Patents

Literature

339results about How to "Fully active" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous flow biological denitrification method based on granular sludge, and apparatus

ActiveCN103663725AStart fastReduce startTreatment with anaerobic digestion processesFiltrationSludge

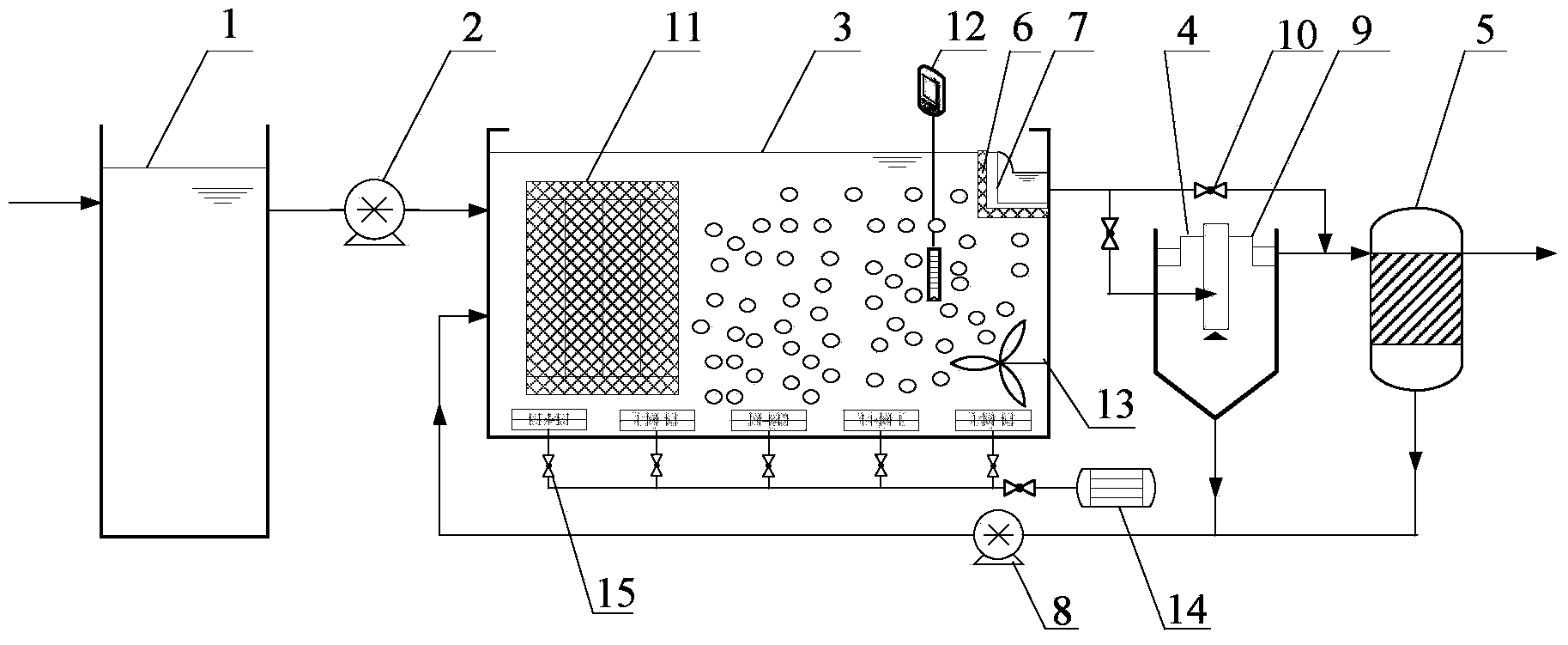

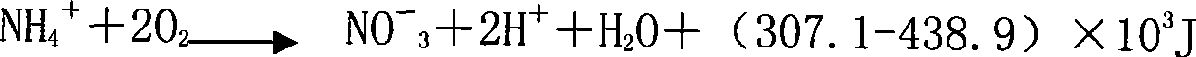

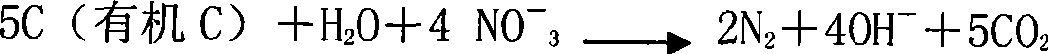

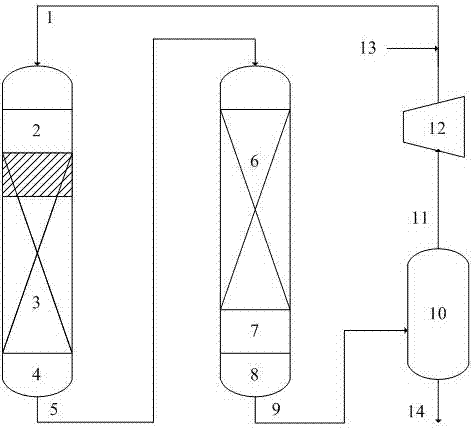

The present invention discloses a continuous flow shortcut nitrification-anaerobic ammonium oxidation biological denitrification method based on granular sludge, and an apparatus. The method comprises: 1) carrying out sludge inoculation culture, and carrying out an active sludge adaptation period; 2) starting a shortcut nitrification-anaerobic ammonium oxidation reaction; 3) performing an anaerobic ammonium oxidation granular sludge formation and growth period; and 4) performing a stable operation period of a granular sludge continuous flow system. The apparatus comprises a water inlet tank, a bioreactor, a sedimentation tank and a hydraulic screen filter, wherein the water inlet tank, the bioreactor, the sedimentation tank and the hydraulic screen filter are sequentially communicated, the influent of the water inlet tank is communicated with high ammonia nitrogen wastewater, the effluent is communicated with the bioreactor, the concentrated sludge on the bottom of the sedimentation tank is communicated with the bioreactor through a sludge reflux pump, a fixation filler, a stirrer, a filtration screen and an aeration head communicated with an air compressor are arranged inside an anoxic reactor, the sedimentation tank is provided with a clear overflow port communicated with the hydraulic screen filter through a pipeline, the effluent of the hydraulic screen filter is the final effluent, and the retained granular sludge refluxes to the bioreactor.

Owner:BEIJING JIAOTONG UNIV

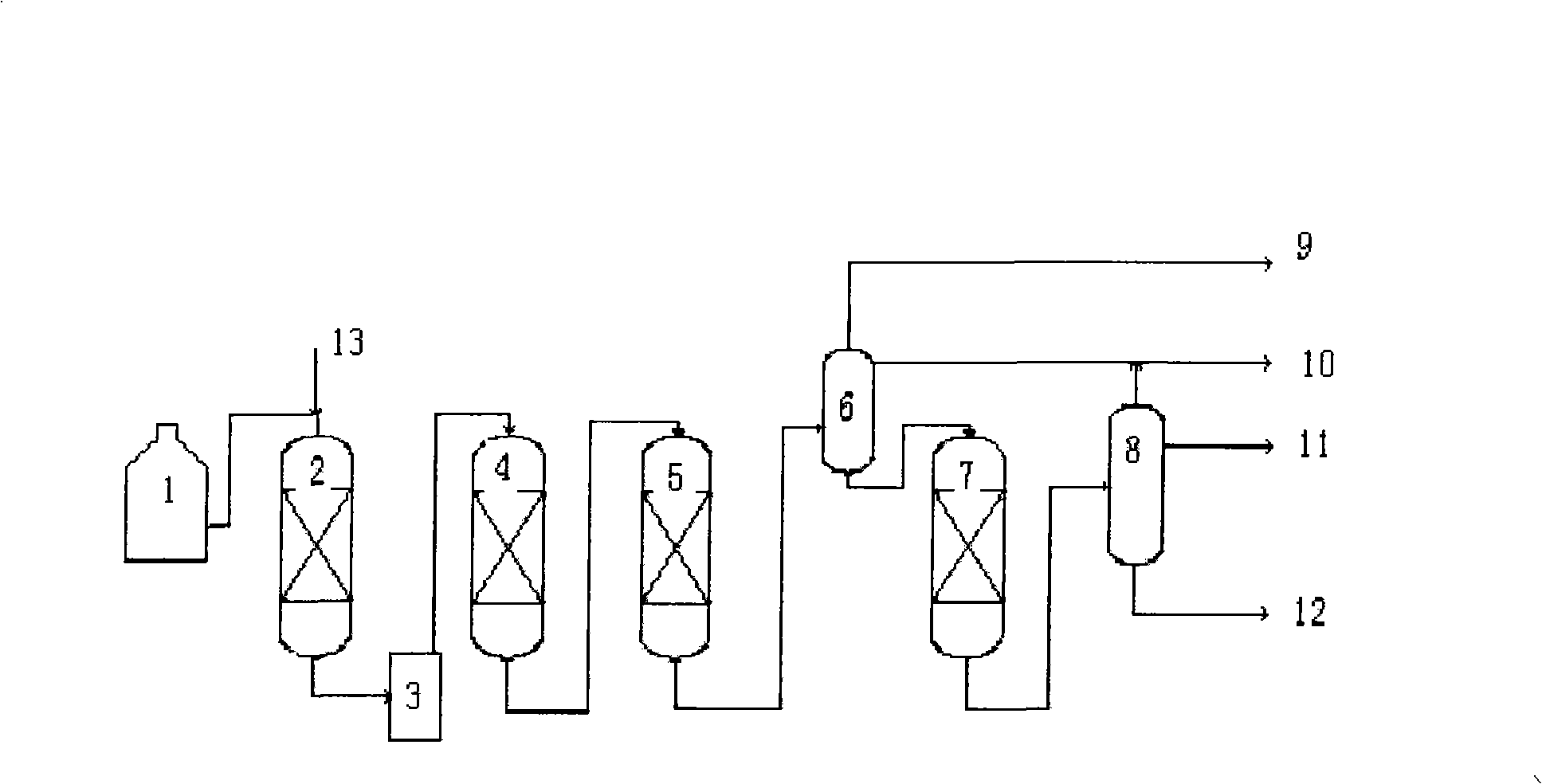

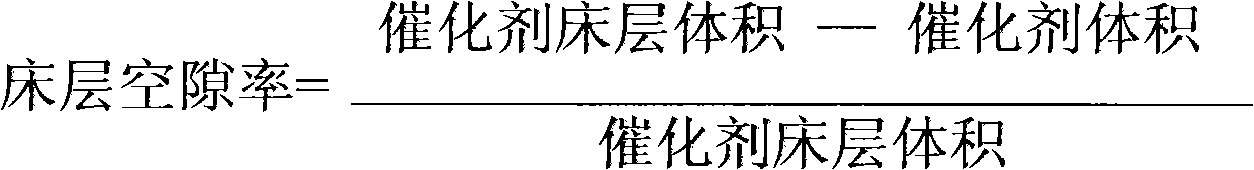

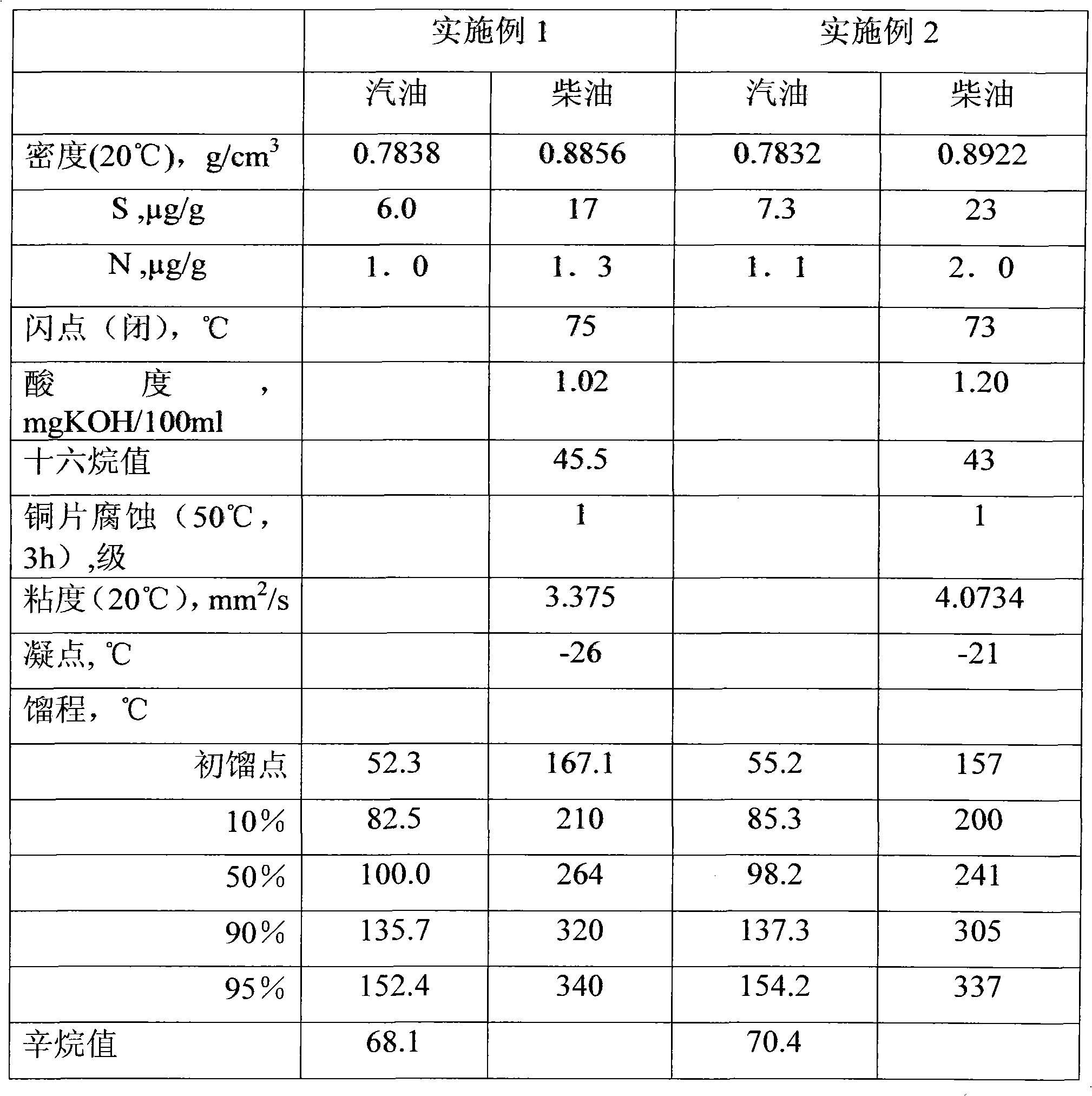

Coal tar multistage hydrogenation treatment technique

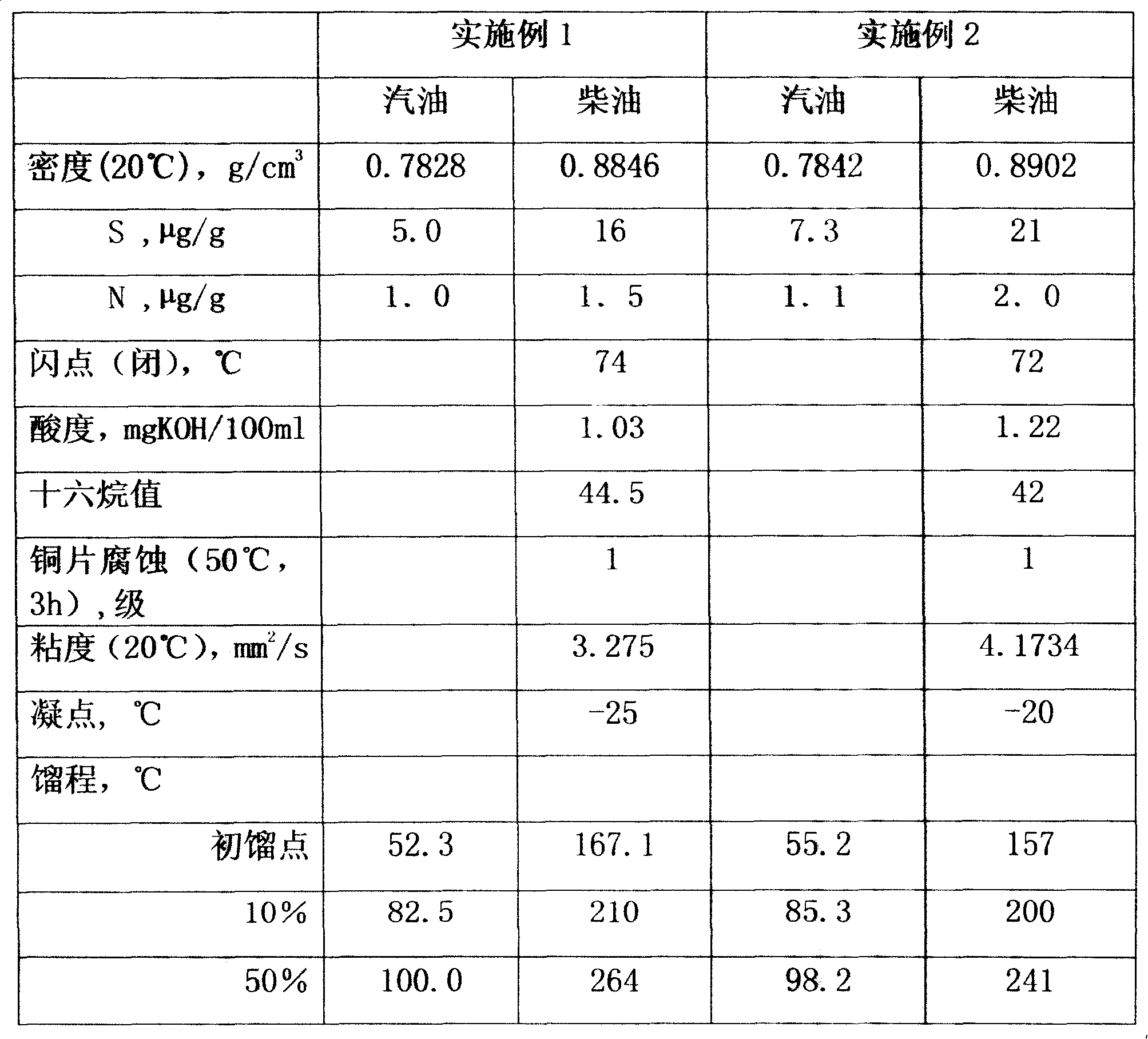

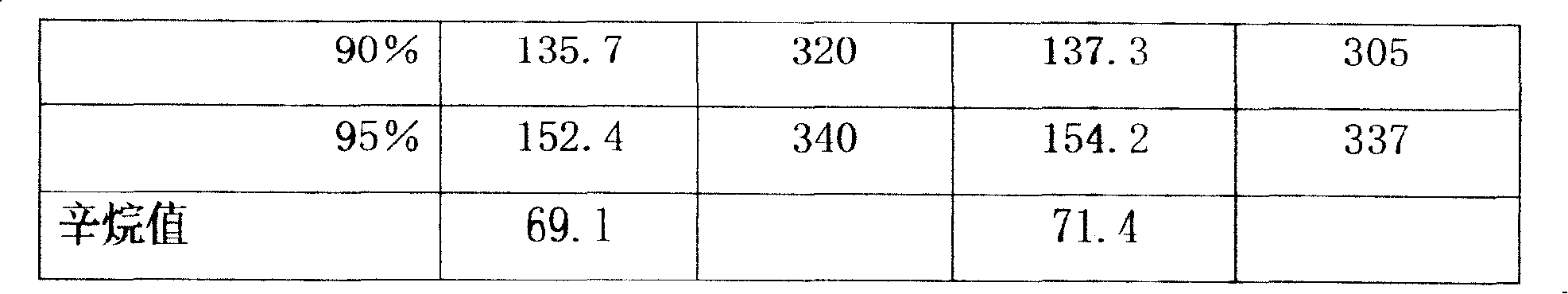

ActiveCN101240193AFully activeSolve cokingTreatment with hydrotreatment processesHydrogenation reactionGasoline

