Patents

Literature

363results about "Poultry transferring/conveying devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for processing slaughter animals and/or parts thereof provided with a transportation system

ActiveUS7133742B2Digital data processing detailsControl devices for conveyorsTransport systemEngineering

Owner:STORK PMT

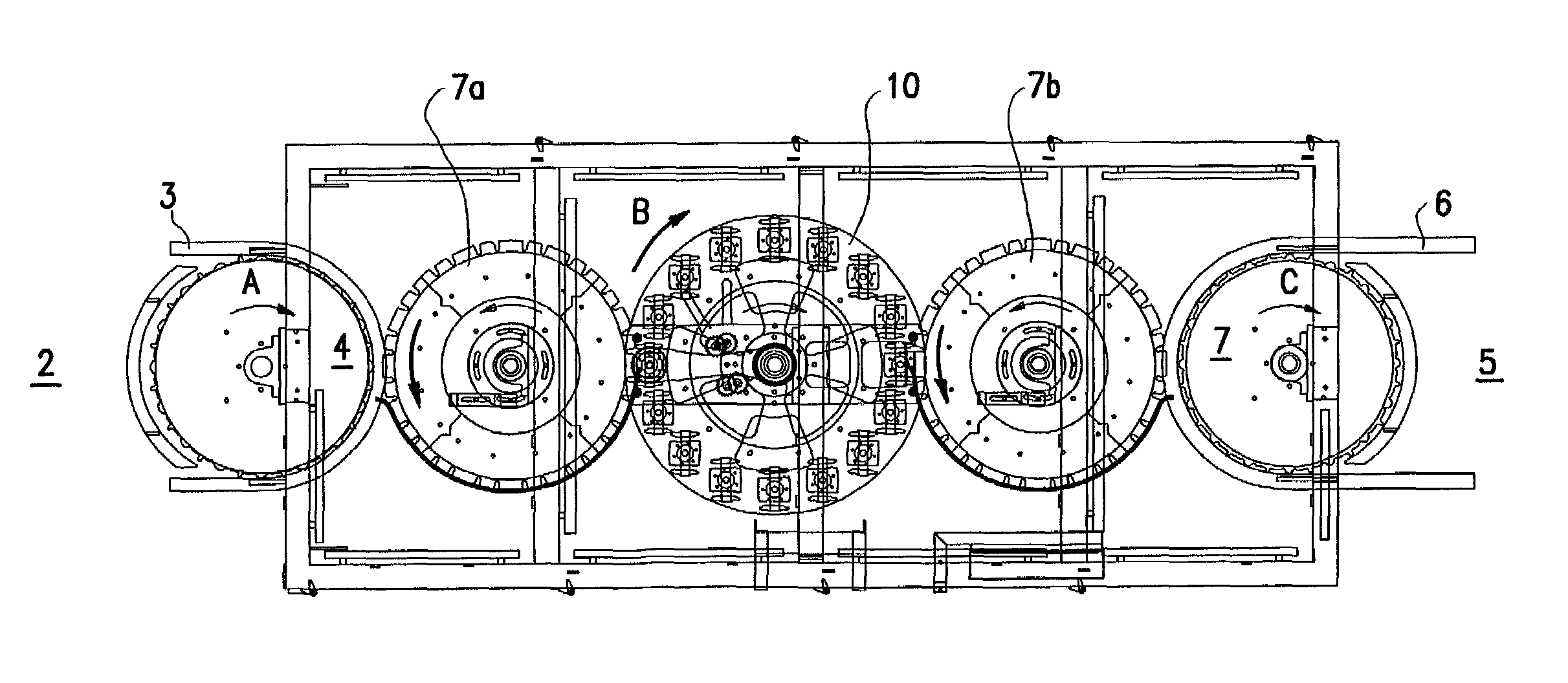

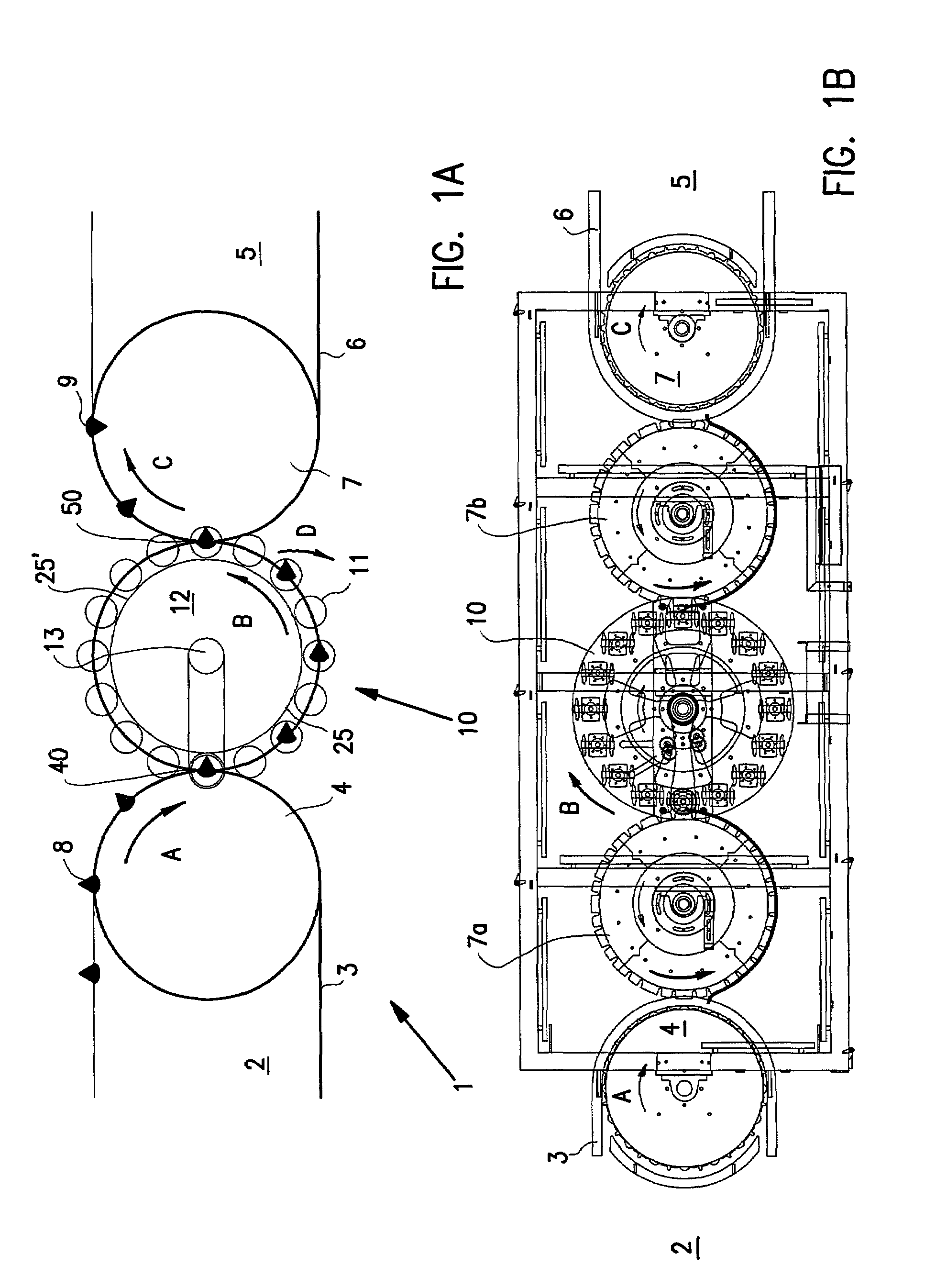

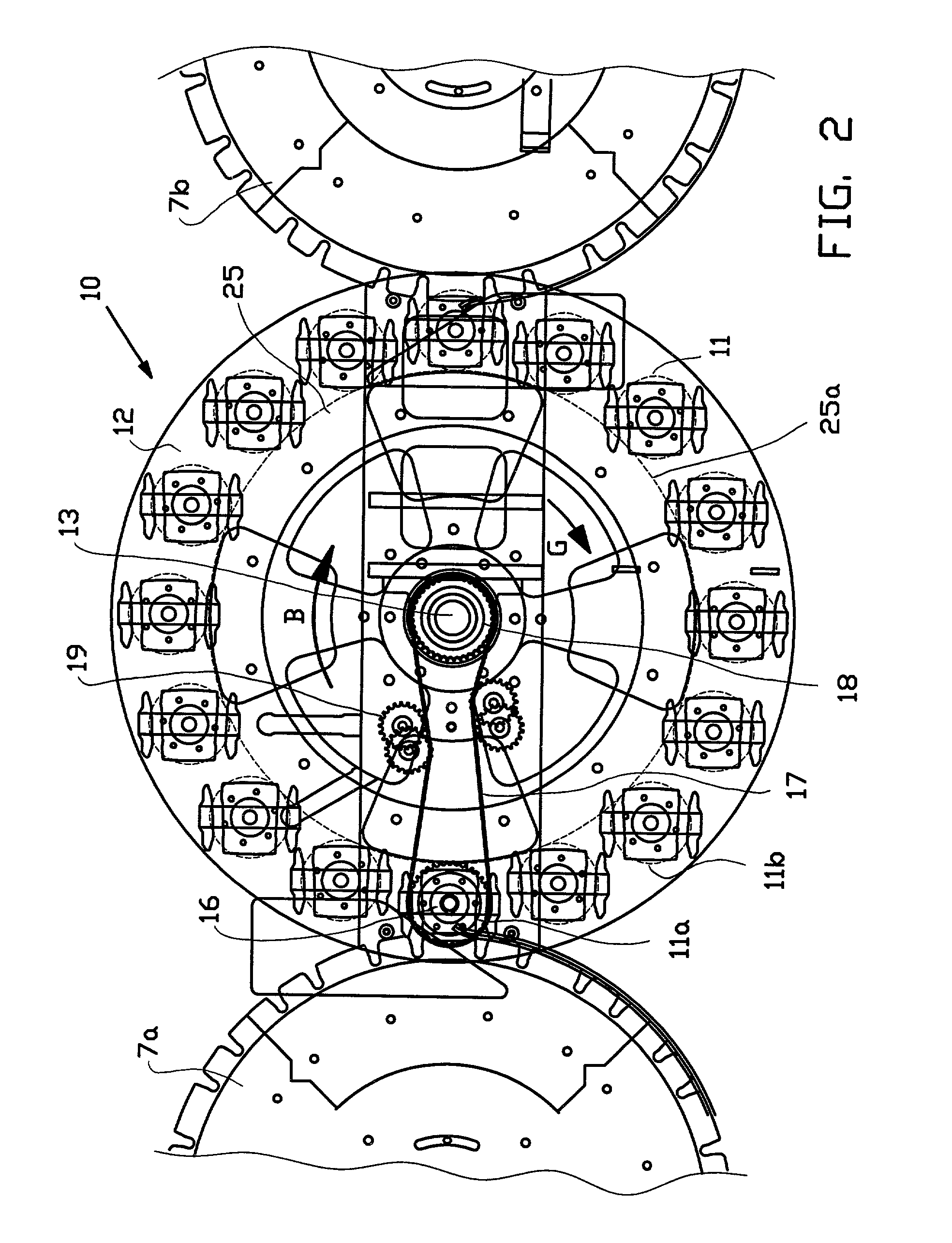

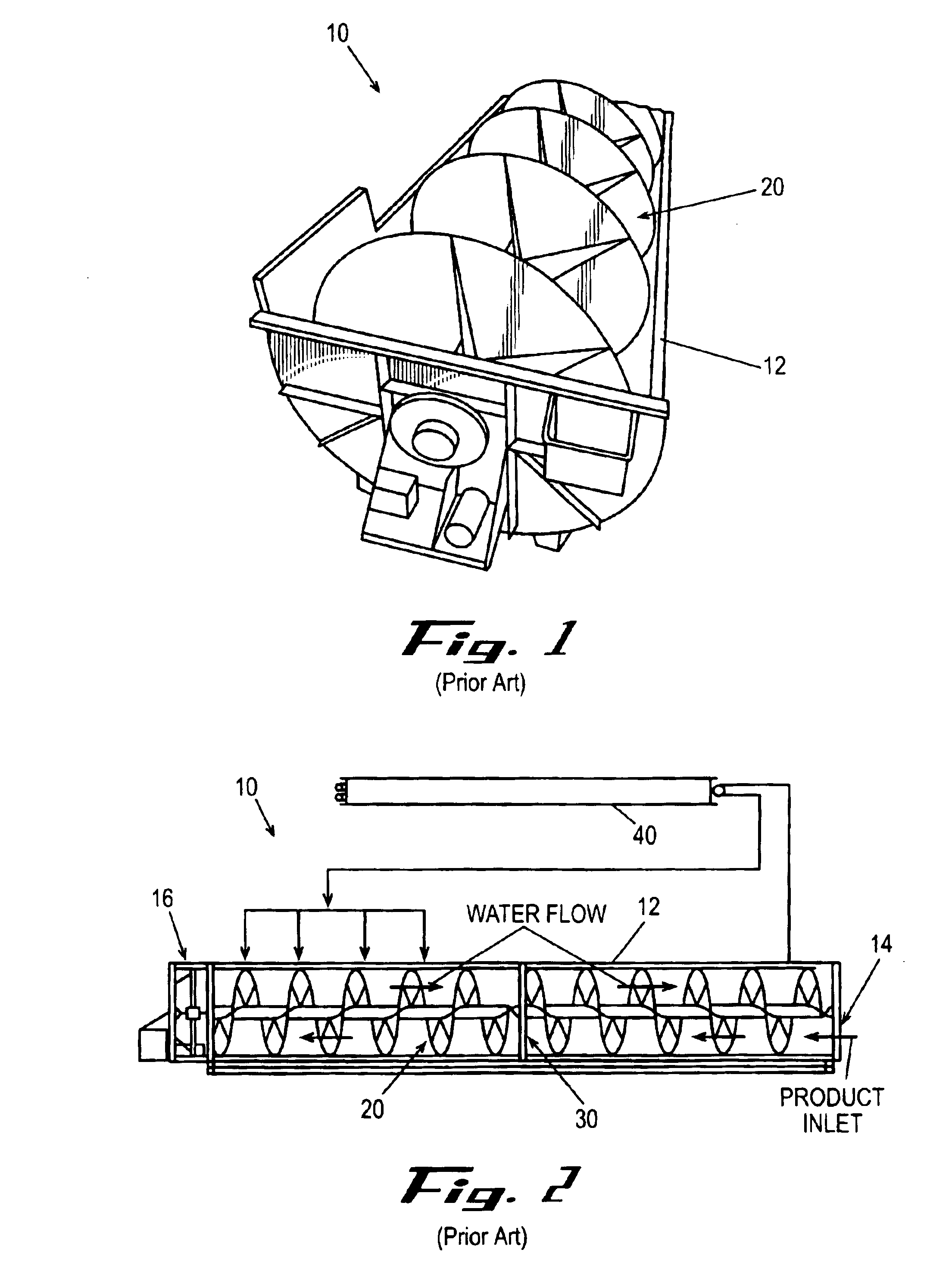

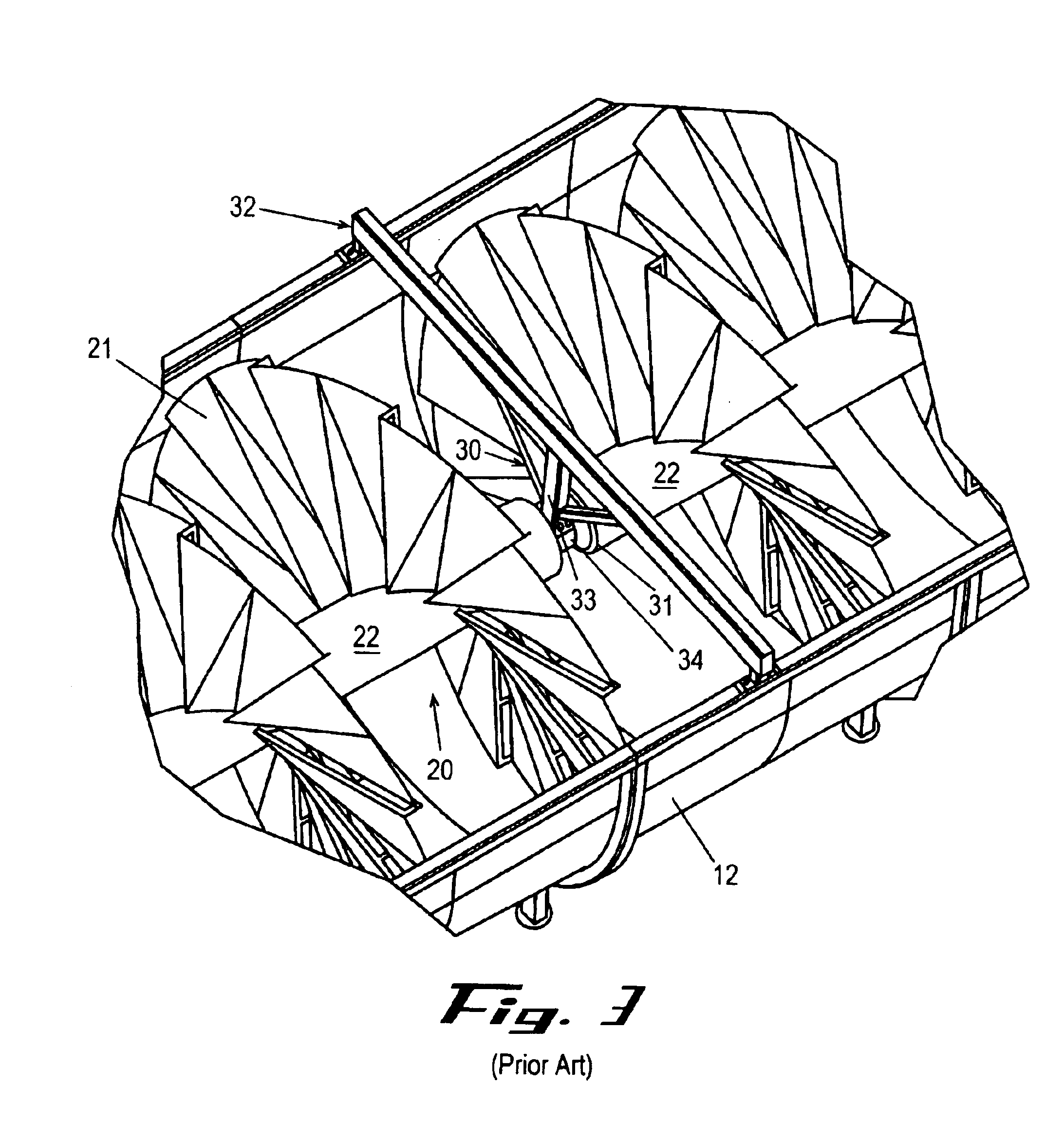

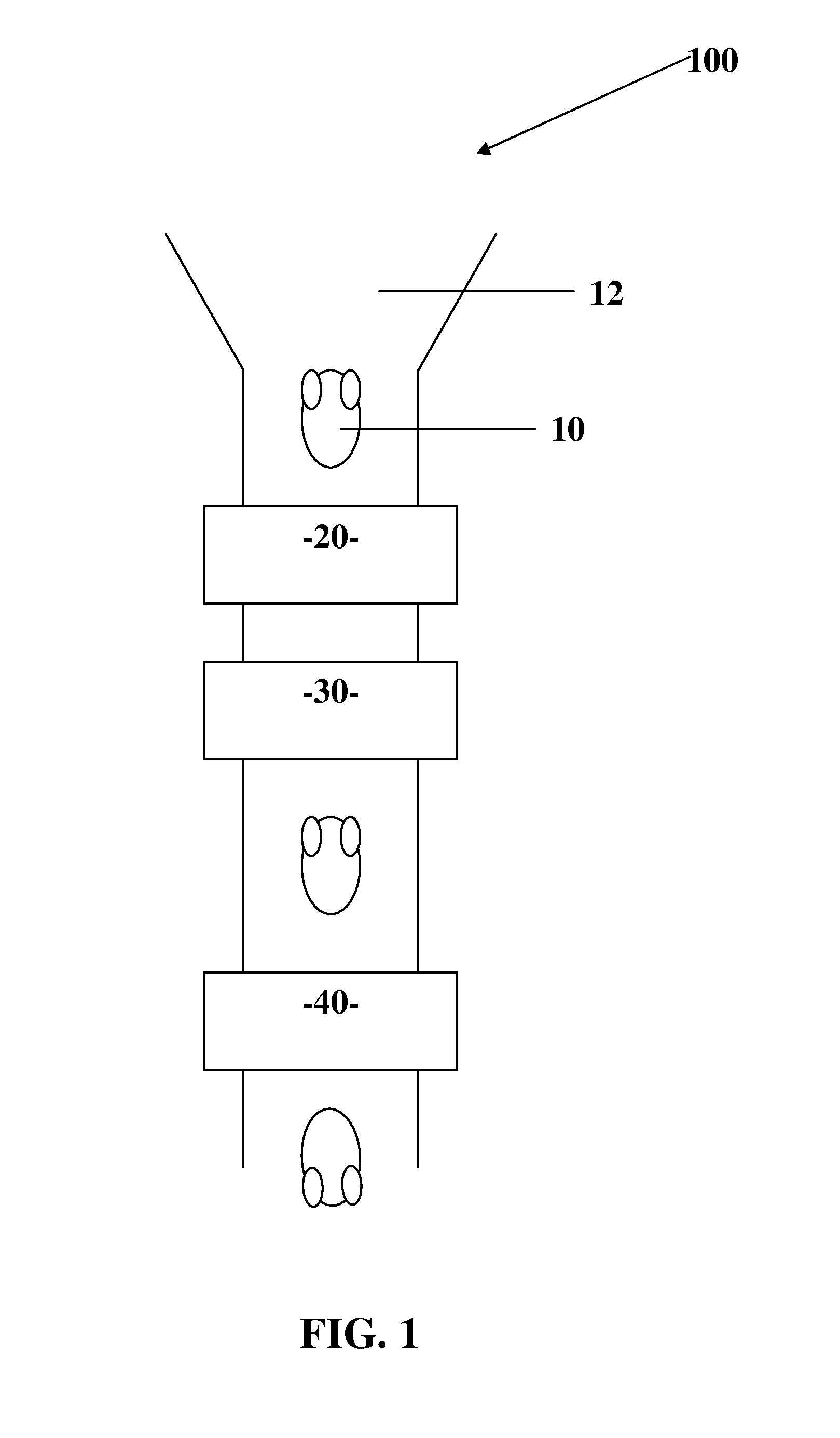

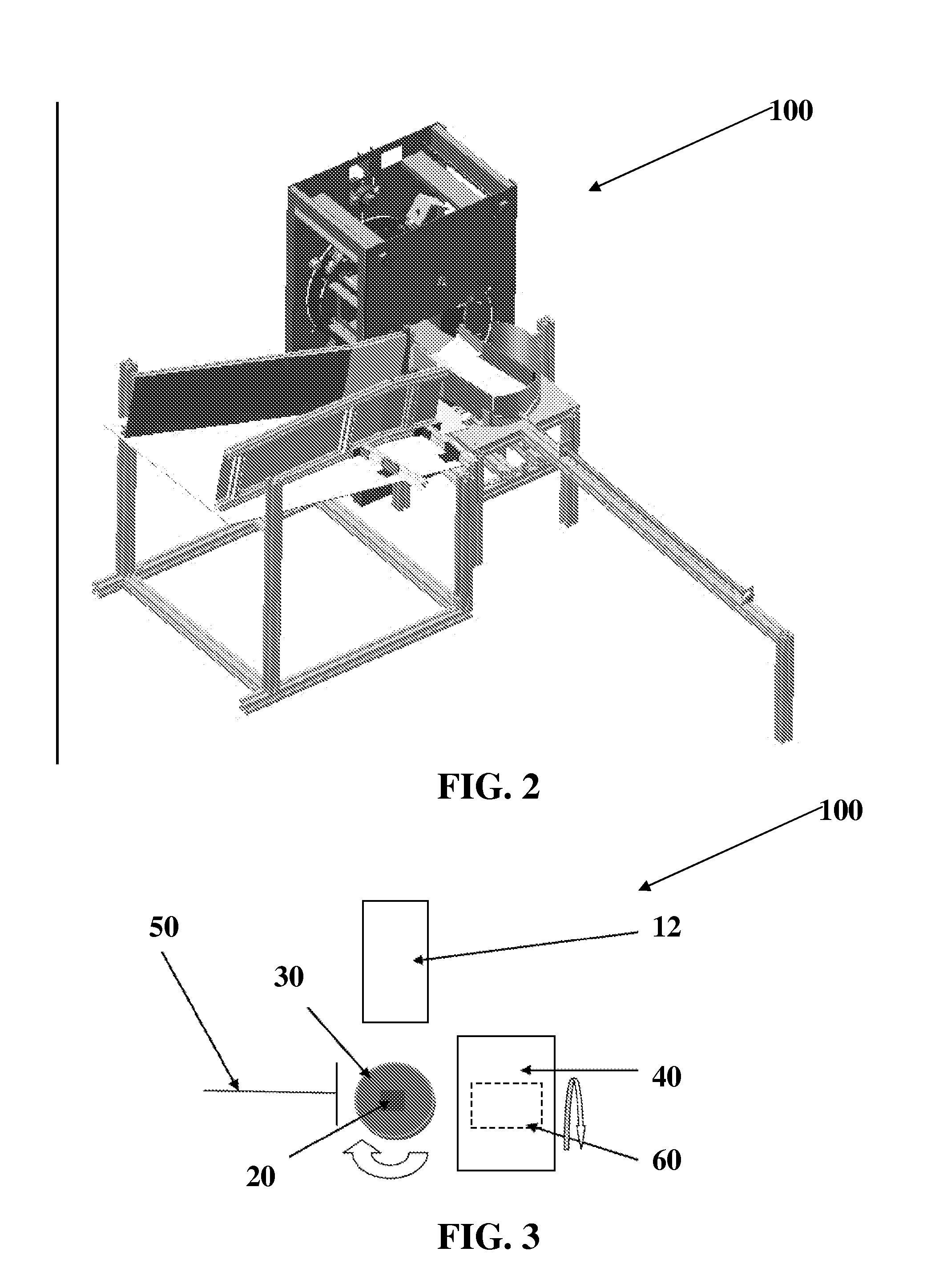

Apparatus for transferring poultry carcasses

InactiveUS7018283B2Meat processing plantsSlaughterhouse arrangementsEngineeringMechanical engineering

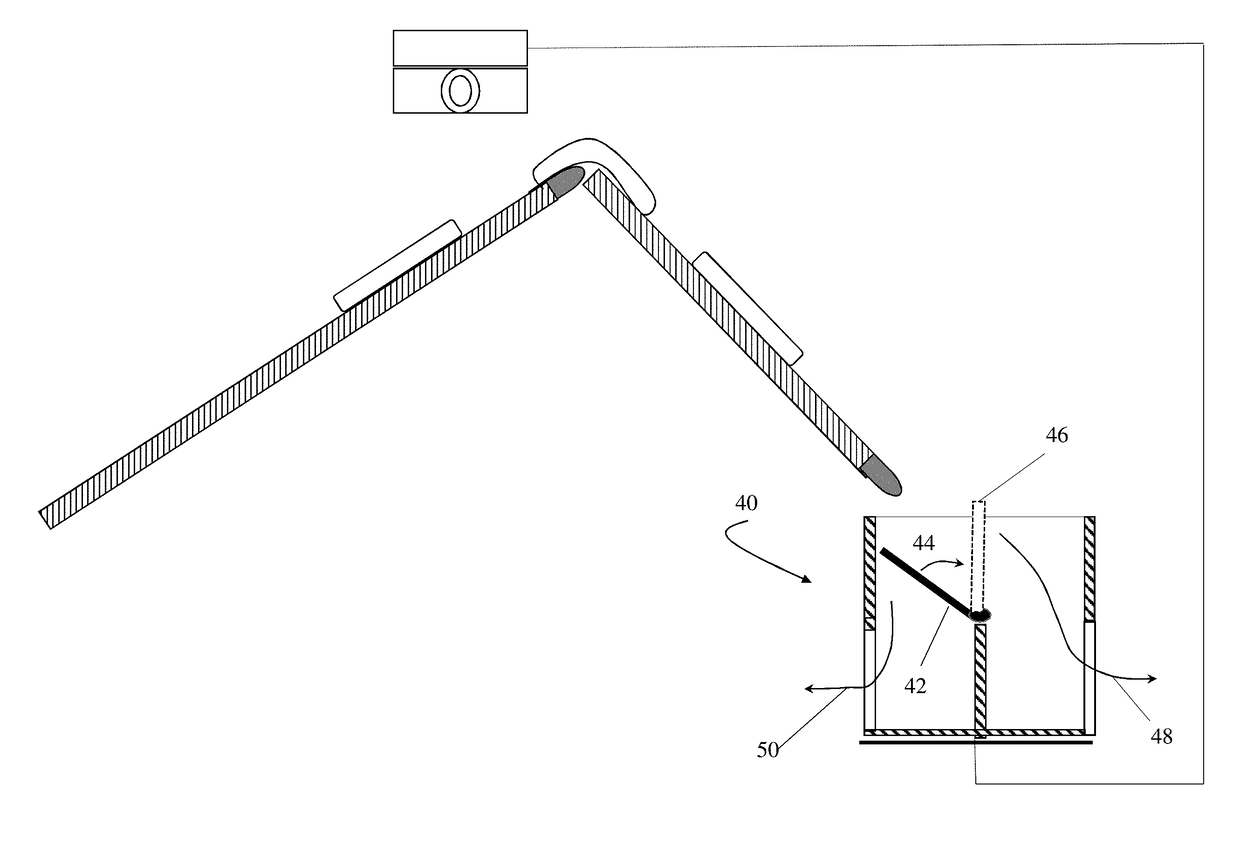

Apparatus for transferring poultry carcasses from a first overhead conveyor to a second overhead conveyor, including a transfer wheel rotatable about a shaft and disposed between the first and the second overhead conveyors. The apparatus also includes a receipt point and a discharge point, the receipt point being disposed between the first overhead conveyor and the transfer wheel, the discharge point being disposed between the transfer wheel and the second overhead conveyor, and the receipt and discharge points are disposed on a centerline of the transfer wheel. The apparatus further includes a plurality of holders, each holder being configured to receive one of the carcasses from the first overhead conveyor at the receipt point and to discharge the carcass to the second overhead conveyor at the discharge point. Each holder has a first orientation at the receipt point and a second orientation at the discharge point, and the first and second orientations are relative to the centerline and are the same.

