Patents

Literature

529 results about "Vanadium Compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium is the 20th most abundant element in the earth's crust; metallic vanadium is rare in nature (known as the mineral vanadium, native vanadium), but vanadium compounds occur naturally in about 65 different minerals.

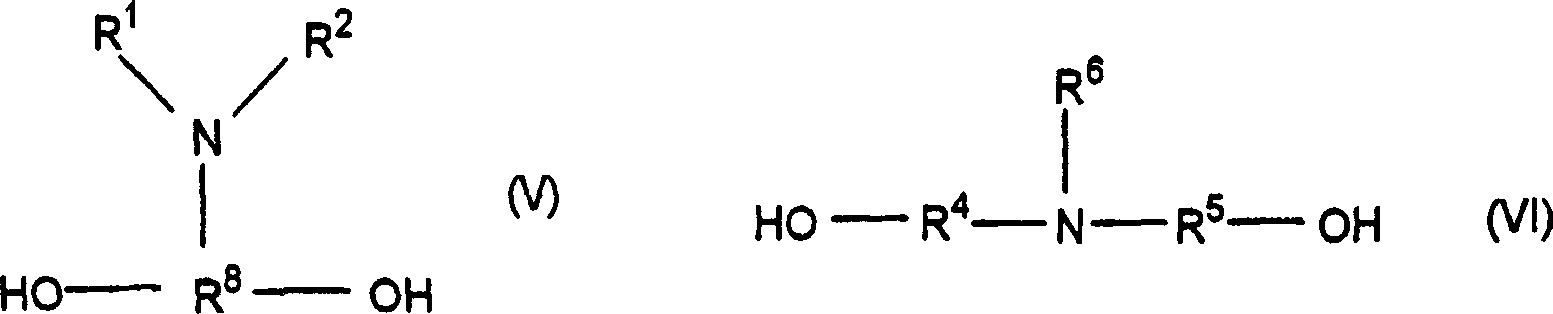

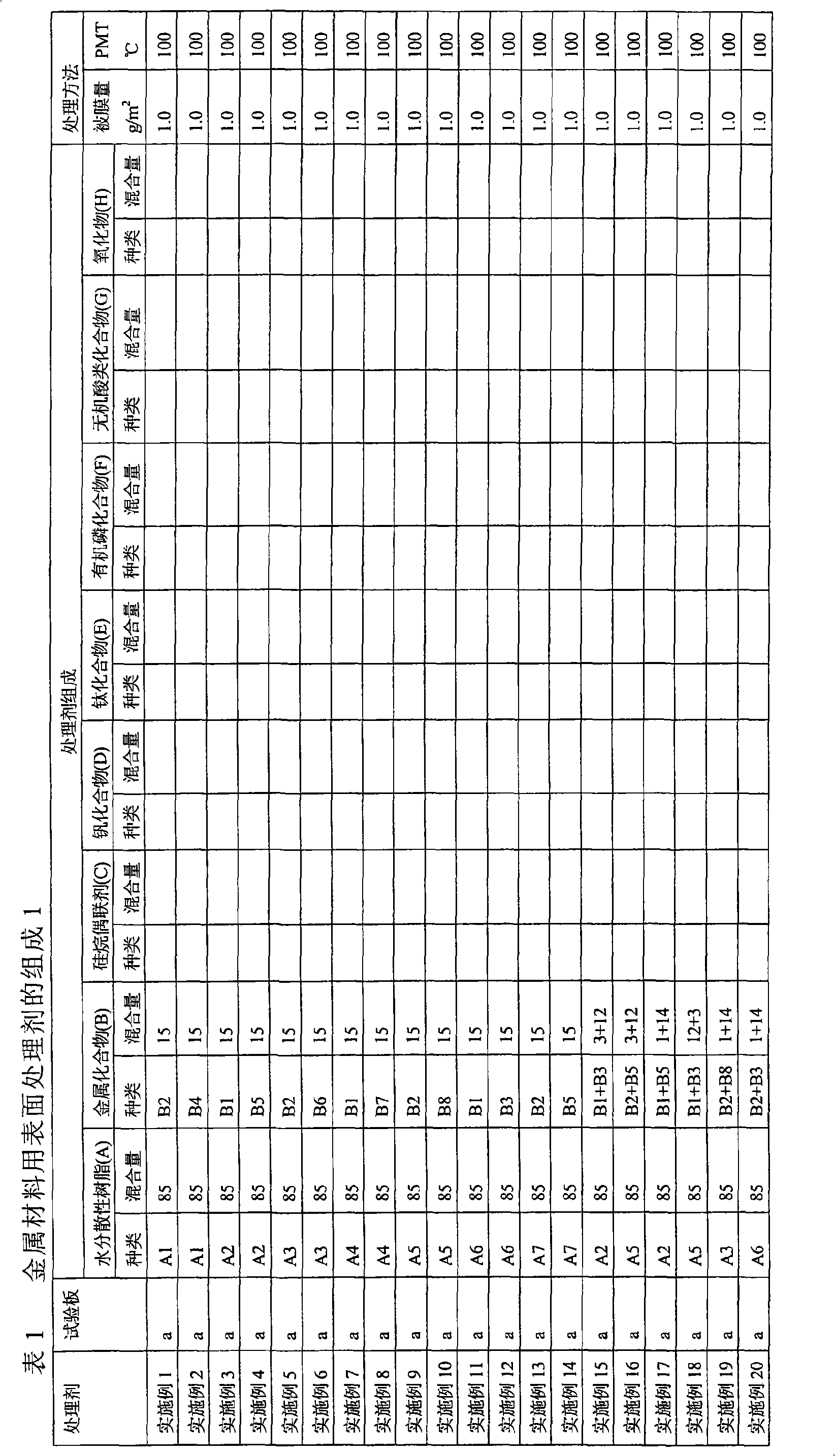

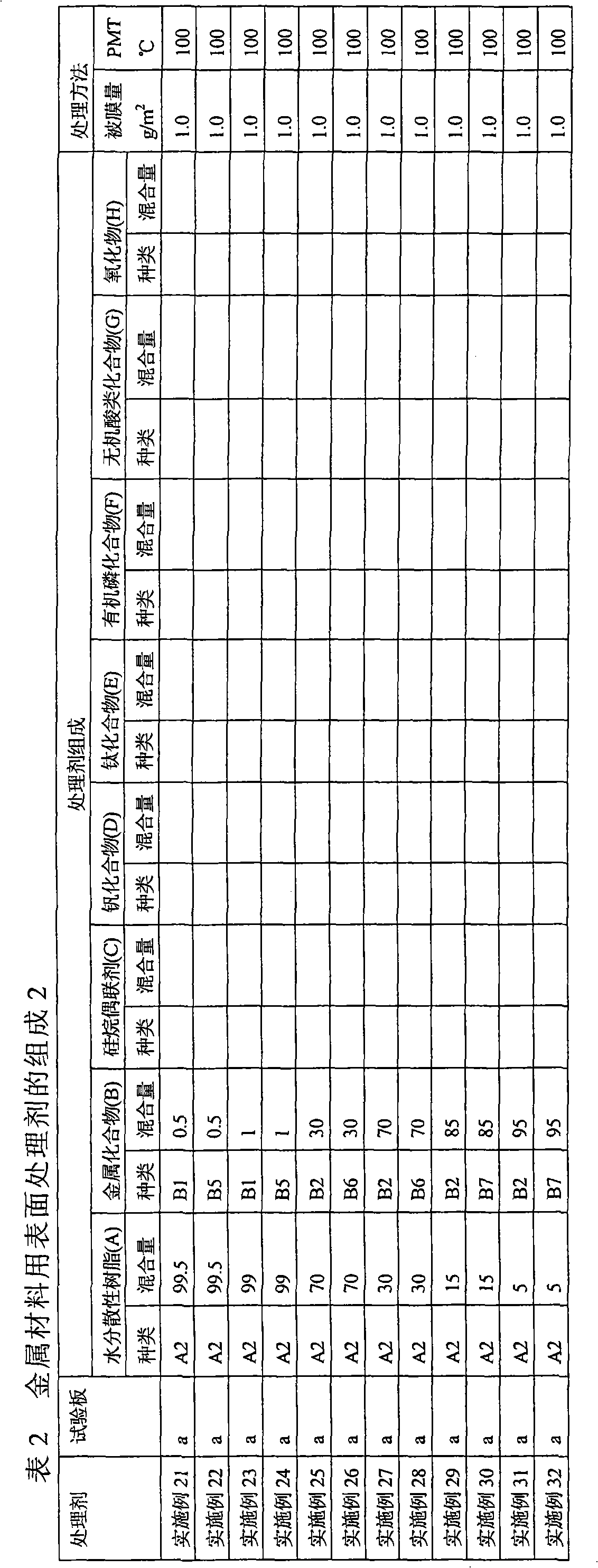

Composition and process for treating metal surfaces and resulting article

InactiveUS6736908B2Superior corrosion resistance and alkali resistance and fingerprint resistanceOther chemical processesPretreated surfacesVanadium CompoundsMaterials science

A metal treating composition comprising at least a specific type of dissolved and / or dispersed organic resin, a dissolved vanadium compound in which the valence of vanadium is from 3 to 5, and a dissolved compound that contains at least one of the metals Zr, Ti, Mo, W, Mn, and Ce can provide metal surfaces with superior corrosion resistance, alkali resistance, and fingerprint resistance. The composition contains no chromium to cause pollution problems and / or require pollution abatement.

Owner:NIHON PARKERIZING

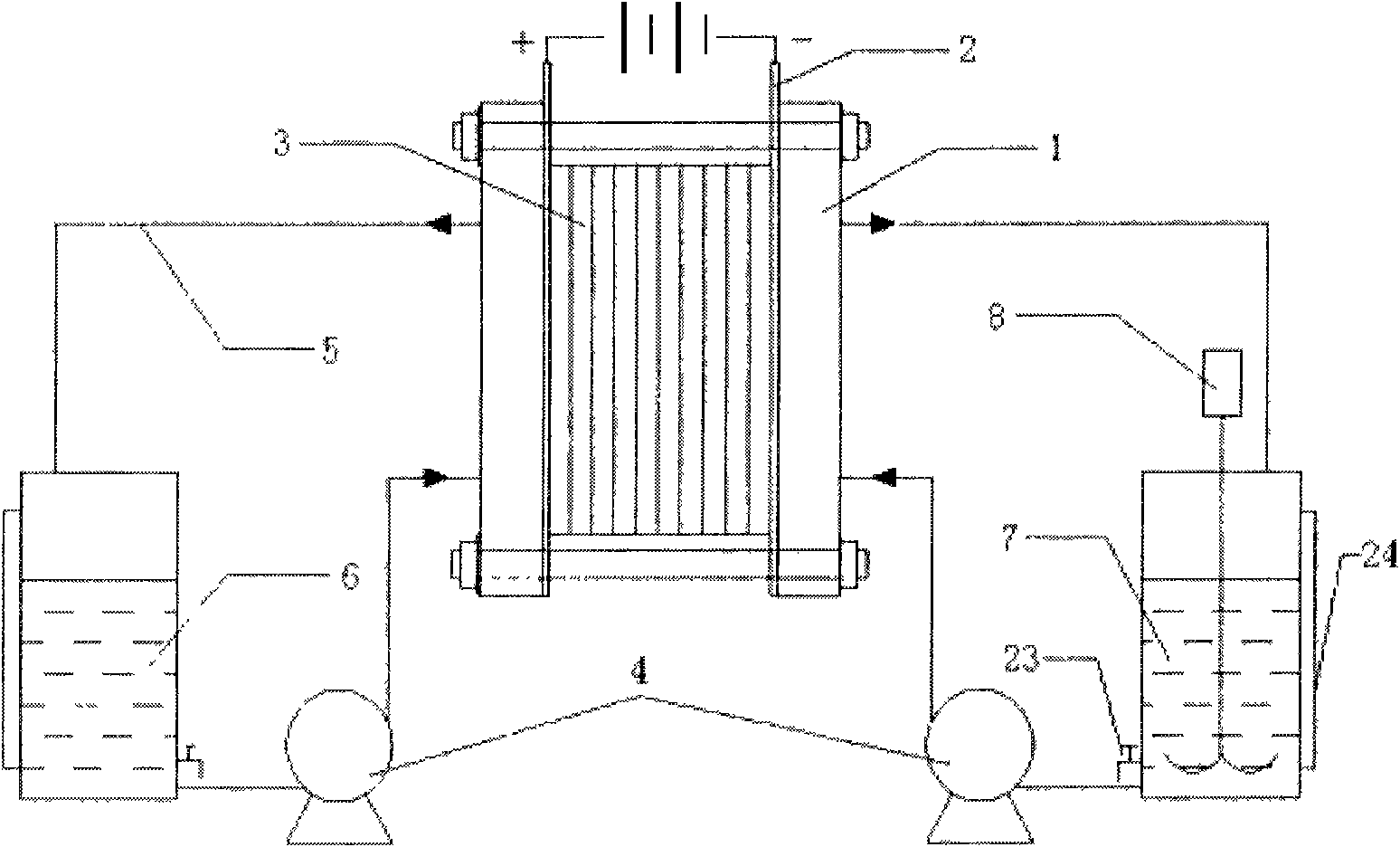

Method for preparing vanadium battery solution or adjusting capacity and special device thereof

InactiveCN101619465ARapid responseContinuous operationElectrolysis componentsRegenerative fuel cellsVanadium CompoundsOxygen

