Patents

Literature

149results about How to "Process energy saving and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

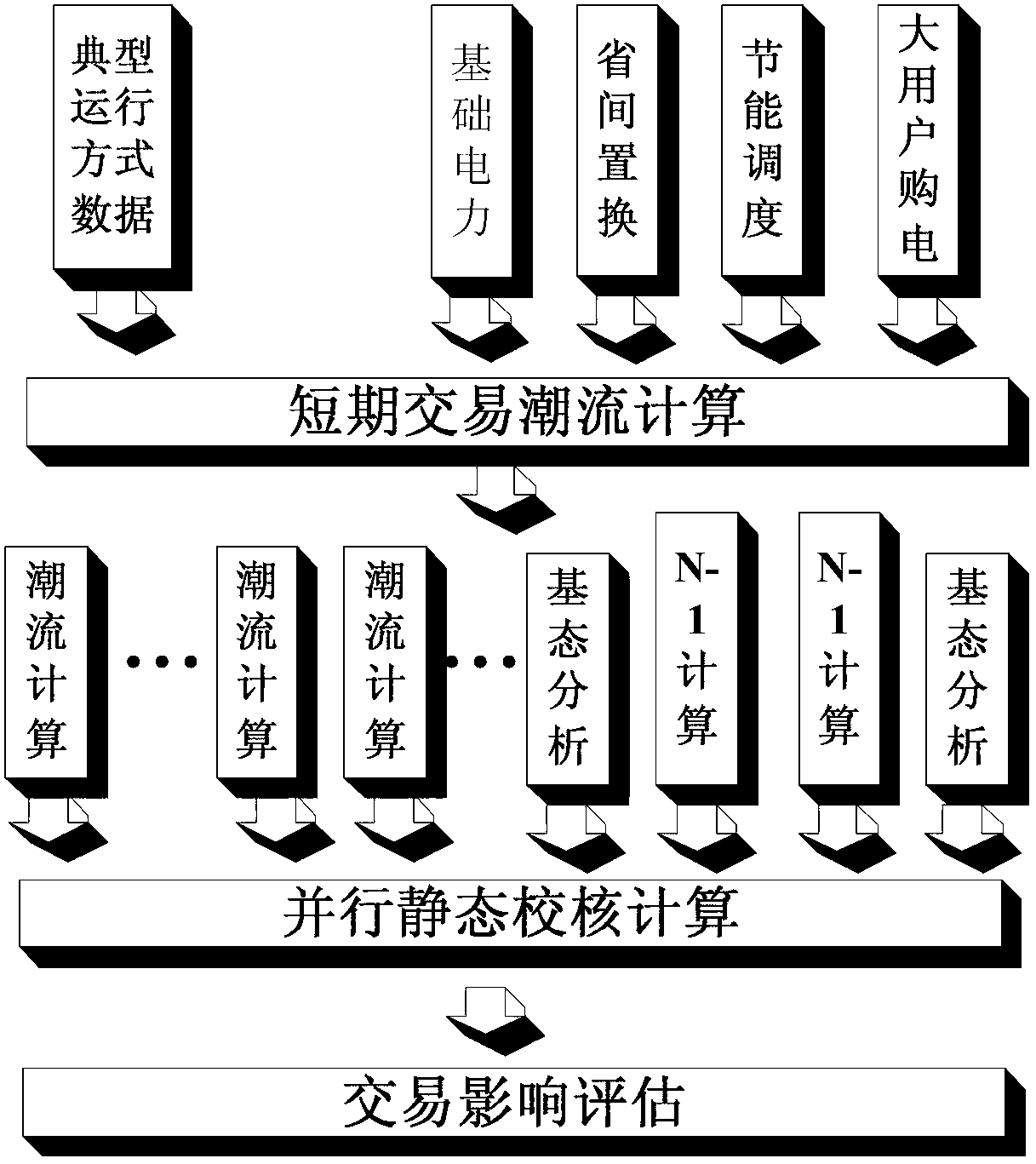

Method for checking short-term trade plan safety

ActiveCN103020853AImprove calibration calculation efficiencyCalculation speedBuying/selling/leasing transactionsInformation technology support systemElectric power systemPower grid

The invention relates to a method of the field of electrical power system planning and computational analyzing, and in particular relates to a method for checking short-term trade plan safety. The method comprises the following steps of: 1, short-term trade plan load flow calculation; 2, short-term trade ground state load flow analysis; 3, short-term trade plan static state load flow analysis; 4, short-term trade plan impact assessment; and 5, short-term trade parallel check. The method for checking the short-term trade plan safety provided in the invention is easy to realize, and moreover, power grid load flow which reflects the execution condition of short-term trade can be obtained; and the requirements from aspects of energy conservation, environmental friendliness and safe, stable and economic operation of a conventional power grid on technological innovation are satisfied.

Owner:CHINA ELECTRIC POWER RES INST +1

Preparing method for transparent conductive oxide film

ActiveCN102646759ASimple process equipmentGood film uniformitySemiconductor devicesElectrically conductiveChemistry

The invention relates to the semiconductor photoelectric material field, and provides a preparing method for transparent conductive oxide film. The method includes the following steps: step one, obtaining a sol solution of zinc salt or indium salt and doped metal salt, wherein, viscosity of the sol ranges from 15m Pa.s to 20 m Pa.s, concentration of zinc or indium in the zinc salt or the indium salt ranges from 0.1 mol / L to 1 mol / L, the mole ratio of zinc and the doped metal salt is between 0.001 and 0.03, and the mole ratio of indium and the doped metal salt is between 0.05 and 0.15; step two, immersing media into the sol solution and allowing the mixture to stand for 1s to 30s, pulling the media out of the sol solution at a speed of 1 cm / min to 300 cm / min, maintaining the media for 0.5 min to 30 min at a temperature in a range of 80 DEG C to 300 DEG C, and cooling the media; step three, repeating step two till the thickness of the film on the media achieves the required thickness, and obtaining the transparent conductive oxide film. The transparent conductive oxide film prepared through the method has the advantages of being high in rate of finished products, capable of preparing film with large areas, high in material using ratio, and suitable for mass production.

Owner:徐东

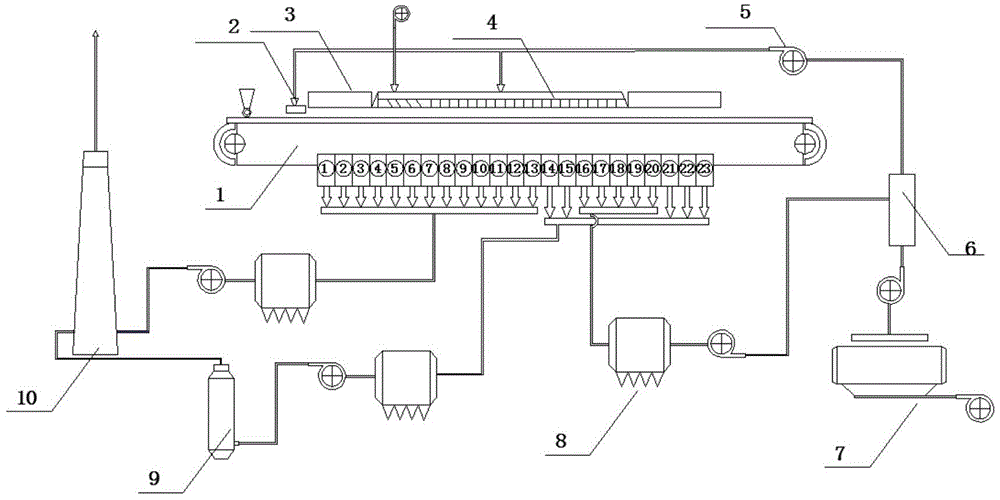

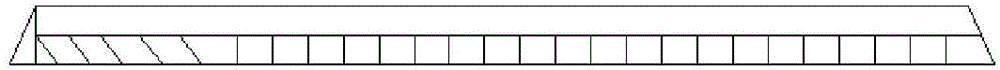

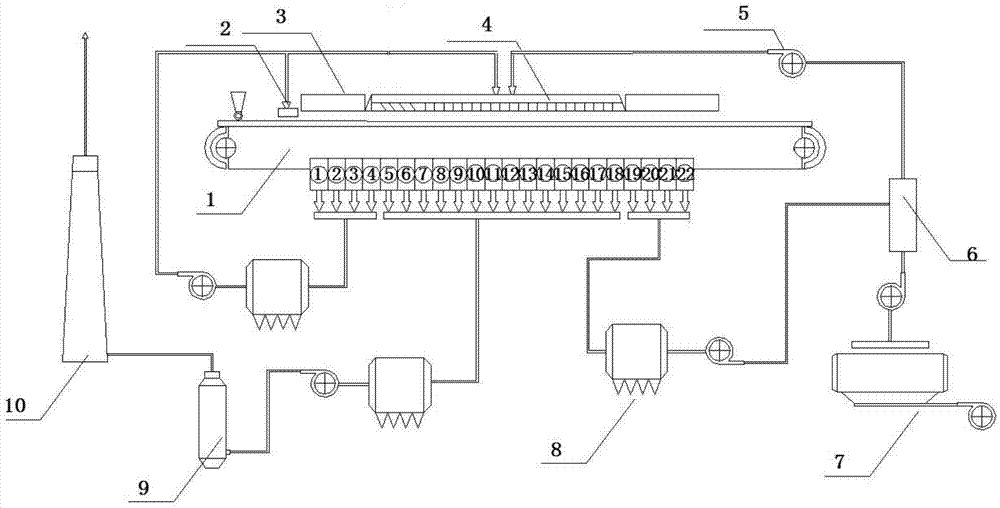

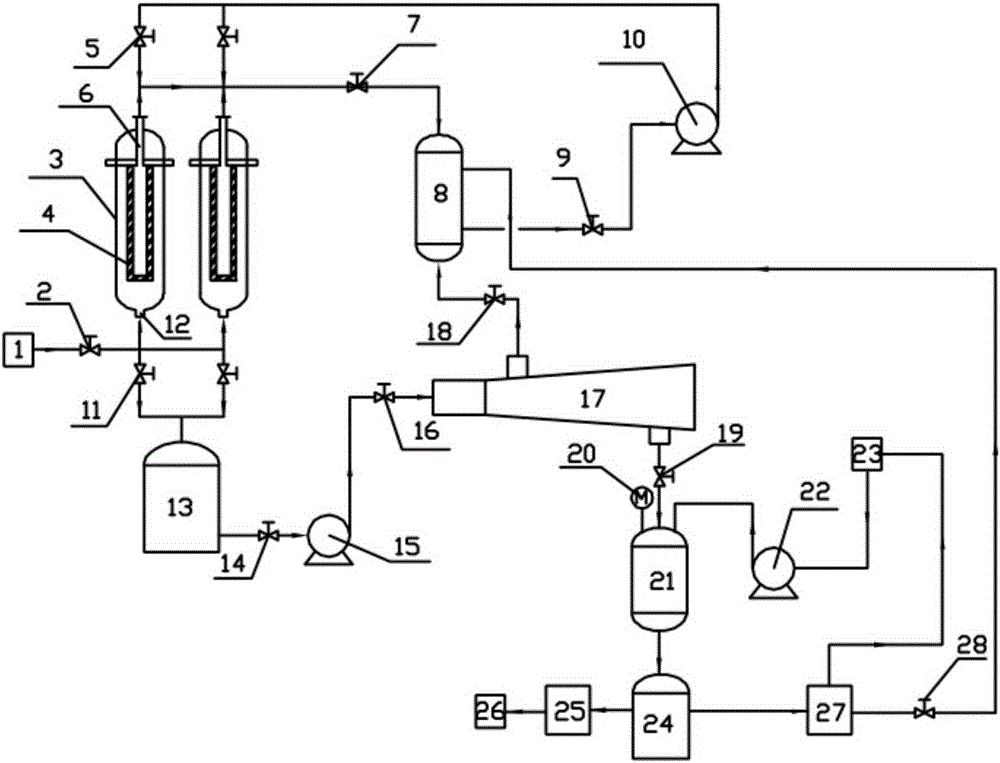

Energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process and system

InactiveCN104132550AReduce purification costsEmission reductionCombustion technology mitigationWaste heat treatmentSulfurDecomposition

The invention relates to an energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process and system. The energy-saving environment-friendly waste gas waste-heat utilization and pollutant purification process includes that sintering waste gas is divided into a low-temperature low-sulfur sintering waste gas, a middle-temperature high-sulfur sintering waste gas and a high-temperature middle-sulfur sintering waste gas according to waste gas temperature and pollutant discharge characteristics; content of sintering waste gas SO2 of the low-temperature low-sulfur is below the national discharge standard, and the SO2 can be directly discharged after dust removal; after the sintering waste gas in a middle-temperature high-sulfur section is subjected to dust removal and desulfurization processing, the SO2 meets the national discharge standard and can be discharged; the sintering waste gas in a high-temperature middle-sulfur section mixed with ring-cold waste gas is led into a sintering machine, and hot-wind igniting and hot-wind sintering are performed. The invention further provides a system for implementing the energy-saving environment-friendly sintering waste gas waste-heat utilization and pollutant purification process. Waste heat of the sintering waste gas can be recycled in classification and gradiently utilized, so that energy can be saved; the low-sulfur waste gas can be discharged directly, so that desulfurization cost of the waste gas is lowered; part of the high-sulfur waste gas participate in circulation, so that total discharge amount of pollutants is decreased, splitting decomposition of dioxin happens due to high temperature, and the purification function of the sintering waste gas is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

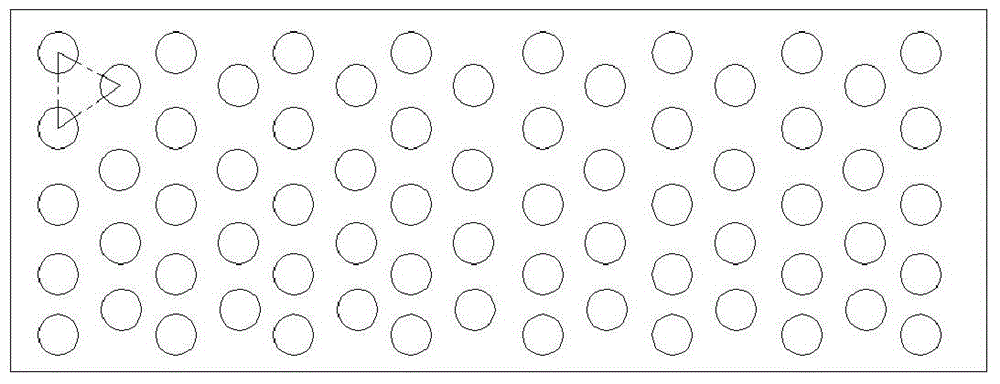

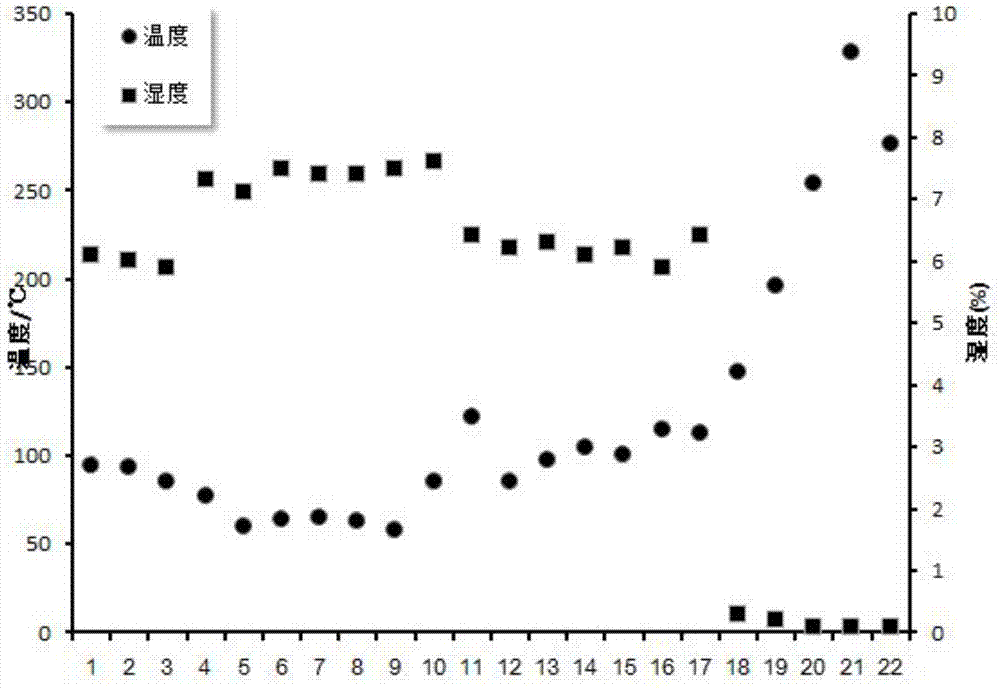

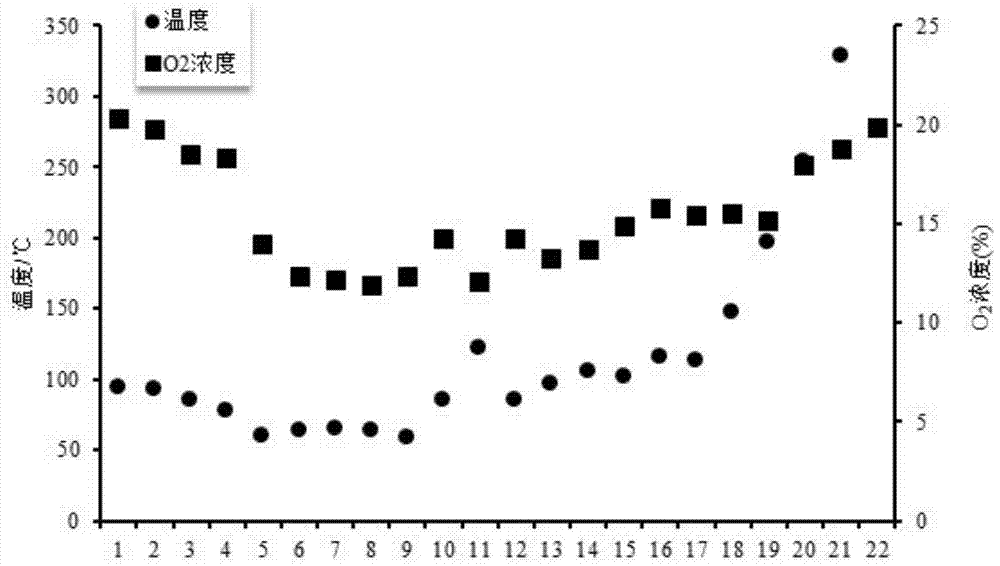

Sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system

ActiveCN104748567ARealize emission reduction controlEmission reductionGas treatmentDispersed particle separationHigh humidityHigh energy

