Patents

Literature

230 results about "Aqueous acetone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting active ingredient of natural leech essence

InactiveCN101108879AHighlight substantive featuresSignificant progressLeech/worm material medical ingredientsLeech-based protease inhibitorsRetention periodAqueous acetone

The invention discloses an extract method of the effective constituent of the Natural hirudin. The method is that the blood-sucking leech is washed cleanly by water and is added with the ethanol water with content of 15 per cent to 25 per cent to soak for 30h to 50h, and then is filtered to gain the filter liquor and dregs of a decoction; the Poecilobdella manillensis waste residue is broken into pieces and is added with aqueous acetone solution with content of 15 per cent to 25 per cent to soak, and then is filtered to gain the filter liquor; after recovering ethanol and acetone from the two-time filter liquor in the vacuum, the filter liquor is combined and frozen and dried in the vacuum conventionally to gain the product. The invention is simple in process, low in cost, higher in yield, good in product quality and long in retention period. The ''three wastes'' are not discharged in the whole production process, and the product can work as the raw material in such three fields as medicine, hairdressing and health food.

Owner:滕海英 +2

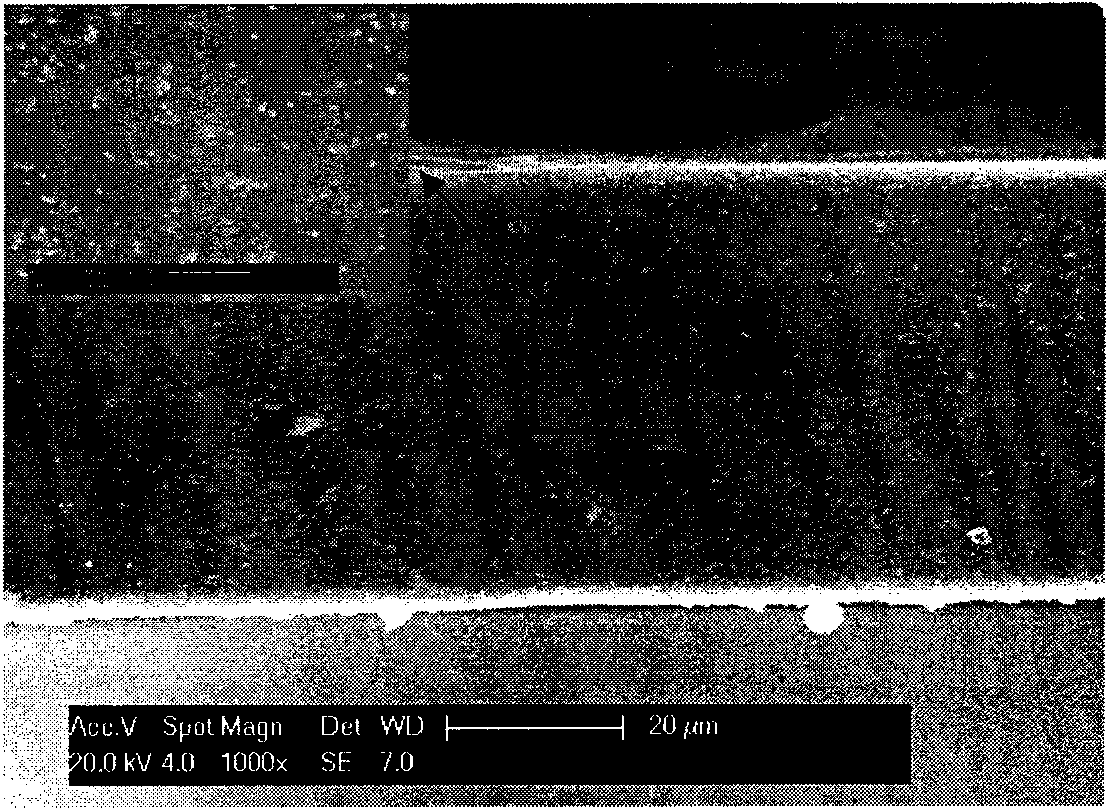

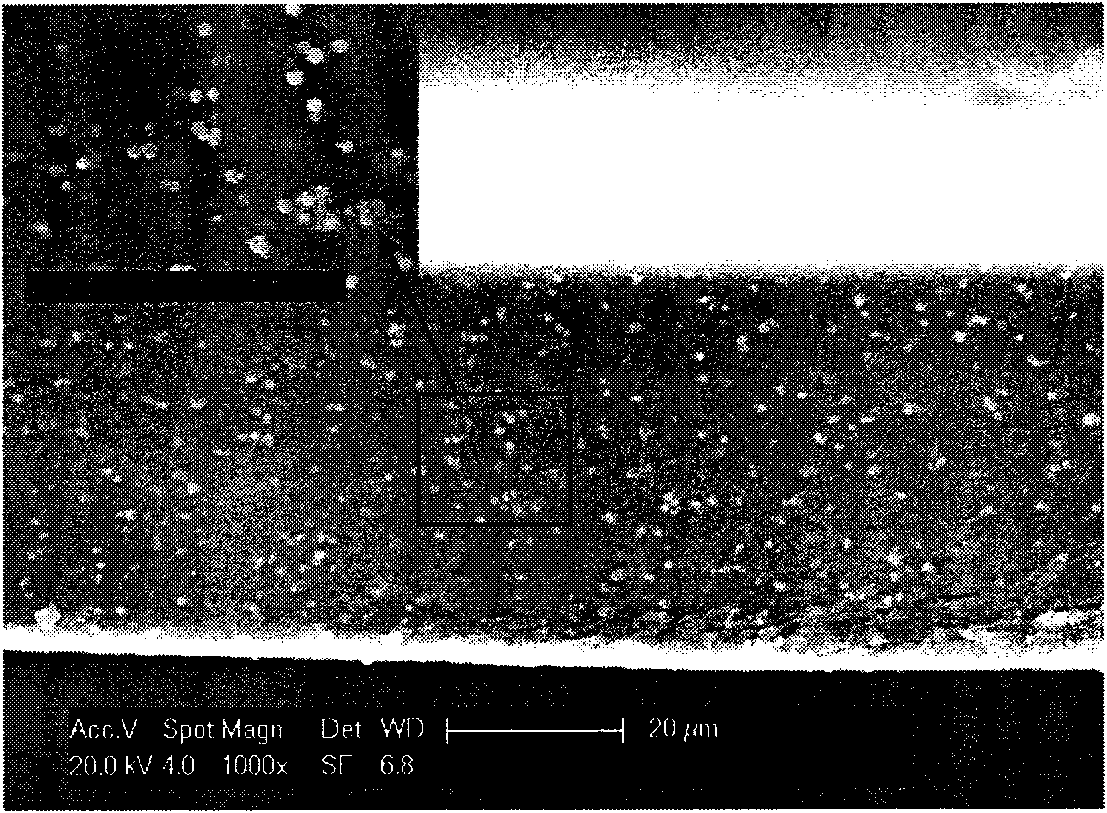

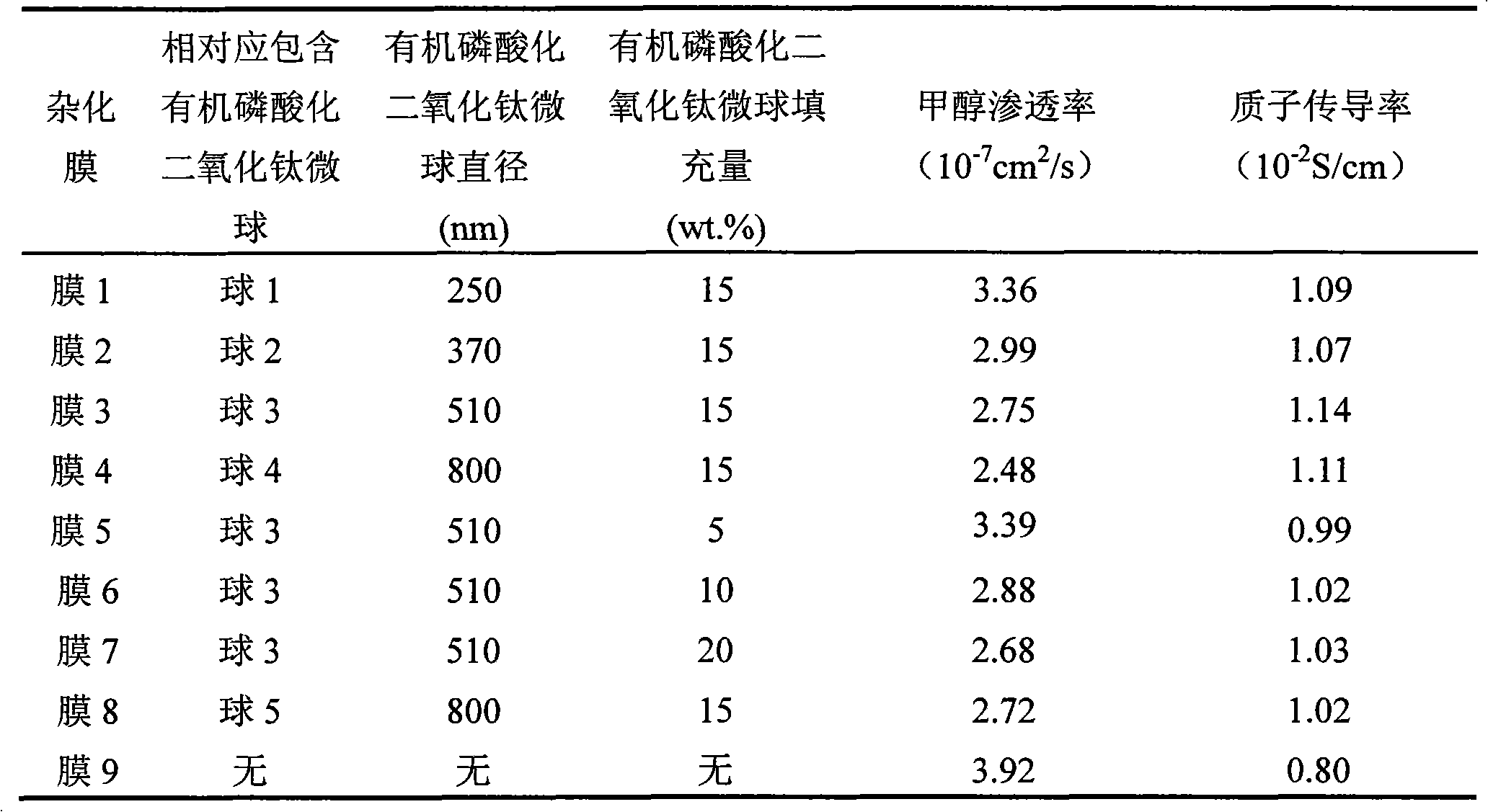

Organic phosphorylated titanium dioxide micrballon-filled chitosan hybrid membrane as well as preparation and application

InactiveCN101624449AEasy to makeUniform and controllable particle sizeCell component detailsSolid electrolyte fuel cellsO-Phosphoric AcidAqueous acetone

The invention relates to an organic phosphorylated titanium dioxide micrballon-filled chitosan hybrid membrane as well as a preparation and an application. The hybrid membrane is prepared by taking tetrabutyl titanate, glycol, organic phosphoric acid and chitosan as raw materials according to the following matching: the mole ratio of tetrabutyl titanate and glycol is 1:30-1:60 to prepare titanium dioxide micrballon, the mass volume ratio of titanium dioxide micrballon and organic phosphoric acid is 1:4-6, the mass ratio of titanium dioxide micrballon and chitosan is 0.05-0.2:1. The preparation method is as follows: the mixed solution of tetrabutyl titanate and glycol are precipitated in acetone water solution, washed and dried to obtain titanium dioxide micrballon which is put into organic phosphoric acid water solution for standing, the micrballon is put into glacial acetic acid water solution for ultrasound dispersion and is added with chitosan to obtain casting solution which subjects to casting on a substrate (glass plate) and is dried to form a membrane for crosslinking in sulphuric acid water solution, then washing and vacuum drying. The titanium dioxide micrballon and the membrane of the invention have rich source of raw materials, low cost and simple operation, and the prepared hybrid membrane has lower methanol permeability and higher proton conductivity, and can be used as direct methanol fuel cell membrane.

