A kind of fly ash-based two-step sintered ceramic permeable brick and its preparation method

A technology for sintering ceramics and fly ash, which is applied in the production of ceramic products, ceramic materials, and clay products. It can solve problems such as low conversion efficiency of raw materials, lower product qualification rate, and cumbersome granulation process, and achieve simplified screening and repetition. The effect of granulation, reduction of raw material cost, simple ingredients and preparation steps

Active Publication Date: 2022-05-31

ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD +1

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The granulation process of this method is cumbersome, and strict screening of brick particles with narrow particle size distribution is used for the preparation of permeable bricks, resulting in repeated granulation and low conversion efficiency of raw materials; a large amount of clay is used as a binder, resulting in waste of resources; The sintering system is easy to cause product cracking and lower product qualification rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

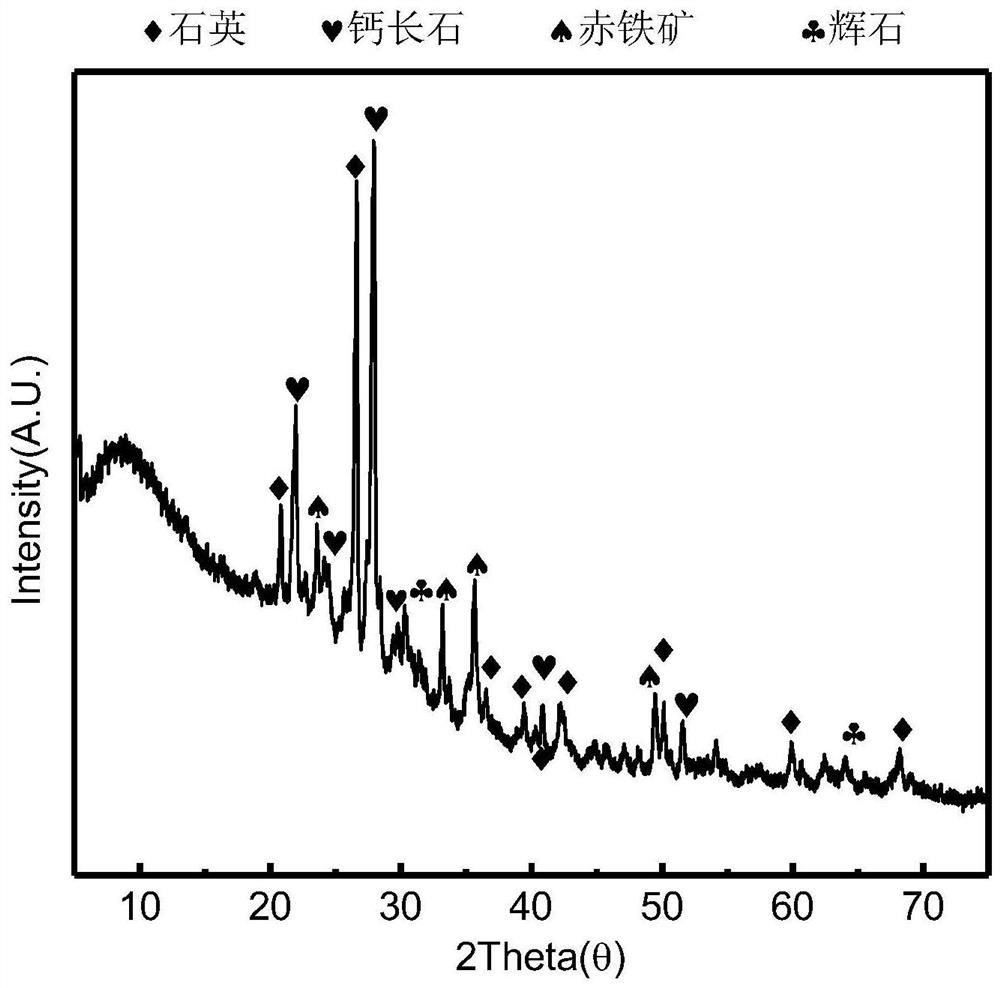

