Patents

Literature

521results about How to "Guaranteed response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for checkpointing a main-memory database

InactiveUS20060004860A1SavingWithout slowing down a transaction level processingData processing applicationsError detection/correctionOriginal dataAuxiliary memory

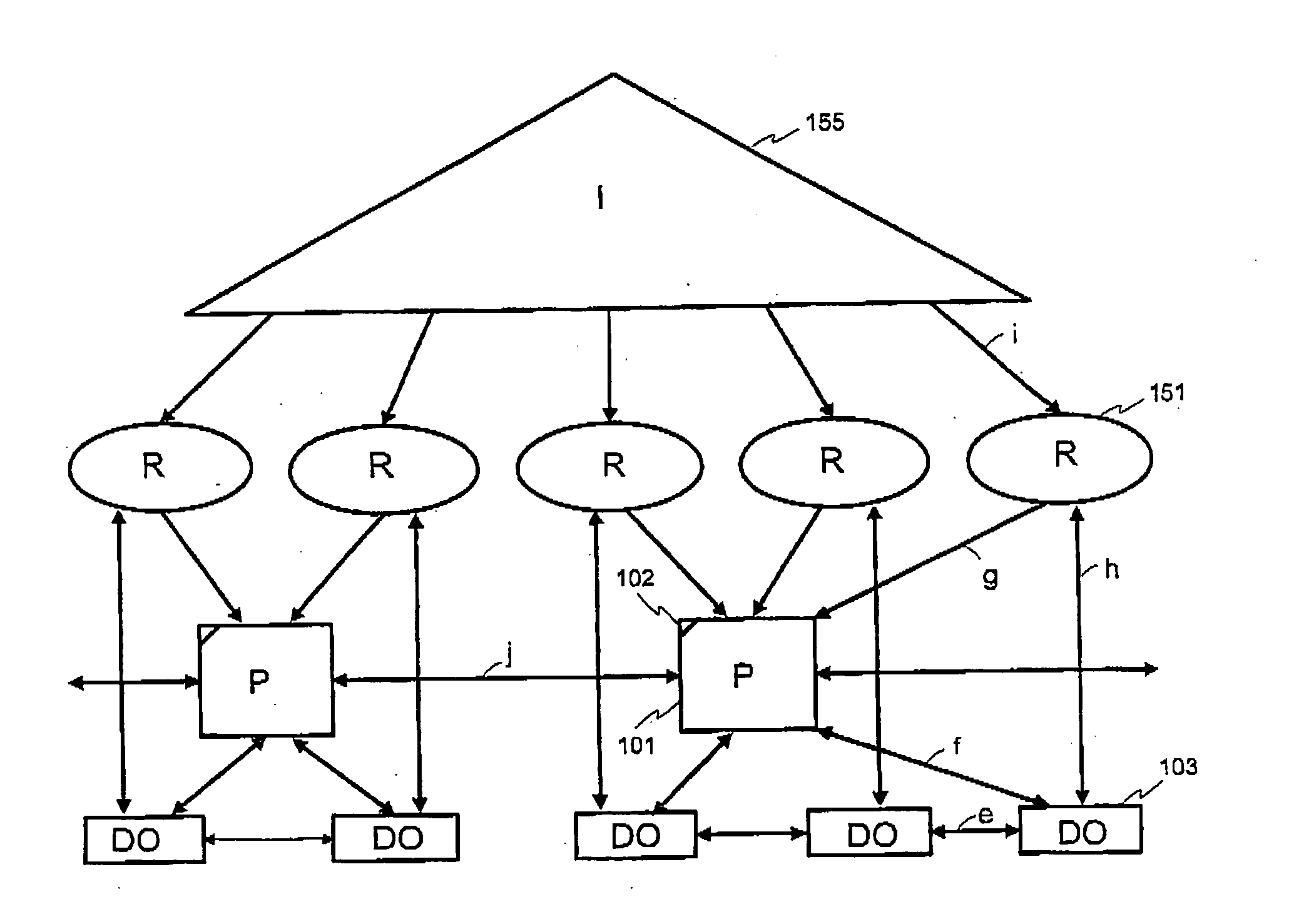

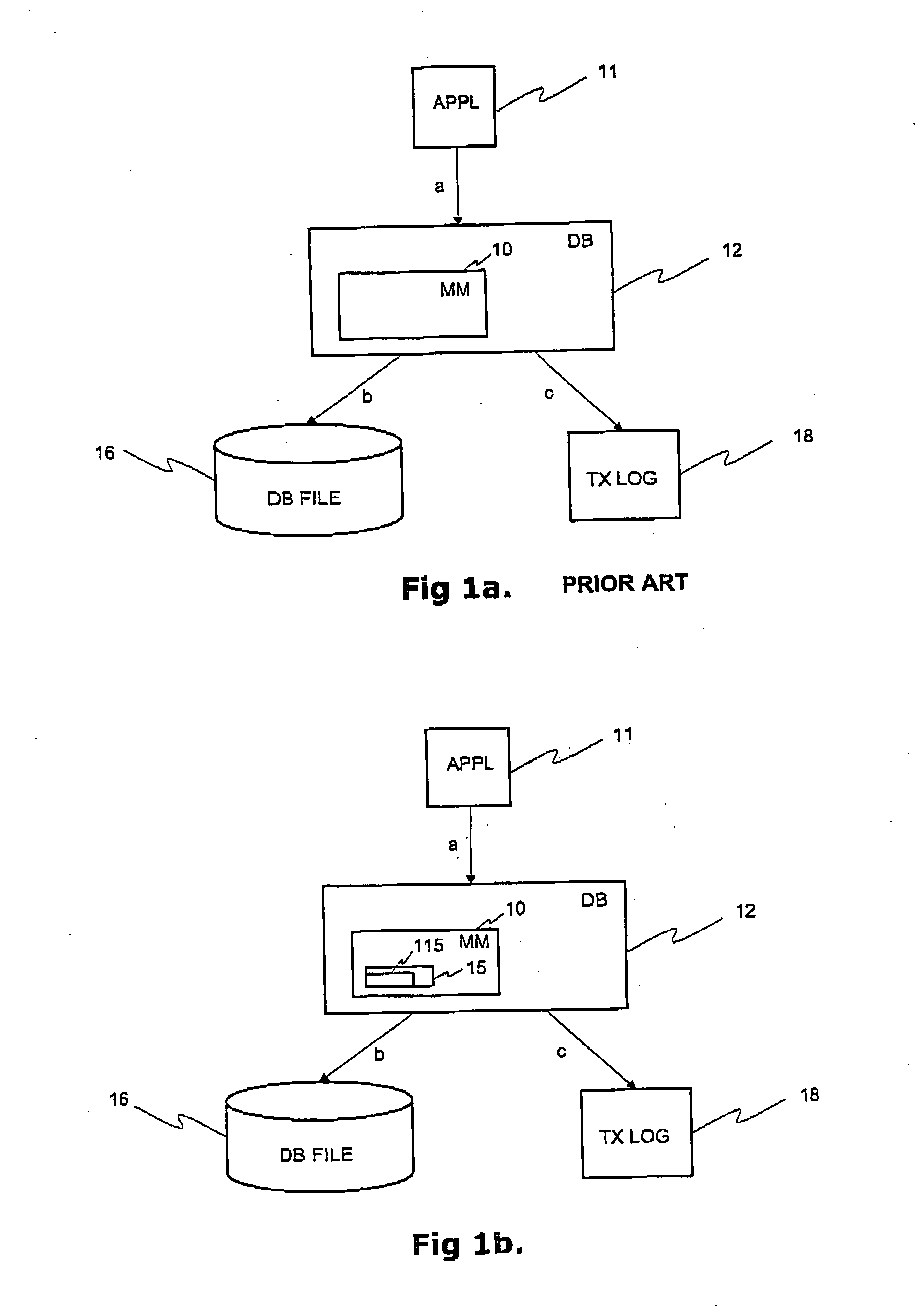

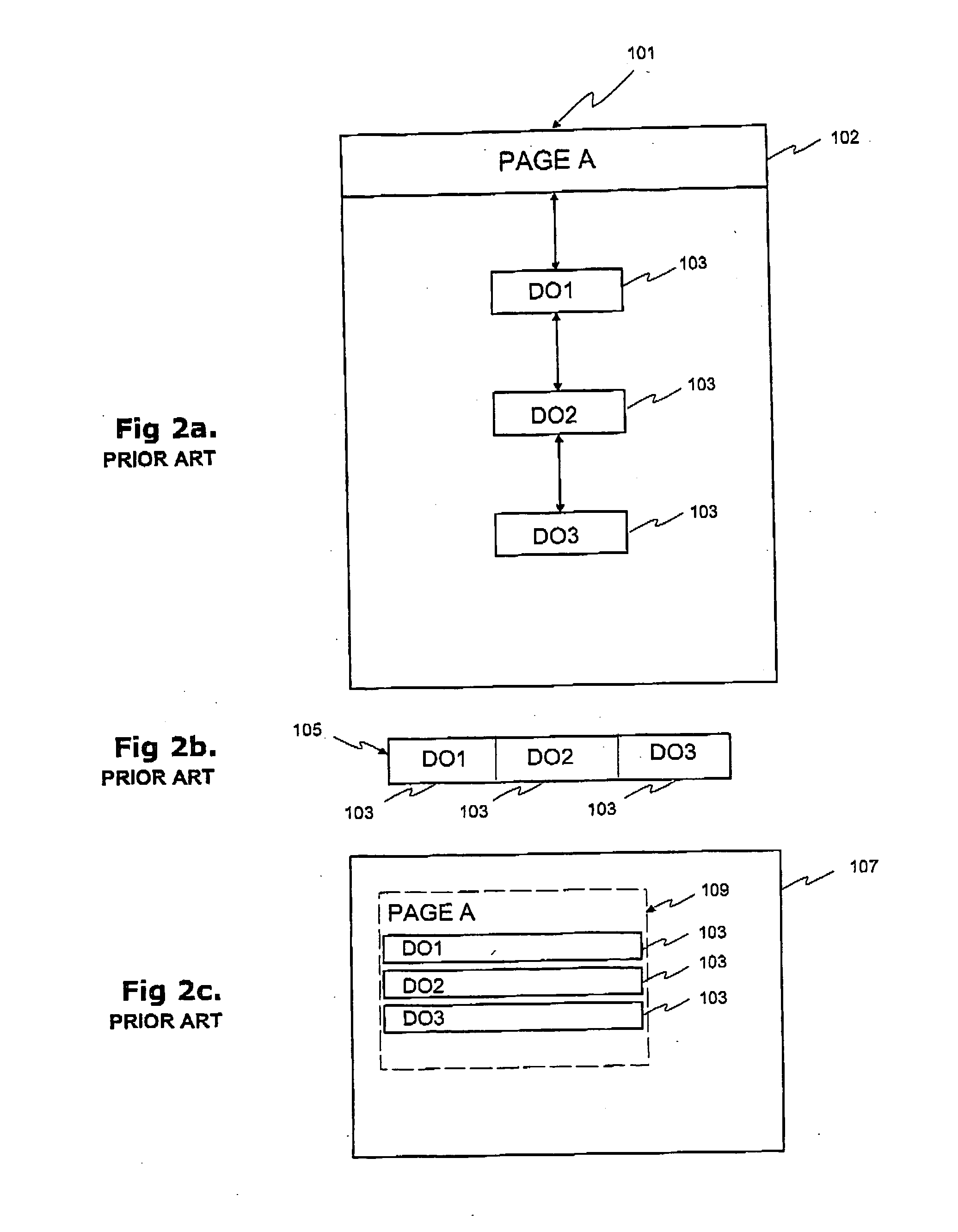

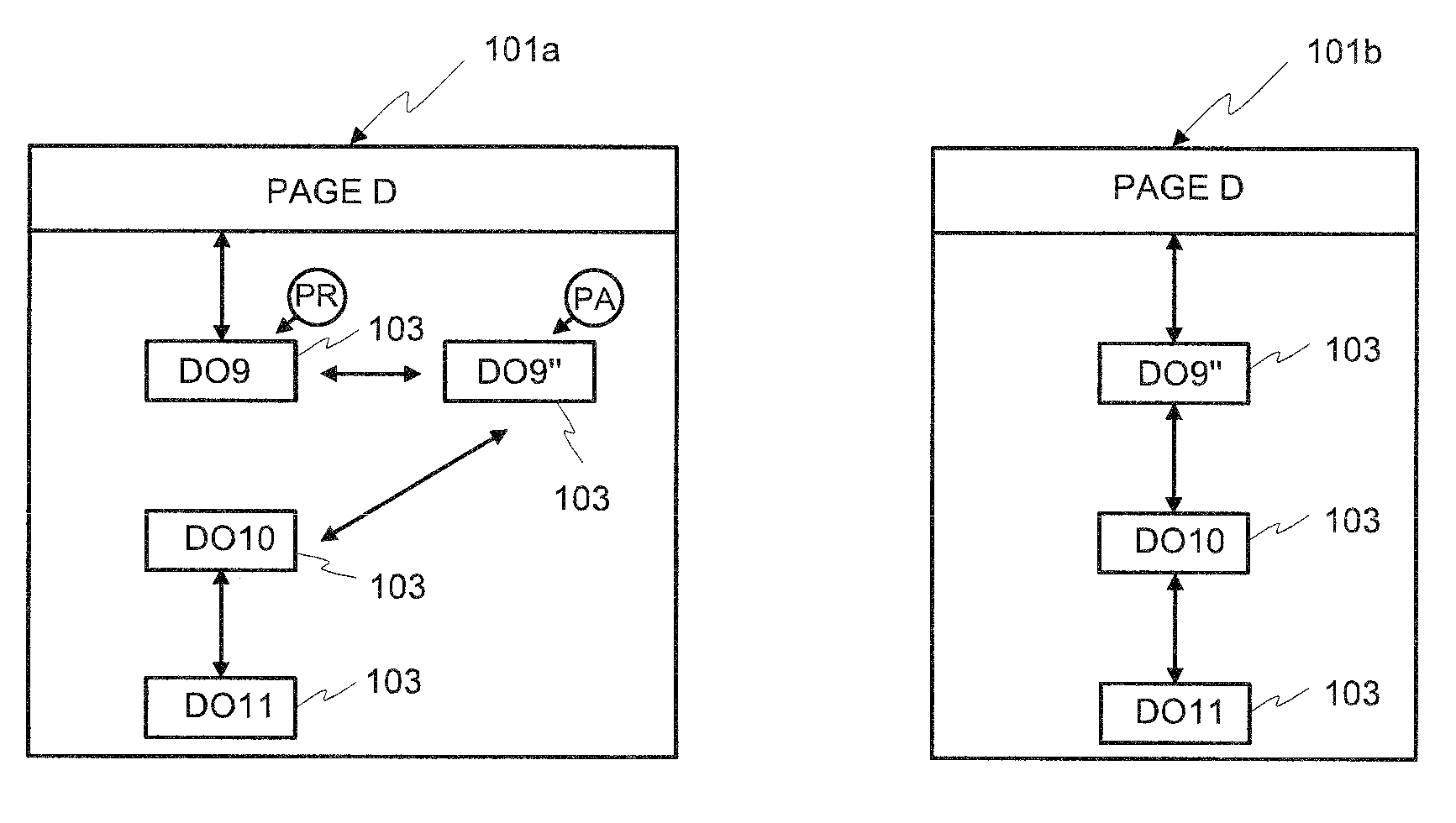

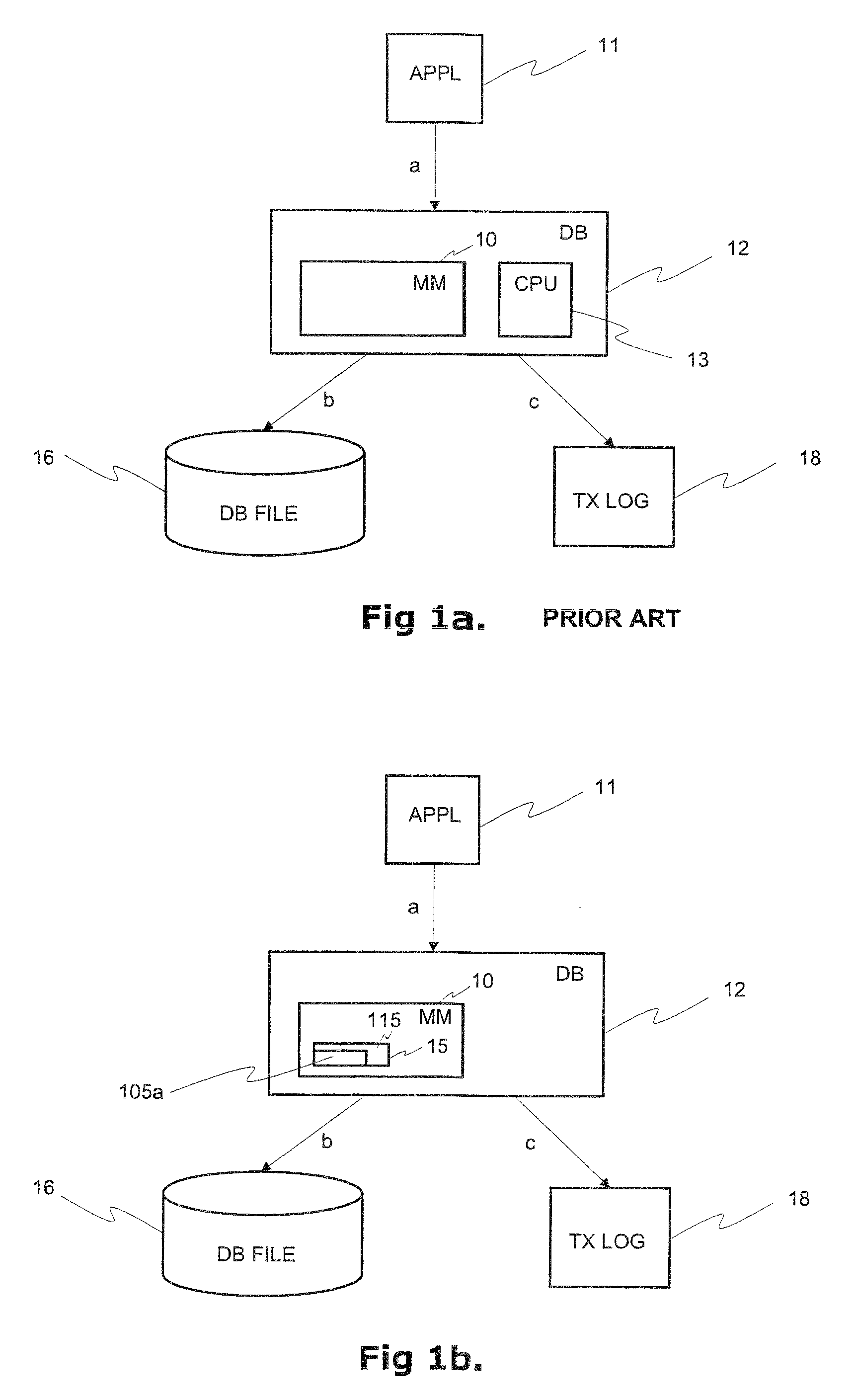

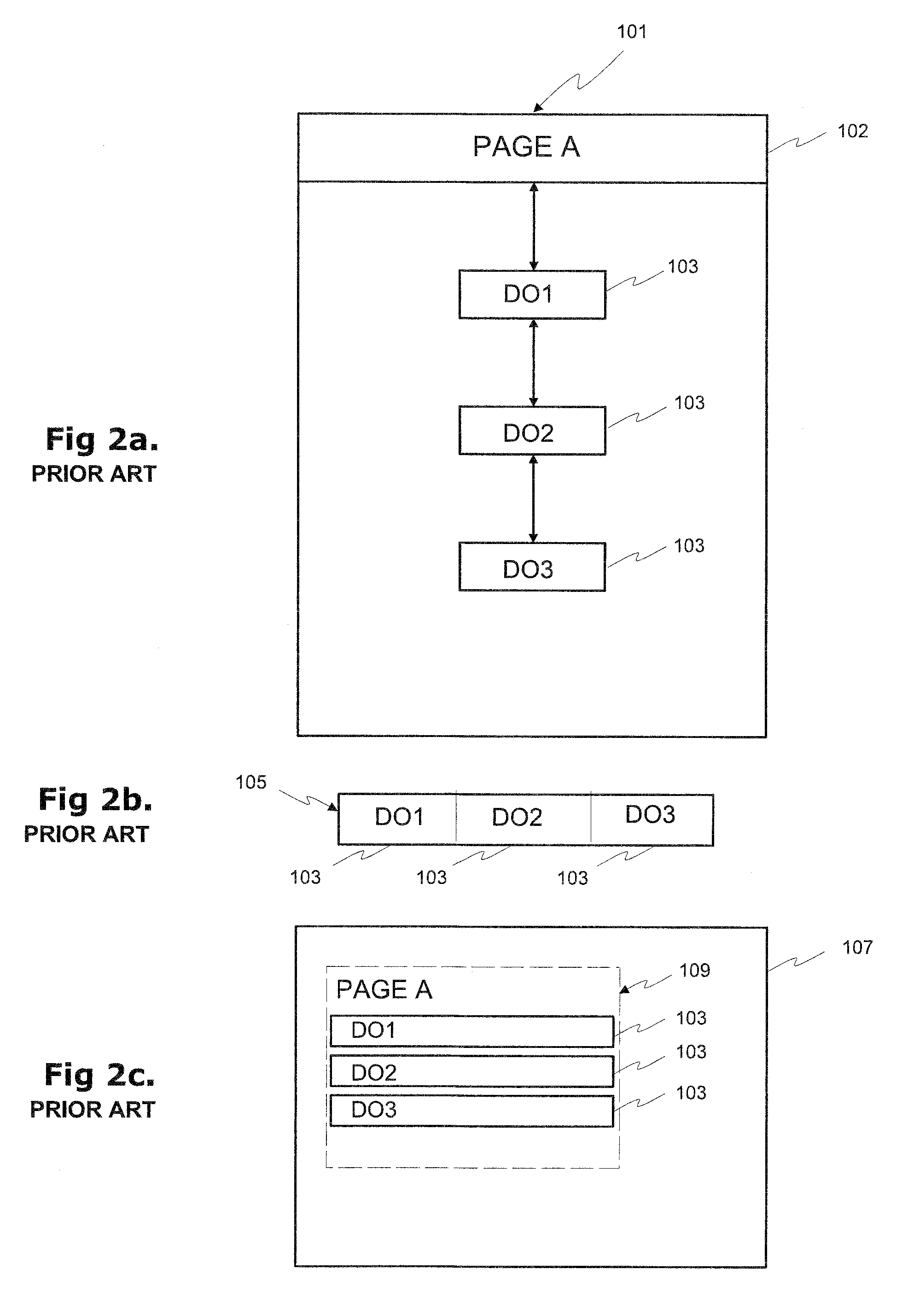

Method for making a consistent checkpoint of a page including at least one data object in a computer system having a primary and secondary storage, and a programmable software. The primary storage has at least one page which includes at least one original data object on the page. The computer system allows at least one write operation to modify at least one data object, and the page is written into the secondary storage during checkpointing. The method includes beginning the checkpointing, including at least one page in the primary storage into a group of pages to be checkpointed, altering at least one data object with at least one data write operation, marking at least one data object resulting from the data write operation, writing at least one of the data objects into the secondary storage, and altering the state of the pending data object to be the original data object.