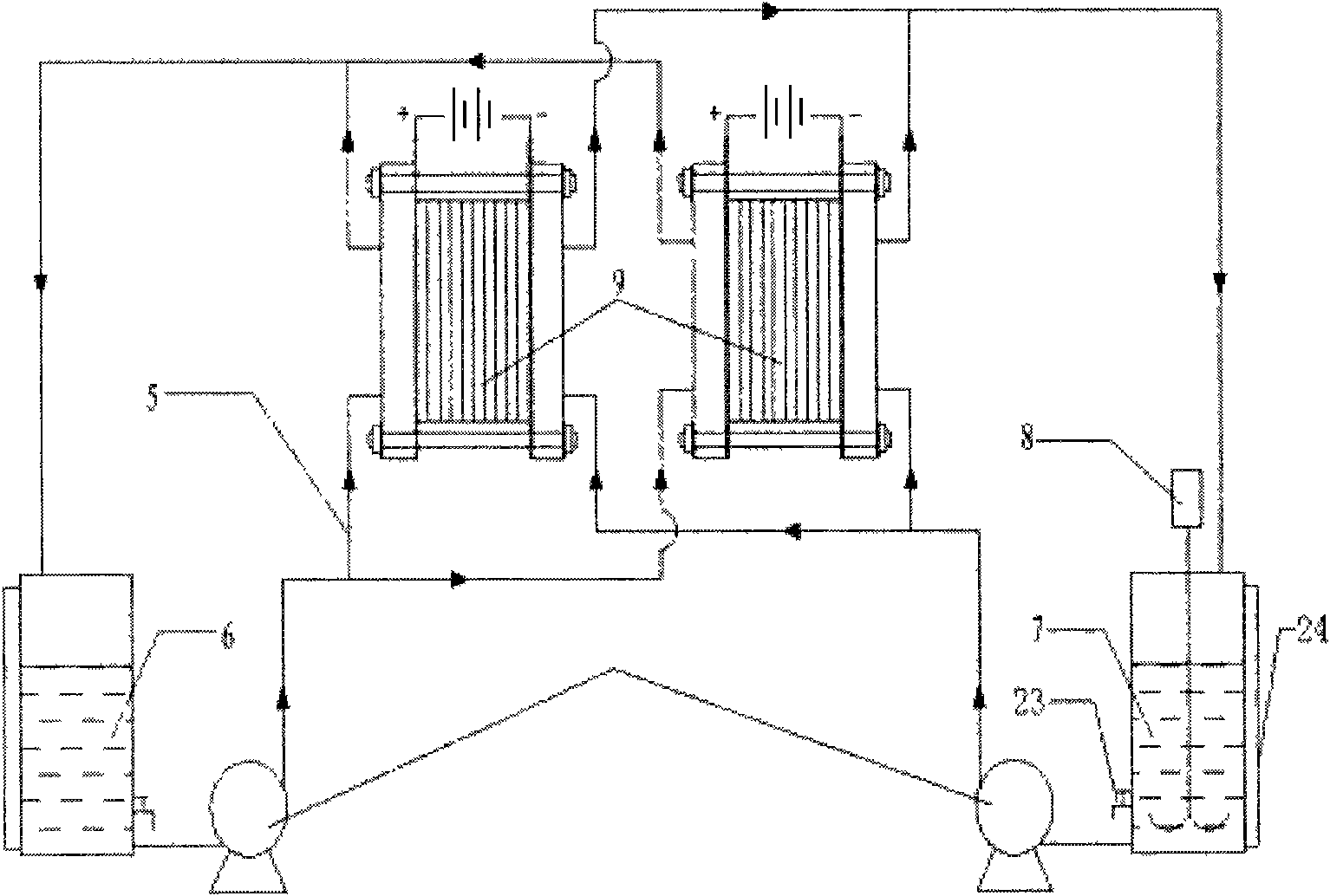

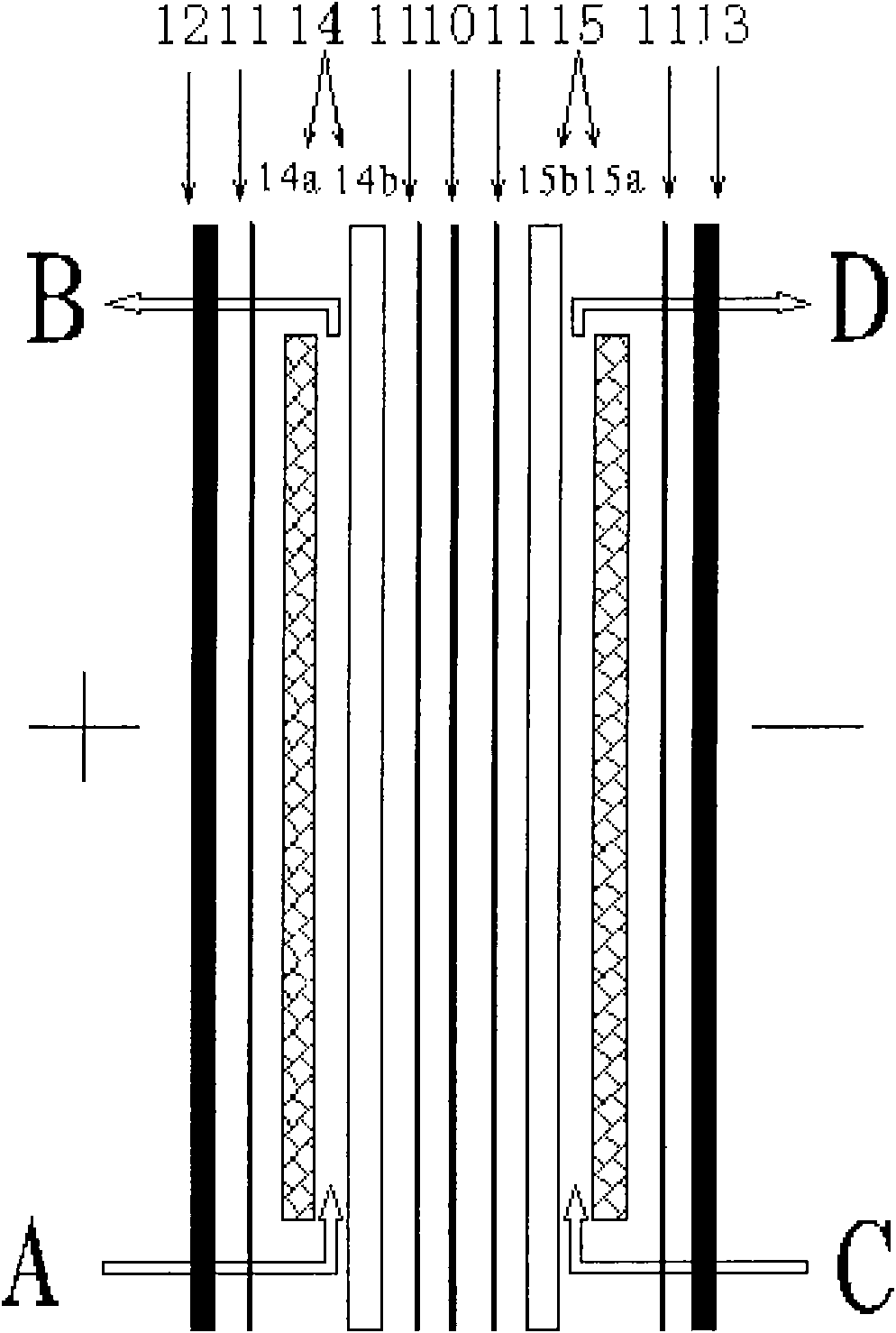

The invention relates to a method for preparing vanadium battery solution or adjusting the capacity, wherein an adopted electrolysis unit comprises an electrolytic cell group, an anode electrolyte storage tank, a cathode electrolyte storage tank, a liquid conveying pipeline and a pump, a mode of forced convection is adopted so that the anode electrolyte and the cathode electrolyte stored in the anode electrolyte storage tank and the cathode electrolyte storage tank respectively flow through the anode and the cathode of the electrolytic cell group respectively, a voltage is applied between the anode and the cathode of the electrolytic cell group to generate direct current capable of generating oxygen and deoxidizing a vanadium compound, and after finishing electrochemical oxidation and reduction reaction, the anode electrolyte and the cathode electrolyte flowing through the anode and the cathode of the electrolytic cell group return to the anode electrolyte storage tank and the cathode electrolyte storage tank. The electrolysis method is applied to preparing electrolyte for a full vanadium liquid stream battery and restoring the capacity of the full vanadium liquid stream battery off line or on line.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

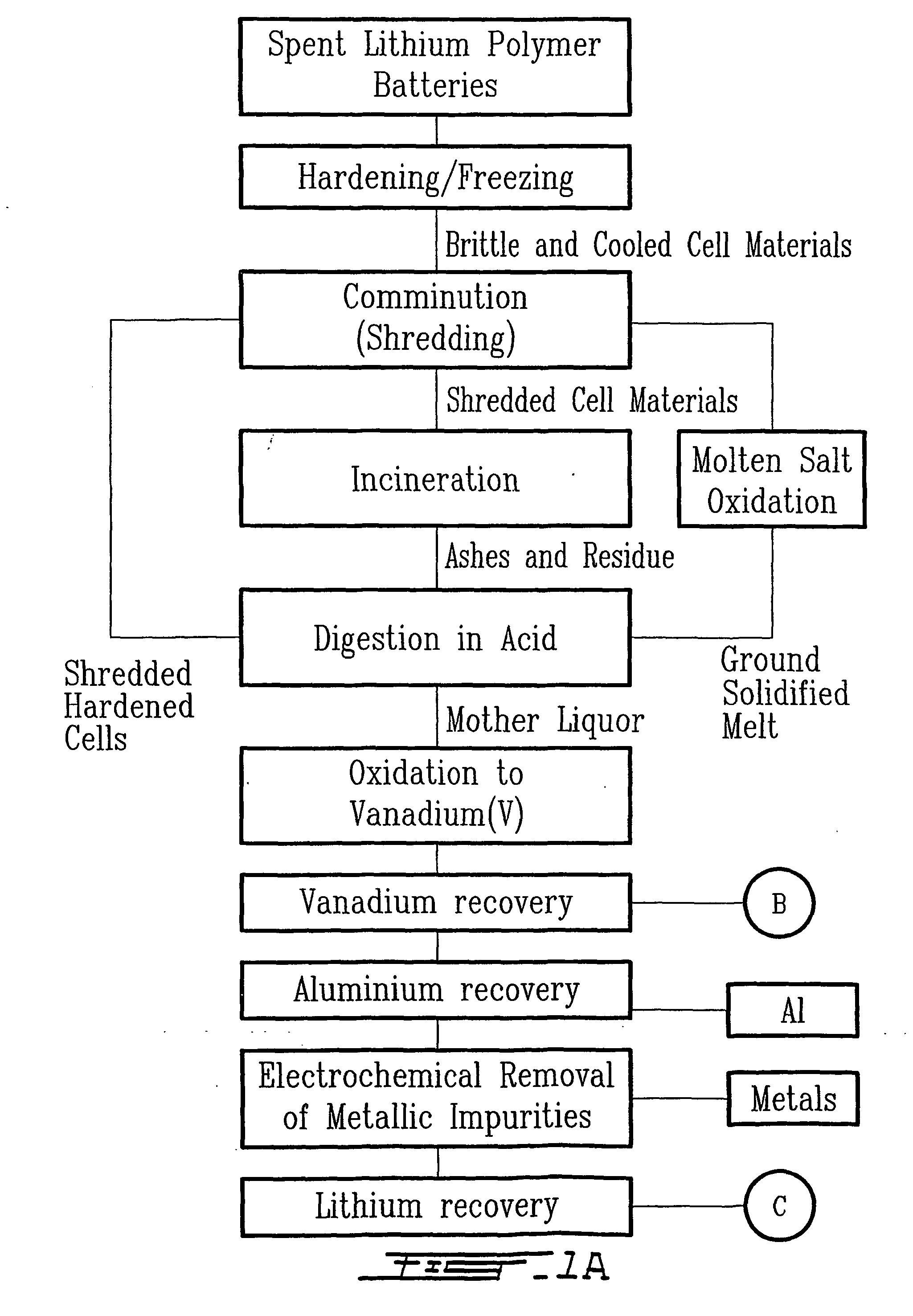

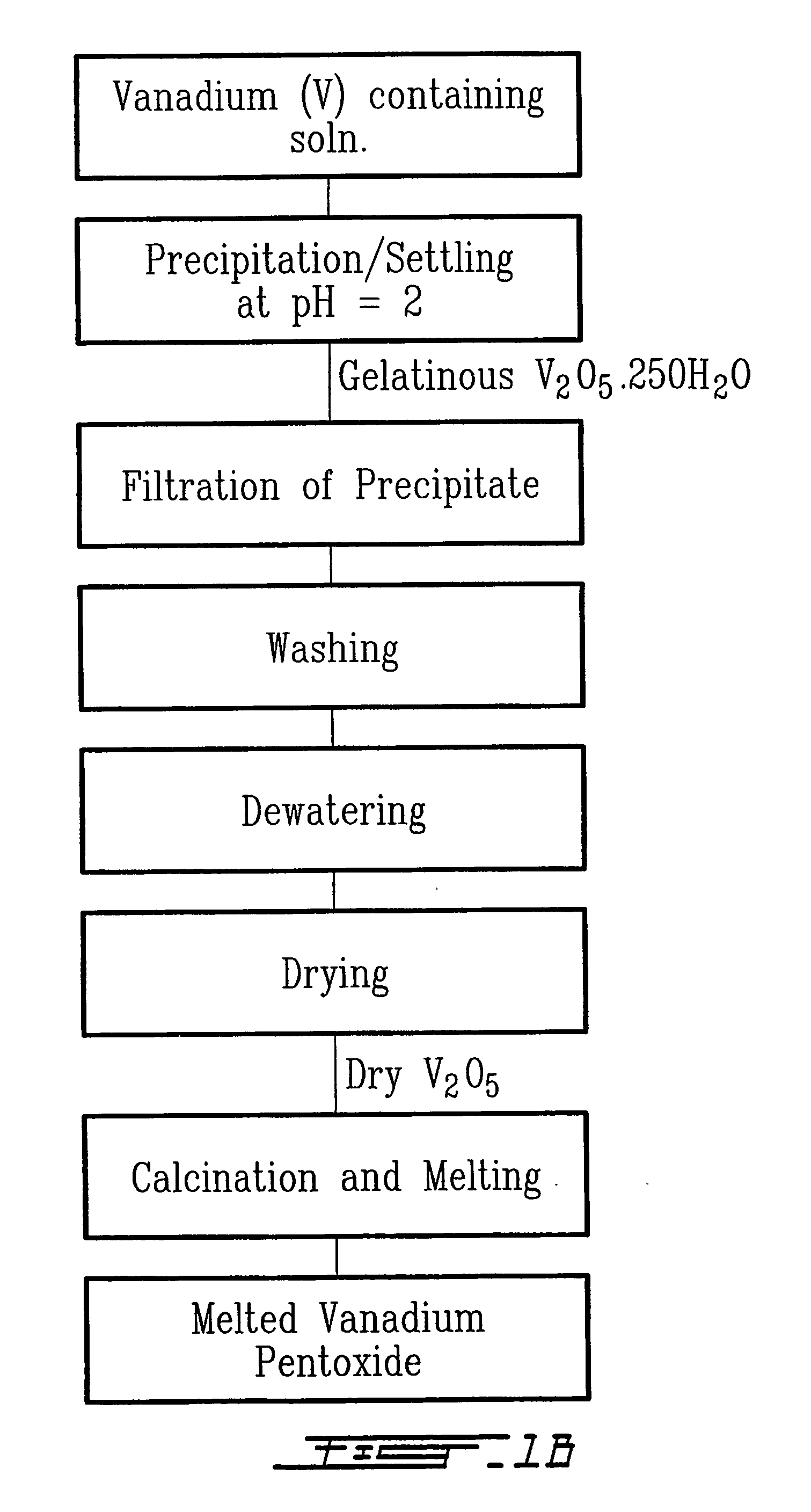

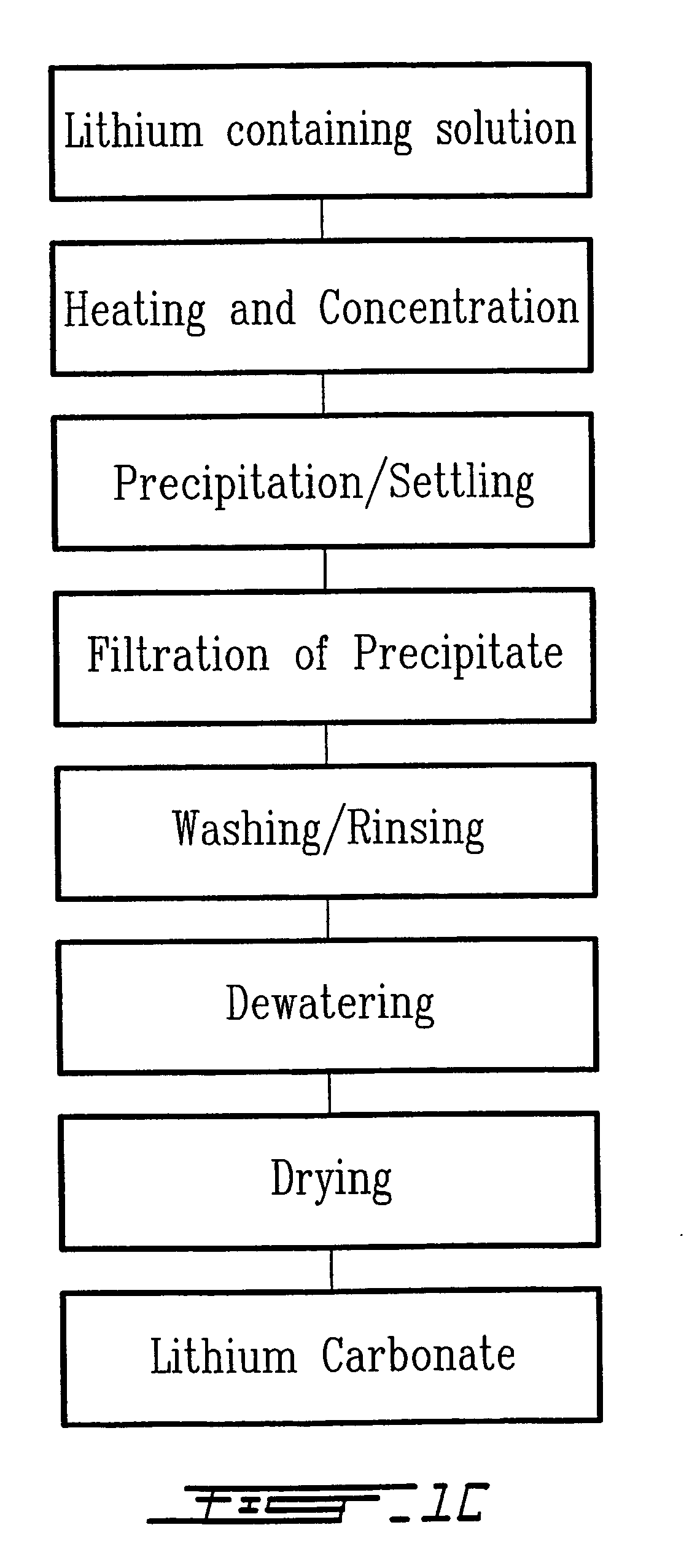

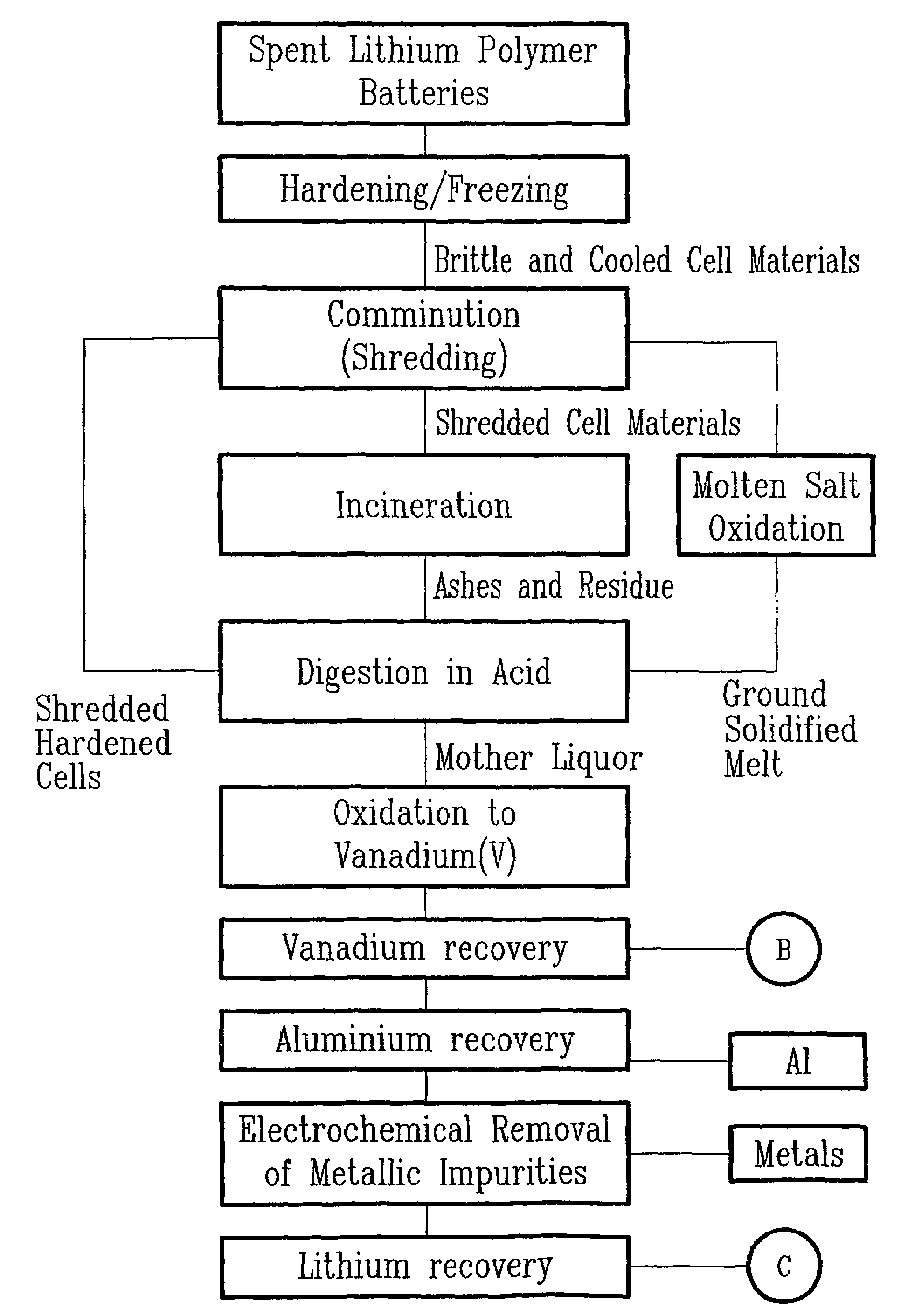

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

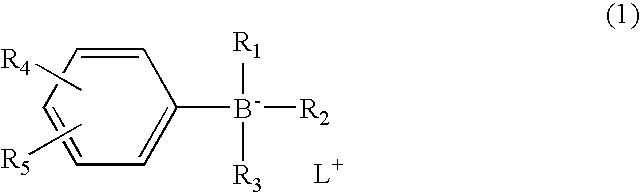

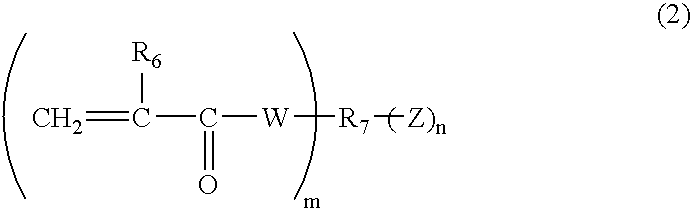

Radical polymerization catalyst and adhesive kit for dental use

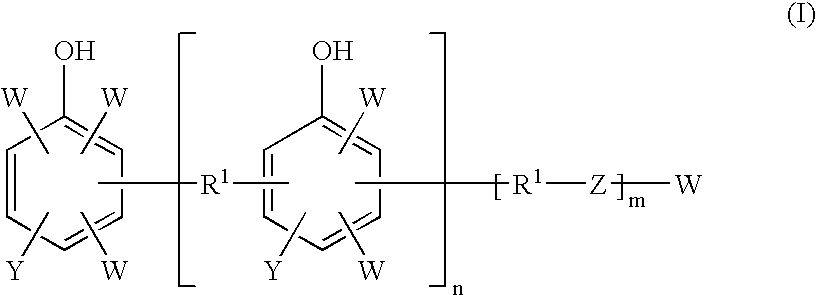

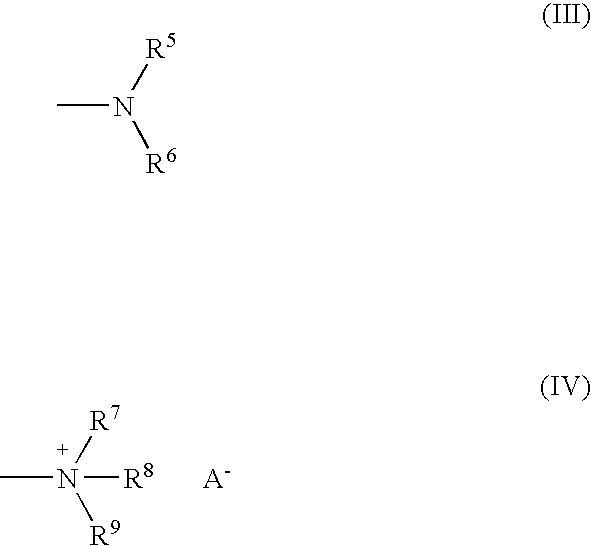

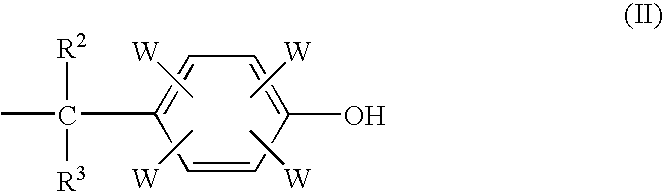

InactiveUS20050009946A1High polymerization activityEasy to handleImpression capsPhysical/chemical process catalystsArylVanadium Compounds

