Patents

Literature

69results about How to "Not prone to precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient anti-static PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) composite material and preparation method thereof

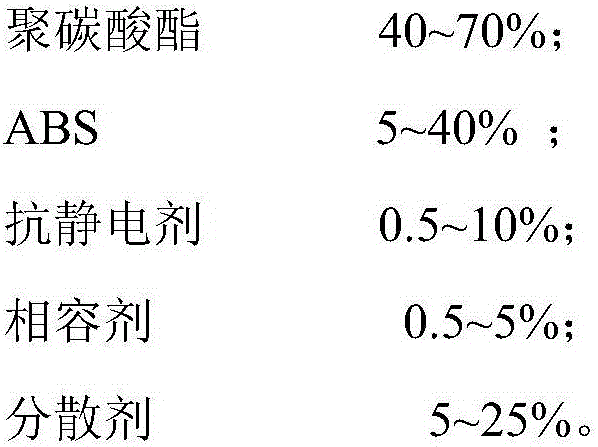

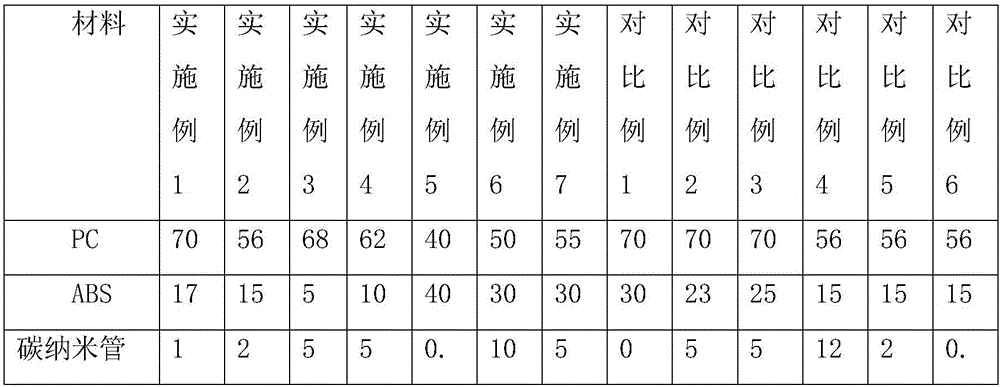

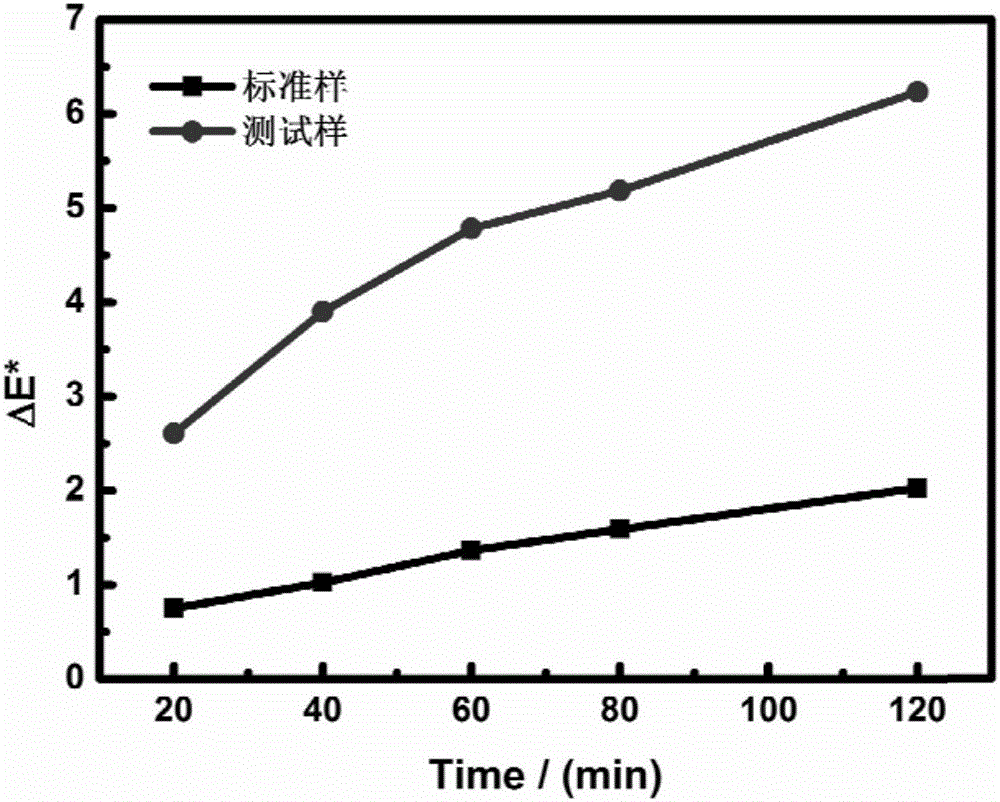

The invention provides an efficiency anti-static PC / ABS (Polycarbonate / Acrylonitrile Butadiene Styrene) composite material and a preparation method thereof. The composite material is prepared from the following components in percentage by weight: 40-70 percent of polycarbonate, 5-40 percent of ABS, 0.5-10 percent of antistatic agent, 0.5-5 percent of compatilizer and 5-25 percent of dispersing agent. The preparation method comprises the following steps: firstly, mixing the antistatic agent, the compatilizer and the dispersing agent in the raw materials according to a certain proportion at the room temperature; performing melt extrusion through double screws to obtain antistatic master batch; extruding the composite material according to a certain proportion, extruding through the double screws, and granulating to obtain the efficient anti-static PC / ABS composite material. The composite material prepared by the method has superior antistatic performance, high chemical performance and attractive appearance.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

Process for producing low-fat sesame paste

InactiveCN104305374ALow in fatHigh protein contentFood preparationProtein contentProcess engineering

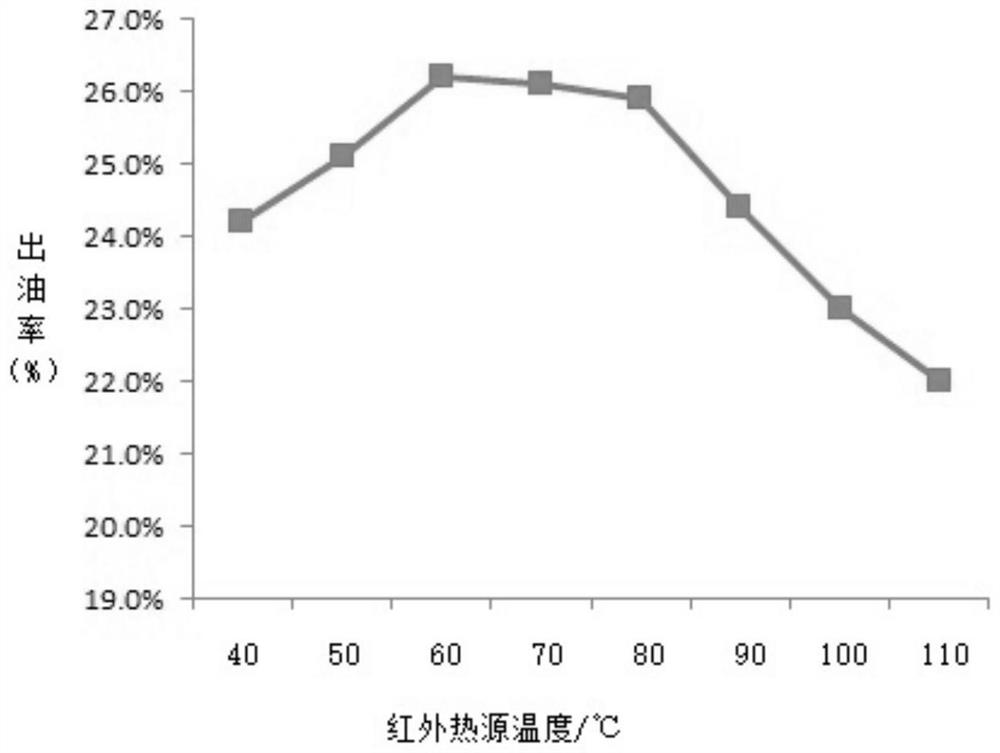

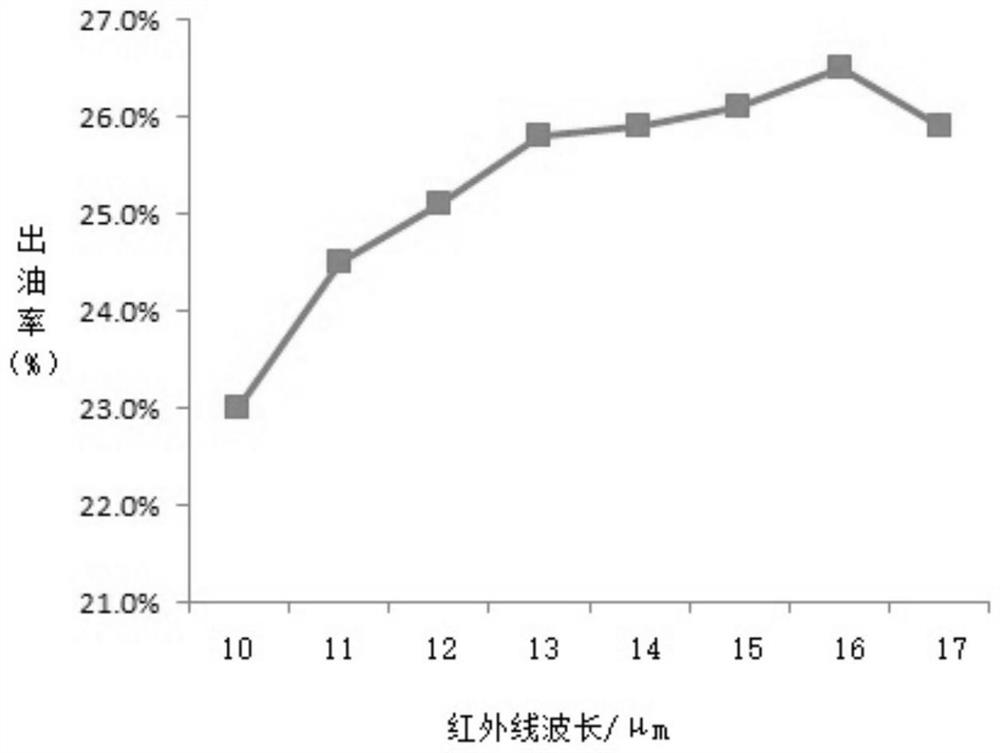

The invention relates to a process for producing low-fat sesame paste. The process specifically comprises the following steps: mechanically pressing the cleaned sesame raw materials to remove partial grease, frying, milling, homogenizing and filling the degreased sesame, thereby obtaining the low-fat sesame paste, wherein the mechanical pressing refers to static hydraulic pressing or power spiral pressing, and the pressure is 10-20 MPa. The pressing equipment can be a hydraulic or spiral oil press, about 10-30 percent of oil in the sesame is removed, and the pressed sesame contains about 20-40 percent of oil. The sesame paste prepared by adopting the process is low in fat content and high in protein content, can be eaten by the crowd suffering from three highs and is high in colloidal stability, and a phenomenon that oil is separated out due to long-term storage is hard to occur.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

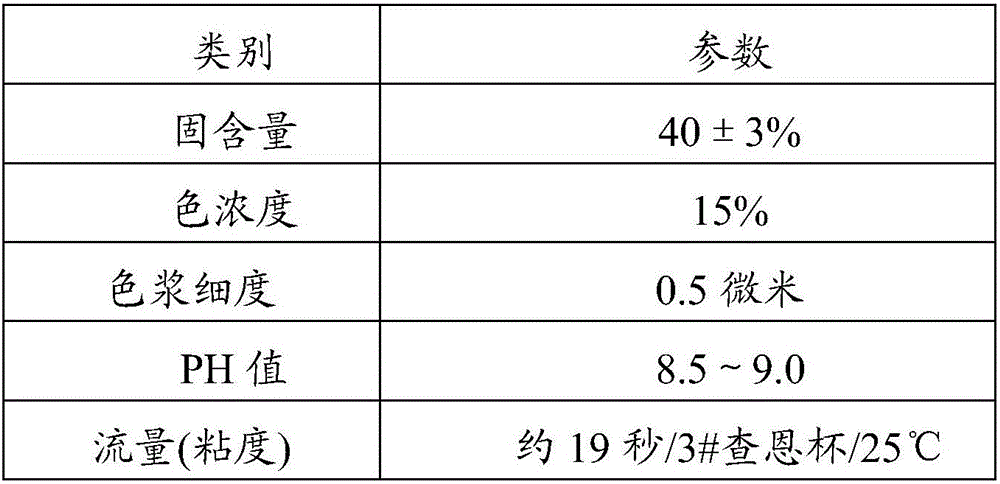

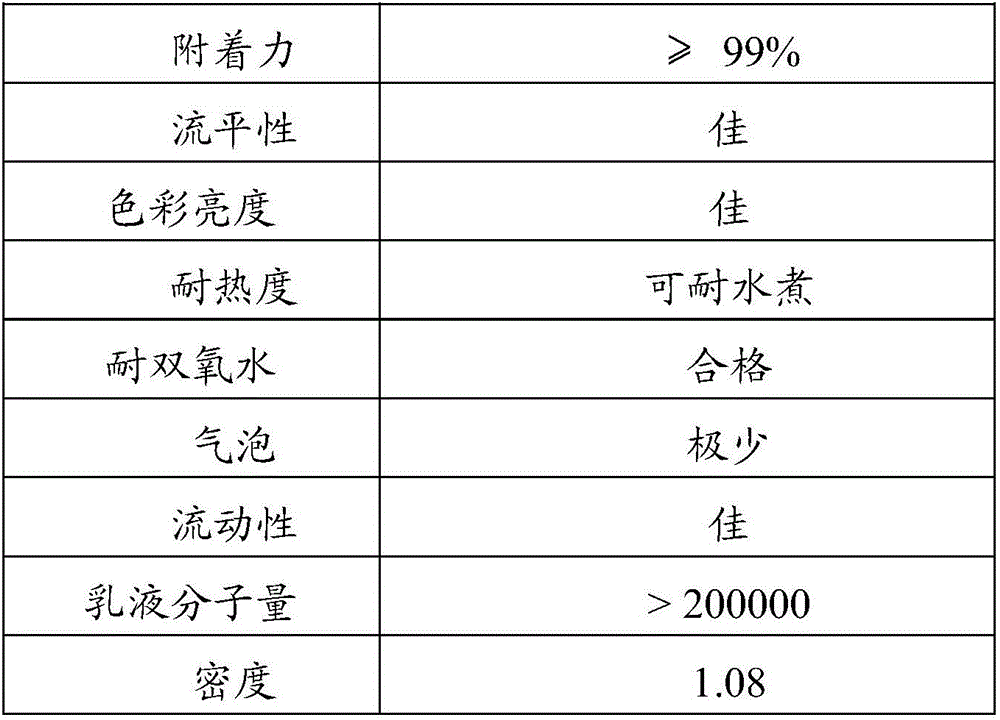

Environment-friendly water-based ink

An environment-friendly water-based ink comprises the following components by mass percent: 12-22% of alcohol-soluble modified acrylic resin, 10-20% of alcohol-soluble modified aldehyde ketone resin, 35-55% of a diluents, 6-12% of methyl ether, 12-20% of pigment, and 2-5% of a functional auxiliary agent. The environment-friendly water-based ink provided by the invention is an alcohol-soluble gravure ink, adopts more than 95% of alcohol as the auxiliary agent to realize gravure production, is stable in ink performance, uniform in texture, strong in tinting strength, not easy to precipitate, and similar with the printing effect of the traditional offset printing, and has certain antistatic function.

