Patents

Literature

32results about How to "Play the role of bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather, as well as preparation method and application of carbon fiber modified non-solvent polyurethane surface layer resin

ActiveCN106397722AGuaranteed to be environmentally friendlyGuaranteed stabilityPolyurea/polyurethane coatingsFootwearPolyresinHydrolysis

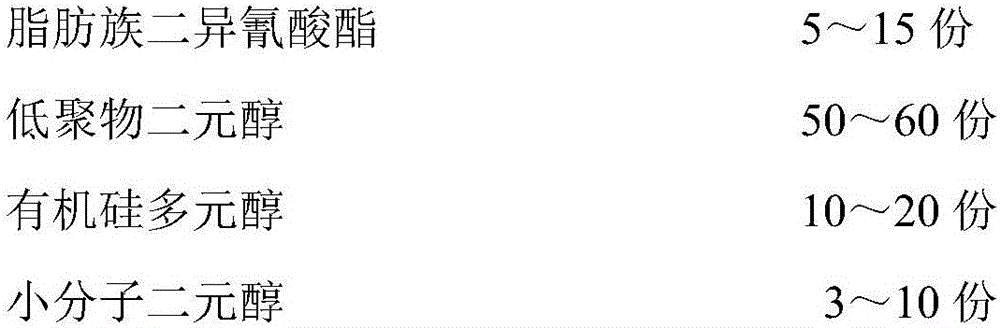

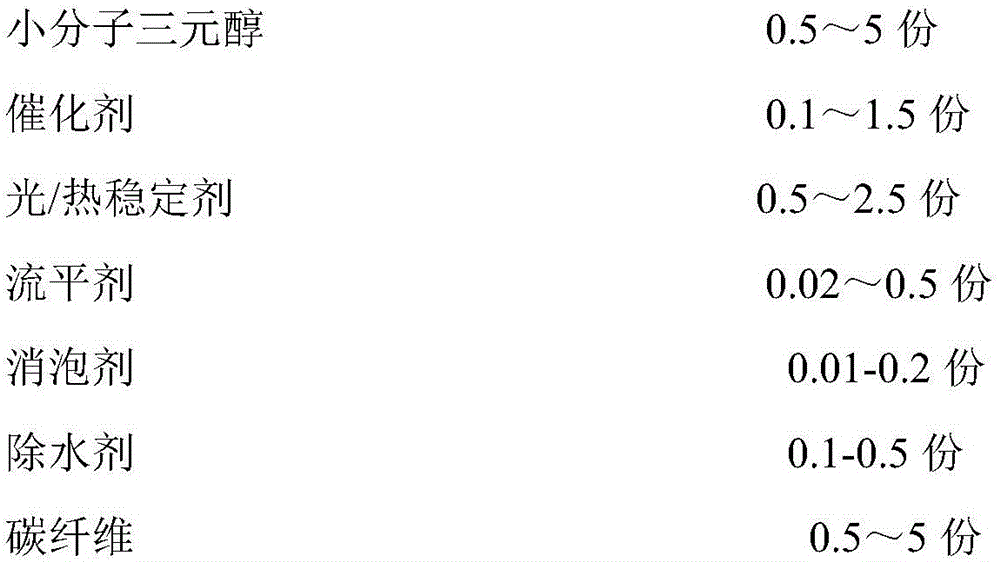

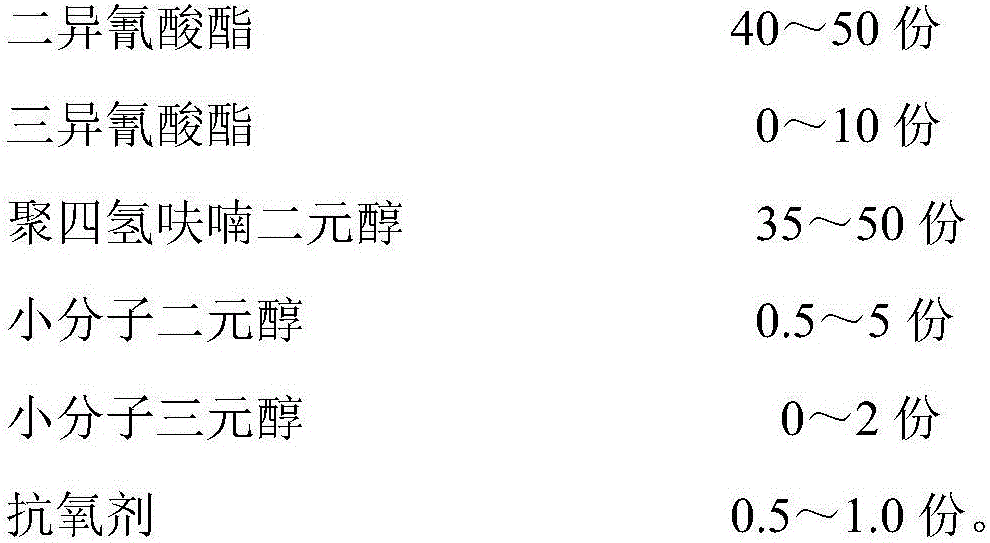

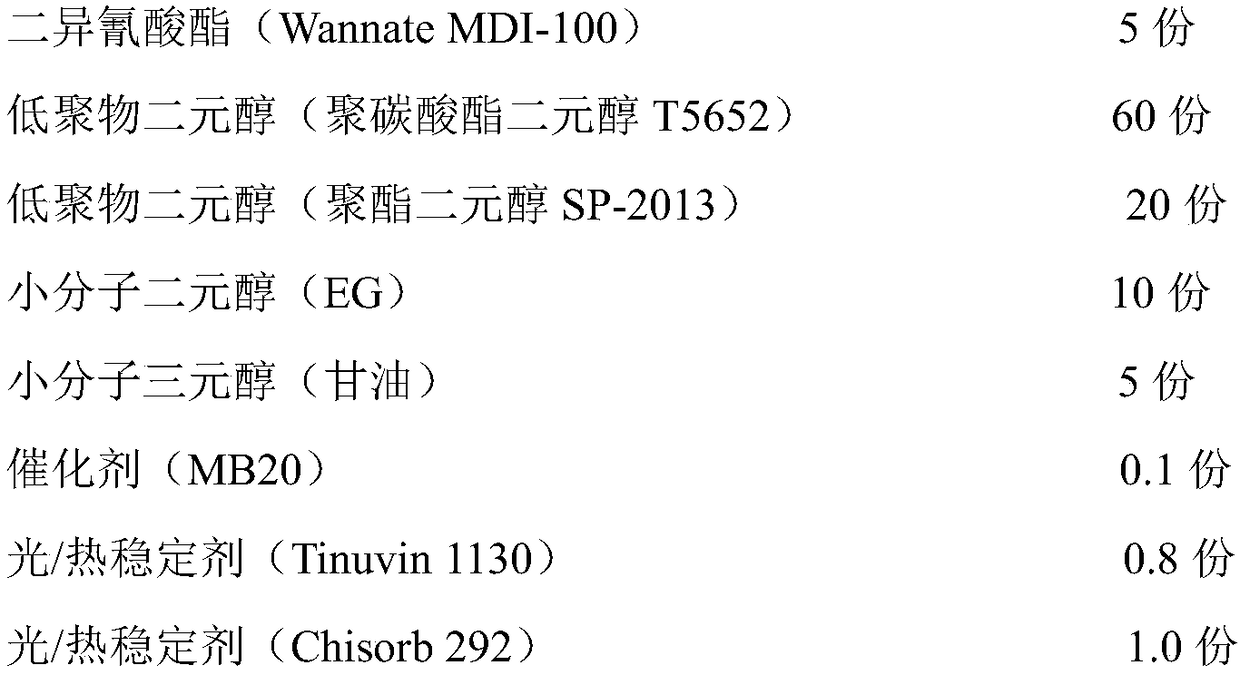

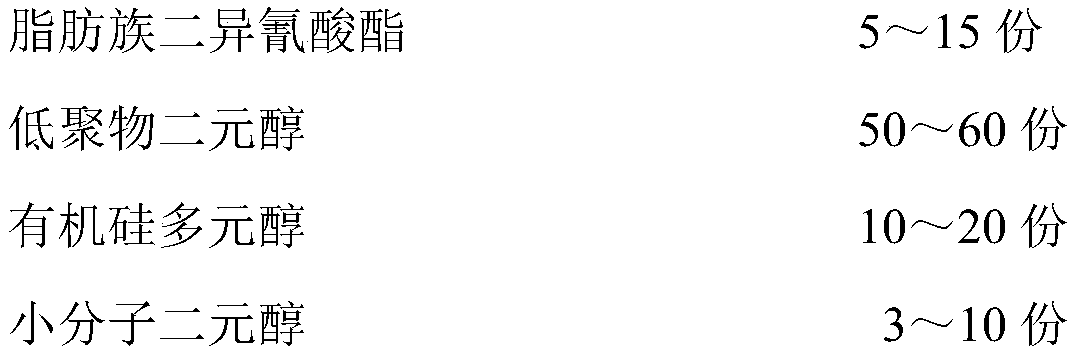

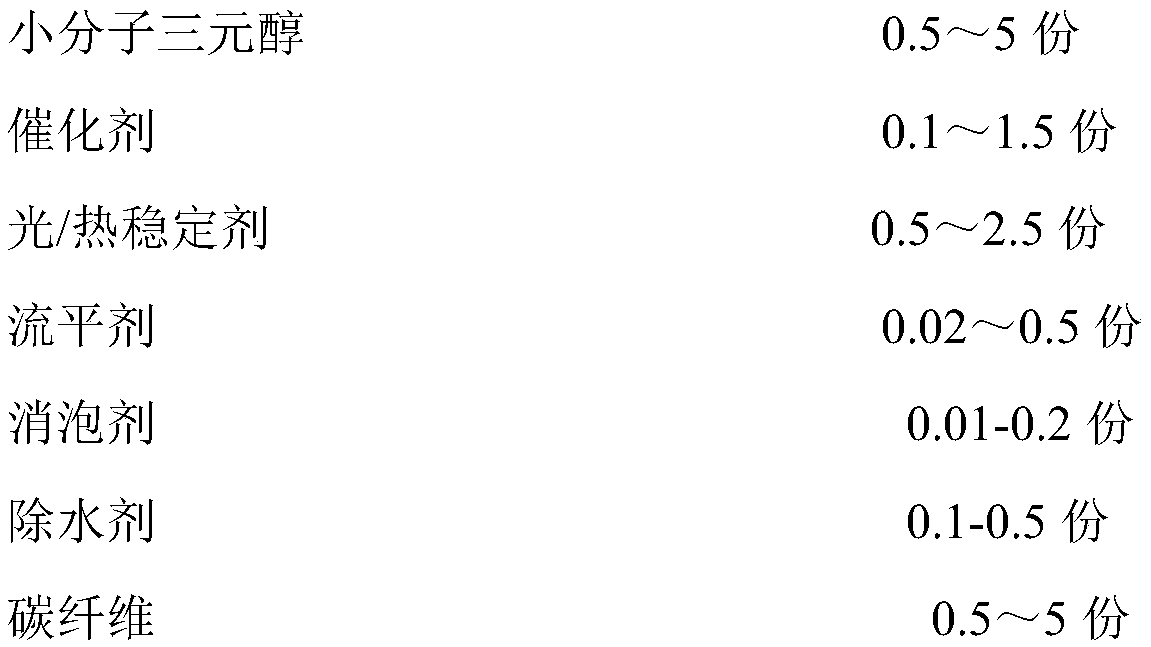

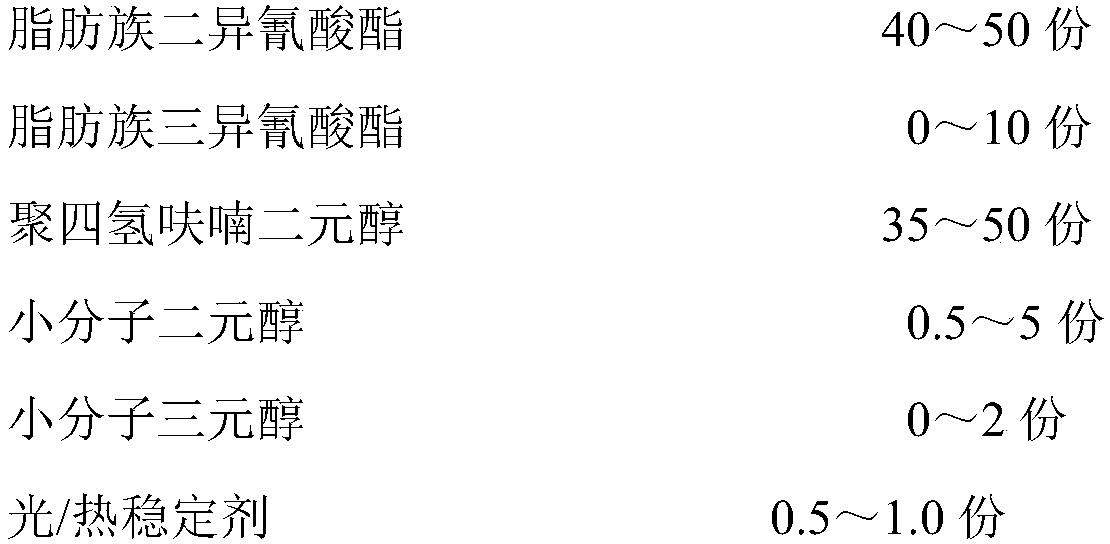

The invention belongs to the field of synthetic leather, and provides carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather. The resin is formed by mixing a component A and a component B according to mass percent being 2:1 to 1:2, wherein the component A comprises 5 to 15 parts of aliphatic diisocyanate, 50 to 60 parts of low polymer dihydric alcohol, 10 to 20 parts of organosilicone polyhydric alcohol, 3 to 10 parts of micromolecule dihydric alcohol, 0.5 to 5 parts of micromolecule trihydric alcohol, 0.1 to 1.5 parts of a catalyst, 0.5 to 2.5 parts of a light / heat stabilizer, 0.02 to 0.5 part of a flatting agent, 0.01 to 0.2 part of a defoamer, 0.1 to 0.5 part of a dehydrator, and 0.5 to 5.0 parts of carbon fiber; the component B comprises 40 to 50 parts of aliphatic diisocyanate, 0 to 10 parts of triisocyanate, 35 to 50 parts of polytetrahydrofuran dihydric alcohol, 0.5 to 5 parts of micromolecule dihydric alcohol, 0 to 2 parts of micromolecule trihydric alcohol, and 0.5 to 1.0 part of a light / heat stabilizer. The invention further provides a preparation method and application of the resin. The tangential breaking strength of carbon fiber modified resin coating can reach 130kN / m or above; for non-solvent sports shoe leather prepared through the method, the peeling strength can reach 90N / 3 cm or above and the hydrolysis resistance can reach 10 weeks or above.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Solvent-free interlayer polyurethane resin for automotive trim leather and preparation method thereof

ActiveCN106220817AReduce usageGuaranteed to be environmentally friendlyRoad vehiclesTextiles and paperOligomerAlcohol