Owner:TIANJIN UNIV

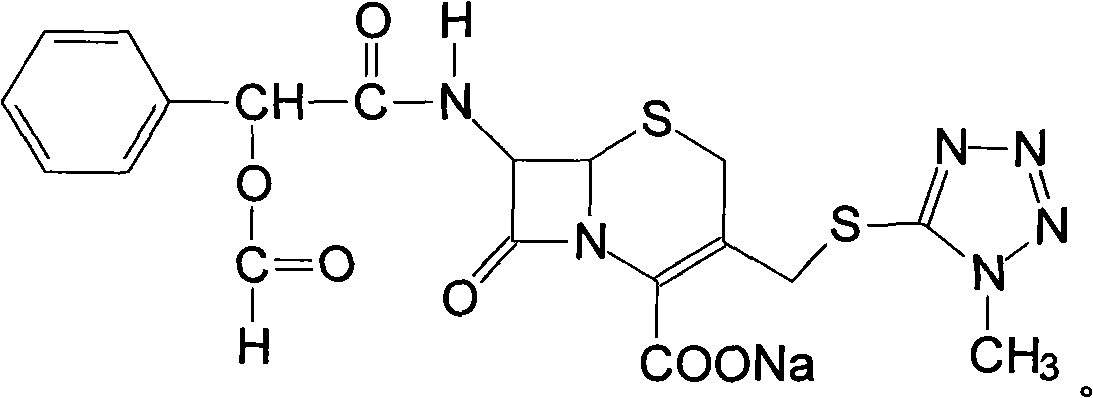

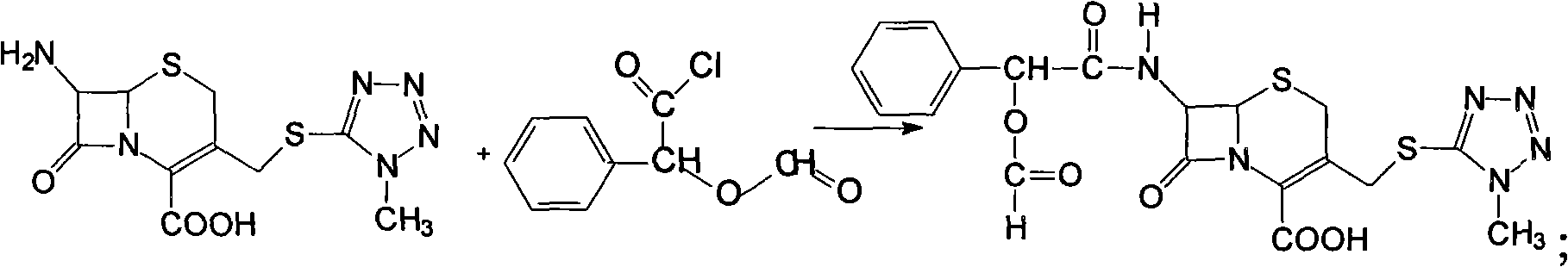

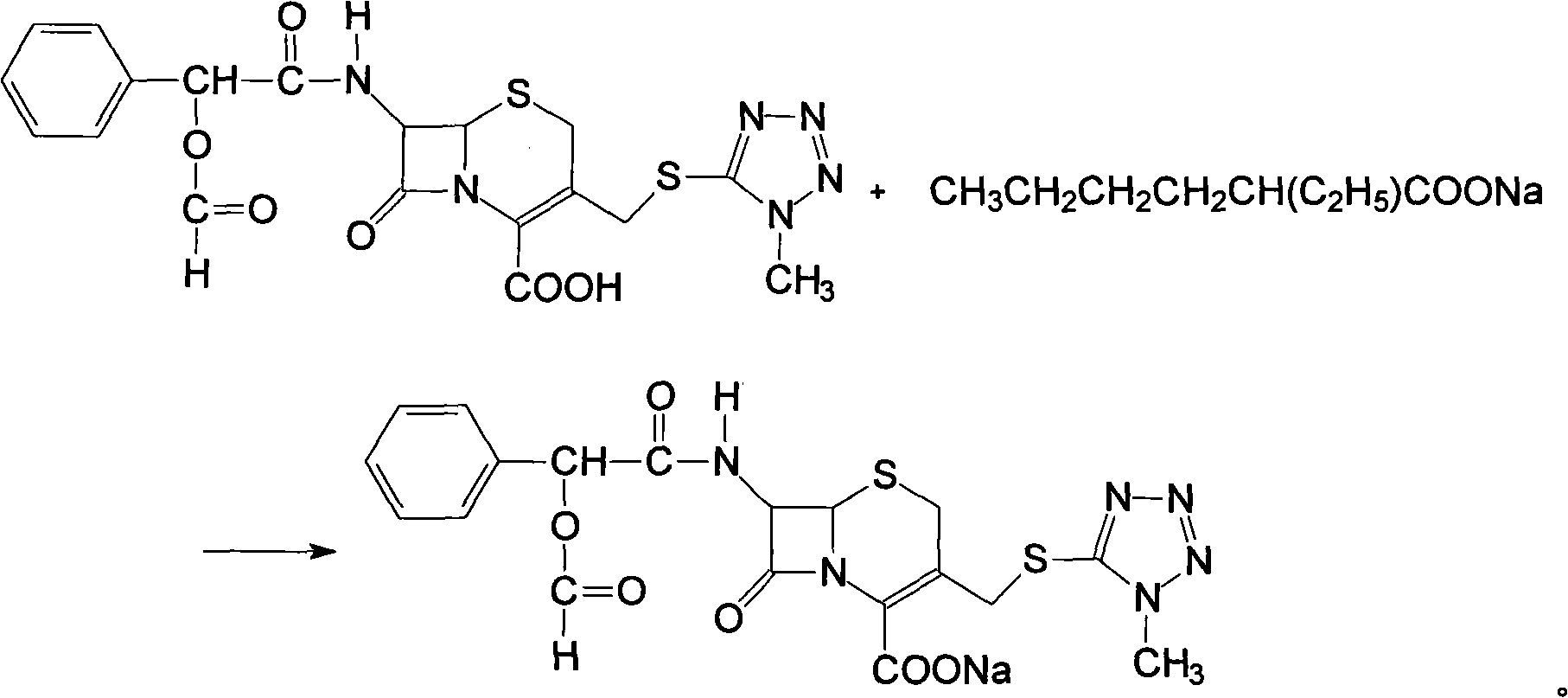

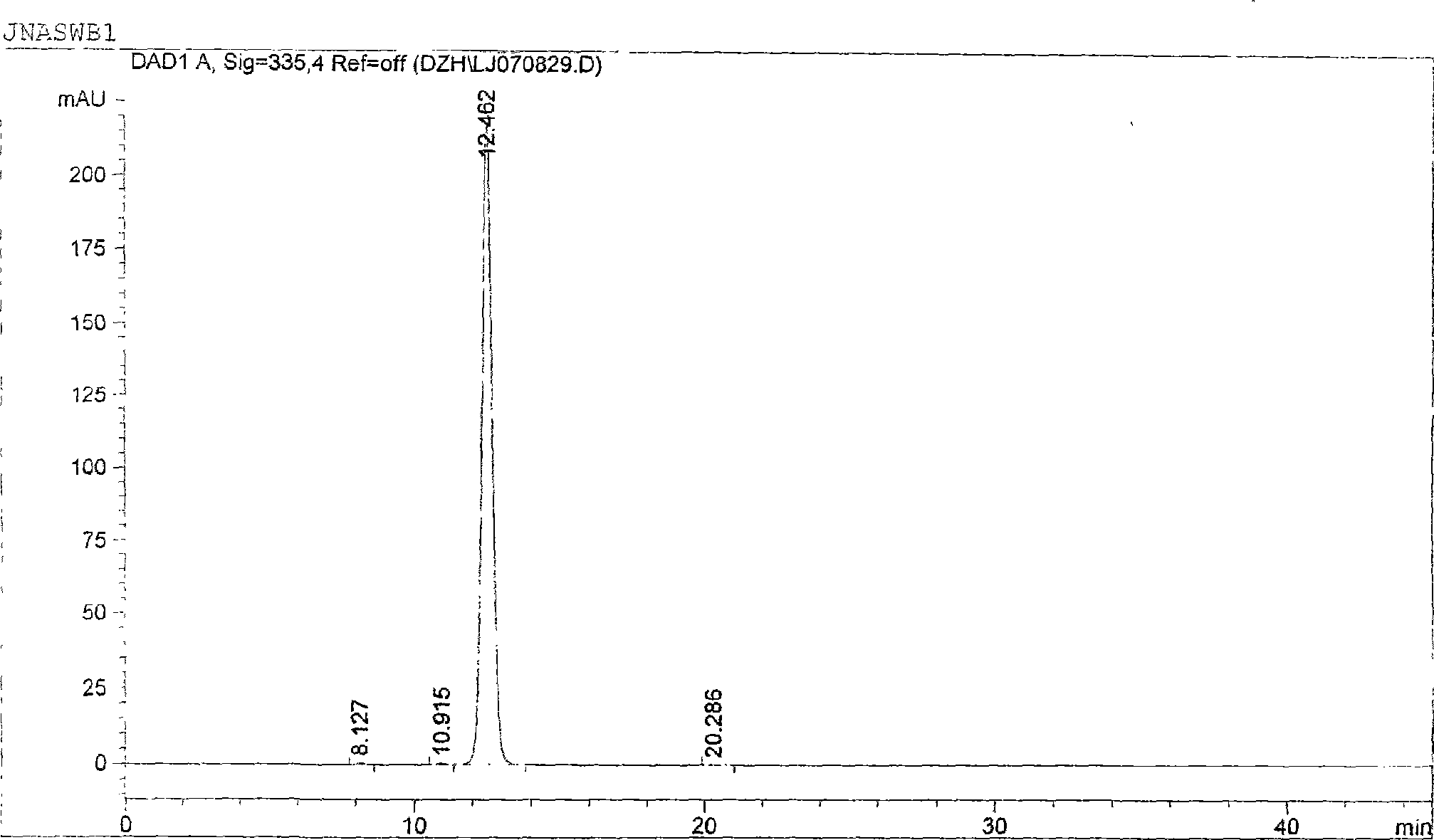

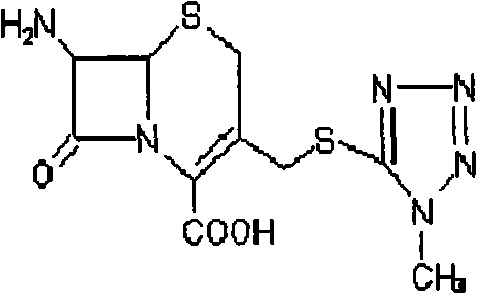

Preparation method of cefamandole nafate

ActiveCN101880290AReduce generationImprove conversion rateOrganic chemistrySodium bicarbonateOrganic acid

The invention discloses a preparation method of cefamandole nafate, which comprises the following steps: (1) suspending 7-amino-3-[(1-methyl-1H-tetrazol-5-yl) S-methyl] -3-cephem-4-carboxylic acid and sodium bicarbonate in an acetone water solution, adding the acetone solution of alpha-formylmandeloyl chloride to carry out a condensation reaction, and preparing 7-D-(2-formyloxy phenylacetamide)-3- [(1-methyl-1H-tetrazol-5-yl) S-methyl]-3-cephem-4-carboxylic acid; and (2) dissolving the 7-D-(2-formyloxy phenylacetamide)-3- [(1-methyl-1H-tetrazol-5-yl) S-methyl]-3-cephem-4-carboxylic acid in acetone to carry out a salification reaction with the acetone solution of organic acid sodium to prepare the cefamandole nafate. The method has the advantages of simple technology, high product yield, high purity, high reaction selectivity and use of no special equipment in production, and is suitable for industrialized production.

