Patents

Literature

253results about "Working-up tar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Effective integration of solvent deasphalting and ebullated-bed processing

InactiveUS7214308B2Reduced light gas yieldImprove hydrogen efficiencyTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyReactor systemHeavy crude oil

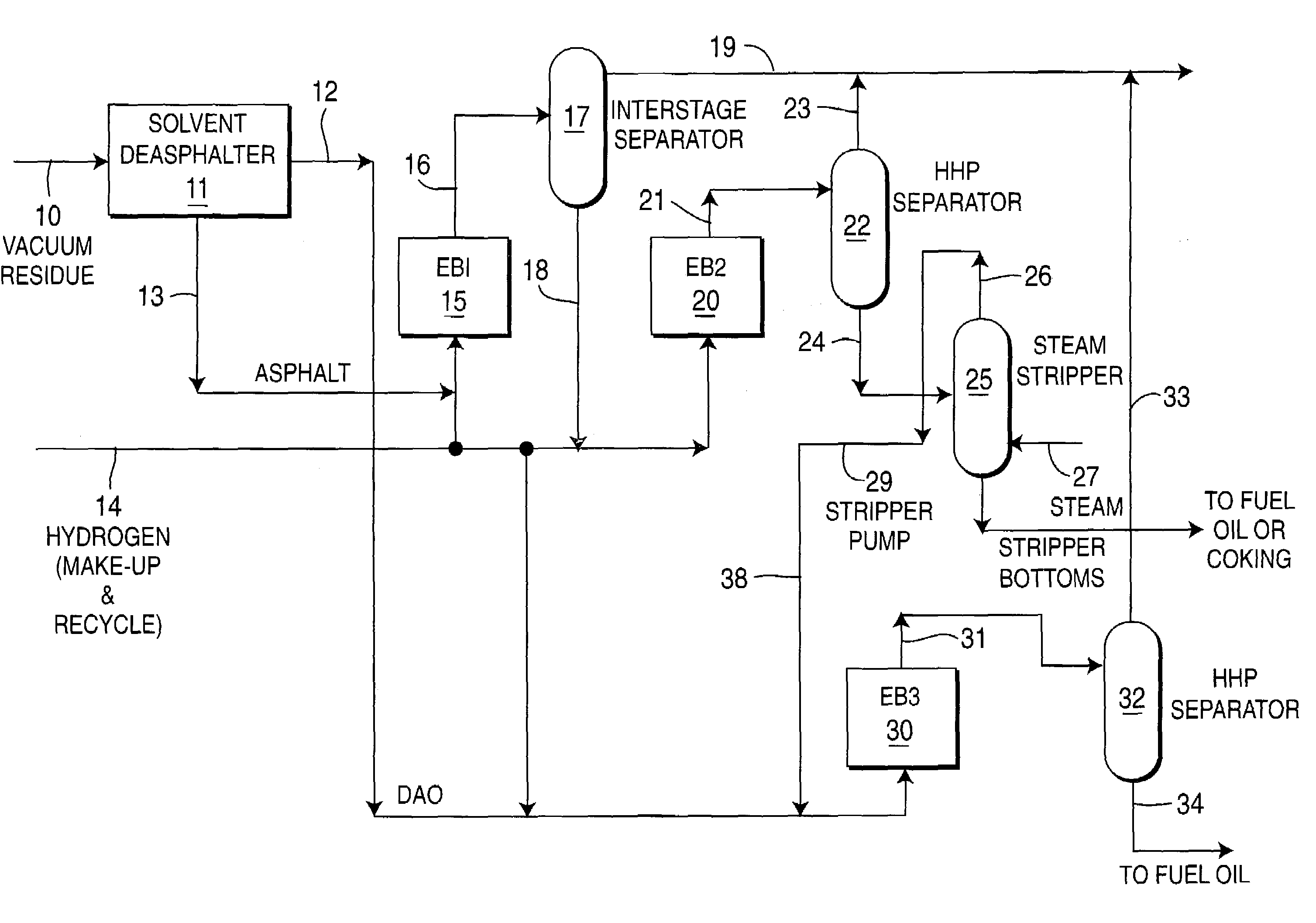

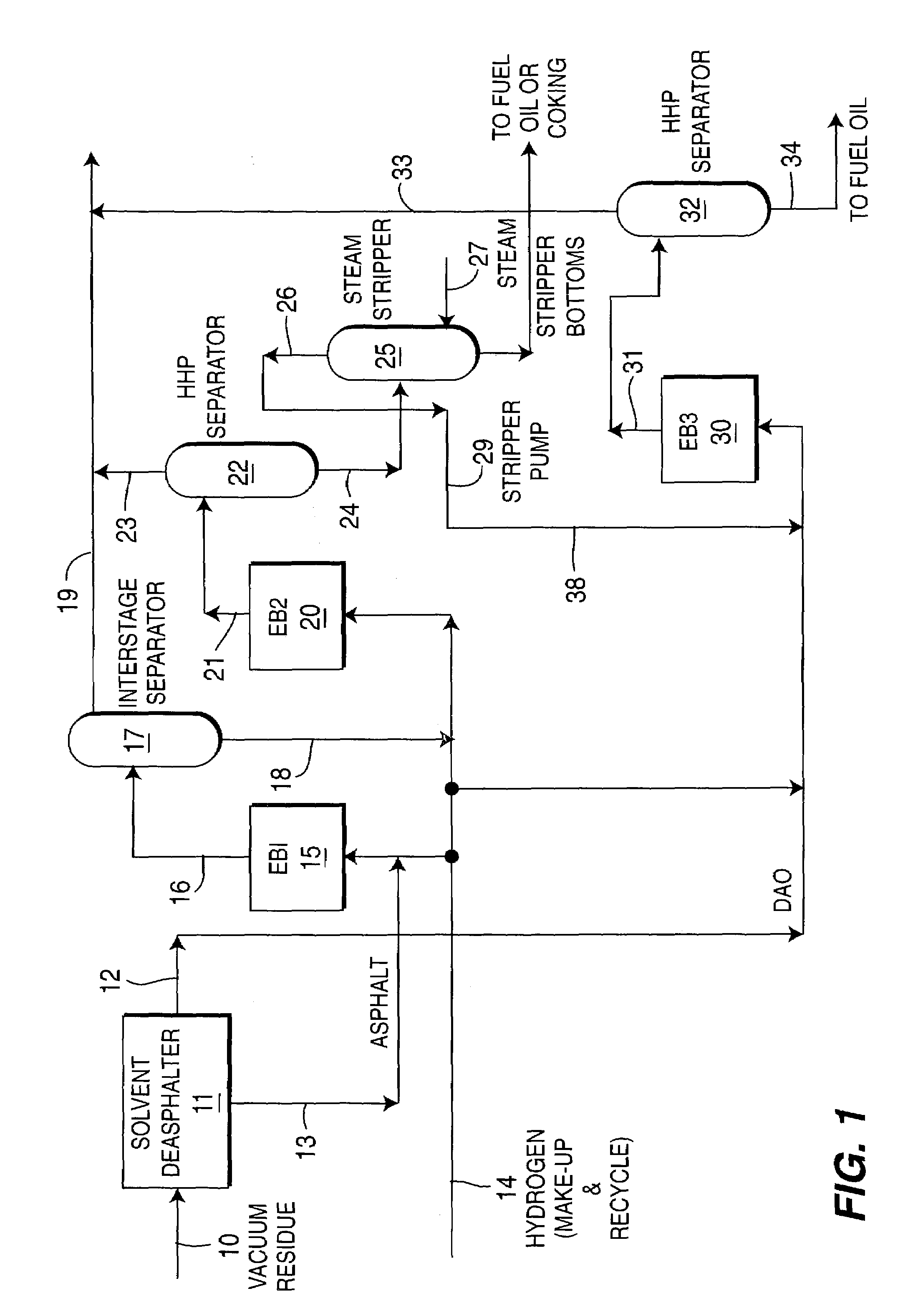

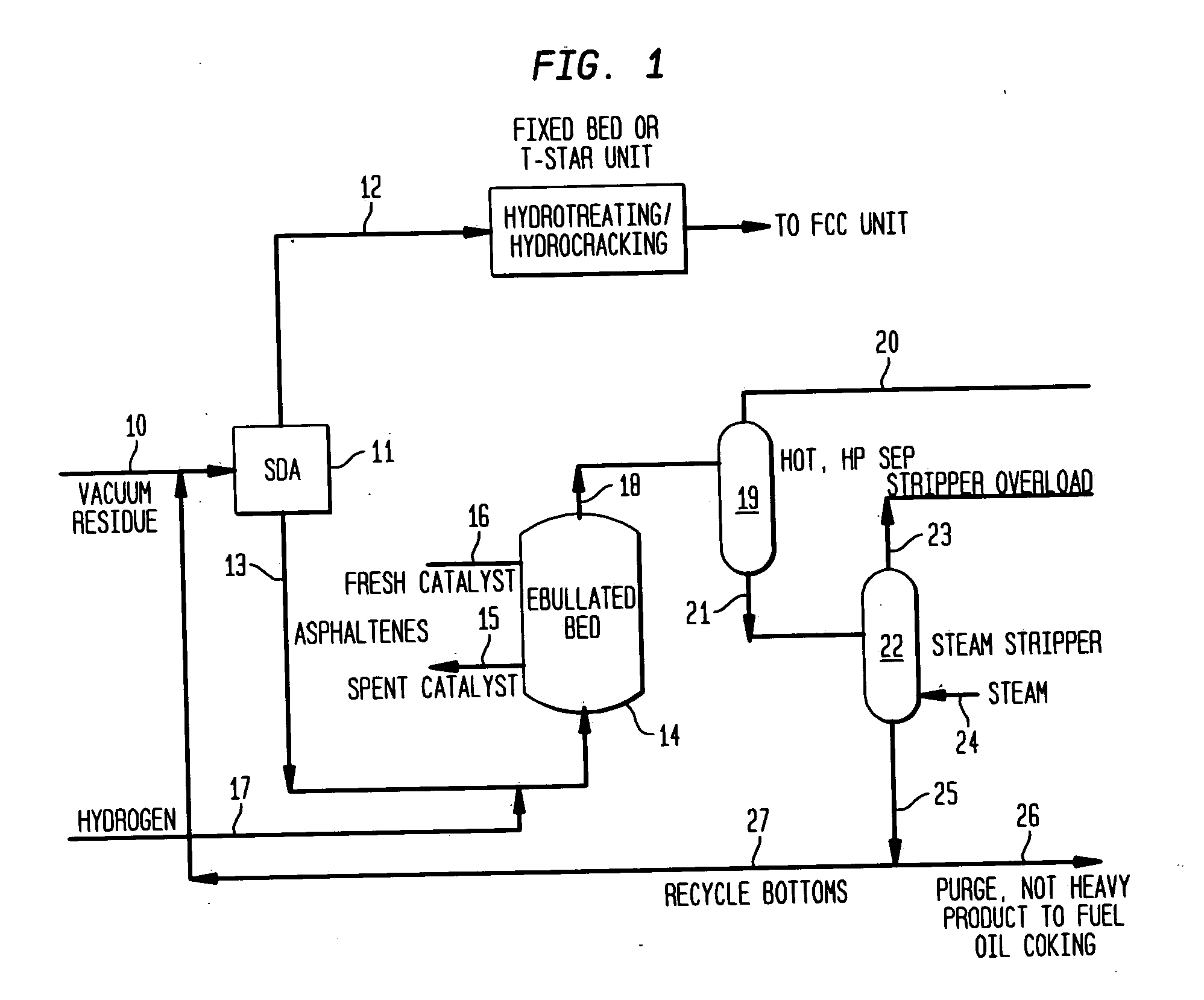

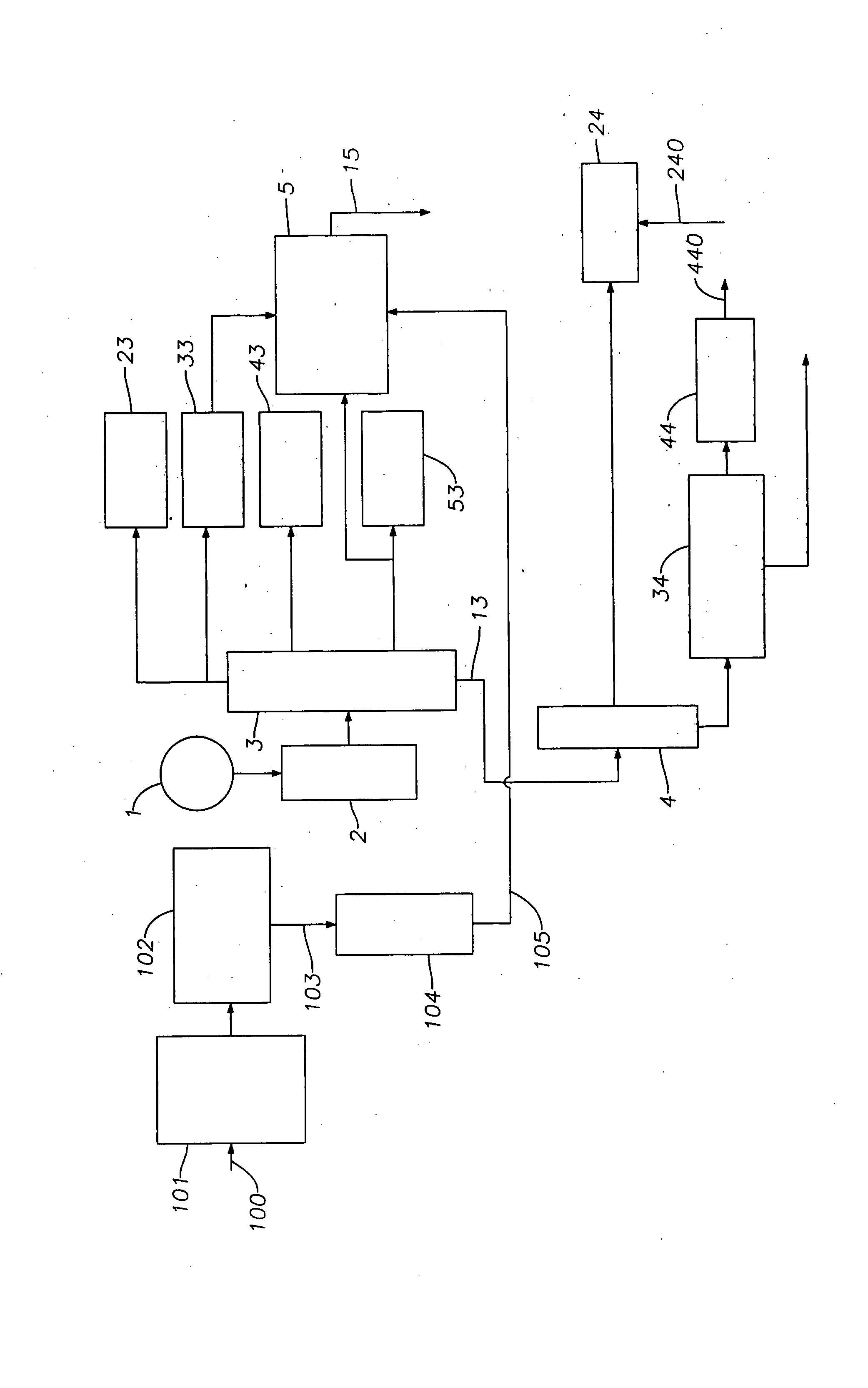

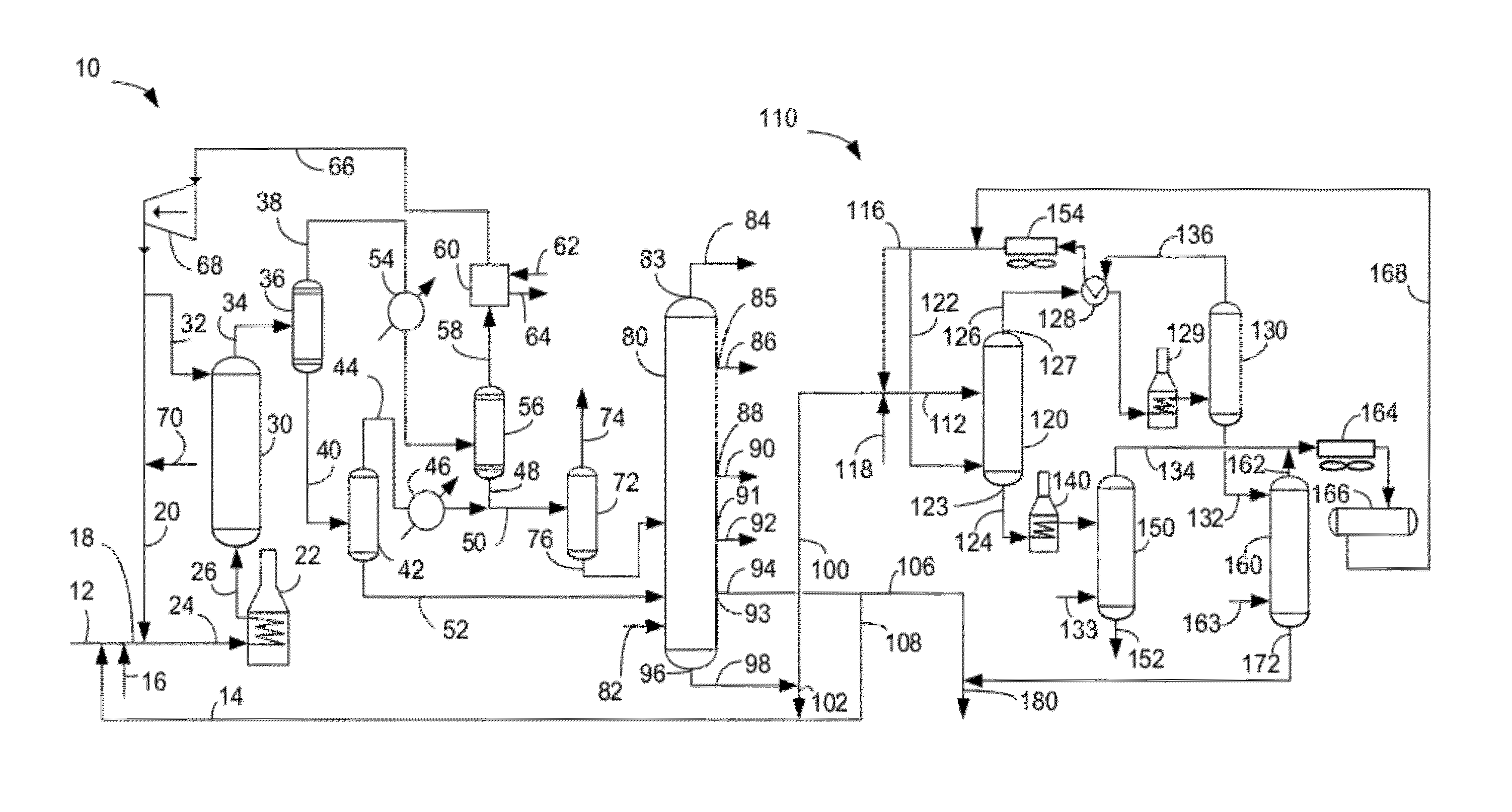

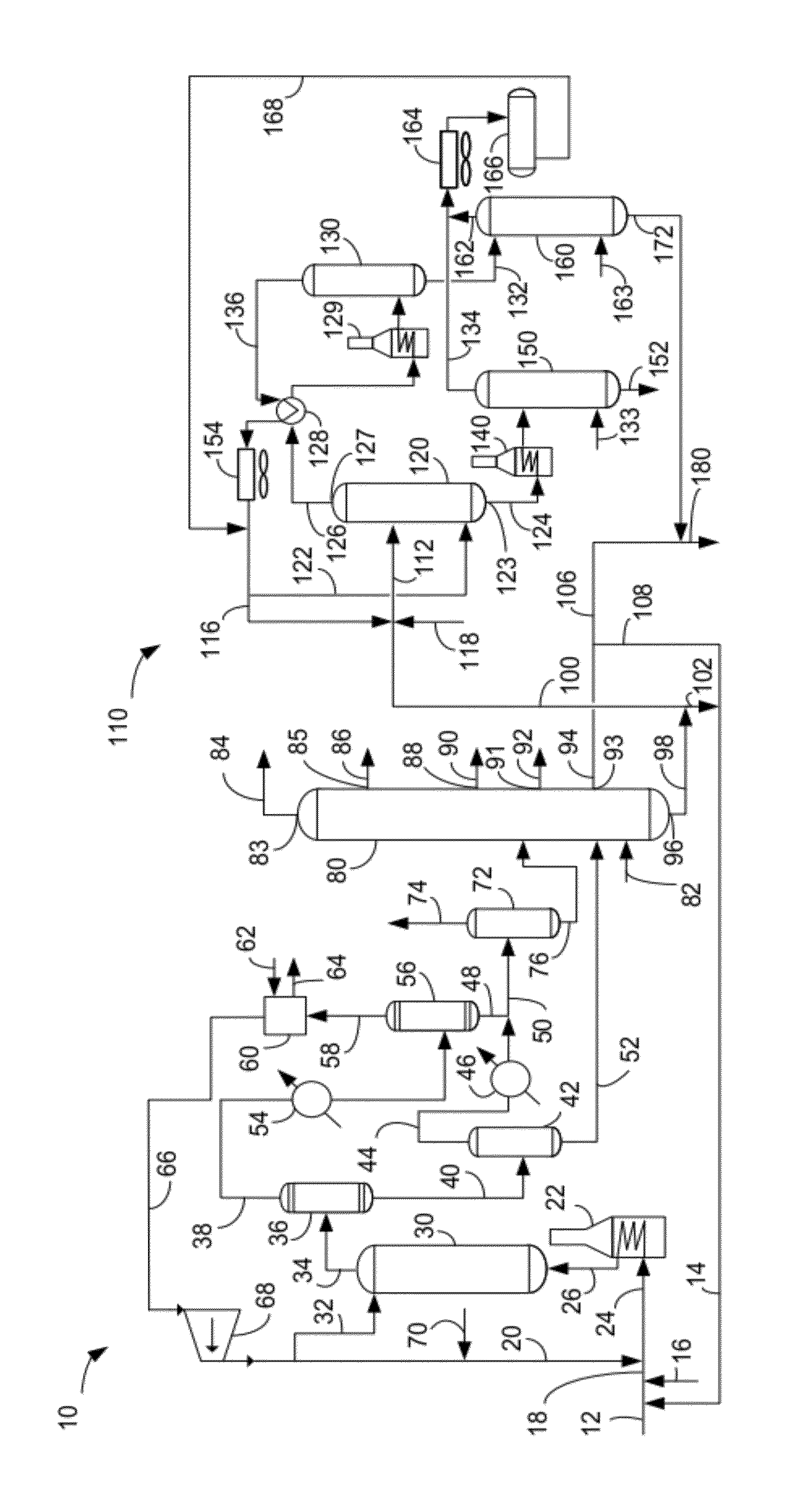

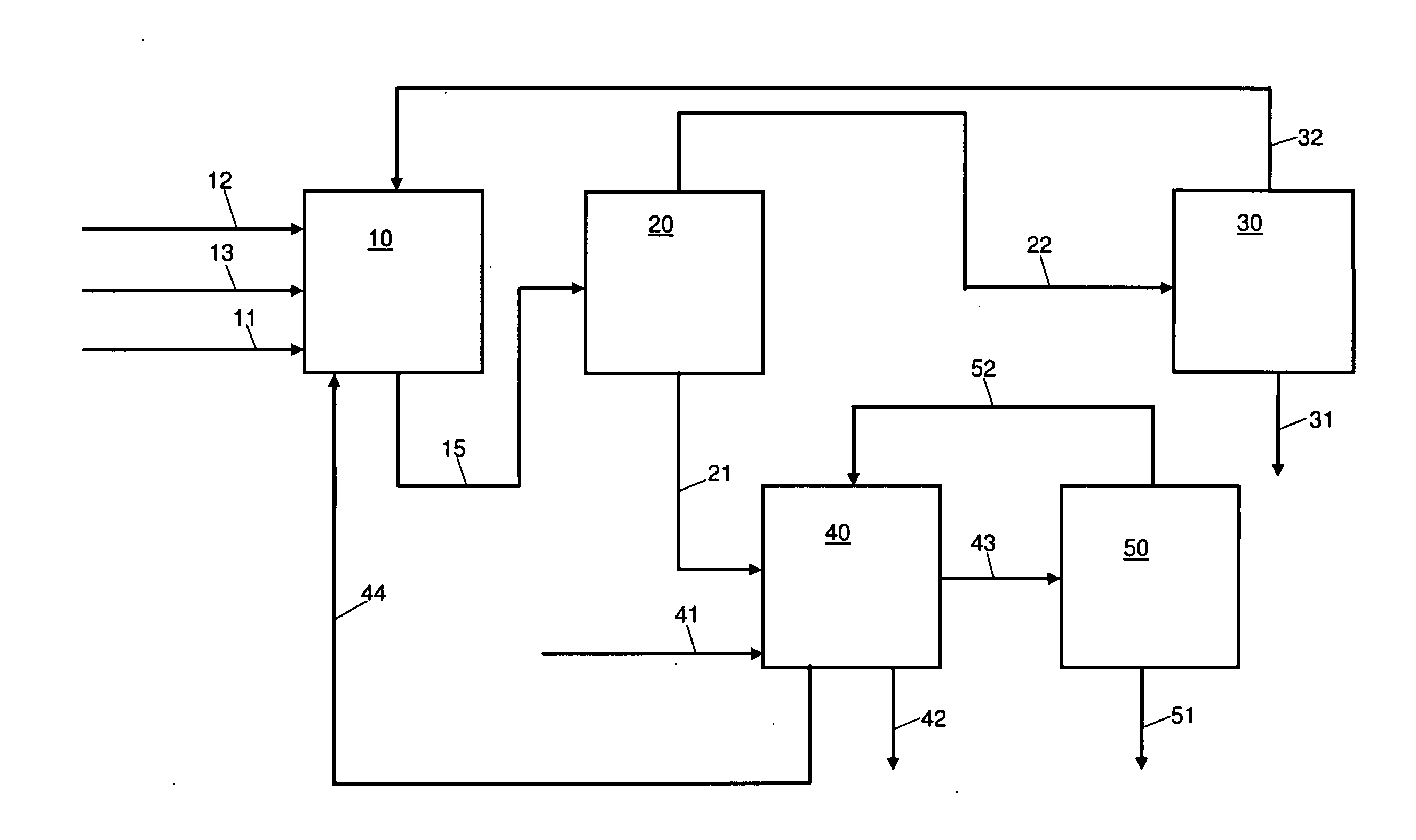

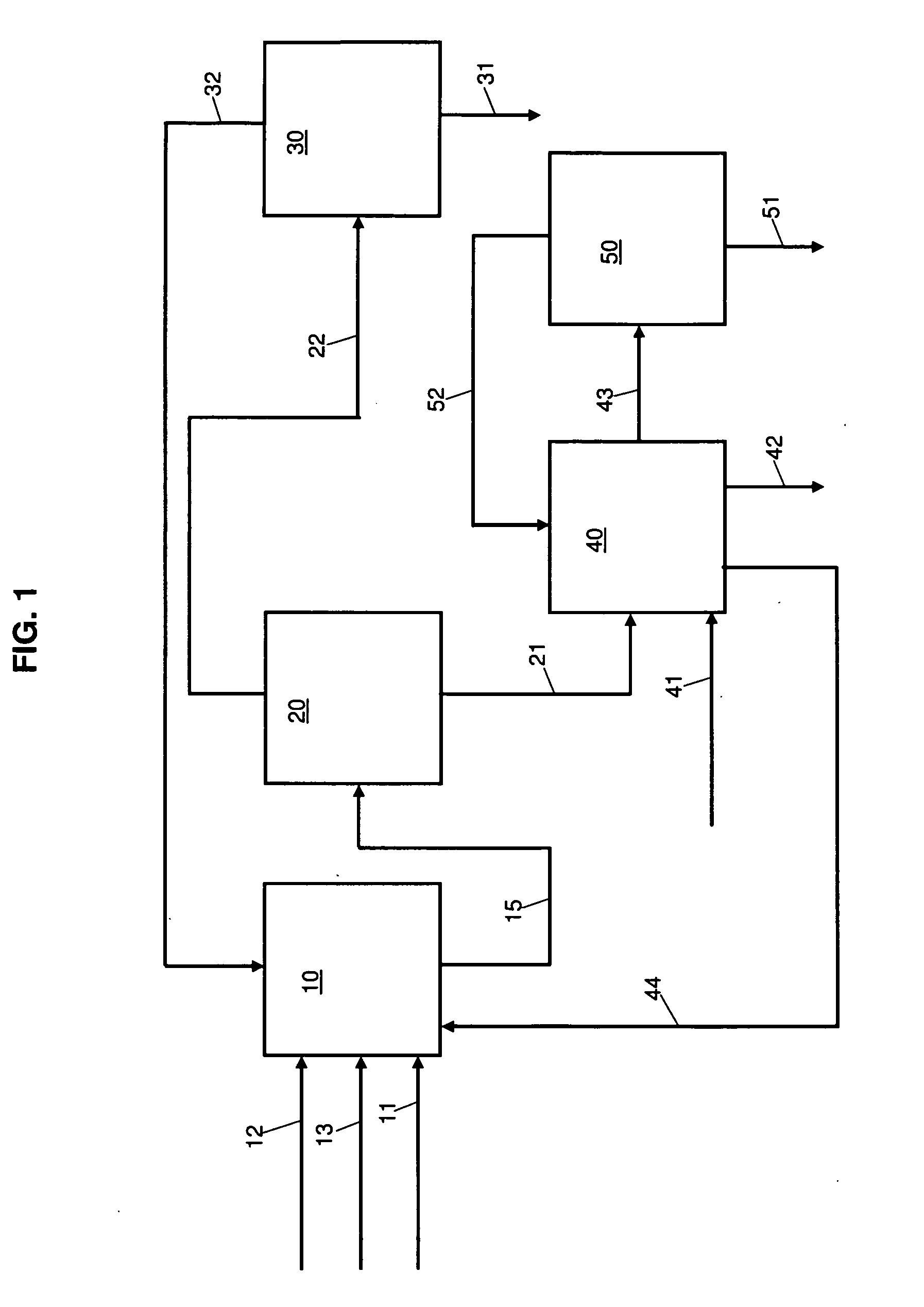

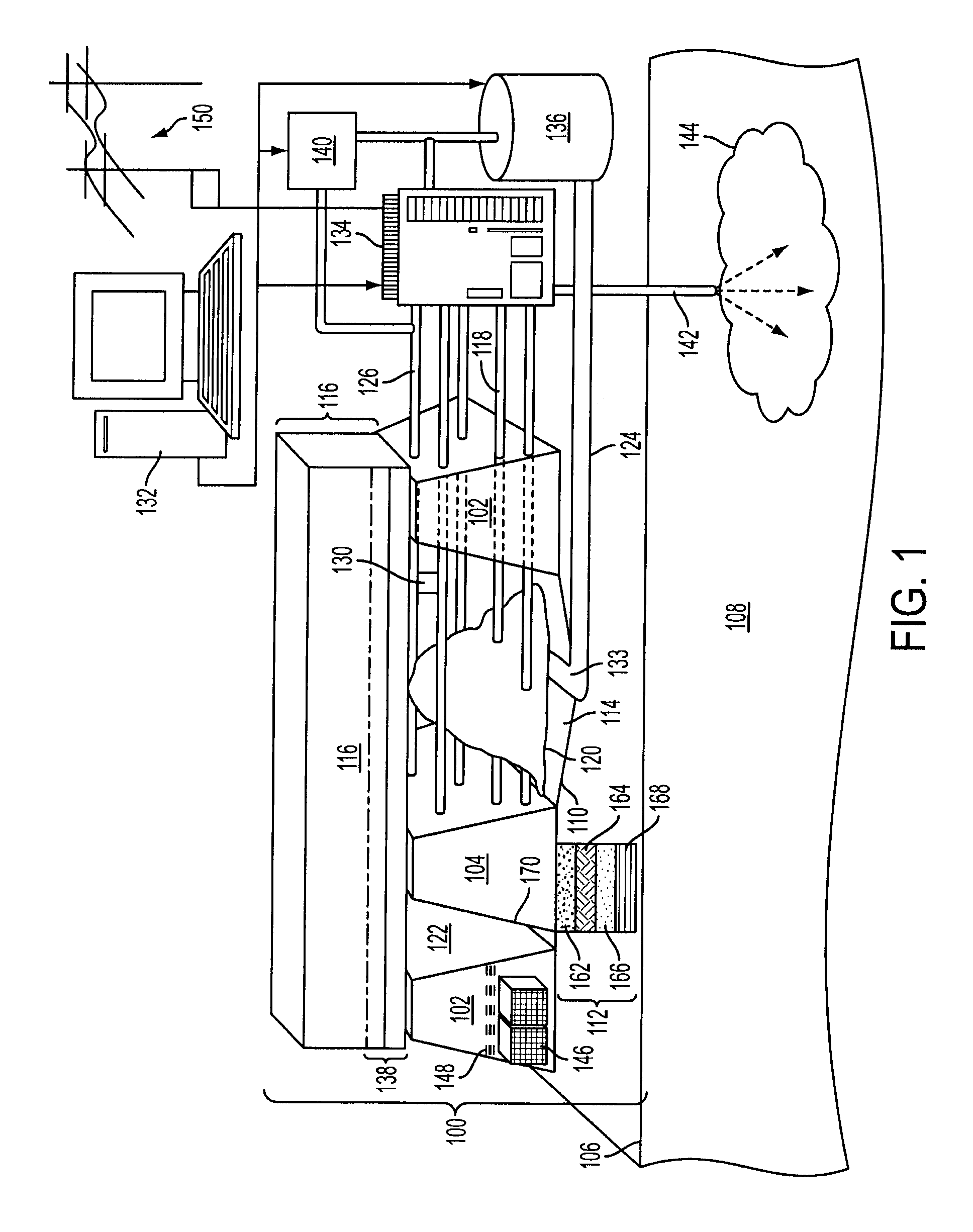

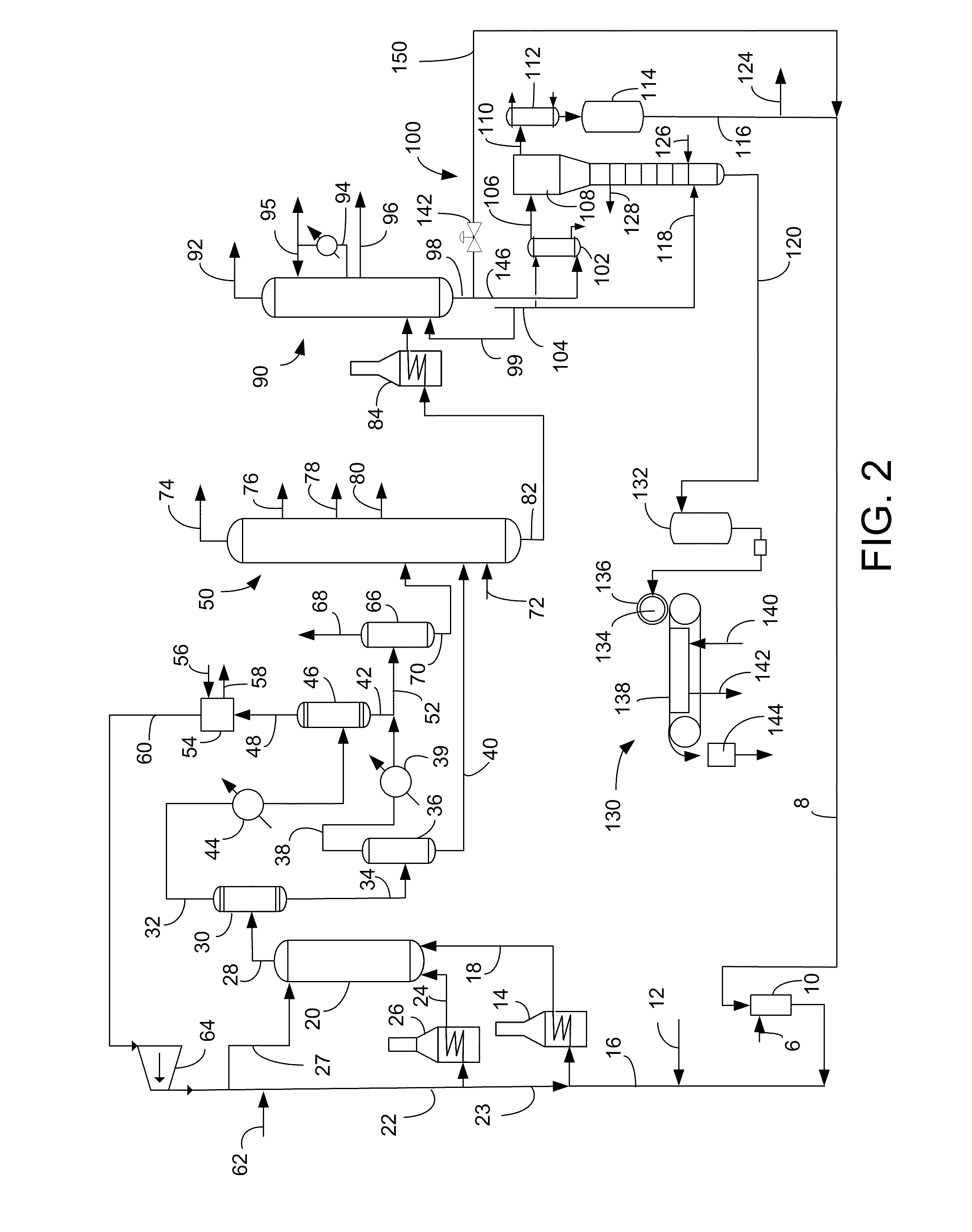

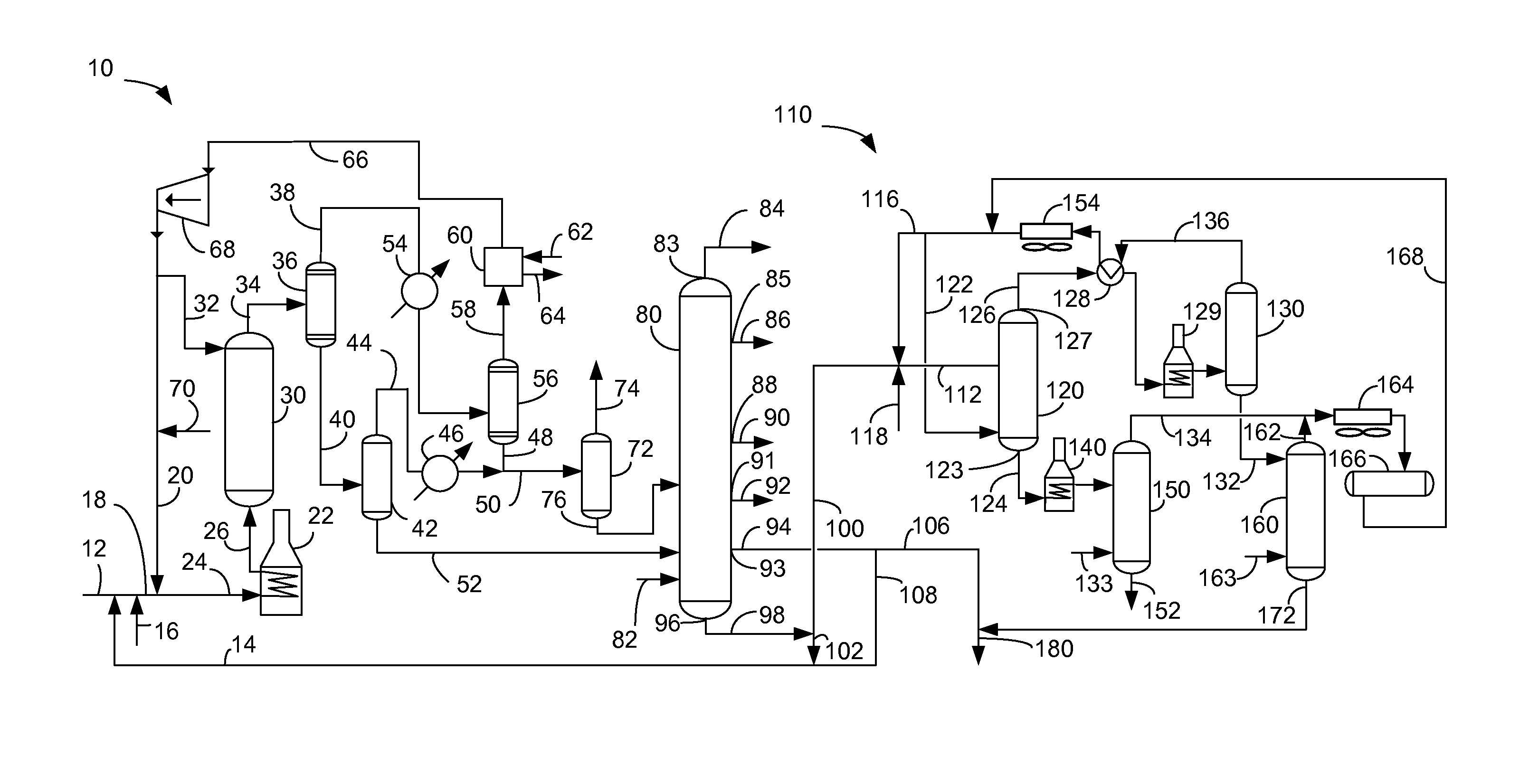

This invention relates to a novel method for economically processing vacuum residue from heavy crude oils by selectively processing the difficult and easy components in reactors whose design and operating conditions are optimized for the specific feed. The process utilizes an integrated solvent deasphalting (SDA) / ebullated-bed design wherein the heavy vacuum residue feedstock is initially sent to an SDA unit operated with C4 / C5 solvent to achieve a high deasphalted oil (DAO) yield. The resulting SDA products, namely asphaltenes and DAO are separately treated in ebullated-bed reactor(s) systems whose design and operating conditions are optimized for a particular feedstock. The resulting net conversion, associated distillate yield and product qualities are greatly improved relative to treatment of the entire residue feedstock in a common ebullated-bed reactor system.