Owner:SOLID INFORMATION TECH

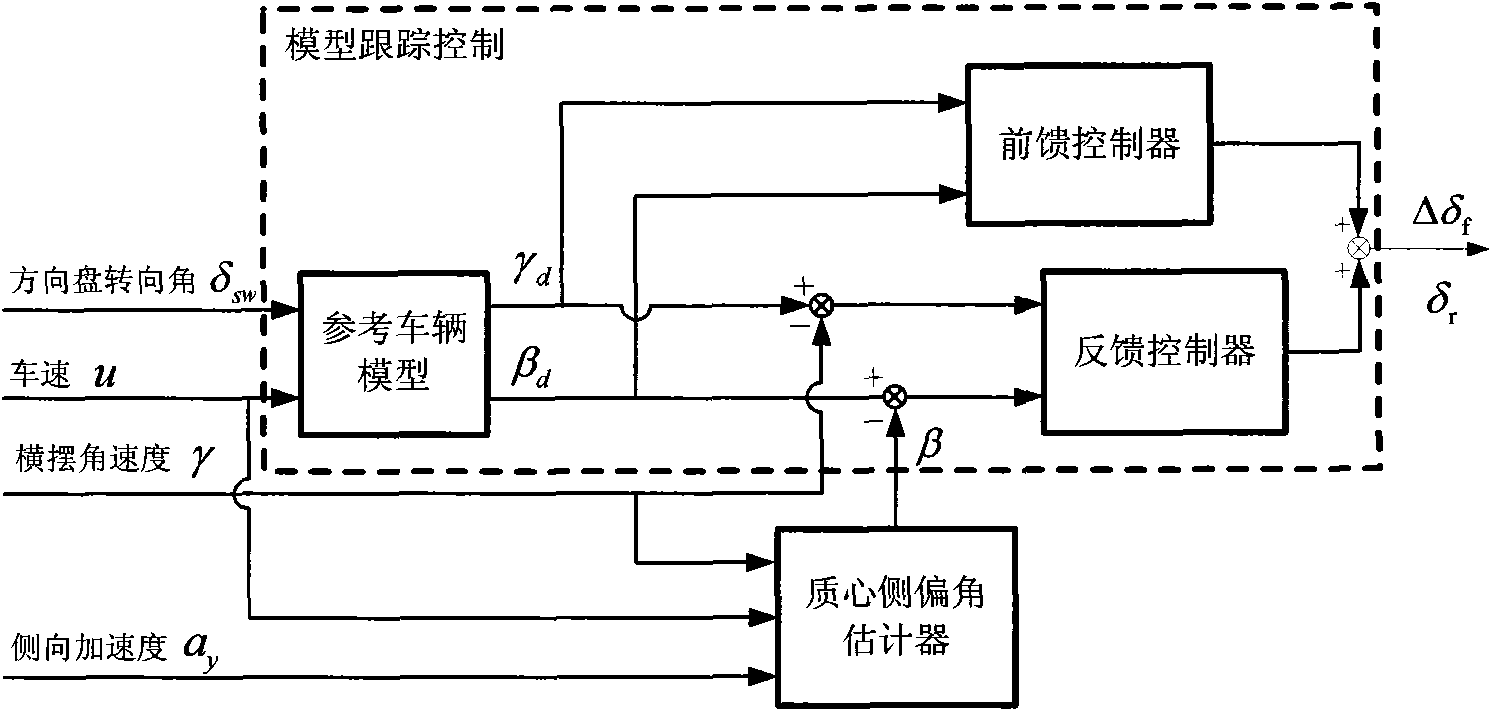

Front wheel and rear wheel drive steering control system of automobile

InactiveCN101618733ARealize active steeringImprove lateral dynamicsSteering linkagesAutomatic steering controlDriver/operatorSteering control

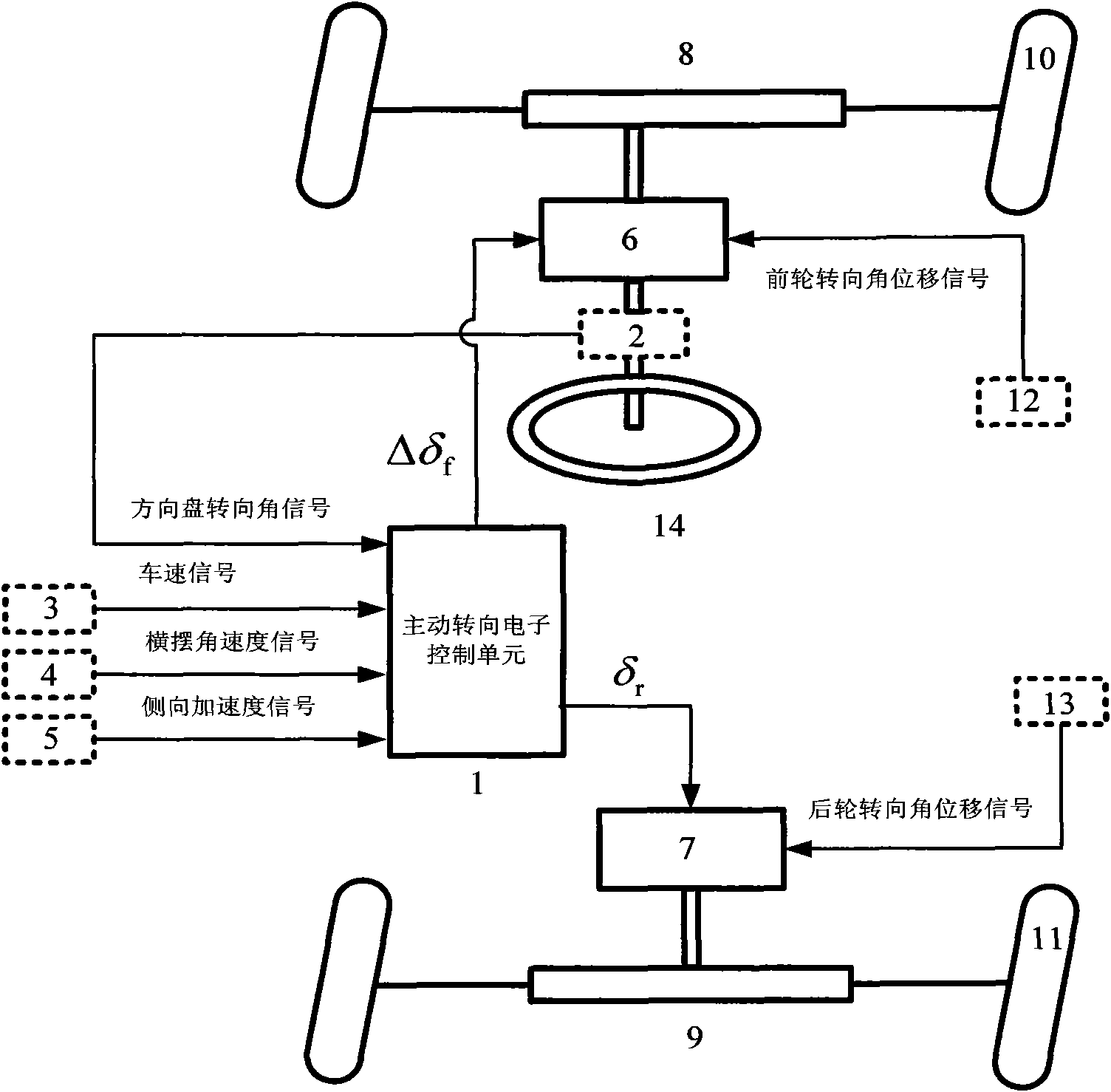

The invention relates to a front wheel and rear wheel drive steering control system of an automobile in the technical field of automobile engineering. Steering wheel steering angle sensors are respectively connected with a drive turning electronic control unit; one end of each steering wheel steering angle sensor is connected with a steering wheel, and the other end of each steering wheel steering angle sensor is connected with a front wheel steering motor servo control unit; the front wheel steering motor servo control unit is respectively connected with a front wheel steering angle displacement sensor and a front wheel steering execution mechanism; a rear wheel steering motor servo control unit is respectively connected with a rear wheel steering angle displacement sensor and a rear wheel steering execution mechanism; the front wheel steering execution mechanism is connected with a front wheel, and the rear wheel steering execution mechanism is connected with a rear wheel. The invention combines front wheel drive steering and rear wheel drive steering, improves the lateral dynamic performance of the automobile, the driving characteristics of a driver and the operating stability of the automobile, changes a steering angle of the front wheel and the rear wheel in real time according to the drive working condition and a running parameter of the automobile and ensures that the automobile response follows the output response of a reference automobile model.

Owner:SHANGHAI JIAO TONG UNIV

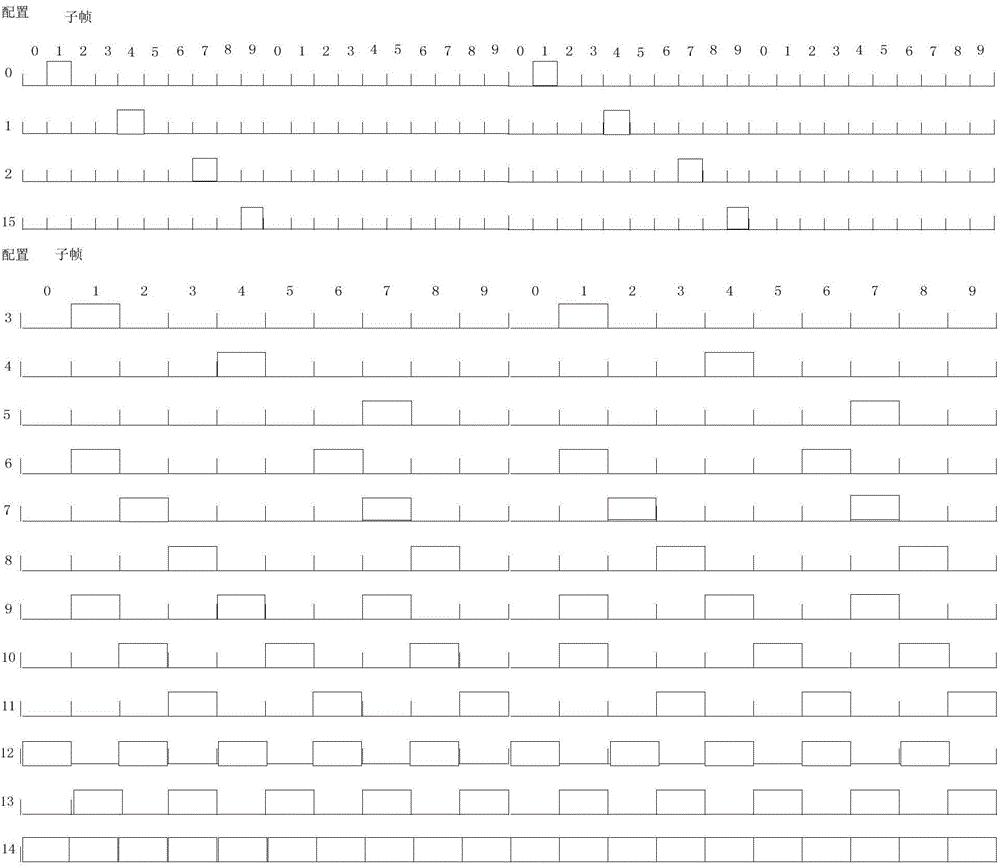

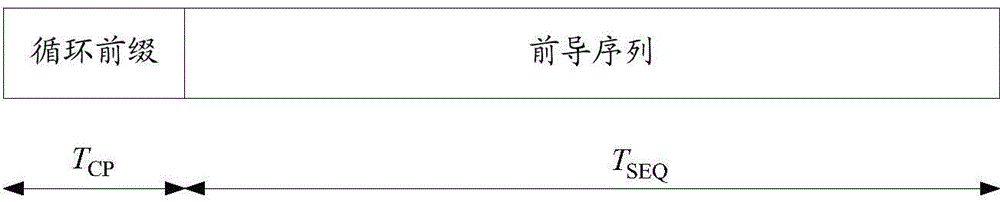

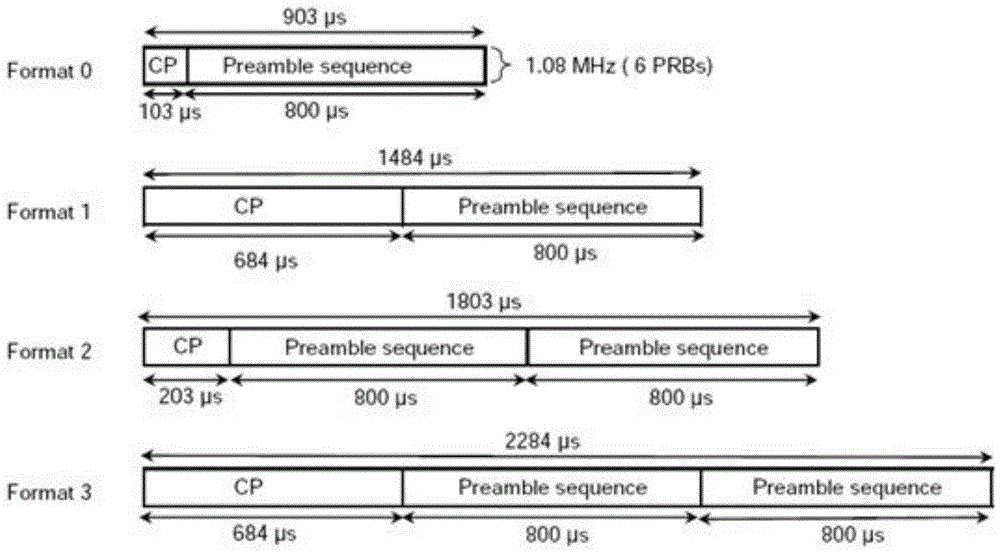

Random access method, base station and user device

InactiveCN106304383AGuaranteed responseAssess restrictionNetwork topologiesComputer scienceUser equipment

The present invention discloses a random access method, a base station and a user device. The method comprises: after a cluster network starts, the base station sends cluster network information to a user device in a district covered by the base station, wherein the user device in the covered district includes a common user device and a cluster user device; after the cluster user device receives the cluster network information, it is determined that a common PRACH configuration index table stops using and a preset special PRACH configuration index table starts to use; the base station sends PRACH configuration parameters, wherein the PARCH configuration parameters include the PRACH frequency domain resource offset and the PRACH configuration index numbers; the cluster user device determines the time-frequency resource required when sending the random access front leading according to the PRACH configuration parameters and the preset special PRACH configuration index table; and the base station detects the random access front leading sent by the cluster user device on the corresponding time-frequency resource and sends the random access response message to the cluster user device.

Owner:ZTE CORP

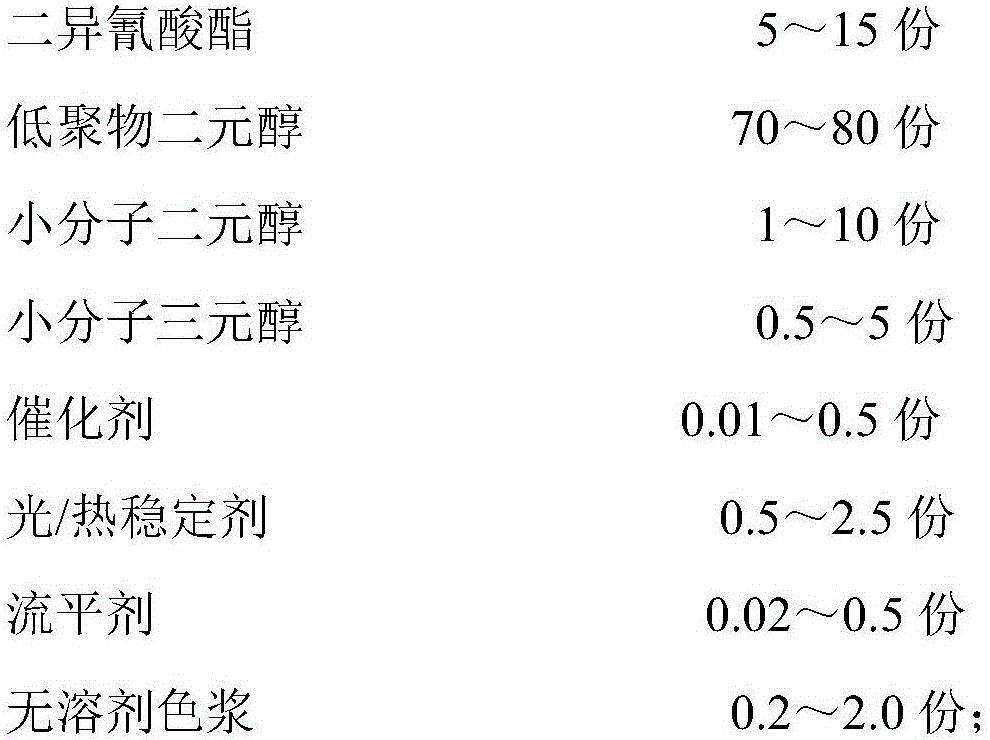

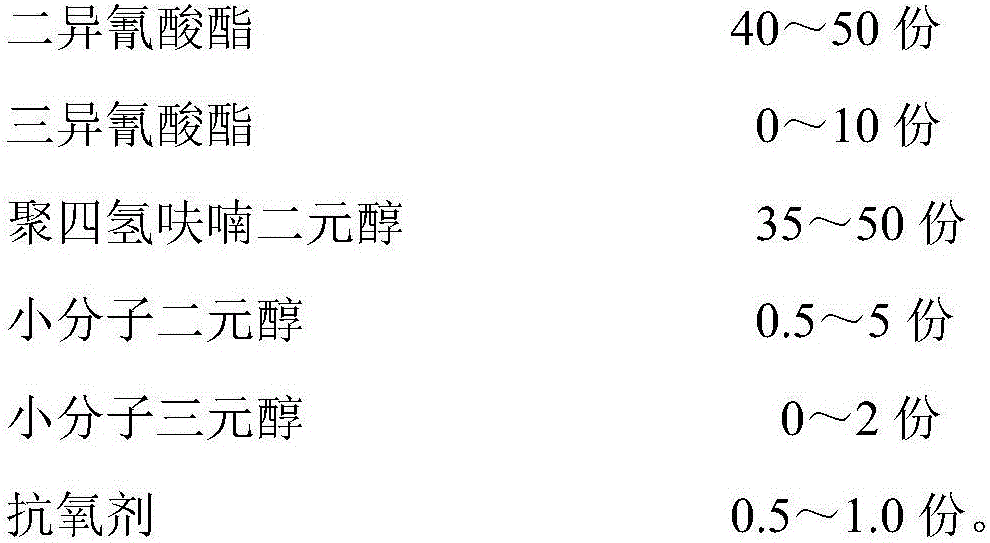

Carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather, as well as preparation method and application of carbon fiber modified non-solvent polyurethane surface layer resin

ActiveCN106397722AGuaranteed to be environmentally friendlyGuaranteed stabilityPolyurea/polyurethane coatingsFootwearPolyresinHydrolysis

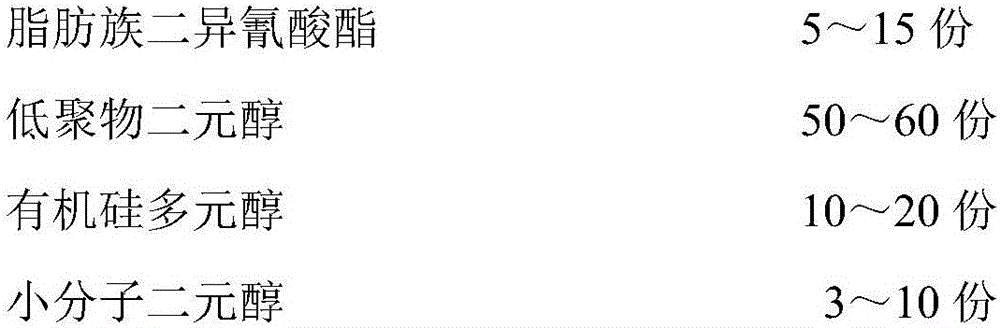

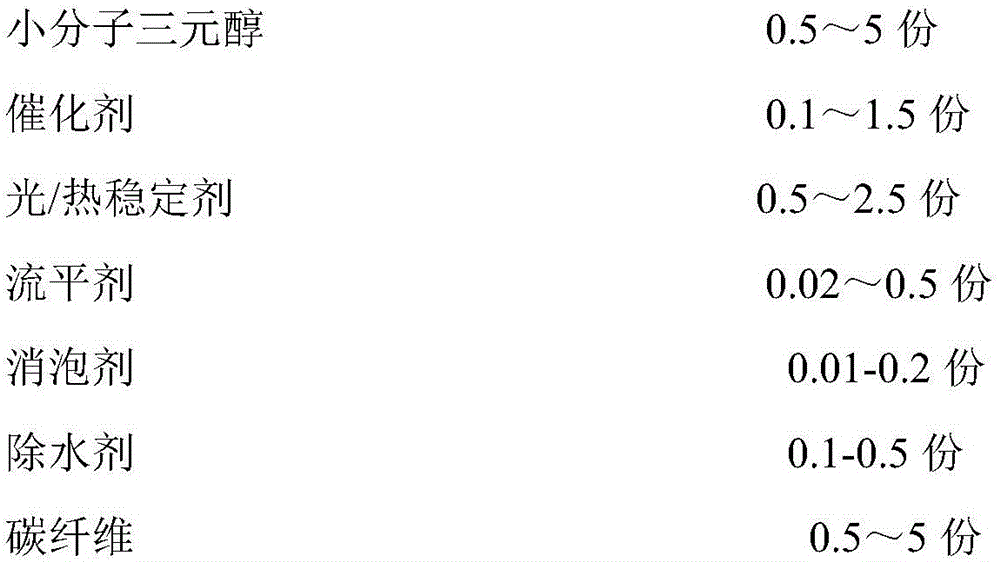

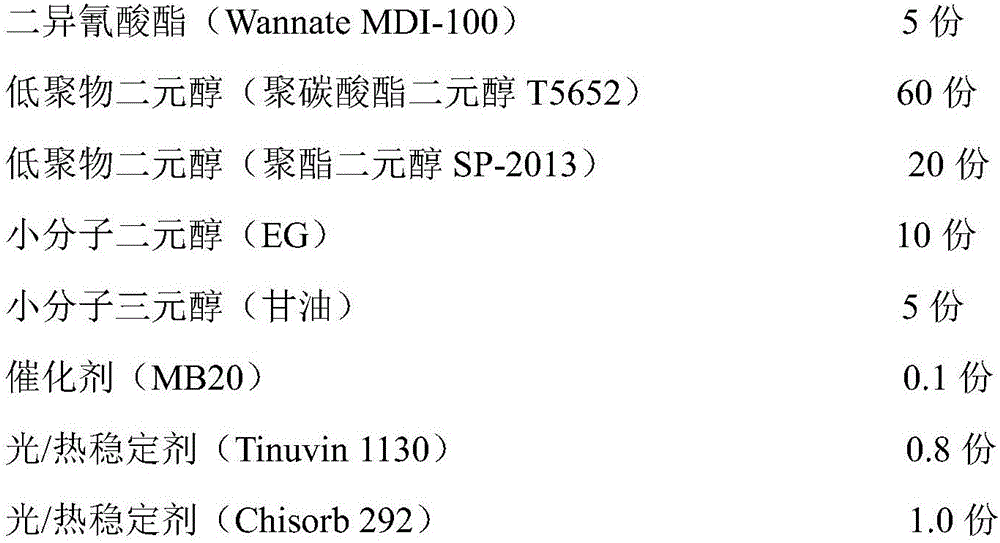

The invention belongs to the field of synthetic leather, and provides carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather. The resin is formed by mixing a component A and a component B according to mass percent being 2:1 to 1:2, wherein the component A comprises 5 to 15 parts of aliphatic diisocyanate, 50 to 60 parts of low polymer dihydric alcohol, 10 to 20 parts of organosilicone polyhydric alcohol, 3 to 10 parts of micromolecule dihydric alcohol, 0.5 to 5 parts of micromolecule trihydric alcohol, 0.1 to 1.5 parts of a catalyst, 0.5 to 2.5 parts of a light / heat stabilizer, 0.02 to 0.5 part of a flatting agent, 0.01 to 0.2 part of a defoamer, 0.1 to 0.5 part of a dehydrator, and 0.5 to 5.0 parts of carbon fiber; the component B comprises 40 to 50 parts of aliphatic diisocyanate, 0 to 10 parts of triisocyanate, 35 to 50 parts of polytetrahydrofuran dihydric alcohol, 0.5 to 5 parts of micromolecule dihydric alcohol, 0 to 2 parts of micromolecule trihydric alcohol, and 0.5 to 1.0 part of a light / heat stabilizer. The invention further provides a preparation method and application of the resin. The tangential breaking strength of carbon fiber modified resin coating can reach 130kN / m or above; for non-solvent sports shoe leather prepared through the method, the peeling strength can reach 90N / 3 cm or above and the hydrolysis resistance can reach 10 weeks or above.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