Owner:HAINAN HULUWA PHARMA GRP CO LTD

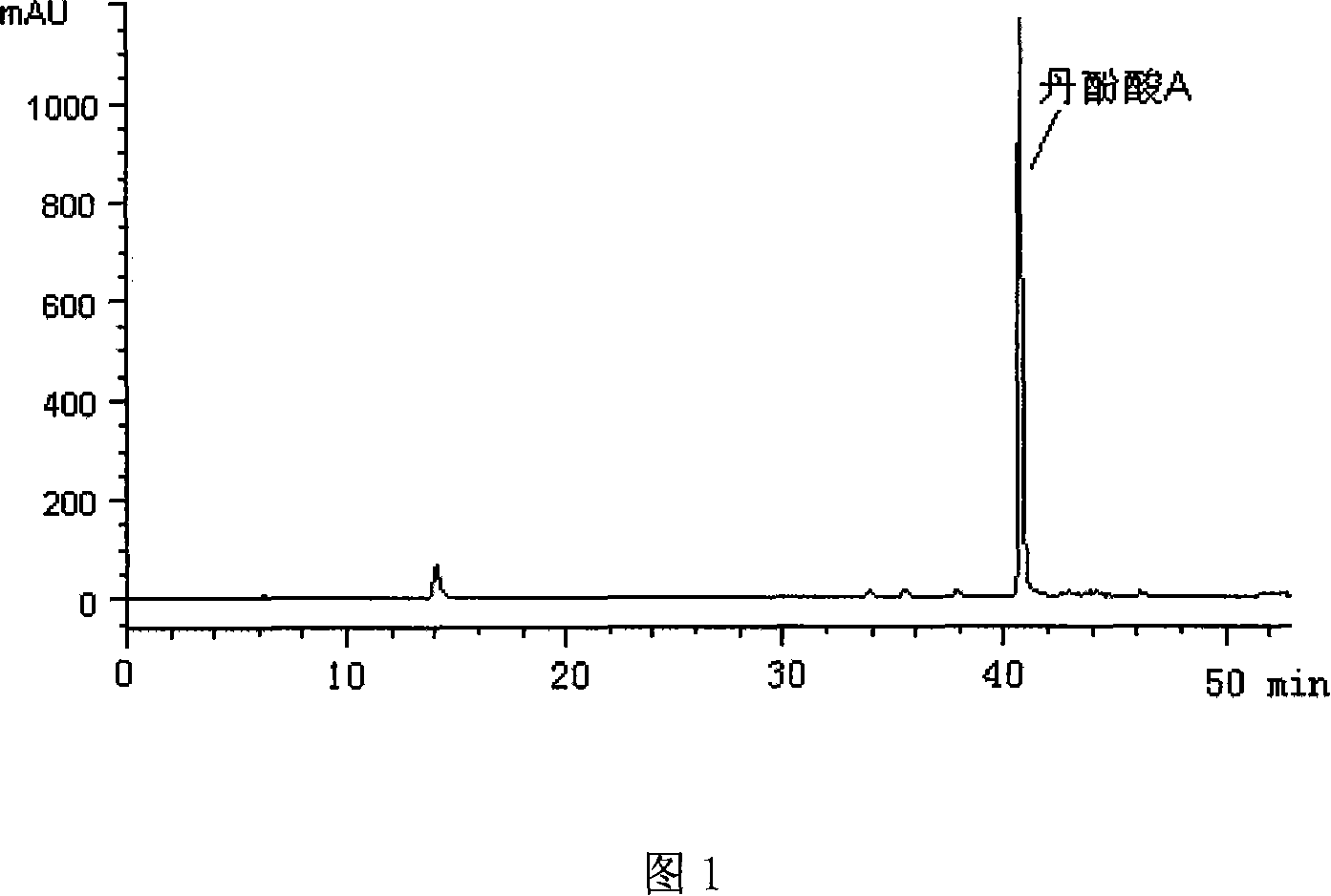

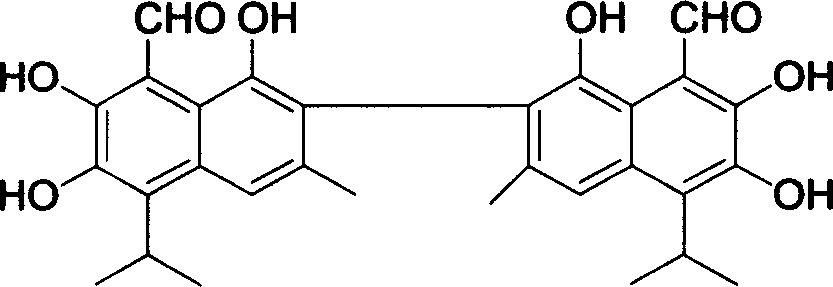

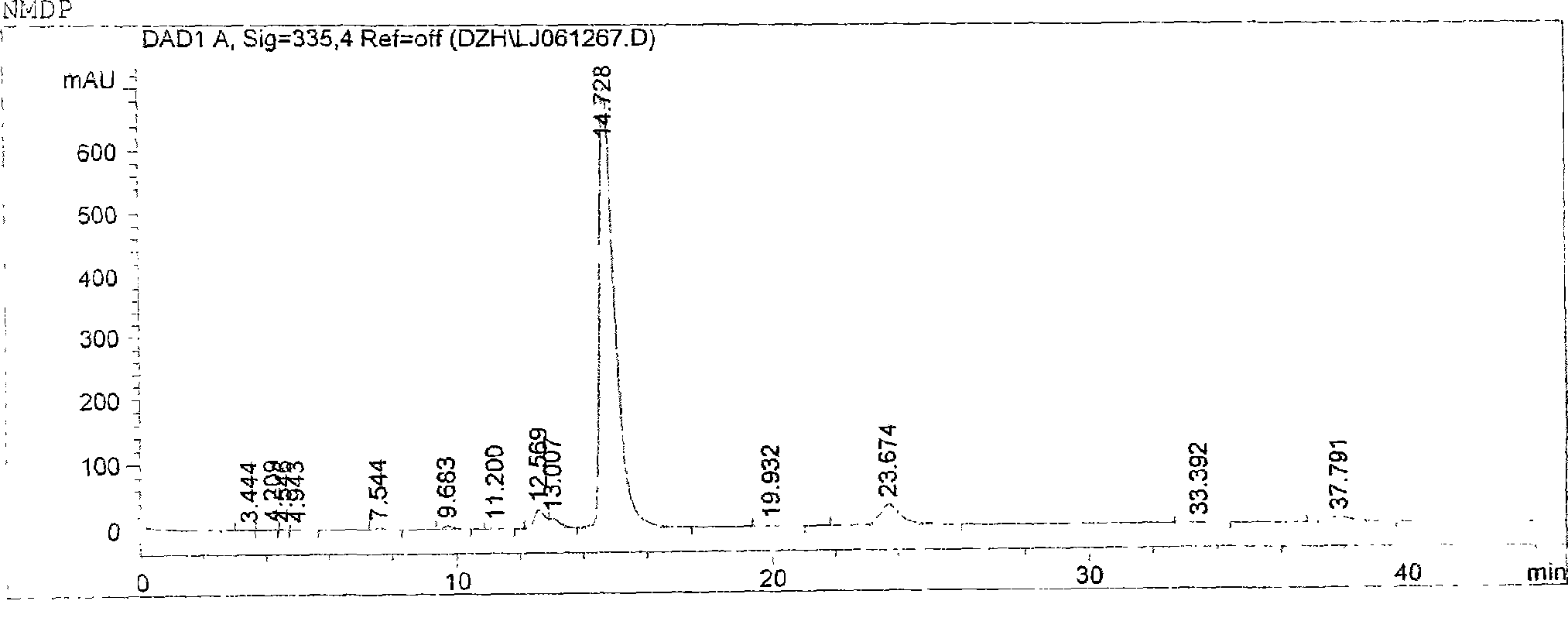

Method for extracting and purifying salvianolic acid A

InactiveCN101130498AHigh purityReach the purpose of separating and purifying salvianolic acid ACarboxylic acid esters separation/purificationPlant ingredientsAqueous acetoneSolvent

The invention discloses an extracting and purifying method of salviol acid A, which comprises the following steps: adopting salvia miltiorrhizae medicine materical crude slice or powder as raw material; using solvent to extract; condensing to obtain the condensate of salvia miltiorrhizae; obtaining high-purity product through protein adsorption and solvent extracting method; using gelatin or egg albumin to sediment salviol acid A; dissolving the salviol acid A through acetone solution; analyzing; extracting through organic solvent to obtain the high-purity product with receiving rate over 0. 3% and purity over 90%. The invention has advantages of reasonable design, high extraction rate, good purity, stable property, simple technique and low manufacturing cost without column chromatography, which is fit for industrial manufacturing.

Owner:ZHEJIANG UNIV

One-step prepn process of acid gossypol derivative with acid and acetone aqua

InactiveCN1887838AHigh extraction rateShort processing cycleChemical recyclingCarbonyl compound separation/purificationAqueous acetoneFormate

The present invention relates to preparation of gossypol derivative, and is especially one-step process of preparing gossypol derivative, such as gossypol acetate and gossypol formate as medicine material, in great amount and high efficiency through heating acidic acetone aqua. By means of extraction with acidic acetone aqua at 35-65 deg.c, concentrating, stilling to crystallize, separating, washing and refining, gossypol derivative is prepared. The process of the present invention has the features purify high yield, low cost, simple apparatus, short production period, easy refining, etc.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Preparation method of phyllemblic tannin

InactiveCN102327314AReduce dissolutionImprove extraction efficiencyEsterified saccharide compoundsAntibacterial agentsAqueous acetoneTannin

The invention discloses a preparation method of phyllemblic tannin. In the preparation method, phyllemblic dried fruits are used as raw materials. The process flow mainly comprises three parts: firstly, extracting grease substances in a phyllemblic medicinal material with supercritical carbon dioxide fluid and carrying out ultrasound extraction to obtain an extraction solution; secondly, condensing the extraction solution, adding a gelatine solution and centrifuging, dissolving a precipitate with an acetone water solution and filtering gelatine to obtain a preliminary purified solution; and thirdly, feeding the preliminary purified solution to macroporous resin for purifying, eluting with water and an ethanol water solution, condensing an eluent, freezing and drying to obtain the phyllemblic tannin. The preparation method disclosed by the invention is carried out below 50 DEG C and the change of chemistry and structure of tannin components in the conventional heat reflow extraction process caused by over-high temperature is avoided, so that the tannin with higher purity can be obtained by using the method and the tannin content in the product is greater than 55 percent. In addition, the method has a short extraction period, is safe and is suitable for industrial production. The invention lays a foundation for deeply researching pharmacological activities of the phyllemblic tannin components and a medicinal preparation.

Owner:NANJING ZELANG AGRI DEV

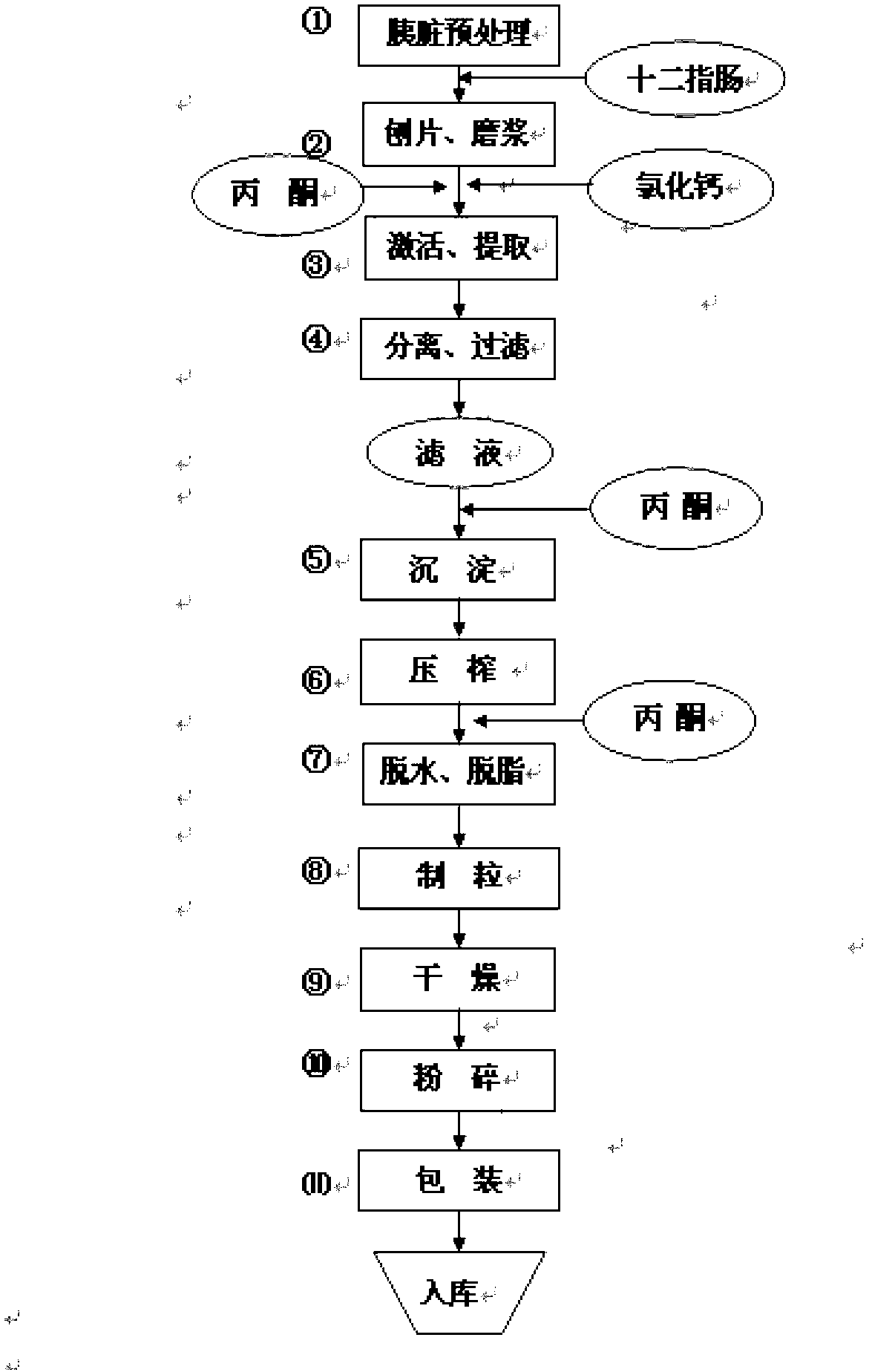

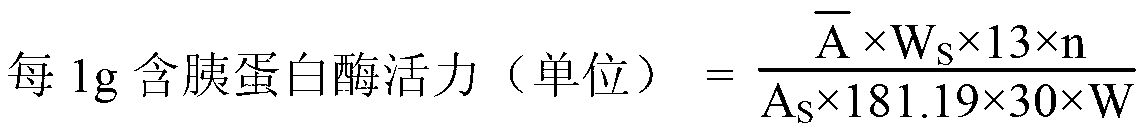

Novel production process of pancreatin

ActiveCN103215246AHigh yieldHyperamylaseDigestive systemPancreatinAqueous acetoneBiological activation

