Preparation process of alpha-amyrin fine particle

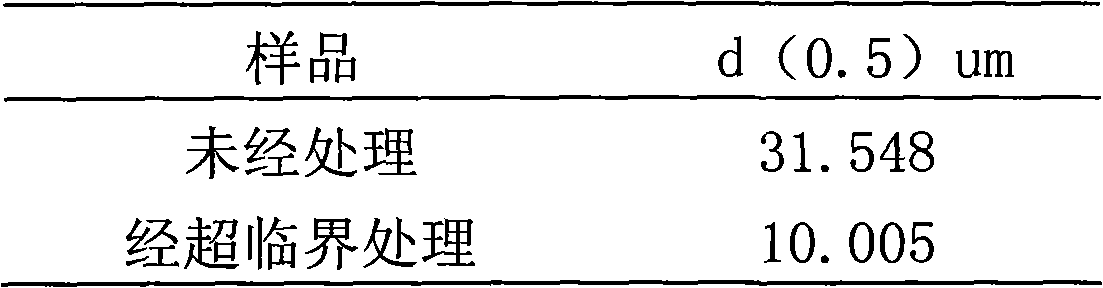

A technology of balsamic resin and fine particles, which is applied in the technical field of preparing α- balsamic resin fine particles by supercritical fluid crystallization technology, can solve the problems of side effects and organic solvent residues, reduce toxic and side effects, improve anti-fatigue, The effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

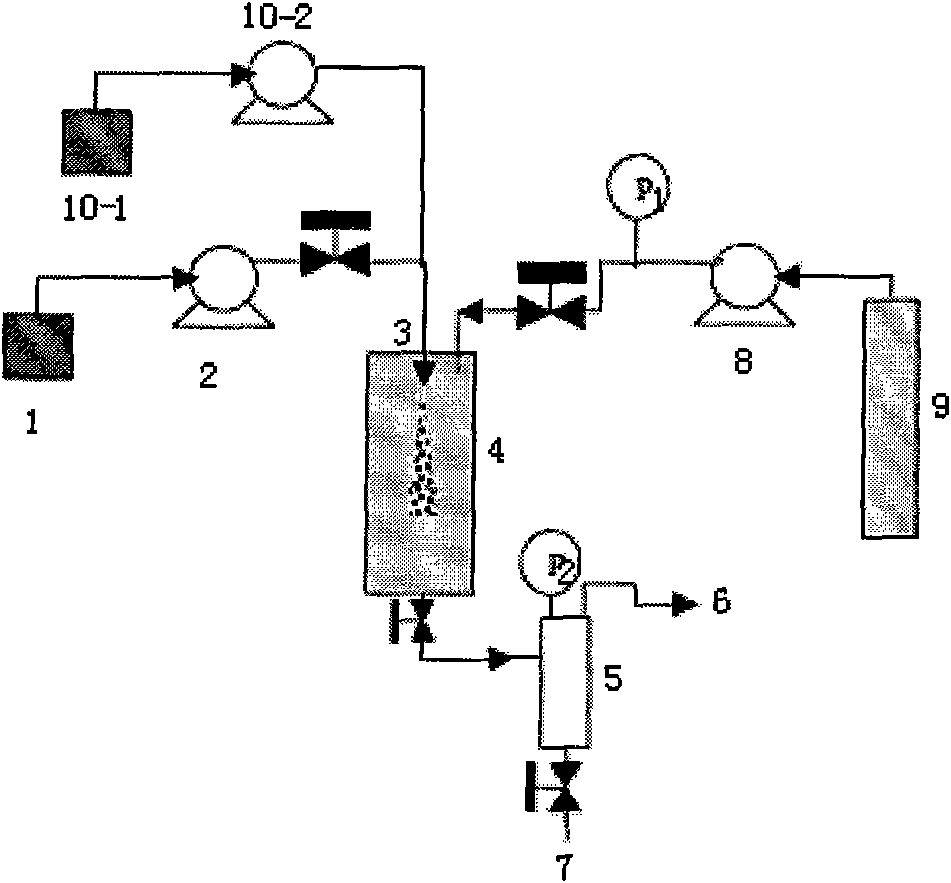

[0033] Embodiment 1: a kind of preparation technology of α-amyresin alcohol fine particle, use existing supercritical fluid anti-solvent equipment, it is characterized in that it is made of following steps:

[0034] (1) Configure α-amyresin liquid: control the system pressure of the equipment to 12Mpa, the melting temperature to 45°C, the spray distance to 10cm, and the nozzle temperature to 45°C. After the indicators are stable, inject 60ml of α-amyresinol solution with a flow rate of 1ml / min;

[0035] Dissolve the 0.5% α-amyl alcohol solution 1 in ethanol, and input it into the equipment system through the high performance liquid chromatography solution pump 2; the dissolution temperature is 40°C, and the equipment system pressure is 12MPa;

[0036] Entrainer 10-1 is absolute ethanol, and the flow rate is 20ml / min;

[0037] (2) Carbon dioxide feed: the CO in the steel cylinder 2 9 Enter the supercritical fluid anti-solvent equipment system into the crystallization kettle...

Embodiment 2

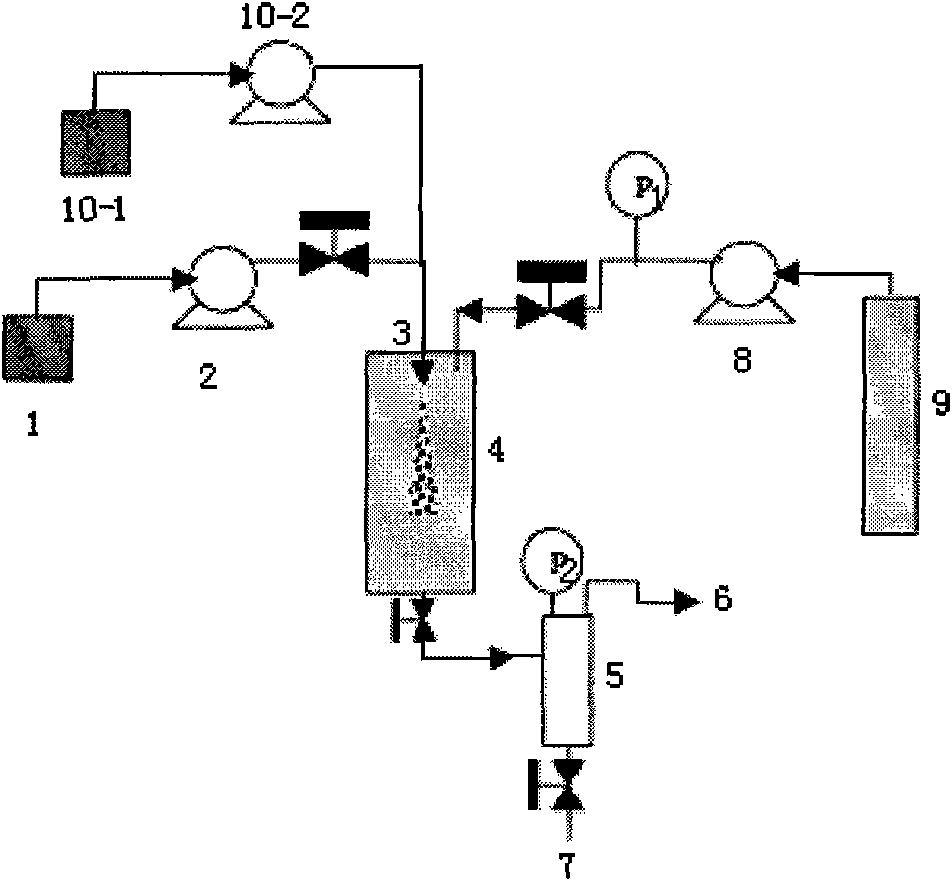

[0041] Embodiment 2: a kind of preparation technology of α-amyresin alcohol fine particle, use existing supercritical fluid anti-solvent equipment, it is characterized in that it is made of following steps:

[0042] (1) Configure α-amyresin liquid: control the system pressure of the equipment to 12Mpa, the melting temperature to 45°C, the spray distance to 10cm, and the nozzle temperature to 45°C. After the indicators are stable, inject 60ml of α-amyresinol solution with a flow rate of 1ml / min;

[0043] Concentration is that 0.5% α-amyresin alcohol solution 1 is dissolved in ethanol, and its proportioning is ethanol: α-amyresin alcohol=100:2; In the equipment system by high performance liquid chromatography solution pump 2 input; Dissolving temperature The temperature is 40℃, and the equipment system pressure is 12MPa;

[0044] Entrainer 10-1 is acetone, and the flow rate is 1.5ml / min;

[0045] (2) Carbon dioxide feed: the CO in the steel cylinder 2 Enter the supercritical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com