Dye-sensitized solar cell module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

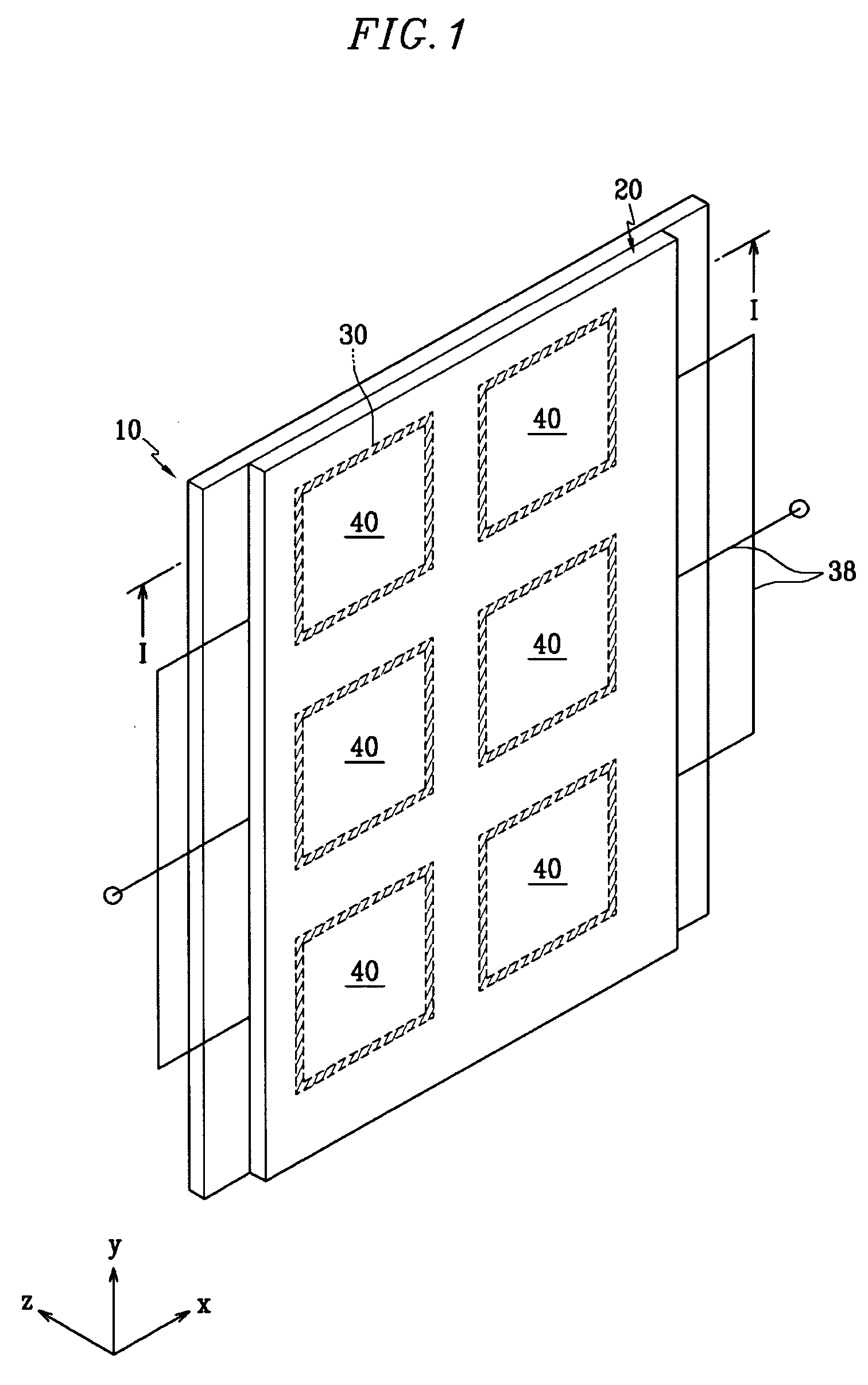

[0073]FIG. 4 is a partially exploded perspective view of the dye-sensitized solar cell module according to the present invention. A plurality of unit cells 40 are series-coupled to one another, as indicated by a dotted arrow 45, using insulation regions 42, 44 formed on the first or the second substrate 10, 20. That is, the insulation regions 42, 44 are formed on only one of the first or the second substrates 10, 20 between the unit cells 40 that are to be series-coupled, and the unit cells 40 are series-coupled to one another through the other substrate. In this embodiment, as parallel connection is not required, separate connectors are not required, and it is only necessary to receive the voltage at the two ends 47, 49 of the series-coupled unit cells 40.