The invention discloses a coal-tar oil multistage hydrogenation craft, which belongs to coal chemical industry technology area. The method of the invention is that coal-tar oil fraction oils like impurities, sols, high content, asphaltenes, oxygen element, and so on, with high content or entire fraction are delivered into pre-hydrogenation reaction chamber by pump and are carried on pre-hydrogenation processing, then are successively followed by hydrogenation and demetallization, and depth hydrogenation reaction. After carried on separation of water and lightweight components, the generative fluid enters into a hydrocracking reactor, passes by a distiller to get gasoline fractions, diesel oil and hydrocracking tail oil out. Compared with the prior art, the invention can guarantee the long-period stability operation of the installation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment process for garbage leachate

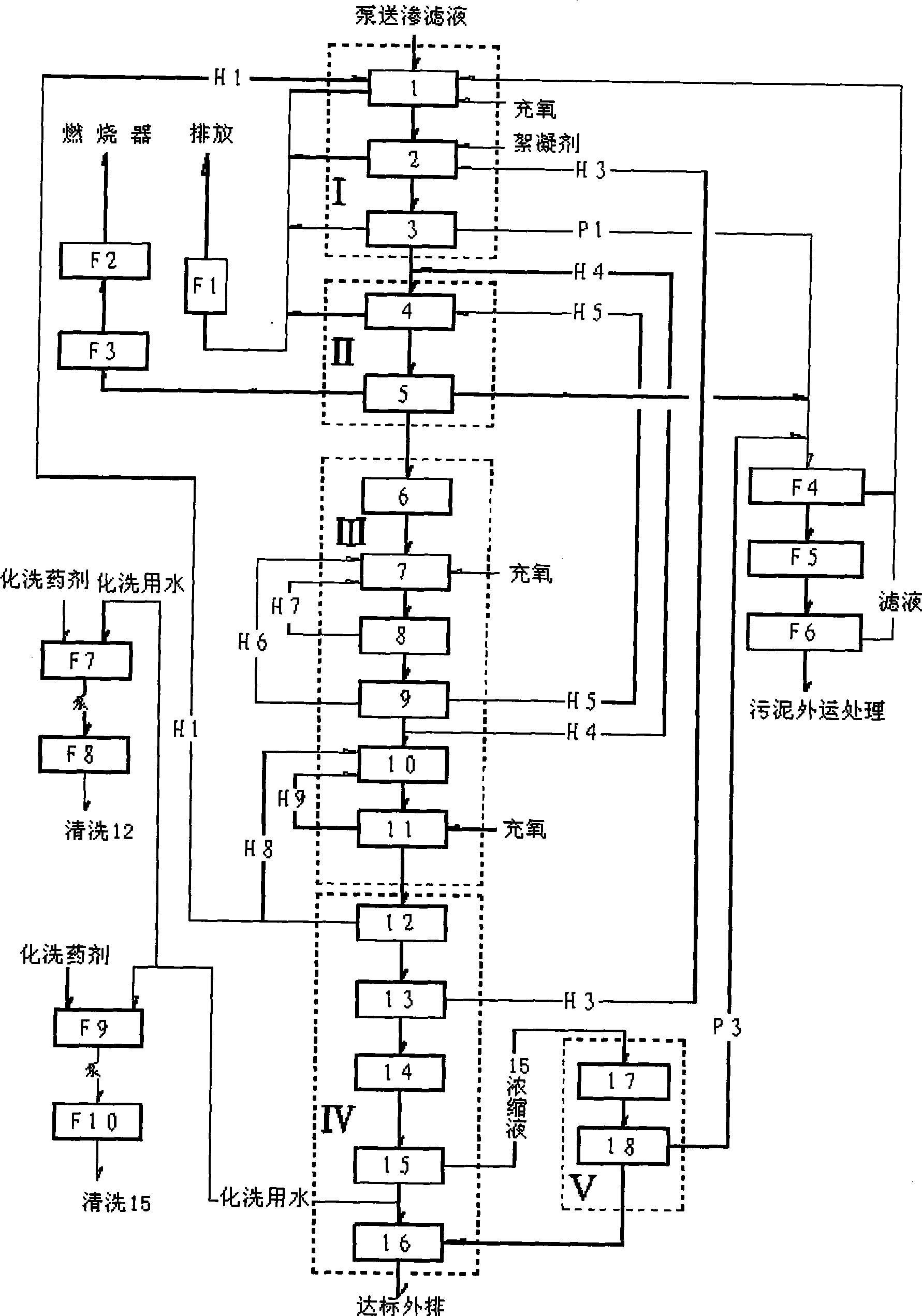

ActiveCN101428938AImprove biodegradabilityPrevent rancidityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationHydrolysis

The invention discloses a method for treating landfill leachate, which orderly comprises flocculation precipitation pretreatment, hydrolysis pre-acidification treatment, anaerobic treatment, aerobic treatment comprising shortcut nitrification-denitrification and secondary nitrification-denitrification, membrane separation treatment and oxidation flocculation treatment. The method has the advantages of having higher removal rate of ammonia nitrogen and lower energy consumption, realizing the up-to-standard discharge of leachate concentrated solution, ensuring sound operation of the whole system, greatly lowering the oxidation-reduction potential in the anaerobic reaction, and improving the anaerobic treatment effect, thereby making the landfill leachate fully meet the first-level discharge standard of the Integrated Wastewater Discharge Standard.

Owner:浙江永峰环保科技股份有限公司 +1

Hydrogenation process for producing catalytically cracked material

ActiveCN101020843AImprove processing depthExpand sourceRefining to eliminate hetero atomsHydrogenation processResidual oil

The hydrogenation process for producing catalytically cracked material includes the successive contacting and reaction of the mixture of material oil and hydrogen with hydrogenation protecting agent, residual oil hydrogenating and demetallizing agent and residual oil hydrogenating and desulfurizing agent, cooling the reaction resultants, and separating obtain hydrogen-rich liquid and gas products. The catalyst includes hydrogenation protecting agent in 2-10 vol%, residual oil hydrogenating and demetallizing agent in 5-70 vol%, and residual oil hydrogenating and desulfurizing agent 20-93 vol%. The present invention makes it possible to produce high quality catalytically cracked material via adding residual oil in 5-50 wt% into gas oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Immobilized enzyme biological catalyst, preparation method and application

InactiveCN101058824AReduce dosageImprove distributionImmobilised enzymesChemical industryDielectricPotassium

The invention relates to an immobilized enzyme biocatalyst and the manufacturing method and application. The immobilized enzyme biocatalyst regards tubular hollow silica dioxide dielectric hole material as a carrier external surface, inner surface and micropore in the wall of which are fixed biological enzyme molecule. The method includes physical adsorption cast investment or chemical coupling / crosslinking method; the biocatalyst is provided with good enzyme dispersibility and high carrying quantity, high recovery ratio of enzymatic activity, low enzyme flow rate. The invention can fix penicillin acylating enzyme, glucose oxidase, peroxidase, cytase and so on, which also can be used for removing sugar in protein, removing sugar in total egg, removing oxygen in food , microbiological sensing device, antibiosis and disinfection reaction, wherein immobilized penicillin acylating enzyme biocatalyst can be used to hydrolyze penicillin potassium and manufacture 6-APA.

