Patents

Literature

63results about How to "Low solvent residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

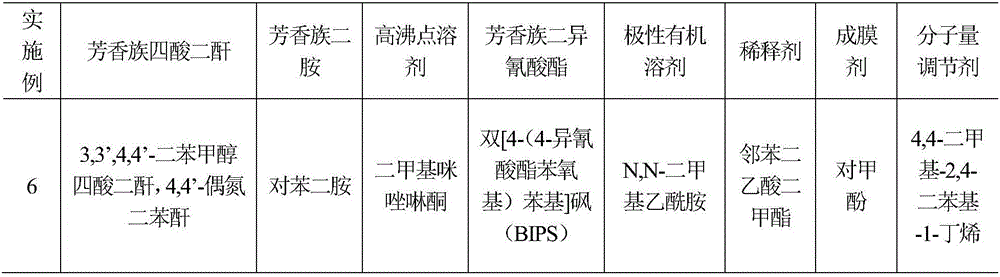

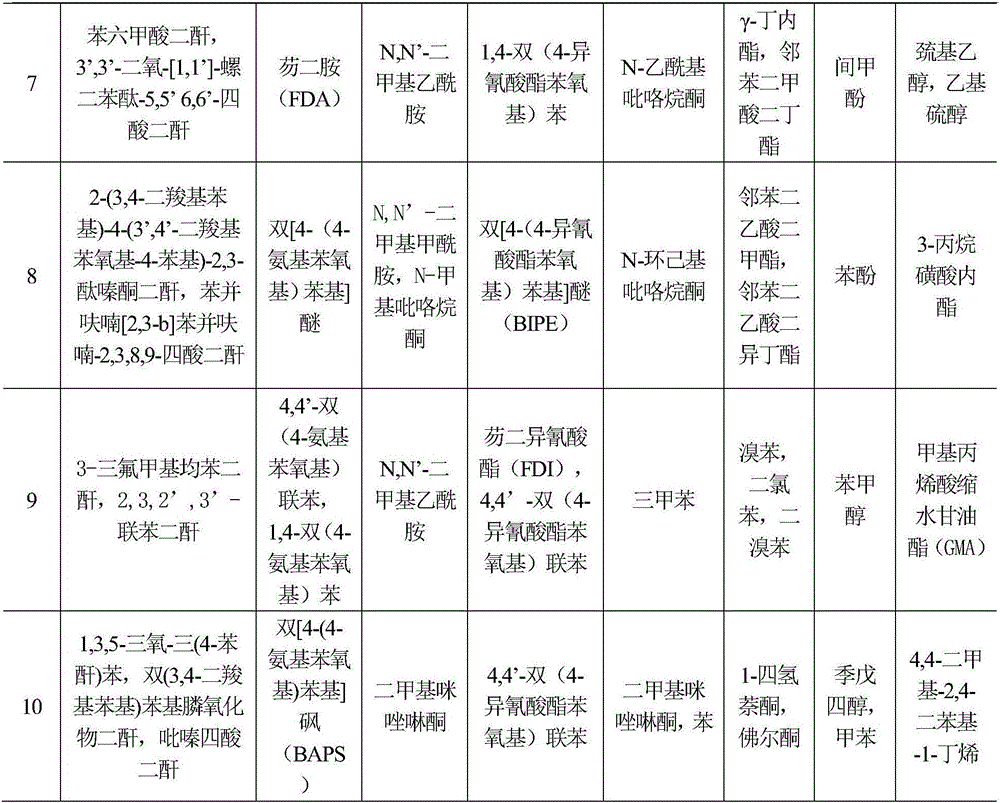

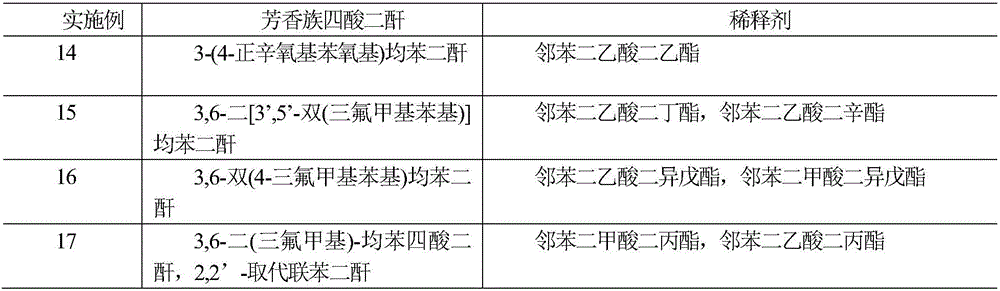

Method for preparing polyimide nano-film

The invention provides a method for preparing a polyimide nano-film. The method comprises the steps: firstly, synthesizing polyimide resin from aromatic tetracid dihydride, aromatic diamine and aromatic diisocyanate; and then, mixing the polyimide resin, a polar organic solvent, a diluent, a film forming agent and a molecular weight regulator so as to obtain a polyimide solution system, then, carrying out nano-scale uniform spreading on a clean substrate by dint of the action of a mechanical external force of 0.5N to 30N, and then, carrying out an imidization method, thereby preparing the polyimide nano-film. According to the film, the high-temperature resistance is 10 seconds at the high temperature of 400 DEG C to 750 DEG C, and the electrical insulation property is that the dielectric constant is 1.5 to 4.5 at the frequency of 103Hz. Compared with the prior art, the polyimide nano-film prepared by the method has the advantages of excellent surface physical properties and stable chemical properties, high-temperature resistance, electrical insulation properties and chemical corrosion resistance.

Owner:SHAANXI UNIV OF SCI & TECH

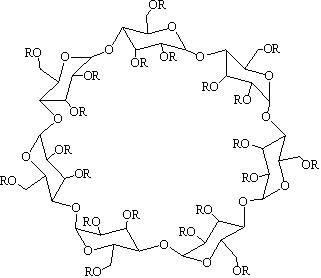

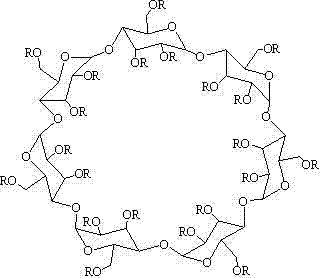

Method for preparing hydroxypropyl-beta-cyclodextrin

ActiveCN102040675AWill not cause decompositionLow impurity contentMacromolecular non-active ingredientsNanofiltrationPharmaceutic Adjuvant

The invention discloses a method for preparing hydroxypropyl-beta-cyclodextrin, which comprises the steps of etherification, neutralization, decoloring, nanofiltration, resin purification, and spray drying. The method of the invention is small in pollution, and the yield in weight is more than 80 percent; meanwhile, the product prepared by using the method of the invention is narrow in substituted ratio range and low in impurity content, and can be used as a pharmaceutic adjuvant.

Owner:石药集团中诺药业(石家庄)有限公司

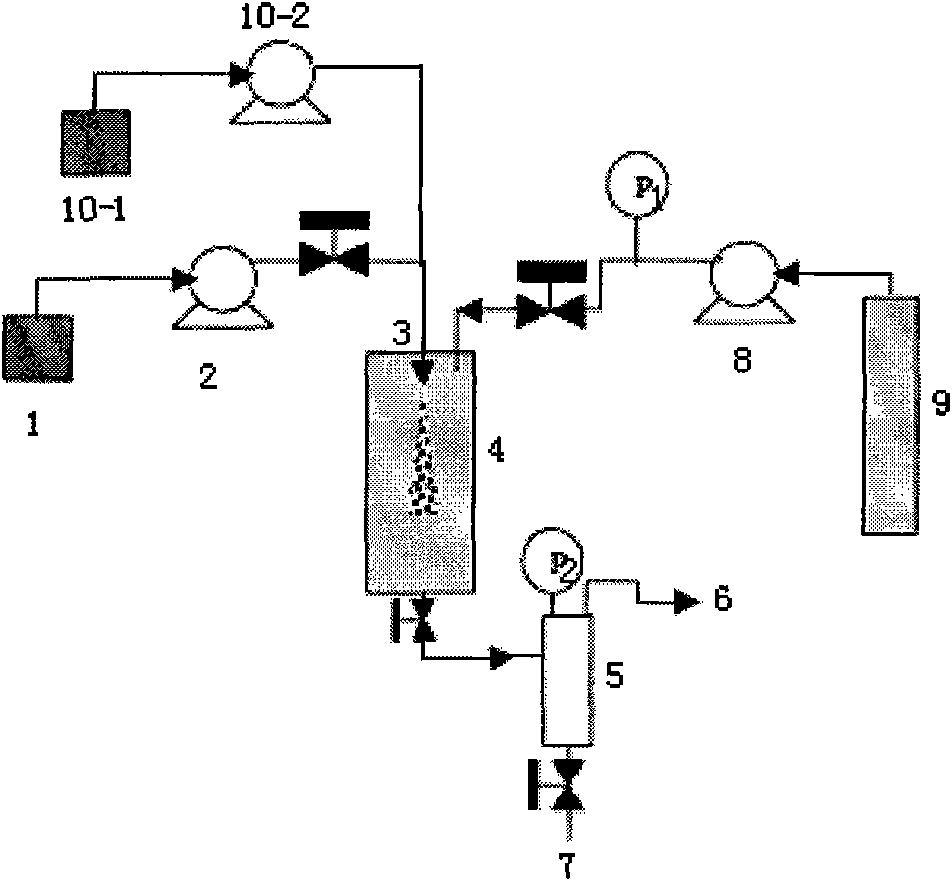

Extracting method for jasmine flower essential oil

InactiveCN104120037ALarge amount of processingLow solvent residueSolvent extractionEssential-oils/perfumesWaxChemistry

The invention discloses an extracting method for jasmine flower essential oil. The extracting method comprises the steps of extracting by petroleum ether or n-pentane to prepare jasmine flower extract, dissolving by alcohol and freezing to remove plant wax impurities, distilling to recycle a solvent alcohol, washing and removing the alcohol to prepare crude jasmine flower essential oil; further separating the crude jasmine flower essential oil by supercritical CO2 extraction to remove residual solvent to prepare the jasmine flower essential oil with pure flavor. According to the extracting method, supercritical CO2 extraction is carried out on treated jasmine flower extract, so that advantages of low cost and great treatment capacity for extracting fresh jasmine flowers by the solvent and the advantages of high efficiency and no solvent residue of supercritical CO2 extracting and separating are sufficiently combined to realize small solvent residual quantity and low cost, and therefore, the extracting method disclosed by the invention is suitable for producing the jasmine flower essential oil on a large scale.

Owner:GUANGXI FORESTRY RES INST

Method for preparing clindamycin phosphate powder injection raw medicine

ActiveCN101439022AChange the dosage ratioChange centrifugationAntibacterial agentsPowder deliverySolubilityClindamycin Phosphate

The invention discloses a preparation method for a clindamycin phosphate powder injection raw medicine which comprises the steps: (a) purification is carried out on a crude product of clindamycin phosphate; (b) crystallization and crystal growth are carried out on filter liquor after the filter liquor is arranged in a crystallization tank; (c) centrifugal separation and washing are carred on crystallization liquor; (d) fast temperature raising and drying are carried out on a clindamycin phosphate wet finished product. The preparation method for the clindamycin phosphate powder injection raw medicine has the advantages of favorable water solubility, uniform crystal form particles, small specific volume, big bulk density, low solvent residue, and the like. The method also simplifies the process operation, and dramatically enhances the product yield.

Owner:华北制药华胜有限公司

Method for separating and purifying fatty acid ester of lutein in high content from resin of marigold oil

ActiveCN1872839ASolvent with low boiling pointLow solvent residueOrganic chemistryNatural dyesSolventChemistry

This invention discloses a method for separating and purifying high-content xanthophyl fatty acid ester from tagetes oleoresin. The content of xanthophyl fatty acid ester obtained is 70-80%, wherein the content of all-trans xanthophyl ester is 90-95%. The method has such advantages as low solvent residue, high yield and simple operation, and is suitable for mass production.

