Surface treatment for metal materials, surface treatment process, and surface- treated metal materials

A technology for surface treatment agents and metal materials, applied in metal material coating technology, devices for coating liquid on the surface, metal layered products, etc., can solve uneconomical, insufficient corrosion resistance of damaged parts, and heat-resistant discoloration Insufficient technical aspects of corrosion resistance and chemical resistance, etc., to achieve the effect of high utilization value and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated more concretely together with the effect of this invention, these Examples are only illustrations, and this invention is not limited to these Examples.

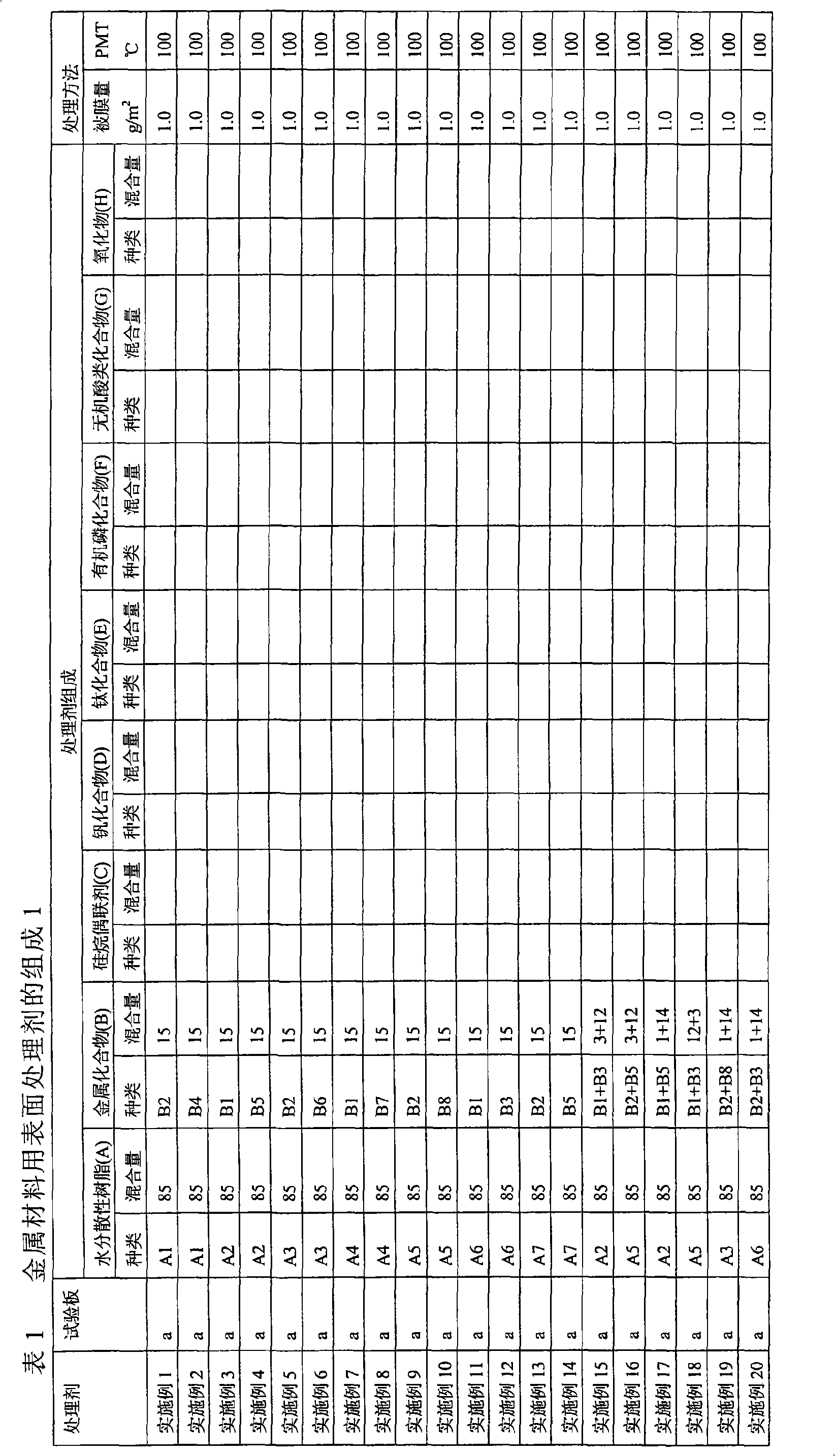

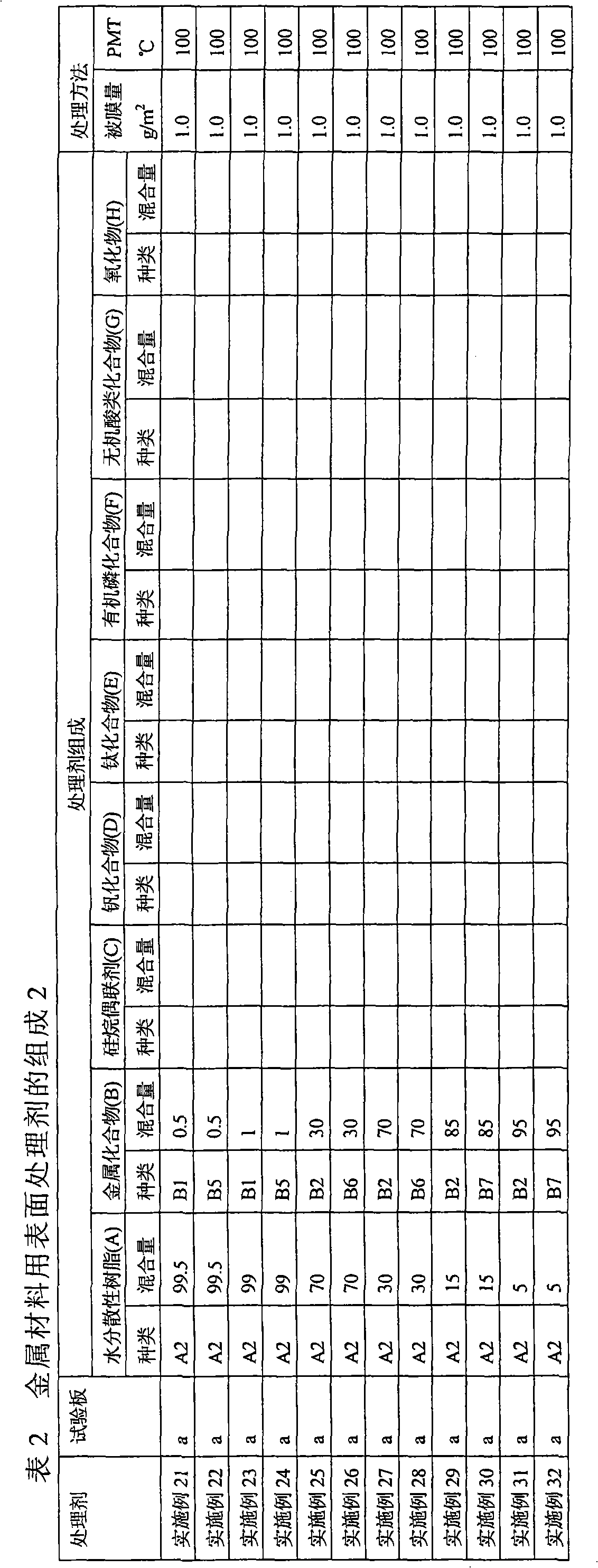

