High-quality olive oil processing technology

A processing technology, olive oil technology, applied in the direction of edible oil/fat, fat oil/fat production, fat oil/fat refining, etc., can solve the problems of reducing the nutritional value of olive oil, low oil yield, poor quality of olive oil, etc., to achieve Avoid long-term high-temperature treatment, increase oil yield, and retain nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

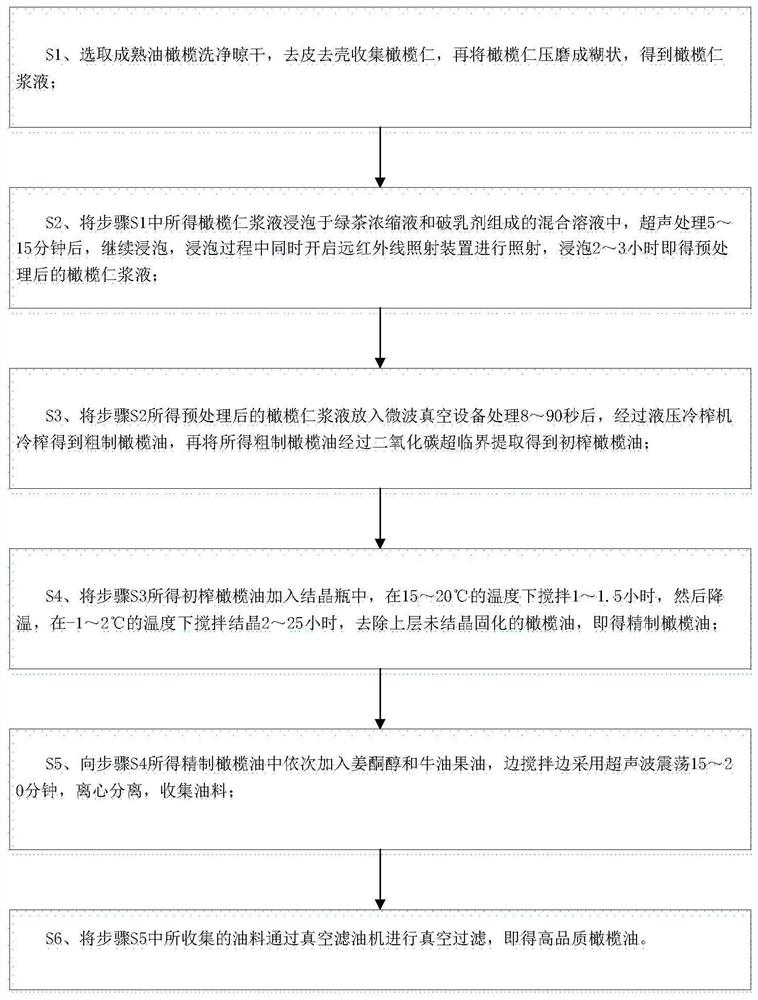

[0056] refer to figure 1 Shown, a kind of high-quality olive oil processing technology, comprises the following steps:

[0057] S1. Select mature olives, wash and dry them, peel and shell them to collect olive kernels, and then press and grind the olive kernels into a paste to obtain olive kernel slurry;

[0058] S2. Soak the olive kernel slurry obtained in step S1 in a mixed solution composed of green tea concentrate and demulsifier, and after ultrasonic treatment for 15 minutes, continue soaking. During the soaking process, turn on the far-infrared irradiation device at the same time to irradiate, and soak for 2 hours. Pretreated olive kernel slurry;

[0059] Wherein, the weight-number ratio of olive kernel slurry, green tea concentrate, and demulsifier is 1:0.08:0.18;

[0060] Wherein, the ultrasonic processing frequency is 800 Hz;

