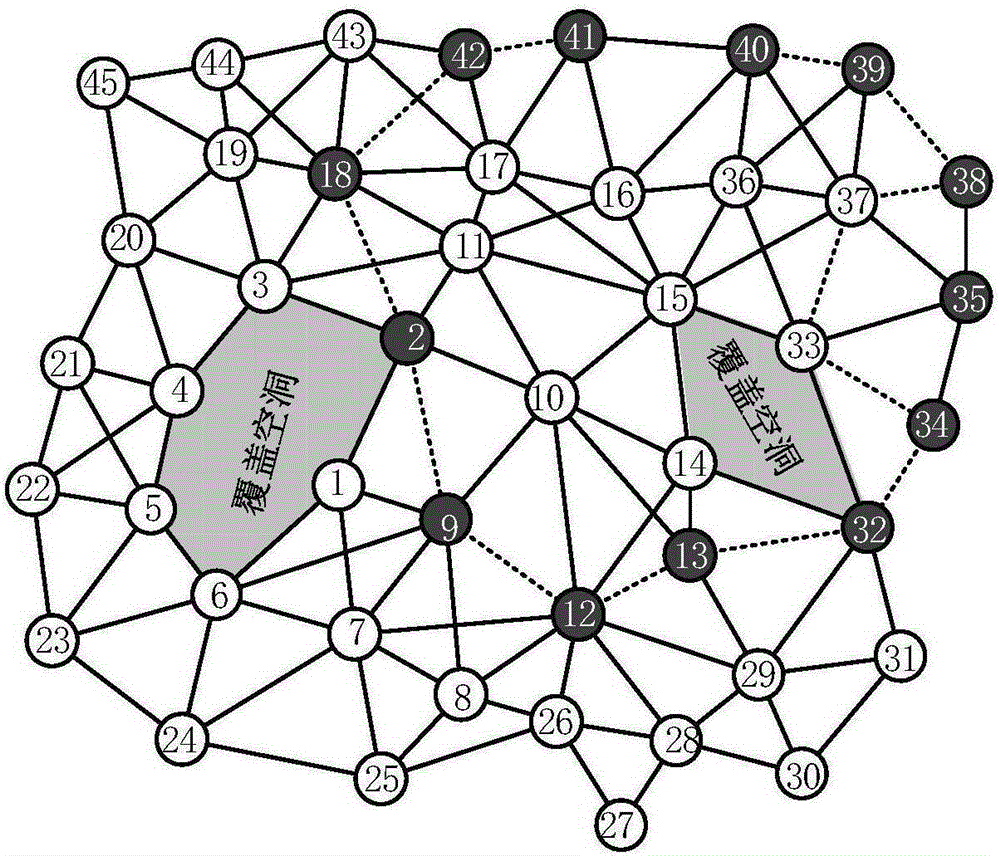

Wireless sensor network edge node recognition method independent of position information

ActiveCN105357732AWork around a bug that requires node location informationLower deployment costsNetwork topologiesClosed loopEdge node

The invention provides a wireless sensor network edge node recognition method independent of position information. The method comprises the steps: firstly determining a 1-hop neighbor node and a 2-hop neighbor node of a current node; determining a 2-hop neighbor of the current node and determining whether the combination set of the 1-hop neighbor and 2-hop neighbor can form a closed loop or not; determining the shortest path tree T of a control node in the closed loop; determining the current node to be an edge node if the depth of the shortest path tree T is less than 3, or else, compressing the closed loop; and judging the current node to be the edge node if the compressed closed loop comprises the 2-hop neighbor node of the current node. The method can precisely recognize a boundary node in a wireless sensor network through employing node connection information and a node surrounding enclosing thought, achieves the recognition of the edge of the wireless sensor network and the edge node of a coverage hole under the condition of no node coordinate position information based on the connection information between nodes, and irons out a defect that a conventional recognition algorithm needs node position information. The recognition precision is greater than 90%.

