Patents

Literature

53results about How to "Speed up leaching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

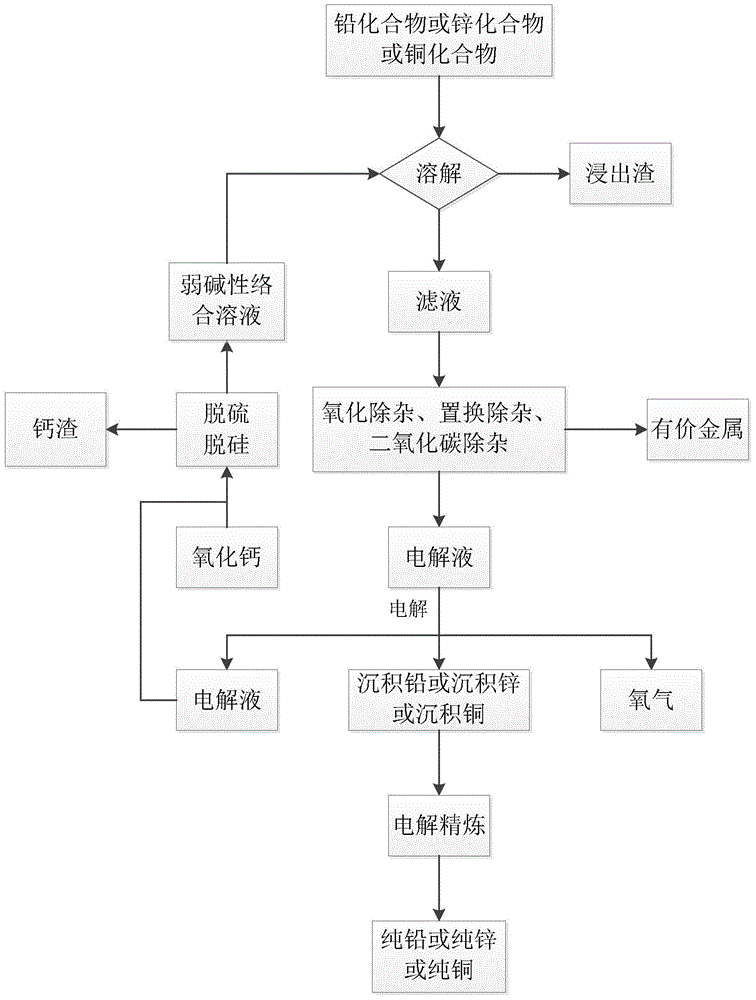

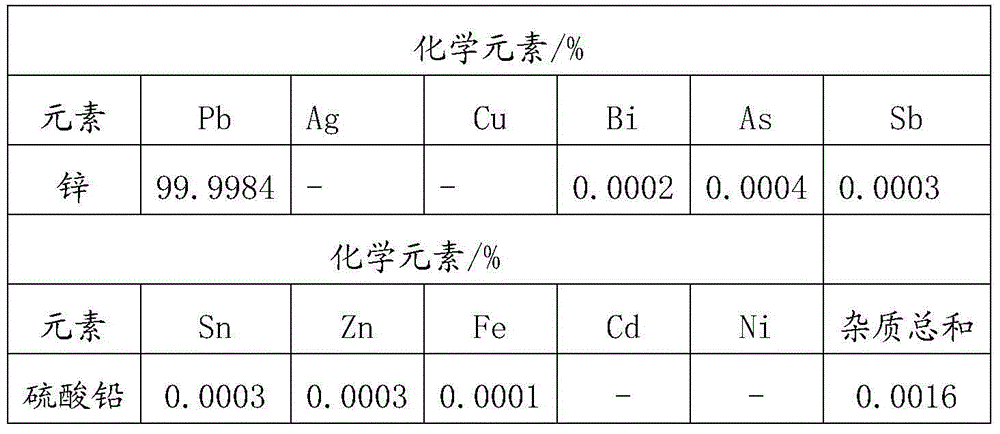

Method for electrolyzing metals through wet method

InactiveCN105274565AImprove leaching rateIncrease profitPhotography auxillary processesProcess efficiency improvementElectrolysisOxygen

The invention provides a process for electrolyzing and refining lead, zinc and copper through a wet method. The process includes the specific steps that an alkalescent complexing solution with high complexing capacity is selected as a leaching solution and all valuable metals are leached out; impurities of the leaching solution are removed through a metal replacement mode; deposited lead or deposited zinc or deposited copper and oxygen are obtained through an electrolytic method; then the solution is subjected to desulfuration and desilicication through calcium oxide or calcium hydroxide; and finally, the lead or the zinc or the copper is obtained after being refined. The alkalescent complexing solution is adopted for leaching and electrolyzing, so that the problems that the leaching rate is low and metal silicates and ferrates are hard to dissolve in terms of current metal smelting with the wet method are solved. Compounds of calcium or barium are adopted for desulfuration of metal sulfates, so that the problem of high desulfuration cost caused by current desulfuration through sodium carbonate or sodium hydroxide is solved. The potential of hydrogen (pH) value of the alkalescent complexing solution is controlled to be 7.5-13.5, the electrolytic voltage is substantially lowered, and the energy consumption is effectively reduced.

Owner:北京中金瑞丰环保科技有限公司

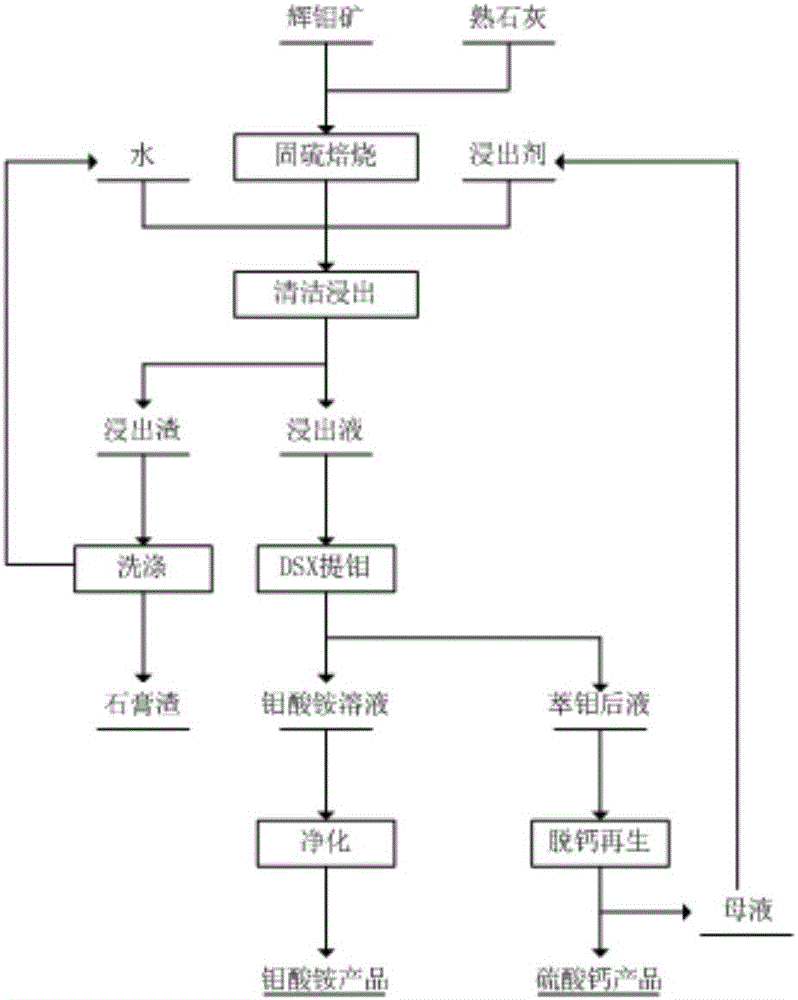

Efficient and clean molybdenum smelting method

ActiveCN105838908AHigh recovery rateSpeed up leachingProcess efficiency improvementEvaporationRaffinate

The invention provides an efficient and clean molybdenum smelting method. The method comprises the steps that lime sulphur-fixed roasting is conducted on molybdenite through a gradient heat preservation method; roasted products are leached with a leaching agent, namely roasted product, and molybdenum-contained leach liquid is obtained; the molybdenum-contained leach liquid is sequentially treated by an acid phosphorus extraction system for extracting molybdenum, and an ammonium hydroxide / ammonium salt system for back-extracting molybdenum, and molybdenum-contained strip liquid and molybdenum raffinate are obtained; impurities in the molybdenum-contained strip liquid are removed through a Mg(OH)2 one-step precipitation method, evaporation and concentration are conducted, and ammonium molybdate products are obtained; and sulfuric acid is added into the molybdenum raffinate for regeneration, calcium sulphate dihydrate products are obtained, and regenerated liquid serves as a leaching agent and is returned back to the leaching process. By the adoption of the method, molybdenum mineral raw materials can be cleaned and treated efficiently, and ammonium molybdate can be prepared, the molybdenum recovery rate reaches 99%, the sulfur fixing rate reaches 98% or over, reagent consumption is low, the production period is short, the process is easy to control, the reaching residue quantity is greatly reduced, zero emission of waste water is achieved, and industrialized application is achieved easily.

Owner:CENT SOUTH UNIV

Method for producing high-purity nanometer zinc oxide by using ammonia process decarburization of steel plant dust

The invention discloses a method for producing high-purity nanometer zinc oxide by using ammonia process decarburization of steel plant dust. The method for producing high-purity nanometer zinc oxide by using ammonia process decarburization of steel plant dust comprises the following steps of: carrying out leaching with an ammonia-ammonium carbonate solution as the leaching agent, adding 0.3-0.5kg of sodium fluosilicate into the leaching agent per cubic meter to obtain a leaching solution, then adding 50-60kg white lime into the leaching solution per cubic meter to carry out heating decarburization, and carrying out purification and impurity removal and then refining treatment. According to the method, the ammonia process is used for treating steel plant dust, and the existing ammonia process is adaptively improved, the leaching speed and the leaching rate of zinc in the dust are improved, and zinc oxide with the purity of more than 99.7 percent can be obtained; the method has the advantages of low energy consumption and high efficiency, and thoroughly solves the problem of zinc load of steel plant dust as the leaching agent can be recycled, thereby meeting the requirement of purifying the toxic components including zinc and alkali metals and realizing good production circulation.

