Patents

Literature

41 results about "Weight problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

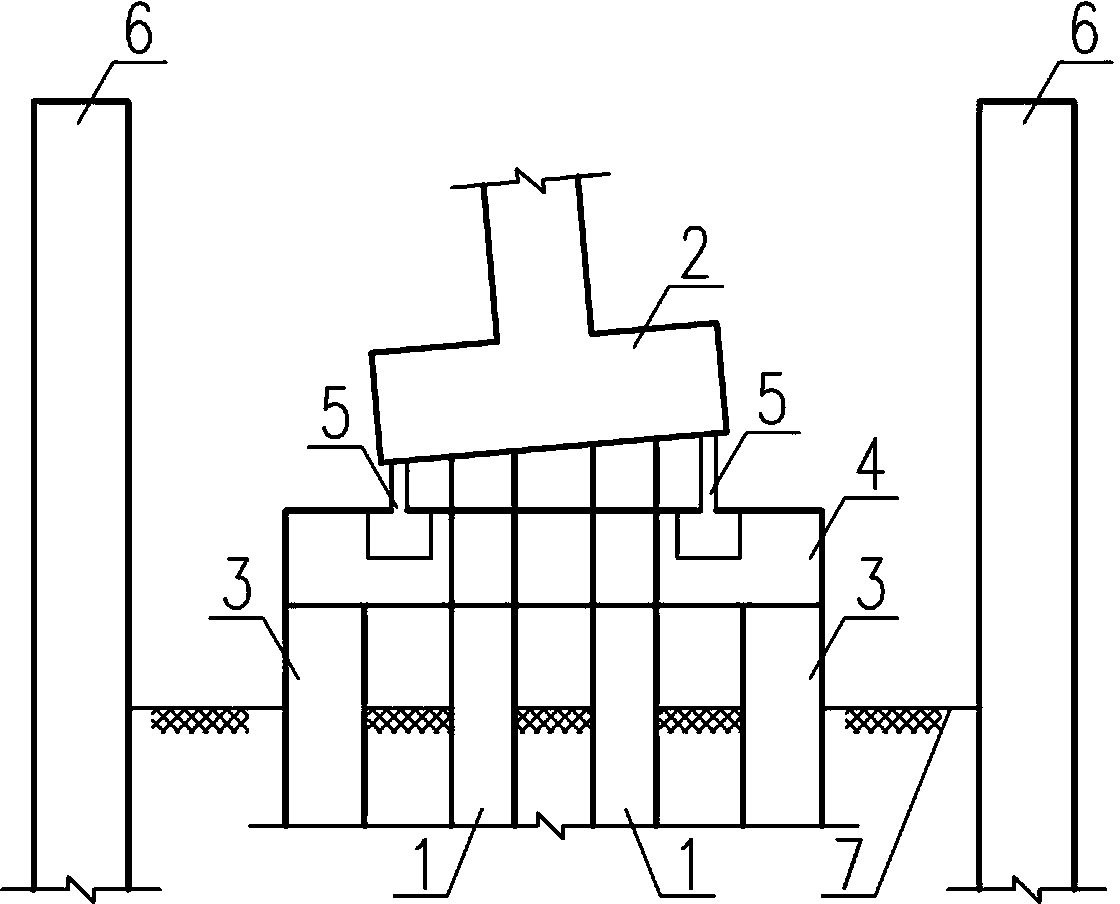

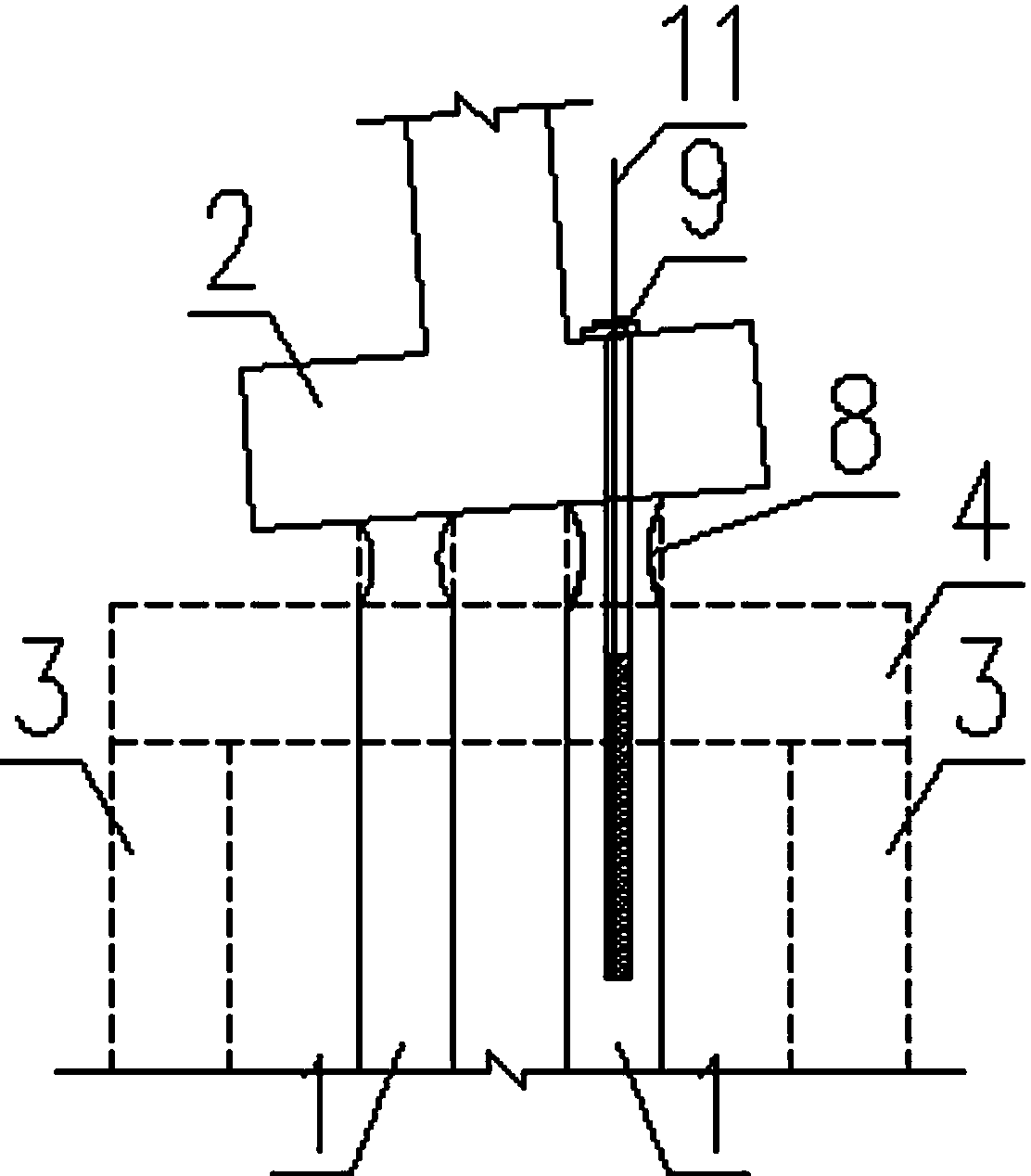

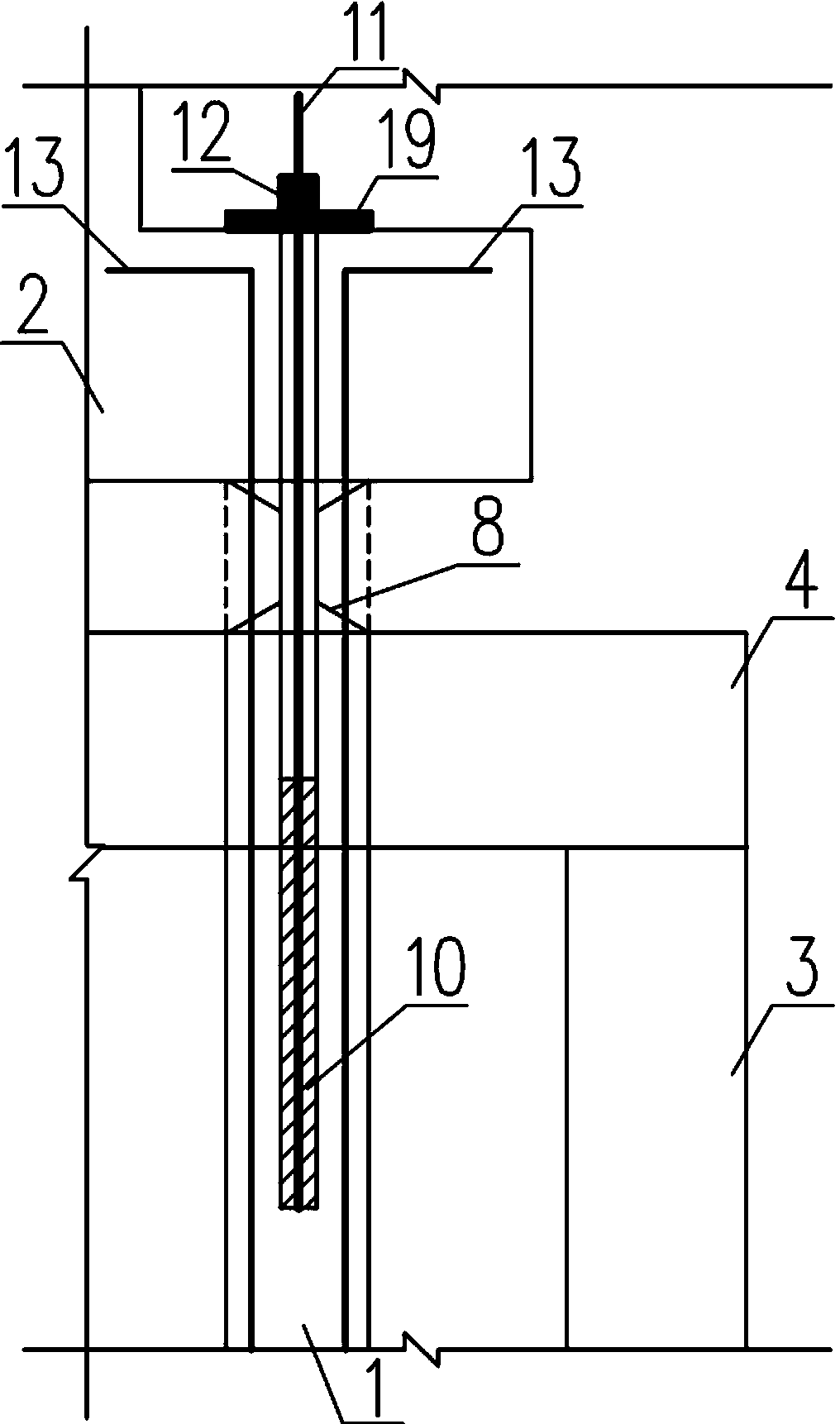

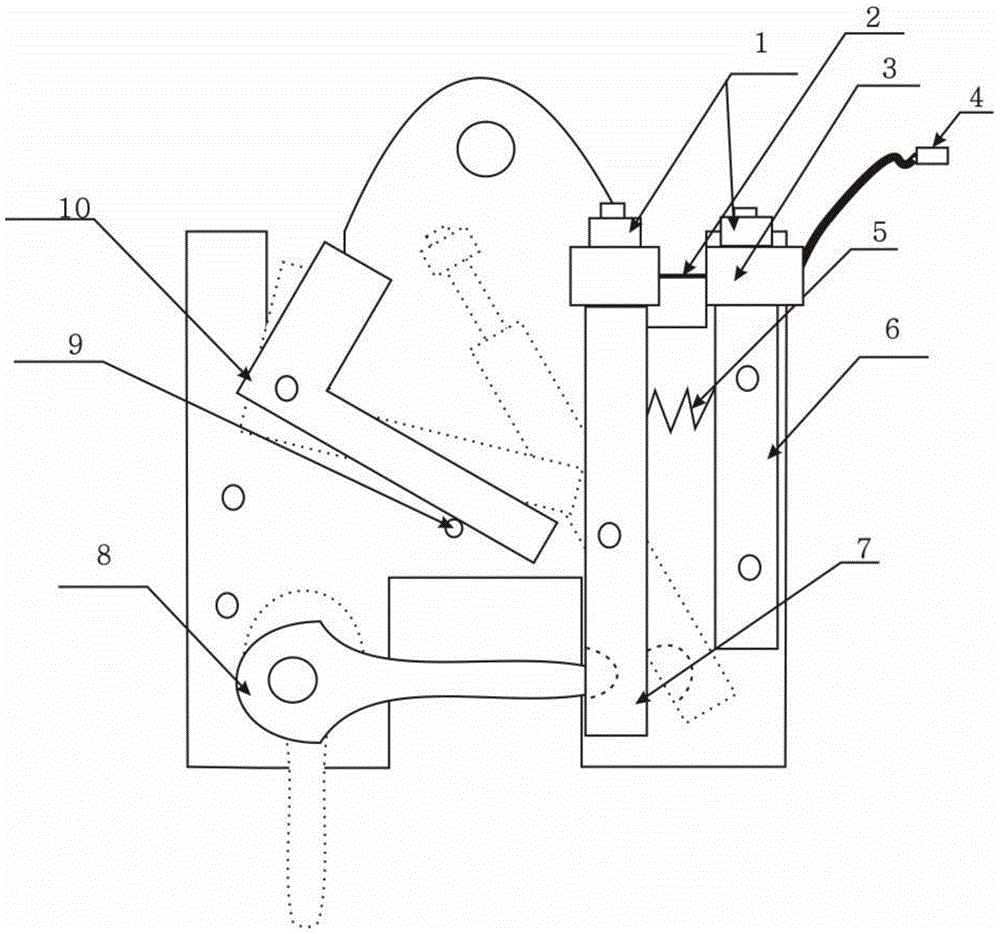

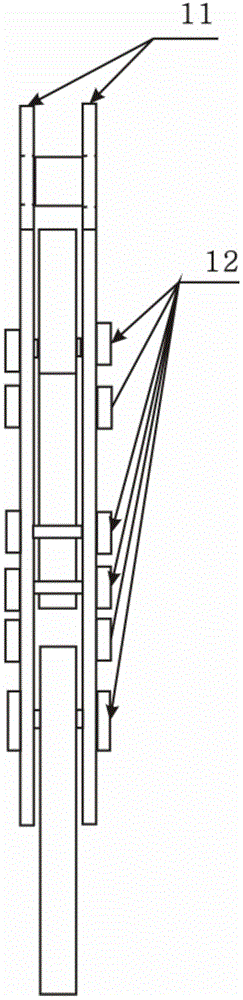

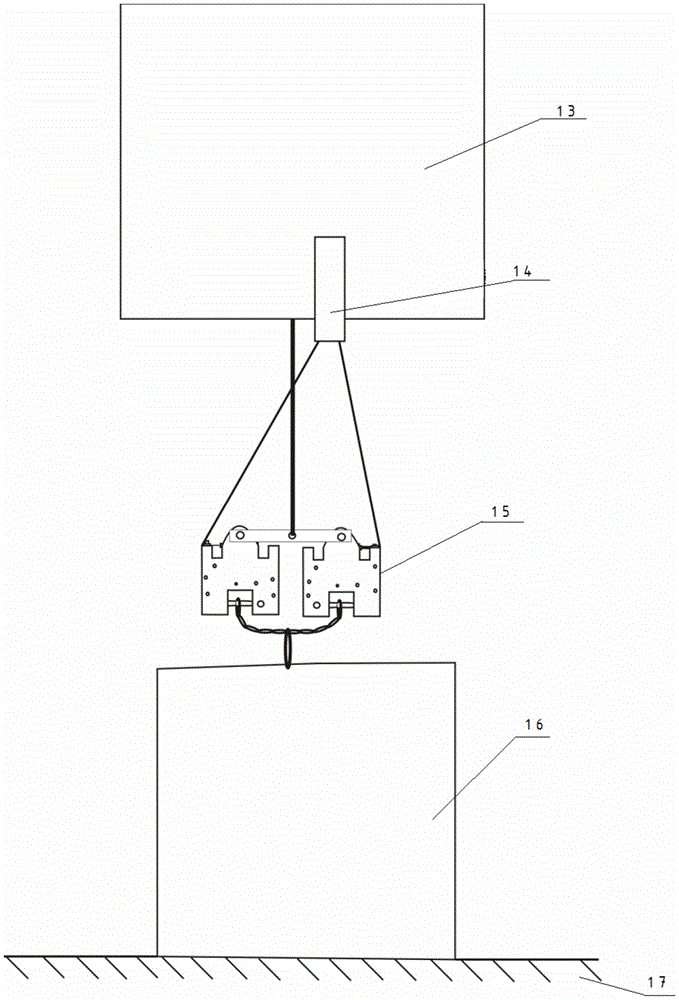

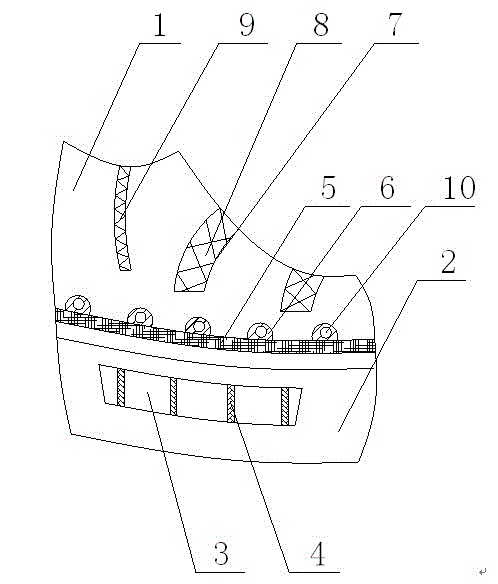

Self-balance anchor counter weight broken pile forced landing rectification method

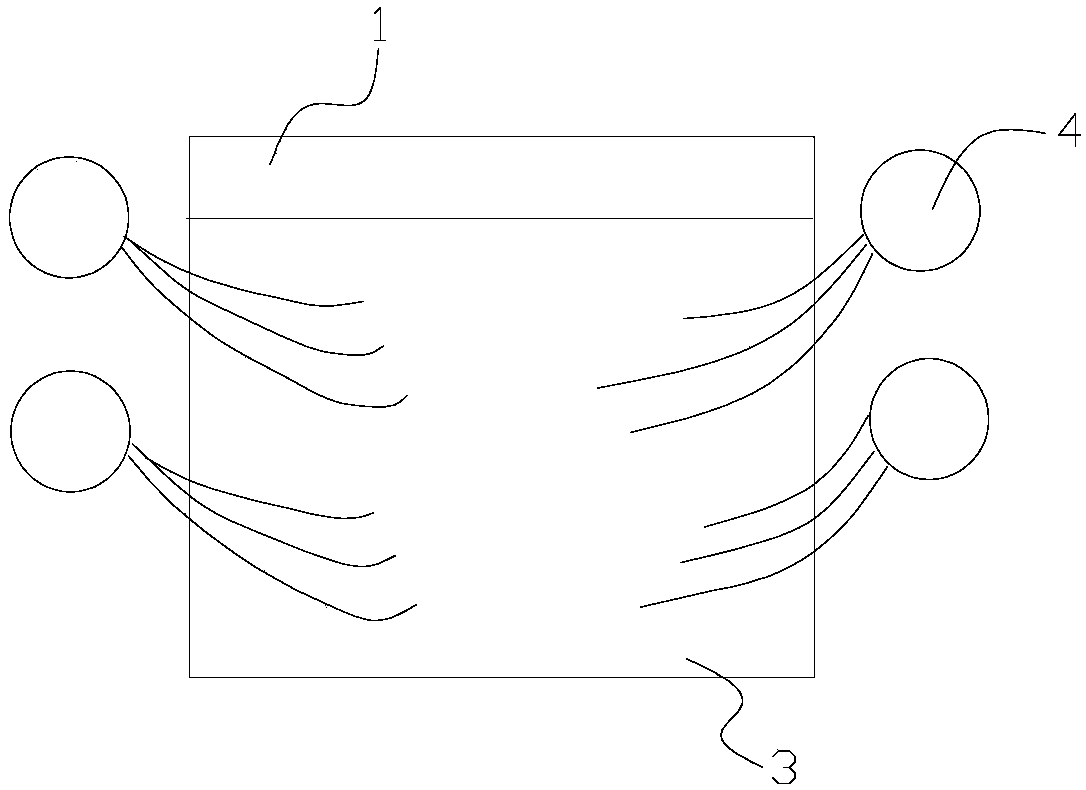

The invention discloses a self-balance anchor counter weight broken pile forced landing rectification method. The self-balance anchor counter weight broken pile forced landing rectification method comprises the following steps of: drilling an anchor rod hole in a foundation pile planned to be truncated; taking the position planned to be truncated as a boundary; taking a lower-part pile body as an anchoring section, an upper-part anchor hole as a free section and a bearing platform which needs to be rectified as an outer anchor bed to form a self-balance anchor; cooperating with various traditional direct broken pile technologies, or artificially arranging a base pile section weakening section on a pile end; buckling the pile body concrete of the section weakening section under the joint action of the upper-part load self weight and the self-balance anchor counter weight to realize the broke pile; realizing the counter weight broken pile forced landing rectification; rectifying building and structure inclination caused by the uneven sedimentation of the pile foundation. According to the self-balance anchor counter weight broken pile forced landing rectification method disclosed by the invention, the self-balance anchor used for assisting the counter weight directly adopts the lower-part pile body of the foundation pile as the anchor rod anchoring section to provide anchoring counter force, the counter weight problem of broken pile forced landing is solved by the ingenious economic means, and therefore the broken pile forced landing can be safer and controllable. According to the self-balance anchor counter weight broken pile forced landing rectification method disclosed by the invention, change and disturbance on the stressed system and the foundation of the building and the structure can be avoided, and the building and the structure can be more safely used after being rectified.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

