Patents

Literature

696 results about "Coal liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal liquefaction is a process of converting coal into liquid hydrocarbons: liquid fuels and petrochemicals. This process is often known as "Coal to X", where X can be many different hydrocarbon-based products. However, the most common process chain is "Coal to Liquid Fuels" (CTL).

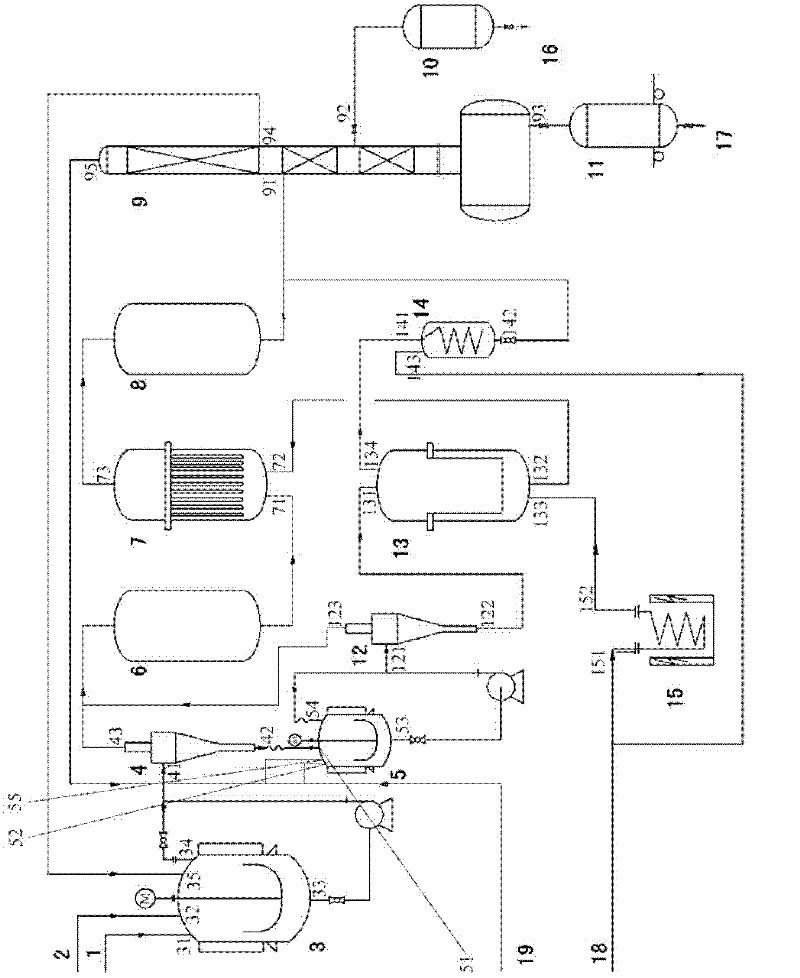

Method for extracting heavy liquefaction oil and intermediate-phase bitumen matter from coal liquefaction residuals and application thereof

ActiveCN101885976ARealize rationalityRealization of high value-added utilizationThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionEvaporationOil water

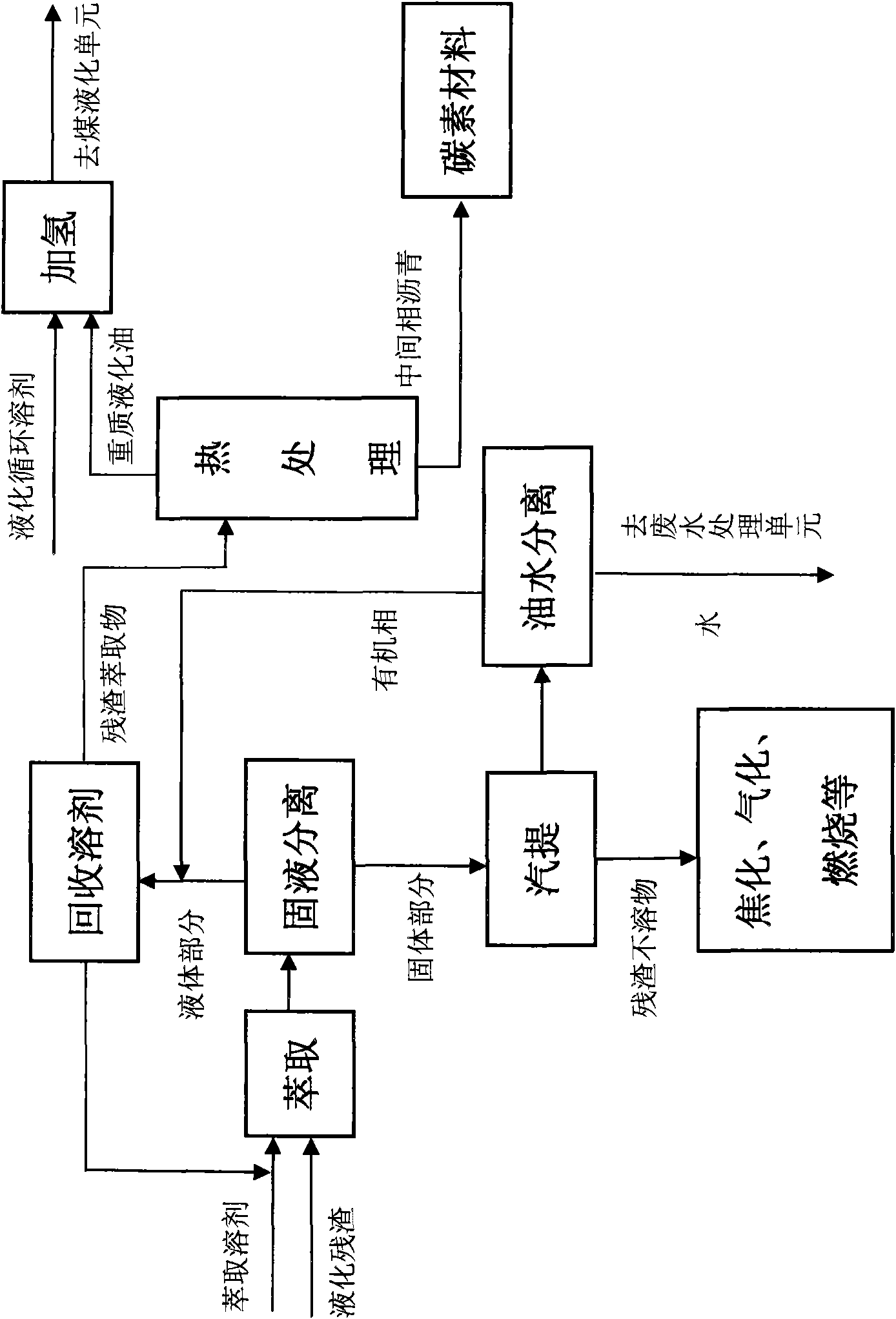

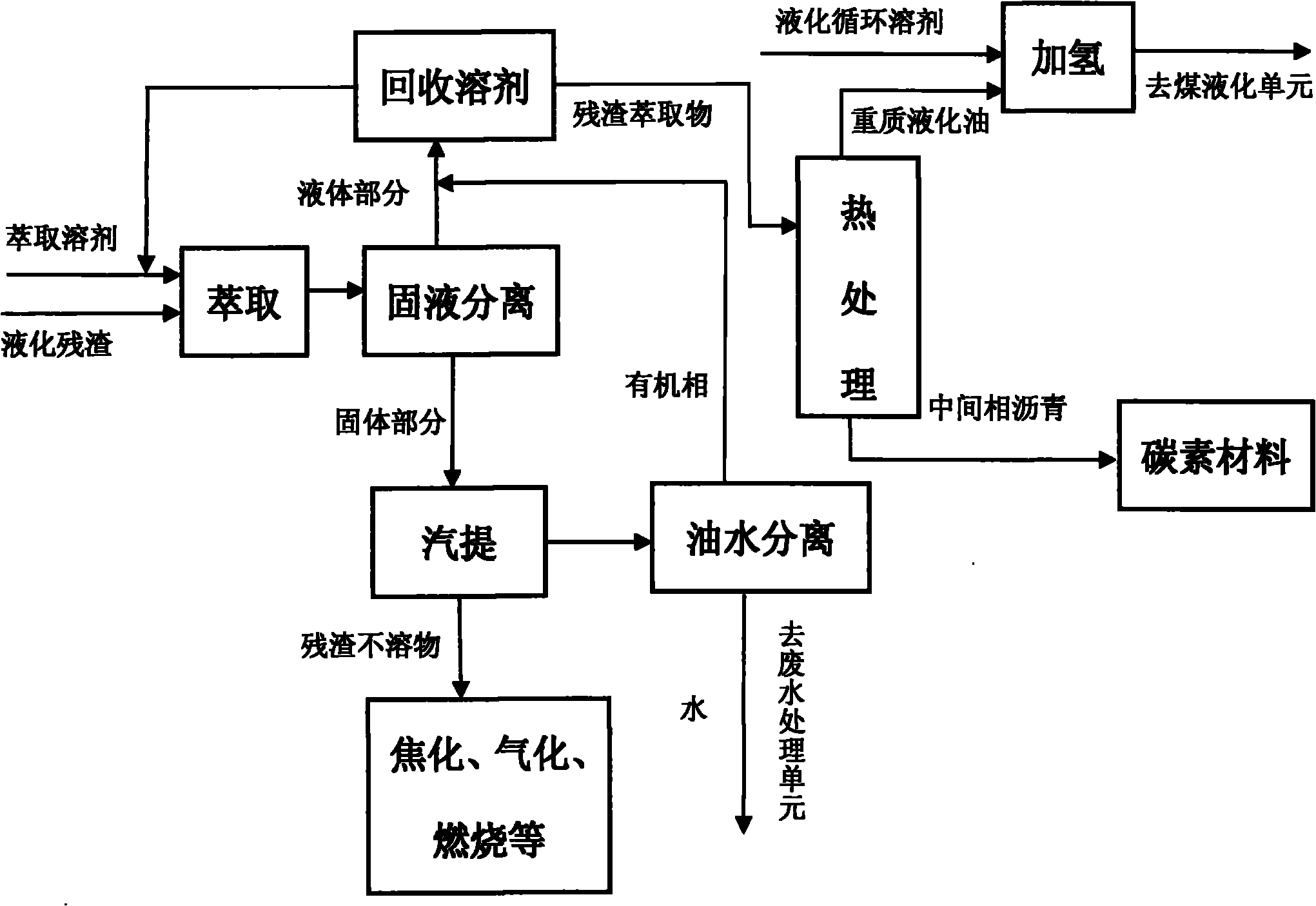

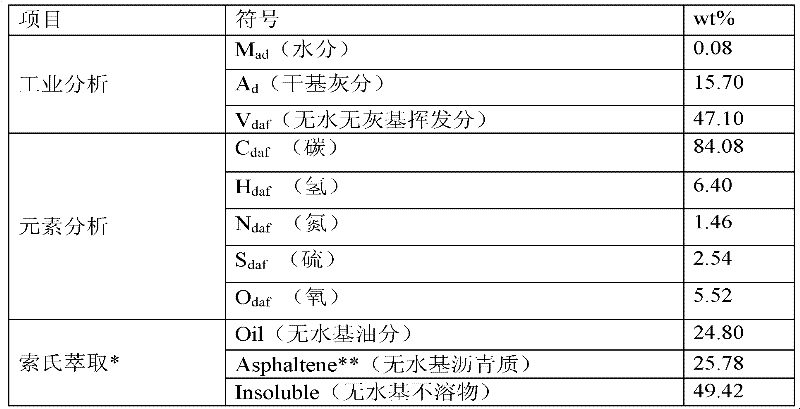

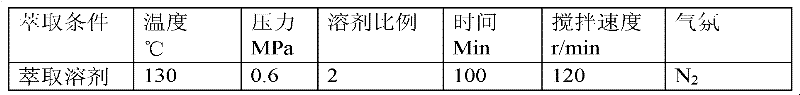

The invention provides a method for extracting heavy liquefaction oil and an intermediate-phase bitumen matter from coal liquefaction residuals and application thereof. The method comprises the following steps of: adding coal liquefaction residual powder and an extraction solvent to a stirring kettle together for extraction to obtain extraction liquid and extraction residues; carrying out solid-liquid separation on the obtained extraction liquid and extraction residues; carrying out steam stripping on the obtained extraction residues, and recovering an organic phase after oil-water separation; mixing the extraction liquid with the organic phase, and then delivering into a solvent recovery unit; recovering the extraction solvent for recycling use or being returned to a liquefaction productprocessing unit by using a distillation method and / or an evaporation method, wherein residuals obtained after the extraction solvent is recovered are liquefaction residual extractives; delivering theobtained liquefaction residual extractives into a heat treatment unit, and separating the heavy liquefaction oil from the intermediate-phase bitumen matter by using a heating dry distillation method;and adding the obtained heavy liquefaction oil and other recycling solvents in a direct liquefaction process to a coal liquefaction solvent hydrogenation unit together.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

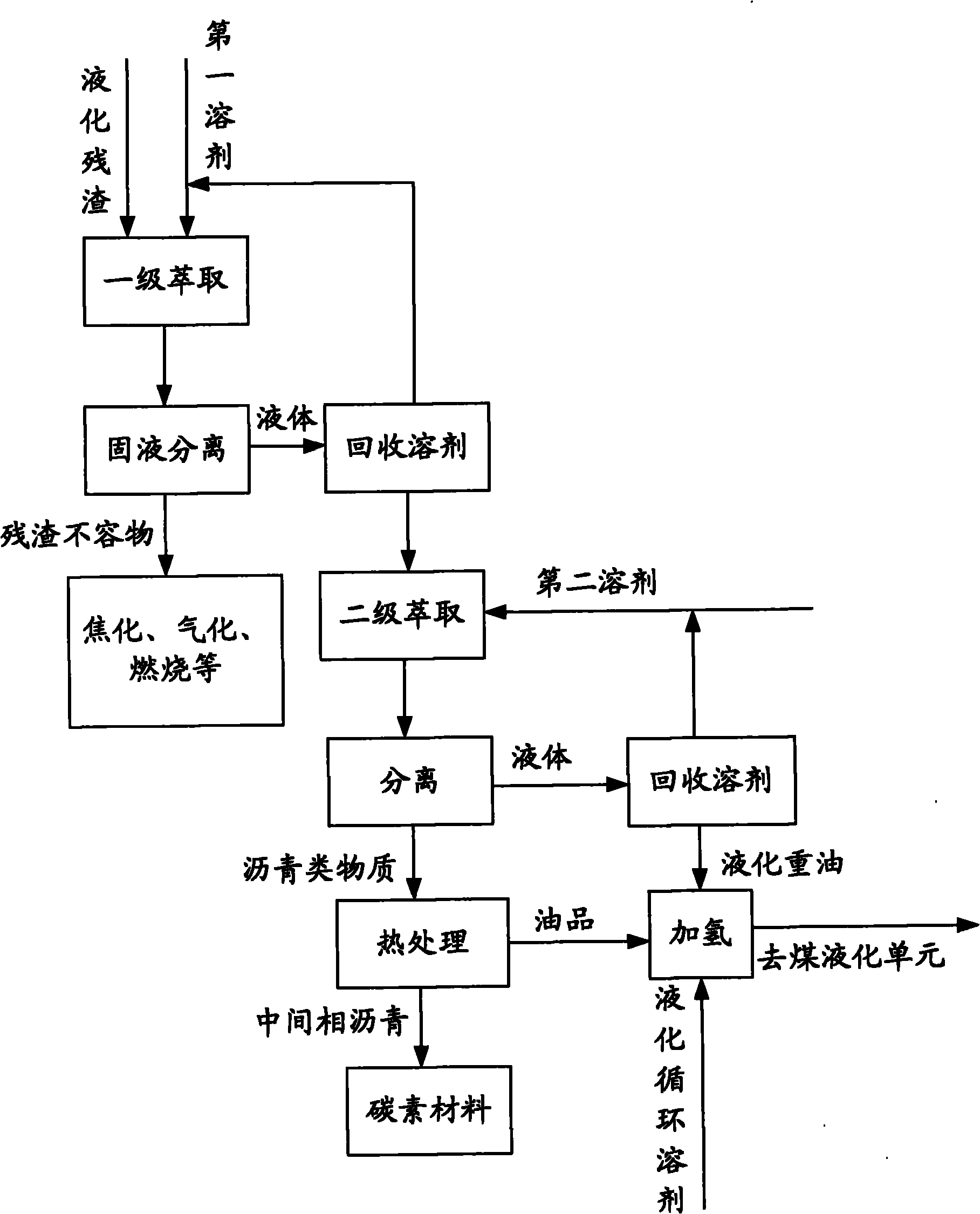

Extraction method of direct coal liquefaction residues and application of extracts

ActiveCN101962560ASimple processOperational securityWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventAsphalt

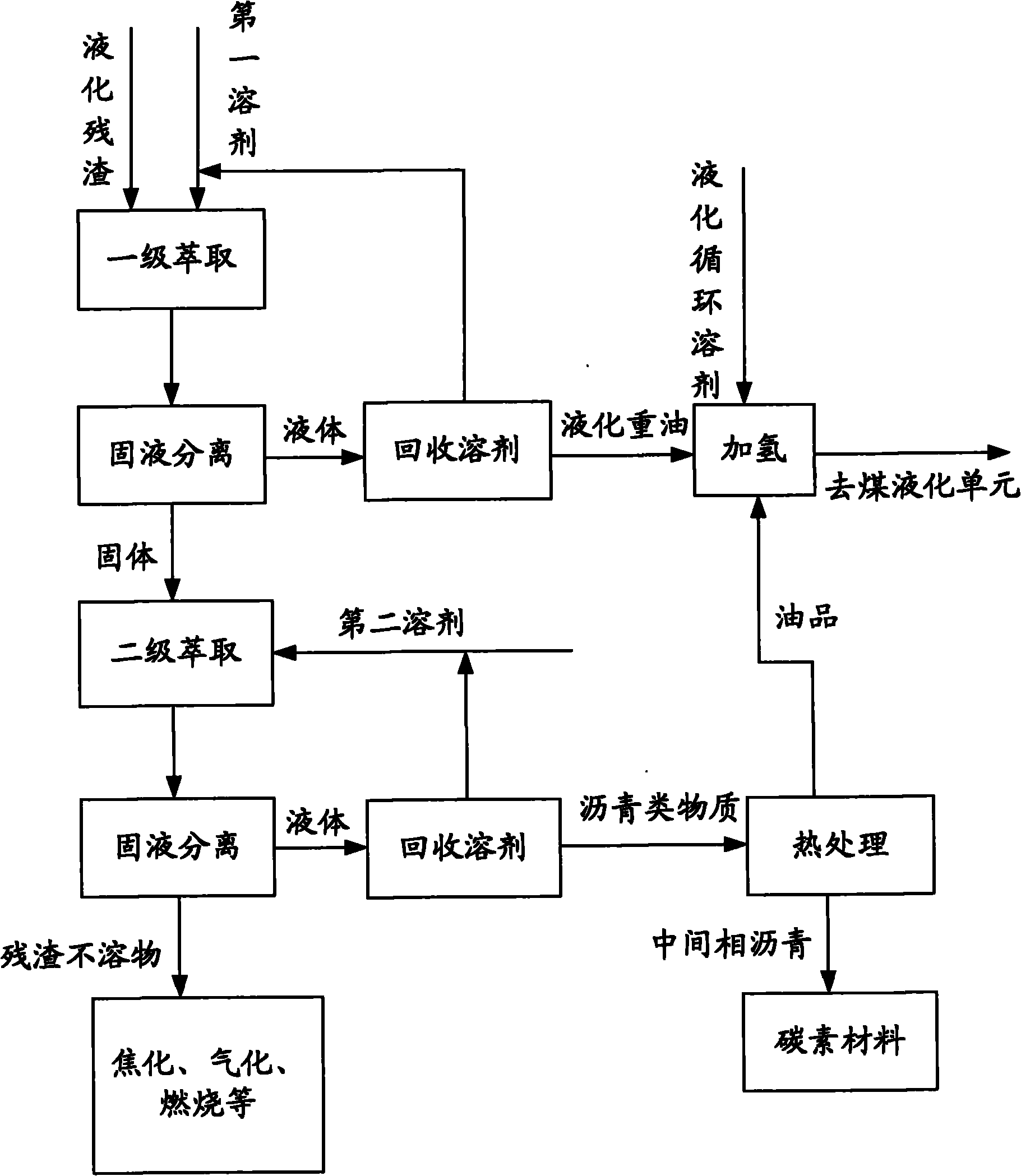

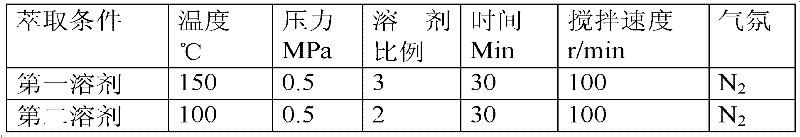

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a), recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent, obtaining heavy liquefied oil after recovering the first solvent, carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; c) mixing solid obtained through solid-liquid separation of extracts obtained after primary extraction with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained after secondary extraction, obtaining asphaltic substances after recovering the second solvent from the obtained liquid in the solvent recovery unit and carrying out heat treatment on the asphaltic substances by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for improving solidifying point of Fischer-Tropsch wax

InactiveCN103980940AImprove stabilityHigh melting pointPetroleum wax recoveryChemical industryTwo step

The invention relates to a method for preparing high-melting-point refined wax capable of being applied to plastics, rubber processing, wood processing, food processing and other industries and particularly relates to a method for improving the solidifying point of Fischer-Tropsch wax. According to the method for preparing high-melting-point refined wax with excellent performances, distillation refining is carried out on light-weight oil serving as a raw material by means of continuous high-vacuum distillation, wherein the light-weight oil is produced by indirect coal liquefaction; According to the technical scheme, the method comprises two steps, namely, firstly, feeding the raw material in an evaporator by a feed pump so as to heat and evaporate the oil components and other low-boiling-point substances under the conditions of high temperature and high vacuum degree; secondly, feeding the coal-based synthetic oil without oil components and other low-boiling-point substances into a distiller, heating and evaporating the coal-based synthetic oil products by using heat-conduction oil under extremely high vacuum condition, condensing and capturing in a condenser to obtain the target product. The method disclosed by the invention can be widely used in the field of chemical industry.