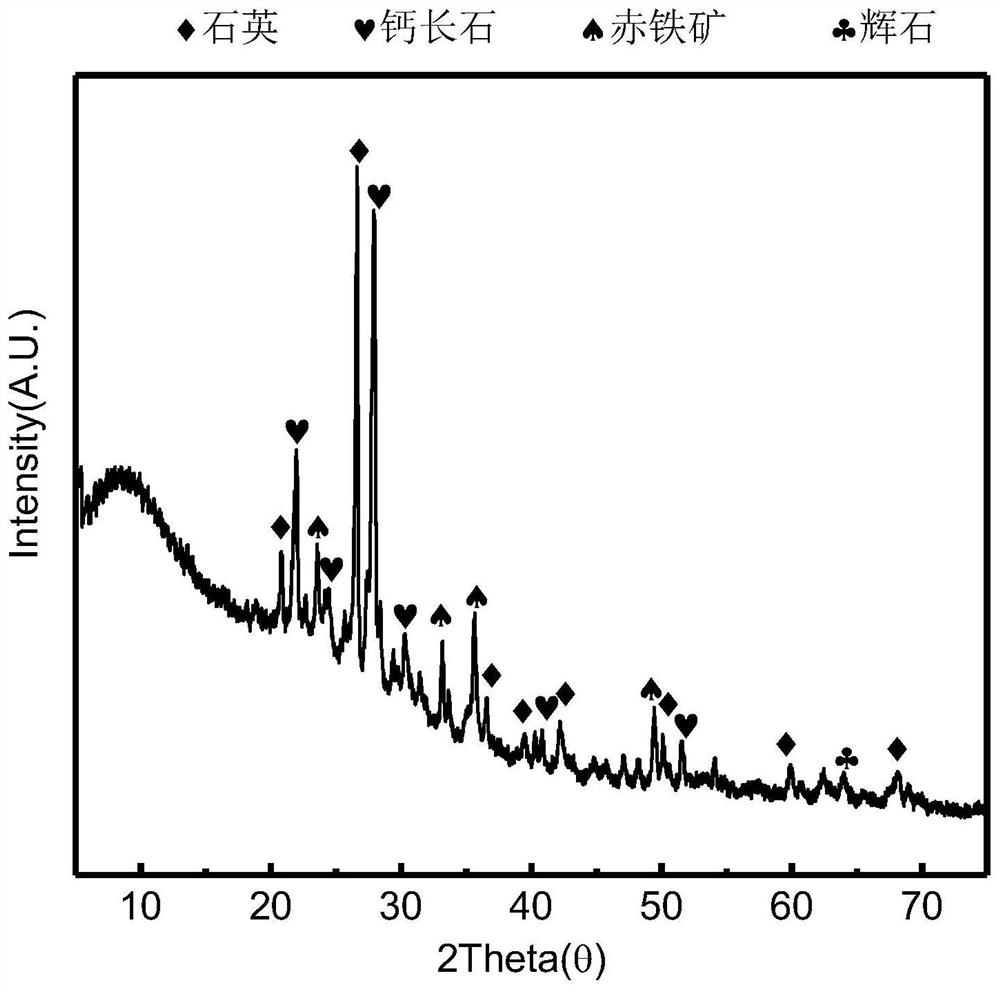

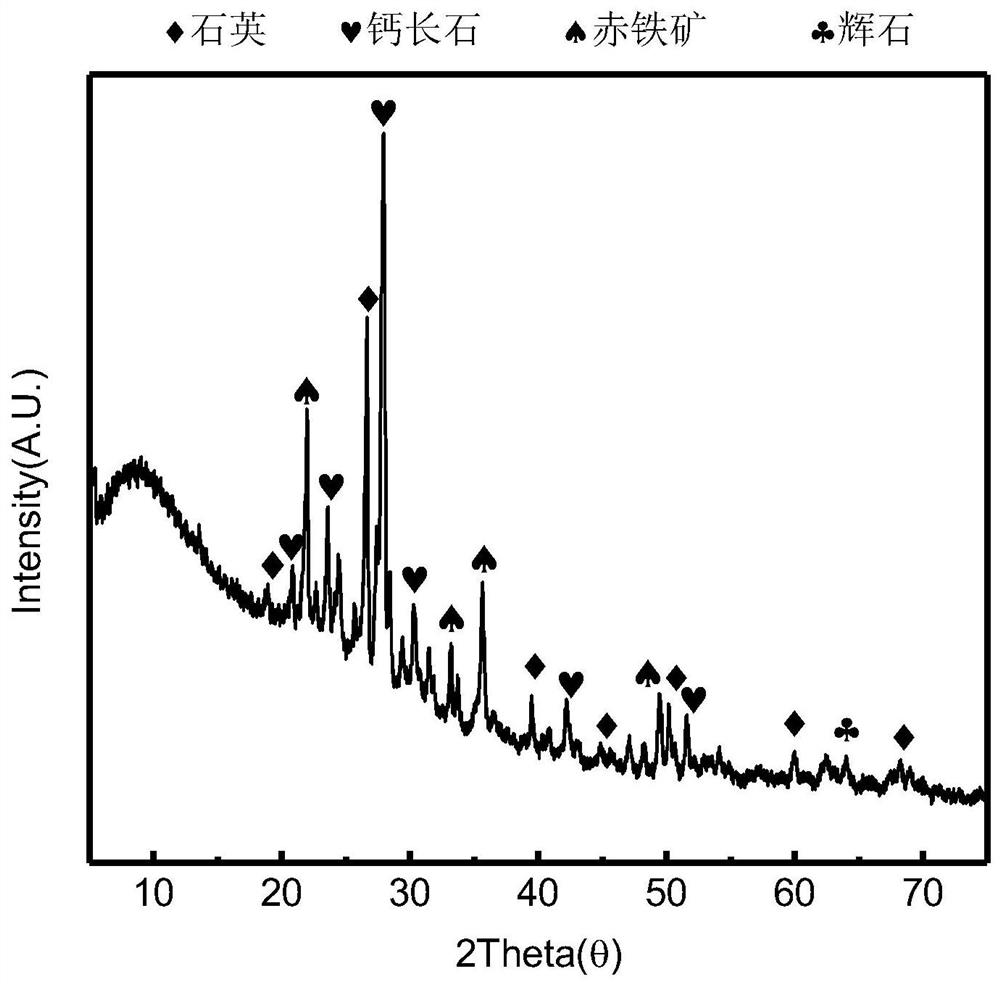

The invention belongs to the field of environment-friendly ceramics and building materials, and specifically discloses a fly ash-based ceramic permeable brick sintered in two steps and a preparation method thereof. The preparation method of the present invention comprises the following steps: (1) mixing Class C fly ash and tailings with water evenly, and preparing mud granules through a granulator; (2) pressing the mud granules to obtain a wet billet; (3) Naturally age the wet body and dry it in an oven to prepare a dry body; (4) Sinter the dry body using a two-step method, the first sintering is at 400-600°C for 10-50min, and the second sintering is at 1000-600°C Sintering at 1400°C for 1‑2h, the fly ash-based ceramic permeable brick can be obtained. The fly ash ceramic permeable brick prepared by the invention is light in weight and good in durability, can be widely used in laying permeable pavements and squares, and can bring good environmental protection and economic benefits.

Description

