Benzene-free environmentally friendly composite ink and preparation method thereof

An ink and environmental protection technology is applied in the field of special composite ink for mustard packaging bags and its preparation, which can solve the problems of poor packaging barrier performance, decreased surface peeling strength, and blackened packaging appearance, and achieves improved production efficiency and good composite strength. , Overprinting effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

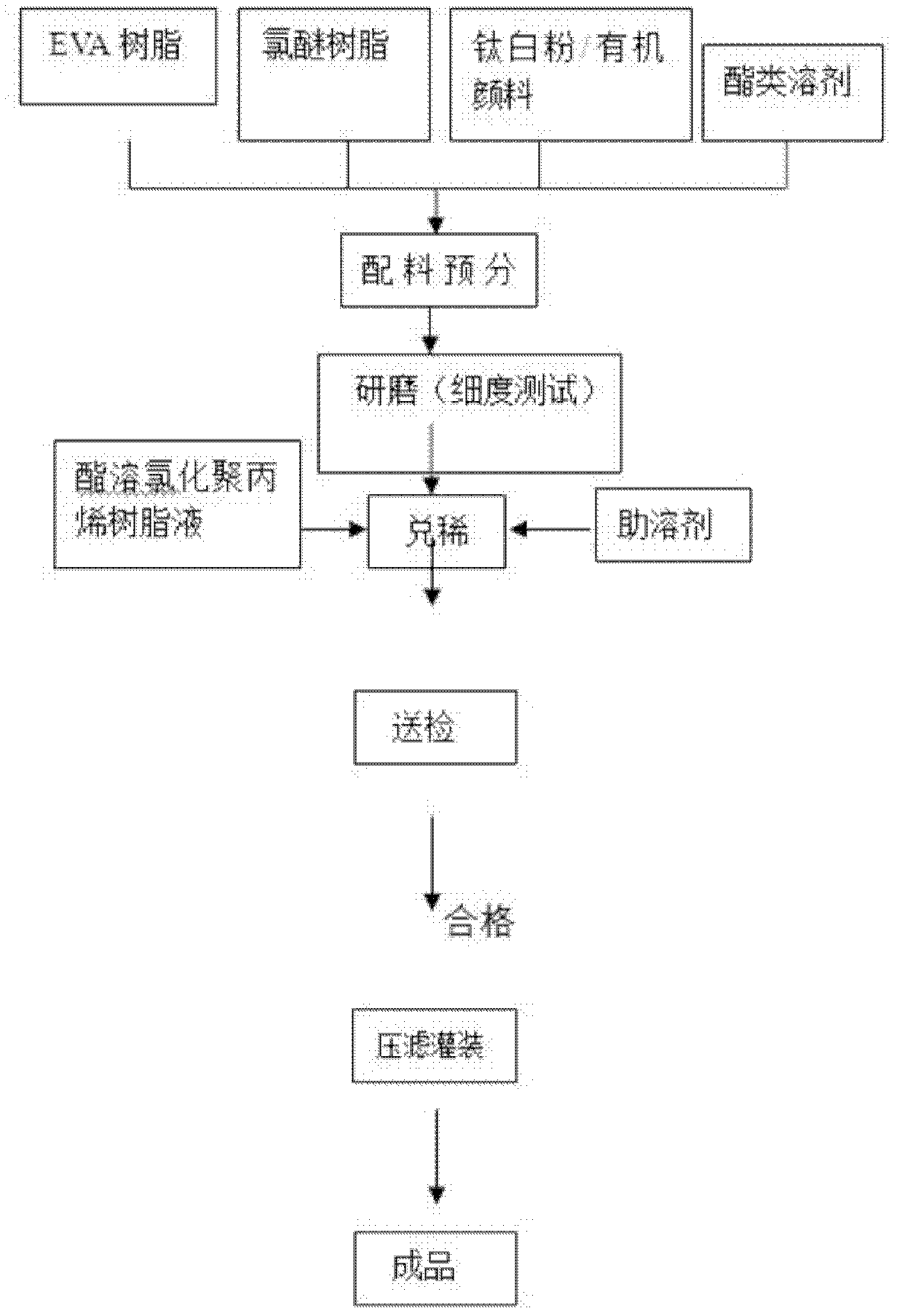

Method used

Image

Examples

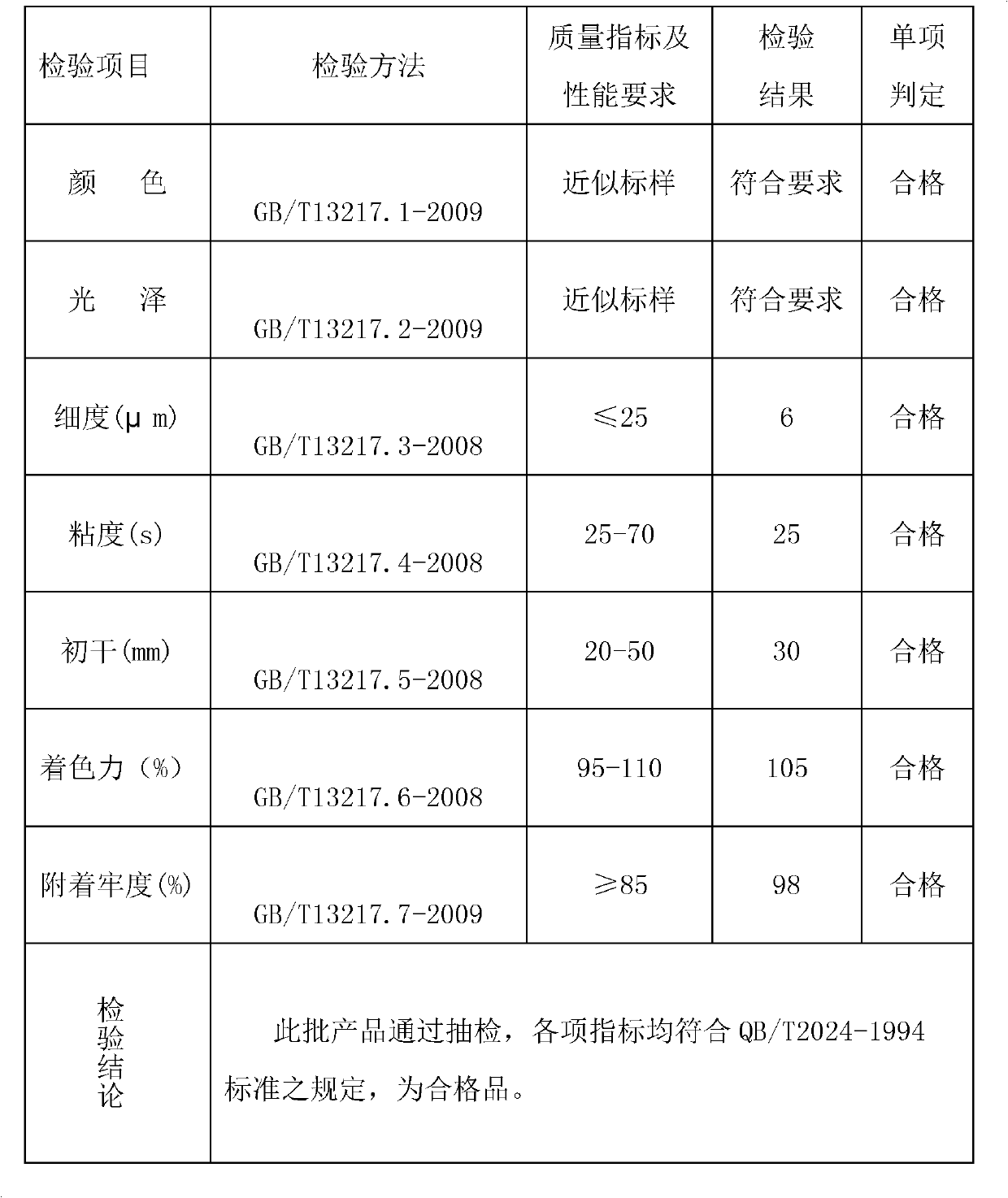

Embodiment 1

[0037] A: chlorinated EVA resin liquid 25%, chlorine ether resin liquid 15%, dispersant 0.3%, ester solvent 11.4%;

[0038] B: Rutile titanium dioxide 28%, matting powder 0.3%;

[0039] C: 12% ester-soluble chlorinated polypropylene resin solution, 8% co-solvent.

[0040] Prepare as follows:

[0041] (1), batching pre-dispersion: Put the chlorinated EVA resin liquid, chlorinated ether resin liquid, dispersant, and ester solvent of part A into a high-speed disperser, adjust the rotating speed to 700 rpm, and initially disperse for 5 minutes; Put the rutile titanium dioxide / organic pigment and matting powder into a high-speed disperser, adjust the speed to 700 rpm, and then disperse for 5 minutes; finally adjust the speed to 1200 rpm, and disperse for 30 minutes to obtain a white ink semi-finished product, which is ready for use;

[0042] (2), sanding process: put the white ink semi-finished product in step (1) into the sand mill, adjust the feed pressure ≤ 0.1Mpa, sand mill t...