Owner:ZHONGBEI UNIV

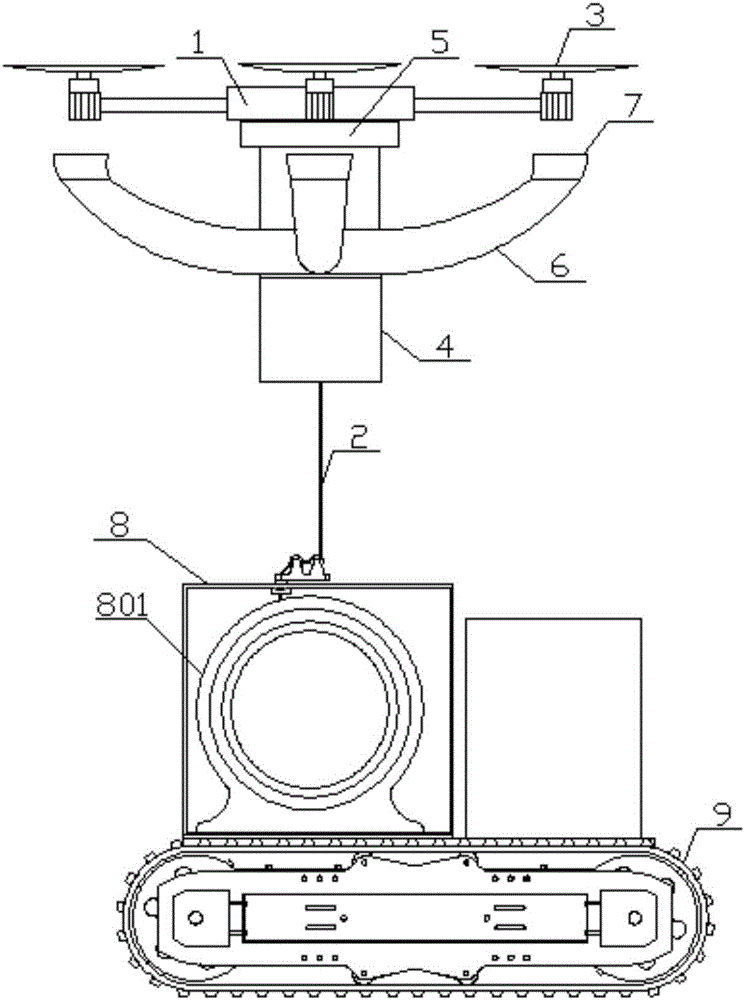

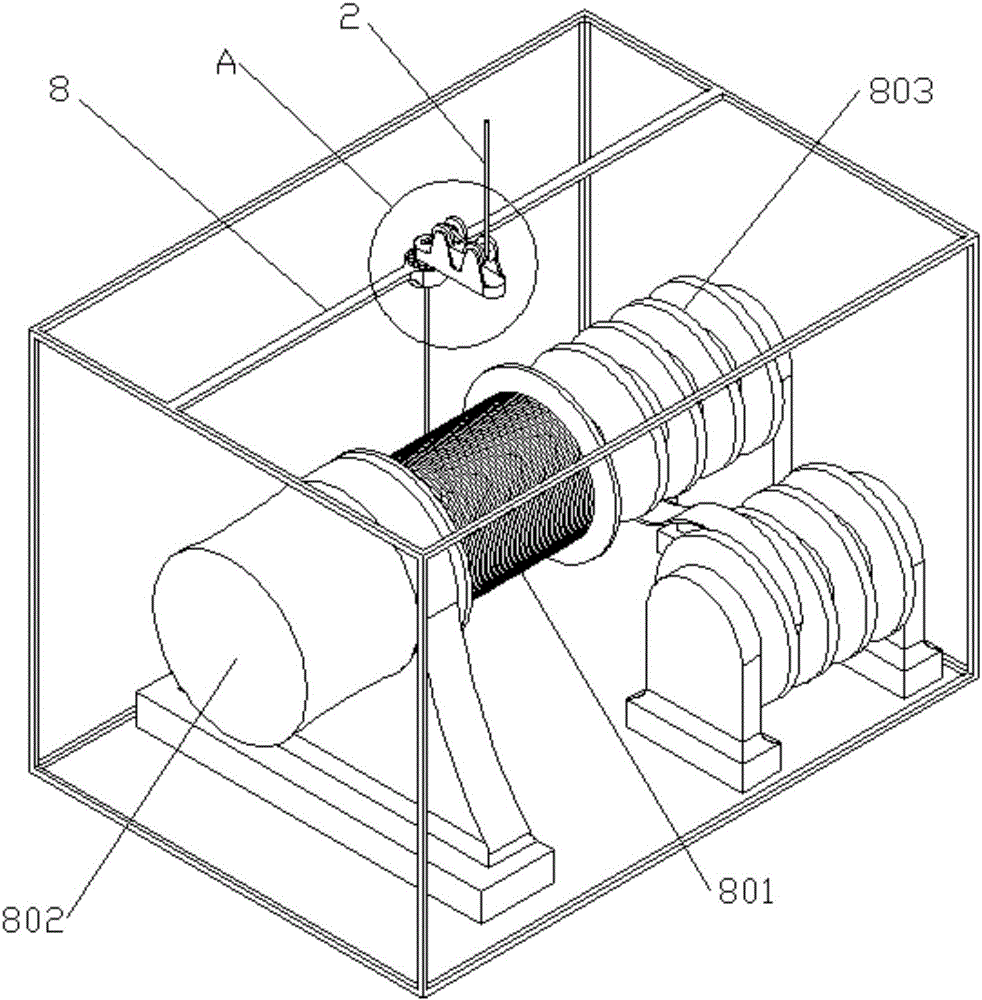

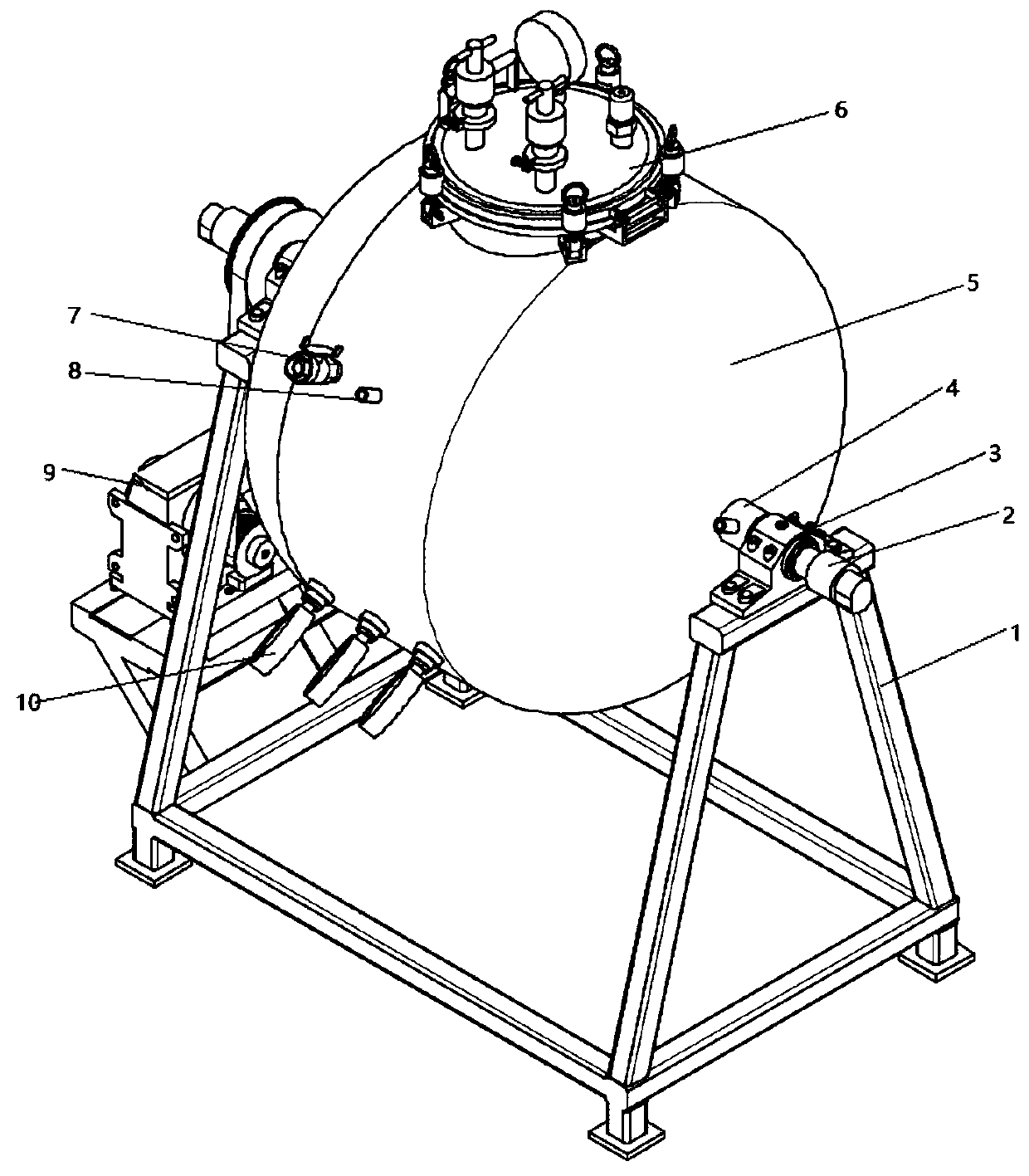

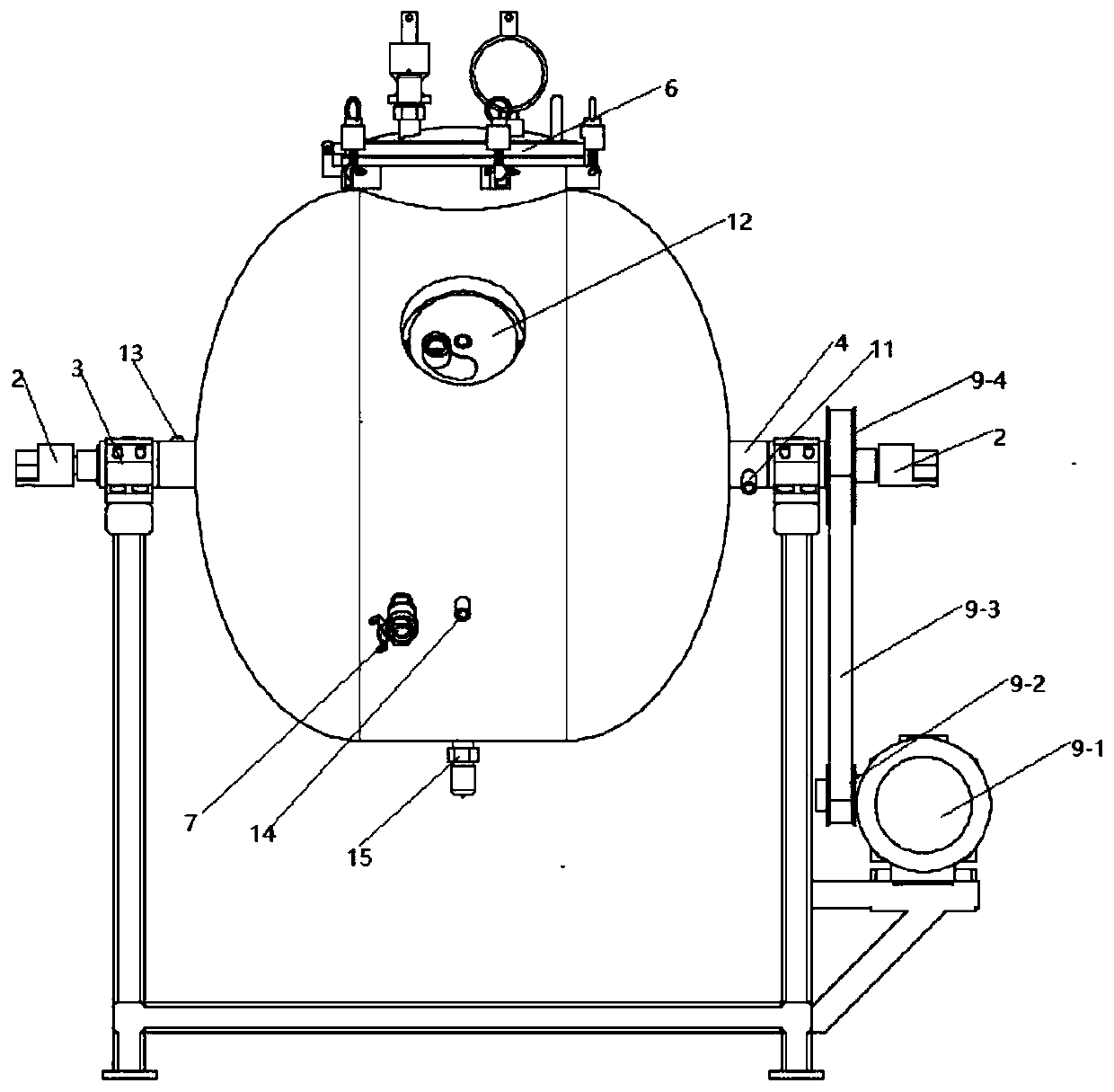

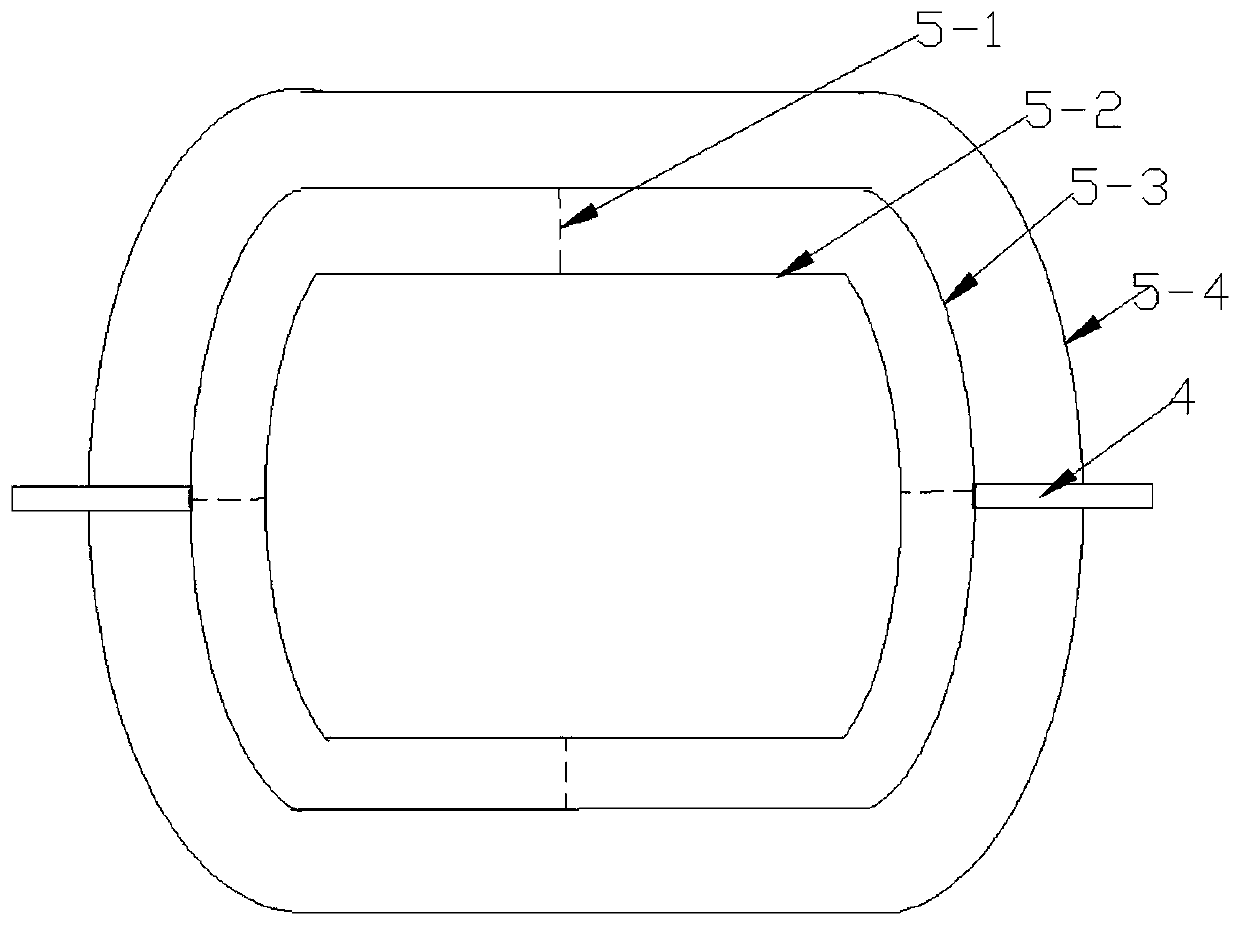

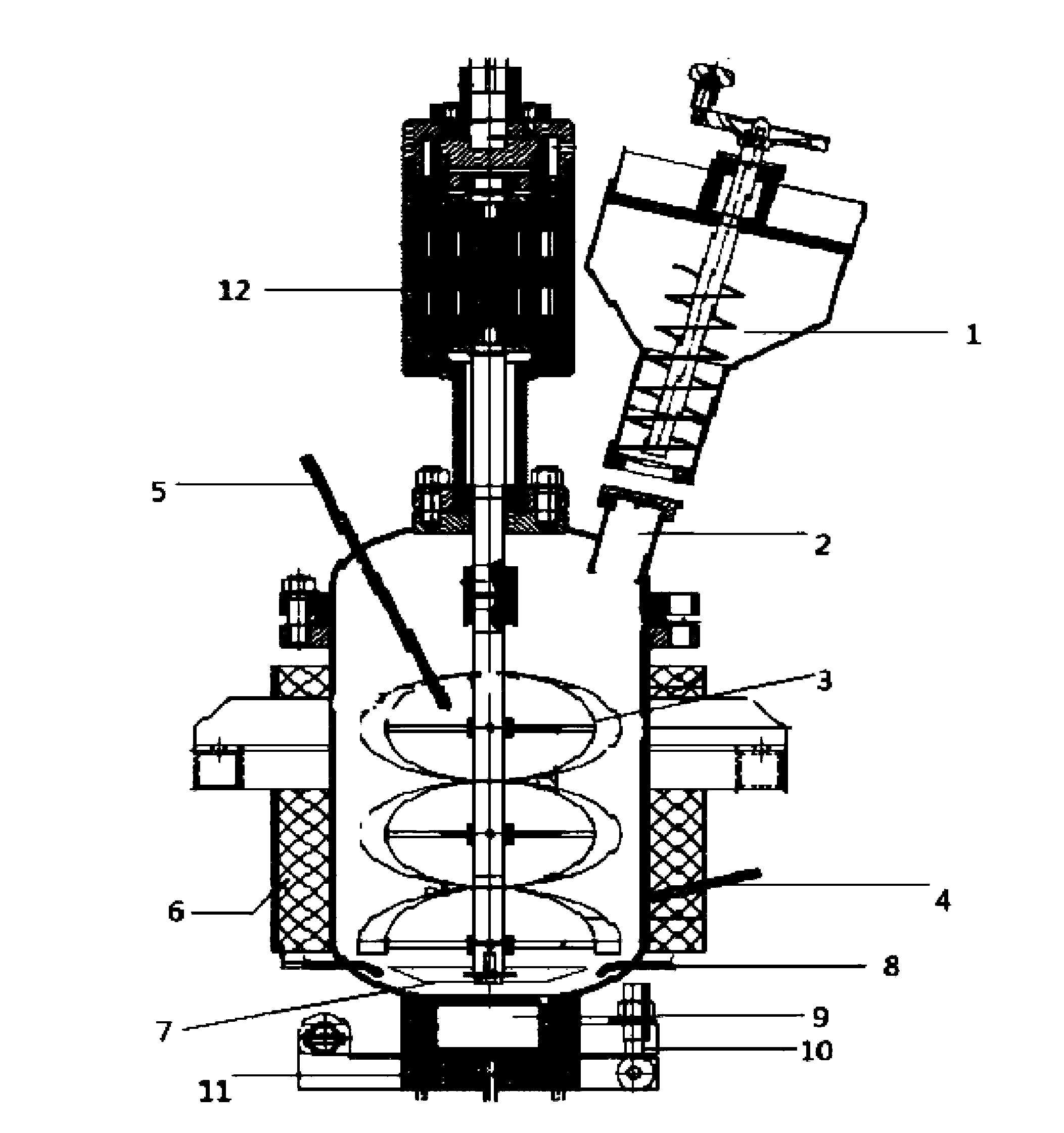

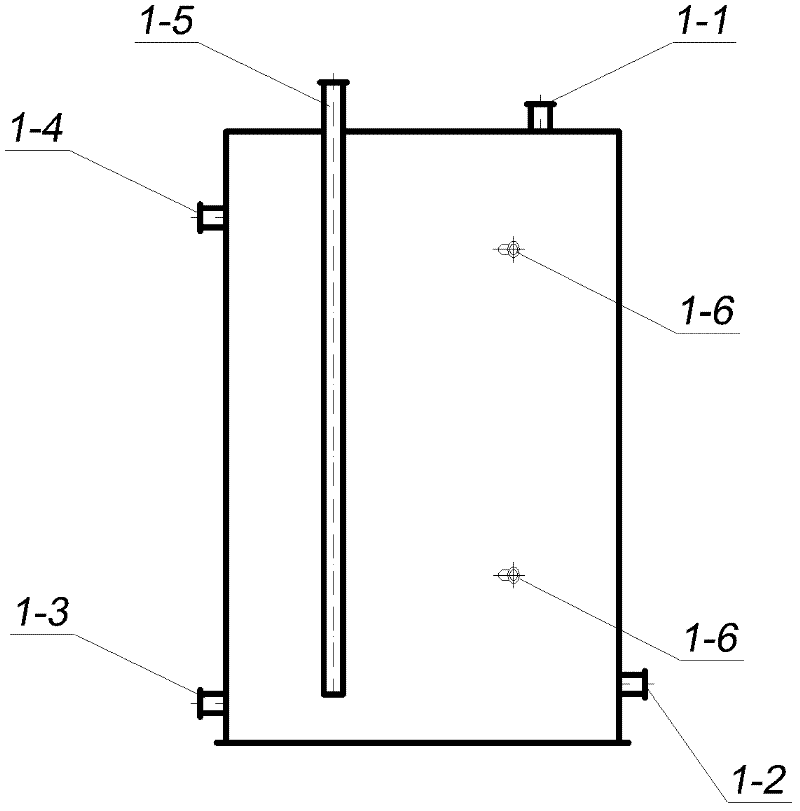

Controllable integral rotary solid-state fermentation tank

InactiveCN110066706AEasy to manufactureSmooth rotationAlcoholic beverage preparationWater dischargeAgricultural engineering

Disclosed is a controllable integral rotary solid-state fermentation tank. The controllable integral rotary solid state fermentation tank comprises a rack, the top of the rack is connected with two hollow rotating shafts through bearing bases separately, the two hollow rotating shafts are provided with a water inlet and a water outlet respectively, the ends of the hollow rotating shafts are connected with rotary joints respectively, and the hollow rotating shafts are connected with a driving device; a tank body is fixed between the two hollow rotating shafts and comprises an outer-layer shell,an intermediate layer and an inner container, and the intermediate layer is connected with the inner container through a rib plate; the tank