A kind of fly ash-based two-step sintered ceramic permeable brick and preparation method thereof technical field The invention belongs to the field of environment-friendly ceramics and building materials, be specifically related to a kind of ceramics sintered by fly ash-based two-step method Permeable brick and preparation method thereof. Background technique The fly ash contains a large amount of SiO 2 , Al 2 O 3 , CaO, Fe 2 O 3 and other oxides, the composition is similar to clay, and the particles are It is fine, so it can be used for ceramic preparation without pretreatment. According to the level of CaO content in fly ash, fly ash can be divided into It is Class C fly ash (CaO>10%) and Class F fly ash (CaO<10%). In addition to the properties of pozzolan, Class C fly ash also has pozzolanic properties. Shows gelling properties and has certain hydraulic properties. With the development and implementation of the concept of building a "sp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B38/00C04B33/132C04B33/13C04B33/135C04B33/32

CPCC04B38/0038C04B33/1328C04B33/13C04B33/32C04B33/132C04B33/1352C04B2235/602C04B2235/606C04B2235/656C04B2235/6562C04B2235/6567C04B2235/5427C04B2235/96Y02P40/60

Inventor 杨家宽吕瑞斌张元赏梁莎张力陈烨丁得龙李喜龙郑俊杰李星吾施园胡敬平肖可可侯慧杰

Owner ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com