Owner:SYSTATE GROUP

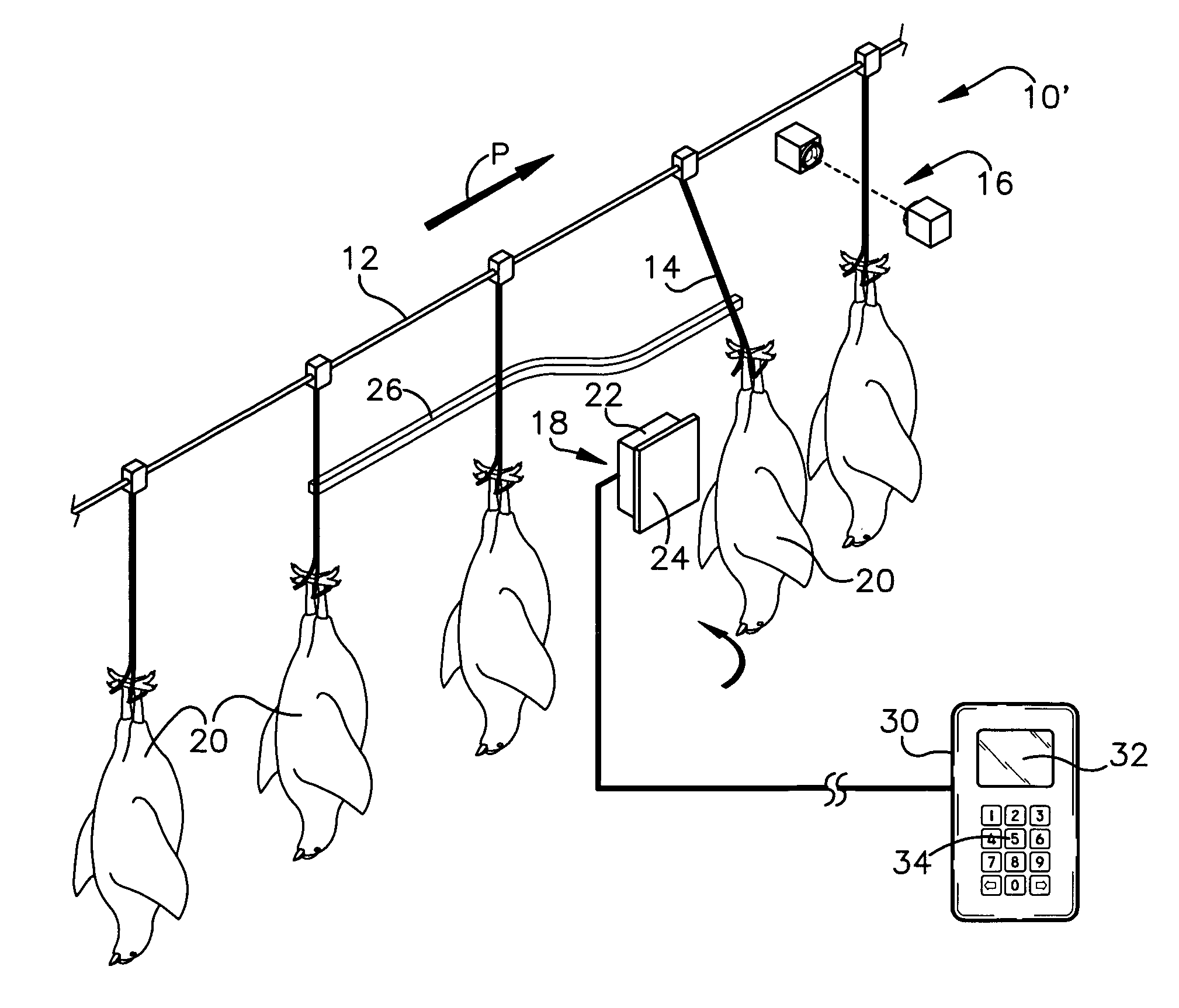

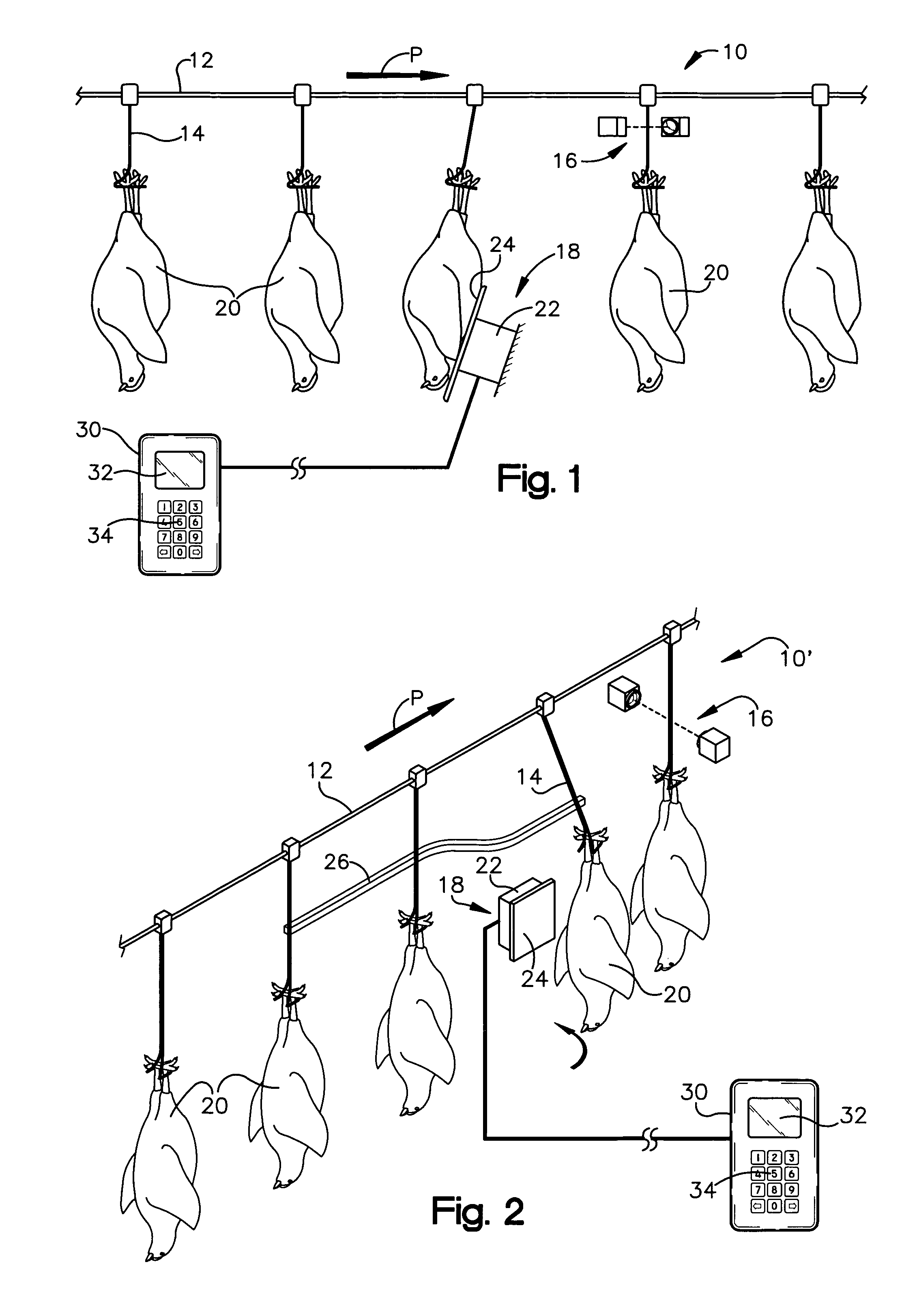

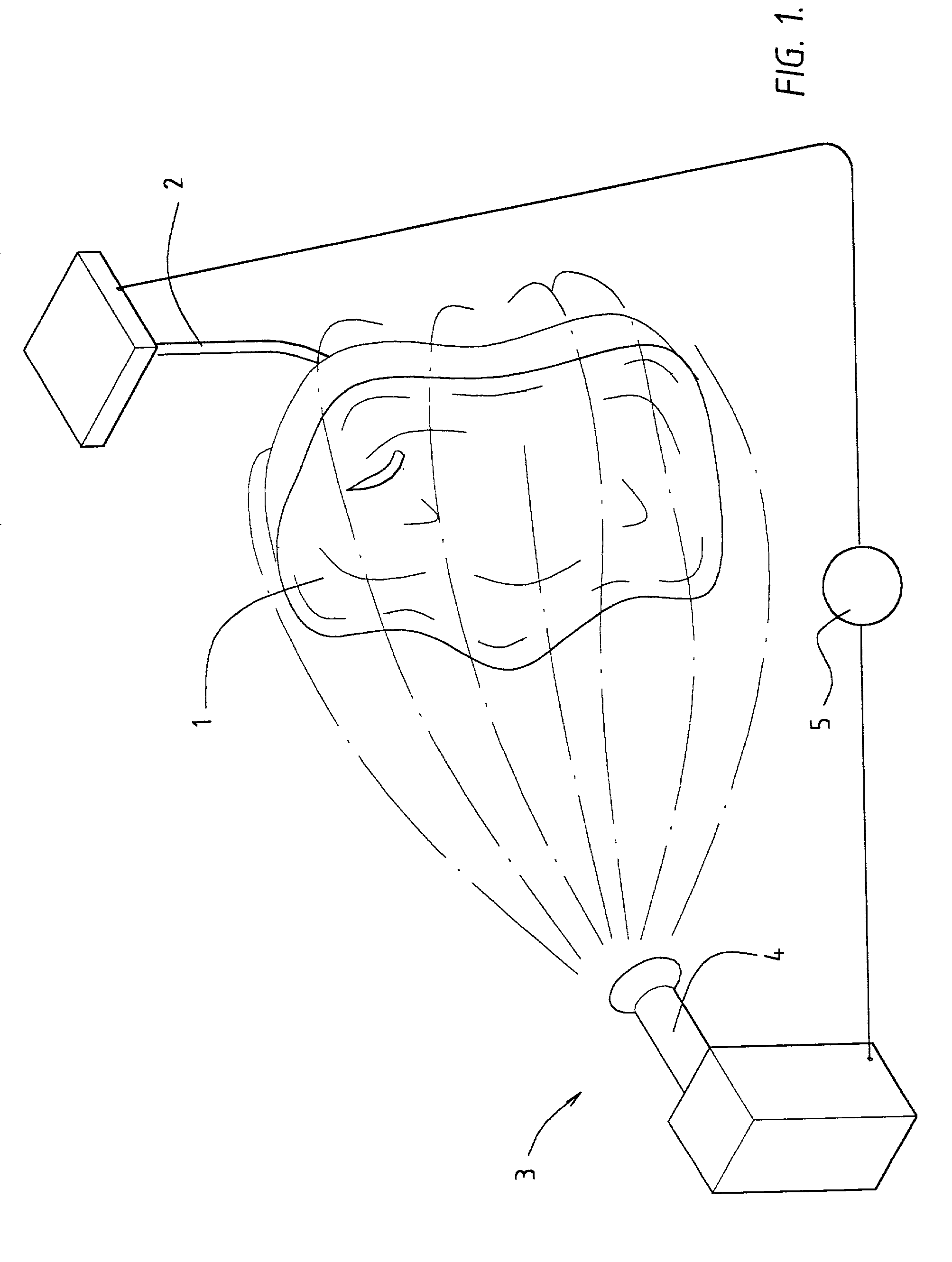

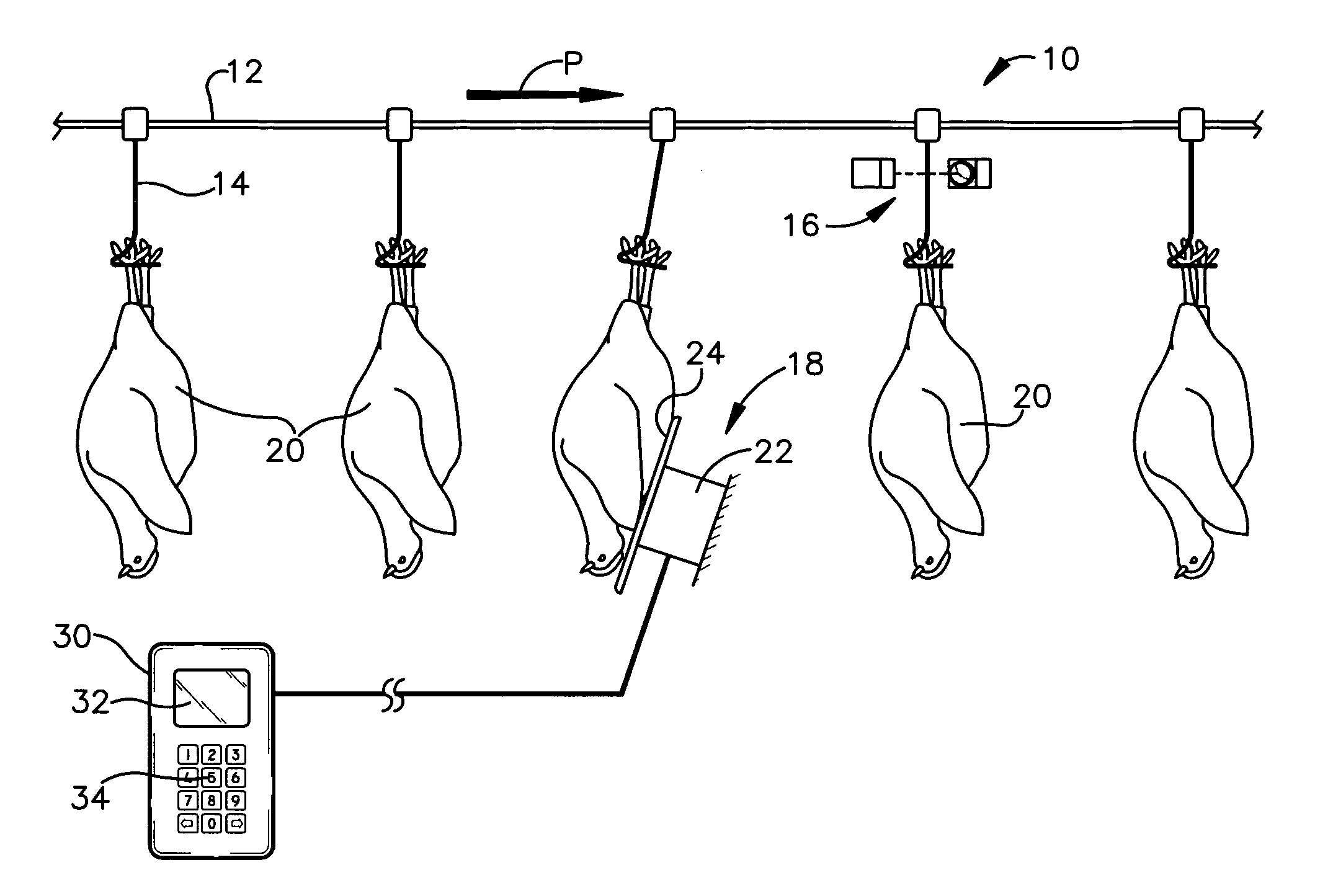

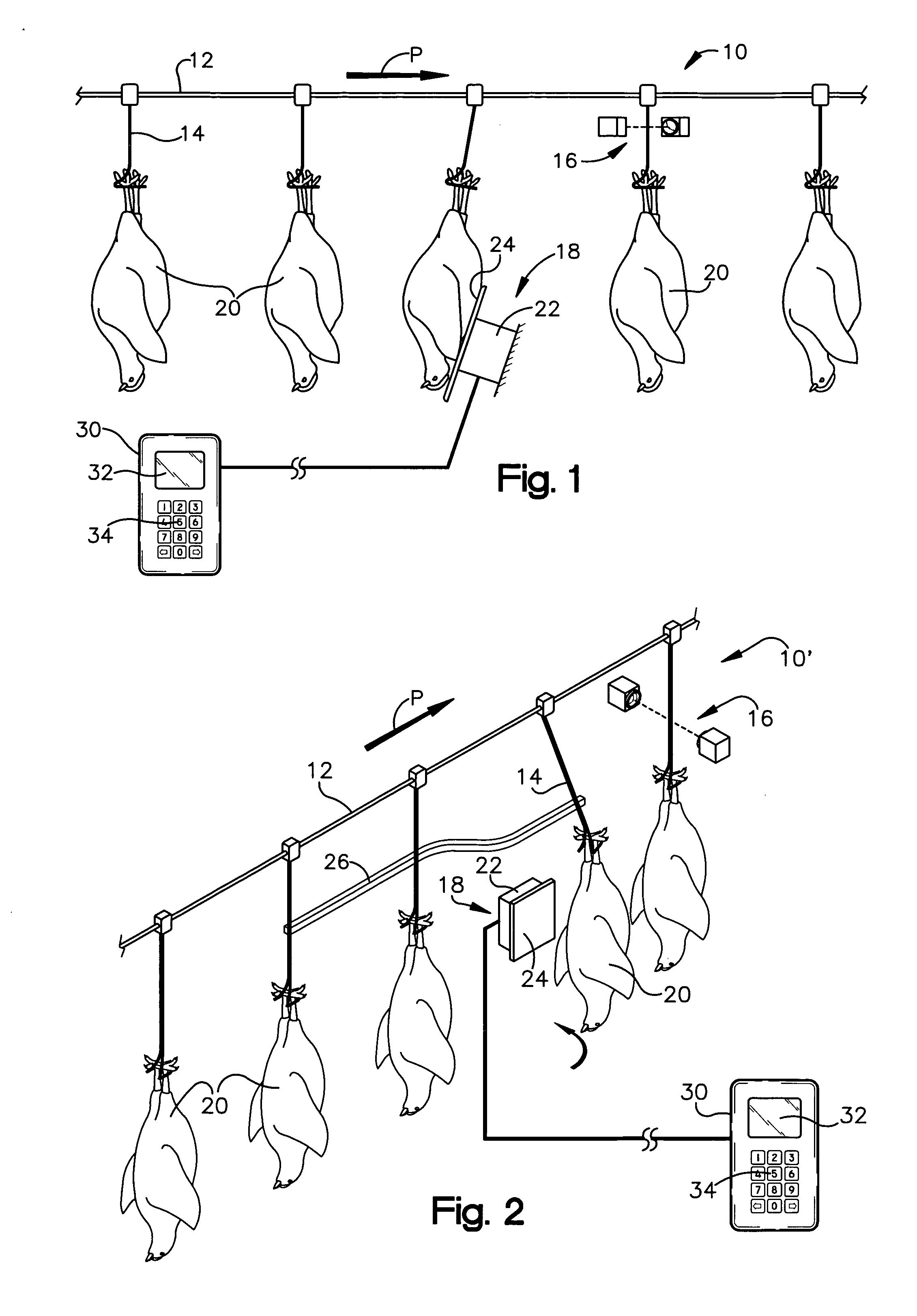

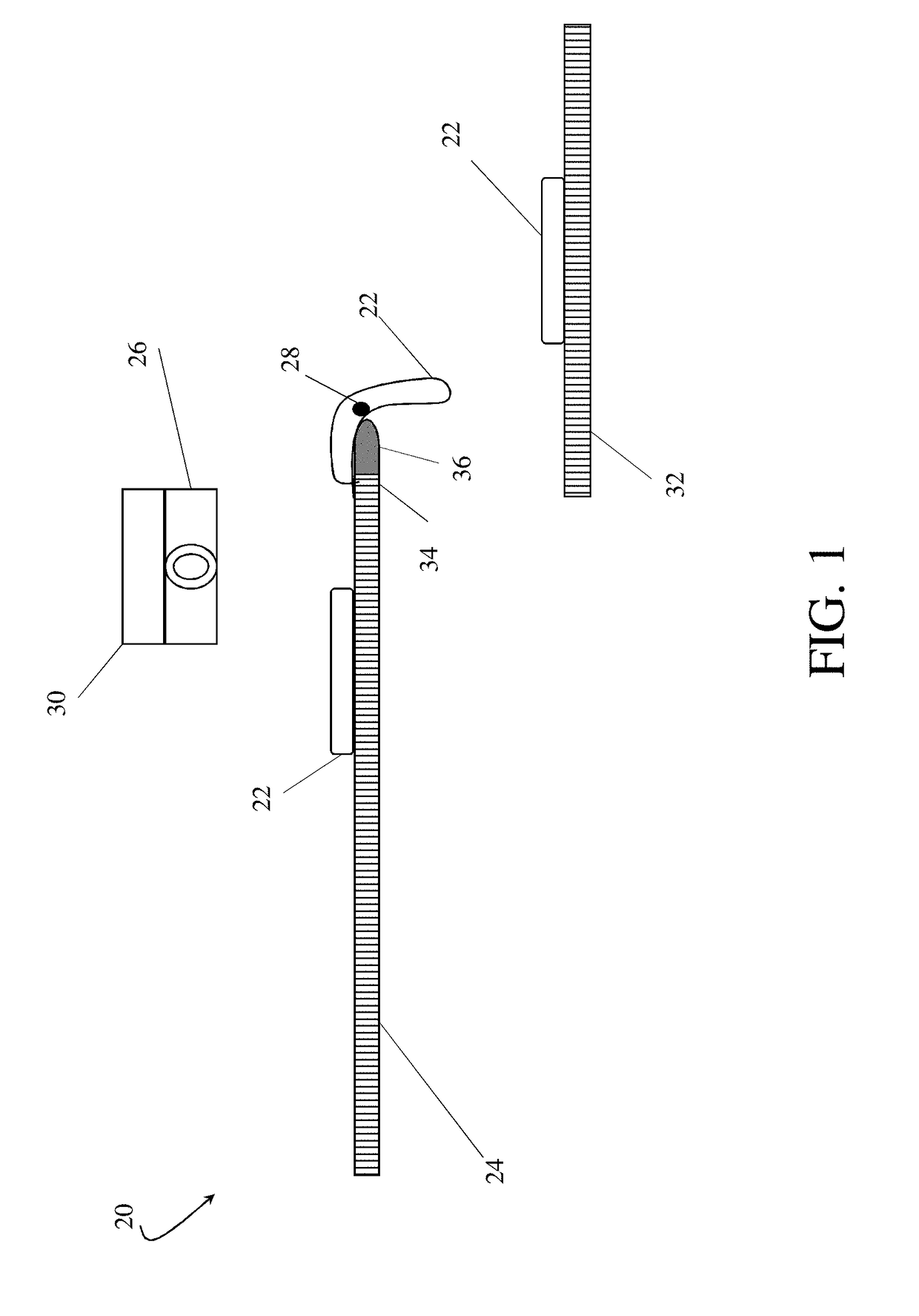

Overhead poultry conveying and counting system

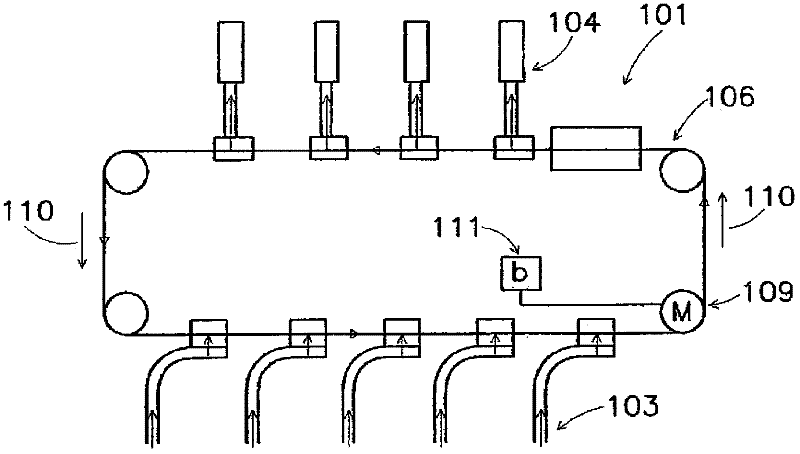

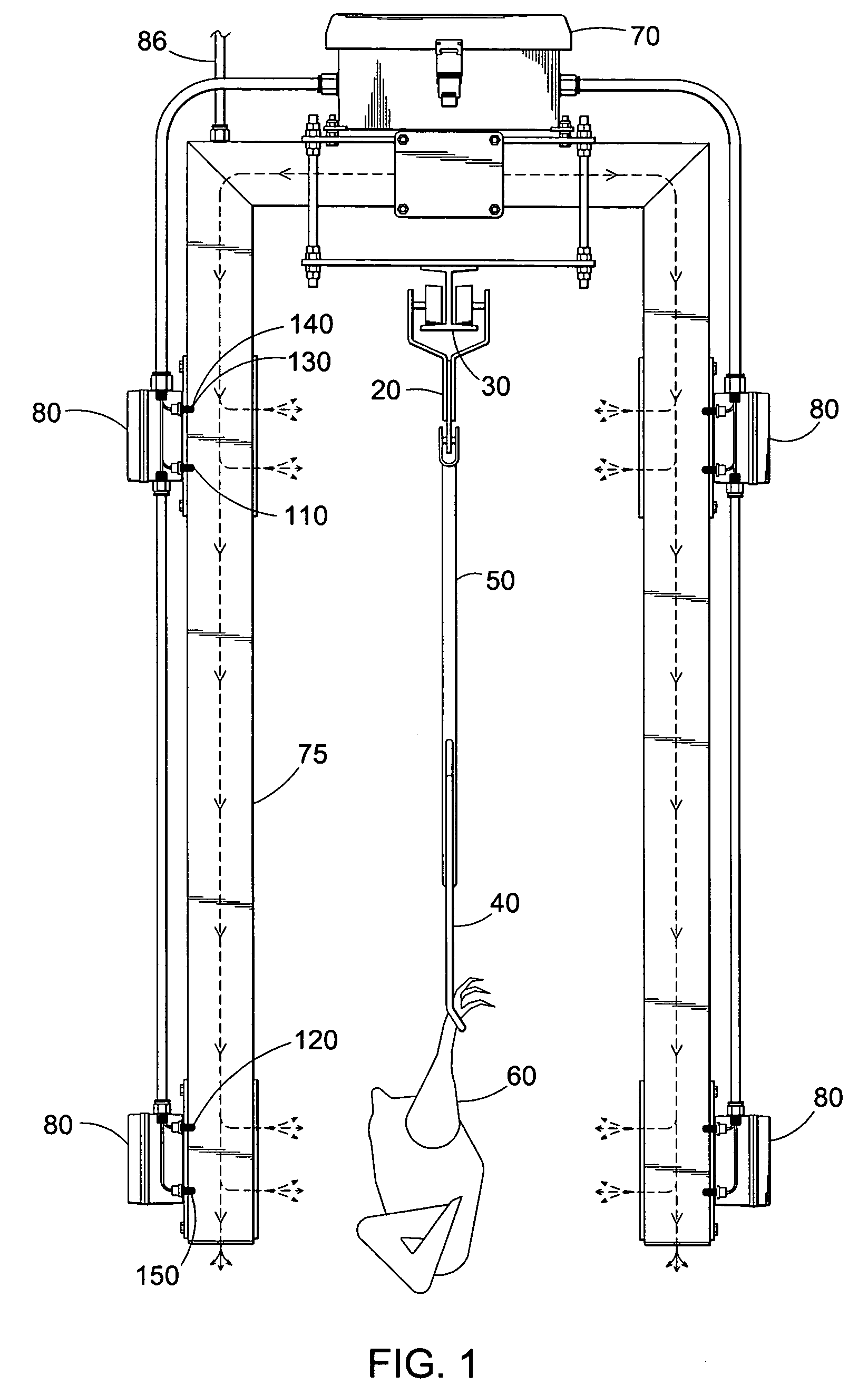

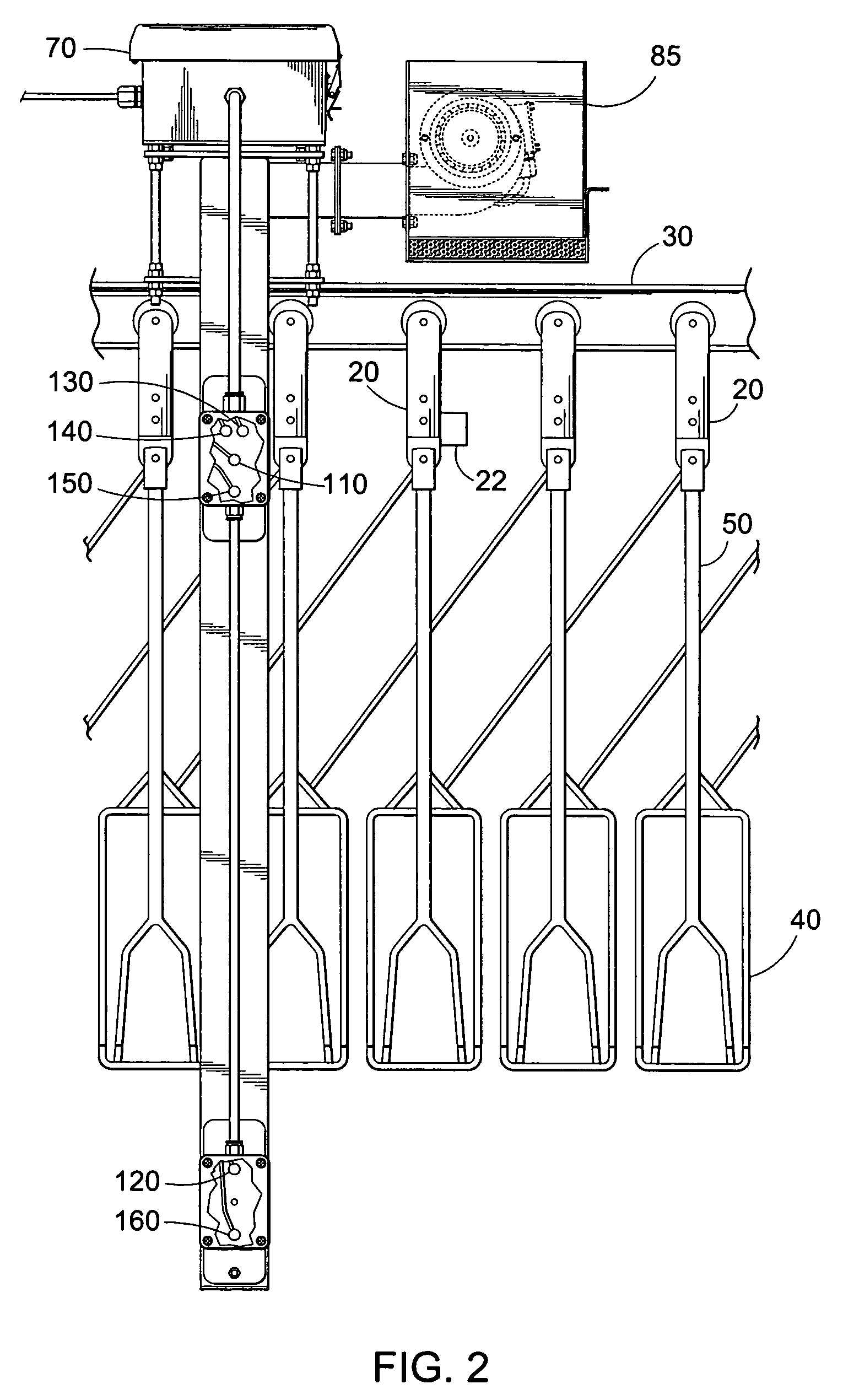

A system and method of counting poultry carcasses conveyed by an overhead shackle conveying system. Poultry carcasses are suspended from shackles of an overhead conveying system and moved along a path of travel defined by the overhead conveying system. The carcasses are directed to engage a force detecting device. The force detecting device generates a signal, such as an electrical signal, when the impacted by a carcass, a magnitude of the electrical signal is proportional to a force of impact of the carcass on the force detecting device. The electrical signal is transmitted to a counter. The counter analyzes the electrical signal and increments a carcass count each time a force in a carcass identifying range is measured.

Owner:BETTCHER INDUSTRIES

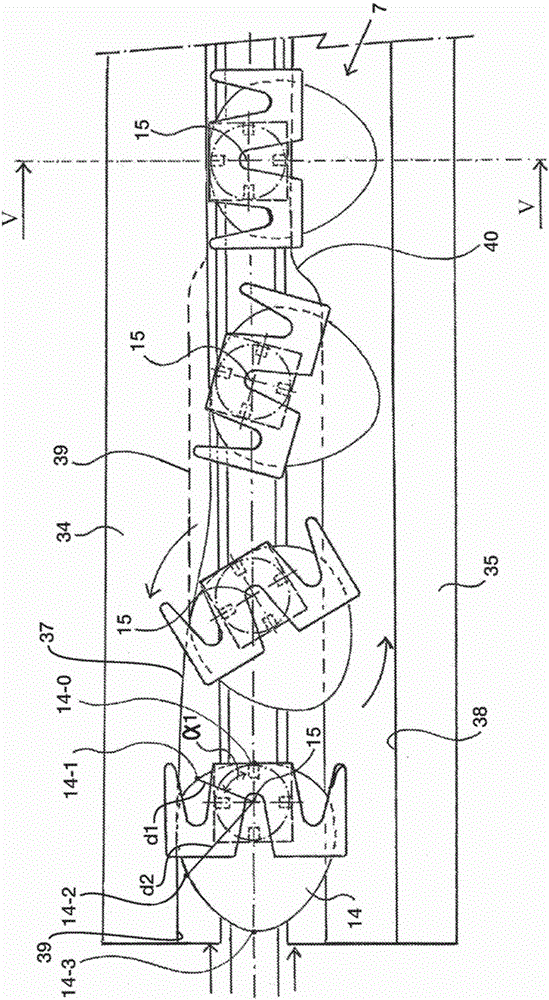

Overhead conveyor system for conveying packaging trays

InactiveCN102361806AReduce occupancySmall footprintConveyorsPackagingEngineeringHorizontal orientation

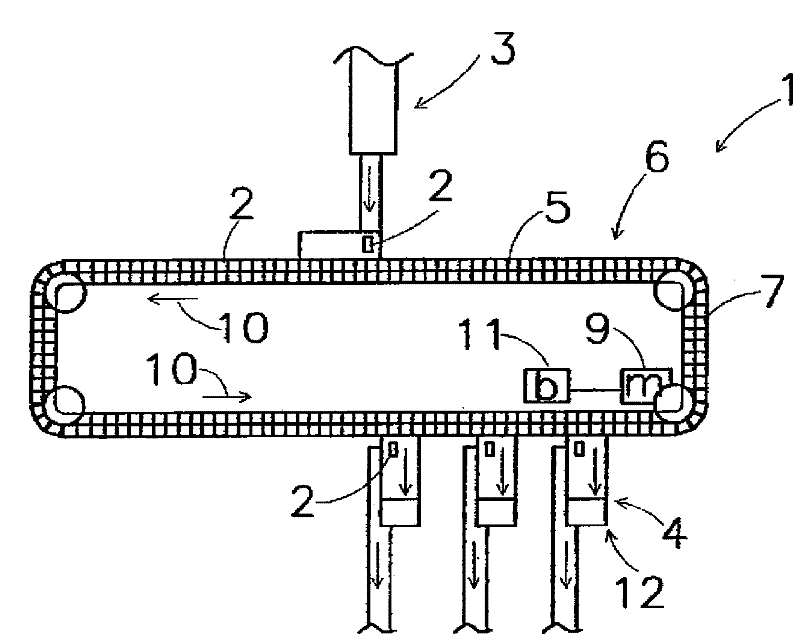

The invention relates to conveyor system (1) for conveying packaging trays (2), for food products for example, from one or more import stations (3) to one or more export stations (4). The conveyor system is provided with an endless conveyor track comprising a rail (5), a multiplicity of trolleys which are movably connected to the rail (5), and a multiplicity of tray carriers (7) which are each coupled to the rail (5) via at least one trolley. Each tray carrier (7) is provided with a support member, preferably a support platform, configured for supporting at least one packaging tray. The use of a conveyor system (1) of this type for conveying packaging trays has the advantage over the use of a roll track, for example, that the system takes up relatively little floor space. Preferably, the import stations (3) and the export stations (4) are provided with an import device and export device respectively for feeding, in a position with a substantially horizontal orientation, the packaging trays into and out of the tray carriers. This allows open trays to be conveyed.

Owner:MAREL STORK POULTRY PROCESSING

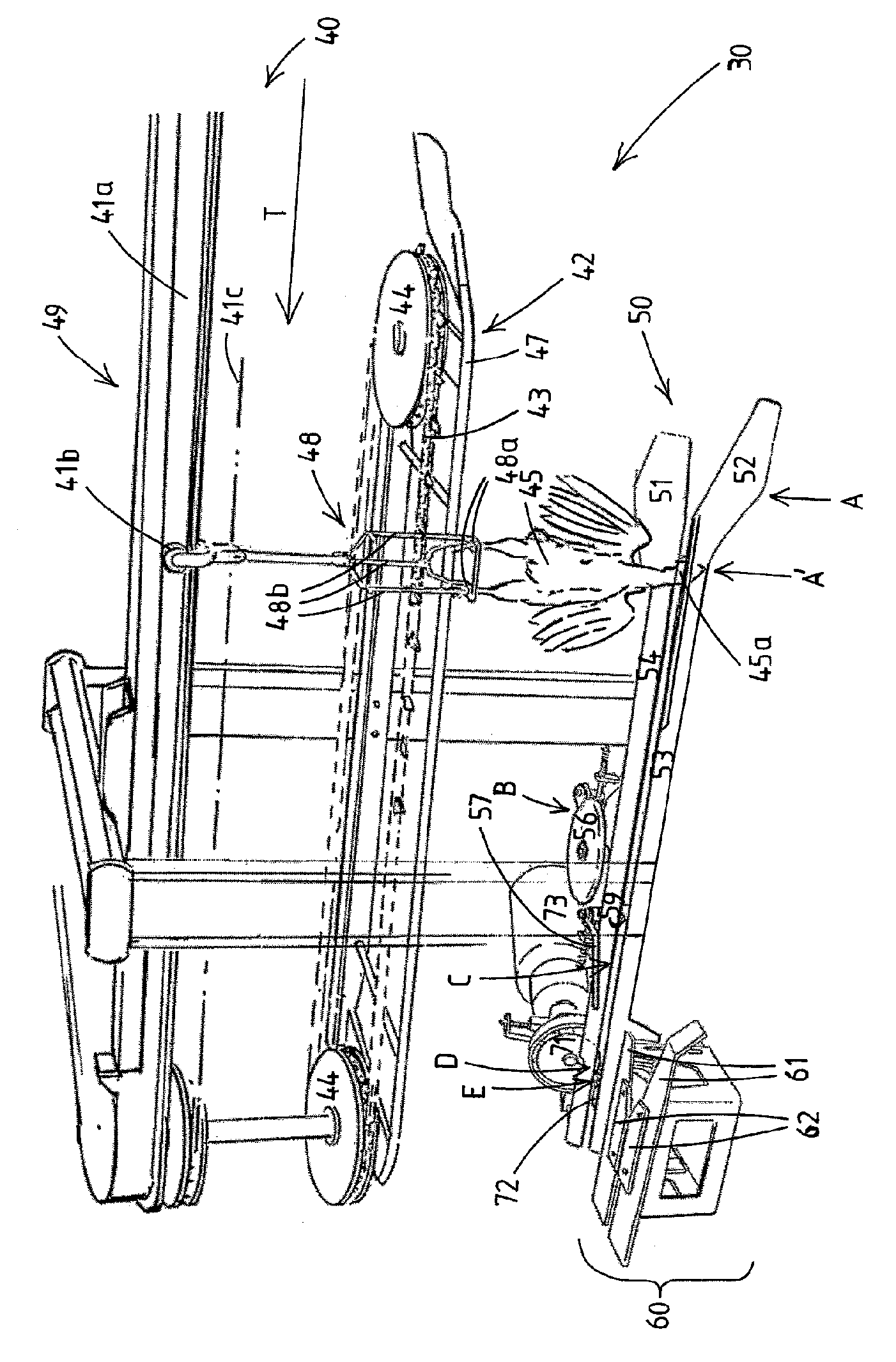

Slaughtering installation and method

The present invention relates to a slaughtering installation for processing poultry which installation is adapted to be used in combination with a conveying assembly (40) for conveying poultry which is suspended from their legs in a transport direction T. The slaughtering installation comprising a killing device with poultry positioning means for positioning the neck region of the poultry suspended from the conveying assembly, the killing device further comprising cutting means for cutting into the neck and thereby opening at least one blood vessel in the neck region of the poultry. According to the invention, the positioning means comprise a back neck guide (54) along which the back side of the neck of the poultry is guided, and a breast neck guide (53) along which the breast side of the neck of the poultry is guided.