Owner:BEIJING UNIV OF CHEM TECH

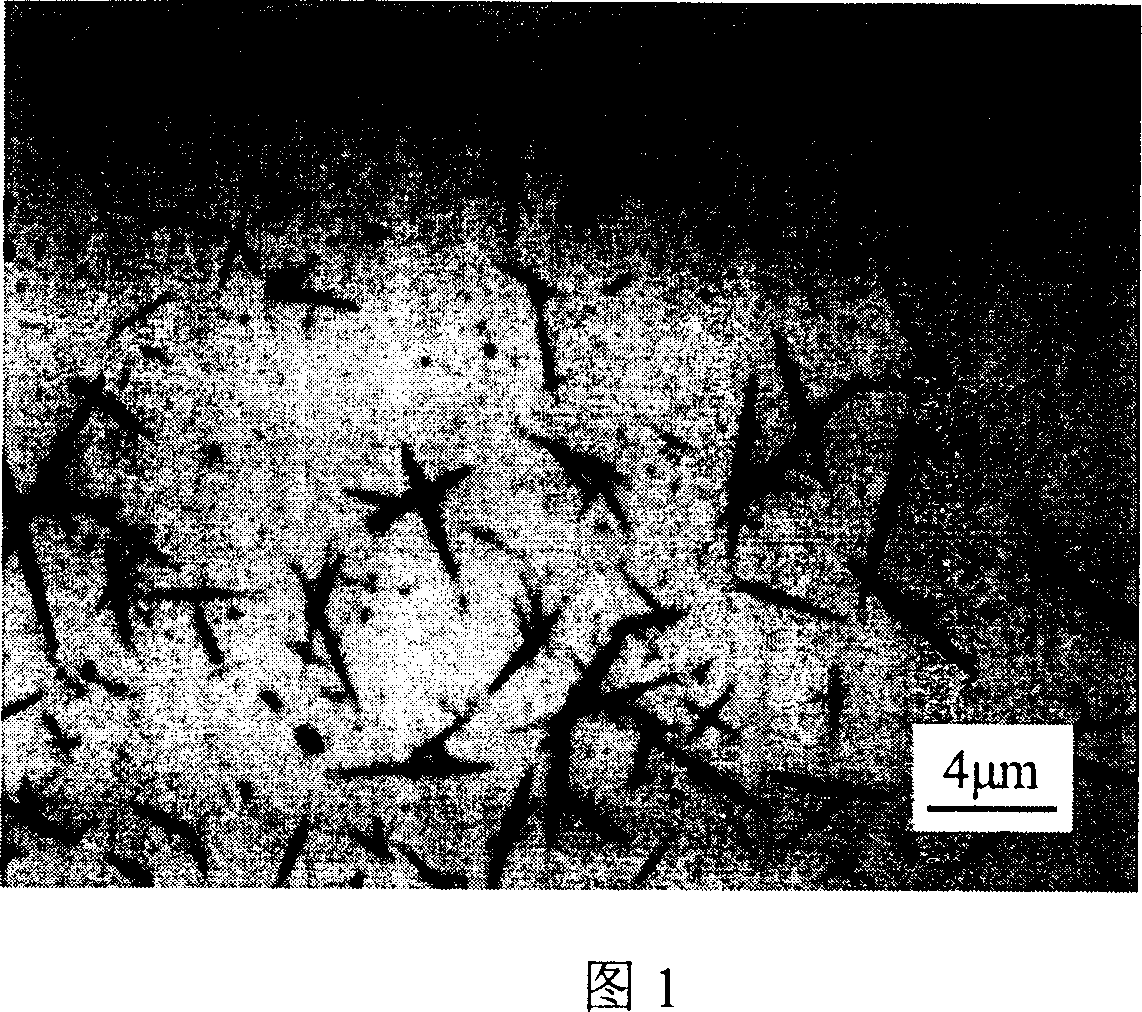

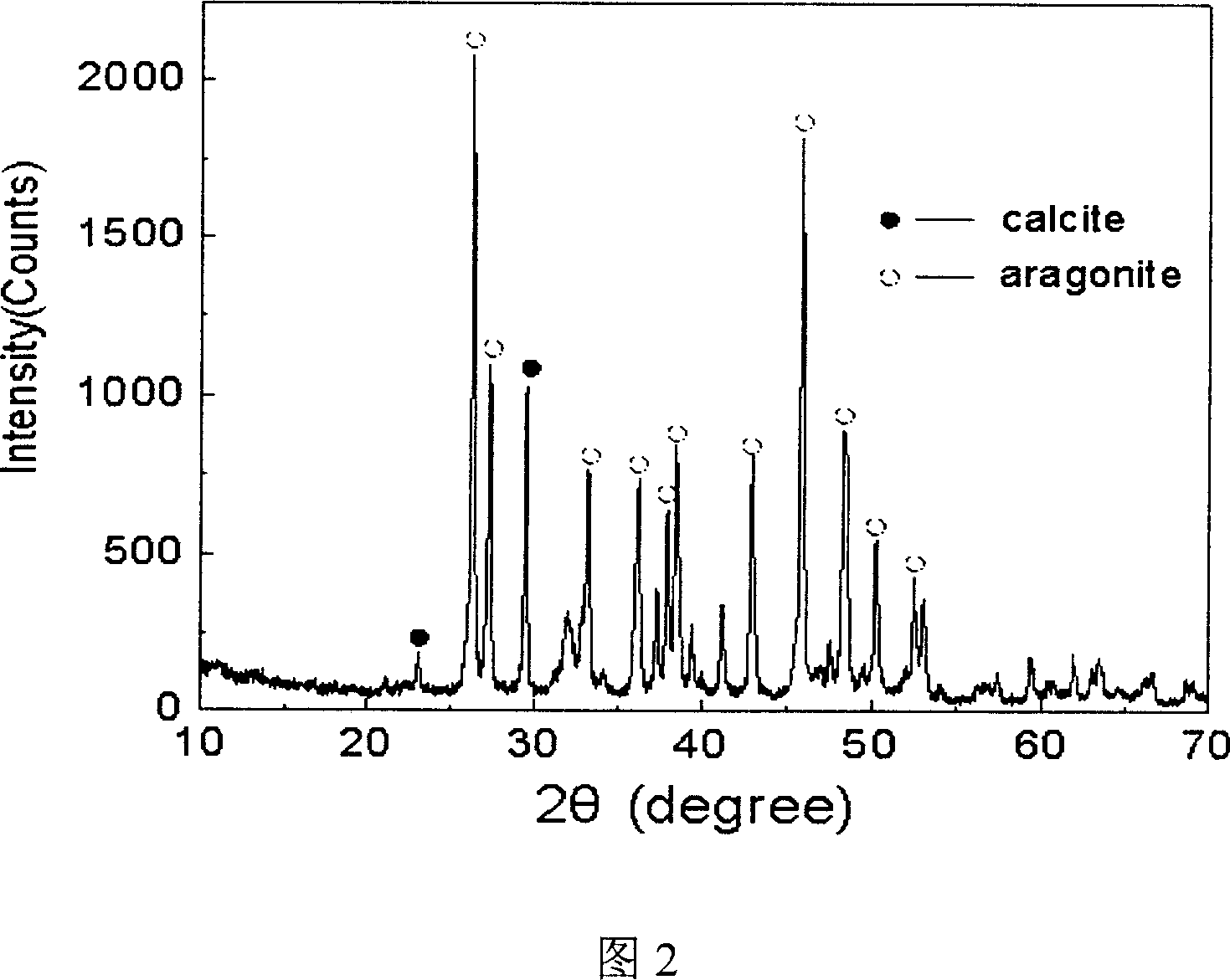

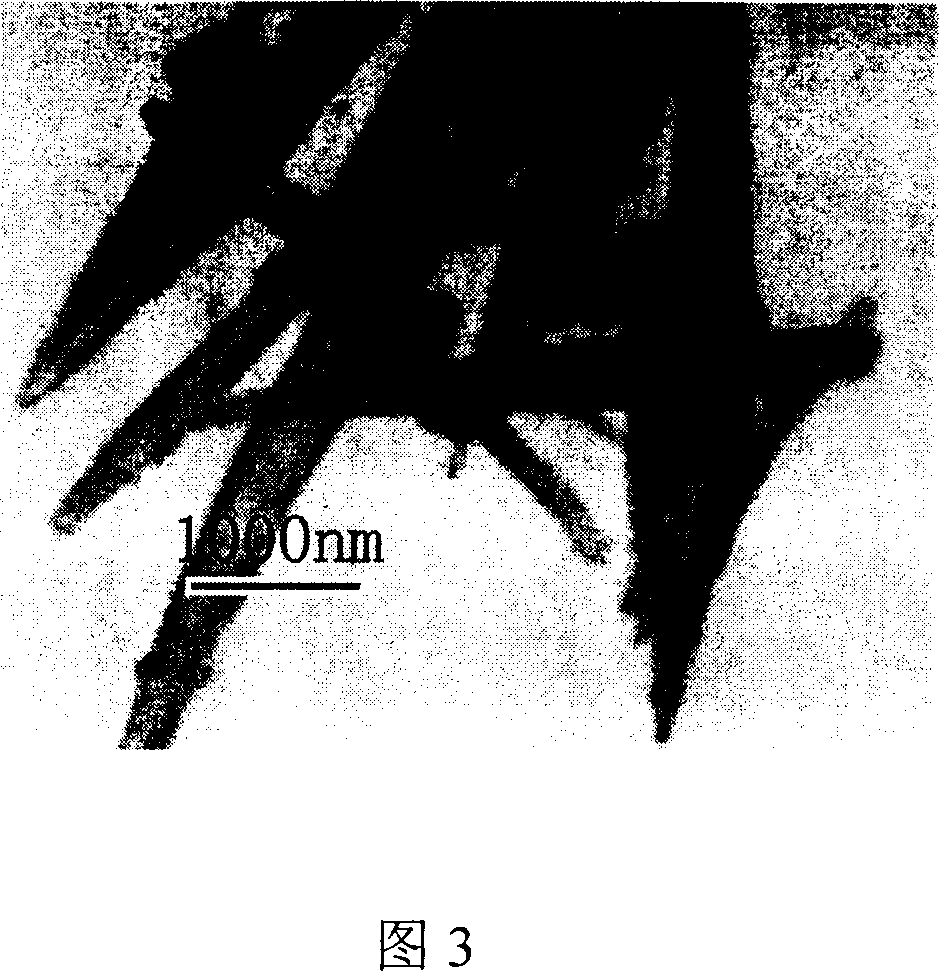

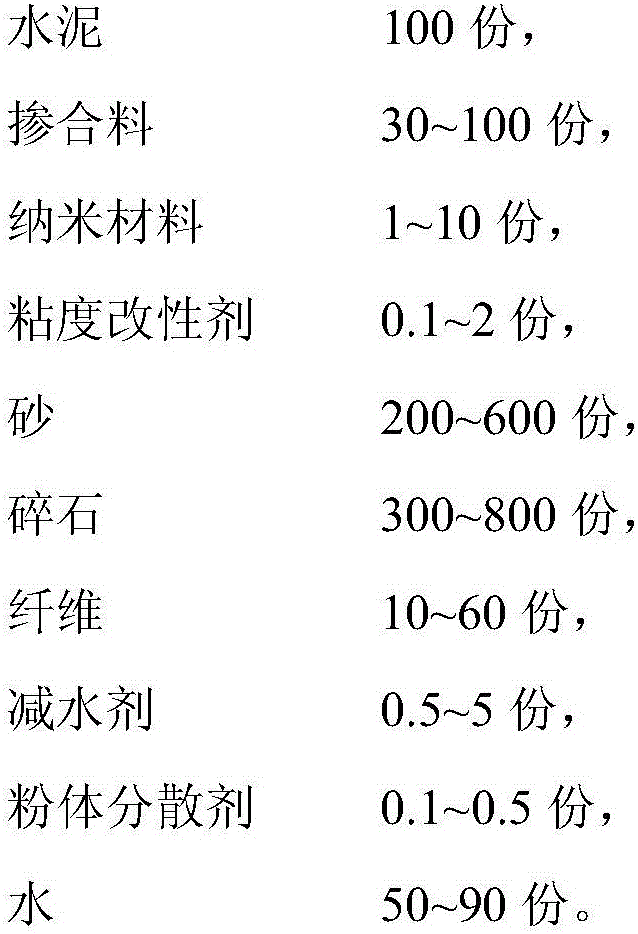

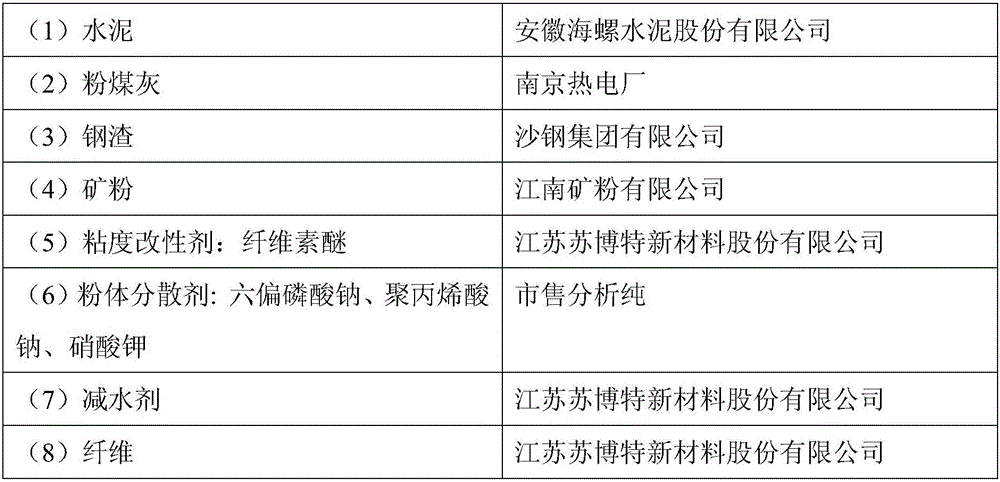

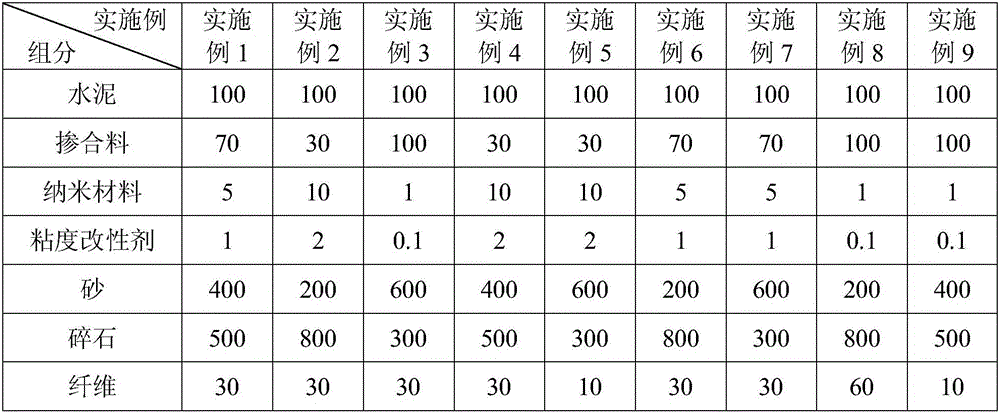

Concrete with common strength and high elastic modulus and preparation method thereof

The invention discloses concrete with common strength and high elastic modulus and a preparation method thereof. The concrete with common strength and high elastic modulus, disclosed by the invention, is prepared from the following components in parts by mass: 100 parts of cement, 30-100 parts of an admixture, 1-10 parts of a nano material, 0.1-2 parts of a viscosity modifier, 200-600 parts of sand, 300-800 parts of crushed stones, 10-60 parts of fibers, 0.5-5 parts of a water reducing agent, 0.1-0.5 part of a powder dispersant and 50-90 parts of water. After the concrete with common strength and high elastic modulus, disclosed by the invention, is subjected to standard curing or natural curing for 28d, the strength grade of the concrete is C40-C50, and the elastic modulus can reach 50GPa or more; and the concrete has excellent working performance and endurance performance.

Owner:JIANGSU SOBUTE NEW MATERIALS

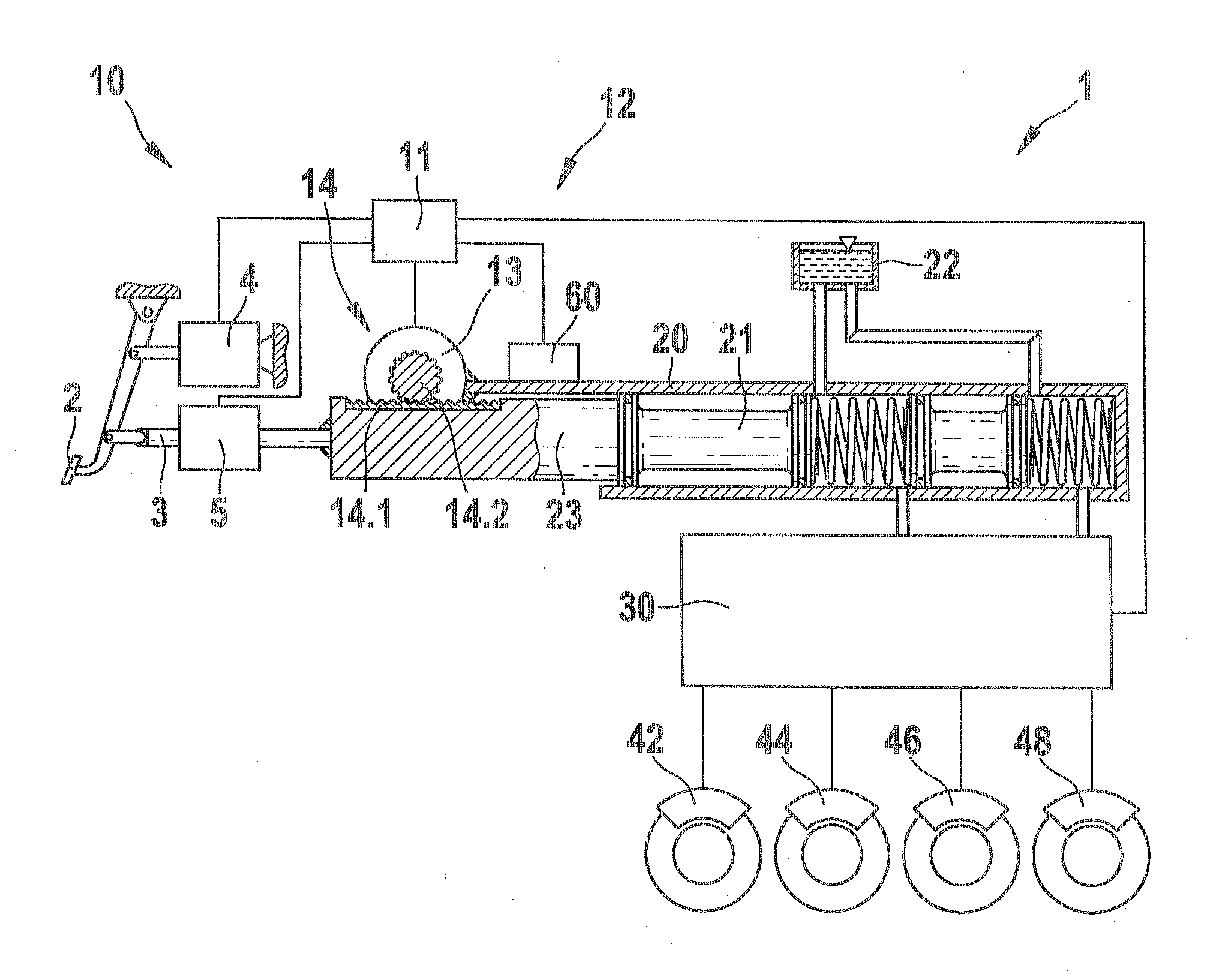

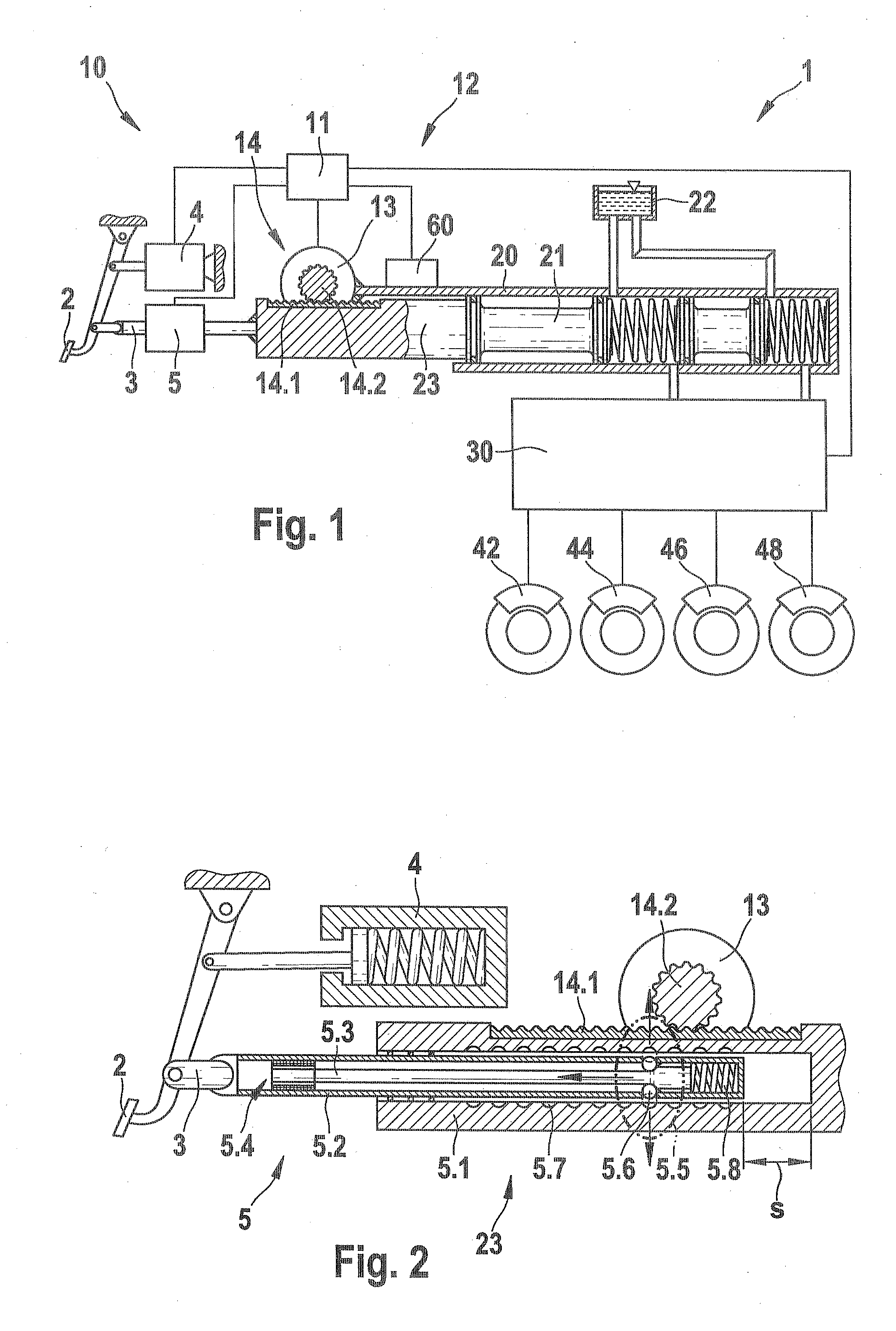

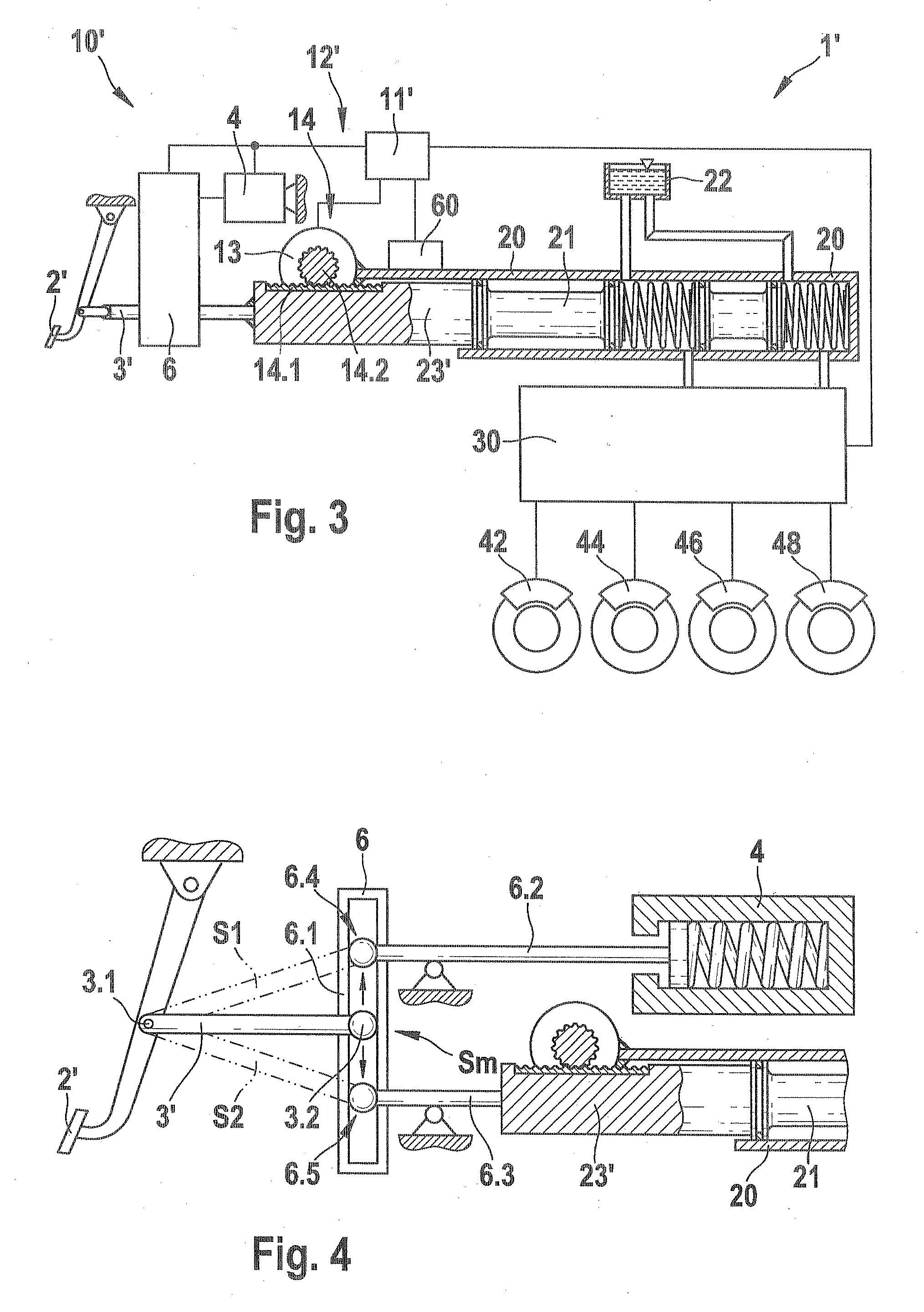

Brake system for a vehicle

InactiveUS20100114444A1Achieve feedbackFully activeAnalogue computers for trafficComputations using stochastic pulse trainsAudio power amplifierPiston

The invention relates to a braking system (1) comprising an actuator unit (10), said actuator unit comprising a brake pedal (2), a pedal simulator (4), and a brake servo (12), and a main brake cylinder (20) by way of which at least one wheel brake (42, 44, 46, 48) may be actuated, said wheel brake having a braking pressure that may be predetermined, wherein the brake pedal (2) or the brake servo (12) acts on the main brake cylinder (20) to increase or decrease a braking force. According to the invention, during a first operating mode, preferably a brake-by-wire operating mode, the braking force amplifier (12), controlled by an analysis and control unit (11), generates an outside force that acts on a piston (21) of the main brake cylinder (20), wherein the actuator unit (10) comprises a first transmission device (5) that, controlled by the analysis and control unit (11), mechanically decouples the brake pedal (2) from the piston (21) of the main brake cylinder (20) as a function of predetermined criteria during the first operating mode, or couples the brake pedal (2) to the piston (21) of the main brake cylinder (20) such that the pedal force generated at the brake pedal (2) additionally acts at least partially on the piston (21) of the main brake cylinder (20).

Owner:ROBERT BOSCH GMBH

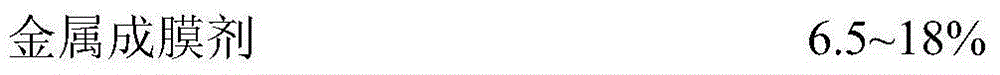

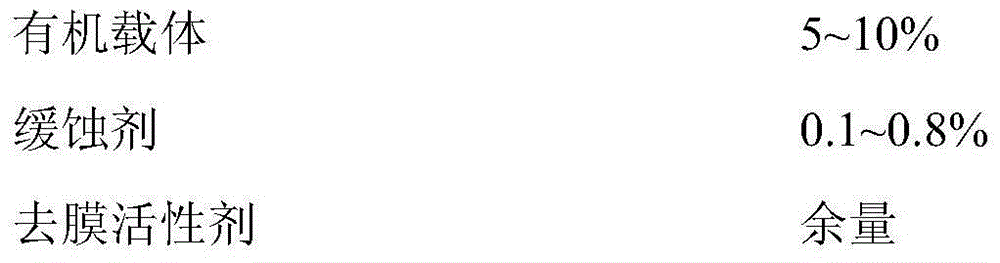

Cleaning-free solid-state scaling powder for aluminum low-temperature soldering and preparing method

ActiveCN104607826AFacilitate spreadingBarrier against electrochemical corrosionWelding/cutting media/materialsSoldering mediaActive agentAluminium

The invention discloses cleaning-free solid-state scaling powder for aluminum low-temperature soldering and a preparing method. According to the weight percentage, the cleaning-free solid-state scaling powder comprises raw materials of 6.5%-18% of metal film-forming agents, 5%-18% of organic carriers, 0.1%-1.8% of corrosion inhibition agents and the allowance of film removing active agents. The film removing active agents are composite salt of organic amine and acid. The cleaning-free solid-state scaling powder is suitable for lead-free solder wires with solid-state scaling powder contained in a core, and the powder can be used for automatic welding, manual soldering iron welding or flame spraying welding. The core-contained solder wires prepared with the scaling powder have the advantages that tinning speed is high, splashing is low, irritating smoke is avoided, post-welding residues do not have corrosiveness, a welding point has great electrochemical corrosion resistance, a contact service time is long, the wires are suitable for assembling welding of an aluminum coated layer circuit board and an aluminum soldering pin electronic element and brazing of an aluminum electric cable wire, an aluminum radiator and aluminum heat exchanging equipment.

