Patents

Literature

73results about How to "Alleviate coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

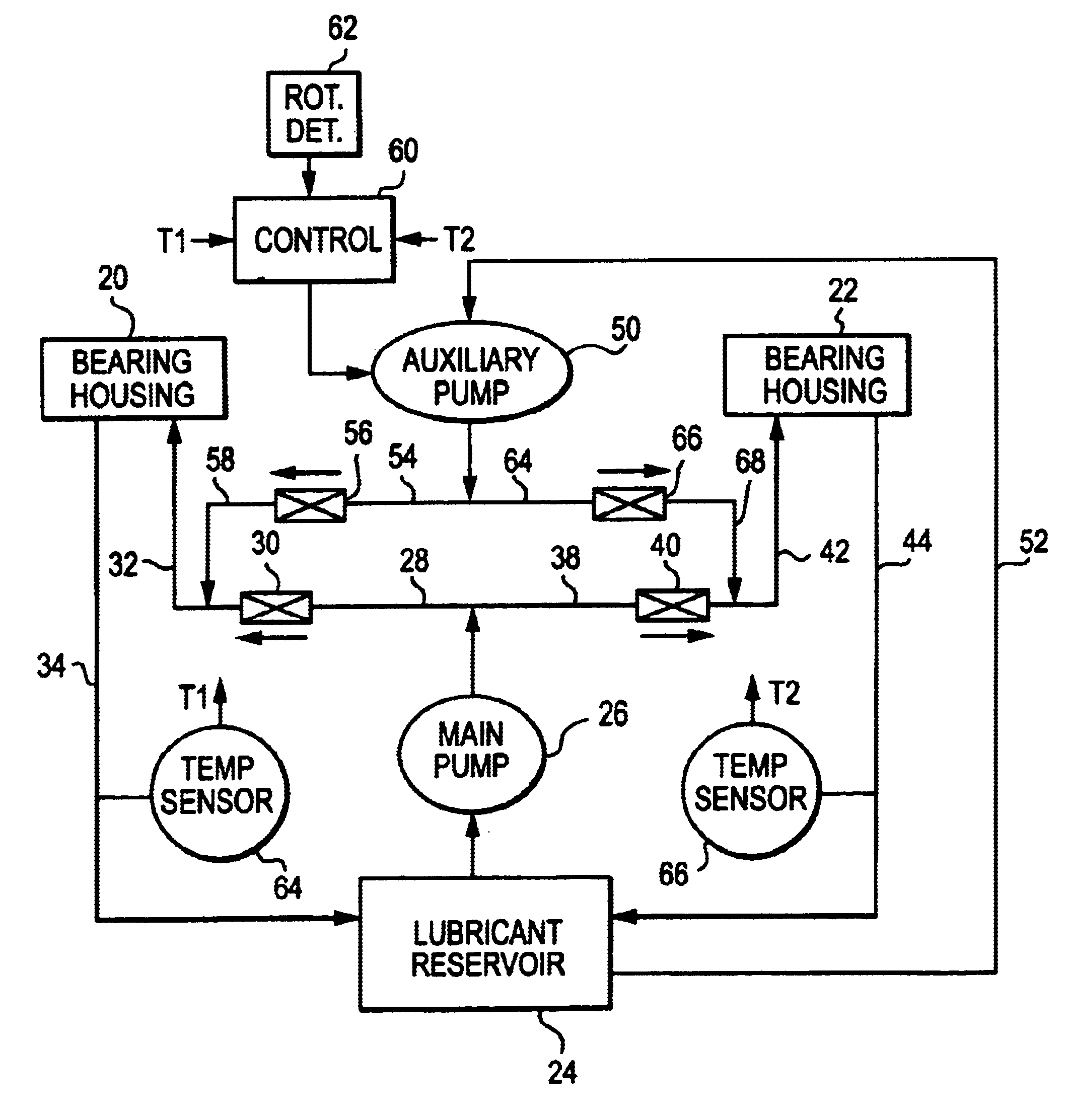

Apparatus for reducing coking in gas turbine bearings

InactiveUS6886324B1Alleviate cokingGas turbine plantsTurbine/propulsion lubricationEngineeringTurbine

The bearings of a gas turbine are supplied with a lubricant from a reservoir by a main pump, when the turbine is operating. When the turbine is shut down and rotation ceases, the main pump also shuts down. When this occurs, an auxiliary pump is placed into operation to continue to supply the bearings with the lubricant until such time as the bearings have sufficiently cooled, at which point the auxiliary pump is shut down.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

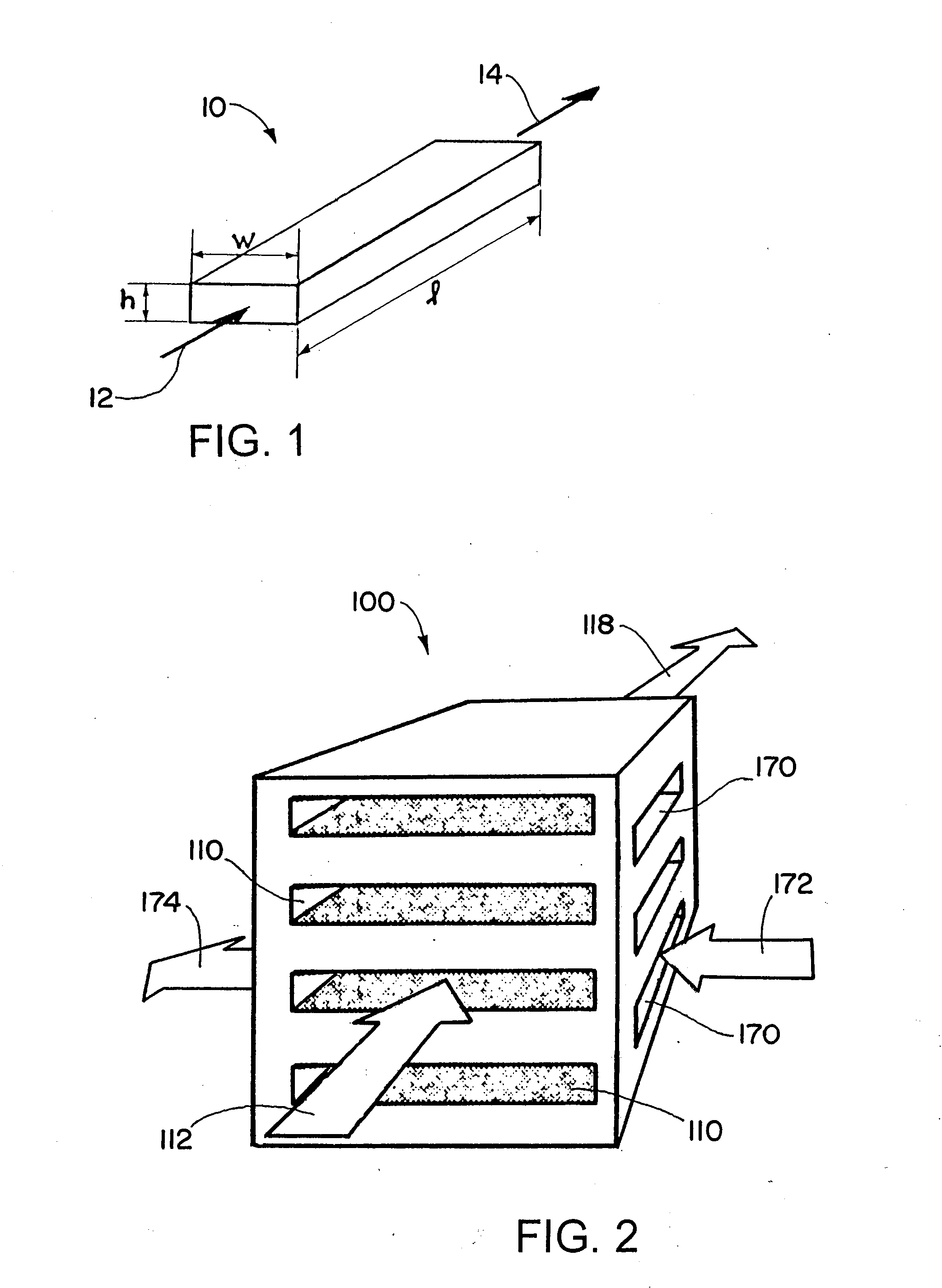

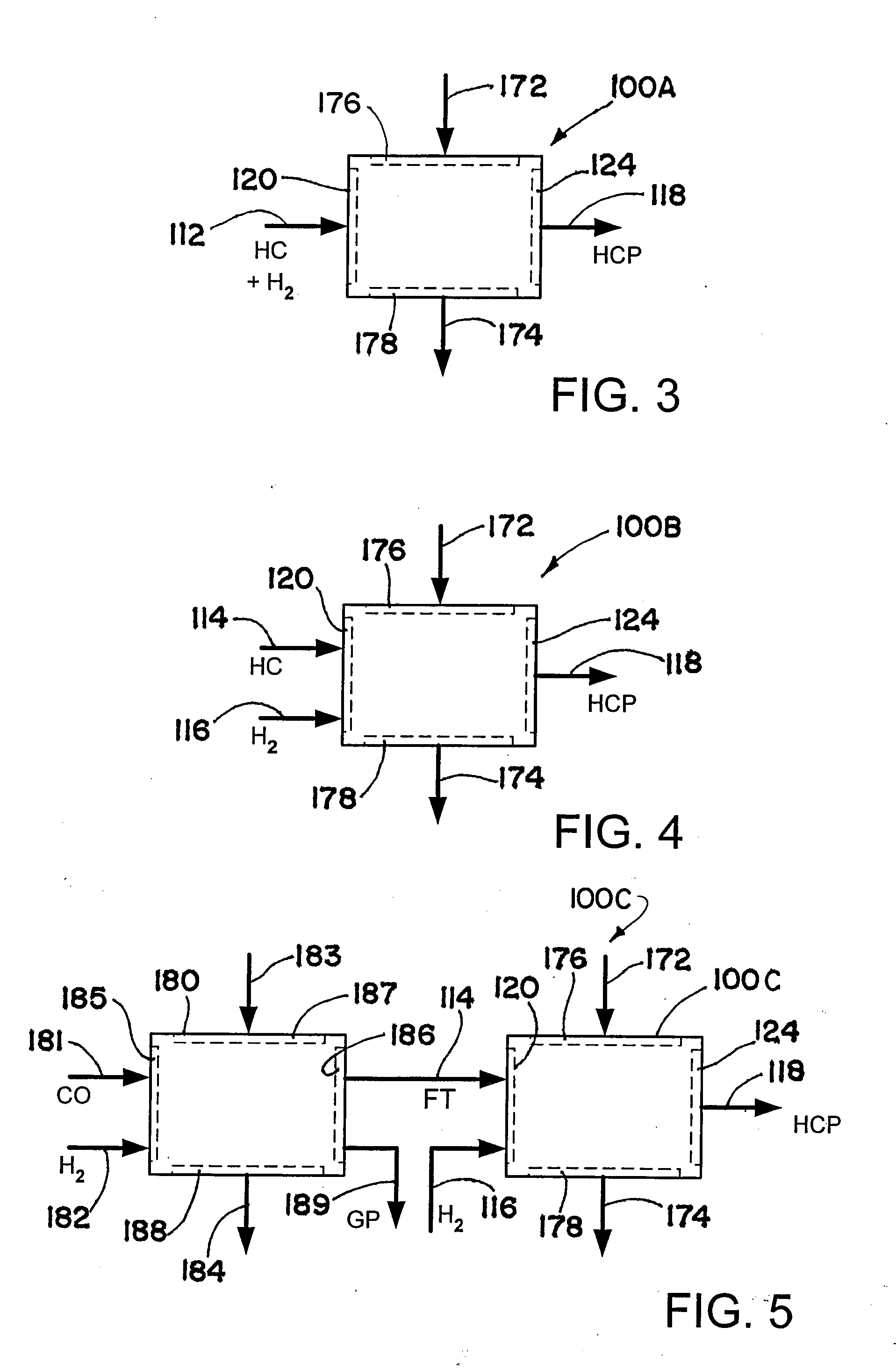

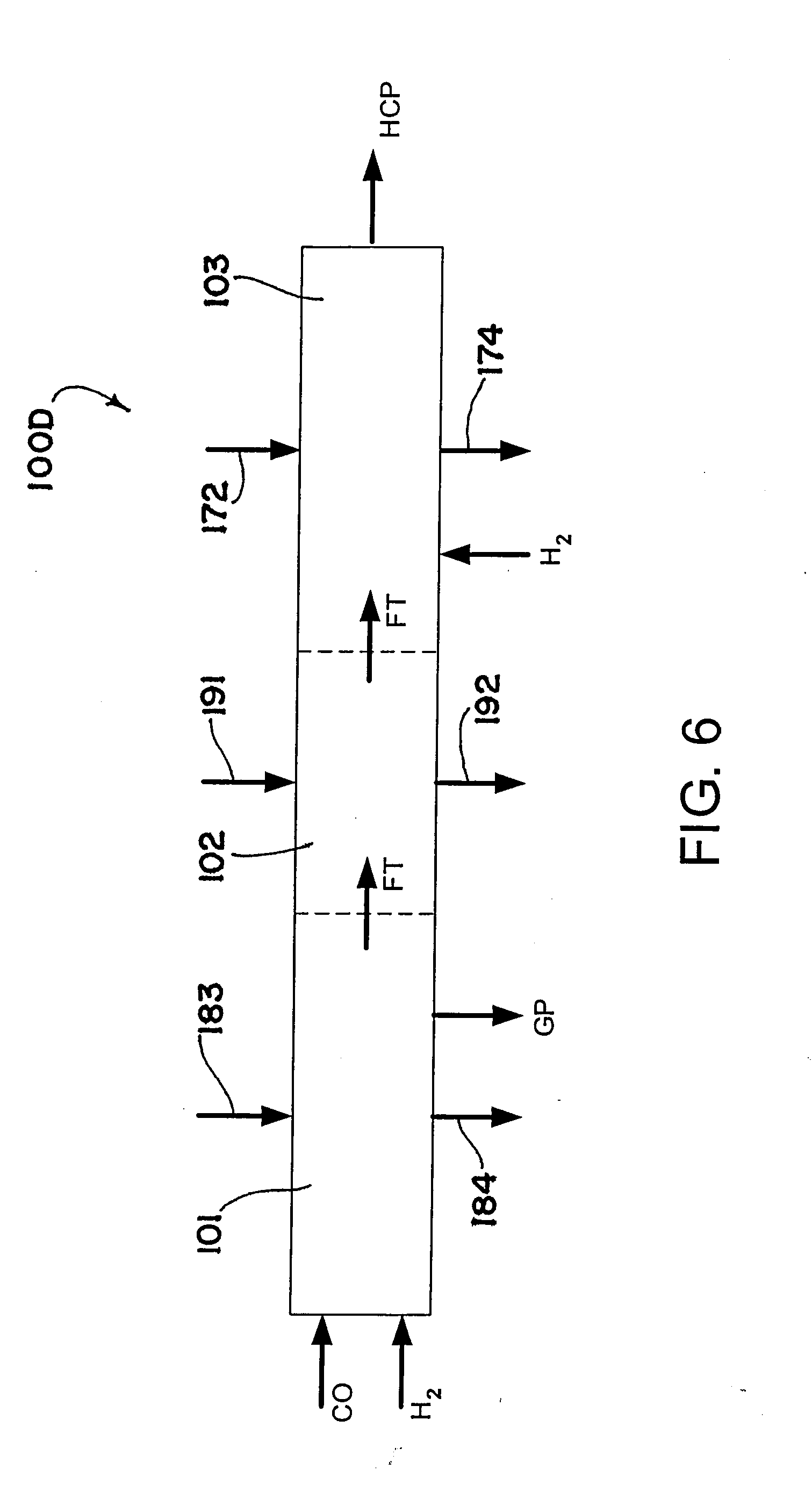

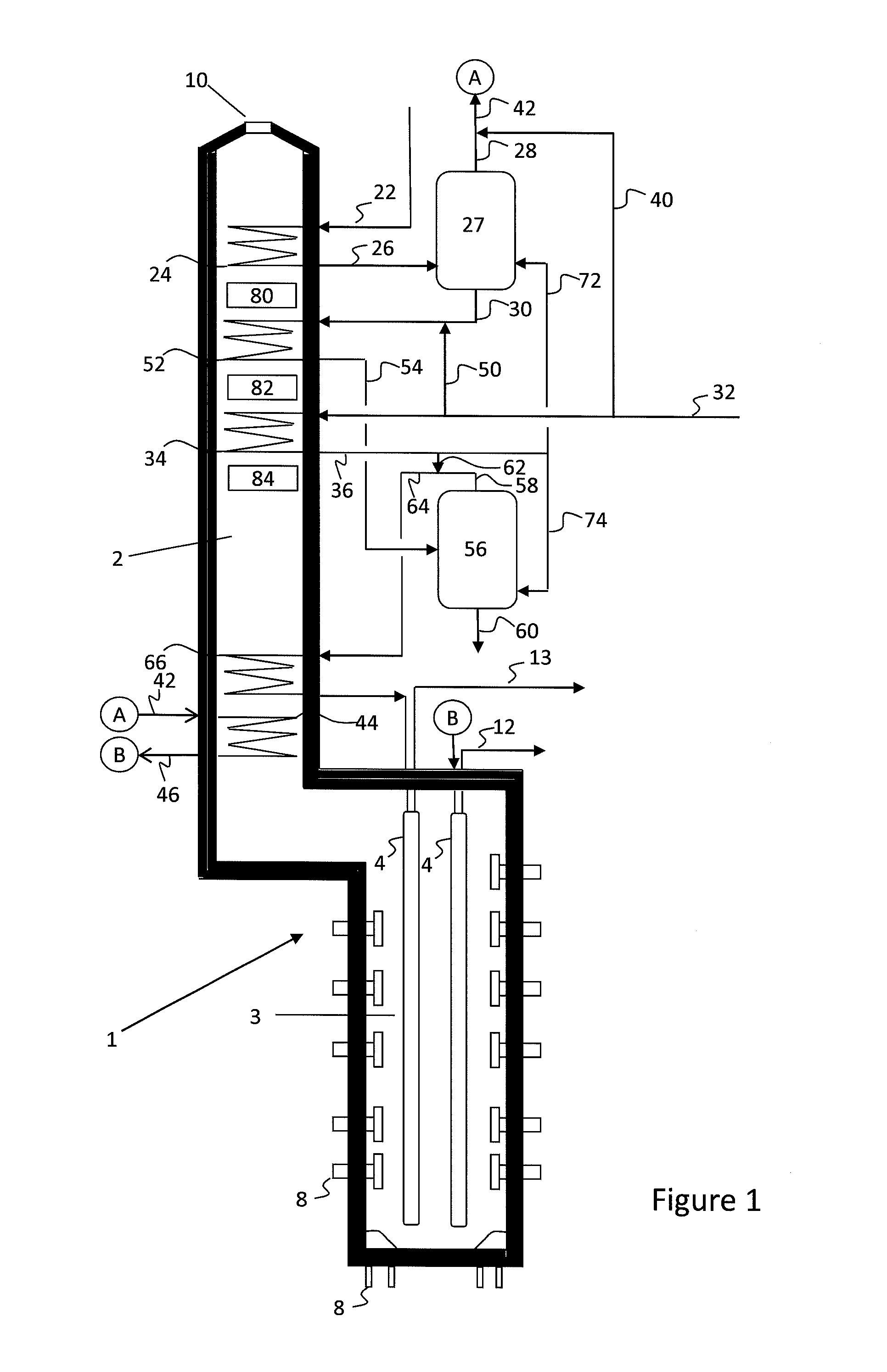

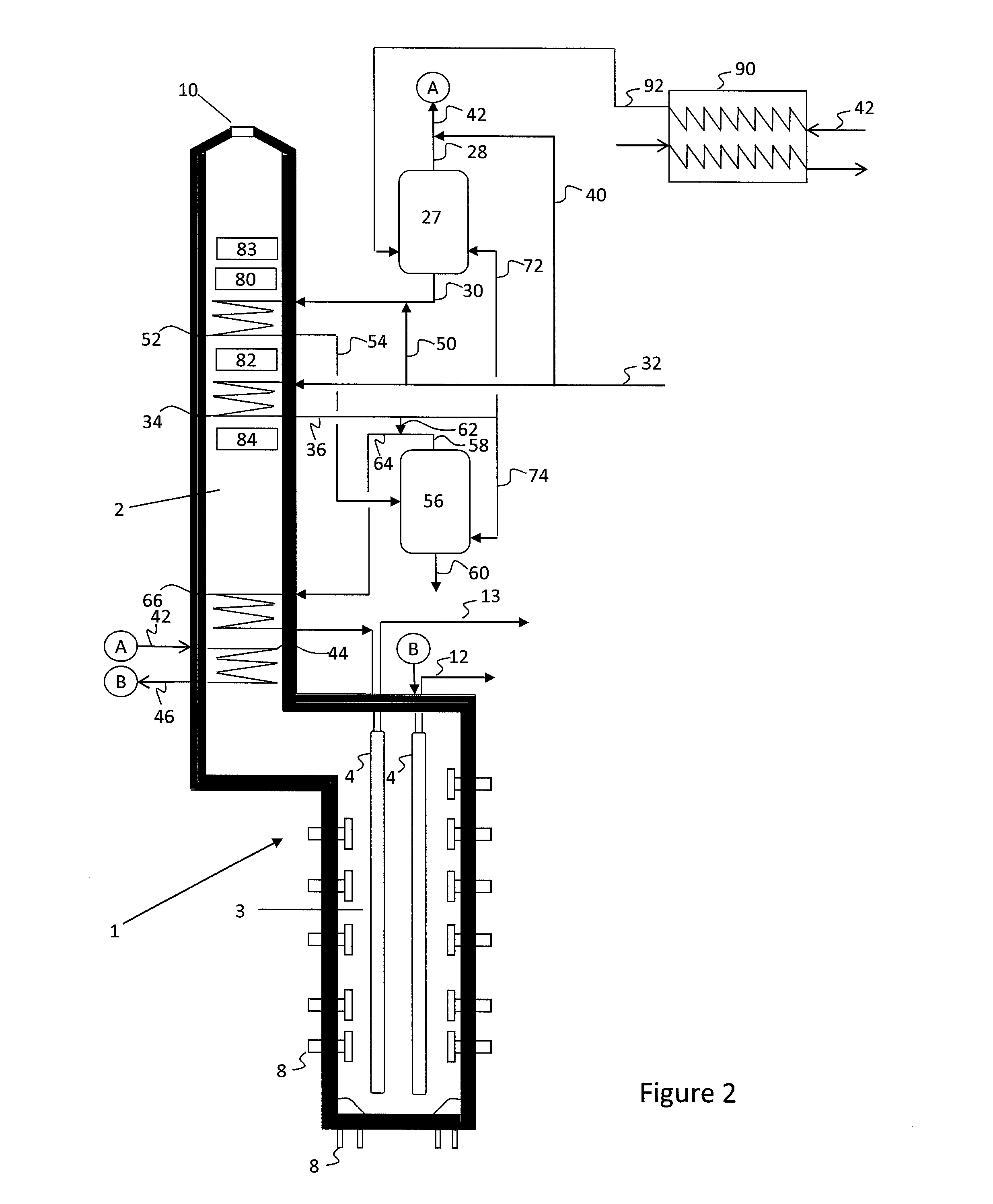

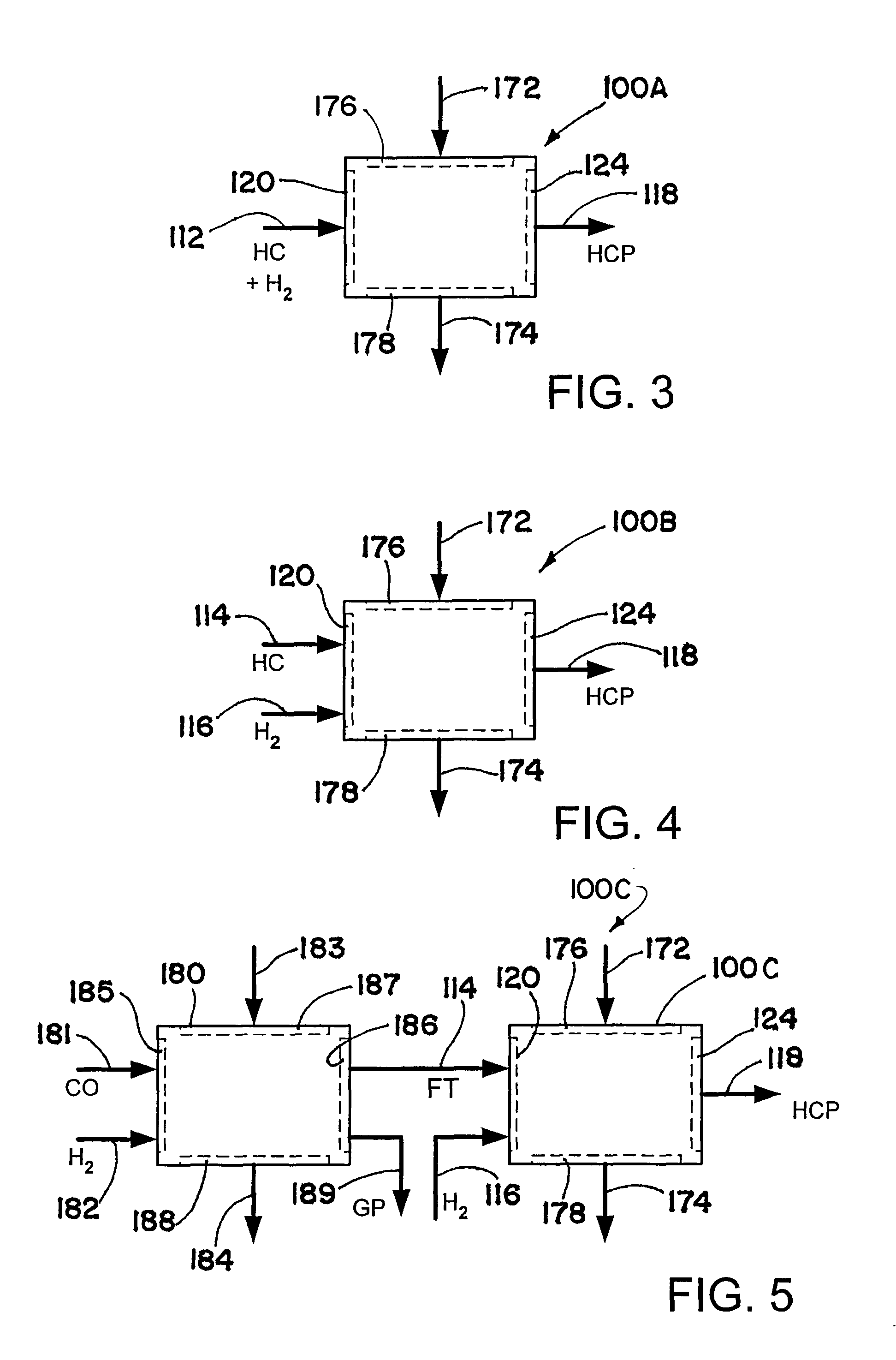

Process and apparatus employing microchannel process technology

InactiveUS20100174124A1High selectivityAlleviate cokingOrganic compound preparationChemical/physical/physico-chemical microreactorsChemistry

This invention relates to a process for conducting a hydrocracking or a hydrotreating process in a microchannel reactor. This invention also relates to a process and apparatus for flowing a vapor and liquid into a plurality of microchannels in a microchannel processing unit.