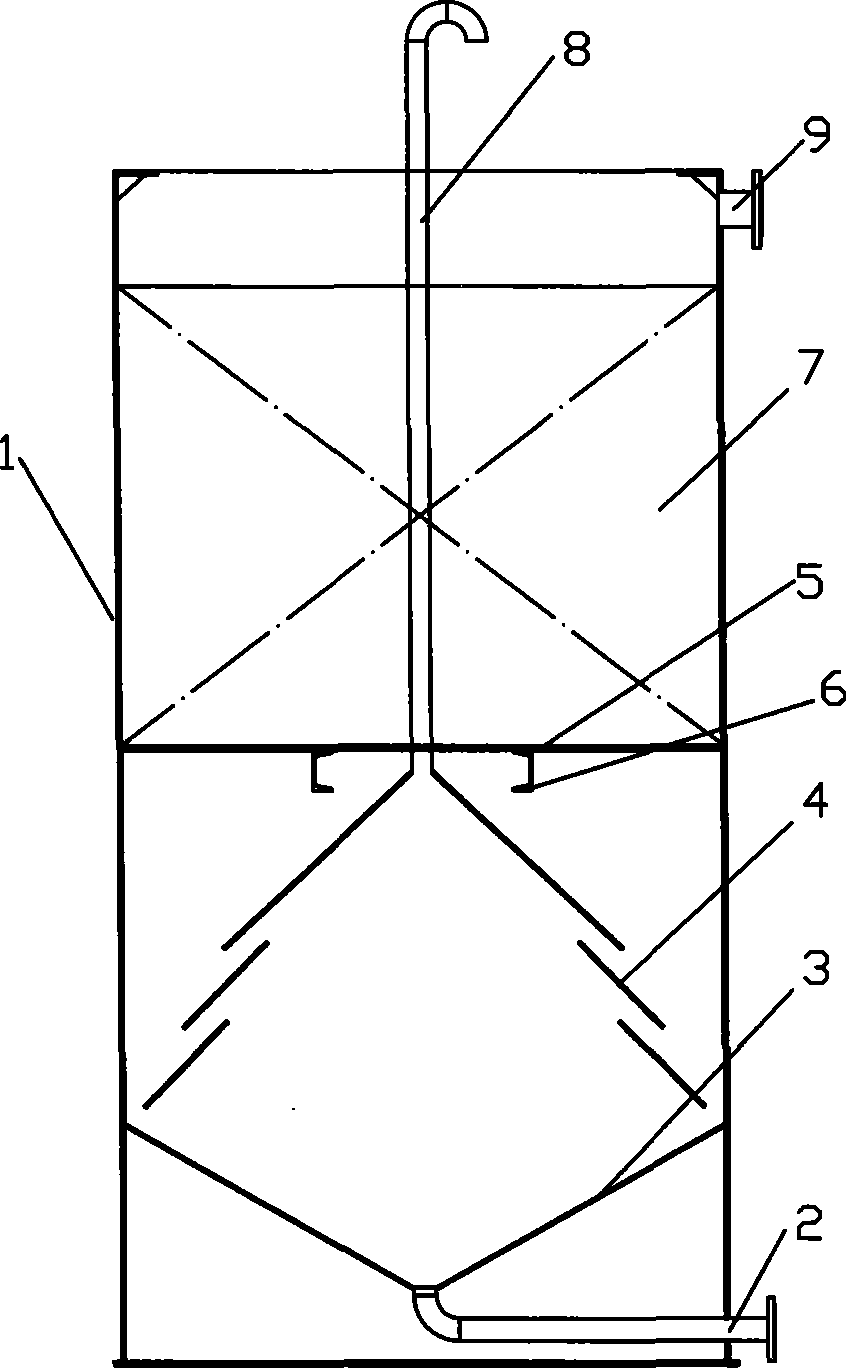

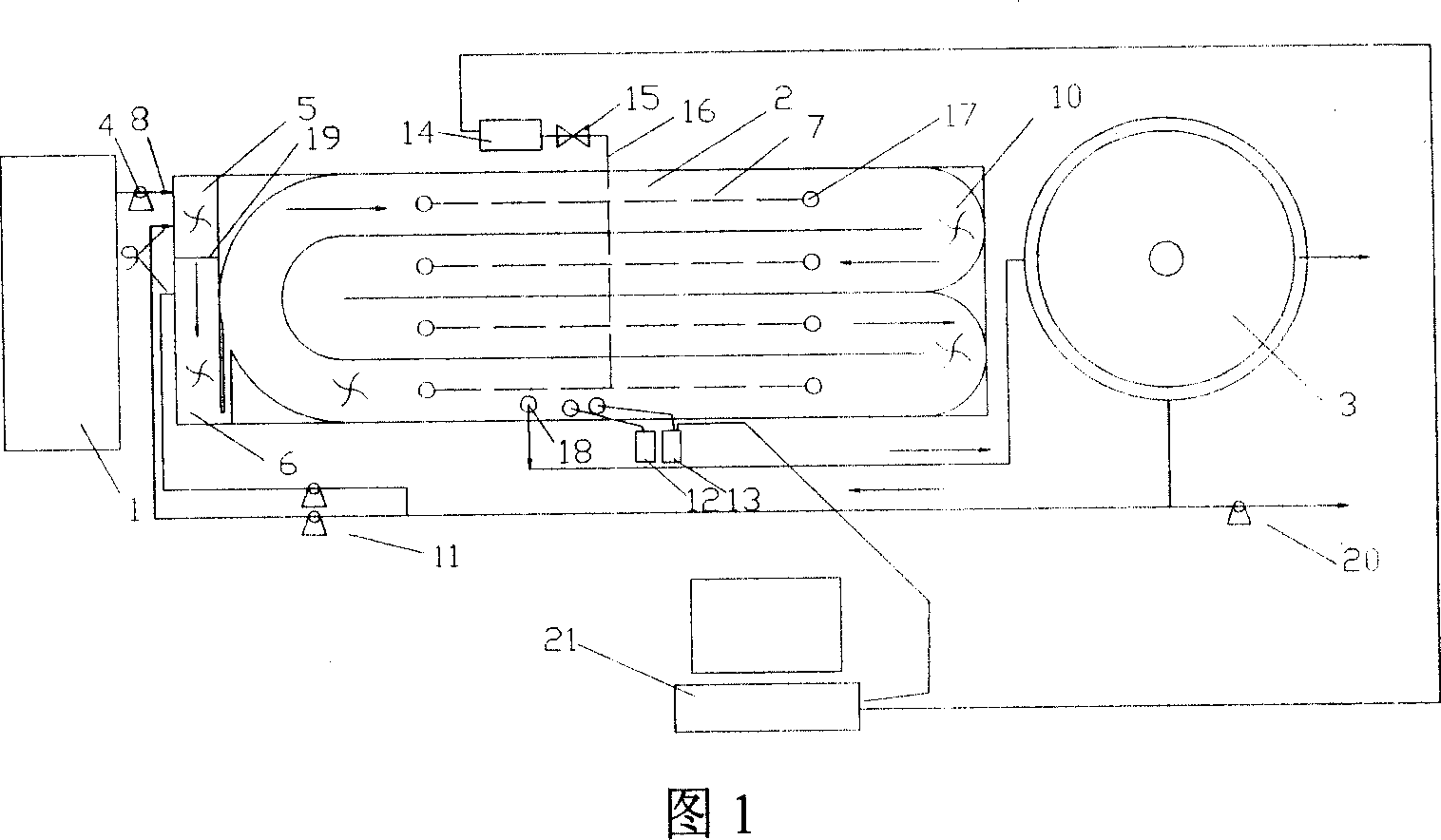

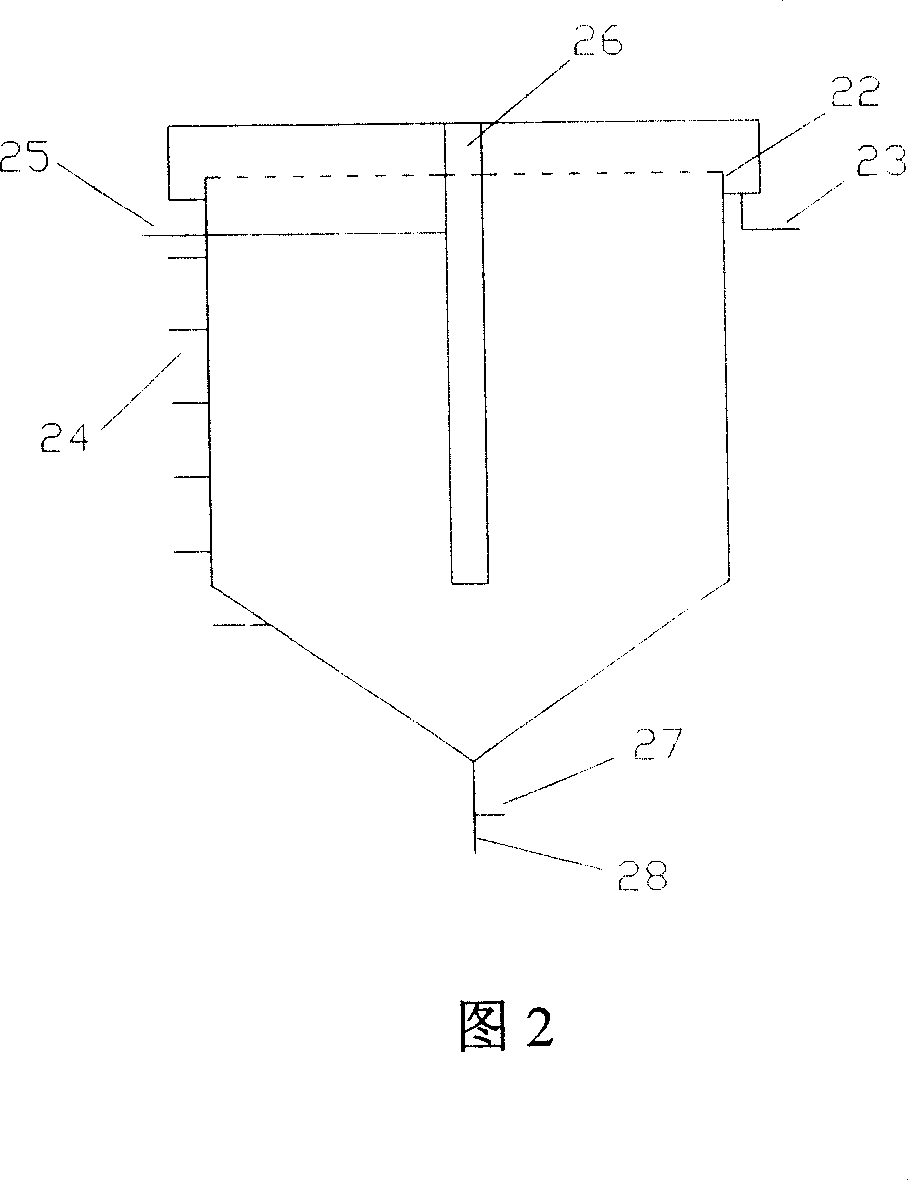

Domestic sewage treatment process and apparatus

InactiveCN101475284AImprove reaction efficiencyGuaranteed responseTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationConstructed wetland

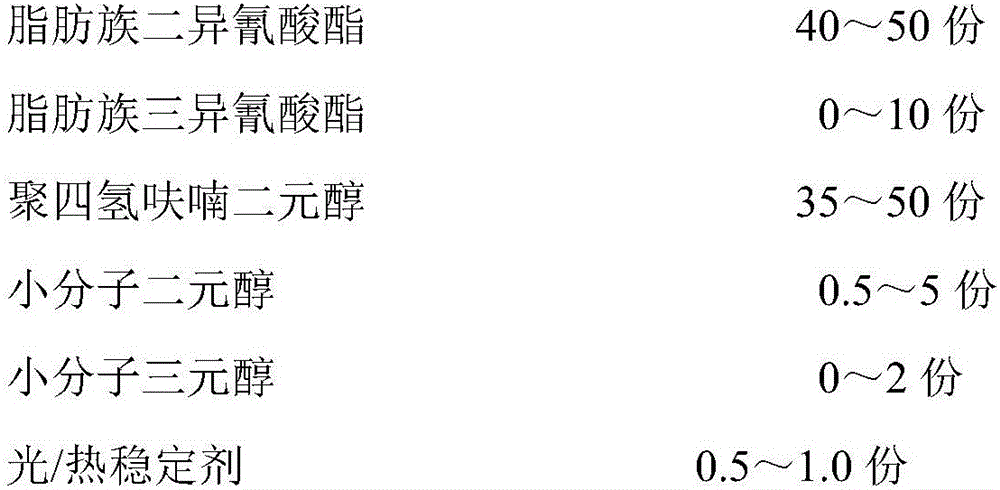

The invention discloses a domestic sewage treatment process, which comprises the following steps that: sewage enters an anaerobic pond to carry out a degrading reaction after being filtered, outlet water automatically flows into a middle adjusting pond, and outlet water of an artificial wetland pond part flows back to the middle adjusting pond; water of the middle adjusting pond enter oxygen lack environment, high-concentration mud in the sewage is discharged to the anaerobic pond, and NO2-NO3-N ions in circulating water are subjected to denitrification under the oxygen lack environment; the outer water after an oxidation reaction automatically flows into an aerobiont reaction tower; and the outlet water of the aerobiont reaction tower automatically flows into the artificial wetland pond of which the inside is provided with emergent aquatic plants, floating plants, fish and shrimps. The invention also discloses domestic sewage treatment equipment. On the basis of the prior domestic sewage treatment mode, the method sufficiently utilizes the low cost of an anaerobic wetland method and the high efficiency of an aerobiont method, and greatly reduces the cost of the water treatment. The whole flow does not needed to add medicines, and reduces the cost. Power consumption only comes from a lifting pump of the middle adjusting pond, and energy consumption is greatly saved.

Owner:江苏百纳环境工程有限公司

Control method and device of A2/O oxidation trench technology synchronous nitration and denitrification

InactiveCN1948184AFix stability issuesSolve the problem of low compliance rateTreatment with aerobic and anaerobic processesIt equipmentFrequency conversion

The present invention relates to an A2 / O oxidation channel process synchronous nitrification and denitrification control method and its equipment, belonging to the field of domestic sewage biodenitrogenation technology. It is characterized by that said method includes the following steps: utilizing DO on-line monitoring apparatus to monitor the macroscopic aerobic-anoxic environment formed in oxidation channel aeration basin; utilizing ORP on-line monitoring apparatus to monitor the microscopic aerobic-anoxic environment formed in oxidation channel aeration basin; and utilizing computer to control frequency conversion air blower to control aeration quantity so as to ensure that the macroscopic and microscopic nitrification reaction and denitrification reaction can be simultaneously implemented.

Owner:江门市国祯污水处理有限公司

LED photocuring non-solvent type photosensitive transfer printing adhesive for cover plate glass substrate and preparation method thereof

ActiveCN105062405AStrong responsivenessImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNon solventAdhesive

The invention discloses LED photocuring non-solvent type photosensitive transfer printing adhesive for a cover plate glass substrate. The photosensitive transfer adhesive comprises aliphatic polyurethane acrylate, an acrylate reactive diluent, a photoinitiator, an acrylic auxiliary and a silane coupling agent. The LED photocuring non-solvent type photosensitive transfer printing adhesive for the cover plate glass substrate is free of solvents and environmentally friendly, integrates advantages of the transfer printing technology and advantages of the photosensitive technology, and can be particularly used for development through a pure water neutral developing solution. The LED photocuring non-solvent type photosensitive transfer printing adhesive for the cover plate glass substrate has excellent physical performance, resistant to solvents, resistant to cold and hot impact and good in adhesion with the substrate after being cured. The adhesive force of an adhesive layer and the substrate is larger than 4B and environmental pollution is little especially after a boiling test. The problem that existing UV adhesive is poor in adhesion on cover plate glass and not resistant to boiling or solvents is solved, industrial requirements are met, production cost of enterprises is reduced, and benefits are brought to the enterprises.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

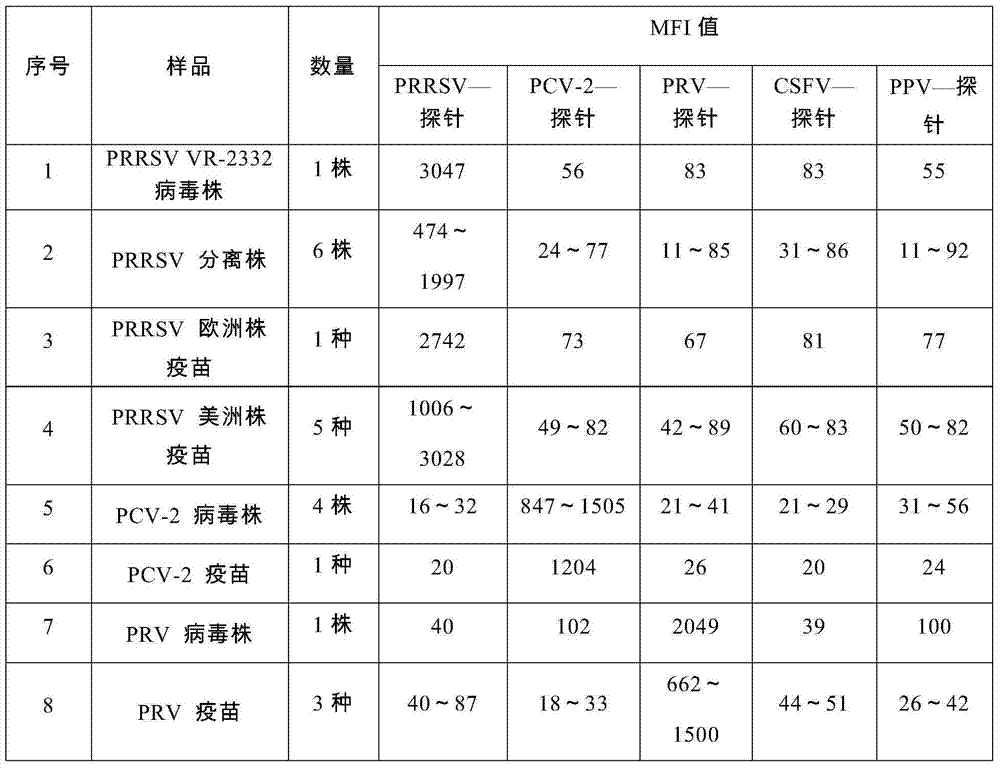

Nucleic acids of liquid-phase gene chip for synchronously detecting five porcine viruses and detection method thereof

ActiveCN104328218AHigh detection sensitivityStrong specificityMicrobiological testing/measurementMicroorganism based processesClassical swine fever virus CSFVMultiplex

The invention provides a set of nucleic acids of a liquid-phase gene chip for synchronously detecting five porcine viruses, which comprise forward and reverse primers and hybrid probes for porcine reproductive and respiratory syndrome virus (PRRSV), porcine circovirus type 2 (PCV2), porcine pseudorabies virus (PRV), classical swine fever virus (CSFV) and porcine parvovirus (PPV). The invention also provides a multiplex liquid-phase chip high-flux molecular biology detection method of the five porcine viruses. According to the method, porcine virus nucleic acids in the sample to be detected are extracted to perform multiplex unsymmetric nucleic acid amplification / multiplex liquid-phase gene chip (suspension chip) combined detection, thereby synchronously and accurately detecting and identifying the five porcine viruses in the sample to be detected. The method has the advantages of high specificity, high sensitivity, high stability, high flux and high detection speed, and is simple to operate.