Owner:MAREL STORK POULTRY PROCESSING

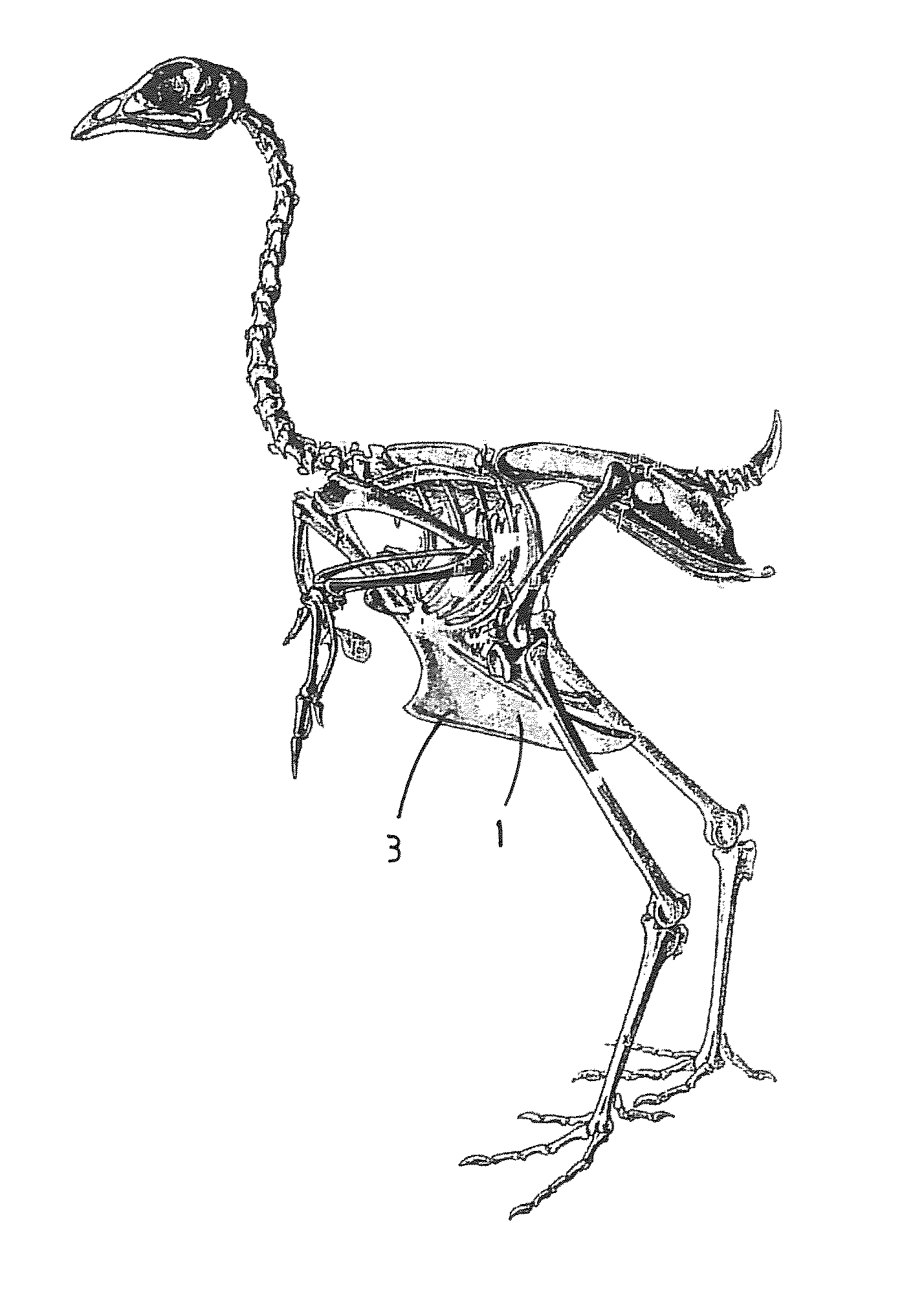

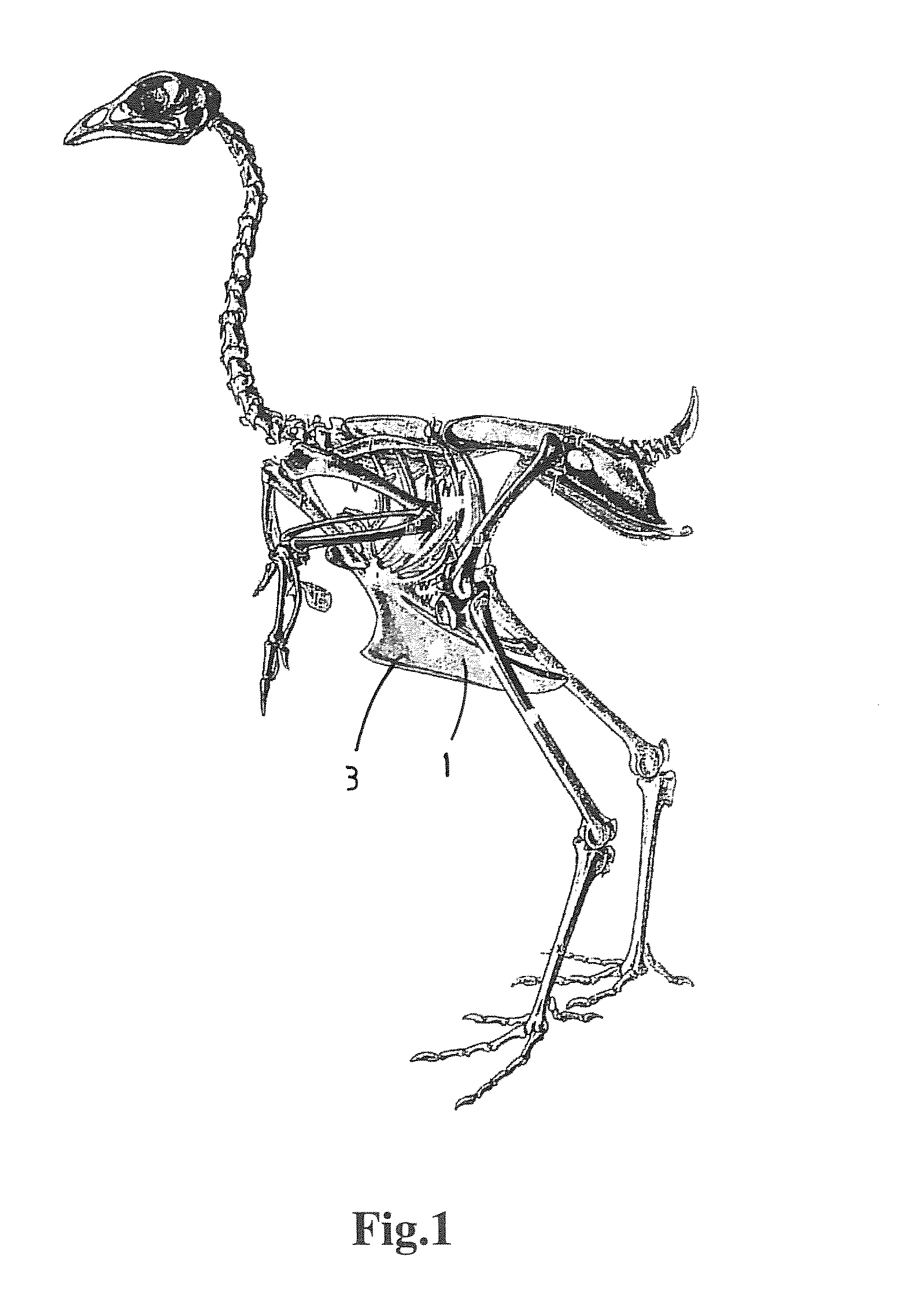

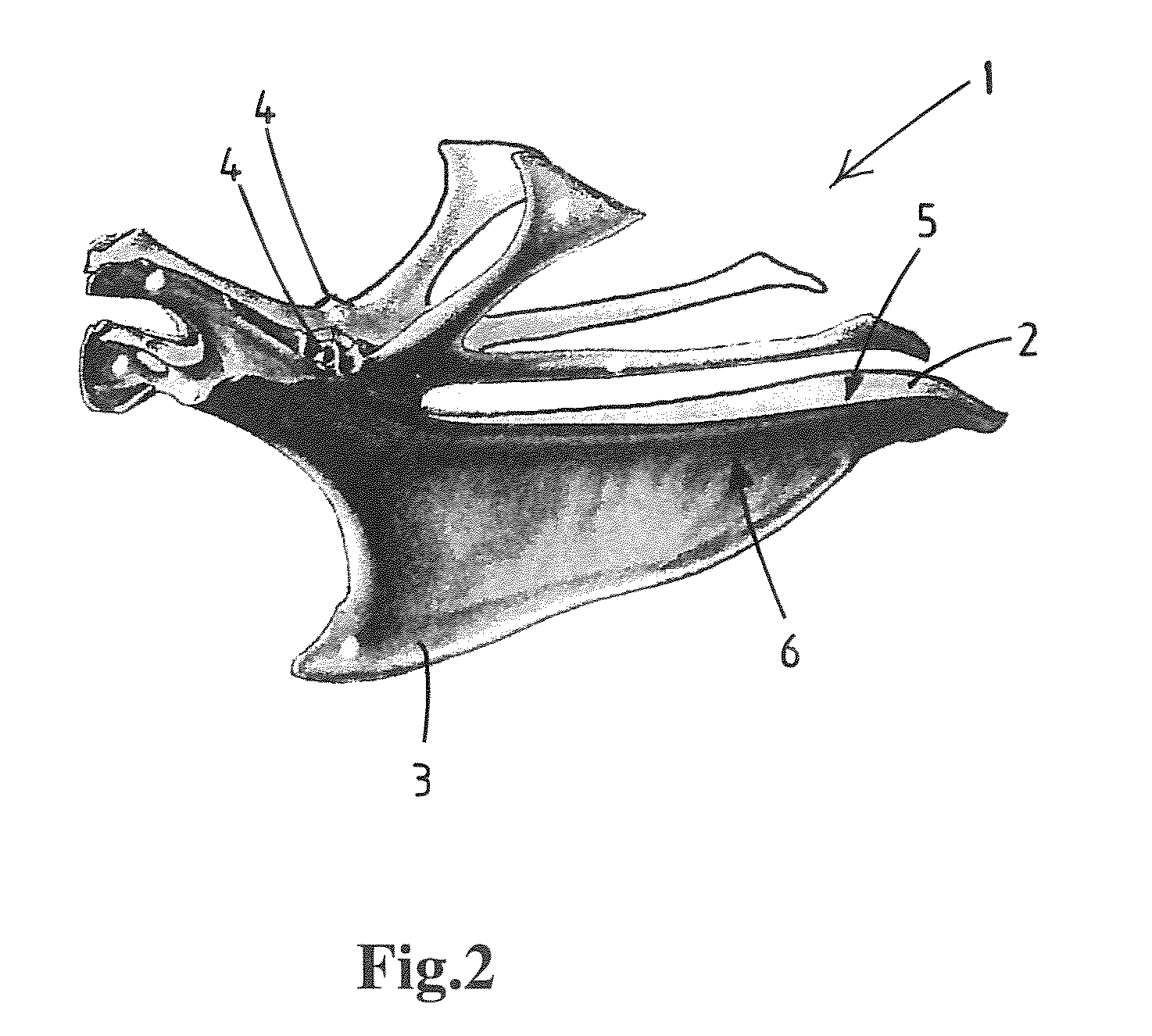

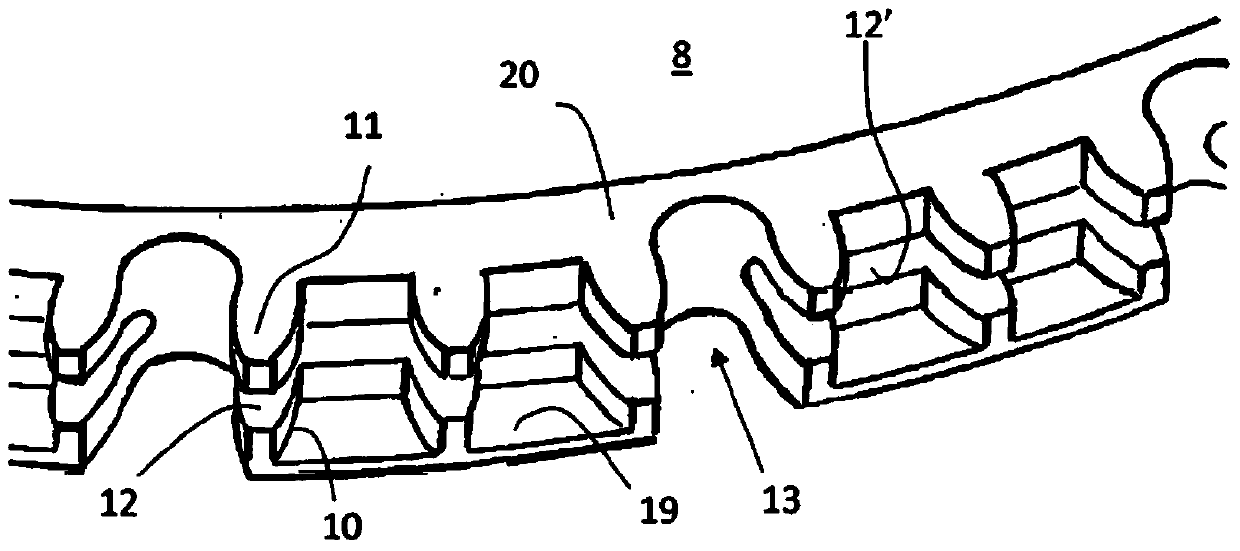

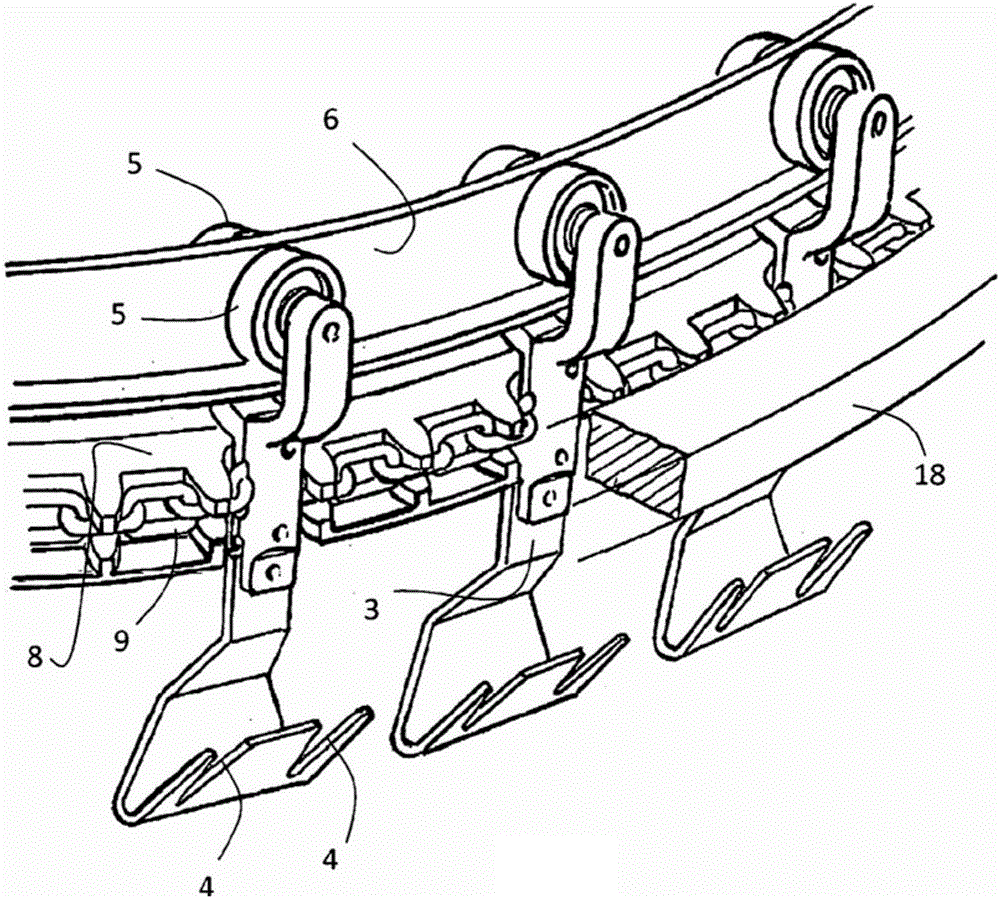

Carrier for supporting a carcass part of slaughtered poultry

ActiveUS9173413B2Avoid partialHold positionPoultry processing support devicesPoultry transferring/conveying devicesMedial partEngineering

A carrier for supporting a carcass part of slaughtered poultry includes a carrier body having a support surface for engaging at least a part of the inner face of the carcass part, a hook for holding the carcass part on the carrier body, a positioning element for positioning the carcass part relative to the carrier, which has a dome shaped engagement end for engaging the inner face of the carcass part, and is moveable between a retracted position and an extended position in which the dome shaped engagement end of the positioning element protrudes from the support surface of the carrier body. The positioning element is arranged such relative to the support surface of the carrier body that in its extended position, the dome shaped engagement end of the positioning element engages the inner face of the carcass part at or adjacent to the facies visceralis sterni of the sternum in the region between the left and right margo costalis of the sternum.

Owner:MAREL STORK POULTRY PROCESSING

Adding an additive to a meat product

Owner:MAREL STORK POULTRY PROCESSING

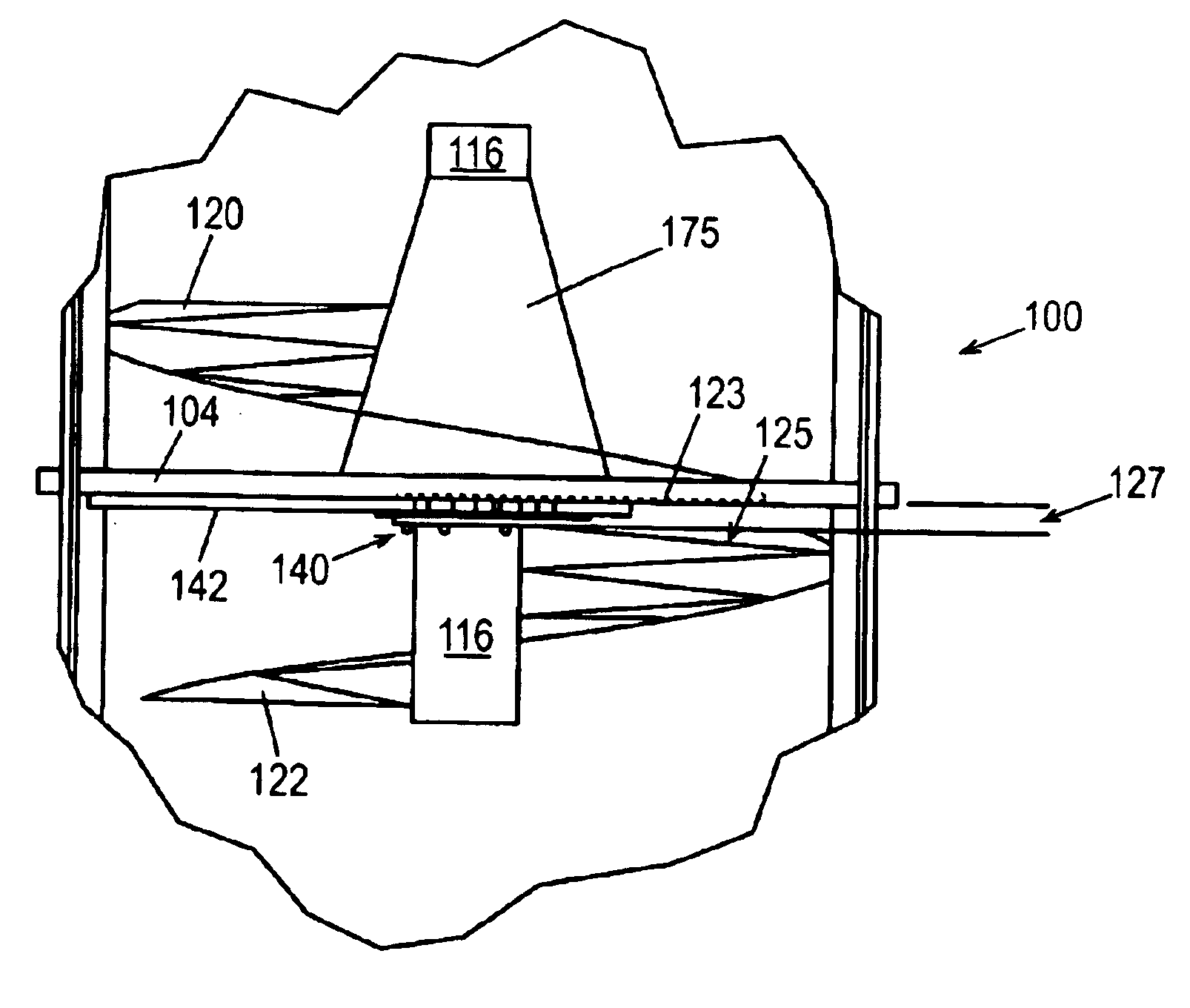

Hanger bearing for auger type poultry chiller with cone deflector

InactiveUS6951273B2Trend downStationary refrigeration devicesMeat/fish preservation by freezing/coolingMechanical engineeringChiller

A poultry chiller 100 has a hanger 140 suspended from the upper portion of the tank 102 that supports the bearing block 160 of the auger shaft 112 between the auger blades. A conical bird deflector 175 is mounted on the auger shaft and radially deflects the birds away from the bearing block as the birds are urged across the bearing block.

Owner:MORRIS & ASSOCS

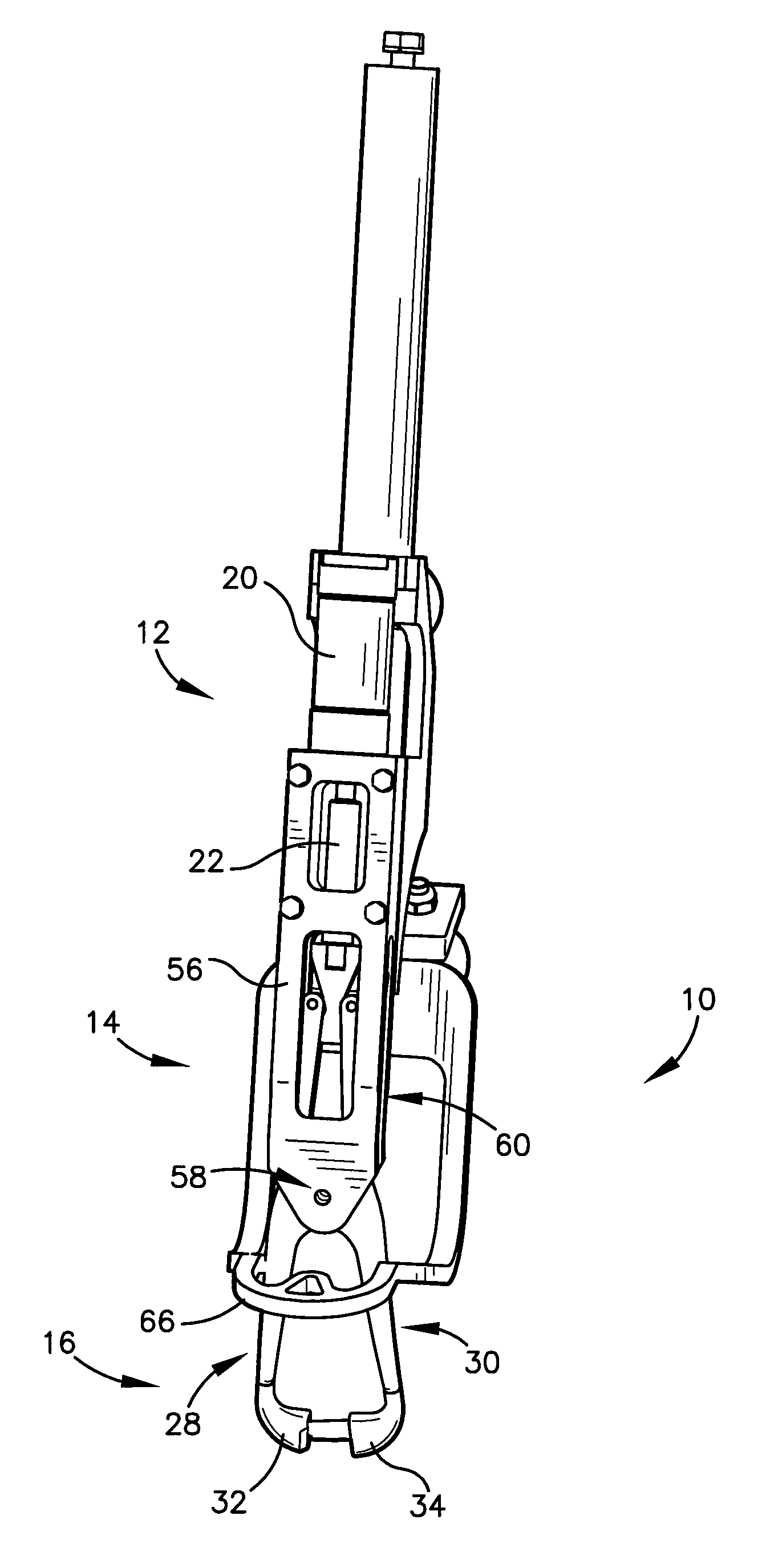

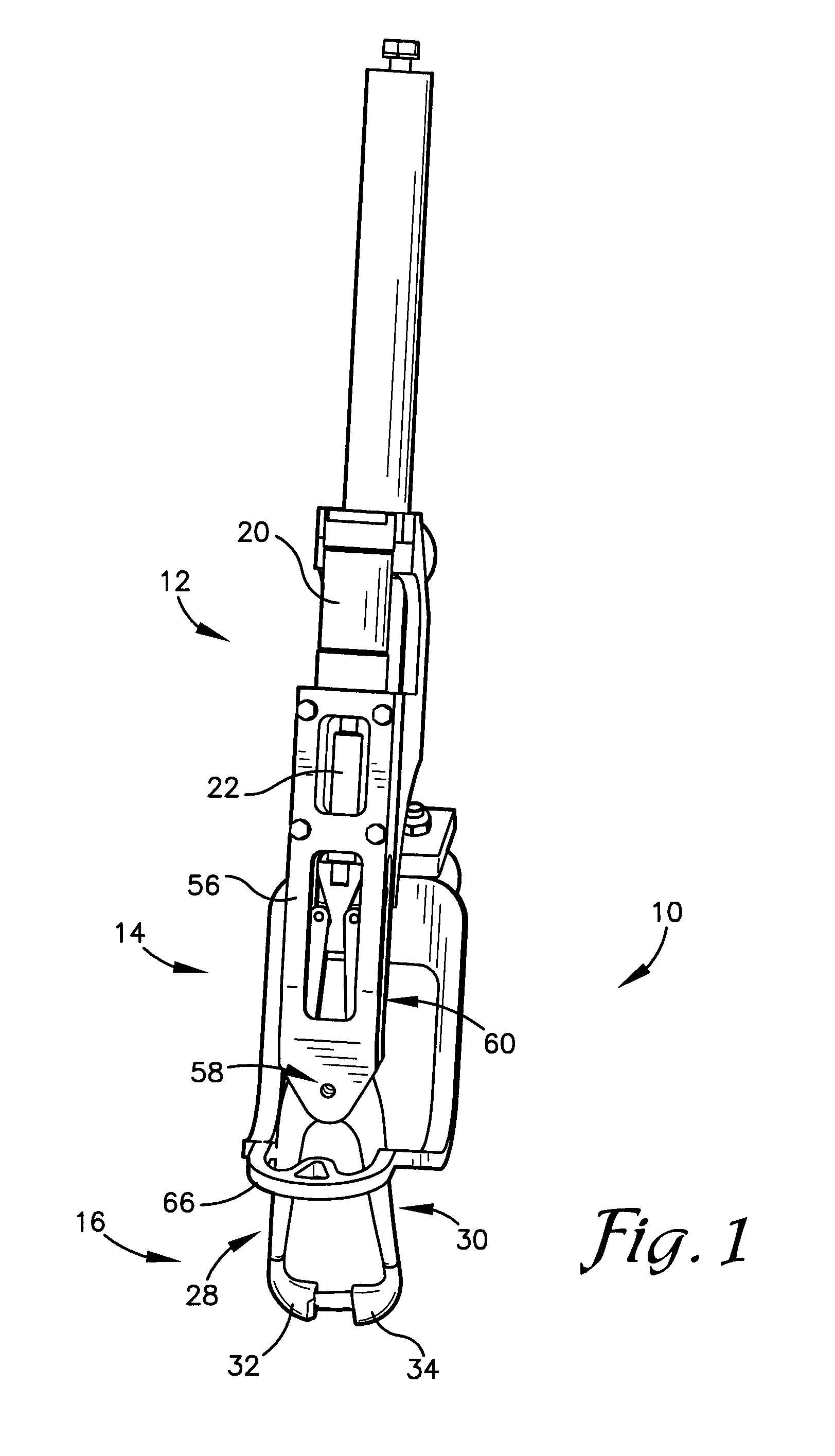

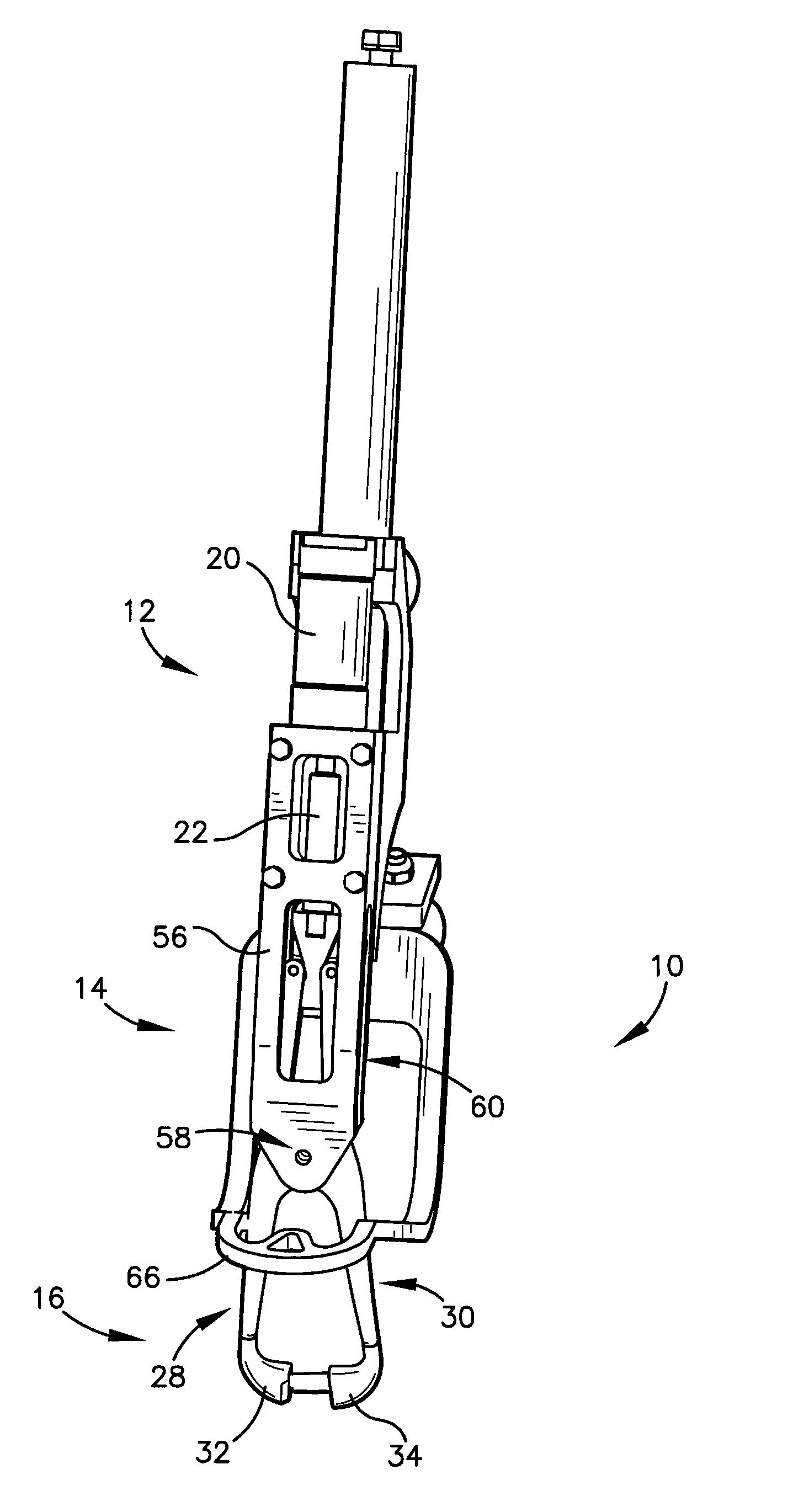

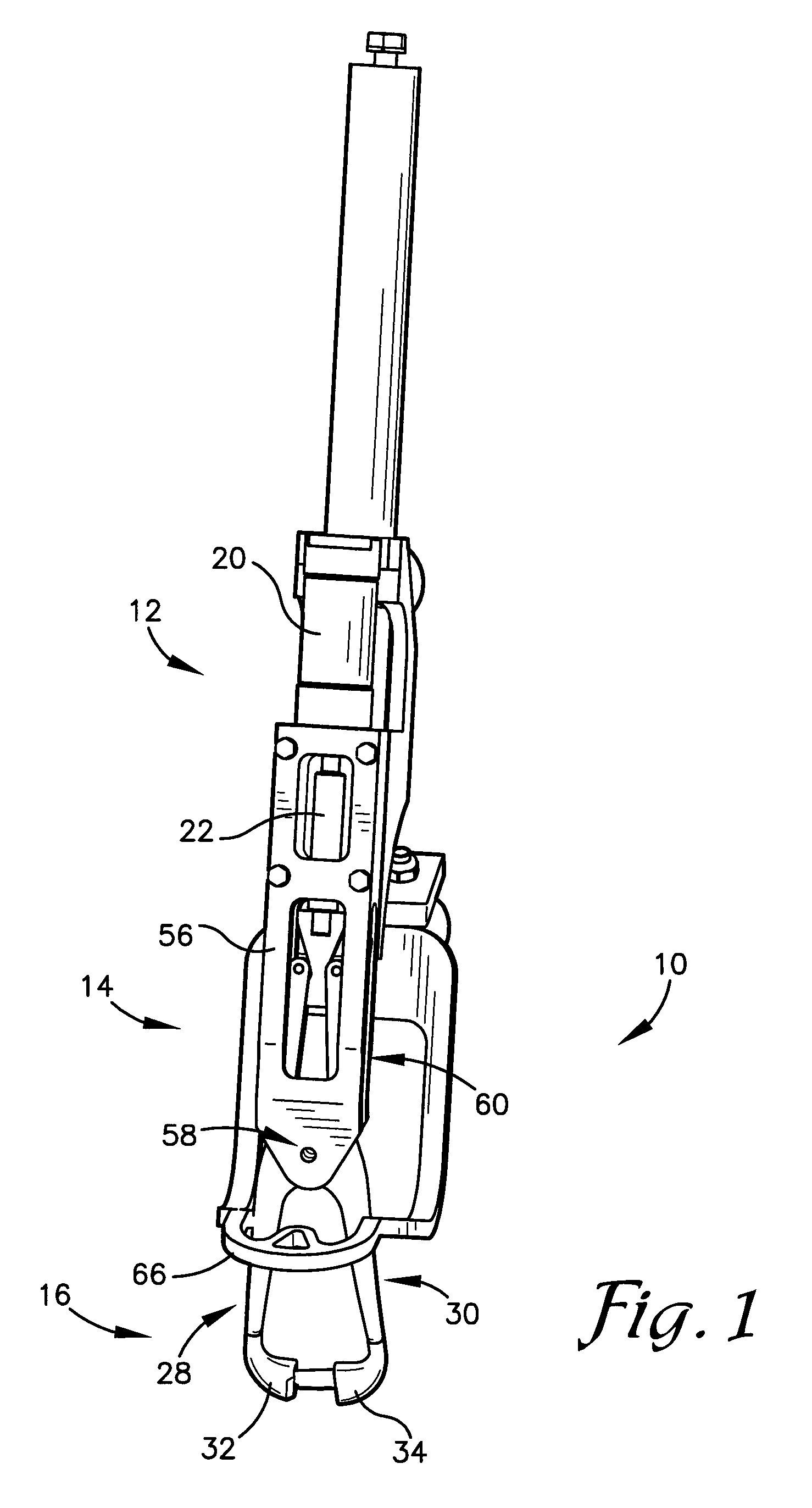

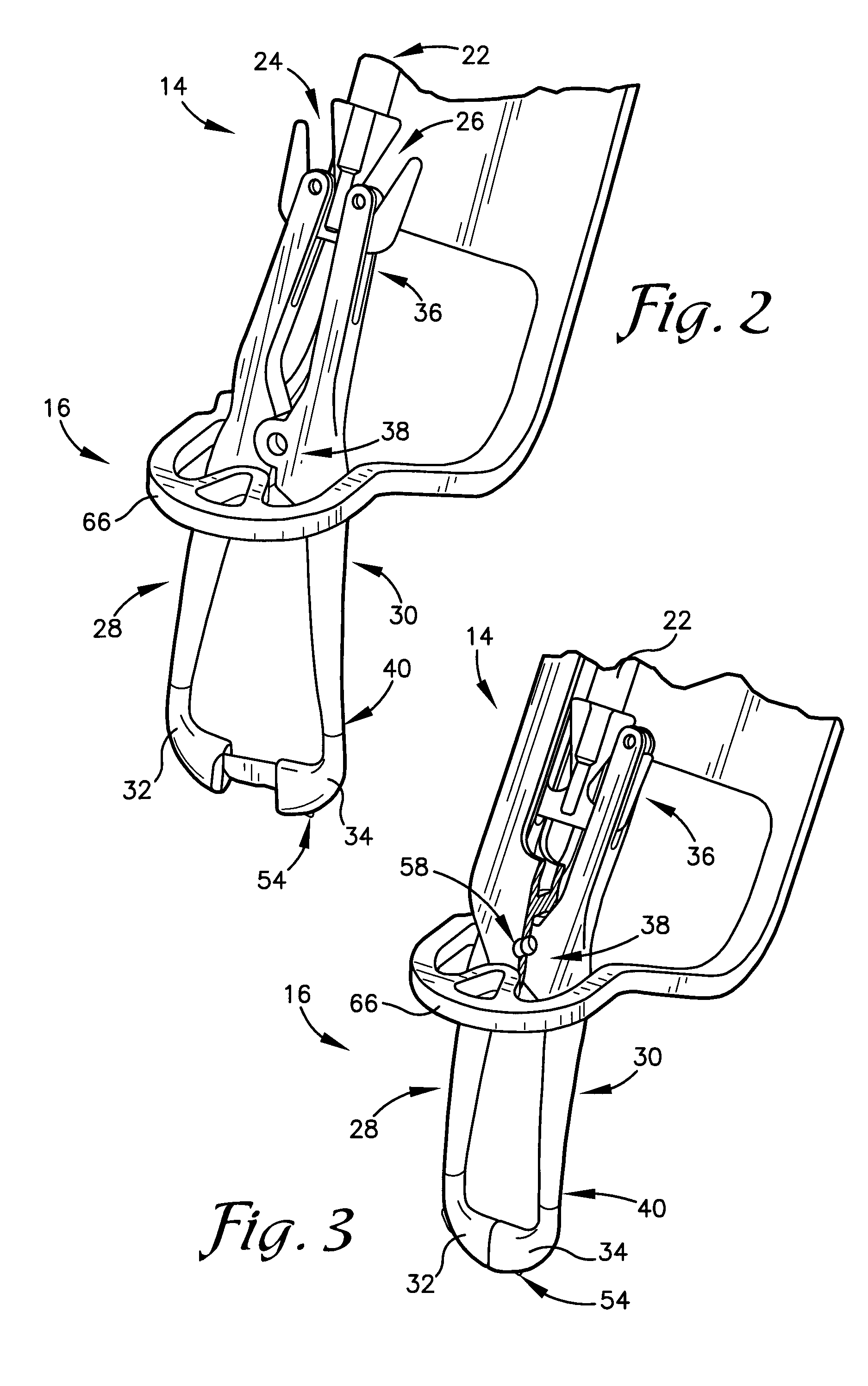

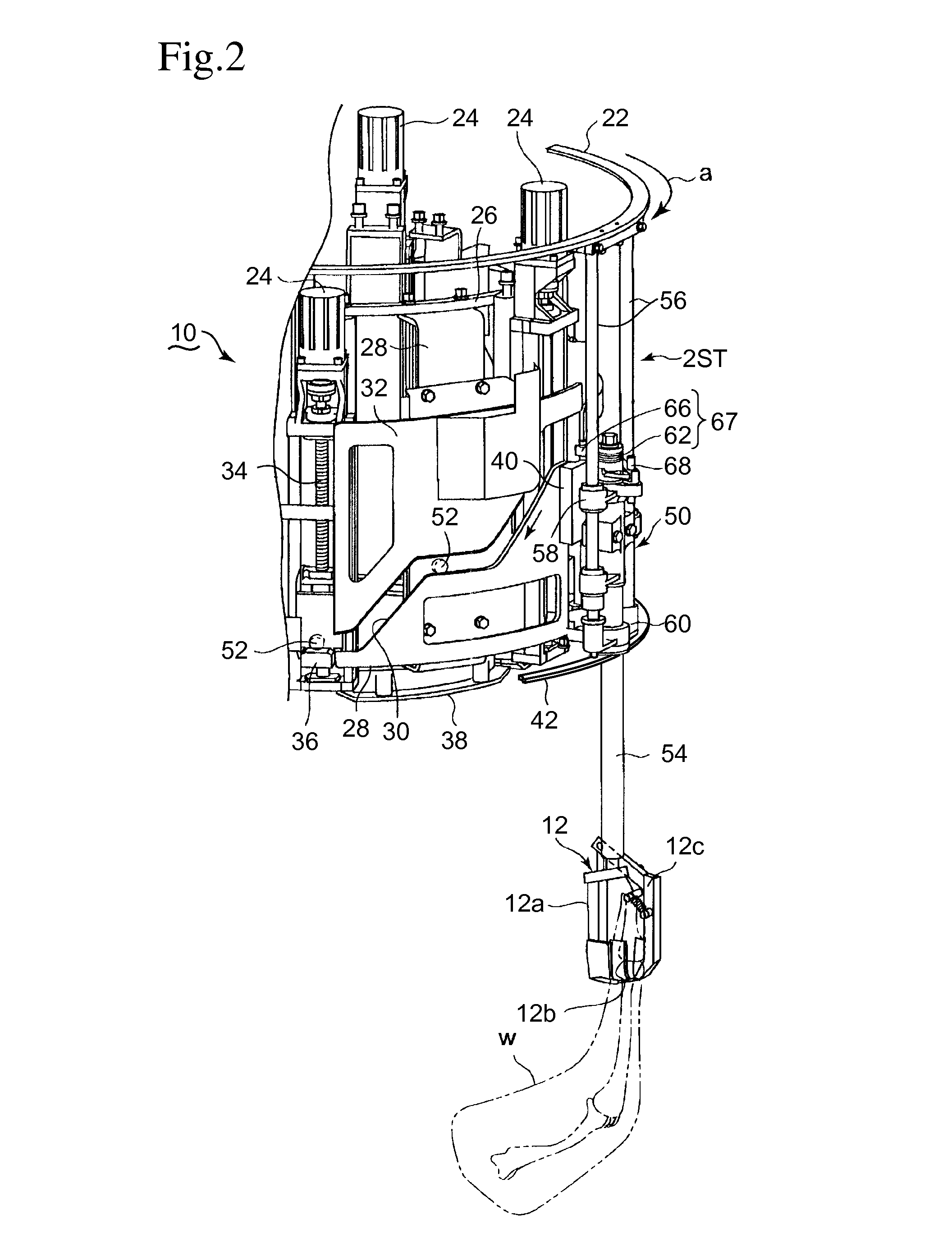

Device and method for clamping and cutting

ActiveUS7500910B2Avoid pollutionAnimal stomach clearancePoultry eviscerating devicesEngineeringContamination

A device (10) and method for clamping or otherwise securing an esophagus between the crop and certain internal organs, including the viscera, and substantially simultaneously cutting or otherwise separating, or weakening for subsequent predictable separation, the esophagus at or near the clamped location, thereby avoiding pulling apart the crop and the resulting contamination of the carcass.