Owner:JIANGSU DAREGLOBAL PRINTING CO LTD

Production process of instant maize germ powder

The invention relates to a production process of instant maize germ powder. The instant maize germ powder is prepared through raw material preprocessing, beating, enzymolysis, enzyme inactivation, colloid milling, sterilization, high-pressure homogenization and spray drying by taking maize germ meal as a raw material; the enzymolysis is carried out by adding medium-temperature alpha-amylase accounting for 0.2%-0.4% of the dry weight of the maize germ meal, and the starch hydrolysis DE value (Dextrose Equivalent value) of maize germ meal slurry which is subjected to enzymolysis is controlled between 18% and 22%; the prepared homogenized maize germ meal slurry achieves the easiness for the spray drying, and a finished product does not absorb moisture, so that the dissolution stability of the maize germ powder is enhanced, the deposition has small possibility of appearing in the dissolving process, and the maize germ powder is not caked and agglomerated when being dissolved in water; and the additional value of maize germ meal is increased. The instant maize germ powder obtained through the method disclosed by the invention achieves the protein content more than 23%, is in a faint yellow color and is fast in dissolution; and the dissolved instant maize germ powder is uniform in state and achieves the product dissolution time less than 27 seconds without any unpleasant odor.

Owner:鲁洲生物科技(辽宁)有限公司 +2

Preparation method of plain cheese sauce

The invention discloses a preparation method of plain cheese sauce. The preparation method comprises the following steps: fermenting whole milk powder by lactobacillus to obtain lactobacillus fermentation broth, then adding milk fat, carrying out enzymolysis by adopting lipase and protease to obtain milk enzymatic hydrolysate, and then adding salt, aginomoto and sugar for carrying out high-temperature thermal reaction to prepare the plain cheese sauce. According to the invention, the preparation process is natural, the cheese sauce is natural and harmonious in flavor, milk powder is taken as the main material, so that the cost is effectively controlled, heating is carried out for generating the Maillard reaction, so that the flavor and the mouthfeel are further promoted, and therefore, the cheese sauce has unique characteristics, can meet the hobby of the Chinese people for sweet aroma, and has a wide market prospect.

Owner:上海馥松食品有限公司

Preparation method of rigid polyurethane foam heat insulation and energy saving material

The invention provides a preparation method of a rigid polyurethane foam heat insulation and energy saving material. The preparation method comprises the following steps of S1, preparing a black material and a white material with the weight ratio being (1.1-1.2) to 1, wherein the black material is isocyanate, and the white material is prepared by mixing the following raw materials in parts by weight: 70-95 parts of polyether polyol, 15-25 parts of deionized water, 6-9 parts of expanded vermiculite, 3-6 parts of acrylic resin, 2-3 parts of organosilicon oil foam stabilizer, 3-6 parts of rock wool fiber, 2-6 parts of bagasse fiber, 5-9 parts of nanometer calcium carbonate, 0.1-0.3 part of N,N-dimethyl cyclohexyl amine and 4-6 parts of modified tin catalyst; and S2, uniformly mixing the whitematerial in advance, then mixing the black material and the white material, foaming a mixture with a high-pressure foaming machine, injecting a foamed product into a die, and performing formation toobtain the rigid polyurethane foam heat insulation and energy saving material. The preparation method can reduce use of a chemical solvent and improves the heat insulation performance of a whole polyurethane material at the same time.

Owner:GUANGXI JISHUN ENERGY TECH

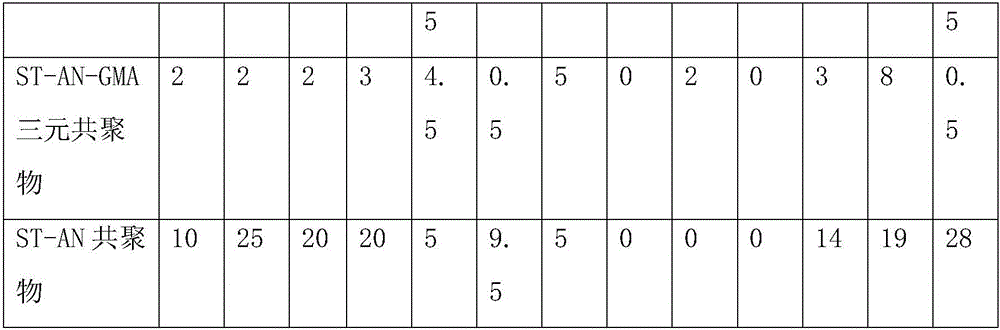

Test method for light resistance of titanium dioxide

InactiveCN105738271AShort test cycleThe operation process is simple and convenientWeather/light/corrosion resistancePreparing sample for investigationTitanium dioxideTriethanolamine

The invention relates to a test method for light resistance of titanium dioxide. The test method includes the following steps that 1, a melamino-formaldehyde resin water solution is prepared and contains triethanolamine, ethyl alcohol and melamino-formaldehyde resin, and the mass fraction of the melamino-formaldehyde resin is 20-50%; 2, titanium dioxide is dispersed in the melamino-formaldehyde resin water solution, and the concentration of titanium dioxide is 0.1-0.5 g / mL; 3, a glass slide is coated with the mixture and then placed in a drying oven and dried to obtain a film; 4, the dried film is taken out and put into a printing-down machine with an iodine gallium light to be exposed under the blazing sun for a long time, and chromatic aberration delta E value before and after the step of exposure under the blazing sun for a long time is tested. The test method is short in test period, the operation process is simple, storage time is long, precipitation does not occur easily, and test results are high in accuracy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Aqueous semitransparent pigment type colorant used for carpentry paint and preparation method thereof

The invention discloses an aqueous semitransparent pigment type colorant used for carpentry paint and a preparation method thereof. The aqueous semitransparent pigment type colorant contains the following materials by weight percent: 20-40% of aqueous linseed oil, 20-40% of anba powder or transparent ferric oxide pigment and organic pigment, i.e. permanent yellow, rose Bengal and black pigment, 2-5% of aerosil, 1-3% of aqueous dispersant, 10-20% of propanediol and 10-20% of water. The preparation method of the aqueous semitransparent pigment type colorant comprises the following steps: (1) adding the aqueous linseed oil into a container; (2) then, adding the propanediol and the water into the container; (3) then, adding the aqueous dispersant into the container, and uniformly stirring and mixing the materials; (4) finally, adding the aerosil, the anba powder or the transparent ferric oxide pigment into the container; (5) uniformly stirring the materials, and then grinding the materials into 15 UM to be qualified by a grinder so as to be used. The invention can be used for the wiping and coating process of pseudo-classic furniture or American furniture.

Owner:深圳市圣马斯科技有限公司

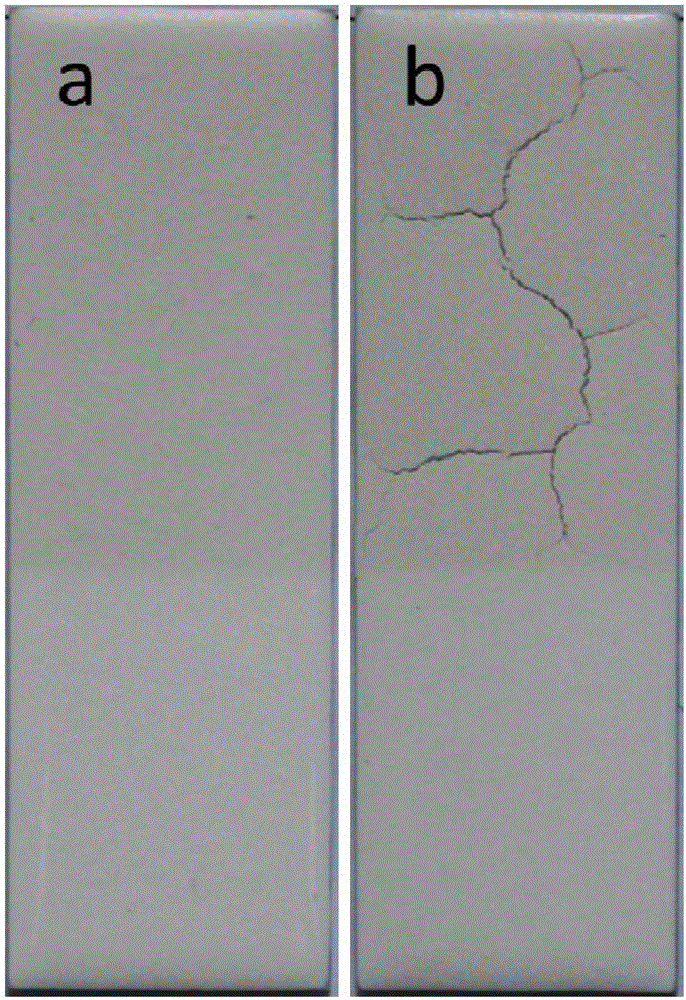

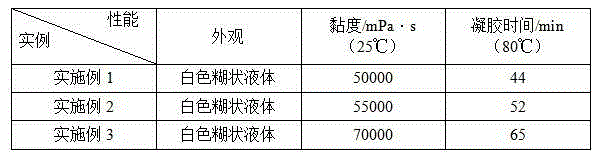

Latent curing system used for moulding prepregs at medium or low temperature and method for preparing latent curing system

The invention belongs to the field of composite material, and specifically discloses a latent curing system used for moulding prepregs at a medium or low temperature and a method for preparing the latent curing system. The latent curing system comprises 10-50 parts of epoxy resin, 50-100 parts of a latent curing agent, 40-80 parts of a liquid room-temperature reactive curing agent, and 1-10 parts of an accelerant. The preparation method comprises the following steps: uniformly mixing the latent curing agent and the liquid room-temperature reactive curing agent; adding epoxy resin and the accelerant to carry out a reaction at the temperature of 60 to 100 DEG C for 2-6 hours; and finally obtaining a paste liquid that is the latent curing system used for moulding prepregs at a medium or low temperature. According to the invention, the latent curing system is used for moulding at a medium or low temperature, the curing temperature of the latent curing agent is reduced, and the pasty form is beneficial to uniformly dispersing the latent curing system in the epoxy. The latent curing system is simple in operation of preparation technology and is suitable for large-scale industrial production.