Owner:SHANXI LUAN MINING GRP

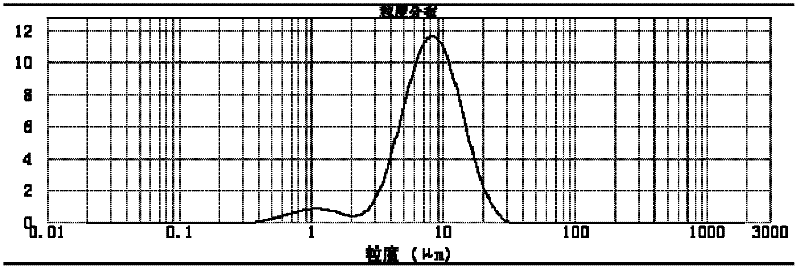

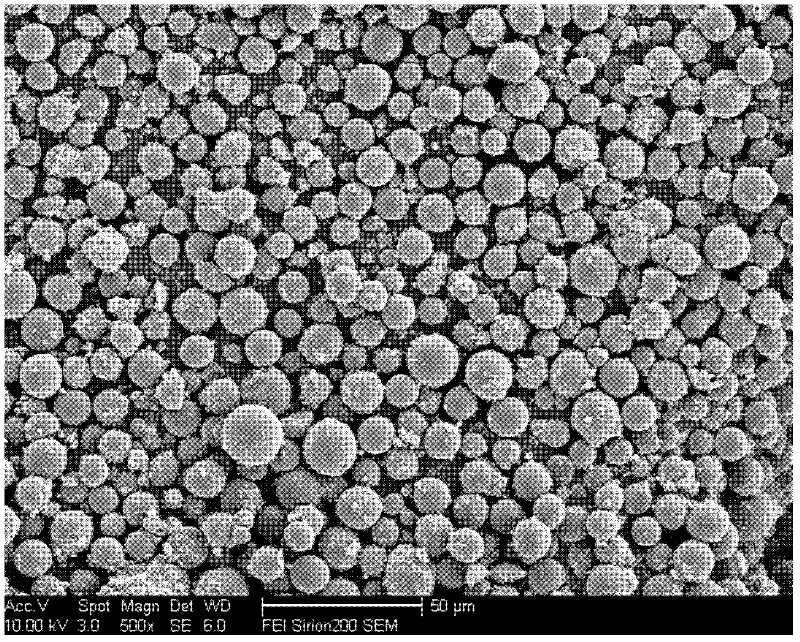

Preparation method of mesophase carbon microspheres from coal liquefaction residues

InactiveCN102225755ANarrow particle size distributionSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansMicrosphereQuinoline

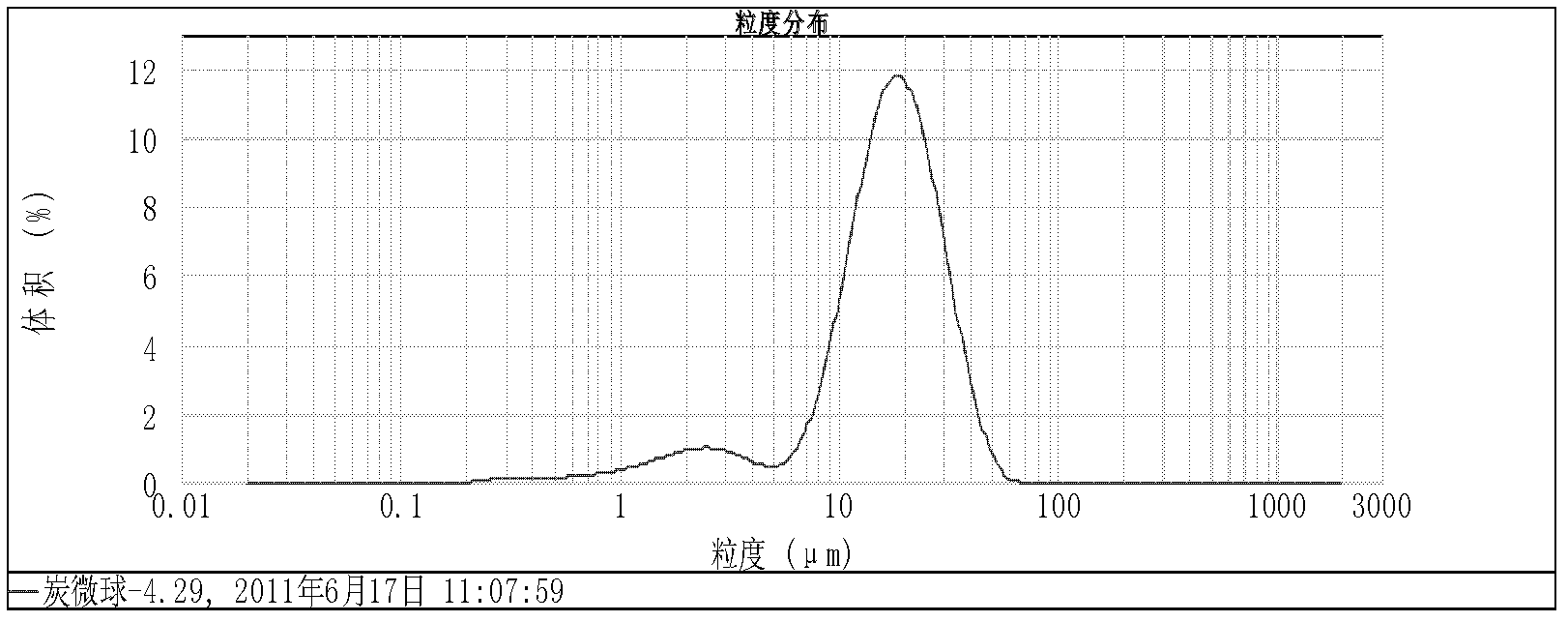

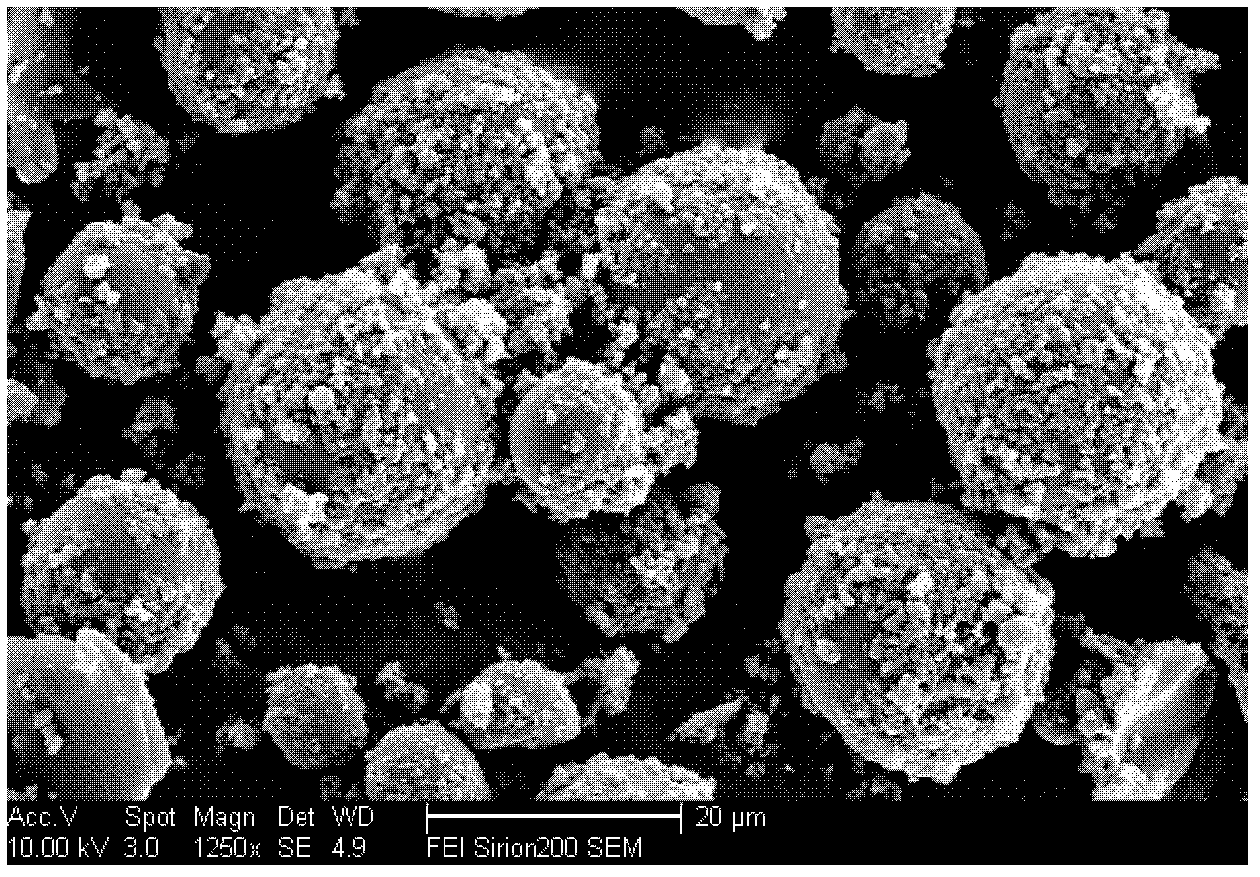

The invention discloses a preparation method of mesophase carbon microspheres from coal liquefaction residues serving as raw materials, which comprises the following steps of: firstly carrying out solvent extraction on the coal liquefaction residues, then carrying out a series of processing to obtain refined asphalt with different contents of quinoline insoluble substances, and carrying out thermal polycondensation reaction on the refined asphalt in the presence of a chemical auxiliary agent and a nucleating accelerator at the temperature of 380-450 DEG C, the pressure of 0-5 MPa and the stirring rotation speed of 40-500 r / min for 1-20 hours to obtain the mesophase microspheres. According to the invention, the chemical auxiliary agent and the nucleating accelerator can be added during theheat treatment process to improve the yield and narrow the particle size distribution of the mesophase carbon microbeads, and the mesophase carbon microspheres are prepared from the coal liquefactionresidues serving as the raw materials and have the advantages of low cost, simple preparation process, high yield (up to 35%), narrow particle size distribution, good sphericity, etc.

Owner:ZIBO MINING GRP

Solvent-enhanced biomass liquefaction

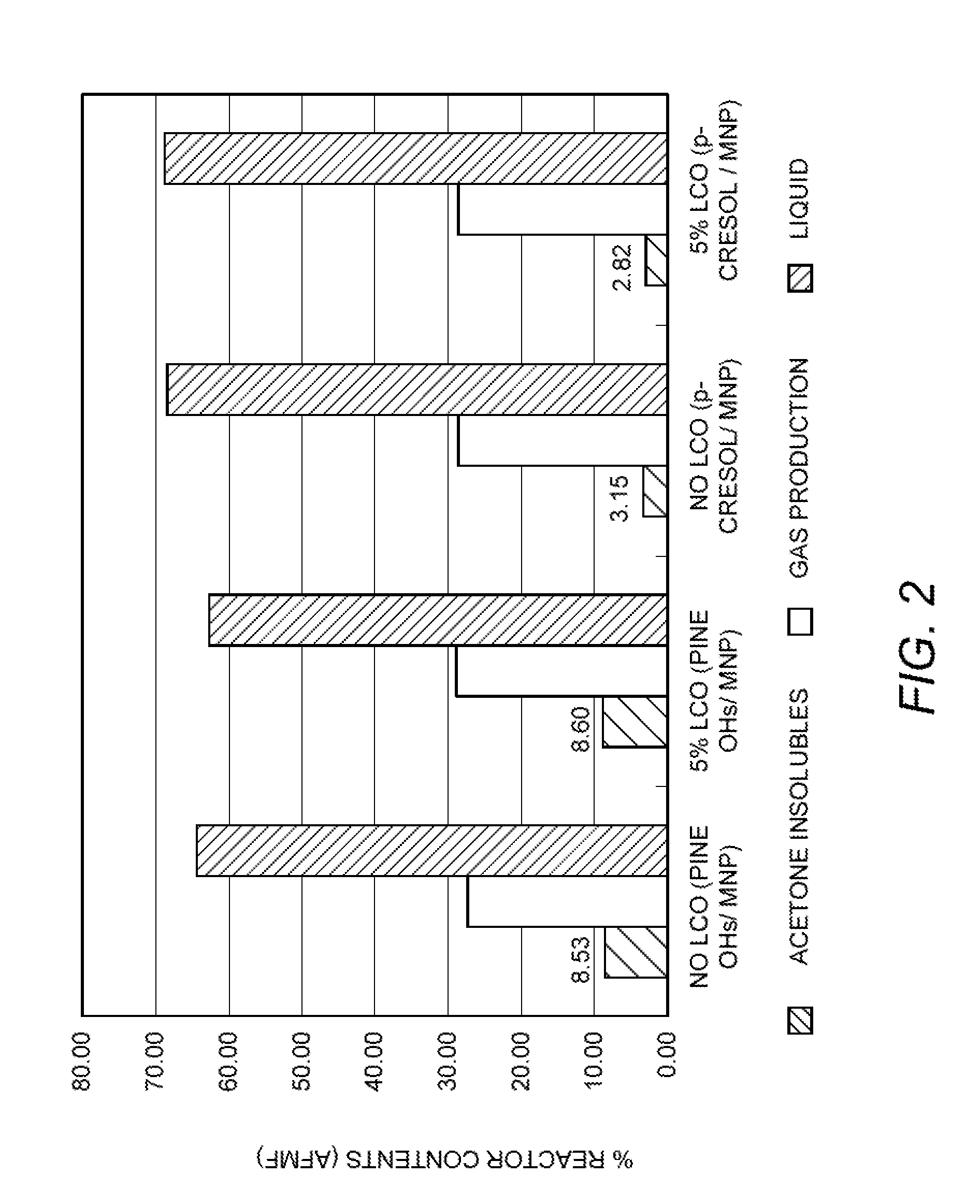

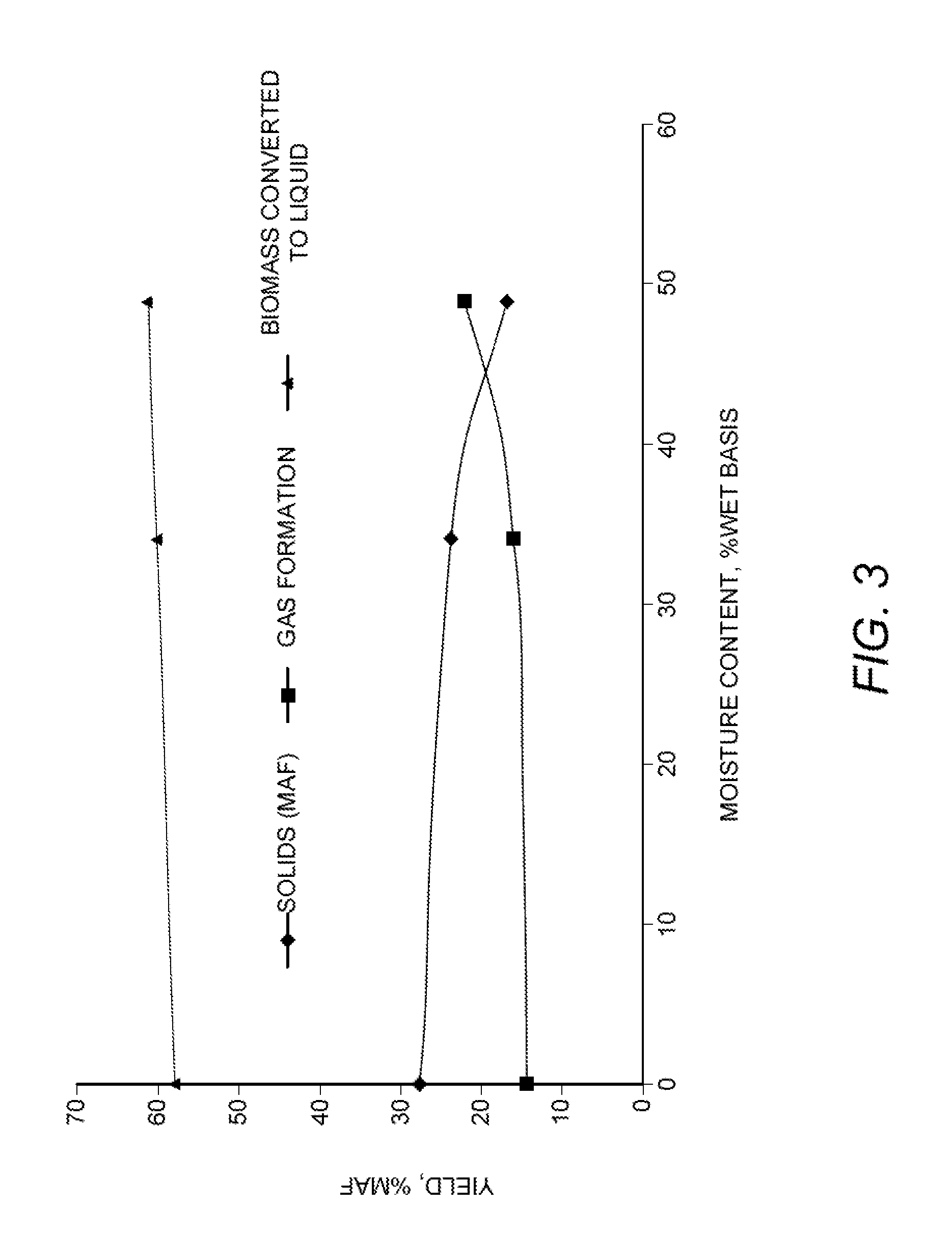

InactiveUS20120005949A1Conducive to liquefactionReduce side effectsSolvent extractionLiquid carbonaceous fuelsLiquid productHydrogen

The present invention provides an improved method for solvent liquefaction of biomass to produce liquid products such as transportation fuel. The method uses a novel solvent combination that promotes liquefaction relatively quickly, and it reduces the need to transport large amounts of hydrogen or hydrogen-carrying solvents. It operates at lower pressure than previous methods, does not require a catalyst or hydrogen gas or CO input, and provides very high conversion of biomass into a bio-oil that can be further processed in a petroleum refinery. It also beneficially provides a way to recycle a portion of the crude liquefaction product for use as part of the solvent combination for the biomass liquefaction reaction.

Owner:CLE HLDG

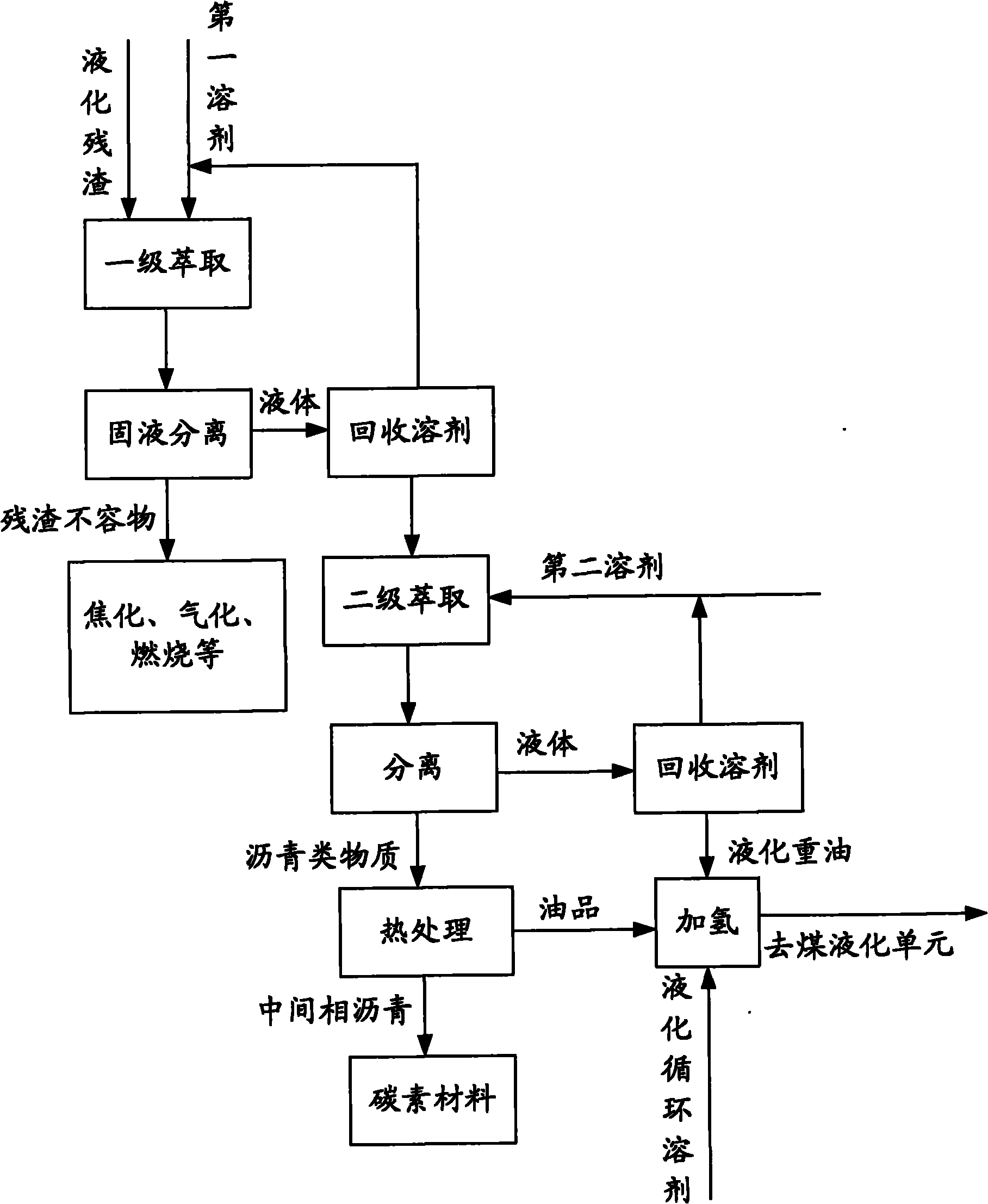

Extraction method of direct coal liquefaction residues and application of extracts

ActiveCN101962561AMake full use ofSimple processWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventThermal treatment

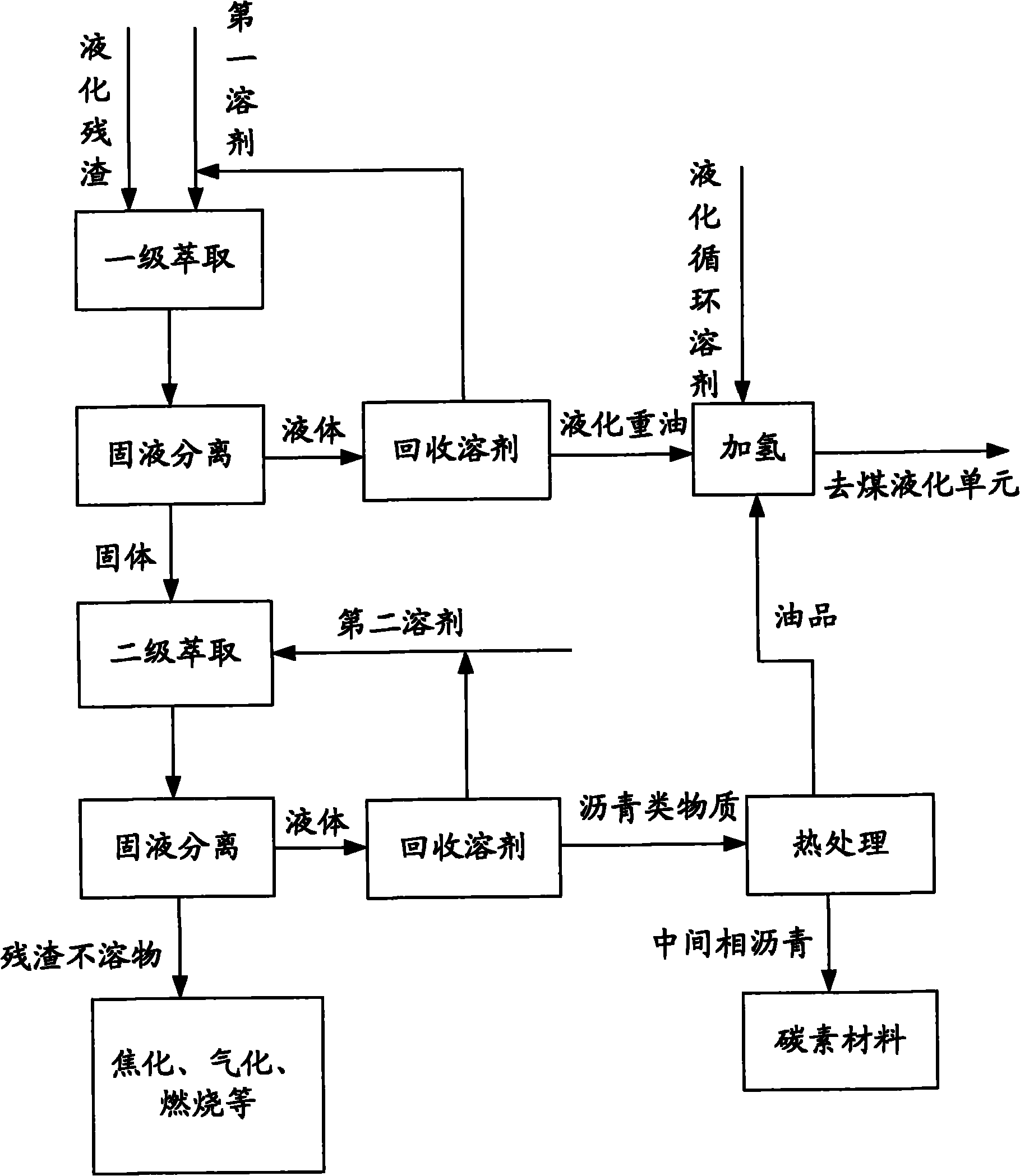

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a) and recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent; c) obtaining extracts after recovering the first solvent and mixing the extracts with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained in the step c), obtaining heavy liquefied oil after recovering the second extraction solvent from the obtained liquid in the solvent recovery unit and then carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; and e) carrying out heat treatment on the asphaltic substances obtained in the step d) by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for preparing activated carbon by utilizing direct coal liquefaction residue

