Patents

Literature

959 results about "Processing plants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

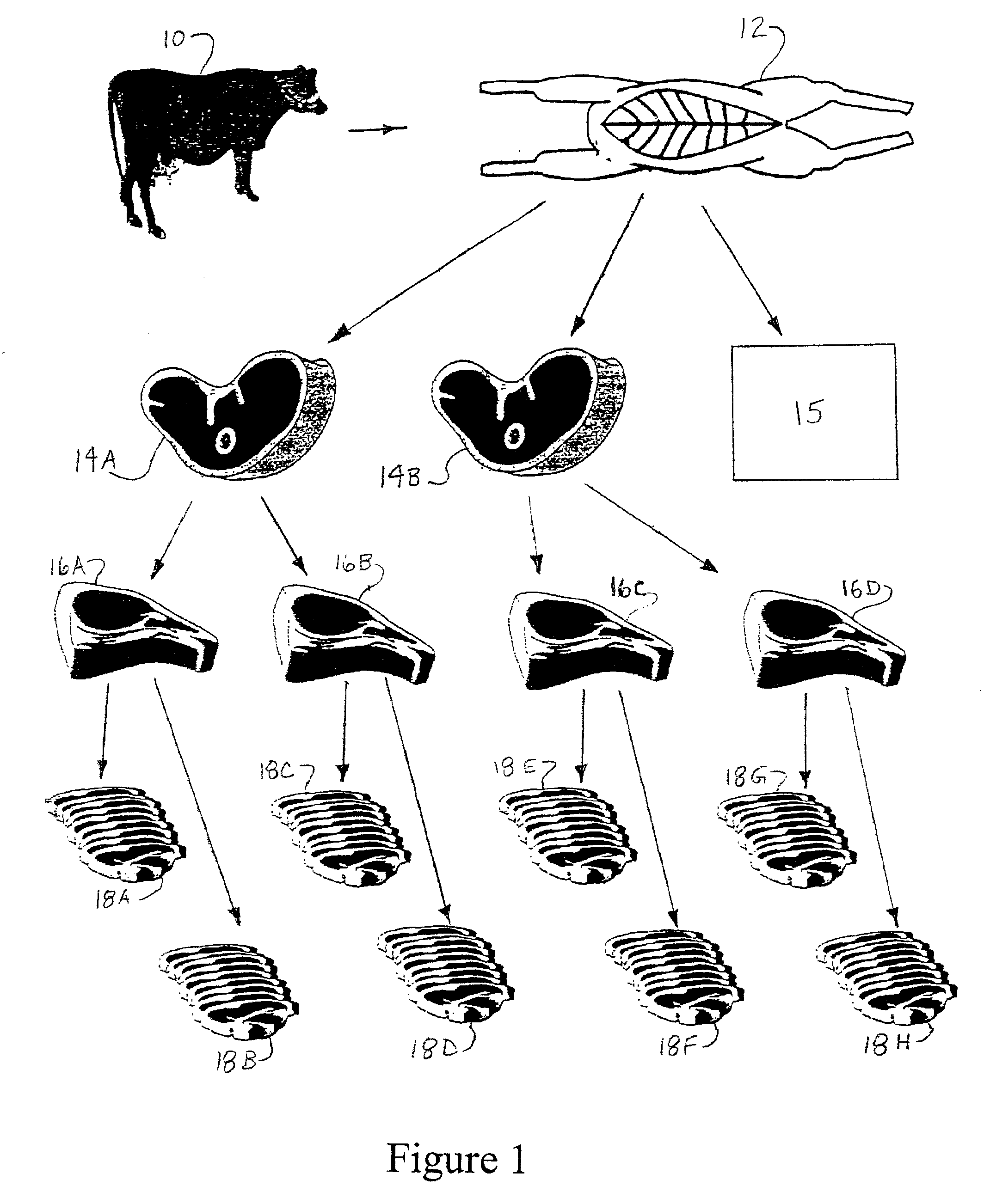

A processing only plant is a plant that receives animal carcasses and packs the meat for production. A cold storage plant stores meat that was processed at a remote meat processing plant. Meat processing plants are designed to streamline food production in order to ensure an adequate supply of quality food.

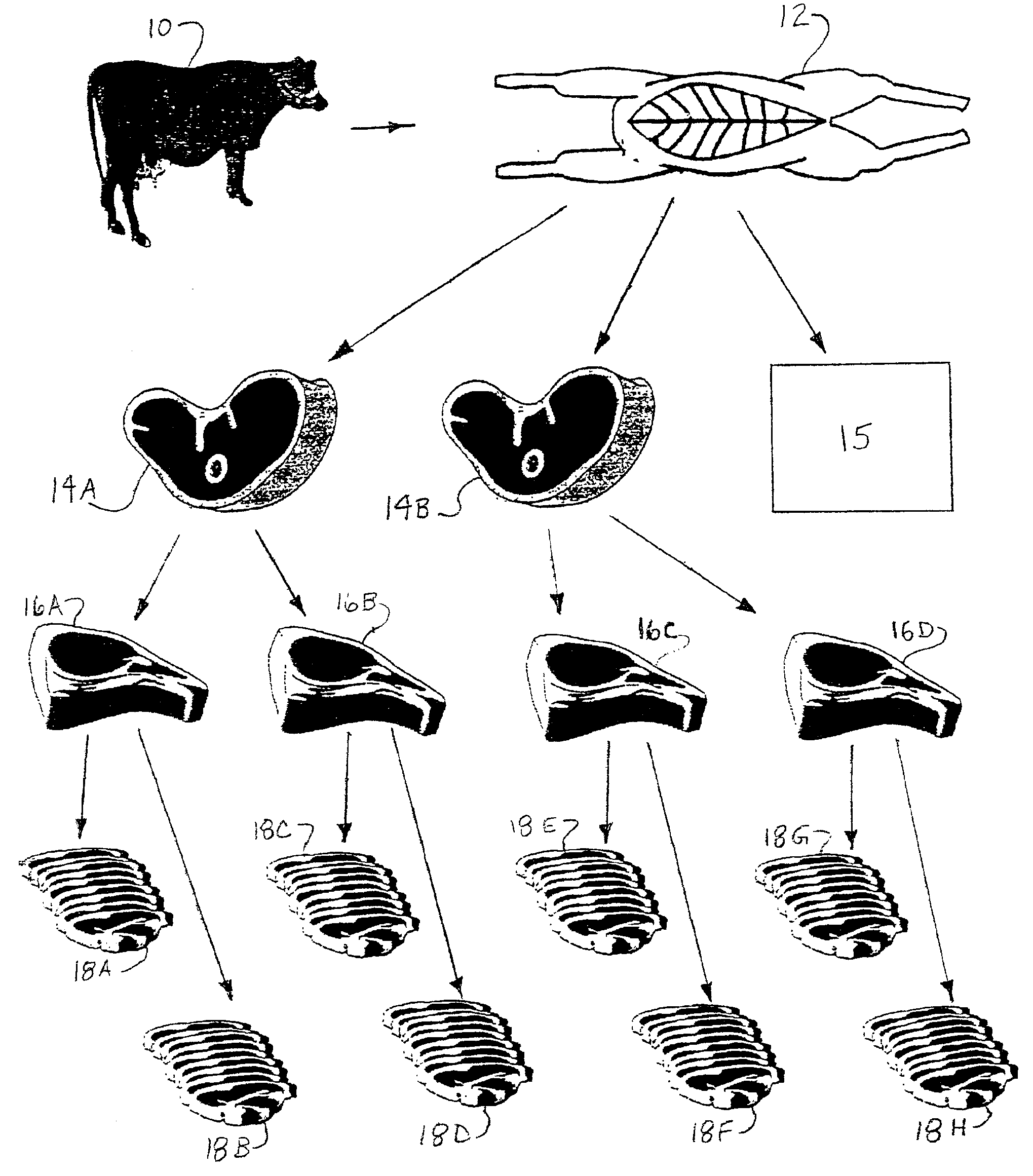

Method of linking a food source with a food product

A method of linking source units of food with product items that include at least a portion of one or more of the source units of food, where a conversion process produces a plurality of product items from a plurality of source units (e.g., at a meat processing plant). A conversion algorithm is created to estimate within a desired confidence level a range of the amount of time required by the conversion process to produce a product item from one or more of the source units of food. A range of an amount of conversion time required to produce a selected product item is estimated by applying the conversion algorithm. The estimated range amount of conversion time for the selected product item is subtracted from the time of exit from the conversion process for the selected product item to generate an estimated time range of entry. Each source unit having a time of entry into the conversion process within the estimated time range of entry is identified.