Owner:浙江可明生物医药有限公司

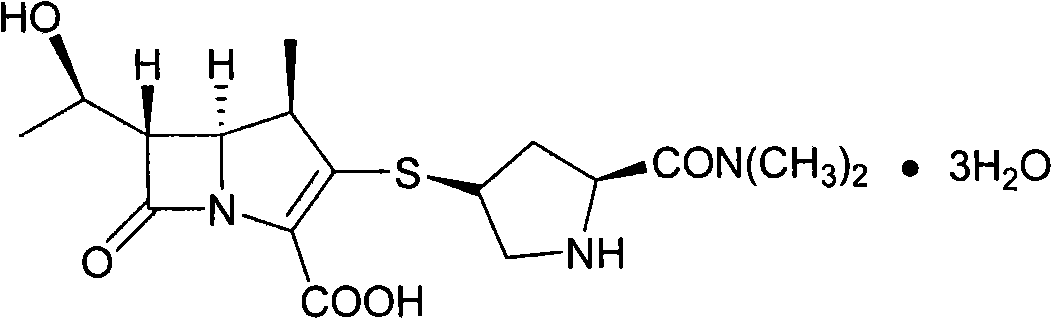

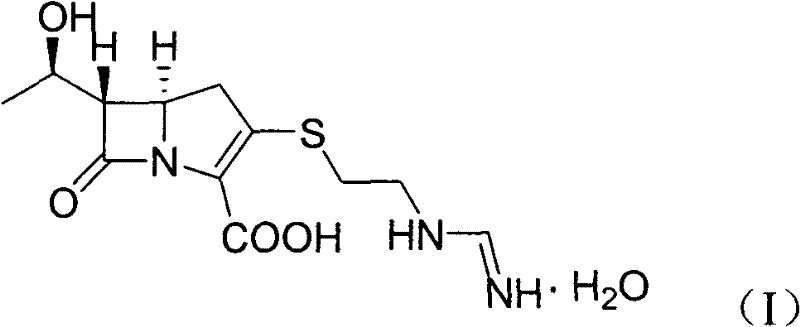

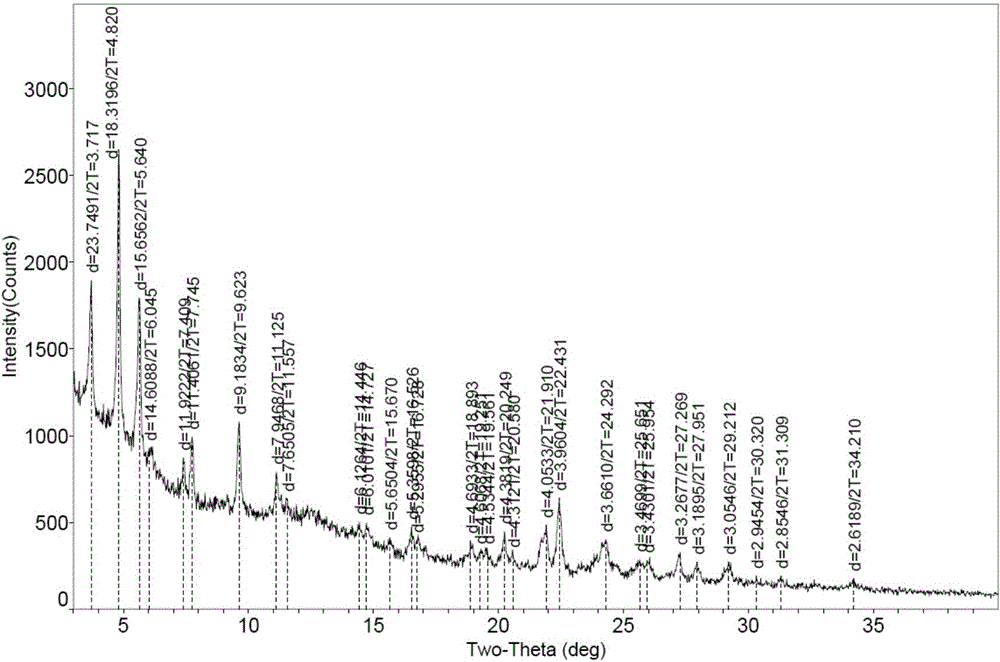

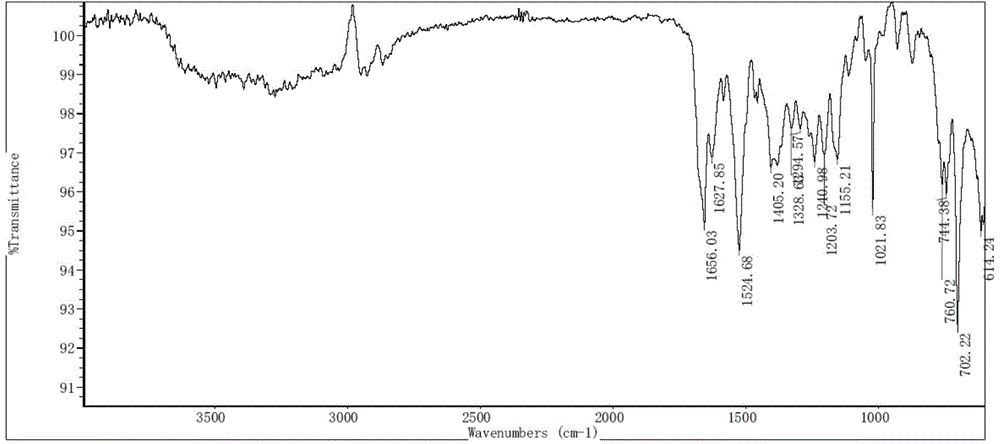

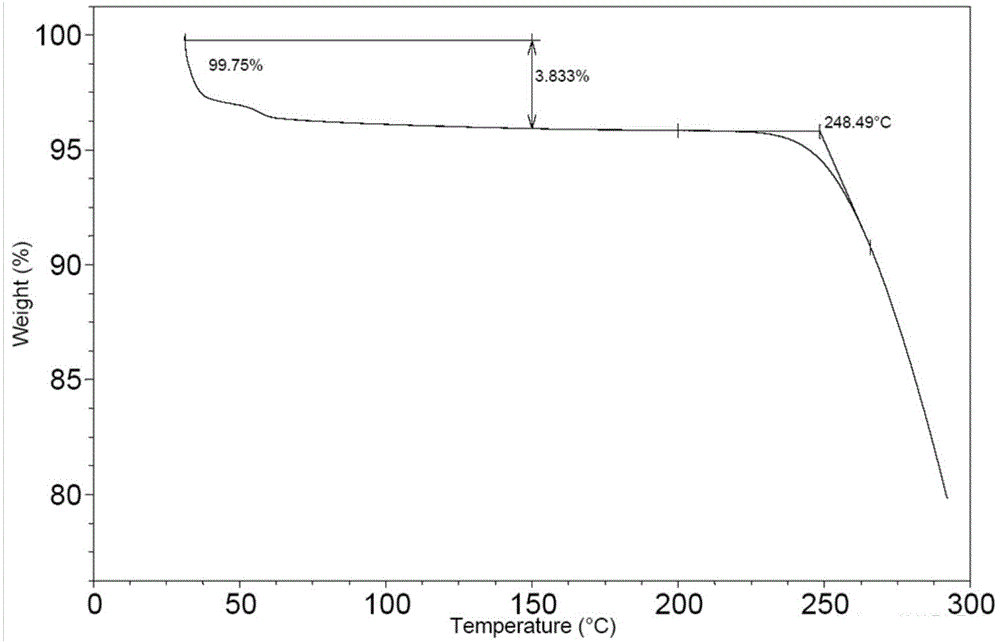

Preparation method of Meropenem trihydrate crystals

The invention discloses a refining method of Meropenem trihydrate crystals, comprising the following steps of: dissolving a crude Meropenem product in water the temperature of which is 30-70 DEG C to obtain a solution I; treating the solution I by activated carbon and filtering at 5-30 DEG C to obtain a solution II; crystallizing the solution II at 0-10 DEG C and filtering to obtain a solution III and the Meropenem trihydrate crystals; adding an organic solvent to the solution III further, and recovering Meropenem. The method is simple and easy to implement, and the obtained Meropenem trihydrate crystals have super high purity and super-low solvent residuals, meet the requirements of the method for preparing the Meropenem and is suitable for industrial production.

Owner:SHENZHEN HAIBIN PHARMA

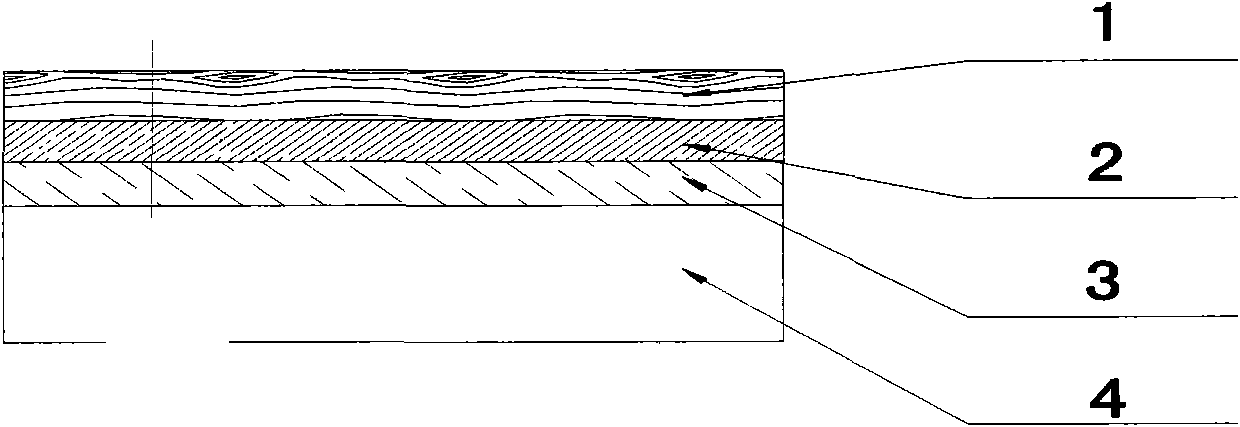

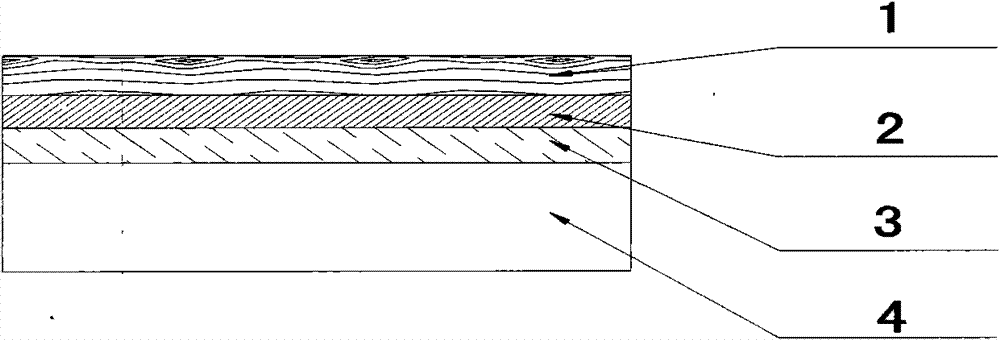

Vacuum aluminum plating ground paperboard and production method thereof

ActiveCN102002895ATo achieve the printing effectLow solvent residueSpecial paperPaper/cardboardScreen printingPaperboard

The invention relates to a vacuum aluminum plating ground paperboard and a production method thereof, which belong to the technical field of package materials and printing materials. The vacuum aluminum plating ground paperboard comprises a paper base material, a ground coating layer and an aluminum plating layer. The production method comprises the following steps of: 1. making a ground coating mixing body; 2. coating a layer of ground coating mixing body on a paper substrate 4 for forming the ground coating layer; and 3. placing the paperboard comprising the ground coating layer with the grounding effect into a vacuum aluminum plating system, directly plating aluminum on the ground surface of the ground coating layer of the paperboard and forming the aluminum plating layer. The production method has the following advantages of simple process, no glue water layer, high production efficiency and no solvent volatilization, and belongs to the environmental-protection production process. The paperboard has exquisite and vivid ground effect and rich metal texture, and the produced ground paperboard can reach the screen painting effect through ordinary offset printing or gravure printing. A large amount of ink is saved, and the solvent volatilization and the solvent residue of printed products are greatly reduced.

Owner:YANTAI BOYUAN TECH MATERIALS

Method for producing pepper oil with stable quality and high spicy degree

The invention discloses a method for producing pepper oil with stable quality and a high spicy degree. The method includes the steps that (1) dry pepper raw materials are crushed, steam distillation is carried out, and pepper aromatic oil is obtained after oil-water separation; (2) pepper powder obtained after steam distillation is extracted through ethyl acetate, solvents with pepper resin are obtained through filtering, 5% sodium hydroxides are added into the solvents, heating and stirring are carried out for two hours, then the solvents are cooled to be at the room temperature, ethyl acetate solvents are obtained after separation, activated carbon is added for adsorption, the solvents are obtained after filtering, reduced pressure distillation is carried out for concentration, and pepper oil resin with the high spicy degree and good fluidity is obtained; (3) pepper aromatic oil obtained in the step (1) and the pepper resin obtained in the step (2) are mixed, and a pepper oil product with stable quality is obtained. The proportion of pepper spicy substances and pepper aromatic substances is controllable, the content of pectin and polysaccharide is little, foreign flavor does not exist, the smell and flavor are pure, the fluidity is good, meanwhile, the oil solubility is good, emulsifier does not need to be added during dissolving, suspended matter and sediments do not exist, and transparency is high.