Owner:BEIJING UNIV OF CHEM TECH

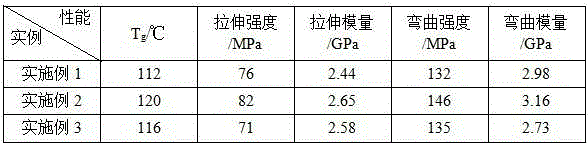

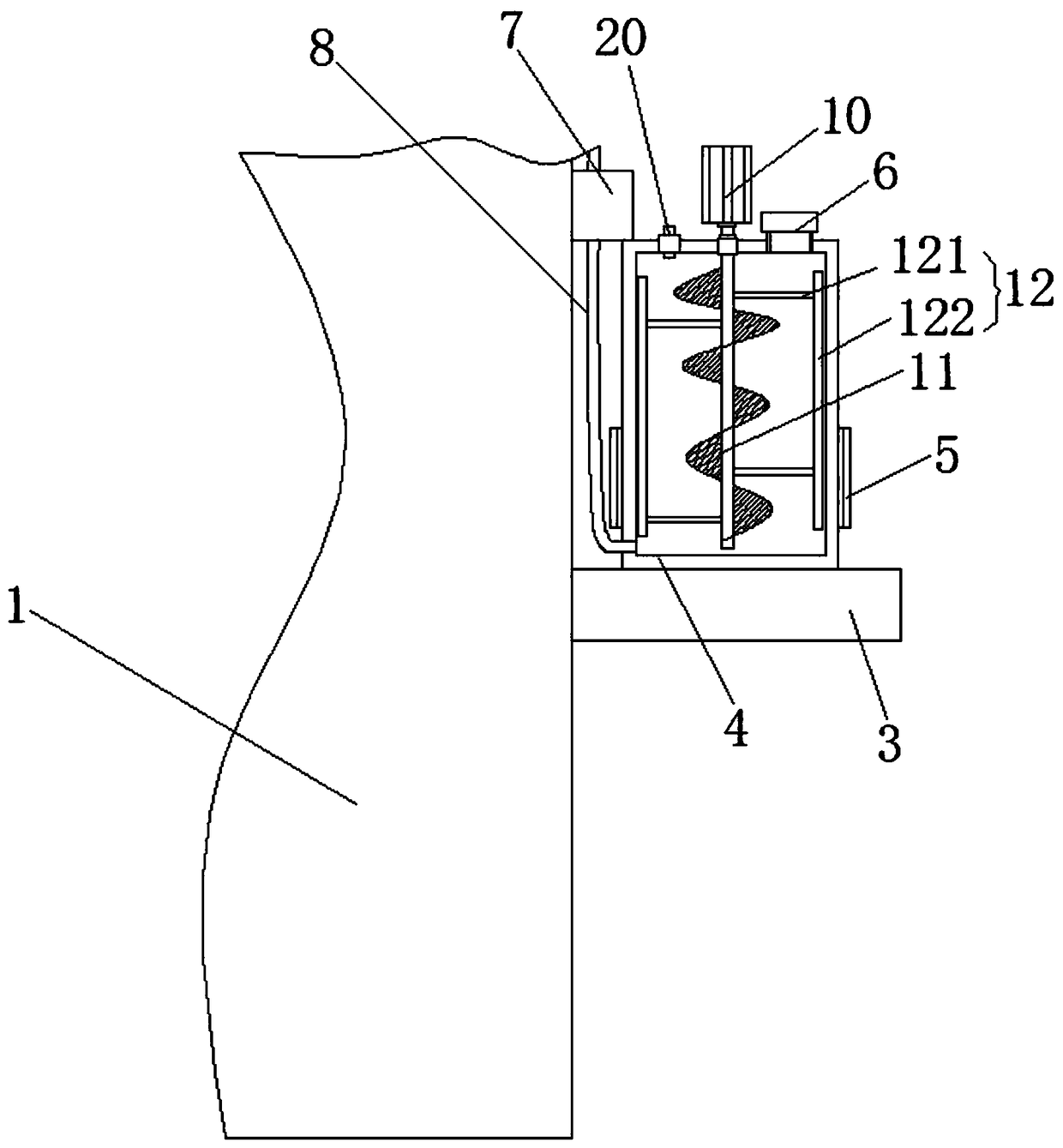

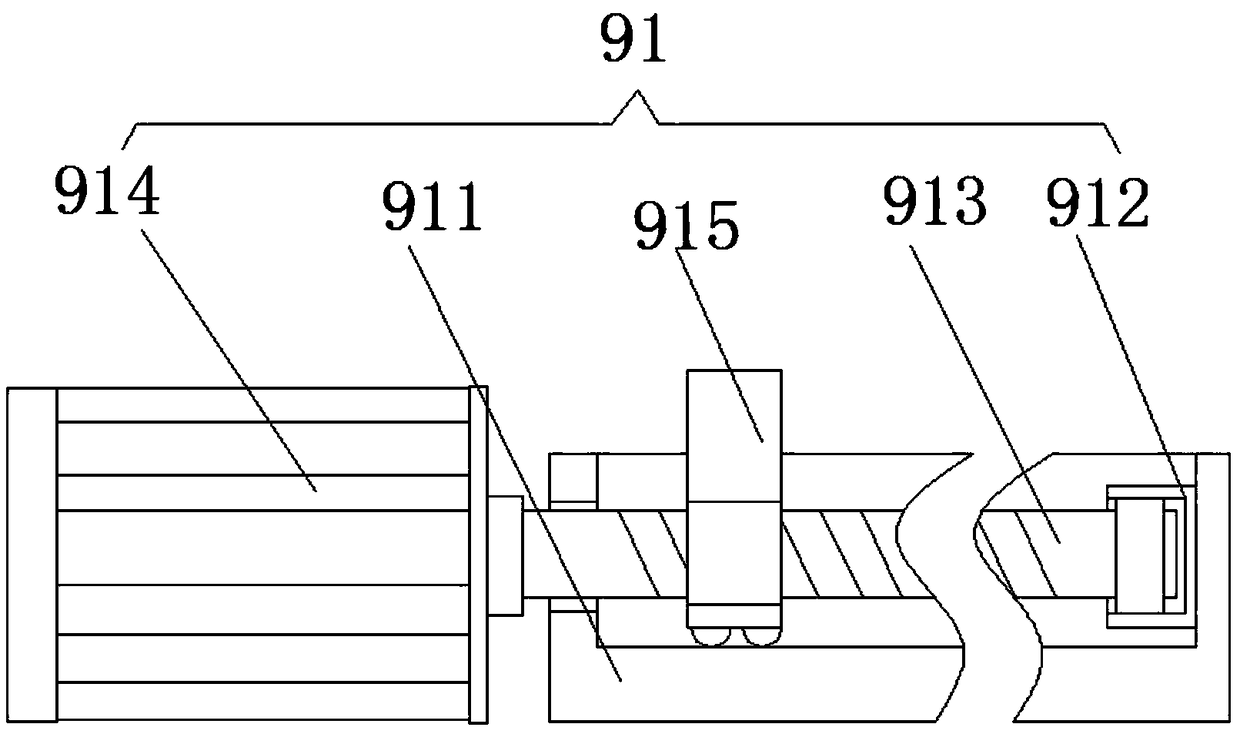

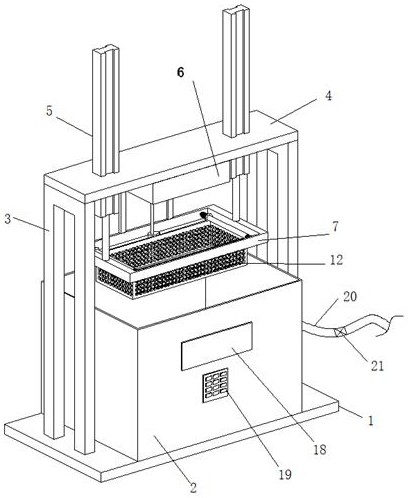

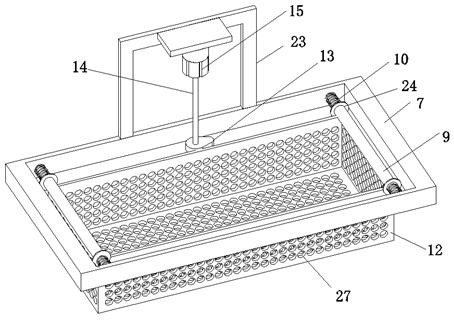

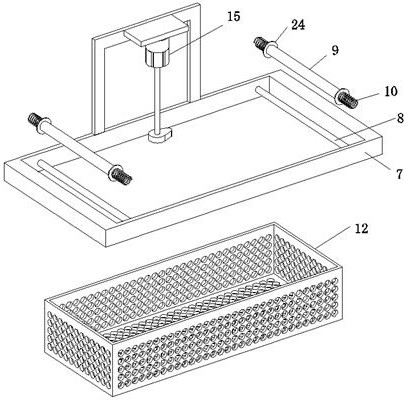

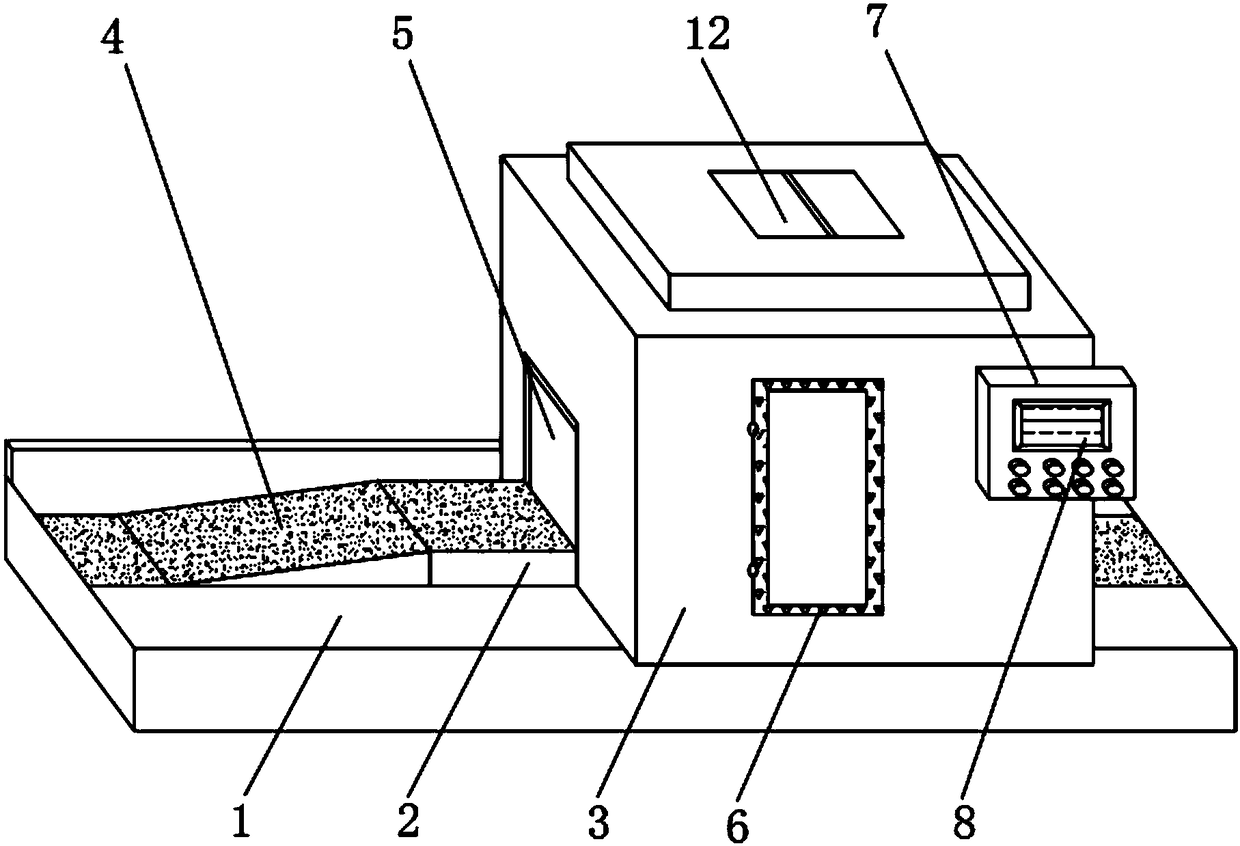

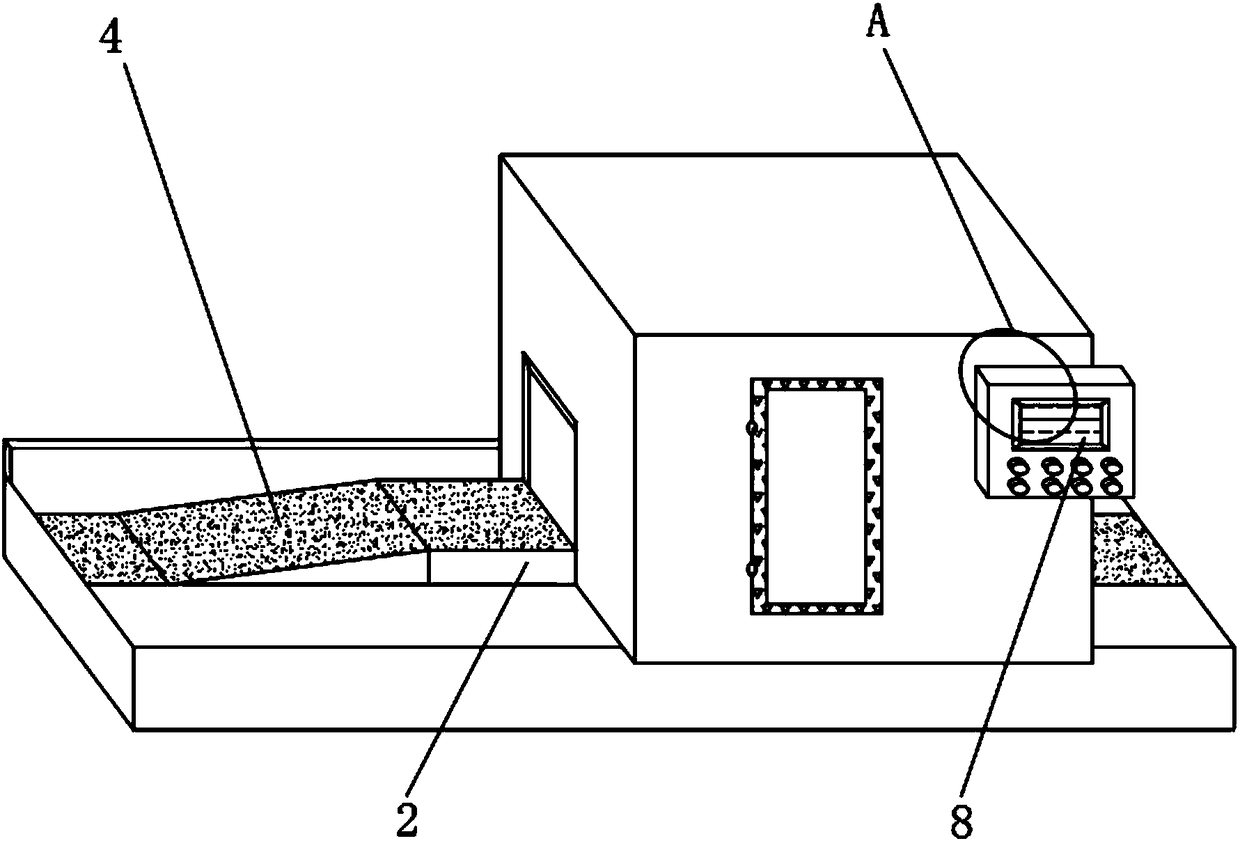

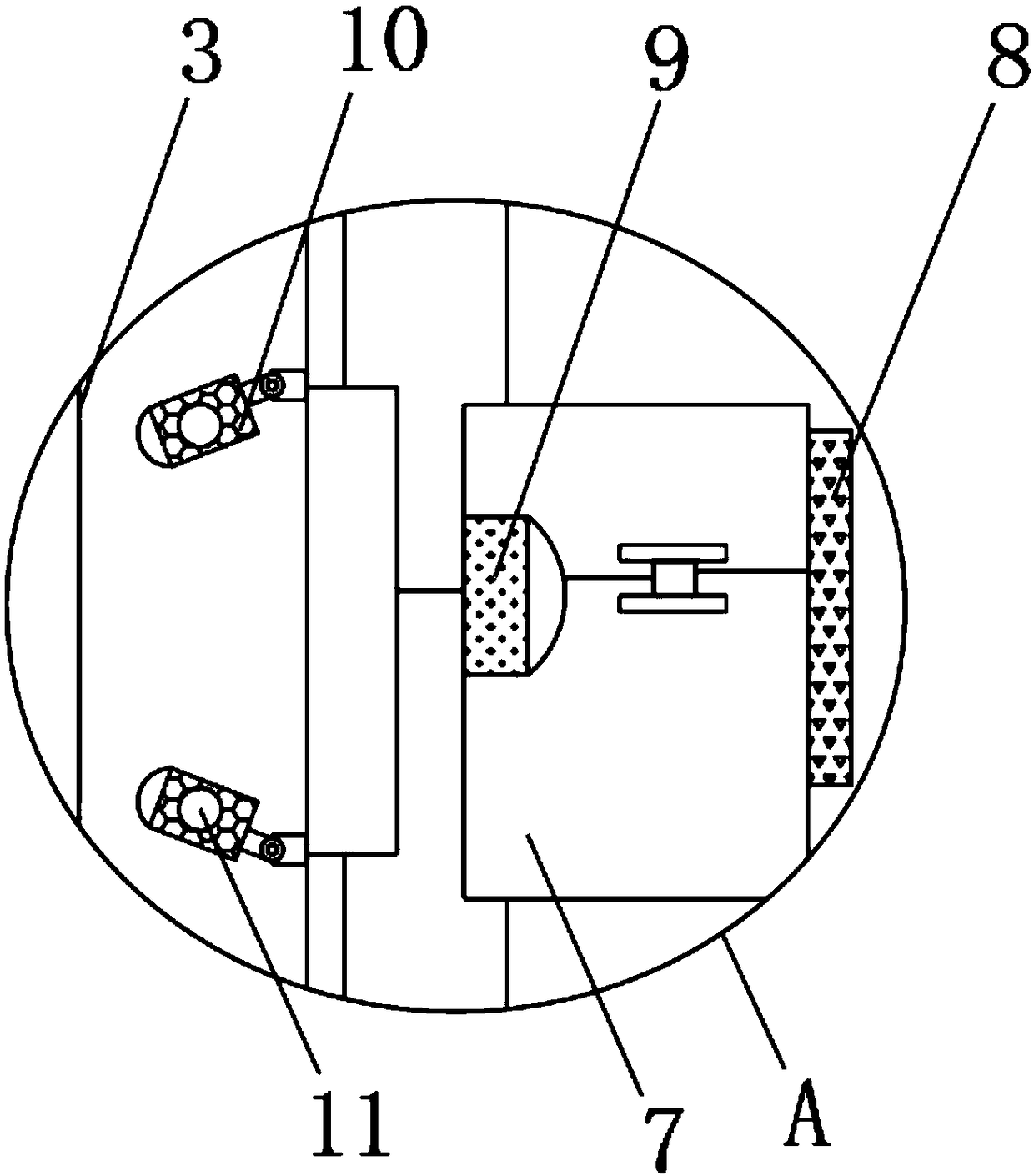

Glue dispensing device for filter production processing

InactiveCN109277261APrevent curingNot prone to precipitationLiquid surface applicatorsRotary stirring mixersEngineeringMechanical engineering

The invention discloses a glue dispensing device for filter production processing. The glue dispensing device comprises a machine frame, wherein a control panel is arranged on the front surface of themachine frame, a supporting plate is fixedly connected to one side of the machine frame, a glue box is fixedly arranged at the top of the supporting plate, a heating tape sleeves the surface of the glue box, a glue injection pipe communicates with the top of the glue box, one side of the glue box communicates with a glue pump, the top of the machine frame is provided with a glue dispensing assembly, the glue dispensing assembly communicates with the glue pump, a first motor is fixedly arranged at the top of the glue box, the output shaft of the first motor is fixedly connected with a stirringblade, the stirring blade is located in the glue box, scraping assemblies are fixedly connected to the two sides of the stirring blade, and the other side of the machine frame is fixedly provided with a conveying belt. According to the glue dispersing device, the problem that glue solution is easy to solidify due to rapid reduction of the temperature in the circulation process is solved, and theglue dispensing effect is influenced.