body is provided with a discharging port, a sampling port,an interlayer water inlet, an outlet, an interlayer water discharge port, a yellow water discharge port and thermometers; the discharging port, the sampling port, the yellow water discharge port andthe thermometers run into the inner container. The integral rotary fermentation tank with controllable parameters for solid fermentation solves the problems that internal environmental parameters of existing cellars are not easy to monitor, the automation degree is not high, a lot of manpower and material resources are consumed, microbial structures are easily destroyed by existing solid-state fermentation tanks, the material fermentation is uneven, and the fermentation efficiency is low.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

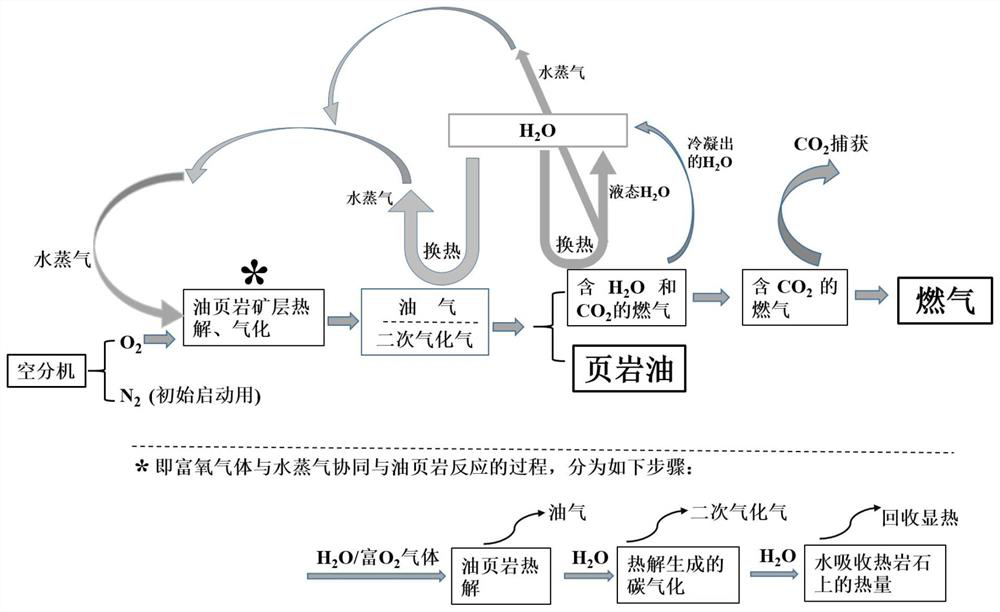

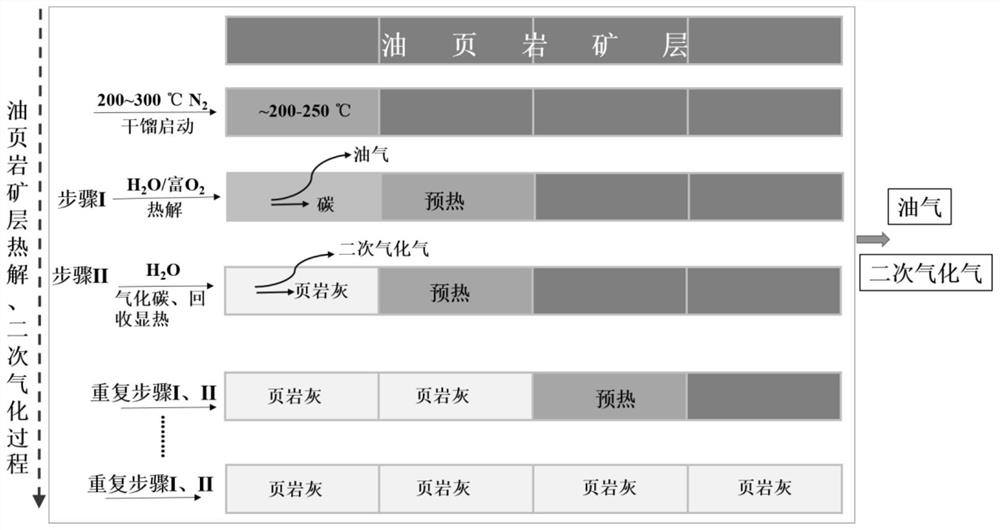

Method for extracting shale oil and high-calorific-value fuel gas by self-heating type underground dry distillation of oil shale

ActiveCN113374460AImprove utilization efficiencyAchieve recyclingMultiple-effect/fractional condensationFluid removalThermodynamicsWater vapor

The invention discloses a method for extracting shale oil and high-calorific-value fuel gas by self-heating type underground dry distillation of oil shale. The method has the advantages that the dry distillation is completed by the synergistic reaction of oxygen-enriched gas and water vapor and the oil shale, so that the pyrolysis reaction is promoted, the reaction of the oil shale is thorough, and the self-cracking dry distillation process is formed by the coupled heat release / heat absorption pyrolysis reaction; after the dry distillation is started, the required heat is mainly provided by the heat released by low-temperature oxidizing of fixed carbon produced by cracking of the oil shale, the remained fixed carbon is gasified into the fuel gas of H2, CO and the like, and the high-temperature sensible heat produced after the dry distillation reaction is also recycled; the problems of complicated oil and gas extraction systems by dry distillation of the oil shale, large management difficulty, low oil yield and the like are solved; and the operation is simple, the extraction cost is lower, the extraction efficiency and resource utilization rate are higher, the emission of three wastes is little, the environment benefit is obvious, and the like.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