Owner:周顺

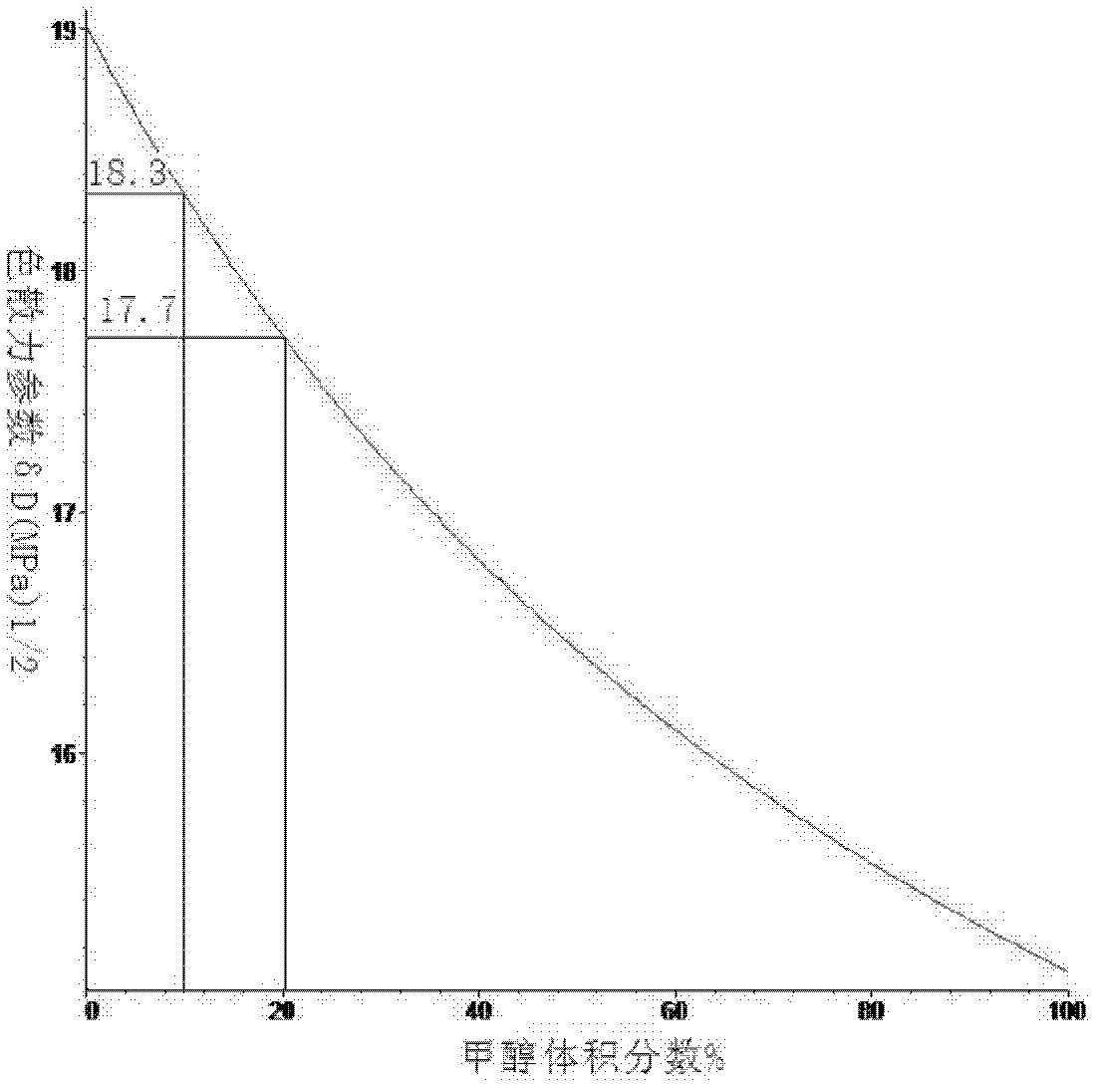

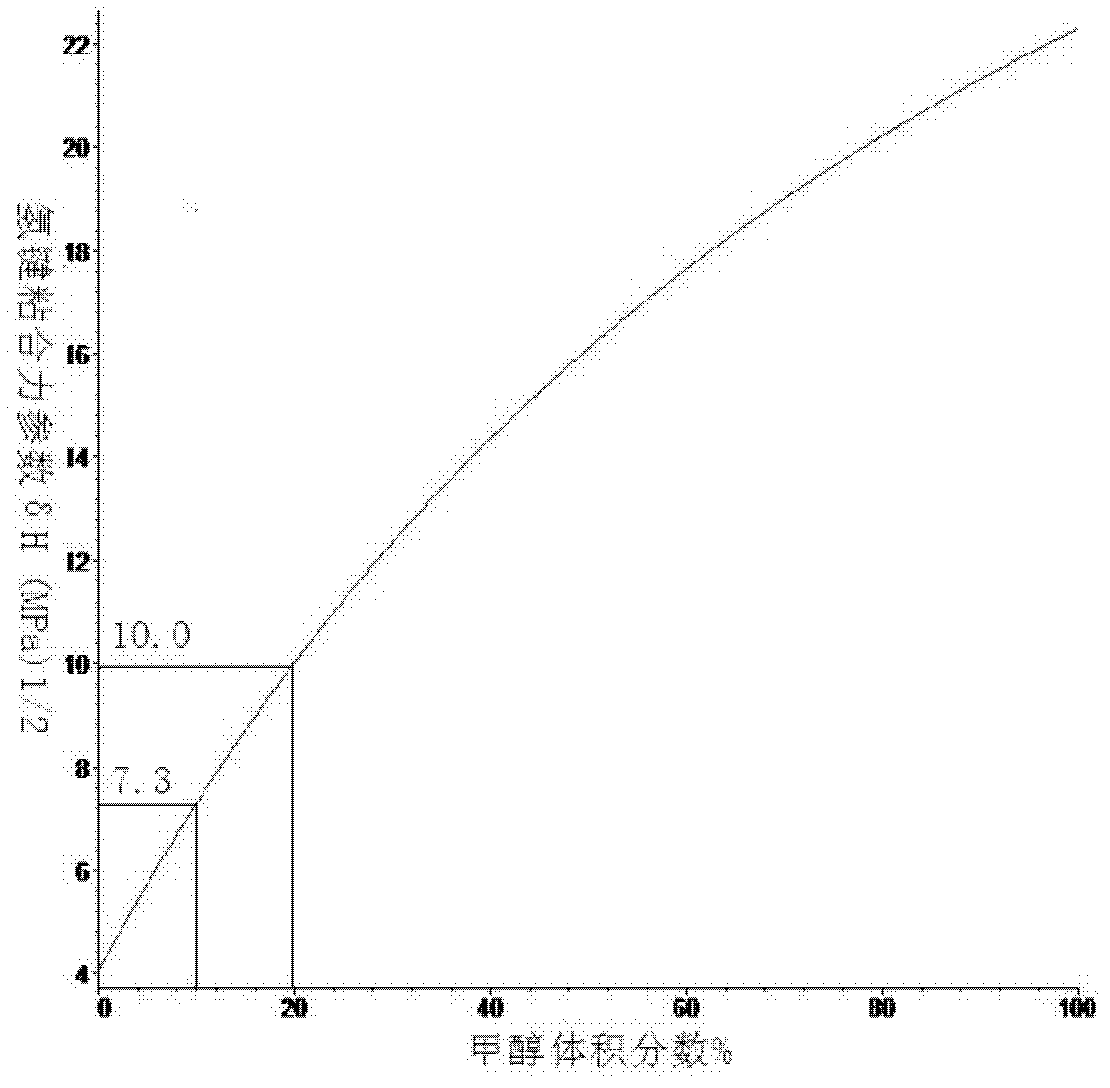

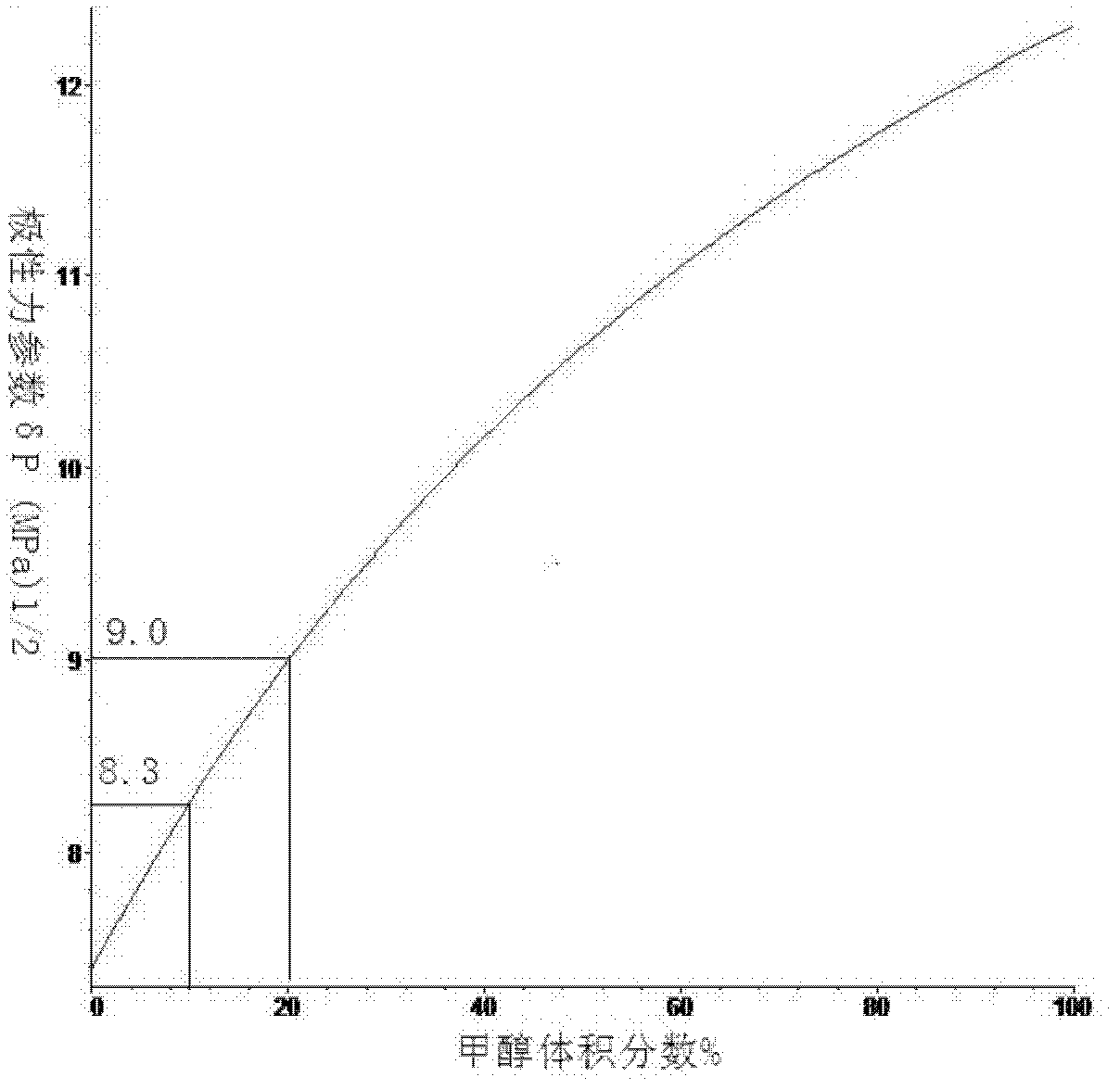

Method for preparing graphene through phase peeling of graphite by using mixed solvent

InactiveCN103172053ATo overcome the deficiency of low concentrationReduce reunionGrapheneSolventCvd graphene

The invention relates to a method for preparing graphene through phase peeling of graphite by using a mixed solvent. The method comprises the following steps: 1, preparing a mixed solvent composed of at least two organic solvents having boiling points of not greater than 100DEG C; 2, adding powdery graphite to the mixed solvent to prepare a mixed solution of the powdery graphite, putting the mixed solution of the powdery graphite in an ultrasonic machine, carrying out water-bath ultrasonic treatment, and centrifuging through using a centrifuge; and 3, taking a supernatant obtained after the centrifuging with a pipette to obtain a graphene dispersion uniformly dispersed in the mixed solvent. The method enables the Hansen solubility parameters of the mixed solvent to reach the Hansen solubility parameters of graphene as possible through adjusting the volume ratio of the organic solvents in order to obtain a solvent which is most suitable for peeling and dispersing graphene, and the solvent is used to carry out the phase peeling of graphene.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Nano-chalss natural lycopene product and its preparing process

InactiveCN1365626AOvercoming various technical difficulties in filling soft capsulesReduce manufacturing costFood preparationLycopeneOrganic chemistry