Owner:CRYOVAC ILLC

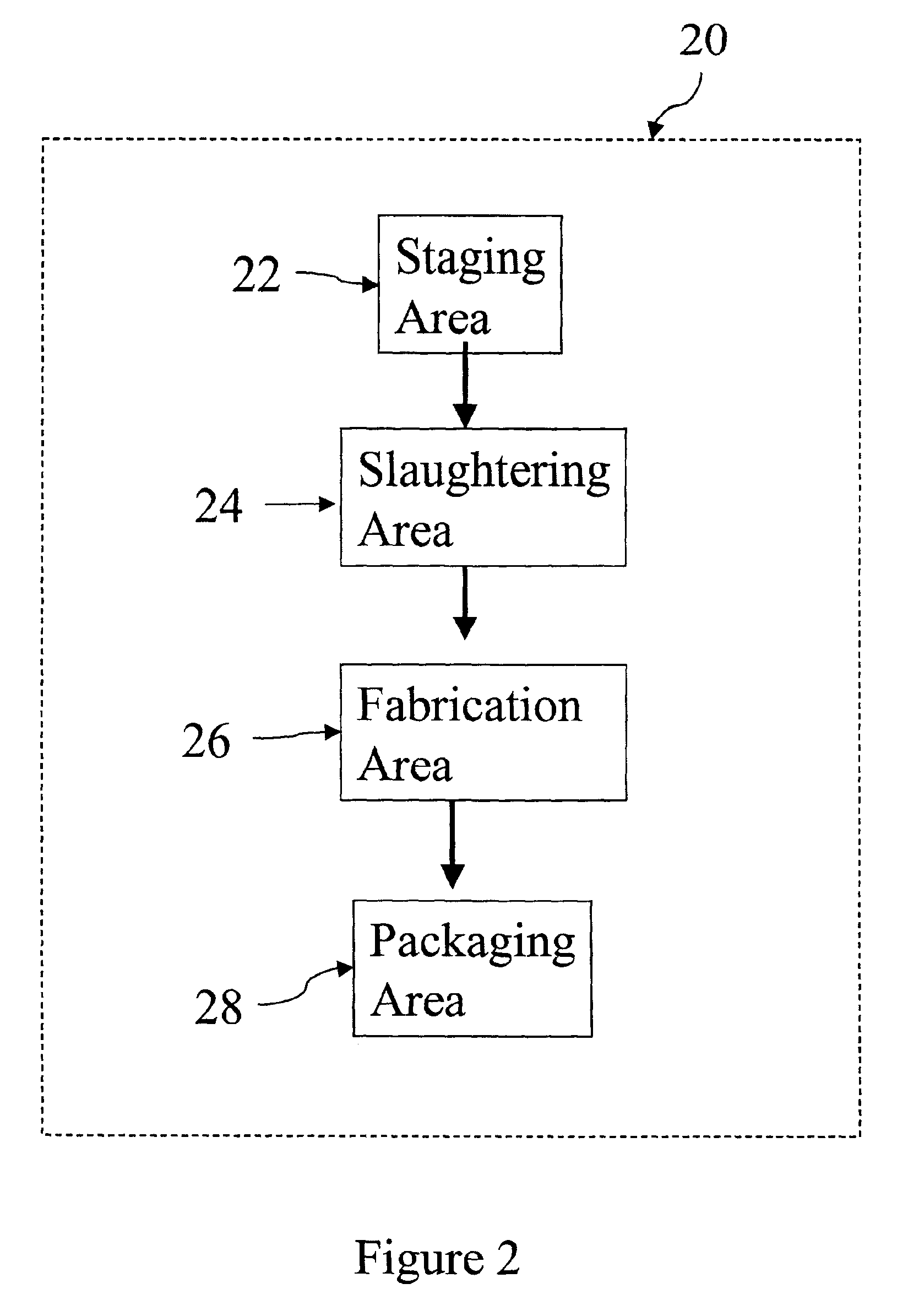

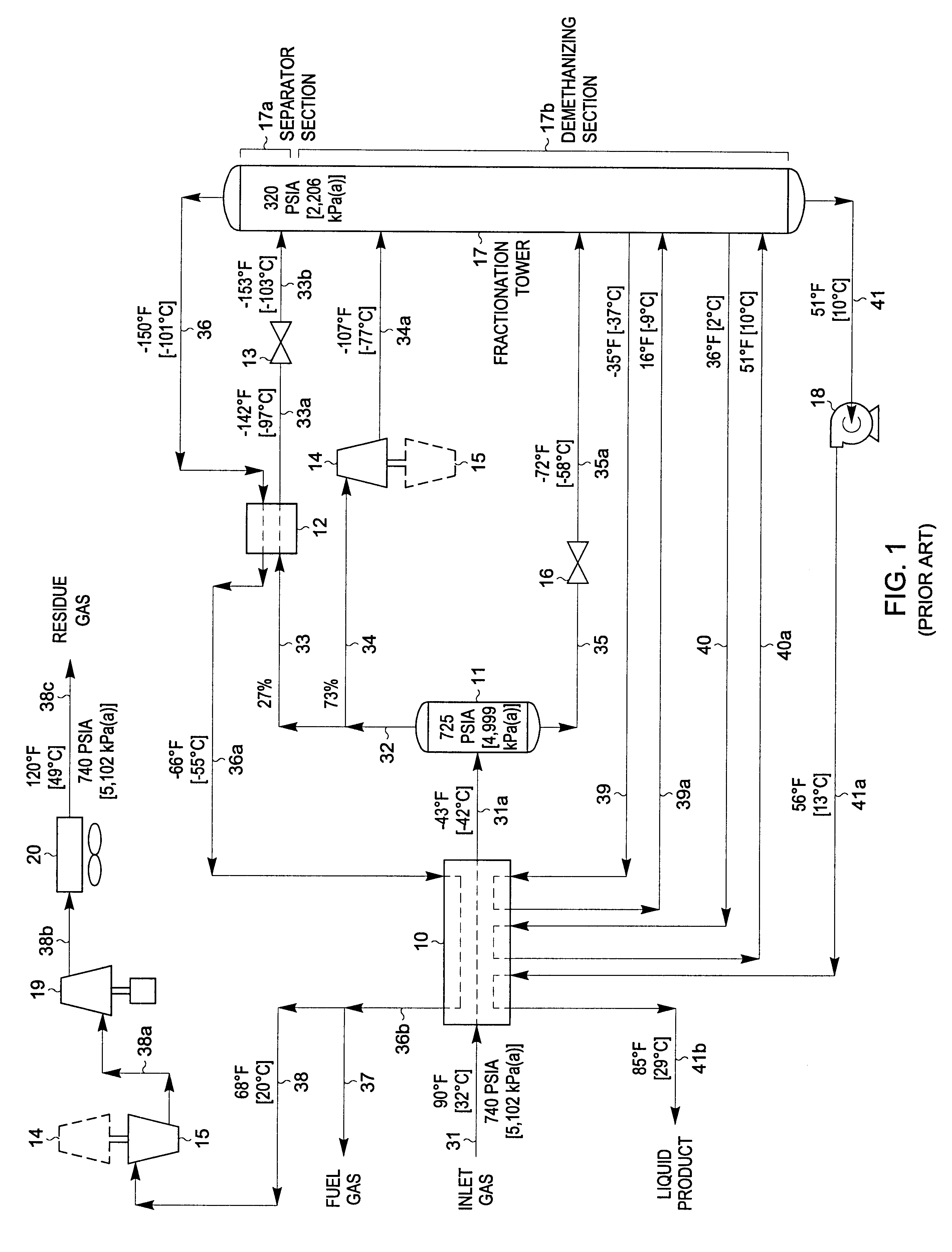

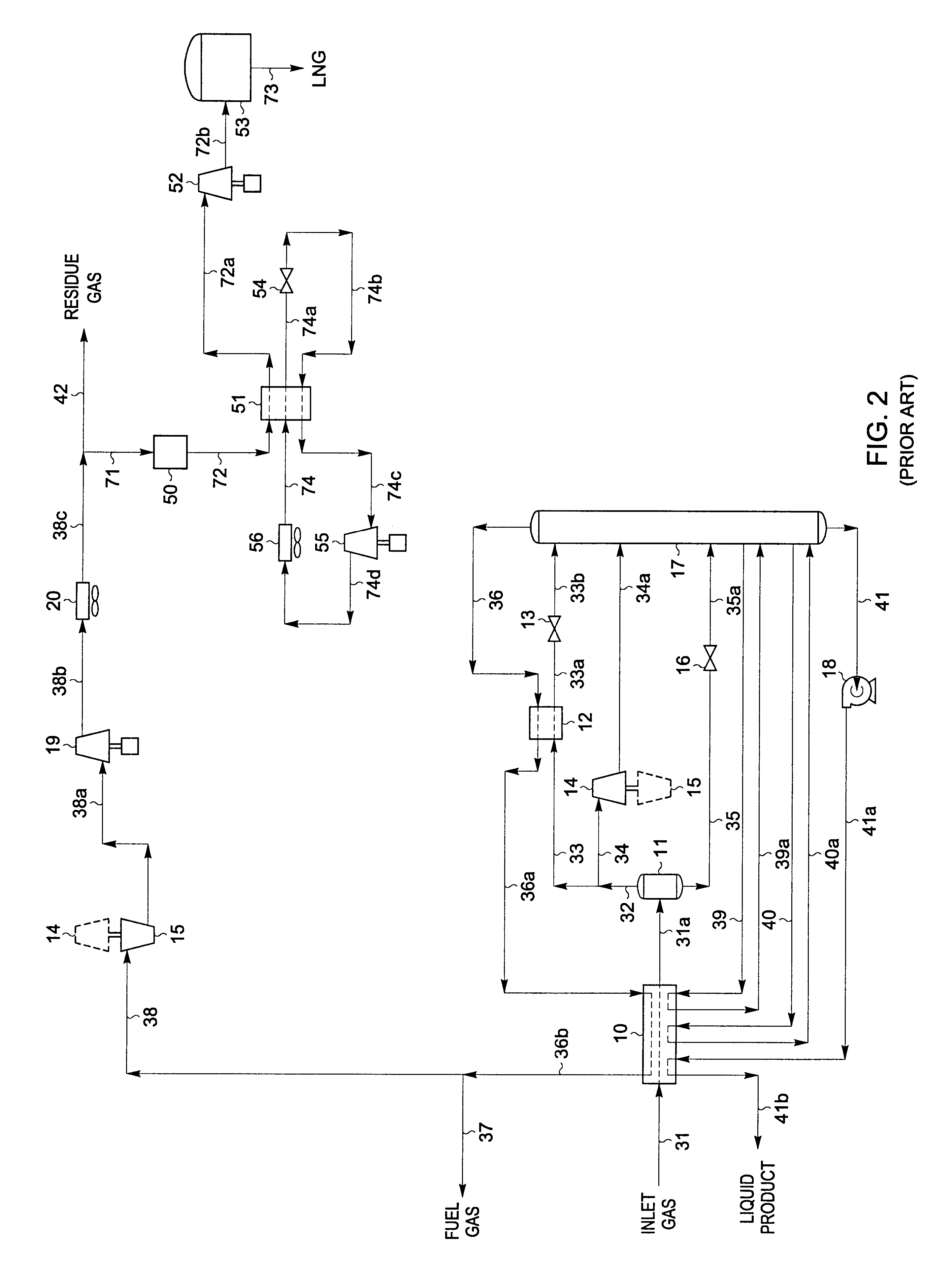

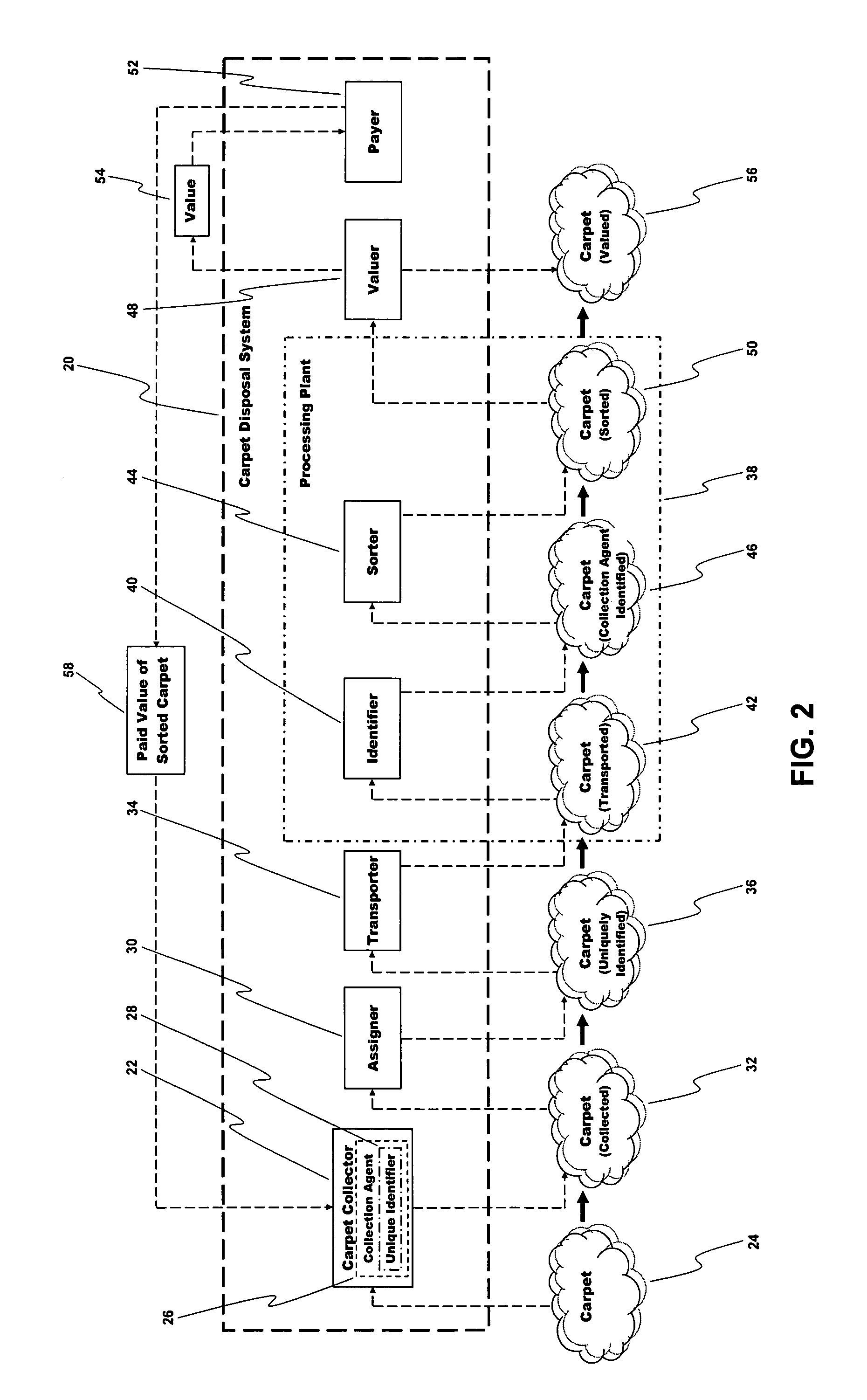

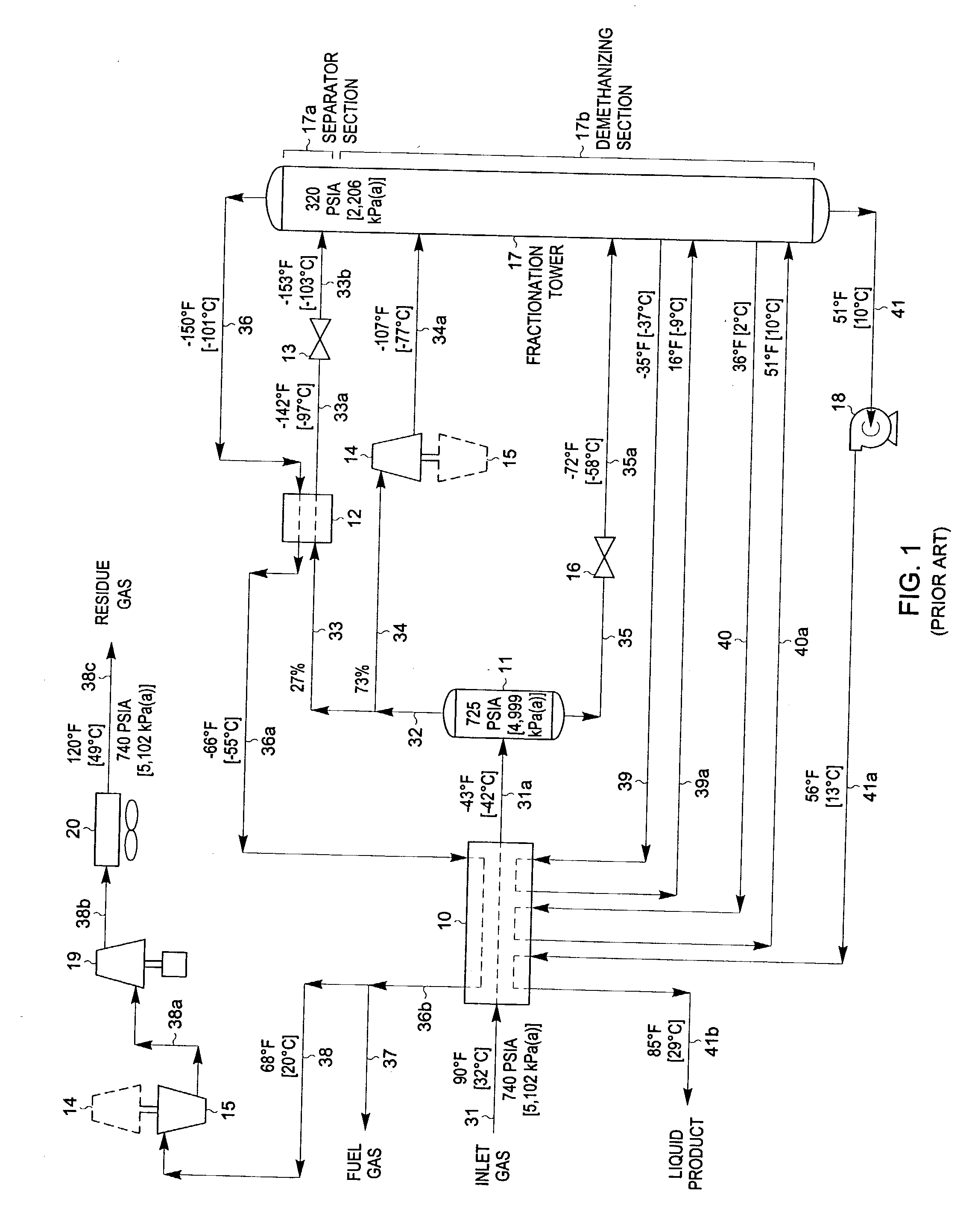

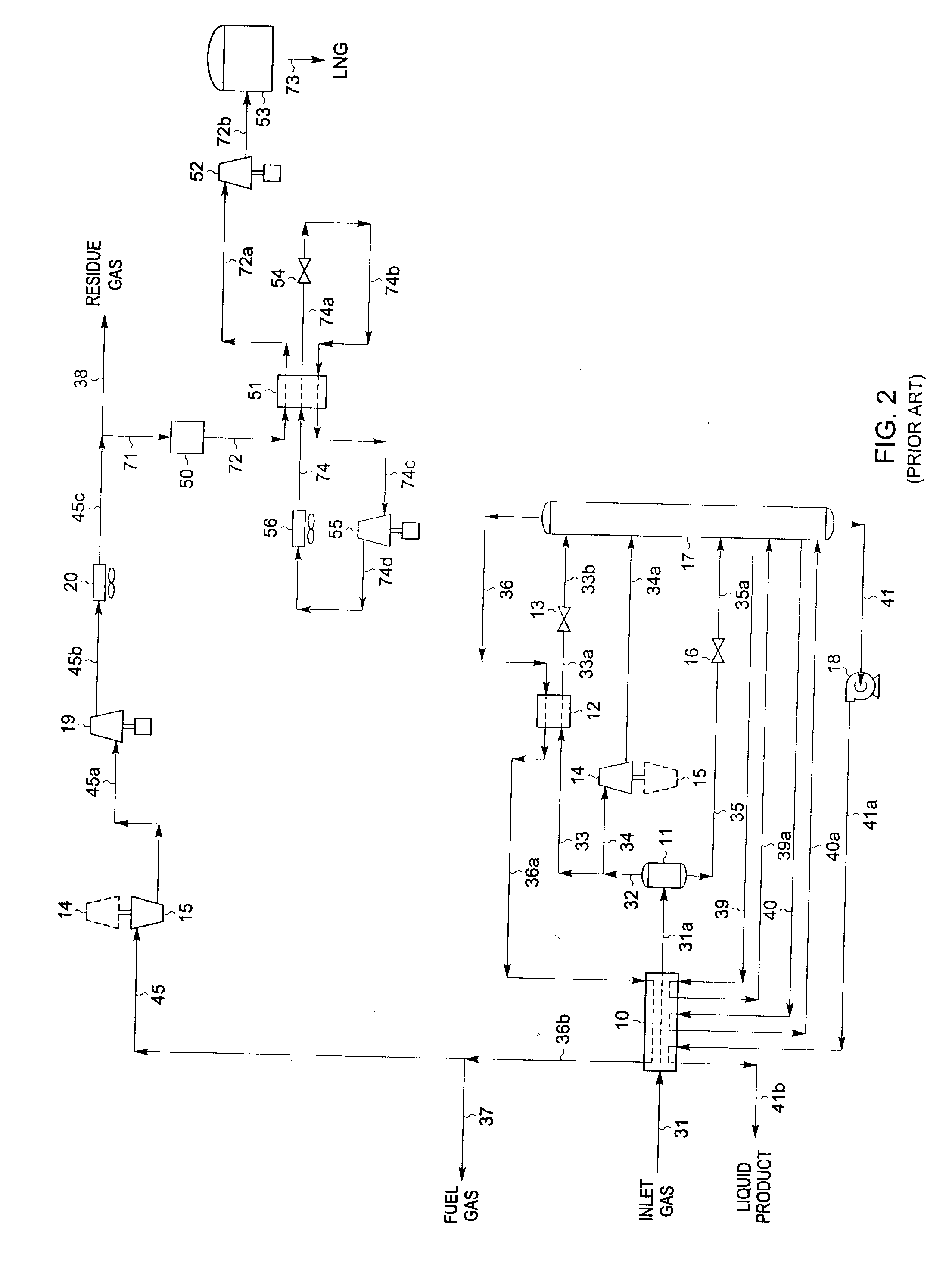

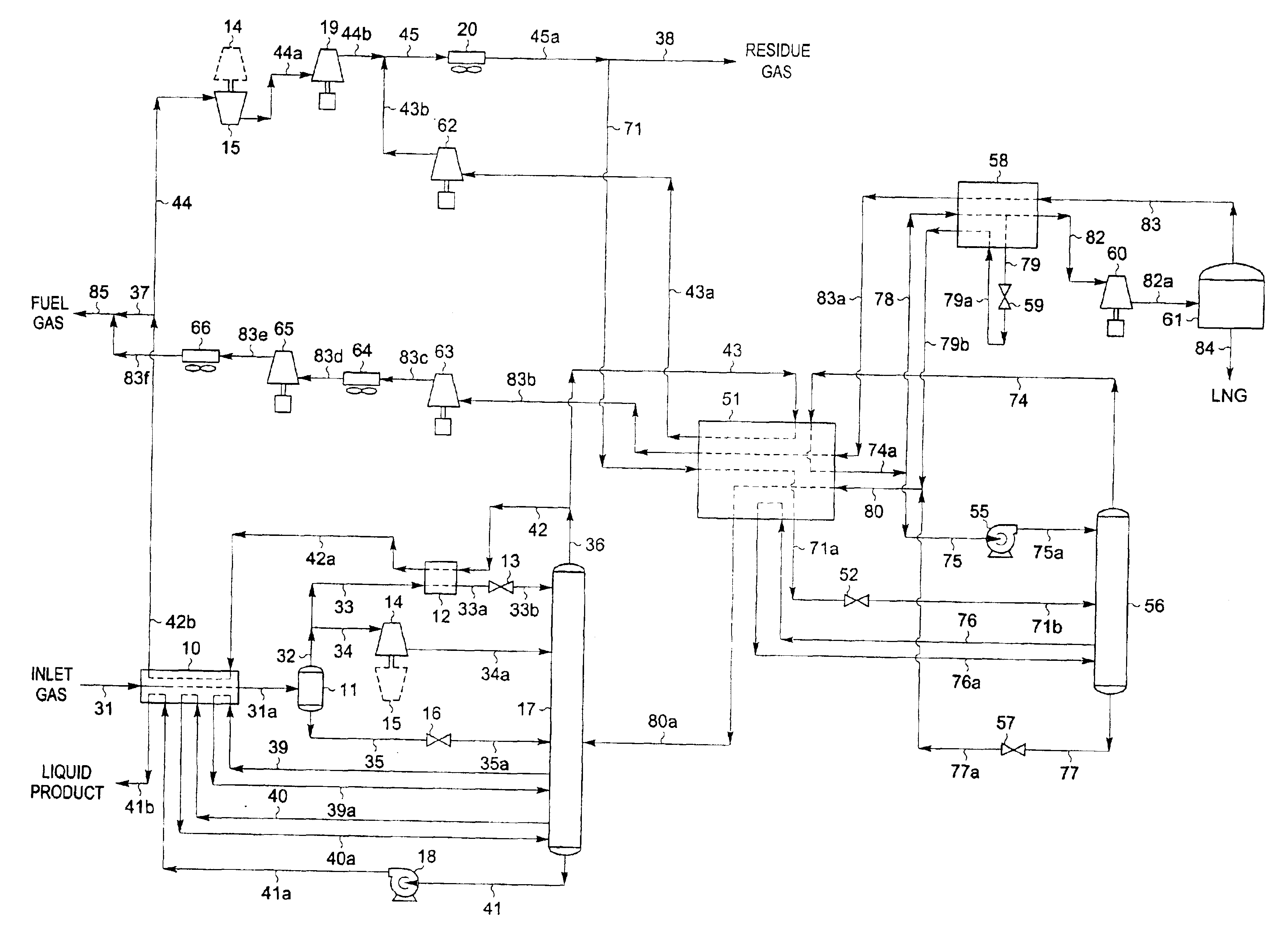

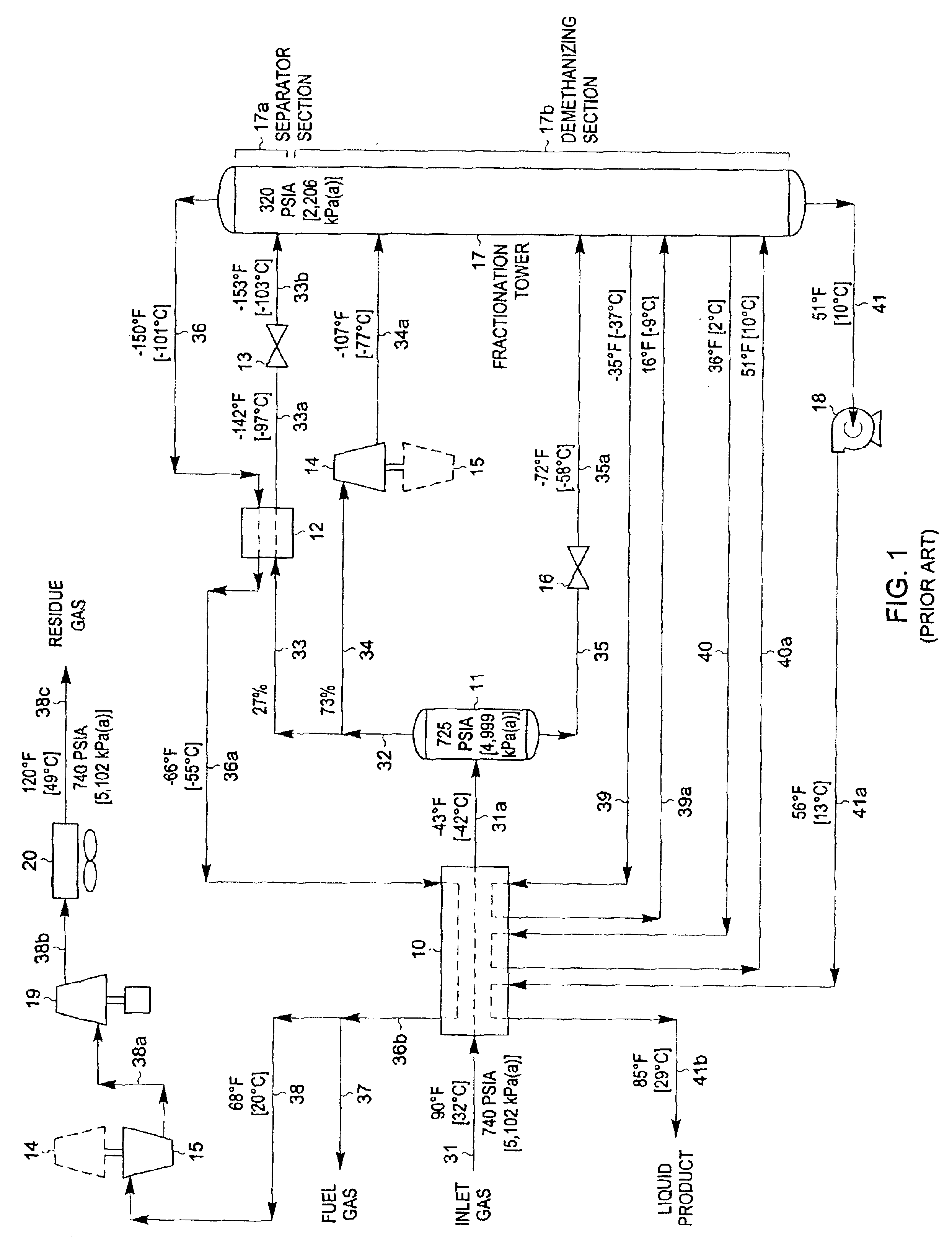

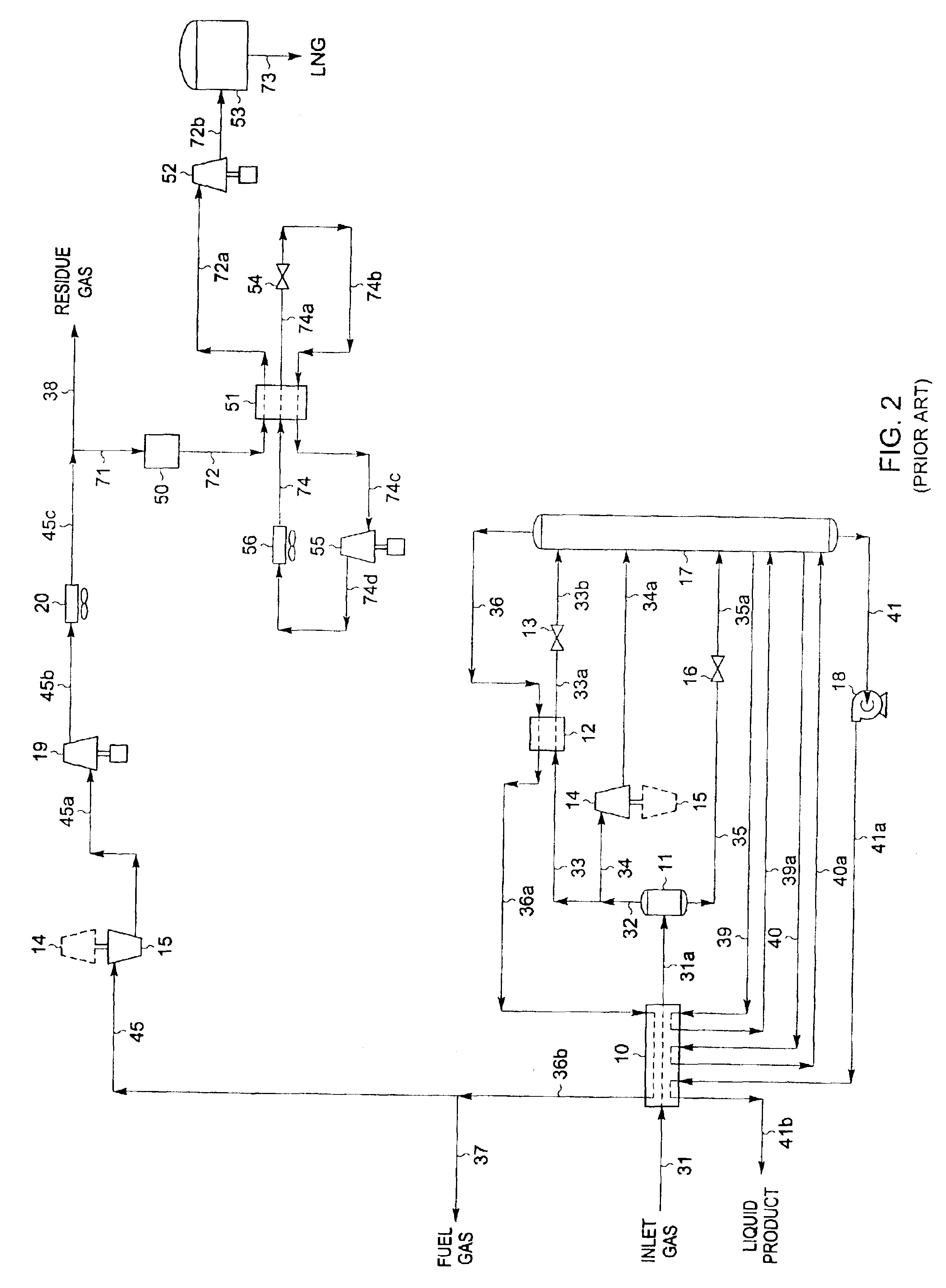

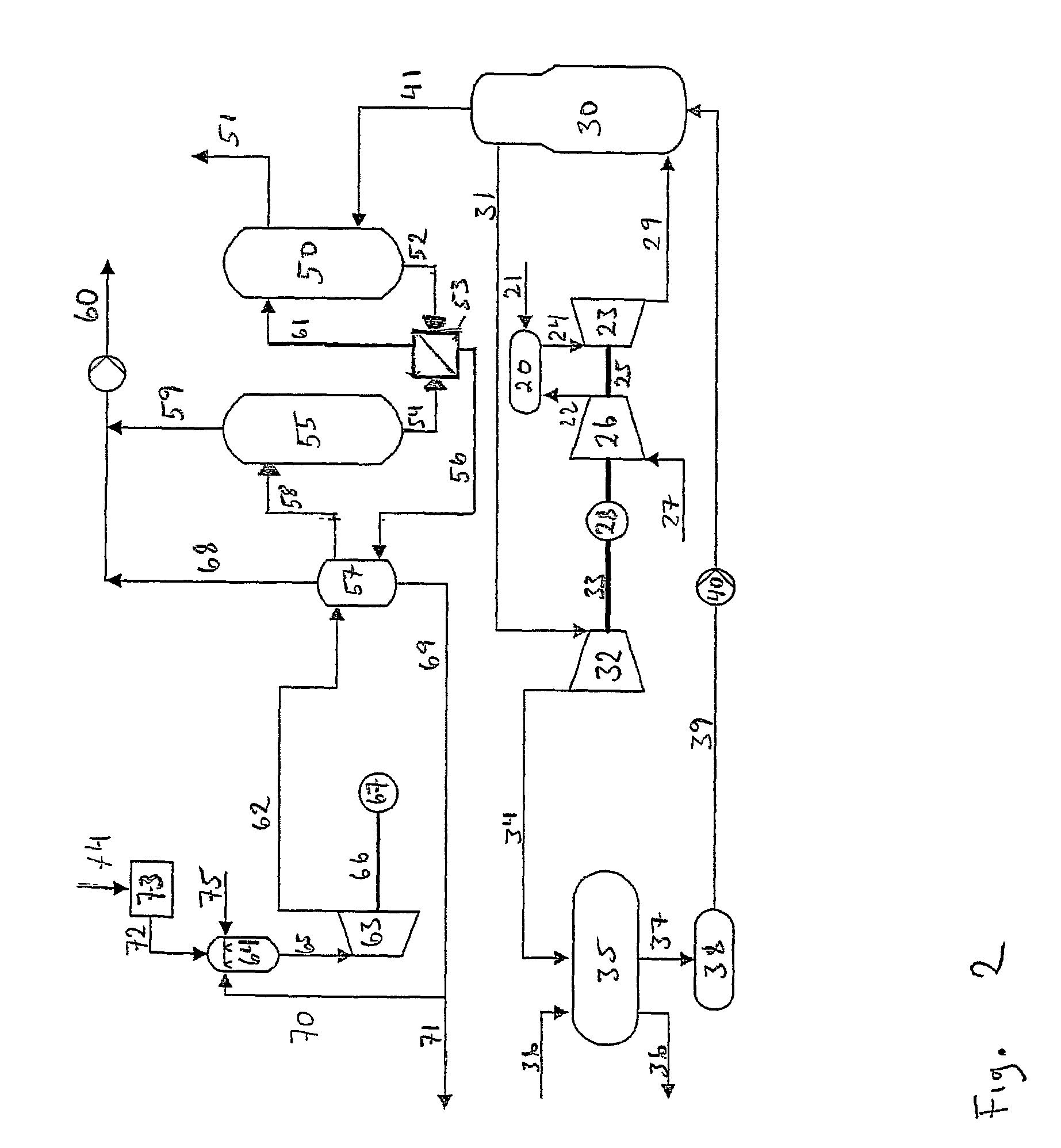

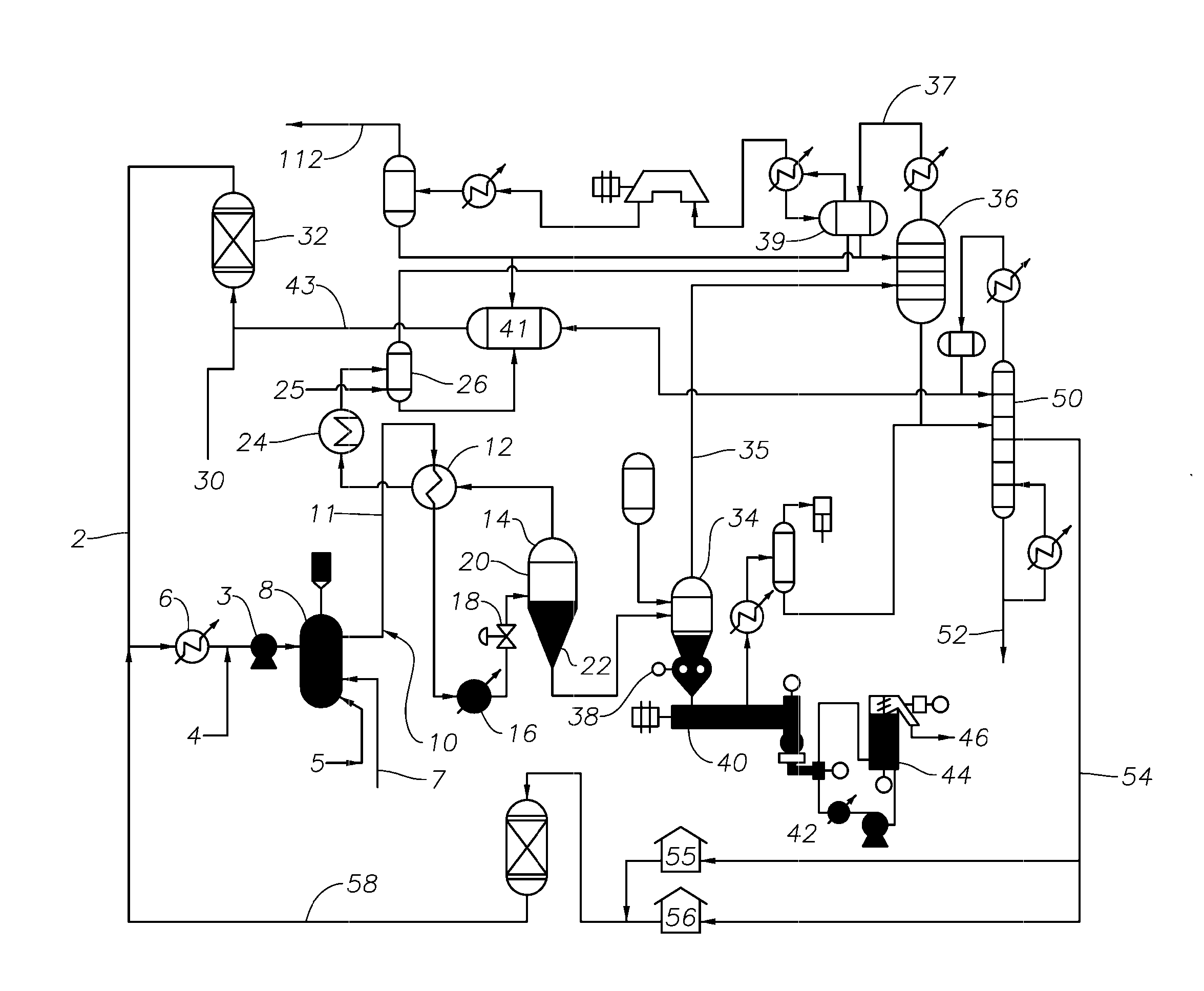

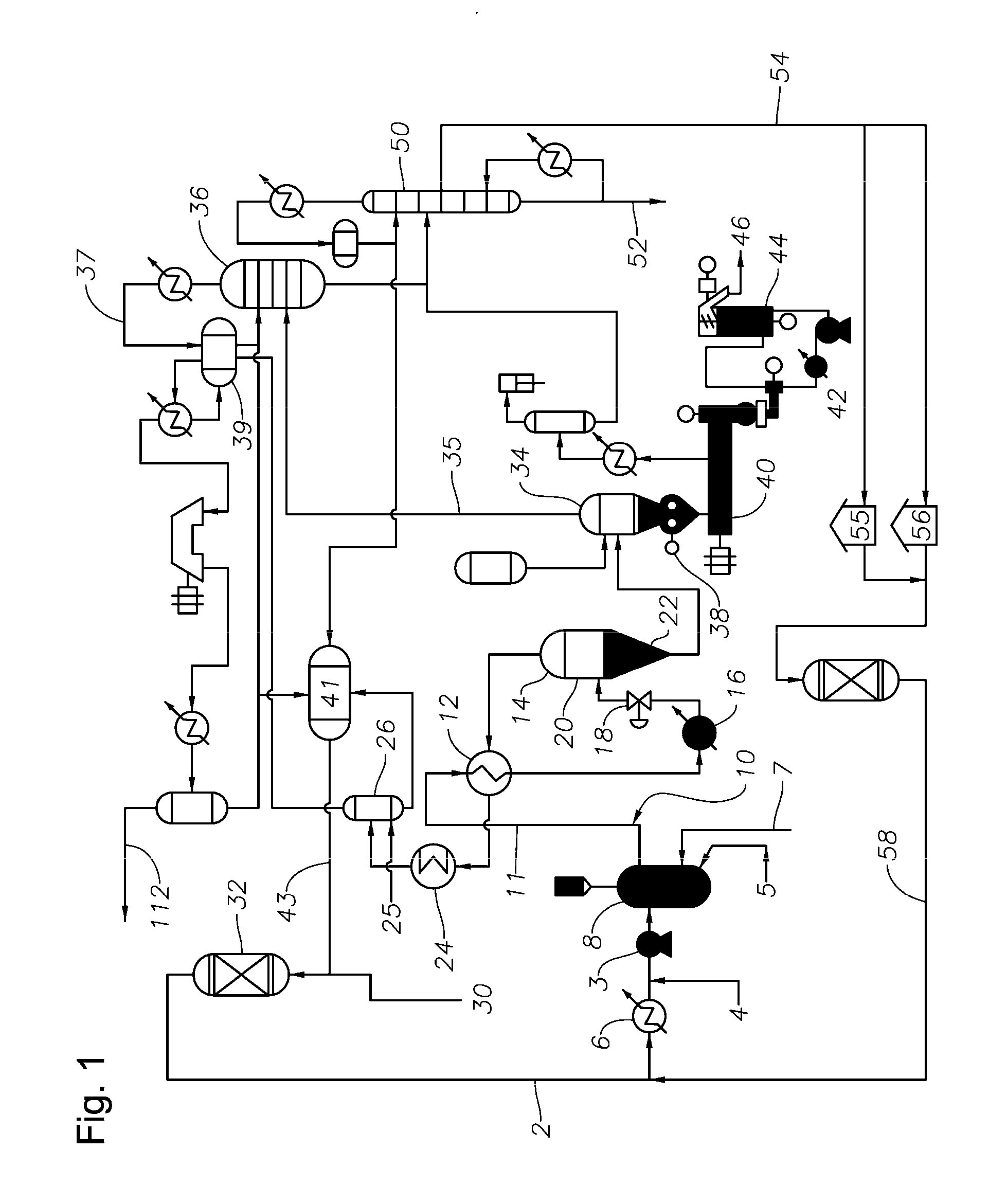

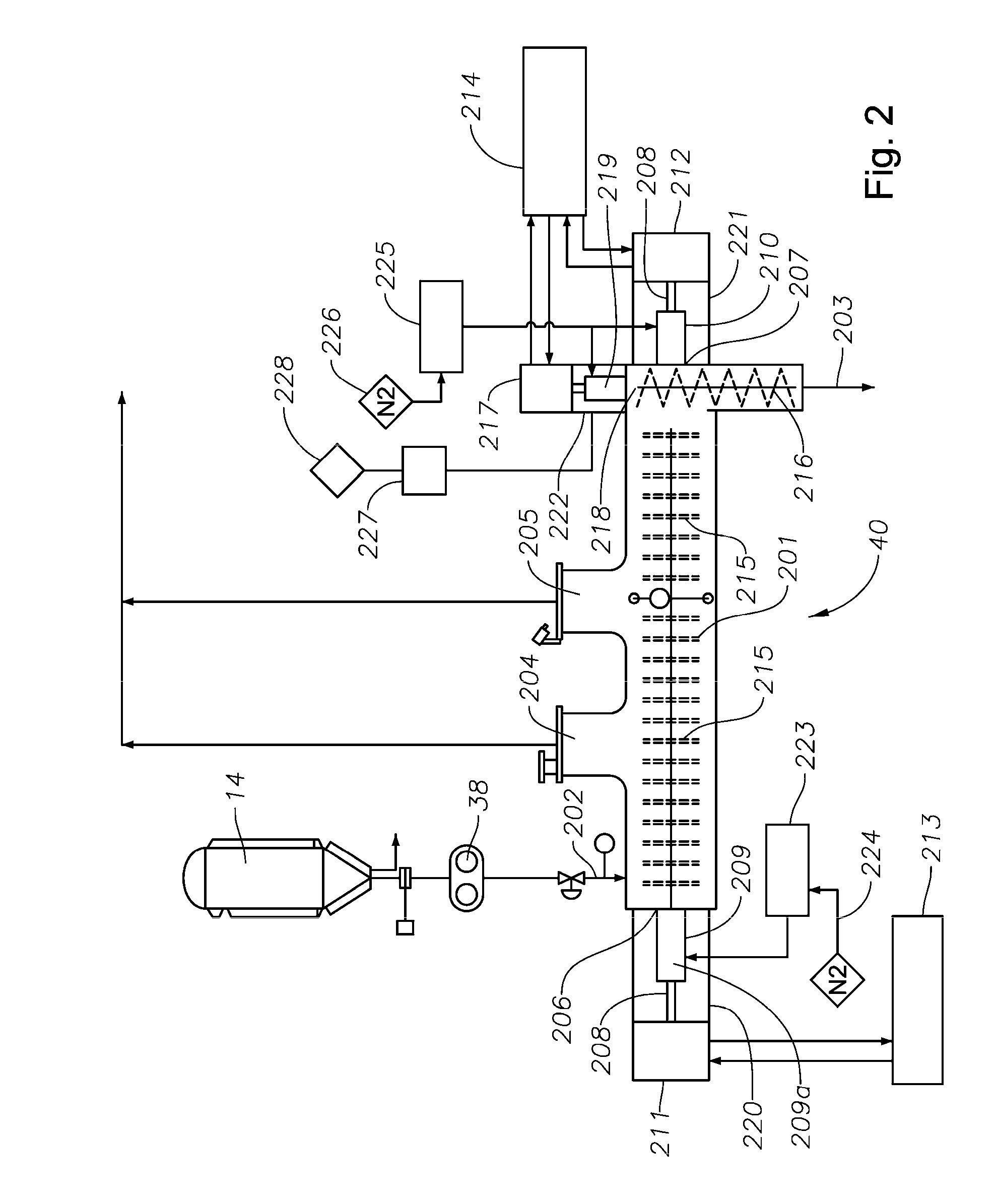

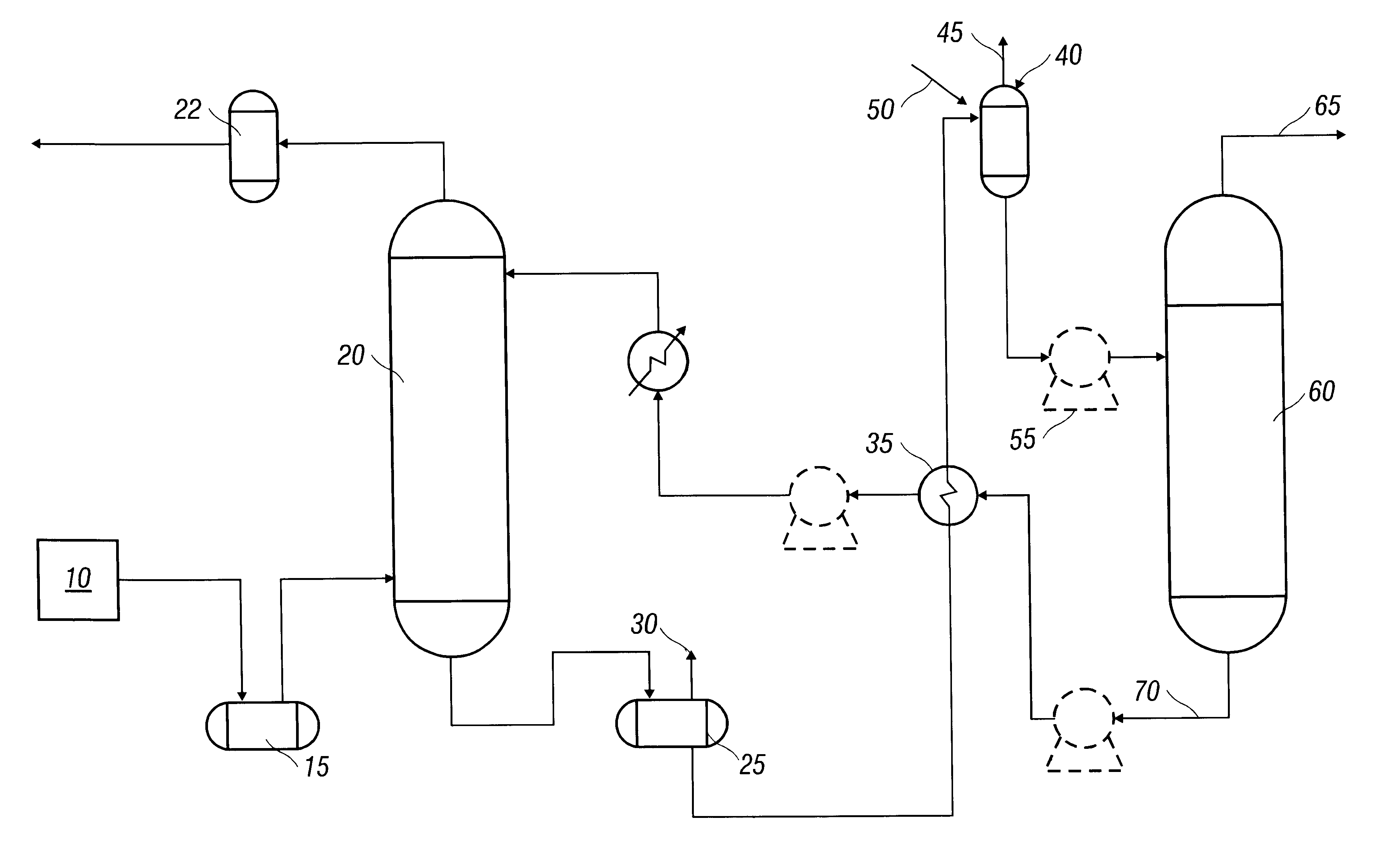

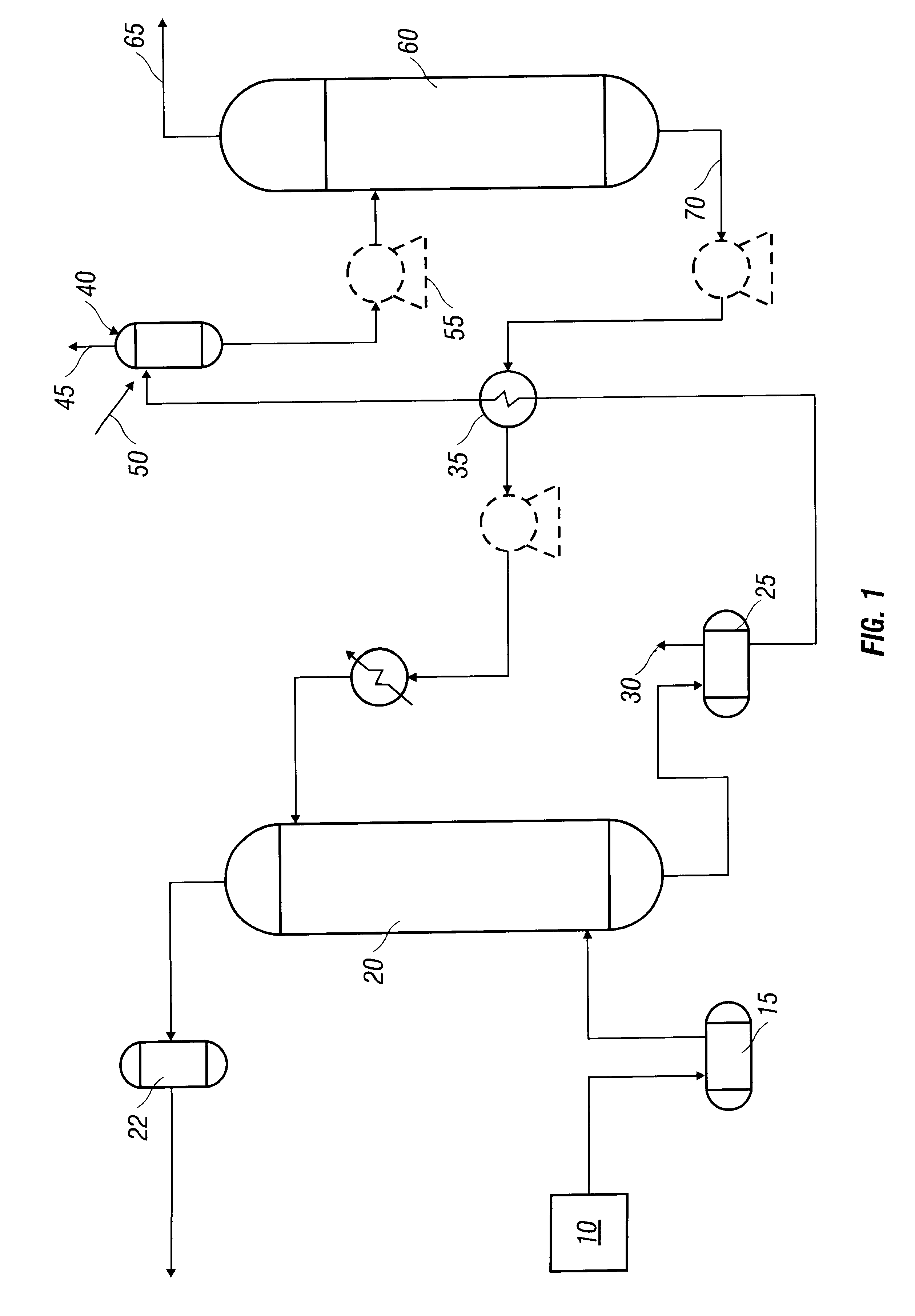

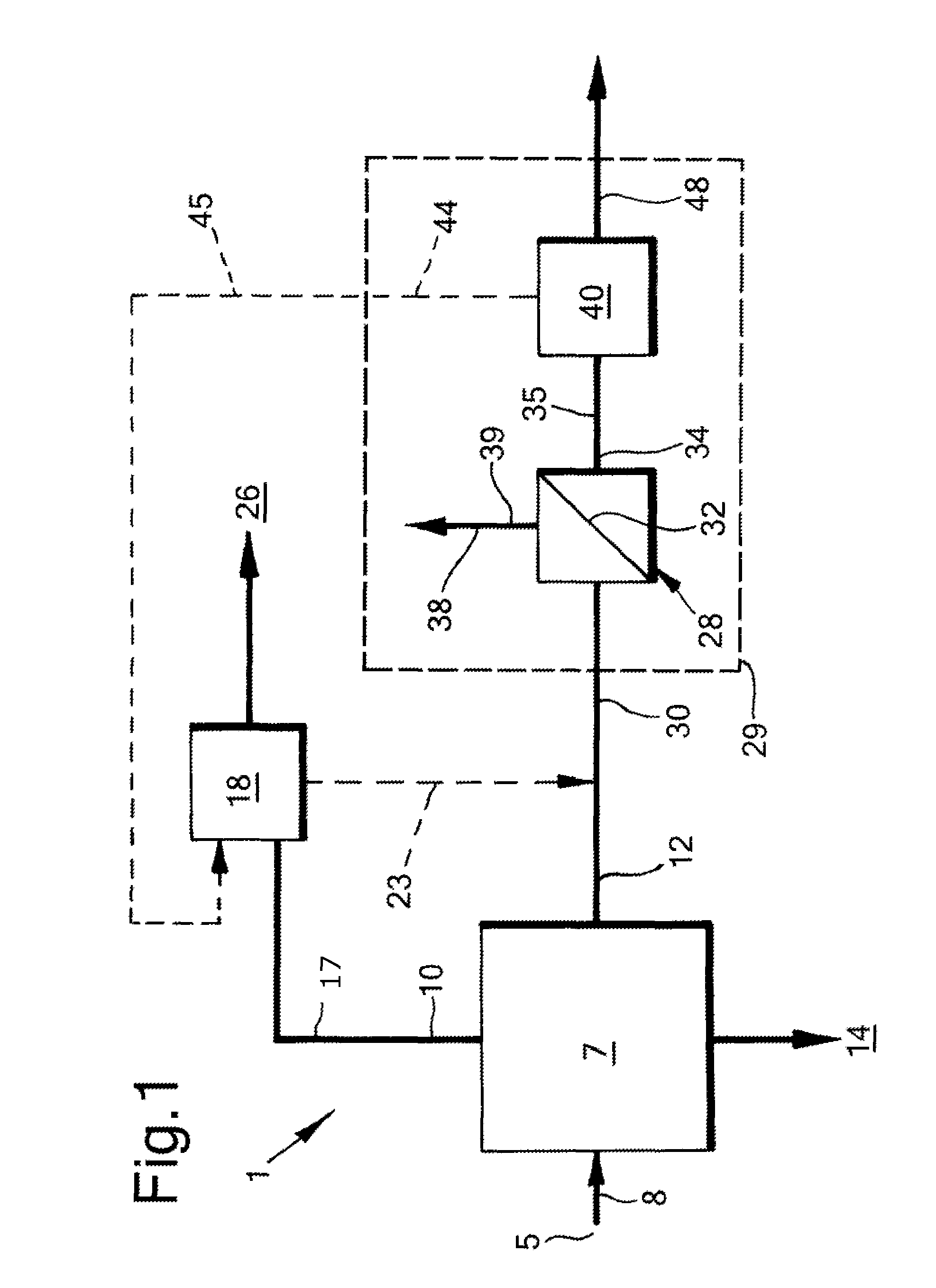

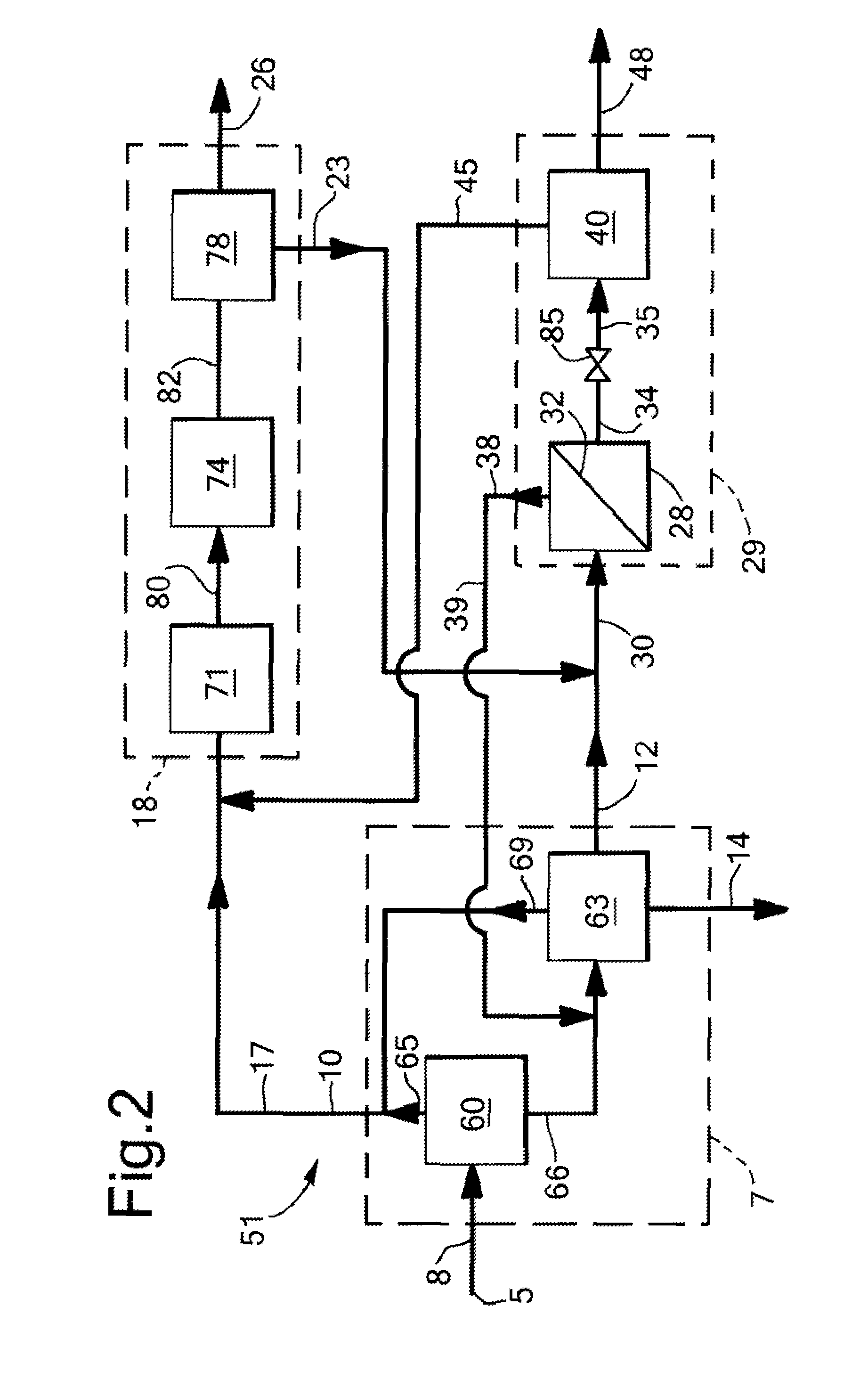

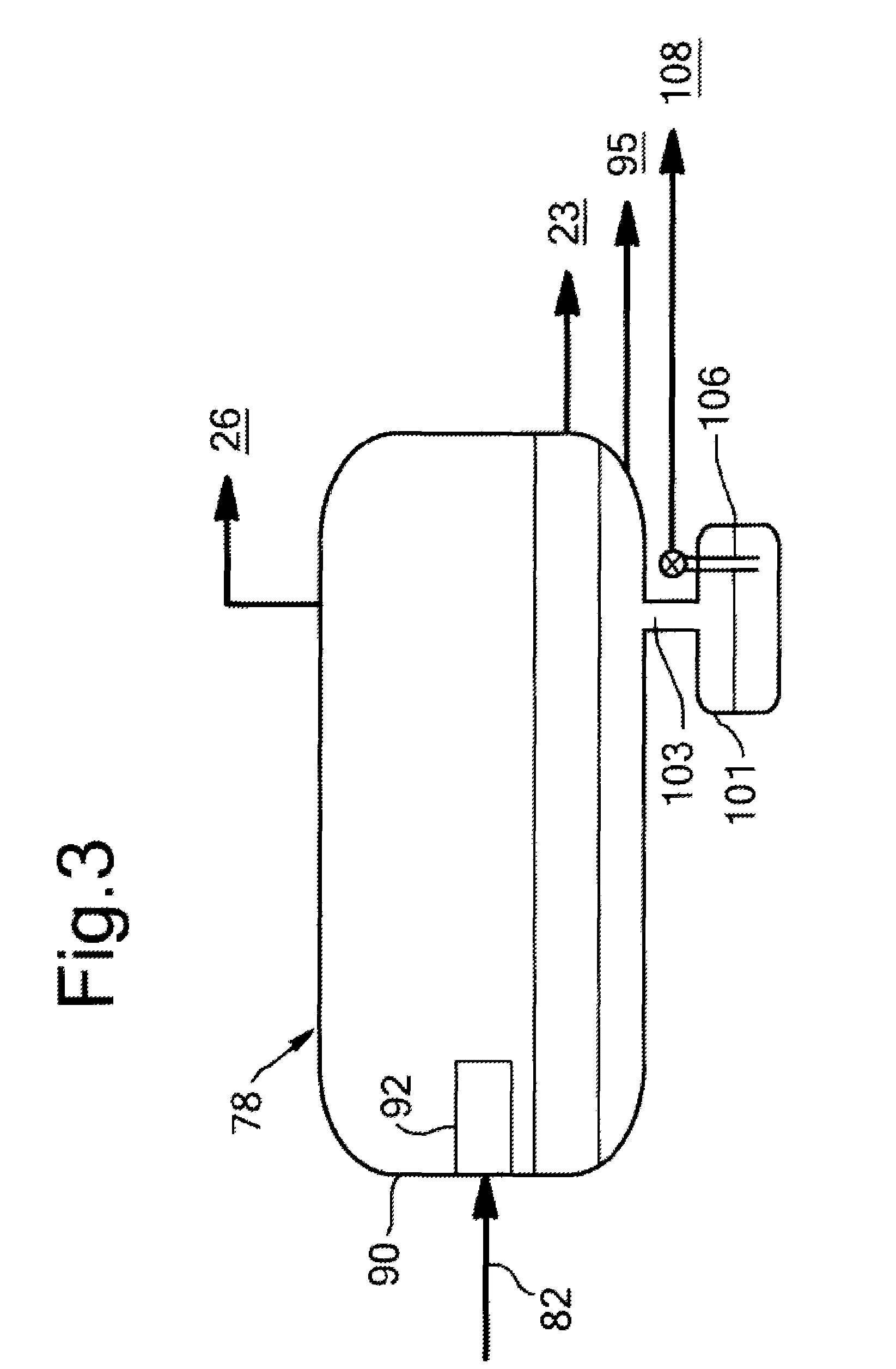

LNG production in cryogenic natural gas processing plants

A process for liquefying natural gas in conjunction with processing natural gas to recover natural gas liquids (NGL) is disclosed. In the process, the natural gas stream to be liquefied is taken from one of the streams in the NGL recovery plant and cooled under pressure to condense it. A distillation stream is withdrawn from the NGL recovery plant to provide some of the cooling required to condense the natural gas stream. The condensed natural gas stream is expanded to an intermediate pressure and supplied to a mid-column feed point on a distillation column. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas, and is routed to the NGL recovery plant so that these heavier hydrocarbons can be recovered in the NGL product. The overhead vapor from the distillation column is cooled and condensed, and a portion of the condensed stream is supplied to a top feed point on the distillation column to serve as reflux. A second portion of the condensed stream is expanded to low pressure to form the liquefied natural gas stream.

