Patents

Literature

5768results about How to "The process steps are simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods and apparatus for forming uniform particle layers of phosphor material on a surface

InactiveUS20100291313A1Easy to controlHigh bulk densityLiquid surface applicatorsElectric shock equipmentsPhosphorStatic electricity

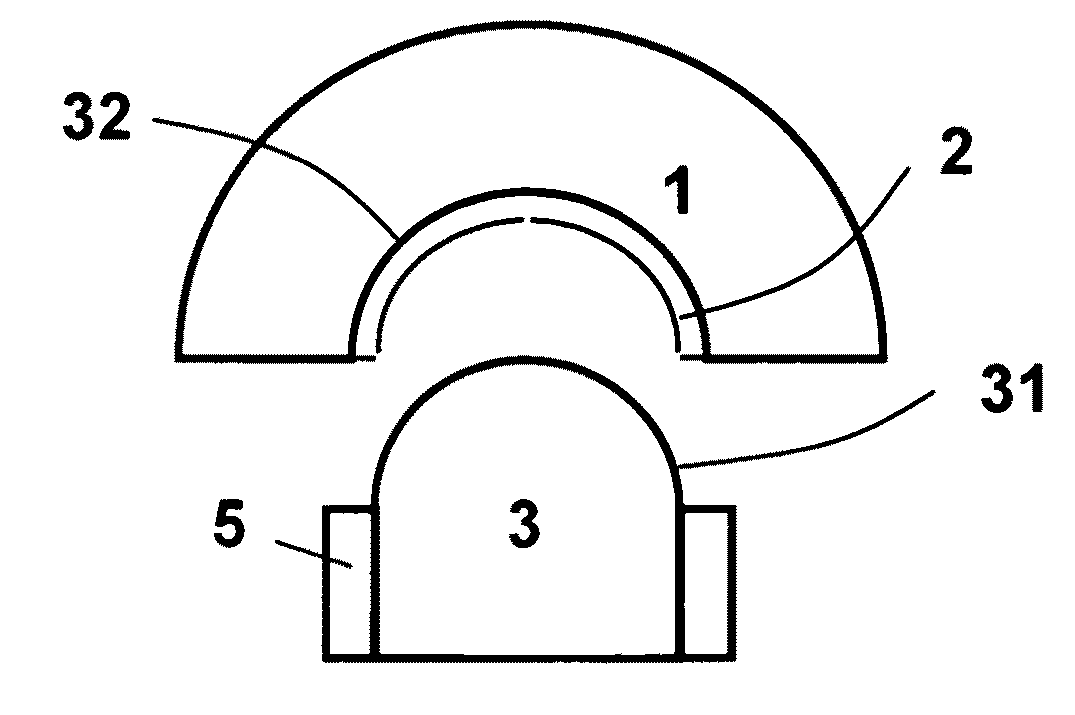

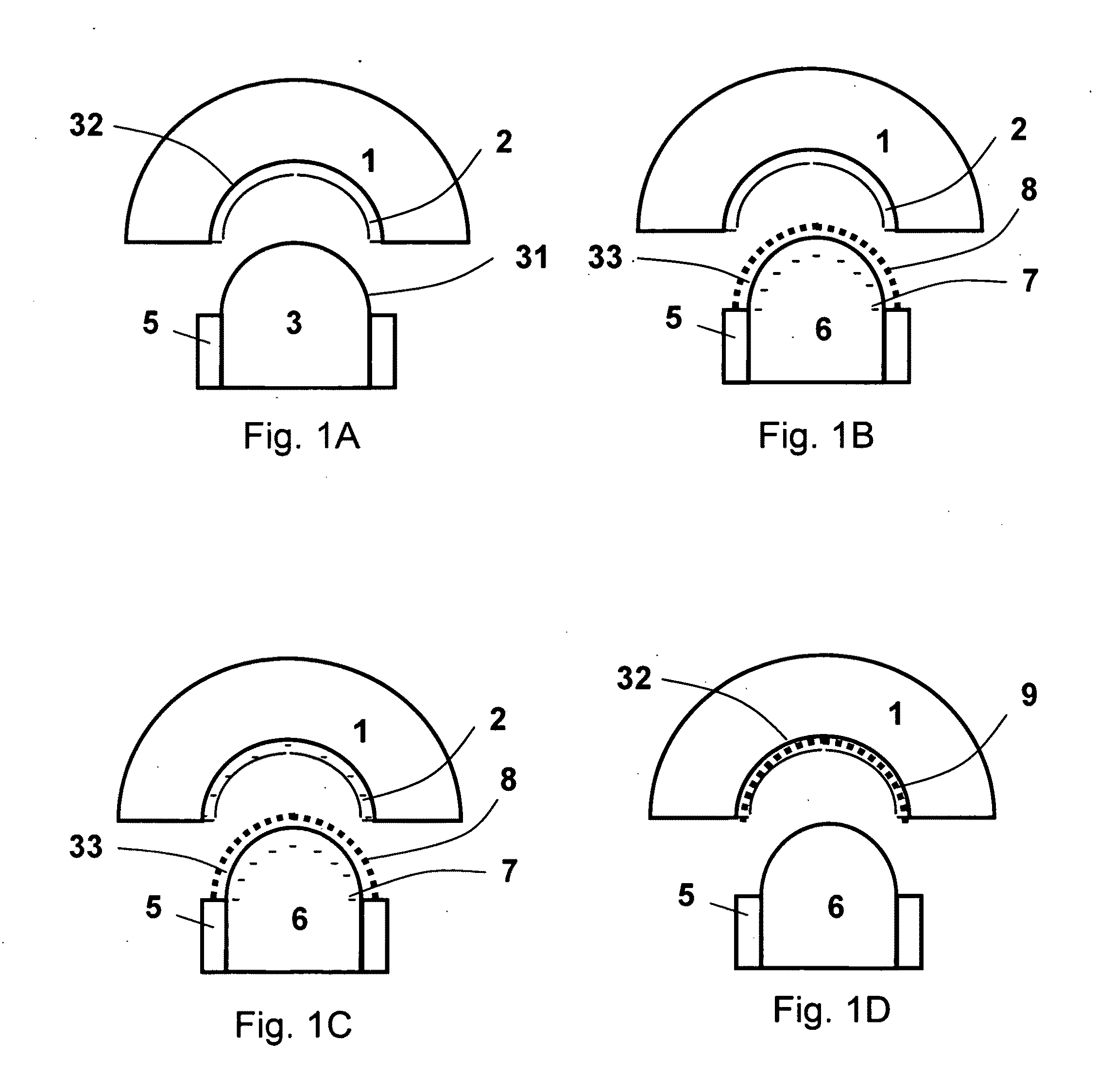

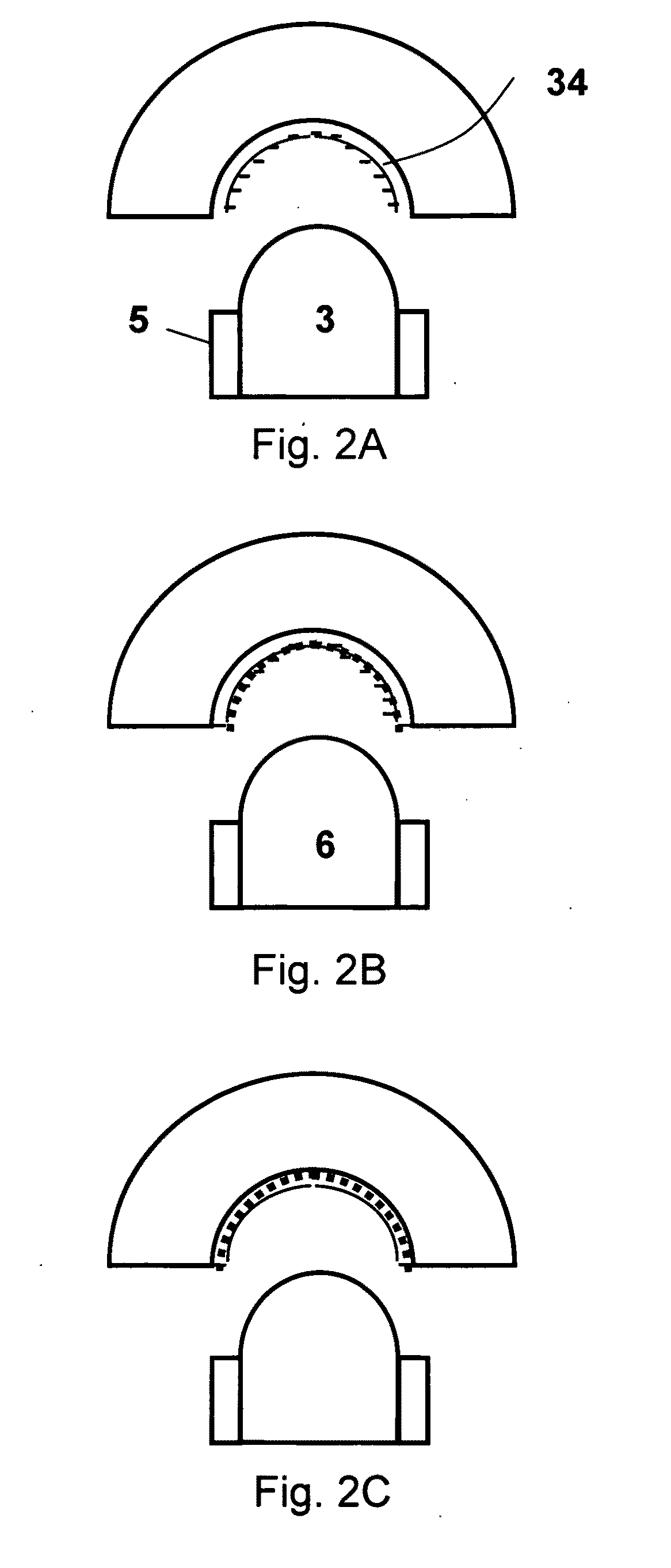

A method for forming a layer of an LED phosphor material includes disposing a first surface in a proximity of a powder that includes an LED phosphor material, forming electrostatic charges on the first surface, and forming a layer of the LED phosphor material on the first surface at least partially by using the electrostatic charges. In an embodiment, the method includes disposing the first surface in an interior of a chamber and forming an airborne distribution of the powder in the interior of the chamber in a vicinity of the first surface. In another embodiment, the method includes providing a reservoir of the powder and applying to said phosphor powder an electrostatic charge opposite to that of said electrostatic charge on the first surface.

Owner:ACHROLUX

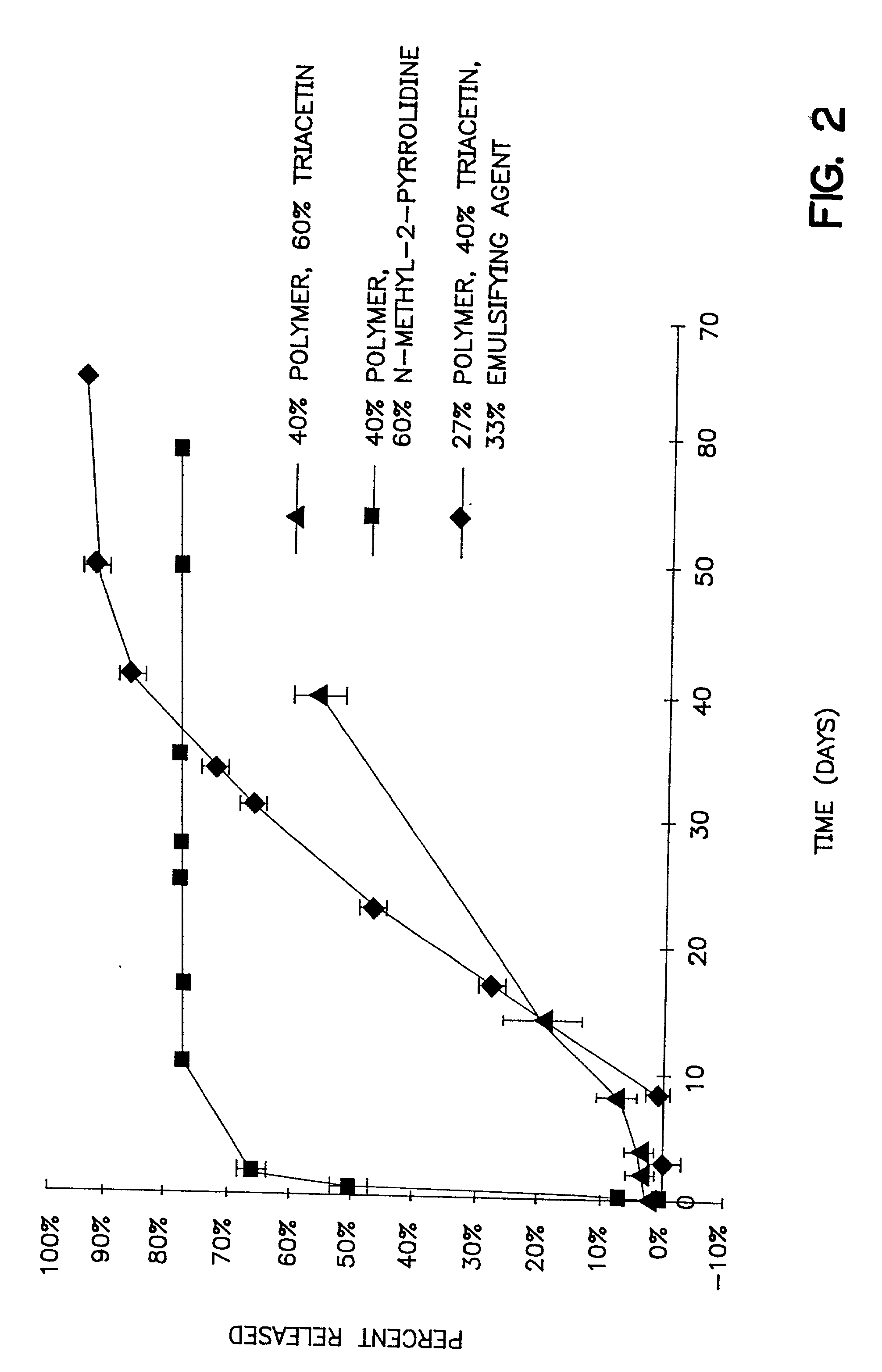

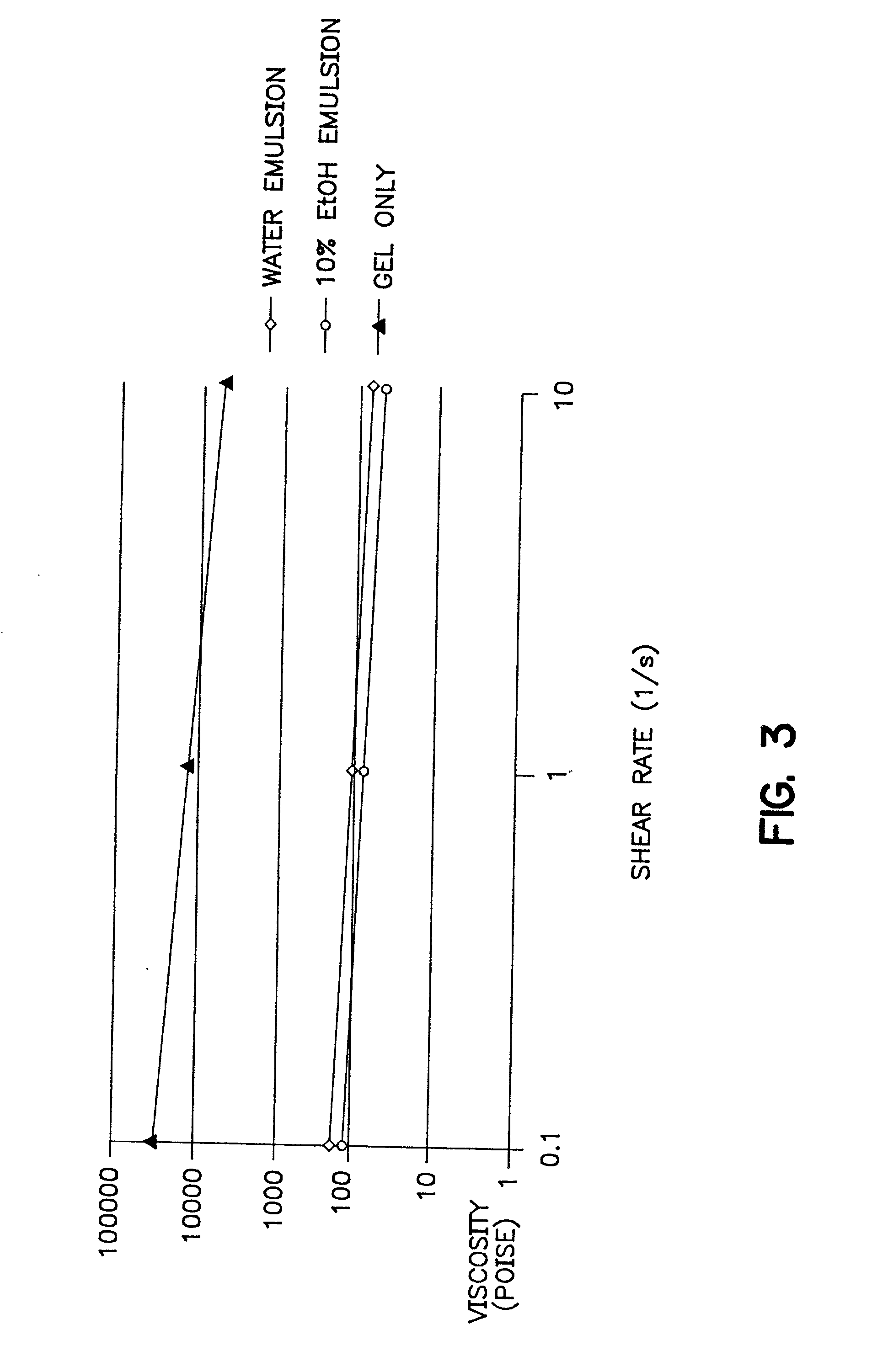

Injectable depot gel composition and method of preparing the composition

InactiveUS20020034532A1The process steps are simpleHarden fastPowder deliveryPeptide/protein ingredientsSolventPolymer chemistry

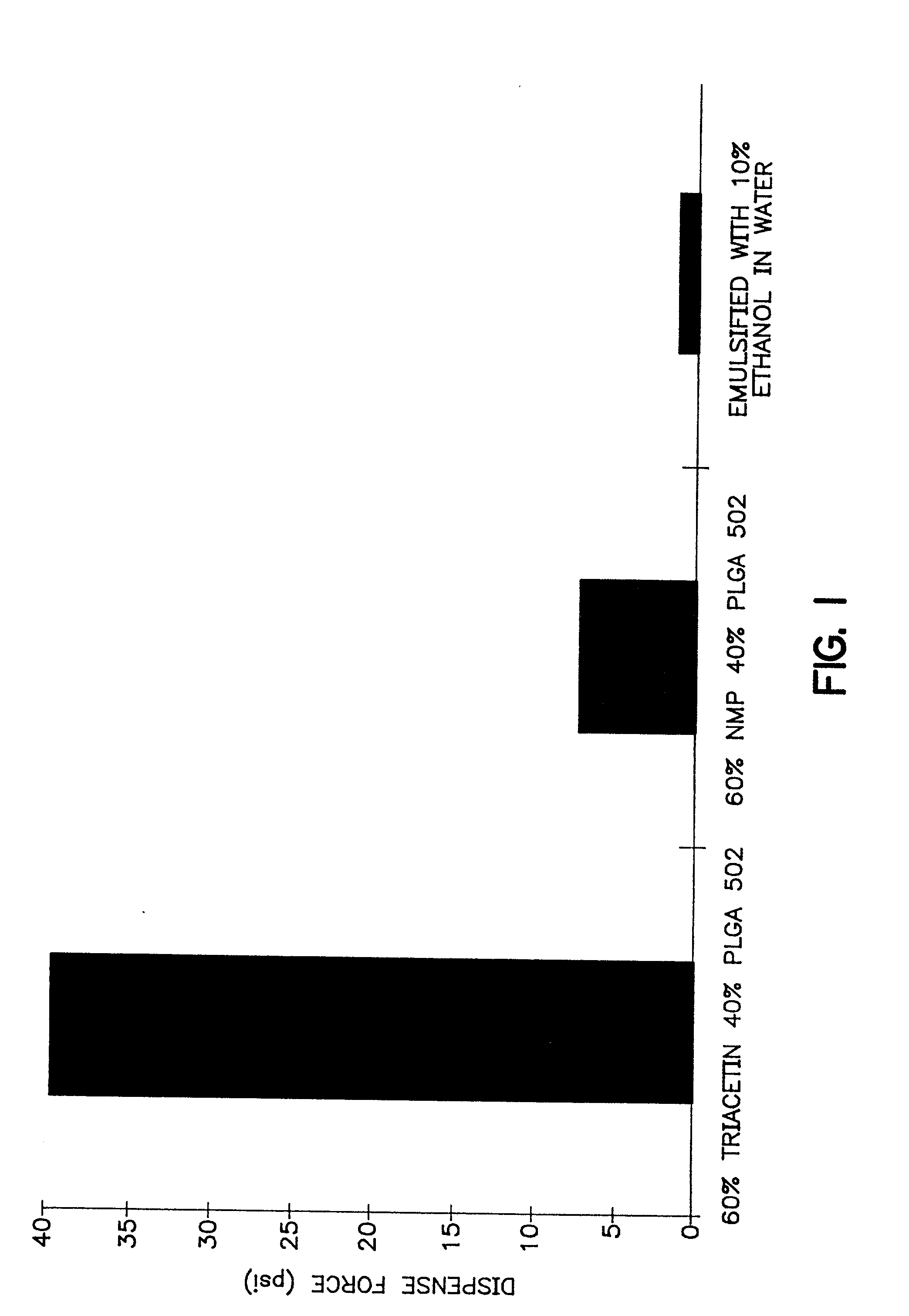

An injectable depot gel composition containing a polymer, a solvent that can dissolve the polymer and thereby form a viscous gel, a beneficial agent; and an emulsifying agent in the form of a dispersed droplet phase in the viscous gel. The injectable depot gel composition can be prepared by mixing the polymer and the solvent so that the solvent dissolves the polymer and forms a viscous gel. The beneficial agent is dissolved or dispersed in the viscous gel and the emulsifying agent is mixed with the beneficial agent containing viscous gel. The emulsifying agent forms a dispersed droplet phase in the viscous gel to provide the injectable depot gel composition. The injectable depot gel composition can deliver a beneficial agent to a human or animal with a desired release profile.