Owner:VELOCYS CORPORATION

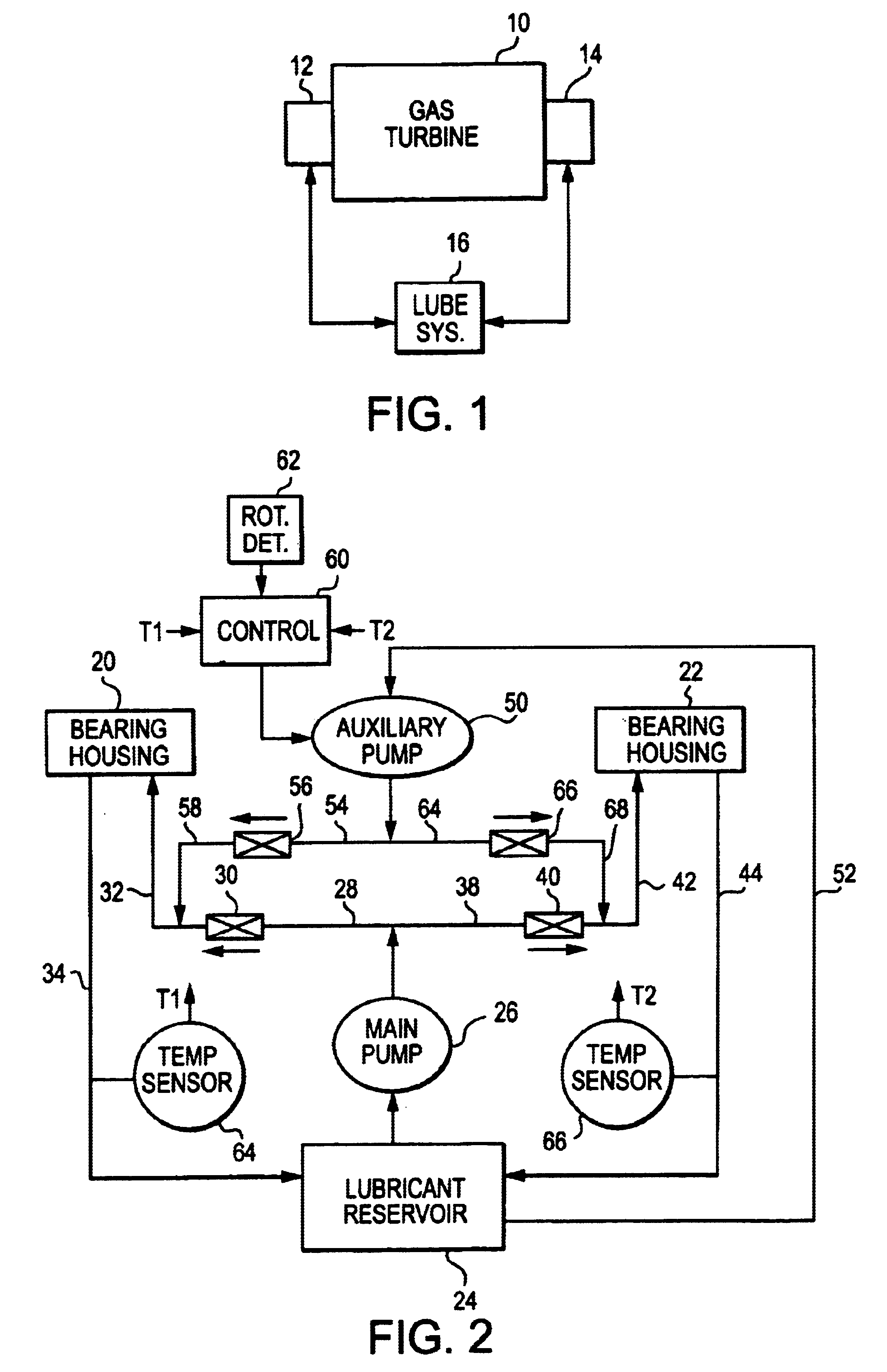

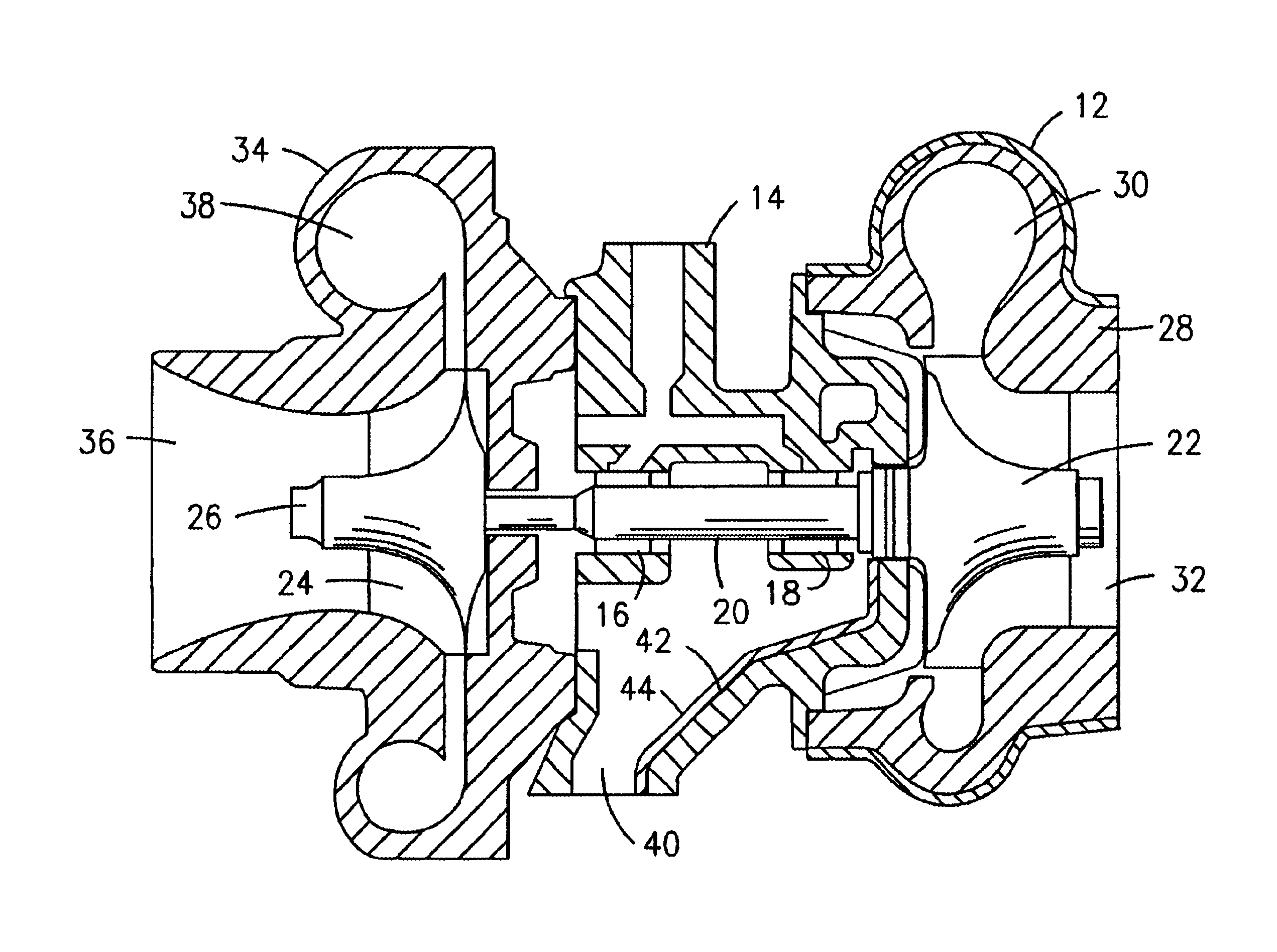

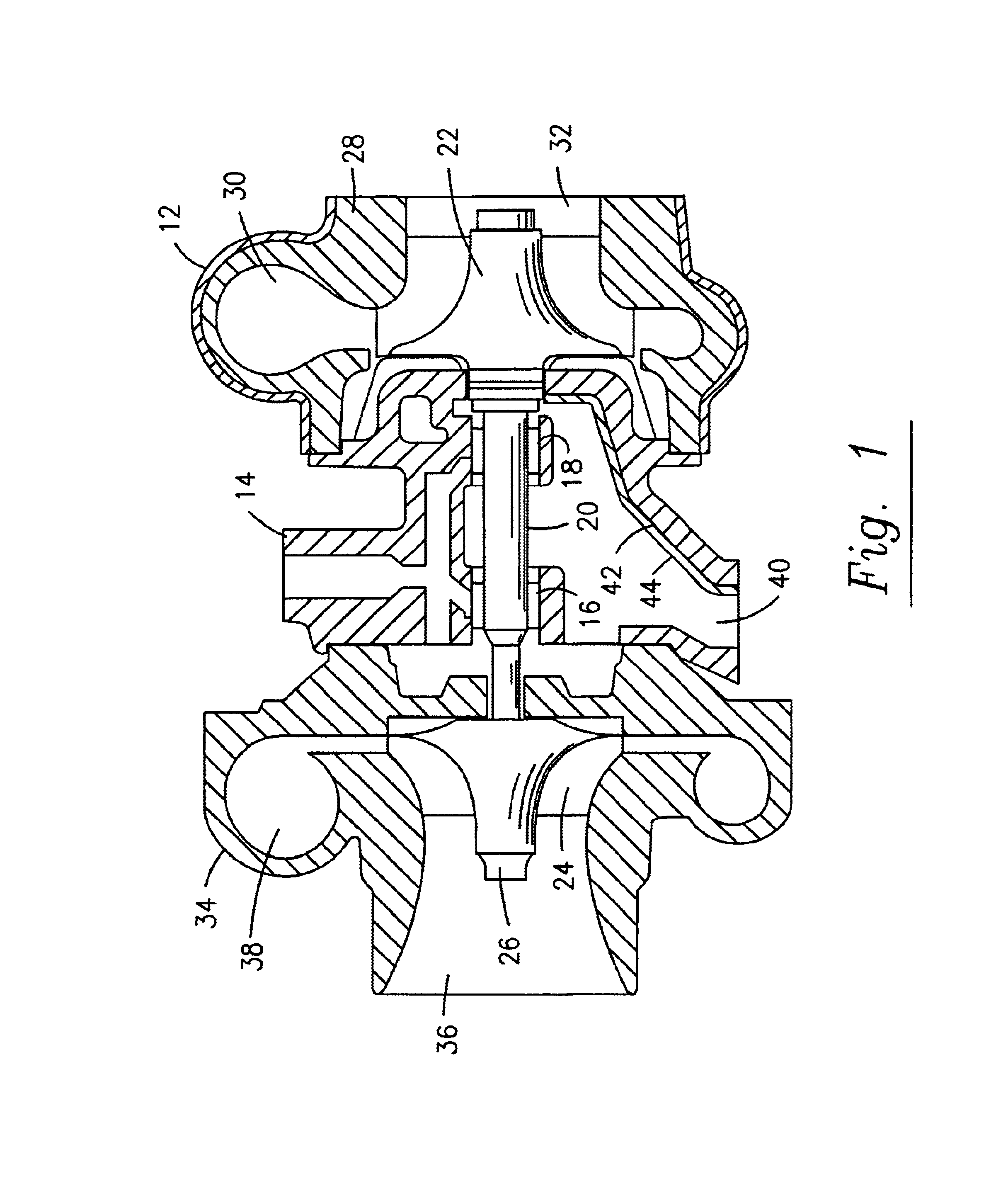

Turbocharger with reduced coking

InactiveUS6874998B2Increasing weightIncreasing volumePump componentsLayered productsTurbochargerEngineering

A turbocharger including means for preventing or reducing coking, particularly following engine shutdown, without noticeably increasing weight or volume of the turbocharger. The turbocharger bearing housing (14) has defined therein a lubrication flow path for bearing lubricant and a lubricant drain gallery (40) below a shaft (20), and in accordance with the invention at least a portion of a wall (42) of the lubricant drain gallery (40) is coated with an oil repellant and / or heat insulating coating (44).

Owner:BORGWARNER INC

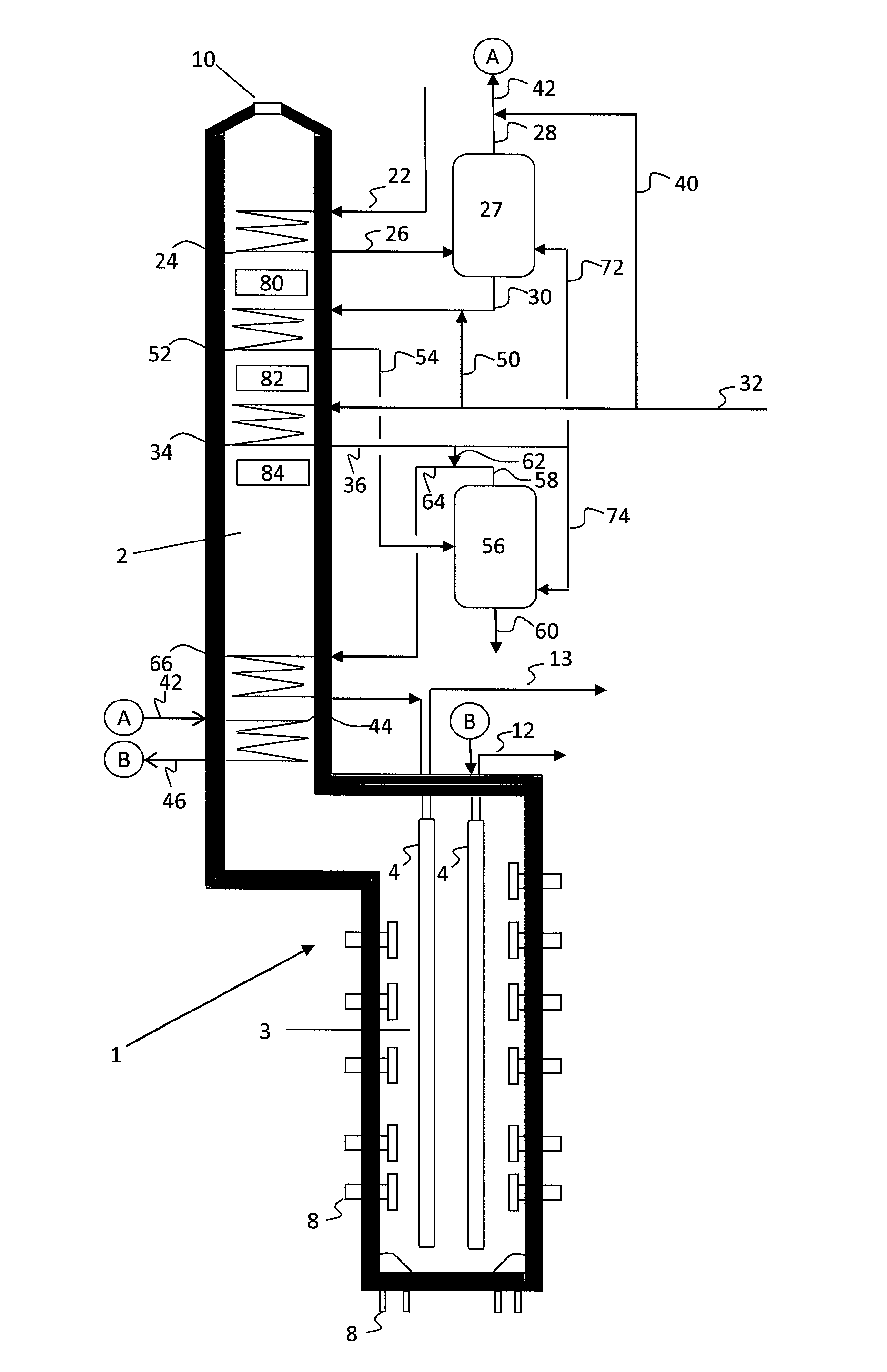

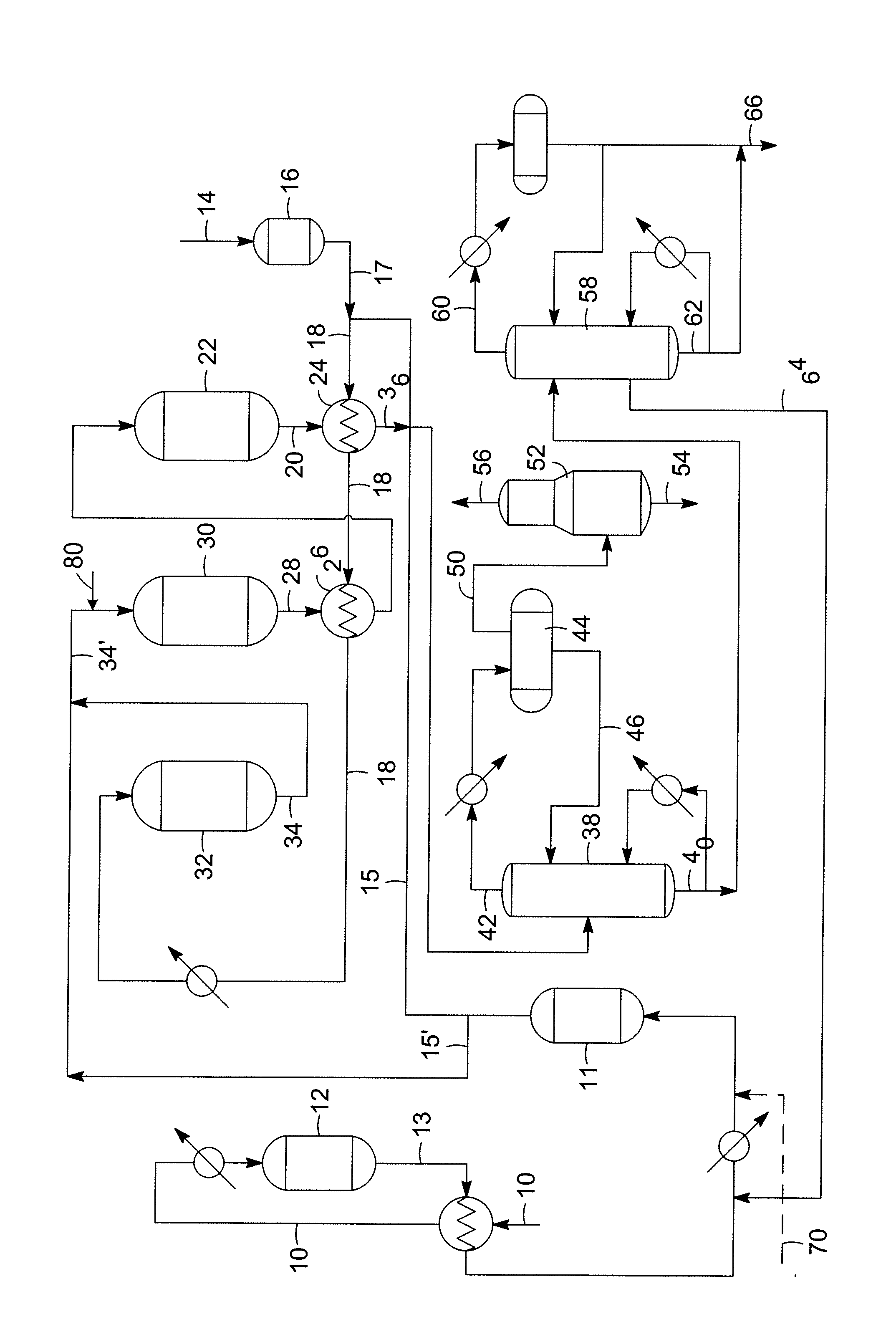

Thermal cracking of crudes and heavy feeds to produce olefins in pyrolysis reactor

ActiveUS20160097002A1Alleviate cokingReduce foulingThermal non-catalytic crackingTreatment with plural serial stages onlyHydrocarbon mixturesReactor system

Systems and processes for efficiently cracking of hydrocarbon mixtures, such as mixtures including compounds having a normal boiling temperature of greater than 450° C., 500° C., or even greater than 550° C., such as whole crudes for example, are disclosed.

Owner:LUMMUS TECH LLC

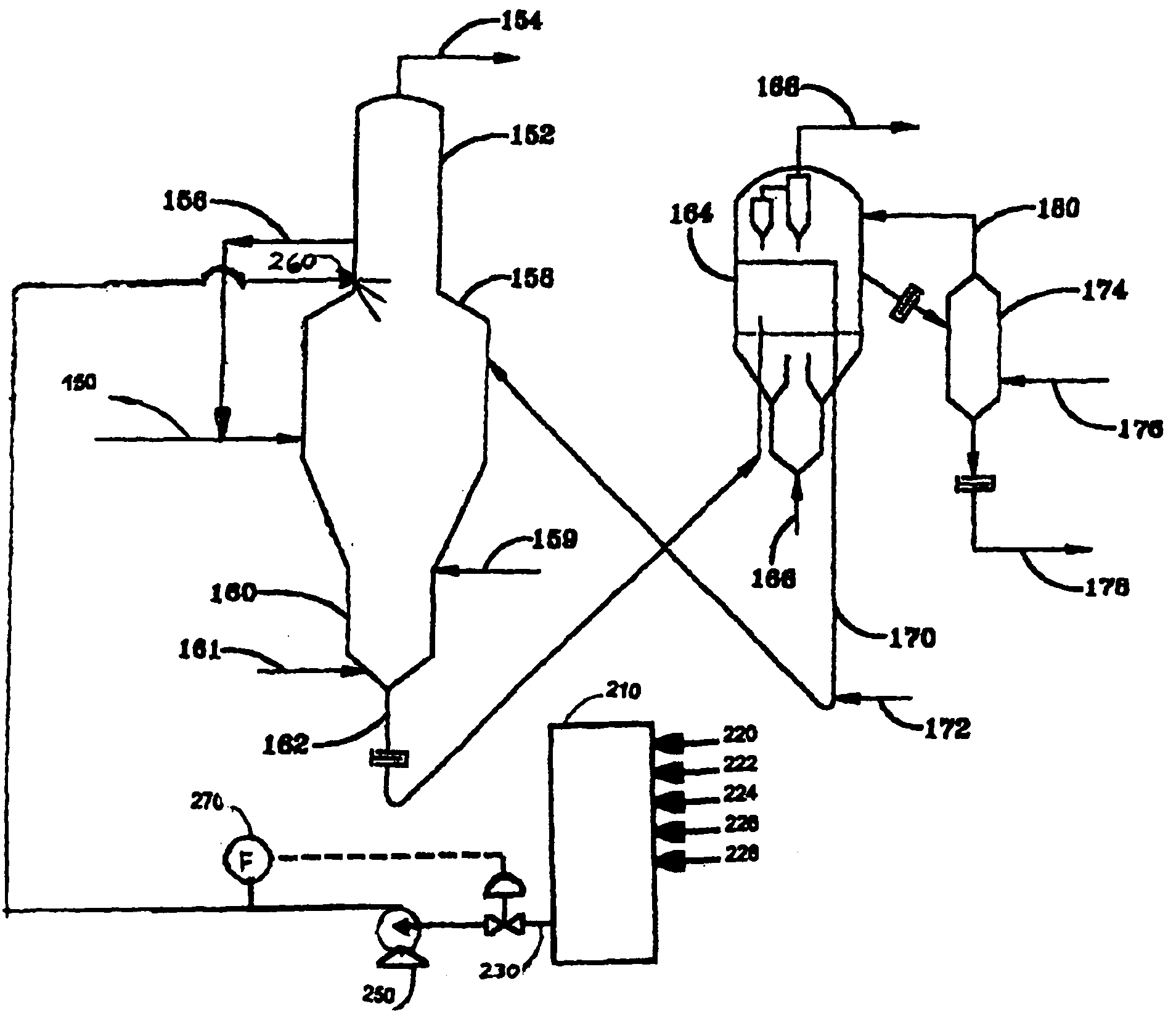

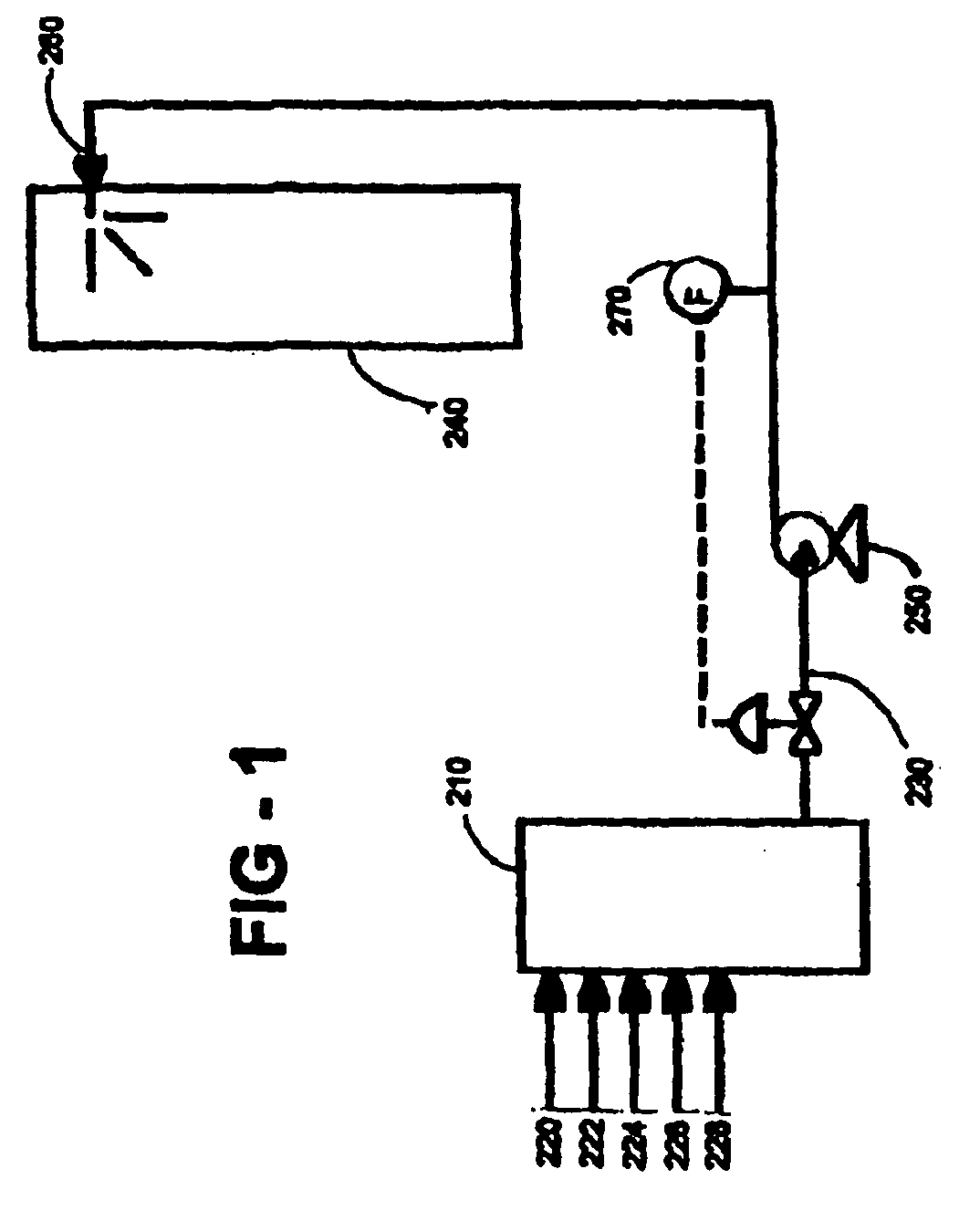

System and Method for Introducing an Additive into a Coking Process to Improve Quality and Yields of Coker Products