Owner:ORTLOFF ENGINEERS

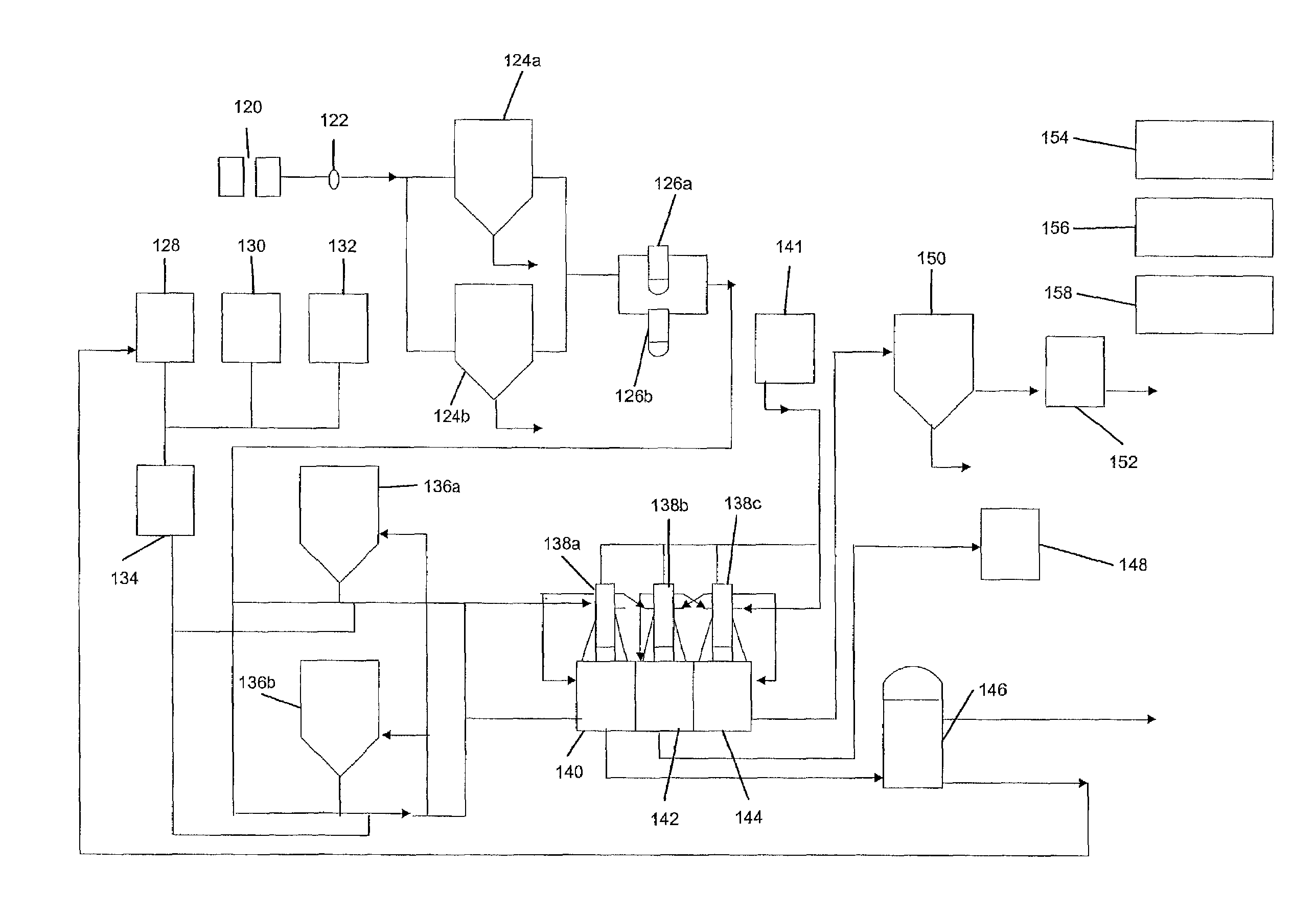

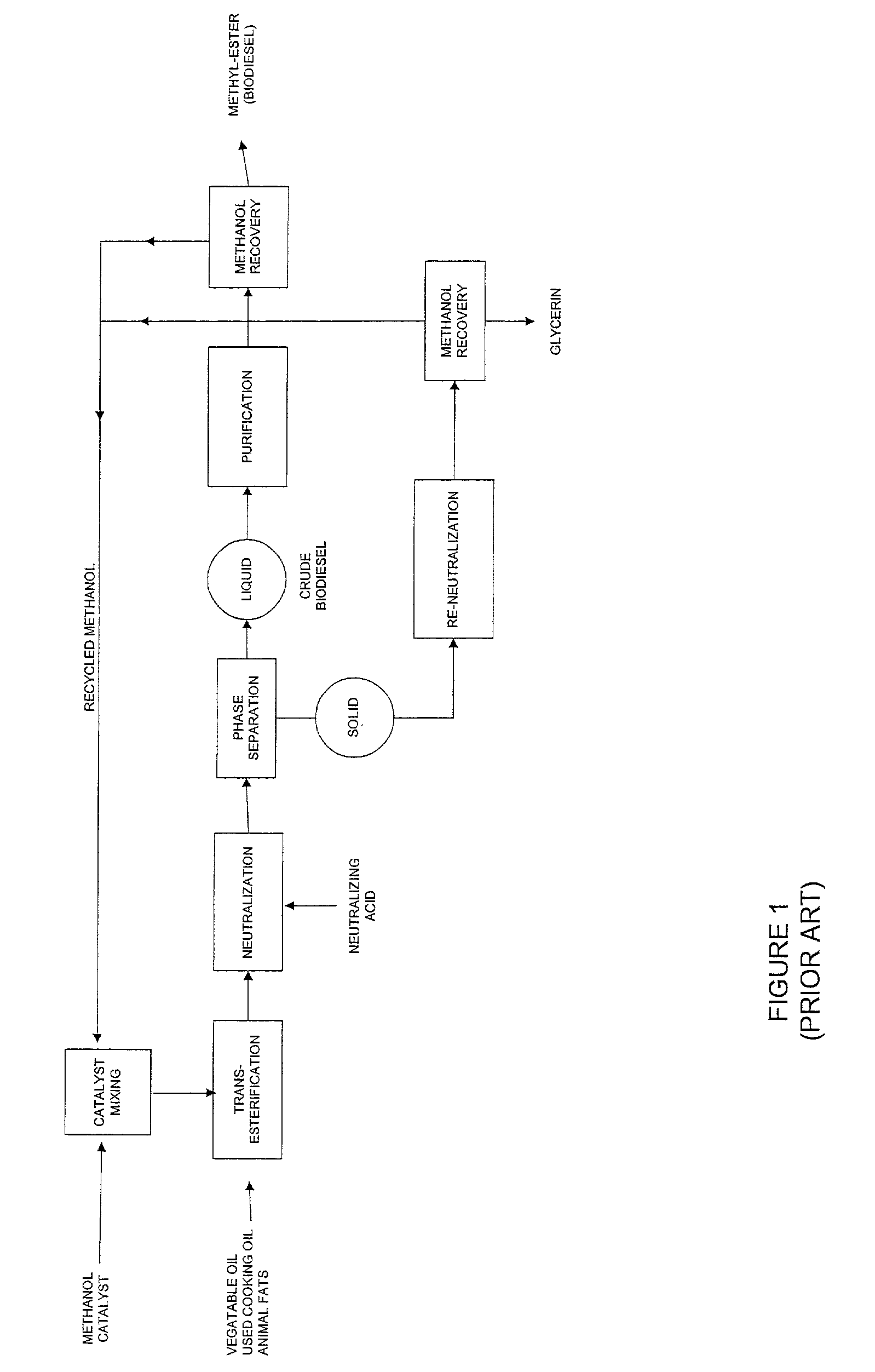

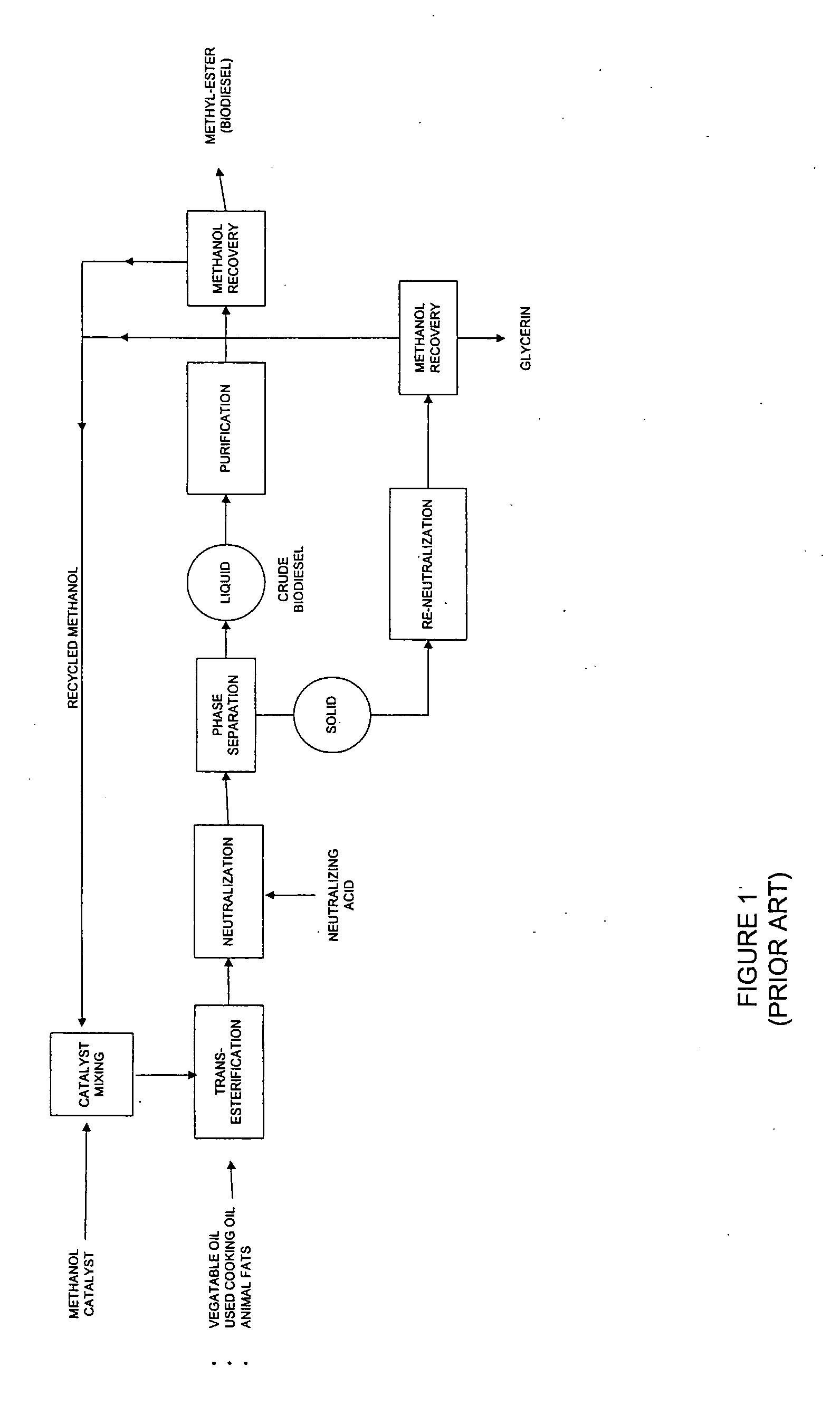

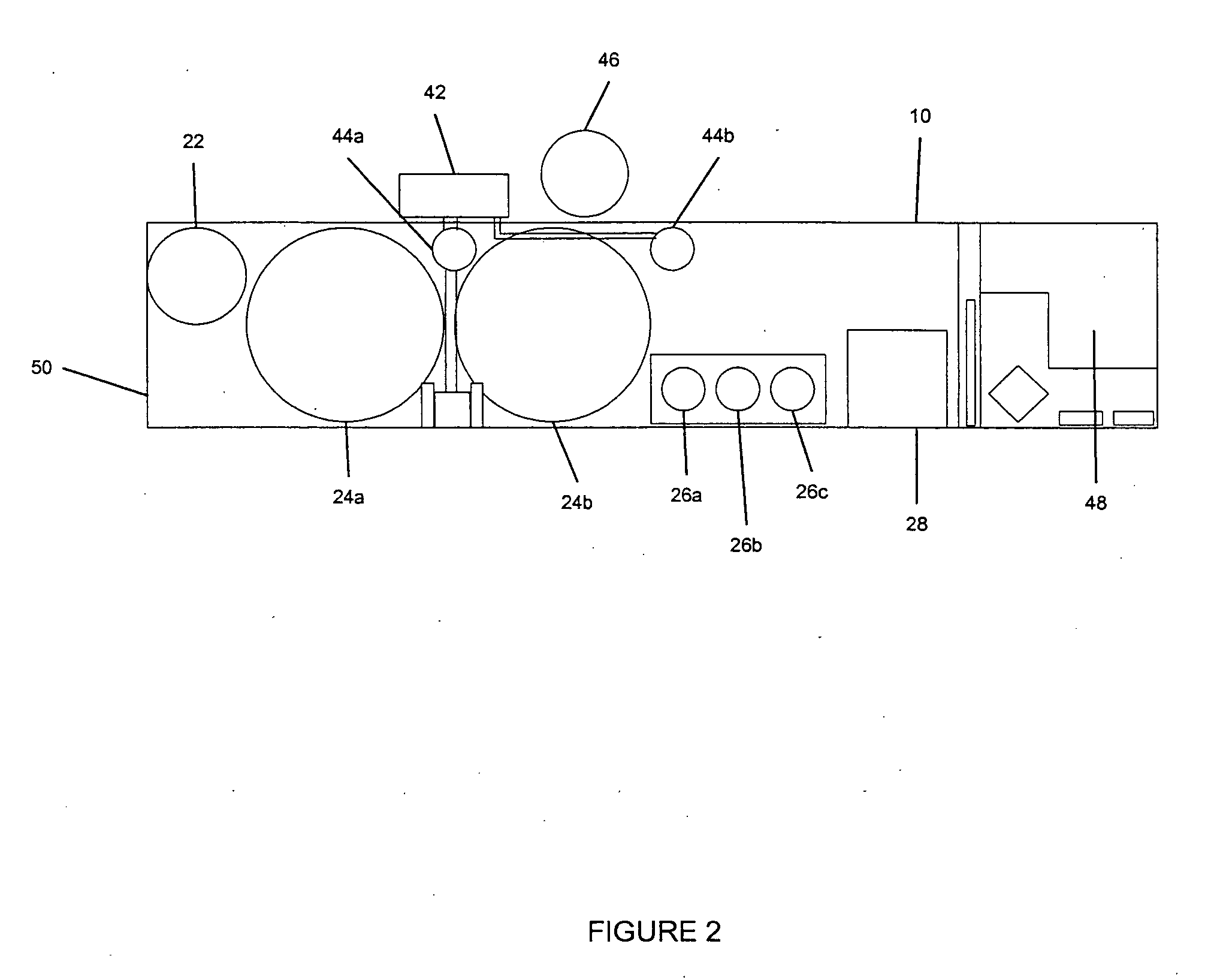

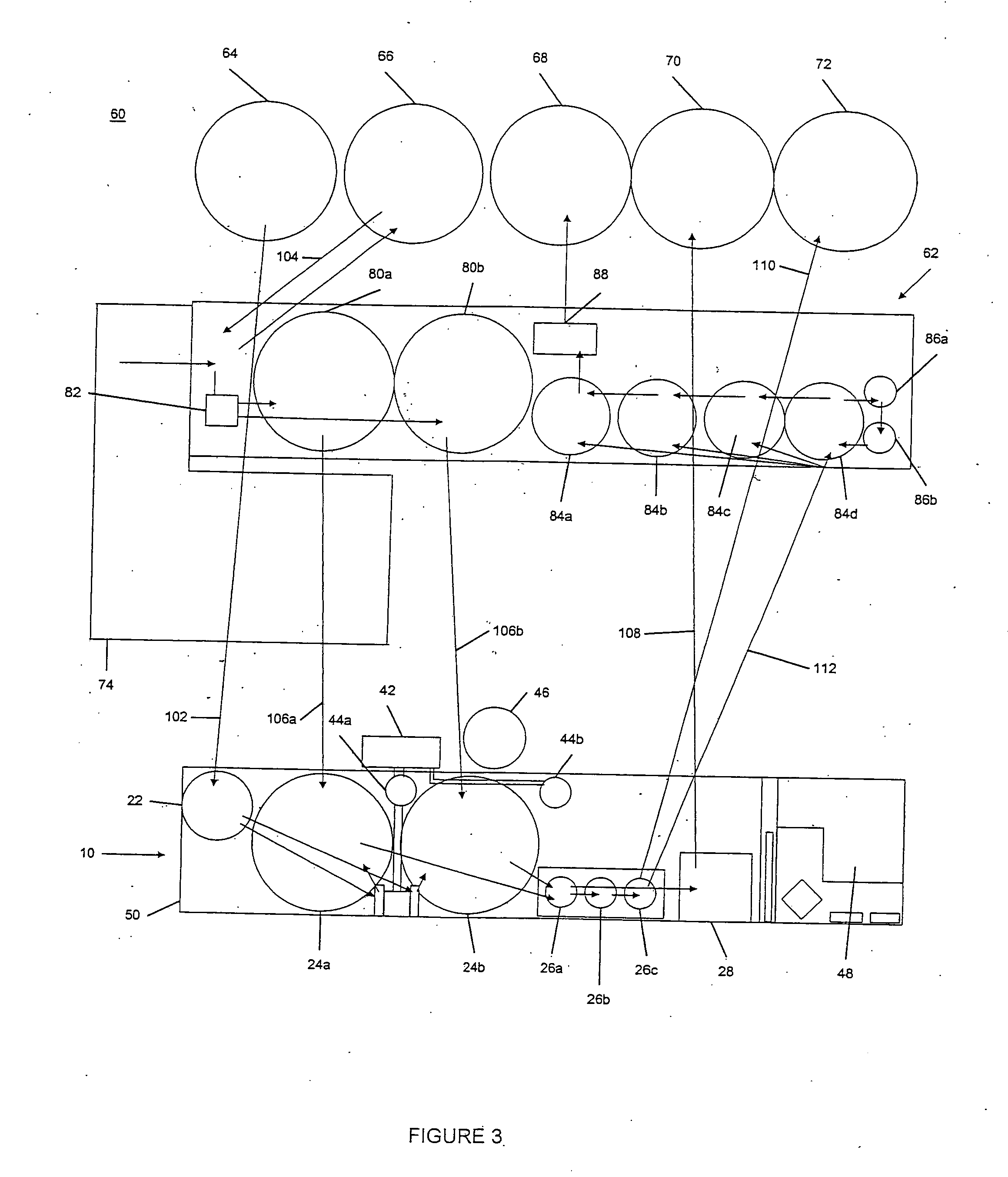

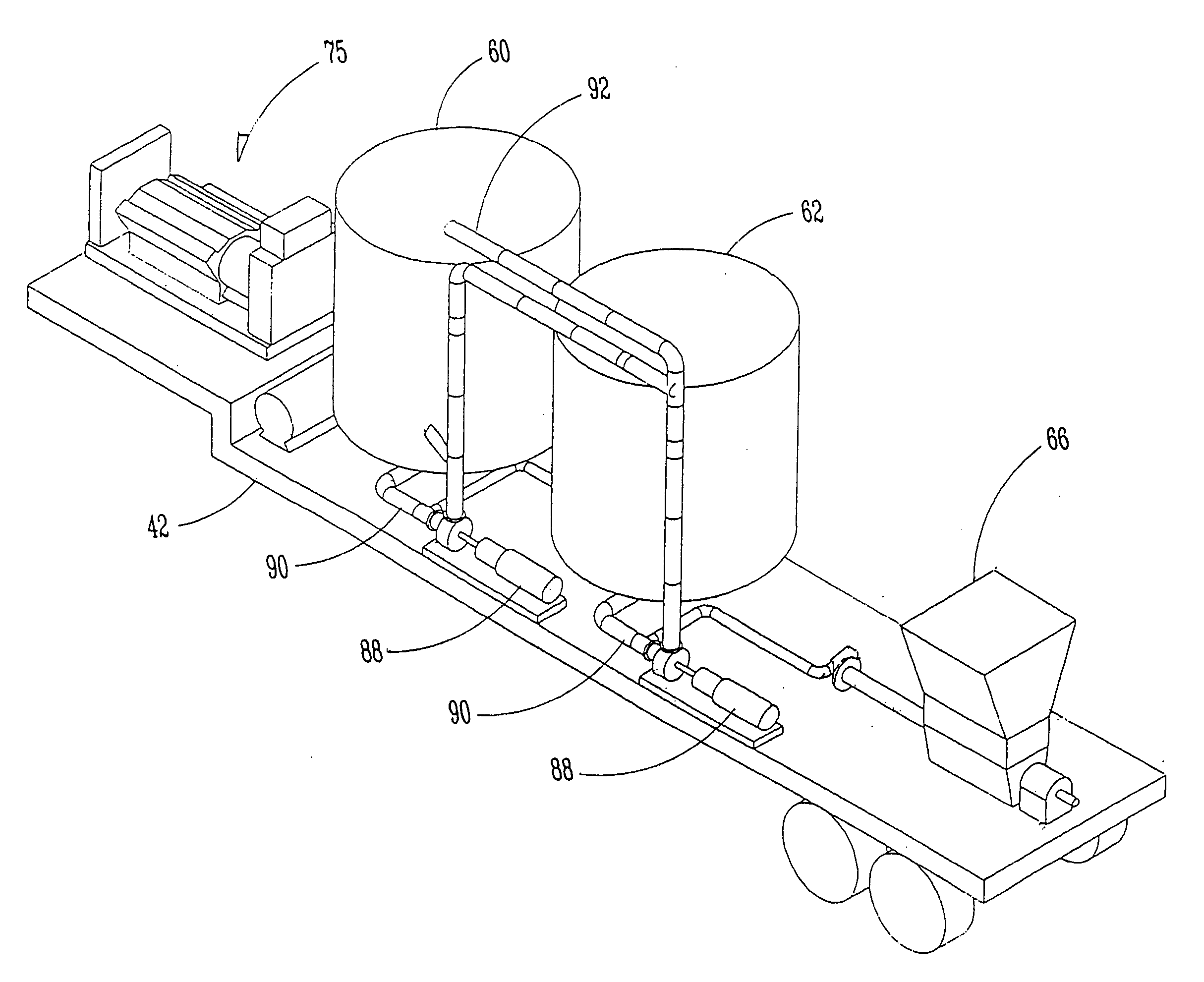

Biodiesel production unit

In a first aspect, systems and methods for producing biodiesel fuel include a modular production unit incorporated onto a single platform or into a housing for ease of relocatability. The modular production unit preferably includes a mixing unit, a reactor unit, a separation unit, a distillation unit, and a filtering unit, all incorporated onto or into a self-contained platform or housing that is able to be easily relocated. In a second aspect, the modular production unit is combined with additional fixed and / or relocatable components to provide a biodiesel processing plant. In a third aspect, a raw materials processing system and method includes a roller barrel adapted for recovery, transportation, and introduction of recycled oil feedstock into a biodiesel manufacturing process. The raw materials processing system preferably includes a hot box for filtering and heating the raw recycled oil feedstock.

Owner:BIODIESEL IND

Unified web-based system for the delivery, scoring, and reporting of on-line and paper-based assessments

InactiveUS20060003306A1Reduce processing timePrecise positioningMechanical appliancesError checkThe Internet

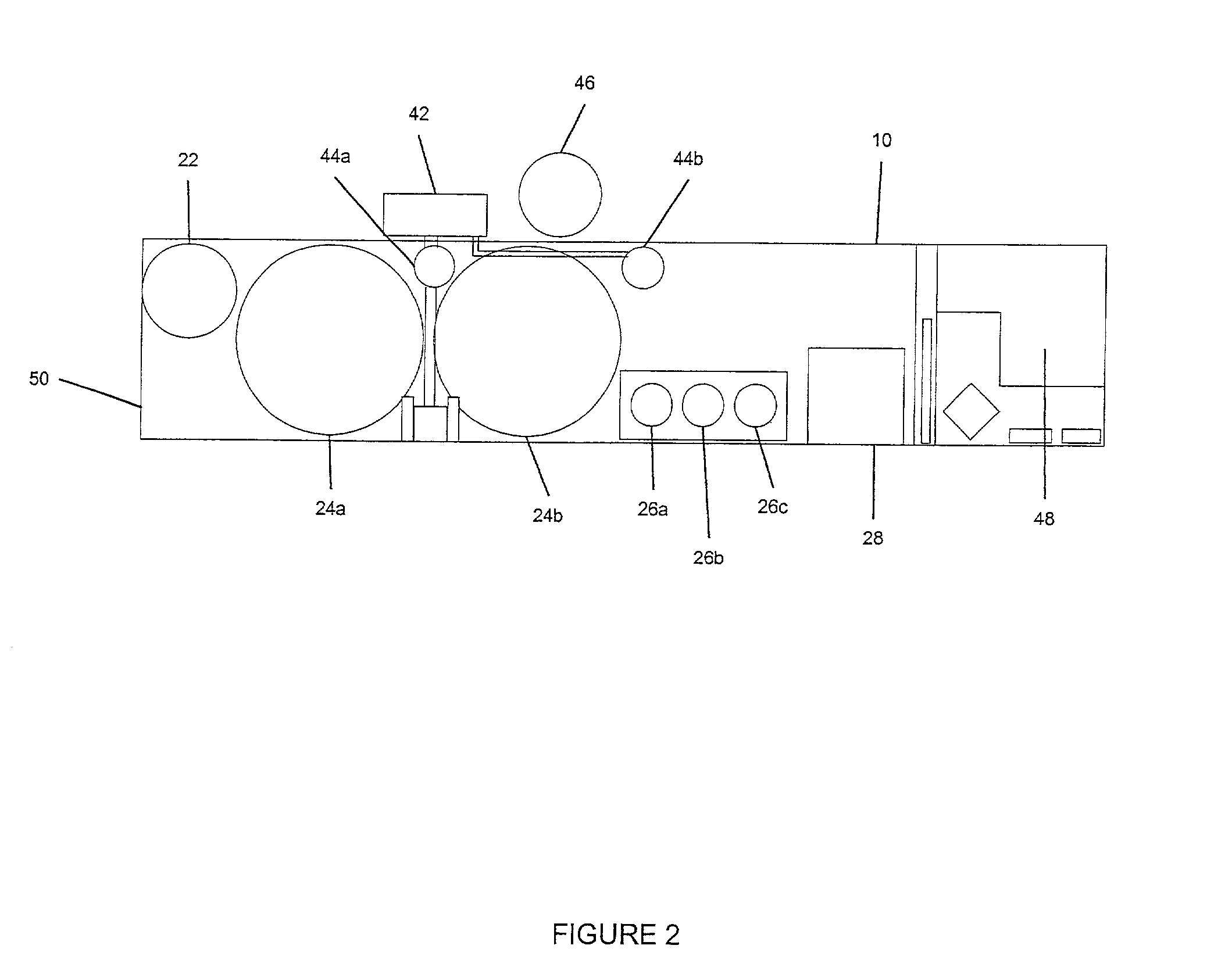

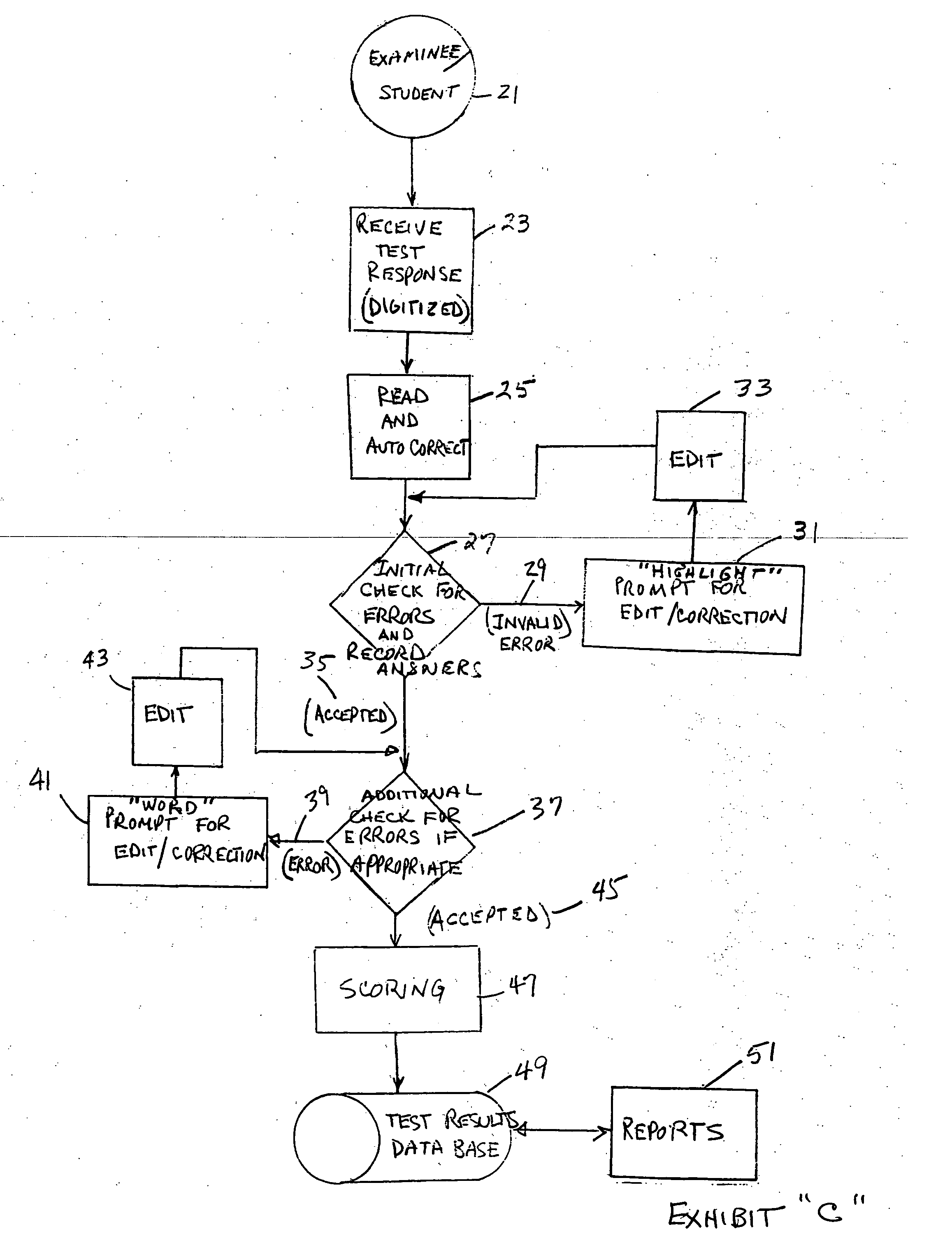

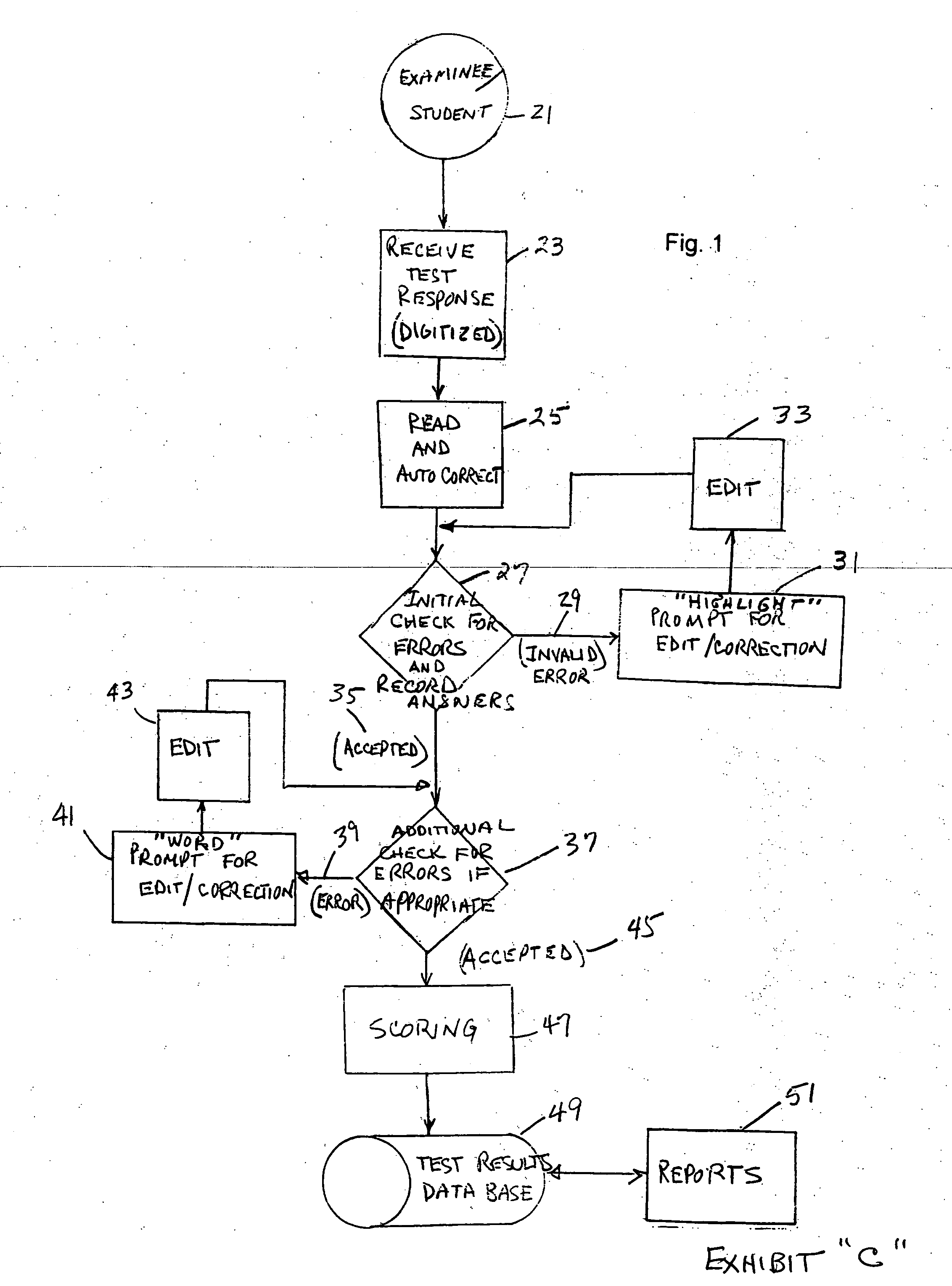

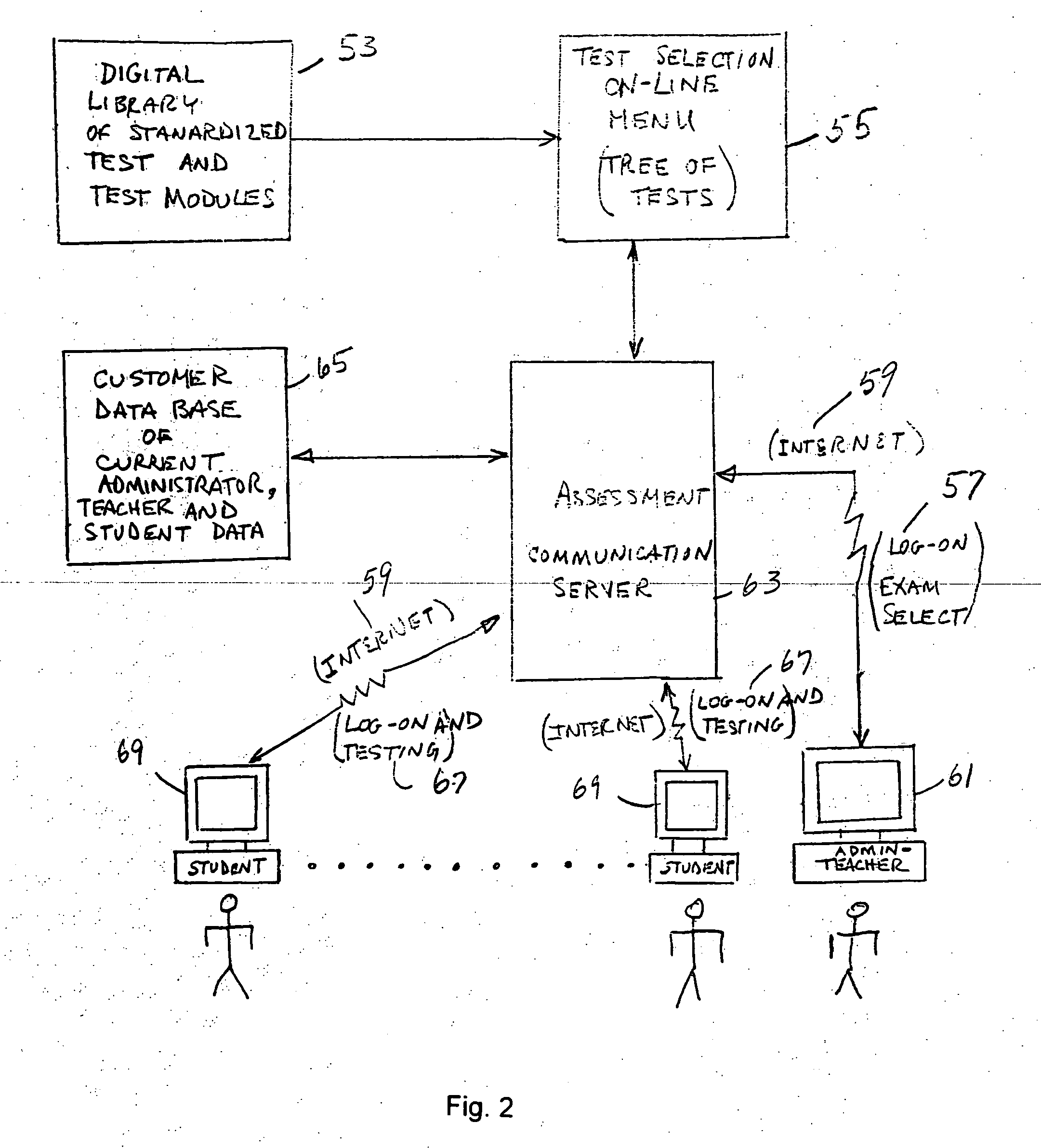

A hardware and software implemented, standardize testing, scoring and reporting system has a network interface, being either LAN or the Internet. A test is selected from a library, assigned to a group of examinees, and a record is made of the assignment. The test is available on-line, or downloaded, or both. Downloaded tests are saved as PDF files and printed into booklets. Examinees record answers on bubble sheets, which are scanned at the customer site or shipped to a processing plant. Individual scanned answer sheets provided data for individual scanned records. Scanning software performs an initial auto-correct and then performs an initial check for errors in scanned records. Tests are batched for later inspection. Scanned records with errors are classified as invalid and the test papers are separated. Prompts are generated for a human test paper inspection and scanned record editing. Accepted batches of scanned records are sent to a scanned records server where a second scanned records error check is performed. Prompts are sent to the appropriate scanning station for further human editing of invalid scanned records. Once all records are valid they are scored and the test results stored in a database, which is accessed by a reporting subsystem associated with an on-line server.

