Fermented milk with flavor of coconuts and preparation method of fermented milk

A technology for fermented milk and coconut, applied in dairy products, milk preparations, applications, etc., can solve the problems of bad flavor and rough tissue state of skim fermented milk, so as to enhance the immune function of the human body, maintain the balance of flora, and relieve symptoms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Raw material formula (see Table 1):

[0033] Table 1 Raw materials and content

[0034] raw material

Mass percentage (%)

skim milk powder

9.5

White sugar

7.0

coconut oil

3.0

SVV-111

0.002

water

Make up to 100%

[0035] 2. Preparation process:

[0036] 1) Mix skimmed milk powder, coconut oil and sugar with water preheated to 40°C, stir at 600 rpm for 20 minutes, and mix well;

[0037] 2) Homogenize at 70°C and 18MPa, sterilize at 110°C for 300 seconds, put the sterilized material into a milk buffer tank and cool to 42°C, inoculate the starter SVV-111 (including Streptococcus thermophilus and Lactobacillus delbrueckii Bulgarian subspecies), fermented at 42°C for 6 hours until the acidity reached 75°T;

[0038] 3) When the temperature drops to 15°C, carry out aseptic filling, and cool to 6°C to obtain the produc...

Embodiment 2

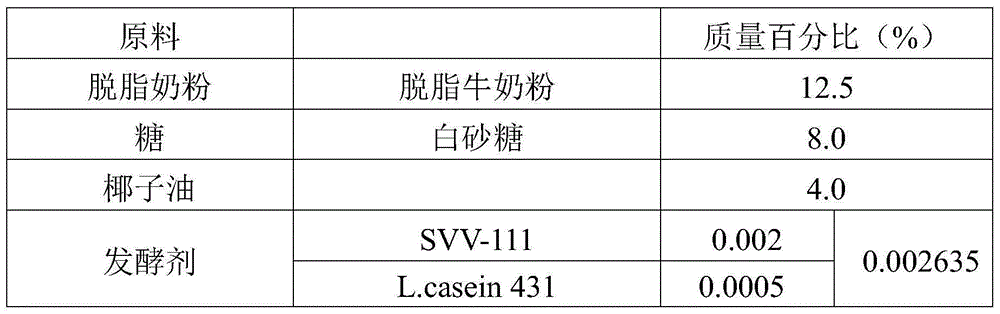

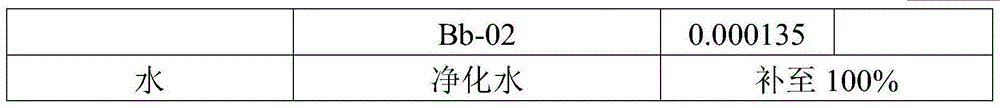

[0040] 1. Raw material formula (see Table 2):

[0041] Table 2 Raw materials and content

[0042]

[0043]

[0044] 2. Preparation process:

[0045] 1) Mix skimmed milk powder, coconut oil and sugar with water preheated to 40°C, stir at 600 rpm for 20 minutes, and mix well;

[0046] 2) Homogenize at 70°C and 18MPa, sterilize at 110°C for 300 seconds, put the sterilized material into a milk buffer tank and cool to 42°C, inoculate the starter SVV-111 (including Streptococcus thermophilus and Lactobacillus delbrueckii Bulgarian subspecies), L.casein431 (including Lactobacillus casein) and Bb-02 (including Bifidobacterium bifidum), fermented at 42°C for 6 hours until the acidity reached 75°T;

[0047] 3) Aseptic filling is carried out when the temperature drops to 20° C., and it is cooled to 2° C. to obtain the finished product. Test indicators: the protein content is 3.92%, the fat content is 3.61%, and the solid content is 21.96%.

Embodiment 3

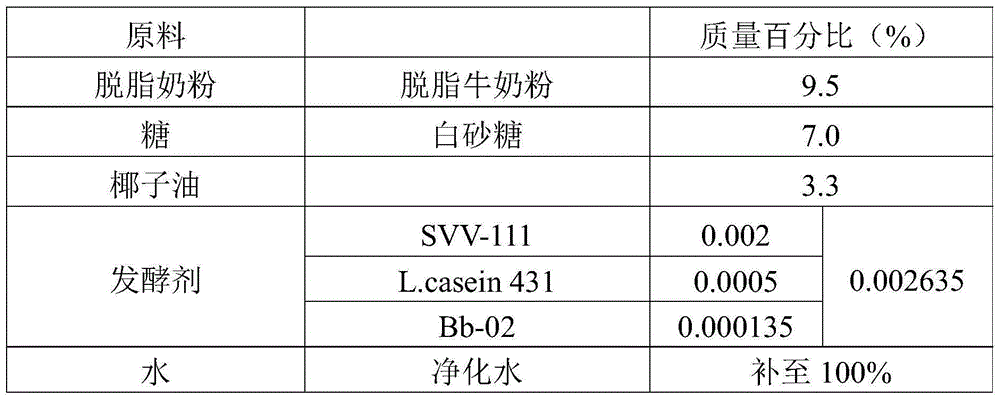

[0049] 1. Raw material formula (see Table 3):

[0050] Table 3 raw materials and containing

[0051]

[0052] 2. Preparation process:

[0053] 1) Mix skimmed milk powder, coconut oil and sugar with water preheated to 50°C, stir at 400 rpm for 40 minutes, and mix well;

[0054] 2) Homogenize at 60°C and 20MPa, sterilize at 95°C for 360 seconds, put the sterilized material into the milk buffer tank and cool to 38°C, inoculate the starter SVV-111, L.casein431 and Bb-02, at 38°C Ferment for 5 hours until the acidity reaches 70°T;

[0055] 3) Aseptic filling is carried out when the temperature drops to 20° C., and it is cooled to 2° C. to obtain the finished product. Test indicators: the protein content is 3%, the fat content is 3%, and the solid content is 16.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com