Owner:INST FR DU PETROLE

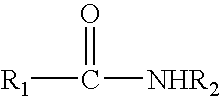

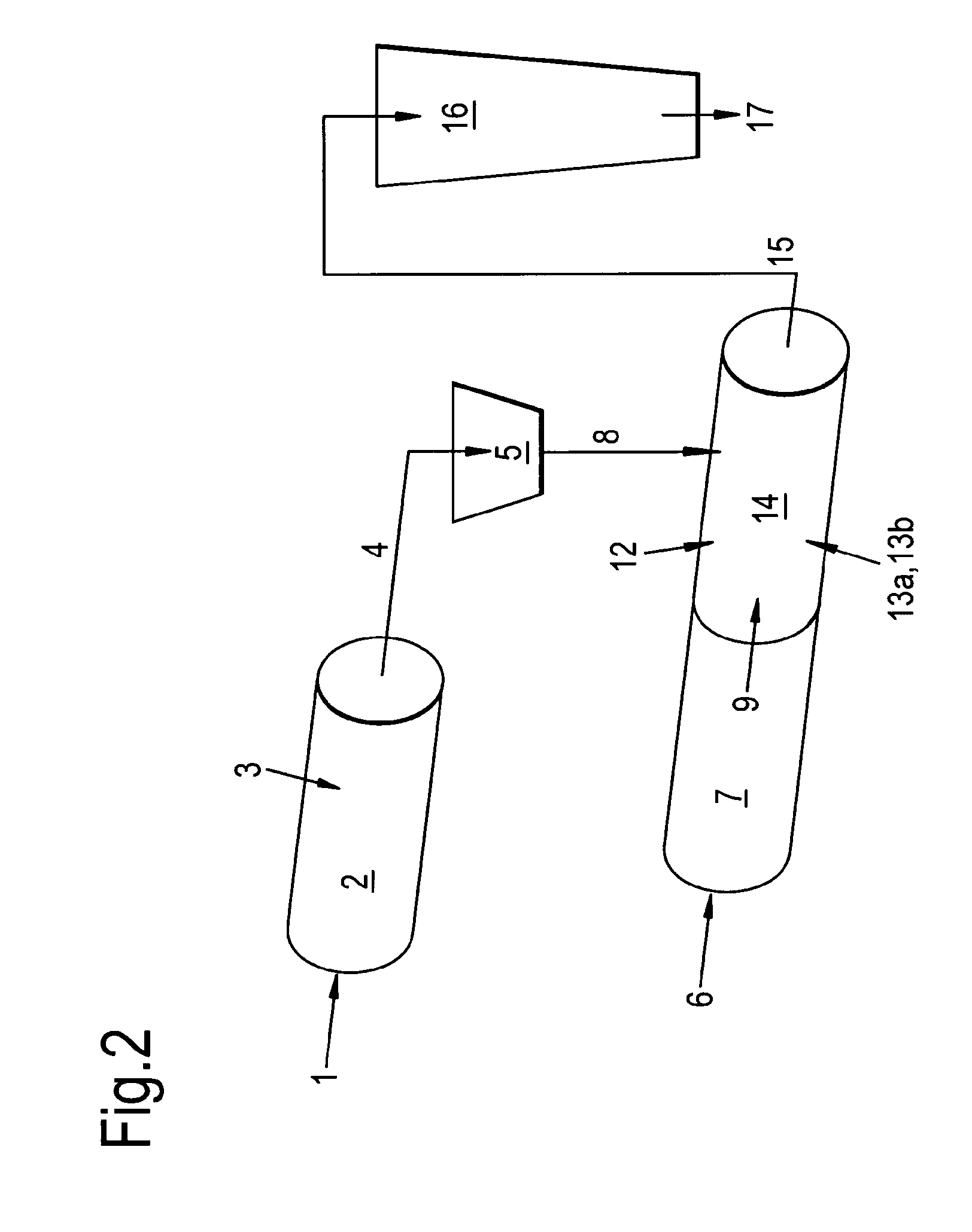

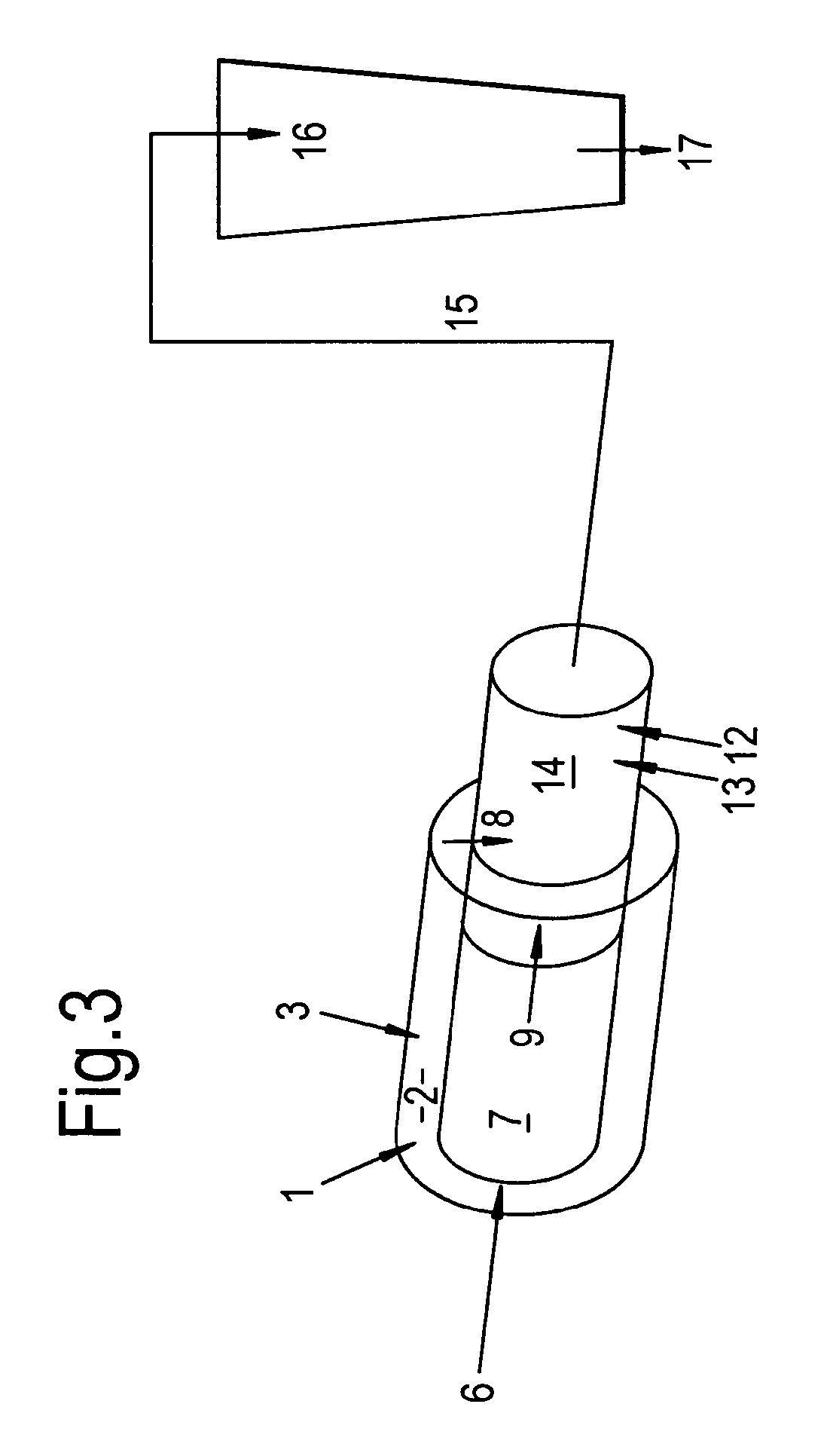

Integrated SDA and ebullated-bed process

ActiveUS20060118463A1Most efficientMinimizing chanceTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyBiochemical engineeringFixed bed

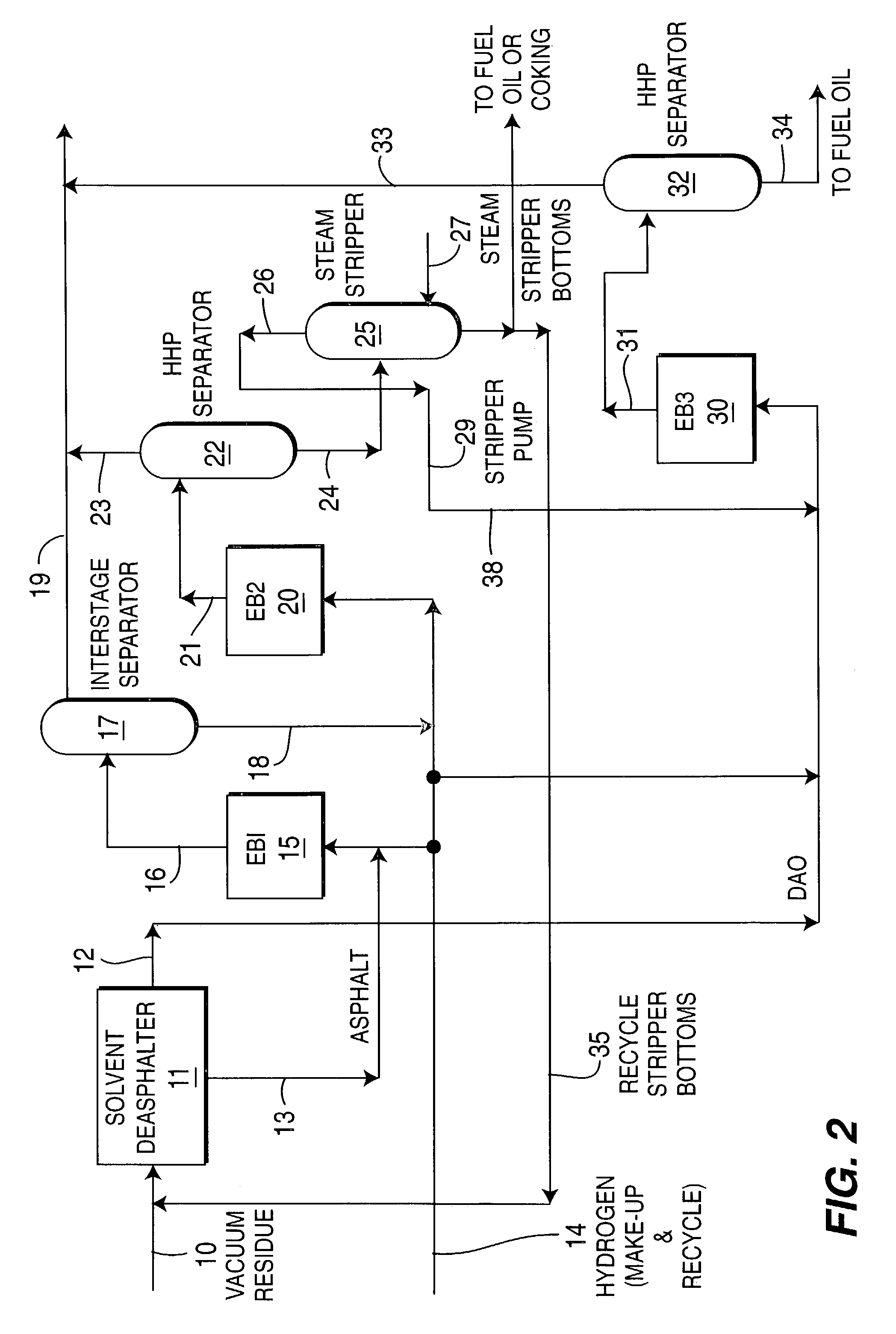

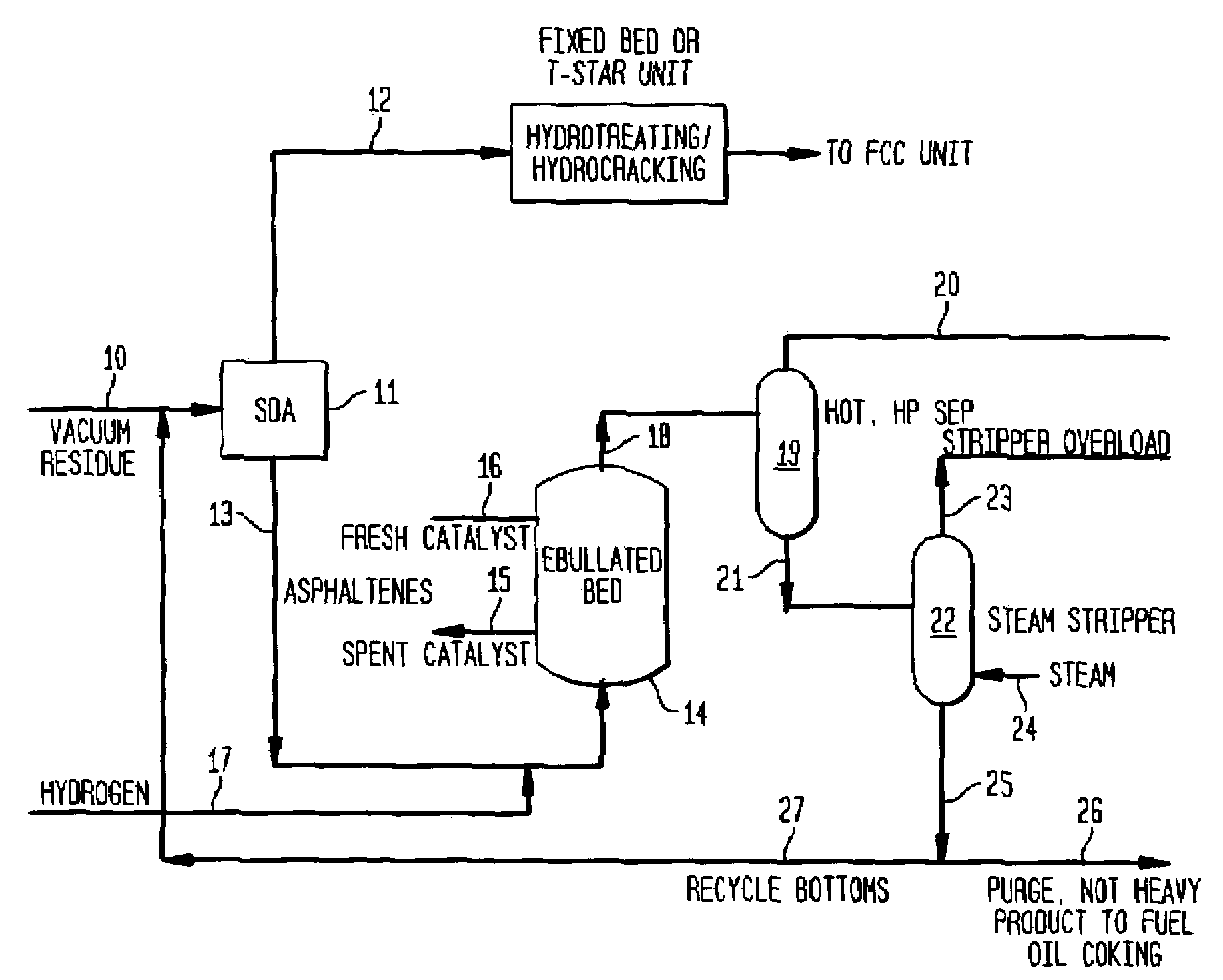

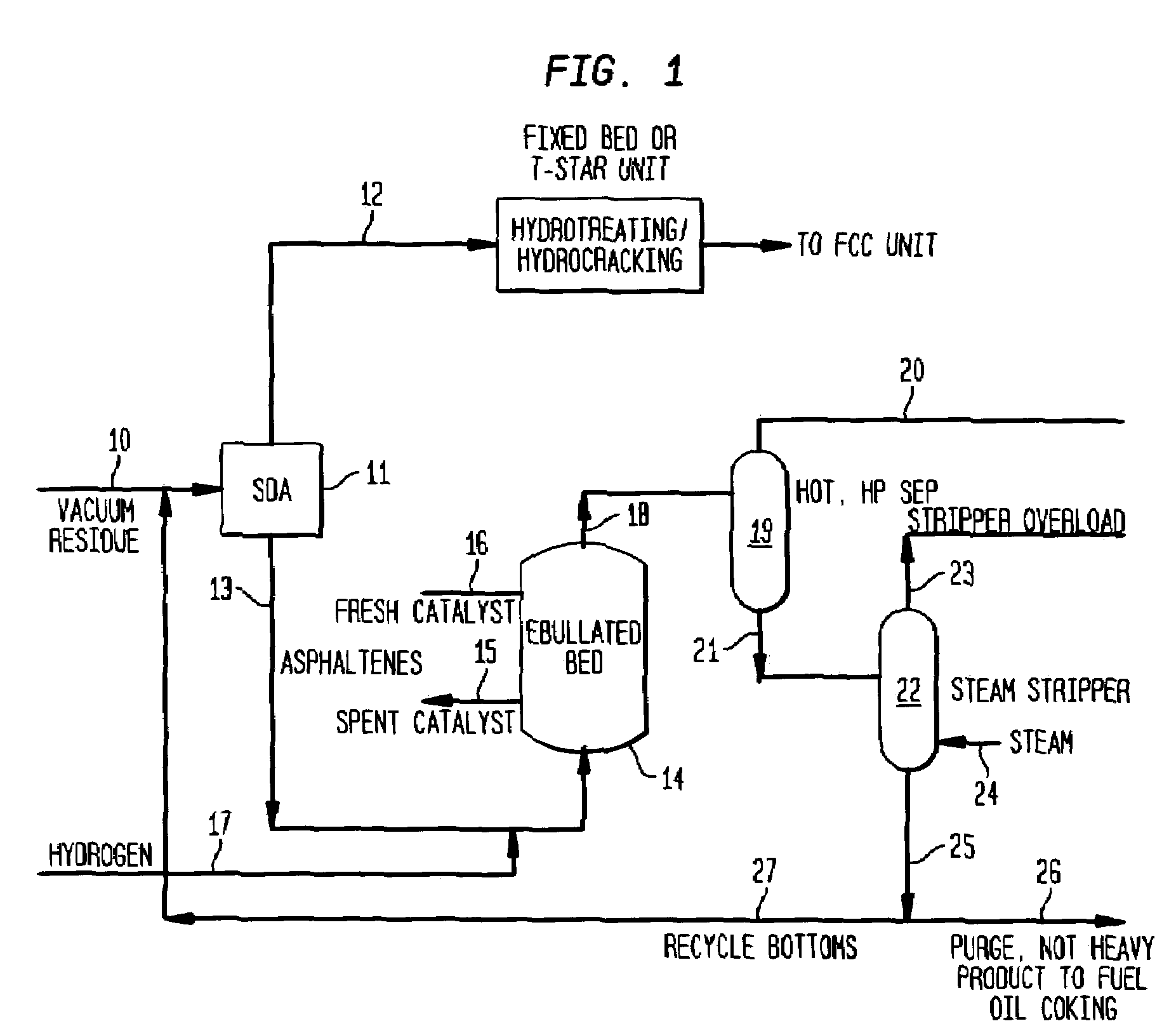

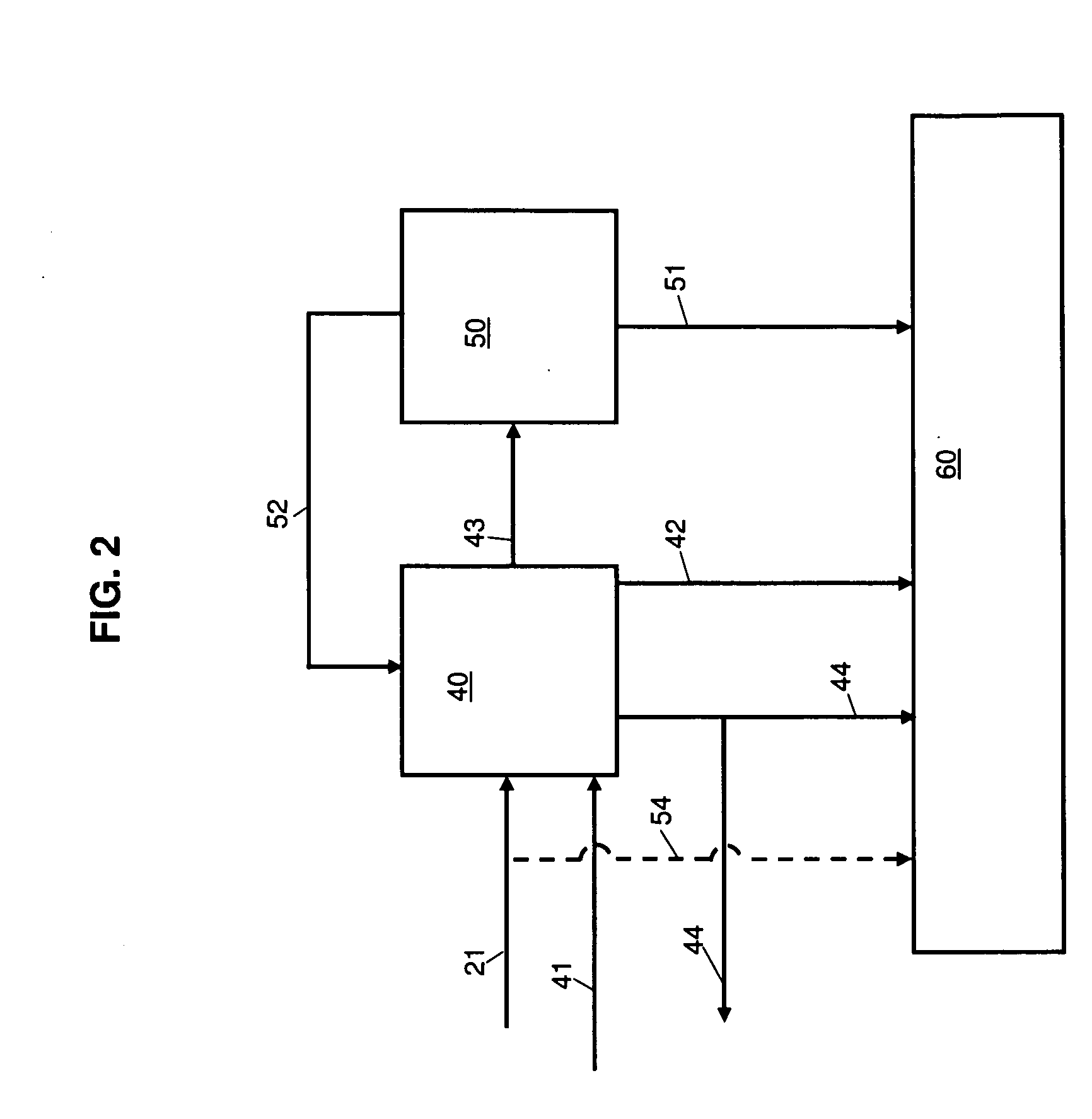

This invention relates to a novel integrated method for economically processing vacuum residue from heavy crude oils. This is accomplished by utilizing a solvent deasphalter (SDA) in the first step of the process with a C3 / C4 / C5 solvent such that the DAO product can thereafter be processed in a classic fixed-bed hydrotreater or hydrocracker. The SDA feed also includes recycled stripper bottoms containing unconverted residue / asphaltenes from a downstream steam stripper unit. The asphaltenes from the SDA are sent to an ebullated-bed reactor for conversion of the residue and asphaltenes. Residue conversion in the range of 60-80% is achieved and asphaltene conversion is in the range of 50-70%. The overall residue conversion, with the DAO product considered non-residue, is in the range of 80 W %-90 W % and significantly higher than could be achieved without utilizing the present invention.