The invention provides a sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system. According to the process, sintering flue gas is divided into low-temperature high-oxygen low-humidity section sintering flue gas, medium-temperature low-oxygen high-humidity section sintering flue gas and high-temperature high-oxygen low-humidity section sintering flue gas according to the emission characteristics of flue gas temperature and oxygen concentration and humidity. The low-temperature high-oxygen low-humidity section sintering flue gas is subjected to dust removal and then is led into a sintering machine for hot air sintering and hot air ignition. The medium-temperature low-oxygen high-humidity section sintering flue gas is subjected to dust removal and desulfurization treatment. The high-temperature high-oxygen low-humidity section sintering flue gas is mixed with cooling machine waste gas and then is led into the sintering machine for hot air sintering. The sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system can conduct staged utilization on flue gas waste heat, recover low-temperature sensible heat in flue gas, enable carbon monoxide left in the sintering flue gas to be secondarily combusted and reduce the energy consumption in the sintering process on the premise that the quality and yield of sintered ores are ensured. Cyclic flue gas utilization is achieved, the pollutant emission quantity of unit sintering ores and total emission quantity of the sintering flue gas are reduced, and the sintering flue gas waste heat staged cyclic utilization and pollutant emission reducing process and system have very high energy-saving emission-reduction value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Roll-formed alkali slag and building rubbish plate

InactiveCN106316246AHeat of hydrationImprove impact resistanceConstruction materialSlagCarbonization

The invention discloses a roll-formed alkali slag and building rubbish plate, and belongs to the technical field of building material preparation. The roll-formed alkali slag and building rubbish plate comprises a surface layer and a middle material layer, and a fiberglass mesh is laid between the surface layer and the middle material layer. Industrial waste residues and building rubbish are adopted as raw materials, the advantages of being high in solid waste utilization rate and low in price and cost are achieved, the potential hydration activity of the alkali slag and the the building rubbish is fully utilized, and waste is turned into wealth. The roll-formed alkali slag and building rubbish plate has the advantages of being high in wear resistance, low in heat of hydration, high in impact resistance, low in contractibility rate, good in fatigue resistance, high in carbonization resistance, good in durability and the like, and can be widely applied to the building fields of inner wallboards, outer wallboards and the like. The process has the advantages of being simple, low in price and environmentally friendly, saving energy and the like, and is suitable for volume production.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Starch-based hollow porous carbon microsphere and preparation method thereof

ActiveCN104045074AHigh porosityUniform pore sizeChemical recyclingMaterials preparationMetal catalyst

The invention discloses a starch-based hollow porous carbon microsphere and a preparation method thereof, belonging to the technical field of porous carbon material preparation. The preparation method comprises the steps of: with starch as a precursor, dispersing a catalyst in the precursor, carrying out carbonization catalysis, and cleaning the metal catalyst to realize the preparation of the porous carbon microsphere. The porous carbon microsphere prepared by using the method is of a hollow porous structure, has the specific surface area of 300-1000m<2> / g and the porosity of 40-70% and contains a great number of nanometer holes with the aperture of 5-200nm. The method has the characteristics of simple process, low cost, short production period, easiness for mass production, catalyst recycling and the like; in addition, raw materials are pollution-free, renewable, wide in source, low in cost and high in carbon content.

Owner:GUANGXI NORMAL UNIV

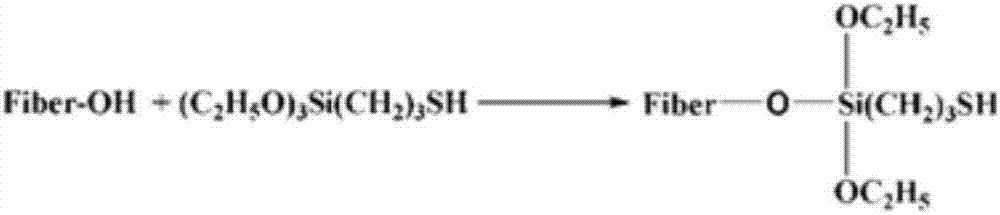

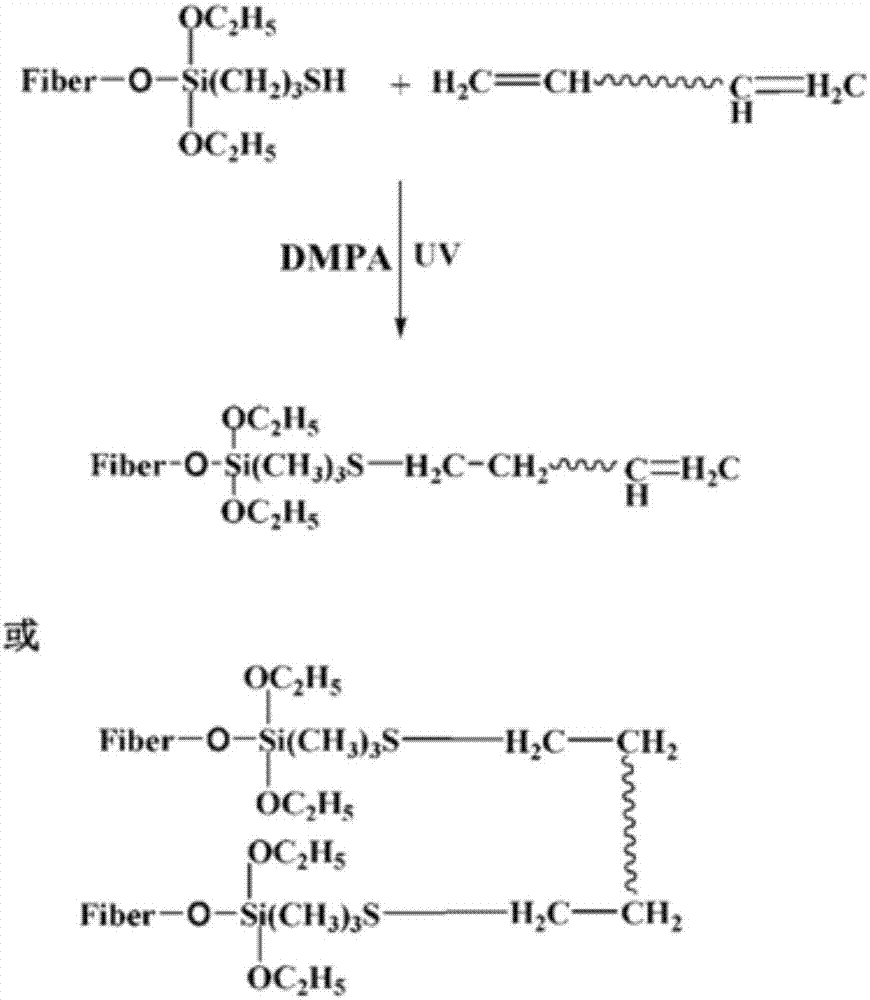

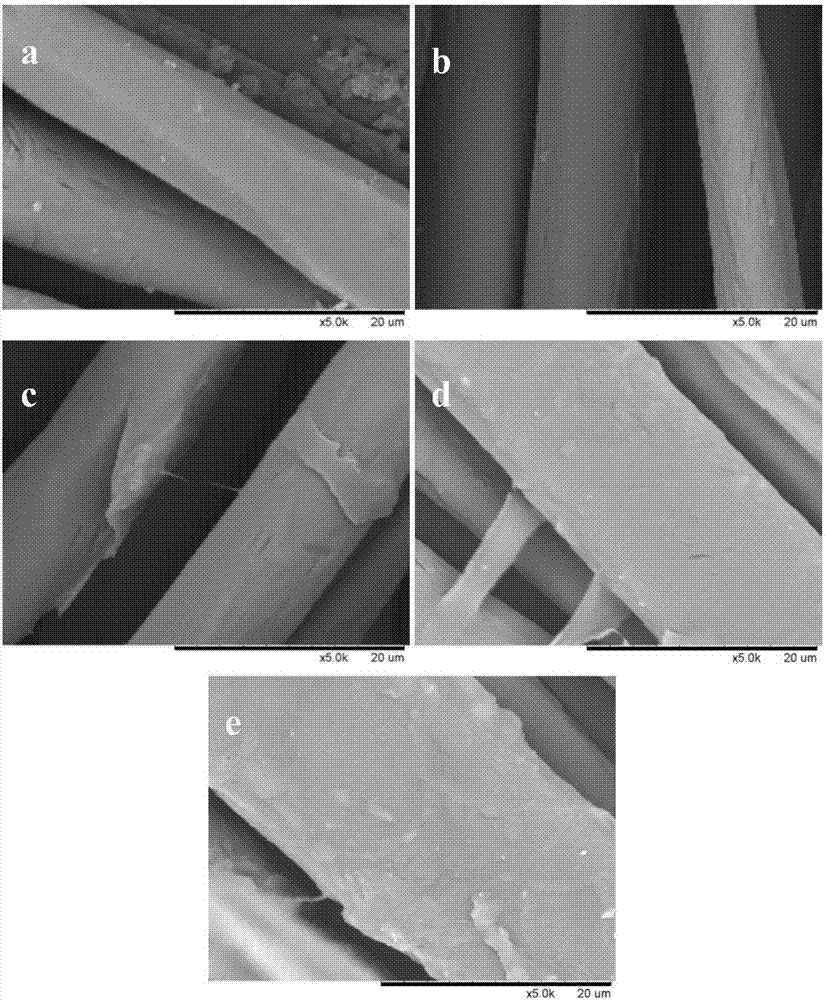

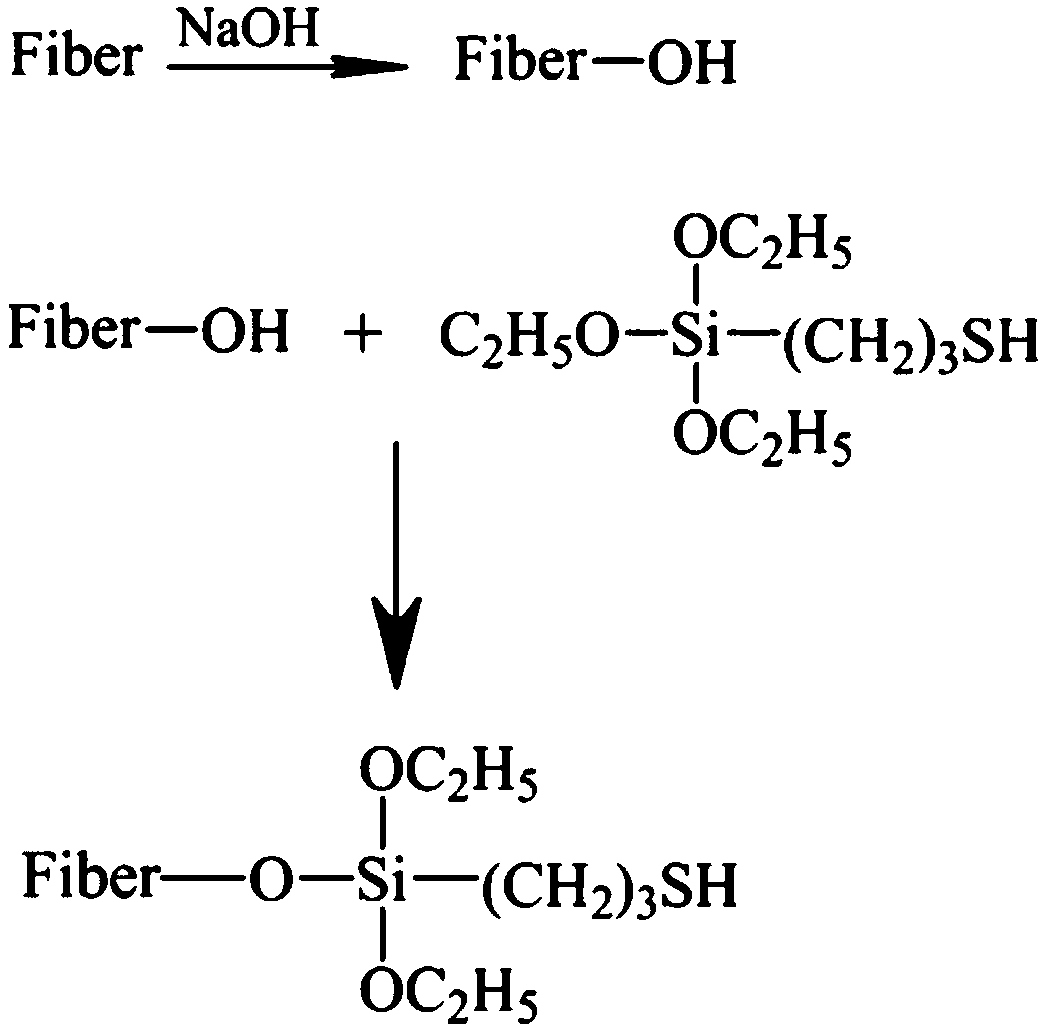

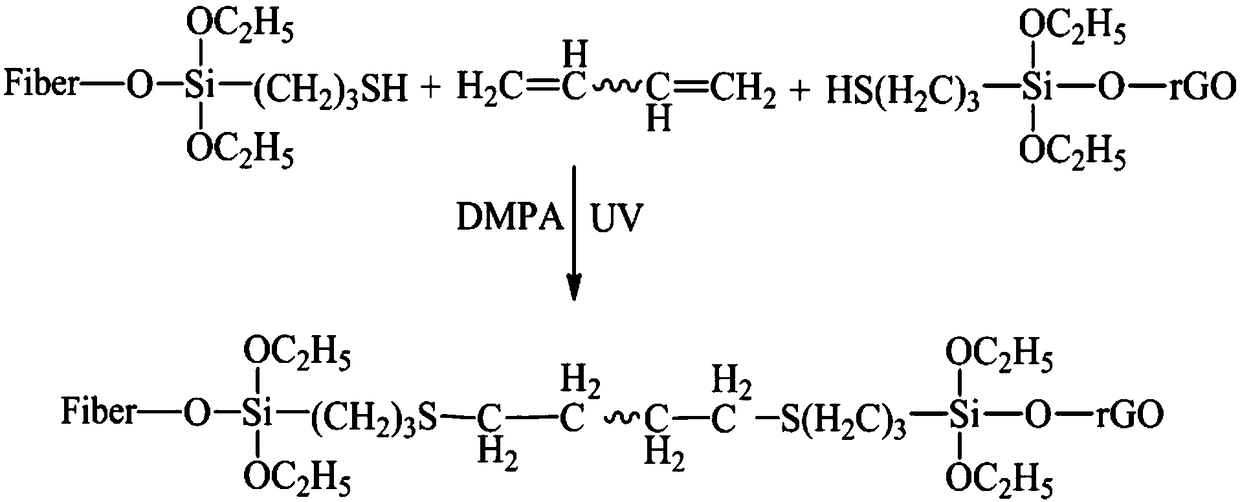

Click chemistry-based cotton fabric durable anti-crease finishing method

InactiveCN107299529AHarm reductionProcess energy saving and environmental protectionVegetal fibresTriethoxysilaneSilanes

The invention relates to a click chemistry-based cotton fabric durable anti-crease finishing method. The click chemistry-based cotton fabric durable anti-crease finishing method comprises the following steps: putting coarsened cotton fabric into a 3-thiopropyl triethoxy silane solution and performing sulfydryl modification to obtain sulfydryl modified cotton fabric; ultrasonically mixing photocurable waterborne polyurethane acrylate, sulfydryl silane and a photoinitiator to obtain finishing liquid; dipping the sulfydryl modified cotton fabric into the finishing liquid and performing ultraviolet curing to obtain the durable anti-crease cotton fabric. The method provided by the invention is simple in operation, high in efficiency, energy-saving and environmentally friendly; after finishing is conducted, the anti-crease effect is remarkable, the durability is high, and the influence on the whiteness of the fabric is little. After the cotton fabric is finished by the anti-crease process, the wearability can be improved, the application field can be enlarged, and the requirements of people on flat appearance and wear comfortability of clothes can be met.