The invention discloses a novel production process of pancreatin, belonging to the technique of medicine manufacturing. The production process comprises the following steps of: unfreezing raw materials, polishing tablets, grinding into pulp, activating, separating, filtering, precipitating, squeezing, degreasing, palletizing, drying and crushing, wherein 0.2-0.5% CaCl2 is adopted as an activating agent in the step of activation, a 10-30% acetone solution is adopted for extraction, the extraction temperature is 5-15 DEG C, and the time is 8-20 hours. The productivity of pancreatin produced by using the production process is remarkably improved, and the ratios of pancreatic lipase and amylopsin are remarkably improved; and on such basis, the steps are further adjusted and optimized, so that the steps cooperate with one another so as to obtain a complete optimized production process, the pancreatin yield is about 14%, and the main indexes are that the trypsin content is about 3600 U / g, the amylopsin is about 100000 U / g, and the pancreatic lipase content is about 43000 U / g, and achieve the standard of exported pancreatin.

Owner:CHONGQING AOLI BIOPHARM

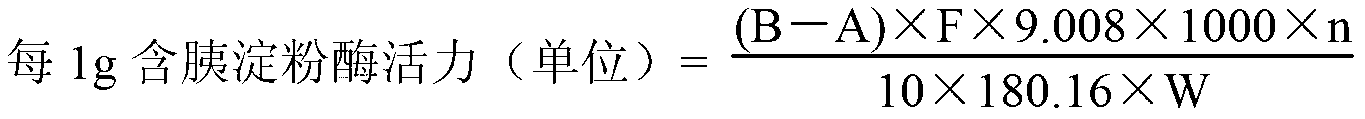

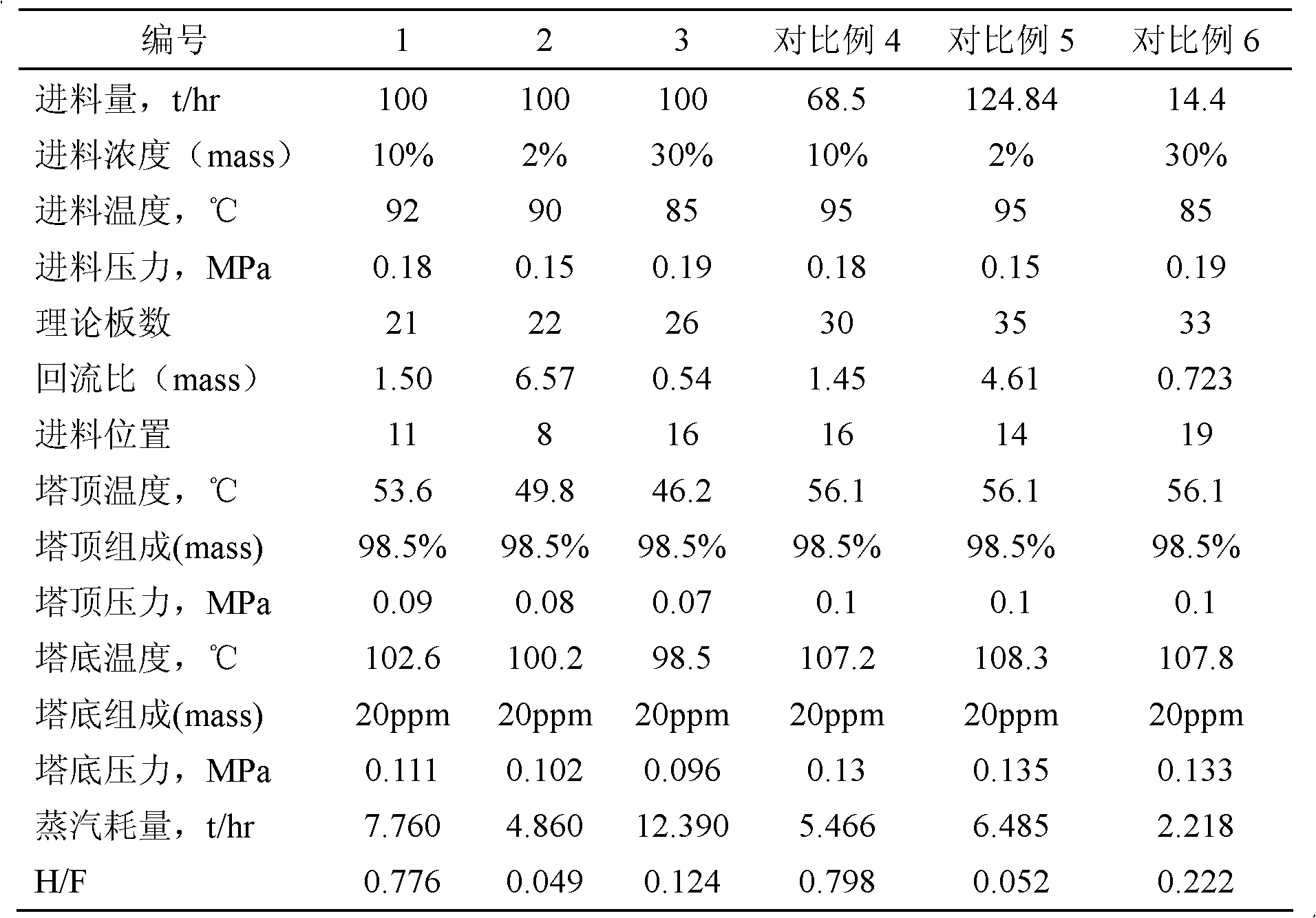

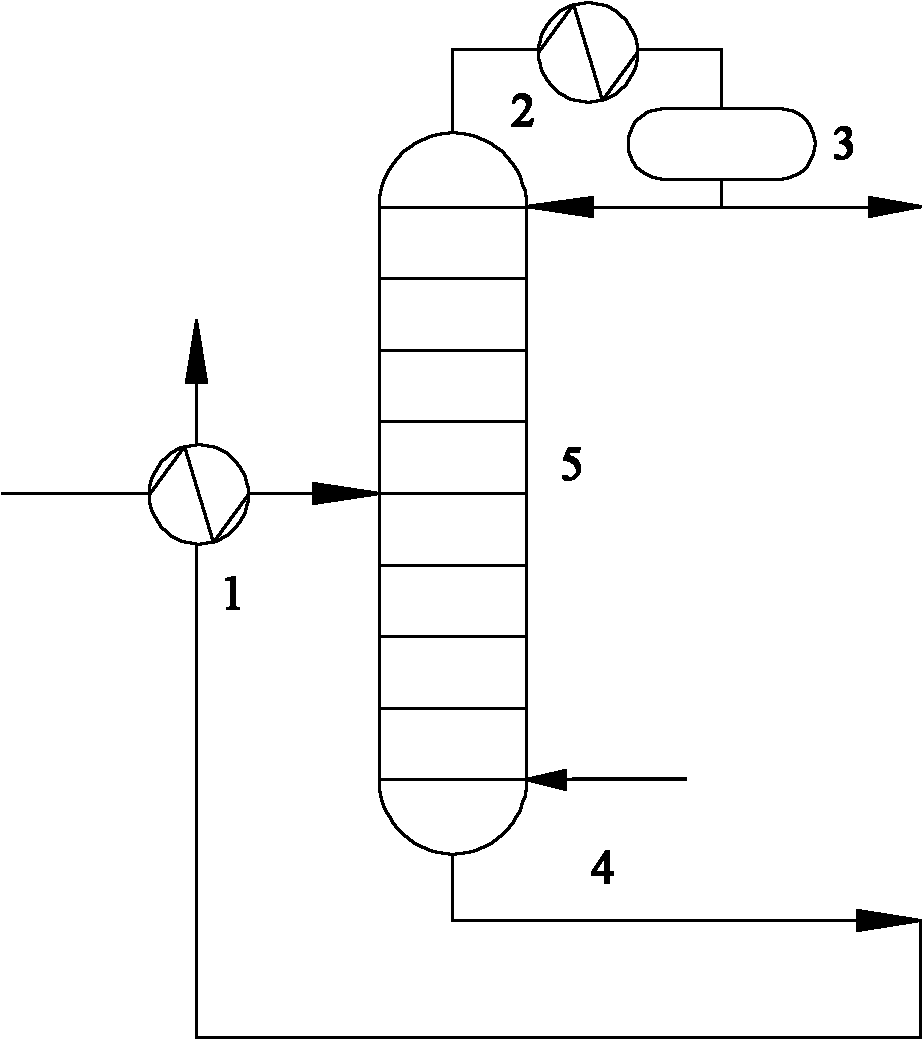

Method for recovering acetone from dilute acetone water solution by reduced-pressure steam stripping type rectification

ActiveCN102115436AReduce dosageReduced distillation operating costsCarbonyl compound separation/purificationRefluxAqueous acetone

The invention discloses a method for recovering acetone from a dilute acetone water solution by reduced-pressure steam stripping type rectification, which comprises steps as follows: an acetone-containing dilute solution and a high-temperature kettle liquid discharged from a tower kettle in a rectifying tower exchange heat through a heat exchanger, and the acetone-containing dilute solution enters the rectifying tower among 8#-16# tower plates of the rectifying tower after the temperature reaches 85-95 DEG C; the operating pressure intensity of the tower top is 0.07-0.09 MPa; the operating pressure intensity of the tower kettle is 0.120-0.130 MPa; and after the tower top distillate of the rectifying tower is cooled to 40-55 DEG C by a condenser, part of the distillate is recovered as an acetone product, and part of the distillate is used as reflux, wherein the reflux ratio of reflux mass to product mass is controlled within (0.5-6.6):1. The invention decreases the consumption of cooling water for steam on the top of the condensing tower as well as the consumption of tower bottom steam for heating, thereby lowering the operating cost for rectification. The invention has the characteristics of high accuracy, high sensitivity, high speed, convenience and the like, and can be easily implemented in industry.

Owner:ZHUHAI CELLULOSE FIBERS CO LTD

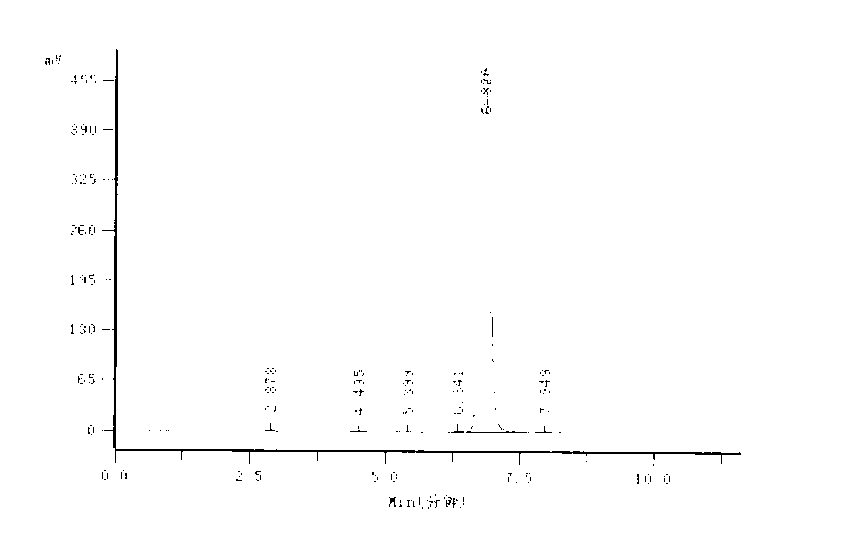

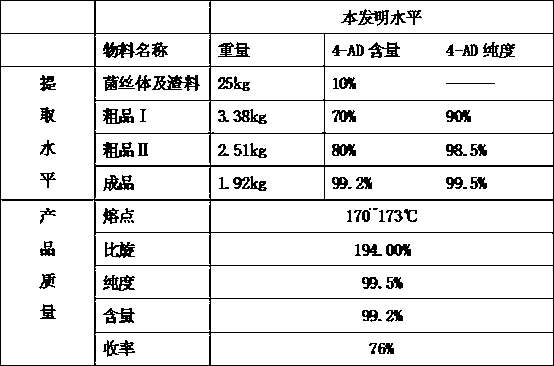

Method of extracting 4- androstenedione from plant sterol fermentation liquor

The invention discloses a method of extracting 4-androstenedione from plant sterol fermentation liquor. Particularly, 4-androstenedione crude products (I) and unreacted plant sterol are extracted from mycelium and slag charges which are separated from the fermentation liquor and soaked by acetone; the 4-androstenedione crude products (I) are dissolved and crystallized by acetone aqueous solution with a concentration of 50% so that crude products (II) are obtained; and the crude products (II) are recrystallized by alcohol so that pure 4-androstenedione is obtained, wherein the ratio of the alcohol to water is 1:10, and the unreacted plant sterol is recrystallized by the alcohol so that recovered plant sterol is obtained, wherein the ratio of the alcohol to water is 1:10. The method of extracting the 4-androstenedione from the plant sterol fermentation liquor is good in extraction effect, high in product purity, easy to operate, few in number of types of solvents used, capable of reducing environmental pollution, low in cost, short in process route and suitable for industrialized production. The unconverted plant sterol can be recovered and recycled.