Owner:安徽威成精密制造有限公司

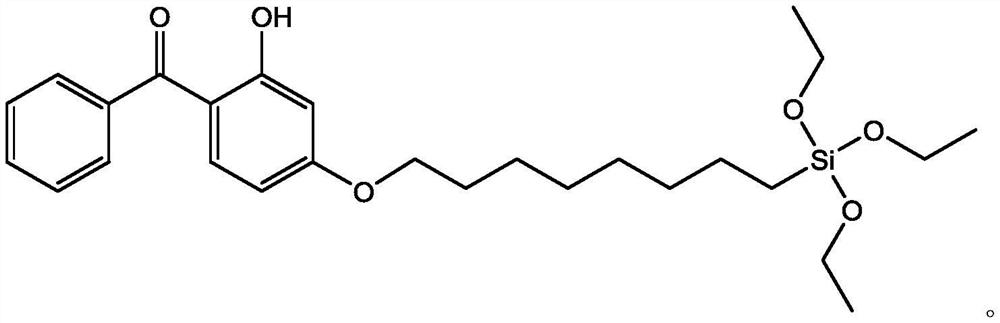

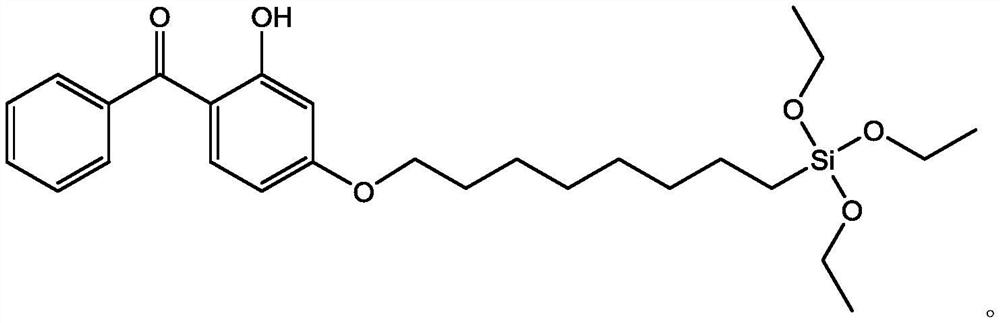

High-shading type double-color TPU (thermoplastic polyurethane) film and production process thereof

The invention belongs to the technical field of TPU films, and particularly relates to a high-shading type double-color TPU film and a production technology thereof.The two faces of the high-shading type double-color TPU film are a black film and a white film respectively, and the black film is prepared from, by weight, 100 parts of TPU masterbatch and 30-50 parts of silane coupling agent modified carbon black. According to the high-shading type double-color TPU film, the black film and the white film are arranged on the two faces of the high-shading type double-color TPU film respectively, the white film outwards contributes to reflecting light rays and heat and has a good heat insulation effect, the black film can play a shading role, and the black film outwards can effectively absorb heat and contributes to increasing the internal temperature; the double-color TPU film can be applied to scenes with different requirements; besides, the carbon black added in the black film is silane coupling agent modified carbon black, so that the dispersion effect of the carbon black in TPU can be effectively improved, the dispersion uniformity is improved, agglomeration is avoided, the influence on the mechanical property of the film is reduced, and meanwhile, a better shading effect is achieved.

Owner:昆山红苹果塑胶新材料有限公司

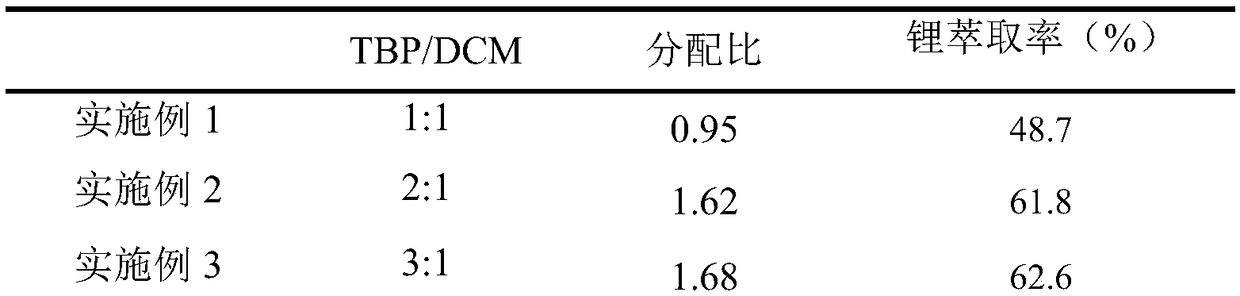

Method for extracting lithium from strong-acidic electrolyte solution system

InactiveCN108893604AGood compatibilityLow viscosityProcess efficiency improvementSolution systemDichloromethane

The invention provides a method for extracting lithium from a strong-acidic electrolyte solution system. The method comprises the following steps: (1) preparing an organic phase, wherein the organic phase contains an extracting agent and a diluting agent, the extracting agent is tributyl phosphate (TBP), the diluting agent is dichloromethane (DCM), and the volume ratio of TBP to DCM is (1-8) to 1;(2) preparing a water phase, wherein the water phase is an LiCl-AlCl3-CaCl2-H2O system, the concentration of LiCl is controlled at 50ppm-500ppm, and the molar ratio of Li to Al to Ca is 1 to (20-60)to (5-20); (3) adding HCl into the water phase so as to regulate the acidity to 1M-5M; (4) continuing to add a co-extracting agent FeCl3.6H2O into the water phase, and controlling the molar ratio of iron to lithium at (1-6) to 1; and (5) mixing the organic phase obtained in the step (1) with the water phase obtained in the step (4) in a volume ratio of (0.5-5) to 1, stirring at the room temperature for 3-20 minutes, and standing for separation. By utilizing the method provided by the invention, the once extraction rate of lithium reaches over 60%, the problem that the lithium is difficult to extract under a strong acidic condition is solved, and the method is good in selectivity, simple in operation, easy for two-phase separation and low in cost and can be used for extracting lithium froma coal ash acid leaching solution.

Owner:SHANXI UNIV

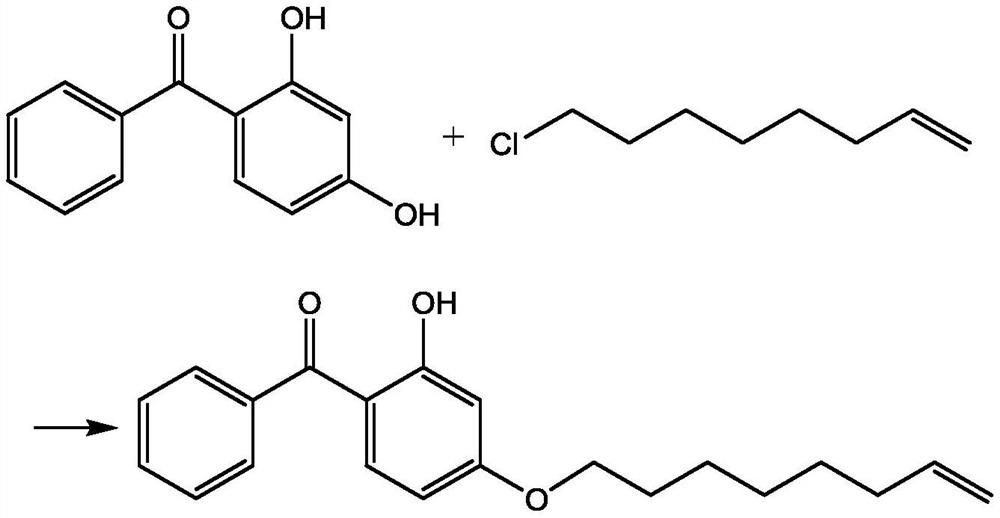

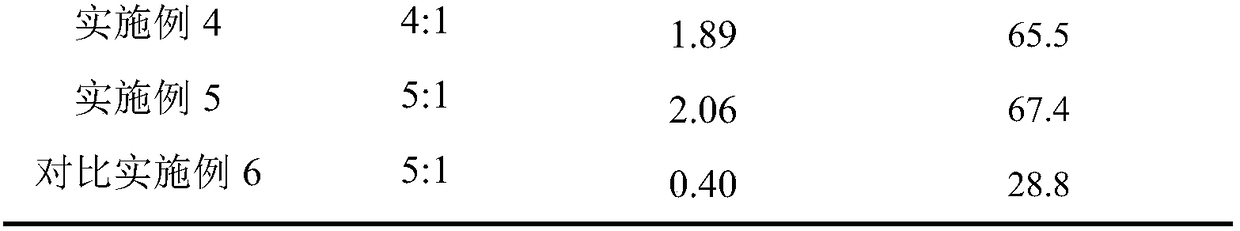

Environment-friendly anti-oxidation imitated gold stamping mucilage and preparing method thereof

PendingCN111485435AImprove printing effectImprove aestheticsDyeing processTextile printerPolymer science