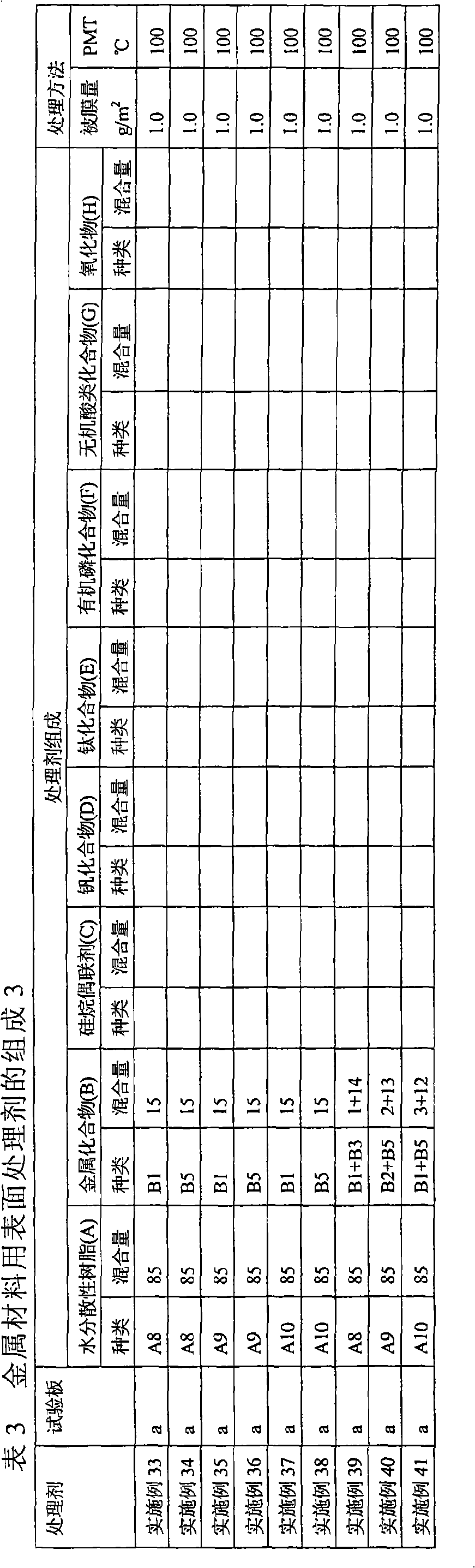

[0101] Hereinafter, for the case where hot-dip galvanized steel sheets, galvanized steel sheets or magnesium-aluminum alloy sheets are used as test materials, the preparation of the surface treatment agents (Tables 1 to 7), test materials and their properties of the examples and comparative examples are described in sequence. Pretreatment and surface treatment, description of evaluation methods, interpretation of evaluation results, and evaluation results (Tables 8 to 14). Hereinafter, the test and the result of the case where the cold-rolled steel plate was used as a test material are demonstrated.

[0102] 1. Preparation of surface treatment agent

[0103] Using the combinations and ratios shown in Tables 1 to 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com