Patents

Literature

317results about How to "Easy to realize industrial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

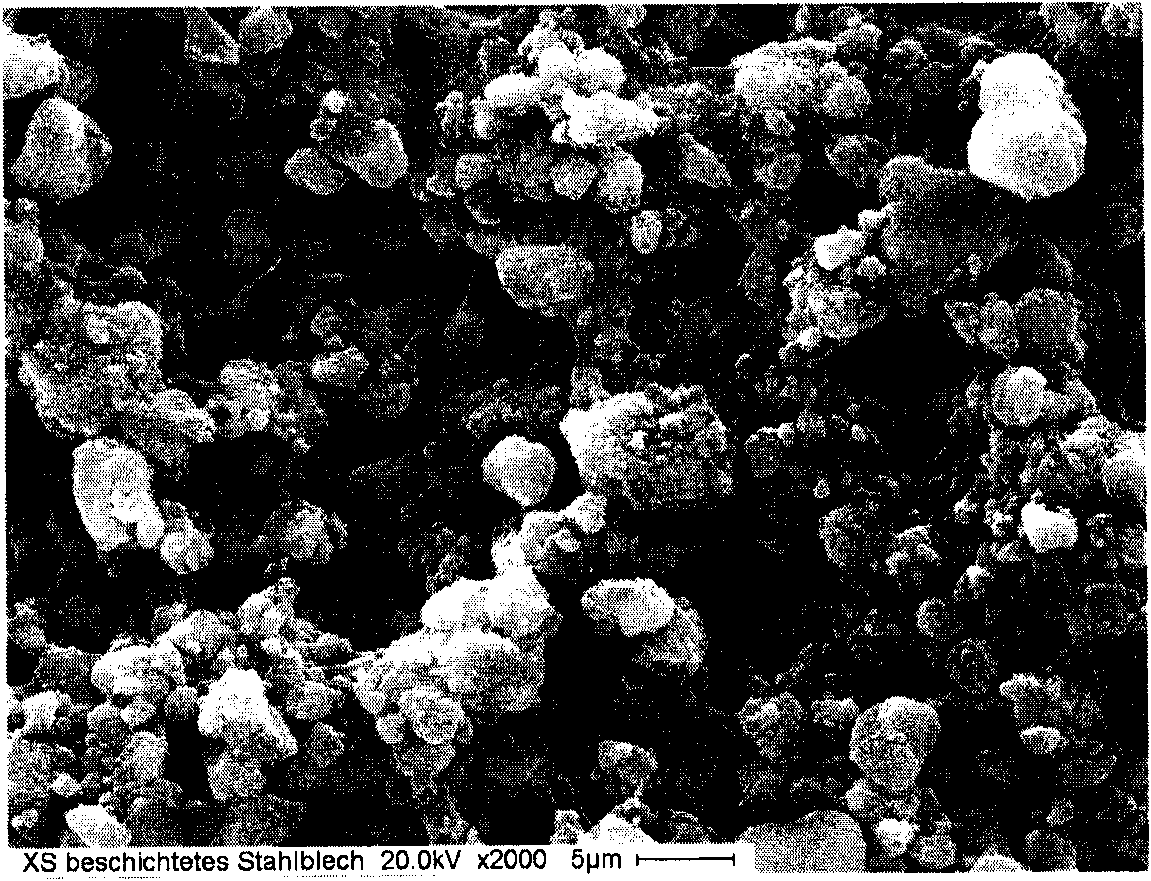

Super-hydrophobic coating material, preparation method thereof and super-hydrophobic coating

InactiveCN102051120AThe preparation method is simple and easy to obtainEasy to realize industrial applicationCoatingsOrganic solventHydrogen

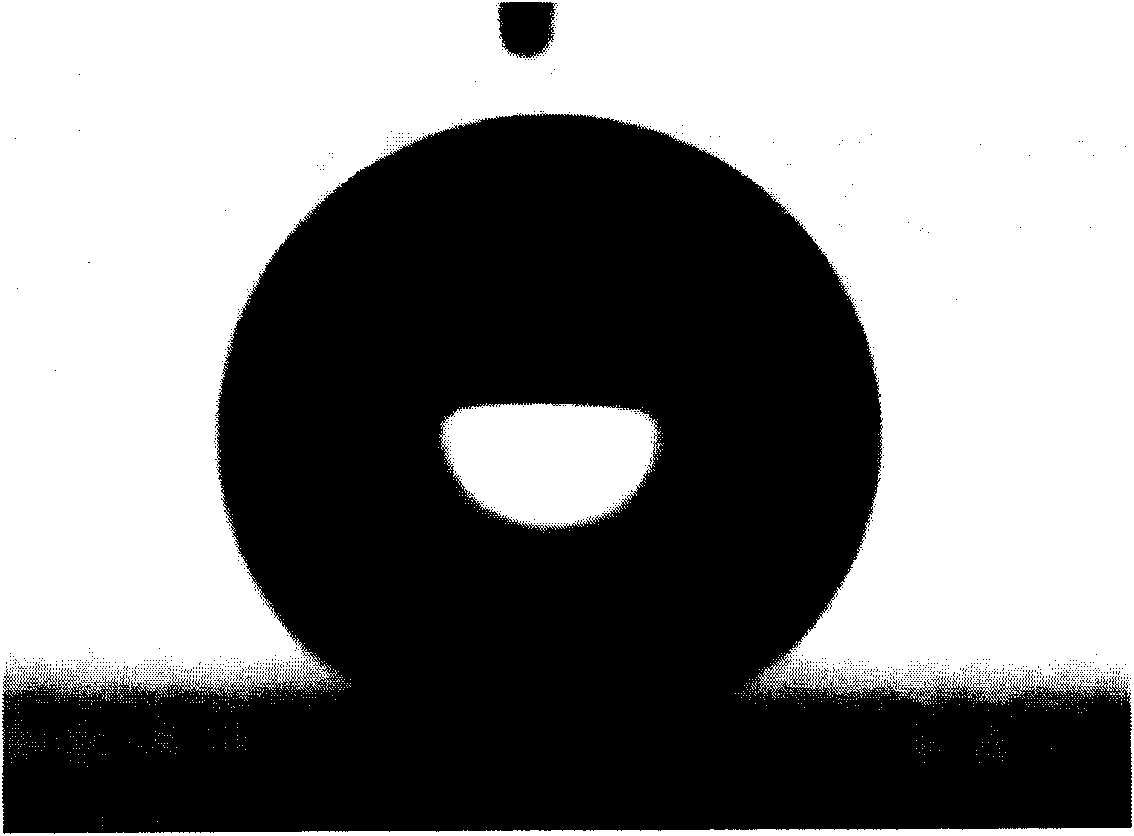

The invention provides a super-hydrophobic coating material, which comprises water or emulsifier or organic solvent, a polysiloxane compound having more than three silicon-hydrogen bonds and solid particles. The invention also provides the preparation method of the super-hydrophobic coating material and the preparation method of a super-hydrophobic coating. The invention provides the super-hydrophobic coating material which is prepared by a simple method, has high mechanical strength, is durable, practical and capable of self-cleaning and the preparation method of the super-hydrophobic coating material. The super-hydrophobic coating material provided by the invention can solidify in a wider temperature range and is applicable to substrates made of various materials such as metal, glass and high polymer materials.

Owner:HENKEL KGAA

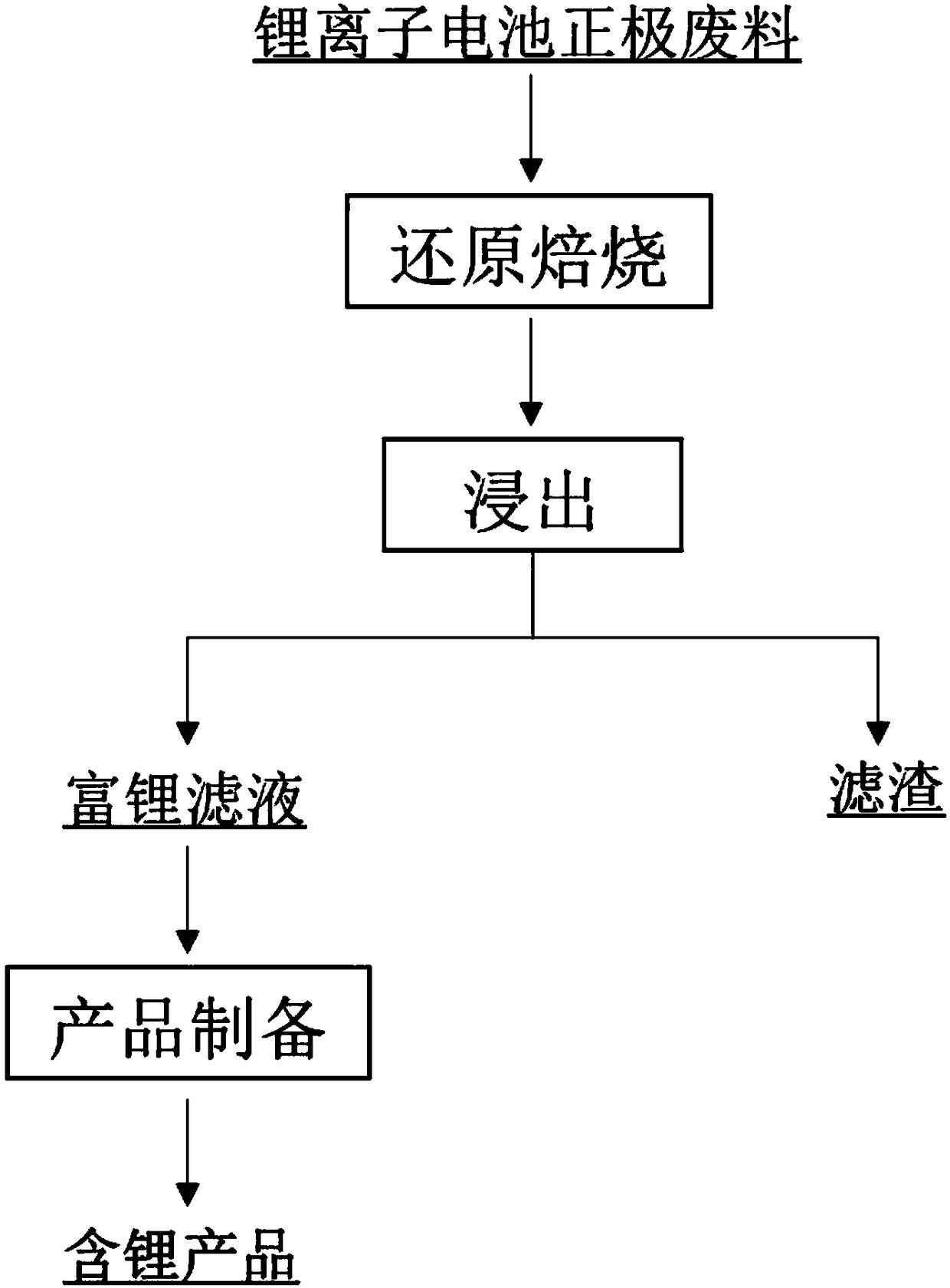

Method for recovering lithium from lithium-containing electrode waste material

InactiveCN108220607AShort leaching timeHigh recovery rateLithium oxides/hydroxidesLithium carbonates/bicarbonatesSlagScrap

The invention provides a method for recovering lithium from a lithium-containing electrode waste material. The method comprises the following steps of (1) roasting the lithium-containing electrode waste material under a reducing atmosphere, after roasting, cooling under a protective atmosphere to obtain a reduced material, leaching the reduced material through a leaching agent, and carrying out solid-liquid separation to obtain a lithium-containing solution and solid slags; (2) preparing the lithium-containing solution in the step (1) into a lithium-containing product. According to the methodprovided by the invention, a reducing gas is adopted for reducing roasting, so that the roasting temperature is low, and the energy consumption is less; and one-step leaching is carried out after reducing, so that high-efficient separation of lithium and other metal elements can be realized, the concentration of the lithium in the leaching agent is high, the recovery rate of the lithium is greatlyimproved, the recovered lithium-containing product has high purity, and in addition, other transition metal elements in the waste electrodes can be further recovered. The method provided by the invention is short in flow, low in cost, and easy to realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

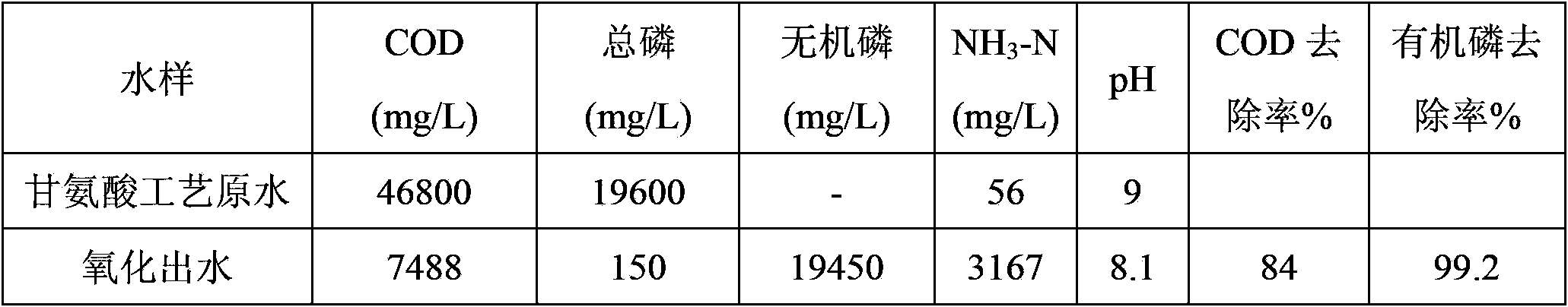

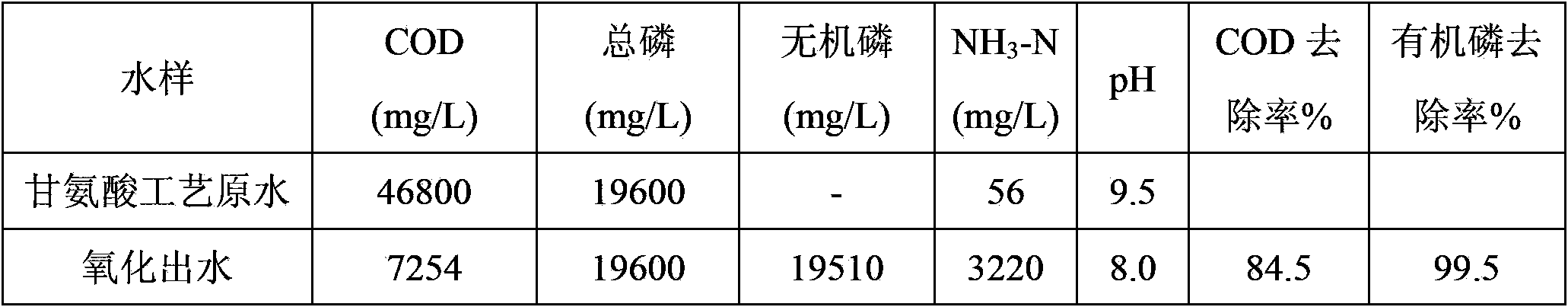

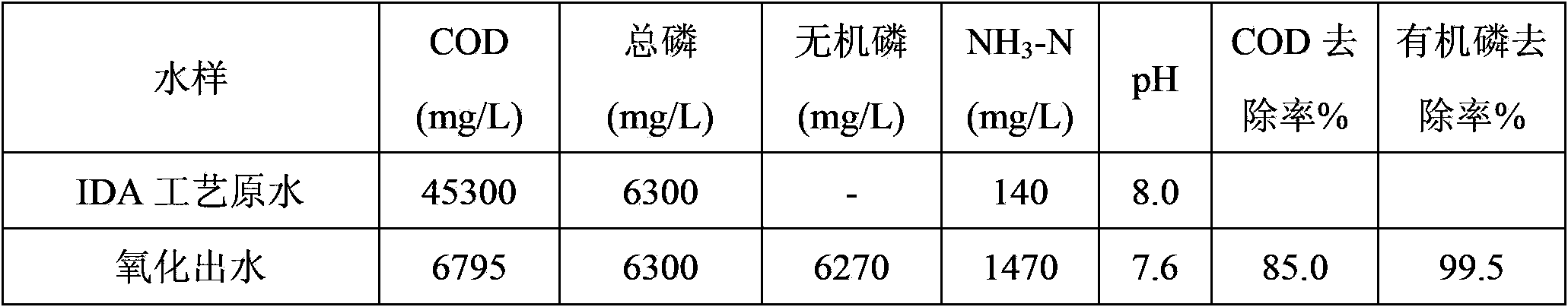

Catalytic wet oxidation pretreatment method of glyphosate production wastewater

ActiveCN103663667AHigh activityReduce dosageMultistage water/sewage treatmentWater/sewage treatment by oxidationPretreatment methodChemical oxygen demand

The invention relates to a catalytic wet oxidation pretreatment method of glyphosate production wastewater, comprises the following steps: firstly regulating pH value to be more than 8 and less than 10, adding a multi-component homogeneous catalyst and carrying out oxidative degradation on pollutants in wastewater for 0.3-2 hours by using a continuous catalytic wet oxidation device with air as an oxidizing agent at the reaction temperature of 210-230 DEG.C and the reaction pressure of 2-4MPa, wherein the catalyst is a soluble transition metal salt mixture. By adopting the method for treating the glyphosate production wastewater, the organic phosphorus conversion rate is high, the COD (chemical oxygen demand) removal rate is high, the biodegradability of the wastewater can be improved, and the secondary pollution is avoided. The method has the advantages that the catalyst activity is high, low in cost and easy to get, reaction conditions are relatively mild, and continuous operation is easily implemented; the glyphosate production wastewater can be discharged in standard through the combined process of catalytic wet oxidation pretreatment-routine technical dephosphorization and deamination-biochemistry, and the industrialized application prospect is great.

