Patents

Literature

166results about "Poultry deboning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

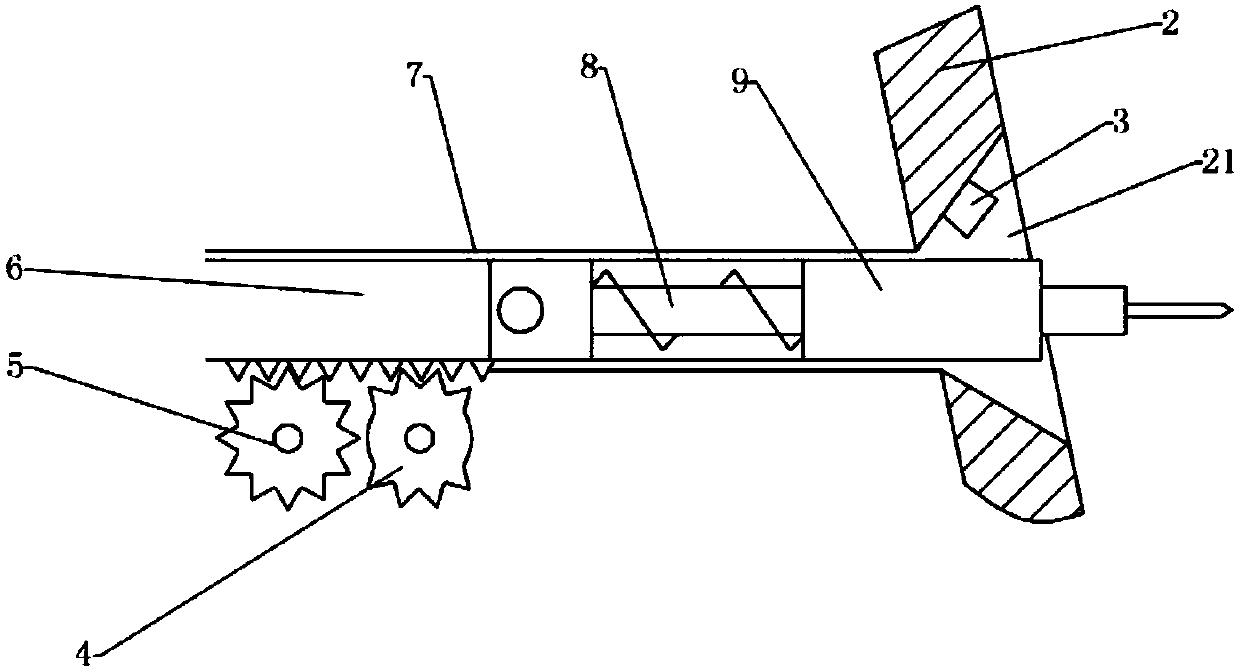

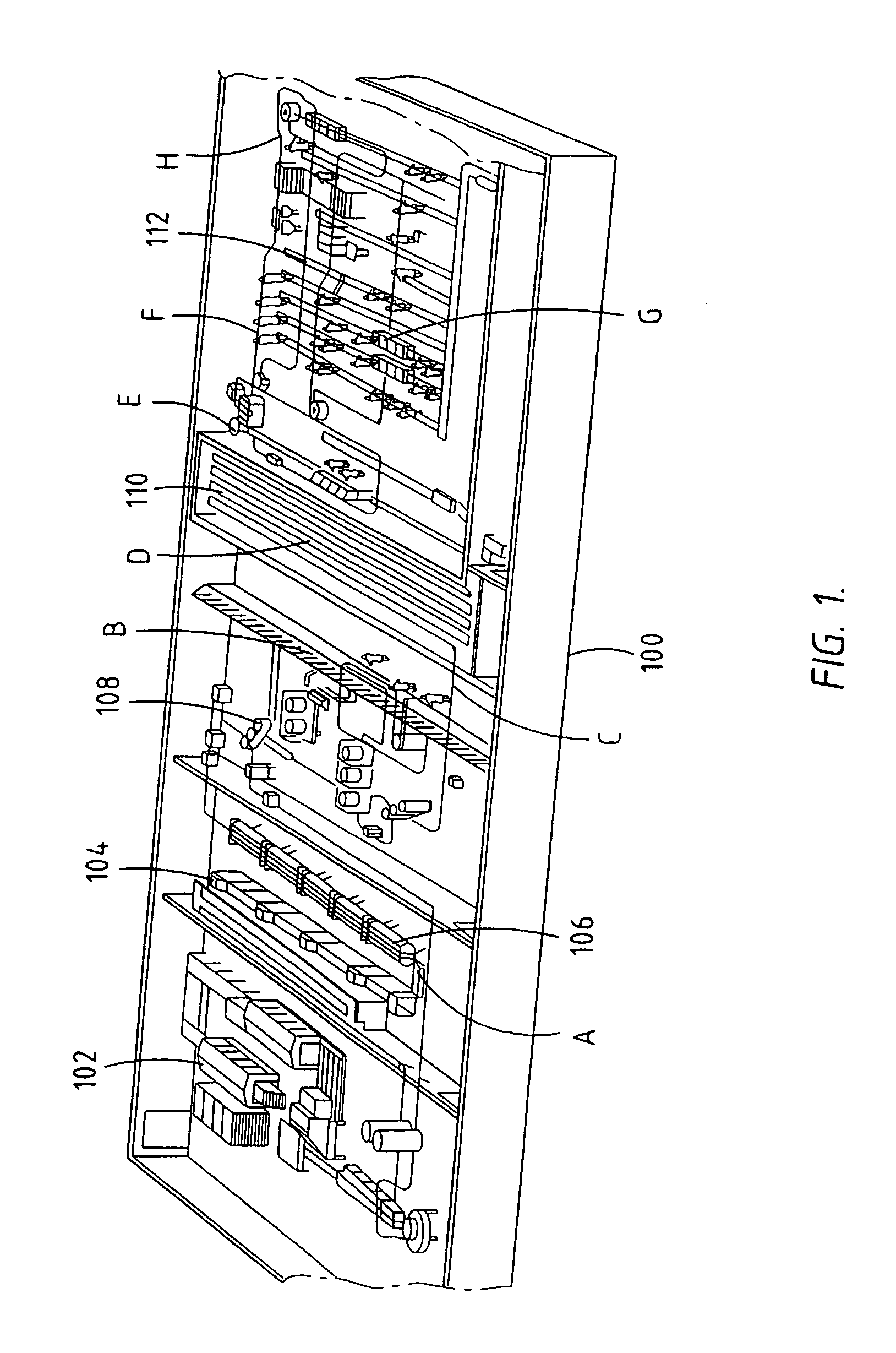

Method for separating meat and bone of fowl and device used by the method

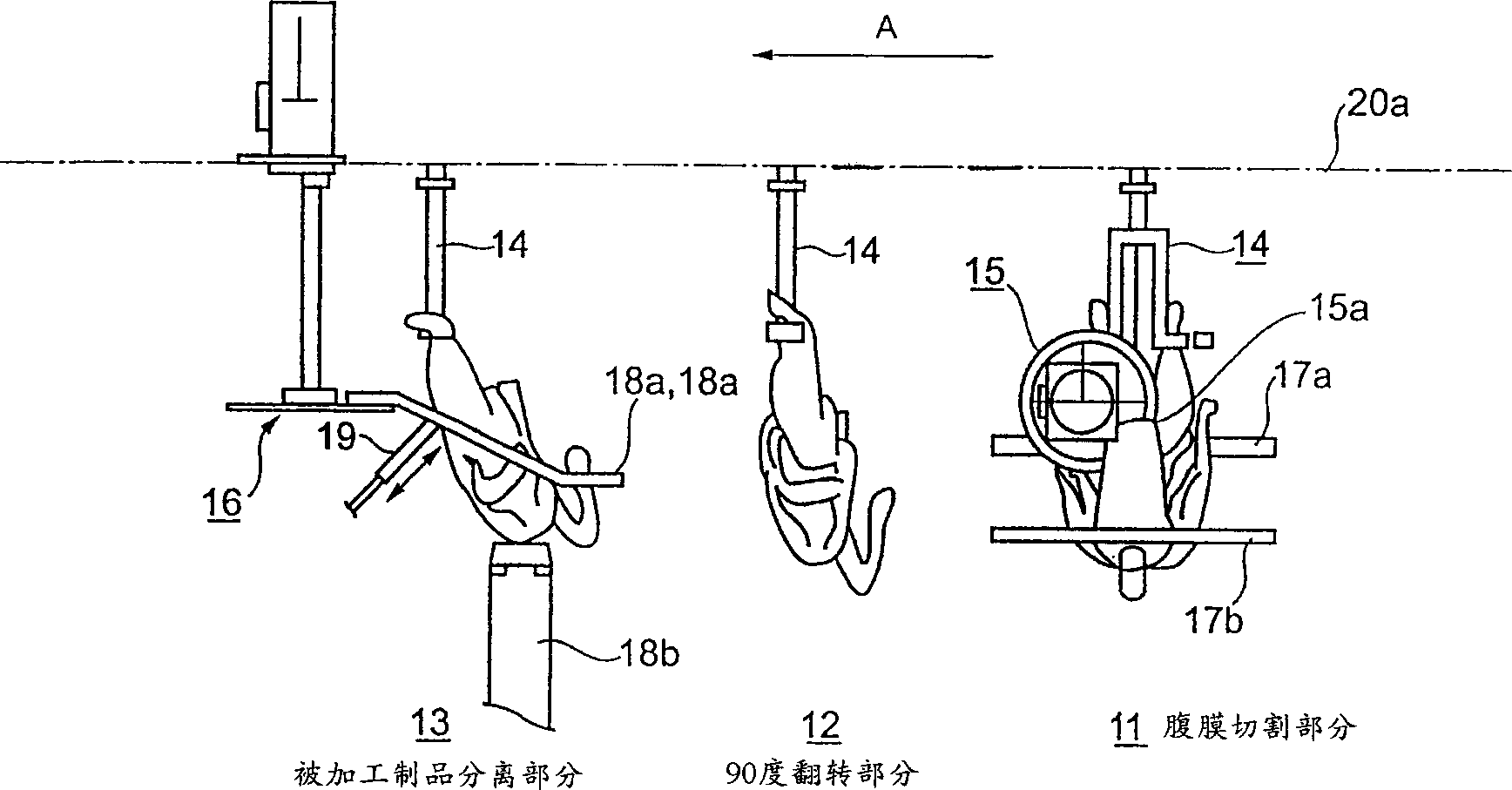

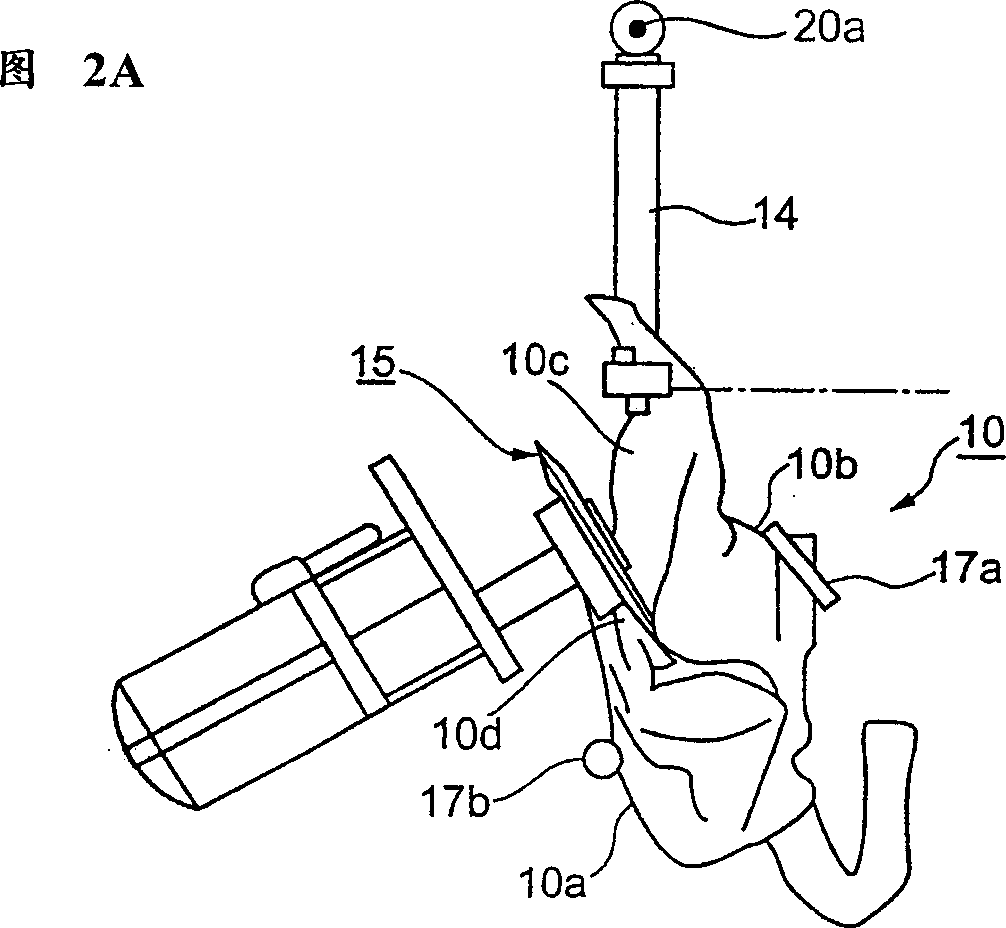

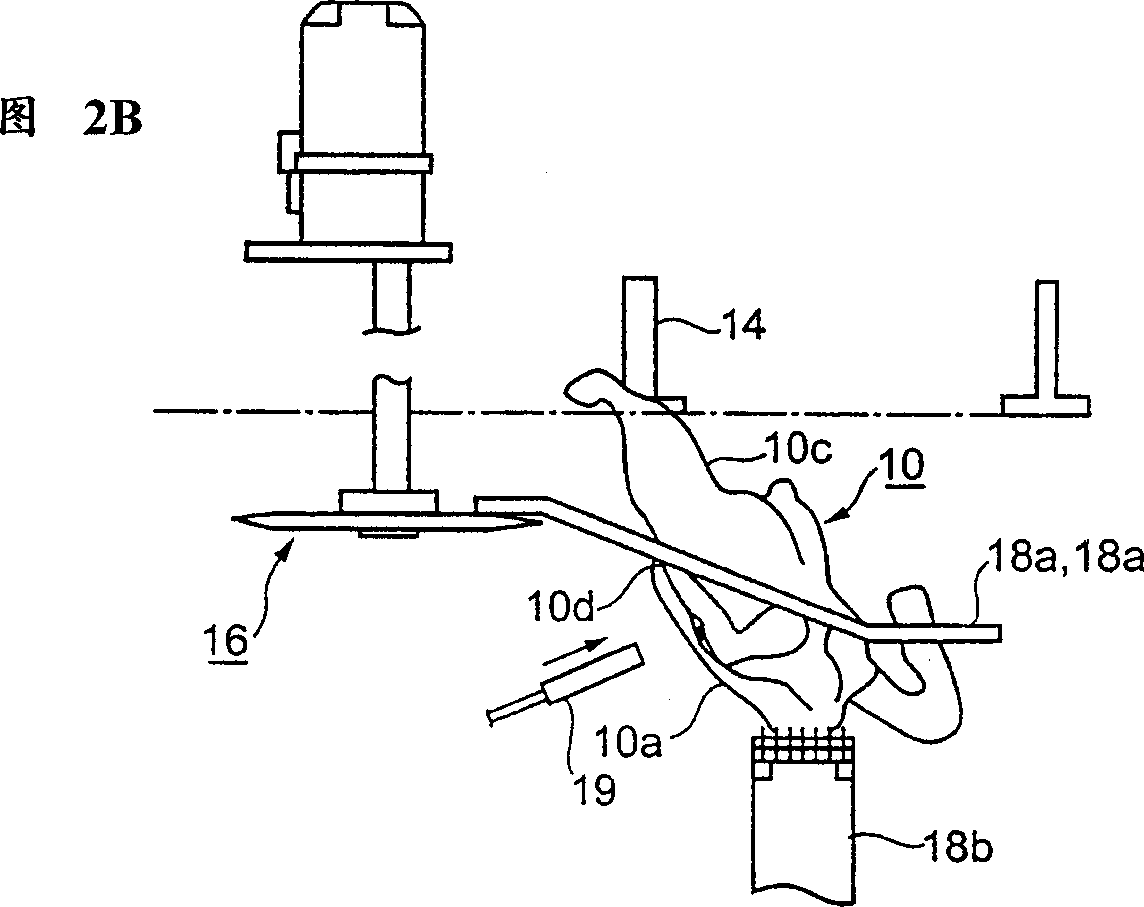

The present invention provides a first processing step and a second processing step in the case where the hollow carcass of the poultry is broken down into a lower carcass including the thighs and the back part, and an upper carcass including the remaining part of the rib-containing breast and back parts. , in the first processing step, when the hollow body is transported in a suspended state, the hollow body is cut from the thigh root through the tail end of the intestinal bone without cutting the spine; in the second processing step, the femoral part is cut The tendon and connective tissue are cut, that is, the thigh is peeled off. The present invention performs the above processing steps with high productivity. The first processing step includes a conveying line, a peritoneal cutting part, a 90-degree turning part and a processed product separation part. The second processing step consists of a conveyor with teeth, which conveys the lower body half hooked at the femur through an underside running belt; a parallel moving conveyor arranged under the conveyor with teeth for peeling off the thighs of the lower body half; A parallel guide plate is arranged under the lower running belt.

Owner:MAYEKAWA MFG CO LTD

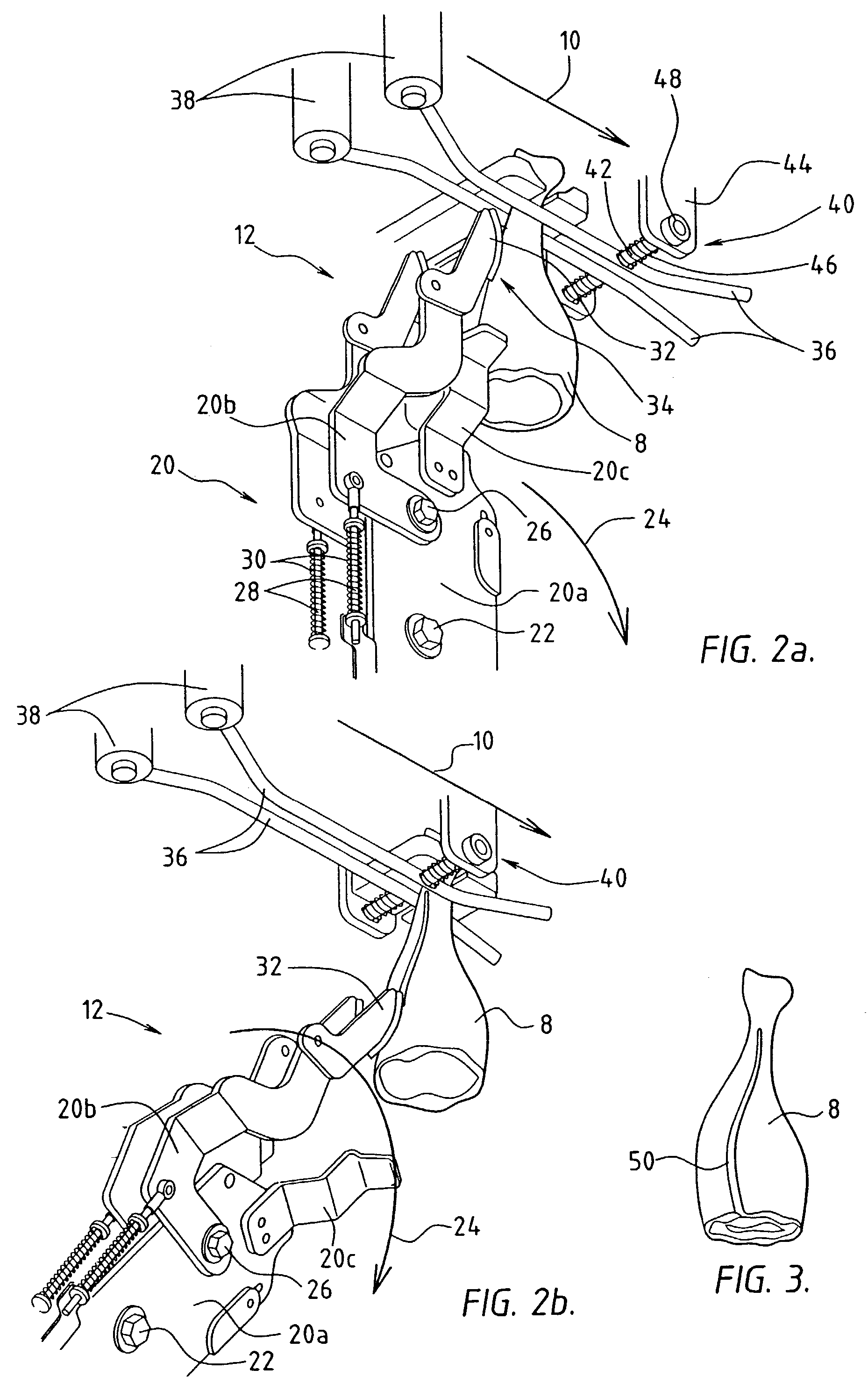

Method and device for processing a poultry leg

InactiveUS7059954B2Drawback can be obviatedEliminate needMeat holding apparatusPoultry skinningEngineeringTarsal Joint

In a method and device for processing a poultry leg which is hanging from a carrier and comprises at least a drumstick, the operations are carried out: cutting into the drumstick substantially around the drumstick in the vicinity of the tarsal joint by means of at least one incision; and at least partially separating a part of the leg which comprises the at least one incision. The carrier is moved onwards during the cutting.

Owner:STORK PMT

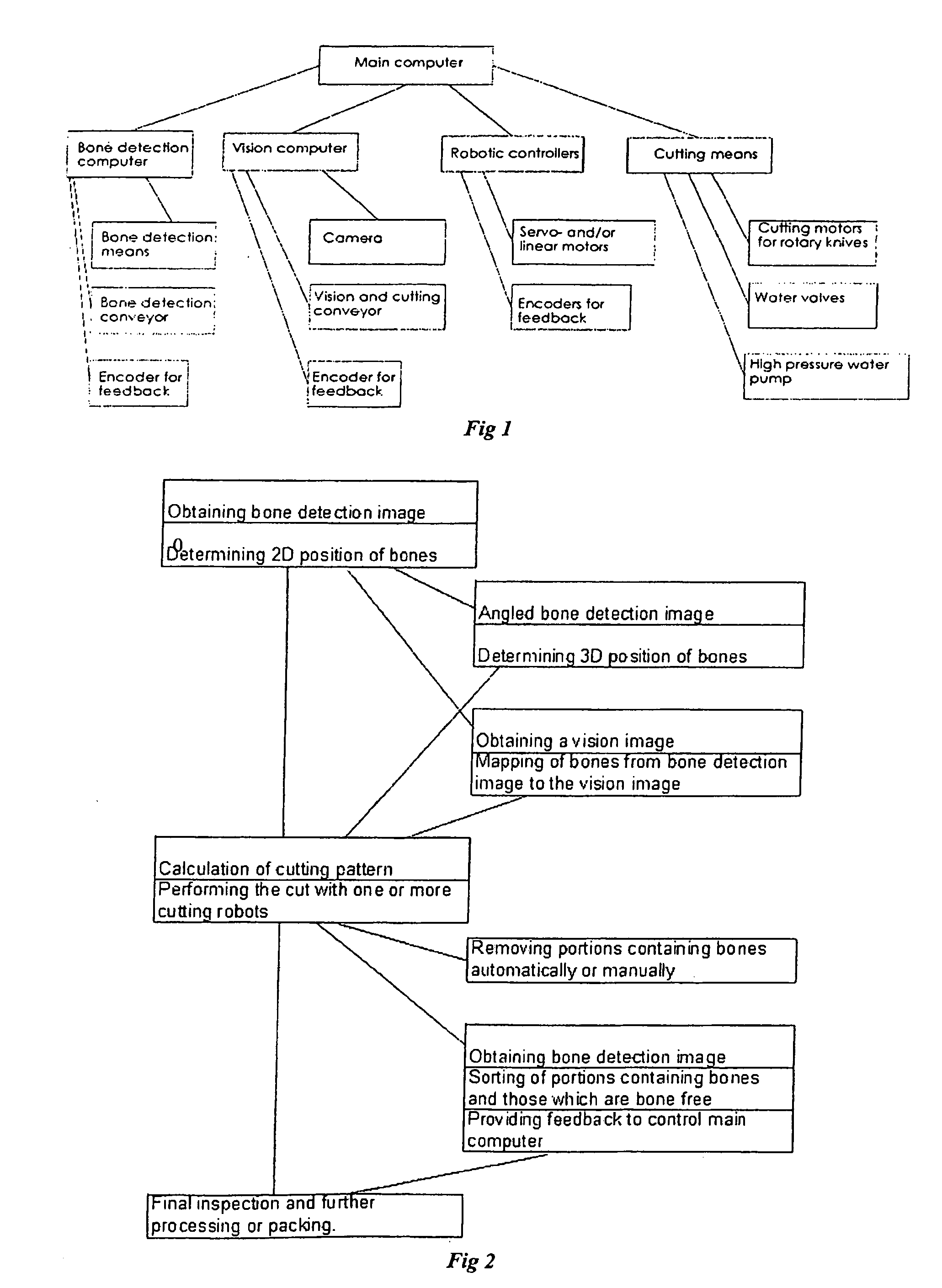

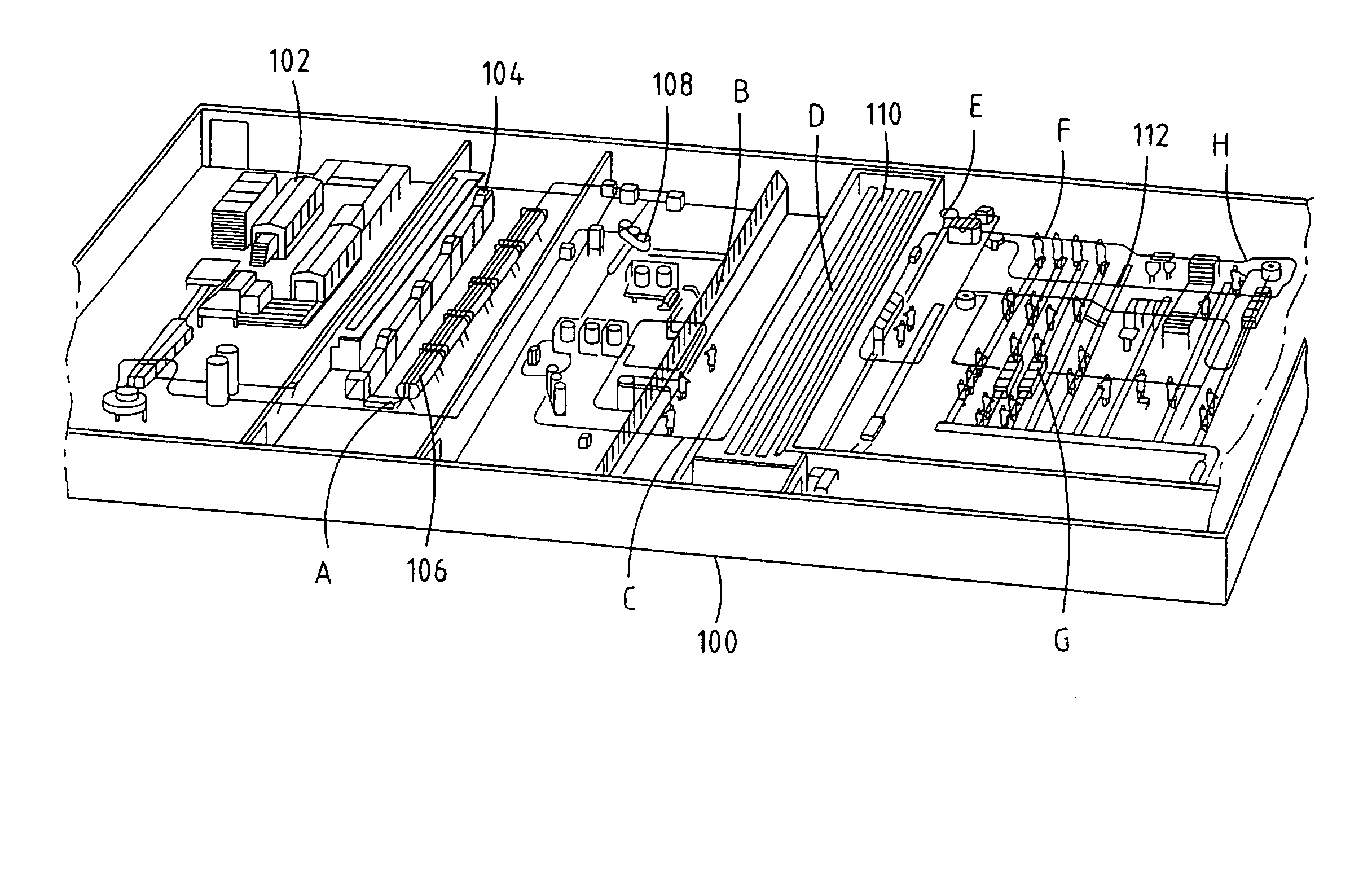

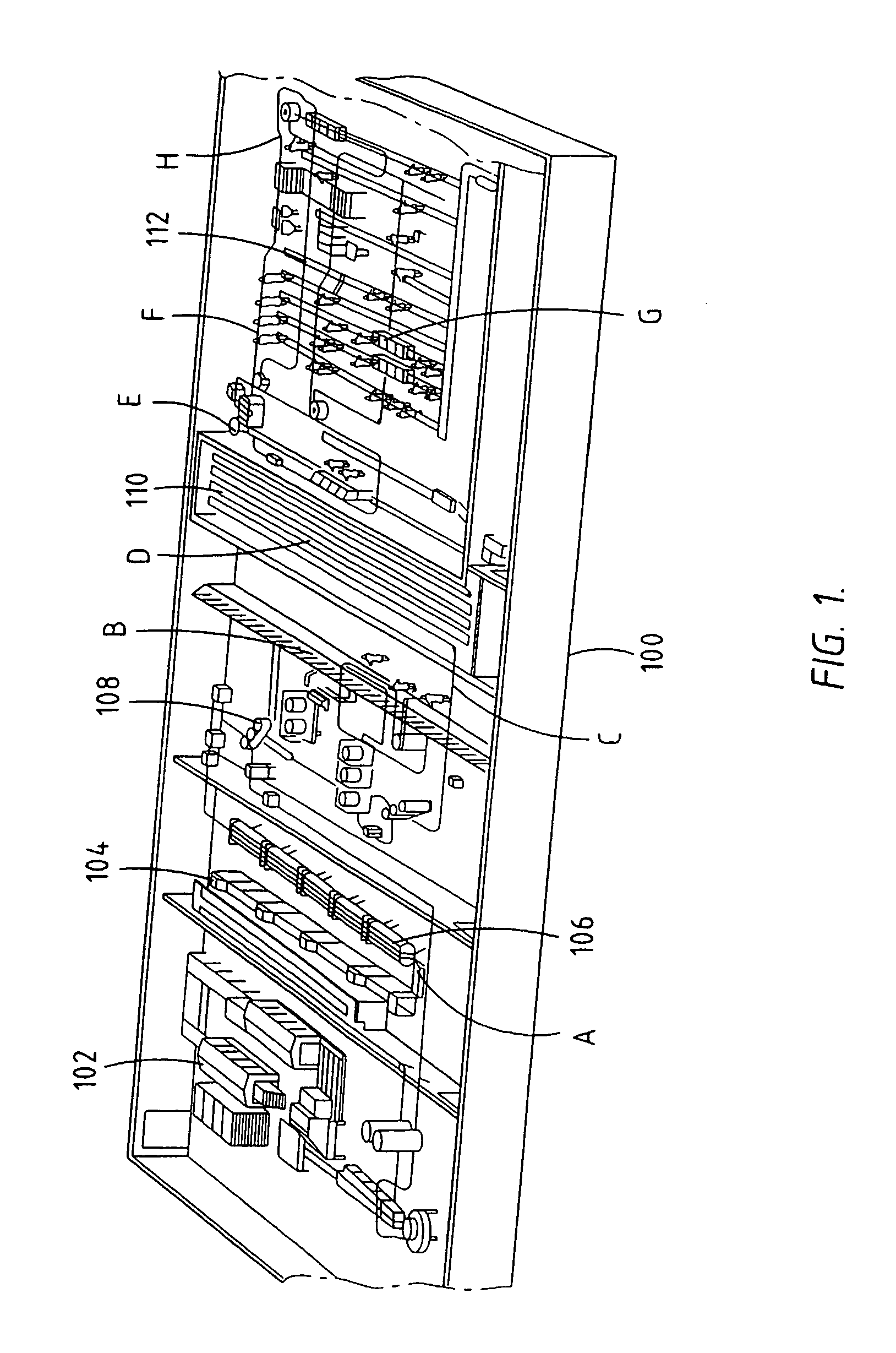

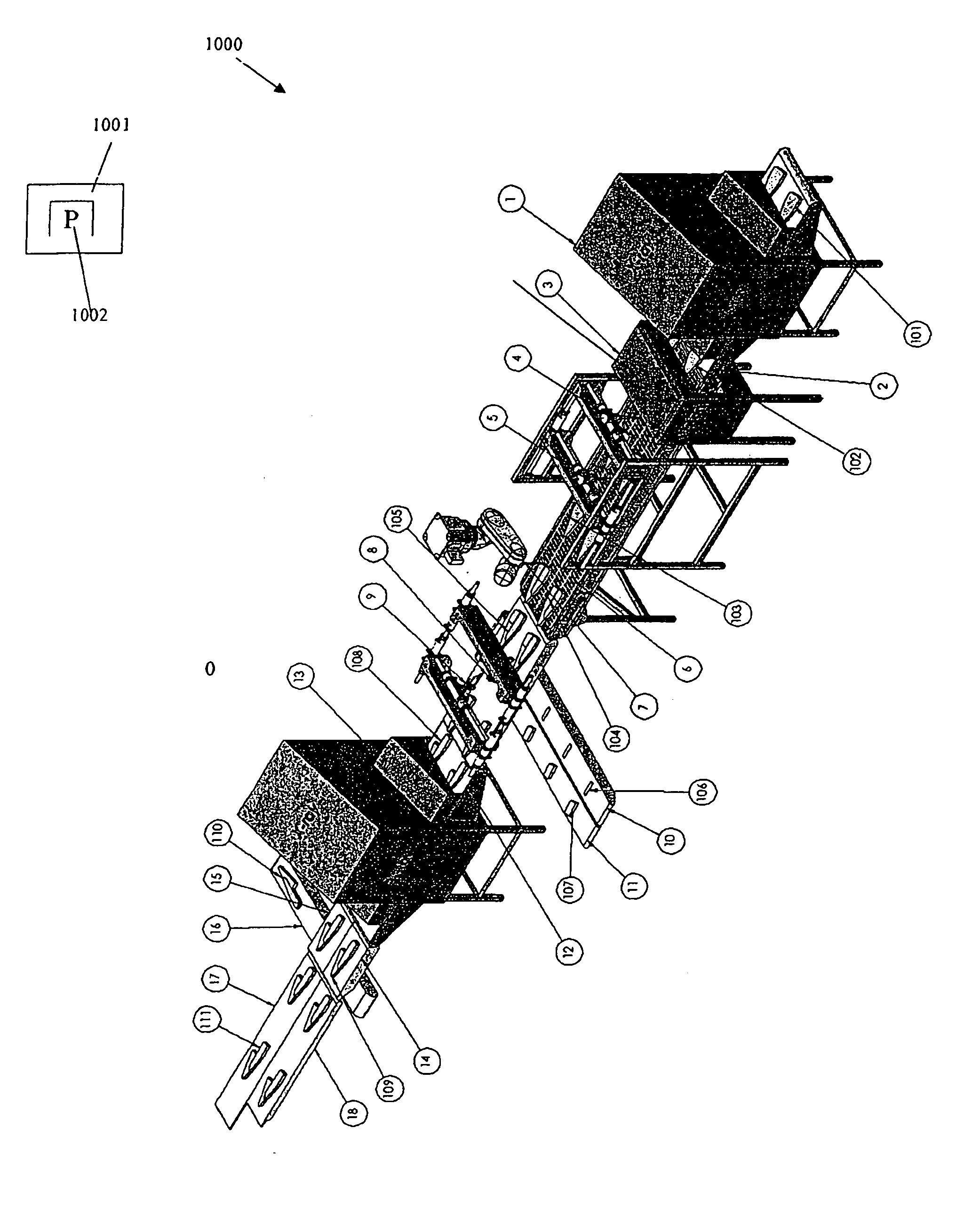

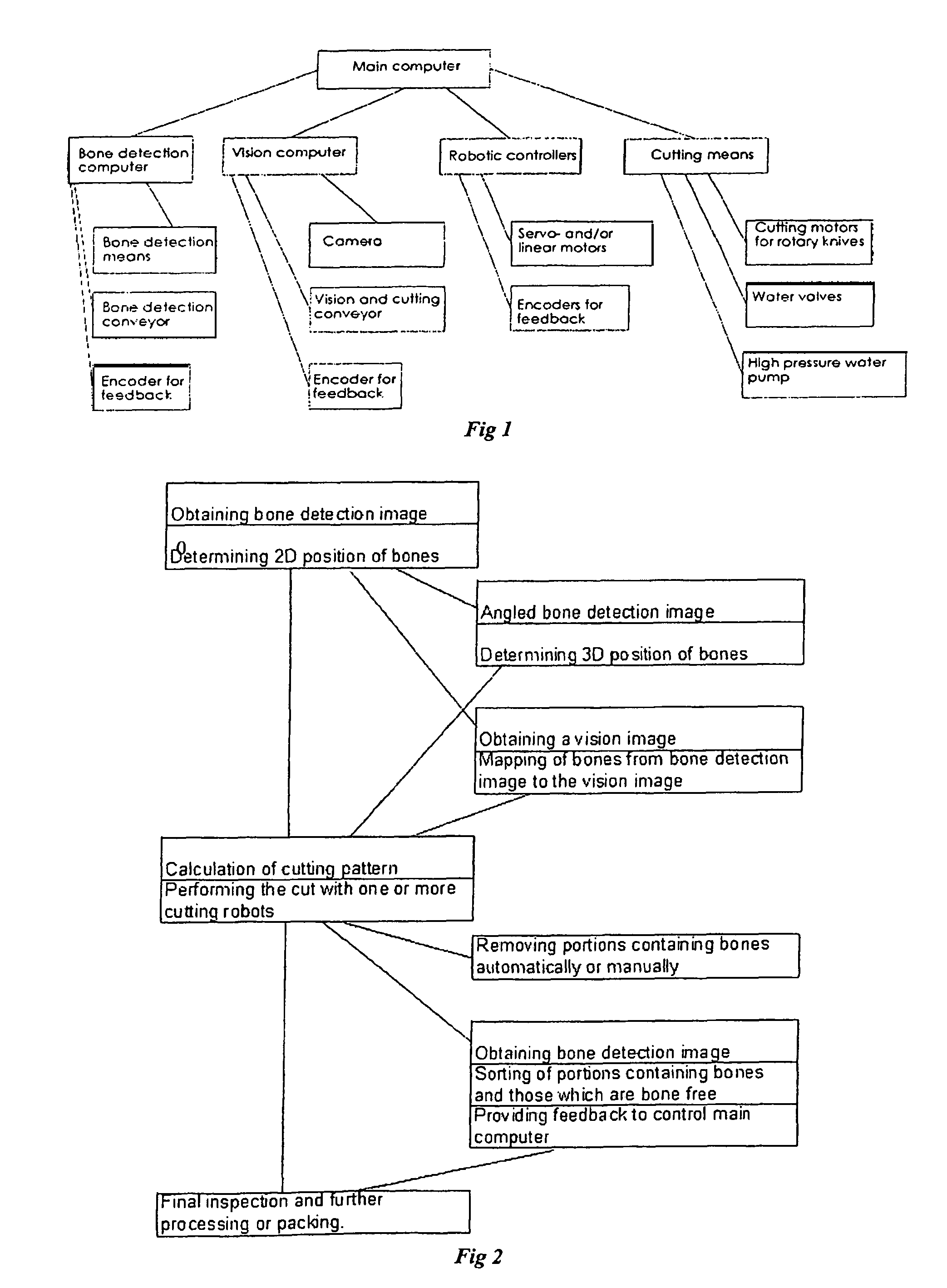

Food processing apparatus for detecting and cutting tough tissues from food items

ActiveUS20120307013A1Increase cutting outputMitigate, alleviate or eliminate onePoultry deboningCharacter and pattern recognitionX-rayX ray image

A food processing apparatus for detecting and cutting tough tissues from food items such as fish, meat, or poultry. At least one x-ray machine associated to a first conveyor for imaging incoming food items on the first conveyor based on a generated x-ray image indicating the location of the tough tissues in the food items. A vision system supplies second image data of the food items subsequent to the imaging by the x-ray machine. The second image data including position related data indicating the position of the food items on the second conveyor prior to the cutting. A mapping mechanism determines an estimated coordinate position of the food items on the second conveyor by utilizing the x-ray image and tracking position data. The processor compares the estimated coordinate position of the food items to the actual position on the second conveyor based on the second image data.