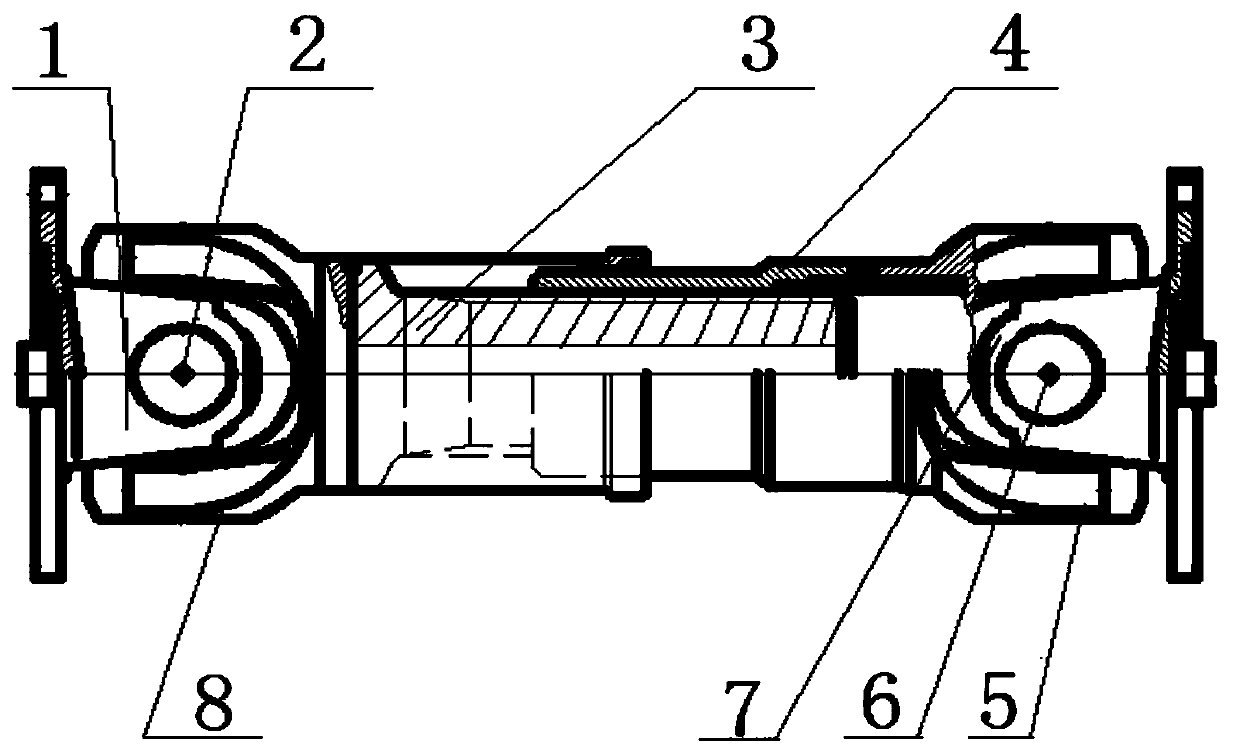

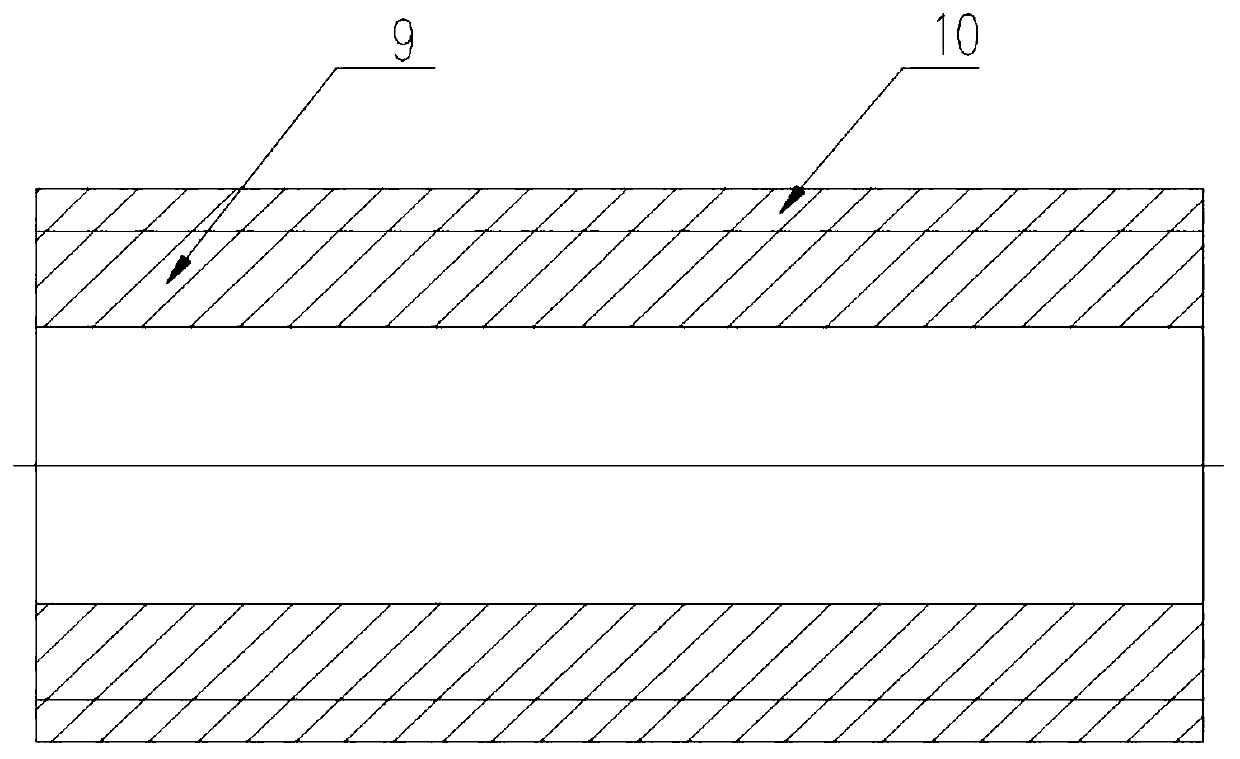

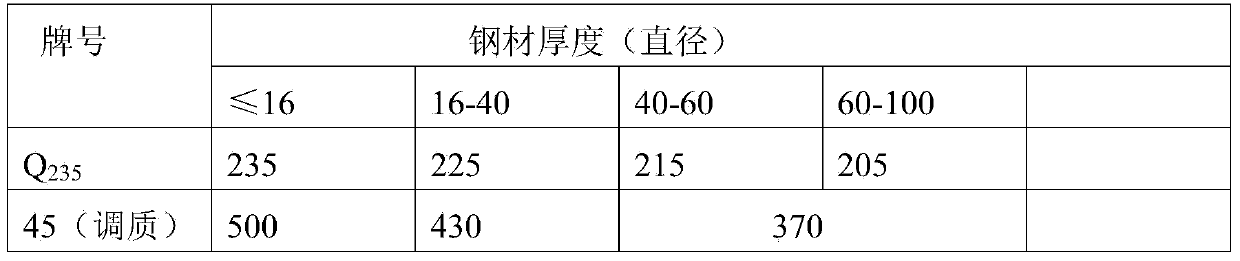

Cross-shaft type universal coupling with spline pair

InactiveCN104196903AExtended service lifeImprove heat treatment effectYielding couplingCouplingThick wall

The invention provides a cross-shaft type universal coupling with a spline pair. The cross-shaft type universal coupling comprises two flange forks, two cross-shaft assemblies, a spline shaft, a spline sleeve and two welding forks, the spline shaft is made of a tempered 45# seamless thick-walled steel pipe, the outer wall of a pipe body is an outer spline, and the interior of the pipe body is hollow. The cross-shaft type universal coupling has the advantages that the spline shaft is made of the tempered 45# seamless thick-walled steel pipe instead of a round-steel bar, so that under the premise of guaranteeing the original design bearing capacity, manufacturing materials of the spline shaft can be saved, usability of the spline shaft can be improved, service life of the spline shaft can be prolonged, and cost performance of products has more market competitive advantages.