Owner:中国中化股份有限公司 +2

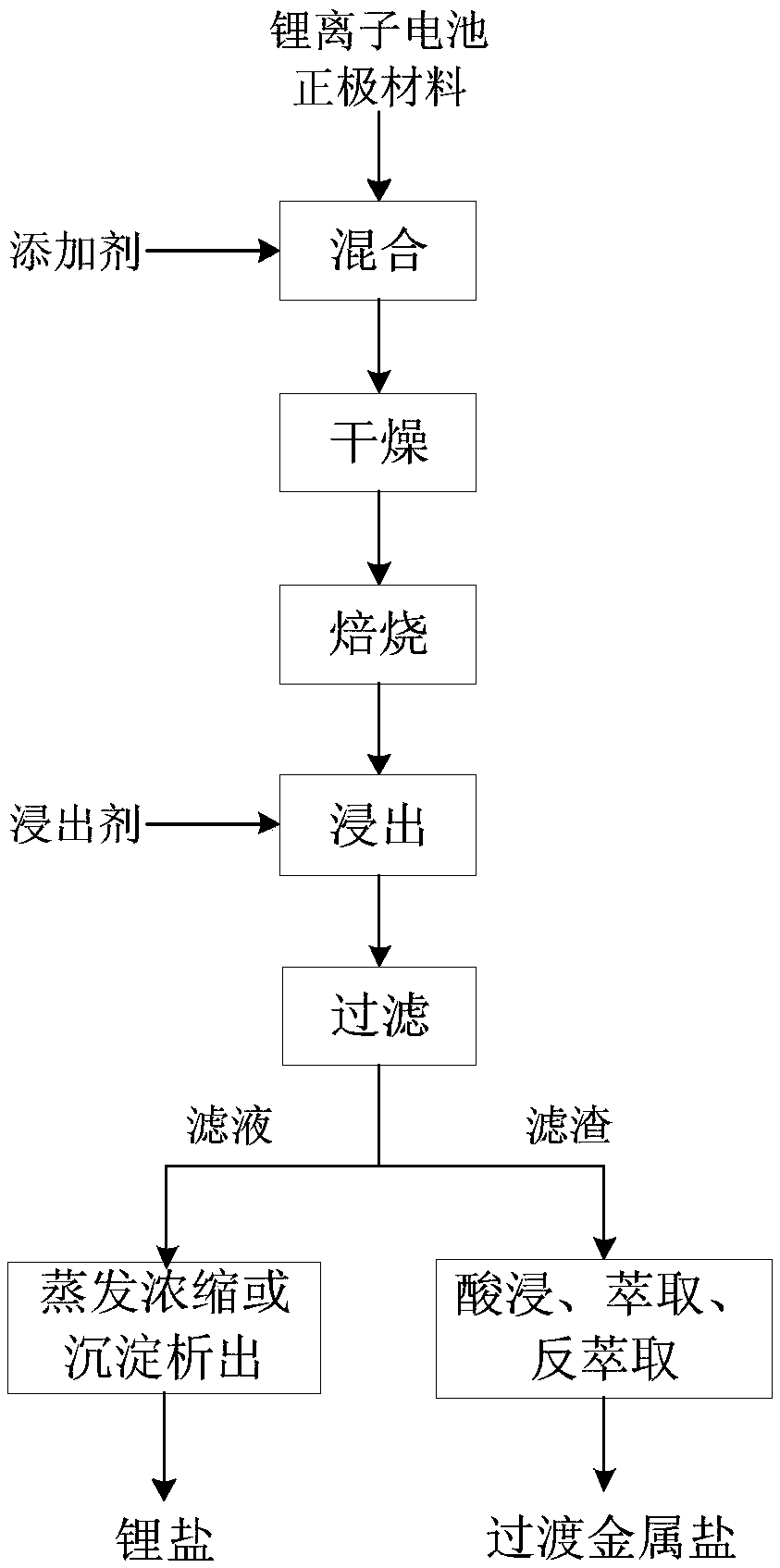

Method for selectively recycling positive electrode materials for lithium ion batteries

ActiveCN108832215AImplement selective extractionEasy to separateWaste accumulators reclaimingProcess efficiency improvementLiquid wasteSlag

The invention provides a method for selectively recycling positive electrode materials for lithium ion batteries. The method comprises the following steps: carrying out transformation processing aftermixing the recycling positive electrode materials for lithium ion batteries with an additive; leaching an obtained transformation product with a leaching agent, and carrying out solid-liquid separation to obtain a lithium-rich solution and a solid slag; and preparing the obtained lithium-rich solution into a lithium salt and the obtained solid slag into a transition metal salt. According to the method, recycling of valuable metals in the positive electrode materials for lithium ion batteries is realized by using in situ crystal transformation and mild leaching methods, particularly, selectiveextraction for lithium is realized, the recycle rate reaches 95% or above, and the recycle rate of other valuable metals such as nickel, cobalt and manganese reaches 98% or above; the method is shortin flow, other impurity ions are not introduced, the product purity is high, secondary pollution and liquid waste disposal can also be avoided, the recycle cost is saved, and the method is easy to realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

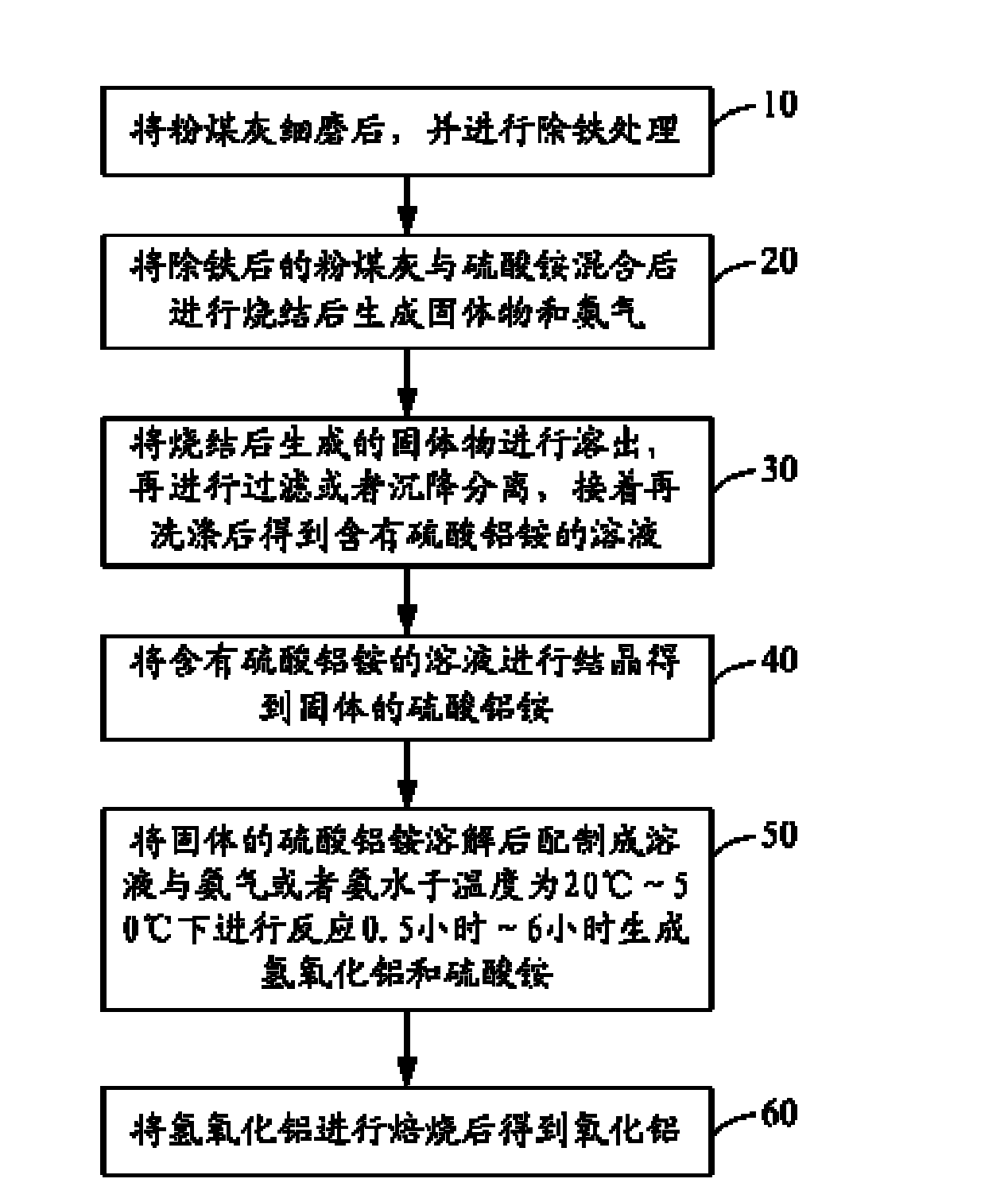

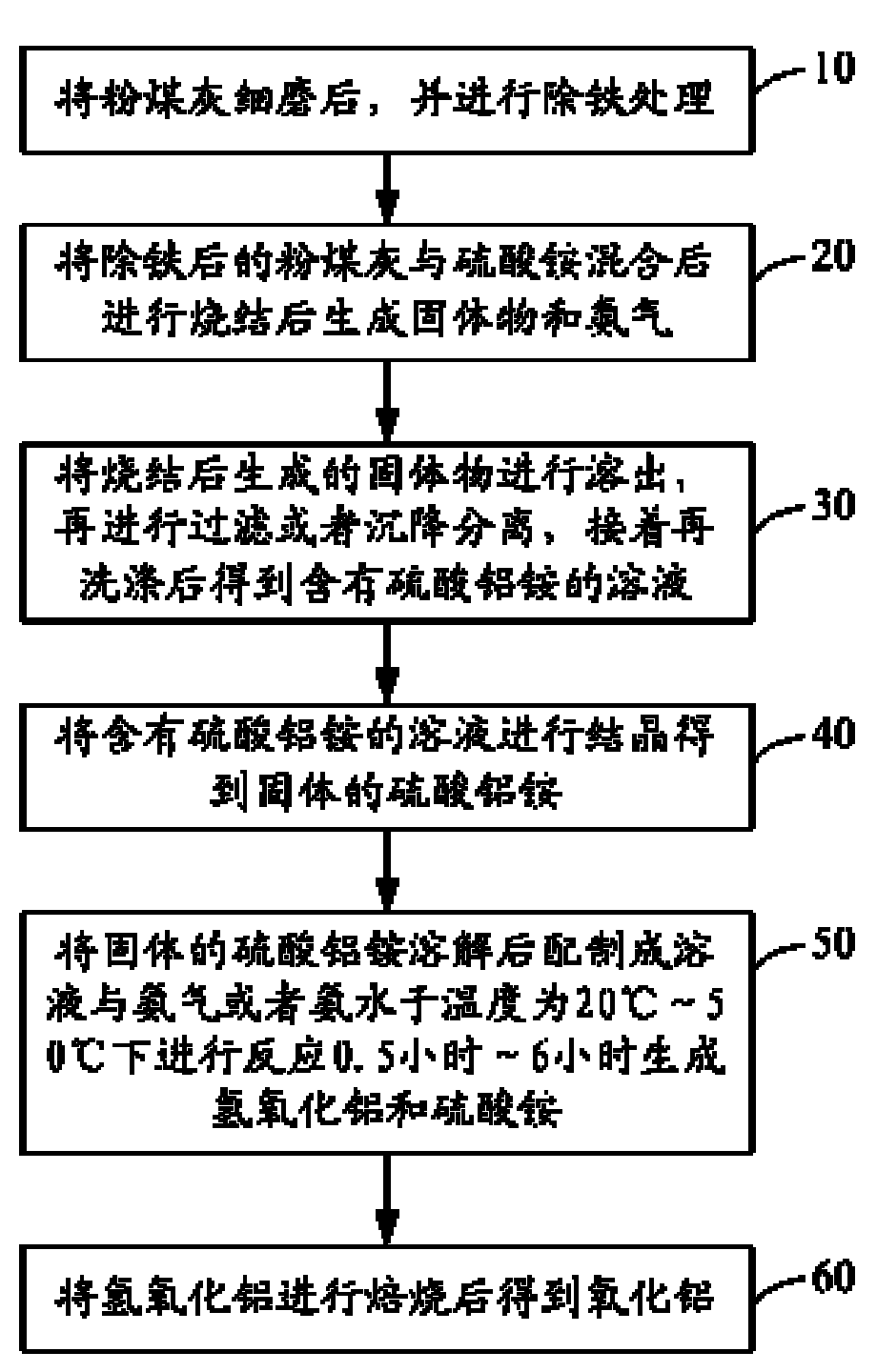

Method for extracting aluminum oxide from pulverized flue ash

ActiveCN102120593ALess corrosiveLess residueAluminium oxides/hydroxidesAluminium hydroxideAluminum ammonium sulfate

The invention relates to a method for extracting aluminum oxide from pulverized flue ash. The method comprises the following steps of: finely grinding the pulverized flue ash, and deironing; mixing the deironed pulverized flue ash and ammonium sulfate and then sintering to generate solid and ammonia gas; dissolving out the solid generated through sintering, then filtering or settling out, washing to obtain a solution containing aluminum ammonium sulfate; crystallizing the solution containing the aluminum ammonium sulfate to obtain solid aluminum ammonium sulfate; dissolving the solid aluminum ammonium sulfate, then preparing into a solution which reacts with the ammonia gas or ammonia water for 0.5-6h at a temperature of 20-50 DEG C to generate aluminum hydroxide and ammonium sulfate; roasting the aluminum hydroxide to obtain the aluminum oxide. The method for extracting the aluminum oxide from the pulverized flue ash is simple, ensures that less byproduct is produced and is easy to realize industrial application.

Owner:北京世纪地和控股有限公司

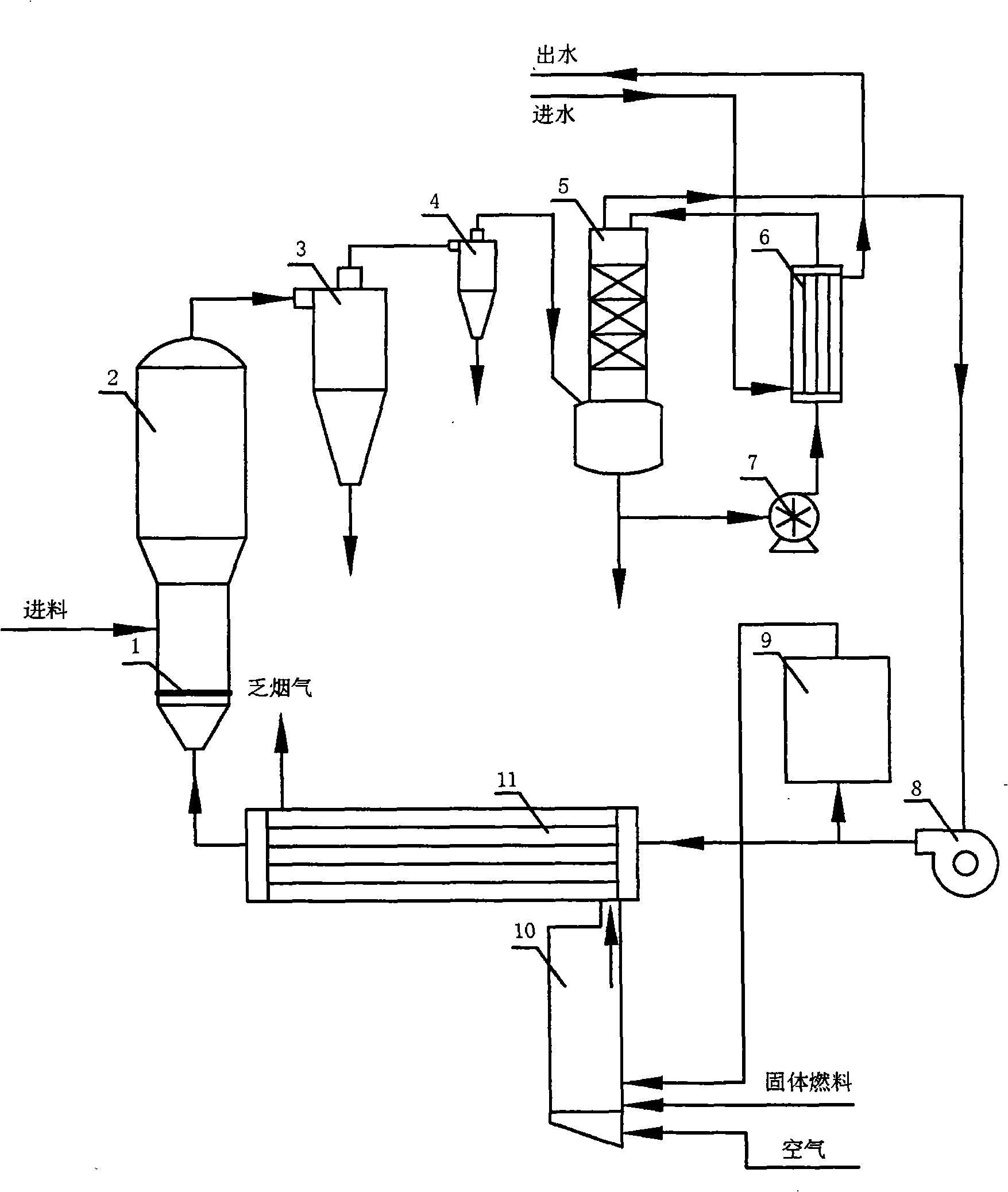

Industrial continuous agricultural and forestry biomass fast pyrogenation oil refining method and device thereof

InactiveCN101525545AAvoid settingSimple structureLiquid hydrocarbon mixture productionProduct gasEngineering

The present invention relates to an industrial continuous agricultural and forestry biomass fast pyrogenation oil refining method and a device thereof. The invention belongs to the technical field of biomass regeneration utilization and changing into energy. The crushed and dried agricultural and forestry biomass material is delivered into a pyrolysis reactor from the base for reacting. The carbon and pyrolysis are generated, wherein the pyrolysis enters a condenser along with the circulating gas. The bio-oil obtained after condensing the pyrolysis gas and incoagulable gas enter a reacting system for being heated by a combustion furnace for recycling. The fast pyrogenation oil refining method and the device of the invention use the incoagulable gas generated in the system as circulating fluidizing agent gas and heat supplying gas for high-efficiently executing the fast pyrogenation, gas-solid separation, condensing oiling of agricultural and forestry biomass and furthermore realizing the excellent circulation in the system. The device of the invention also has the advantages of reasonable structure of reactor, compact mechanism, stable operation of whole device, and suitability for industrial continuous production.