InactiveCN102153081AExpand sourceImprove coal liquefaction technologySolid waste disposalAcid washingCarbonization

The invention provides a method for preparing activated carbon by utilizing direct coal liquefaction residue as a raw material. The method includes the steps as follows: (1) adding smashed direct coal liquefaction residue together with KNO3, KOH and absolute alcohol into water, stirring to be uniform under room temperature, and later drying the obtained mixture to obtain a dry material; (2) placing the prepared dry material in a carbonization furnace, conducting preoxidation in the atmosphere of air, conducting carbonization-activation in the atmosphere of inertia gas, and then obtaining coarse activated carbon; and (3) acid-washing and deashing the prepared coarse activated carbon to obtain finished activated carbon. The method is simple in preparation process route, uses conventional equipment and has universality to the raw material. The obtained activated carbon has not only characteristics of high specific surface area, developed micropores and low ash content, but also controllable output, higher productivity, suitability for production in batches, and better technological and economic benefits.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

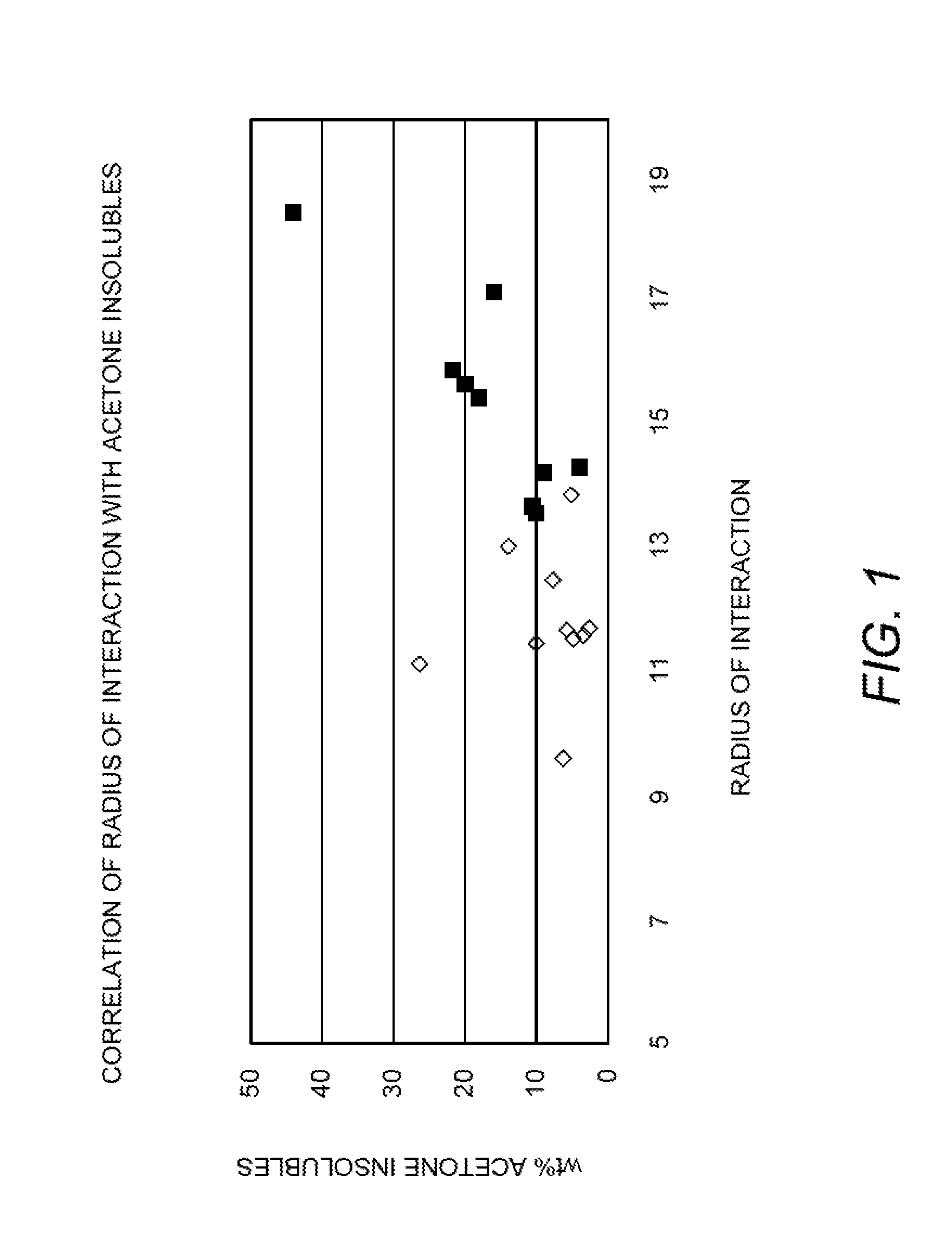

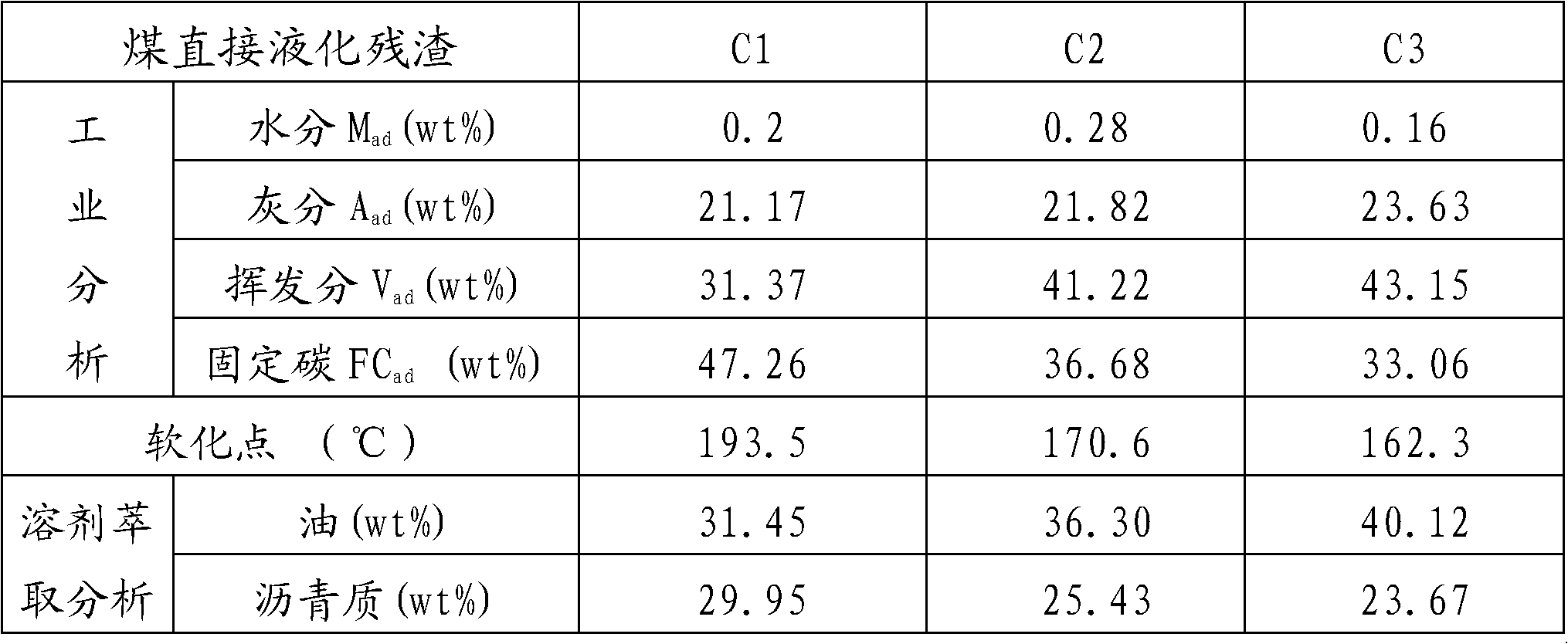

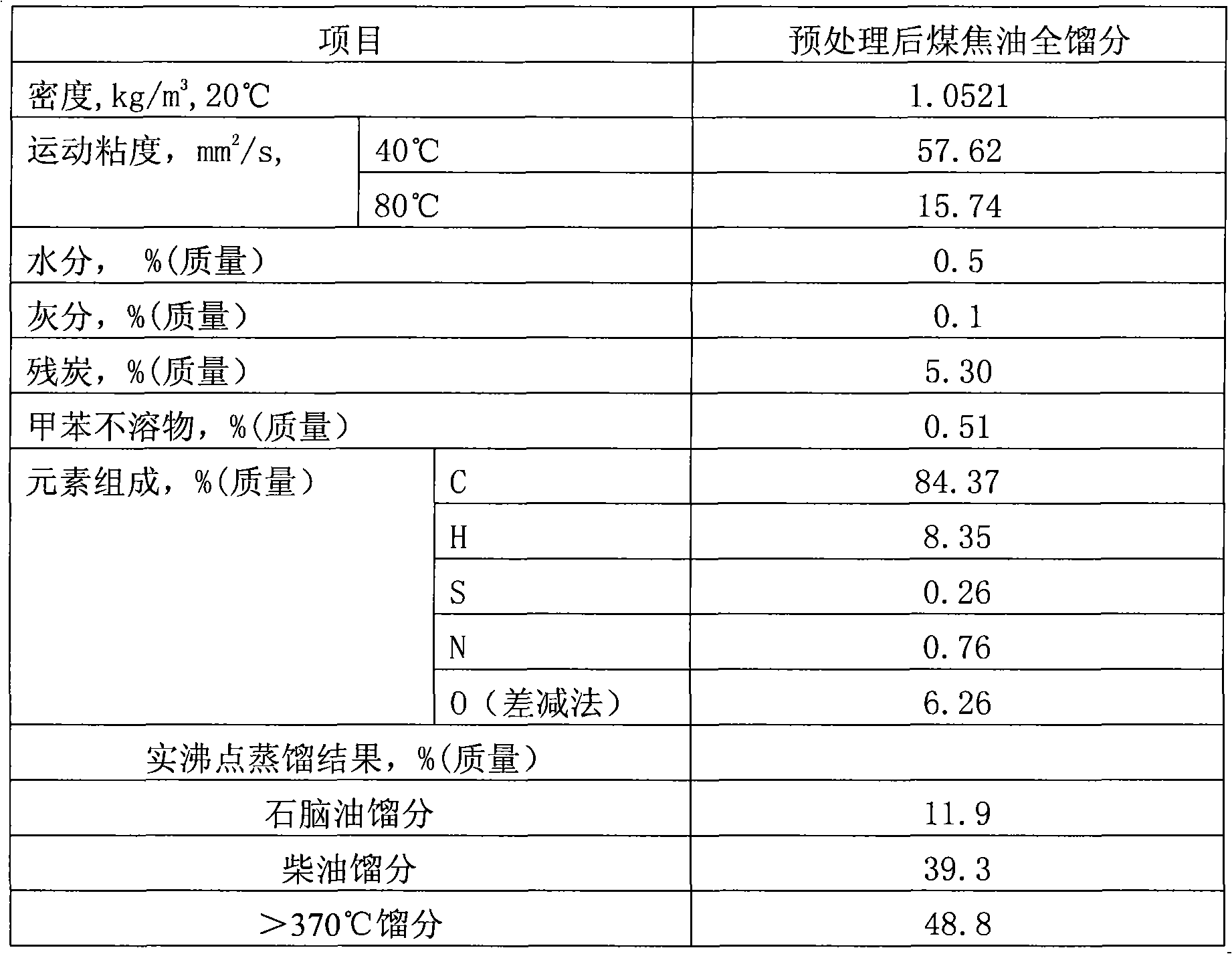

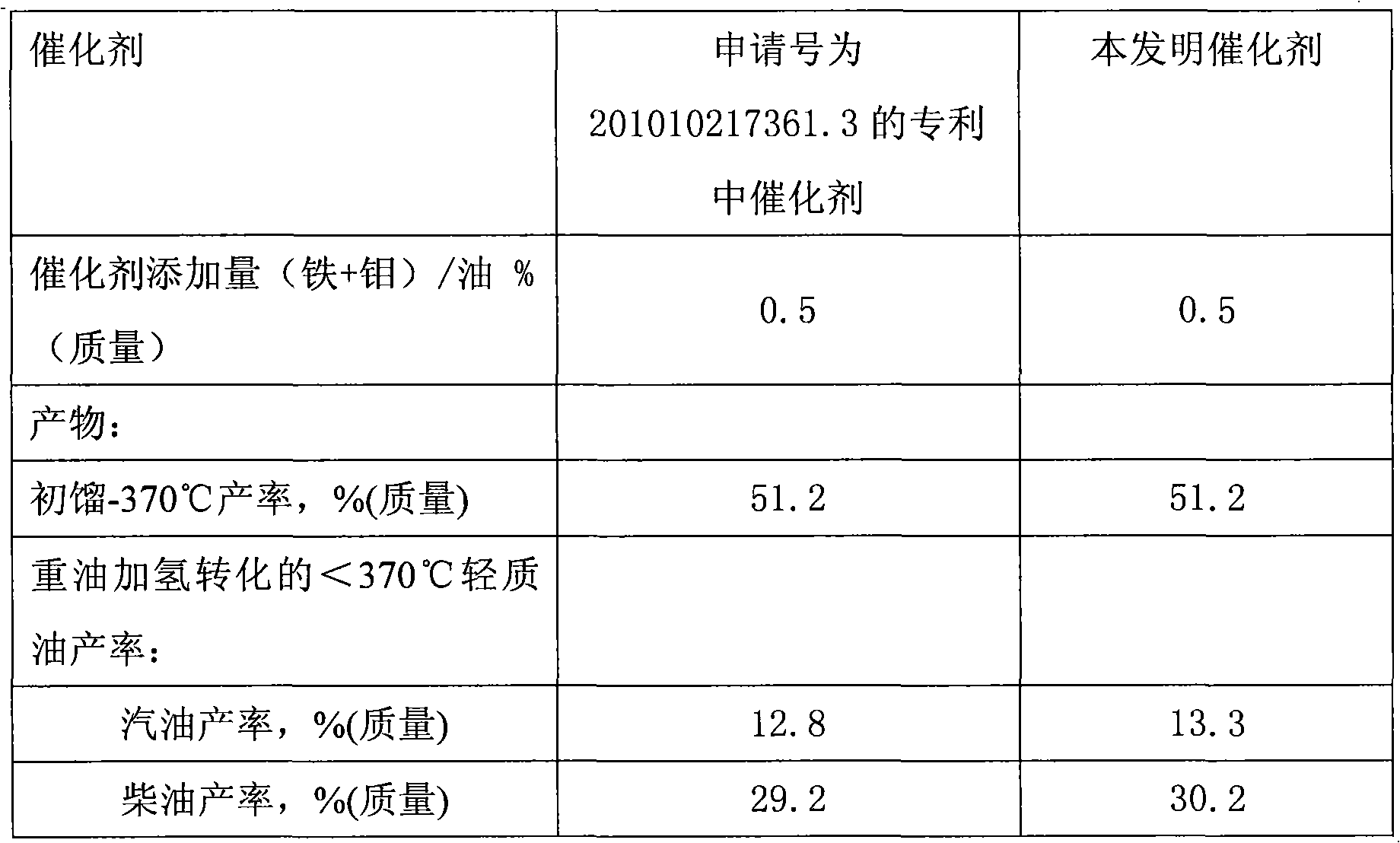

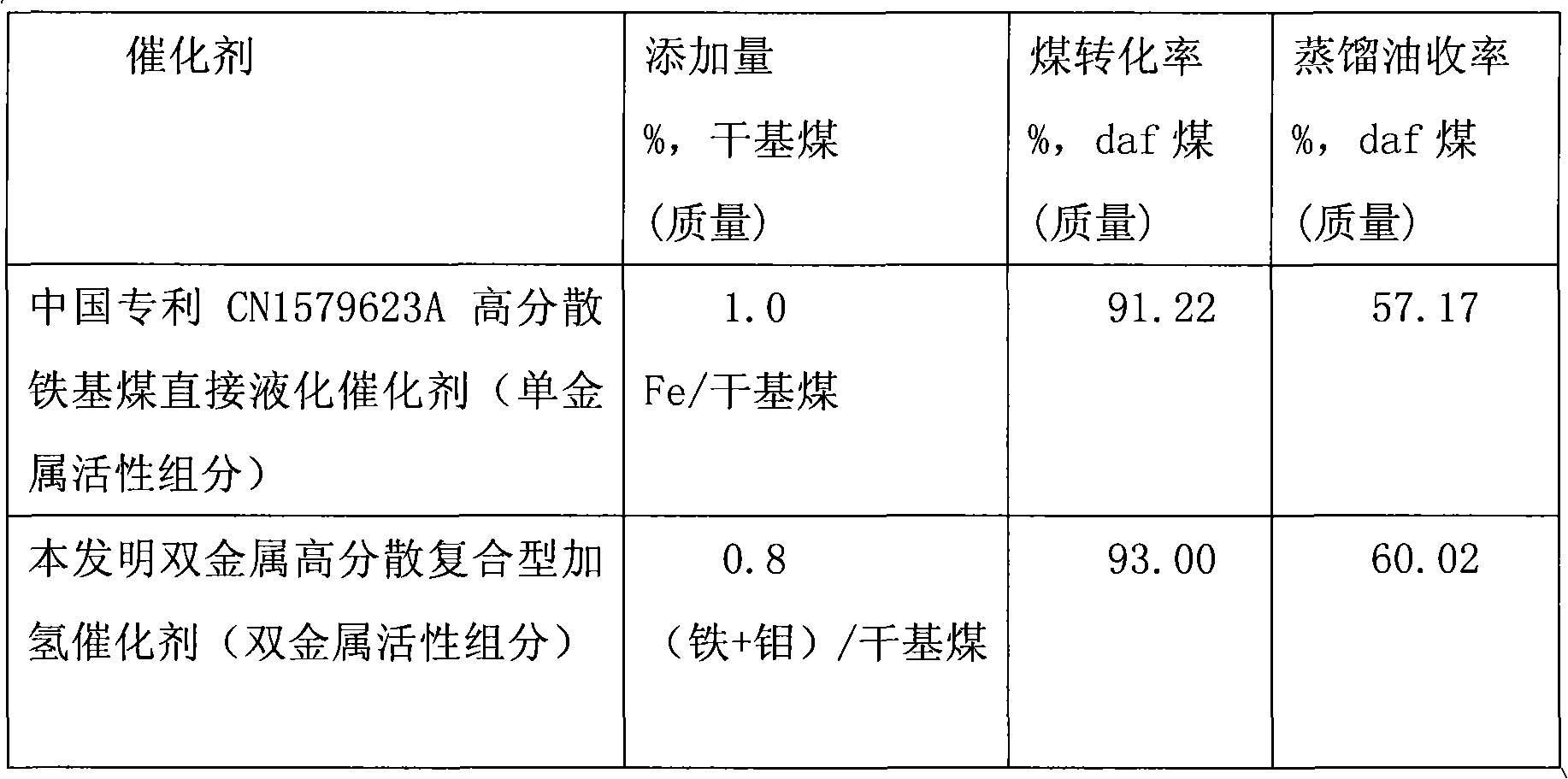

Bimetal or multi-metal high-dispersion composite coal tar hydrogenation catalyst and preparation method thereof

ActiveCN102380396AHigh activityReduce manufacturing costLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesSolubilityCobalt

The invention relates to a bimetal or multi-metal high-dispersion composite coal tar hydrogenation catalyst and a preparation method thereof. The catalyst comprises molecular high-activity components of one or a plurality of mixtures of water-solubility salt compounds of metal from molybdenum, nickel, tungsten or cobalt, nanometer low-activity components gamma-FeOOH grains and micro or sub nanometer carrier pulverized coal, the activity components are uniformly and highly dispersed on the surfaces of the carrier pulverized coal, the catalyst is micro or sub nanometer fine powder and is high in activity, particles of the activity components are small and are highly uniformly dispersed on the surface of a carrier, the utilization quantity of the catalyst is low, cost is reduced, and the bimetal or multi-metal high-dispersion composite coal tar hydrogenation catalyst can be widely applied to coal tar hydrogenation or coal liquefaction.

