SiC single crystal growth crucible, SiC single crystal manufacturing method, and SiC single crystal manufacturing apparatus

A single crystal, crucible technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of temperature difference, use, ineffective utilization of SiC raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

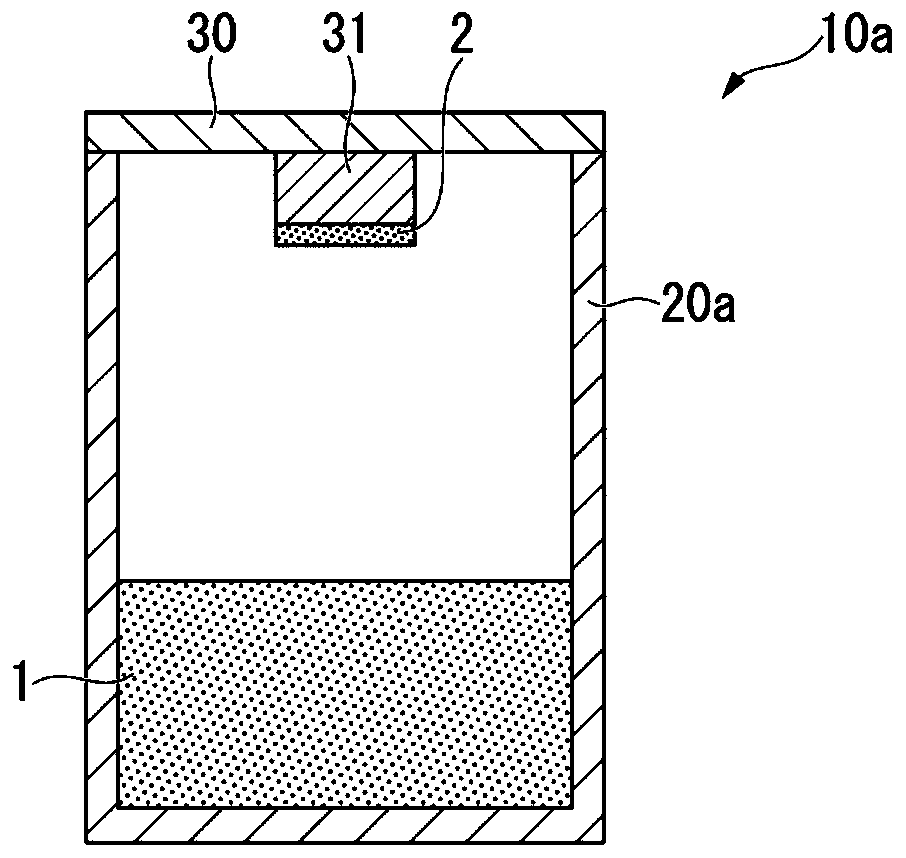

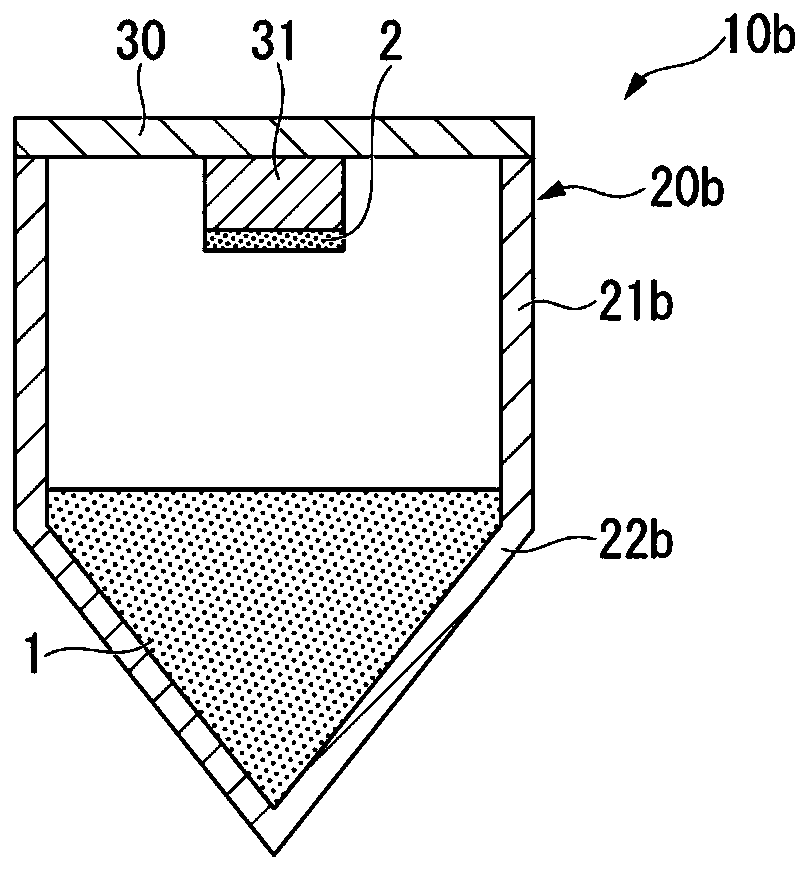

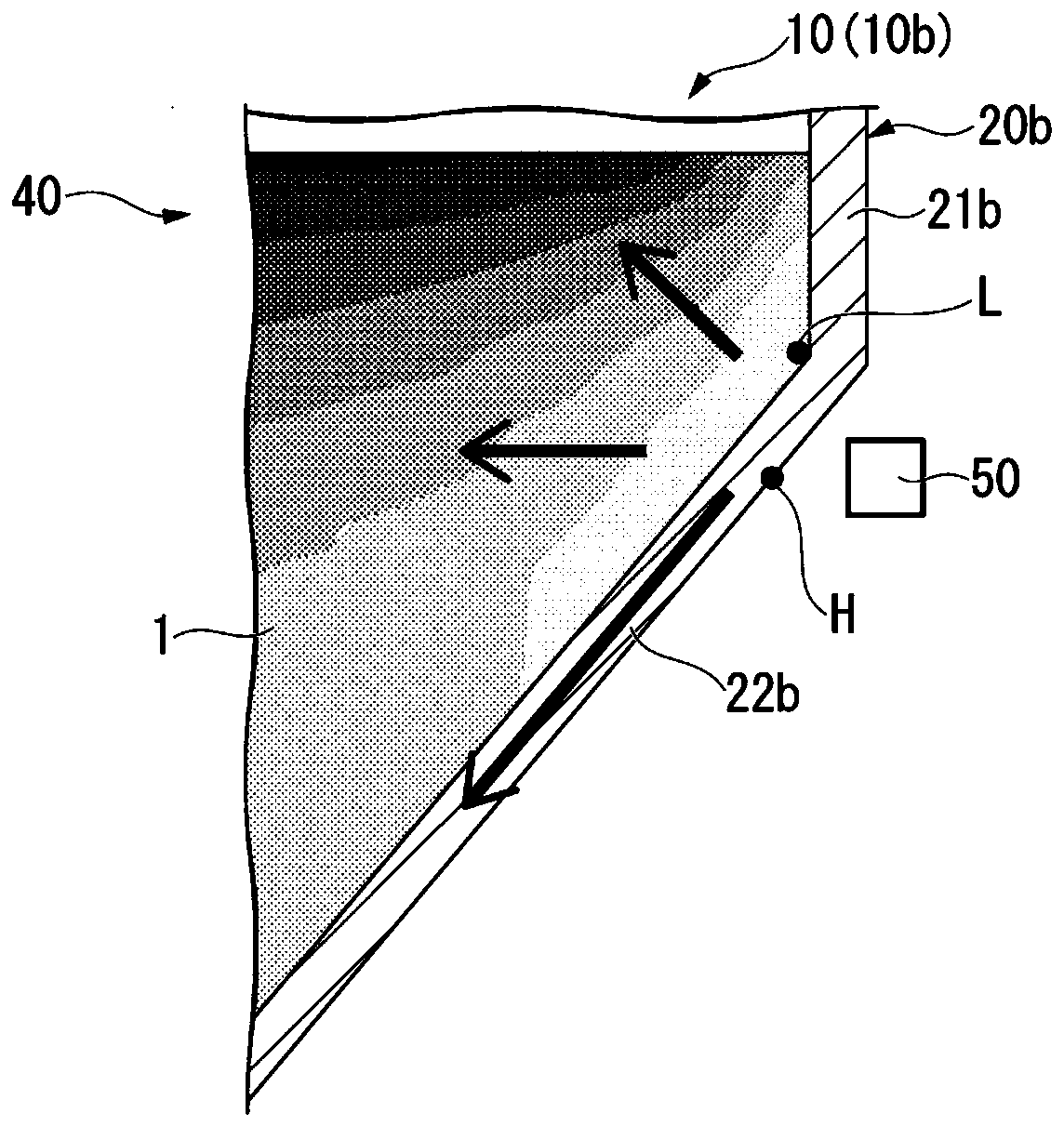

[0087] Figure 7 is a schematic cross-sectional view showing the SiC single crystal manufacturing apparatus used in the simulation of Example 1. FIG.

[0088] The SiC single crystal production apparatus 41 includes a SiC single crystal growth crucible 10 and a heater 50 . The SiC single crystal manufacturing apparatus 41 has a symmetrical structure around the central axis of the SiC single crystal growth crucible 10 . The crucible 10 for SiC single crystal growth is figure 2 The crucible 10b for SiC single crystal growth is shown. The filling height of the SiC raw material 1 filled in the raw material storage part 20 b was set to 180 mm. The arrangement position of the heater 50 was set to a position where the height of the narrowing start position L of the narrowing part 22b with respect to the heating center H was 20 mm above. That is, the heating center H is a height position of 160 mm from the lowermost part of the raw material.

[0089] In order to reduce the calcul...

Embodiment 2

[0092] In addition to setting the crucible 10 for SiC single crystal growth as Figure 4 The simulation was performed under the same conditions as in Example 1 except for the illustrated SiC single crystal growth crucible 10c. show the result in Figure 8 .

Embodiment 3

[0094] In addition to setting the crucible 10 for SiC single crystal growth as Figure 5 The simulation was performed under the same conditions as in Example 1 except for the illustrated SiC single crystal growth crucible 10d. show the result in Figure 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com