Owner:INSPECTION & QUARANTINE TECH CENT OF GUANGDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

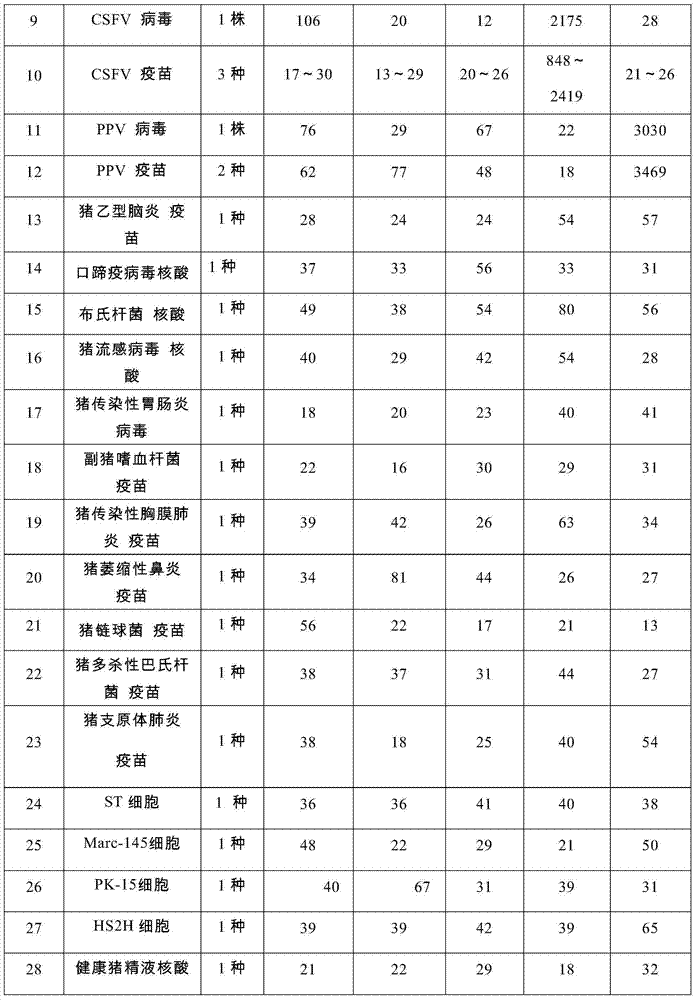

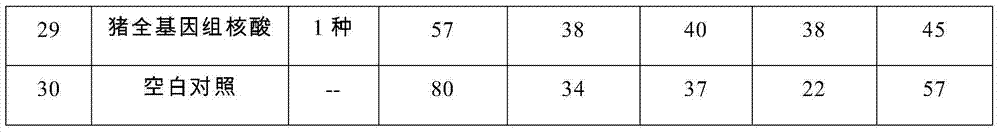

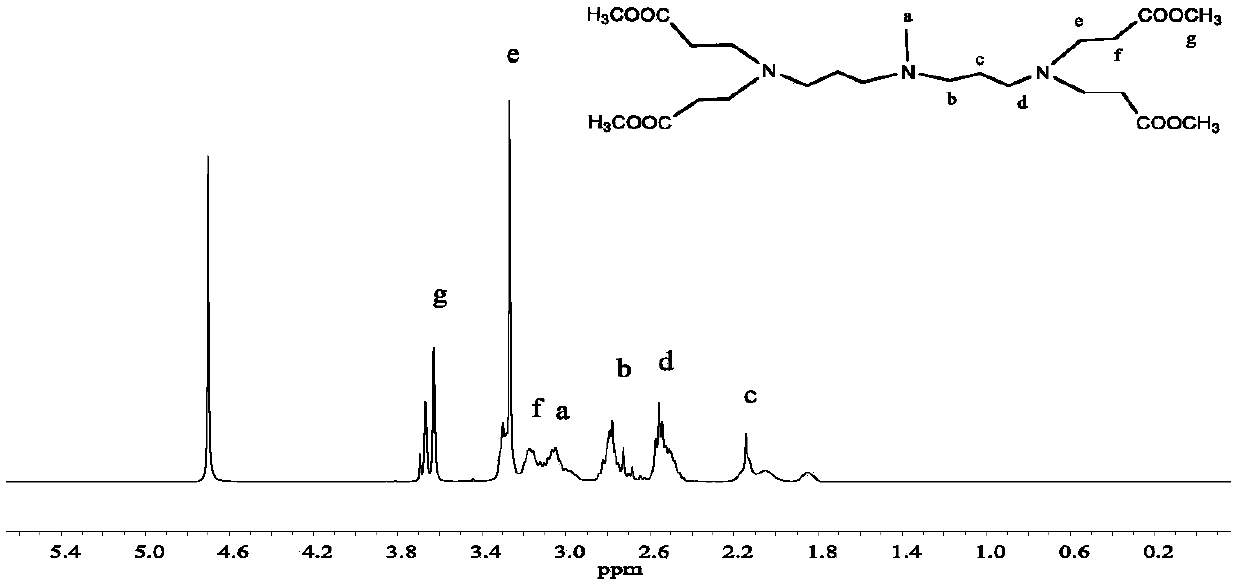

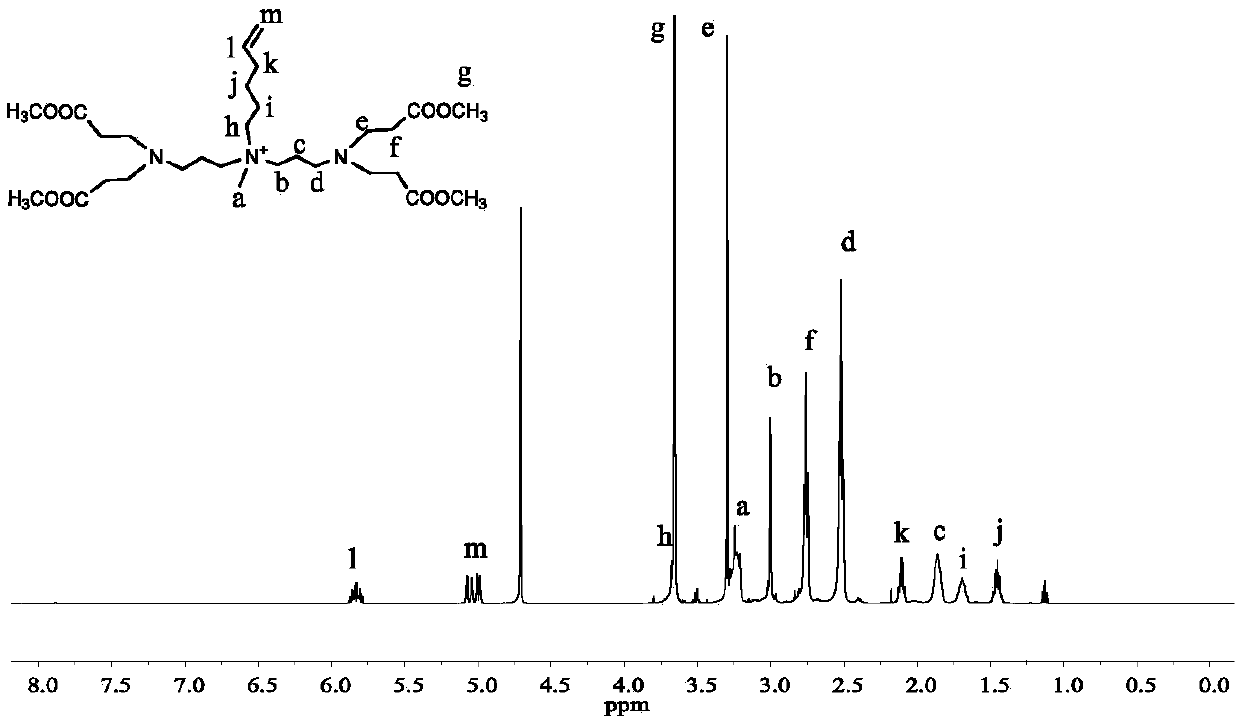

Preparation method of dentritic tetrameric cationic quaternary ammonium surface activity monomer

InactiveCN108033895AEasy to purifyRaw materials are easy to getOrganic compound preparationTransportation and packagingSolvent1-Hexene

The invention relates to a preparation method of a dentritic tetrameric cationic quaternary ammonium surface activity monomer, which includes steps of fully mixing methyl acrylate and monomer 3, 3-diamido-N-methyldipropylamine and then performing addition reaction; adding 6- bromine-1-hexene to perform quaternization reaction; depressurizing and removing solvent; then adding absolute ether as precipitator to wash for three times; adding N, N-dimethyl-1, 3-propane diamine to perform amidation; depressurizing and removing excessive N, N-dimethyl-1, 3-propane diamine to perform amidation; addinglong-chained monomer 1-dodecyl bromide to perform quaternary amination reaction; after finishing the reaction, repeatedly washing for over three times to obtain the pure dentritic tetrameric cationicquaternary ammonium surface activity monomer. The preparation method is easy to obtain raw materials, simple in synthesis step and product purification, high in yield, safe in use, convenient to store, low in temperature required by the process, simple and easy-controlled operation, low in energy consumption, wide in application prospect; the preparation method is applicable to the industrial production.

Owner:SHANDONG UNIV

Solvent-free interlayer polyurethane resin for automotive trim leather and preparation method thereof

ActiveCN106220817AReduce usageGuaranteed to be environmentally friendlyRoad vehiclesTextiles and paperOligomerAlcohol

The invention provides a solvent-free interlayer polyurethane resin for automotive trim leather and preparation method thereof. The solvent-free interlayer polyurethane resin is composed of an A component and a B component in a mass ratio of (2.5: 1)-(1: 2.5) through the mixing; the A component is composed of diisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol, catalyst, light / heat stabilizer, flatting agent and solvent-free color paste; the B component is composed of diisocyanate, triisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol and antioxidant. The polyurethane resin prepared by the method disclosed by the invention can be used as the interlayer for the automotive trim leather, the high temperature durable performance and various mechanical properties of the automotive leather can be effectively guaranteed while meeting the hydrolysis resistance of the automotive leather product; the peeling strength of the prepared automotive leather product reaches up to 145N / 3cm, the hydrolysis resistance can reach the condition that the peeling strength still reaches up to 135N / 3cm after 10 weeks.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Preparation method of hydrogenated bisphenol A epoxy resin

The invention relates to a preparation method of hydrogenated bisphenol A epoxy resin. The preparation method comprises the steps of raw material pre-treatment, ring-opening addition and etherifying, ring-closing epoxidation, product post-treatment and the like. The specific steps are as follows: based on hydrogenated bisphenol A and epoxy chloropropane as raw materials, adding solvent; performing ring-opening etherifying by taking Lewis acid as a catalyst to produce chlorohydrin ether immediate; recovering part of the solvent, adding alkali solution and performing ring-closing dechlorinating reaction; carrying out post-treatment steps such as neutralizing, extracting, water washing, vacuum desolventizing to obtain hydrogenated bisphenol A epoxy resin, wherein the epoxide equivalent of the product is 210-240g / eq; the hydrolyzable chlorine content is not more than 1000ppm; the inorganic chloride content is not more than 10ppm; the viscosity is 2000-5000mPas at 25 DEG C; and the volatile component content is not more than 0.1%. The preparation method of hydrogenated bisphenol A epoxy resin has the advantages of stable process, low material and energy consumption, few by-products, simple water-washing and separating operation and high product yield, therefore, the preparation method can be applied in large-scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

Method for checkpointing a main-memory database

InactiveUS7587429B2Without slowing down a transaction level processingReduce usageData processing applicationsError detection/correctionOriginal dataSoftware engineering

Method for making a consistent checkpoint of a page including at least one data object in a computer system having a primary and secondary storage, and a programmable software. The primary storage has at least one page which includes at least one original data object on the page. The computer system allows at least one write operation to modify at least one data object, and the page is written into the secondary storage during checkpointing. The method includes beginning the checkpointing, including at least one page in the primary storage into a group of pages to be checkpointed, altering at least one data object with at least one data write operation, marking at least one data object resulting from the data write operation, writing at least one of the data objects into the secondary storage, and altering the state of the pending data object to be the original data object.

Owner:SOLID INFORMATION TECH

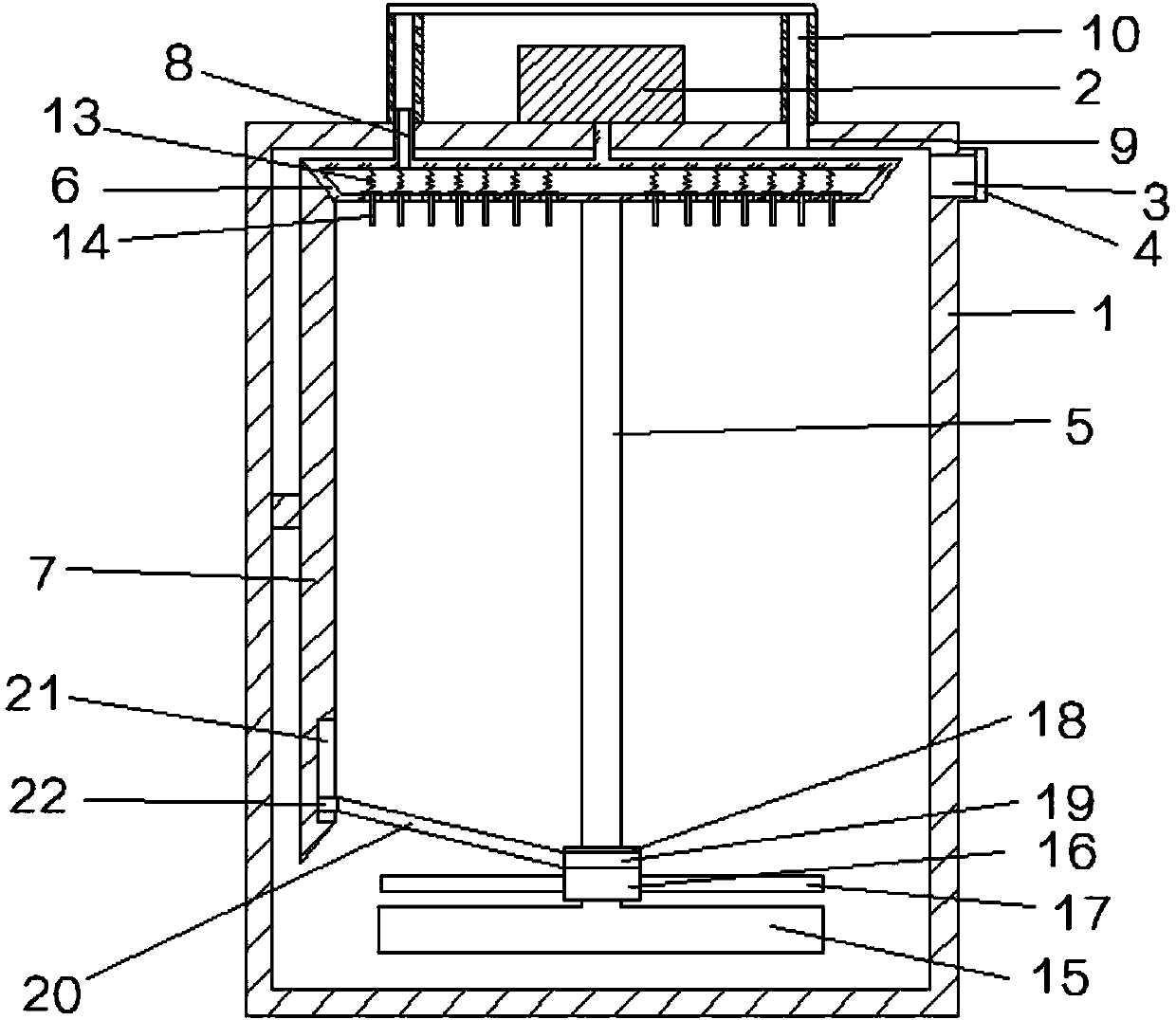

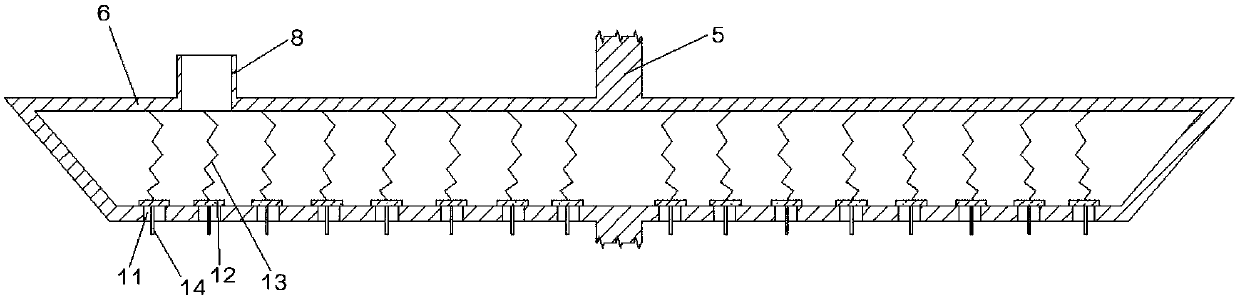

Automatic intermittent feeding stirring apparatus

ActiveCN108031420AAchieve stirring effectAchieve openShaking/oscillating/vibrating mixersRotary stirring mixersDrive shaftMaterial storage

The invention belongs to the technical field of mixers with rotary stirring devices in fixed containers, and particularly discloses automatic intermittent feeding stirring apparatus. The apparatus comprises a stirring box, a motor fixed on the upper end surface of the stirring box, a driving shaft fixedly connected with the motor, a hollow material storage plate which is provided with teeth on theside surface, fixedly connected with the driving shaft and positioned inside the stirring box, blades which are fixedly connected with the driving shaft and positioned inside the stirring box, a bevel gear meshed with the material storage plate and rotatably connected with the side wall of the stirring box, and a sliding sleeve slidably connected with the driving shaft. A stirring plate is fixedly connected to the sliding sleeve; a rotating ring is slidably connected with the sliding sleeve; a connecting rod is hinged to the rotating ring; the other end of the connecting rod is hinged to thebevel gear; second through holes are formed in the lower end surface of the material storage plate; baffle plates for sealing the second through holes are arranged on the second through holes, a spring is fixedly connected on the upper end surface of each baffle plate; and the other end of each spring is fixedly connected with the upper wall of the material storage plate. The apparatus provided bythe invention is mainly used for the synthesis and preparation of chemical reagents.

Owner:徐州天骋智能科技有限公司

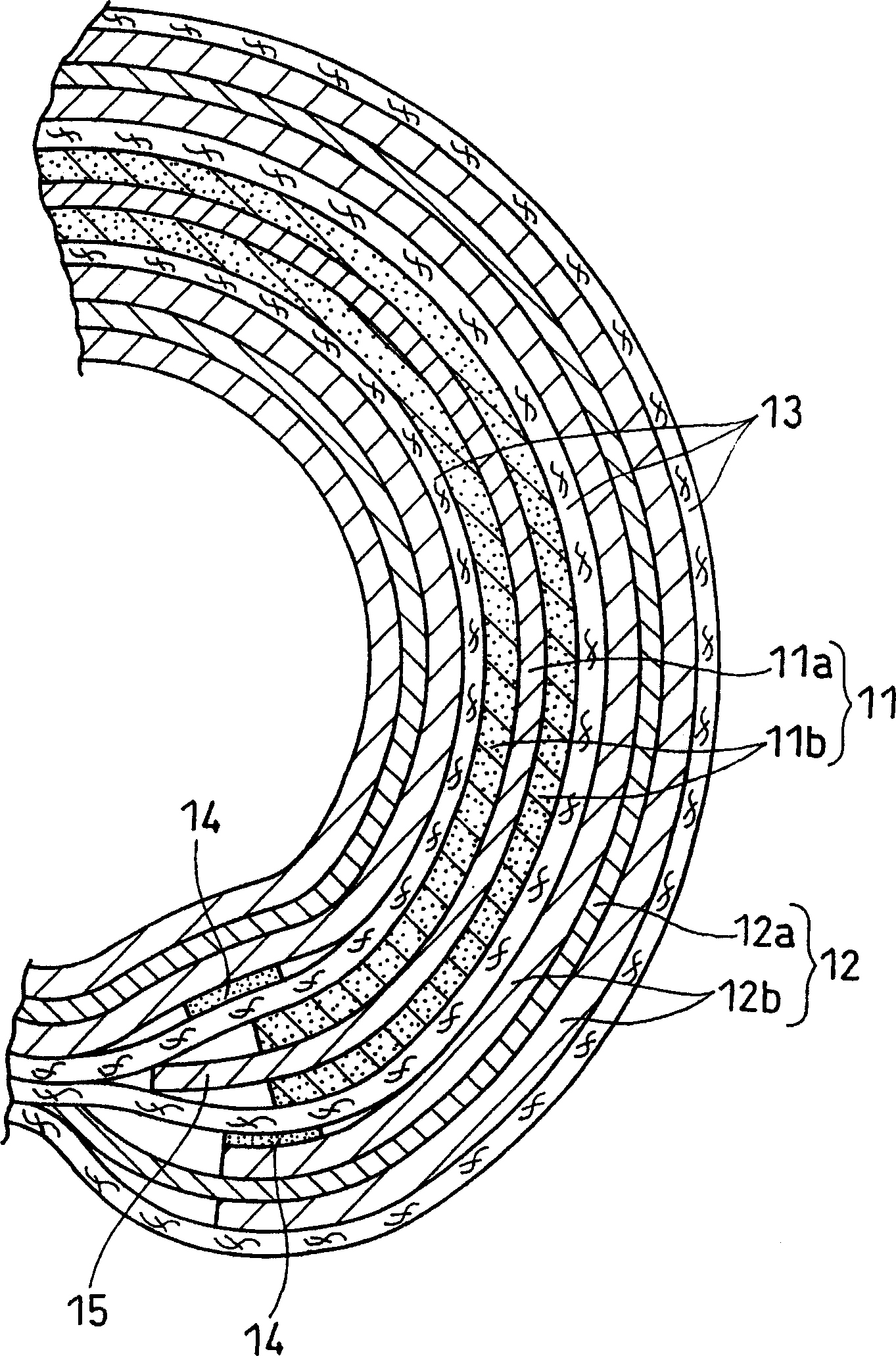

Lithium ion secondary cell

InactiveCN1728439AGuaranteed responsePrevent internal short circuitFinal product manufactureSecondary cellsLithiumPhysics

The present invention provides a lithium ion secondary battery including: an electrode group including a belt-like positive electrode and a belt-like negative electrode that are wound with a separator interposed therebetween; and a can with a bottom for accommodating the electrode group, wherein the positive electrode has a positive electrode current collector and a positive electrode mixture layer carried on the positive electrode current collector, the negative electrode has a negative electrode current collector and a negative electrode mixture layer carried on the negative electrode current collector, and a porous heat-resistant layer is partially provided between the separator and at least one of the positive electrode mixture layer and the negative electrode mixture layer. Since a porous heat-resistant layer is thus placed, a high performance lithium ion secondary battery capable of efficiently preventing internal short circuit due to overheating while preventing decrease in battery characteristics can be provided.