Owner:BRODBECK KEVIN J +1

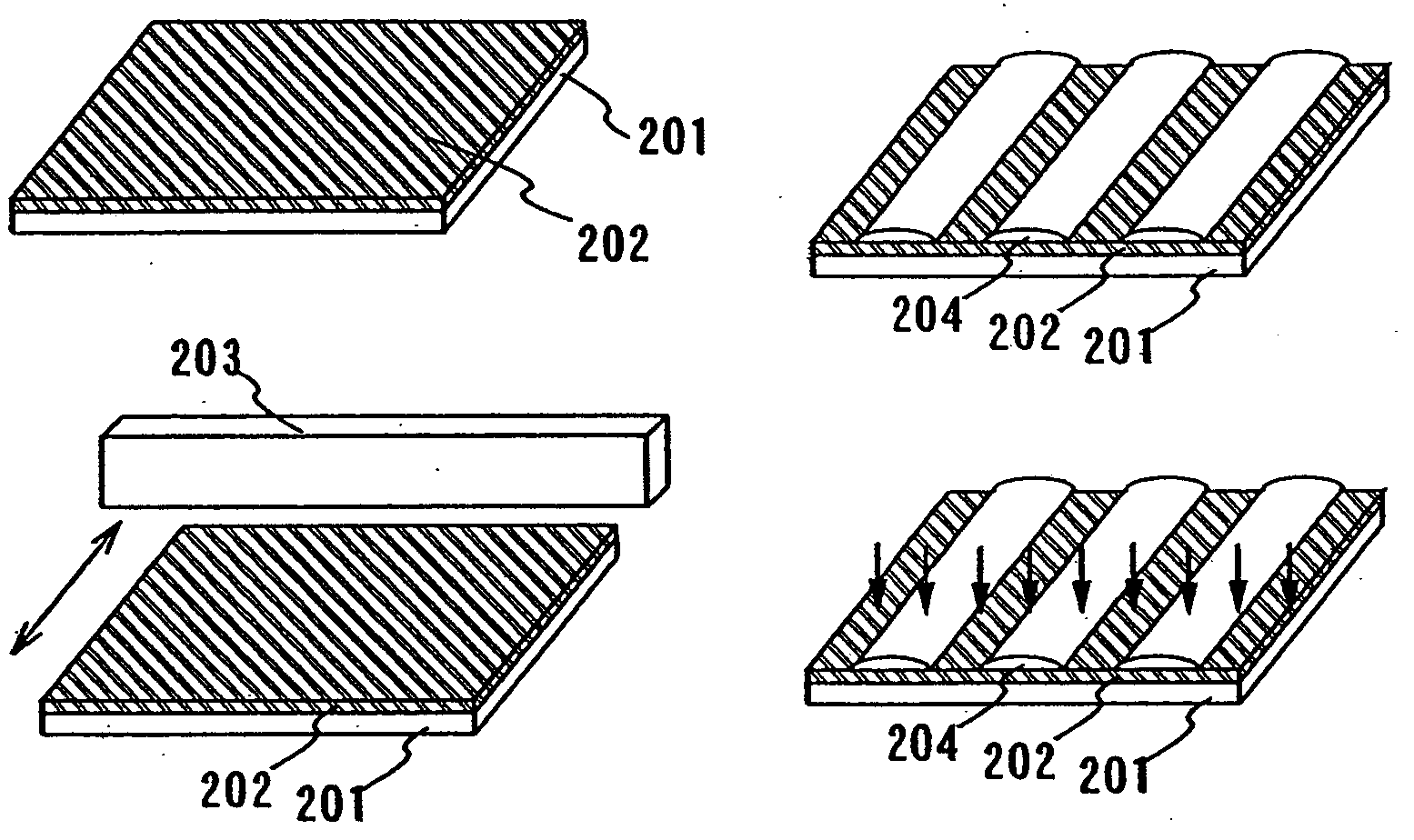

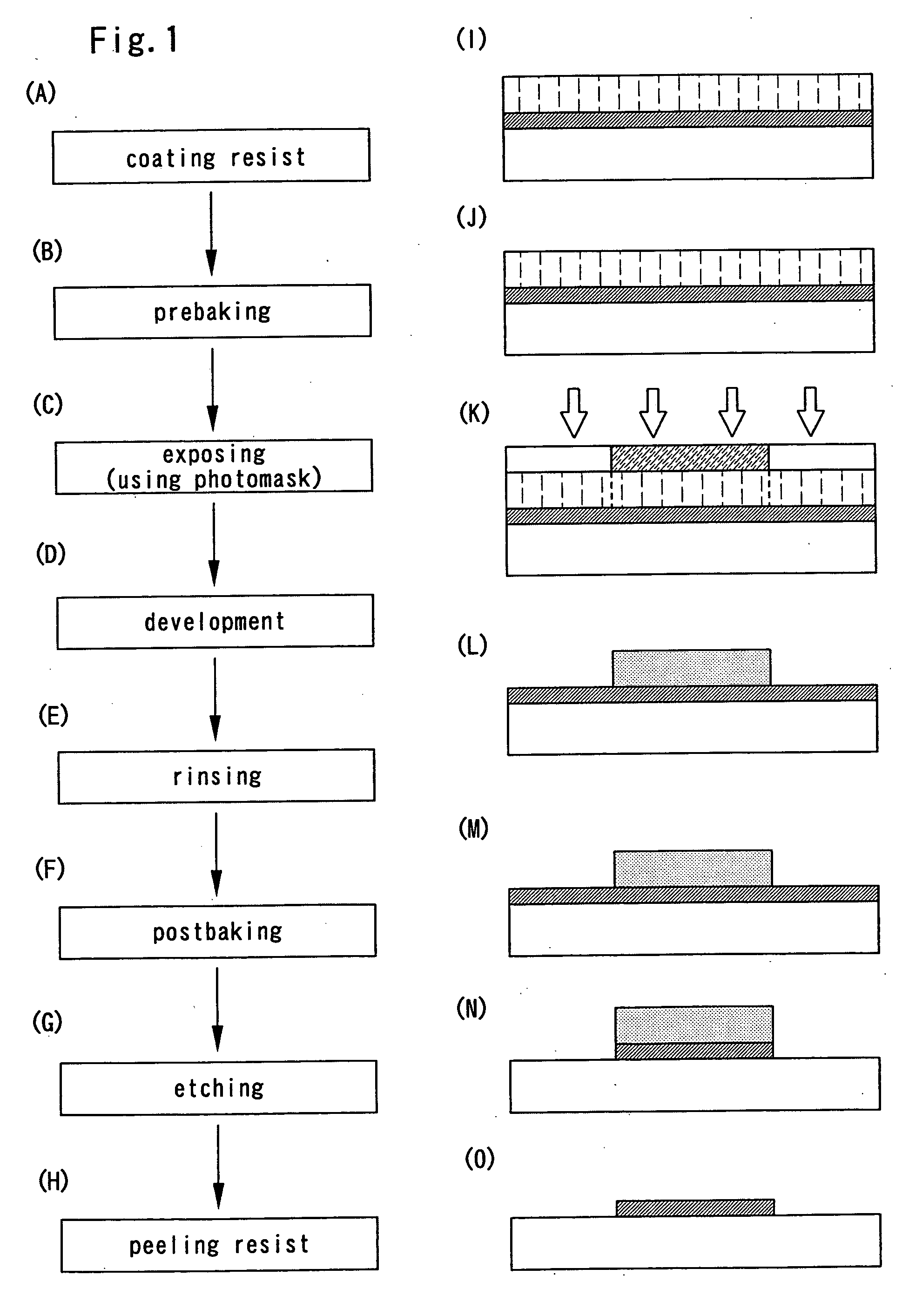

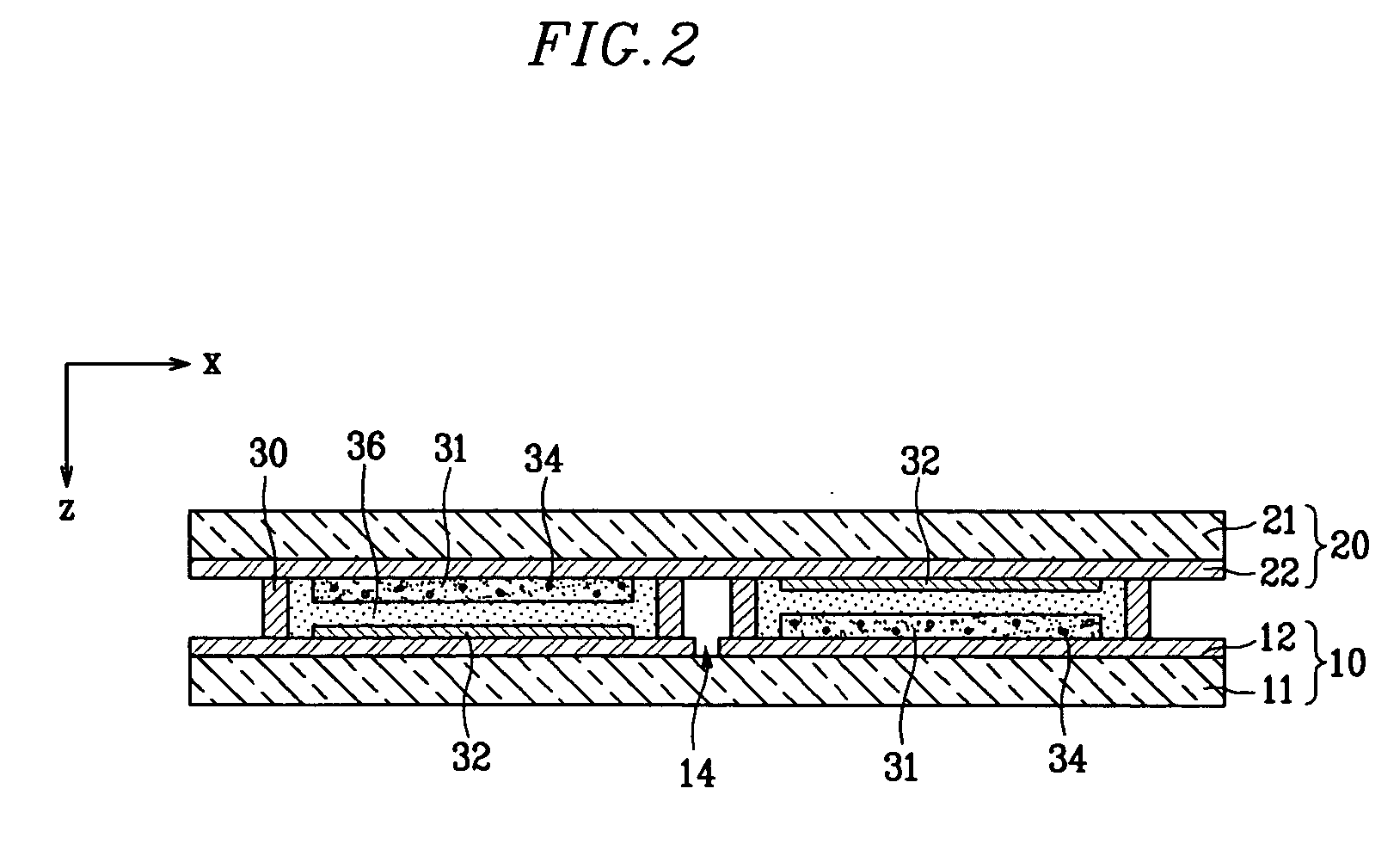

Manufacturing method for display device

InactiveUS20050013927A1Manufacturing cost be reduceReduce in sizeSolid-state devicesSemiconductor/solid-state device manufacturingResistFree space

With an interconnected fabrication step using the prior art photolithography, major portions of resist, interconnected material, and process gas necessary during plasma processing are wasted. Furthermore, a pumping means such as a vacuum system is necessary. Therefore, the whole equipment is increased in size. Consequently, as the processed substrate is increased in size, the manufacturing cost is increased. Accordingly, a means consisting of directly spraying the resist and interconnected material as liquid drops on necessary locations over the substrate to delineate a pattern is applied. Also, a means consisting of performing a chemical vapor deposition process such as ashing or etching at or near atmospheric pressure is applied.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor memory device and method for fabricating the same

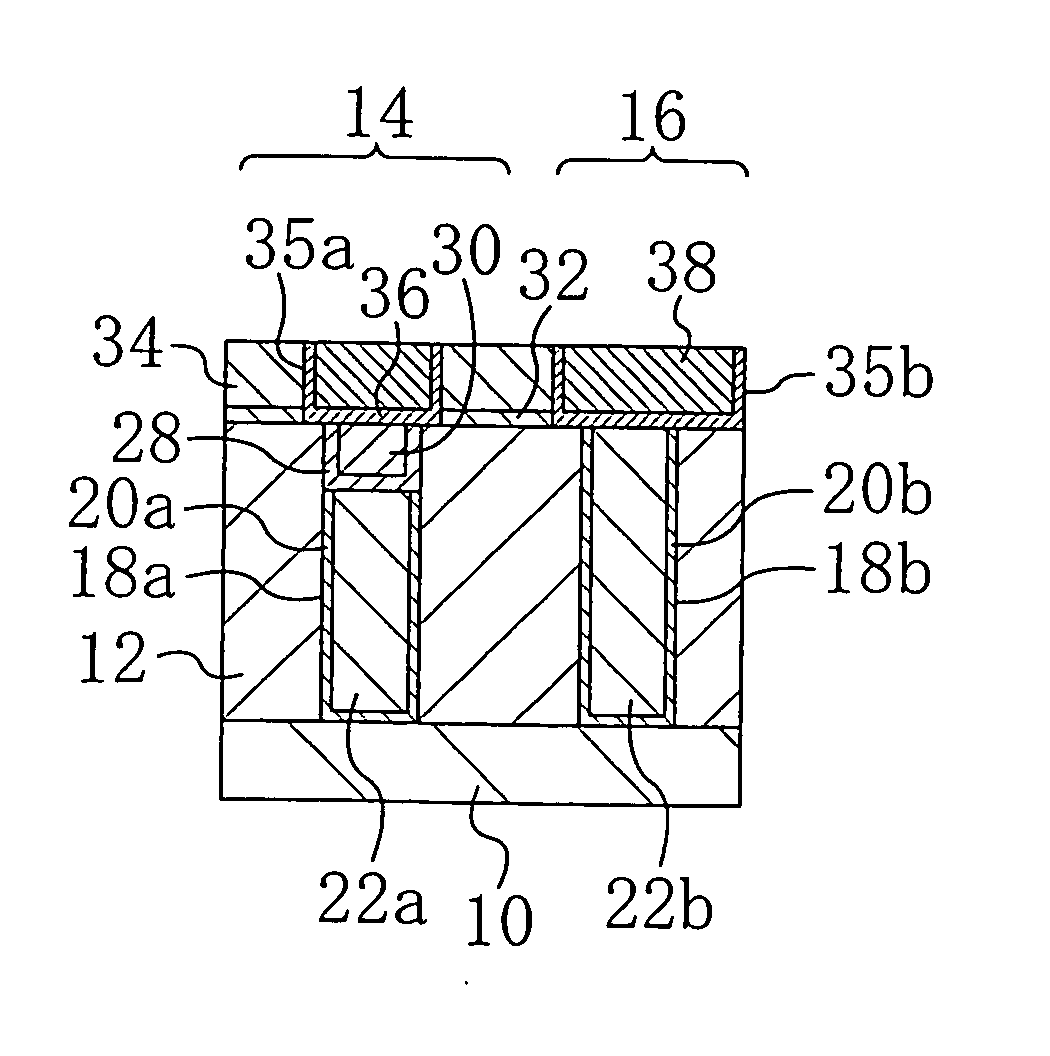

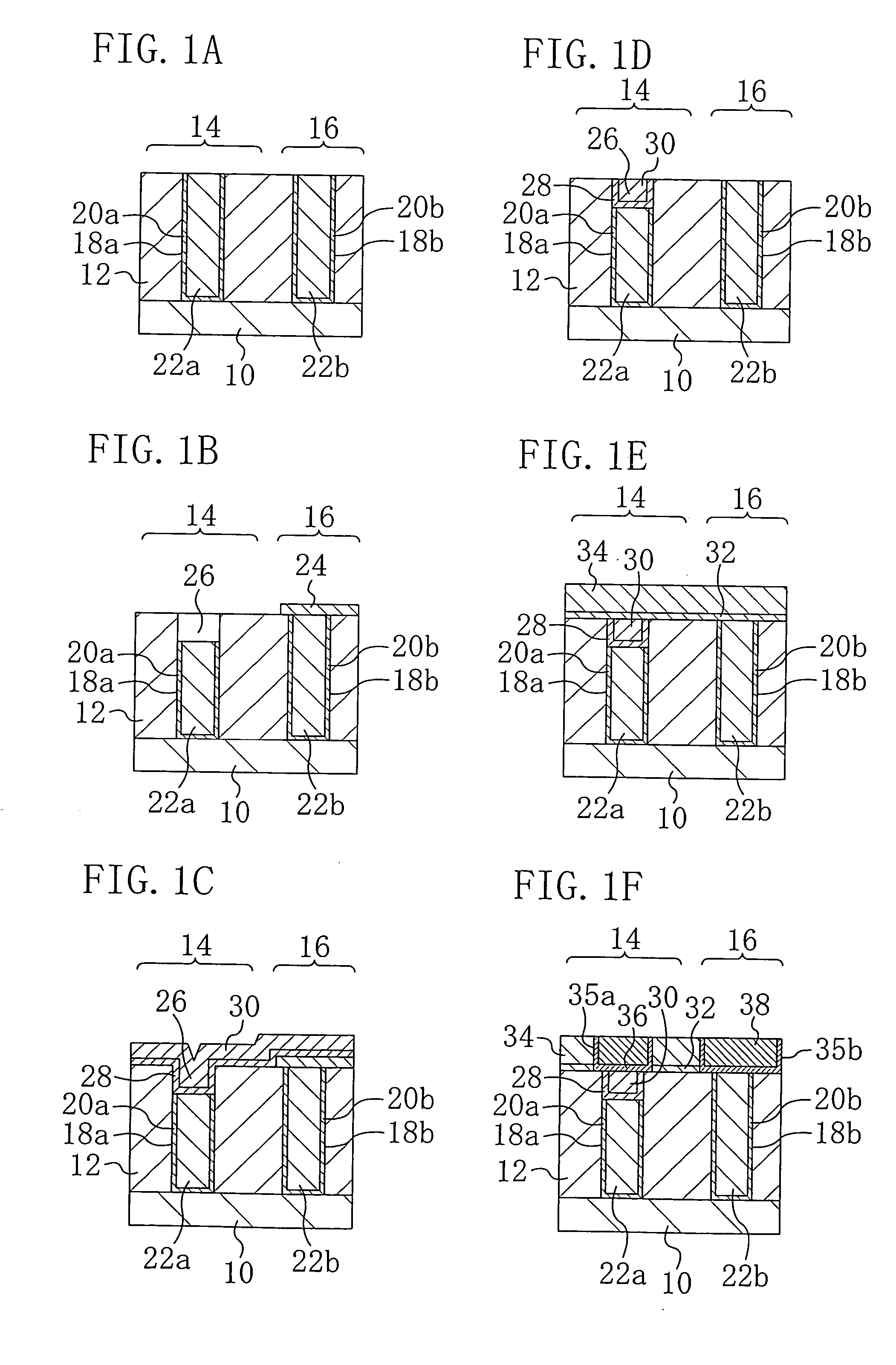

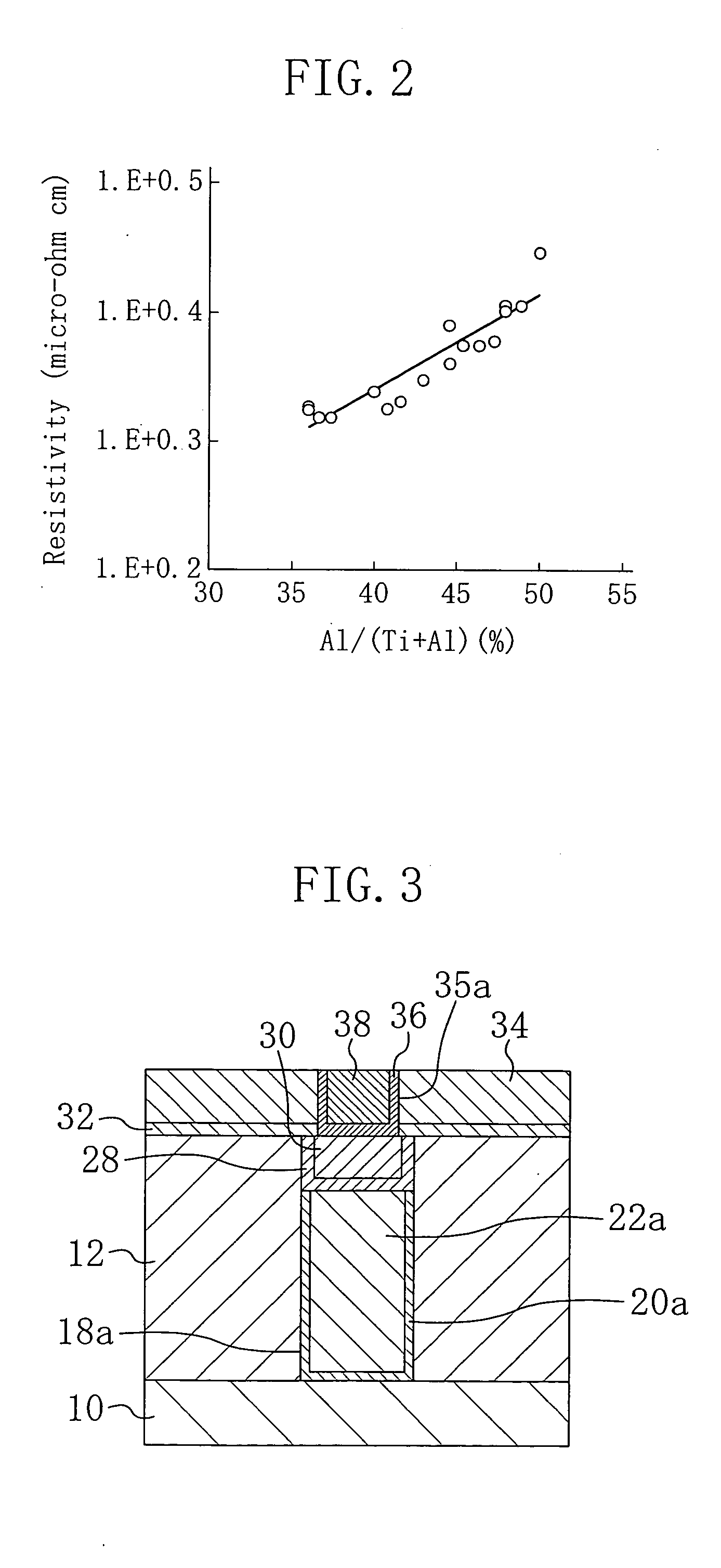

ActiveUS20050006681A1Small sizeImprove consistencySemiconductor/solid-state device detailsSolid-state devicesLogical partEngineering

In a fabrication method according to the present invention, a first insulating film and tungsten plugs are formed over a substrate including a logic section and a memory section. An upper portion of one of the tungsten plug located in a memory section is removed, thereby forming a recess. A resistance heating element film covering side and bottom surfaces of the recess and a storage element film filling the recess with the resistance heating element film interposed between the storage element film and the plug are formed. Then, a Cu interconnect is formed on the storage element film. Thus, it is possible to make the process step of forming the resistance heating element film and the storage element film have higher consistency with a logic process.

Owner:TAIWAN SEMICON MFG CO LTD

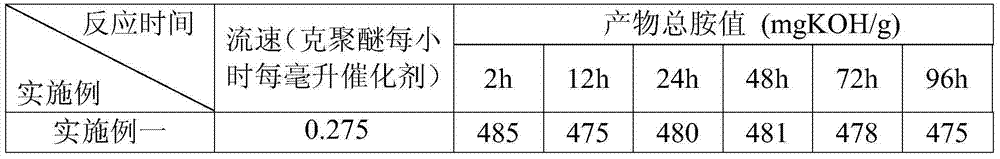

Process of producing small molecular weight polyether amine by continuous method

ActiveCN104119239AReduce the impactThe process steps are simpleOrganic compound preparationAmino-hyroxy compound preparationHydrogenMetal catalyst

The invention relates to a process of producing small molecular weight polyether amine by a continuous method. A continuous method fixed bed process is adopted, polyether, liquid ammonia and hydrogen are used as raw materials, 2-6 reactors which are fixed bed reactors or tubular reactors are connected in series and each reactor is internally filled by a Raney metal catalyst or a supported metal catalyst, respectively; under the reaction condition of certain temperature, pressure and molar proportion, the raw materials are sequentially reacted through the reactors to obtain polyether amine, the molecular weight of which is 100-1000. The process provided by the invention is simple in step. Multiple reactors and a compound catalyst system are adopted, so that the influence of generated water in the reaction to the catalyst efficiency is effectively reduced, and the yield and the conversion ratio of reaction are improved.

Owner:WUXI ACRYL TECH

Process for producing polymethylmethacrylate molding materials with a neutral color

Products based on polymethylmethacrylate (PMMA) so resistant to yellowing and so highly transparent that even the edges of plates produced from this material have a neutral colour, i.e. do not display any yellow tone. This effect is obtained by the admixture of 5 to 50 ppm inorganic, reducing phosphorus compounds after polymerisation. This enables the brightener content to be reduced under 10 ppb, and so the end product may also be used in contact with foodstuffs.

Owner:EVONIK ROEHM GMBH

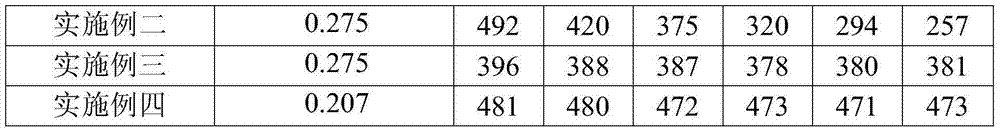

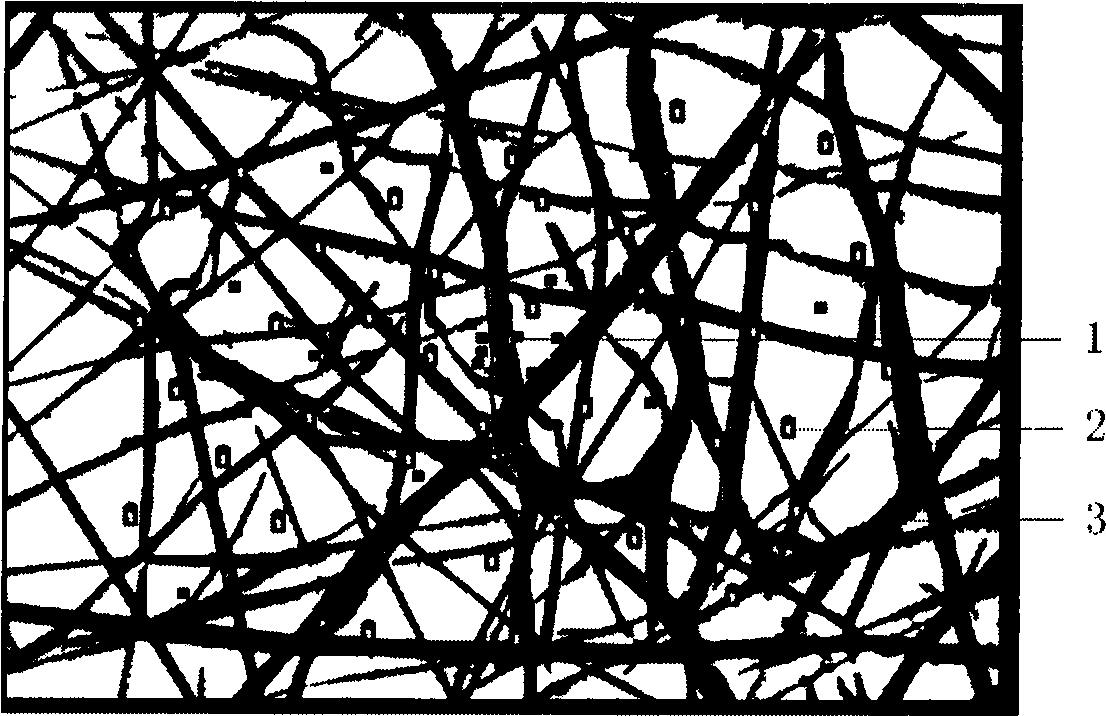

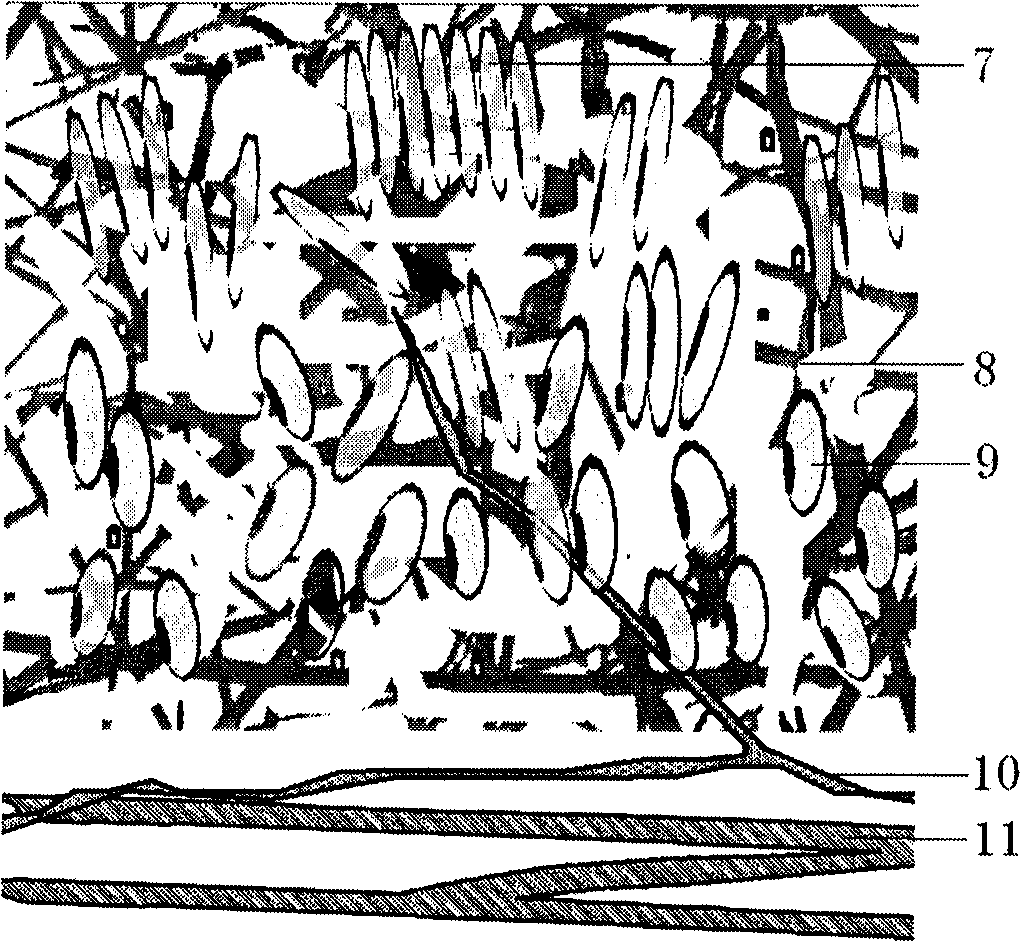

Nano artificial dura mater with multi functional-layers and preparation method thereof