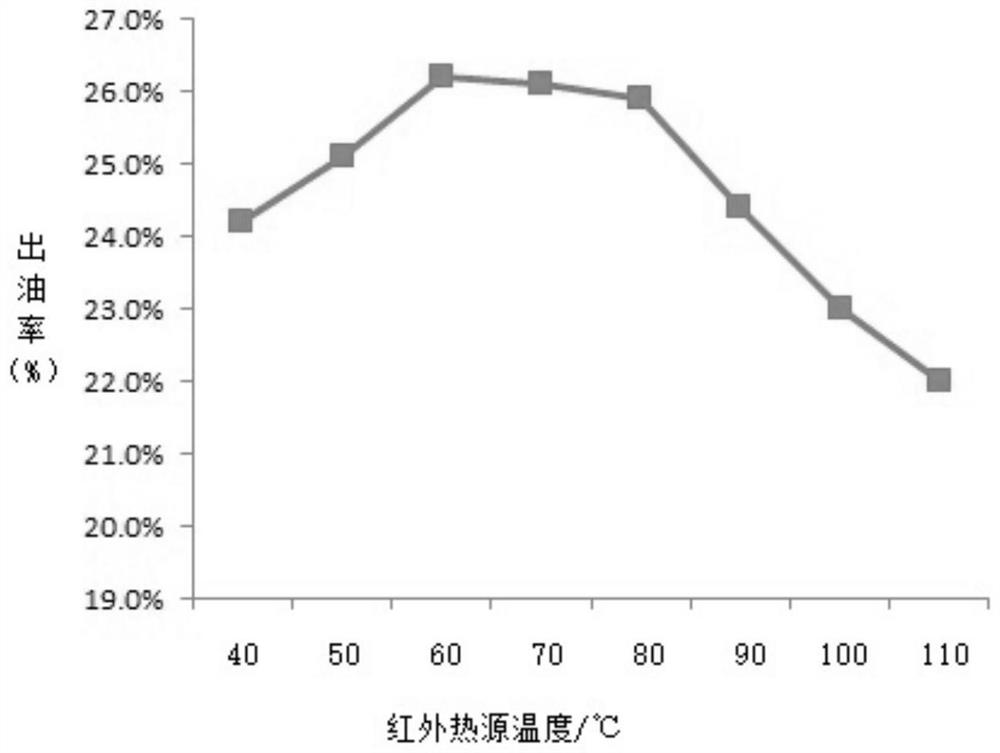

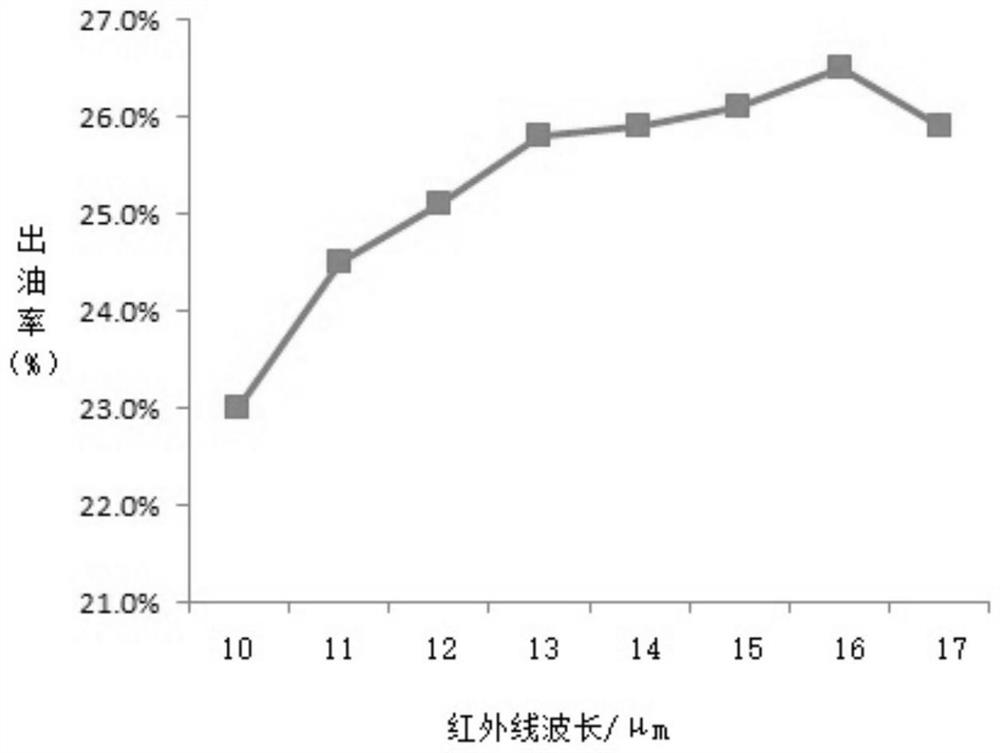

[0061] Among them, the temperature of the infrared heat source of the far-infrared irradiation device is 60°C, and the wavelength of infrar...

Embodiment 2

[0073] A kind of high-quality olive oil processing technology, comprises the following steps:

[0074] S1. Select mature olives, wash and dry them, peel and shell them to collect olive kernels, and then press and grind the olive kernels into a paste to obtain olive kernel slurry;

[0075] S2. Soak the olive kernel slurry obtained in step S1 in a mixed solution composed of green tea concentrate and demulsifier, after ultrasonic treatment for 15 minutes, continue soaking, and turn on the far-infrared irradiation device for irradiation during the soaking process, and soak for 3 hours. Pretreated olive kernel slurry;

[0076] Wherein, the weight-number ratio of olive kernel slurry, green tea concentrate, and demulsifier is 1:0.08:0.18;

[0077] Wherein, the ultrasonic processing frequency is 800 Hz;

[0078] Among them, the temperature of the infrared heat source of the far-infrared irradiation device is 60°C, and the wavelength of infrared rays generated is 16 μm;

[0079] S3,...

Embodiment 3

[0089] A kind of high-quality olive oil processing technology, comprises the following steps:

[0090] S1. Select mature olives, wash and dry them, peel and shell them to collect olive kernels, and then press and grind the olive kernels into a paste to obtain olive kernel slurry;

[0091] S2. Soak the olive kernel slurry obtained in step S1 in a mixed solution composed of a green tea concentrate and a demulsifier, and after ultrasonic treatment for 15 minutes, continue soaking for 3 hours to obtain the pretreated olive kernel slurry;

[0092] Wherein, the weight-number ratio of olive kernel slurry, green tea concentrate, and demulsifier is 1:0.08:0.18;

[0093] Wherein, the ultrasonic processing frequency is 800 Hz;

[0094] S3. Put the pretreated olive kernel slurry obtained in step S2 into microwave vacuum equipment for 72 seconds, then cold press through a hydraulic cold press to obtain crude olive oil, and then undergo supercritical extraction of carbon dioxide to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com