According to the present invention, there are disclosed a radical polymerization catalyst comprising an aryl borate compound, an acidic compound and a +tetravalent and / or +pentavalent vanadium compound; and a curable composition, a dental composition, a dental adhesive, a dental pretreatment agent, a dental adhesive kit, etc. all containing the radical polymerization catalyst.

Owner:TOKUYAMA CORP +1

Composition and process for treating metal surfaces and resulting article

InactiveUS20030213533A1Increase resistanceOther chemical processesPretreated surfacesVanadium CompoundsPhysical chemistry

A metal treating composition comprising at least a specific type of dissolved and / or dispersed organic resin, a dissolved vanadium compound in which the valence of vanadium is from 3 to 5, and a dissolved compound that contains at least one of the metals Zr, Ti, Mo, W, Mn, and Ce can provide metal surfaces with superior corrosion resistance, alkali resistance, and fingerprint resistance. The composition contains no chromium to cause pollution problems and / or require pollution abatement.

Owner:NIHON PARKERIZING

Surface treatment liquid, surface treatment method and tin-plated steel sheet by surface treatment

ActiveCN101545107AExcellent resistance to sulfur spotsExcellent paint wettingMetallic material coating processesPhosphateManganese

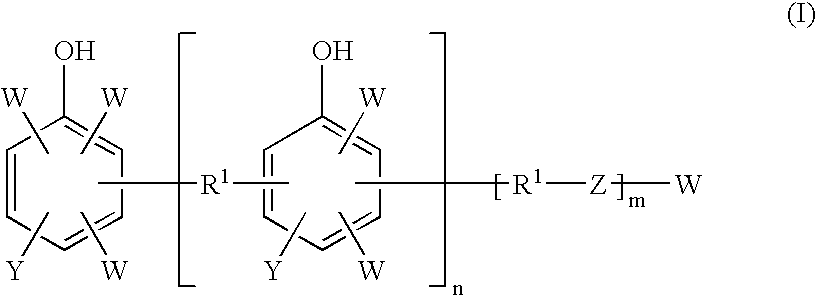

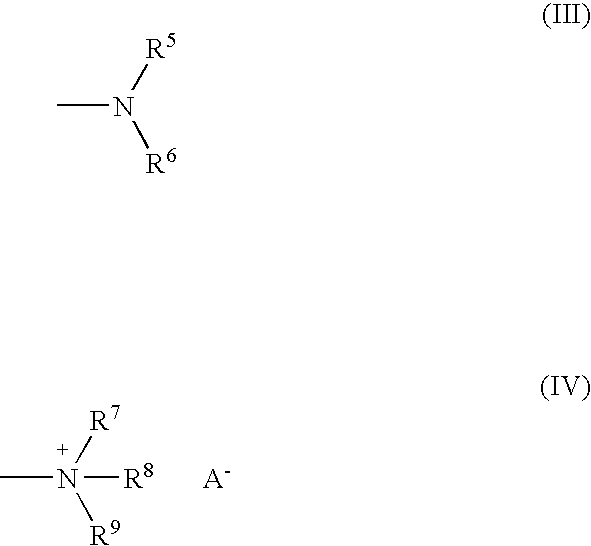

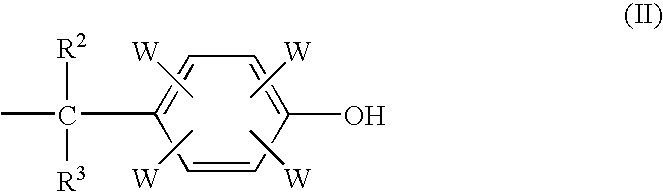

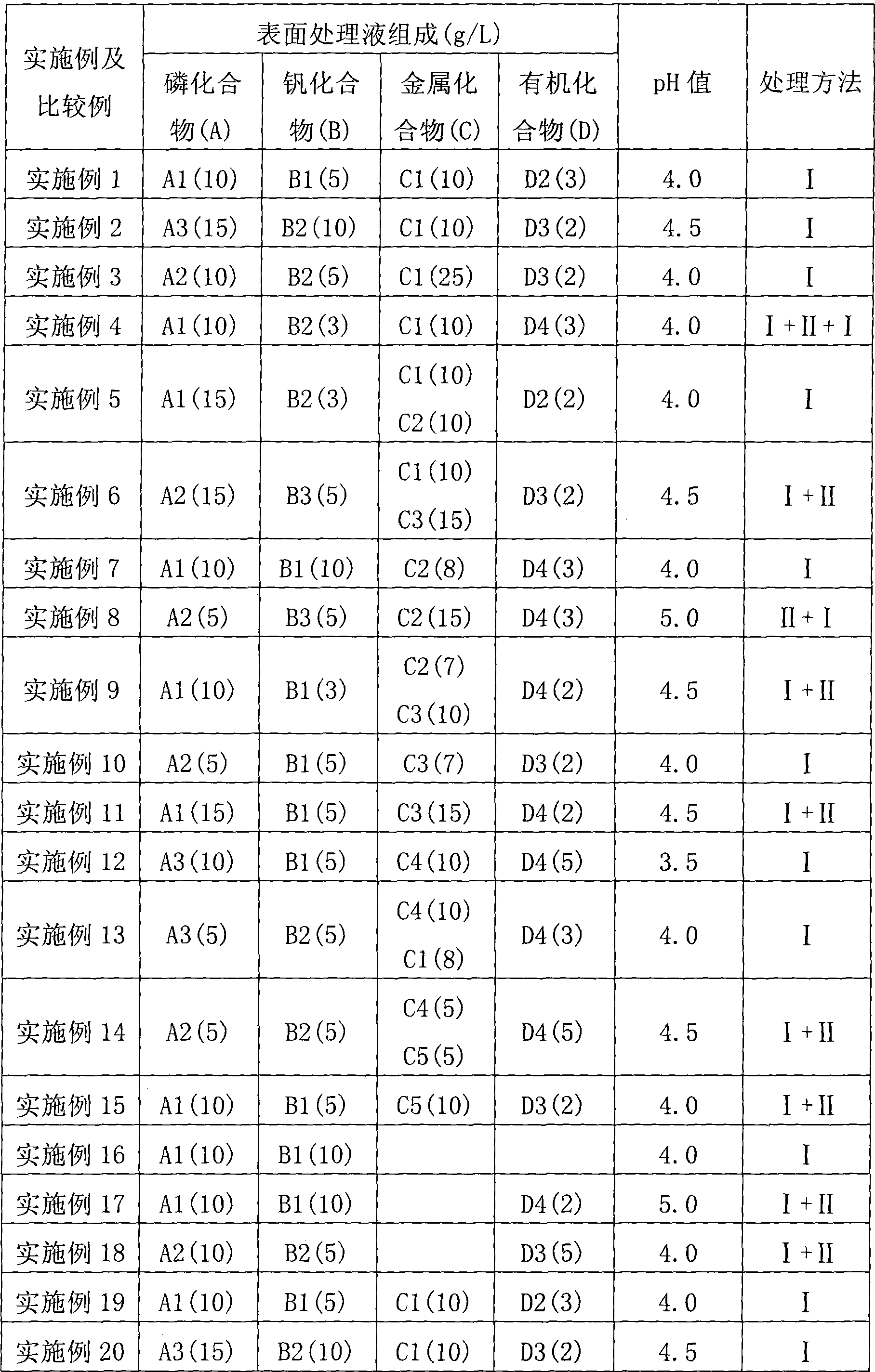

The invention provides a surface treatment liquid used for tin-plated steel sheets, which contains 1 to 50 g / L of phosphorus compound, 1 to 20 g / L of vanadium compound, 1 to 30 g / L of compound selected from one or more of molybdenum, zirconium, titanium, manganese and tungsten metal compounds, and 1 to 10 g / L of one or more compounds with at least one functional group of hydroxyl, carbonyl, carboxyl and phosphate. The invention also provides a surface treatment method using the surface treatment liquid, and a tin-plated steel sheet treated by the surface treatment liquid. By using the surface treatment liquid and the surface treatment method of the invention, chromium which is unfavorable for the environment is not contained in the process of producing the tin-plated steel sheets, and the cost is low. The tin-plated steel sheet has favorable sulfide spot resistance, paint wetting performance, coating adhesion and processing performance.

Owner:BAOSHAN IRON & STEEL CO LTD

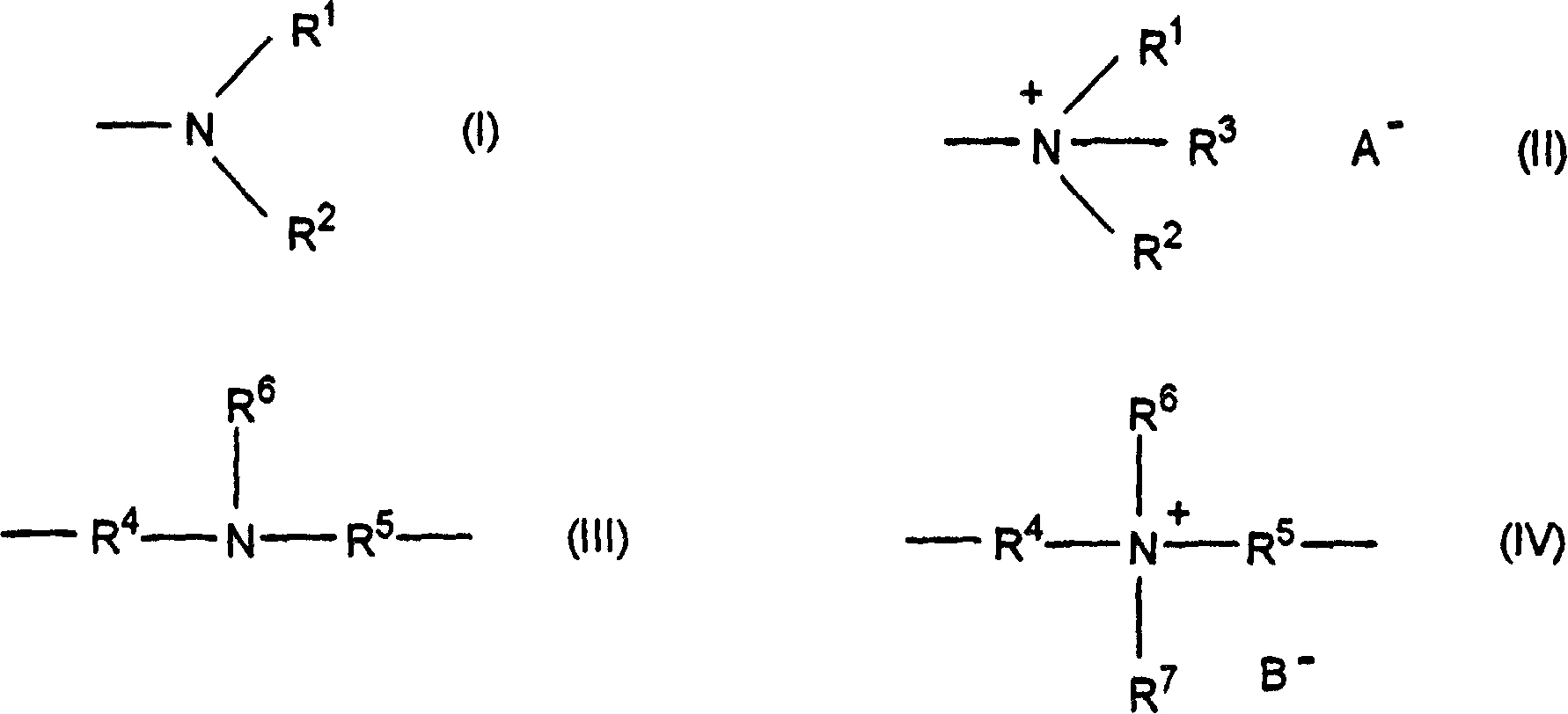

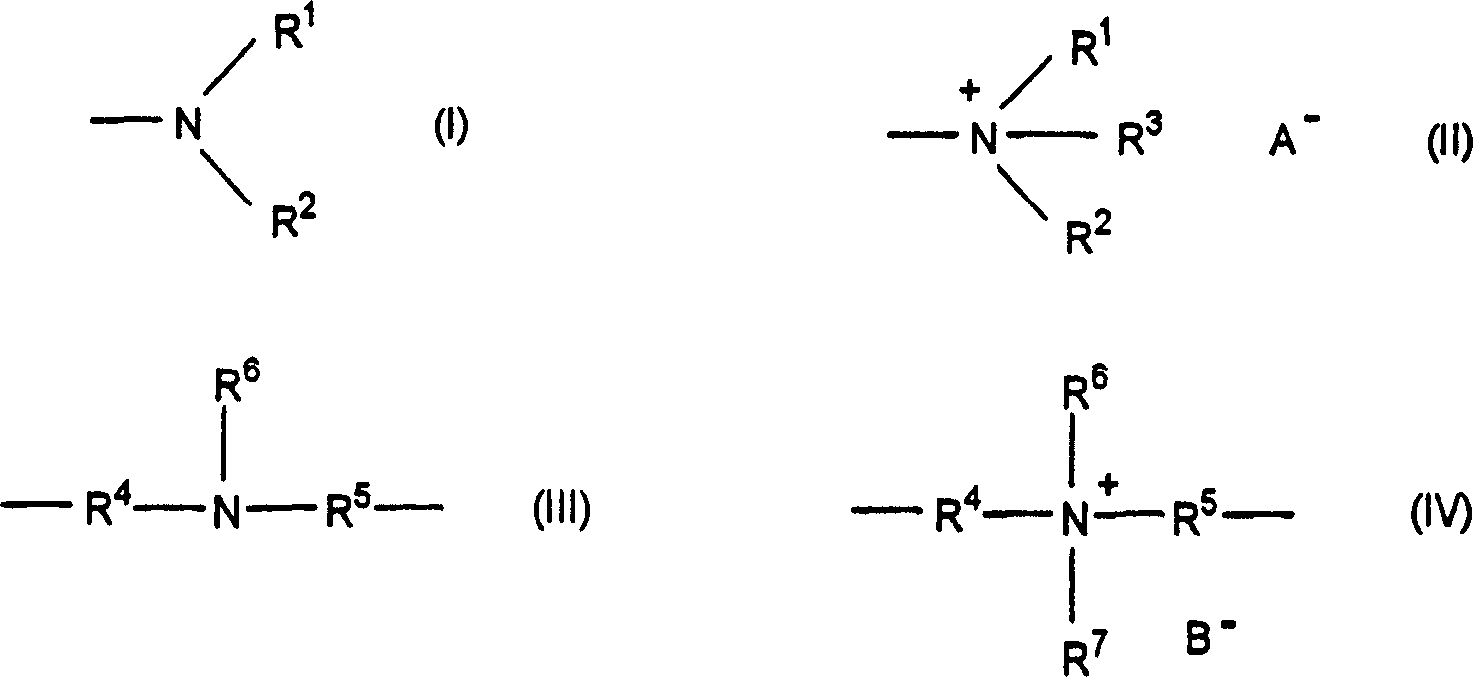

Surface treatment agent for metal, surface treatment method for metallic material, and surface-treated metallic material

InactiveCN101048476AImprove corrosion resistanceGood alkali resistancePolyurea/polyurethane coatingsMetallic material coating processesVanadium CompoundsEmulsion

An agent for treating metal surfaces which comprises an aqueous medium and, incorporated therein, (A) a cationic urethane resin which is water-soluble or in an aqueous emulsion form, (B) a cationic polycondensation product obtained from a phenol compound and an aldehyde, and (C) a zirconium compound and / or titanium compound. A coating film formed from the treating agent imparts excellent corrosion resistance and alkali resistance to a metallic material. When the proportion of the urethane resin (A) is equal to or higher than that of the polycondensation product (B), yellowing resistance can be also imparted. By incorporating a metal compound (D) containing a specific metal, excellent blacking resistance also can be imparted. Furthermore, by incorporating an acid ingredient (E) and a vanadium compound (F), a further improvement in performances can be attained.