Owner:SOUTH CHINA UNIV OF TECH

Titanium-silicon molecular sieve compound catalyst and preparation method thereof

ActiveCN102451763AGood catalyticAchieve direct catalytic conversionOrganic-compounds/hydrides/coordination-complexes catalystsBulk chemical productionHydration reactionFixed bed

The invention discloses a titanium-silicon molecular sieve compound catalyst and a preparation method thereof. The method comprises the following steps of: fully mixing a titanium-silicon molecular sieve, an acid molecular sieve, a polymeric monomer polyene-based compound and a pore forming agent; undergoing a polymerization reaction in the presence of an initiator; smashing an obtained lump solid catalyst; adding into a halogenated hydrocarbon for swelling; and extracting and activating with a solvent to obtain a molded titanium-silicon molecular sieve compound catalyst. Due to the adoption of the catalyst obtained in the invention, a corresponding process for preparing a corresponding diol compound by performing alkene epoxidation and undergoing a one-step hydration reaction can be realized, the problem of difficulty in separating titanium-silicon catalyst powder from a reaction solution can be solved simultaneously, and the reaction efficiency is increased. The catalyst is particularly suitable for catalytic reaction processes for preparation of ethylene glycol from ethylene, preparation of 1,2-propylene glycol from ethylene, alkene epoxidation, preparation of alcohol ether by etherification, and the like with a fixed bed process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technique for hydrogenation of coal oil

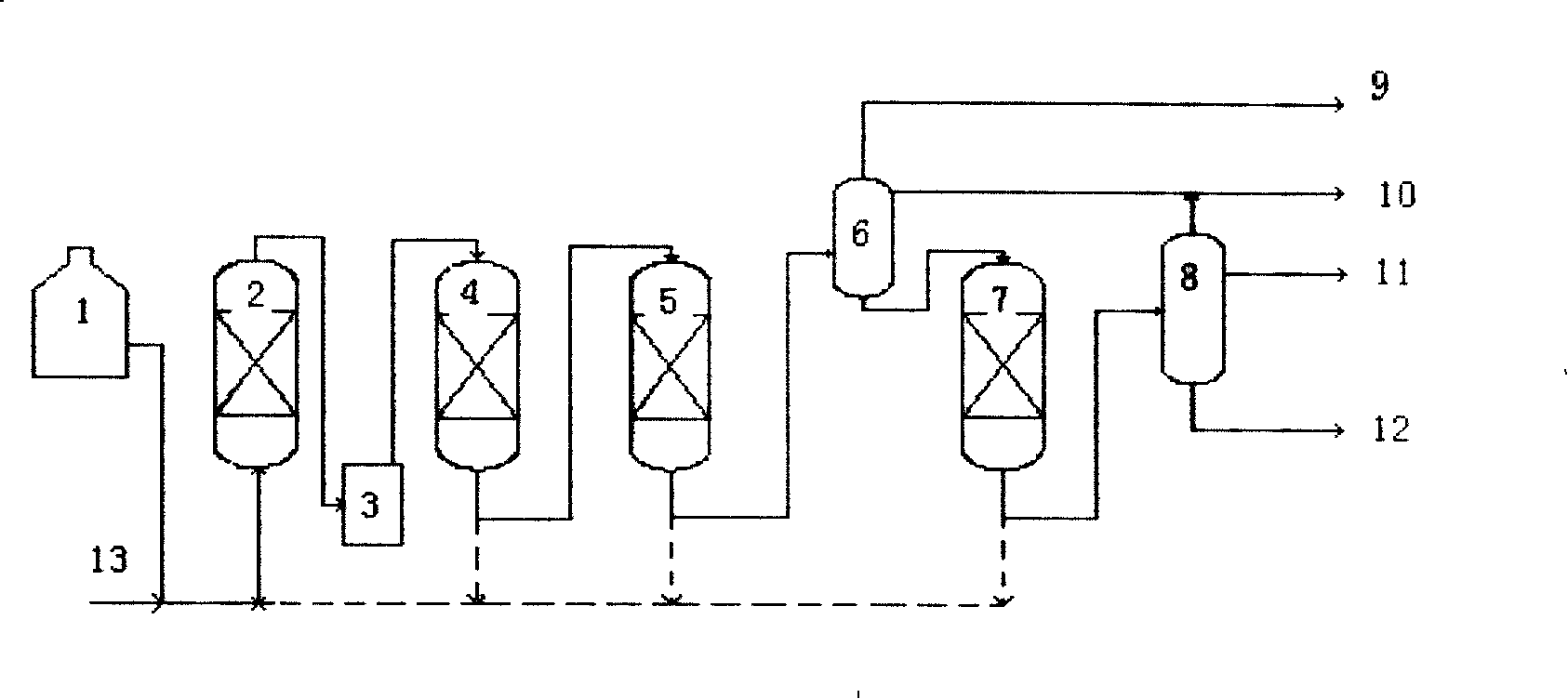

ActiveCN101343545AUniform and stable suspensionEasy to removeTreatment with hydrotreatment processesWorking-up tarCoal tar distillateGasoline

The invention discloses a coal tar hydrogenation processing method. The method of the invention comprises the steps that coal tar distillated oil or a full distillating pump with high content of impurities, colloid, asphaltene and oxygen elements is fed into a pre-hydrogenating reactor, the hydrogenation pre-treatment is performed under a certain reaction condition, the tiny impurities suspending in oil are separated through a separating device such as a filter and the like, then hydrogenating demetalization and deep hydrogenation refined reaction are performed in sequence, after water and light component are separated, and the material flow generated by the reaction enters into the hydrocracking reactor, thus gasoline fraction, diesel oil and hydrocracking tail oil are cut through a distilling device. Compared with the prior art, the method of the invention can ensure the device of long period of stable operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