InactiveUS20090152165A1Promotes cokingImprove cokingThermal non-catalytic crackingTreatment with plural serial cracking stages onlyBoiling pointTar

Gas oil components, coking process recycle, and heavier hydrocarbons are cracked or coked in the coking vessel by injecting an additive into the vapors of traditional coking processes in the coking vessel. The additive contains catalyst(s), seeding agent(s), excess reactant(s), quenching agent(s), carrier(s), or any combination thereof to modify reaction kinetics to preferentially crack or coke these components. The quenching effect of the additive can be effectively used to condense the highest boiling point compounds onto the catalyst(s), thereby focusing the catalyst exposure to these target reactants. With a catalyst to crack these highest boiling point materials, this mechanism can effectively increase the catalyst's selectivity, thereby increasing its efficiency and reducing catalyst requirements and costs. Selective, catalytic conversion of the highest boiling point materials in the coking process product vapors (coker recycle and / or ‘heavy tail’ of the heavy coker gas oil) may be accomplished with an exemplary embodiment of the present invention in varying degrees. Exemplary embodiments of the present invention can also provide methods to control the (1) coke crystalline structure and (2) the quantity and quality of volatile combustible materials (VCMs) in the resulting coke. Pet coke from this process may have unique characteristics with substantial utility.

Owner:ETTER ROGER G

Isomerization of Benzene-Containing Feedstocks

ActiveUS20080287724A1Reduce the temperatureMinimize undesirable hydrocracking reactionHydrocarbon by isomerisationHydrocarbon by hydrogenationAlkaneBenzene

The benzene content in a gasoline pool is reduced by a process that hydrogenates a benzene-containing isomerization zone feedstream. The additional cyclic hydrocarbons produced by the saturation of benzene can be processed in the isomerization zone for ring opening to increase the available paraffinic feedstock or the isomerization zone can be operated to pass the cyclic hydrocarbons through to a product recovery section. The isomerization zone feedstream is treated to remove contaminants and dried before entering the hydrogenation zone.

Owner:UOP LLC

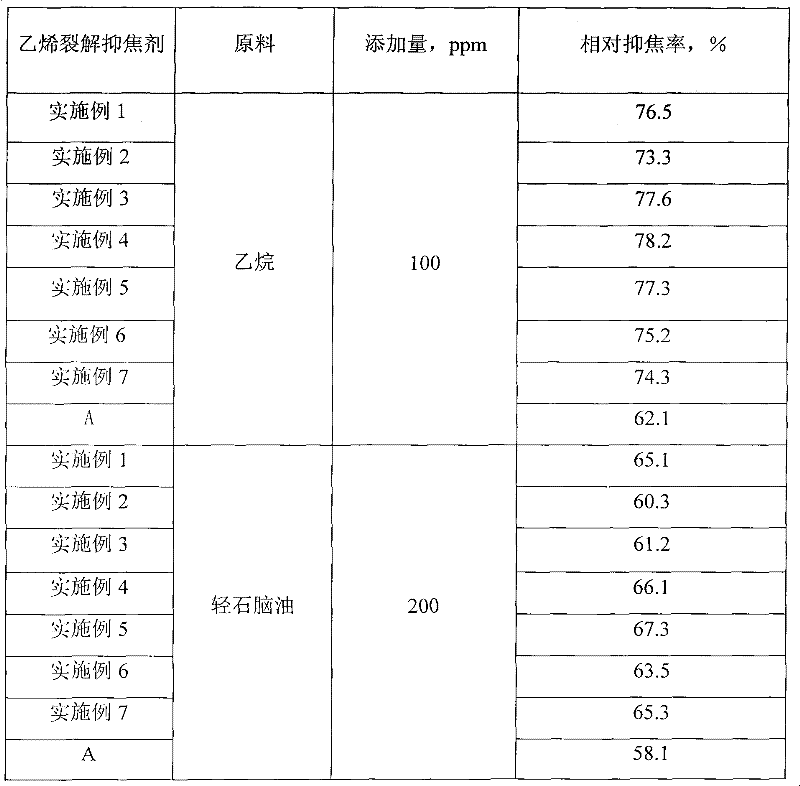

Coke inhibitor for ethylene cracking

ActiveCN101747927AAlleviate cokingGood focus reduction effectThermal non-catalytic crackingPhenyl phosphateSolvent

The invention relates to coke inhibitor for ethylene cracking, which comprises the following component by weight percentage: 20% to 60% of sulfur-containing compound, 5% to 10% of passivator, 1% to 10% of film-forming agent, 5% to 15% of polymerization inhibitor, 1% to 10% of decoking agent and 25% to 45% of solvent, wherein the sulfur-containing compound is particularly dialkyl disulfide, dialkyl sulfide, di-alkylphenol sulfide, diphenyl sulfide, diphenyl disulfide, thiophene or thioxene; and the passivator is particularly triphenyl phosphate, triethyl phosphate, di-octyl-phenyl-phosphate, tributyl phosphate, thiophosphate trilaurate, diethyl-phosphorodi-thioate or triacyl piperidine phosphate, and the passivator is preferably triphenyl phosphate or di-octyl-phenyl-phosphate. The coke inhibitor of the invention for ethylene cracking is capable of effectively relieving the coking condition of an ethylene cracking tube, ensuring the good coke-inhibiting effect, obviously increasing the operation cycle of cracking and reducing the air-decoking time. Therefore, the coke inhibitor of the invention has wide applicable range in the coke inhibition of gaseous light dydrocarbon and naphtha.

Owner:金浦新材料股份有限公司

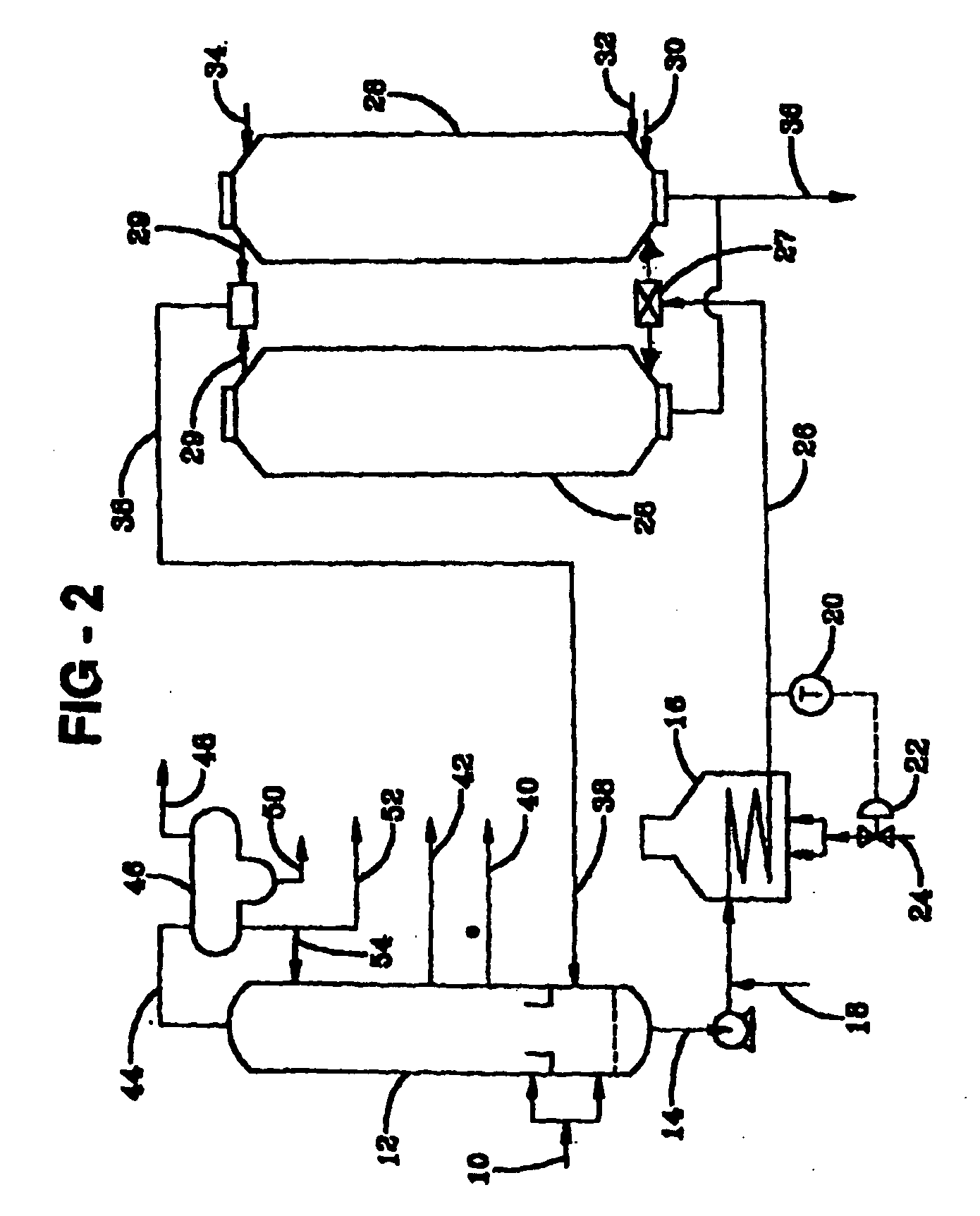

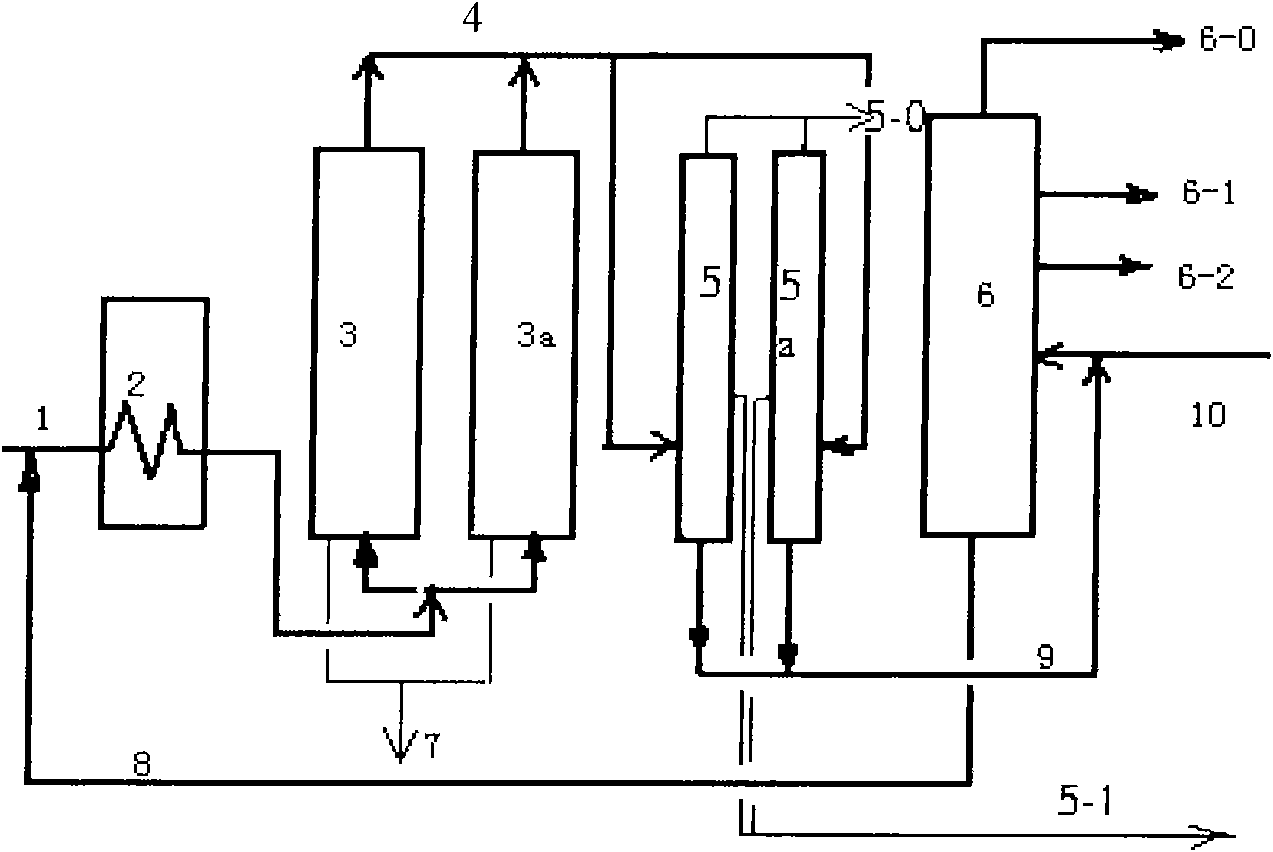

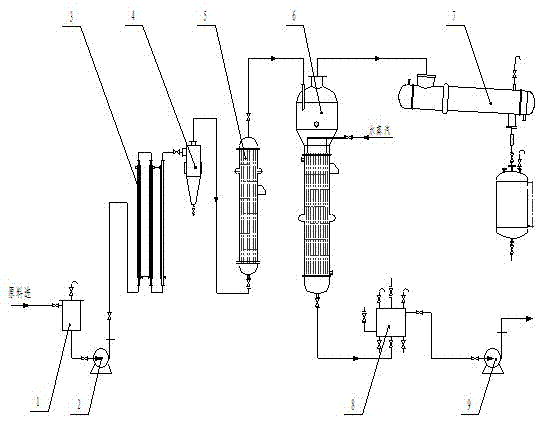

Combined processing method capable of improving coking liquid-phase product yield

ActiveCN101619237ALow costReduce operating costsThermal non-catalytic crackingVacuum distillationWaxEconomic benefits

The invention discloses a combined processing method capable of improving coking liquid-phase product yield. In the method, coke powder is removed from high-temperature oil gases produced by a delayed coking device in a coke powder-removing tank, light components are extracted at the same time, heavy components enter a reduced pressure distillation device to separate a wax oil fraction, and obtained vacuum residues are used as delayed coking feed. The method avoids product fractionation in the prior coking fractional distillation column, thereby greatly reducing investment and operation cost.The method improves the yield of coking waxy oil and ensures the quality of the coking waxy oil. With the increase of the extraction amount of the coking waxy oil, the amount of coking circulation oil is greatly reduced and the processing capacity of the coking device is improved, so the economic benefits are increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