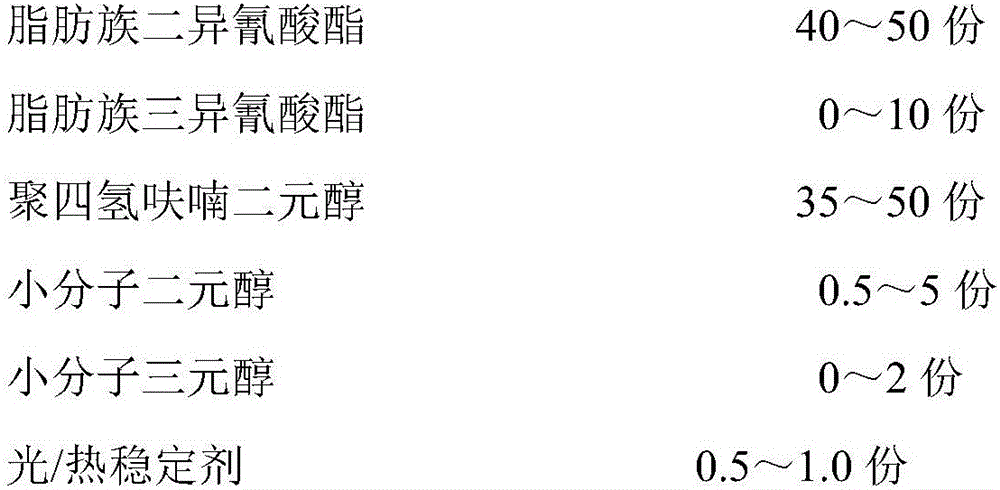

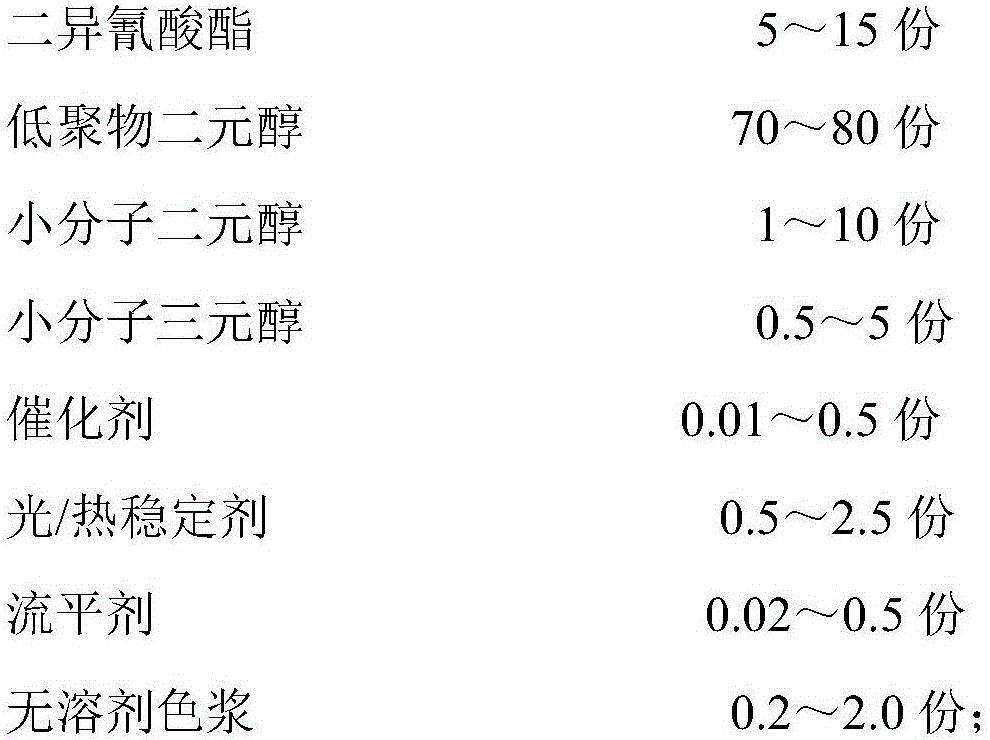

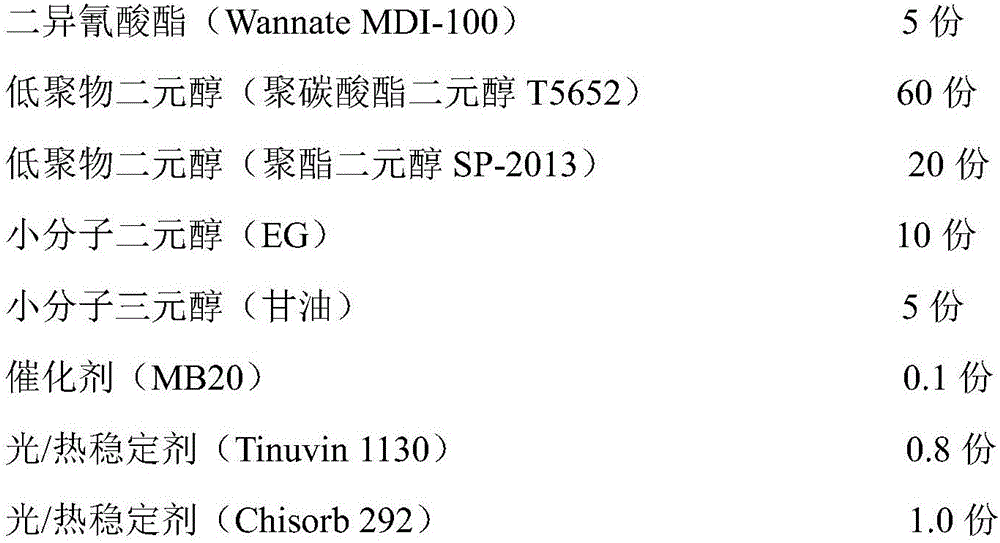

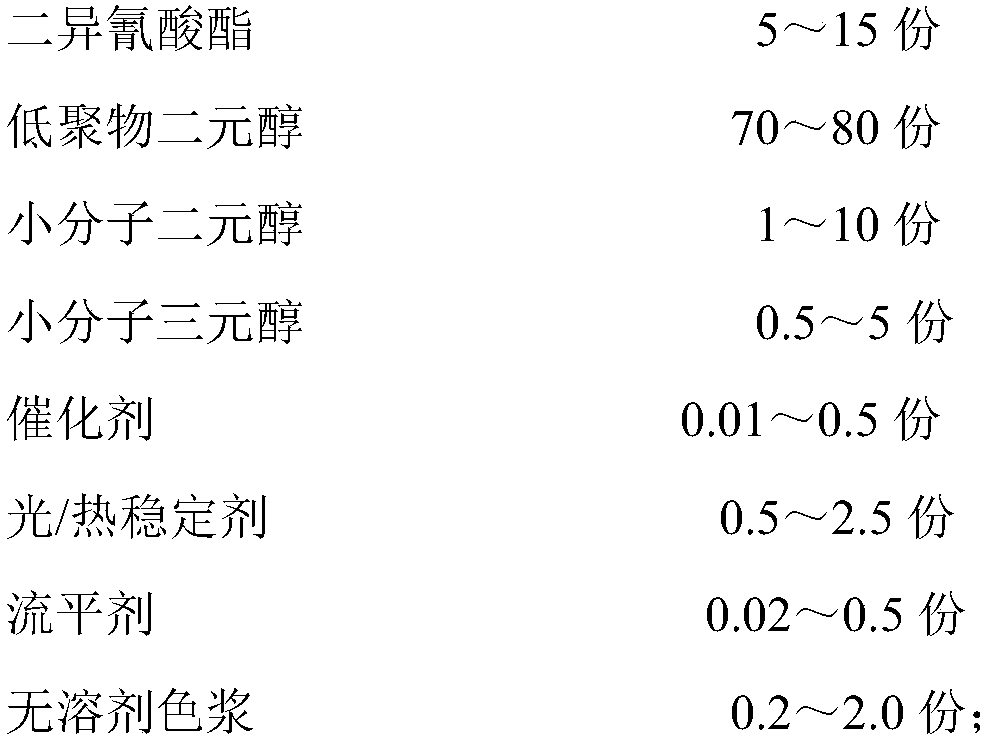

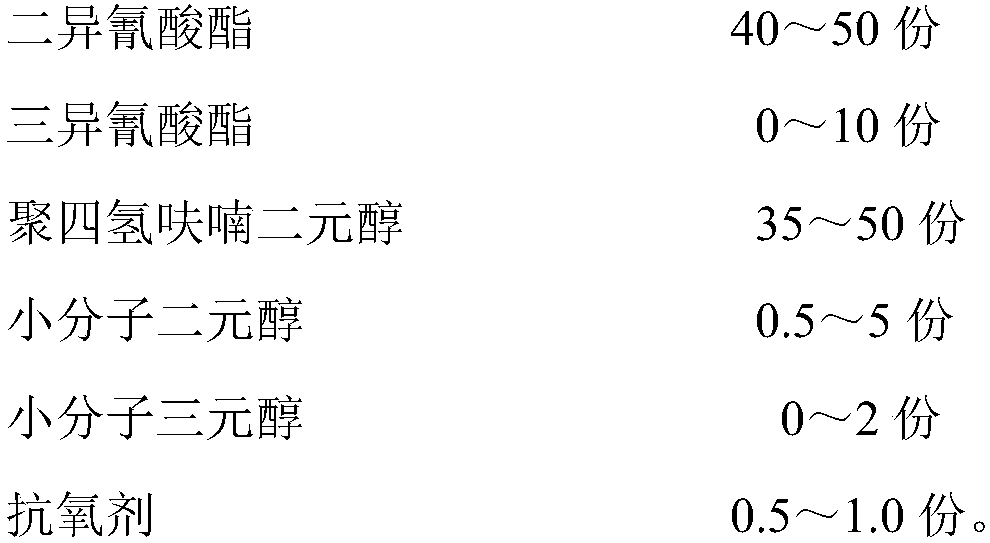

The invention provides a solvent-free interlayer polyurethane resin for automotive trim leather and preparation method thereof. The solvent-free interlayer polyurethane resin is composed of an A component and a B component in a mass ratio of (2.5: 1)-(1: 2.5) through the mixing; the A component is composed of diisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol, catalyst, light / heat stabilizer, flatting agent and solvent-free color paste; the B component is composed of diisocyanate, triisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol and antioxidant. The polyurethane resin prepared by the method disclosed by the invention can be used as the interlayer for the automotive trim leather, the high temperature durable performance and various mechanical properties of the automotive leather can be effectively guaranteed while meeting the hydrolysis resistance of the automotive leather product; the peeling strength of the prepared automotive leather product reaches up to 145N / 3cm, the hydrolysis resistance can reach the condition that the peeling strength still reaches up to 135N / 3cm after 10 weeks.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