Owner:SICHUAN JUHONG TECH

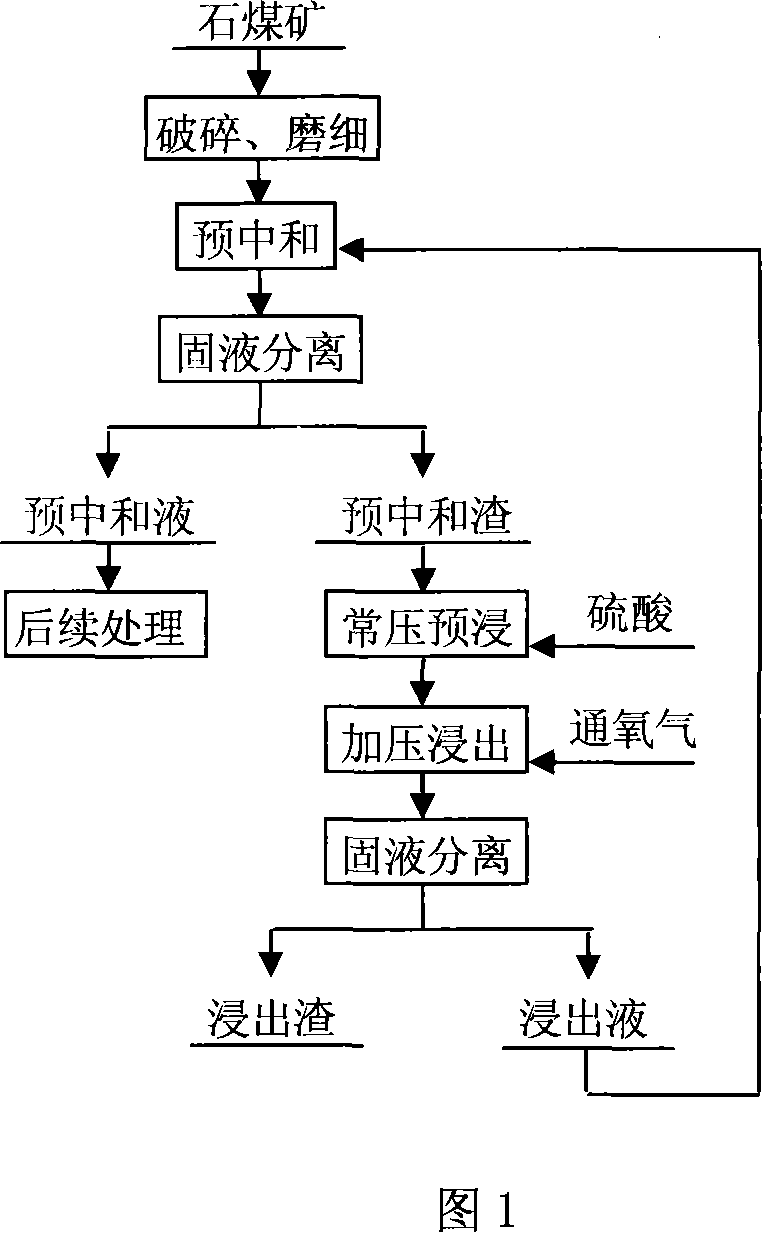

Combined vanadium leaching method for stone coal

InactiveCN101225480AIncreased oxidation conversion rate and leaching rateEfficient leachingProcess efficiency improvementPressure reactorLeaching rate

The invention relates to a new method for jointly leaching vanadium, which adopts the processes of stone coal pre-neutralization, atmospheric pressure pre-impregnation and oxygen leaching. The method comprises following steps: pre-neutralizing acid-consuming impurities in stone coal ore using residual acid in pressure leaching liquor; directly pumping pre-neutralization dreg into a pressure reactor for oxygen pressure intensified leaching after the atmospheric leaching. The new method for jointly leaching vanadium has the advantages of greatly improving the oxidation and transformation rate of the vanadium, high leaching rate of vanadium in stone coal up to 82%, comprehensively utilizing the residual acid in the leaching liquor, high utilization ratio of the residual acid up to 85%, greatly reducing sulfate consumption in vanadium extraction process, and saving production cost.

Owner:KUNMING UNIV OF SCI & TECH

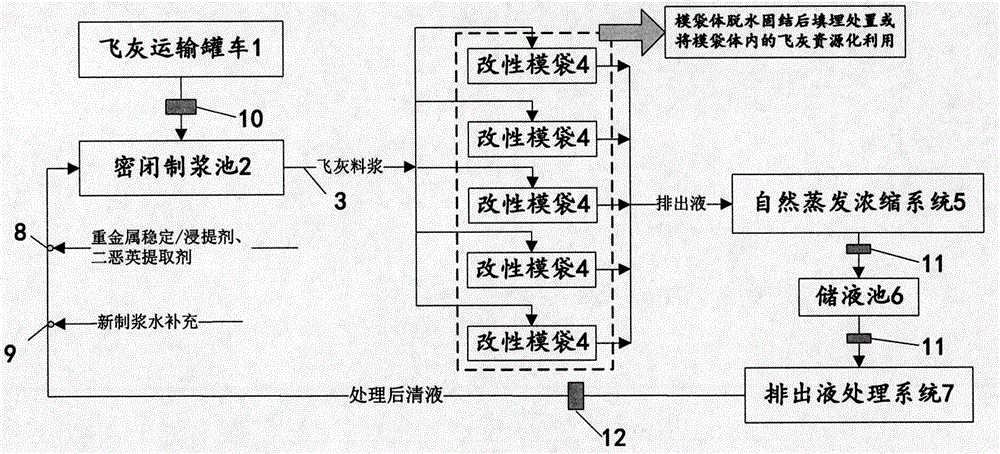

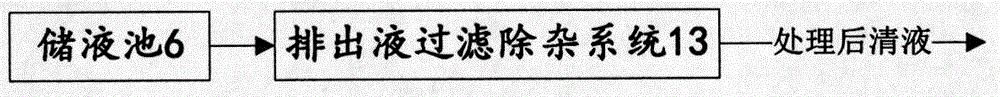

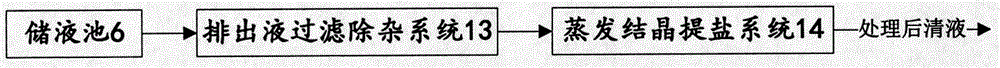

Household garbage incineration fly ash wet-method mold bag treatment method and system

ActiveCN106734045ASimplify processingExpansion of storage capacity utilization factorSolid waste disposalLandfill technologiesHeavy metalsResource utilization

The invention discloses a household garbage incineration fly ash wet-method mold bag treatment method. By means of three links of fly ash slurrying, fly ash slurry conveying and fly ash slurry dewatering / hydrating solidification, fly ash homogenizing, heavy metal and dioxin detoxifying, desalting and spontaneous hydrating solidification forming are achieved sufficiently at the same time; fly ash in mold bags after solidification meets related national standard requirements, solidified mold bag bodies can be subjected to landfill disposal, and fly ash can be taken out of the mold bags to be subjected to resource utilization; and liquid drained out of the mold bags is subjected to natural evaporation and concentration through a landfill space, after heavy metal and dioxin are recycled and impurities are filtered and removed, the liquid is recycled, or after further salt removing is carried out, the liquid is recycled. The invention further discloses a household garbage incineration fly ash wet-method mold bag treatment system. The household garbage incineration fly ash wet-method mold bag treatment method and system can overcome the defects of traditional fly ash dry-method landfill and a water washing pretreatment technology in large-scale industrial application, fly ash homogenizing, detoxifying, desalting, spontaneous hydrating solidification and landfill integrated treatment can be achieved, a basis is laid for follow-up fly ash resource utilization, the treatment cost is low, and the household garbage incineration fly ash wet-method mold bag treatment method and system can be applied to large-scale industrial production.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Method for producing high-purity zinc oxide by steel mill smoke dust ash ammonia method decarburization

ActiveCN102849782AGood dispersionImprove liquidityZinc oxides/hydroxidesSolid waste disposalDecarburizationAlkali metal

The invention discloses a method for producing a high-purity zinc oxide by steel mill smoke dust ash ammonia method decarburization. The method includes that an ammonia-water-ammonium-bicarbonate solution is utilized as a leaching agent for leaching, 0.3-0.5kg of sodium fluosilicate is added into the per cubic meter of the leaching agent, and after the leaching, 50-60kg of slaked limes are added in per cubic meter of a leaching agent liquid to perform warming decarburization. According to the method, the ammonia method is applied to smoke dust ash treatment, prior ammonia methods are subjected to adaptable improvement, the leaching speed and the leaching rate of zinc in the smoke dust ash are improved, zinc oxide with a large specific surface area can be obtained, simultaneously the purity can reach above 99.7%, by means of the method, the energy consumption is low, the efficiency is high, the leaching agent can be recycled, the problem of zinc load in the steel mill blast furnace smoke dust can be thoroughly solved, the purifying requirements for harmful ingredients of zinc and alkali metal in the steel mill can be met, virtuous circle of production is achieved, valuable ferrum and carbon resources in the steel mill can be recycled, the ferrum and carbon are enriched, the energy is saved, and good economic benefits are achieved.