Owner:CCTEG CHINA COAL RES INST

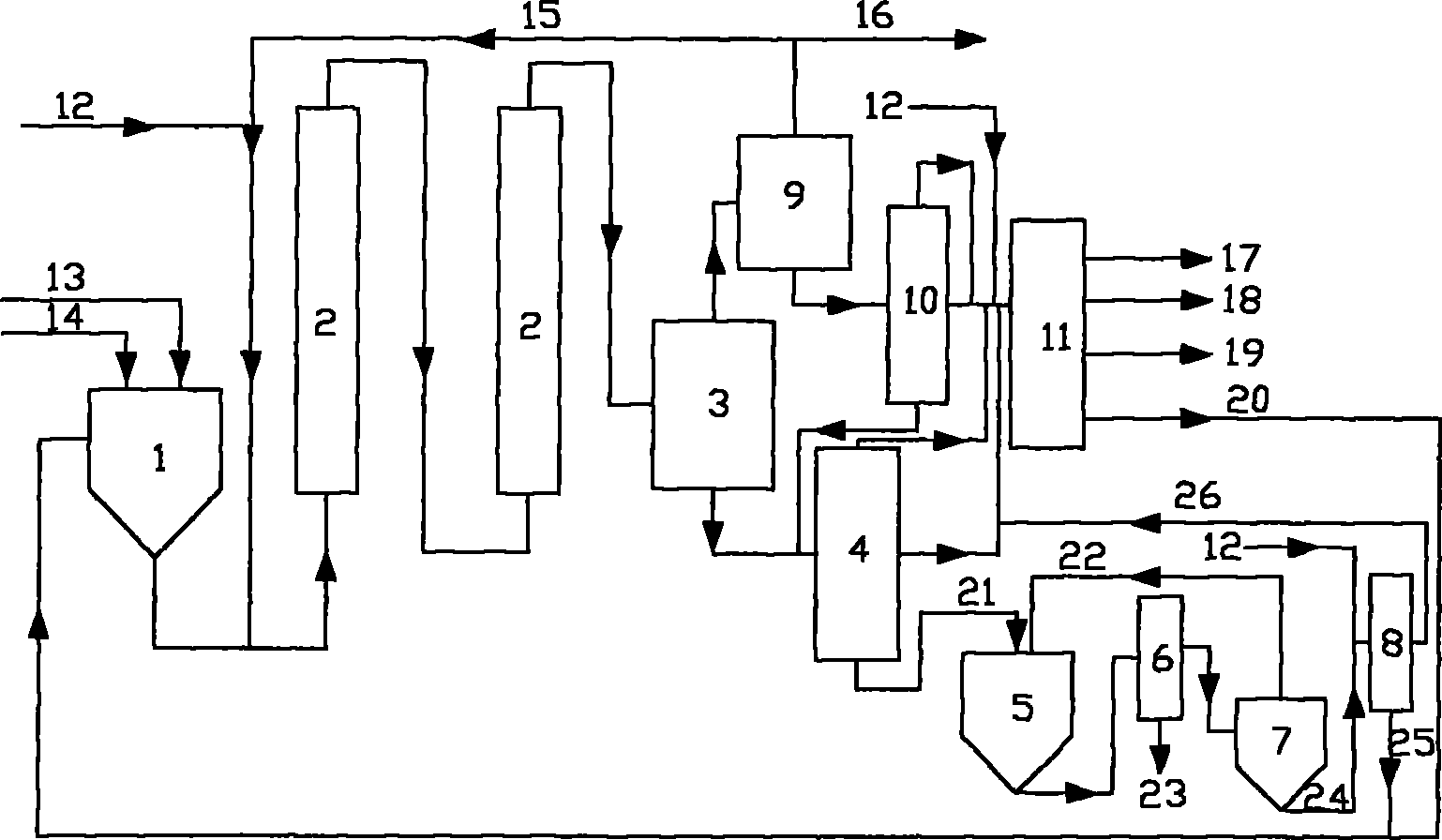

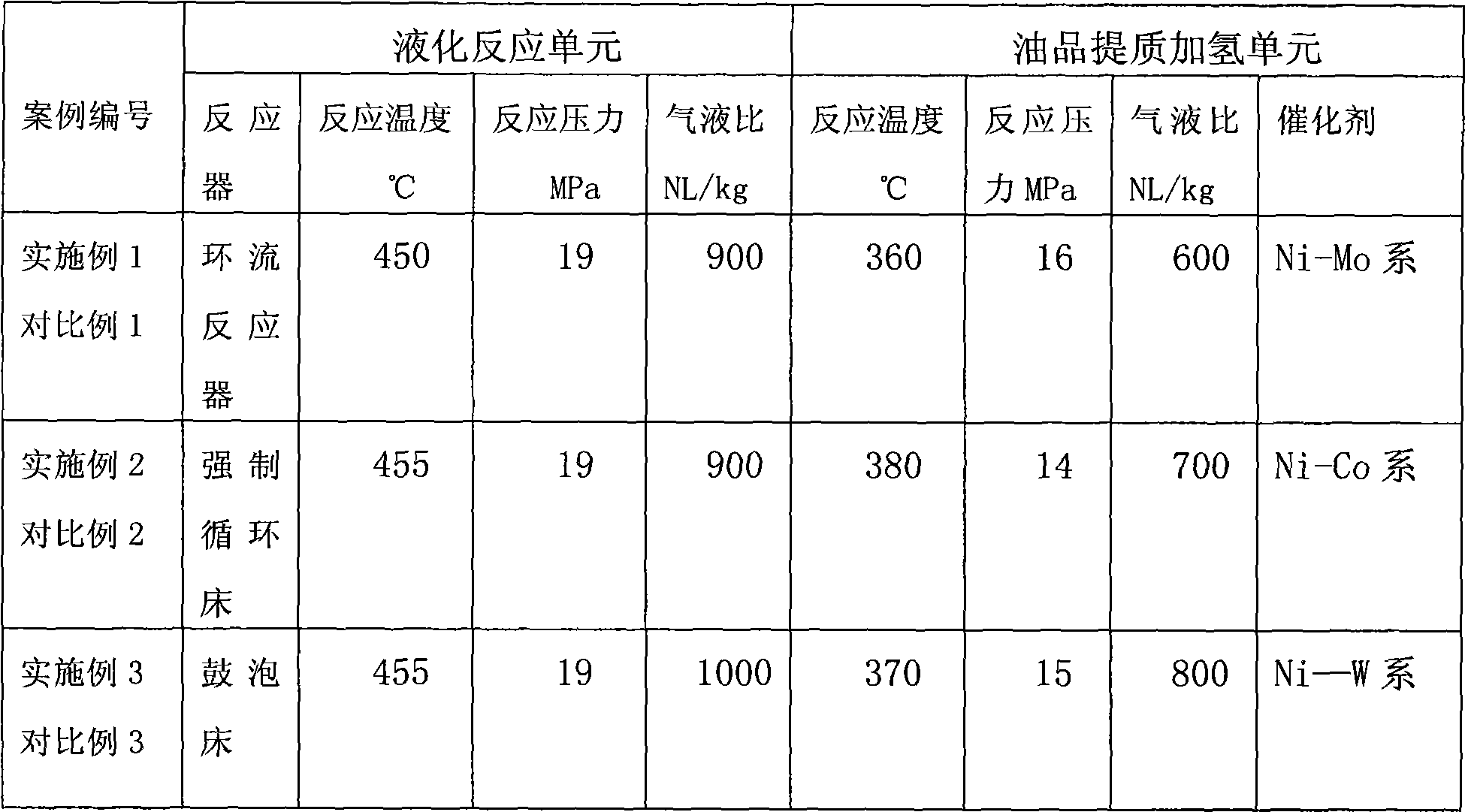

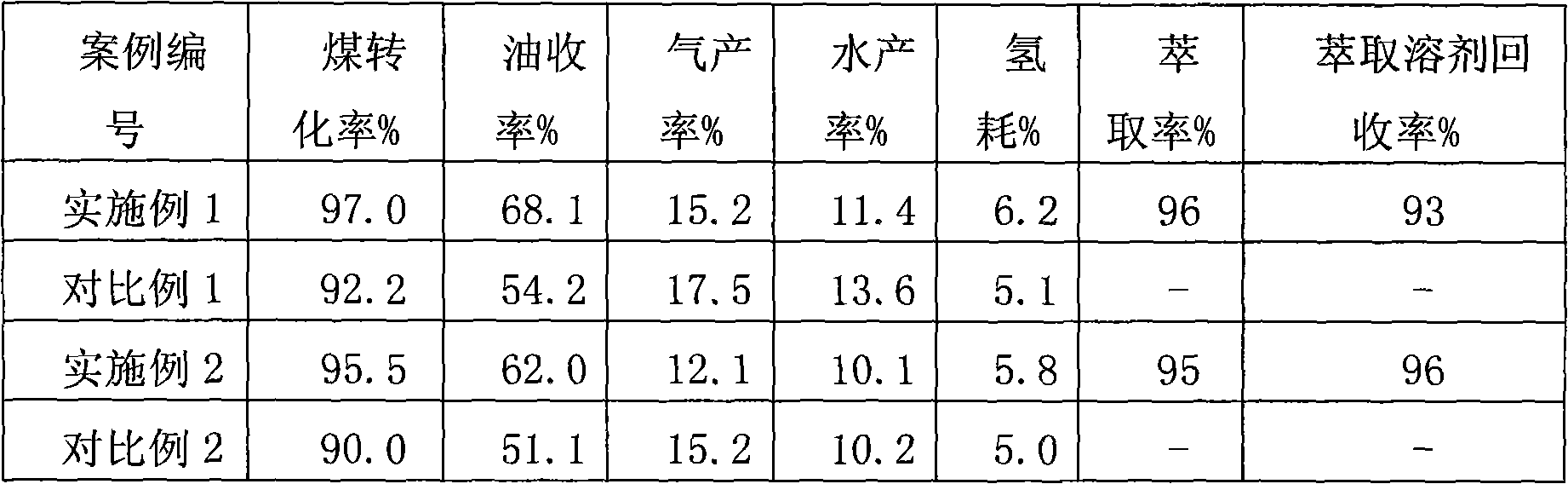

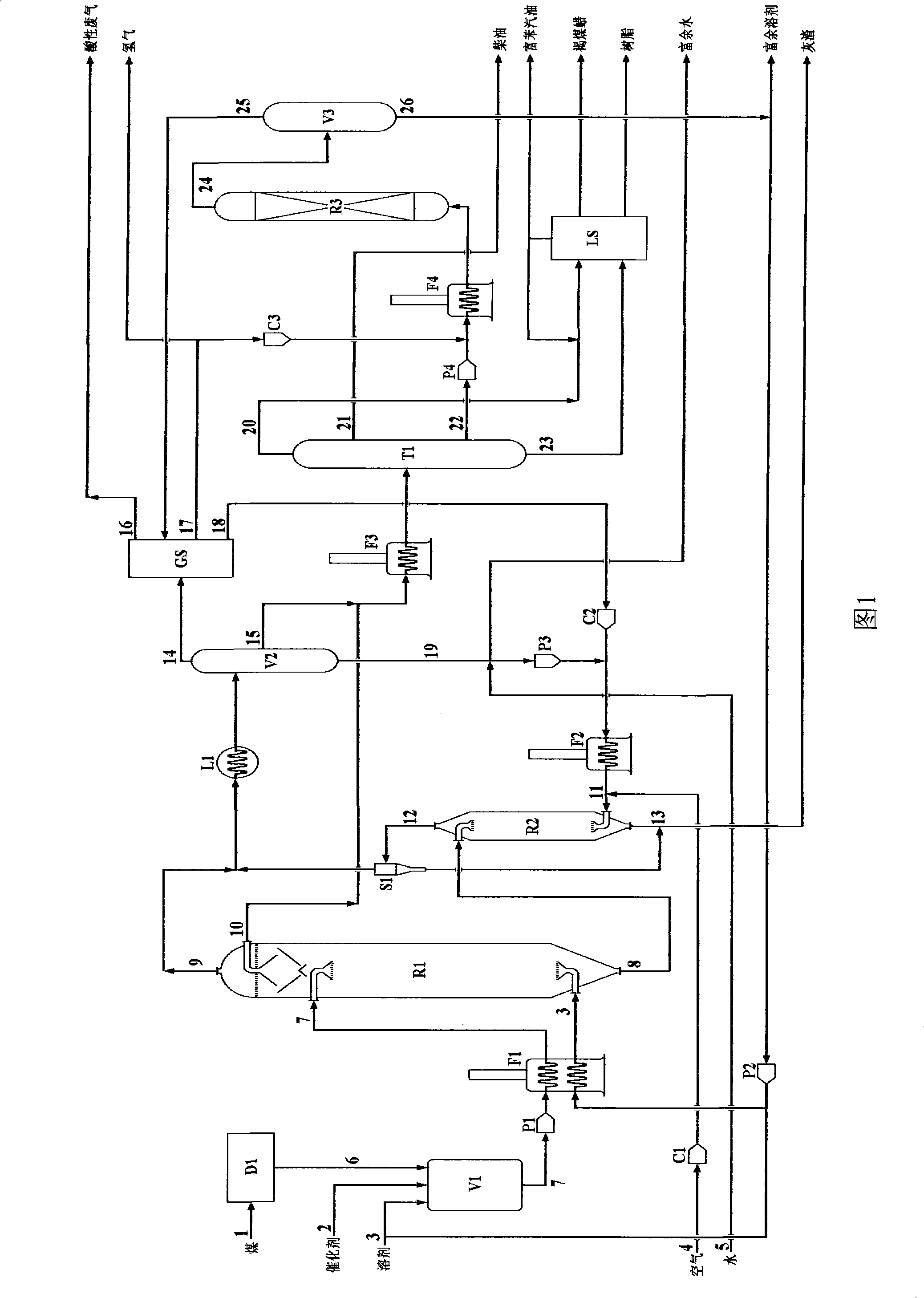

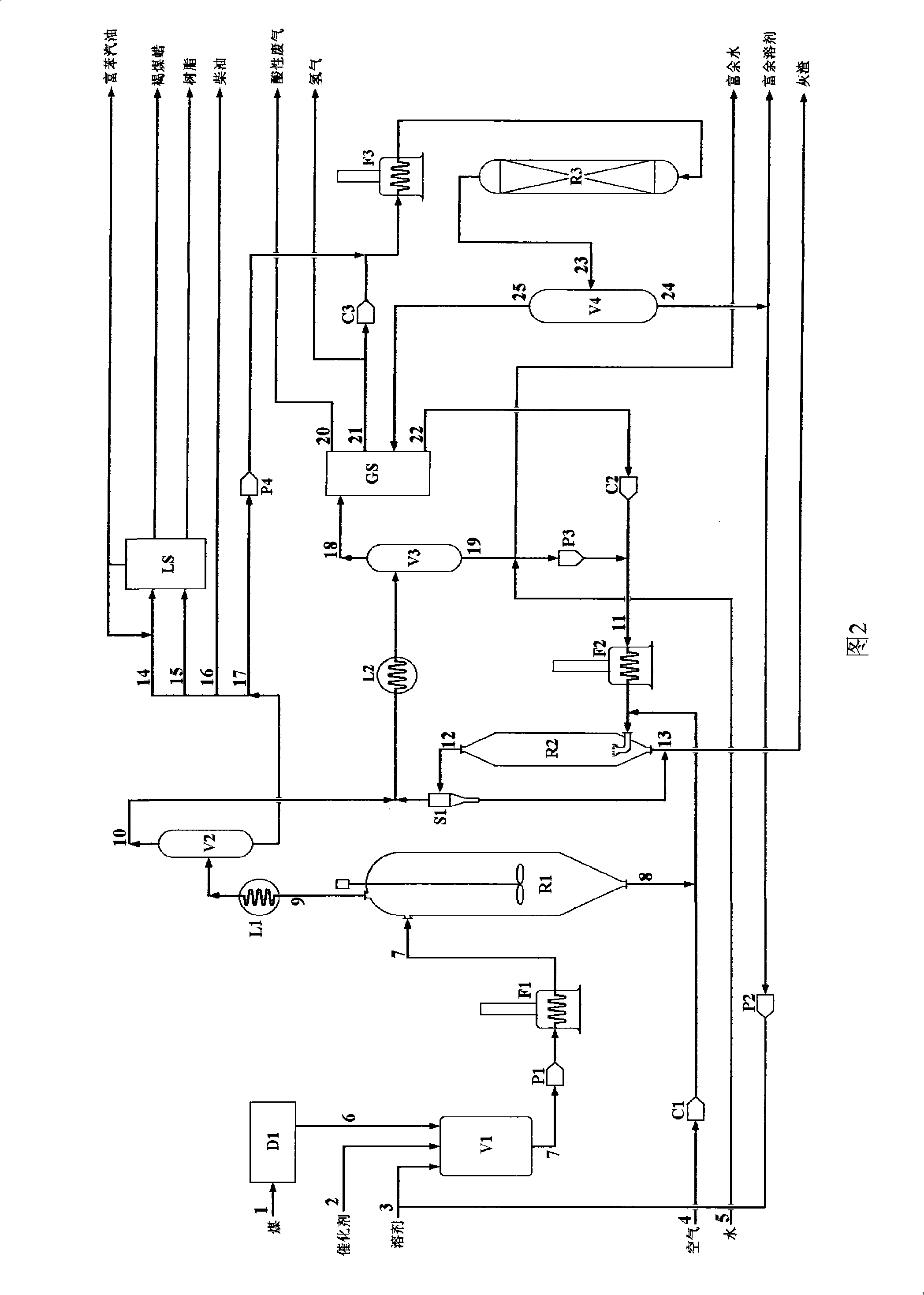

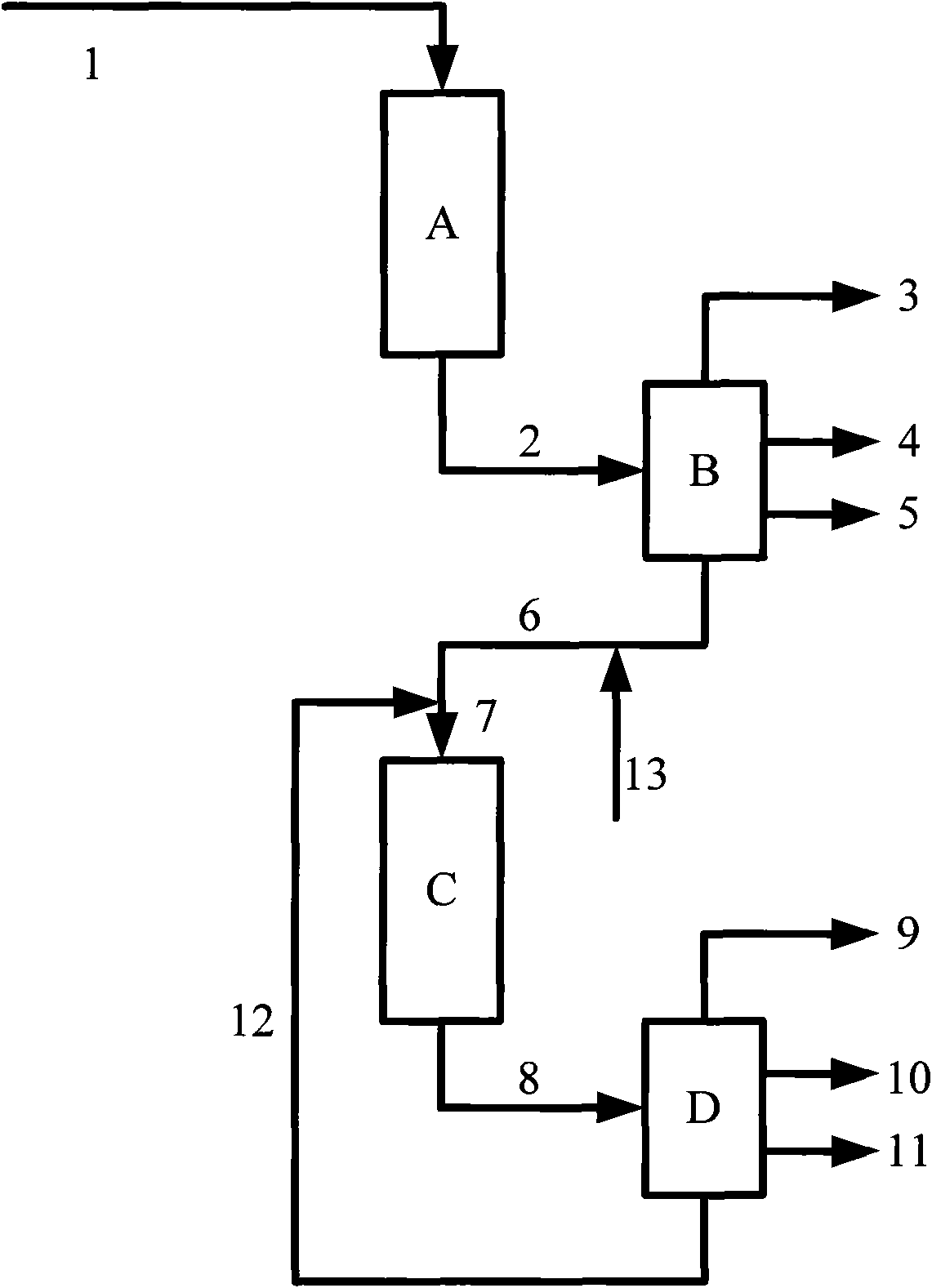

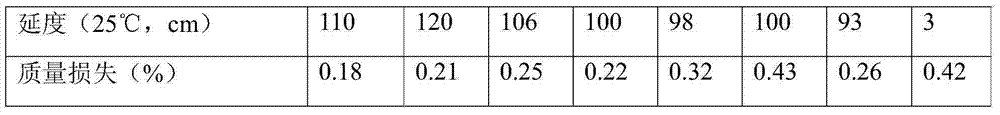

Method for directly liquefying coals with function of maximizing utilization of liquefied residues

ActiveCN102010741AGreat operating flexibilityHigh air hold-upLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesEconomic benefitsOil separation

The invention relates to a method for directly liquefying coals with a function of maximizing utilization of liquefied residues. The method comprises the following technical steps: preparing coal paste; carrying out hydrotreating and liquefaction on the coal paste; carrying out oil separation treatment on the obtained oil product; carrying out upgrading and hydrotreating on the obtained product; carrying out hot extraction on the residues and then carrying out solid-liquid separation on the residues; and recovering the solvent; and carrying out hydrotreating treatment on the mixture of heavy oils and asphalt materials so as to obtain the final product, then taking the heavy oils as recycled solvent to prepare the coal paste, and the like. The method provided by the invention has the advantages that because of organically combining the liquefaction process and the residue extraction, the utilization of liquefied residues is maximized, the conversion rate of coal is improved, the yieldsof light and middle oils subjected to coal liquefaction are improved by 10 to 60 percent, and the quality of oil is improved, thereby greatly enhancing the economic benefits of direct coal liquefaction plants and improving environment protection; and the method provided by the invention has important economic and social significances, and can widely be applied to the field of coal direct liquefaction.

Owner:CHINA COAL RES INST

Method for preparing nanometer carbon fiber/foam coal through taking coal liquefaction residues as raw materials

The method for preparing nanometer carbon fiber / foam coal through taking coal liquefaction residues as raw materials belongs to the scientific and technological field of coal materials of the scientific and technological branch of inorganic non-metallic materials. The method takes the coal liquefaction residues as the coal source of the foam coal, and compounds metallic / foam coal compound materials through the supercritical foaming method or the formwork method, and prepares the nanometer carbon fiber / foam coal compound materials through the chemical vapor deposition of organic matter. The method fully utilizes the characteristics of metallic accelerating agent containing abundant coal organic matter, iron-contained compound and the like in the coal liquefaction residues, and prepares metallic / foam coal compound materials, and the nanometer carbon fiber completely covers on the surface of the foam coal after the chemical vapor deposition. The novel nanometer carbon fiber / foam compound materials have the structural characteristics of solid foam and hollow nanometer carbon fiber. And the method is expected to be used in the fields of catalyzer and a catalyzer carrier, a fuel battery electrode material, high-effective sorbent of a fixed bed reactor and the like.

