Slag, carbide slag and ceramsite high-strength wall thermal insulation material and preparation method thereof

A technology of thermal insulation material and calcium carbide slag, which is applied in the field of high-strength wall materials and its preparation, can solve the problems of poor fire resistance, complicated construction, and high price of wall materials, and achieve the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A kind of slag, calcium carbide slag and ceramsite high-strength wall insulation material, its preparation method has the following steps:

[0049] (1) Ceramsite pretreatment

[0050] After soaking the ceramsite in tap water at room temperature for 24 hours, filter off the surface moisture until the surface is saturated and dry, and set aside.

[0051] (2) Weighing and mixing

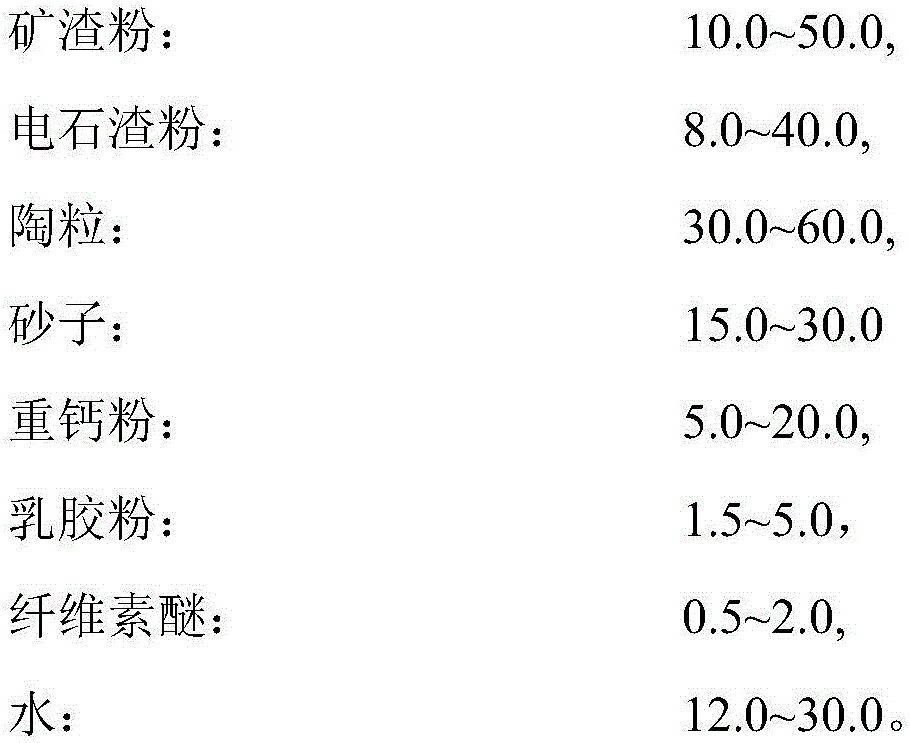

[0052] In terms of parts by mass, 30-60 of the pretreated ceramsite, 8-40 of slag powder, 15-30 of sand, 5-20 of heavy calcium powder, 1.5-5.0 of latex powder, and 0.5-2.0 of cellulose ether.

[0053] Put the weighed raw materials into the concrete mixer, mechanically stir for 2-6 minutes, and the speed is 60-80r / min.

[0054] (3) Add water and stir

[0055] Add 12.0-30.0% of water to the above-mentioned dry stirring material (by mass parts), and mechanically stir for 6-8 minutes at a speed of 60-80 r / min.

[0056] (4) Product forming

[0057] Put the above-mentioned stirred fresh materials in...

Embodiment 1

[0061] A design and preparation method for producing high-strength wall materials using slag, carbide slag and ceramsite, the preparation method has the following steps:

[0062] (1) Ceramsite pretreatment

[0063] Soak the ceramsite in tap water at room temperature (20±1°C) for 24 hours, filter off the excess water on the surface until it is saturated and dry, and set aside.

[0064] (2) Weighing and mixing

[0065] In terms of parts by mass, prepare pretreated ceramsite 40, slag powder: 15, sand 25, heavy calcium powder 13, latex powder 2.0, cellulose ether 1.2.

[0066] Put the weighed raw materials into a concrete mixer, and mechanically stir for 4 minutes at a speed of 70r / min.

[0067] (3) Add water and stir

[0068] Add 25 g of water (in parts by mass) to the above-mentioned dry stirring material, and mechanically stir for 8 min at a speed of 70 r / min.

[0069] (4) Product molding

[0070] Put the above-mentioned stirred fresh material into a metal mold of specifie...

Embodiment 2

[0074] A design and preparation method for producing high-strength wall materials using slag, carbide slag and ceramsite, the preparation method has the following steps:

[0075] (1) Ceramsite pretreatment

[0076] After soaking the ceramsite in tap water at room temperature for 24 hours, filter off the surface moisture until the surface is saturated and dry, and set aside.

[0077] (2) Weighing and mixing

[0078] In terms of parts by mass, prepare pretreated ceramsite 30, slag powder: 30, sand 25, heavy calcium powder 15, latex powder 2.0, cellulose ether 1.2.

[0079] Put the weighed raw materials into the concrete mixer, mechanically stir for 4 minutes, and the speed is 60r / min.

[0080] (3) Add water and stir

[0081] Add 20 g of water (in parts by mass) to the above-mentioned dry stirring material, and mechanically stir for 5 min at a speed of 60 r / min.

[0082] (4) Product forming

[0083] Put the above-mentioned stirred fresh material into a metal mold of specifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com