Owner:DONGHUA UNIV

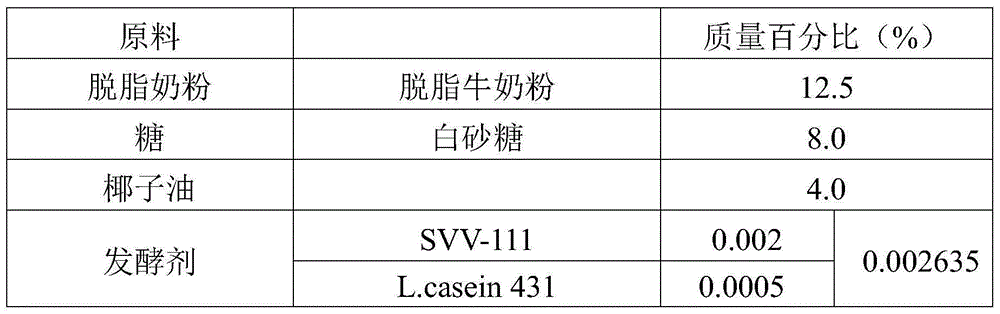

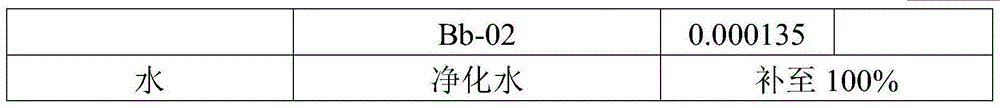

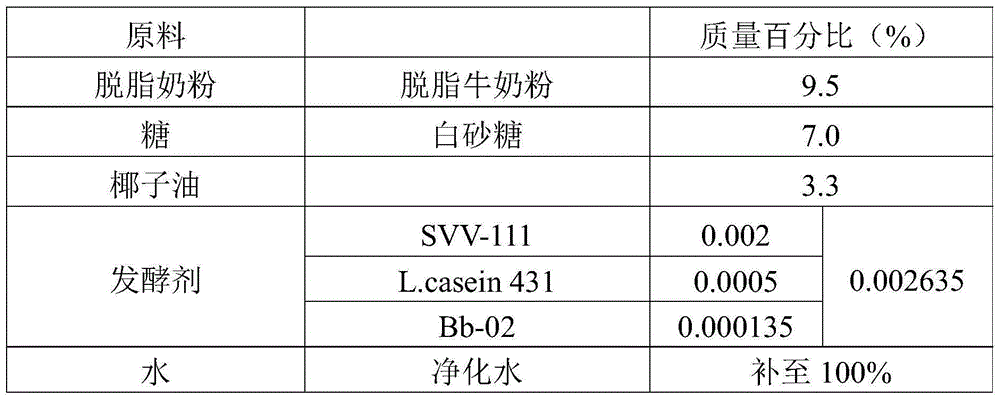

Fermented milk with flavor of coconuts and preparation method of fermented milk

The invention discloses fermented milk with the flavor of coconuts and a preparation method of the fermented milk. The raw materials of the method comprise the following components in percentage by weight: 9.5%-12.5% of nonfat dry milk, 3.0%-4.5% of coconut oil, 7.0%-8.0% of sugar, 0.002%-0.0026% of a fermentation agent, and the balance being water, and the percentage of each of the components presents the percentage of the weight of the component to the percentage by weight of the total weight of the raw materials. The method comprises the following steps: (1) mixing the nonfat dry milk, the coconut oil, the white sugar and the water so as to obtain a mixture, and stirring the mixture; (2) homogenizing the stirred mixture, disinfecting the homogenized mixture, cooling the disinfected mixture, adding the fermentation agent for fermentation until the end acidity is 70-85 DEG T; and (3) pouring the fermented mixture, cooling the poured mixture, and obtaining the fermented milk. The fermented milk with the flavor of the coconuts, disclosed by the invention, is good in homogeneity, fine and smooth in the state of tissues, and rich in flavor, has favorable stability and favorable mouth feel within the shelf life, and has the nutrient health care efficacy. The preparation method of the fermented milk is environmentally-friendly, energy-saving and suitable for industrialized production.

Owner:BRIGHT DAIRY & FOOD

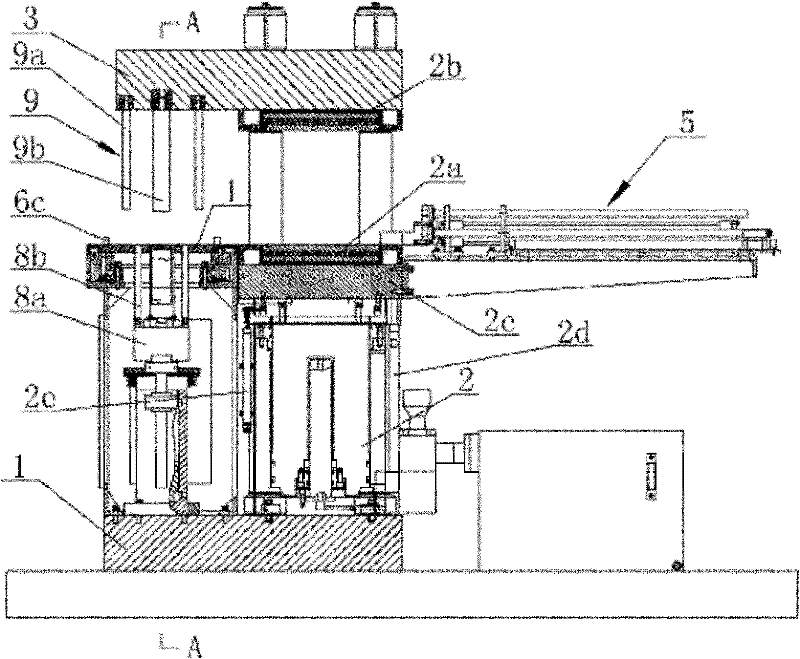

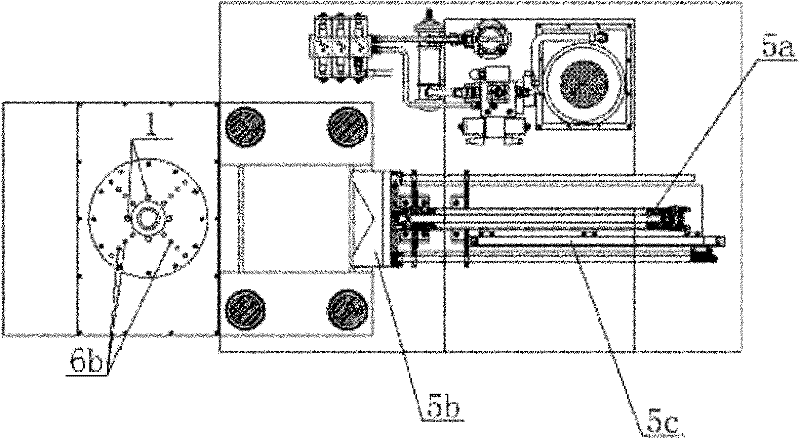

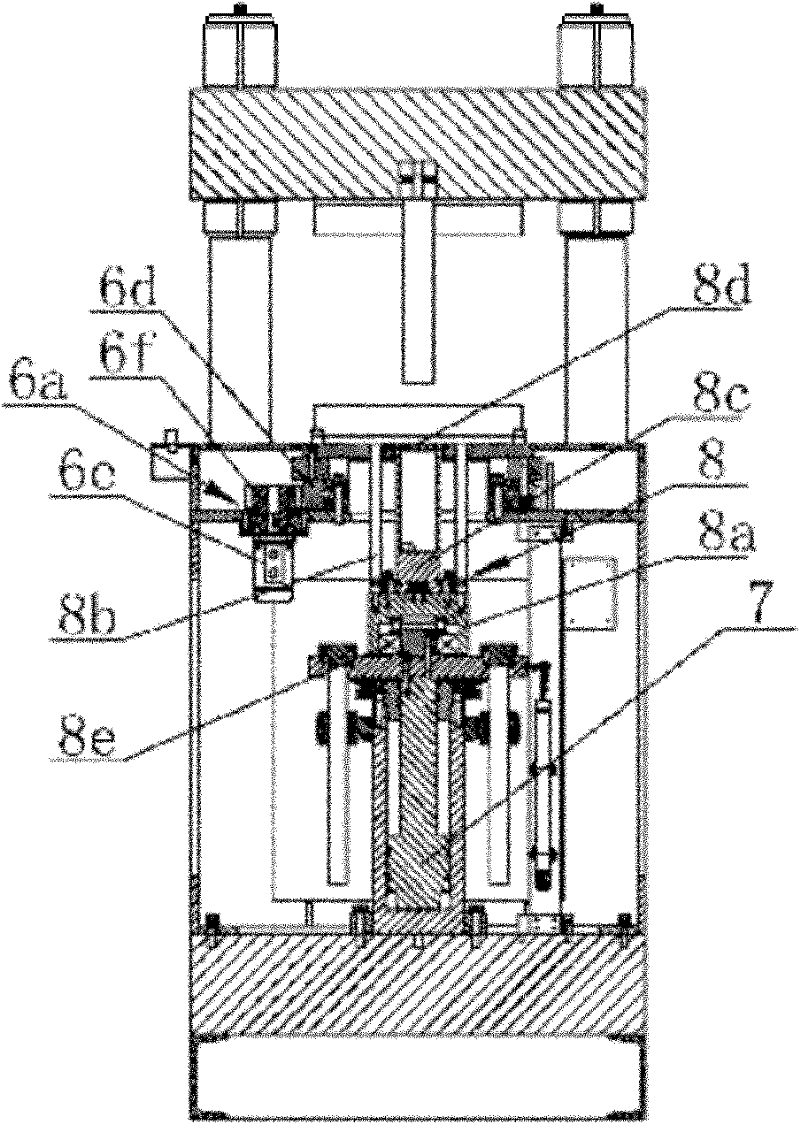

Novel resin grinding wheel forming machine

InactiveCN102173021ACompact structureReduce manufacturing costGrinding devicesDomestic articlesEngineeringGrinding wheel

The invention discloses a novel resin grinding wheel forming machine which belongs to the technical field of grinding wheel forming equipment. The technical scheme is as follows: the novel resin grinding wheel forming machine comprises a frame, wherein a mould closing oil cylinder is arranged on the frame, a lower hot pressure plate is arranged on the power output shaft of the mould closing oil cylinder, a positioning block is arranged on the frame above the lower hot pressure plate, and an upper hot pressure plate corresponding to the lower hot pressure plate is arranged at the bottom of thepositioning block; a grinding wheel forming mould is arranged between the upper hot pressure plate and the lower hot pressure plate, a mould moving mechanism is arranged on one side of the grinding wheel forming mould, a rotary feeding table is arranged on the frame on the other side of the grinding wheel forming mould, and the rotary feeding table is connected with a rotary driving device; and alifting demoulding oil cylinder is arranged below the rotary feeding table, a lower ejector rod mechanism is arranged on the power output shaft of the lifting demoulding oil cylinder, and the lower ejector rod mechanism penetrates through the rotary feeding table and is opposite to an upper ejector rod mechanism fixed at the bottom of the positioning block. The invention aims at providing the novel resin grinding wheel forming machine which is compact in structure, simple to operate, low in production cost, stable to work, convenient to research and develop products and used for forming a grinding wheel.

Owner:DONGHUA MACHINERY

A kind of deoxynojirimycin extraction method

InactiveCN102276515AReduce energy consumptionSave energyOrganic chemistryDeoxynojirimycineReverse osmosis

The invention discloses a method for extracting a deoxynojirimycin monomer. The method comprises the following steps of: soaking a mulberry raw material in acidic aqueous solution, and extracting for 1 to 3 times; adsorbing extracting solution on a cation exchange resin, washing, and eluting by using ammonia water; performing reverse osmosis pre-concentration on eluent, recovering ammonia, dissolving an intermediate in a hydrophilic solvent, performing catalytic conversion, allowing the solution to pass through a gel chromatographic column, and eluting the hydrophilic solvent; recovering the solvent, dissolving in a mixed solvent, allowing the mixed solvent to pass through the chromatographic column, and eluting the mixed solvent; and recovering the mixed solution to obtain pure deoxynojirimycin products. The method is low in energy consumption and environment-friendly, and the pure deoxynojirimycin products with various purity grades of 10 percent, 50 percent, 99 percent and the like.

Owner:SOUTHWEST UNIV

Preparation method of self-adhesive pure polyimide composite paper

ActiveCN108071042ARetain thermal performanceRetain radiation resistancePaper coatingPaper/cardboardFiberPapermaking

The invention relates to a preparation method of self-adhesive pure polyimide composite paper. The preparation method comprises the following steps: under the protection of nitrogen, adding diamine monomers and dianhydride monomers into an aprotic polar solvent for reacting; then, adding a catalyst to perform a polymerization reaction to obtain a polyimide stock solution; filtering, defoaming, diluting, and injecting into a precipitation solution to obtain a polyimide precipitation fibre suspension; washing, filtering and drying to obtain polyimide precipitation fibres; mixing the polyimide precipitation fibres and polyimide chopped fibres to obtain a homogeneous slurry; papermaking, squeezing and drying to obtain polyimide composite paper; performing solvent spraying after-treatment, coldpressing, and drying to obtain the self-adhesive pure polyimide composite paper. According to the preparation method of the self-adhesive pure polyimide composite paper, the solvent spraying after-treatment is adopted, part precipitation fibres are dissolved, and a film-fibre coexisting state is formed after a solvent is removed so that the obtained composite paper has the strength of the film, also has the characteristics of paper, remains original heat resistance, irradiation resistance, electrical performance and the like of polyimide paper, has higher strength, and can meet the application with higher requirement on the environment.

Owner:DONGHUA UNIV

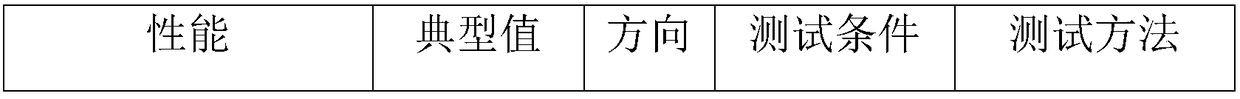

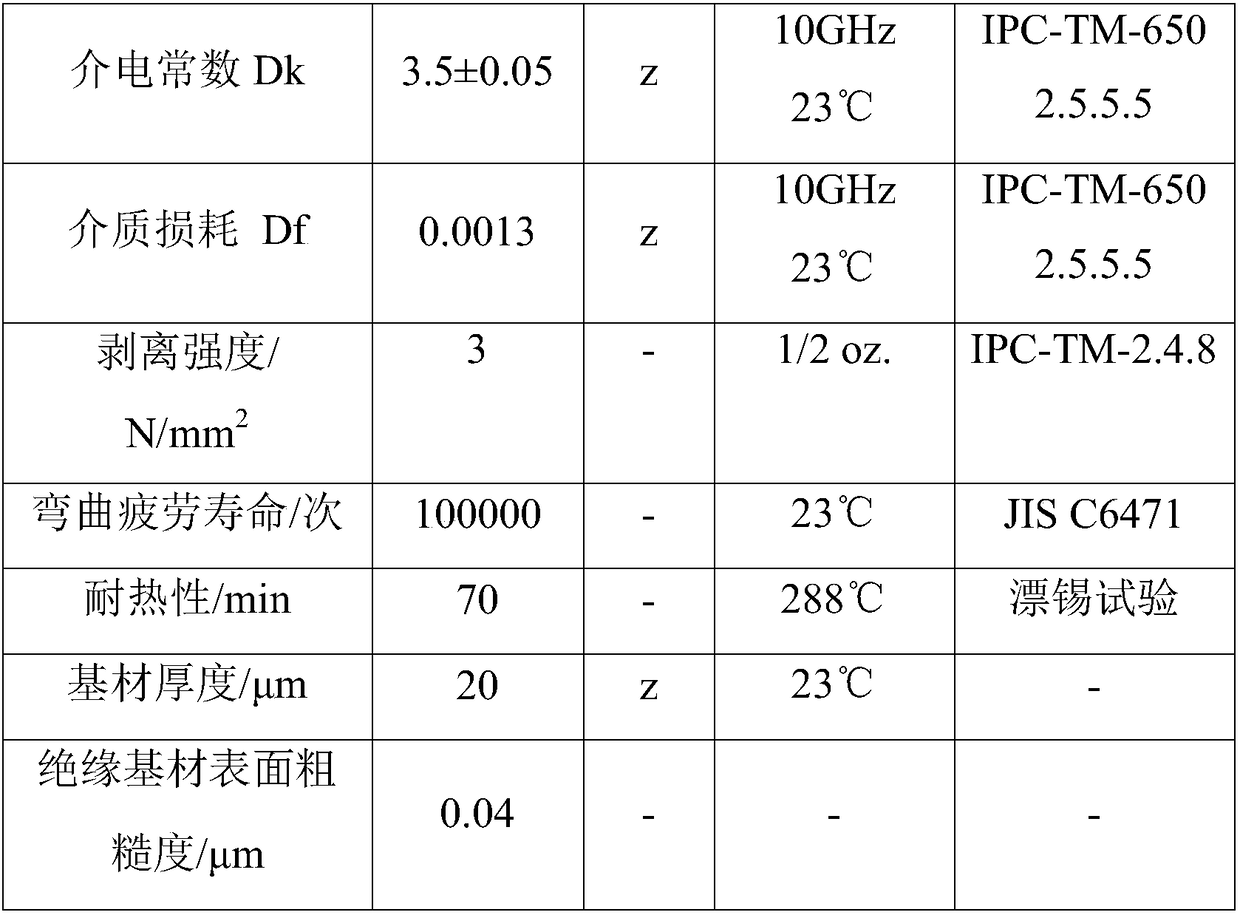

High-frequency high-speed flexible copper-clad plate and preparation method thereof

InactiveCN108901130AProcess energy saving and environmental protectionShort processDielectric materialsVacuum evaporation coatingMass ratioDielectric loss

The invention discloses a high-frequency high-speed flexible copper-clad plate and a preparation method thereof. The high-frequency high-speed flexible copper-clad plate comprises a polymer insulatingbase material and a copper foil; wherein the polymer insulating base material comprises modified dispersed polytetrafluoroethylene, and the thickness ranges from 0.01mm to 0.075mm; the thickness of the copper foil is 2-9 microns; the modified dispersed polytetrafluoroethylene comprises a ceramic material and dispersed polytetrafluoroethylene, wherein the mass ratio of the ceramic material to thedispersed polytetrafluoroethylene is (10-30):(90-70). The preparation method of the high-frequency high-speed flexible copper-clad plate comprises the steps of surface treatment of the ceramic powder,modification of the polytetrafluoroethylene powder, and preparation the high-frequency high-speed flexible copper-clad plate. The method is simple in process, energy-saving and environment-friendly,low in dielectric loss and capable of greatly reducing the thickness and roughness of the copper foil.