Owner:SICHUAN JUHONG TECH

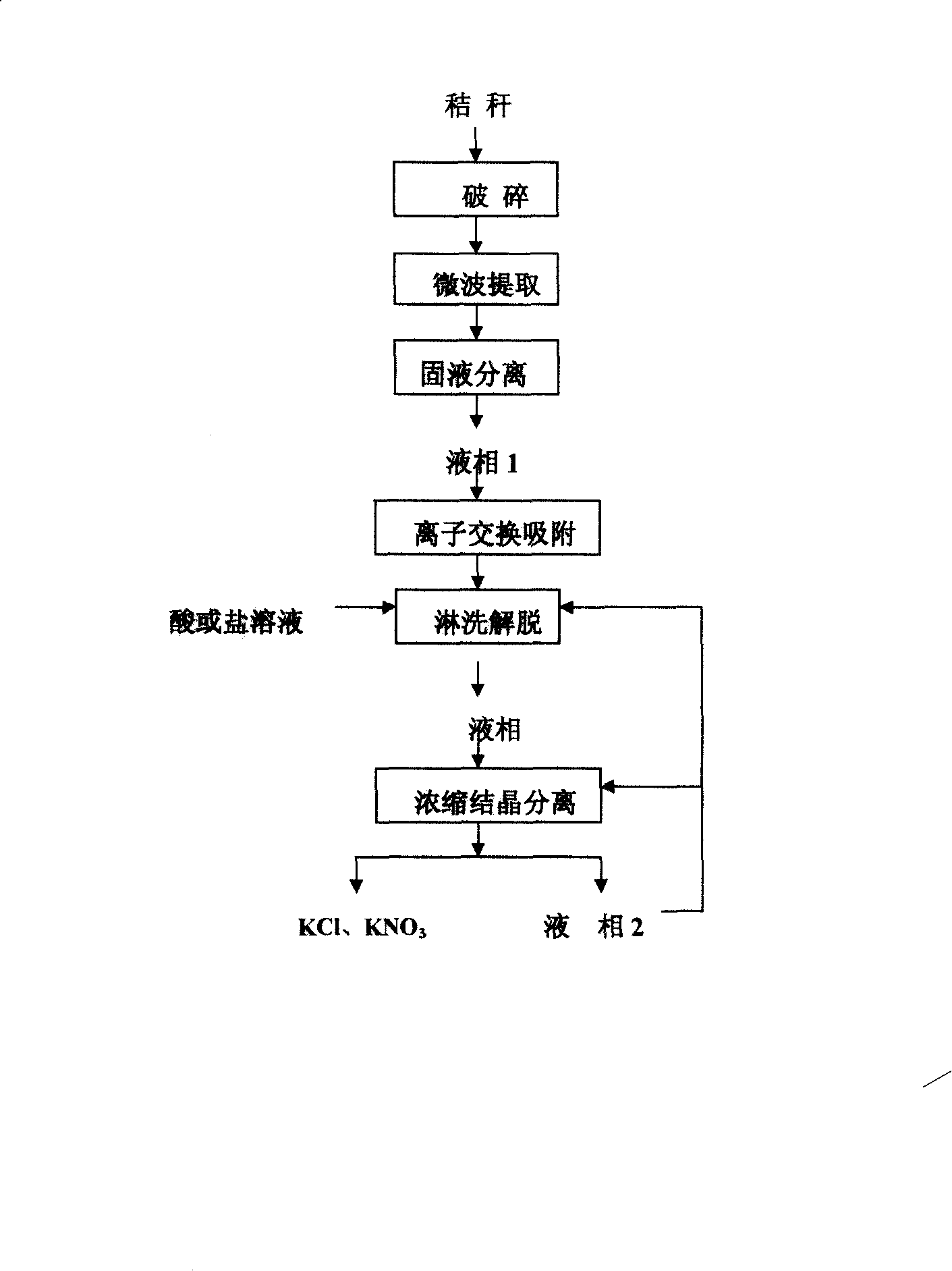

Method for abstracting potassium from straw by microwave technique

InactiveCN101229922ASpeed up leachingImprove leaching rateAlkali metal halidesAlkali metal nitratesIon exchangeChemistry

The invention relates to a method for extracting potassium from straws which adopts the water as leaching agent, uses microwave technique to damage fibrous tissue structure of the straws so that the potassium in the straws are precipitated in the form of ions; ion exchanger such as cation exchange resin or zeolite are used for separating and leaching the potassium in the solution; the solution such as hydrochloride, sulfate, nitric acid and so on are adopted to carry out the extrication; extrication liquid is evaporated, concentrated and crystallized to obtain the corresponding potassium salt products such as potassium chloride, potassium sulfate, potassium nitrate and so on. The experimental result displays that: extraction rate of the potassium in the straws can reach more than 70 percent and the concentration of the potassium in leaching solution can reach 3.6g / l. The method is also applied to the extraction of the potassium in the analog substances like wheat, corns, bamboos, trees and so on.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Novel process for preparing vanadic anhydride from firing residue of vanadium-containing stone coal

InactiveCN101289225ALess investmentAvoid pollutionEnergy inputVanadium oxidesWater useAmmonium metavanadate

The invention relates to a novel technology for preparing vanadium pentoxide by using stone coal ignited residue containing scherbinaite, which comprises the following steps: the stone coal ignited residue containing scherbinaite is directly filled in a cement leaching tank without being smashed or ball-milled, and then leached by a dilute sodium carbonate solution at normal temperature or by heating at the temperature of 60 DEG C to 100 DEG C; the obtained leach solution is adsorbed by resin and desorbed by saturated sodium chloride; the desorbed solution is dephosphorized and then added with ammonium chloride to precipitate vanadium, so as to obtain ammonium metavanadate, and the ammonium metavanadate is pyrolyzed to obtain the vanadium pentoxide. The invention has the advantages that (1) the nubbly stone coal ignited residue containing the scherbinaite is directly filled in the cement leaching tank for leaching so that the investment of fixed assets is saved and the problem of dust pollution in workshop is solved; (2) energy is saved by utilizing the waste heat of a roasting furnace for heating the leach solution, the leaching speed is quickened, the recovery rate is improved and the grade of vanadium contained in the leach solution is enriched; (3) by adopting the dilute sodium carbonate solution to substitute sulphuric acid for warming leaching, per ton of fine vanadium consumes approximately 2 tons of sodium carbonate only, therefore, production cost is saved compared with leaching per ton by sulphuric acid; (4) the water used for working can be recycled, thus realizing zero release; the leach residue is slightly alkaline and meets the national placement standards of general wastes.

Owner:杨秋良

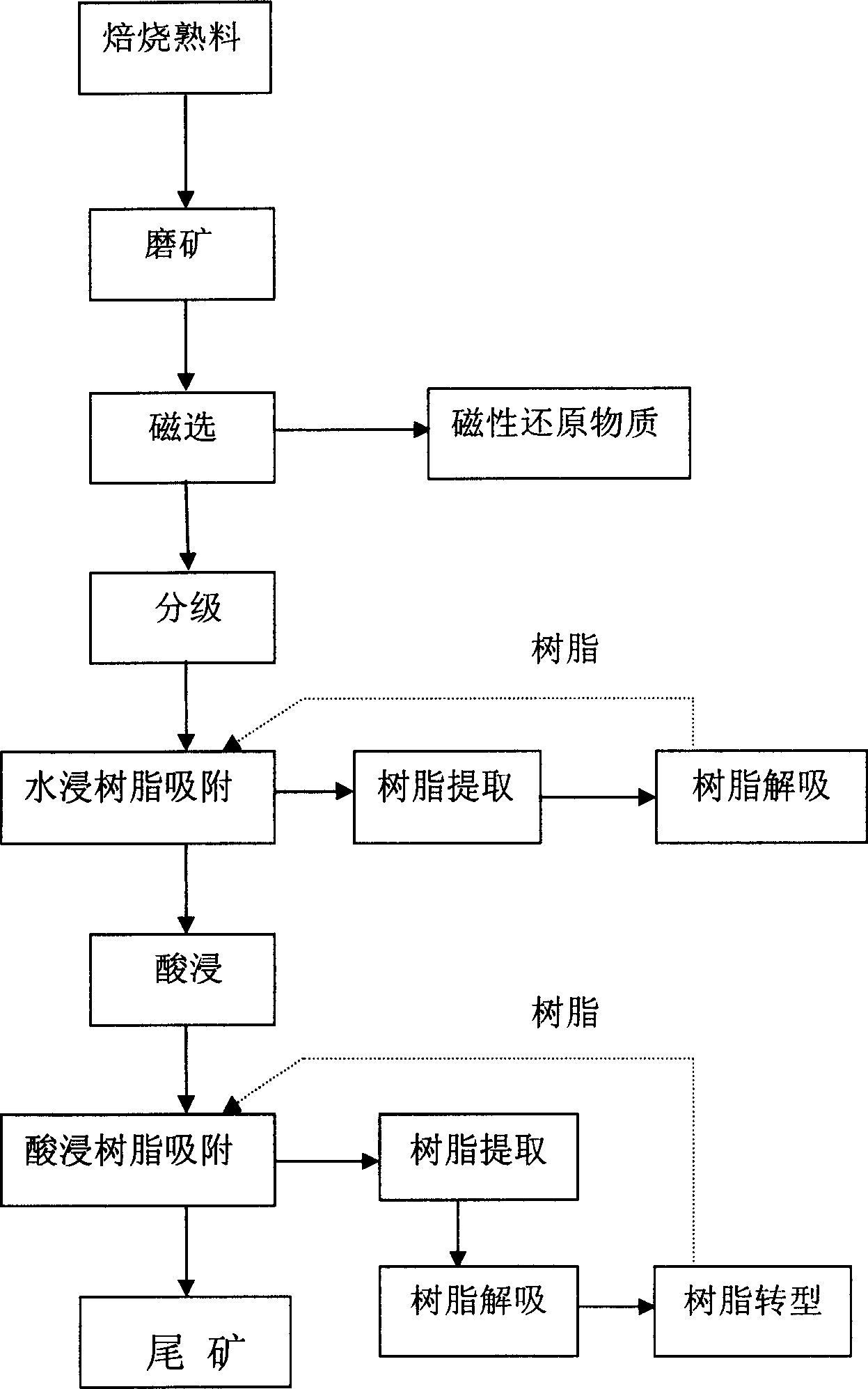

Technique for extracting vanadium pentoxide by the pulp resin method

InactiveCN101003855AReduce concentrationIncrease the leaching concentration gradientProcess efficiency improvementSlurryOxidizing agent

This invention discloses a resin method for extracting V2O5 from ore slurry. The method comprises: (1) wet-milling torrefied ore to fineness less than 0.1 mm, keeping the slurry concentration at 25-40%, introducing into a water-leaching stirring tank, leaching, adding anionic resin 7-15 wt.% of the ore into the water-leaching stirring tank to adsorb vanadium ions, controlling the concentration below 0.1 g / L, and desorbing the saturated resin with alkali solution to obtain desorbed pregnant solution; (2) keeping the ore slurry concentration at 25-40%, adding acid solution, acid-leaching in an acid-leaching stirring tank, adding oxidant and 307 resin 7-15 wt.% of the ore, adsorbing vanadium ions, controlling the concentration below 0.1 g / L, desorbing the saturated resin with alkali solution to obtain desorbed pregnant solution; (3) adding ammonium salts into the desorbed pregnant solutions respectively to precipitate vanadium, torrefying and refining. The method has such advantages as reasonable process, high leaching and adsorption speed, high leaching rate, high adsorption saturation degree, no need for solid-liquid separation, and convenient production control.