Owner:XINJIANG JINQI IND

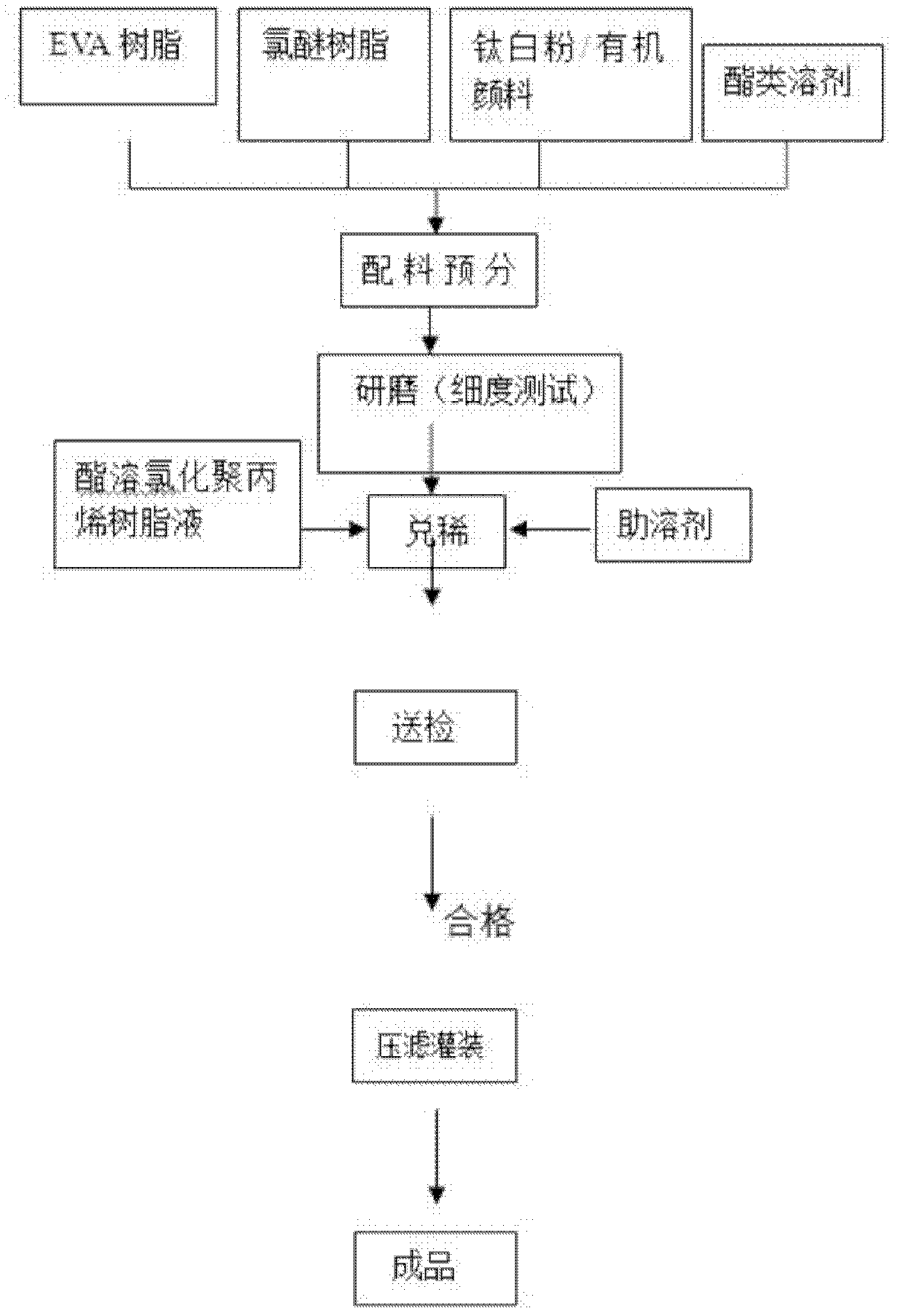

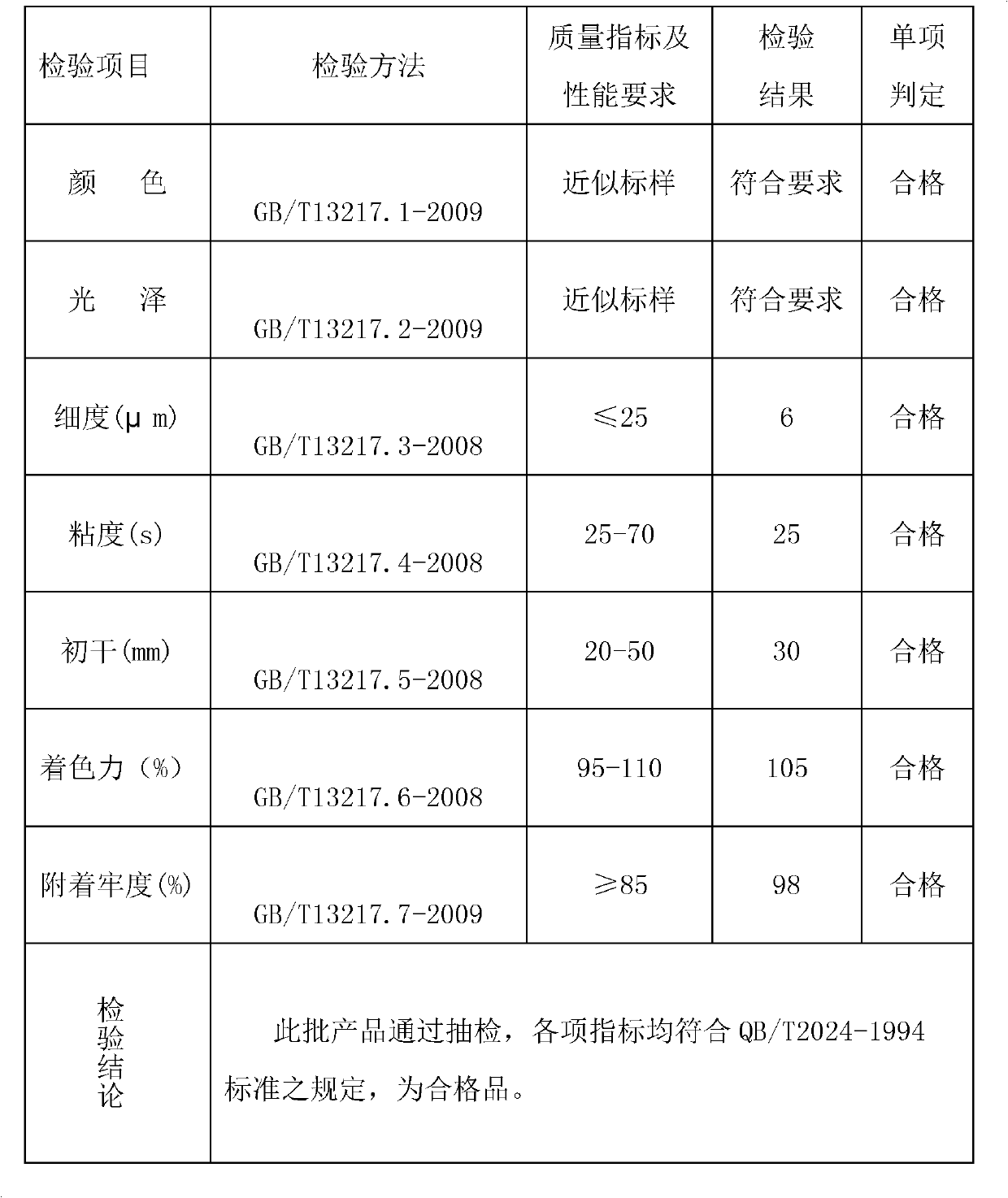

Benzene-free environmentally friendly composite ink and preparation method thereof

The invention discloses a safe and environmentally friendly dedicated composite ink for preserved vegetable packaging bag and preparation method of the composite ink, wherein the dedicated composite ink mainly comprises the raw materials of A of chlorinated EVA (ethylene vinyl acetate) resin solution, chlorinated polyether resin solution, a dispersing agent and esters solvent, B of rutile titanium dioxide / organic pigments and a matting agent, and C of ester dissolved chlorinated polypropylene resin solution, solubilizers and the like. The preparation method comprises the following steps of pre-dispersing the raw materials, sanding, adjusting ink and the like. According to the invention, the ink product is the benzene-free environmentally friendly inks by using imported ester dissolved chlorinated polypropylene resin as the main binder and does not contain benzenes and ketones organic solvents, is extremely low in solvent residue and can meet the requirements of boiling and sterilizing of the OPP (oriented polypropylene) / / VMPET (biaxially-oriented polyethylene terephthalate) / / PE (poly ethylene) structure packaging bags.

Owner:重庆宏图新材料科技有限公司

Printing ink with high heat resistance

The invention discloses a printing ink with high heat resistance. The printing ink is prepared from the following constituents in parts by weight: 5-10 parts of 1053 organic silicon resin, 2-4 parts of 9801 organic silicon resin, 1-2 parts of 804 organic silicon resin, 4-6 parts of thermoplastic acrylic resin, 10-15 parts of an alcohol-dissolving polyurethane solution, 9-10 parts of ternary hydroxyl-modified vinyl resin copolymer, 20-25 parts of a pigment, 20-25 parts of acetic acid, 22-25 parts of ethanol, 1-2 parts of ethyl acetate, 3-4 parts of acrylonitrile butadiene rubber, and 4-5 parts of acetone, wherein the mass concentration of the alcohol-dissolving polyurethane solution is 20-25%. The printing ink disclosed by the invention is high in heat resistance, is free of any change in color, any deformation and glue phenomenon when the temperature is larger than 100 DEG C, and is suitable for printing various materials; furthermore, the adhesive force is high, so that the pigment is durable and free of falling off; the printing ink is quick in drying, and the solvent on the printed material after printing is low in residual quantity, so that physical and psychological health for printing ink makers, pressmen and printed material users is guaranteed.

Owner:JURONG MAOYUAN WEAVING FACTORY

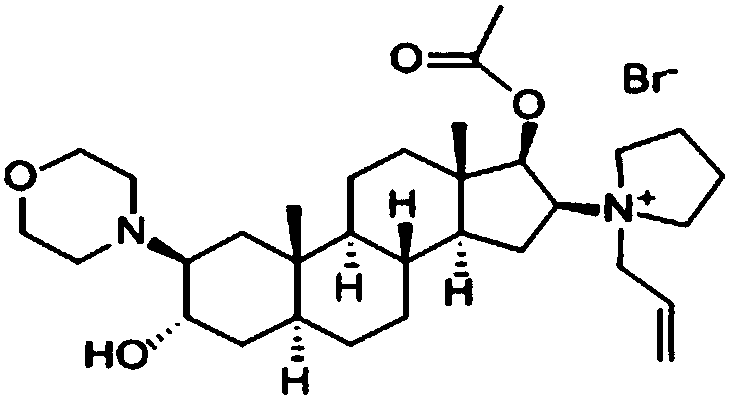

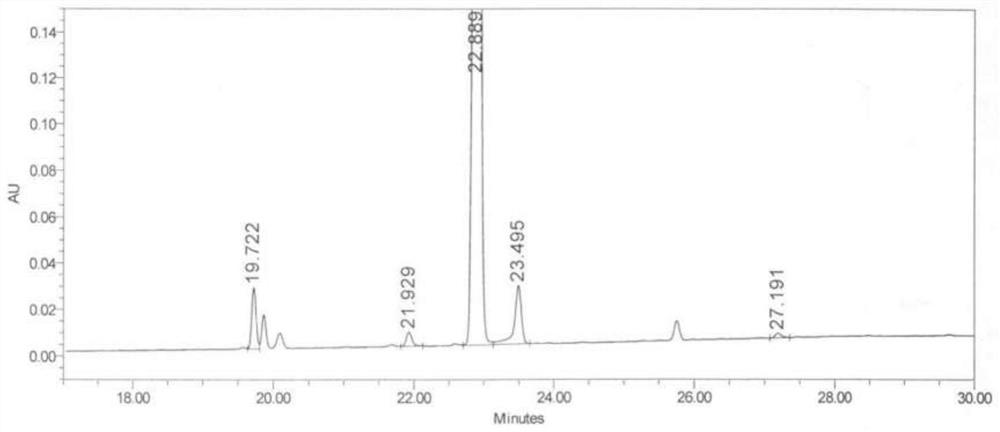

Preparation method of high-purity rocuronium bromide

The invention provides a preparation method of high-purity rocuronium bromide. The preparation method comprises the steps of enabling a rocuronium bromide crude product to be dissolved in acetone water solution, filtering, vacuum-concentrating, adding normal heptane for homogenizing, pulping and the like. The provided preparation method of the high-purity rocuronium bromide has many advantages ofextremely low solvent residual quantity, extremely high HPLC purity, extremely low related substance content, extremely high stability and the like.

Owner:江苏盈科生物制药有限公司

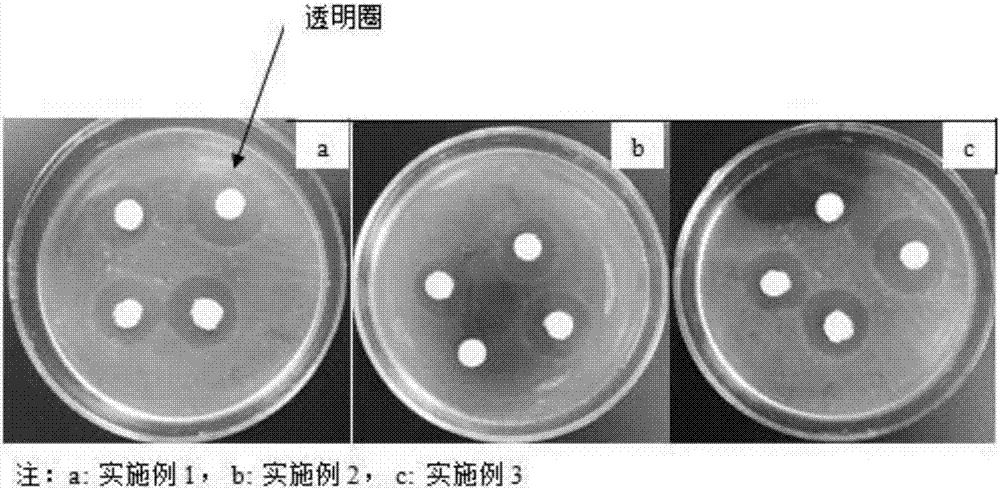

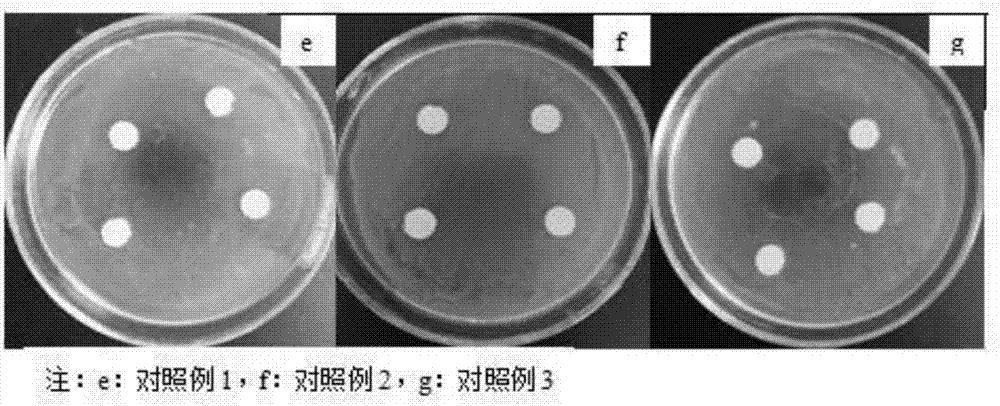

Natural Salvia miltiorrhiza polysaccharide-containing compound antibacterial liquid soap and preparation method thereof

InactiveCN107157801AAvoid influenceLow solvent residueCosmetic preparationsToilet preparationsChemistryTrisodium citrate

The invention discloses a natural Salvia miltiorrhiza polysaccharide-containing compound antibacterial liquid soap and a preparation method thereof, and belongs to the field of daily chemicals in order to solve the problem of poor antibacterial activity of existing liquid soaps. The liquid soap comprises, by weight, 0.1-8% of dodecyl dimethyl betaine, 0.3-5% of fatty alcohol-polyoxyethylene ether, 1-12% of coconut oil fatty alcohol diethanolamide, 1-10% of alkyl glucosides, 5-10% of propylene glycol, 0.1-0.5% of vitamin E, 10-20% of Salvia miltiorrhiza polysaccharide extract, and the balance of distilled water; and the pH value of the obtained solution is adjusted to 6.0-7.0 by using a citric acid-citrate buffer solution. Flavonoid compounds in the extract are added as an addition component, extracted Salvia miltiorrhiza crude polysaccharides used as a functional factor are purified multiple times to become an antibacterial functional component, so the natural Salvia miltiorrhiza polysaccharide-containing compound antibacterial liquid soap provided by the invention has the advantages of high decontamination ability, good antibacterial property, non-toxicity, and no irritation.