Owner:广州市东泓氟塑料股份有限公司

Dust removal purification device and method for crude coal tar

InactiveCN105327550AGuaranteed uptimeEasy to handleFiltration circuitsTar working-up by solvent extractionDistillationTar

The invention discloses a dust removal purification device and method for crude coal tar. The dust removal purification device comprises a backwashing filter, a horizontal decanter centrifuge, a residual oil buffer tank, a purified tar tank, a factice tank, a vacuum filter, a dryer and a distillation apparatus, wherein a filter element is arranged in a cavity of the backwashing filter, and dust-containing coal tar is purified continuously through filtering and backwashing of the filter element; residual oil after backwashing enters the horizontal decanter centrifuge for liquid-solid separation, and purified tar and factice are obtained. In order to increase the recovery rate of the purified tar sufficiently, the factice is extracted with a recycling solvent, and final products of a system comprise purified coal tar and dry cinders. The backwashing filter and the horizontal decanter centrifuge are adopted to cooperate with the solvent extraction system for dust removal purification of the crude coal tar, through graded and stepped treatment, the treating capacity of the system is improved sufficiently while the coal tar is recovered to the greatest extent, besides, the solvent is recycled, and energy saving and environmental protection are realized.

Owner:SHAANXI YANCHANG PETROLEUM GRP

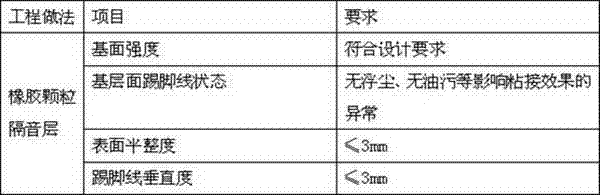

Rubber particle sound-insulation and vibration-damping cast-in-place floor construction method

The invention discloses a rubber particle sound-insulation and vibration-damping cast-in-place floor construction method. The rubber particle sound-insulation and vibration-damping cast-in-place floor construction method comprises the steps of cleaning the base layer of a floorslab, preparing rubber particle layer materials in the site, immediately paving a rubber particle sound-insulation and vibration-damping layer, maintaining the paved rubber particle sound-insulation and vibration-damping layer for 12-24 hours until the rubber particle sound-insulation and vibration-damping layer is solidified, and paving a decoration layer on the maintained pavement layer. The rubber particle sound-insulation and vibration-damping cast-in-place floor construction method is energy-saving, environment-friendly, and capable of improving the use ratio of renewable resources. The rubber particle layer not only is good in sound insulation performance but also has a moisture-proof function and an anti-condensation function. Decoration floorslab, especially wood floorslab is enabled to be kept dry. The common quality problem of deformation of the wood floorslab is solved. In addition, construction space is saved and construction cost is reduced compared with a constitutional type sound-insulation layer due to the fact that the rubber particle sound-insulation layer is adopted for construction.

Owner:LONGXIN CONSTR GRP

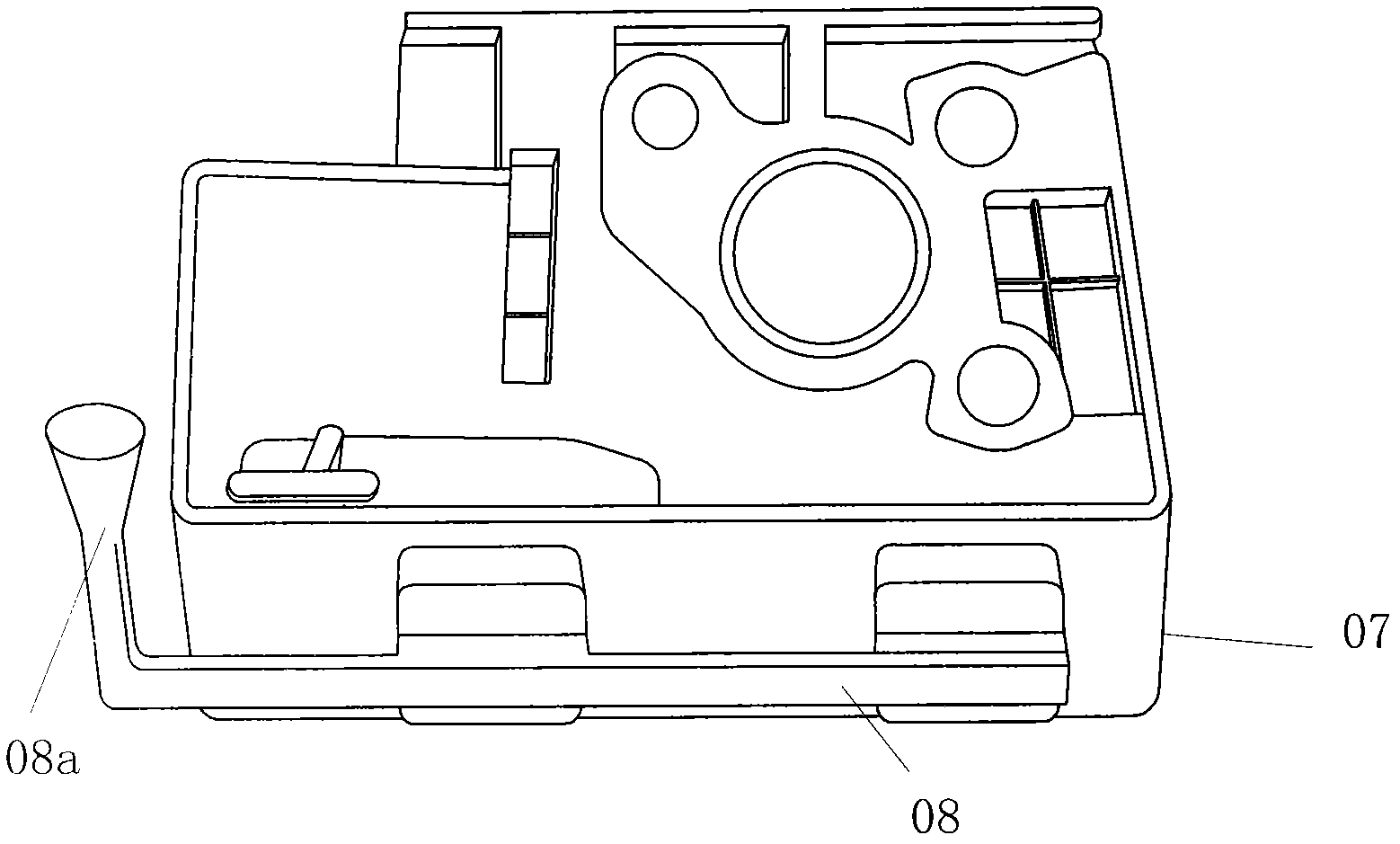

Casting mold for single cylinder diesel body, external casting mold for horizontal parting multi-cylinder diesel body and cast parts, and energy-saving low-carbon casting process of external casting mold

The invention provides an energy-saving low-carbon casting process for a single cylinder diesel body, which comprises manufacture of the mold, wherein a resin sand and triethylamine curing technique is used during the manufacture of an external mold; a mold gate is located at a spindle hole of the diesel body; and an exhaust port is arranged on a balance axle hole of the diesel body. By using thenovel process provided by the invention, defects of the single cylinder diesel production in the prior art, such as low quality, low efficiency, high energy consumption, serious pollution and intensive labor, can be solved. The invention also provides the mold used in the process. The invention further provides an external casting mold for the horizontal parting multi-cylinder diesel body and thecast parts, and the casting process of the external casting mold.

Owner:平遥县嵘兴机械制造有限公司

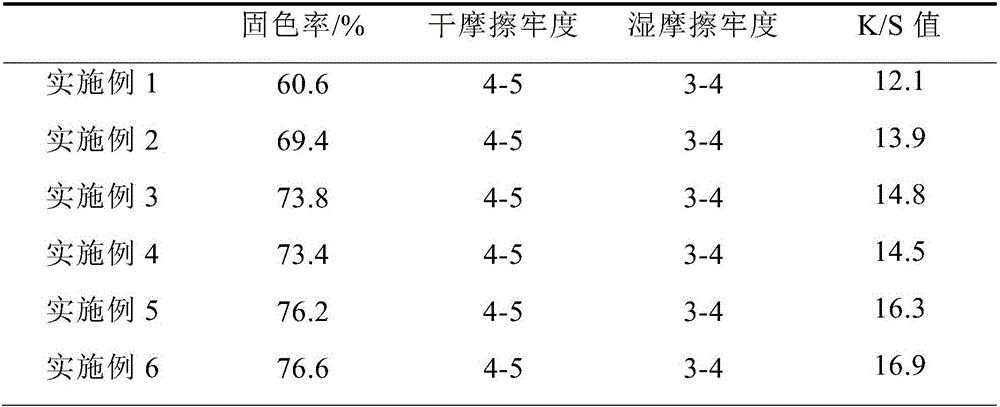

Novel environment-friendly dyeing method for jeans apparel

InactiveCN105926316AGood effectExcellent moisture resistance color fastDry-cleaning apparatus for textilesDyeing processPigmentChemistry

The invention provides a novel environment-friendly dyeing method for jeans apparel. The novel environment-friendly dyeing method specifically comprises the following steps: (1) pretreatment: desizing; (2) preparation of a modified solution; (3) pad drying; (4) preparation of dye liquor; (5) dyeing and padding of jeans apparel; (6) finishing of the jeans apparel. According to the novel environment-friendly dyeing method for the jeans apparel, a sizing agent on the apparel is removed by desizing; by the adoption of cationic modification treatment, natural medicinal plant extract pigment dye for dyeing and jeans apparel finishing, satisfactory environment-friendly jeans cloth can be prepared, and the effect is obvious; the jeans apparel has excellent advantages of resistance to wet color, resistance to wash color, sun durability, long service life and the like, and is higher in practical value; the process is energy-saving and environment-friendly, and the jeans apparel does not contain formaldehyde.

Owner:太仓红桥服饰有限公司

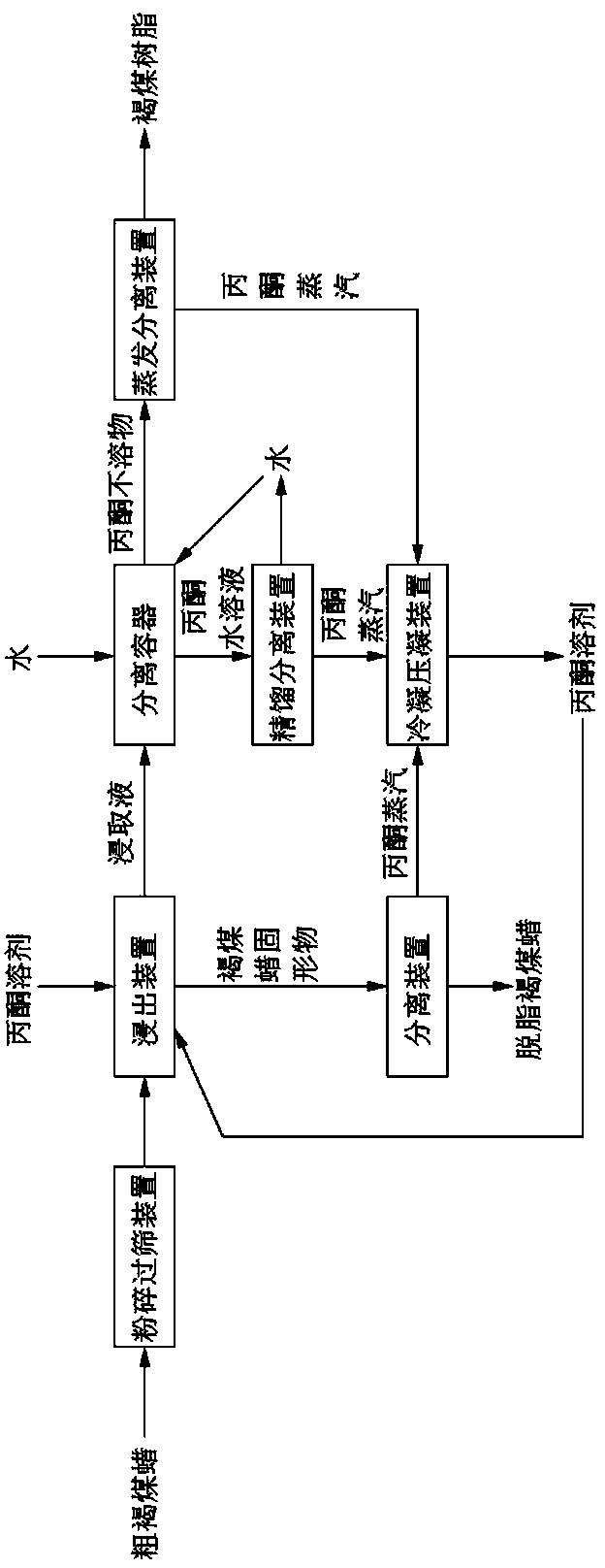

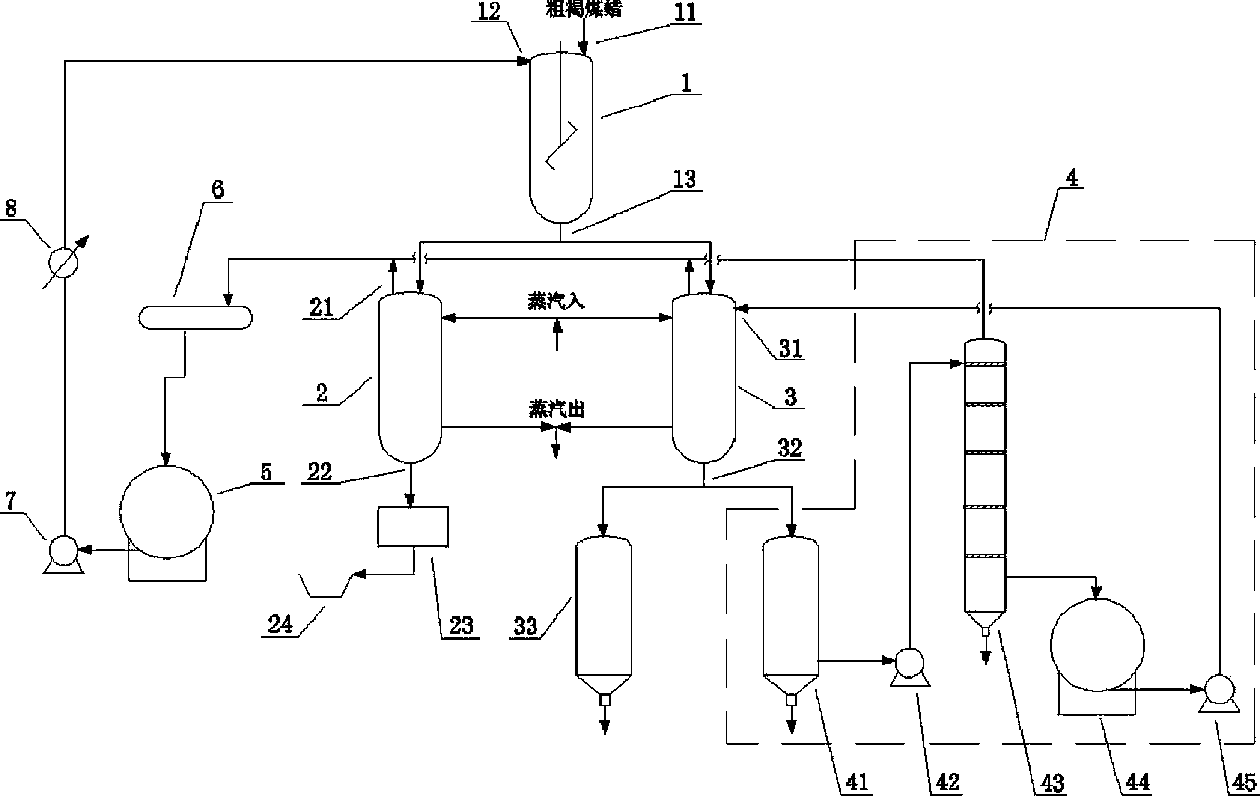

Energy-saving efficient resin-removing method and device for coarse lignite wax

ActiveCN103897734AEasy to recycleConsumableMineral wax recovery/refiningAqueous acetoneAqueous solution