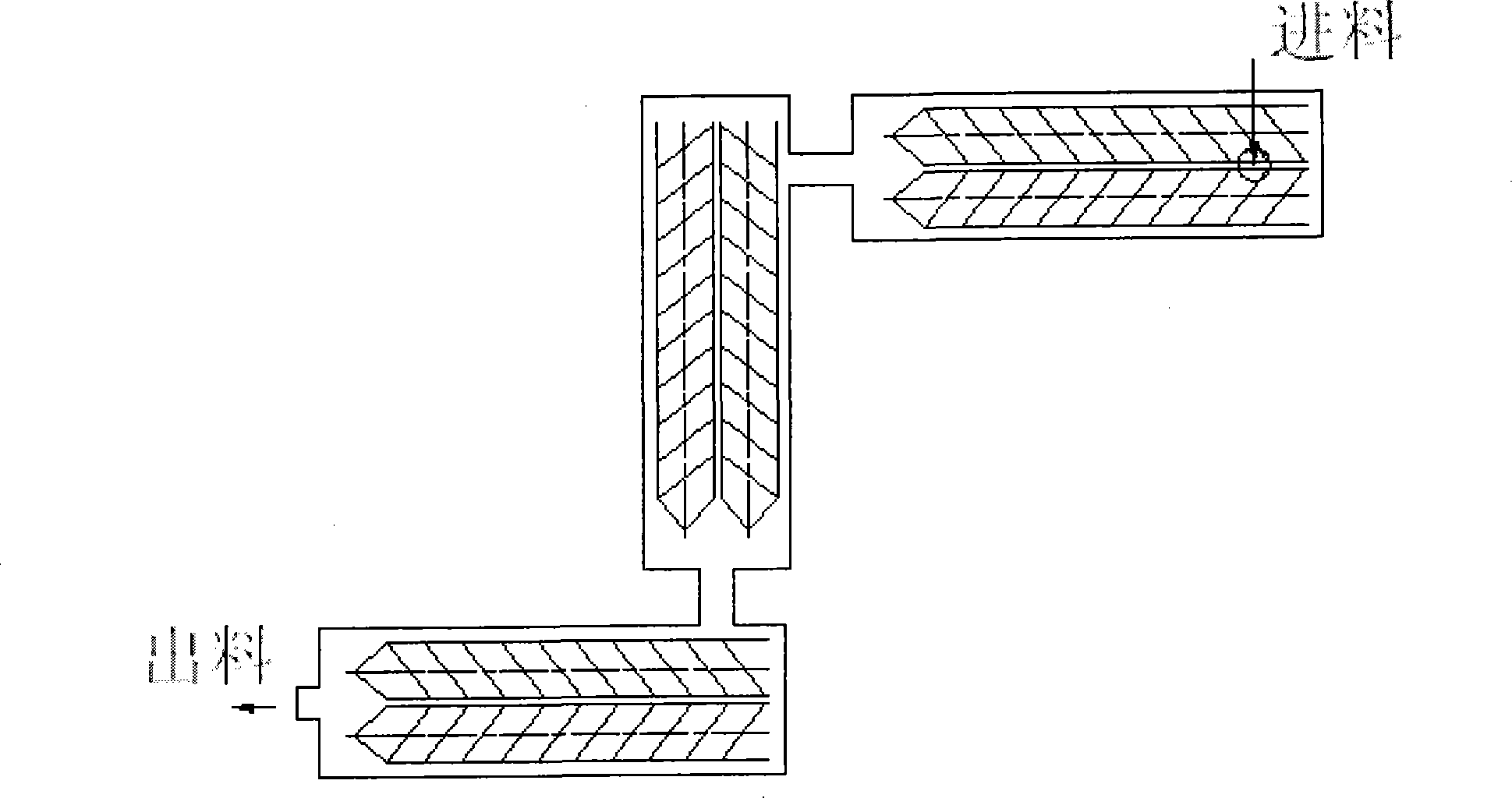

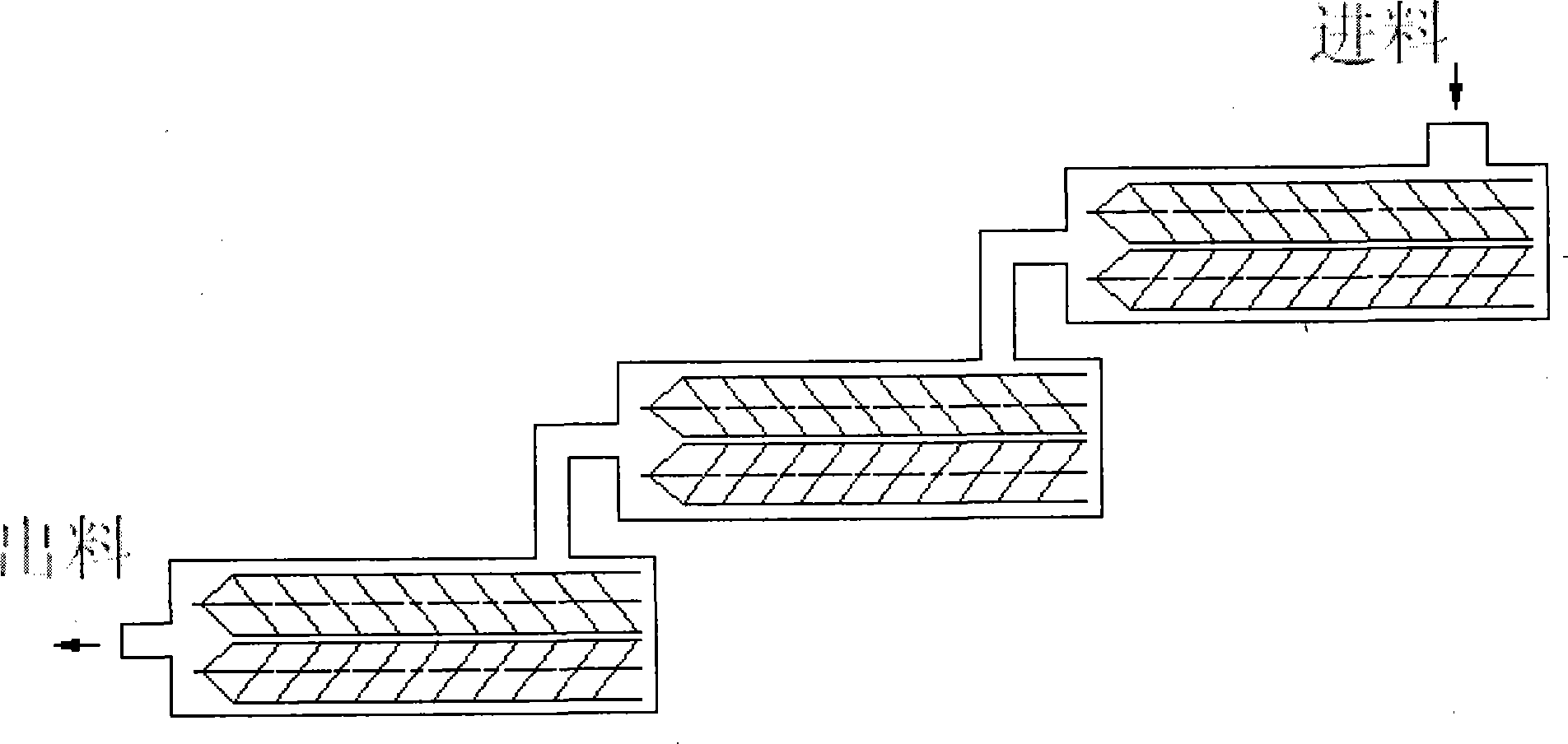

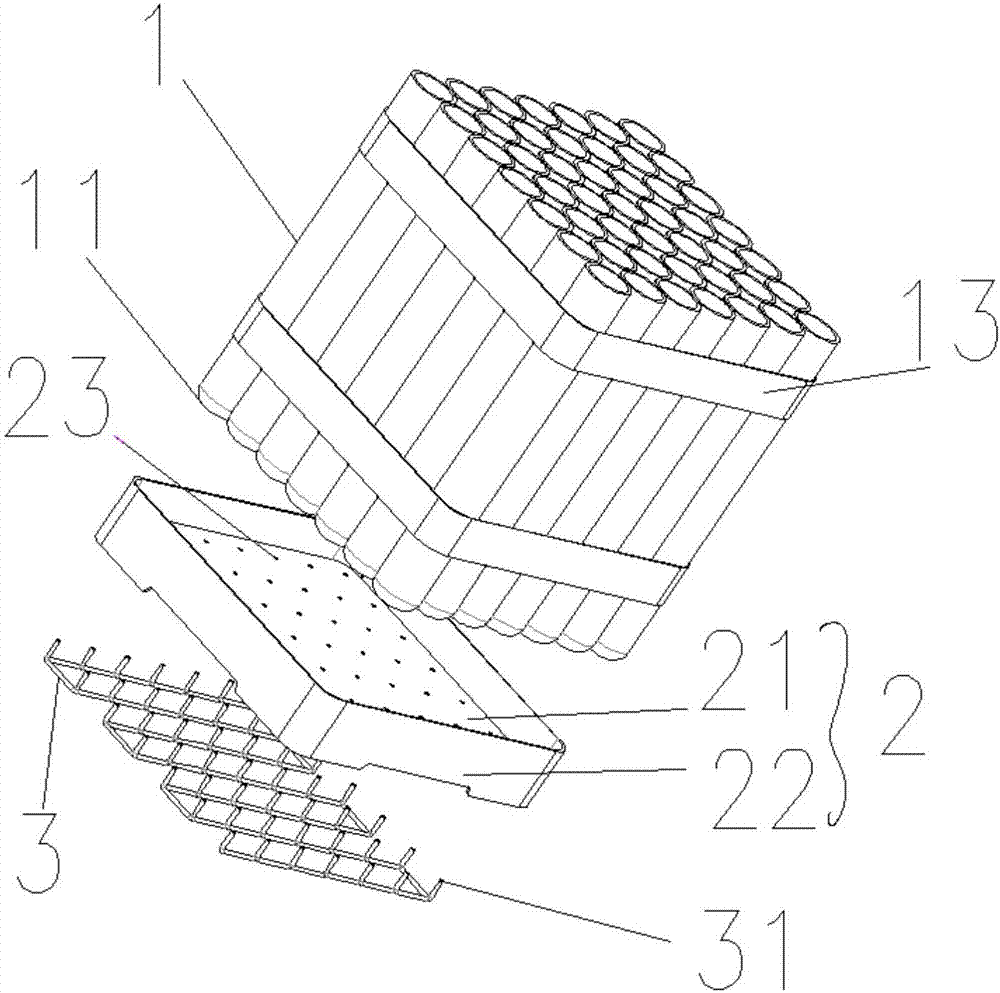

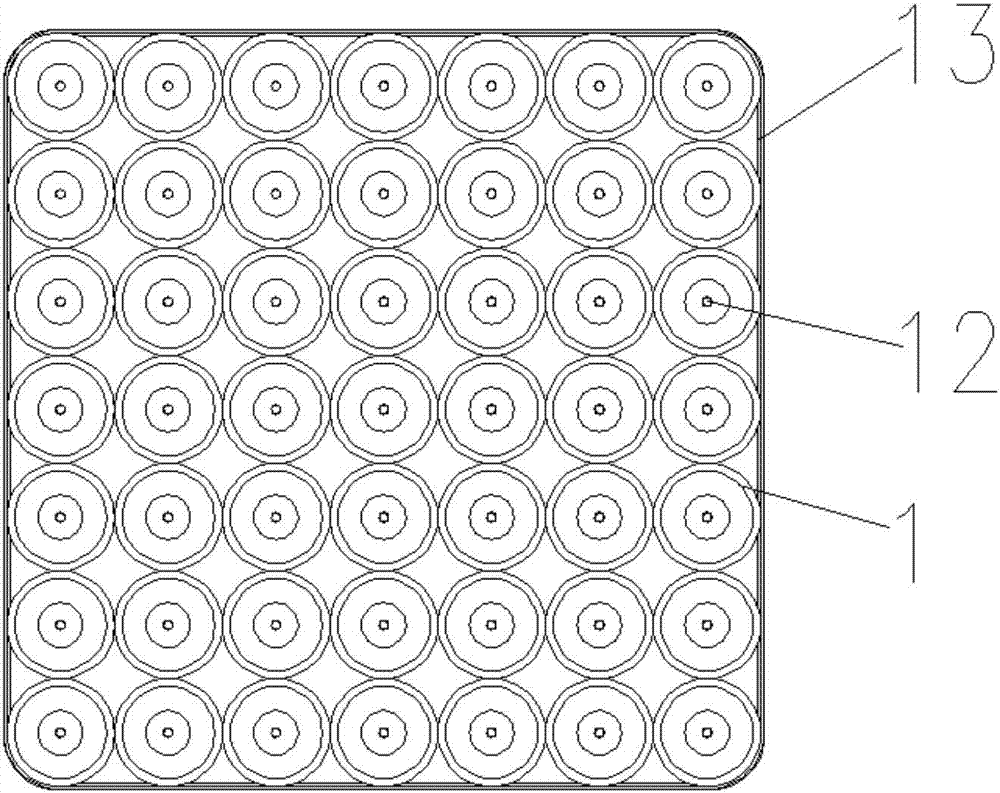

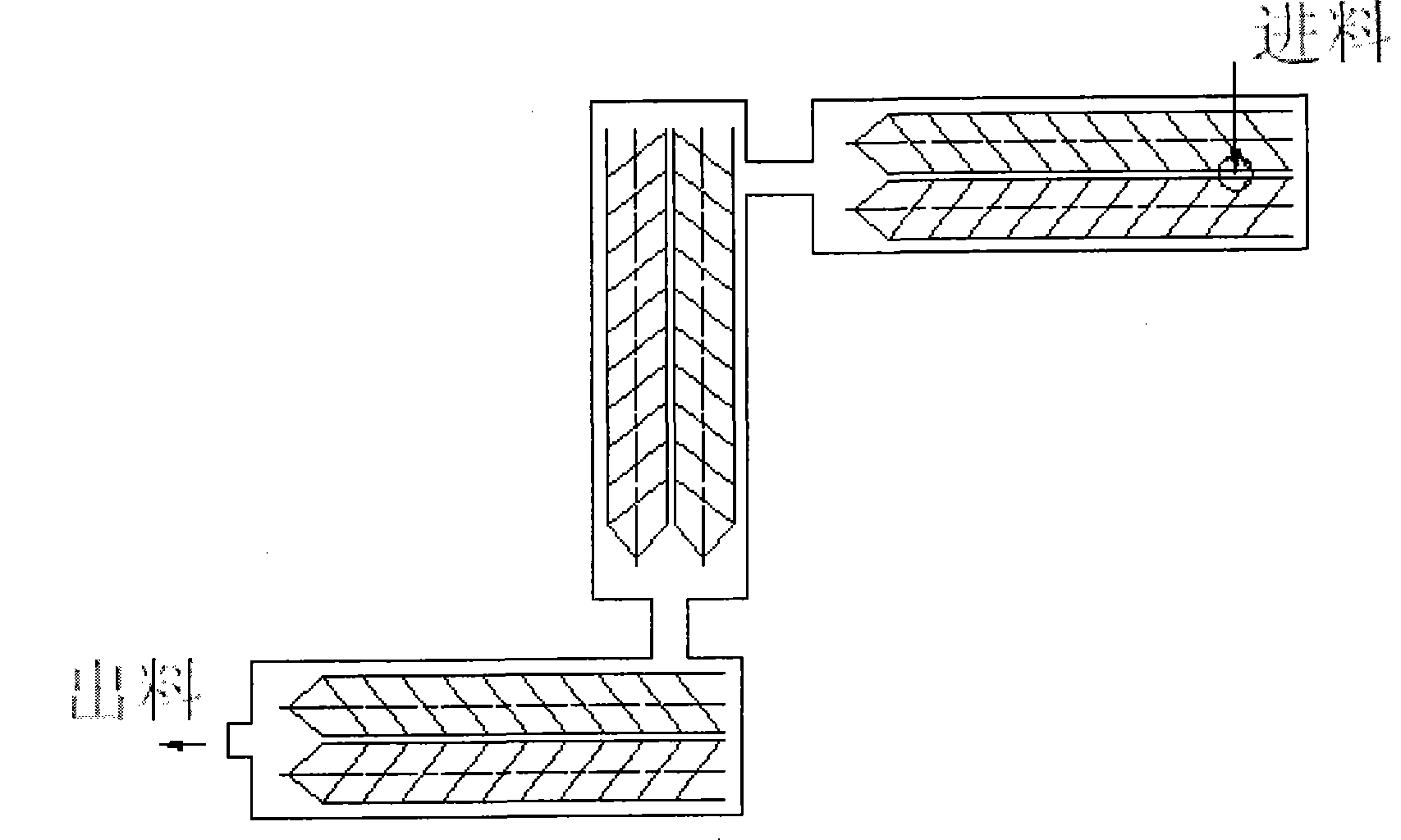

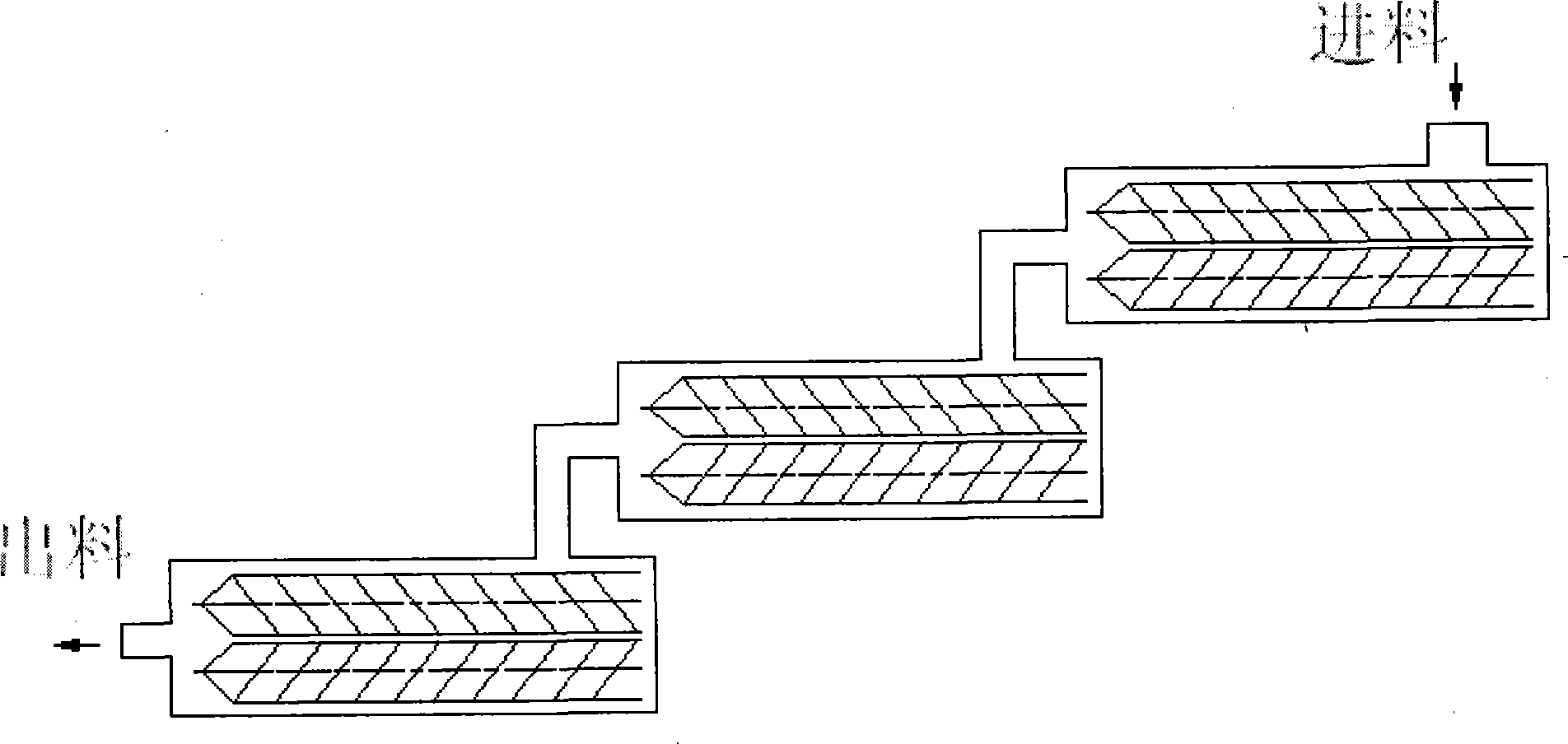

Continuous polymerization reaction device for producing poly-p-phenylene benzo dioxazole

ActiveCN101245143AWell mixedHigh molecular weightMonocomponent synthetic polymer artificial filamentWorking temperatureDiameter ratio

The invention discloses a continuous polymerization device which prepares PBO, which relates to a continuous polymerization device. The invention brings about solutions to the stirring problems caused by the high viscosity of PBO polymer and to the low molecular weight problems existed in the polymer which is prepared by current manufacturing process. The discharge hole of the pre-polymerization reactor of the invention is communicated with the charging hole of screw extruder unit which consists of 2-10 full-bay screw extruders which are connected by in-line platform combination or staging pack; wherein the screw, screw barrel, the charging hole, the discharge hole are acid-resisting and corrosion-resisting; the working temperature for screw is 20-300 DEG C, the extrusion pressure for the screw extruder is 0.1-30 MPa, the diameter D for the screw is 20-200 mm, the length-diameter ratio L / D for the screw is 10-60, the rotation speed is 1-1000r / min, and the vacuum degree in the screw is minus 0.1 MPa. The continuous polymerization device has the advantages of improved molecular weight, quick reaction speed, short manufacturing cycle, uniform material mixture and full reaction, which can realize continuous operation and is conductive to commercial process.

Owner:HARBIN INST OF TECH

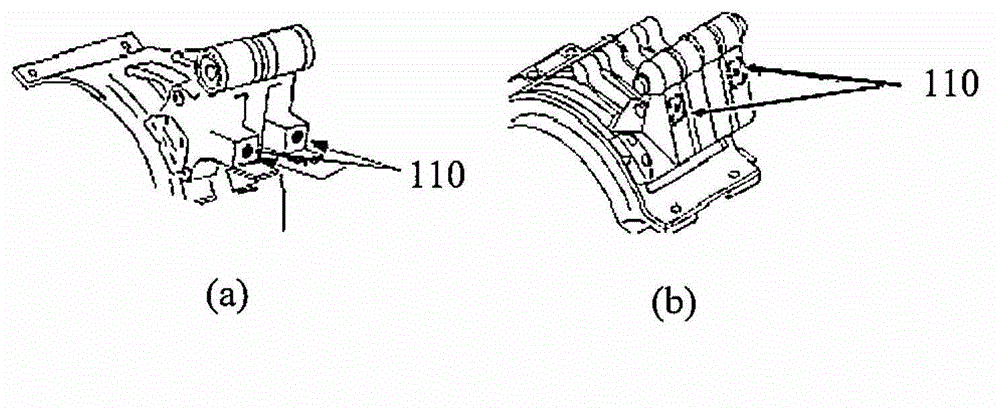

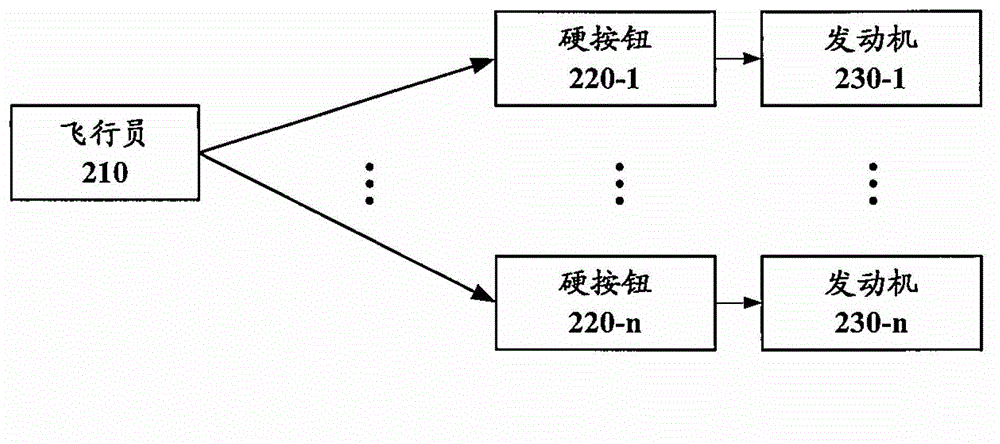

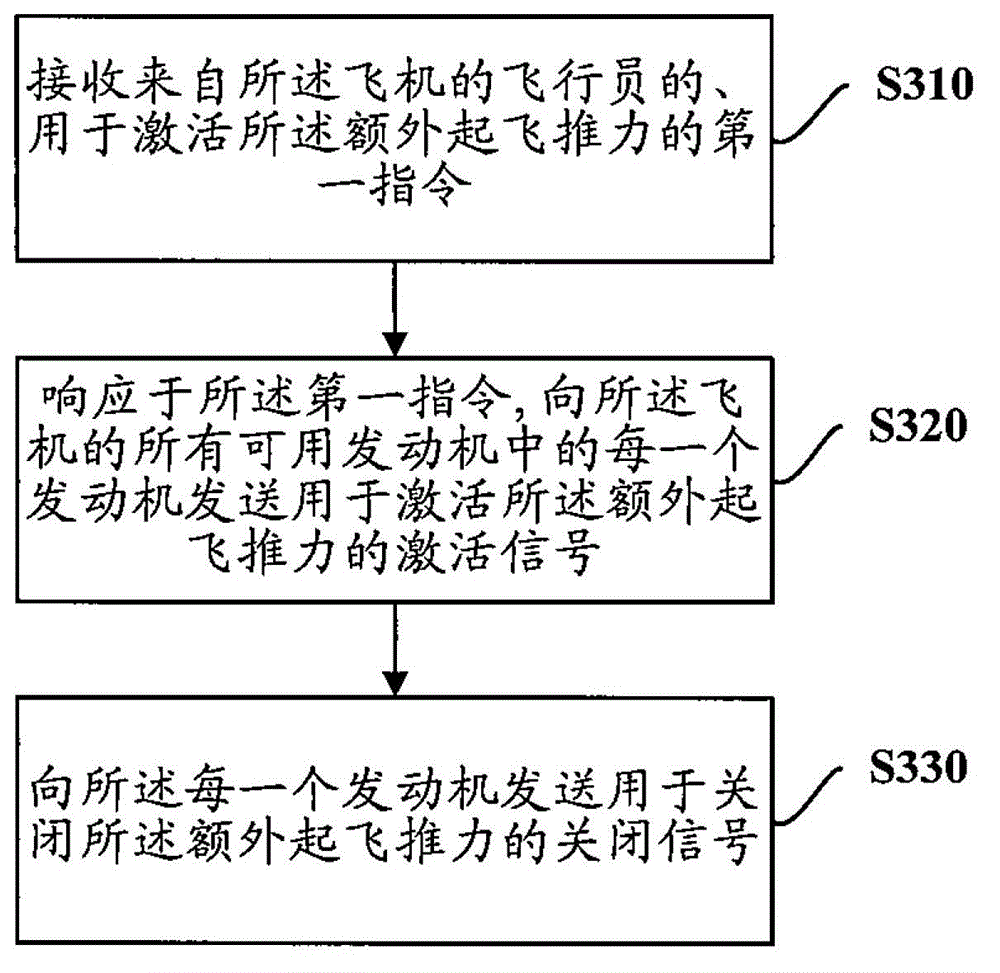

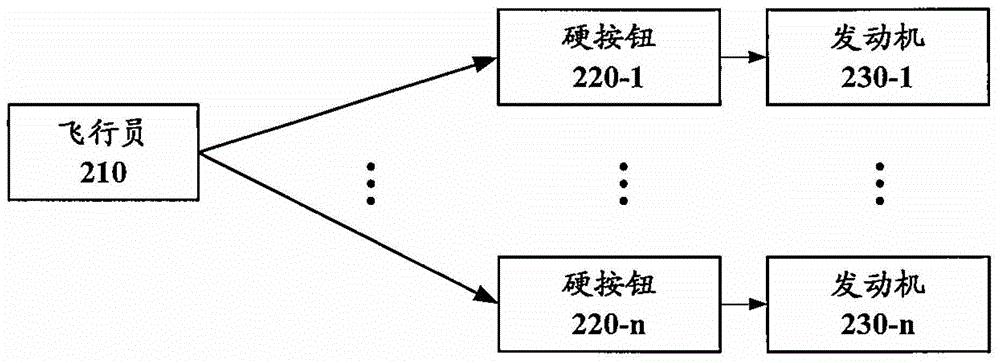

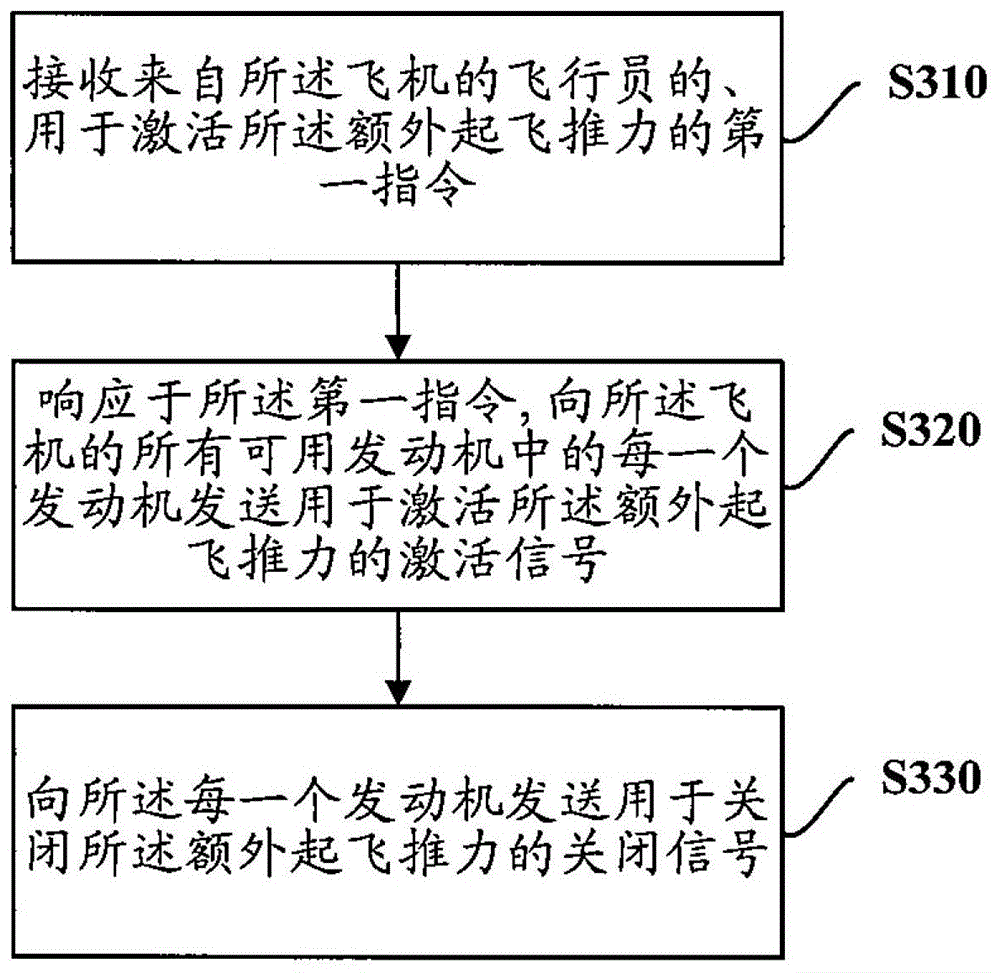

Method and device for controlling additional takeoff thrust of plane

ActiveCN103057711AReduce the burden onAvoid misuseAircraft power plantsBiological activationWeight problem

The invention relates to a method and device for controlling additional takeoff thrust of a plane. The method includes: receiving a first instruction for activating the additional takeoff thrust from a pilot of the plane, responding the first instruction, and sending activating signals for activating the additional takeoff thrust to each engine of available engines of the plane. After the additional takeoff thrust is activated, the pilot only needs to push a throttle lever to a normal takeoff position, and the additional takeoff thrust can be achieved. The pilot only needs to send one instruction to activate the additional takeoff thrust of each engine, and single-activation misoperation in a traditional scheme is avoided. Additionally, the first instruction can be received by a software button, and the activating signals are transmitted through a bus of the plane. Activation and closing of the additional takeoff thrust can be achieved without special buttons and transmission lines, and therefore a weight problem and an arrangement problem in the traditional scheme are solved.