Owner:GANSU NORMAL UNIV FOR NATTIES

Method for producing walnut oil

InactiveCN104531344AReduce churnLow boiling pointFatty-oils/fats refiningFatty-oils/fats productionFiberCrude fibre

The invention discloses a process method for producing walnut oil by using walnut powder as a raw material. The method comprises the steps of sequentially cleaning, leaching, squeezing, filtering, degumming, deacidifying, washing and deodorizing the walnut powder raw material to prepare the finished product walnut oil. According to the method, the leaching process is performed before the squeezing process, so that high oil content, few crude fibers and other disadvantageous factors including difficulty in directly squeezing of the walnut powder can be avoided; a butane leaching method under an undercritical condition is adopted in the leaching step, so that desolvation is easy, and few product nutritional ingredients are lost. The method is simple in process and convenient to operate, and the produced walnut oil product completely accords with the index of high-grade oil specification in national standard, and the product quality of the walnut oil is guaranteed.

Owner:HANDAN CHENGUANG PRECIOUS OIL

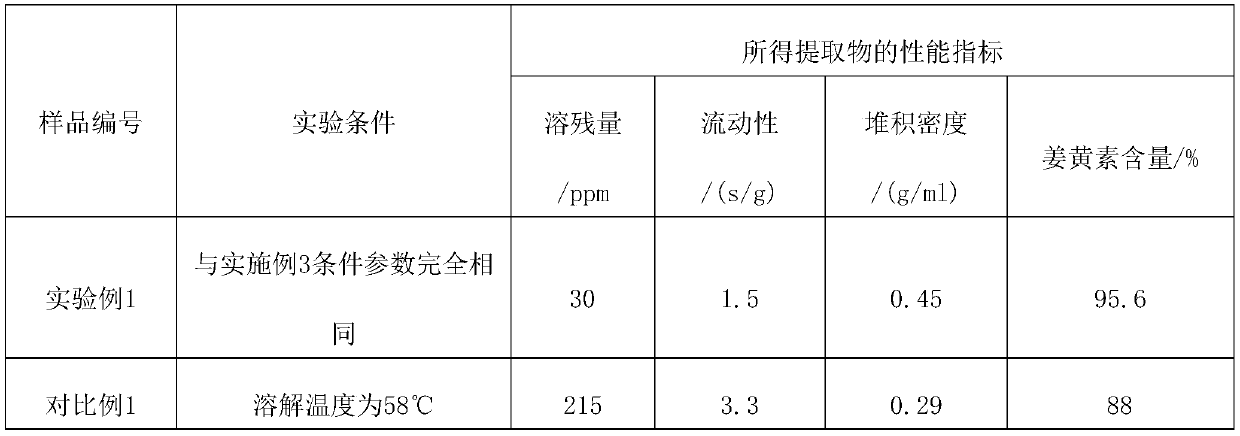

High-quality curcumin product as well as production method and application thereof

ActiveCN110771892ALow solvent residueLow active content lossCosmetic preparationsMake-upBiochemical engineeringProcess engineering

The invention provides a high-quality curcumin product as well as a production method and application thereof. The high-quality curcumin product is low in solvent residue, good in fluidity and high instacking density. The method for producing the curcumin product comprises the following steps that a certain proportion of a crystallizing agent is added by taking a curcuma extract as a raw material, heating or reflux and cooling crystallization continues after dissolving at high temperature, a curcumin crude product is obtained after centrifuging or filtering, and the high-quality curcumin is obtained after further drying. The high-quality curcumin can be used as an additive for foods, medicines, feeds, cosmetics and the like.