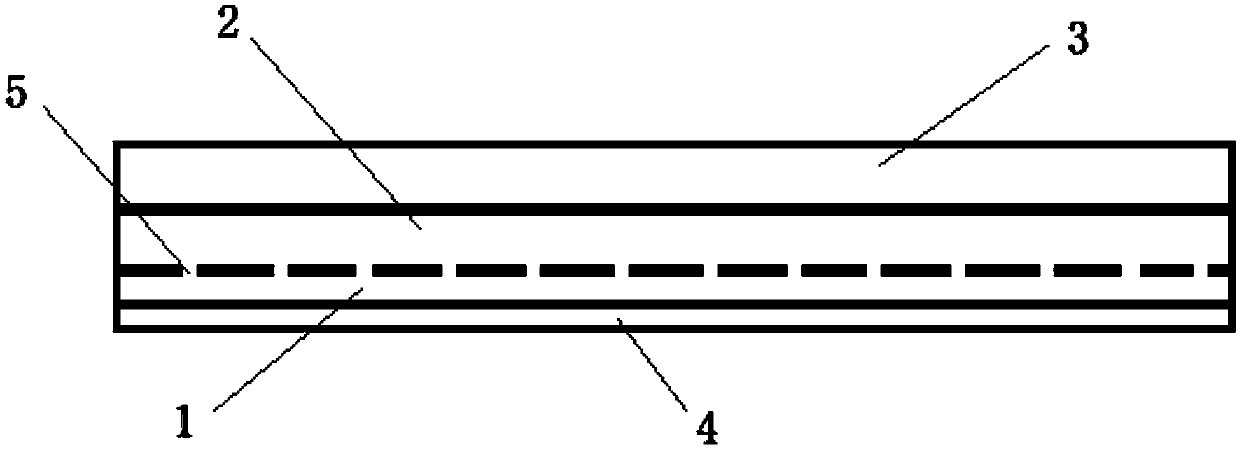

Anode plate of lithium ion battery and its preparation method

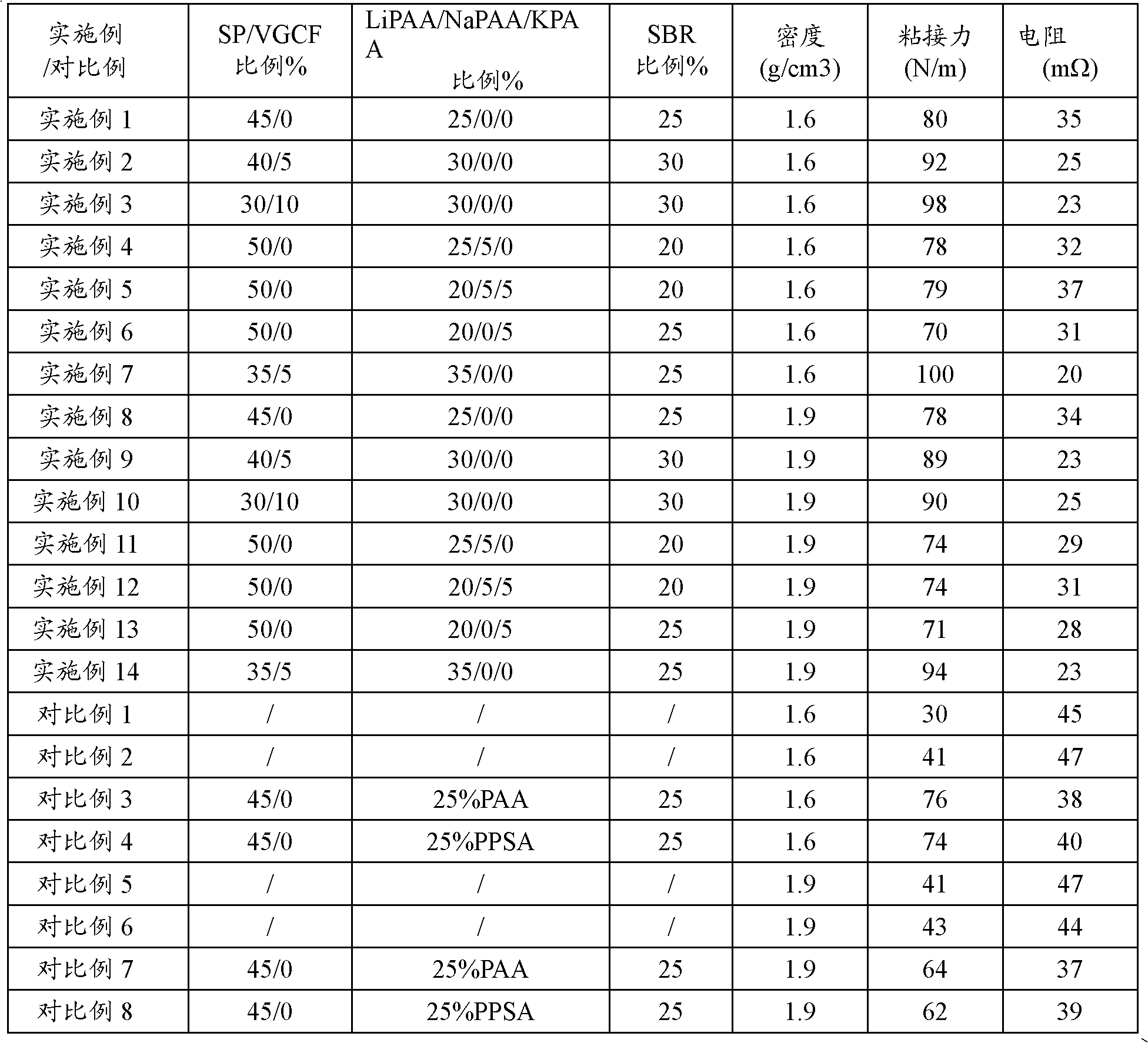

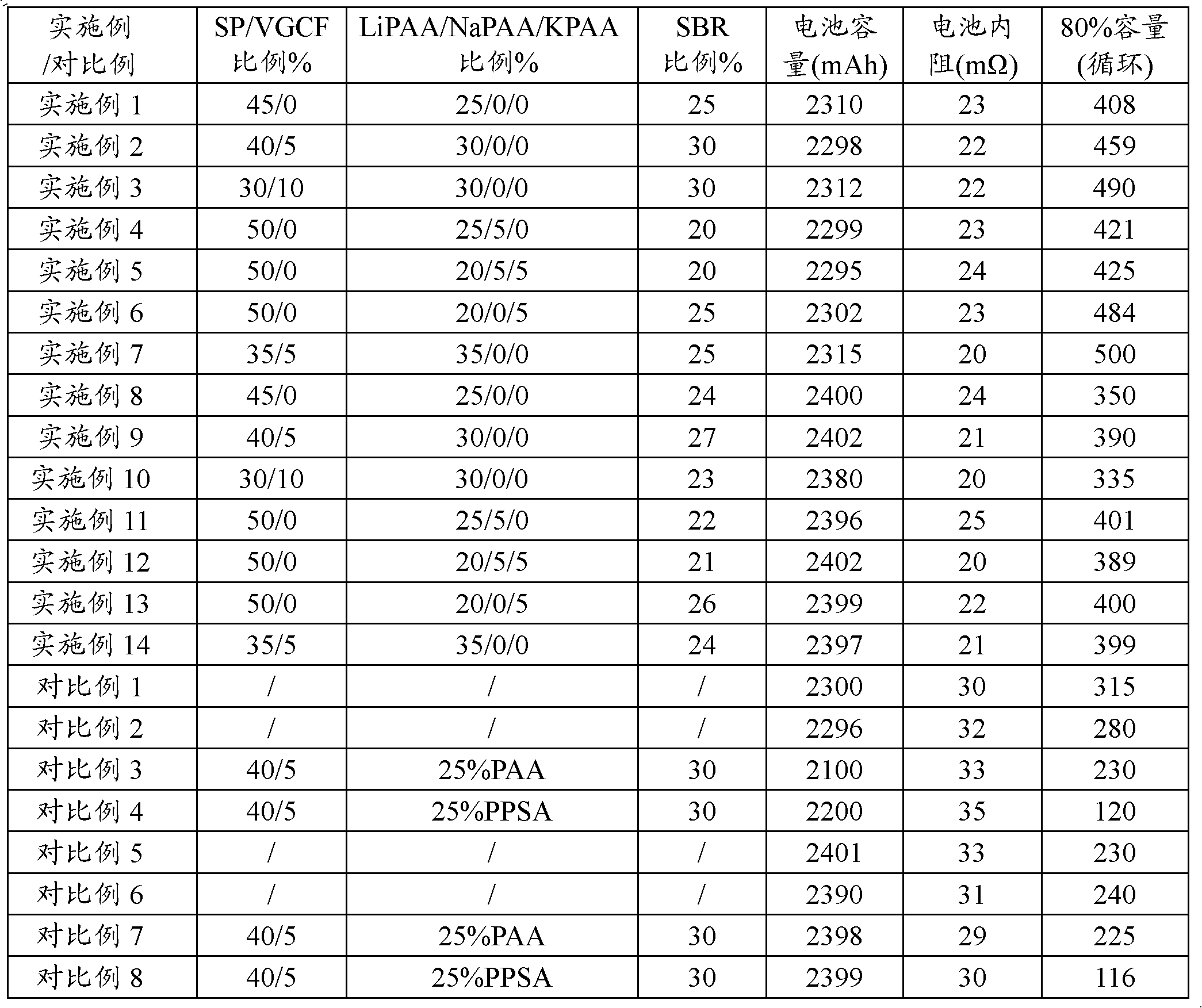

InactiveCN102522524AGuaranteed stabilityGood cushioningNon-aqueous electrolyte accumulator electrodesCurrent collectorCarbon black

The invention discloses an anode plate of a lithium ion battery, which comprises an anode current collector and an anode active substance layer, a processing layer is distributed between the anode current collector and the anode active substance layer, the processing layer contains 30-50% of conductive carbon black, 25-50% of alkali metal polyacrylates and 20-40% of aqueous latex by weight percentage. In the anode plate of the lithium ion battery, the conductive carbon black in the processing layer is capable of enhancing the conductivity between the anode current collector and the anode active substance layer; due to the existence of a carboxyl functional group, the alkali metal polyacrylates possess good bonding performance, and are capable of obviously enhancing the bonding among the anode current collector, the processing layer and the anode active substance layer; the aqueous latex possesses auxiliary bonding effect, and possesses high elasticity to provide the good flexibility to the processing layer, thereby the buffer effect can be acted at the processing layer interface when the alloy anode is expanded, and the alloy expansion stress release is performed. The invention also discloses a preparation method of the anode plate of the lithium ion battery.

Owner:NINGDE AMPEREX TECH +1

Self-lubricated wearing-resistant rubber material and preparation method thereof

PendingCN110240758AGood high temperature resistanceExcellent oil resistance, wear resistanceCarbon blackCarbon nanotube

The invention discloses a self-lubricated wearing-resistant rubber material which is prepared from the following raw materials in parts by weight: 60-80 parts of ethylene-propylene-diene monomer rubber, 20-30 parts of nitrile rubber, 4-5 parts of zinc methacrylate, 2-3 parts of carbon nanotubes, 30-40 parts of modified white carbon black, 4-5 parts of zinc oxide, 1-2 parts of sulfur, 2-3 parts of accelerant, 1-2 parts of an anti-aging agent, 1-2 parts of paraffin and 10-11 parts of a lubricant. The invention further discloses a preparation method of the rubber material. Commixed rubber of the ethylene-propylene-diene monomer rubber and the nitrile rubber is adopted as a rubber matrix, and the zinc methacrylate and the carbon nanotubes are adopted as assistant crosslinkers, so that the rubber matrix with excellent properties can be obtained; due to adoption of the modified white carbon black, mechanical properties and the abrasion damage resistance of the rubber material can be improved; due to adoption of the lubricant, the rubber material has excellent self-lubricating performance, after a lubricant TP16 migrated to a surface is abraded, a lamellar structure, which is very liable to slide and move, of molybdenum disulfide plays a very good role of abrasion reduction, and thus the rubber material can be further protected.

Owner:NINGGUO ZHENGDAO RUBBER & PLASTIC PARTS

Preparation method of diamond enhanced tungsten carbide composite spherical crown button with gradient structure

ActiveCN104439248AAvoid abnormal growthReduce sintering thermal stressPolycrystalline diamondBoron nitride

Owner:江西耀升钨业股份有限公司

Preparation method for thermal formation of protective composite coating on ultrahigh-strength steel

ActiveCN109055890ANot easy to fall offHigh bonding strengthSolid state diffusion coatingMicro nanoSilicon alloy

The invention belongs to the technical field of metal surface treatment, and in particular, relates to a preparation method for thermal formation of a protective composite coating on ultrahigh-strength steel. The preparation method comprises surface pretreatment of a steel plate, preparation of a penetrating agent, coating of the penetrating agent, high-temperature permeation of zinc and aluminum,double-glow plasma permeation of an aluminum silicon alloy and plasma oxidation. The preparation method can form a protective coating of a four-layer structure on the surface of the ultrahigh-strength steel; the protective coating consists of a Fe-Zn and Fe-Al intermetallic compound diffusion layer, a Zn-enriched layer, an aluminum silicon alloy layer and a micro-nano oxide layer in sequence frominside to outside; the composite coating is simple in preparation process and stable in quality, and solves the difficulty of giving consideration to both high-temperature oxidation and incision corrosion resistance; and as the surface of the coating has the super-hydrophobic characteristic, the industrial production is easily realized.

Owner:NANJING XINGQIAO Y TEC AUTOMOBILE PARTS CO LTD

Rooting agent and preparation method thereof

InactiveCN106359374AAdaptableStrong rooting abilityBiocidePlant growth regulatorsIndoleacetic AcidsSugar

The invention discloses a rooting agent. The rooting agent comprises the following raw materials by weight: 80 to 120 parts of powder of Ludwigia perennis, 35 to 65 parts of powder of Alternanthera philoxeroides, 2 to 4 parts of white sugar, 4 to 6 parts of pine needle powder, 0.8 to 1.5 parts of powder of Berberis wilsonae and a proper amount of 3-indoleacetic acid, 3-indolebutyric acid and yellow soil. A preparation method for the rooting agent comprises the following steps: (1) preparation of the powders of the raw materials; (2) preparation of yellow soil water; (3) fermentation and (4) blending. The rooting agent mainly uses Ludwigia perennis and Alternanthera philoxeroides as main raw materials which are easily available and common farmers can prepare the rooting agent by themselves; and the prepared rooting agent has strong rooting capability since Ludwigia perennis has strong propagation capability and can promote rapid rooting of crops, and since Alternanthera philoxeroides is fast in reproduction speed and good in adaptation capability, the rooting agent can promote metabolism of newborn roots of crops and accelerate growth of the newborn roots of the crops.

Owner:贵州苗林王绿色生物科技有限公司

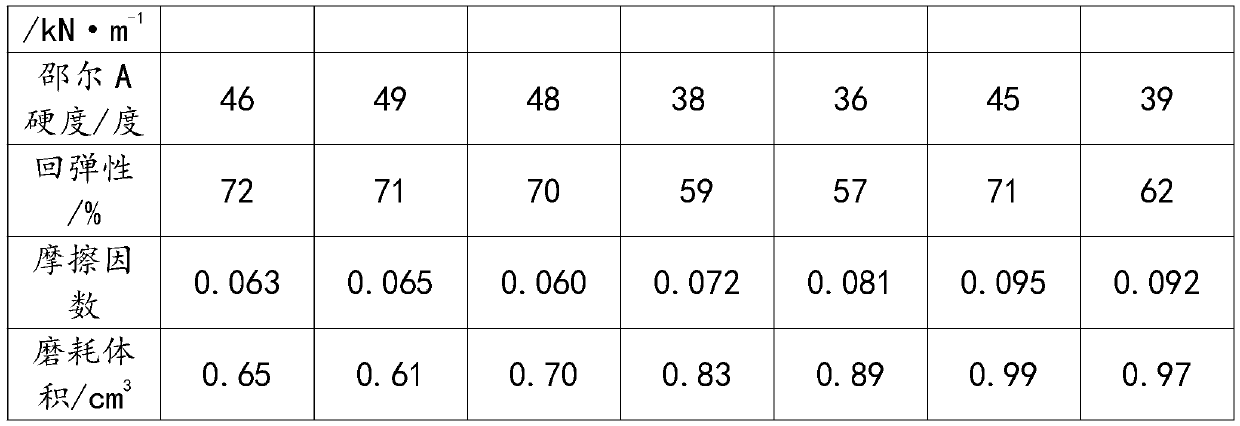

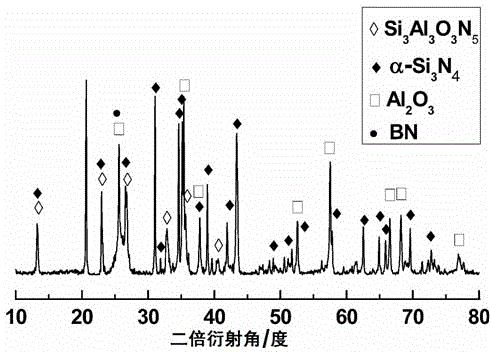

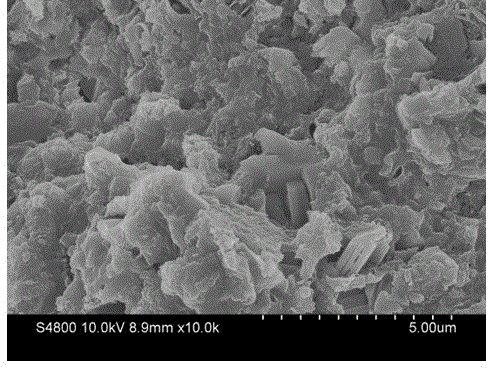

Si-Al-O-N-B multiphase ceramic material and preparation method thereof

The invention discloses a Si-Al-O-N-B multiphase ceramic material and a preparation method thereof. The preparation method of the Si-Al-O-N-B multiphase ceramic material comprises the steps of pressing mixed powder comprising 25-55 parts by weight of silicon nitride, 10-40 parts by weight of aluminum nitride and 5-40 parts by weight of aluminum oxide into a biscuit, then soaking the biscuit in liquid precursor borazine of BN, and then performing crosslinking solidification, pyrolysis and sintering, wherein the dielectric constant is smaller than 6. The multiphase ceramic material disclosed by the invention is difficult to crack; the preparation process is simple, process parameters can be adjusted according to the properties of a target product, and meanwhile, the problem that the shaping of a complex component is difficult can be solved by using the good rheological property of the precursor.

Owner:NAT UNIV OF DEFENSE TECH

A kind of middle layer polyurethane resin for solvent-free automotive interior leather and preparation method thereof

ActiveCN106220817BReduce usageGuaranteed to be environmentally friendlyRoad vehiclesTextiles and paperOligomerAlcohol

The invention provides a solvent-free interlayer polyurethane resin for automotive trim leather and preparation method thereof. The solvent-free interlayer polyurethane resin is composed of an A component and a B component in a mass ratio of (2.5: 1)-(1: 2.5) through the mixing; the A component is composed of diisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol, catalyst, light / heat stabilizer, flatting agent and solvent-free color paste; the B component is composed of diisocyanate, triisocyanate, oligomer dihydric alcohol, micromolecular dihydric alcohol, micromolecular trihydric alcohol and antioxidant. The polyurethane resin prepared by the method disclosed by the invention can be used as the interlayer for the automotive trim leather, the high temperature durable performance and various mechanical properties of the automotive leather can be effectively guaranteed while meeting the hydrolysis resistance of the automotive leather product; the peeling strength of the prepared automotive leather product reaches up to 145N / 3cm, the hydrolysis resistance can reach the condition that the peeling strength still reaches up to 135N / 3cm after 10 weeks.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

High-yield mango planting method

InactiveCN109121631APlay the role of bondingAvoid churnFertilising methodsCultivating equipmentsEconomic benefitsHigh yielding

The invention provides a high-yield mango planting method, and relates to the technical field of planting. The high-yield mango planting method includes steps of (1), pretreating planting fields; (2),pretreating seedlings; (3), planting the seedlings; (4), carrying fertilization management. The high-yield mango planting method has the advantages that fertilizers and the planting method are reasonably matched with one another, and accordingly mangoes planted by the aid of the high-yield mango planting method are high in survival rate and growth quality; root dipping treatment is carried out before the seedlings are planted, accordingly, rooting of the seedlings can be promoted, and the survival rate can be increased; pertinent fertilization is carried out according to the growth characteristics of the mangoes after field planting is carried out, accordingly, the mangoes can quickly and healthfully grow, the mangoes planted by the aid of the high-yield mango planting method are high inquality, and the economic benefits can be greatly increased for fruit growers.