Owner:COMAC +1

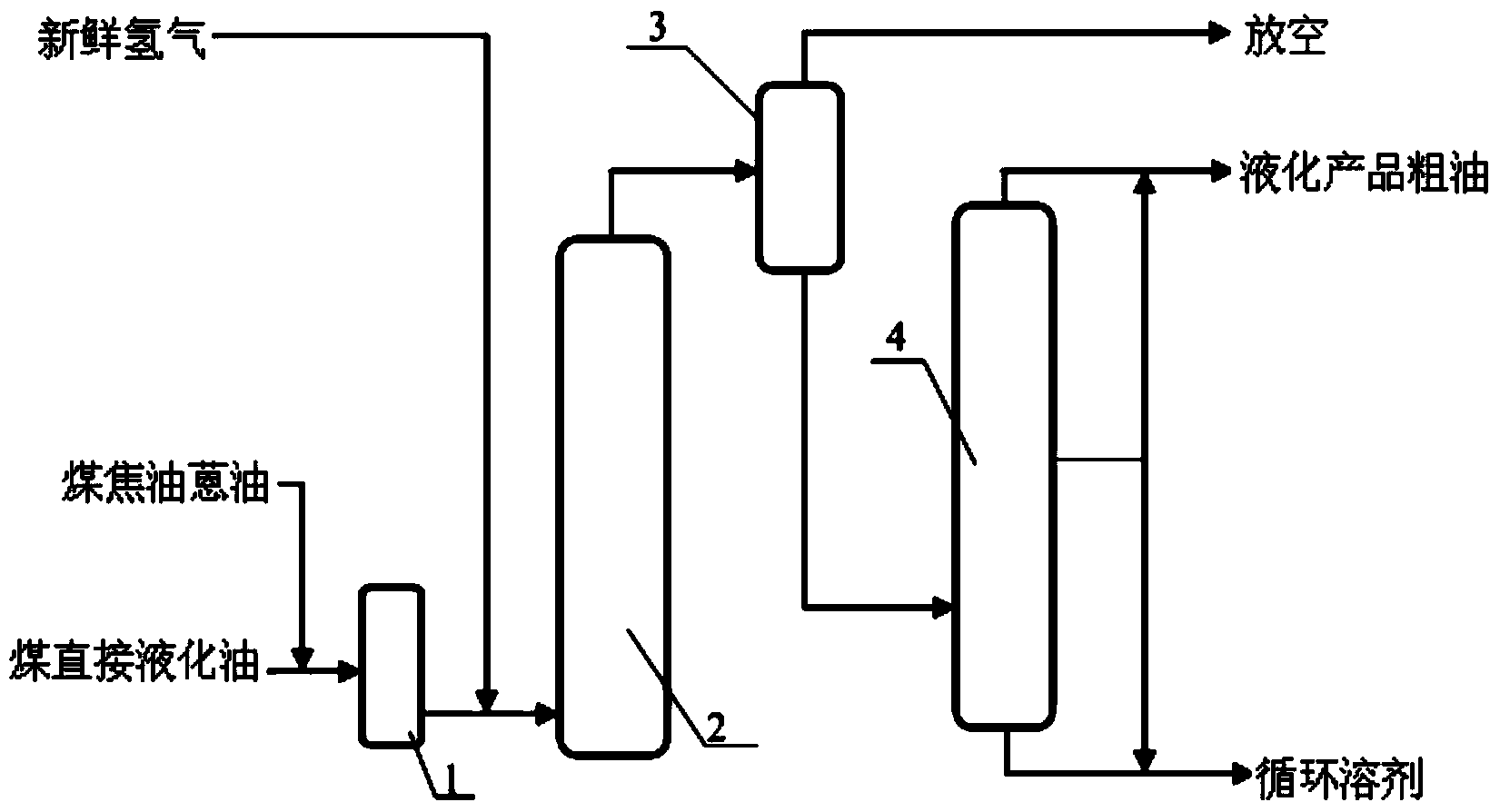

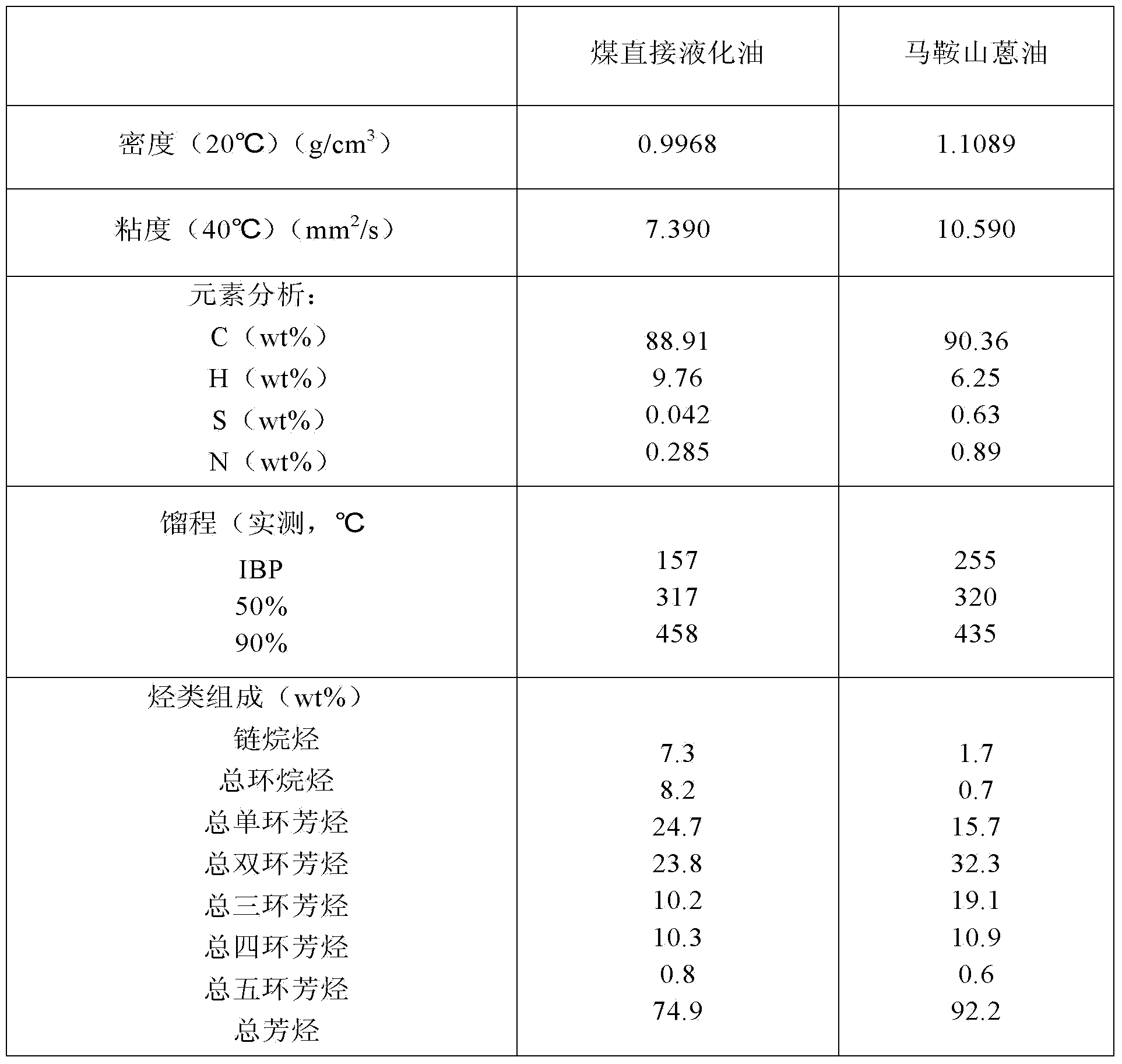

Direct coal liquefaction circulation solvent and preparation method and application of direct coal liquefaction circulation solvent

ActiveCN103468315AHigh economic valueHigh yieldLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesAnthraceneFractionation

The invention provides a direct coal liquefaction circulation solvent and a preparation method and application of the direct coal liquefaction circulation solvent. The preparation method comprises the steps that S1, hydrogenation is carried out on a mixture of coal tar anthracene oil and direct coal liquefaction oil to obtain a hydrogenation product, S2, fractionation is carried out on the hydrogenation product to obtain light-weight distillate oil, middle-weight distillate oil and heavy-weight distillate oil, and S3, the heavy-weight distillate oil is mixed with a part of middle-weight distillate oil to obtain the direct coal liquefaction circulation solvent. According to the preparation method, on one hand, a large amount of aromatic hydrocarbon is contained in the coal tar anthracene oil, the hydrogenation product is rich in components such as tetrahydronaphthalene, therefore, the hydrogen supply capacity of the circulation solvent can be obviously improved, and the yield of direct coal liquefaction oil is improved; on the other hand, a part of high value-added gas and diesel oil distillate with the boiling range lower than 350DEG C in the direct coal liquefaction circulation solvent is substituted with the coal tar anthracene oil, the diesel oil yield is improved, in addition, the light-weight problem of an existing circulation solvent can be relieved, and deposition and coking of materials in a reactor in the direct coal liquefaction technological process are relieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