The invention discloses an energy-saving efficient resin-removing method and device for coarse lignite wax. The resin-removing method comprises the following steps: smashing coarse lignite wax and sieving the smashed coarse lignite wax by a 0.5-3.0mm sieve; then, leaching the sieved lignite wax particles and acetone in a solid-to-liquid ratio of 1:1-1:8kg / L at constant temperature for 2-4 hours and separating to obtain a leaching liquid and a solid; placing the solid in a separating device, and heating, evaporating and removing residual acetone to obtain degreased lignite wax; placing the leaching liquid in a separating container, adding water to separate resin from acetone, and carrying out solid-liquid separation to obtain acetone insolubles and an acetone aqueous solution; and recovering acetone by rectifying the acetone aqueous solution; and evaporating the acetone insolubles to obtain walchowite. The degreasing device comprises a degreasing kettle, a ceride-removing desolventizing tank, a resin desolventizing separating tank, a rectifying device, an acetone storage tank and a condenser. According to the energy-saving efficient resin-removing method and device disclosed by the invention, as resin in lignite wax is easy to dissolve in acetone at constant temperature, wax and asphaltos are not dissolved, and the resin content in wax is reduced by digestion and separation at constant temperature, so that the device is simple and energy-saving and environment-friendly in process.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

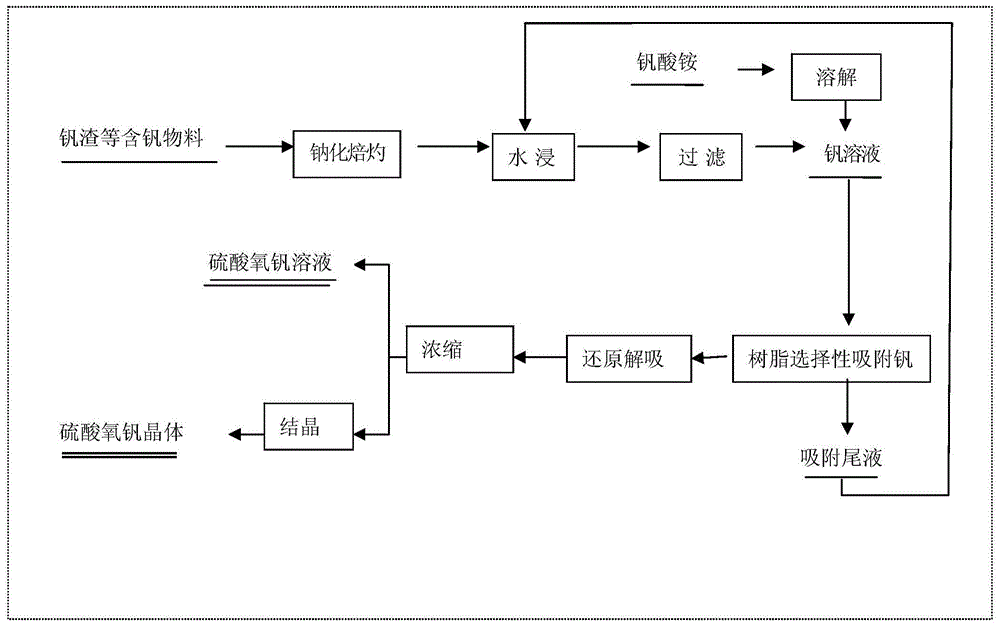

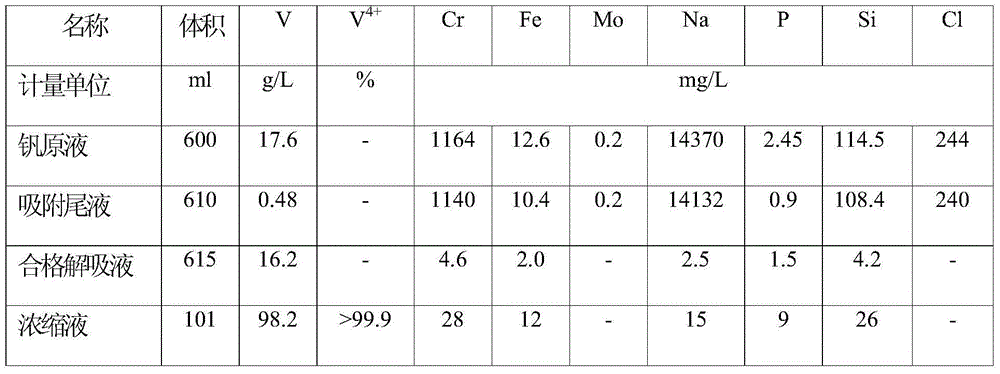

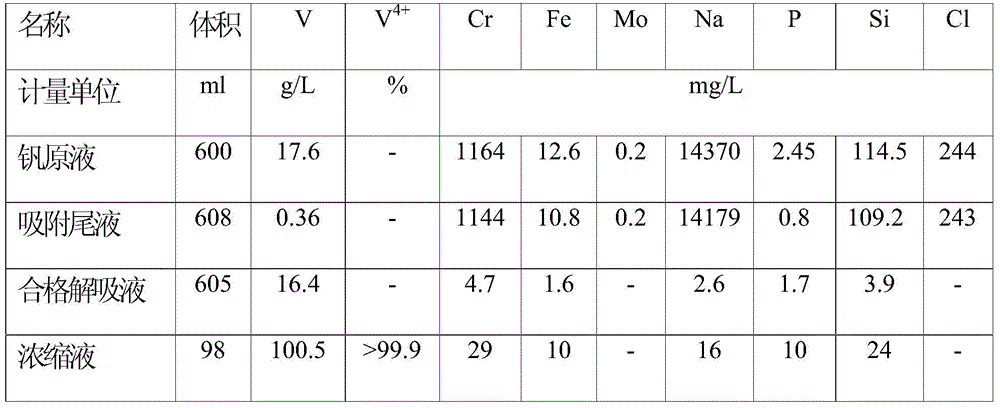

Method for preparing vanadyl sulfate

ActiveCN104310476ATo achieve the purpose of purificationProcess energy saving and environmental protectionVanadium compoundsVanadyl sulfatePhysical chemistry

The invention provides a method for preparing vanadyl sulfate. According to the method, a technical process that ion exchange resin is adopted to selectively adsorb vanadium and reduce and desorb vanadium so as to directly prepare vanadyl sulfate is adopted, so that a middle process in which powder high-purity vanadium pentoxide is prepared is canceled. In addition, as the decontamination process is evolved into direct selective pure vanadium extraction, contamination and the labor and material consumption in the decontamination process are avoided, the operation procedure is greatly simplified. Compared with a conventional vanadyl sulfate preparation process, the method has the advantages of short procedure, high vanadium yield, low cost, no waste discharge and the like.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY +2

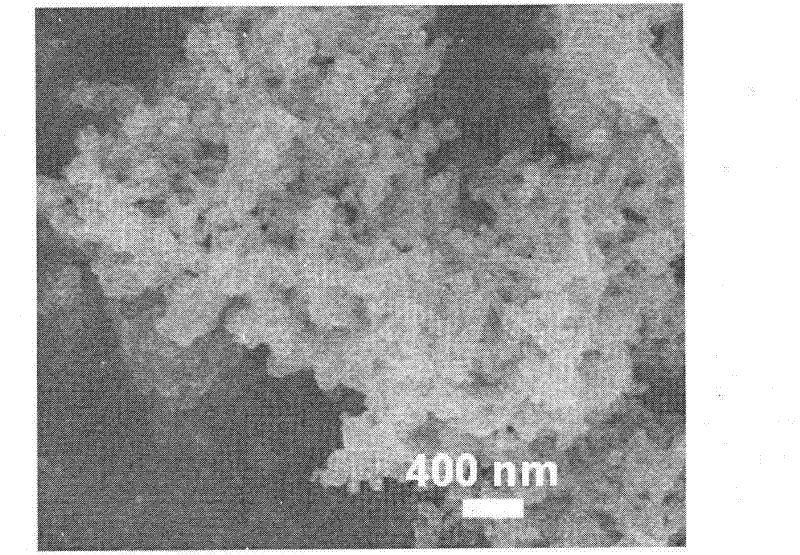

Method for preparing surfactant-directed grown superfine bismuth molybdate nano rods

InactiveCN102502834ARegular shapeUniform sizeMolybdeum compoundsNanotechnologySolventControllability

The invention provides a method for preparing surfactant-directed grown superfine bismuth molybdate nano rods. In the preparation process, bismuth nitrate and ammonium molybdate are used as raw materials, distilled water is used as a solvent, cetyl trimethyl ammonium bromide surfactant is used as a structure directing agent, and a bismuth molybdate functional nano material is prepared in a controllable mode under the action of microwave radiation. The diameter of the superfine bismuth molybdate nano rods is 80 to 100 nanometers, and the length of the nano rods is 400 to 600 nanometers; and the nano rods have smooth surface and uniform size. In a microwave radiation heating system, the material properties of the bismuth nitrate solution and the ammonium molybdate solution and the type of the surfactant play an important role in shape control of the product; and the method has the remarkable advantages of energy conservation, environment friendliness, high yield, high process condition controllability and the like. The superfine bismuth molybdate nano rod material prepared by adopting the technology has regular shape and uniform size, and is expected to provide a necessary technical foundation for the fields of photocatalysis, luminous functional devices and the like in the future.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

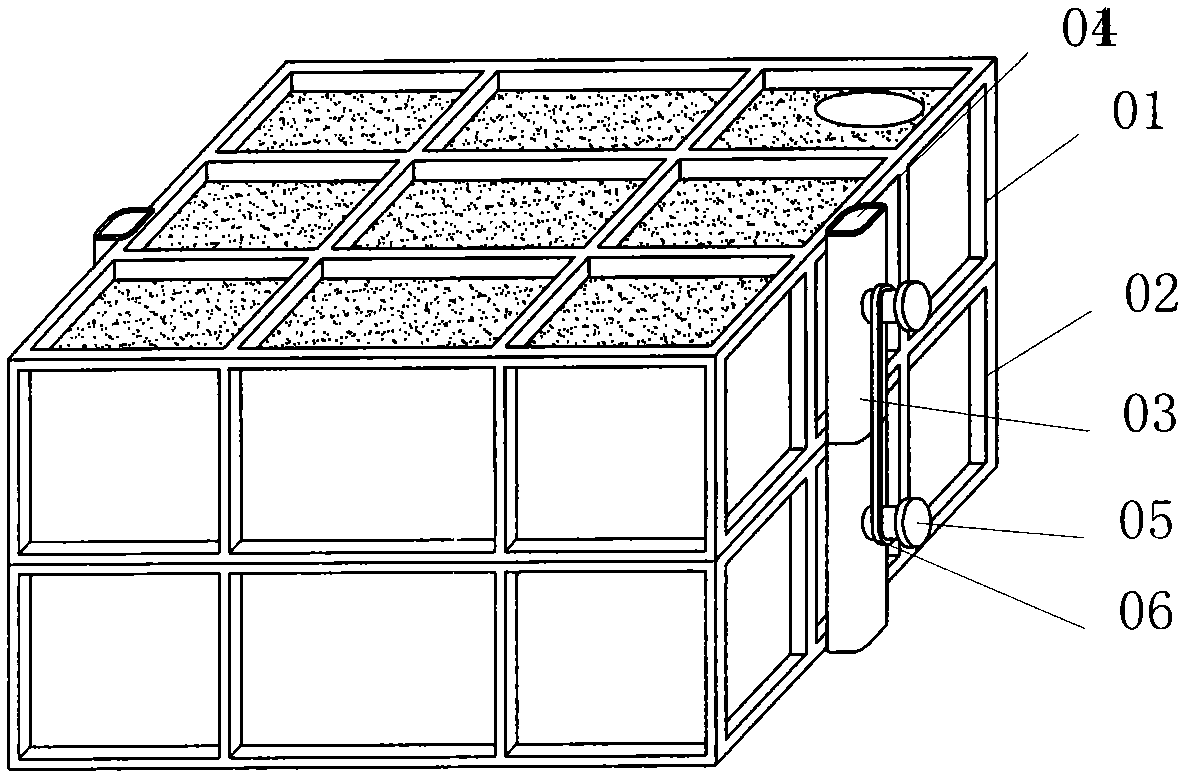

Equipment for purifying trichlorosilane

ActiveCN103449448AImprove efficiencyReduce manufacturing costHalogenated silanesTowerPolycrystalline silicon

The invention discloses equipment for purifying trichlorosilane. The equipment is a first rectifying and purifying device and used for conducting first rectifying and purifying treatment on trichlorosilane so as to obtain purified trichlorosilane and first rectifying residual liquid, wherein the first rectifying and purifying device consists of a first rectifying tower, a second rectifying tower and a third rectifying tower which are connected in series, the rectifying of the first rectifying tower is conducted at the temperature of 60-100DEG C and the pressure of 0.2MPa according to the reflux ratio of (10-50):1; the rectifying of the second rectifying tower is conducted at the temperature of 100-140DEG C and the pressure of 0.5MPa according to the reflux ratio of (20-50):1; the rectifying of the third rectifying tower is conducted at the temperature of 60-80DEG C and the pressure of 0.2MPa according to the reflux ratio of (20-50):1. The equipment can be utilized for effectively purifying the trichlorosilane, and is simple, safe, energy-saving and environment-friendly and low-cost in technique, the purity of the purified trichlorosilane is high, the purified trichlorosilane can be effectively utilized for producing polycrystalline silicon, and the produced waste liquor can be recycled.