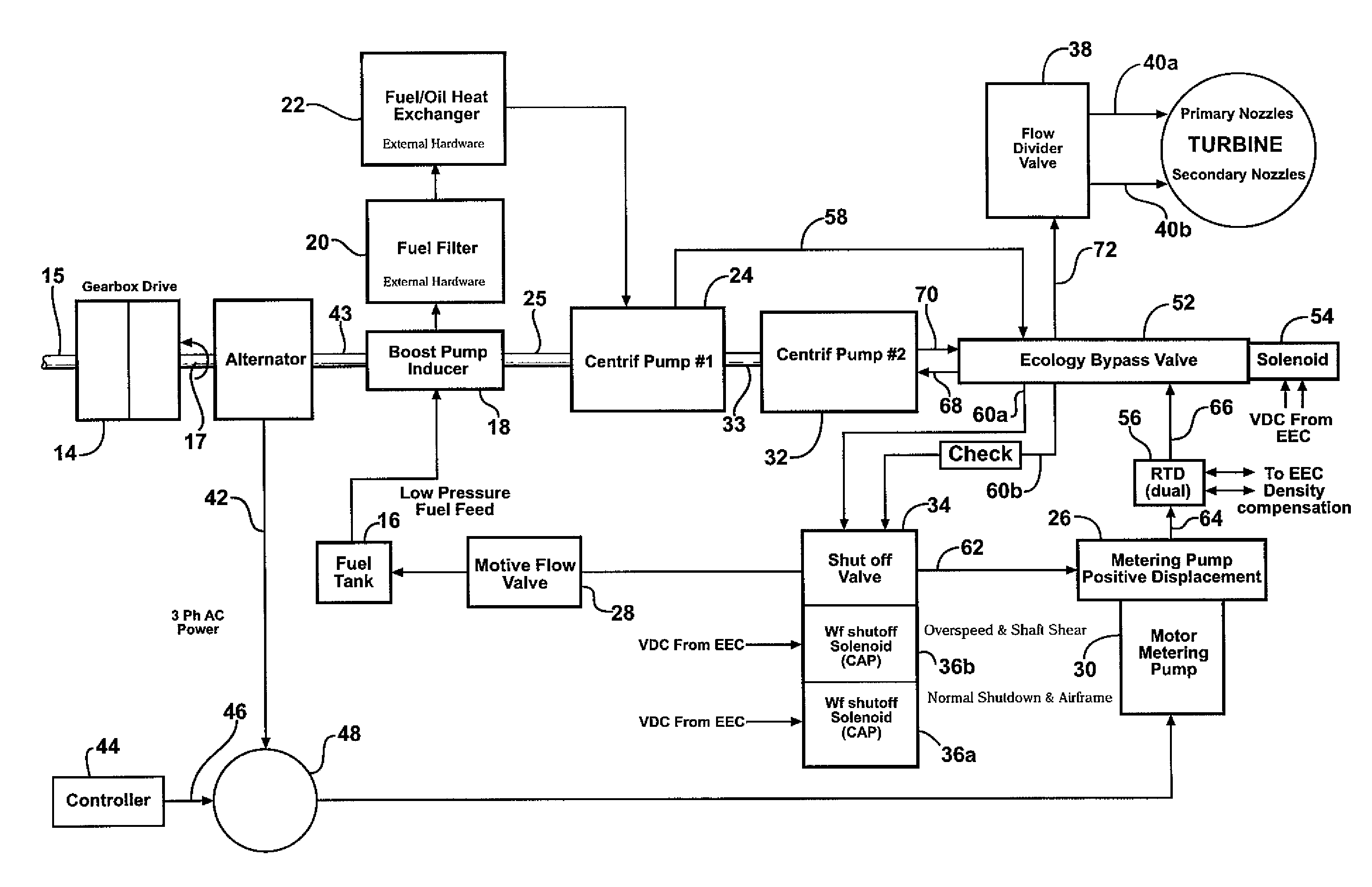

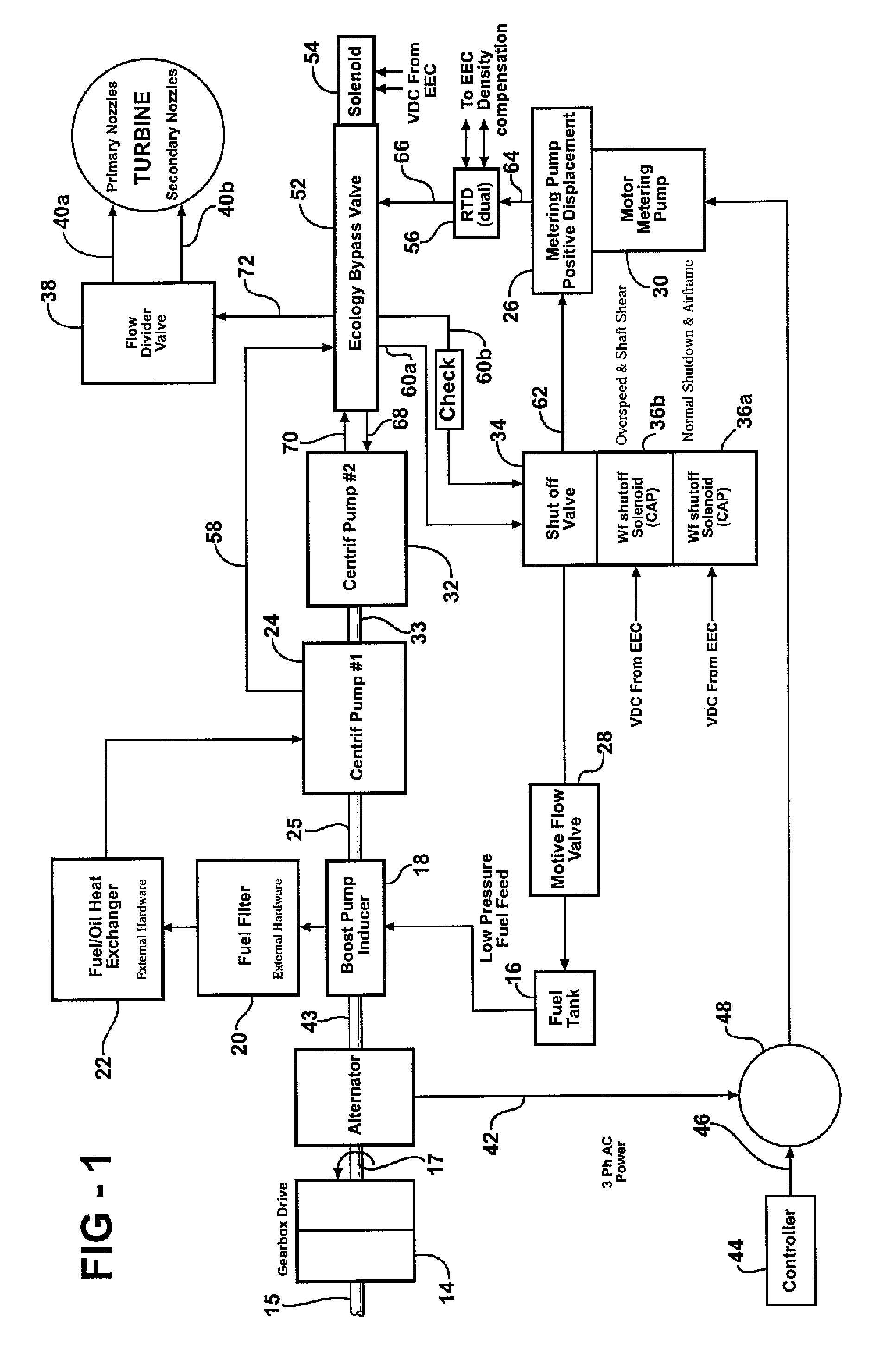

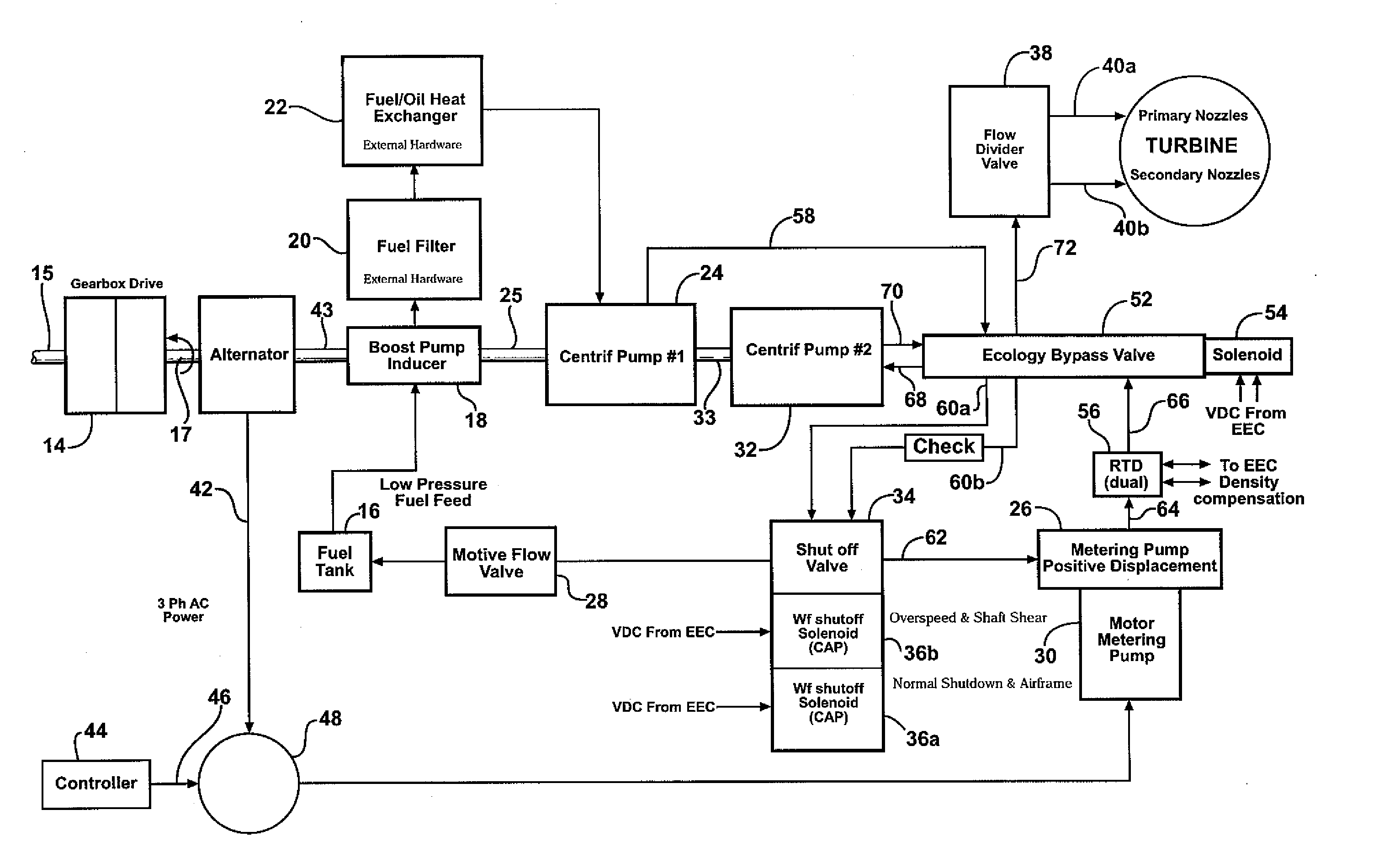

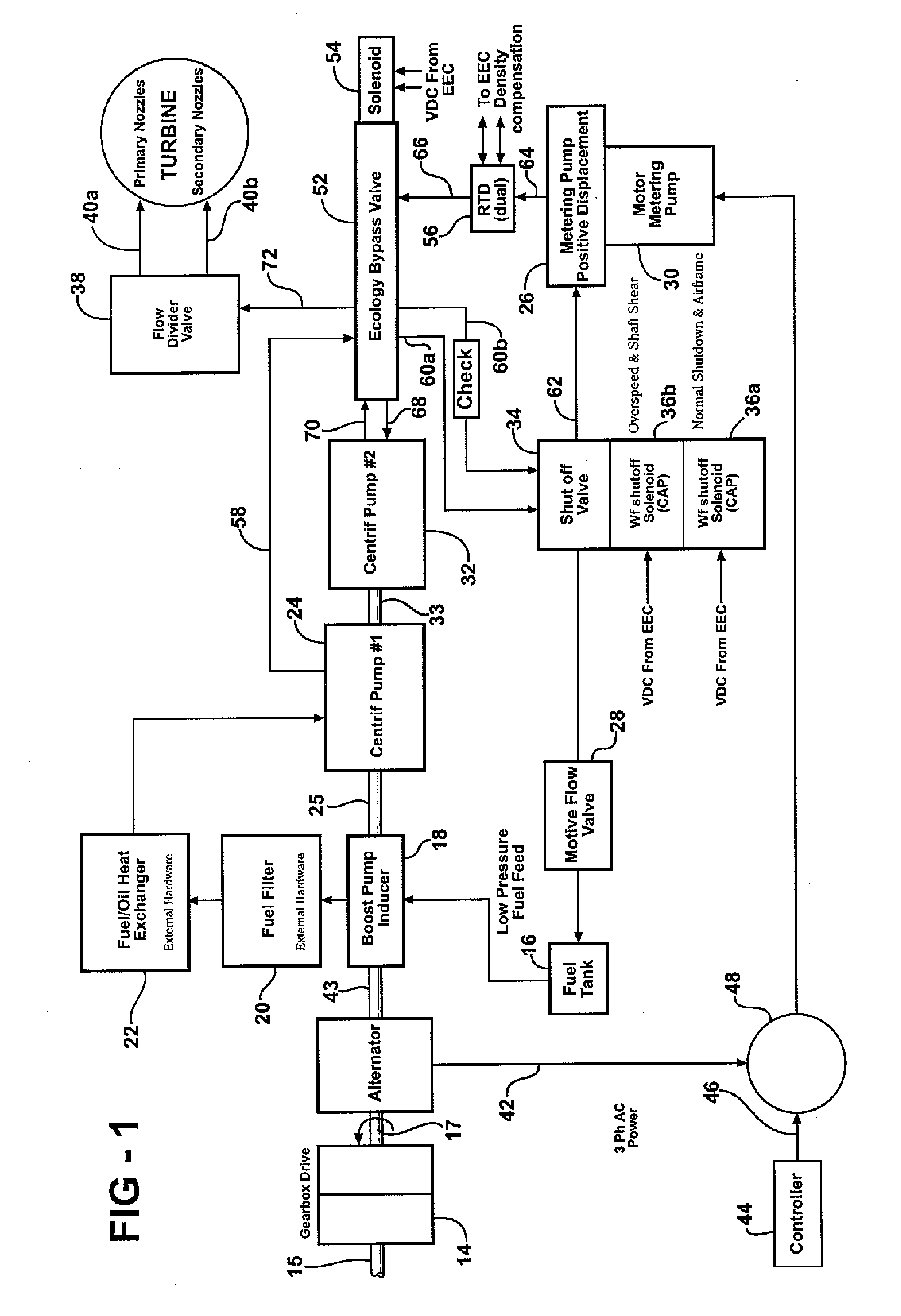

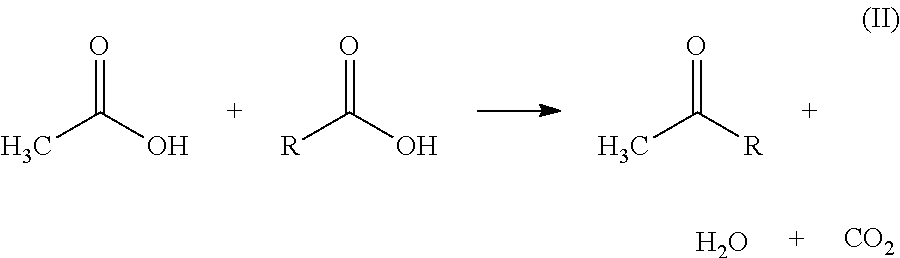

Metering demand fuel system

ActiveUS7845177B2Alleviate cokingReduce flowTurbine/propulsion fuel deliveryGas turbine plantsFuel tankBypass valve

A fuel system includes first and second drive assemblies that are independently drivable relative to one another. The second drive assembly has a speed that is selectively controlled based upon a desired fuel flow. A non-positive displacement pump is driven by the first drive assembly. The non-positive displacement pump provides a desired fuel pressure for the fuel system. A positive displacement pump is driven by the second drive assembly. The positive displacement pump meters a desired volume in response to the speed of the second drive assembly in a first rotational direction. The fuel flows from the pumps and passes through a bypass valve that acts as a minimum pressure shut-off valve. During shut-down of the first drive assembly, the bypass valve is opened by a solenoid and the rotational direction of the second drive assembly is reversed to a second rotational direction to evacuate fuel from the system with the positive displacement pump and return the fuel to the fuel tank.

Owner:HAMILTON SUNDSTRAND CORP

Metering demand fuel system

ActiveUS20080028742A1Alleviate cokingReduce flowTurbine/propulsion fuel deliveryGas turbine plantsFuel tankEngineering

A fuel system includes first and second drive assemblies that are independently drivable relative to one another. The second drive assembly has a speed that is selectively controlled based upon a desired fuel flow. A non-positive displacement pump is driven by the first drive assembly. The non-positive displacement pump provides a desired fuel pressure for the fuel system. A positive displacement pump is driven by the second drive assembly. The positive displacement pump meters a desired volume in response to the speed of the second drive assembly in a first rotational direction. The fuel flows from the pumps and passes through a bypass valve that acts as a minimum pressure shut-off valve. During shut-down of the first drive assembly, the bypass valve is opened by a solenoid and the rotational direction of the second drive assembly is reversed to a second rotational direction to evacuate fuel from the system with the positive displacement pump and return the fuel to the fuel tank.

Owner:HAMILTON SUNDSTRAND CORP

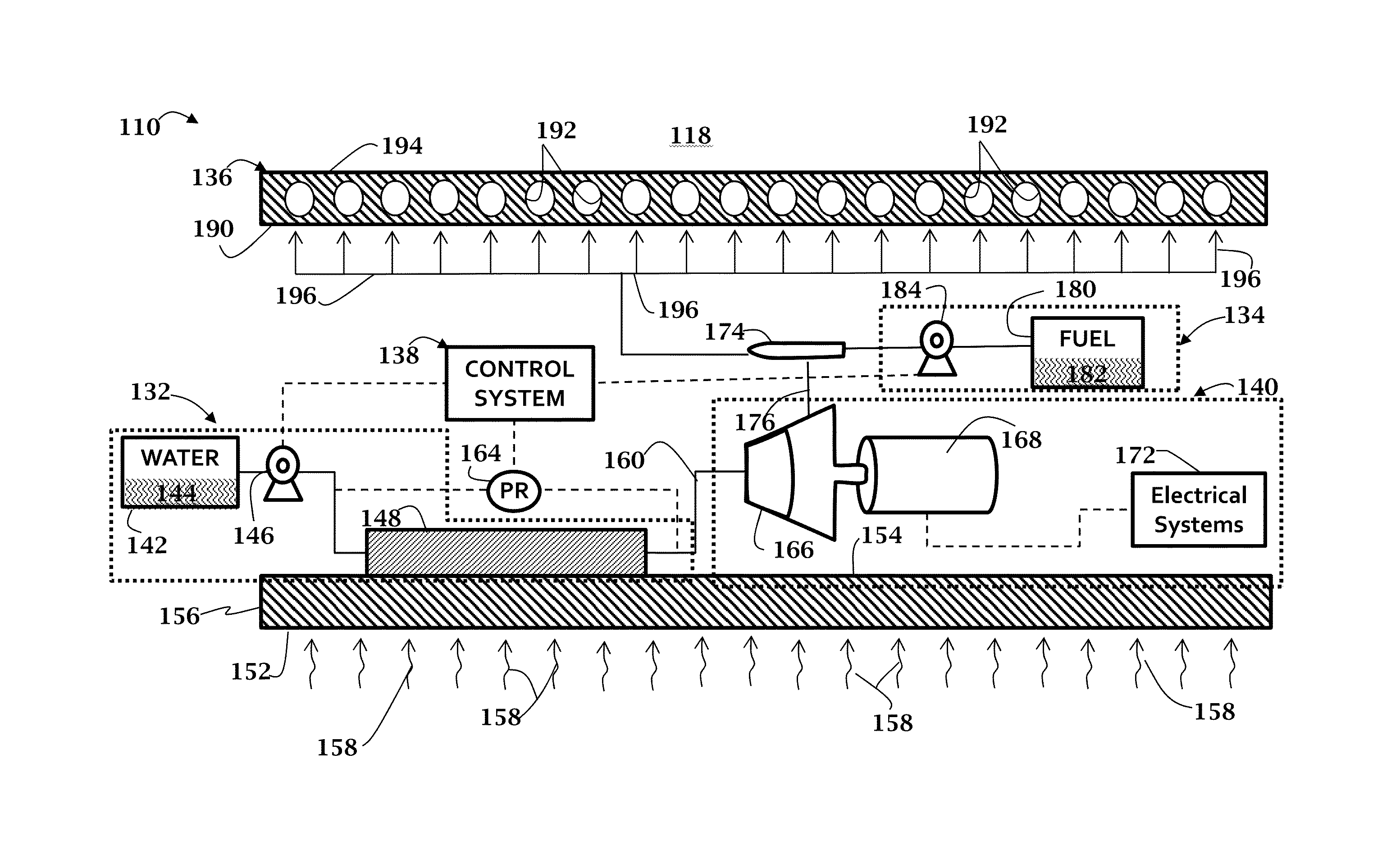

High-speed vehicle power and thermal management system and methods of use therefor

InactiveUS20150315971A1Alleviate cokingPower plant cooling arrangmentsEngine fuctionsThermal management systemEngineering

A thermal management and power generation system for a hypersonic vehicle. The thermal management and power generation system comprising a fluid supply having a volatile fluid and a fuel supply having an endothermic fuel. A first heat exchanger, fluidically coupled to the fluid supply, absorbs heat from a first portion of the hypersonic vehicle, which vaporizes the volatile fluid. A mixing apparatus, fluidically coupled to the first heat exchanger and the fuel supply combines the vaporized volatile fuel and endothermic fuel. A second heat exchanger, fluidically coupled to the mixing apparatus, absorbs heat from a second portion of the hypersonic vehicle and decomposes the endothermic fuel by endothermic pyrolysis. A heat engine, fluidically coupled to the first heat exchanger and the mixing apparatus, is configured to generate an electrical power for use by the hypersonic vehicle. The vaporized volatile fluid mixed with the endothermic fuel within the second heat exchanger reduces coking caused by the endothermic pyrolytic decomposition of the endothermic fuel as compared to an endothermic pyrolytic decomposition of an endothermic fuel not having a vaporized volatile fluid mixed therewith.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