Owner:新疆汇友矿业设计研究院(有限公司)

Method for producing high-purity zinc oxide by steel plant smoke ash ammonia method

The invention discloses a method for producing high-purity zinc oxide by a steel plant smoke ash ammonia method, comprising the following steps of: adding slaked lime of which the weight is 3-5% of the weight of steel plant smoke ash before leaching for activating in a stirring way, leaching the steel plant smoke ash which is activated in a stirring way by taking ammonia water-carbon ammonium liquid as leaching agent, and adding 0.3-0.5kg of sodium fluosilicate into each cubic meter. An ammonia method is applicable to the treatment of smoke ash, and the existing ammonia method is adaptively improved, so that the zinc leaching speed and leaching rate in the smoke ash can be improved. The treatment method disclosed by the invention is low in energy consumption, and high in efficiency, thoroughly solves the problem of the zinc load of the steel plant blast furnace smoke since leaching agent is recycled, meets the purification requirement of the steel plant to the harmful ingredients such as the zinc and the alkali metal, reaches the virtuous circle of the production, and not only saves the energy resources but also creates the good economic benefit.

Owner:SICHUAN JUHONG TECH

Method of using low-grade zinc oxide ore to produce high-purity zinc oxide

ActiveCN102863009AReduce energy consumptionImprove adaptabilityZinc oxides/hydroxidesLower gradeLow graded

The invention discloses a method of using low-grade zinc oxide ore to produce high-purity zinc oxide. The method includes: using ammonia water-ammonium bicarbonate solution for leaching, adding 0.3-0.5kg of sodium fluorosilicate into per stere of ammonia water-ammonium bicarbonate solution, and pre-stilling ammonia before the step of purification for impurity removal. The ammonia process is applied to treatment of low-grade zinc oxide ore, and the existing ammonia process is modified in terms of adaptability, so that speed and rate in leaching zinc from the low-grade zinc oxide ore are increased. The purity of zinc oxide can be higher than 99.7% by adopting the calcination temperature ranging from 350DEG C to 450 DEG C, and high economic value is obtained; in addition, the treatment method is low in energy consumption and high in efficiency, and leaching agent can be recycled; and final leaching residues obtained from leaching treatment are undamaged in original ore composition structure and can be used for brick making and the like, so that dual purposes of economy and environment friendliness are achieved.

Owner:SICHUAN JUHONG TECH

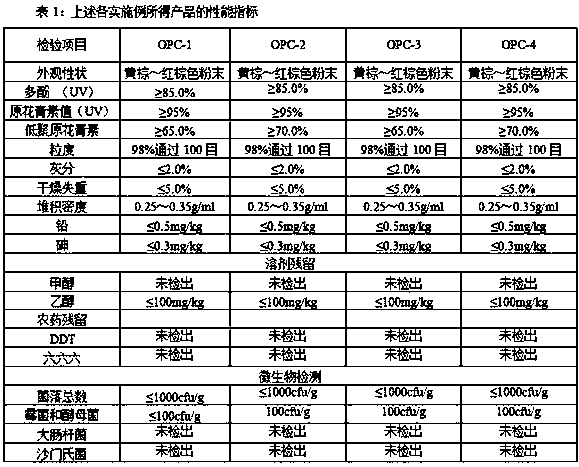

Method for extracting and separating proanthocyanidins from lycium ruthenicum murr

InactiveCN108690099AImprove qualityIncrease osmotic pressureOrganic chemistrySimulated moving bedInternational market

The invention discloses a method for extracting and separating proanthocyanidins from lycium ruthenicum murr. According to the method, a high-speed shearing wall-breaking technology, a macroporous resin mixed simulated moving bed enrichment technology and a nanofiltration membrane separation and purification technology are adopted as core technologies, lycium ruthenicum murr with the highest content of proanthocyanidins is used as a raw material, and green solvents water and ethanol are used as solvents to develop a proanthocyanidins industrialization technology and its products in line with the international mainstream product specifications. The content of proanthocyanidins in the obtained product is greater than or equal to 85%, OPC: 65%-80%, and polyphenol content is greater than or equal to 85%. The process not only helps improve the purity and yield of oligoprocyanidins, but also meets the requirements of industrial production on raw materials, solvent use, production route, production process safety, product color, yield and purity. The process is a pure green production process. by the process, there is organic residues, output is high, and product quality can reach the standards of mainstream products in the international market. The product can be used as a raw material for food, health food and special medical uses.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Reduction leaching method for cobalt-copper mixed oxidized ores

ActiveCN105861822ASpeed up leachingImprove leaching rateProcess efficiency improvementAutomatic controlElectrochemistry

Disclosed is a reduction leaching method for cobalt-copper mixed oxidized ores. The method is characterized by including the following steps that the cobalt-copper mixed oxidized ores are crushed, a conductive fortifier is uniformly mixed with the crushed ores to obtain a mixture, and the mixture is added into an electrolytic cell to make contact with a cathode; sulfuric acid or hydrochloric acid is added into the electrolytic cell and serve as a leaching agent and an electrolyte, and reduction leaching is performed while electrochemical parameters are controlled; and in the reduction leaching process, gelatin is added into the electrolyte to serve as an additive, liquid-solid separation is performed after reduction leaching is finished, filter residues are washed with hot water, and leachate containing copper, cobalt and other valuable metals and washing liquid are obtained. By means of the reduction leaching method for the cobalt-copper mixed oxidized ores, addition of a reducing agent is not needed, the leachate containing the cobalt, the copper, nickel and other valuable metals can be obtained, and preferential separation of the copper and the cobalt can be achieved; and the problems of bringing in impurities and polluting environment due to addition of the reducing agent can be avoided. The reduction leaching method for the cobalt-copper mixed oxidized ores is simple in process and low in cost, and automatic control and large scale production can be achieved.

Owner:GUANGDONG INST OF RARE METALS

Method for extracting shrimp sauce from euphausia superba powder by bulking, prilling and leaching

The invention discloses a method for extracting shrimp sauce from euphausia superba powder by bulking, prilling and leaching. The method is characterized by comprising the steps of: 1, mixing euphausia superba powder with starch or plant material powder rich in starch, wherein the weight percentage of euphausia superba powder is 50-100%; 2, adjusting water of mixed material till the water content is 10-40%; 3, importing the mixed material to an extrusion priller to bulk and prill to obtain bulked particles which are 2-10mm long, wherein the prilling temperature is 80-140 DEG C and the die head pressure is 10-120Bar; 4, adjusting water of the bulked particles by a drier till the water content is 4-12%; and 5, importing the bulked particles into a fat leaching device to extract euphausia superba sauce. The method provided by the invention has the characteristic of good prilling effect.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Bioleaching process of sulfide mineral ore or concentrate or tailing containing alkaline veinstone

InactiveCN100422358CHigh activitySpeed up leachingProcess efficiency improvementThiobacillus ferrooxidansMetal leaching

A biological extracting technology for the ore or ore comcentrate or tailings of sulfide containing alkaline vein rock includes separating and culturing the bacterial mixture of thiobacillus ferrooxidan and microspirillum ferrooxidan in 9K culture medium, naturalizing culture in the water in which said ore to be extracted and pyrite ore or sulfur are immersed, enlarge culture, mixing the ore tobe extracted with pyrite ore and sulfur powder, stacking, and showing the bacteria contained high-Fe liquid for extracting metal. Its advantages are short period, high extracting speed and rate, and low cost.

Owner:有研资源环境技术研究院(北京)有限公司

Ginseng sorghum solid-state fermented wine and its preparation method

ActiveCN103320271AReduce churnEasy to replaceAlcoholic beverage preparationNutritive valuesAdditive ingredient

The invention relates to the field of brewing technique and discloses a ginseng sorghum solid-state fermented wine and its preparation method. The preparation method provided by the invention comprises the following steps: crushing barley, pea and dry ginseng, uniformly mixing, sieving, adding water into powders to prepare a starter blank, and culturing to obtain a fermentation block starter; carrying out steaming, stacking fermentation and anaerobic fermentation on sorghum, ginseng, wheat bran and rice husk which are used as fermentation raw materials, and finally distilling to obtain the ginseng sorghum solid-state fermented wine. According to the invention, white spirit is prepared from raw materials of ginseng and sorghum by a solid-state fermentation method. By the action of Kaoliang spirit base, nutritional ingredients and fragrance of ginseng are integrated into the whole fermentation process of white spirit, total saponins of panax ginseng are kept to the maximum and are more easily absorbed by human body, other beneficial substances also can be obtained, and utilization rate of nutritive value of ginseng is effectively raised.