Owner:VANTAGE TECH KNOWLEDGE ASSESSMENT

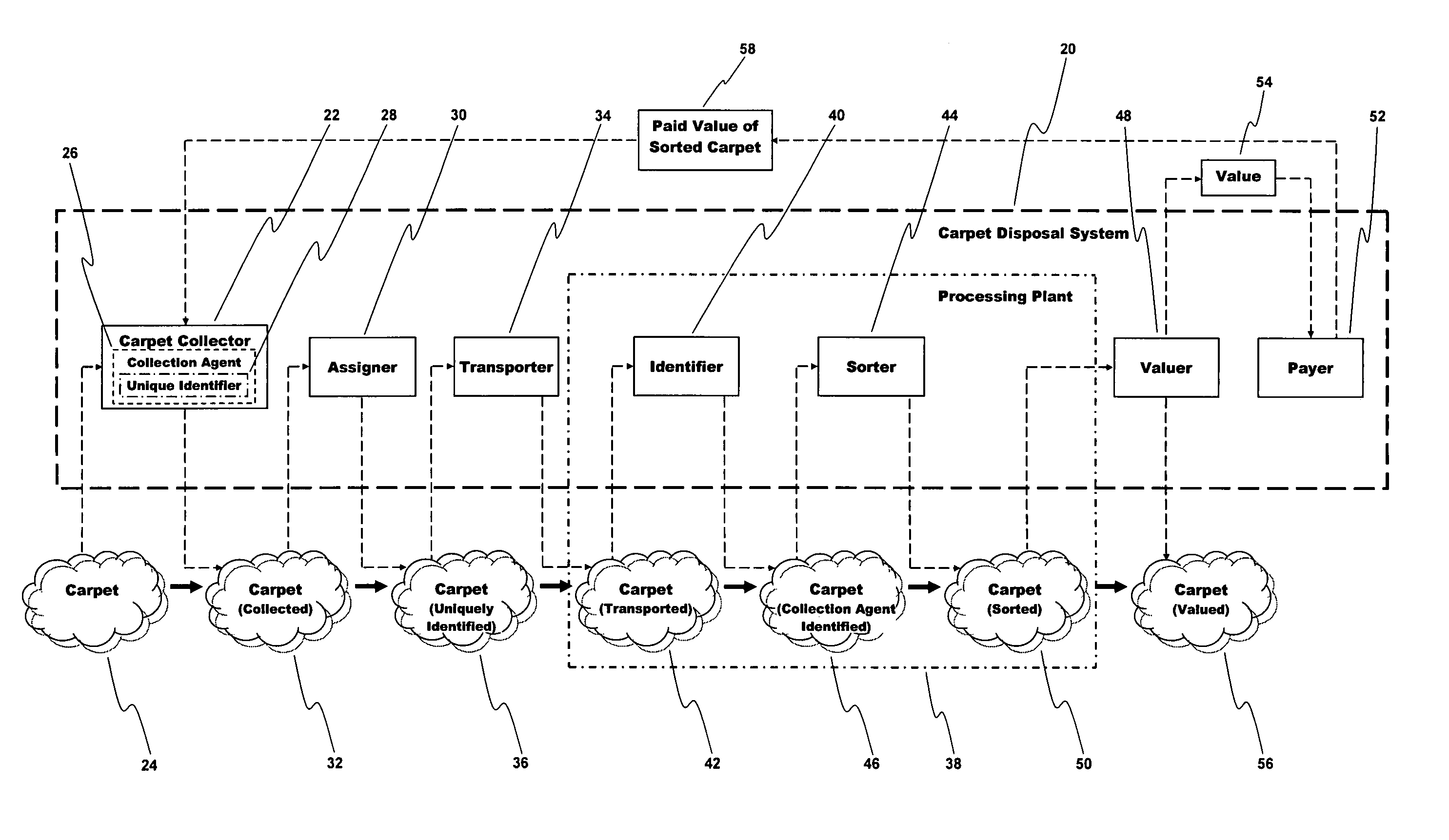

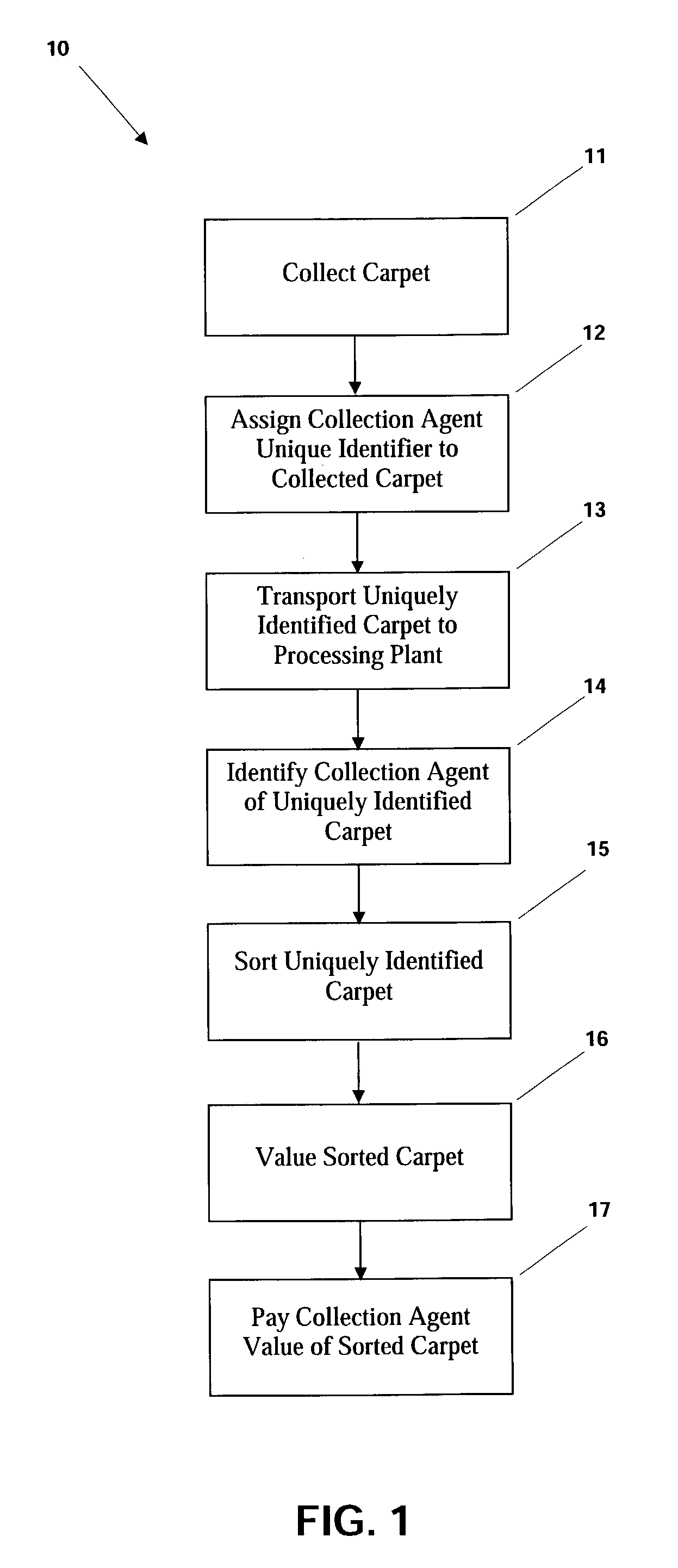

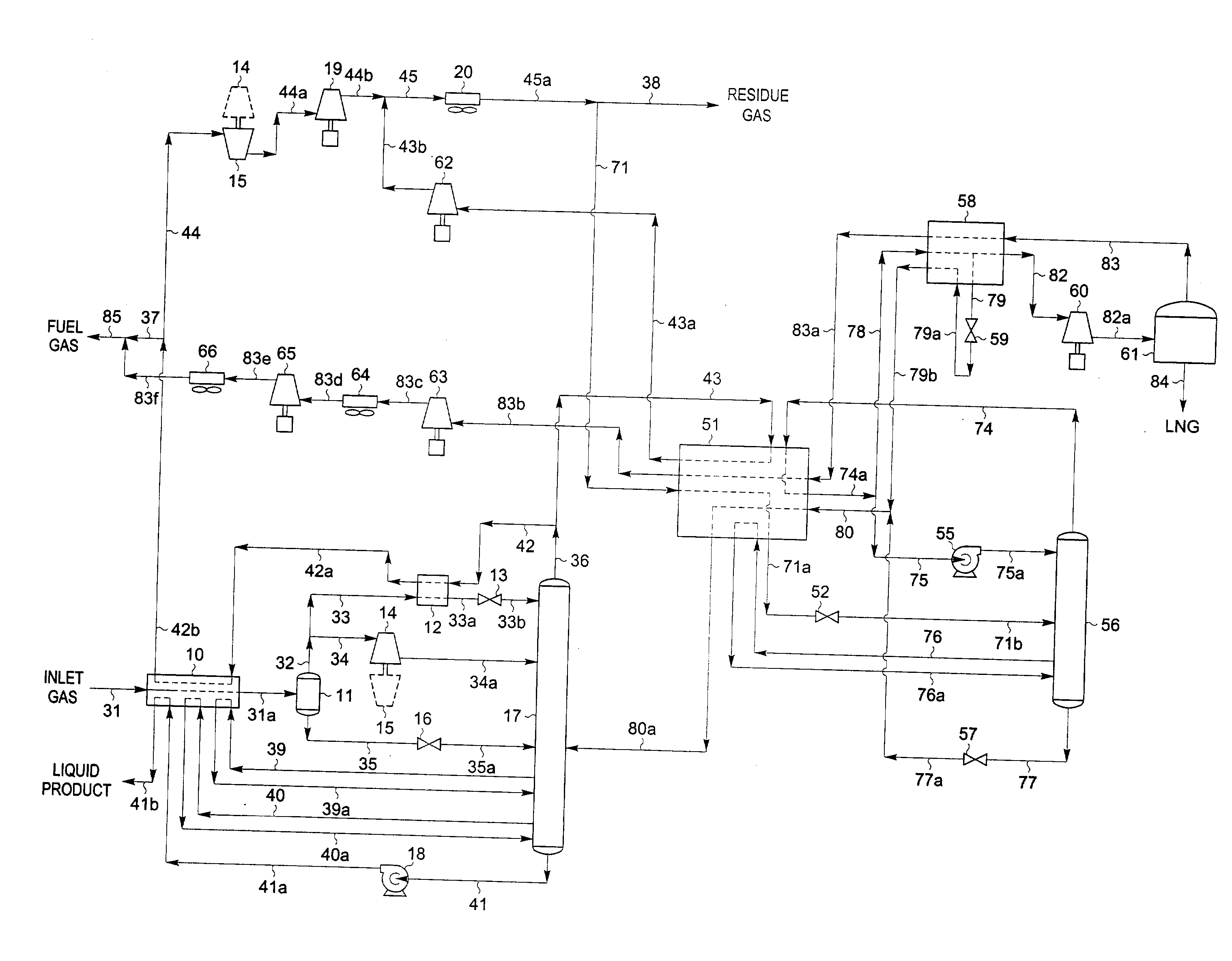

System for gathering discarded post-consumer carpet, for recycling

InactiveUS6953119B1Efficient collectionInteract smoothly and efficientlyPlastic recyclingCharacter and pattern recognitionUnique identifierHandling system

A carpet disposal method, comprising: collecting carpet, performed by a collection agent having a unique identifier; assigning the collection agent unique identifier to the collected carpet; transporting the uniquely identified carpet to a processing plant; identifying the collection agent of the uniquely identified carpet at the processing plant; sorting the uniquely identified carpet; valuing the sorted carpet; paying the identified collection agent the value of the sorted carpet; and carpet disposal system comprising: a carpet collector that collects carpet, a collection agent having a unique identifier; an assigner that assigns the collection agent unique identifier to the collected carpet; a transporter that transports the uniquely identified carpet to a processing plant; an identifier that identifies the collection agent of the uniquely identified carpet; a sorter that sorts the uniquely identified carpet; a valuer that values the sorted carpet; a payer that pays the identified collection agent the sorted carpet value.

Owner:ENVIRONX

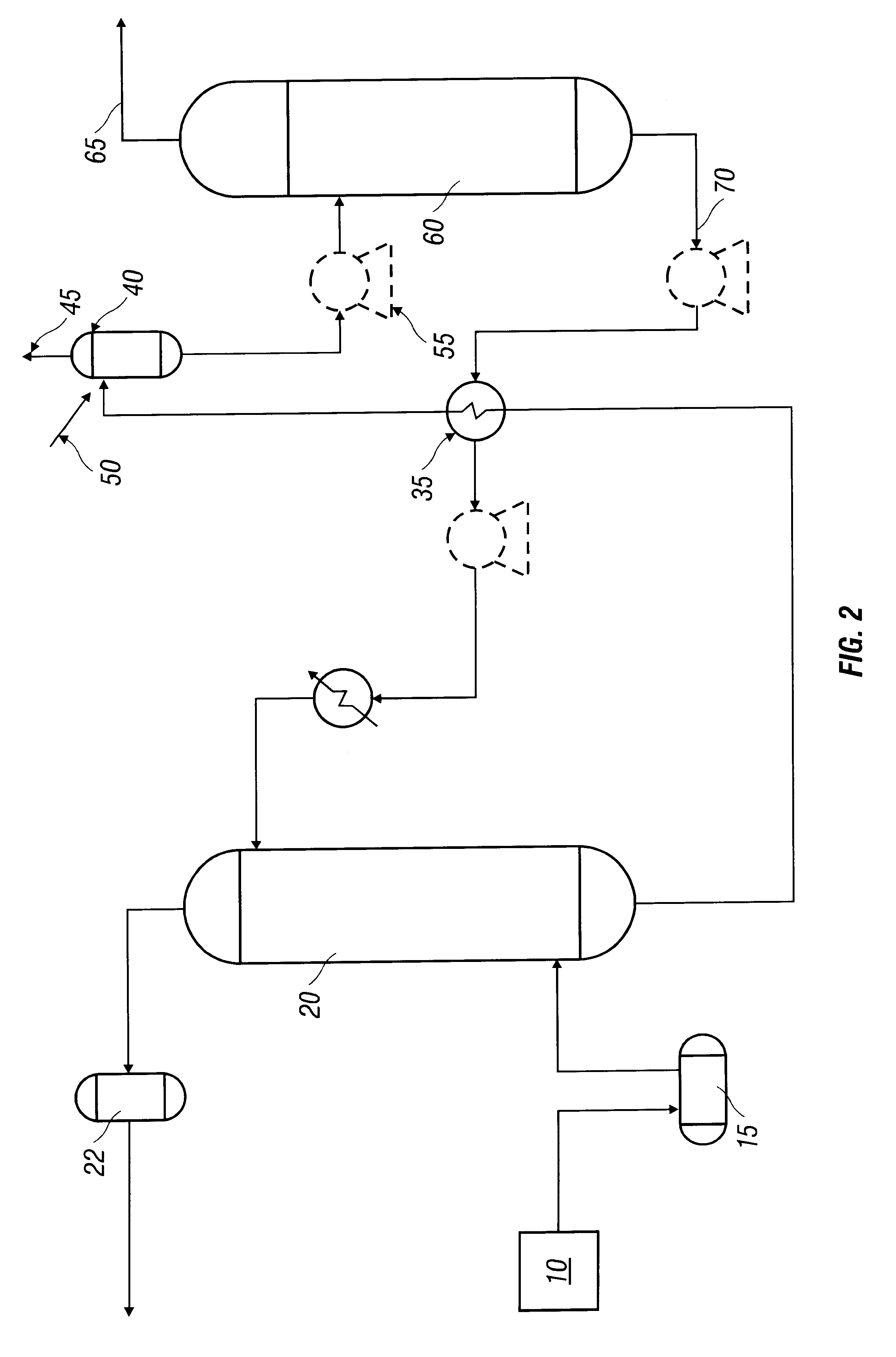

LNG production in cryogenic natural gas processing plants

A process for liquefying natural gas in conjunction with processing natural gas to recover natural gas liquids (NGL) is disclosed. In the process, the natural gas stream to be liquefied is taken from one of the streams in the NGL recovery plant and cooled under pressure to condense it. A distillation stream is withdrawn from the NGL recovery plant to provide some of the cooling required to condense the natural gas stream. A portion of the condensed stream is expanded to an intermediate pressure and then used to provide some of the cooling required to condense the natural gas stream, and thereafter routed to the NGL recovery plant so that any heavier hydrocarbons it contains can be recovered in the NGL product. The remaining portion of the condensed stream is expanded to low pressure to form the liquefied natural gas stream.

Owner:ORTLOFF ENGINEERS

LNG production in cryogenic natural gas processing plants

InactiveUS6889523B2Improve efficiencyConsiderable capital and operating costSolidificationLiquefactionCompressed natural gasNatural-gas processing

A process for liquefying natural gas in conjunction with processing natural gas to recover natural gas liquids (NGL) is disclosed. In the process, the natural gas stream to be liquefied is taken from one of the streams in the NGL recovery plant and cooled under pressure to condense it. A distillation stream is withdrawn from the NGL recovery plant to provide some of the cooling required to condense the natural gas stream. A portion of the condensed stream is expanded to an intermediate pressure and then used to provide some of the cooling required to condense the natural gas stream, and thereafter routed to the NGL recovery plant so that any heavier hydrocarbons it contains can be recovered in the NGL product. The remaining portion of the condensed stream is expanded to low pressure to form the liquefied natural gas stream.

Owner:ORTLOFF ENGINEERS

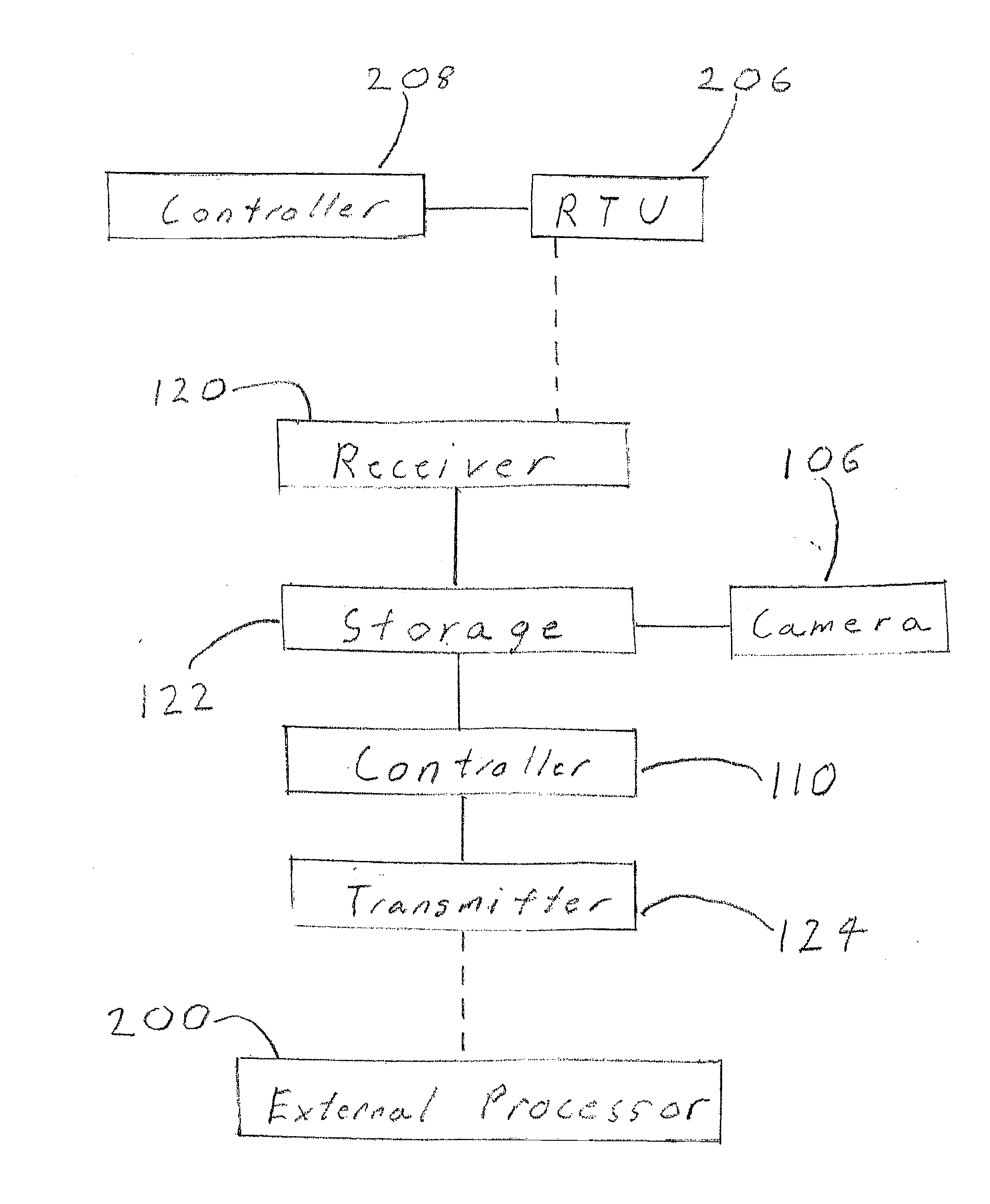

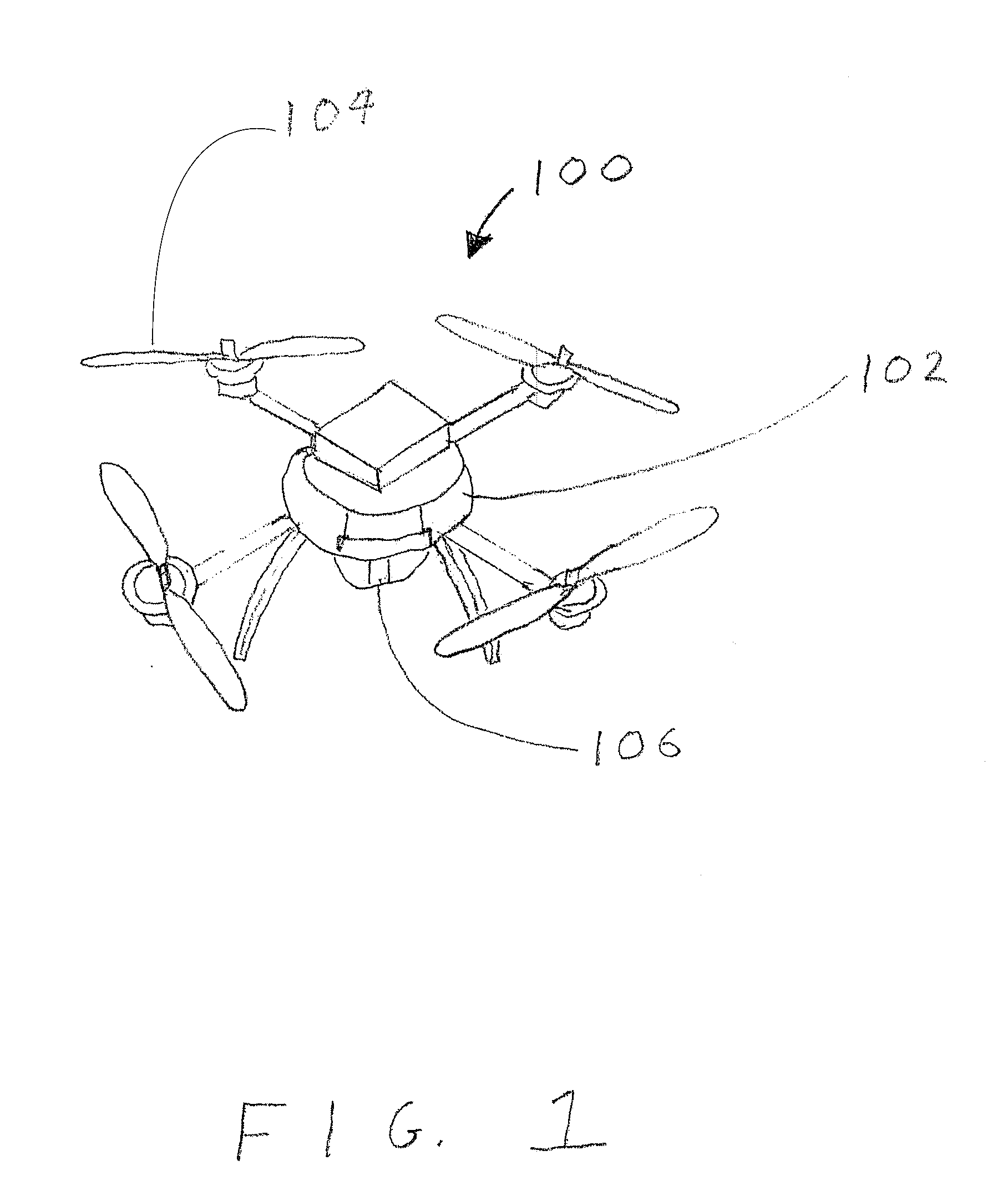

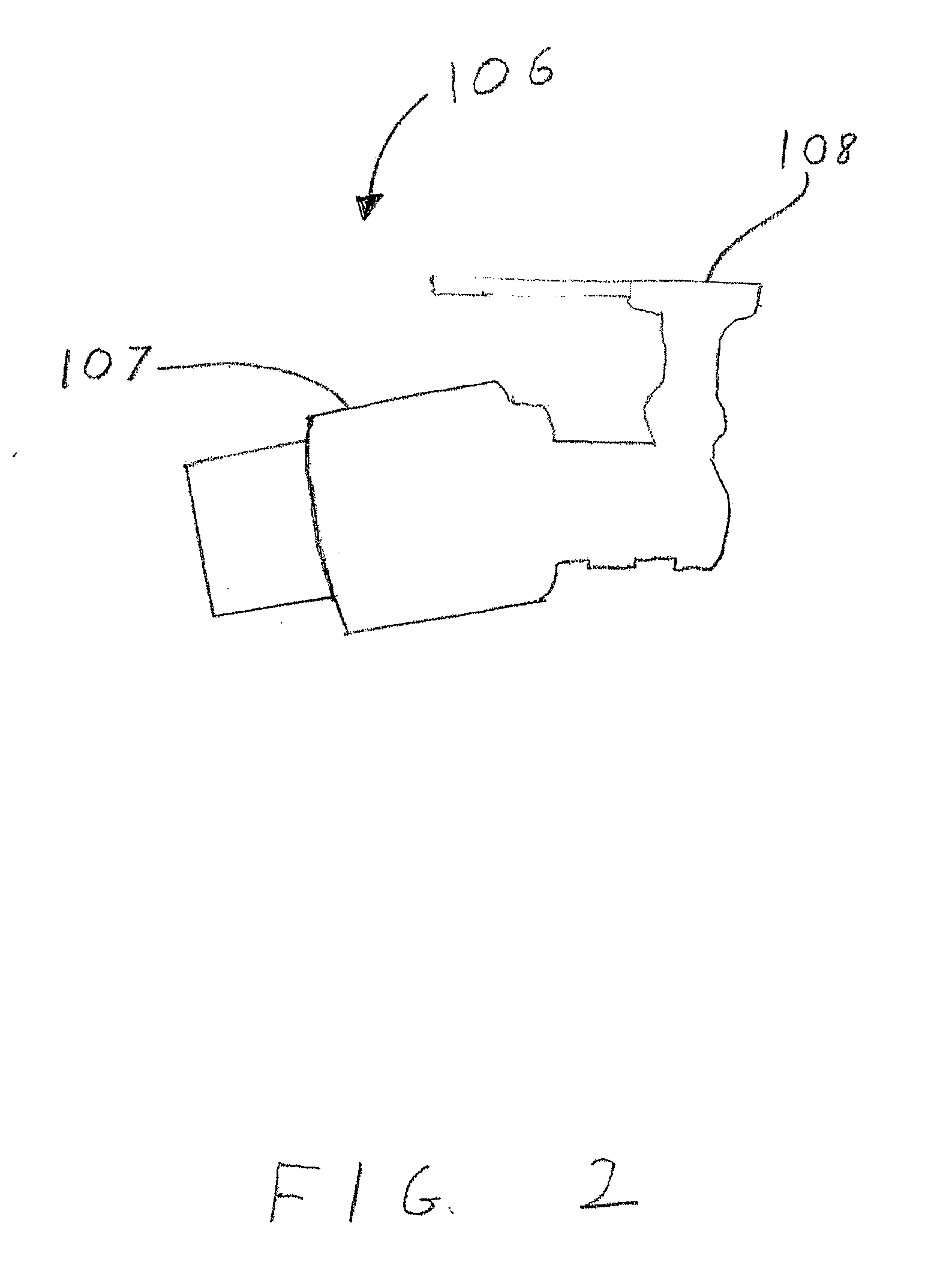

Systems, Methods and Devices for Collecting Data at Remote Oil and Natural Gas Sites

InactiveUS20160144959A1Efficient Safety ManagementAvoid collisionAircraft componentsSamplingParticulatesFeedback control

Systems, methods and devices are provided for collecting operational data at remote oil and natural gas sites, such as wells, and or processing and refinery plants. One such system comprises a remote transmitter and / or controller at the site and an unmanned aerial vehicle (UAV), such as a drone aircraft, configured for aerial dispatch to the remote site and wireless connection to the remote transmitter for subsequent relay or upload of data to an external processor. The UAV may include still or video cameras for collecting images around the well site that can be uploaded and transmitted to the external processor. The system may also include logic-based applications allowing for feedback control of the well site to change operational parameters based on the received data. The system may also include a variety of sophisticated sensor devices on the UAV or located at the remote site to collect additional operational data, such as airborne particulate and / or toxic gas concentrations, audio files of pumps or other equipment and levels and properties of produced water and other fluids.

