Electron beam-cured coating-containing vacuum aluminized sanding card paper and manufacturing method thereof

An electron beam curing and vacuum aluminum plating technology, applied in the field of packaging materials and decorative materials, can solve the problems of inappropriate printing of fine lines, insufficient volatilization of ink solvents, affecting the quality of packaging items, etc. The effect of reducing solvent residue and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

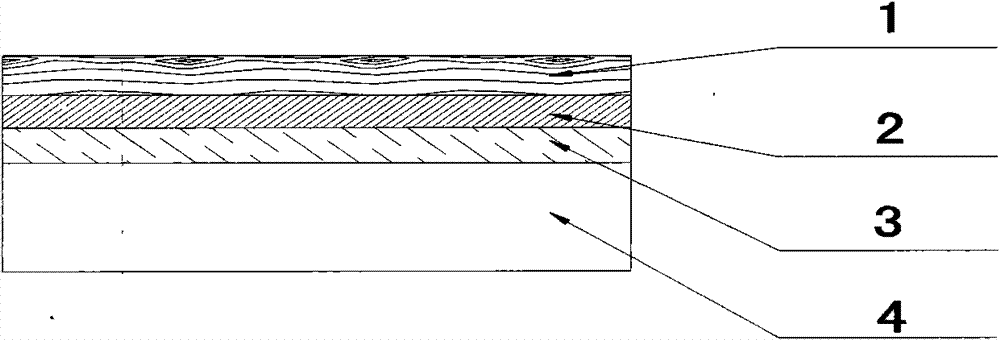

Image

Examples

Embodiment 1

[0028] (1) Take 40 parts by mass of epoxy acrylic prepolymer, 25 parts of tripropylene glycol diacrylate, 6 parts of monofunctional methacrylate, 10 parts of polyethylene glycol acrylate, mix well, and prepolymerize at room temperature for more than 24 hours , To form a suitable electron beam curing liquid composition coating, add 1 part by mass of frosted powder (gas phase silica), first use a high-speed disperser for pre-dispersion to eliminate large particles of frosted powder, and then emulsify and disperse with an emulsifier to make the frosted The powder is fully dispersed in the liquid composition coating to form a homogeneous body.

[0029] (2) Coat the homogeneous body on 80g / m with a 200 mesh wire roller 2 On the smooth surface of the paper substrate, the coated paper substrate enters the electron beam irradiation room at a speed of 600-1000 meters for irradiation under nitrogen protection, the irradiation voltage is 120KV, and the irradiation dose is 23000-27000KG y m / m...

Embodiment 2

[0032] (1) Take 45 parts by mass of epoxy acrylic prepolymer, 32 parts of tripropylene glycol diacrylate, 8.5 parts of monofunctional methacrylate, 14.5 parts of polyethylene glycol acrylate, mix well, and prepolymerize at room temperature for more than 24 hours , To form a suitable electron beam curing liquid composition coating, add 3 parts by mass of frosted powder (gas phase silica), first use a high-speed disperser for pre-dispersion to eliminate large particles of frosted powder, and then use an emulsifier to emulsify and disperse to make the frosted The powder is fully dispersed in the liquid composition coating to form a homogeneous body.

[0033] (2) Coat the homogenate on 120g / m with a 250 mesh wire roller 2 On the smooth surface of the paper substrate, the coated paper substrate enters the electron beam irradiation room for irradiation under the protection of nitrogen. The irradiation voltage is 120KV and the irradiation dose is 23000-27000KG y m / min, after curing, an e...

Embodiment 3

[0036] (1) Take 50 parts by mass of epoxy acrylic prepolymer, 35 parts of tripropylene glycol diacrylate, 15 parts of monofunctional methacrylate, 20 parts of polyethylene glycol acrylate, mix well, and prepolymerize at room temperature for more than 24 hours , To form a suitable electron beam curing liquid composition coating, add 5 parts by mass of frosted powder (gas phase silica), first use a high-speed disperser for pre-dispersion to eliminate large particles of frosted powder, and then use an emulsifier to emulsify and disperse to make the frosted The powder is fully dispersed evenly in the liquid composition to form a homogeneous body.

[0037] (2) Use a 300-mesh wire roller to coat the homogenate on 200g / m 2 On the smooth surface of the cardboard, the coated cardboard enters the electron beam irradiation room at a speed of 600-1000 m / min for irradiation under the protection of nitrogen, the irradiation voltage is 120KV, and the irradiation dose is 23000-27000KG y m / min, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com