High-temperature-resistant and high-thermal-conductivity non-stick coating, method for preparing same and application of high-temperature-resistant and high-thermal-conductivity non-stick coating

A non-stick coating and high thermal conductivity technology, applied in fireproof coatings, polyester coatings, coatings, etc., can solve the problems of high temperature resistance and insufficient thermal conductivity, and achieve good thermal conductivity, no toxic side effects, and simple and controllable production methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

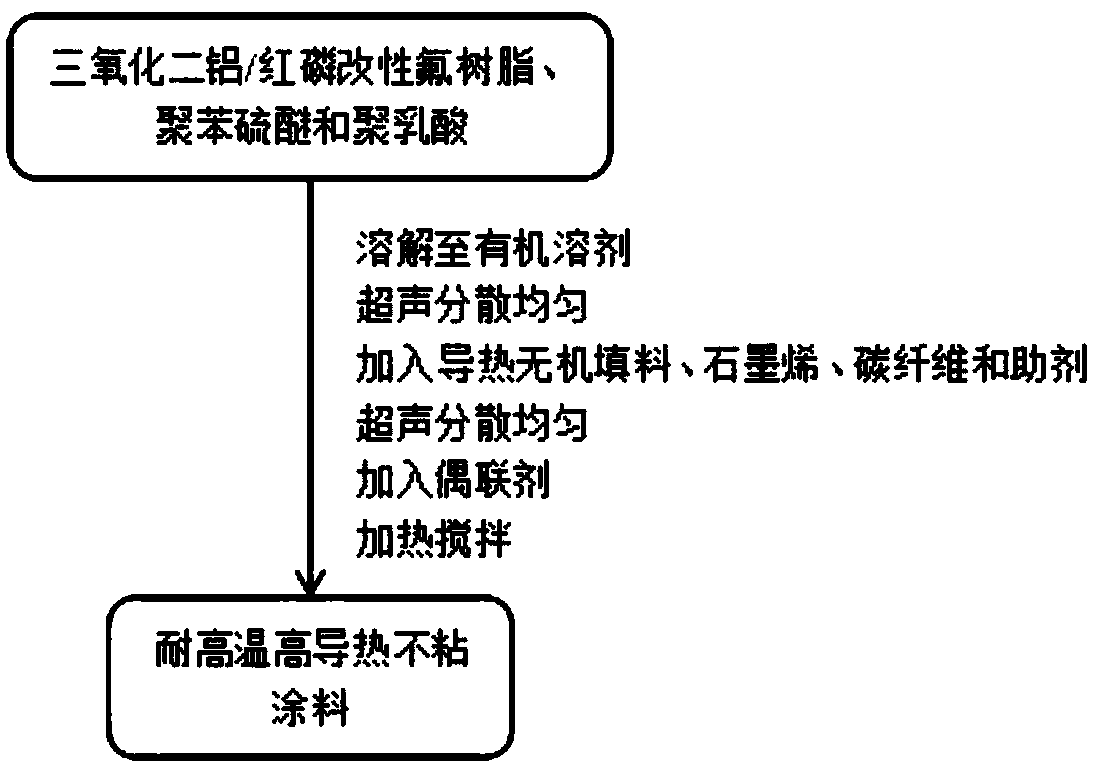

Method used

Image

Examples

Embodiment 1

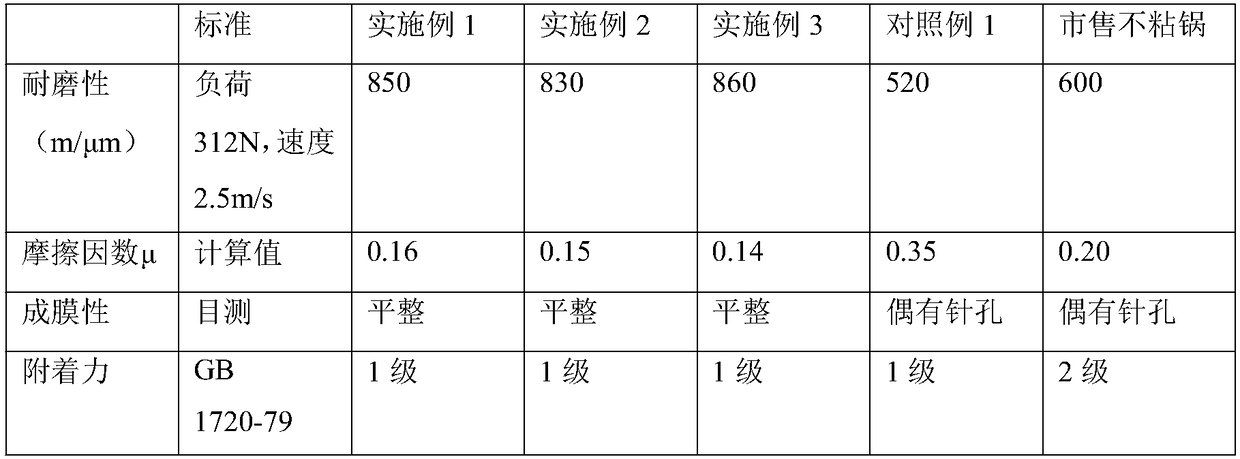

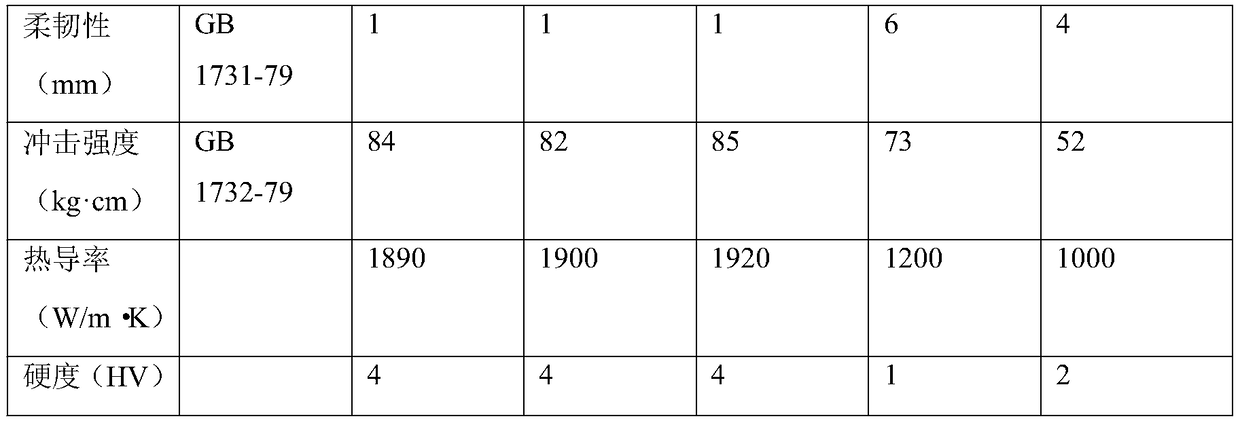

[0049] Embodiment 1 Preparation of high temperature resistant high thermal conductivity non-stick coating

[0050] Raw material composition:

[0051] 100 parts of aluminum oxide / red phosphorus modified fluororesin;

[0052] 50 parts of polyphenylene sulfide;

[0054] 30 parts of carbon fiber;

[0055] 40 parts of polylactic acid;

[0056] 10 parts of boron nitride, 10 parts of silicon carbide;

[0057] 10 parts of γ-mercaptopropyltrimethoxysilane;

[0058] 20 parts of auxiliary agent;

[0059] The auxiliary agent is composed of the following raw materials according to the mass percentage: polyether polyester modified organosiloxane 22%, polyoxypropylene glyceryl ether 13%, acrylic resin polyurethane copolymer resin 15%, tetrakis [β-(3, 5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 15%, propyl p-hydroxybenzoate 20% and ceramic powder 10%.

[0060] Aluminum oxide / red phosphorus modified fluororesin is prepared by the follo...

Embodiment 2

[0064] Embodiment 2 Preparation of high temperature resistant high thermal conductivity non-stick coating

[0065] Raw material composition:

[0066] 120 parts of aluminum oxide / red phosphorus modified fluororesin;

[0067] 70 parts of polyphenylene sulfide;

[0068] Graphene 70 powder;

[0069] 50 parts of carbon fiber;

[0070] 70 parts of polylactic acid;

[0071] 30 parts of silicon dioxide;

[0072] 20 parts of γ-aminopropyltriethoxysilane;

[0073] 30 parts of auxiliary agent;

[0074] The auxiliary agent is composed of the following raw materials according to mass percentage: polyether polyester modified organosiloxane 22%, polyoxypropylene glyceryl ether 13%, polyurethane modified nitrocellulose 15%, dioctadecyl alcohol ester 15% %, propylparaben 20% and ceramic powder 10%.

[0075] Aluminum oxide / red phosphorus modified fluororesin is prepared by the following method:

[0076] Add a mixed solvent composed of dimethylformamide and xylene into the reaction kett...

Embodiment 3

[0079] Embodiment 3 Preparation of high temperature resistant high thermal conductivity non-stick coating

[0080] Raw material composition:

[0081] 112 parts of aluminum oxide / red phosphorus modified fluororesin;

[0082] 65 parts of polyphenylene sulfide;

[0083] Graphene 61 powder;

[0084] 45 parts of carbon fiber;

[0085] 60 parts of polylactic acid;

[0086] Zinc oxide 15, aluminum oxide 12 parts;

[0087] 15 parts of γ-(2,3-epoxypropoxy)propyltrimethoxysilane;

[0088] 24 parts of auxiliary agent;

[0089] The auxiliary agent is composed of the following raw materials according to mass percentage: 22% polyacrylic acid, 13% emulsified silicone oil, 15% acrylate modified butadiene resin, bis(3,5-tertiary butyl-4-hydroxybenzene base) sulfide 15%, potassium sorbate 10%, sorbic acid 10% and ceramic powder 10%.

[0090] Aluminum oxide / red phosphorus modified fluororesin is prepared by the following method:

[0091] Add a mixed solvent composed of dimethylformamide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com