Owner:CHENGUANG BIOTECH GRP CO LTD

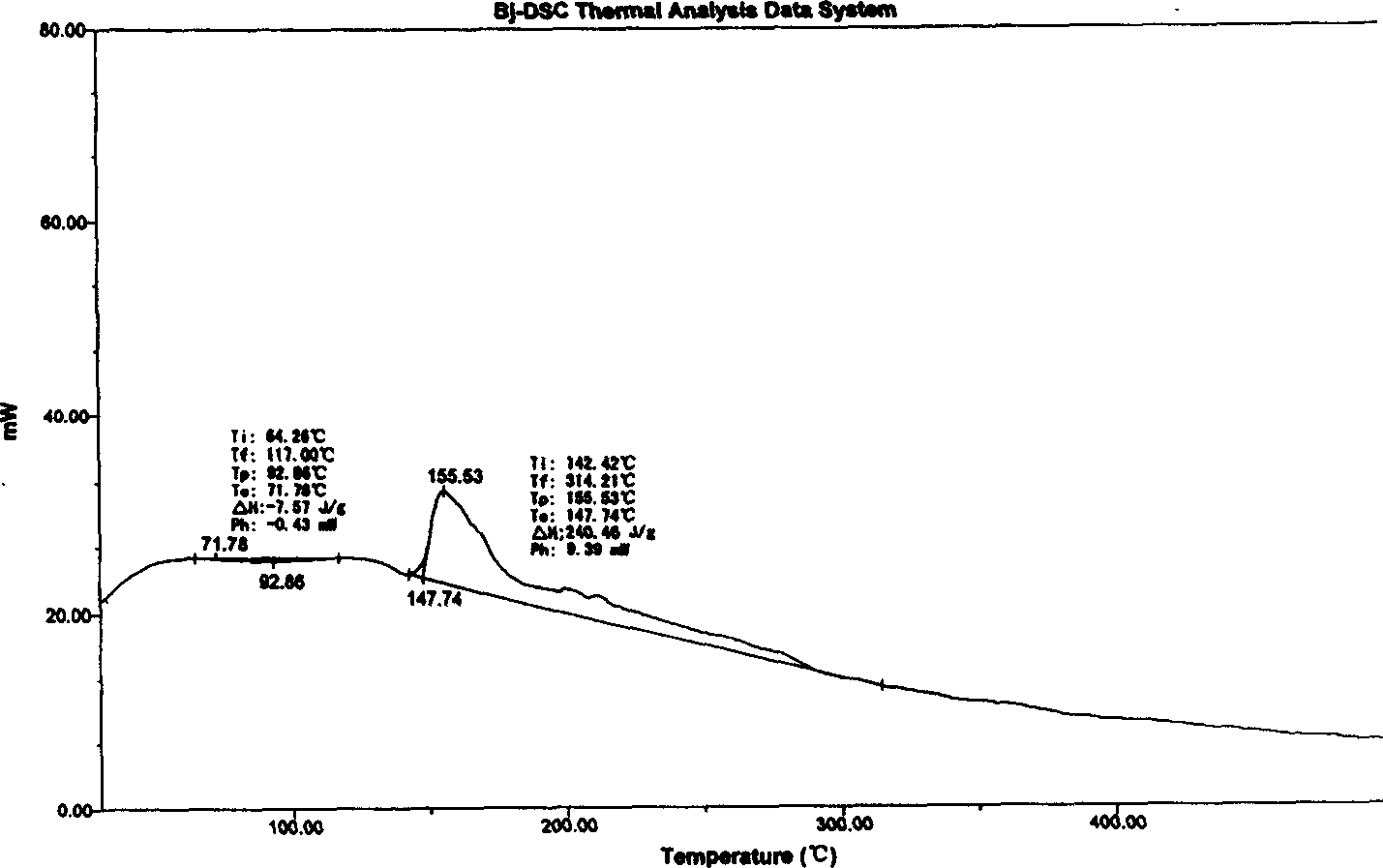

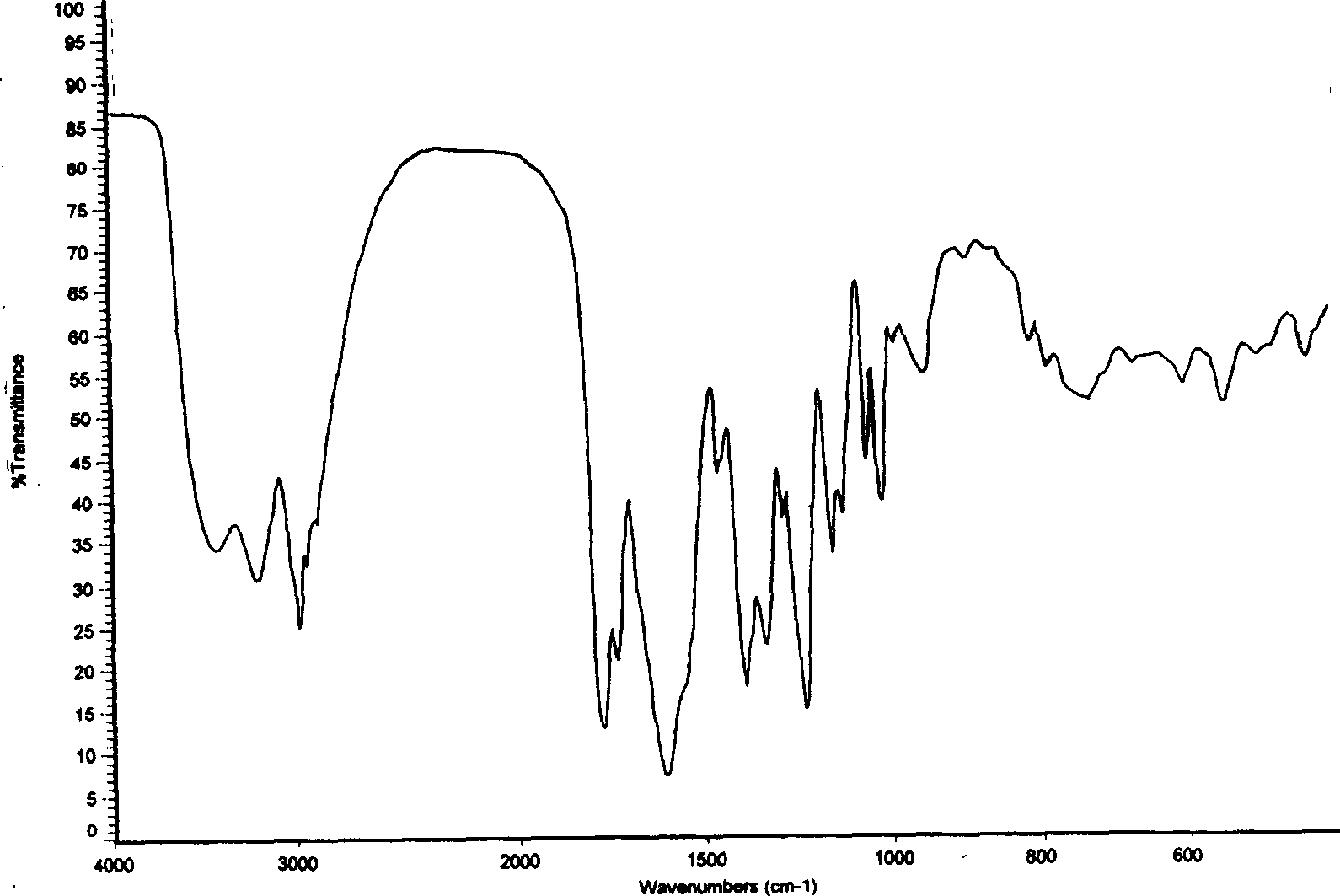

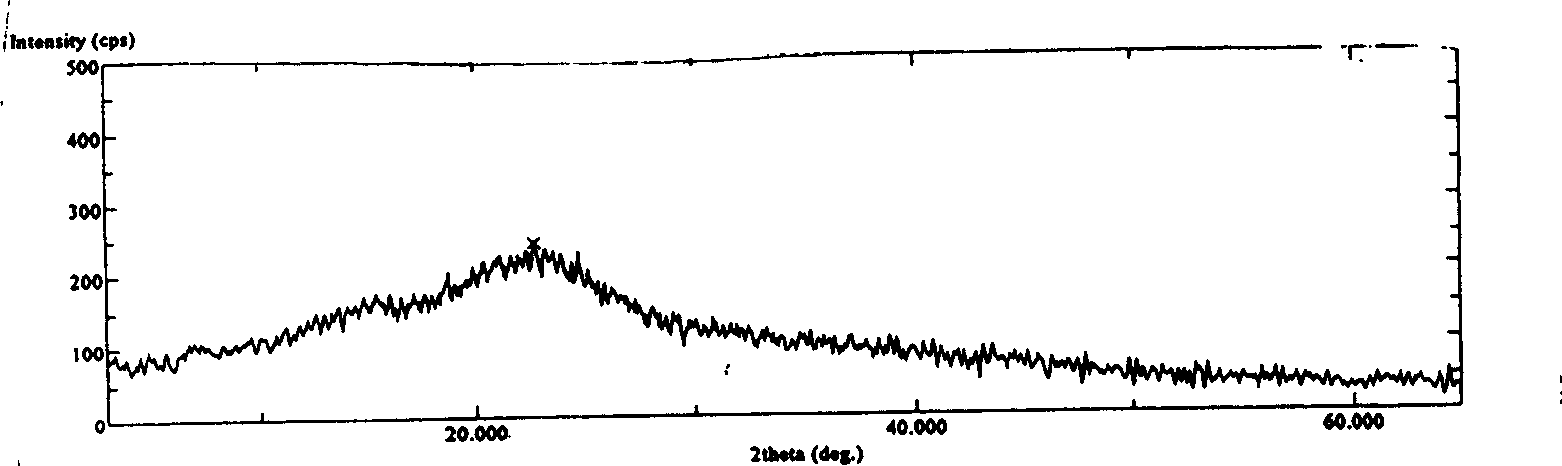

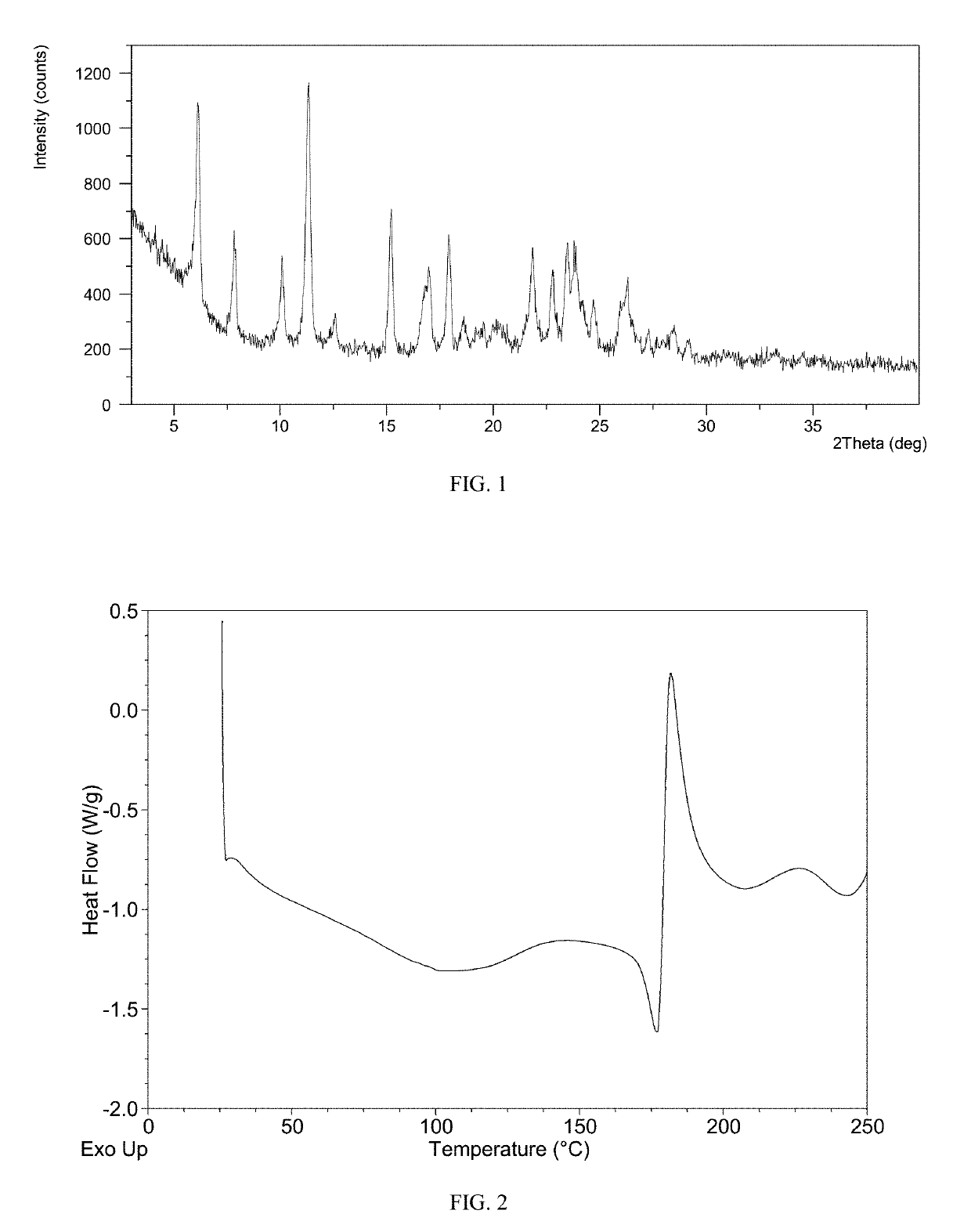

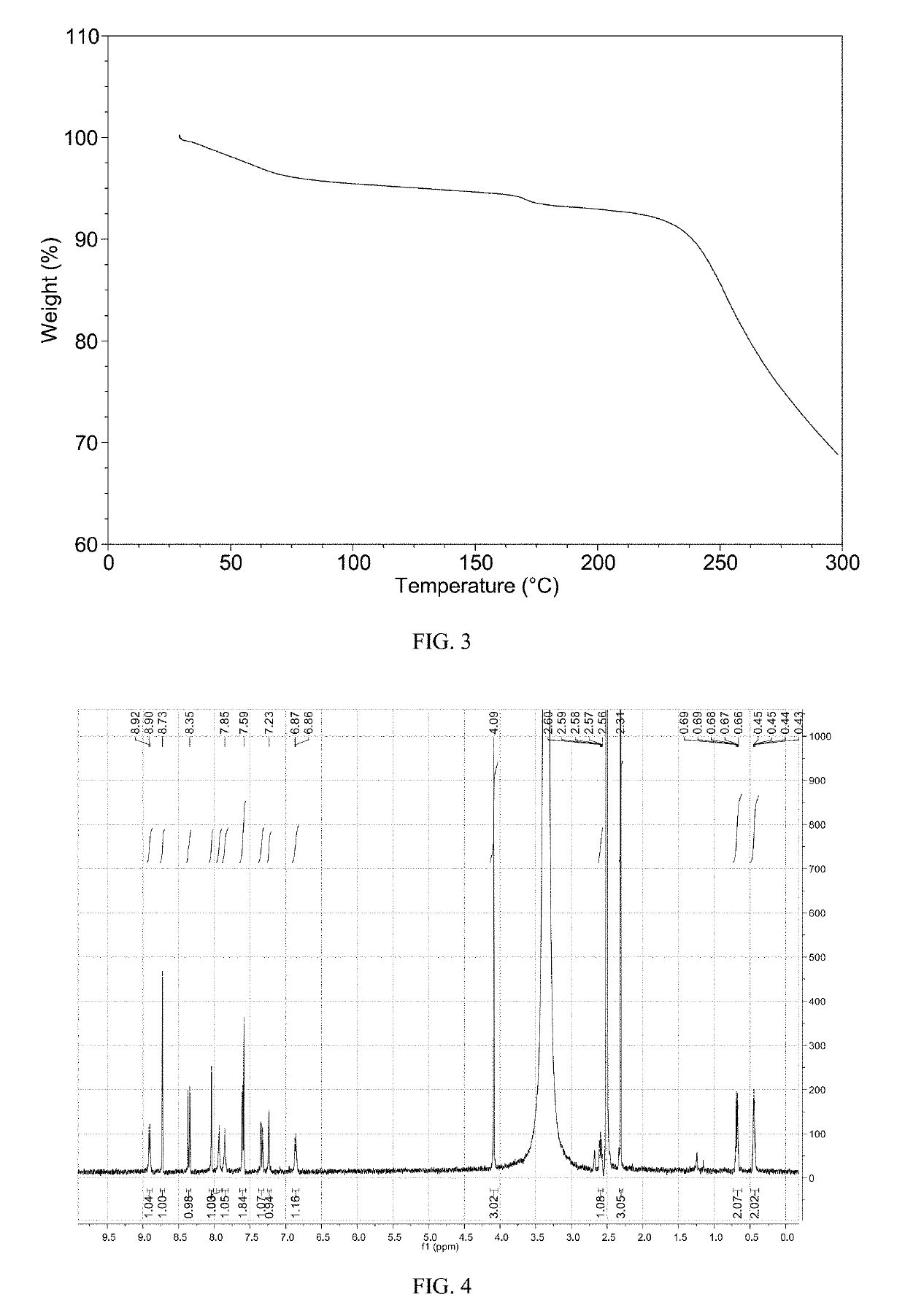

Amorphous cephalosporin

ActiveCN1594323ALow solvent residueHigh clarityAntibacterial agentsOrganic active ingredientsSolventCephalosporin

The invention discloses an amorphous cefathiamidine solid which is characterized by X-ray diffraction atlas, differential scanning calorimetry (DSC) and infrared spectroscopic data. The solid can be prepared through cryodesiccation, spray drying and precipitation process.

Owner:GUANGZHOU BAIYUNSHAN PHARM CO LTD

Scrapable water-based ink for gravure printing and preparation method thereof

The invention discloses a scrapable water-based ink for gravure printing. The scrapable water-based ink is prepared from 45-50 parts of a water-based color paste, 35-40 parts of a water-based acrylicemulsion, 0.2-0.5 part of a dispersing agent, 5-10 parts of water, 0.1-0.3 part of a defoamer and 0.2-0.4 part of a leveling agent. The crapable water-based ink for gravure printing adopting the abovestructure has the advantages that compared with a traditional oil-based ink, by taking the water as a solvent, the volatilization of harmful substances is avoided, the environmental pollution is reduced, and the damage to the production personnel and user health is avoided.

Owner:廊坊市安鼎新材料科技有限公司

Preparation method of solvent compound adhesive

InactiveCN101818042AGood releaseLow solvent residuePolyureas/polyurethane adhesivesMacromolecular adhesive additivesSolventAdhesive

The invention discloses a solvent compound adhesive and a preparation method thereof. The preparation method comprises the following steps: taking polyether glycol, diisocyanate, polyalcohol, dicarboxylic acid, epoxy resin and ethyl acetate with molecular weight of 400-1000 as raw materials; preparing a main agent and a curing agent; and then mixing the obtained main agent and the curing agent proportionally to obtain the double-component solvent compound adhesive. The adhesive has good bonding strength, low solvent residual quantity, high safety and environmental protection, thus solving the problem of high residual quantity of the solvent adhesive in winter.

Owner:BEIJING COMENS NEW MATERIALS

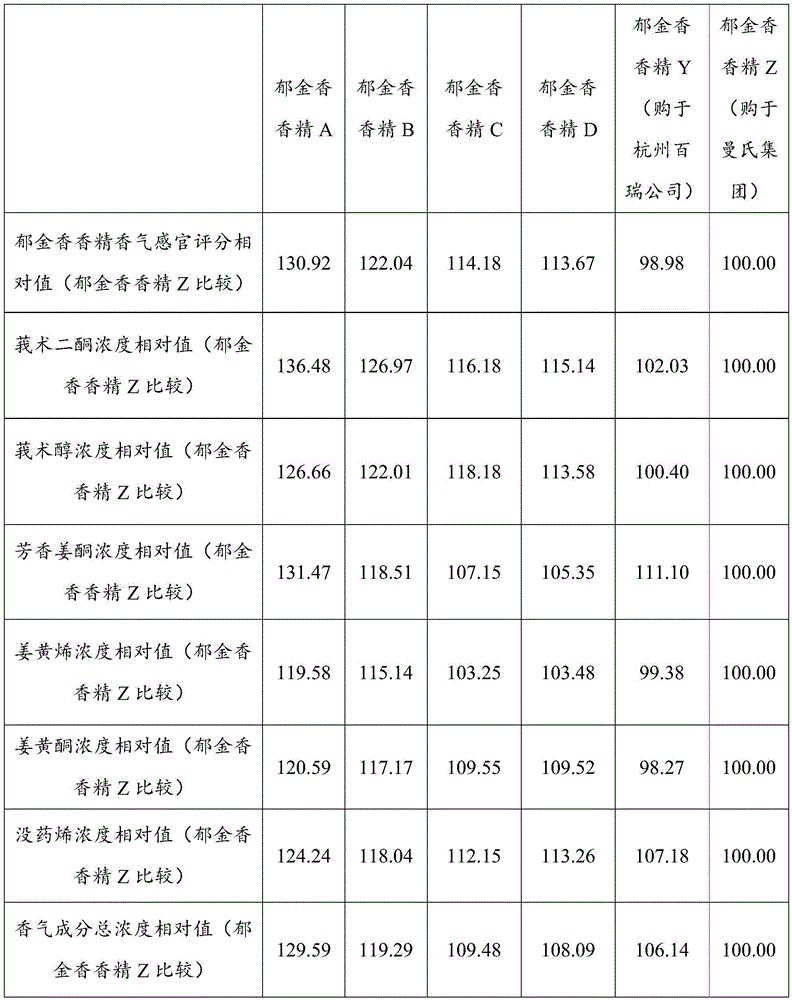

Extraction method for tulip essence

InactiveCN105602729ALow solvent residueReduces damage to heat-sensitive ingredientsEssential-oils/perfumesSolventChemistry

The invention especially relates to an extraction method for tulip essence, which belongs to the technical field of deep processing of tulip. The objective of the invention is to overcome the problems of a low recovery rate, low efficiency, a great number of solvent residuals and reduction in aroma sensory quality and aroma component concentration of products due to destroy of heat-sensitive components caused by high temperature in conventional extraction methods. The extraction method for tulip essence in the invention comprises the following steps: step 1, preliminary crushing; step 2, microjet crushing; step 3, preparation of extract; step 4, enzymatic hydrolysis; step 5, extraction; and step 6, purification. The flowers and leaves of tulip successively undergo the step 1 to the step 6, so a tulip essence product is obtained.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