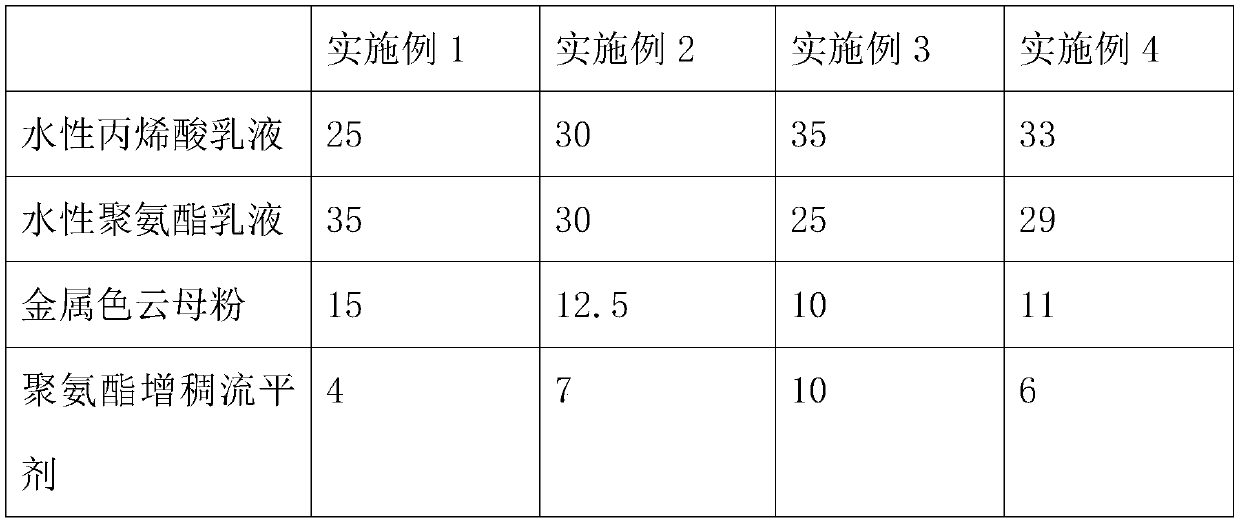

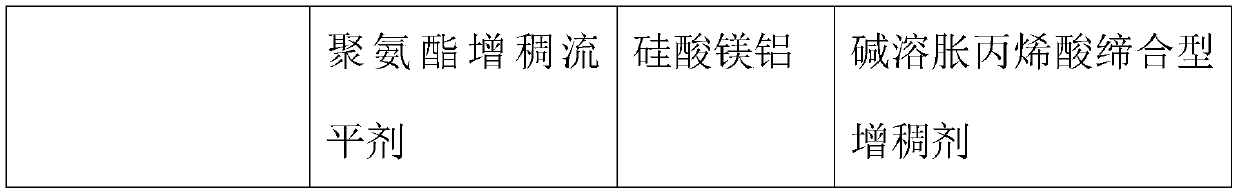

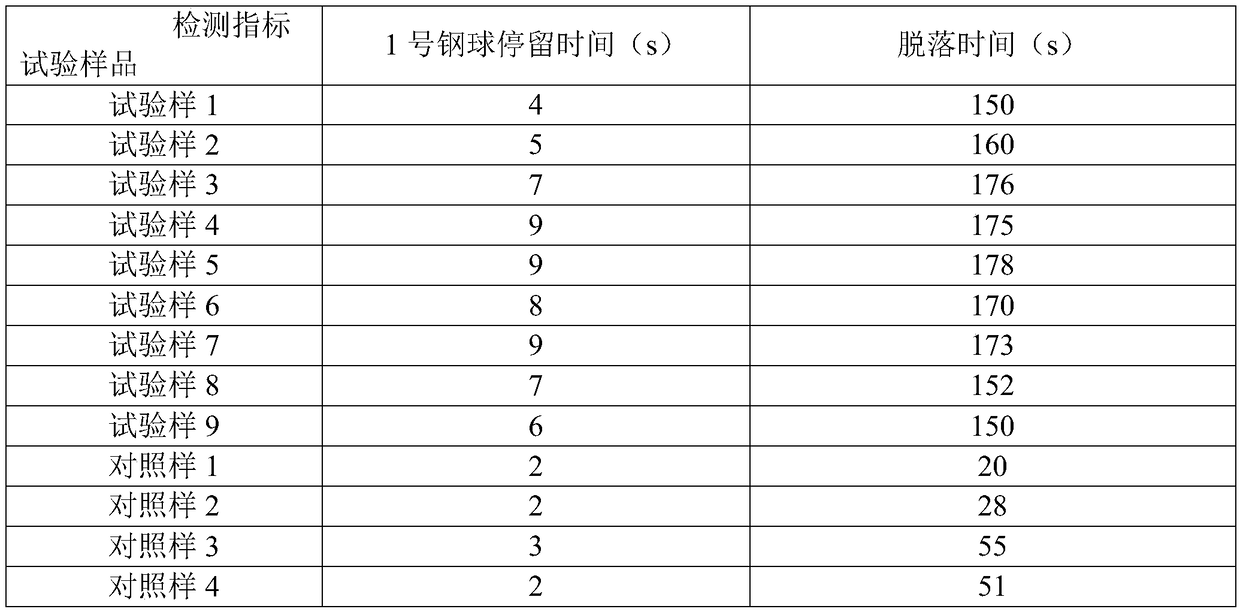

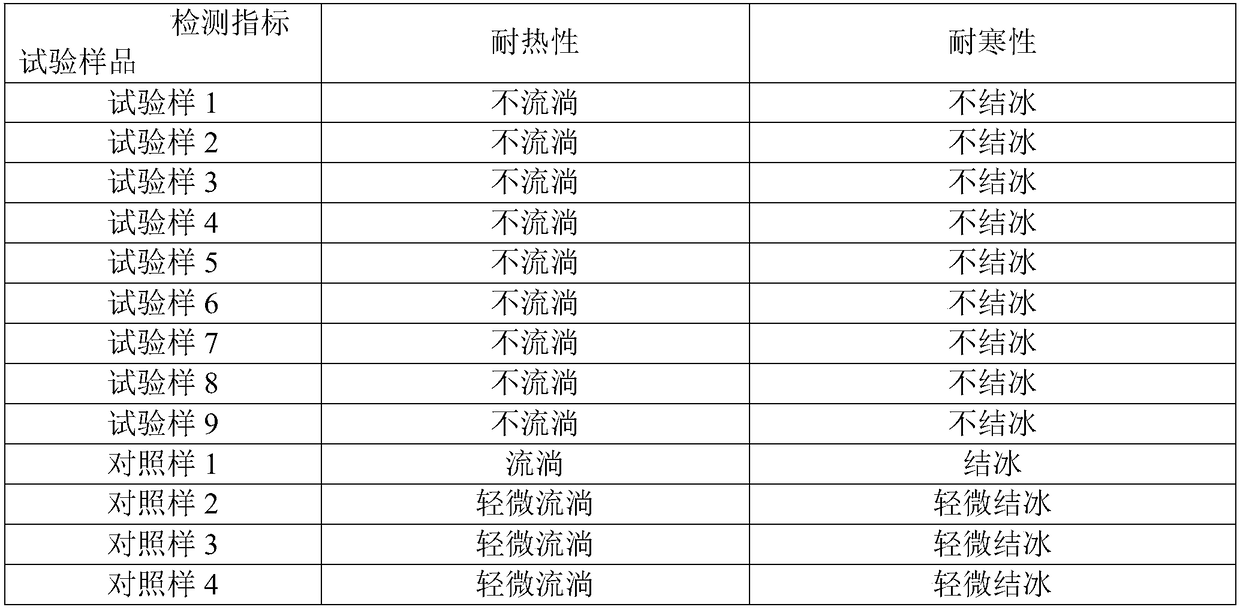

The invention relates to the technical field of printing mucilage, in particular to environment-friendly anti-oxidation imitated gold stamping mucilage which comprises the following components including, by mass, 25-35 parts of water-based acrylic emulsion, 25-35 parts of waterborne polyurethane emulsion, 10-15 parts of metal color mica powder and 4-10 parts of a thickening agent. The invention also relates to a preparation method of the environment-friendly anti-oxidation imitated gold stamping mucilage. The preparation method comprises the following steps of (1) adding the water-based acrylic emulsion and the water-based polyurethane resin into a reaction container, and performing stirring for 10-20 minutes to form a pre-mixture; and (2), adding the metal color mica powder into the pre-mixture, performing stirring for 30-50 minutes, adding the thickening agent, performing stirring for 20-30 minutes, and performing filtering to obtain the environment-friendly anti-oxidation imitated gold stamping mucilage. The imitated gold stamping mucilage is not prone to being oxidized, and the effect of better maintaining the metal color is facilitated.

Owner:广州明诺新材料科技有限公司

Hydrogel and process using hydrogel to produce cooling plaster

ActiveCN108403622ANot prone to precipitationModerate adhesivenessHydroxy compound active ingredientsAntipyreticDihydroxyaluminum aminoacetateAcetic acid

The invention discloses hydrogel and a process using the hydrogel to produce a cooling plaster and belongs to the technical field of cooling plaster production. The hydrogel comprises 70-81 parts of glycerin, 11-18 parts of resin powder, 3.9-4.9 parts of thickening agent, 0.35-0.45 part of dihydroxyaluminum aminoacetate, 0.25-0.33 part of ethylenediamine tetraacetic acid disodium, 16-18 parts of polyvinyl pyrrolidone, 7.5-8.8 parts of 10wt% tartaric acid aqueous solution, 0.85-1 part of waterborne preservative, 1.0-1.25 parts of cooling agent, 1.6-1.9 parts of anhydrous alcohol and 170-200 parts of deionized water, wherein the resin powder comprises at least one of H106 and HQ841. The hydrogel is good in adhesiveness and stripping strength, is mild and non-irritant, and cannot easily damage the skin.

Owner:杭州求是医学科技有限公司

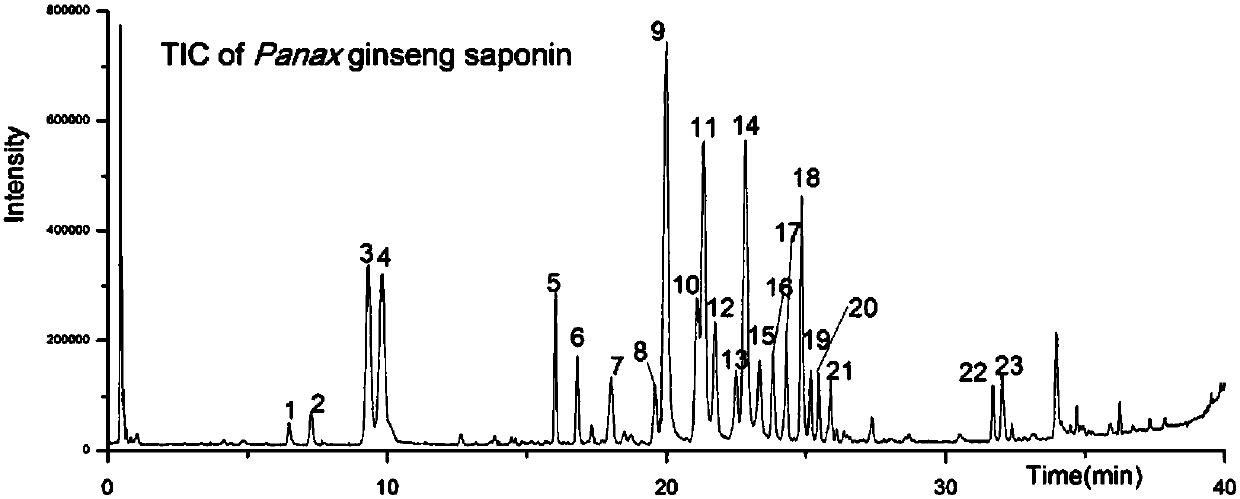

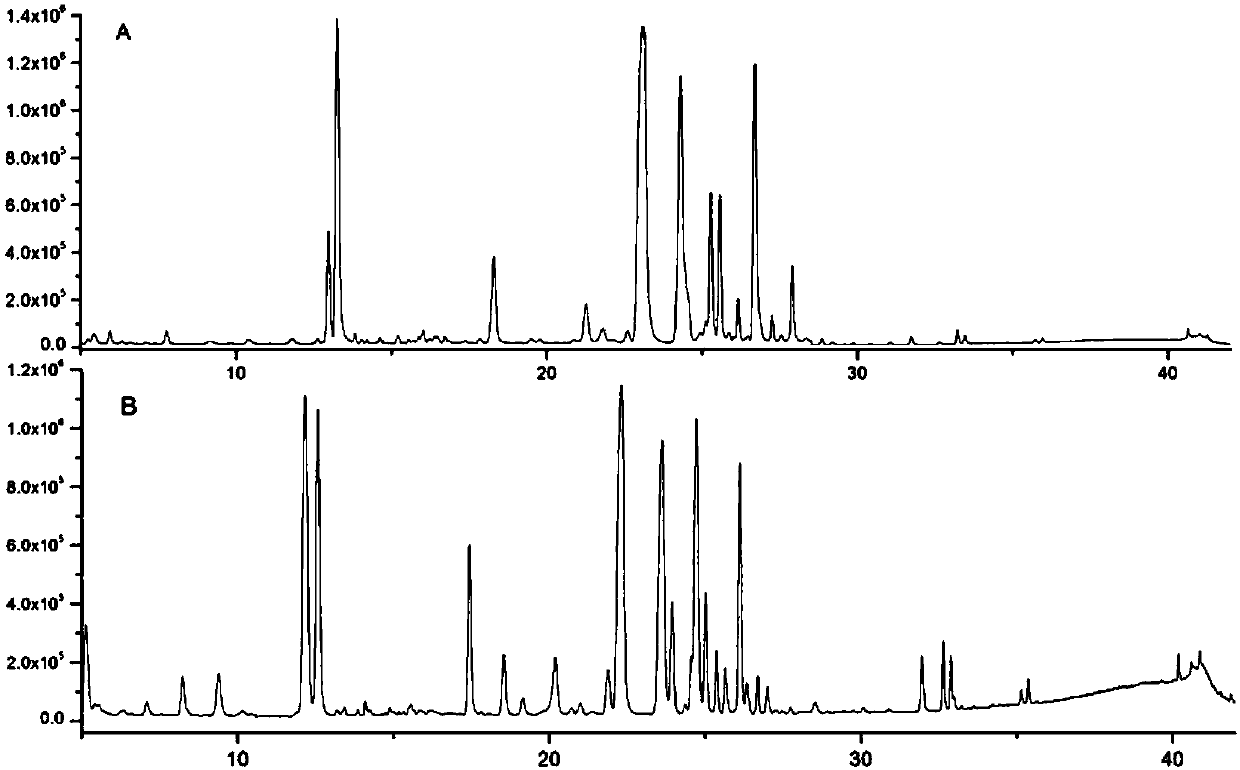

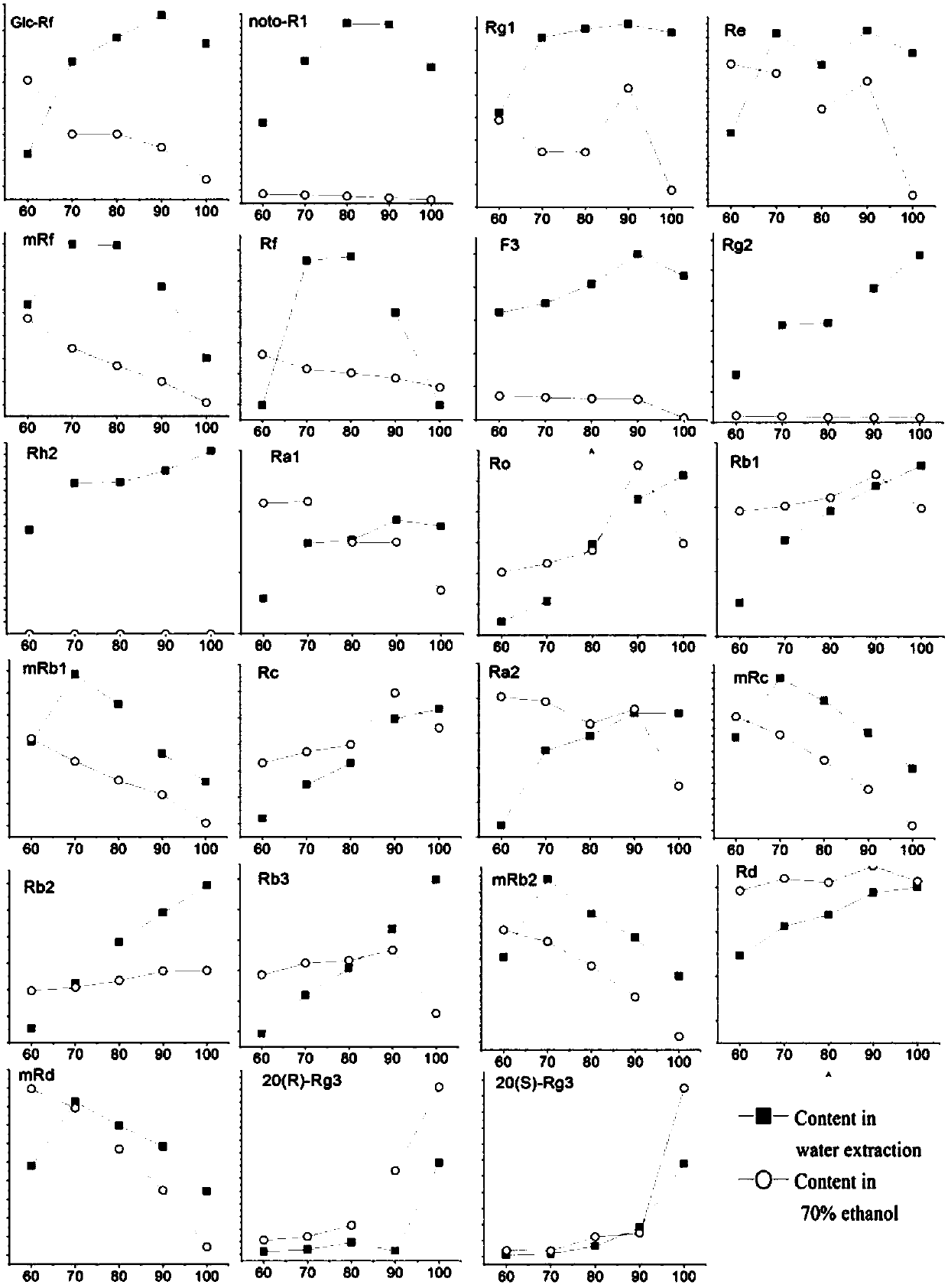

Panax ginseng small molecule oral liquid and preparation method thereof

PendingCN107752001AIncrease profitAvoid overdissolvingFood preservationNatural extract food ingredientsSolubilityGINSENG EXTRACT

The invention relates to the technical field of traditional Chinese medicine health food, in particular to panax ginseng small molecule oral liquid and a preparation method thereof. According to the method, small molecule polyose components in panax ginseng are selectively extracted through the difference of solubility in a low-temperature interlayer heating manner, meanwhile slightly soluble saponin components are converted into deglycosylation small molecule saponin components through hydrolysis reaction of saponin components in a slightly acidic condition of the saponin components, and finally saponin components in crude drugs are obtained through ethanol extraction. The panax ginseng small molecule oral liquid is high in use ratio of crude drugs, high in rear saponin content, and stable in product properties.