Owner:INST FR DU PETROLE

Method for processing ethylene tar

The invention discloses a method for processing ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid and carbon residue in the ethylene tar. The light fraction passes through a hydrogenation protection reaction zone, a hydrofining reaction zone and a hydrocracking reaction zone sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction is used as a universal type carbon fiber asphalt stock. The method for processing the ethylene tar makes full use of the total fraction of the ethylene tar and increases the additional value of the ethylene tar. In addition, the method enables the arene after hydrostturation in the ethylene tar to open ring, crack moderately and / or isomerize by selecting two types of hydrocracking catalysts to perform grading loading so as to obtain the diesel oil fraction with condensation point less than -40 DEG C in high yield and obtain a side product high-octane gasoline fraction at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

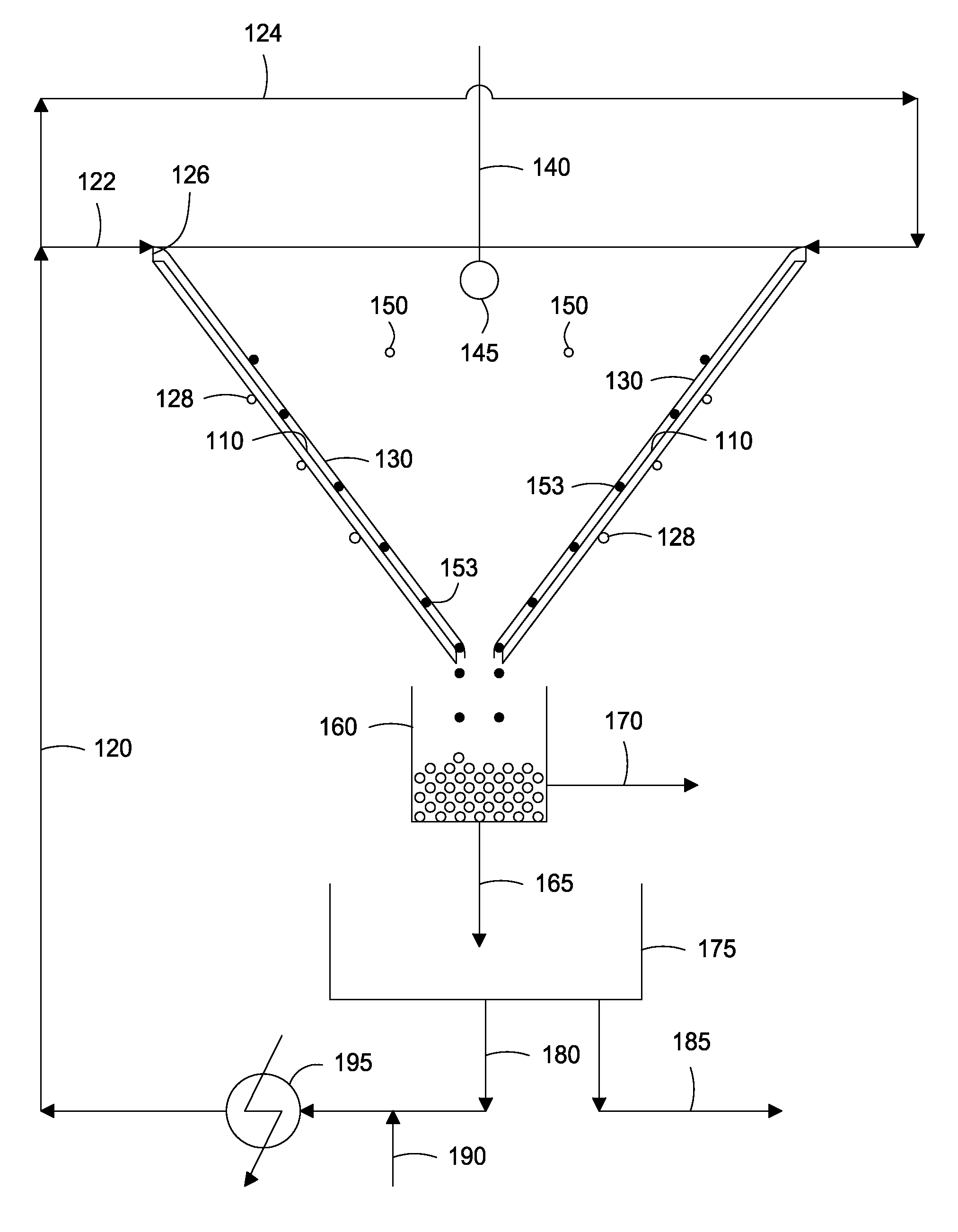

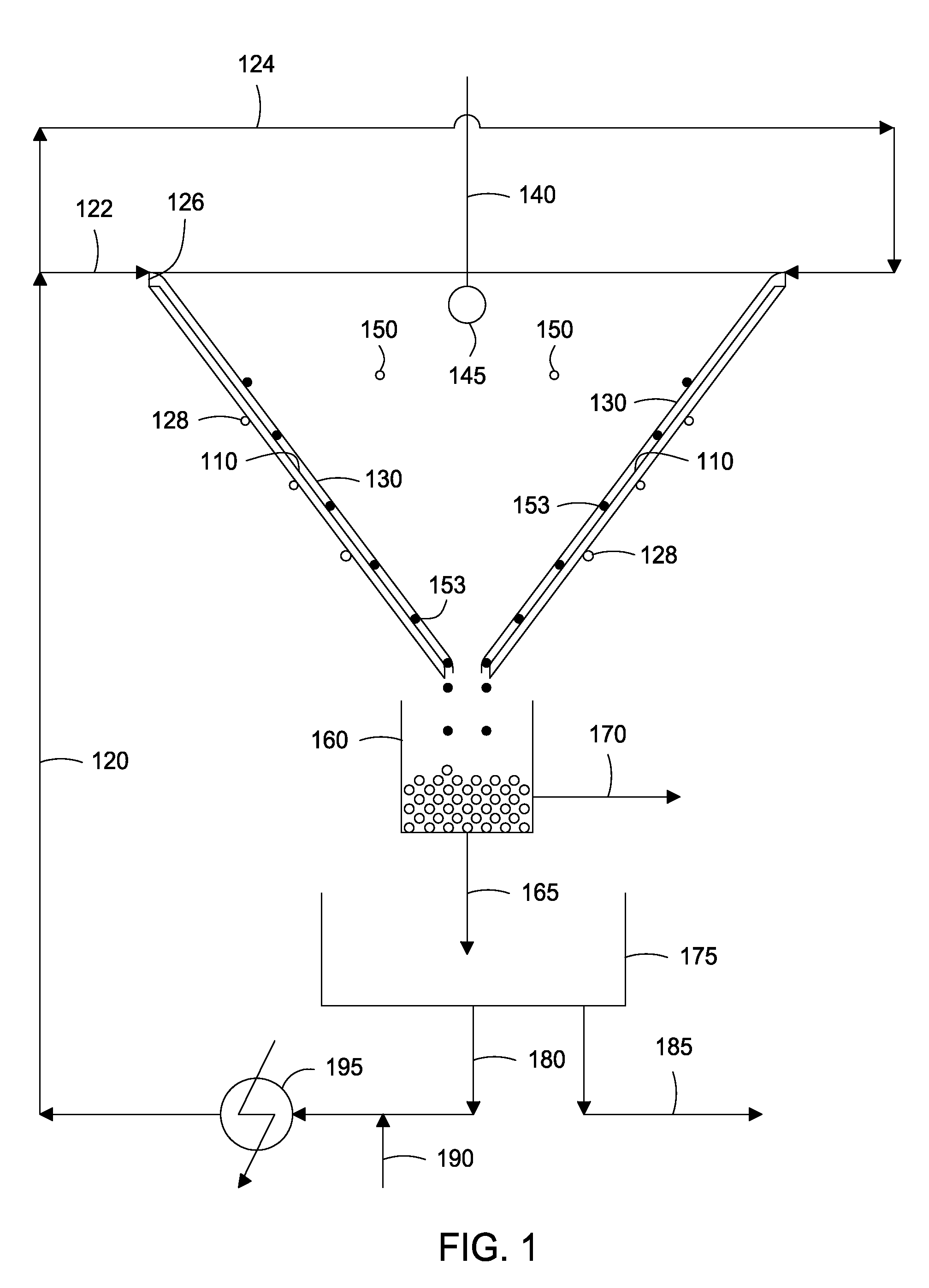

Hot asphalt cooling and pelletization process

ActiveUS7968020B2Granulation by liquid drop formationAuxillary shaping apparatusProcess systemsAsphalt

Owner:KELLOGG BROWN & ROOT LLC

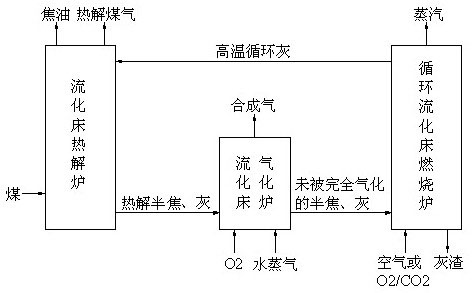

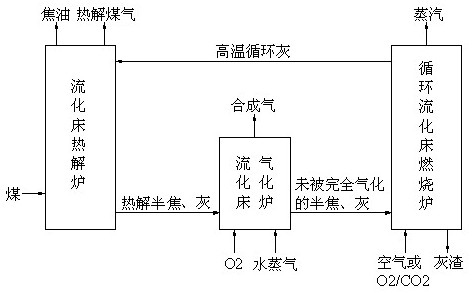

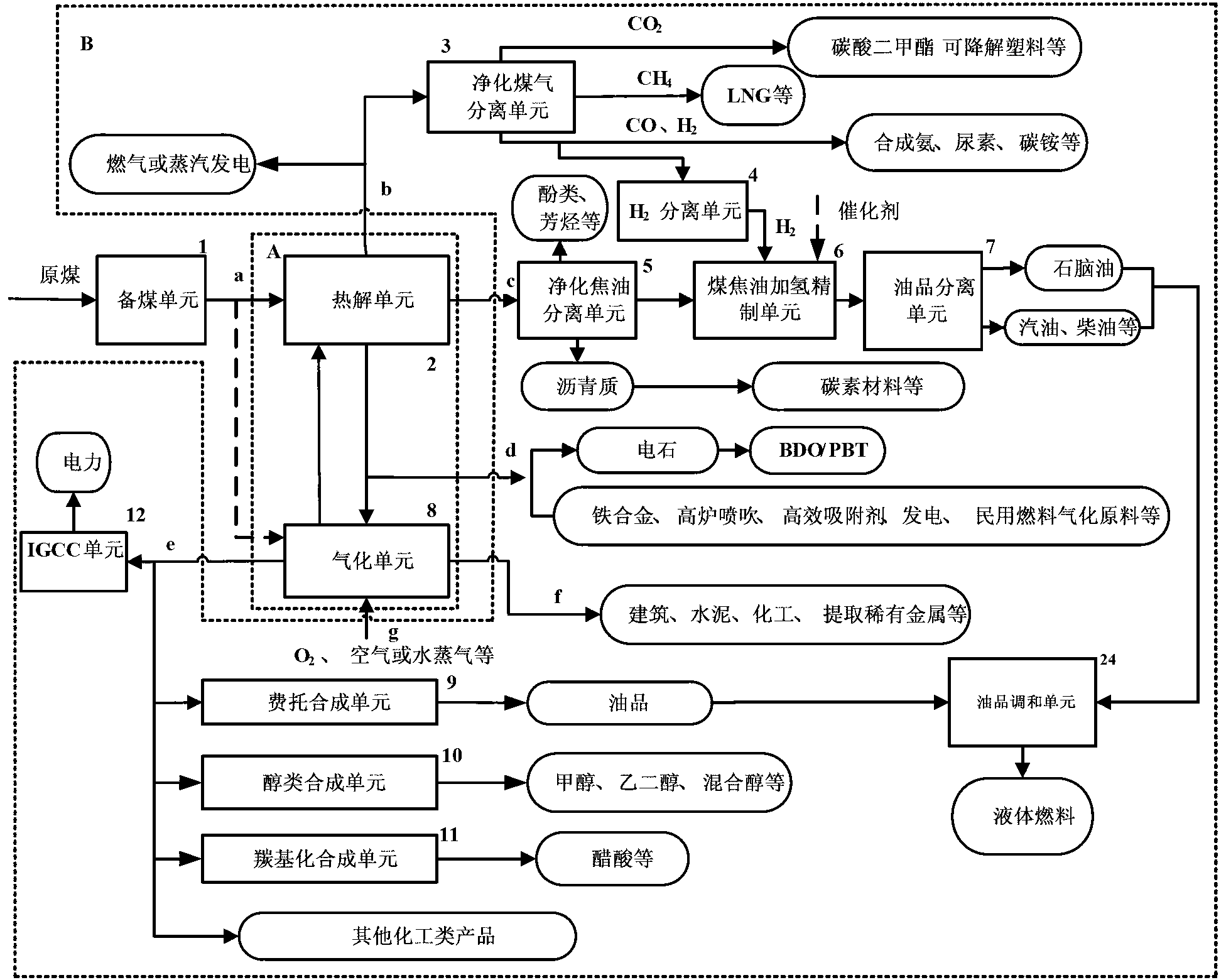

Three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method

InactiveCN102504842AImprove conversion efficiencyImprove utilization efficiencyDirect heating destructive distillationTreatment with hydrotreatment processesFluidized bed gasifierSyngas

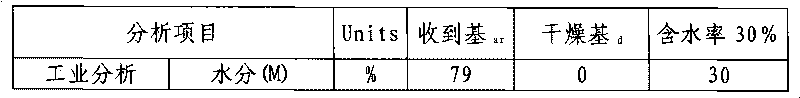

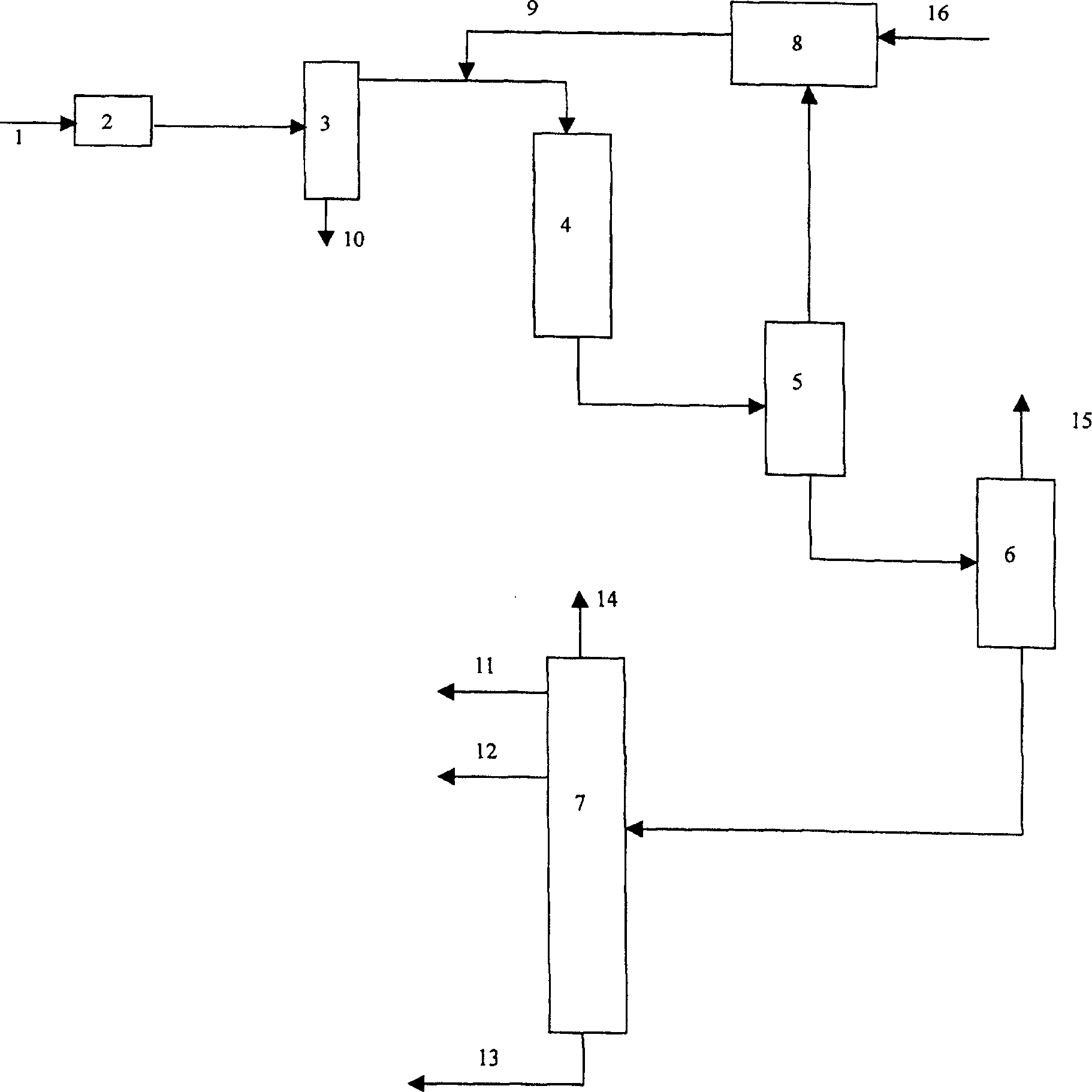

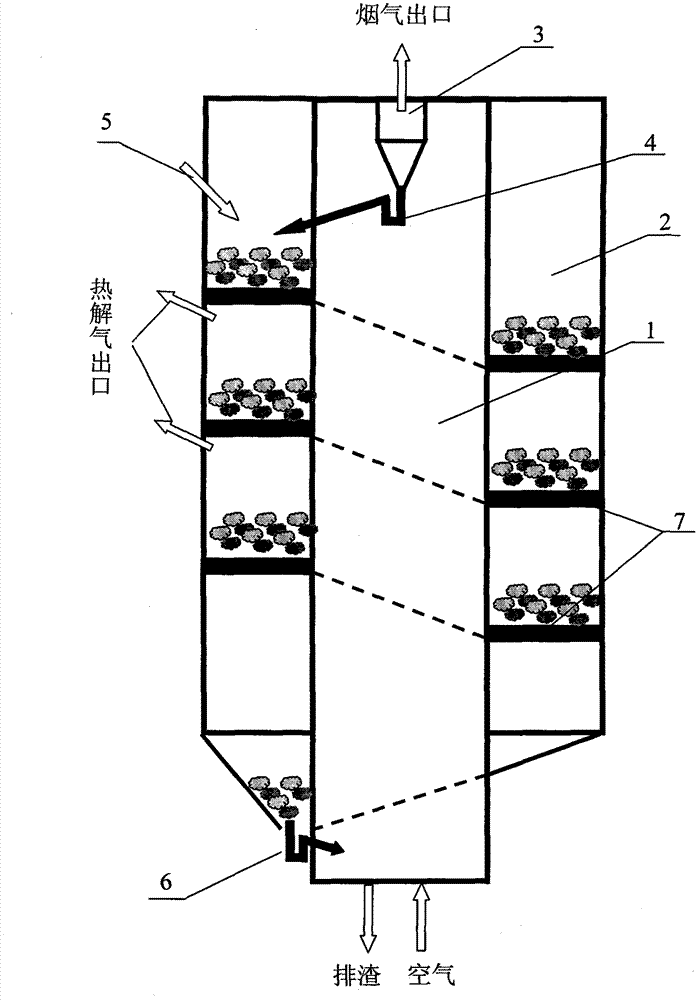

The invention discloses a three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method. The method comprises the following steps of: mixing coal and high temperature circulating ash serving as a solid heat carrier in a fluidized bed pyrolysis furnace, pyrolyzing to separate out volatile, cooling and separating the volatile to obtain tar and pyrolysis gas, conveying pyrolysis semi-coke generated by pyrolyzing the coal to a fluidized bed gasification furnace, performing gasification reaction by using water vapor and O2 as gasification agents to prepare synthesis gas, conveying the semi-coke which is incompletely gasified in the gasification furnace to a circulating fluidized bed combustion furnace, blowing air for the conventional combustion or blowing O2 / CO2 for oxygen-enriched combustion, heating the circulating ash serving as the solid heat carrier, and producing gasification agent vapor required by the gasification furnace by using high temperature flue gas generated by combustion. The method has the advantages that: the tar, the pyrolysis gas and the synthesis gas are co-produced through coal pyrolysis, gasification and combustion cascade utilization, the gasification condition of the semi-coke is reduced, and good economic benefits and social benefits are achieved.

Owner:ZHEJIANG UNIV

Sludge or organic garbage high-low temperature coupling themolysis method

InactiveCN101708938AFlexible to adapt to changes in natureSimple processSludge treatment by pyrolysisBiofuelsSludgeCarbonization

The invention provides a sludge or organic garbage high-low temperature coupling themolysis method which is characterized in that: the method comprises the following steps: step I: the sludge or organic garbage is fed in a low temperature drying depolymerizing furnace; material with partial carbonization is used as raw material of soil organic fertilizer; step II: the material with partial carbonization, generated in pyrolysis, is fed into a middle temperature carbonizing furnace for carrying out carbonization; the obtained bio-organic carbon is used as raw material of soil organic fertilizer or soil conditioner; step III: the material with partial carbonization, bio-organic carbon and one or more than two mixtures of the sludge, straws or organic garbage are fed in a high-temperature pyrolysis furnace for gasification; step IV: fixed carbon remained in a high-temperature depolymerizing furnace after aerogenesis is fed in a high-temperature sub-fusion activated device, and then oxygen-enriched air enters in, and then liquid in a regulating solution storage tank is prayed in for regulation, and then, compound charcoal is obtained after being cooled. The method has high efficiency, simple steps and diversified products.

Owner:SHANGHAI DISHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Integrated SDA and ebullated-bed process

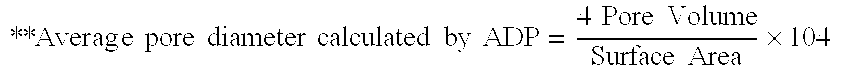

ActiveUS7279090B2Wide pore catalystMost efficientTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyBiochemical engineeringFixed bed

This invention relates to a novel integrated method for economically processing vacuum residue from heavy crude oils. This is accomplished by utilizing a solvent deasphalter (SDA) in the first step of the process with a C3 / C4 / C5 solvent such that the DAO product can thereafter be processed in a classic fixed-bed hydrotreater or hydrocracker. The SDA feed also includes recycled stripper bottoms containing unconverted residue / asphaltenes from a downstream steam stripper unit.The asphaltenes from the SDA are sent to an ebullated-bed reactor for conversion of the residue and asphaltenes. Residue conversion in the range of 60-80% is achieved and asphaltene conversion is in the range of 50-70%. The overall residue conversion, with the DAO product considered non-residue, is in the range of 80 W %-90 W % and significantly higher than could be achieved without utilizing the present invention.

