System for correction of harmonic content in electric power circuit, system for control of electric motors, and refrigeration compressor

A technology for power circuits and compressors, applied in the field of refrigeration compressors and systems with harmonic content, can solve the problems of economic infeasibility, cumbersomeness, and high energy consumption of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] Example 1 - System for correcting harmonic content of current in a power circuit in a refrigeration compressor.

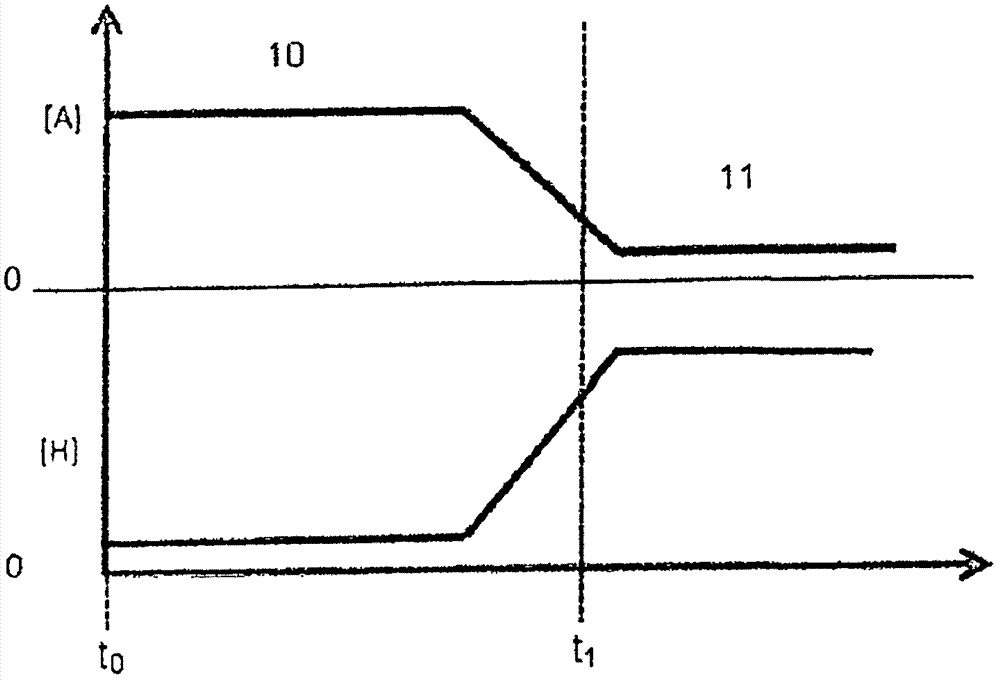

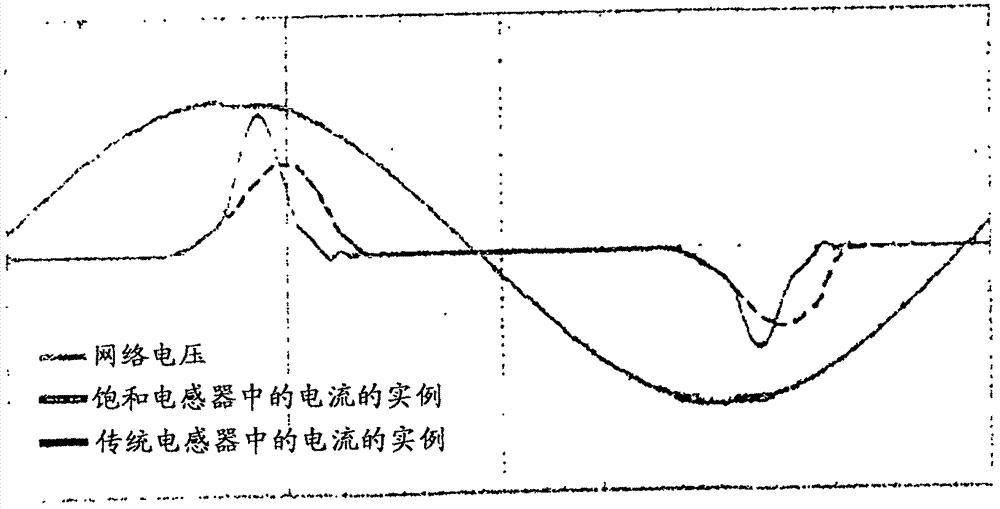

[0038] The invention provides a system for correcting harmonic content in a power circuit comprising an inductor (L) as a reactive element. The core of the inductor is dimensioned to be small, but to meet the maximum current requirements of the converter controlling the motor, which in this embodiment is a frequency converter, under maximum load conditions. In this embodiment, the maximum load condition is the maximum load condition of cooling (10), where the motor operating maximum temperature also occurs. In this embodiment, the core of the inductor is sized to operate in the saturation region during the cool down cycle (10) of the compressor with variable capacity.

[0039] Such as figure 1 It can be seen in , that at times when the motor current is high, ie, during the cool down cycle (10), the inductor operates with the core saturated and thus exhibit...

example 3

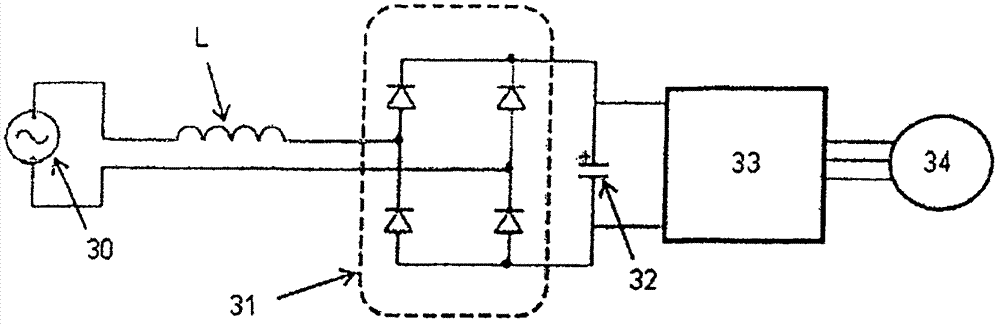

[0046] Example 3 - System for controlling an electric motor equipped with a harmonic content reduction circuit with an inductor located upstream.

[0047] In one embodiment, such as image 3 As shown, an inductor (L) is inserted into the electric motor control circuit (34) with one terminal connected to the power supply (30) and the other terminal connected to the rectification system (31).

example 4

[0048] Example 4 - System for controlling an electric motor equipped with a harmonic content reduction circuit with an inductor located downstream.

[0049] In another embodiment, such as Figure 4 As shown, an inductor (L) is inserted with one terminal connected to the frequency converter (33) and capacitive filter (32) and the other terminal connected to the frequency converter (33). The connection of the inductor (L) to the system for controlling the electric motor (34) can take many forms and is not limited to the two presented embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com