Owner:北京海润川投资咨询有限公司

Technological method for treating carbolic acid waste water by electrochemical oxidation

InactiveCN1935679AExtended service lifeSimple processWater/sewage treatment by electrochemical methodsWater useElectrolysis

The invention discloses a process and method of electrolyzing and oxidizing phenol-containing waste water using Ti-base Sn-Sb metal oxide electrode as anode, belonging to water processing field. And the process uses Ti-base Sn-Sb metal oxide electrode as anode and Cu (or stainless steel) as cathode to electrolyze and oxidize the phenol-containing waste water, where the Ti-base Sn-Sb metal oxide anode is made from polymeric precursor by thermolysis. And it can fast degrade the phenol and the degradation intermediate product of the phenol-benzoquinone into aliphatic organic matters to be biochemically processed, thus able to largely raise follow-up biochemical processing efficiency. And it has simple process flow, strong operability, high current efficiency, and stable and reliable processing effect, easy to implement industrialized application.

Owner:YANGZHOU UNIV

Silicon nitride ceramic slurry, preparation method of silicon nitride ceramic slurry and application of silicon nitride ceramic slurry in preparing silicon nitride cast film

The invention provides silicon nitride ceramic slurry, a preparation method of the silicon nitride ceramic slurry and application of the silicon nitride ceramic slurry to preparation of a silicon nitride cast film. The preparation method comprises the following steps of mixing silicon nitride powder, a sintering aid, a dispersant and a solvent, performing first ball milling, then adding an adhesive and a plasticizer for secondary ball milling, and performing vacuum defoaming to obtain slurry, wherein the mass ratio of the silicon nitride powder, the sintering aid, the dispersant and the solvent is 100 to (5-15) to (49-67) to (2-3.5) to (10-20) to (10-40); and performing tape casting and drying on the slurry to obtain a smooth, uniform, dense, gentle and agreeable Si3N4 biscuit which is benefical to forming processing and sintering in a later period. The silicon nitride ceramic slurry obtained by the method is uniform, is low in viscosity, high in solid content, simple in preparation technology and liable to realize industrialization and is suitable for tape casting.

Owner:SHANGHAI UNIV

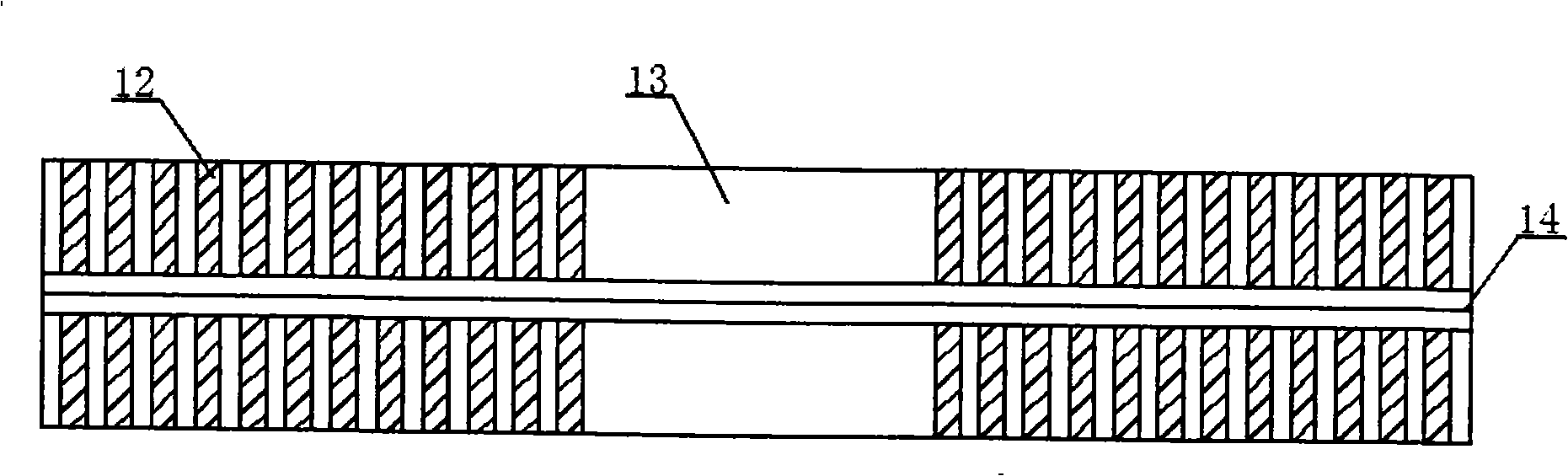

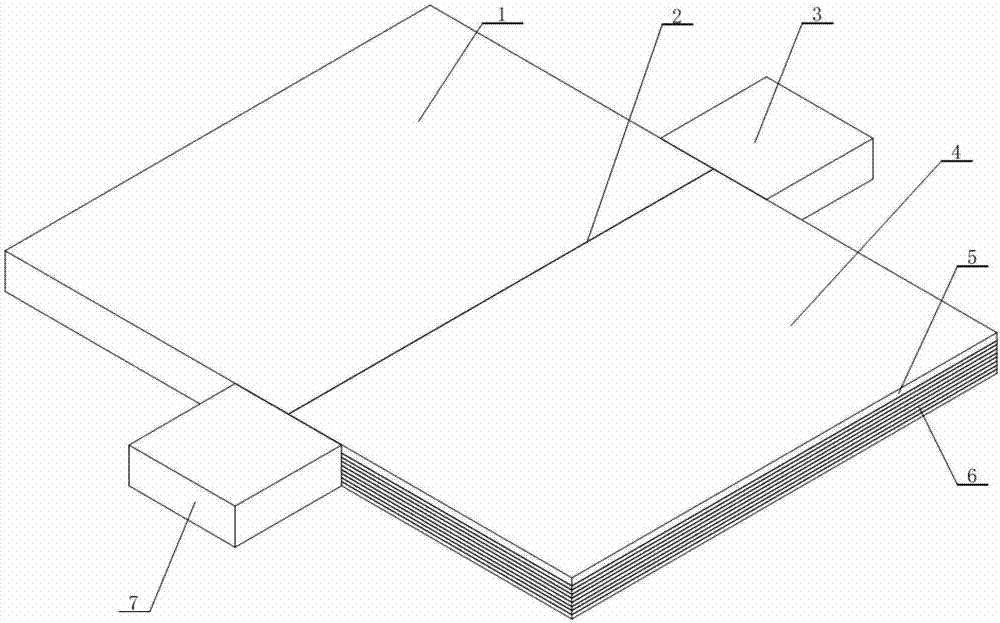

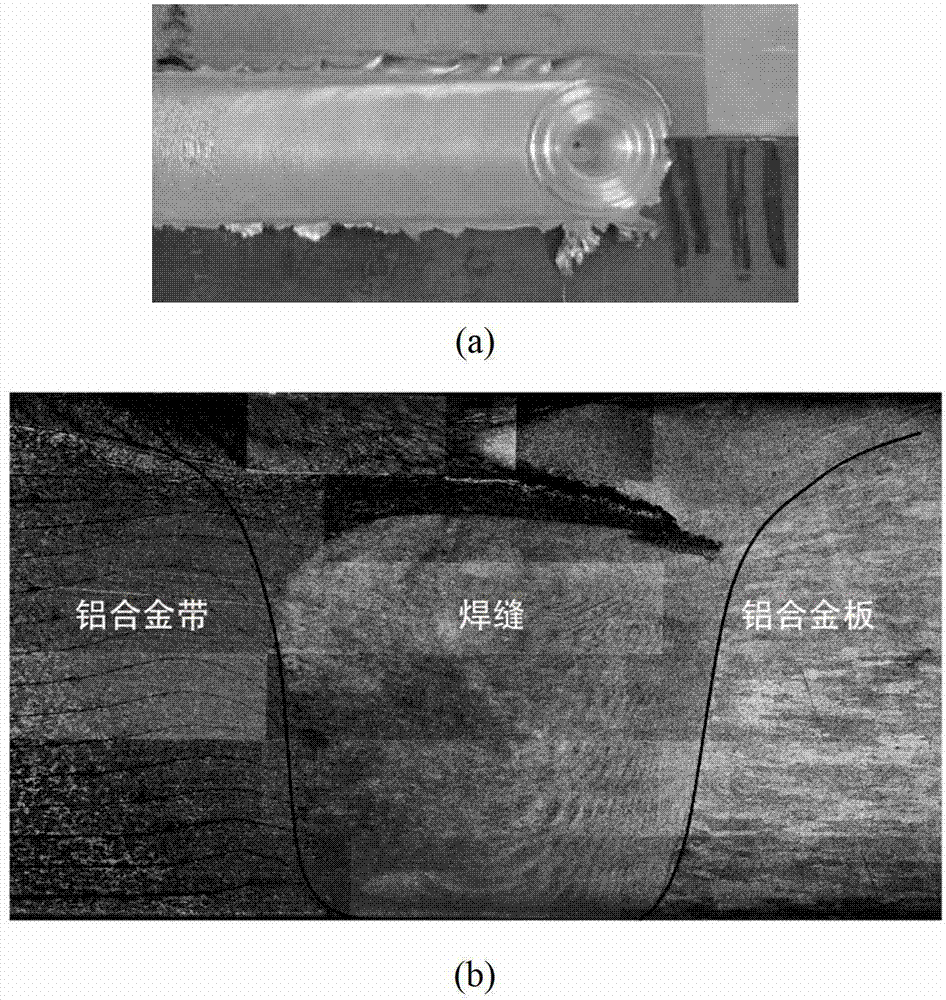

Welding method for multi-layer metal strip

ActiveCN102873454AQuality improvementGuaranteed electrical conductivityNon-electric welding apparatusMetal stripsControllability

The invention relates to a welding method for a multi-layer metal strip. The method is characterized by comprising the following steps of: stacking the multi-layer metal strip to be welded to reach the required thickness, and aligning the multi-layer metal strip with the weld of another stacked multi-layer metal strip or metal plate; fixing a welding guiding plate of which the thickness is the same as that of the multi-layer metal strip to be welded at the starting end of a weld joint along the welding direction; selecting a stirring head, wherein the diameter of a shaft shoulder of the stirring head is 2 to 3 times the plate thickness, the length of a stirring needle on the stirring head is 0.05 to 0.2mm less than the plate thickness, and the press amount of the shaft shoulder is 0.1 to 0.3mm; and selecting rotation speed and welding speed according to a welding material, and welding. The method is energy-saving and environment-friendly, an operation process is greatly simplified, and production efficiency is improved; the quality of a joint is improved, the conductivity of the joint is ensured, and production cost is reduced; controllability is high, and industrial application is easy to implement; and the obtained joint has a compact structure, does not have any pore or crack and is slightly deformed, the operation process is simple, the production period is short, efficiency is high, and the production cost is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

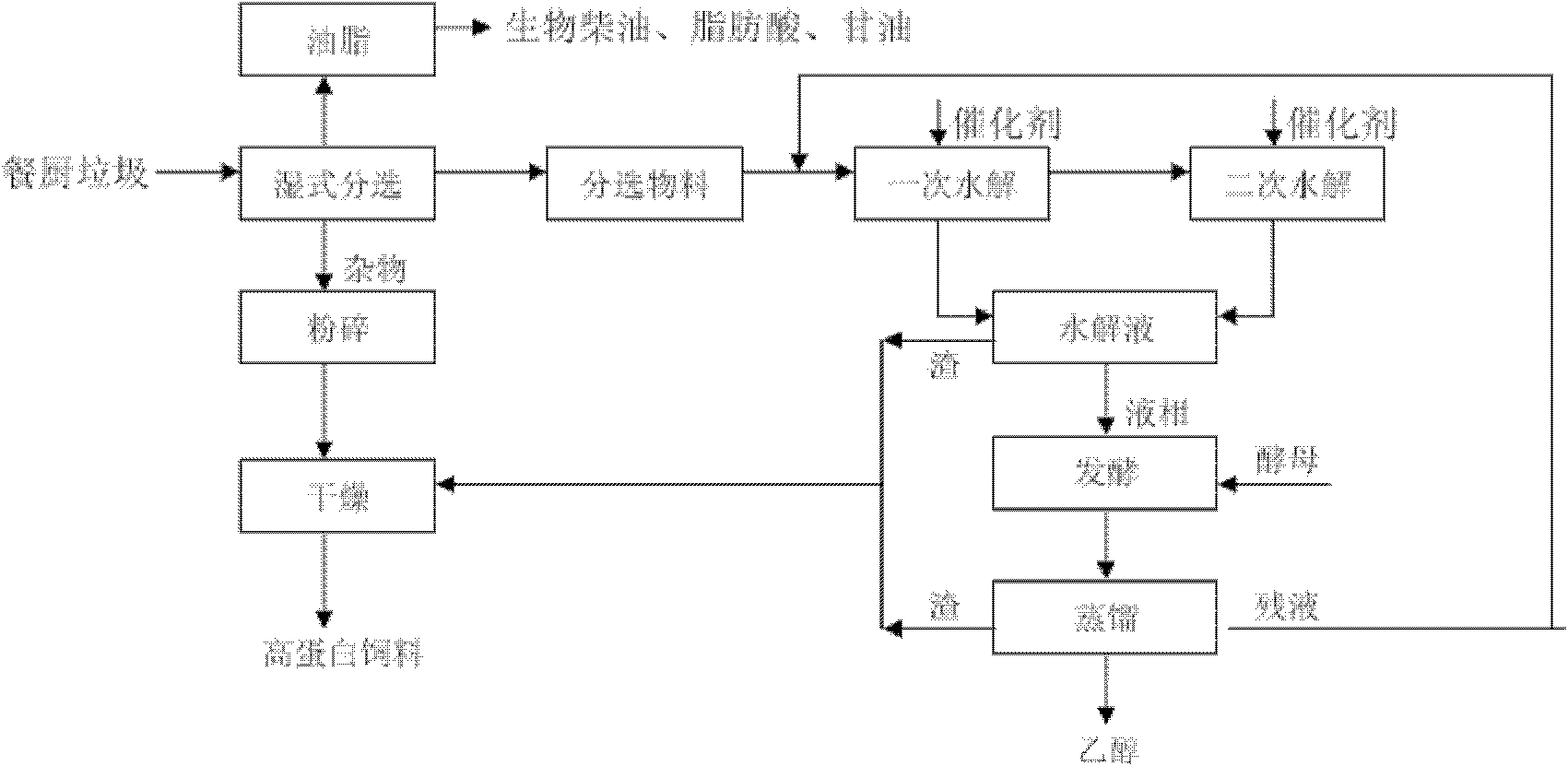

Recycling method for cleaning and processing kitchen waste

InactiveCN101890423AIncrease the degree of hydrolysisCompletely hydrolyzedFatty oils/acids recovery from wasteSolid waste disposalOil and greaseOperational costs

The invention relates to a waste processing method, in particular to relate to a recycling method for cleaning and processing kitchen waste and comprising the following steps: sorting, separating and recovering grease, performing secondary hydrolysis on materials after grease separation and recovery, further fermenting hydrolysis liquid and preparing solid residue obtained by sorting, hydrolysis and fermentation into feed. The invention has the following beneficial effects: economic and reasonable technologies suitable for industrialized application are adopted, thus greatly lowering processing cost; regenerative recycled products can be prepared with wide application and high additional value; and the production process is clean and environment-friendly, closed cycle of materials can be realized, secondary pollutants are prevented, and the recycled products have wide application, low operation cost and high economic benefit.

