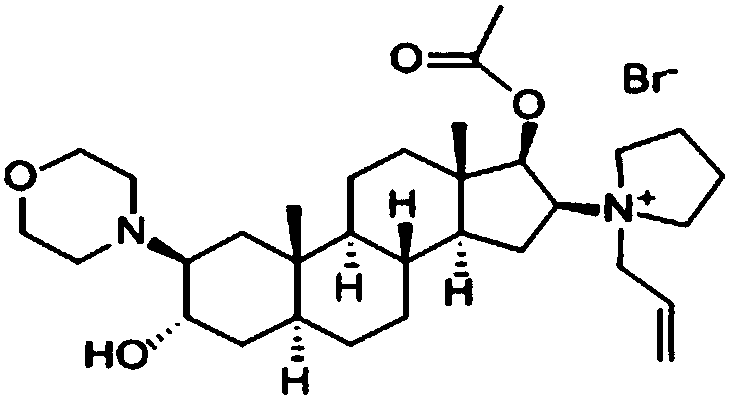

Preparation method of high-purity rocuronium bromide

A high-purity technology of rocuronium bromide, which is applied in the field of preparation of high-purity rocuronium bromide raw materials for non-depolarizing muscle relaxants, can solve the problem that conventional workshops are not suitable for industrial operation, and the safety of workshops has high requirements. The residual solvent of rocuronium bromide raw material can not fully meet the requirements and other problems, and achieve the effect of low cost, high stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of rocuronium bromide crude product:

[0037] Referring to Example 3 of patent US2006 / 0058275, the raw material (2β, 3α, 5α, 16β, 17β)-2-(4-morpholino)-16-(1-pyrrolyl)-androsta-3,17-di Alcohol-17-acetate (1200g) and 3-bromopropene (3600ml) were added to 5000ml of acetonitrile, stirred and reacted at room temperature for 3 hours, the reaction solution was slowly added to 30000ml of vigorously stirred ether, and the precipitated Roku Filtrate with ammonium bromide and dry overnight in vacuum to obtain crude rocuronium bromide.

[0038] The preparation of rocuronium bromide finished product:

[0039] Step 1) Dissolve 1.1 kg of rocuronium bromide crude product in 3 liters of 10% acetone aqueous solution, filter, and concentrate under reduced pressure to obtain a foamy solid ①;

[0040] Step 2) Add 0.9 kg of foamy solid ① and 4.4 kg of n-heptane into the homogenizer, after homogeneous dispersion, filter under nitrogen protection to obtain solid ②;

[0041]...

Embodiment 2

[0044] The preparation of rocuronium bromide crude product:

[0045] Referring to Example 2 of patent US2006 / 0058275, the raw material (2β, 3α, 5α, 16β, 17β)-2-(4-morpholino)-16-(1-pyrrolyl)-androsta-3,17-di Alcohol-17-acetate (120g) and 3-bromopropene (320ml) were added to 480ml of acetonitrile, stirred and reacted at room temperature for 3 hours, the reaction solution was slowly added to 2880ml of vigorously stirred ethyl acetate, and the precipitated Rocuronium bromide was filtered and vacuum dried overnight to obtain crude rocuronium bromide.

[0046] The preparation of rocuronium bromide finished product:

[0047] Step 1) rocuronium bromide crude product 100g is dissolved in the 12% acetone aqueous solution of 300ml, filters, and concentrates under reduced pressure, obtains foamy solid ①;

[0048] Step 2) Add 90 g of foamy solid ① and 540 g of n-heptane into a homogenizer, after homogeneous dispersion, filter under nitrogen protection to obtain solid ②;

[0049] Step 3...

Embodiment 3

[0052] The preparation of rocuronium bromide crude product:

[0053] The raw material (2β,3α,5α,16β,17β)-2-(4-morpholino)-16-(1-pyrrolyl)-androst-3,17-diol-17-acetate (120g ), 3-bromopropene (320ml) were added to 1000ml of dichloromethane, stirred and reacted at room temperature for 15 hours, the reaction solution was slowly added to 4000ml of vigorously stirred methyl tert-butyl ether, and the separated out rocuronium bromide Filter and dry overnight in vacuum to obtain crude rocuronium bromide.

[0054] The preparation of rocuronium bromide finished product:

[0055] Step 1) rocuronium bromide crude product 100g is dissolved in the 15% acetone aqueous solution of 300ml, filters, and concentrates under reduced pressure, obtains foamy solid ①;

[0056] Step 2) Add 90 g of foamy solid ① and 450 g of n-hexane into a homogenizer, after homogeneous dispersion, filter under nitrogen protection to obtain solid ②;

[0057] Step 3) Add 90 g of n-hexane to 90 g of solid ②, stir and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com