Owner:BAADER FOOD SYST USA INC

Apparatus for weighing slaughterhouse products and method for using the same

The invention provides a device for weighing slaughter products. The device comprises conveying means for conveying the slaughter products, the conveying means comprising a frame, two pulley means which are connected to the frame a fixed distance apart, being rotatable about two respective first vertical axes of rotation, an endless flexible conveying element which is passed over the two pulley means, which conveying element extends along a rectilinear weighing path between the two pulley means, a guide extending along a conveying path, hooks for the slaughter products, which hooks are connected to the conveying element at regular intervals and which are each provided with a guide elements for guiding cooperation with the guide. The device further comprises weighing means for weighing slaughter products that are present within the weighing section and reducing means for reducing tensile stress in the conveying element insofar as it extends in the weighing section, said reducing means comprising transmission means that are operative between the two pulley means. The transmission means comprise a gear transmission with at least two meshing gears which are rotatable about respective second vertical axes of rotation, wherein the second axis of rotation of one of the at least two gears is in line with a first vertical axis of rotation, and wherein the second axis of rotation of another of the at least two gears is in line with the other first vertical axis of rotation.

Owner:MAREL STORK POULTRY PROCESSING

Device and method for clamping and cutting

ActiveUS20090042497A1Avoid pollutionAnimal stomach clearancePoultry eviscerating devicesEngineeringContamination

A device (10) and method for clamping or otherwise securing an esophagus between the crop and certain internal organs, including the viscera, and substantially simultaneously cutting or otherwise separating, or weakening for subsequent predictable separation, the esophagus at or near the clamped location, thereby avoiding pulling apart the crop and the resulting contamination of the carcass.

Owner:BAADER FOOD SYST USA INC

System and method for assessment of a workpiece in a continuous flow process

A system for measuring physical properties of a workpiece in motion which includes a conveyance assembly for conveying the workpiece, a scanning assembly for scanning the workpiece, and a measurement assembly for measuring at least one physical property of the workpiece while the workpiece is in motion.

Owner:JOHN BEAN TECH CORP

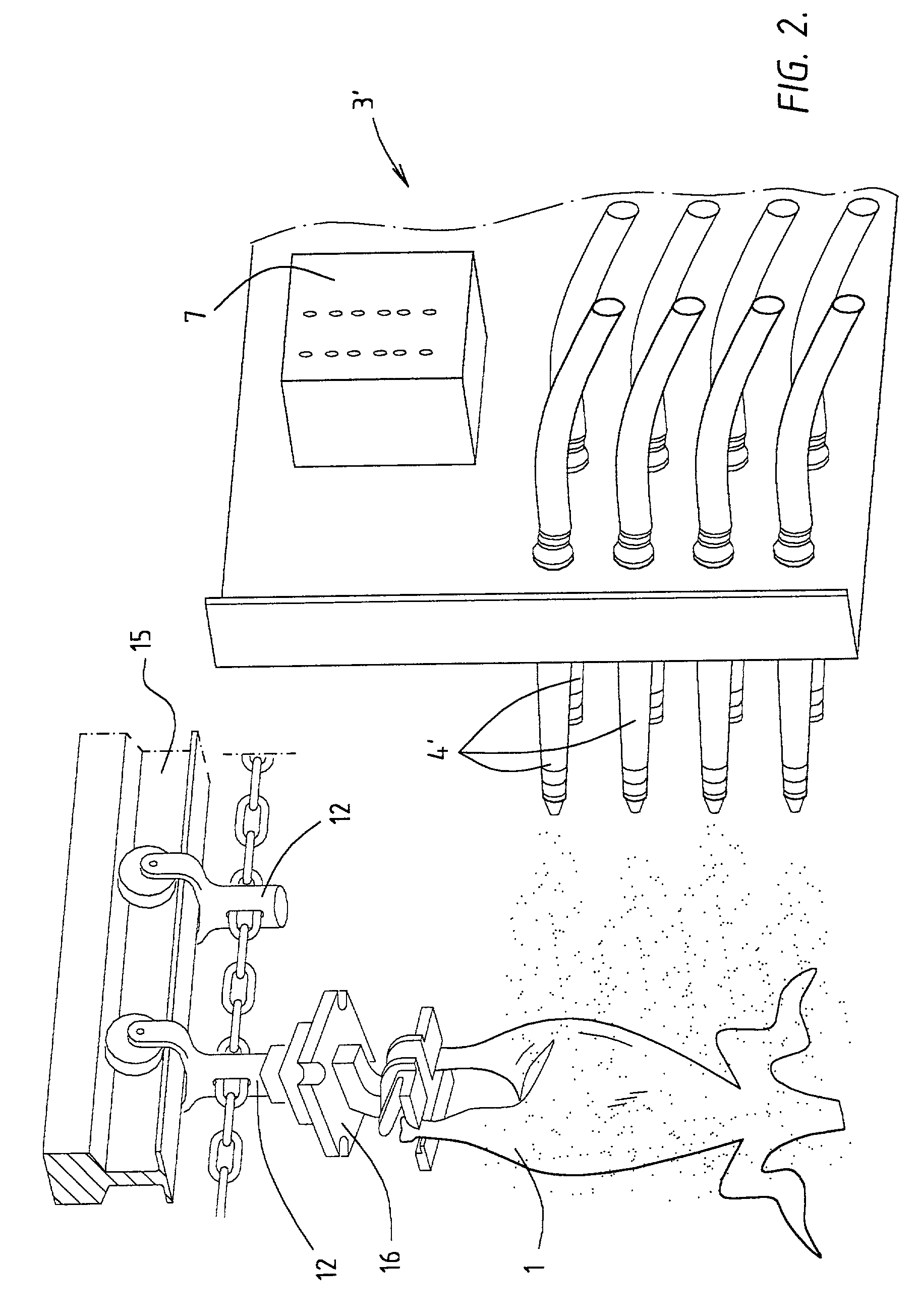

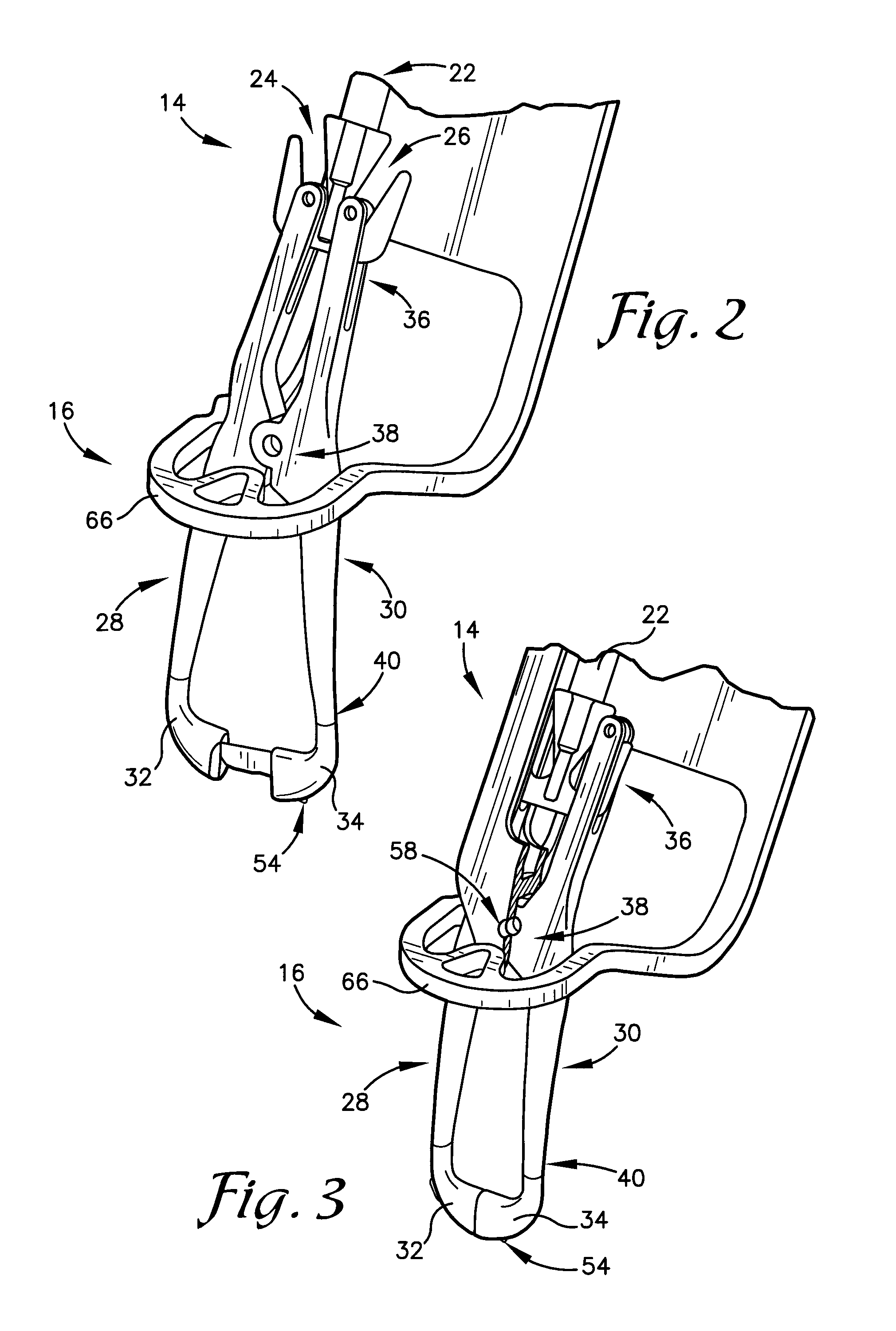

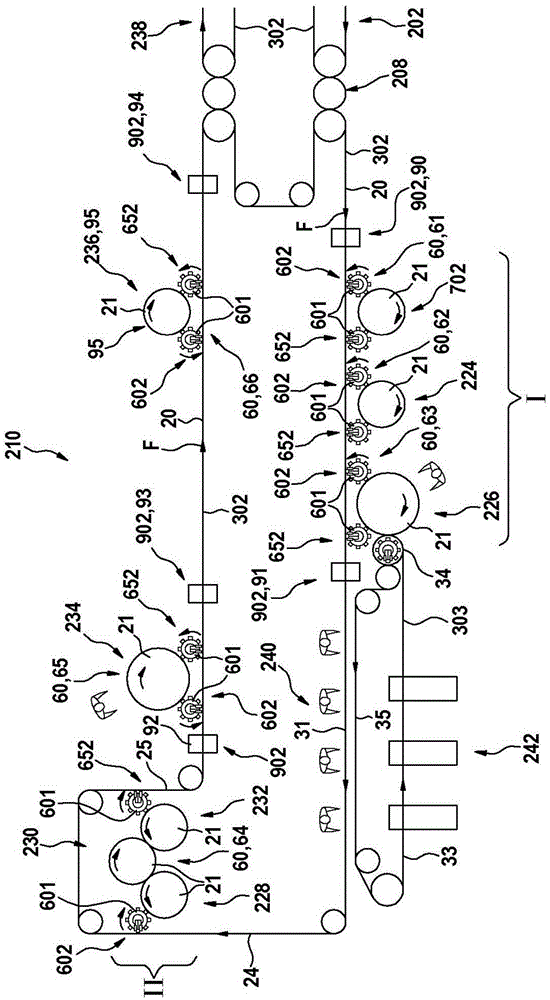

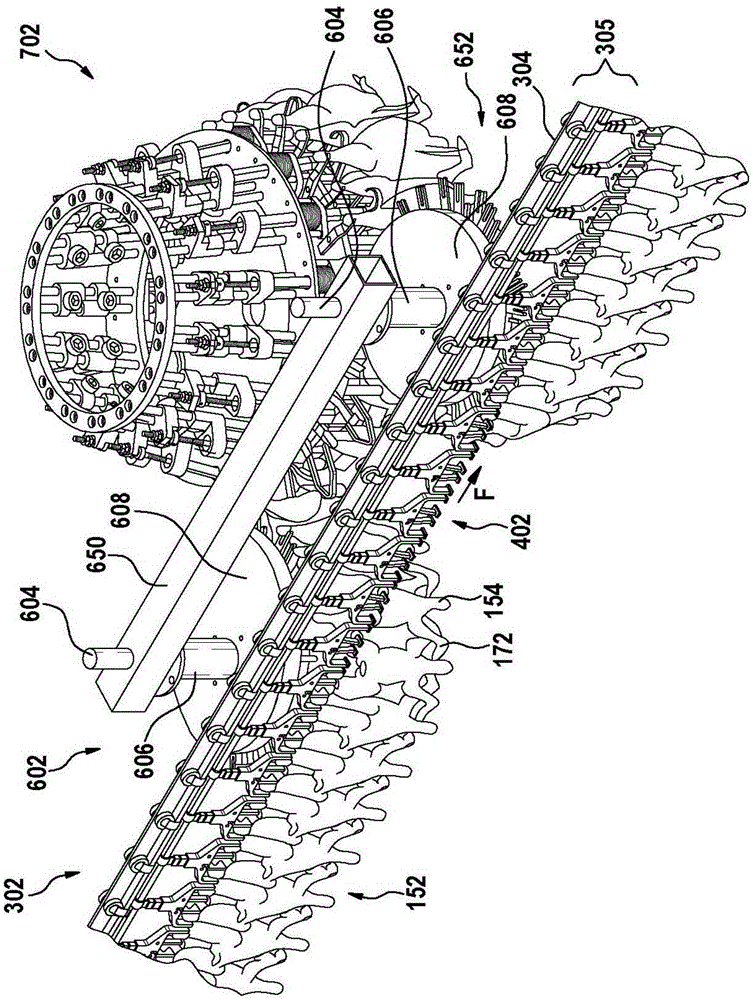

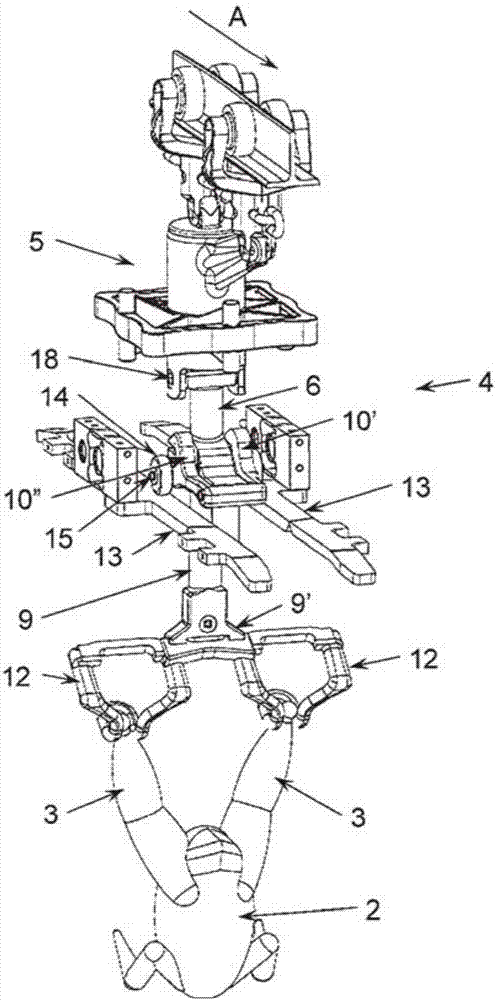

Processing device for processing slaughtered and plucked poultry carcasses, comprising poultry-support devices and poultry-processing devices

ActiveCN105307959AConveyorsPoultry eviscerating devicesEngineeringElectrical and Electronics engineering

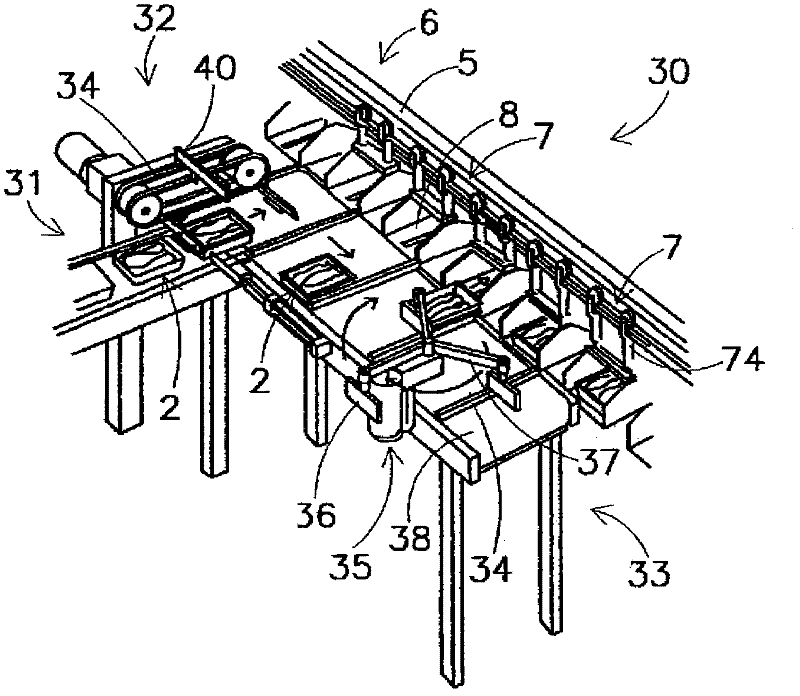

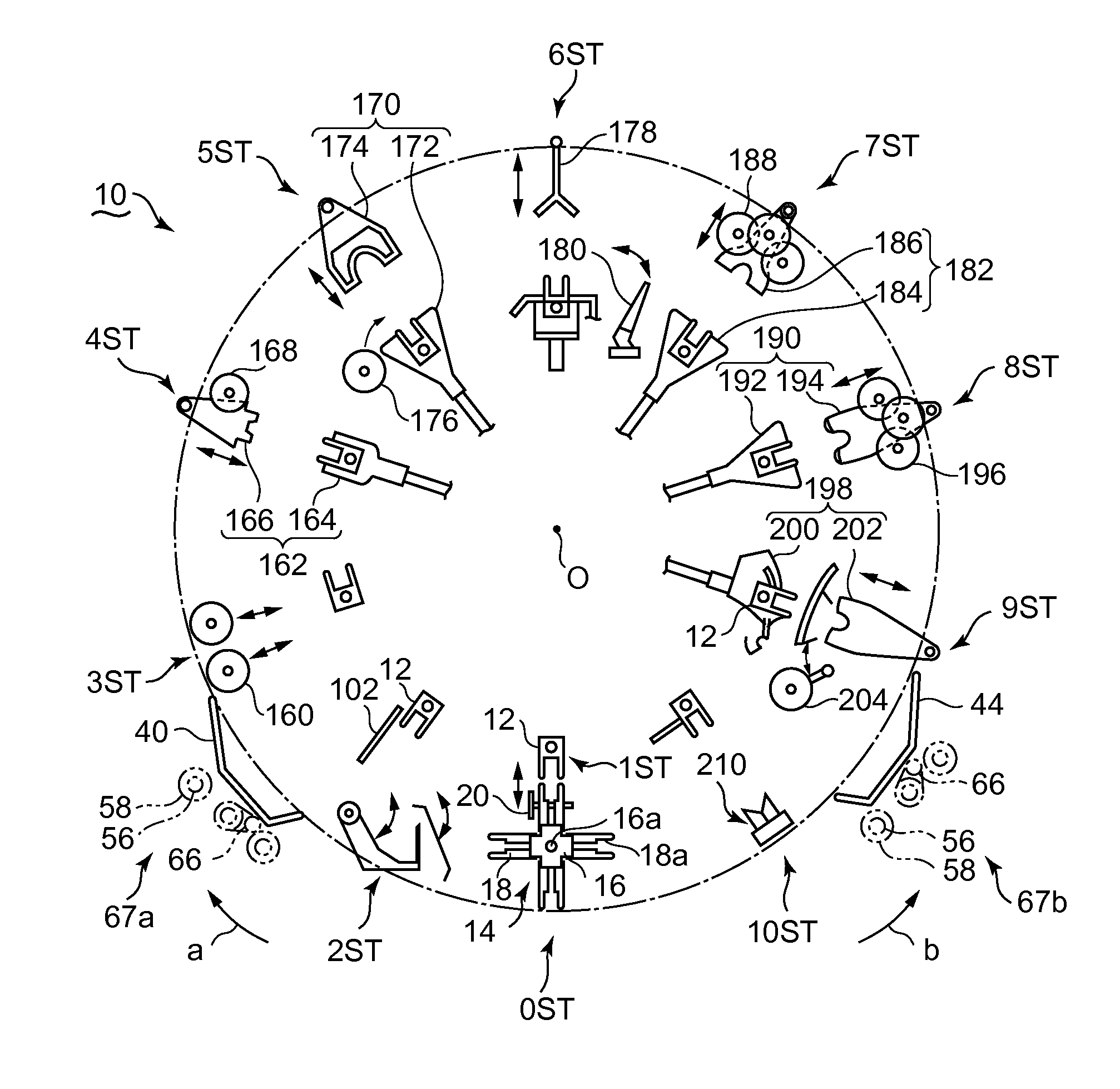

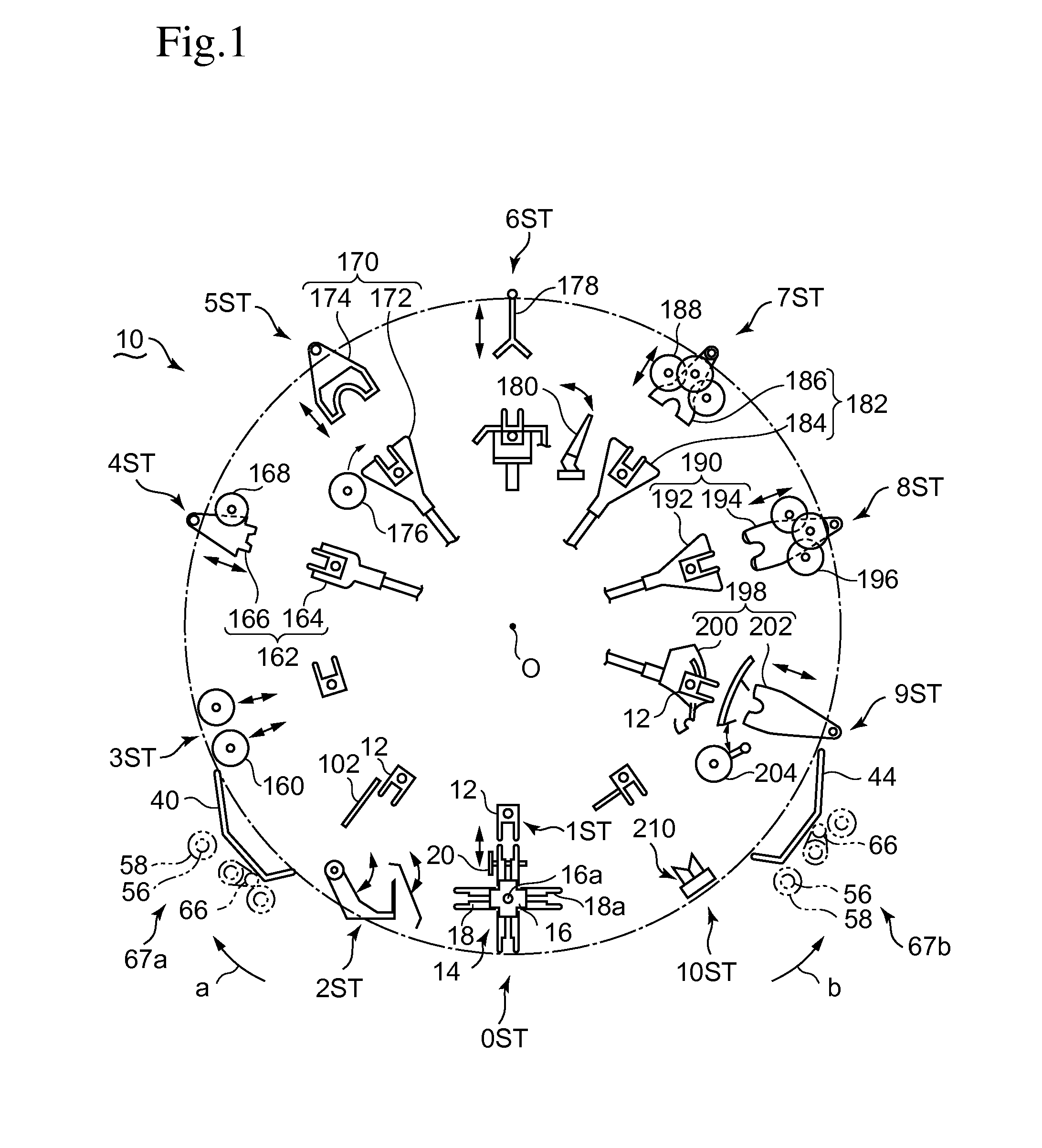

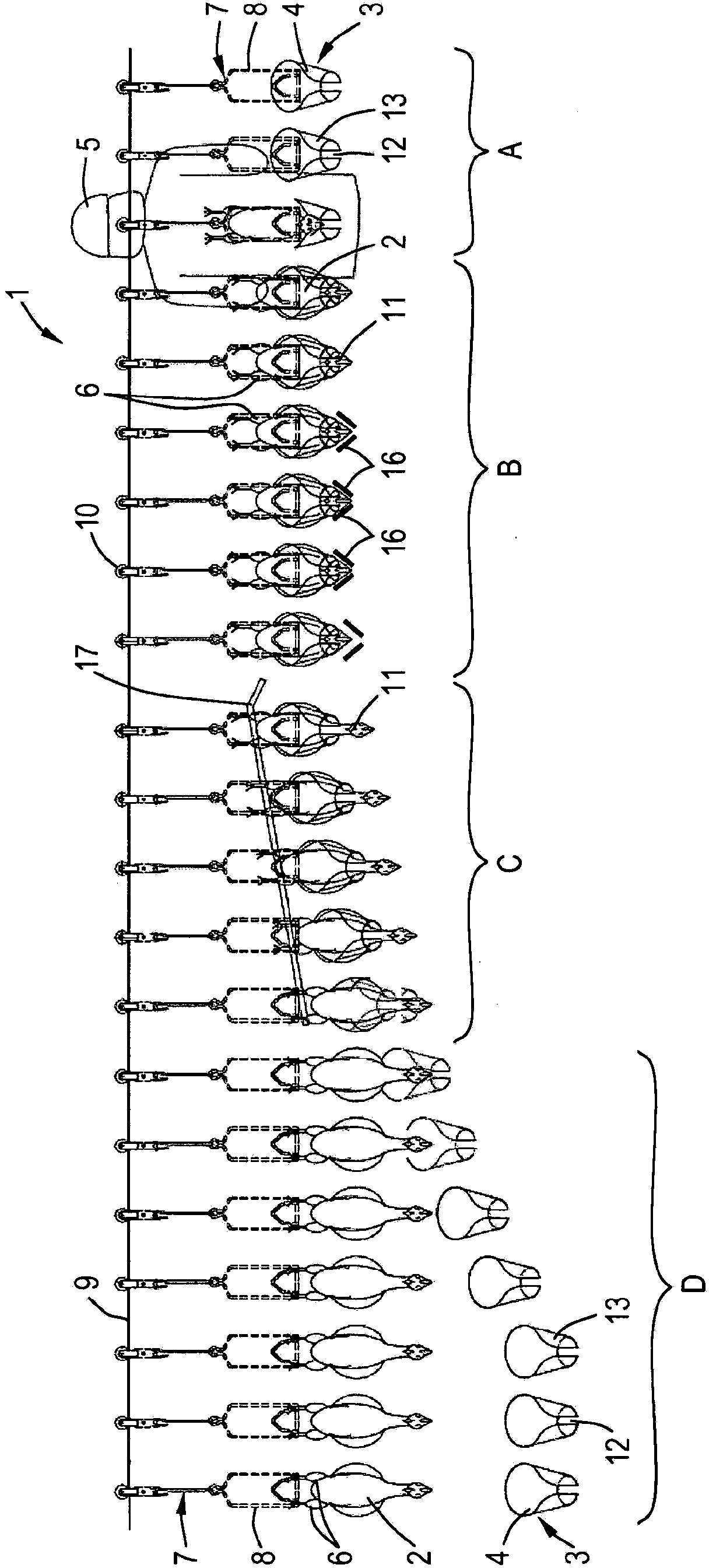

The invention relates to a processing device (210) for processing slaughtered and plucked poultry carcasses (152), having multiple processing devices (21) that are equipped to transport poultry carcasses (152) separately from a main conveying device (302) for processing purposes using a processing retaining means (820) which can be moved on a circumferential path. The processing device (210) has transfer stations (60; 51-66) which are arranged in a row along a main conveying line (20) in which the poultry carcasses (152) are conveyed in a suspended manner using support devices (402). Each processing device (21) is paired with a transfer station (60; 61-66) formed by a transfer pair (601) which has two rotational transferring devices (602, 652). The first rotational transferring device (602) removes poultry carcasses (152) from the support devices (402) and transfers the poultry carcasses to the processing retaining means (820) of the processing device (21). The second rotational transferring device (652) removes the processed poultry carcasses (152) from the processing retaining means (820) and transfers the poultry carcasses to the support devices (402). Each support device (402) has a pair (401) of supports (41, 42) with receiving portions (40.1, 40.2) for limbs (11, 12) of the poultry carcasses (152) and comprises a support controller (410). Each support (41, 42) is equipped with a controllable retaining device (403; 405) which is connected to the support controller (410) via a control element (444, 454) that controls a retaining part of the limb receiving portion (40.1, 40.2). In an open position of the controllable retaining part, the limb receiving portion (40.1, 40.2) is open so that the poultry carcass limbs (11, 12) are inserted and removed without being clamped, and the limb receiving portion contacts the poultry carcass limbs (11, 12) only in a closed position of the retaining part. The poultry processing device (21) has a processing controller to which the processing retaining means (820) is connected and by means which the processing retaining means can be moved into different positions along the retaining means circumferential path, namely a starting position for receiving the poultry carcasses, at least one processing position, and an end position for removing the poultry carcasses.

Owner:BAADER FOOD SYST DENMARK AS

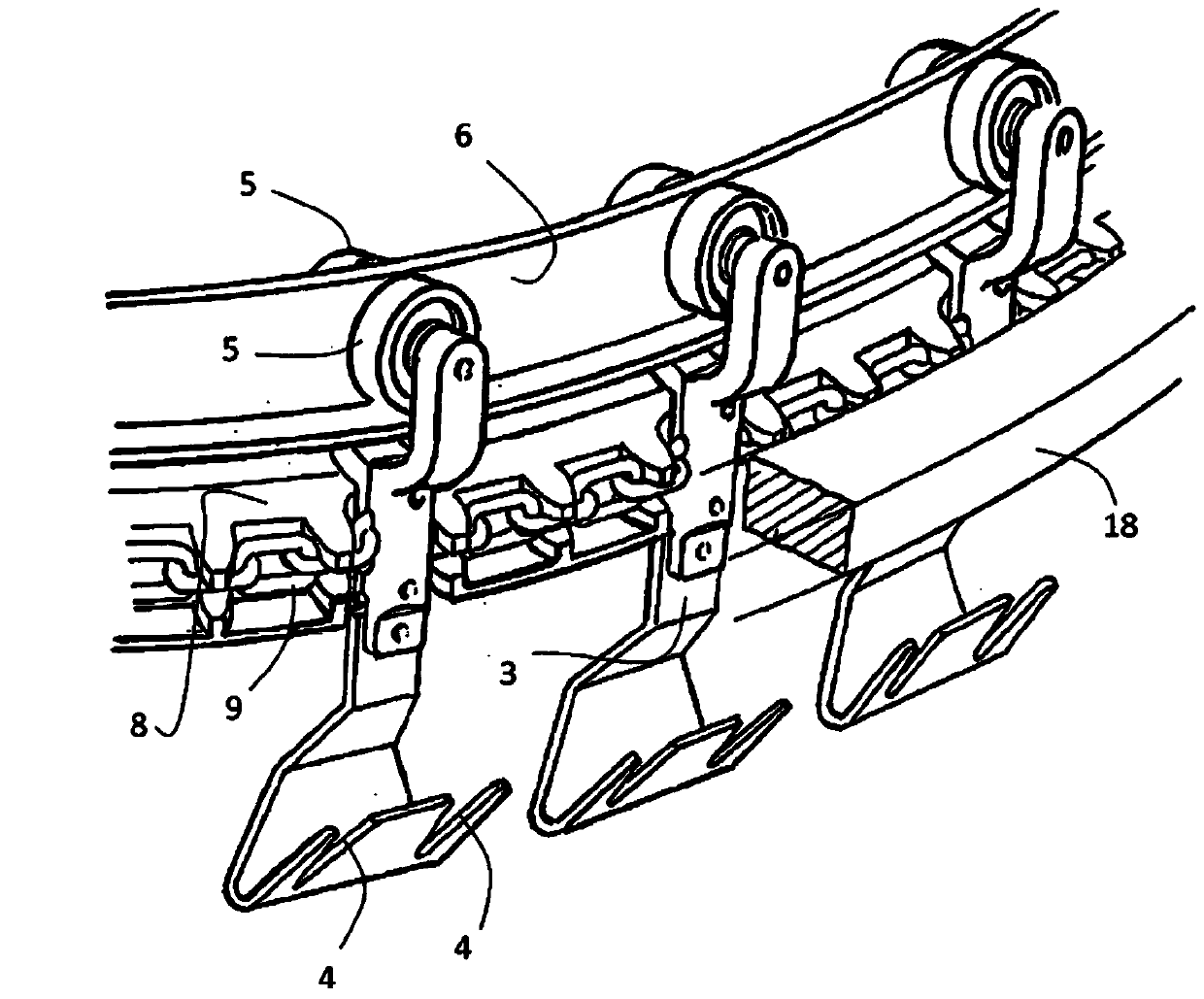

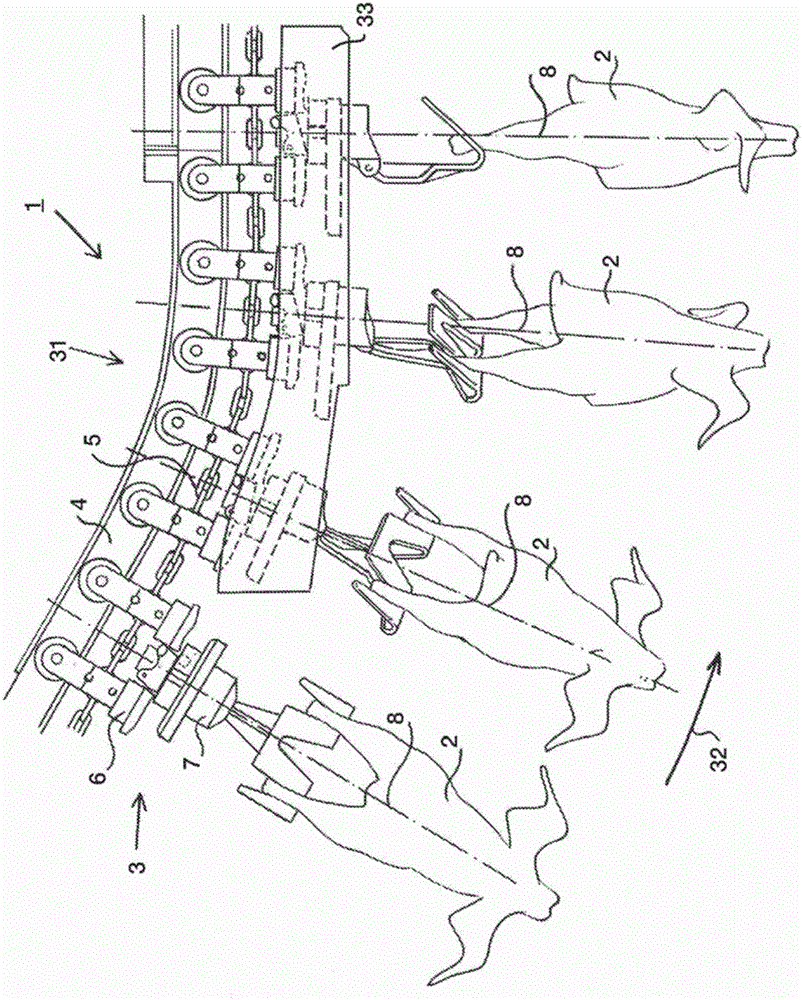

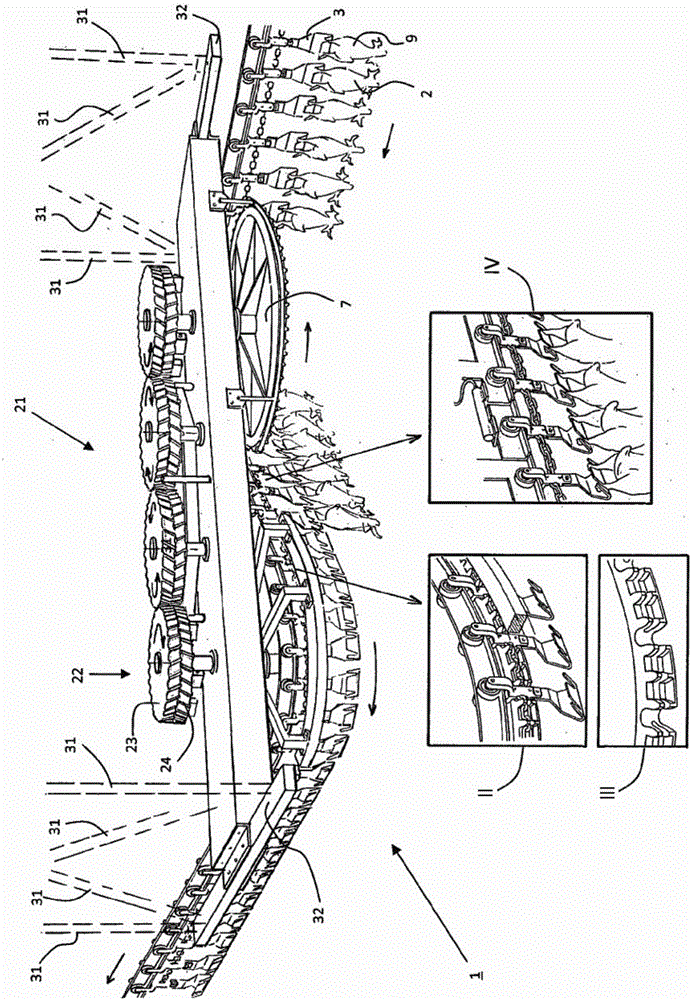

Device and method for changing the orientation of slaughter products

ActiveCN106163289AAvoid damageIncrease the lengthPoultry shacklesPoultry transferring/conveying devicesVertical planeEngineering