Owner:SHANDONG DONGYAO PHARMACEUTICAL CO LTD

Preparation technique of high-purity scutellarin raw medicine

The invention relates to a method for preparing scutellarin bulk drug with a purity above 99%. The method comprises the following steps: (1) adopting macroporous resin with a type of D101 or AB-8 macroporous resin, and water as a solvent, and filling a column; (2) preparing a breviscarpin on-column solution; (3) feeding the on-column solution in the step (2) into the macroporous resin column in the step (1), eluting with water as an eluent until the eluate substantially becomes colorless, and collecting the eluate; (4) concentrating the eluate under the reduced pressure at 60 to 70 DEG C into 1 / 10 to 1 / 20 of the original volume; (5) adding acetone or ethanol with the amount 10-15 times of the concentrate, stirring, standing, precipitating, filtering, and washing out the mother liquid in the precipitate with acetone to obtain a breviscarpin salt; and (6) adding 30% to 50% acetone aqueous solution with the amount 5-10 times of the volume of the breviscarpin salt, stirring, regulating the pH to 1-2 with organic acid, standing, filtering to obtain precipitate, and washing with water to neutrality to obtained the scutellarin bulk drug with high purity.

Owner:KUNMING LONGJIN PHARMA

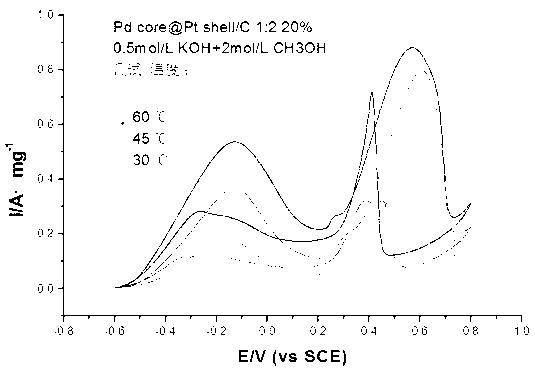

Photochemical preparation method for Pd core @Pt shell nanometer catalyst

InactiveCN102836707AThe size is easy to controlSimple preparation processCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystAqueous acetone

The invention provides a photochemical preparation method for a Pd core @Pt shell nanometer catalyst and relates to a preparation method for a catalyst. The preparation method comprises the following steps: taking and mixing PdCl2 aqueous solution, polyethylene glycol and acetone aqueous solution, thereby obtaining a mixed solution a; taking and mixing H2PtCl6 aqueous solution, polyethylene glycol and acetone aqueous solution, thereby obtaining a mixed solution b; irradiating the mixed solution a by adopting ultraviolet rays, thereby obtaining a nanometer Pd colloidal solution c; mixing the solution c with the mixed solution b, thereby obtaining a mixed solution d; irradiating the mixed solution d by adopting the ultraviolet rays, thereby obtaining a Pd core @Pt shell nanometer colloidal solution e; and under the condition of the colloidal solution e obtained through stirring, immersing a carbon carrier for 2-24h, leaching and washing with de-ionized water till no chlorine exists, thereby obtaining the Pd core @Pt shell nanometer catalyst. The catalyst nanometer grain obtained according to the technology has a core-shell compound structure; the size of the grain is easily controlled and the monodispersity is excellent; and the preparation method is widely applied to the field of low-temperature fuel cells.

Owner:SHENYANG INST OF ENG

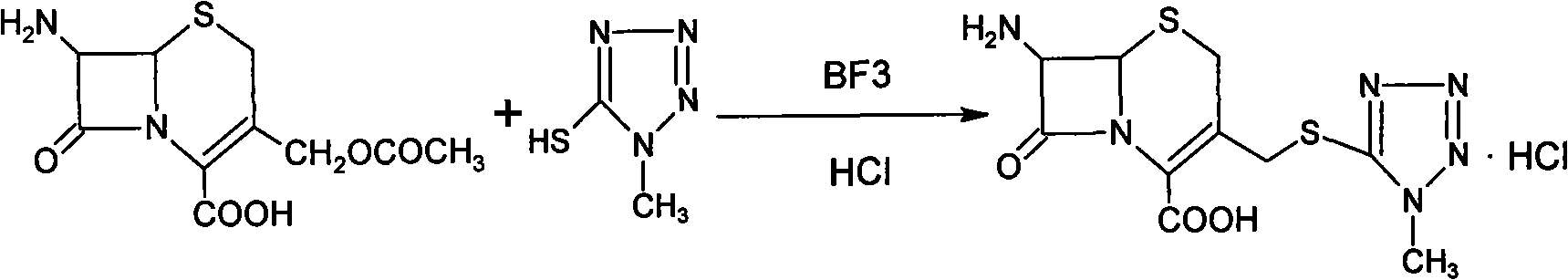

Method for synthesizing cephalosporin intermediate

The invention discloses a method for synthesizing a cephalosporin intermediate, which comprises the following steps: 1, adding 1-methyl-5-mercaptotetrazole and 7-amino-cephalosporanic acid into acetonitrile with stirring, heating the solution, and adding a boron trifluoride complex compound into the solution; 2, adding a proper amount of active carbon into the solution, stirring and filtering thesolution, washing the carbon by using aqueous solution of acetone containing hydrochloric acid, and merging filtrate; 3, adding the merged filtrate into the aqueous solution of acetone, stirring the solution, slowly dripping alkali solution till the pH value of the solution is 2.0 to 3.5, and growing crystals for 1 to 2 hours; and 4, filtering the solution, transferring the filtrate to another container, reclaiming the acetonitrile and the acetone, washing the obtained crystals twice to trice by using the acetone, filtering the solution, and then drying the crystals under vacuum. Aiming at the problem that the conventional method for synthesizing the cephalosporin intermediate is not suitable for industrialized production, the invention provides the method for synthesizing the cephalosporin intermediate; the method is simple and convenient to operate, is suitable for industrialized production and has high yield; and the prepared 7-ATCA.HCl has high purity.

Owner:SHANGHAI NEW ASIA PHARMA

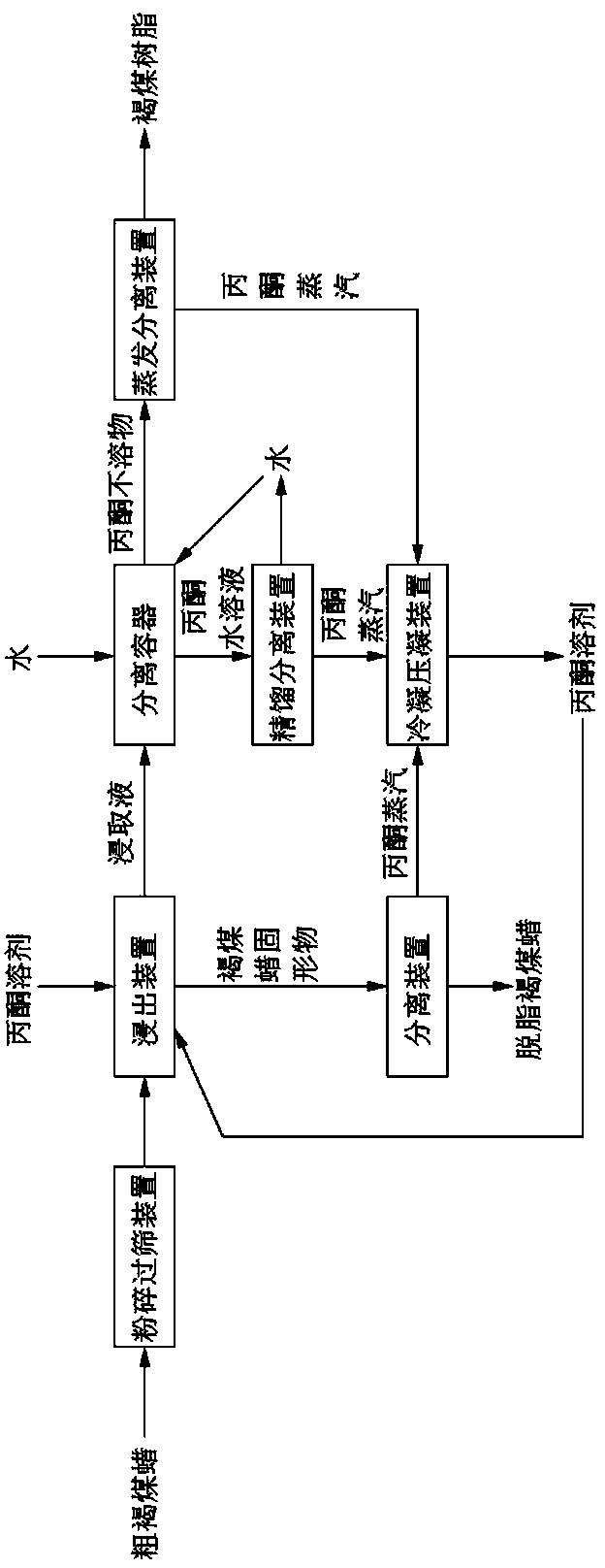

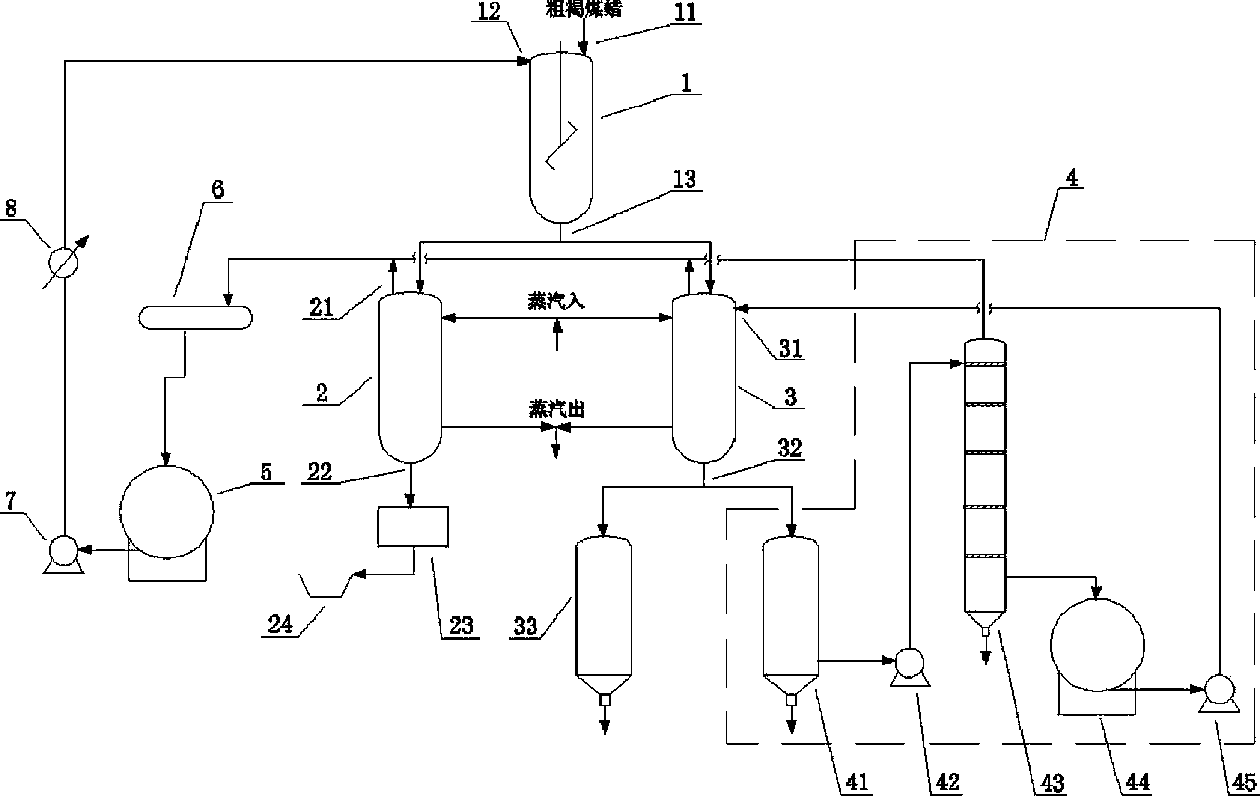

Energy-saving efficient resin-removing method and device for coarse lignite wax

ActiveCN103897734AEasy to recycleConsumableMineral wax recovery/refiningAqueous acetoneAqueous solution