Owner:VALKA EHF

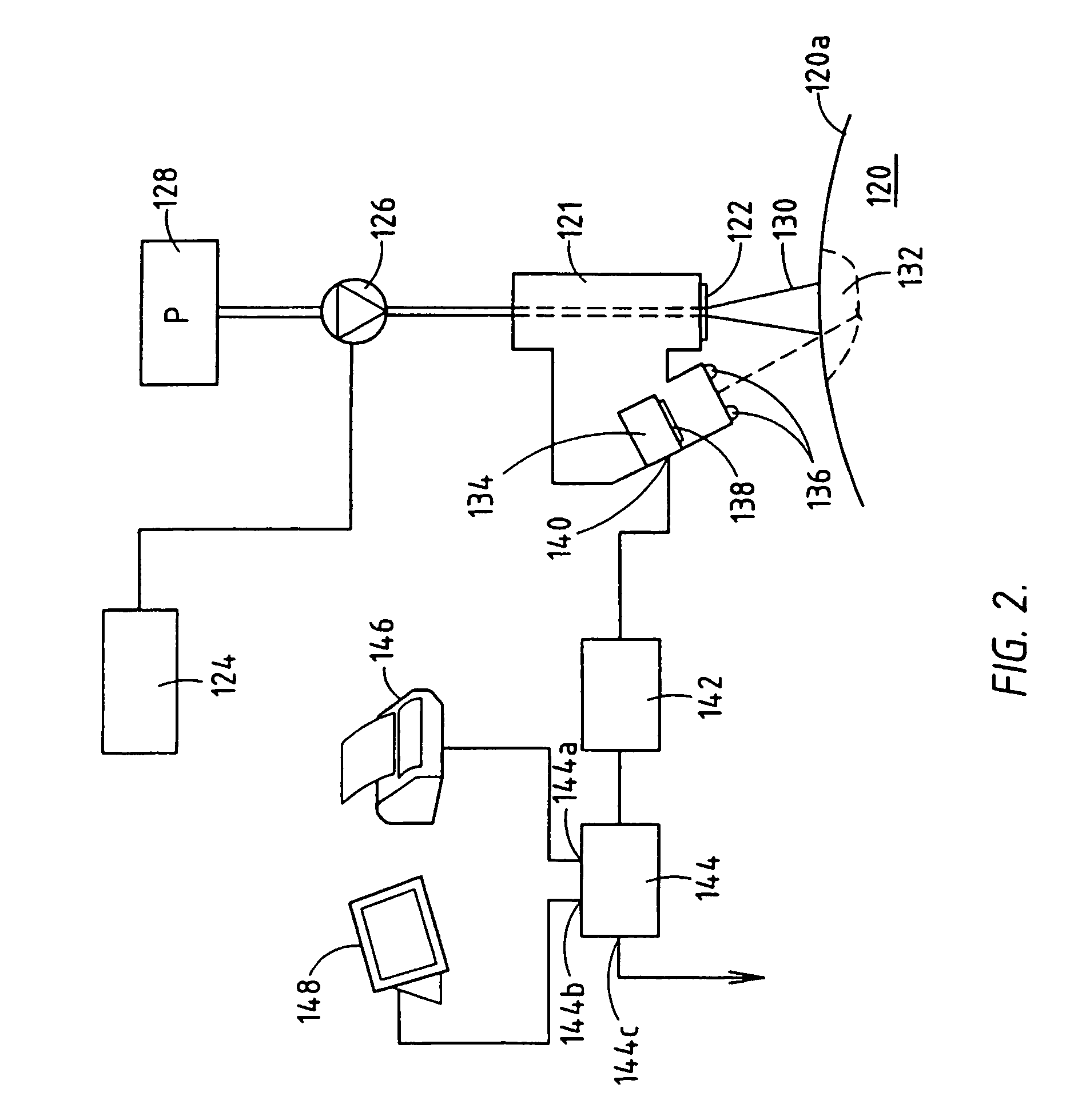

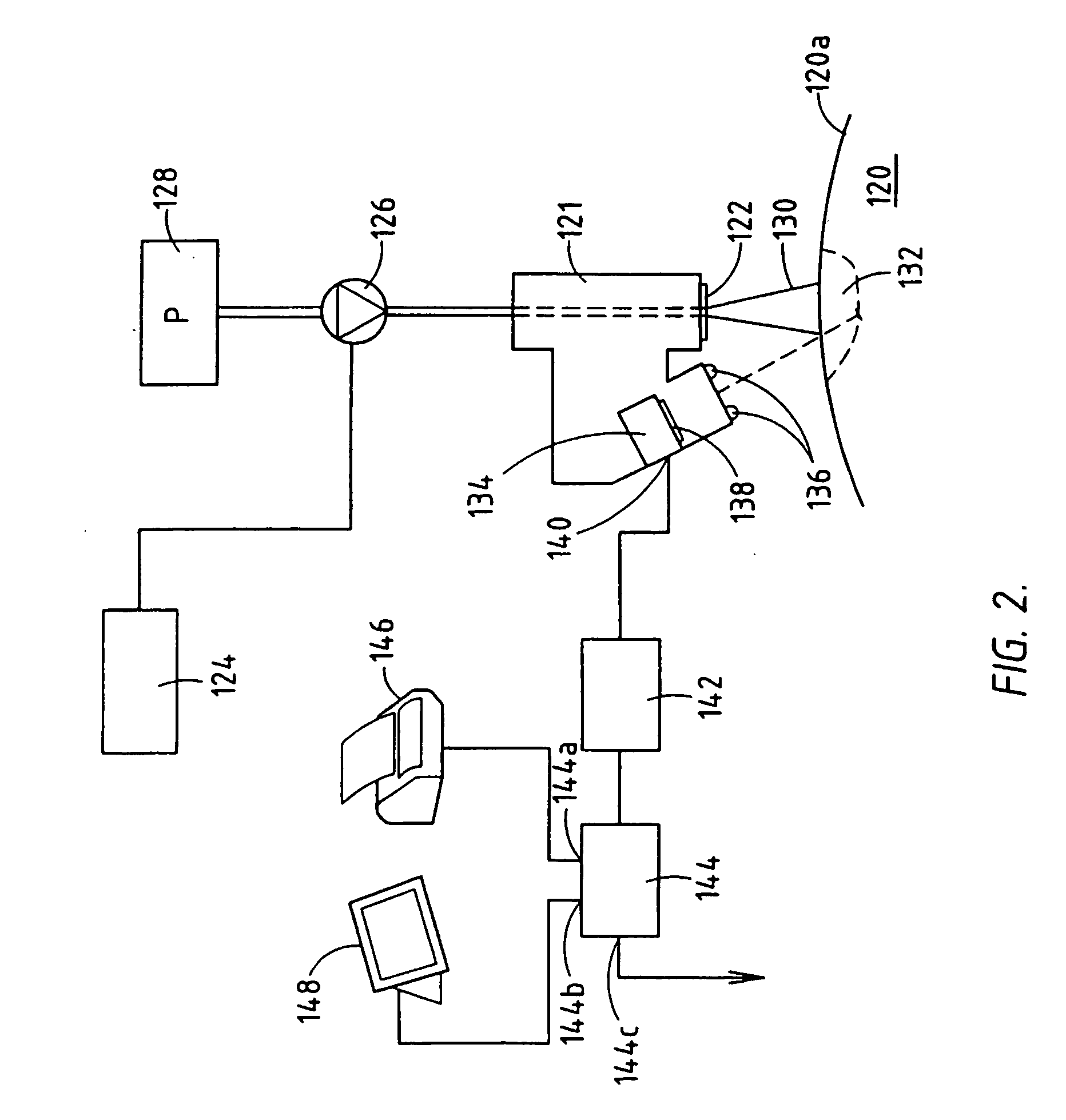

Method for processing poultry

InactiveUS7249998B2Electric current slaughtering/stunningPoultry deboningEngineeringMachining process

A method is described for processing poultry, comprising the steps of supplying live poultry, stunning the live poultry in a stunning device, placing the stunned poultry into product carriers advanced along a conveyor, killing the poultry and removing the feathers from the dead poultry in a plucking device. Downstream of the plucking device, the poultry is exposed to an electrical stimulation, an electrical voltage (V1) being applied across the carcass of the poultry. A method is further described for controlling process parameters, especially the time and duration of execution of working steps in a process of mechanized working of slaughtered poultry, the tenderness of a specified meat portion being evaluated prior to a due processing step and, after this evaluation, the important process parameters for the particular processing step being set to an optimal value.

Owner:STORK PMT

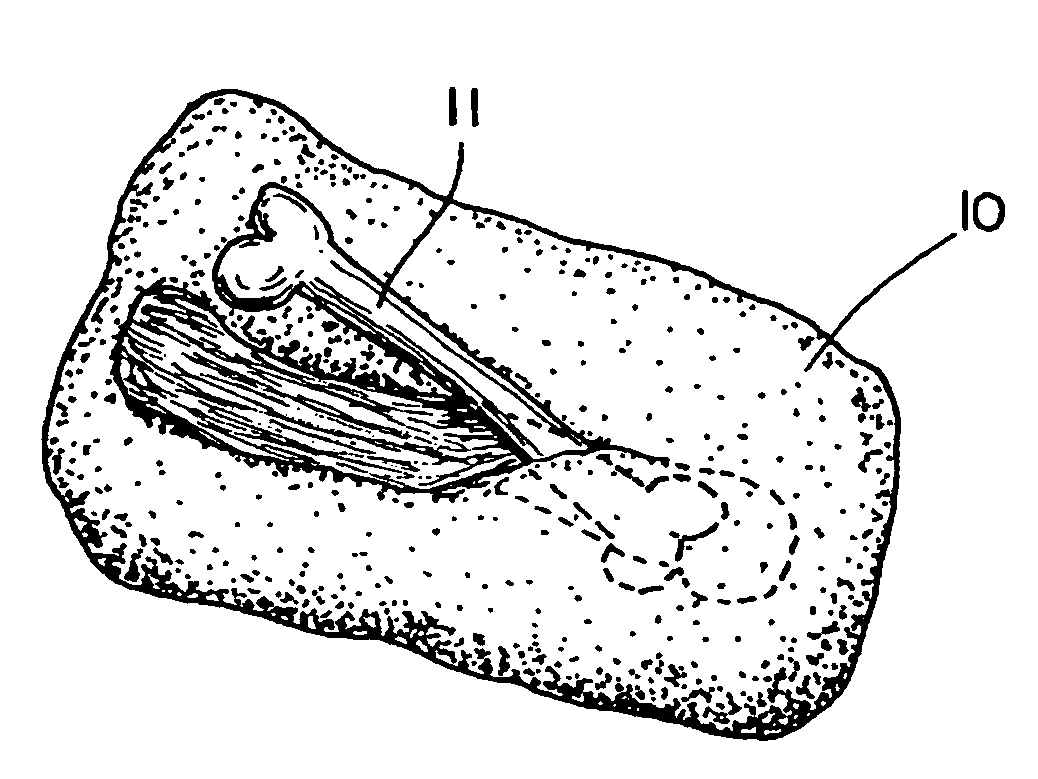

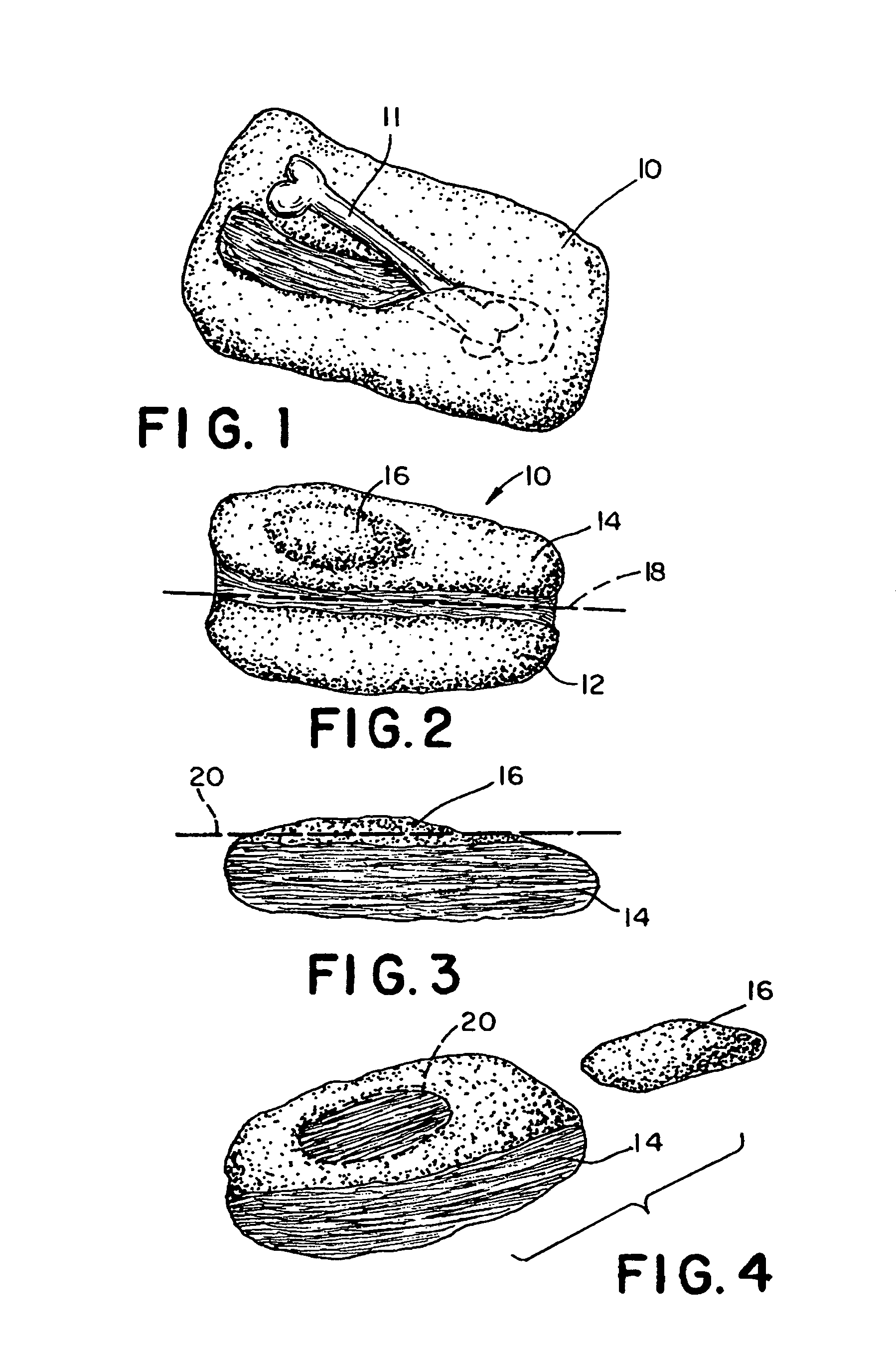

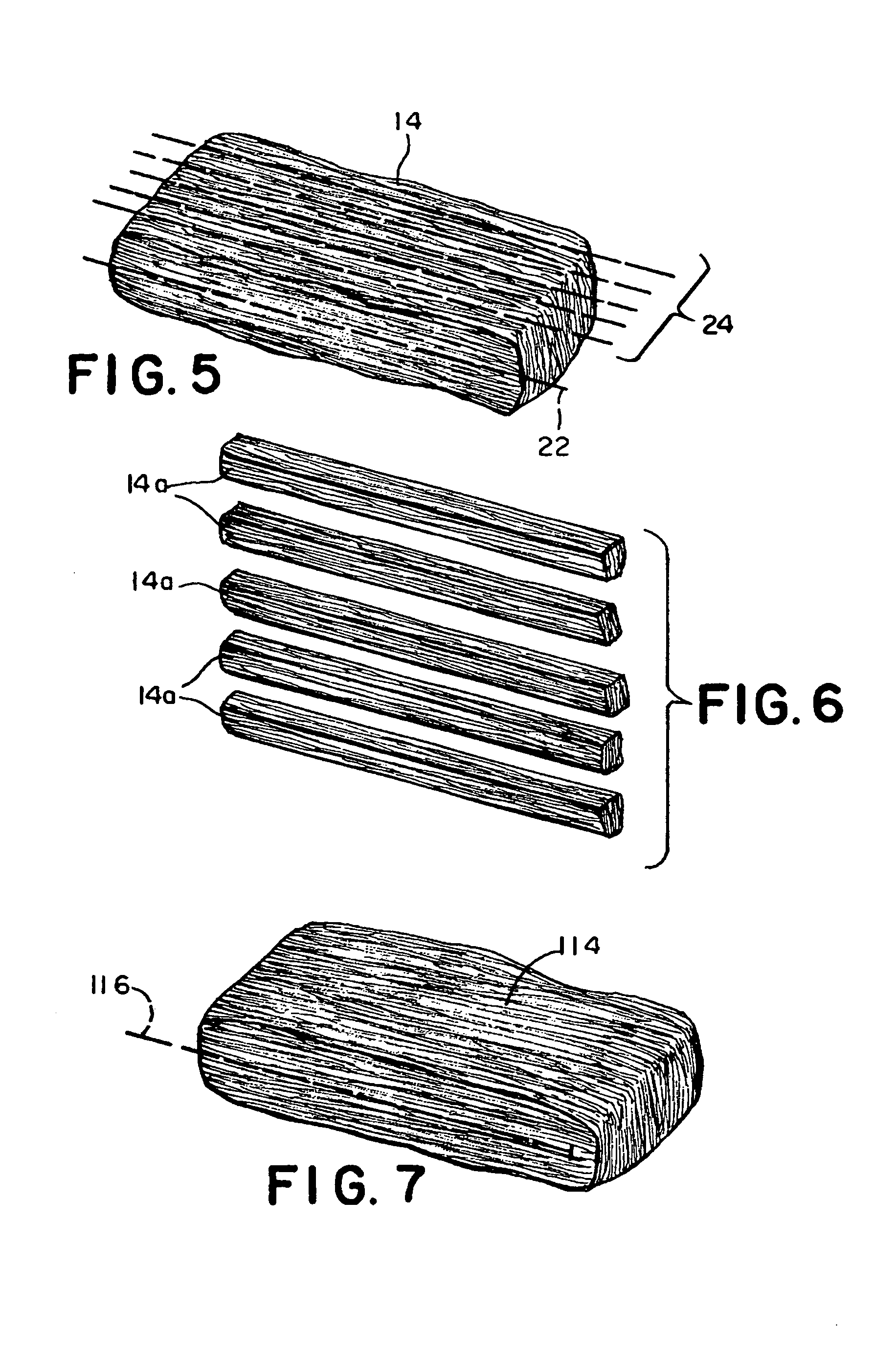

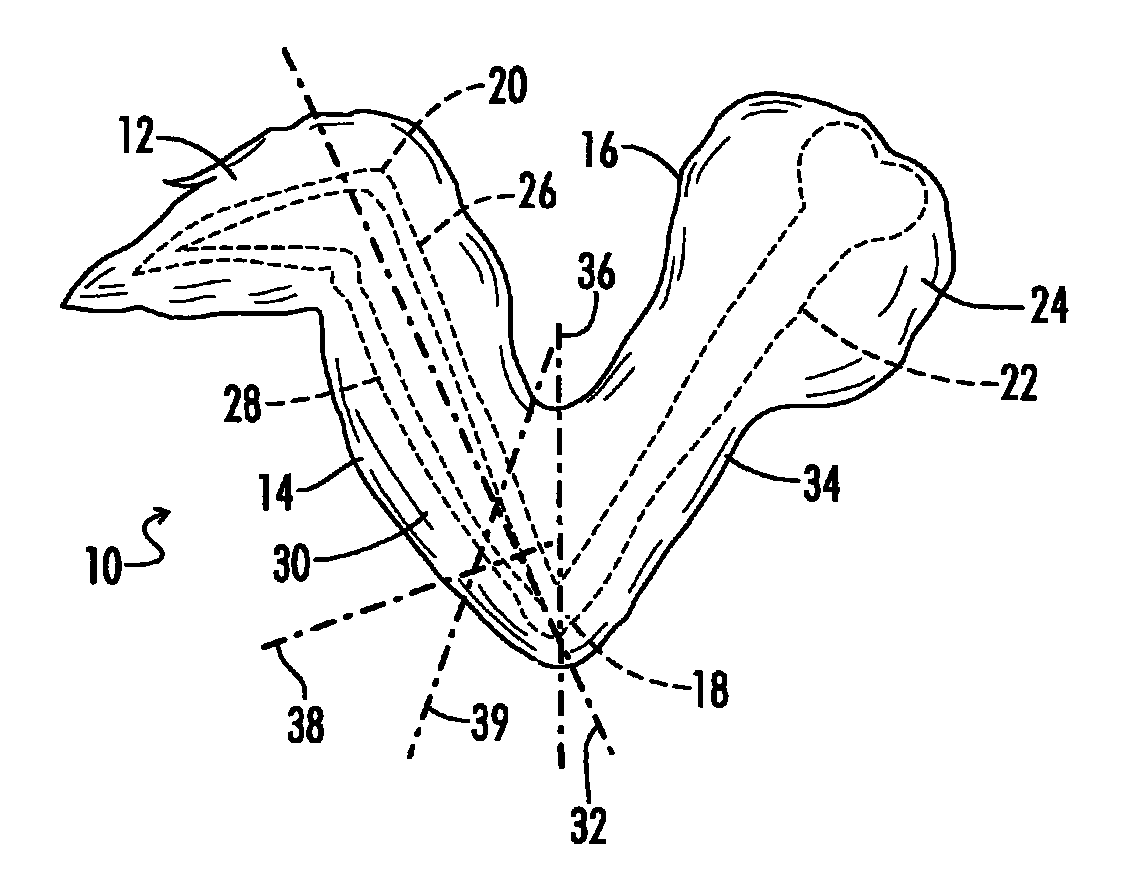

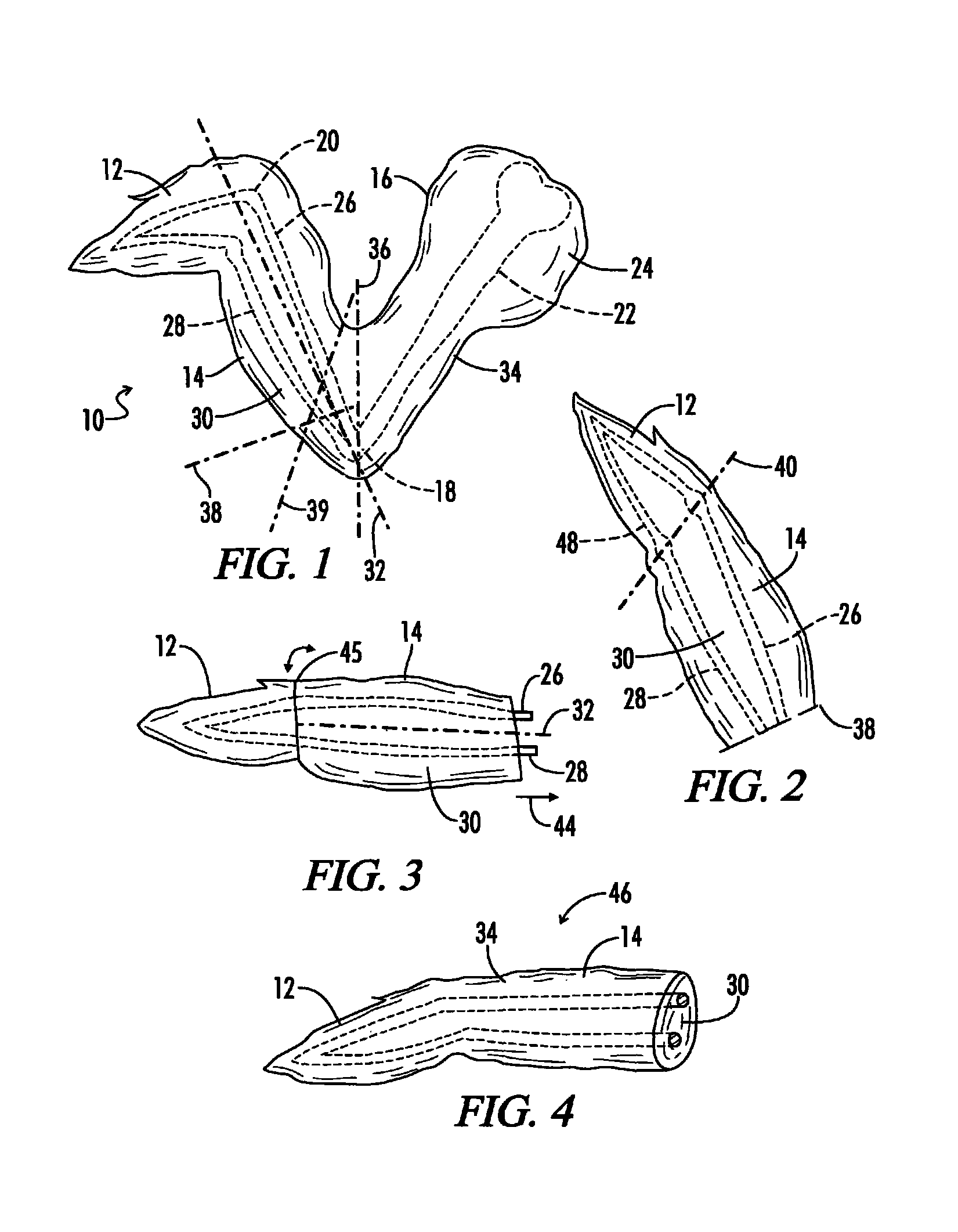

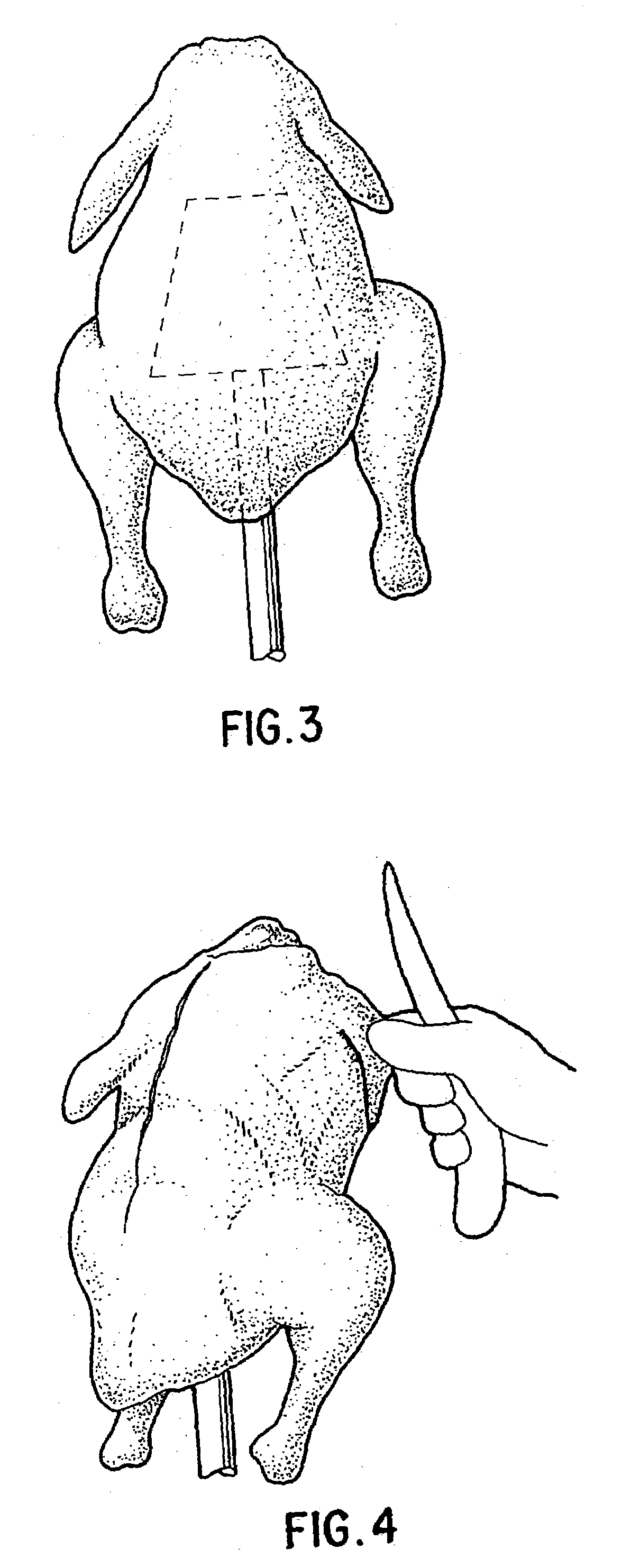

Method of making food products from the thigh of a bird and food products made in accordance with the method

A method of cutting the thigh of a bird forms a boneless thigh meat product. The thigh has a bone, first and second lateral sides, top and bottom surfaces, a thin muscle proximate the first lateral side and a thick muscle proximate the second lateral side. The method comprises removing the bone and any other inedible components from the thigh to provide a boneless thigh. The boneless thigh is cut from the top surface to the bottom surface along a first cut line to remove the thin muscle. The thick muscle is cut along a second cut line extending generally parallel to the top surface to remove a small top (red) muscle. The thick muscle is then cut along a third cut line extending generally parallel to the top and bottom surfaces and generally half way between the top and bottom surfaces to create two generally equal sized thigh meat pieces. The generally equally sized thigh meat pieces are cut along a plurality of generally parallel, generally equally spaced, generally longitudinally extending fourth cut lines to create a plurality of elongated boneless thigh meat strips.