Owner:OIL & GAS IT LLC

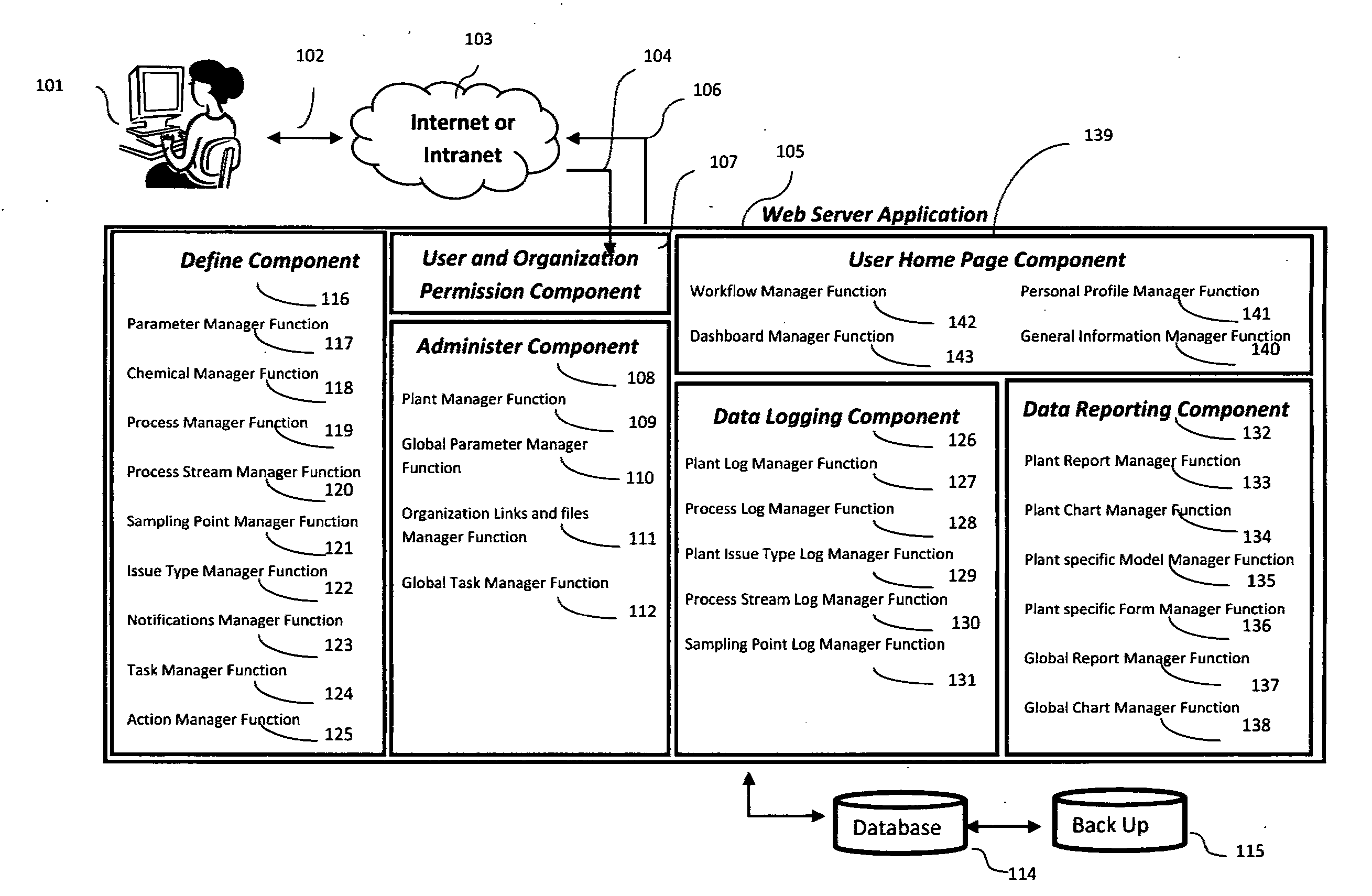

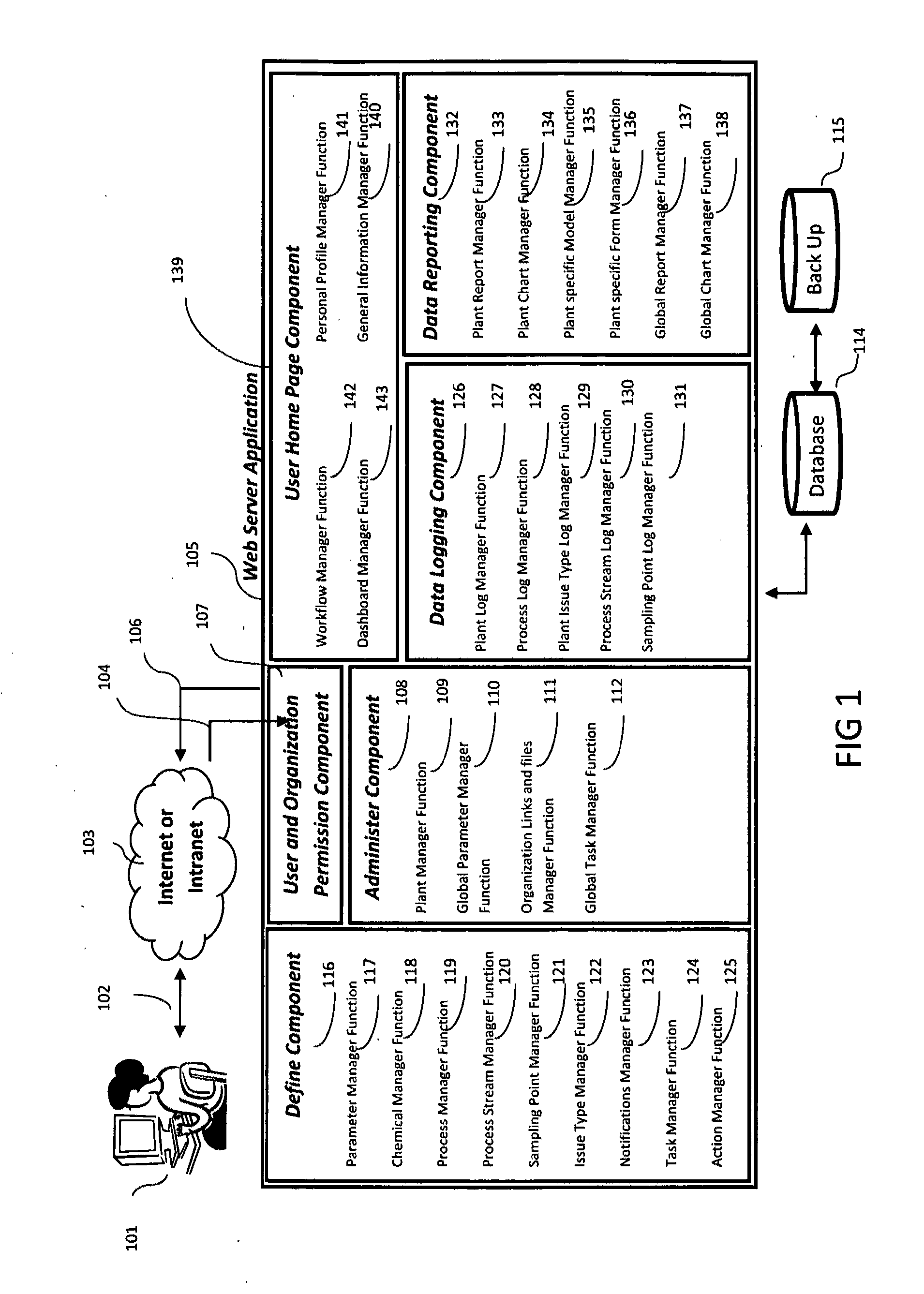

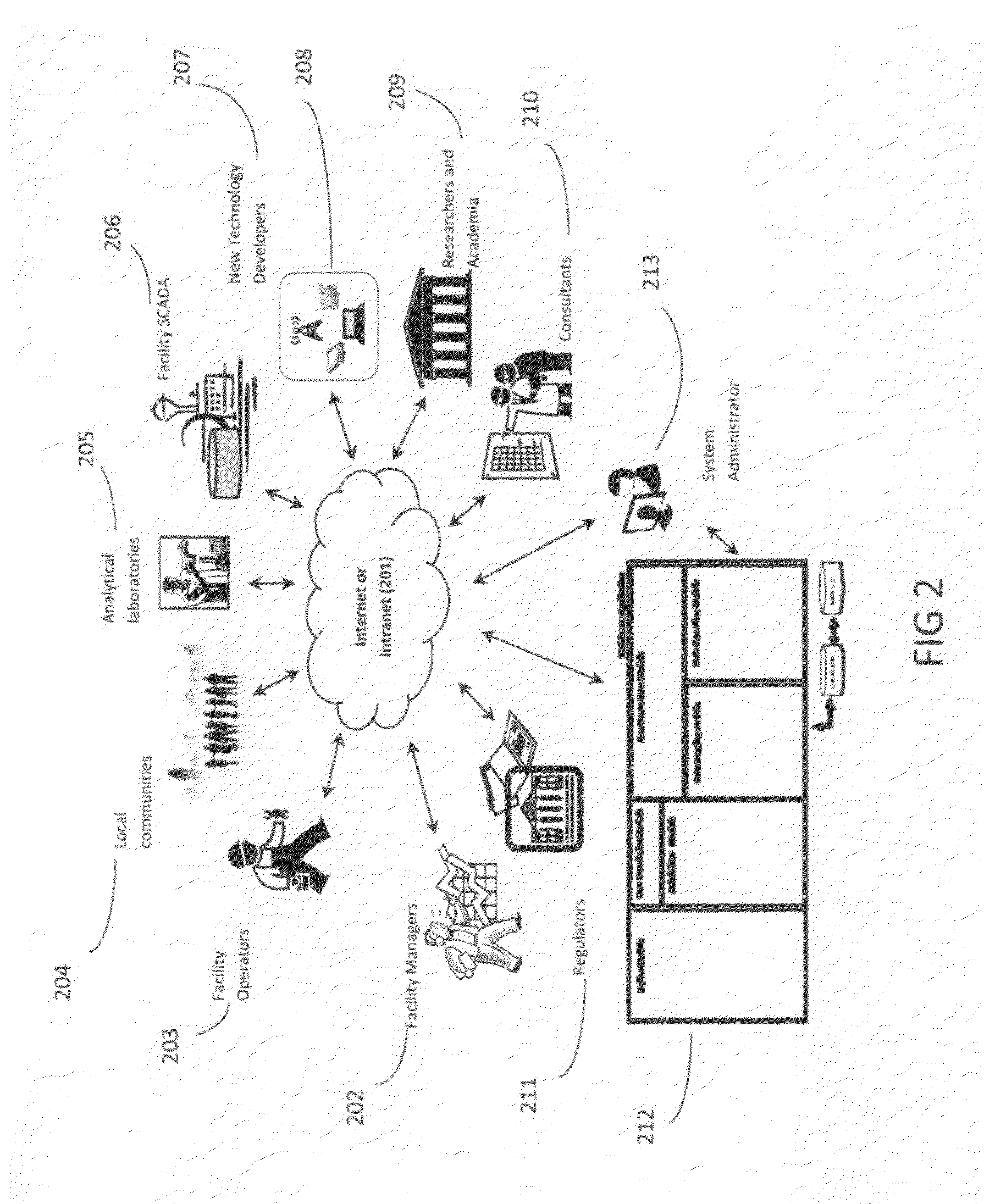

Form-based user-configurable processing plant management system and method

A computer-implemented system and method for defining the processes in a processing plant are disclosed. In one embodiment, the system uses input forms to allow a user to define the processes, chemicals, process streams, and sampling points in the plant in a way that requires no programming code to be written by the person defining the plant. In one embodiment, the electronic form-based user-configurable system can be used to configure and manage multiple plants belonging to one organization. The plant definition can be used to log information about the plant. The logged information can be used to generate reports or charts. Logging, reporting, and charting can be managed using input forms and without the user needing to write any computer code.

Owner:FLOWATCH

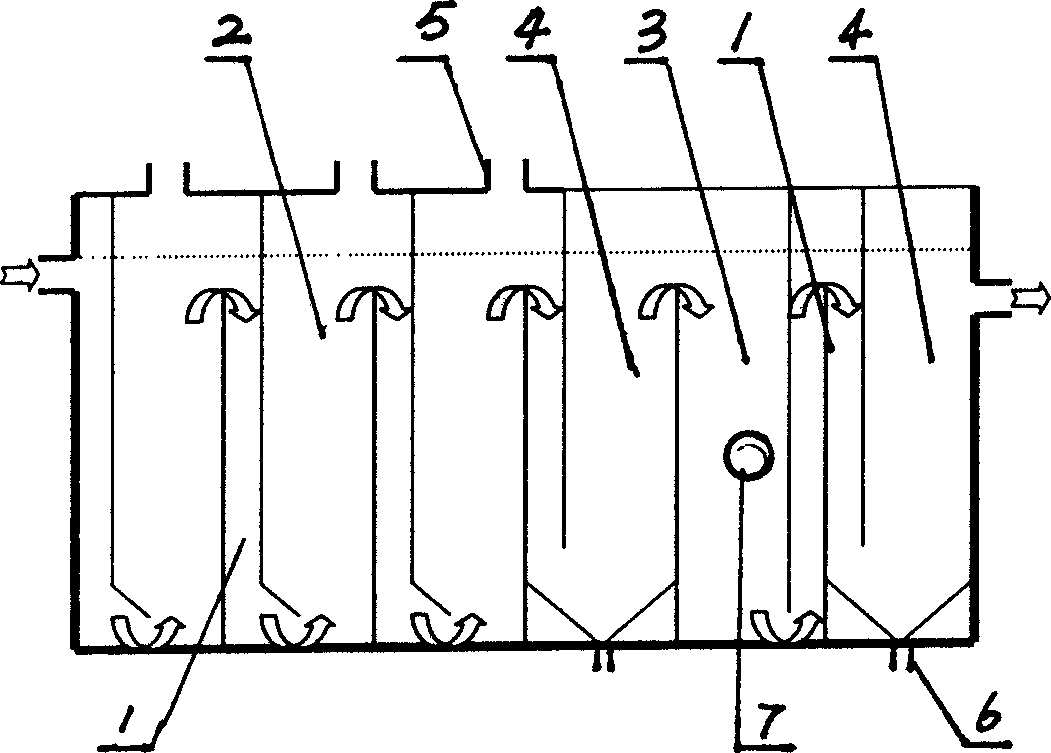

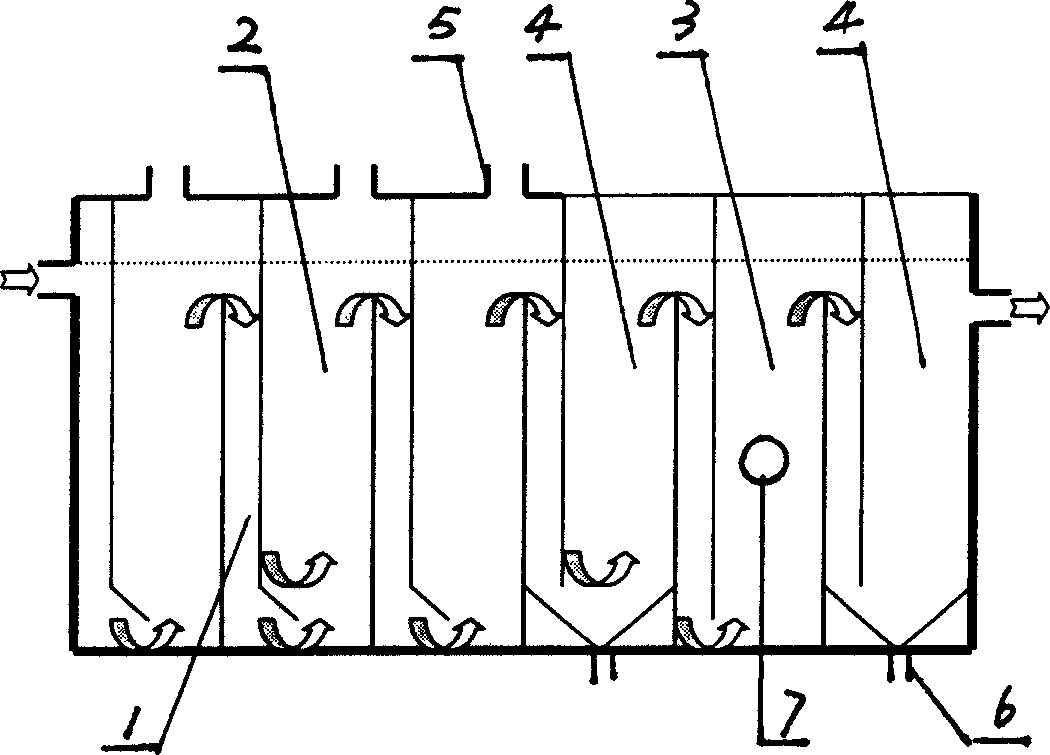

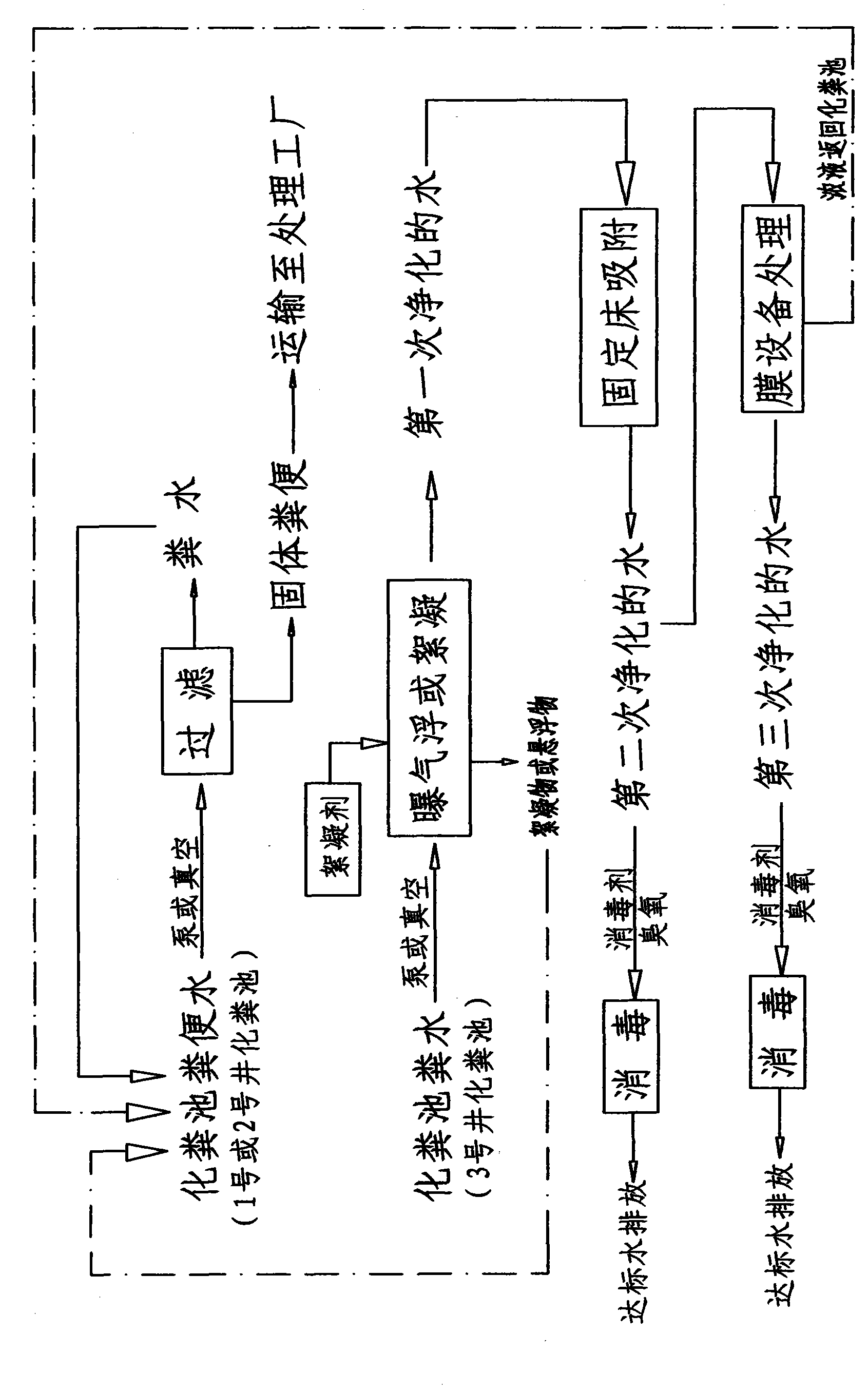

Integrative processing plant for high concentration organic wasted water

InactiveCN1541956AFully activeEasy to handleMultistage water/sewage treatmentSedimentation settling tanksHigh concentrationFrost crack

The present invention relates to one kind of integral high concentration waste water processing apparatus. The apparatus has aerobic baffle plate reactor, water collecting settling tank, aerobic reaction tank or biological contact oxidizing tank and settling tank connected via vertical baffle plates. The unique separating structure and the plug flow mode make each reactor capable of domesticating and culturing microbe colony adaptive to the water quality and environment condition. The present invention is favorable to utilizing the activity of the anaerobic bacteria colony, raising the processing effect and stability of the system and simplifying the system structure. The present invention has small coverage area, low system cost, low power consumption and no frost crack of pipeline.

Owner:NORTHWEST NORMAL UNIVERSITY

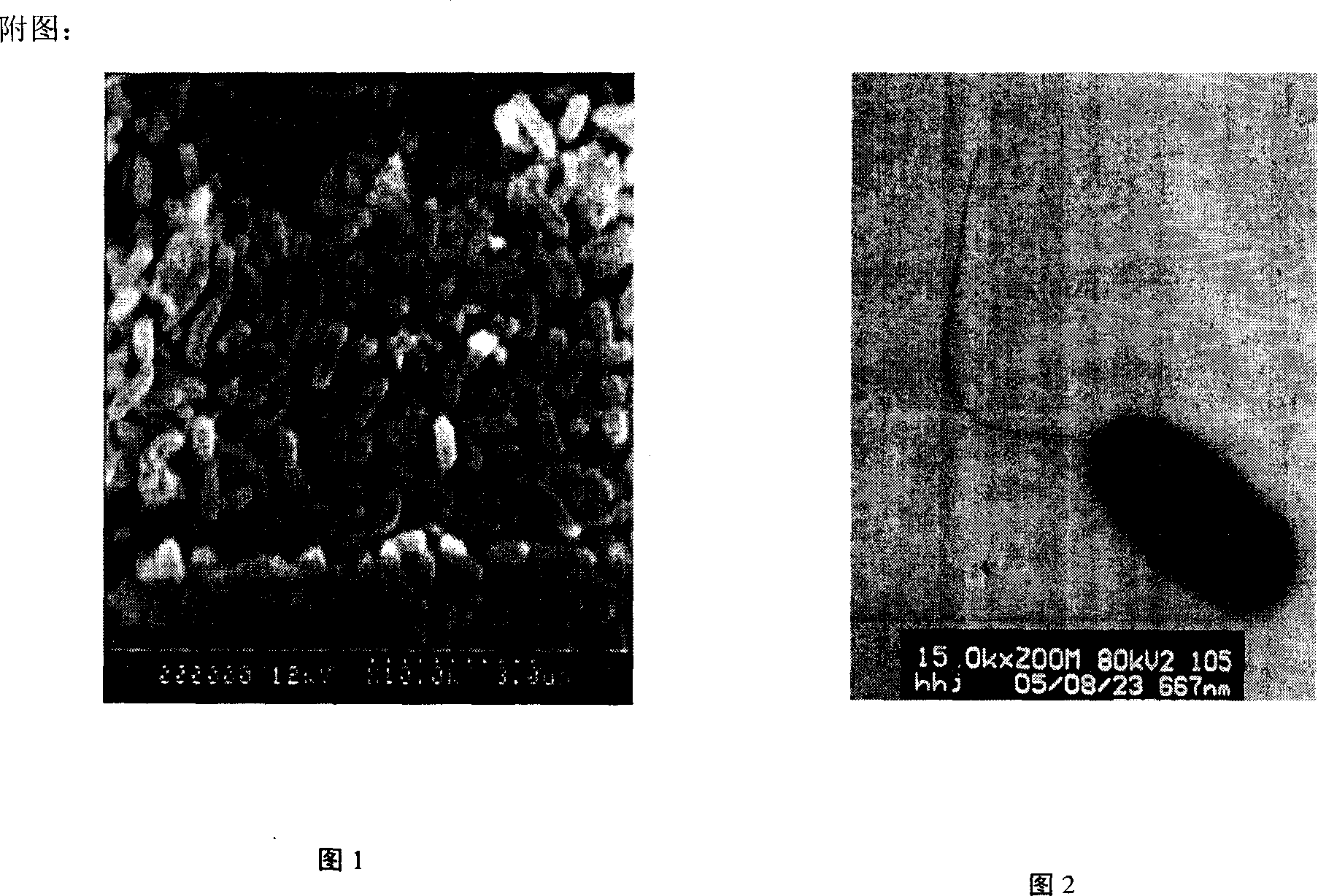

Pseudomonas stutzeri JSD-008 and its degradation function for organophosphorus pesticide

InactiveCN101096644APromote degradationBacteriaMicroorganism based processesChlorpyrifosMethyl parathion

The invention discloses a Pseudomonas stutzeri JSD-008 and degradation for organophosphorus pesticide, which is preserved in the 'Chinese germ management committee center (CGMCC)' with preservation number at CGMCC No.1738, wherein the strain is separated from the soil at pollution discharge pore of pesticide processing plant polluted by organophosphorus pesticide; the thallus and ferment liquid with the thallus can be degradation agent of organophosphorus pesticide to degrade the chlorpyrifos into trichlopyridinenol and methyl parathion into nitrophenol; fitting for rapid in-situ rehabilitation polluted by field soil pesticide.

Owner:谢明

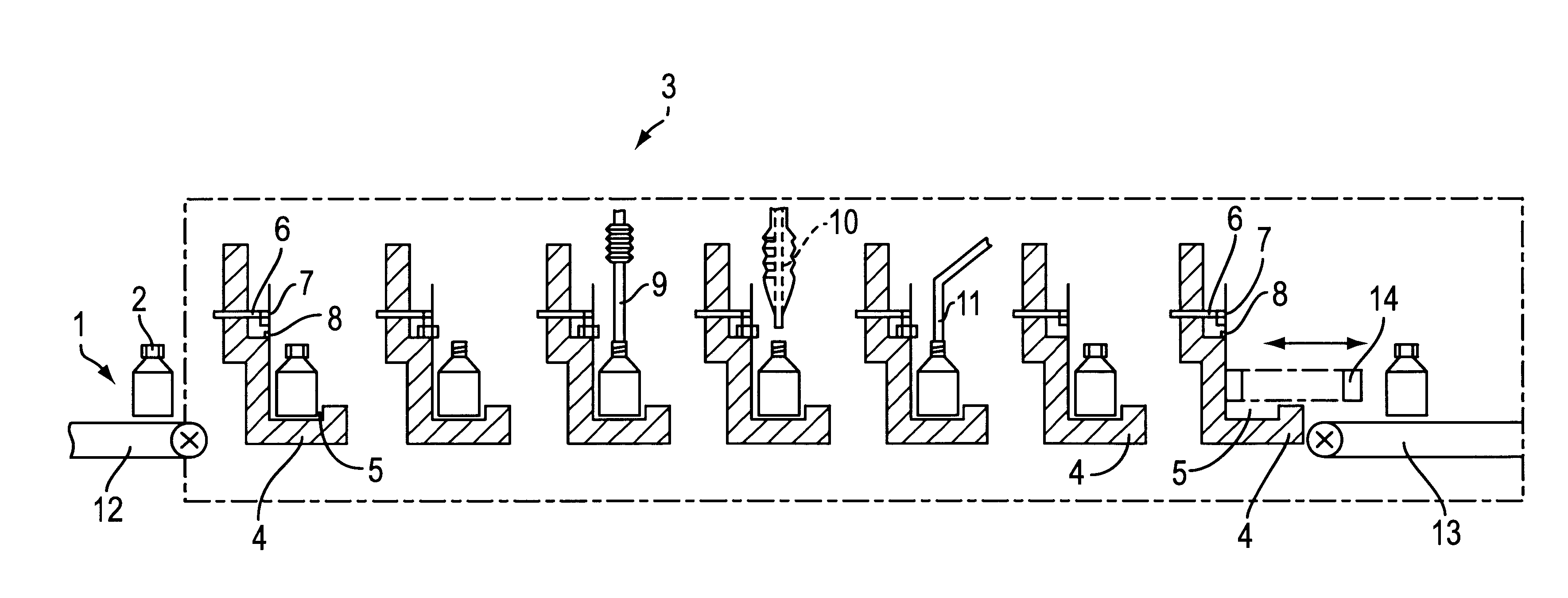

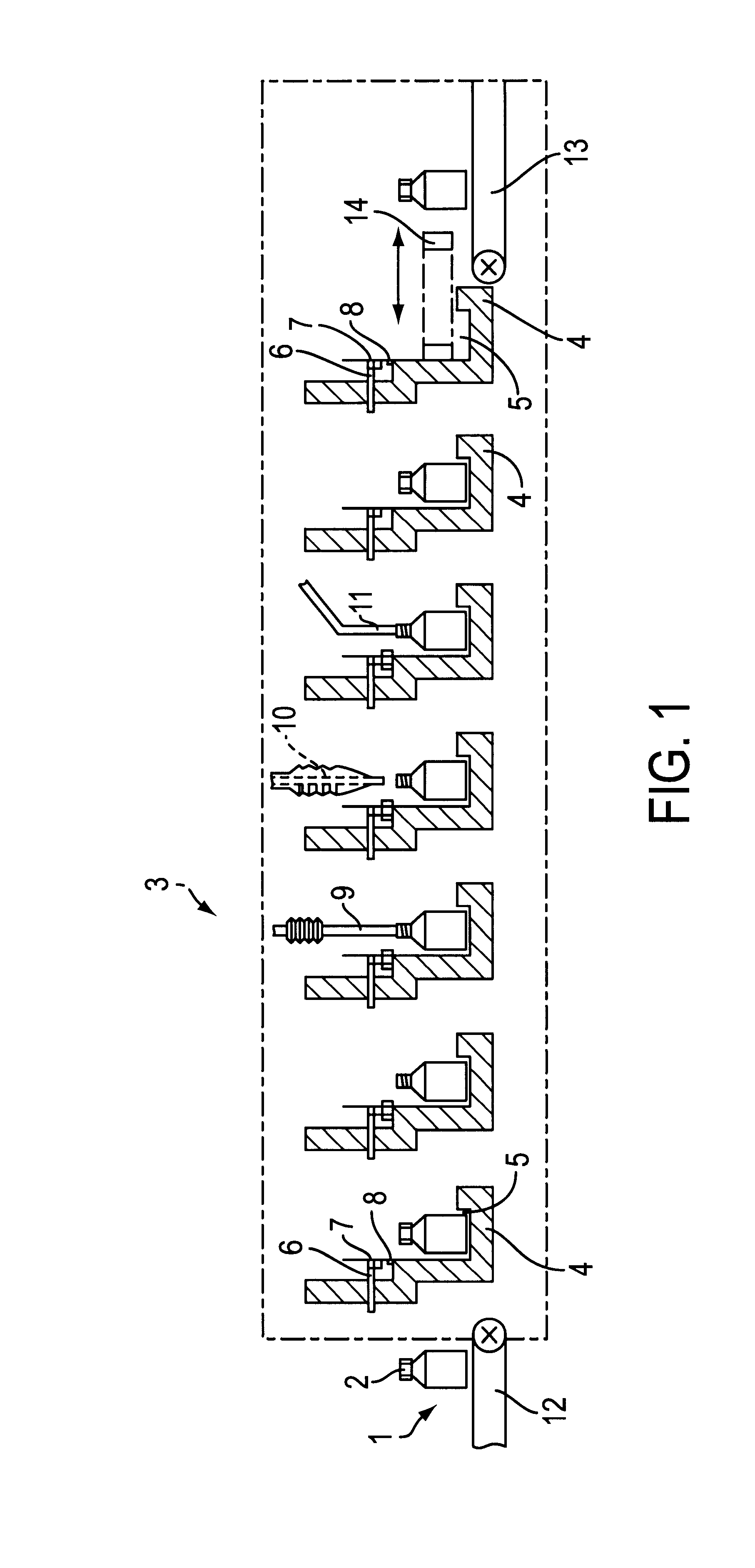

Method of handling, filling and sealing packaging containers

InactiveUS6256964B1Simplify handling and transportAvoid damage and dirt contaminationOpening closed containersPower operated devicesHermetic packagingProcessing plants

A method of handling, filling and sealing prefabricated packaging containers that are provided with a closure device is disclosed. The packaging containers are transported in the closed state to a processing plant in which the closure device is opened, the packaging container and closure device are sterilized, and thereafter the packaging container is filled with the desired liquid contents. The same closure device that was removed from the packaging container is then reapplied to seal the container.