Owner:DALIAN UNIV OF TECH

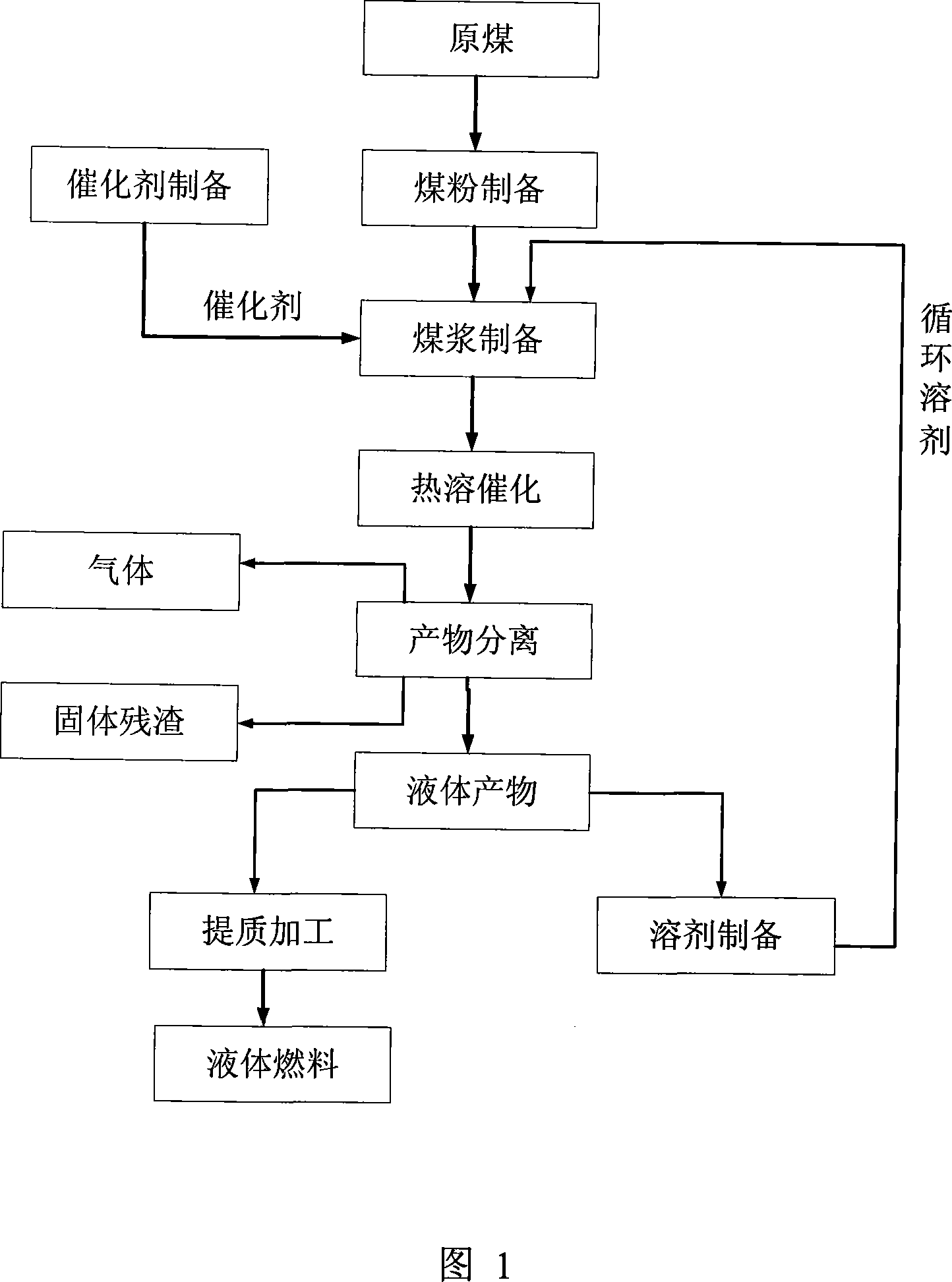

Thermally dissolving and catalytic method for preparing liquid fuel by lignite as well as catalyst and solvent used therefor

ActiveCN101182421AMild operating conditionsSimple preparation equipmentOrganic-compounds/hydrides/coordination-complexes catalystsMolybdeum compoundsLiquid productForming gas

The invention belongs to the technological field of coal chemical processing and discloses a heat dissolving and catalyzing method using brown coal to prepare liquid fuel. The method comprises the following steps: 1) the brown coal is smashed and dried to prepare pulverized coal; 2) the pulverized coal, solvent and catalyst are stirred and mixed well to prepare coal slurry; wherein, the weight percent of the pulverized coal is 30 percent to 40 percent; the weight percent of the solvent is 60 percent to 70 percent; the quantity of the added catalyst is 0.5 percent to 1 percent of the weight of the pulverized coal; 3) the coal slurry is dissolved by heat and catalyzed to prepare heat dissolved and liquefied products; wherein, the temperature is 390 DEG C to 450 DEG C; the pressure is 5.0MPa to 9.0MPa; the reaction time is 30 minutes to 60 minutes; 4) the heat dissolved and liquefied products are separated to form gas-phase, liquid-phase and solid-phase products; 5) the liquid products are extracted and processed to form liquid fuel. The invention also discloses catalyst and solvent used in the method. The operation condition of the method of the invention is mild; the conversion ratio of the organic substances in the brown coal can achieve a higher level; after being processed, the liquid fuel product can be used for preparing engine fuel suiting national standards; and the preparation equipment is simple; the investment is small; the cost is low; and the invention is a coal liquefaction method suiting the national conditions of China.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

Intermediate phase asphalt and preparation method thereof

InactiveCN103194254AHas a streamlined structureHigh aromaWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansResource utilizationDistillation

The invention provides intermediate phase asphalt and a preparation method thereof. The preparation method comprises the following steps that A, mixing coal liquefaction residuals with an extraction solvent, stirring, extracting, and carrying out centrifugal separation to form an extraction liquid; B, carrying out atmospheric or reduced pressure distillation on the extraction liquid to form an extraction refined substance; and C, carrying out a polymerization reaction on the extraction refined substance at constant 400-450 DEG C and at constant 0.1-3.0MPa in an inert gas atmosphere for 5-16 hours to form the intermediate phase asphalt. According to the preparation method, under the condition that no catalyst is added, the intermediate phase asphalt in a good streamline structure is prepared, and serves as a carbon precursor for further preparing various carbon materials; the flow of a whole technical process is relatively simple; operation is convenient and safe; utilization potential of asphalt substances in the coal liquefaction residuals is fully exerted; the application field of the coal liquefaction residuals is expanded; and the resource utilization ratio is increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Mesophase pitch and preparation method thereof

ActiveCN104004536AHigh carbon contentModerate carbon-hydrogen ratioWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionOrganic solventSolvent

The invention provides a method for preparing mesophase pitch from direct coal liquefaction residues. The method mainly comprises the following steps: 1, extracting the direct coal liquefaction residues by using an organic solvent I to obtain extracted pitch; 2, dissolving the extracted pitch by using a polar organic solvent II, and carrying out solvent recovery on the soluble part to obtain refined pitch; 3, carrying out thermal polycondensation on the obtained refined pitch at a high temperature to obtain a thermal polycondensation product; and 4, carrying out reduced pressure flash evaporation on the thermal polycondensation product to obtain the mesophase pitch. The invention also provides the mesophase pitch. The spinnable indexes of the mesophase pitch are characterized in that the softening point, the aromatic carbon rate and the quinoline insoluble substance content of the mesophase pitch are 250-280DEG C, not lower than 0.9 and 35-45% respectively.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for direct liquefaction and comprehensive utilization of ravens

ActiveCN101280207AImprove resource utilization efficiencyLow equipment requirementsHydrogenLiquid hydrocarbon mixture productionLiquid productHydrogen

The invention discloses a method of direct liquefaction of the lean coal and comprehensive utilization. The method includes that under mild condition, proper catalyst and hydrogen-donor solvent are used; the feed coal is processed with liquefaction reaction under the situation that the gas hydrogen is not adopted; the main product is liquid fuel and the by products include montan wax, resin and organic compounds with high values; meanwhile, the liquefaction generation water, the generation gas and the non-transformed residual coal can be used to produce liquid products; the liquid products can be processed with hydro-grading to obtain needed hydrogen; the method of direct liquefaction of the lean coal and comprehensive utilization not only can reduce the device requirement and the energy consumption of the coal liquefaction technique, but also can improve the resource utilization benefits of the lean coal greatly.

Owner:CHINA PETROLEUM & CHEM CORP +1

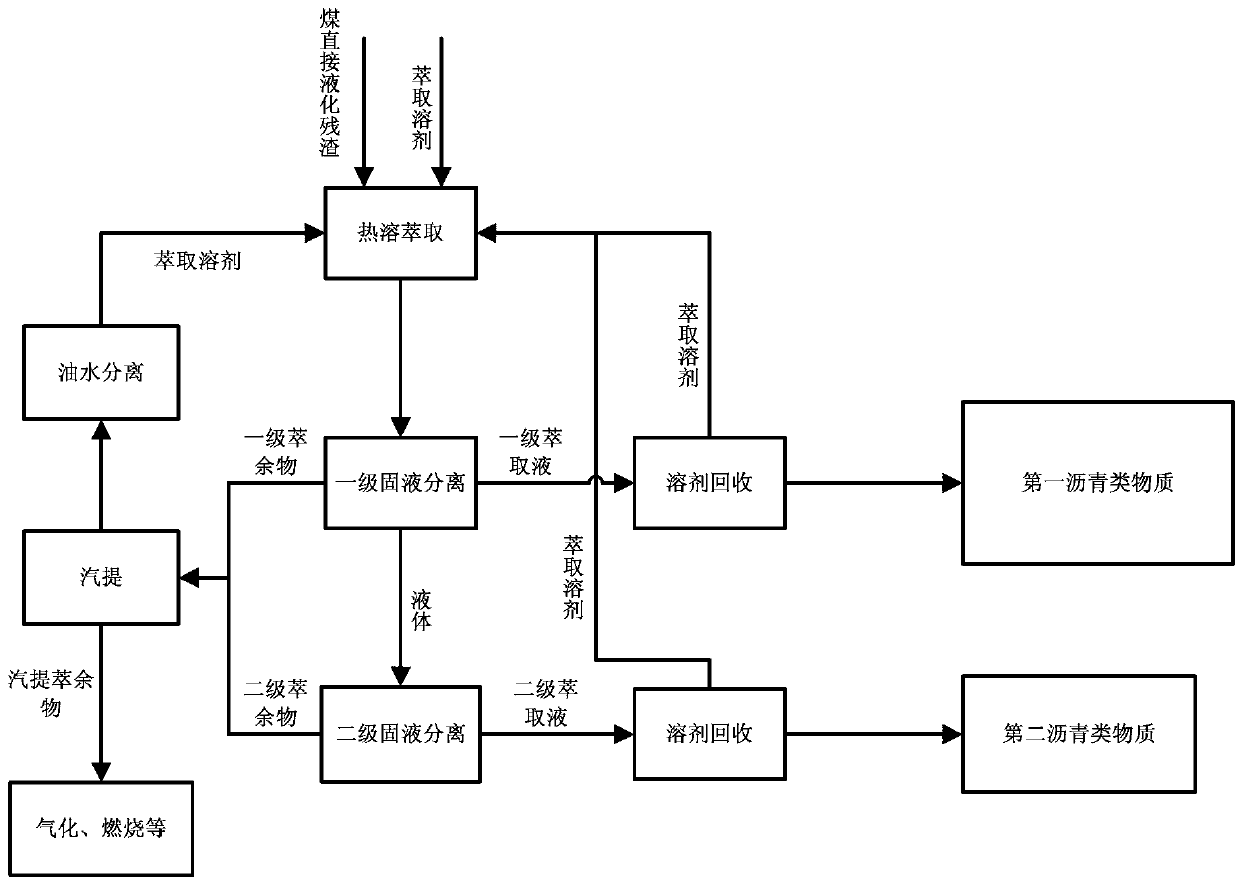

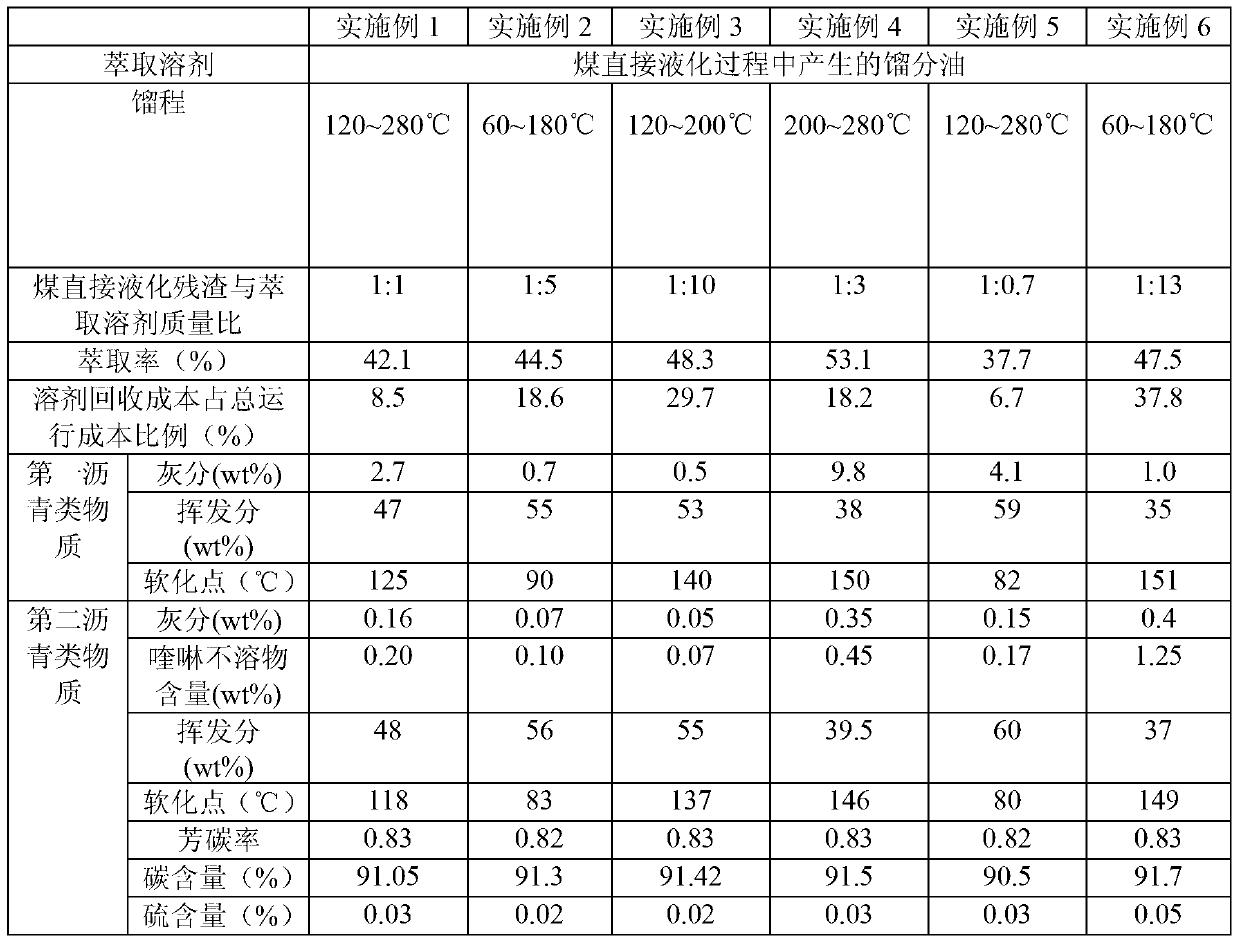

Asphalt substance separated from direct coal liquefaction residues and method and application thereof

ActiveCN103275744ALow ash contentModerate volatileWorking-up pitch/asphalt/bitumen by selective extractionRaffinateAsphalt

The invention discloses an asphalt substance separated from direct coal liquefaction residues and a method and application thereof. The method comprises the following steps of: S1, mixing the direct coal liquefaction residues and an extraction solvent, and performing thermosol extraction to obtain a thermosol extraction mixture; S2, performing primary solid-liquid separation on the thermosol extraction mixture to obtain primary extraction liquid and primary raffinate; S3, performing secondary solid-liquid separation on part of the primary extraction liquid to obtain secondary extraction liquid and secondary raffinate; and S4, performing solvent recovery on the remaining primary extraction liquid to obtain a first asphalt substrate, and performing solvent recovery on the secondary extraction liquid to obtain a second asphalt substrate, wherein the extraction solvent is the distillate oil produced in a coal liquefaction process. The ash content in the asphalt substrate mixture is low, the volatile components are moderate, and the softening point is higher; and the liquefied heavy oil in the asphalt substrate does not need to be separated, and the asphalt substance can be reasonably utilized as the raw material of carbon materials of different levels according to different properties of mixtures.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method of preparing carbon fiber by using coal to directly liquefy residue-based asphalt vinyl material

InactiveCN102733008AEfficient use ofSimple preparation routeFibre chemical featuresCarbon fibersSorbent

The method of the present invention provides a Method of preparing a spinnable mesophase and carbon fiber by using coal to directly liquefy residue-based asphalt vinyl material. According to the invention, the residue-based asphalt vinyl material which is subjected to direct coal liquefaction as a raw material, and the method comprises the following steps: grinding the asphalt vinyl material, and then placing in a high temperature tube type furnace or a high pressure reaction kettle under the inert gas protection, and preparing under the temperature of 200-500 DEG C and the pressure of 0.1-10 MPa to obtain the spinnable mesophase, performing processes of melt spinning, preoxidation and carbonization treatment on the mesophase to prepare the carbon fiber. The invention has the advantages of simple preparation method, conventional equipment, cheap raw material, good product quality and environmental protection, and is a method for high-value utilization of coal resource. The prepared carbon fiber can be used for high performance aerospace materials, adsorbents with high efficiency, separating agents, catalysts and catalyst carriers and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

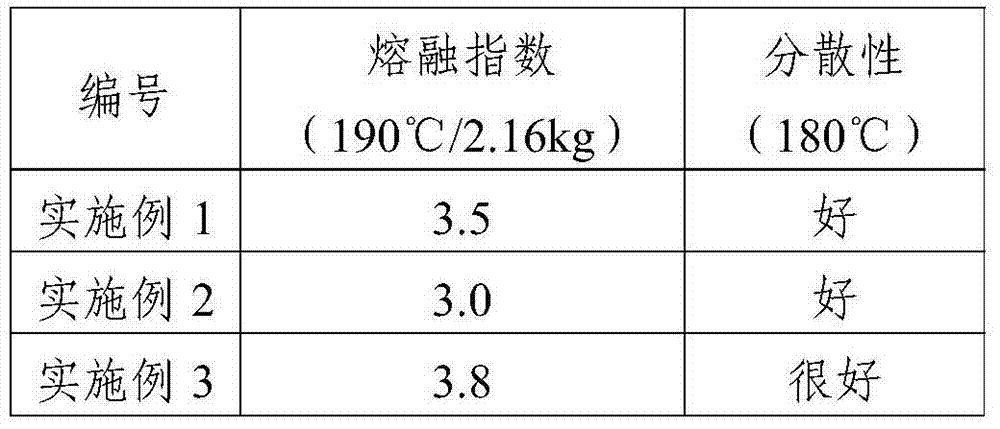

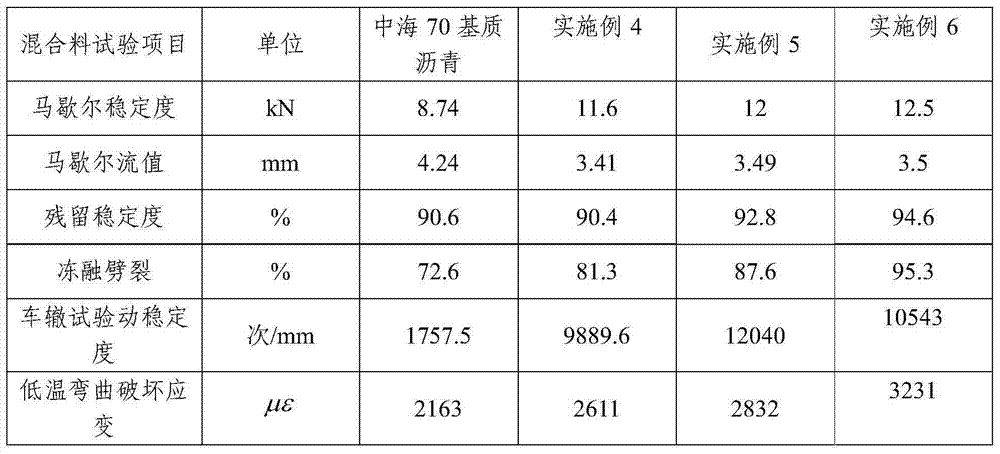

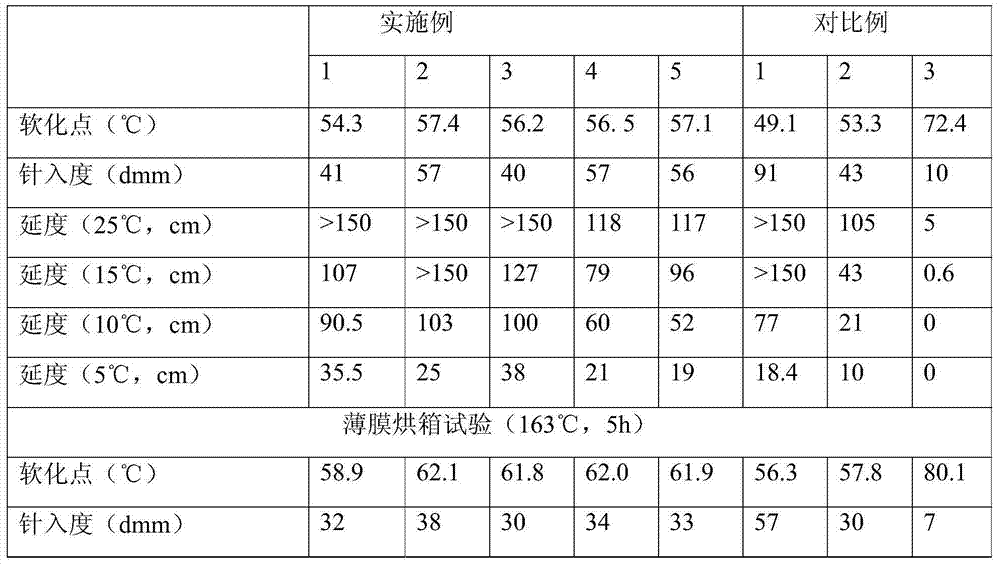

Anti-rutting additive containing direct coal liquefaction residue as well as preparation method and application thereof

The invention belongs to the field of road engineering and provides an anti-rutting additive containing direct coal liquefaction residue. The anti-rutting additive containing direct coal liquefaction residue comprises the direct coal liquefaction residue, a thermoplastic elastomer and an additive, wherein the weight ratio of the direct coal liquefaction residue to the thermoplastic elastomer is 1 to (1-4), and the additive accounts for 5-20% of the sum of the weights of the direct coal liquefaction residue and the thermoplastic elastomer. Based on resource conservation and environmental friendliness, comprehensive advantages of the direct coal liquefaction residue and macromolecules are utilized, so that the prepared asphalt mixture has excellent anti-rutting performance and good low-temperature performance and durability, construction cost is reduced while anti-rutting performance of a road is improved when the prepared asphalt mixture is applied to a middle surface layer, and service life of the road is prolonged.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

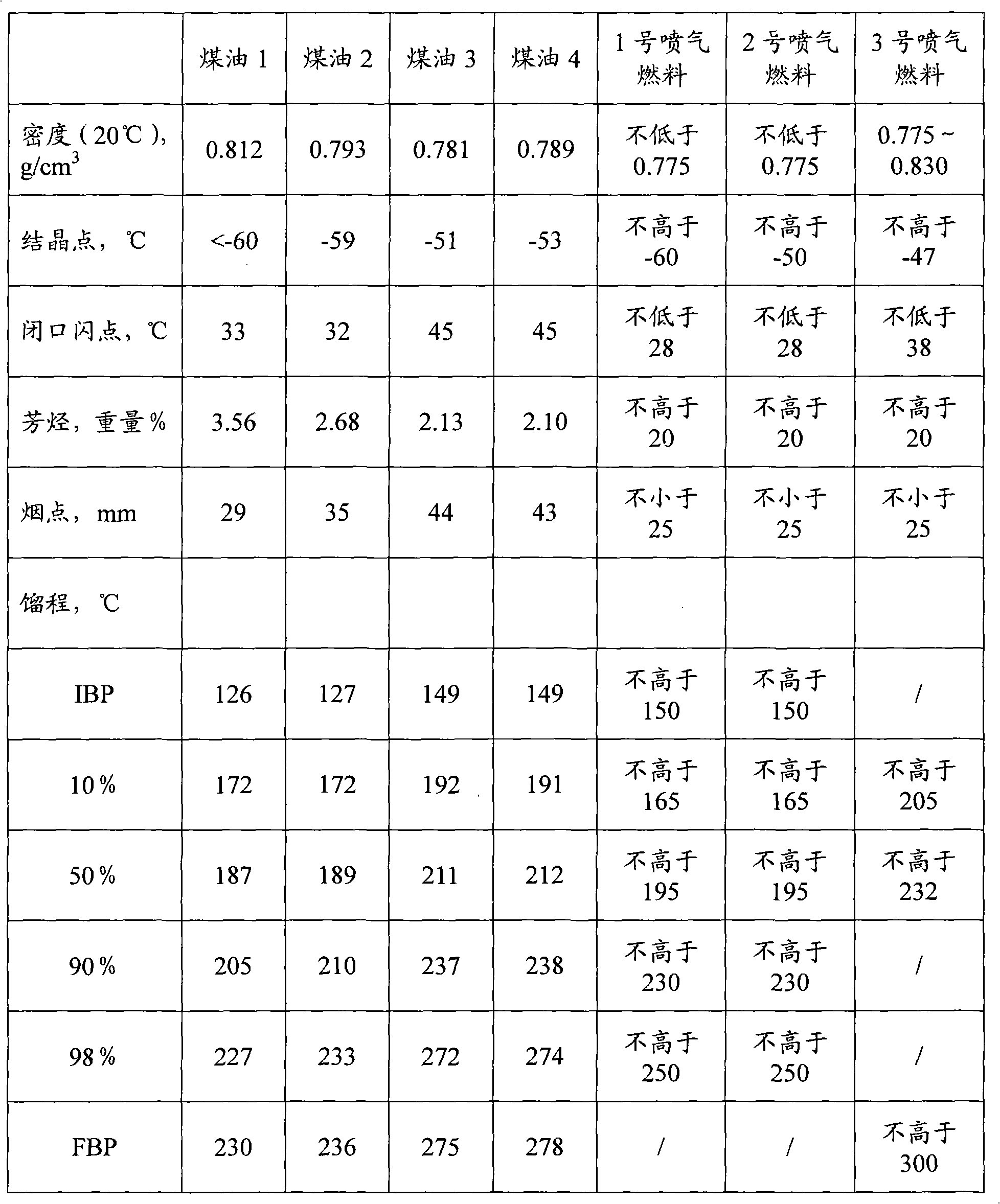

Method for producing jet fuel or jet fuel blending component

ActiveCN101928599ARelaxed reaction conditionsLow operating costTreatment with hydrotreatment processesJet fuelCoal liquefaction

The invention discloses a method for producing a jet fuel or a jet fuel blending component. A mixed oil is obtained by mixing a Fischer-Tropsch synthesis fuel and a direct coal liquefaction oil; and the jet fuel or jet fuel blending component is obtained by hydrorefining, hydrocracking, isocracking and fractionating the mixed oil. According to the method provided by the invention, two prepared coal oils can be converted into the high-quality jet fuel or jet fuel blending component. Compared with hydro-upgrading of the direct coal liquefaction oil, the method has the advantages of mild reaction conditions, low device investment cost and low operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for stalk liquefaction preprocessing to prepare fuel ethyl hydrate raw material

InactiveCN101298744ASmall granularityRealize comprehensive utilizationPaper material treatmentCelluloseProviding material

The invention relates to a pre-treatment method for straw 'liquefying' to provide material for fuel alcohol preparation. The method adopts powders (10.0 parts of mass) of crop straws and phenols or polyalcohol compound (10 to 100 parts of mass) which is firstly pre-heated by 10 to 30 minutes under a temperature of 30 to 200 DEG C with the effect of acid catalyst (0.5 to 10 parts of mass) for a reaction of 30 to 240 minutes; after the reaction, the compound is washed, neutralized, filtered and dried to obtain a solid appearing as a color from citron yellow, yellow, bight brown to seal brown; wherein, the solid includes 64.0 to 70,0 percent of fibrin and 4.1 to 7.6 percent of lignin. The method adopts the 'liquefying' process to carry out pre-treatment to fibrin biomass of straws with high straw fibrin content and low granularity after pre-treatment to realize effective separation of fibrin and lignin, etc. so as to provide the better material for preparing fuel alcohol with straws and to conserve energy cost and avoid contamination to environment.