The invention discloses an energy-saving efficient resin-removing method and device for coarse lignite wax. The resin-removing method comprises the following steps: smashing coarse lignite wax and sieving the smashed coarse lignite wax by a 0.5-3.0mm sieve; then, leaching the sieved lignite wax particles and acetone in a solid-to-liquid ratio of 1:1-1:8kg / L at constant temperature for 2-4 hours and separating to obtain a leaching liquid and a solid; placing the solid in a separating device, and heating, evaporating and removing residual acetone to obtain degreased lignite wax; placing the leaching liquid in a separating container, adding water to separate resin from acetone, and carrying out solid-liquid separation to obtain acetone insolubles and an acetone aqueous solution; and recovering acetone by rectifying the acetone aqueous solution; and evaporating the acetone insolubles to obtain walchowite. The degreasing device comprises a degreasing kettle, a ceride-removing desolventizing tank, a resin desolventizing separating tank, a rectifying device, an acetone storage tank and a condenser. According to the energy-saving efficient resin-removing method and device disclosed by the invention, as resin in lignite wax is easy to dissolve in acetone at constant temperature, wax and asphaltos are not dissolved, and the resin content in wax is reduced by digestion and separation at constant temperature, so that the device is simple and energy-saving and environment-friendly in process.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

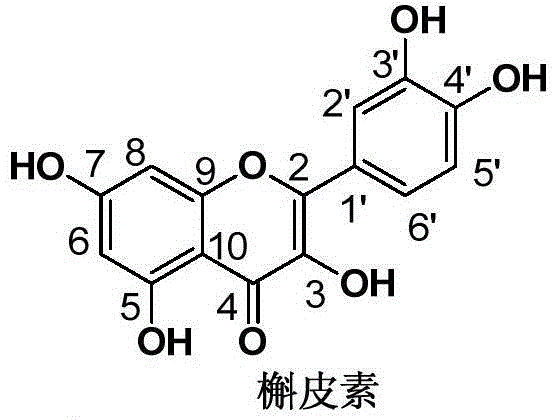

Method for extracting quercetin from eleocharis tuberosa peels

ActiveCN104592185AScientific and reasonable designEasy to separateOrganic chemistryChromatographic separationAqueous acetone

The invention discloses a method for extracting quercetin from eleocharis tuberosa peels and belongs to the field of natural organic chemistry. The method is characterized by comprising the following steps of by using an acetone aqueous solution as a solvent, extracting quercetin from the eleocharis tuberosa peels, extracting an extract with ethyl acetate, separating an extractant with a middle-pressure MCI column chromatography and a polyamide column chromatography and purifying with Sephadex LH-20 gel and silica gel column chromatography to obtain a quercetin product of which the content of quercetin is not less than 95%. The method opens up a novel way for extracting and separating quercetin from natural plants, the good separation effect is achieved, the product is high in purify, the eleocharis tuberosa peels, which are always regarded as wastes, are changed into treasure, the selected chromatographic material MCI, polyamide and gel can be repeatedly used, the raw materials are easily available and are rich in resources, the method is low in production cost, the large-scale production can be performed and the method meets the needs of pharmaceutical industry.

Owner:HEZHOU UNIV

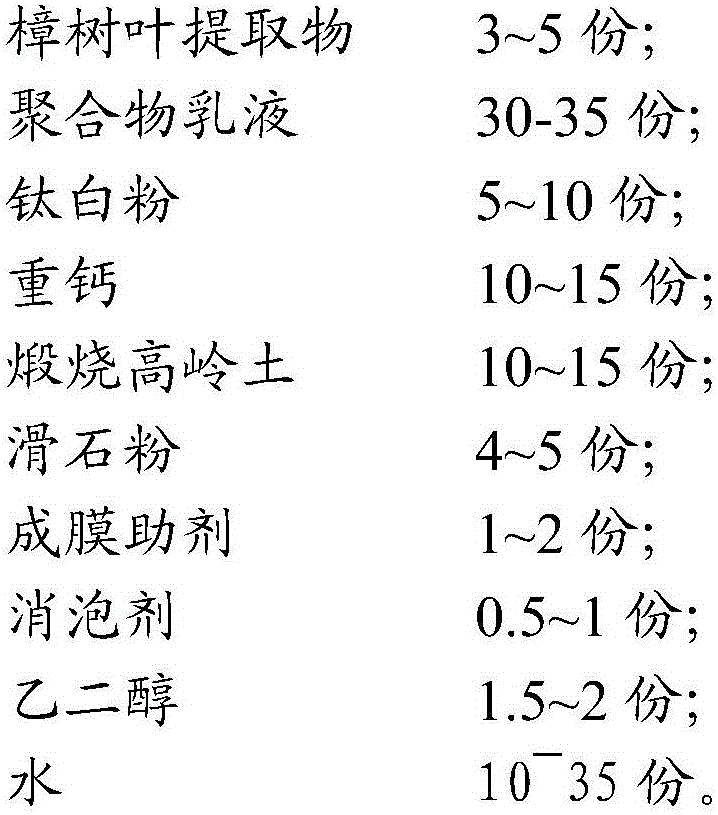

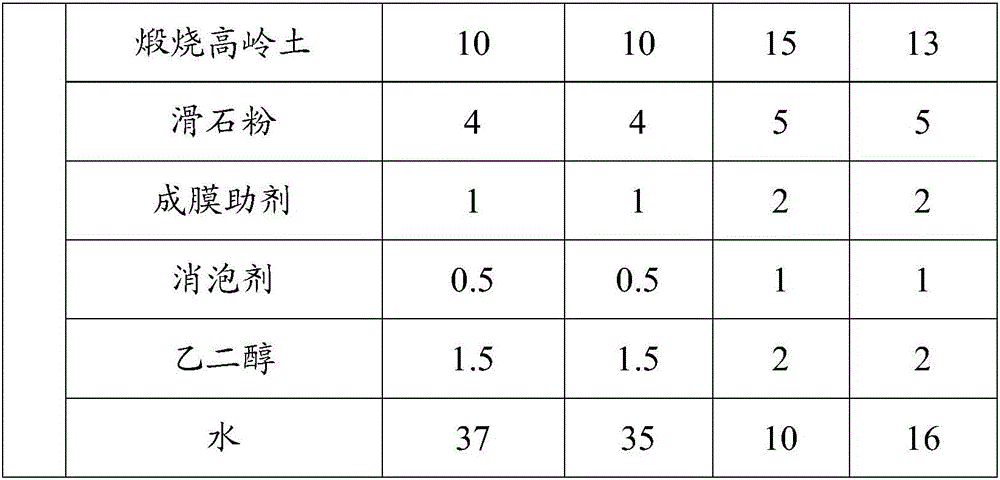

Plant antimicrobial paint

InactiveCN106497425AImprove mildew resistanceExtended shelf lifeAntifouling/underwater paintsPaints with biocidesAqueous acetoneFreeze-drying

The invention discloses plant antimicrobial paint. The plant antimicrobial paint is prepared from extracts from leaves of camphor trees, a polymer emulsion, titanium dioxide, coarse whiting, calcined kaolin, talcum powder and acceptable additives in the paint. The extracts from the leaves of the camphor trees is dry powder prepared by that fresh leaves of the camphor trees is dried for 10 hours at a low temperature of 45 DEG C, and then subjected to crushing and screening. According to the weight ratio of 1:20, the dry powder of the leaves of the camphor trees is subjected to Soxhlet reflux extraction for 8 hours at about 80 DEG C with an acetone aqueous solution with the concentration of 50%, and an extracting solution is obtained; the extracting solution is distilled and then subjected to freeze drying, and the plant antimicrobial paint is prepared. The plant antimicrobial paint has the advantages that the extracts from the leaves of the camphor trees serve as a high-efficiency mildew preventive which has excellent anti-mold properties, so that the plant antimicrobial paint is long in shelf life, and the paint film is not prone to going moldy after the paint used for brush coating; the extracts from the leaves of the camphor trees are natural plant extracts, so the paint is environmentally friendly and free of toxicity and harm to human body; the paint is reasonable in composition and low in cost and has an excellent application value, and the compatibility among all the compositions is good.

Owner:中山市丽莎涂料有限公司

Longan seed polyphenol extraction and purification method and application of longan seed polyphenol in preparing polyphenol whitening cosmetics

ActiveCN104473825AGood at inhibiting tyrosinaseAnti-wrinkleCosmetic preparationsToilet preparationsSolubilityPurification methods

The invention discloses a longan seed polyphenol extraction and purification method and application of the longan seed polyphenol in preparing polyphenol whitening cosmetics. The method comprises the following steps: respectively treating longan seed powder with anhydrous acetone and a 50-70% acetone water solution three times, merging the second and third filtrates, and recovering the acetone to obtain the polyphenol; and purifying the extracted polyphenol with a macroporous adsorbent resin, and carrying out vacuum concentration to a dry state to obtain the purified polyphenol. The method has the advantages of high extraction rate and recoverable organic solvent; water in the extracting solution does not need to be evaporated by heating; the room-temperature or low-temperature treatment is beneficial to protecting the product and saving the energy; the purified product has higher solubility; and the method is convenient for compounding the product, provides a brand-new application for longan seeds, develops four cosmetics with wide market prospects (polyphenol whitening nutritive facial cleanser, polyphenol whitening nutritive toner, polyphenol whitening nutritive lotion and polyphenol whitening nutritive cream), and also provides a wide-prospect way for integrated application and development of longan seeds.

Owner:广东创美抗衰老研究有限公司

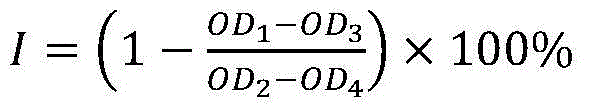

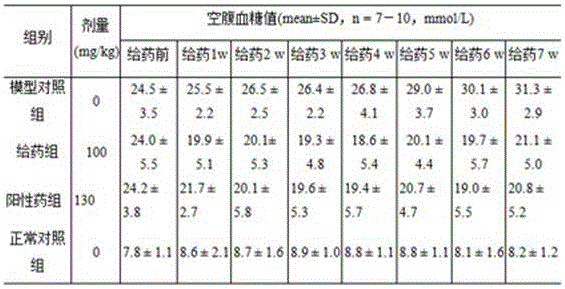

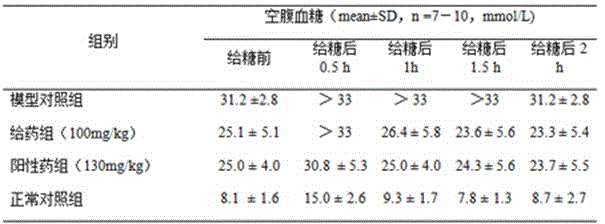

Dendrobium loddigesii rolfe extract and anti-diabetic application thereof

The invention relates to a dendrobium loddigesii rolfe extract and anti-diabetic application thereof. The dendrobium loddigesii rolfe extract is obtained by quenching stems of dendrobium loddigesii rolfe into an acetone water solution and separating and purifying an extract through resin. An experiment proves that the dendrobium loddigesii rolfe extract has significant hypoglycemic activity, and can be used for treatment and healthcare of diabetes. The invention further provides an anti-diabetic pharmaceutical composition and a health food containing the dendrobium loddigesii rolfe extract.