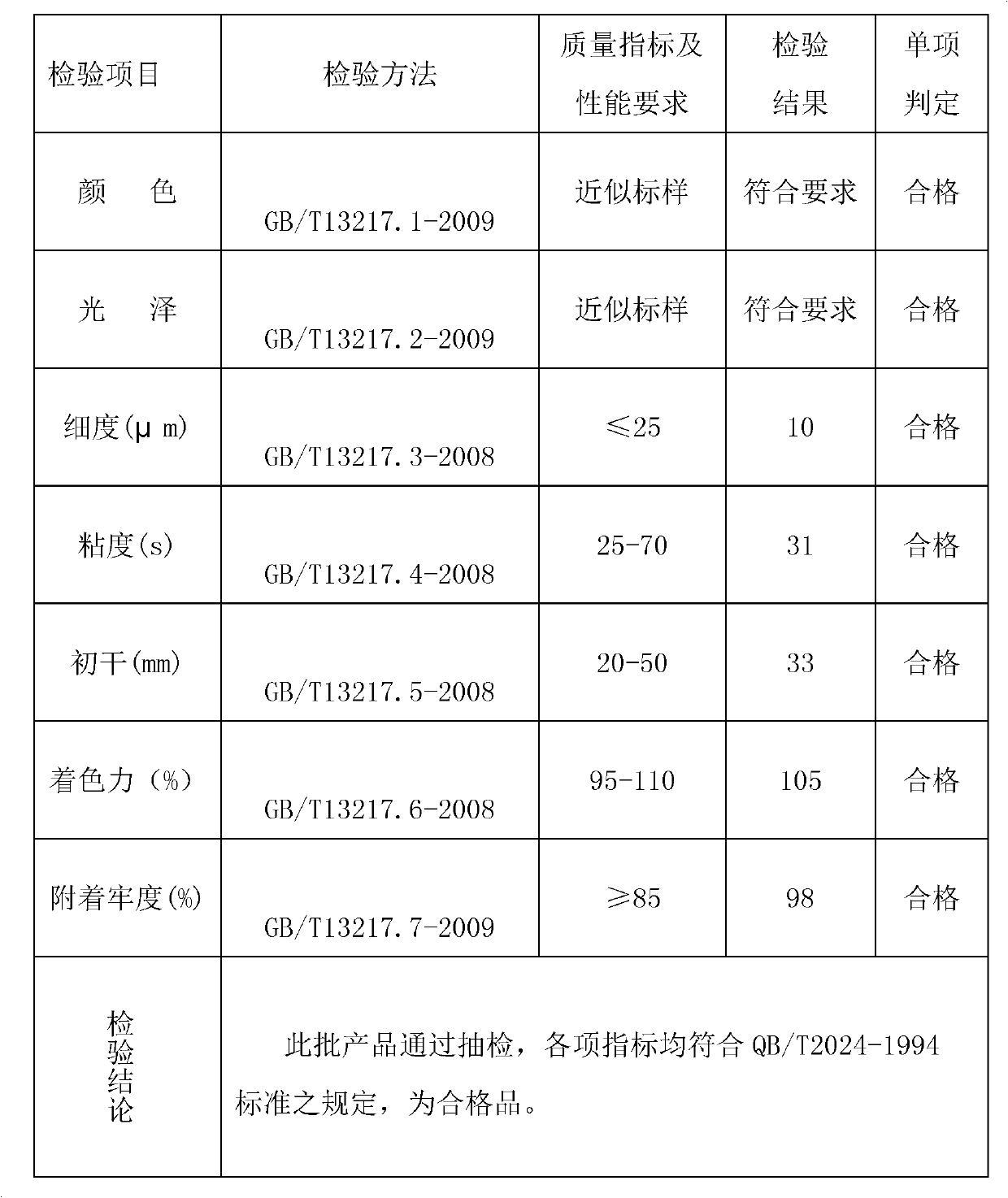

Embodiment 2

[0045] A: chlorinated EVA resin solution 26%, chloroether resin solution 14%, dispersant 0.4%, ester solvent 12%;

[0046] B: Rutile titanium dioxide 29%, matting powder 0.4%;

[0047] C: 11.2% ester-soluble chlorinated polypropylene resin solution, 7% co-solvent.

[0048] Prepare as follows:

[0049] (1), batching pre-dispersion: Put the chlorinated EVA resin liquid, chlorinated ether resin liquid, dispersant, and ester solvent of part A into a high-speed disperser, adjust the rotating speed to 700 rpm, and initially disperse for 5 minutes; Put the rutile titanium dioxide / organic pigment and matting powder into a high-speed disperser, adjust the speed to 700 rpm, and then disperse for 5 minutes; finally adjust the speed to 1200 rpm, and disperse for 30 minutes to obtain a white ink semi-finished product, which is ready for use;

[0050] (2), sanding process: put the white ink semi-finished product in step (1) into the sand mill, adjust the feed pressure ≤ 0.1Mpa, sand mill ...

Embodiment 3

[0053] A: chlorinated EVA resin liquid 27%, chlorine ether resin liquid 12%, dispersant 0.5%, ester solvent 11%;

[0054] B: Rutile titanium dioxide 30%, matting powder 0.5%;

[0055] C: 11% ester-soluble chlorinated polypropylene resin solution, 8% co-solvent.

[0056] Prepare as follows:

[0057] (1), batching pre-dispersion: Put the chlorinated EVA resin liquid, chlorinated ether resin liquid, dispersant, and ester solvent of part A into a high-speed disperser, adjust the rotating speed to 700 rpm, and initially disperse for 5 minutes; Put the rutile titanium dioxide / organic pigment and matting powder into a high-speed disperser, adjust the speed to 700 rpm, and then disperse for 5 minutes; finally adjust the speed to 1200 rpm, and disperse for 30 minutes to obtain a white ink semi-finished product, which is ready for use;

[0058] (2), sanding process: put the white ink semi-finished product in step (1) into the sand mill, adjust the feed pressure ≤ 0.1Mpa, sand mill tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com