Owner:TETRA LAVAL HLDG & FINANCE SA

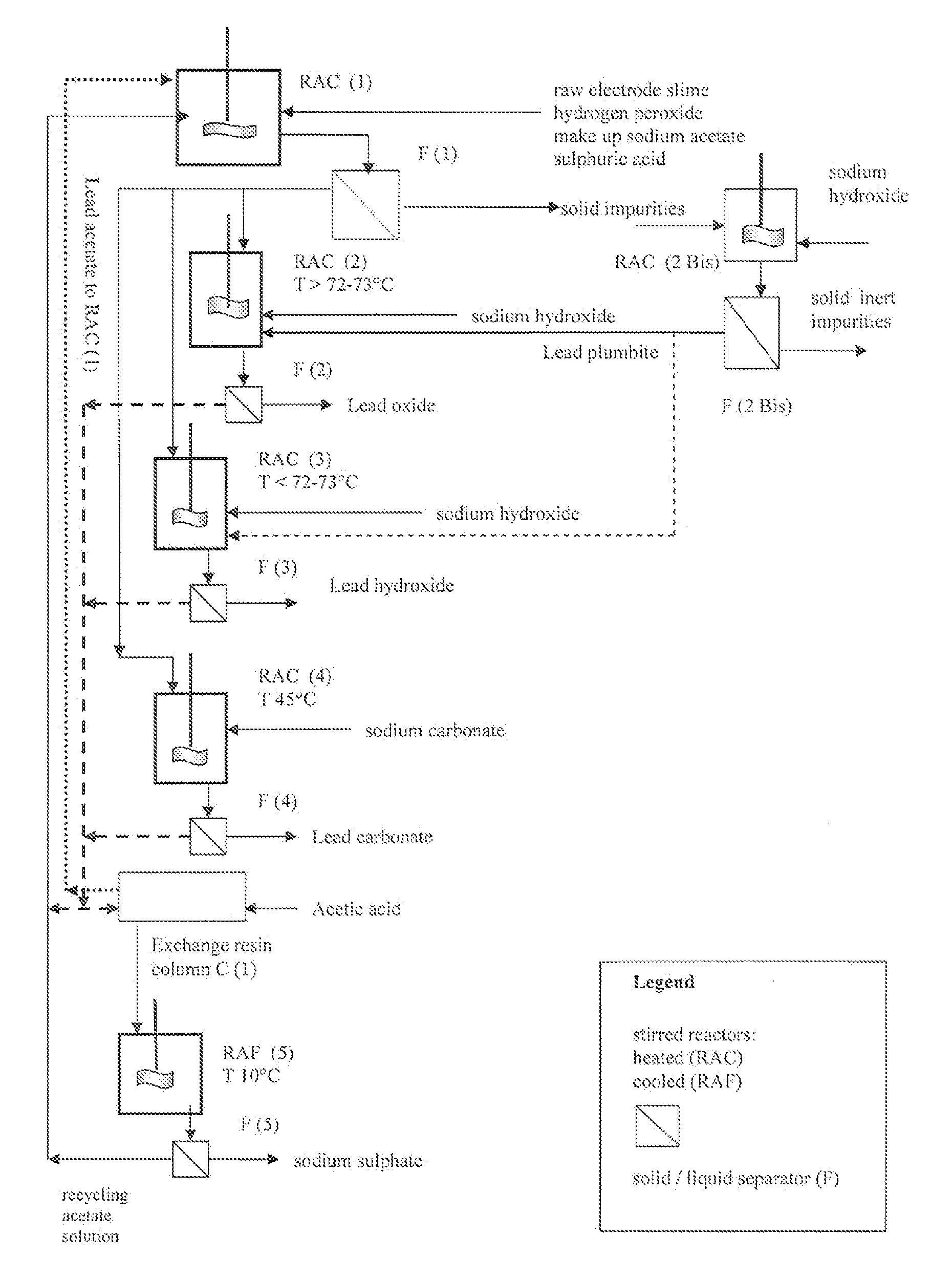

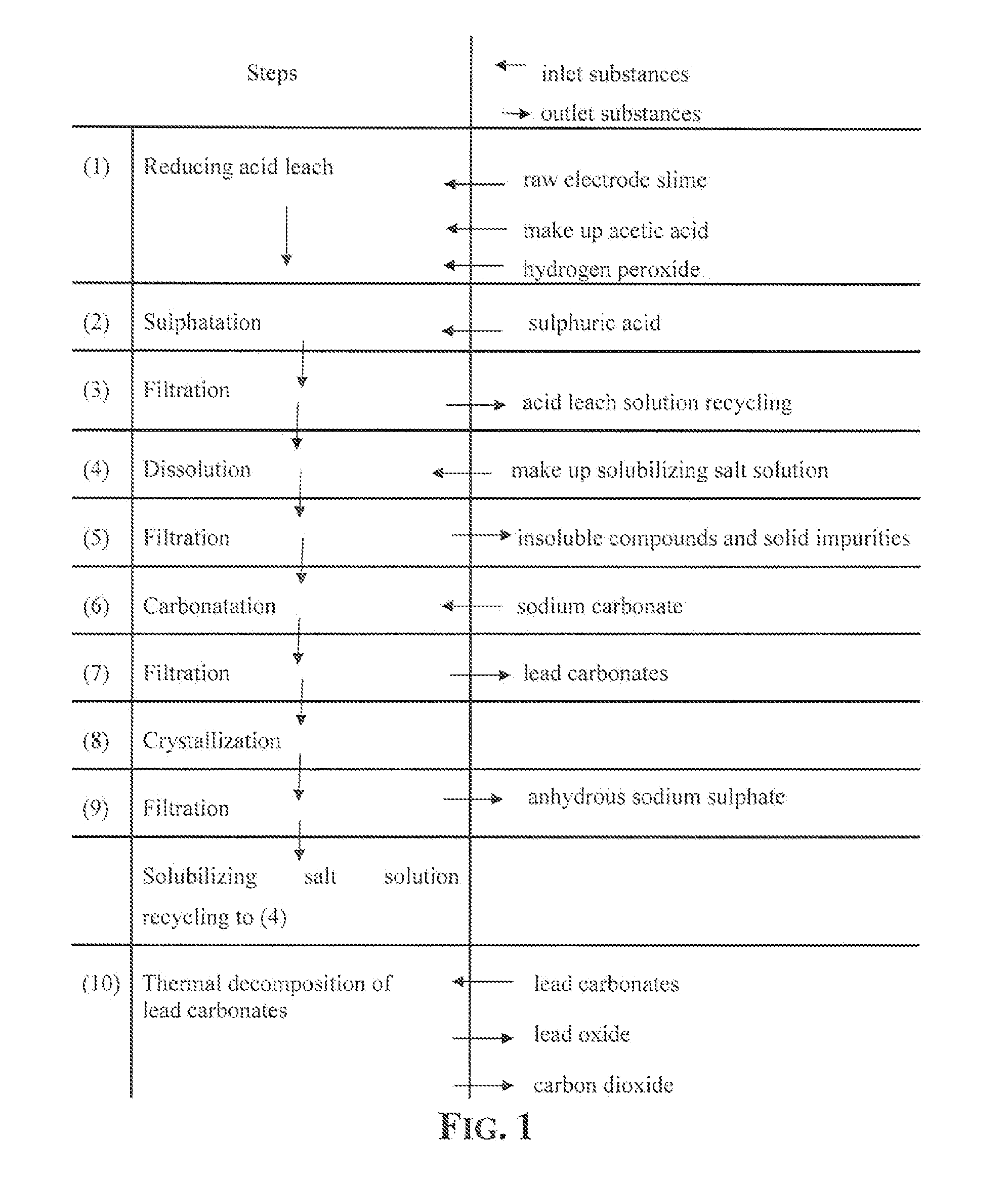

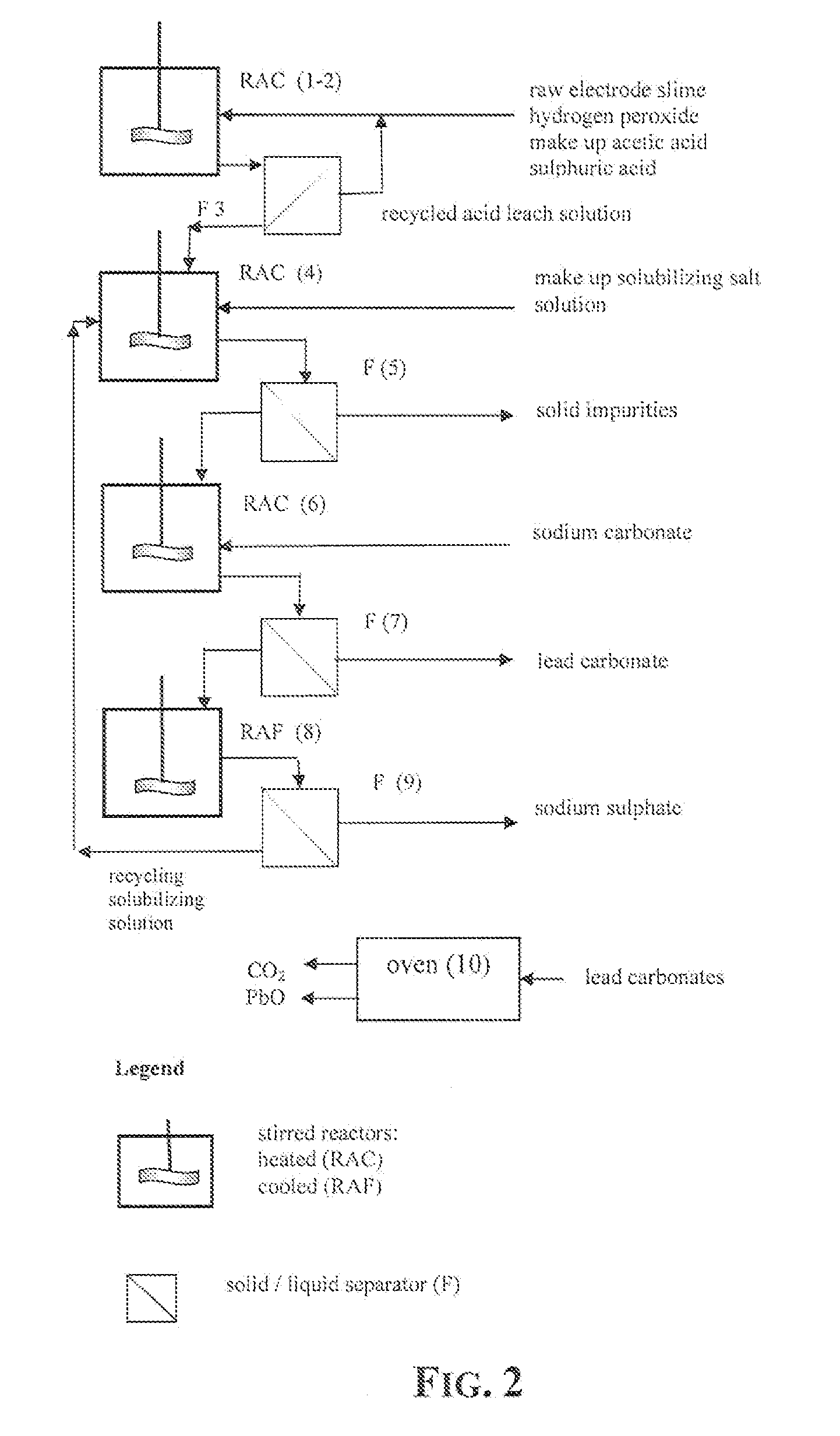

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

Bioorganically-augmented high value fertilizer

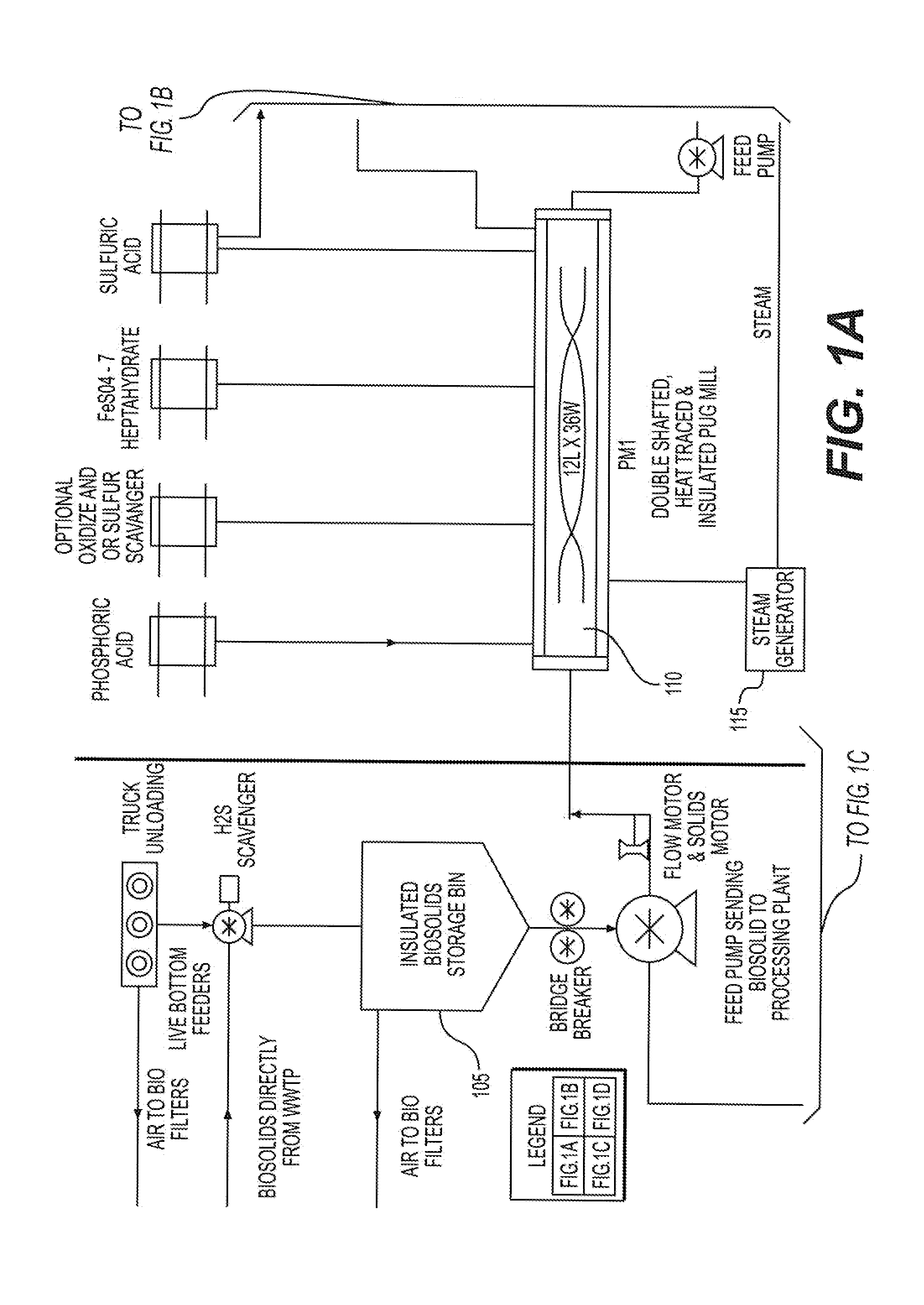

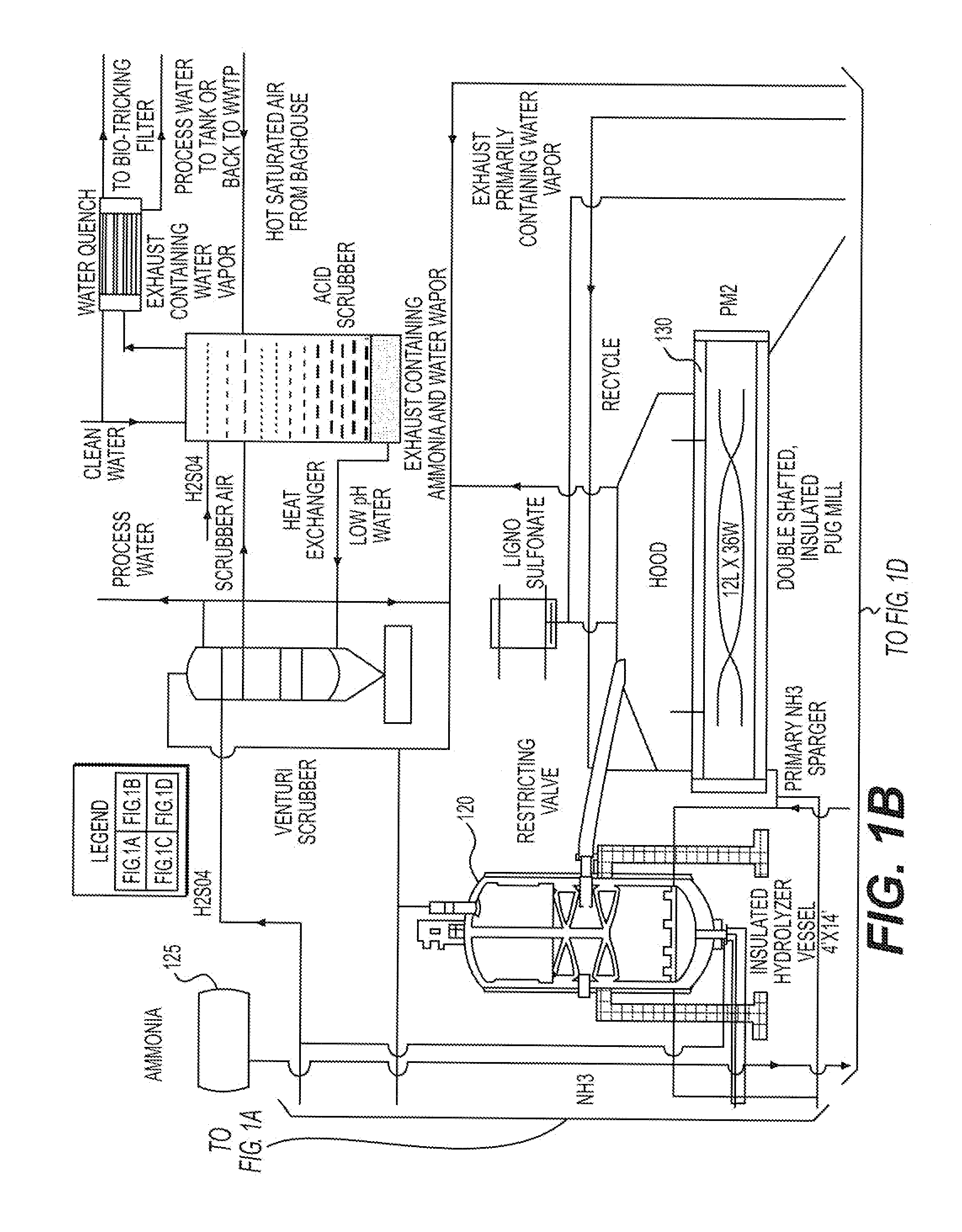

ActiveUS20110154873A1Method is newBio-organic fraction processingExcrement fertilisersClosed loopNitrogen

The invention is directed to processes for treating biosolids that result in high-value, nitrogen-containing, slow-release, organically-augmented inorganic fertilizer that are competitive with less valuable or more costly conventional commercially manufactured fertilizers. The process involves conditioning traditional waste-water biosolids and processing the conditioned biosolids continuously in a high throughput manufacturing facility. The exothermic design and closed loop control of the primary reaction vessel decreases significantly the amount of power necessary to run a manufacturing facility. The process utilizes green technologies to facilitate decreased waste and enhanced air quality standards over traditional processing plants. The fertilizer produced from recovered biosolid waste is safe and meets or exceeds the United States Environment Protection Agency (USEPA) Class A and Exceptional Quality standards and is not subject to restrictions or regulations.

Owner:GENERATE LENDING LLC +1

Pathogen reduction using chloramines

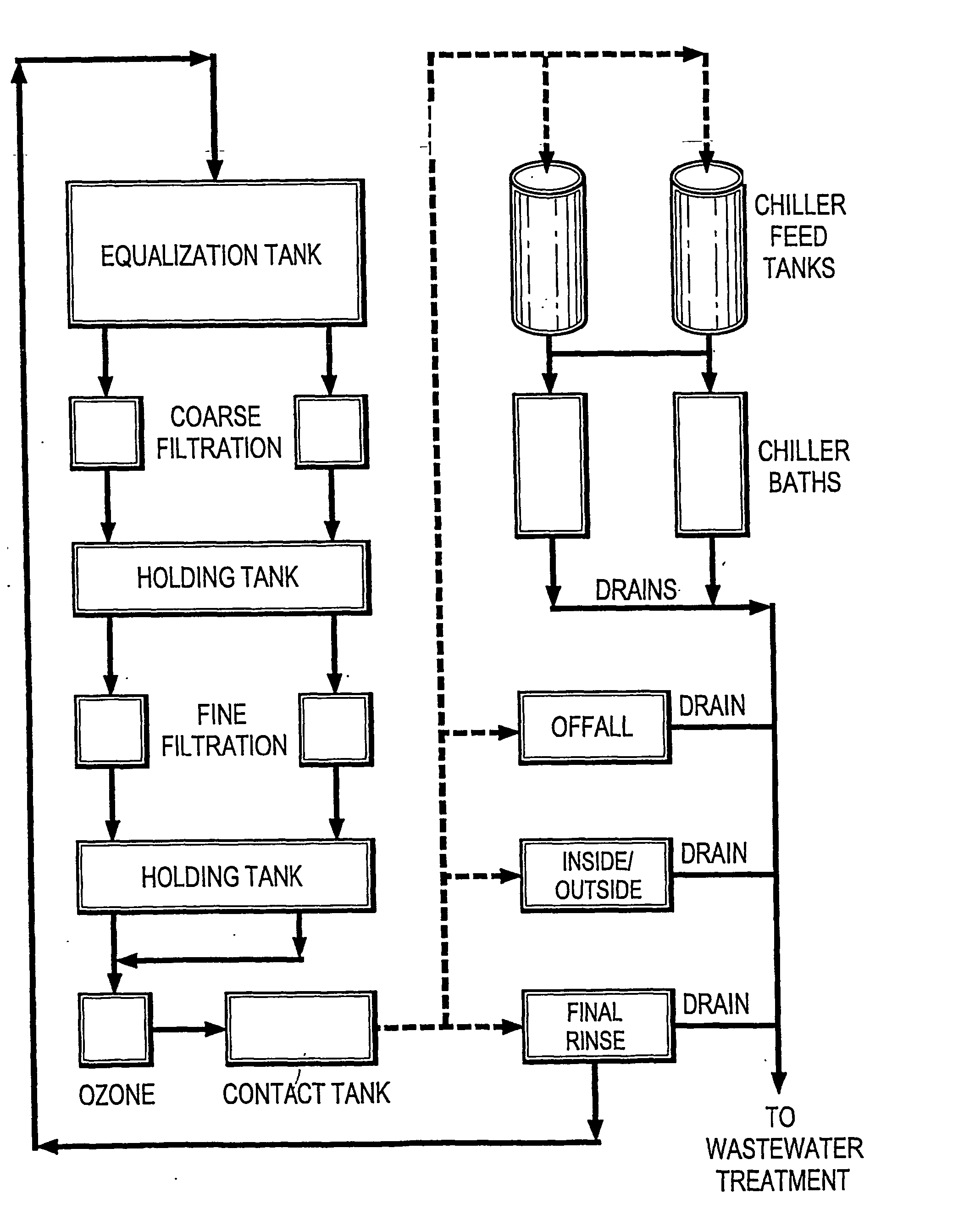

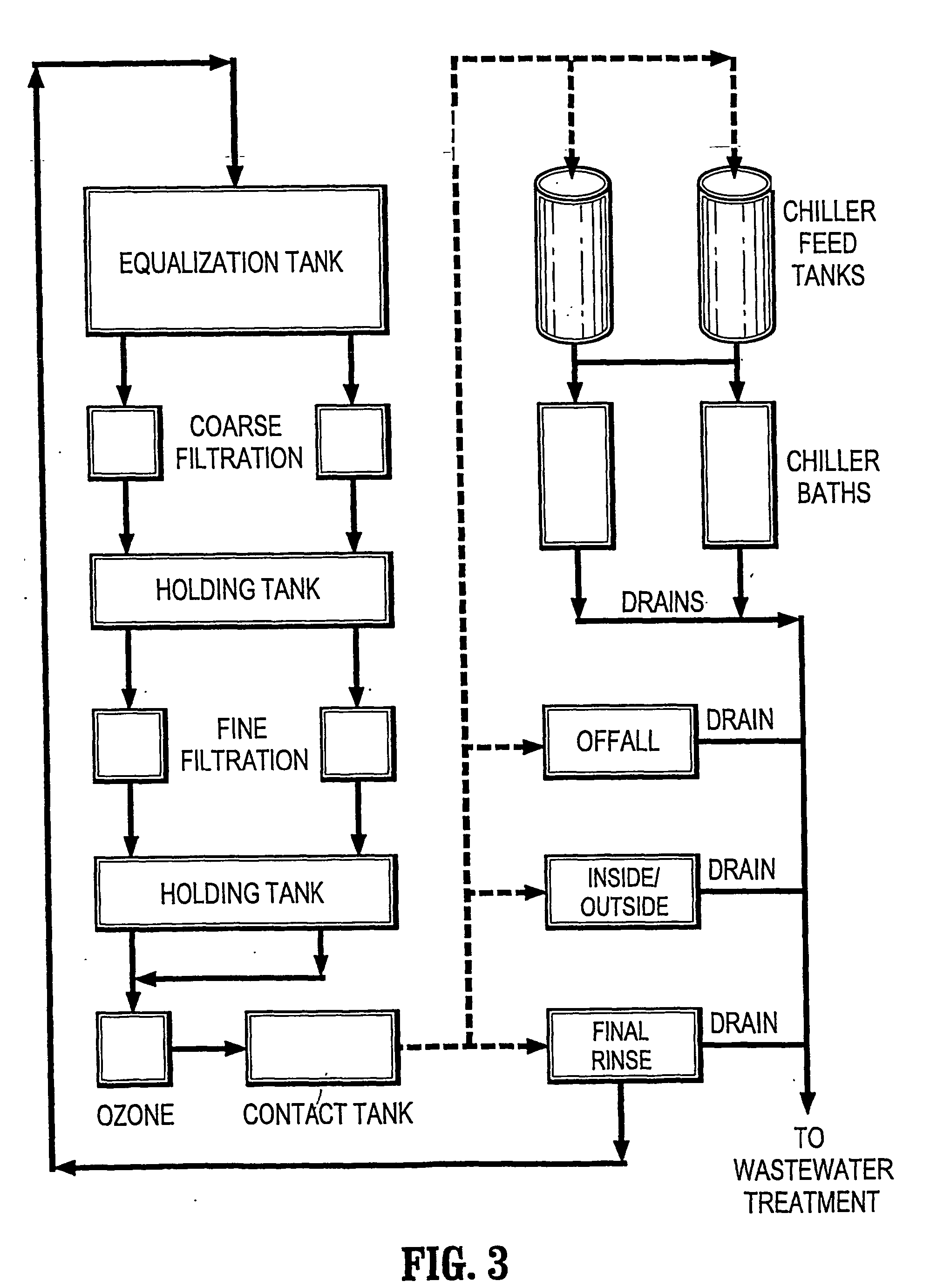

InactiveUS20050211643A1Good effectEasy to receiveWaste water treatment from animal processingWater/sewage treatment by substance additionMicroorganismChloramine B

A method and apparatus for implementing pathogen reduction within a poultry processing or food processing plant that uses water that has been treated with chloramines at an advantageous dosage before being introduced to the production process at processing steps. The water treated with chloramines may be from a fresh water source or reclaimed water from the processing plant. The reintroduction of the treated reclaimed water advantageously causes a dramatic reduction in the levels of microorganisms associated with poultry processing, while substantially conserving water use.

Owner:ZENTOX CORP

Production system and method

In a first aspect, systems and methods for producing biodiesel fuel include a modular production unit incorporated onto a single platform or into a housing for ease of relocatability. The modular production unit preferably includes a mixing unit, a reactor unit, a separation unit, a distillation unit, and a filtering unit, all incorporated onto or into a self-contained platform or housing that is able to be easily relocated. In a second aspect, the modular production unit is combined with additional fixed and / or relocatable components to provide a biodiesel processing plant. In a third aspect, a raw materials processing system and method includes a roller barrel adapted for recovery, transportation, and introduction of recycled oil feedstock into a biodiesel manufacturing process. The raw materials processing system preferably includes a hot box for filtering and heating the raw recycled oil feedstock.

Owner:BIODIESEL IND

Anti-microbial granules

InactiveUS20060188580A1Reduce releaseIncrease ionic strengthPowder deliveryHeavy metal active ingredientsBiotechnologyEpoxy

Antimicrobial granules comprising granular materials coated with antimicrobial metal agents for use in various surface coating and grouting materials are provided. The antimicrobial granules have utility in imparting durable, safe, inexpensive and powerful antimicrobial properties to materials into which they are incorporated, such as epoxy coating and grouts for surgical theaters, public washrooms, and food processing plants. The granules further are capable of imparting a timed-release dosage of antimicrobial agents so that the effectiveness of the coating is palpable for extended periods.

Owner:CORRO SHIELD INT

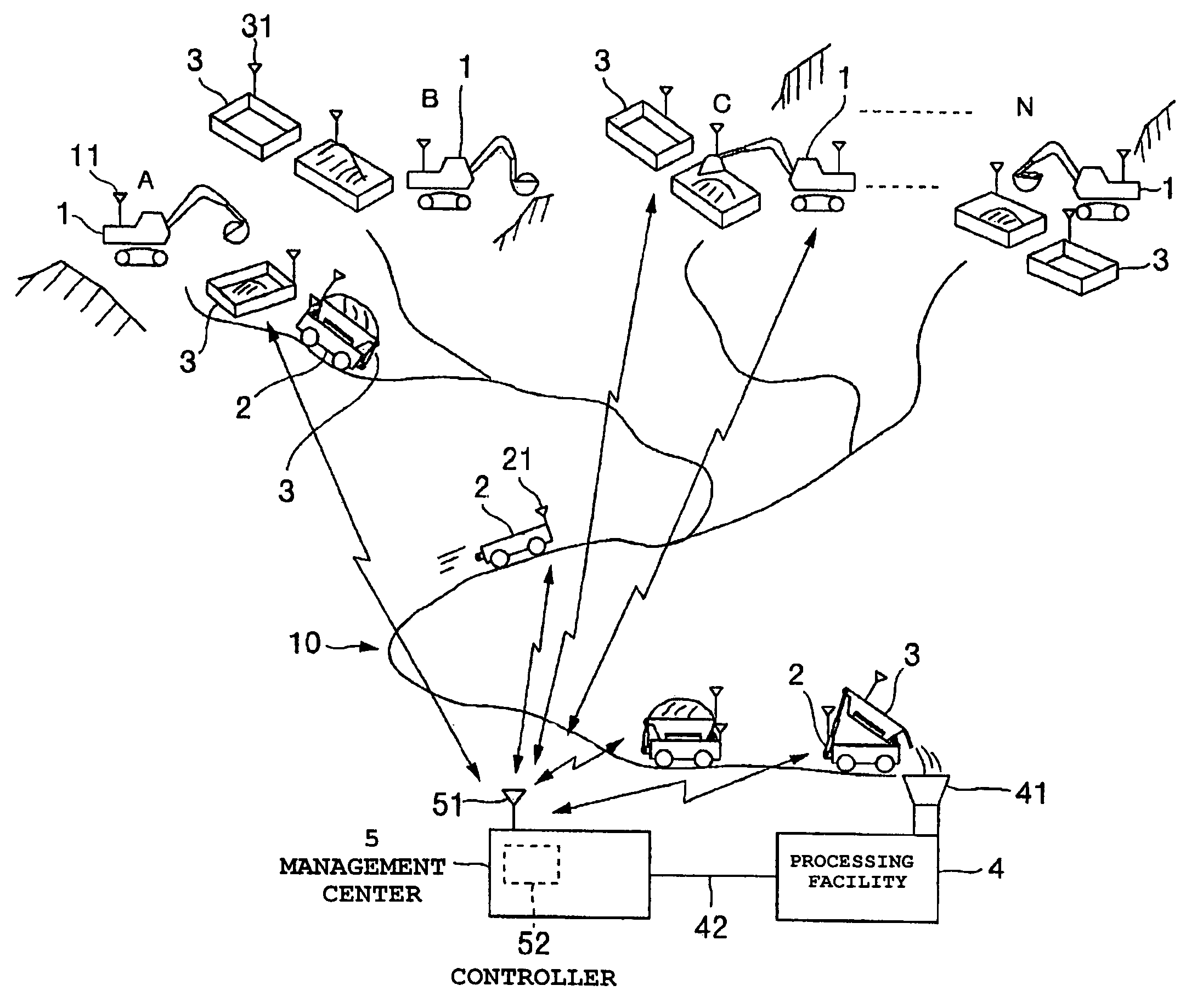

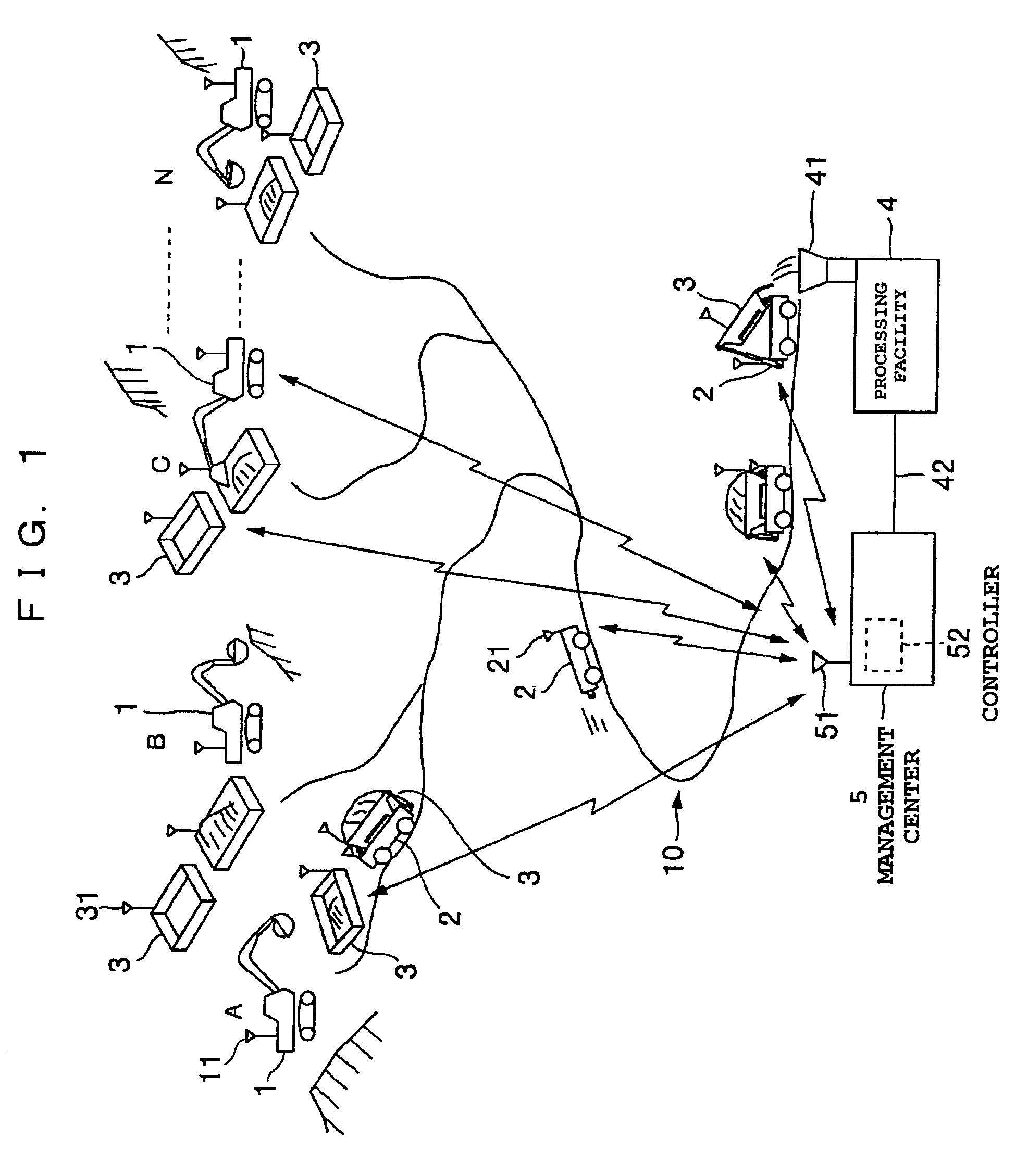

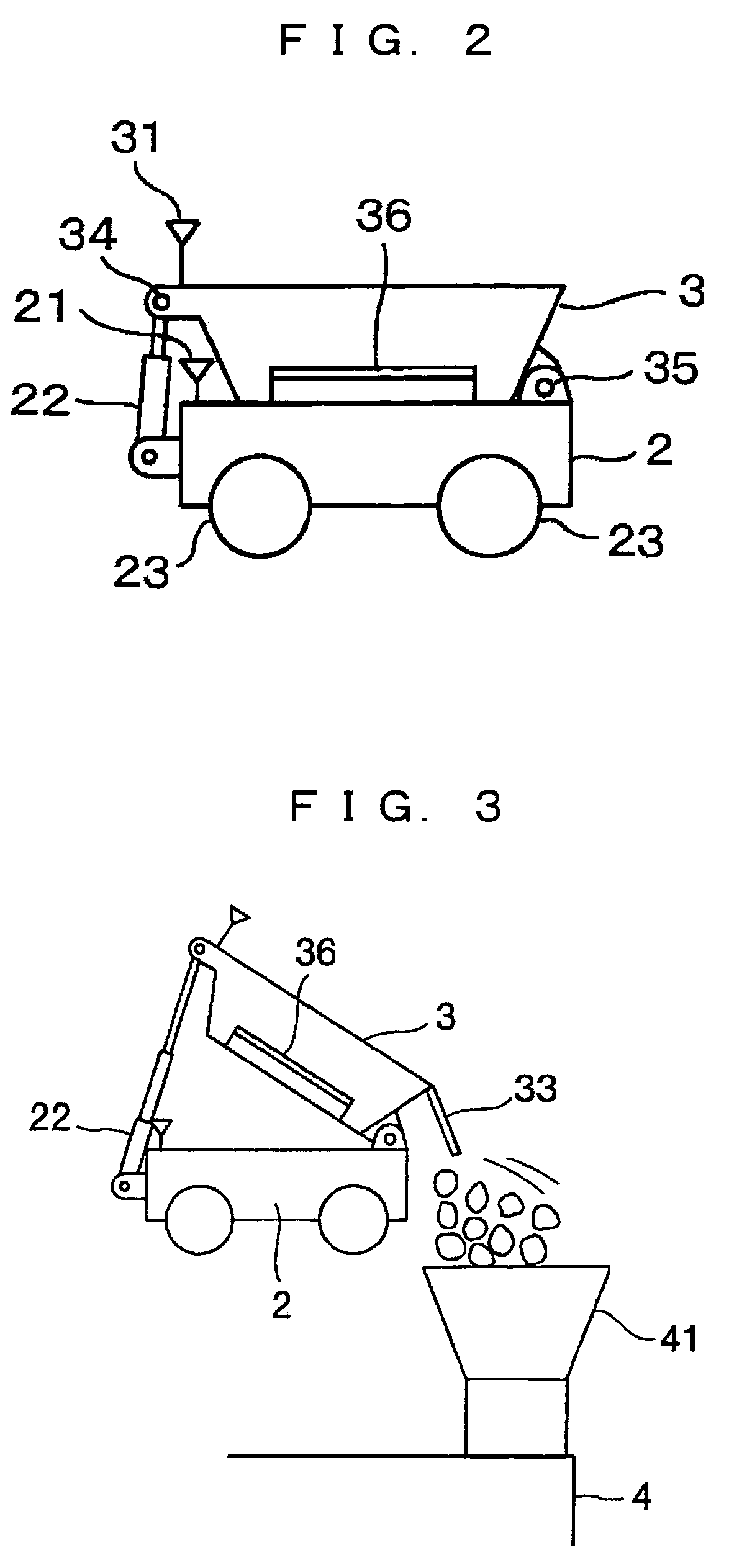

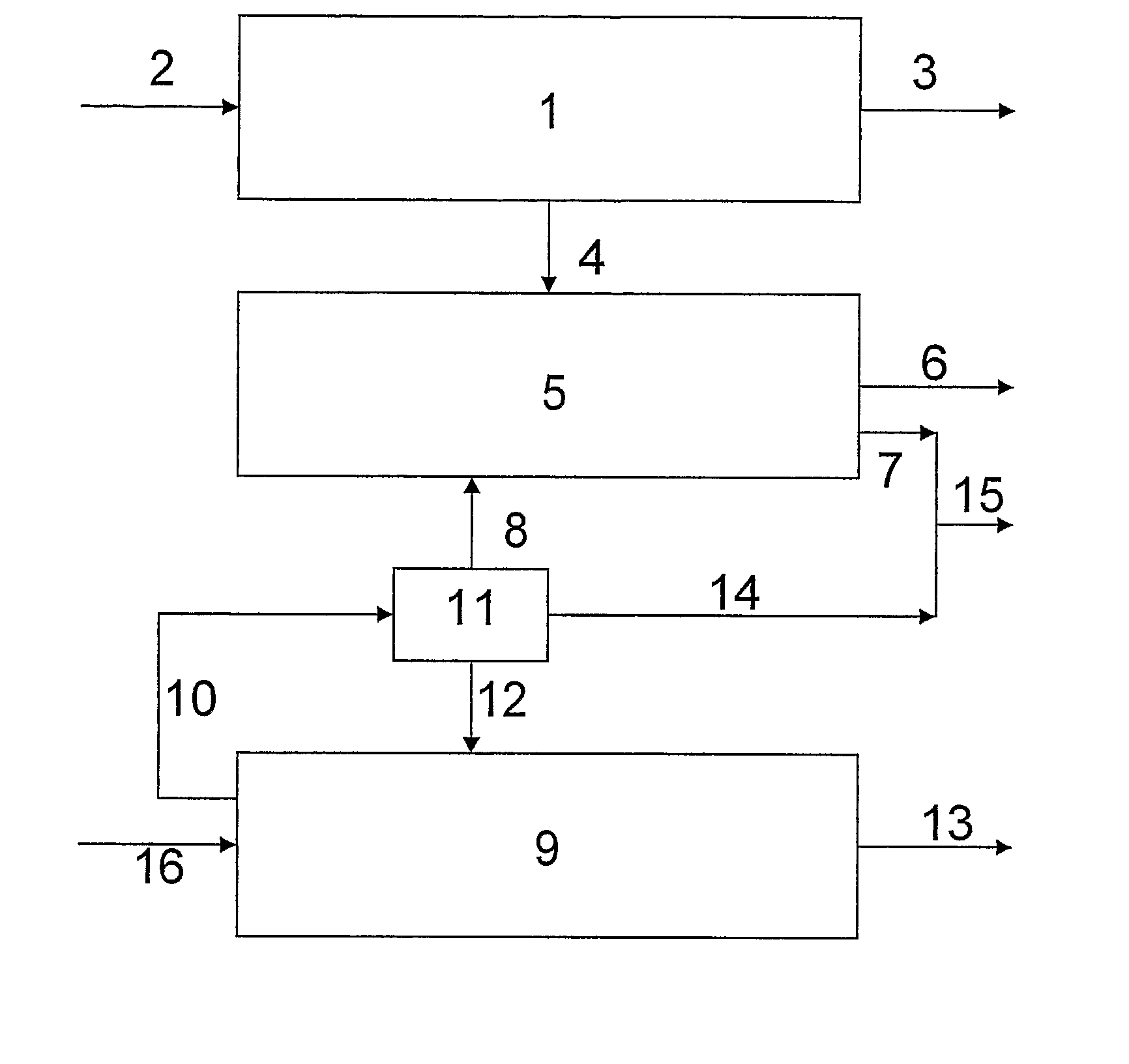

Mine transportation management system and method using separate ore vessels and transport vehicles managed via communication signals

InactiveUS6988591B2Same effectLow costData processing applicationsComputer controlTransportation management systemProcessing plants

A mine transportation management system capable of reducing cost by reducing the number of transportation vehicles is provided. For this purpose, the system includes a plurality of self-propelled vehicles and a plurality of vessels each having a communication section, and each being identifiable, which are connectable to and separable from each other. A loading machine having a communication section, which loads an object into at least one of the vessels. A management center, which has a communication section, selects a vessel to be transported and selects a self-propelled vehicle for transporting the selected vessel based on a transportation demand signal from a processing facility, and transmits a transportation command signal to the selected self-propelled vehicle to connect to the selected vessel and to travel to the processing facility.