ActiveCN101507661AReliable strengthGood flexibilityFilament/thread formingProsthesisHydrophobic polymerDura mater

The invention provides a nano artificial dura mater with a plurality of functional layers, which comprises a structure with at least two layers; the layer facing the brain is a hydrophobic anti-adhesion electrospun layer; and the layer back to the brain is a hydrophilic nano cytoskeletal layer. The invention also provides a method for preparing the nano artificial dura mater, which comprises the following steps: preparing an electrospun solution of a hydrophobic polymer; preparing an electrospun solution of a hydrophilic polymer; preparing the prepared electrospun solution of the hydrophobic polymer into the hydrophobic anti-adhesion electrospun layer through static spinning; and preparing the hydrophilic nano cytoskeletal layer on the anti-adhesion electrospun layer from the prepared electrospun solution of the hydrophilic polymer through static spinning, receiving a membrane structure, and obtaining the nano artificial dura mater. The mechanical features of the nano artificial dura mater can meet the requirements on tensile strength and flexibility of adaptation diseases; and the nano artificial dura mater can be freely cut as required, and has wide application prospect.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

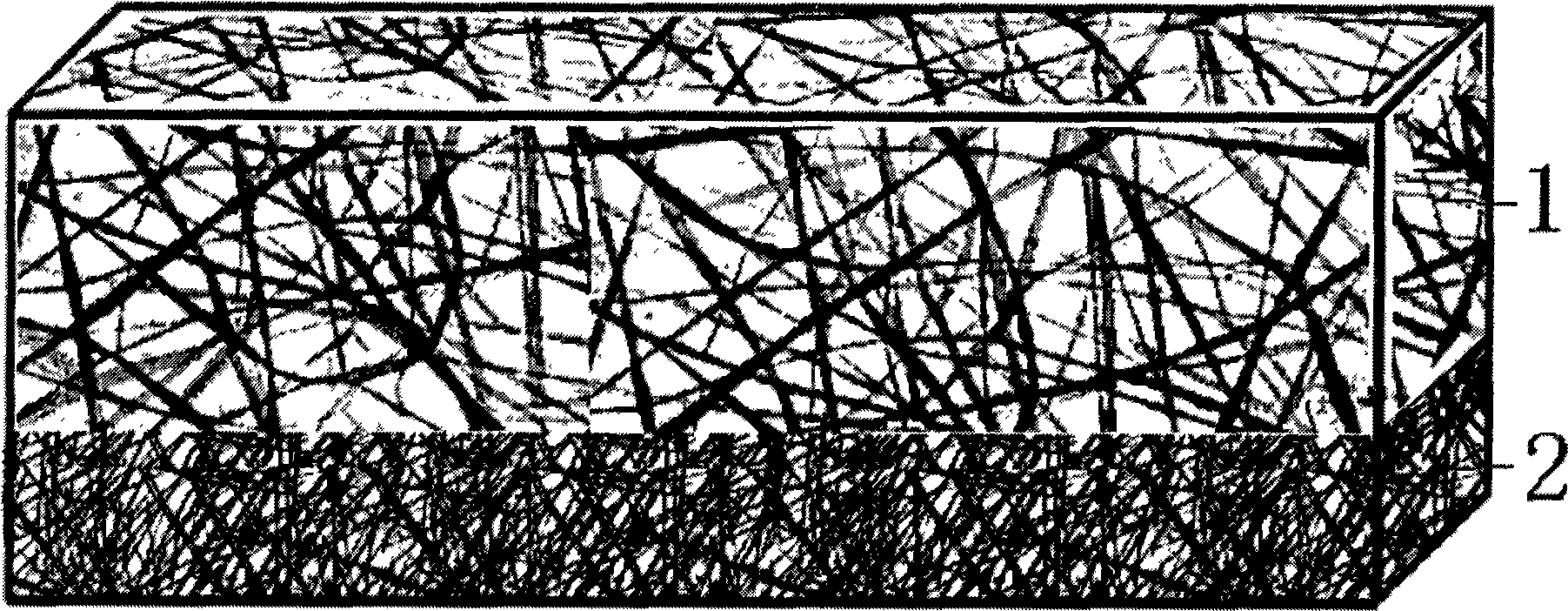

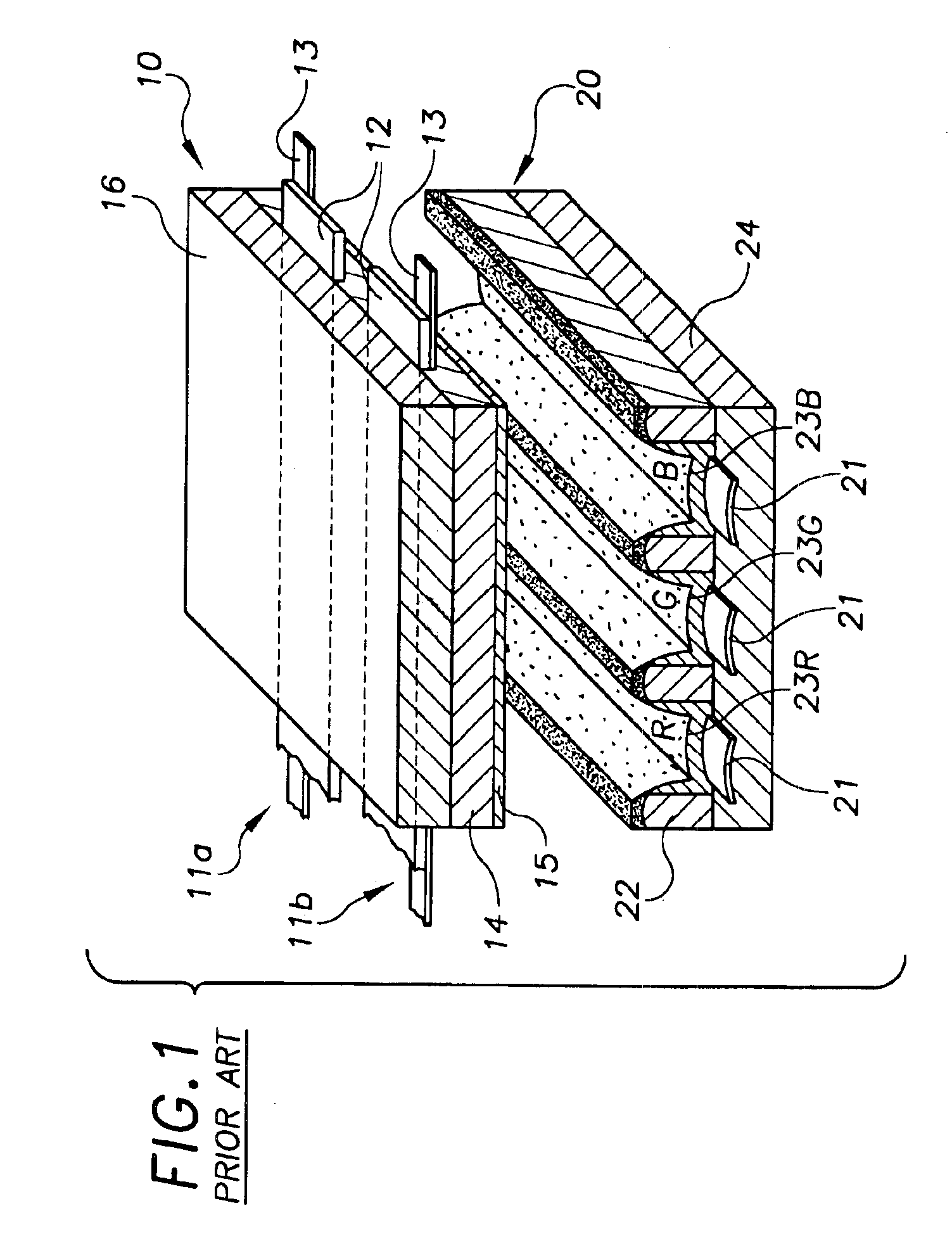

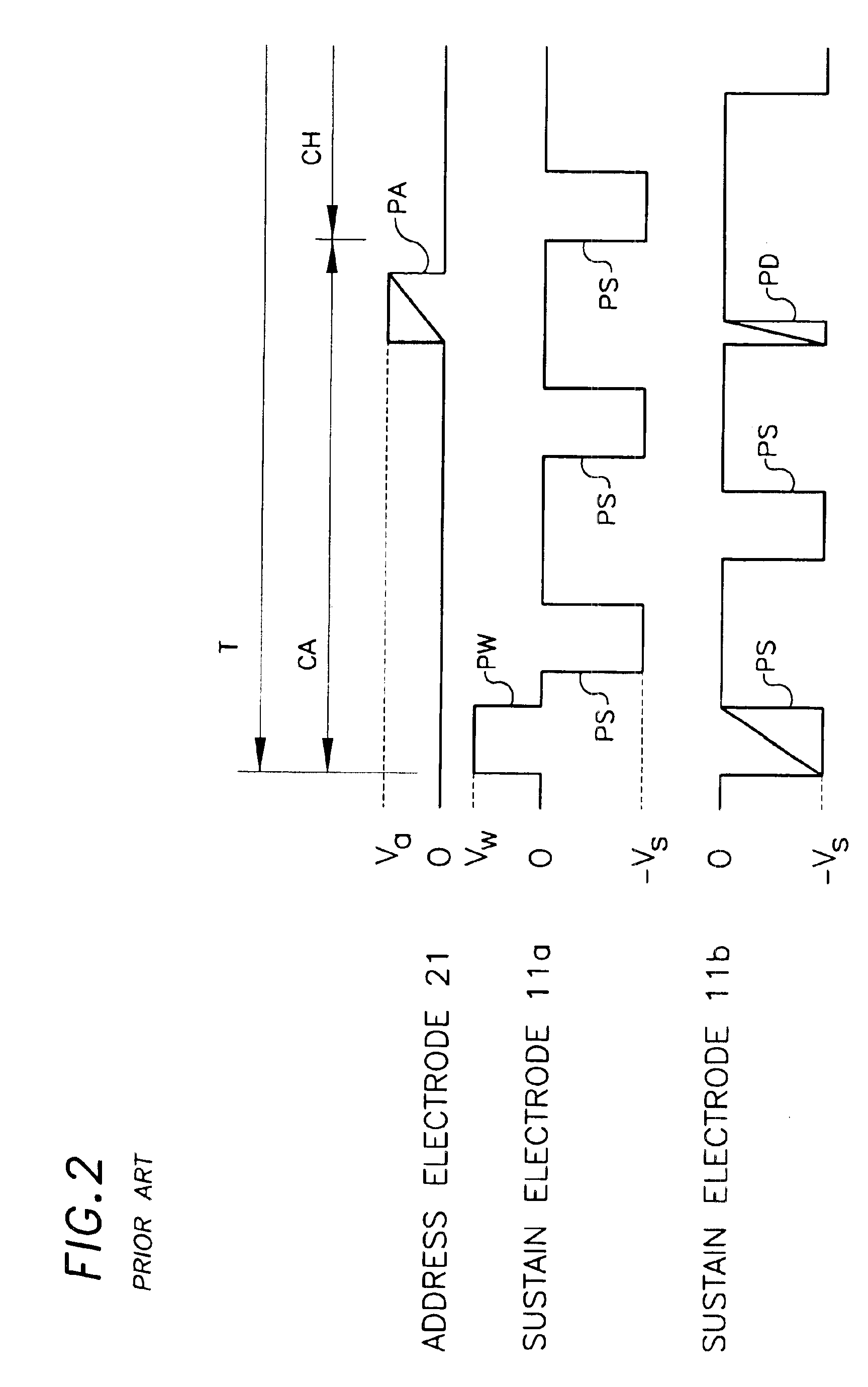

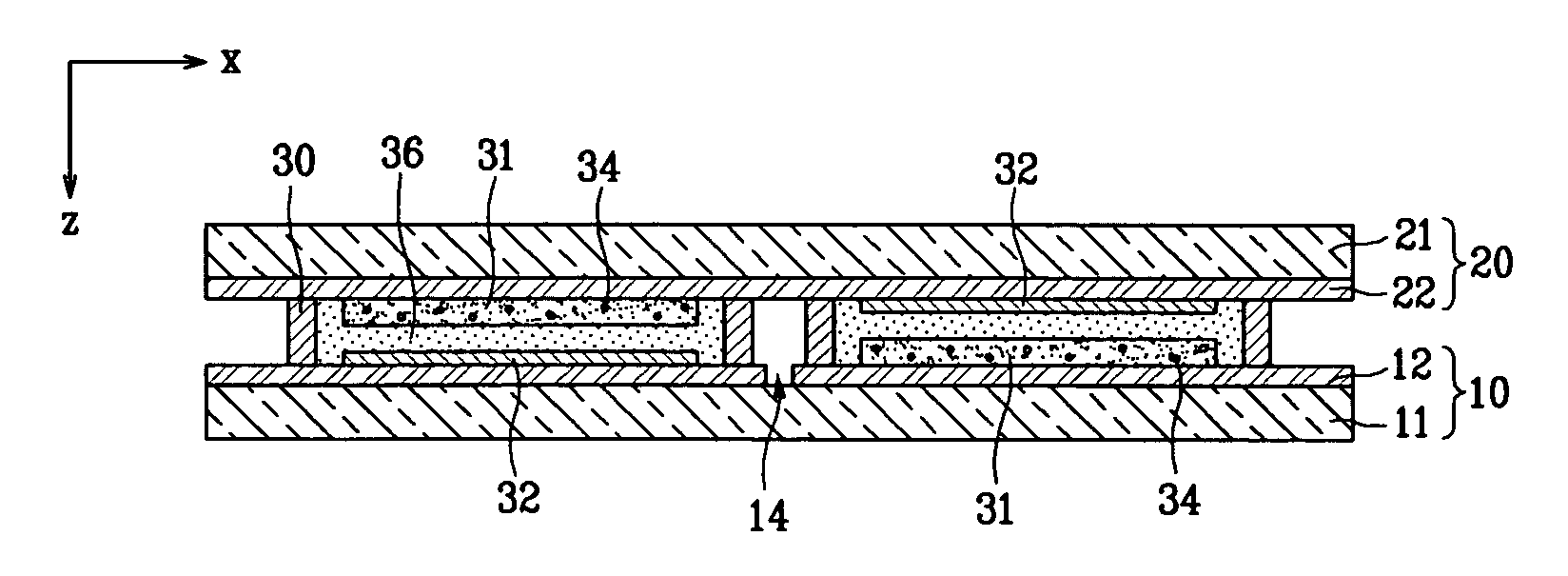

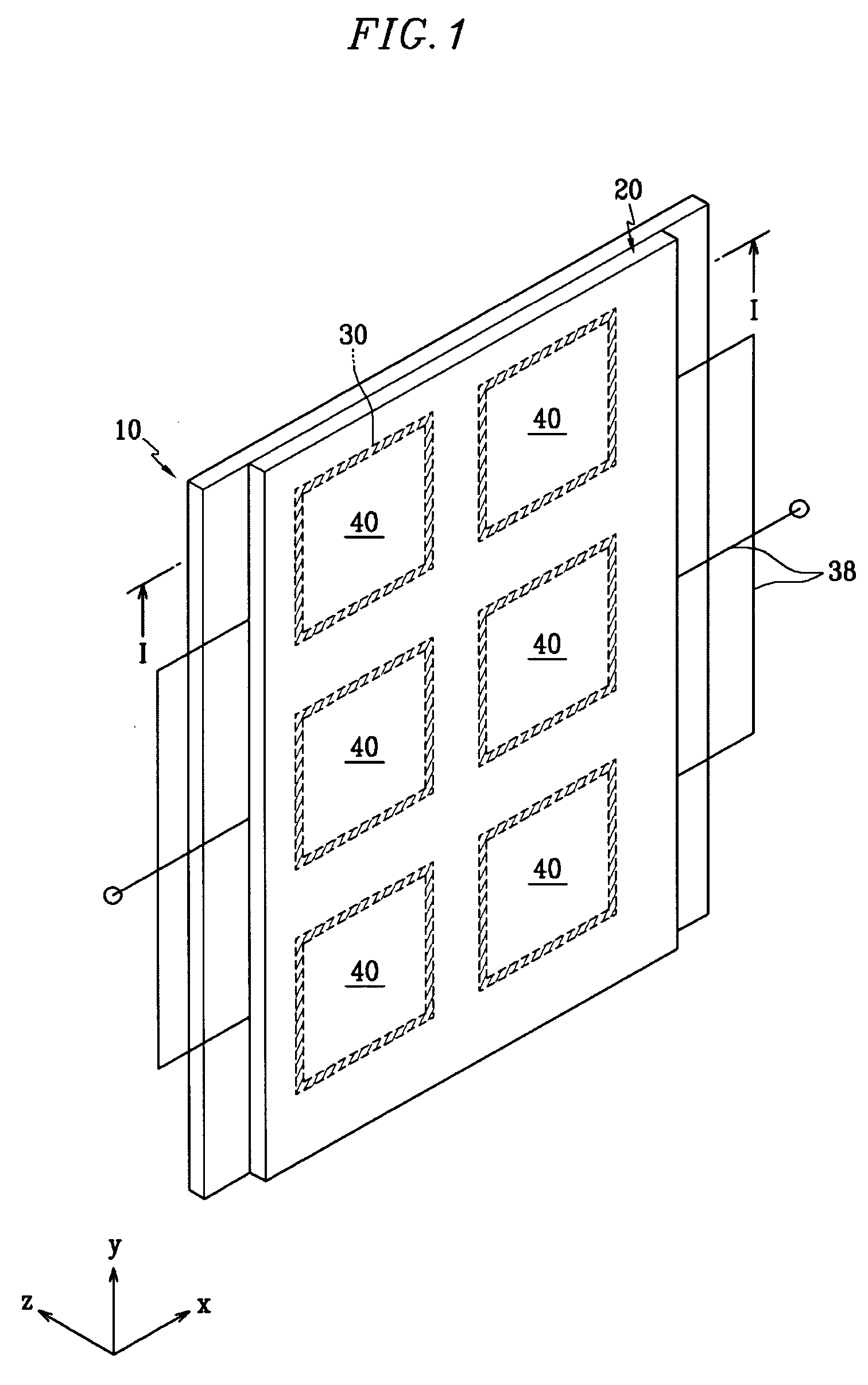

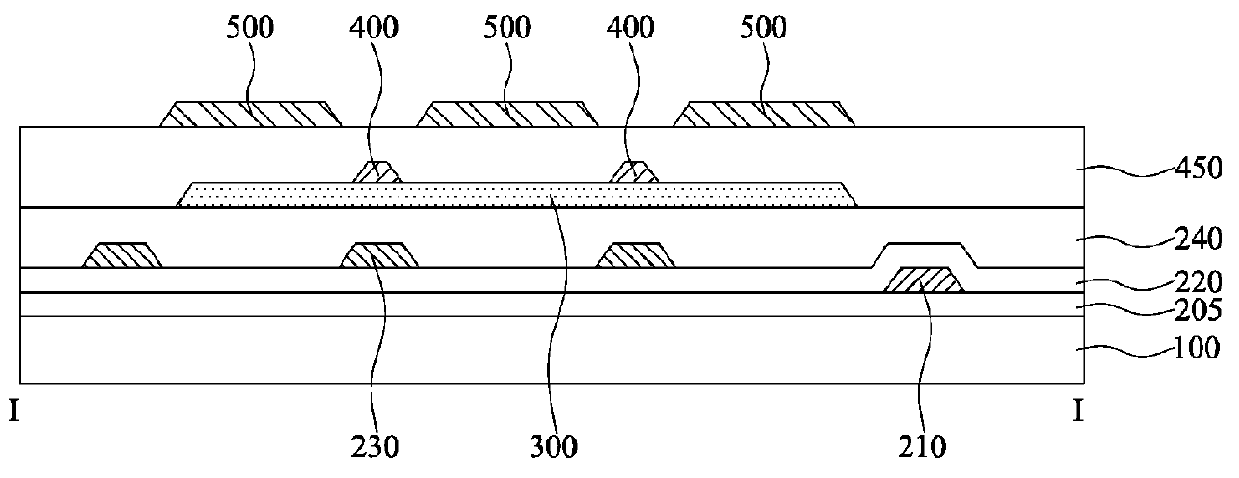

Drive control system for a fiber-based plasma display

InactiveUS6946803B2Lower cost of capitalImprove discharge efficiencyGlass making apparatusStatic indicating devicesFiberDisplay device

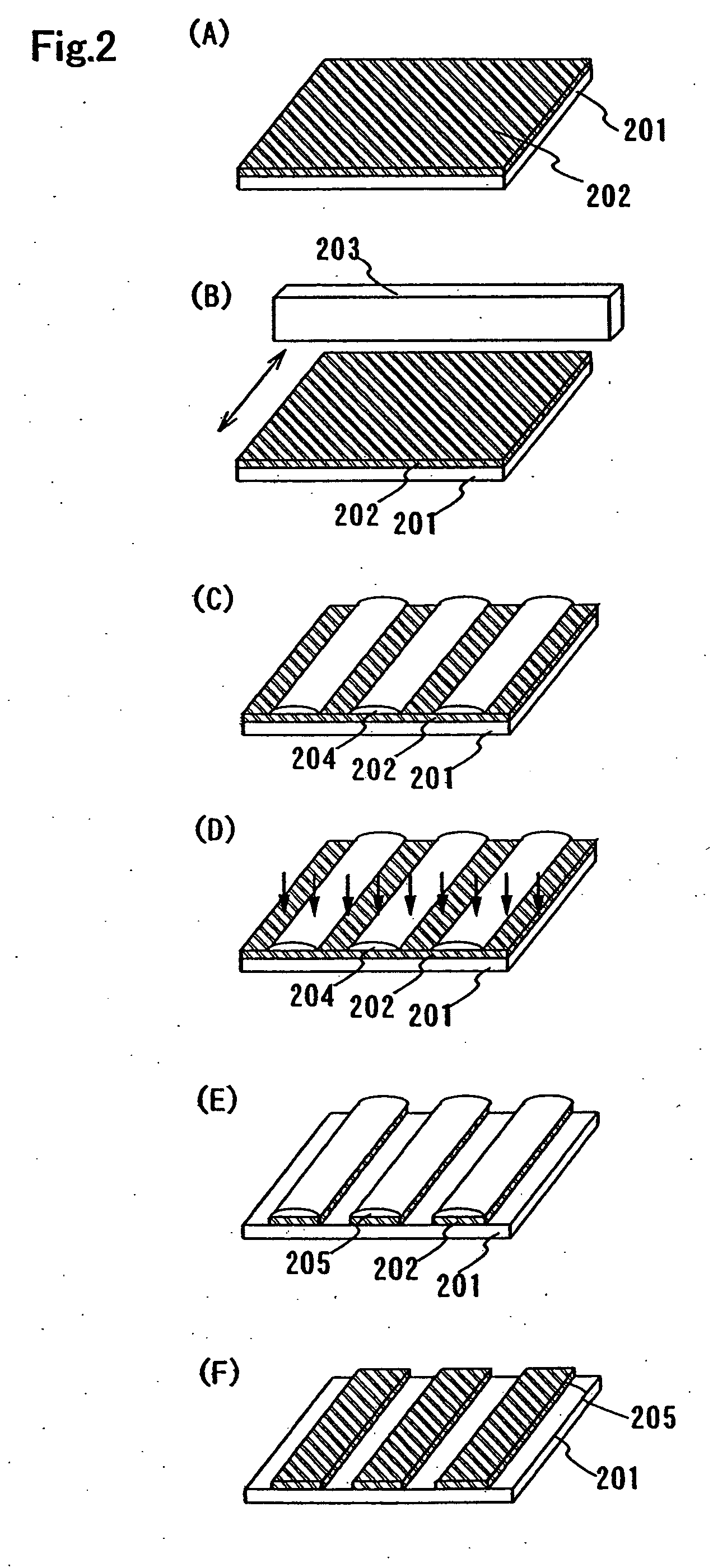

A full color fiber plasma display device includes two glass plates sandwiched around a top fiber array and a bottom fiber array. The top and bottom fiber arrays are substantially orthogonal and define a structure of the display, with the top fiber array disposed on a side facing towards a viewer. The top fiber array includes identical top fibers, each top fiber including two sustain electrodes located near a surface of the top fiber on a side facing away from the viewer. A thin dielectric layer separates the sustain electrodes from the plasma channel formed by a bottom fiber array. The bottom fiber array includes three alternating bottom fibers, each bottom fiber including a pair of barrier ribs that define the plasma channel, an address electrode located near a surface of the plasma channel, and a phosphor layer coating on the surface of the plasma channel, wherein a luminescent color of the phosphor coating in each of the three alternating bottom fibers represents a subpixel color of the plasma display. Each subpixel is formed by a crossing of one top fiber and one corresponding bottom fiber. The plasma display is hermetically sealed with a glass frit. The sustain and address electrodes are brought out through the glass frit for direct connection to a drive control system.

Owner:MOORE CHAD BYRON

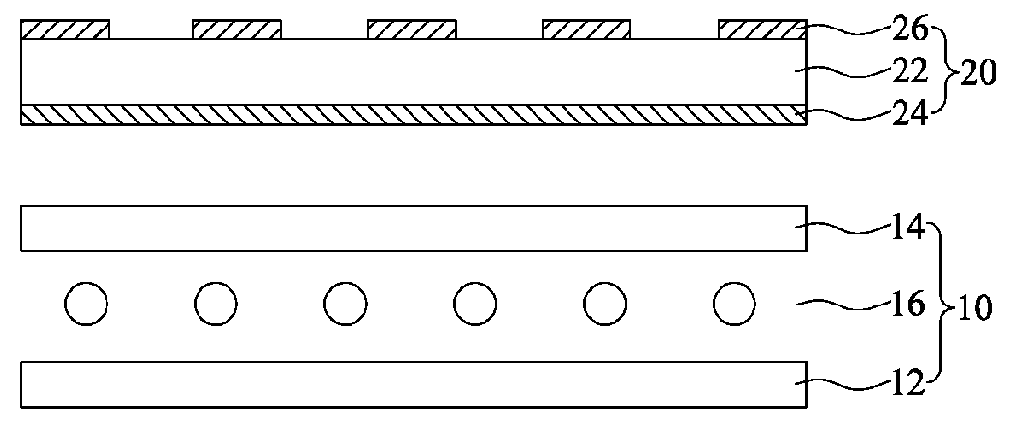

Dye-sensitized solar cell module

InactiveUS20050236037A1Simplify process stepLow production costLight-sensitive devicesPV power plantsDye-sensitized solar cellEngineering

A high capacity dye-sensitized solar cell module where a plurality of unit cells are simultaneously formed at a substrate in a simplified manner with increased light absorption efficiency. The dye-sensitized solar cell module includes first and second conductive substrates facing one another with regions for a plurality of unit cells. First and second electrodes are formed on the first or the second substrate such that the first and the second electrodes face one another at the respective unit cells. A dye is adsorbed at the first electrode. The space between the first and the second substrates at the respective unit cells is filled with an electrolyte. Insulation regions are formed on at least one of the first and the second substrates between a pair of unit cells neighboring to one another. The pattern of insulation regions, on one or both of the substrates, results in the unit cells being coupled in series, in parallel, or in a combination manner.