Owner:SUN YAT SEN UNIV

Method for extracting flavonoid compound from marigold residue

InactiveCN102516335AProcess parameters are reasonableSimple process routeSugar derivativesSugar derivatives preparationAqueous acetoneImpurity

The invention discloses a method for extracting a flavonoid compound from a marigold residue. The method comprises the steps of: (1) conducting extraction on the marigold residue with an acetone water solution so as to obtain a crude extraction solution; (2) concentrating the crude extraction solution so as to obtain a concentrated solution, which is then cooled to obtain a crude extract; and (3) eluting the crude extract with n-hexane so as to obtain a fat-soluble impurity removed crude extract, which is then eluted by a sodium hydrogen phosphate-citric acid buffer solution, thus obtaining a product. The method of the invention takes a marigold residue as the raw material, which is subjected to crushing, sieving, as well as rapid and effective extraction of a flavonoid substance by a water solution of the organic solvent. And through concentration, precipitation, drying, and purification, an obtained yellow substance has a flavonoid compound content of over 90g RE / 100g. The method provided in the invention has the advantages of reasonable technical parameters, simple technological path, simple and safe operation, high yield, low equipment and production cost, and great practical value as well as social and economic benefits.

Owner:CHINA AGRI UNIV

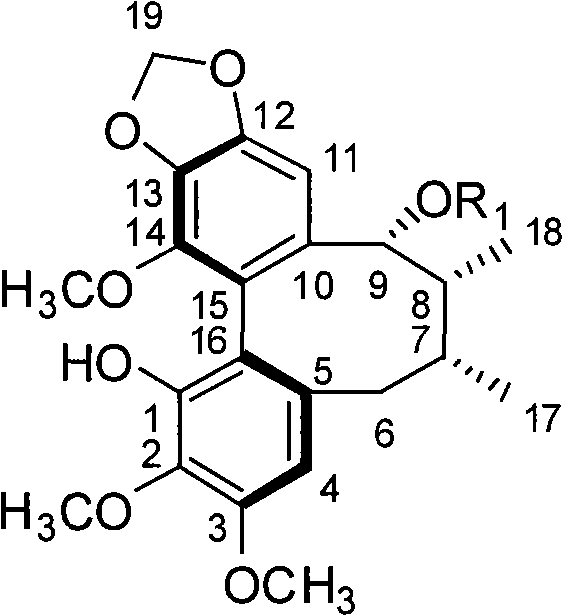

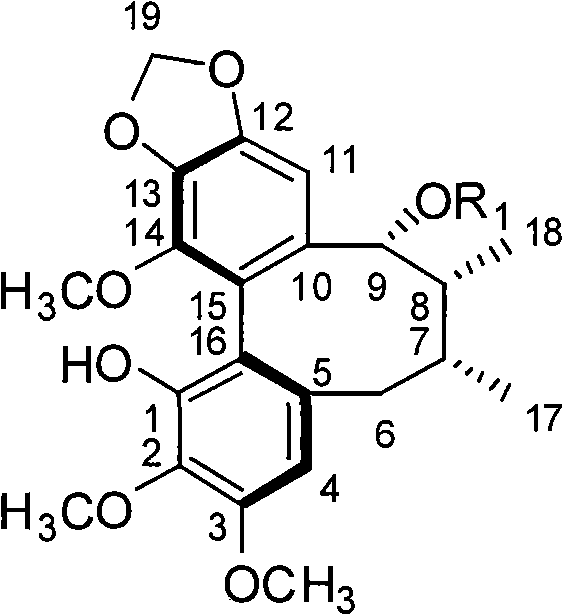

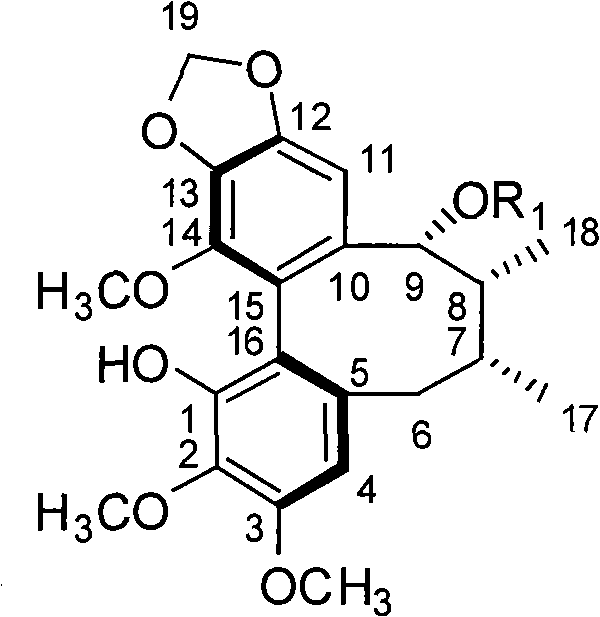

Dibenzocyclooctadiene lignan, preparation method and use thereof

InactiveCN101555242AGood anti-inflammatory effectEasy to prepareOrganic chemistryAntipyreticAqueous acetoneDibenzocyclooctadiene lignan

The invention discloses a dibenzocyclooctadiene lignan and a preparation method thereof. The preparation method comprises the following steps of taking roots and stems of Kadsura coccinea (Lem.) A C. as raw materials, smashing the raw materials, then using acetone water solution with the volume concentration of 50-95 percent for extracting for 1-10 times with each time lasting 5-50 hours, mergingextract liquid, concentrating, obtaining a liquid extract, then sequentially using cyclohexane, chloroform, ethyl acetate and n-butanol for extracting, and carrying out column chromatography on the part of a chloroform layer by using a silica gel column, thereby obtaining the dibenzocyclooctadiene lignan. The lignan has good anti-inflammation effect and good application prospect in the preprationof anti-inflammation drugs, thereby having significant and positive significance.

Owner:SUZHOU UNIV

Method for preparing high-purity 4'-epi-daunorubicin

InactiveCN102190691AHigh puritySimple methodSugar derivativesSugar derivatives preparationAqueous acetoneDaunorubicin

The invention provides a method for preparing high-purity 4'-epi-daunorubicin, which comprises the following steps of: a) loading the treated 4'-epi-daunorubicin fermentation liquor on macroporous weak acid resin, and eluting by using aqueous solution of acetone or methanol added with hydrochloric acid; b) evaporating the 4'-epi-daunorubicin eluent to dryness, dissolving in water, and extracting by using chloroform; and c) loading the 4'-epi-daunorubicin extracting solution on nonpolar adsorption resin, and eluting by using aqueous solution of acetone to obtain the 4'-epi-daunorubicin. The method has simple steps, is suitable for large-scale industrial production, and has high commercial value; and the final purity of the prepared 4'-epi-daunorubicin is improved to over 97 percent.

Owner:SHANGHAI INST OF PHARMA IND CO LTD

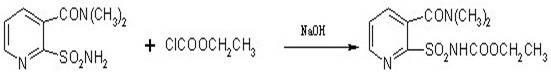

Method for synthesizing 2-ethoxycarbonylaminosulfonyl-N,N-dimethyl nicotinamide

ActiveCN102382049ASimple and thorough separationHigh yieldOrganic chemistryEthyl chloroformateAqueous acetone

The invention relates to a novel method for synthesizing 2-ethoxycarbonylaminosulfonyl-N, N-dimethyl nicotinamide. 2-ethoxycarbonylaminosulfonyl-N,N-dimethyl nicotinamide is prepared by the following steps of taking liquid alkali as an acid binding agent; performing reaction of 2-aminosulfamide-N,N-dimethyl nicotinamide and ethyl chloroformate; adding 2-aminosulfamide-N,N-dimethyl nicotinamide into an acetone aqueous solution, adding ethyl chloroformate and liquid alkali into acetone aqueous solution while stirring; preserving heat till the completion of the reaction, distilling and recyclingacetone; filtering; separating; and drying to obtain the finished product. The product prepared by the method saves energy and reduces consumption and achieves the environmental safety; no pollutantssuch as carbon dioxide and salt-containing waste water are generated; and the yield and the content of the 2-ethoxycarbonylaminosulfonyl-N,N-dimethyl nicotinamide is high.

Owner:ANHUI FENGLE AGROCHEM

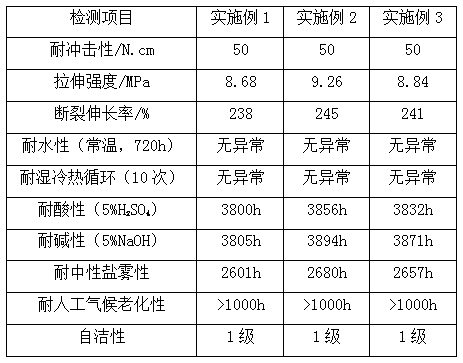

Strong-weatherability epoxy resin powder coating and preparation method thereof

InactiveCN108264821AStrong resistance to heat and humidityImprove corrosion resistanceFireproof paintsAnti-corrosive paintsMonomer compositionEpoxy

The invention relates to the technical field of an epoxy resin powder coating, and more specifically relates to a strong-weatherability epoxy resin powder coating and a preparation method thereof. Thestrong-weatherability epoxy resin powder coating is prepared by epoxy resin, a curing agent, hydroxyl silicone oil, a silane coupling agent, salicylic acid, an acetone aqueous solution, polyvinylidene fluoride, polyvinyl fluoride or polytetrafluoroethylene, an ABS resin monomer composition, an initiator, water, an inorganic mineral filler, a levelling agent and an UV absorbent. The epoxy resin ismixed with hydroxyl silicone oil and the silane coupling agent to form organosilicon modified epoxy resin, the organosilicon modified epoxy resin is mixed with a mixture of polyvinylidene fluoride, polyvinyl fluoride or polytetrafluoroethylene, and the ABS resin monomer composition, and extrusion moulding is carried out to obtain the epoxy resin powder coating, the epoxy resin participates in anorganic silicone resin system, the material and the ABS resin composition form a high-molecular polymerization structure through polyvinylidene fluoride for further modification, and the strong-weatherability epoxy resin powder coating has the advantages of damp heat resistance, corrosion resistance, strong weatherability, good mechanical property, convenient preparation, concise process, and safety and non toxicity.

Owner:ZHEJIANG HUACAI NEW MATERIAL CO LTD

Method for extracting mulberry root ketone C

InactiveCN102040611AReduce dissolutionSolve the problem of small processing volumeOrganic chemistryAqueous acetoneSilica column

The invention relates to a method for extracting mulberry root ketone C. The process method provided by the invention comprises the following steps: crushing white mulberry root-bark into small grains; carrying out ultrasonic extraction for 2-3 times by utilizing an alkali aqueous solution the pH value of which is 9-11; regulating the pH value to 7-8 by the extraction; absorbing by adding macroporous resin; eluting by an ethanol solution; recycling ethanol after eluting; regulating the acidity, and precipitating; dissolving the precipitates in acetone, and then, adding a silicagel column for separating; carrying out gradient elution by an acetone aqueous solution; concentrating and crystallizing; recrystallizing by a methanol chloroform solution; and drying to obtain a product. The method provided by the invention has the advantage of simple operation and solves the difficulty that the conventional silicagel column separation can not expand the production, and the content of the obtained product is relatively high.

Owner:NANJING ZELANG MEDICAL TECH

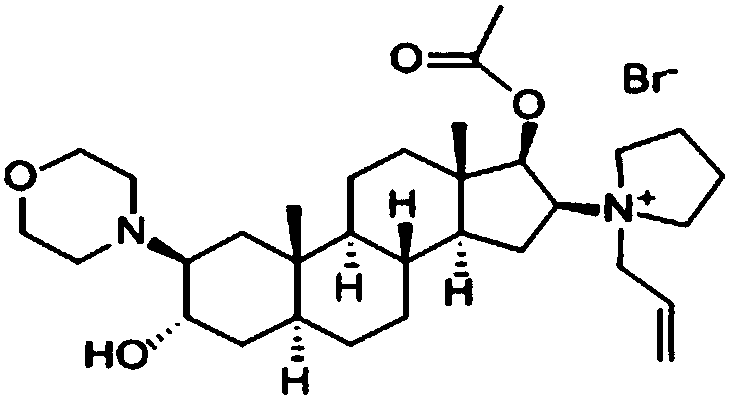

Preparation method of high-purity rocuronium bromide

The invention provides a preparation method of high-purity rocuronium bromide. The preparation method comprises the steps of enabling a rocuronium bromide crude product to be dissolved in acetone water solution, filtering, vacuum-concentrating, adding normal heptane for homogenizing, pulping and the like. The provided preparation method of the high-purity rocuronium bromide has many advantages ofextremely low solvent residual quantity, extremely high HPLC purity, extremely low related substance content, extremely high stability and the like.