Owner:CHANGCHUN UNIV OF CHINESE MEDICINE

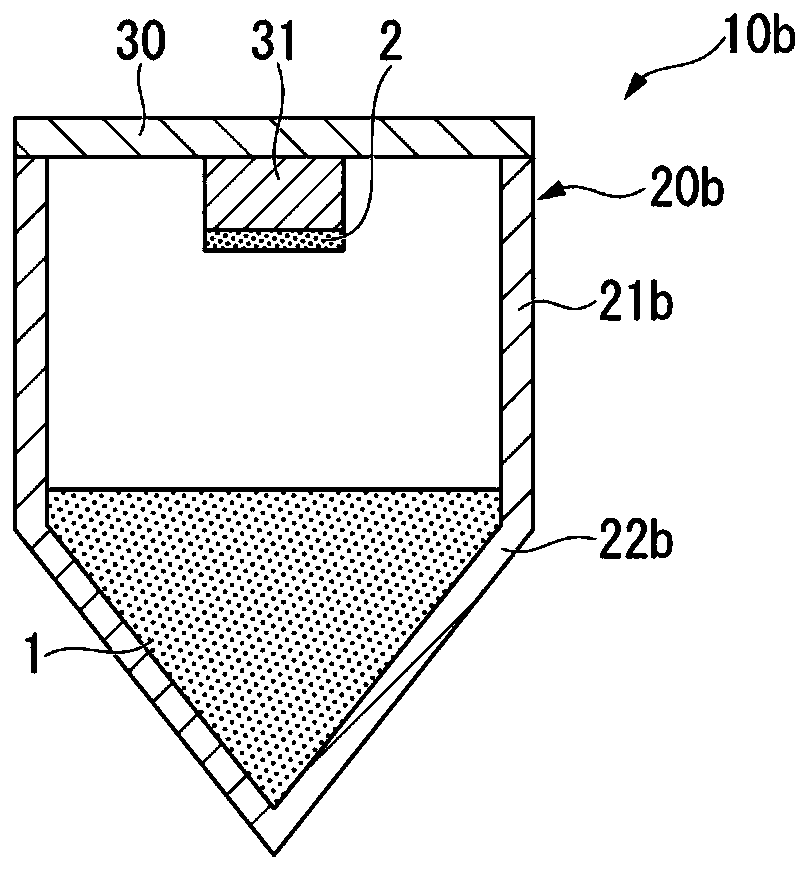

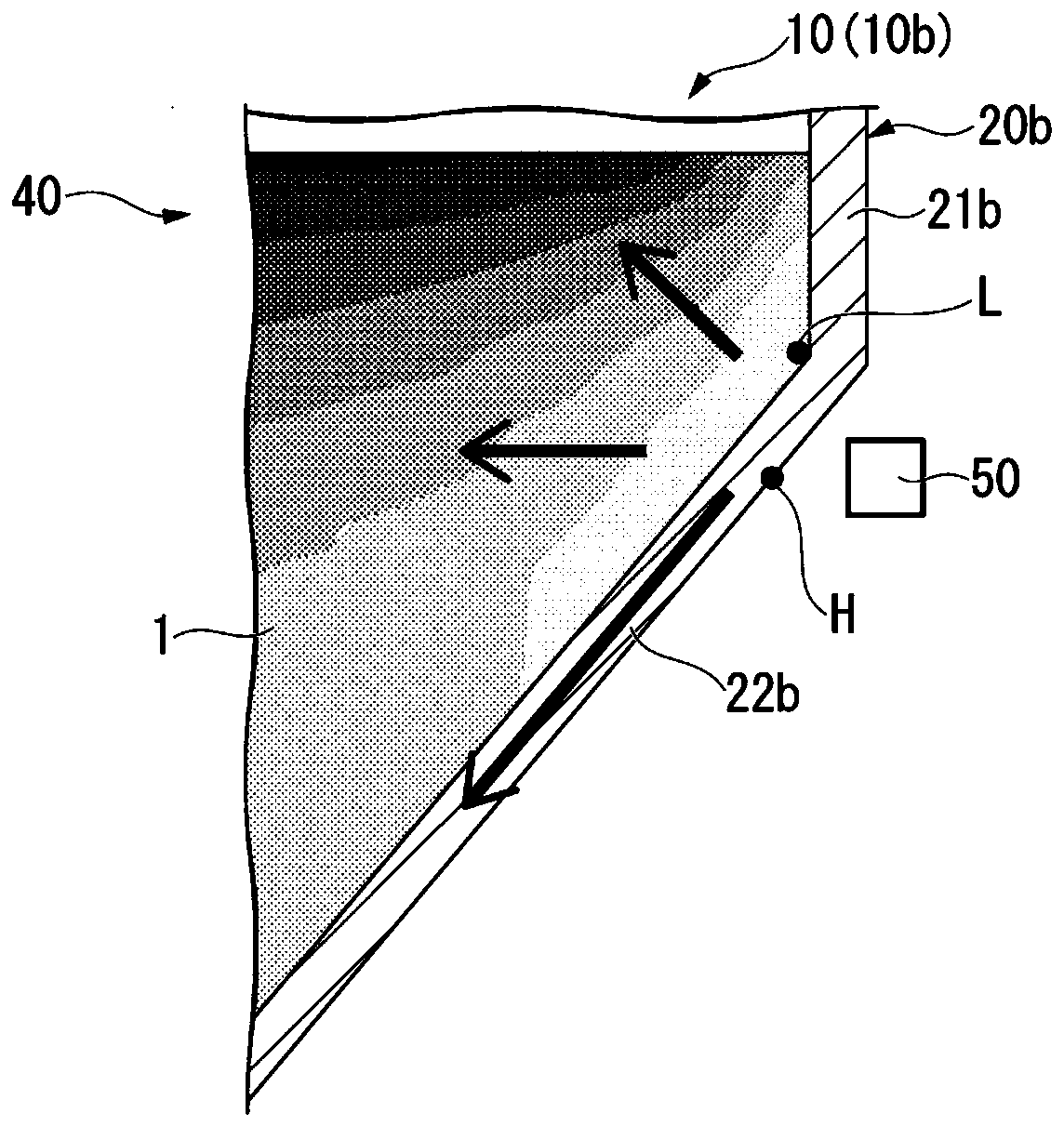

SiC single crystal growth crucible, SiC single crystal manufacturing method, and SiC single crystal manufacturing apparatus

ActiveCN111424311ANot prone to precipitationAfter-treatment apparatusPolycrystalline material growthCrucibleSingle crystal growth

The present invention relates to a SiC single crystal growth crucible, a SiC single crystal manufacturing method using same, and a SiC single crystal manufacturing apparatus. The SiC single crystal growth crucible includes a raw material accommodation portion which accommodates a SiC raw material; and a seed crystal support portion which supports a seed crystal disposed on an upper portion of theraw material accommodation portion, wherein the raw material accommodation portion has a tapered portion an inner surface of which is tapered off downward.

Owner:RESONAC CORPORATION

Rattan dyeing equipment for rattan plaited handicraft processing

ActiveCN112659300AUniform dyeingGood dyeing effectWood treatment detailsReed/straw treatmentMechanical engineeringPneumatic cylinder

The invention relates to the technical field of rattan dyeing, in particular to rattan dyeing equipment for rattan plaited handicraft processing. The rattan dyeing equipment comprises a base and a dyeing pool, the dyeing pool is fixed to the upper end of the base, and a pair of supporting frames is further fixed to the upper end face of the base and symmetrically arranged on the left side and the right side of the dyeing pool; a top frame is jointly fixed to the top ends of the pair of supporting frames, a pair of pneumatic cylinders is installed on the top frame, a rectangular frame is jointly fixed to the telescopic ends of the pair of pneumatic cylinders, a pair of round rods is fixed between a front rod and a rear rod of the rectangular frame, sliding sleeves are slidably installed on the outer walls of the pair of round rods, and the outer wall of each round rod is sleeved with a pair of first reset springs. The pair of first reset springs are arranged on the front side and the rear side of the sliding sleeve respectively, a dyeing disc is jointly welded to the bottom ends of the pair of sliding sleeves, and a cam abuts against the rear side wall of the dyeing disc. The dyeing disc swings back and forth to drive the rattans to swing back and forth, so that the rattans are dyed more uniformly, and the dyeing effect is better.

Owner:安徽御美藤藤柳工艺品有限公司

Method for preparing stable dispersive type magnetorheological fluid

ActiveCN106816254ANot prone to precipitationImprove stabilityMagnetic liquidsPolymer networkMagnetization

The invention relates to a method for preparing a stable dispersive type magnetorheological fluid, and belongs to the technical field of preparation. The method includes: using absolute ethyl alcohol and deionized water as a dispersion medium, using a polyethylene glycol 4000 as a stabilizer, using potassium peroxodisulfate as an initiator, and allowing styrene and acrylic acid to polymerize to form emulsion in the nitrogen atmosphere; using nano ferroferric oxide as magnetic particles, and using carboxylic groups on surfaces of poly (styrene-acrylic acid) to absorb the nano ferroferric oxide; dissolving dopamine in water in an alkaline condition to dissolve oxygen, forming a polymer network as a support structure in an emulsion system, and finally performing magnetization in a magnetic field. The prepared stable dispersive type magnetorheological fluid can avoid flocculent precipitate due to aggregation of particles, has excellent stability and dispersibility; the settlement is less than 3% after standing is formed for 24 hours, the settlement is less than 17% after standing is performed for 3 months, and a hardening phenomenon will not occur after the magnetorheological fluid is stored for more than 3 years.

Owner:山东格新精工有限公司

Full-automatic leather working glove processing impregnator

InactiveCN108311338ATrack location in real timeImprove dipping effectPretreated surfacesCoatingsLiquid-crystal displayEngineering

The invention discloses a full-automatic leather working glove processing impregnator which comprises a base and a drying tank, wherein a conveying platform and an impregnator main body are arranged on the outer side of the upper end of the base; the conveying platform is fixedly connected with the impregnator main body; a conveyer belt is moveably mounted on the outer surface of the upper end ofthe conveying platform; a sample feeding hole is formed close to the part above the conveyer belt in the outer surface of one end of the impregnator main body. Due to adoption of a liquid crystal display, an automatic rotation monitor, a peddle stirrer and a drying tank, the full-automatic leather working glove processing impregnator disclosed by the invention is capable of tracking the positionsof gloves in real time, the positions can be also displayed on the liquid crystal display, then operators can handle the machining process, glue liquids can be uniformly mixed, precipitate is not easily caused, the gluing effect of gloves can be improved, a relatively rapid drying speed can be achieved, the production efficiency can be improved, meanwhile, through hot air drying, the surfaces of gloves can be relatively solidly bonded, the impregnator is applicable to different working conditions, and relatively good application prospects can be achieved.

Owner:浙江倬瑜服饰有限公司

Process for preparing medicinal syrup

InactiveCN1682691AReduce oxidationReduce degradationOrganic active ingredientsPharmaceutical delivery mechanismSolubilityPolymer science

The medicine syrup preparing process includes heating pure water to 100 deg.c, cooling to 65-85 deg.c, adding medicine and supplementary material while stirring for dissolving medicine and supplementary material completely, adding sucrose and heating to 80-100 deg.c while stirring for dissolving, and filtering while the syrup is hot. The present invention is suitable for compounding syrup with inferior solubility medicine, and has low temperature, less medicine oxidation, degradation and volatilization, less generation of reducing sugar, low cost and other advantages.

Owner:丰丽妍

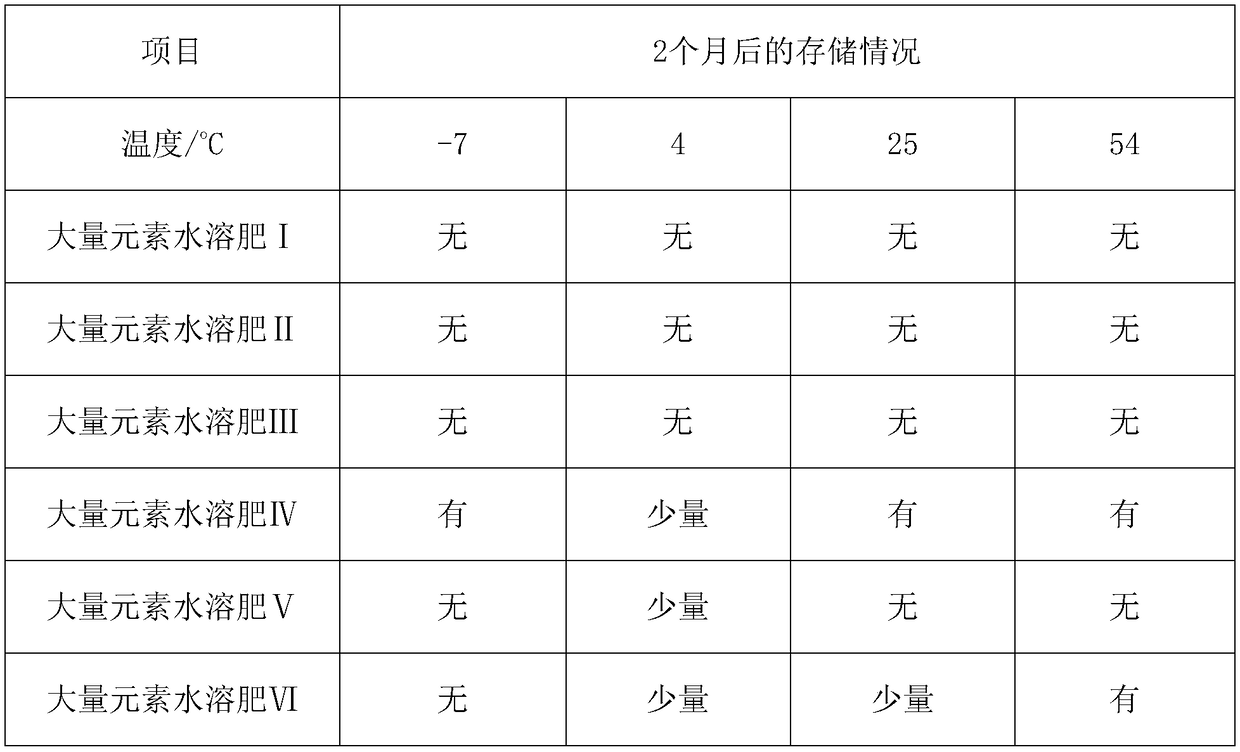

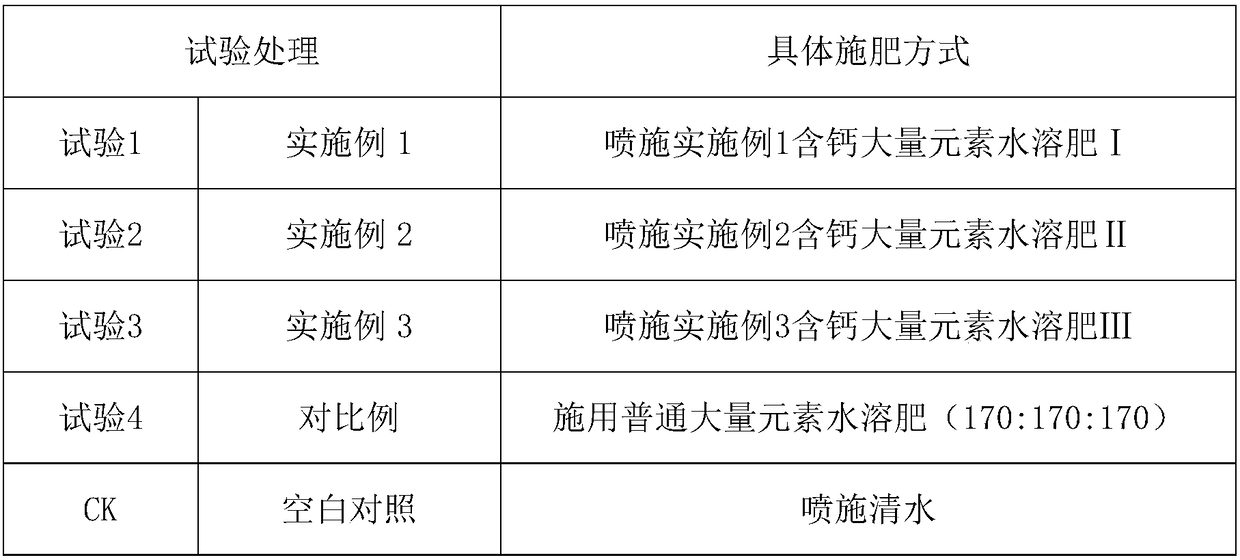

Stable calcium-containing massive-element water-soluble fertilizer and preparation method thereof