Owner:BANK OF AMERICA NAT TRUST & SAVINGS ASSOC +1

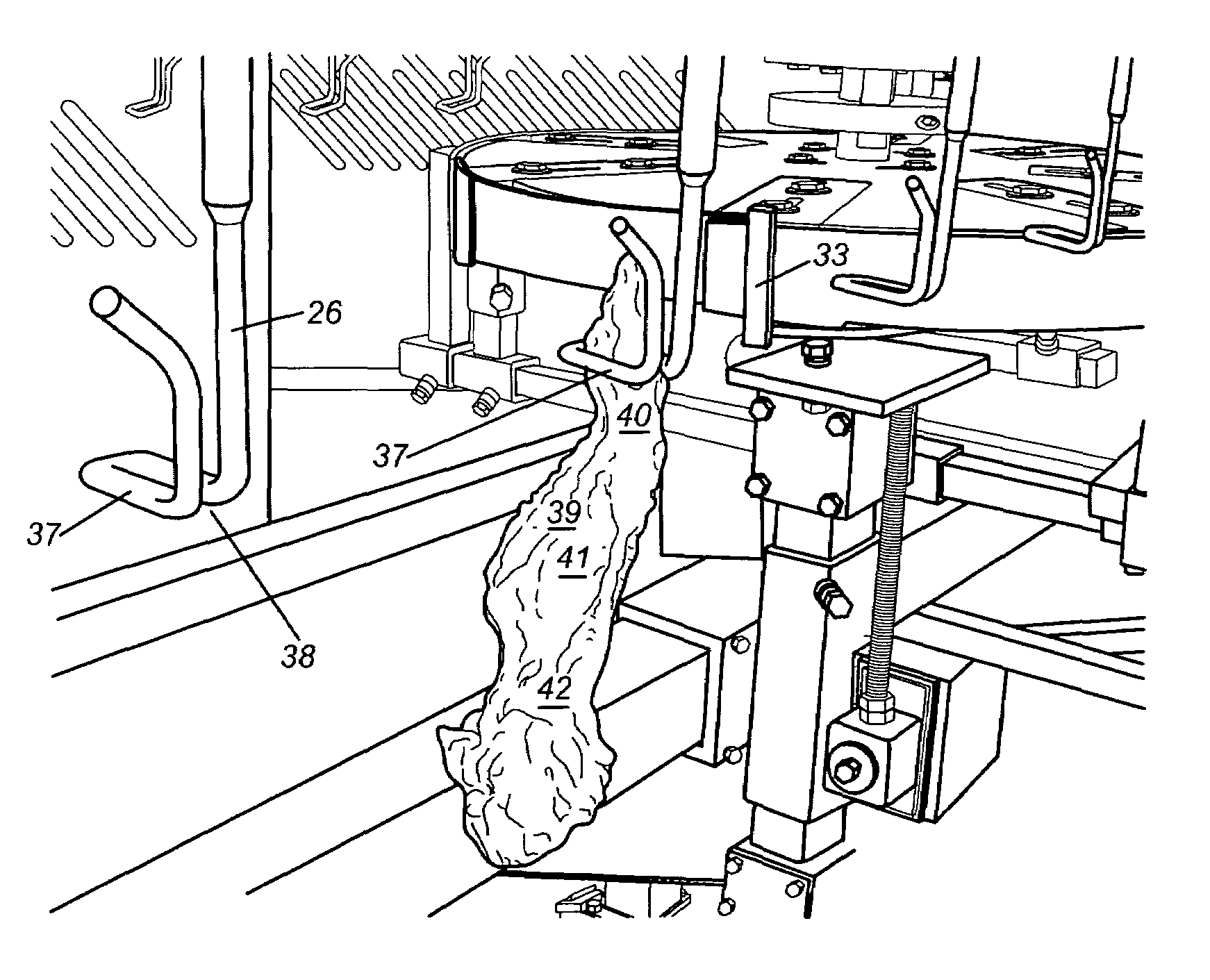

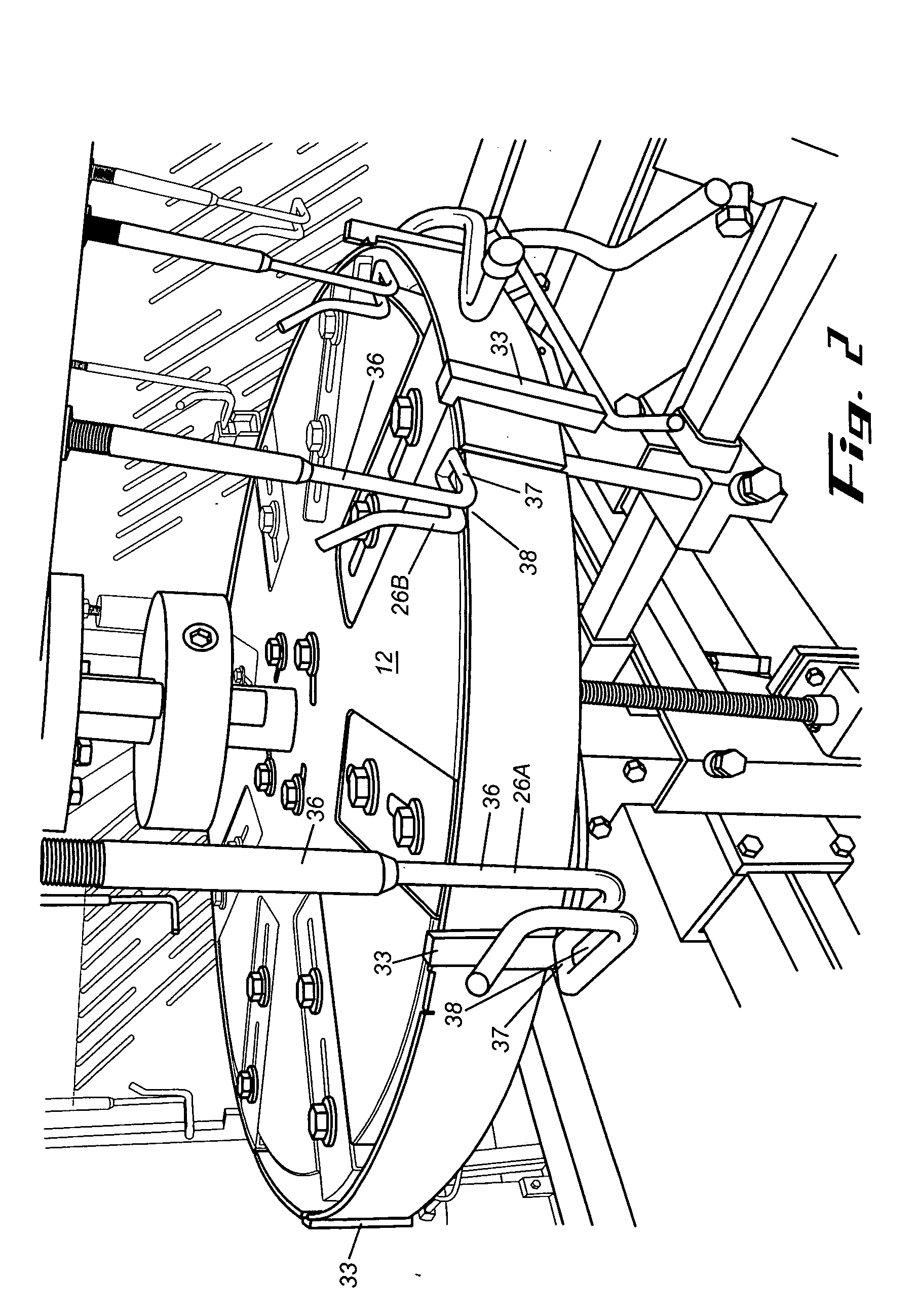

Poultry wing separator and partial deboner

Poultry wings are suspended by their tip segments and oriented so that their outside surfaces face one side of the processing path, with right wings oriented with their elbows leading, and left wings oriented with their elbows trailing. The lower, primary segments are bent at the elbow joints by a bending guide, laterally and upwardly about an elbow guide, opening the elbow joints. The open joints are cut so as to release the primary segments. The mid-wing segments are compressed and the bone ends are moved laterally from the wing tip segments, causing the bone ends of the mid-wing segments to pop out of the tip segments. In both instances, the bones of the segments are exposed in the final products, so when the products are cooked, the exposed bone ends are free of grease, etc. and are suitable for grasping by the fingers of the hand for eating as finger food.

Owner:SYSTATE GROUP

Poultry wing separator and partial deboner

InactiveUS20050186897A1Residue reductionPoultry deboningMeat processing plantsEngineeringRight flank

Poultry wings are suspended by their tip segments and oriented so that their outside surfaces face one side of the processing path, with right wings oriented with their elbows leading, and left wings oriented with their elbows trailing. The lower, primary segments are bent at the elbow joints by a bending guide, laterally and upwardly about an elbow guide, opening the elbow joints. The open joints are cut so as to release the primary segments. The mid-wing segments are compressed and the bone ends are moved laterally from the wing tip segments, causing the bone ends of the mid-wing segments to pop out of the tip segments. In both instances, the bones of the segments are exposed in the final products, so when the products are cooked, the exposed bone ends are free of grease, etc. and are suitable for grasping by the fingers of the hand for eating as finger food.

Owner:SYSTATE GROUP

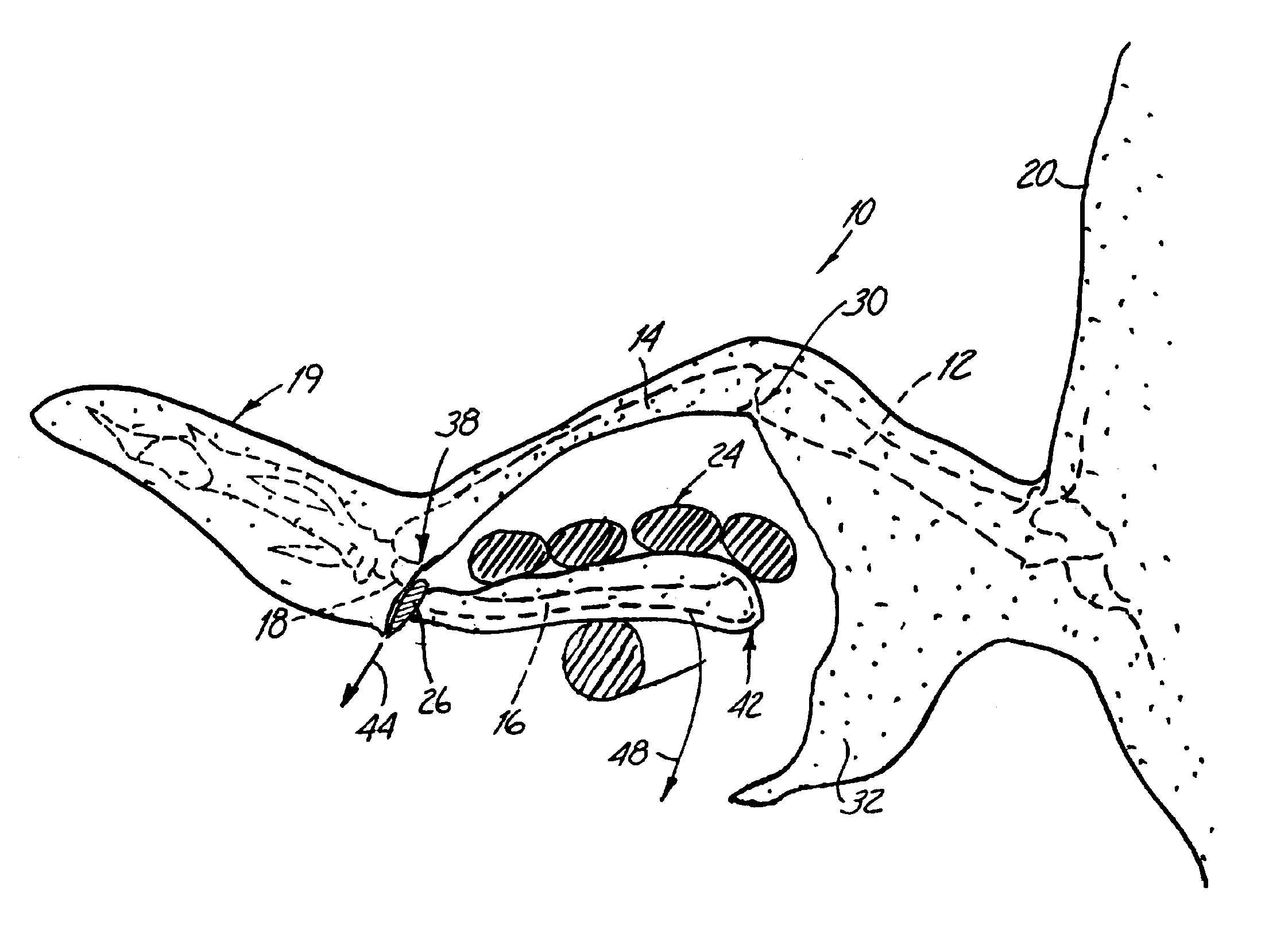

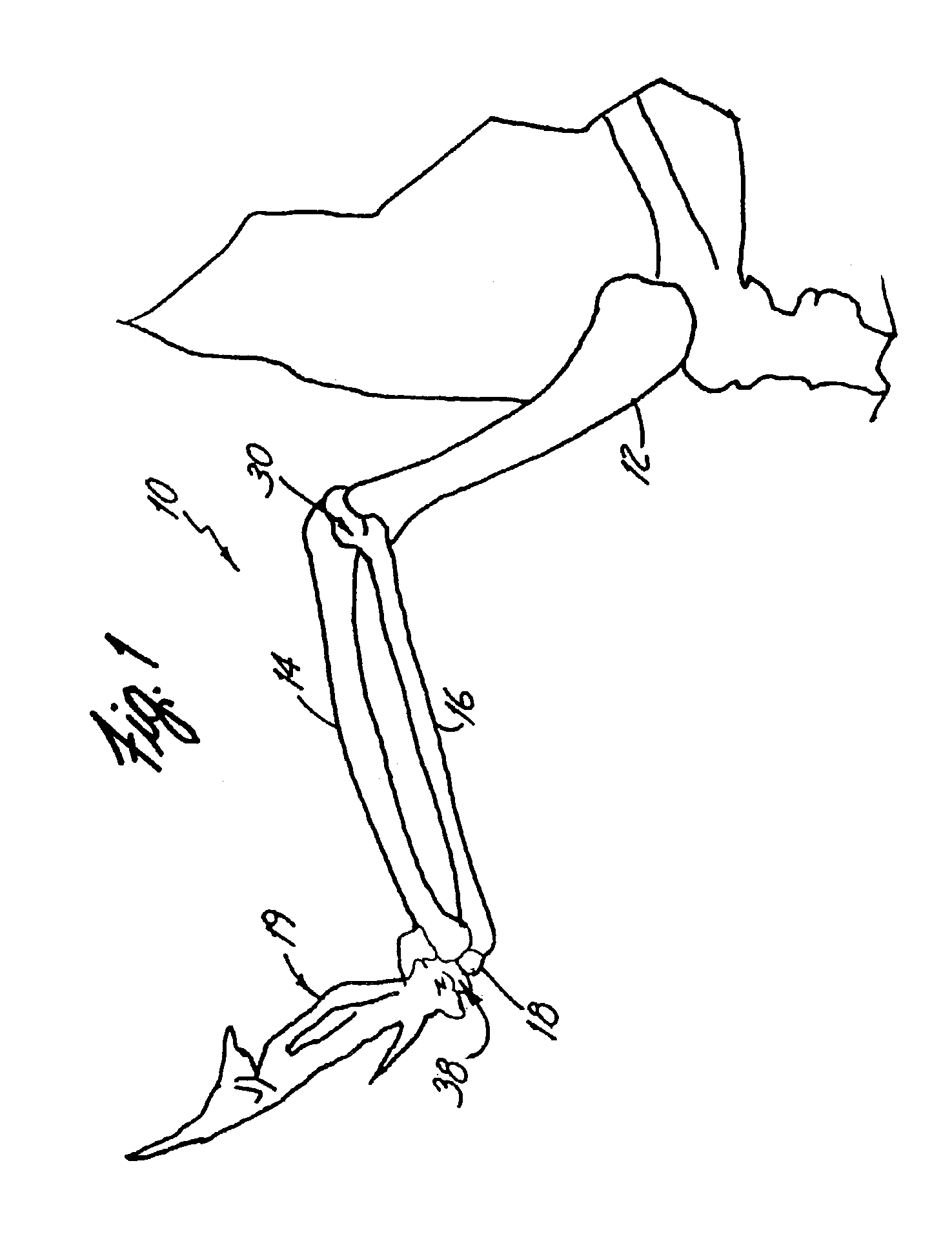

Method for making a fowl wing cut and the resultant product

The present invention is a method for cutting a fowl to create a meat cut which includes the radius bone and muscles (meat) adhering to the radius bone. The method involves separating the radius bone and muscles adhering to the radius bone from the carcass of the fowl, and then removing the radius bone and muscles adhering to the radius bone from the carcass of the fowl. The meat cut may be produced with the cutaneous tissues attached to the muscles adhering to the radius bone or with the cutaneous tissues removed from the muscles adhering to the radius bone to produce a skinless meat cut. The resulting meat cut contains a larger percentage of meat and is easier to consume. Alternatively, a portion of the muscles (meat) adhering to the radius bone can be removed to create a meat cut having less meat.

Owner:V H COOPER & COOPER FARMS PROCESSING

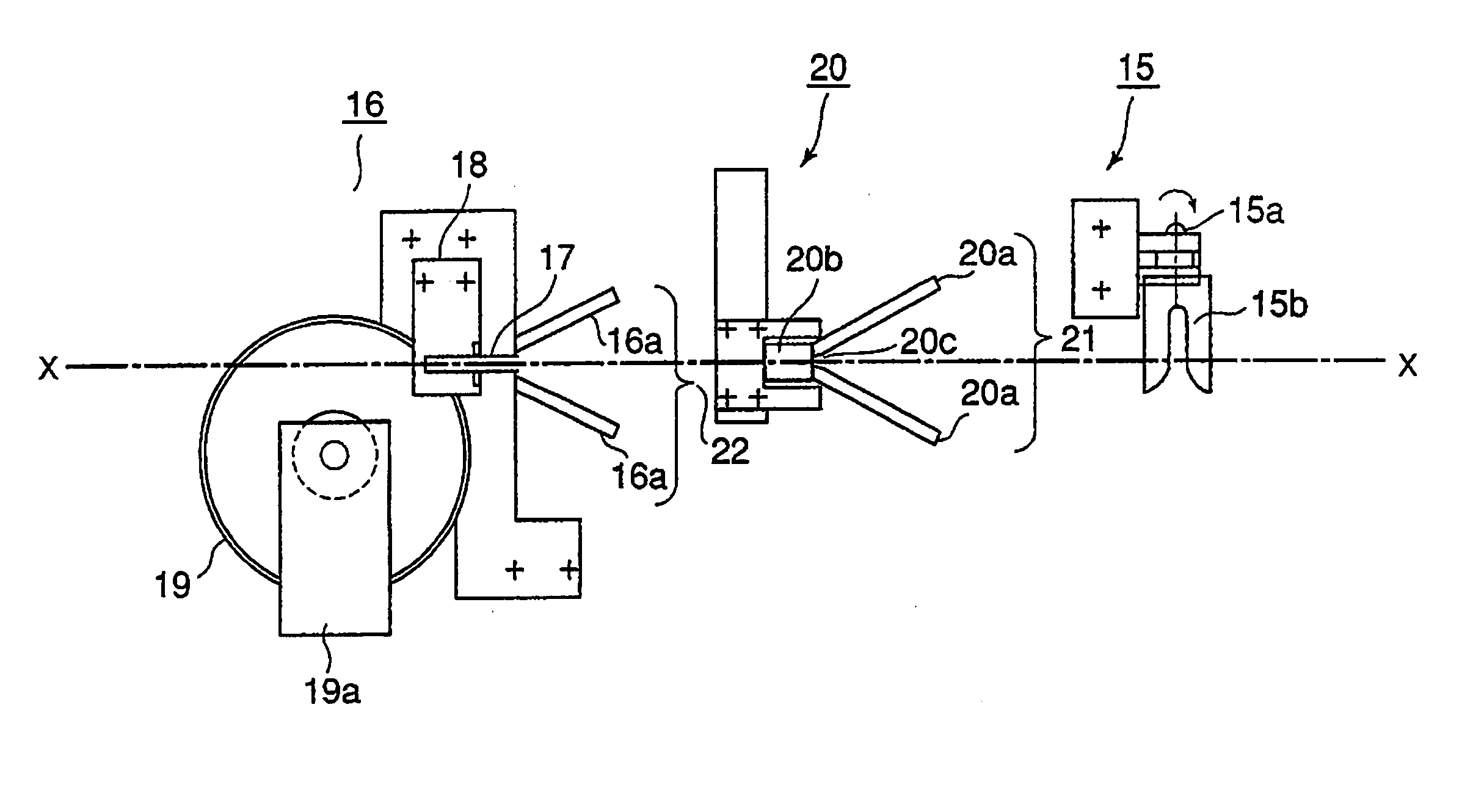

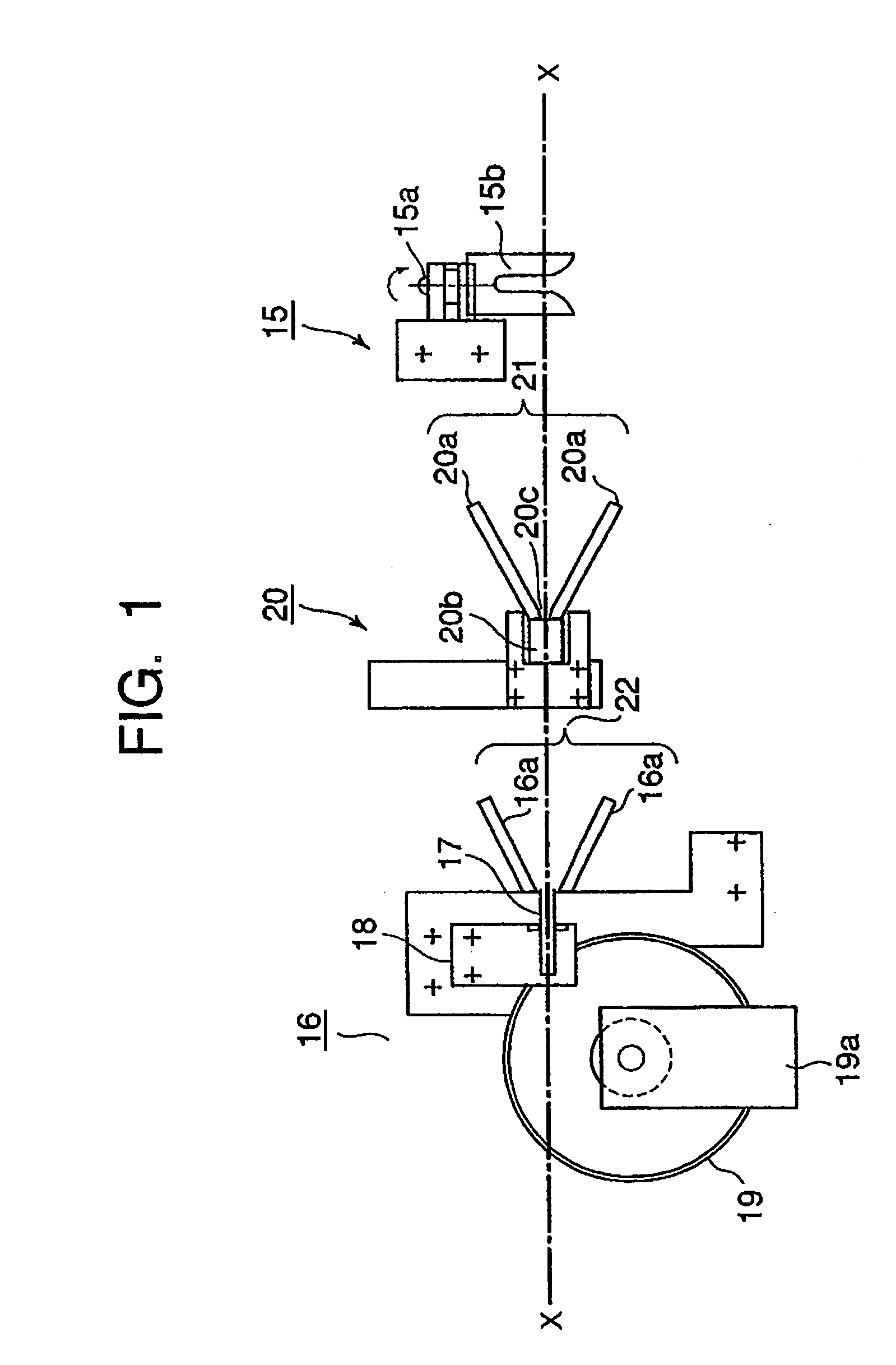

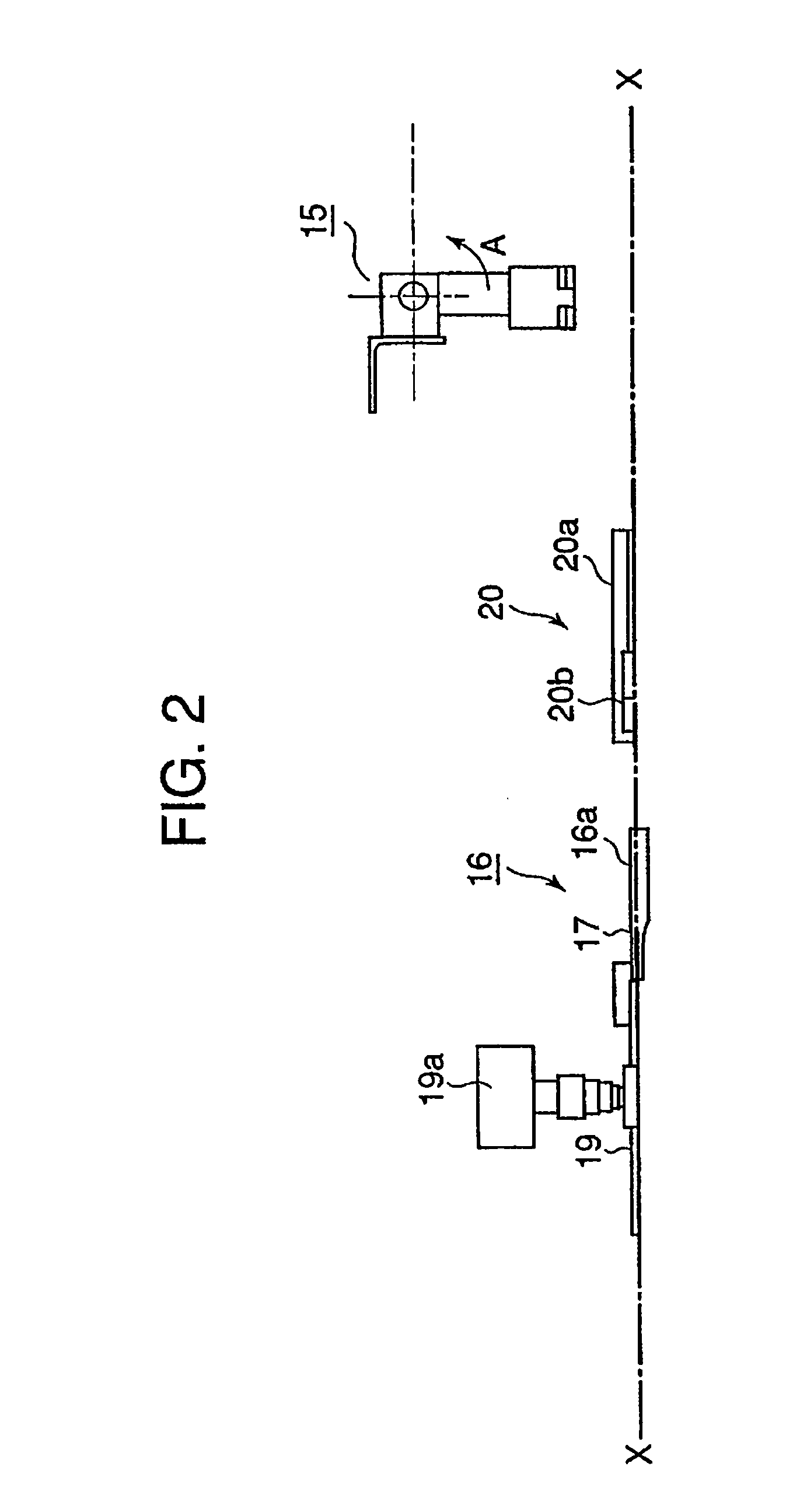

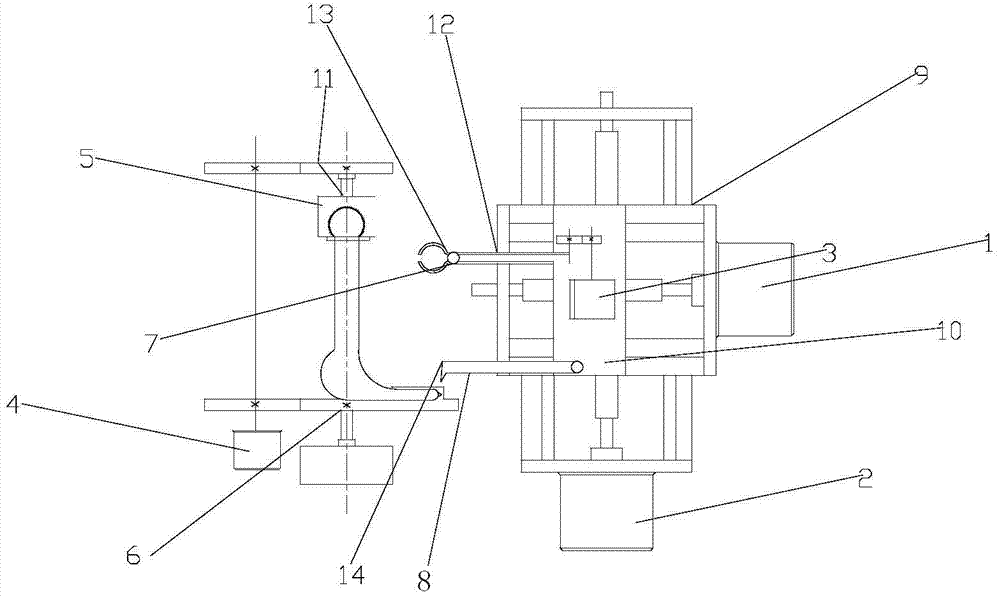

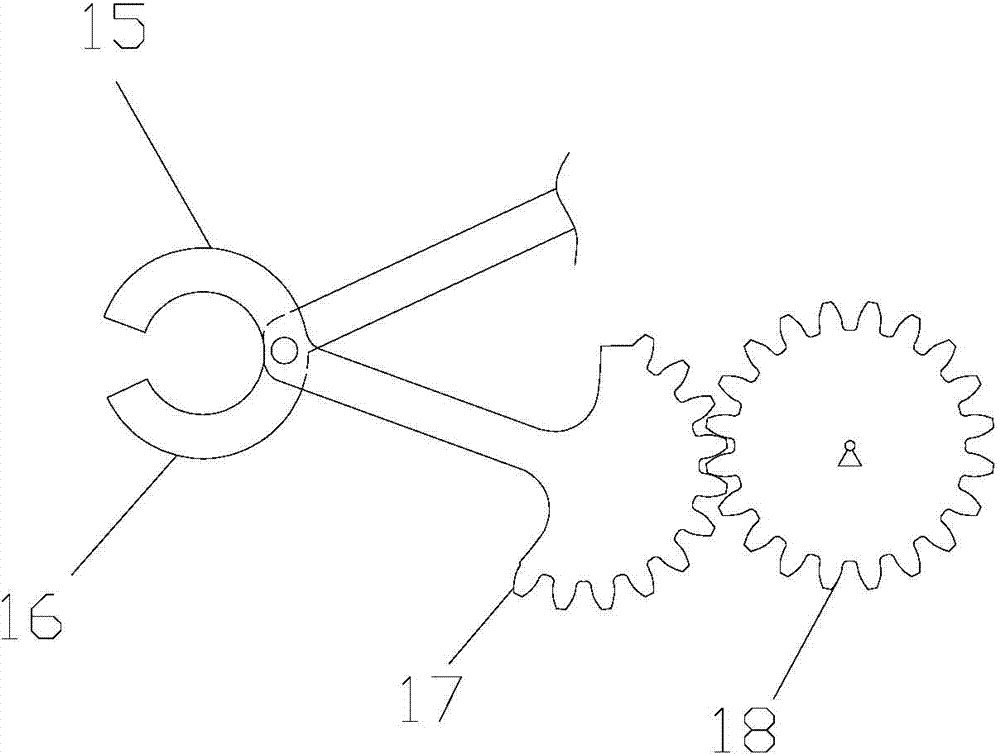

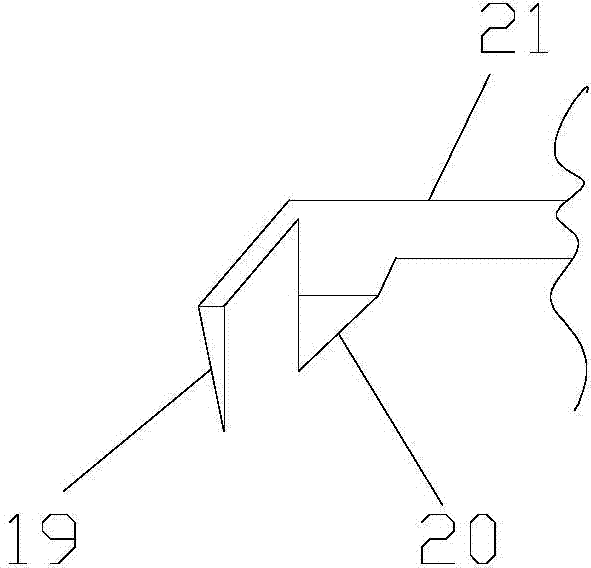

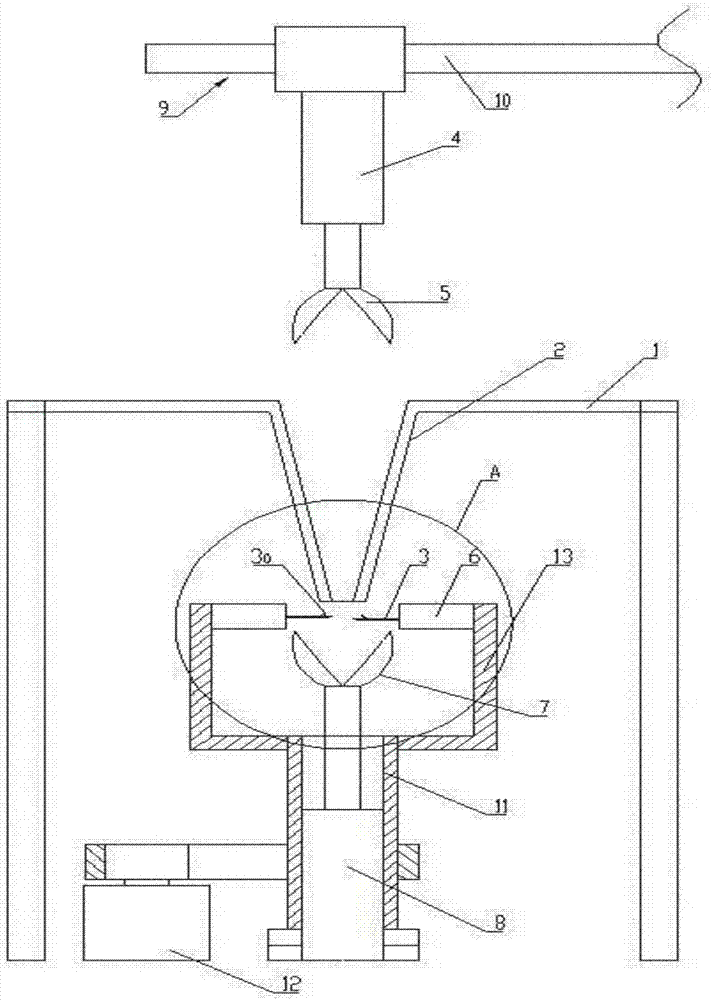

Method and apparatus for separating thigh meat and oyster meat

A method and apparatus are provided for separating thigh meat and oyster meat from the thighbone automatically without detecting the boundary of the white cap at an end of the thigh bone and the meat including thigh meat and oyster meat and inserting a cutter into the detected boundary part in the final operation of deboning a thigh-with-bone of an edible beast and bird. The apparatus of the invention for separating thigh meat and oyster meat is composed of a clamper 15, a Y-shaped guide-with-a-groove 20, and a Y-shaped guide-with-a-cutter 16 downstream of the guide 20 provided on the transfer line of the clamper, both guides being provided such that the open end side of Y-shape of each guide is directed toward upstream of transfer of the clamper.