Owner:SAMSUNG SDI CO LTD

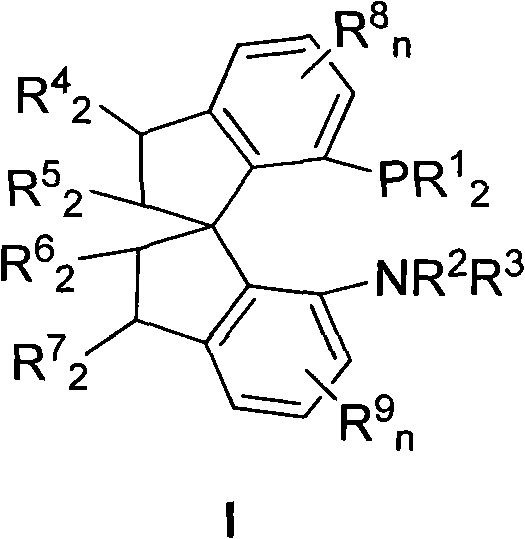

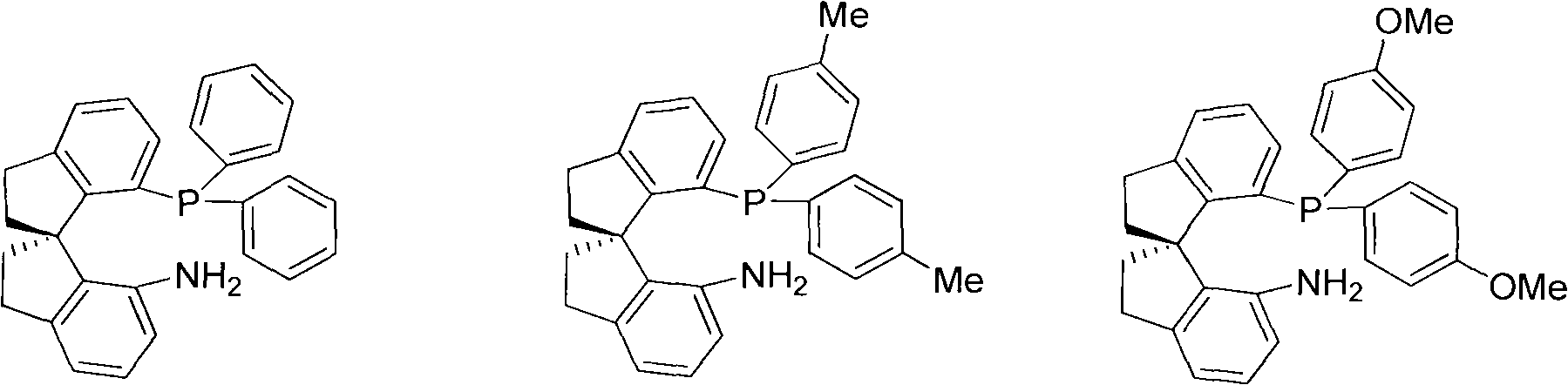

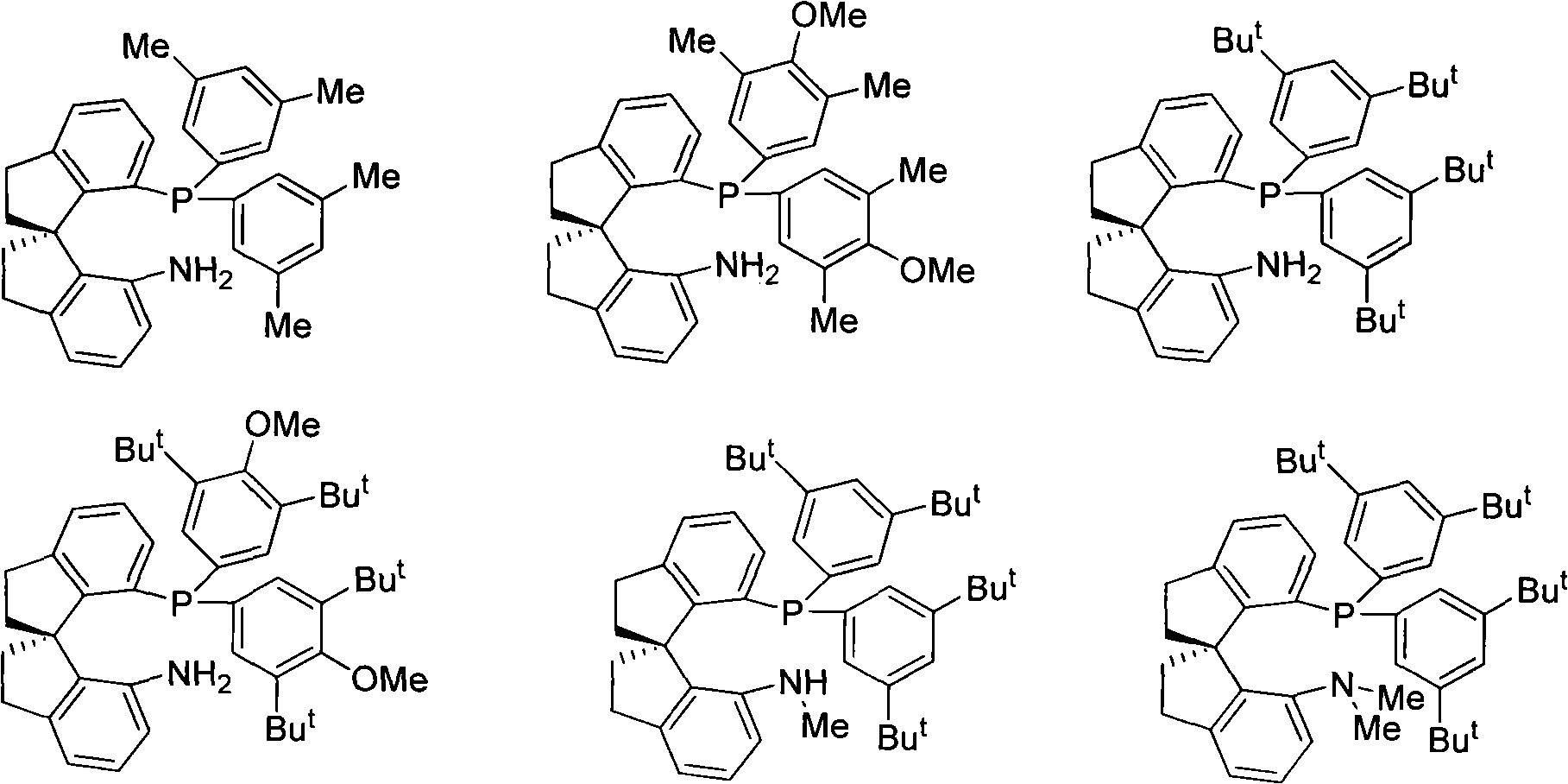

Chiral spiro aminophosphine ligand compound and synthesis method as well as application thereof

InactiveCN101671365AHigh reactivityHigh enantioselectivityOrganic compound preparationGroup 5/15 element organic compoundsIridiumSynthesis methods

The invention relates to a chiral spiro aminophosphine ligand compound and a synthesis method as well as an application thereof. The chiral spiro aminophosphine compound contains a compound with a structure shown in I, or a racemic body or an optical isomer thereof, or a catalyzed acceptable salt thereof, wherein the main structure characteristic is with a chiral spirobiindane matrix. The chiral spiro aminophosphine compound can be synthesized by taking 7-diaryl / phosphito-7'-carboxy-1, 1'-spirobiindane or substituted 7-diaryl / phosphito-7'-carboxy-1, 1'-spirobiindane as chiral starting materials, which has optical activity and spiro matrix. The chiral spiro aminophosphine compound can be used as a chiral ligand for an asymmetrically catalyzed hydrogenation of an iridium catalyzed carboxy compound and achieves high yield and enantioselectivity (97%ee). The reactive activity is also high and the consumption of the catalyst can be reduced to 0.01% molar.

Owner:NANKAI UNIV

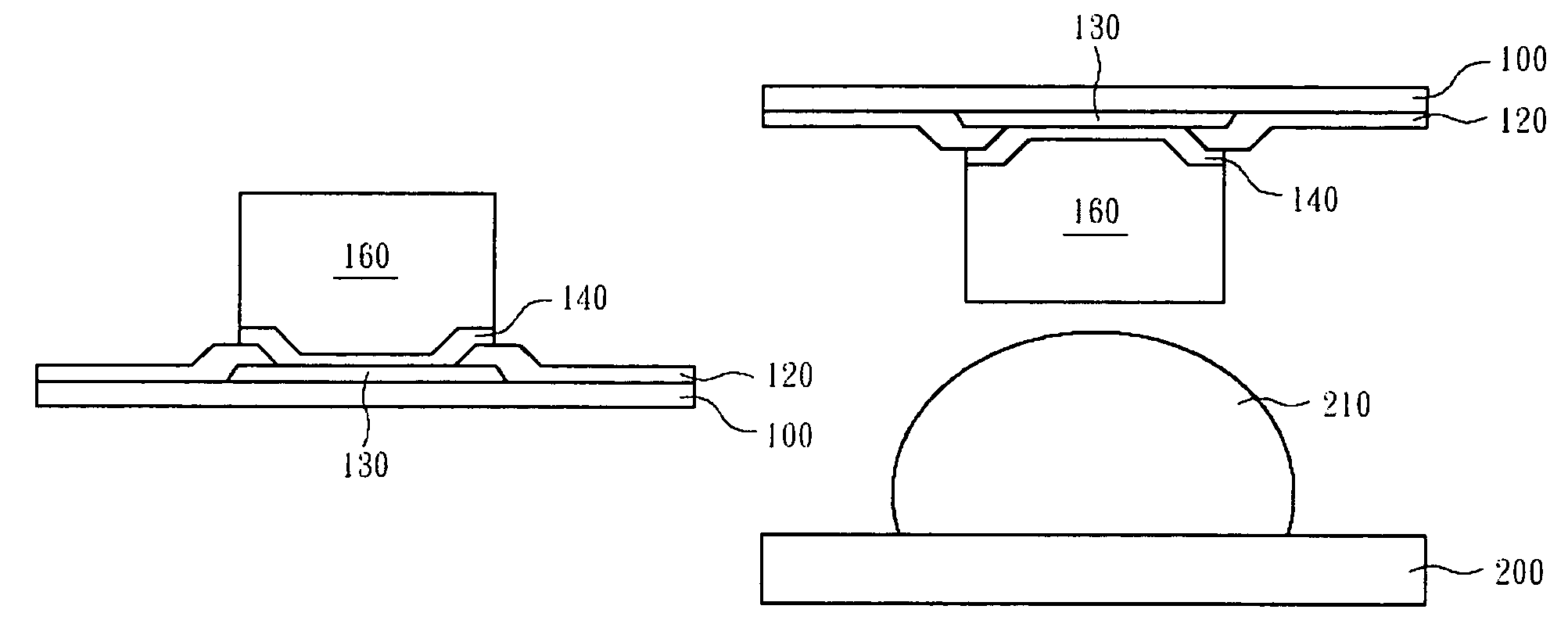

Flip-chip packaging process using copper pillar as bump structure

ActiveUS7476564B2Improve controllabilityPrevent oxidationFinal product manufactureSemiconductor/solid-state device detailsPrismCopper

A flip-chip packaging process is disclosed. The present invention is featured in forming a copper pillar on a wafer, forming a solder on a substrate; and enabling the solder to substantially cover the entire externally-exposed surface of the copper pillar, thereby connecting the copper pillar to the substrate. The copper pillar of the present invention can be such as a prism or a cylinder.

Owner:ADVANCED SEMICON ENG INC

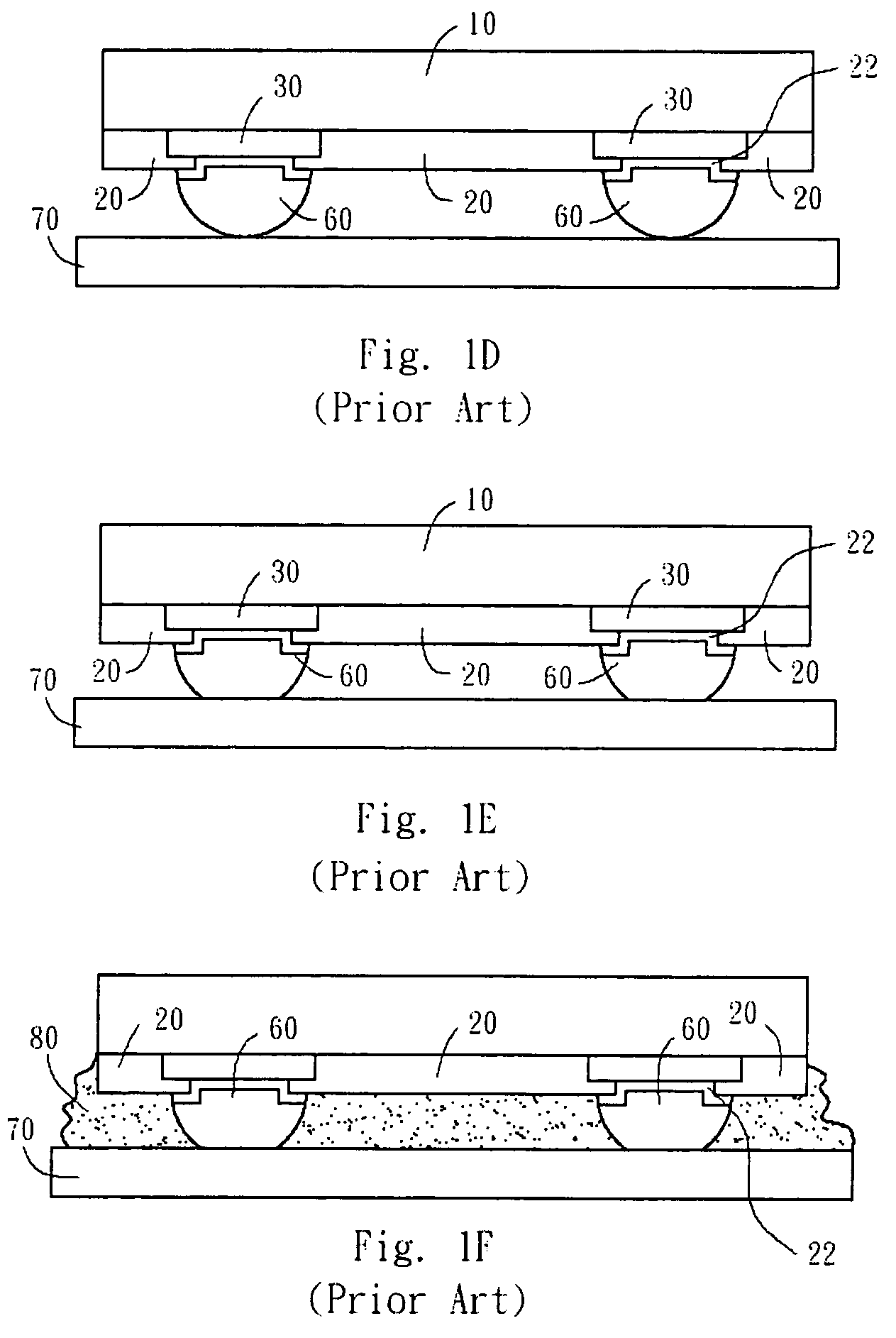

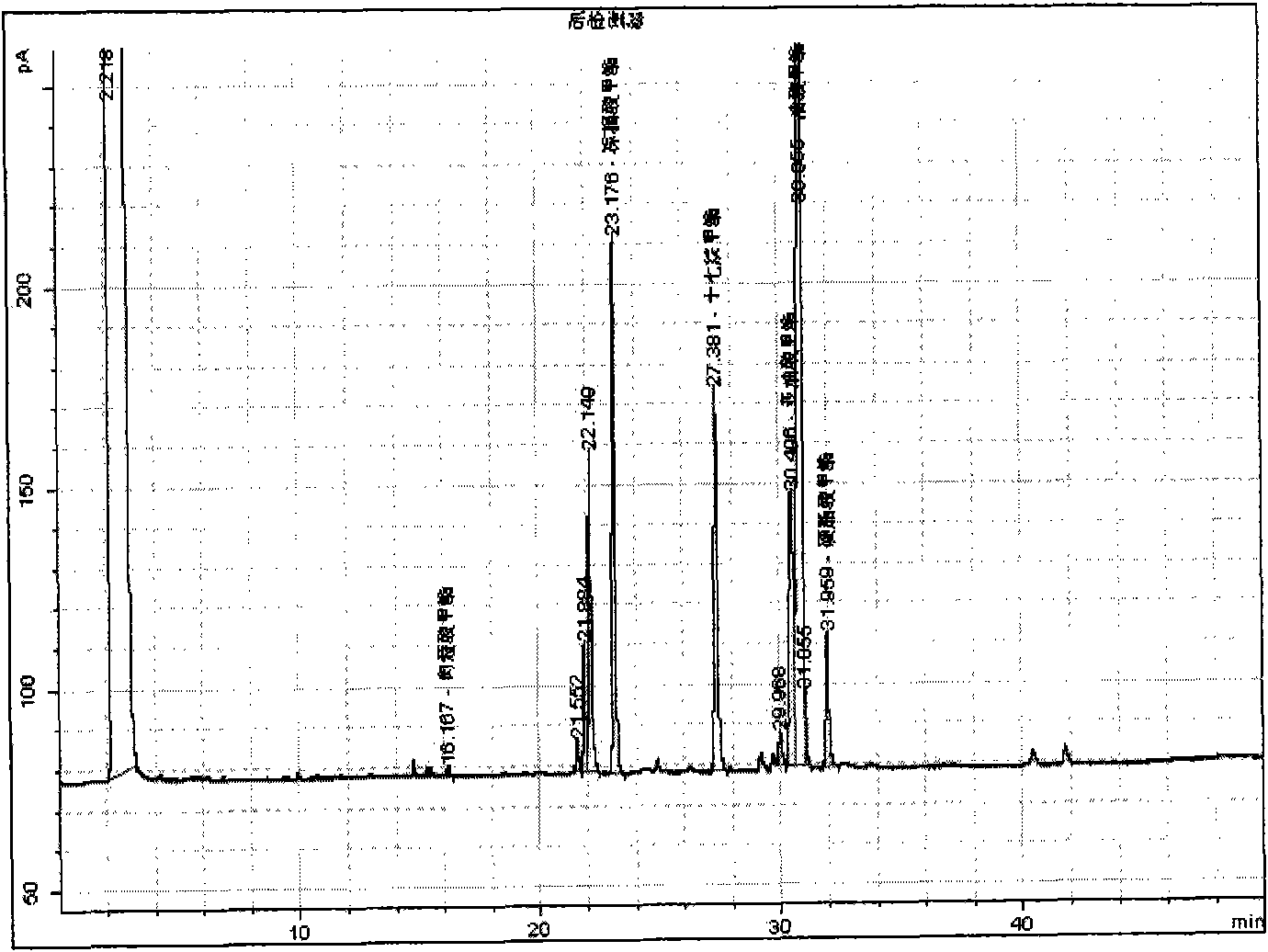

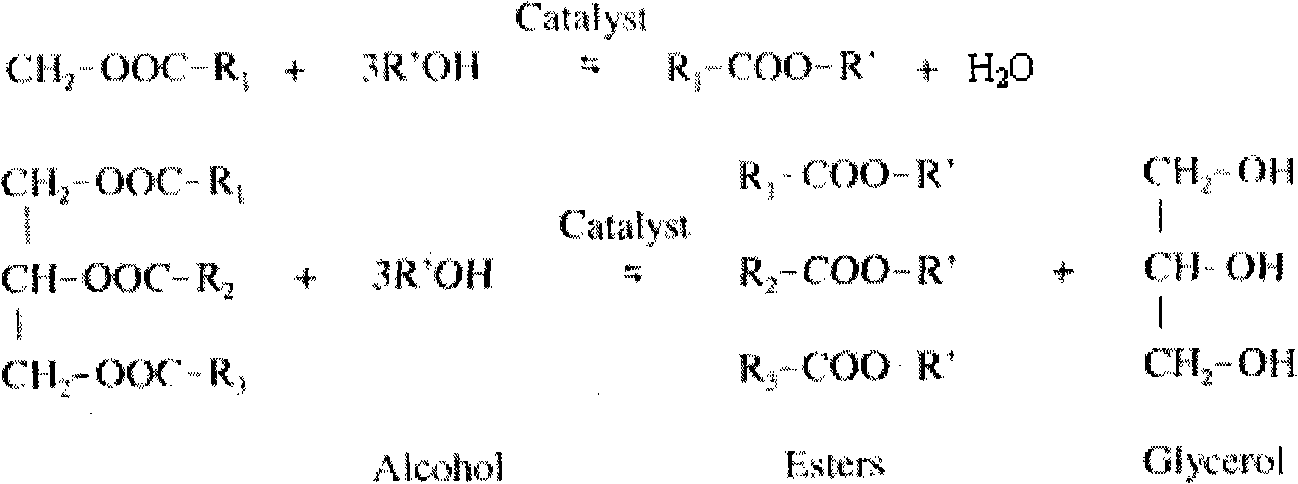

Biomass energy prepared by one-step method of microalgae

ActiveCN101580857AWon't happenRelieve pressurePreparation by ester-hydroxy reactionBiofuelsDownstream processingBiodiesel

The invention provides a method for preparing biodiesel from microalgae. The method comprises the following steps of: a. changing collected microalgae from the wet algae into algae block or algae powder; b. mixing a catalyst into low-carbon alcohol, directly adding the algae block or the algae powder obtained by the step a, and carrying out ester exchange reaction to prepare the biodiesel; c. after the reaction is stopped, adding an organic solvent for extracting reaction solution which is divided into organic solvent phase used for extraction, low-carbon alcohol water-adding phase and algae mud; and d. after the extraction is completed, collecting the organic solvent phase used for extraction, removing the organic solvent by distillation, and obtaining oily liquid, namely crude products of the biodiesel. After preparing the biodiesel, the steps that the low-carbon alcohol water-adding phase is used circularly after dewatered by a solid drying agent, and the produced algae mud is used for producing biogas by biological fermentation are added. The invention completes the oil extraction of microalgae and biodiesel production by one step, simplifies the technique steps and equipment, saves cost; the sulphuric acid and low-carbon alcohol used for production can be recovered, then dewatered by drying, then utilized repeatedly, the cost is reduced, the final product is neutral, does not need washing and reduces the downstream processing pressure; and simultaneously, chlorophyll is mainly concentrated in the low-carbon alcohol, reduces the interference of the chlorophyll to the color of the product and does not need the step of decoloring.