Owner:NIHON PARKERIZING

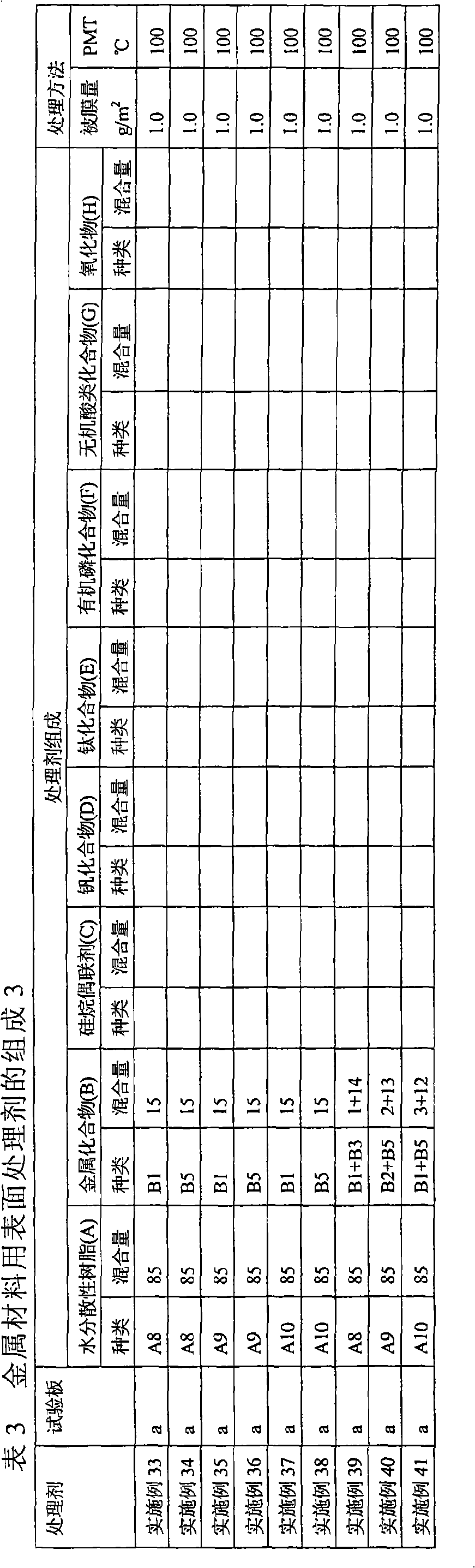

Surface treatment for metal materials, surface treatment process, and surface- treated metal materials

InactiveCN101326308AImprove use valueImprove corrosion resistanceLiquid surface applicatorsMetallic material coating processesChromium freeWater dispersible

A surface treatment for metal materials obtained by incorporating an anionic water-dispersible resin (A) having a glass transition temperature of 0 DEG C or above and at least one member (B) selected from the group consisting of alkali metal silicates and basic zirconium compounds in water, wherein the alkali metal silicates have M2O / SiO2 mass ratios of 1 / 1000 to 6 / 10 with M being at least one element selected from the group consisting of lithium, sodium and potassium; a surface treatment process; and surface-treated metal materials. The invention provides a chromium-free surface treatment for metal materials which is useful for imparting excellent corrosion resistance, chemical resistance, thermal discoloration resistance and weather resistance to metal materials. Additional incorporation of one or more members selected from among silane coupling agents, vanadium compounds, titanium compounds, organophosphonic acids, polyhydric alcohol phosphates, inorganic acids, salts thereof, metal fluorides, and metal oxides brings about further improvement in the performance of the treatment.

Owner:NIHON PARKERIZING

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

Surface treating agent with excellent alkali resistance and solvent resistance and for zinc coated steel plate

ActiveCN1887449AEasy to handleGood alkali resistancePretreated surfacesAnti-corrosive paintsTectorial membraneSolvent

The present invention relates to surface treating agent for zinc coated steel plate, and is especially one kind of surface treating agent with excellent alkali resistance and solvent resistance for zinc coated steel plate. The surface treating agent is water solution, which consists of fluoric acid with 4 or more fluorine atoms and at least one of Ti, Zr and Si atome in 0.1-5.0 wt%; phsosphorus containing compounding 0.01-0.5 wt%; one or more organic silicon coupling agent with amino group containing at least one active hydrogen atom 10-20 wt%, one or more organic silane coupling agent with at least one epoxy group 25-50 wt%; at least one kind of cationic or non-ionic water soluble polyurethane resin 30-60 wt% and vanadium compound 0.1-1.0 wt%. It is used in forming protecting film with excellent performance on the surface of zinc coated steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Conversion coating compositions

InactiveUS6764553B2Reduce the smellExcellent characteristicsOther chemical processesSolid state diffusion coatingVanadium CompoundsHydrophilic coating

Owner:HENKEL KGAA

Modified vanadium compound, producing method thereof, redox flow battery electrolyte composite and redox flow battery electrolyte producing method

InactiveUS6872376B2Improve solubilityEasy to prepareCell electrodesRegenerative fuel cellsVanadium CompoundsSulfate

Owner:THE KANSAI ELECTRIC POWER CO +1

Surface treated steel plate excellent in corrosion resitance electroconductivity and appearance of coating film

ActiveUS20060177685A1Hot-dipping/immersion processesRecord information storageO-Phosphoric AcidPhosphate

The present invention provides a surface-treated steel sheet including a steel sheet; a plating layer provided on at least one of the surfaces of the steel sheet, the plating layer containing at least one metal selected from the group consisting of zinc and aluminum; a first layer film provided on the surface of the plating layer and containing (α) 1 to 2000 mg / m2 of silica in terms of SiO2, (β) a total of 1 to 1000 mg / m2 of phosphoric acid groups in terms of P, (γ) a total of 0.5 to 800 mg / m2 of at least one metal selected from the group consisting of Mg, Mn, and Al in terms of a metal element, and (δ) 0.1 to 50 mg / m2 of a tetravalent vanadium compound in terms of V; and a second layer film formed to a thickness of 0.1 to 5 μm on the first layer film and containing a resin (A) having at least one type of functional group selected from the group consisting of OH and COOH groups, and at least one rust-proofing additive (B) selected from the group consisting of (a) a phosphate, (b) Ca ion-exchanged silica, (c) a molybdate, (d) silicon oxide, and (e) at least one organic compound selected from the group consisting of triazoles, thiols, thiadiazoles, thiazoles, and thiurams. The surface-treated steel sheet has excellent corrosion resistance without containing hexavalent chromium in a coating, and also has excellent conductivity and coating appearance.

Owner:JFE STEEL CORP

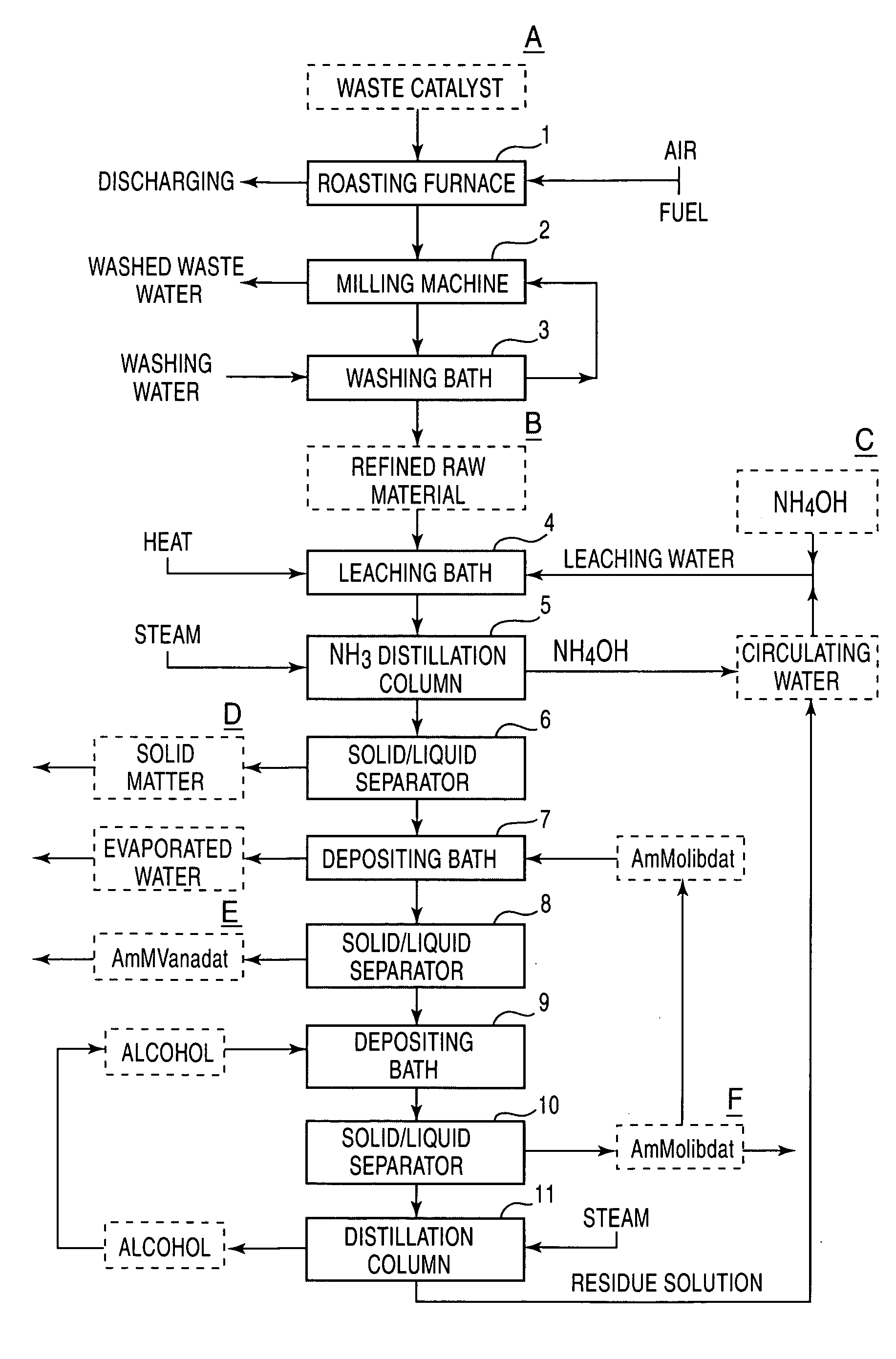

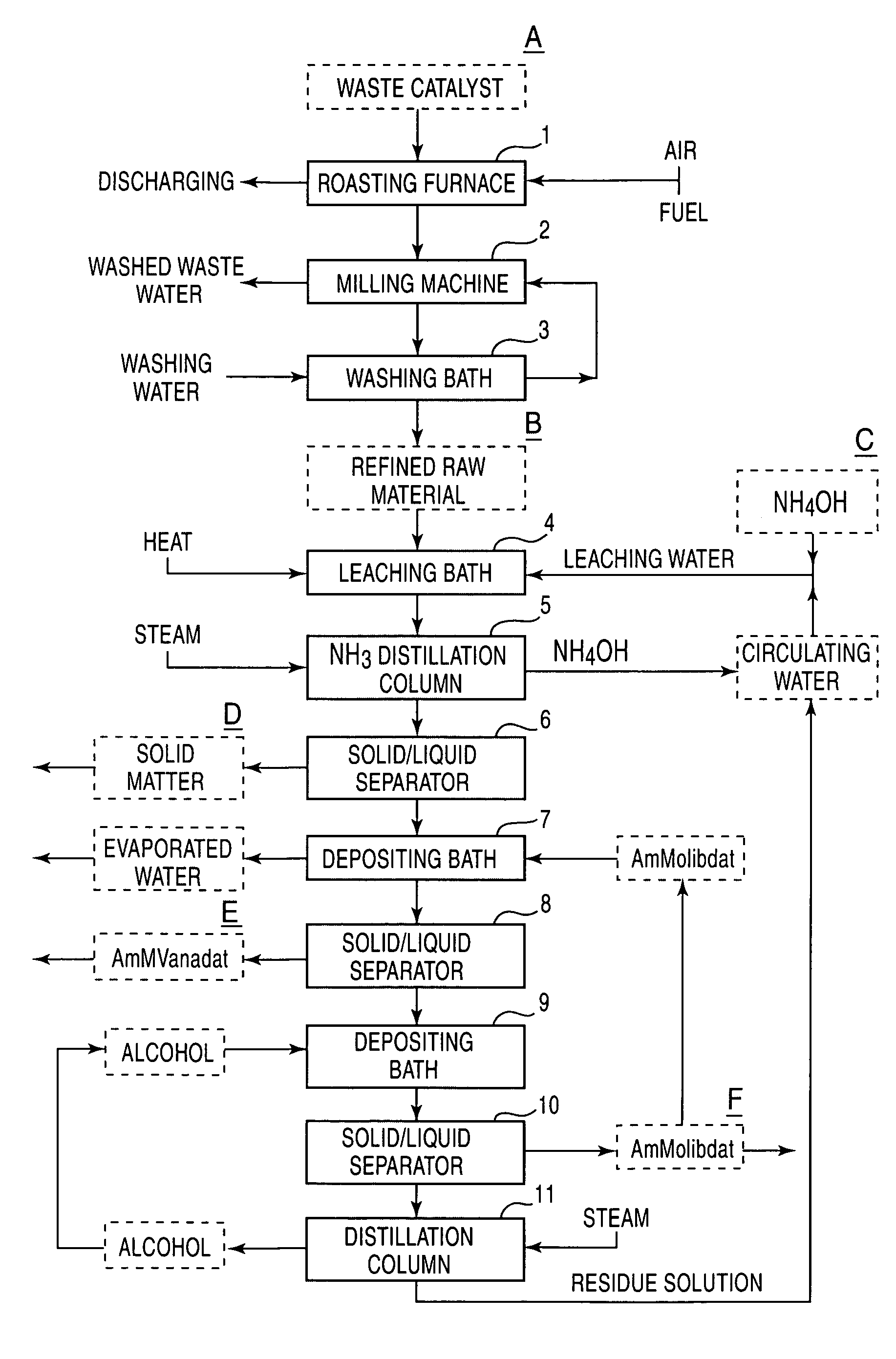

Process for separating and recovering valuable metals

InactiveUS20040213717A1Speed up leachingProceed efficientlyOther chemical processesTantalum compoundsVanadium CompoundsAlcohol

The present invention provides a process for economically separating and recovering valuable metal components, with no many kinds of chemicals being used, with no waste water that causes environmental pollution being discharged, and also perfectly no by-products being formed by means of simple steps. The present invention includes a step of leaching a raw material containing at least vanadium oxides and molybdenum oxides with ammonia-containing leaching water to obtain a leached solution containing a vanadium compound and a molybdenum compound, a step of adding ammonium orthomolybdate to the leached solution to separate and recover the deposited ammonium metavanadate from a first solution for separation, a step of adding a water-soluble alcohol to the separated solution to separate and recover the deposited ammonium orthomolybdate from a second solution for separation, a step of distilling the second solution for separation to separate and recover the water-soluble alcohol and a residue-solution, a step of adding at least a portion of the residue solution to the ammonia-containing leaching water as the portion thereof, and a step of returning a portion of the recovered ammonium orthomolybdate and a total of a recovered, water-soluble alcohol to the system for reusing.