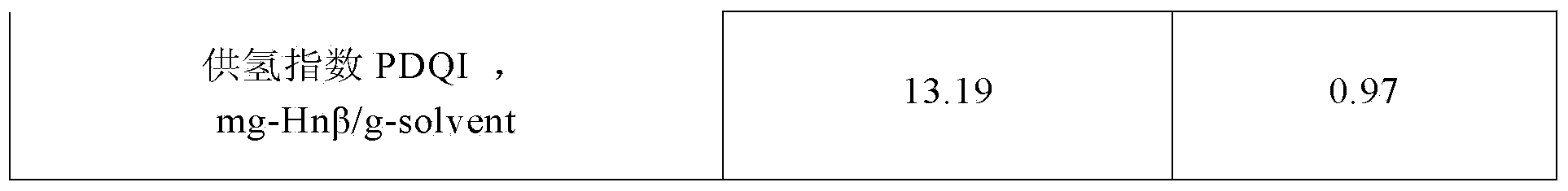

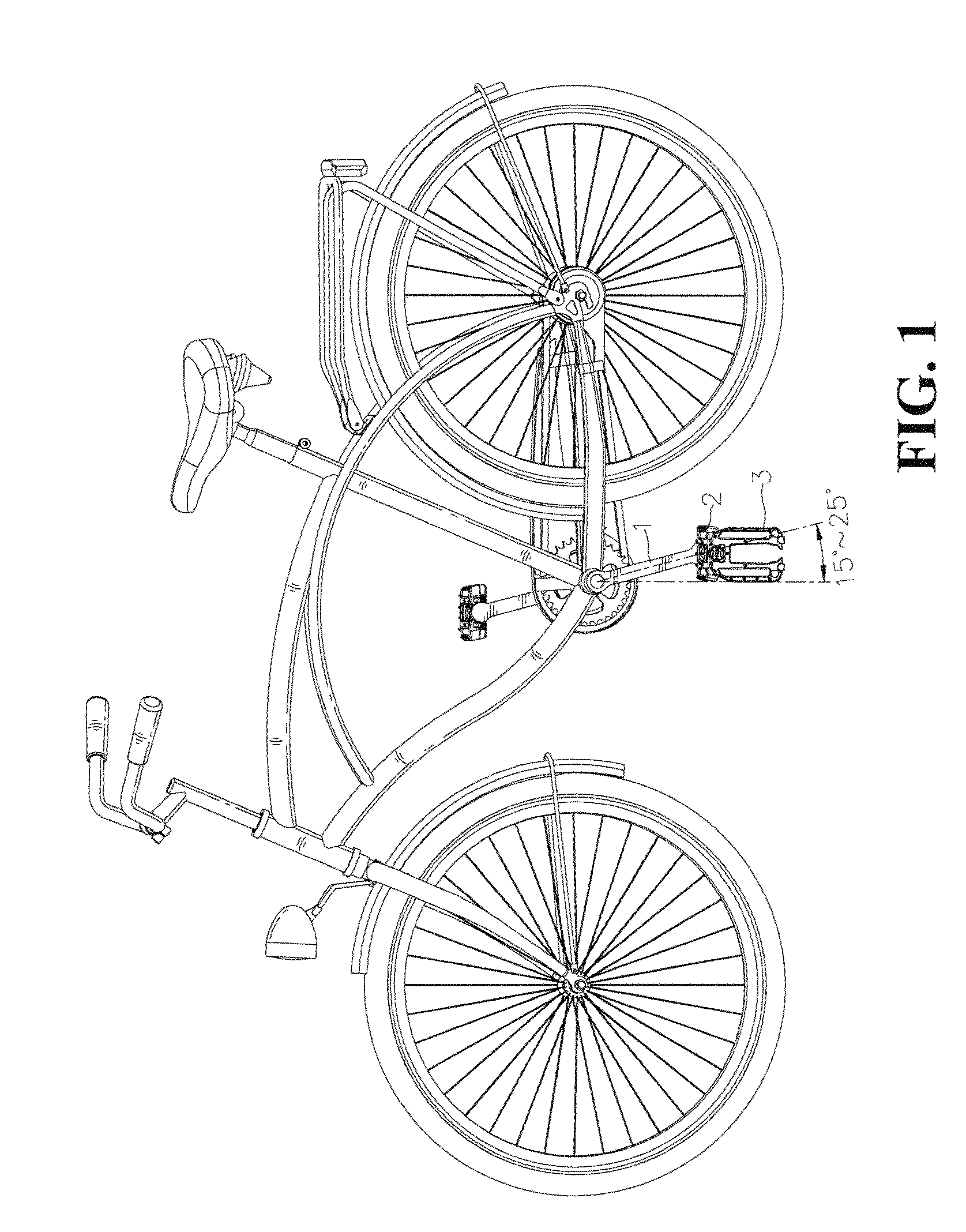

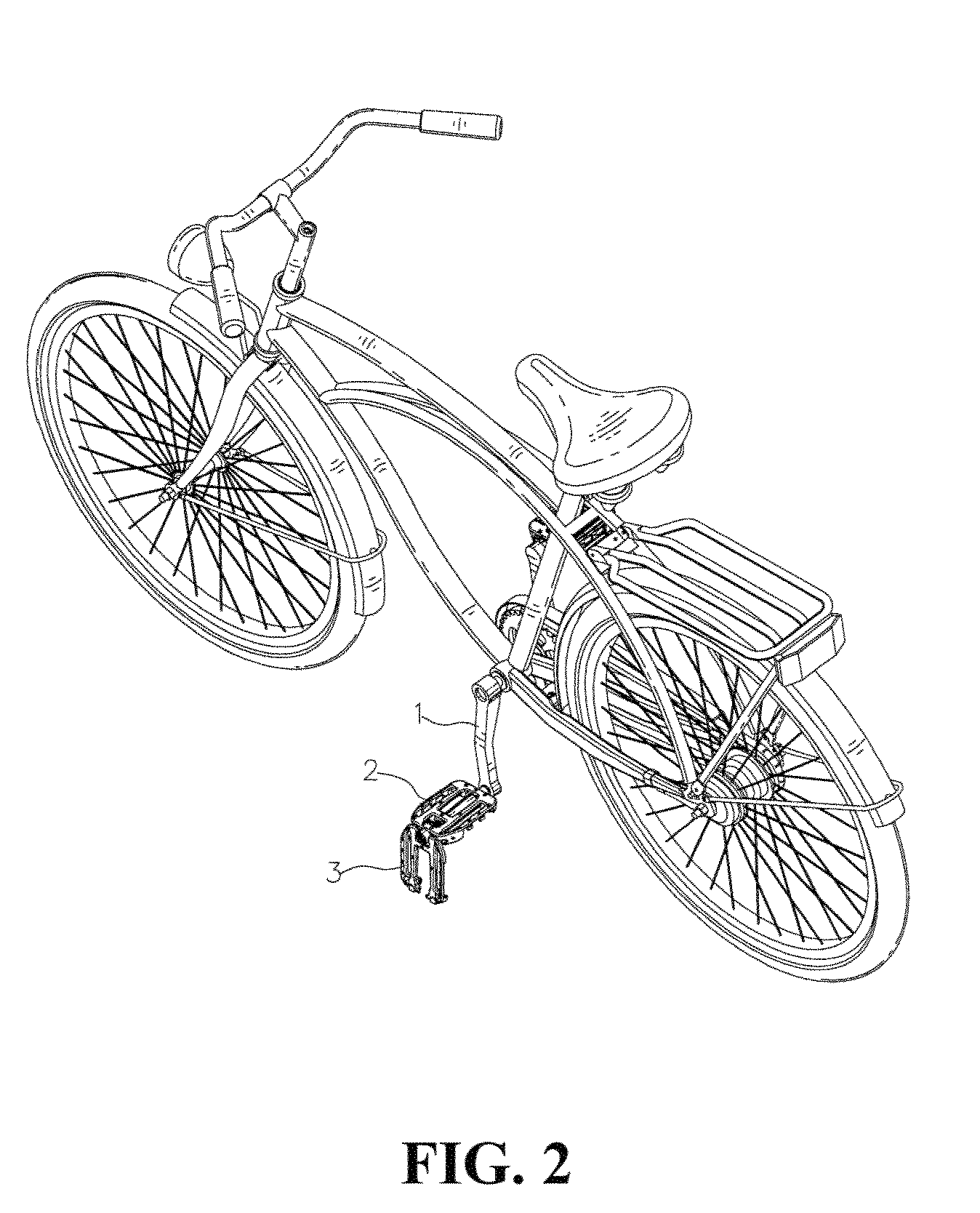

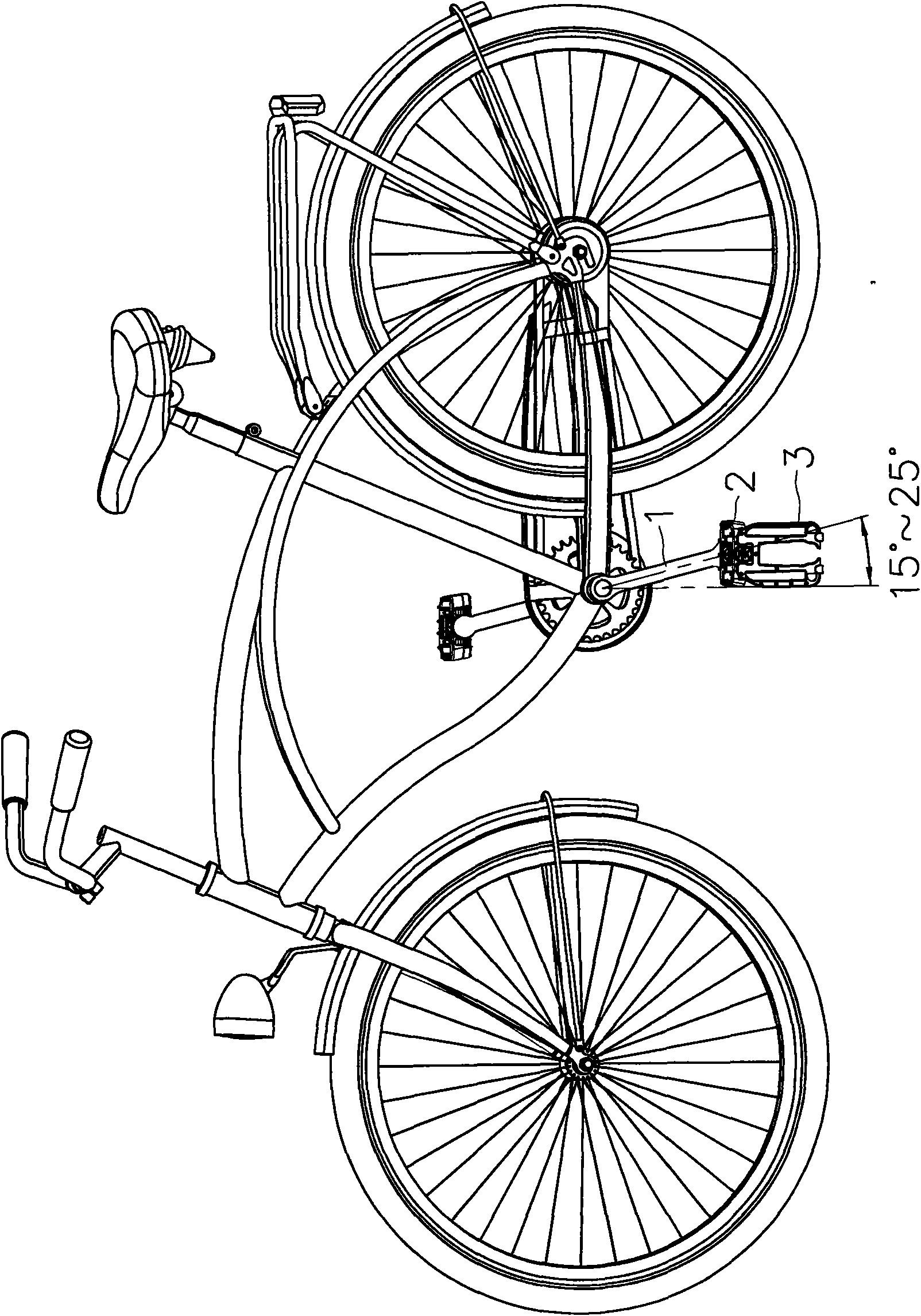

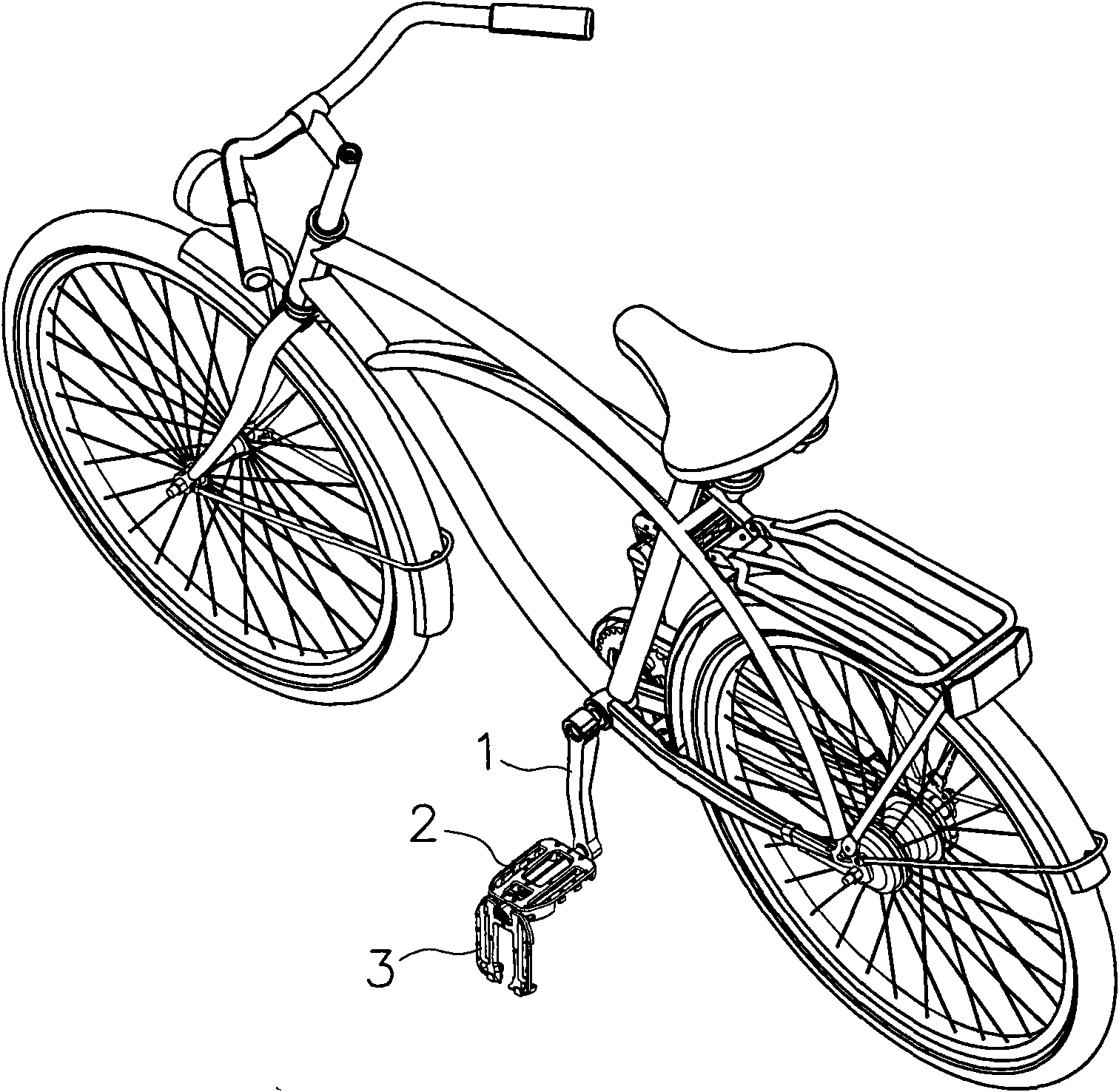

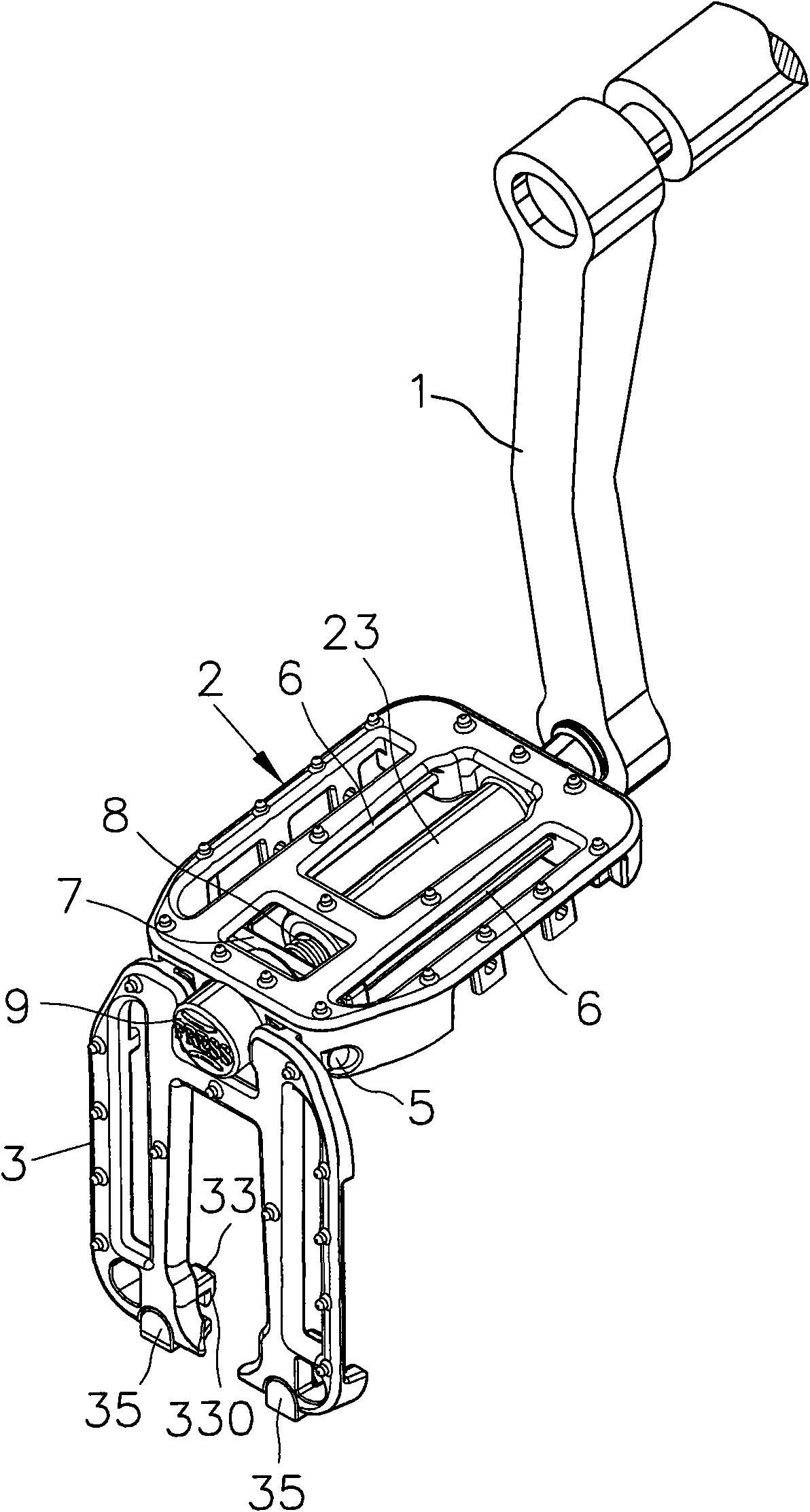

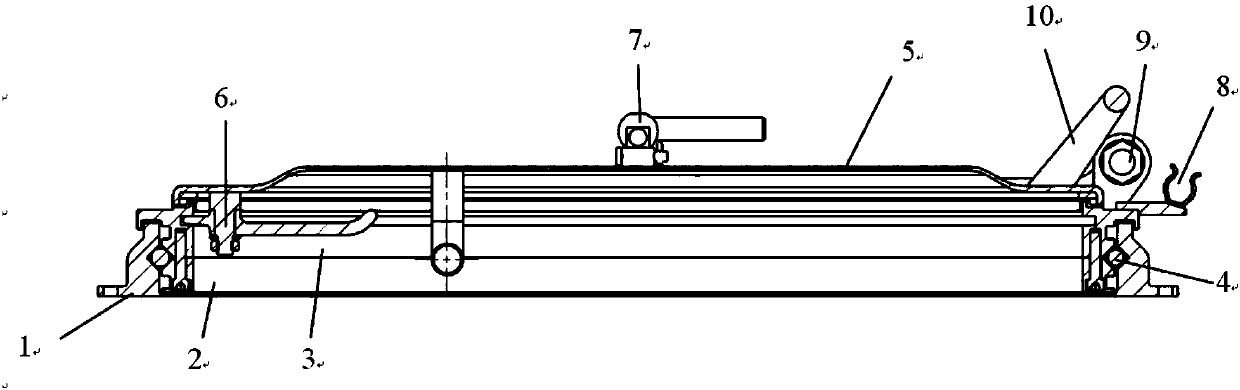

Pedal Kickstand

InactiveUS20100201099A1Reduce weightLow production costVehicle cranksCycle standsEngineeringWeight problem

The present invention relates to the technical field of bicycles, particularly relates to a pedal kickstand. The pedal kickstand of the present invention comprises a pedal, and an earth stand capable of being folded mounted to the outer side of the pedal by pin joint; when the earth stand is unfolded outward to stand on the ground, the bicycle can be held upright steadily. The present invention is mounted to a bicycle and the pedal kickstand is connected to the crank of the bicycle; when the earth stand is unfolded outward for a specific angle, the bicycle can be held upright; for the pedal kickstand provided by the present invention directly utilizes the pedal as the kickstand, the potential hazard caused by the conventional kickstand being exposed can be eliminated, and at the same time, it will not cause the weight problem of additionally mounting a kickstand; it is more beautiful as a whole.

Owner:DONGGUAN SHUNCHUEN METAL PROD

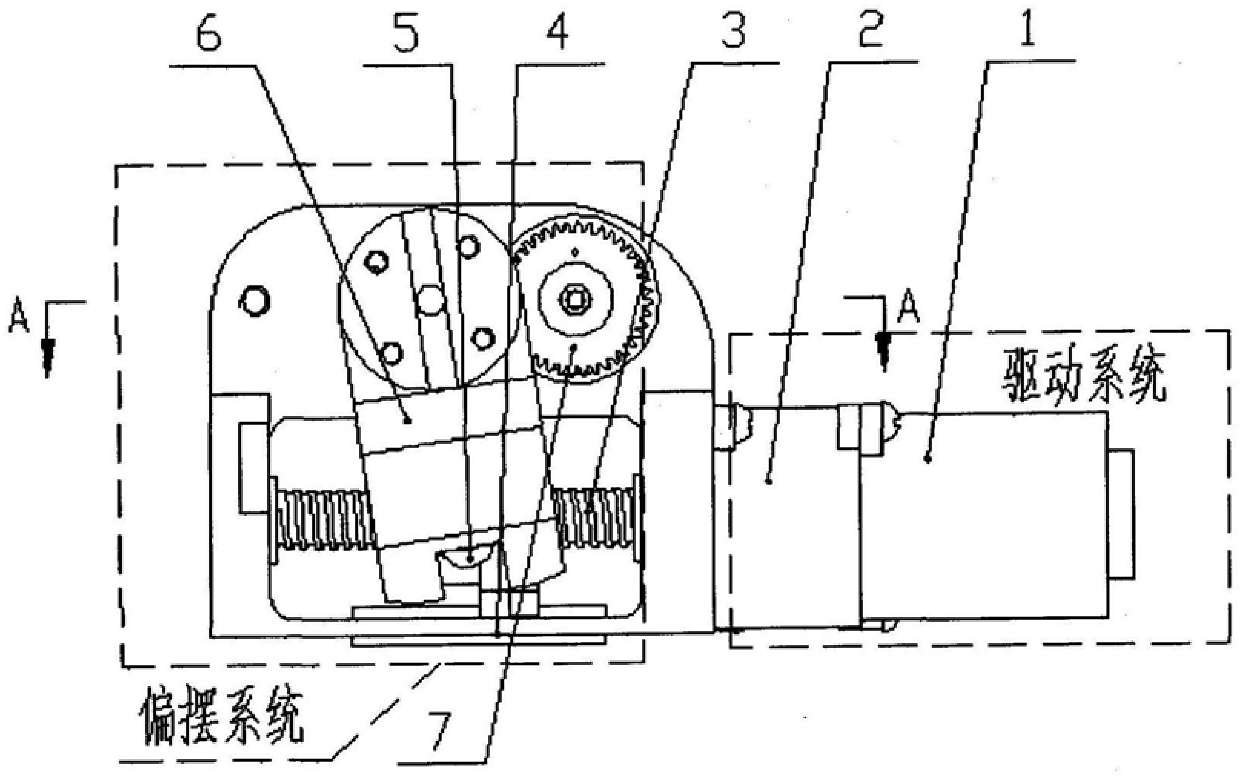

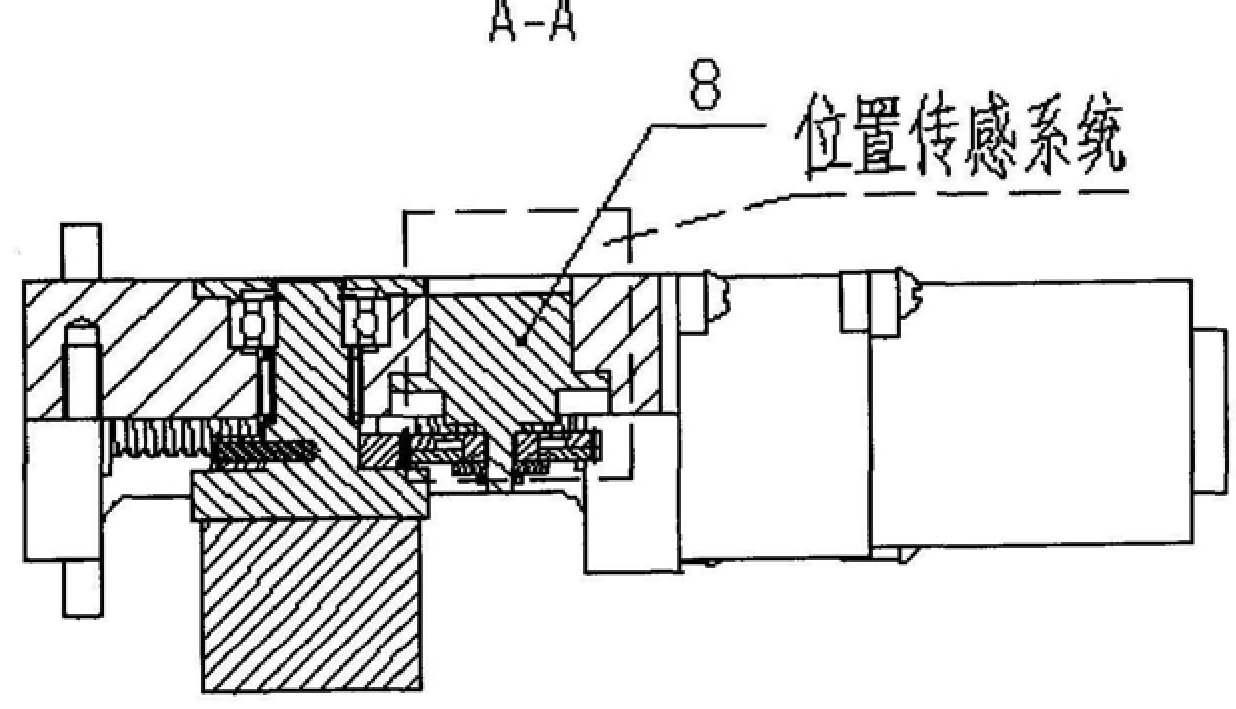

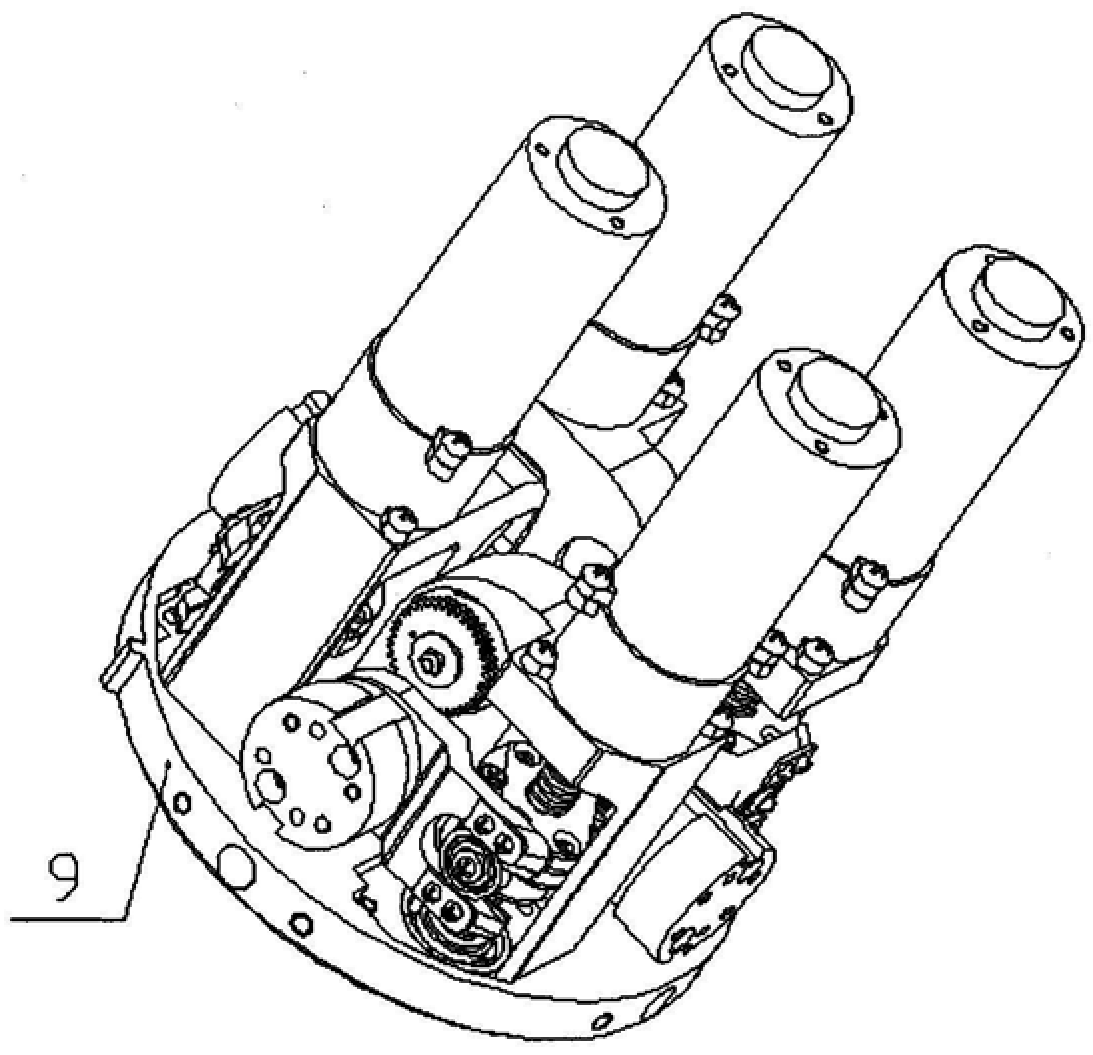

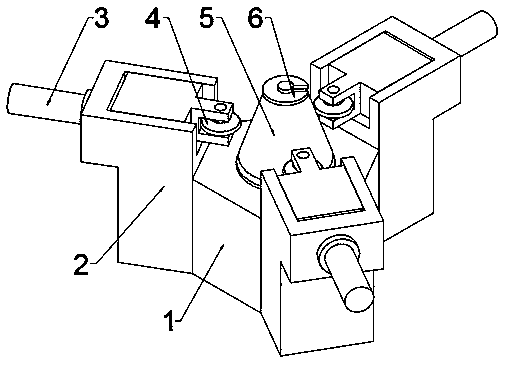

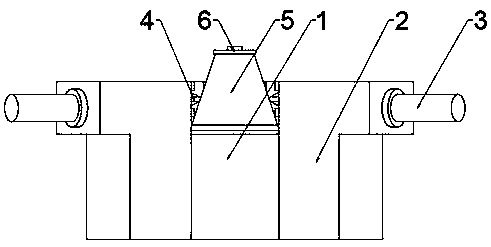

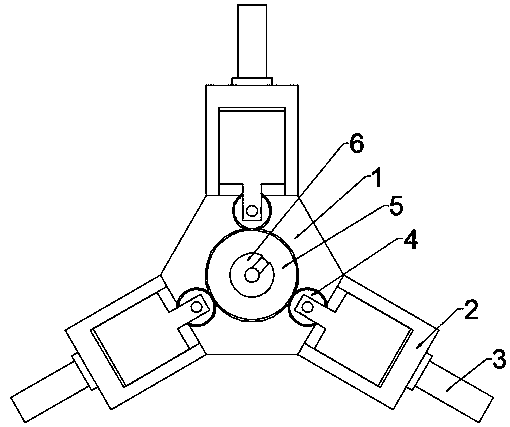

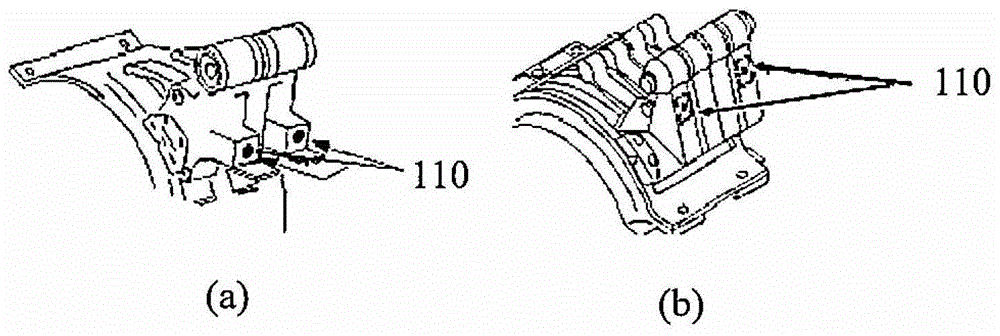

Steering gear system Swing type electric servo mechanism

InactiveCN106342385BSolve miniaturizationSolve the problem of lightweightMechanical energy handlingGear wheelYaw system

A yaw-type electric servo mechanism for a steering gear system, using a rare-earth motor as a driving source, after the torque is increased through a reduction box, it is transmitted to the output of the yaw system, which can drive the load to swing with a limited rotation angle, and the yaw system will swing The angle is fed back to the swing position signal of the control system through the potentiometer. The transmission scheme combining NGW planetary gearbox and ball screw is adopted, and four yaw-type servo mechanisms are evenly and symmetrically arranged on the end cover of the steering gear with an installation section diameter of 80-120mm. The servo system and drive circuit are placed in the gaps of the four yaw-type servo mechanisms, which saves space, facilitates system installation, and is conducive to the layout of the whole bomb, creating favorable conditions for the miniaturization of missiles. The compact structure layout is better than harmonic gear transmission The solution reduces the volume by 40% and the weight by 25%, and solves the problem of miniaturization and light weight of the steering gear. <pb pnum="1" / >

Owner:LINQUAN AEROSPACE MOTOR CO LTD

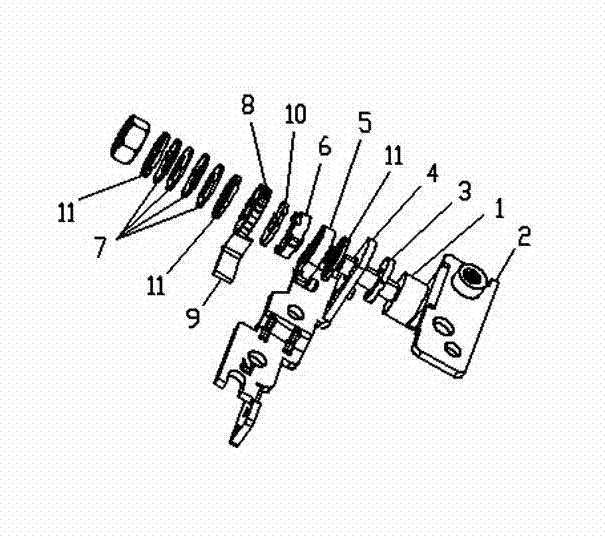

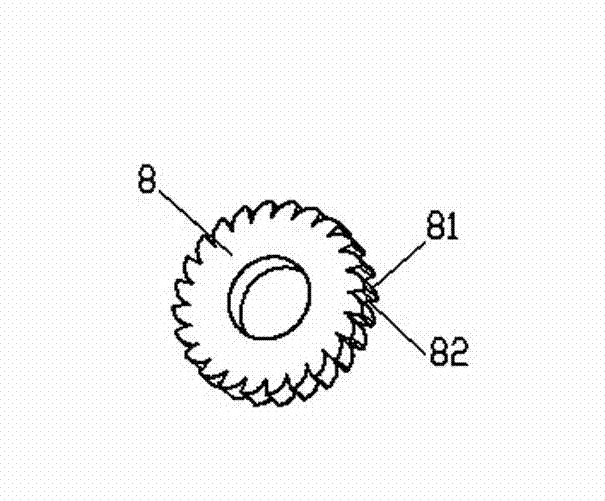

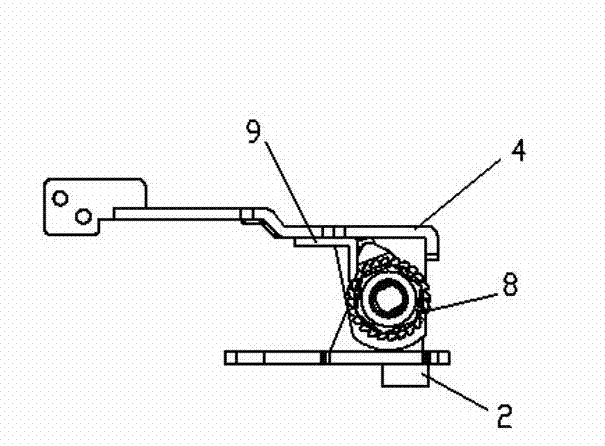

Easy-opening and hard-closing rotation shaft

ActiveCN102478048AImprove conveniencePrevent early fallPivotal connectionsEngineeringMechanical engineering

The invention discloses an easy-opening and hard-closing rotation shaft, which comprises a rotating shaft and a fixation frame. The rotating shaft is provided with a backstop sheet, a bearing frame, several disk elastic sheets and a nut in order. One end of the rotating shaft is in fixed connection with the fixation frame, and the other end is fastened by the nut. A gear sheet is installed between the bearing frame and the disk elastic sheets on the rotating shaft. By adding a gear sheet and a clamping column, a screen can be prevented from dropping in advance during closing due to weight problem. Thus, the rotation shaft of the invention improves the convenience of laptop operation, and also considers the intrinsic quality and performance of a product.