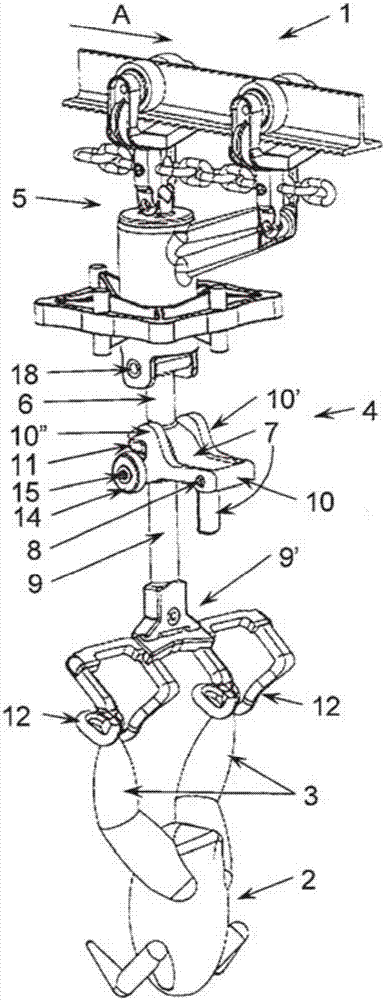

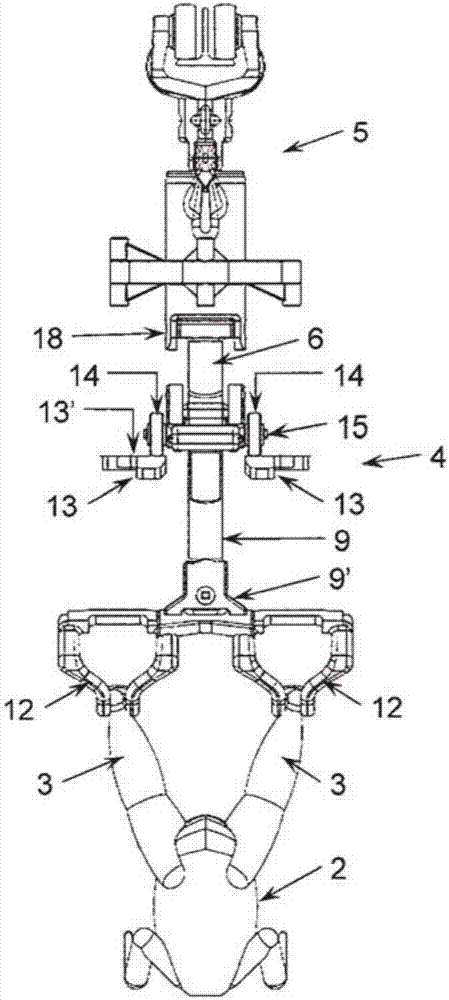

The invention provides a device for changing the orientation of slaughter products, comprising an endless guide (4) extending along a conveying path, product carriers (3) which are movable along the guide. Each carrier comprises a base part (6) and a rotary part (7) connected to the base part. The base part is provided with at least one runner (10) which cooperates with the guide during operation of the device. The rotary part is provided with an engagement part and with a suspension part connected to the engagement part for suspending a slaughter product from the suspension part. The rotary part is rotatable about an axis of rotation that extends in a vertical plane perpendicular to the conveying path. The device further comprises at least one operating element disposed beside the conveying path, which is configured to cooperate with the engagement part for causing the rotary part to rotate about the axis relative to the base part. The conveying path comprises an arcuate section (31) extending in a vertical plane, wherein the product carriers are present on the outer side of the arc. The operating element is disposed beside the arcuate section for causing the rotary parts of the product carriers to rotate at least in part about the associated axes of rotation during passage of the product carrier through the arcuate section, wherein the rotary part cannot pivot about a horizontal pivot axis that extends perpendicular to a vertical plane parallel to the arcuate section during passage of the associated product carrier through the arcuate section.

Owner:MAREL STORK POULTRY PROCESSING

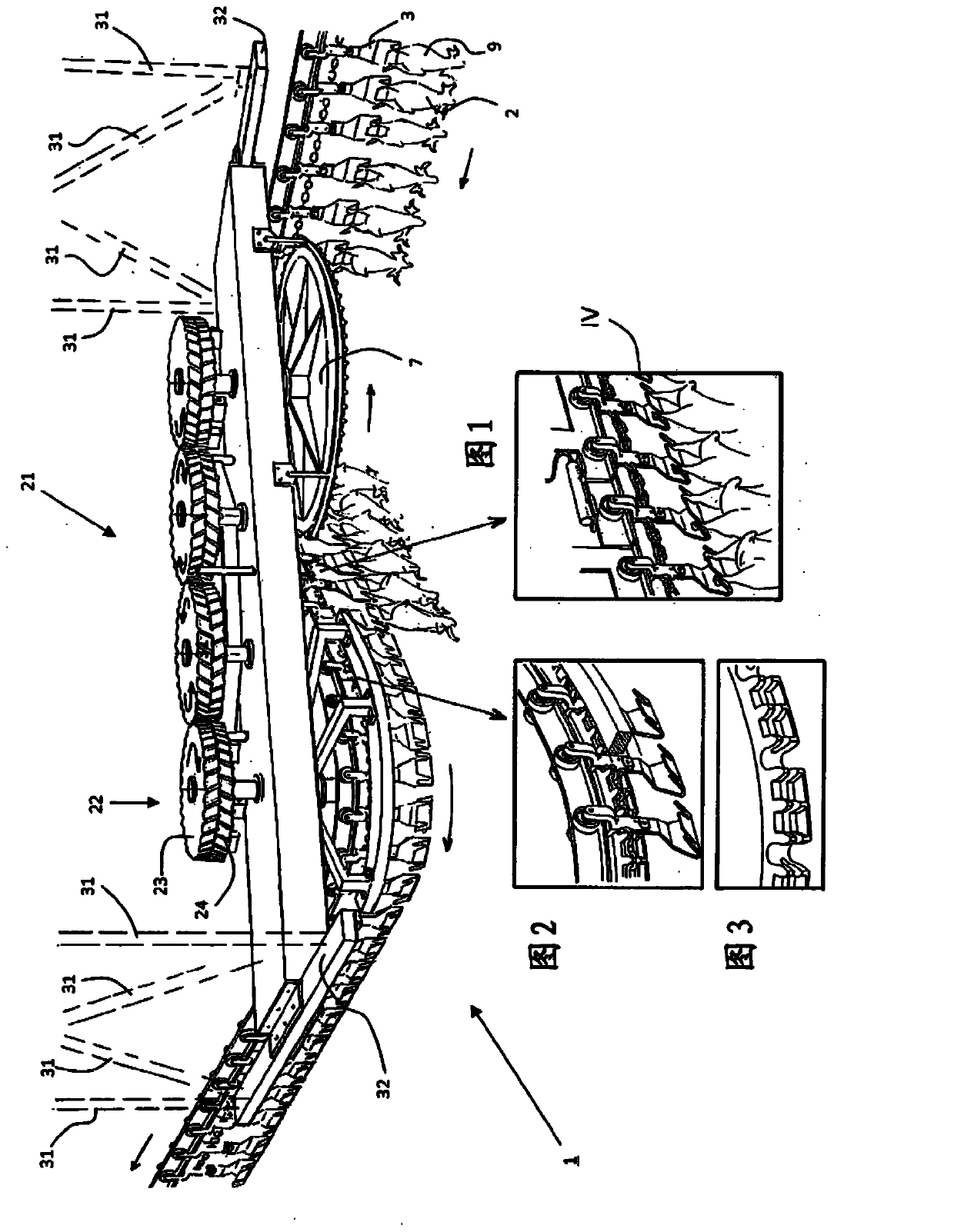

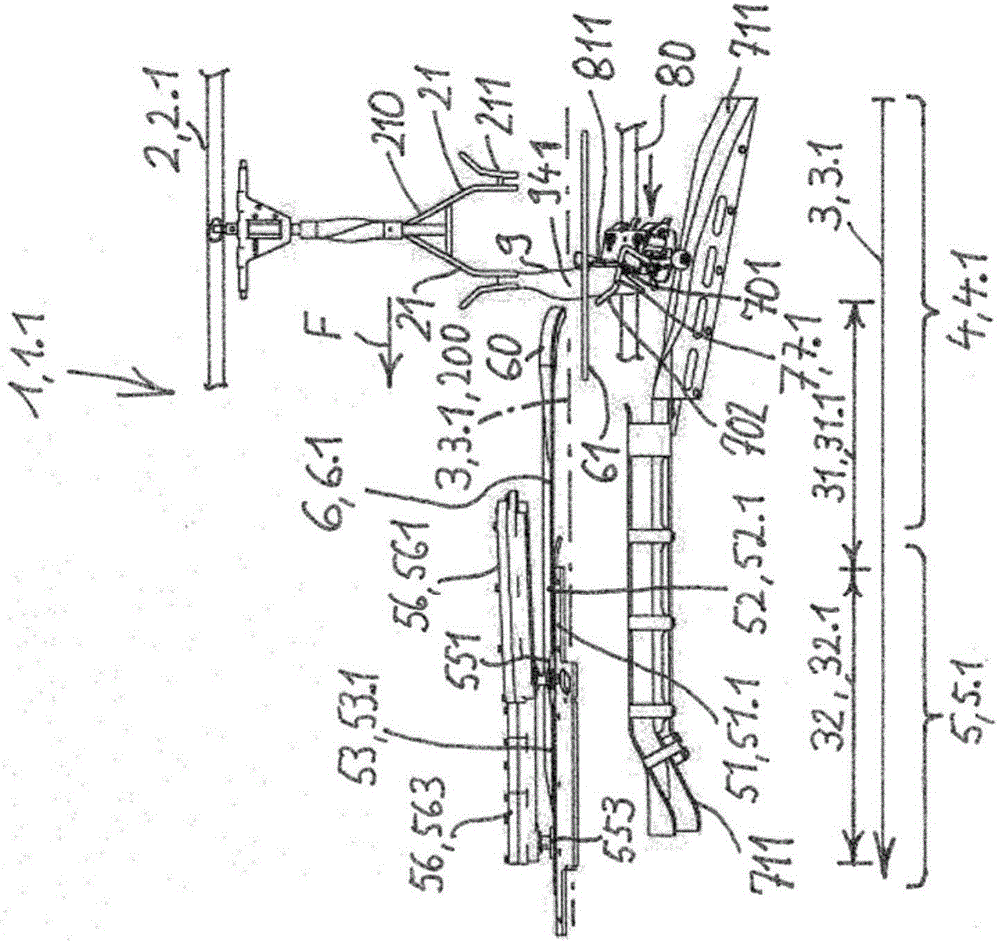

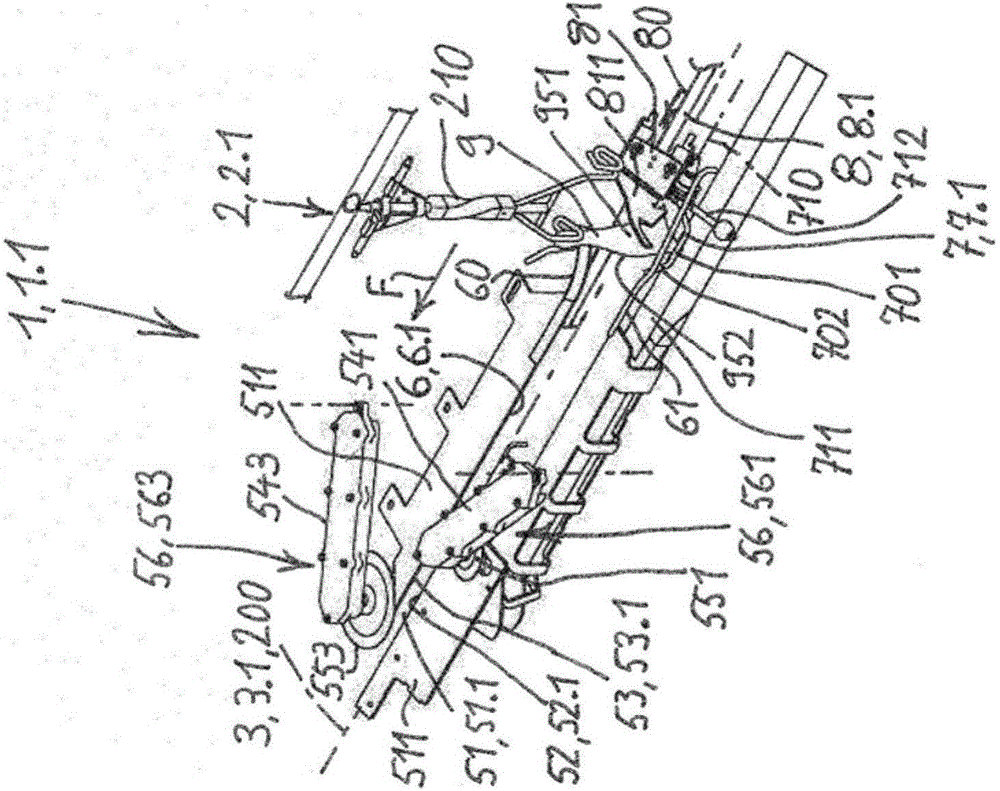

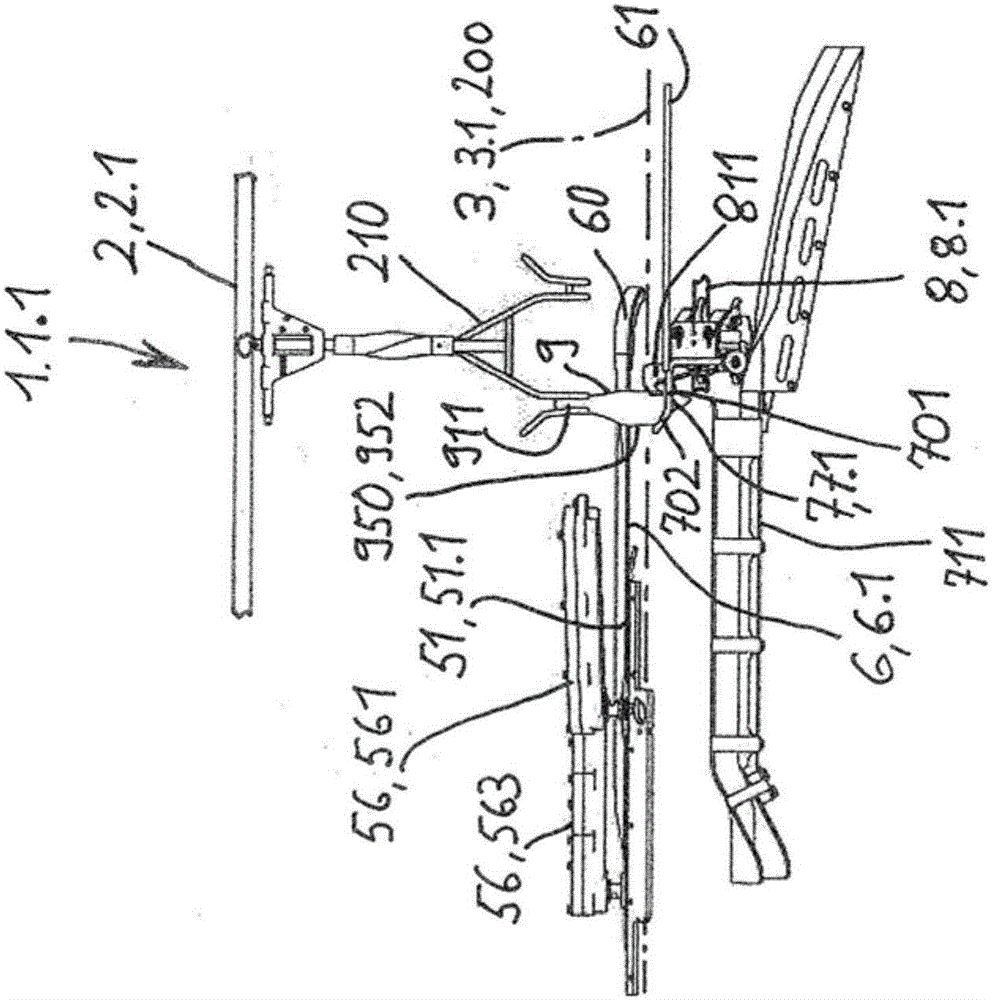

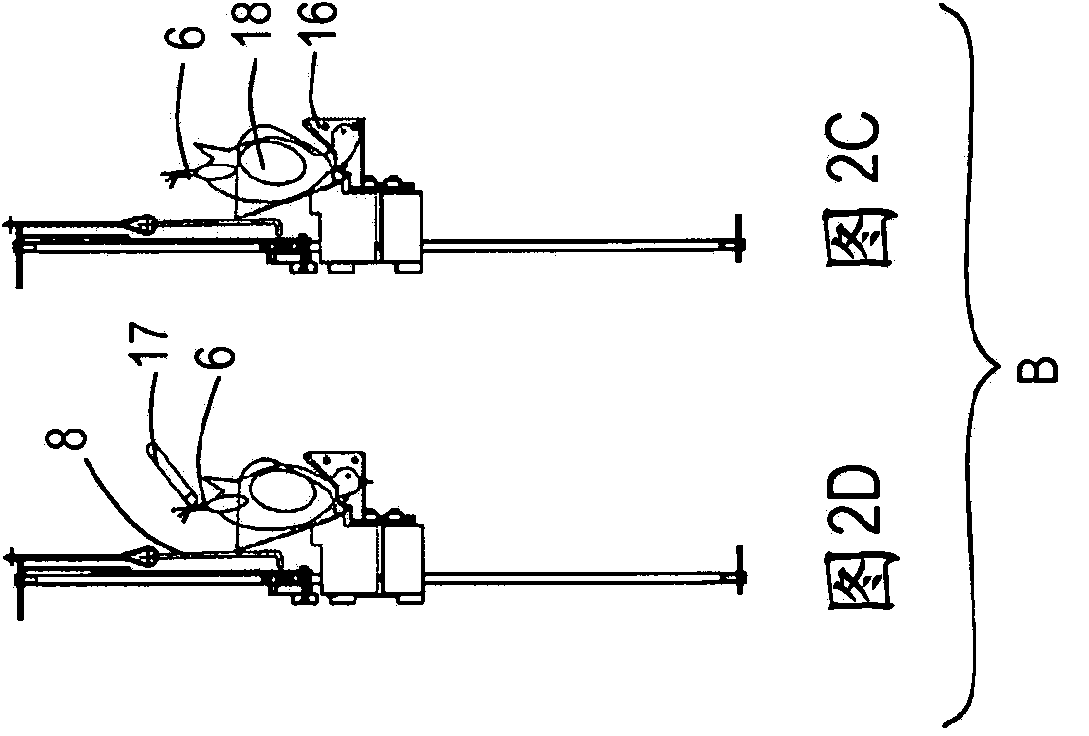

Positioning device for positioning poultry legs conveyed in single file in the conveying direction along a conveyor section and the method comprising said positioning for removing the thigh meat from poultry legs

A positioning device (1) for positioning poultry legs (9) conveyed hung in single file comprises a flexing device (4) for flexing and positioning the poultry legs and a stationary holding and guiding device (5). The flexing device (4) forms a hooking device for suspending the poultry leg (9) at the region of the knee joint (93) in a holding and guiding slot (51) of the holding and guiding device (5). Travelling positioning elements (7) are formed by driven press elements which grip the poultry leg (9) from below on an axial leg side (940) to flex and lift said leg. Each travelling positioning element (7) forms, with a stationary positioning element (6), a functional pair of positioning elements (6, 7). One of the two positioning elements (6, 7) engages in the hollow of the knee (95) of the poultry leg (9) while the other positioning element (6.2; 7.1) is configured for placement on the thigh (92) on the front side (941) of the leg. Processing stations (56) can be arranged along the holding and guiding slot (51). In a method, carried out during the conveying, for removing the thigh meat from the poultry legs (9) conveyed in single file, said poultry legs are axially conveyed in a first said positioning device (1.1) with a transverse leading lateral side (950) of the leg and in a second said positioning device (1.2) with an axially leading knee cap side (940) of the leg. Cuts are made at the front side (941) of the leg and at the back side (942) of the leg along the first stationary holding and guiding slot (51.1). Cuts are made at the lateral sides (950) of the poultry leg along the second stationary holding and guiding slot (51.2), and the thigh meat (922) is pushed to the proximal end of the thigh bone (921).