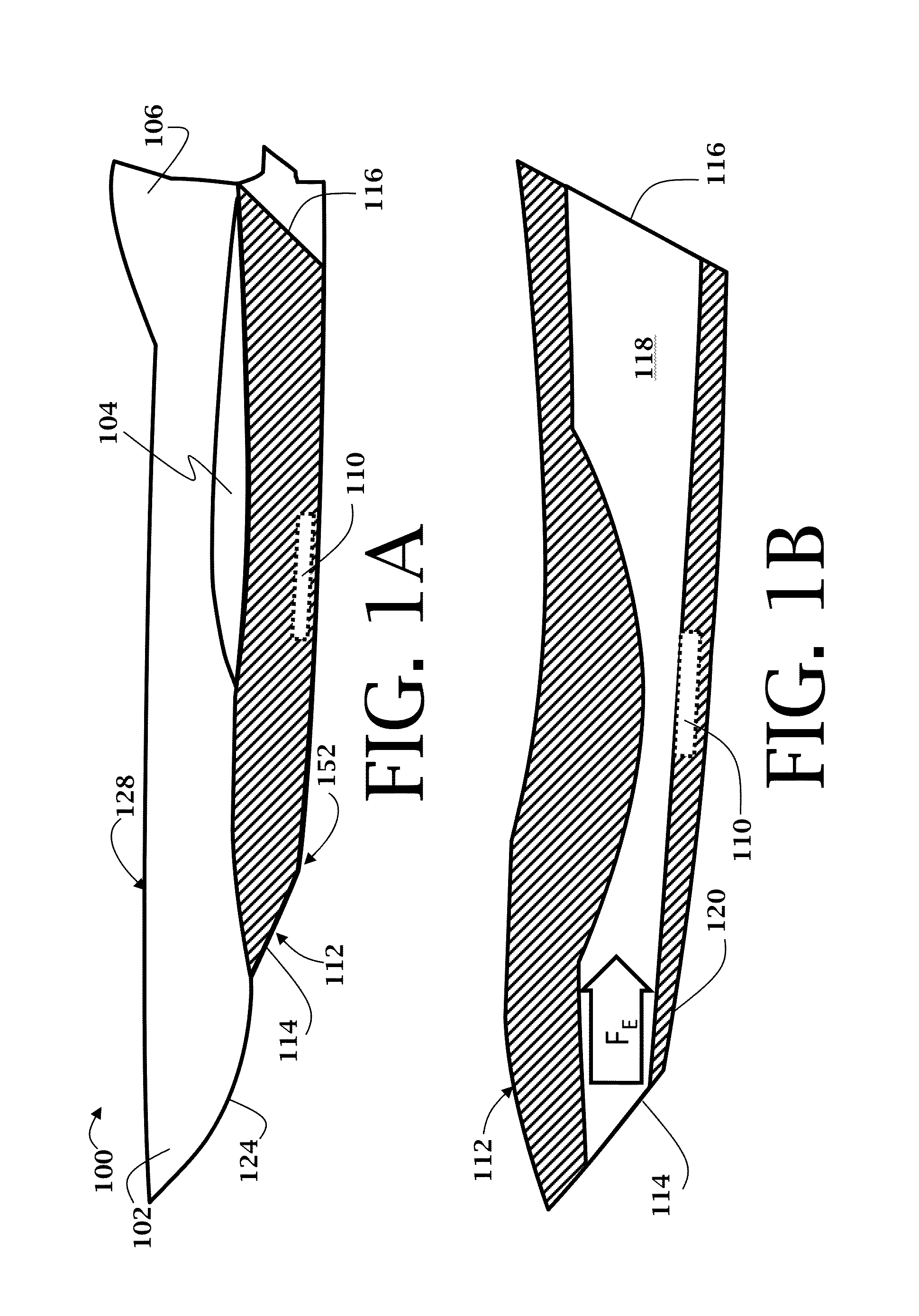

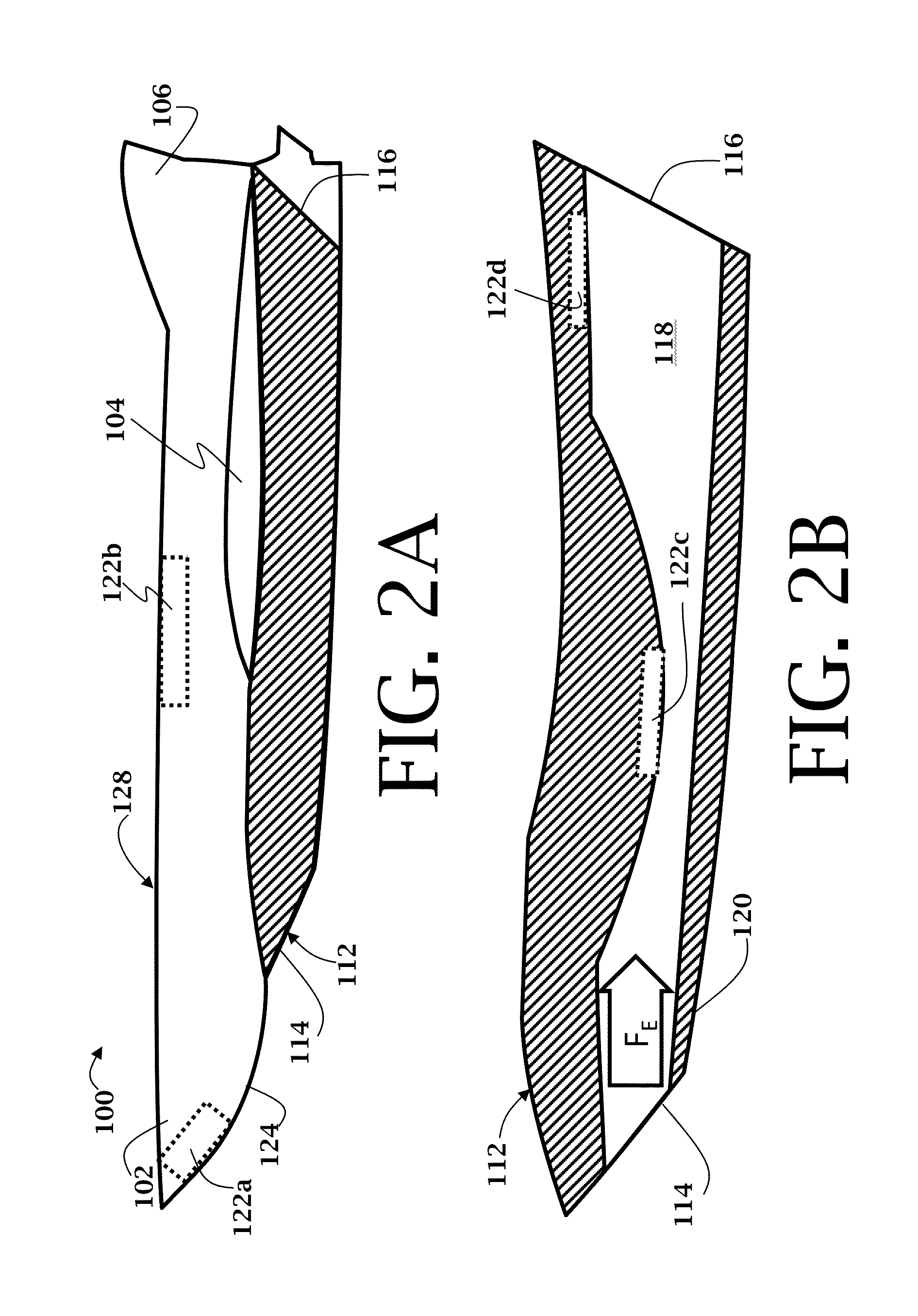

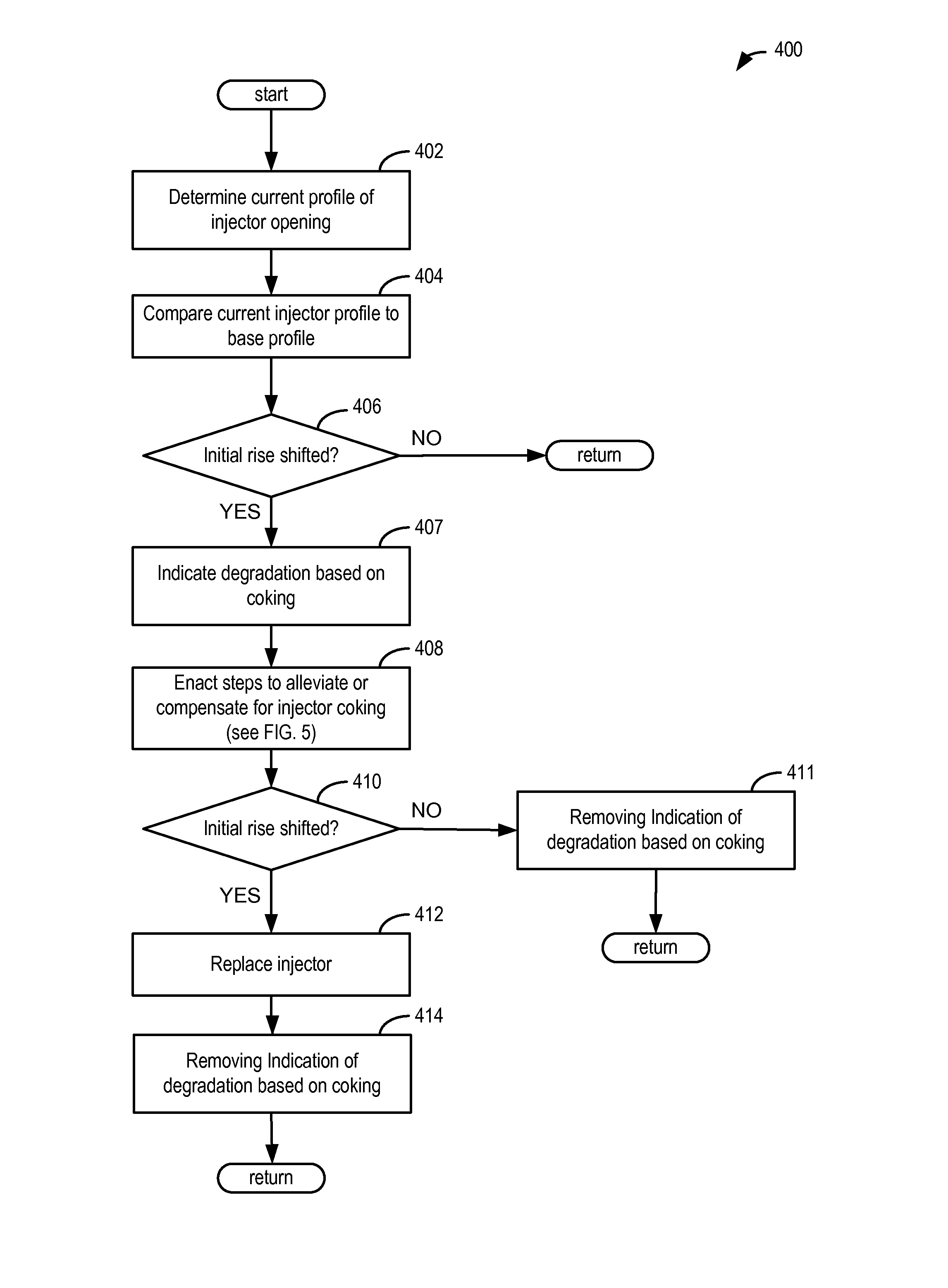

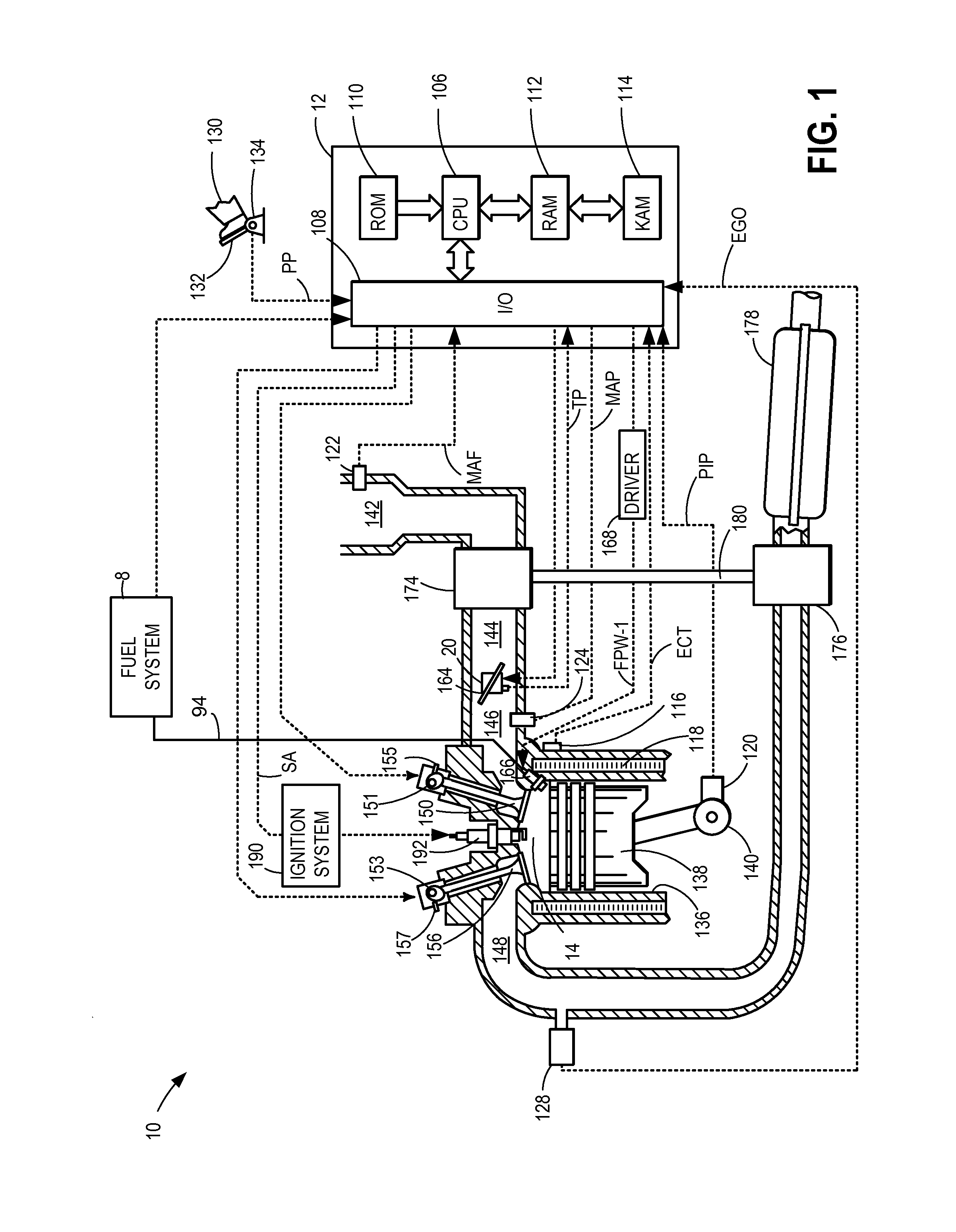

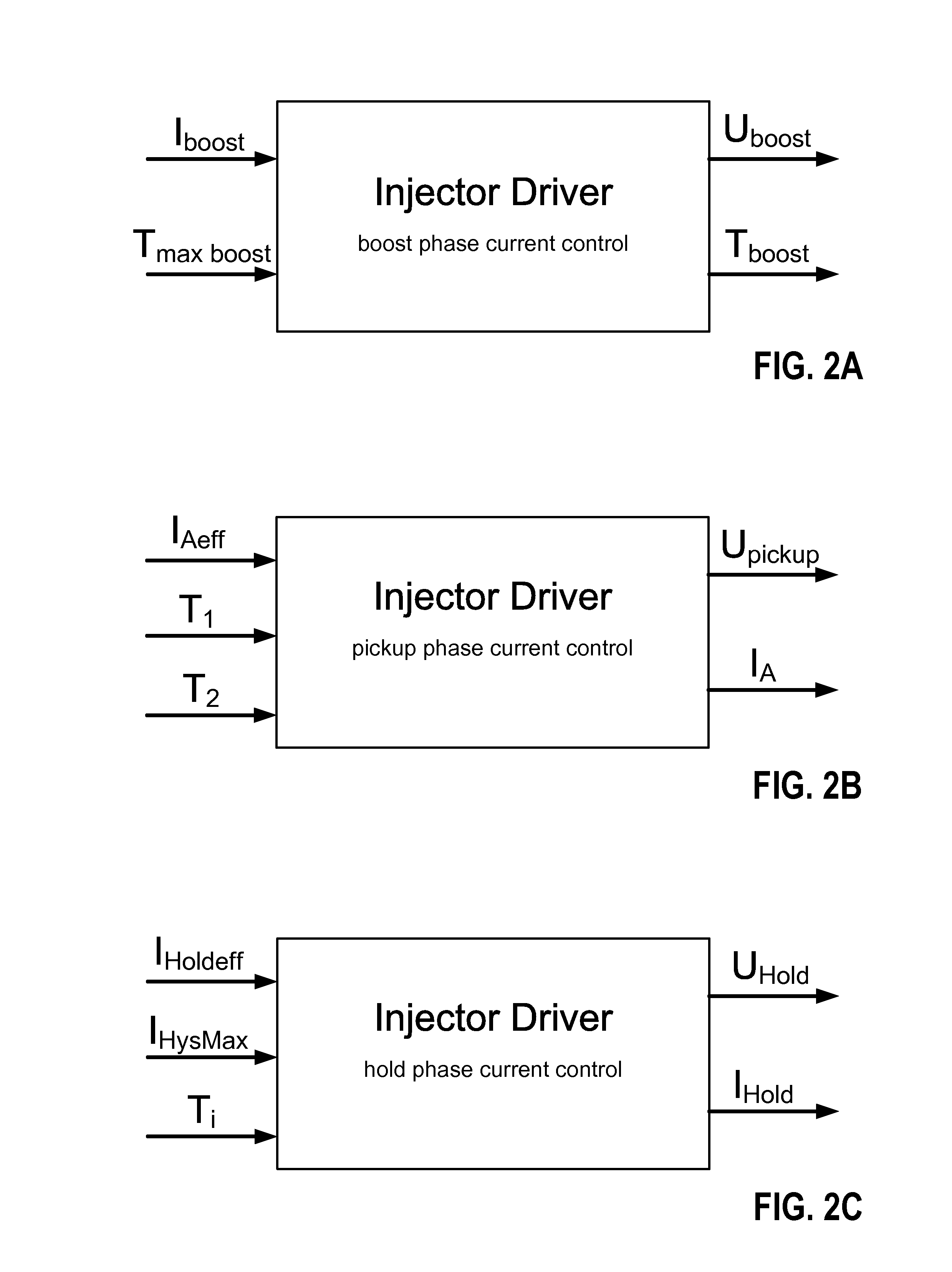

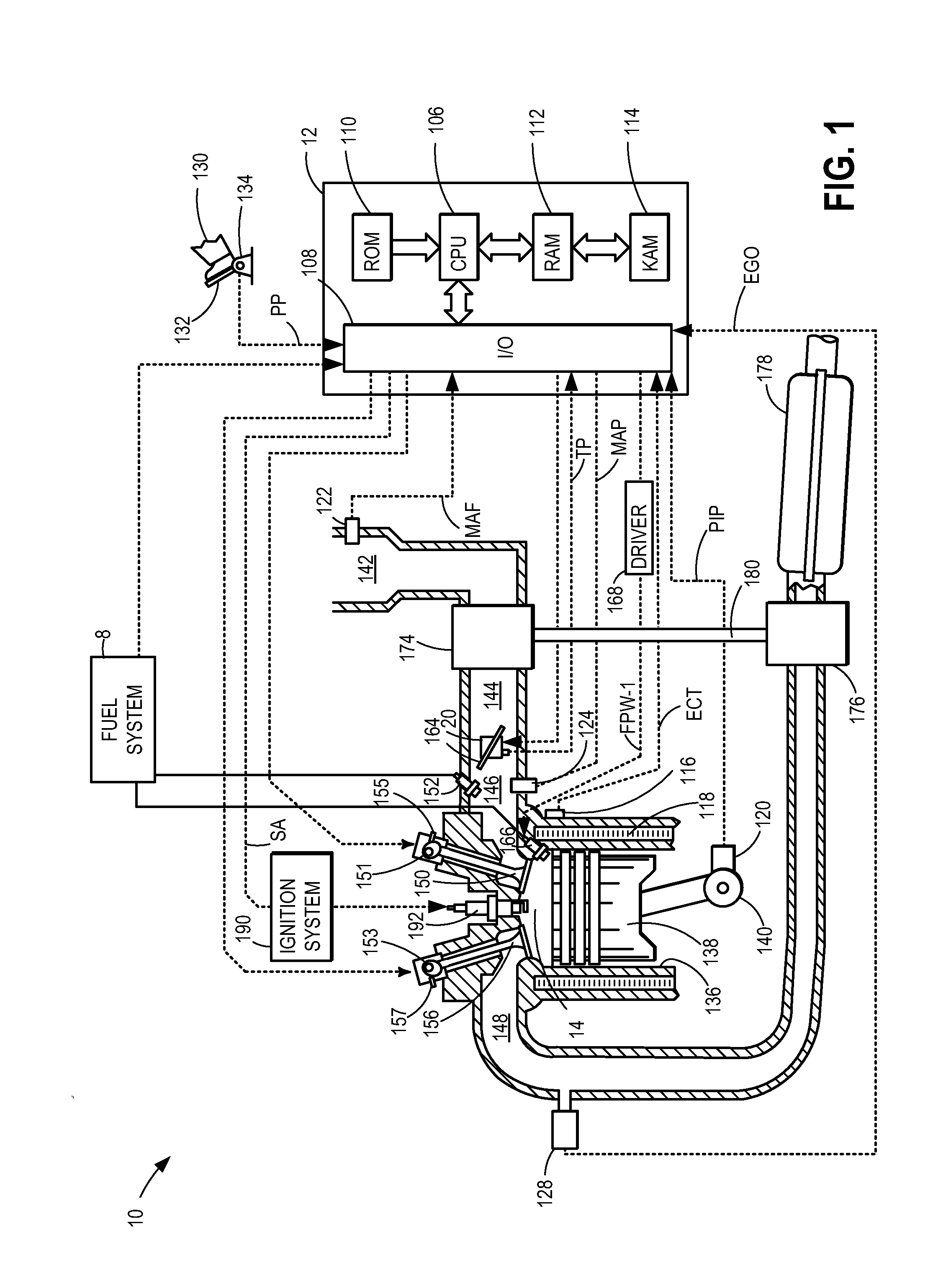

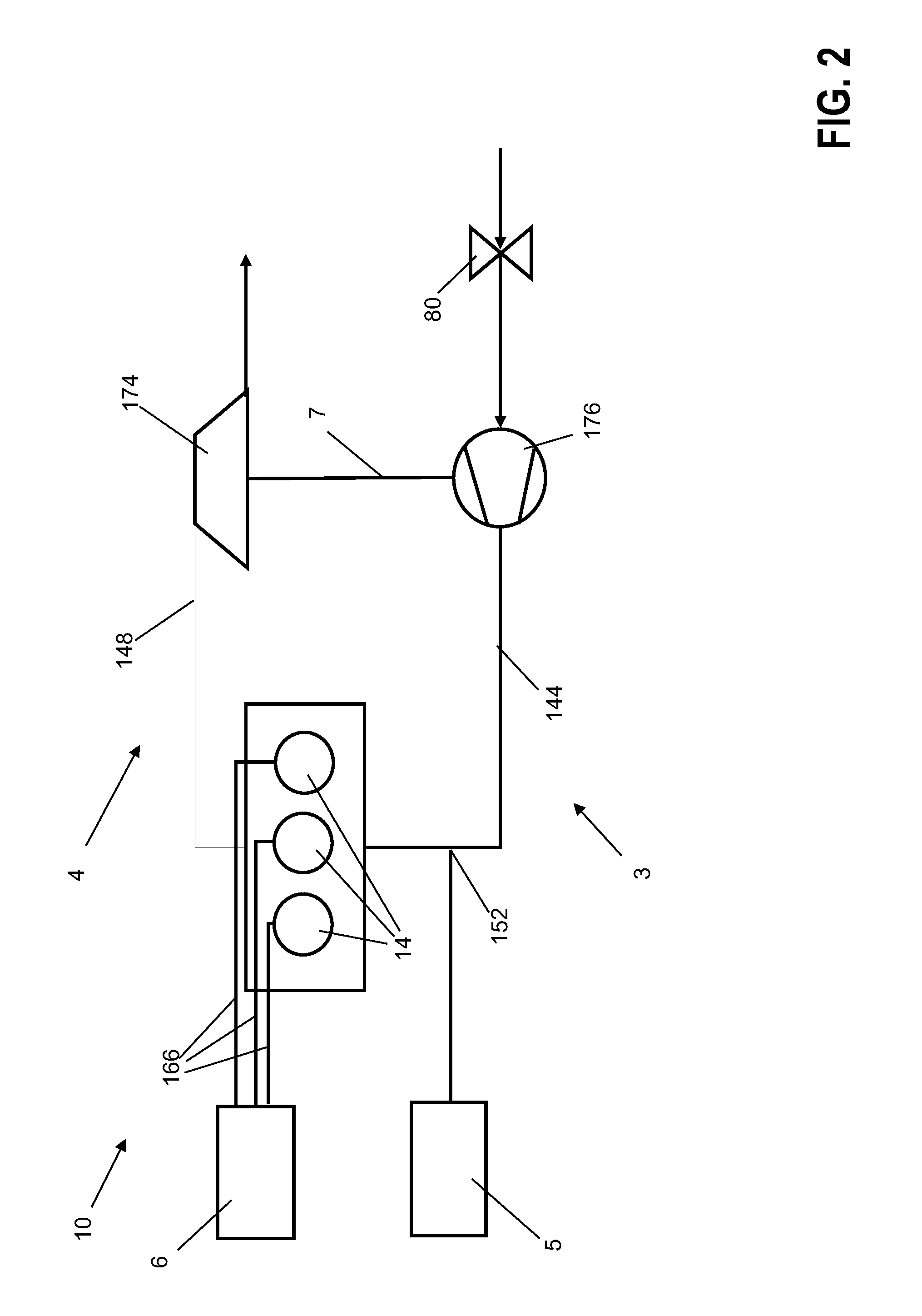

System and method for injector coking diagnostics and mitigation

InactiveUS20140318498A1Accurate identificationEasy to operateElectrical controlFuel injection apparatusBiological activationInjector

A system and method for compensating for, or alleviating accumulation of, coking residues on fuel injectors is disclosed. The method includes adjusting an engine operating parameter based on a shift in a fuel injector current profile during an initial current rise of injector activation.

Owner:FORD GLOBAL TECH LLC

Method of making organohalosilanes

Owner:DOW SILICONES CORP

Hydrogenation combined process

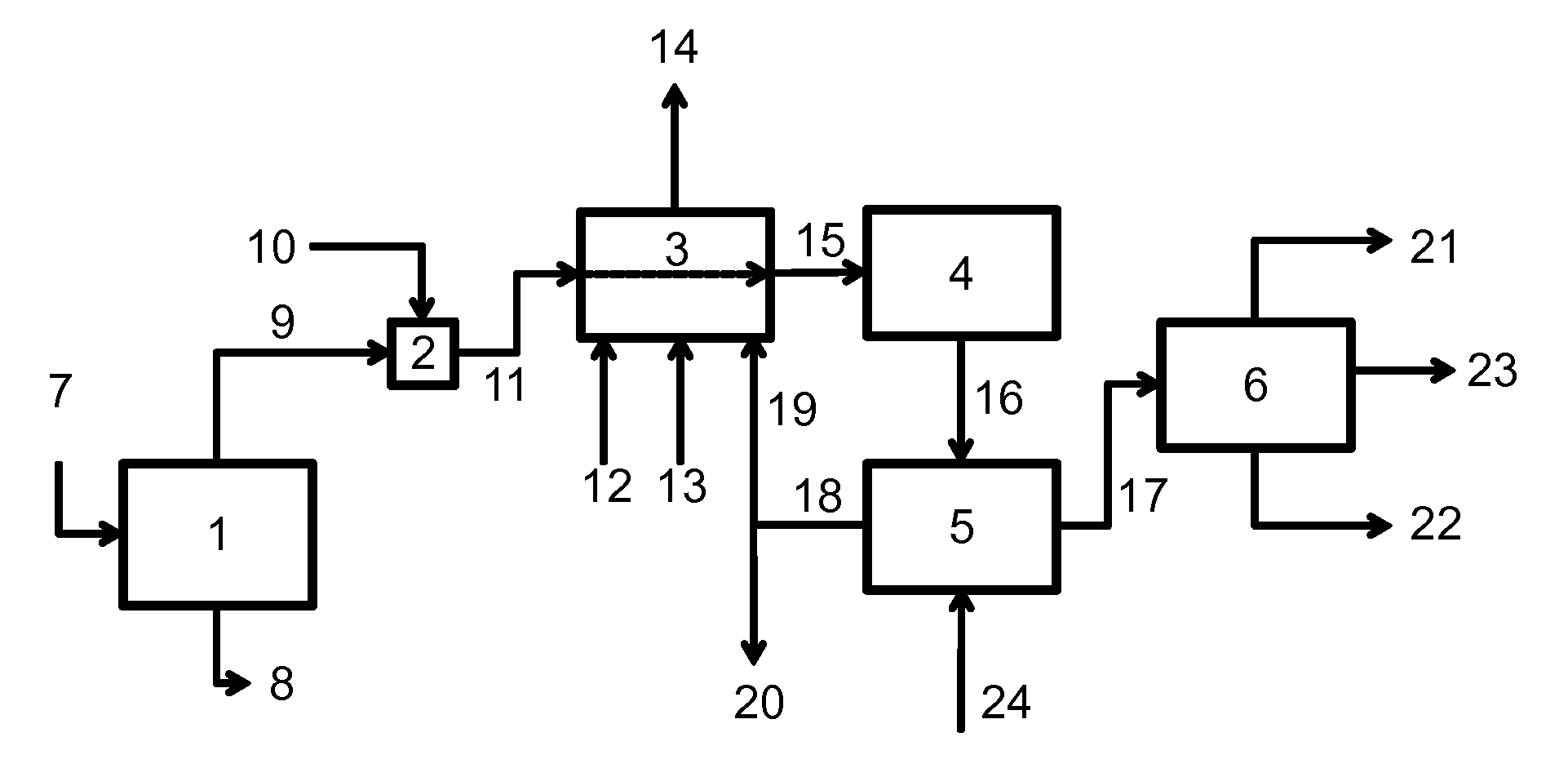

InactiveCN102533324AFlexible adjustment of raw materialsAlleviate cokingTreatment with hydrotreatment processesOperating costChemistry

The invention discloses a hydrogenation combined process, which includes: raw oil is divided into two parts, one part is heated and mixed with hydrogen and enters a fluidized bed reactor, the other part is mixed with a suspension bed catalyst, heated and then mixed with the hydrogen to enter a suspension bed reactor, reaction products of the fluidized bed reactor and reaction products of the suspension bed reactor enter a separating system to be separated, separated hydrogen serves as recycle hydrogen to be reused, separated light oil is discharged from a device, all separated heavy oil is discharged from the device, or a part of the heavy oil is circulated to the suspension bed reactor, and the other part of the heavy oil is discharged from the oil. The hydrogenation combined process can process high asphaltene, colloid, sulfur, high residual carbon, high metal heavy oil and high metal residual oil, and has the advantages of being simple in technological process, flexible to operate, strong in raw material adaptability, long in device operating cycle, low in investment and operating cost and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boiler coke restraining and removing agent

InactiveCN103254962AEasy to loosenPromote combustionSolid fuelsFuel additivesEngineeringPulverized fuel ash

The invention relates to a boiler coke restraining and removing agent capable of reducing and removing coal-fired boiler coke blocks. The boiler coke restraining and removing agent comprises the following components in percentage by weight: 5%-15% of swelling agent, 0.1%-5% of high-temperature retaining agent, and 1%-5% of oxidant. The swelling agent nitrate can penetrate into the coke, so that oxygen gas can be released inside the coke blocks to promote the carbon deposition layers inside the coke blocks to combust and promote the coke blocks to loosen; the high-temperature retaining agent can be retained in a furnace within a long time, so that on the one hand, the formation of bonded cokes is blocked, and on the other hand, the bonded cokes are gradually loosened and drop; the oxidant can be used for oxidizing ferrous oxide in the coal ash, improving the smelting point of combustion products, improving a crystallization process of solid particles, and effectively relieving coking and contaminating of the fused combustion products in a furnace chamber and a heated surface.

Owner:SNTO TECH GRP

Boiler coke preventing and eliminating agent

ActiveCN102786998AHigh melting pointPromote crystallizationSolid fuelsFuel additivesEngineeringTitanium

The invention discloses a boiler coke preventing and eliminating agent by taking kaolin as the main raw material. The boiler coke preventing and eliminating agent comprises the following compositions in mass percent: 1-99.9% of kaolin, 0.05-98% of alumina compound, 0.01-20% of titanium compound, 0.01-50% of magnesium compound, 0.01-30% of calcium compound and 0.001-5% of copper compound. The boiler coke preventing and eliminating agent is correspondingly added to fuel, the melting point of a combustion product is directly increased, and the coking and contamination of molten combustion product on a hearth and a heated surface are effectively relieved in the high-temperature combustion process of the fuel.