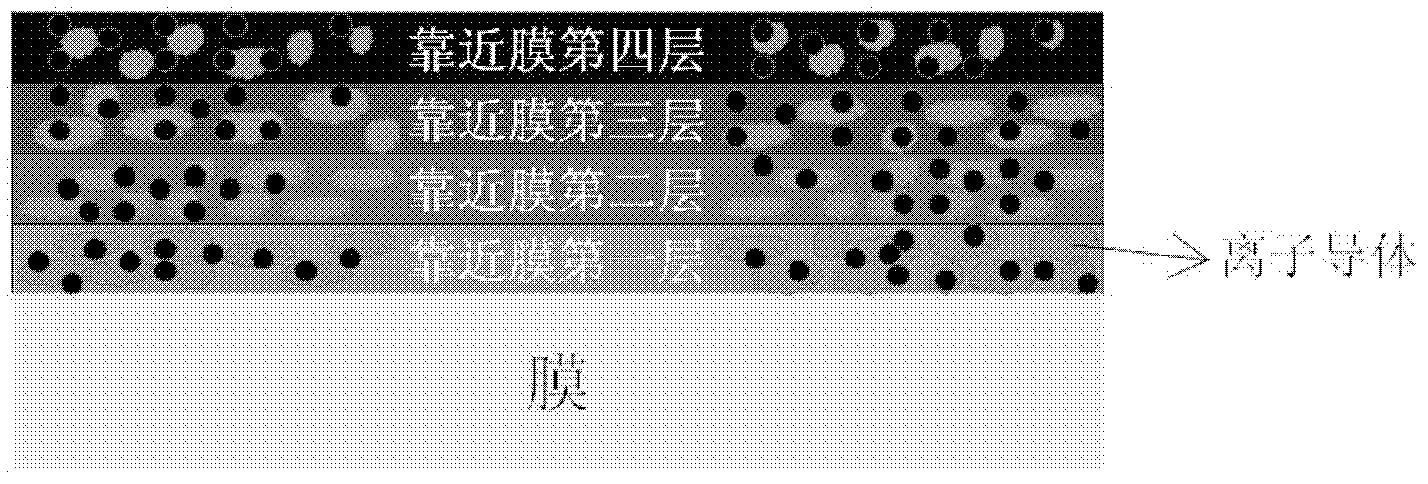

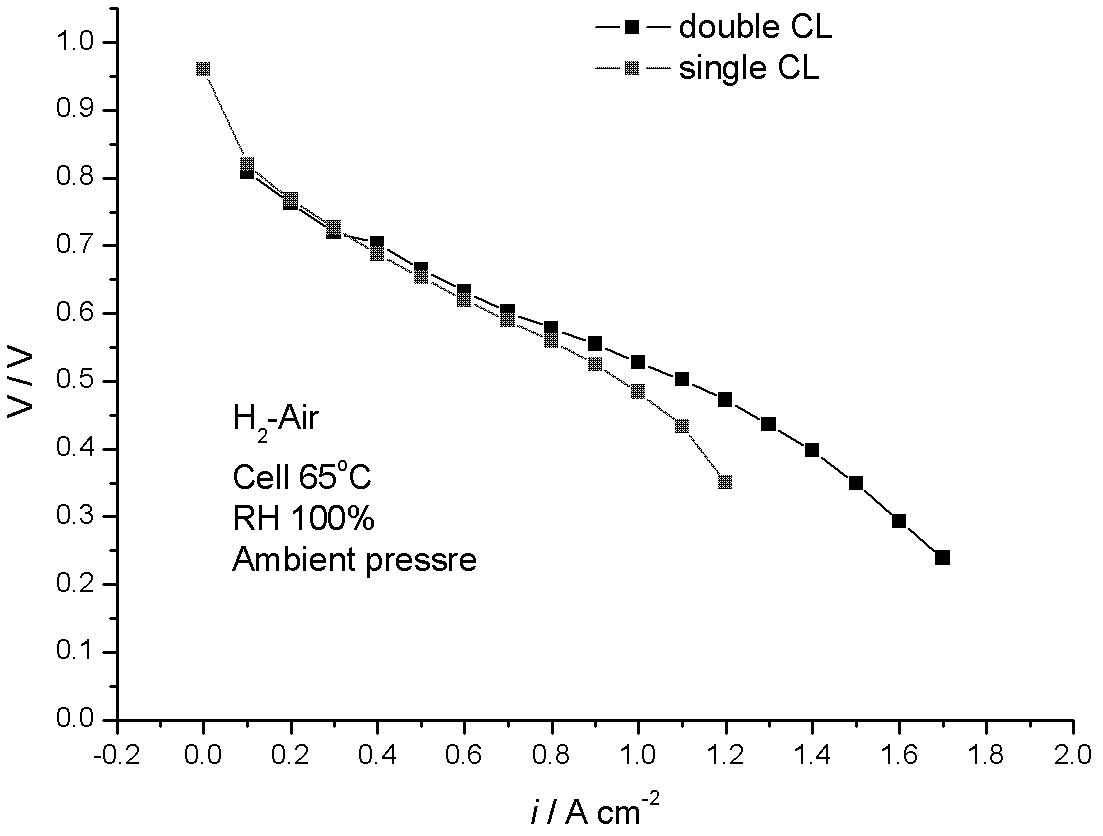

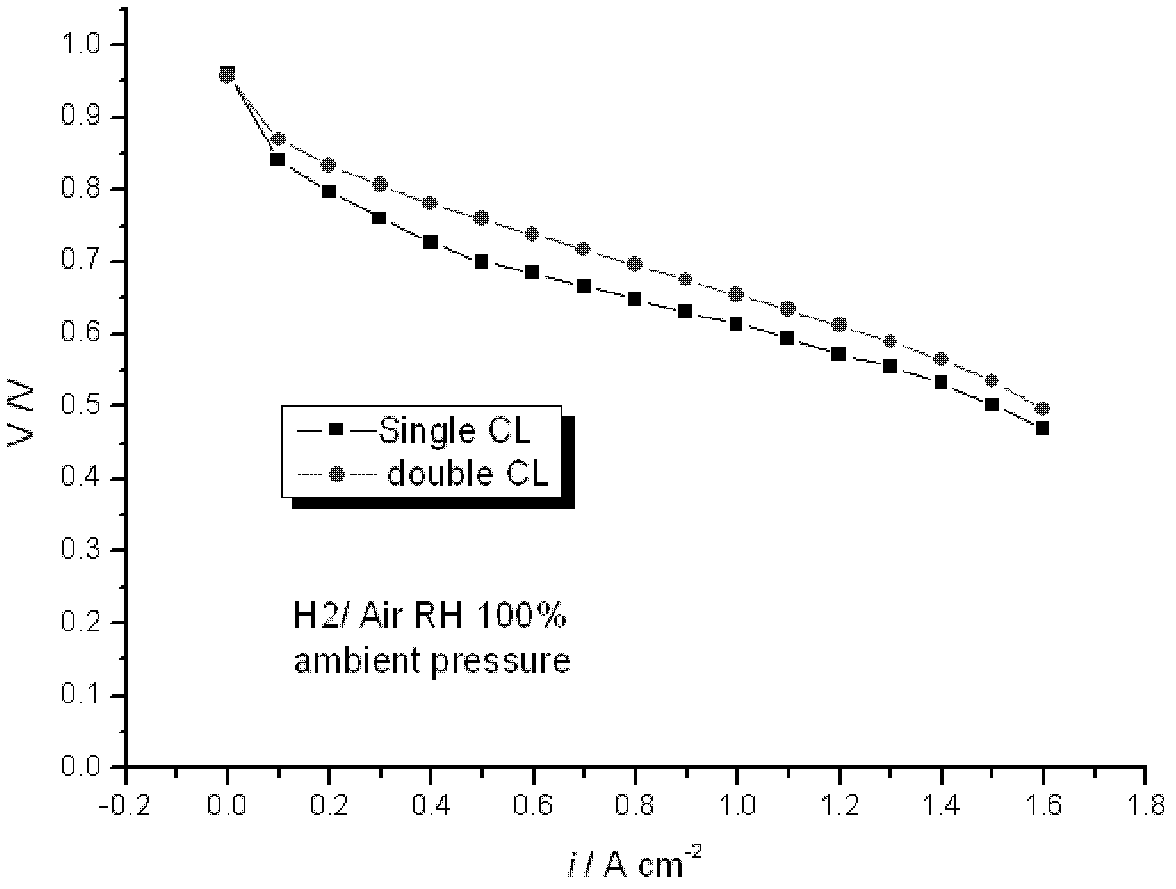

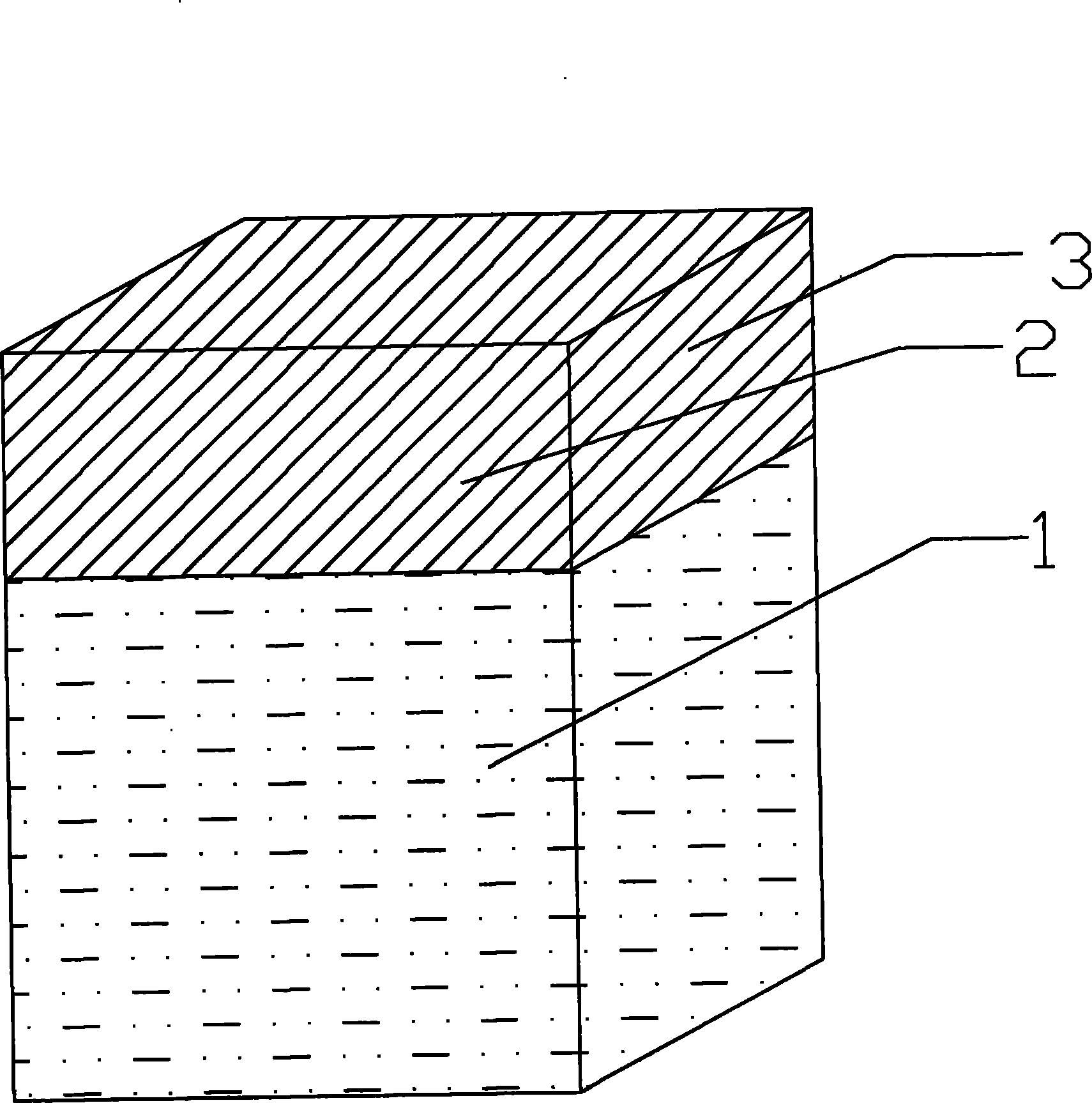

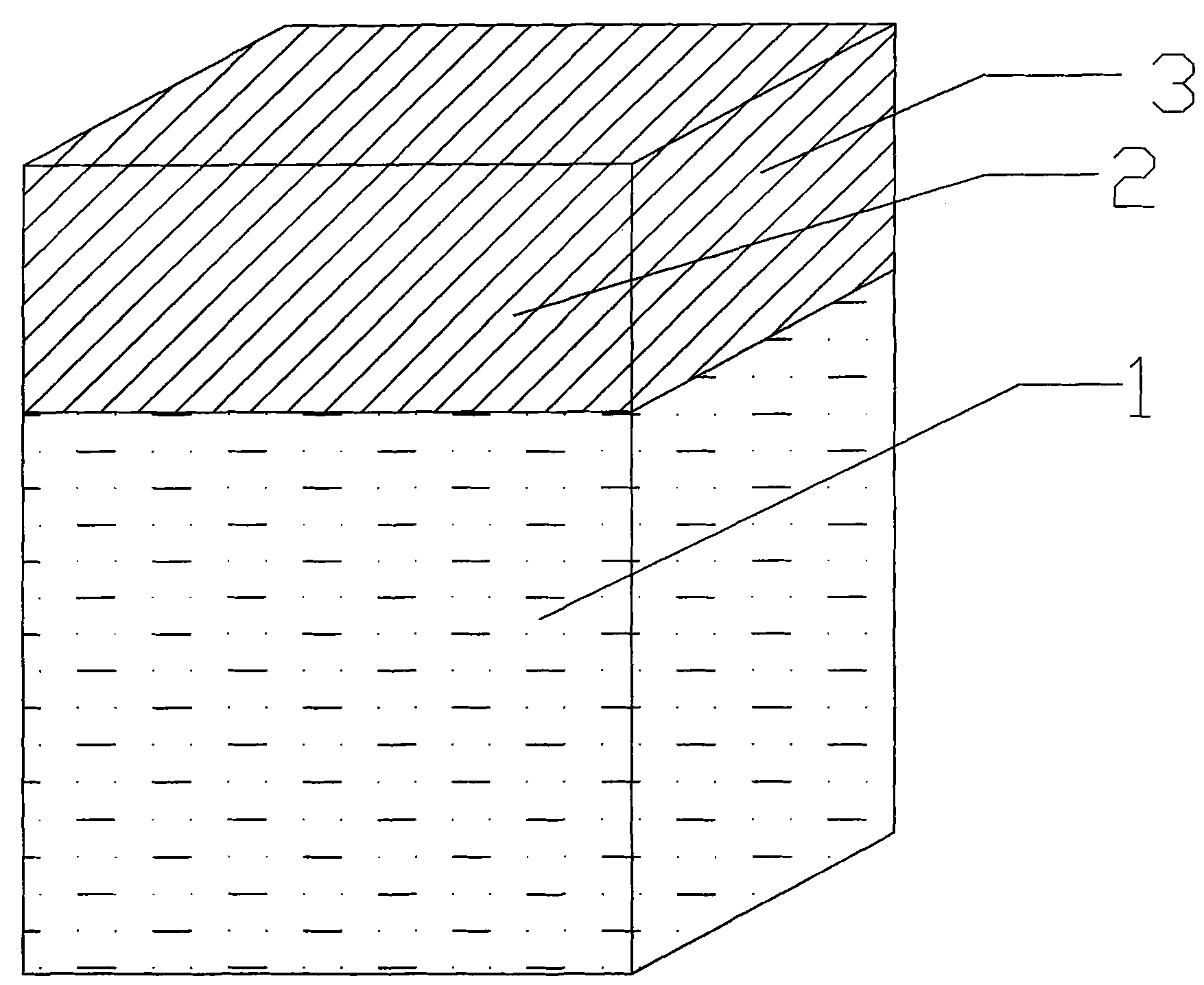

Catalyst layer structure capable of effectively reducing fuel cell platinum (Pt) loading capacity

The invention provides a catalyst layer structure capable of effectively reducing fuel cell platinum (Pt) loading capacity. A catalyst layer is composed of a plurality of layers of single catalyst layers in different ingredients, and catalyst Pt loading capacity, ion conductor type, Pt loading capacity and a preparation process of each layer are different, so that the purposes of improving catalyst utilization rate and reducing the Pt loading capacity can be realized. In the reaction time of fuel cells, oxygen molecules diffuse from the catalyst layers to the interiors of the catalyst layers, and react with hydrogen protons moved from anodes. According to characteristics of the reaction of the fuel cells, oxygen diffuses from diffusion layers to the interiors of the catalyst layers and reacts with the hydrogen protons transmitted from the anodes to produce water. In the design of the catalyst layer structure, the Pt concentration and the ion conductor concentration of a catalyst layer close to the membrane side are improved in an emphasis mode so that reaction efficiency under intermediate and low current density is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

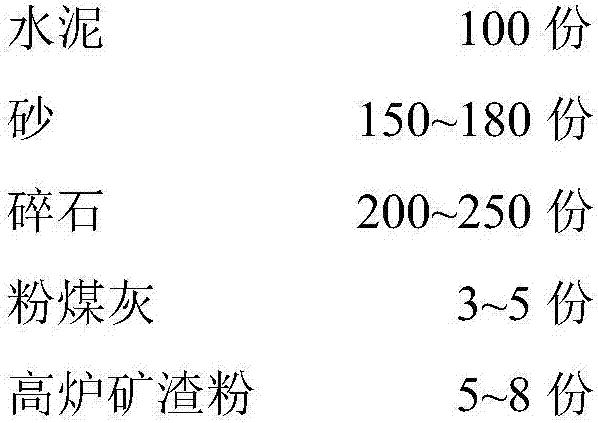

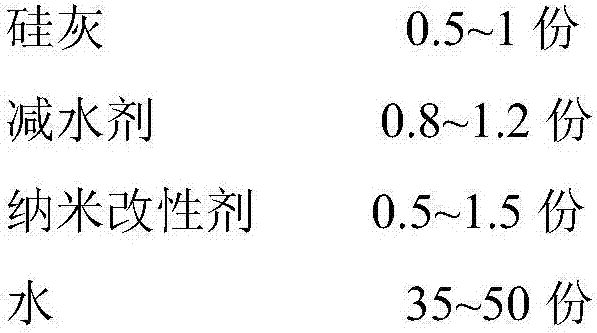

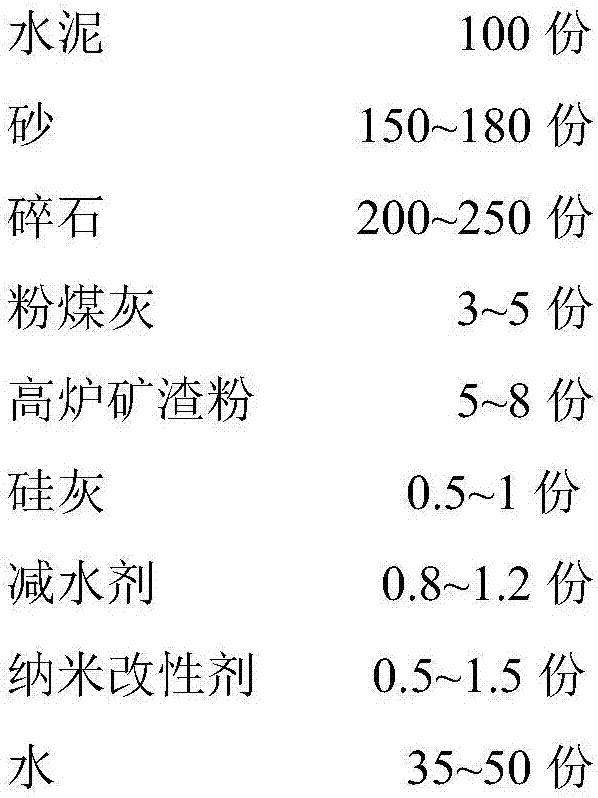

Preparing method of nano-modified high permeability resistant concrete

InactiveCN107032734ATake full advantage of stackingGive full play to the synergistic effectSolid waste managementChipsealSlag

The invention relates to building material engineering, and aims at providing a preparing method of nano-modified high permeability resistant concrete. The preparing method comprises the steps of conducting dry stirring on cement, sand, gravel, fly ash, blast-furnace slag powder and silica fume, and mixing the mixture evenly; mixing a nanometer additive, a water reducing agent and water which accounts for half the weight evenly, and adding the nanometer additive, the water reducing agent and the water which accounts for half the weight into the mixture for stirring; then adding the water which accounts for the other half the weight and continuing to conducting mixing; conducting discharging, and putting the new mixture into molds; conducting maintenance according to a conventional maintenance mode after removing the molds to obtain the nano-modified high permeability resistant concrete. According to the preparing method of the nano-modified high permeability resistant concrete, the limitation of the influence of a single mineral component on the performance of the concrete is solved, through the combination of the multifunctional composition, the effect of function superposition and synergy is achieved, the composite multifunctional composition can effectively optimize the concrete structure grain composition, and by optimizing the internal pore structure of the concrete, the aim of improving the permeability resistance is achieved. The grain composition optimization is conducted on the concrete structure by utilizing the nanometer additive, the high activity and the microcrystal nuclear effect of nano-particles are given full play to at the same time, and the permeability resistance of the concrete structure is improved.

Owner:ZHEJIANG UNIV

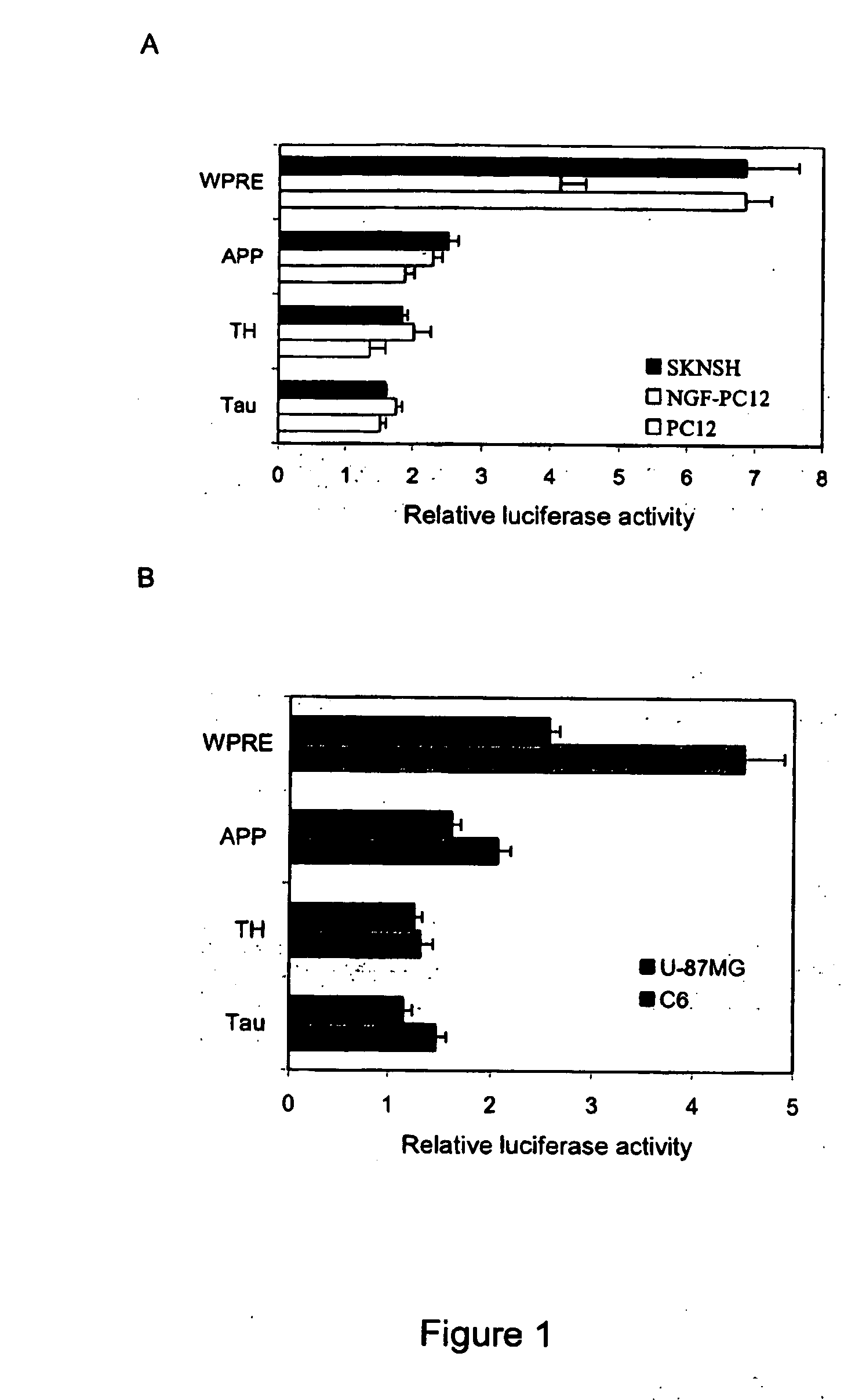

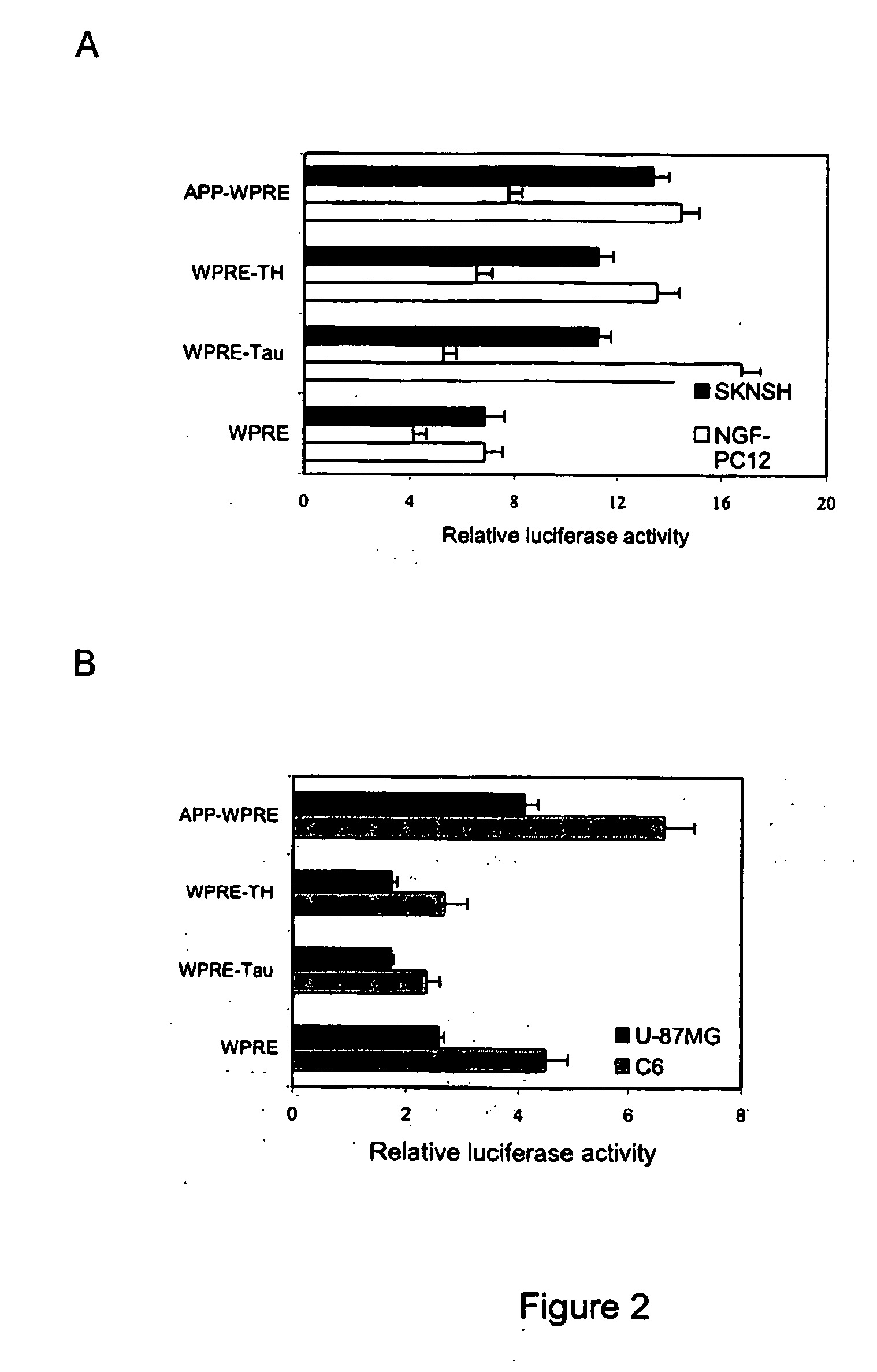

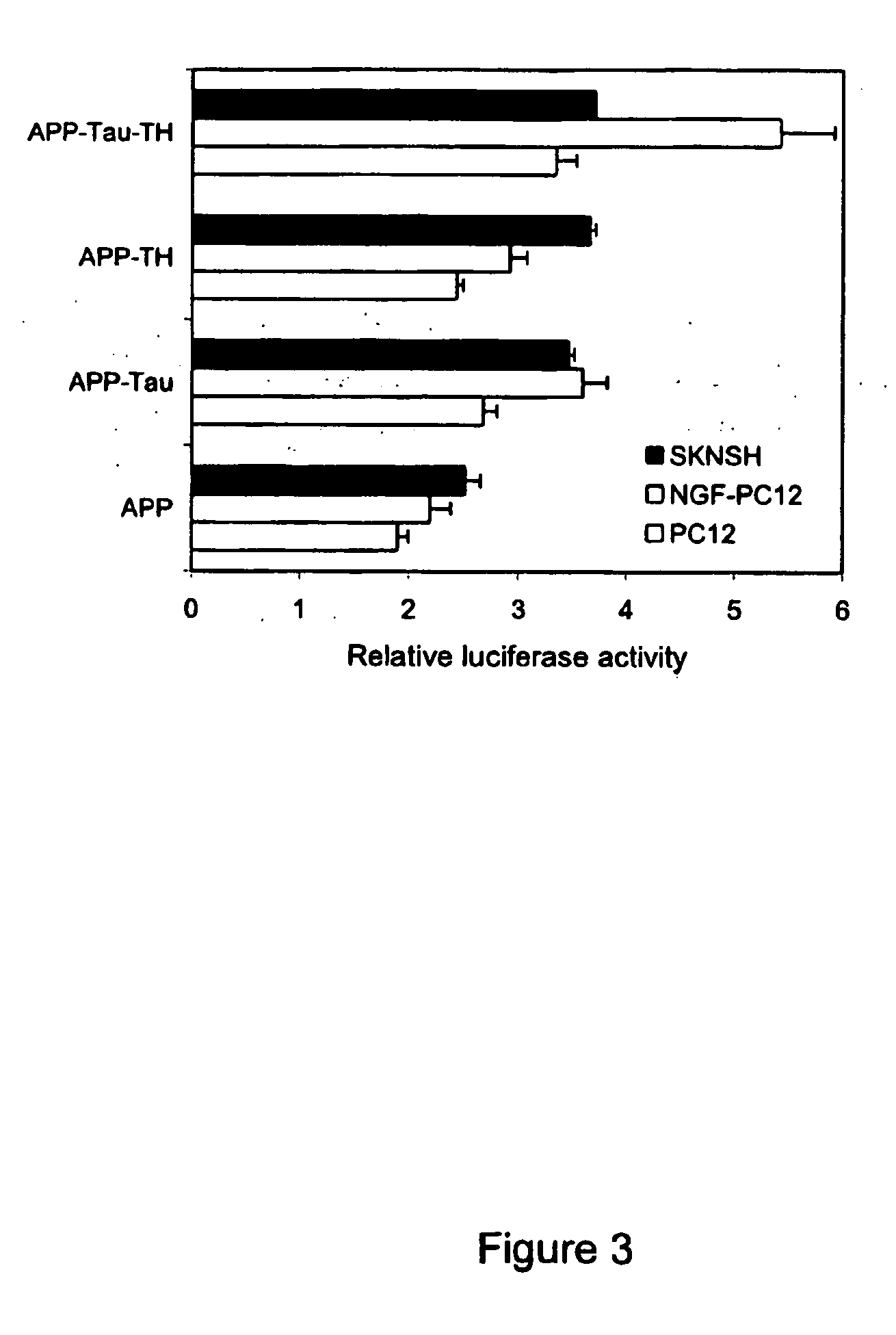

Optimization of transgene expression in mammalian cells

InactiveUS20060051331A1Increase capacityIncrease transgene expressionSenses disorderFungiTransgeneMammalian cell