Owner:KUNSHAN VOSO HINGE ELECTRONICS TECH

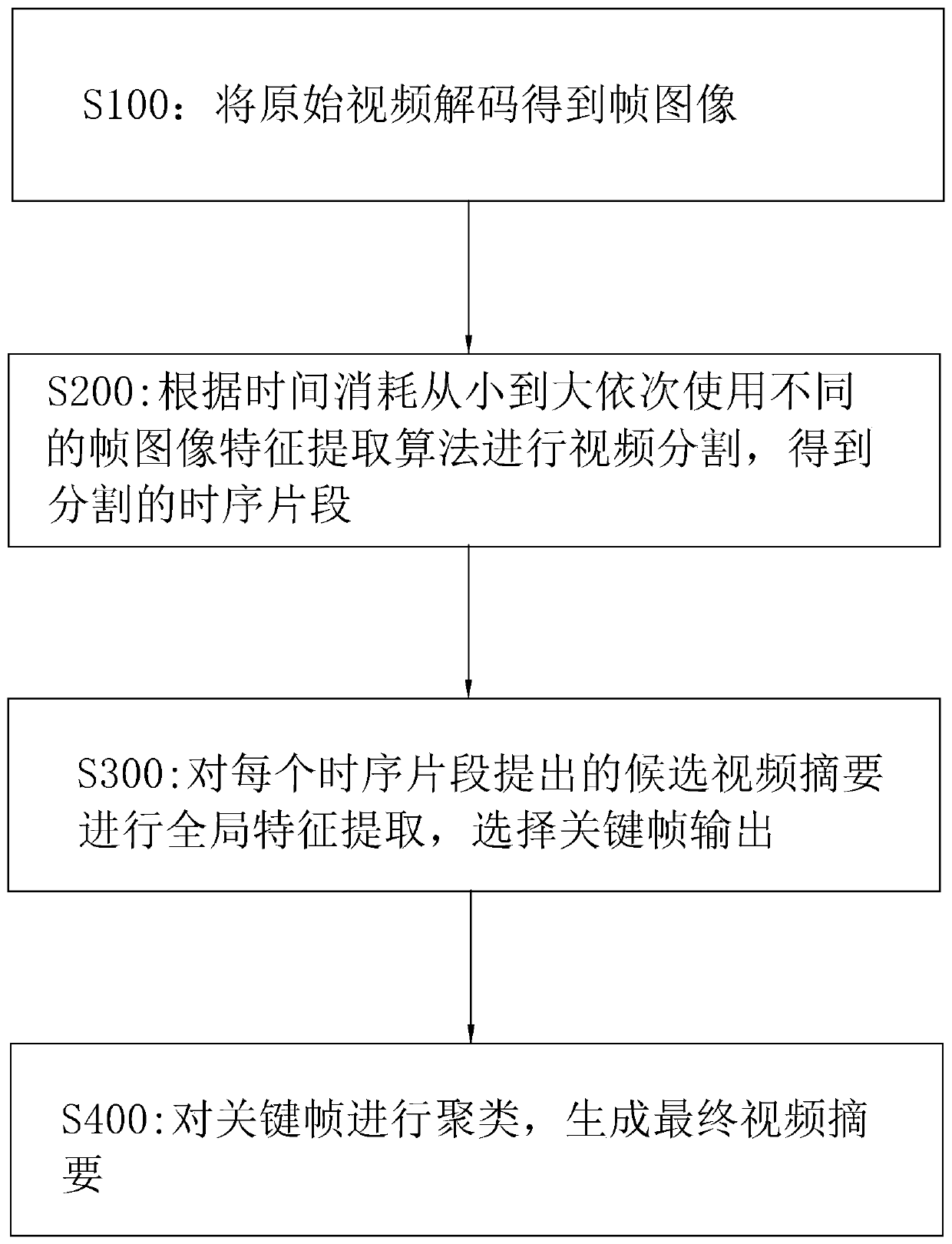

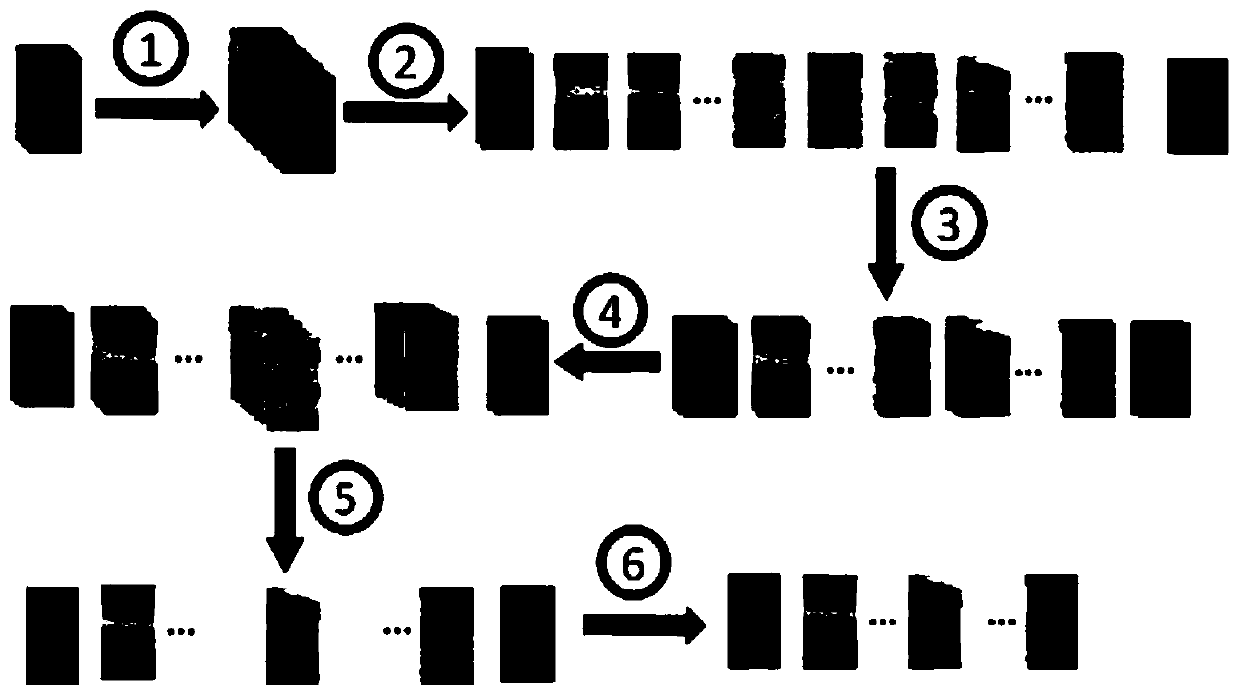

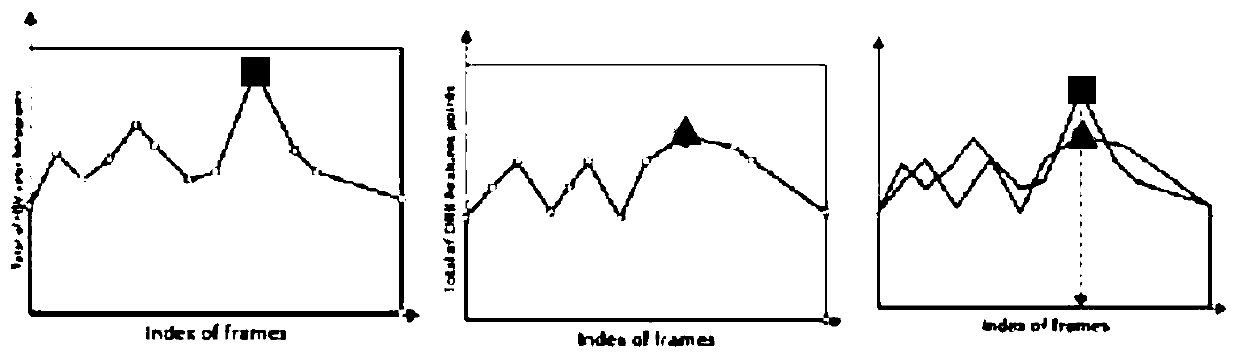

Video abstract extraction method, video abstract extraction system, video abstract extraction device and storage medium

InactiveCN110381392AEasy to keepReduce time consumptionCharacter and pattern recognitionSelective content distributionComputer graphics (images)Feature extraction algorithm

The invention discloses a video abstract extraction method, a video abstract extraction system, a video abstract extraction device and a storage medium. Different frame image feature extraction algorithms are sequentially used for hierarchical clustering from small to large according to time consumption, frame images needing to be processed are reduced layer by layer, finally, global features areextracted from candidate video abstracts proposed for each obtained segmented video clip, and a final video abstract is generated. Compared with an existing method, the method does not need to consider different feature weight problems, time consumption is greatly reduced, and the method has the advantages of being good in robustness, high in speed and good in effect.

Owner:WUYI UNIV

Pedaled parking stand

ActiveCN101797940AEliminate potential hazardsNo weight issuesVehicle cranksCycle standsParking spaceEngineering

Owner:DONGGUAN SHUNCHUEN METAL PROD

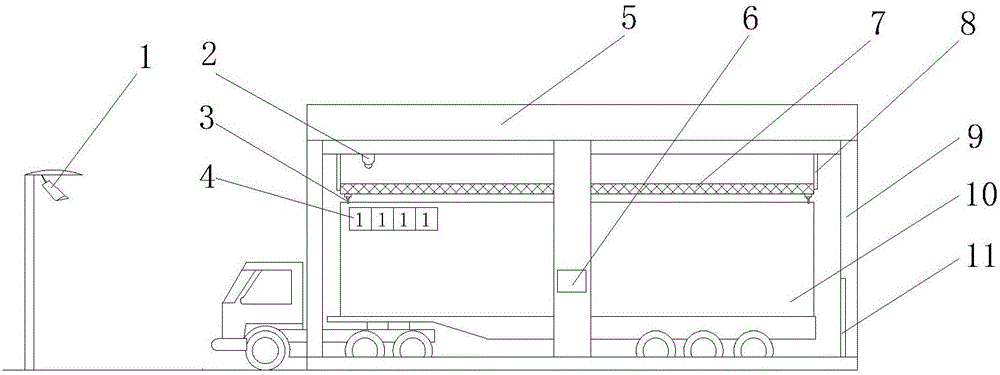

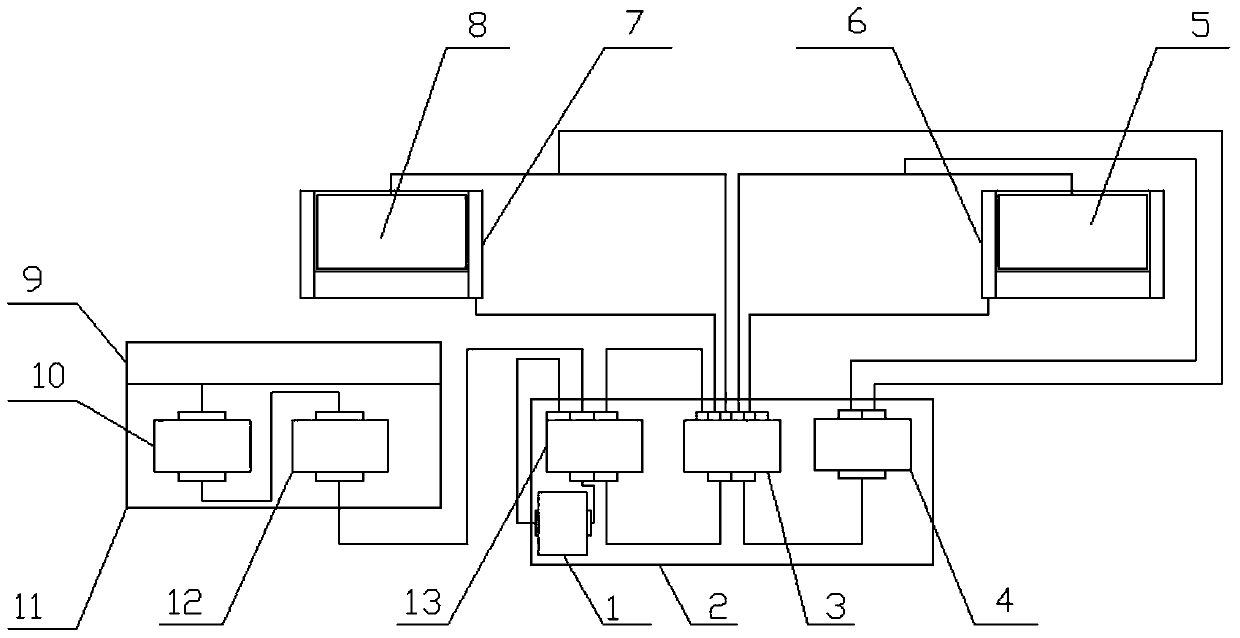

Container declared total weight weighing system

InactiveCN105953878ASolve the weight problemGuaranteed normal navigationSpecial purpose weighing apparatusTablet computerData platform

The invention discloses a container declared total weight weighing system which comprises the components of an image acquisition unit, a weighing channel, a container with an RFID label, a remote data platform and an intelligent pushing terminal. The image acquisition unit extracts information of a vehicle which enters the weighing channel and information of the container with the RFID label, and transmits the information to the remote data platform. The weighing channel hoists the container on the vehicle which passes through the channel and performs weighing, and performs feedback of weight information to the remote data platform. The remote data platform transmits the weight information to the intelligent pushing terminal and a national declaring organization. The intelligent pushing terminal is a smart phone or a panel computer or a smart watch. The container declared total weight weighing system can quickly and accurately acquire the container declared total weight, thereby radically setting a weight problem in ship loading and ensuring safe navigation of the ship. The container declared total weight weighing system supplies verified data for cargo weight declaring of importers and exporters by the custom department, thereby greatly improving weighing efficiency and reducing weighing cost.

Owner:初庆瀚 +1

Preparation method of light unmanned plane wing with high strength and low density

InactiveCN105543744ASolve technical problems in the extrusion processAchieve strengthUnmanned aerial vehiclesRoom temperatureFree cooling

The invention relates to a preparation method of a light unmanned plane wing with high strength of low density. (1) preparing a magnesium alloy ingot; (2) annealing after machining of the magnesium alloy ingot; (3) carrying out extrusion preparation: respectively heating the magnesium alloy ingot obtained in step (2), a die and an extrusion barrel; (4) extruding the magnesium alloy ingot obtained in step (3) to obtain a profile and dragging, (5) cutting the profile obtained in step (4); (6) machining a product obtained in step (5), then quenching, carrying out aging treatment, and then naturally cooling to room temperature; (7) machining the material obtained in step (6) so as to obtain the required unmanned plane wing. The preparation method is simple in process and easy to implement, can effectively solve the weight problem of the unmanned plane while ensuring the strength of the product, can improve flight efficiency, flight height and safety, and can reduce fuel consumption.

Owner:QINGHAI TSAIDAM QINGYUAN MAGNESIUM SCI & TECH CO LTD

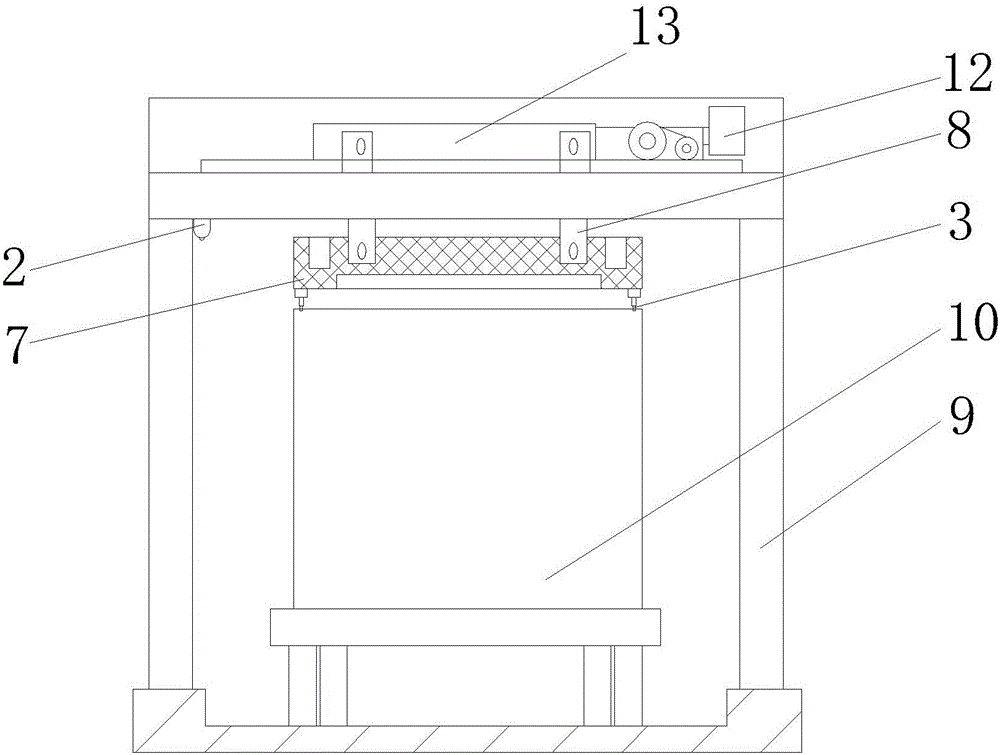

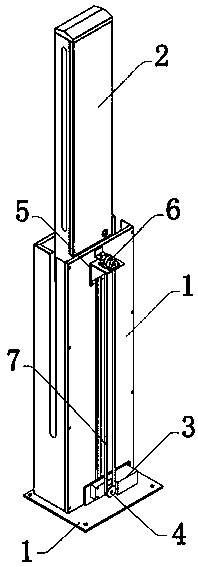

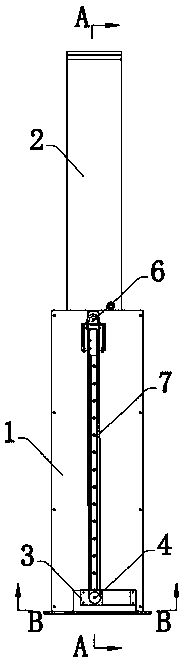

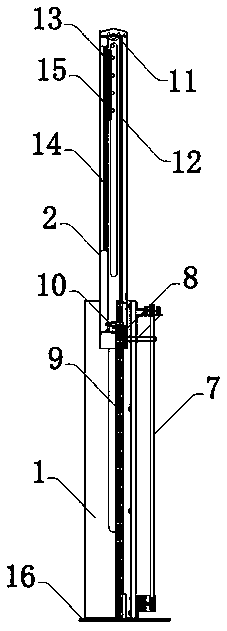

Intelligent safe elevating guardrail

PendingCN110409348ASolve the weight problemSimple structureTraffic restrictionsRoadway safety arrangementsEngineeringDrive motor

The invention discloses an intelligent safe elevating guardrail comprising two groups of frames, two groups of elevating racks, and a plurality of groups of protection ropes. The elevating racks are slidably connected with the upper ends of the inner sides of the frames, and the protection ropes are connected between the two groups of elevating racks. The bottom parts of the front side surfaces ofthe frames are fixedly provided with first driving motors, the output shafts of which are provided with lower synchronous belt pulleys. The front side surfaces of the frames are fixedly connected with L-shaped installation boards by bolts. The intelligent safe elevating guardrail is advantageous in that the structure is simple, and by adopting the box-shaped structure, the appearance is tidy andnovel, and the elevating racks can carry out the upward and downward elevating motions to realize the opening and the closing of the protection ropes, and therefore the unmanned management of the intermittent releasing places can be solved, the application range is wide, the fault rate is low, the service lifetime is long, the safety performance is high; the guardrail adopts the protection ropes having the flexible structures, and the protection ropes do not droop during the large-span use, and therefore the safety performance is excellent, the weight problem of the rigid connection can be solved, and the dropping problem of the flexible structure can be also solved.

Owner:深圳市复兴智能设备中心(有限合伙)