Owner:Y K YSK TECHNOSYST

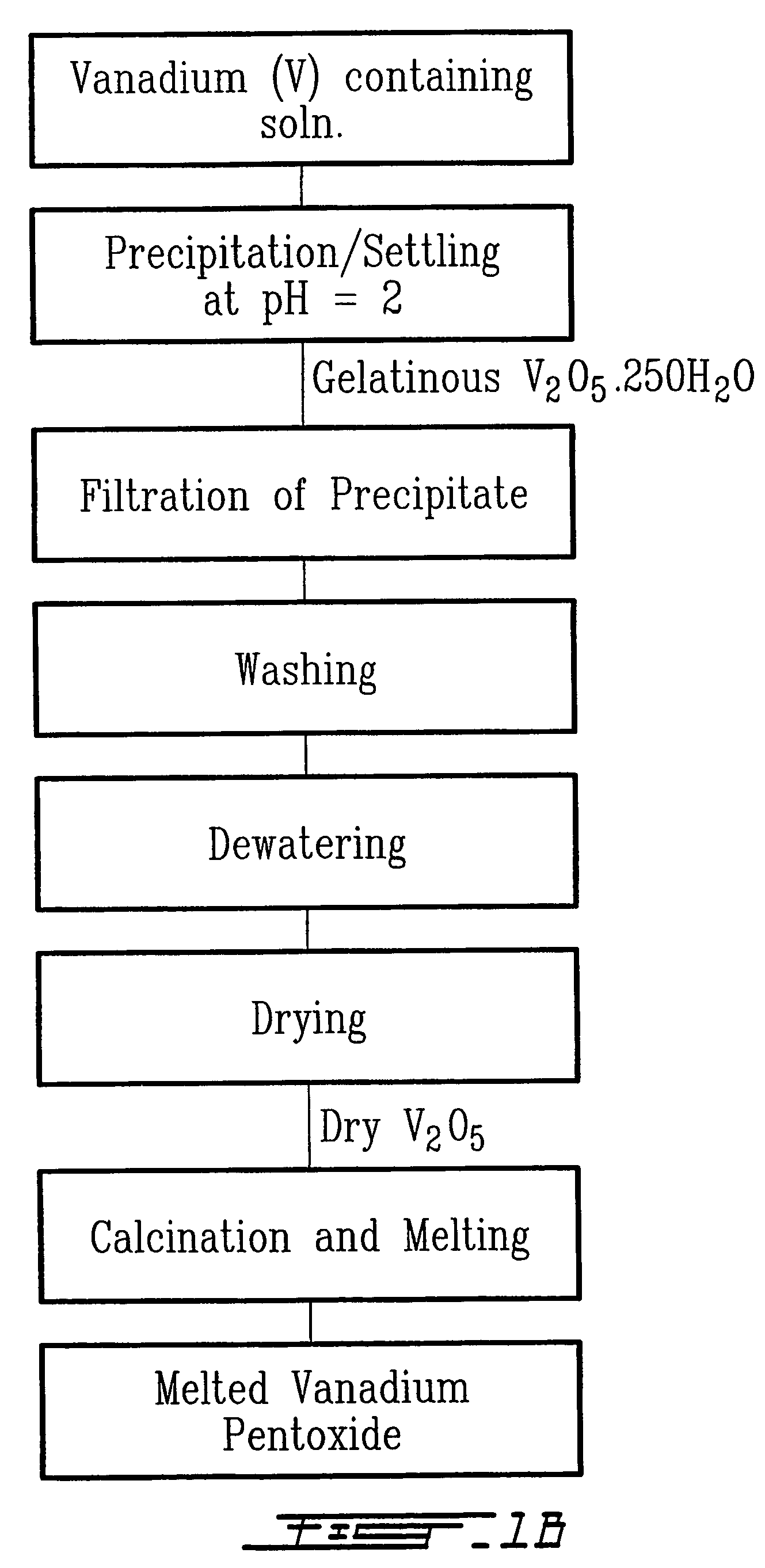

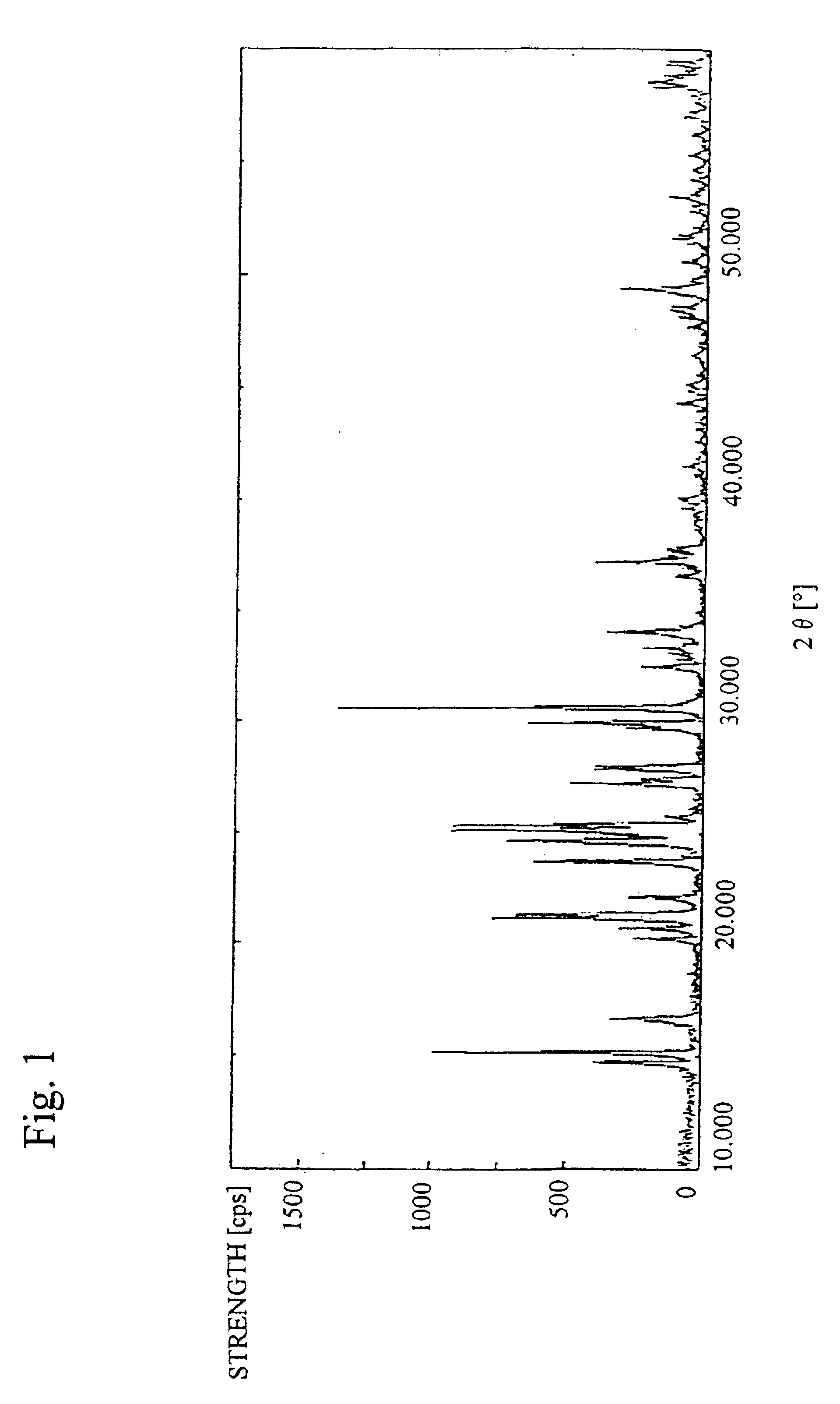

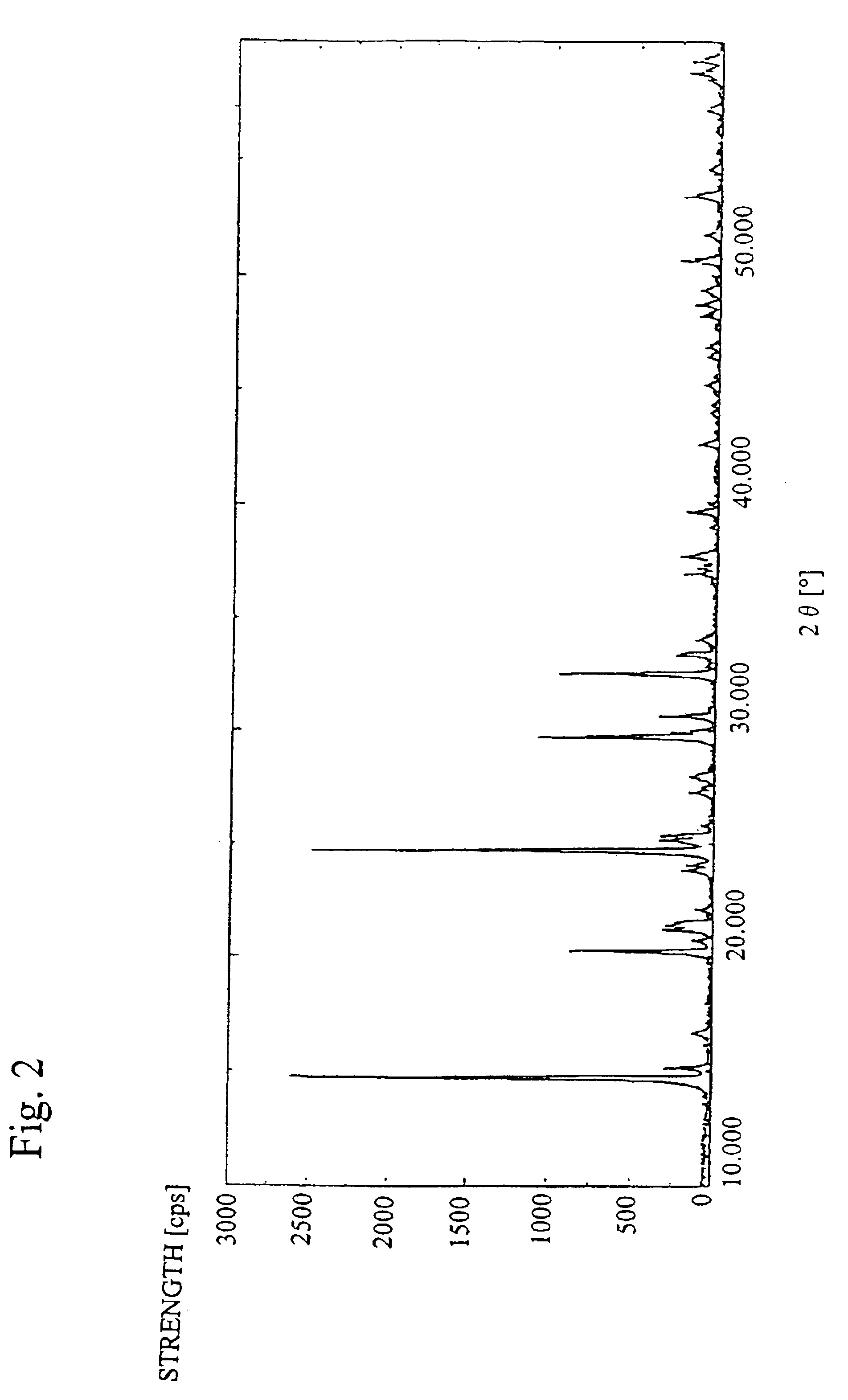

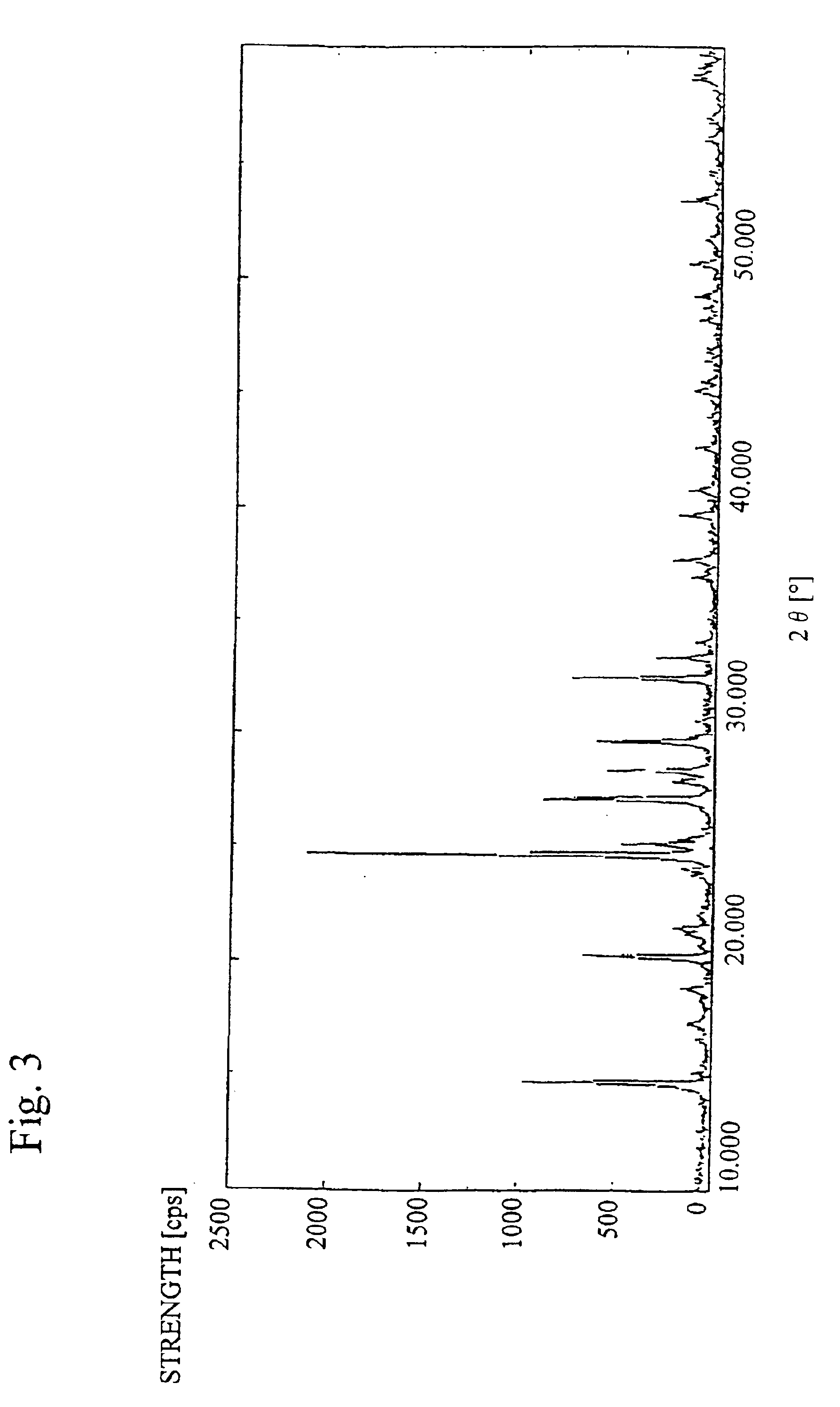

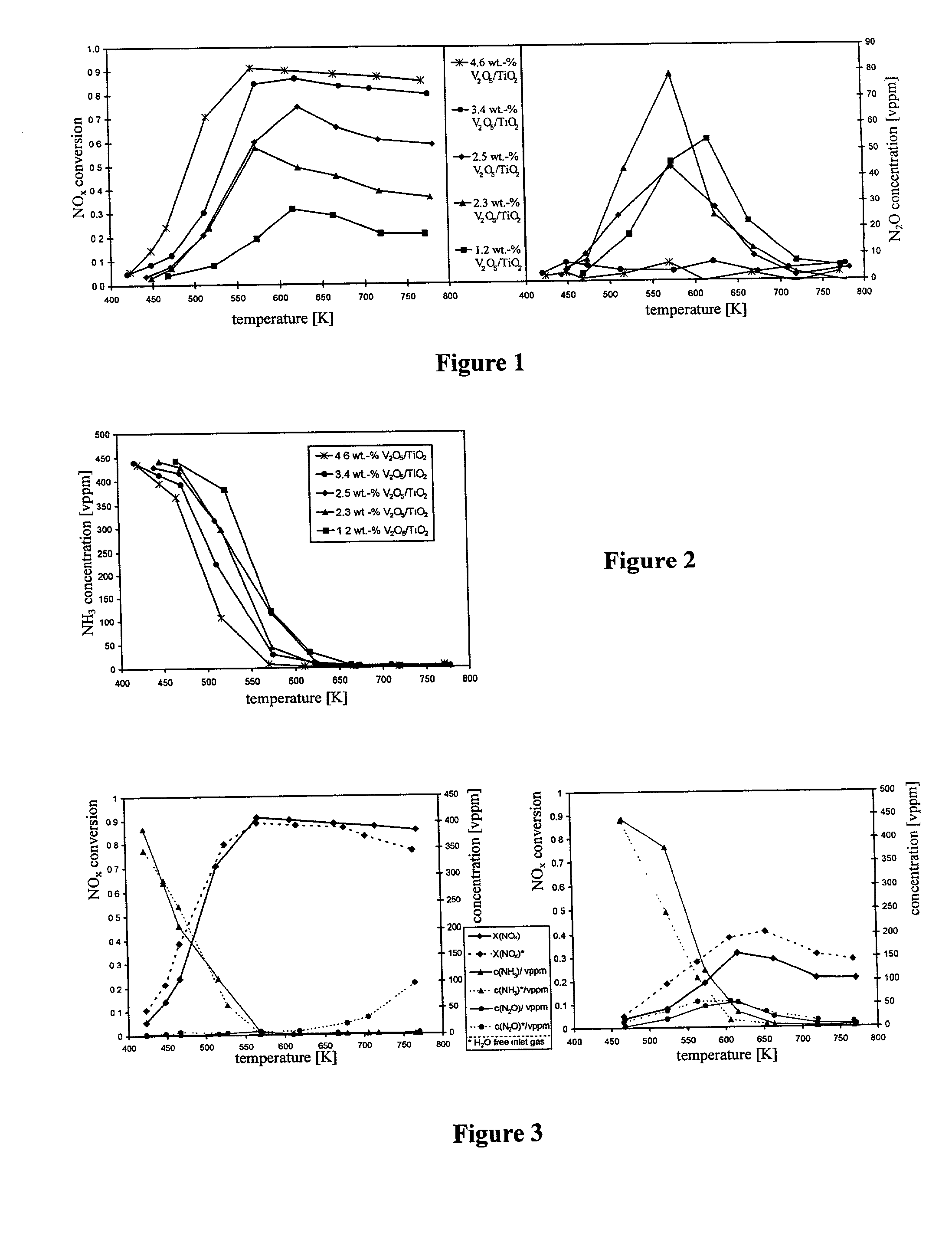

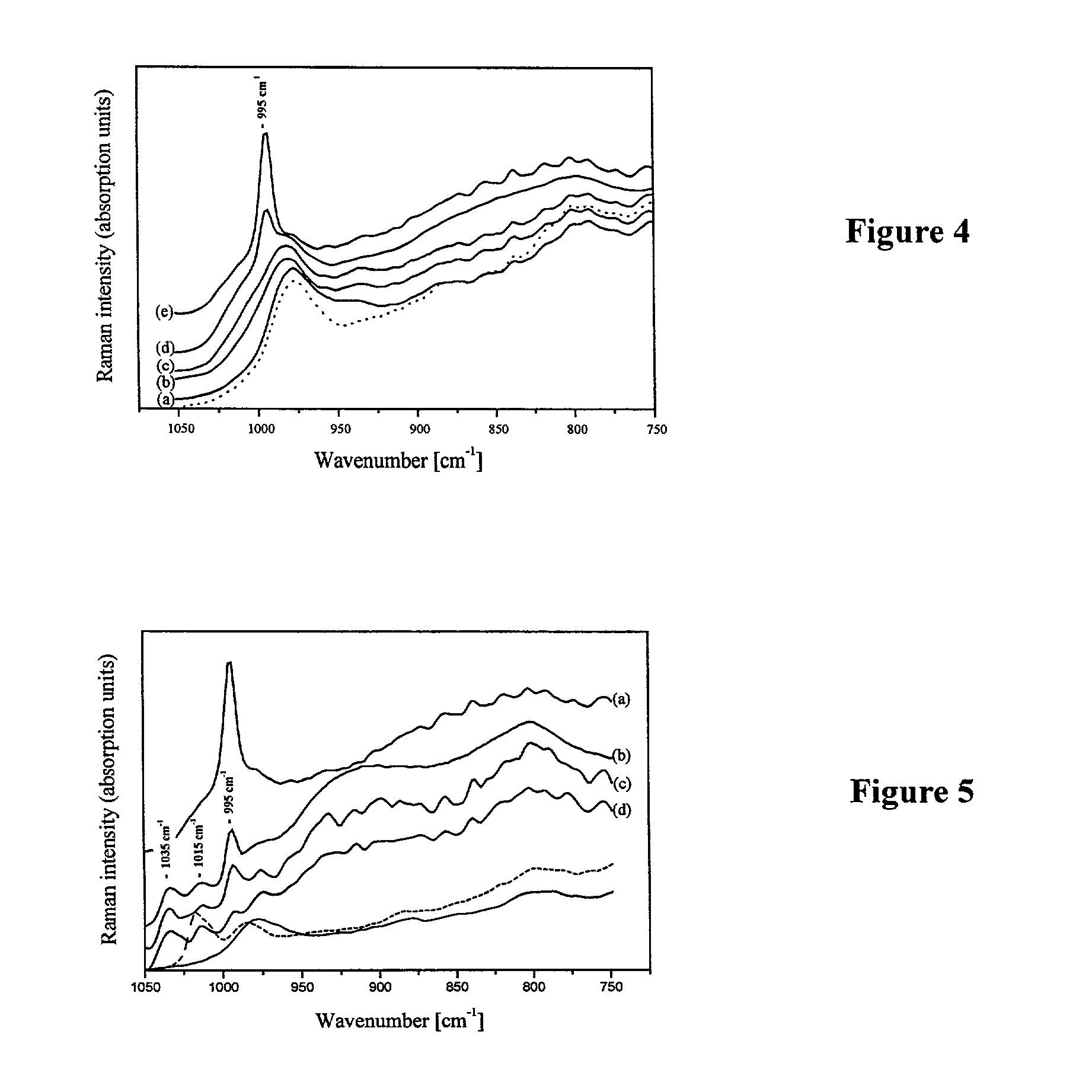

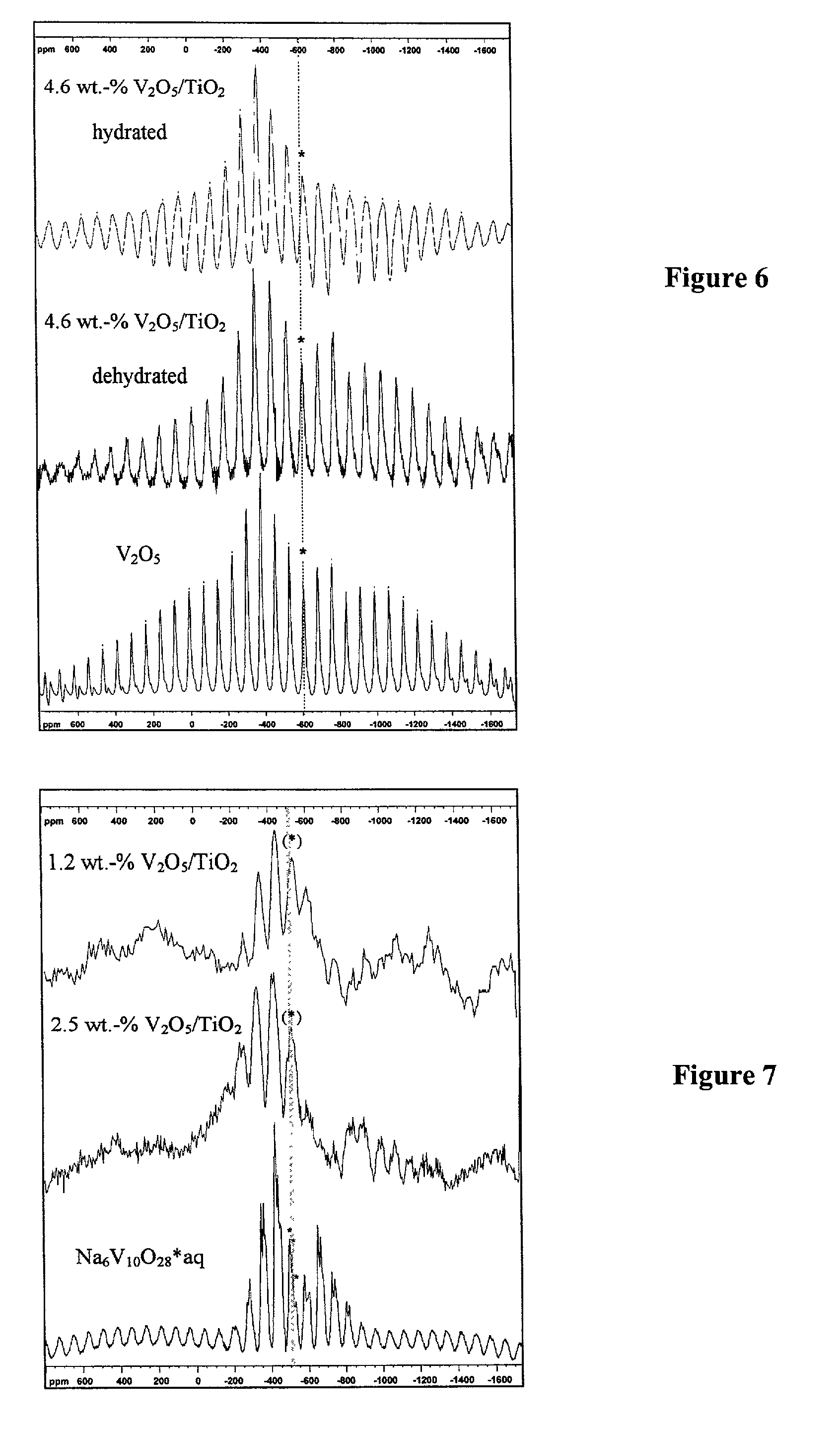

Process for the preparation of a vanadia SCR-catalyst supported on titania

InactiveUS20010049339A1Easy to controlGood dispersionExhaust apparatusDispersed particle separationVanadium CompoundsAmmonium metavanadate

The invention concerns a process for the preparation of a vanadia SCR-catalyst supported on titania. The process is characterized in that the catalyst is prepared by dispersing titania in an ammonium metavanadate (NH4VO3) solution, adjusting the pH of the solution to a value of 7.0-7.1 by NH4OH and HNO3, stirring the resulting suspension for a time sufficient for complete adsorption of the vanadium compound on titania, filtering the suspension and drying and calcining the resulting catalyst compound.

Owner:DMC2 DEGUSSA METALS CATALYSTS CERDEC

Process for separating and recovering valuable metals

InactiveUS7182926B2Control generationSuitable for useOther chemical processesTantalum compoundsAmmonium orthomolybdateAmmonium metavanadate

A process for economically separating and recovering valuable metal components, with few kinds of chemicals being used, with no waste water that causes environmental pollution being discharged, and also perfectly no by-products being formed by means of simple steps. The process includes a step of leaching a raw material containing at least vanadium oxides and molybdenum oxides with ammonia-containing leaching water to obtain a leached solution containing a vanadium compound and a molybdenum compound, a step of adding ammonium orthomolybdate to the leached solution to separate and recover the deposited ammonium metavanadate from a first solution for separation, a step of adding a water-soluble alcohol to the separated solution to separate and recover the deposited ammonium orthomolybdate from a second solution for separation, a step of distilling the second solution for separation to separate and recover the water-soluble alcohol and a residue solution, a step of adding at least a portion of the residue solution to the ammonia-containing leaching water as the portion thereof, and a step of returning a portion of the recovered ammonium orthomolybdate and a total of a recovered, water-soluble alcohol to the system for reusing.

Owner:Y K YSK TECHNOSYST

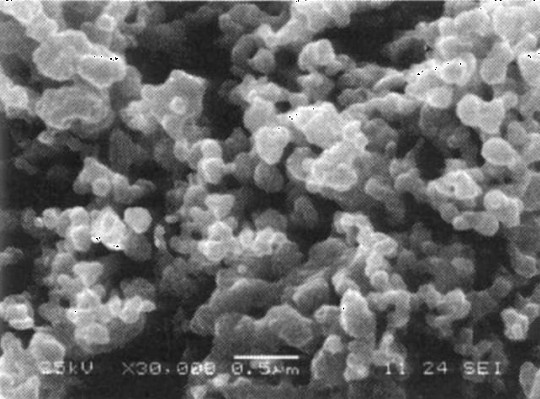

Preparation method of nano-structure WC-Co composite powder

InactiveCN102350506AWell mixedOvercoming coarse compound salt crystallizationChromium CompoundsVanadium oxide

The invention discloses a preparation method of a nano-structure WC-Co composite powder, and belongs to the field of an alloy preparation method. The method comprises the following steps in sequence: adding a carbonic powder material which is excessive to tungsten, vanadium and chromium carbides into water-soluble saturated mixed aqueous solution of tungsten-containing compound, cobalt-containing compound, chromium-containing compound and vanadium-containing compound to adsorb the saturated composite salt solution; dehydrating and drying to form a nano-scale composite salt thin layer on the surface of the carbonic powder material; removing crystal water out of the composite salt at the temperature below 500 DEG C under a condition of isolating air, and decomposing the composite salt into composite oxide of tungsten oxide, chromium hemitrioxide, vanadium oxide and cobalt oxide, further heating, and reducing and carbonizing the composite oxide on the surface of the carbonic powder material to generate the WC-Co nano-structure composite powder at the temperature below 850 DEG C. The preparation is a simpler and more reliable novel preparation method of the nano WC-Co composite powder by a direct carbonization method.