Owner:PANASONIC CORP

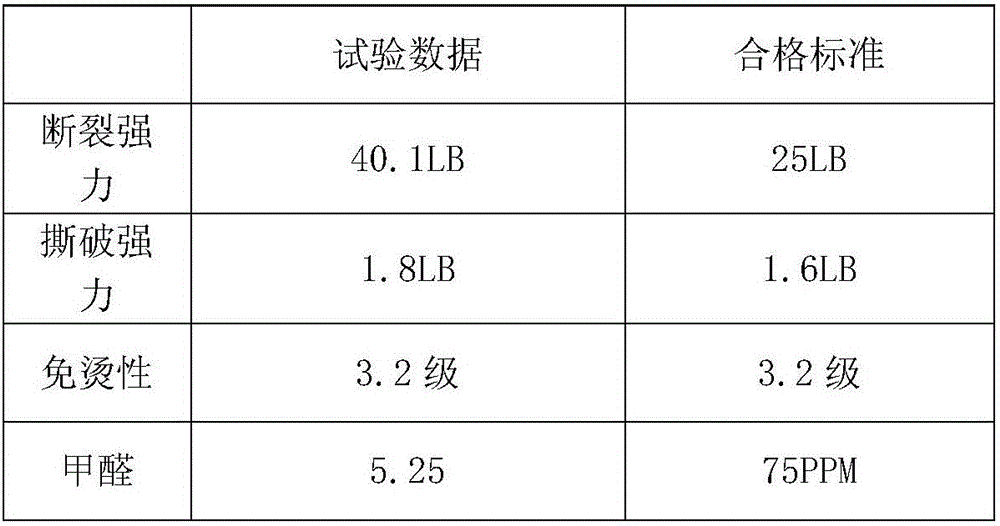

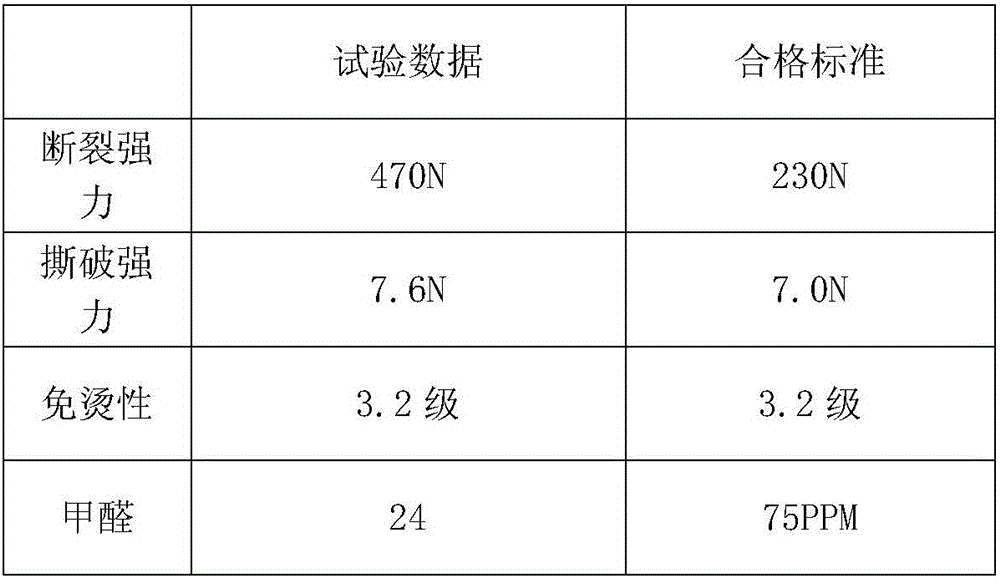

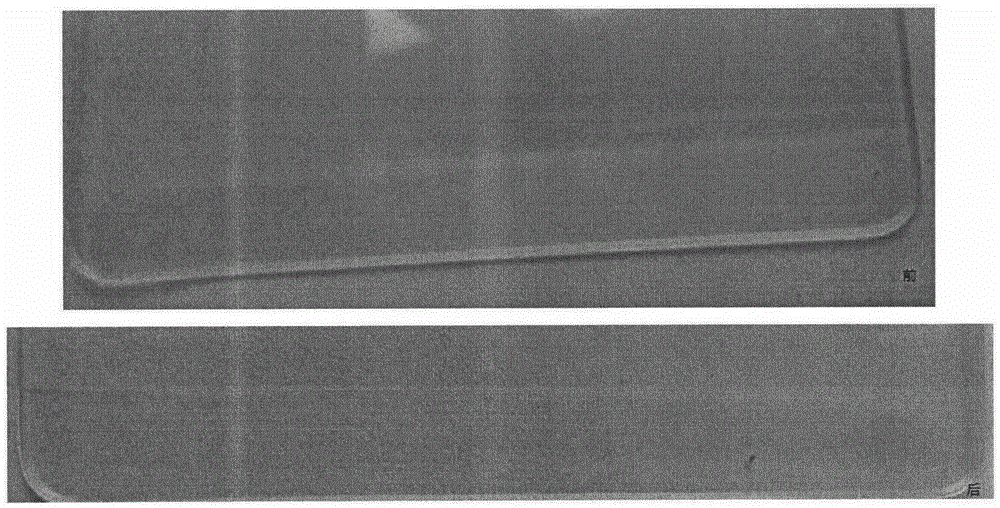

Non-iron finishing method for piece-dyed pure cotton fabric

InactiveCN105714559AGuaranteed responsePrevent strong damageSucessive textile treatmentsLiquid/gas/vapor removalFiberEngineering

The invention provides a non-iron finishing method for piece-dyed pure cotton fabric. The non-iron finishing method is characterized by comprising technological processes in sequence as follows: cloth turning, singeing, desizing and scouring, bleaching, mercerizing, liquid ammonia finishing, non-ironing, baking, washing, tentering, pre-shrinking as well as checking and packaging, wherein an intelligent non-iron technology is adopted for the fabric, resin and fibers are subjected to a crosslinking reaction sufficiently, formaldehyde and strength loss caused by resin residues are avoided, strength repair is avoided in a dyeing and finishing process, the content of formaldehyde of a cloth cover can be reduced, and the increase of formaldehyde can be prevented; with the adoption of non-iron finishing, the appearance of the fabric washed 5 times with an AATCC 124 method can reach level 3.2 or higher, and the content of formaldehyde is 60 PPM or lower through testing with a JIS L1041:2011 / 8.1.4B method. The processed fabric is soft and comfortable to wear, is environment-friendly and has an excellent non-iron effect.

Owner:鲁丰织染有限公司

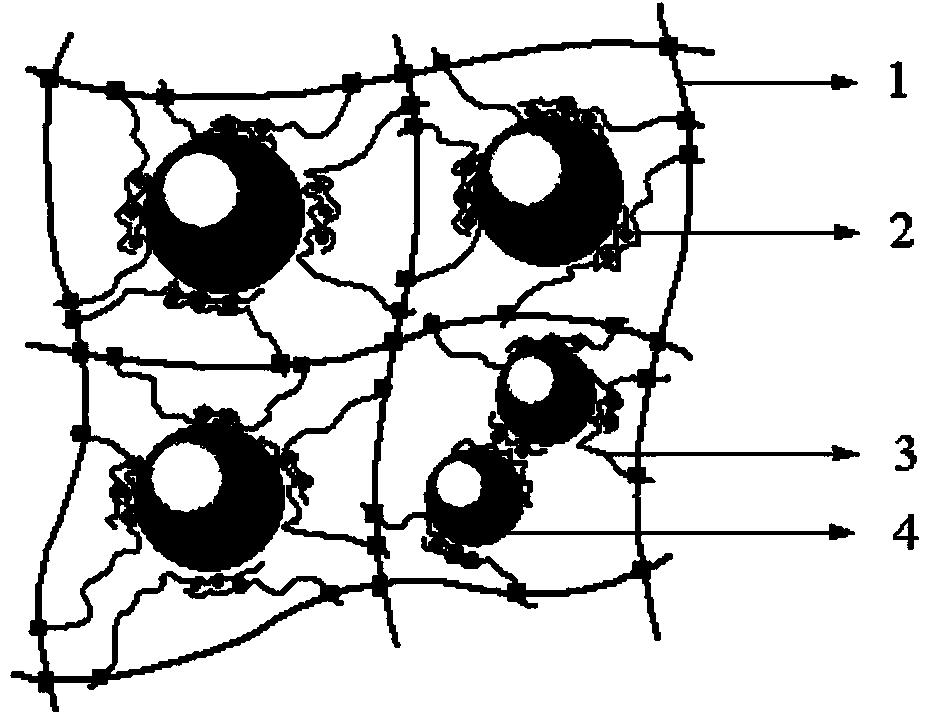

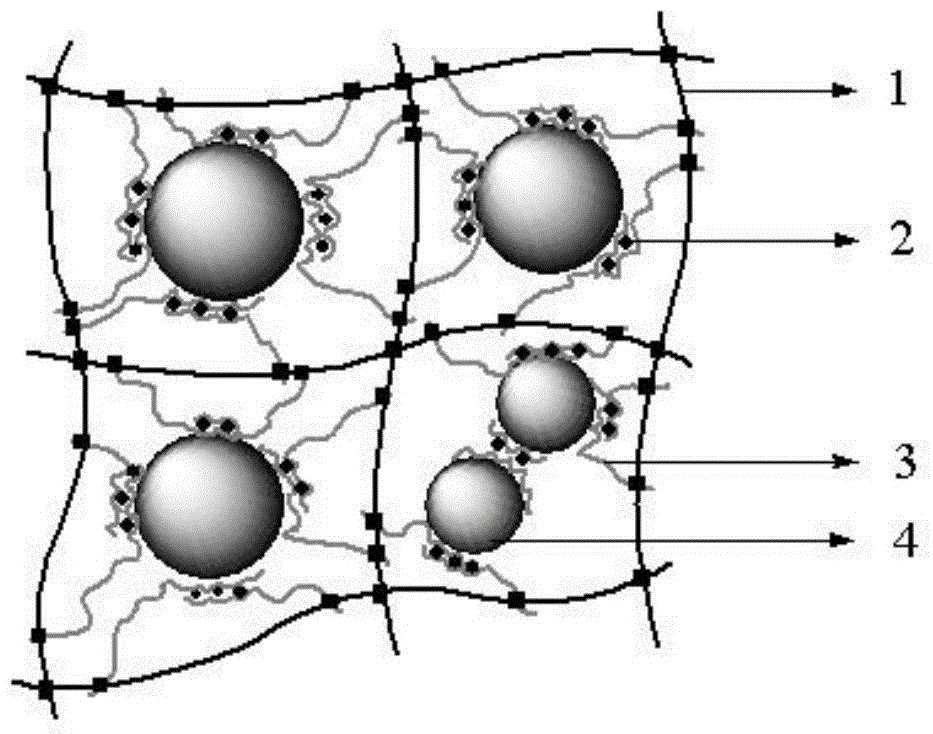

Prepn of nanometer reactive polymer microgel

The improved positive phase-micro-emulsion polymerization process of the present invention comprises adding emulsifier, initiator, long-chain flexible monomer, functional monomer, polyfunctionality monomer, etc. the heat initiating system of methyl acrylate or styrene monomer, synthesis of homogeneous transparent or semi-transparent nanometer polymer microgel at mild condition in controlled batchrange and then transferring into oil phase to form reactive non-aqueous dispersant microgel liquid. By means of the great amount of reactive functional groups, the microgel may be used in regulating rheological property of paint, preparing pigment moistening dispersant, etc.

Owner:FUDAN UNIV

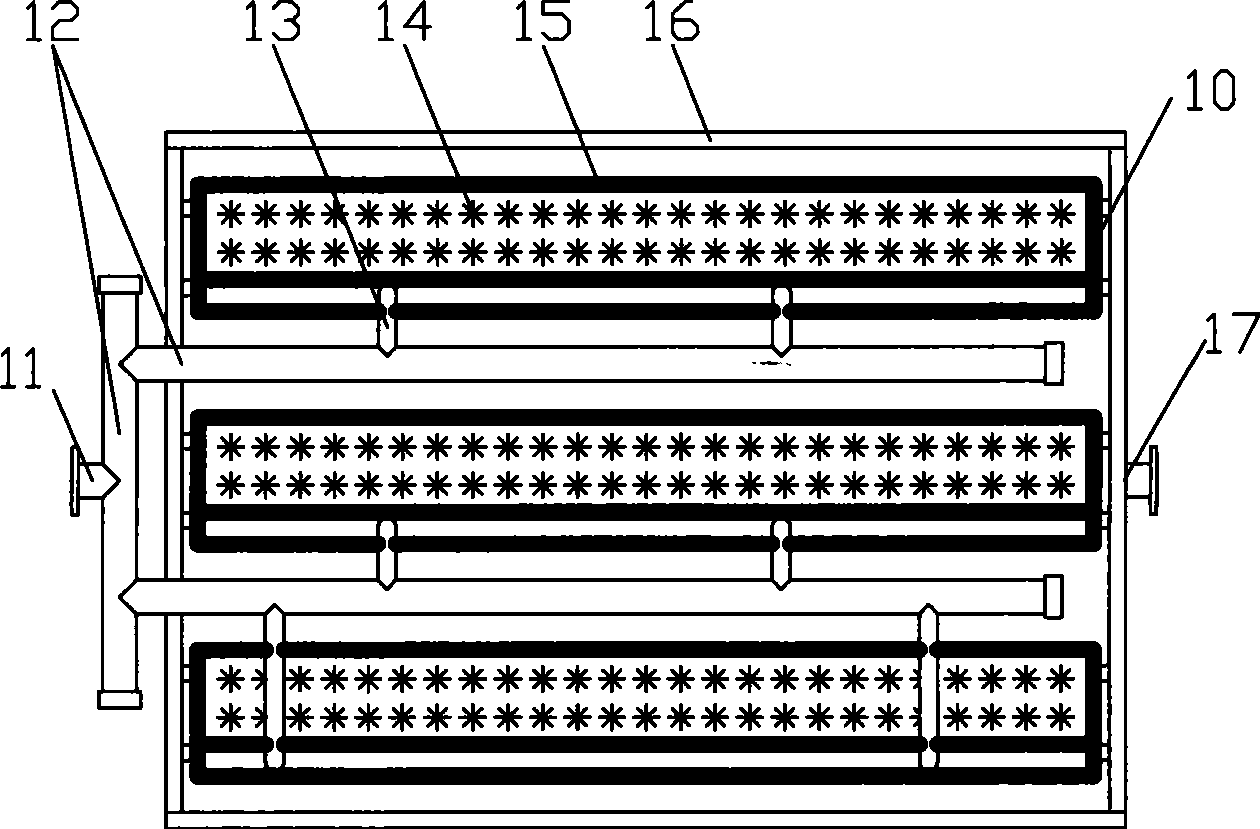

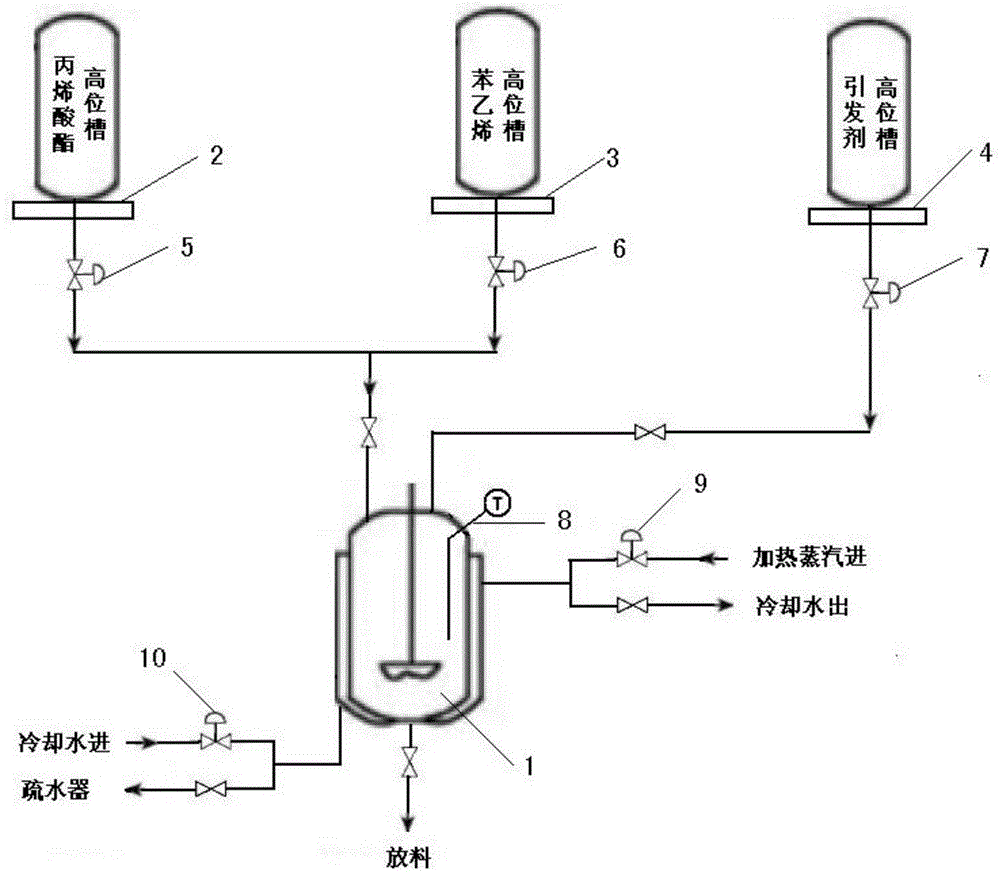

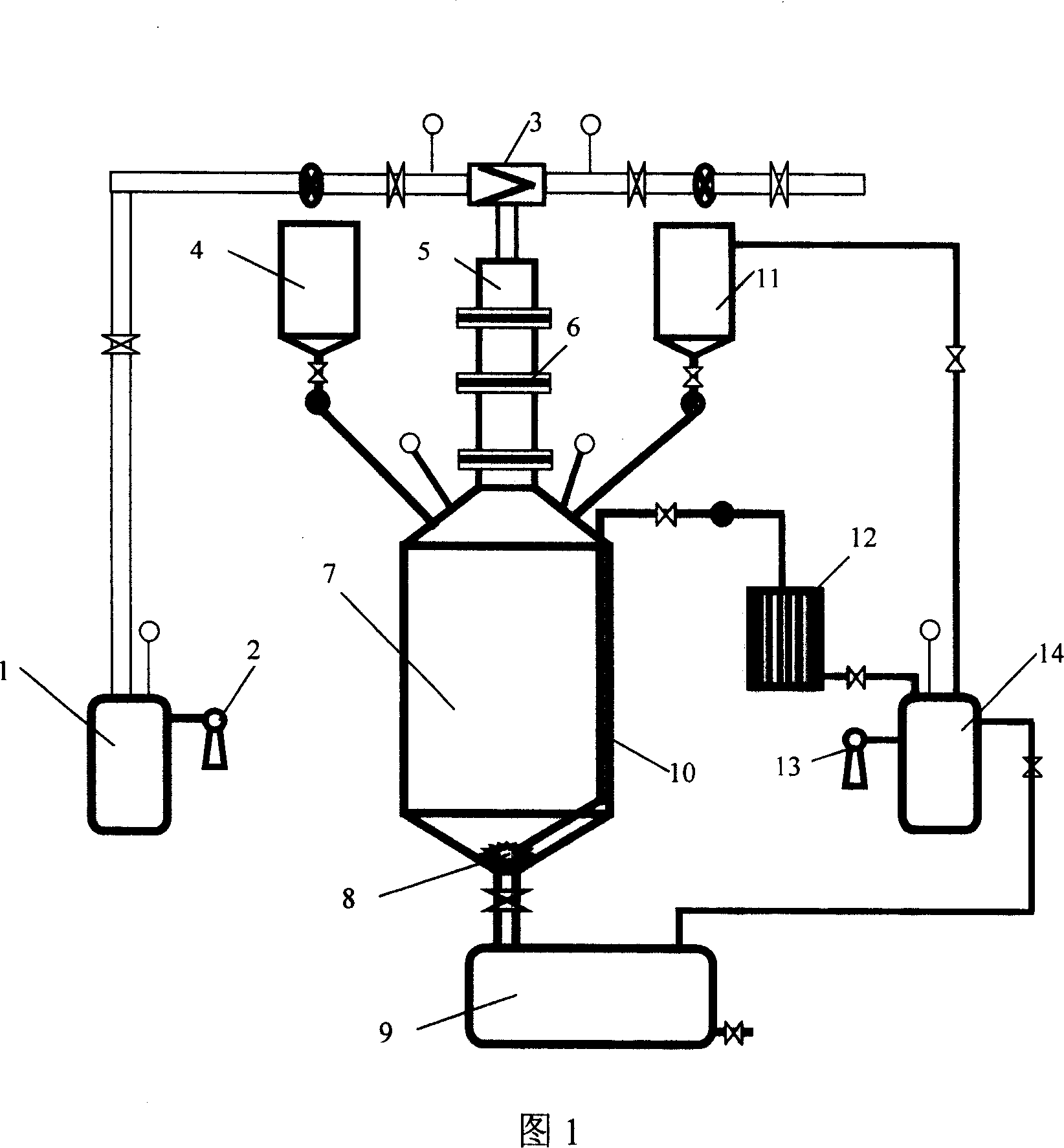

Automated production device for styrene-acrylic emulsion mixing and automated control method of automated production device

ActiveCN104014293AGuaranteed responseEnsure productivityChemical/physical/physico-chemical stationary reactorsTotal factory controlAutomatic controlEmulsion

The invention discloses an automated production device for styrene-acrylic emulsion mixing and an automated control method of the automated production device. The automated production device comprises a PLC (programmable logic control) system, a polymerization reaction kettle, an overhead acrylate tank, an overhead styrene tank and an overhead initiator tank, wherein a weight sensor is arranged at the bottom of each overhead tank and is connected with the PLC system; a control valve is arranged on each of an acrylate feeding pipe, a styrene feeding pipe and an initiator feeding pipe and is connected with the PLC system; a temperature sensor is arranged on the polymerization reaction kettle and is connected with the PLC system; a control valve is arranged on each of a heated steam pipe and a cooling water pipe and is connected with the PLC system. The automated control method comprises the step that the PLC system automatically adjusts an acrylate feeding control valve, a styrene feeding control valve, an initiator feeding control valve, a heated steam control valve and a cooling water control valve to control the feeding amount and the feeding speed of acrylate solution, styrene solution and an initiator solution and the temperature of the polymerization reaction kettle. The feeding amount and the feeding speed of materials and the flow of heated steam and cooling water are adjusted according to the change of reaction temperature by using the PLC system, so that the temperature of polymerization reaction is stable, and the production safety and the product quality are ensured.