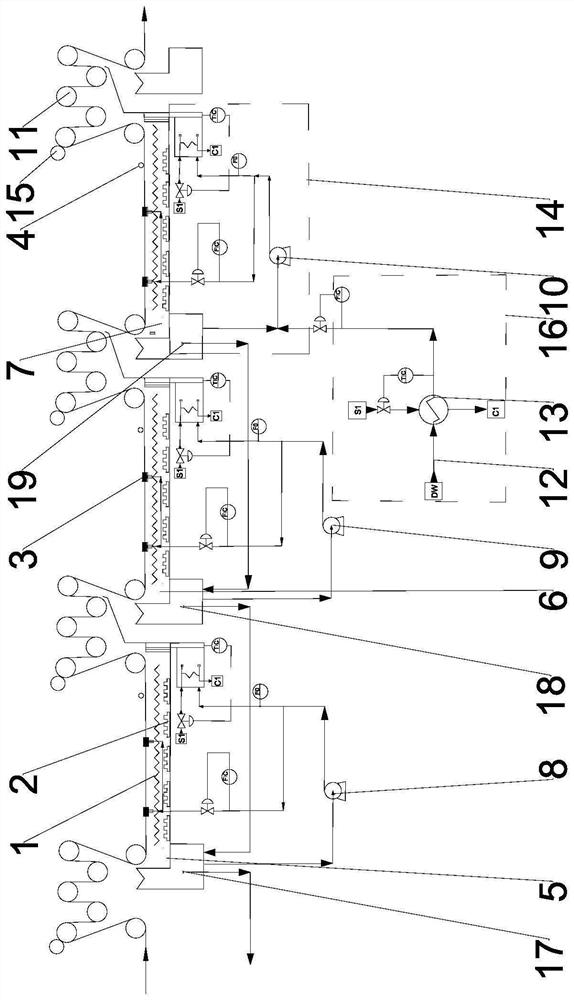

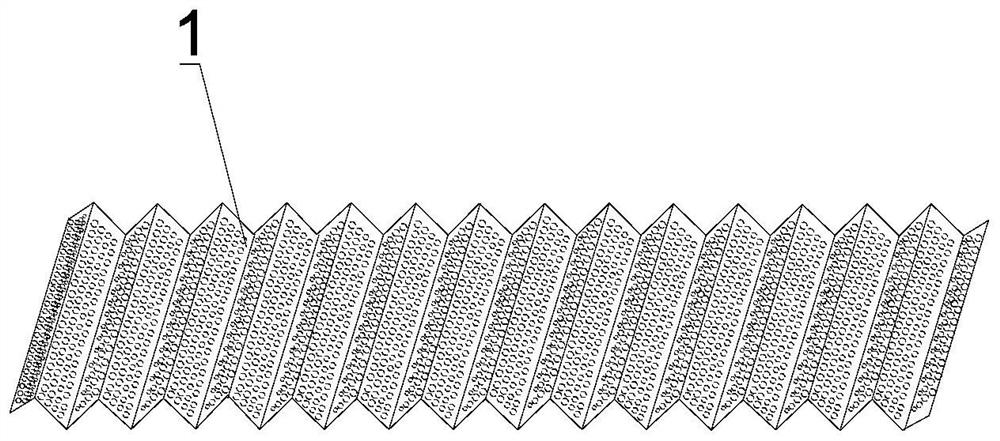

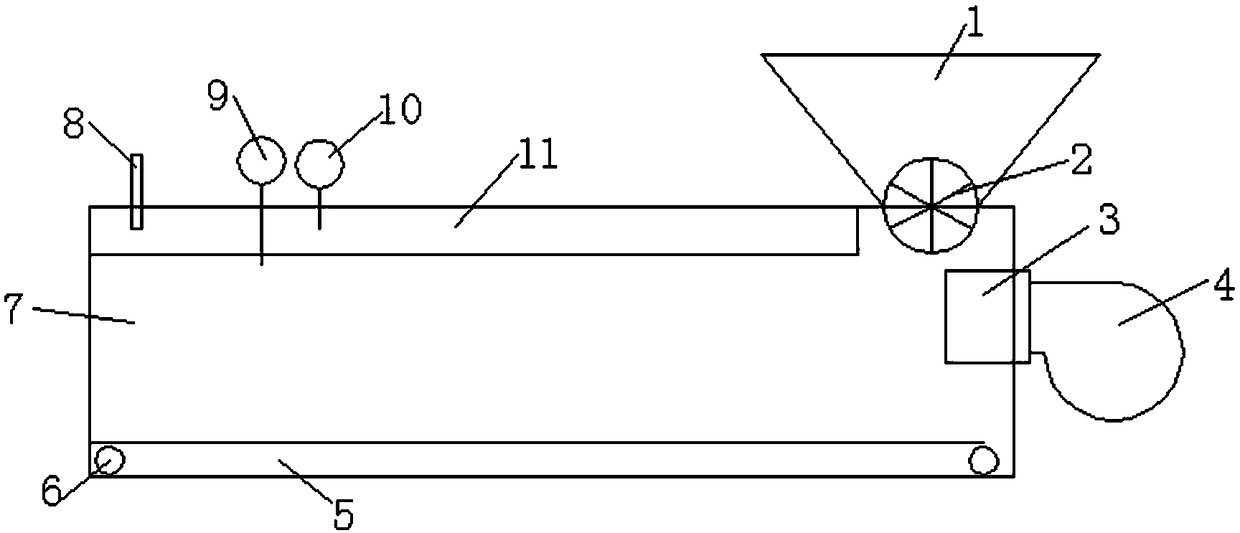

Three-stage boiling water drafting device and method for large-tow carbon fiber precursor production

PendingCN114381816APhenomena affecting qualityEfficient industrial washingArtificial thread manufacturing machinesArtificial filament washing/dryingYarnCarbon fibers

The invention relates to a three-stage boiling water drafting device and a three-stage boiling water drafting method for large-tow carbon fiber precursor production, which solve the technical problems of difficult drafting and easy generation of broken filaments, broken filaments and wool balls during wet spinning, and are provided with a three-stage boiling water drafting tank, a desalted water replenishing temperature control device and seven traction cooling rollers, the third-stage boiling water drafting tank is connected with a desalted water replenishing temperature control device; a flow guide plate, an ultrasonic vibrator group module, a washing module assembly, a cascade gourd-shaped yarn guide rod and a boiling water circulating temperature control system are arranged in each stage of drafting groove of the three-stage boiling water drafting groove, the ultrasonic vibrator group module is located at the bottom of each stage of drafting groove of the three-stage boiling water drafting groove, and the flow guide plate is located above the ultrasonic vibrator group module; the water washing module assembly and the cascade gourd-shaped yarn guide rod are both located above each stage of drafting groove of the three-stage boiling water drafting groove, and the cascade gourd-shaped yarn guide rod is located at the front end of each stage of drafting groove of the three-stage boiling water drafting groove. The method can be widely applied to industrial large-tow production of polyacrylonitrile fiber precursors.

Owner:山东永成新材料有限公司

Purification method of baloxavir marboxil and derivatives thereof

ActiveCN112552315AHigh purityLarge particle sizeOrganic chemistry methodsBiochemistryPerylene derivatives

The invention relates to a purification method of baloxavir marboxil and derivatives thereof, which comprises the following steps of: adding a low-molecular alcohol solvent into baloxavir marboxil andderivatives thereof, heating for dissolution, and carrying out crystallizing, filtering, and drying to obtain a purified product. The purified product obtained by the method has the advantages of high purity, proper particle size distribution and no electrostatic adsorption phenomenon, and is beneficial to improving the quality and quality uniformity of medicines and preparations thereof, and beneficial to preparation processing.

Owner:BEIJING AOHE DRUG RES INST +3

Method for preparing Imipenem monohydrate crystals

ActiveCN101891744BEfficient purificationAvoid degradationOrganic chemistryActivated carbonOrganic solvent

The invention discloses a method for preparing Imipenem monohydrate crystals, comprising the following steps: dissolving an Imipenem crude product in water at the temperature of 30-65 DEG C to obtain a solution I; processing the solution I by activated carbon, filtering at the temperature of 5-30 DEG C to obtain a filtrate II; subjecting the filtrate II to precipitation at the temperature of 0-10DEG C, filtering to obtain a filtrate III and purified Imipenem monohydrate crystals; and further adding an organic solvent in the filtrate III, and recovering to obtain an Imipenem monohydrate crudeproduct. The method is simple and feasible, and the obtained Imipenem monohydrate crystals have extra low solvent residue, meets the method requirements on preparing the Imipenem and is suitable for industrialized production.

Owner:SHENZHEN HAIBIN PHARMA

Bortezomib crystal form, preparation method, pharmaceutical composition and application thereof

ActiveCN104693271AGood solubilityLow solvent residueDipeptide ingredientsPeptide preparation methodsSolubilityAnti-Tumor Drugs

The invention relates to the field of medicinal chemistry and particularly relates to a new crystal form of the bortezomib. The invention additionally discloses a preparation of the crystal form and an application in the antineoplastic medicine. The crystal form disclosed by the invention solves the technical problems that the current bortezomib crystal form has bad solubility and weak antioxidant ability and is not good for liquid formulation preparation, and has the advantages of good solubility, high stability and strong antioxidant ability; simultaneously the crystal form prepared by the method disclosed by the invention is high in crystal form purity and safe in medicine use.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST +1

Water-based white ink for surface treatment of base material before code spraying and preparation method of water-based white ink

The invention discloses water-based white ink for surface treatment of a base material before code spraying. The water-based white ink comprises the following components by weight: 11 to 12 parts of awater-based acrylic emulsion, 0.3 to 0.5 part of a dispersing agent, 63 to 65 parts of an inorganic pigment, 5 to 10 parts of water, 25 to 30 parts of auxiliary agents, 0.1 to 0.3 part of a defoamingagent, and 0.2 to 0.4 part of a leveling agent, wherein the water-based acrylic emulsion comprises the following components by weight: 25 parts of butyl methacrylate, 40 parts of styrene, 20 parts ofbutyl acrylate, 10 parts of hydroxypropyl acrylate, 5 to 15 parts of water-soluble solid acrylic resin, 0.5 to 5 parts of an anionic emulsifier, 0.2 to 1.2 parts of ammonium persulfate, 0.5 to 5 parts of a coalescing agent, 0.1 to 1 part of a defoaming agent, 4 to 14 parts of ammonia water, and 40 to 70 parts of deionized water. According to the water-based white ink adopting the structure and used for surface treatment of the base material before code spraying, the water-based acrylic emulsion is used as a connecting material, and the coloring property and the adhesive force of a coating film can be kept, so that the water-based white ink is suitable for surface treatment of a non-polar base material code printing area; and meanwhile, volatilization of harmful substances is avoided by using water as a solvent.

Owner:廊坊市安鼎新材料科技有限公司

Method for preparing hydroxypropyl-beta-cyclodextrin

ActiveCN102040675BWill not cause decompositionLow impurity contentMacromolecular non-active ingredientsNanofiltrationPharmaceutic Adjuvant

The invention discloses a method for preparing hydroxypropyl-beta-cyclodextrin, which comprises the steps of etherification, neutralization, decoloring, nanofiltration, resin purification, and spray drying. The method of the invention is small in pollution, and the yield in weight is more than 80 percent; meanwhile, the product prepared by using the method of the invention is narrow in substituted ratio range and low in impurity content, and can be used as a pharmaceutic adjuvant.

Owner:石药集团中诺药业(石家庄)有限公司

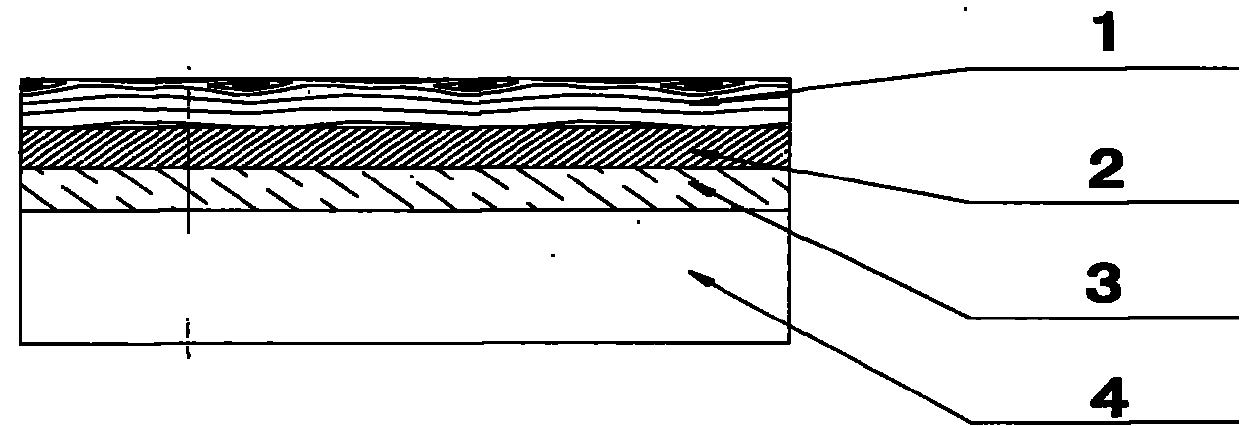

Electron beam-cured coating-containing vacuum aluminized sanding card paper and manufacturing method thereof

ActiveCN102002894BLow solvent residueResidue reductionSpecial paperPaper/cardboardScreen printingPulp and paper industry

The invention relates to electron beam-cured coating-containing vacuum aluminized sanding card paper which has a metal texture and a manufacturing method thereof. The electron beam-cured coating-containing vacuum aluminized sanding card paper is characterized in that an electron beam-cured sanding coating (3) and an aluminized layer (2) are sequentially covered on a paper substrate (4). The manufacturing method comprises the following steps of: preparing an electron beam-cured dope composition with a sanding effect; coating a layer of electron beam-cured dope composition-containing sanding coating on the paper substrate; and directly aluminizing in a vacuum aluminizing system to form the aluminized layer. The card paper can be reclaimed and degraded. In the subsequent process, the card paper can be printed and coated with colour; and then a screen printing effect can be achieved through offset printing or gravure printing. In a manufacturing process of the card paper, no solvent is volatilized; the efficiency is high; and the energy consumption is low. Therefore, the production process is an environmentally-friendly and high-efficient production process.