Owner:MAYEKAWA MFG CO LTD

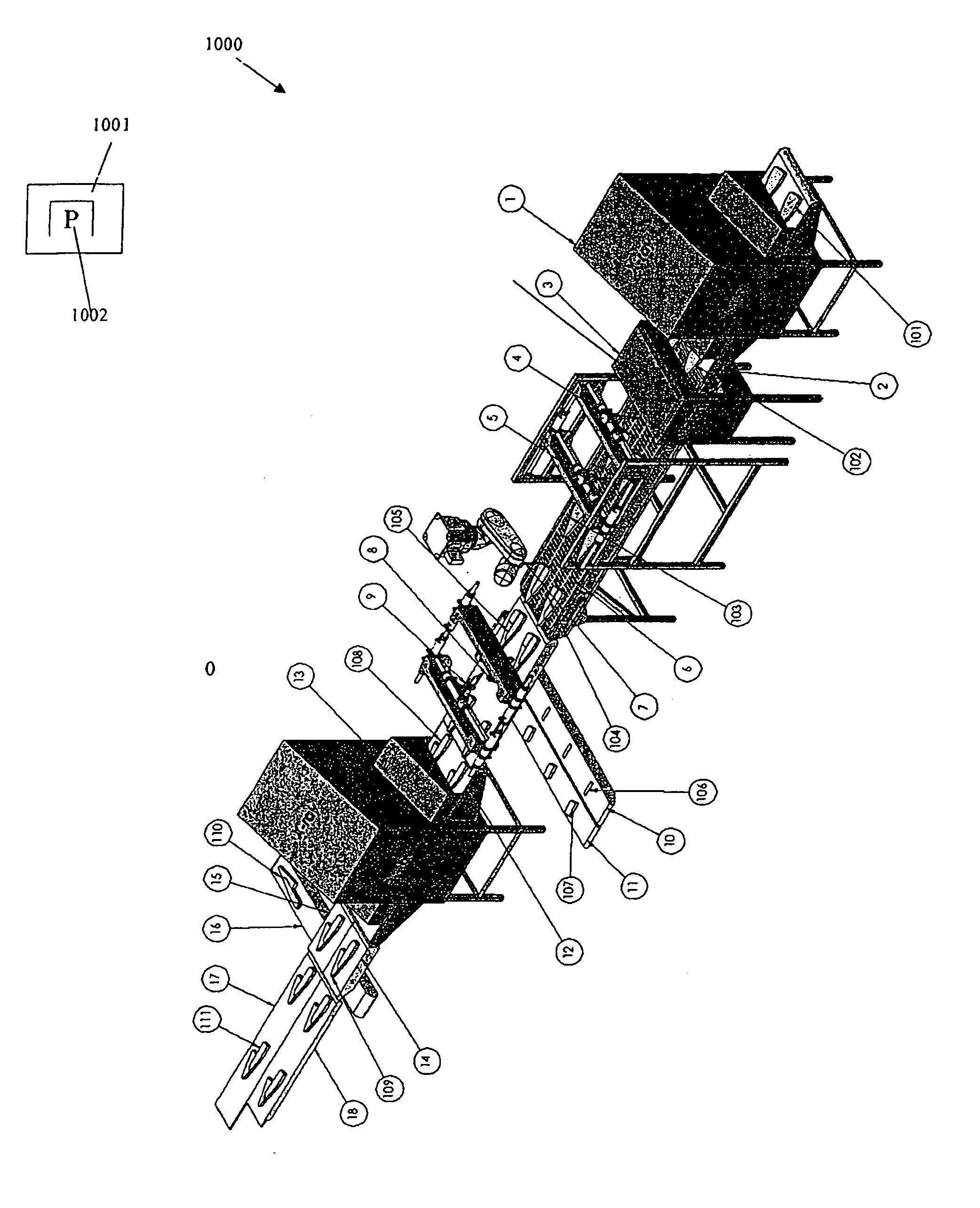

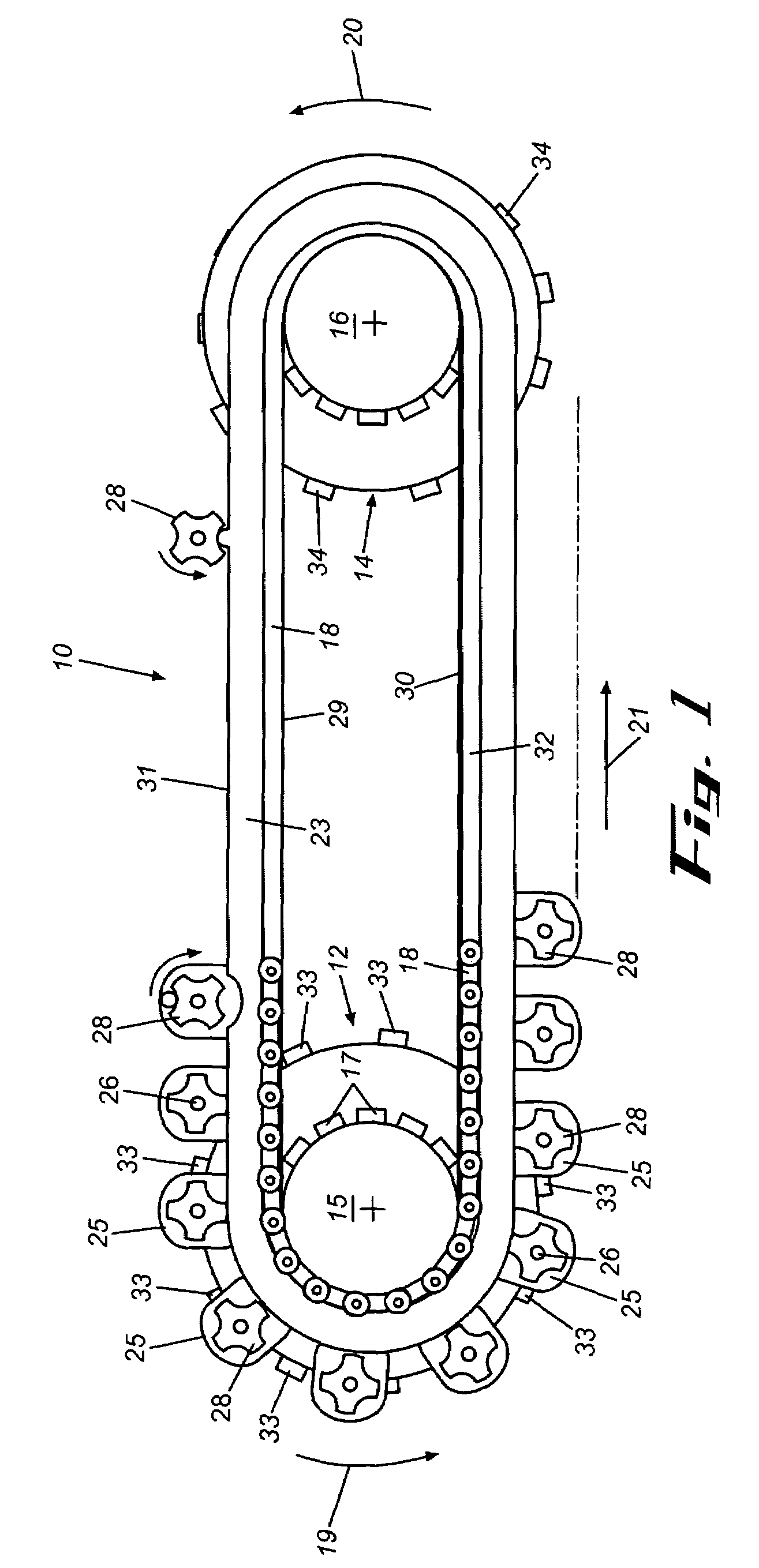

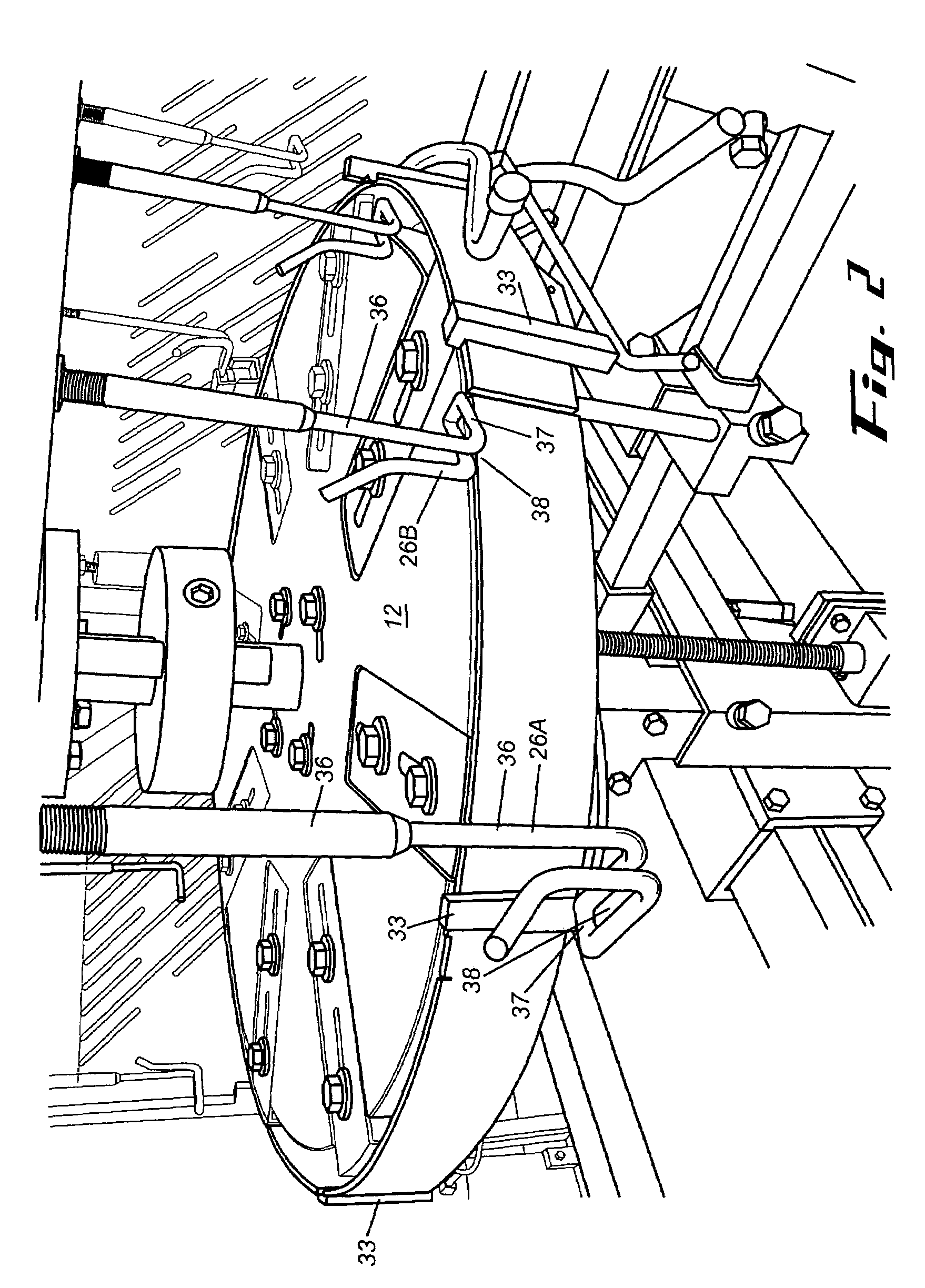

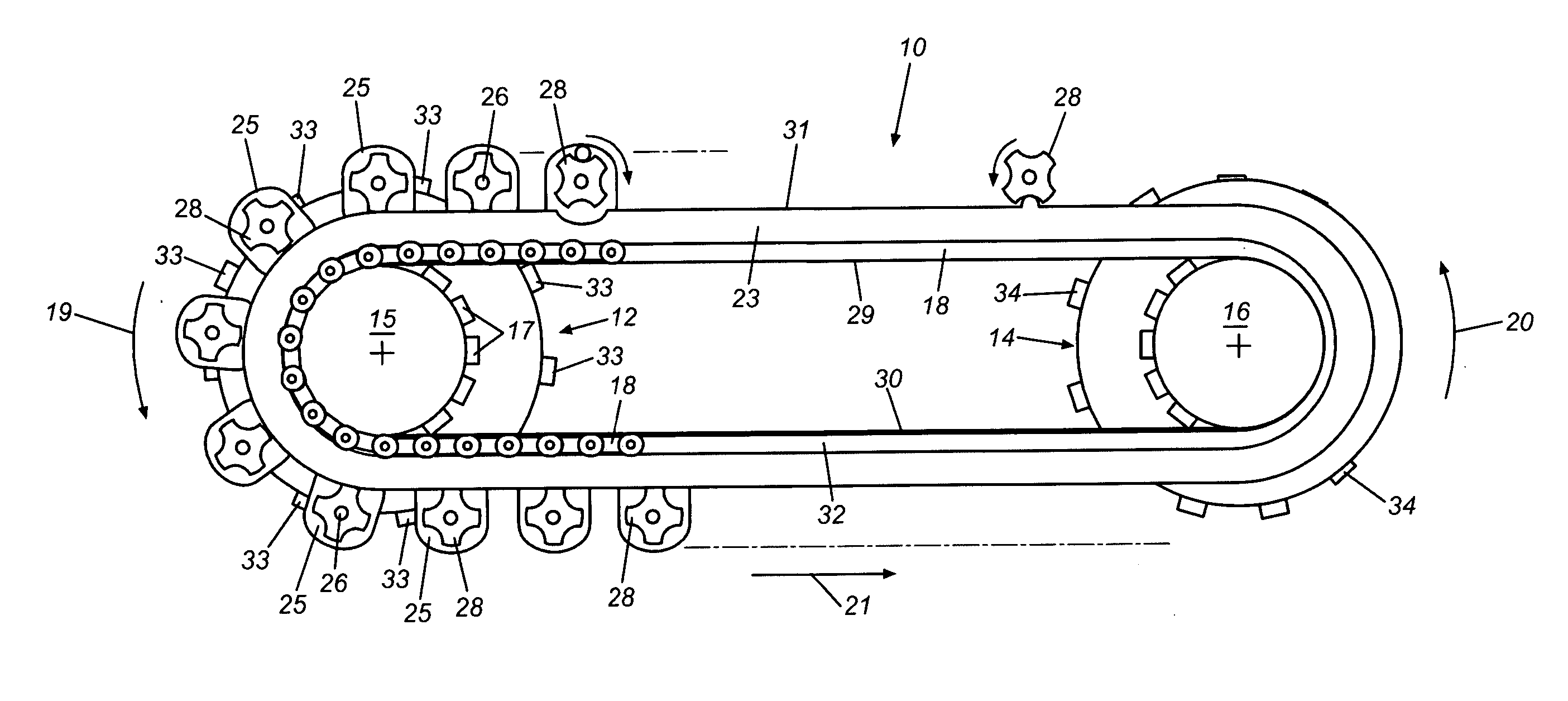

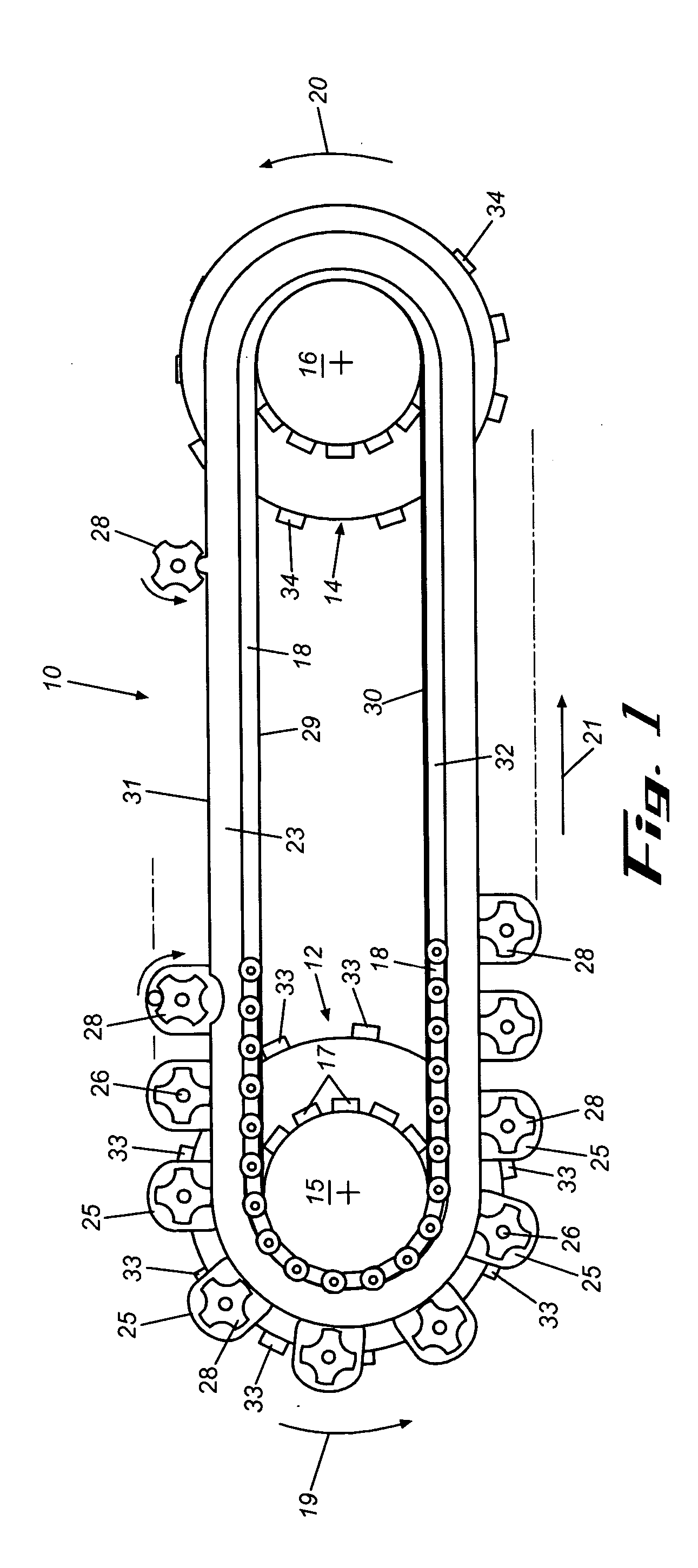

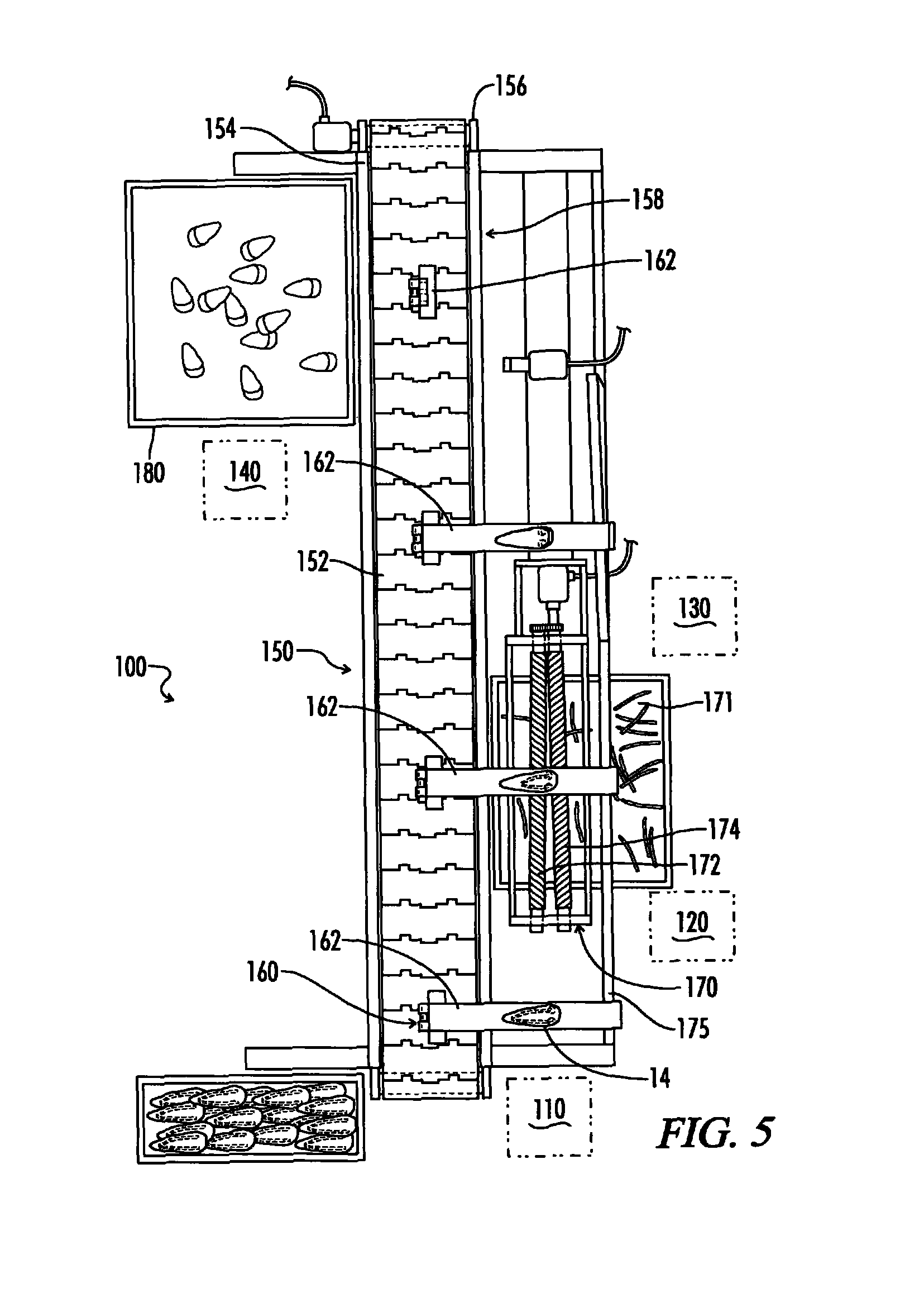

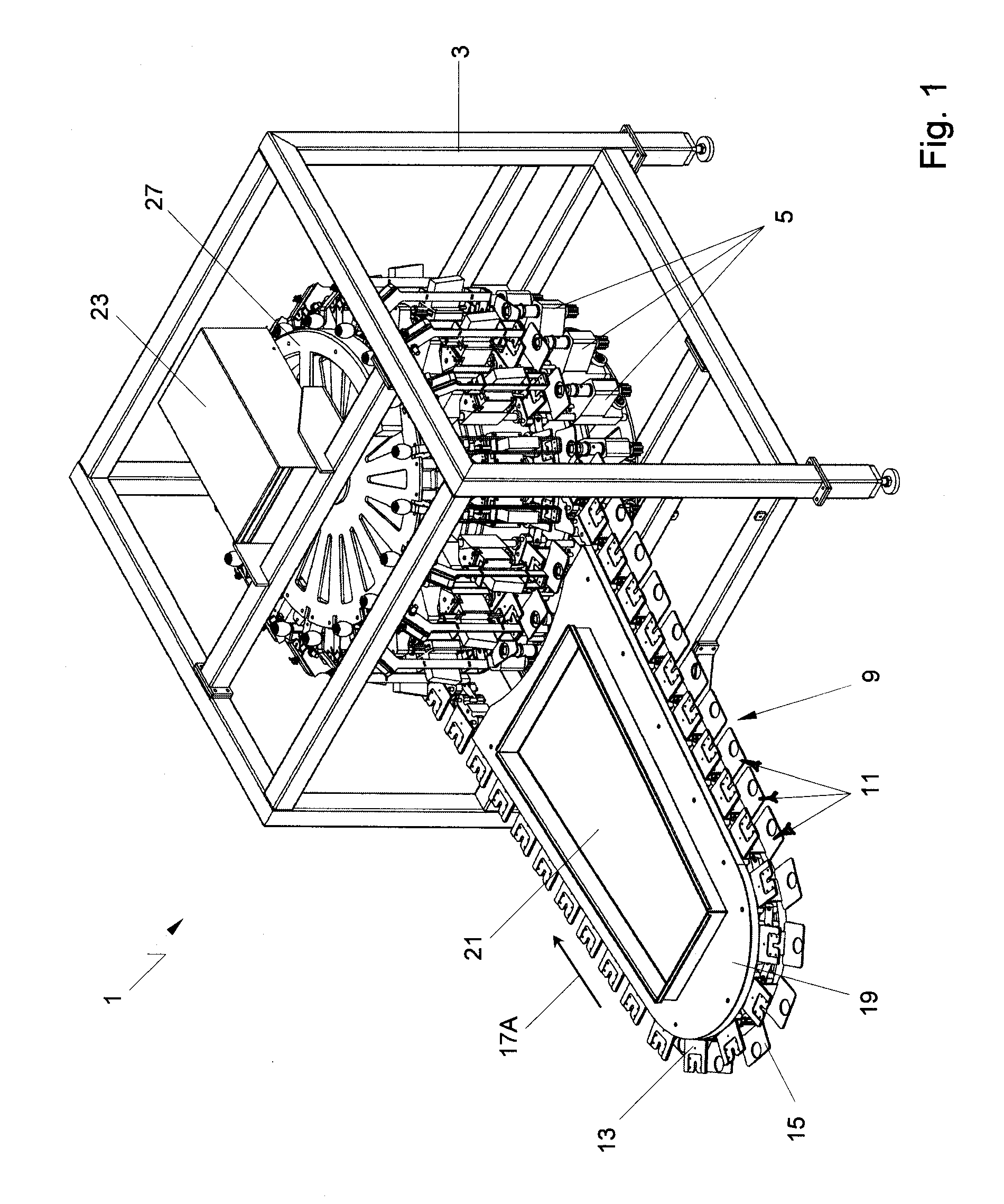

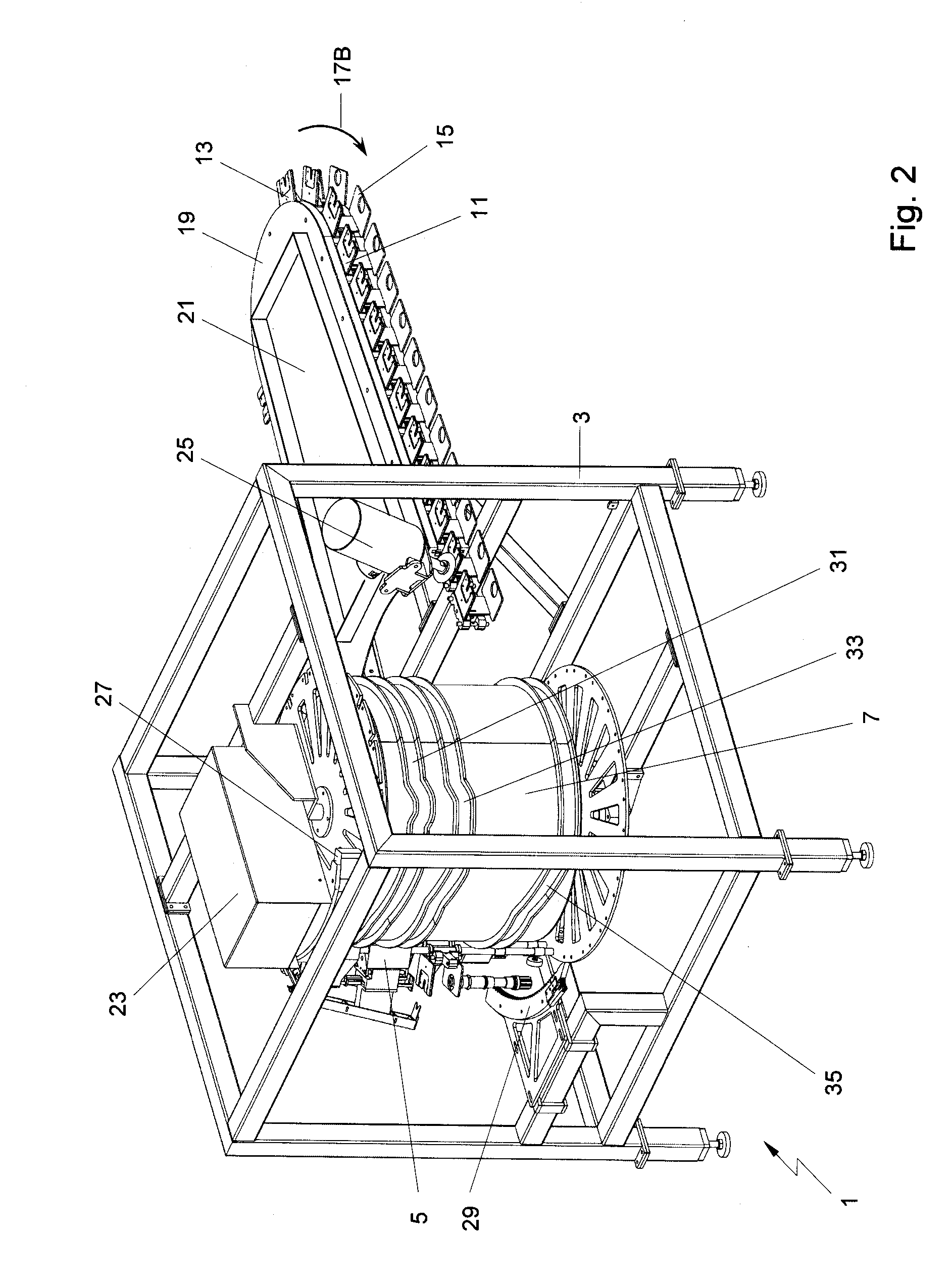

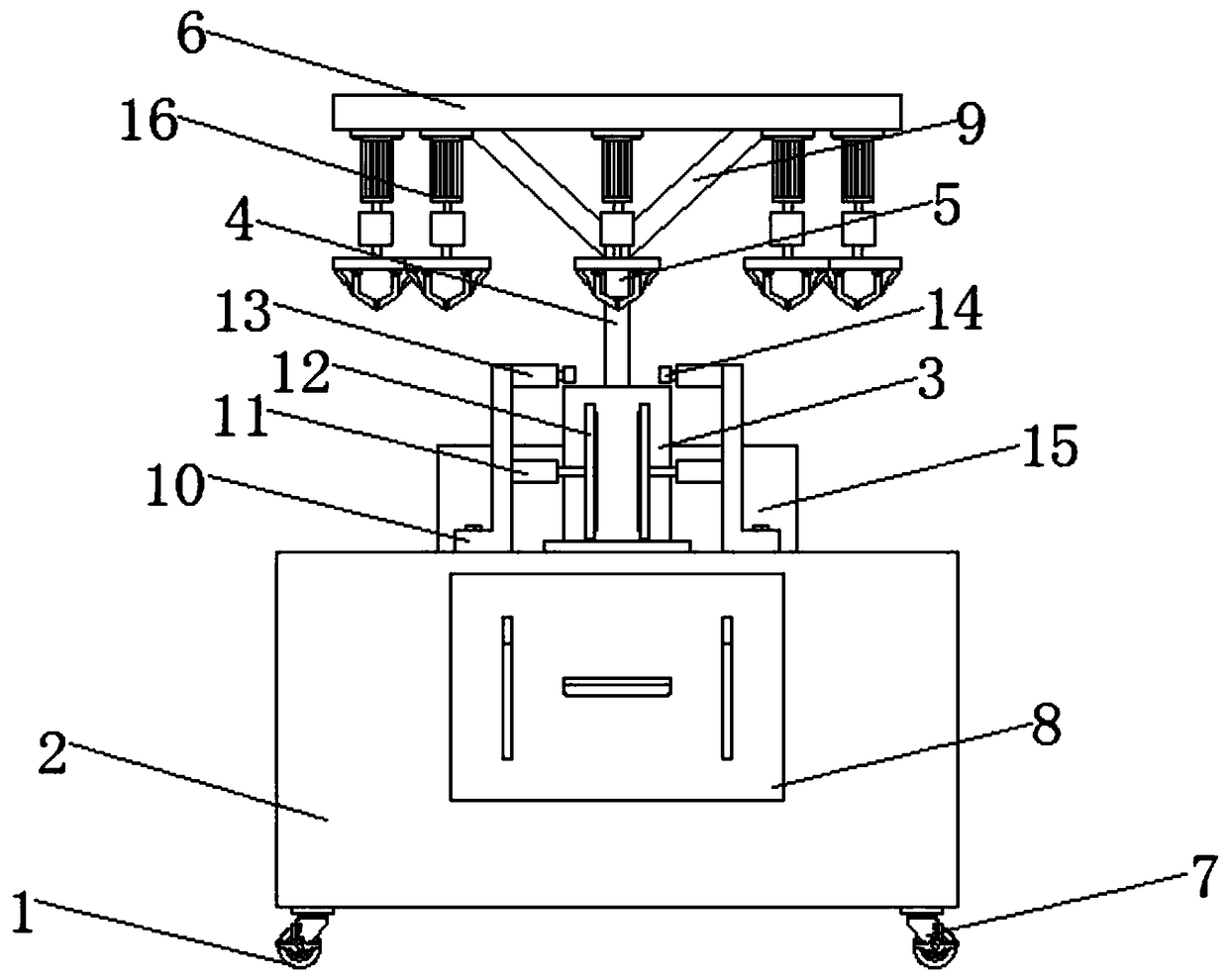

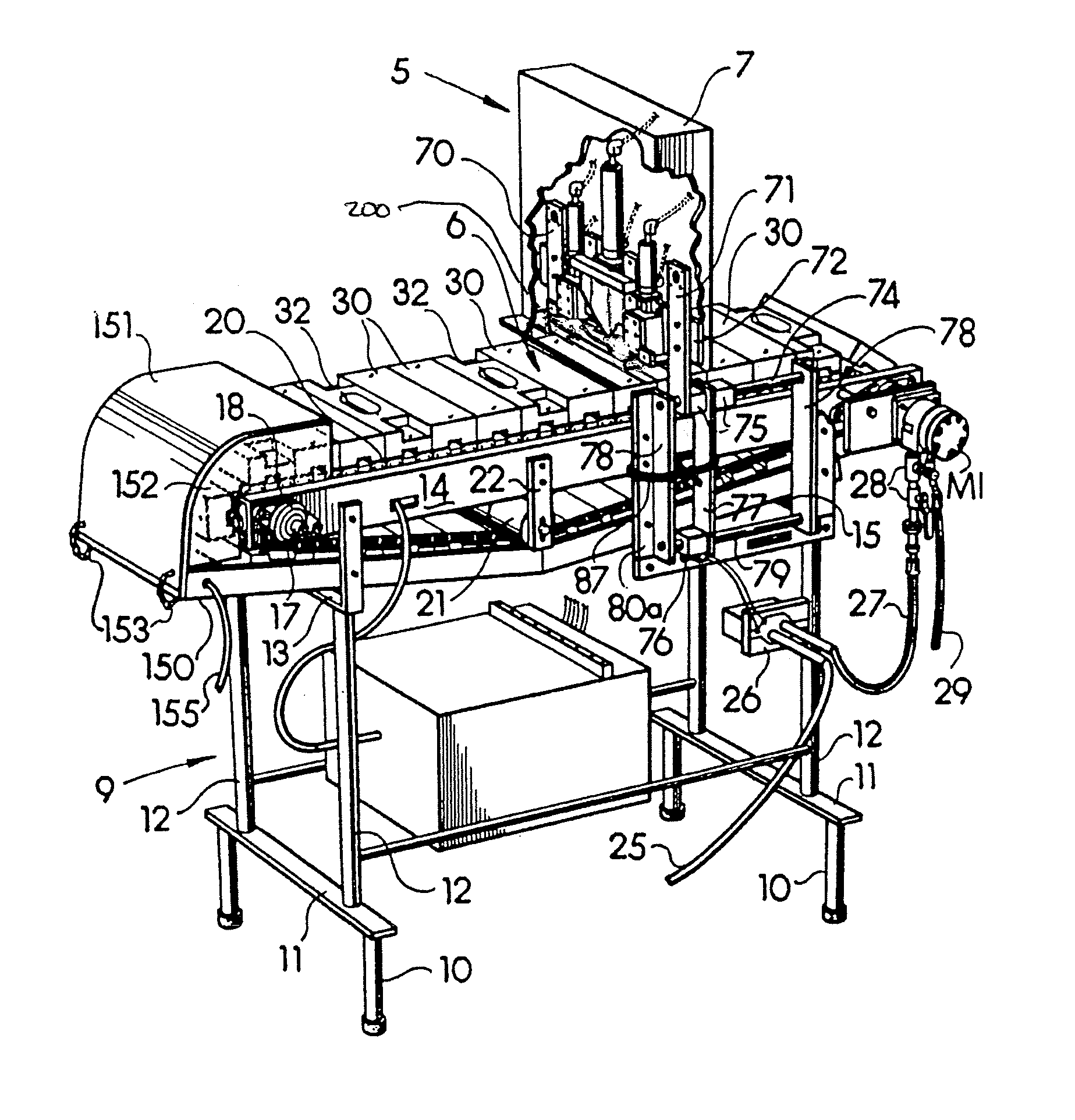

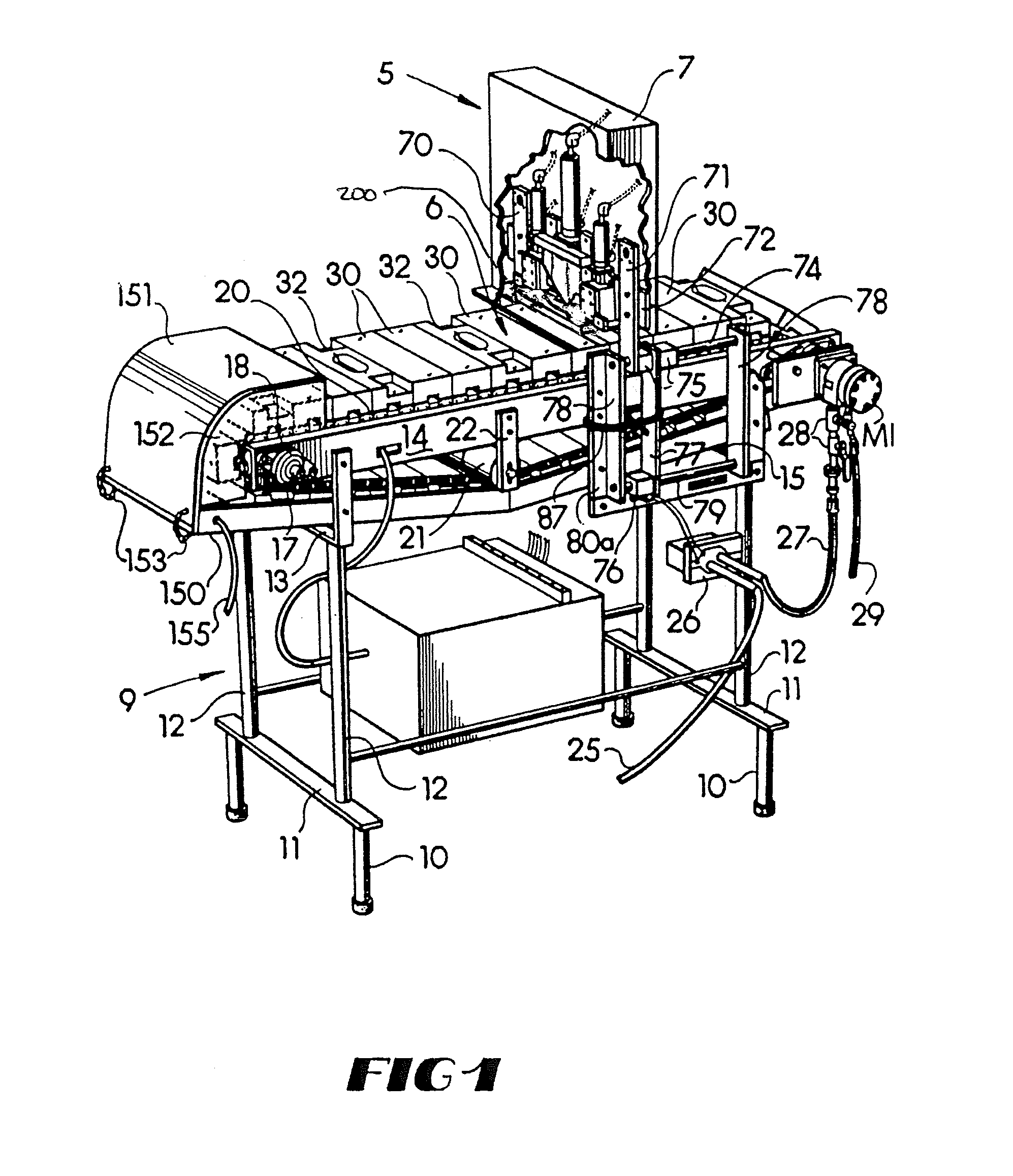

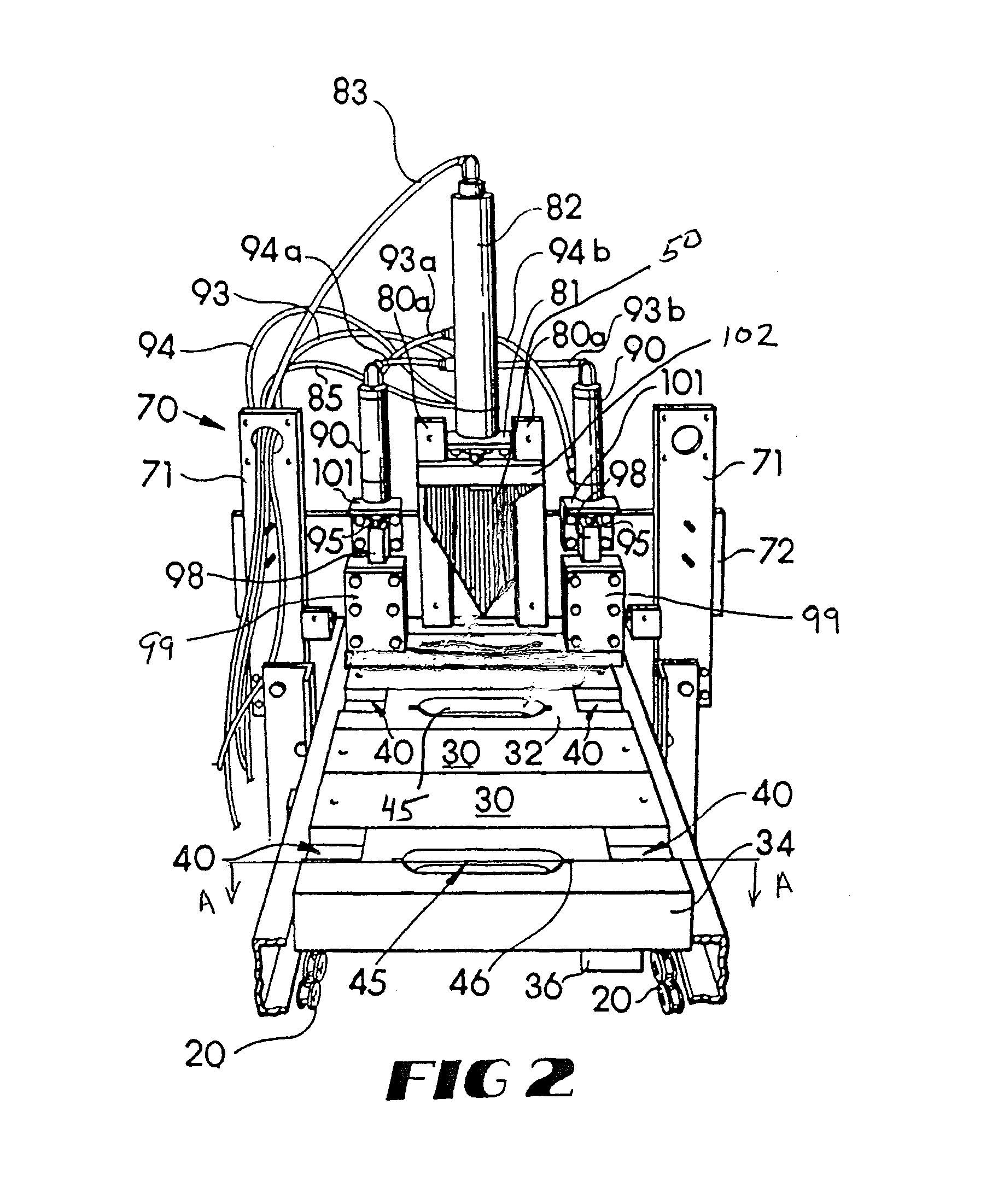

Poultry wing deboning apparatus and method

ActiveUS8591298B1Easy quantityEfficient and economical mannerPoultry deboningFish filletingAerospace engineering

An apparatus and method for deboning a poultry wing including multiple stations. The poultry wing is cut and then placed with bones extending through a plate for engagement by a subsequent rotary disboner. The mechanism includes a convey or with the plates secured thereto and motor and controls for moving the conveyor and plates and rotary deboner.