Owner:武汉市金书环保科技股份有限公司

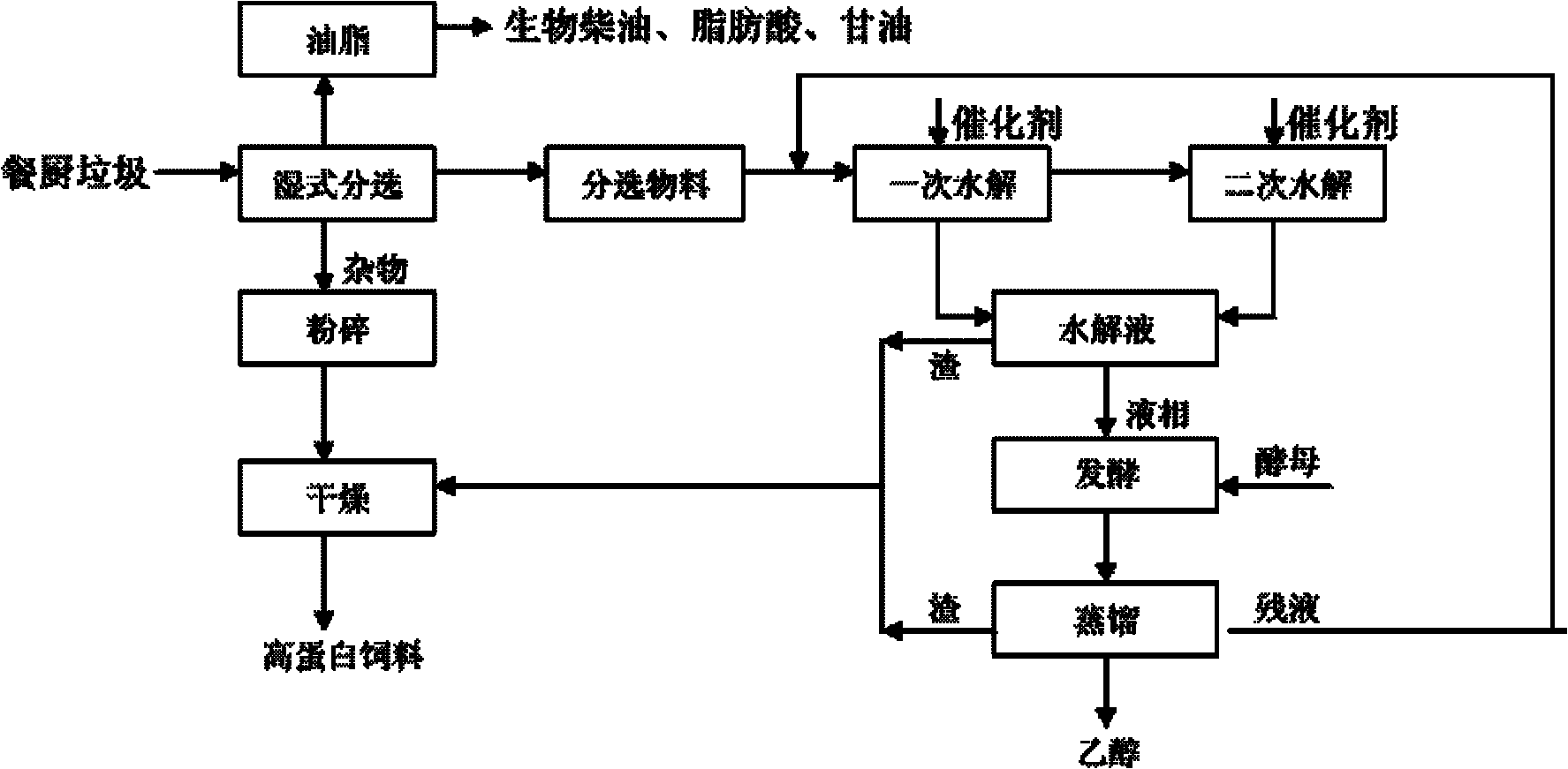

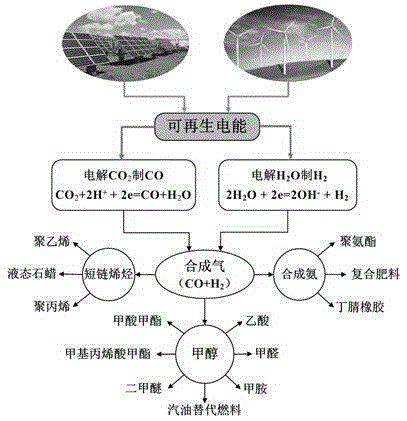

Multi-room diaphragm electrolysis method and device for electroreduction of carbon dioxide into carbon monoxide

ActiveCN105297067AIncrease current densityImprove solubilityCellsSupporting electrolyteComposite electrolyte

The invention relates to a multi-room diaphragm electrolysis method and device for electroreduction of carbon dioxide into carbon monoxide, and belongs to the technical field of carbon dioxide resource utilization. According to the multi-room diaphragm electrolysis method and device, an electrolytic tank is divided into a plurality of electrode rooms through a perfluoro sulfonated ion exchange membrane, and a multi-room diaphragm electrolytic tank with alternately-arranged cathode rooms and anode rooms is formed; a cathode electrolyte is an organic composite electrolyte dissolved with the carbon dioxide, and an anode electrolyte is a water solution containing a supporting electrolyte; a cathode is a metal electrode having high selectivity on carbon monoxide making through electrolysis of the carbon dioxide, and an anode is a noble electrode; and in the electrolytic reaction process, water has an oxidizing reaction with the anode to generate oxygen, the carbon dioxide has a reduction reaction with the cathode to generate the carbon monoxide. By means of the multi-room diaphragm electrolysis method and device, electroreduction of the carbon dioxide into the carbon monoxide can be efficiently and continuously carried out.

Owner:KUNMING UNIV OF SCI & TECH

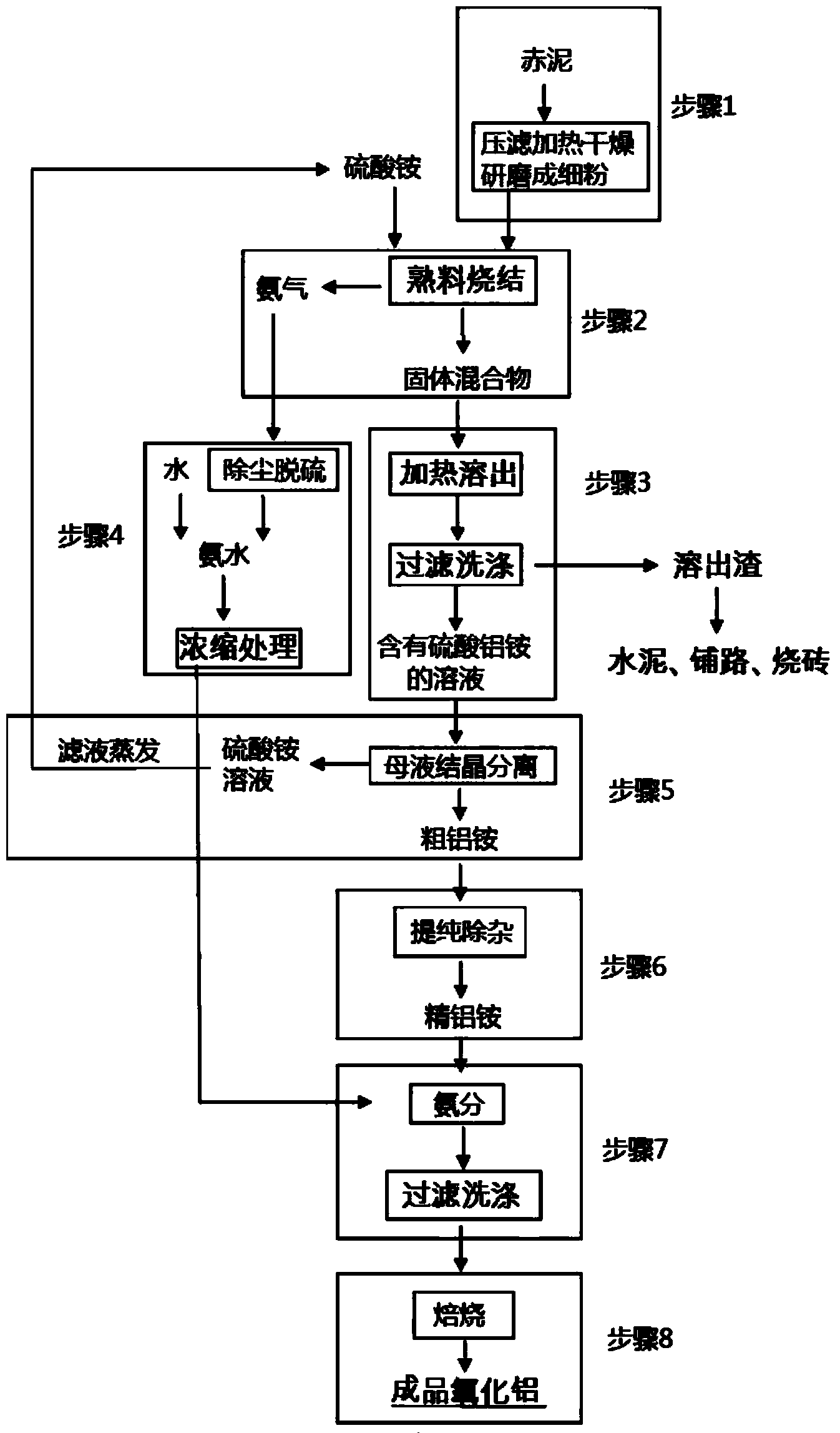

Method for recycling aluminum oxide from red mud

ActiveCN103626213AParticle size range controllableHigh purityAluminium oxides/hydroxidesAluminium hydroxideRed mud

The invention relates to a method for recycling aluminum oxide from red mud. The method comprises the following steps: filtering the red mud by pressing, drying by heating, and grinding the red mud into fine powder; mixing the ground red mud with ammonium sulfate, and sintering to obtain a solid mixture and ammonia gas; pouring the solid mixture into water so as to dissolve out by heating, and separating by filtering to obtain a solution containing ammonium aluminum sulfate; dedusting and desulfurizing the ammonia gas, and absorbing the ammonia gas by water to obtain ammonia water; crystallizing the salt solution containing ammonium aluminum sulfate to obtain crude ammonium aluminum sulfate; dissolving the solid ammonium aluminum sulfate into hot water, cooling, crystallizing, and removing impurity; dissolving the fine ammonium aluminum sulfate obtained after secondary crystallization into water, and reacting with the ammonia water to obtain aluminum hydroxide and ammonium sulfate; calcinating the aluminum hydroxide to obtain the aluminum oxide. In the method for recycling the aluminum oxide from the red mud, the ammonia gas and the ammonium sulfate are recycled, therefore, the cost and byproducts are reduced greatly.

Owner:北京世纪地和控股有限公司

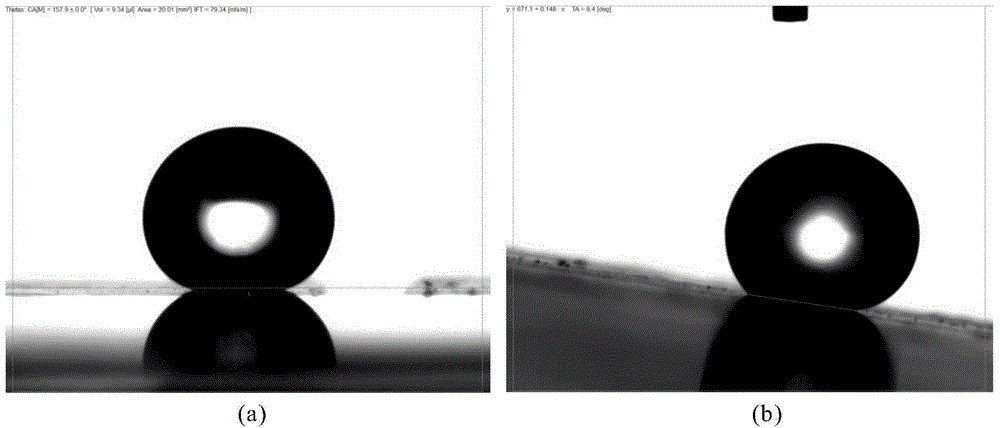

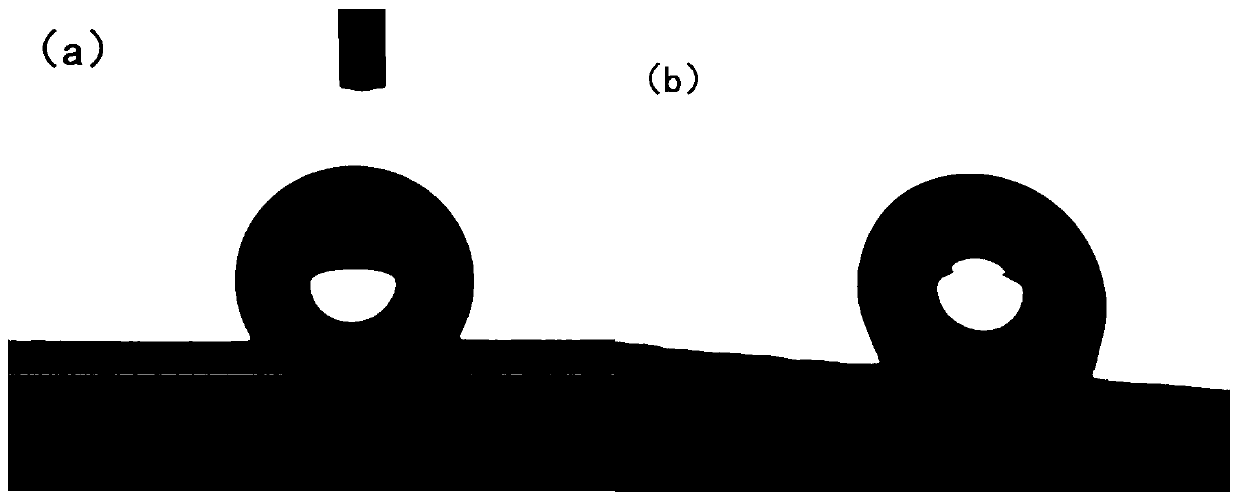

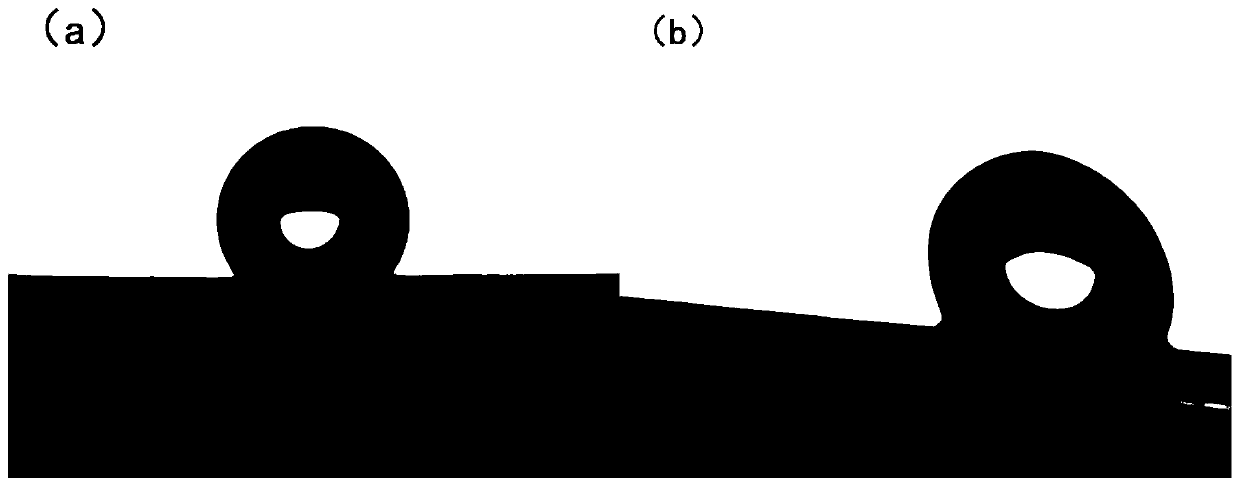

Method for preparing aluminum alloy superhydrophobic self-cleaning surface by using ultrashort pulse laser

InactiveCN104947116AExcellent superhydrophobic propertiesSimple processMetallic substrateSurface modification

The invention relates to a method for preparing an aluminum alloy superhydrophobic self-cleaning surface by using an ultrashort pulse laser, belonging to the technical field of metal substrate surface modification. The method comprises the following steps: carrying out polishing pretreatment on an aluminum alloy sample, cleaning the sample surface respectively with deionized water and anhydrous ethanol, blow-drying with cool air or drying in air, and carrying out surface treatment on the sample by using a laser processing technique after adjusting related technological parameters by an ultrashort pulse laser so as to obtain countless microstructures on the sample surface; and after finishing processing, putting the processed sample into an electrothermal drying box, and baking to obtain the aluminum alloy superhydrophobic surface with a micron-sized mastoid or porous structure on the surface, wherein the surface has the self-cleaning function and has excellent friction resistance and corrosion resistance. The preparation method has the advantages of simple technique, high efficiency, low energy consumption, low cost and environment friendliness, is convenient to operate, and can easily implement industrial application.

