Anti-rutting additive containing direct coal liquefaction residue as well as preparation method and application thereof

An anti-rutting additive, a technology of direct coal liquefaction, applied in building components, building insulation materials, buildings, etc., to achieve good low-temperature cracking performance, improve stability, and reduce segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Extrude 4000g of TPE, 2000g of coal direct liquefaction residue, 480g of naphthenic oil, and 60g of C5 petroleum resin at 120°C using a twin-screw extruder (Zhangjiagang Chuangjia Machinery Co., Ltd., SJ series), and then pass through an air-cooled mold Noodle granulation equipment (Nanjing Guangda Rubber and Plastic Machinery Factory) granulated to obtain anti-rutting additives.

[0042] The particle sizes obtained after granulation are all less than 4mm, and the melt index is 3.5g / 10min (190°C, 2.16kg). The density is 1.085g / cm 3 .

Embodiment 2

[0044]Extrude SBS3200g, coal direct liquefaction residue 2000g, rubber oil 480g, C9 petroleum resin 460g at 120°C with a single-screw extruder (Zhangjiagang Chuangjia Machinery Co., Ltd., SJ series), and then air-cool the die surface Pelletizing equipment (Nanjing Guangda Rubber and Plastic Machinery Factory) granulated to obtain anti-rutting additives.

[0045] The particle sizes obtained after granulation are all less than 4mm, and the melt index is 3.0g / 10min (190°C, 2.16kg). The density is 1.1.05g / cm 3 .

Embodiment 3

[0047] Extrude 2000g of SBS, 2000g of coal direct liquefaction residue, 480g of rubber oil, and 480g of C9 petroleum resin at 120°C using a single-screw extruder (Zhangjiagang Chuangjia Machinery Co., Ltd., SJ series), and then cut through the air-cooled die surface. Granulation equipment (Nanjing Guangda Rubber and Plastic Machinery Factory) was used to granulate to obtain anti-rutting additives.

[0048] The particle sizes obtained after granulation are all less than 4mm, and the melt index is 3.8g / 10min (190°C, 2.16kg). The density is 1.045g / cm 3 .

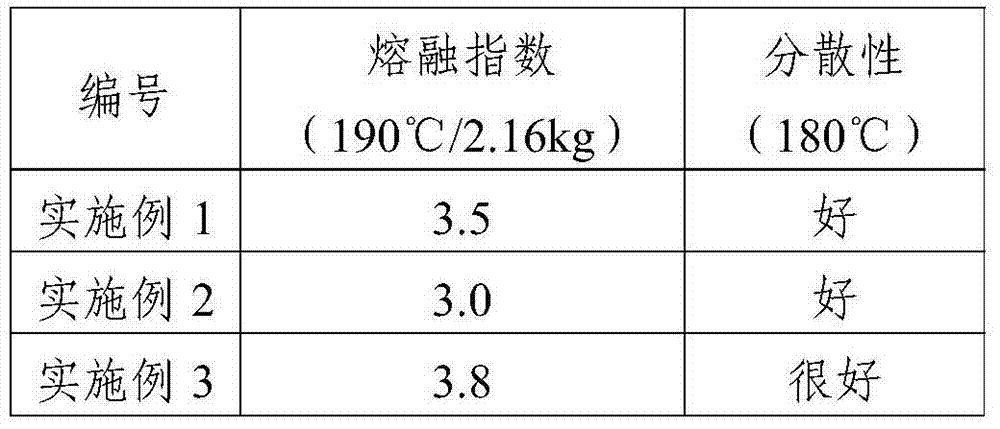

[0049] The melt index of the anti-rutting additive obtained in Examples 1-3 was tested. And put the above additives into the asphalt mixture to observe the dispersion uniformity, see Table 2.

[0050] Table 2 Melt index and dispersibility results

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com