Owner:THREE DICK FARMS

Food processing apparatus for detecting and cutting tough tissues from food items

ActiveUS9095147B2Increase cutting outputMitigate, alleviate or eliminate onePoultry deboningCharacter and pattern recognitionX-rayX ray image

A food processing apparatus for detecting and cutting tough tissues from food items such as fish, meat, or poultry. At least one x-ray machine associated to a first conveyor for imaging incoming food items on the first conveyor based on a generated x-ray image indicating the location of the tough tissues in the food items. A vision system supplies second image data of the food items subsequent to the imaging by the x-ray machine. The second image data including position related data indicating the position of the food items on the second conveyor prior to the cutting. A mapping mechanism determines an estimated coordinate position of the food items on the second conveyor by utilizing the x-ray image and tracking position data. The processor compares the estimated coordinate position of the food items to the actual position on the second conveyor based on the second image data.

Owner:VALKA EHF

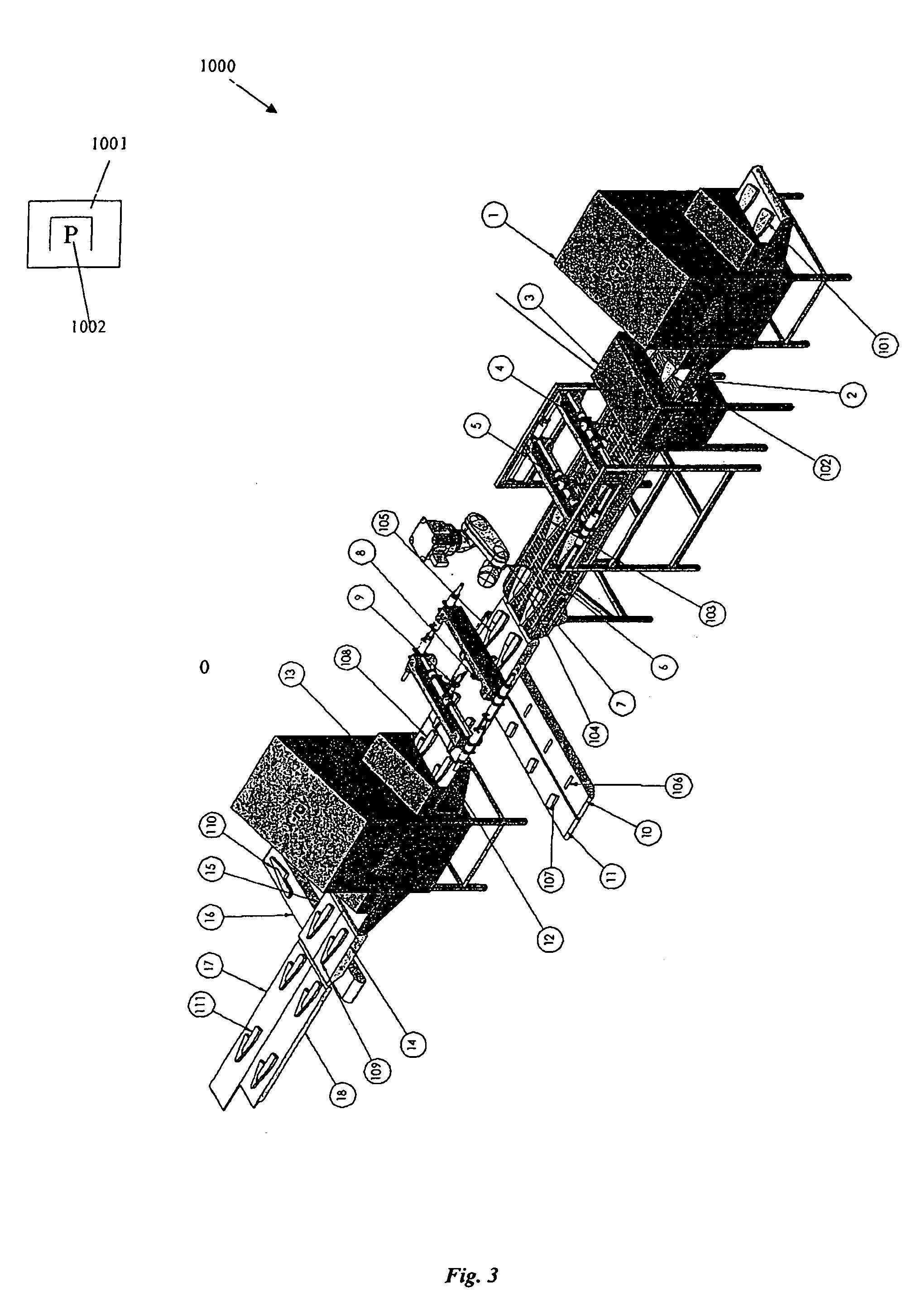

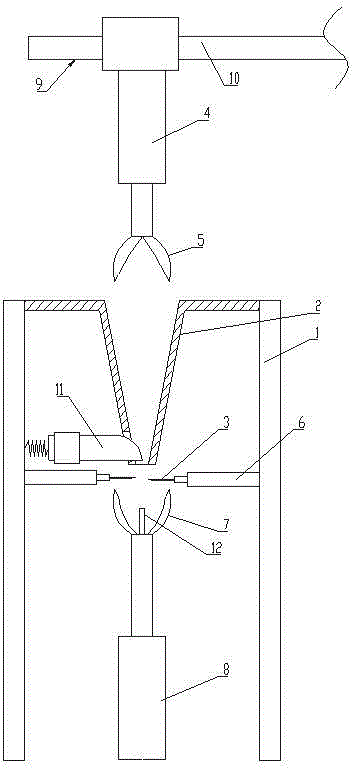

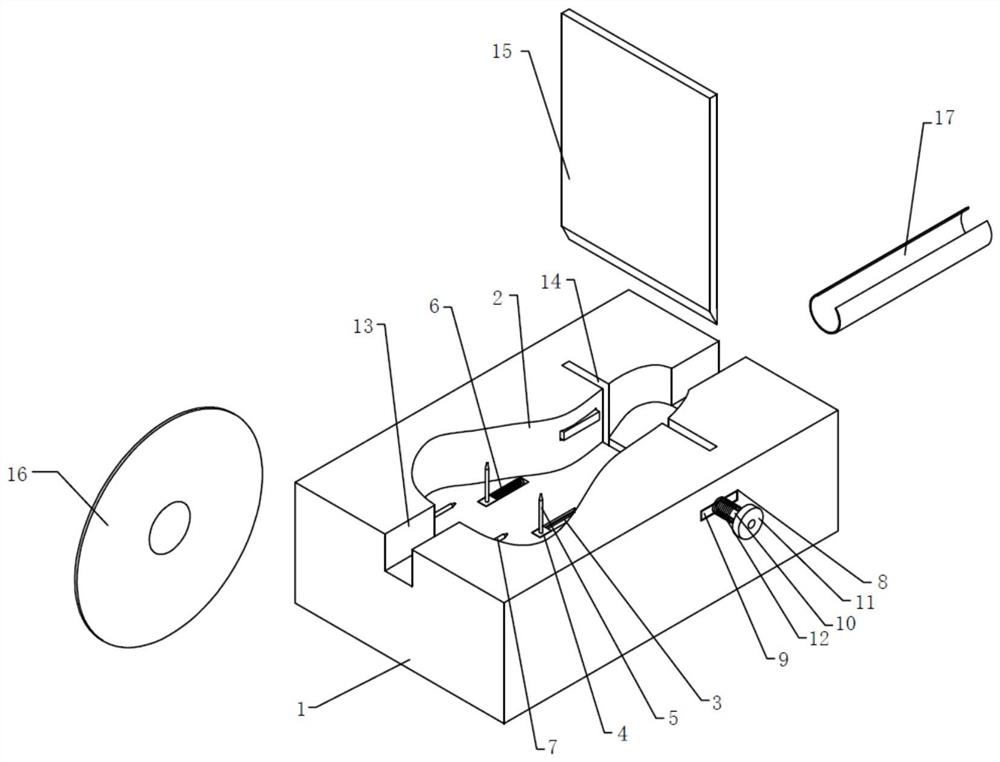

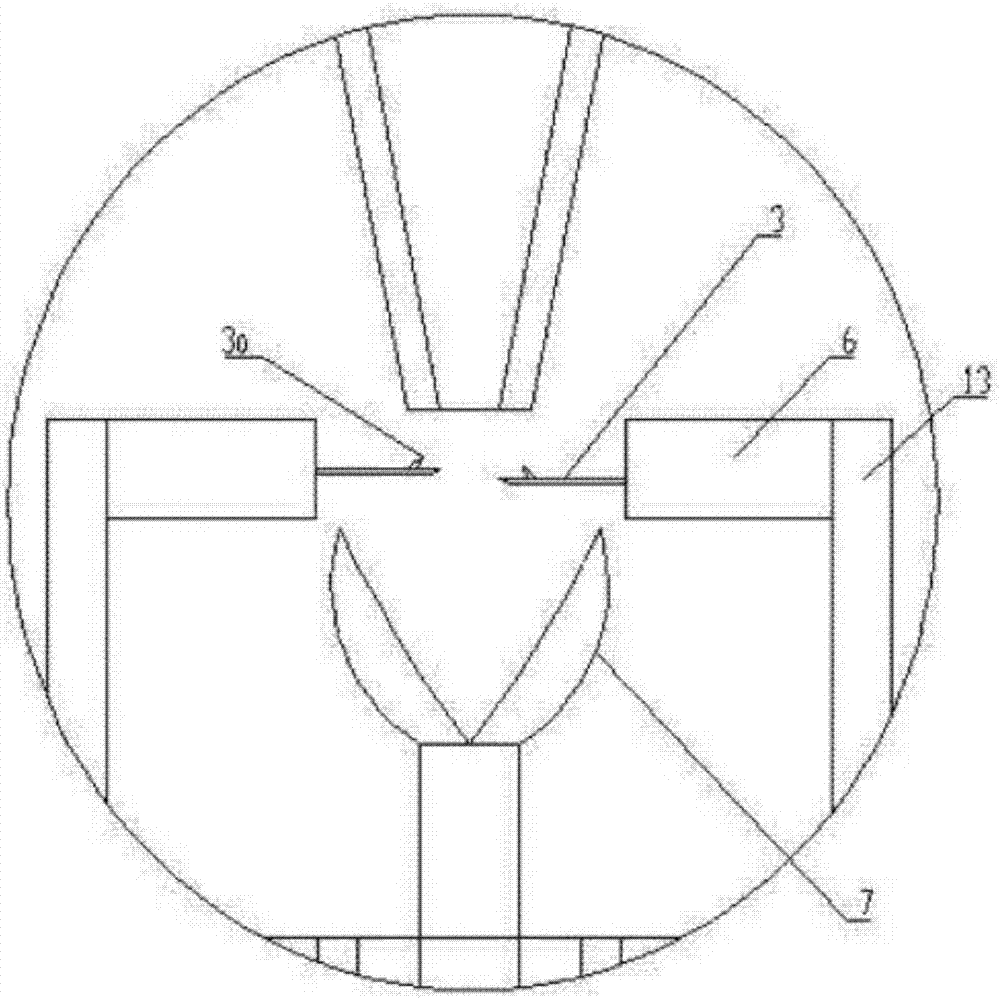

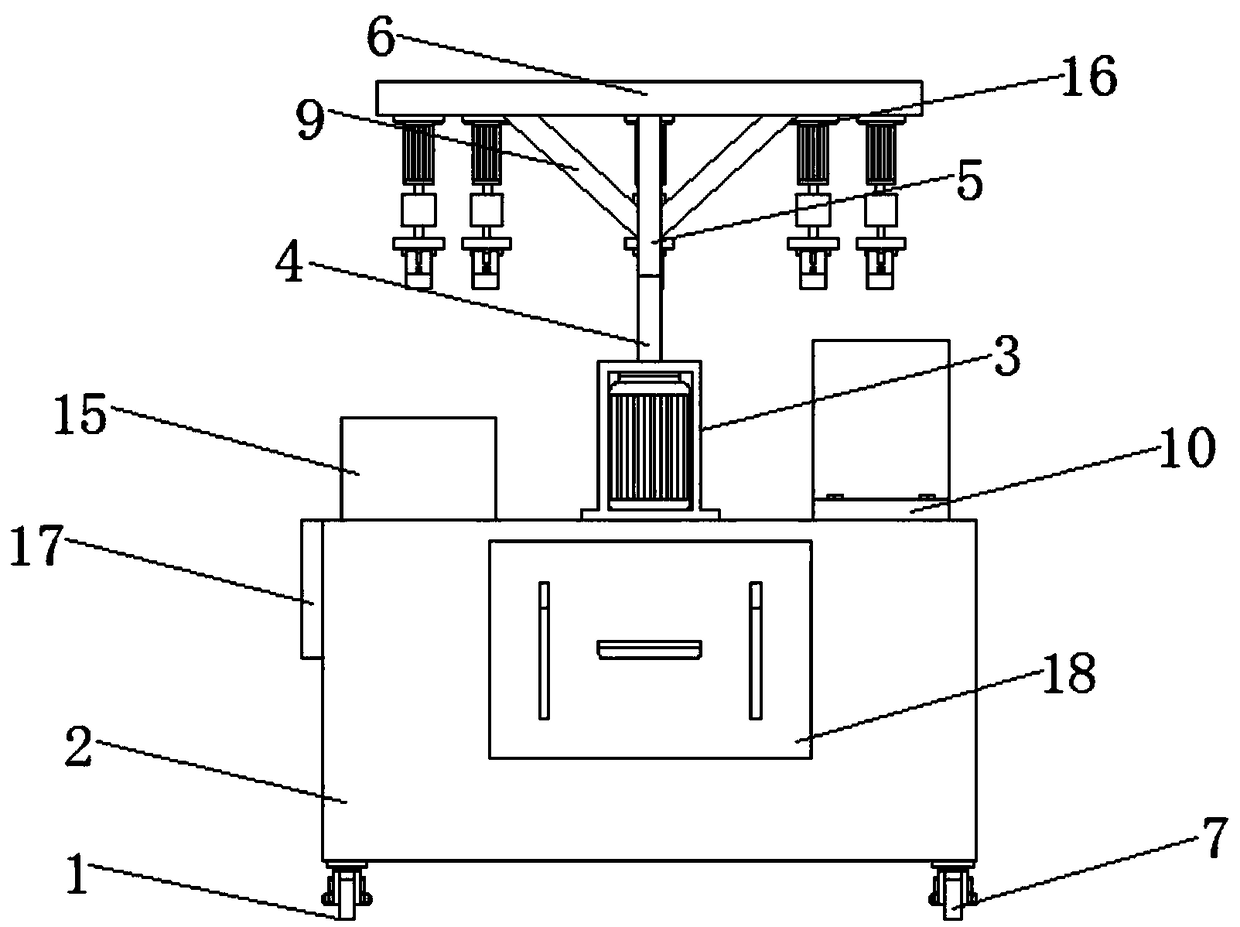

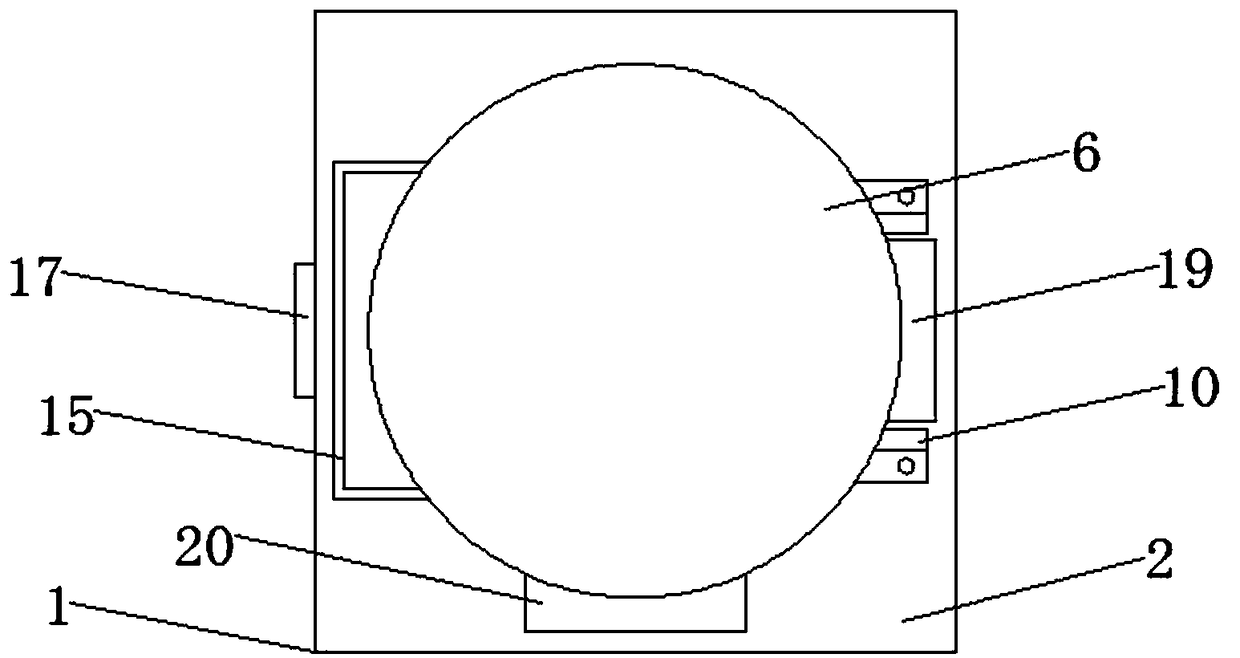

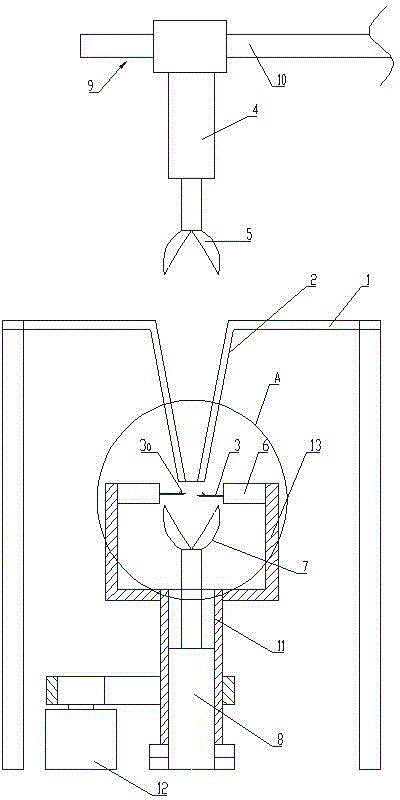

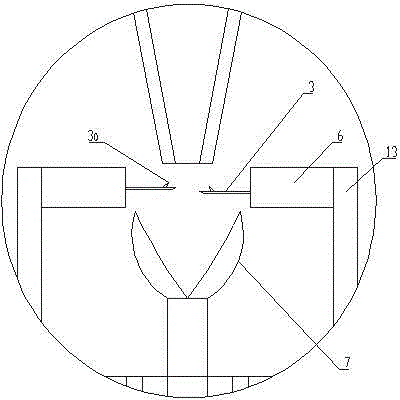

Automatic boning machine for chicken feet

The invention discloses an automatic boning machine for chicken feet. The automatic boning machine comprises a rack and a chicken feet positioning barrel arranged on the rack, wherein two bone scraping knives with blade points opposite to each other are arranged below the chicken feet positioning barrel, and the bone scraping knives are in sliding match with the rack; the automatic boning machine further comprises a first mechanical arm vertically arranged above the chicken feet positioning barrel and a first actuating mechanism for controlling the first mechanical arm to move up and down, as well as a second actuating mechanism connected with the bone scraping knives, and a bone pulling mechanism, wherein the two bone scraping knives can move opposite to each other under driving of the second actuating mechanism and clamp the chicken feet through the respective blade points; and the bone pulling mechanism comprises a second mechanical arm arranged at the lower part of the space between the two bone scraping knives and a third actuating mechanism for controlling the second mechanical arm to move up and down. With the adoption of the automatic boning machine for chicken feet, the technical problem that the existing manual boning operation is high in labor intensity, high in labor cost and low in production efficiency is solved.