Owner:南京幸庄科技创新产业园管理有限公司

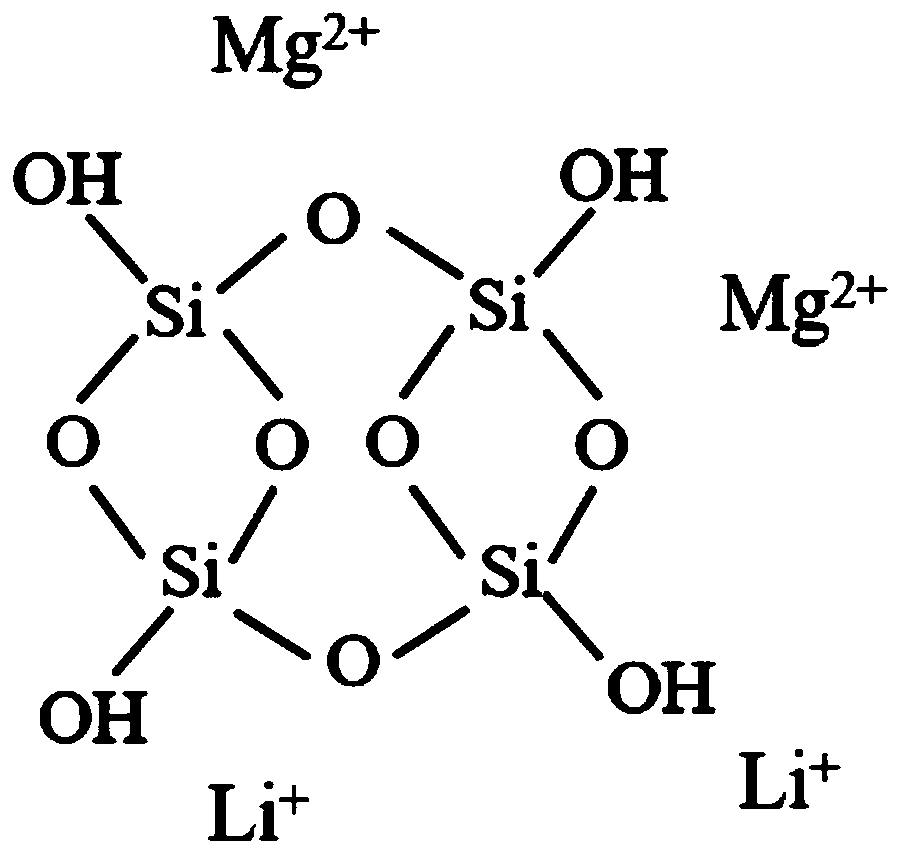

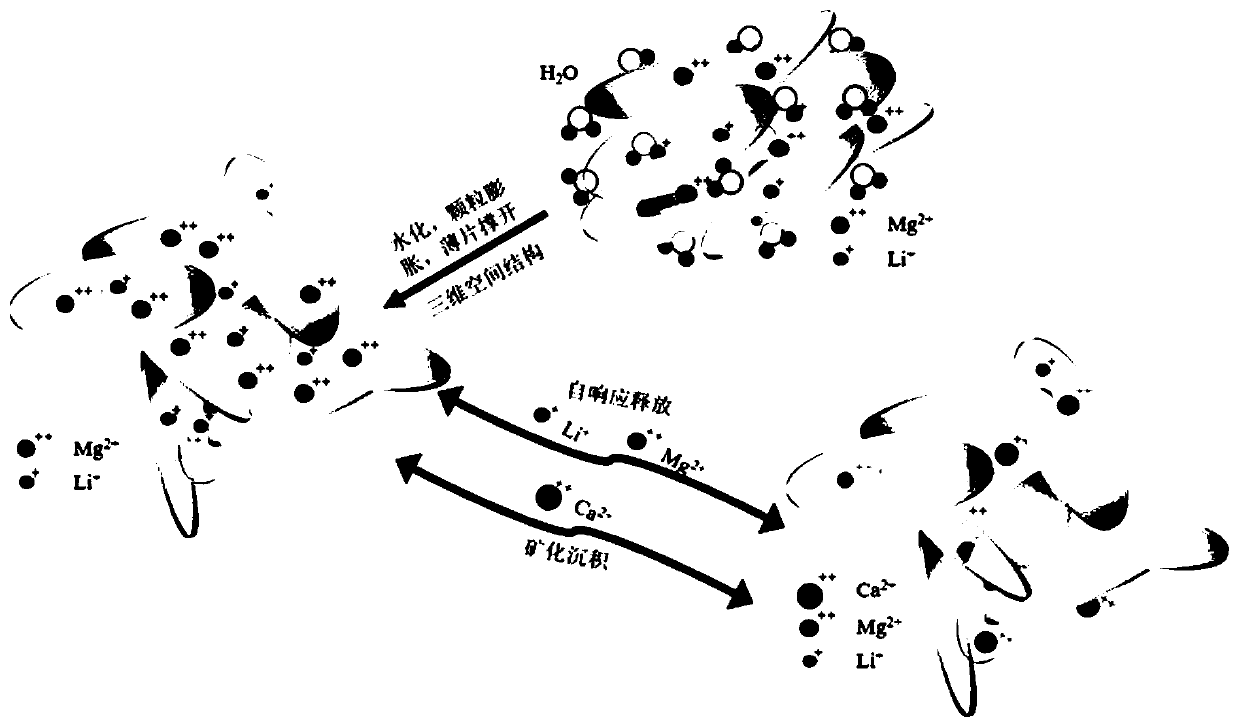

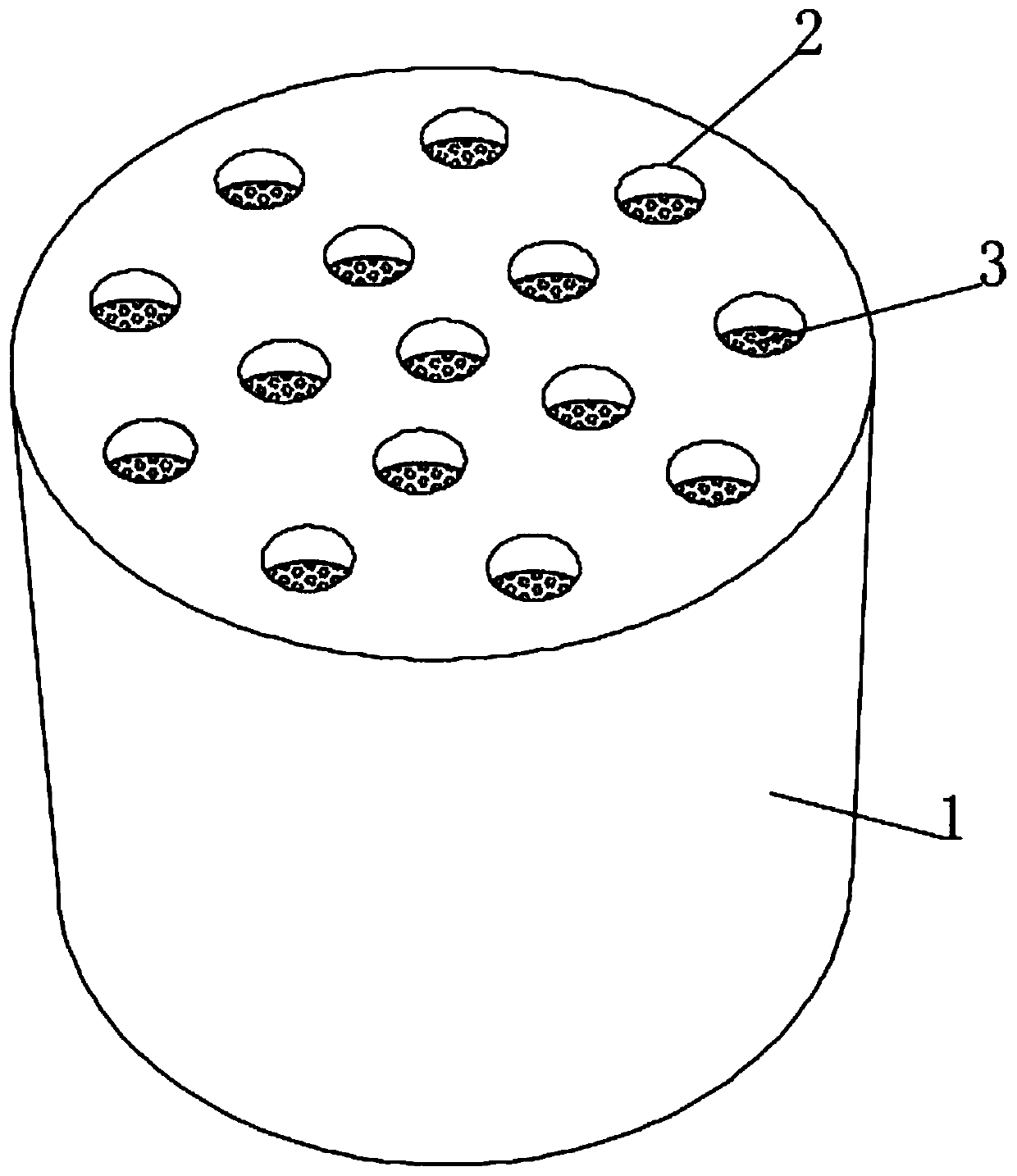

Bioactive bone repair scaffold and preparation method thereof

ActiveCN110368524ASave materialLow costAdditive manufacturing apparatusTissue regenerationChemistryMagnesium

The invention discloses a bioactive bone repair scaffold and a preparation method thereof. The bioactive bone repair scaffold is prepared from, by mass, 55-85% of a degradable polymer serving as a matrix, and 5-15% magnesium lithium silicate and 10-30% of magnesium which serve as a reinforcement phase. The preparation method of the scaffold comprises the following steps of 1) preparation of magnesium lithium silicate hydrogel, 2) preparation of a mixture, 3) preparation of 3D printing raw material particles and 4) 3D printing of the bioactive bone repairing scaffold. The internal and externalstructures of the scaffold can be subjected to customized design, no organic solvent is added, the multi-component interface bonding is good, and the mechanical strength requirement(0.2-80 MPa) of thecancellous bone can be met; self-responding sustained-release of functional ions induces sedimentation of hydroxyapatite on the surface of the scaffold, the bone and cartilage injury can be synergistically repaired, customizedpreparation of the bioactive bone repair scaffold is achieved, and the application prospects of the scaffold in the field of rehabilitation treatment of the bone and cartilage injury and the like are broadened.