ActiveCN109336678AAvoid pollutionEnhance dextrin activityCalcareous fertilisersAlkali orthophosphate fertiliserDissolutionNuclear chemistry

The invention discloses a stable calcium-containing massive-element water-soluble fertilizer and a preparation method thereof. The preparation method comprises the modification of hydroxypropyl-beta-cyclodextrin, the preparation of modified hydroxypropyl-beta-cyclodextrin chelated calcium, the preparation of trace element mother liquor and preparation of the stable calcium-containing massive-element water-soluble fertilizer. The modified hydroxypropyl-beta-cyclodextrin in the stable calcium-containing massive-element water-soluble fertilizer has the uniqueness of internal hydrophobicity and external hydrophilicity, and plays roles in carrying out chelation for calcium fixing and promoting the dissolution of calcium sulfate, and improving the stability of calcium ions; the calcium sulfate raw material is cheap and easy to obtain, and tripolyphosphate and the calcium ions are less likely to precipitate, so that the stability in the using process is improved; a synergist has good salt tolerance and is capable of avoiding flocculation after the fertilizer is dissolved; and a bacteriostatic agent is capable of inhibiting the surface and interior part of the water-soluble fertilizer frombreeding of bacteria and fungi.

Owner:ANHUI HUILONG GRP WUHE ECOLOGICAL FERTILIZER CO LTD

Water-based ink dedicated for gravure surface printing of plastic film, and plastic film

InactiveCN106221367AImprove working environmentFire Hazard PreventionInksCoatingsWater basedWear resistant

The invention relates to ink, in particular to water-based ink dedicated for the gravure surface printing of a plastic film, and the plastic film. The water-based ink dedicated for the gravure surface printing of the plastic film is prepared from the following raw materials: 30 parts of polycarbonate emulsion, 15-20 parts of pigment, 20-30 parts of propyl alcohol, 2-5 parts of accessory ingredient, 1-2 parts of wear-resistant agent, 2-3 parts of ammonia water and 30-50 parts of deionized water. The water-based ink has the beneficial effects that the water-based ink does not contain any volatile organic solvents, the working environment of operation personnel is improved, and fire hazard hidden dangers caused by static electricity and flammable solvents can be avoided. The water-based ink is neutral and has the advantages of good ink stability and good printing adaptation, and ink viscosity can be regulated by the deionized water in a use process, and operation difficulty is lowered.

Owner:FUJIAN HUIYIMEI ENVIRONMENTAL PROTECTION MATERIALTECH CO LTD

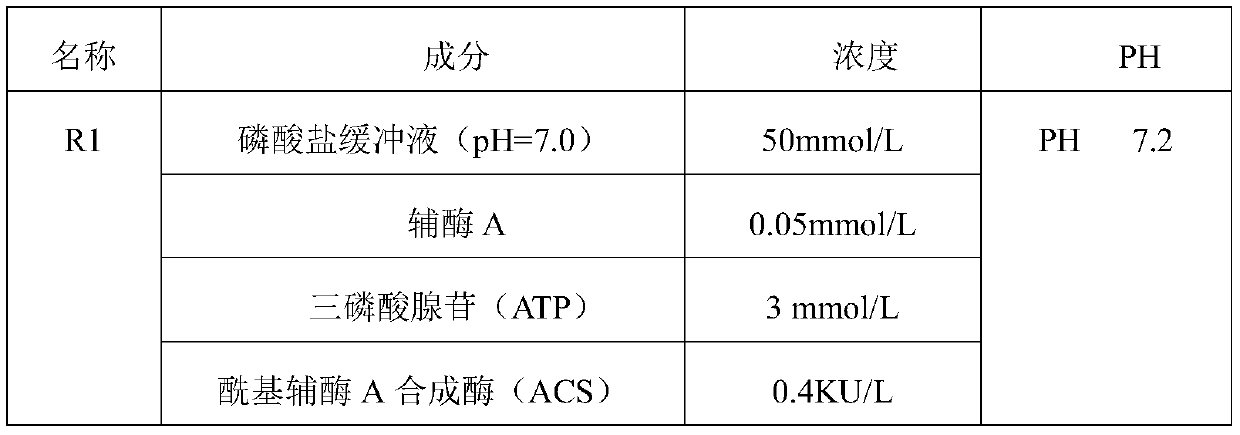

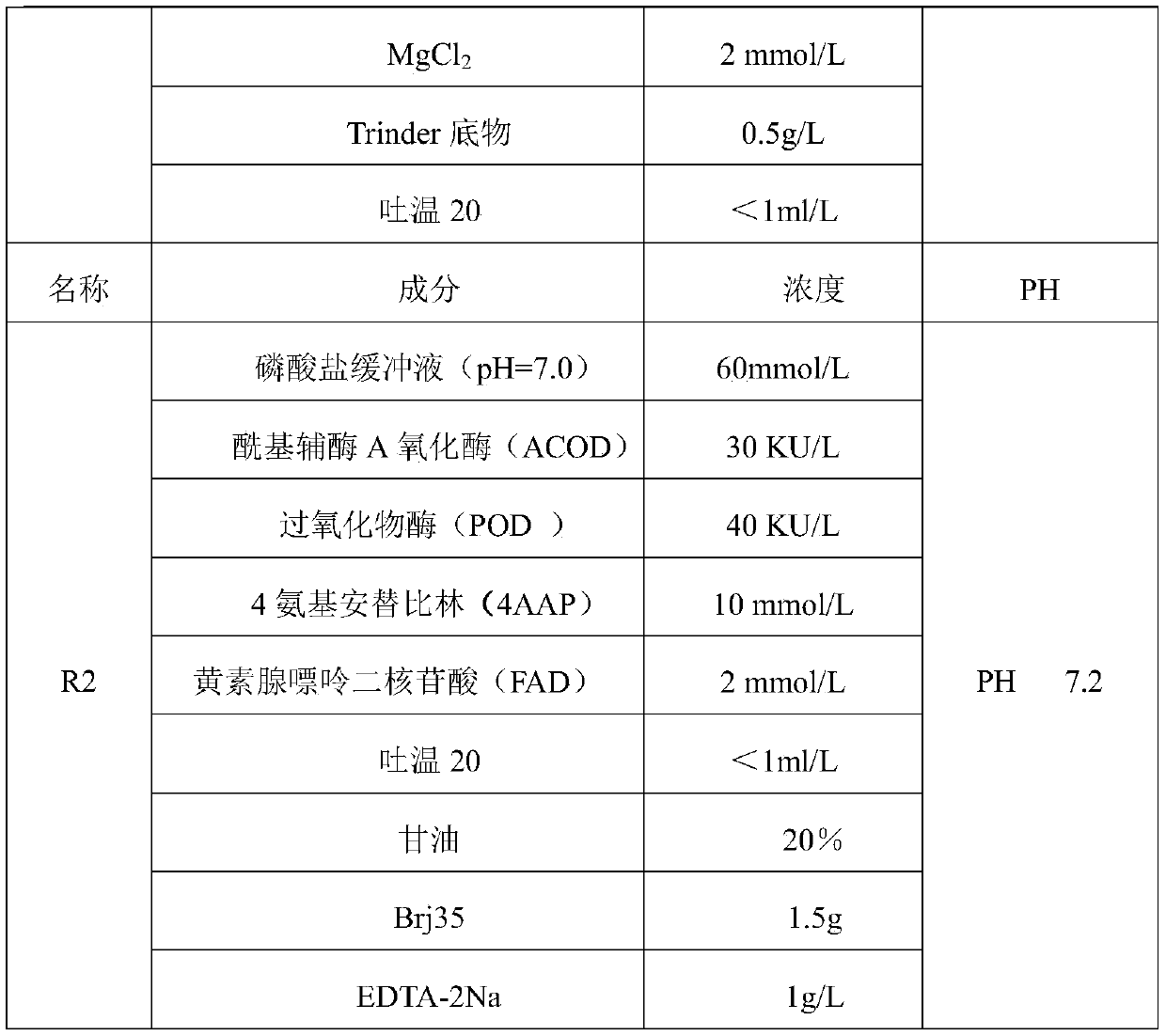

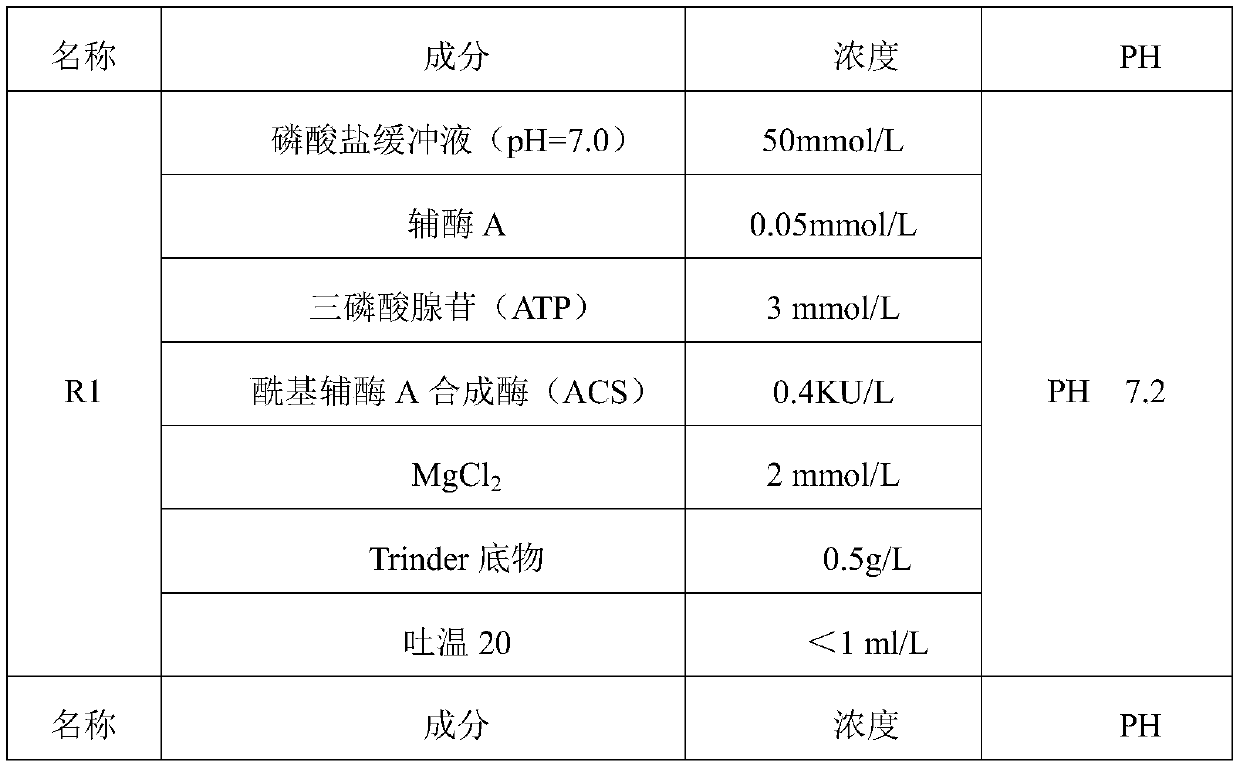

A kind of free fatty acid determination kit and preparation method thereof

ActiveCN106191213BHigh viscosityLow viscosityMicrobiological testing/measurementAcyl Coenzyme A SynthetasesAcyl-coenzyme A oxidase

The invention relates to the technical field of free fatty acid determining, in particular to a free fatty acid determining kit. The kit comprises a reagent R1 and a reagent R2, wherein the R1 is prepared from coenzyme A, triphosadenine, acyl coenzyme A synthetase, MgCl2, a Trinder substrate and Tween-20, and has the pH of 7.2; the R2 is prepared from flavin adenine dinucleotide, 4 amino-antipyrine, peroxidase, acyl coenzyme A oxidase, Tween-20, glycerinum, 1 to 1.5g / L of brij35-1 and ethylene diamine tetraacetic acid disodium salt and has the pH of 7.2. By adding different combinations of protein protecting agents, the enzyme activity stability is prolonged; the 37-DEG C stability of the enzyme is prolonged from 7 days to 10 days; the enzyme denaturation is slowed down; the reagent R2 cannot easily generate precipitate.

