A device and method for synchronously displaying explosive package weight information in different places

A technology of synchronous display and explosive packs, applied in static indicators, instruments, etc., can solve the problems of large time difference, large influence of human factors, and untimely adjustment of medicine box weight, so as to improve production efficiency, improve product qualification rate, The effect of solving the unstable weight of explosive packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

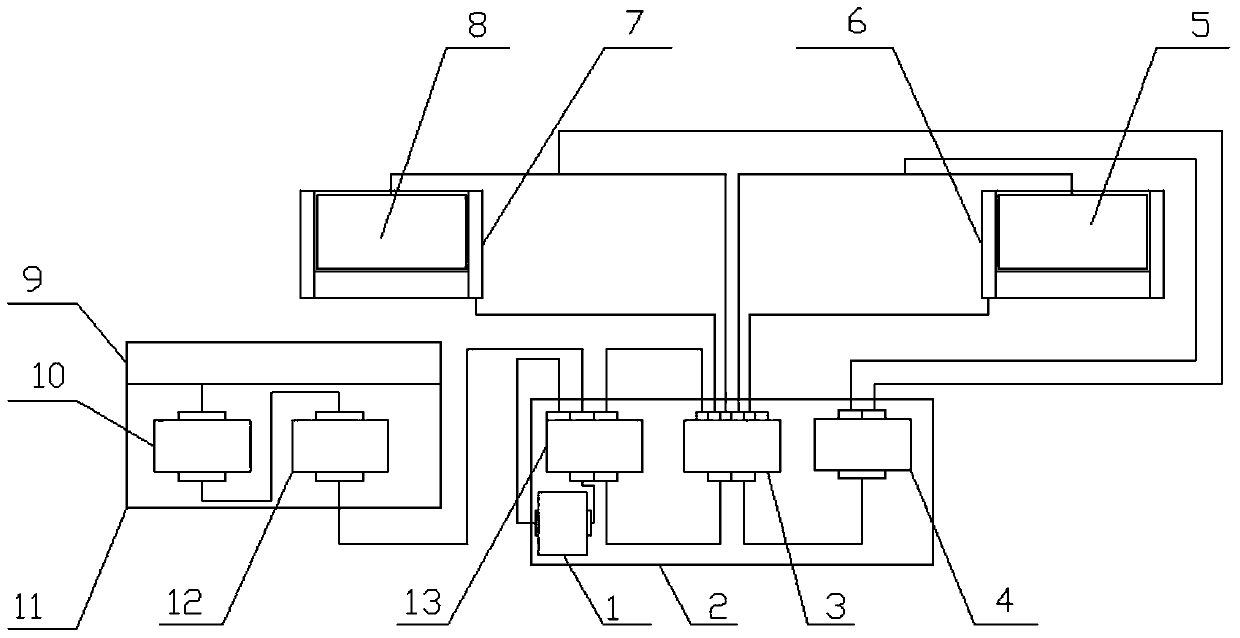

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0025] Such as figure 1 A device for synchronously displaying explosive package weight information in different places includes a weighing module 9, a conversion module 10, a sending module 12, a receiving module 13, a control module 3, a display module A5, a display module B8 and a PCB board A2. The output port of the weighing module 9 is connected to the input port of the conversion module 10, the output port of the conversion module 10 is connected to the input port of the sending module 12, the output port of the sending module 12 is connected to the input port of the receiving module 13, and the receiving module 13 The output end of the control module is connected with the input port of the control module 3, and the receiving module 13 and the control module 3 are integrated o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com