Owner:CHINA ENFI ENGINEERING CORPORATION

Rolling-formed fly ash-construction waste slab material

InactiveCN106431122AHeat of hydrationImprove impact resistanceSolid waste managementGlass/slag layered productsCarbonizationShock resistance

The invention discloses a rolling-formed fly ash-construction waste slab material and belongs to the technical field of preparation of building materials. The slab material comprises a surface layer and a middle material layer, wherein glass fiber grid cloth is laid between the surface layer and the middle material layer. According to the rolling-formed fly ash-construction waste slab material, industrial waste residues and construction wastes serve as raw materials, so that the slab material has the characteristics of high solid waste utilization ratio, low price and low cost; and the potential hydration activity of fly ash and the construction wastes is fully used, so that the waste is changed into the valuable. The rolling-formed fly ash-construction waste slab material has the characteristics of light weight, high strength, low hydration heat, high shock resistance, low shrinkage, good fatigue resistance, high carbonization resistance, good durability and the like, thereby being capable of being extensively applied to the construction fields of interior wall slabs, exterior wall slabs and the like.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

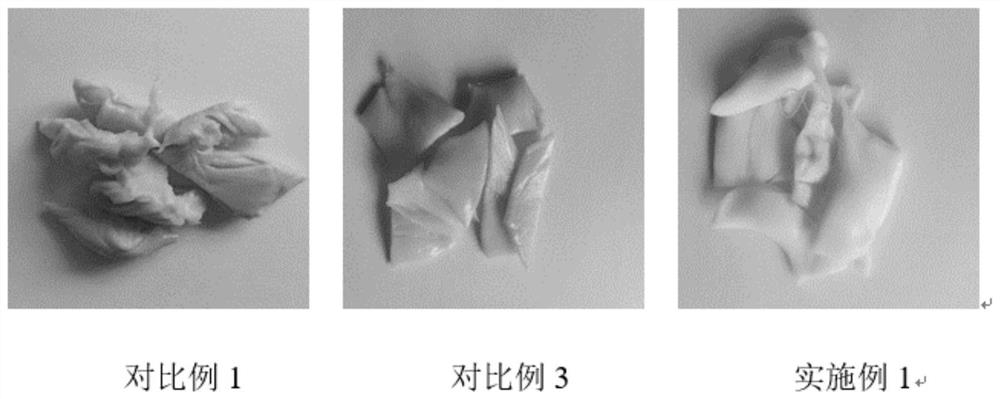

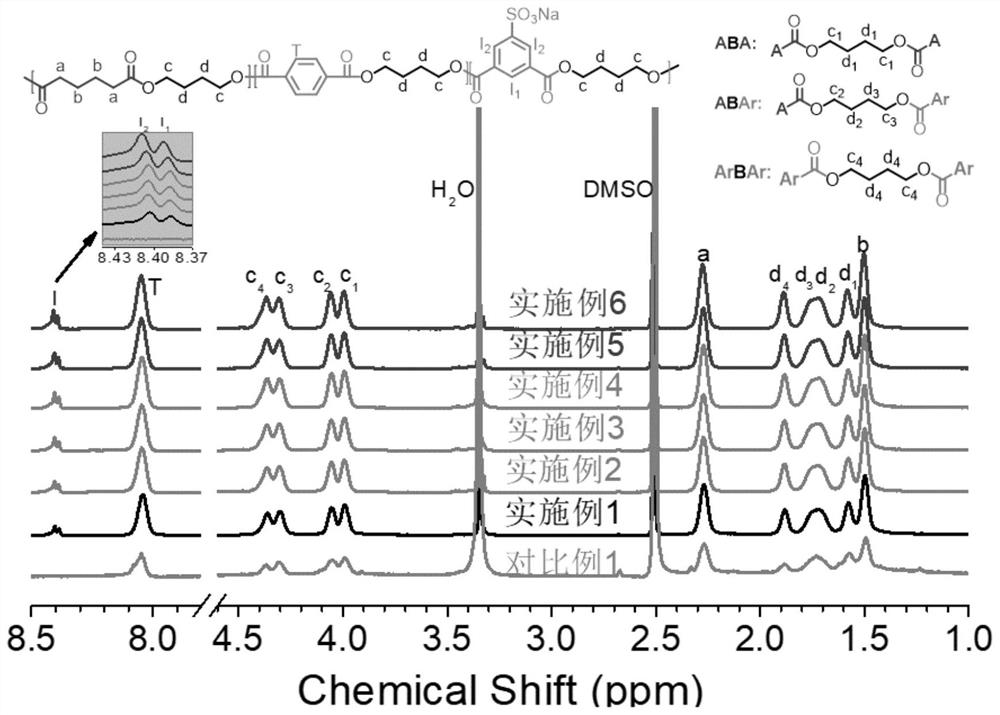

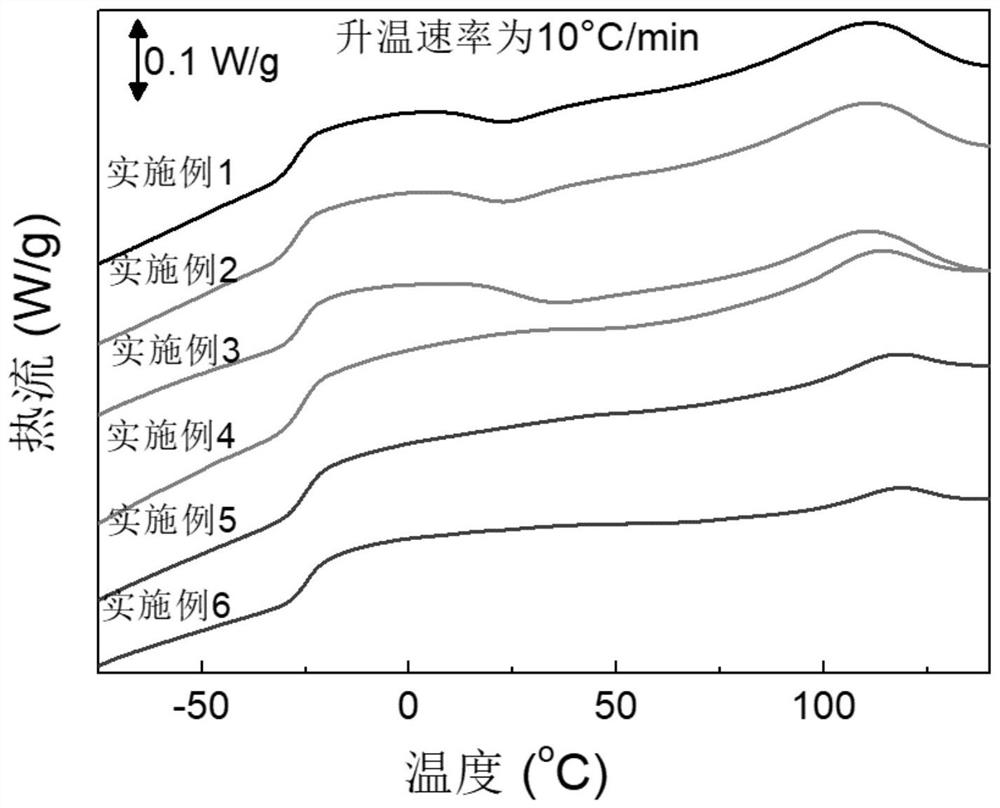

Biodegradable polyester with high gas barrier property and preparation method and application thereof

The invention discloses a biodegradable polyester with high gas barrier property and a preparation method and application of the biodegradable polyester. The biodegradable polyester comprises a binaryacid structural unit and a dihydric alcohol structural unit, wherein in terms of 100 mol% of the total amount of the dibasic acid structural units, the dibasic acid structural units comprise 80-94 mol% of non-sulfonic dibasic acid residues and 6-20 mol% of sulfonic dibasic acid residues, and the sum of the aromatic sulfonic dibasic acid residues and the aromatic non-sulfonic dibasic acid residuesaccounts for 0-60 mol% of the total amount of dibasic acid structural units. The biodegradable sulfonated polyester has the advantages of being high in gas barrier property, light in color and lusterand the like, the raw materials of the preparation method are easy to obtain, the process is energy-saving and environment-friendly, discoloration side reactions of products in the polymerization process can be inhibited, and industrialization is achieved through utilization.

Owner:ZHEJIANG UNIV

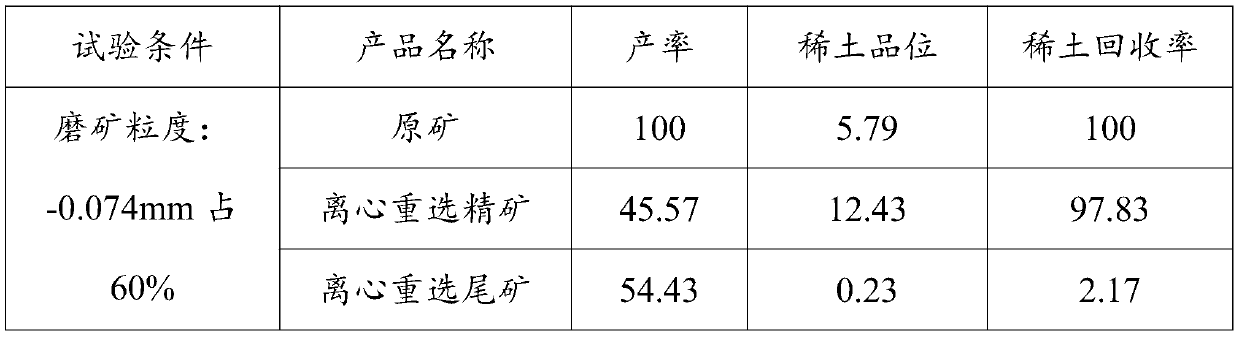

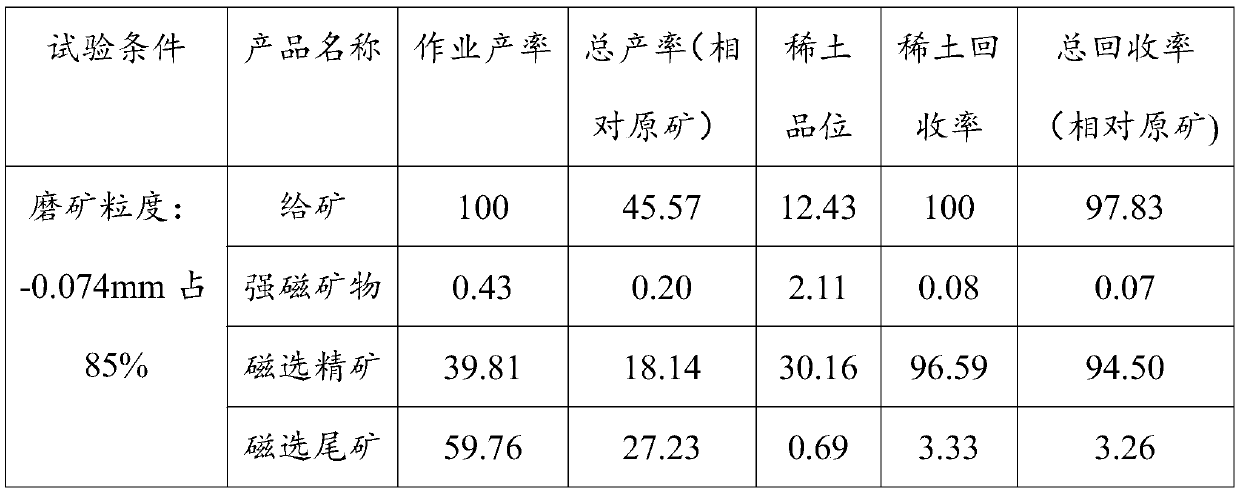

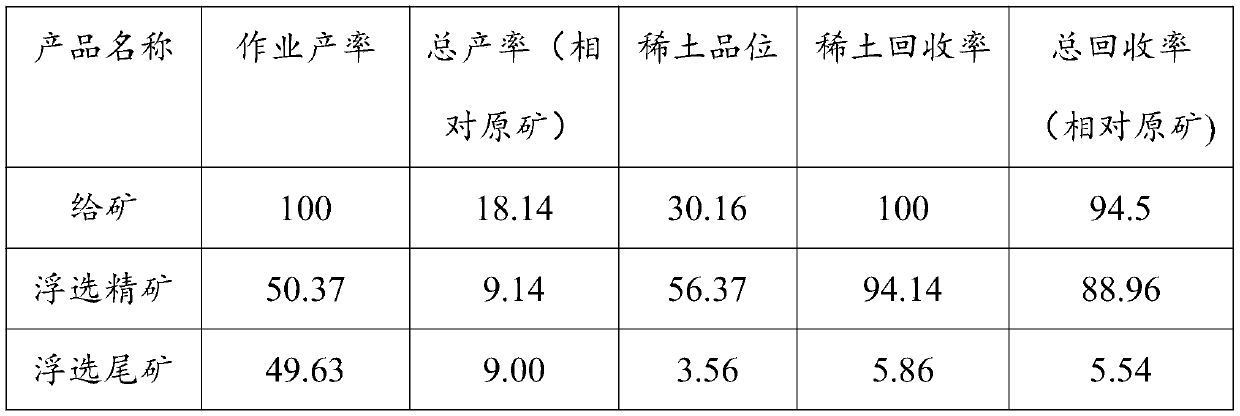

Beneficiation method applied to superconduction magnetic separation of rare earth ore

InactiveCN111346742AReduce the amount of oreReduce volumeHigh gradient magnetic separationCentrifugesMining engineeringWater resources

The invention discloses a beneficiation method applied to superconduction magnetic separation of a rare earth ore, and aims to solve the technical problems of higher economical loss and resource wastecaused by lower recovery rate of a rare earth resource in a traditional rare earth beneficiation process. The substantial process of the beneficiation method is as follows: firstly, a raw ore of therare earth ore is crushed and grinded; the tailing discarding is performed on the rare earth ore in advance by centrifugal reselection; then, a reselected concentrate is grinded, and a superconductionmagnetic separator is used for superconduction weak magnetic separation to remove high-magnetism mineral impurities; then, superconduction strong magnetic separation is performed to obtain a rare earth rough concentrate; and finally, flotation is performed on the rare earth rough concentrate to obtain a high-grade rare earth concentrate. The beneficiation method greatly improves the sorting precision and efficiency, and reduces consumption of a total flotation medicament and consumption of a water resource through a breakthrough-developed reselection-superconduction magnetic separation-flotation process, so that the energy consumption and the operation cost are reduced, efficient sorting and utilization of the rare earth resource are implemented, and the grade and recovery rate of the rare earth ore are greatly improved.

Owner:JIANGXI UNIV OF SCI & TECH

Honeysuckle compound drink and preparation method thereof

InactiveCN106173729AHigh content of active ingredientsThe effect of homology of medicine and food is outstandingFood ingredient functionsVitamin CChlorogenic acid

The present invention discloses honeysuckle compound drink and a preparation method thereof. The honeysuckle compound drink comprises the following raw materials in mass ratios: 60-80% of distilled honeysuckle liquid, 5-15% of polysaccharide and flavone extractum, 0.5-2% of volatile oil (containing linalool, honeysuckle ethanol and geraniol), 0.5-2% of chlorogenic acids, 1-5% of bifidus factors, 5-10% of a sweetness adjusting agent, and 0.02-0.05% of vitamin C. The preparation method consists of the following steps: material selecting, distilled honeysuckle liquid preparing, blending, filtering and filling, sterilizing, detecting and packaging, and storing. The heat clearing and toxin removing honeysuckle compound drink is designed for children, and the bifidus factors, vitamin C and other materials beneficial to children's physical and mental health are added, so that the drink is good in taste and nutrient-rich, can regulate the beneficial flora in intestines, supplement energy, improve absorption, and enhance immunity, is simple in production processes and low in costs, does not need to consume a large amount of water and electricity, and is green, environmentally protective, energy-saving, and suitable for industrial production.

Owner:HUBEI CHUTIANSHU PHARMA

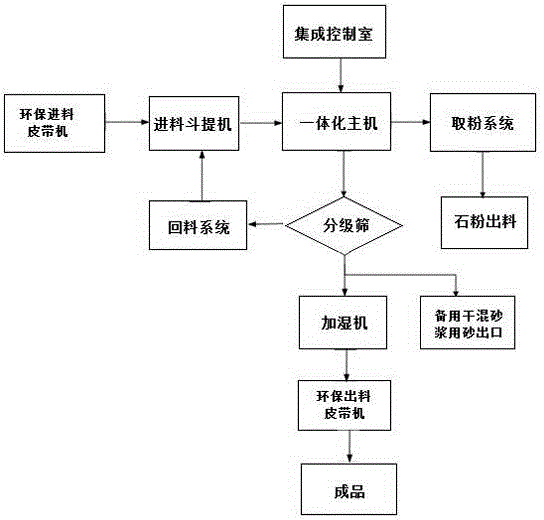

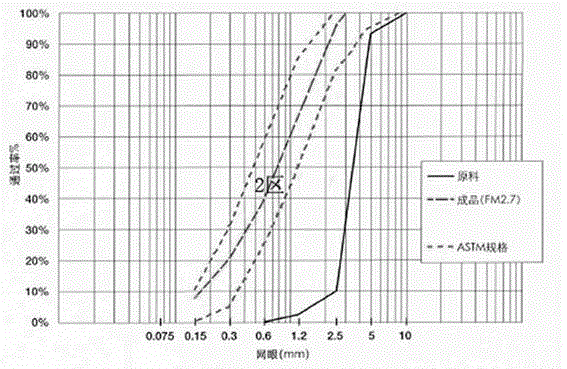

Dry sand making process

The invention discloses a dry sand making process, comprising the following procedures: crushing treatment, sieving treatment, coarse particle humidification treatment and standby dry sand treatment. The process integrates striking, milling and rocking by stones; meanwhile, stone-powder separation is achieved; kinetic energy required by a main engine is greatly reduced; the produced product is stable in grading, good in particle shape, and adjustable in fineness modulus; the overall process adopts a separation technique, so that energy conservation and environmental protection are achieved; the finished product is stable in grading, good in particle shape, and free of needle-like sand, and is a polyhedron, and is similar to a globoid shape; the fineness modulus (2.3-3.0) and the particle content (below 5%) are adjustable; all performance indexes accord with the 'standard of sand for construction' GB14684-2011; the processing cost per ton is saved by 60% in comparison with international and domestic similar products; the sand making cost is greatly reduced; and the crushing application range is wide.