The present invention relates to vectors, compositions and methods for delivering transgenes into mammalian cells. The invention also relates to genetic constructs and recombinant cells suitable to produce such transgenes. The invention more particularly relates to a vector suitable for transgene delivery into mammalian cells, wherein said vector comprises a chimeric genetic construct comprising a transgene operably linked to at least two distinct posttranscriptional regulatory elements functional in mammalian cells. This invention can be used in experimental, research, therapeutic, prophylactic or diagnostic areas.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Second-active-center-containing catalyst hydrogenation apparatus startup method

ActiveCN106947527AImprove usage activityConvenience and Economic PathwayTreatment with hydrotreatment processesProduct gasChemistry

The present invention discloses a startup sulfurization method of a hydrocracking apparatus. According to the present invention, with the grading use of the ex-situ presulfided catalyst, the hydrogenation catalyst containing the second active center is pre-protected with the hydrogen sulfide gas produced in the heating process while a certain auxiliary gas can be selectively injected according to different preparation methods of the second active center catalysts, such that the wet startup is converted into the dry startup; and the activity of the catalyst can be improved with the method of the present invention, and the method is suitable for the sulfurization startup process of the hydrogenation catalyst containing the second active center.

Owner:CHINA PETROLEUM & CHEM CORP +1

Biological treatment method for waste mud in petroleum and natural gas exploration drilling work

ActiveCN101830614AEasy to handleThe role and effect are obviousBiological sludge treatmentWell drillingWater source

The invention discloses a biological treatment method for waste mud in petroleum and natural gas exploration drilling work, which is characterized by comprising the following steps of: a, forming a microbial treatment layer, namely inoculating special microbial strains to the waste mud in a weight ratio of 3-5: 100, mixing the strains and the waste mud uniformly, stirring the mixture and natural soil with water content of 10 to 10 percent and grain diameter of less than 0.5 centimeter uniformly according to the density condition of the waste mud in a following mode to form the microbial treatment layer, adding the natural soil in an amount which is 2.5 to 3 times that of the waste mud into the waste mud with density of 1 to 1.5kg / L, adding the natural soil in an amount which is 2 to 2.5 times that of the waste mud into the waste mud with density of 1.5 to 2.5kg / L, and controlling the water content of the microbial treatment layer to be between 25 and 30 percent; b, treating the soil; and c, treating plants. The method can solve the technical problem that effusion enters underground water to pollute a water source because the natural soil with high water content and large grain diameter is easily scoured by hard rain under the condition that pollutants in a pretreatment mixture are not yet effectively degraded in the prior art.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Amino acid-containing water-soluble fertilizer added with sugar alcohol and preparation method thereof

The invention provides an amino acid-containing water soluble fertilizer added with sugar alcohol and a preparation method thereof. The amino acid-containing water-soluble fertilizer added with sugar alcohol is prepared from the following raw materials: amino acid, calcium salt and water as well as 5-10wt% of sugar alcohol. The amino acid-containing water-soluble fertilizer is of a calcium element type, the sugar alcohol is added to be used as a chelating agent of the calcium element; by virtue of reasonable ratio of sugar alcohol to amino acid to calcium salt, the sugar alcohol and the calcium element are chelated to form a stable micromolecule chelate; since sugar alcohol has permeation and wetting properties, absorption and transportation efficiency of the chelated calcium element is improved; meanwhile, amino acid can promote calcium absorption and also can promote photosynthesis, so that chlorophyll content is increased. Therefore, under the combined action of sugar alcohol and amino acid, the amino acid-containing water-soluble fertilizer added with sugar alcohol has high utilization rate, can improve the conveying speed of plant nutrients, can enhance calcium absorption of plants and can increase sugar content of the plants.

Owner:BEYONDCHEM LIFE TECH

Titanium-silicon molecular sieve and resin composite catalyst and preparation method thereof

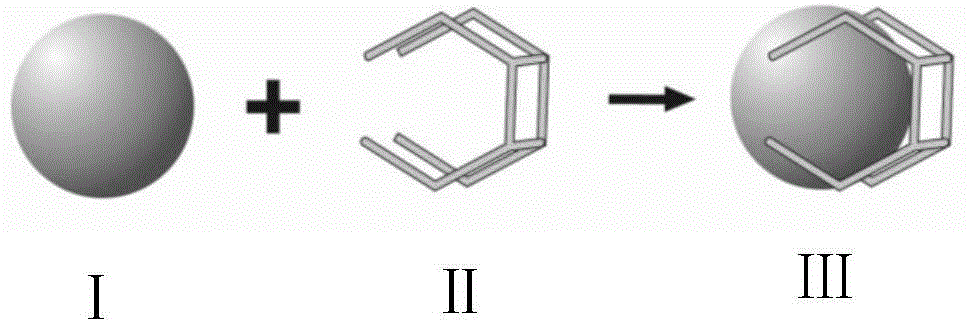

ActiveCN102049304AGood catalytic effectImprove reaction efficiencyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventMolecular sieve

The invention discloses a titanium-silicon molecular sieve and resin composite catalyst and a preparation method thereof. The catalyst mainly comprises a titanium-silicon molecular sieve and resin. The preparation method comprises the following steps of: fully mixing titanium-silicon molecular sieve powder, a polymeric monomer and a porogen, performing polymerization reaction in the presence of an initiator to obtain a blocky solid catalyst, crushing, adding into halogenated hydrocarbon for swelling, and performing solvent extraction to obtain a formed catalyst. The catalyst prepared by the method solves the problem that titanium-silicon catalyst powder and reaction liquid are difficult to separate, improves reaction efficiency, is applied to the catalytic reaction process of olefin epoxidation in a fixed bed process, and has good catalytic effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for regenerating waste lubricating oil,

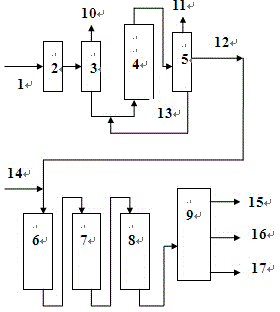

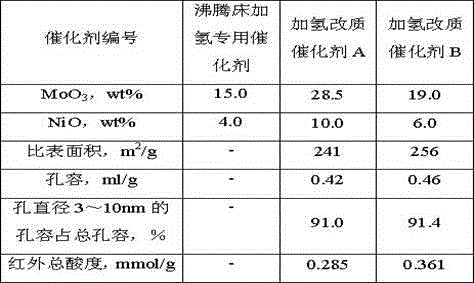

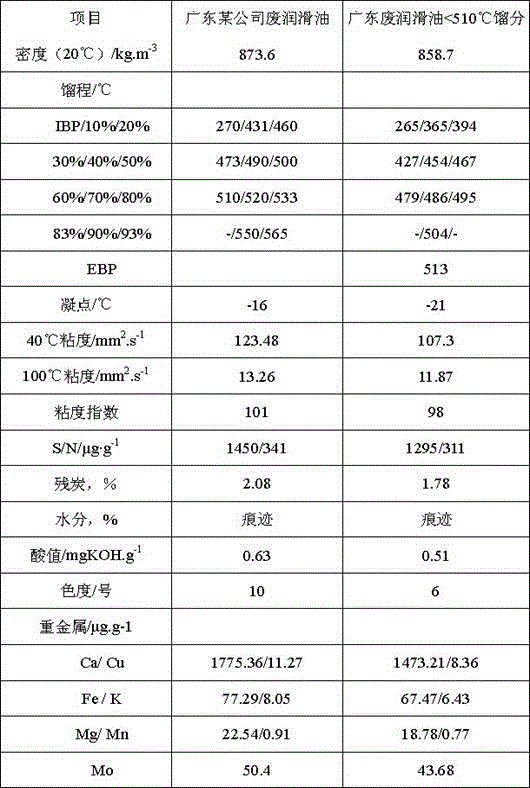

ActiveCN105733793AAdvantages of multi-stage hydrogenationHigh yield utilizationTreatment with hydrotreatment processesLubricant compositionHydrogenFluidized bed

The present invention discloses a hydrogenation method for regenerating waste lubricating oil. The method includes the following steps: conducting electro-desalting on waste lubricating oil, sending the waste lubricating oil into a flash column, separating dissolving water and part of light oil, sending the bottom materials into a fluidized bed reactor, and conducting hydrogenation pretreatment reaction; separating reaction effluents, mixing an obtained liquid fraction with hydrogen, sending the mixture into a hydrotreating reaction zone, sending an effluent from the hydrotreating reaction zone into a hydrogenation modification reaction zone, sending a hydrogenation modification effluent into a hydrogenation supplement refining reaction zone, carrying out hydrogenation supplement refining reaction; and isolating the hydrogenation supplement refining products to obtain base oil for lubricating oil. Compared with the prior art, the method of the present invention can treat whole fraction of waste lubricating oil; the base oil product for lubricating oil has high yield and good quality; and the method can ensure a long-term stable operation of a device, and achieve efficient utilization of waste lubricating oil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing middle distillate oil through hydrocracking

ActiveCN103254929AGood choiceQuality improvementMolecular sieve catalystsHydrocarbon oil crackingAdhesiveDistillation

The invention relates to a method of producing middle distillate oil through hydrocracking. A distillation range of raw materials is between 250-570 DEG C; a nitrogen content is 0.1-2000 [mu]g / g; and a catalyst is composed of 20-65 % of amorphous silica-alumina, 8-25 % of macroporous alumina, 8-25 % of an adhesive, 4-40 % of a composite molecular sieve, 1.5-5 % of an extrusion aid, 12-30 % of VIB-group metal oxides, 3-10 % of VIII-group metal oxides, and 0.1-5 % of VA-group metal oxides, wherein the composite molecular sieve is composed of an AlSBA-15 / Y mediated-microporous composite molecular sieve and a [beta]microporous molecular sieve. The catalyst is relatively high in catalytic activity and middle distillate oil selectivity, and can be used to produce heavy naphtha, jet fuel, diesel oil, tail oil, etc.; and the produced products are good in quality.

Owner:PETROCHINA CO LTD

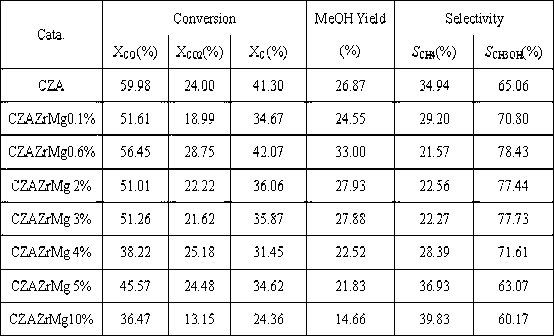

Auxiliary agent-modified catalyst for CO-CO2 co-hydrogenation synthesis of methanol

InactiveCN102716749AReduce pollutionHigh selectivityOrganic compound preparationHydroxy compound preparationHigh carbonHigh selectivity

The invention discloses an auxiliary agent-modified catalyst for CO-CO2 co-hydrogenation synthesis of methanol. The auxiliary agent-modified catalyst comprises Cu, Zn, Al, Zr and Mg. A mass ratio of (CuZnAl): (ZrMg) is (90.0 to 99.9%): (0.1 to 10%). A mole ratio of Cu: Zn: Al is m: n: l, wherein m is in a range of 5.0 to 6.5; n is in a range of 3.0 to 4.5; and l is equal to 10-m-n. A mole ratio of Zr: Mg is (1.0 to 3.0): (1.0 to 2.0). The auxiliary agent-modified catalyst has a high carbon conversion ratio in CO-CO2 co-hydrogenation synthesis of methanol, and has high selectivity of methanol in products. A preparation method of the auxiliary agent-modified catalyst has simple processes and is prone to industrialization.

