Method for recycling aluminum oxide from red mud

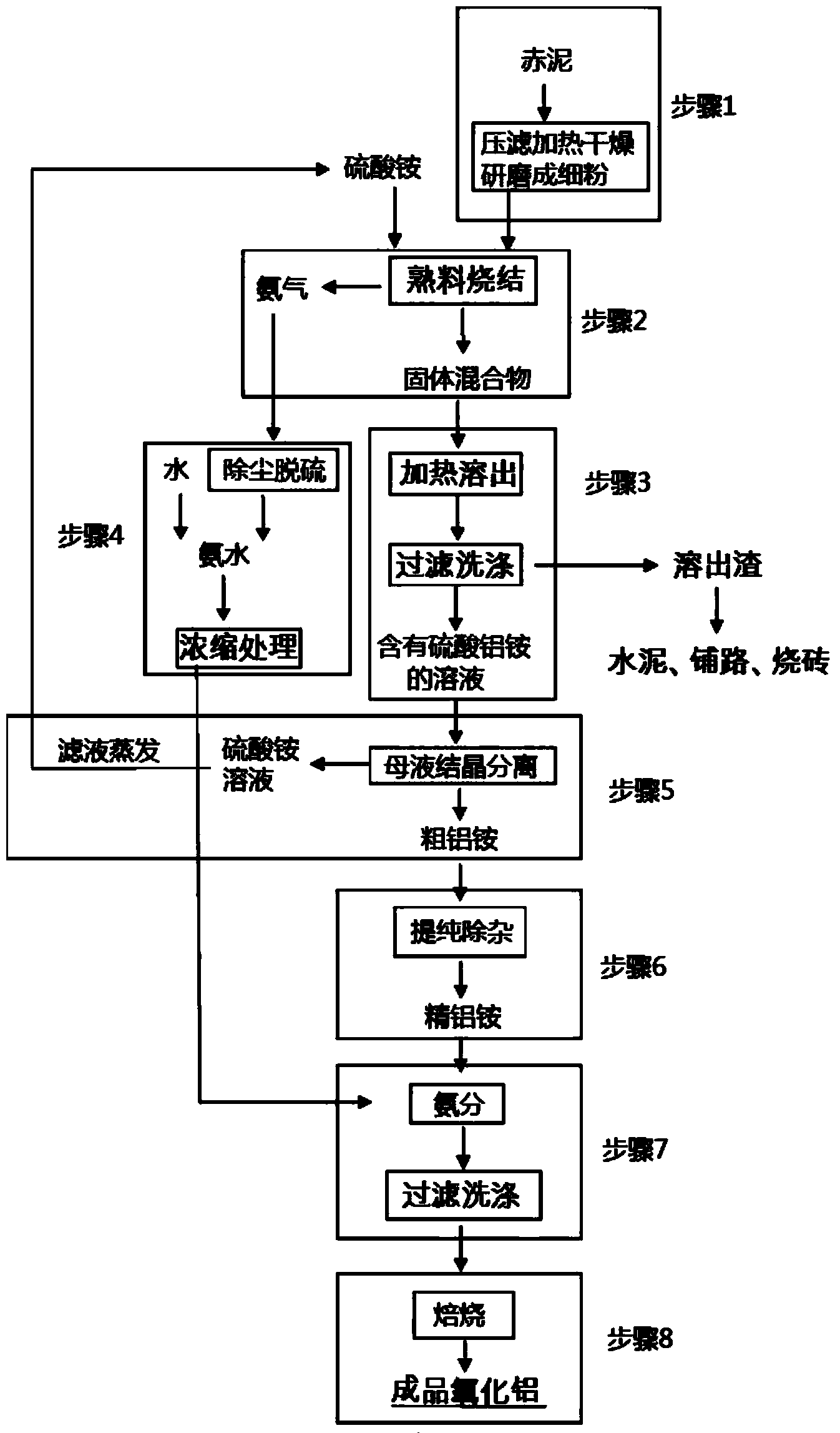

A technology of alumina and aluminum hydroxide, applied in the direction of alumina/hydroxide, etc., can solve the problems of low recovery rate, low raw material price, high recovery cost, etc., and achieve small residue, easy particle size range, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Dry the red mud containing 18% alumina and grind it to 200 meshes. The mass ratio of red mud and ammonium sulfate is 1:0.5. The ground mixture is weighed and sintered. The sintering temperature is 280°C and the sintering time is 0.5 hours. Dissolve the sintered clinker with water at 75°C under normal pressure, and the dissolution rate of aluminum oxide in the obtained crude aluminum ammonium solution is 75%. The aluminum ammonium sulfate solution is cooled to 10°C to crystallize, and the crude aluminum ammonium solution is recrystallized to remove iron. , titanium and other impurities to obtain refined aluminum ammonium crystals, and then dissolve the obtained refined aluminum ammonium crystals to prepare a 0.1mol / L aluminum ammonium sulfate solution, and then pass through ammonia water to decompose, NH 3 The molar ratio to aluminum ammonium sulfate is 3.2:1, the reaction temperature is 30°C, and after 0.5h of reaction, the aluminum hydroxide solid is obtained after was...

Embodiment 2

[0054] Dry the red mud containing 22% alumina and grind it to 600 meshes. The mass ratio of red mud and ammonium sulfate is 1:3. The ground mixture is weighed and sintered. The sintering temperature is 420°C and the sintering time is 2.5 hours. Dissolve the sintered clinker with water at 98°C under normal pressure, and the dissolution rate of aluminum oxide in the obtained crude aluminum ammonium solution is 85%. The aluminum ammonium sulfate solution is cooled to 10°C to crystallize, and the crude aluminum ammonium solution is recrystallized to remove iron. , titanium and other impurities to obtain refined aluminum ammonium crystals, and then dissolve the obtained refined aluminum ammonium crystals to prepare a 0.22mol / L aluminum ammonium sulfate solution, and then pass through ammonia water to decompose, NH 3 The molar ratio to ammonium aluminum sulfate is 4:1, and the reaction temperature is 55°C. After reacting for 2 hours, the aluminum hydroxide solid is obtained after wa...

Embodiment 3

[0056] The red mud containing 25% alumina was dried and ground to 1000 mesh, and the ground mixture was weighed according to the mass ratio of red mud and ammonium sulfate as 1:5 for sintering. The sintering temperature was 580°C and the sintering time was 6 hours. Water the sintered clinker at 5kgf / cm 2 Dissolution at 140°C, the dissolution rate of alumina in the obtained crude aluminum ammonium solution is 90%, the aluminum ammonium sulfate solution is cooled to 5°C to crystallize, the crude aluminum ammonium solution is recrystallized to remove impurities such as iron and titanium to obtain refined aluminum ammonium crystals, and then dissolve the obtained crude aluminum ammonium crystals to prepare a 0.5mol / L aluminum ammonium sulfate solution, and then pass through ammonia water to decompose, NH 3 The molar ratio to ammonium aluminum sulfate is 4:1, the reaction temperature is 60°C, and after 3 hours of reaction, the aluminum hydroxide solid is obtained after washing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com