Owner:TAI ZHOU TENG DA CONSTR ENG MACHINERY

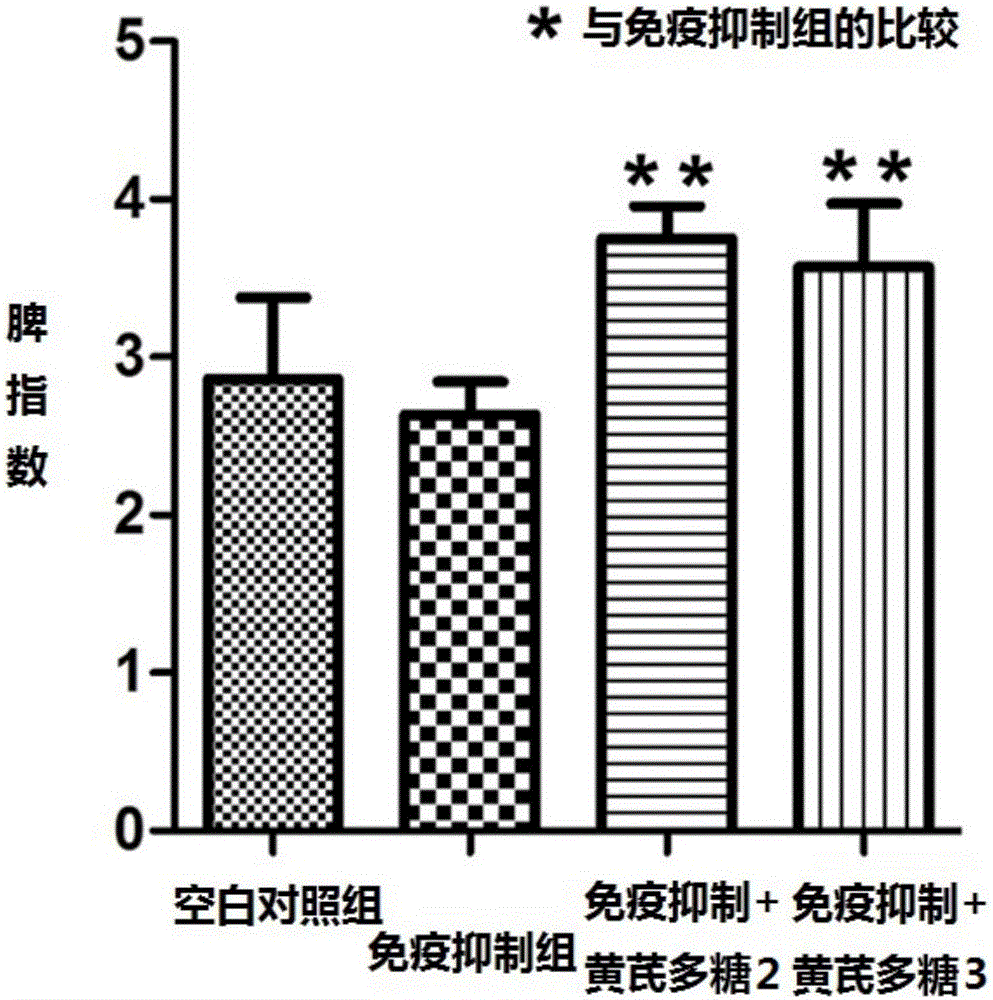

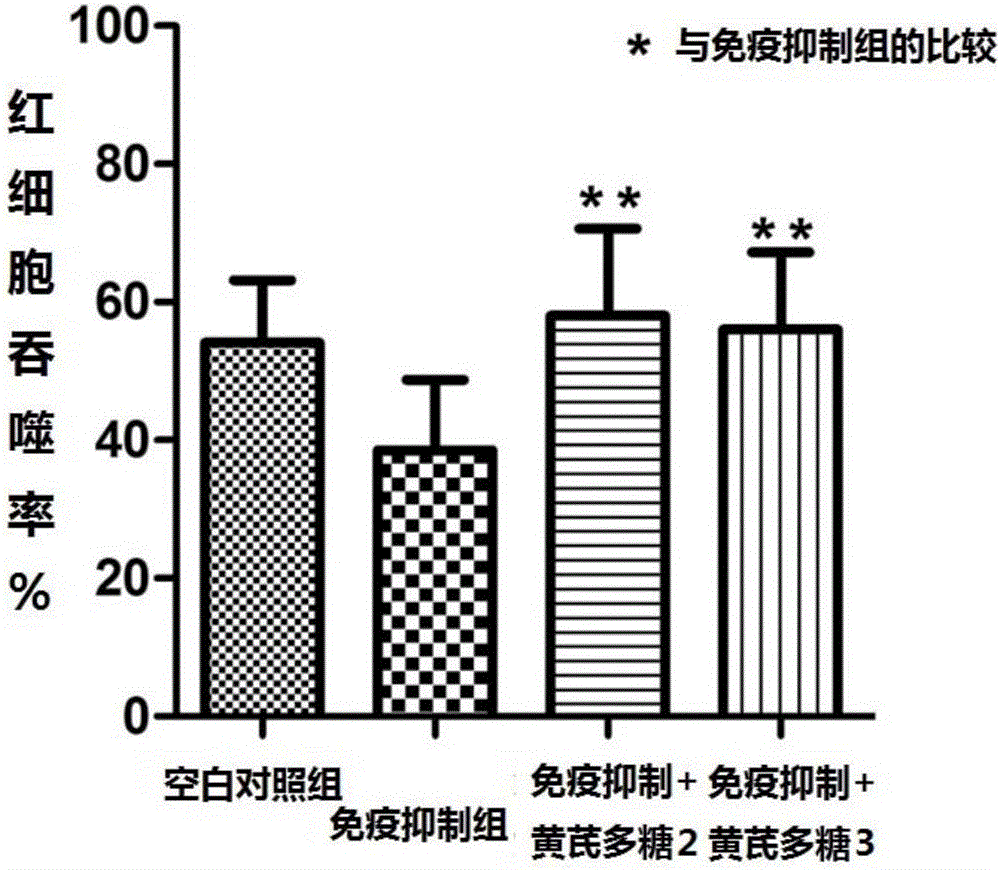

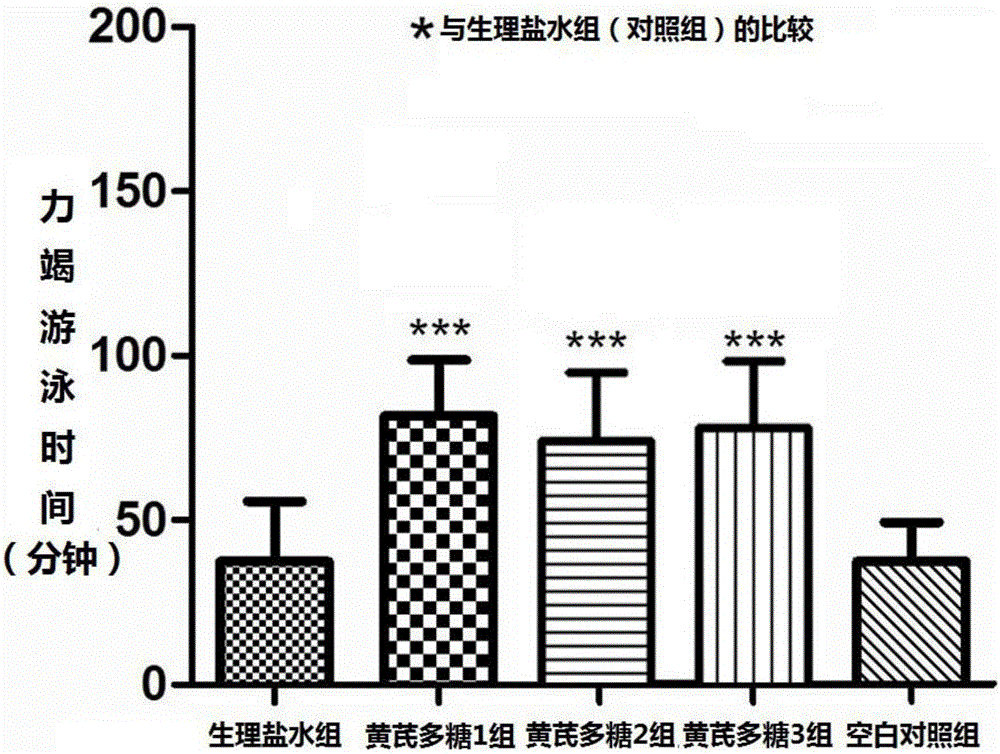

Functional astragaluspolysaccharide drink with functions of immunity enhancement and fatigue resistance and preparation technology of functional astragalus polysaccharide drink

InactiveCN105995354AHigh transparencyGreat tasteNatural extract food ingredientsFood ingredient functionsSuspended particlesAdditive ingredient

The invention relates to a functional astragalus polysaccharide drink with functions of immunity enhancement and fatigue resistance and a preparation technology of the functional astragalus polysaccharide drink. The preparation method comprises steps as follows: a dry astragalus root is cleaned, dried in air and then smashed into astragalus powder; purified water is added for reflux extraction; ethanol is used for polysaccharide precipitation, a precipitate is dried, purified water is added to dissolve the precipitate, and then a clarifying agent is added for standing and clarification; centrifugation is performed for obtaining supernatant, and the supernatant is a concentrated liquid of astragalus polysaccharide; the concentrated liquid of the astragalus polysaccharide is evenly mixed with drink additives and purified water, wherein the drink per kg contains 200-400 mg of the astragalus polysaccharide, 4.5-6 g of lysine, 1-1.5 g of inositol, 8-32 g of citric acid, 10-20 mg of nicotinamide, 260-390 mu g of folic acid, 1.4-2.1 mg of vitamin B6, 2.4-3.6 mu g of vitamin B12, 0.02-0.1 mg of lactic acid, 20-60 g of a sweetening agent and the balance of purified water. The functional astragalus polysaccharide drink tastes comfortable without medicine flavor, is golden yellow, has high transparency with no suspended particles or sediment, has health-care function and good effect and has a single characteristic ingredient.

Owner:GANSU HEBO LONG PHARMA TECH CO LTD

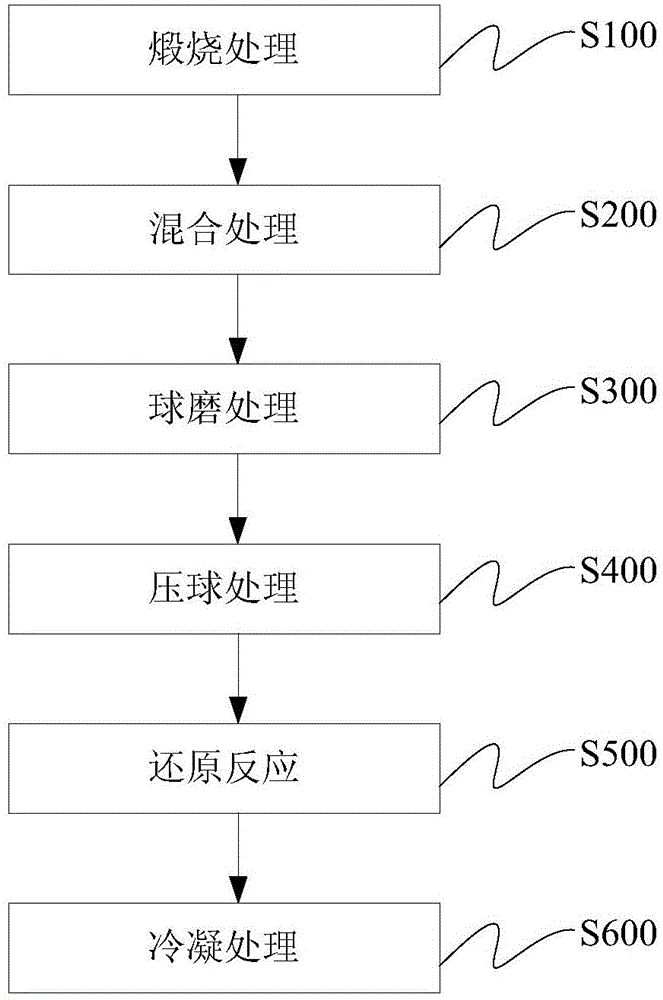

Method for preparing magnesium

The invention discloses a method for preparing magnesium. The method comprises the following steps: calcining dolomite in a rotary kiln to obtain calcined dolomite and tail gas; mixing the calcined dolomite with ferrosilicon and fluorite to obtain a mixture; performing ball-milling on the mixture to obtain a granular mixture; briquetting the granular mixture to obtain pelletized materials; arranging the pelletized materials into a feeding region in a rotary hearth furnace, gradually heating the pelletized materials in the feeding region in a preheating region and a heating region, and performing reduction reaction on the pelletized materials in a high-temperature region to obtain magnesium steam, flue gas and furnace slag; condensing the magnesium steam to obtain magnesium. The method disclosed by the embodiment of the invention is simple in process and low in energy consumption; the reduction reaction is carried out by adopting the rotary hearth furnace, so that magnesium can be continuously produced, the yield is increased, and efficient production of magnesium can be carried out.

Owner:SHENWU TECH GRP CO LTD

Environmentally-friendly dyeing method of cotton and ramie fabric

InactiveCN105937184AGood effectGood practical valueCarbon fibresDry-cleaning apparatus for textilesCellulaseEngineering

The invention discloses an environmentally-friendly dyeing method of a cotton and ramie fabric. The method concretely comprises the steps of weaving, desizing, cellulase finishing, baking, dyeing, softener application, baking, non-iron finishing and packaging. A slurry on clothes can be removed through desizing, and biological polishing finishing and the non-iron finishing are adopted to make the satisfactory cotton and ramie fabric. The fabric has obvious effects and very good practical values, and the method has the advantages of energy saving, environmental protection, realization of very good wet treatment fastness and solarization resistance of the cotton and ramie fabric dyed through the method, and solving of the color light change and easy fading in the prior art.

Owner:TAICANG QIANJING CHEM FIBER FACTORY

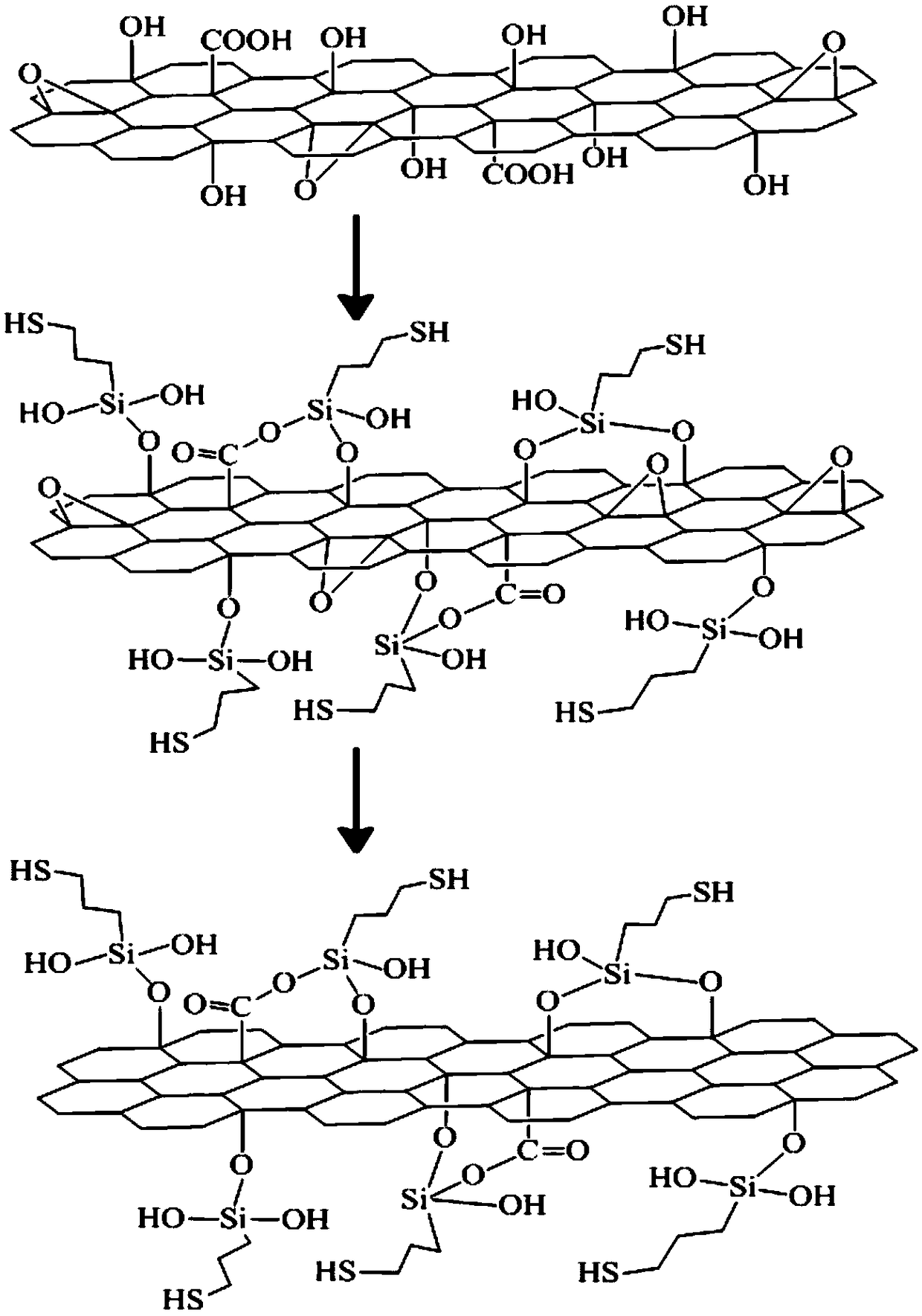

Polyester fabric moisture absorbing, sweat releasing and heat conducting finishing method based on click chemistry

ActiveCN108691208AProcess environmental protectionReduce the harm to the human bodyFibre typesChemistryPolyester

The invention relates to a polyester fabric moisture absorbing, sweat releasing and heat conducting finishing method based on click chemistry. The method comprises the following steps of preparing sulfydryl-modified polyester fabric, preparing sulfydryl-modified reduced graphene oxide, preparing finishing liquid and preparing moisture absorbing, sweat releasing and heat conducting polyester fabric. The method has the advantages that the pre-treated sulfydryl polyester fabric, the sulfydryl reduced graphene oxide and a polyurethane moisture absorbing and sweat releasing finishing agent are enabled to form firm chemical bonds through the click chemistry, so that the polyester fabric can obtain good moisture absorbing, sweat releasing and heat conducting performance; the operation is simple,a process is environmentally-friendly, energy-saving and efficient, and the wearability of the polyester fabric can be greatly improved; and the prepared moisture-absorbing and sweat-releasing polyester fabric has no influence on hand feeling and strength.