Owner:BAADER FOOD SYST DENMARK AS

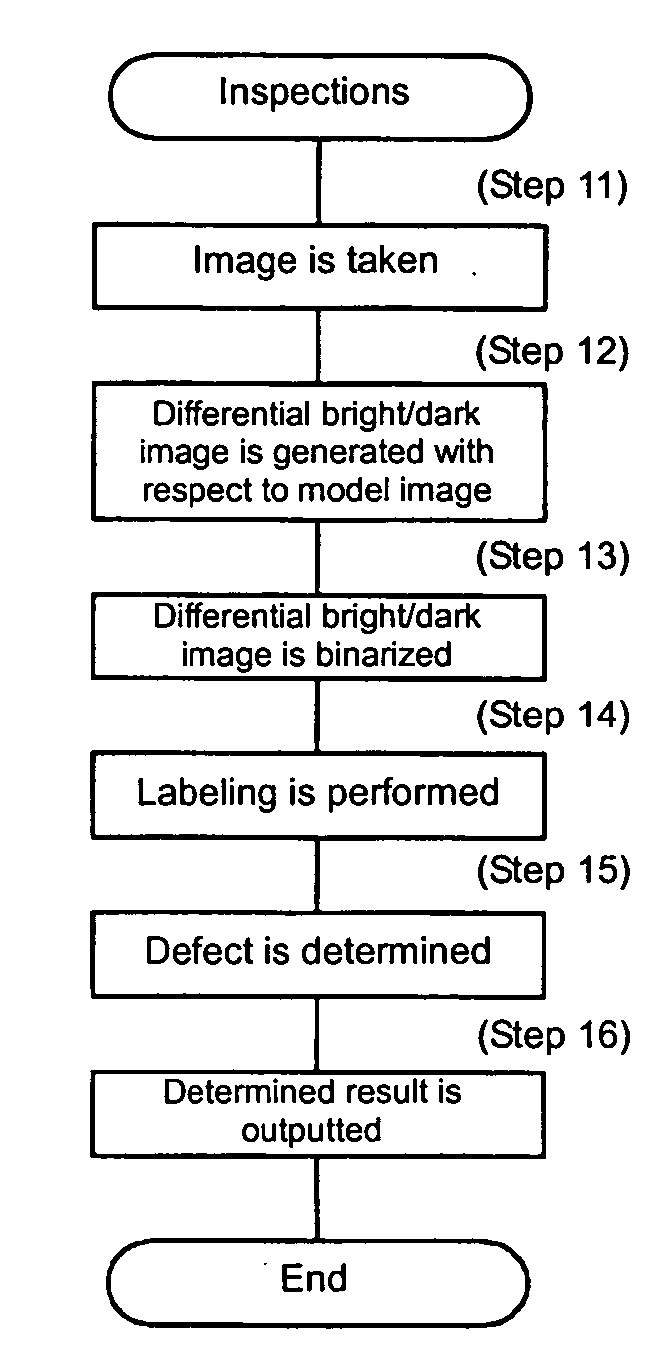

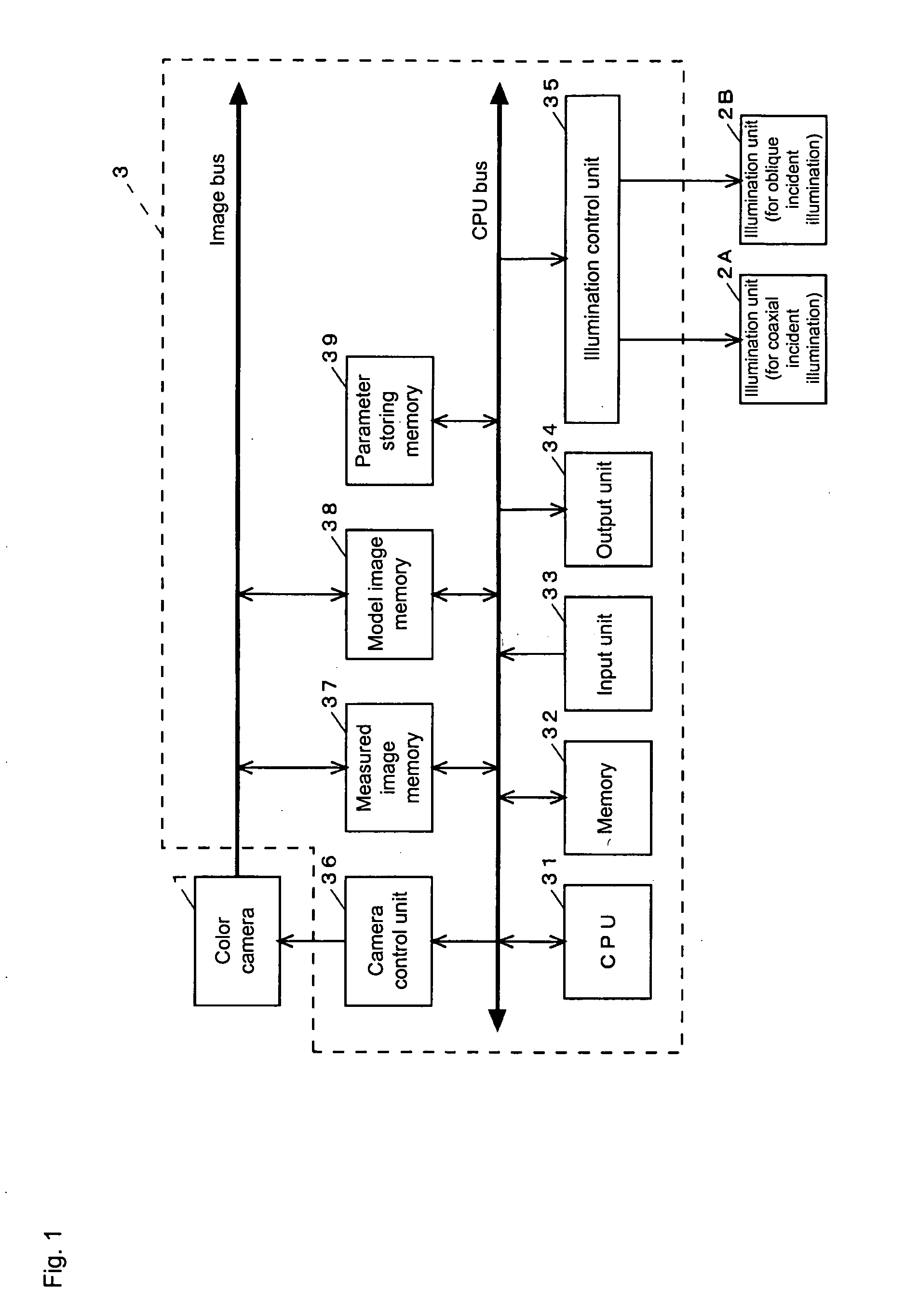

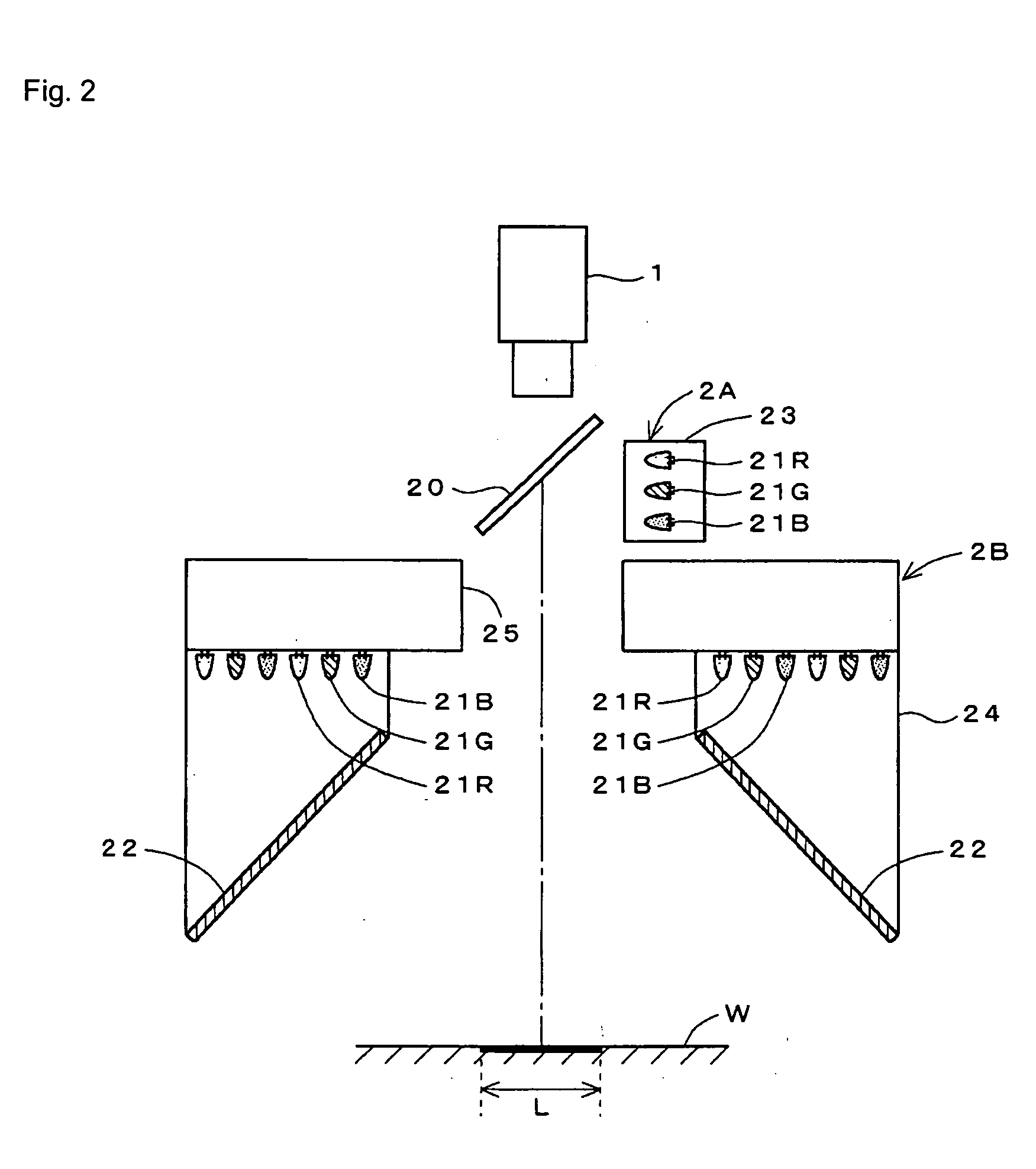

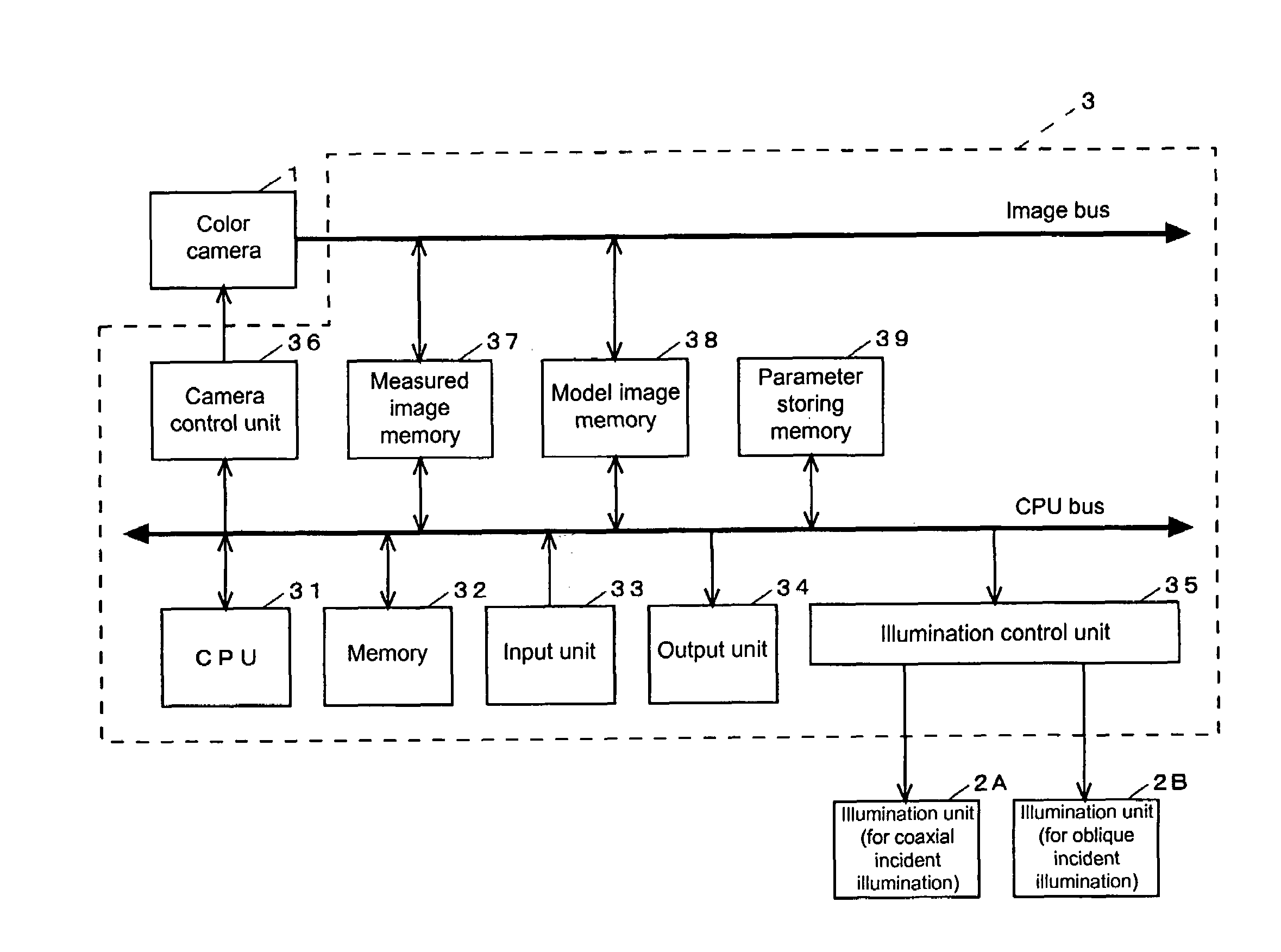

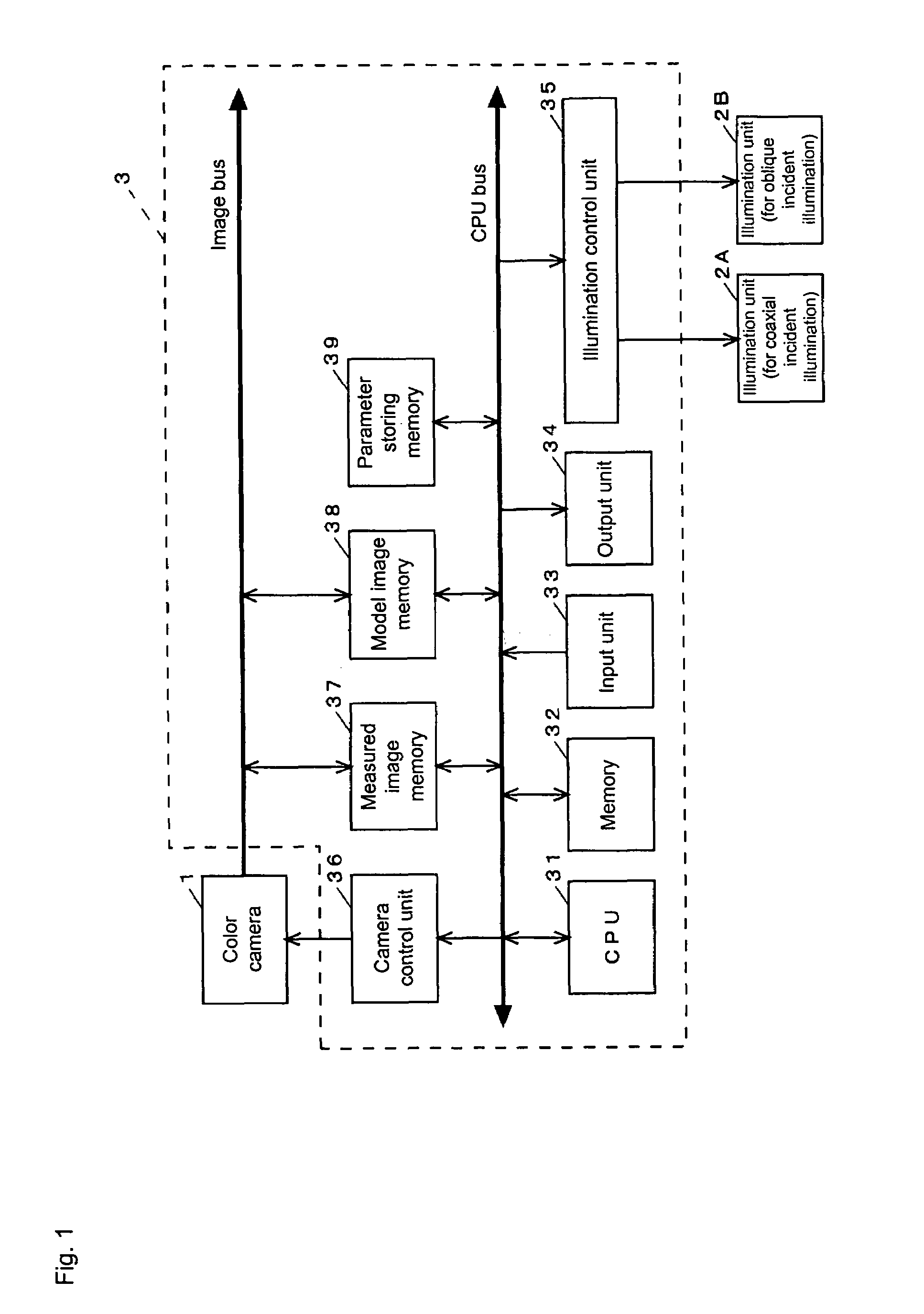

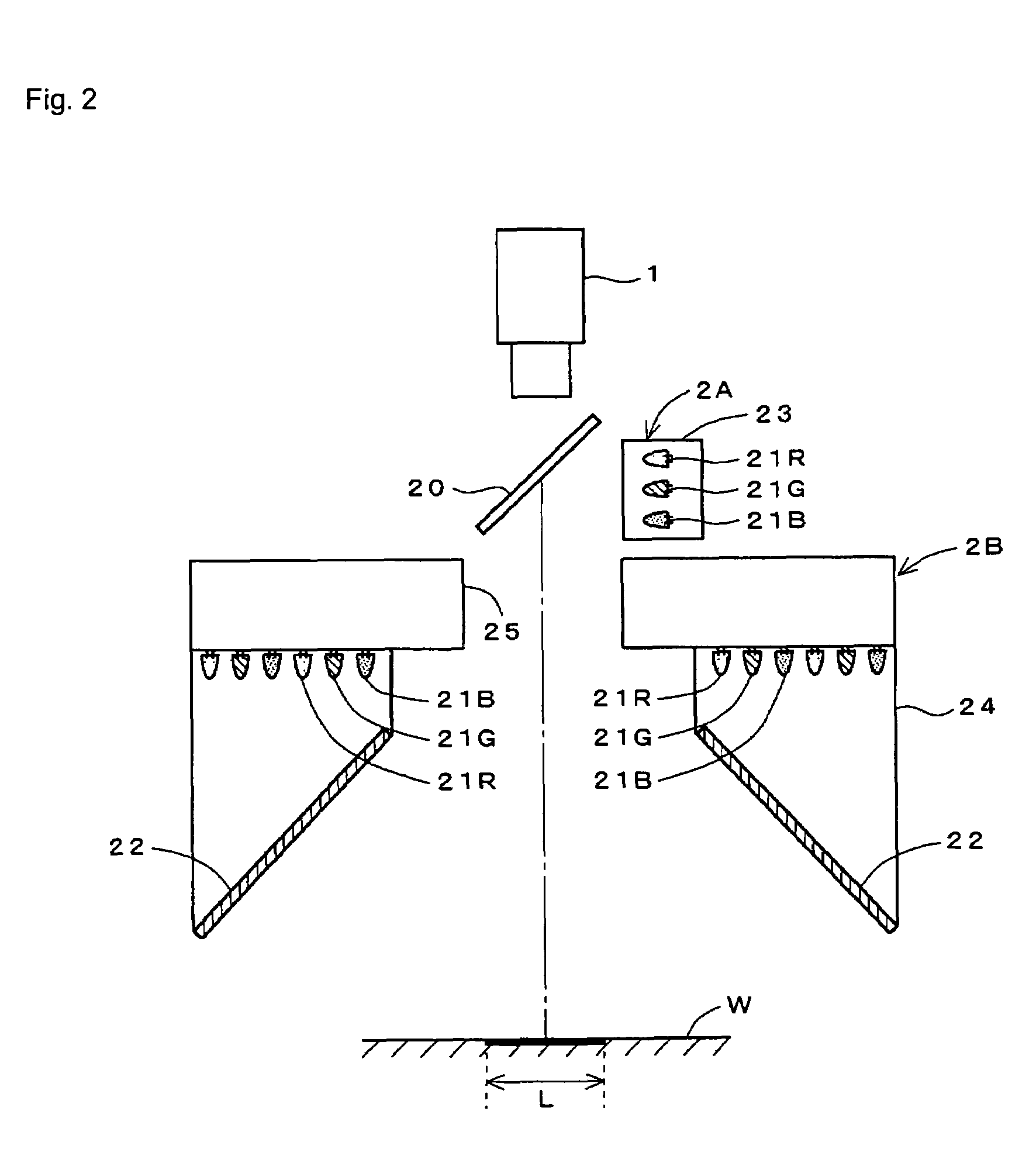

Defect inspection method and defect inspection system using the method

InactiveUS20060251315A1Efficient detectionImprove accuracyImage enhancementImage analysisOptoelectronicsLight source

Owner:ORMON CORP

Overhead poultry conveying and counting system

A system and method of counting poultry carcasses conveyed by an overhead shackle conveying system. Poultry carcasses are suspended from shackles of an overhead conveying system and moved along a path of travel defined by the overhead conveying system. The carcasses are directed to engage a force detecting device. The force detecting device generates a signal, such as an electrical signal, when the impacted by a carcass, a magnitude of the electrical signal is proportional to a force of impact of the carcass on the force detecting device. The electrical signal is transmitted to a counter. The counter analyzes the electrical signal and increments a carcass count each time a force in a carcass identifying range is measured.

Owner:BETTCHER INDUSTRIES

Passive Systems And Methods For Shackling Products

InactiveUS20110136422A1Simple processSimplified downstream subsystems to handle the birdsMeat processing plantsPoultry shacklesPoultry productEngineering

Owner:GEORGIA TECH RES CORP

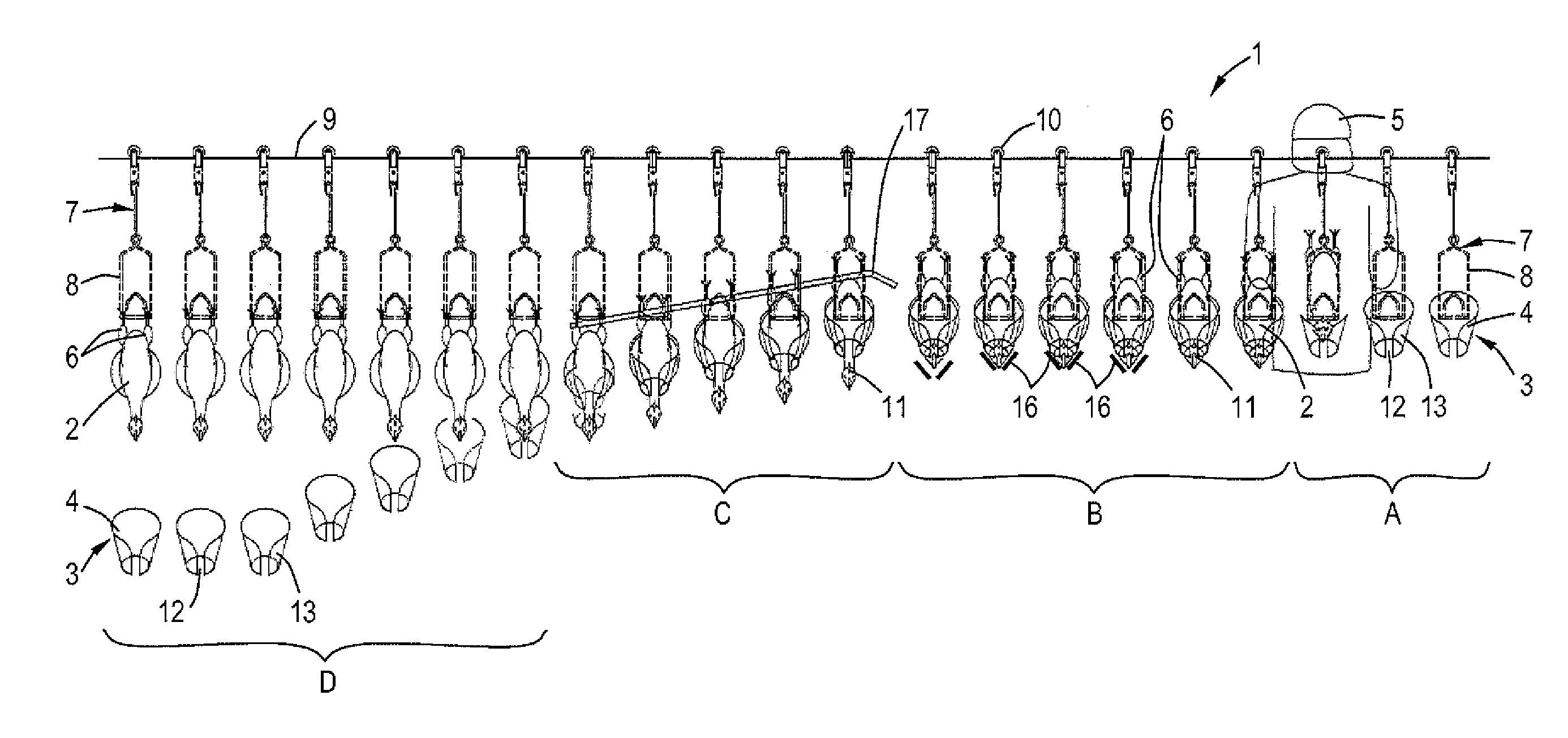

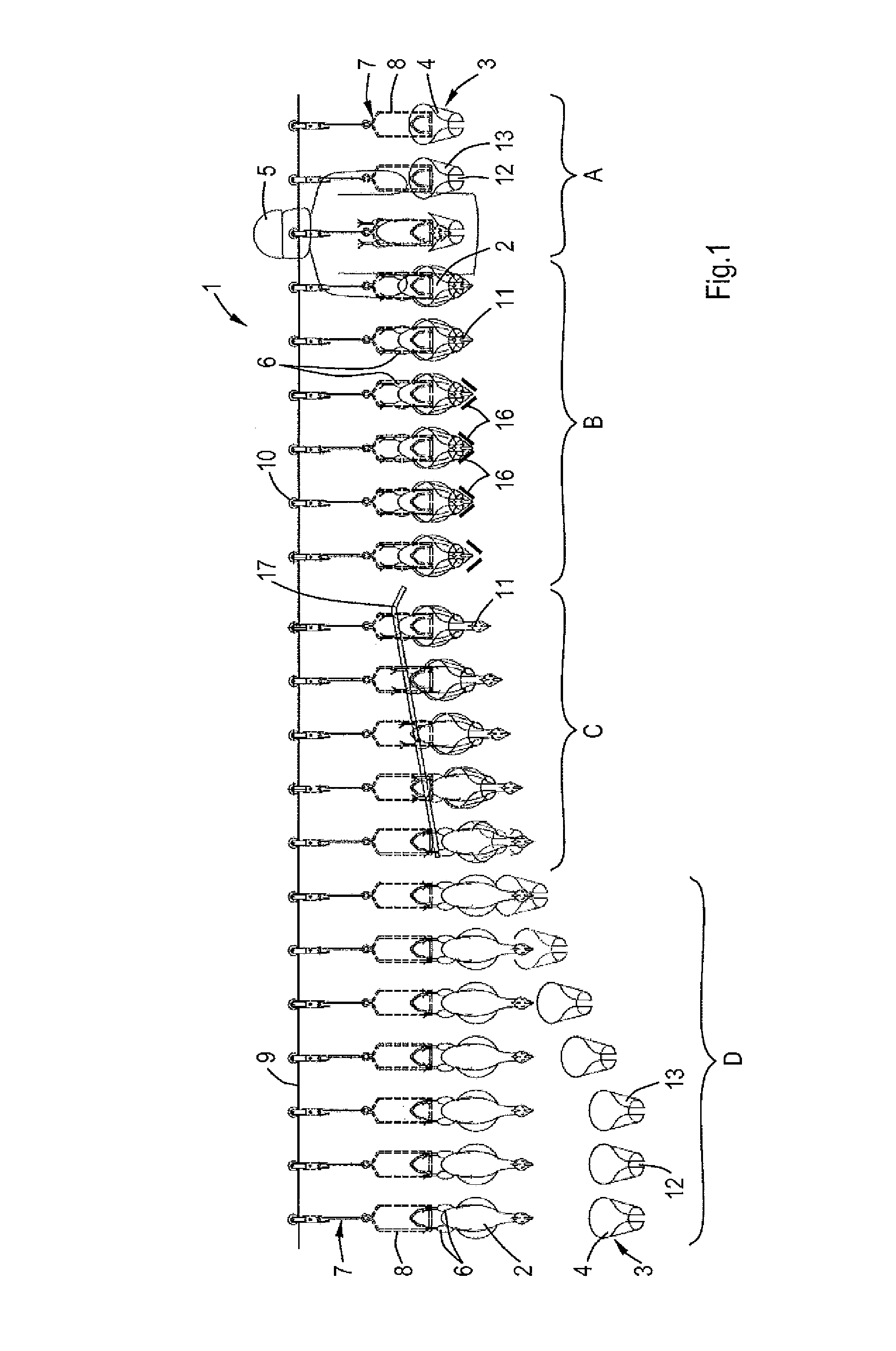

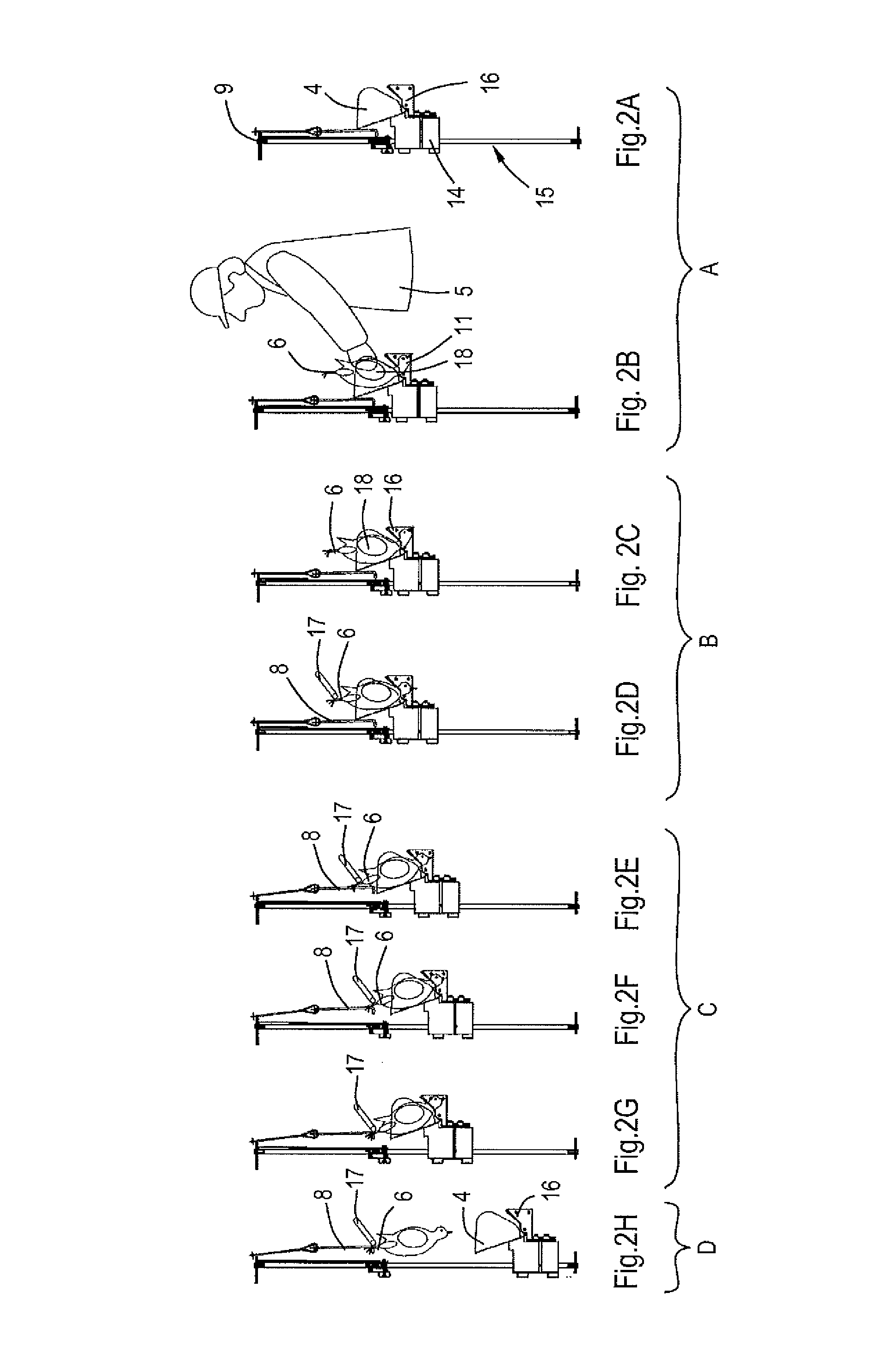

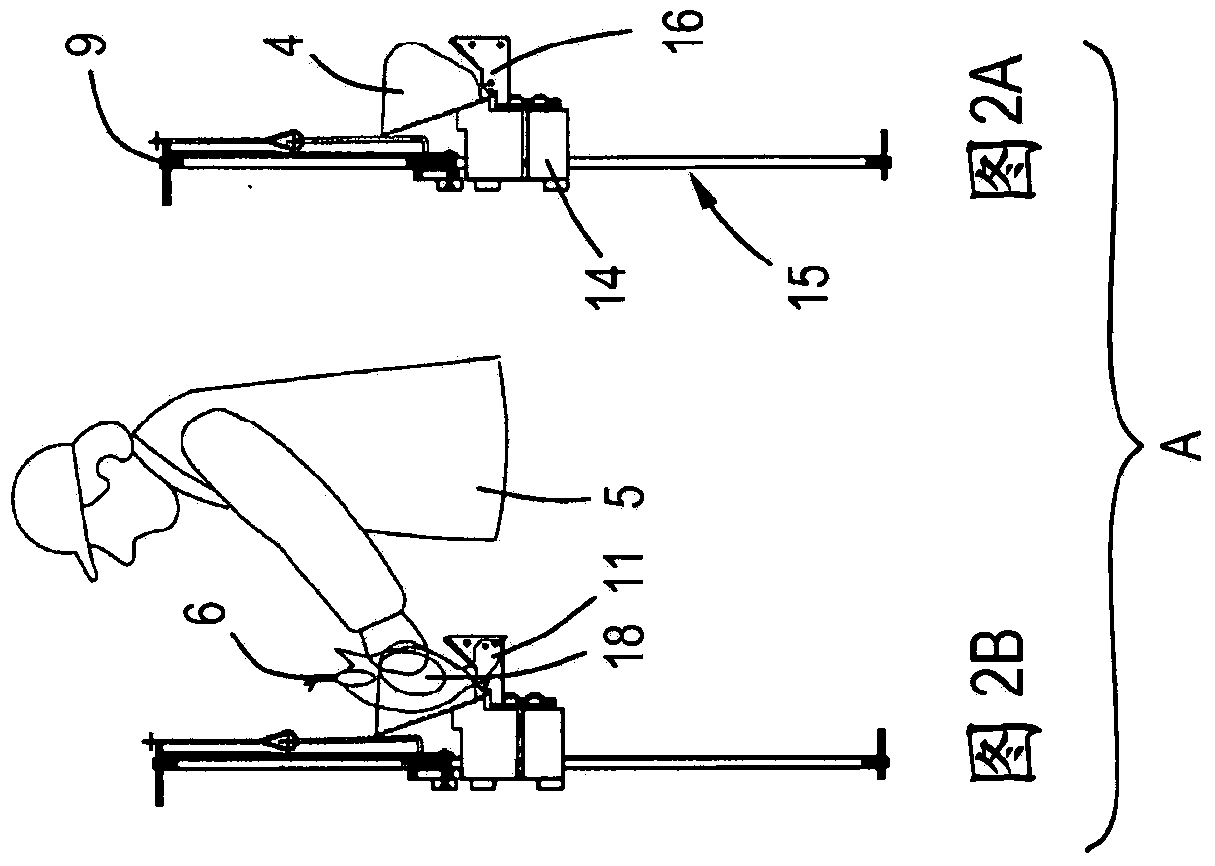

Method and installation for handling poultry

InactiveUS9179684B2Reduce stressFree from injuryPoultry/fish slaughtering/stunningSlaughterhouse arrangementsEngineering

The present invention relates to a method for handling poultry, such as chicken, turkey, geese, duck and quail, comprising the steps of (i) taking the poultry; (ii) placing the poultry in a confinement such that the poultry legs extend from the confinement; and (iii) coupling the poultry legs to a handling unit, and to an installation for handling poultry, such as chicken, turkey, duck and quail that takes the poultry and places the poultry in a confinement such that the poultry legs extend from the confinement; and the poultry legs are coupled to the handling unit.

Owner:TOPKIP

Counting apparatus and method for a poultry processing plant

InactiveUS7378642B2High precisionAccurate countFish sortingMaterial analysis by optical meansEngineeringProcessing plants

A counting system for a poultry processing plant that uses conveyors is disclosed. Two types of conveyors are addressed, one where poultry hang from the conveyor and one where the carcasses are supported above the conveyor. The sensors are located at different levels to sense elements of the carriers as well as poultry. Logic within the system compares the readings of the sensors to determine whether a chicken is present and whether to increment the total. Additionally, the sensors are recessed in steel tubing on mounting plates which support their own cover plates. The sensors can thereby be adjusted for alignment while the cover plates move with the sensors. The cover plates are easily removed for cleaning and put back into position without blocking the sensors. Air is blown through the steel tubing to keep a positive air pressure in the tubing to prevent dirt from entering the openings.

Owner:JONES CLYDE B

Device and method for deboning bone-in leg

ActiveUS9326527B2Increase productionQuality improvementPoultry deboningPoultry transferring/conveying devicesThighKnee Joint

In a deboning process, a knee joint length is measured in a work loading section of a first process station, and incision making of a thigh meat portion is performed in a second process station based on the measured knee joint length. At the same time, the entire length of a work is measured, and the knee joint length is calculated from previously collected data based on the measured entire length of the work. Positioning of a cutting blade and a meat separator is performed based on these values in subsequent process stations, and cutting of a tendon adhering to a knee joint and tearing of thigh meat are performed. A thigh bone is separated from a lower thigh in a further process station.

Owner:MAYEKAWA MFG CO LTD

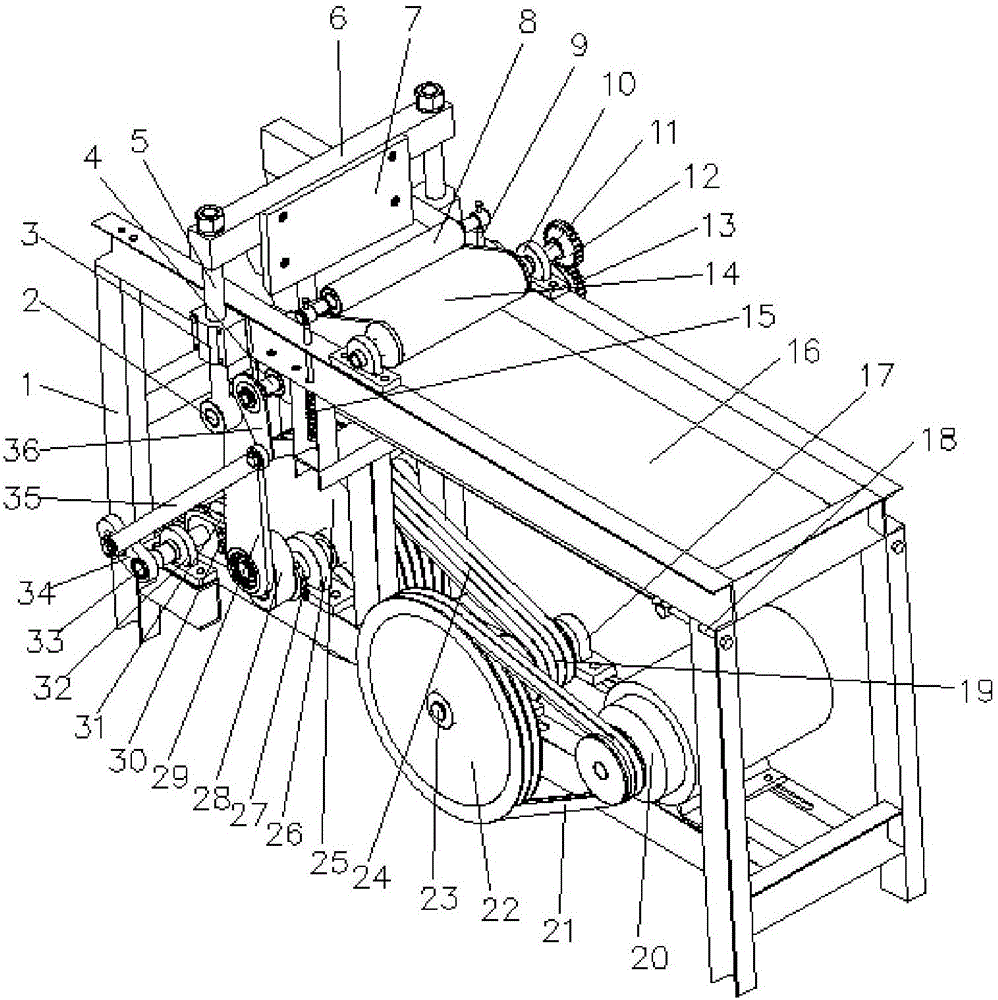

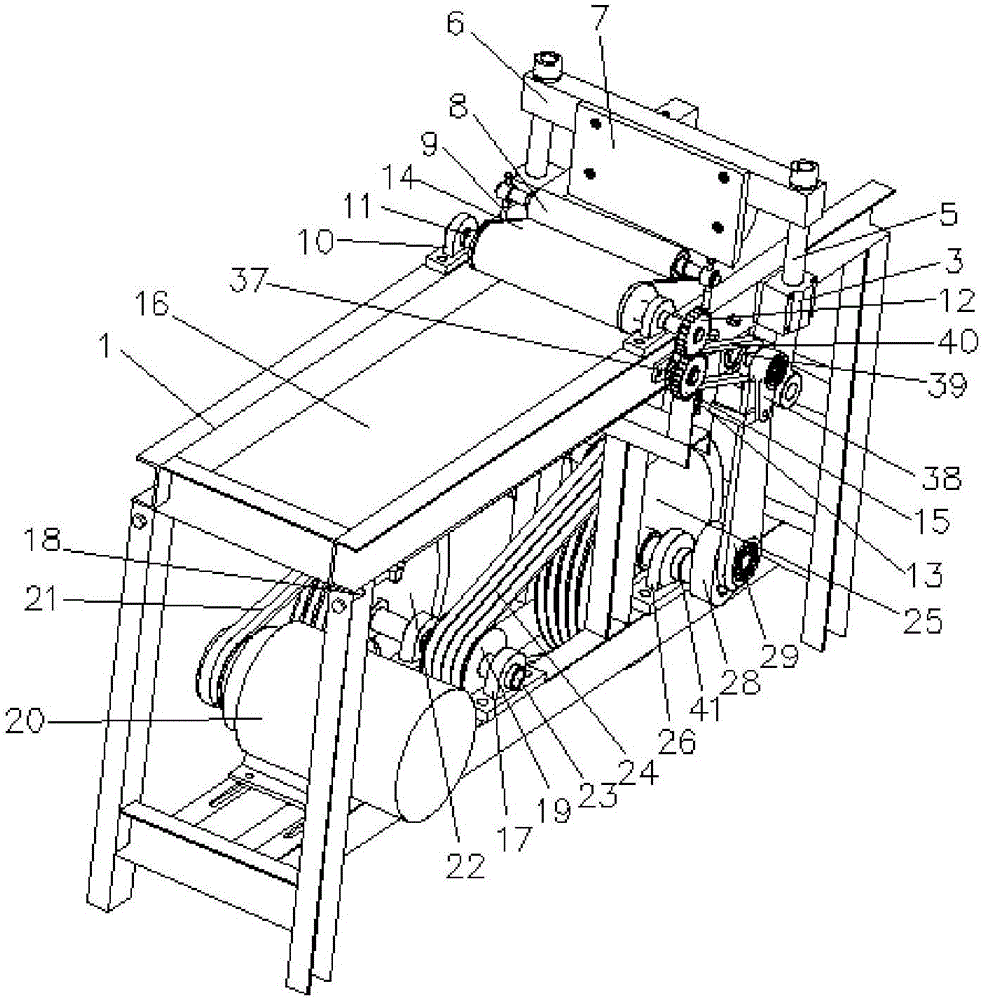

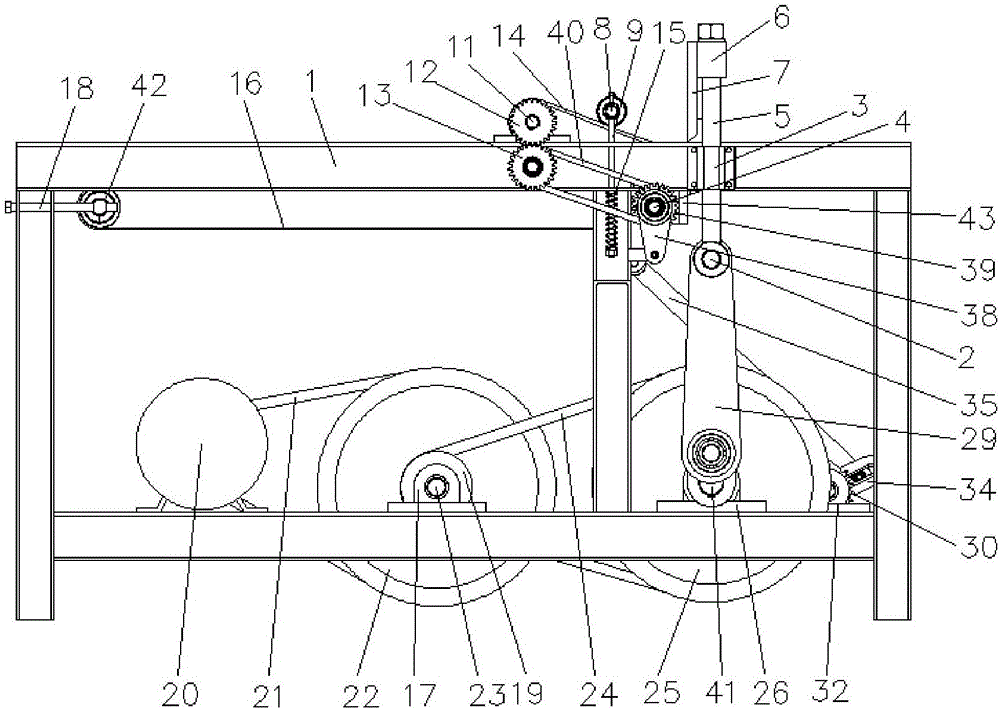

Full-automatic poultry meat dicing device

InactiveCN106819045ASafe and reliable workImprove transmission efficiencyPoultry processing support devicesPoultry transferring/conveying devicesEngineeringHigh transmission

The invention discloses a fully automatic poultry meat cutting device, which belongs to the technical field of poultry meat processing. The full-automatic poultry meat cutting device includes a support and a feeding belt installed on the support, a cutting mechanism, a pressing mechanism and a transmission mechanism, the cutting mechanism is located at one end of the support and the cutting opening of the cutting mechanism is connected One end of the feeding belt is matched, the pressing mechanism is located above the feeding belt and close to one end of the cutting mechanism, the pressing mechanism is connected with the bracket, and the feeding belt, cutting mechanism and pressing mechanism are all connected with the transmission mechanism Connection, linkage is realized through the transmission mechanism. The invention has high transmission efficiency, has the function of pressing the meat piece, can fix the poultry piece at the cutting edge, not only can cut the boned poultry meat, but also can effectively solve the problem that the existing technology cannot be fixed on the workbench and cause cutting out The size of the meat pieces is different, and the meat pieces are easy to splash, causing the meat pieces to be polluted and wasted and increasing the labor cost of cleaning the contaminated meat pieces.

Owner:GUANGXI CHUNMAO INVESTMENT CO LTD

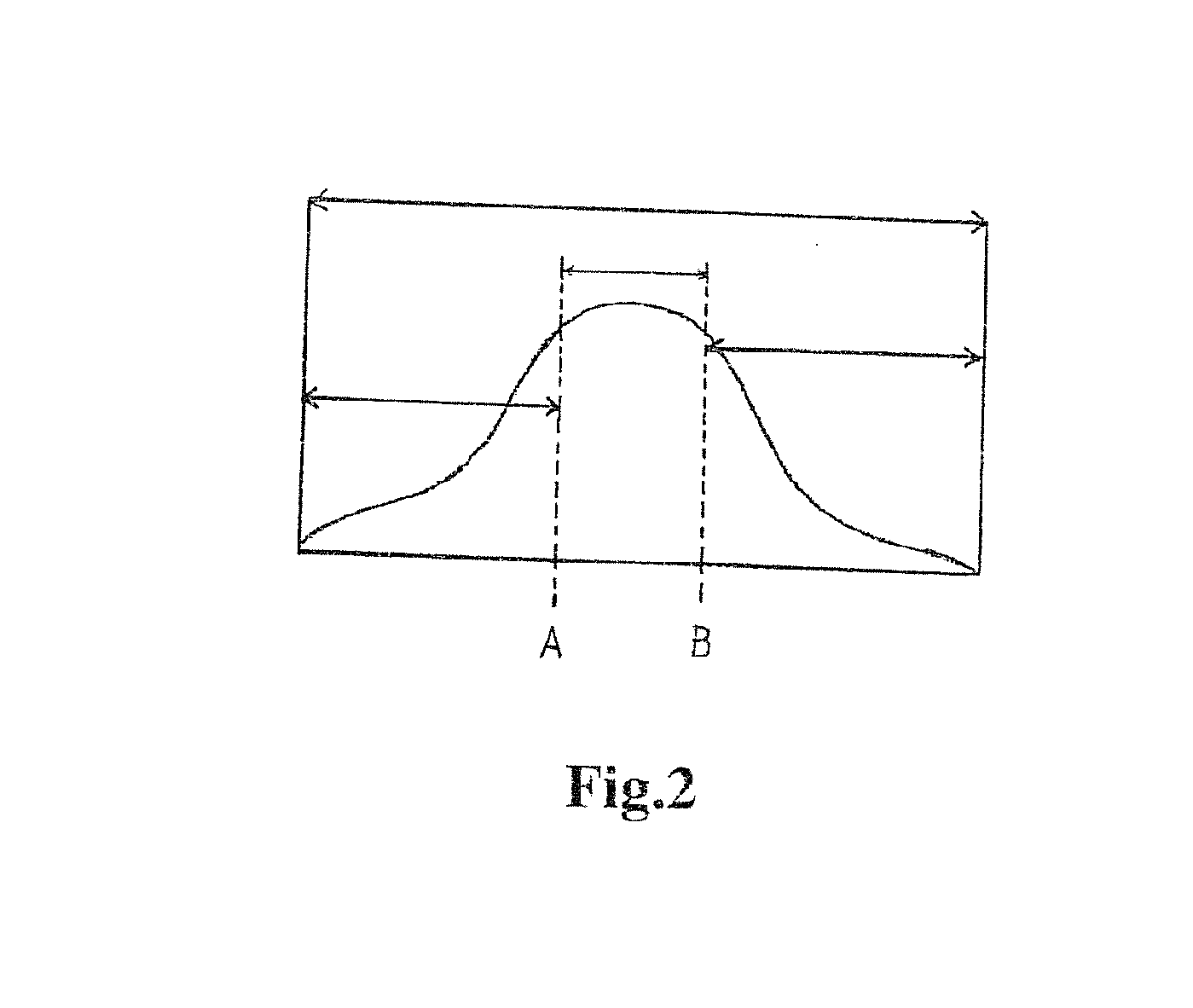

Imaging system for sorting poultry meat with wooden breast myopathy

The image sorting system sorts normal chicken breast meat fillets from chicken fillets that exhibit wooden breast myopathy (i.e. WB fillets). In the preferred embodiment, a camera and associated controller gather data and construct a digital image of a chicken breast fillet as it travels on a conveyer belt. The digital image is used to calculate a centroid (i.e. center of mass) of the fillet. As the fillet moves over a nose of the conveyor belt and free-falls to a lower conveyor belt, the controller determines the distance between the fillet centroid and a reference point (preferably the conveyer belt axis of rotation). If the distance exceeds a predetermined minimum distance, the fillet is designated a WB fillet.

