Self-lubricated wearing-resistant rubber material and preparation method thereof

A wear-resistant rubber and self-lubricating technology, applied in the rubber field, can solve the problems of rubber parts failure, worn rubber raw materials, single use, etc., and achieve the effect of improving high temperature resistance, excellent high temperature resistance, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

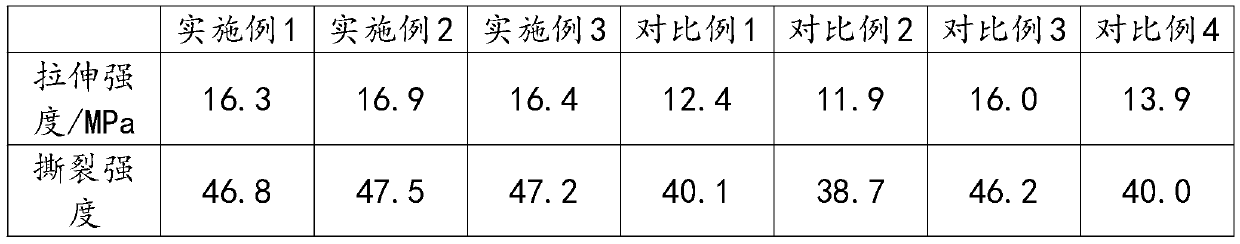

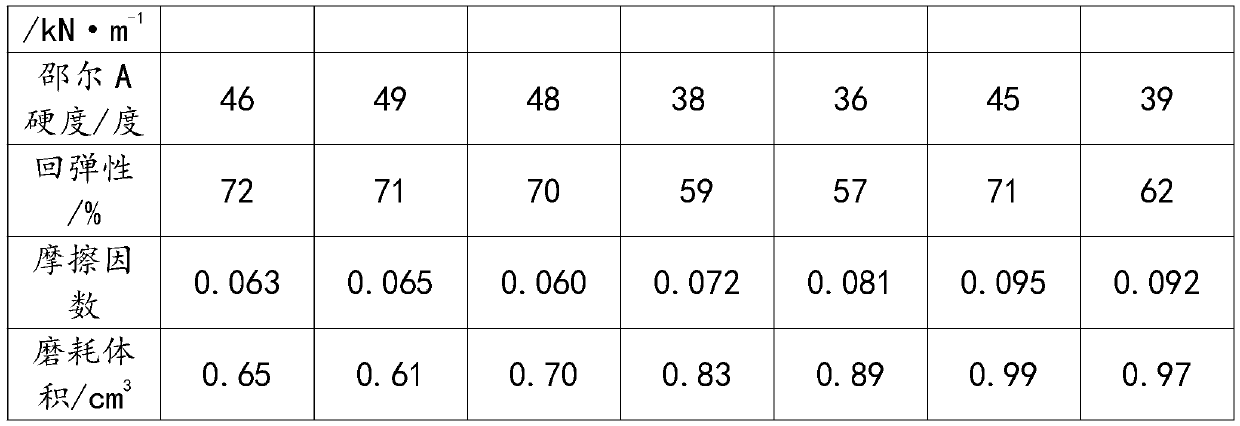

Examples

preparation example Construction

[0039] The preparation method of described rubber material, comprises the steps:

[0040] The first step is to set the initial temperature of the internal mixer to 90°C and the rotational speed to 70r / min. First, add EPDM rubber, nitrile rubber, zinc methacrylate and carbon nanotubes. After banburying for 5 minutes, the modified Add neutral white carbon black, banbury for 2 minutes, finally add zinc oxide, accelerator, anti-aging agent, paraffin and lubricant, continue banburying for 3 minutes, and then discharge glue;

[0041] The second step is to set the roll distance of the open mill to 1mm, the roll temperature to 50°C, and the roll speed to 20r / min, wrap the rubber material after banbury mixing on the open mill, add sulfur after wrapping, and then use The "left and right three knives" method is used to knead it evenly, adjust the roller distance to 0.2mm, and then make a triangular bag 6 times, and then adjust the roller distance to 1.6mm to exhaust the film, and the fil...

Embodiment 1

[0045] A self-lubricating wear-resistant rubber material, made of the following raw materials in parts by weight: 60 parts of EPDM rubber, 20 parts of nitrile rubber, 4 parts of zinc methacrylate, 2 parts of carbon nanotubes, 30 parts of modified white carbon black 4 parts of zinc oxide, 1 part of sulfur, 2 parts of accelerator, 1 part of antioxidant, 1 part of paraffin, 10 parts of lubricant;

[0046] The lubricant comprises oleic acid amide and nano molybdenum disulfide, and the mass ratio of oleic acid amide and nano molybdenum disulfide is 2:8;

[0047] Described rubber material is made by following steps:

[0048] The first step is to set the initial temperature of the internal mixer to 90°C and the rotational speed to 70r / min. First, add EPDM rubber, nitrile rubber, zinc methacrylate and carbon nanotubes. After banburying for 5 minutes, the modified Add neutral white carbon black, banbury for 2 minutes, finally add zinc oxide, accelerator, anti-aging agent, paraffin and...

Embodiment 2

[0052] A self-lubricating wear-resistant rubber material, made of the following raw materials in parts by weight: 70 parts of EPDM rubber, 25 parts of nitrile rubber, 4.5 parts of zinc methacrylate, 2.5 parts of carbon nanotubes, 35 parts of modified white carbon black 4.5 parts of zinc oxide, 1.5 parts of sulfur, 2.5 parts of accelerator, 1.5 parts of antioxidant, 1.5 parts of paraffin, 10.5 parts of lubricant;

[0053] The lubricant comprises oleic acid amide and nano molybdenum disulfide, and the mass ratio of oleic acid amide and nano molybdenum disulfide is 2:8.5;

[0054] Described rubber material is made by following steps:

[0055] The first step is to set the initial temperature of the internal mixer to 90°C and the rotational speed to 70r / min. First, add EPDM rubber, nitrile rubber, zinc methacrylate and carbon nanotubes. After banburying for 5 minutes, the modified Add neutral white carbon black, banbury for 2 minutes, finally add zinc oxide, accelerator, anti-agin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com