Owner:DONGHUA UNIV

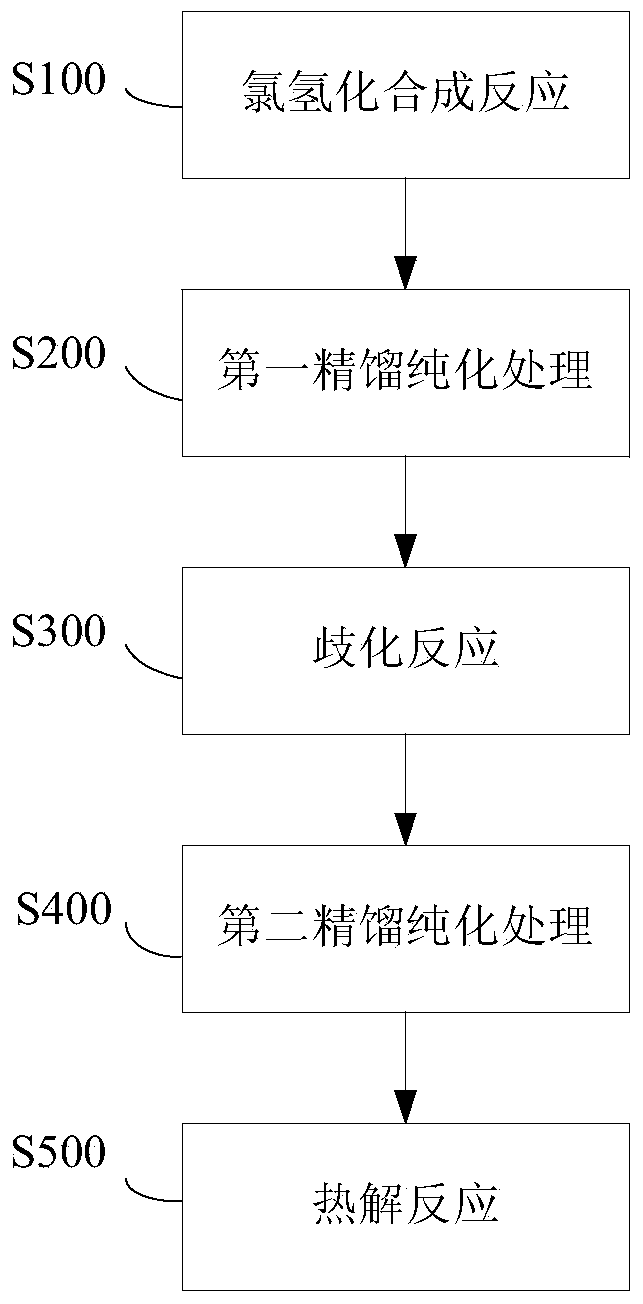

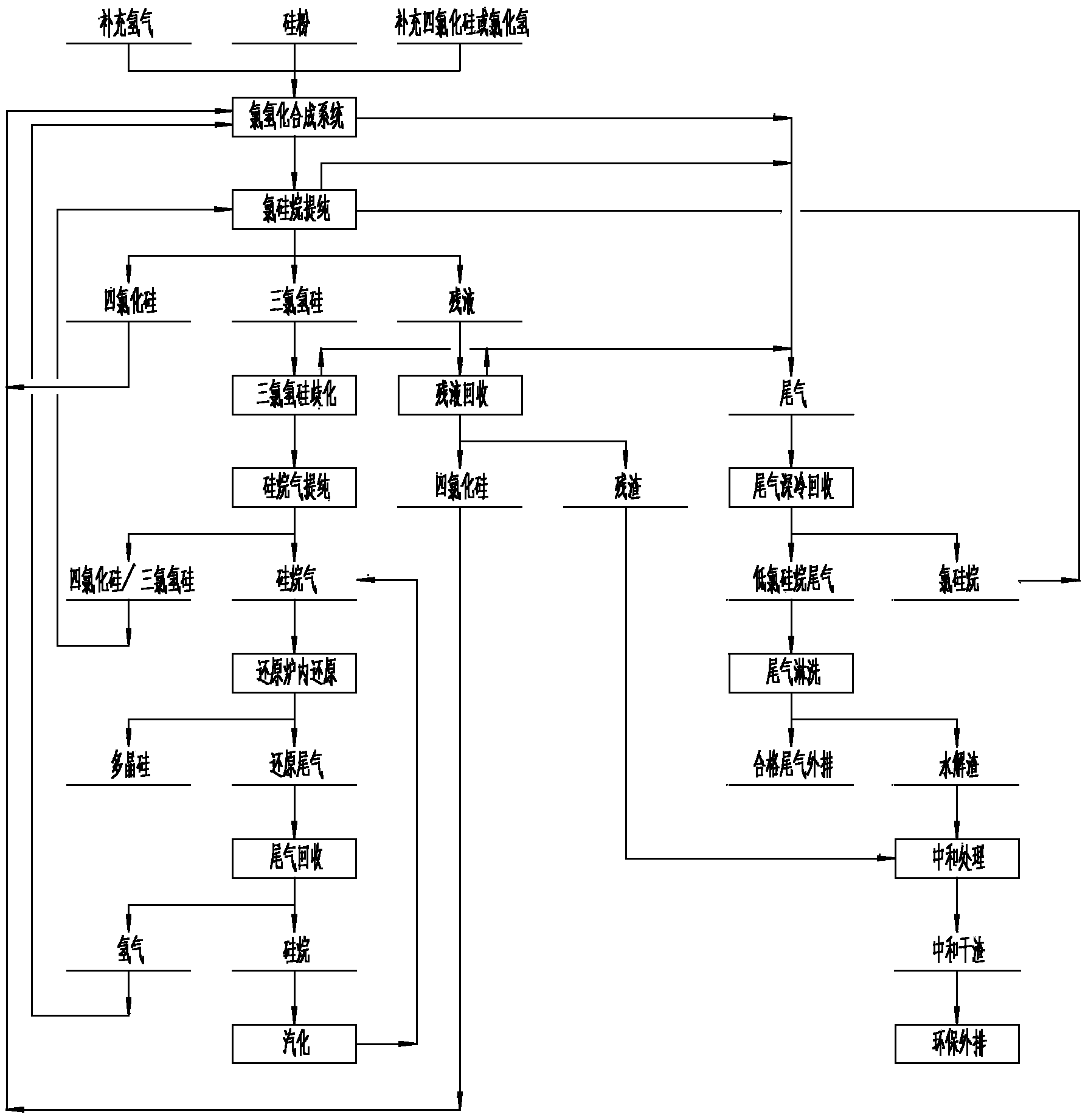

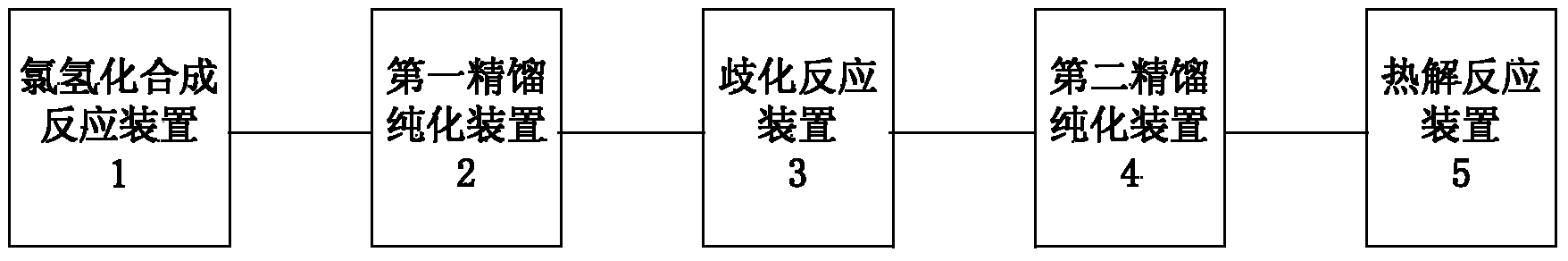

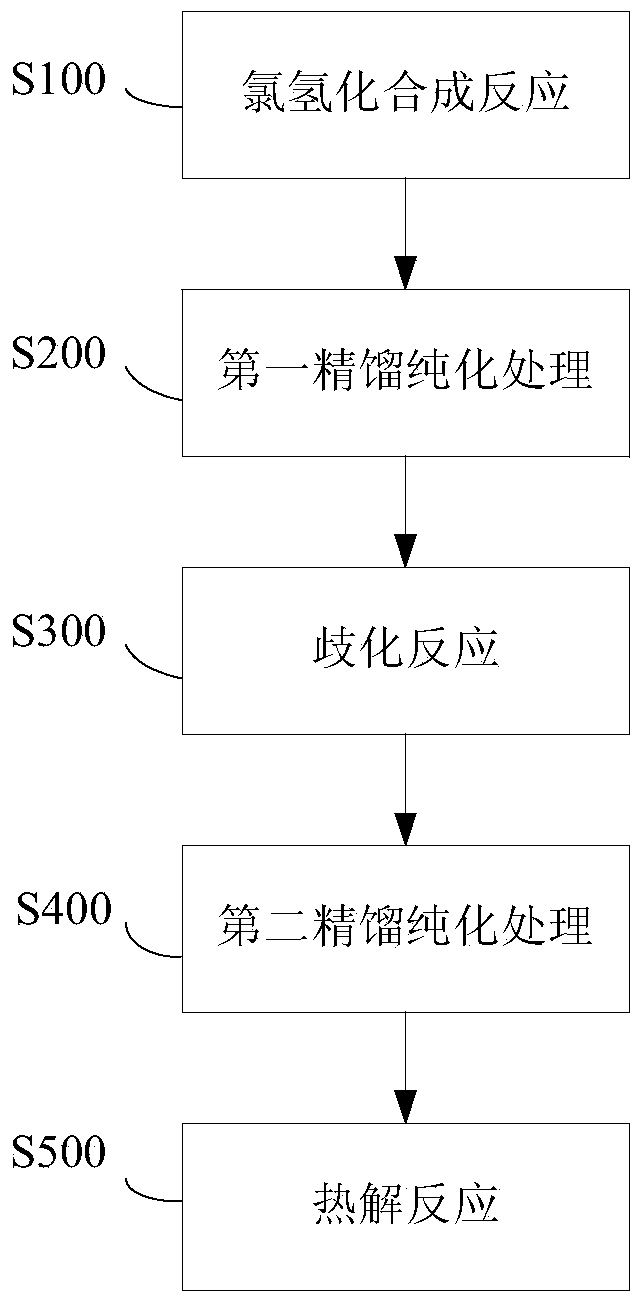

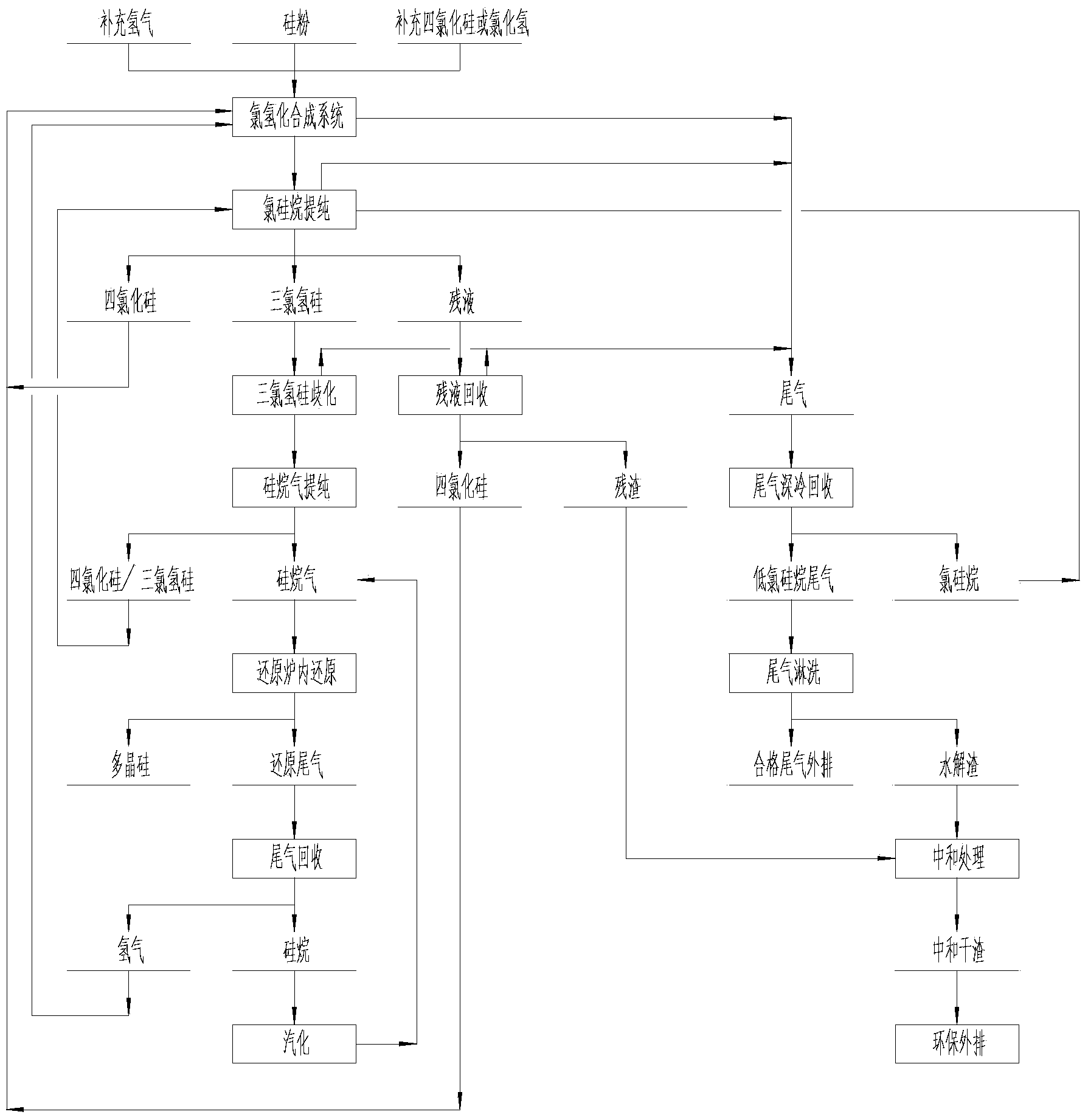

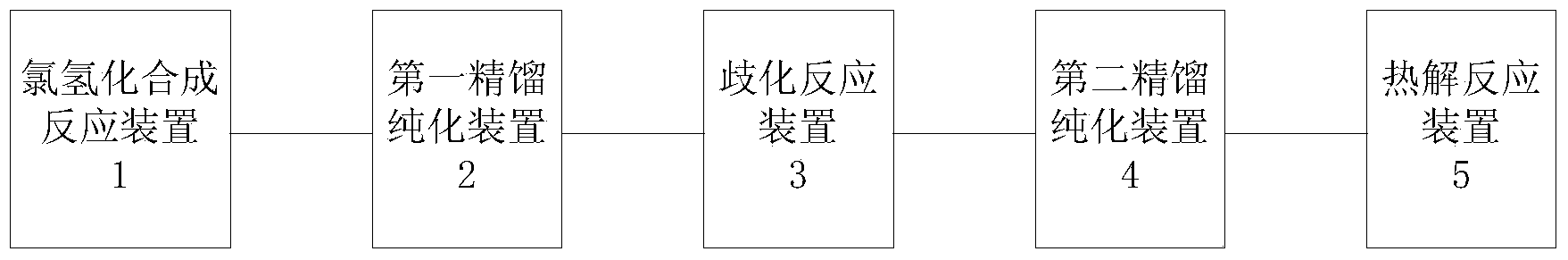

Equipment for preparing trichlorosilane

The invention discloses equipment for preparing trichlorosilane. The equipment comprises a hydrochlorination synthesis reaction device, and a first distillation purification device, wherein the hydrochlorination synthesis reaction device is used for carrying out hydrochlorination synthesis reaction on ganister sand, hydrogen and at least one material selected from hydrogen chloride and silicon tetrachloride, so as to obtain a hydrochlorination synthesis reaction product containing the trichlorosilane; the first distillation purification device is used for carrying out first distillation purification treatment on the hydrochlorination synthesis reaction product containing the trichlorosilane, so as to obtain the trichlorosilane and first refined raffinate. By using the equipment, the trichlorosilane can be effectively prepared; the process related to the equipment is simple, safe, energy-saving and environment-friendly, low in cost, and high in purity of produced trichlorosilane; the generated tail gas and waste residue can be recycled, so as to achieve the environmental requirements.

Owner:CHINA ENFI ENGINEERING CORPORATION

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com