Owner:US SEC AGRI

Defect inspection method and defect inspection system using the method

InactiveUS7446864B2Improve accuracySuitable for detectionImage enhancementImage analysisOptoelectronicsLight source

Owner:ORMON CORP

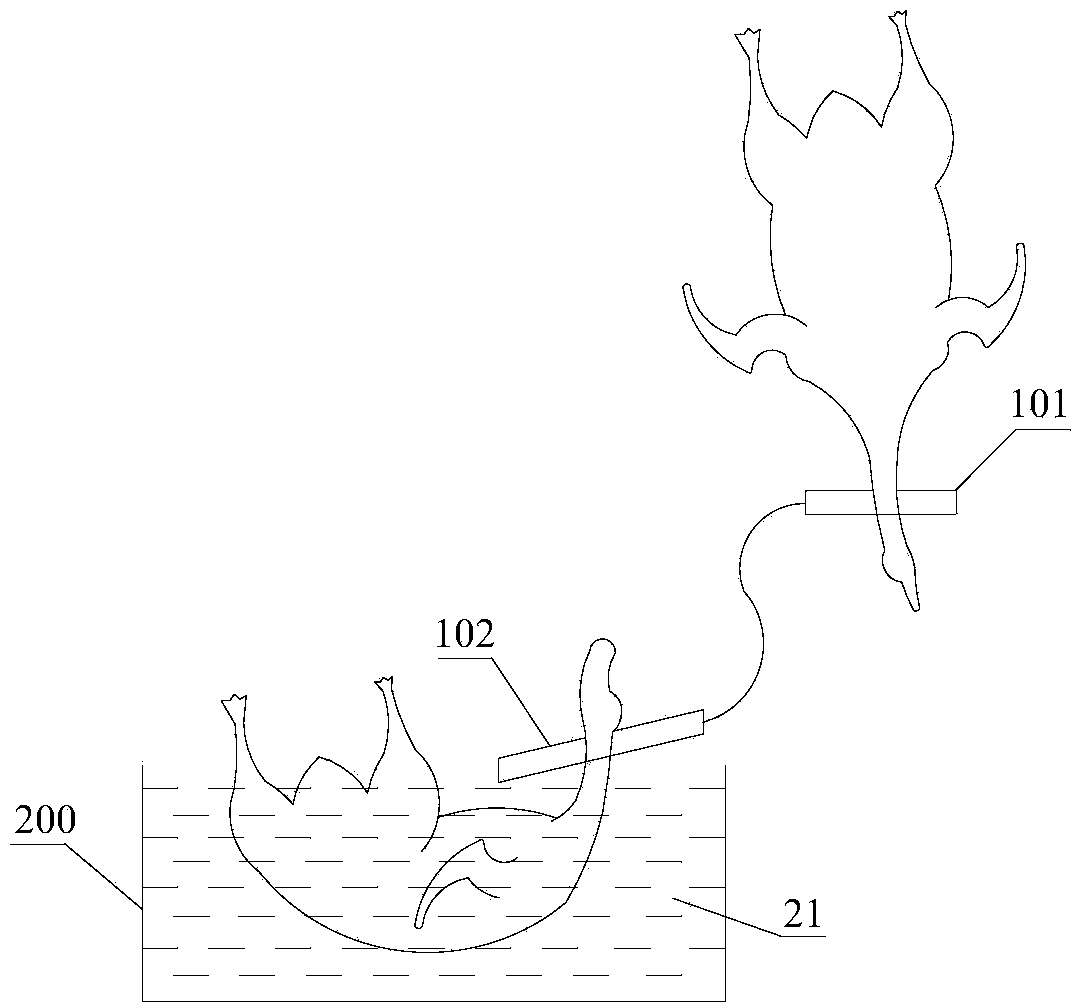

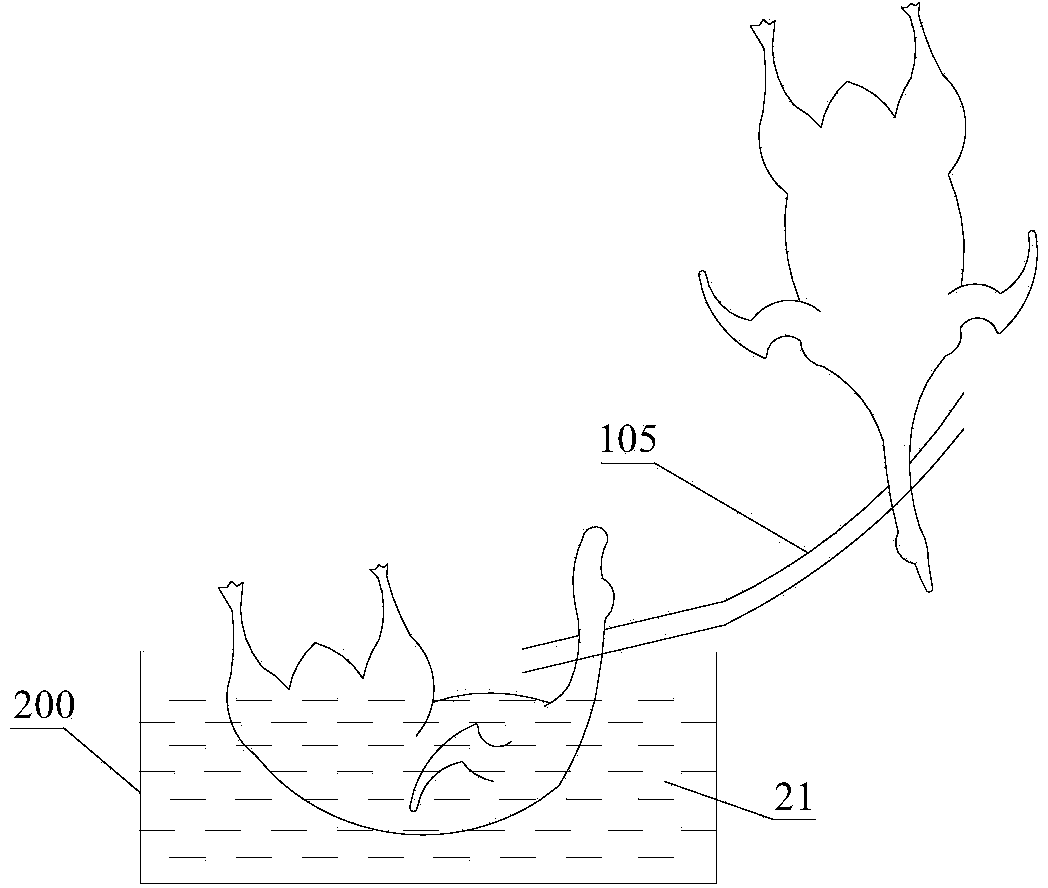

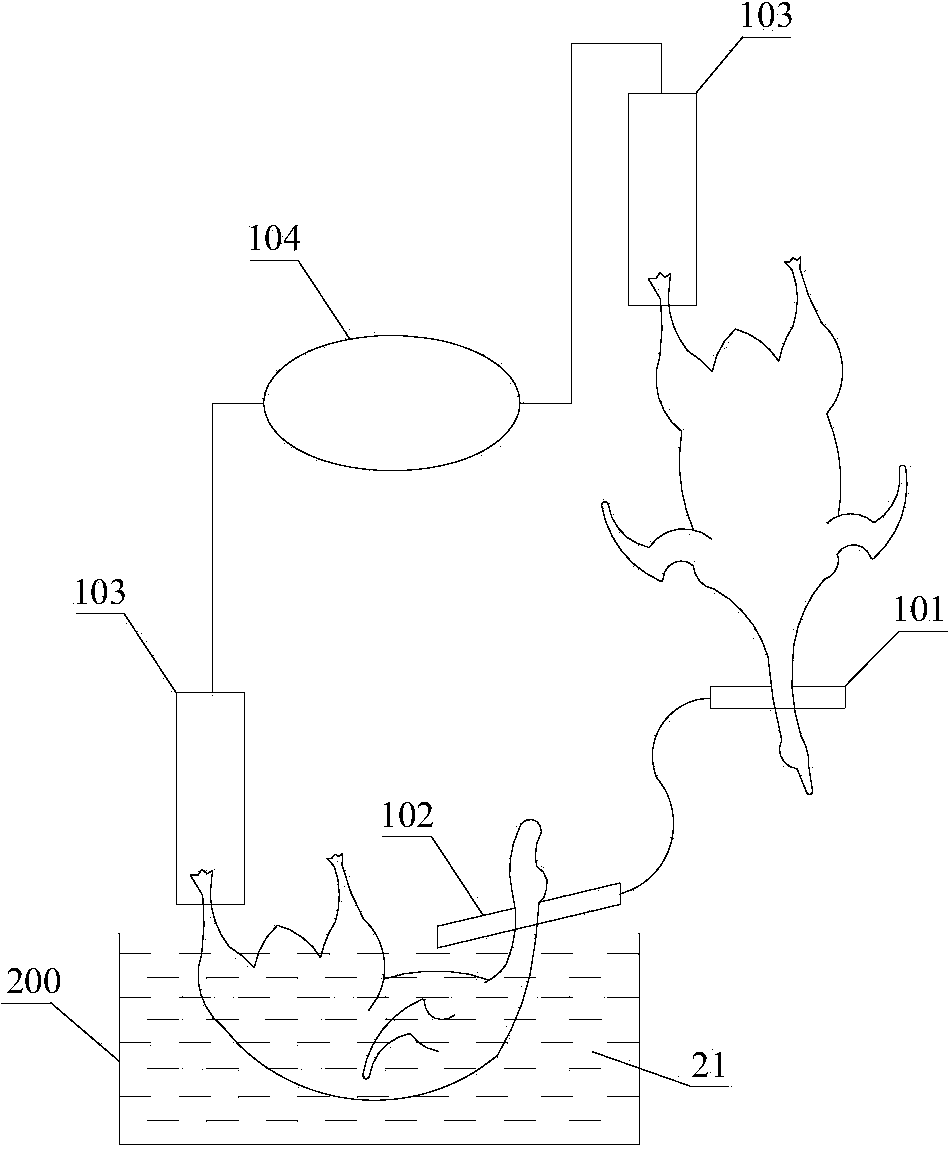

Automatic duck head hanging device, waxdip delivery system and method for waxdip delivery system

InactiveCN104286133ASimple structureReduce labor costsPoultry processing support devicesPoultry transferring/conveying devicesWaxNose

The invention discloses an automatic duck head hanging device, a waxdip delivery system and a method for the waxdip delivery system, wherein the device is arranged above a waxdip tank and comprises an enter module through which duck heads can automatically enter and can be clamped before duck billets vertically enter the waxdip tank; the device also comprises an operation module through which the duck heads of the duck billets are placed upwards after the duck billets transversely enter the waxdip tank, wherein the wax liquid of the waxdip tank is not greater than the top of each duck neck in depth. Through the automatic duck head hanging device, the waxdip delivery system and the method for the waxdip delivery system, the following advantages are realized: I, the structure is simple and manual waxdip can be replaced, so that the manual cost is reduced; II, the operation is simple and the situation that duck noses are blocked by sticks for waxdip is avoided, so that the defect that edible wax easily enters mouths and heads of the ducks is overcome, the automation degree is remarkably enhanced and the waxdip working efficiency is improved; III, purposes of energy conservation and environmental protection are achieved as wax shells can be formed on the surfaces of the ducks through the control of the waxdip delivery system, so as to avoid extra loss of ducks and edible wax, ensure high quality and safety of food and provide convenient working conditions for personnel.

Owner:BEIJING GOLDEN STAR DUCK

Apparatus For Weighing Slaughterhouse Products And Method For Using The Same

The invention provides a device for weighing slaughter products. The device comprises conveying means for conveying the slaughter products, the conveying means comprising a frame, two pulley means which are connected to the frame a fixed distance apart, being rotatable about two respective first vertical axes of rotation, an endless flexible conveying element which is passed over the two pulley means, which conveying element extends along a rectilinear weighing path between the two pulley means, a guide extending along a conveying path, hooks for the slaughter products, which hooks are connected to the conveying element at regular intervals and which are each provided with a guide elements for guiding cooperation with the guide. The device further comprises weighing means for weighing slaughter products that are present within the weighing section and reducing means for reducing tensile stress in the conveying element insofar as it extends in the weighing section, said reducing means comprising transmission means that are operative between the two pulley means. The transmission means comprise a gear transmission with at least two meshing gears which are rotatable about respective second vertical axes of rotation, wherein the second axis of rotation of one of the at least two gears is in line with a first vertical axis of rotation, and wherein the second axis of rotation of another of the at least two gears is in line with the other first vertical axis of rotation.

Owner:MAREL STORK POULTRY PROCESSING

Method and installation for handling poultry

The present invention relates to a method for handling poultry, such as chicken, turkey, geese, duck and quail, comprising the steps of (i) taking the poultry; (ii) placing the poultry in a confinement such that the poultry legs extend from the confinement; and (iii) coupling the poultry legs to handling means, and to an installation for handling poultry, such as chicken, turkey, duck and quail, comprising means for taking the poultry and placing the poultry in a confinement such that the poultry legs extend from the confinement; and means for coupling the poultry legs to handling means.

Owner:TOPKIP

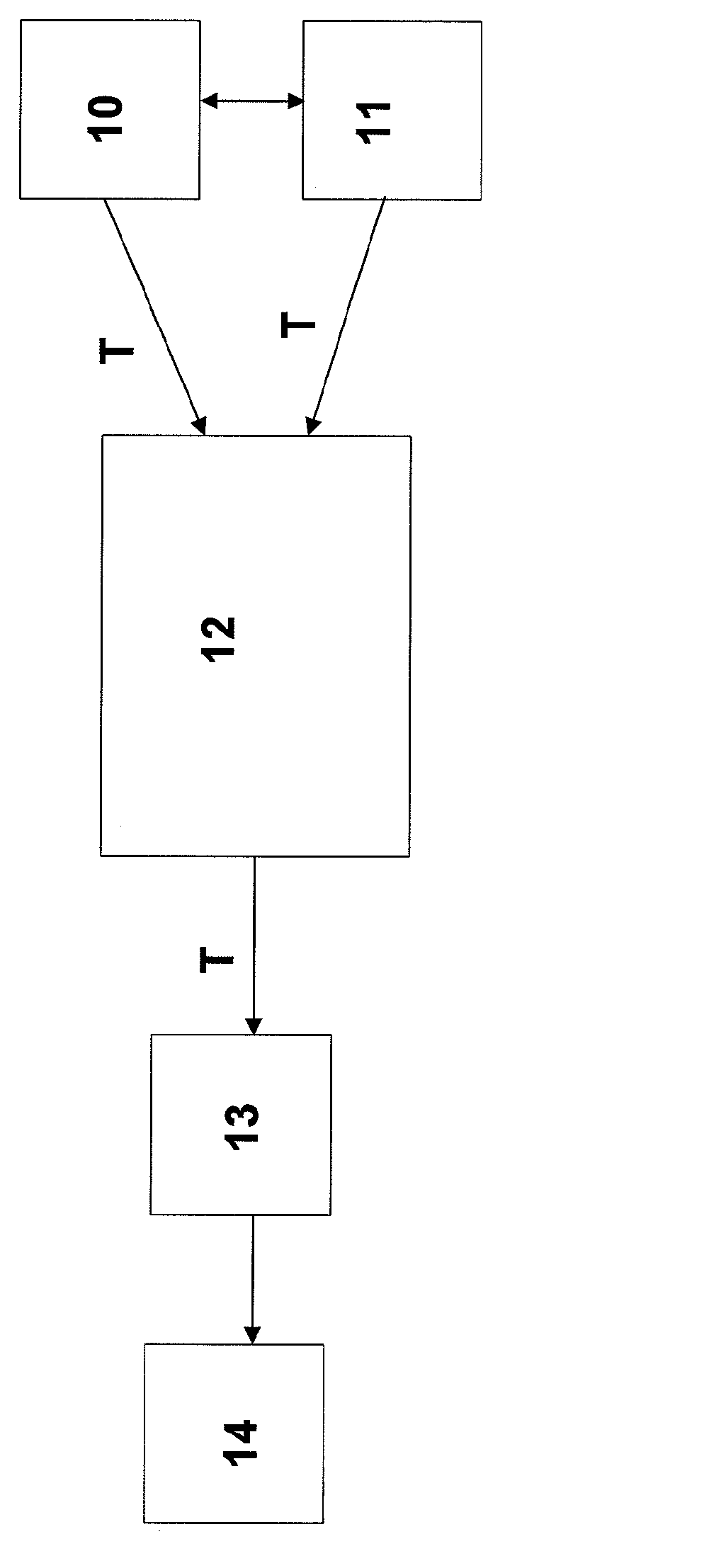

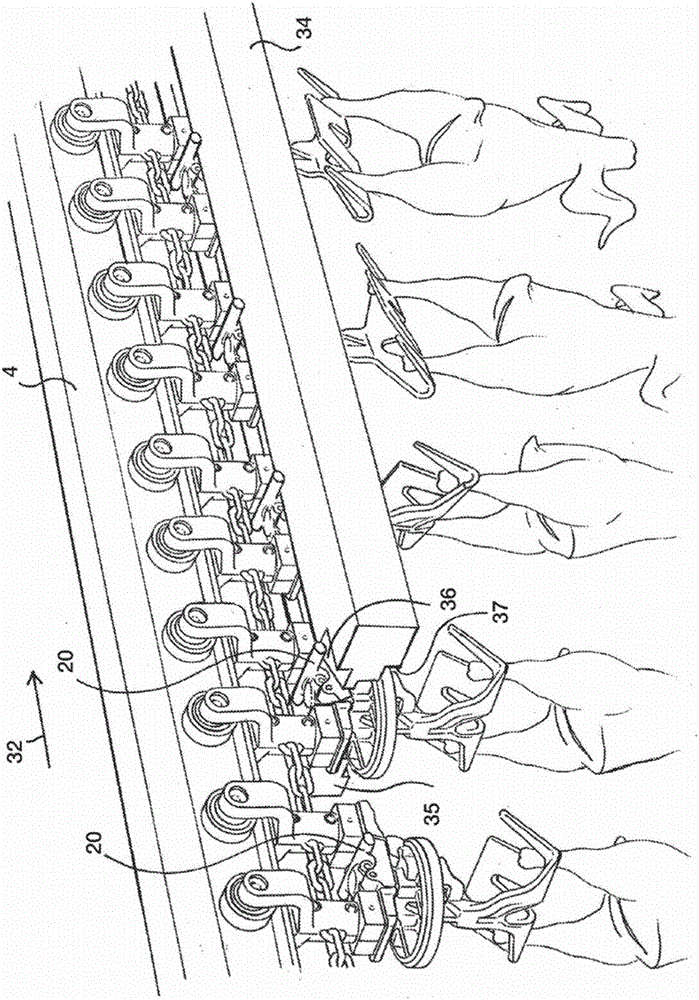

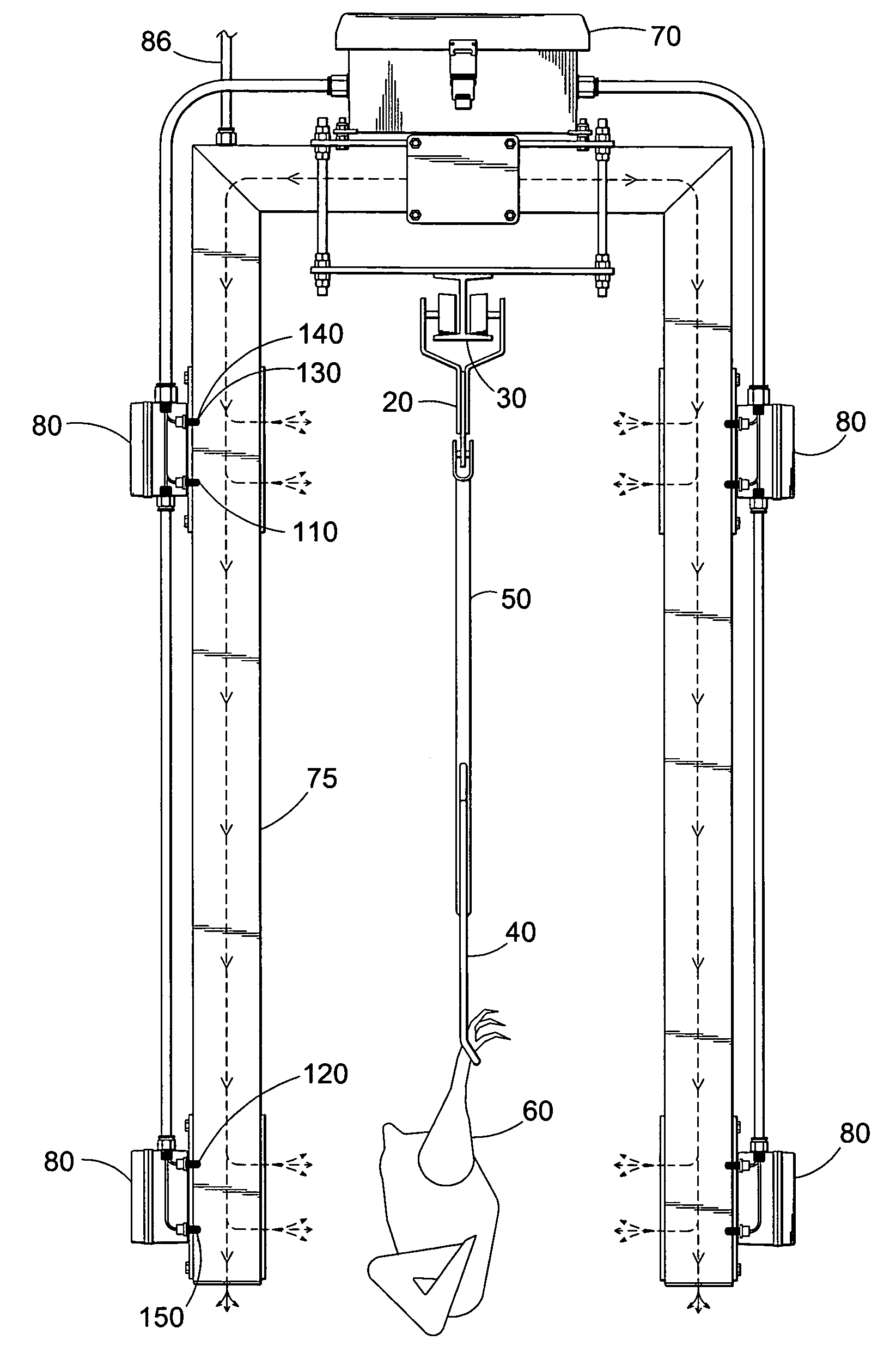

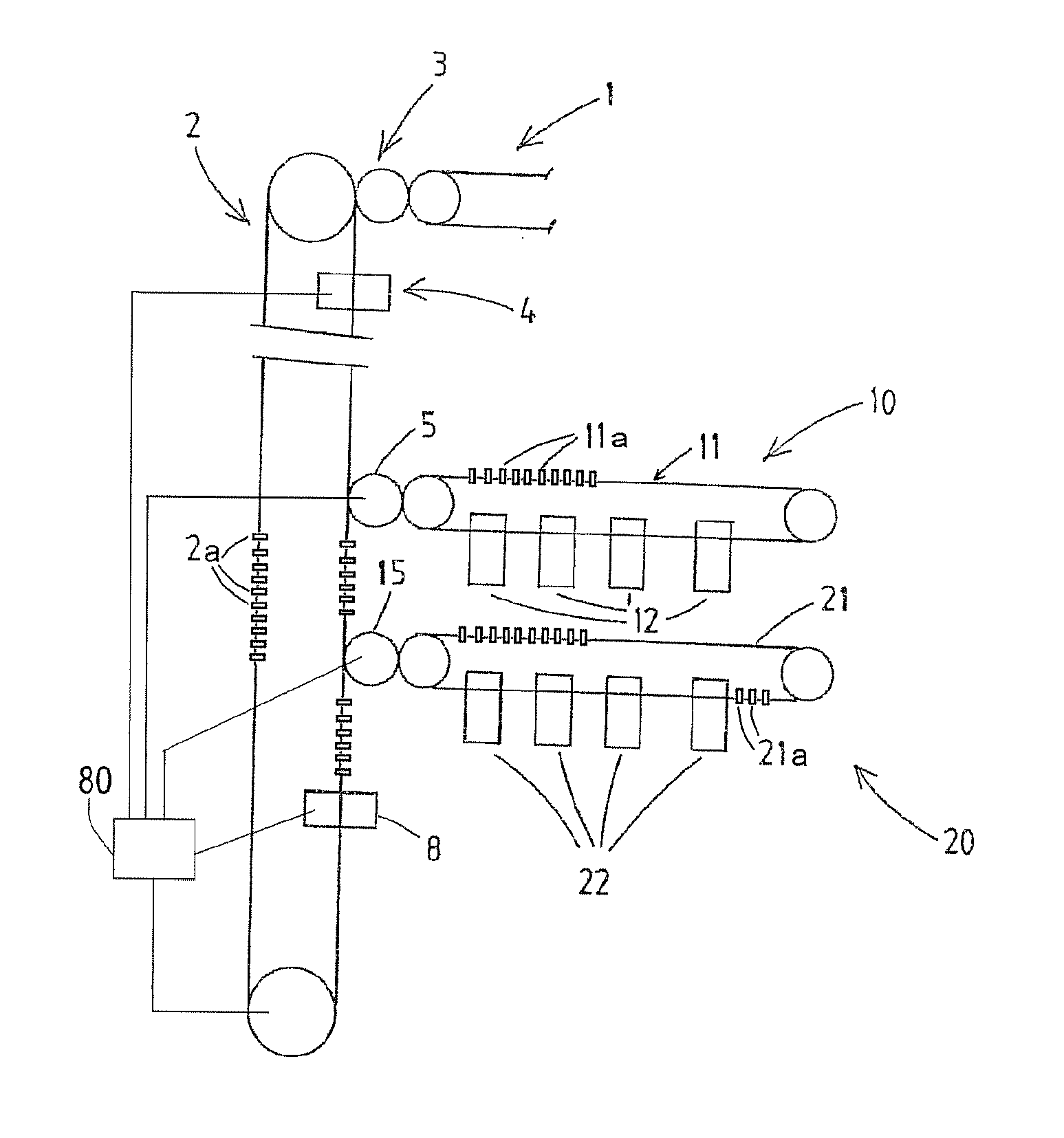

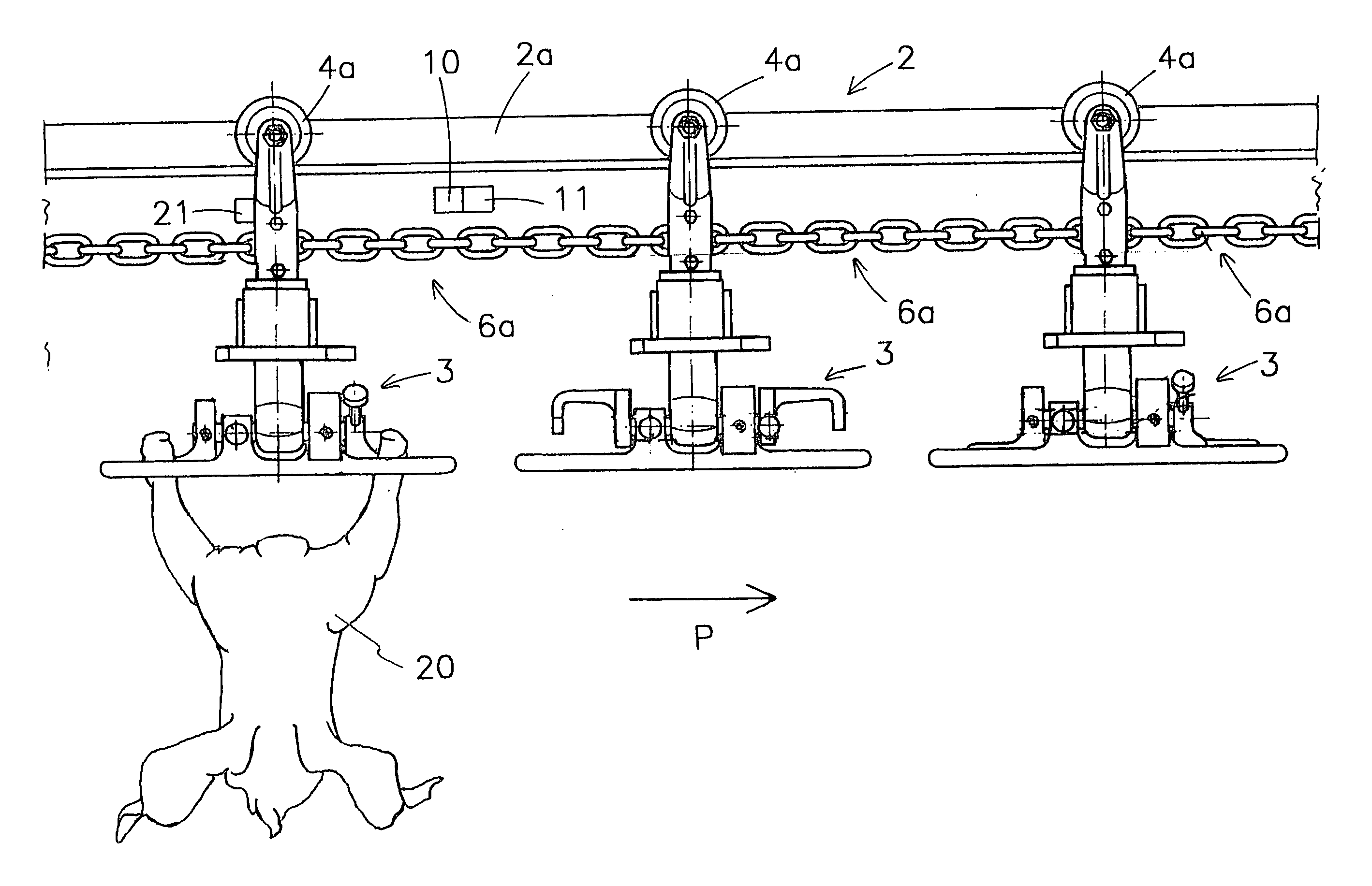

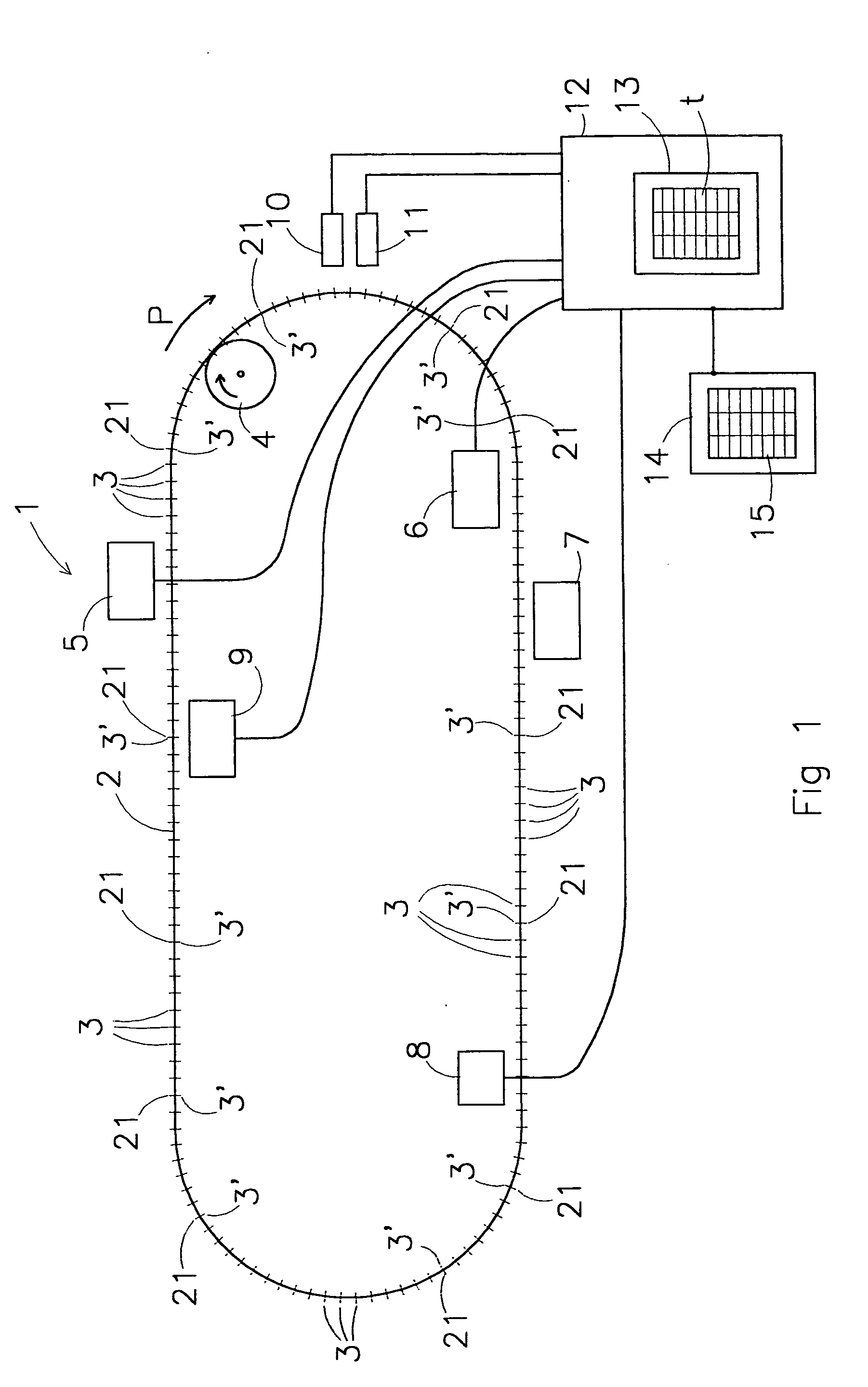

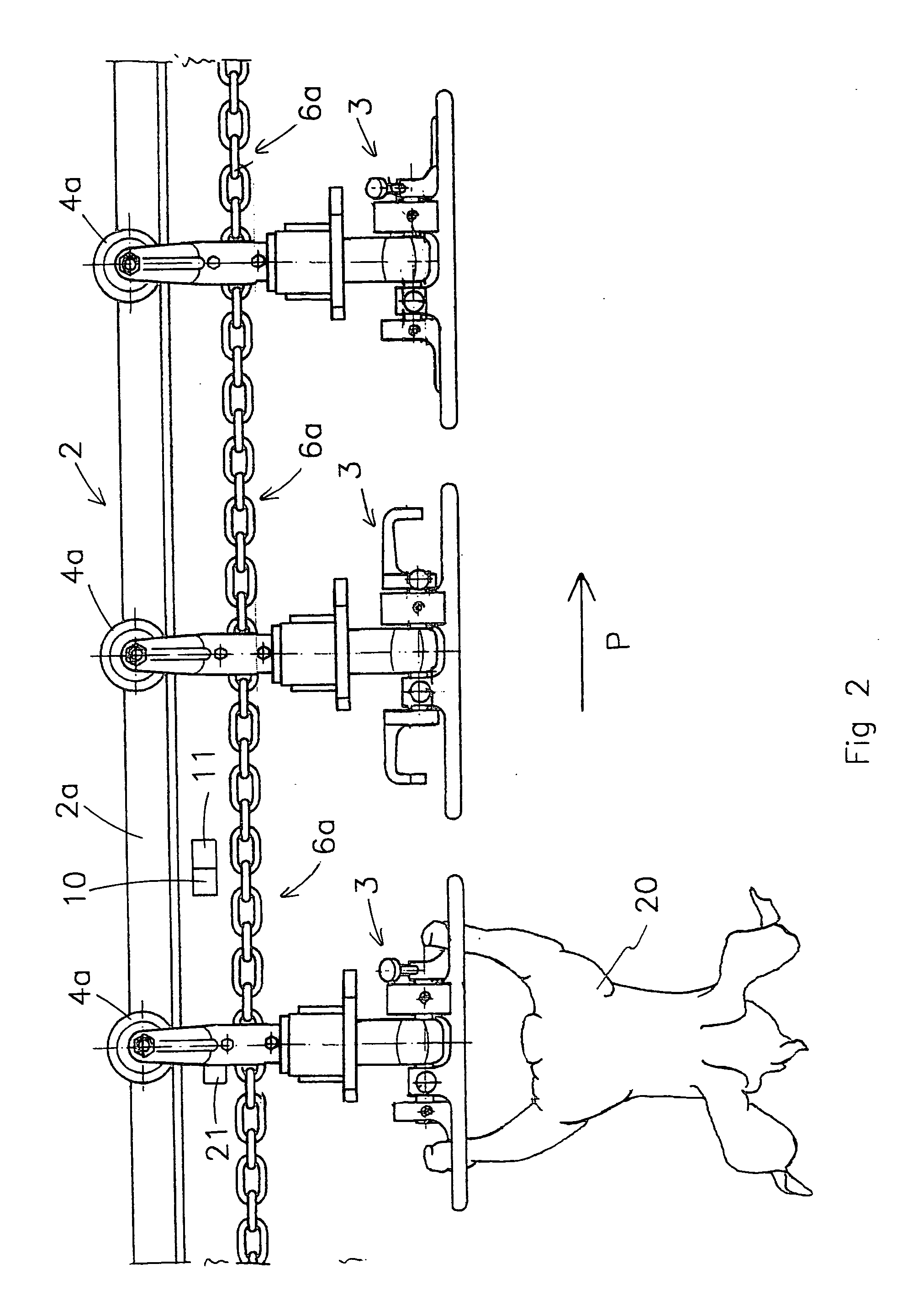

Method and installation for processing slaughtered poultry

ActiveUS20150150272A1Raise the possibilityAvoid a lot of problemsMeat processing plantsSlaughterhouse arrangementsEngineeringFodder

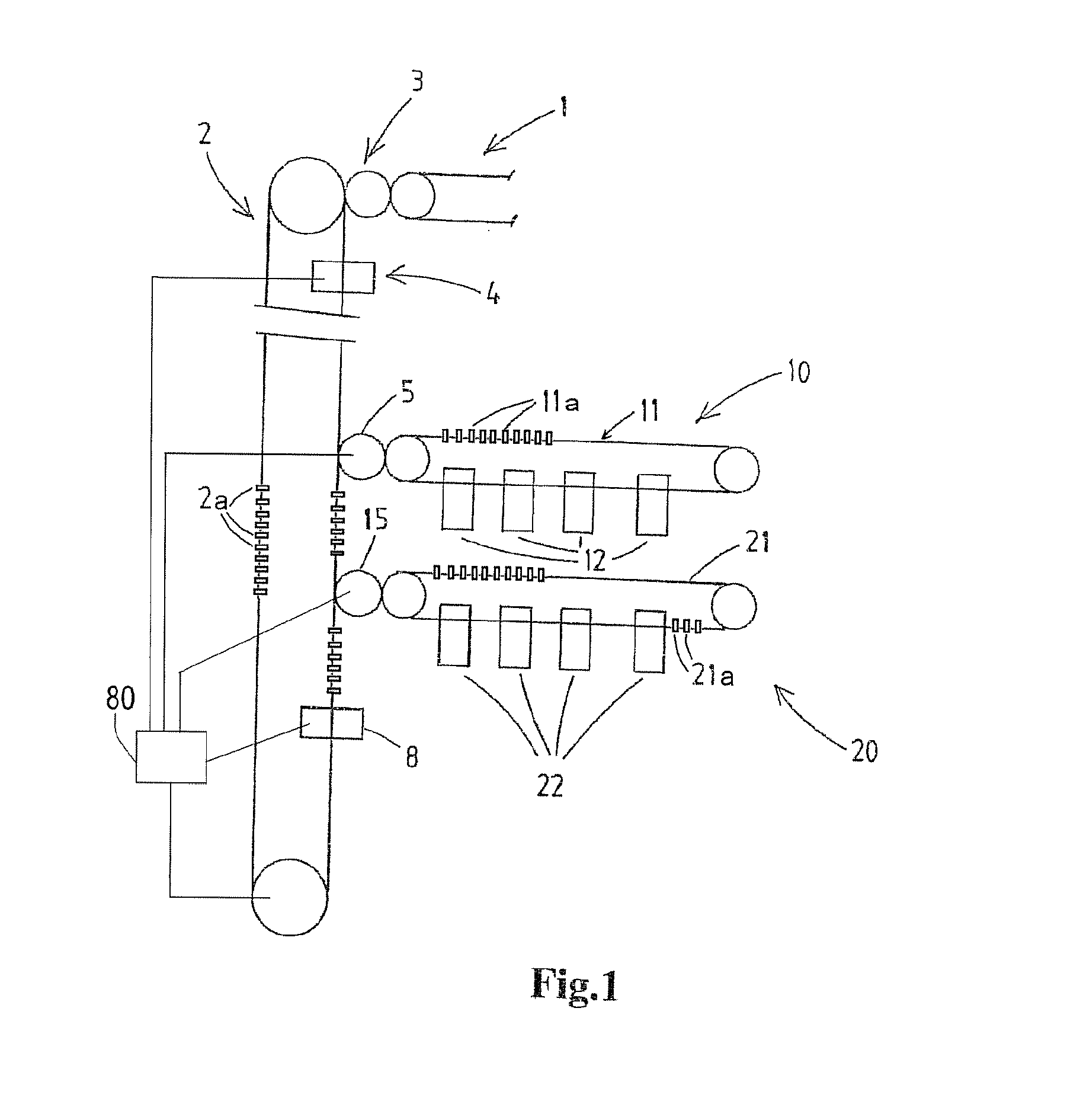

Method for processing slaughtered poultry, wherein oven-ready carcasses of slaughtered poultry are conveyed by a feed conveyor (2), said feed conveyor having an endless track and carriers (2a) that are moved along said track, the feed conveyor carrier being adapted to support one carcass suspended from its legs. Each individual carcass is subjected at least one of: a determination of the individual carcass weight by a weighing device (4), a determination of the individual carcass size by an imaging device. For dividing the carcasses into parts use is made of a first cut-up line (10) and a second cut-up line (20), wherein each cut-up line has an associated cut-up line conveyor (11, 21), said cut-up line conveyor having an endless track and carriers (11a, 21a) that are moved along said track, each cut-up line conveyor carrier being adapted to support one carcass suspended from its legs. Each cut-up line comprises one or more cutting devices (12, 22) arranged along the track, which one or more cutting devices divide a carcass supported by a cut-up line conveyor carrier into parts.