Owner:HUBEI UNIV OF TECH

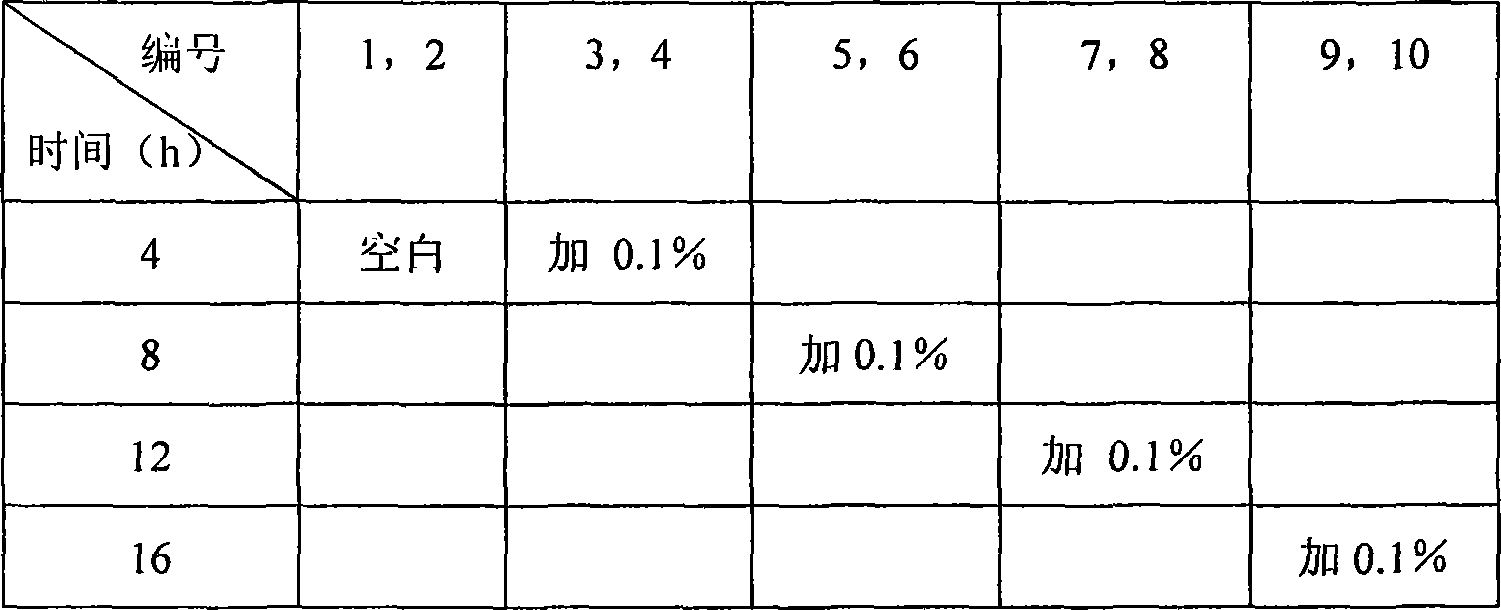

Processing method for utilizing heavy metal to restore plant residues

InactiveCN102517447AReduce volatilityEasy for industrial applicationProcess efficiency improvementAshingEnvironmental chemistry

The invention discloses a processing method for utilizing heavy metal to restore plant residues, which comprises cleaning and draining the plant residues after restoration, enabling granularity of debris to be between 2mm and 8mm after smashing, mixing plant debris and a fixing agent according to a proportion of mass ratio of 2-5:1, ashing for 4-6h under the condition of 400-800 DEG C, spraying gas generated by ashing, and mixing ash generated after ashing into corresponding metal ores to perform further smelting and recycling or use acid spray to purify heavy metal by-products. The processing method is large in processing quantity and remarkable in reduction, plant quality loss accounts for 85-98% of the total mass, and volatilization quantity of the heavy metal is reduced by 80-90%. The processing method is low in cost, reduces secondary pollution to the environment, and has good practical application prospects in the aspect of metal recycling.

Owner:KUNMING UNIV OF SCI & TECH

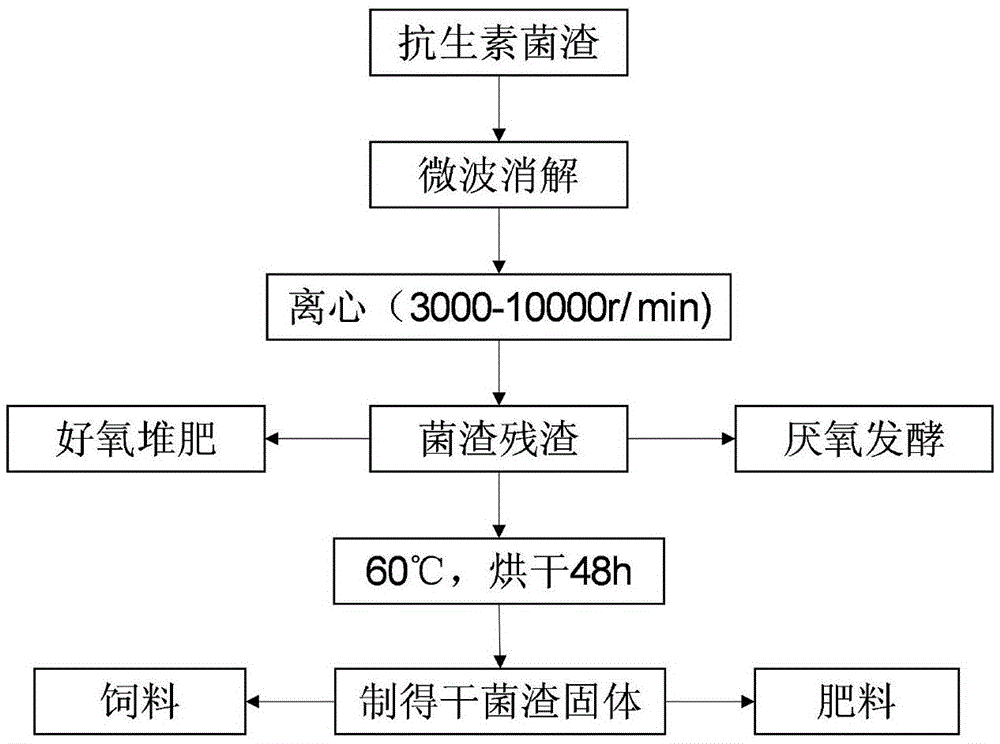

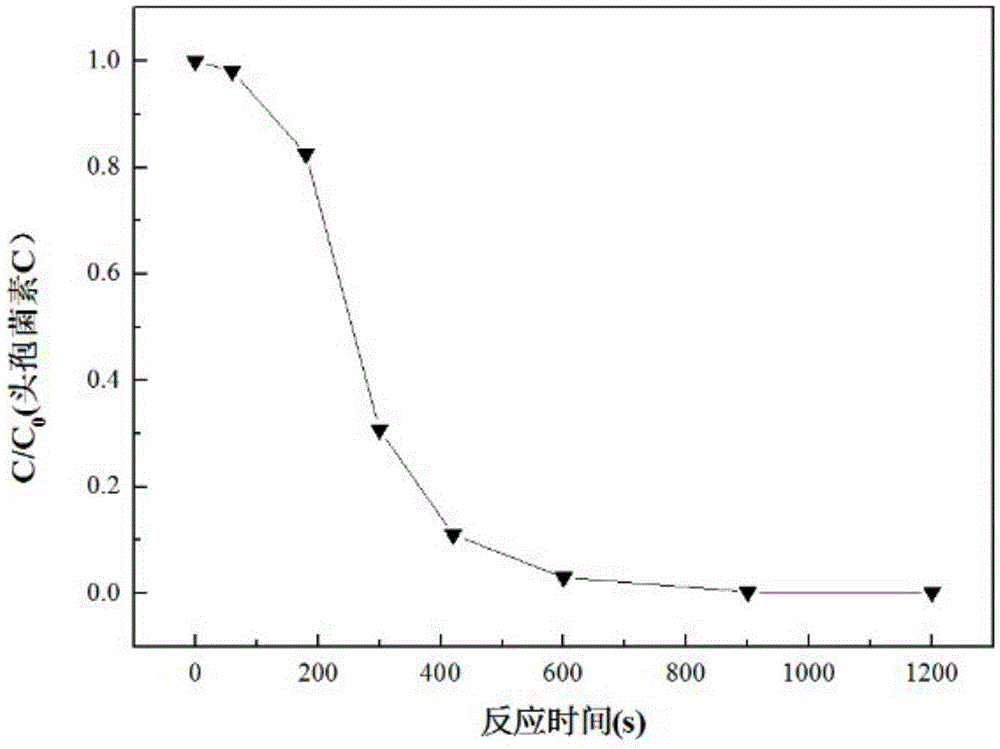

Treatment method and application of antibiotic bacterial residues

InactiveCN105537251ALow moisture content requirementRealize resourcesTransportation and packagingSolid waste disposalAfter treatmentAntibiotic Y

The invention relates to a treatment method and an application of antibiotic bacterial residues, and aims to solve problems that existing bacterial residue treatment methods are long in period, still have the environmental risk after treatment and the like. The method comprises steps as follows: 1) fresh bacterial residues are placed in a reaction tank, the moisture content is controlled between 85% and 95%, and the bacterial residues are evenly mixed; 2) the reaction tank containing the bacterial residues is placed in a microwave reactor, heated to 100 DEG C by a microwave generator with the microwave power of 100-900 W and kept for 10 min; 3) the antibiotic bacterial residues after the reaction are subjected to centrifugal separation, and obtained bacterial residues are precipitated and dried. With the adoption of the method, antibiotic residues in the bacterial residues can be removed quickly, and harmless treatment and recovery of the bacterial residues are realized.

Owner:HARBIN INST OF TECH

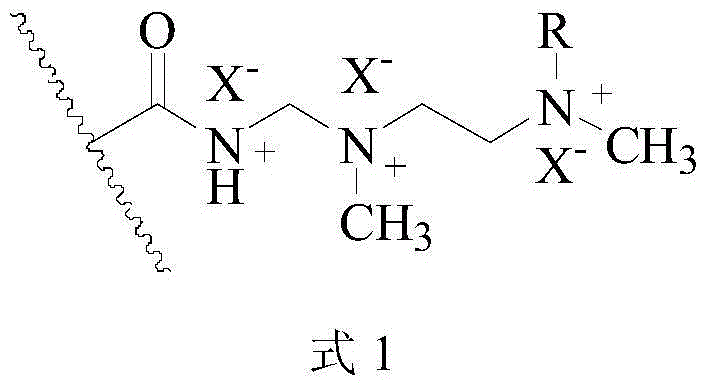

Method for deeply removing molybdenum from tungstate solution through ion exchange process

The invention discloses a method for deeply removing molybdenum from a tungstate solution through an ion exchange process. According to the method, multi-amine weak basic anion exchange resin is employed for selectively adsorbing and removing thiomolybdate anion from the tungstate solution subjected to sulfur substitution. The method is good in molybdenum removal effect and easy for desorption, the desorption process does not need adding an oxidant, and the service life of resin is substantially prolonged. Also the method is short in flow, simple in operation and low in cost, and is easy for industrialized application.

Owner:CENT SOUTH UNIV

Method for improving tensile strength of carbon fiber by utilizing graphene

InactiveCN103015157AHigh tensile strengthActive carbon atomsCarbon fibresHeating/cooling textile fabricsCarbon fibersFiber bundle

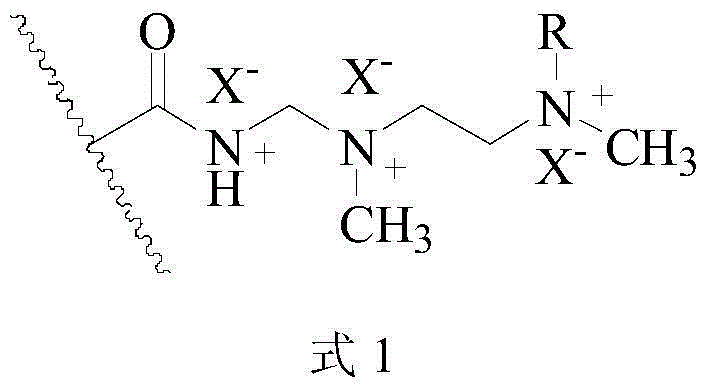

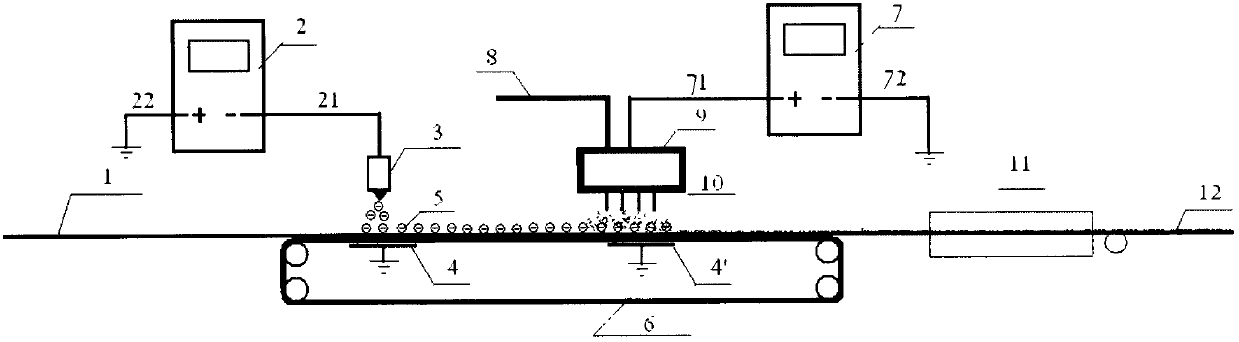

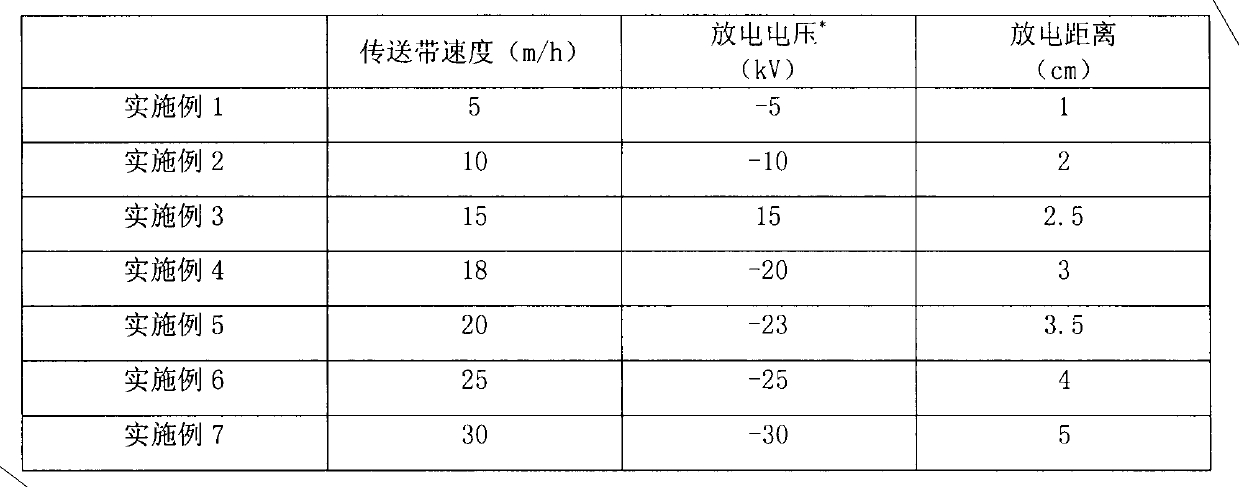

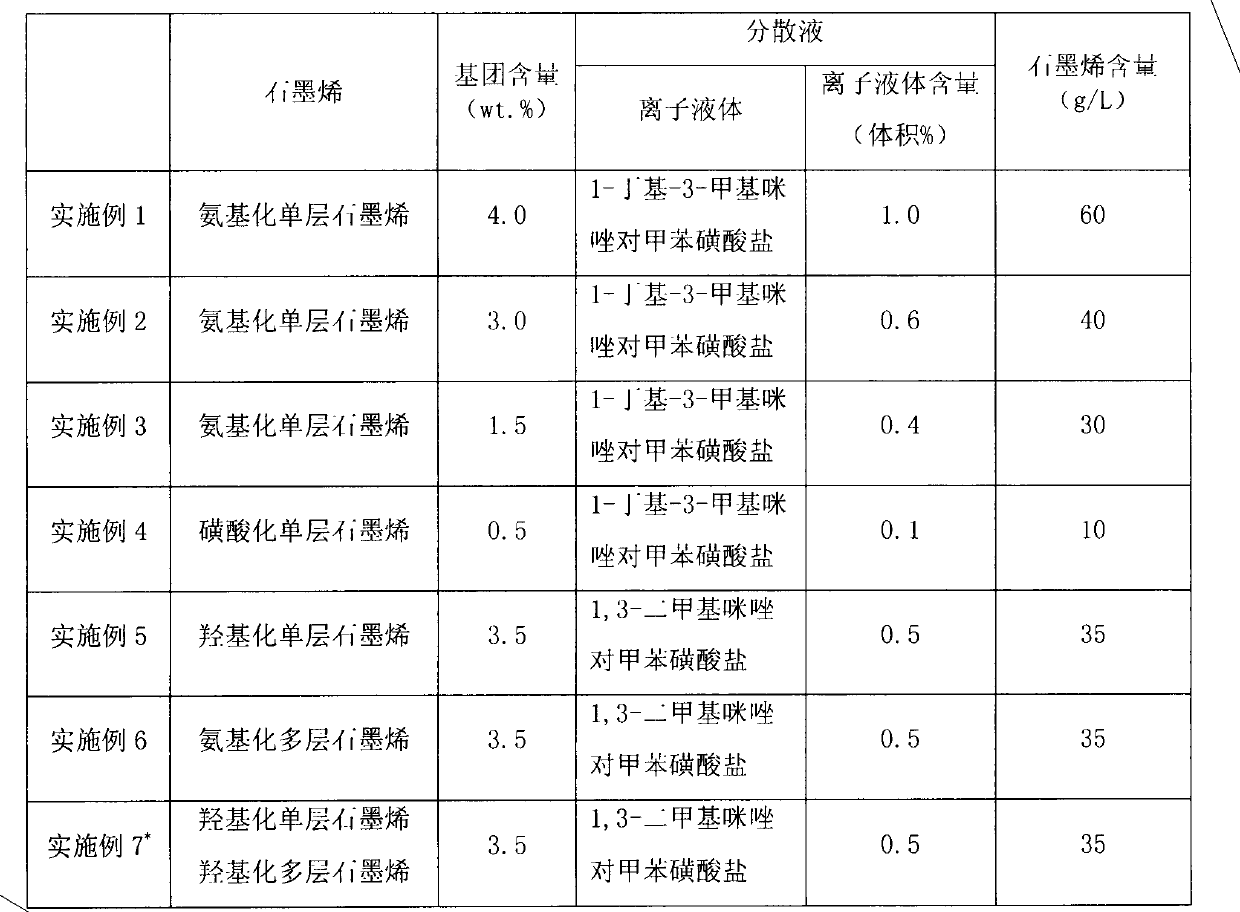

The invention relates to a method for improving tensile strength of a carbon fiber by utilizing graphene. An improved electric atomization deposition method is adopted for planting graphene into surface structure defects of the carbon fiber, so as to improve the strength of the carbon fiber. The method provided by the invention comprises the following steps of: 1) transmitting a pre-oxidized and carbonized carbon fiber bundle into a high-voltage corona discharge area, carrying out corona discharge under high voltage of minus 5kV to minus 30kV, wherein the advancing speed is 5-30m / h, so that a certain amount of negative charge is taken along in the surface structure defects of the carbon fiber; 2) preparing graphene, distilled water and small amount of dispersing agent into uniform and stable suspension, wherein functional graphene selected from amination graphene, sulfonation graphene and hydroxylation graphene is adopted, and the dispersing agent is one of imidazole benzene sulfonate ionic liquids; 3) applying positive static electricity of 20-50kV to the graphene suspension, flattening the charged carbon fiber bundle and grounding to form a spraying fluid acceptor, and then planting the graphene into the surface structure defects of the carbon fiber by virtue of electric atomization deposition, wherein deposit is controlled to be 1000:(0.1-4) in weight ratio of the carbon fiber to the graphene; and 4) carrying out heat treatment on the carbon fiber bundle under the insert gas argon atmosphere at the temperature of 300-1600 DEG C after atomization deposition is carried out by virtue of the graphene. The tensile strength of the carbon fiber can be improved by more than 130%.