Owner:SOUTHEAST UNIV

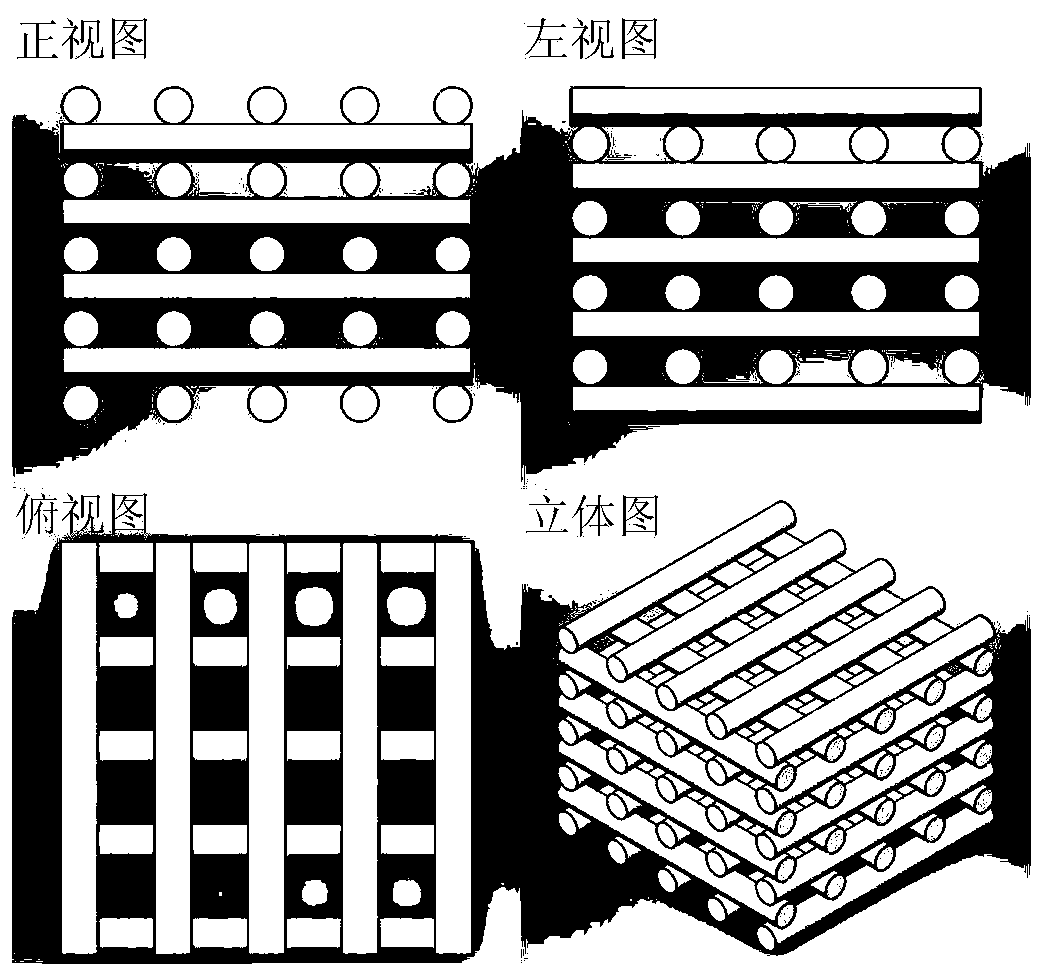

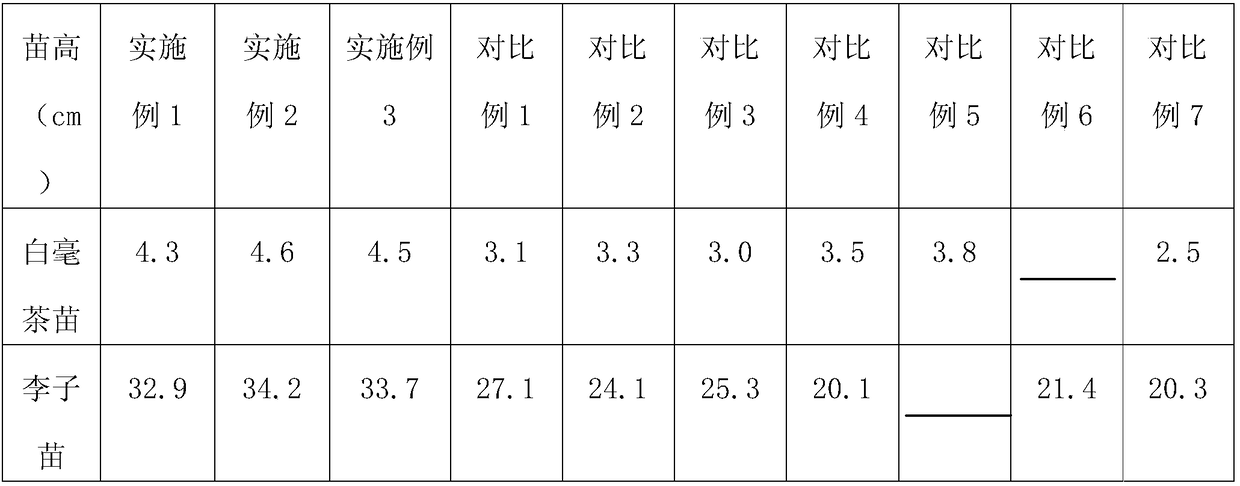

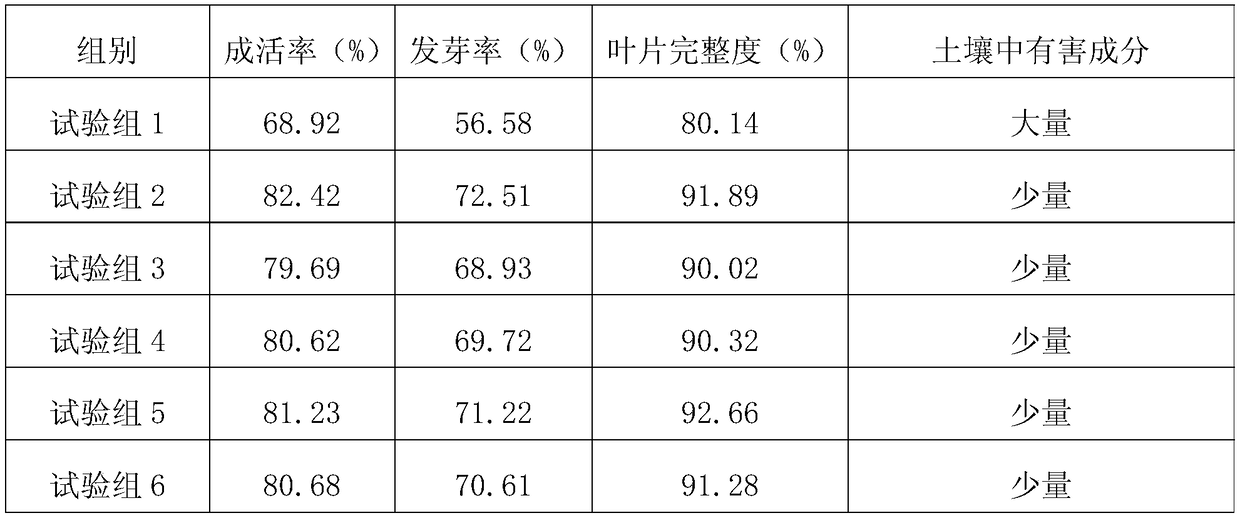

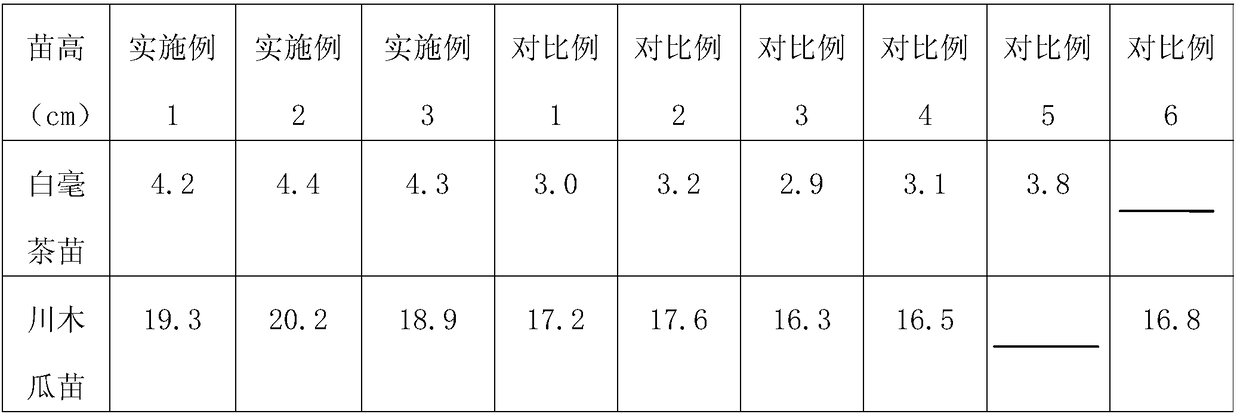

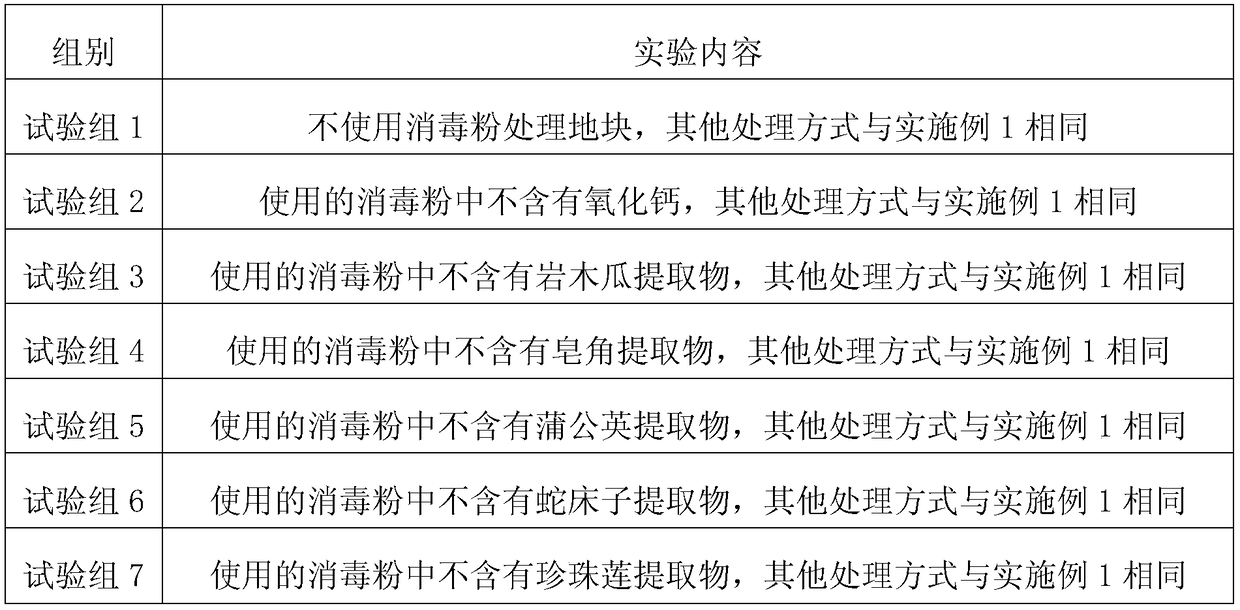

Interplanting method of Lingyun pekoe teaandprunussalicinalindl

InactiveCN108966985AImprove the ecological environmentPromote a virtuous circleBiocideBio-organic fraction processingEcological environmentPrunus

The invention provides an interplantingmethod of Lingyun pekoe tea and prunussalicinalindl, and relates to the technical field of planting. The interplanting method of Lingyun pekoe tea and prunussalicinalindl comprises the following steps of (1) land parcelpreparation, (2) cultivation for pekoe teaseedlings, (3) planting of the pekoe tea seedlings, (4) pre-treatment ofprunussalicinalindlseedlings, (5) interplanting of the prunussalicinalindl seedlings and (6) water and fertilizer management; by utilizing the height difference and required different illumination intensities of the prunussalicinalindl and the Lingyun pekoe tea, a stereoscopiccultivation mode is adopted,the Lingyun pekoe tea and the prunussalicinalindlare interplanted, prunussalicinalindl trees are planted in a pekoe tea garden, the ecological environment of the tea garden can be improved, the virtuous cycle of the ecological system of the tea garden is facilitated, and tea trees can promote the growth of the prunussalicinalindl trees, and the win-win result is achieved.

Owner:广西浪伏茶业股份有限公司

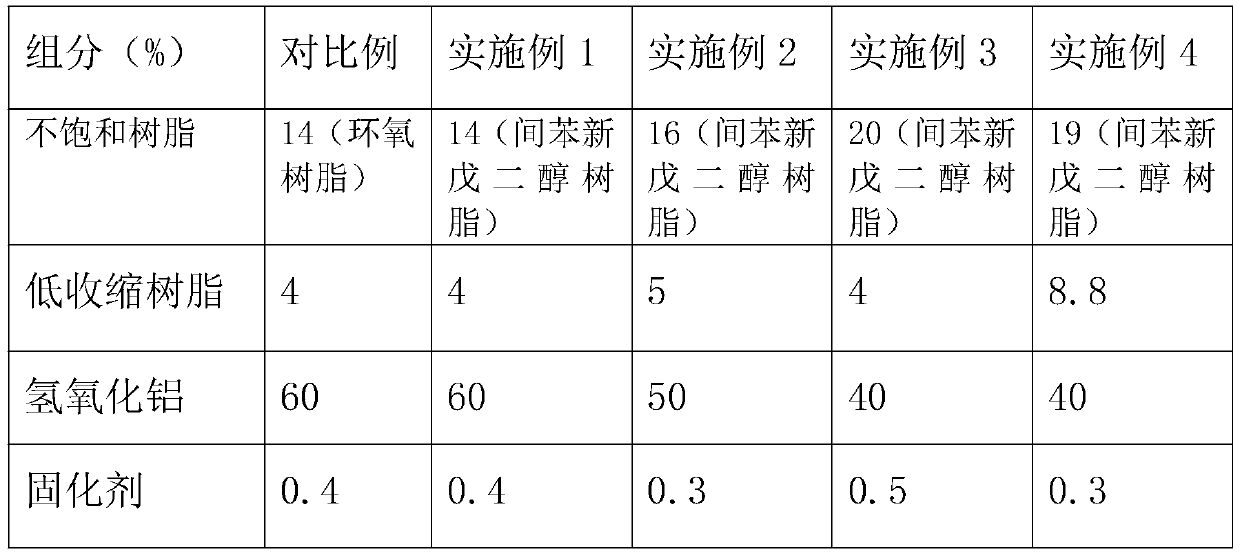

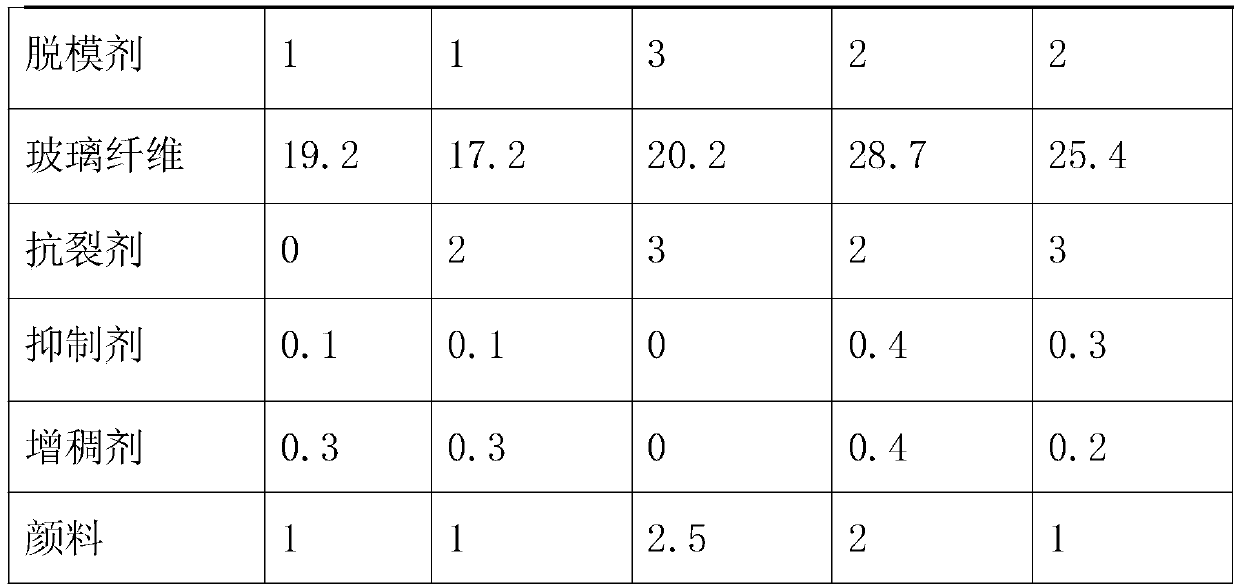

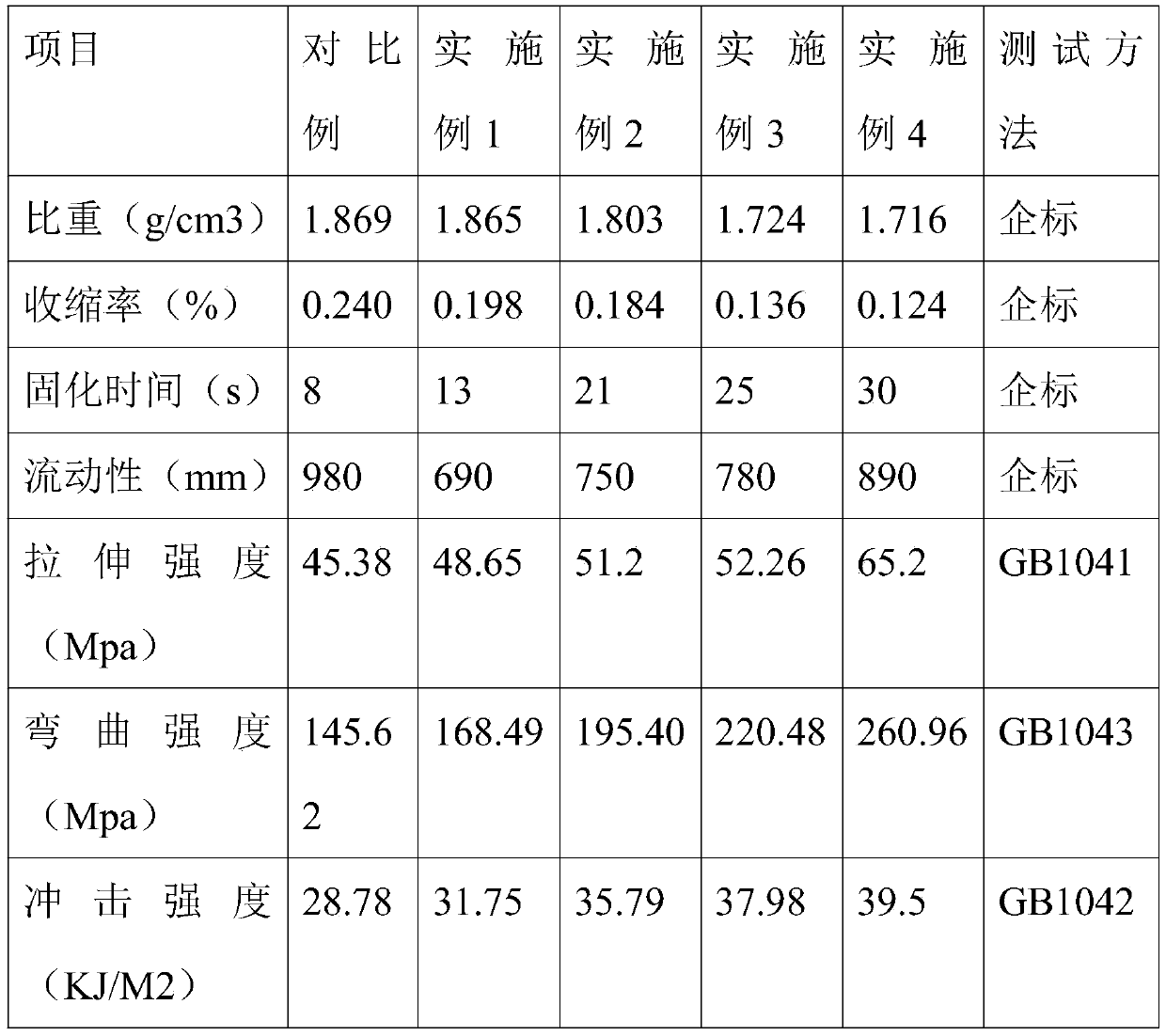

BMC (Bulk molding compound) material for high-speed rails and production method thereof

The invention discloses a BMC (Bulk molding compound) material for high-speed rails. The BMC material is prepared from resin, aluminum hydroxide, curing agents, release agents, glass fibers and anti-cracking agents, wherein the resin is a mixture of unsaturated resin and low shrink resin; the anti-cracking agents are PE (Polyethylene), NBR (Nitrile-butadiene rubber), PS (Polystyrene), PVAC (Polyvinyl acetate) or EVA (Ethylene-vinyl acetate copolymer). The invention further discloses a production method of the BMC material for the high-speed rails. According to the BMC material disclosed by theinvention, by adding the anti-cracking agents into the BMC material, when the BMC material is moulded, the anti-cracking agents can infiltrate into micro-cracks of the resin to fill the cracks, and abonding effect is achieved, so that the shrinkage of a resin material can be lowered, and the surface flatness of the material is improved, thereby reducing vibration during the use of a product; inaddition, the anti-cracking agents can improve the stability and fatigue resistance of the resin material under vibration and prolong the service life of the product.