Owner:江苏盈科生物制药有限公司

Anticorrosive tough coating material for outdoor communication tower, and preparation method thereof

InactiveCN110684440AGood dispersionGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsXylyleneFiber

The invention discloses an anticorrosive tough coating material for an outdoor communication tower, and a preparation method thereof, wherein the anticorrosive tough coating material is prepared fromthe following raw materials by weight: 12-18 parts of a polytrifluorochloroethylene resin, 35-45 parts of a bisphenol A type epoxy resin, 8-12 parts of polyphenylmethylsiloxane, 2-6 parts of alpha,omega-dihydroxy polydimethylsiloxane, 2-6 parts of amino-modified polysiloxane, 2-6 parts of hexamethyldisilazane, 2-6 parts of gas-phase nanometer silicon dioxide, 7-11 parts of silicon carbide short fibers, 12-16 parts of mica iron oxide powder, 2-8 parts of xylene, 10-20 parts of an acetone aqueous solution and 1-3 parts of a polyamine mixed curing agent. According to the invention, the prepared anticorrosive tough coating material has excellent anticorrosive performance, weather resistance and good elasticity; and by coating the communication tower with the anticorrosive tough coating material, the coating is compact, has excellent anticorrosive, anti-aging, hydrophobic, stain-resistant and impact-resistant effects, can well adapt to severe environments, and effectively prolongs the service life of the communication tower.

Owner:广西凯威铁塔有限公司

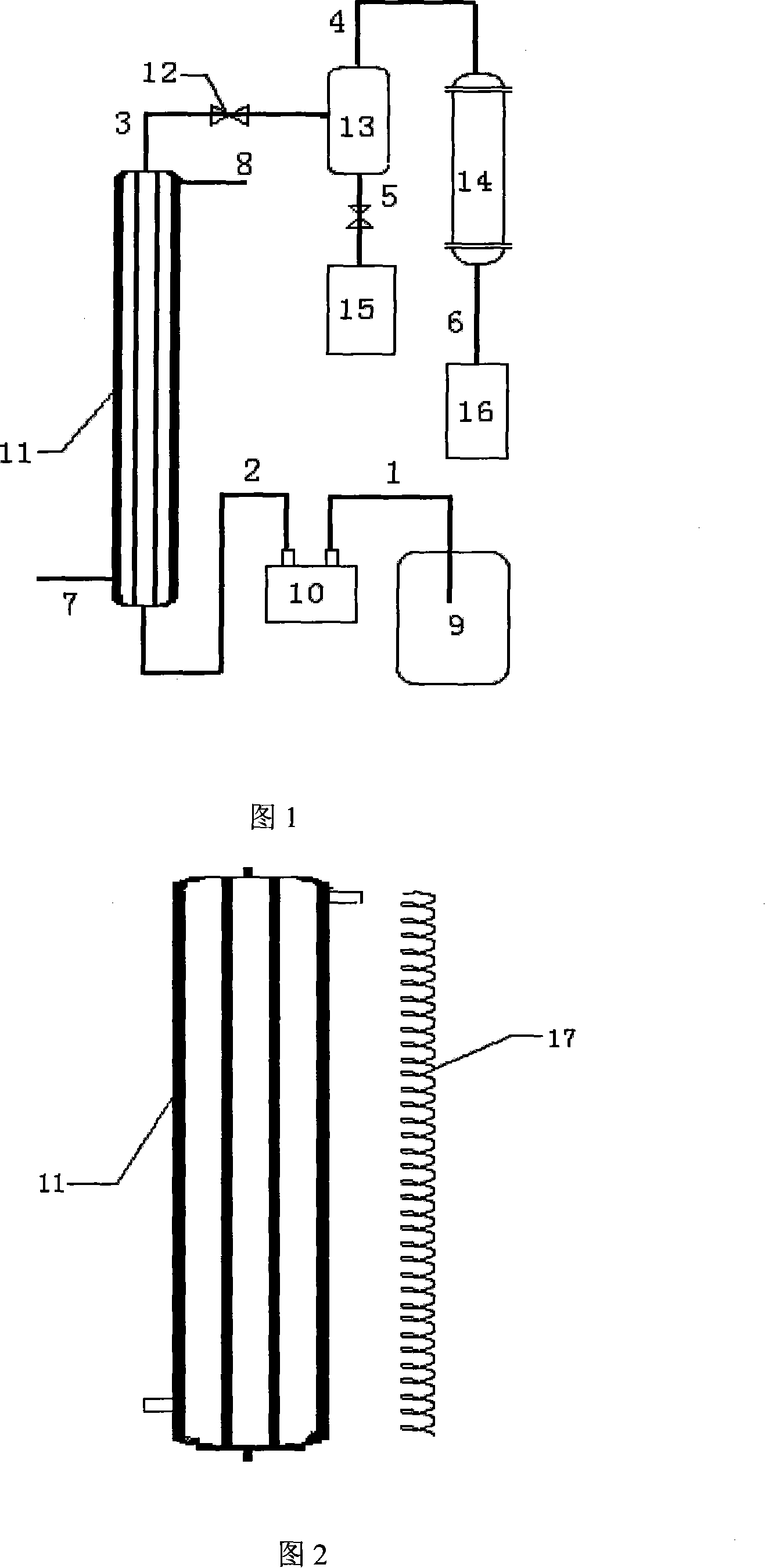

Production method for continuous synthesizing vinylmethylketone by one-step and device thereof

InactiveCN101104580AHigh yieldReduce circulationOrganic compound preparationCarbonyl compound preparationAqueous acetoneHigh pressure

The invention provides a method to synthesize vinylmethylketone continuously and the equipments thereof. The method is that: mix aqueous acetone solution and formalin according to a certain volume ratio and then add vitriol to the mixed solution; send the mixed solution to a reactor continuously with a high-pressure pump and make the reaction liquid flow out of the reactor continuously; cool, neutralize and rectify the reaction liquid to get vinylmethylketone. The acetone not used in the reaction is recycled to circulate in the reaction. The equipments include a raw material jar, a liquid feeding pump connected with the reactor through a pipeline. The reactor is provided with an empty tube or a spiral flow guiding stainless steel wire inside; a bushing is arranged at the outside of the reactor and a heat conduction oil circulation pipeline is arranged inside the bushing; the reactor is also provided with a reaction liquid output pipeline which is connected to a flash tank through a throttle; the flash tank is connected to a condenser through a pipeline and is also connected to a distiller through a pipeline. The invention has the advantages that the raw materials are easy to get; the process is simple and the production is stable and is easy to control; the equipments are of great throughputs; the yield of vinylmethylketone is high and the acetone circulation amount is small and the energy consumed is little.

Owner:FUZHOU UNIV

Preparation method of self-support transparent conductive graphene film

The invention provides a preparation method of a self-support transparent conductive graphene film, comprising the following steps: pulling up a layer of graphene oxide A by using a filter membrane so as to obtain a material I; soaking the material I in an aqueous solution of organic amine so as to prepare a material II; pulling up a layer of graphene oxide B by using the material II so as to obtain a sandwich composite material; wetting the obtained sandwich composite material with an aqueous solution of acetone until the material is softened, and then soaking the material with acetone until the filter membrane is completely dissolved so as to obtain a material IV; and reducing graphene oxide in the material IV so as to obtain the self-support transparent conductive graphene film. According to the invention, organic amine is used, and a substrate is thoroughly removed by firstly wetting to play a 'perforating' role and then replacing a solvent system, so that the film can not be damaged easily in an operation process, integral steps are simple, the operation is easy, and the prepared film can be very large and thin and simultaneously has high light transmittance and favorable flexibility and conductibility.

Owner:HEFEI UNIV OF TECH

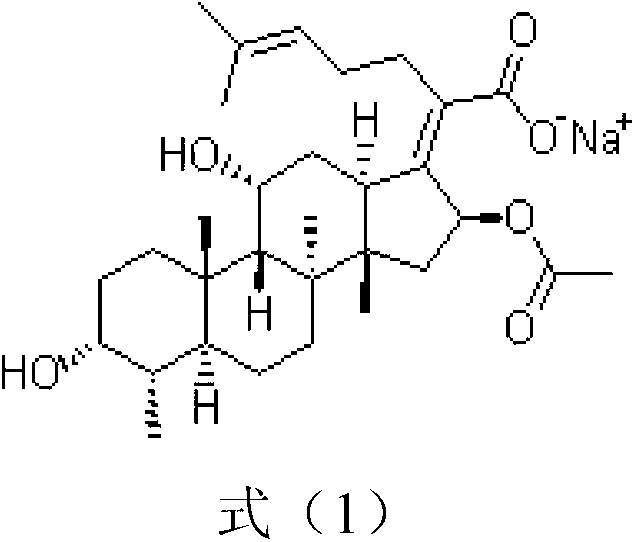

Sodium fusidate crystallization method

The invention provides a sodium fusidate crystallization method which comprises the following steps: a, preparing a sodium fusidate solution by taking a acetone water solution as solvent; b, heating the sodium fusidate solution, feeding acetone while stirring, reducing the feeding rate when the sodium fusidate solution is turbid, and standing for crystallization after the feeding operation is finished; and performing solid-liquid separation, leaching the obtained solids with acetone, and then drying to obtain sodium fusidate crystals. According to the invention, the method is simple to operate and low in cost; and the sodium fusidate crystals prepared by the method are stable in crystal form and favorable in flowability.

Owner:NCPC NEW DRUG RES & DEV

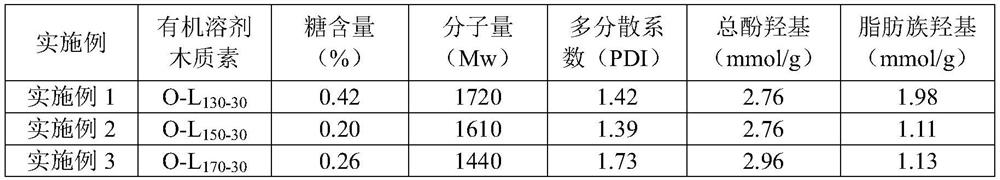

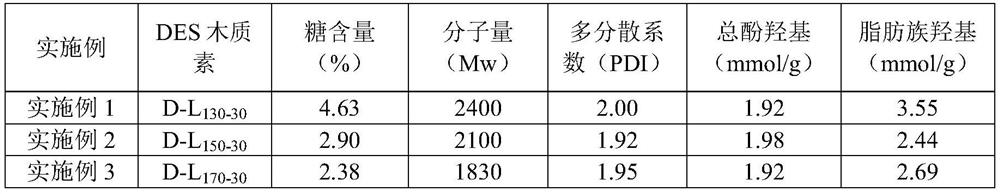

Method for pretreating eucalyptus graded lignin and co-producing furfural based on DES two-phase system

ActiveCN113956299AImprove solubilityEffective dissociationLignin derivativesAqueous acetonePtru catalyst

The invention aims to provide a method for pretreating eucalyptus graded lignin and co-producing furfural based on a DES two-phase system. The method comprises the following steps of: (1) pretreatment of raw materials: crushing, dewaxing and drying; (2) preparation of DES: mixing a hydrogen bond acceptor and a hydrogen bond donor, performing heating and stirring until the mixture is uniform and transparent; and (3) pre-treating graded lignin and co-producing furfural by using the two-phase system: 1) blending the raw material, DES, an organic solvent and a catalyst, and adding the mixture into a reaction kettle for reaction; 2) performing cooling after the reaction is finished, and separating the mixture to obtain a eutectic reaction mixture and an organic extraction phase; and 3) carrying out rotary evaporation on an eluent obtained by washing the eutectic reaction mixture with an acetone / aqueous solution and the organic extraction phase, and then carrying out acid water precipitation, centrifugation and freeze drying to respectively obtain the DES lignin and the organic solvent lignin. According to the method, lignin with different fractions and high purity and good uniformity is obtained through a one-step method, and furfural is co-produced.

Owner:BEIJING FORESTRY UNIVERSITY

Extraction method for pigment of vaccinium bracteatum leaves

InactiveCN107337934ALarge amount of pigment dissolvedImprove extraction efficiencyNatural dyesHigh concentrationAqueous acetone

The invention firstly discloses a method for extracting the leaf pigment of black rice tree. The extraction method comprises the steps of producing a pigment precursor by using the leaves of the black rice plant as a raw material, and then producing the pigment through processes such as enzyme-catalyzed oxidation, polyamide column purification, spray drying and the like. Compared with the existing technology, the present invention has the following advantages: 1, it dries and breaks the leaves of black rice leaves, which increases the reaction area of the leaves of black rice leaves, and makes the extraction of pigment more fully; 2, utilizes organic solvents to carry out Extraction, large amount of pigment dissolution, high extraction efficiency; 3. Select a higher concentration of ethanol aqueous solution or acetone aqueous solution as the extraction solvent, which can precipitate the dissolved macromolecular protein, thereby filtering and removing it, and the filtering effect is more significant; 4. Using Membrane filtration is a physical impurity removal, which not only has low energy consumption and low pollution, but also can reduce the decomposition of pigment due to high temperature and improve the recovery rate of pigment.

Owner:NANJING WEIZHOU FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com