Owner:INST FR DU PETROLE

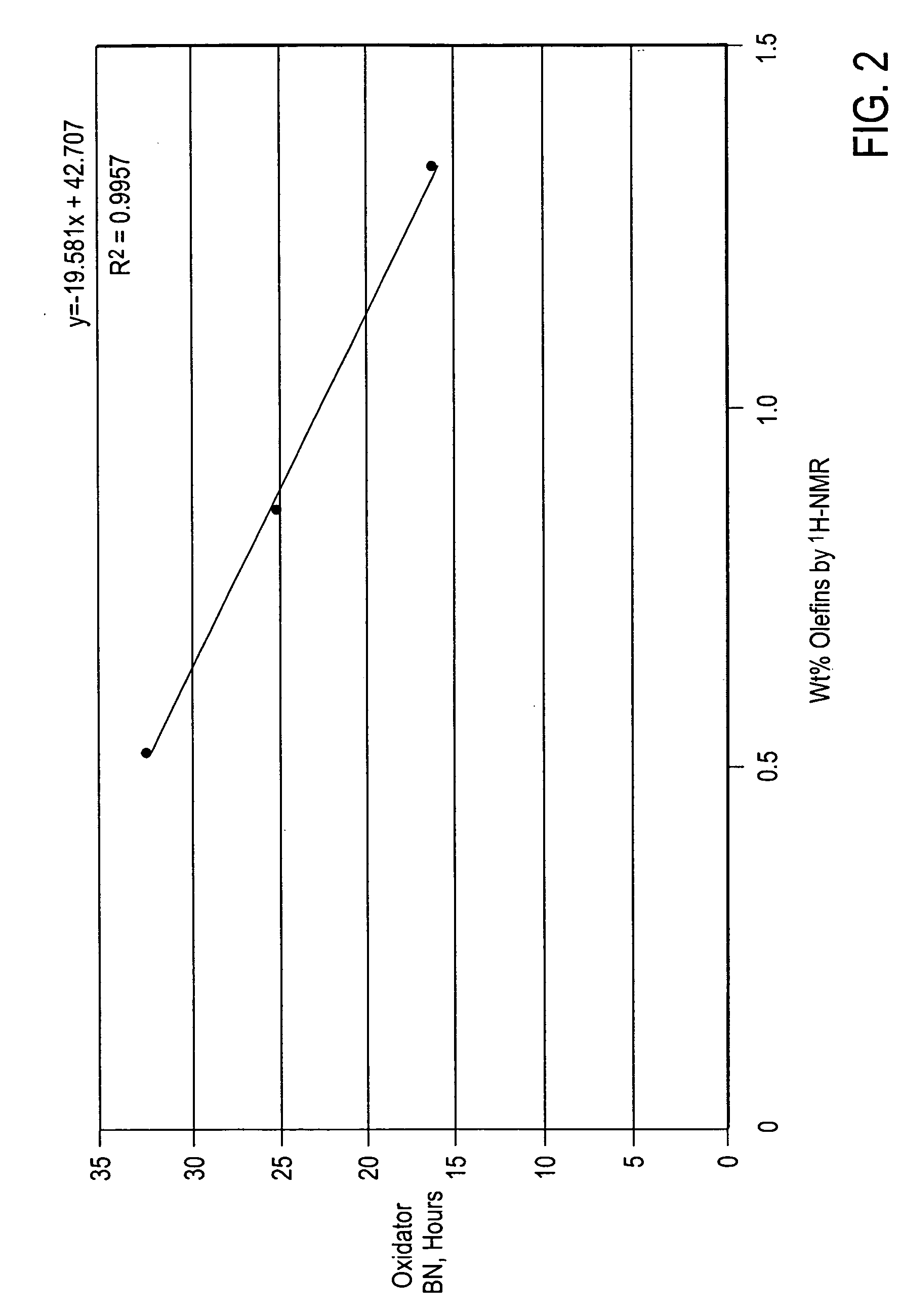

Process to enhance oxidation stability of base oils by analysis of olefins using ¹H NMR

InactiveUS20060237344A1Refining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationOxidation stabilityBase oil

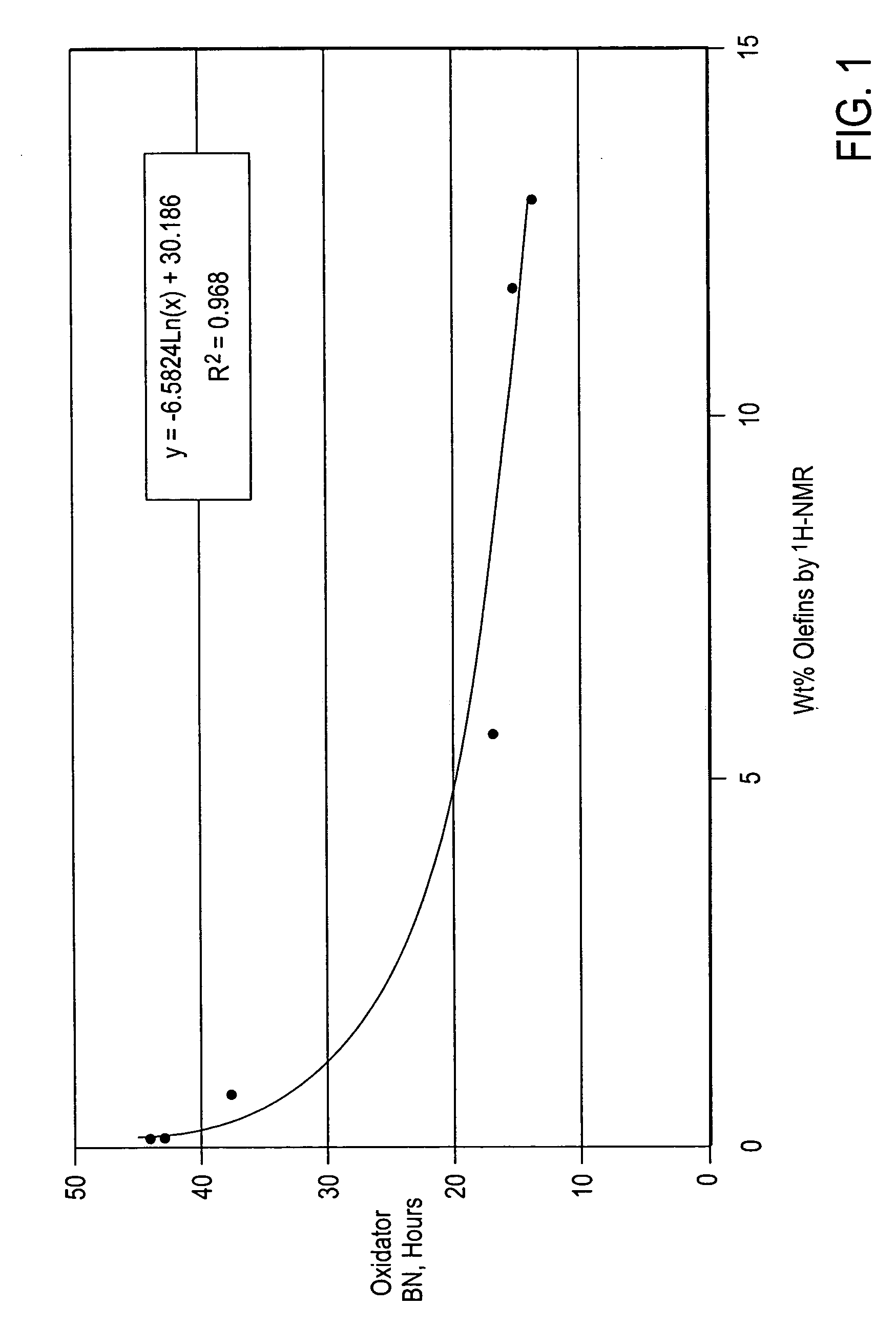

A process for producing a lubricating base oil having high oxidation stability, wherein the feed used to prepare the lubricating base oil contains at least 5 wt. % olefms, said process comprising (a) determining the weight percent of olefins present in the feed by means of 1H NMR; (b) hydroprocessing the feed under hydroprocessing conditions selected to reduce the amount of olefins present to a target value which has been pre-determined by means of 1H NMR to produce a lubricating base oil having the desired oxidation stability; and (c) collecting a lubricating base oil having the selected oxidation stability from the hydroprocessing zone.

Owner:CHEVROU USA INC

Pretreatment method of coal tar

ActiveCN101012385ARetain light and heavy componentsIncrease profitWorking-up tarPretreatment methodPre treatment

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Chemical composition of matter for the liquefaction and dissolution of asphaltene and paraffin sludges into petroleum crude oils and refined products at ambient temperatures and method of use

ActiveUS20060035793A1Resists separationHigh viscosityTransportation and packagingWorking-up tarParaffin waxSludge

Owner:MALCERA

Lubricating base oil and lubricating oil composition

The invention provides a lubricating base oil with a saturated component content of 90% by mass or greater, a proportion of cyclic saturated components of no greater than 40% by mass of the saturated components, a viscosity index of 110 or greater, an aniline point of 106 or greater and an ε-methylene proportion of 14-20% of the total constituent carbons, as well as a lubricating oil composition comprising the lubricating base oil.

Owner:NIPPON OIL CORP +1

Disposition of steam cracked tar

ActiveUS20080116109A1Increase productionEasy to useWorking-up pitch/asphalt/bitumenTreatment with hydrotreatment processesSulfurGasoline

Owner:EXXONMOBIL CHEM PAT INC

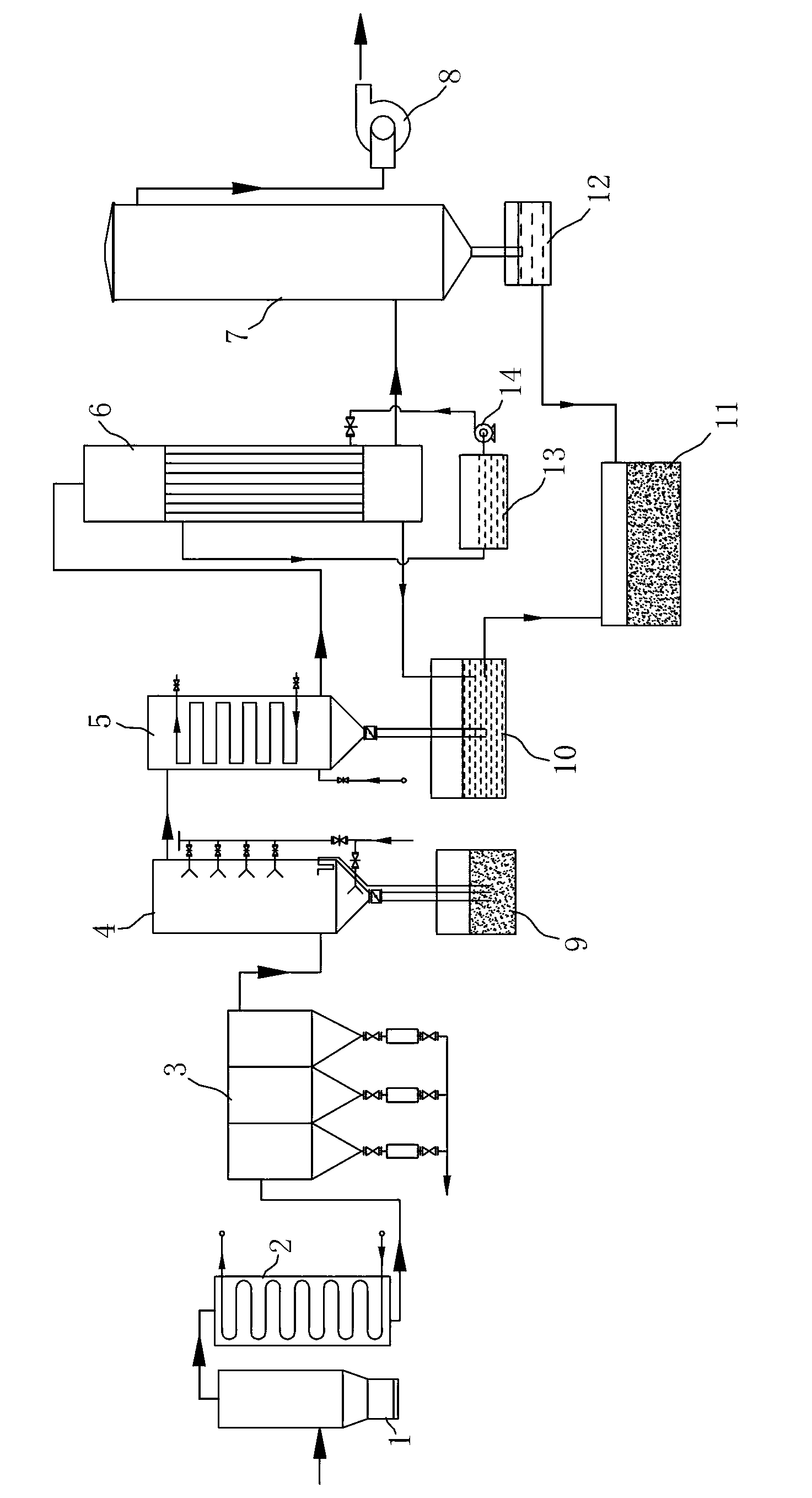

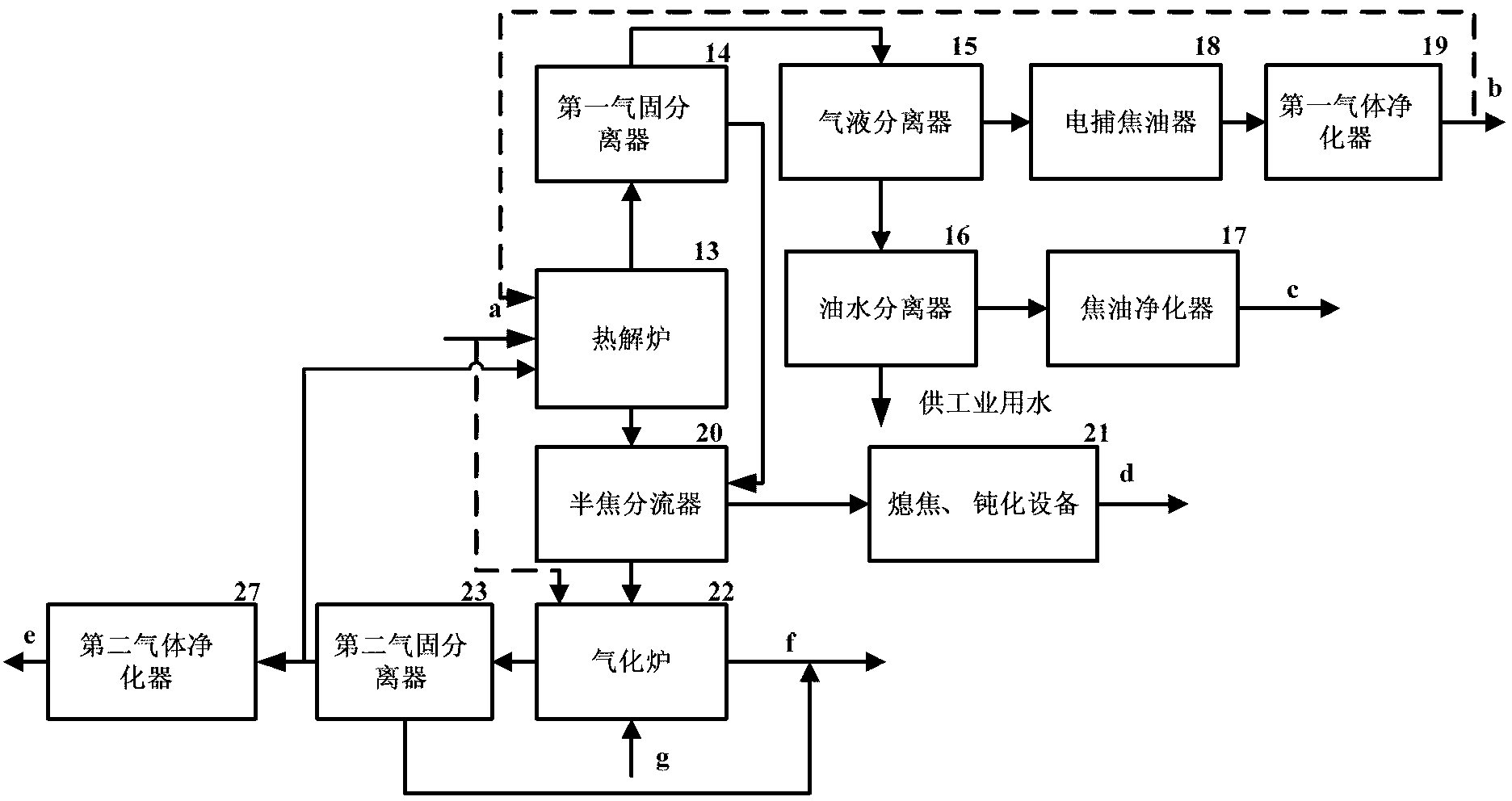

Process for dust removing, cooling and tar oil recovering of pyrolysis coal gas

The invention discloses a process for dust removing, cooling and tar oil recovering of pyrolysis coal gas. The process adopts an overheater, a high-temperature dust remover, an accident quench tower, a waste heat recovering boiler, an indirect cooling device and an electrical tar precipitator which are connected in sequence, and comprises the following steps: pyrolysis coal gas is fed into the overheater to be cooled to 400-700 DEG C, fed into the high-temperature dust remover to be subjected to dust removing, fed into the waste heat recovering boiler to be cooled to 50-100 DEG C and condensed to separate out water and tar oil, fed into the indirect cooling device to be cooled to 10-30 DEG C and further condensed to separate out water and tar oil, and finally fed into the electrical tar precipitator, so that the carried tar oil mist and water mist are recovered. According to the process, dust particles in the coal gas are removed by high-performance dust removing equipment before condensing of tar oil, so as to prevent tar oil and dust separated out through condensation in the coal gas cooling process from being mixed together, improve the quality of tar oil and avoid the problems of equipment blockage and high dust content of tar oil.

Owner:ZHEJIANG UNIV

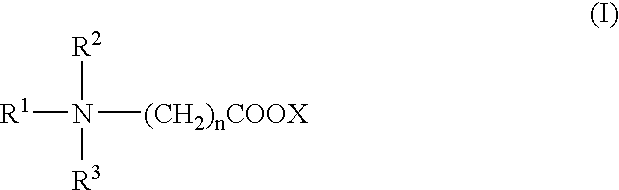

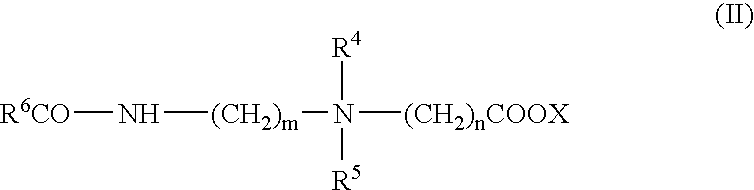

Low-viscosity opacifiers free from anionic surface-active agents

The invention relates to wax-based opacifier preparations containing (a) at least one amphoteric surfactant, (b) at least one fatty acid partial glyceride, (c) at least one fatty acid polyglycol ester and optionally (d) a polyol, with the proviso that the ratio by weight of (a) to (b) is between 10:1 and 4:1 and the ratio by weight of (b) to (c) is between 1:1 and 5:1 and the preparations are free from anionic surfactants.

Owner:COGNIS DEUT GMBH & CO KG

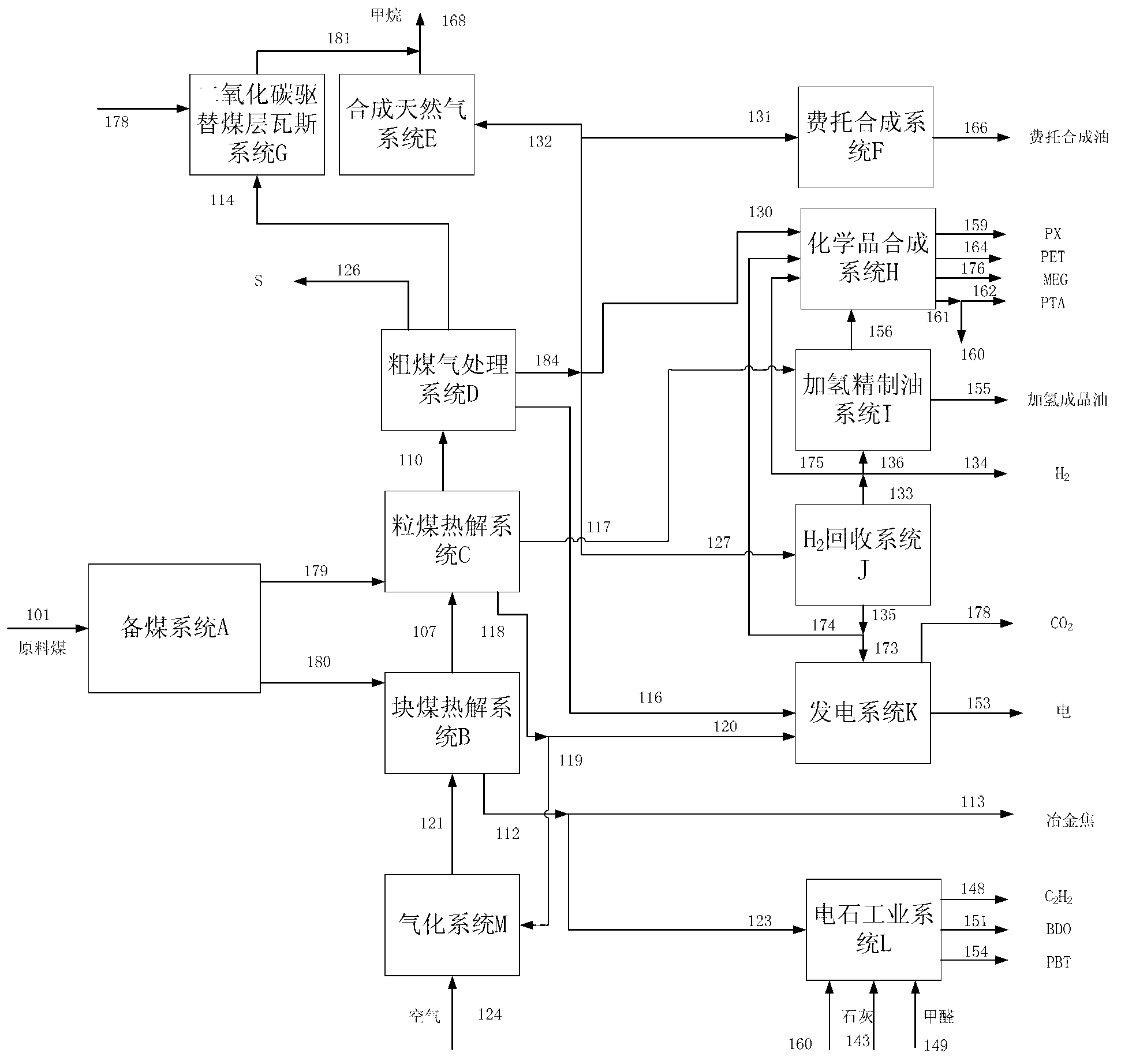

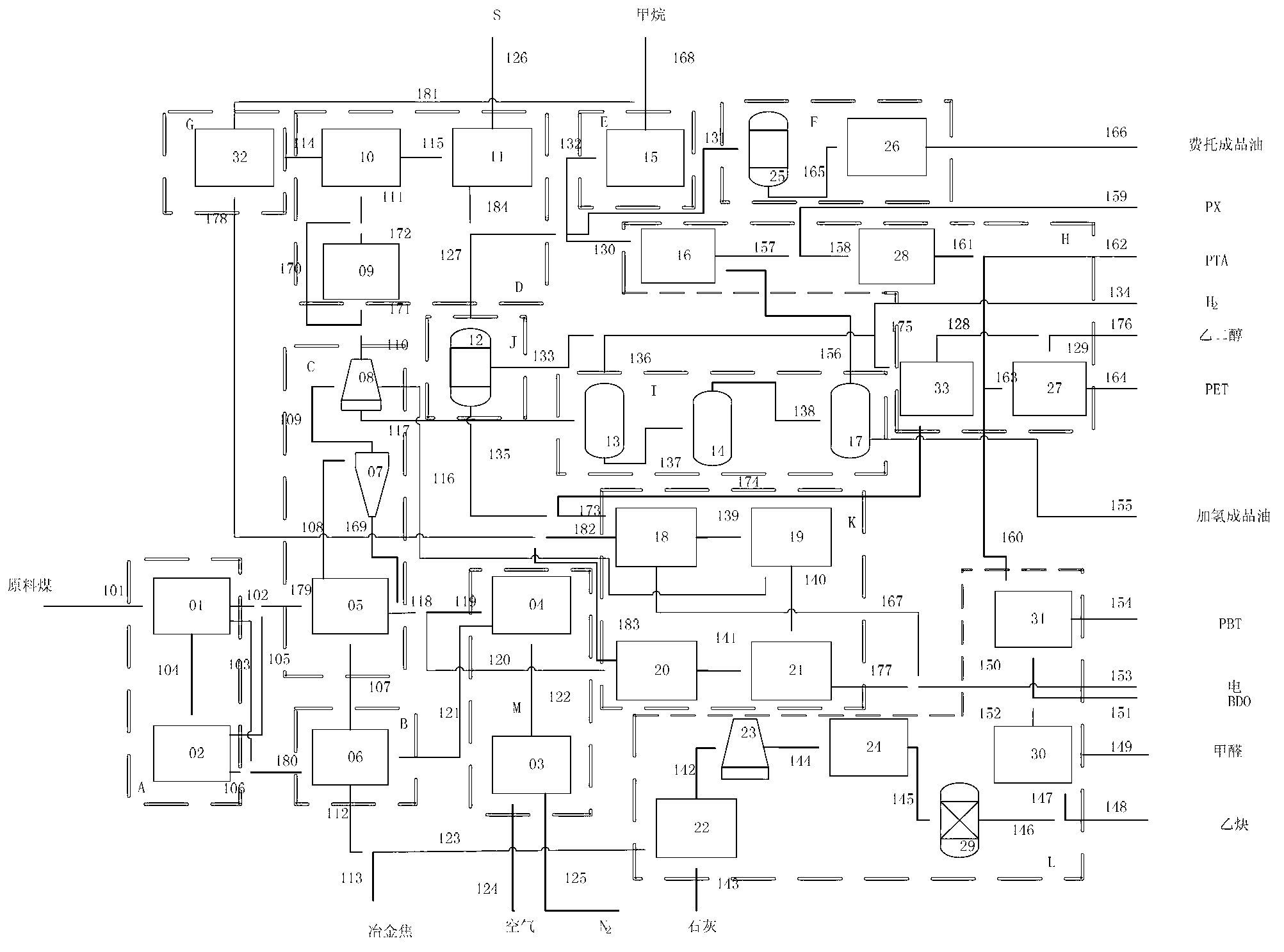

Omnibearing coproduction system and method by utilizing coal grading

ActiveCN103160294AImprove applicabilityAchieve self-balancingDirect heating destructive distillationEnergy inputHeat carrierCarbide

The invention provides an omnibearing coproduction system and method by utilizing coal grading. A standby coal system is respectively connected with a lump coal pyrolysis system and a pea coal pyrolysis system; a gasification system uses air as an input, semicoke generated by the pea coal pyrolysis system as a raw material, and generated gasified coal gas as a heat carrier of the lump coal pyrolysis system; lump coal pyrolysis oil gas generated by the lump coal pyrolysis system is used as a heat carrier of the pea coal pyrolysis system, part of generated lump coke is output as metallurgical coke, and the rest lump coke is used as a raw material for preparing carbide; pyrolysis coal gas generated by the pea coal pyrolysis system enters a crude gas treatment system, generated pyrolysis tar is used for hydrogenation grading, and generated semicoke is respectively used as semicoke for power generation and semicoke for gasification; and the crude gas treatment system uses pyrolysis coal gas generated by the pea coal pyrolysis system as a raw material, generated recovery waste heat is applied to a waste heat boiler of a power generation system, and generated carbon dioxide enters a carbon dioxide displaced coal gas system.