Owner:南通市华夏时丽网络科技服务有限公司

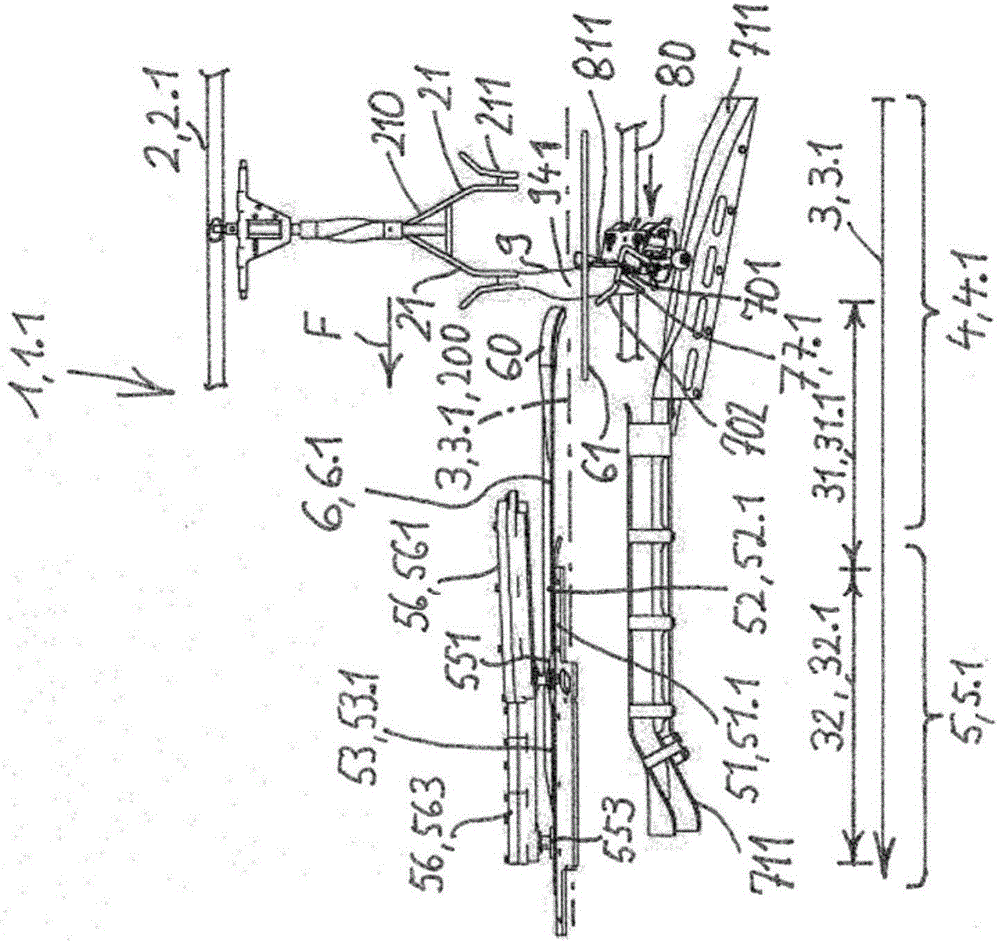

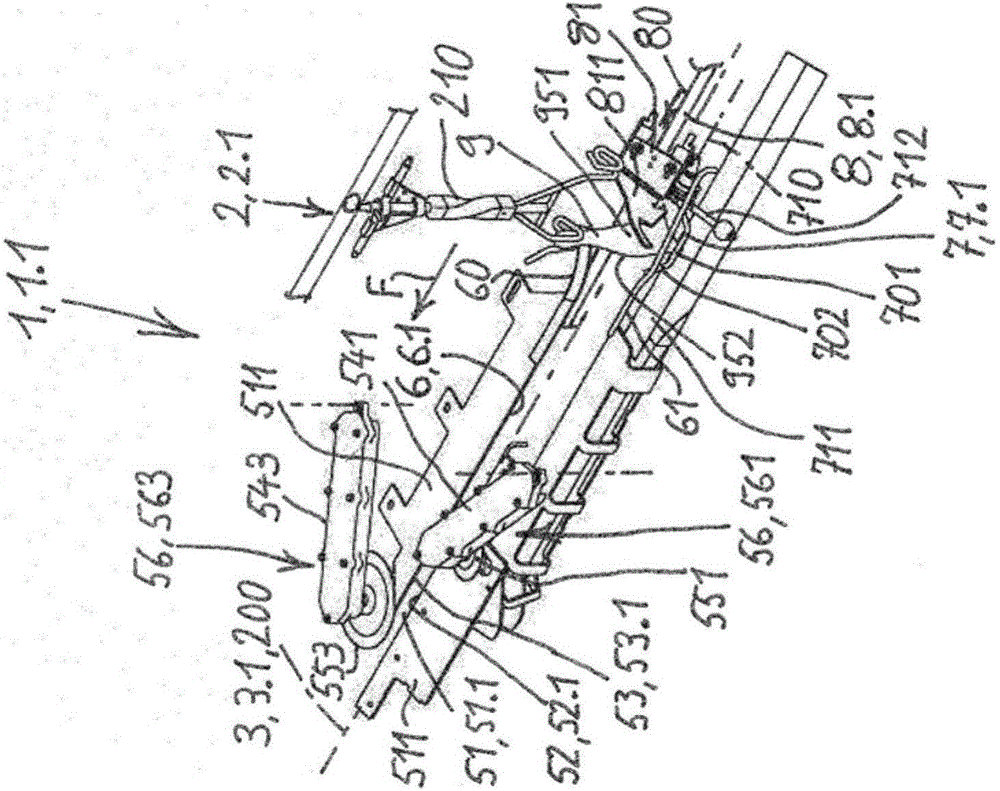

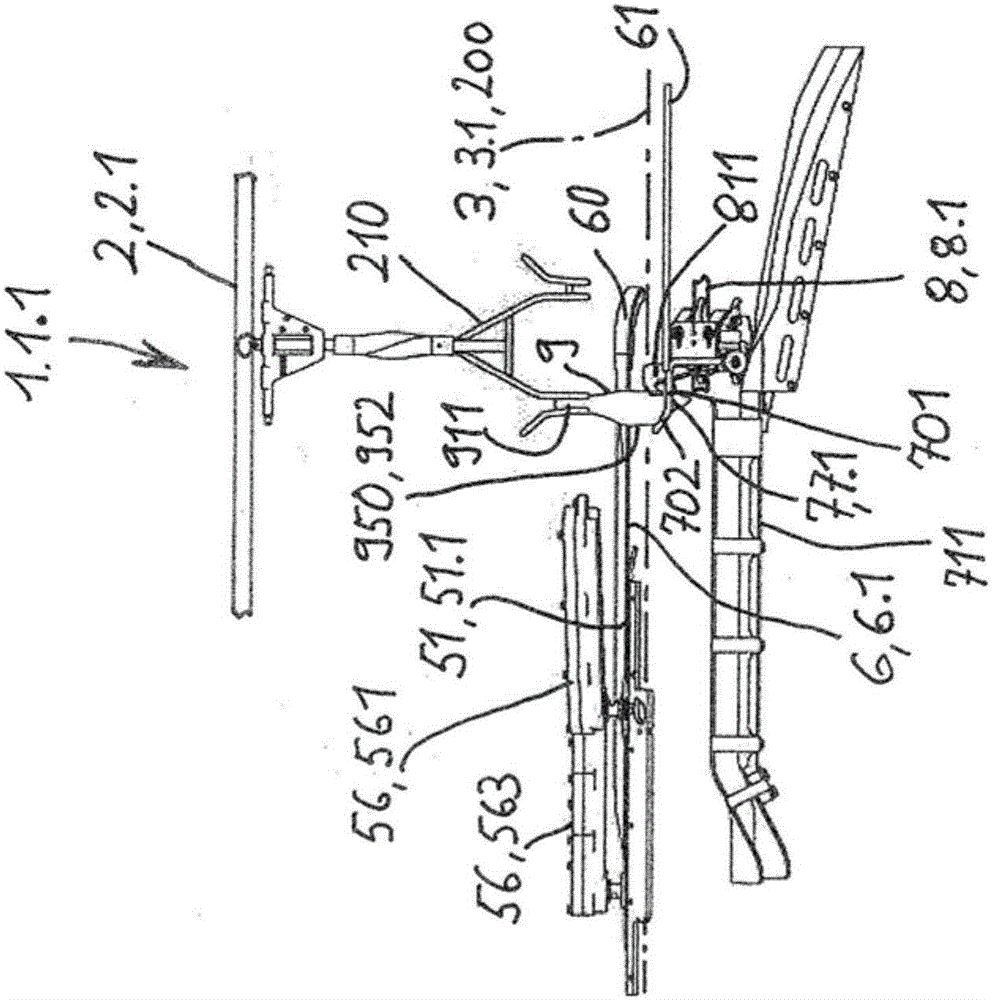

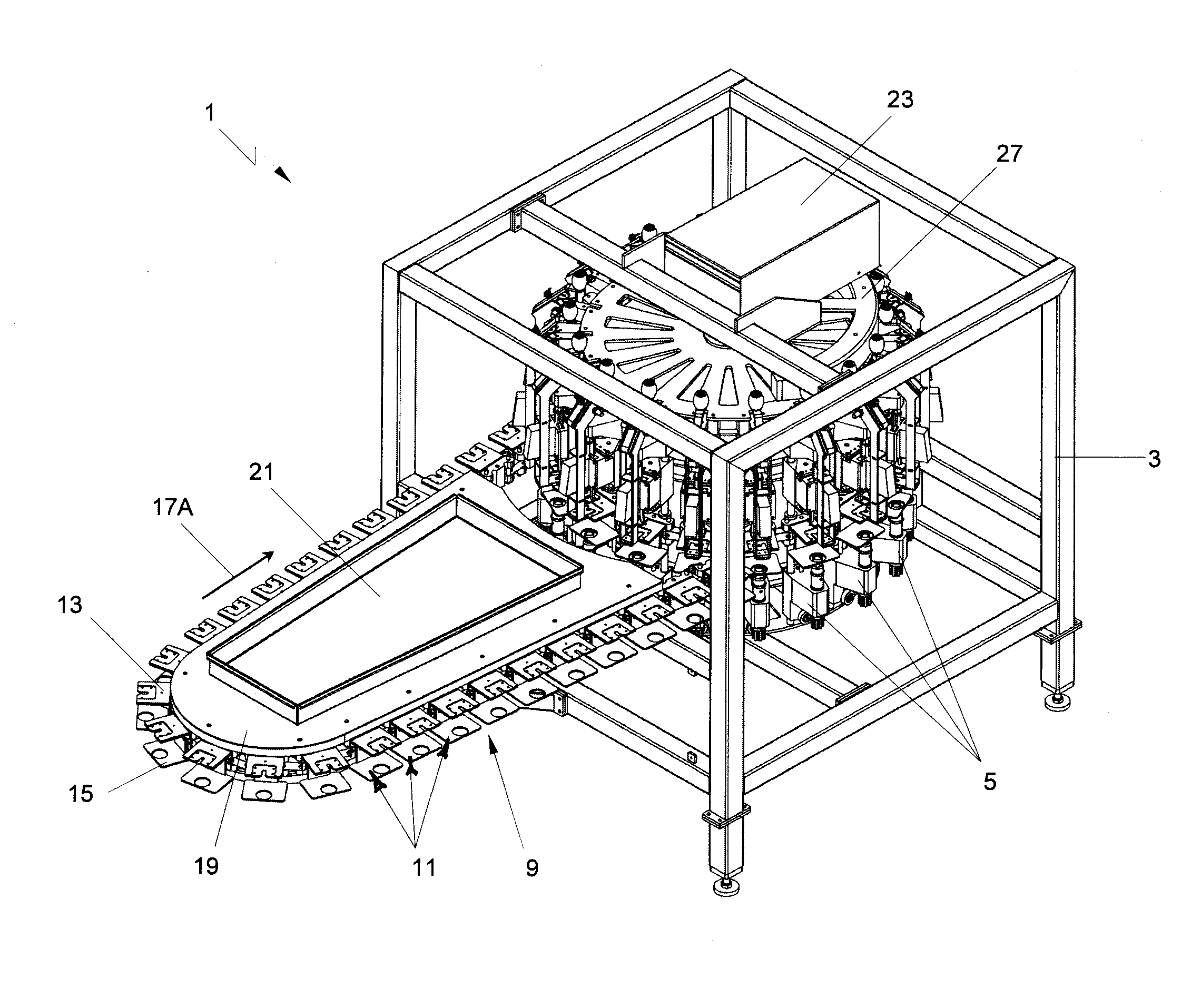

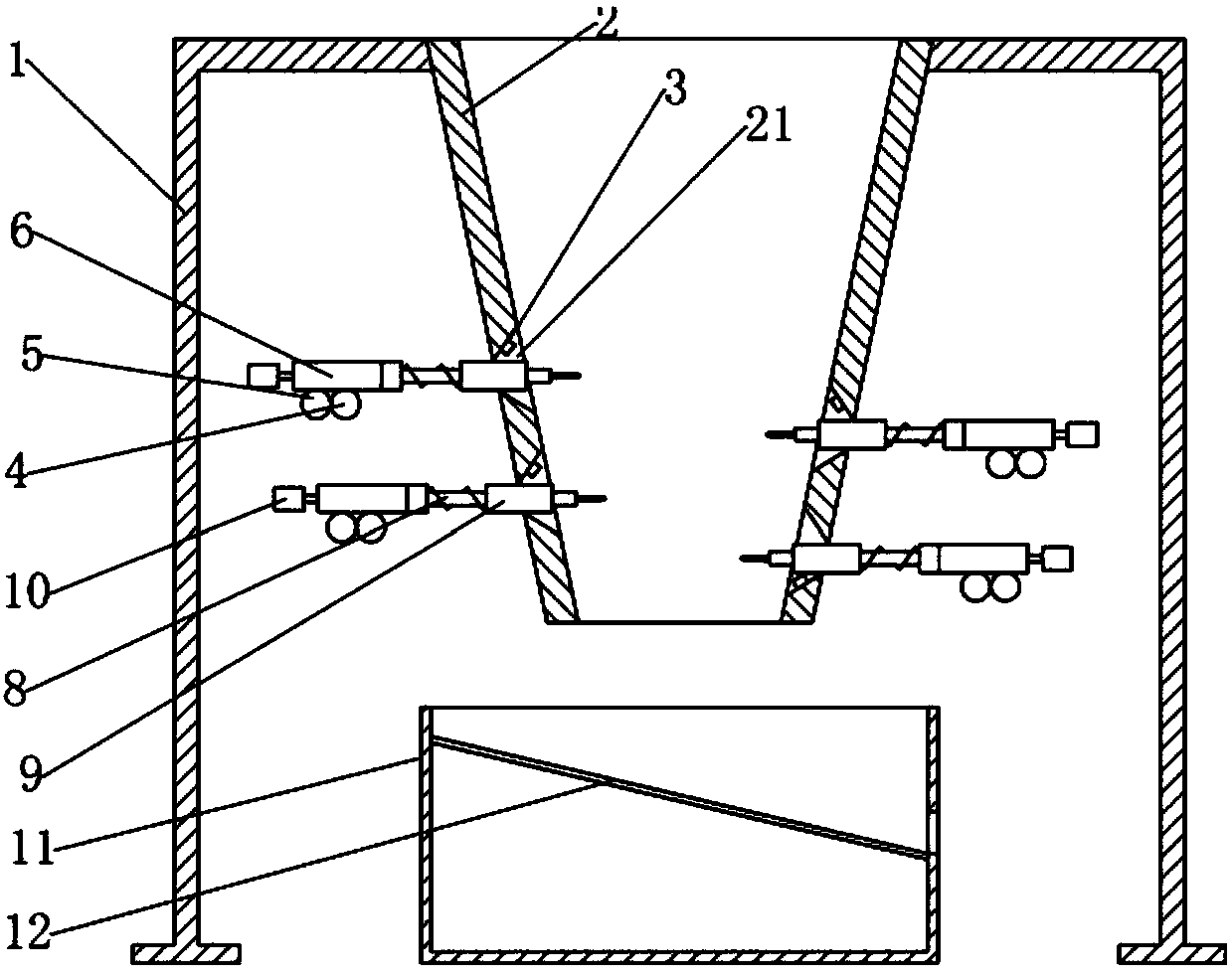

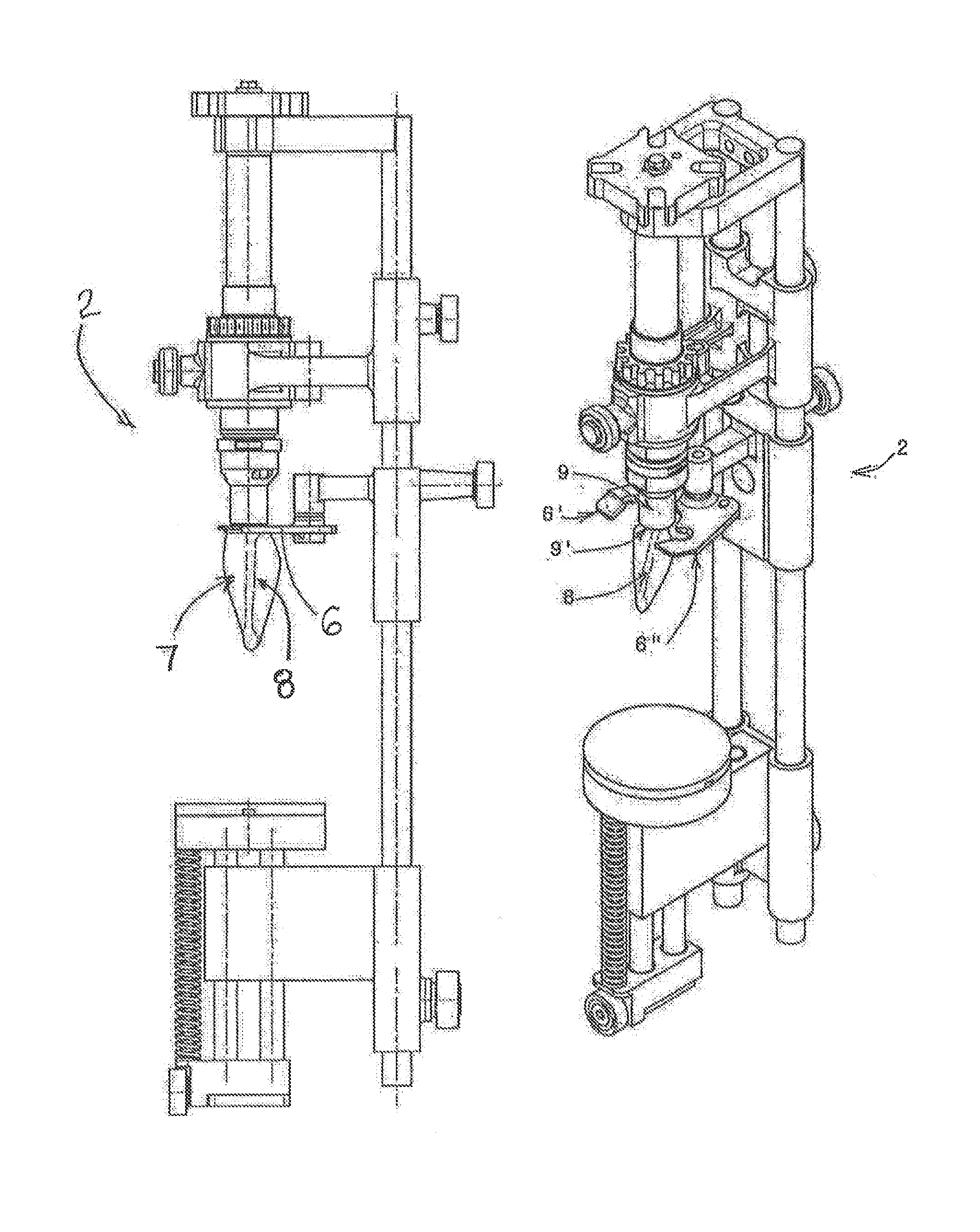

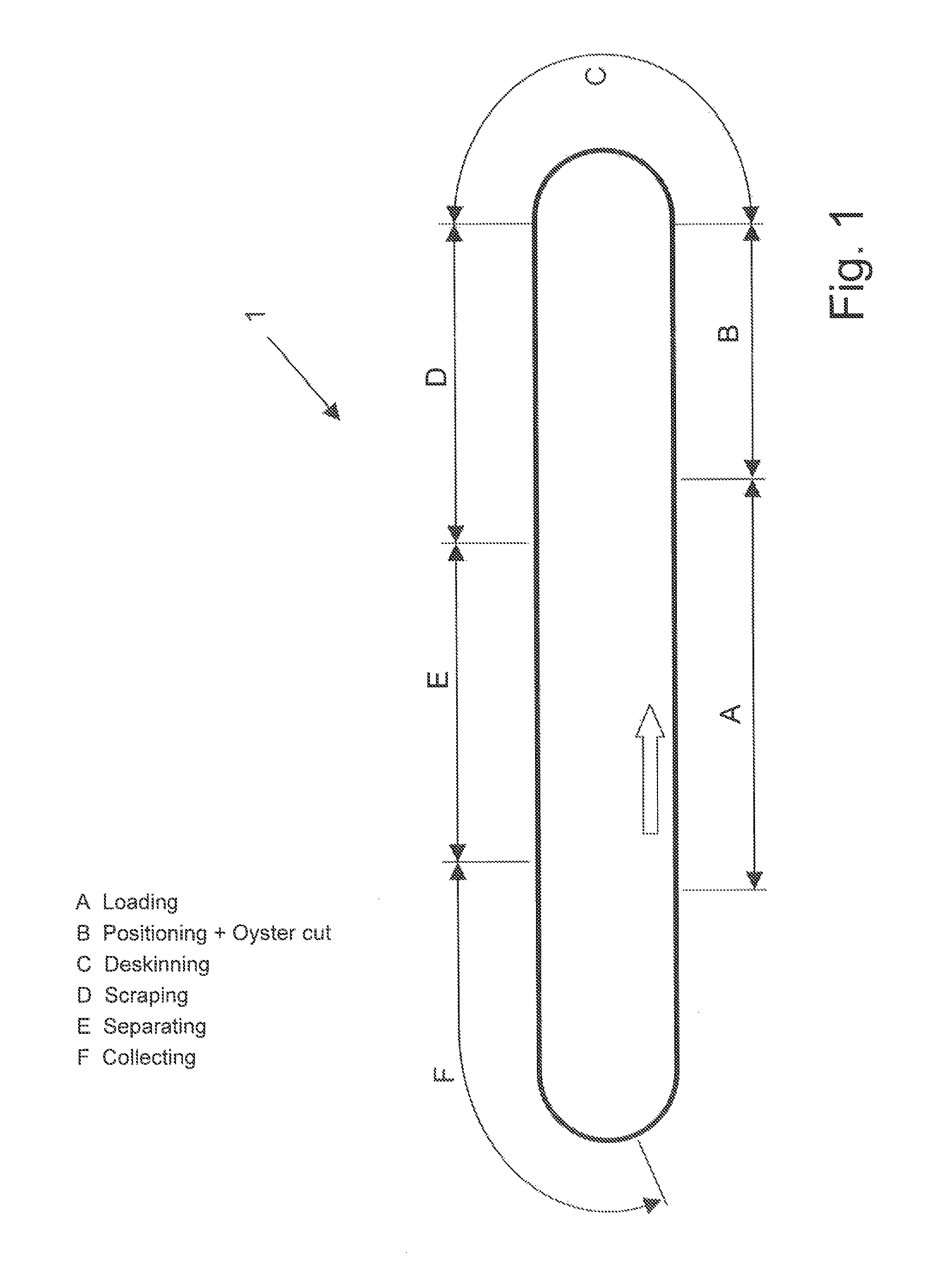

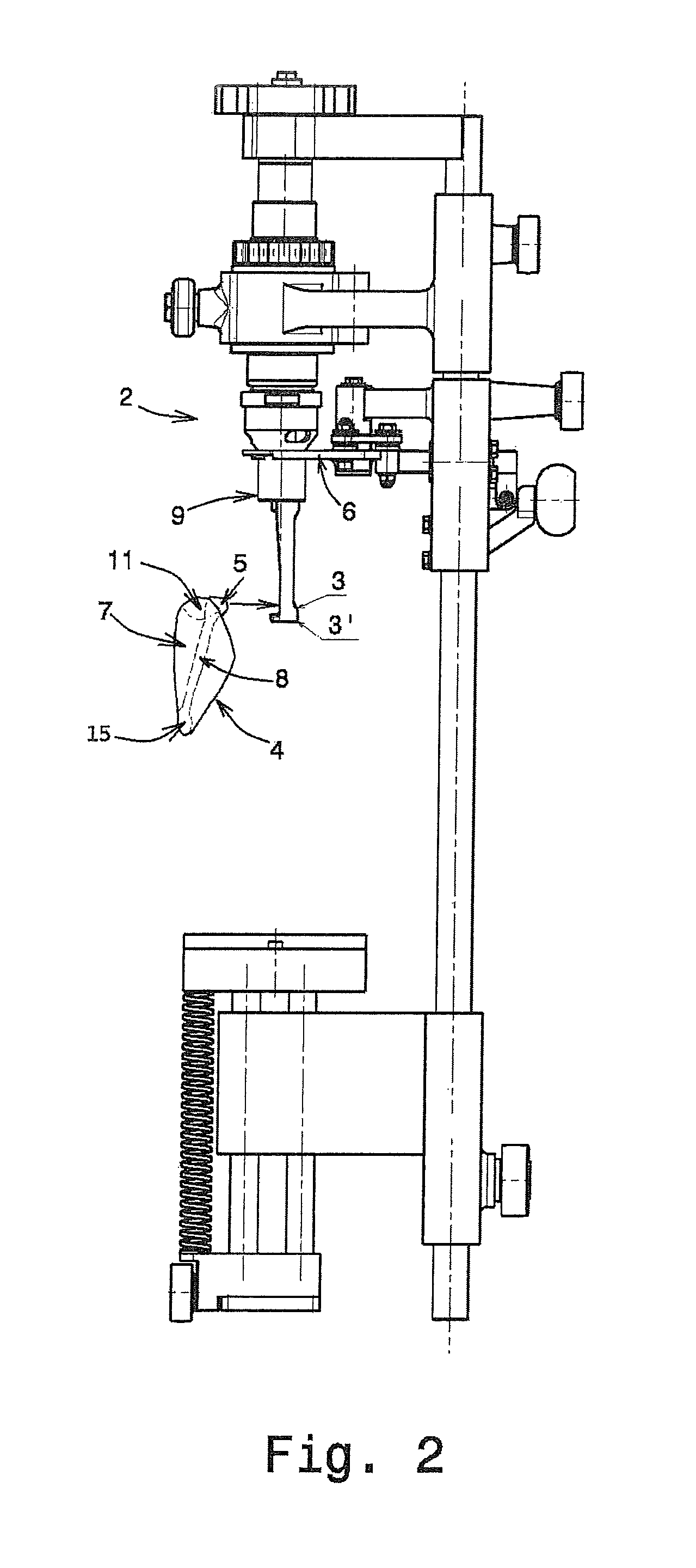

Positioning device for positioning poultry legs conveyed in single file in the conveying direction along a conveyor section and the method comprising said positioning for removing the thigh meat from poultry legs

A positioning device (1) for positioning poultry legs (9) conveyed hung in single file comprises a flexing device (4) for flexing and positioning the poultry legs and a stationary holding and guiding device (5). The flexing device (4) forms a hooking device for suspending the poultry leg (9) at the region of the knee joint (93) in a holding and guiding slot (51) of the holding and guiding device (5). Travelling positioning elements (7) are formed by driven press elements which grip the poultry leg (9) from below on an axial leg side (940) to flex and lift said leg. Each travelling positioning element (7) forms, with a stationary positioning element (6), a functional pair of positioning elements (6, 7). One of the two positioning elements (6, 7) engages in the hollow of the knee (95) of the poultry leg (9) while the other positioning element (6.2; 7.1) is configured for placement on the thigh (92) on the front side (941) of the leg. Processing stations (56) can be arranged along the holding and guiding slot (51). In a method, carried out during the conveying, for removing the thigh meat from the poultry legs (9) conveyed in single file, said poultry legs are axially conveyed in a first said positioning device (1.1) with a transverse leading lateral side (950) of the leg and in a second said positioning device (1.2) with an axially leading knee cap side (940) of the leg. Cuts are made at the front side (941) of the leg and at the back side (942) of the leg along the first stationary holding and guiding slot (51.1). Cuts are made at the lateral sides (950) of the poultry leg along the second stationary holding and guiding slot (51.2), and the thigh meat (922) is pushed to the proximal end of the thigh bone (921).

Owner:BAADER FOOD SYST DENMARK AS

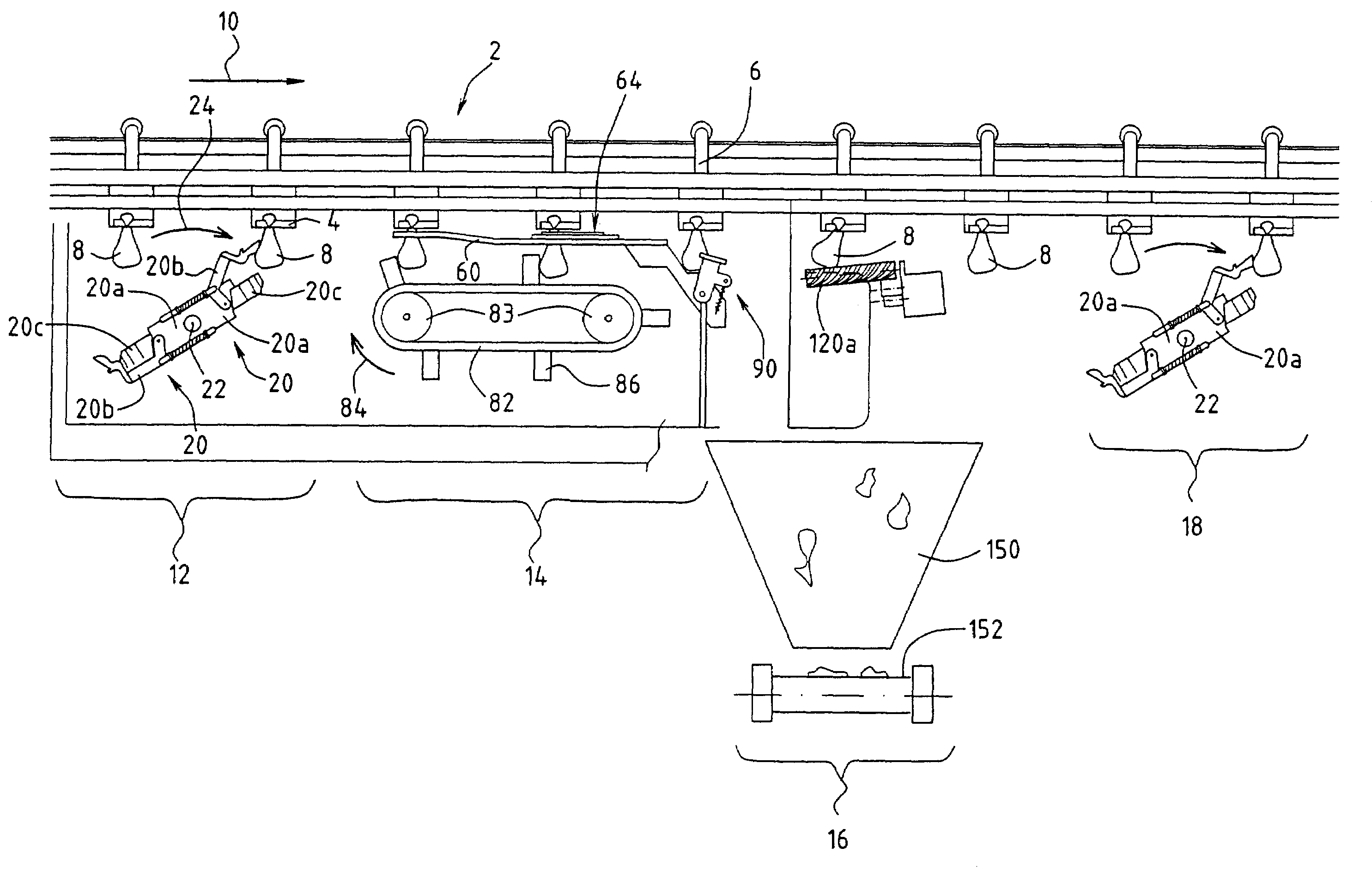

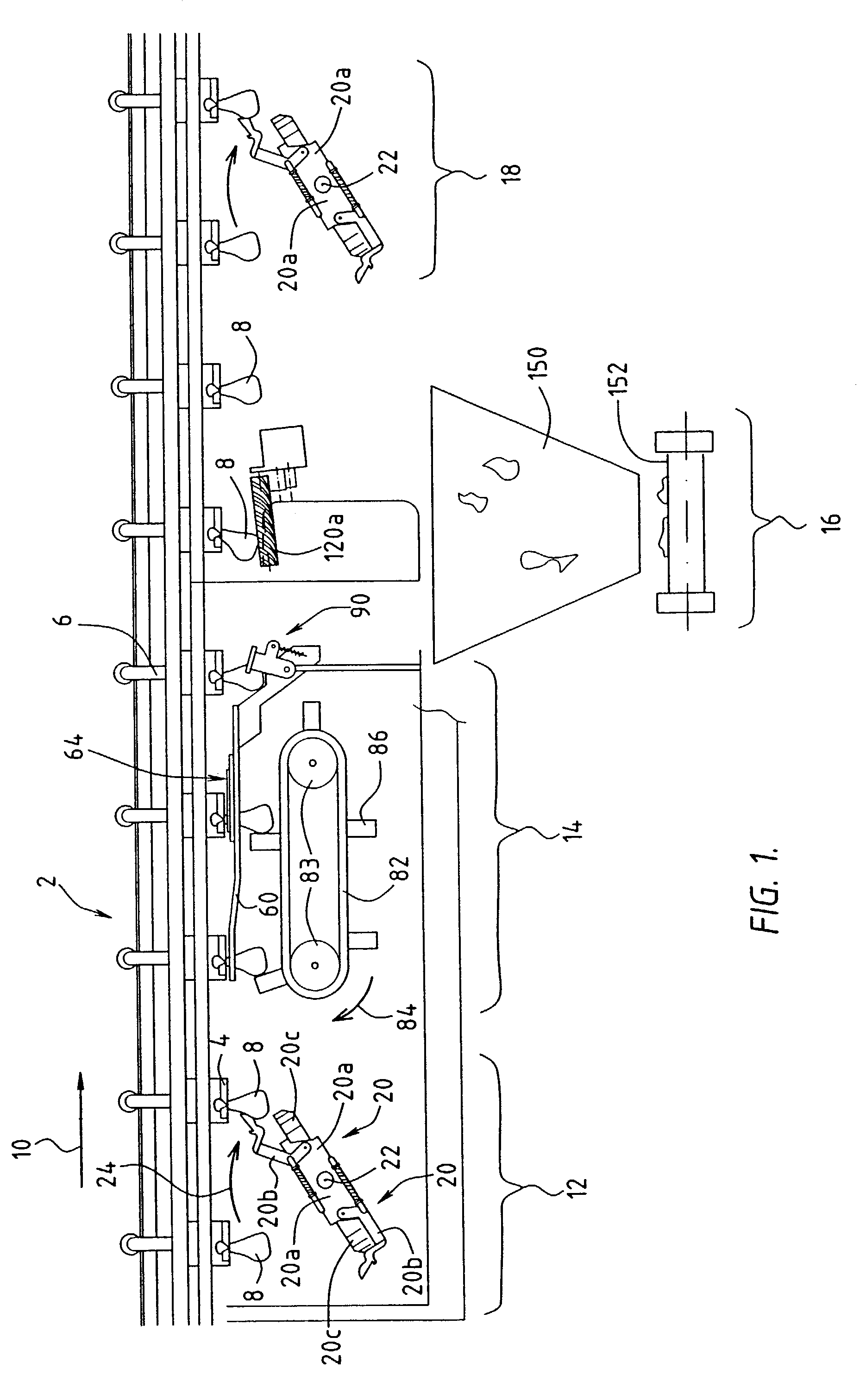

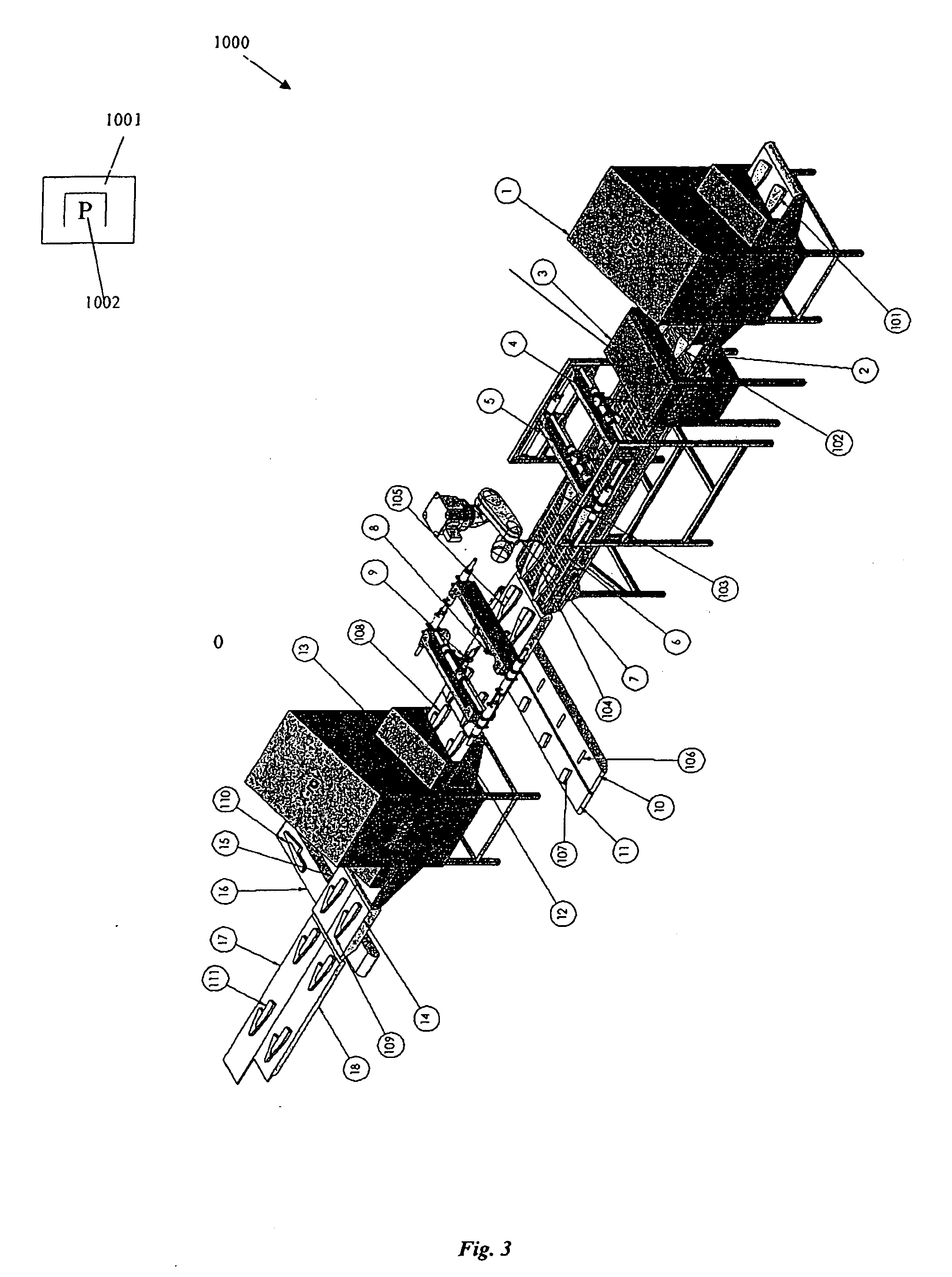

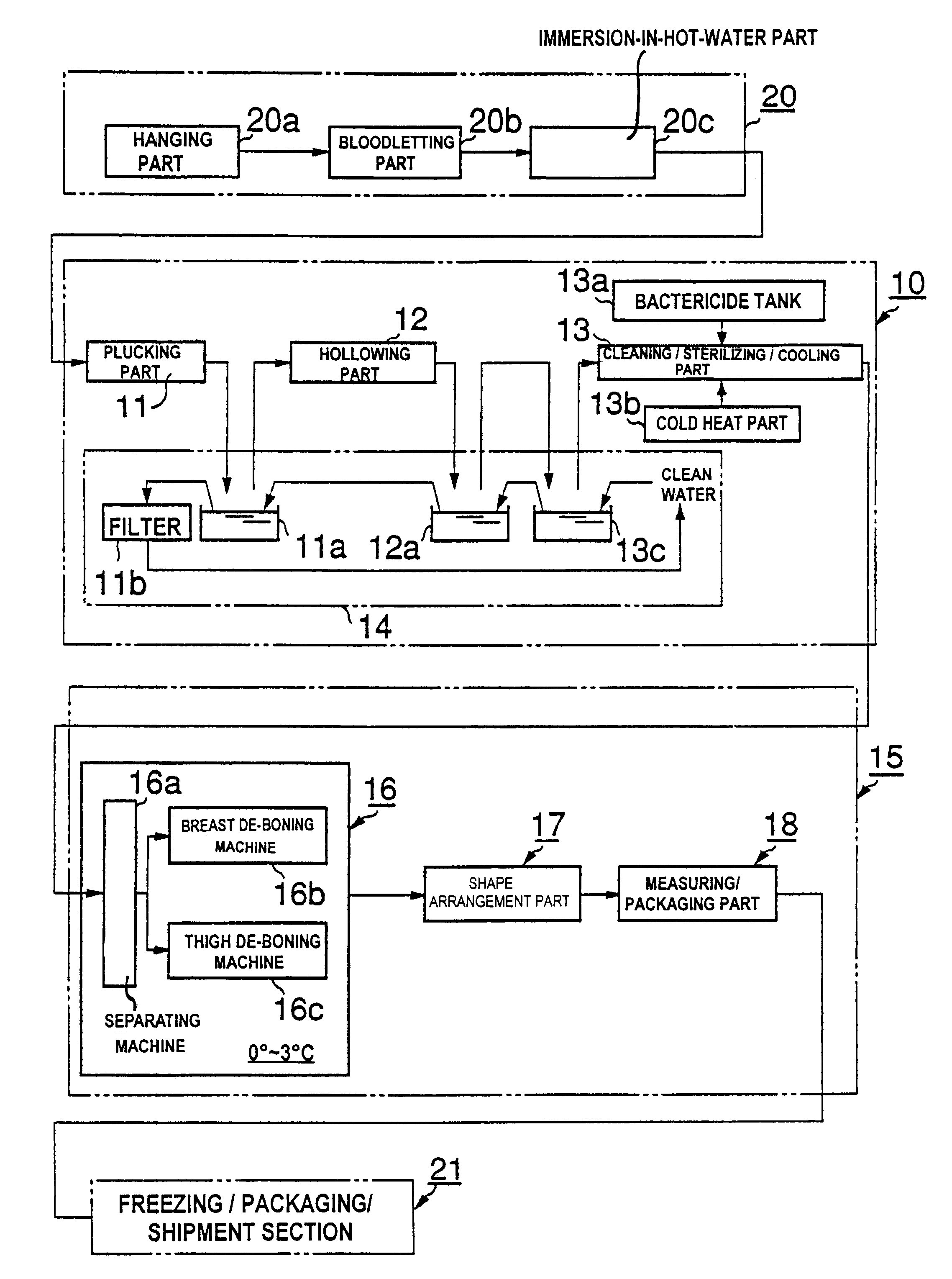

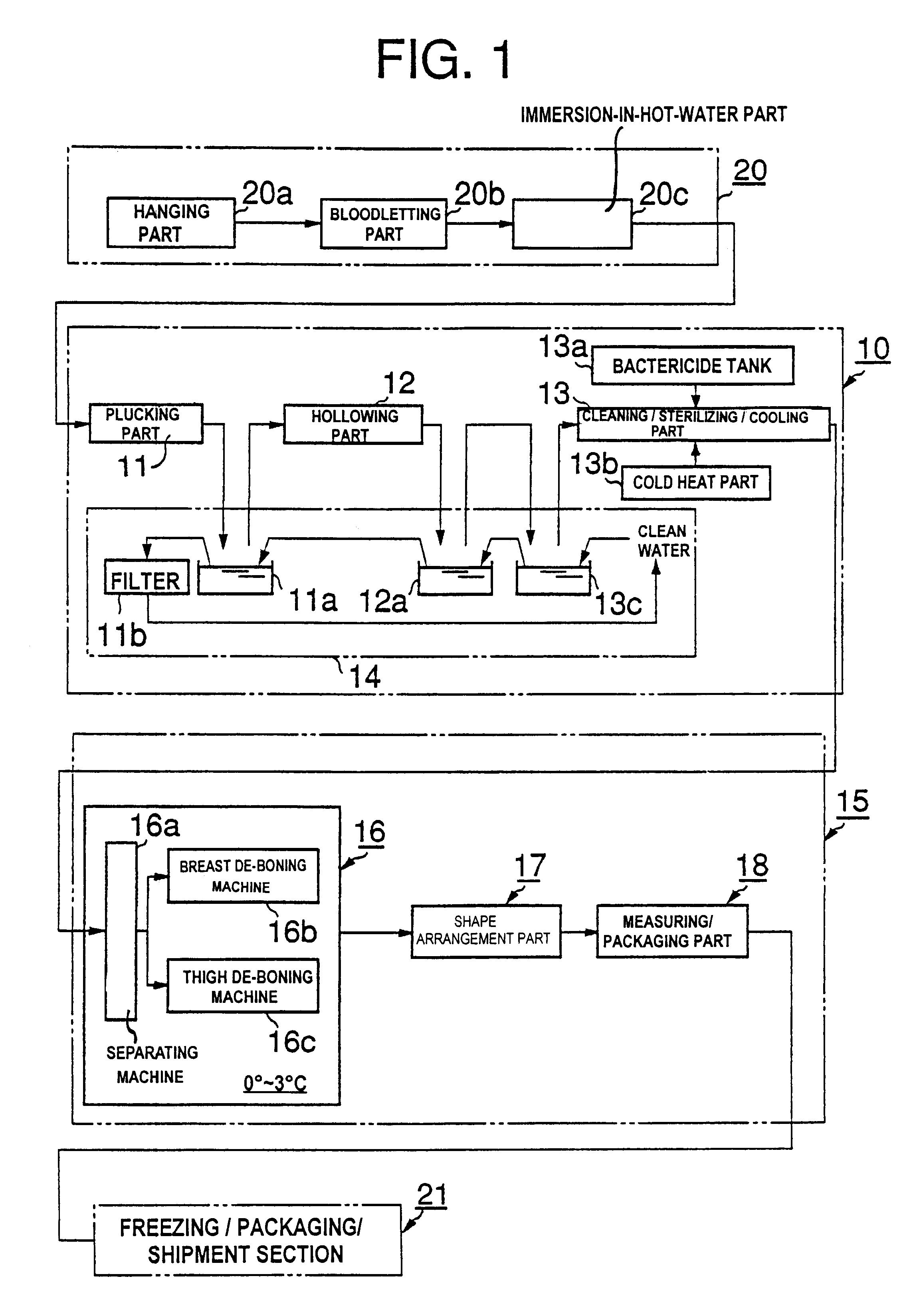

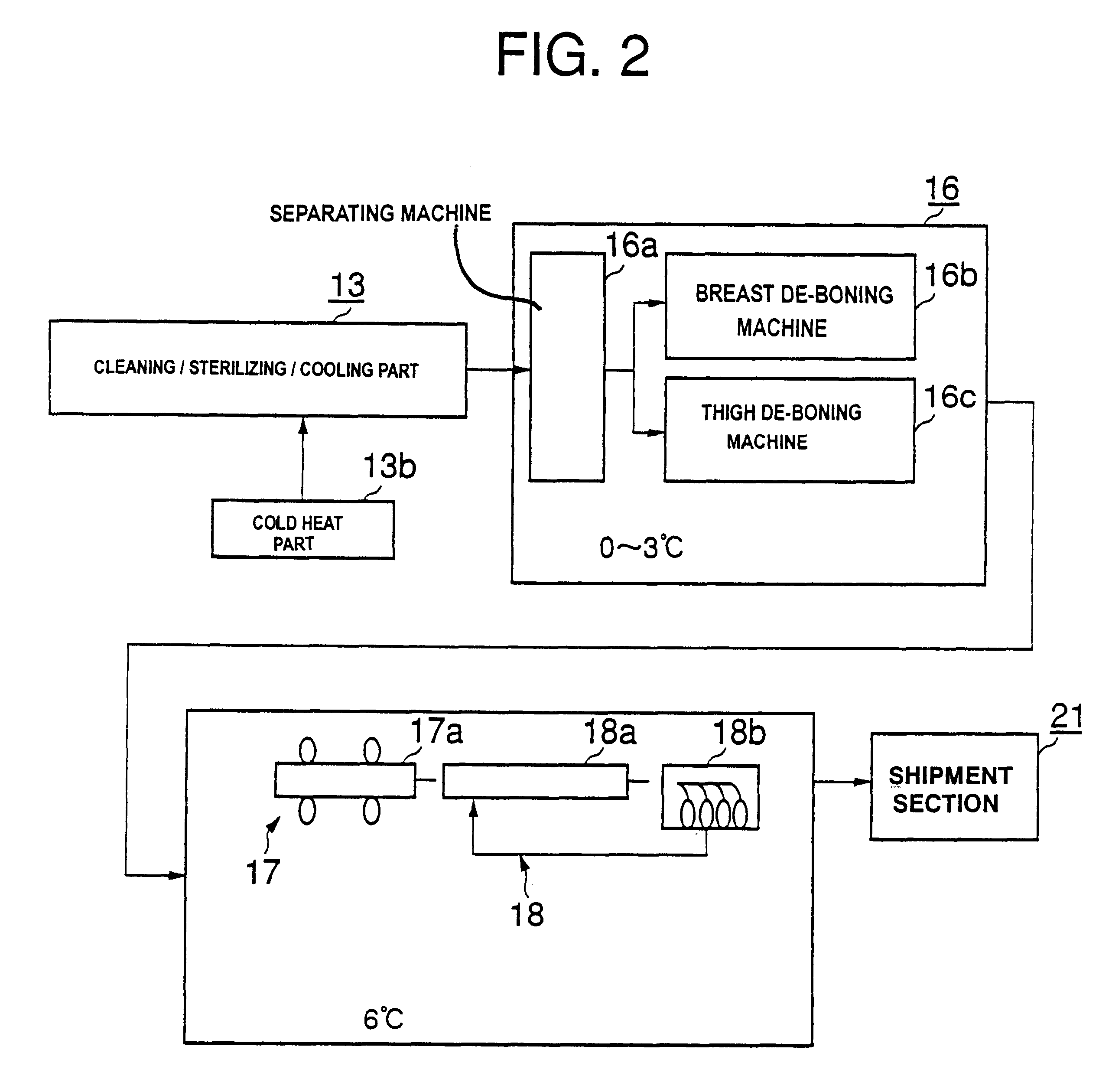

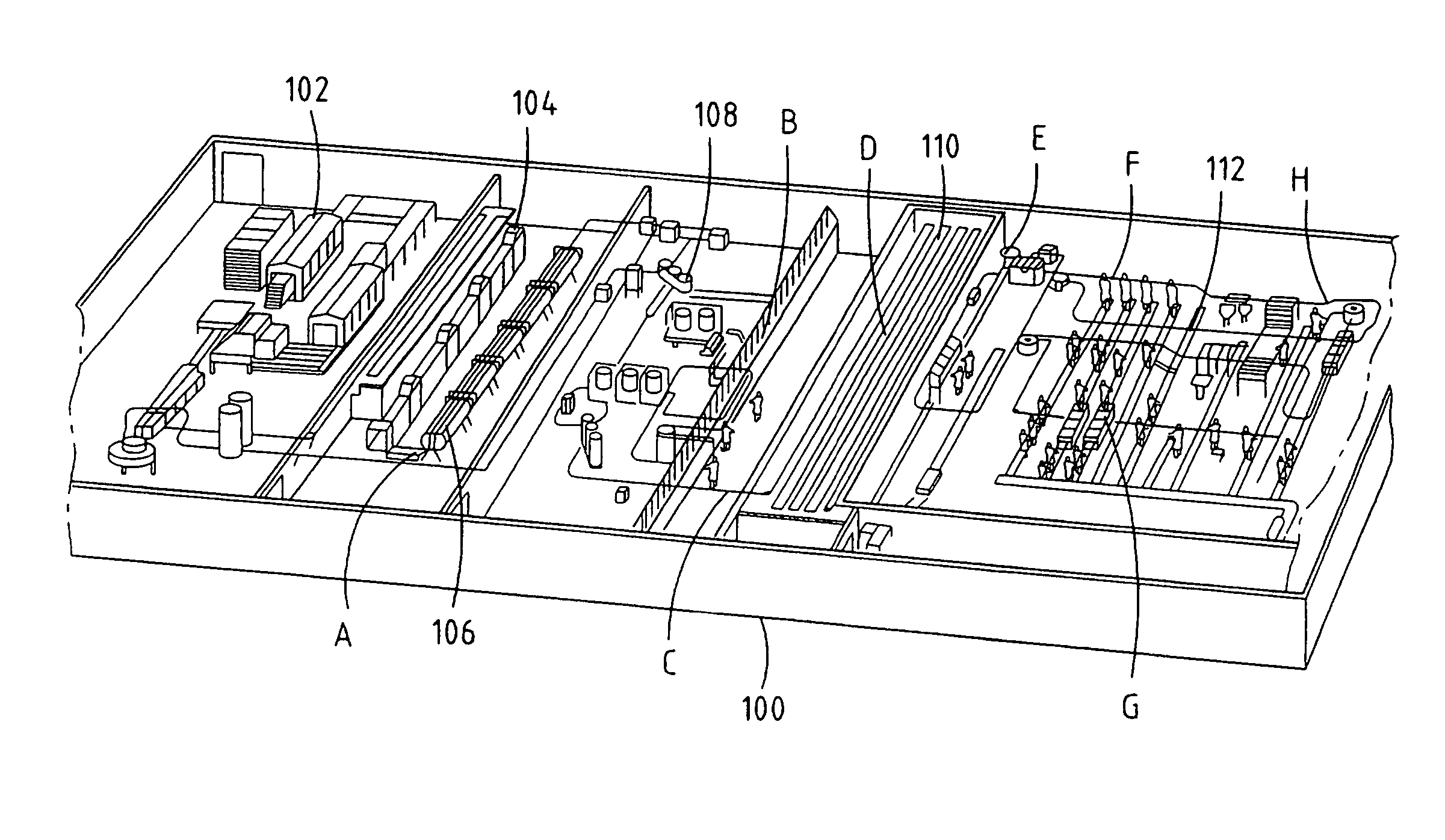

Poultry processing method and system

A poultry treatment system relating to dissection, shape arrangement, and dispensing treatment, which can prevent the growth of bacteria in cleaning, cooling, and succeeding treatment processes for making possible the securing of the least contaminated state (the number of common live bacteria carried by a packed article of 2 kg is 102), composed of; a pretreatment section 20 comprising hanging part 20a, bloodletting part 20b, immersion-in-hot-water part 20c; a treatment section 10 comprising a plucking part 11, hollowing part 12, cleaning / sterilizing / cooling part 13, and water-washing part 14; a dissecting / dispensing / packaging section comprising a automatic dissection part 16, shape arrangement part 17, dispensing / packaging part 18; and shipment section 21.