Owner:周丽琴

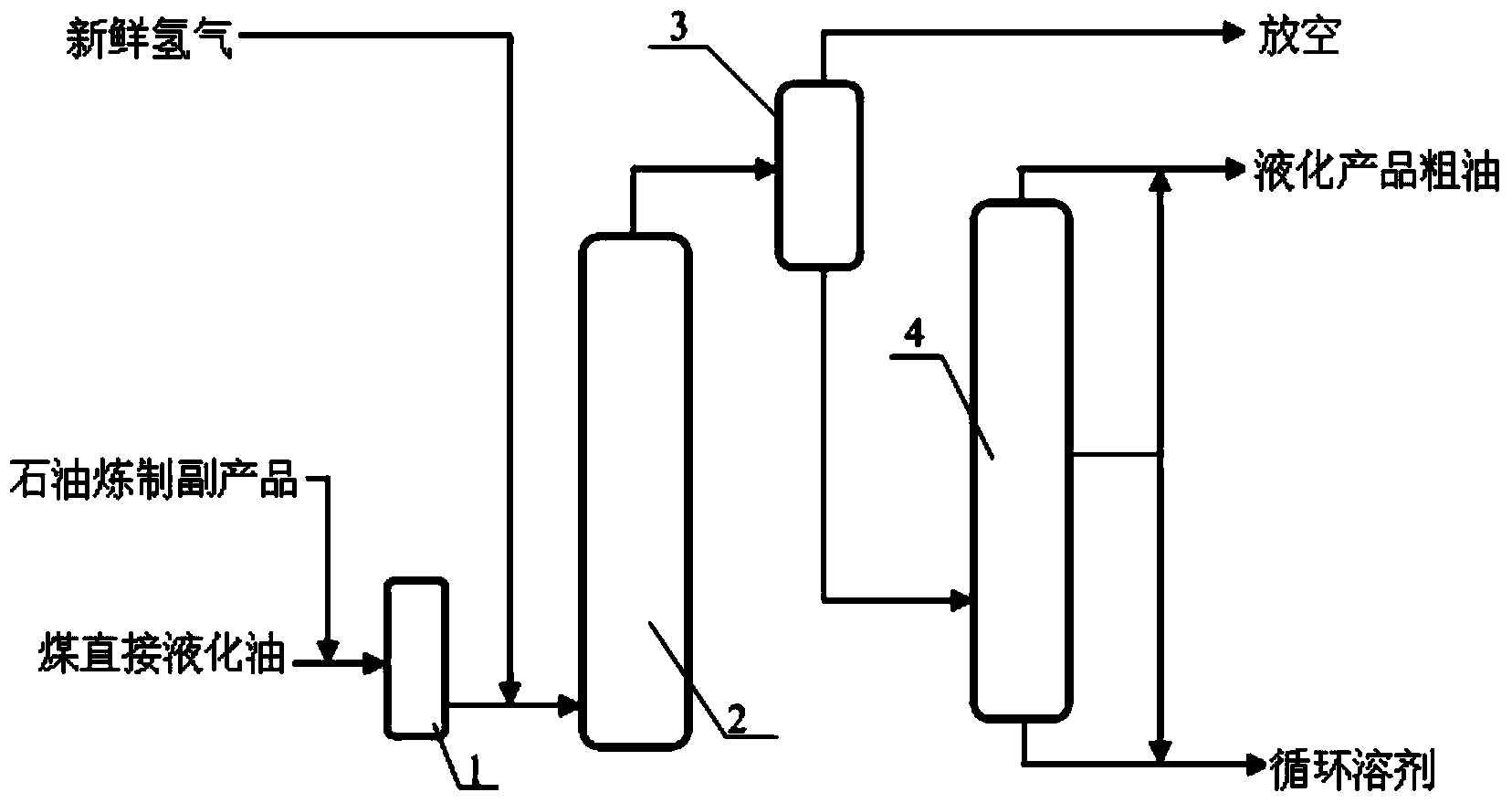

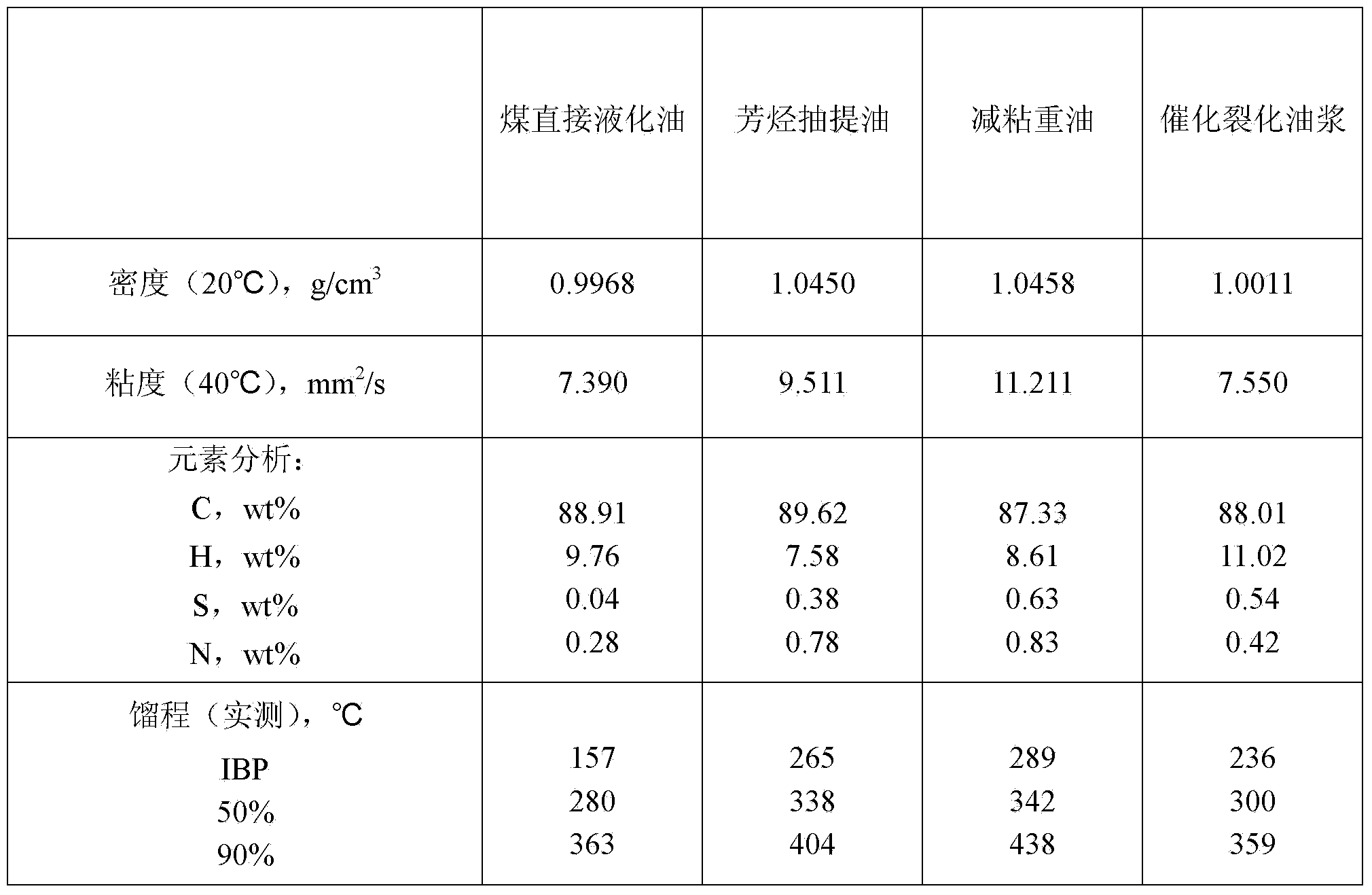

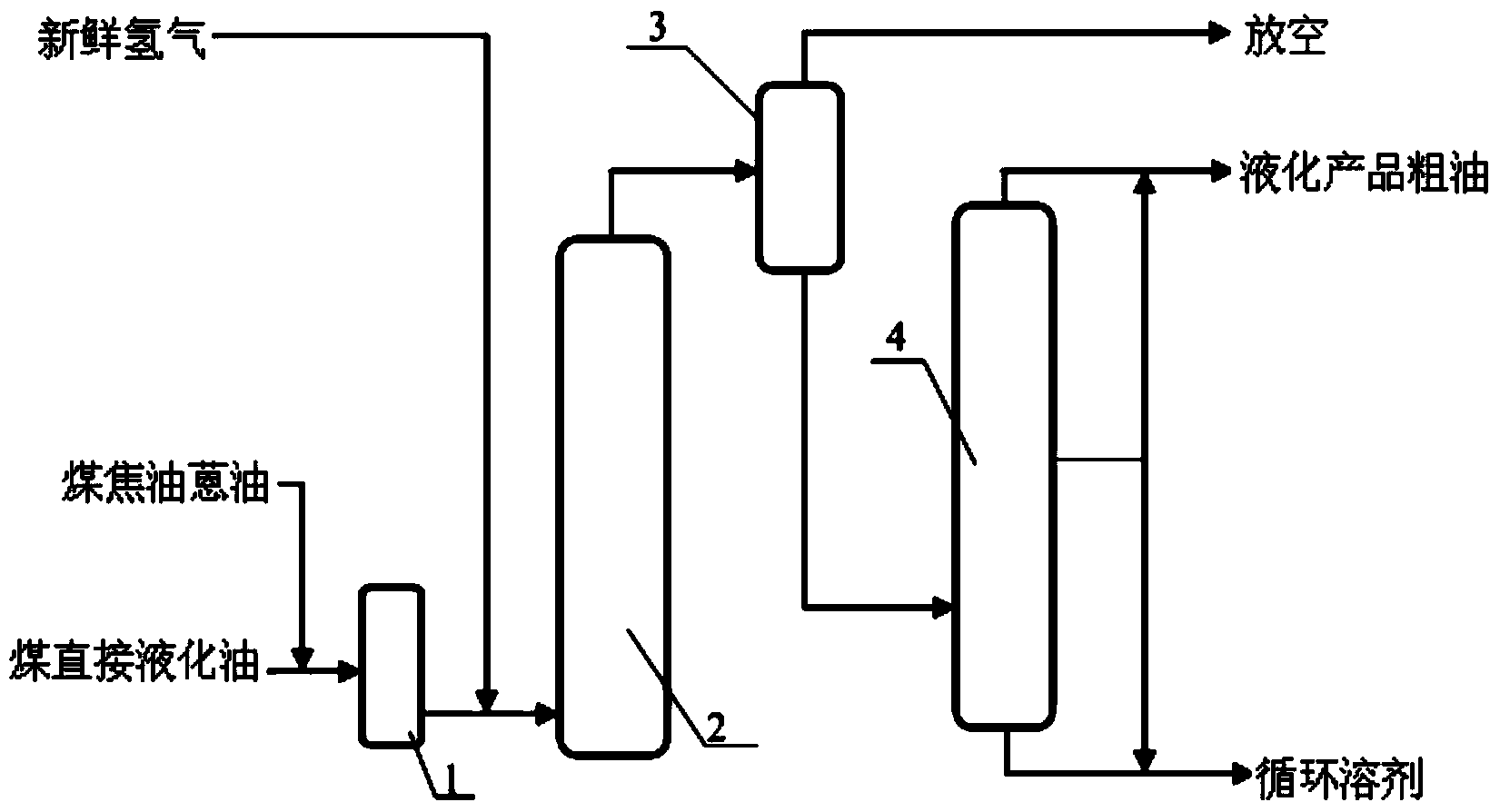

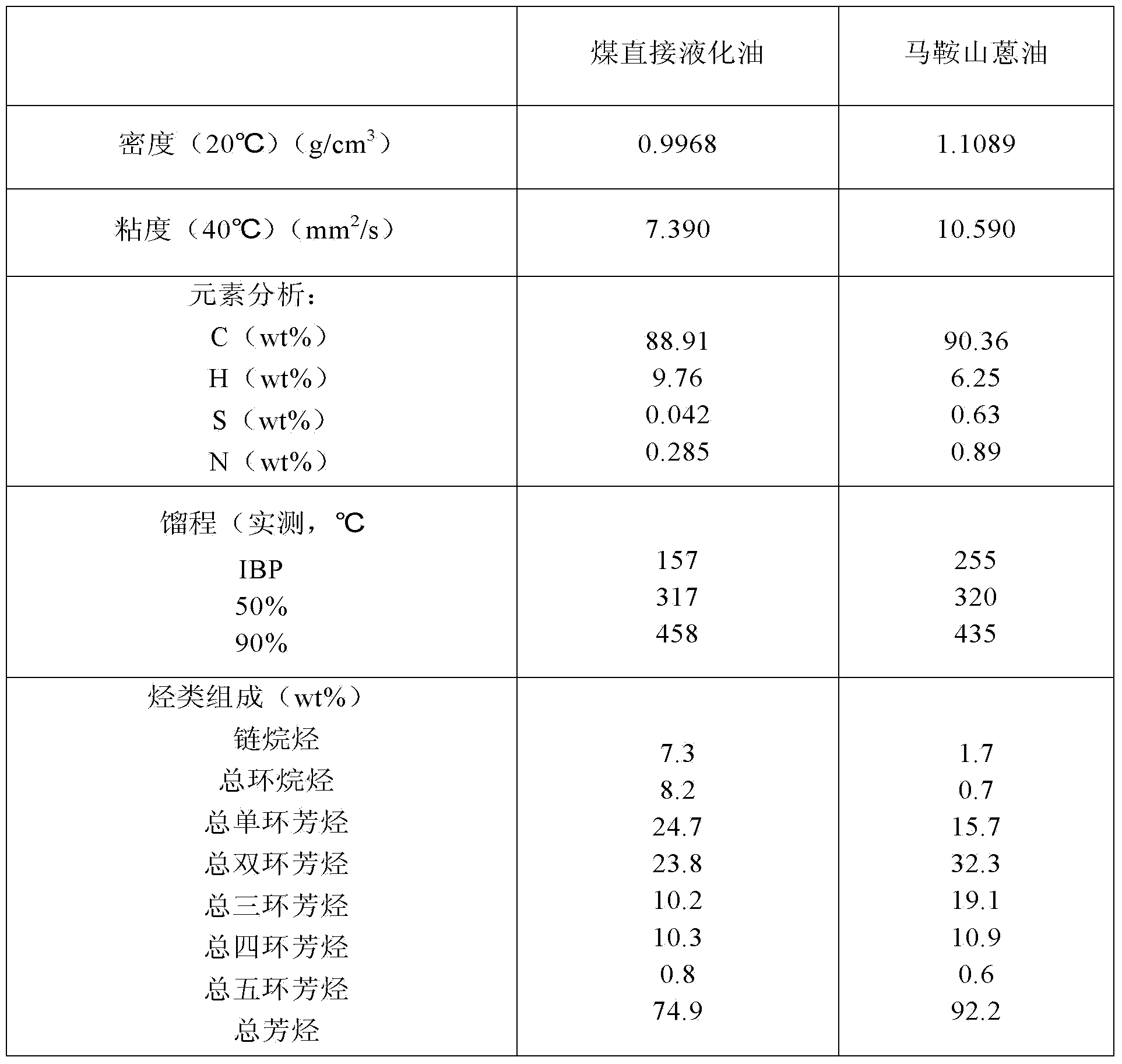

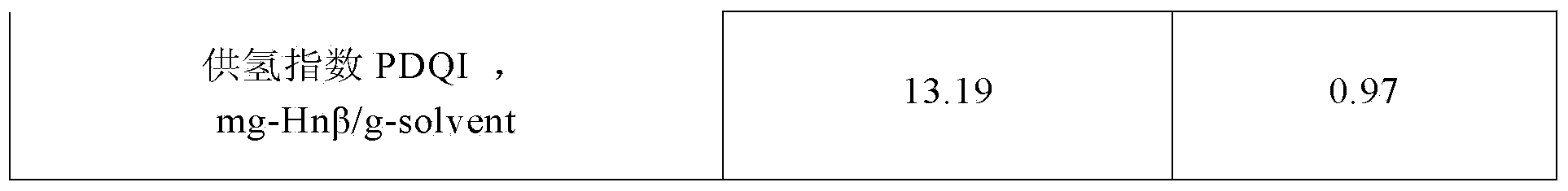

Direct coal liquefaction cycle solvent, preparation method thereof and application thereof

ActiveCN103468314ASolve the problem of low utilization valueImprove hydrogen supply capacityLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesSolventHydrogen supply

The invention provides a direct coal liquefaction cycle solvent, a preparation method of the direct coal liquefaction cycle solvent and application of the direct coal liquefaction cycle solvent. The preparation method comprises the steps of S1, carrying out hydrogenation on a mixture of petroleum refining secondary products and direct coal liquefaction oil, and obtaining a hydrogenation product, S2, fractionating the hydrogenation product, and obtaining light distillate oil, medium distillate oil and heavy distillate oil, and S3, mixing the heavy distillate oil with a part of the medium distillate oil, and obtaining the direct coal liquefaction cycle solvent. In the preparation method of the direct coal liquefaction cycle solvent, on one hand, a large amount of arene is contained in the petroleum refining secondary products, the hydrogenation product is rich in components such as tetrahydronaphthalene, therefore, the hydrogen supplying capacity of the direct coal liquefaction cycle solvent can be obviously improved, and the yield of the direct coal liquefaction oil is improved; on the other hand, a part of high-added-value diesel distillate with the boiling range lower than 350 DEG C in the direct coal liquefaction cycle solvent is substituted with the petroleum refining secondary products, the diesel yield is improved, the economical efficiency of the coil liquefaction technology is remarkably improved, and the problem that an existing cycle solvent gets light can be solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Steam cracking processes

ActiveUS20140121432A1Promote rapid vaporization of the liquid feed stockReduces coke formationThermal non-catalytic crackingPressurized chemical processCracking reactionConvection

The present disclosure provides a steam cracking process, comprising heating a liquid feed stock in a convection section of a cracking furnace and subsequently conveying the material to a radiant section of the cracking furnace for cracking reaction therein, wherein a monoolefin-containing stream is conveyed to the cracking furnace for cracking reaction through at least one of modes A to C.

Owner:CHINA PETROCHEMICAL CORP +1

Process for the conversion of oxygenates to olefins

InactiveUS20140005455A1Improve the immunityAlleviate cokingMolecular sieve catalystsMolecular sieve catalystOxygenateEther

The present invention relates to a process for converting oxygenates to olefins, comprising(1) providing a gas stream comprising one or more ethers;(2) contacting the gas stream provided in (1) with a catalyst,the catalyst comprisinga support substrate anda layer applied to the substrate,the layer comprising one or more zeolites of the MFI, MEL and / or MWW structure type.

Owner:BASF AG

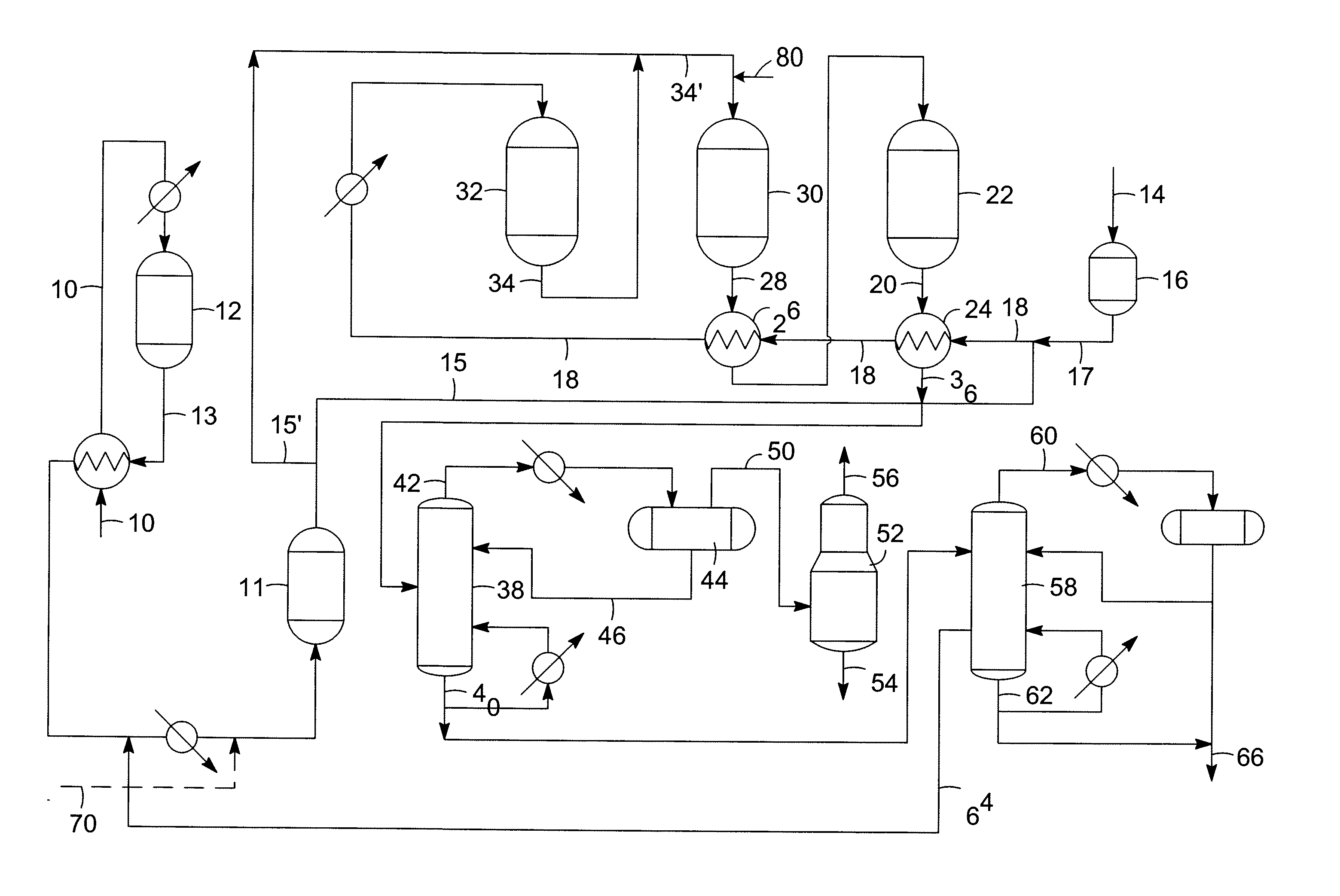

Process and apparatus employing microchannel process technology

InactiveUS8747656B2High selectivityAlleviate cokingCatalytic crackingOrganic compound preparationChemistryProcess engineering

This invention relates to a process for conducting a hydrocracking or a hydrotreating process in a microchannel reactor. This invention also relates to a process and apparatus for flowing a vapor and liquid into a plurality of microchannels in a microchannel processing unit.

Owner:VELOCYS CORPORATION

Direct coal liquefaction circulation solvent and preparation method and application of direct coal liquefaction circulation solvent

ActiveCN103468315AHigh economic valueHigh yieldLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesAnthraceneFractionation

The invention provides a direct coal liquefaction circulation solvent and a preparation method and application of the direct coal liquefaction circulation solvent. The preparation method comprises the steps that S1, hydrogenation is carried out on a mixture of coal tar anthracene oil and direct coal liquefaction oil to obtain a hydrogenation product, S2, fractionation is carried out on the hydrogenation product to obtain light-weight distillate oil, middle-weight distillate oil and heavy-weight distillate oil, and S3, the heavy-weight distillate oil is mixed with a part of middle-weight distillate oil to obtain the direct coal liquefaction circulation solvent. According to the preparation method, on one hand, a large amount of aromatic hydrocarbon is contained in the coal tar anthracene oil, the hydrogenation product is rich in components such as tetrahydronaphthalene, therefore, the hydrogen supply capacity of the circulation solvent can be obviously improved, and the yield of direct coal liquefaction oil is improved; on the other hand, a part of high value-added gas and diesel oil distillate with the boiling range lower than 350DEG C in the direct coal liquefaction circulation solvent is substituted with the coal tar anthracene oil, the diesel oil yield is improved, in addition, the light-weight problem of an existing circulation solvent can be relieved, and deposition and coking of materials in a reactor in the direct coal liquefaction technological process are relieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