Owner:TIANJIN POLYTECHNIC UNIV

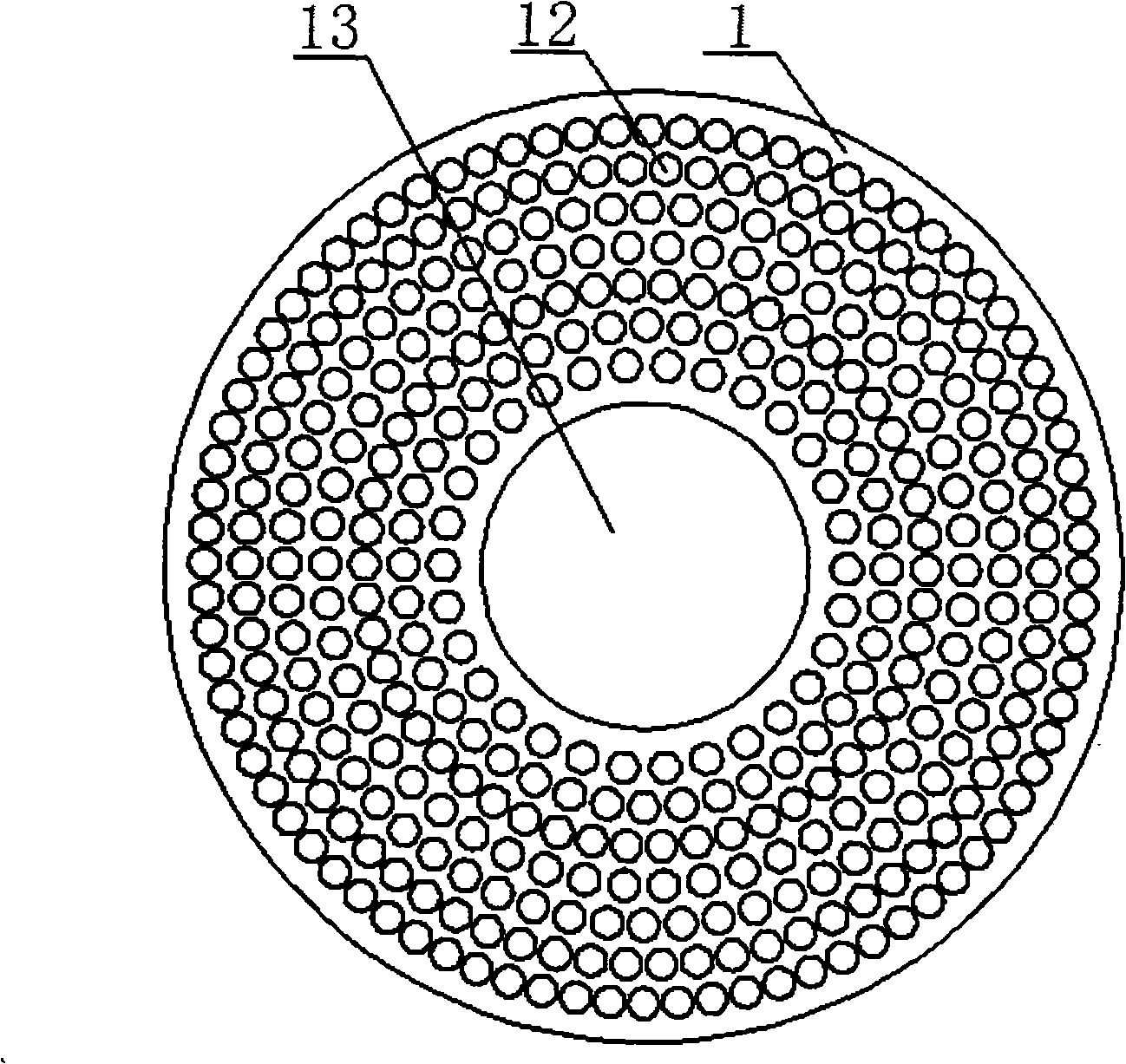

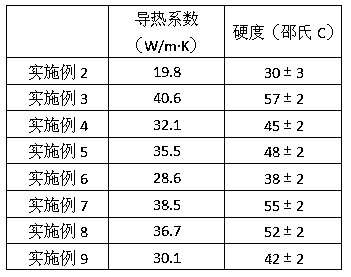

Preparation method of silicone rubber pad

The invention discloses a preparation method of a silicone rubber pad. The preparation method includes the following steps that 1, a nanocarbon material is added to silicone rubber, and after uniform kneading is conducted, a nanocarbon-silicone rubber mixture is obtained; 2, inorganic thermal conductivity power, a catalyst and a mixture composed of simethicone and hydrogen containing silicone oil are added to the nanocarbon-silicone rubber mixture, and rubber compound is obtained after open milling is conducted; 3, physical orientation is adopted for the rubber compound, and a sample pad with the nanocarbon material arranged in the silicone rubber in an oriented mode is obtained; 4, the sample pad is vulcanized, and the finished silicone rubber pad is obtained. By means of the preparation method, nanocarbon can be arranged in the silicone rubber in an oriented mode, a regular nanocarbon oriented thermal conductivity network structure is formed, and thus a product with an ultrahigh thermal conductivity coefficient is obtained.

Owner:DEYANG CARBONENE TECH

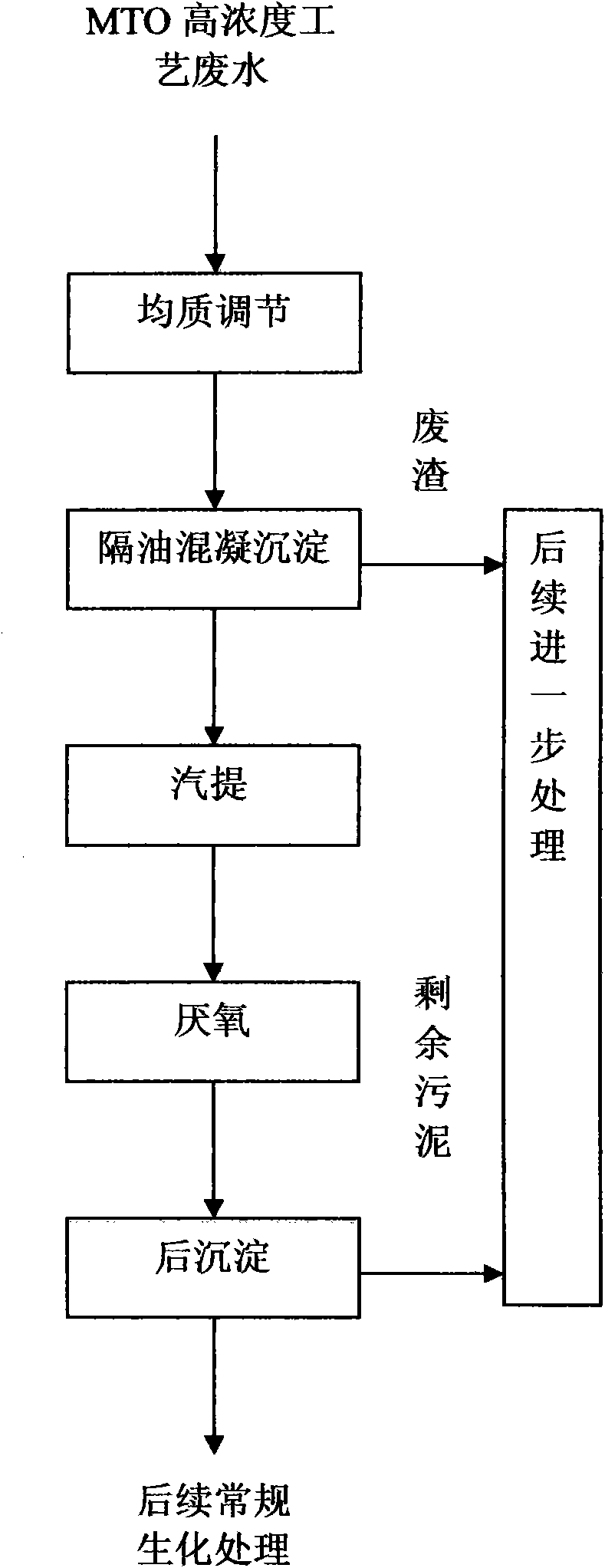

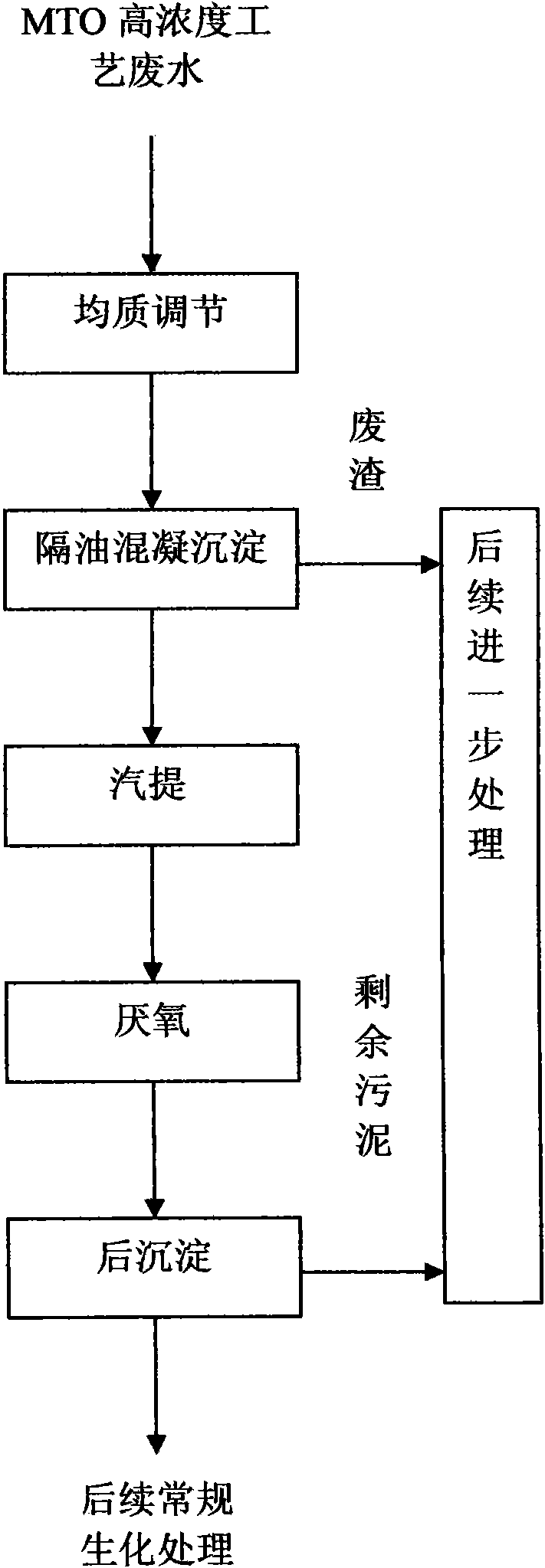

Treatment method of high-concentration process waste water during methanol-to-olefin process

ActiveCN102442744AReduce contentEasy to handleEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationPost precipitation

The invention relates to a treatment method of organic chemical waste water in the waste water treatment technical field, specifically to a treatment method of high-concentration process waste water during methanol-to-olefins (MTO) process, wherein after the MTO high-concentration process waste water is treated by the treatment flow of homogeneous regulation, oil-removing coagulating sedimentation, steam stripping, anaerobic treatment and post-precipitation, and corresponding condition, the COD of the waste water is reduced to be less than 500 mg / L from about 50000 mg / L, and the removal rate is more than 99%. The treatment method of high-concentration process waste water during methanol-to-olefin process has stable treatment effect, and simple and convenient operation, is easy to commercially produce and can be used for pre-treating MTO high-concentration process waste water before entering the normal sewage treatment plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

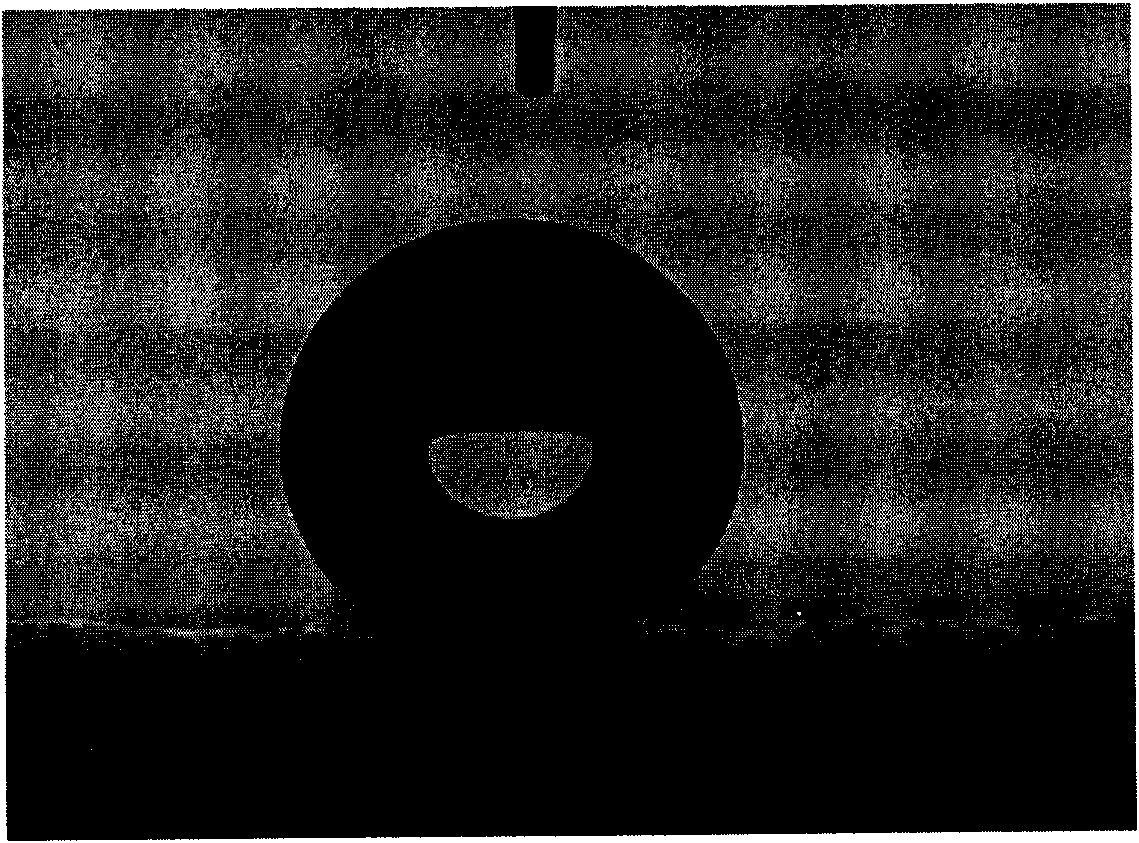

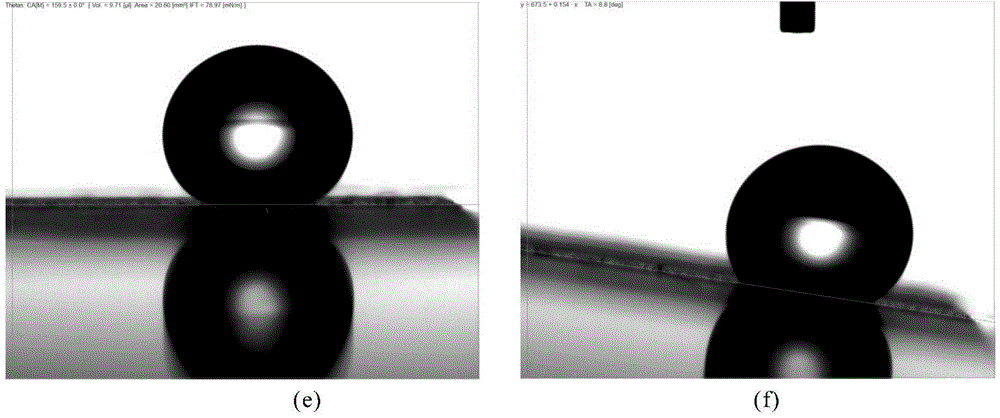

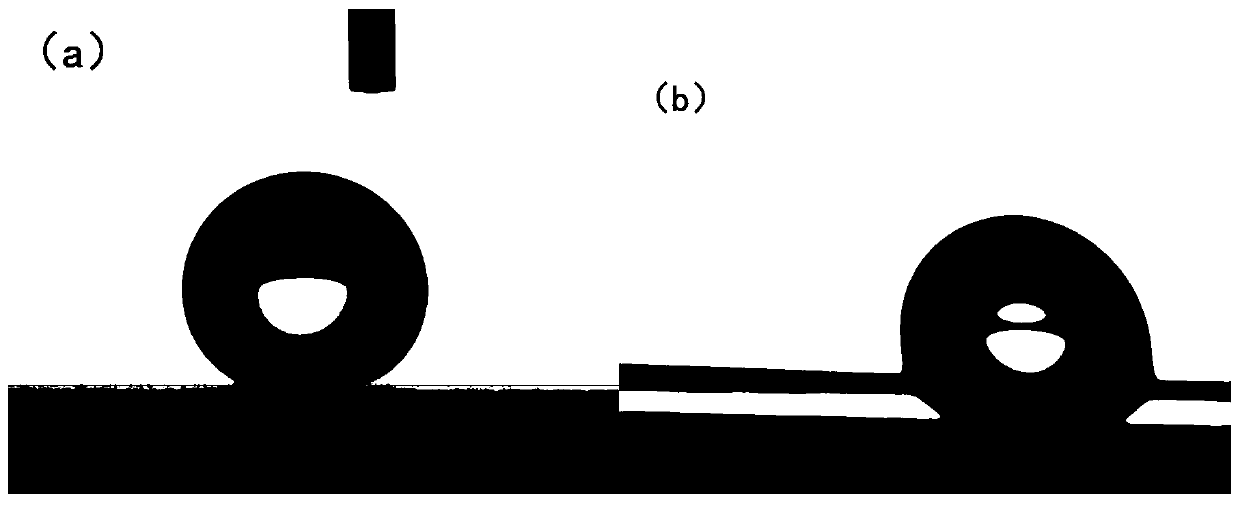

Titanium alloy super hydrophobic-super hydrophilic surface and preparing method and application of titanium alloy super hydrophobic-super hydrophilic surface