Owner:MAYEKAWA MFG CO LTD

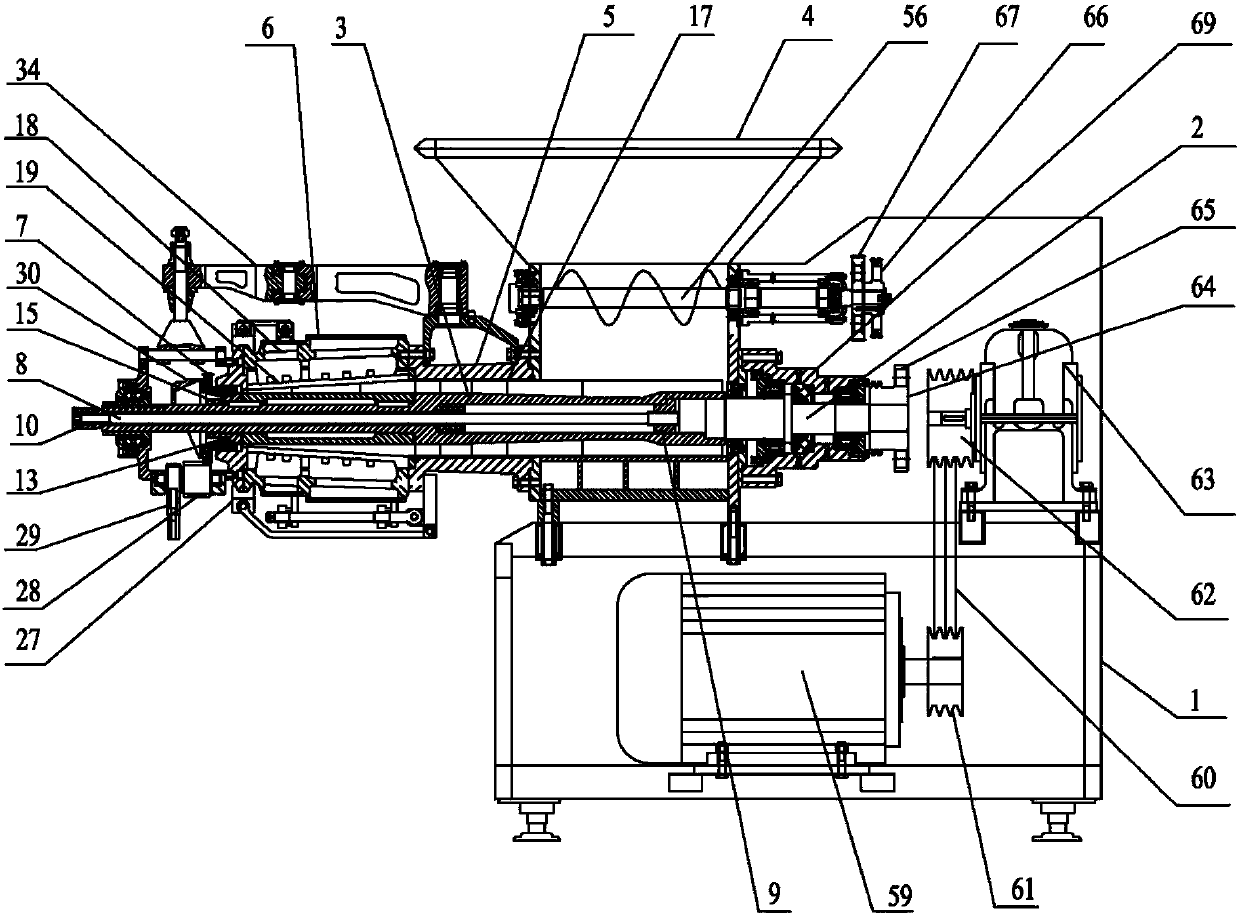

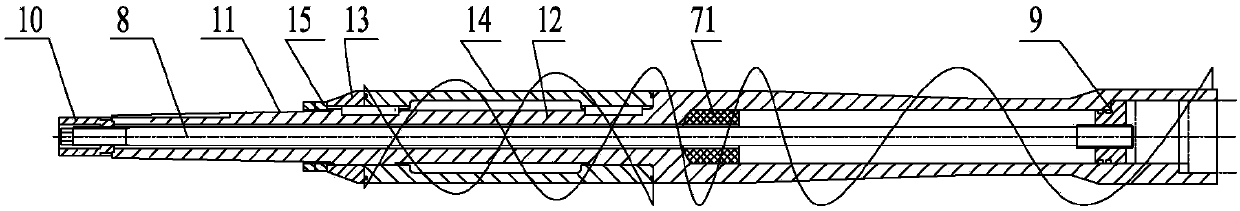

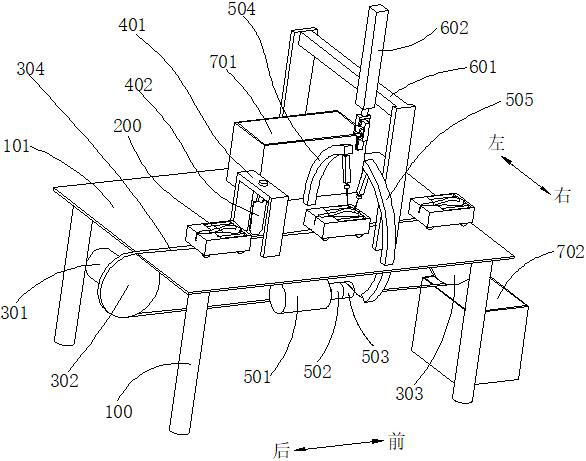

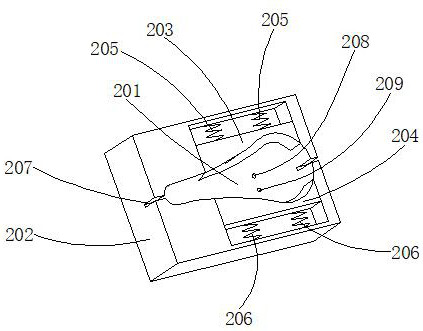

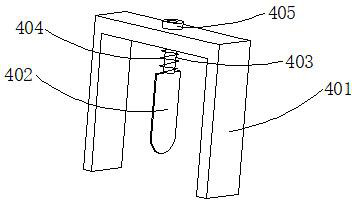

Fully automatic chicken feet deboning machine

The present invention discloses a fully automatic chicken feet deboning machine. The machine includes a fixture for fixing poultry soles, an ossa cruris removing knife assembly, a phalange removing knife assembly, and a cross sliding table mechanism for driving the above-mentioned ossa cruris and phalange removing knife assemblies to move in the horizontal and vertical direction. The fully automatic chicken feet deboning machine replaces manual operations, enables batch production of boneless chicken feet, and helps to improve industrial efficiency and realize mechanization and intellectualization.

Owner:CHONGQING JIAOTONG UNIVERSITY

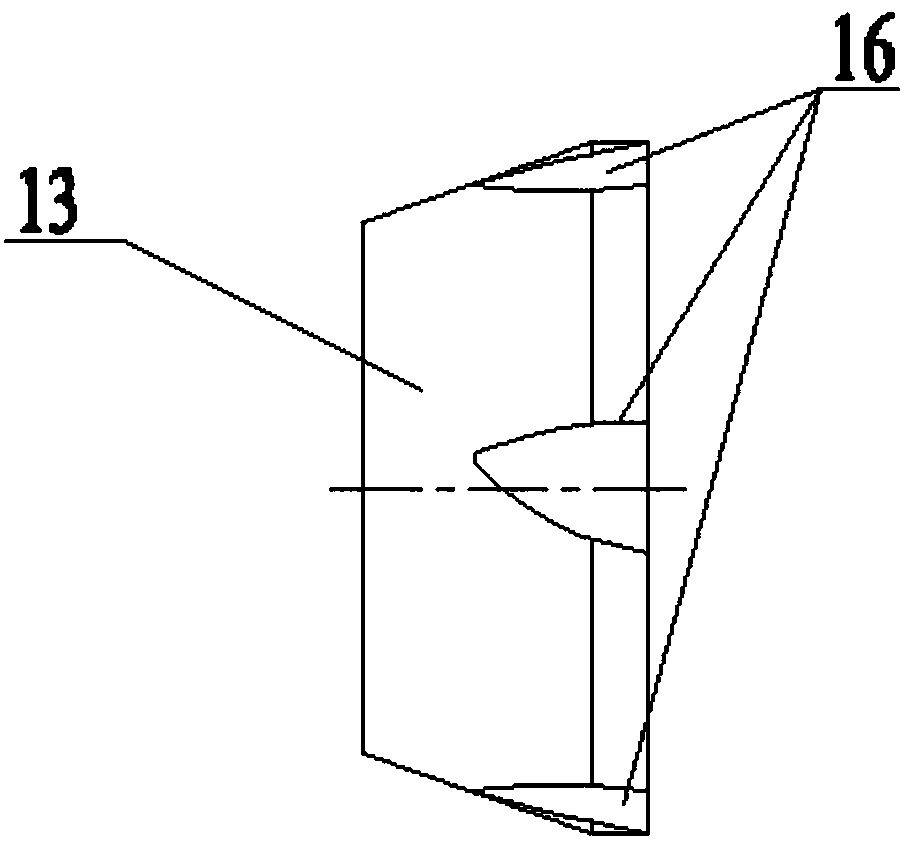

Method and Apparatus for Removing a Sleeve of Meat from an Animal Part Having Bone with Knuckles on Each of its Opposite Ends

A method of removing a sleeve of meat (D) from an animal part having a bone with a first knuckle (B) on one of two opposite ends of an elongate bone shaft (A) and a second knuckle (C) on another of the two opposite ends. The method includes the steps of engaging the bone of the animal part with a part of a meat stripper (13) between its first knuckle (B) and the sleeve of meat (D) and engaging the bone by a knuckle gripper (71) between the part of the meat stripper (13) and the first knuckle (B). The method continues with moving the meat stripper (13) and the knuckle gripper (71) away from one another, while stripping and gathering the sleeve of meat (D) towards the second knuckle (C). In a subsequent step the method discontinues moving away the meat stripper (13) and knuckle gripper (71) from one another upon the part of the meat stripper (13) engaging the second knuckle (C). A further method step then advances a meat cutter (51) in a direction towards the meat stripper (13) opposite of the knuckle gripper (71) to cut the sleeve of meat (D) gathered by the meat stripper (13) circumferentially around the second knuckle (C). The method finishes by retracting the meat cutter (51), disengaging the knuckle gripper (71), removing the bone from the gathered sleeve of meat (D) and from the meat stripper (13), and collecting the gathered sleeve of meat (D) for further processing. An apparatus for performing the method according to this method is also disclosed.

Owner:FOODMATE

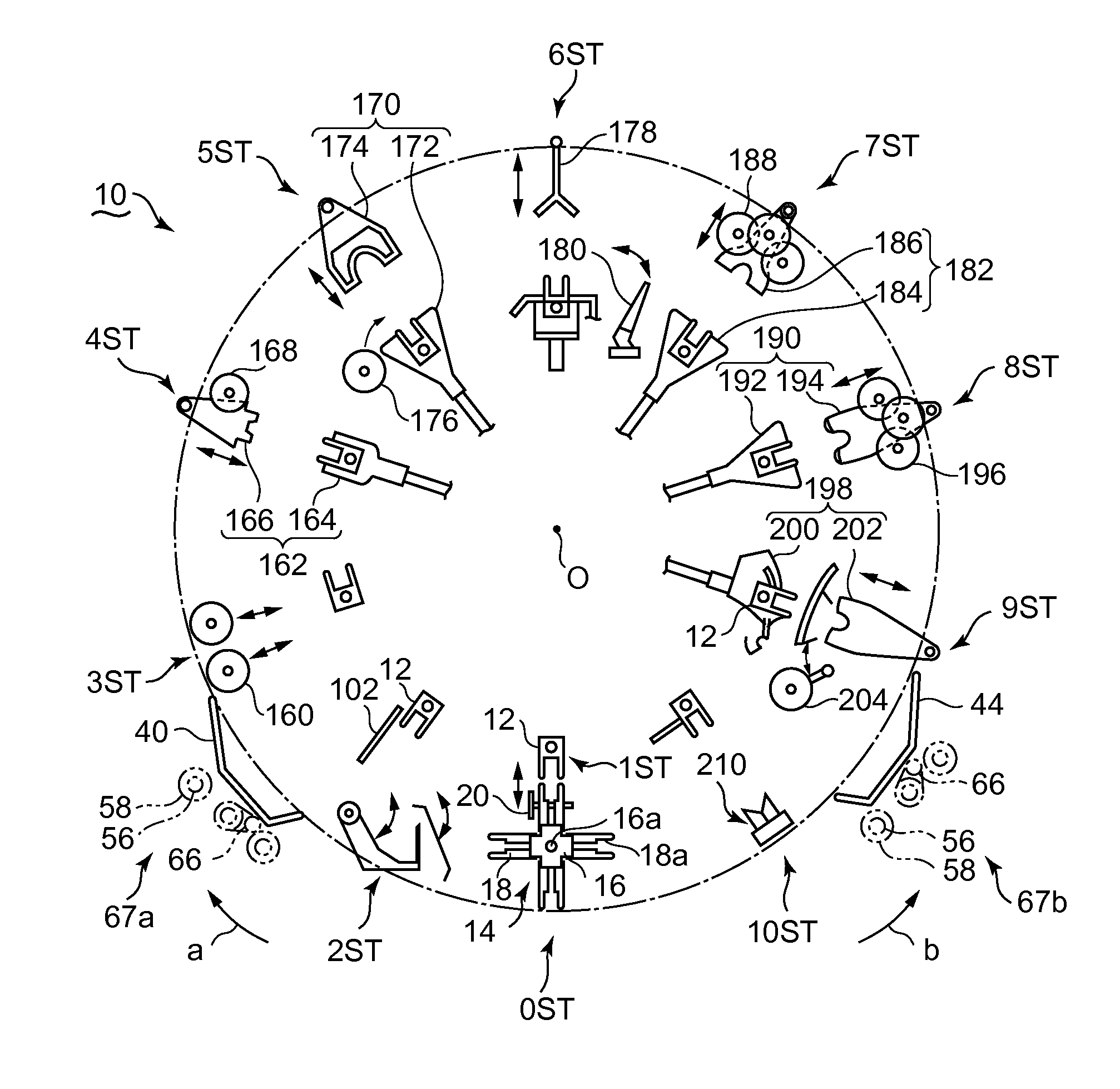

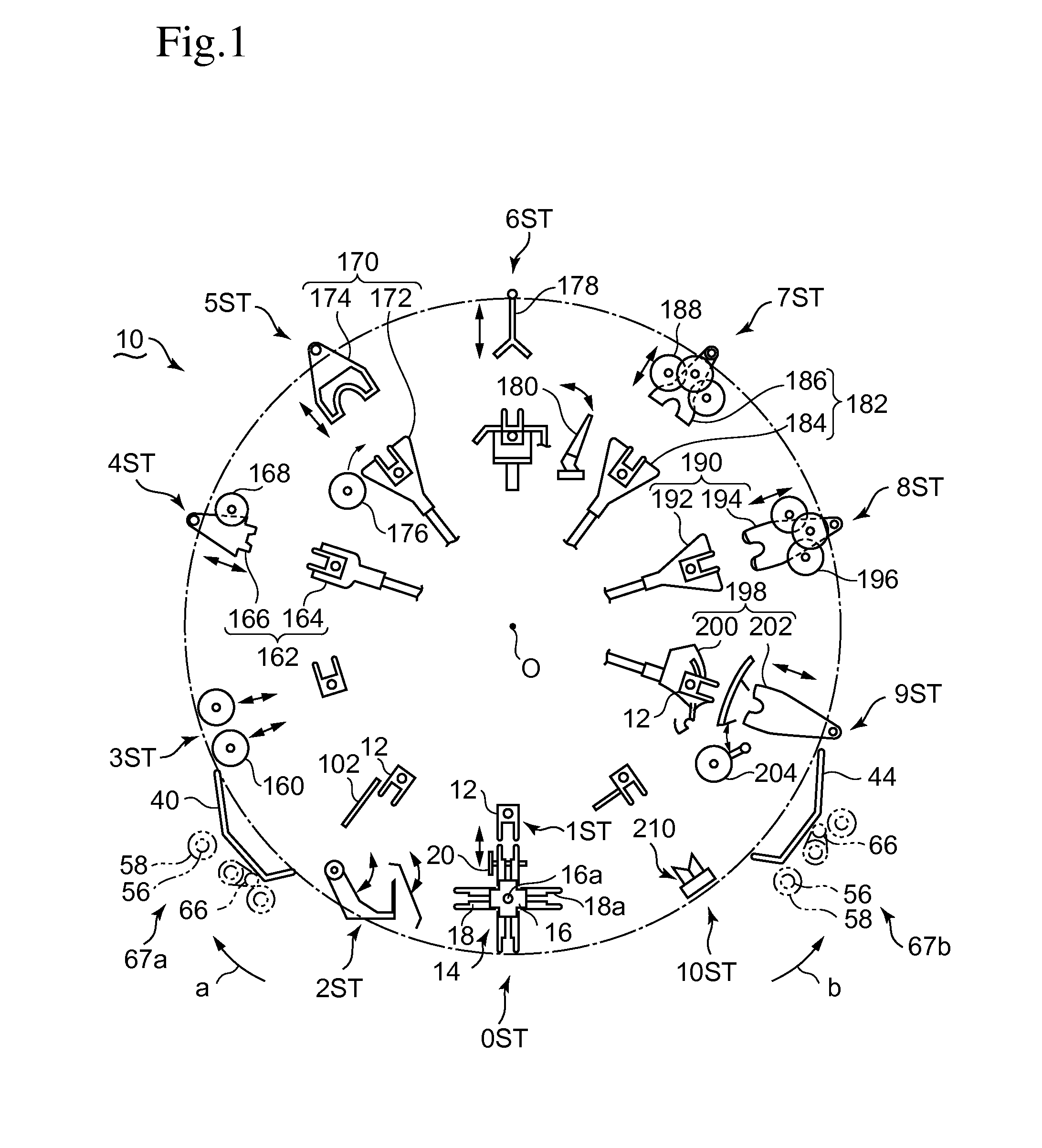

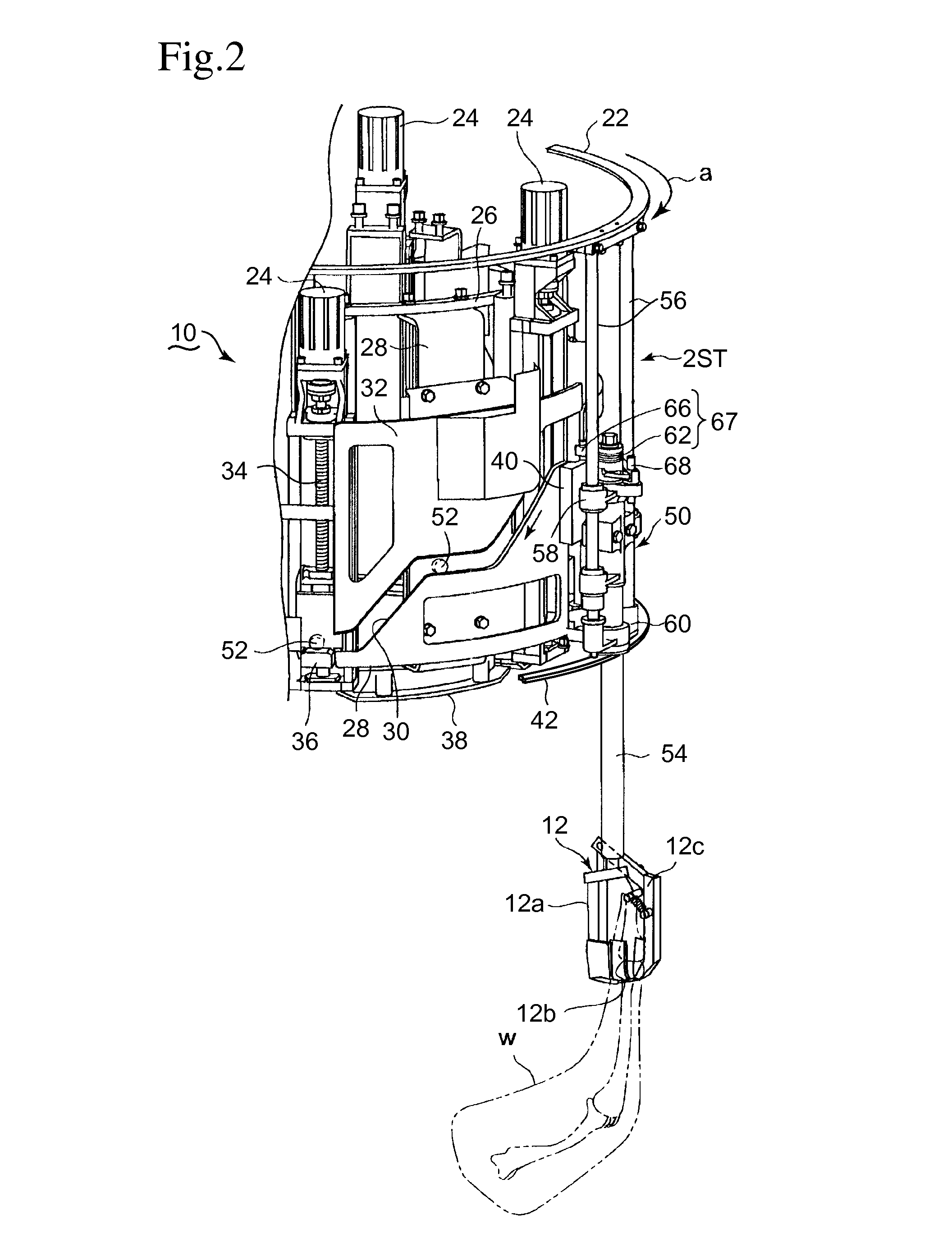

Device and method for deboning bone-in leg

ActiveUS9326527B2Increase productionQuality improvementPoultry deboningPoultry transferring/conveying devicesThighKnee Joint

In a deboning process, a knee joint length is measured in a work loading section of a first process station, and incision making of a thigh meat portion is performed in a second process station based on the measured knee joint length. At the same time, the entire length of a work is measured, and the knee joint length is calculated from previously collected data based on the measured entire length of the work. Positioning of a cutting blade and a meat separator is performed based on these values in subsequent process stations, and cutting of a tendon adhering to a knee joint and tearing of thigh meat are performed. A thigh bone is separated from a lower thigh in a further process station.

Owner:MAYEKAWA MFG CO LTD

Efficient bone and meat separation device and method

The invention discloses an efficient bone and meat separation device and method. The device comprises a separation mold, a drumstick placing cabin is arranged in the separation mold; a pair of slidinggrooves are formed in the bottom of the drumstick placing cabin; sliding blocks are movably arranged in the sliding grooves. An extrusion spring is further movably arranged in each sliding groove. One end of the extrusion spring is fixedly connected to the side edge of each sliding block; the ends, away from the sliding blocks, of the extrusion springs are fixedly connected to the inner walls ofthe sliding grooves. Extrusion blocks are fixedly mounted at the ends, away from the telescopic baffles, of the telescopic connecting rods. An ankle bag cutting knife, a side leg cutting blade and a bone and meat separation knife are sequentially arranged along the moving line of the separation mold; the ankle bag cutting knife is movably cooperated with an ankle bag cutting groove. According to the efficient bone and meat separation device and method, complete bones are removed so that bones and meat are fully separated, the separated meat is not doped with broken sclerotin, meanwhile, the complete meat structure of meat products is reserved, and the taste and the additional value of the meat products are improved.

Owner:BENGBU COLLEGE

Flesh separating machine

ActiveCN107690282AEasy to separateImprove separation rateBone cleaning devicesPoultry deboningDrive shaftEngineering

The invention discloses a flesh separating machine which comprises a machine frame, a driving mechanism, a transmission shaft, a screw shaft, a feeding hopper, a pressurizing part and a flesh separating part. The separating screw shaft part is a conical screw shaft, and the flesh separating part is also a conical component coaxially sleeved on the outer periphery of the separating screw shaft; theinner wall of the separation screw shaft is provided with a clearance fit with the outer wall of the separation screw shaft part; the side wall of one end of the separation part near the pressurizingpart is provided with a clearance gap; a control valve is arranged on the outer periphery of the front end of the separation screw shaft part and the front end of the separation screw shaft part; a slag discharge gap is arranged; the screw shaft is a hollow screw shaft which is internally provided with an adjusting rod; one end of the transmission shaft is fixedly provided with a connecting part.One end of the adjusting rod is screwed with the connecting part, and the other end of the adjusting rod extends out of the screw shaft and extends out of the flesh separating part. The flesh separating machine makes the inner wall of the flesh separation part and the outer wall of the spiral shaft always in a relatively stable gap fit state, which improves the service life.

Owner:SUNBY MACHINERY CO LTD

Chicken claw bone removing device and working method thereof

The invention discloses a chicken claw bone removing device. The device comprises a rack, a chicken claw positioning cylinder arranged on the rack and a bone pulling mechanism, wherein two boning knives with opposite knife points are arranged at the bottom of the chicken claw positioning cylinder; the bone pulling mechanism comprises a second manipulator arranged below the position between the two boning knives and a third execution mechanism for controlling the second manipulator to move up and down; the chicken claw bone removing device further comprises a rotating shaft and a motor for driving the rotating shaft to rotate, an annular fixing frame is coaxially arranged above the rotating shaft, the two boning knives are rotationally and symmetrically arranged on the fixing frame around the center axis of the fixing frame, and the boning knives are in sliding fit with the fixing frame in the radial direction of the fixing frame. With the adoption of the chicken claw bone removing device, chicken claw bone removal automation is realized, and the technical problems of high labor intensity, high labor force cost and low production efficiency of manual bone removal at present are solved.

Owner:山东鸿毅食品有限公司

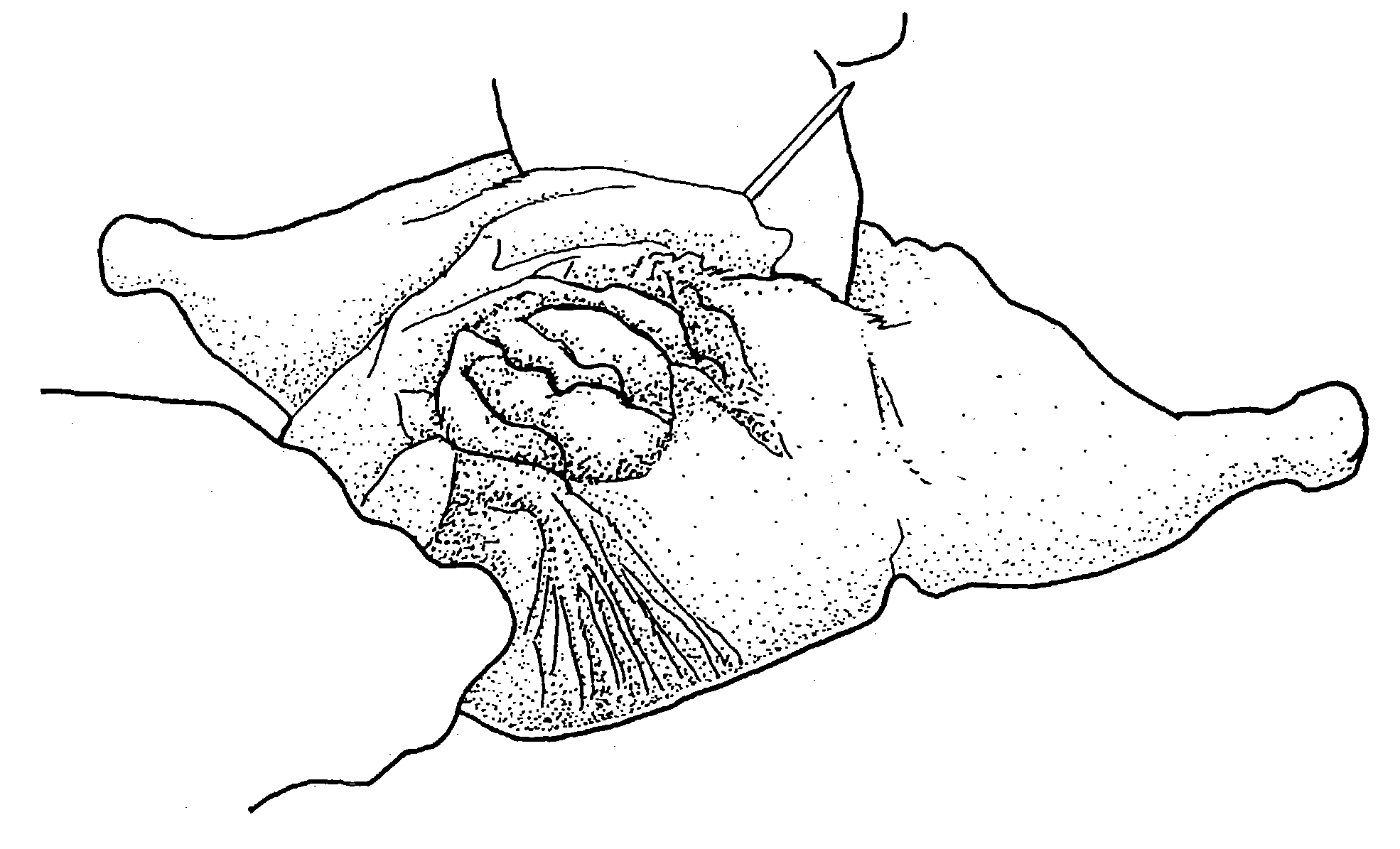

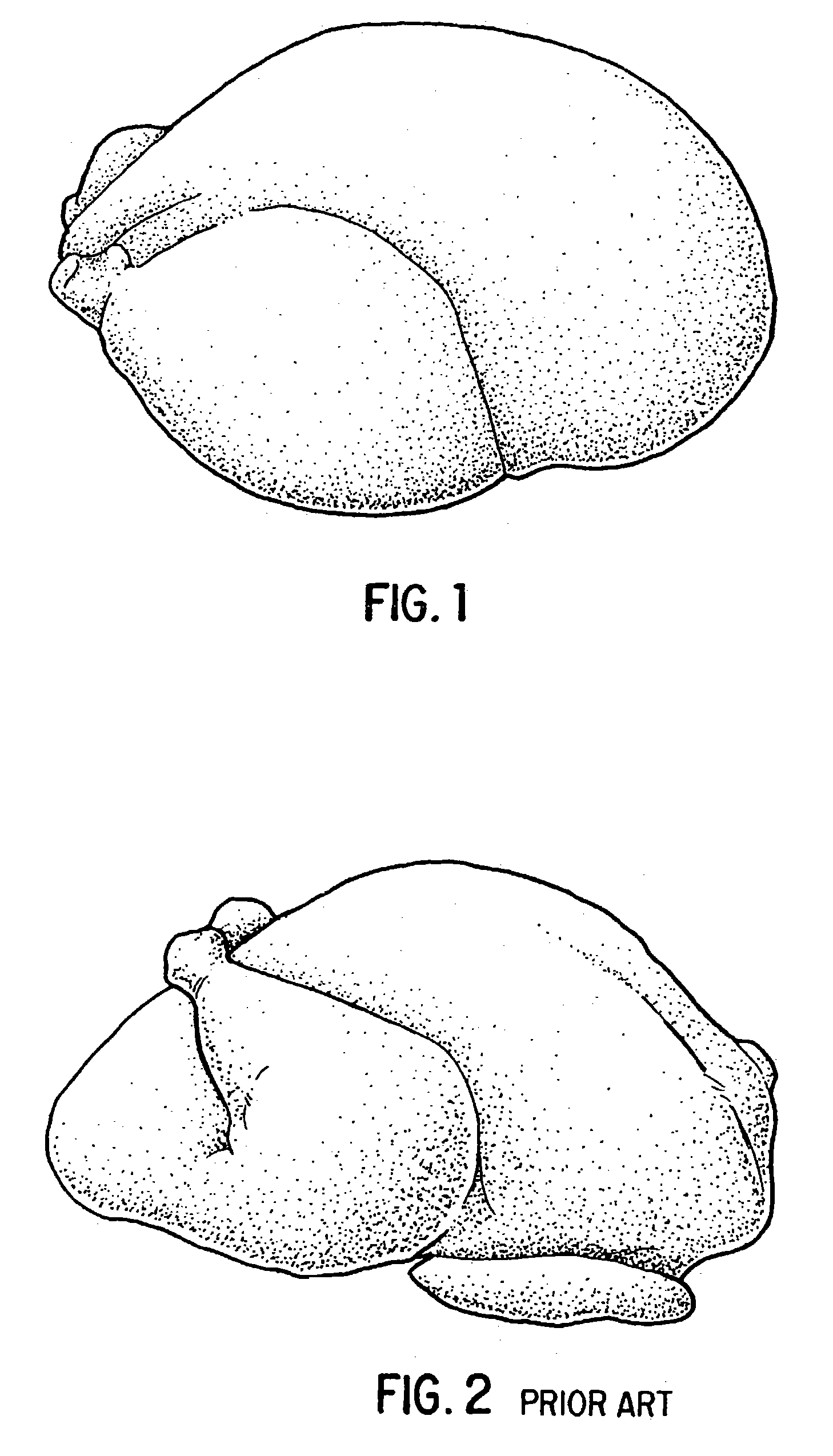

Semi-boneless poultry product

The present invention relates to a semi-boneless poultry product and a method of making thereof wherein bones of a poultry carcass are removed and the remaining meat portion of the carcass forms an integral butchered cut that can be stitched closed and trussed, wrapped or netted to appear as a whole poultry carcass. The poultry product prepared in this way retains the aesthetic appearance of a whole poultry carcass, but is more easily prepared and served.