Owner:ENN SCI & TECH DEV

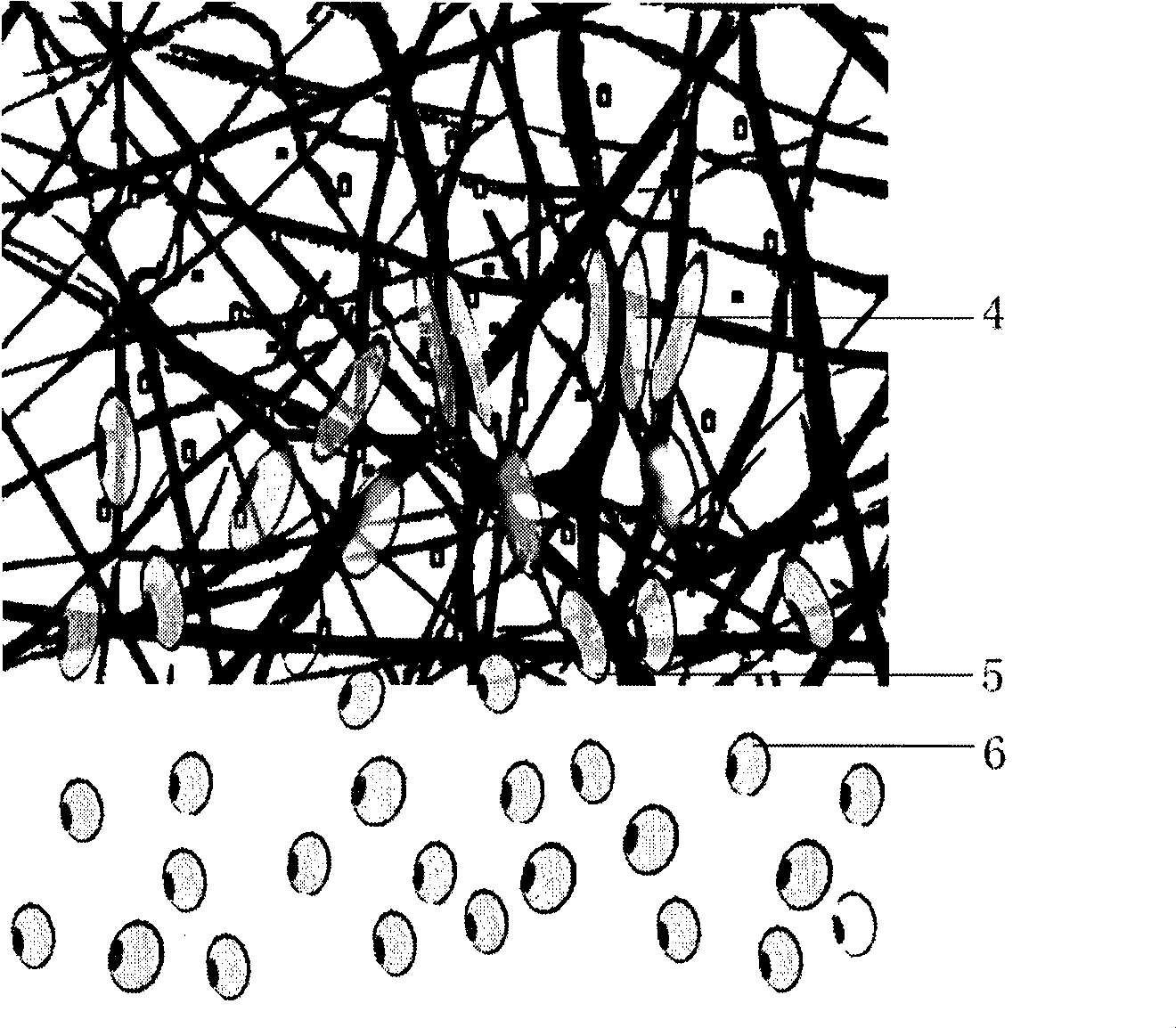

Medical anti-sticking membrane and preparation method thereof

The invention provides a medical anti-sticking membrane and a preparation method thereof. The anti-sticking membrane comprises a nanometer frame and hydrosol attached thereon. The hydrosol is internally packed with one or several kinds of styptic medicament or / and anti-sticking medicament. The invention also provides a preparation method of the anti-sticking membrane, comprising the following steps of: preparing electro-spinning solution, styptic medicament and / or anti-sticking medicament-containing hydrosol solution and crosslinker solution; receiving static spinning with the crosslinker solution to obtain the nanometer frame; printing the styptic medicament and / or anti-sticking medicament-containing hydrosol solution onto the nanometer frame by an ink-jet printer, and solidifying the hydrosol solution to obtain the anti-sticking membrane. The anti-sticking membrane has good capability and biological compatibility, and nontoxicity as well as nonirritant, can be completely degraded and absorbed, is compounded with controllably released styptic medicament or / and anti-sticking medicament, has controllable degrading time and speed, and conquers defects of the prior art.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Nano bionic wound-surface cover and preparation method thereof

ActiveCN101507835AAddress barriers to developmentAvoid inconvenienceProsthesisElectrospinningEngineering

The invention provides a nanometer bionic wound-surface cover and a preparation method thereof. The nanometer bionic wound-surface cover comprises a nanometer bionic bracket and hydrosol attached to the bracket, wherein the hydrosol covers one or a plurality of cytokines. The preparation method for the nanometer bionic wound-surface cover provided by the invention comprises the steps of preparingan electrostatic-spinning solution, a cytokine-containing hydrosol solution and a crosslinker solution, preparing the nanometer bionic bracket by use of electrostatic spinning, using an ink-jet printer to print the cytokine-containing hydrosol solution onto the nanometer bionic bracket, and the like, wherein electrostatic spinning and printing can be repeated so as to form the wound-surface covers different in thickness. The preparation method adopts an in-situ autologous stem-cell engineering technique and adopts stem-cell chemotactic factors to attract autologous stem cells to directionally migrate, enter a wound surface and be differentiated according to designed requirements, thereby avoiding inconvenience caused by using viable cells, achieving rehabilitation effects the same with orbetter than that of using the viable cells and having broad application prospects.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

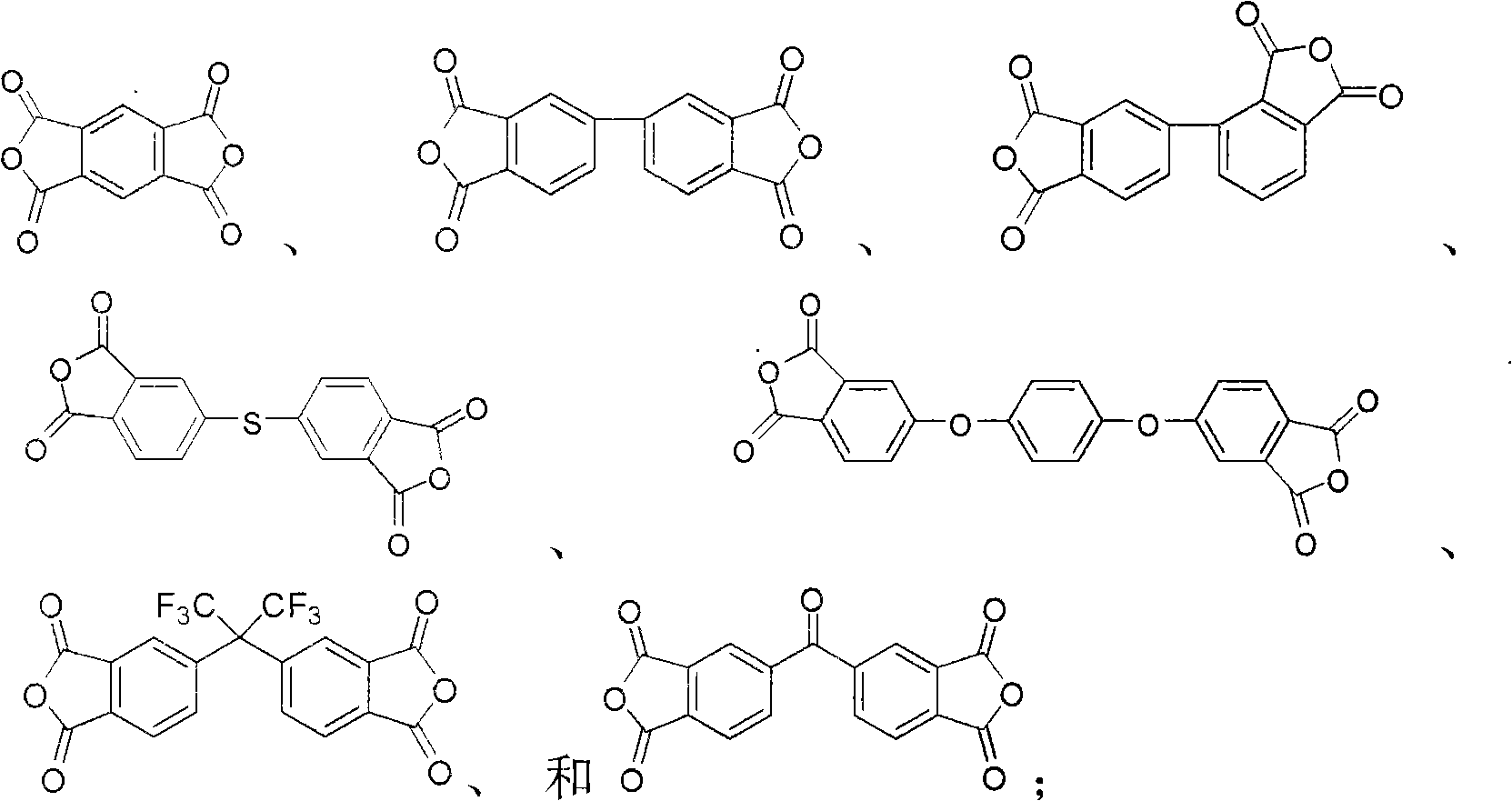

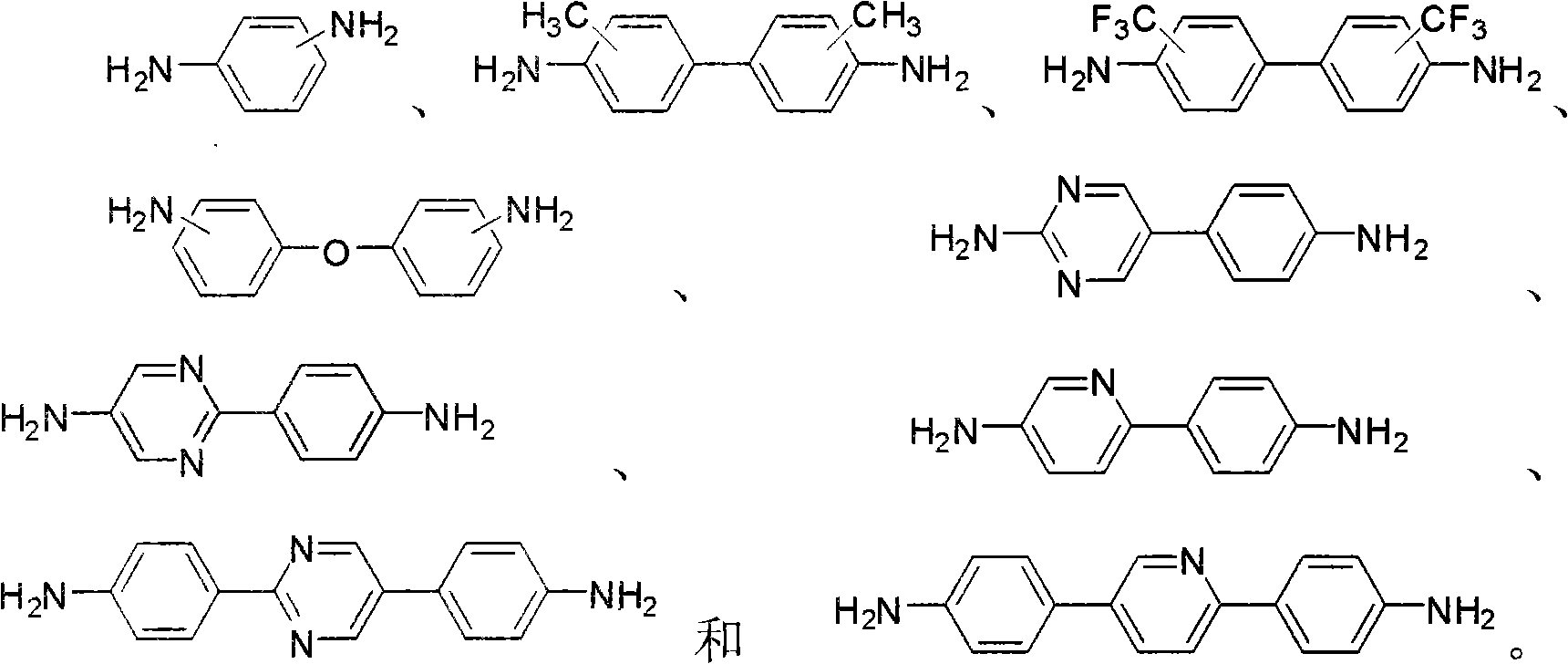

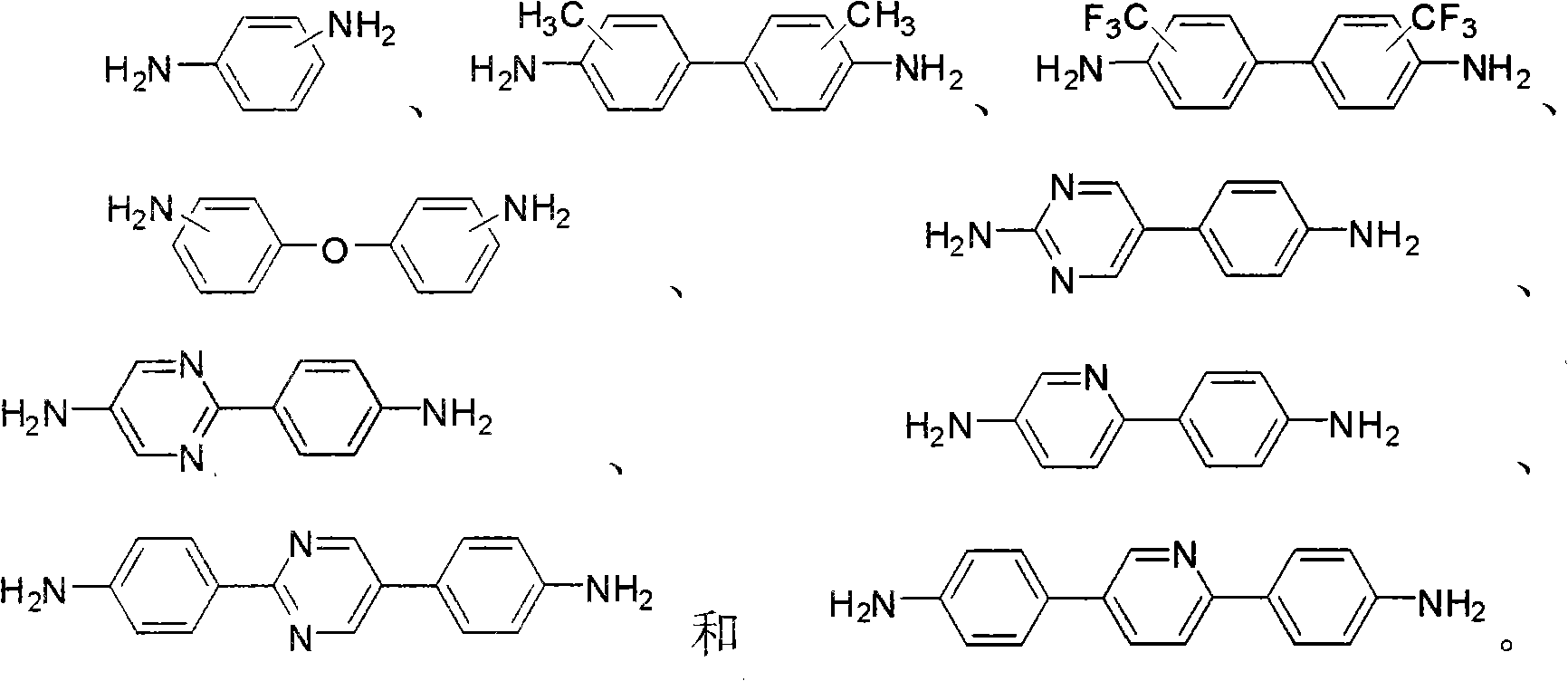

Method for preparing polyimide fiber

ActiveCN101338462AHigh strengthHigh modulusSynthetic polymer filament chemical after-treatmentMonocomponent polyamides artificial filamentFiberTemperature control

The invention relates to a preparation method of polyimide fiber. The procedures and conditions of the preparation method are as follows: (1) precursor acid polyamine solution used for spinning is made by fasculating diamine and dianhydride monomer; (2) the preparation of the polyimide fiber adopts dry-wet spinning process; (3) the polyimide fiber is imidized; and (4) the polyimide fiber undergoes the heat drawing under the temperature of 300 to 500 DEG C, and the drawing multiple of the fiber is 1 to 7 times. Imide process adopts a gradient heating-up thermal treatment furnace so as to overcome the defects of the inaccurate temperature control and the non-feasibility of the prior double thermal furnace process. The preparation method has simple process and is easy for continuous production. The prepared polyimide fiber has stronger strength and high modulus and can be used under the temperature of over 300 DEG C. In addition, the polyimide fiber has UV irradiating resistance property, a higher limited oxygen index and corrosion resistance, so the polyimide fiber can be widely applicable for the reinforced fiber of composite materials, a cable sheath, a cable reinforcing core, the mooring rope of vehicle and vessel and the filtering materials of high temperature or radioactive substance, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method for graphene/aramid fibre 1414 nano-fibre composite membrane

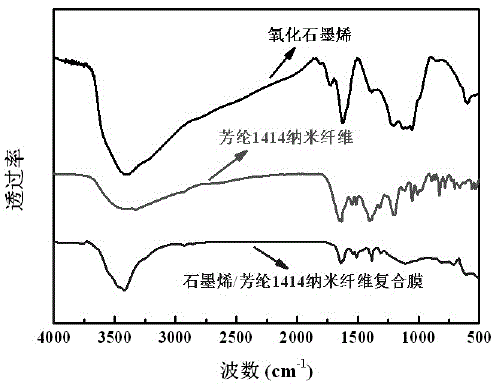

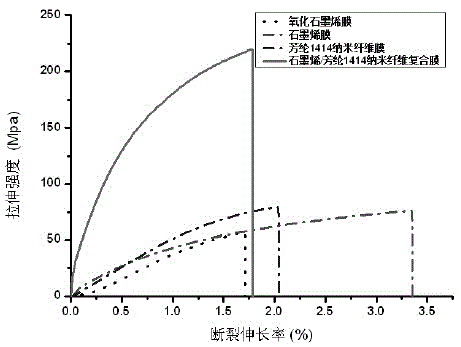

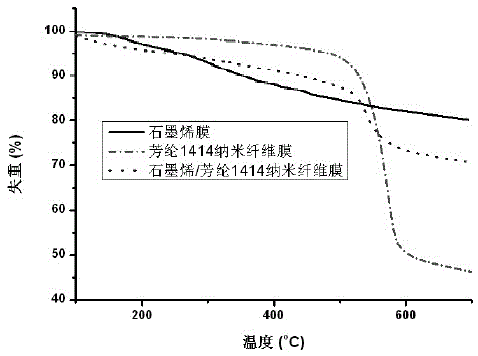

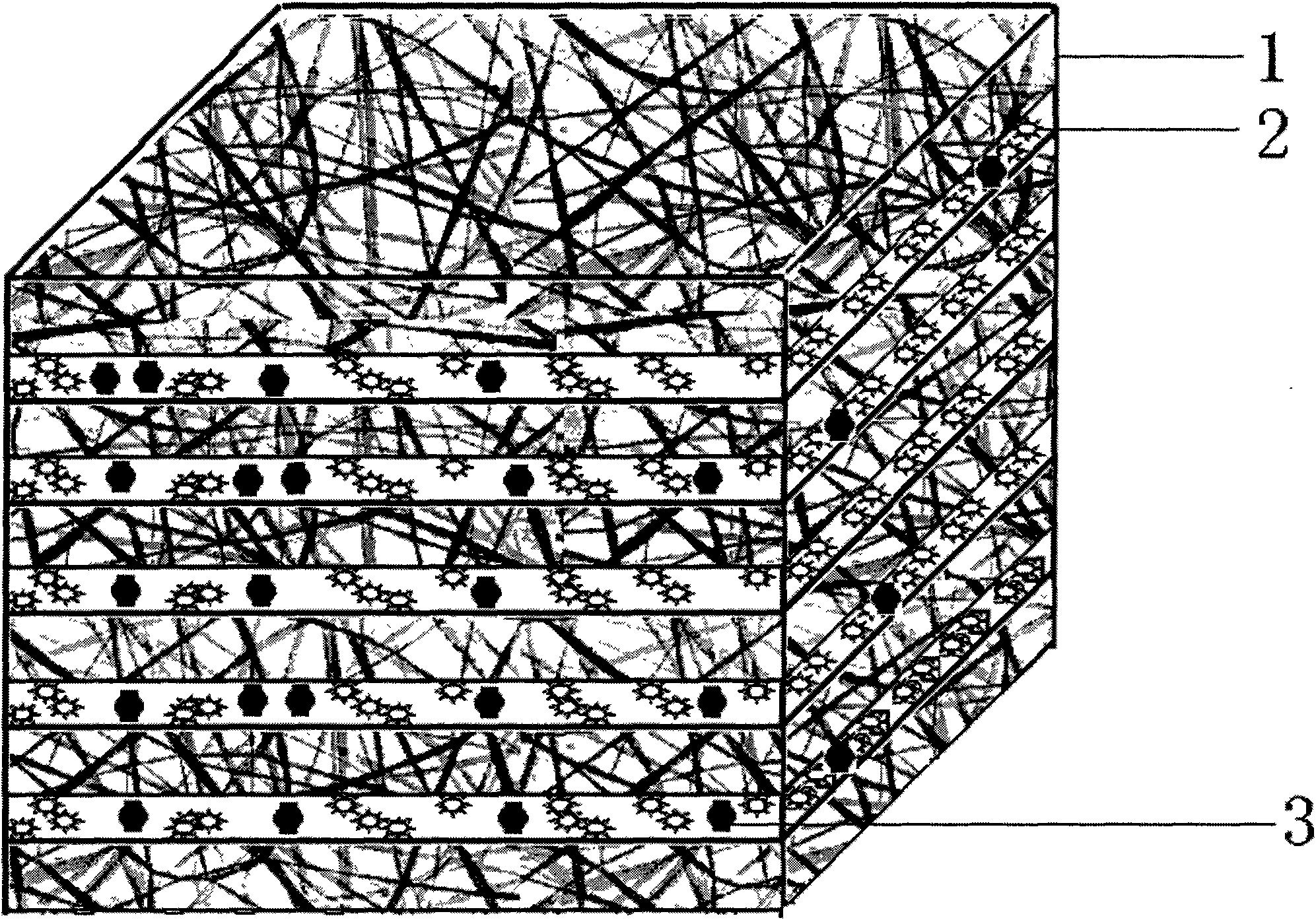

The invention discloses a preparation method for a graphene / aramid fibre 1414 nano-fibre composite membrane, comprising the following steps of: performing nano-fibrillation on aramid fibre 1414 yarns via the solution system of dimethyl sulfoxide and potassium hydroxide; slowly adding dimethyl sulfoxide solution for oxidizing graphene, sequentially centrifuging, dispersing, performing suction filtration and film formation, and thus obtaining oxidized graphene / aramid fibre 1414 nano-fibre composite membrane; and reducing via hydroiodic acid, washing, drying, and thus obtaining the graphene / aramid fibre 1414 nano-fibre composite membrane. The tensile strength and the Young modulus of the graphene / aramid fibre 1414 nano-fibre composite membrane obtained by the preparation method disclosed by the invention can achieve 209.4 Mpa and 29.5 GPa respectively, thus showing excellent mechanical property; simultaneously, the conductivity of the graphene / aramid fibre 1414 nano-fibre composite membrane can achieve 175 S / m, thus being excellent in conductance; and a thermogravimetric analysis shows that the graphene / aramid fibre 1414 nano-fibre composite membrane is good in heat stability.

Owner:SHANGHAI JIAO TONG UNIV

Catalyst system for preparing vinyl chloride by hydrochlorinating acetylene and preparation and application thereof

ActiveCN101879464AEasy to prepareImprove conversion rateCatalyst carriersPreparation by halogen halide additionManganeseIonic liquid

The invention discloses a catalyst system for preparing vinyl chloride by hydrochlorinating acetylene, and preparation and application thereof. The catalyst system comprises a catalyst carrier and a catalyst, wherein the catalyst carrier is pyridine ionic liquid, and the catalyst is one or any combination of more than two of tin, palladium, gold, copper, manganese, bismuth, mercury and rhodium. The preparation method for the catalyst system comprises a step of dissolving the catalyst in the catalyst carrier. Acetylene gas and hydrogen chloride gas are mixed and then reacted in the presence of the catalyst system. The preparation process realizes a liquid phase reaction for preparing the vinyl chloride by hydrochlorinating the acetylene, avoids the loss of the catalyst system, is more environment-friendly and safer, and improves the conversion rate of the acetylene and the selectivity of the vinyl chloride.

Owner:于志勇

Artificial articular cartilage based on autologous cells and preparation method thereof

ActiveCN101574543AImprove mechanical propertiesAvoid inconvenienceJoint implantsElectrospinningHYDROSOL

The invention provides artificial articular cartilage based on autologous cells and a preparation method thereof. The artificial articular cartilage comprises a nano bionic support and hydrosol adhered to the nano bionic support, wherein one or more cytokines are coated into the hydrosol. The invention also provides the method for preparing the artificial articular cartilage, which comprises the following steps: preparing an electrostatic spinning solution, a cytokine-containing hydrosol solution and a crosslinking agent solution; using the crosslinking agent solution to receive electrostatic spinning so as to prepare the nano bionic support; and using an ink jet printer to print the cytokine-containing hydrosol solution on the nano bionic support, and curing the hydrosol to obtain the artificial articular cartilage. The three-dimensional support adopted by the invention has ideal degradation speed and is degraded after the regeneration of an articular cartilage layer, can meet the requirement of actual clinical application, can be completely degraded, and has good abrasion resistance and lubricity so as to be capable of replacing the cartilage before the regeneration of the articular cartilage layer.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

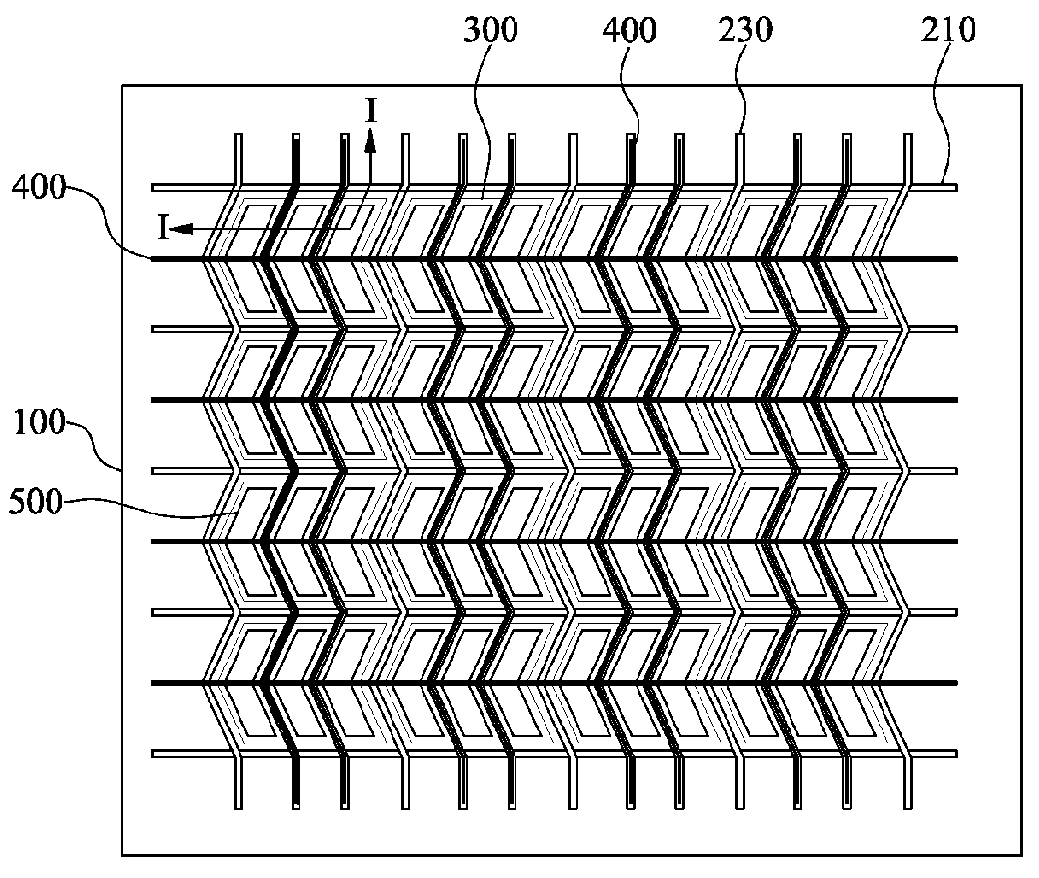

Liquid Crystal Display Device and Method for Manufacturing the Same

ActiveUS20120127414A1Reduce thicknessThe process steps are simpleStatic indicating devicesCoatingsLiquid-crystal displayEngineering

A liquid crystal display device and a method for manufacturing the same are disclosed. The liquid crystal display device comprises gate and data lines arranged to cross each other on a substrate to define a plurality of pixels; a pixel electrode formed in each of the plurality of pixels; a common electrode forming an electric field together with the pixel electrode, patterned to sense a touch of a user; a sensing line discontinuously formed on the common electrode and electrically connected with the common electrode; a jump line formed below the common electrode to electrically connect discontinuous portions of the sensing line with one another; and first and second connection electrodes for electrically connecting the jump line with the sensing line, wherein the first connection electrode is connected with the jump line, and the second connection electrode is connected with the sensing line and the first connection electrode respectively.