Owner:JIANGSU ROKEE HEAVY IND TECH

Printing process of polyester fabric

InactiveCN103103821APromote the degree of puffingReduce high energy consumptionDyeing processDithionous acidEngineering

The invention discloses a printing process of a polyester fabric. The printing process comprises the steps of printing, evaporating, reduction clearing, and shaping drying, wherein a low-temperature dyeing carrier is added in the printing step, and the quantity of the added dyeing carrier is 1%-7% of the weight of color paste; an evaporation condition of low temperature and constant pressure is adopted in the evaporation step, the temperature is 90-130 DEG C, and the time is 5-10 minutes; a reduction clearing solution comprises the ingredients of 0.5g / L-3g / L sodium hydrosulfite, a 4mL / L-7mL / L sodium hydroxide solution with the mass concentration of 35% and a 3g / L penetrating agent, the temperature in the reduction clearing step is 45-60 DEG C, and the treatment time is 15-20 minutes; and high-temperature width expansion shaping is adopted in the shaping drying step, the temperature is 110-140 DEG C, and the treatment time is 20-50 seconds. The printing process of the polyester fabric can be used for implementing continuous low-temperature evaporation and color fixation of the polyester fabric with low energy, and can effectively overcome the defect of high-temperature evaporation needed by a conventional disperse dye printing process applied to polyester fabric printing.

Owner:CHANGSHU QINDA KNITTING PRINTING & DYEING

Post-treatment method for strengthening pretreatment effect of lignocellulose raw material through pulping

InactiveCN103849664AReduce pollutionIncrease the refining processBiofuelsWaste based fuelCelluloseEnzymatic hydrolysis

The invention relates to a post-treatment method for strengthening the pretreatment effect of lignocellulose raw material through pulping. The post-treatment method comprises the following steps: (1) subjecting a lignocellulose raw material to a preliminary treatment; (2) subjecting the lignocellulose raw material obtained in the step (1) to a pretreatment; (3) adjusting the solid content of the lignocellulose raw material obtained in the step (2), then subjecting the lignocellulose raw material to a pulping treatment in a pulping machine; (4) subjected the lignocellulose pulp obtained in the step (3) to an enzymatic hydrolysis treatment and a bioprocess treatment. The post-treatment method has the following advantages: the lignocellulose, which has been subjected to a pretreatment, is pulped; thus the particle size of the lignocellulose raw material is decreased, so the contact surface between the lignocellulose and enzyme in the enzymatic hydrolysis process is enlarged, the enzymolysis speed and efficiency are promoted, the pretreatment effect of the lignocellulose raw material is strengthened, the energy consumption and cost of the pretreatment is reduced, moreover, the pulped lignocellulose has a good fluidized property, thus the processing efficiency is improved, and the risk that the raw material is infected by bacterium after the pretreatment is reduced too.

Owner:EAST CHINA UNIV OF SCI & TECH

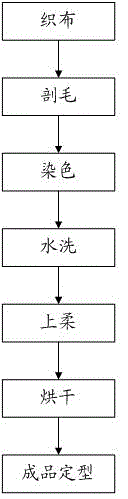

Processing technology for warp knitting warp direction strip-type plush fabric

InactiveCN104963077AFluffyGuaranteed uniformityFabric breaking/softeningWarp knittingPolyesterHigh energy

The invention discloses a processing technology for warp knitting warp direction strip-type plush fabric. The processing technology comprises the following specific steps of weaving, fur splitting, dyeing, washing, softening, drying and finished product shaping. By means of the mode and the processing technology for the warp knitting warp direction strip-type plush fabric, a small circular knife is allocated to each warp direction strip-type tweed, shearing is carried out on each strip-type tweed along the warp direction middle position in the mode of shearing yarn one by one, the evenness of the length of plush is guaranteed, the original stress of the shorn plush spun polyester thread is kept, the stress between yarns on which high-temperature dyeing and shaping are carried out is not reduced, the fluff is full of fluffiness, the high-energy-consumption and high-exhaust-gas emission technology processes are reduced, the production cost is reduced, and the three-dimension, the flexible degree and the fluff flexible degree far surpass products manufactured through the traditional technology.

Owner:常熟市天字织造有限公司

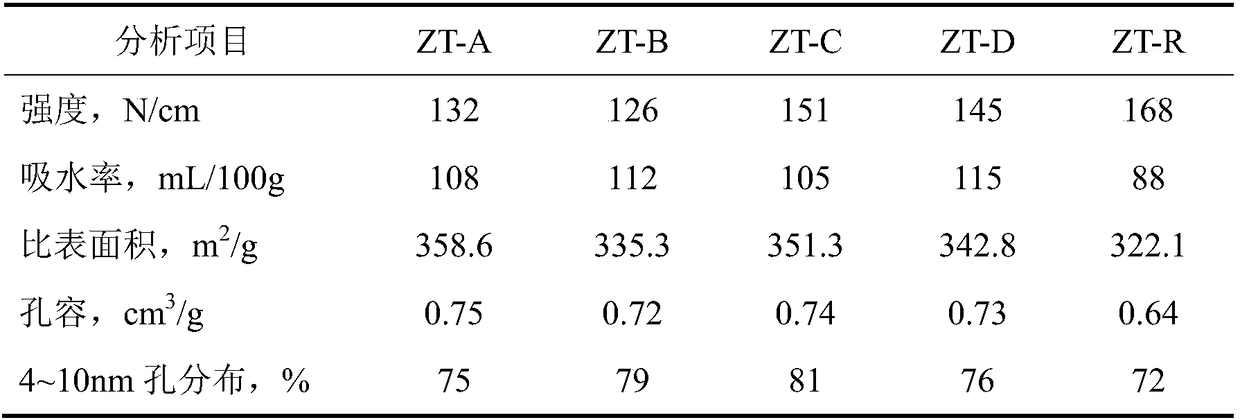

Preparation method of hydrogenation catalyst carrier

InactiveCN109158131AEmission reductionAvoid destructionCatalyst carriersRefining to eliminate hetero atomsOrganic acidAluminium hydroxide

The invention relates to a preparation method of a hydrogenation catalyst carrier. The method comprises the following steps of: adding a little high-viscosity aluminum hydroxide dry glue powder in a pseudo-boehmite gel precursor to serve as a binding agent so as to carry out uniform mixing; adding organic acid to serve as a peptizing agent; adding a high-molecular compound to serve as a pore enlarging agent; adding one or more of compounds containing Ti, Si, B, Zr, P or F to serve as a performance additive, or not adding the performance additive; and carrying out mixing and kneading in a kneading machine to obtain a plastic, taking the plastic to carry out moulding, and carrying out drying and roasting to obtain a finished carrier. Through preparing the hydrogenation catalyst carrier by adoption of the method, effective linkage between pseudo-boehmite powder production and catalyst carrier processing can be realized, the process can be simplified, the high-energy consumption step and discharge of pollutants such as wastewater and waste gas in the production process can be decreased, and damages caused to an aluminum hydroxide pore structure by intermediate steps can be avoided at the same time; and the method has the advantages of being low in processing cost, environmentally friendly and excellent in carrier performance.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Circulation cooling device for chute of soda recovery furnace

ActiveCN102230292AAvoid overall overheatingCorrosion resistanceFurnace coolingRegeneration of alkali lyeSalt waterEngineering

The invention discloses a circulation cooling device for a chute of a soda recovery furnace. A cooling water channel is provided with a desalted water inlet, a drain outlet, an overflow vent, a sealing water pipe and a liquid level meter interface, wherein the sealing water pipe is inserted below the liquid surface of the cooling water channel, the liquid level meter interface is connected with aliquid level transmitter; a desalted water outlet at the bottom of the cooling water channel is connected with a circulation cooling water pipe, the outlet of a frequency variable water pump is connected to a cooling water inlet of a heat exchanger, a cooling water outlet of the heat exchanger is connected to the water inlet of a chute water jacket at the lower end of the chute water jacket by virtue of the circulation cooling water pipe, the water outlet of the chute water jacket at the upper end of the chute water jacket is connected to the sealing water pipe of the cooling water channel, the desalted water inlet is arranged at the top of the cooling water channel, the desalted water pipe is used for introducing the desalted water into the cooling water channel by virtue of the desaltedwater inlet, and the desalted water pipe is provided with a regulating valve. The circulation cooling device disclosed by the invention has simple structure, low operation energy consumption, less water discharge and automatic operation; and a crack of the chute water jacket can be timely alarmed, and an accident is prevented.