InactiveCN109732195AExcellent superhydrophobic propertiesReduce adhesionHeat exchange apparatusLaser beam welding apparatusHigh concentrationCondensation heat transfer

The invention discloses a titanium alloy super hydrophobic-super hydrophilic surface. Multiple sub arrays are distributed on the surface of a titanium alloy. Multiple super hydrophobic areas and multiple super hydrophilic areas in each sub array are arranged alternately in a wedge shape or a triangular shape, and super hydrophilic gathering areas are distributed between the sub arrays. The super hydrophobic surface has the good super hydrophobic performance, drop adhesion is very little, and rolling is extremely easy; drops can be adsorbed by the super hydrophilic areas, the drops at the top ends of the super hydrophilic areas in the wedge shape or the triangular shape can rapidly move towards the bottom of the wedge shape or the triangular shape under the drive of Plath pressure generatedby the wedge shape or the triangular shape, the super hydrophilic areas arranged alternately with the super hydrophilic areas can repel directional transportation of the drops, under the synergisticeffect of the super hydrophobic areas and the super hydrophilic areas, the condensation small drops can be gathered into the hydrophilic gathering area constantly, high-concentration-ratio self-driving water gathering is achieved, disengaging of the drops is accelerated, and therefore the condensation heat transfer efficiency is improved. The invention provides a preparing method and application of the titanium alloy super hydrophobic-super hydrophilic surface.

Owner:HUBEI UNIV OF TECH

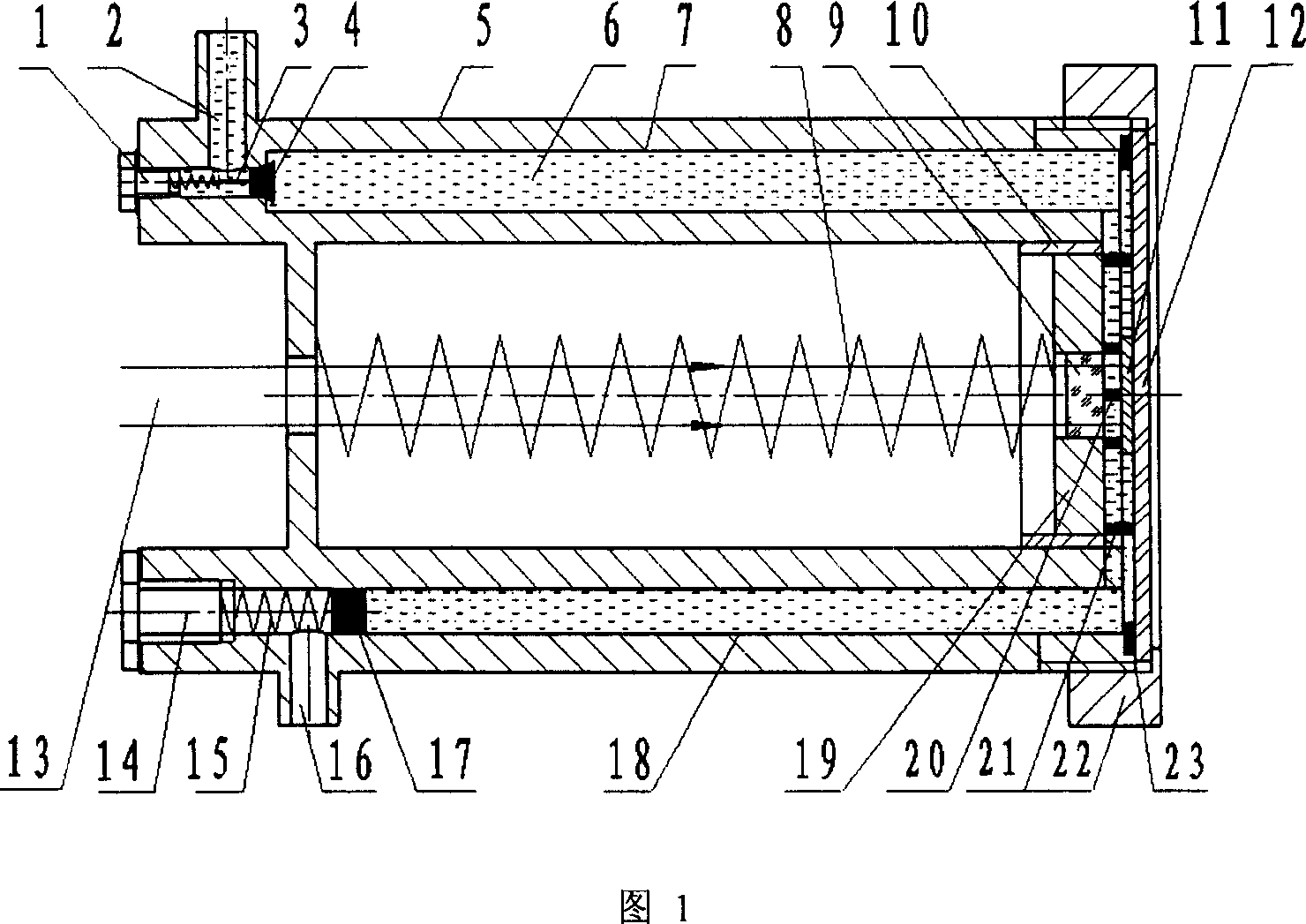

Method and apparatus of continuous collision reinforcement by laser

InactiveCN1928127AEasy to realize industrial applicationRealize automatic processingManufacturing technologySystems design

The present invention relates to special machining and manufacture technology, and is especially continuous impacting high energy short pulse laser apparatus and process for reinforcing metal material. The apparatus is provided with sliding block, flexible working film, cushion block, liquid exhausting piston and other parts to form a flowing constraint liquid medium layer capable of being replaced automatically through liquid inflow in the liquid inlet and the liquid outflow in the liquid outlet. The present invention has properly designed system to integrate the constraint liquid medium essential for laser impacting and the coating skillfully, so as to realize continuous laser impact reinforcing treatment without needing constraint layer fixing and coating. The present invention can also realize online assembling or repairing impact reinforcement.

Owner:JIANGSU UNIV

Method for cleaning and producing dioscorea zingiberensis saponin with microbial technology adopted

The invention provides a method for cleaning and producing dioscorea zingiberensis saponin with microbial technology adopted, and belongs to the field of bioengineering. The method solves the problems that in the existing dioscorea zingiberensis industry, wastewater and waste residues are large in drainage amount, and dioscorea zingiberensis starch is not utilized effectively. The method includes the following steps: releasing dioscorea zingiberensis saponin with microorganism adopted firstly, obtaining fermentation liquor containing the dioscorea zingiberensis saponin and the starch; and then processing the starch in the fermentation liquor with a two-enzyme method adopted and obtaining hydrolyzed sugar, and further releasing the dioscorea zingiberensis saponin; conducting solid-liquid separation on dioscorea zingiberensis mash; gathering the hydrolyzed sugar and the dioscorea zingiberensis saponin with microfiltration and nanofiltration membrane separation adopted in sequence, or obtaining intracellular products and dioscorea zingiberensis saponin through specific microbial fermentation separation, and obtaining the dioscorea zingiberensis saponin by hydrolysis of glycosidase and a small amount acid and extraction of a small amount of organic solvent on concentrated dioscorea zingiberensis saponin solution. According to the method, the yield coefficient of the dioscorea zingiberensis saponin is high (90-95%), wastewater quantity is little in the process of production, degree of contamination is low, microbial treatment is low in cost and short in use time, the dioscorea zingiberensis starch is recycled fully, and the method has a great industrial application promotion value in the dioscorea zingiberensis industry.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for effectively producing 1,3-propanediol by modifying permeability of cell membrane

InactiveCN101230362AImprove permeabilityGuaranteed normal growthMicroorganism based processesFermentationMetaboliteCell membrane

The invention relates to a method of effectively producing 1, 3-propylene glycol by changing the membrane permeability, which adds nonionics to change the membrane permeability, effectively promotes the cell growth, and increases the concentration of 1, 3-propylene glycol which is the finished product of fermentation. The utility model has the technical process that as follows: adding the second-class germ culture into the fermentation culture; adding nonionics which can improve the membrane permeability to the fermentation culture; the nonionics reduce the resistance of the oxygen and nutrient substance from entering the cell, promote the cell growth, enhance the secreting of metabolite to the extra-cellular area, reduce the accumulation of metabolite in cell, and facilitate the elimination of inhibition of product and sub product, in particular the inhibition of cell growth and cell catalytic activity by 1, 3-propylene glycol. The concentration of the fermentation product--1, 3-propylene glycol is increased by 10 to 70 percent. With simple technical process and low production cost, the invention is easy to be industrially applied.

Owner:SOUTHEAST UNIV

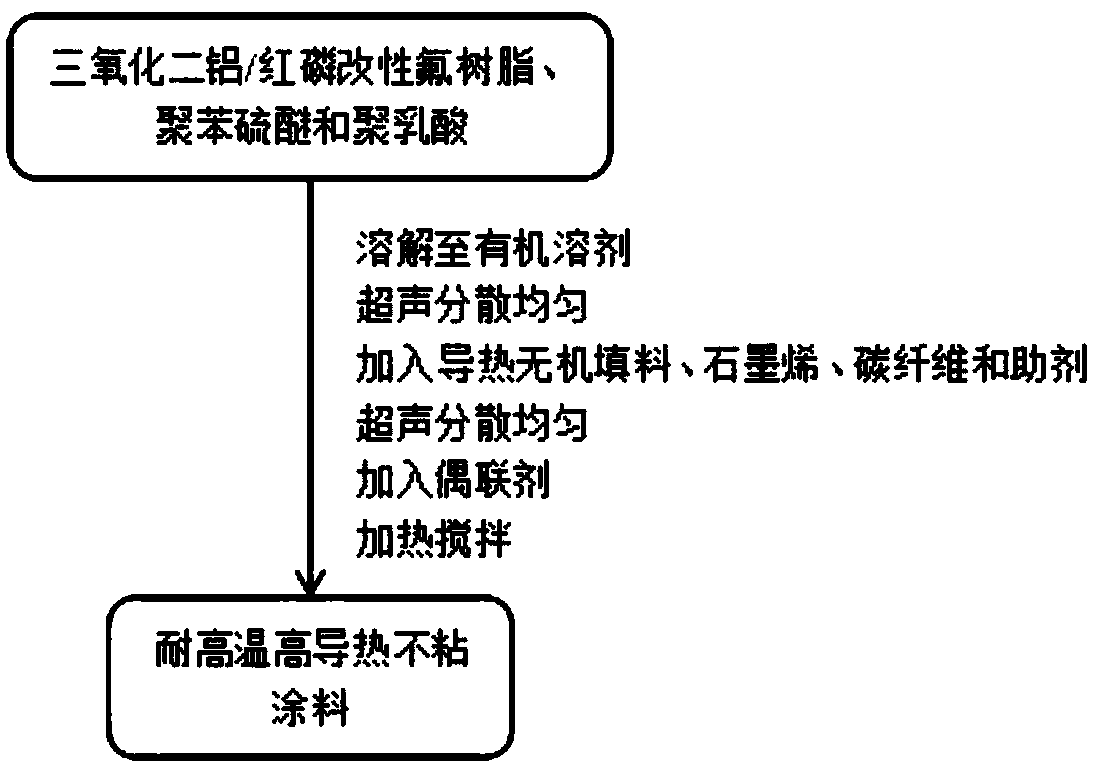

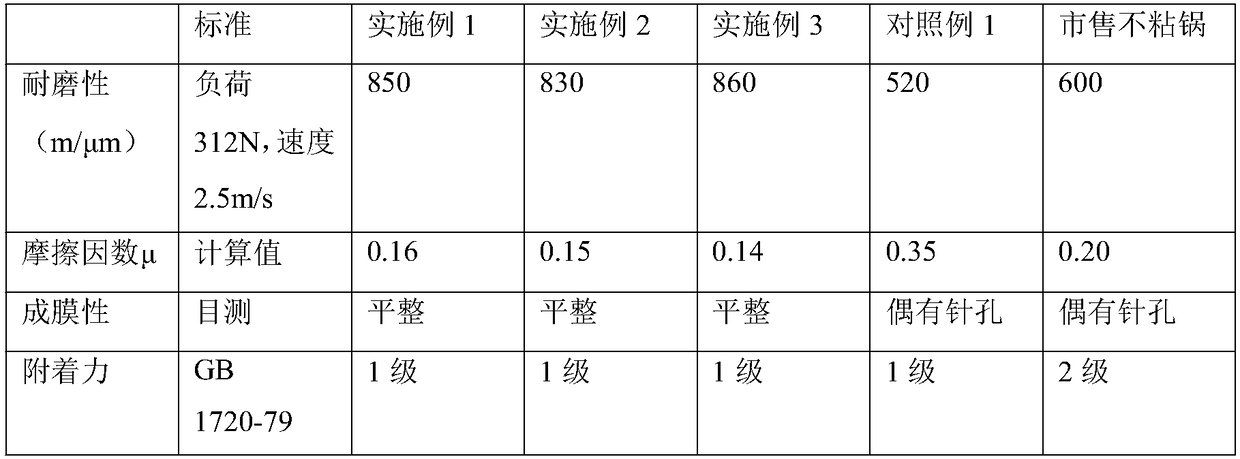

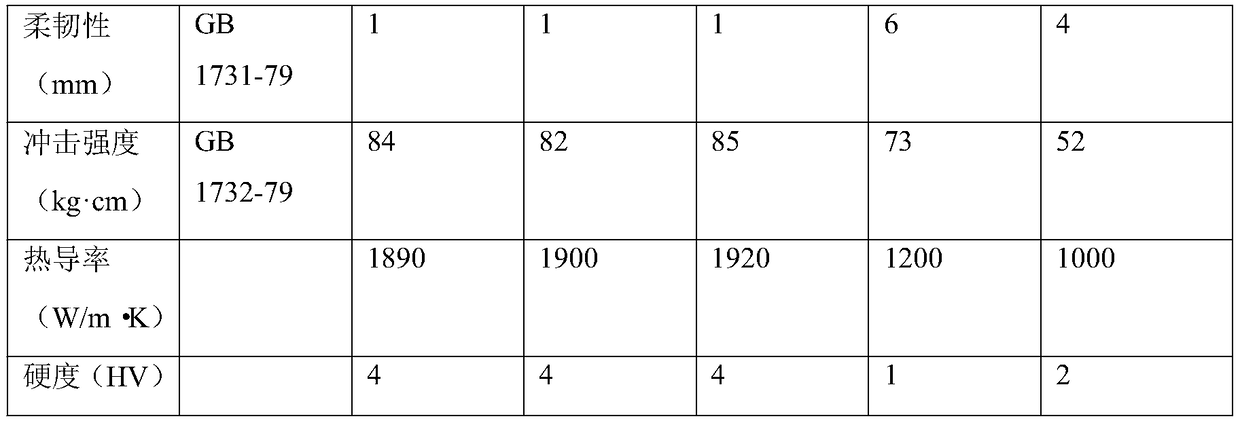

High-temperature-resistant and high-thermal-conductivity non-stick coating, method for preparing same and application of high-temperature-resistant and high-thermal-conductivity non-stick coating

ActiveCN108893009AGood high temperature resistanceGood thermal conductivityFireproof paintsPolyester coatingsAluminiumSulfide

The invention provides high-temperature-resistant and high-thermal-conductivity non-stick coating. The high-temperature-resistant and high-thermal-conductivity non-stick coating is prepared from raw materials including, by weight, 100-120 parts of aluminium sesquioxide / red phosphorus modified fluorine resin, 50-70 parts of polyphenylene sulfide, 50-70 parts of graphene, 30-50 parts of carbon fibers, 40-70 parts of polylactic acid, 20-30 parts of thermal conduction inorganic fillers, 10-20 parts of coupling agents and 20-30 parts of auxiliaries. The auxiliaries comprise leveling agents, defoaming agents, film-forming agents, antioxidants, preservatives and ceramic powder. The high-temperature-resistant and high-thermal-conductivity non-stick coating has the advantages that the raw materialsfor the prepared high-temperature-resistant and high-thermal-conductivity non-stick coating can come from wide sources, a method for manufacturing the high-temperature-resistant and high-thermal-conductivity non-stick coating is simple and controllable, coatings prepared from the high-temperature-resistant and high-thermal-conductivity non-stick coating can be used at the high temperatures of 400-500 DEG C for a long term without influence on the performance, and accordingly the high-temperature-resistant and high-thermal-conductivity non-stick coating has a broad application prospect.