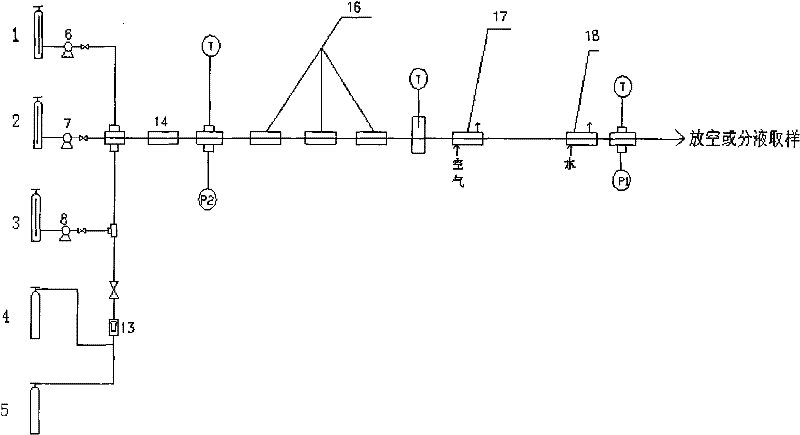

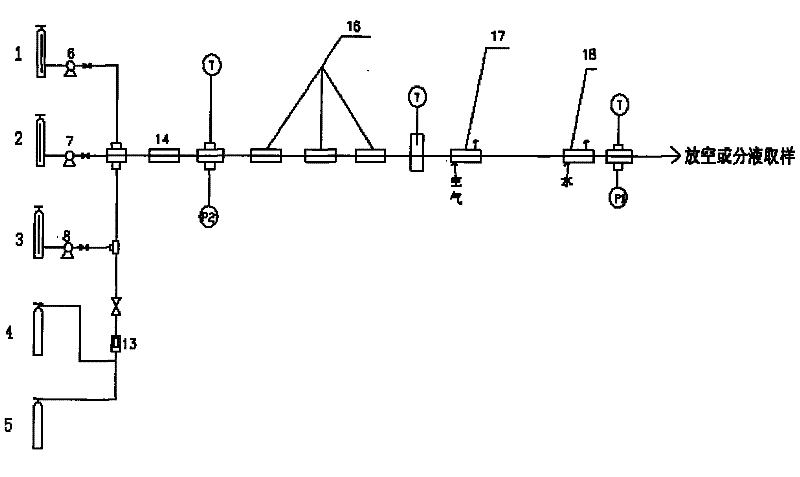

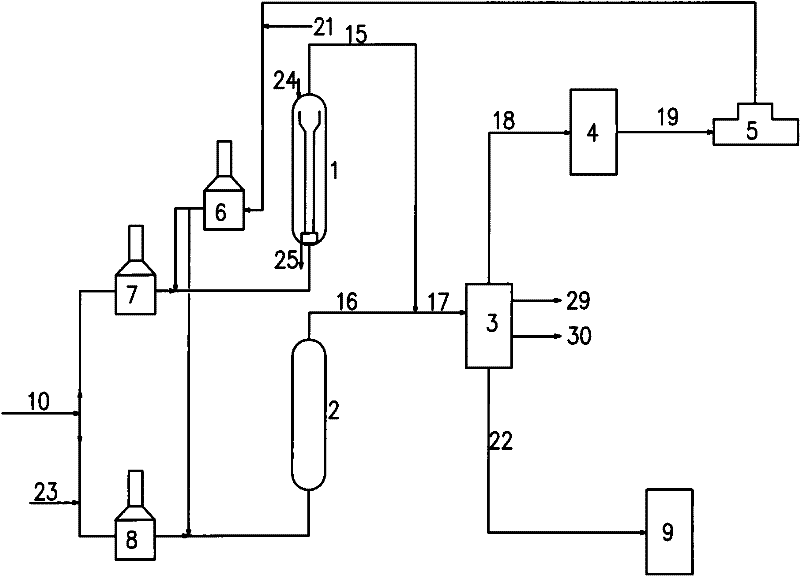

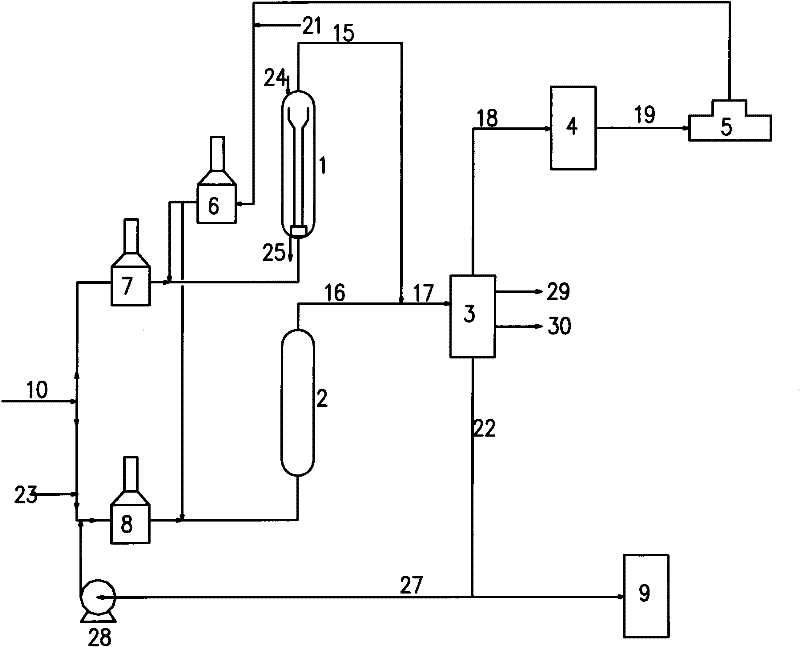

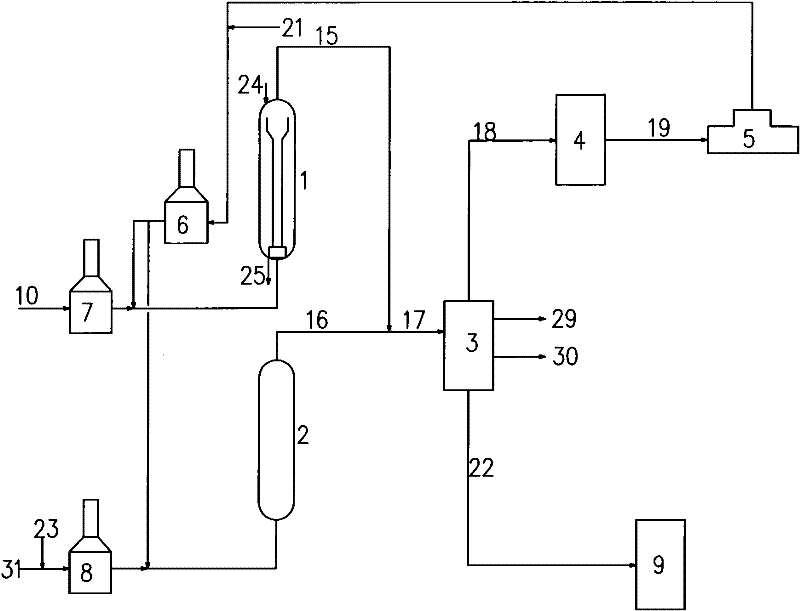

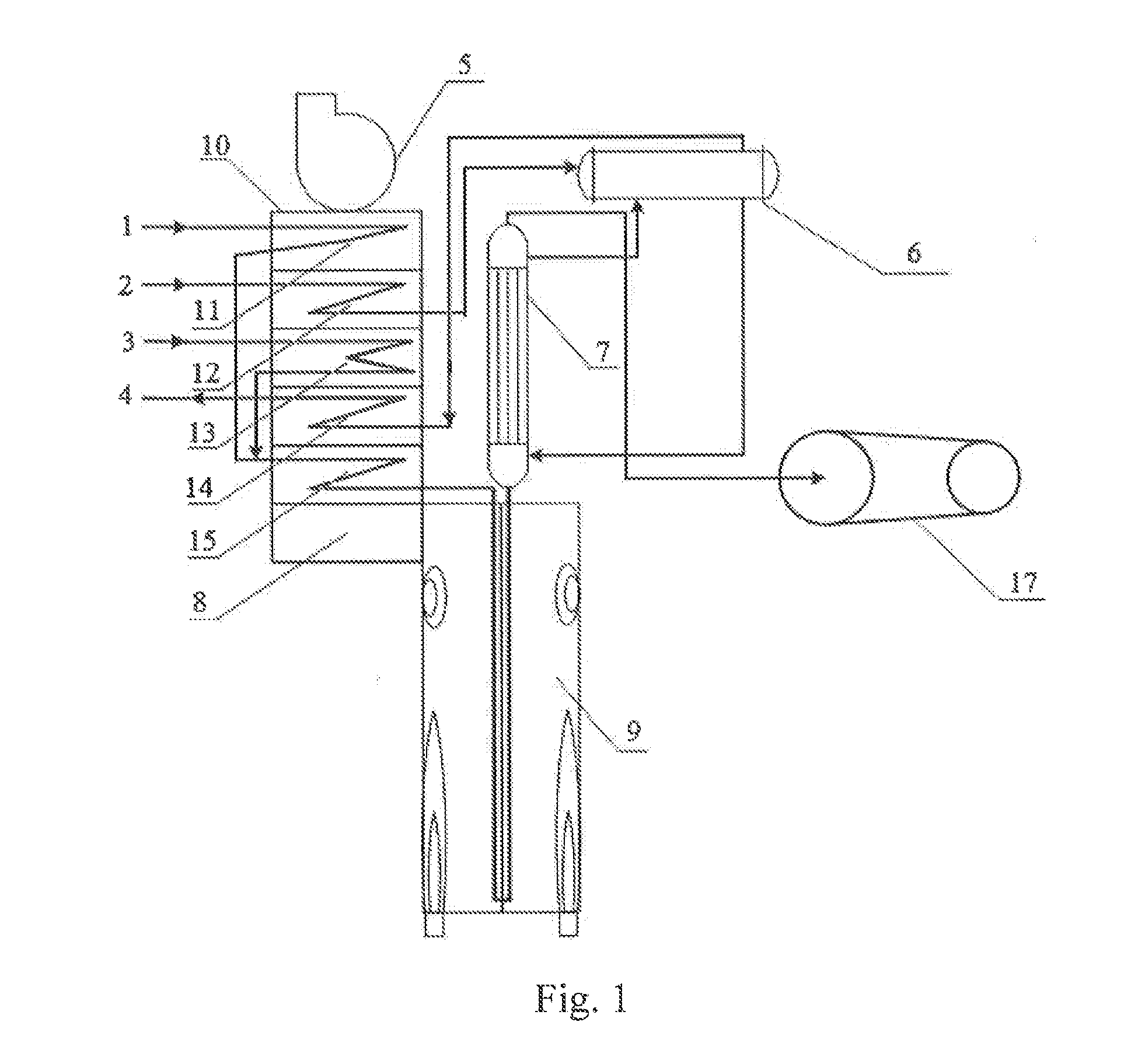

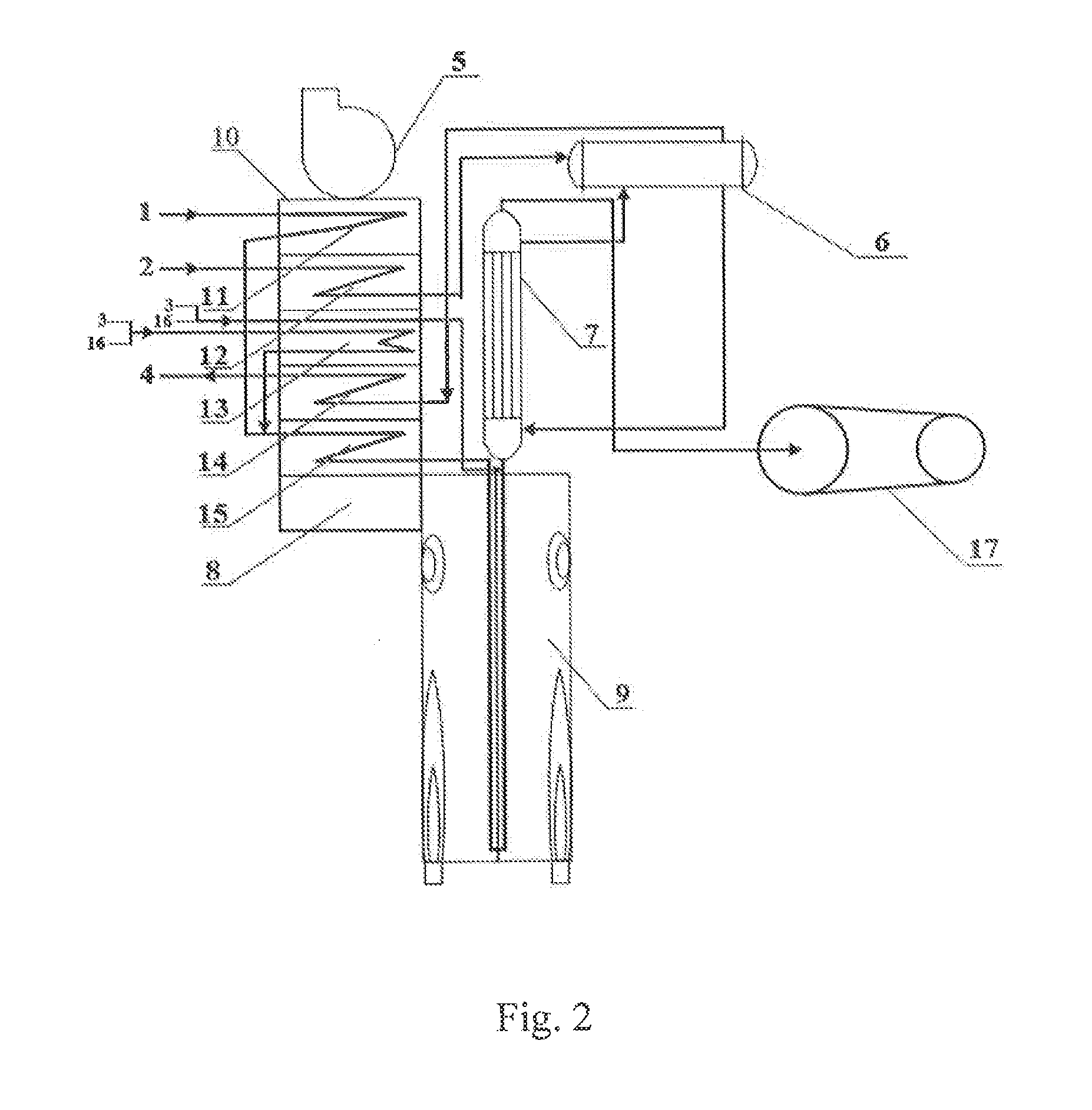

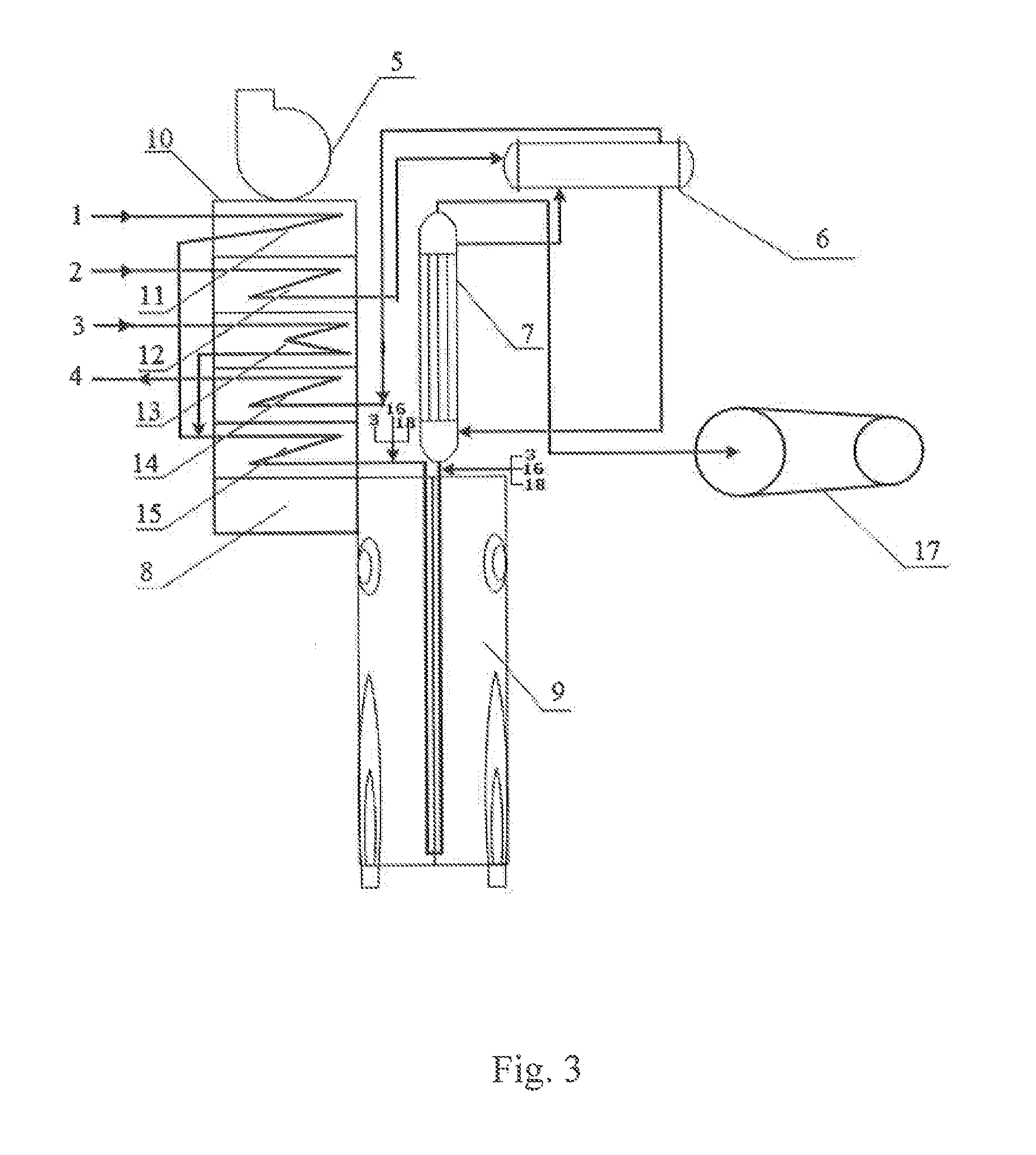

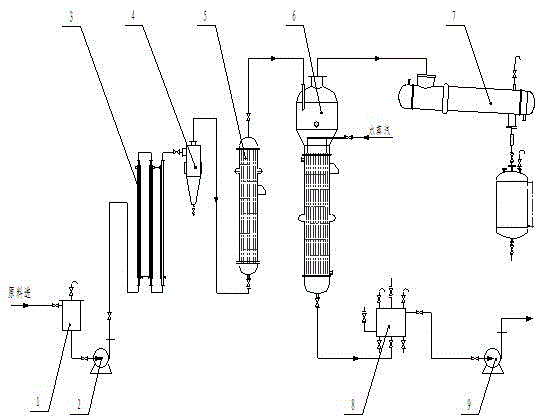

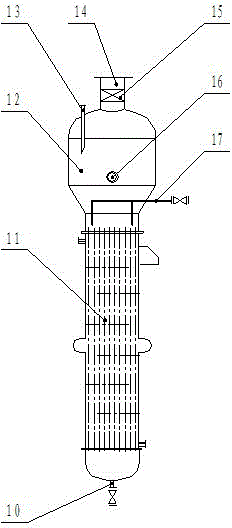

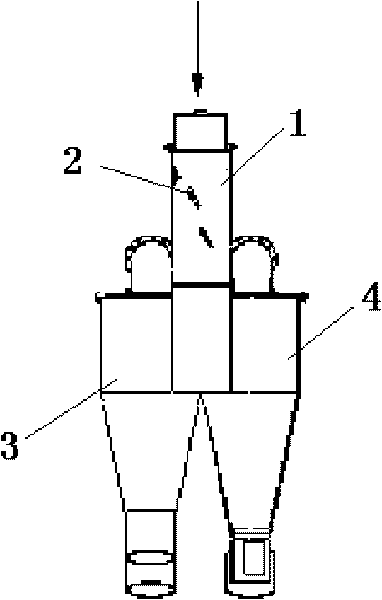

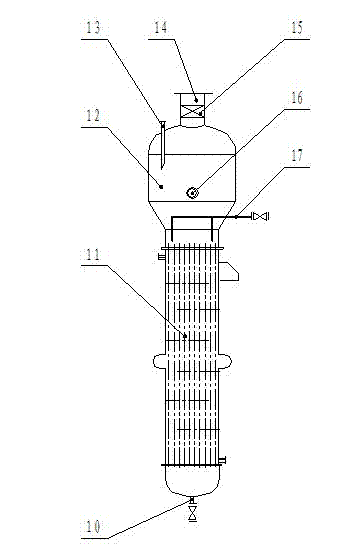

Method and apparatus for continuously and rapidly separating pyrolysis oil

InactiveCN102827633BAlleviate cokingPrevent static electricityTreatment with plural serial refining stagesLiquid hydrocarbon mixture productionWaste rubberProcess engineering

The invention discloses a method and an apparatus for continuously and rapidly separating a pyrolysis oil, which is characterized in that a waste rubber, a waste plastic or the pyrolysis oil generated by thermal cracking of biomass is filtered and enters into a first preheater, the preheated pyrolysis oil enters into a cyclone hydraulic separator in a tangential direction, and enables spiral movement downwardly, the impurities spirally flow downwards to an outlet of a cone base due to inertial centrifugal force, the pyrolysis oil is discharged from a center tube at the top and enters into a second preheater for heating, then enters into an evaporator, the certain temperature is kept in the evaporator, steam is continuously introduced in the evaporator, the steam carries the distilled components enter into a condenser from the top of the evaporator together for condensate recovery, and the heavy components are sent from the bottom of the evaporator and cooled to obtain the finished product. The apparatus comprises a filter, a charge pump, the first preheater, the cyclone hydraulic separator, the second preheater, the evaporator in series, the top of the evaporator is connected to the condenser, the bottom of the evaporator is connected to a cooler. The method and apparatus for continuously and rapidly separating the pyrolysis oil have the advantages of high automation degree, and convenient and easy operation.

Owner:JIANGSU QIANGLIN BIO ENERGY +1

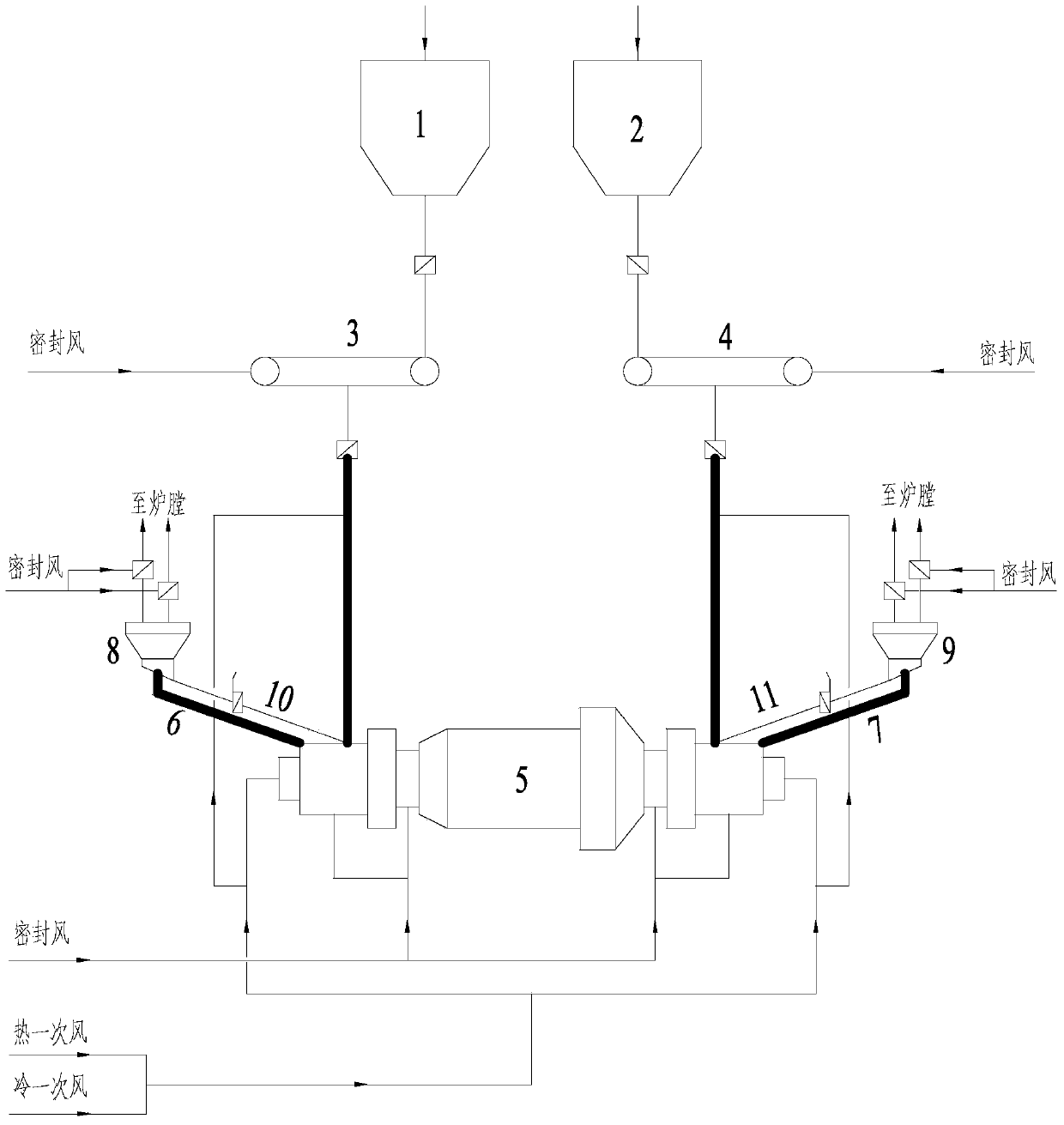

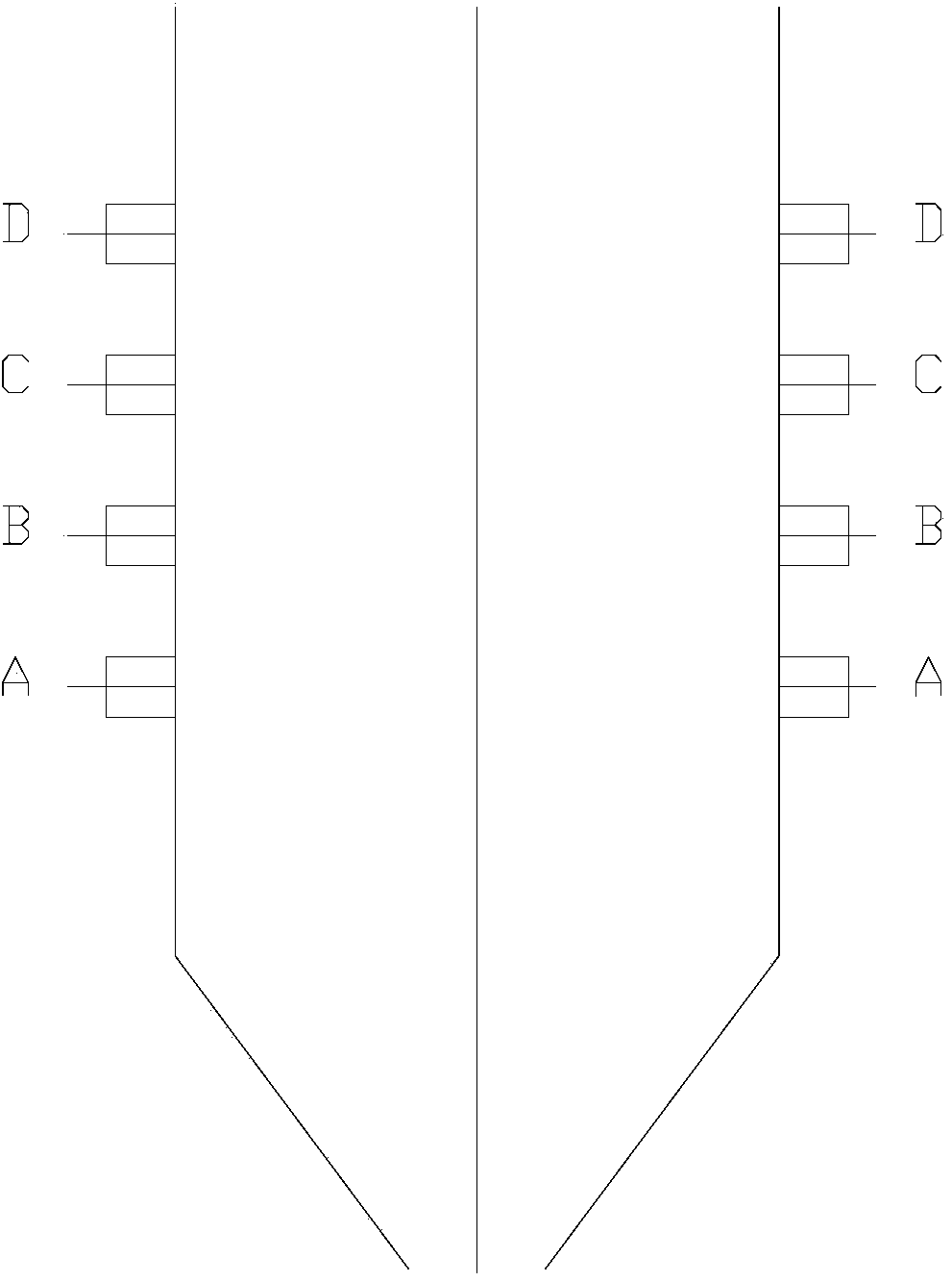

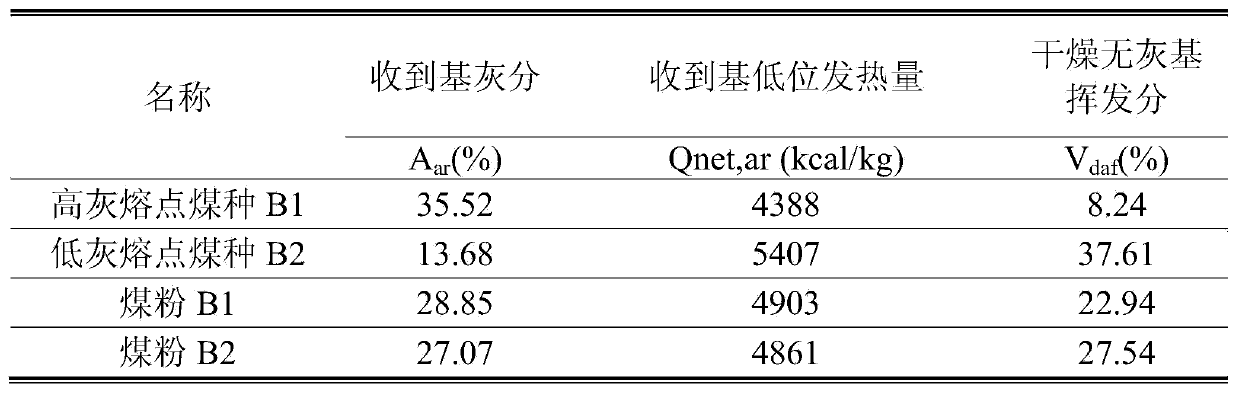

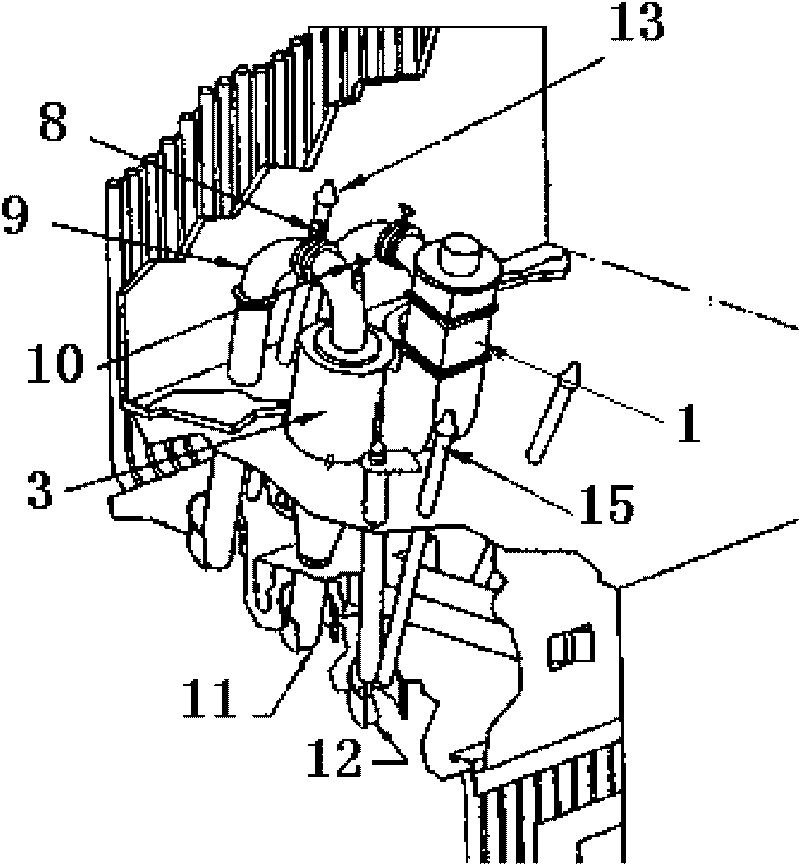

System and method of blending combustion of coal type with low ash melting point in coal-fired utility boiler

ActiveCN104180384AEnsure safetyLower furnace temperatureLump/pulverulent fuel preparationPulverizerProcess engineering

The invention discloses a system and method of blending combustion of a coal type with a low ash melting point in a coal-fired utility boiler and belongs to the technical field of coal-fired utility boiler operation. The coal-fired utility boiler is equipped with a positive-pressure, direct-firing, double-in and double-out steel ball coal pulverizer; the method of blending combustion of coal type with the low ash melting point in the coal-fired utility boiler comprises the following steps: the coal type with the low ash melting point and a coal type with a high ash melting point are sent into the steel ball coal pulverizer from one end of the positive-pressure, direct-firing, double-in and double-out steel ball coal pulverizer respectively; after thorough mixing and grinding, powder is uniformly output from two ends of the steel ball coal pulverizer; after the blending, compared with the melting point of the coal type with a low ash melting point, the melting point of the blended ash is increased to a relatively large extent; under various boiler loading, through adjusting the belt rotational speeds of coal feeders that correspond to the coal type with the low ash melting point and the coal type with the high ash melting point, the mixing proportion control is realized on the coal type with the low ash melting point. The system and method of blending combustion of coal type with the low ash melting point in the coal-fired utility boiler can improve the combustion and utilization proportion of the coal type with the low ash melting point to the utmost extent, on the basis of effectively relieving the boiler from coking and ensuring the safe operation of the boiler; the cost of fuel is reduced; the economical efficiency in the operation of the coal-fired utility boiler machine set is improved.