Owner:CHINA LIGHT IND WUHAN DESIGN ENG CO LTD

Method for producing biological oil by sweet potato full-matrix fermentation

InactiveCN101948884AReduce high temperature gelatinizationReduce high energy consumptionBiofuelsMicroorganism based processesVegetable oilBiodiesel

The invention provides a method for producing biological oil by sweet potato full-matrix fermentation, comprising the following steps: adding dried potato powder or fresh sweet potato and sodium hydroxide with the concentration of 3% based on the material-liquid mass-volume ratio of 1:5-10, hydrolyzing for 5-10 hours and adjusting pH to 5.0-6.0; adding the obtained hydrolysate to 40-80u / g of alpha-amylase and 150-300u / g of glucoamylase in terms of per gram of starch and meanwhile inoculating 5-15% (V / V) of oleaginous yeast seed liquid for simultaneous saccharification and fermentation, wherein, shake-flask fermentation control conditions of oleaginous yeast are as follows: the inoculation quantity is 5-15%, the culture temperature is 26-30 DEG C, the revolving speed of a shaker is 180-220r / min and the fermentation time is 3-6 days; and finally extracting the oil. In the method, by a sweet potato simultaneous saccharification and fermentation process, a cheap and available sweet potato resource is taken as a raw material without adding other culture medium components, thus reducing energy consumption during the production process and lowering production cost. The biological oil composition obtained by microbes is similar to that of vegetable oil and can be taken as the raw material for producing biodiesel; and compared with other process routes, the method of the invention has obvious industrialization advantages.