Owner:丁政然

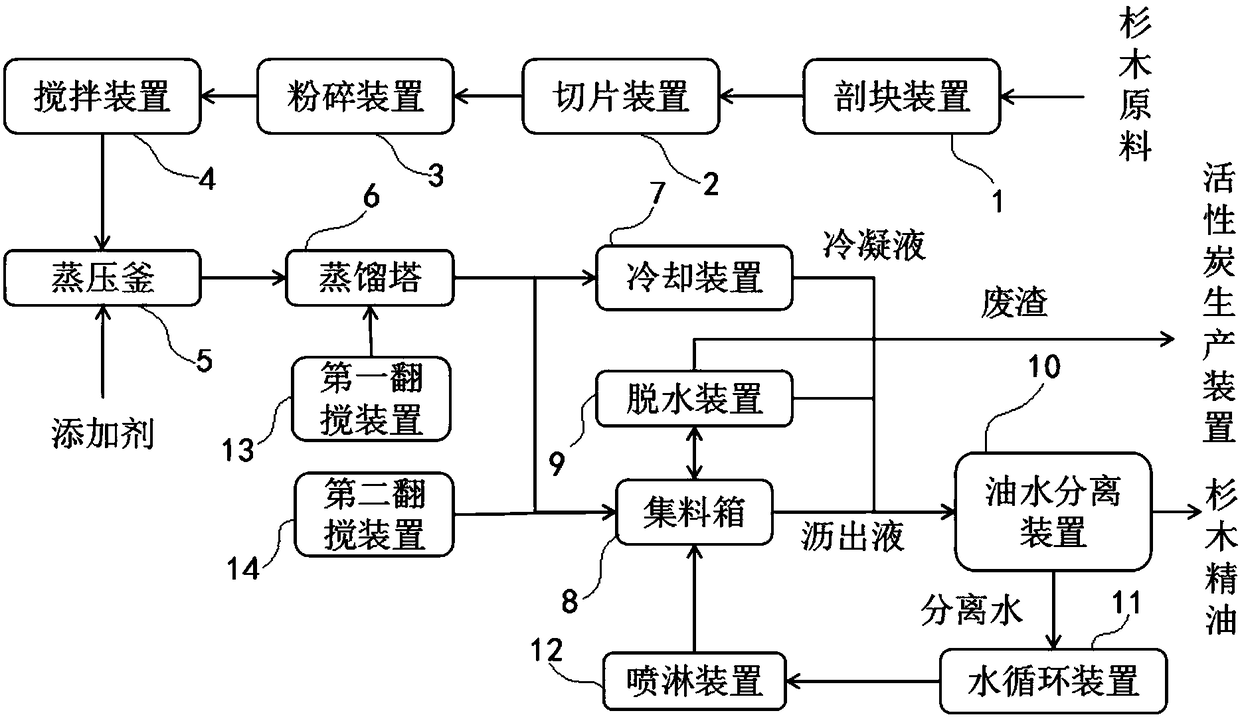

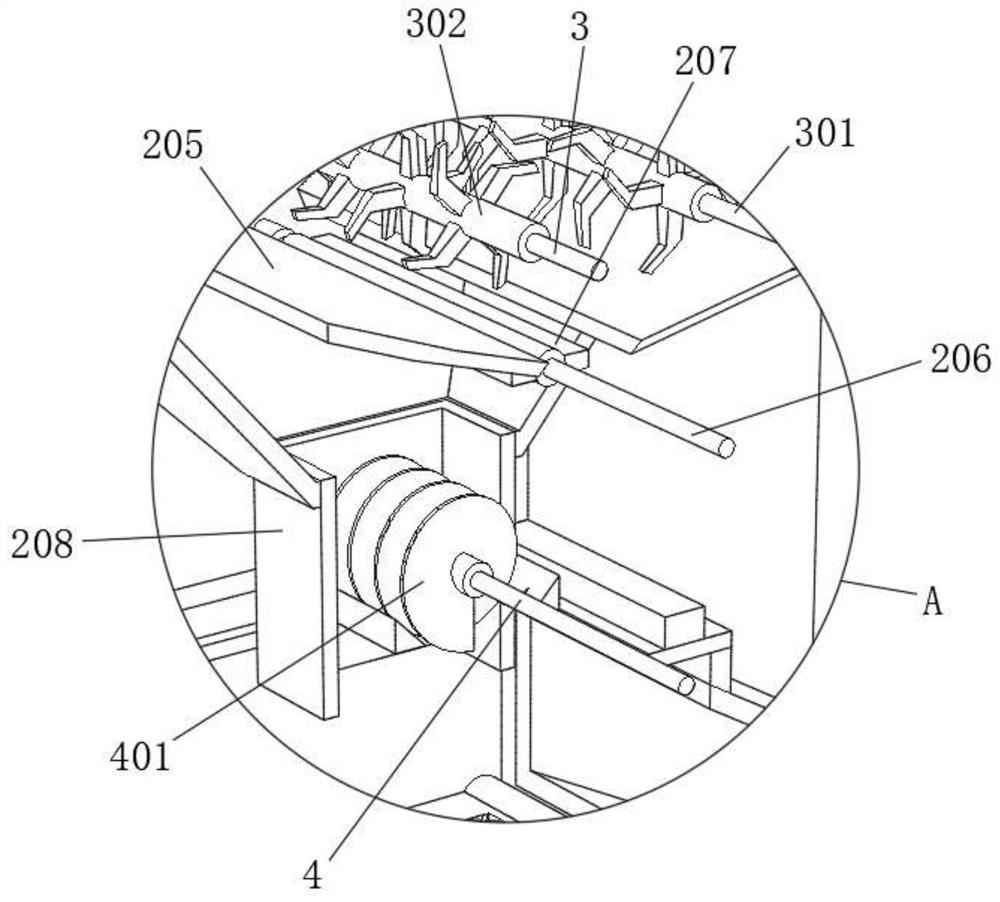

Production device and production method of cedarwood essential oil

InactiveCN108410580AIncrease distillation rateReduce structural strengthEssential-oils/perfumesPectinaseProcess engineering

The invention discloses a production device and a production method of cedarwood essential oil, and relates to the technical field of extraction of the cedarwood essential oil. The production device comprises a block cutting device, a slicing device, a smashing device, a stirring device, a still kettle, a distillation column, a cooling device, a material collecting box, a dehydration device, an oil-water separating device, a water circulating device, a spraying device, a first stirring device and a second stirring device, wherein the block cutting device, the slicing device, the smashing device and the stirring device are sequentially connected through a special delivery device; and the still kettle is communicated with a feeding port of the distillation column through a conveying belt. Cellulase and pectinase are added into the still kettle to conduct heat preservation and pressure preservation to degrade cell walls of cedarwood cells, the structural strength of the cedarwood cells reduces, the dehydration device and the material collecting box conducts dehydration and spraying repeatedly, and thus the problems that the utilization rate of existing materials is not high enough, the processing process of cedarwood powder is not perfect, and the yield of the cedarwood essential oil is not high enough are solved.

Owner:FUJIAN XINLYULIN PROD DEV

Method for producing high-purity zinc oxide by ammonia method using low-grade zinc oxide ores

ActiveCN102863008AGood dispersionImprove liquidityZinc oxides/hydroxidesEnvironmental resistanceBrick

The invention discloses a method for producing high-purity zinc oxide by an ammonia method using low-grade zinc oxide ores. The method comprises the following steps of: adding 3-5% of slaked lime to low-grade zinc oxide ores to be treated for performing mixing and activation before leaching, controlling water in the mixture at 8-10% by mass percentage, adding 0.3-0.5kg of sodium fluorosilicate to per cubic meter of leaching agent, and preferably adding surfactant and dicyandiamide, wherein an ammonia pre-distillation step can be further added simultaneously, therefore, on the one hand, the leaching speed and the leaching rate of zinc in the low-grade zinc oxide ores are increased, and on the other hand, a lower calcination temperature is preferred, zinc oxide with a greater specific surface area and with the purity up to 99.7% and more can be obtained, and the obtained zinc oxide has high economic value; in addition, the treatment method is low in energy consumption and high in efficiency, and the leaching agent can be recycled. The final leaching residues after performing leaching treatment do not damage the original composition and structure of minerals and can still be used to brick-making, thereby achieving economical and environmental-friendly dual purposes.

Owner:SICHUAN JUHONG TECH

External use medicinal liquor capable of promoting blood circulation to remove blood stasis, diminishing inflammation and killing pain

InactiveCN109303811AFacilitated DiffusionEasy to replaceHydroxy compound active ingredientsAntipyreticOlive leafHas active ingredient

The invention discloses external use medicinal liquor capable of promoting blood circulation to remove blood stasis, diminishing inflammation and killing pain. The external use medicinal liquor is prepared from the following raw materials: yellow wine, herba geranii, olive leaf, radix bupleuri, ramulus mori, radix gentianae macrophyllae, radix angelicae pubescentis, colored mistletoe herb, flos rhododendri, flos carthami, suberect spatholobus stem, herba lycopodii, radix aconiti preparata, borneol, caulis lonicerae, shaddock peel, radix glycyrrhizae, pine nut and radix rubiae. After raw materials, except the yellow wine and the borneol, are mixed, enzymatic hydrolysate is added for enzymolysis for 1-2 hours; drying at the temperature of 70-80 DEG C until the mass percent of water content is 40-50%, and then adding borneol and yellow wine to be dipped for three times; for the first time, all raw materials are dipped in the yellow wine for 3-6 days; for the second time, all raw materialsare dipped in two times of volume of yellow wine for 6-10 days; for the third time, all raw materials are dipped in the yellow wine for 10-15 days. A specific technology is adopted to maximize the medicine effect of effective ingredients; alcohol fully enters medicine material cells, effective ingredients are fully dissolved, diffused and replaced, and leaching speed and effects are improved.

Owner:CHONGQING JIALI LIQUOR IND

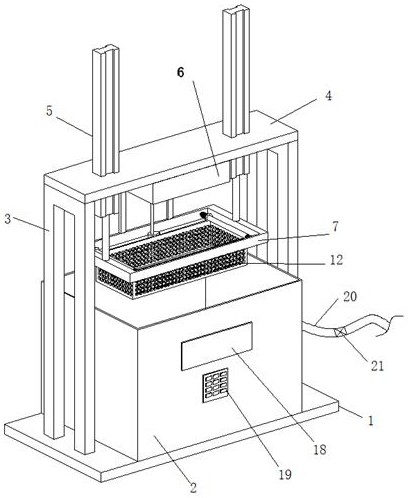

Rattan dyeing equipment for rattan plaited handicraft processing

ActiveCN112659300AUniform dyeingGood dyeing effectWood treatment detailsReed/straw treatmentMechanical engineeringPneumatic cylinder

The invention relates to the technical field of rattan dyeing, in particular to rattan dyeing equipment for rattan plaited handicraft processing. The rattan dyeing equipment comprises a base and a dyeing pool, the dyeing pool is fixed to the upper end of the base, and a pair of supporting frames is further fixed to the upper end face of the base and symmetrically arranged on the left side and the right side of the dyeing pool; a top frame is jointly fixed to the top ends of the pair of supporting frames, a pair of pneumatic cylinders is installed on the top frame, a rectangular frame is jointly fixed to the telescopic ends of the pair of pneumatic cylinders, a pair of round rods is fixed between a front rod and a rear rod of the rectangular frame, sliding sleeves are slidably installed on the outer walls of the pair of round rods, and the outer wall of each round rod is sleeved with a pair of first reset springs. The pair of first reset springs are arranged on the front side and the rear side of the sliding sleeve respectively, a dyeing disc is jointly welded to the bottom ends of the pair of sliding sleeves, and a cam abuts against the rear side wall of the dyeing disc. The dyeing disc swings back and forth to drive the rattans to swing back and forth, so that the rattans are dyed more uniformly, and the dyeing effect is better.