Owner:绍兴金创意塑化电器有限公司

Planting method of high-yield bayberry

InactiveCN109168921AGuaranteed normal growthPromote growthBiocideBio-organic fraction processingDiseasePest control

The invention discloses a planting method of high-yield bayberry, which is characterized by including the following steps: orchard selection and arrangement, bayberry seedling pretreatment, hole digging and planting, rational topdressing of fertilizer, prevention and control in winter, and pest and disease control. A unique Chinese medicine liquid is prepared to replace the traditional pesticides.The Chinese medicine liquid has the advantages of good pest and disease control effect, no residue and difficult development of resistance, and well guarantees the quality of bayberry. The use effects obtained in five consecutive years show that the comprehensive average morbidity of bayberry treated with the Chinese medicine liquid is reduced by 20-30% compared with traditional pesticides. An organic fertilizer with a unique formula is used, which can improve the permeability, water retention property and fertilizer retention capacity of soil and prevent soil diseases and pests. The organicfertilizer integrates the advantages of yield increase, high efficiency, long-term effect, soil improvement and soil-borne disease inhibition, costs low, has no residue or pollution, and improves thequality of bayberry.

Owner:安徽源沃生态农业开发有限公司

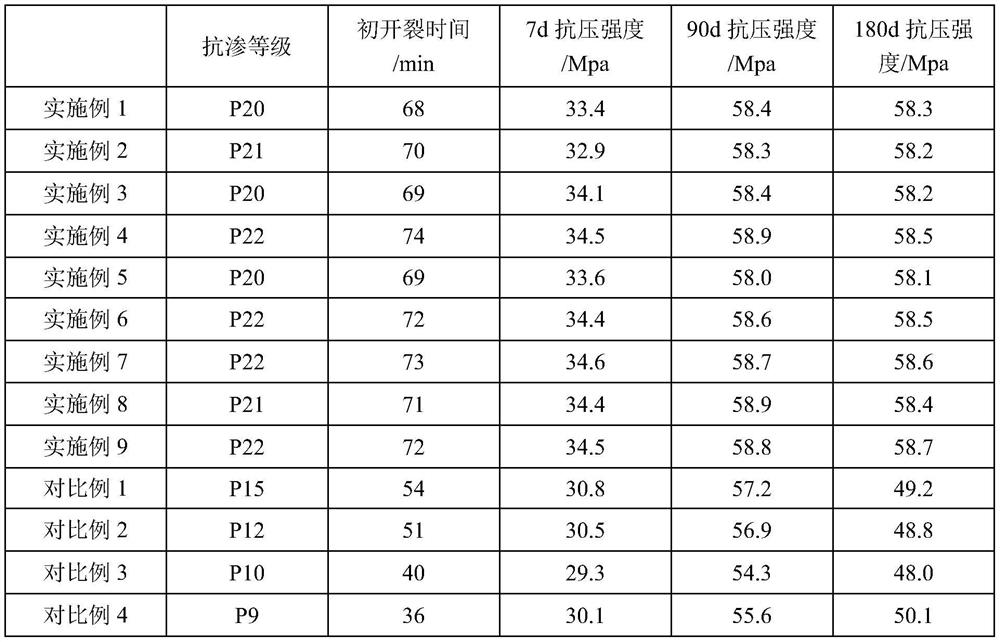

A kind of self-healing anti-cracking concrete and preparation method thereof

ActiveCN112979244BAvoid expansionPlay the role of bondingGlass making apparatusSolid waste managementGlass fiberCalcium bicarbonate

The application relates to the field of concrete, and specifically discloses a self-healing anti-cracking concrete, which is prepared from the following raw materials by weight: 100-110 parts of Portland cement, 10-15 parts of fly ash, and 140 parts of fine sand. -160 parts, 200-220 parts of stones, 40-45 parts of water, 16-20 parts of calcium chloride, 10-15 parts of calcium bicarbonate, 0.7-1.4 parts of water reducing agent, 16- of glass fiber tube with adhesive injection 20 parts, 17-22 parts of glass fiber tubes injected with citric acid solution; it has the advantages of timely repairing effect and preventing cracks from continuing to expand; in addition, a preparation method of self-healing crack-resistant concrete is also provided.

Owner:BEIJING ZEHUA ROAD & BRIDGE ENG CO LTD

A protective coating for ultra-high-strength steel and a preparation method for the ultra-high-strength steel protective coating

ActiveCN109266061BPlay the role of bondingAct as a skeletonFireproof paintsAlkali metal silicate coatingsMaterials scienceArgon gas

The invention discloses a protective paint for ultra-high-strength steel and a preparation method of an ultra-high-strength steel protective coating. The preparation method includecomprises the following steps: preparing the paint; removing impurities from an ultrahigh-strength steel sheet; spraying the paint to the surface of the impurity-removed ultrahigh-strength steel sheet through atomization, wherein the spraying amount of the paint is 0.2-0.3 kg / m<2>; curing the painted ultrahigh-strength steel sheet at the temperature of 120-150 DEG C for 4-6 h; subjecting the painted ultrahigh-strength steel sheet to plasma oxidation at the temperature of 600-620 DEG C, simultaneously injecting argon and oxygen with the pressure of 30-50 MPa according to the volume ratio of 2:1 to 4:1 during plasma oxidation, and preserving the temperature for 30-60 min. The protective paint and the preparation method have the advantages that the preparation process is simple, the quality is stable, a good cutprotection effect and a high temperature protection effect are achieved, and the surface has a superhydrophobic property.

Owner:NANJING INST OF TECH +1

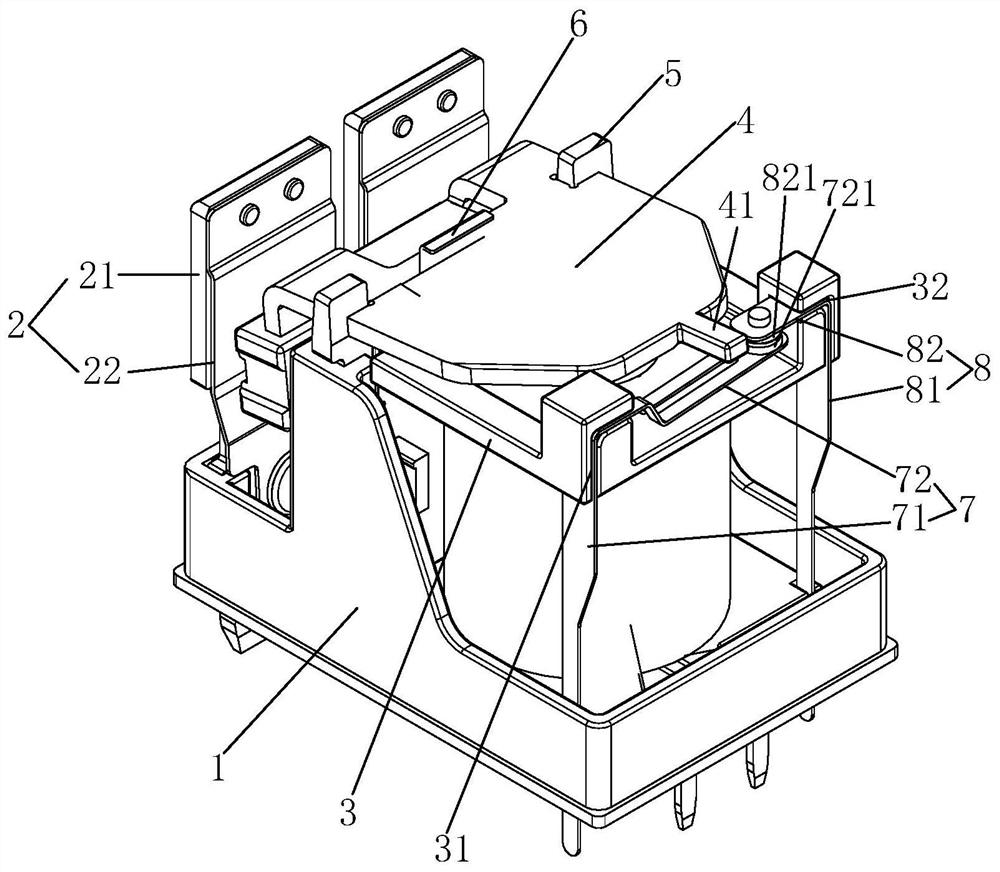

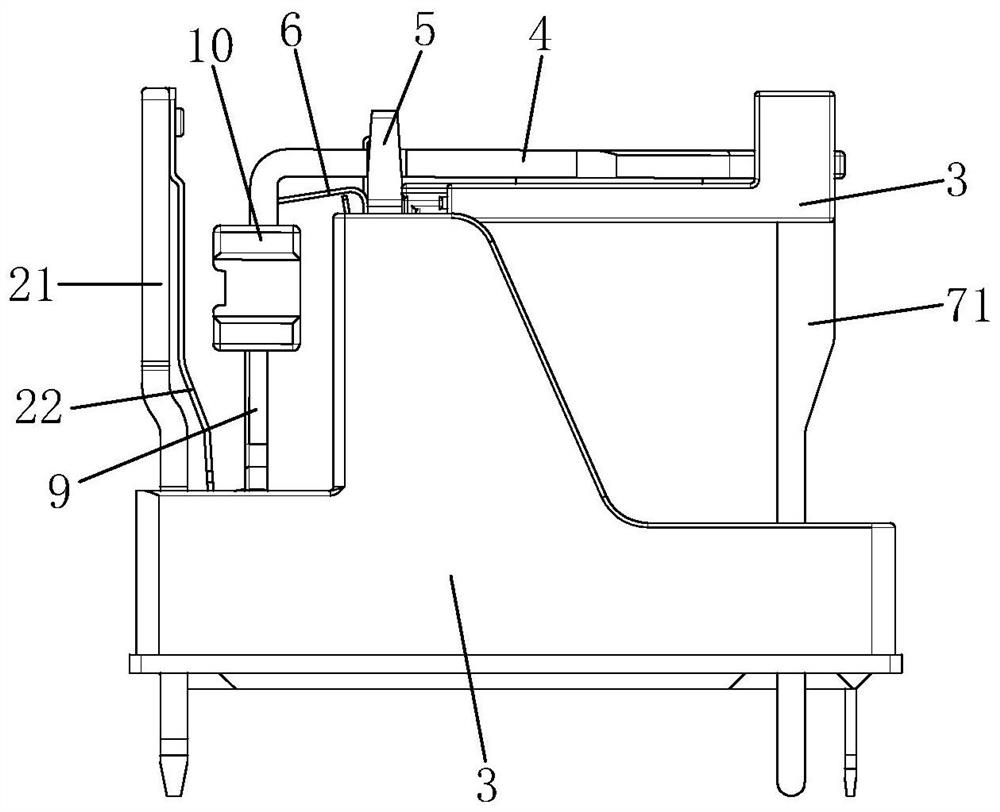

Electromagnetic relay capable of resisting short-circuit current

PendingCN112086319AImprove the ability to resist short-circuit currentReliable contactElectromagnetic relay detailsNon-polarised relaysMechanical engineeringElectrical current

The invention discloses an anti-short-circuit current electromagnetic relay. The relay comprises a base, a magnetic circuit part, a static spring part and a movable spring part, wherein the static spring part comprises a static spring leading-out sheet and an elastic static spring sheet, the static spring leading-out sheet is arranged on the base, a static contact is arranged on the static springsheet, and the static spring sheet is connected with the static spring leading-out sheet; and the static reed generates partial electrodynamic force towards the movable reed in a power-on state, and the electrodynamic force can resist electrodynamic repulsive force borne by the static contact. Due to the design of the static spring part, the capacity of a short-circuit resistant circuit can be improved, the static contact and the movable contact are reliably contacted, the bounce of the contacts is reduced, contact stability of the contacts is improved, an additional transmission structure does not need to be added, parts are reduced, structural complexity is reduced, and meanwhile, the product size is reduced to a certain extent.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

Integrated battery box and box body thereof

PendingCN110649189AReduce heat lossIncrease profitSecondary cellsCell component detailsPhysicsEngineering

The invention provides an integrated battery box and a box body thereof, which can solve the problem of low energy density of the battery box in the prior art. The integrated battery box in the invention comprises a box body and a battery module arranged in the box body, wherein the box body comprises a heat insulation layer and a cold plate which are arranged in the box body, the heat insulationlayer and the cold plate are sequentially arranged on the bottom wall of the box body, and the box body and the cold plate are both bonded with the heat insulation layer, or the cold plate and the heat insulation layer are fixed on the bottom wall of the box body through fasteners. Through the two assembly modes, the use of parts in the battery box can be reduced, so that the weight and the volumeof the battery box are reduced, and the energy density of the battery box is improved.

Owner:郑州深澜动力科技有限公司

Preparation method of protective composite coating for hot forming of ultra-high strength steel

ActiveCN109055890BNot easy to fall offHigh bonding strengthSolid state diffusion coatingCoated surfaceSilicon alloy

The invention belongs to the technical field of metal surface treatment, and in particular, relates to a preparation method for thermal formation of a protective composite coating on ultrahigh-strength steel. The preparation method comprises surface pretreatment of a steel plate, preparation of a penetrating agent, coating of the penetrating agent, high-temperature permeation of zinc and aluminum,double-glow plasma permeation of an aluminum silicon alloy and plasma oxidation. The preparation method can form a protective coating of a four-layer structure on the surface of the ultrahigh-strength steel; the protective coating consists of a Fe-Zn and Fe-Al intermetallic compound diffusion layer, a Zn-enriched layer, an aluminum silicon alloy layer and a micro-nano oxide layer in sequence frominside to outside; the composite coating is simple in preparation process and stable in quality, and solves the difficulty of giving consideration to both high-temperature oxidation and incision corrosion resistance; and as the surface of the coating has the super-hydrophobic characteristic, the industrial production is easily realized.