Owner:LG DISPLAY CO LTD

Method for preparing magnetic biochar from straw

InactiveCN105536700AOptimize structural configurationMeet greenOther chemical processesAlkali metal oxides/hydroxidesIron saltsCarbonization

A method for preparing magnetic biochar from straw includes the step of selecting of a straw material, wherein wheat straw, corn straw, rice straw or cotton straw is selected as the straw material, the straw material is pretreated by cleaning, then the straw material is dipped with a trivalent iron salt solution, and filtered by vacuum, then a filter cake is dried, and a finished magnetic biochar product can be obtained by carbonization treatment in inert gas conditions. The magnetic biochar can be obtained by dipping the straw material in the trivalent iron salt solution by a pyrolysis process, and a new way for the use of straw is provided.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

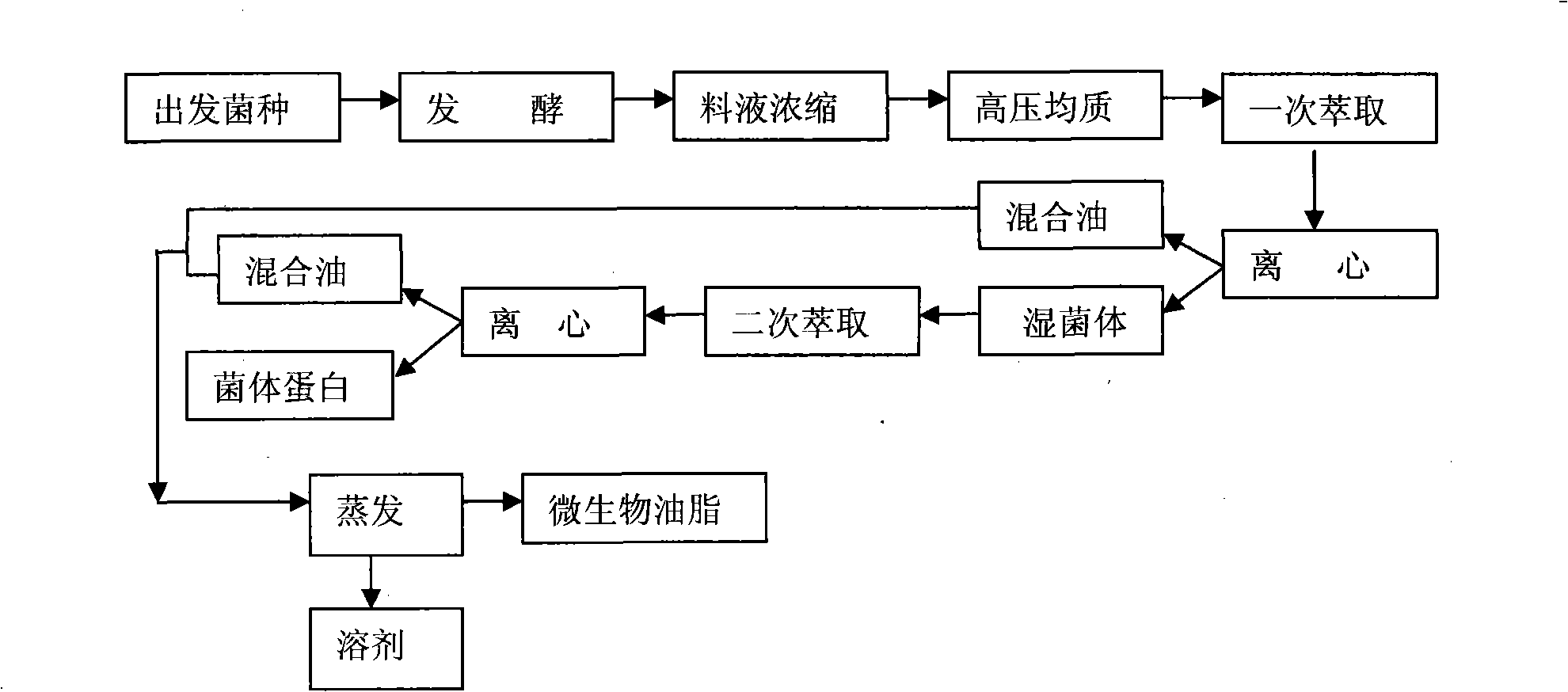

Separation and extraction method of microbial oil

InactiveCN101323865AHigh yieldSimple and fast operationMicroorganism based processesFermentationMicrobial oilOrganic solvent

A method for separating and extracting microbial oil comprises the following steps: (1) microbial strains are inoculated for fermentation; (2) the obtained fermentation liquor is concentrated to remove 45 percent to 55 percent of water in the fermentation liquor so as to obtain the concentrated fermentaton liquor; (3) the concentrated fermentation liquor is fed into a high pressure homogenizer with the pressure of 70 to 130MPa to carry out cell-crushing; (4) an extractive solvent is added, and after two times of extraction, the upper layer organic solution phase is separated and collected to obtain mixed oil; and (5) at last, the solvent in the mixed oil is vaporized and recycled to obtain the microbial oil. The method combines the fermented solution concentration with the high pressure homogenization technology to carry out cell crushing, and then adopts the two-time extraction to collect the contained oil and obtain bacterial protein accordingly. The process improves the original method which needs the steps, such as the separation of strains, drying, grinding and granulation, etc., thus greatly simplifying the technology, improving efficiency and reducing production cost. The method homogenizes the fermented solution under high pressure after concentration, which promotes the utilization rate of facilities, and reduces energy consumption.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Bitumen production-upgrade with common or different solvents

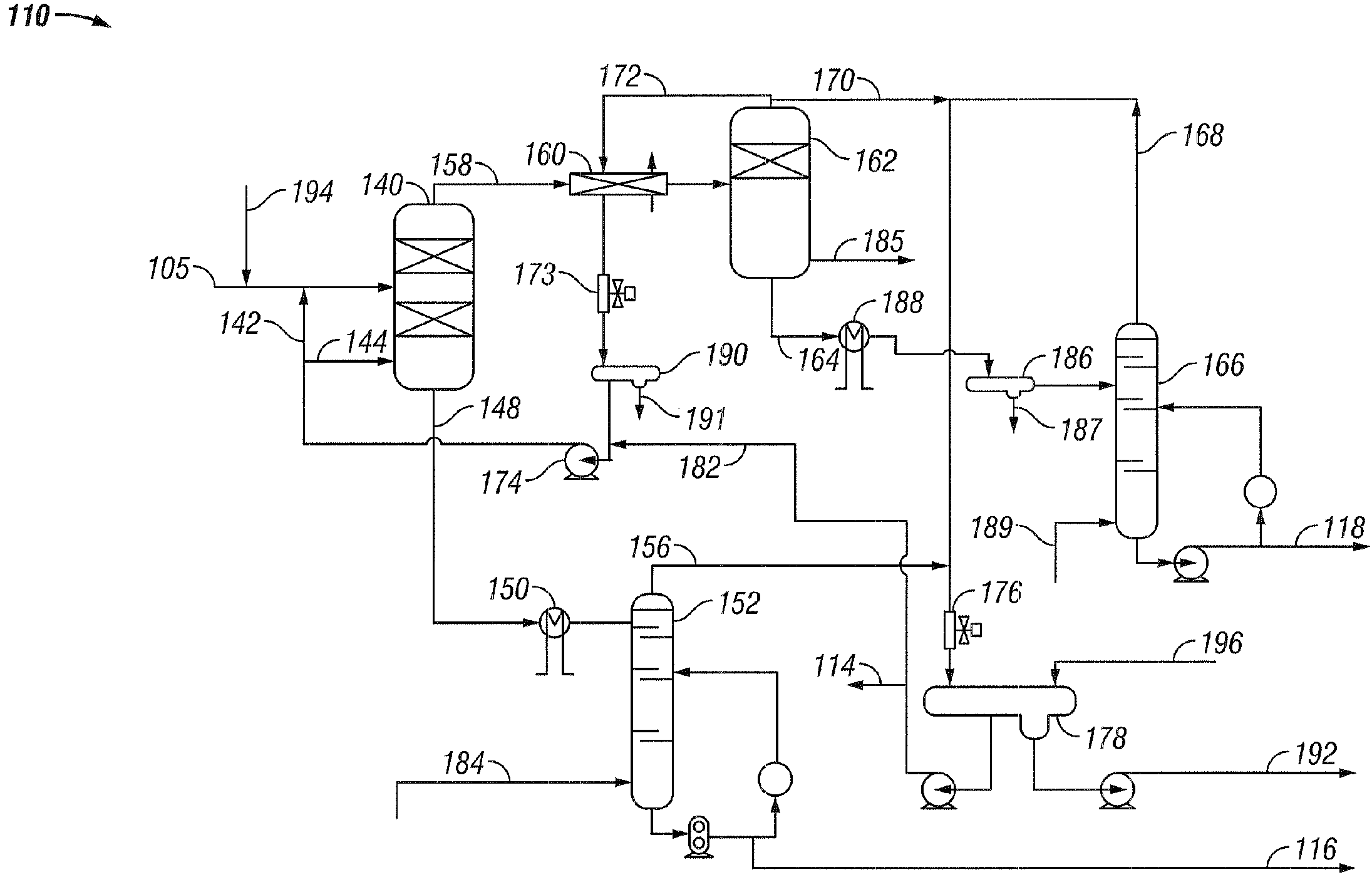

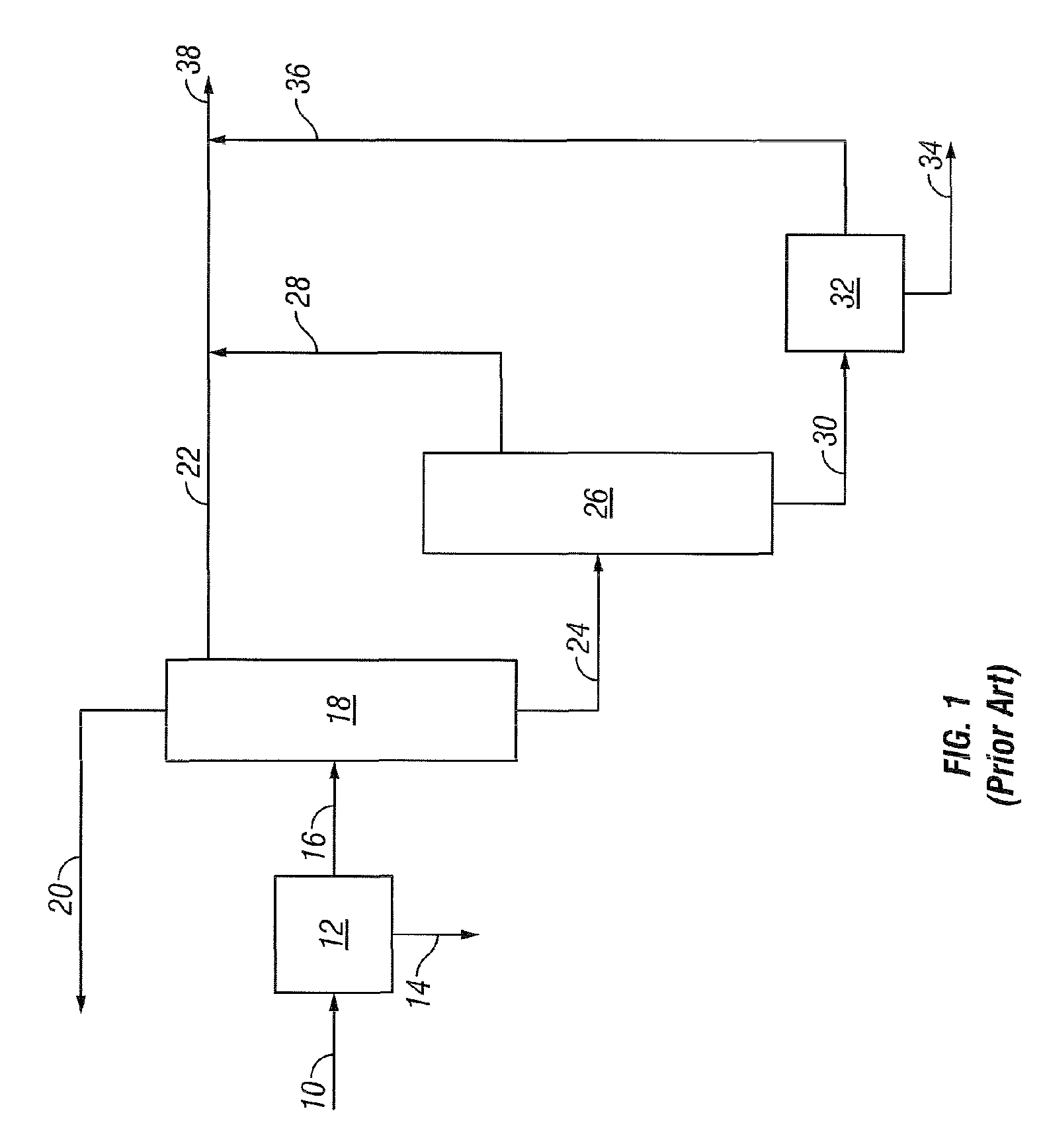

ActiveUS7749378B2Reduce capital investmentReduce operating expensesWorking-up pitch/asphalt/bitumen by selective extractionRefining by water treatmentDiluentWater fraction

Disclosed is a process for the upgrading of heavy oils and bitumens, where the total feed to the process can include heavy oil or bitumen, water, and diluent. The process can include the steps of solvent deasphalting 110 the total feed 105 to recover an asphaltene fraction 116, a deasphalted oil fraction 118 essentially free of asphaltenes, a water fraction 112, and a solvent fraction 114. The process allows removal of salts from the heavy oils and bitumens either into the aqueous products or with the asphaltene product.

Owner:KELLOGG BROWN & ROOT LLC

Production method for through wafer interconnection construction

ActiveCN101483149AMitigate Thermal MismatchThe process steps are simpleSemiconductor/solid-state device manufacturingParyleneParasitic capacitance

The invention discloses a through wafer interconnect structure preparation method comprising: 1. bonding a bonding silicon device wafer on a silicon wafer substrate; 2. thinning the silicon device wafer, etching the silicon device and forming a blind hole; 3. coating a layer of pattern dielectric material (such as poly-p-xylene) on the silicon device wafer; 4. etching the pattern dielectric substance layer, etching the dielectric material at the bottom of the blind hole, keeping a blind hole side wall; forming a dielectric substance hole on the substrate and enabling the dielectric substance hole and the blind hole coaxial; 5. depositing a layer of conductive material on the dielectric substance hole as a conductive layer and forming a conductive hole; 6. re-depositing a layer of pattern dielectric substance on the conductive layer; 7. forming a solder micro-convex point on the conductive layer. The invention simplifies the process steps, reduces the process time and the cost; depresses a parasitic capacitance, improves a interconnect electrical behavior, suits for the RF three-dimensional interconnection structure; releases the thermal mismatch between the conductive material and the silicon and greatly reduces the thermal mechanical stress.

Owner:HUAZHONG UNIV OF SCI & TECH

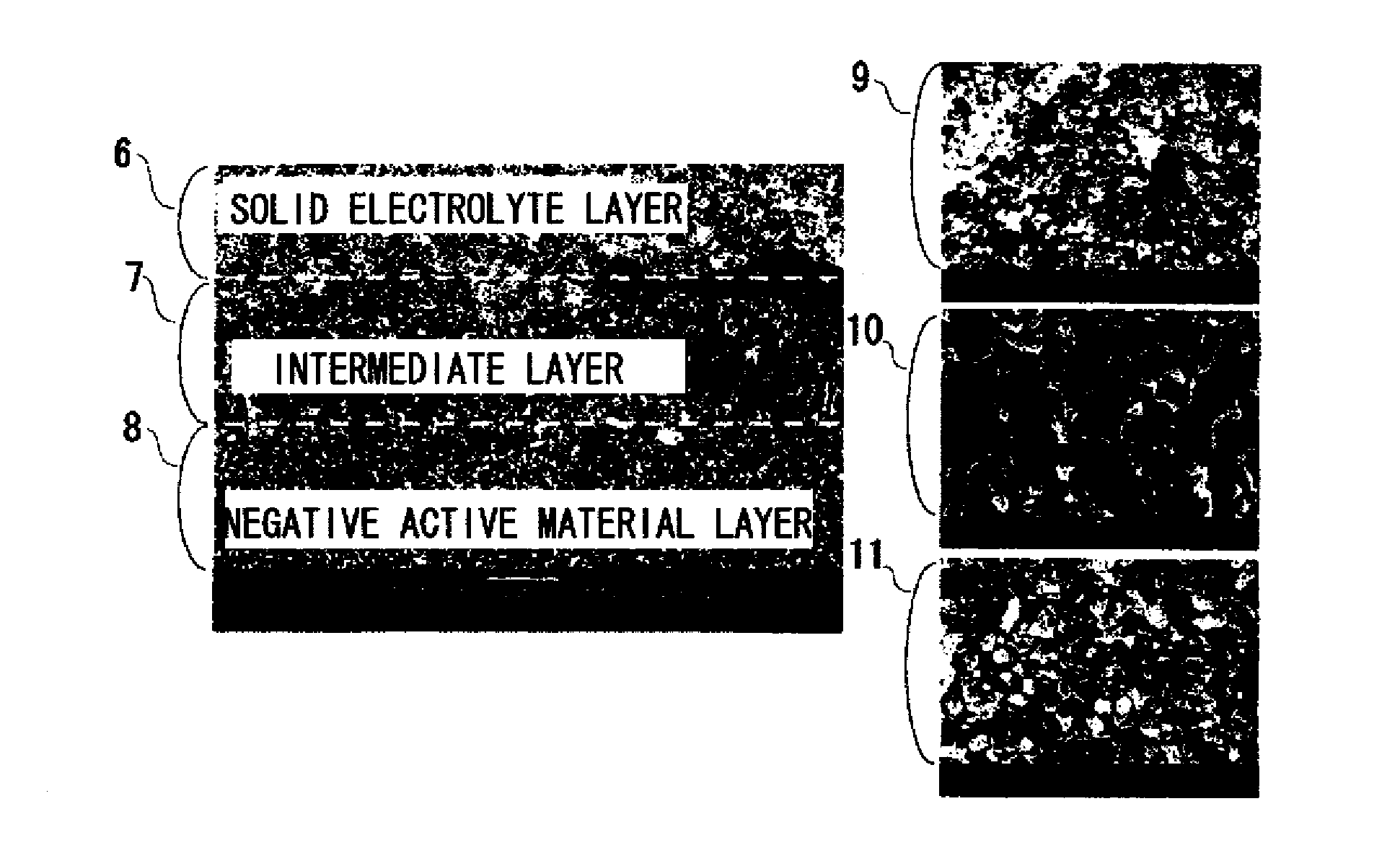

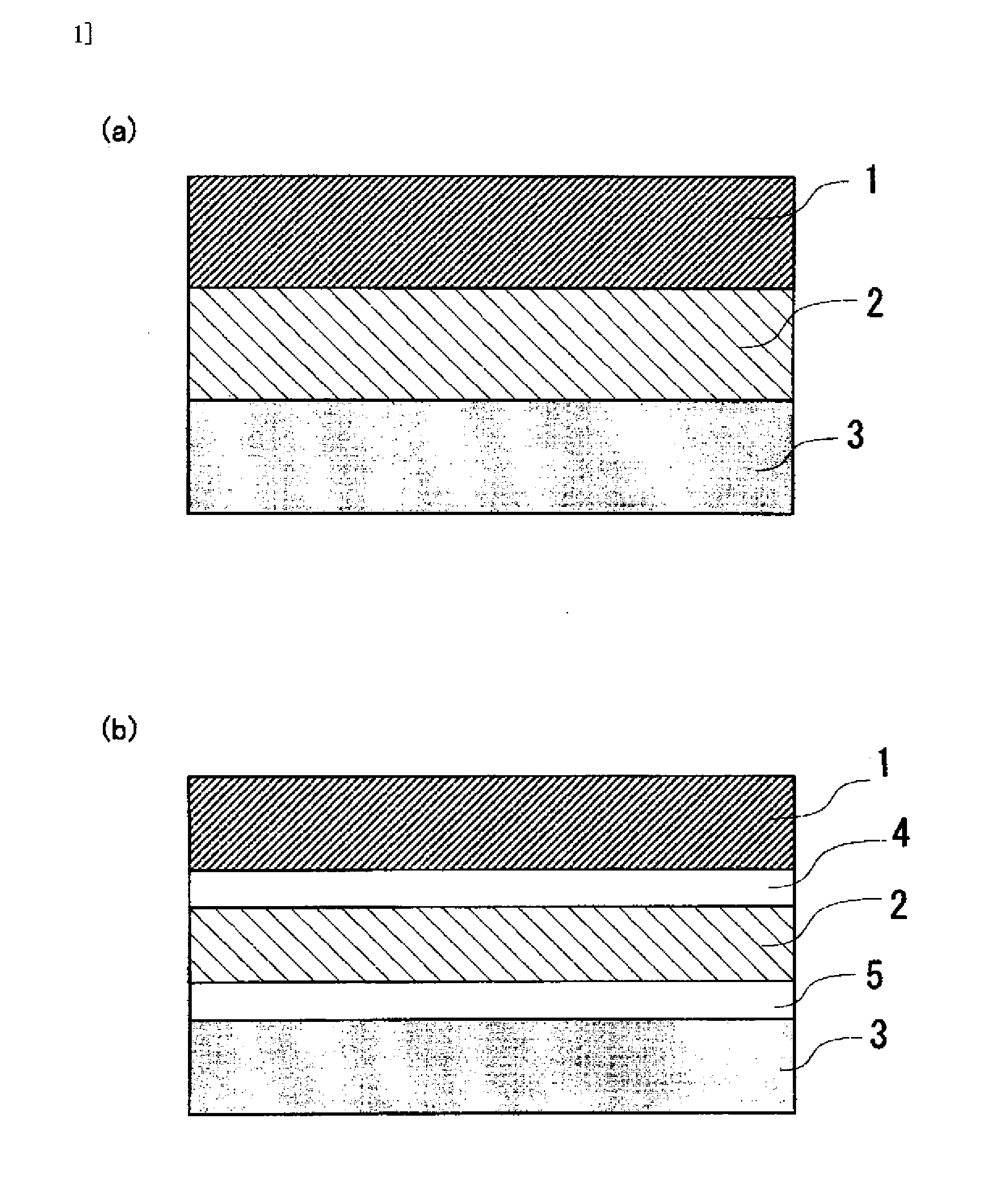

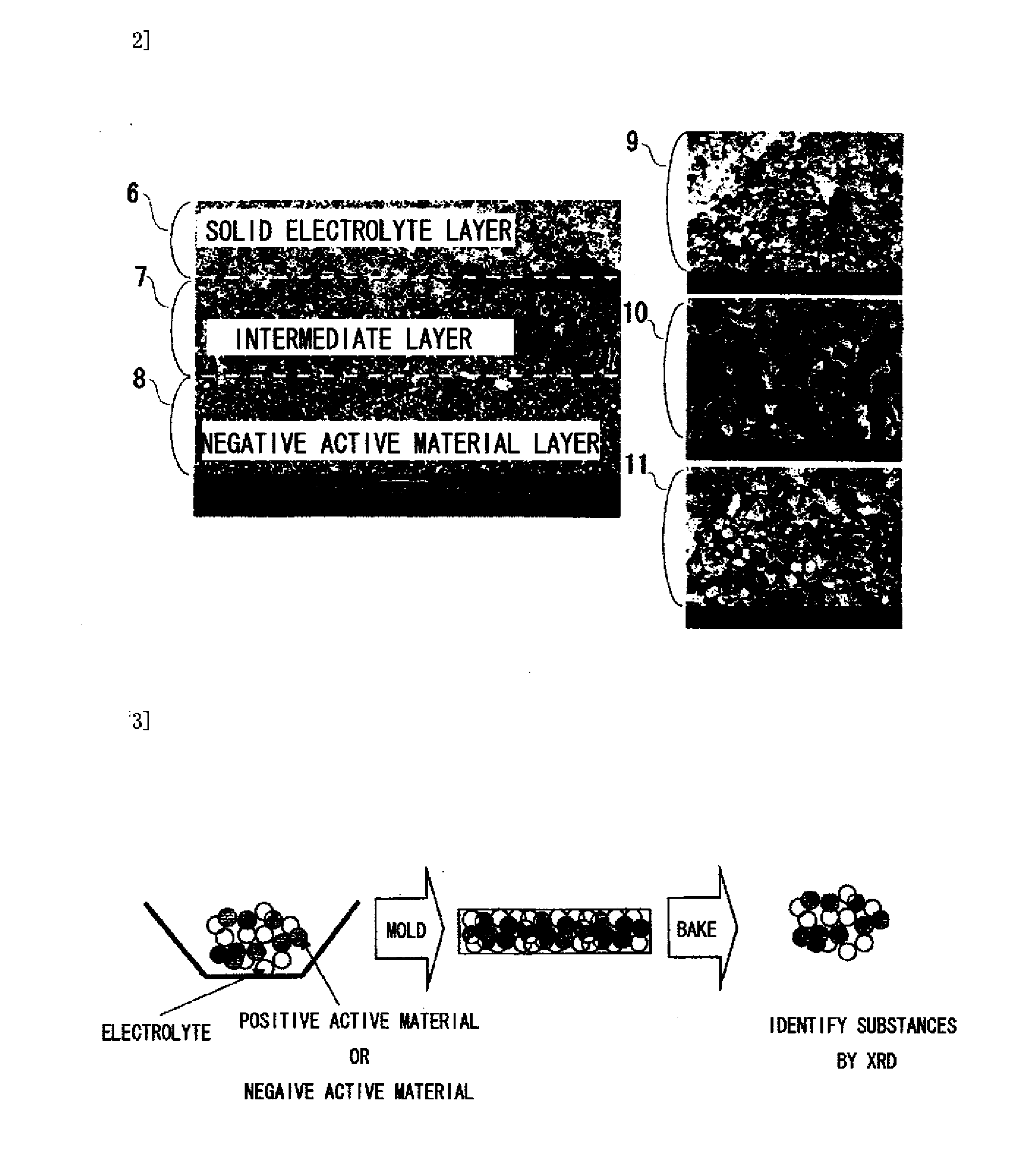

Lithium ion rechargeable battery and process for producing the lithium ion rechargeable battery

InactiveUS20100216032A1Enhanced interface bindingReduce interface resistanceFinal product manufactureElectrode carriers/collectorsCooking & bakingLithium

Conventional ion rechargeable batteries having an electrode layer on an electrolyte layer suffer from an impurity layer formed at the interface, degrading performance. Conventional batteries with no such impurity layer have a problem of weak interface bonding. In the present invention, in a baking process step after an electrode layer is laminated on an electrolyte layer, materials for an electrode layer and an electrolyte layer are selected such that an intermediate layer formed of a reaction product contributing to charging and discharging reactions is formed at the interface of the electrode layer and the electrolyte layer. In addition, a paste that an active material is mixed with a conductive material at a predetermined mixing ratio is used to form a positive electrode layer and a negative electrode layer. Reductions in electrode resistance and interface resistance and improvement of charging and discharging cycle characteristics are made possible.