Owner:安徽御美藤藤柳工艺品有限公司

Edible fungus seasoning liquid production method by using edible fungus waste as raw material

ActiveCN105533614ARealize comprehensive utilizationEmission reductionFood scienceBiotechnologyFlavor

The present invention discloses an edible fungus seasoning liquid production method by using edible fungus waste as a raw material. The viscous edible fungus seasoning liquid with a mellow edible fungus characteristic flavor and is characterized in by using the edible fungus waste as a raw material and being produced by cleaning, water emulsion, extraction, filtration, vacuum concentration, homogenization, sterilization, filling and sealing, inverted bottle sterilization and cooling, casing label marking, code spraying, and encasement. The seasoning liquid can be used as a seasoning go with oil-fried, fried, stir-fried, and blended meals, and can also be blended into a cup of edible fungus soup with a delicious flavor by a direct addition of water. The edible fungus seasoning liquid can be subjected to a large-scale industrial production. The produced edible fungus seasoning liquid can be stored at room temperature, and conduct circulation and sales.

Owner:CHENGDU SHIWEITIAN TECH CO LTD

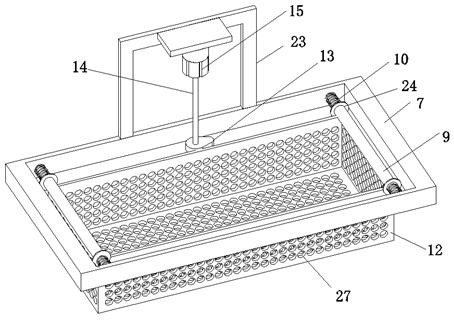

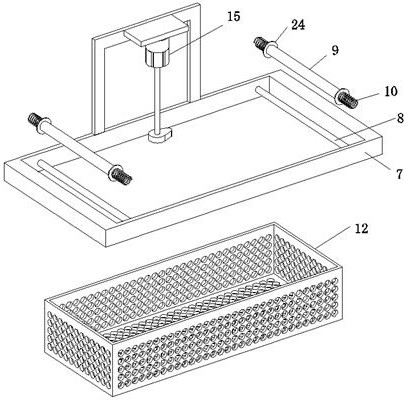

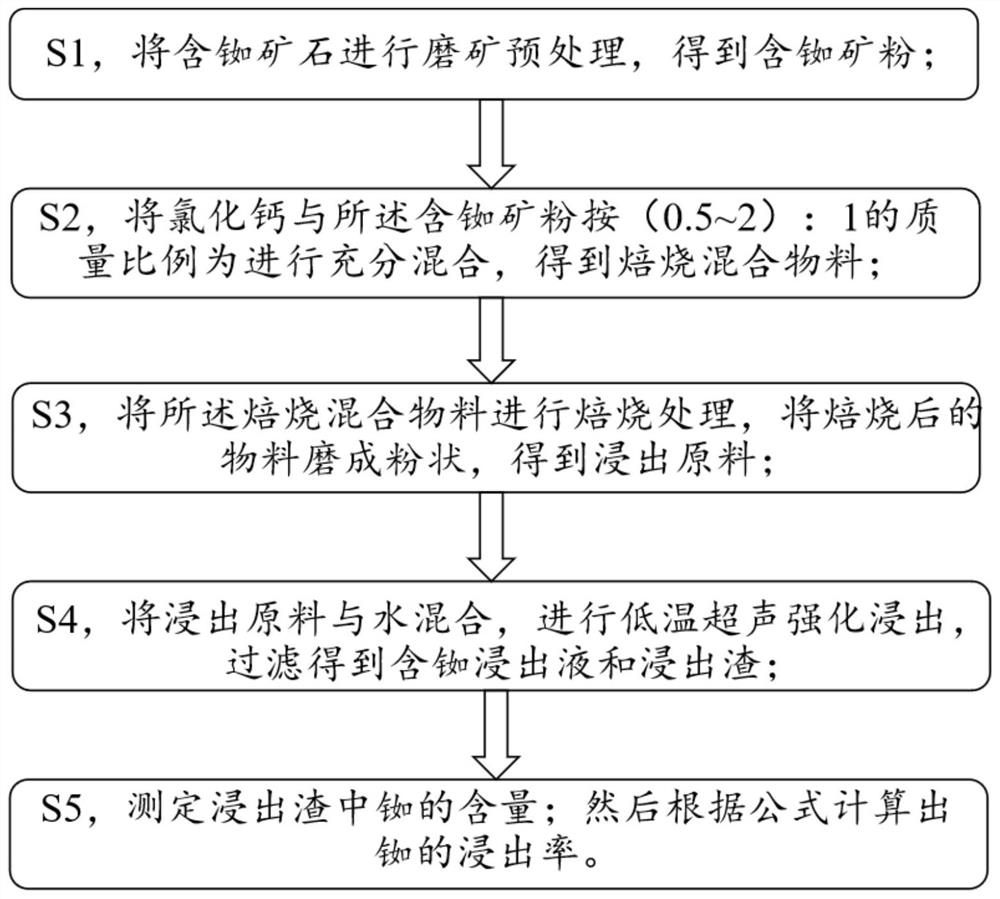

Method for extracting rubidium from rubidium-containing ore through ultrasonic strengthening

ActiveCN113337734AAvoid long leaching timesImprove extraction efficiencyProcess efficiency improvementGrindingLeaching rate

The invention provides a method for extracting rubidium from rubidium-containing ore through ultrasonic strengthening. The method comprises the following steps: placing the rubidium-containing ore in an ore grinding machine for ore grinding, and taking the obtained ore powder as an experimental raw material; putting a material obtained by fully mixing calcium chloride and ore powder into an alumina crucible, roasting at the temperature of 700-900 DEG C, preserving heat for 15-35 minutes, cooling to room temperature after reaction, grinding the reacted material into powder by using an ore grinding machine to serve as a leaching raw material, putting the roasted material into water, performing low-temperature ultrasonic enhanced leaching at the leaching temperature of 30-50 DEG C for 15-35 minutes, and obtaining leaching liquid and leaching residues. Under a low-temperature system, high leaching rate and leaching speed can be realized, the method has the advantages of energy conservation, rapidness and high efficiency, the extraction time of the rubidium extraction process is remarkably shortened, the process conditions are improved and simplified, the rubidium element is efficiently extracted under the low-temperature or normal-temperature energy-saving condition, and the leaching effect can reach 98% or above.

Owner:WUHAN UNIV OF SCI & TECH

Hibiscus manihot L tea for preventing and treating prostatitis and preparation method thereof

InactiveCN105941705ASweet tasteFragrancePre-extraction tea treatmentUrinary disorderManihotOfficinalis

The invention belongs to the field of healthcare products, and particularly relates to a hibiscus manihot L tea for preventing and treating prostatitis and a preparation method thereof. The hibiscus manihot L tea is prepared from Hibiscus manihot L, honeysuckle, Oldenlandia diffusa, dianthus superbus, lalang grass rhizome, Mangnolia officinalis flowers, fructus amomi and Hibiscus manihot L tea leaves. The Hibiscus manihot L tea is reasonable and scientific in compatibility, all the components are cooperated to achieve the effects of clearing away heat and toxic materials, inducing diuresis for treating strangurtia, activating blood to promote menstruation, achieving antisepsis and anti-inflammation, enhancing immunity and the like, prostatitis can be prevented, the reinfection risk is lowered, the remarkable relief effect is achieved for the prostate gland, the preparation technology is simple, the advantages of high leaching efficiency and high leaching speed are achieved, the characters are stable, the service life is long, color, aroma and taste are perfect completely, and the requirement for high quality and fast pace of modern people is met.

Owner:GUANGZHOU JINAN BIOMEDICINE RES & DEV CENT

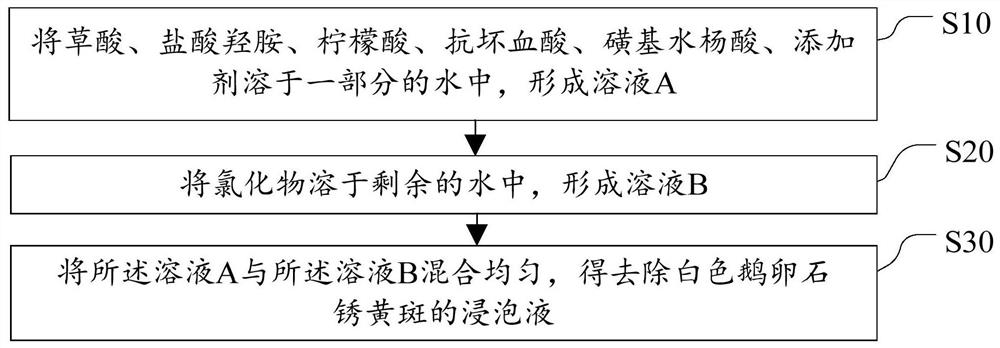

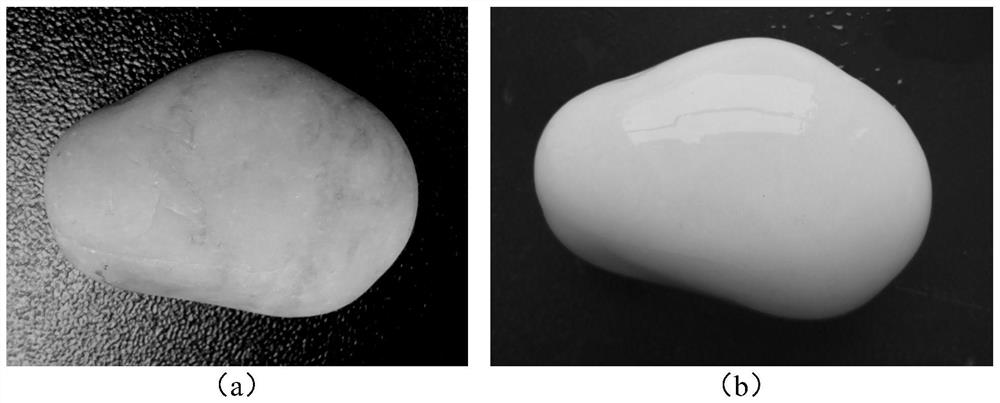

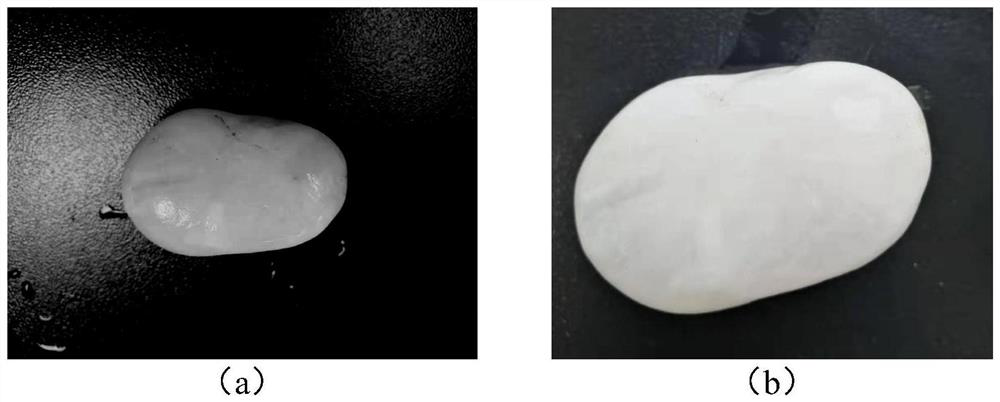

Soaking solution for removing rusty yellow spots of white cobblestones, preparation method thereof, and method for removing rusty yellow spots of white cobblestones