Owner:SHAANXI COAL & CHEM TECH INST

Composition of hydrocarbon fuel

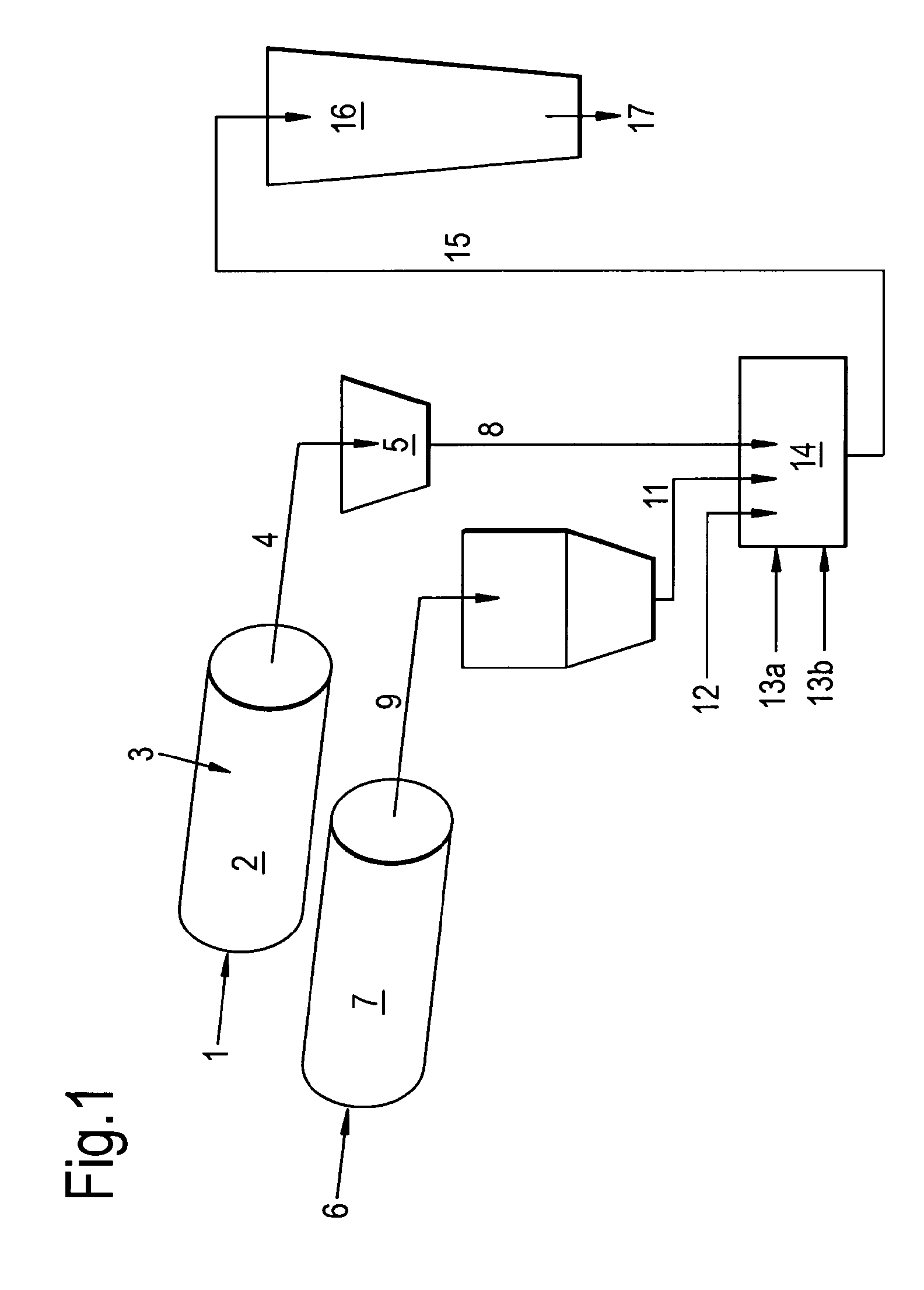

Slurry hydrocracking a heavy hydrocarbon feed produces a HVGO stream and a pitch stream. At least a portion of the pitch stream is subjected to SDA to prepare a DAO stream low in metals. The DAO is blended with at least a portion of the HVGO stream to provide turbine or marine fuel with acceptable properties for combustion in gas turbines or for marine fuel grades.

Owner:UOP LLC

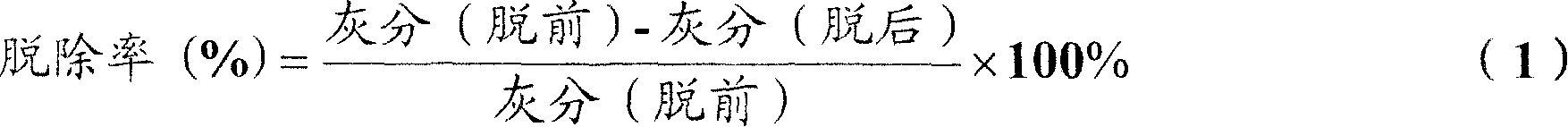

Electric field purifying process of coal-tar oil

ActiveCN100999675AAvoid poisoningAvoid cloggingWorking-up tarRefining by electric/magnetic meansPtru catalystGasoline

The electric field coal tar purifying process includes the technological steps of preparing mixed oil, the first stage of electric purifying, the second stage of electric purifying, the third stage of electric purifying, draining waste water, etc. The experiments show that the coal tar purifying process of the present invention is superior to available coal tar purifying process, and has the advantages of simple technological process, low running cost, high purifying rate, etc. The present invention can reach coal tar purifying rate over 95 %, and the purified coal tar may be used in producing gasoline and diesel oil through hydromodification with no corrosion to the production apparatus, no catalyst poisoning, no blocking of the reactor bed layer and long production apparatus running period.

Owner:SHENMUFUYOU ENERGY TECH

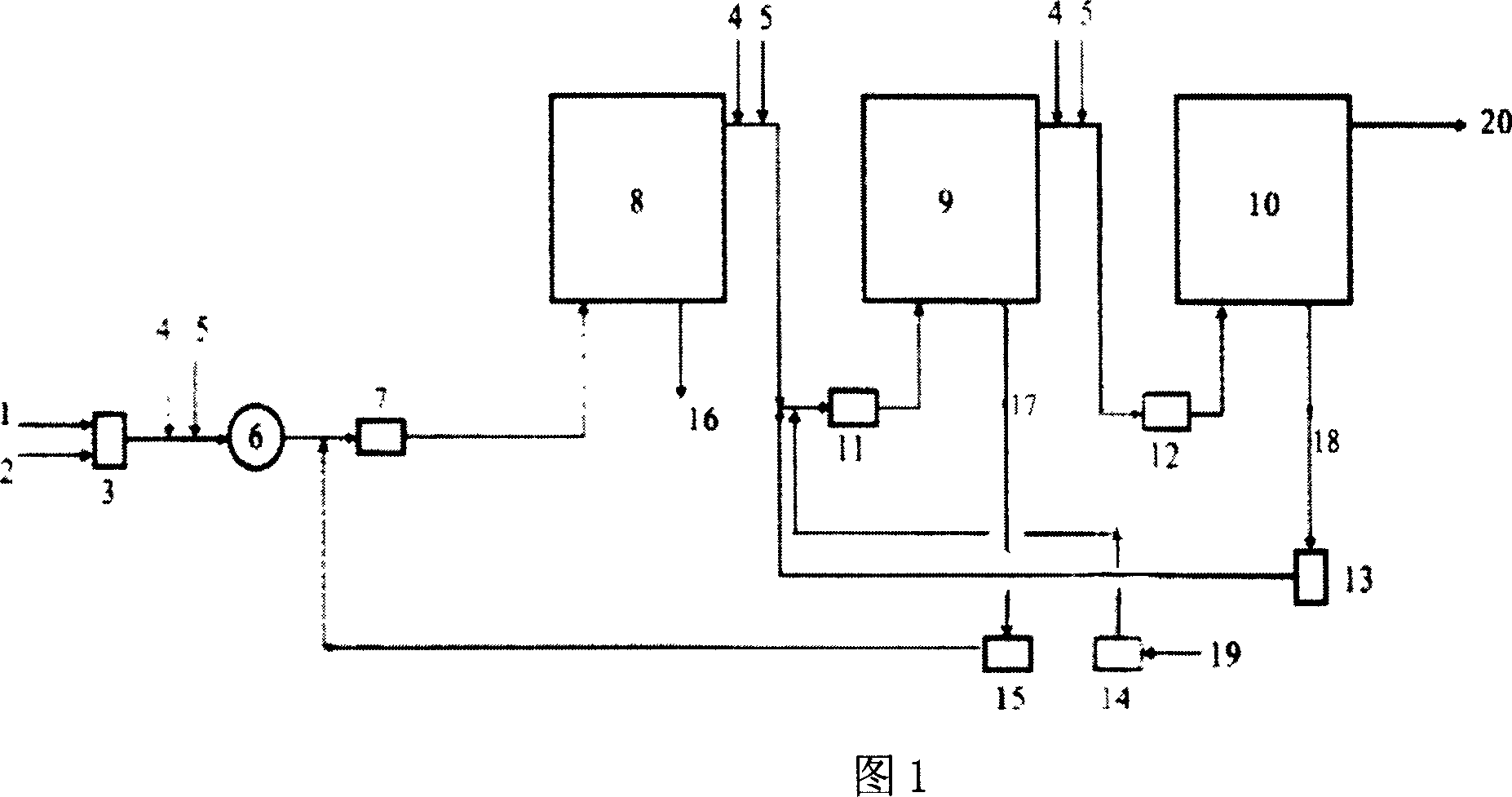

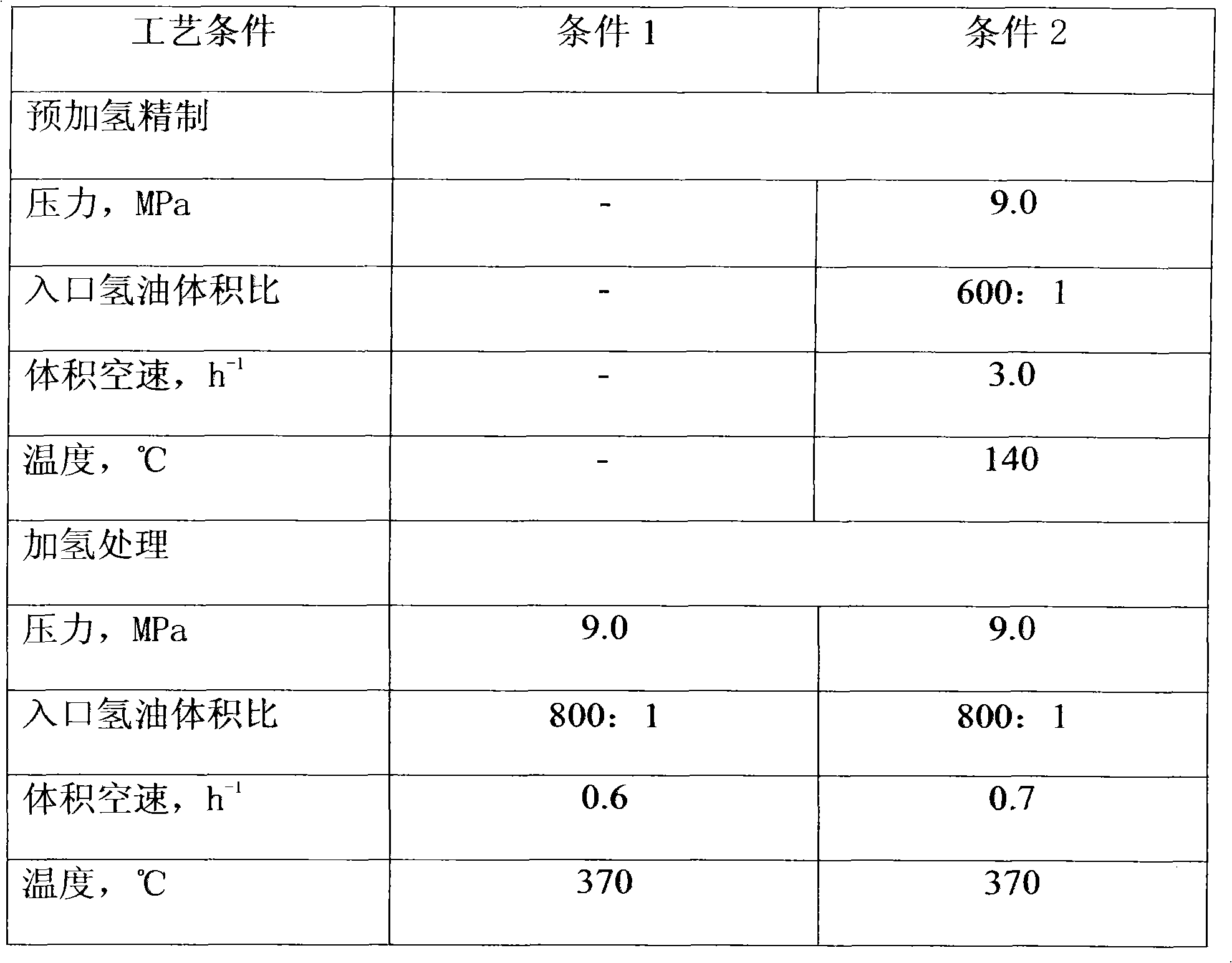

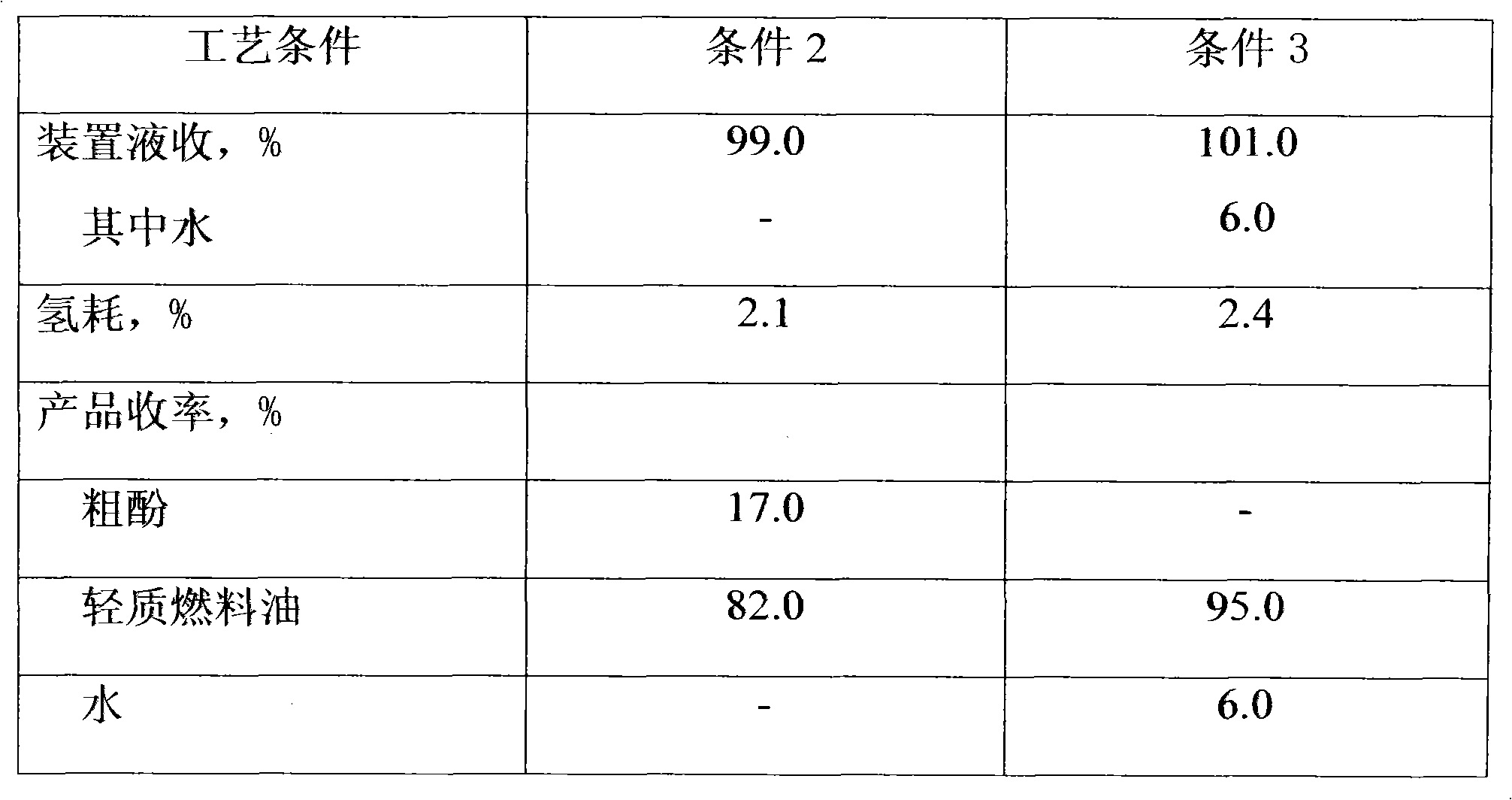

Processing method of medium-low temperature coal tar

ActiveCN102465033AImprove economyOperation cycle solutionOrganic chemistryOrganic compound preparationSlagFuel oil

The invention discloses a processing method of medium-low temperature coal tar. According to the method, whole fraction of the medium-low temperature coal tar which has been undergone dehydration and slag removal is firstly distilled to obtain a light fraction and a heavy fraction. The heavy fraction is used as modified asphalt or heavy fuel oil and the like. A phenolic compound is separated from the light fraction by an acid-base extraction method so as to obtain a crude phenol product. Hydrogenation saturation of alkene from dephenolized raw oil is carried out by a hydro-pretreating method. The prehydrogenation raw oil contacts with a main hydrofining catalyst for desulphurization, nitrogen removal, aromatic saturation and other reactions. In comparison with the prior art, by the adoption of the method provided by the invention, components which influence long-term operation of a hydrogenation device can be fundamentally removed; the operation period of the device can be obviously prolonged; the crude phenol product can be obtained; and the utilization rate of raw materials and the whole economy of a processing device can be raised.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technique for hydrogenation of coal oil

ActiveCN101343545AUniform and stable suspensionEasy to removeTreatment with hydrotreatment processesWorking-up tarCoal tar distillateGasoline

The invention discloses a coal tar hydrogenation processing method. The method of the invention comprises the steps that coal tar distillated oil or a full distillating pump with high content of impurities, colloid, asphaltene and oxygen elements is fed into a pre-hydrogenating reactor, the hydrogenation pre-treatment is performed under a certain reaction condition, the tiny impurities suspending in oil are separated through a separating device such as a filter and the like, then hydrogenating demetalization and deep hydrogenation refined reaction are performed in sequence, after water and light component are separated, and the material flow generated by the reaction enters into the hydrocracking reactor, thus gasoline fraction, diesel oil and hydrocracking tail oil are cut through a distilling device. Compared with the prior art, the method of the invention can ensure the device of long period of stable operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Asphalt production from solvent deasphalting bottoms

ActiveUS20090301931A1Minimizing conventional waste handling demandEliminate wasteWorking-up pitch/asphalt/bitumen by selective extractionWorking-up tarEffective solutionDesorption

A cost-effective solution is provided for eliminating refinery process waste, including spent catalytic and non-catalytic adsorbent materials, as well as adsorbate process reject materials derived from desorption, while minimizing conventional waste handling demands. An asphalt composition includes asphalt and spent adsorbent material from a solvent deasphalting unit. The asphalt can comprise asphaltic material obtained from a solvent deasphalting unit, and spent adsorbent material in the asphalt composition was previously utilized in the solvent deasphalting unit. The asphalt composition can also include process reject materials.

Owner:SAUDI ARABIAN OIL CO

Methods of transporting heavy hydrocarbons

ActiveUS20090250380A1Easy to pumpUnderground miningHydrocarbon purification/separationKerogenDiluent

A method of transporting heavy hydrocarbons can include blending a kerogen oil with a bitumen to form a blended oil sufficient to render the blended oil transportable through an extended pipeline. The blended oil can be substantially free of additional diluents or viscosity modifiers and can be readily pumped through the extended pipeline from a source location to a destination location.