Owner:YANTAI BOYUAN TECH MATERIALS

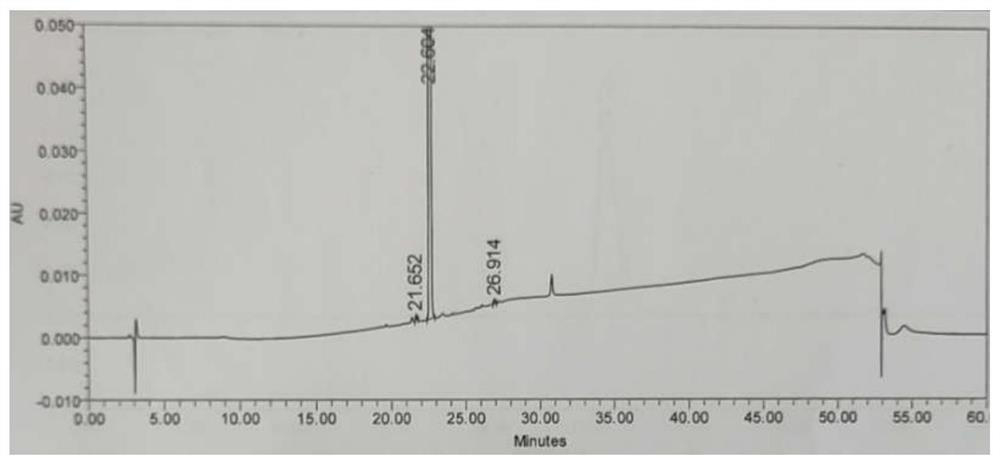

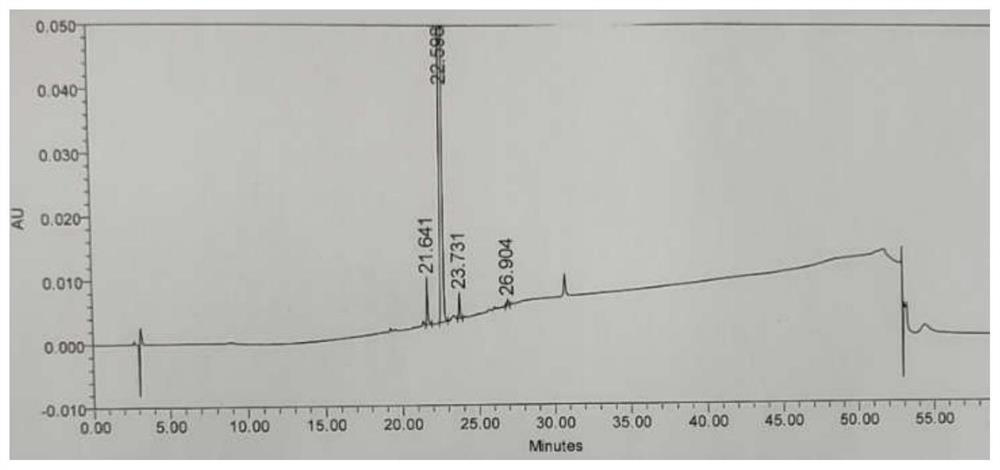

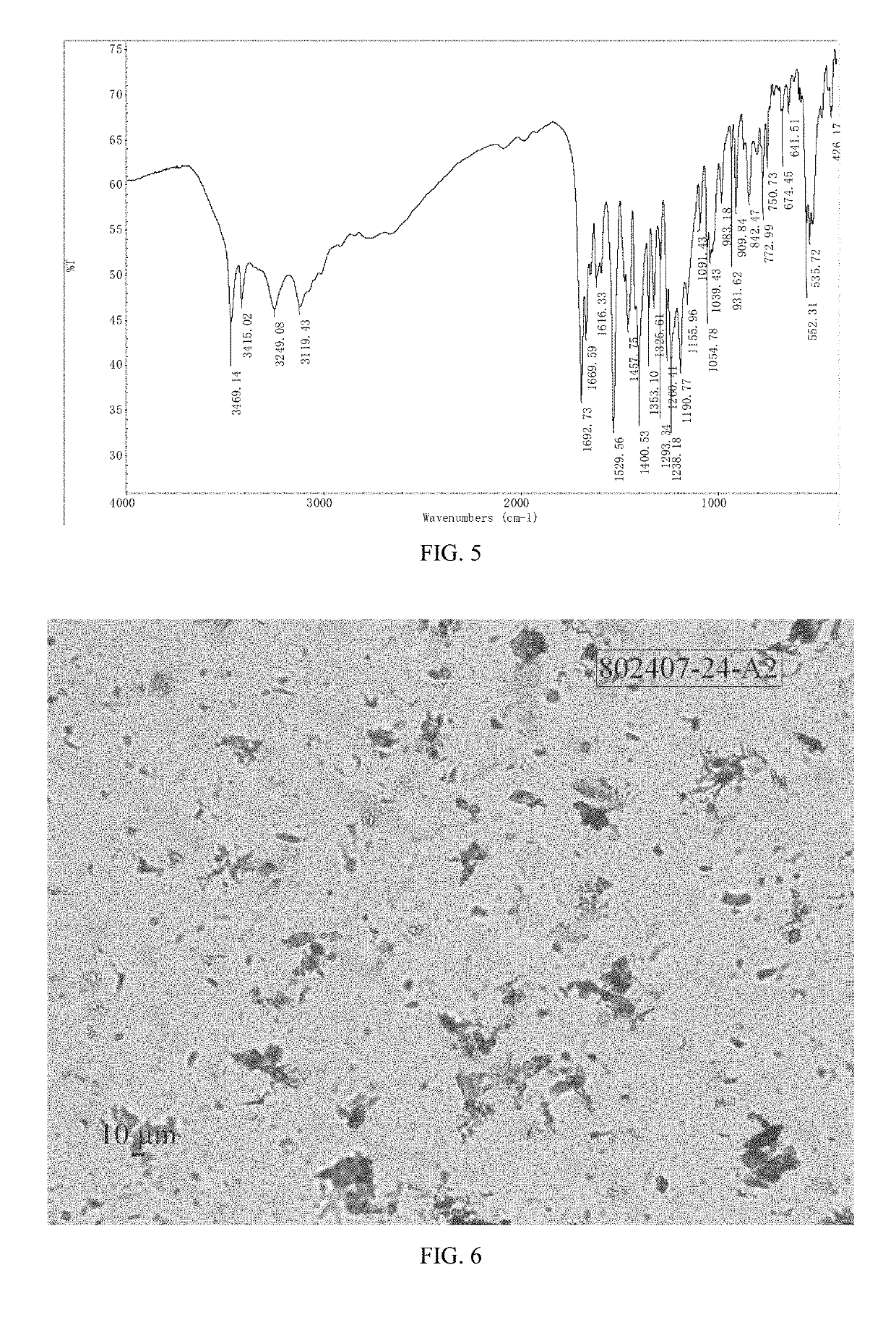

Novel Crystalline Form of Lenvantinib Mesylate and Process of Preparation Thereof

ActiveUS20190218184A1Improve solubilityImprove stabilityOrganic chemistry methodsAntineoplastic agentsSolubilityLenvatinib Mesylate

The present disclosure relates to a novel crystalline form of lenvatinib mesylate and the preparation method thereof. The novel crystalline form of mesylate of the present disclosure can be used for treating invasive and differentiated thyroid cancer. The novel crystalline form of mesylate of the present disclosure has good solubility, stability, and remarkable purification effect in process. The preparation method of this novel crystalline form is simple, low cost, and has an important value for future optimization and development of the drug.

Owner:CRYSTAL PHARMATECH CO LTD

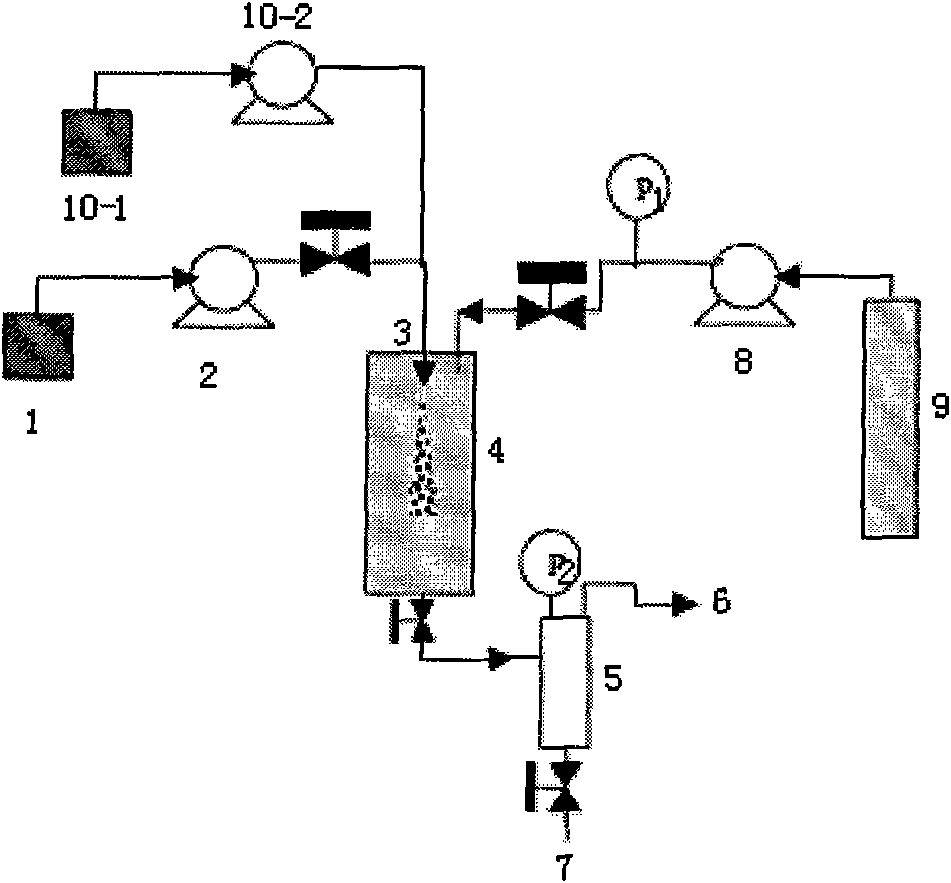

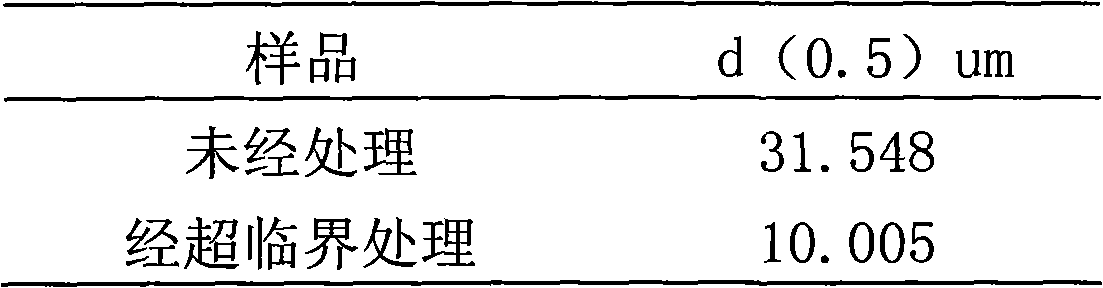

Preparation process of alpha-amyrin fine particle

InactiveCN102091077AImprove solubilityGood curative effectAntibacterial agentsOrganic active ingredientsSolubilityAnti solvent

The invention relates to a preparation process of an alpha-amyrin fine particle, which uses the traditional supercritical fluid anti-solvent equipment. The preparation process of the alpha-amyrin fine particle comprises the following steps of: (1) preparing alpha-amyrin liquid; (2) feeding carbon dioxide; (3) crystallizing and separating out alpha-amyrin; and (4) detecting. The preparation process is suitable for alpha-amyrin raw materials, can prepare the ultrafine particles which are beneficial to the absorption of a human body and can enhance the solubility and the curative effect of the alpha-amyrin and reduce the use cost and the toxic side effect; and in addition, the alpha-amyrin ultrafine particle prepared by the process has unique clinical advantages.

Owner:CHINA NAT ACAD NANOTECH & ENG

Borneol blast drier

InactiveCN109269277ADry fastLow solvent residueDrying gas arrangementsDrying machines with progressive movementsAlcoholEngineering

The invention discloses a borneol blast drier. The borneol blast drier comprises a drying box. A hopper is arranged at one end of the drying box, and a feeder is arranged at the joint of the bottom ofthe hopper and the drying box. A heating box and a draught fan are arranged at the feed end of the drying box. A solvent backflow baffle and a vibratory conveying device are arranged on the inner ring of the drying box. A thermometer and a pressure gauge are arranged on the outer wall of the drying box. The other end of the drying box serves as a discharge end, and a vent valve and an air hole are arranged at the tail of the drying box. A petroleum ether and ethyl alcohol solvent is used for natural borneol in the crystallization process, as the petroleum ether and ethyl alcohol solvent is not beneficial for borneol drying, the solvent of the natural borneol is removed through hot air, drying of the natural borneol can be accelerated, solvent residues are reduced, and the purpose of improving the efficiency is achieved.

Owner:江西植提庄园健康产业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com