Owner:NANJING XINGQIAO Y TEC AUTOMOBILE PARTS CO LTD

A kind of high-yield planting method of mango

InactiveCN109121631BPlay the role of bondingAvoid churnFertilising methodsCultivating equipmentsBiotechnologyEconomic benefits

Owner:南京幸庄科技创新产业园管理有限公司

Metal-impregnated carbon skateboard and preparation method thereof

ActiveCN109836173AReduced assembly stepsStrong binding abilityPower current collectorsAdhesiveCopper

The invention discloses a metal-impregnated carbon skateboard, which comprises a carbon skateboard skeleton, a support frame and a copper layer, wherein the copper layer is formed on the combined interface of the carbon skateboard skeleton and the support frame, and is partially embedded into the carbon skateboard skeleton and the support frame. bracket. The invention further discloses a preparation method of the metal-impregnated carbon skateboard, wherein a carbon skateboard skeleton with a porous structure and a support frame with a porous structure are respectively used, and the carbon skateboard skeleton and the support frame are subjected to adhesion molding by impregnating with a copper liquid to obtain the metal-impregnated carbon skateboard. According to the present invention, thecopper layer partially embedded into the carbon skateboard skeleton and the support frame is arranged between the carbon skateboard skeleton and the support frame by using the shrinkage and flowing characteristics, such that the method does not require the adhesive and the metal net, the assembly step is eliminated, the prepared metal-impregnated carbon skateboard can resist high temperature, andthe bonding force between the carbon skateboard skeleton and the support frame is strong.

Owner:BYD CO LTD

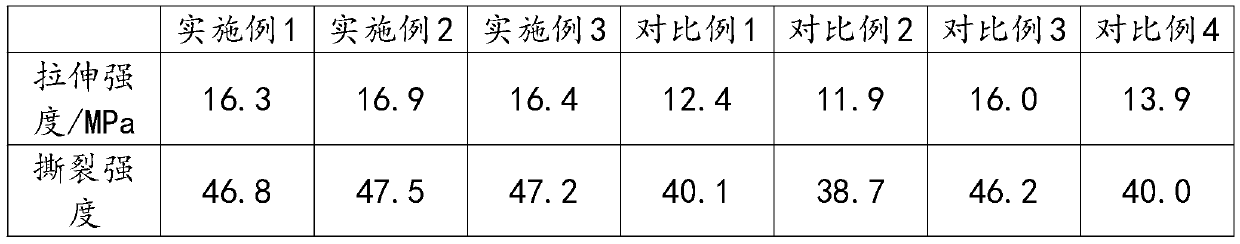

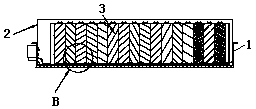

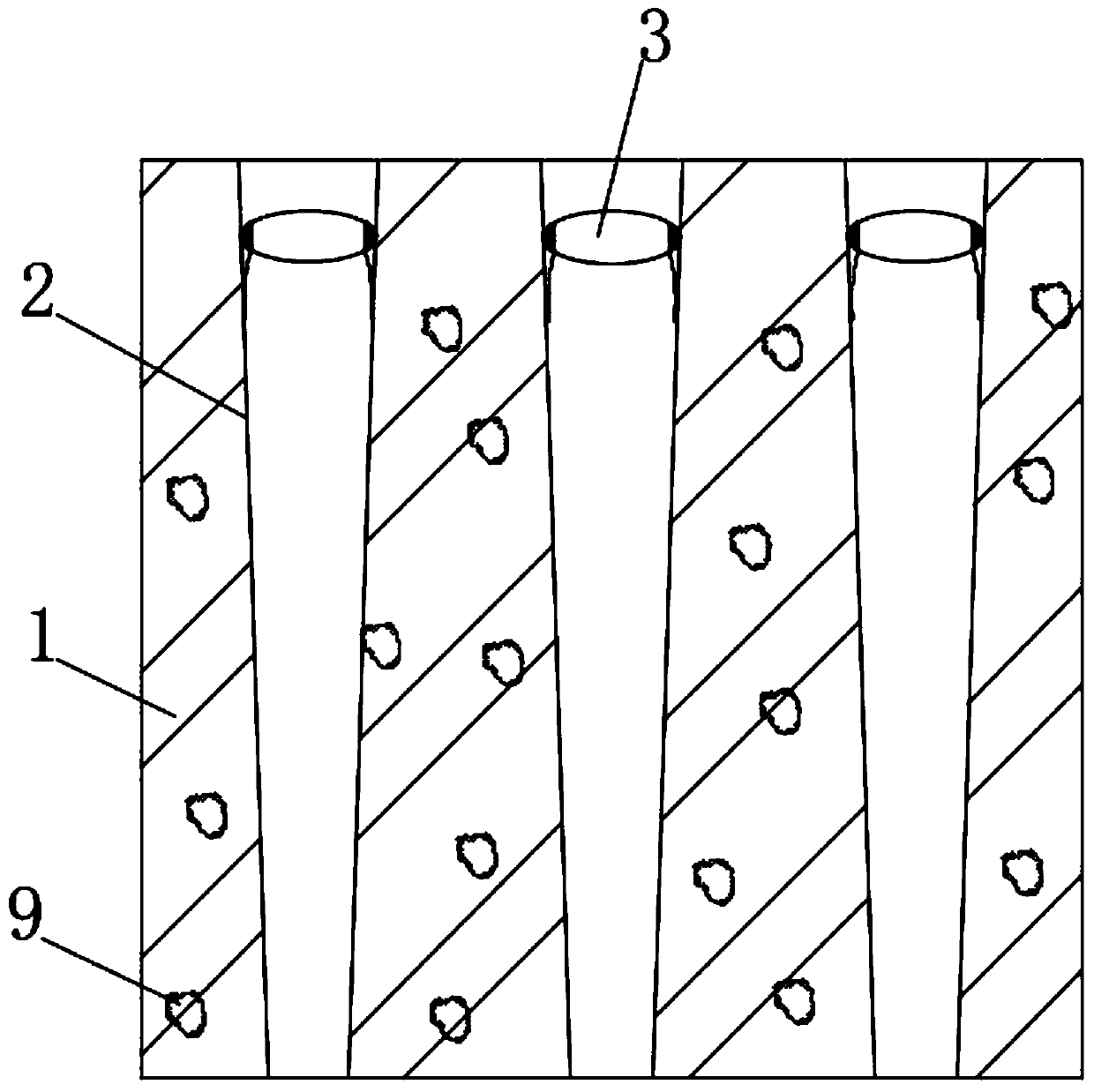

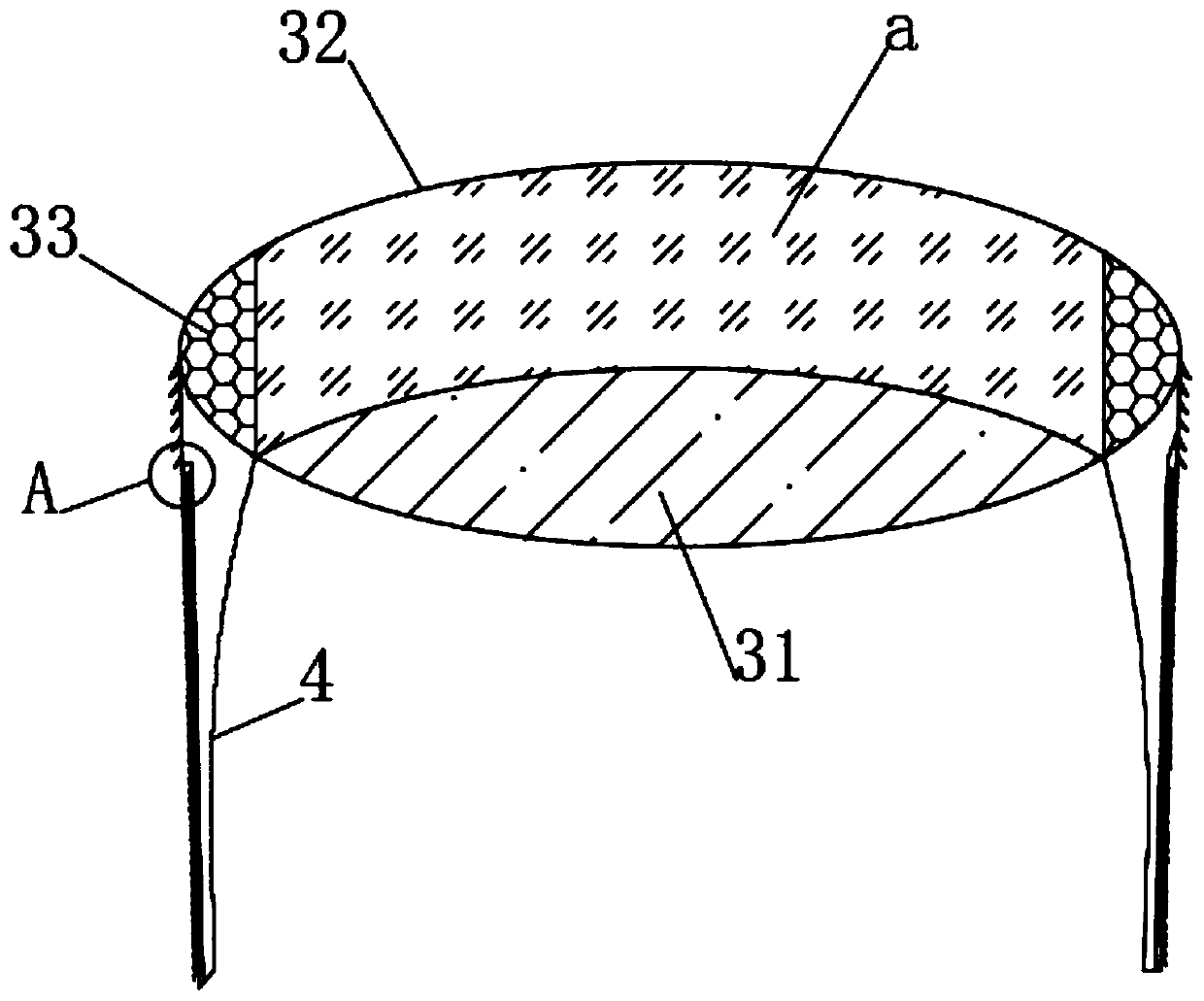

Friction unit for high-speed train brake pad and preparation method thereof

ActiveCN109854650BPollution Reduction ProcessPlay the role of bondingOther chemical processesFriction liningCopper platingAlloy

The invention discloses a friction unit for a high-speed train brake pad and a preparation method thereof. The friction unit comprises a powder metallurgy back plate, a fusing and seeping layer and afriction body which are sequentially sintered into a whole. The fusing and seeping layer is combined with the powder metallurgy back plate and the friction body together in a metallurgy manner after being mutually fused with the powder metallurgy back plate and the friction body. The powder metallurgy back plate is formed by sintering metal powder I in a pressing manner. The fusing and seeping layer is formed by pressing metal powder II. The friction body is formed by pressing metal powder III. According to the friction unit, the fusing and seeping layer forms solid fused alloy completely withthe powder metallurgy back plate and the friction body, prevents corrosion for plating, fusing and seeping of the powder metallurgy back plate and has the function of bonding between the back plate and the friction body. The powder metallurgy back plate is formed by sintering an iron-based material in a pressing manner. In the sintering process, by means of the fusing and seeping layer, the powder metallurgy back plate and the friction body are bonded together, fusing, seeping and copper plating treatment is carried out on the powder metallurgy back plate, and the anti-corrosion function is achieved.

Owner:山东百德瑞轨道交通科技有限公司

High-combustion-rate coal briquette with coal cinder not easy to break

The invention discloses a high-combustion-rate coal briquette with coal cinder not easy to break, and belongs to the field of coal combustion; the invention discloses a high-combustion-rate coal briquette with coal cinder not easy to break. Combustion-supporting particles are arranged in the coal briquette body; oxygen can be supplied to the coal briquette body for supporting combustion during combustion; therefore, the combustion rate of the coal briquette body is improved, the resource waste is effectively reduced, meanwhile, the molten internal combustion-supporting particles can continuously permeate into gaps in the coal briquette body; in combination with the arrangement of the breakage-reducing rubber ring and under the guide action of the wall-attached guide hairs and the deep-layer liquid guide thorns, hot melt adhesive can continuously flow out of the breakage-reducing rubber ring and can seep into the inner wall of the vent hole and cracks of the deeper part of the inner wall of the vent hole; and after combustion is finished, the hot melt adhesive is cured, a certain bonding effect can be achieved on the surface and the interior of the coal cinder at the same time, andtherefore the situation that the coal cinder is broken is effectively avoided, the integrity of the coal cinder is effectively guaranteed, and the cleaning and replacing difficulty of the coal cinderis effectively reduced.

Owner:张宏

A kind of si-al-o-n-b composite ceramic material and preparation method thereof

Owner:NAT UNIV OF DEFENSE TECH

Method for interplanting Lingyun pekoe tea and Sichuan pawpaw

InactiveCN108781971ASufficient lightingImprove the ecological environmentBiocideBioloigcal waste fertilisersEcological environmentHeight difference

The invention provides a method for interplanting Lingyun pekoe tea and Sichuan pawpaw, and relates to the technical field of planting. The method comprises the steps of (1), land parcel preparation;(2), pekoe tea seedling preprocessing; (3), interplanted pekoe tea planting; (4), Sichuan pawpaw preprocessing; (5), Sichuan pawpaw seedling interplanting; (6), water and fertilizer management. According to the method, a three-dimensional culturing mode is adopted according to the height difference and needed illumination intensity difference of the the Lingyun pekoe tea and the Sichuan pawpaw toconduct interplanting of the Lingyun pekoe tea and the Sichuan pawpaw, Sichuan pawpaw trees are planted in a Lingyun pekoe tea garden, the ecological environment of the tea garden can be improved, andthe virtuous cycle of the ecological system of the tea garden is promoted.

Owner:广西浪伏茶业股份有限公司

Oil suction adhesive tape

PendingCN107760224APlay the role of bondingPressure sensitive film/foil adhesivesInterior spaceFiber

The invention relates to an environment-friendly material and particularly relates to an oil suction adhesive tape. The oil suction adhesive tape comprises a drainage layer, an oil suction layer, an adhesive body layer and a protective layer. The lower surface of the adhesive body layer is attached to the protective layer while the upper surface of the adhesive body layer is attached to the oil suction layer, and the oil suction layer is arranged between the drainage layer and the adhesive body layer; a hole running through the upper and lower surfaces is formed in the adhesive body layer, thelower surface of the adhesive body layer is an adhesive surface, the protective layer has a smooth surface, the smooth surface is attached to the lower surface of the adhesive body layer, and the adhesive body layer can be separated from the protective layer under the pull action; the oil suction layer is made from a macromolecular oil suction material which is a threadlike high oil suction gel,the gel is internally provided with a netty space for storing grease, and the drainage layer is formed by embedding long filaments formed by oil suction macromolecular fibers and thermal caking fibersmeridionally or meridionally and zonally to form a fiber net and puncturing the fiber net. The oil suction adhesive provided by the invention has good oil suction and oil resisting properties.