Owner:SOUTHWEST PETROLEUM UNIV

Zinc coated steel plate with excellent alkali resistance and solvent resistance

ActiveCN1887451AGood alkali resistanceGood solvent resistancePolyurea/polyurethane coatingsMetallic material coating processesCompound organicTectorial membrane

The present invention relates to zinc coated steel plate possessing compound organic protecting film with excellent alkali resistance and solvent resistance. The protecting film consists of fluoric acid with 4 or more fluorine atoms and at least one of Ti, Zr and Si atome in 0.1-5.0 wt%; phsosphorus containing compounding 0.01-0.5 wt%; one or more organic silicon coupling agent with amino group containing at least one active hydrogen atom 10-20 wt%, one or more organic silane coupling agent with at least one epoxy group 25-50 wt%; at least one kind of cationic or non-ionic water soluble polyurethane resin 30-60 wt% and vanadium compound 0.1-1.0 wt%. The zinc coated steel plate possesses excellent alkali resistance and solvent resistance as well as excellent corrosion resistance, fingerprint resistance, paint attaching performance, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

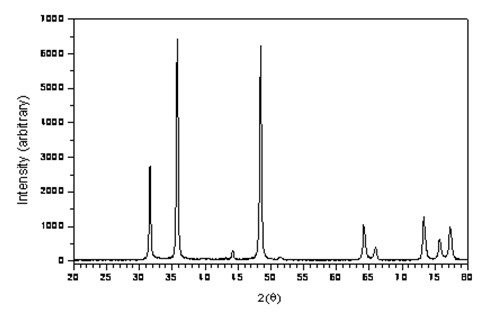

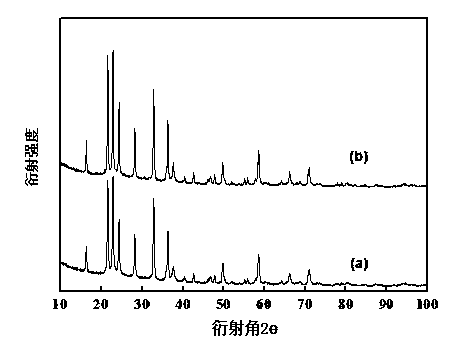

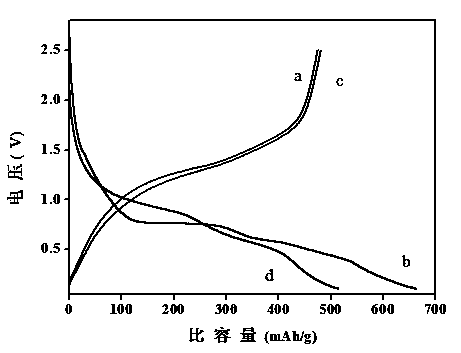

Sol-gel preparation method of lithium vanadate negative electrode material of lithium ion battery

ActiveCN104241626ASmall grain sizeRich sourcesCell electrodesSecondary cellsGel preparationVanadium Compounds

The invention relates to a sol-gel preparation method of a lithium vanadate negative electrode material of a lithium ion battery. The sol-gel preparation method comprises the following steps: sequentially adding a precursor containing a vanadium compound and a precursor containing a lithium compound into water, and stirring fully; then adding a water soluble carbon material which is acted as a chelate and a carbon source, stirring the water solution until dry gel is formed, carrying out vacuum drying until the water content is dried completely, putting a gel body into a porcelain boat, pretreating in the reducing atmosphere or the inert atmosphere, and carrying out sintering reaction in the inert atmosphere or the reducing atmosphere so as to obtain the material. According to the method, the technology is simple, the operation is easy, and moreover, the structure of lithium vanadate and the valence state of vanadium cannot be changed by the existence of the carbon material and the reducing atmosphere. The carbon-coated lithium vanadate material synthesized by the method, which acts as the negative electrode material of the lithium ion battery, has excellent performance and low lithium intercalation potential, and is expected to be as the negative electrode material of the next generation of lithium ion batteries. The synthesis method is suitable for producing the negative electrode material of the high-performance lithium ion battery, namely lithium vanadate.

Owner:SOUTH CHINA UNIV OF TECH

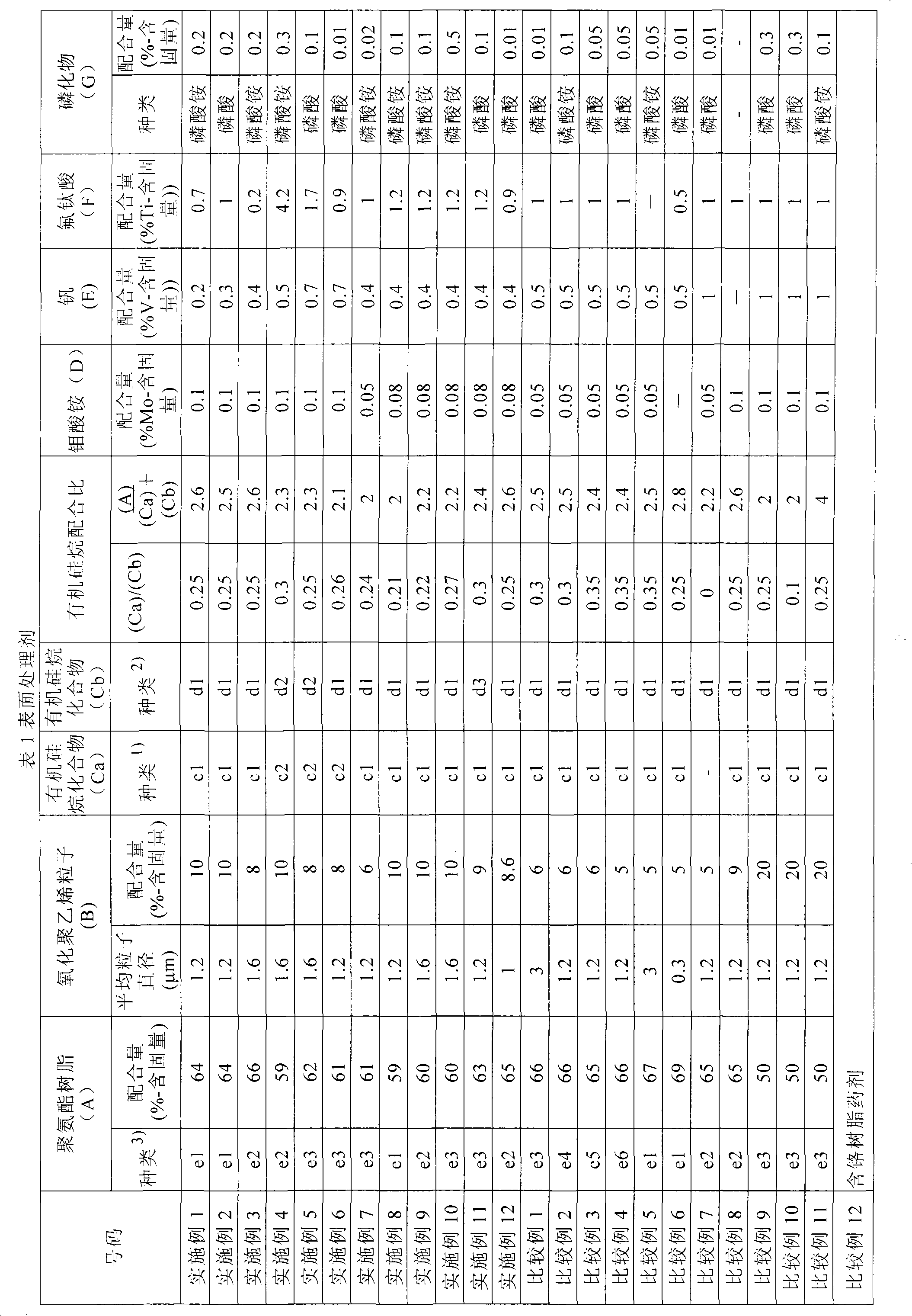

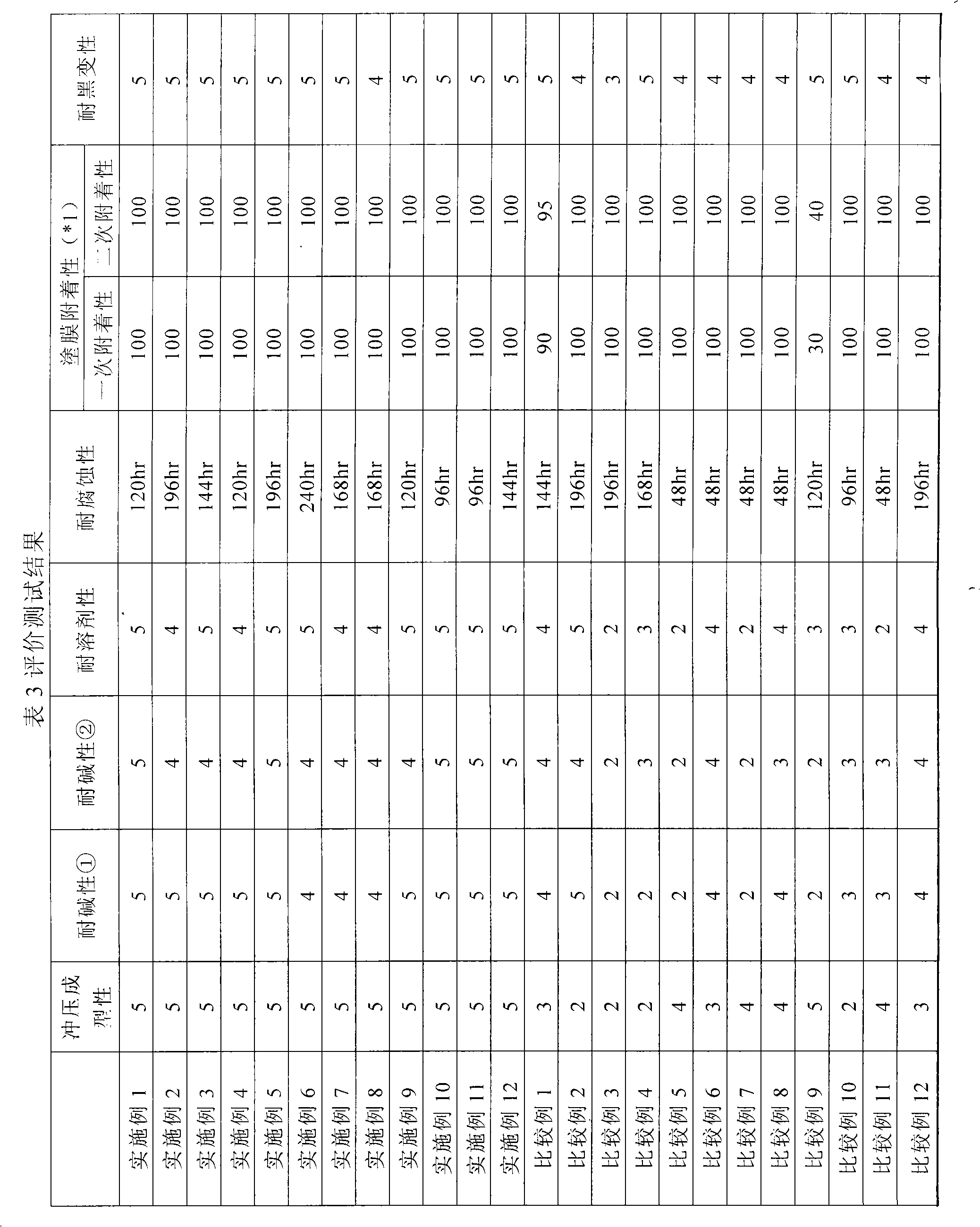

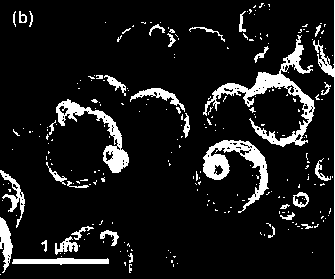

Galvanized steel plate with excellent machining property and alkali and solvent resistance and surface treating agent