Owner:HAINAN UNIVERSITY

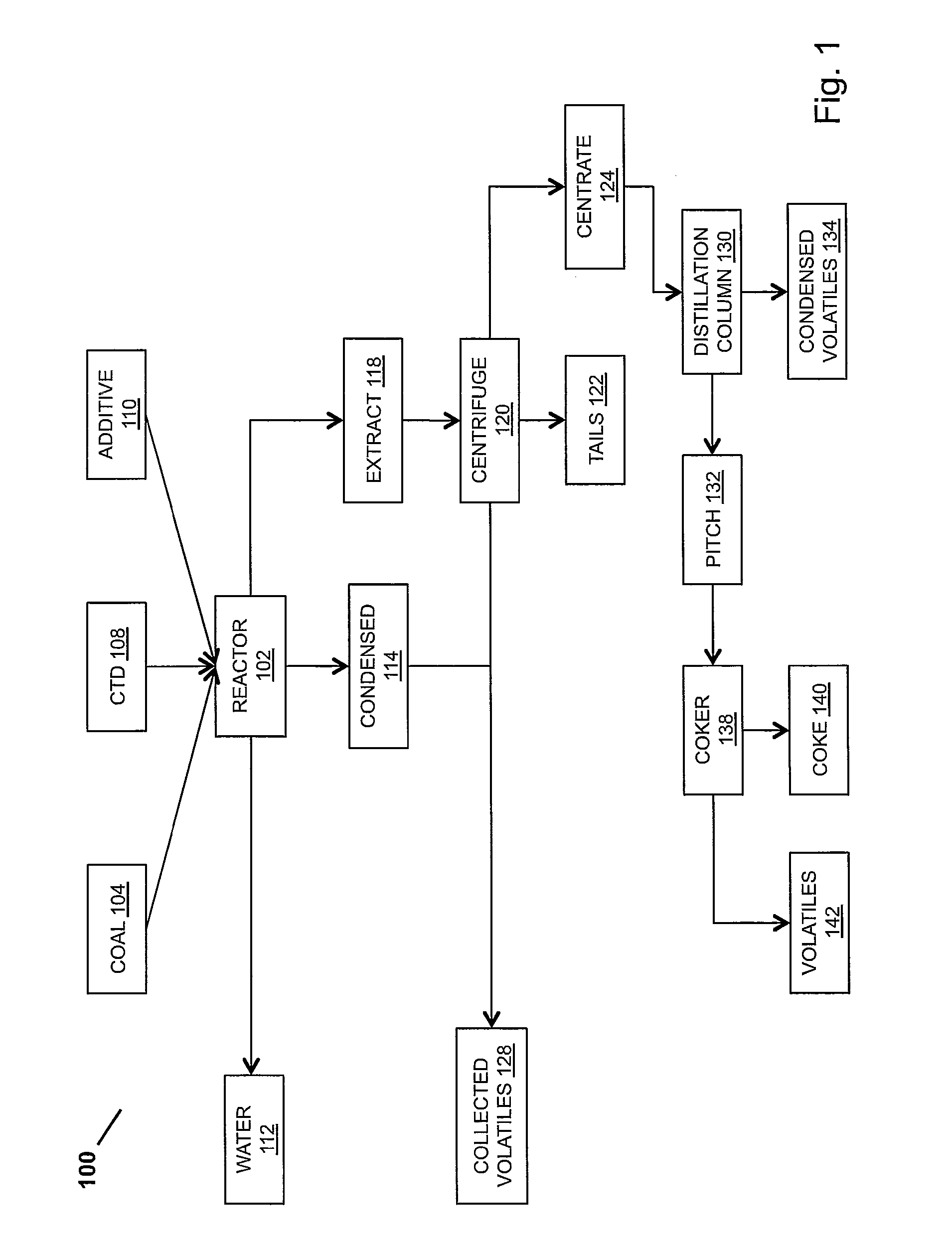

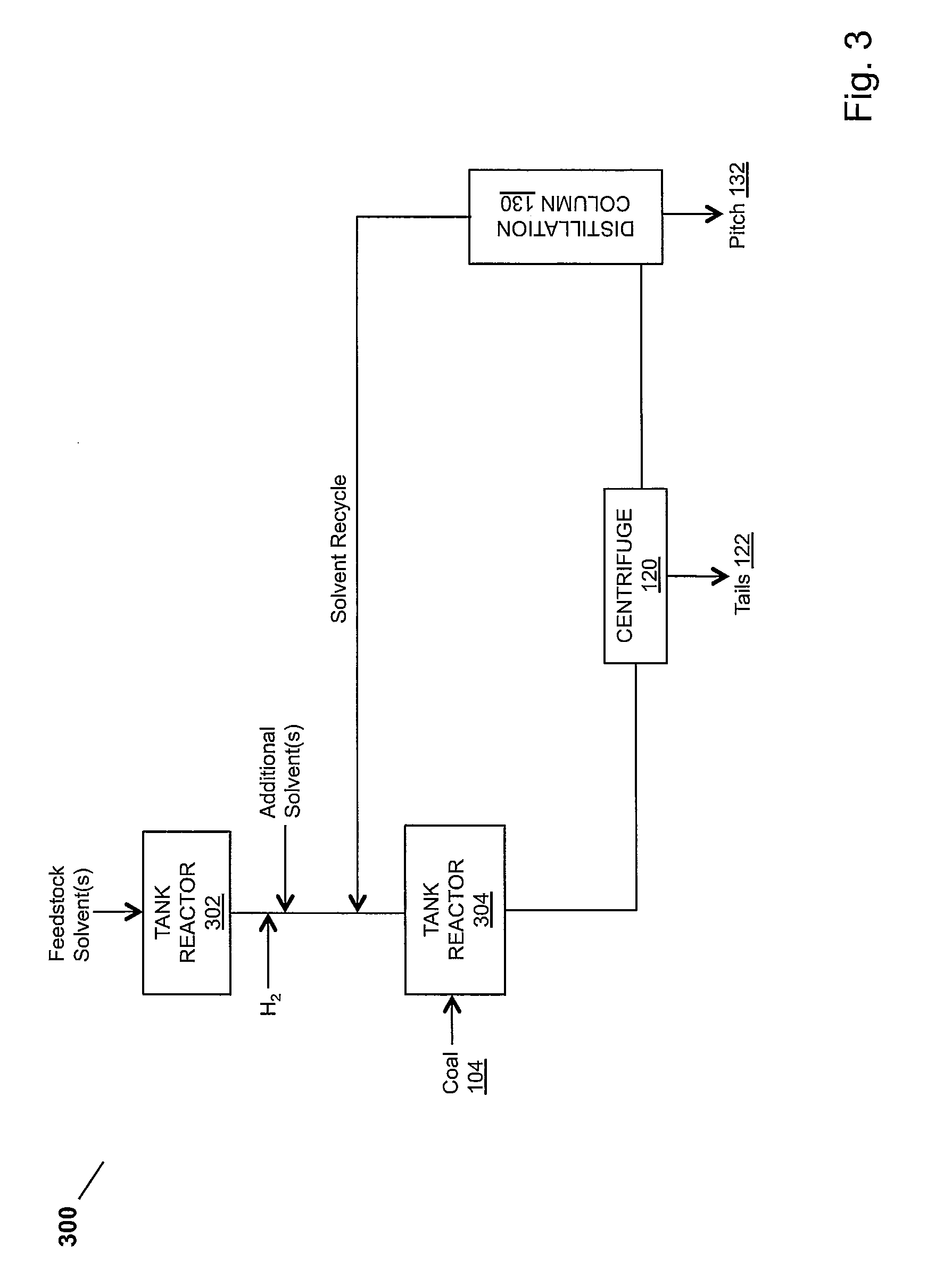

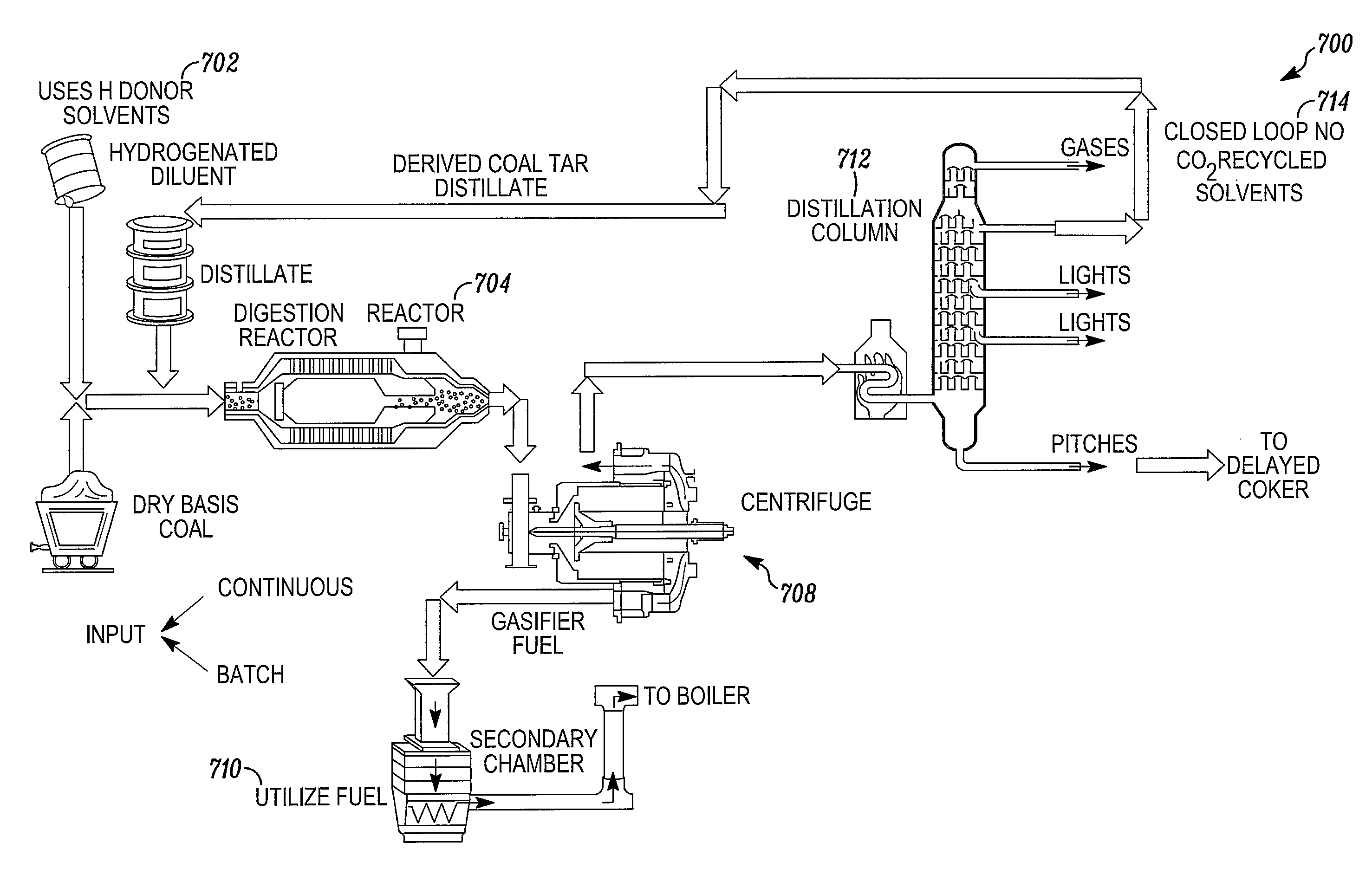

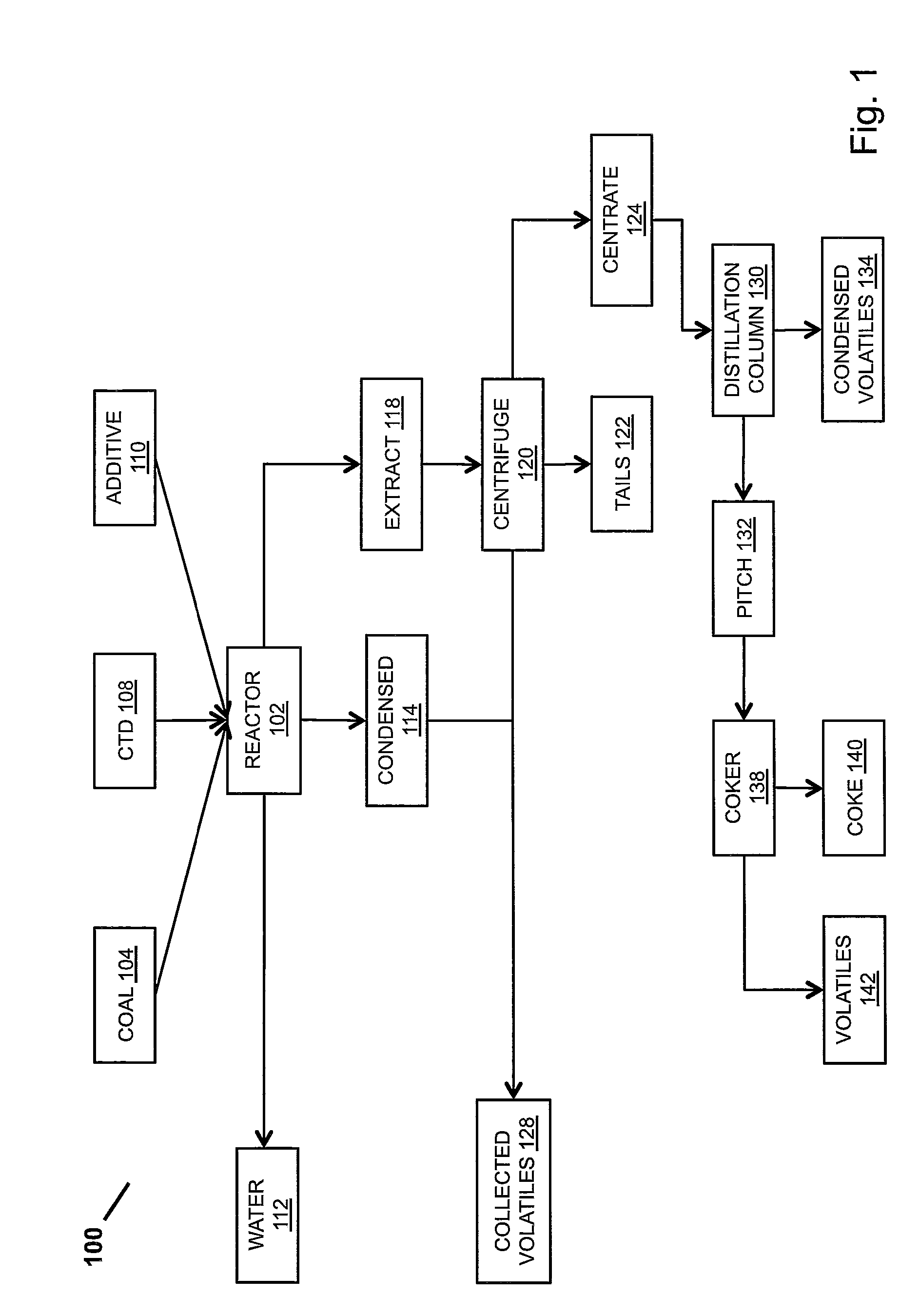

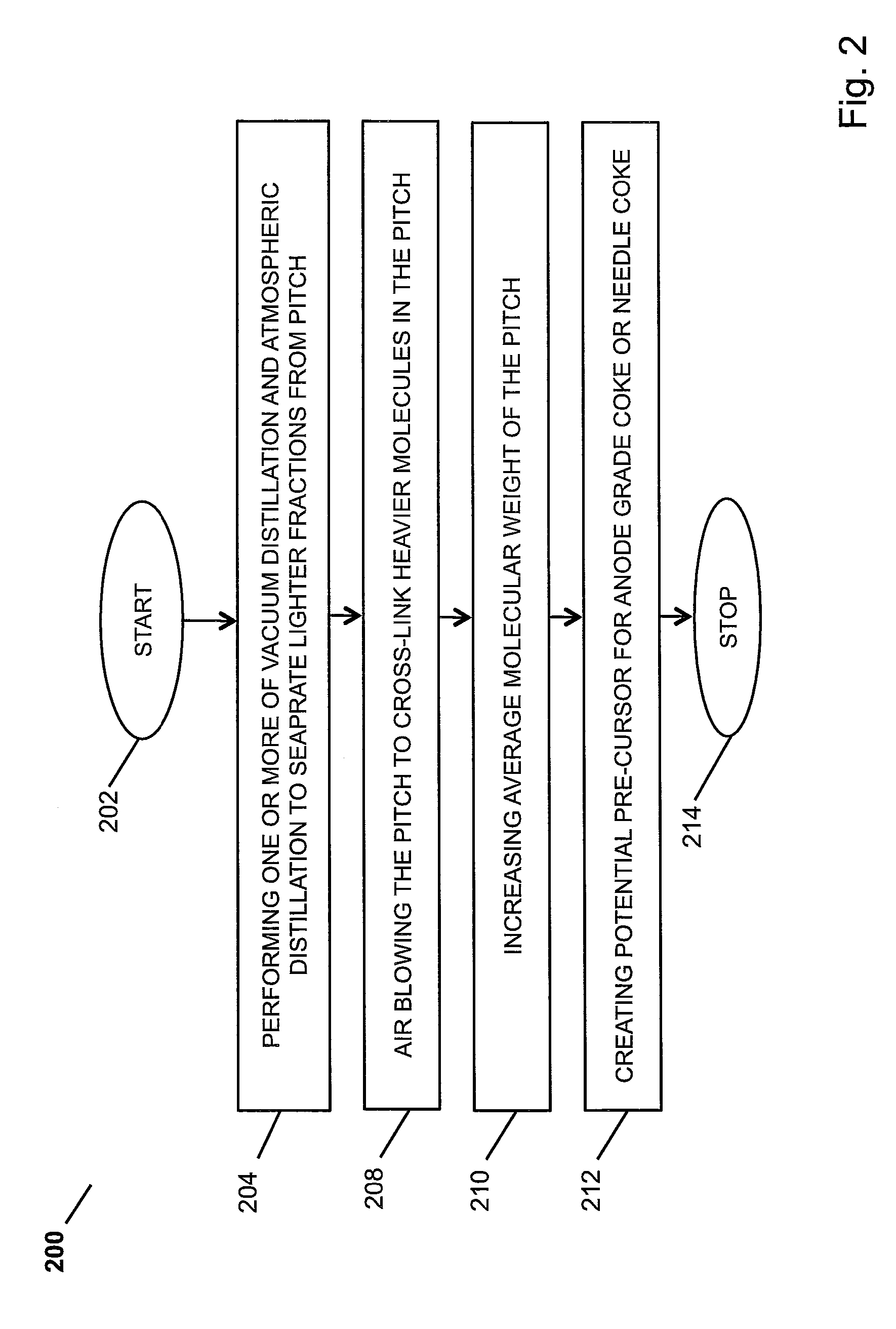

Modular Coal Liquefaction System

InactiveUS20120076703A1Low production costImprove solubilityOven incrustations prevention/removalLiquid hydrocarbon mixture productionTruck-trailerDownstream processing

The present disclosure provides methods and systems of a modular coal liquefaction system. A modular coal liquefaction system may include a reactor for exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, a heater that elevates the temperature of the slurry in the reactor to facilitate liquefying the coal and liberating a volatile matter, and a centrifuge that separates the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing, wherein the reactor, heater, and centrifuge are adapted to be modular. The system may further include a distillation column that distills the de-ashed coal extract to obtain a pitch. The system may further include a coker that cokes at least one of the de-ashed coal extract and the pitch to obtain a coke. The system may be adapted to be modularly disposed on a rail car. The system may be adapted to be modularly disposed on a semi-truck trailer.