Owner:江苏贝多环境科技有限公司

A metal impregnated carbon slide plate and its preparation method

ActiveCN109836173BReduced assembly stepsLower bond resistancePower current collectorsAdhesive glueSlide plate

The invention discloses a metal-impregnated carbon slide, which comprises a carbon slide frame, a bracket and a copper layer, the copper layer is formed between the interface where the carbon slide frame and the bracket are combined, and is partially embedded in the Carbon skateboard skeleton and the brackets. The invention also discloses a method for preparing the metal-impregnated carbon slide. The porous structure of the carbon slide frame and the bracket are respectively used, and the carbon slide frame and the bracket are bonded and formed by impregnating copper liquid to obtain the metal-impregnated carbon slide. The present invention uses the shrinkage and flow characteristics of the copper liquid to set a copper layer partially embedded in the pores of the carbon skateboard skeleton and the bracket between the carbon skateboard skeleton and the bracket. This method does not require adhesive glue and metal mesh, and reduces the steps of assembly. Moreover, the prepared metal-impregnated carbon slide plate can withstand high temperature, and the carbon slide plate skeleton and the bracket have strong bonding ability.

Owner:BYD CO LTD

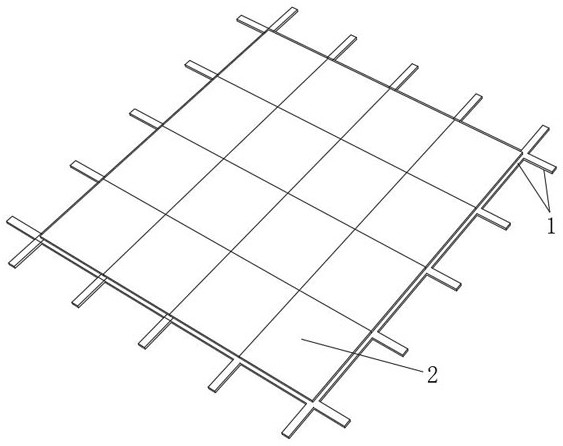

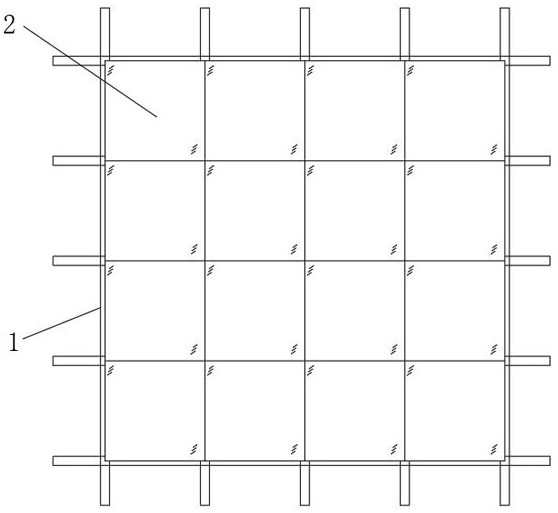

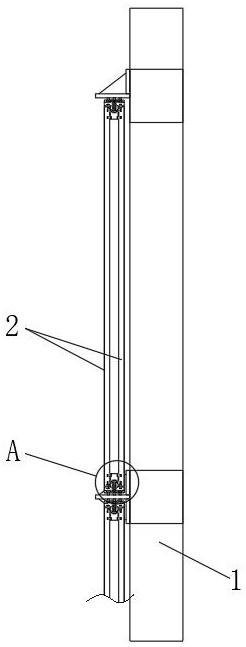

An energy-saving hidden frame glass aluminum composite curtain wall structure

The invention discloses an energy-saving hidden-frame glass-aluminum plate composite curtain wall structure, which belongs to the field of curtain walls. An energy-saving hidden-frame glass-aluminum plate composite curtain wall structure is provided with an adhesive added to the inside of a lateral support panel, and the adhesive is guided through a drawing block To release the outer surface of the ball, and under the action of the liquid equalizing fiber and the equalizing block, it is convenient to achieve a stable connection between the inner surface of the lateral support panel and the glass. Inside the groove, under the action of the installation piece with an inverted "π"-shaped structure in the longitudinal section, it is convenient to quickly locate and assemble the composite double-layer glass, so that it can effectively play the role of positioning and installation. Under the action of the gas sensor, it is convenient to detect the composite The gas content inside the double-layer glass is low, and the inert gas is introduced into the interior of the inflatable main pipe to facilitate the displacement of the air inside the composite double-layer glass, which is convenient to play the role of protection and energy saving.

Owner:山西鼎隆智装科技股份有限公司

A kind of carbon fiber modified solvent-free polyurethane surface layer resin for sports shoe leather and its preparation method and application

ActiveCN106397722BGuaranteed to be environmentally friendlyReduce usagePolyurea/polyurethane coatingsFootwearFiberCarbon fibers

The invention belongs to the field of synthetic leather, and provides carbon fiber modified non-solvent polyurethane surface layer resin for sports shoe leather. The resin is formed by mixing a component A and a component B according to mass percent being 2:1 to 1:2, wherein the component A comprises 5 to 15 parts of aliphatic diisocyanate, 50 to 60 parts of low polymer dihydric alcohol, 10 to 20 parts of organosilicone polyhydric alcohol, 3 to 10 parts of micromolecule dihydric alcohol, 0.5 to 5 parts of micromolecule trihydric alcohol, 0.1 to 1.5 parts of a catalyst, 0.5 to 2.5 parts of a light / heat stabilizer, 0.02 to 0.5 part of a flatting agent, 0.01 to 0.2 part of a defoamer, 0.1 to 0.5 part of a dehydrator, and 0.5 to 5.0 parts of carbon fiber; the component B comprises 40 to 50 parts of aliphatic diisocyanate, 0 to 10 parts of triisocyanate, 35 to 50 parts of polytetrahydrofuran dihydric alcohol, 0.5 to 5 parts of micromolecule dihydric alcohol, 0 to 2 parts of micromolecule trihydric alcohol, and 0.5 to 1.0 part of a light / heat stabilizer. The invention further provides a preparation method and application of the resin. The tangential breaking strength of carbon fiber modified resin coating can reach 130kN / m or above; for non-solvent sports shoe leather prepared through the method, the peeling strength can reach 90N / 3 cm or above and the hydrolysis resistance can reach 10 weeks or above.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

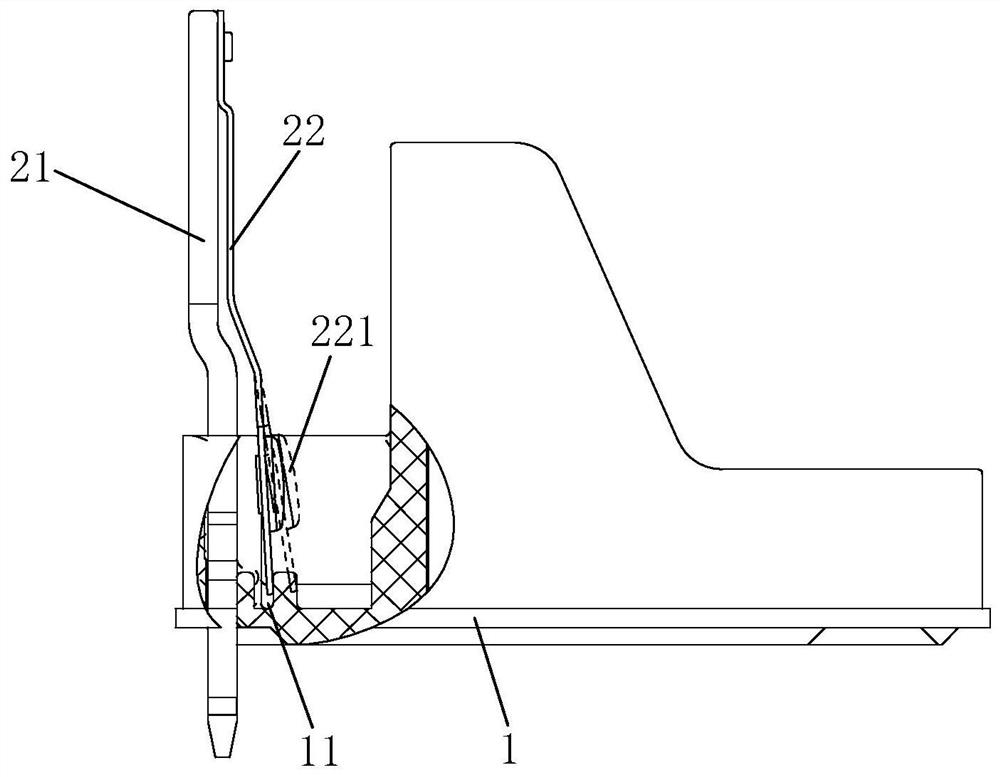

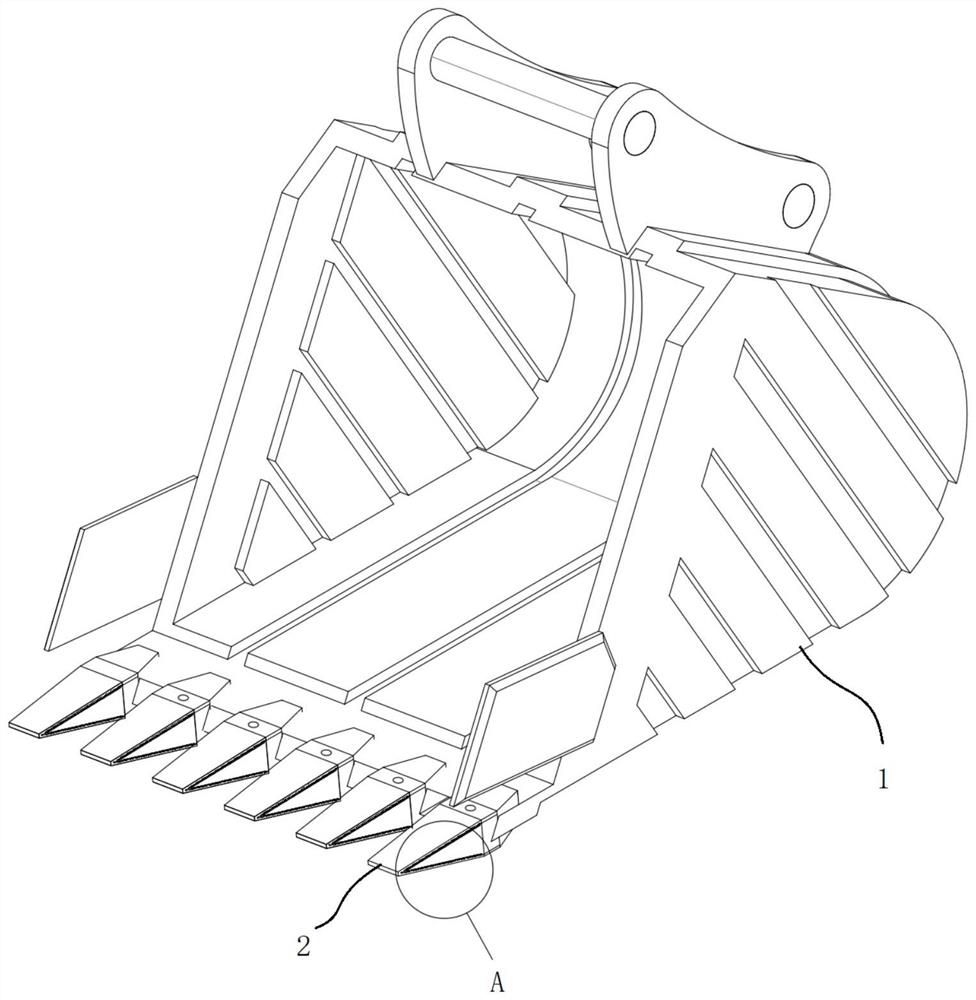

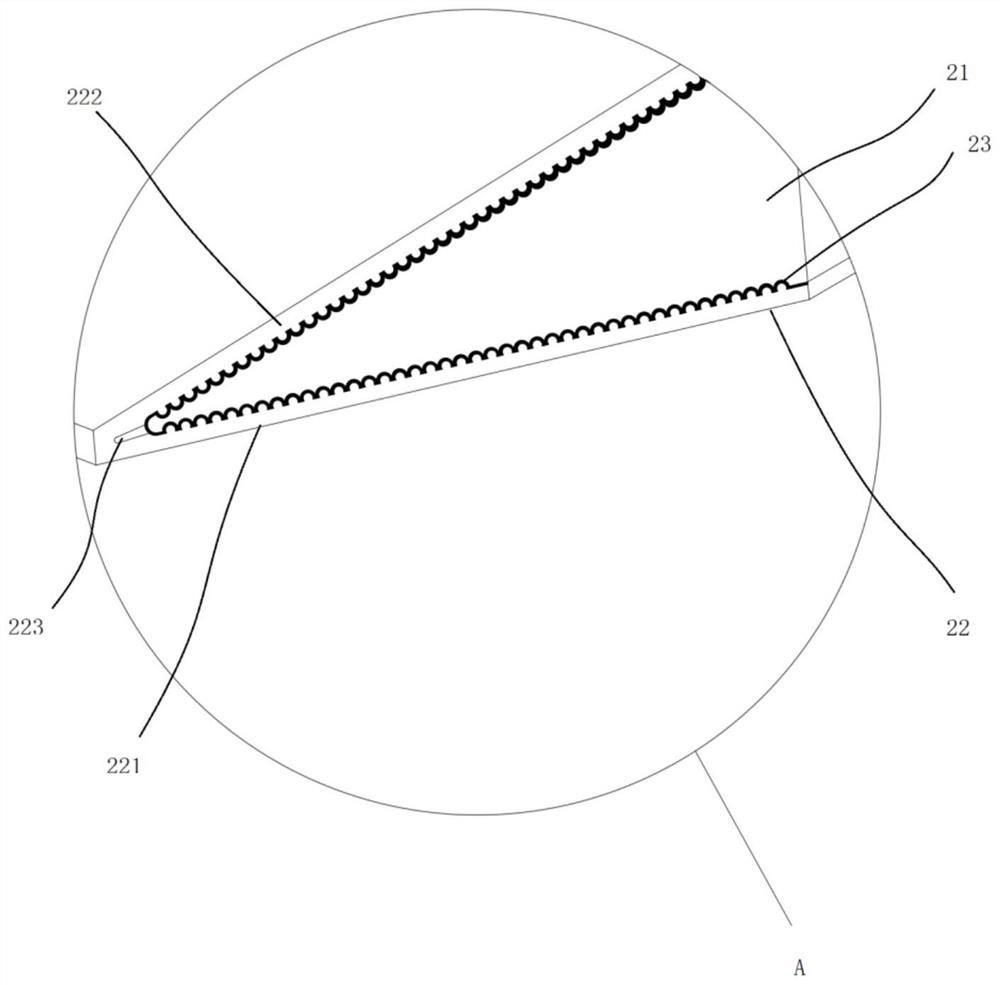

Excavator bucket with shovel blade convenient to replace

PendingCN114232722APlay the role of fillingPlay the role of bondingSoil-shifting machines/dredgersPolystyreneShovel

The excavator bucket comprises an excavator bucket body (1) and the shovel piece (2) connected to the end of an opening of the excavator bucket body (1), the shovel piece (2) comprises a shovel piece inner core (21) fixedly connected with the excavator bucket body (1) and a grinding piece (22) connected to the exterior of the shovel piece inner core (21) in a sleeving mode, and polystyrene foam (23) is arranged between the shovel piece inner core (21) and the grinding piece (22). According to the device, the shovel piece inner core (21) and the grinding piece (22) are filled with polystyrene foam, so that not only is the filling function achieved, but also the bonding function is achieved.

Owner:常州市聚科金属结构件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com