Owner:NAMICS CORPORATION

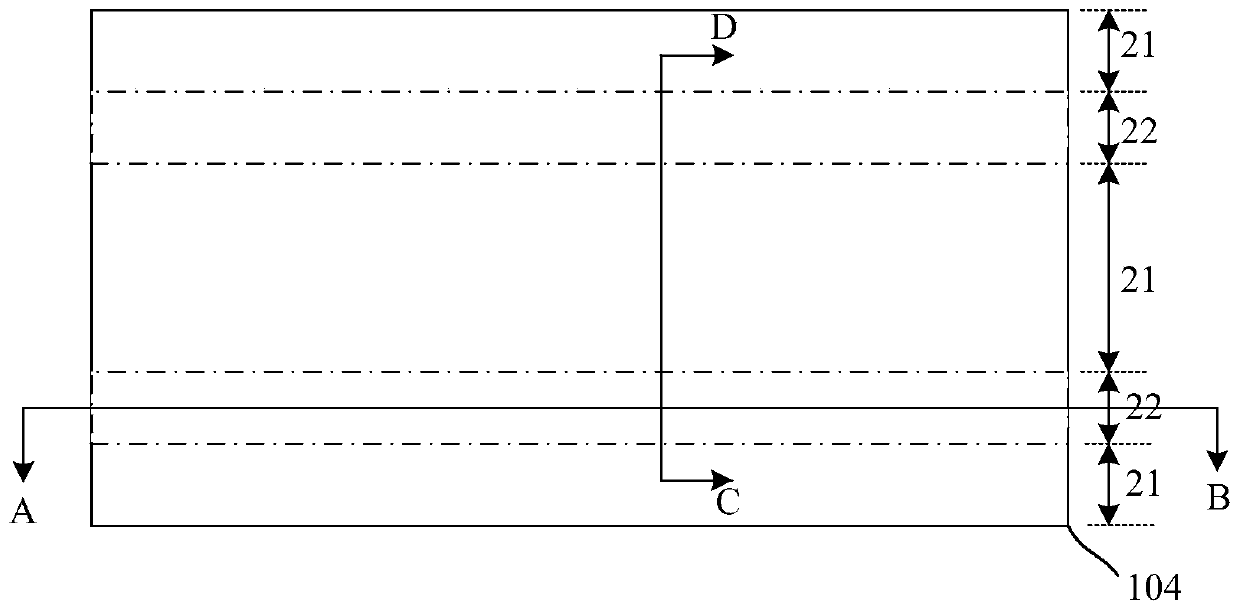

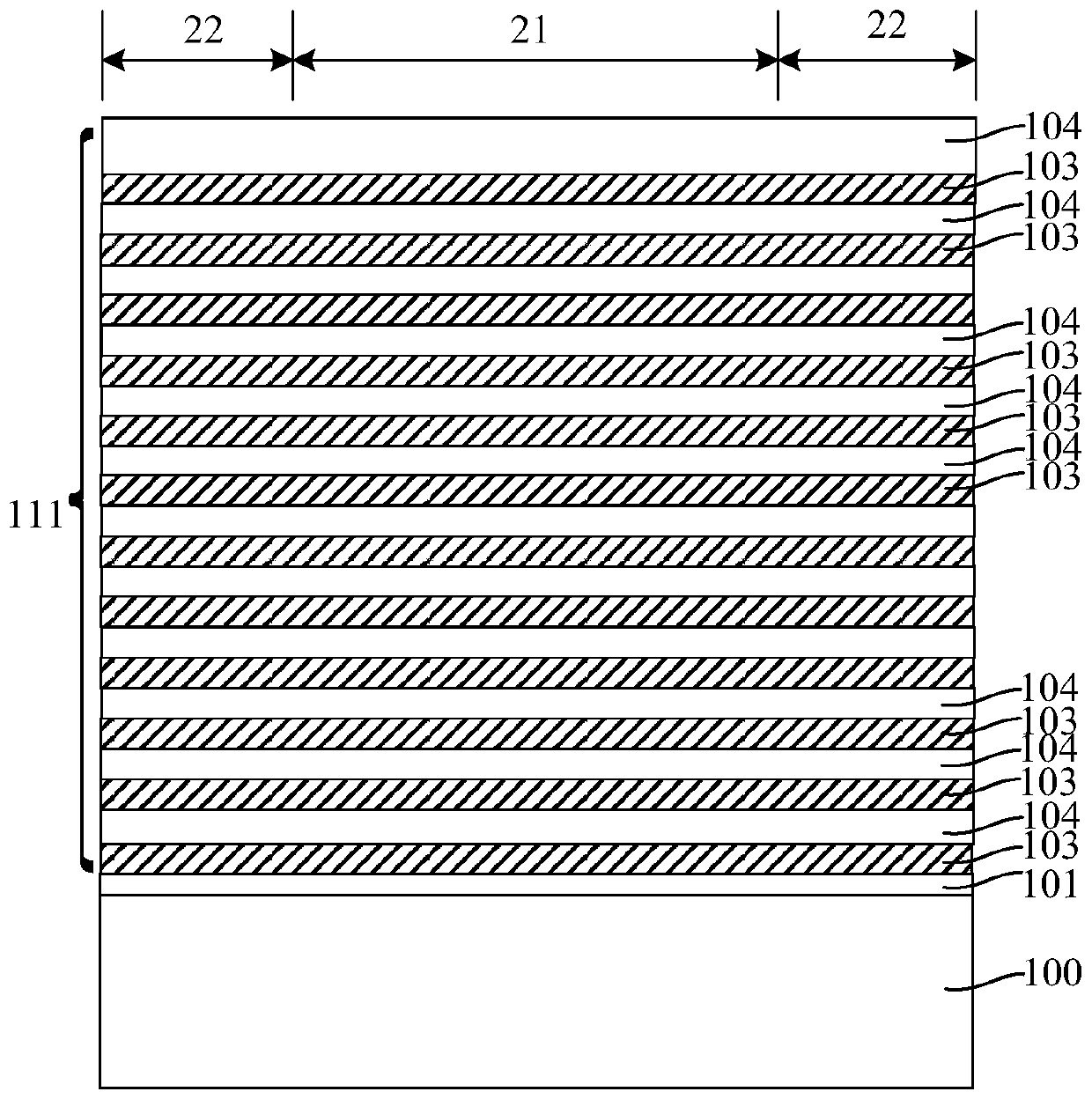

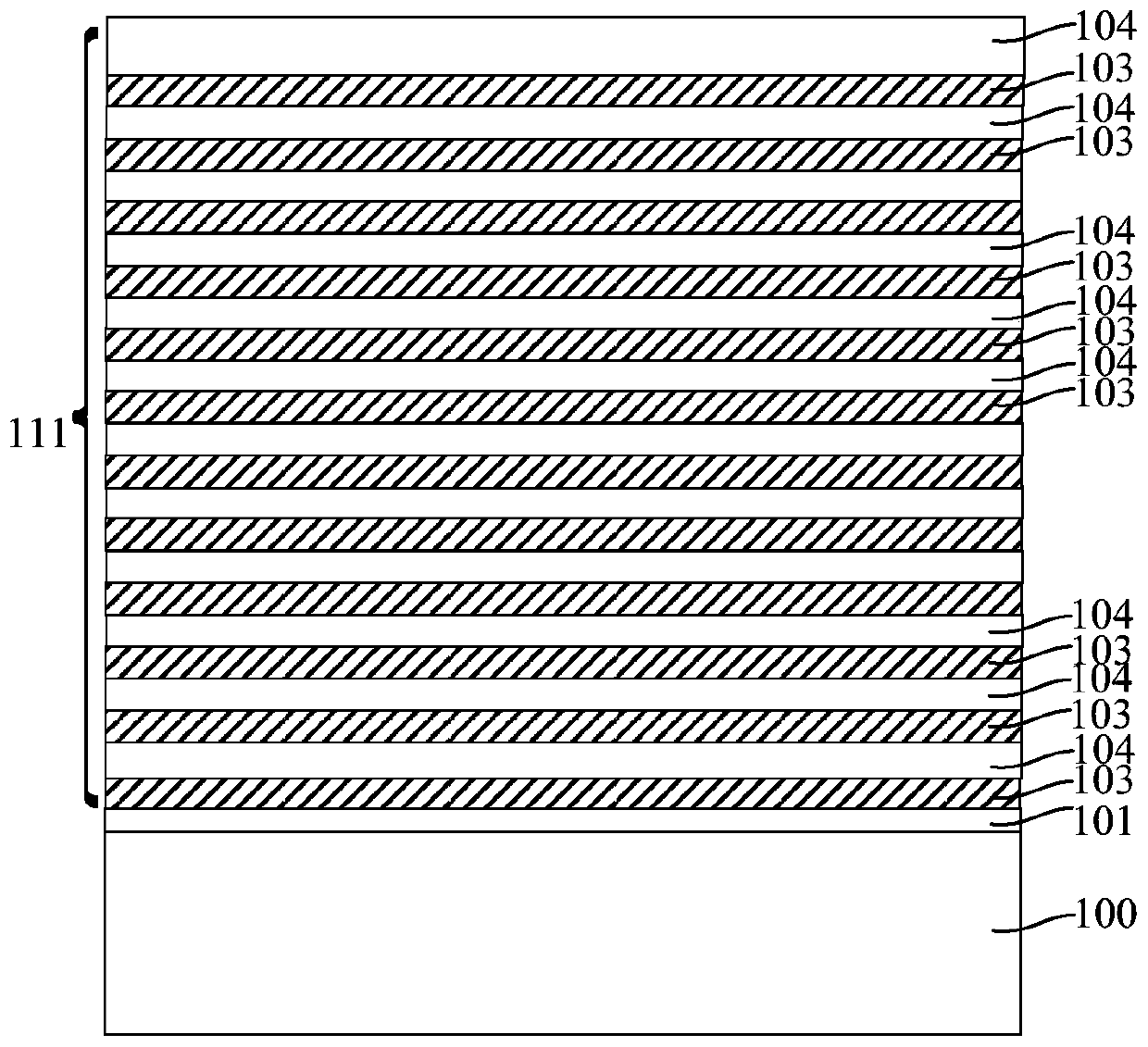

3D NAND memory and forming method thereof

ActiveCN110112134AImprove performanceGuaranteed stabilitySolid-state devicesSemiconductor devicesEngineeringForms Control

A 3D NAND memory and a forming method thereof are disclosed. According to the forming method of the 3D NAND memory, at least one pseudo common source penetrating a stacking structure is formed in gateisolation groove regions, gate isolation grooves penetrating the stacking structure are subsequently formed in the gate isolation groove regions on the two sides of the pseudo common sources, and thegate isolation grooves formed on the two sides of the pseudo common sources expose the corresponding side walls of the pseudo common sources. In the process of forming the gate isolation grooves, inthe process of removing a sacrificial layer after the formation of the gate isolation grooves and in the process of forming control gates and array common sources, the pseudo common sources can support the two side walls of the gate isolation grooves and prevent the two side walls of the gate isolation grooves from deforming or tilting. Thus, the stability of the characteristic dimensions of the formed gate isolation grooves is ensured, and the performance of the 3D NAND memory is improved.