The invention discloses a galvanized steel plate with excellent machining property and alkali and solvent resistance. An organic compound protective film is covered on the surface of the steel plate, wherein the protective film contains the following components in percentage by weight: A) 50 to 70 percent of cationic polyurethane resin of which the elongation percentage is 20 to 100 percent and the glass transition temperature is between 50 and 100 DEG C; B) 5 to 10 percent of oxidized polyethylene particles with the grain diameter (median diameter) of 1 to 2 microns; C) one or more organic silicone coupling agents (Ca) containing at least one active hydrogen of amino functional group and one or more organic silicone coupling agents (Cb) containing at least one epoxy functional group in a weight ratio of the (Ca) to the (Cb) of 0.2 to 0.4, wherein the weight ratio of the total amount of the cationic polyurethane resin (A) to the organic silicone coupling agent is 2 to 3; D) 0.01 to 0.1 percent of ammonium molybdate based on molybdenum element; E) 0.1 to 1.0 percent of vanadium compound based on vanadium element; F) 0.1 to 5 percent of fluorine-containing titanium compound based on titanium element; and G) 0.01 to 0.5 percent of phosphorous compound based on phosphorous element.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Phosphonic acid and polyvinyl alcohol conversion coating

Compositions for preparing coatings on metal substrates include a phosphonic acid, polyvinyl alcohol, an optional catalyst, and optionally an organo-functional silane. The catalyst may be a group IV-B compound, a boron compound, a vanadium compound, or a molybdenum compound. The compositions may be applied from an aqueous carrier to a metal surface and then dried to form a coating imparting good paint adhesion and corrosion resistance to the metal substrate.

Owner:BULK CHEM

Rare-earth-based composite multi-component denitration and dioxin-removing catalyst and preparation method thereof

InactiveCN104841489ASolve pollutionHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationFiberCatalytic decomposition

The invention relates to a rare-earth-based composite multi-component denitration and dioxin-removing catalyst and a preparation method thereof. The rare-earth-based composite multi-component denitration and dioxin-removing catalyst takes titanium dioxide and silicon powder as carriers, and takes tungsten compounds, vanadium compounds, cerium compounds and lanthanum compounds as active components; and under the accompanying of auxiliary materials, all the raw materials are mixed, granulated, kneaded, molded, dried and roasted to prepare the catalyst, wherein the auxiliary materials comprise monoethanolamine, ammonia water, lactic acid, stearic acid, glass fibers, citric acid, PP (Propene Polymer) fibers, cellulose ether, polyoxyethylene and water. The preparation method of the rare-earth-based composite multi-component denitration and dioxin-removing catalyst has a simple process and is safe to operate, and the catalyst has a plurality of functions of denitration, dioxin removal and mercury removal; by adopting a catalytic decomposition technology, the dioxin pollution problem is solved; compared with that of active carbon, the adsorption is relatively complete; and the activity of the catalyst is extremely improved and the temperature use range is expanded.

Owner:SHANDONG AIREP ENVIRONMENTAL TECH CO LTD

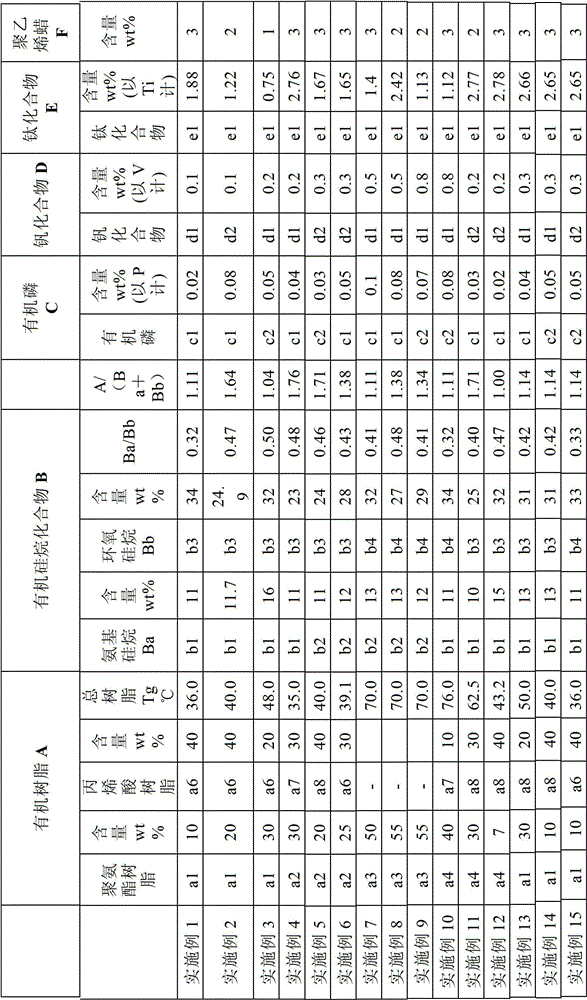

Method for producing a Ti/V supported catalyst for ethylene polymerization and ethylene/alpha - olefin copolymerization

InactiveUS6214759B1High bulk densitySolve the lack of activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOrganic chloride compoundAlpha-olefin

The present invention relates to a method for producing a Ti / V supported catalyst useful in polymerization of ethylene and copolymerization of ethylene and alpha-olefin. The method includes a treatment, by a titanium compound and a vanadium compound, of the magnesium-containing carrier, which is obtained by reaction of an organomagnesium compound of the structure of MgPh2.nMgCl2.mR2O (n=0.37~0.7; m>=1; R2O=ether; Ph=phenyl) with an organic chloride compound in a mole ratio of organic chloride compound / Mg>=0.5, at -20~80° C. According to the method for producing the catalyst, it is possible to provide a catalyst which can control the distribution of molecular weight, and when polymerization is performed using this catalyst, it is possible to restrain the inactivation and to secure a sufficient activity. Moreover, the polymer produced by the use of this catalyst proves to have a high bulk density and an adjusted particle size distribution.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

Method for preparing 2,5-furandicarboxylic acid from biomass compound by electrocatalytic oxidation

ActiveCN108531936AWide range of resources and cheapLow costElectrolytic organic productionLiquid/solution decomposition chemical coatingCatalytic oxidationH shaped

The invention relates to a method for preparing 2,5-furandicarboxylic acid from a biomass compound by electrocatalytic oxidation. The method comprises the following steps: reacting by using an H-shaped electrolytic cell, in an anode compartment, taking a load type catalyst as a working electrode, and dissolving the biomass compound as a reaction substrate in an alkaline solution to obtain an anodesolution; and in a cathode compartment, carrying out electrocatalytic oxidation reaction by taking a platinum sheet as a counter electrode and taking the alkali solution as a cathode solution for 0.5-5 hours under the conditions that the temperature is 30-90 DEG C, the current is 5-50 mA and the cell voltage is 1-10 V, and after reaction is finished, carrying out aftertreatment to obtain the 2,5-furandicarboxylic acid. The technique is gentle in conditions of an electrocatalytic oxidation reaction process, green and pollution-free, high in conversion rate of the raw material and good in FDCAselectivity. Compared with a noble metal catalyst which is generally used in prior art, a metal vanadium compound catalyst used in the invention is low on cost; and consumption of rare precious metalraw materials is avoided.

Owner:ZHEJIANG UNIV OF TECH

Metal surface treatment solution and method of manufacturing steel sheet using the same

InactiveUS20100068396A1Quality improvementSynthetic resin layered productsConductive materialColloidal silicaOrganic acid

Disclosed herein is a metal surface treatment solution that can provide superior corrosion resistance and paint adhesion and method for treating the surface of a steel sheet using the metal surface treatment solution. The metal surface treatment solution includes 9˜13 wt % of an epoxy-based silane coupling agent, 5˜9 wt % of an amino-based silane coupling agent, 0.5˜1 wt % of a vanadium compound, 0.5˜1 wt % phosphoric acid; 0.5˜1 wt % of an organic acid, 0.1˜10 wt % of a Ti-Alkoxide, 0.1˜2 wt % of a chelating agent, 0.1˜5 wt % of a calcium phosphate-based compound, 0.2˜10 wt % of a colloidal silica, and the balance of solvents.

Owner:KIM JONG GI +3

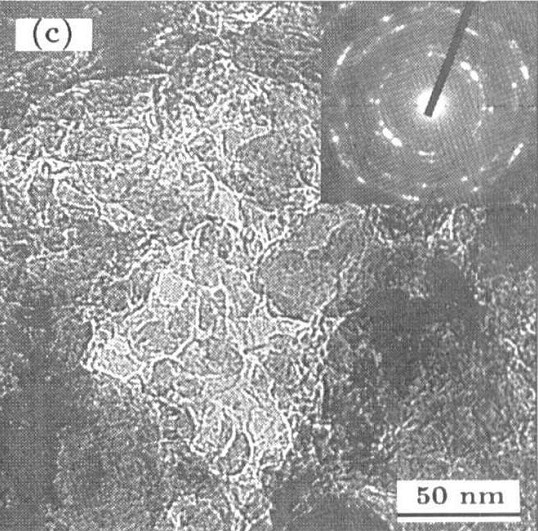

Preparation for visible-light responsible BiVO4 catalyst

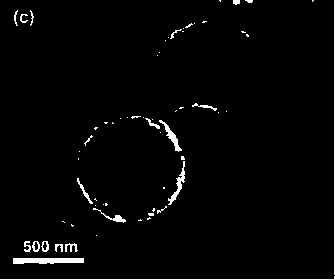

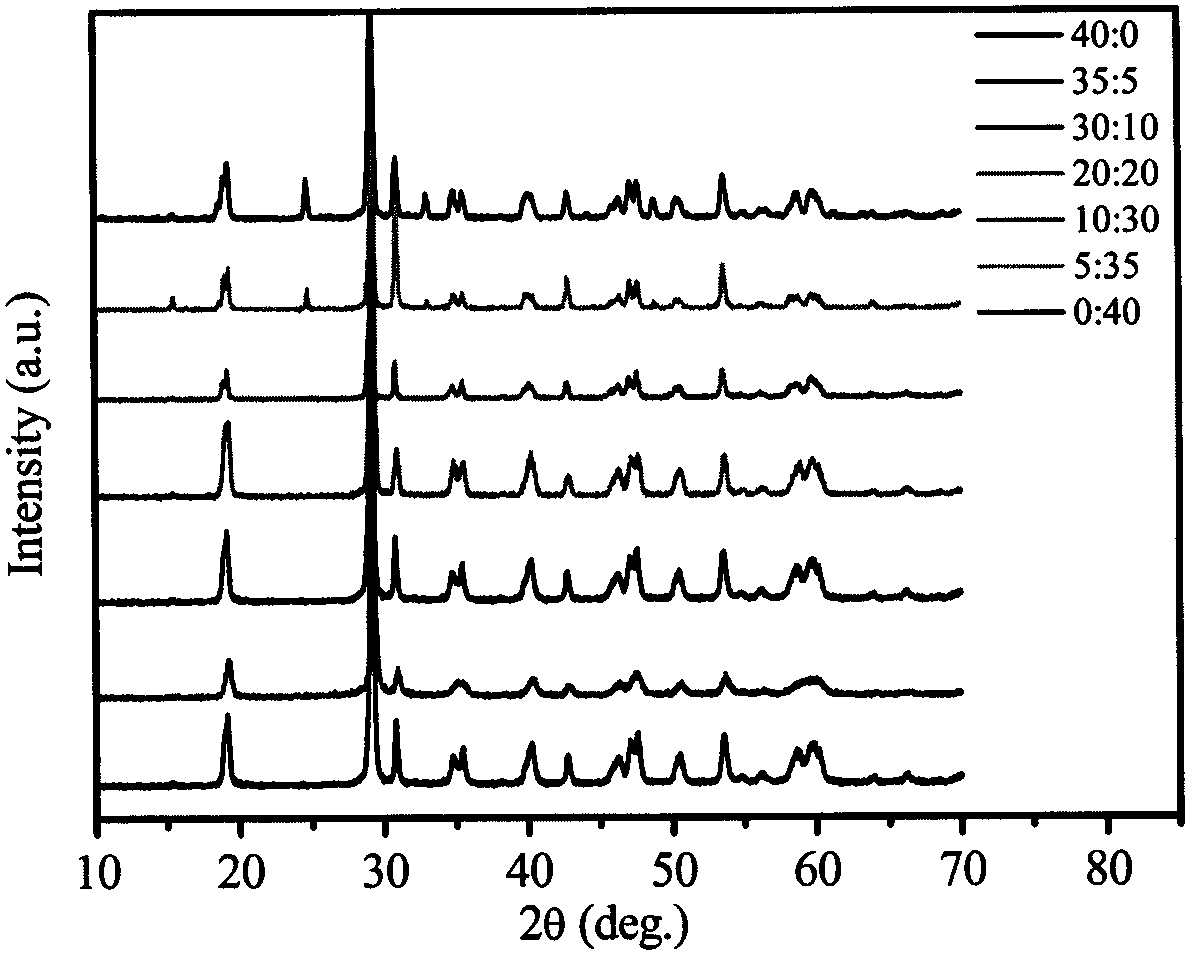

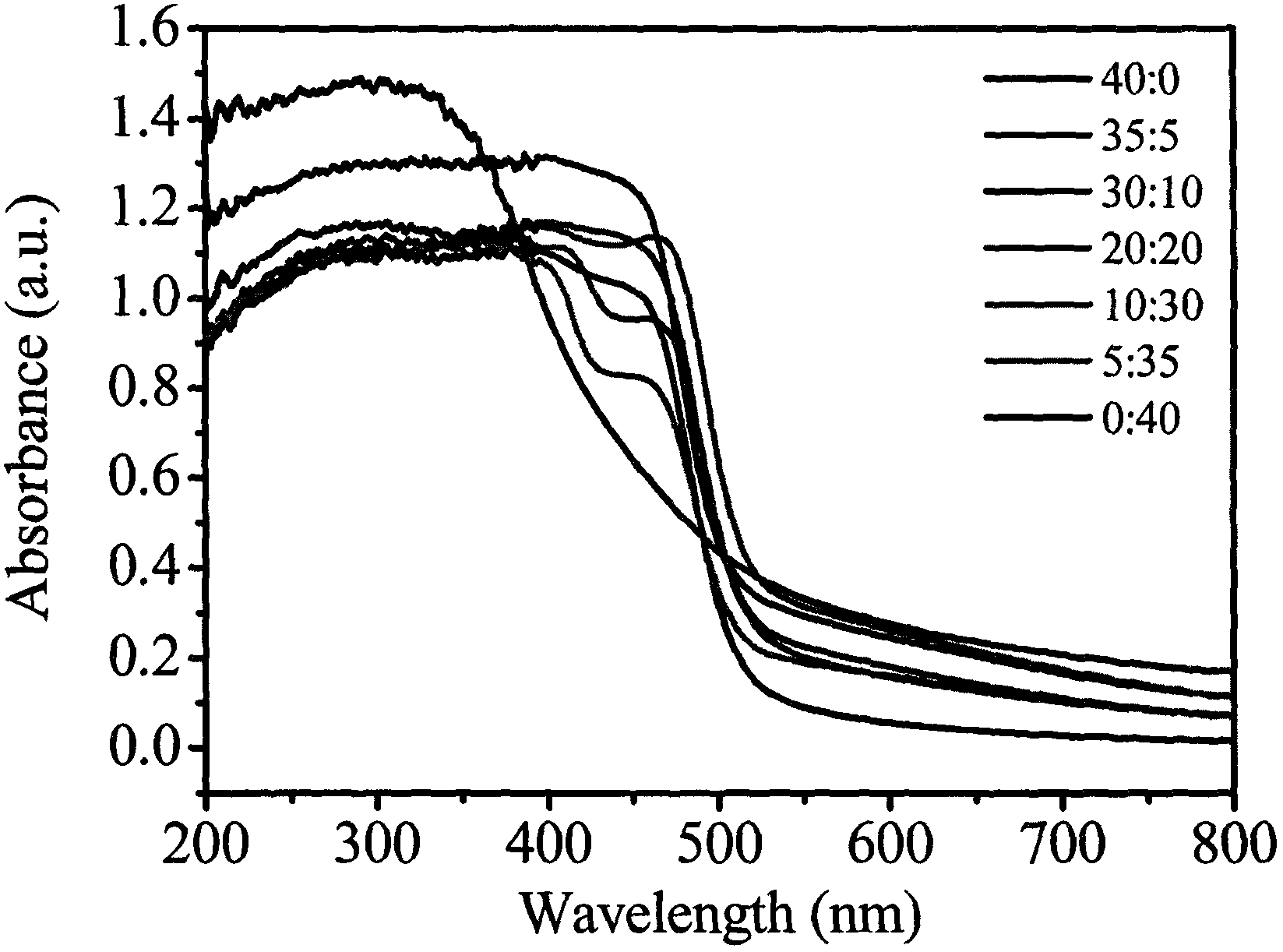

InactiveCN104108753AImprove photocatalytic efficiencyEasy to prepareMaterial nanotechnologyVanadium compoundsVanadium CompoundsAlcohol

The invention discloses a preparation method for a visible-light responsible BiVO4 catalyst. The method comprises: taking a bismuth compound and a vanadium compound respectively as a bismuth source and a vanadium source, taking mixtures of water and an organic alcohol with different ratios as reaction solvents, and performing a hydro-thermal synthesis reaction, so as to obtain a catalytic material in the forms of a nanometer small particle, a nanometer ellipsoid, a flower-shaped structure or a branch structure. The visible-light responsible catalyst containing BiVO4 with different morphologies helps to greatly improve the photocatalysis degradation efficiency when being applied to the field of photocatalytic degradation of pollutants. The preparation method has the advantages of simple operation, mild reaction conditions, low equipment cost, relatively strong visible-light absorption, good visible-light catalytic performance and the like.