Owner:RED LEAF RESOURCES

Method for deep processing coal tar

InactiveCN1916112ASuitable for whole fraction hydrotreatingExpand the scope of processingWorking-up tarGas phaseGasoline

This invention provides a method for hydrogenating coal tar. The method comprises: (1) filtering coal tar to remove solid particles with sizes larger than 25 mum; (2) dehydrating to prevent water from damaging the hydrogenation catalyst; (3) dedusting to remove solid particles with sizes smaller than 25 mum; (4) catalytically hydrogenating in a hydrogenation device to obtain gas-phase and liquid-phase products; (5) sending the liquid-phase products into a fractionation column, and fractionating to obtain gasoline, diesel oil and trail oil fractions. The method can realize all fractions hydrogenation of coal tar.

Owner:WISON ENG

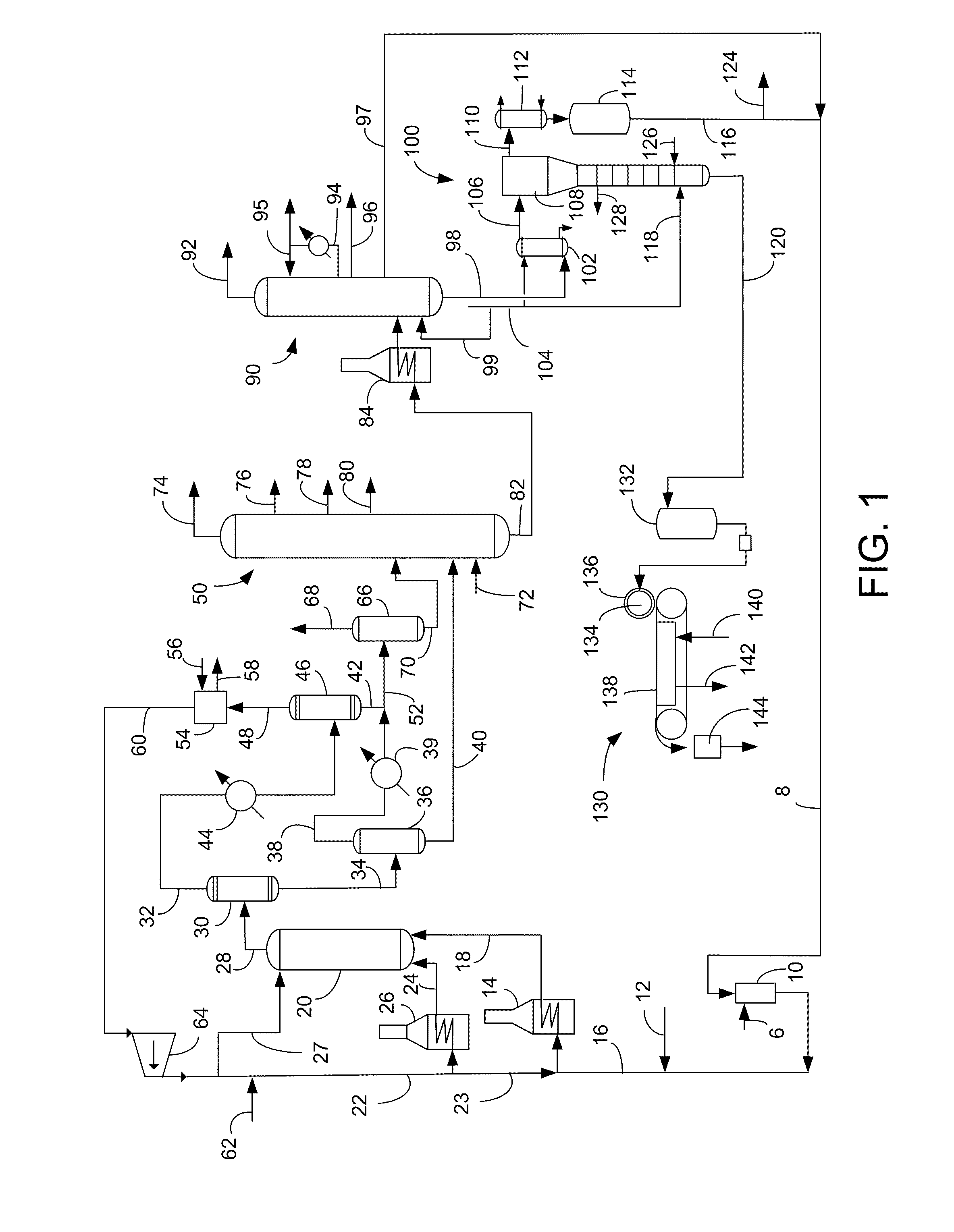

Process for preparing an asphalt mixture

ActiveUS8133316B2Easy to disassembleEasy to provideMixing operation control apparatusClimate change adaptationRoad surfaceMaterial supply

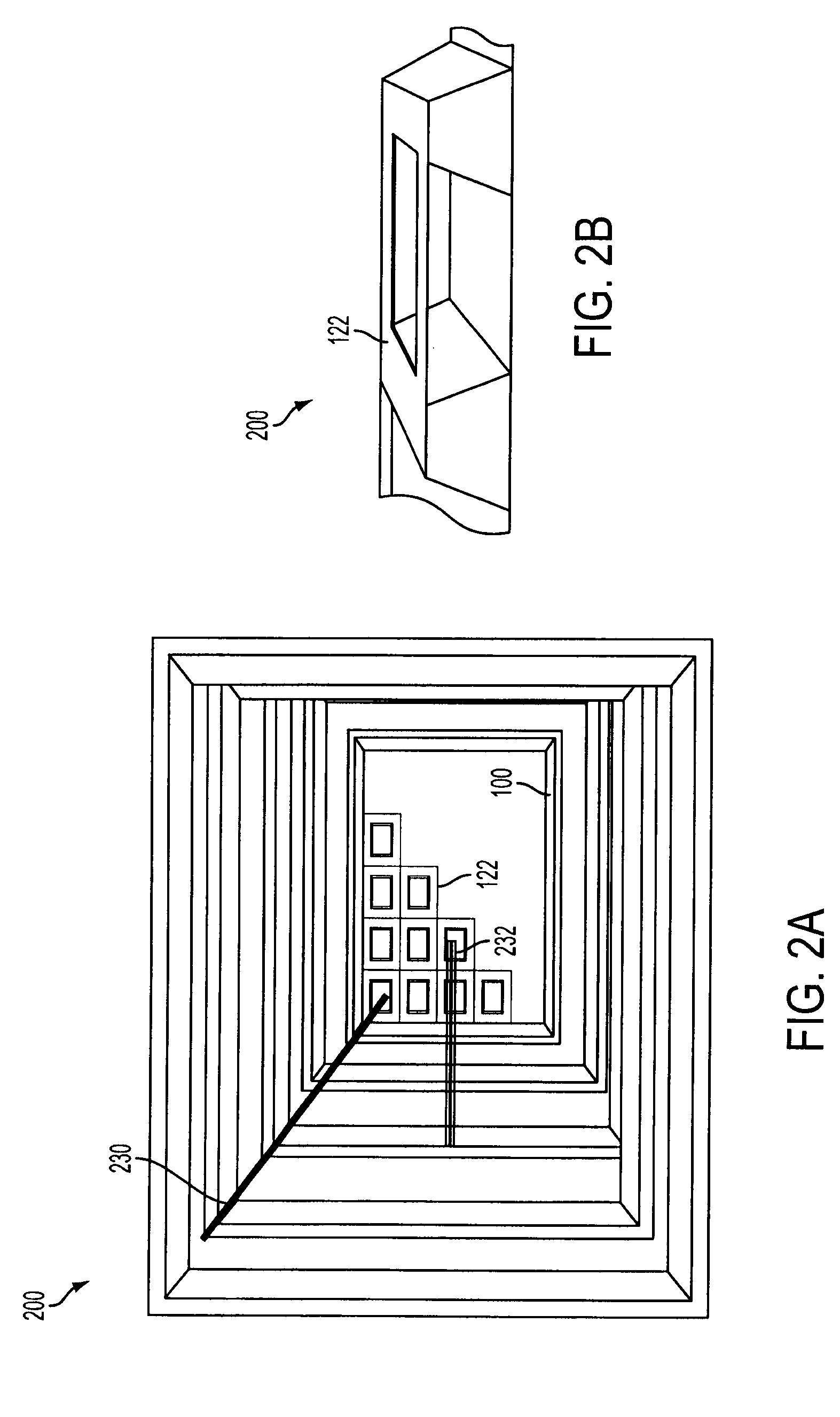

A process for preparing an asphalt mixture from recycled asphalt pavement (RAP), virgin aggregate, filler and first and second binder materials, is disclosed. The process comprises steps of transporting RAP through a first drum; transporting virgin aggregate through a second drum; adding a first binder material to the RAP in the first drum to provide treated RAP; supplying the treated RAP, the virgin aggregate, filler and a second binder material to a mixing zone; and mixing to provide the asphalt mixture.

Owner:SHELL USA INC

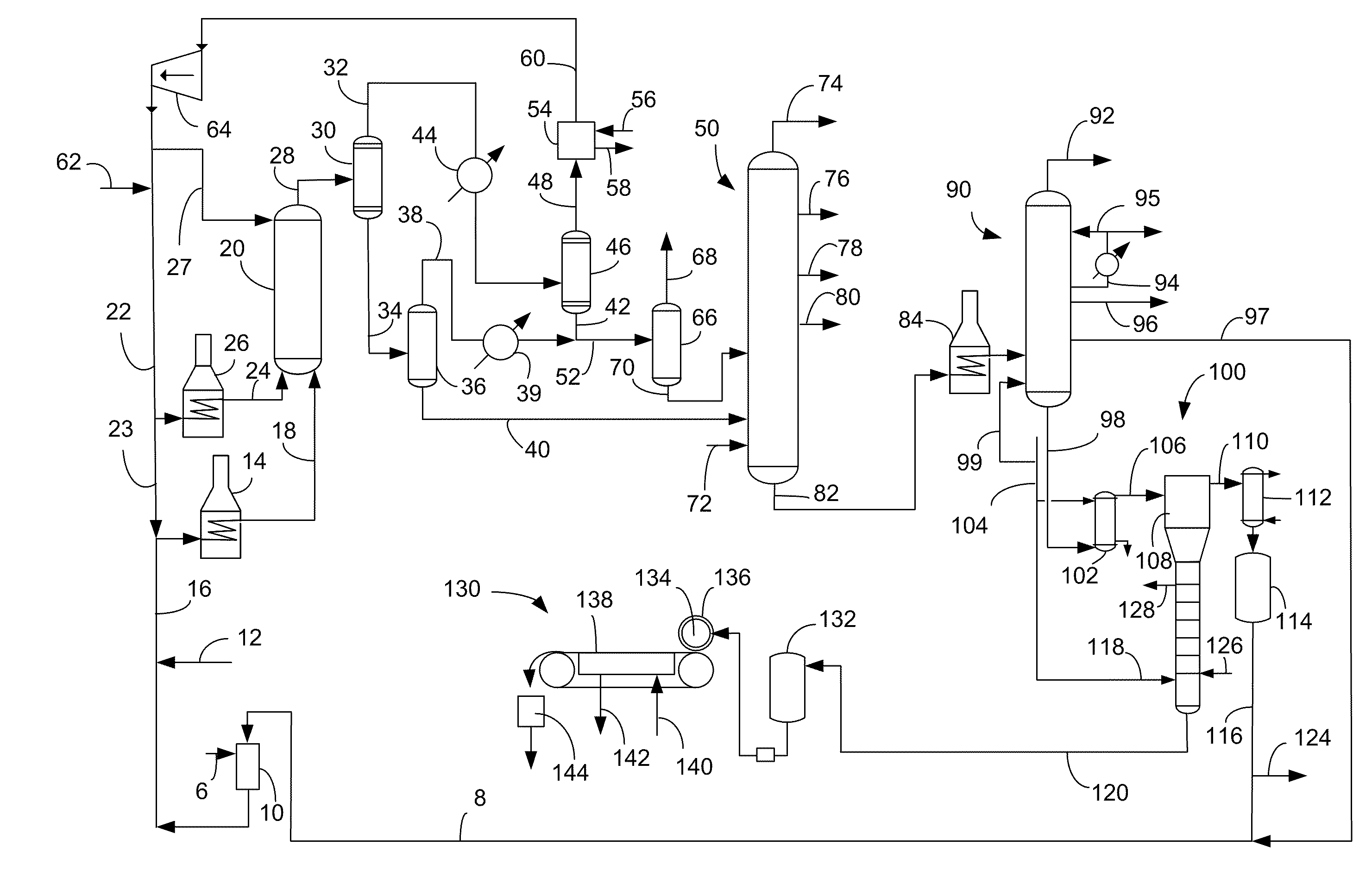

Pitch composition

ActiveUS20100326882A1Alleviate cokingReduce cracking concernWorking-up pitch/asphalt/bitumenWorking-up tarParticulatesSlurry

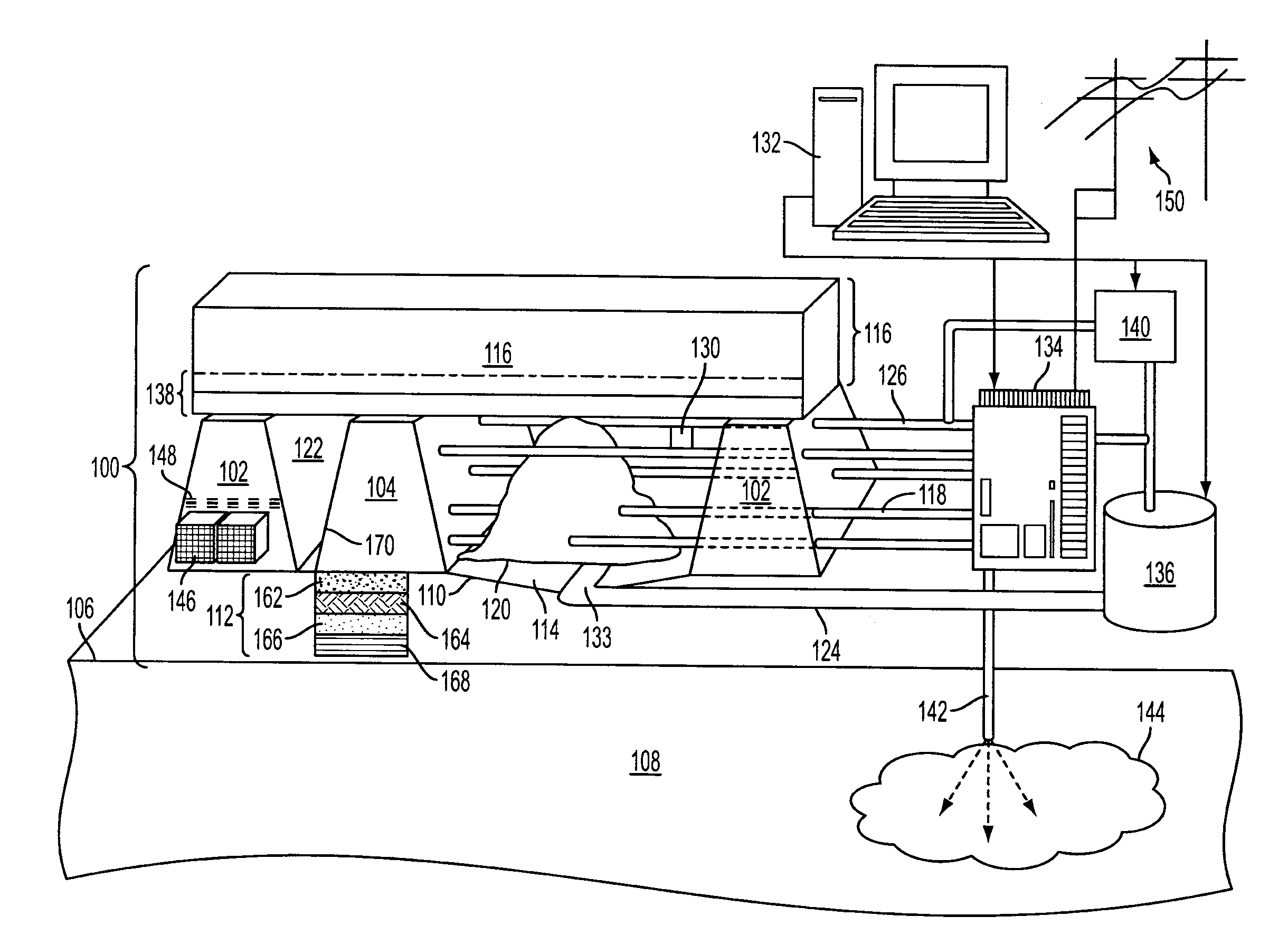

A process and apparatus is disclosed for converting heavy hydrocarbon feed into lighter hydrocarbon products. The heavy hydrocarbon feed is slurried with a particulate solid material to form a heavy hydrocarbon slurry and hydrocracked in a slurry hydrocracking unit to produce vacuum gas oil (VGO) and pitch. A first vacuum column separates VGO from pitch, and a second vacuum column further separates VGO from pitch. As much as 15 wt-% of VGO can be recovered by the second vacuum column and recycled to the slurry hydrocracking unit. A pitch composition is obtained which can be made into particles and transported without sticking together.

Owner:UOP LLC

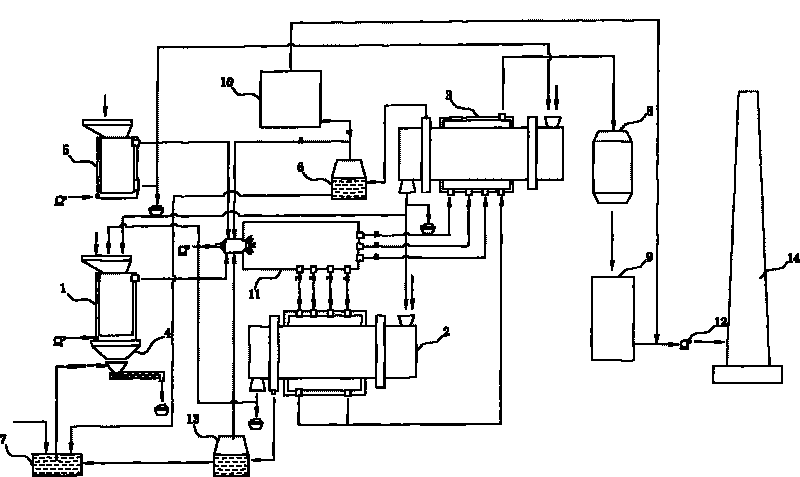

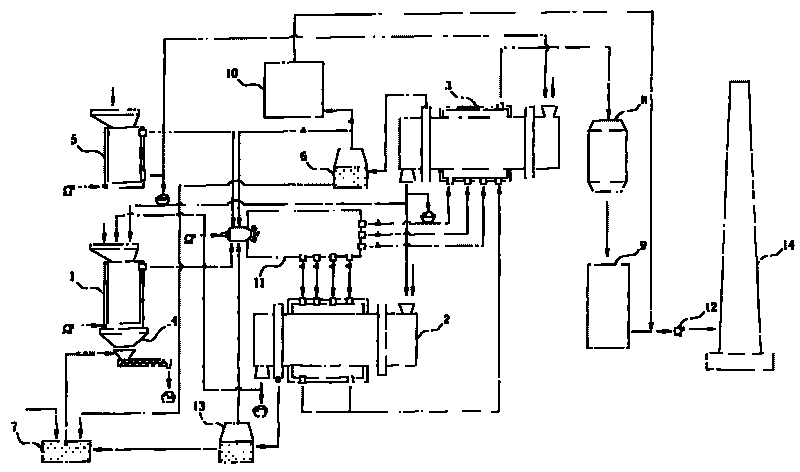

Pyrolysis and combustion coupled circular reaction method and device

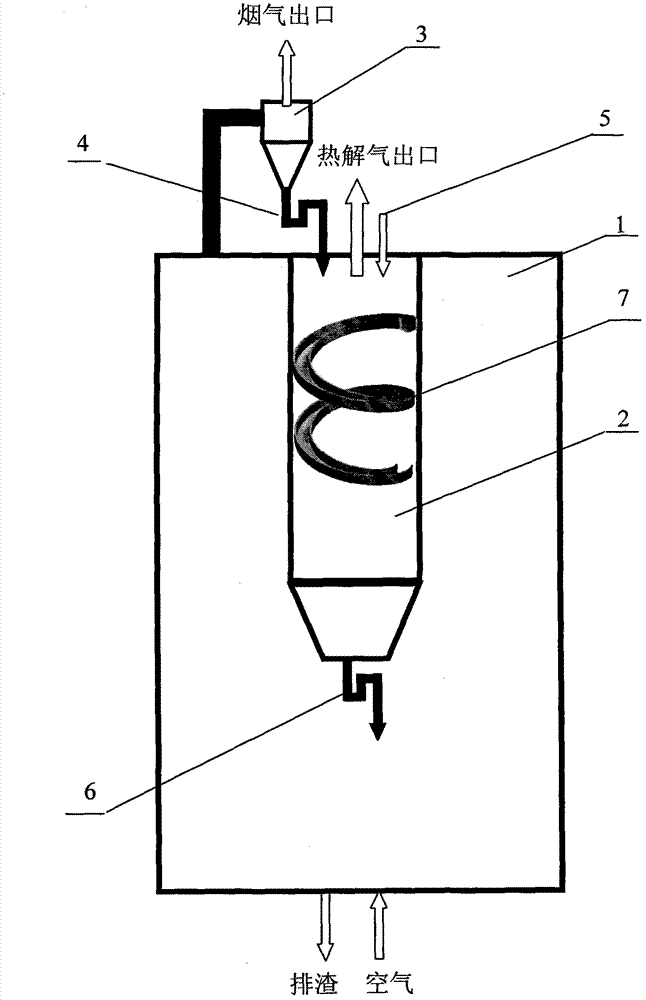

InactiveCN103361087AReduce heat lossImprove thermal efficiencyDirect heating destructive distillationEnergy inputHeat carrierHeat conducting

The invention relates to a pyrolysis and combustion coupled circular reaction method and device. The method and the device are used for converting fine-grained carbon containing materials such as coal, biomasses and oil shale into oil, gas, heat and other products through fast pyrolysis and combustion. The device mainly comprises a fluidized-bed combustion chamber, a pyrolysis chamber and a solid circulation system. Compared with the prior art, the method has the advantages that the pyrolysis and combustion coupling process is shortened due to the integration of the structures and the functions of the pyrolysis and the combustion, and the device is compact in structure, has high degree of integration and high thermal efficiency and occupies a small floor area. The pyrolysis reaction can be carried out by both a high-temperature wall surface or heat-conducting component obtained by combusting semicoke in the fluidized-bed combustion chamber and a solid heat carrier, thus the pyrolysis capacity, the equipment production capacity and the oil, gas and heat recovery rate can be improved.