Owner:MAREL STORK POULTRY PROCESSING

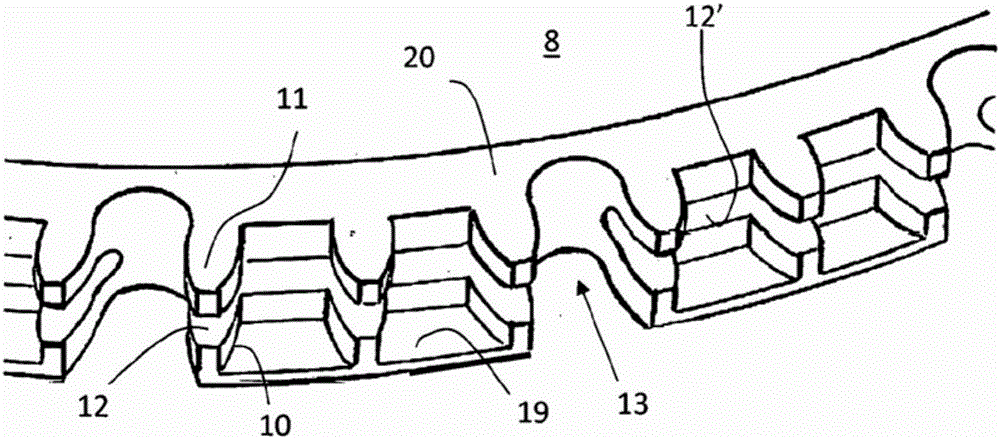

Conveyor line and carrier for poultry used in said conveyor line

ActiveCN106857772APoultry shacklesPoultry transferring/conveying devicesMechanical engineeringEngineering

Conveyor line and carrier comprising hooks for suspending poultry by the legs, and further comprising a carriage for moving the carrier with the suspended poultry along a track of the conveyor line, and arranged with at least a first rotatable vertical rod suspended from the carriage, which first rotatable rod is provided with a sideways extending arm for adjusting an orientation of the poultry or poultry parts with reference to the carriage, wherein near or at the sideways extending arm a frame is provided which is movable up and down with reference to the first vertical rod, wherein a second rod is suspended from said frame, and wherein said movability of the frame causes that the second rod is movable up and down whilst the first rod maintains its altitude, and wherein the hook or hooks for suspending the poultry are provided at a lower end of the second rod.

Owner:MEYN FOOD PROCESSING TECH BV

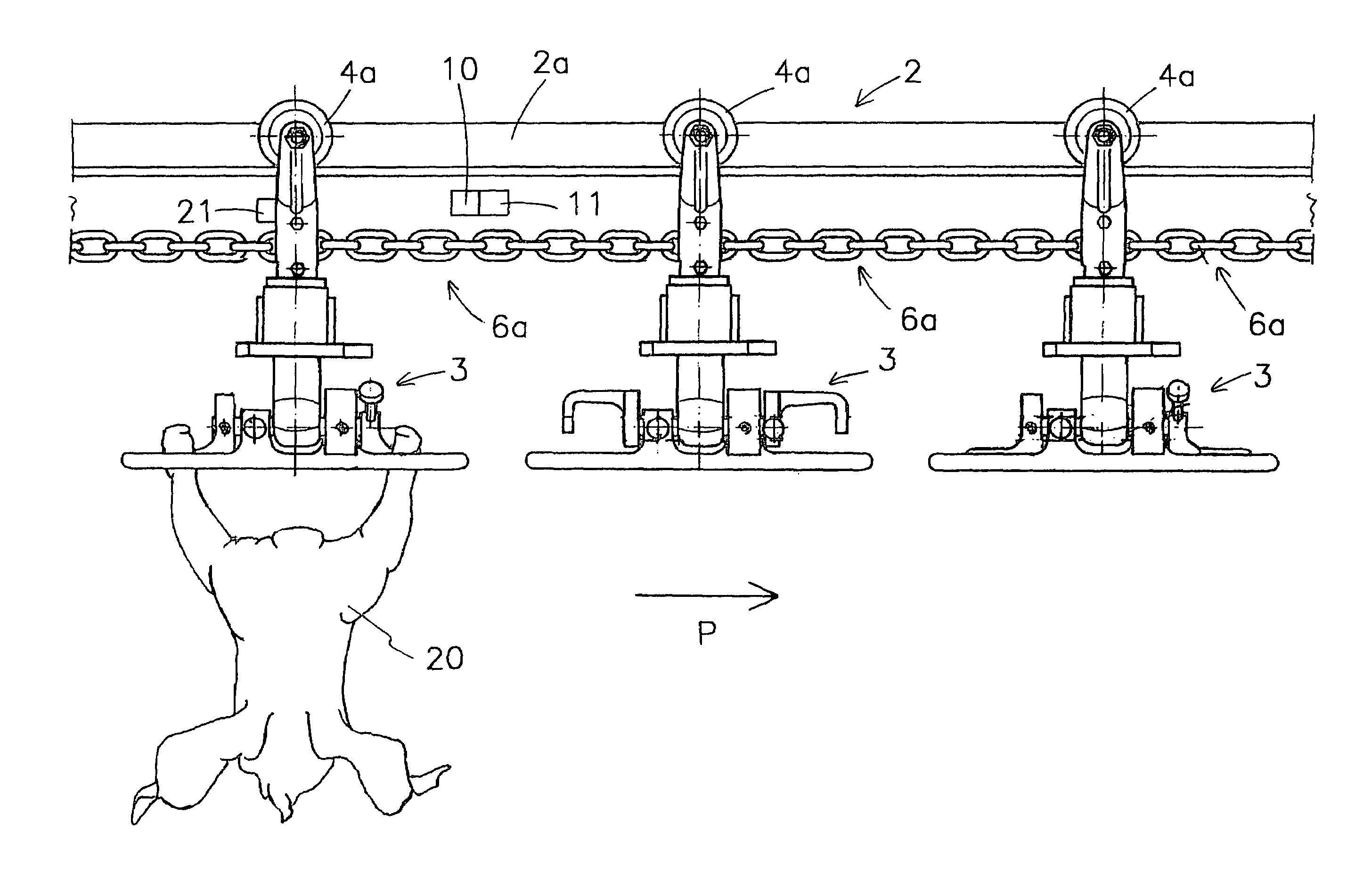

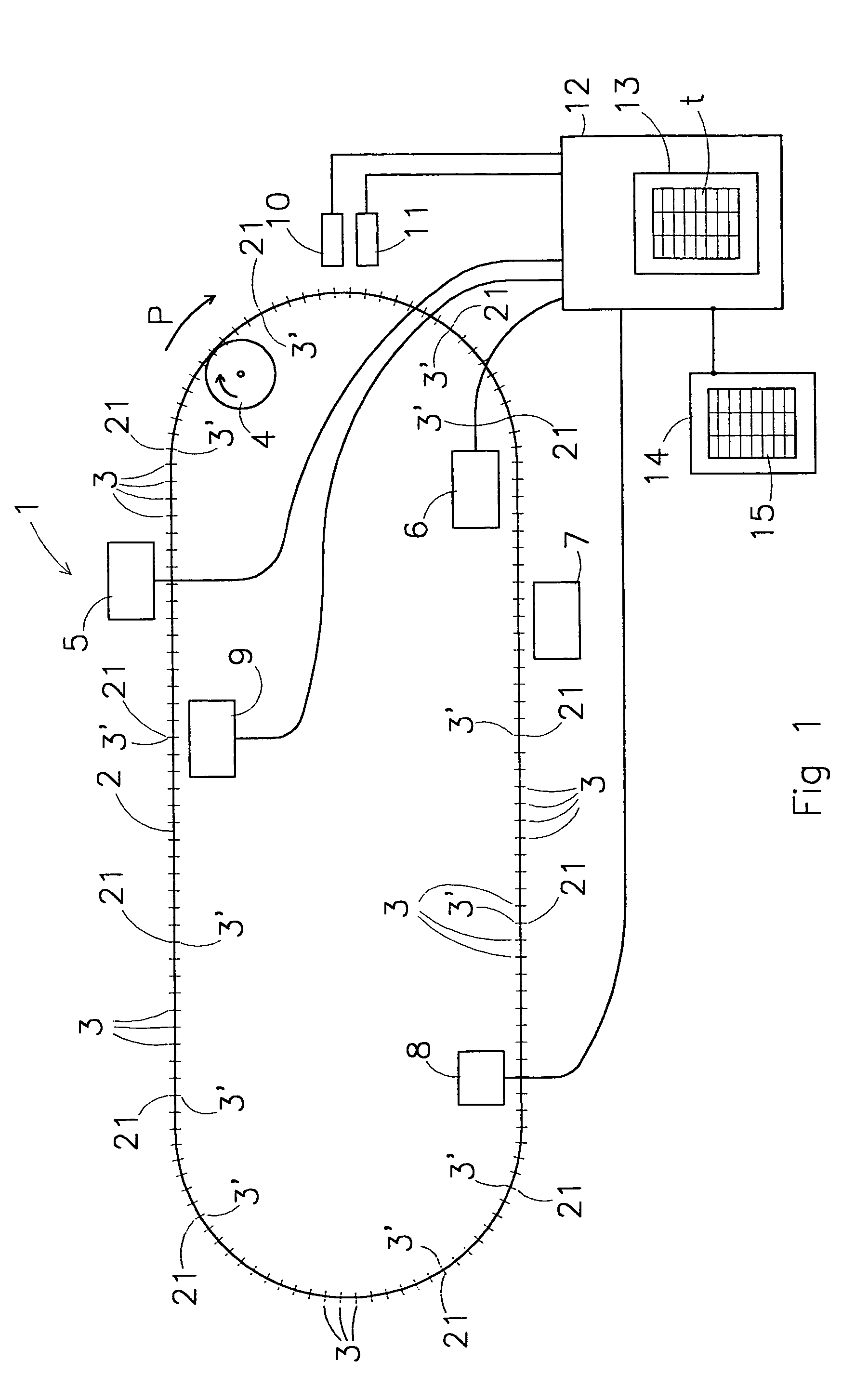

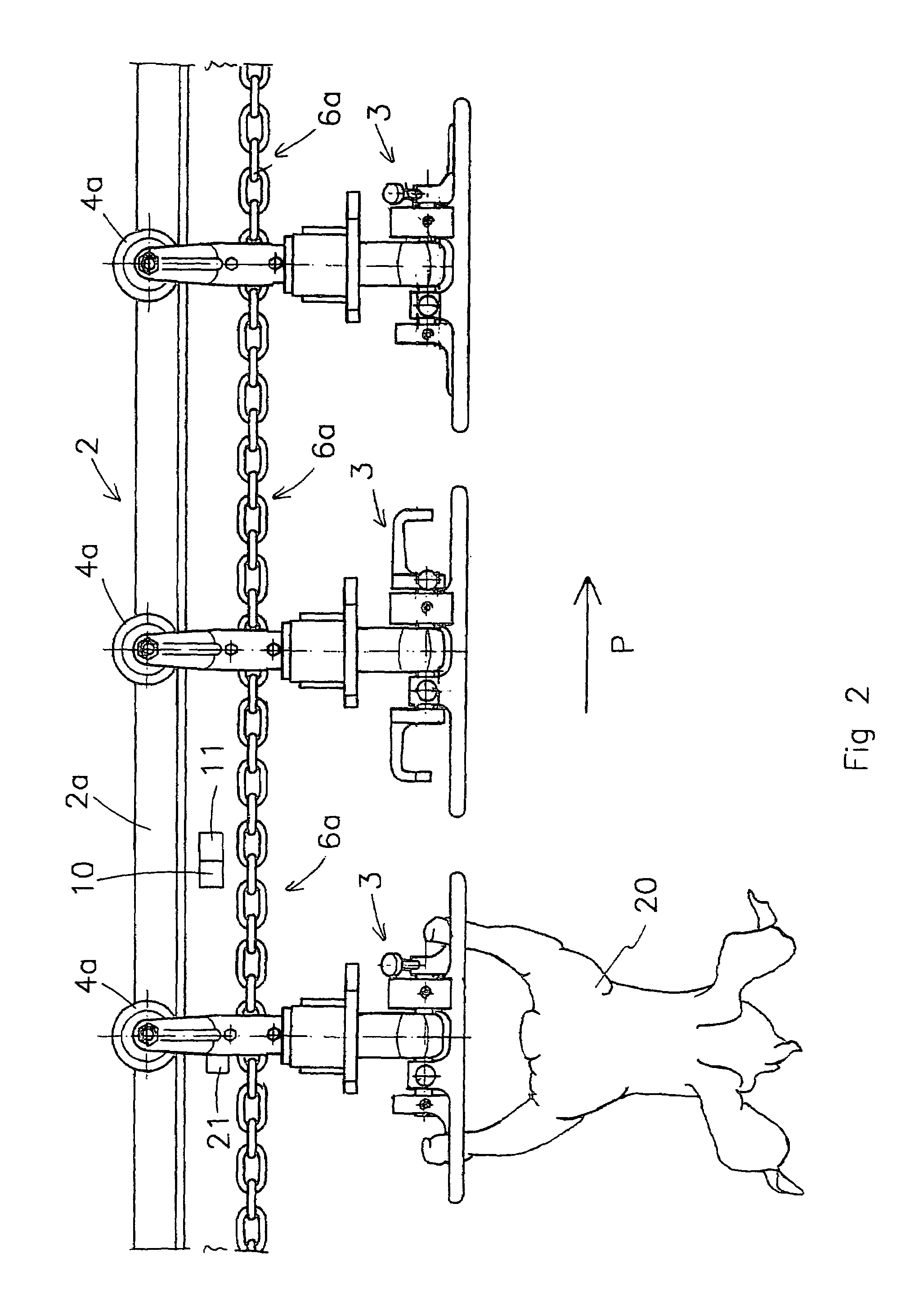

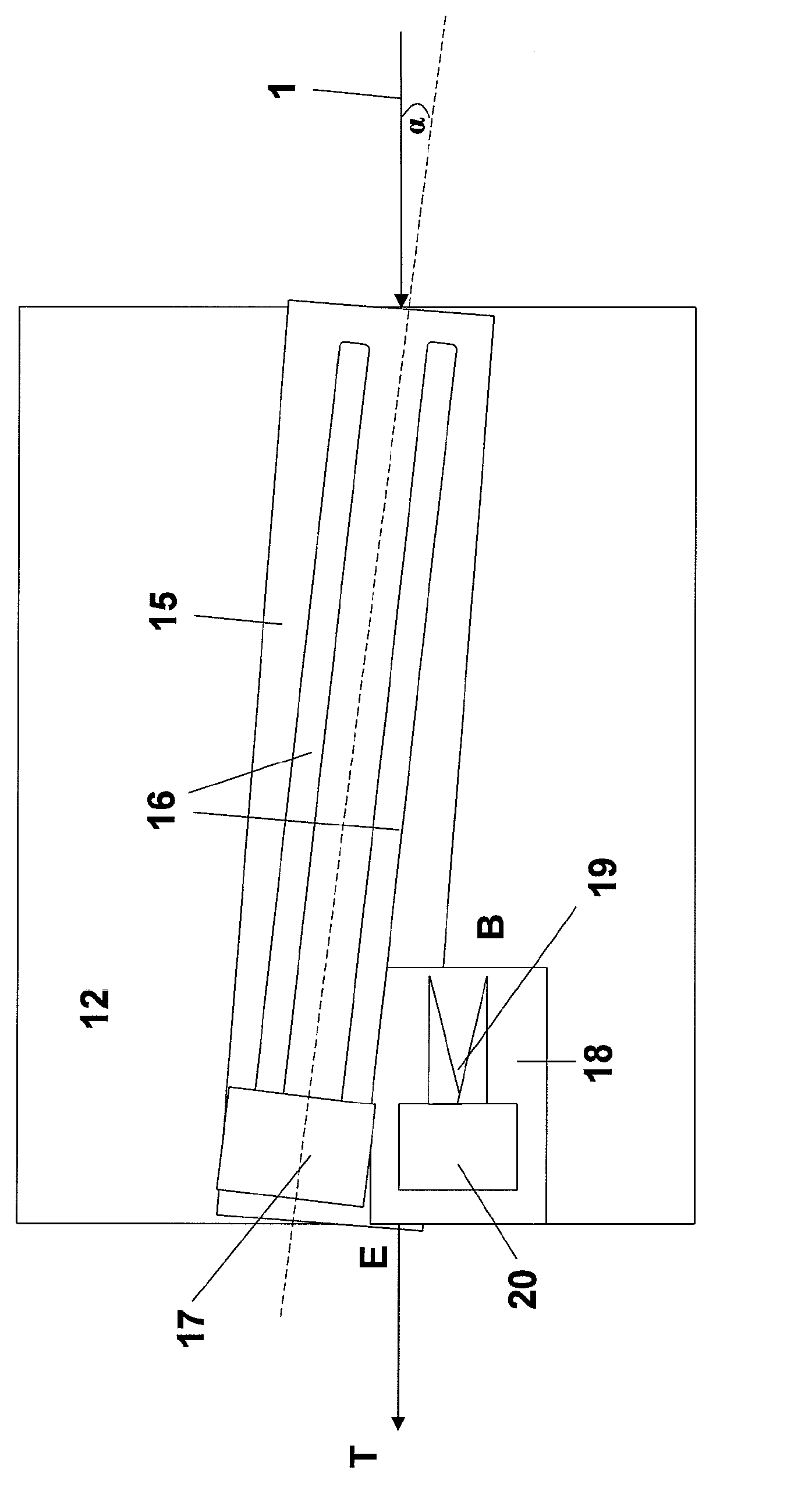

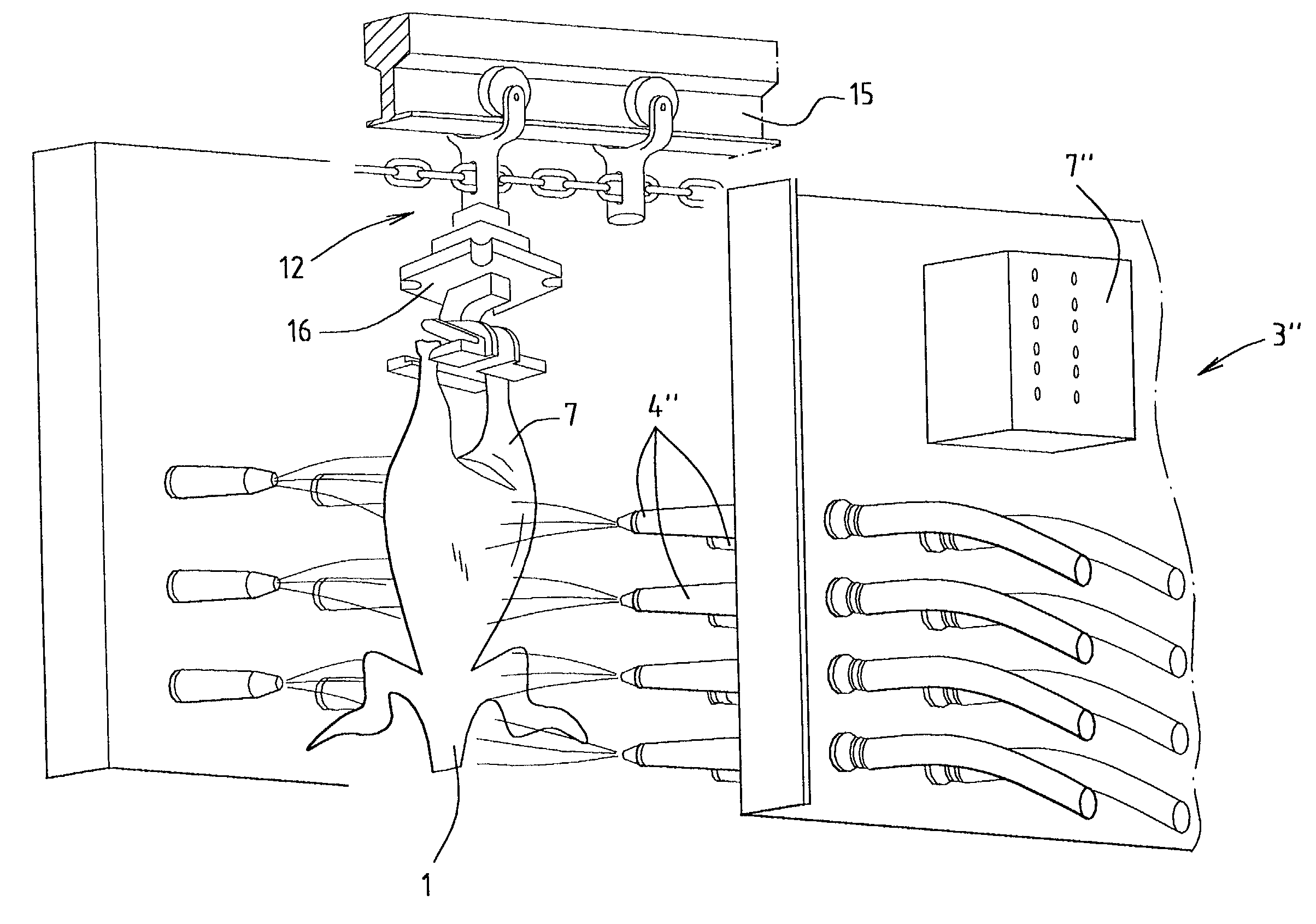

Device and method for processing slaughter animals and/or parts thereof provided with a transportation system

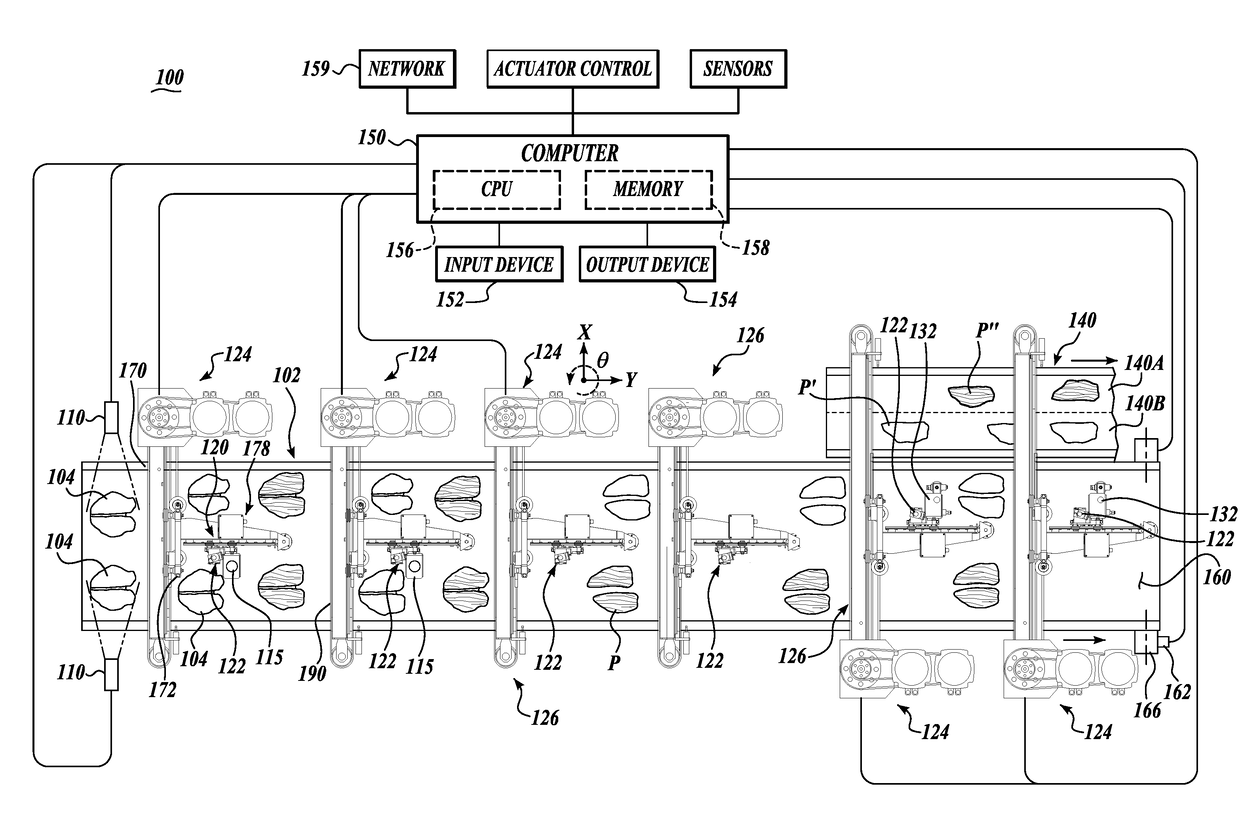

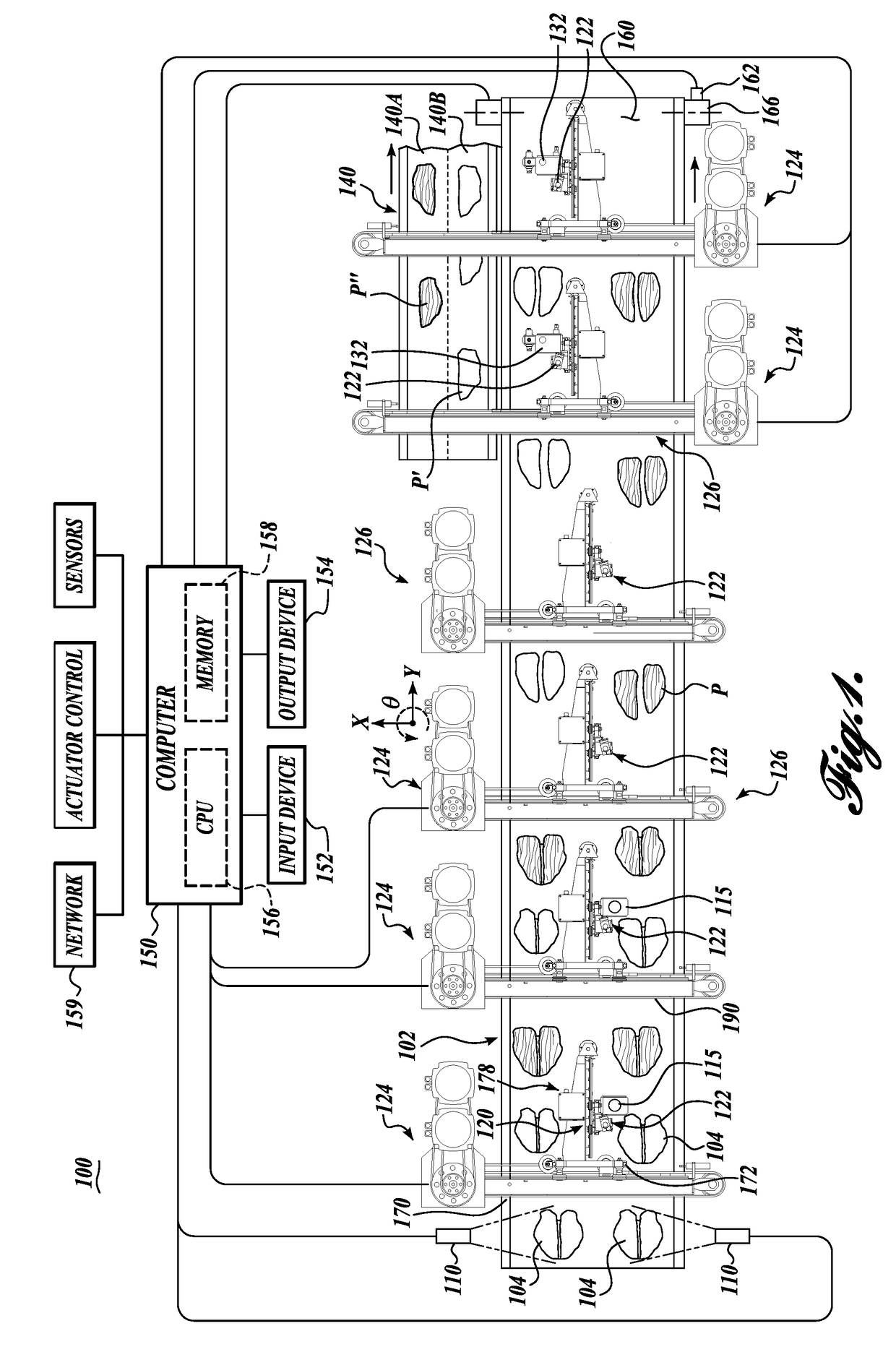

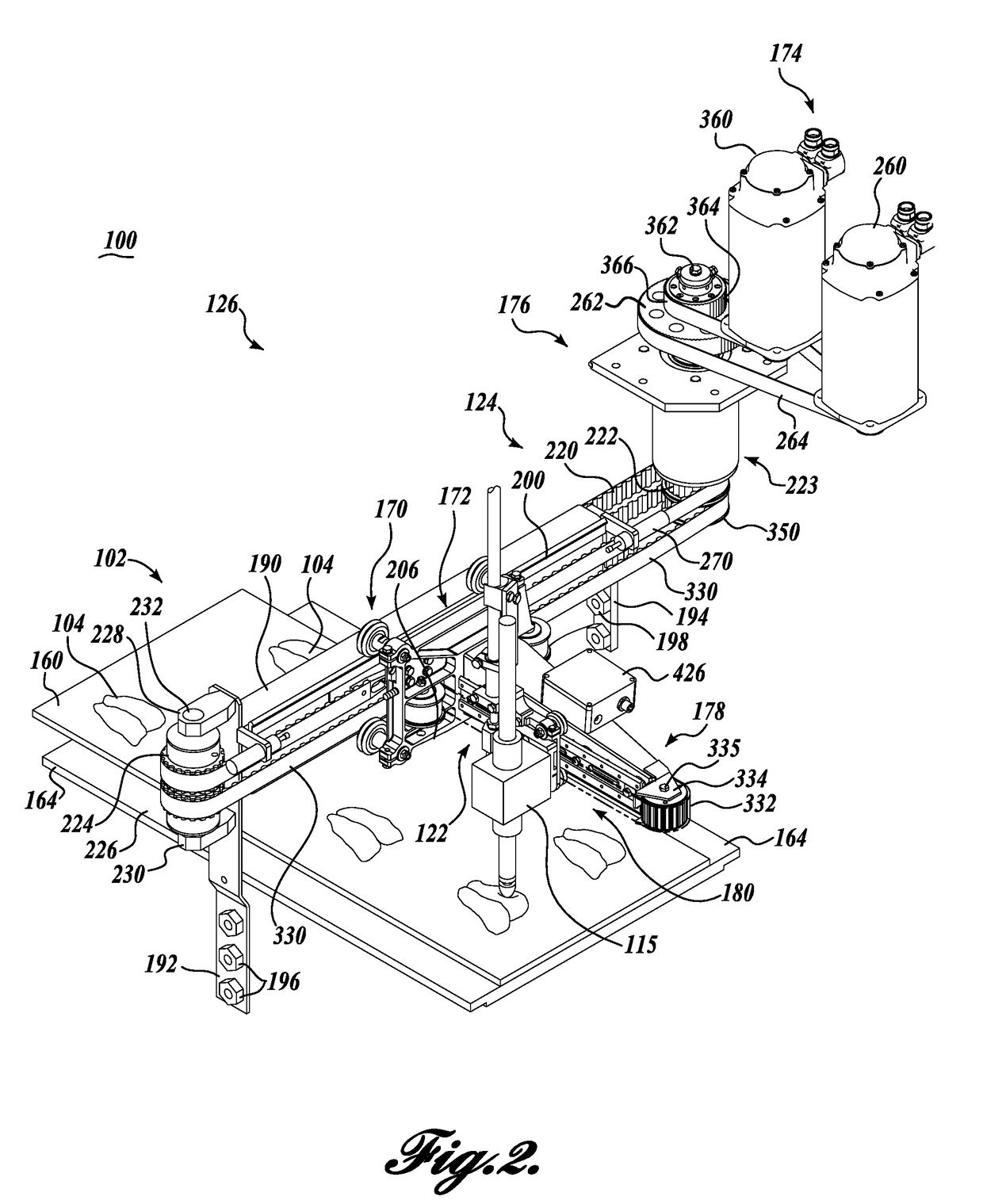

ActiveUS20050061621A1Digital data processing detailsControl devices for conveyorsTransport systemTransit system

A device for processing slaughter animals or parts thereof, for example poultry, comprises a transport system with an endless track and a chain of chain elements which can be moved along the track, wherein a plurality of chain elements are set up as carriers to carry one or more slaughter animals and / or parts thereof. The device furthermore has a delivery station for delivering slaughter animals or parts thereof to the carriers of the transport system, one or more stations being set up along the track of the transport system to perform actions relating to the slaughter animals or parts thereof. The device furthermore has location means for determining the position of the chain in relation to the track, wherein the location means comprise an identifiable chain element which has an associated identification mark, and also an identification sensor set up along the track to detect each identifiable chain element, wherein the remaining chain elements in the chain are designed as unidentifiable chain elements. The location means furthermore comprise a counting device to count the unidentifiable chain elements which pass along a counting station by the track following the passage of an identifiable chain element. Moreover, the location means furthermore comprise electronic memory means with a memory table in which a memory field is provided for each carrier, wherein the location means record a variable in the memory field representing the number of carriers counted by the counting device since the passage of the identifiable chain element located upstream.

Owner:STORK PMT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com