Technique for hydrogenation of coal oil

A process method, coal tar technology, applied in tar processing, hydrotreating process, petroleum industry, etc., can solve problems such as deposition, affecting device operation cycle, and rise in pressure drop of reactor bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

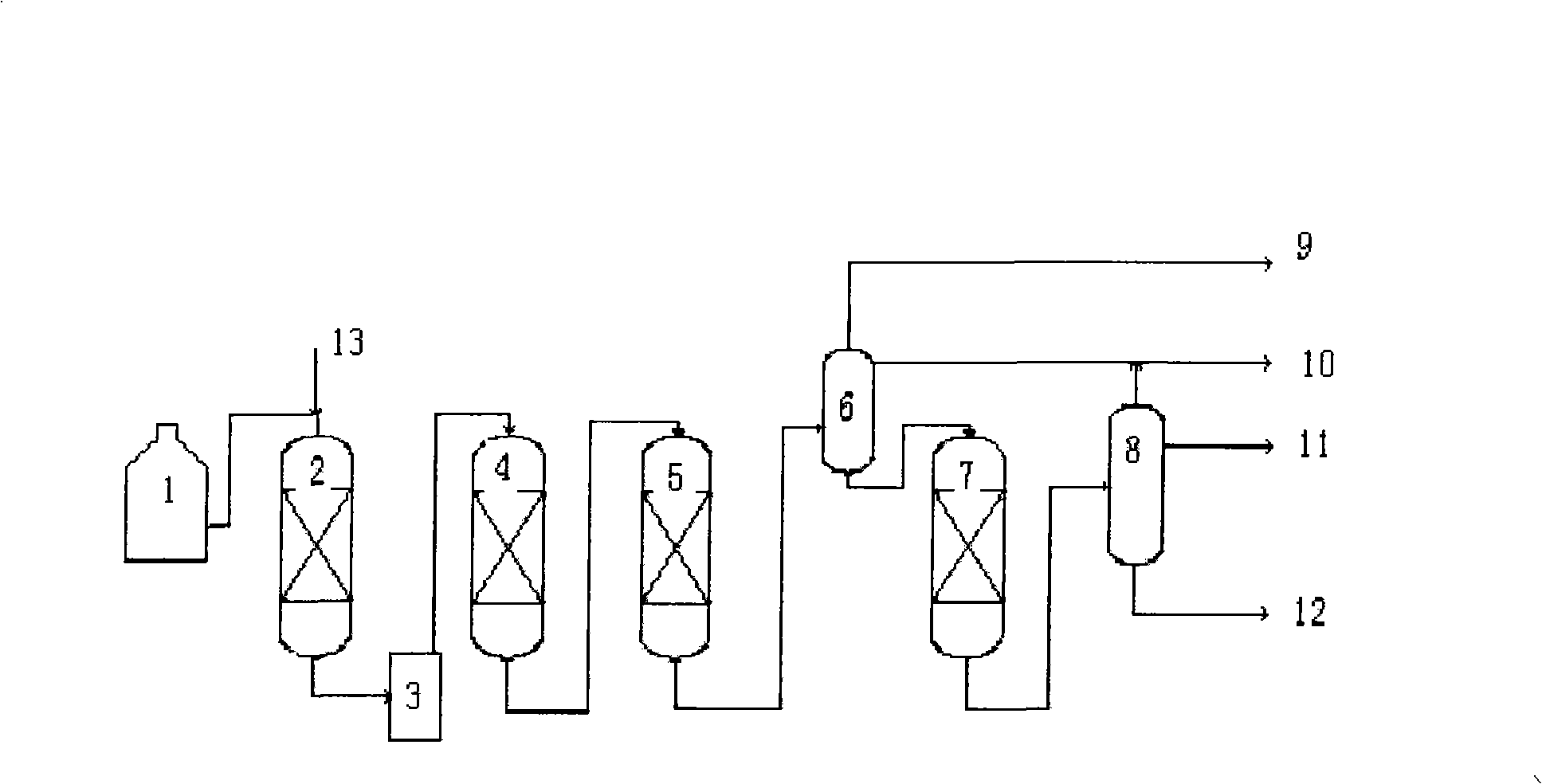

[0027] The serial number 1 is the raw material tank, 2 is the pre-hydrogenation reactor, 3 is the separation device, 4 is the hydrodemetallization reactor, 5 is the deep hydrofining reactor, 6 is the separation device, and 7 is the hydrocracking reactor , 8 is a distillation unit, 9 is water, 10 is gasoline, 11 is diesel oil, 12 is hydrocracking tail oil, 13 is hydrogen, and the rest are pipelines.

[0028] Schematic diagram of the principle process for producing light fuel oil by multi-stage hydrotreating of coal tar ( figure 1 ): First, the coal tar raw material in the raw material tank 1 is mixed with hydrogen and enters a pre-hydrogenation reactor for hydrogenation saturation of unsaturated hydrocarbons. The pre-hydrogenation stream is filtered or separated by a separation device (such as a centrifugal separator) to separate the fine solid particles suspended in the product stream, and then enters the hydrodemetallization reactor, and goes straight to the demetallization r...