Owner:KUNMING UNIV OF SCI & TECH

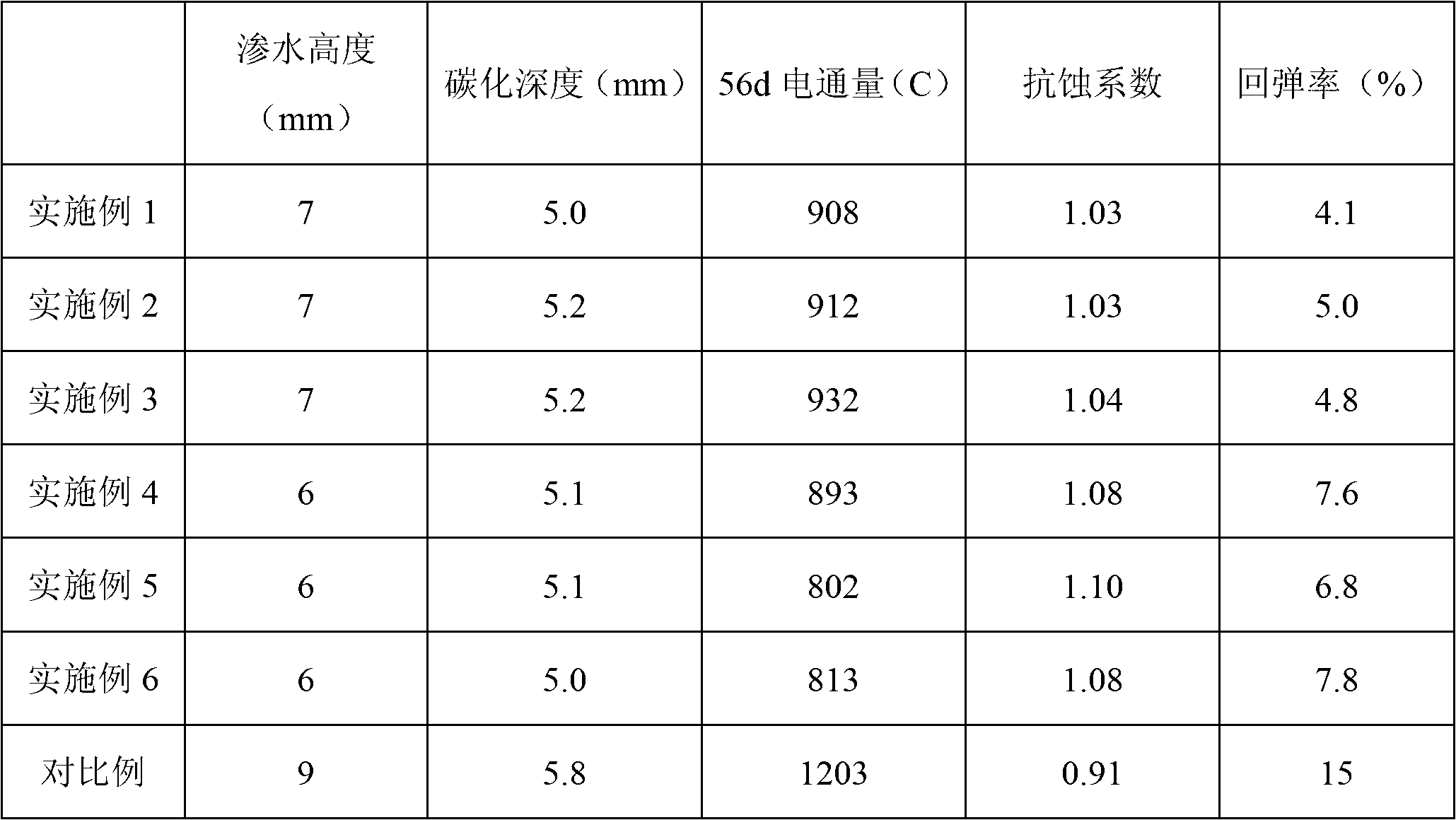

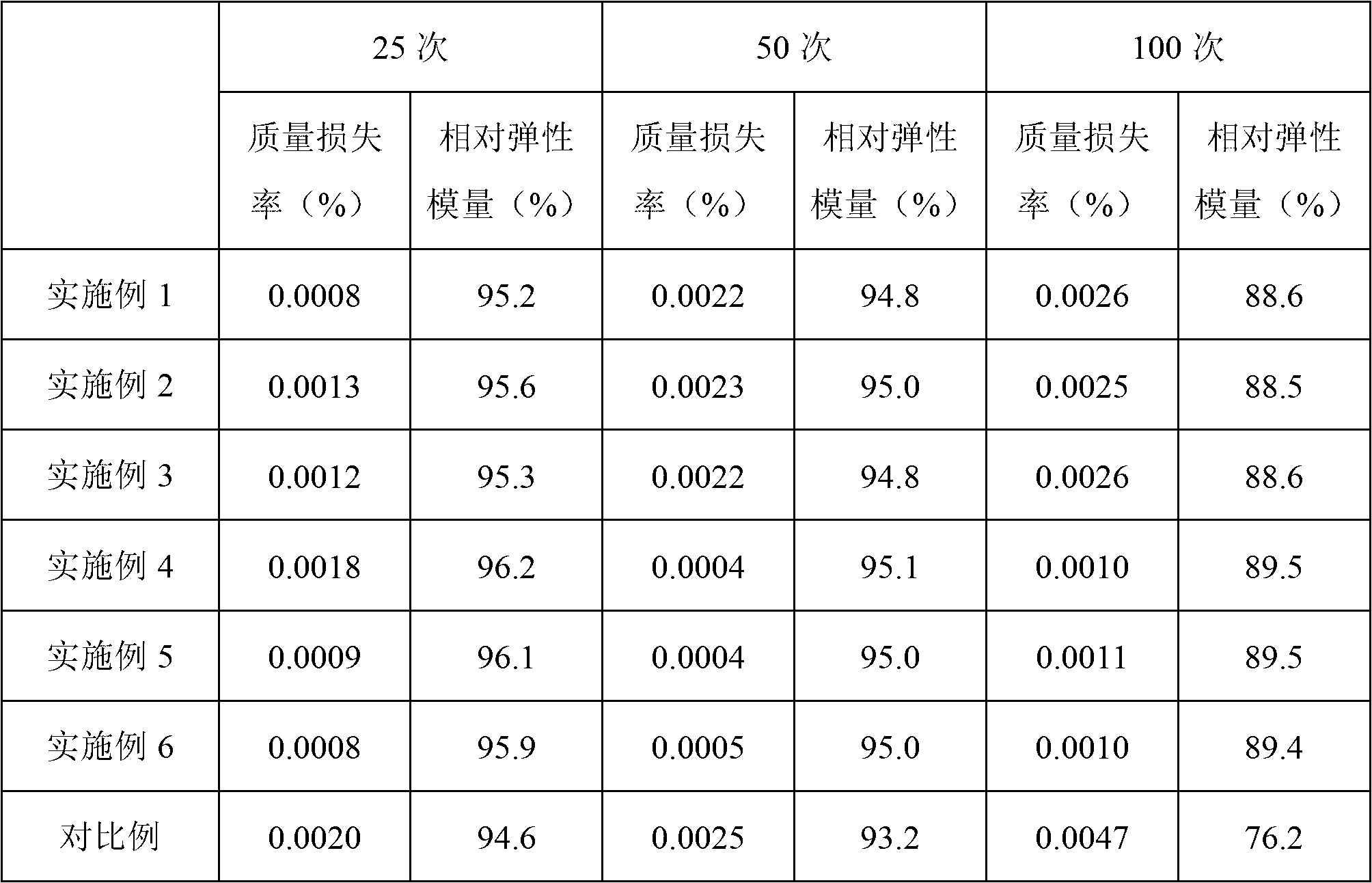

High-performance concrete gel material for tunnel and application thereof

The invention discloses a concrete gel material which comprises cement and silica solution. The invention further discloses a high-performance concrete for tunnel prepared through the concrete gel material provided by the invention. The high-performance concrete is suitable to be applied to injecting concrete, moulding concrete and others. Through the adoption of the concrete gel material or the high-performance concrete for the tunnel provided by the invention for injecting the concrete, the rebound ratio can be effectively reduced and even reduced to 4.1% to the minimum; and the concrete gel material or the high-performance concrete is good in working performance; the obtained concrete finished product is high in early strength, and good in freezing resistance; the waterproof performance and the wearable performance are improved; the quantity of used cement can be reduced; the carbon emission can be reduced; and good economic benefit and environment-friendly benefit are brought.

Owner:中铁西南科学研究院有限公司

Method for preparing titanium silicon molecular sieve catalyst

ActiveCN102049305AGood catalytic effectImprove reaction efficiencyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveTitanium

The invention discloses a method for preparing a titanium silicon molecular sieve catalyst. The method comprises the following steps of: mixing titanium silicon molecular sieve powder, polymer monomer styrene, a polymer monomer multi-alkenyl compound and a pore-forming agent completely; in the presence of an initiator, performing a polymerization reaction; smashing the obtained blocky solid catalyst; adding the smashed catalyst into halohydrocarbon to swell; and performing extraction by using a solvent to obtain the formed titanium silicon molecular sieve catalyst. The titanium silicon molecular sieve catalyst prepared by the method solves the problem that the titanium silicon catalyst powder and reaction solution are difficult to separate and improves the reaction efficiency. The titanium silicon molecular sieve catalyst is applied to a catalytic reaction of alkene epoxidation of a fixed bed process and has excellent catalytic effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

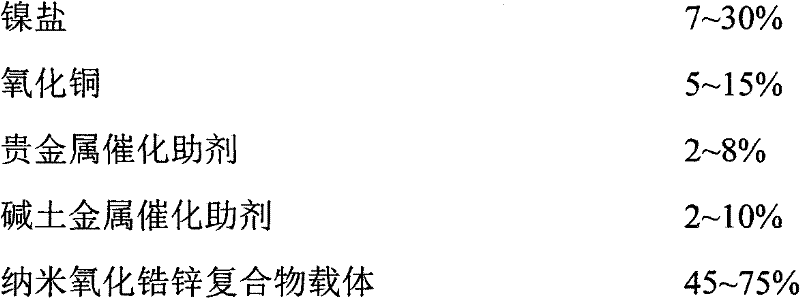

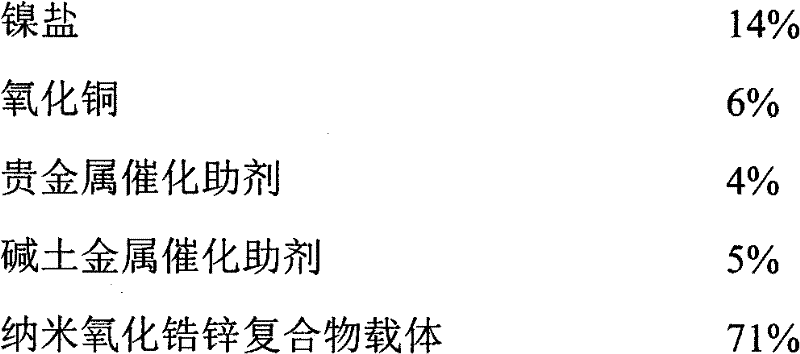

Catalyst for hydrogen production through catalytic cracking of methane and its preparation method

InactiveCN102489311AHigh activityImprove stabilityCatalyst carriersHydrogenAlkaneAlkaline earth metal

Belonging to the technical field of catalysts for hydrogen production through catalytic cracking of methane, the invention relates to a catalyst for hydrogen production through catalytic cracking of methane and its preparation method. The catalyst in the invention is composed of a nickel salt, copper oxide, a precious metal catalytic promoter, an alkaline earth metal catalytic promoter, and a nanometer ZrO-ZnO composite carrier. The method in the invention comprises: taking the nickel salt, the copper oxide, the precious metal catalytic promoter, the alkaline earth metal catalytic promoter, azirconium salt, a zinc salt, and an alkaline precipitating agent as raw materials, first preparing a nanometer ZrO-ZnO composite carrier, then implementing the simple processes of mixing, ultrasonic dispersion, roasting, and moulding, thus obtaining a product. The method in the invention has the advantages of simple process, mild reaction condition, energy saving, sufficient material and liquid utilization, and no discharge of ''three wastes''. The product prepared by the method of the invention has the characteristics of high activity, good dispersibility, and strong temperature resistance, etc. The catalyst prepared by the method provided in the invention can be widely applied in catalytic cracking of methane, ethane and other low carbon alkanes, and is especially suitable for catalyticcracking of methane in a fluidized bed for hydrogen production.

Owner:CHONGQING UNIV

Microorganism-containing fertilizer produced by mycoderm method and production method of fertilizer

The invention provides to a microorganism-containing fertilizer produced by a mycoderm method and a production method of the fertilizer. In the prior art, microorganism bactericides, organic matters, chemical fertilizer and the like are mixed according to a preset formula, and the mixture is subjected to granulation, high-temperature drying, screen separation, cooling and the like so as to produce a finished product. In the production method provided by the invention, the fertilizer without bactericides is granulated, dried, screened and cooled; active bacterium powder is coated on the outer surface of the fertilizer particles at the tail end of the production line by using a film technology; and the microbial content of the whole fertilizer when in detection reaches the technical standard of national regulation so that a film fertilizer is formed. The method provided by the invention is used for producing the fertilizer with active bacterium.

Owner:杨庆理

Method for preparing high-performance concrete additive by using steel slag ball-milling waste residue

The invention discloses a method for preparing high-performance concrete additive by using steel slag ball-milling waste residue, belonging to the technical field of concrete for building materials. The method comprises the steps: ovetails containing metallic iron is separated from the waste residue through a spiral classifier; washed turbid liquid is conveyed into a sedimentation tank; sedimentedtailing slurry with higher water content is pressed to a mud cake with lower water content by a pressure filter; the water content of the tailing slurry is reduced to below 3 percent after drying andcrushing; and then the tailing slurry enters a ball mill to be grinded to 500m<2> / kg, thus obtaining the high-performance concrete additive. The method has the advantages of simple process, low cost,superior performance, obvious effects on improving concrete strength and construction quality and reducing concrete and construction costs and environment pollution, and has significant economical and practical significance for promoting the smooth implementation of strategy of sustainable development of China.

Owner:北京首钢资源综合利用科技开发有限公司 +1

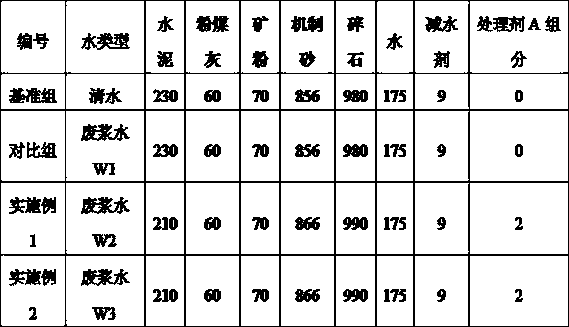

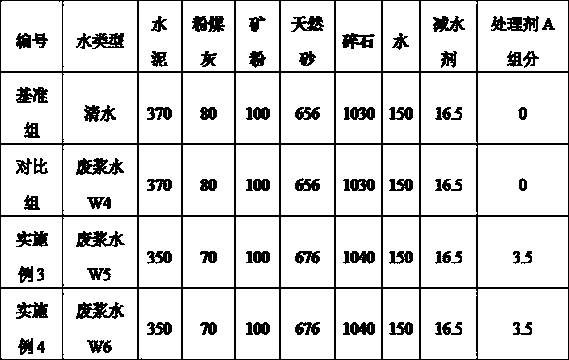

Treatment agent for concrete waste slurry water and method for preparing premixed concrete from waste slurry water

The invention provides a composition for treating concrete waste slurry water. The composition is composed of 15-40 parts of a hydration inducing composition A and 1.0-3.5 parts of a waste slurry water dispersion composition B. The hydration inducing composition A comprises 3-15% of inorganic salt, 3-10% of a nanocrystalline nucleus early strength agent, 2-8% of composite alcohol amine, 2 to 5 percent of polyethylene glycol, 1 to 5 percent of diethylene glycol, 0.1 to 5 percent of a polycarboxylate water reducing agent, 0.05 to 2 percent of a retarder, 0 to 1 percent of a thickener, 0.02 to 0.05 percent of sodium glutamate, and 0.03 to 0.05 percent of hexadecyl trimethyl ammonium bromide, with the balance being water. The waste slurry water dispersion composition B comprises 3-10% of a dispersing agent, 2 to 9 percent of compound alcohol amine, and 6 to 12 percent of a retarder, with the balance being water. The invention also provides a method for preparing premixed concrete by usingthe waste slurry water. According to the composition and the method, the problem that existing wastewater and waste slurry are difficult to directly utilize can be solved, zero emission of the wastewater and the waste slurry of a concrete enterprise is achieved, and the strength of concrete can be guaranteed under the condition that 10-30 kg of a cementing material is reduced for each cubic meterof concrete.