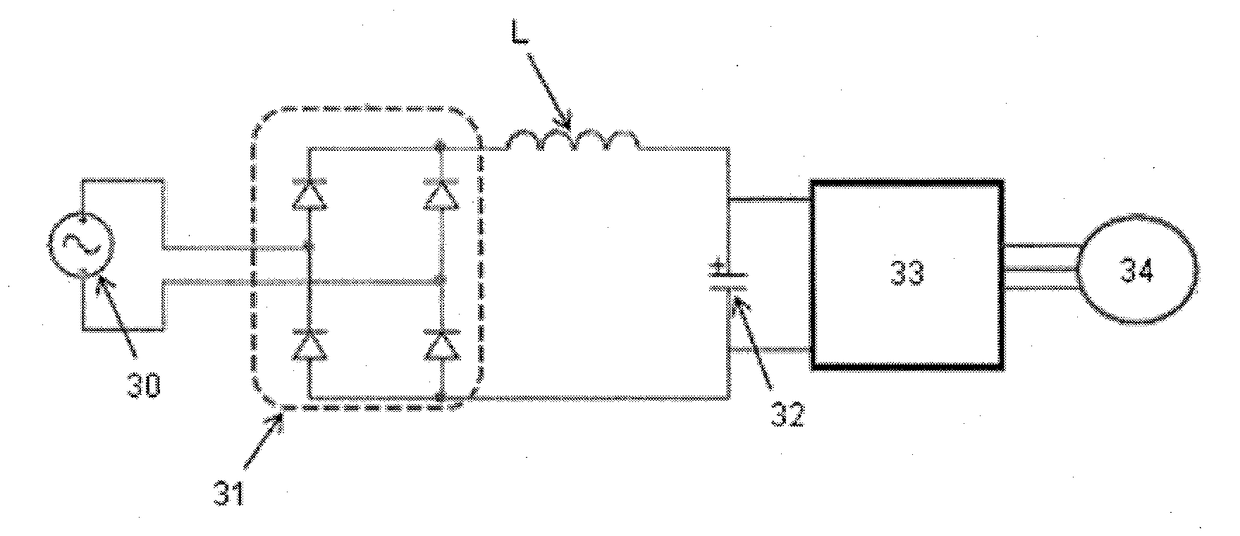

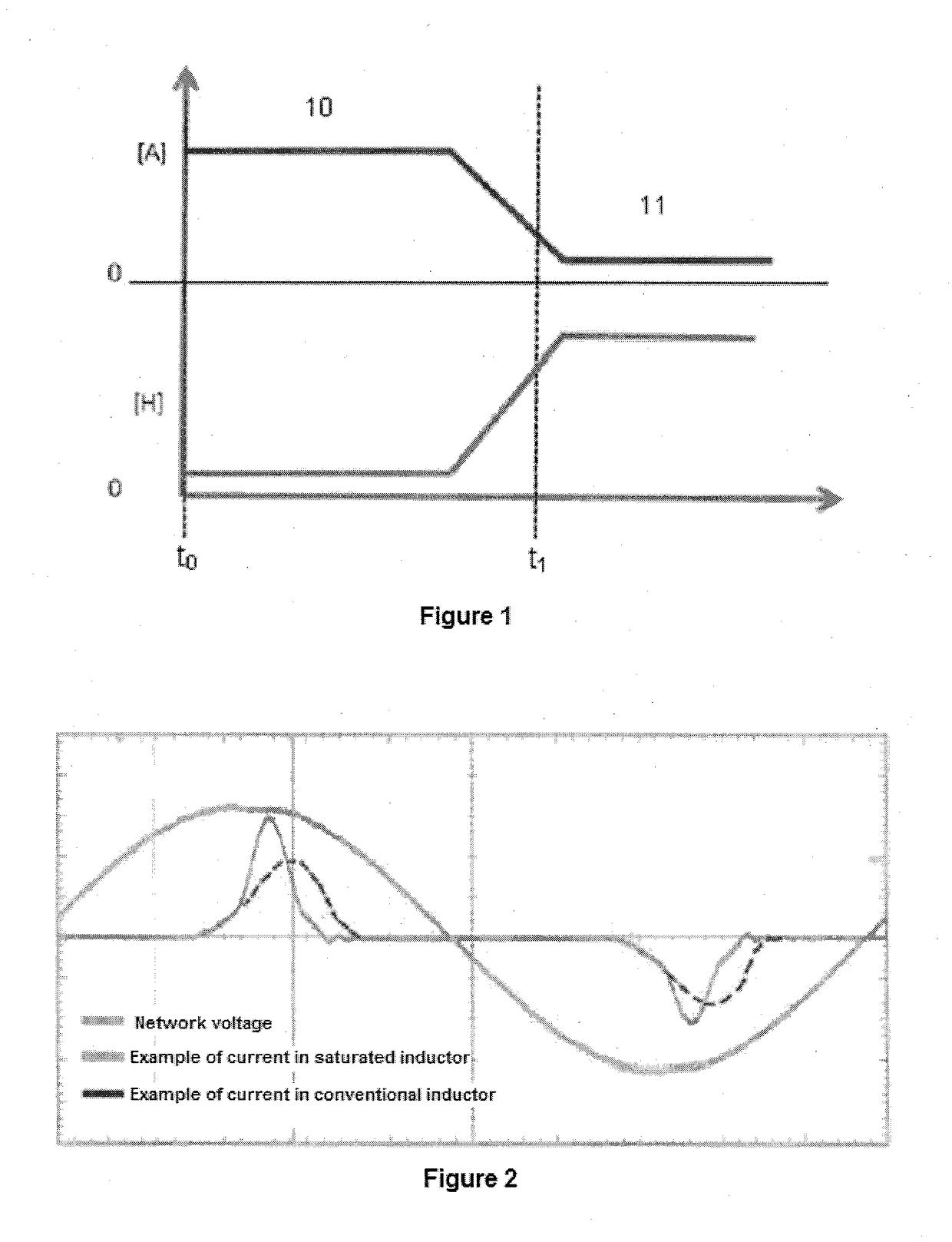

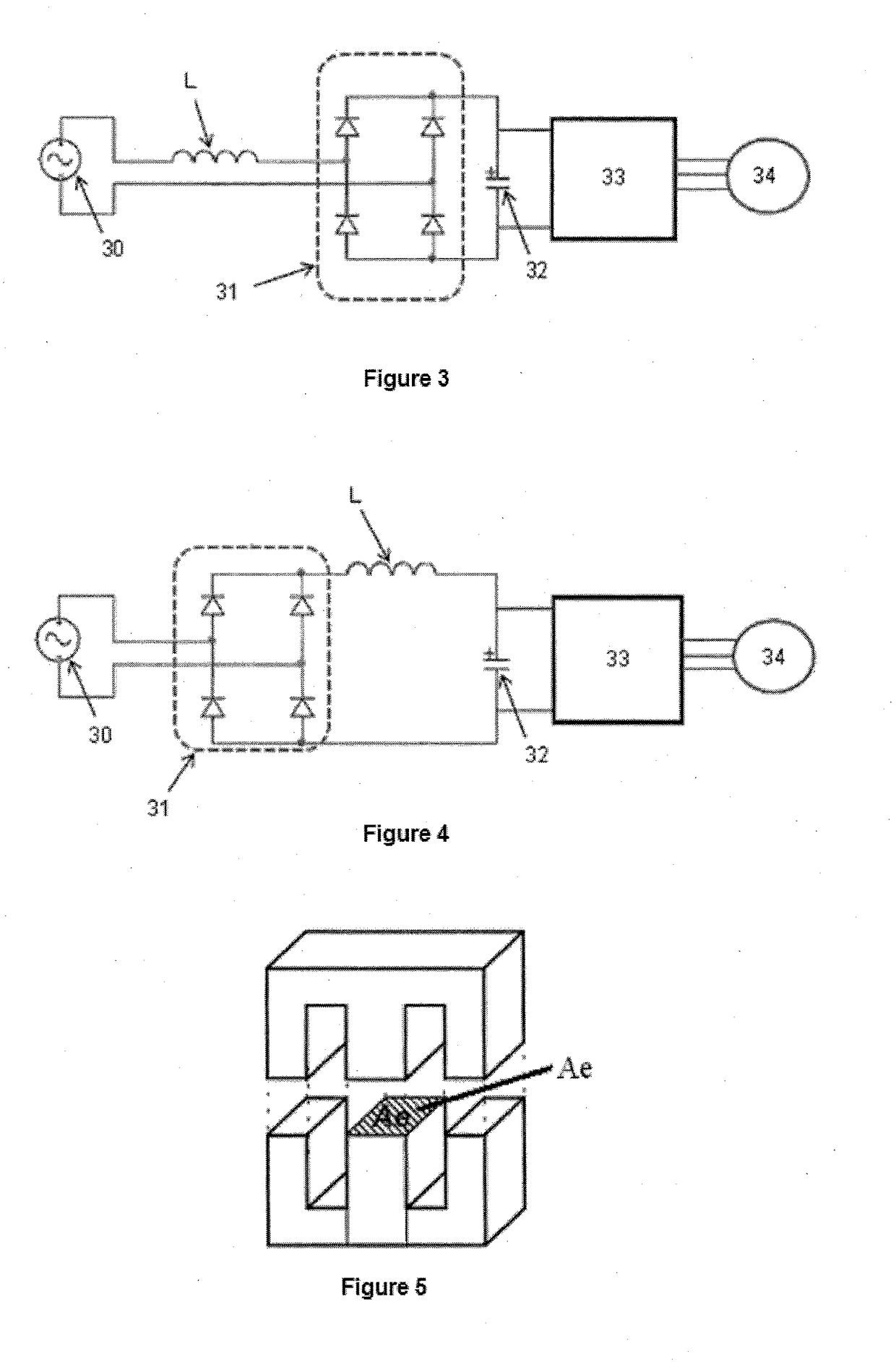

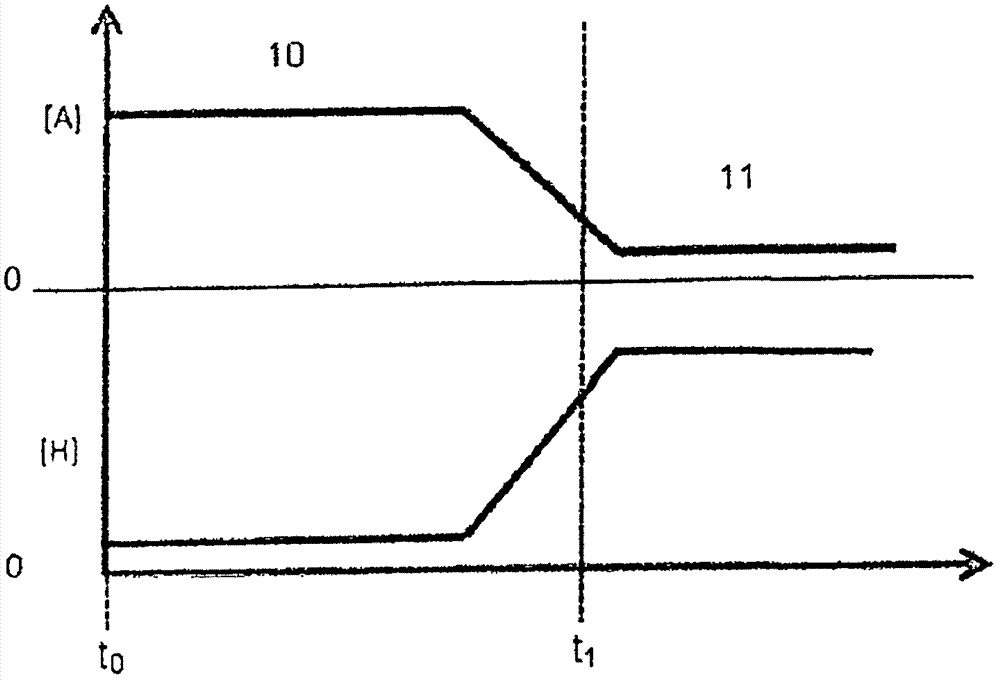

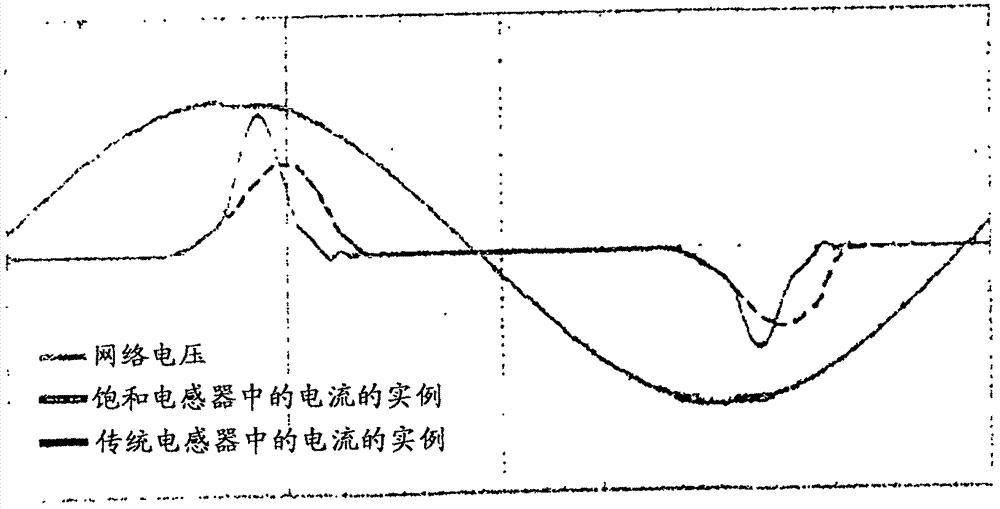

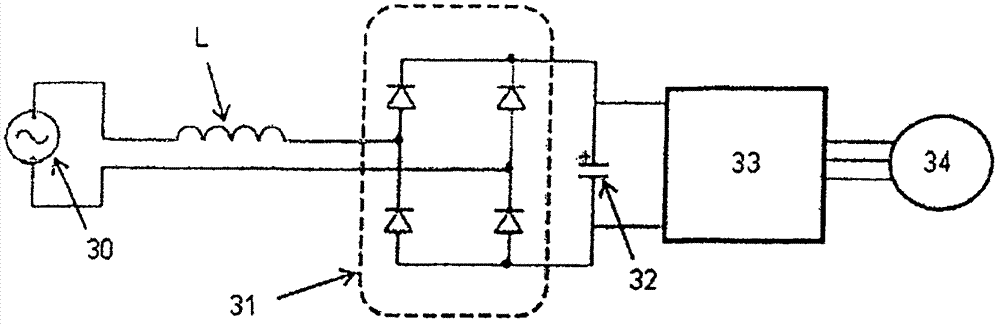

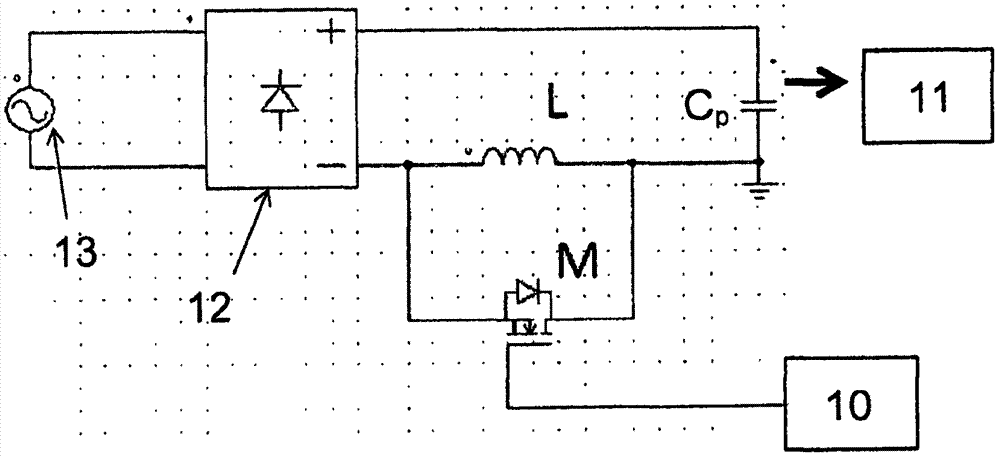

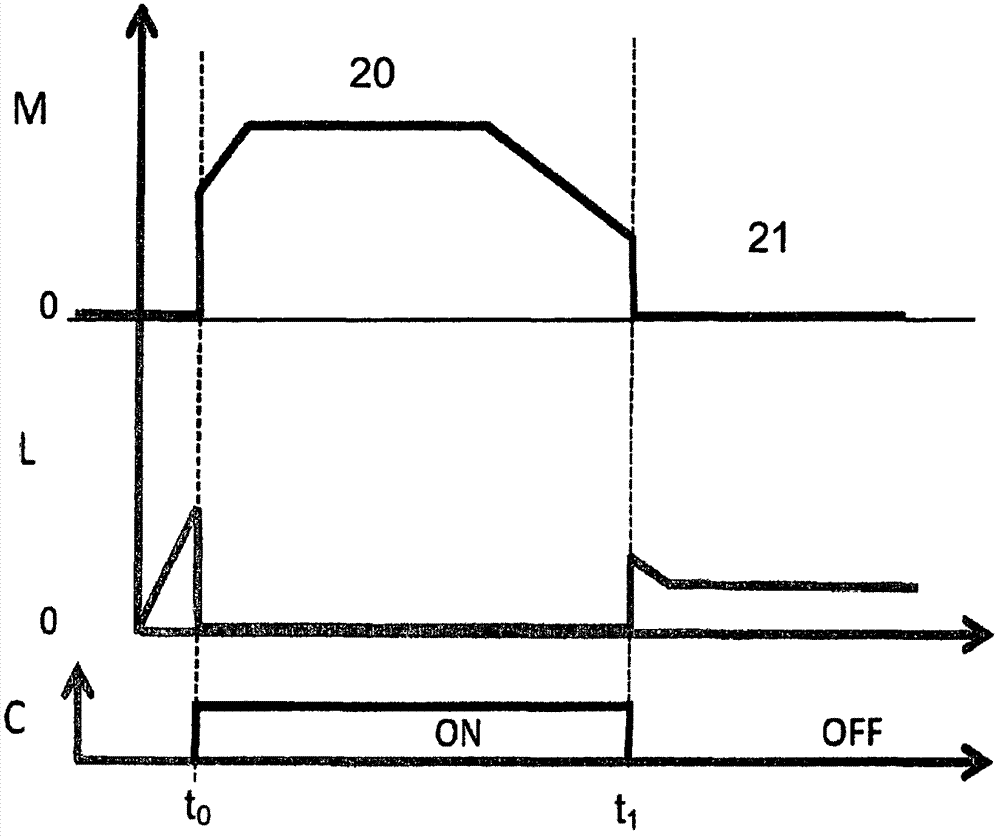

System for Correction of Harmonic Content in Electric Power Circuit, System for Control of Electric Motors, and Refrigeration Compressor

InactiveUS20170257021A1Small dimensionSmall weightAC motor controlAc-dc conversion without reversalRefrigeration compressorElectric power system

The present invention relates to the fields of power electronics and electric motors, and describes a system for correcting harmonic content in power systems. The invention solves the space and weight problem, associated with the core of an inductor for correcting harmonic content, also providing performance advantages of electric motors, such as higher available voltage at maximum load and higher rotational speed at maximum load. The invention is particularly useful in refrigeration compressors.

Owner:WHIRPOOL SA

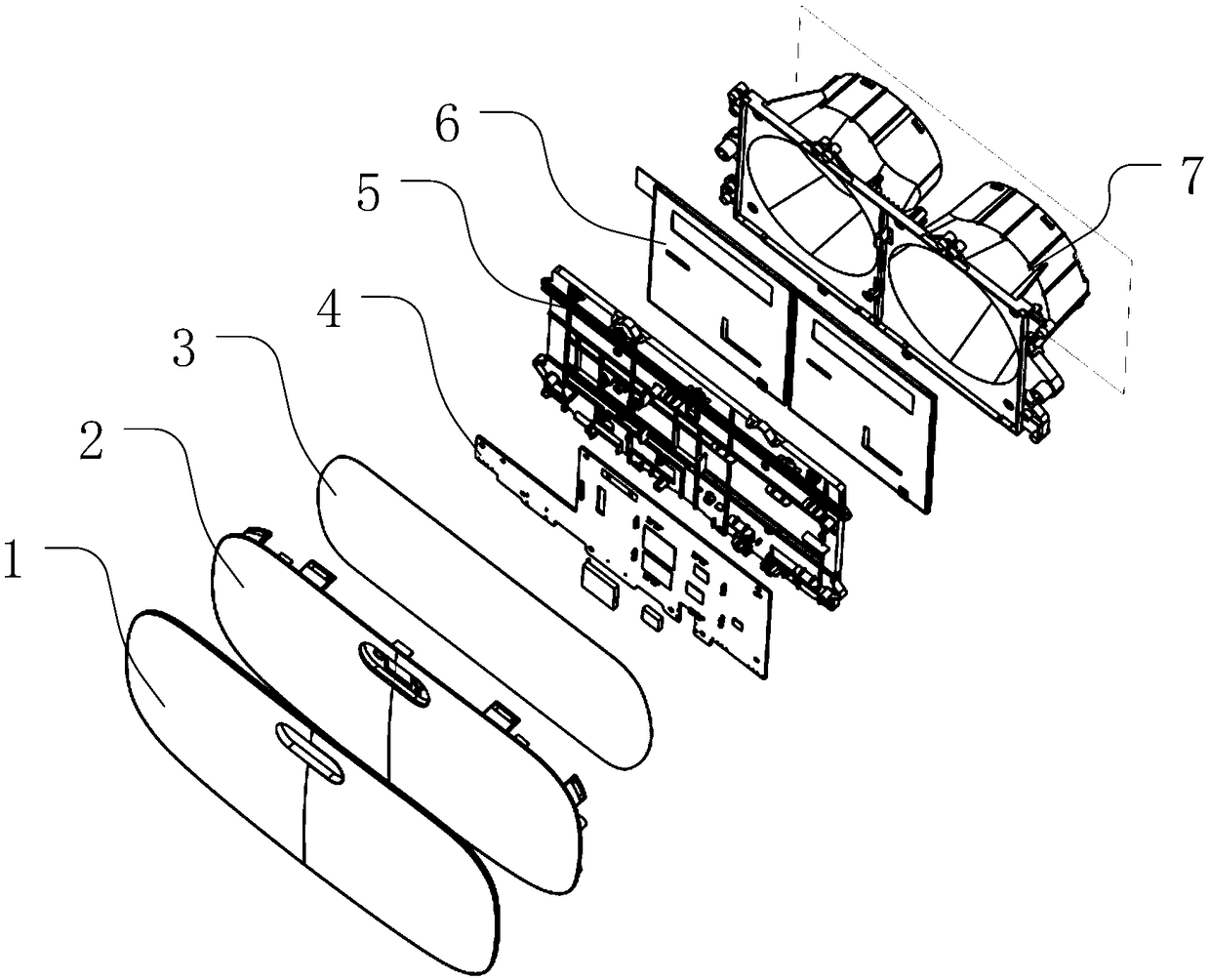

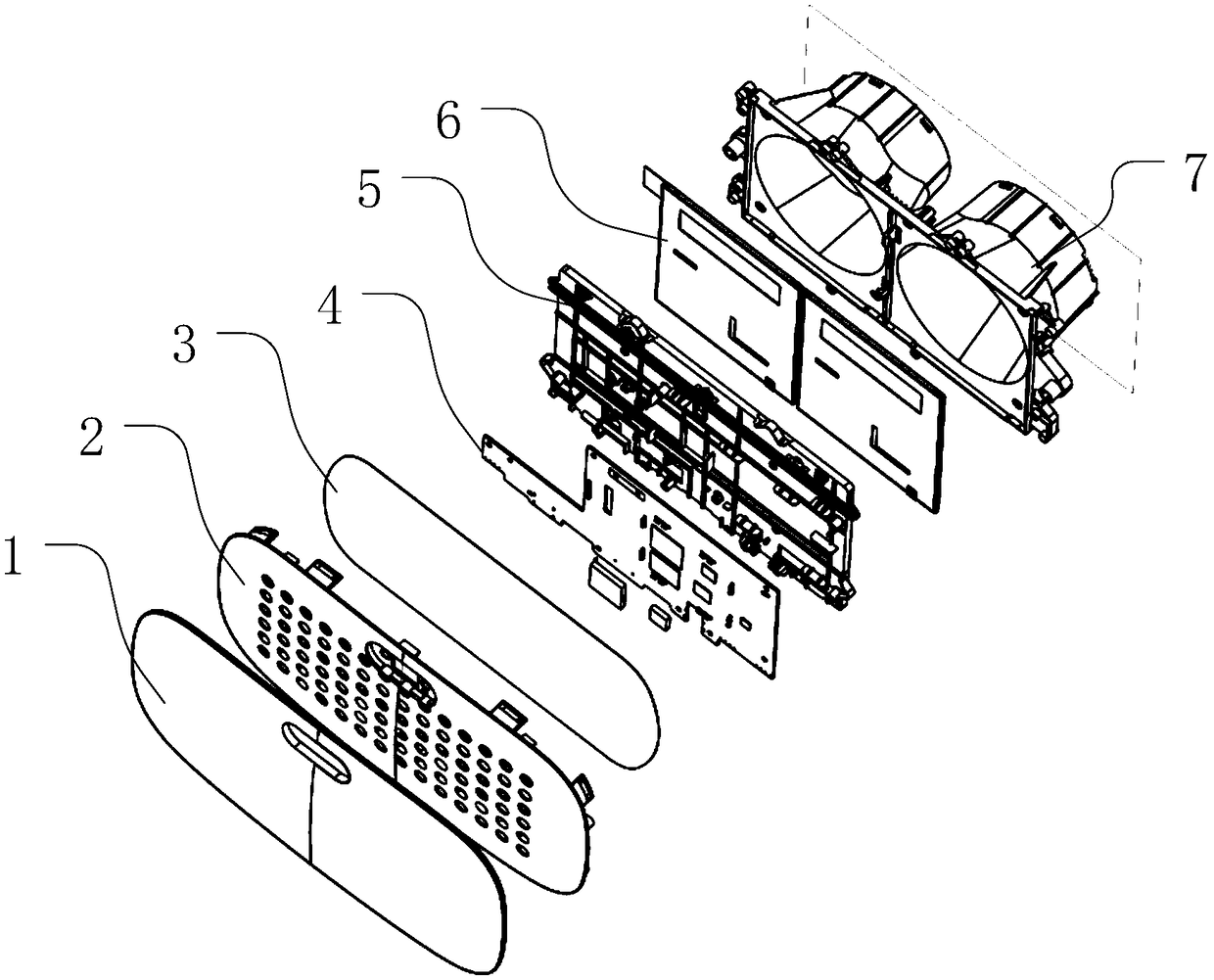

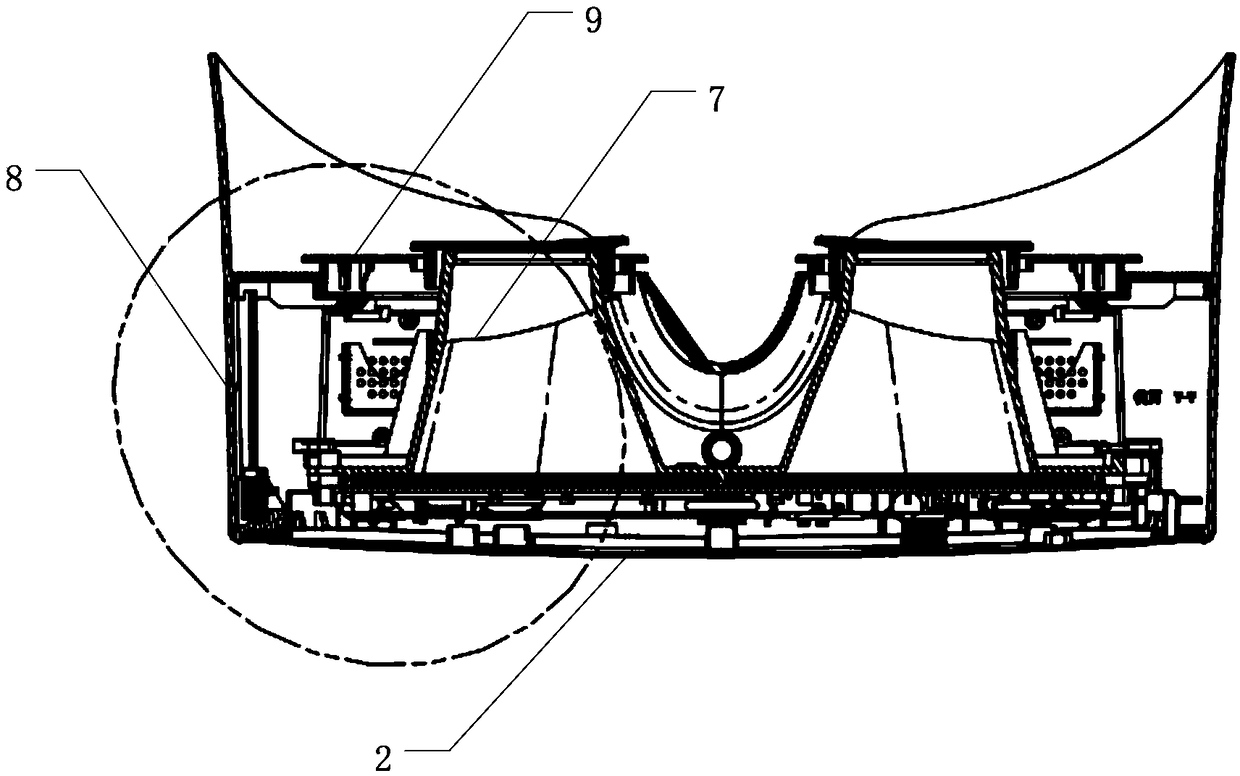

Virtual reality device

PendingCN108761796ARealize heat dissipation and coolingSolve temperature problemsOptical elementsHeat conductingEngineering

The invention discloses a virtual reality device which comprises a front shell, and a mainboard arranged on the inner side of the front shell, wherein the front shell is made of a heat-conducting material; a processing chip and a power management circuit are arranged on the front side of the mainboard; a thermal diffusion membrane is arranged between the inner wall of the front shell and the mainboard; and the thermal diffusion membrane is respectively contacted with the front shell, the processing chip and the power management circuit. With the adoption of a passive heat dissipation manner, the front shell and cooling fins of the virtual reality device are integrated, the front shell is made of the heat-conducting material, the thermal diffusion membrane is arranged between the inner wallof the front shell and the mainboard and contacted with the processing chip and the power management circuit of the mainboard, so that heat generated by operation is rapidly conducted to the front shell and finally dissipated to an external environment, and heat dissipation cooling of the virtual reality device can be realized. Moreover, by taking the front shell as the cooling fins of the virtual reality device, the weight problem brought by added extra cooling fins is solved, the lightweight design is facilitated, and the wearing experience is improved.