Owner:SOUTHWEST UNIVERSITY

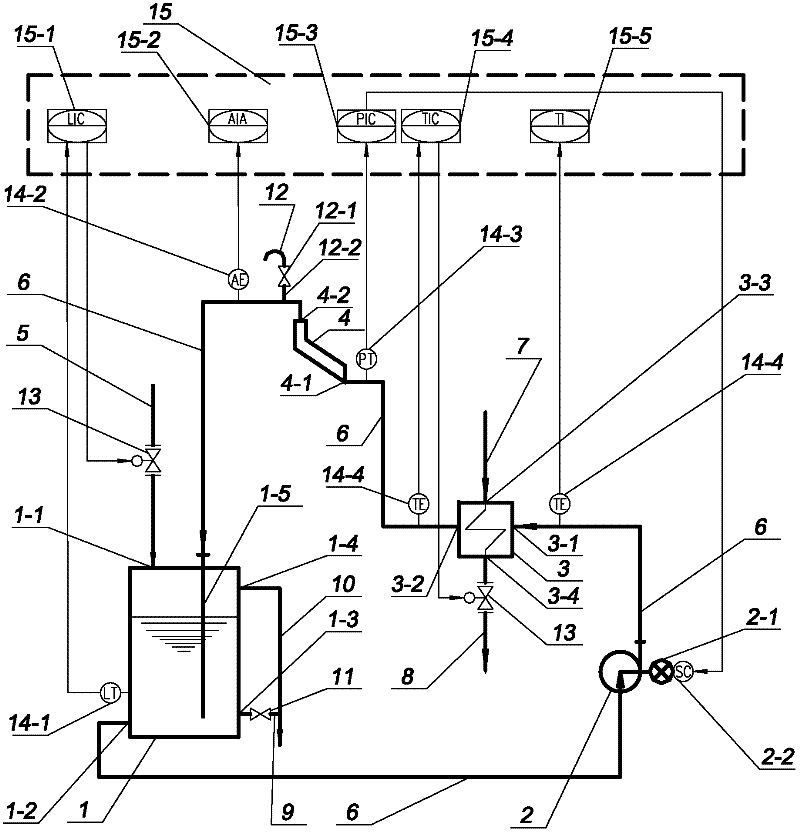

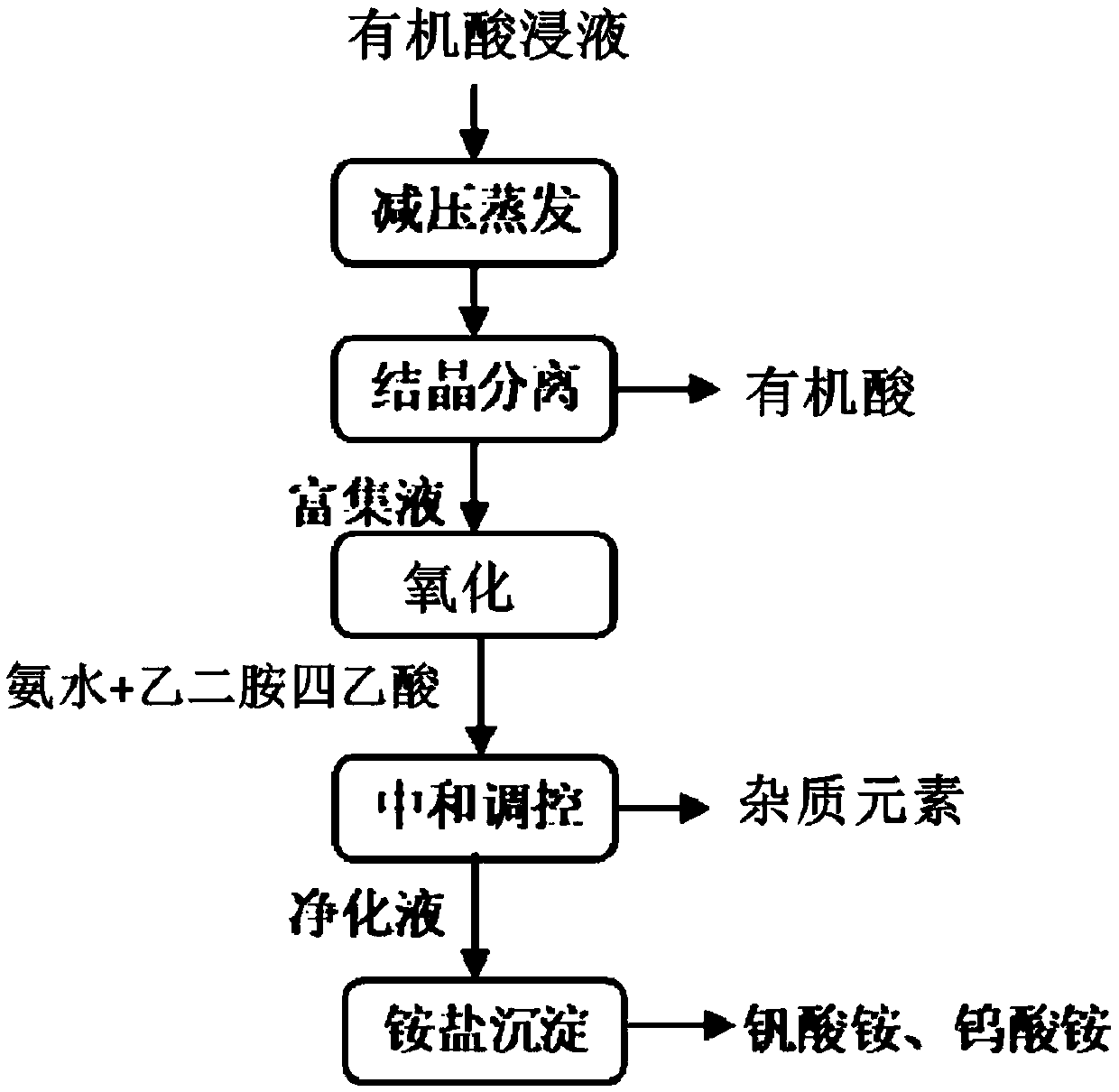

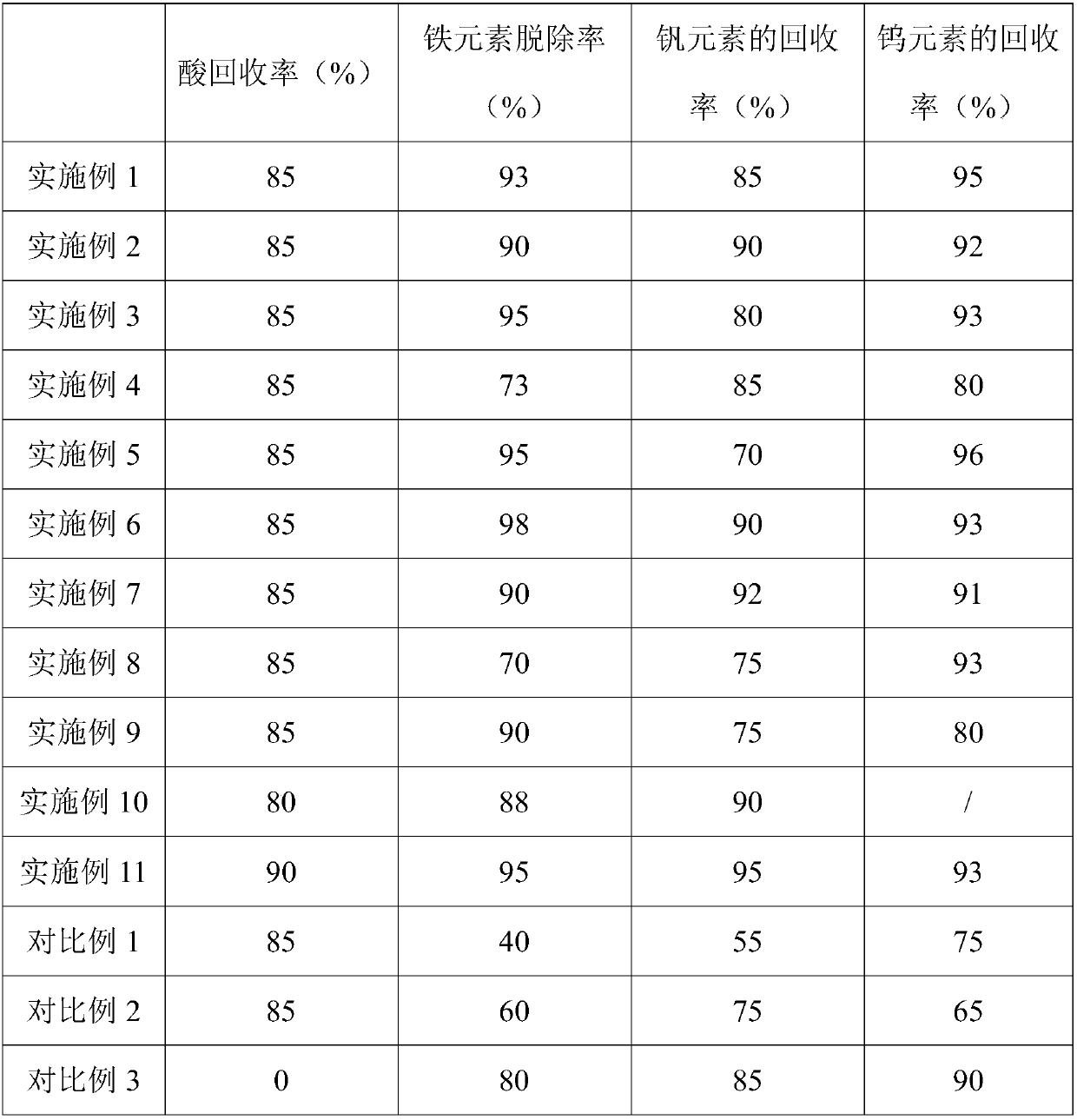

Method for recovering acid liquor and separating vanadium in process of reducing acid leaching vanadium-containing waste catalyst

ActiveCN111485105AImprove leaching rateAchieve recyclingProcess efficiency improvementVanadium CompoundsOrganic acid

The invention relates to a method for recovering acid liquor and separating vanadium in a process of reducing an acid leaching vanadium-containing waste catalyst. The method comprises the following steps: (1) carrying out acid leaching on the vanadium-containing waste catalyst by using an organic acid to obtain an organic acid leaching solution, and separating the organic acid to obtain an enrichment solution; and (2) oxidizing the enrichment solution, removing iron elements in the oxidized enrichment solution to obtain a purification solution, and then carrying out a vanadium element precipitation process on the purification solution to obtain a recovery product, wherein the recovery product is a vanadium compound. According to the method, the organic acid is recovered at first, the recovery rate reaches 80-90%, then the enrichment solution is oxidized, Fe2+ and V4+ in the enrichment solution are oxidized into Fe3+ and V5+ in the oxidation process, then the iron element is removed, the loss of the vanadium element in the iron element removal process is avoided, and the recovery rate of the vanadium compound is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Low energy consumption printing method for continuously performing aging color fixation on terylene fabric at low temperature

InactiveCN102218951APromote the degree of puffingReduce high energy consumptionOther printing apparatusEngineeringDisperse dye

The invention discloses a low energy consumption printing method for continuously performing aging color fixation on a terylene fabric at low temperature. The method comprises the process steps of printing, aging, reduction clearing and shaping drying, wherein in the process step of the printing, an environment-friendly low-temperature dyeing carrier is added, and the added amount is 0.5 to 5 percent of the weight of a color paste; and in the process step of the aging, a low-temperature and normal-pressure aging condition is adopted to perform the aging, the temperature is between 100 and 150 DEG C, and the time is 6 to 15 minutes. The low energy consumption printing method effectively overcomes the defect of high-temperature aging required by the conventional disperse dye printing process applied to terylene fabric printing, and a low energy consumption printing process is provided.

Owner:SUN FAT TEXTILE DYEING & PRINTING SHAOXING

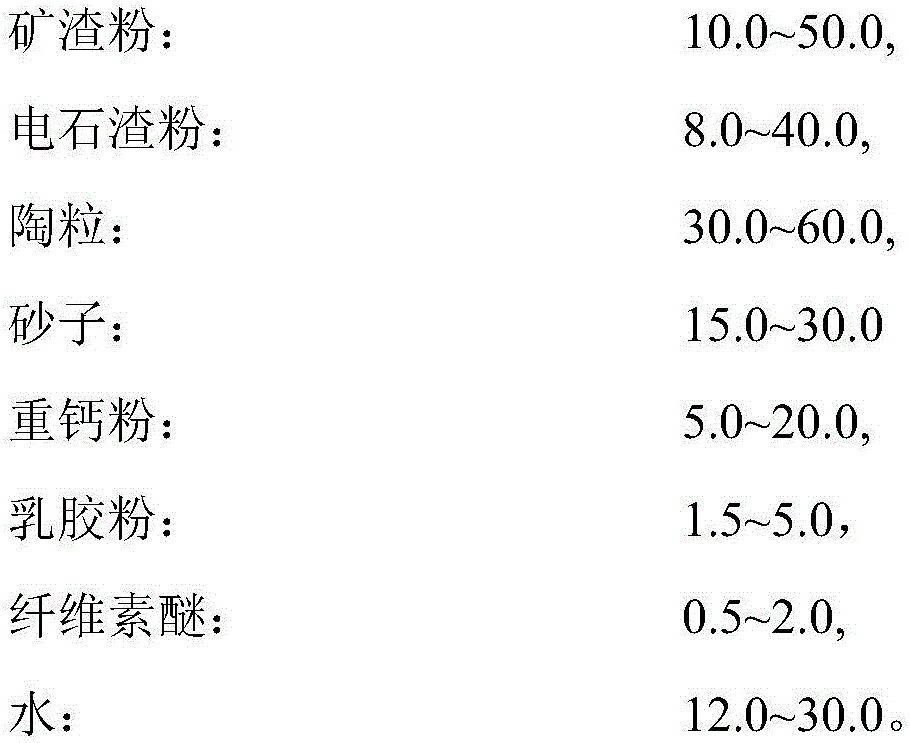

Slag, carbide slag and ceramsite high-strength wall thermal insulation material and preparation method thereof

InactiveCN106747148AReduce high energy consumptionEnergy saving and environmental protectionClimate change adaptationCeramic shaping apparatusEtherCalcium

The invention discloses a slag, carbide slag and ceramsite high-strength wall thermal insulation material and a preparation method thereof. The high-strength wall thermal insulation material is prepared from slag powder, carbide slag powder, ceramsite, sand, calcium carbonate, latex powder, cellulose ether and water; the mass percent is 10.0 to 50.0% of slag powder, 8.0 to 40.0% of carbide slag powder, 30.0 to 60.0% of ceramsite, 15.0 to 30.0 % of sand, 5.0 to 20.0% of calcium carbonate, 1.5 to 5.0% of latex powder, 0.5 to 2.0% of cellulose ether and 12.0 to 30.0% of water. The high-strength wall thermal insulation material disclosed by the invention can improve an internal maintenance function of a cementing system; 28d compressive strength of the wall material can reach 25MPa, and the wall material is small in shrinkage; the slag and the carbide slag serve as the cementing system to replace cement, so that a novel path for resourceful utilization of carbide slag is provided, and high energy consumption required by producing cement is saved; the wall material has excellent thermal insulation performance, high strength, convenience to construction and no independent construction; the materials are wide in source and low in price; compared with a polyphenyl granule macromolecule thermal insulation material, the production cost of the wall material is low.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com