Owner:YANGTZE MEMORY TECH CO LTD

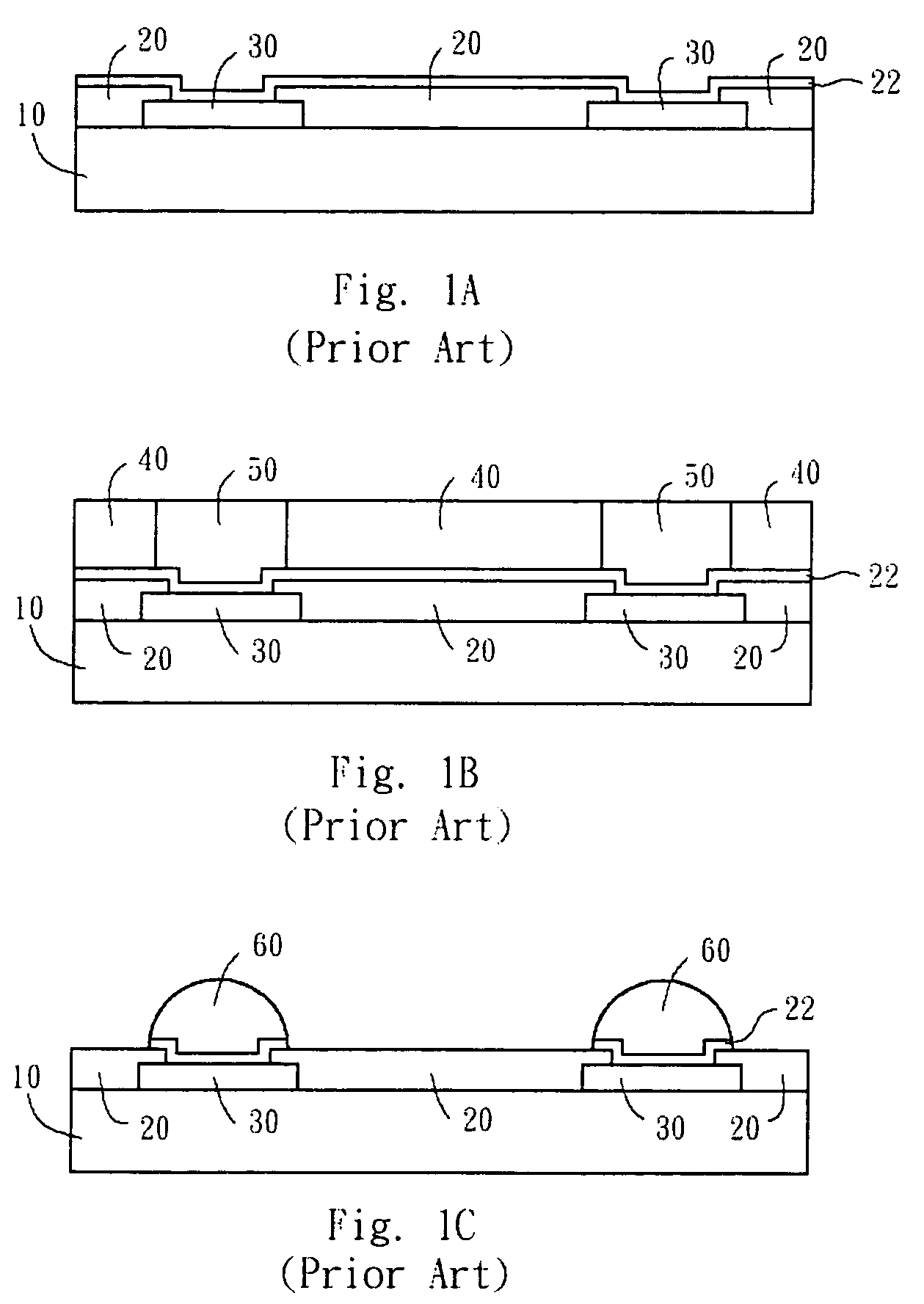

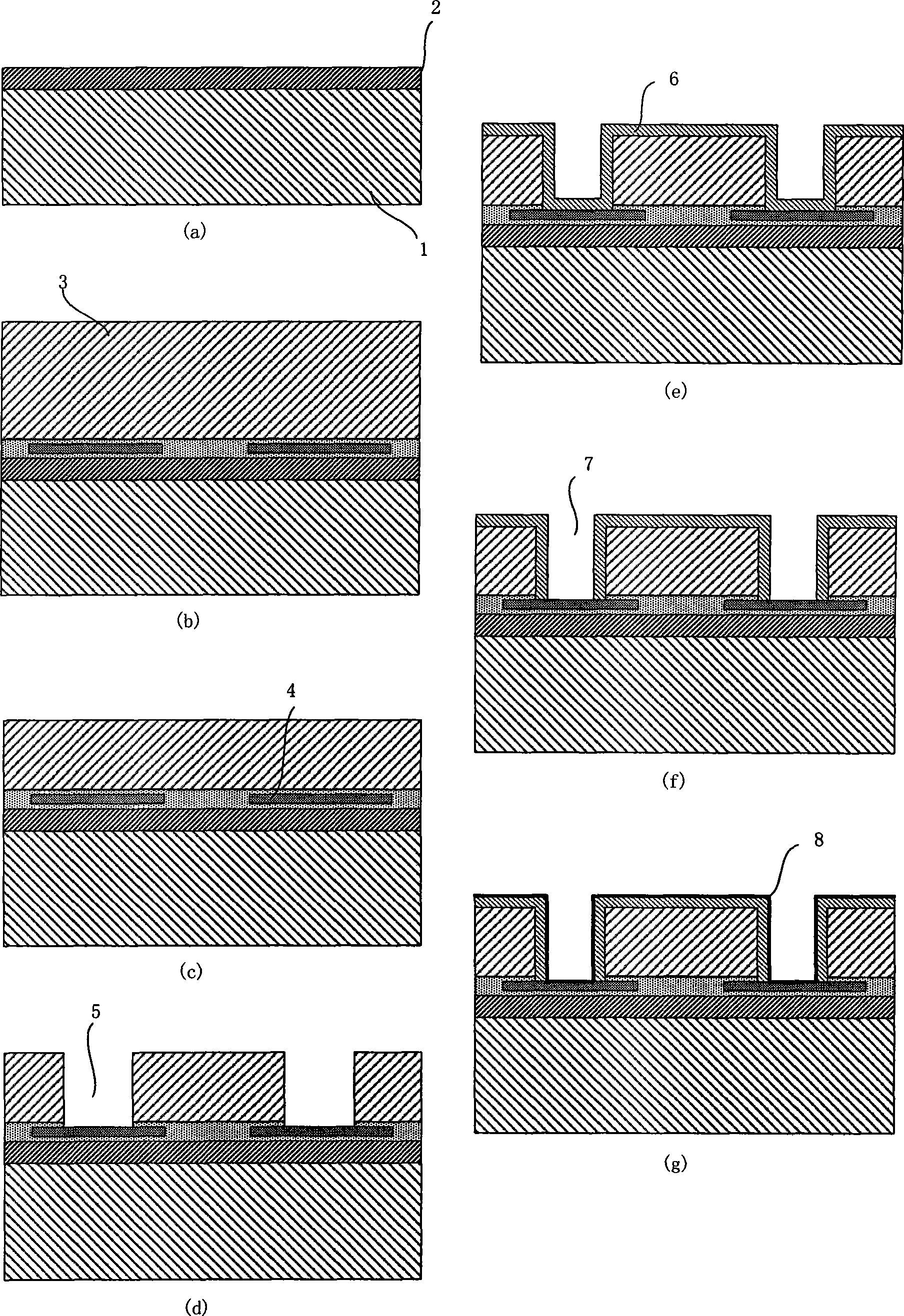

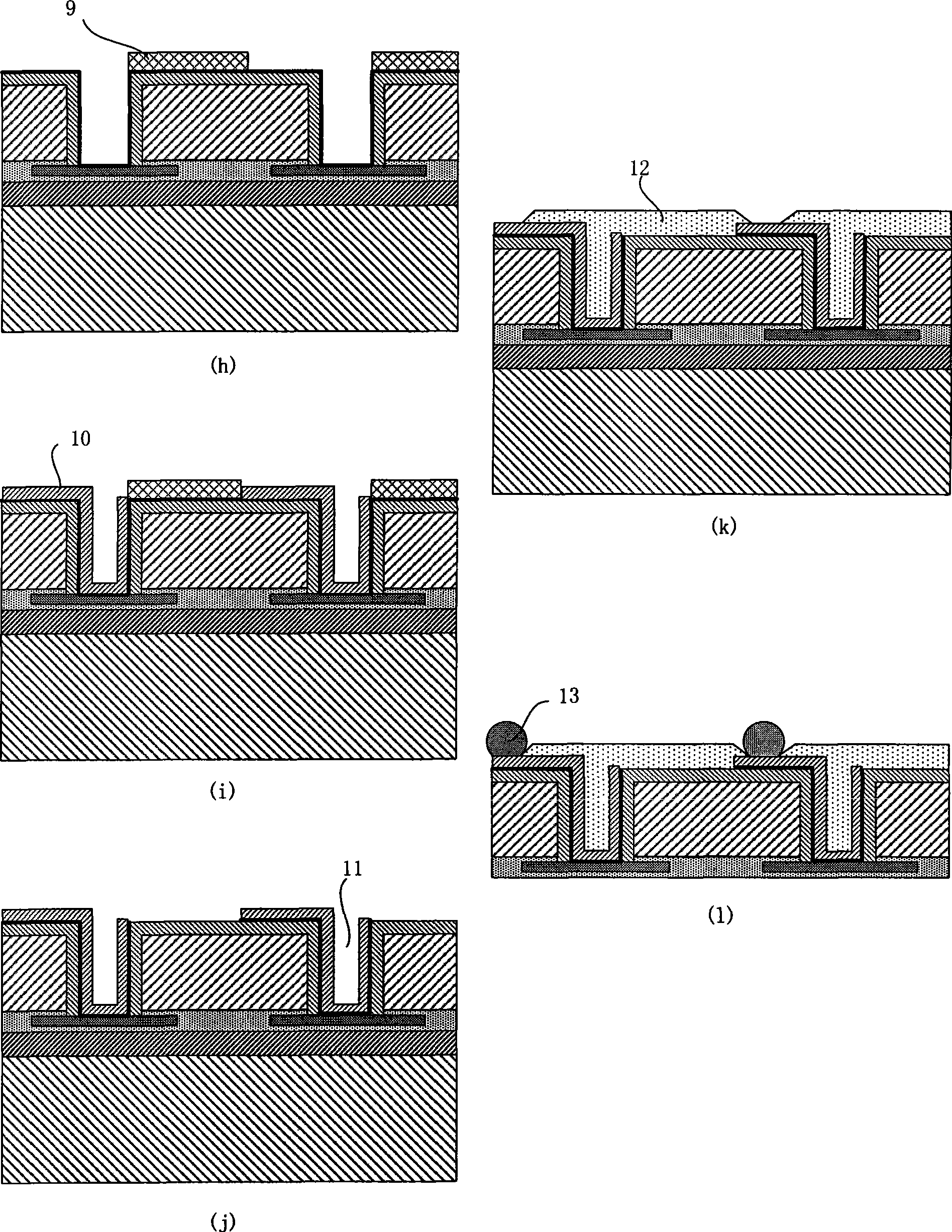

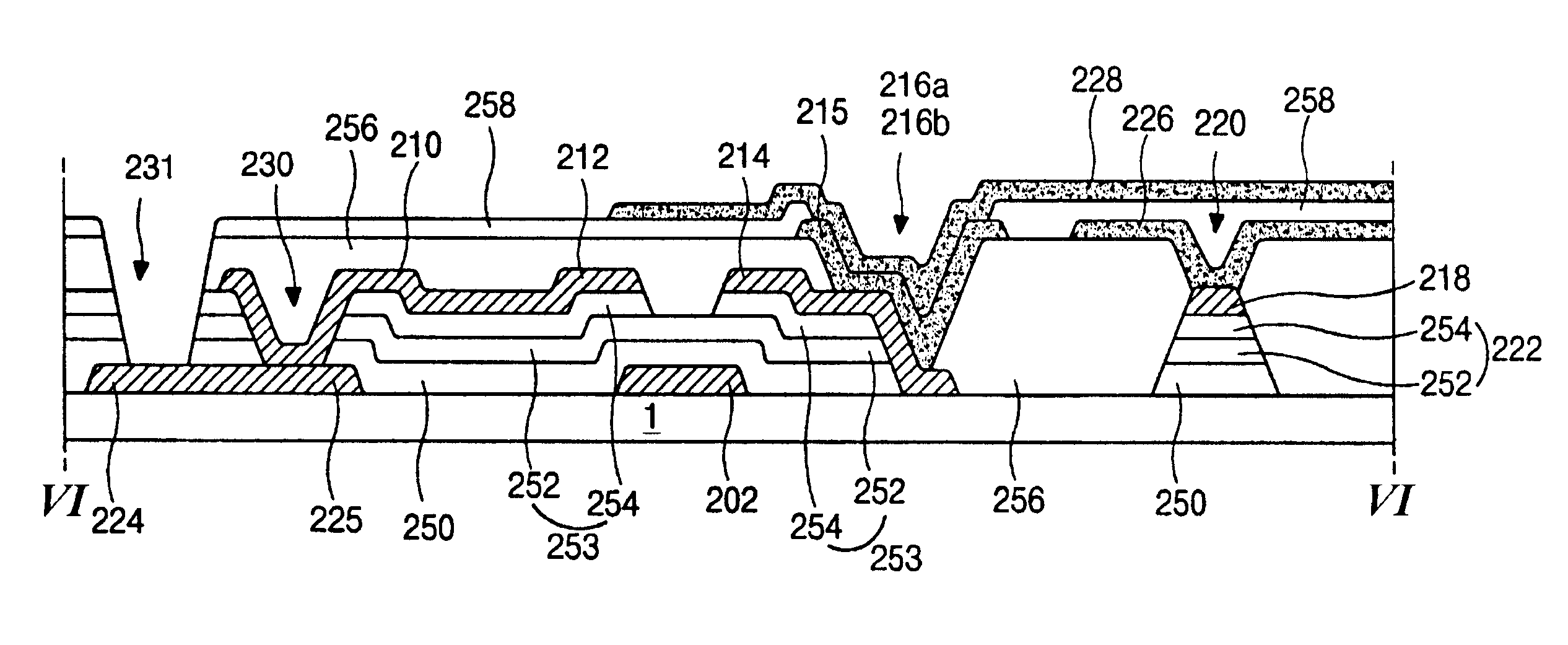

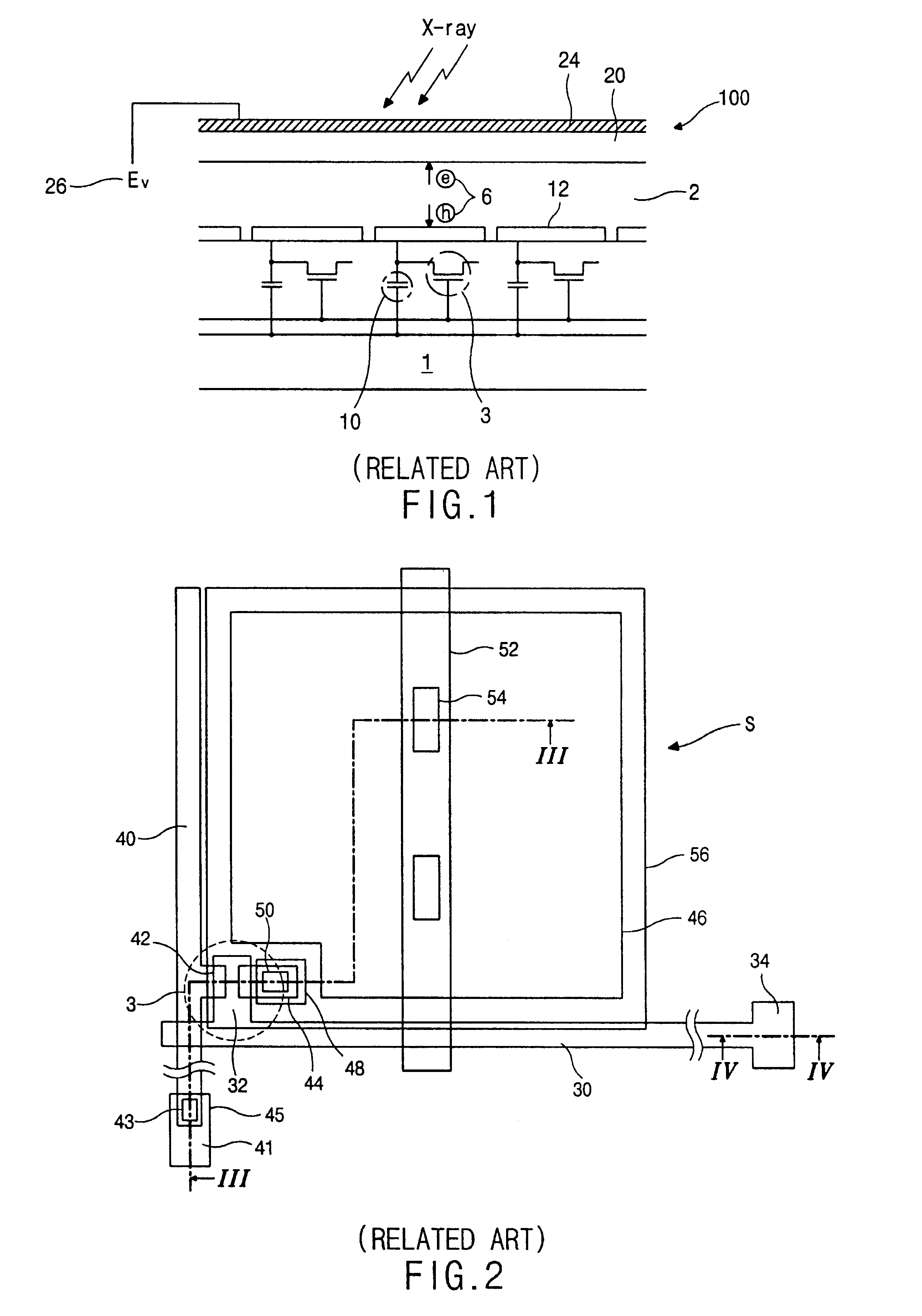

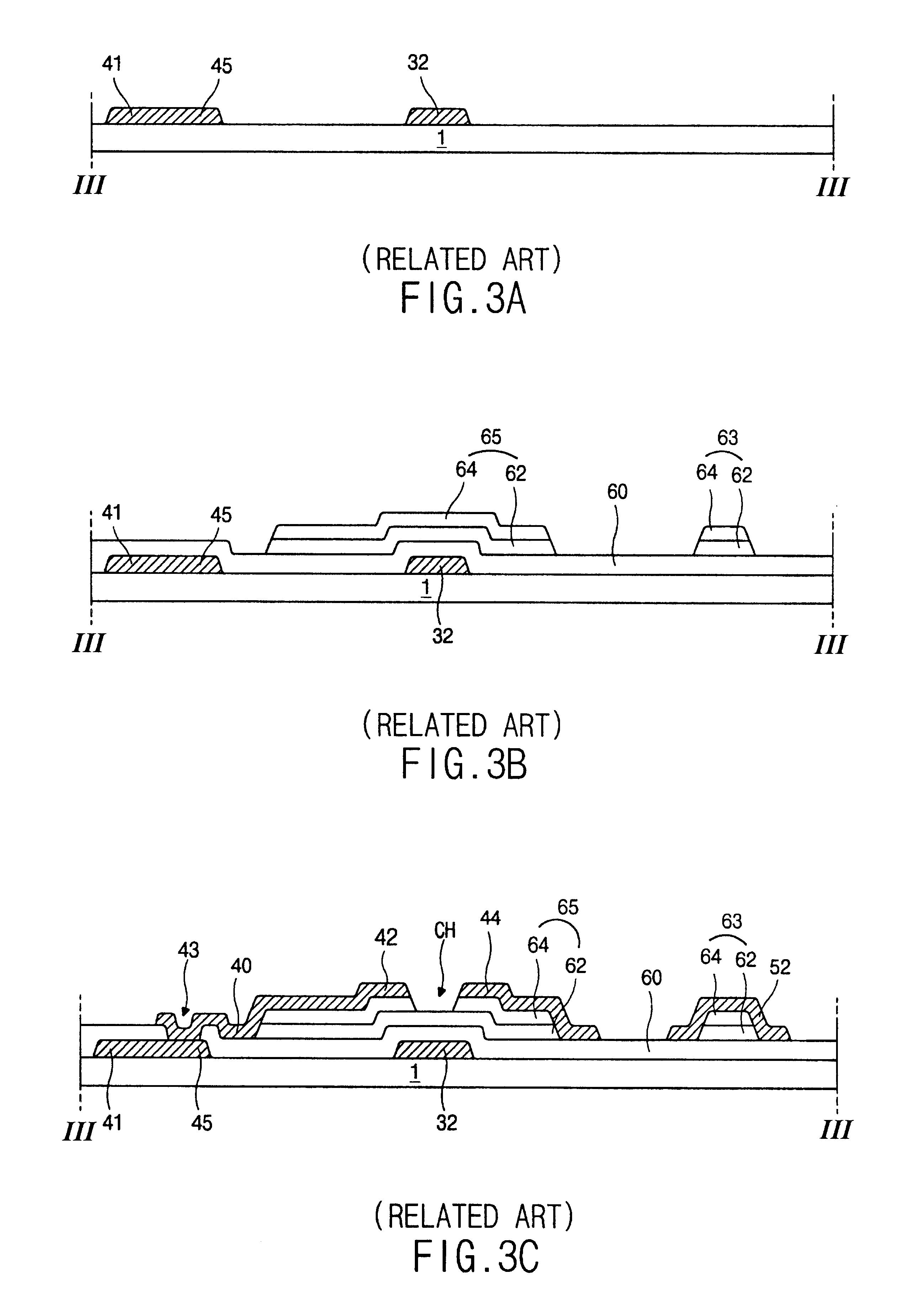

X-ray image sensor and method for fabricating the same

InactiveUS6423973B2The process steps are simpleIncrease productionTelevision system detailsSolid-state devicesInsulation layerAmorphous silicon

An X-ray image sensor fabricated using eight-mask steps. A thin film transistor (TFT) having a gate electrode, a first insulation layer, pure and doped amorphous silicon layers, and source and drain electrodes is on a substrate. An island-shaped first insulation layer, semiconductor layer, and ground line are also formed. A second insulation layer having a first drain contact hole and a ground line contact hole covers the TFT, the substrate, and the ground line. An auxiliary drain electrode on the second insulation layer contacts the drain electrode through the first drain contact hole. A capacitor electrode on the second insulation layer contacts the ground line through the ground line contact hole. A third insulation layer having a second drain contact hole that exposes the auxiliary drain is on the second insulation layer, the auxiliary drain electrode, and the capacitor electrode. A pixel electrode on the third insulation layer contacts the auxiliary drain electrode through the second drain contact hole.

Owner:LG DISPLAY CO LTD

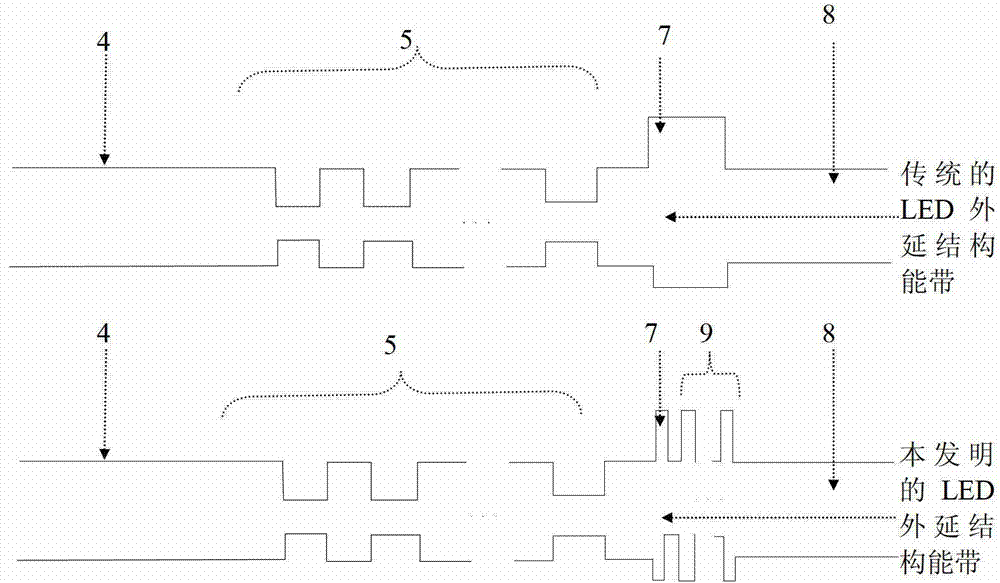

LED (Light Emitting Diode) epitaxial structure with P (Positive) type superlattice and preparation method thereof

ActiveCN103050592AStop SpillFacilitate horizontal expansionSemiconductor devicesPotential wellHigh density

The invention discloses an LED (Light Emitting Diode) epitaxial structure with a P (Positive) type superlattice and a preparation method thereof. The epitaxial structure comprises a substrate, wherein a GaN (Gallium Nitride) buffer layer, an undoped GaN layer, an n (negative) type GaN layer, a multi-quantum well luminous layer, a first P type GaN layer, a P type AlGaN (Aluminium Gallium Nitride) electronic blocking layer and a second P type GaN layer are sequentially arranged on the substrate from bottom to top, and the P type superlattice formed by a PInGaN (P type Indium Gallium Nitride) potential well layer and a PAlGaN potential barrier layer in a periodic interactive overlapping way is arranged between the P type AlGaN electronic blocking layer and the second P type GaN layer. The PInGaN potential well layer in the P type superlattice generates and constrains a great number of holes for the formation of a two-dimensional hole high-density state; the PAlGaN potential barrier layer hinders the escape of the holes; in such a way, the transverse spreading of the holes is improved, the electron overflow can be prevented, the hole injection efficiency is increased and the electron and hole recombination probability is improved; and therefore, the brightness of a chip can be improved by 5-10%.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

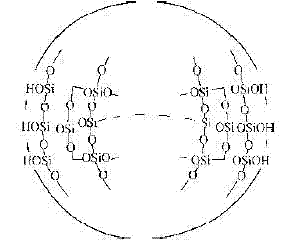

A kind of nano-silica sol modified exterior wall latex paint and preparation method thereof

The invention relates to a nanometer silica sol modified exterior wall emulsion paint. The emulsion paint comprises, by mass, 10-30% of water, 15-30% of an emulsion, 5-10% of a nanometer silica sol, 5-15% of heavy calcium, 1-3% of talc, 0.5-1.5% of propylene glycol, 5-25% of titanium dioxide, 0.05-2% of a wetting agent, 0.5-1% of an antifoaming agent, 0.1-0.5% of a dispersant, 1-2% of a thickening agent, and 0.5-2% of a film forming assistant. The preparation method comprises the following steps: dispersion grinding: adding water, powders and early assistants to a dispenser, grinding, and filtering; and post-treating: adding the emulsion, the nanometer silica sol, later water and later assistants to a dispersed slurry, and adjusting the PH value and the viscosity to prepare the emulsion paint. According to the invention, the exterior wall emulsion paint, which is prepared by completing simple technologies of dispersing, sand milling, filtering and the like, has the advantages of no pollution, low VOC (volatile organic compound) discharge, environmental protection, strong adhesion, and good storage stability, washing resistance, contamination resistance and weather resistance.

Owner:SHENYANG SHUNFENG NEW MATERIAL CO LTD

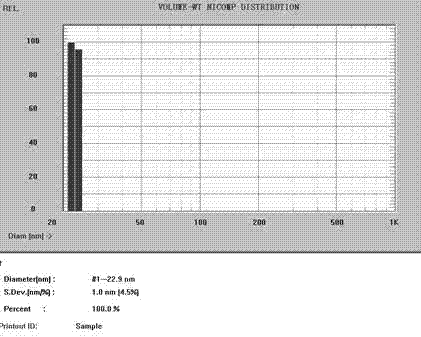

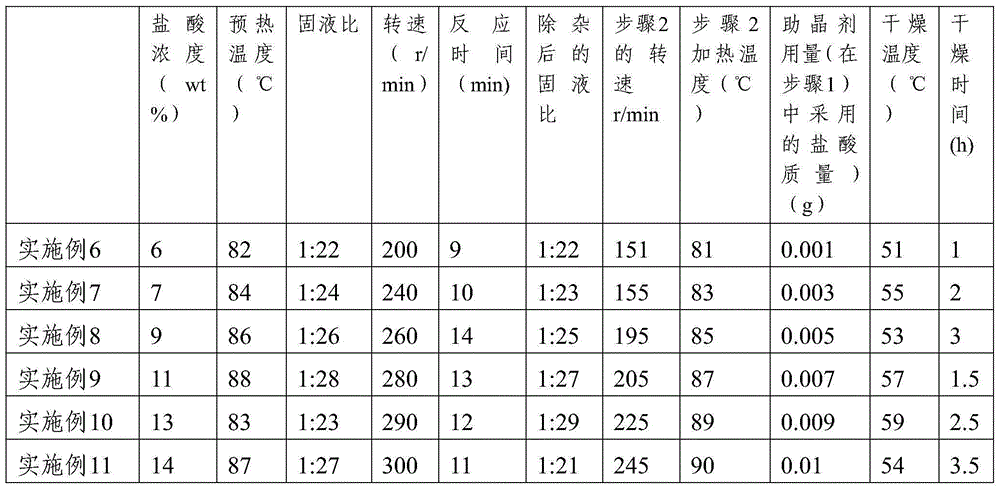

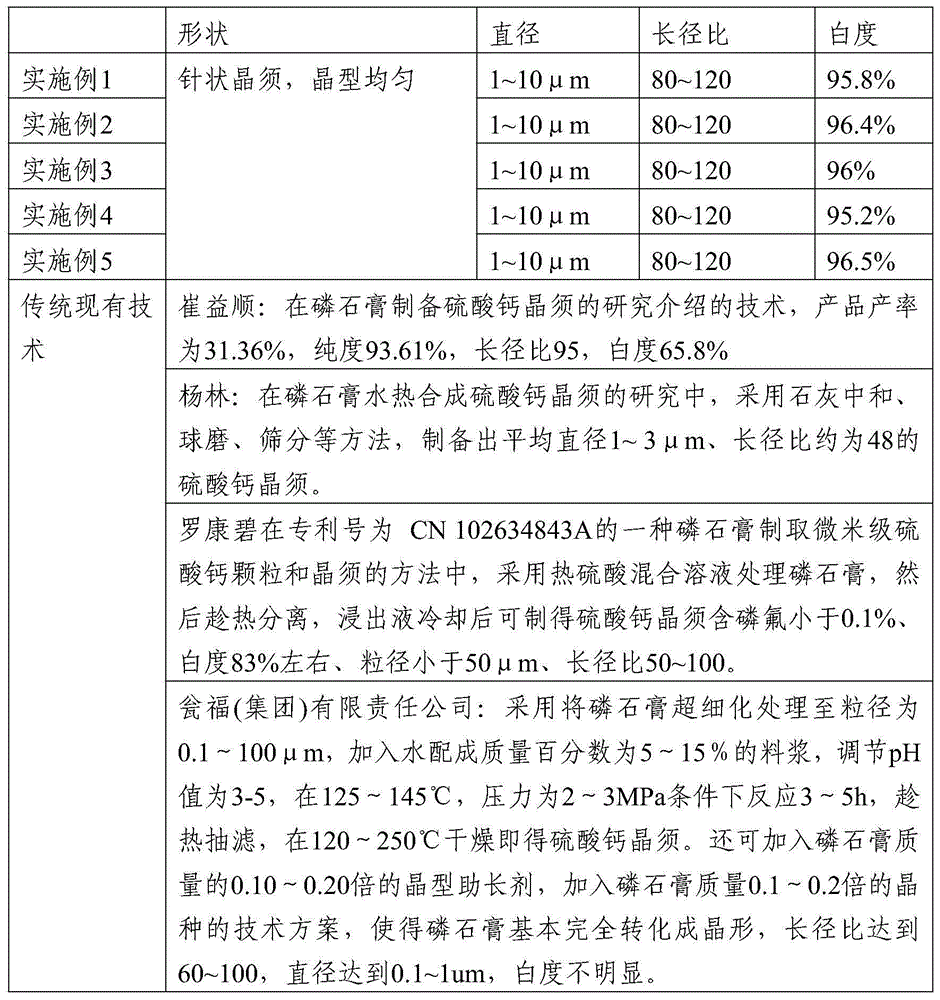

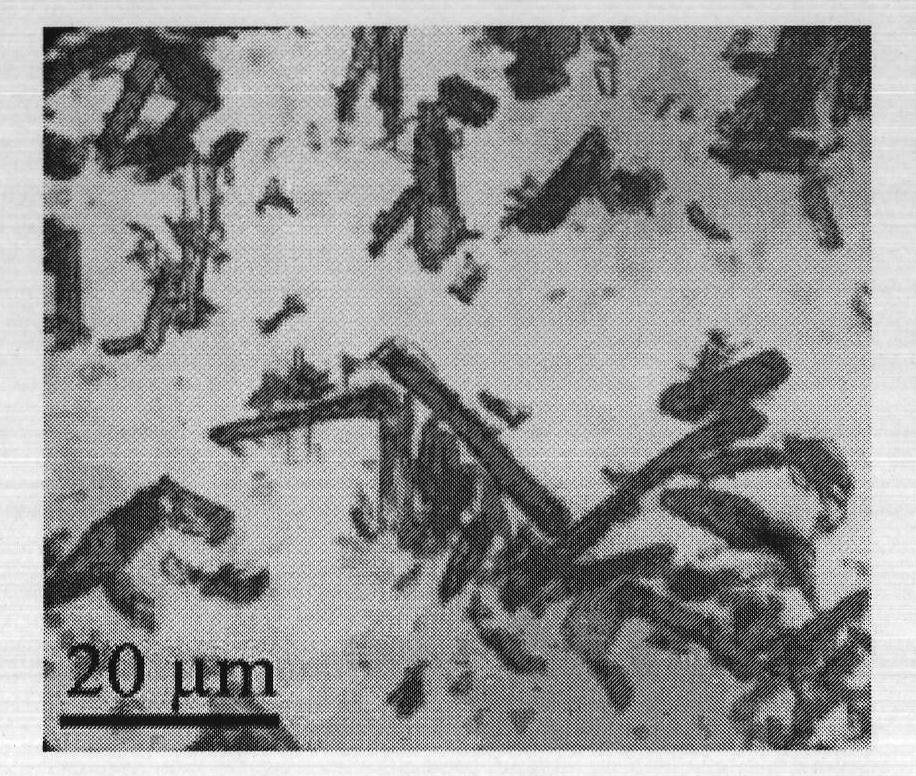

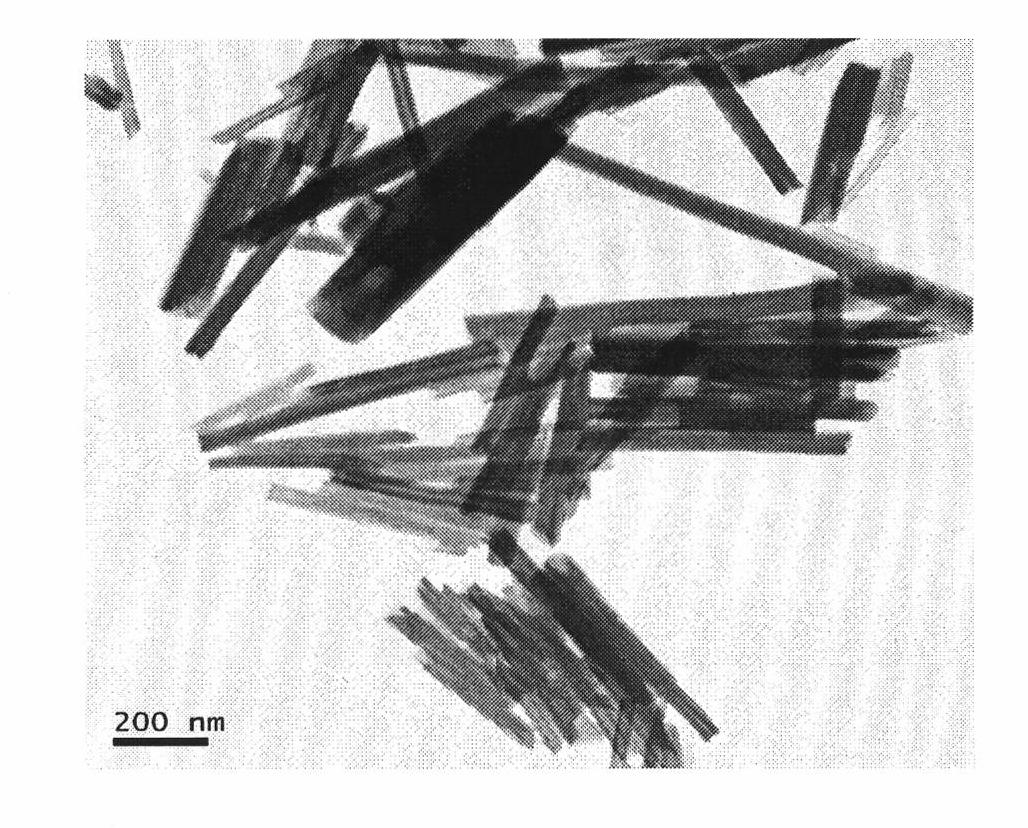

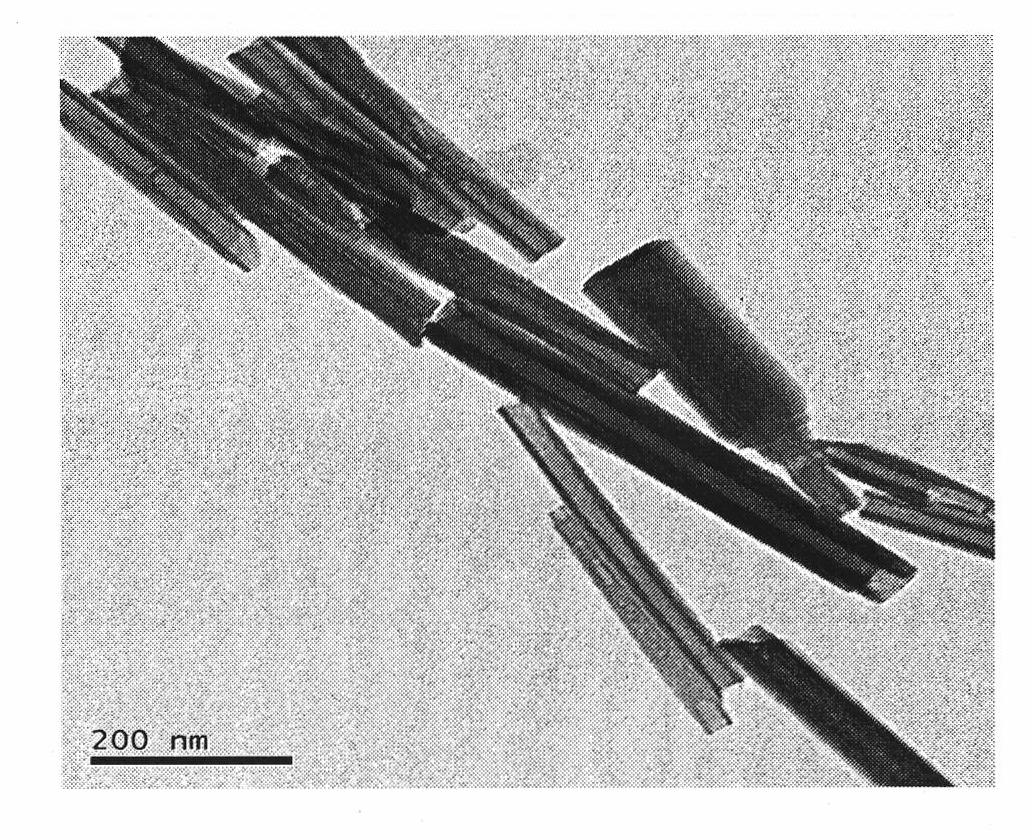

Method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum

InactiveCN104005086ANot to be wastedReduce generation influence ratePolycrystalline material growthFrom normal temperature solutionsProduction rateSulfate

The present invention relates to the technical field of chemical raw material preparation, and particularly to a method for preparing calcium sulfate dihydrate crystal whisker from phosphorus gypsum. The method comprises the following steps: preparing calcium sulfate dihydrate without impurities, preparing a crystal whisker, washing, and drying to obtain the calcium sulfate dihydrate crystal whisker. By preheating hydrochloric acid and matching the hydrochloric acid with phosphorus gypsum at a certain ratio at a constant temperature, the reaction can proceed and the materials is not wasted, the impurities contained in the phosphorus gypsum can be properly removed maximatily, the impact rate of impurities on the generation of calcium sulfate dihydrate crystal whisker is decreased, the content of calcium sulfate component is increased, the production rate of calcium sulfate dihydrate crystal whisker is improved and the production costs of calcium sulfate dihydrate crystal whisker prepared by comprehensively utilizing phosphorus gypsum are reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

Preparation method for nanocrystals cellulose/white carbon black/rubber composite material

The invention discloses a preparation method for a nanocrystals cellulose / white carbon black / rubber composite material. The nanocrystals cellulose (Nanocrystals Cellulose, called NCC for short) is a rod-shaped crystallized product which is obtained by performing acidolysis on microcrystalline cellulose, has the diameter of between 20 and 60 nm and the average length of 300 nm, can serve as a novel reinforcing material for rubber, and has the characteristics of reproducibility, low density, orientation, high strength and the like; moreover, the preparation method is simple and convenient; the cost is low; and the NCC is easy to obtain. Researches discover that a reinforcing effect of the NCC to natural rubber is superior to that of white carbon black; the thermal-oxidative ageing property of the natural rubber is improved very well; simultaneously the heat generation of the composite material is reduced; and the nanocrystals cellulose / white carbon black / a rubber composite material can be prepared by adopting a conventional rubber processing process. The nanocrystals cellulose / white carbon black / a rubber composite material prepared by the invention can be used for manufacturing various vulcanized rubber products.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com