Owner:QINGDAO PICO TECH CO LTD

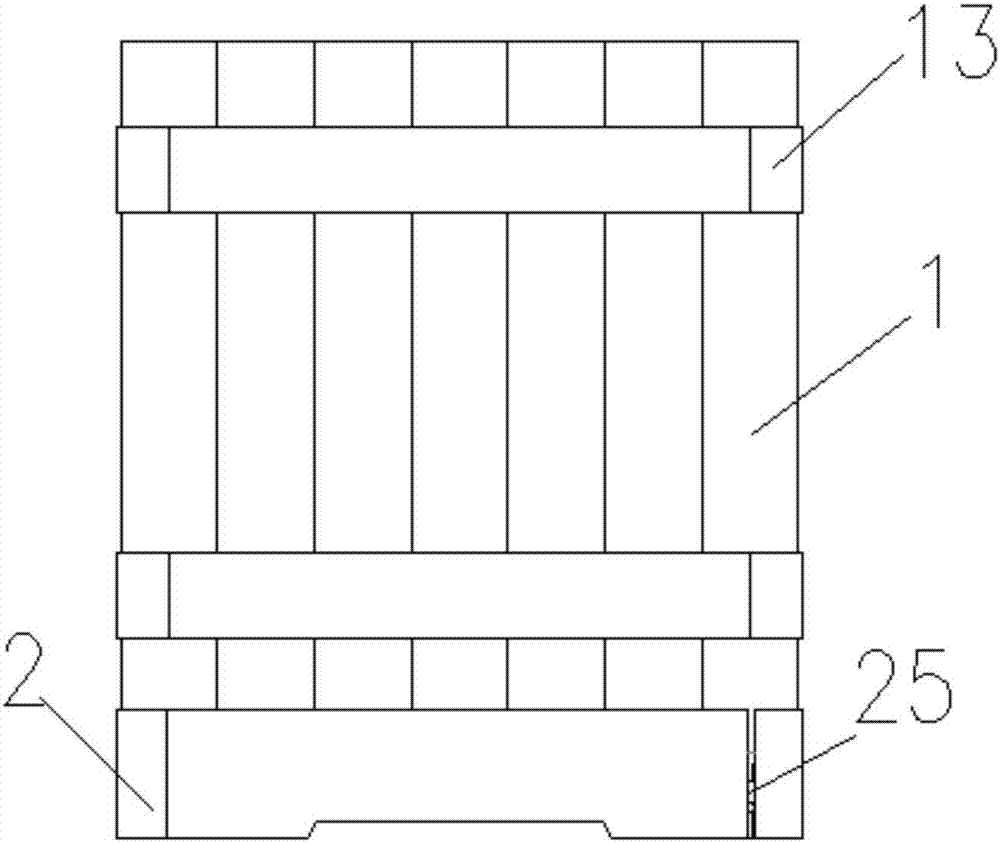

Fireworks paper tube

The invention discloses a fireworks paper tube. The fireworks paper tube comprises a tube body consisting of multiple bobbins, a base arranged at the lower part of the tube body, and a lead inserted into the base from the bottom of the base; the lead is inserted to form a lead column; one end of single bobbin is opened, and the other end is a bottom seal with a glue layer; the bottom seal is formed by extruding the tube body; adhesive layers are arranged between the adjacent bobbins; the bobbins are connected through the adhesive layers to form the tube body; and a first through hole matched with the lead column is formed in the bottom of the tube body. The fireworks paper tube with the structure saves a mud bottom forming procedure, has no mud bottom to achieve cleanness and solve the fireworks transportation weight problem, can preferably prevent the problems of damping of the mud bottom of an inner tube and breakage of the bottom paper tube, and can preferably guarantee the product quality.

Owner:叶兴龙

Vertical spinning machine for tank of cement tanker

InactiveCN110170563AImprove mechanical propertiesEnables a solderless processHollow articlesManufacturing cost reductionAgricultural engineering

The invention discloses a vertical spinning machine for a tank of a cement tanker, and relates to the spinning machine. The vertical spinning machine for the tank of the cement tanker comprises a rack, wherein spinning devices are uniformly distributed on the side surface of the rack and are up-and-down slidably connected to the side surface of the rack; spinning wheels are slidably connected above the spinning devices through hydraulic rods; the movement directions of the hydraulic rods face the middle of the rack; and a fixing mechanism is connected to the inner side of the rack through rotating a drive mechanism. More welding quality problems for traditional tank manufacturing exist, the flaw detection program is complex, and the overall weight problem is hard to solve. Through spinningmanufacturing, a non-welding process of a tank bottom component can be realized, the overall quality is good, light-weight manufacturing can be realized, the manufacturing cost is reduced, and an effective load is increased. Through spinning manufacturing, a mechanical performance of the tank is improved; and a grain structure of a material is changed through spinning, so that the mechanical strength is improved. The vertical spinning machine for the tank of the cement tanker provided by the invention adopts three vertical type rollers for multi-pass spinning so as to be applicable to spinning workpieces in different sizes; and the rollers are hydraulic driven so as to be sufficient in power and good in spinning effect.

Owner:山东京华智能装备有限公司

A method for preparing a high-strength, low-density lightweight UAV wing

InactiveCN105543744BSolve technical problems in the extrusion processAchieve strengthUnmanned aerial vehiclesRoom temperatureHigh intensity

The invention relates to a method for preparing a high-strength, low-density lightweight unmanned aerial vehicle wing. The method comprises the following steps: (1) preparing a magnesium alloy ingot; (2) annealing the magnesium alloy ingot after machining; (3) extrusion preparation : heating the magnesium alloy ingot, mold and extrusion cylinder obtained in step (2) respectively; (4) extruding the magnesium alloy ingot obtained in step (3) to obtain a profile and pulling it; (5) cutting the profile obtained in step (4); (6) The product obtained in step (5) is machined and quenched, and after aging treatment, it is naturally cooled to room temperature; (7) the material obtained in step (6) is machined to obtain the required drone wing. The process of the invention is simple and easy to implement, and the obtained product can effectively solve the weight problem of the drone while ensuring strength, improve flight efficiency, flight height and safety, and reduce fuel consumption.

Owner:QINGHAI TSAIDAM QINGYUAN MAGNESIUM SCI & TECH CO LTD

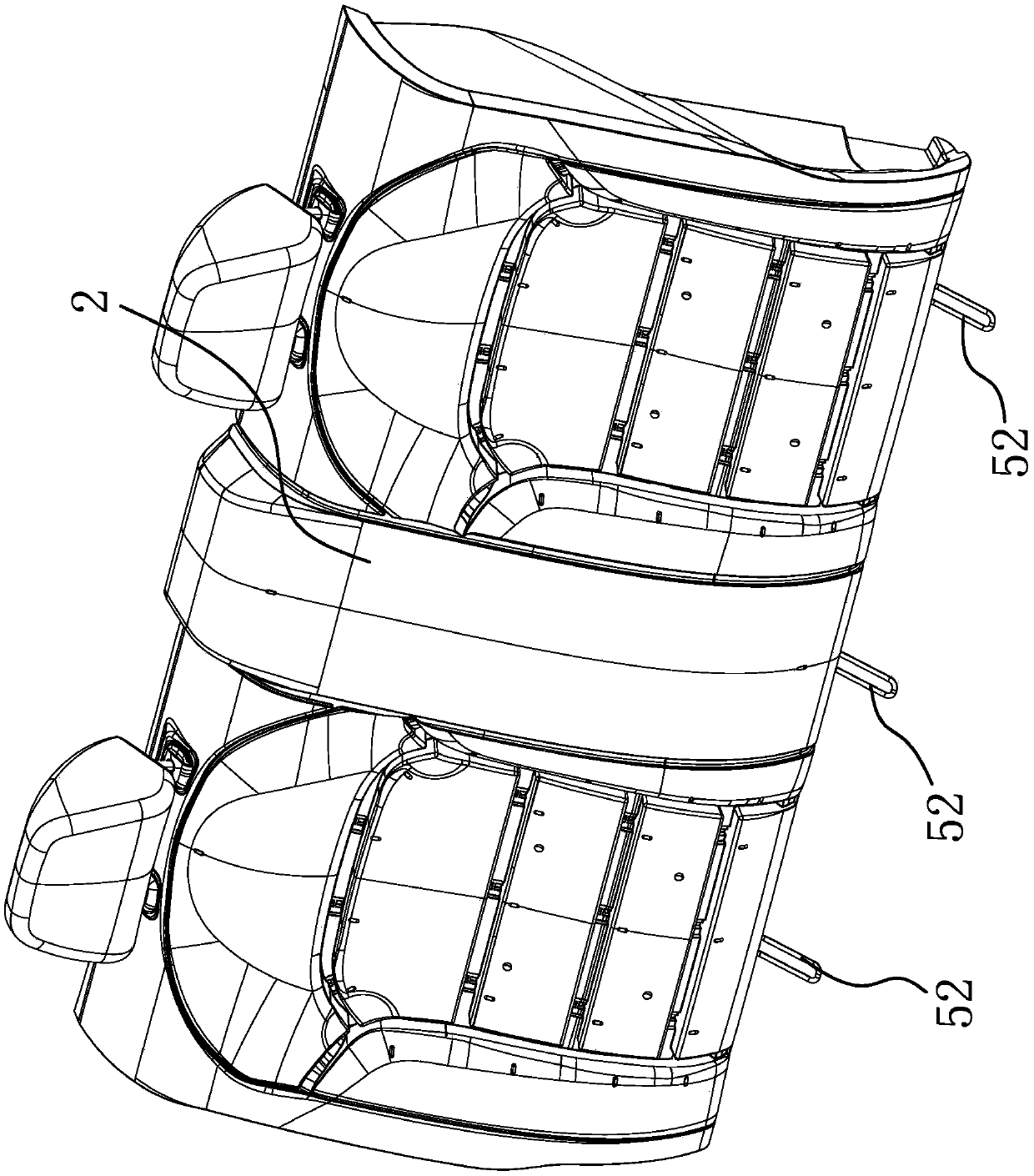

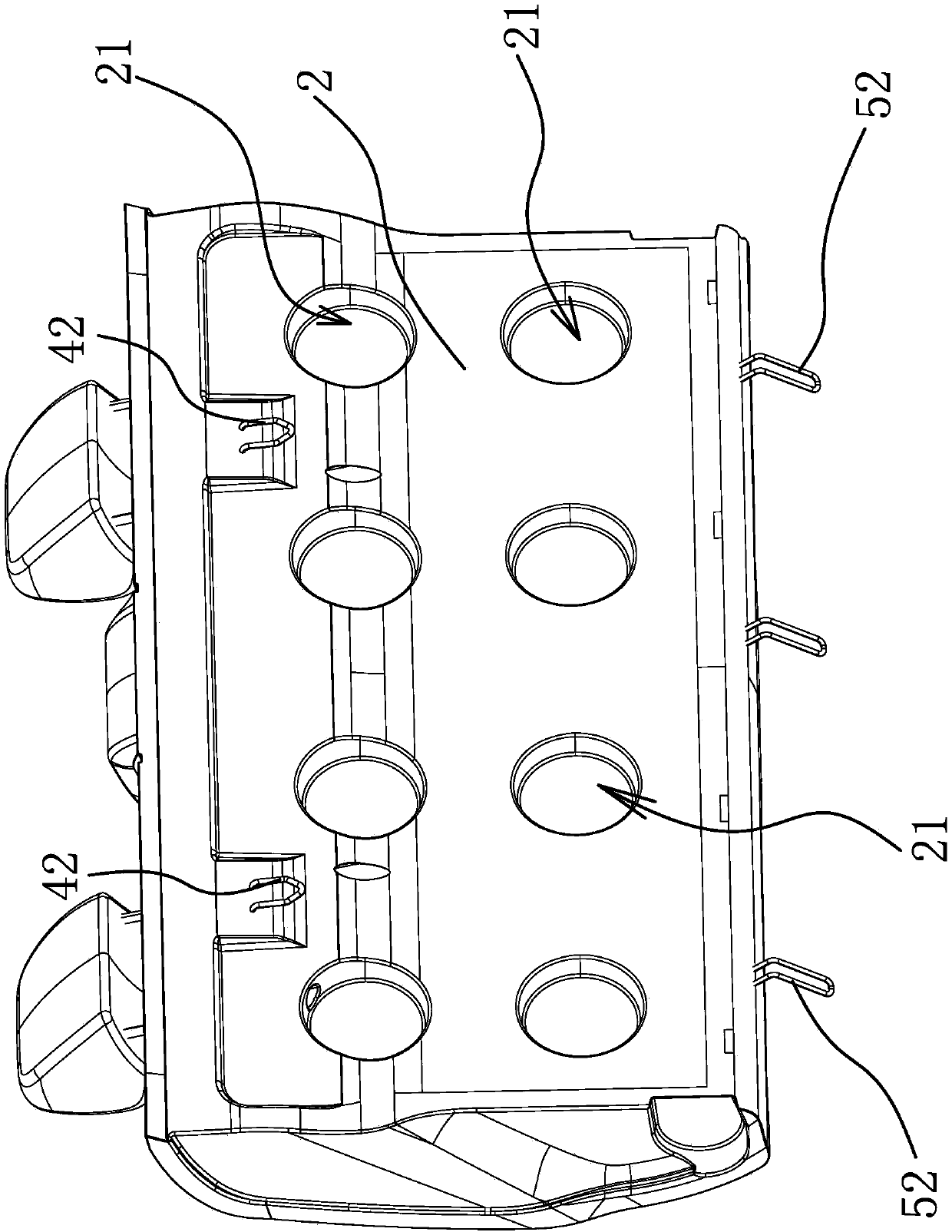

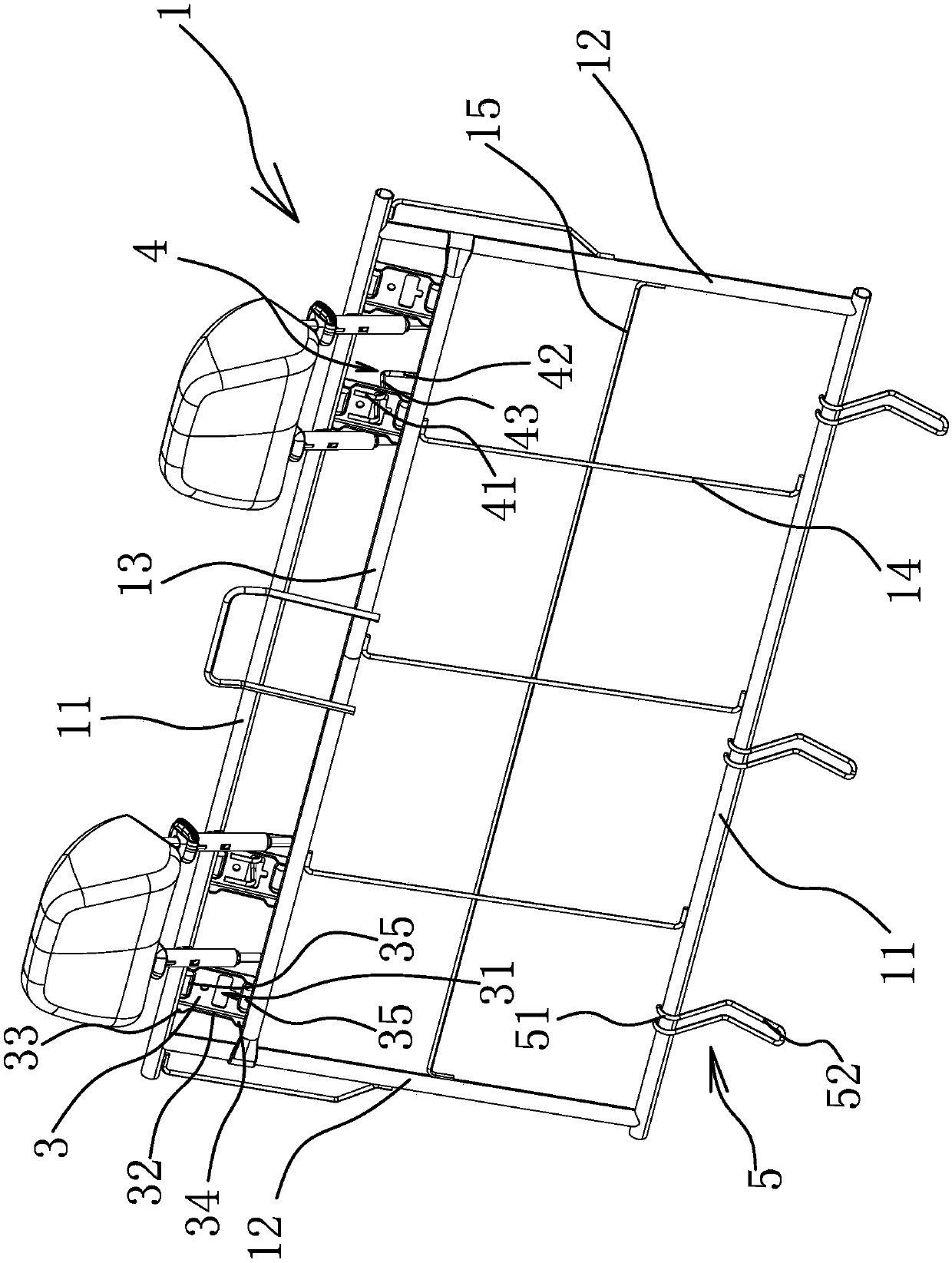

Back row seat

The invention provides a back row seat, and belongs to the technical field of automobile accessories. The problems that an existing automobile back row seat is small in weight and inconvenient to disassemble are solved. The back row seat comprises a supporting frame and a seat cushion body; the supporting frame is in a frame shape and embedded into the seat cushion body, the supporting frame comprises two transverse tubes and two vertical tubes located between the two transverses tubes, an installing tube is arranged between the two transverse tubes, and the two ends of the installing tube areconnected with the two vertical tubes respectively; a positioning plate is arranged between the installing tube and the transverse tube close to the upper end of the supporting frame, an installing hole is formed in the positioning plate, a limiting rod is arranged on the positioning plate, one end of the limiting rod is bent to form a fixing part, the fixing part is arranged upwards, penetratesthrough the installing hole and fits the positioning plate, the other end of the limiting rod penetrates out of the seat cushion body and is bent to form a hook ring capable of being connected with acarframe, and the hook ring is arranged downwards. While the back row seat lightweight design is achieved, the strength of the back row seat can be improved.

Owner:浙江俱进汽摩配件有限公司

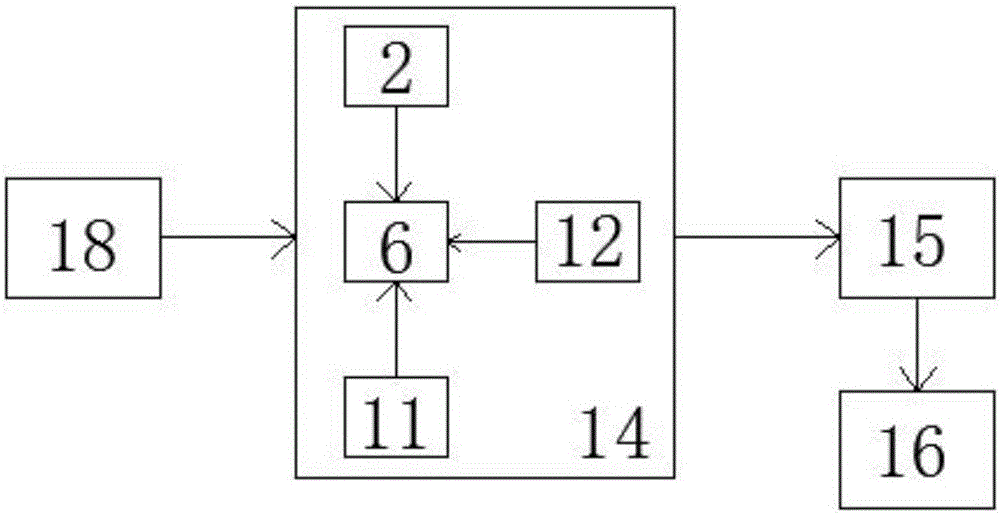

A device and method for synchronously displaying explosive package weight information in different places

InactiveCN105225624BSolve the problem of unstable packaging weightIncrease productivityStatic indicating devicesEffective solutionInstability

The invention discloses a device and method for synchronously displaying explosive package weight information in different places, including a weighing module, a conversion module, a sending module, a receiving module, a control module, a display module A, a display module B and a PCB board A. The output port of the measuring module is connected with the input port of the conversion module, the output port of the conversion module is connected with the input port of the sending module, the output port of the sending module is connected with the input port of the receiving module, and the output port of the receiving module is connected with the input port of the control module The receiving module and the control module are integrated on the PCB board A, and the output ports of the control module are respectively connected to the input ports of the display module A, the display module B and the receiving module. The invention uses the weighing module, display module A, and display module B to display the weight of the medicine box synchronously in the packaging workshop and the charging workshop, effectively solving the problem of unstable packaging weight of explosives in the production of explosive packages, and improving the qualified rate of products.

Owner:GUIZHOU JIULIAN IND EXPLOSIVE MATERIALS DEV

System for correction of harmonic content in electric power circuit, system for control of electric motors, and refrigeration compressor

InactiveCN107222152ASmall sizeSmall weightAC motor controlAc-dc conversion without reversalRefrigeration compressorElectric power system

The present invention relates to the fields of power electronics and electric motors, and describes a system for correcting harmonic content in power systems. The invention solves the space and weight problem, associated with the core of an inductor for correcting harmonic content, also providing performance advantages of electric motors, such as higher available voltage at maximum load and higher rotational speed at maximum load. The invention is particularly useful in refrigeration compressors.

Owner:WHIRPOOL SA

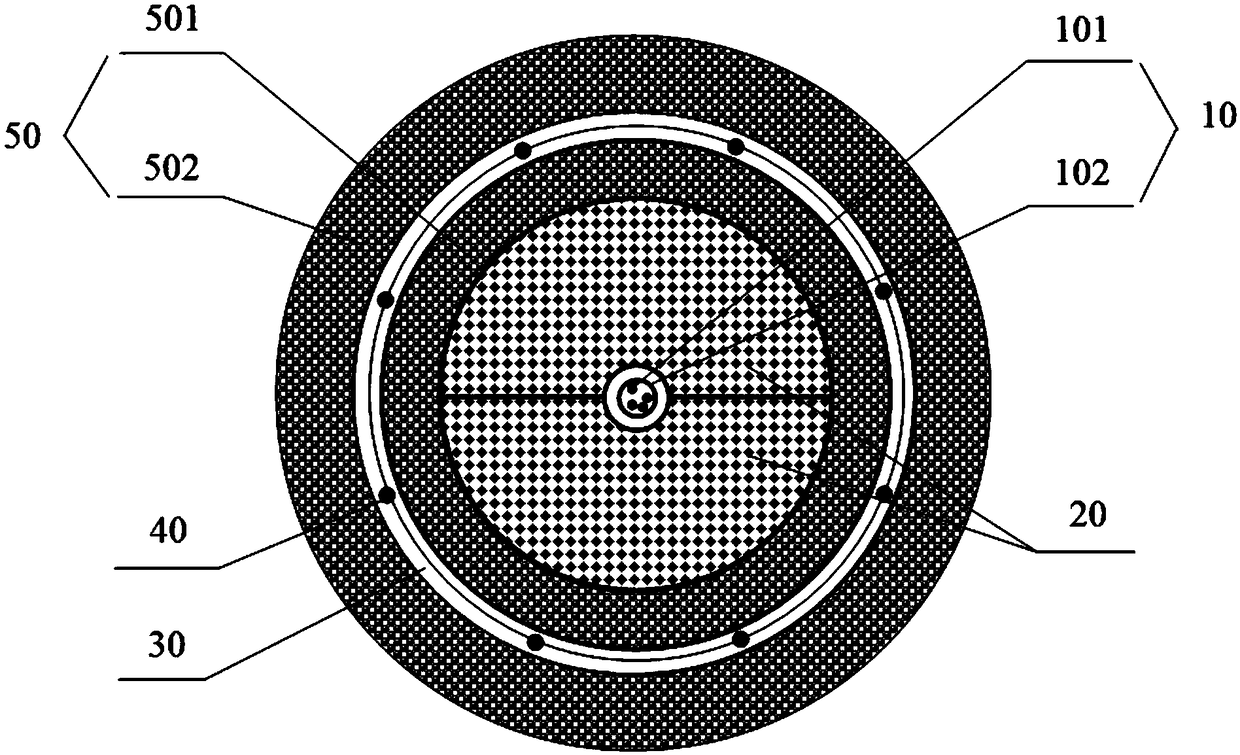

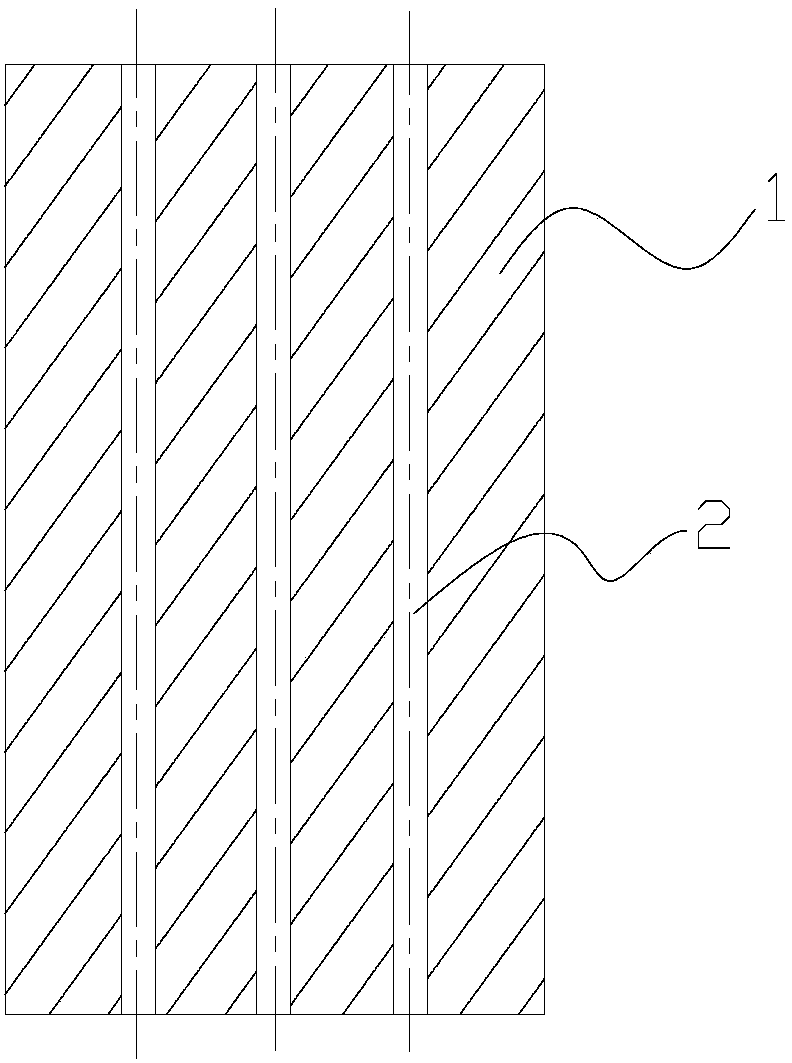

Micro-beam tube tactical optical cable

The invention relates to a micro-beam tube tactical optical cable. The micro-beam tube tactical optical cable comprises a double-layer extrusion TPU layer, a flexible foaming material pipe and a micro-beam tube unit, wherein the double-layer extrusion TPU layer comprises a second TPU layer and a first TPU layer which are arranged from outside to inside, a double-layer flexible film layer is arranged between the second TPU layer and the first TPU layer and comprises a second flexible film layer and a first flexible film layer, and multiple strands of aramid yarns are arranged between the secondflexible film layer and the first flexible film layer; the middle of the flexible foaming material pipe is of a hollow structure, and the flexible foaming material pipe is formed by splicing two flexible foaming material units; and the micro-beam tube unit comprises a micro-beam tube and a plurality of coloring optical fibers arranged in the micro-beam tube from outside to inside. The micro-beamtube tactical optical cable has the advantages of stretching resistance, side pressure resistance, wear resistance, lightness and the like, the disadvantages that an existing metal armored tactical optical cable has a weight problem, and the electromagnetic interference resistance of the existing metal armored tactical optical cable is decreased are overcome, and the micro-beam tube tactical optical cable can meet the military field communication and civil communication requirements in thundering areas.