Owner:湖北尚助化学有限公司

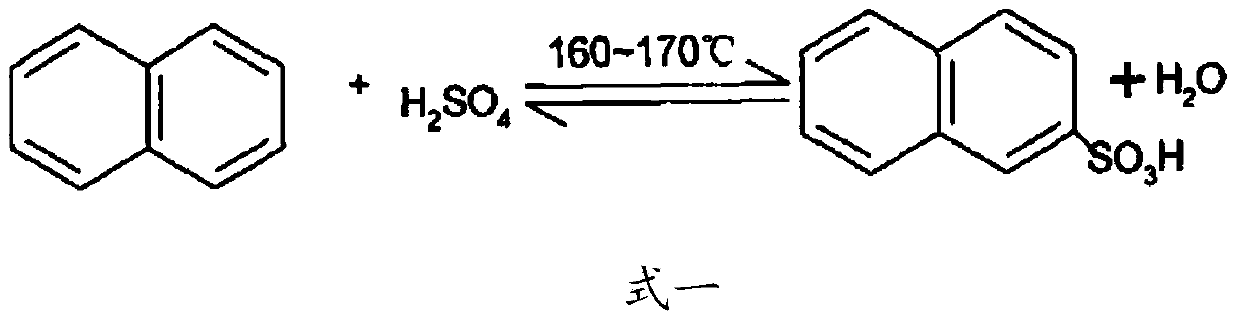

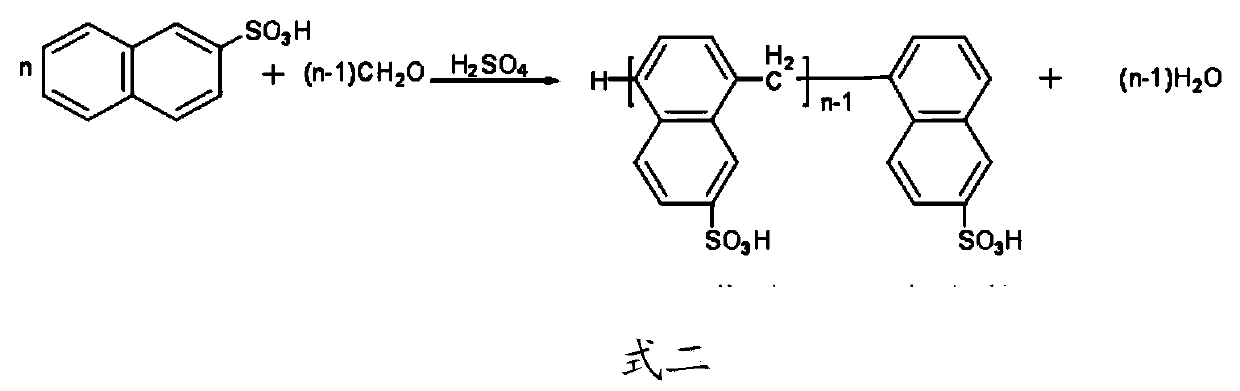

Production method for naphthalene high-concentration water reducer

The invention discloses a production method for a naphthalene high-concentration water reducer. The production method comprises the following steps: (1), preparing industrial naphthalene, 98% concentrated sulfuric acid and 37% formaldehyde in a weight ratio being 1:0.889:0.598; (2), adding the industrial naphthalene; (3), sulfonating, namely adding the concentrated sulfuric acid within 25-30 minutes while rising a temperature of the naphthalene to 150 DEG C; after adding the acid, carrying out sulfonation reaction at 160-165 DEGC; increasing steps of circulating a solvent and removing residual solvent in the sulfonating process, and controlling acidity to 26-27%; (4), hydrolyzing, namely adding water into reaction liquor and hydrolyzing for 15 minutes at 110-125 DEG C; (5), condensing, namely adding the formaldehyde within 2 hours when the temperature is 102 + / -2 DEG C, condensing and preserving the heat to react for 3 hours, and controlling the temperature to 115-125 DEG C and controlling the pressure to 0.10-0.15MPa; and (6), neutralizing. According to the production method, a conversation ratio of a beta-naphthalenesulfonic acid-formaldehyde condensation compound is greatly increased, the time is shortened, the energy consumption is lowered, and the discharge of waste gas is reduced.

Owner:广东瑞安科技实业有限公司

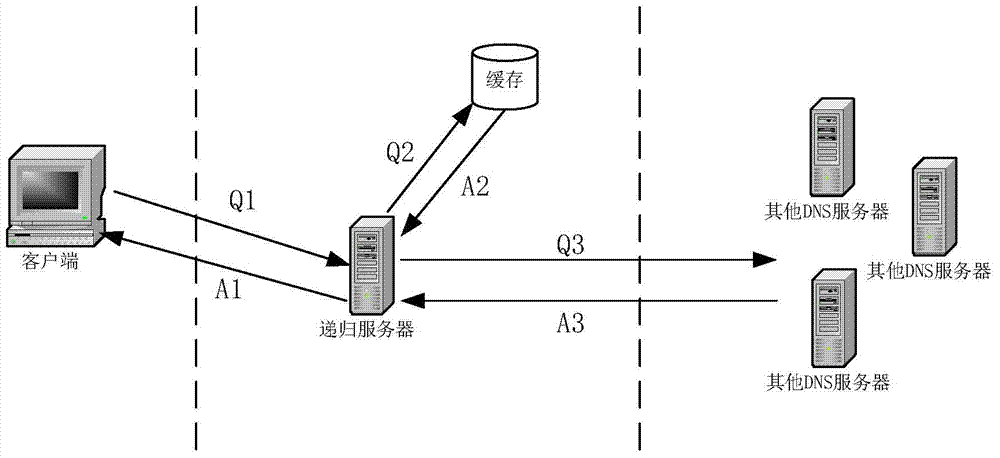

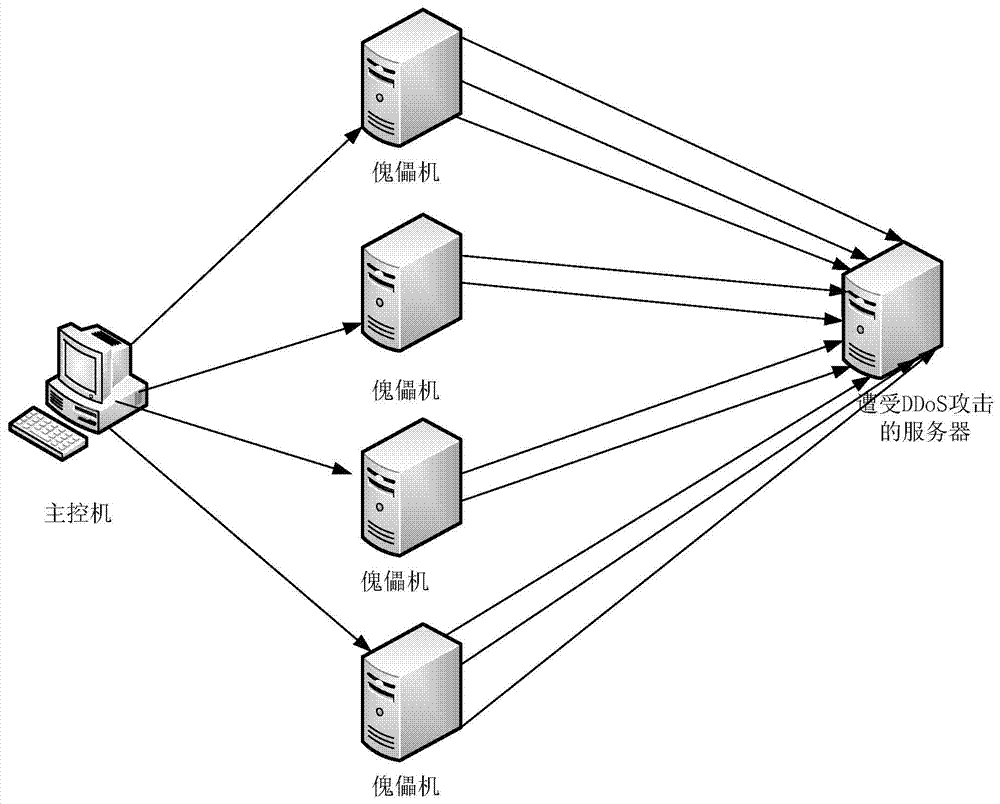

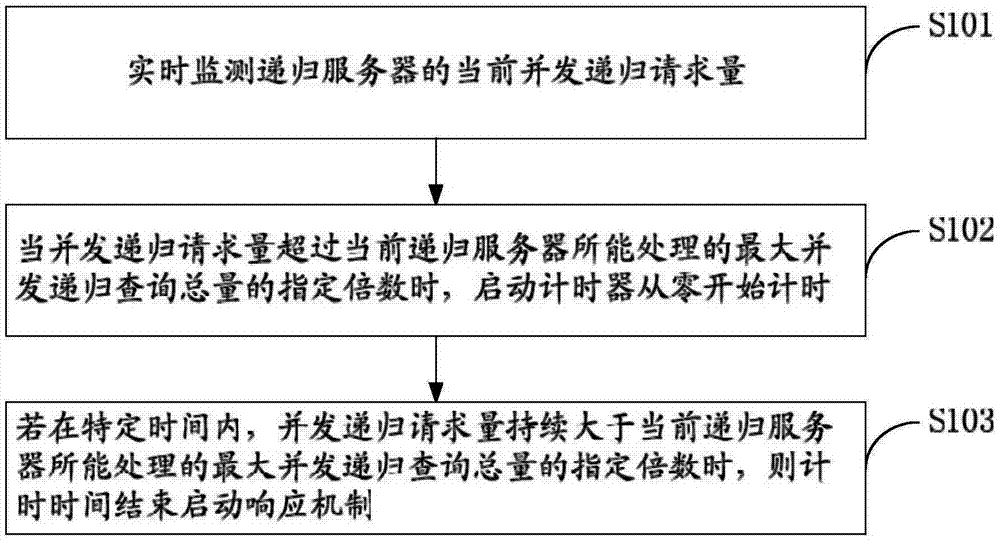

DoS (Denial of Service) and DDoS (Distributed Denial of service) attack resisting method of DNS recursive server

The invention relates to a DoS and DDoS attack resisting method and device of a DNS recursive server. The method comprises monitoring the current concurrent recursive request quantity of the recursive server in real time, and when the recursive request quantity is continuously larger than the designated multiples of the maximum concurrent recursive query total volume that the recursive service can process within a specific time period, starting the response mechanism of a common DNS cache for prefetching and limiting the concurrent recursive query quantity when the specific time period times out. According to the DoS and DDoS attack resisting method of the DNS recursive server, by monitoring the current concurrent recursive request quantity of the recursive server in real time and starting the response mechanism at the appropriate time, the cache hit rate of DNS query can be improved, queries issued by the recursive server to other DNSs can be inhibited, so that server resources and network bandwidth which are occupied during DoS and DDoS attacks can be reduced, so that normal response to analysis requests of legitimate users can be guaranteed to the maximum extent, and safe operation of a DNS system can be maintained.