Owner:张荣光

Composition for removing catalyst powder from catalytic cracking slurry and removal method

ActiveCN101205472AHigh removal rateLow ashWorking-up tarHydrocarbon oil dewatering/demulsificationSlurryOrganic chemistry

The invention provides a compound for removing catalyst fines in FCC oil slurry, containing wetting agent and demulsifying agent; the invention also provides a method using the compound to remove catalyst fines in the FCC oil slurry and a usage of the compound in removing catalyst fines in FCC oil slurry. The ash content of the FCC oil slurry which is removed the catalyst fines can be lowered to less than 0.01 percent, and the cost of the agent which is necessary for removing catalyst fines in each ton of FCC oil slurry is less than 5 Yuan.

Owner:CHINA PETROLEUM & CHEM CORP +1

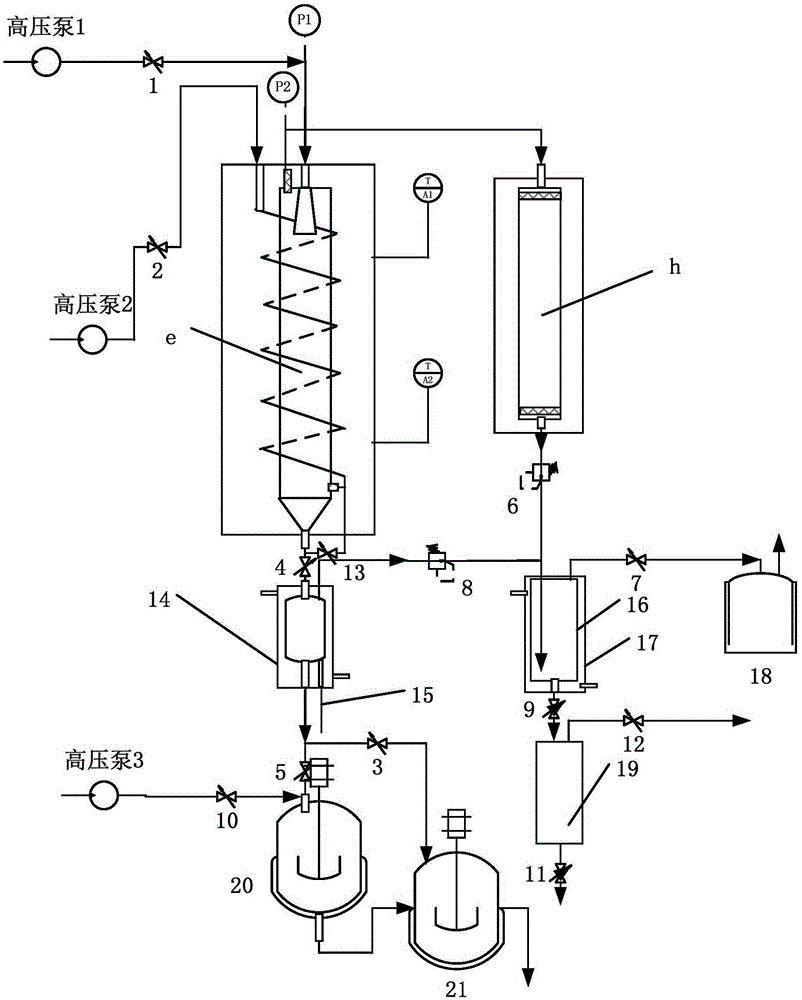

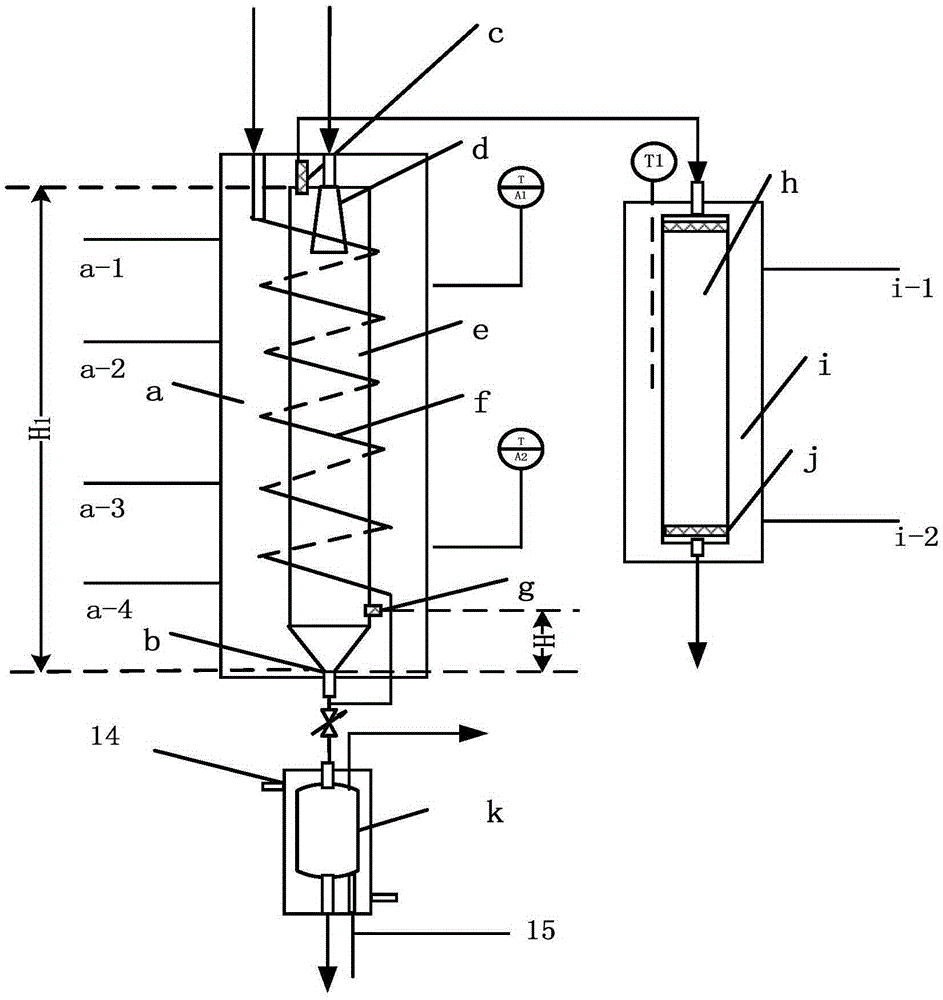

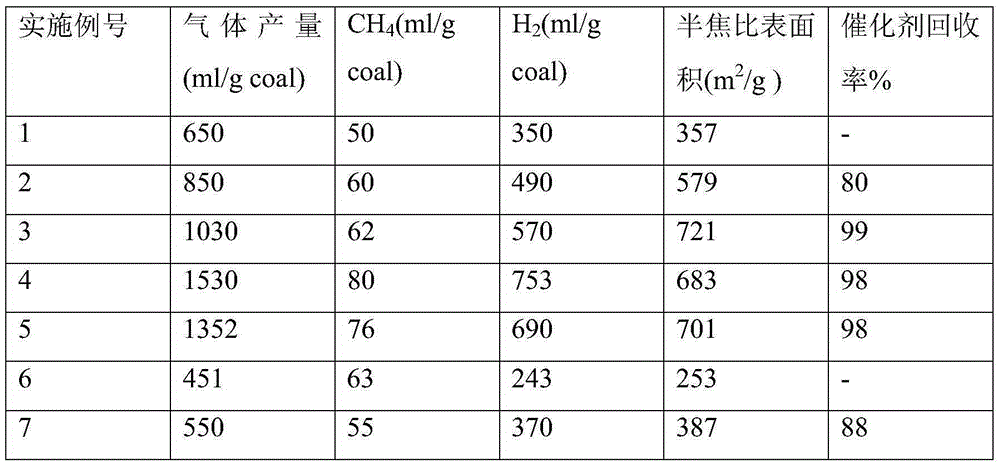

Method and device for preparing active carbon and byproducts of combustion gas and tar through conversion of coal in supercritical water

ActiveCN105349183AStable temperatureUniform temperatureGaseous fuelsWorking-up tarSolubilityMethanation

Provided are a method and device for preparing active carbon and byproducts of combustion gas and tar through conversion of coal in supercritical water. In the method, by utilization of characteristics of high extraction solubility and extremely strong mass and heat transferring performances of a supercritical water high-pressure environment, coal is employed as a raw material to prepare active carbon, high-heating-value gas and tar, and a technology for integration of pyrolysis, gasification and extraction of coal by utilization of supercritical water is achieved. A vertical supercritical water reactor is employed and a catalytic reactor is matched. The supercritical water reactor is mainly aimed to the extraction process and the gasification process, and the matched catalytic reactor is aimed to the methanation process. The method and device have advantages of high thermal efficiency and good economical efficiency.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Composition of hydrocarbon fuel

Slurry hydrocracking a heavy hydrocarbon feed produces a HVGO stream and a pitch stream. At least a portion of the pitch stream is subjected to SDA to prepare a DAO stream low in metals. The DAO is blended with at least a portion of the HVGO stream to provide turbine or marine fuel with acceptable properties for combustion in gas turbines or for marine fuel grades.

Owner:UOP LLC

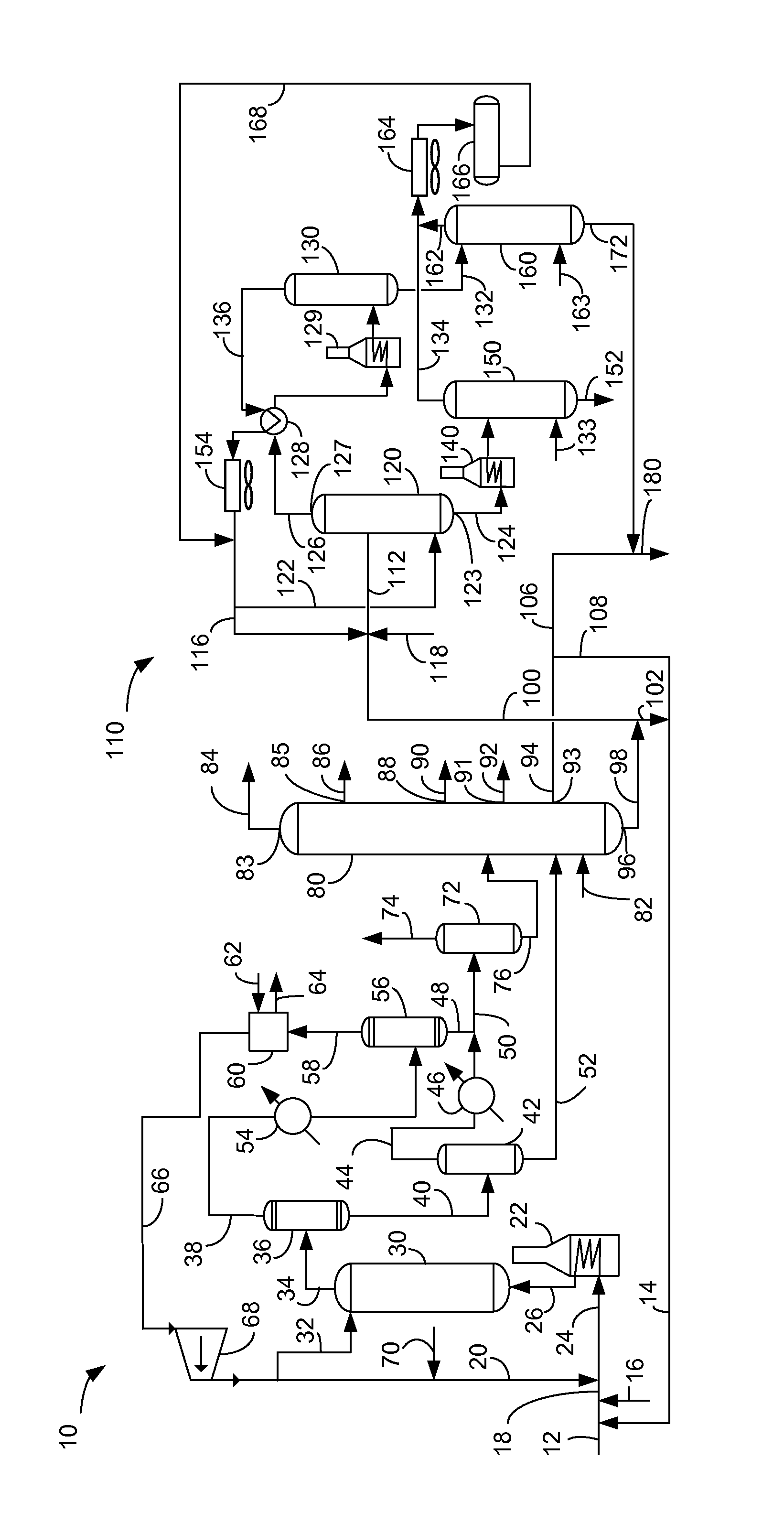

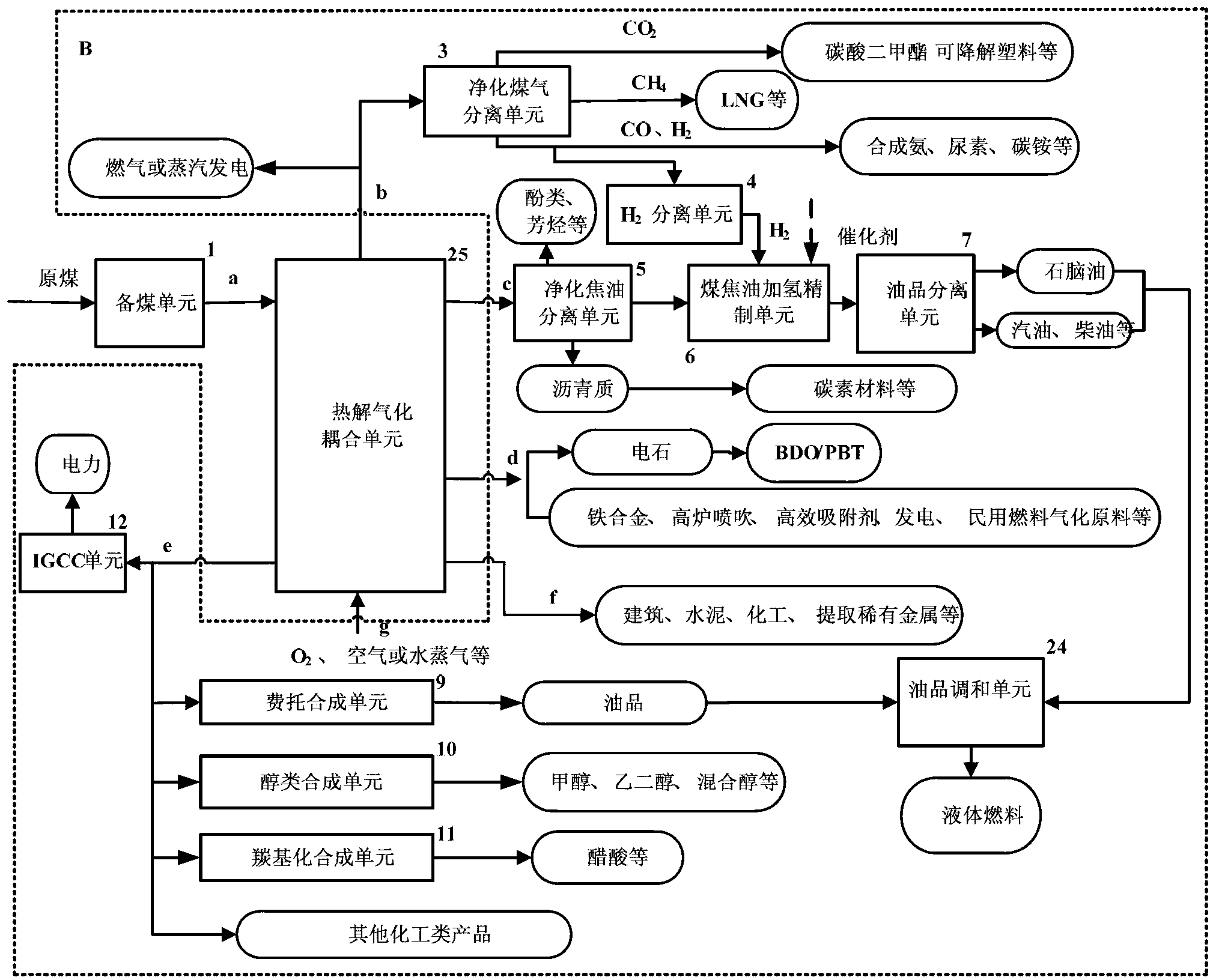

Pyrolysis gasification coupling integrated poly-generation system and process for coal chemical industry

ActiveCN103160296AImprove utilization efficiencyMaximize Utilization EfficiencyUrea derivatives preparationCarbon compoundsElectricityEngineering

The invention provides a pyrolysis gasification coupling integrated poly-generation system and process for the coal chemical industry. The system comprises a coal preparation unit, a pyrolysis-gasification coupling system A and a poly-generation system B, wherein the poly-generation system B comprises a purified gas separation unit connected with the purified gas outlet of the pyrolysis unit, a purified tar separation unit connected with the purified tar outlet of the pyrolysis unit, and a chemical product synthesis unit and an IGCC (Integrated Gasification Combined Cycle) unit which are respectively connected with purified gasification gas outlet of the gasification unit; and the purified tar separation unit is sequentially connected with a coal tar hydrofining unit and an oil product separation unit. The pyrolysis gasification coupling integrated poly-generation system and process can be used for organically combining coal pyrolysis gasification and the production process of oil, gas, chemicals, electricity and heat to realize integration of material conversion and energy conversion, maximize classified utilization, value promotion, utilization efficiency and economical benefit of coal resources, and improve the energy utilization efficiency.

Owner:SHAANXI COAL & CHEM TECH INST

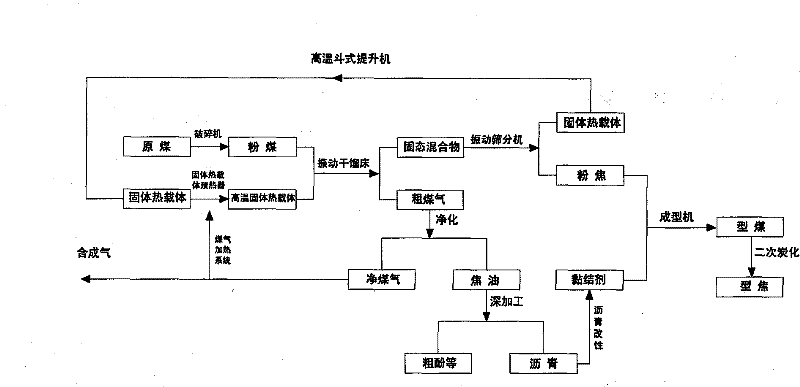

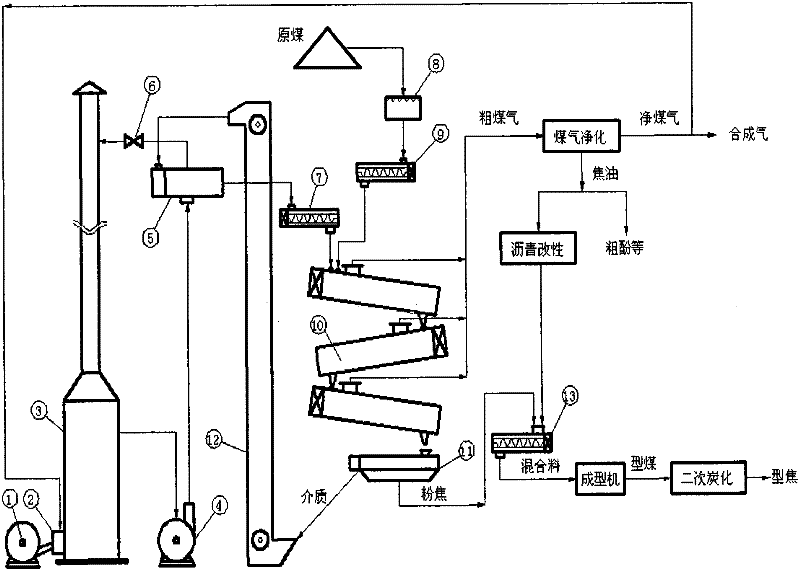

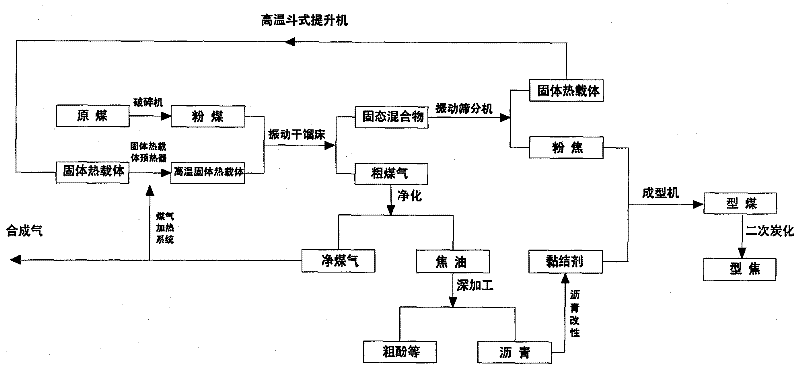

Poly-generation process for pyrolyzing solid thermal carrier via low-rank coal vibration bed

InactiveCN102453489AFast pyrolysisExtended service lifeDirect heating destructive distillationSolid fuelsGeneration processTar

The invention provides a poly-generation process for pyrolyzing a solid thermal carrier via a low-rank coal vibration bed. The process flow is as follows: mixing and retorting coal powder and a high-temperature solid thermal carrier in a vibration carbonization bed; introducing crude gas generated in the retorting process into a gas purification section; carrying out tar deep processing and asphalt modification on the separated tar to prepare crude phenol, an asphalt binder and the like; and carrying out formation and ball pressing on a retorted product powder semi-coke and the asphalt binder as well as other additives, and secondarily carbonizing to prepare a formed coke. In the process provided by the invention, a burning or oxidization phenomenon is not generated during the period of retorting; the product powder semi-coke is low in ash content, high in gas thermal value and high in useful component; the relative motion speed of the solid thermal carrier and the coal powder is small; crude gas does not carry fine coke particles, thereby avoiding adhesion of tar and fine particles on the inner wall of a pipeline and ensuring the long-term operation of a system; and the solid thermal carrier is surrounded by the powder coal, the probabilities of friction and collision between the solid thermal carriers are reduced, and the service life is prolonged. The process provided by the invention is the poly-generation process for pyrolyzing the solid thermal carrier via the low-rank coal vibration bed, and the poly-generation process is practicable in the aspects of technology, materials, cost and the like.

Owner:CHINA UNIV OF MINING & TECH

Popular searches

Hydrocarbon oil cracking Liquid hydrocarbon mixture production Treatment with plural parallel refining stages Bio-feedstock Hydrocarbon oils refining Naphtha treatment Hydrocarbon oils treatment products Working-up pitch/asphalt/bitumen by solidifying/disintegrating Special form destructive distillation Granular/pulverulent flues gasification

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com