Owner:ZHEJIANG COOKER KING COOKER

Method for treating cyanide-containing wastewater in gold cyaniding enterprises

ActiveCN104261624AGood processing effectImprove processing efficiencyWater contaminantsWater/sewage treatment by electrochemical methodsChemistryReclaimed water

The invention discloses a method for treating cyanide-containing wastewater in gold cyaniding enterprises. The method comprises the four steps of electrochemical treatment, chemical oxidation treatment, coagulating sedimentation treatment and biological activated carbon treatment. When the cyanide-containing wastewater is treated, cyanide is electrolyzed by adopting the electrochemical treatment method; coagulating sedimentation is carried out by adding a coagulating agent, and heavy metal pollutants in wastewater can be removed; precipitated wastewater is oxidized by adding a chemical reagent; and finally, pollutants which are hardly removed from wastewater by a chemical method are removed by adopting a biological and physical adsorption method through a biological activated carbon treatment system. According to the method, the four steps are combined together according to the characteristics of complex and hardly treated pollutants in cyanide-containing wastewater of gold production enterprises, and are synergized to carry out deep treatment on the cyanide-containing wastewater of gold production enterprises. The method has the advantages of good treatment effect, high treatment efficiency, stable system operation and simple process flow, and can easily realize industrial application, and the treated wastewater can be returned to a production process flow to be used as reclaimed water or discharged with standard level.

Owner:CHANGCHUN GOLD RES INST

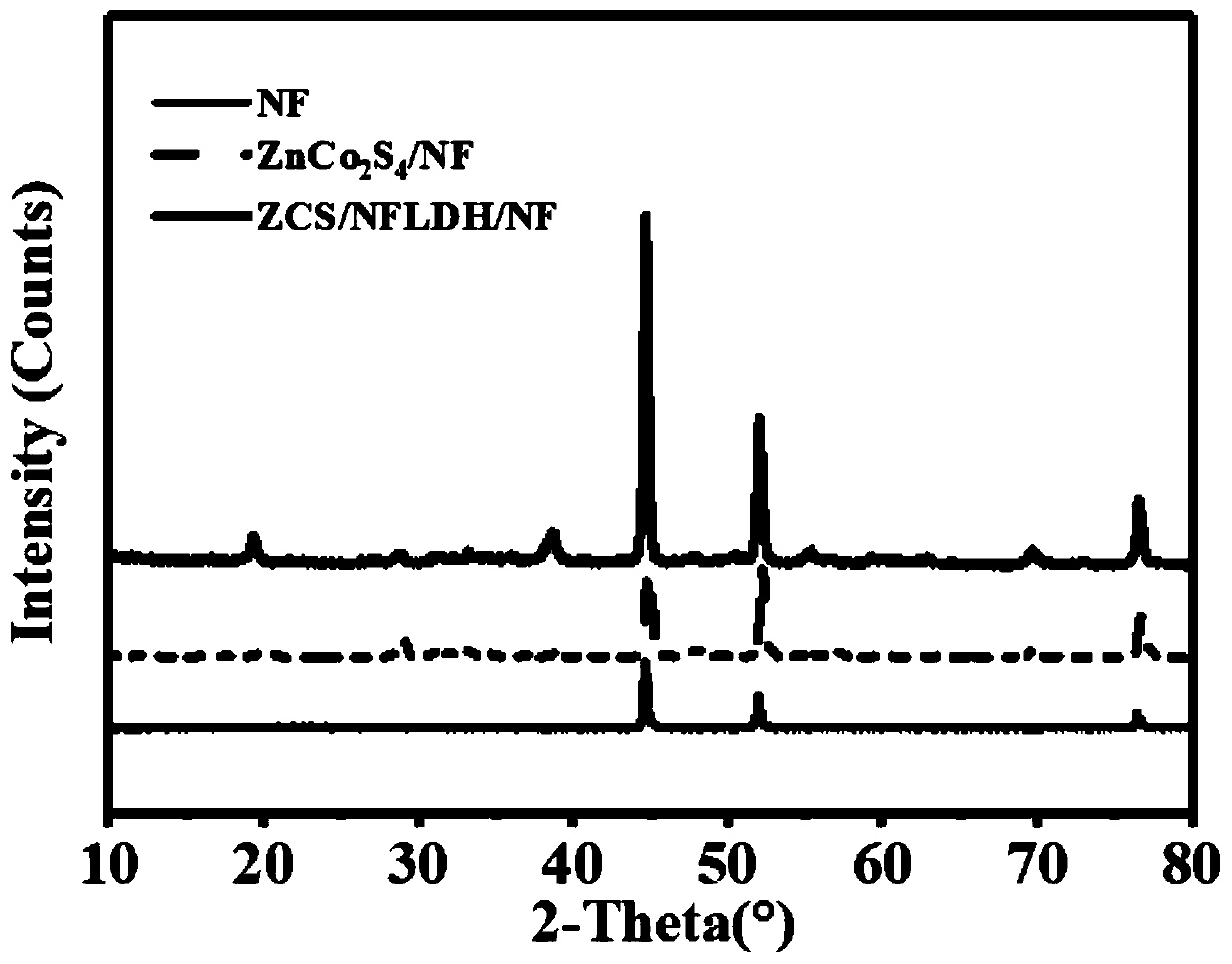

Cobalt zinc bimetallic sulfide based composite electrocatalyst, and preparation method and applications thereof

InactiveCN110465310AHigh reactivityImprove stabilityCatalyst activation/preparationElectrodesHydrogenCobalt

The invention belongs to the technical field of electrocatalysis, and discloses a cobalt zinc bimetallic sulfide based composite electrocatalyst, and a preparation method and applications thereof, andmore specifically relates to a cobalt zinc bimetallic sulfide / nickel iron layered bimetallic hydroxide / foam nickel composite electrocatalyst, and a preparation method and applications thereof. The cobalt zinc bimetallic sulfide / nickel iron layered bimetallic hydroxide / foam nickel composite electrocatalyst is prepared through three-step hydro-thermal method, is low in charge transfer resistance and hydrogen evolution reaction barrier, possesses excellent performance in electrocatalysis hydrogen evolution reaction, is low in cost, simple in operation and technology, and excellent in catalytic performance, and base application research on the material kind in electrocatalysis field is realized.

Owner:JIANGSU UNIV

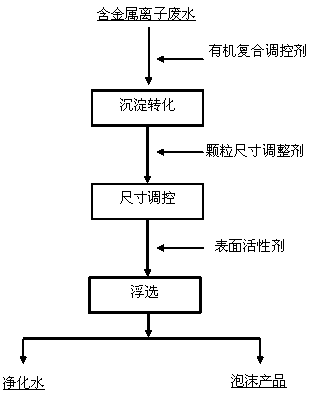

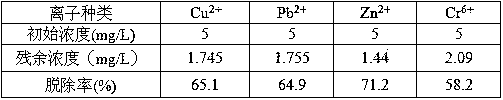

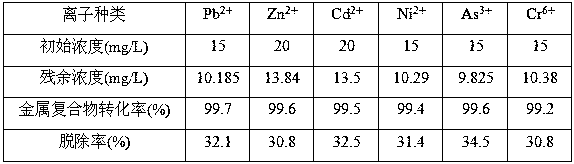

Composite regulating agent and method for precipitation conversion and flotation removal of metal ions in waste water

ActiveCN109761325AEasy to removeEfficient removalWater contaminantsWater/sewage treatment by flocculation/precipitationMetalEnvironmental chemistry

The invention discloses a composite regulating agent and method for precipitation conversion and flotation removal of metal ions in waste water. The flotation removal method comprises the steps that an organic composite regulating agent and a particle size regulating agent are sequentially added into the waste water containing metal ions, and a metal ion precipitation conversion compound is obtained; and a surfactant is added into the mixed solution to serve as a metal compound collecting agent to conduct flotation separation, the flotation residual solution is purified water, and the removalrate of metal ions in the waste water reaches up to 95.0-100%. The method can achieve rapid and efficient removal of the metal ions in the waste water, and can also realize effective enrichment of themetal ions in the water; in addition, the method has the advantages of simple technology and low cost, and industrialized application can be easily achieved.

Owner:ZHENGZHOU UNIV

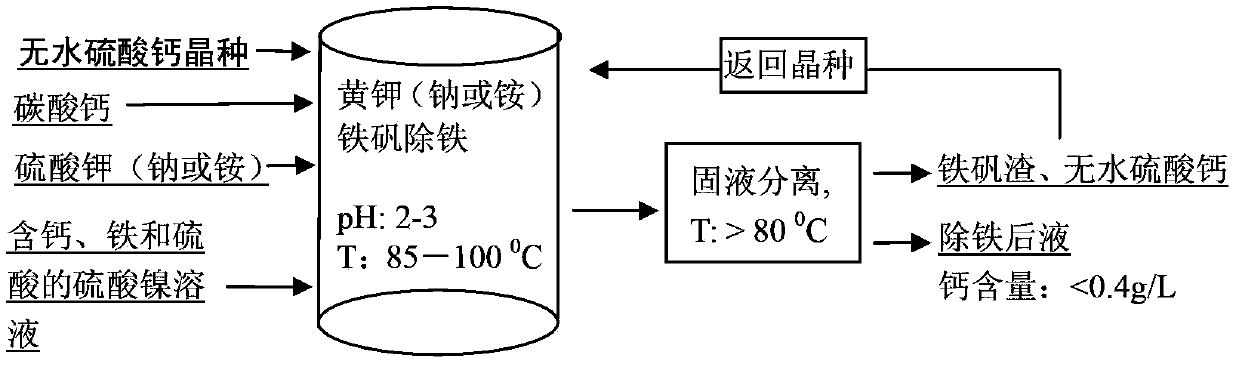

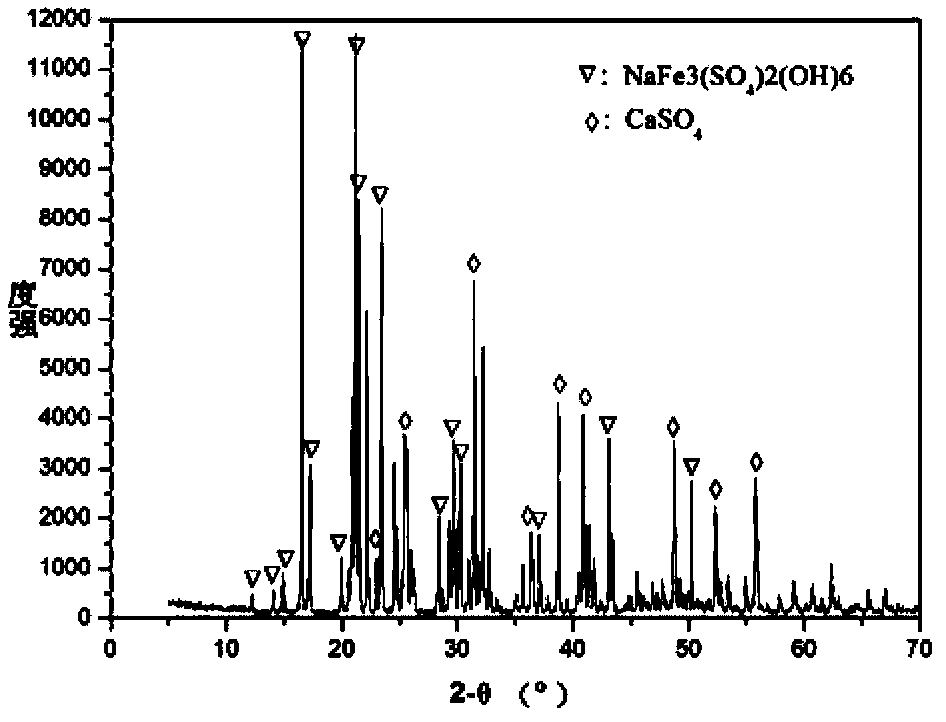

Method for calcium removal during iron precipitation of nickel sulfate solution containing iron and free sulfuric acid

InactiveCN103397185AEliminate hazardsReduce manufacturing costProcess efficiency improvementAnhydrous Calcium SulfateSulfate

Belonging to the technical field of wet metallurgy, the invention relates to a method for calcium removal during iron precipitation of a nickel sulfate solution containing iron and free sulfuric acid. The method includes: during removal of iron from the nickel sulfate solution containing iron and free sulfuric acid, taking calcium carbonate as a pH regulator of the solution, and simultaneously adding an anhydrous calcium sulfate seed crystal, inducing the calcium in the solution to crystallize and precipitate out, and at the end of reaction, conducting filtering immediately, thus obtaining an iron and calcium removed nickel-containing solution. The mass concentration of iron ions in the nickel sulfate solution containing iron and free sulfuric acid is not less than 1g / l, the mass concentration of nickel ions is greater than 10g / l, and the temperature is controlled at 85-100DEG C during calcium removal. The method provided in the invention has the characteristics of simple operation, short technological process, low cost, and good calcium removal effect, etc.

Owner:CENT SOUTH UNIV +1

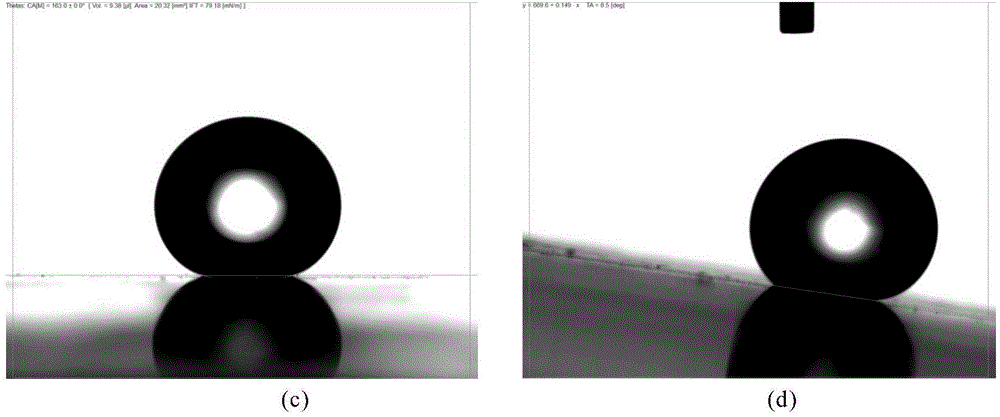

Method for preparing titanium alloy super-hydrophobic anti-frost surface using short pulse laser

ActiveCN104985328AExcellent superhydrophobic propertiesSimple processWelding/soldering/cutting articlesLaser beam welding apparatusTitanium alloyMetallic substrate

The invention relates to a method for preparing titanium alloy super-hydrophobic anti-frost surface using short pulse laser, and belongs to the technical field of surface modification on metal base material. The method comprises preprocessing (polishing) a titanium alloy sample, washing the surface of the sample in an ultrasonic cleaner using deionized water, drying the sample through cold air or airing the sample after the sample is cleaned up, treating the surface of the sample through a short pulse laser after related parameters are adjusted (the laser processing technology), making countless microstructures in the surface of the sample, putting the processed sample into an electrothermal drying box to be roasted after the sample is processed, to obtain the titanium alloy super-hydrophobic anti-frost surface. The surface has micron order papilla structures or crack structures, so the surface is excellent in super-hydrophobic performance and anti-frost performance. The method is simple in technology, convenient to carry out, high in efficiency, low in energy consumption, low in cost and environmental friendly, so the method can be easily applied to industrial application.

Owner:WUHAN JINDUN LASER TECH CO LTD

Cyanide-containing wastewater treating method for gold mine

InactiveCN104071953AEasy to handleImprove processing efficiencyMultistage water/sewage treatmentManufacturing technologyCatalytic oxidation

The invention discloses a cyanide-containing wastewater treating method for a gold mine. The treating method comprises four steps as follows: sulfur dioxide-air oxidation treatment, coagulating sedimentation treatment, ozone or activated carbon catalytic oxidation treatment and biological activated carbon treatment; in the cyanide-containing wastewater treatment, firstly, the sulfur dioxide-air oxidation method is adopted to remove easily removed cyanide; a coagulant is added in the treated wastewater for coagulating sedimentation to remove heavy metal ions in the wastewater; then ozone and the activated carbon are adopted for catalytic oxidation and contaminants such as residual cyanide that is hard to be treated and rhodanate are removed; lastly, through a biological activated carbon treatment system, contaminants that cannot be removed through chemical methods in the wastewater are removed by biological and physical adsorption methods. According to the invention, as technologies of the sulfur dioxide-air oxidation treatment, the coagulating sedimentation treatment, the ozone or activated carbon catalytic oxidation treatment and the biological activated carbon treatment are integrated and coordinated to conduct an advanced treatment on the cyanide-containing wastewater in the gold mine, the treatment efficiency is high, the treated wastewater can return to manufacturing technology processes and serve as renovated water for using or can be emitted up to standard.

Owner:CHANGCHUN GOLD RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com