The invention discloses a soaking solution for removing rusty yellow spots of white cobblestones, a preparation method thereof, and a method for removing the rusty yellow spots of the white cobblestones, and relates to the technical field of treatment of the white cobblestones. The soaking solution for removing the rust yellow spots of the white cobblestones comprises the following components: oxalic acid, chloride, hydroxylamine hydrochloride, citric acid, ascorbic acid, sulfosalicylic acid, an additive and water. Ascorbic acid and sulfosalicylic acid can achieve a synergistic effect, rapidly react with iron oxide in the cobblestones, and can permeate into the cobblestones to react with rust, so that the leaching speed of the iron oxide is increased; and hydroxylamine hydrochloride can quickly react with ferric ions to generate ferrous ions, so that the concentration of the ferric ions in the solution is reduced, and the reaction is promoted to move in the positive direction. The soaking solution for removing the rusty yellow spots of the white cobblestones is free of fluorine and pollution, cannot corrode and peel off the surface layers of the cobblestones, can quickly remove the rusty yellow spots of the cobblestones, and can be continuously used after corresponding components are supplemented according to conditions after being used.

Owner:HUBEI UNIV OF ARTS & SCI

Preparation method of herba gynostemmatis pentaphylli tea by adopting plant-source lactic acid bacterium fermentation

The invention discloses a preparation method of herba gynostemmatis pentaphylli tea by adopting plant-source lactic acid bacterium fermentation, and relates to drinks. The invention especially discloses herba gynostemmatis pentaphylli tea. The herba gynostemmatis pentaphylli tea is prepared by adding a process of performing lactic acid bacterium fermentation during the processes of carrying out fresh leaf treatment, carrying out fixation, carrying out rolling, carrying out fermentation, carrying out deblocking, carrying out drying or carrying out stir-drying. The prepared herba gynostemmatis pentaphylli tea has improved taste, and is free of grassy smell; moreover, leaching rate and retaining amount of gypenoside are increased. In addition, metabolite residues capable of enhancing immunityare produced during the lactic acid bacterium fermentation process; and the metabolite residues and the gypenoside synergistically take an effect so as to better enhance immunity.

Owner:陈子瑾

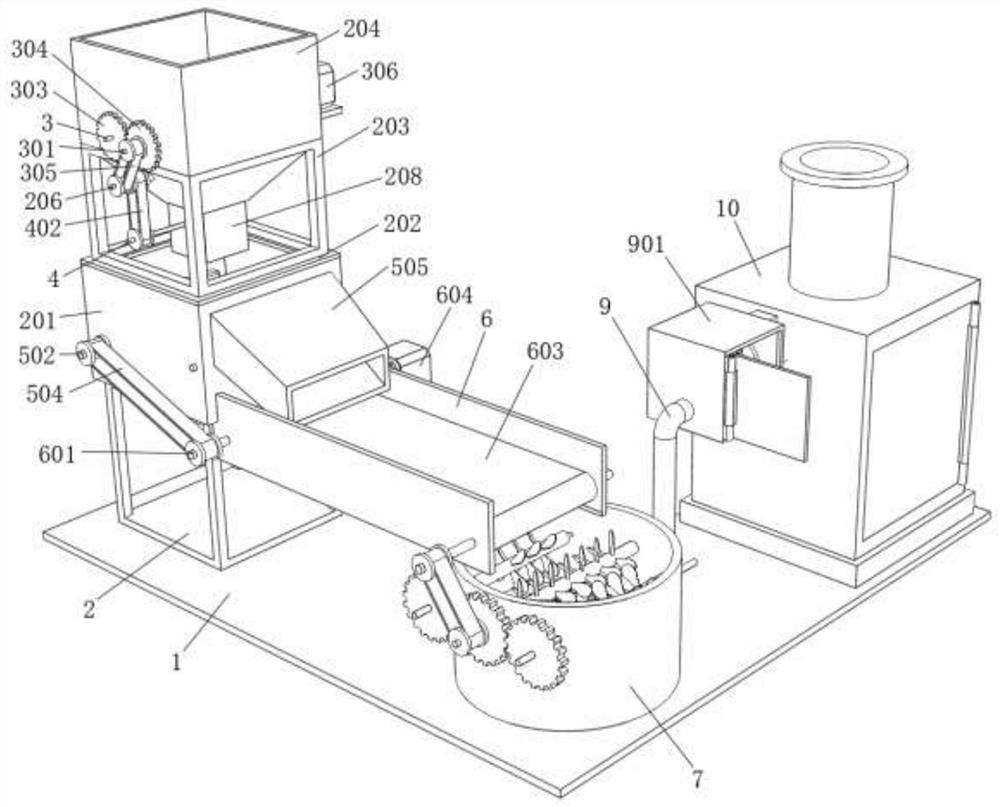

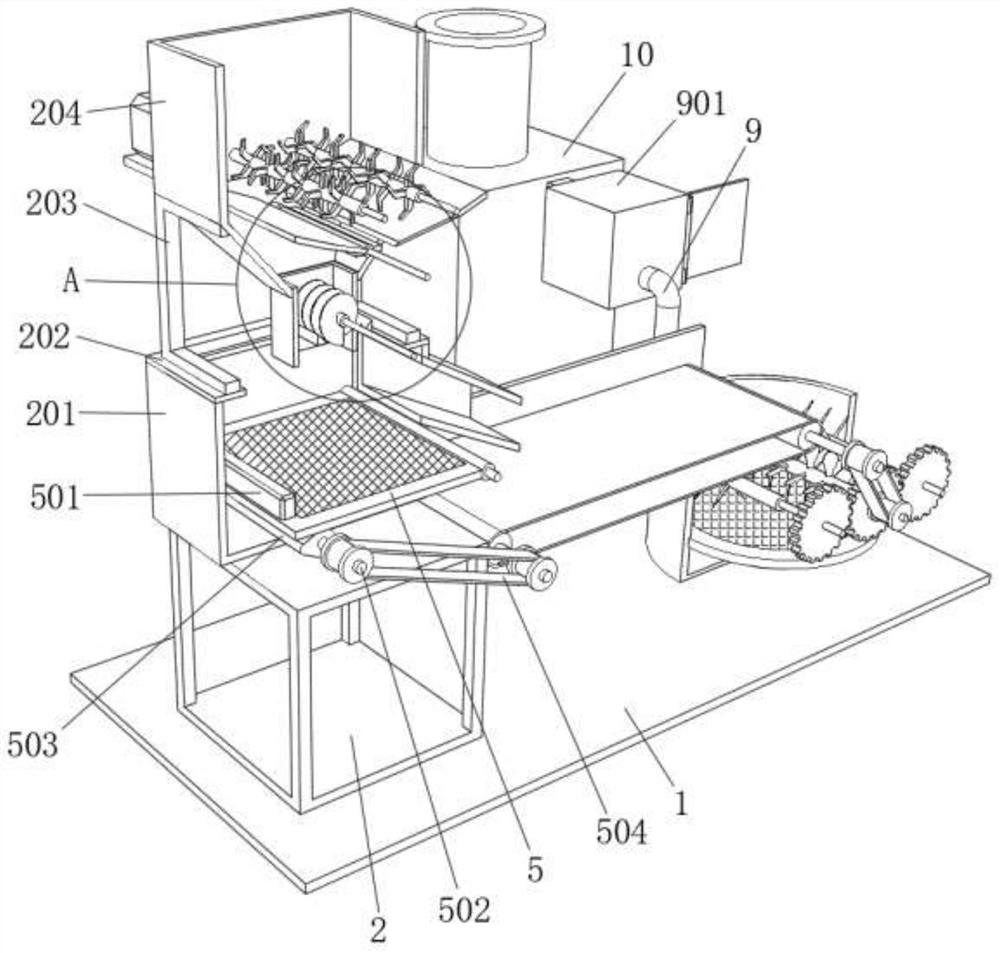

Garbage pyrolysis gasification treatment device

ActiveCN113210397AEasy to handleUniform transferSolid waste disposalGrain treatmentsDrive shaftRefuse Disposals

The invention relates to the technical field of garbage treatment equipment, and discloses a garbage pyrolysis gasification treatment device which comprises a bottom plate. A machine frame is fixedly connected to the upper surface of the bottom plate, a treatment box is fixedly connected to the upper surface of the machine frame, a feeding port is formed in the upper surface of the treatment box, and a hollowed-out plate is fixedly connected to the upper surface of the feeding port; and a supporting frame is fixedly connected to the upper surface of the hollowed-out plate, a same storage hopper is fixedly connected to the inner walls of multiple sides of the supporting frame, a discharging port is formed in the bottom of the storage hopper, a discharging barrel is fixedly connected into the discharging port, a driving shaft, a driven shaft and a rotating rod are rotatably connected to the inner walls of the two sides of the storage hopper, and the two ends of the driving shaft, the two ends of the driven shaft and the two ends of the rotating rod penetrate through the outer walls of the two sides of the storage hopper. Rotating blades cut the outer surface of garbage, the garbage can be conveniently treated by the rotating blades, the garbage can be uniformly transferred through an inclined plate and a rotating plate, blockage caused by garbage classification treatment is avoided, large garbage can be cut, bottle and can garbage can be cut, and liquid in the bottle and can garbage can be concentrated.