Owner:WEST VIRGINIA UNIVERSITY

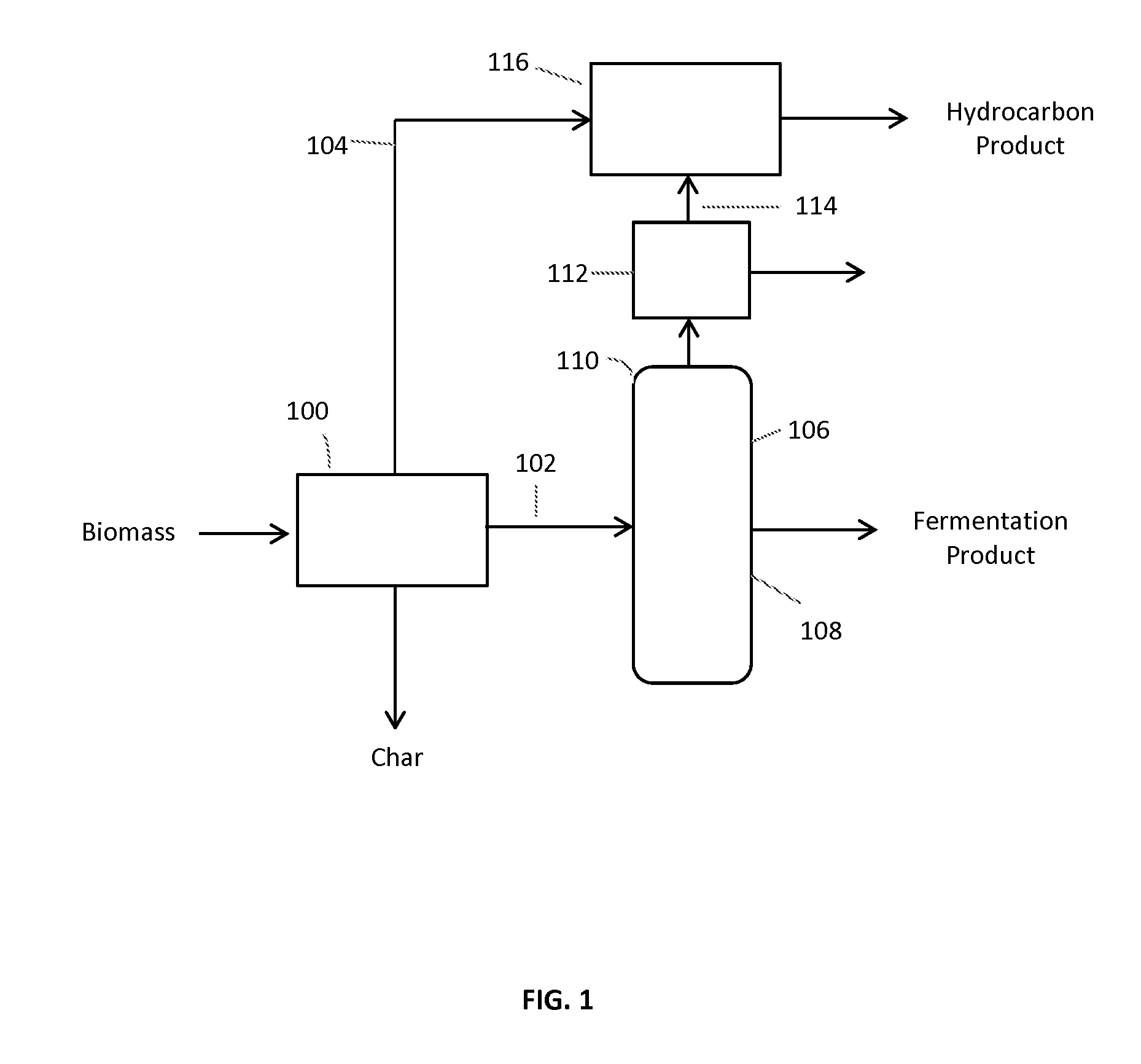

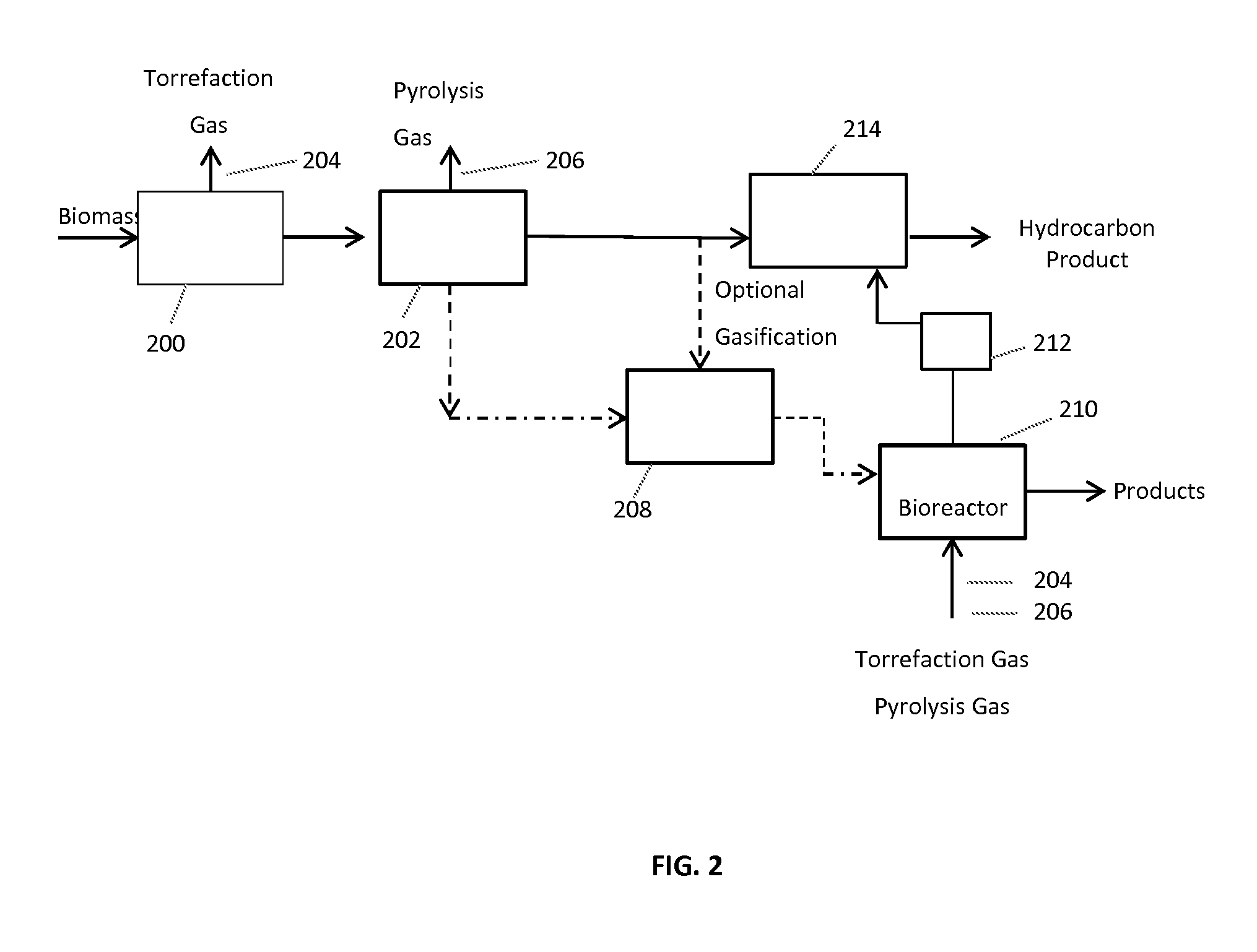

Biomass liquefaction through gas fermentation

InactiveUS20140134686A1Improve filtration efficiencyEasy to separateBiological substance pretreatmentsGas production bioreactorsProduct gasTorrefaction

The invention provides methods and systems for the production of at least one product from the microbial fermentation of a gaseous susbtrate, wherein the gaseous substrate is derived from a biomass liquefaction process. The invention provides a method for improving efficiency of the fermentation by passing biomass accumulated in the fermentation process to the biomass liquefaction process for conversion to a gaseous substrate. In a particular aspect of the invention, the biomass liquefaction process is selected from pyrolysis or torrefaction.

Owner:LANZATECH NZ INC

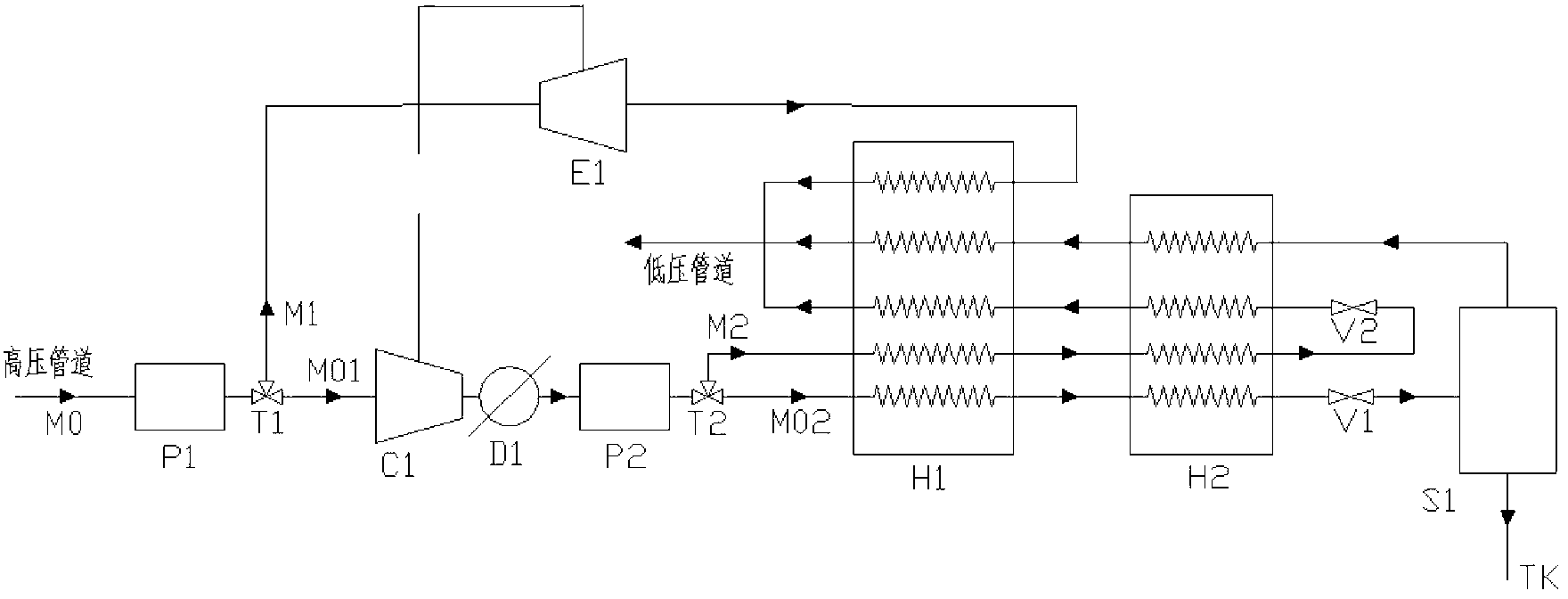

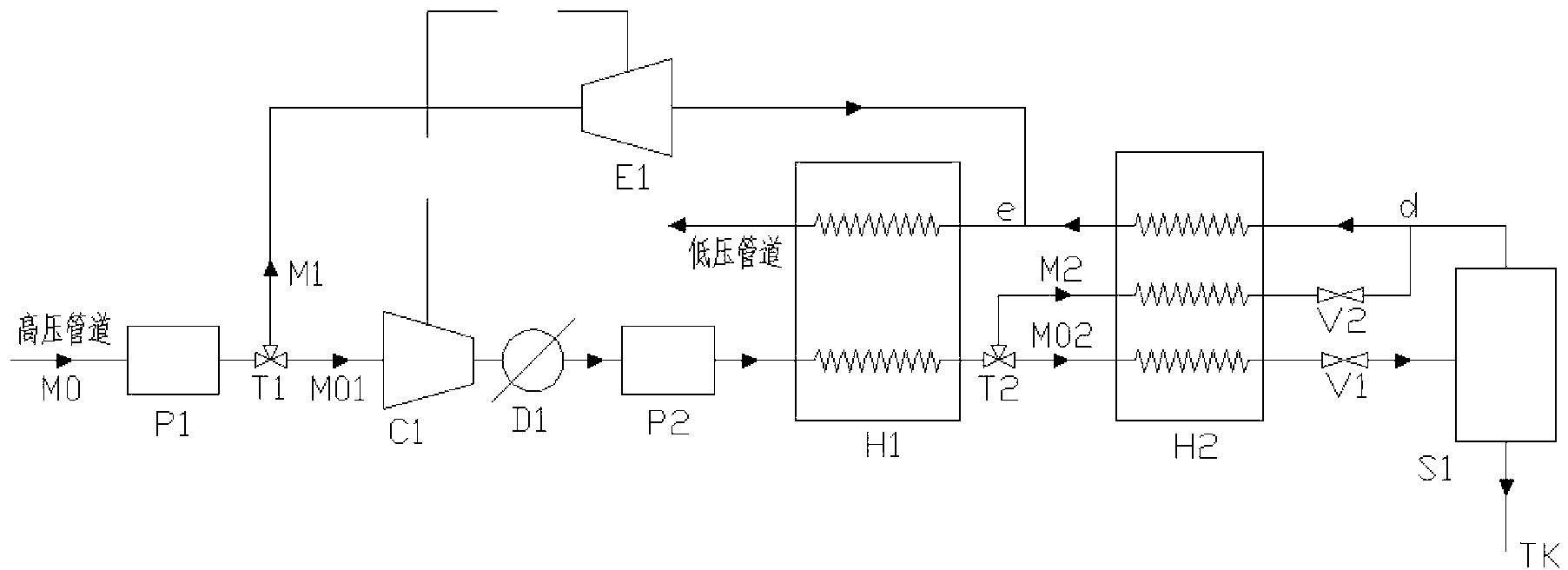

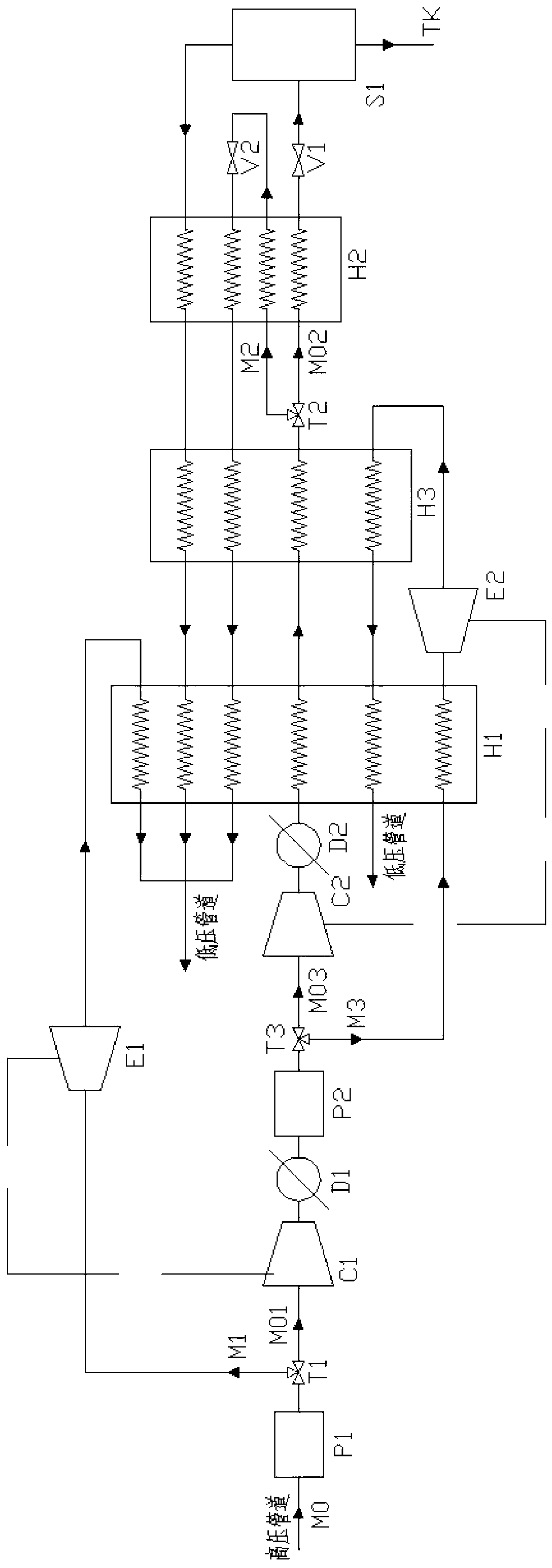

Liquefaction system for producing LNG (Liquefied Natural Gas) by using pressure energy of pipeline

ActiveCN103017480ALiquefaction achievedReduce the pressure of purificationSolidificationLiquefactionVapor–liquid separatorGas phase

The invention relates to a gas liquefaction system, and particularly relates to a liquefaction system for producing LNG (Liquefied Natural Gas) by using pressure energy of a pipeline. Natural gas from a high-pressure pipe is divided into natural gas in a liquefaction branch, natural gas in a first pre-cooling branch and natural gas in a main cooling branch, wherein the natural gas in the liquefaction branch is from the high-pressure pipeline, is sequentially compressed and cooled, then obtains heat in a backheating heat exchanger, and enters a gas-liquid separator after being throttled; a separated liquid phase is produced LNG; a gas phase enters a low-pressure pipeline after the cold energy is recycled by the backheating heat exchanger; the natural gas in the first pre-cooling branch enters the low-pressure pipeline after being expanded by an expanding machine after the cold energy is recycled in a heat regenerator; and the natural gas in the main cooling branch and the natural gas in the liquefaction branch are separated behind a cooler, the natural gas in the main cooling branch is cooled by the backheating heat exchanger and then throttled and expanded, and finally enters the low-pressure pipeline after the cold energy is recycled by the backheating heat exchanger. According to the liquefaction system, the LNG can be produced by using the pressure of the pipelines, compressors are driven by output works of the expanding machine without additional energy consumption.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

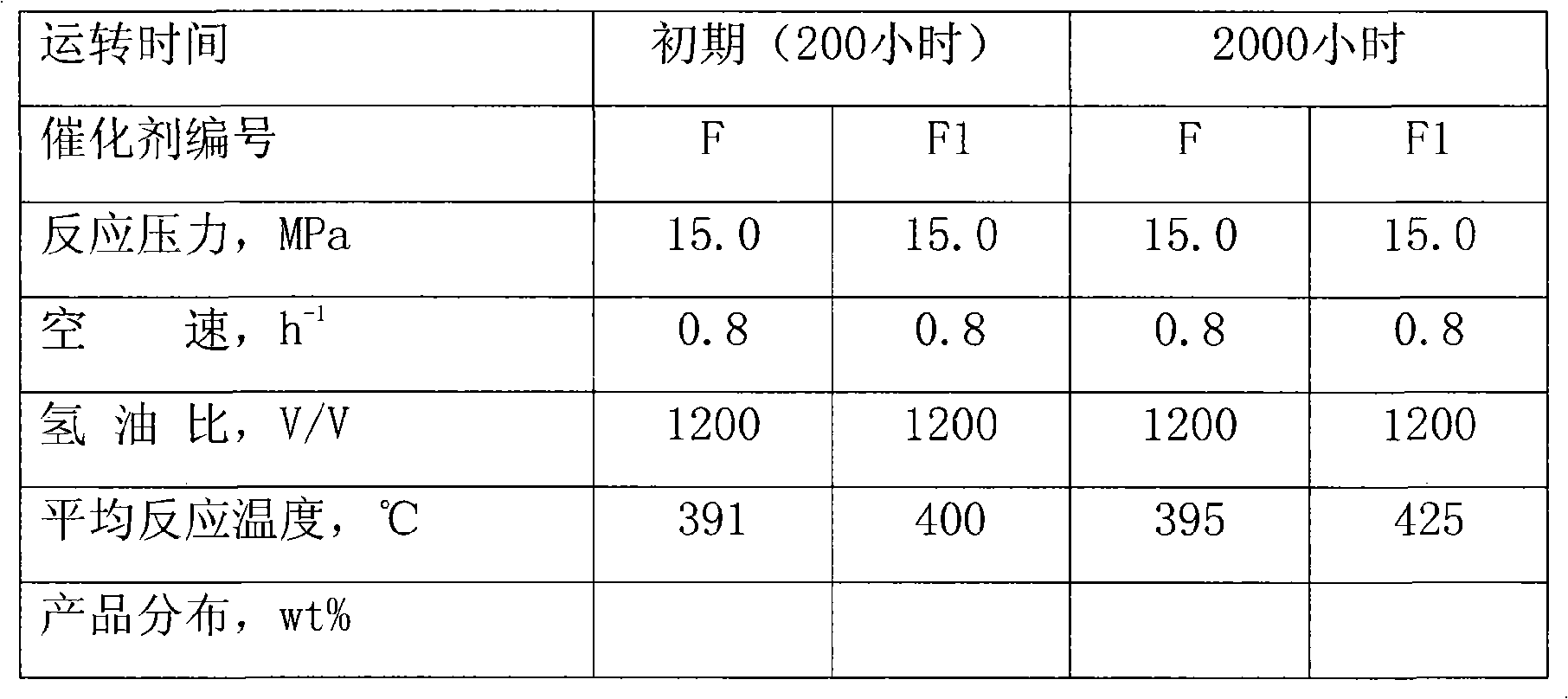

Process for producing high-performance catalyst for hydrocracking

ActiveCN101402048AImprove nitrogen toleranceExtended service lifeMolecular sieve catalystsHydrocarbon oil crackingPolymer scienceRare earth

The invention relates to a method for preparing a high-performance hydrocracking catalyst, which comprises the following steps: preparing amorphous aluminium-silicon into a paste material of which the pH value is between 3.0 and 5.5, evenly mixing Y zeolite solid powder of modified rare earth with the paste material of the amorphous aluminium-silicon, and then drying and dehydrating the mixture to prepare a moldable paste so as to prepare a catalyst carrier through molding, drying, and calcining, and finally obtaining the final hydrocracking catalyst by loading hydrogenation metal components through an impregnation method. The hydrocracking catalyst prepared by the method has the advantages of high activity and middle oil selectivity, and strong nitrogen resisting performance and water resistance, thus the hydrocracking catalyst can be used in the process of an unrefined single-stage hydrocracking, which not only can be used for processing heavy oil fraction of oil, but also can be used for processing heavy raw materials of other sources, such as the heavy distillate of coal liquefaction oil.