Owner:KOMATSU LTD

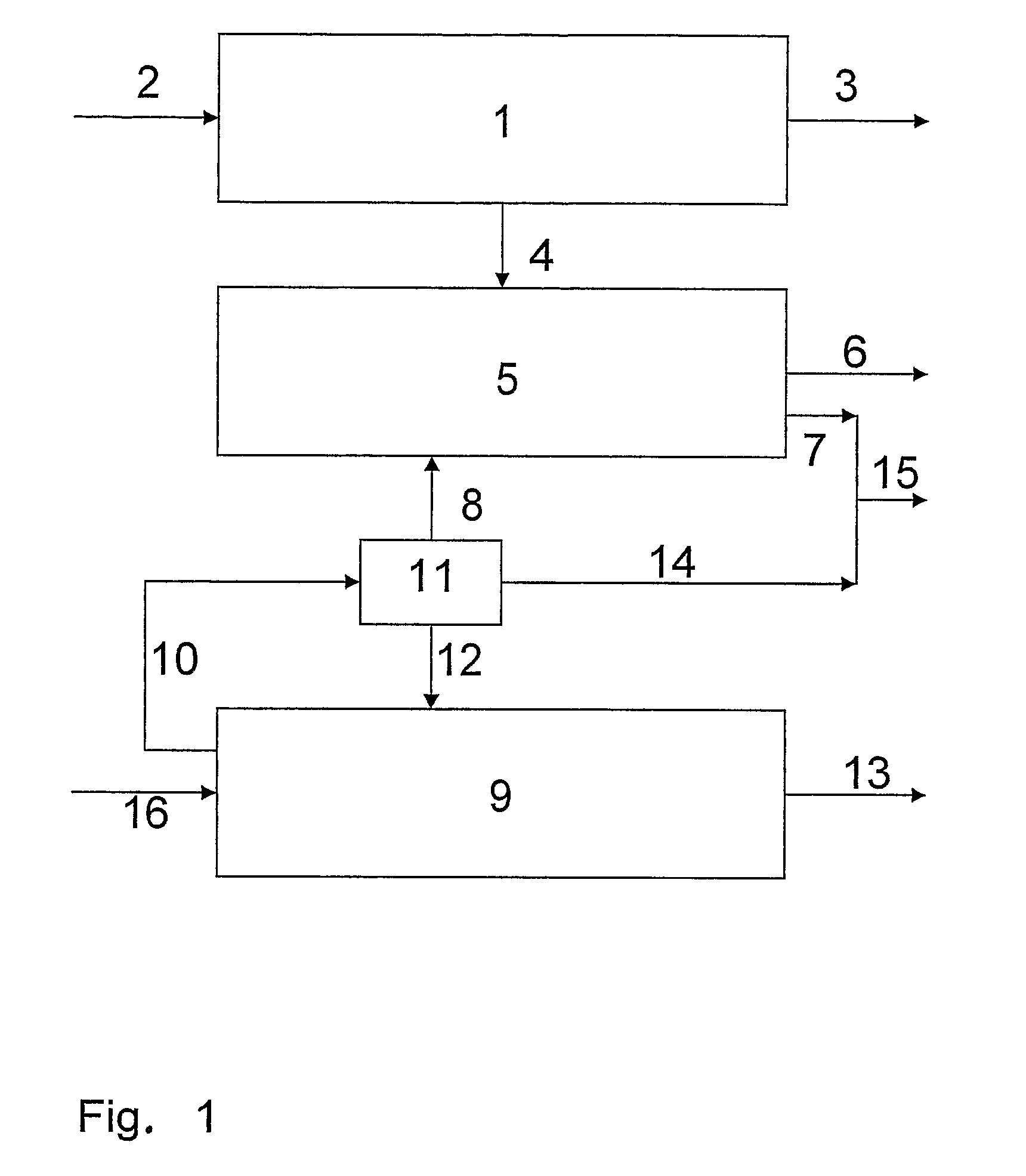

Method and plant for removing carbon dioxide from flue gas

InactiveUS8043588B2Reduce energy costsEasy to modifyCombination devicesLiquid degasificationThermal energyDesorption

Owner:CO2 NORWAY +1

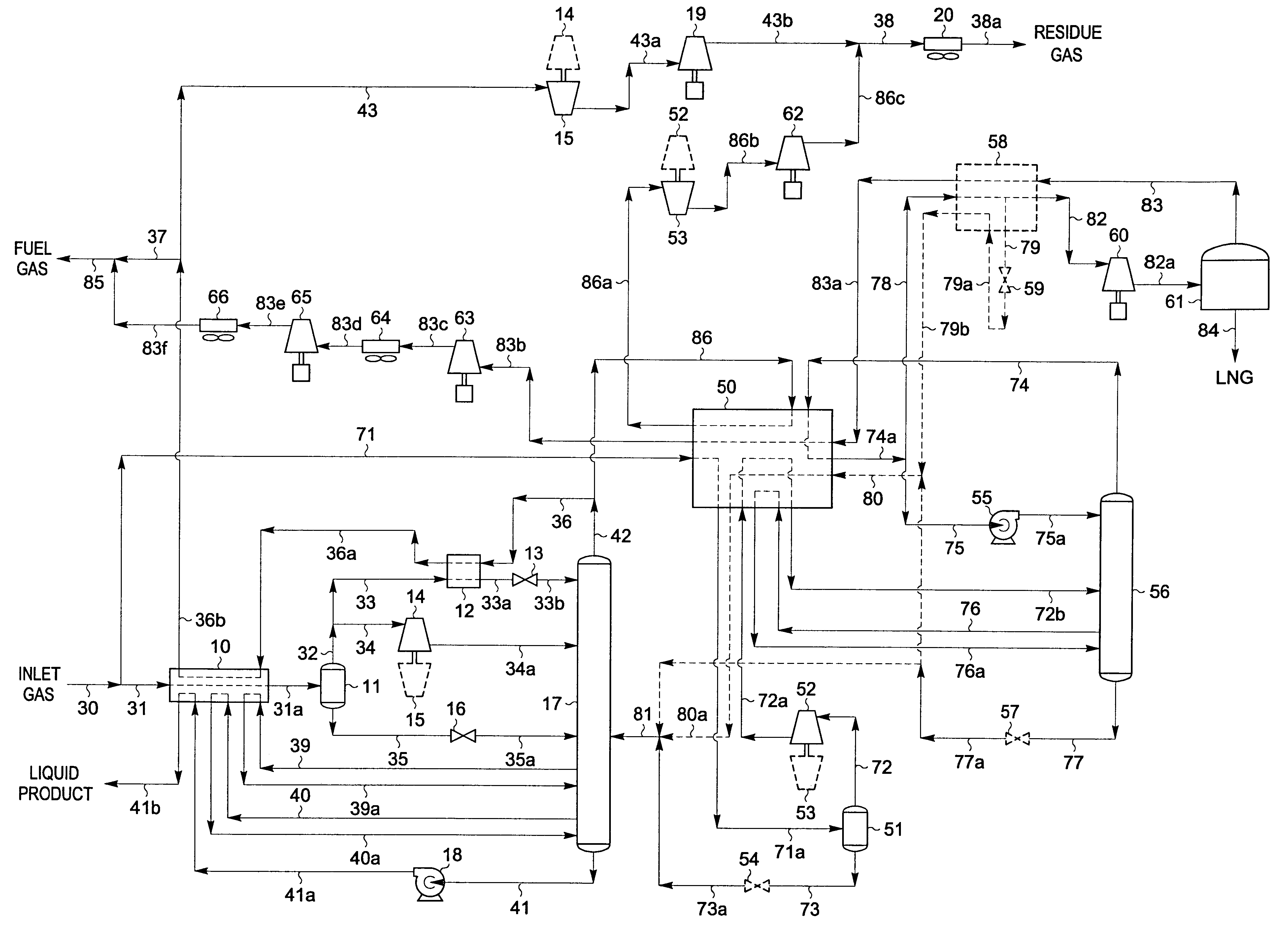

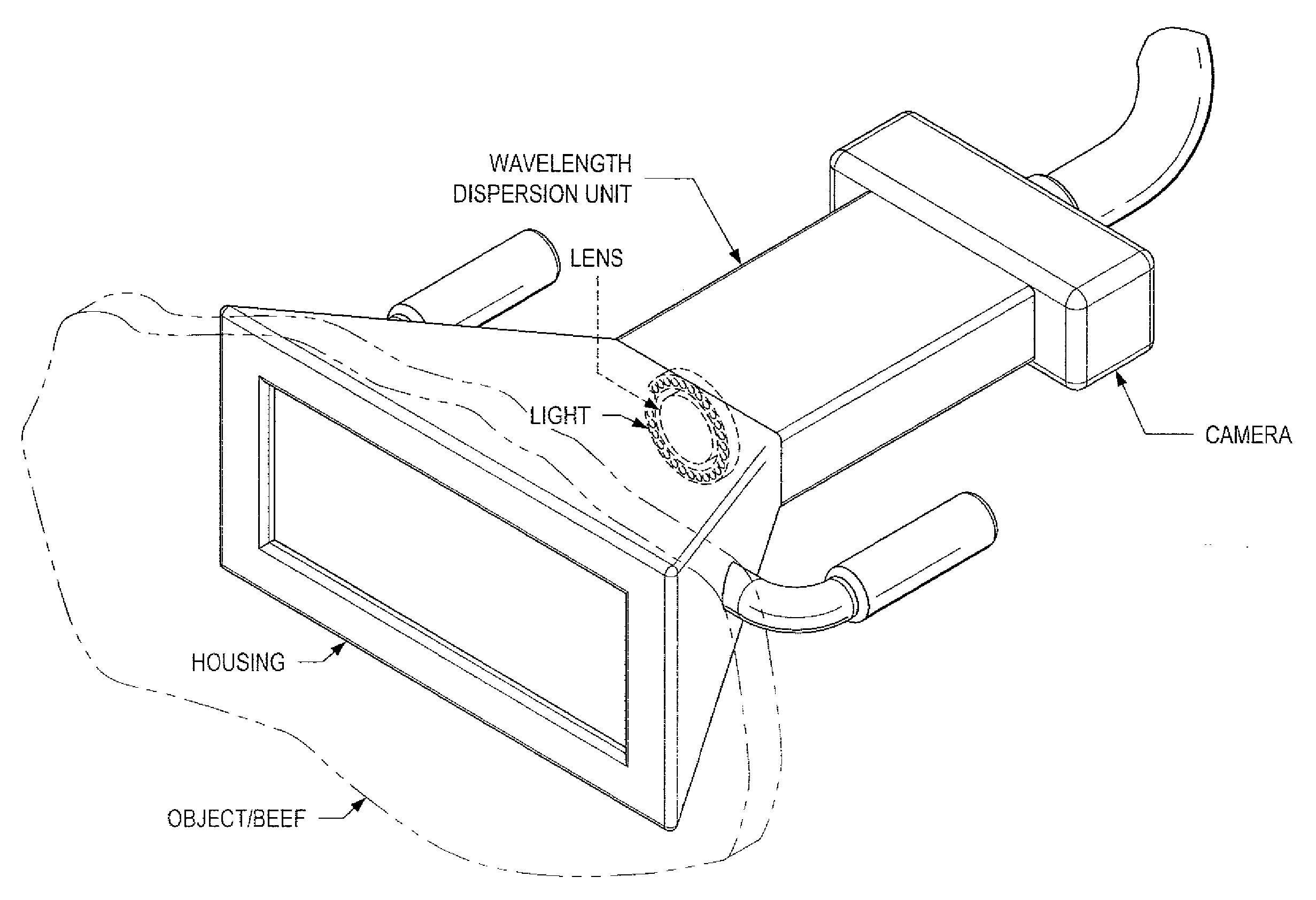

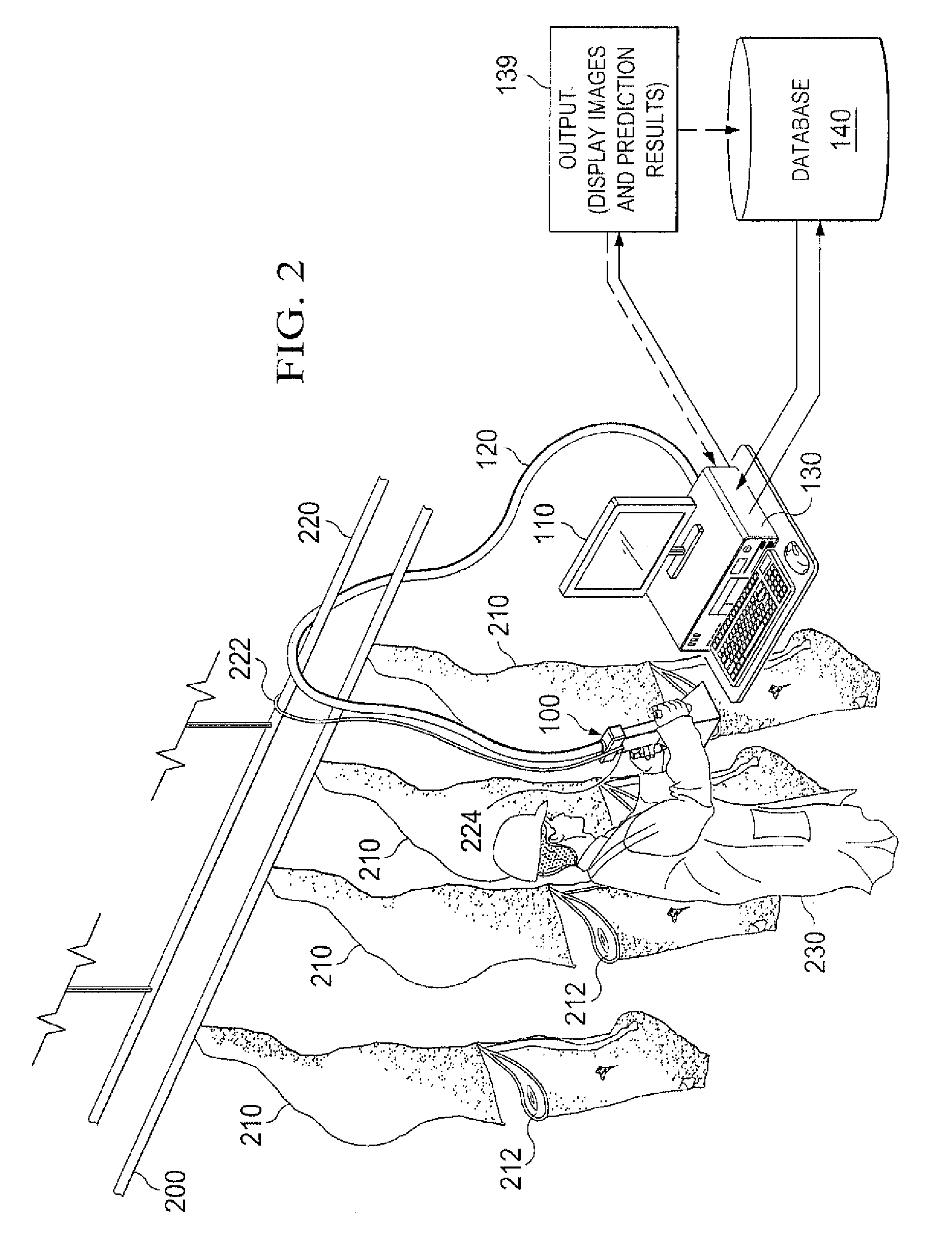

System and Method for Analyzing Properties of Meat Using Multispectral Imaging

ActiveUS20110273558A1Eliminates lag and delayRapid and objective determinationImage enhancementImage analysisMeat tendernessIndustrial setting

A system and method for obtaining multispectral images of fresh meat at predetermined wavelength bands at a first time, subjecting the images to analysis in an image analysis system comprising a computer programmed to perform such analysis, and outputting a forecast of meat tenderness at a later point in time. Predetermined key wavelength bands are precorrelated with a high degree of prediction of meat tenderness and / or other properties of meat and are used in the multispectral system and method. A system and method for determining the key wavelengths is also disclosed. The multispectral imaging system and method is suitable for use in an industrial setting, such as a meat processing plant. The system and method is useful in a method for determining quality and yield grades at or near the time of imaging in lieu of visual inspection with the unaided human eye, increasing efficiency and objectivity.

Owner:CARNE TENDER LLC

Vacuum Devolatilizer

Provided is a vacuum devolatilizer for use in a polymer manufacturing or processing plant. The devolatilizer comprises a vacuum chamber having an inlet for a polymer melt, an outlet for a polymer melt, a vacuum port through which volatiles may be removed and a stirrer shaft port for the entry of a stirrer shaft. The stirrer shaft passes through the at least one stirrer shaft port and extends into the vacuum chamber and carries an agitation means. The stirrer shaft seal is associated with each stirrer shaft port for sealing against the stirrer shaft and each stirrer shaft seal has an external portion outside the vacuum chamber. The devolatilizer is provided with a motor located outside of the vacuum chamber for rotating shaft and comprises means for blanketing the external portion of the stirrer shaft seal with a low oxygen content gas or vapor, e.g., nitrogen, helium, steam, or carbon dioxide.

Owner:EXXONMOBIL CHEM PAT INC

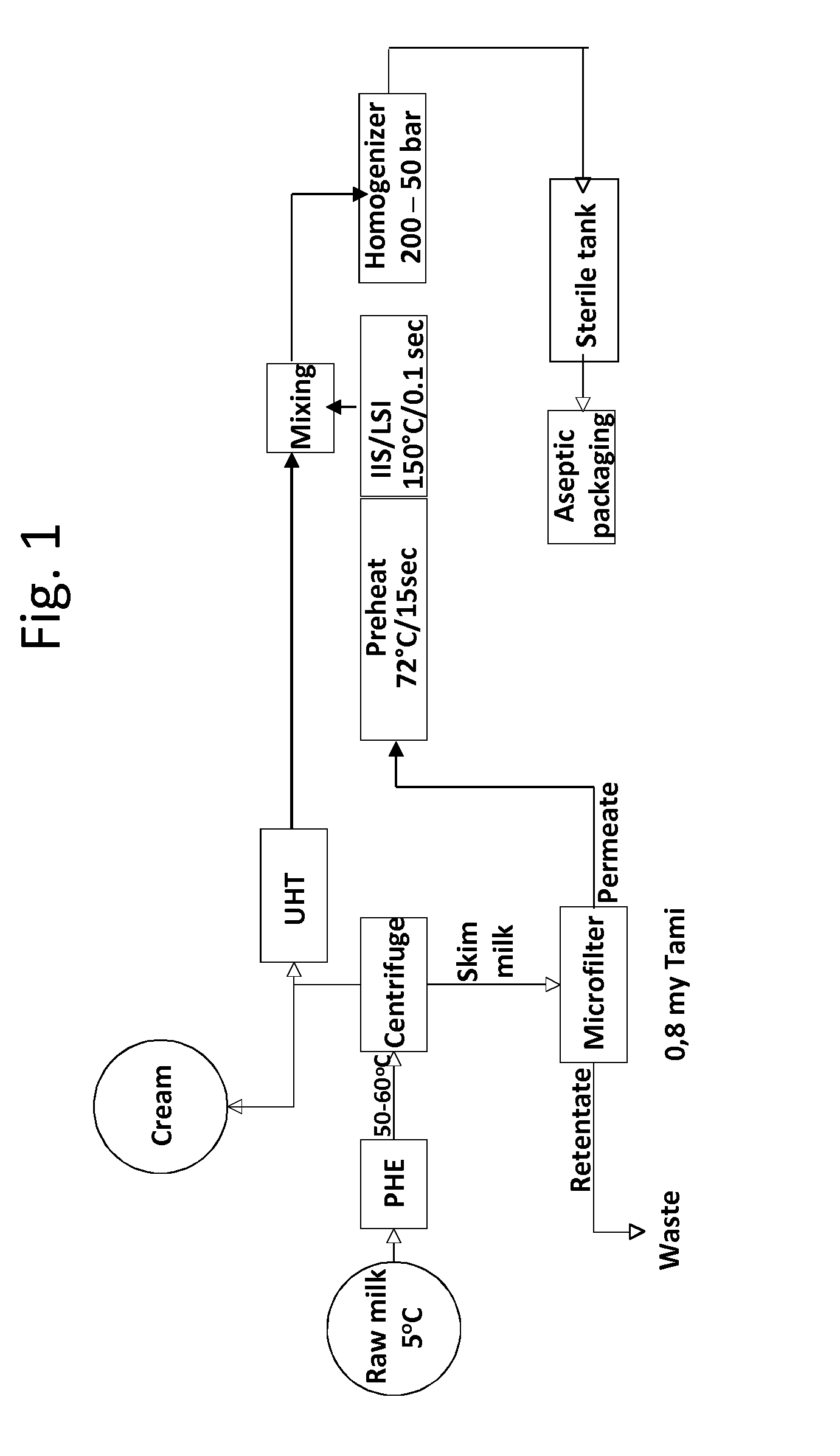

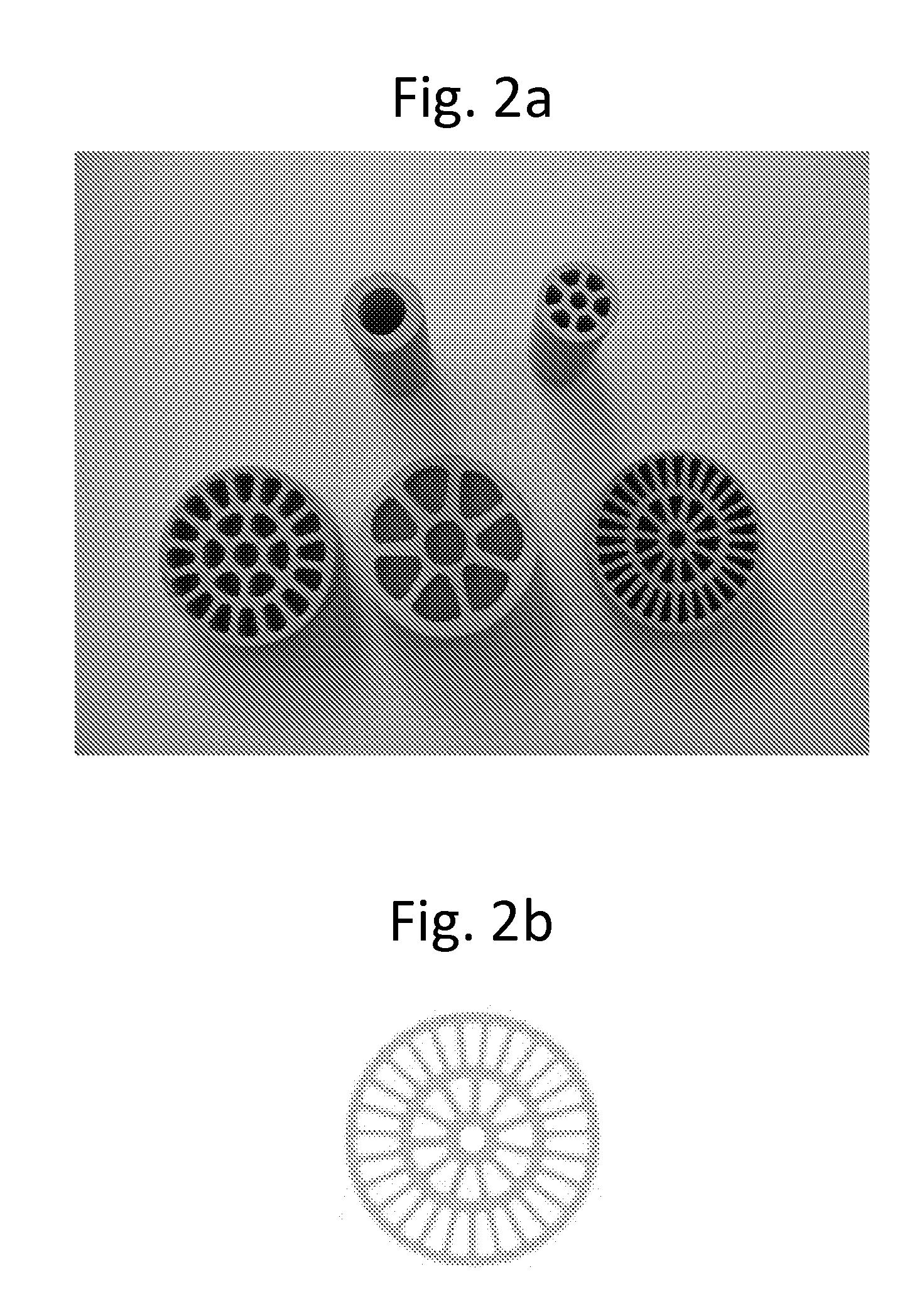

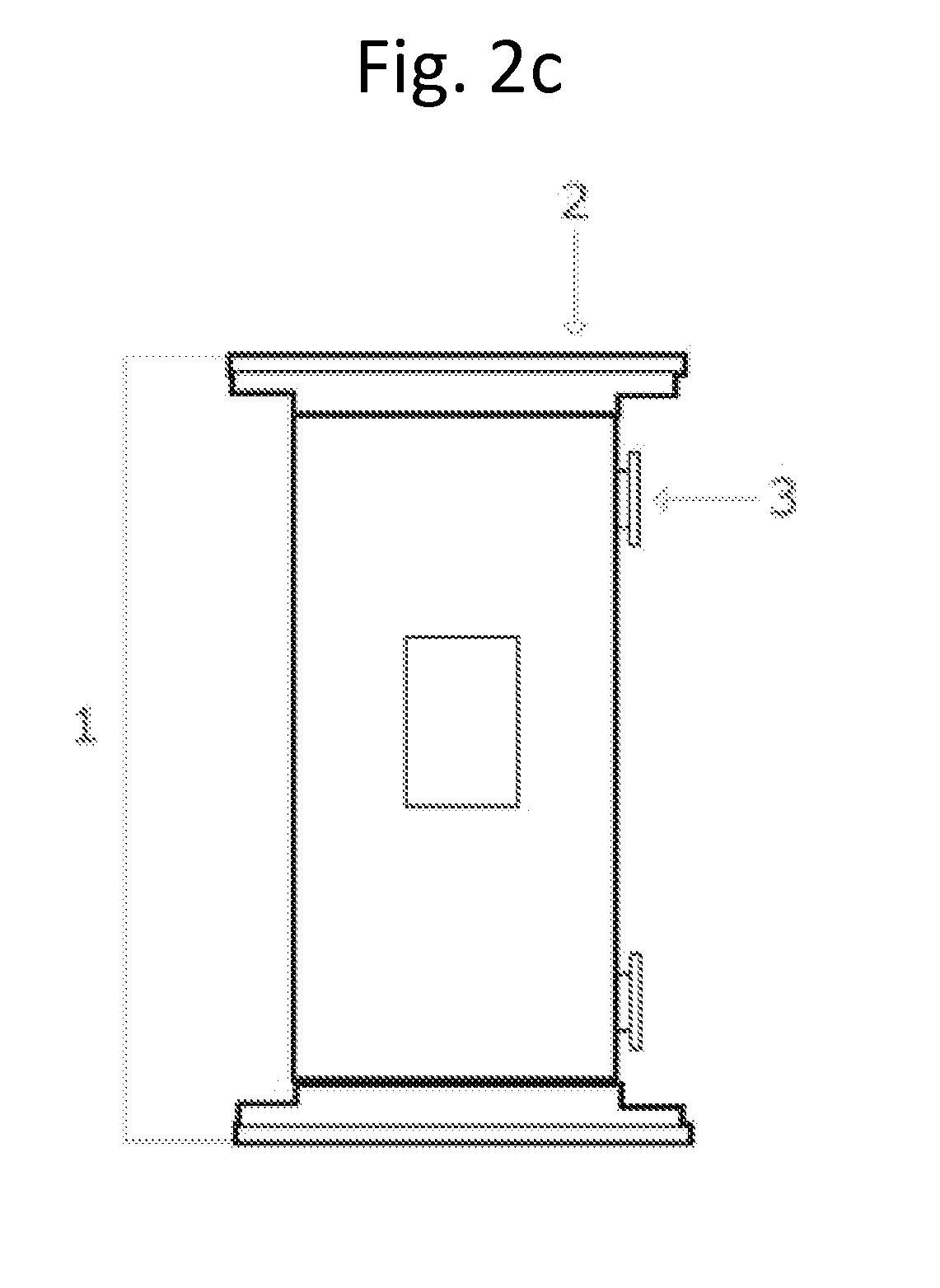

Long shelf life milk and milk-related products, and a process and milk processing plant for their manufacture

InactiveUS20120015082A1Extended shelf lifeHigh energy consumptionMilk preparationDough treatmentPhysical separationProcessing plants

The present invention relates to long shelf life milk or milk-related products as well as to a method for producing such long shelf life products and a milk processing plant for the implementation of the method. The method of the invention is characterised by the combination of physical separation of microorganisms and a high temperature treatment for at most 200 msec, and the resulting product has been found to have advantageous properties.

Owner:ARLA FOODS AMBA

Method for preparing bleached chemi-mechanical pulp fore culture paper making by using cotton wood to process remainder

ActiveCN101613975ATake advantage ofEnergy saving and environmental protection in pulping processPretreatment with water/steamPulp bleachingHigh intensityProcessing plants

The invention discloses a method for preparing bleached chemi-mechanical pulp fore culture paper making by using cotton wood to process remainder, which belongs to the field of pulp refining for making paper. The method mainly comprises presteaming, double screw extrusion, chemical impregnation, high-consistency pulp refining by a double-screw fiberizer, adding medicament in the pulp refining process, high-consistency stay, middle-consistency pulp refining and other steps. The pulp refining process adopts single-section double-screw extrusion and single-section alkaline hydrogen peroxide impregnation, has simple process flow and compact equipment, completely adopts home equipment and saves the investment. The chemi-mechanical pulp prepared by processing cotton wood remainder through the method has the characteristics of high bulk, strength, whiteness and the like, and is suitable for pulp to be used for paper making of medium-high grade culture paper. The method achieves the cleanness and high-efficiency utilization of the remainder of the cotton wood processing factories, and is suitable for medium-small paper making enterprises for producing culture paper dependent on outsourcing goods.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Dry-mixed mortar with waste stone dust in stone mining and processing plant as aggregate and filler

InactiveCN101538139APromote environmental protectionEcologically goodSolid waste managementStone dustMetakaolin

The invention belongs to the technical field of civil engineering material, specifically relates to a dry-mixed mortar with waste stone dust in stone mining and processing plant as aggregate and filler. The dry-mixed mortar is composed of 0.08-5mm of waste stone dust, 0-0.08 mm of waste stone dust, cement, fly ash, metakaolin, calcium hydroxide and water holding thickening agent; with the dry-mixed mortar of the invention adopted, the waste stone dust accounting for 55-75% of the weight of the mortar product can be recycled, thus being environmentally friendly and ecologically friendly. The dry-mixed mortar of the invention not only makes good use of waste material but also features good environmental protection; in addition, the mortar features good water retention rate, fine Constructability, high index of strength and durability, low shrinkage factor and certain crack-resistant property. With all the advantages, the product of the invention can be widely applied to plastering, masonry and land disposal of civil engineering projects of all types.

Owner:湖北昂富新型材料有限公司

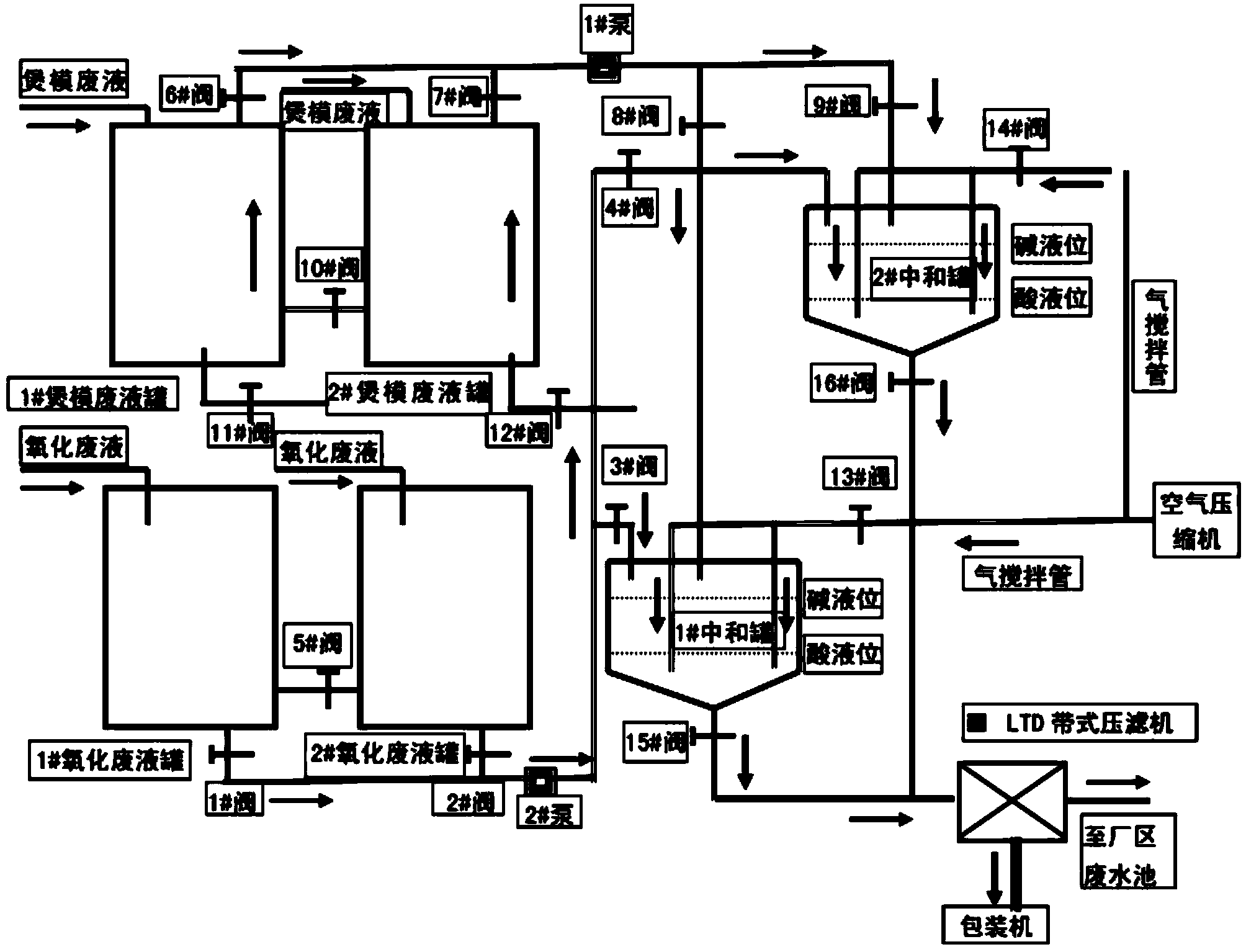

System for neutralizing treatment of demoulding waste liquor and anodic oxidation waste liquor and recovery of aluminum ions of aluminum processing plant

ActiveCN103451436ALower resistanceSimple structureWater contaminantsWaste water treatment from metallurgical processAluminum IonHydrogen

The invention discloses a system for neutralizing treatment of demoulding waste liquor and anodic oxidation waste liquor and recovery of aluminum ions of an aluminum processing plant. The system comprises an alkaline system, an acidic system, a neutralizing system, a pneumatic agitating system and a filter press and packaging system, wherein the alkaline system and the acidic system are respectively connected to the neutralizing system through pipelines; the pneumatic agitating system is arranged in the neutralizing system; the filter press and packaging system is arranged at the back of the neutralizing system through a pipeline; and another pipeline connected with a wastewater tank is arranged on the filter press and packaging system. The alkaline system is composed of a No 1 demoulding waste liquor tank, a No 2 demoulding waste liquor tank, a No 1 pump and pipelines. The neutralizing system is composed of a No 1 neutralizing tank, a No 2 neutralizing tank and pipelines. According to the system, oxidization waste liquor and demoulding waste liquor of the aluminum processing plant are conveyed to a neutralizing tank to be subjected to complete harmless treatment within pH (Potential of Hydrogen) of 6 to 8; a large amount of aluminium hydroxide byproducts can be recovered; and the cost of treating waste liquor can be greatly decreased.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