Owner:上海艾尔天合环境科技有限公司

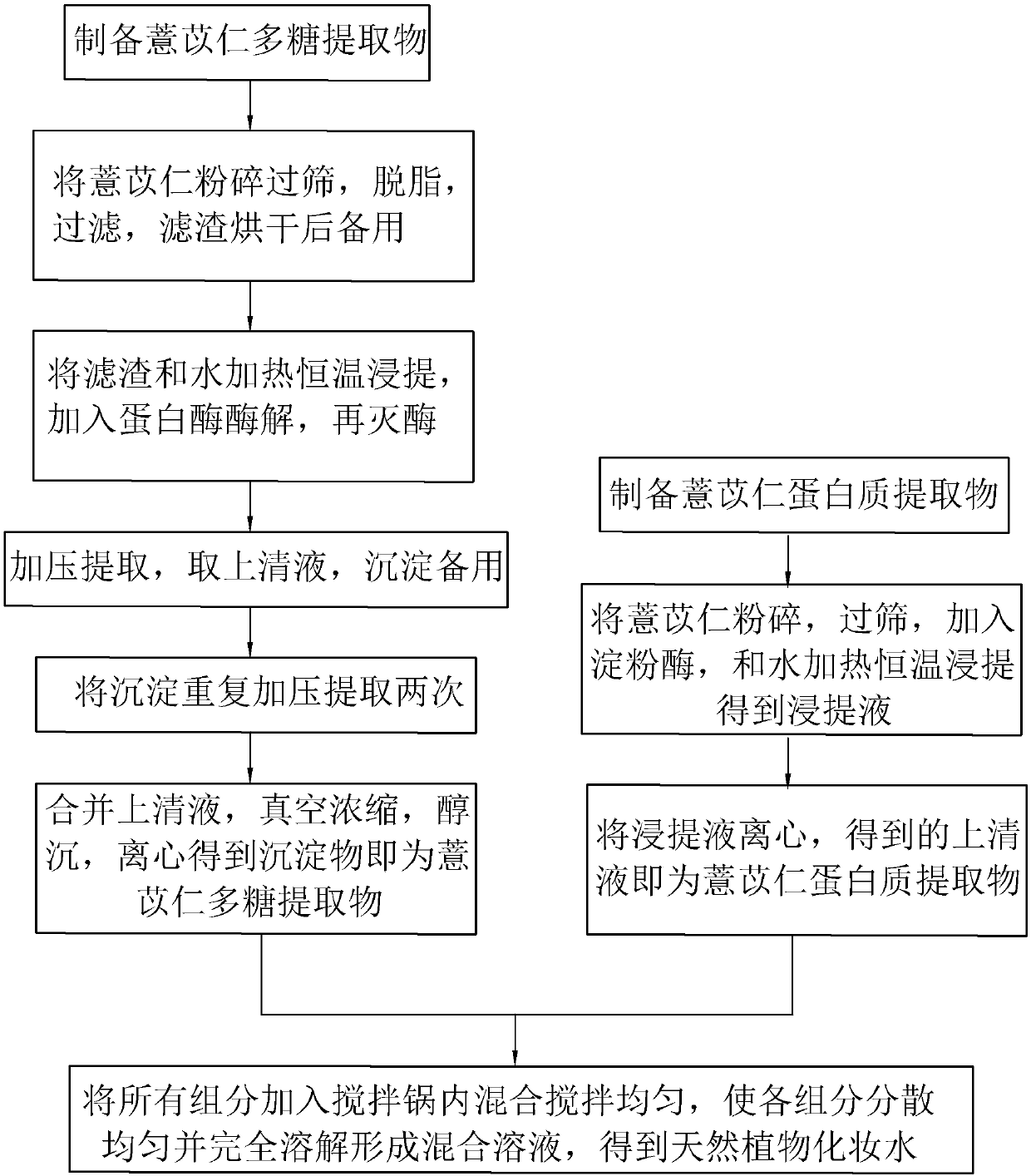

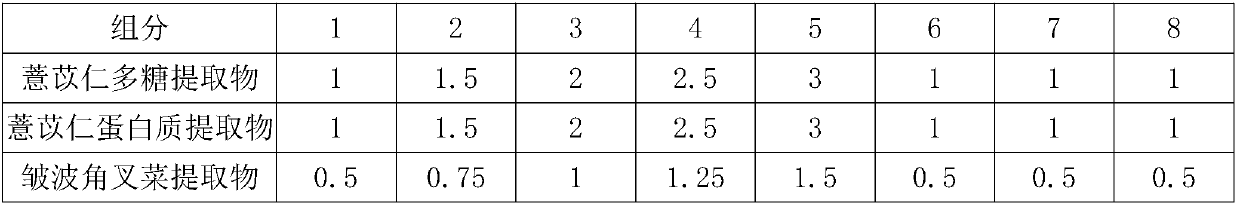

Natural plant toning lotion, and extracting and deep processing process thereof

InactiveCN107714554AAdjustment of statusStay soft and smoothCosmetic preparationsToilet preparationsCarrageenanDissolution

The invention discloses a natural plant lotion and its extraction and deep processing technology, and relates to the technical field of cosmetics. Wherein the natural plant lotion includes the following components in parts by weight: 1-3 parts of coix seed polysaccharide extract; 1-3 parts of coix seed protein extract; 0.5-1.5 parts of wrinkled carrageen extract; 1-3 parts of moisturizing agent 5 parts; 6-10 parts of film-forming agent; 0.1-1 part of antisensitizer; 0.1-0.5 part of preservative; make up to 100 parts of water. The compound use of wrinkled carrageen extract, coix seed polysaccharide extract and coix seed protein extract can synergistically enhance the moisturizing, whitening and repairing effects; by adding aloe vera leaf extract, dense Luomu leaf / stem extract and ginkgo biloba extract further improve the hydrating, moisturizing, whitening, freckle and wrinkle removing effects of lotion; impurities are removed by degreasing, and protease is added to enzymatically hydrolyze the protein in coix seed, making polysaccharides easier Dissolution, combined with microwave and pressure extraction process, improves the leaching speed and extraction rate of polysaccharides.

Owner:爱乐星丽化妆品制造(上海)有限公司

Cleaning device for machinery capable of quickly removing water

The invention discloses a cleaning device for machinery capable of quickly removing water. The cleaning device comprises a machine body, a cleaning barrel, a vibration motor and a box door; a water pump is mounted at the top of the machine body; the right side of the water pump is connected with a water inlet pipe; a flow separation pipe is arranged at the bottom of the water pump; a spraying headis connected below the flow separation pipe; a water flowing hole is fixed at the bottom of a cleaning barrel; connecting springs are mounted around the cleaning barrel; waste water collecting barrels are arranged below the connecting springs; the bottoms of the waste water collecting barrels are connected with water outlet pipes; the vibration motor is connected with the cleaning barrel throughvibration rods; a connecting plate is arranged above the vibration rods; and an observation window is mounted in middle of the box door. The cleaning device for machinery capable of quickly removing the water is provided with the vibration rods on the left and right sides of the cleaning barrel; and the vibration rods are connected with the vibration motor, so that the object cleaning speed is accelerated, dripping of the water on the surfaces of objects can be accelerated, and the working efficiency is improved.

Owner:GUIZHOU UNIV

Stainless steel oxide skin treatment method

ActiveCN109735714ASpeed up leachingImprove leaching efficiencyProcess efficiency improvementAmmonium sulfateAmmonium sulphide

The invention discloses a stainless steel oxide skin treatment method. A stainless steel oxide skin is subjected to ball milling and screening; the undersize materials is added into a sulfuric acid, the sulfuric acid with the undersize materials is put into a high-pressure reaction kettle, sulfur dioxide is introduced into the reaction kettle for leaching at a high temperature, and then the material is filtered; ammonia water is added into an obtained filtrate to adjust the pH value of the solution, an ammonium sulfide solution is added into the solution to precipitate nickel, ammonia water isadded into an obtained first filtrate to precipitate, the first filtrate is filtered to obtain second filter residues and a second filtrate; after being washed, the second filter residues are mixed with alkali, air is introduced to calcine, the mixture is subjected to fine grinding, and then hot water is added for washing, the hot water with the mixture is filtered to obtain a third filtrate andthird filter residues, the third filtrate is subjected to concentrating and crystallizing to obtain sodium chromate, and the third filter residues are subjected to drying and crushing to obtain iron oxide red; nickel precipitates are added into a sulfuric acid and sodium chlorate to react so as to obtain a nickel sulfate solution, and the nickel sulfate solution is subjected to concentrating and crystallizing to obtain nickel sulfate crystals; and the obtained second filtrate is subjected to concentrating and crystallizing to obtain ammonium sulfate crystals. The method is simple to process, short in flow, high in material recovery rate, low in cost and high in profit.

Owner:鲍君杰

Method for producing high-purity zinc oxide by steel mill smoke dust ash ammonia method decarburization

ActiveCN102849782BGood dispersionImprove liquidityZinc oxides/hydroxidesSolid waste disposalDecarburizationAlkali metal

The invention discloses a method for producing a high-purity zinc oxide by steel mill smoke dust ash ammonia method decarburization. The method includes that an ammonia-water-ammonium-bicarbonate solution is utilized as a leaching agent for leaching, 0.3-0.5kg of sodium fluosilicate is added into the per cubic meter of the leaching agent, and after the leaching, 50-60kg of slaked limes are added in per cubic meter of a leaching agent liquid to perform warming decarburization. According to the method, the ammonia method is applied to smoke dust ash treatment, prior ammonia methods are subjected to adaptable improvement, the leaching speed and the leaching rate of zinc in the smoke dust ash are improved, zinc oxide with a large specific surface area can be obtained, simultaneously the purity can reach above 99.7%, by means of the method, the energy consumption is low, the efficiency is high, the leaching agent can be recycled, the problem of zinc load in the steel mill blast furnace smoke dust can be thoroughly solved, the purifying requirements for harmful ingredients of zinc and alkali metal in the steel mill can be met, virtuous circle of production is achieved, valuable ferrum and carbon resources in the steel mill can be recycled, the ferrum and carbon are enriched, the energy is saved, and good economic benefits are achieved.

Owner:SICHUAN JUHONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com