Owner:胜帮科技股份有限公司

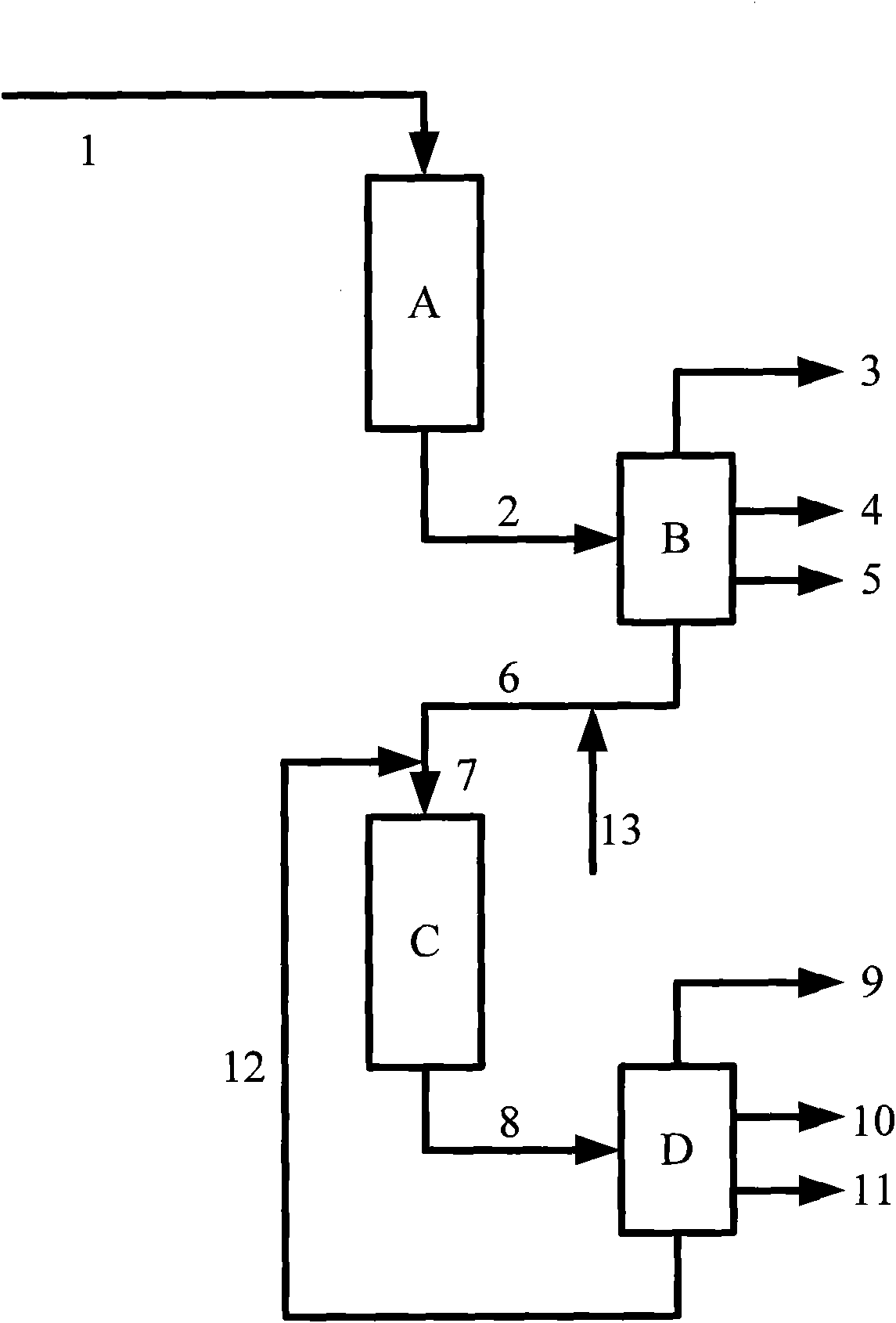

Road asphalt modifier containing direct coal liquefaction residue, modified road asphalt, and preparation methods of road asphalt modifier and modified road asphalt

ActiveCN104513488ASolve high value-added utilizationSolving the Mass Exploitation ProblemBuilding insulationsAsphaltPetroleum

The present invention discloses a road asphalt modifier containing direct coal liquefaction residue, a modified road asphalt, and preparation methods of the road asphalt modifier and the modified road asphalt. According to the present invention, direct coal liquefaction residue, a petroleum heavy oil component and a polymer are completely mixed at a temperature of higher than the residue softening point to prepare the road asphalt modifier, and the road asphalt modifier and a substrate petroleum asphalt are completely and uniformly mixed at a low temperature to obtain the modified road asphalt, wherein the road asphalt modifier has the low price, and the direct coal liquefaction residue can be effectively and economically utilized through the road asphalt modifier.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for extracting heavy liquefied oil and kerite substance from residue of direct coal liquefaction

ActiveCN102399566AHigh extraction rateEasy to recycleLiquid hydrocarbon mixture productionFiltrationDistillation

The invention provides a method for extracting heavy liquefied oil and kerite substances from residues of direct coal liquefaction. The method comprises steps of: a) adding coal residue powder and a first solvent into an extraction apparatus for extraction; b) carrying out solid-liquid separation on an extraction mixture and a raffinate from step a) by a first cyclone separator to obtain a liquid mixture and an underflow mixture; c) sending the underflow mixture from step b) and a second solvent to a re-extraction apparatus for re-extraction to obtain a mixture; d) carrying out a second solid-liquid separation on an extraction mixture and a raffinate from step c) by a second cyclone separator too obtain a liquid mixture and an underflow mixture; e) carrying out precise filtration on a clear liquid mixture from step b) and a re-extracting clear liquid mixture from step e) in a precision filtering device and sending a filtrate to a distillation separator; f) carrying out pressurizing coarse filtration on the underflow mixture from step d) and sending a filtrate part and a clear liquid mixture treated with precise filtration to a distillation separator; g) separating the extraction mixture in the distillation separator.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Method for preparing mesocarbon microbeads by copolycondensation

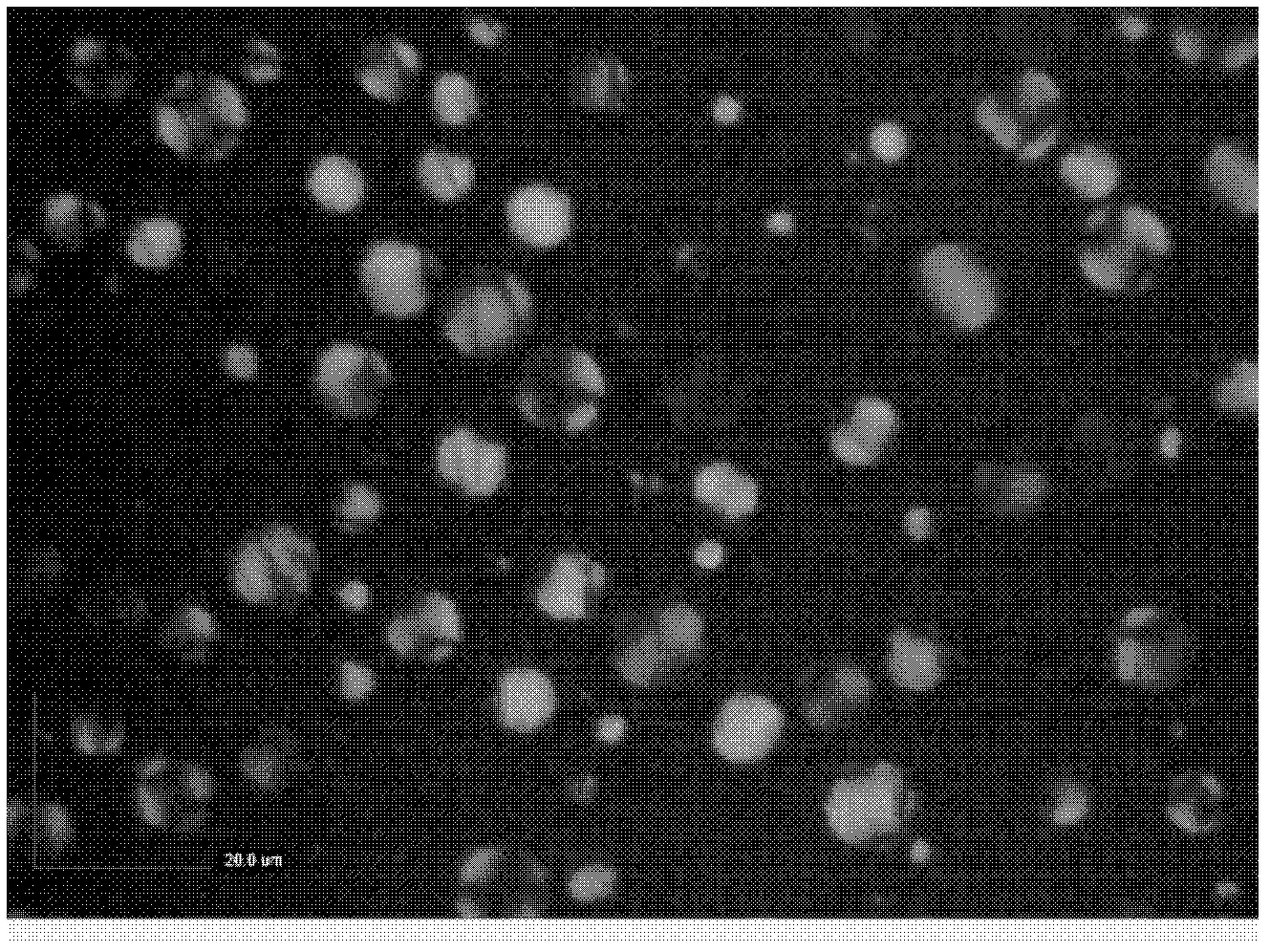

InactiveCN102491307ASolve the uniform dispersionNarrow particle size distributionCarbon preparation/purificationOrganic solventMicrosphere

The invention provides a method for preparing mesocarbon microbeads by copolycondensation, which belongs to the technical field of deep processing of coal and is characterized by comprising the following process procedures of: mixing coal tar pitch with coal liquefaction residue pitch in proportion, further heating the mixture at 300-350 DEG C till a low velocity state is obtained, reacting at 390-450 DEG C under a pressure of 0.2-2MPa for 5-12h after stirring uniformly to generate pitch containing the mesocarbon microbeads, subsequently washing with light fraction of coal tar and an organic solvent to obtain the mesocarbon microbeads. According to the invention, the coal tar pitch and the coal liquefaction residue pitch are used as raw materials in copolycondensation reaction; the problems that a large quantity of nucleation promoter needs to be added in preparation of MCMB (mesocarbon microbeads) by using the coal liquefaction residue as the raw material, especially in industrial scale, and the addition of the large quantity of nucleation promoter results in homodisperse are solved; furthermore, no compatilizer needs to be added. The prepared MCMB is narrower in particle size distribution, the yield can reach 30% and the product has good sphericity.

Owner:ZIBO MINING GRP

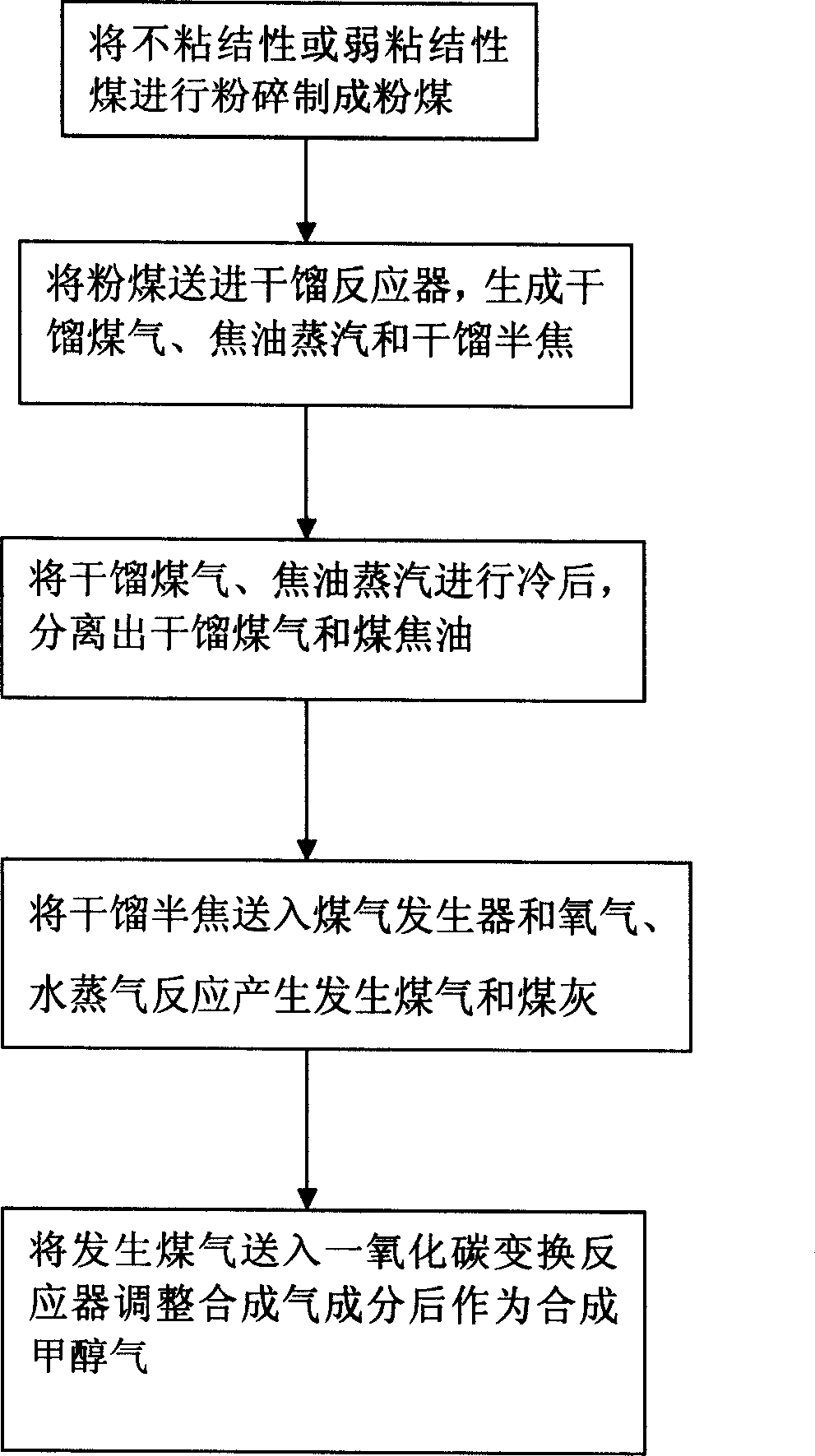

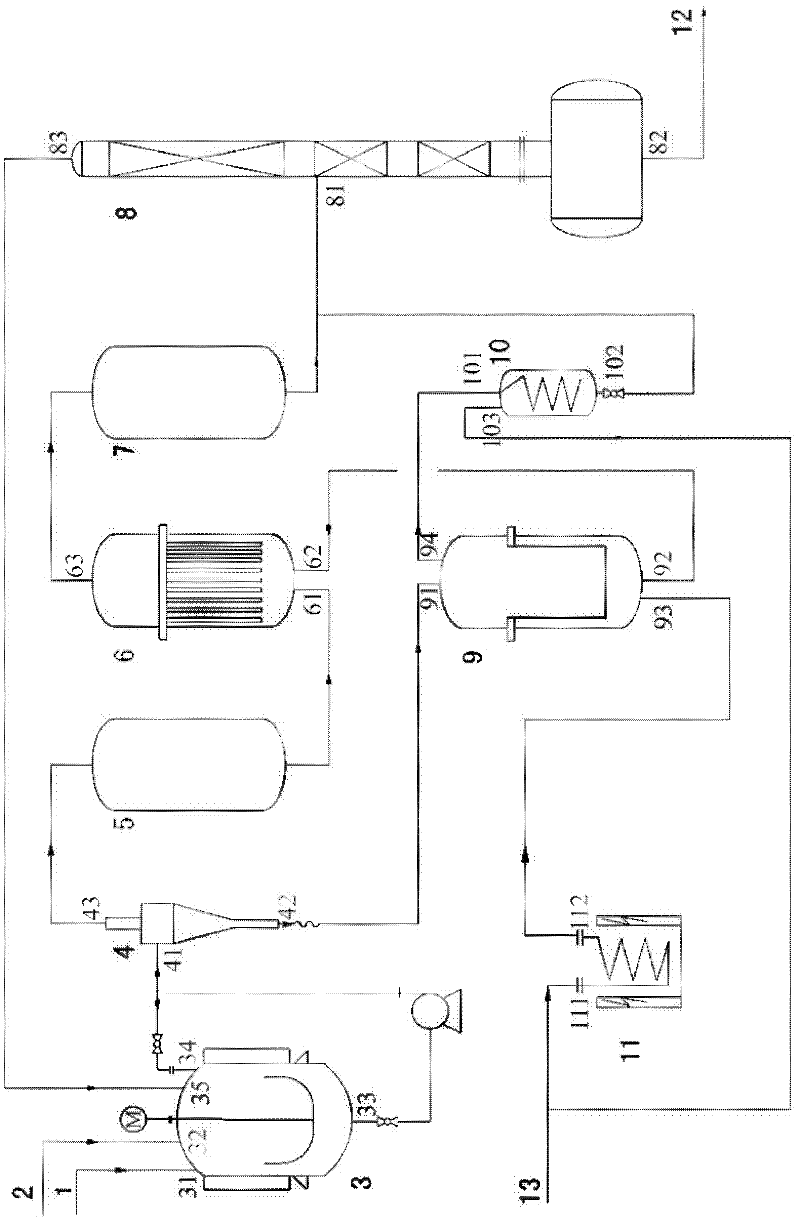

Technology of preparing synthetic gas using non agglomerating or weak agglomerating coal fluidized destructive distillation

ActiveCN1912070AIncrease profitHigh yieldCombined combustion mitigationGasification with fuel pre-distillationLiquid productWater vapor

The invention discloses a process for making synthetic gas by non-adhesive or low-adhesiveness coal fluidized carbonization, comprising the steps of: crushing non-adhesive or low-adhesiveness coal into fine coal; feeding the fine coal into a carbonization reactor and producing coal gas, tar steam and semicoke; cooling the coal gas and tar steam, and extracting the coal gas and coal tar; feeding the semicoke into a coal gas generator to react with oxygen gas and water steam to produce generated coal gas and coal ash; feeding the generated coal gas into a CO conversion reactor to regulate composition of the synthetic gas and act as synthetic methanol gas. And the utilization ratio of raw materials can be 100%. And the oil yield of fine coal fluidized carbonization is high. And the produced semicoke can completely turn into generated coal gas, and finally only coal ash is left. And the yield of liquid products by carbonization and liquid products synthetized by synthetic gas is higher than that of liquid products by coal liquefaction.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

Method for extracting heavy liquefied oil from residue of coal direct liquefaction, extracted heavy liquefied oil, and application thereof

ActiveCN102399565AHigh extraction rateReduce solid impurity contentLiquid hydrocarbon mixture productionDistillationFiltration

The invention provides a method for extracting heavy liquefied oil from the residue of coal direct liquefaction, extracted heavy liquefied oil, and an application thereof. The method comprises steps that: (a) coal liquefaction residue powder and an extraction solvent are mixed in a residue extraction apparatus, and the residue is extracted, such that heavy liquefied oil in the residue is extracted into the solvent; (b) solid-liquid separation is carried out upon the extraction mixture and the extraction residue obtained in the step (a) by using a cyclone separator, such that a supernatant mixture and an underflow mixture are obtained; (c) fine filtration is carried out upon the supernatant mixture obtained in the steps (b), and the filtrate is delivered in to a distillation separation apparatus; (d) pressure-rough-filtration is carried out upon the underflow mixture obtained in the step (b), the obtained filtrate is processed through fine filtration, and the obtained filtrate is delivered into the distillation separation apparatus; (e) the filtration mixture is separated in the distillation separation apparatus; the solvent is recovered and reused; and heavy liquefied oil with a solid impurity content lower than 0.1wt% is obtained. Between the step (d) and the step (e), a step (f) can be included. The steps (f) is that: the filtration residue obtained in the rough-filtration process in the step (d) is dried through meat medium back flushing; and the residual solvent is recovered and delivered into the distillation separation apparatus.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

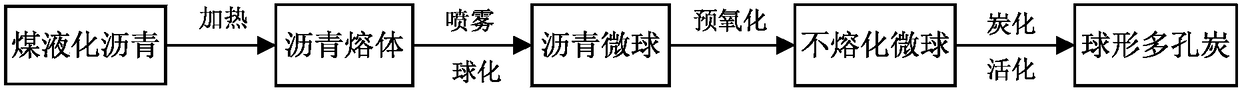

Spherical porous carbon and preparation method thereof

The invention provides a spherical porous carbon and a preparation method thereof. The preparation method comprises the following steps of: carrying out heating treatment on the coal liquefied asphaltto obtain an asphalt melt; carrying out spraying and drying treatment on the asphalt melt to obtain an asphalt microsphere, carrying out pre-oxidation on the asphalt microsphere to obtain a non-melted asphalt microsphere; carbonizing and activating the non-melted asphalt microsphere to obtain spherical porous carbon. The method prepares spherical porous carbon by using coal liquefied asphalt as araw material, high-value utilization of the asphaltene in the coal liquefaction oil slag can be carried out, and the characteristics of high aromatic degree, high carbon content, easy polymerizationor cross-linking are fully utilized. Furthermore, the preparation method of the spherical porous carbon has the advantages of simple steps, strong continuous operability, high sphere-forming rate, high sphericity and adjustable micro-sphere particle diameters.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

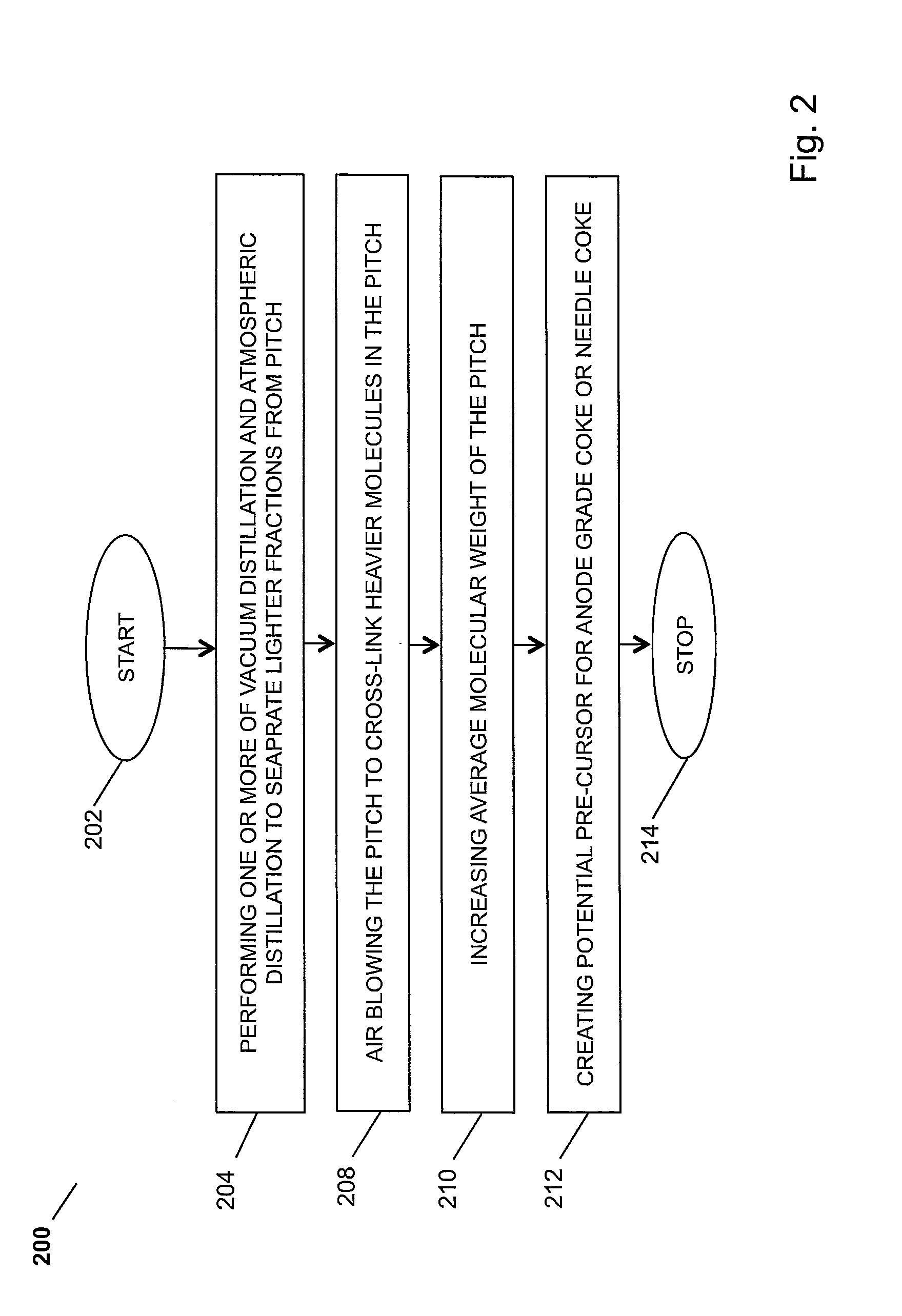

Hydrogenated Vegetable Oil in Coal Liquefaction

InactiveUS20120091042A1Low production costImprove solubilitySolid fuelsLiquid carbonaceous fuelsDownstream processingVegetable oil

The present disclosure provides methods and systems for coal liquefaction using a hydrogenated vegetable oil. A method of obtaining a de-ashed coal extract includes exposing a coal to a hydrogenated vegetable oil in the presence of a coal-derived solvent to form a slurry, elevating the temperature of the slurry to facilitate liquefying the coal and liberating a volatile matter, and separating the insoluble components from the slurry to obtain a de-ashed coal extract, wherein the coal extract is suitable for downstream processing.

Owner:WEST VIRGINIA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com