Owner:中拓生物有限公司

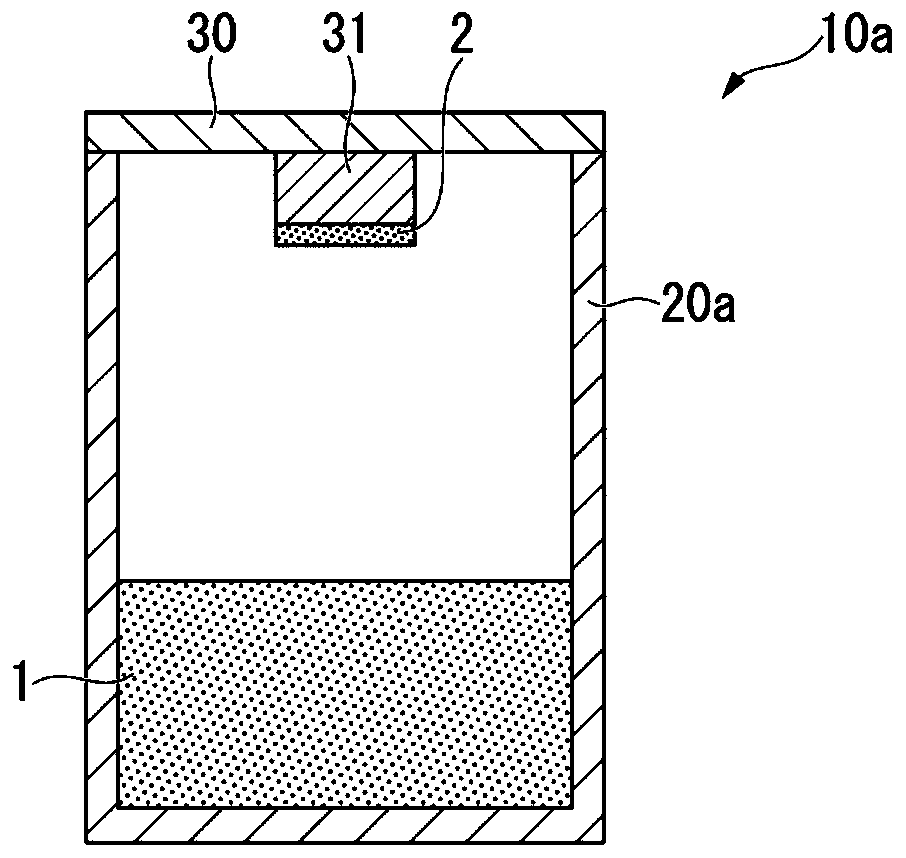

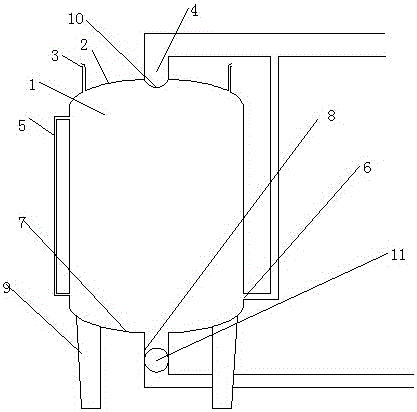

Storage tank storing MBS raw material

InactiveCN105059761ANot prone to precipitationQuality assuranceLarge containersProcess engineeringHolding tank

The invention discloses a storage tank storing an MBS raw material. The storage tank comprises a tank body (1). An upper end socket (2) is arranged at the upper end of the tank body (1). Exhaust ports (3) are formed in the left end and the right end of the upper end socket (2) respectively. A first raw material inlet (4) is formed in the end of the upper end socket (2). A filtering net (10) is arranged below the first raw material inlet (4). A liquidometer (5) is arranged on the left side of the tank body (1). The liquidometer (5) is communicated with the tank body (1) through a pipeline. A second raw material inlet (6) is formed in the right lower side of the tank body (1). A lower end socket (7) is arranged at the bottom of the tank body (1), a raw material outlet (8) is formed in the end of the lower end socket (7), and the lower portion of the raw material outlet (8) is connected with an adjusting valve (11). The storage tank has the beneficial effects that raw material deposition can be reduced, the pressure in the tank can be kept constant, and the phenomenon of wall bonding is reduced.

Owner:湖州杨氏塑料助剂有限公司

Process for processing bean beverage

InactiveCN106261430AGreat tasteIncrease the degree of emulsificationFood preparationFood ingredient as emulsifierIcing sugarPowder mixture

The invention provides a process for processing a bean beverage. The process is characterized in that the solid beverage is composed of 30-40% of bean flour-peanut powder mixture, 55-65% of powdered sugar, 1-4% of milk powder or 2-6% of Chinese date-wolfberry extract, wherein the peanut powder in the bean flour-peanut powder mixture accounts for 5-15%, most of bean skin is removed from beans, and peanut kernels are all peeled. Since a dry method ultrafine grinding process is adopted for the peanut kernels matched into the bean, the product taste is good, and the bean beverage has natural fragrance. The product has pharmacological effects of the beans, is rich in nutritional ingredient, simple and convenient in process and low in cost, and is a nourishing all natural beverage.

Owner:TIANJIN HENGAN FOOD

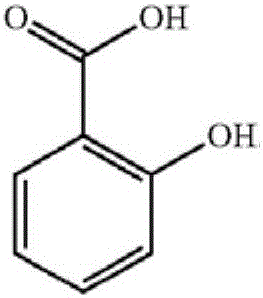

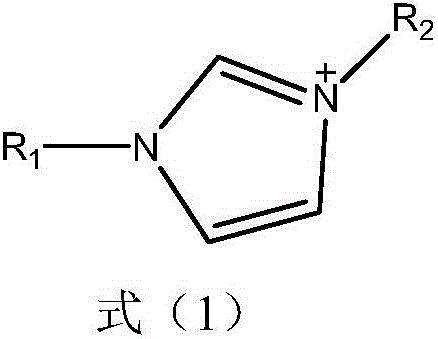

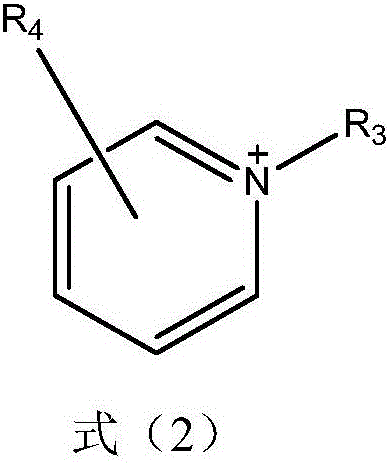

Salicylic acid mixture, preparing method of salicylic acid mixture, salicylic acid ionic liquid solution and application of ionic liquid

InactiveCN106265697AIncrease concentrationImprove stabilitySalicyclic acid active ingredientsInorganic non-active ingredientsSalicylic acidVaseline

The invention provides a salicylic acid mixture, a preparing method of the salicylic acid mixture, a salicylic acid ionic liquid solution and application of ionic liquid in improving the concentration and / or stability of salicylic acid in the salicylic acid mixture. Based on the total weight of the salicylic acid mixture, the salicylic acid mixture is prepared from, by weight, 20-60% of salicylic acid, and a solvent of the salicylic acid mixture is selected from at least one of water, Vaseline, liquid paraffin, wool fat and silicon oil. Salicylic acid in the salicylic acid mixture is high in concentration and stability.

Owner:武汉软件工程职业学院

Plastic base material surface coating

InactiveCN103173113AGood chemical stabilityRapid responsePolyurea/polyurethane coatingsPolymer scienceChemical stability

The invention discloses a plastic base material surface coating. The coating comprises carbamido monomer modified hydroxyl styrene acrylic emulsion synthesized by adopting a seed emulsion process, wherein the carbamido monomer modified hydroxyl styrene acrylic emulsion comprises 2 to 3 parts of composite emulsifier, 50 parts of deionized water, monomer pre-emulsification liquid I and a monomer pre-emulsification liquid II. The coating is high in chemical stability and high in reaction rate, can be used for eliminating precipitation and solidification phenomena, and has the advantages of good quality indexes, high gelling rate, high viscosity, long service life, low water absorption, convenience in preparation, low cost and high water resistance.

Owner:NINGBO SANLI NEW MATERIALS

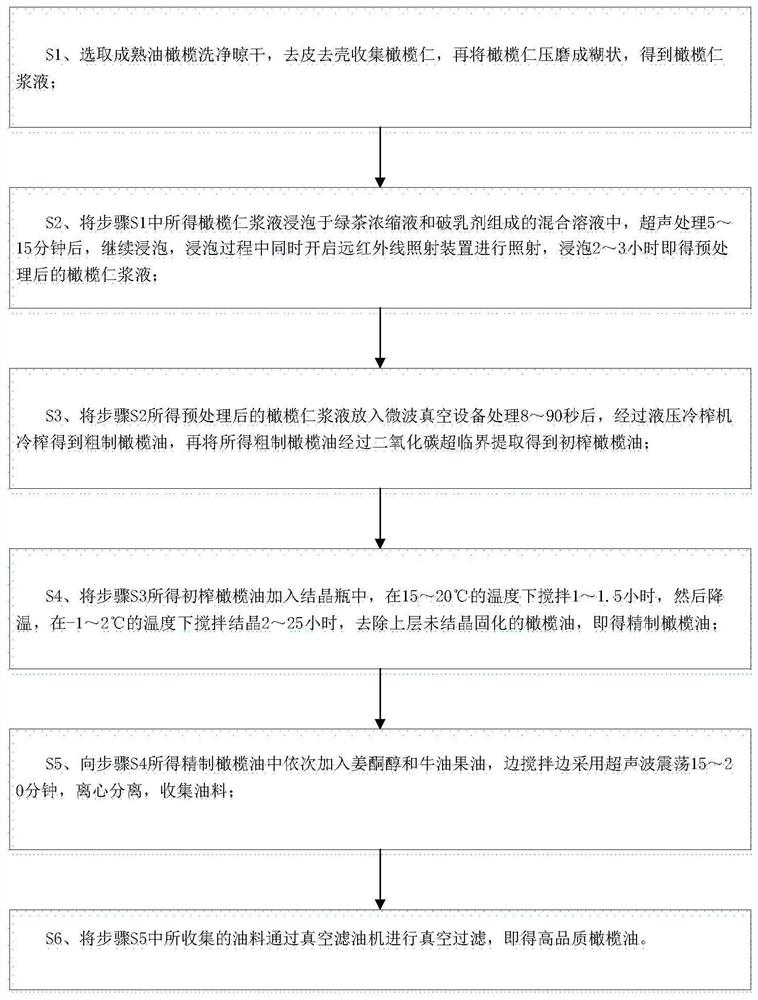

High-quality olive oil processing technology

InactiveCN113749156ARetain nutritional valueReduce the value of methoxyanilineFatty substance preservation using additivesFatty-oils/fats refiningUltrasonic oscillationTemperature treatment

The invention discloses a high-quality olive oil processing technology which comprises the following steps: S1, selecting mature olive, cleaning, airing, peeling, shelling, and grinding into paste to obtain olive kernel pulp; S2, soaking the olive kernel pulp in a mixed solution composed of a green tea concentrated solution and a demulsifier, and performing ultrasonic treatment to obtain pretreated olive kernel pulp; S3, treating in microwave vacuum equipment, performing cold pressing through a hydraulic cold pressing machine, and performing carbon dioxide supercritical extraction to obtain virgin olive oil; S4, cooling the virgin olive oil, stirring and crystallizing, and removing uncrystallized and solidified olive oil on the upper layer to obtain refined olive oil; S5, adding zingiberone alcohol and avocado oil into the refined olive oil, carrying out ultrasonic oscillation and centrifugal separation, and collecting an oil material; and S6, carrying out vacuum filtration on the oil material. The processing technology is simple, safe and environment-friendly, the oil yield is increased, addition of chemical substances and long-time high-temperature treatment are avoided, the nutritional value in the olive oil is effectively reserved, and the anisidine value of the olive oil is reduced.

Owner:心之源(上海)食品股份有限公司

A polyester thermoplastic elastomer

The invention relates to a polyester thermoplastic polyurethane elastomer, which comprises the following raw material components: 20-35 parts by weight of polyisocyanate, 50-75 parts by weight of polyester polyol, and 2-10 parts by weight of chain extender. The thermoplastic polyurethane obtained by adopting the method of the invention can be extruded, injected, and the like to quickly obtain a molded product with high transparency and low precipitation on the surface. Two different aliphatic small molecule diols A and diol B are polycondensed with straight-chain aliphatic small molecule diols to obtain polyester polyols, and cooperate with specific carbon atom chain extenders and polyisocyanates , the finally obtained polyester thermoplastic polyurethane elastomer exhibits obvious low precipitation performance. In addition, even if small molecule additives such as lubricants and additives are added to the material, the product of the present invention is still not prone to precipitation. More importantly, the product processed from the product of the present invention has excellent transparency and molding speed.

Owner:ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

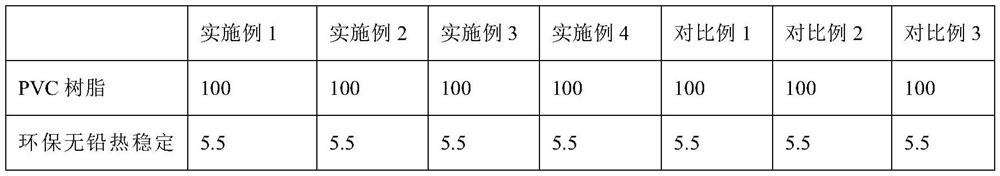

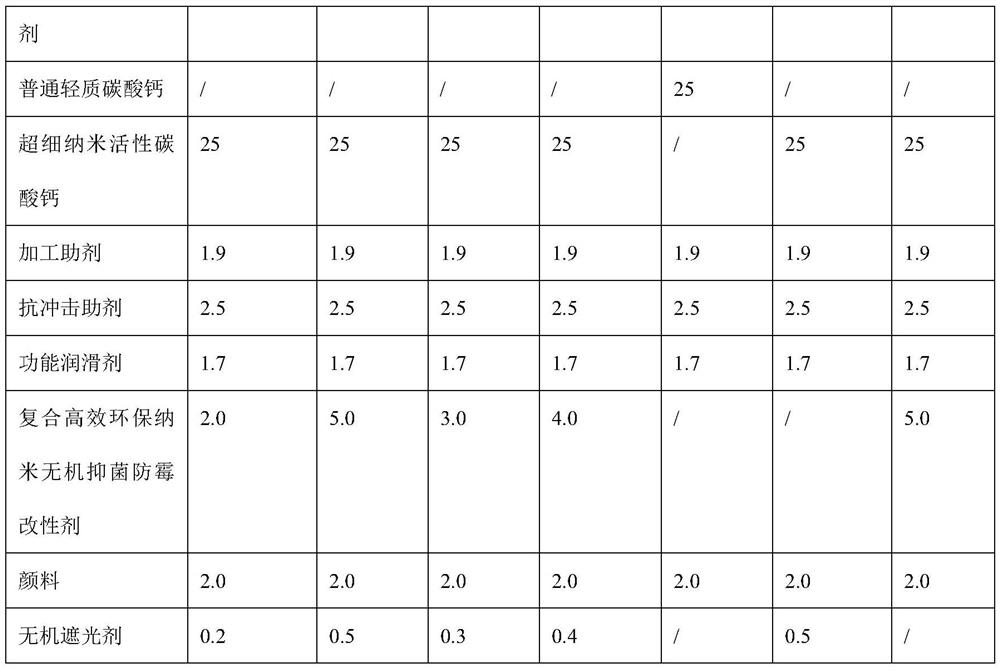

PVC-U drainage pipe fitting as well as preparation method and application thereof

The invention discloses a PVC-U drainage pipe fitting as well as a preparation method and application thereof. The performance of the PVC-U drainage pipe fitting is improved by using an environment-friendly lead-free heat stabilizer, superfine nano active calcium carbonate and a composite efficient environment-friendly nano inorganic antibacterial mildew-proof modifier, the pipe fitting is not easy to migrate, separate out and discolor, the appearance smoothness and brightness of the pipe fitting are obviously improved, the flow resistance is small, and the pipe fitting has good physical and mechanical properties of wear resistance and impact resistance; the pipe fitting has the advantages of excellent hydrophobic performance, smooth and flat surface, low interface free energy and difficult adhesion of a carrier and silt, so that the pipe fitting has the advantages of extremely strong dirt resistance, small flow resistance, difficult scaling and discoloration, and longer service life; and the antibacterial and mildew-proof effects are lasting, safe and efficient, a pipeline system is not easy to block, and the pollution of mildew to water quality is avoided.

Owner:茂名联塑建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com