Owner:HAINAN NORMAL UNIV

Therapeutic compositions

InactiveUS6946151B2Lower blood sugar levelsSlow onsetBiocideOrganic active ingredientsDiseaseAntioxidant

An oral composition, suitable as a hypoglycemic agent, includes an isolate from the leaves of Gymnema sylvestre, having a specified molecular weight. The isolate has a molecular weight at least about 3000 Daltons as determined by molecular weight cut-off filtration. Glucose metabolism in a human patient can be regulated by dosage forms that contain the aforesaid isolate from the leaves of Gymnema sylvestre, in combination with a non-metabolizable, water-swellable polysaccharide such as the exudate of Sterculia urens, and a water-soluble polysaccharide such as guar gum. Optionally, the present oral compositions can include a physiologically acceptable calcium source, a physiologically acceptable metal carbonate salt, a physiologically acceptable chromium salt, and / or a physiologically acceptable vanadium compound. In addition, antioxidants such as ascorbic acid, cholecalciferol, d-α-tocopherol, the carotenoids, lycopene, lutein, and the like, can be included as well. The present compositions are useful for amelioration of cholesterolemia, obesity, chronic complications of diabetes and prophylaxis for patients predisposed to the foregoing.

Owner:AYURVEDIC LIFE INT LLC

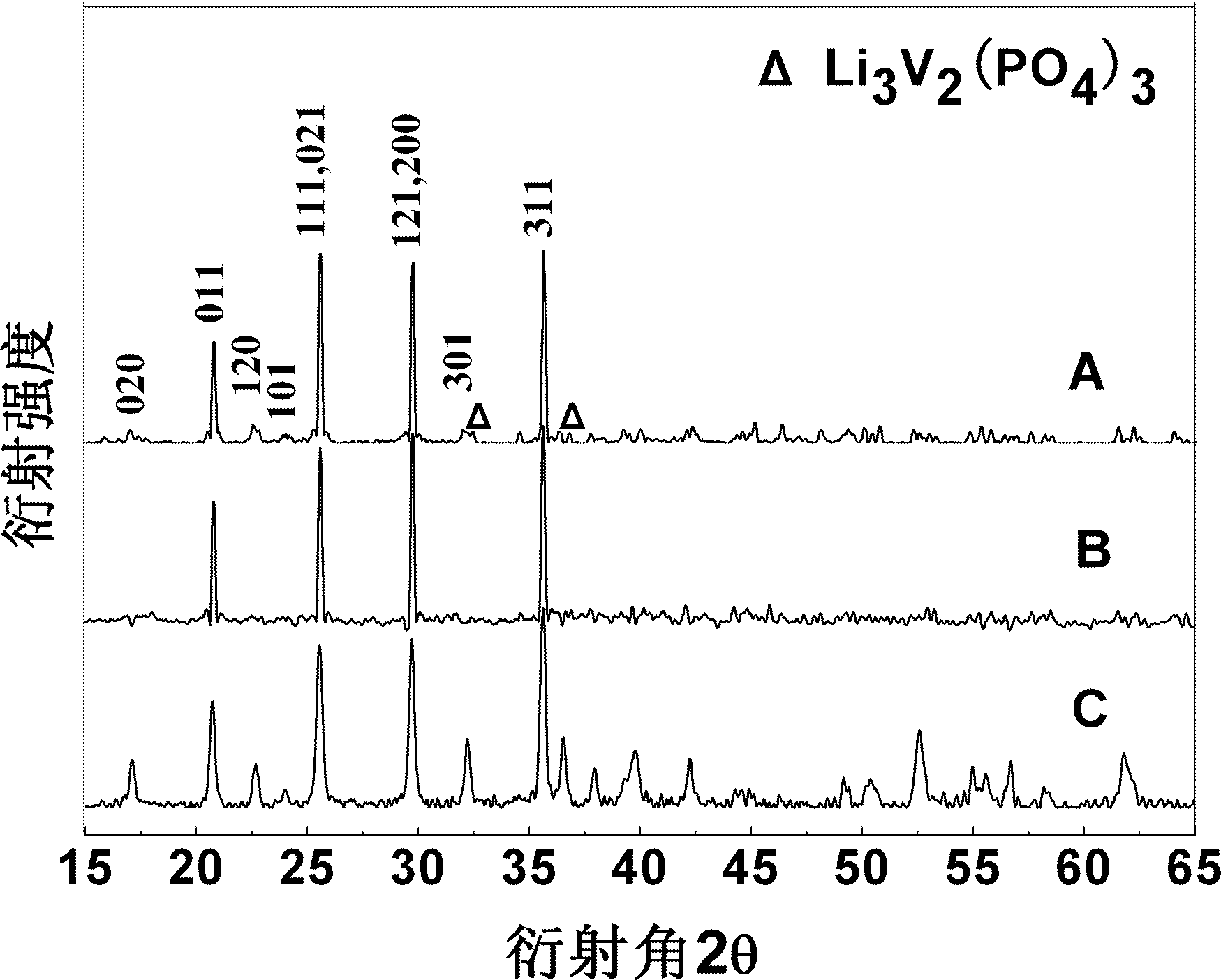

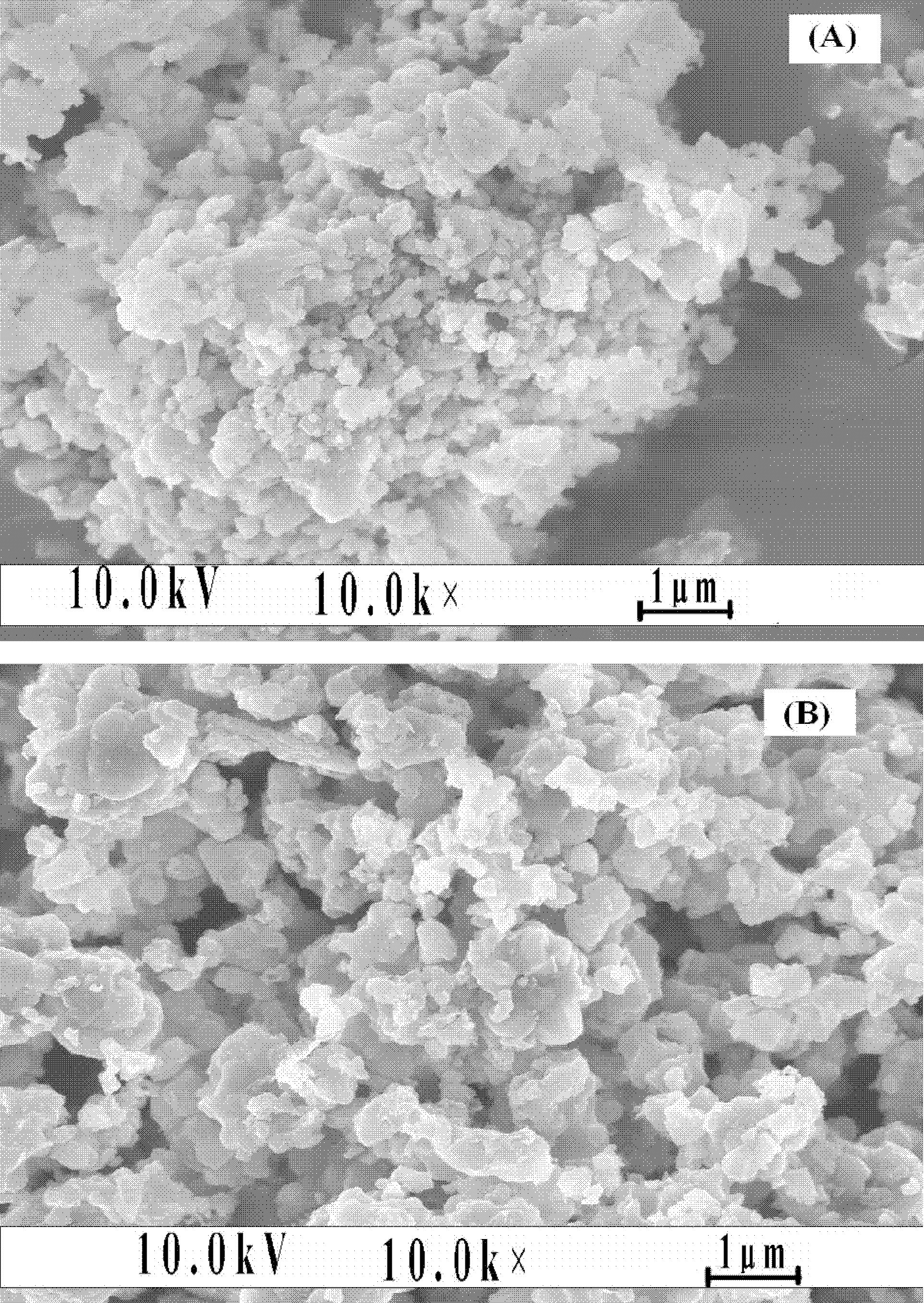

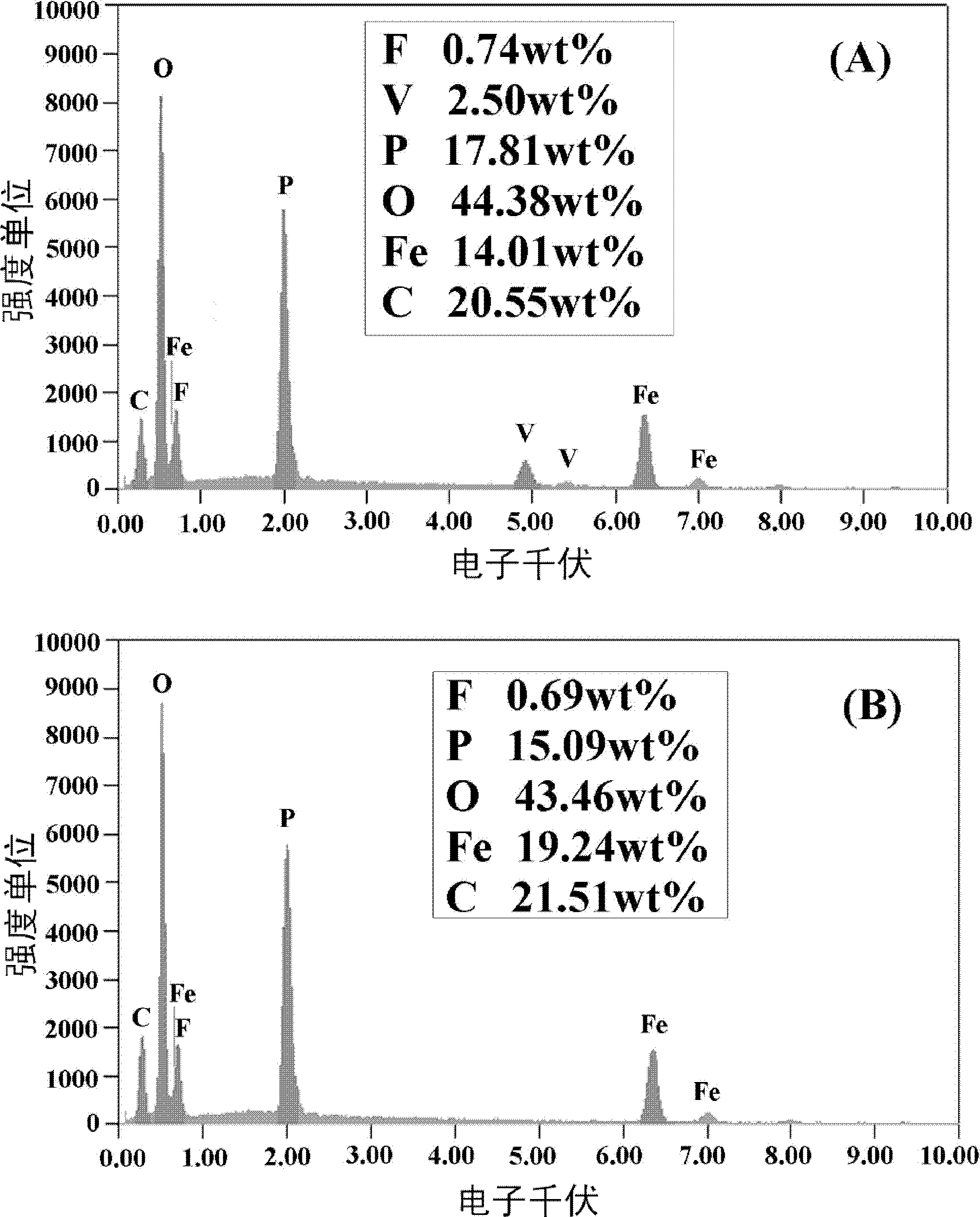

Fluorine and vanadium ion-doped lithium iron phosphate material and preparation method thereof

InactiveCN102583300AIncrease powerIncrease specific energyCell electrodesPhosphorus compoundsPhosphateDischarge potential

The invention discloses a fluorine and vanadium ion-doped lithium iron phosphate material and a preparation method thereof. The fluorine and vanadium ion-doped lithium iron phosphate material has a general chemical formula of LiFe1-yVy(PO4)1-xF3x / C, wherein x is equal to or greater than 0.01 and less than or equal to 0.5; y is equal to or greater than 0.01 and less than or equal to 0.5; and the sum of x and y is equal to or greater than 0.02 and less than or equal to 1.0. The preparation method provided by the invention comprises the following steps of mixing one or more lithium salts, one or more ferric salts, one or more phosphates, one or more carbon sources and doping agents of one or more fluorides and one or more vanadium compounds according to a certain ratio, adding a mixing medium into the mixture, carrying out ball milling mixing, carrying out pre-sintering, carrying out calcining at a high temperature, cooling, and grinding to obtain the fluorine and vanadium ion-doped lithium iron phosphate material. The preparation method provided by the invention realizes synthesis of the fluorine and vanadium ion-doped lithium iron phosphate material by a carbothermal reduction method which is obtained by improvement of the traditional solid phase method. The fluorine and vanadium ion-doped lithium iron phosphate material has excellent multiplying power charge-discharge performances and discharge potential platform electrochemical performances. The preparation method has simple processes, low energy consumption and low costs of raw materials, and is convenient for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

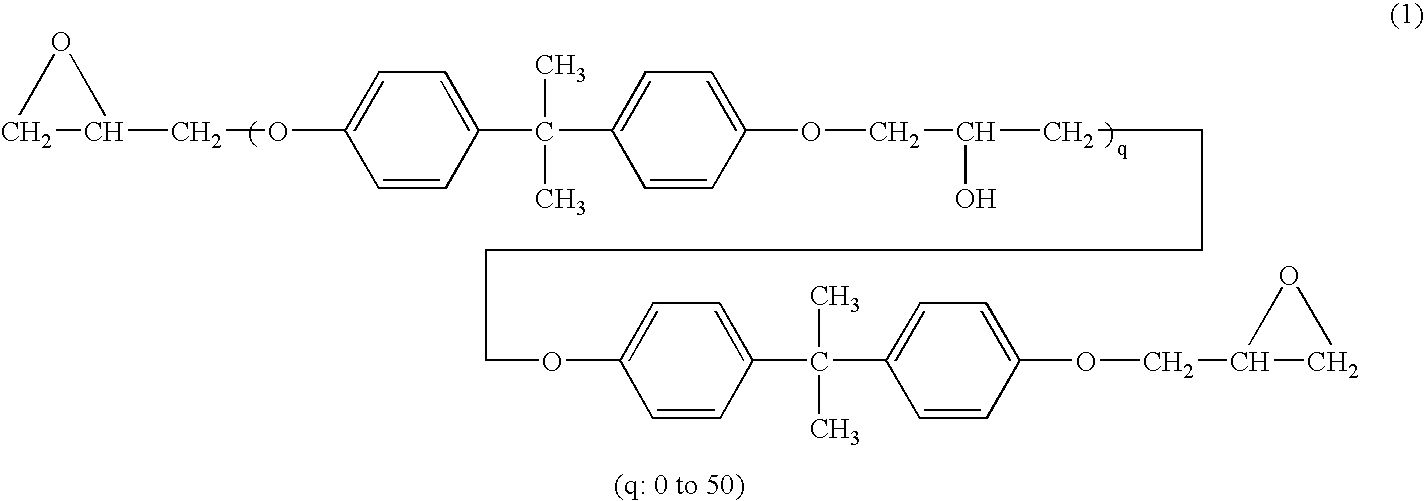

Anticorrosive coating composition

ActiveCN101560358AImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsVanadium CompoundsVitrification

The invention provides an anticorrosive coating composition, comprisng (A) flexible organic modified bisphenol epoxy resin, prepared from 5 to 15 weight% of flexible organic part and 50 to 55 weight% of bisphenol epoxy resins by reacting, (B)solidifying agent and (C)anticorrosive paint, wherein the flexible organic part is selected from C4 to C36 fatty polybasic acid, acrylic resin with the glass transition temperature of -20 to 50 DEG C and polyester resin with the glass transition temperature of -20 to 50 DEG C, the anticorrosive paint(C) is preferably non-chromium anticorrosive paint mixture containing vanadium compound and silicon-containing compound such as metal silicates, phosphates and the like.

Owner:KANSAI PAINT CO LTD

Galvanizing steel strip with good conductivity, high corrosion resistance and fingerprint resistance, surface treatment agent and treatment method

ActiveCN102746778AImprove conductivityImprove corrosion resistancePretreated surfacesAnti-corrosive paintsFunction groupCorrosion

Provided is a galvanizing steel strip with good conductivity, high corrosion resistance and fingerprint resistance, a surface treatment agent and a treatment method. The galvanizing steel strip is covered with a fingerprint-resistant film, wherein the film composition comprises: polyurethane and / or acrylic organic resin (A), with the weight percentage thereof being 40% to 60%; an organic silane coupling agent (Ba) containing one or more amino function groups which has at least one active hydrogen, and an organic silane coupling agent (Bb) containing at least one epoxy function group the number of which is more than one, with the weight ratio of Ba to Bb being from 0.3 to 0.5 and the weight percentage of the organic silane coupling agent being 38% to 53%; organo phosphorous compounds (C), with the weight percentage of phosphorus element being 0.01% to 0.1%; vanadium compounds (D), with the weight percentage of vanadium element being 0. 1% to 1.0%; titanium compounds or fluorine-containing titanium compounds (E), with the weight percentage of titanium element being 0. 1% to 3.0%; and polyethylene wax, with the weight percentage thereof being 1% to 3% of the film.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com