Owner:INTERNET DOMAIN NAME SYST BEIJING ENG RES CENT +1

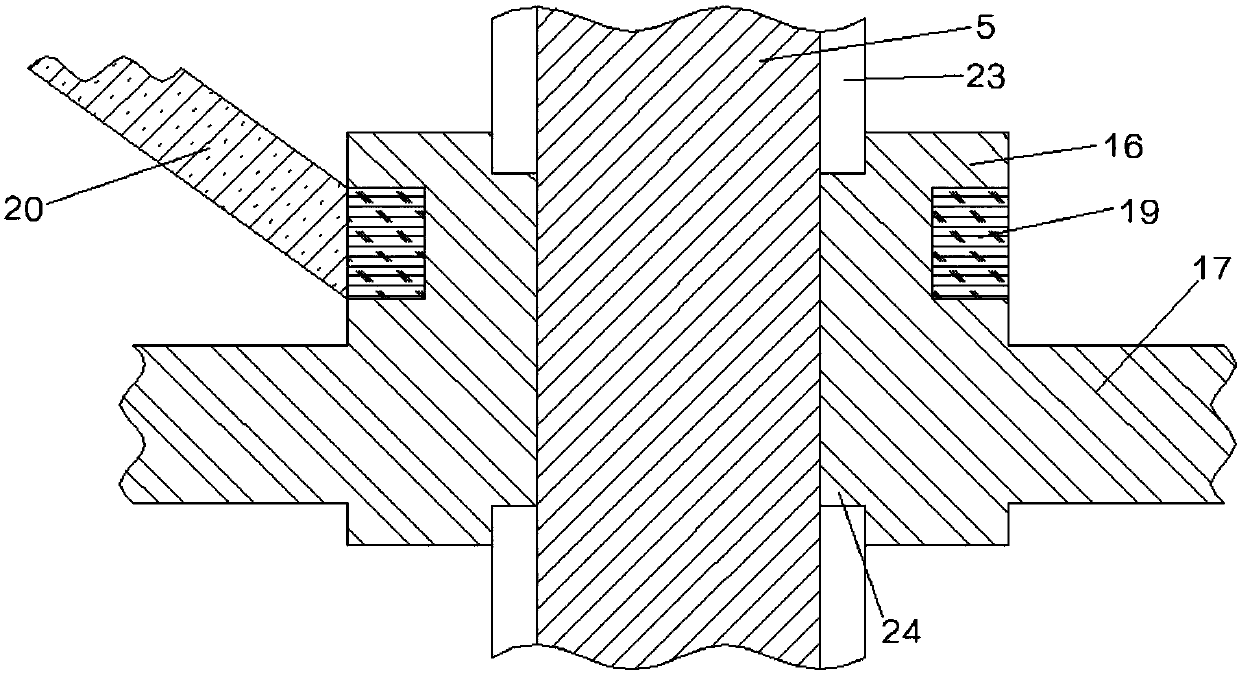

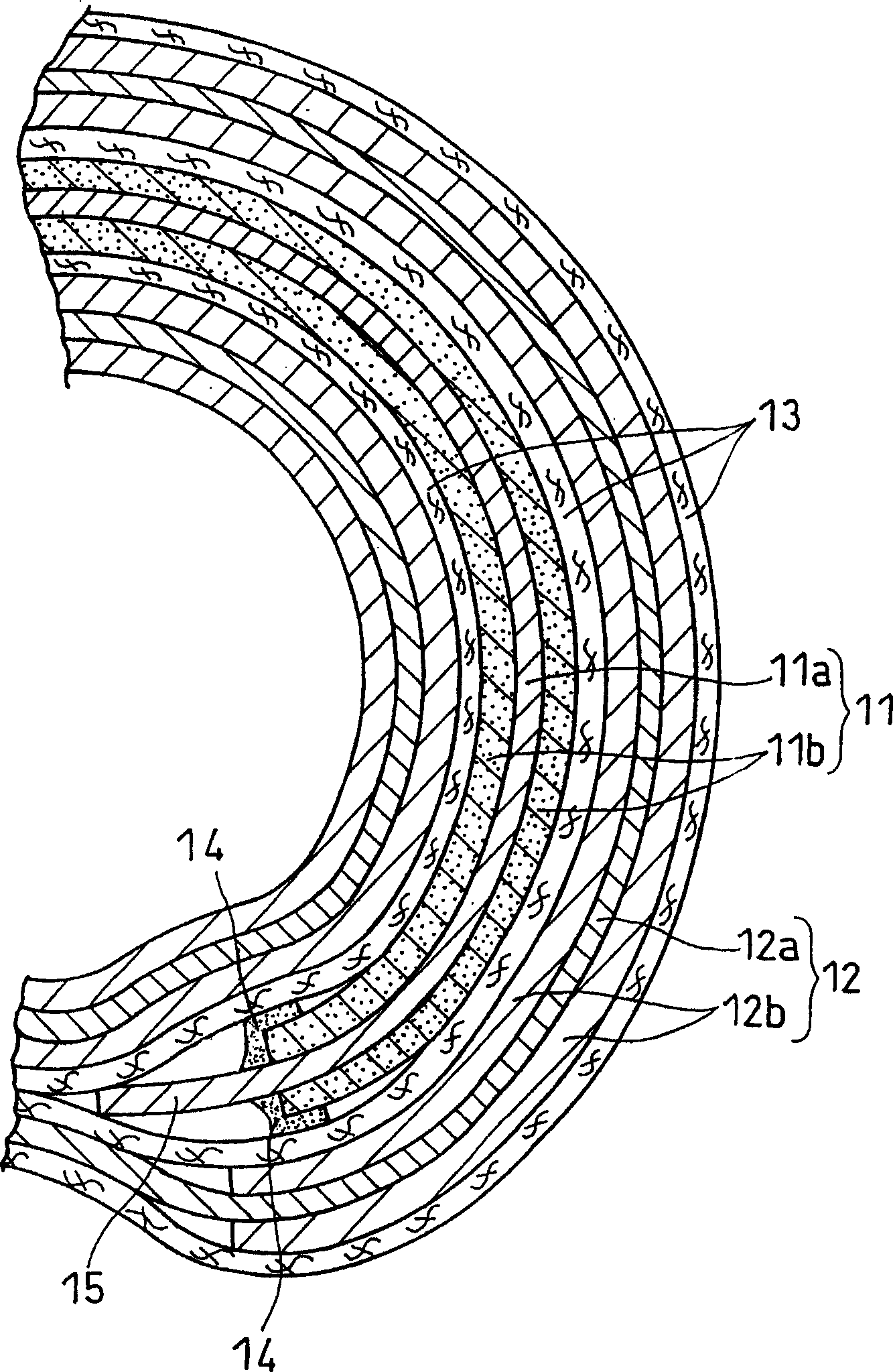

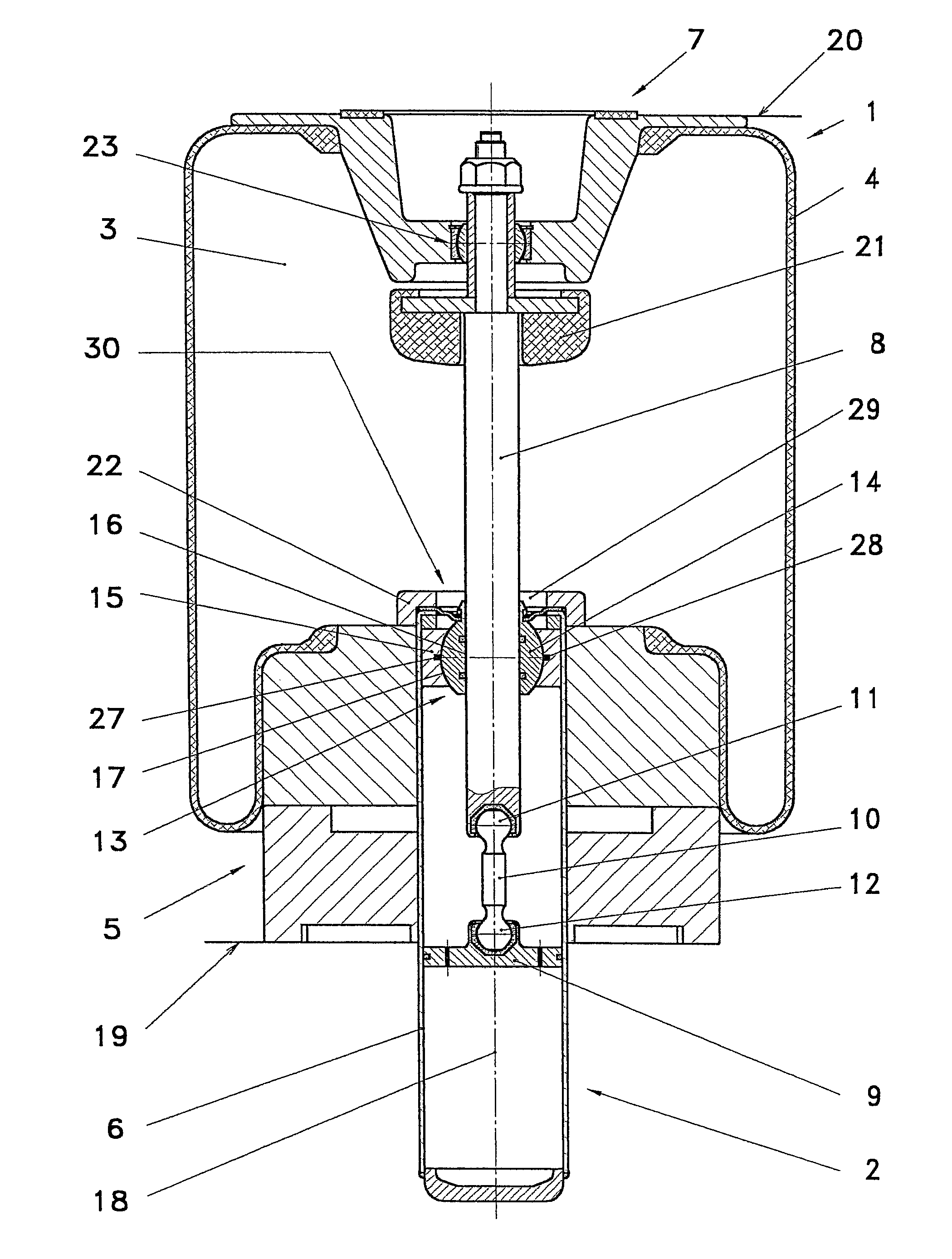

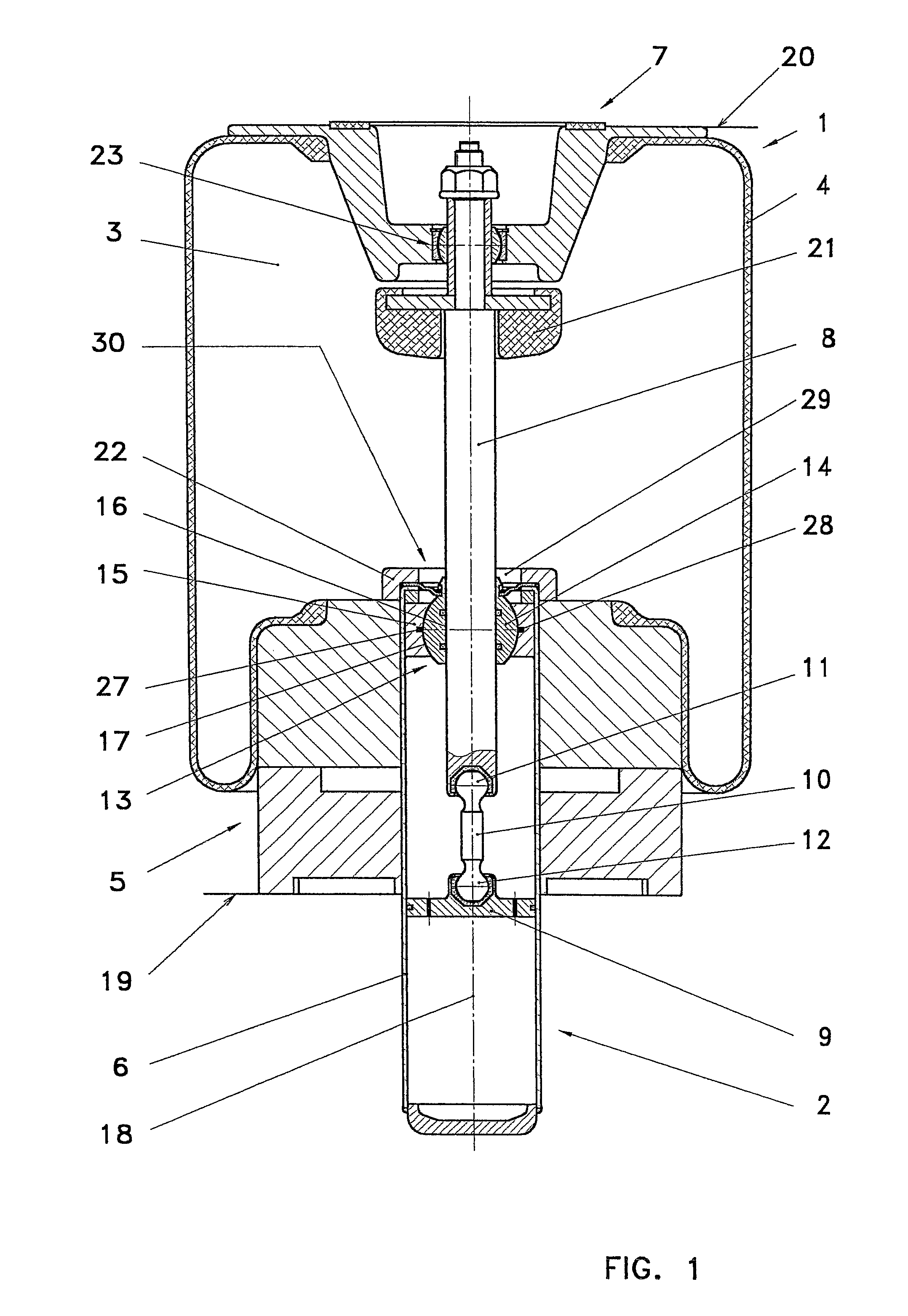

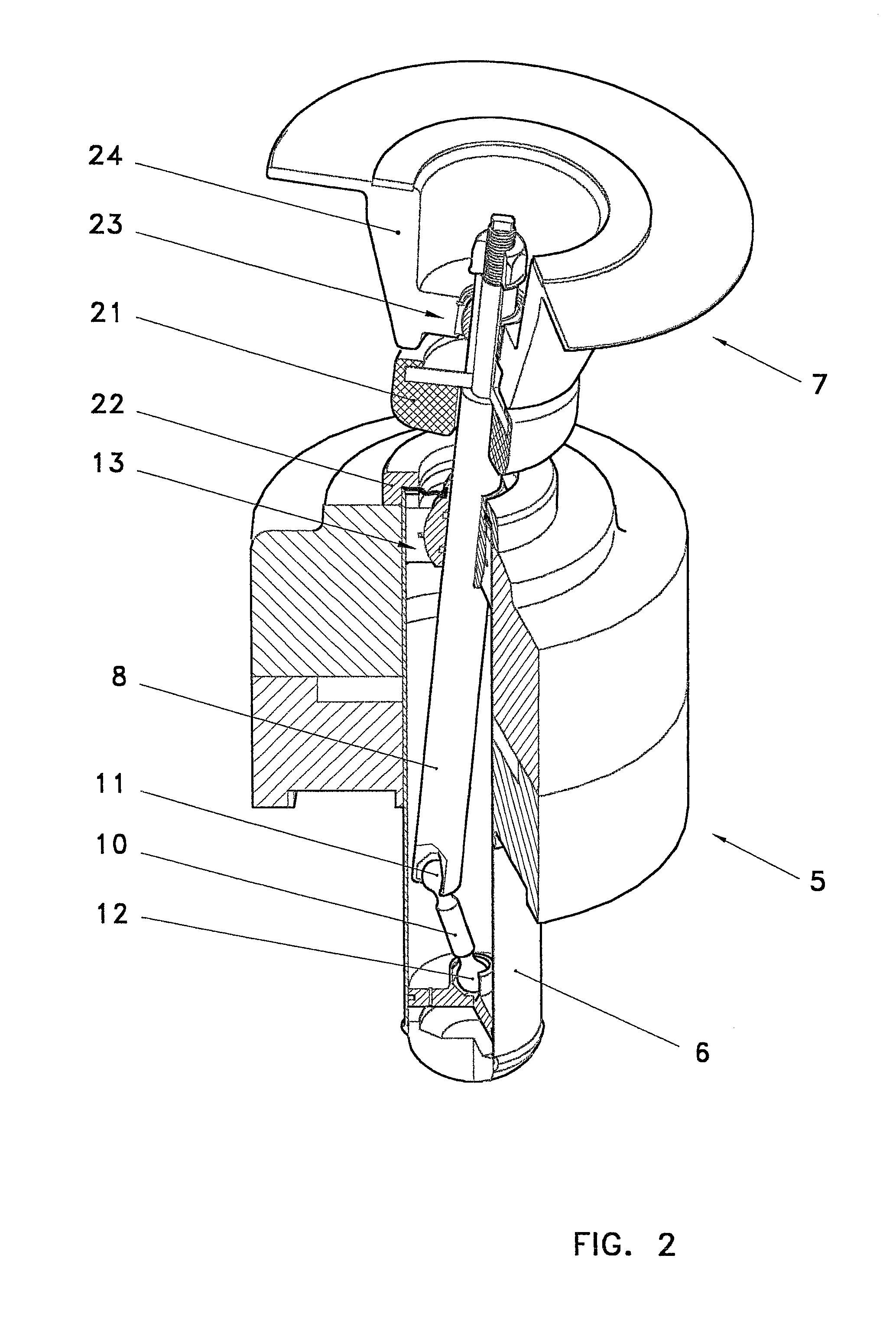

Pneumatic spring vibration damper assembly unit

InactiveUS7487957B2Extended service lifeImproved force transmissionLiquid springsResilient suspensionsControl theoryPiston rod

A pneumatic spring-vibration damper unit is provided for absorbing shocks on wheels and chassis parts of motor vehicles. A variable air chamber is delimited by a rolling bellows which is disposed between a first subassembly that is fixed to the vehicle body and is provided with a vibration damper system and a second subassembly that is fixed to the vehicle chassis and is movable therewith. A piston rod connects the first subassembly located at the vehicle body end and the second subassembly located at the chassis end and whose free end located at the vehicle body end is accommodated inside a cylinder tube of the vibration damper system so as to be longitudinally movable by means of a piston. The piston rod (8) is guided within the cylinder tube (6) of the vibration damper system (2) so as to be longitudinally movable with the aid of a drag bearing arrangement (13). This allows the longitudinal axis of the piston rod to be angularly deflected relative to the central longitudinal axis (18) of the cylinder tube (6) while a joining element (10) which is fastened to the piston rod (8) and the piston (9) by a respective ball-and-socket joint unit (11, 12) is positioned between the piston rod (8) and the piston (9).

Owner:MENTOR GRAPHICS CORP +1

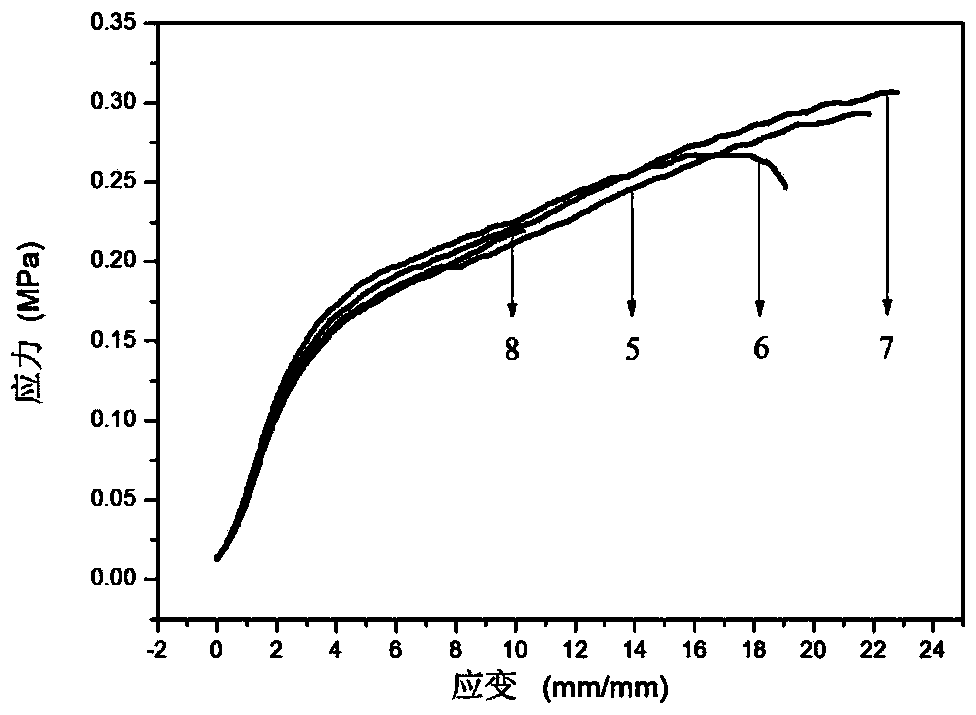

Preparation method of high-strength double-network nano hectorite composite aquagel

The invention discloses a preparation method of a high-strength double-network nano hectorite composite aquagel. The method comprises the following steps: preparing a nano hectorite water solution with cooled boiled distilled water, and dissolving sodium alginate, acrylamide, a crosslinking agent, an initiator and a catalyst in the hectorite water solution, quickly transferring the prepared solution into a glass mold, putting the sealed mold in a 45-55 DEG C environment, and keeping the temperature to react for 2-6 hours; and taking out the formed aquagel in the mold, immersing in a 0.1-1M CaCl2 water solution for 2-6 hours, and taking out to obtain the high-strength double-network nano hectorite composite aquagel. Compared with the traditional aquagel, the composite aquagel has higher strength and percentage of elongation, thereby satisfying the application demands for human cartilage restoration, tissue engineering and other aspects.

Owner:QILU UNIV OF TECH

Preparation method of high-strength dual-mesh nano-meter titanium dioxide composite hydrogel

The invention discloses a preparation method of a high-strength dual-mesh nano-meter titanium dioxide composite hydrogel. The preparation method comprises the following steps: preparing a nanometer TiO2 water solution by using cooled boiling distilled water, dissolving sodium alginate, acrylamide, a crosslinking agent, an initiator and a catalyst in the TiO2 water solution, rapidly transferring the prepared solution into a glass mould, placing the sealed mould in an environment of a temperature of 45-55 DEG C for performing an insulation reactor for 2-6h; and taking hydrogel formed in the mould out and then dissolving the hydrogel in a CaCl2 water solution with a concentration of 0.1-1M for 2-6h, and taking out to obtain the high-strength dual-mesh nano-meter titanium dioxide composite hydrogel. Compared with a conventional hydrogel, the high-strength dual-mesh nano-meter titanium dioxide composite hydrogel disclosed by the invention is relatively high in strength and elongation so as to meet application demands of the high-strength dual-mesh nano-meter titanium dioxide composite hydrogel on aspects of human body cartilage repair, tissue engineering and the like.

Owner:QILU UNIV OF TECH

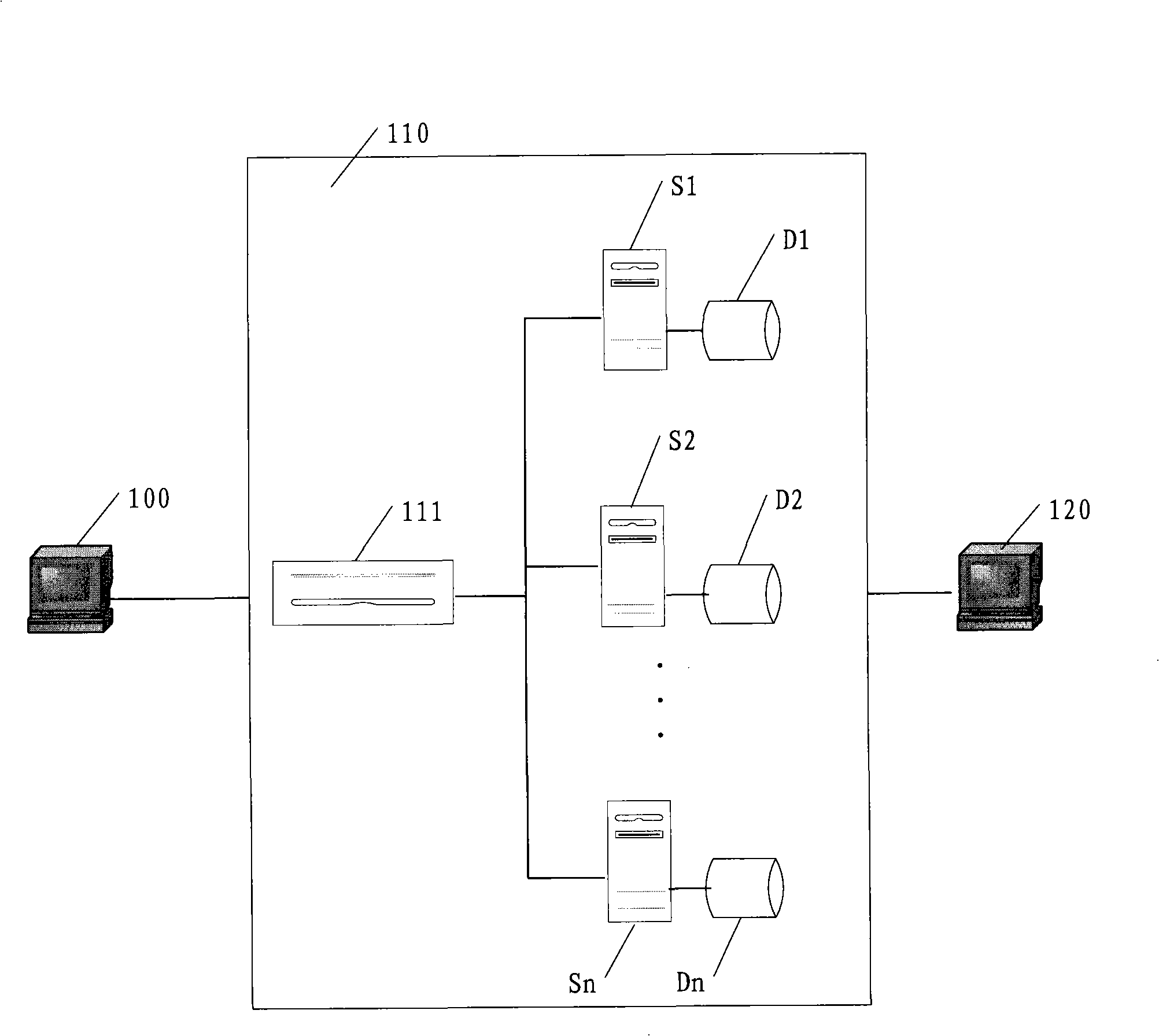

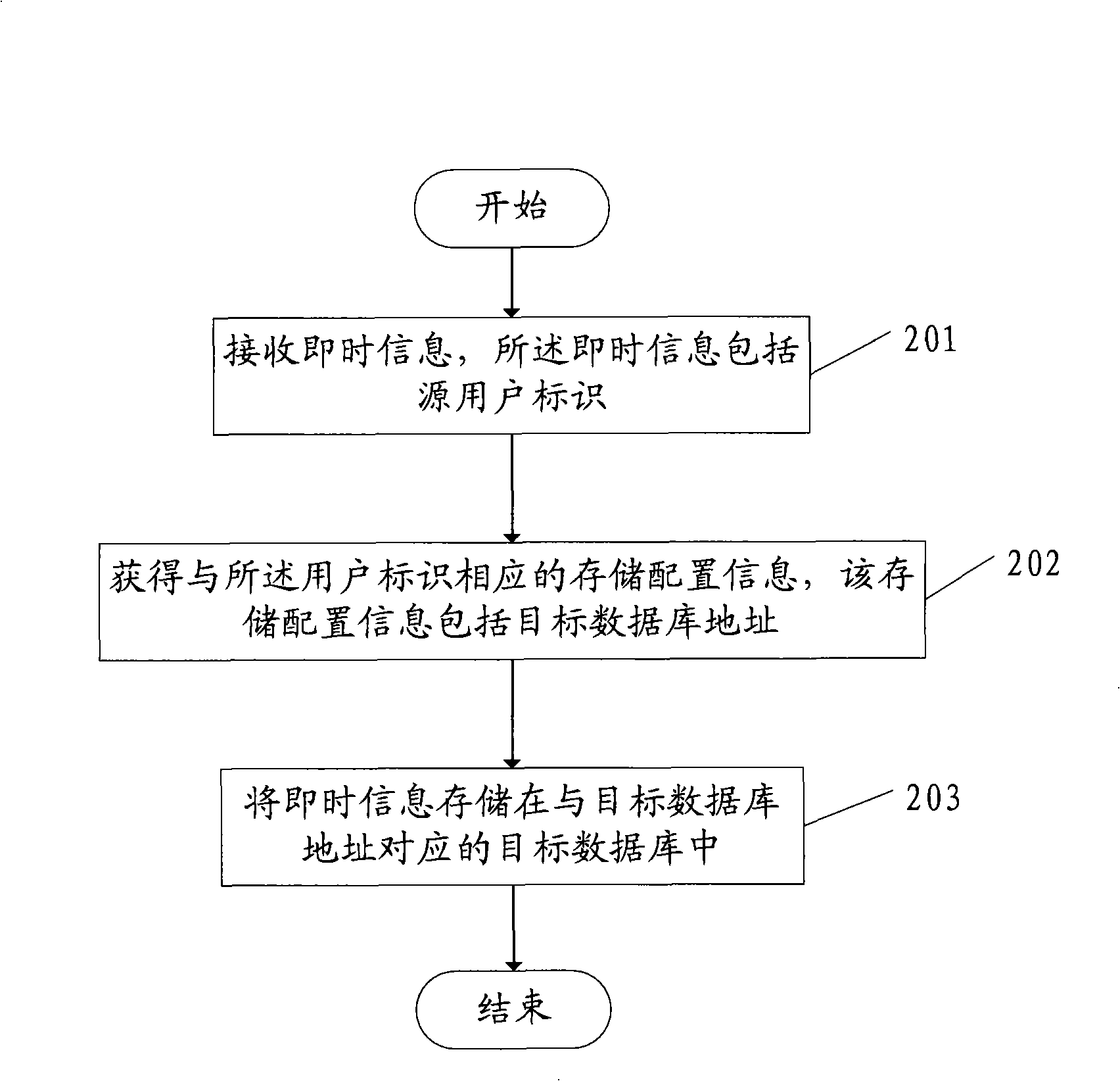

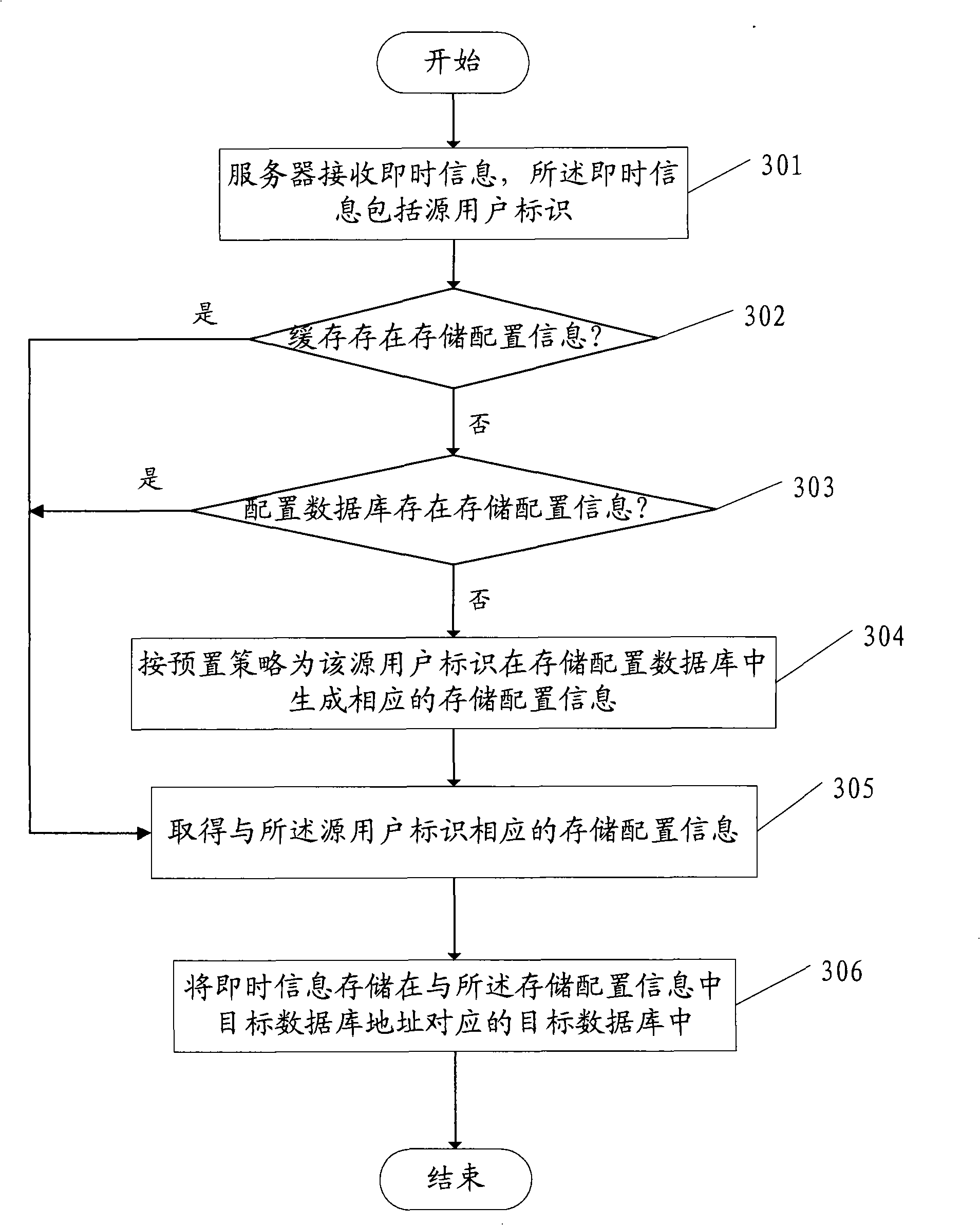

Method and system for storing instant information

InactiveCN101330431ASafety of tradementGood trade creditStore-and-forward switching systemsInformation storageData mining

The invention discloses an instant message storage method and a system thereof. The method comprises the following steps: receiving an instant message comprising user identification; acquiring storage allocation information corresponding to the user identification, which comprises a target database address; storing the instant message in a target database corresponding to the target database address. In this way, instant messaging records related to a user are stored in the target database corresponding to the user identification in a centralized manner, so as to avoid the problems such as low searching efficiency and high cost in the prior art caused by traversing each server in a cluster in order to acquire the instant messaging records of the user, and prevent the server performance from being affected thereby.