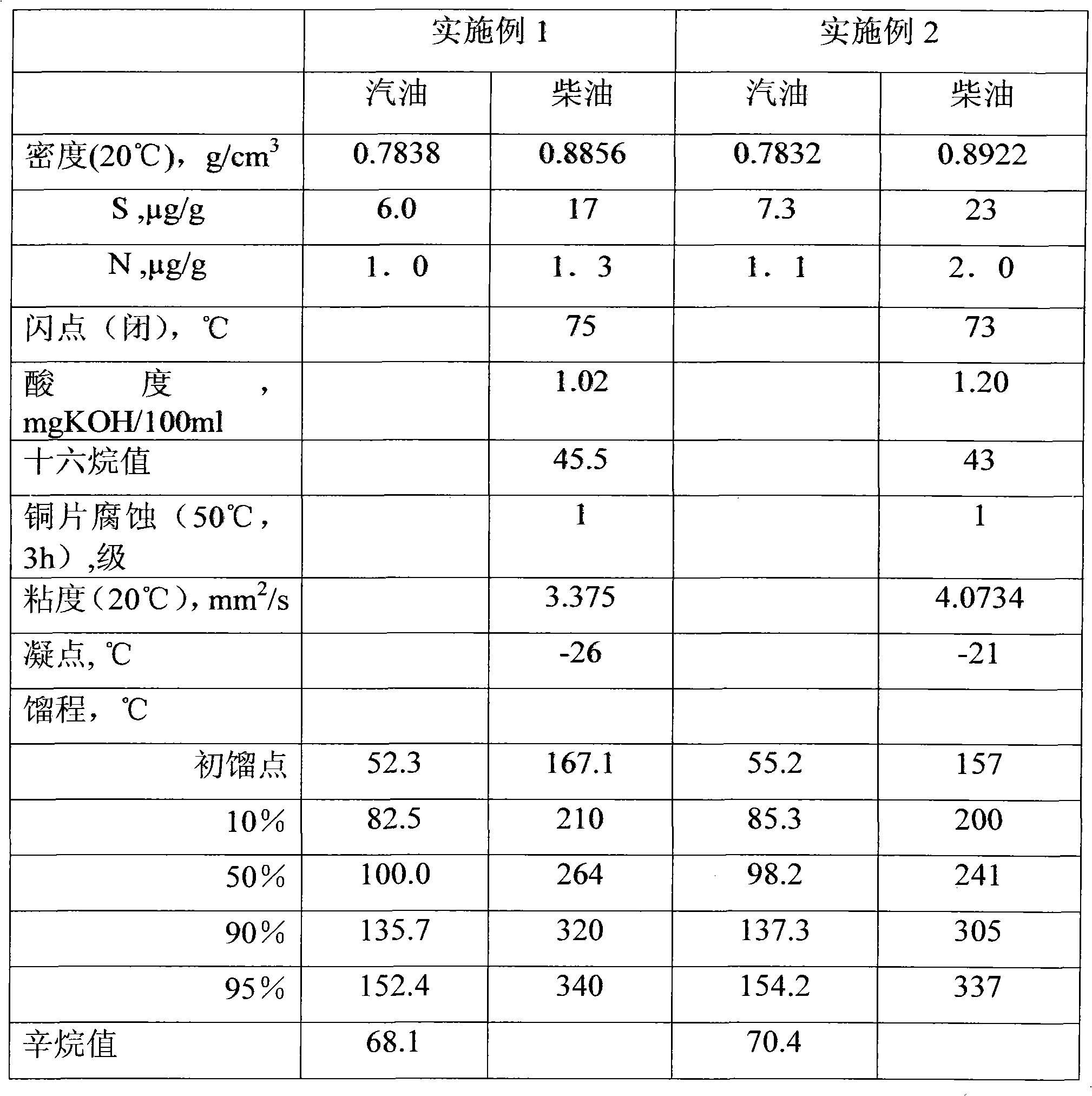

Embodiment 1-2

[0037] This example is a hydrogenation test of high-temperature coal tar distillate oil using a multi-stage combined process of graded loading, and each reactor adopts the operation mode of gas-liquid parallel flow and downward flow. Among them, the properties of coal tar raw materials are: Density (20°C): 1.1365g / cm 3 , carbon residue: 3.4%; sulfur: 6000μg / g, nitrogen: 10000μg / g, saturated content: 0%; aromatic content: 69.1%; colloid: 27.9%, asphaltene: 3%; mechanical impurity content: 1.8% . First, the coal tar raw material in raw material tank 1 is mixed with hydrogen and then enters the fixed bed prehydrogenation reactor for hydrodeoxygenation and unsaturated hydrocarbon hydrogenation reaction. The mechanical impurity content in the prehydrogenation reaction effluent is 1.7%. The reaction effluent is separated into fine solid particles by a centrifugal separation device (LW220 horizontal screw sedimentation centrifuge produced by Taixing Gaoda Centrifuge Co., Ltd.), and ...

Embodiment 3-4

[0044] This example is a hydrogenation test of high-temperature coal tar whole distillates using a multi-stage combined process of graded packing. Among them, the properties of the whole fraction of coal tar are: Density (20°C): 1.1653g / cm 3 , carbon residue: 23.4%; sulfur: 6800μg / g, nitrogen: 12000μg / g, saturated content: 0.17%; aromatic content: 33.1%; pectin: 10.73, asphaltenes: 56%; mechanical impurity content: 4.8%. The operation process of this test is basically the same as that of Example 1, except that the composition of the catalyst in the pre-hydrogenation reactor is: FZC-102: Catalyst B: Catalyst C ratio is 30:40:30. The content of mechanical impurities in the pre-hydrogenation reaction effluent was 4.7%, and the pre-hydrogenation reaction effluent was filtered (CLBY-302A type automatic backwash filter produced by Beijing Kelijie Water Industry) to separate fine solid particles. The mechanical impurity content is lower than 10μg / g. The reaction conditions and test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com