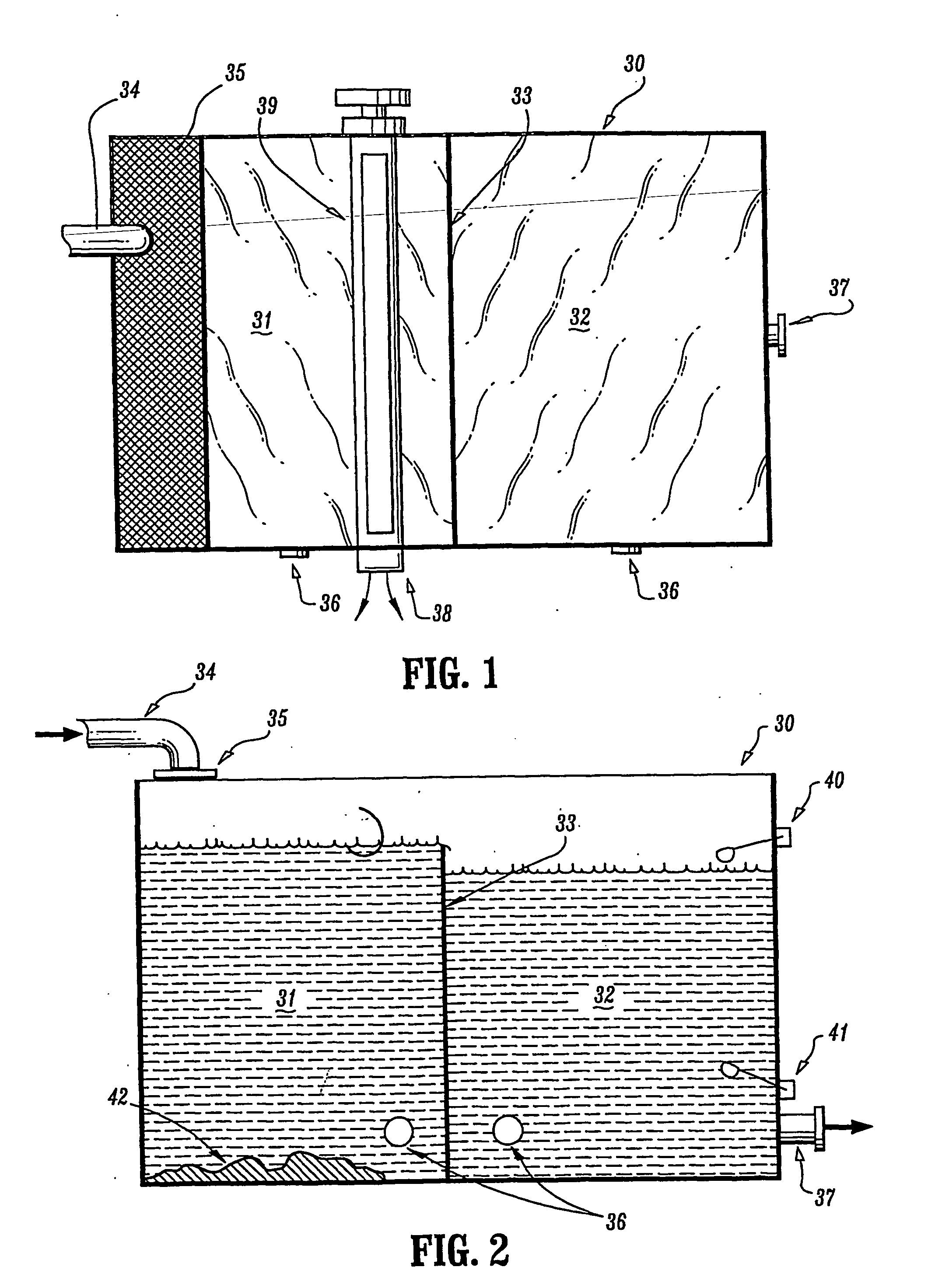

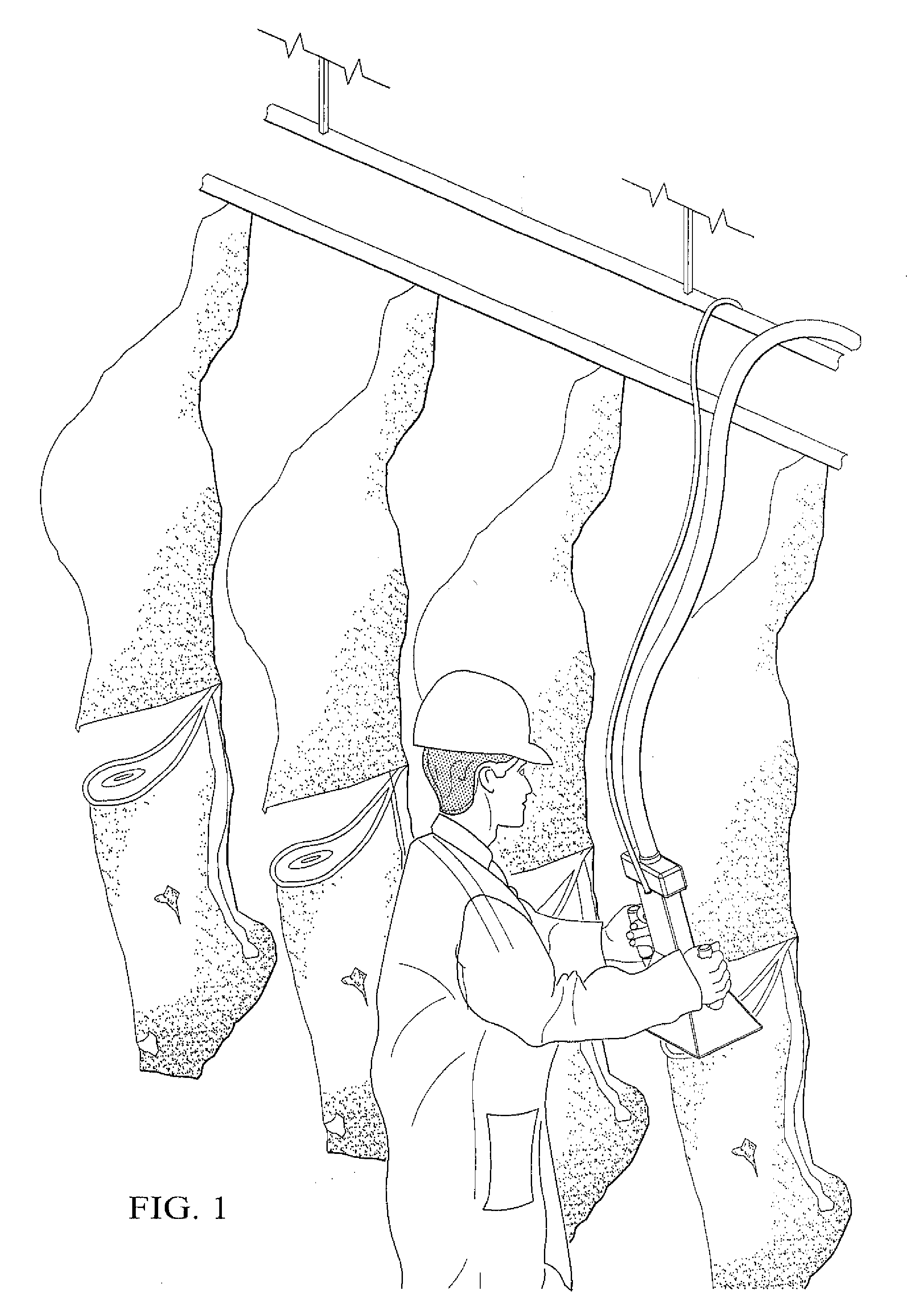

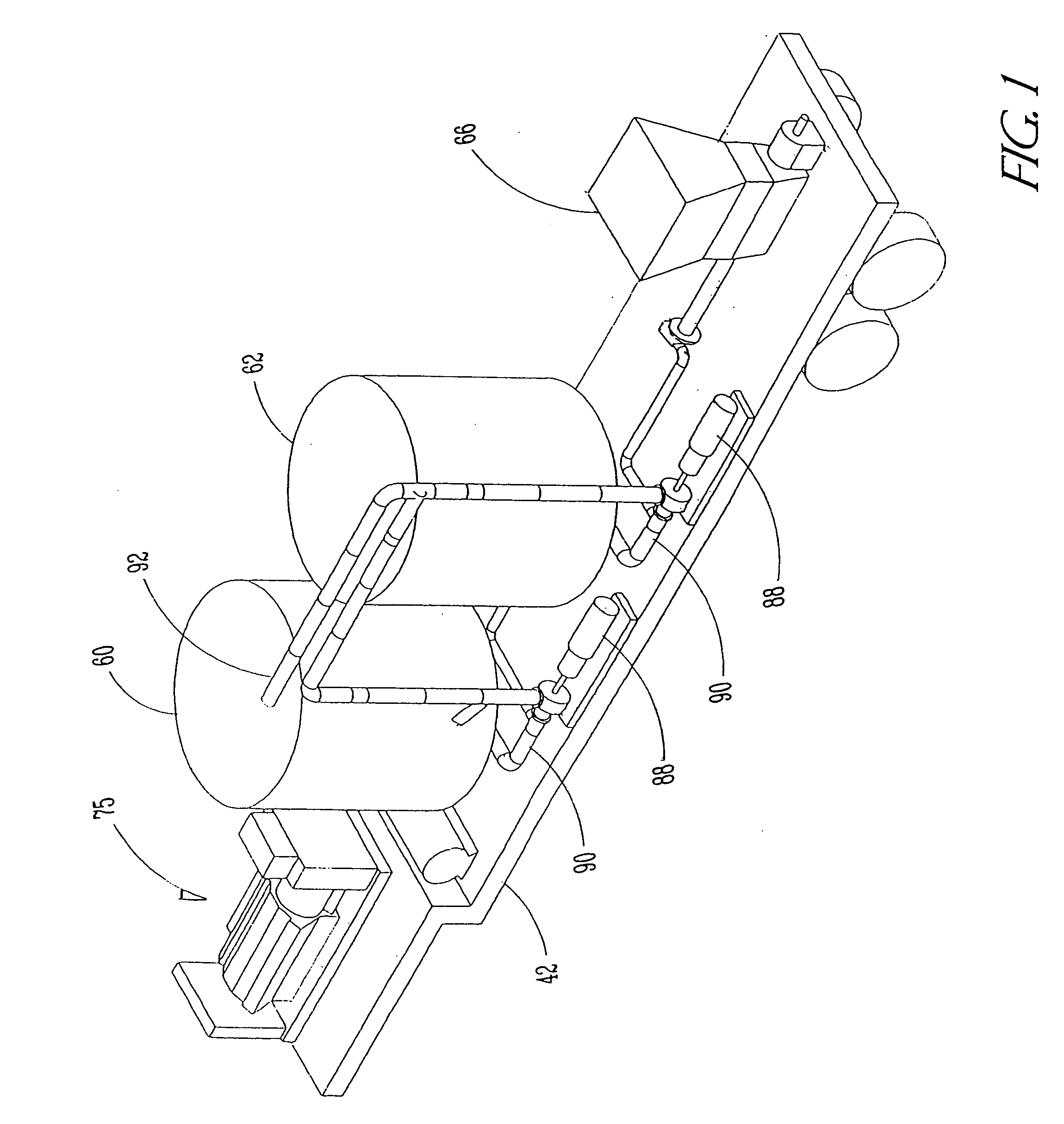

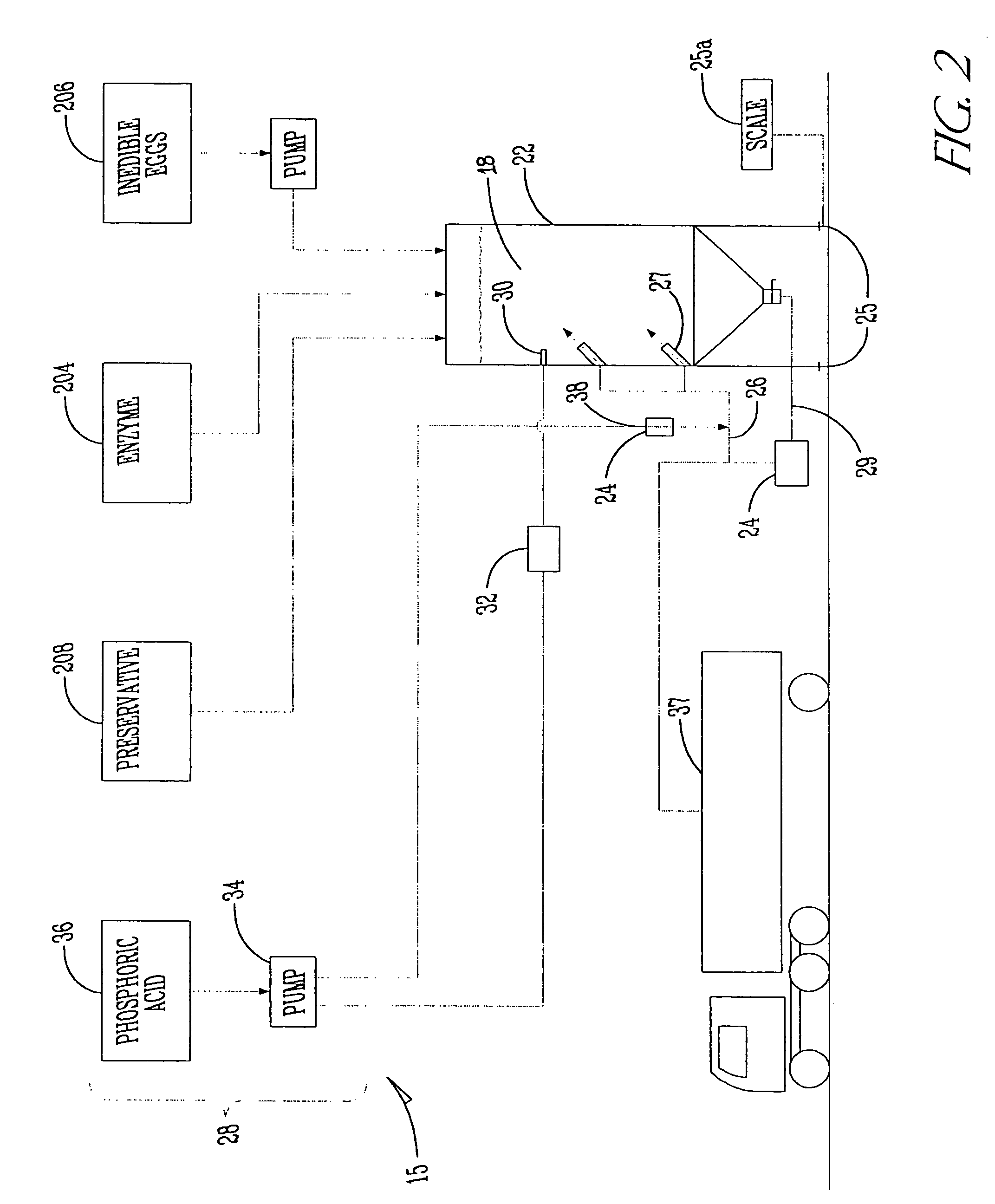

Apparatus for natural recycling of protein waste

ActiveUS20040265993A1Minimizing growth of bacteriaEfficient processBioreactor/fermenter combinationsSlaughtering animals fettering apparatusTruck-trailerProcessing plants

An apparatus and process for naturally recycling poultry carcasses for use as a nutritional supplement, the apparatus generally consists of four modules: an enzymatic digest medium mixing assembly that self adjusts for pH; a mobile grinding assembly mounted on a truck trailer; a digesting and emulsifying assembly which includes a heated tank and separator; and a drying system. Carcasses are loaded into the grinder, and the ground carcasses are pumped into a storage tank with the enzymatic digest medium to produce a protein soluble mixture. The particle size of this mixture is then further reduced, and transported to a centralized and stationary processing plant for digesting and emulsifying. The remaining emulsified proteins are then dried. The resulting pellet-like pieces are uniformly sized for packaging.

Owner:NATURALLY RECYCLED PROTEINS INC +1

Apparatus and method for exclusively removing VOC from regeneratable solvent in a gas sweetening system

A method for removing residual VOC components from a fluid stream used in the sweetening of sour gas at gas processing plants. In a retrofit configuration, the method includes interposing a supplemental VOC removal station after a primary VOC removal station in an absorbent fluid stream. The absorbent fluid stream incorporates fluid into which sour gas components and VOC have been absorbed from a treated gas stream such as produced natural gas. The primary VOC removal station is configured to remove an initial portion of the absorbed VOC from the absorbent fluid stream. The supplemental VOC removal station is configured to liberate a portion of residual absorbed VOC remaining in the absorbent fluid stream downstream from the primary VOC removal station. Further, the supplemental VOC removal station is configured to avoid liberating absorbed sour gas components from the absorbent fluid stream. Alternatively, a single, but enhanced performance VOC removal station is utilized to liberate a sufficient proportion of the absorbed VOC from the absorbent fluid stream.

Owner:FRONDORF MATTHEW T

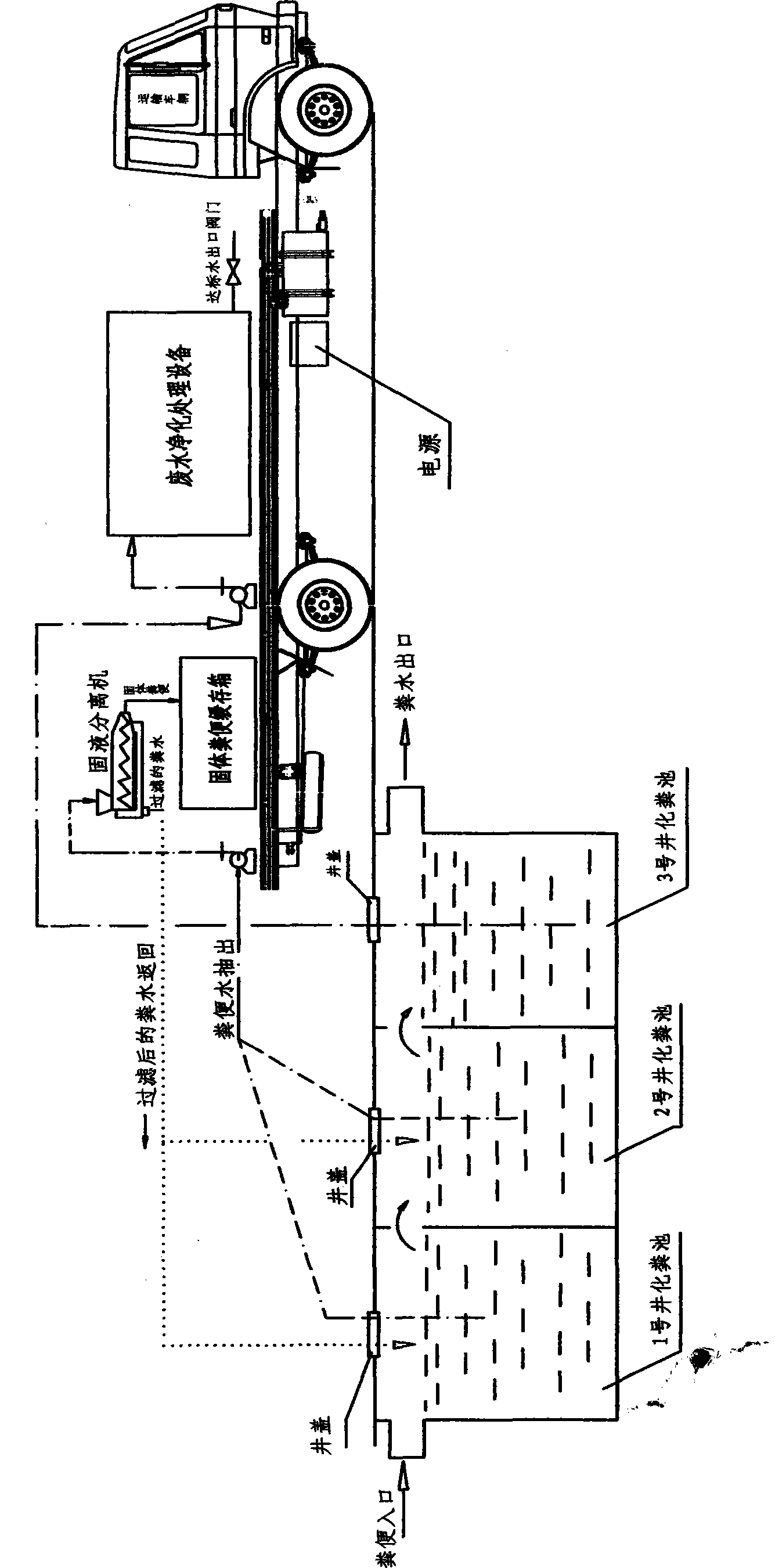

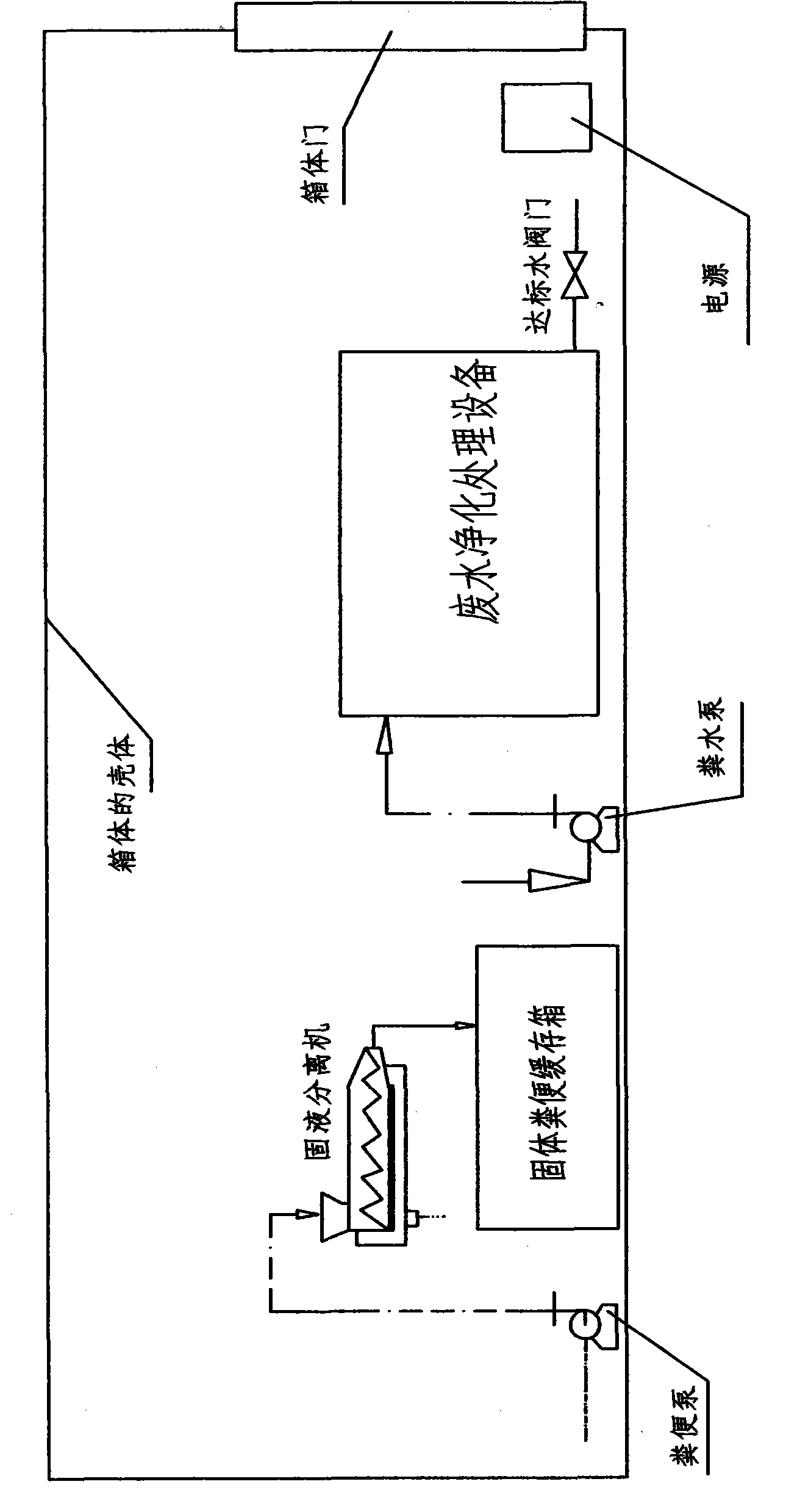

Purification treatment method of fecal water of movable toilet

InactiveCN104250051AReduce shipping costsAvoid pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWastewaterProcessing plants

The invention discloses a purification treatment method of fecal water of a movable toilet, to be more specific, according to the method, fecal water treatment purification equipment arranged on a transport vehicle or fecal water treatment purification equipment arranged in a movable box body is used for drawing out or removing solid stool in a toilet septic tank, and purification up-to-standard treatment discharge of the fecal water in the toilet septic tank can be performed; according to the method, solid-liquid separation of the fecal water in the septic tank can be performed on the spot of the septic tank, purification up-to-standard treatment of the wastewater can be realized, the separated solid manure can be transported to a specified processing plant, transportation cost of treatment of the fecal water in the toilet can be greatly reduced, unpleasant odor emitted in the transportation traditional process of the fecal water and environmental pollution caused by running, dripping and leakage can be overcome, and the purification treatment method has obvious novelty and creativity and good industrial applicability.

Owner:茂禾生态科技有限公司

Method for reducing the mercury content of natural gas condensate and natural gas processing plant

InactiveUS20100147745A1Avoid typingMembranesGas treatmentNatural-gas condensateNatural-gas processing

A method for reducing the mercury content of natural gas condensate, comprising the steps of providing a nanofiltration membrane having a feed side and a permeate side; contacting the natural gas condensate with the feed side of the membrane; and obtaining a mercury-depleted natural gas condensate at the permeate side of the membrane; and a natural gas processing plant comprising a condensate workup section including a nanofiltration membrane separation unit for reducing the mercury content of natural gas condensate.

Owner:SHELL OIL CO

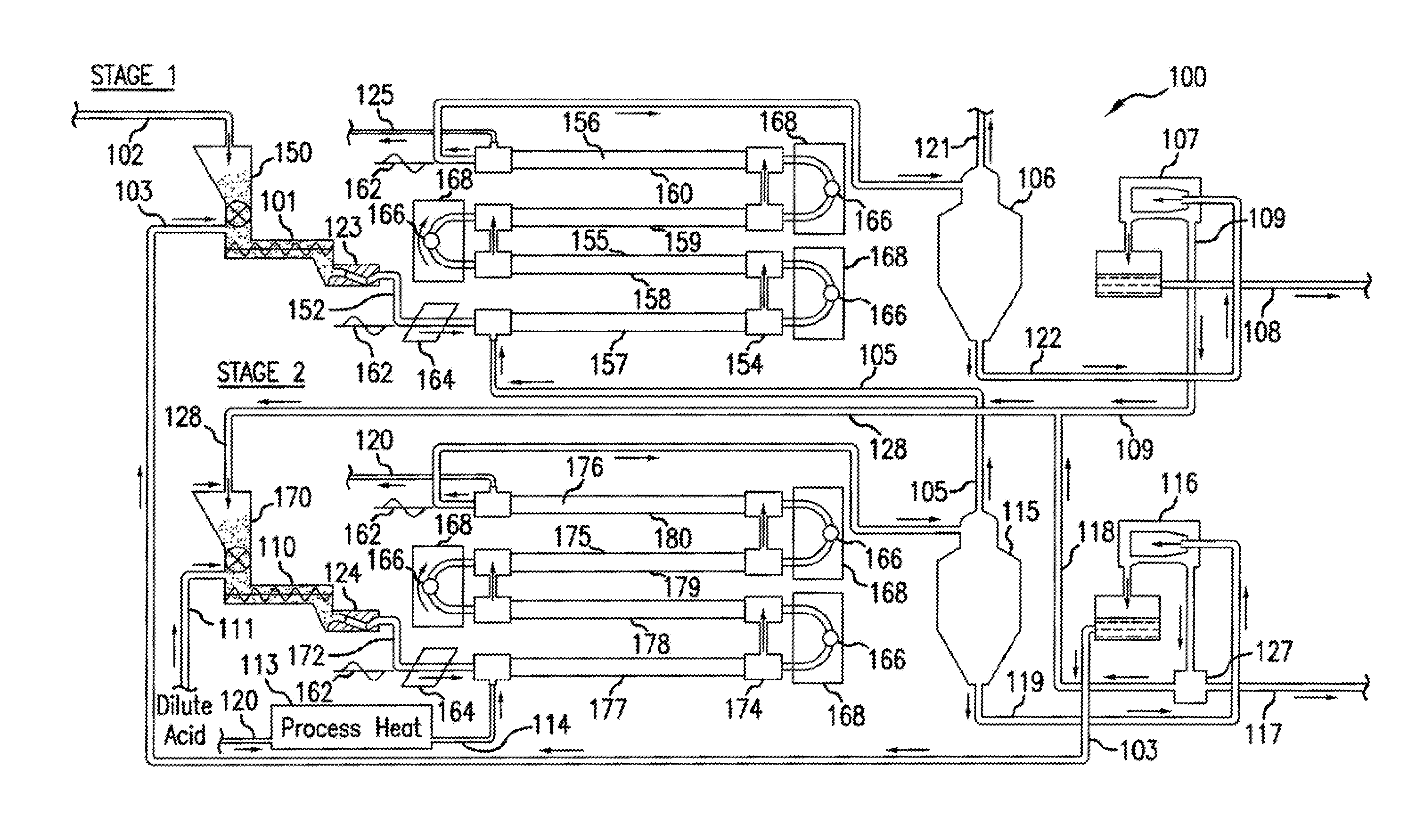

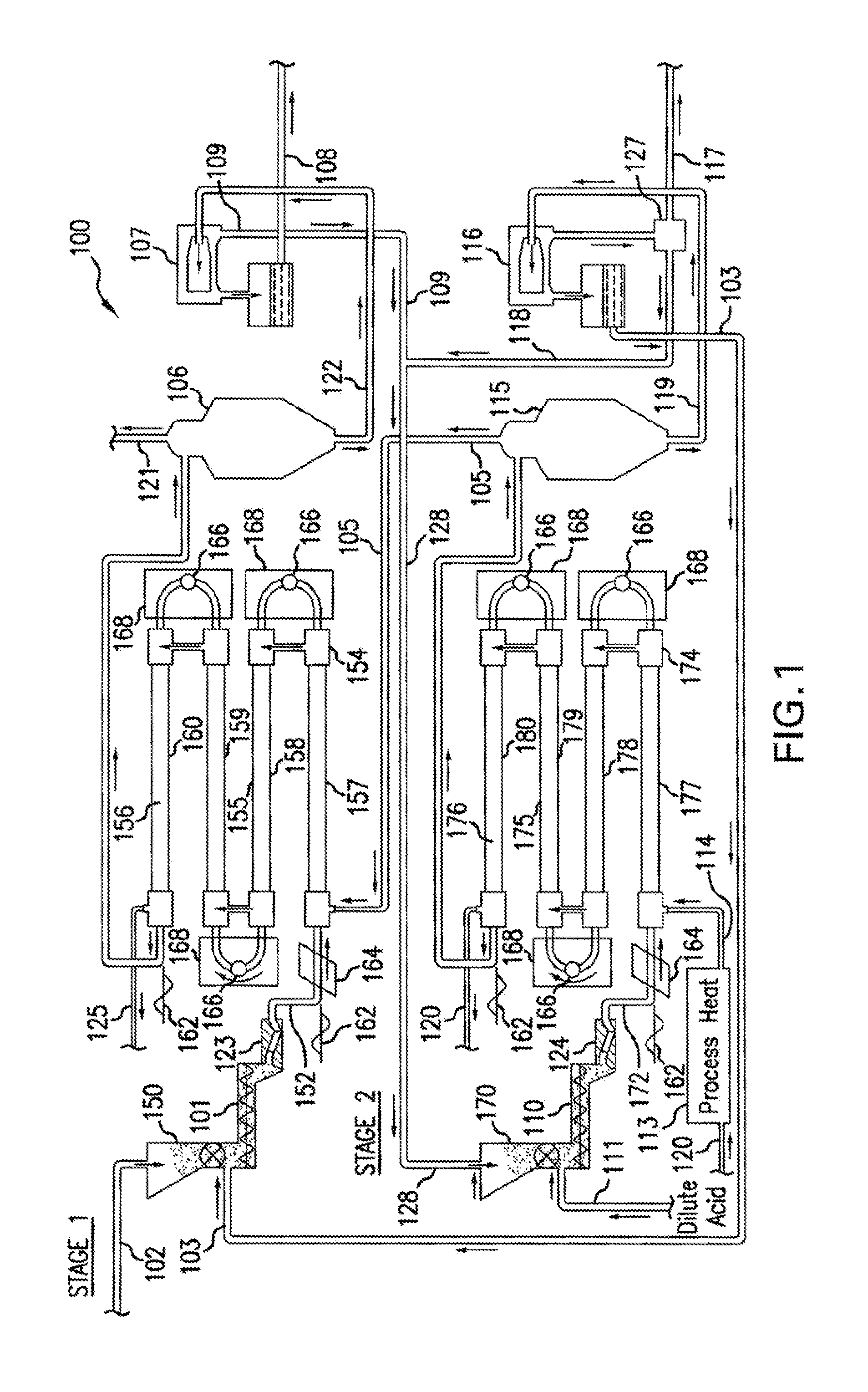

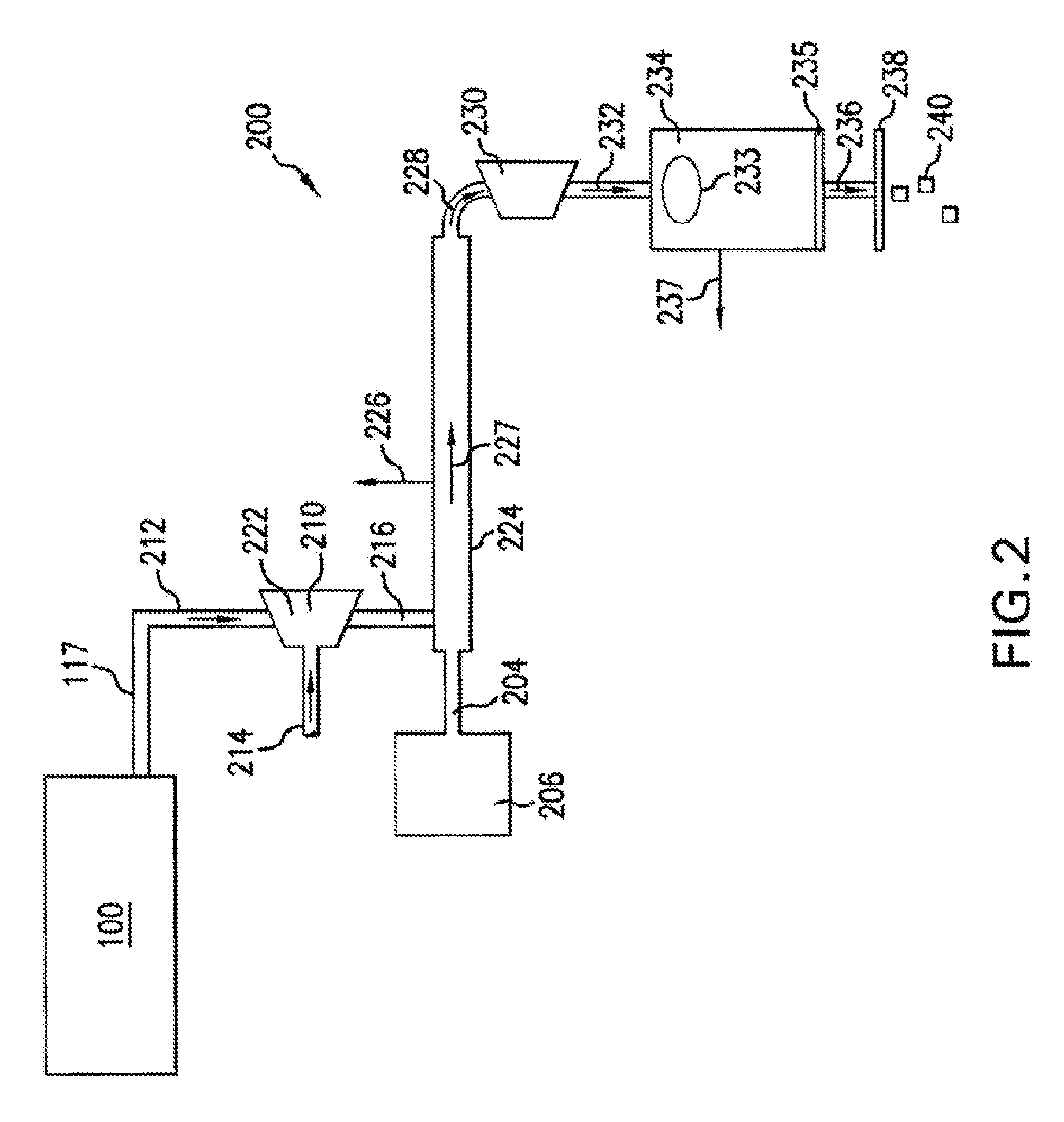

Self-contained, high efficiency cellulose biomass processing plant

InactiveUS20110060132A1Improve efficiencyImprove operationSolid waste disposalTransportation and packagingEnergy supplyHigh effectiveness

A self-contained, high efficiency cellulose biomass processing plant includes sources of quantum-based wave energy to facilitate the dilute acid hydrolysis of hemi-cellulose and alpha-cellulose bond. The sources of quantum-based wave energy supply one or more of, and suitably a combination of ultrasonic waves, ultraviolet waves, magnetic waves and direct current to facilitate fracture of the intermolecular bonds. An integrated plant is also provided which combines the cellulose biomass processing plant with apparatus for converting high protein residue into a finished high grade protein product. Due to the high efficiency resulting from use of quantum-based wave energy, the plant uses less energy, and can be small and portable.

Owner:LEWIS TED C

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com