Owner:江西省建材科研设计院有限公司

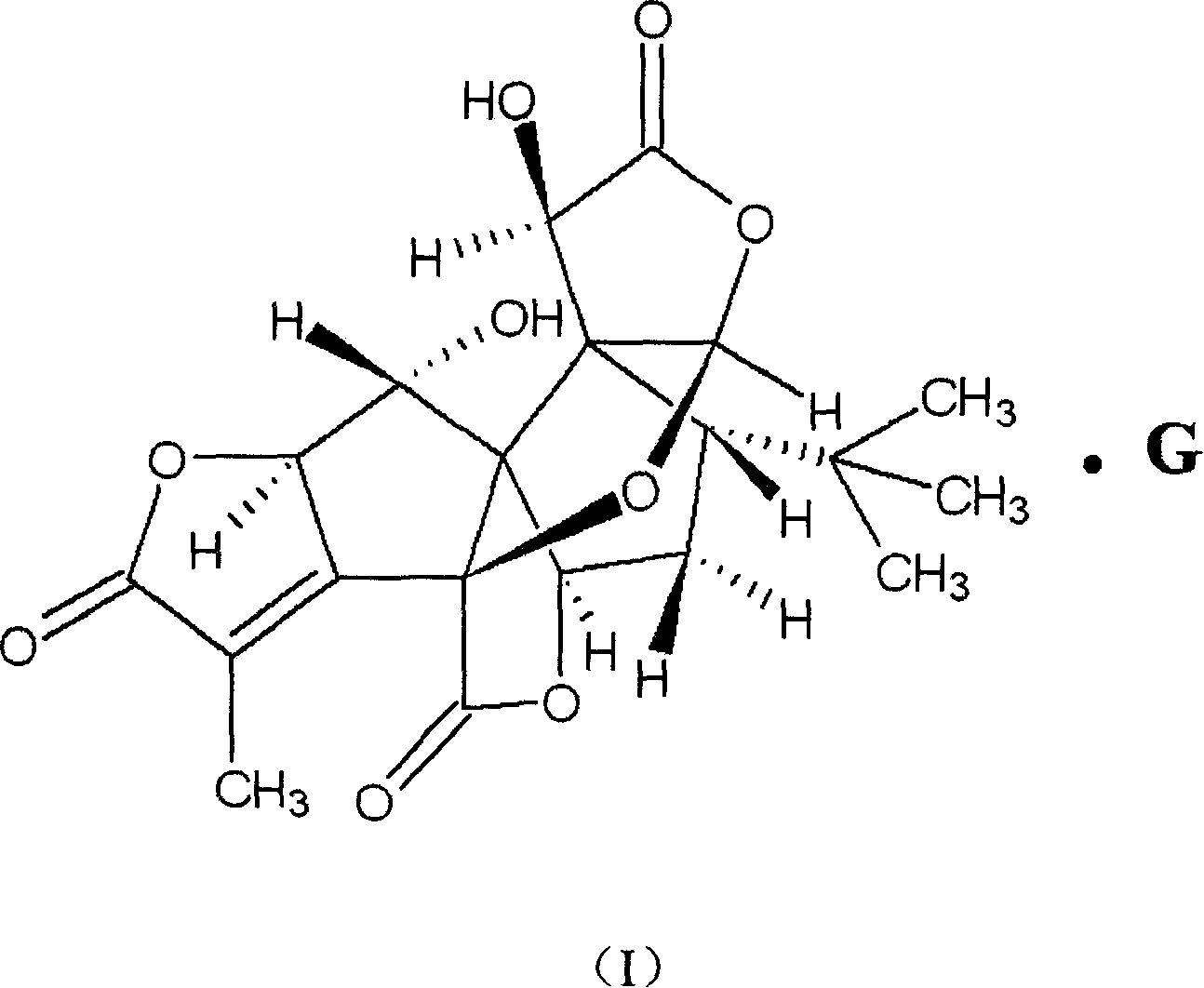

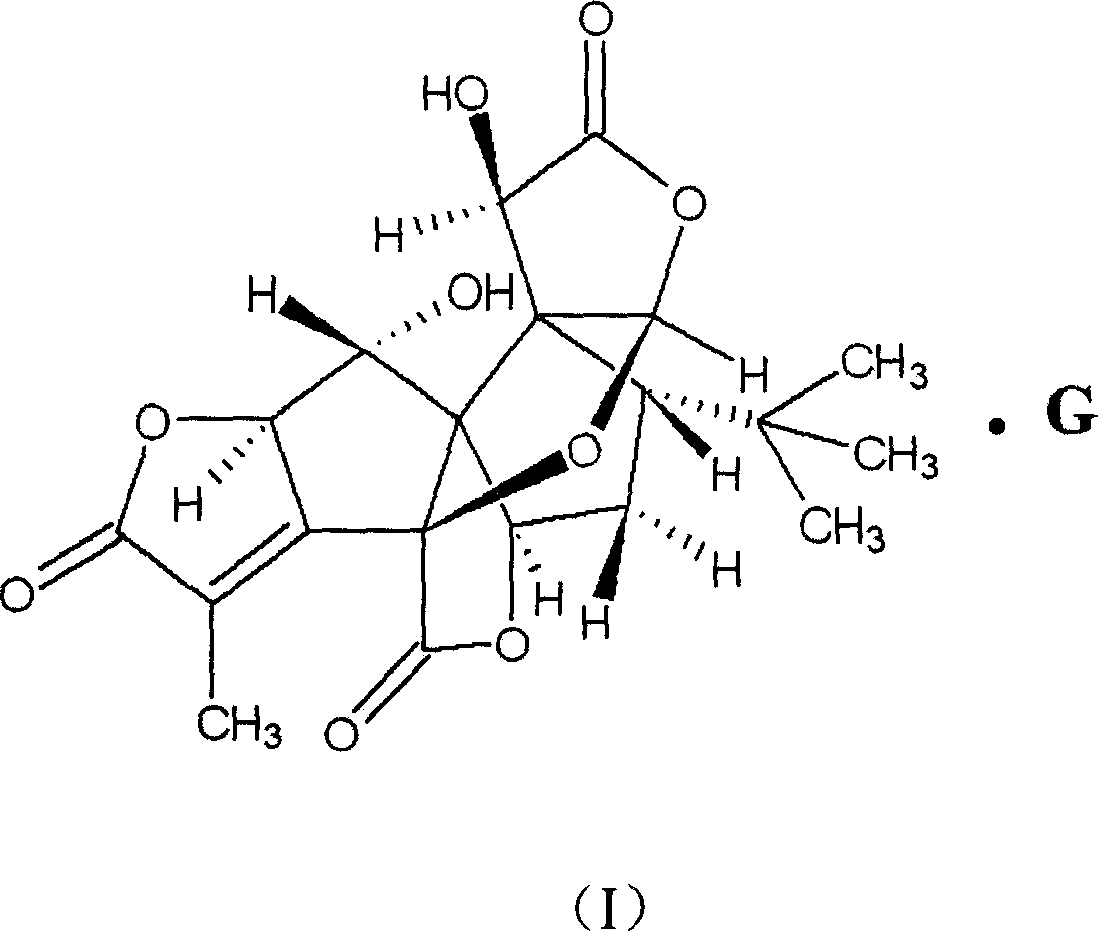

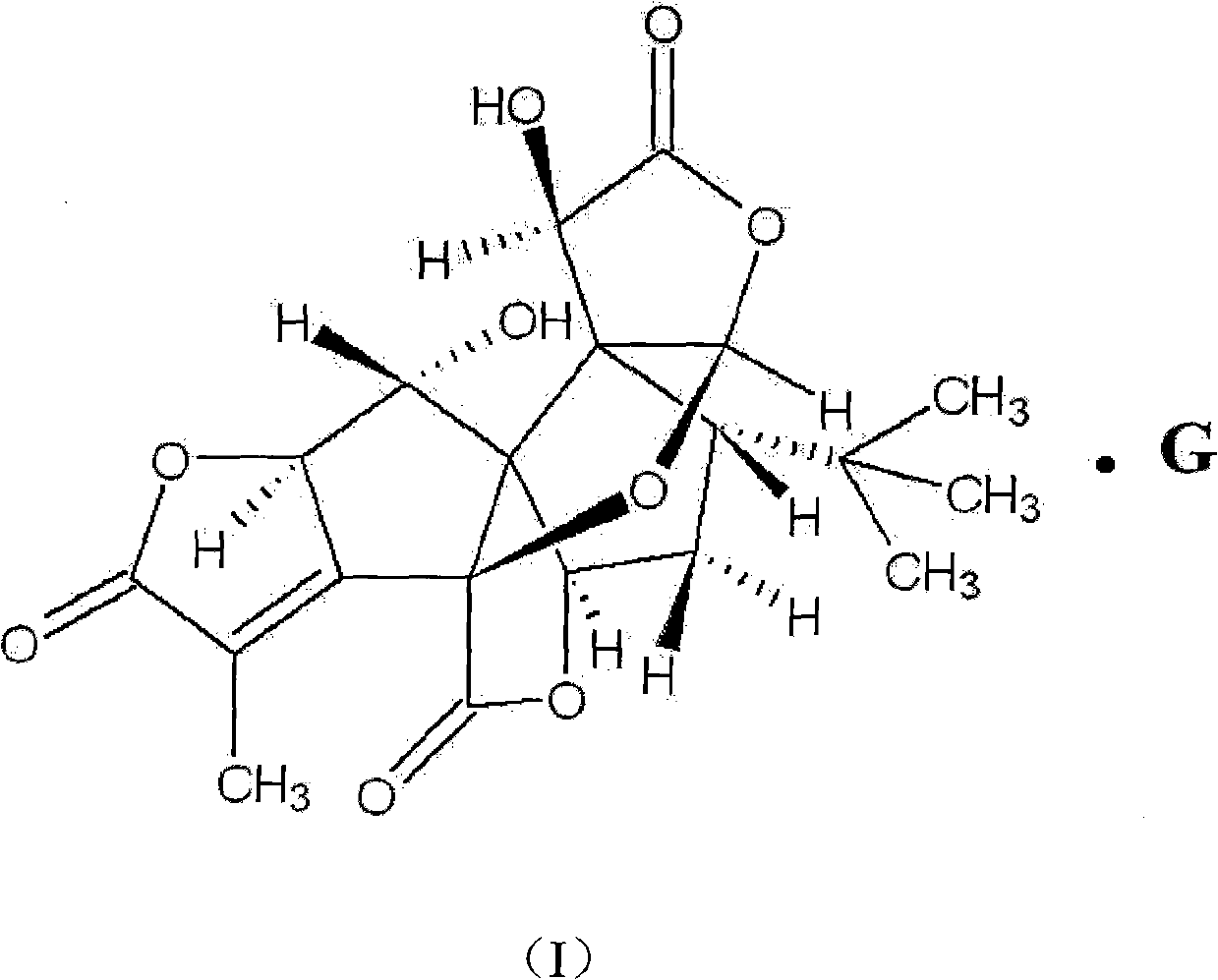

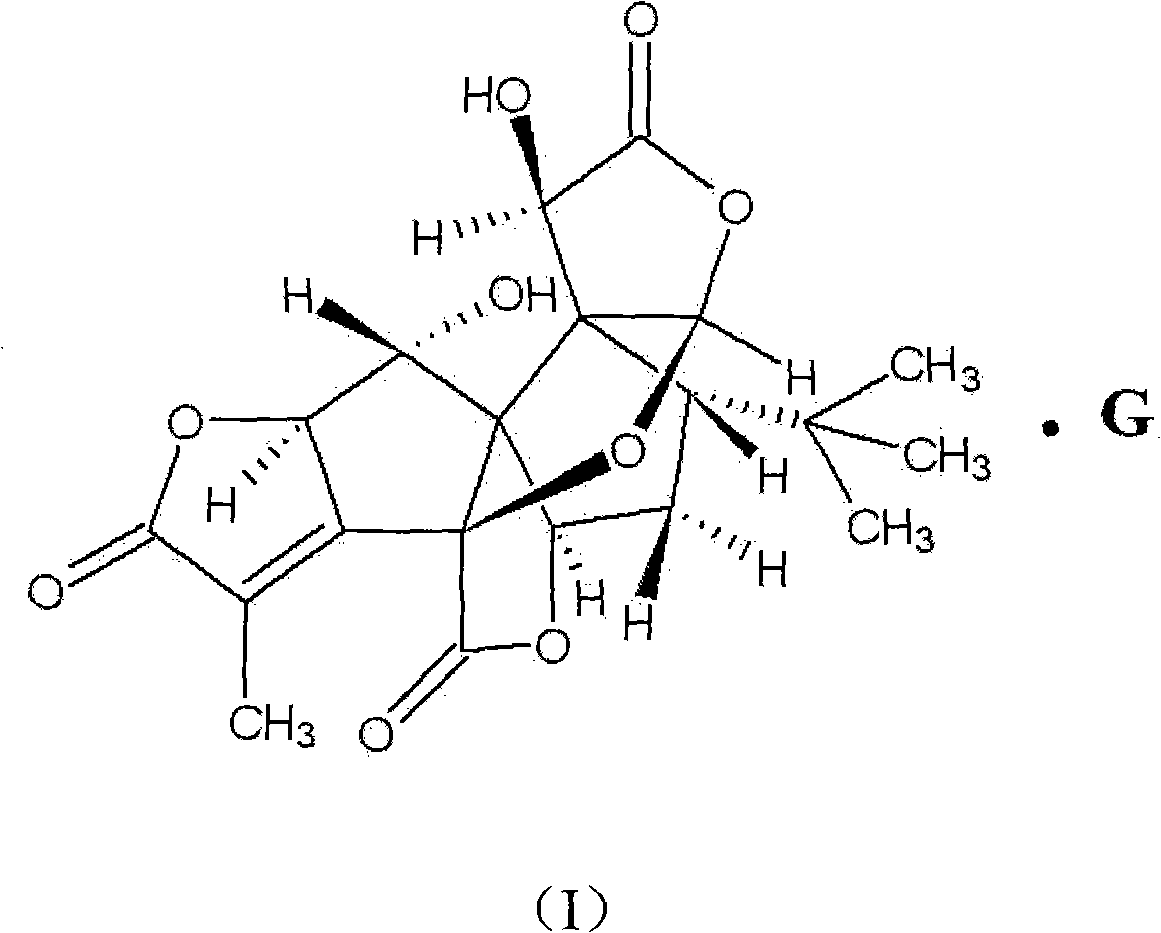

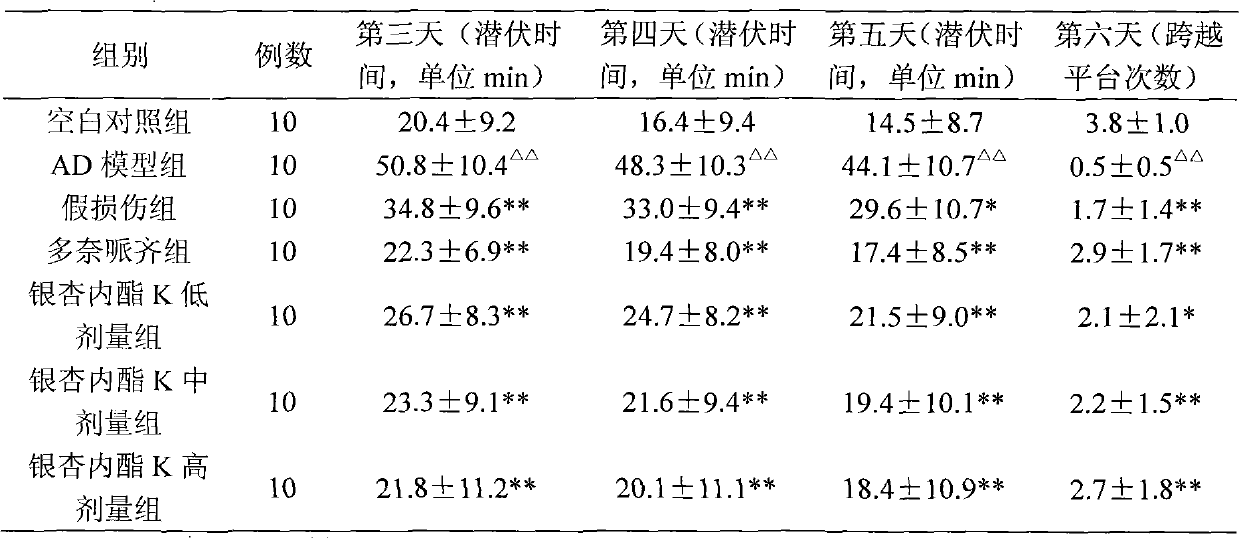

Bilobalide k and complex thereof, preparation method and use for the same

ActiveCN1919848AImprove pharmacological activityNuclear pyknosis reliefOrganic active ingredientsOrganic chemistrySolubilityDrug carrier

The invention discloses a preparing method and application of bilobalide K with general formula as (I), which is characterized by the following: G is alkaline material; possessing stability and water-solubility.

Owner:JIANGSU KANION PHARMA CO LTD

Ginseng micro-powder tablet and preparation method thereof

InactiveCN103784487AIncrease concentrationFully activeAntinoxious agentsPill deliveryAdditive ingredientMedicine

The invention relates to a preparation method of a ginseng micro-powder tablet. The method includes the following steps of selecting raw materials, conducting drying, sterilizing, freezing grinding, dry granulating and tabletting, and obtaining the ginseng micro-powder tablet. The invention further provides the ginseng micro-powder tablet prepared through the method. The ginseng micro-powder tablet is attractive in appearance and low in surface pitting rate and fracture rate, and the hardness, the disintegration degree and friability of the ginseng micro-powder tablet meet the requirements for tablet quality. According to the method, the extraction process is omitted, a large amount of ethyl alcohol for extraction solvent can be saved, the production cycle is greatly shortened, and production cost can be greatly reduced. Most importantly, all natural ingredients of ginseng are kept.

Owner:SHAN DONG DONG E E JIAO

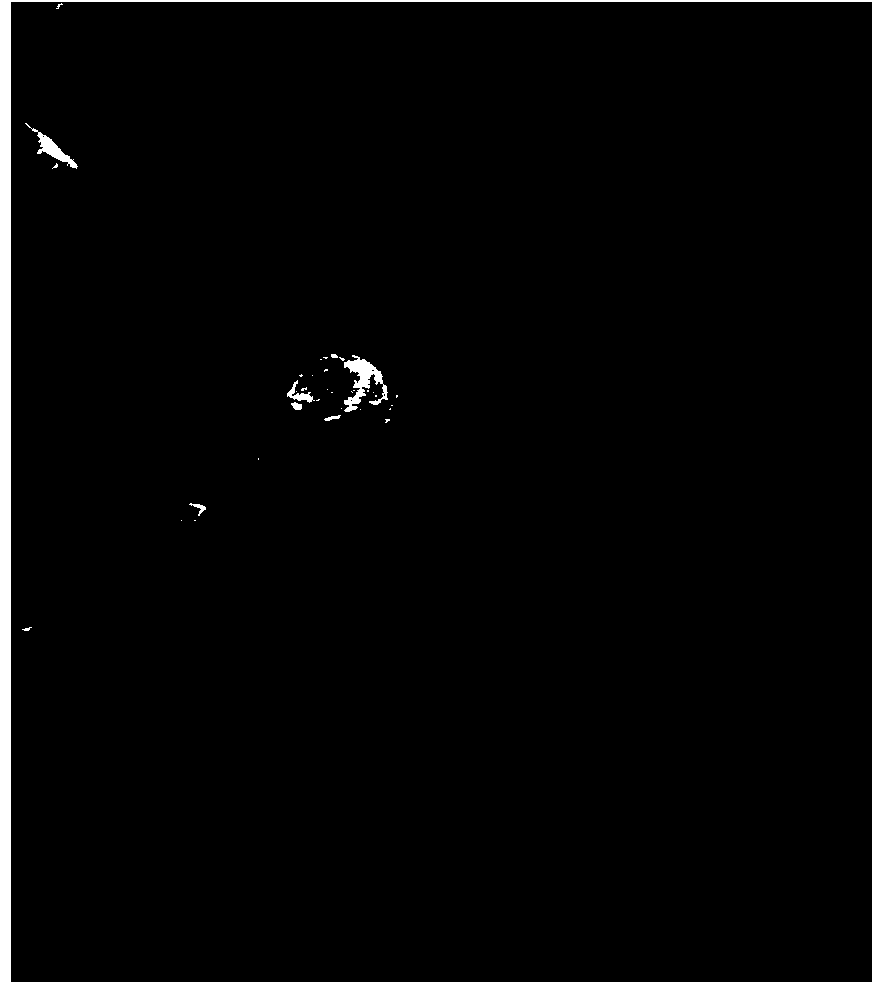

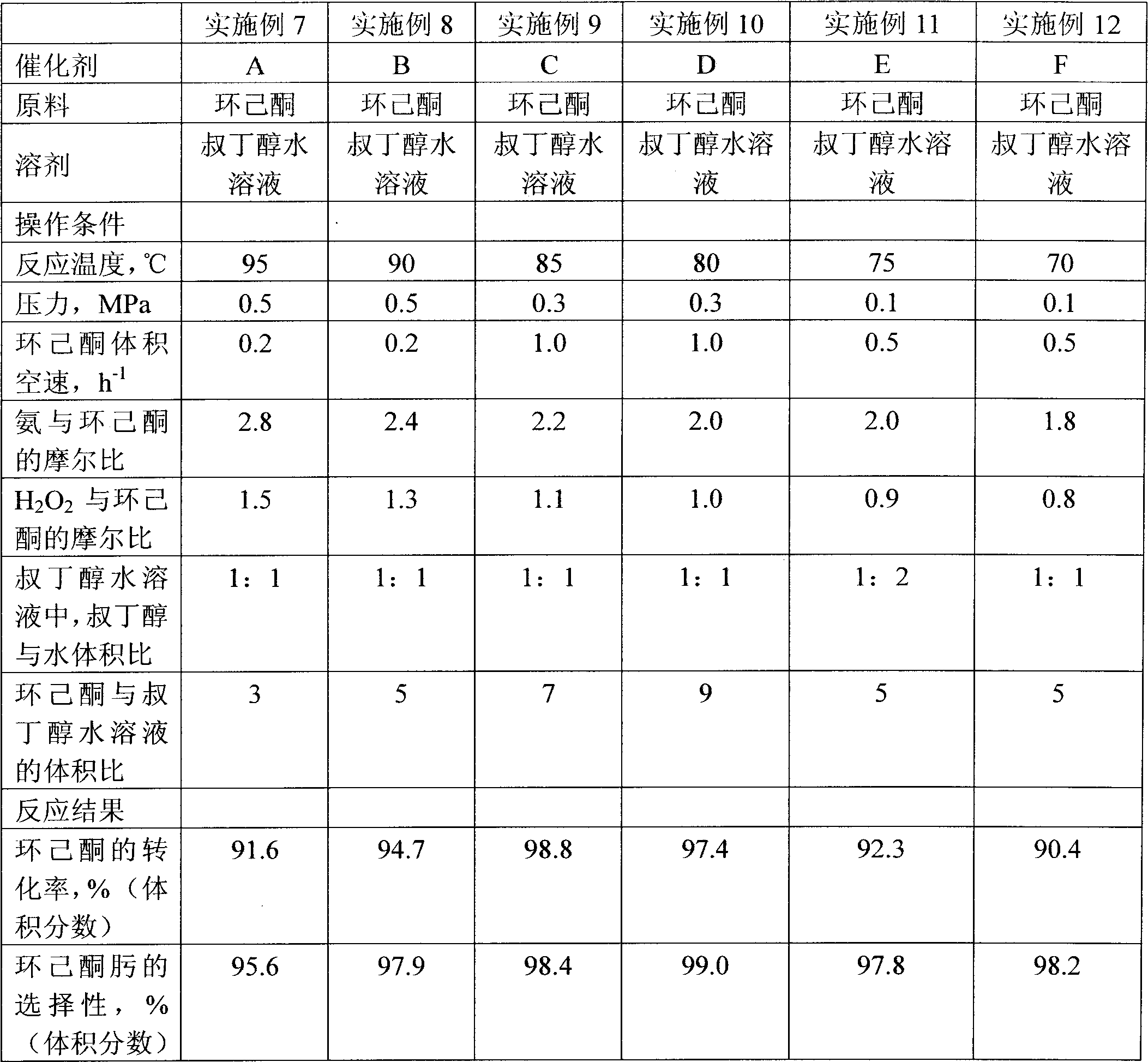

Ammoxidation method for cyclohexanone

ActiveCN102311363BAvoid easy separationImprove reaction efficiencyMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveHalohydrocarbon

A composite catalyst of Ti-Si molecular sieve and resin, preparation method and application thereof are disclosed. The catalyst is mainly consisted of Ti-Si molecular sieve and resin. The preparation method is as follows: mixing Ti-Si molecular sieve, polymerizing monomers, and pore-forming materials sufficiently in the presence of an initiator; then perfoming polymerization reaction to obtain a catalyst solid; adding the catalyst solid into halohydrocarbon to swell; solvent extracting to obtain a shaped catalyst.The obtained catalyst may be applied in the catalytic reactions of olefine epoxidation and cyclohexanone ammoxidation to prepare cyclohexanone oxime with fixed bed process, thus simplifying the operation steps, improving the slectivity for the target product, at the same time, solving the difficult problem of separating the catalyst powder containing Ti-Si molecular sieve from the reaction liquid, and increasing the reaction efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ginkgolides K and compound thereof as well as preparation method and use thereof

ActiveCN102002052ASolve technical problemsMaintain natural structureOrganic active ingredientsNervous disorderGinkgolidePharmaceutical drug

The invention discloses a compound of ginkgolides K of which a general formula is shown in (I), and a composition is prepared by mixing the ginkgolides K compound and pharmaceutically-acceptable medicine carrier, wherein G is alkaline substances. The invention also discloses a preparation method of the compound and treatment use thereof. In the invention, the ginkgolides K compound changes the physical property of the ginkgolides K, thereby the invention has the advantages of good stability, and the ginkgolides K compound has good water-solubility and higher stability. In the compound, a natural structure of the ginkgolides K can be kept, and when the compound is used as an effective component to enter the human body, the activity of the ginkgolides K can be fully developed to achieve theaim of treating an illness.

Owner:JIANGSU KANION PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com