third embodiment

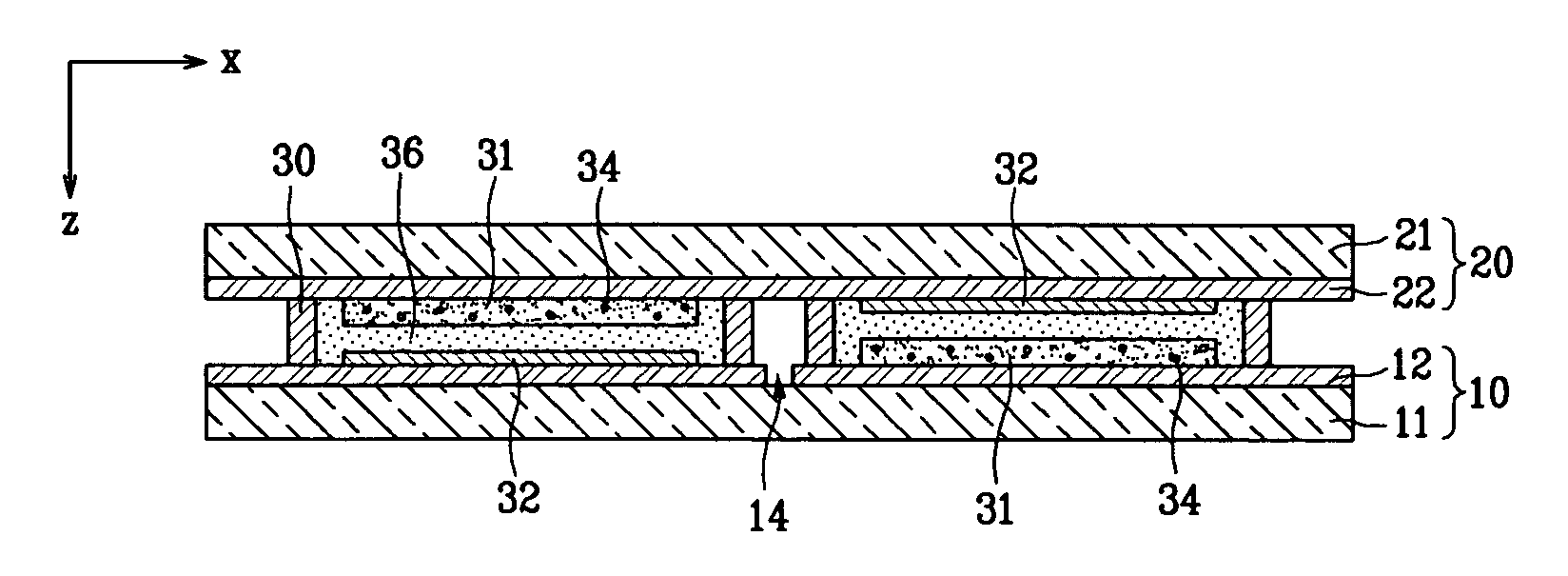

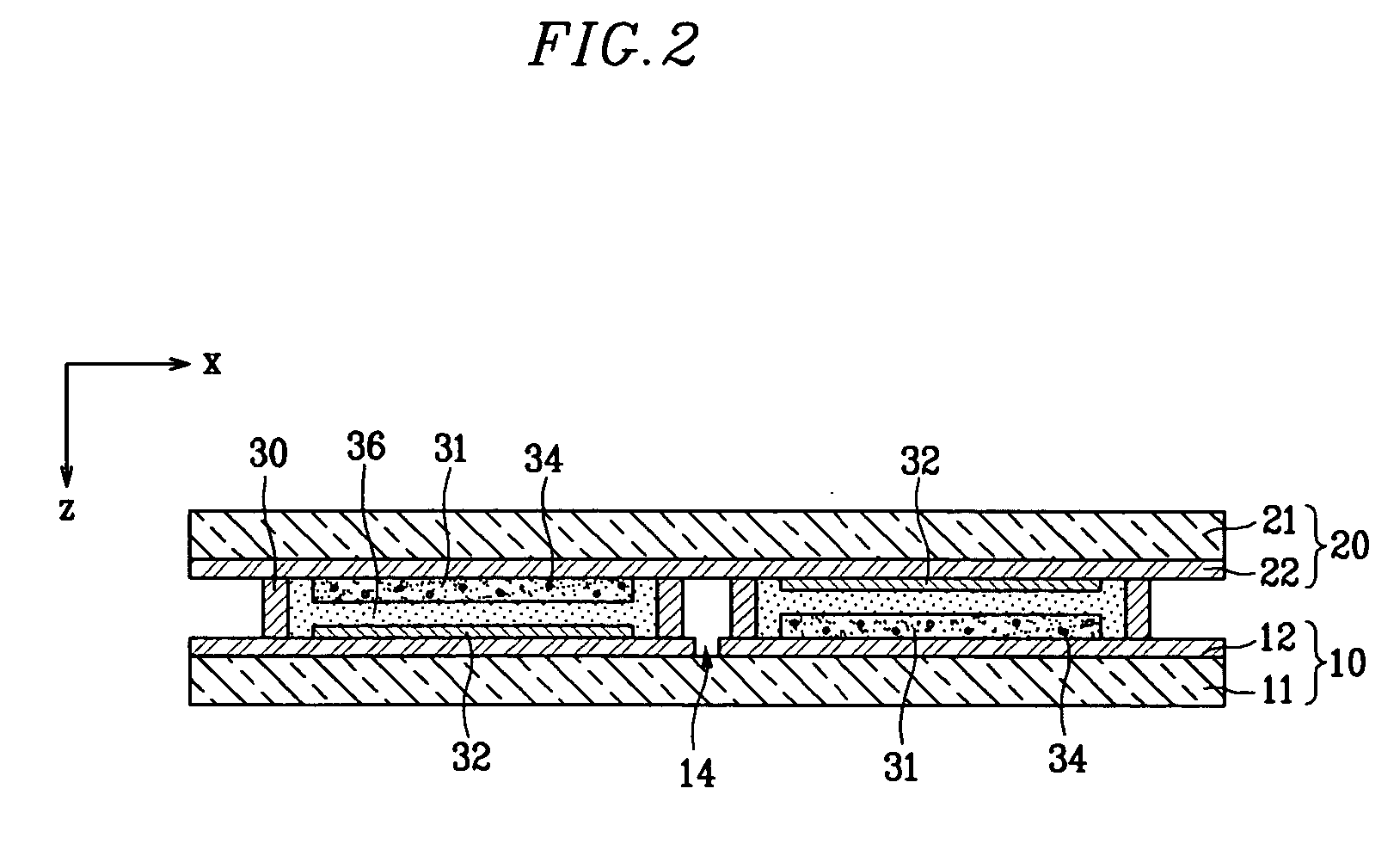

[0074]FIG. 5 is a partial cross-sectional view of the dye-sensitized solar cell module according to the present invention.

[0075] In this embodiment, a separate reflective plate 46 is externally mounted to the first or the second substrate 10, 20. In one exemplary embodiment, the reflection plate 46 is placed opposite the entrance side of sunlight.

[0076] The reflective plate 46 may be formed with a metallic material, an oxide, a nitride, a carbonaceous compound or a polymer film, and the reflectivity thereof may be established to be in the range of 5-100%.

[0077] As shown in FIG. 5, in case the reflective plate 46 is installed external to the first substrate 10, the sunlight, incident upon the second substrate 20 and passing through the first substrate 10, is reflected by the reflective plate 46, and reenters the second substrate 20. Accordingly, as compared to the case where the reflective plate 46 is absent, a larger amount of sunlight can be absorbed, thereby enhancing the energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com