Owner:ALIBABA GRP HLDG LTD

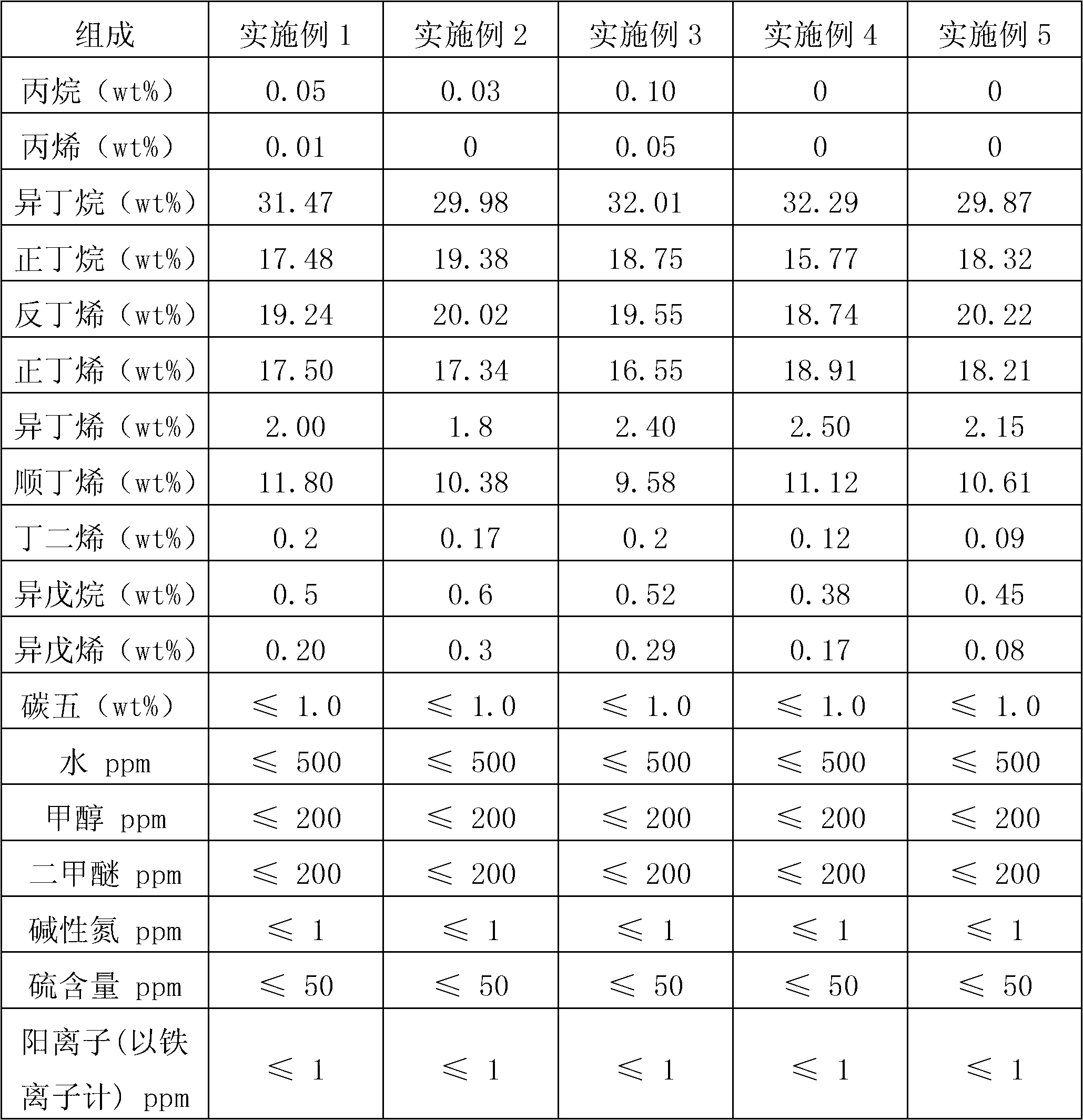

Etherified C4 superimposition esterification cogeneration method of isooctane and sec-butyl acetate

InactiveCN102701969AExpand the scope of procurementGuaranteed supplyOrganic compound preparationCarboxylic acid esters preparationHeteropoly acidDistillation

The invention discloses an etherified C4 superimposition esterification cogeneration method of isooctane and sec-butyl acetate. The etherified C4 superimposition esterification cogeneration method of the isooctane and the sec-butyl acetate comprises the following steps: (1), passing an etherified C4 raw material through a reactor filled with a solid acidic catalyst, performing superimposition reaction under reaction conditions that the reaction temperature is 60-90 DEG C and the pressure is 0.8-1.6Mpa, and distilling a superimposition reaction product to obtain the refined C4 raw material on the top of a distillation tower and obtain C8 olefin, with iso-octene as a main part, at the bottom of the distillation tower; and (2) mixing and preheating the refined C4 raw material with acetic acid, passing the mixture through an esterification reactor filled with an esterified heteropoly acid catalyst, and reacting under reaction conditions that the temperature is 70-110 DEG C and the pressure is 1.0-1.4Mpa to obtain the sec-butyl acetate. The superimposition reaction is high in selectivity; the procurement index of the C4 raw material of the sec-butyl acetate is lowered; the supply of the raw material is ensured; and the generated C8 olefin can be used as a high-octane gasoline component, thus improving the economic benefit.

Owner:WEIFANG YIXING CHEM TECH

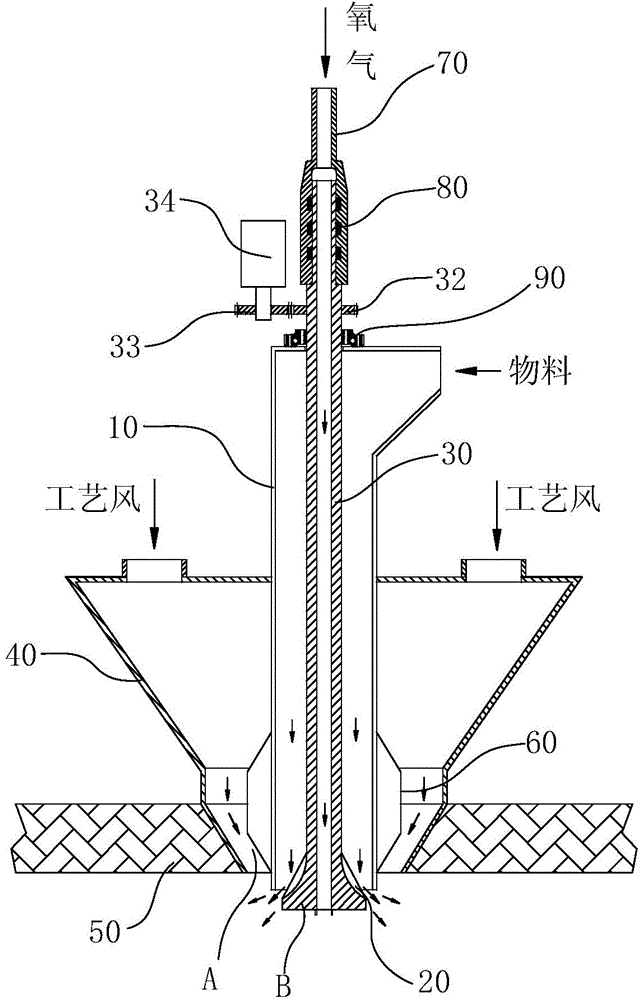

Jet nozzle of concentrate

ActiveCN104388695ASufficient dispersion of kinetic energyGuaranteed responseCharge manipulationEngineeringTower

The invention discloses a jet nozzle of concentrate used in a copper smelting flash furnace. The jet nozzle comprises a distributor arranged inside a water-cooled sleeve, wherein rotary shifting sheets are arranged on the distributor located at the material-outlet end of a lower tube end of the water-cooled sleeve, and a driving mechanism drives the distributor to rotate to provide kinetic energy for dispersion to the passing material; when the concentrate material is delivered toward the jet nozzle of concentrate, the material enters a passage formed between the distributor and the water-cooled sleeve, falls under the action of gravity, acquires kinetic energy under the action of the rotary shifting sheets so that the concentrate material can evenly fall, be dispersed and be fully mixed with peripheral process air and the reaction effect of evenly mixed concentrate material in a reaction tower can be further ensured.

Owner:TONGLING NON FERROUS METAL GROUP CORP

Metal surface polyisocyanurate modified polyurethane sandwich panel and production method thereof

InactiveCN103497305AImprove flame retardant performanceImprove heat resistanceMetal layered productsPolyesterSurface layer

The invention relates to a metal surface polyisocyanurate modified polyurethane sandwich panel and a production method thereof. The sandwich panel is used for cold storage thermal insulation. The sandwich panel comprises an upper metal surface layer, a lower metal surface layer and a polyisocyanurate modified polyurethane foam plastic core layer. The core layer is formed by intensive mixing reaction of compound polyether polyester polyols (white material) and polyisocyanurate (black material) which are 100:100-200 by weight ratio through a high-pressure foaming machine. The compound polyether polyester polyols comprises polyhydric alcohols, foam stabilizer, catalyst, cross-linking agent, flame retardant, water and foaming agent which are 100:1-5:1-5:2-6:5-25:0.5-3:10-30 by weight ratio. The polyhydric alcohols, the catalyst, the flame retardant and the foam stabilizer are all compounded by at least two kinds. The polyisocyanurate is high-functionality polyaryl polymethylene isocyanate. The metal surface polyisocyanurate modified polyurethane sandwich panel is good in flame retardance, excellent in weather fastness and high in size stability, and B1 standards are reached totally.

Owner:SHANDONG PLANT PANEL

Chlorine dioxide gas generating apparatus

InactiveCN101024493AImprove conversion rateGuaranteed responseChlorine oxidesChemistrySodium chlorate

The invention relates to a chlorine dioxide gas generating device that includes a reactor, gas washing device and air aeration head. Under the condition of passing hot air into reactor through air aeration head, the sodium chlorate solution would take reaction with hydrochloric acid to generate mixture gas of chlorine and chlorine dioxide. CPVC material filled with sodium chlorite solid is installed in gas washing device, which is used to transfer chlorine to chlorine dioxide to gain high purity chlorine dioxide gas. The gas washing device is multilevel structure that installs detonation separating board between gas washing device and reactor. The invention has high yield of chlorine dioxide, and the purity could reach 98%, yield could reach 95%. The high purity chlorine dioxide could be used for sterilization.

Owner:ZHONGBEI UNIV

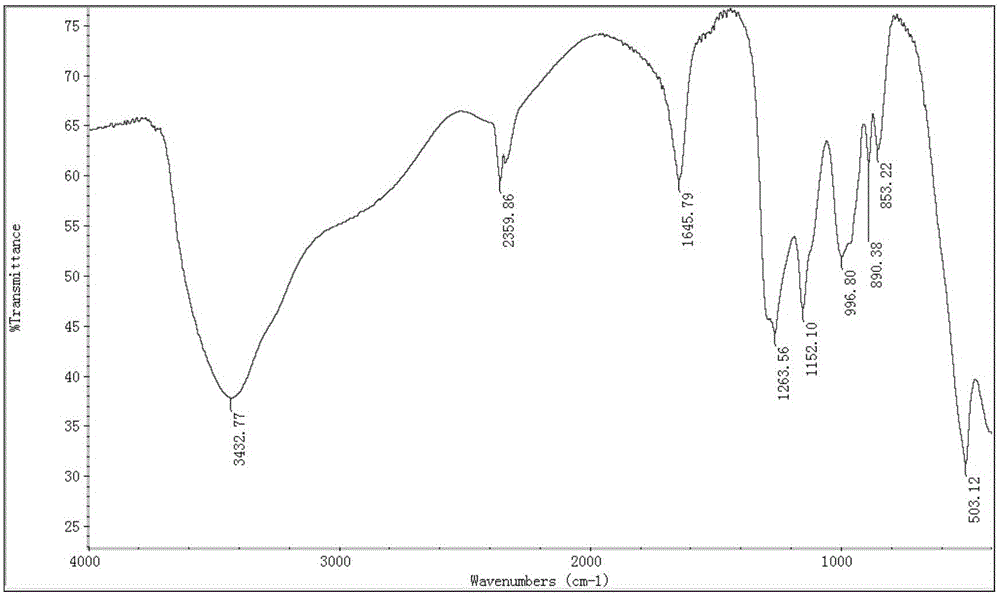

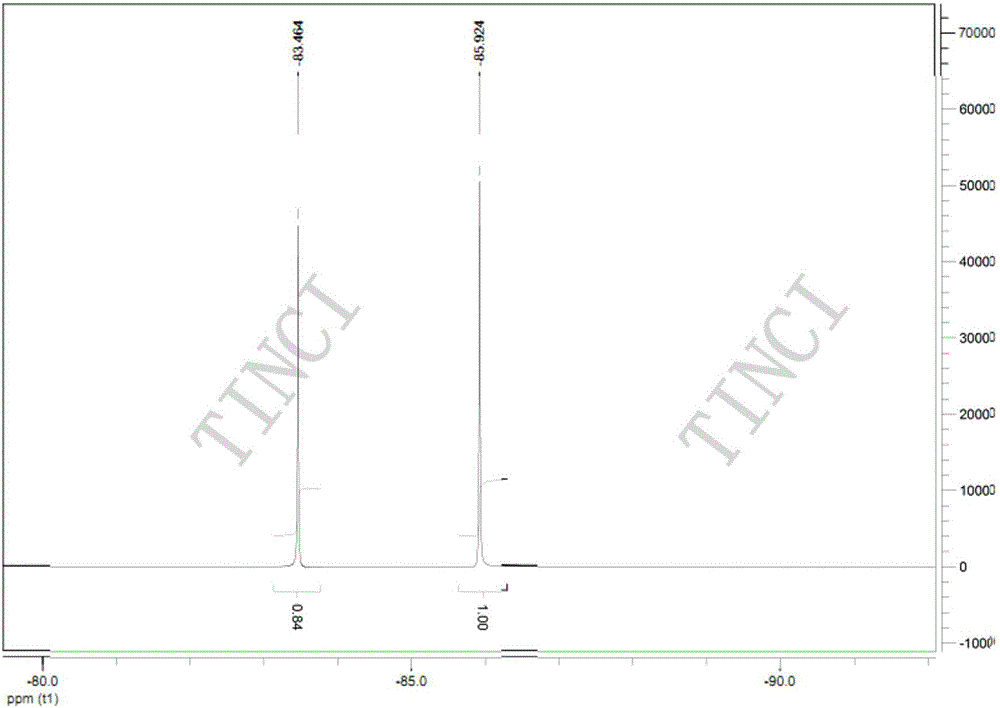

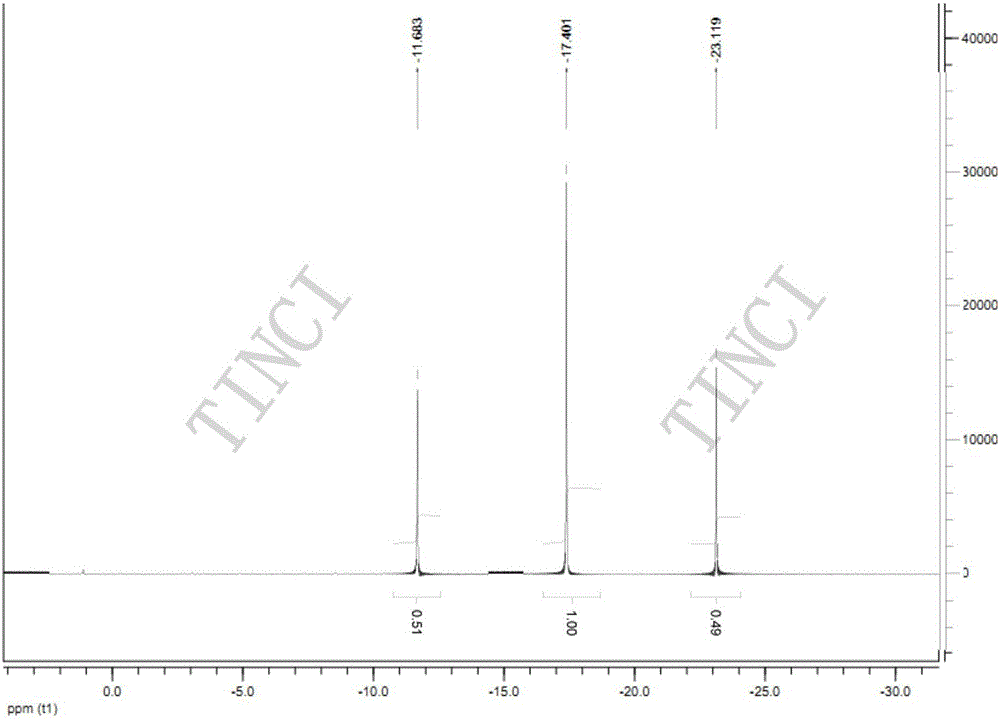

Method for preparing difluorophosphates

The invention belongs to the technical field of lithium-ion batteries and particularly relates to an efficient method for preparing difluorophosphates. The method comprises the following steps: metering a hexafluorophosphate solution with the concentration being 5wt% to 50wt% and a cyclosiloxane or an acetal, then, introducing the metered materials to a microchannel reactor, carrying out a reaction for 60 to 900 seconds at the temperature of 20 DEG C to 150 DEG C, carrying out membrane filtration on an obtained reaction solution, and then, carrying out concentrating and drying, thereby obtaining a corresponding difluorophosphate product. The method disclosed by the invention has the advantages that the process route is simple, the raw materials are readily available, the reaction efficiency is high, the energy consumption is low, the product purity is high, and the like.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

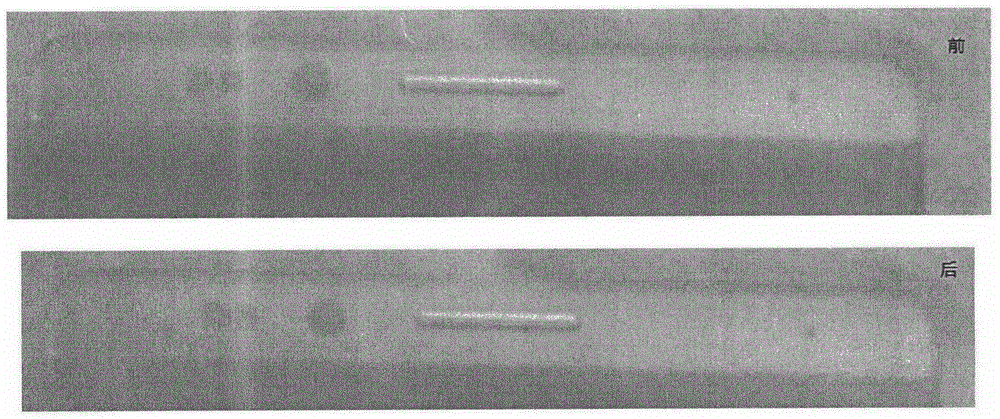

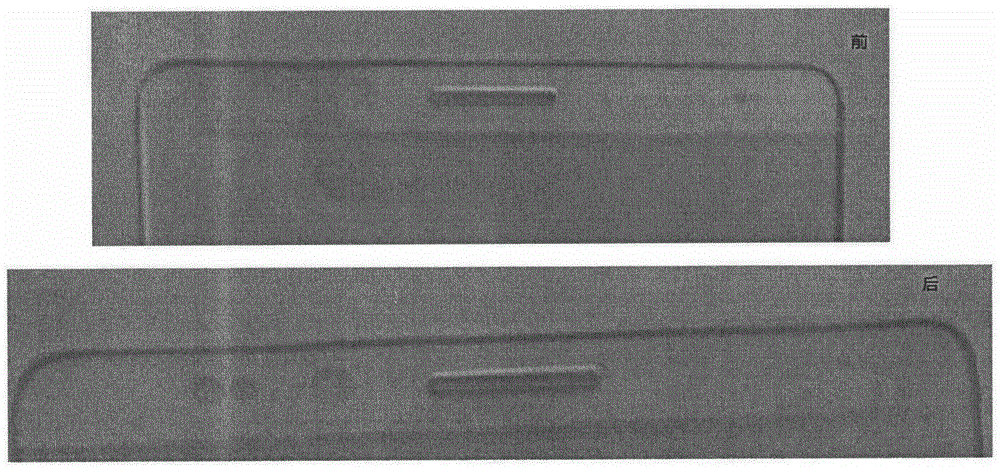

Transfer processing method for glass base material of cover board

ActiveCN105259737AStrong responsivenessImprove adhesionPhotomechanical exposure apparatusMicrolithography exposure apparatusNon solventHigh energy

The invention discloses a transfer processing method for a glass base material of a cover board. The transfer processing method comprises the following steps: coating the surface of the glass base material of the cover board with an LED photo-curable non-solvent photosensitive transfer adhesive; covering a film diaphragm; carrying out a procuring exposure with an LED light source at a low energy of 100-200mJ / cm<2>; removing the film diaphragm, and dissolving an unexposed part adhesive with a developing solution; blowing or drying residual developing solution; and finally carrying out secondary curing on the developed transfer adhesive with the LED light source at a high energy of 1,000-2,000mJ / cm<2>, thereby finishing transfer processing of the glass base material of the cover board. According to the technology disclosed by the invention, the problems that an existing UV adhesive is poor in adhesion to glass of the cover board, poor in boiling resistance and poor in solvent resistance are solved; the industry requirements are met; the production cost of enterprises is reduced; and the benefits of the enterprises are improved.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

Preparation method for heavy oil catalytic cracking catalyst

ActiveCN105772074AHigh strengthGuaranteed responseCatalytic crackingMolecular sieve catalystsMolecular sieveSlurry

The invention provides a preparation method for a heavy oil catalytic cracking catalyst.The preparation method includes the steps that pseudo-boehmite, clay, alumina sol and inorganic acid are added to a reaction still firstly and mixed to be uniform to form matrix slurry, the pH value of the matrix slurry is adjusted to be 0.5 to 2.0 through the acid adding amount, stirring is conducted for 0.5-2 h, then an alkaline medium is added to the matrix slurry to adjust the pH value to be 3.5-5.5, curing is conducted for 1-12 h, a molecular sieve is added, catalytic cracking catalyst slurry is formed in a homogenized mode, the obtained catalytic cracking catalyst slurry is subjected to spray drying, and then the catalyst is obtained.According to the preparation method, on the premise that the anti-abrasion strength of the catalyst is guaranteed, the hole volume of the catalyst can be increased, and the heavy oil cracking capacity of the catalyst can be improved.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com