Rattan dyeing equipment for rattan plaited handicraft processing

A technology for dyeing equipment and handicrafts, applied in wood processing utensils, manufacturing tools, reed/straw treatment, etc., can solve the problems of uneven coloring of rattan, inconvenient to drain, low processing efficiency, etc., and achieve better dyeing effect. , Improve processing efficiency and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

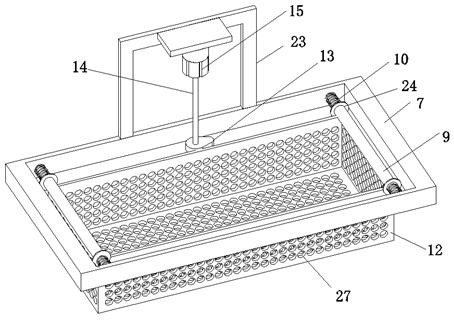

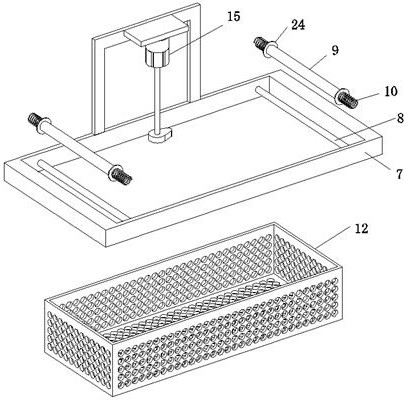

[0038] Embodiment 2 On the basis of Embodiment 1, several second return springs 22 are fixedly installed between the dyeing tray 12 and the front and rear rods of the rectangular frame 7 .

[0039] When this embodiment is in use, the setting of the second return spring 22 makes the dyeing disc 12 swing back and forth more stably, and the vibration phenomenon will not easily occur.

Embodiment 3

[0041] Embodiment 3 On the basis of embodiment 2, the bottom end surface of the cam 13 is also fixed with a stirring rod 28, the height of the stirring rod 28 is greater than the height of the dyeing disc 12, the stirring rod 28 is coaxially arranged with the rotating shaft 14, and the stirring rod 28 The outer wall of the bottom end is fixed with stirring blade 11.

[0042] During the use of this embodiment, the driving motor 15 drives the cam 13 to rotate and at the same time drives the stirring blade 11 to rotate. The rotation of the stirring blade 11 can promote the dyeing solution to mix more evenly and prevent precipitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com