Owner:HUANENG POWER INTERNATIONAL +3

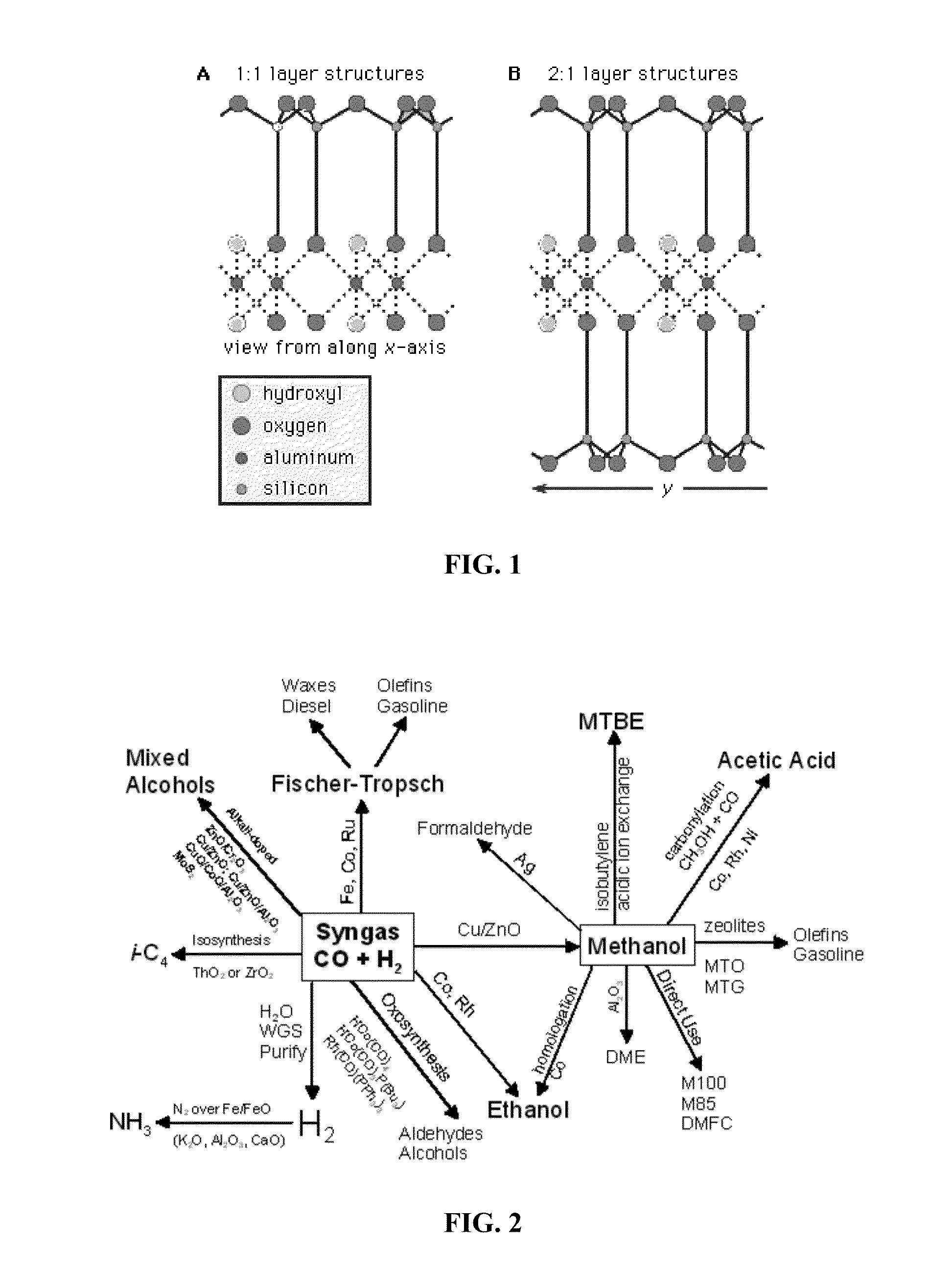

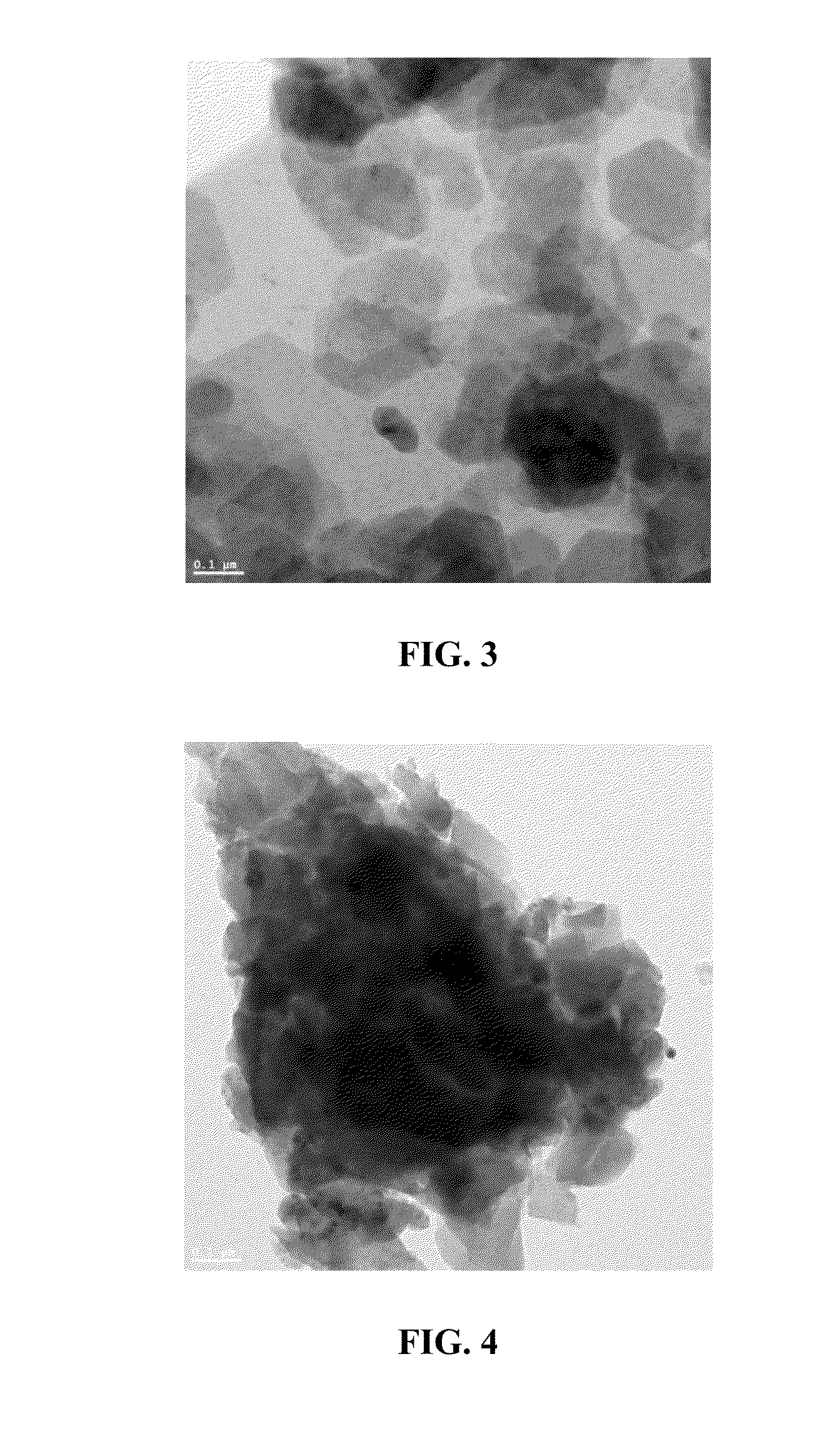

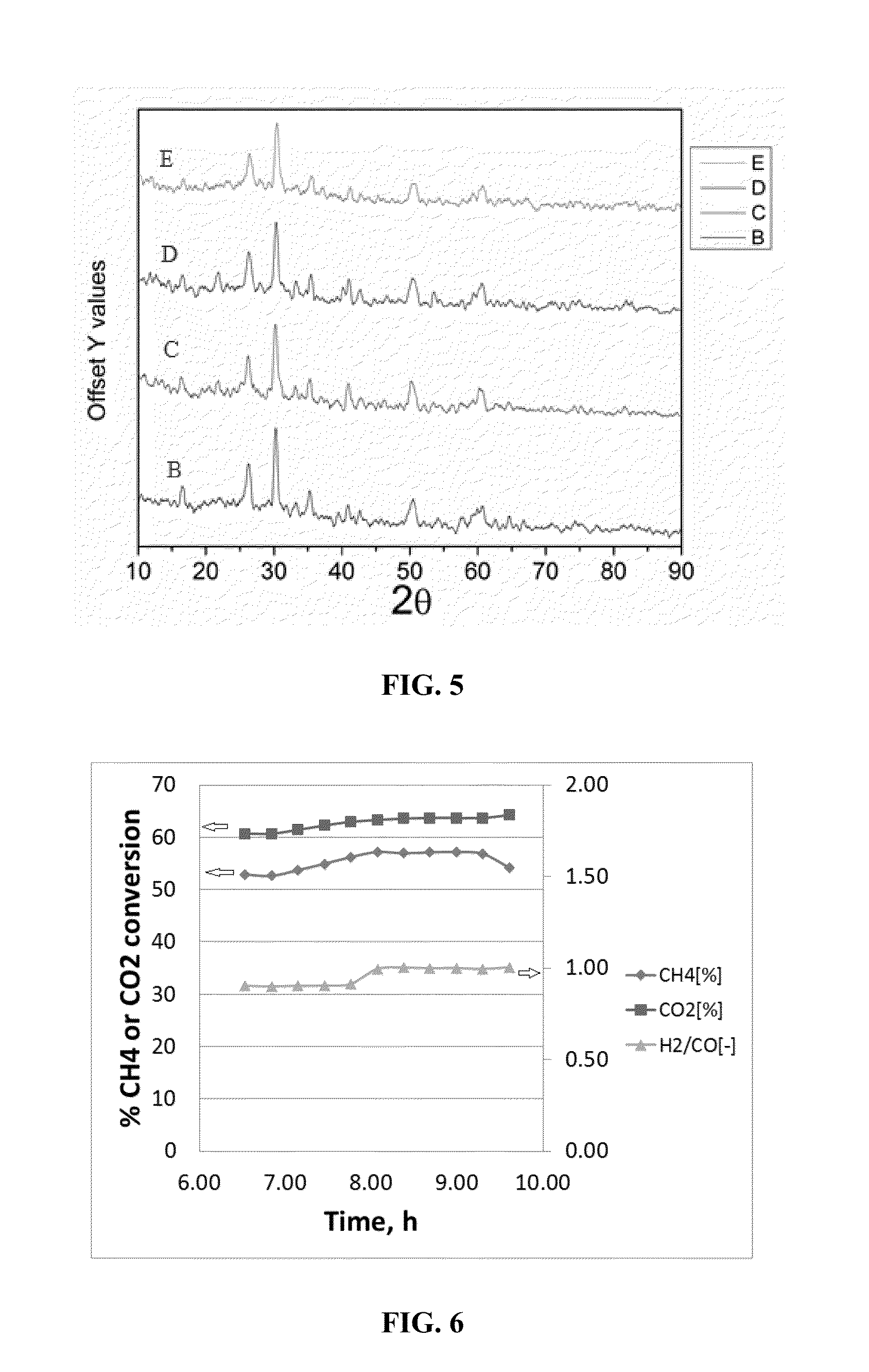

Clay mineral supported catalysts

Disclosed is a hydrocarbon gas reforming supported catalyst, and methods for its use, that includes a catalytic material capable of catalyzing the production of a gaseous mixture comprising hydrogen and carbon monoxide from a hydrocarbon gas, and a clay support material comprising a clay mineral, wherein the catalytic material is attached to the clay support material.

Owner:SABIC GLOBAL TECH BV

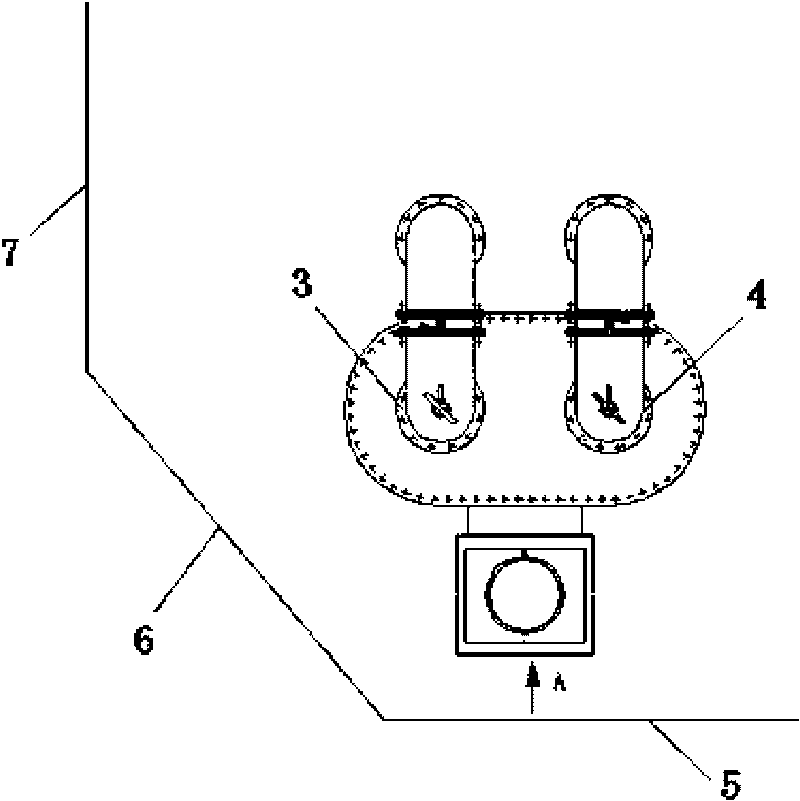

Condense-dilute type double-cyclone cylinder pulverized coal burner and pulverized coal boiler using same

ActiveCN101737773AIncrease oxygen concentrationAlleviate cokingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCyclonic separation

The invention discloses a condense-dilute type double-cyclone cylinder pulverized coal burner which comprises a pulverized coal entrance channel, a pulverized coal concentrator and two cyclone separation type burners communicated with the pulverized coal entrance channel. The burner is characterized in that the pulverized coal concentrator is arranged in the pulverized coal entrance channel; and a blade in the pulverized coal concentrator inclines towards the side away from a boiler side wall and a wing wall adjacent to the pulverized coal concentrator along the flowing direction of pulverized coal so as to divide a pulverized coal airflow into a condense part and a dilute part. The invention changes a traditional double-cyclone cylinder burner into a condense-dilute type and has more obvious effect on reducing the discharge of NOx. Aiming at the reformation of an original burner, the condense-dilute type double-cyclone cylinder pulverized coal burner is the equipment having smallest changes, lowest cost and easiest implementation, a more effective measure for solving side (wing) wall coking under a current coal condition and can create a good condition for the safe and stable operation of boilers.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Method and apparatus for continuously and rapidly separating pyrolysis oil

InactiveCN102827633AAlleviate cokingPrevent static electricityTreatment with plural serial refining stagesLiquid hydrocarbon mixture productionWaste rubberProcess engineering

The invention discloses a method and an apparatus for continuously and rapidly separating a pyrolysis oil, which is characterized in that a waste rubber, a waste plastic or the pyrolysis oil generated by thermal cracking of biomass is filtered and enters into a first preheater, the preheated pyrolysis oil enters into a cyclone hydraulic separator in a tangential direction, and enables spiral movement downwardly, the impurities spirally flow downwards to an outlet of a cone base due to inertial centrifugal force, the pyrolysis oil is discharged from a center tube at the top and enters into a second preheater for heating, then enters into an evaporator, the certain temperature is kept in the evaporator, steam is continuously introduced in the evaporator, the steam carries the distilled components enter into a condenser from the top of the evaporator together for condensate recovery, and the heavy components are sent from the bottom of the evaporator and cooled to obtain the finished product. The apparatus comprises a filter, a charge pump, the first preheater, the cyclone hydraulic separator, the second preheater, the evaporator in series, the top of the evaporator is connected to the condenser, the bottom of the evaporator is connected to a cooler. The method and apparatus for continuously and rapidly separating the pyrolysis oil have the advantages of high automation degree, and convenient and easy operation.

Owner:JIANGSU QIANGLIN BIO ENERGY +1

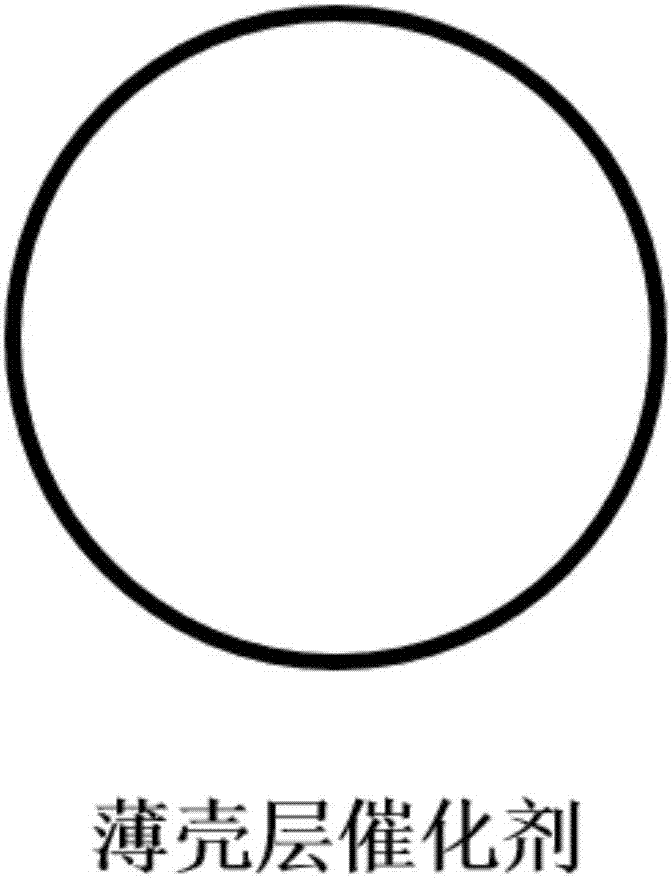

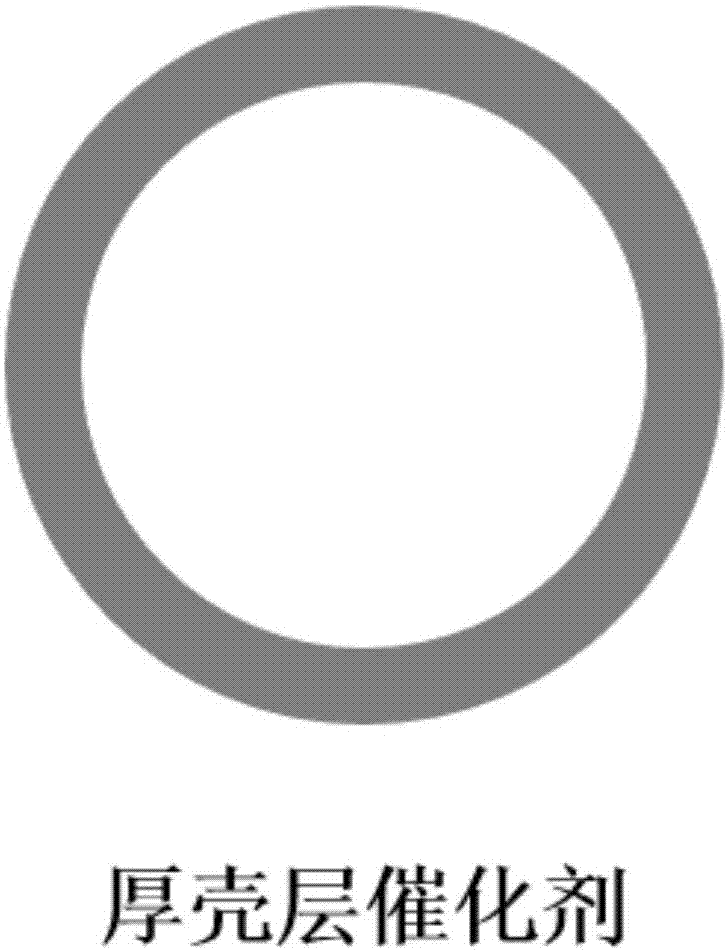

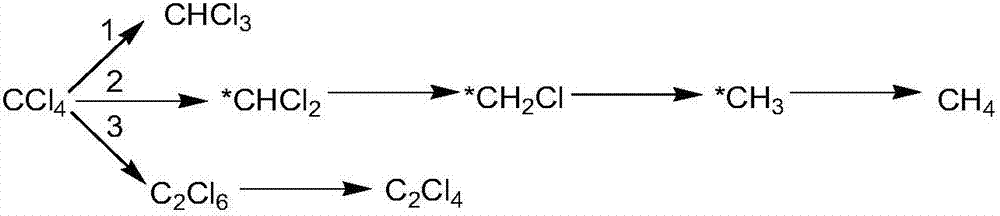

High-efficiency catalyst for producing chloroform by gas phase hydrogenation of carbon tetrachloride

InactiveCN107876046AReduce generationImprove conversion ratePreparation by dehalogenationCatalyst activation/preparationSorbentGas phase

The invention relates to a high-efficiency catalyst for producing chloroform by gas phase hydrogenation of carbon tetrachloride. The high-efficiency catalyst is mainly characterized in that the activeingredient platinum is distributed in a thick-shell layer permeation form on a carrier alumina. According to the catalyst, the precious metal platinum serves as the active ingredient, the introduction amount of the platinum is 0.1-1% of the total mass of the carrier, the carrier is alumina of being spherical, strip-shaped or in the other shapes, and the carrier is pre-treated by adopting an organic acid competitive adsorbent, so that the active ingredient platinum is distributed in the thick-shell layer permeation form on the carrier. Compared with a catalyst without being subjected to organic acid pretreatment, the catalyst has high activity, conversion rate and selectivity under the same operating conditions, capable of effectively reducing the production of harmful conjugate impuritiessuch as hexachloroethane and tetrachloroethylene, and has long service life. The catalyst is applied to industrial production, and when the transformation capacity of the carbon tetrachloride is maintained at 40-50Kg / day.Kg, the catalyst can be continuously operated by 180 days or longer, and the transformation rate and selectivity are respectively maintained at 98% or 70% or higher.

Owner:JIANGSU LEE & MAN CHEM +2

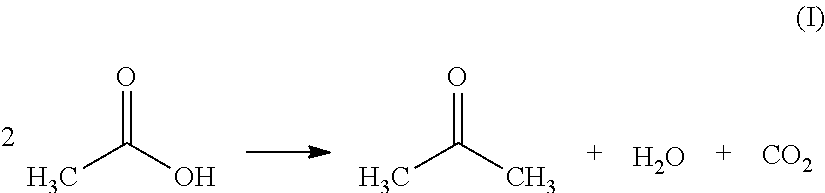

Process for reducing emissions of volatile organic compounds from the ketonization of carboxylic acids

ActiveUS8779208B2Efficiently and inexpensively destroyedReduce compoundingOrganic compound preparationCarbonyl compound preparation by condensationCombustionKetonic acids

Disclosed is a process for reducing the emission of volatile organic compounds that are produced during the ketonization of carboxylic acids to ketones. The ketonization of carboxylic acids produces a gaseous by-product stream containing carbon dioxide and volatile organic compounds. This gaseous by-product stream can be fed to a direct-fired furnace used to heat the ketonization reaction feed streams where the volatile organic compounds are destroyed by combustion in the furnace. The carbon dioxide stream further acts as a diluent for the fuel to the furnace.

Owner:EASTMAN CHEM CO

Internal combustion engine which can be operated with liquid and with gaseous fuel and a method for operating an internal combustion engine of this kind

ActiveUS20140102405A1Reduce heat exposureAlleviate cokingInternal combustion piston enginesOutput powerCompressed natural gasExternal combustion engine

The application describes a system for an engine comprising a direct injection nozzle for injecting gaseous fuel into a cylinder of an engine in a second operating mode; an intake injection nozzle for injecting liquid fuel into an intake port of the engine in a first operating mode; and a valve gear suitable to adjust timing of opening and closing of an inlet valve. Preferential injection of a gaseous fuel such as compressed natural gas directly into the cylinder increases efficiency and allows for reduced heat exposure to the lesser used liquid gas injectors mounted in the intake port, reducing coking of these injectors.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com