Owner:SHENZHEN SDG INFORMATION CO LTD

a fireworks paper tube

The invention discloses a fireworks paper tube. The fireworks paper tube comprises a tube body consisting of multiple bobbins, a base arranged at the lower part of the tube body, and a lead inserted into the base from the bottom of the base; the lead is inserted to form a lead column; one end of single bobbin is opened, and the other end is a bottom seal with a glue layer; the bottom seal is formed by extruding the tube body; adhesive layers are arranged between the adjacent bobbins; the bobbins are connected through the adhesive layers to form the tube body; and a first through hole matched with the lead column is formed in the bottom of the tube body. The fireworks paper tube with the structure saves a mud bottom forming procedure, has no mud bottom to achieve cleanness and solve the fireworks transportation weight problem, can preferably prevent the problems of damping of the mud bottom of an inner tube and breakage of the bottom paper tube, and can preferably guarantee the product quality.

Owner:叶兴龙

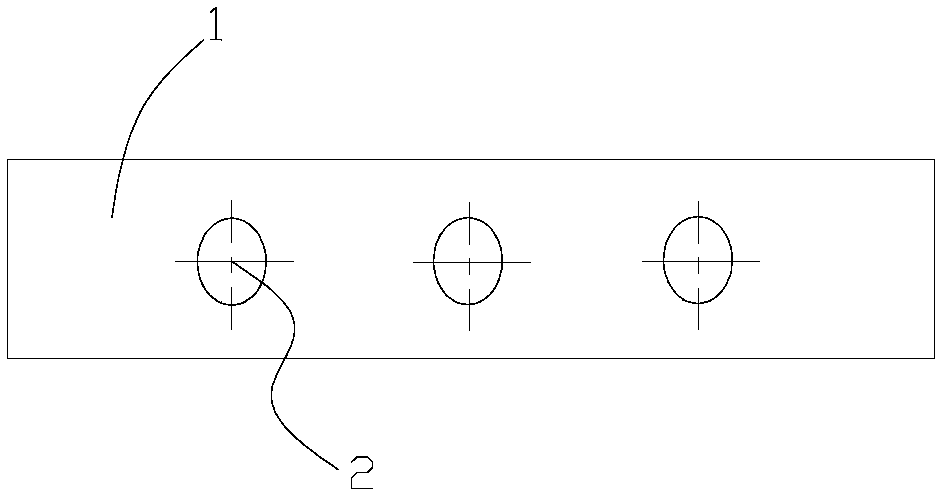

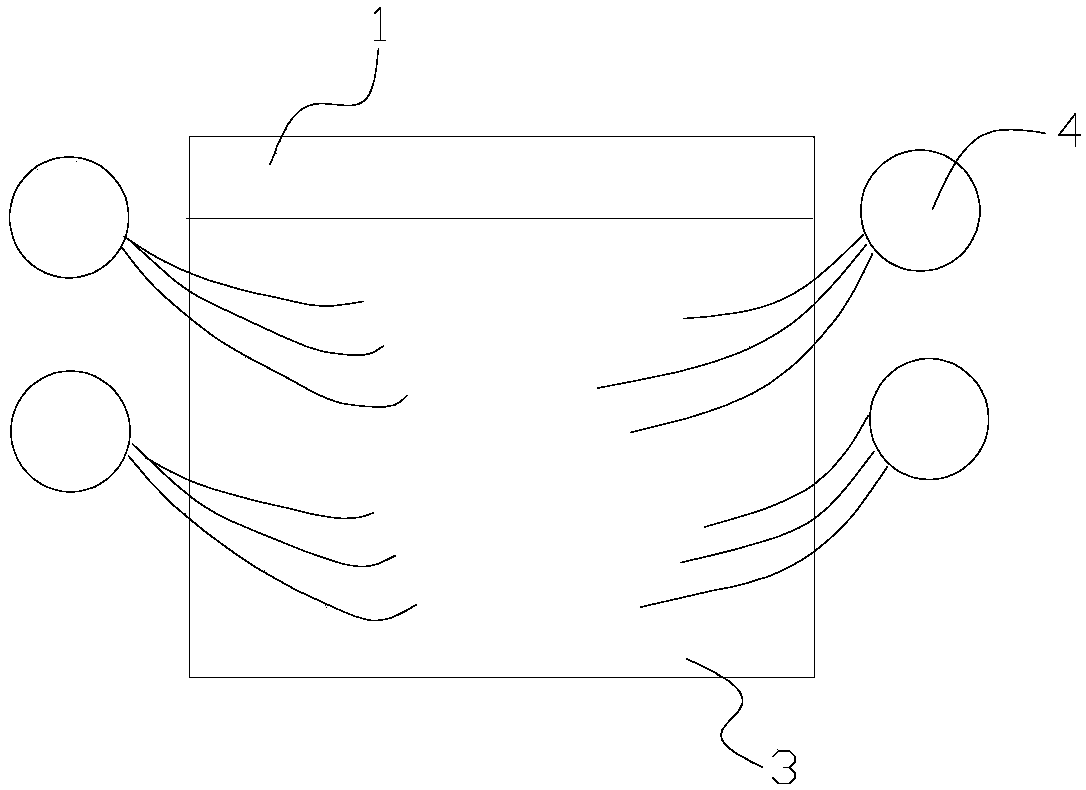

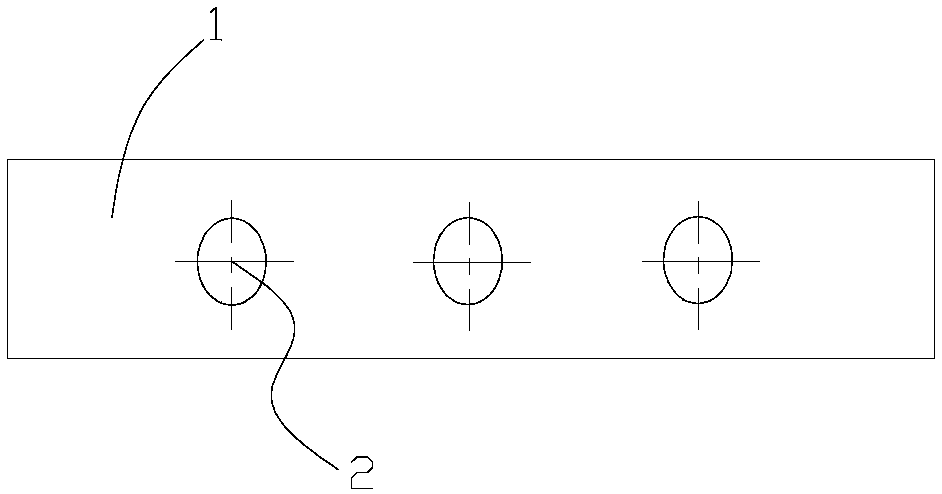

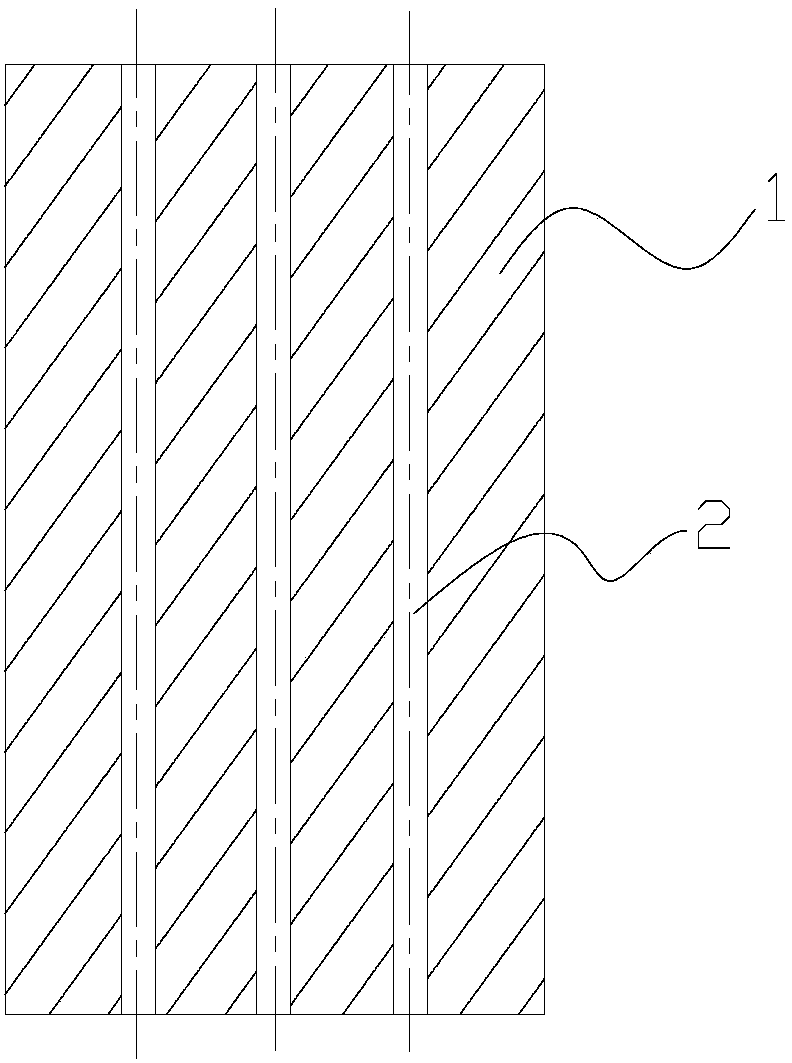

Resin board for diamond wire cutting silicon wafer and degumming treatment method

The invention relates to an efficient energy-saving environment-friendly resin plate for a diamond wire cutting silicon wafer. The resin plate is fixed to one side of a silicon ingot needed to be cut;the filler of the resin plate is glass fiber powder; the density of the resin plate is 0.6g / cm<3> when the thickness of the resin plate is controlled at 25mm by adding the glass fiber powder; at least two through holes are formed in the middle of the resin plate along the thickness direction of the resin plate, and the through holes are uniformly distributed in a spaced manner. According to the efficient energy-saving environment-friendly resin plate for the diamond wire cutting silicon wafer provided by the invention, the cutting efficiency can be improved, the processing efficiency of silicon wafer slicing time is improved, and the utilization ratio of equipment is improved; the use level of degumming and washing water is reduced; the weight of the integral resin plate is reduced, the light weight problem for treatment of the resin plate as a waste is solved, and the resin plate plays roles of being energy-saving and environment-friendly.

Owner:江苏美科太阳能科技股份有限公司

Method and apparatus for controlling additional take-off thrust of an aircraft

ActiveCN103057711BExtra takeoff thrust achievedAircraft power plantsBiological activationWeight problem

The invention relates to a method and device for controlling additional takeoff thrust of a plane. The method includes: receiving a first instruction for activating the additional takeoff thrust from a pilot of the plane, responding the first instruction, and sending activating signals for activating the additional takeoff thrust to each engine of available engines of the plane. After the additional takeoff thrust is activated, the pilot only needs to push a throttle lever to a normal takeoff position, and the additional takeoff thrust can be achieved. The pilot only needs to send one instruction to activate the additional takeoff thrust of each engine, and single-activation misoperation in a traditional scheme is avoided. Additionally, the first instruction can be received by a software button, and the activating signals are transmitted through a bus of the plane. Activation and closing of the additional takeoff thrust can be achieved without special buttons and transmission lines, and therefore a weight problem and an arrangement problem in the traditional scheme are solved.

Owner:COMAC +1

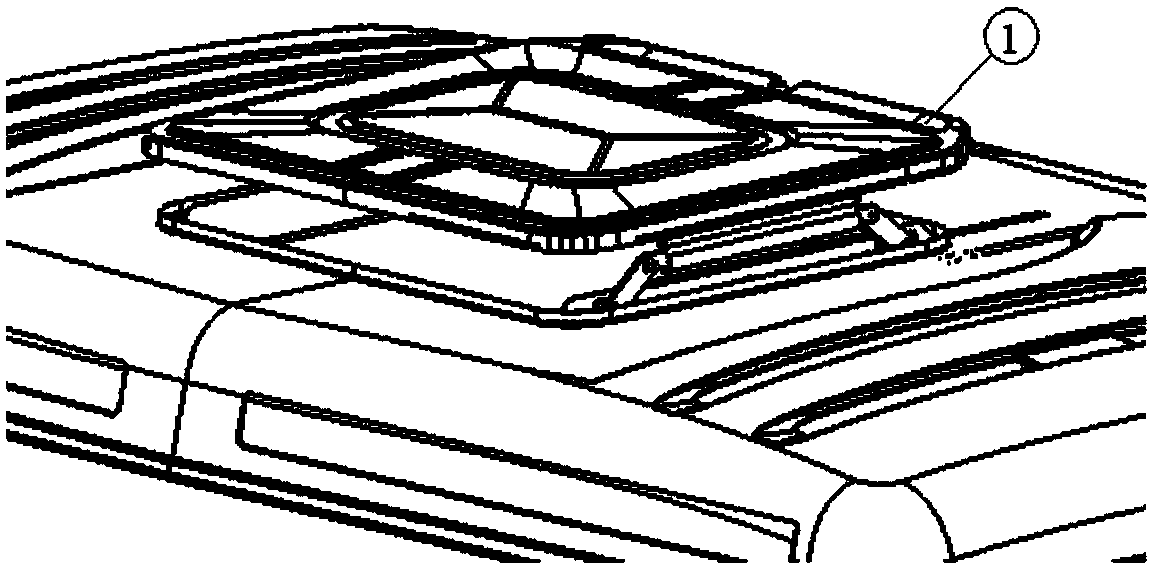

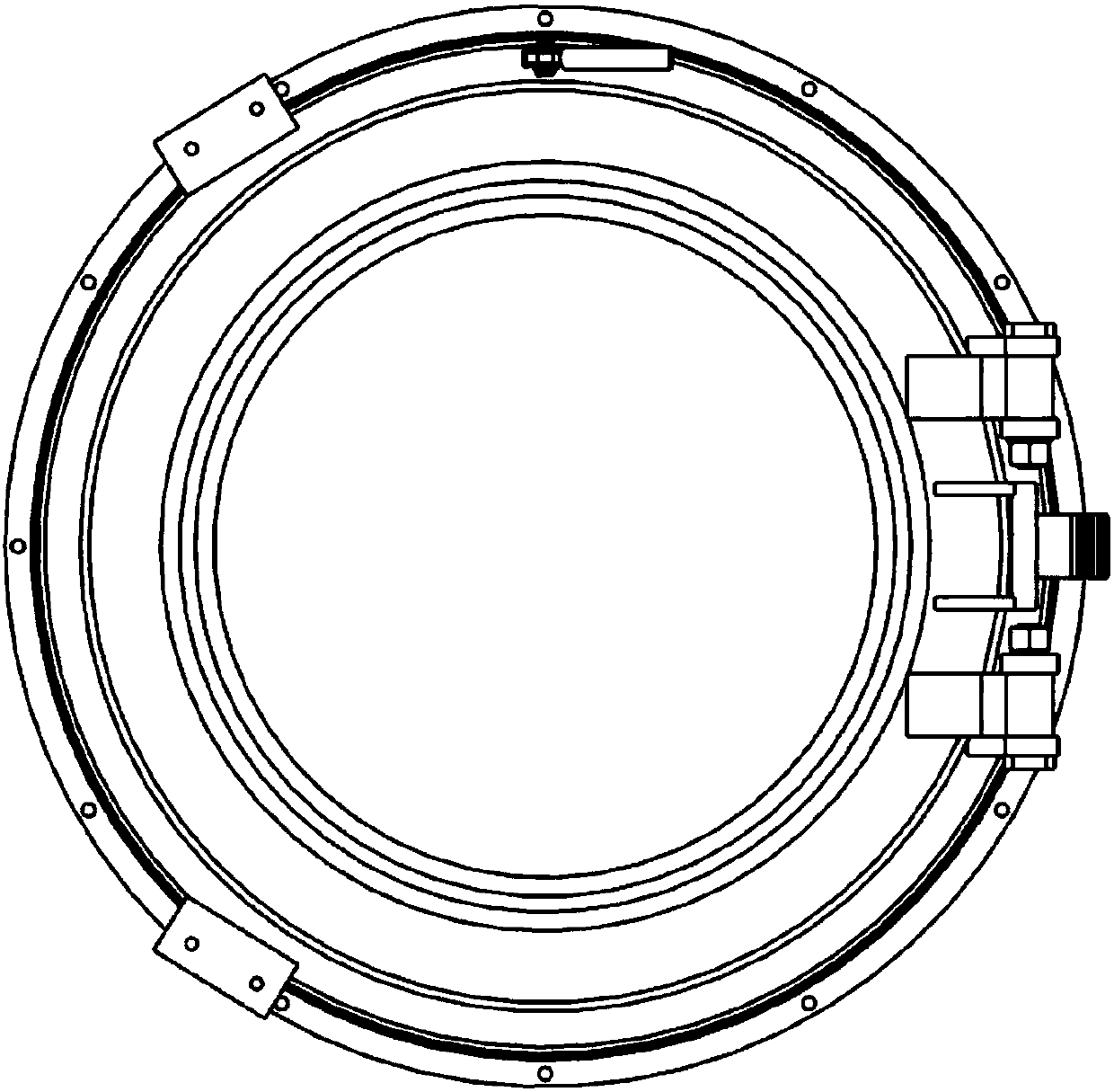

Heavy truck top cover assembly structure with rotating skylight device

PendingCN107933267AAvoid askingSolve the problem that the rotating sunroof with a weight of 20-100kg cannot be installedSuperstructure subunitsRoofsTruckWeight problem

The invention discloses a heavy truck top cover assembly structure with a rotating skylight device and belongs to the technical field of vehicles. The heavy truck top cover assembly structure is usedto solve the problems that a skylight on an existing heavy truck cannot be omnidirectionally rotated and used and a functional expansion module cannot be mounted on the skylight. The heavy truck top cover assembly structure with the rotating skylight device includes the rotating skylight device and a top cover assembly. The rotating skylight device includes a fixed ring, an upper movable ring, a lower movable ring, a roll ball, a cover plate, a positioning clamp spring and a positioning support. The problems that the requirements for a multifunctional skylight device cannot be met and a rotating skylight with a weight of 20-100 kg cannot be mounted on the heavy truck are solved. The skylight in the heavy truck top cover assembly structure is safe and reliable in use, and the limitation isflexible and convenient.

Owner:BEIBEN TRUCKS GRP

Efficient energy-saving environment-friendly resin plate for diamond wire cutting silicon wafer and degumming method

The invention relates to an efficient energy-saving environment-friendly resin plate for a diamond wire cutting silicon wafer. The resin plate is fixed to one side of a silicon ingot needed to be cut;the filler of the resin plate is glass fiber powder; the density of the resin plate is 0.6g / cm<3> when the thickness of the resin plate is controlled at 25mm by adding the glass fiber powder; at least two through holes are formed in the middle of the resin plate along the thickness direction of the resin plate, and the through holes are uniformly distributed in a spaced manner. According to the efficient energy-saving environment-friendly resin plate for the diamond wire cutting silicon wafer provided by the invention, the cutting efficiency can be improved, the processing efficiency of silicon wafer slicing time is improved, and the utilization ratio of equipment is improved; the use level of degumming and washing water is reduced; the weight of the integral resin plate is reduced, the light weight problem for treatment of the resin plate as a waste is solved, and the resin plate plays roles of being energy-saving and environment-friendly.

Owner:江苏美科太阳能科技股份有限公司

System for harmonic content correction in power electric circuit, system for electric engine control, and cooling compressor

ActiveCN106856367ASmall sizeSuitable designAC motor controlElectric motor controlRefrigeration compressorElectric power system

The invention discloses a system for harmonic content correction in a power electric circuit, a system for electric engine control, and a cooling compressor. The invention relates to the field of power electronics and electric engines, and describes a harmonic content correction system in power systems. The invention solves the space and weight problem associated with the core of a harmonic content correction inductor, also providing performance advantages of electric engines, such as higher available voltage at full load and higher rotational speed at full load. The invention is particularly useful in refrigeration compressors. The disclosed harmonic content correction system comprises a switching device (M) associated with a reactive element (L).

Owner:EMPRESA BRASILEIRA DE COMPRESSORES SA (EMBRACO)

Continuous polymerization reaction device for producing poly-p-phenylene benzo dioxazole

ActiveCN101245143BWell mixedHigh molecular weightMonocomponent synthetic polymer artificial filamentWorking temperatureDiameter ratio

The invention discloses a continuous polymerization device which prepares PBO, which relates to a continuous polymerization device. The invention brings about solutions to the stirring problems caused by the high viscosity of PBO polymer and to the low molecular weight problems existed in the polymer which is prepared by current manufacturing process. The discharge hole of the pre-polymerization reactor of the invention is communicated with the charging hole of screw extruder unit which consists of 2-10 full-bay screw extruders which are connected by in-line platform combination or staging pack; wherein the screw, screw barrel, the charging hole, the discharge hole are acid-resisting and corrosion-resisting; the working temperature for screw is 20-300 DEG C, the extrusion pressure for thescrew extruder is 0.1-30 MPa, the diameter D for the screw is 20-200 mm, the length-diameter ratio L / D for the screw is 10-60, the rotation speed is 1-1000r / min, and the vacuum degree in the screw isminus 0.1 MPa. The continuous polymerization device has the advantages of improved molecular weight, quick reaction speed, short manufacturing cycle, uniform material mixture and full reaction, whichcan realize continuous operation and is conductive to commercial process.

Owner:HARBIN INST OF TECH

Fusible release device for underwater mooring heavy objects and using method thereof

The invention relates to a fuse type release device for heavy objects in an underwater anchorage system and a method for using the same. The wire fixing rod and the fuse wire movable rod are connected by a spring, the fuse wire movable rod is provided with a groove, and one end of the rotating release rod is placed in the groove of the fuse wire movable rod; the fuse wire movable rod and the fuse wire fixed rod Both are provided with fixing bolts, and the fuse wire movable support rod can be pushed by the horizontal push rod, so that the fuse wire seat is fixed in the fixing bolts of the fuse wire movable support rod and the fuse wire fixed support rod; one end of the fuse wire is connected to the acoustic transponder through the cable. connected. It can solve the problem that the fuse wire cannot bear heavy loads, and the invention can realize the release of heavy loads, expand the application range of the electric fuse release technology, and meet the needs of practical underwater applications.

Owner:OCEAN UNIV OF CHINA +1

Ventilating high-heeled shoes convenient to wear

The invention discloses a pair of ventilating high-heeled shoes convenient to wear. Each shoe comprises a high-heeled shoe upper body and a heel, and is characterized in that the heel is provided with a transverse long-striped channel; the through hole is internally provided with a spring for connecting the high-heeled shoe upper body with the heel; the bottom of the high-heeled shoe upper body is provided with an insole; the insole is provided with a high-low bulge; the outer surface of the high-heeled shoe upper body is provided with a plurality of transverse strips; the transverse strips are provided with ventilating grids; and a zip fastener is arranged at one side of the heel of the high-heeled shoe upper body. The ventilating high-heeled shoes convenient to wear have the advantages that the heel is internally provided with the through hole, so that the weight problem of the high-heeled shoes is solved, and the pain feeling is reduced in a walking process due to the fact that the elasticity of the shoes is better; and the ventilating grids of the high-heeled shoe upper body increase the ventilation of the shoes and the comfortable feeling of the shoes is increased.

Owner:NANTONG OERSTED SHOES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com