Owner:PERDUE HLDG

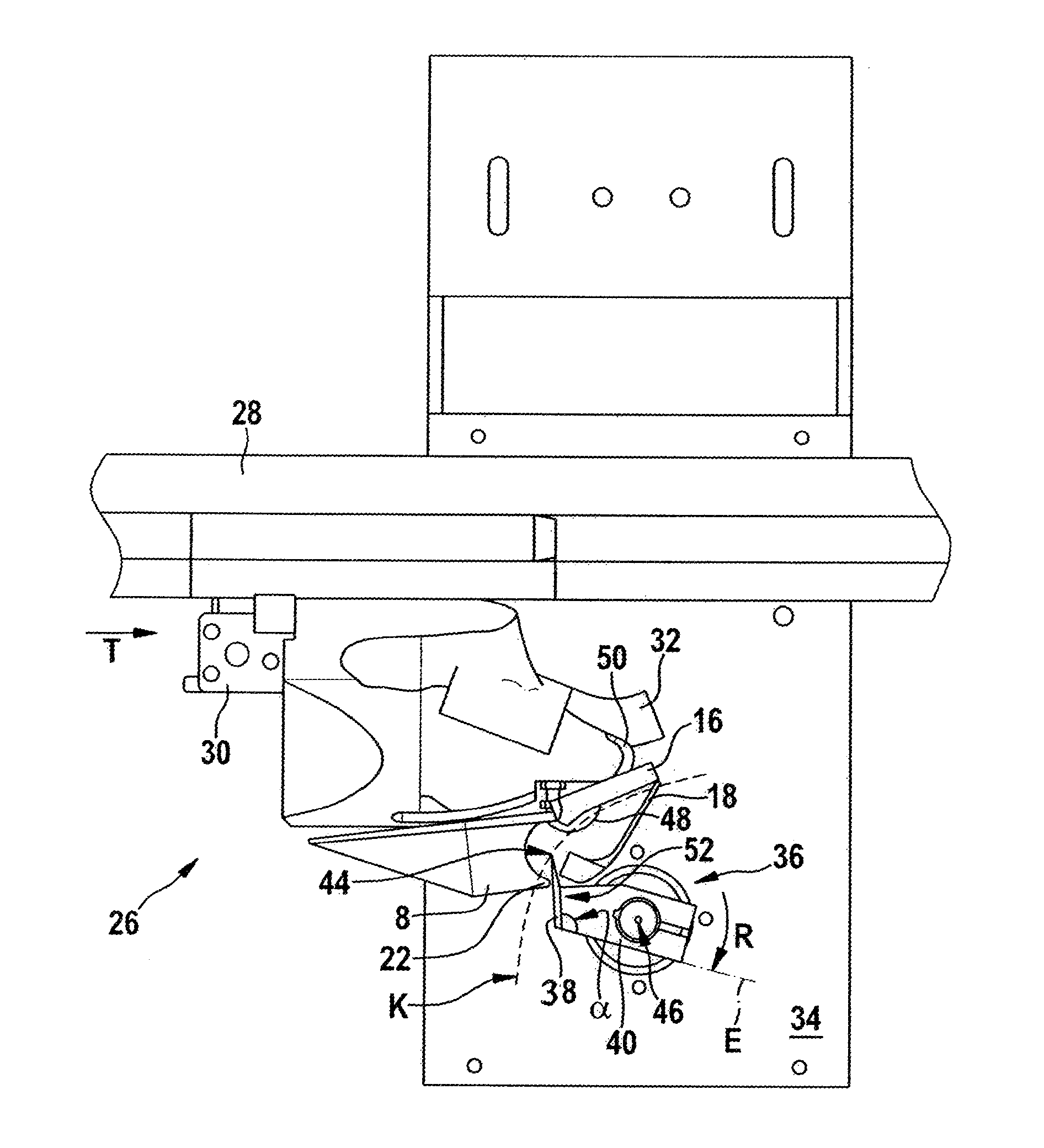

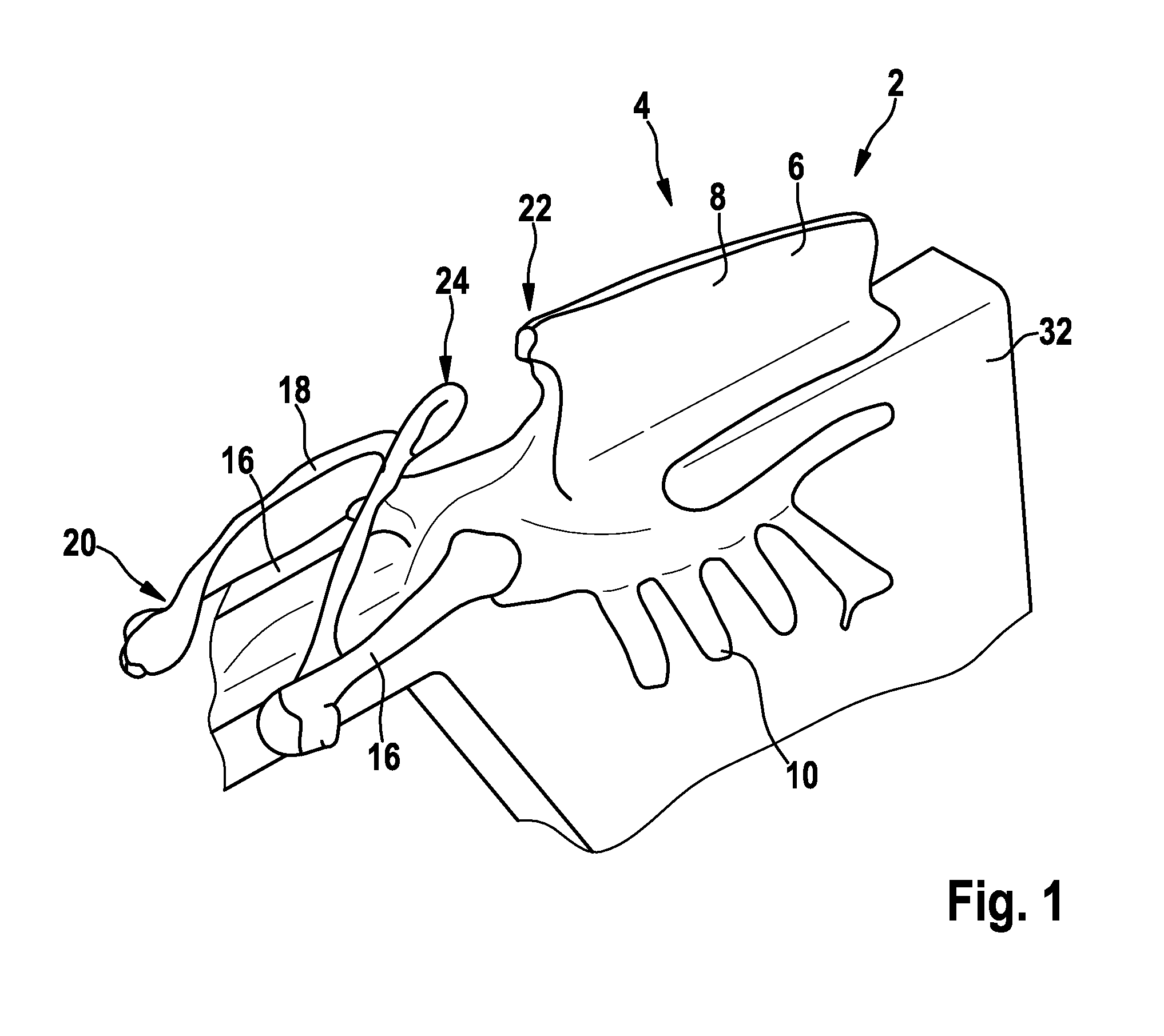

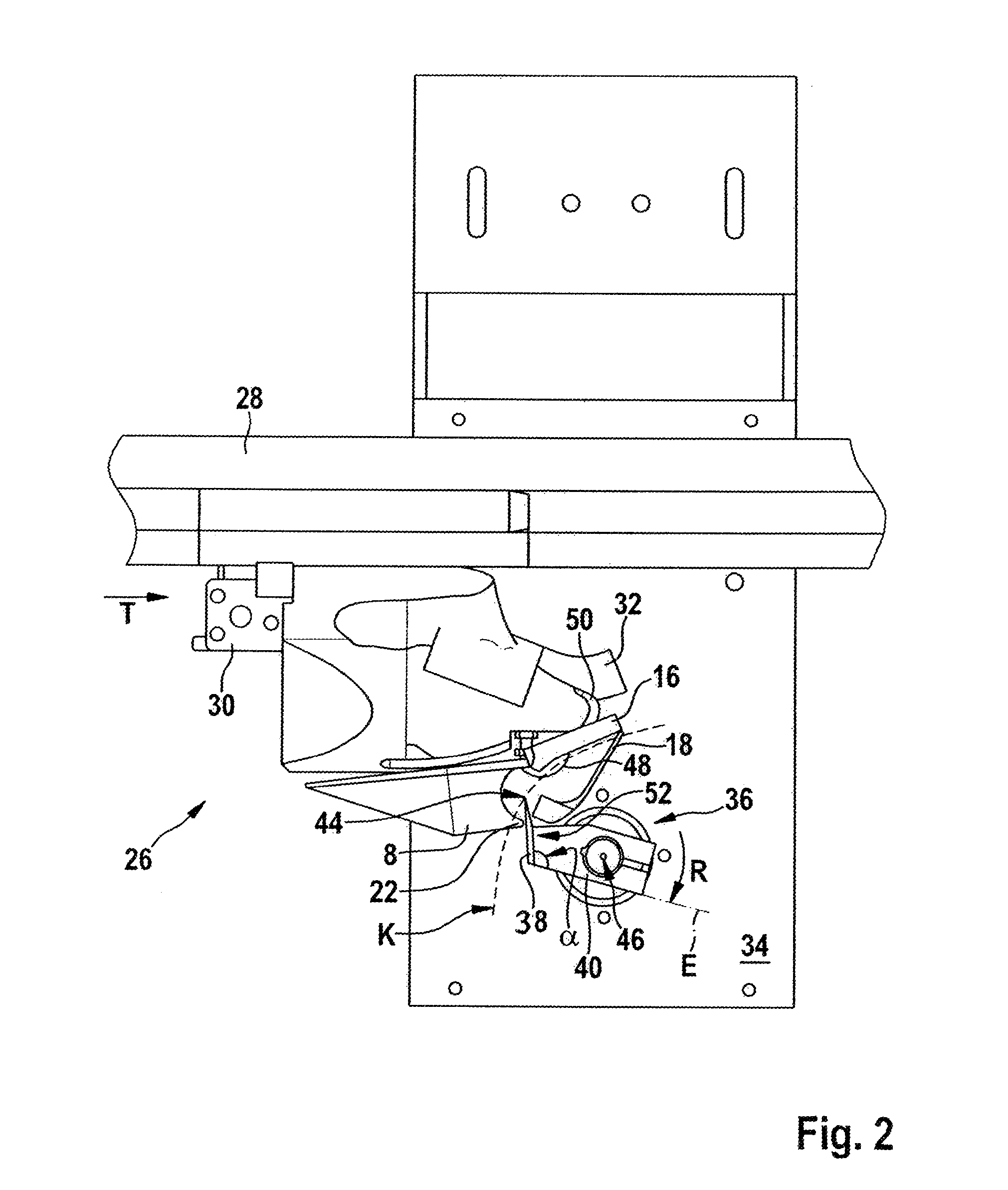

Apparatus and method for separating the wishbone from eviscerated poultry carcasses

ActiveUS8801508B2Simple and reliable processImprove processing speedPoultry deboningFish filletingRotational axisEngineering

Owner:NORDISCHER MASCHINENBAU RUD BAADER GMBH CO KG

Automatic chicken foot boning machine

The invention discloses an automatic chicken foot boning machine. A workbench is arranged at the bottom of a boning machine body, a Y355 motor is mounted in the middle of the top of the workbench, thetop end of the Y355 motor is fixedly connected with a rotary shaft, a fulcrum rod is mounted on the top of the rotary shaft, a top plate is mounted on the top of the fulcrum rod, a clamp is mounted on the outer side of the bottom end of the top plate, a foot collecting groove is formed in the front side of the top of the workbench, L-shaped supporting plates are mounted on the two sides of the foot collecting groove, first electric push rods are mounted in the middles of the L-shaped supporting plates, cutting plates are mounted at one ends of the first electric push rods, second electric push rods are mounted at the top ends of the L-shaped supporting plates, and bone scraping plates are mounted at one ends of the second electric push rods. The cutting plates and the bone scraping platesare used in cooperation, chicken foot skin can be cut off from chicken bones through the cutting plates, the chicken foot skin can be peeled off from the chicken bones through the bone scraping plates, the cutting plates and the bone scraping plates mutually collaborate, the integrity of boning of the chicken feet is guaranteed, the defects existing in existing manual boning are avoided, and theworking efficiency of the boning machine body is improved.

Owner:吉林德翔食品有限公司

Chicken claw bone removal device

The invention discloses a chicken claw bone removal device. The chicken claw bone removal device comprises a frame, a chicken claw positioning cylinder arranged on the frame and boning knives which comprise opposite cutter points and are arranged at the bottom of the chicken claw positioning cylinder, also comprises a bone drawing mechanism which comprises a second manipulator arranged below a position between the two boning knives and a third actuator for controlling up-down motion of the second manipulator, and also comprises a rotation shaft and a motor for driving the rotation shaft to rotate, wherein an annular fixing frame is coaxially arranged above the rotation shaft, the two boning knives are rotatingly and symmetrically arranged on the fixing frame around a middle shaft of the fixing frame, and the boning knives are in a sliding fit relationship with the fixing frame along the radial direction of the fixing frame. The chicken claw bone removal device realizes chicken claw bone removal automation and solves the technical problem that the existing chicken claw bone manual-removal process has high labor intensity, a high labor cost and low production efficiency.

Owner:南通市华夏时丽网络科技服务有限公司

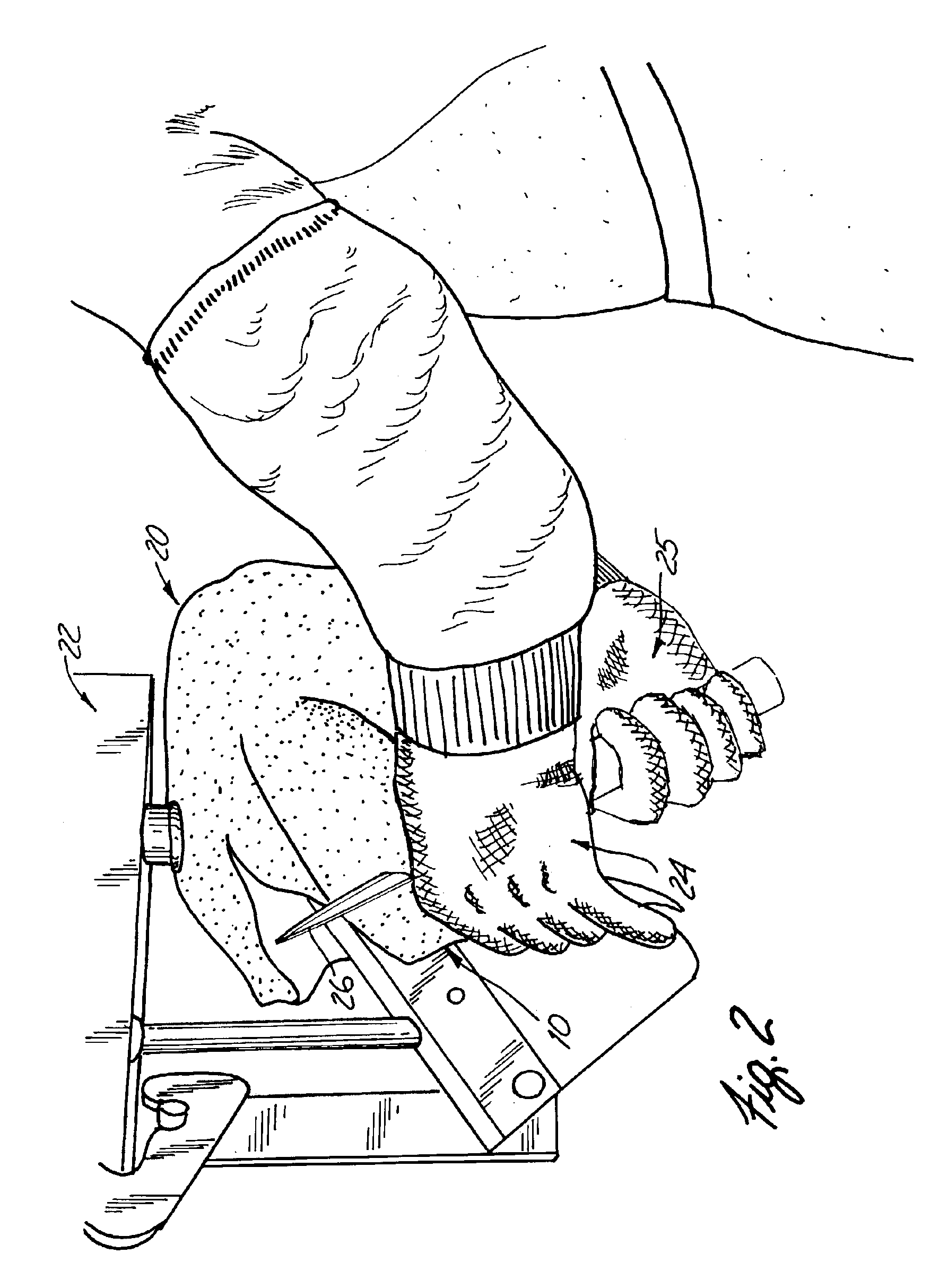

Method and apparatus for cutting the second joint of a poultry wing and product therefrom

InactiveUS8342919B1Reduce manufacturing costStable structurePoultry deboningDividing poultryReciprocating motionSacroiliac joint

A conveyor with juxtaposed blocks moves along a path of travel, certain of the blocks have recesses which receive second joints of the wings of poultry. The second joints are arranged sidewise to the path of travel of the conveyor, in the recesses and are successively passed beneath a support frame where a hold down plate and knife is reciprocated as the support frame is towed by the conveyor to cut the flesh and skin between the ulna and radius bones and one or both cartilages, which join the ends of the bones. When cutting a cartilage, the bones are urged apart as the cut is made.

Owner:MAUER JAMES E +1

Automatic chicken foot deboning machine

The invention provides an automatic chicken foot deboning machine and relates to the field of food processing. The automatic chicken foot deboning machine comprises a stand, wherein positioning tubesare fixed on the stand, through holes are formed in two sides of the outer wall of each positioning tube, airbags are installed on the side walls with the through holes, deboning devices are installedon two sides of each positioning tube, each deboning device comprises a driving part and a deboning knife, each driving part comprises a first gear, a second gear and a rack, and the first gear, thesecond gear and the rack are meshed with each other; a motor is also arranged on each first gear, sliding chutes are formed in the stand, the sliding chutes are communicated with the through holes, and the racks are arranged in the sliding chutes; the tail parts of the deboning knives are hinged with the racks, torsion springs are arranged between the deboning knives and the racks, the head partsof the deboning knives are pinpoint-shaped, cutting parts are formed between the head parts and the tail parts, sleeves are arranged on the outer sides of the cutting parts and the sleeves are connected with the tail parts of the deboning knives through springs. According to the scheme, the deboning knives are driven by the motors to break the chicken foot bones and then the chicken foot bones arepicked out, thereby realizing automatic deboning of chicken feet and being capable of thoroughly removing the chicken foot bones.

Owner:CHONGQING CHUANRUI YUCHU FOOD

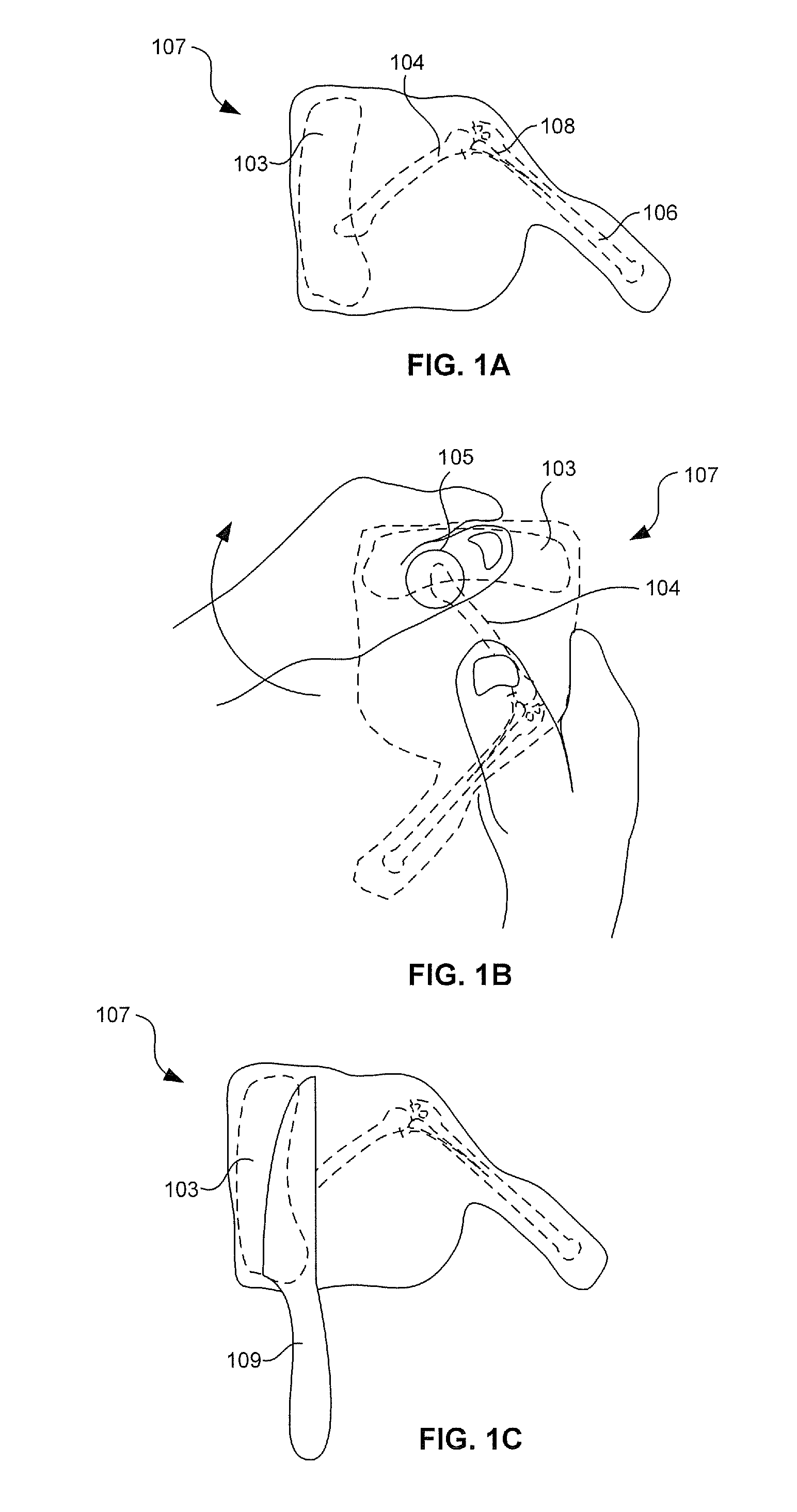

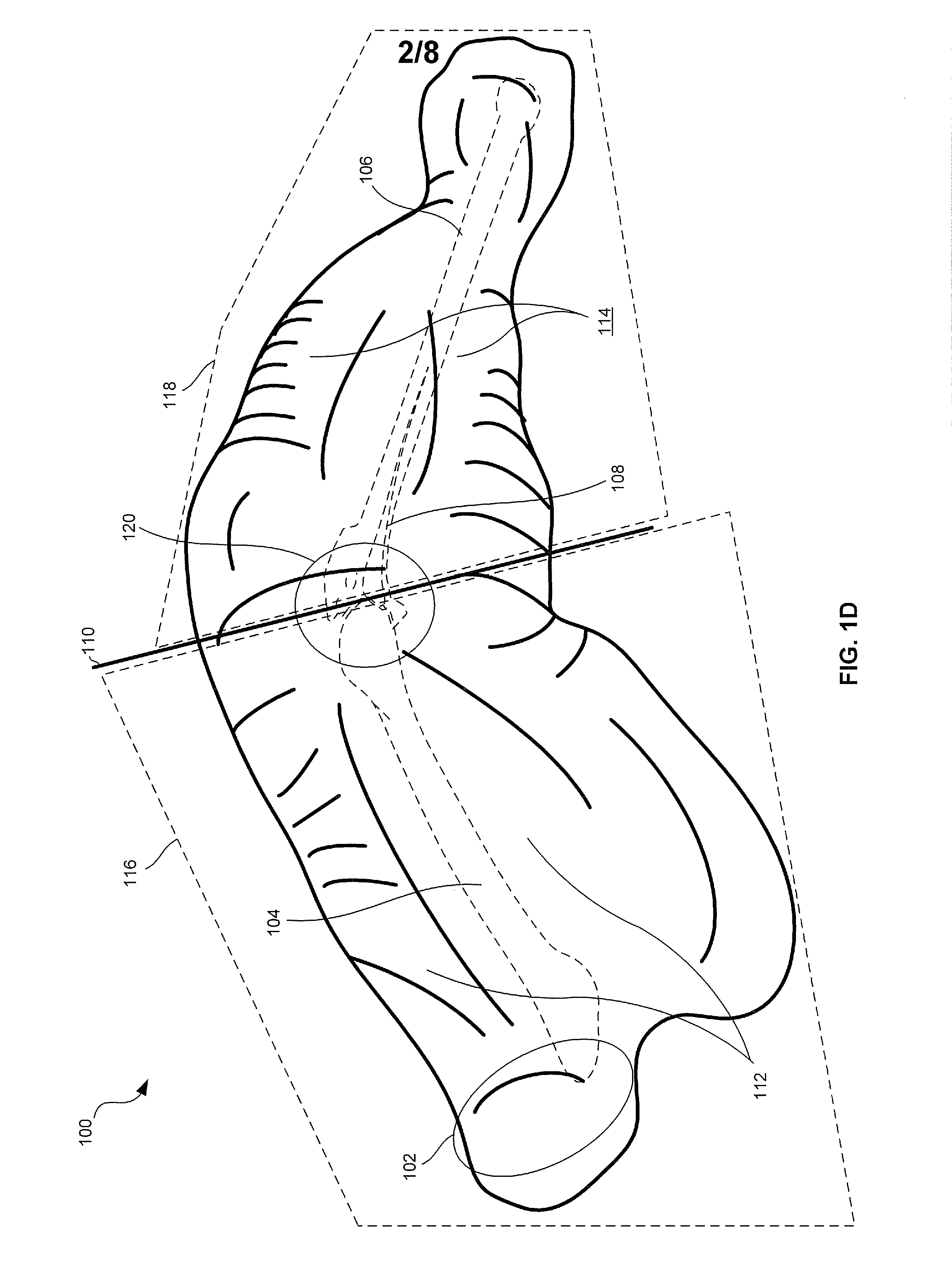

Method and apparatus for harvesting thigh meat and oyster meat from a poultry thigh

ActiveUS9155316B2Increase productionEnsure complete separationPoultry deboningPoultry processing support devicesThighKnee Joint

A method and apparatus are provided for harvesting thigh meat and oyster meat from a poultry thigh that includes a thigh bone with a hip knuckle and a knee knuckle. The poultry thigh is held at a knuckle, after which meat present on the thighbone below the knuckle is scraped from the thighbone away from the knuckle. The meat is subsequently separated from the thighbone and collected for further handling. The poultry thigh is suspended from the hip knuckle and the oyster meat is disconnected from the hip knuckle prior to scraping the meat from the thighbone away from the hip knuckle.

Owner:MEYN FOOD PROCESSING TECH BV

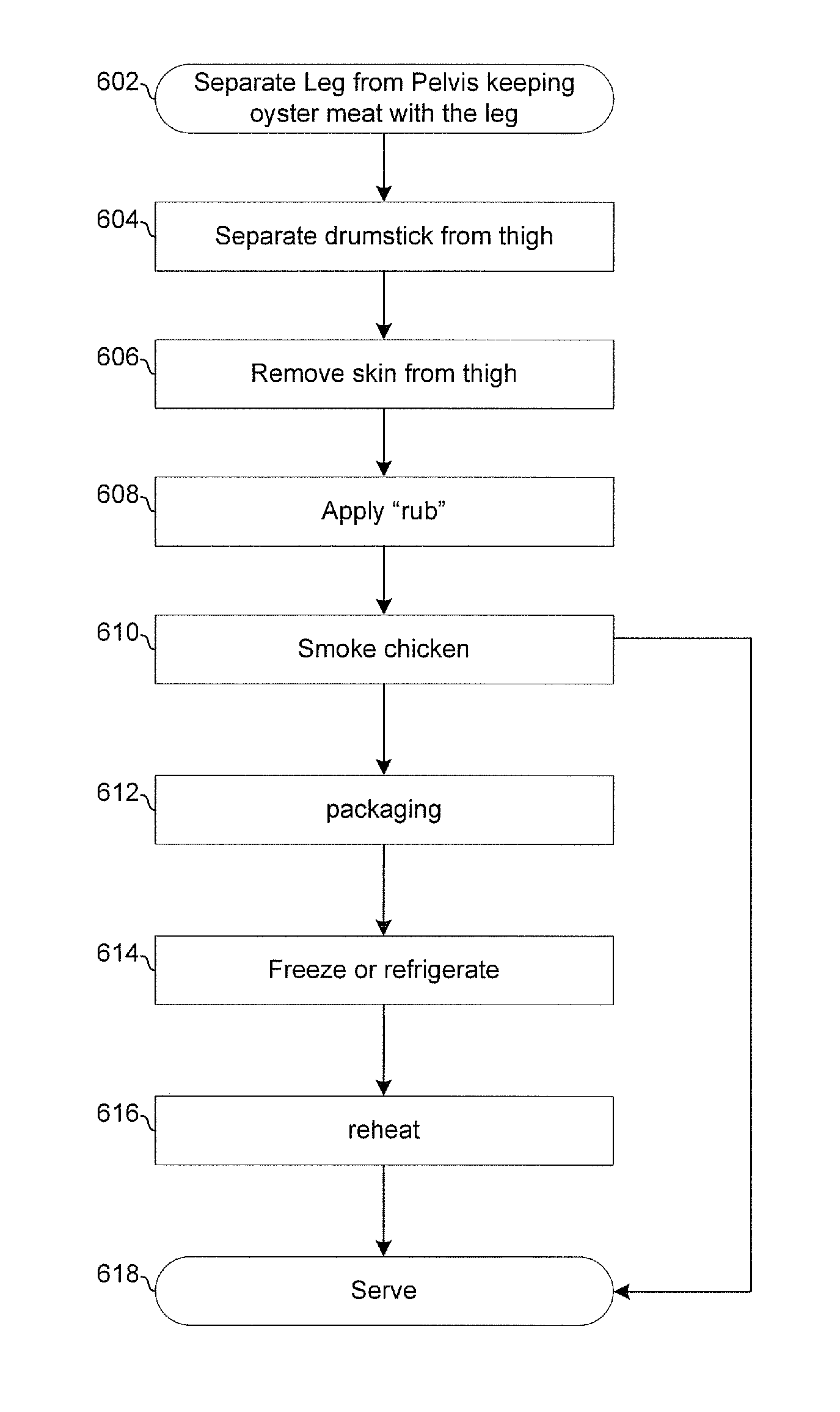

Method for preparing a chicken thigh product

Aspects of a method for preparing a chicken thigh product are provided. In this regard, a chicken thigh product may be prepared by seasoning and smoking a skinless bone-in oyster-cut chicken thigh, where the skinless bone-in oyster-cut chicken thigh comprises a thigh bone, thigh meat, and oyster meat. Preparing the chicken thigh product may comprise separating an uncooked chicken leg from an uncooked chicken carcass such that the oyster meat is separated from the pelvis of the uncooked chicken carcass and remains attached to the uncooked chicken leg. The skinless bone-in oyster-cut chicken thigh may be smoked until a texture of the skinless bone-in oyster-cut chicken thigh is substantially similar to the texture of cooked pork ribs.

Owner:KNUCKMAN ALAN

Method for processing poultry

InactiveUS20050014460A1Electric current slaughtering/stunningPoultry deboningEngineeringElectrical stimulations

A method is described for processing poultry, comprising the steps of supplying live poultry, stunning the live poultry in a stunning device, placing the stunned poultry into product carriers advanced along a conveyor, killing the poultry and removing the feathers from the dead poultry in a plucking device. Downstream of the plucking device, the poultry is exposed to an electrical stimulation, an electrical voltage (V1) being applied across the carcass of the poultry. A method is further described for controlling process parameters, especially the time and duration of execution of working steps in a process of mechanized working of slaughtered poultry, the tenderness of a specified meat portion being evaluated prior to a due processing step and, after this evaluation, the important process parameters for the particular processing step being set to an optimal value.

Owner:STORK PMT

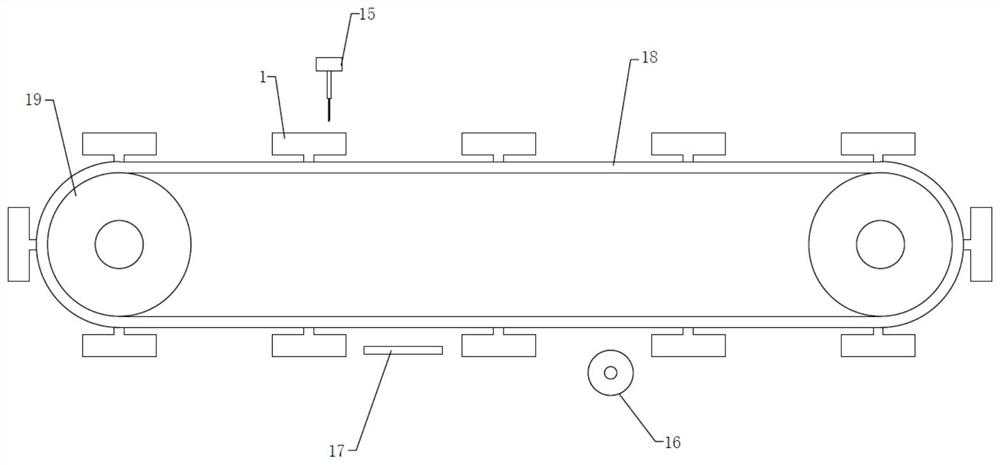

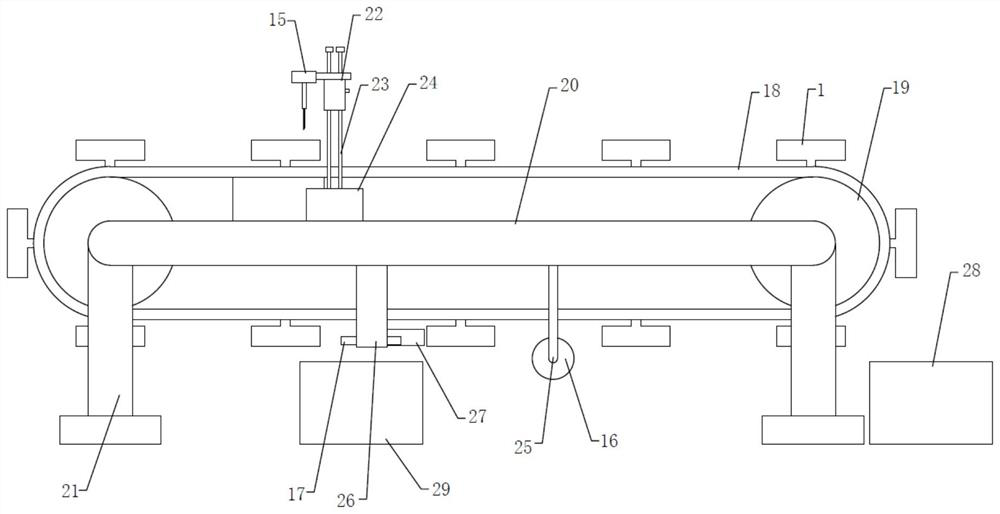

Chicken leg boning equipment

InactiveCN111887285ASimple structureEasy to operatePoultry deboningPoultry transferring/conveying devicesAnatomyEngineering

The invention discloses chicken leg boning equipment. The chicken leg boning equipment comprises a rack, a circulating conveying module, a dissection module, a breaking-off module, a gripping module and a plurality of traveling blocks, wherein the circulating conveying module, the dissection module, the breaking-off module and the gripping module are all mounted on the rack, the traveling blocks are sequentially mounted on the circulating conveying module and are driven by the circulating conveying module to do reciprocating circulating motion, and a cavity for placing a chicken leg is formedin each traveling block; and the breaking-off module comprises a guiding driving unit, a left telescoping unit and a right telescoping unit, the left telescoping unit and the right telescoping unit are separately inserted into the corresponding chicken leg from the two sides of an incision during outstretching, the guiding driving unit is used for drawing the two telescoping units after the left telescoping unit and the right telescoping unit outstretch, and thus, the two telescoping units can swing towards mutual-outlying directions so as to break off the corresponding chicken leg from the incision and expose chicken leg bones. The chicken leg boning equipment is simple in structure and good in boning effect.

Owner:从海彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com